Integral abutment bridge structure based on composite flexible piles and construction method thereof

An integral abutment and construction method technology, which is applied in the direction of foundation structure engineering, bridges, bridge parts, etc., can solve the problems of high horizontal rigidity of ordinary concrete piles, concrete cracking, fracture failure of pile foundation structure sections, etc., and achieve high temperature absorption Performance, improve the mechanical performance, the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

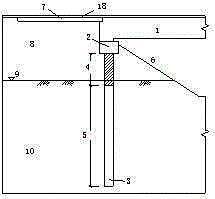

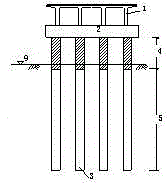

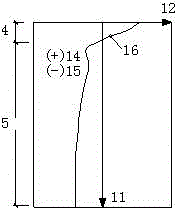

[0031] refer to Figure 1 to Figure 8

[0032] An integral abutment bridge structure based on composite flexible piles, including an abutment 2 lying along a slope protection 6, the abutment is supported by a number of vertical flexible piles 3 embedded in the slope protection, and the flexible piles are buried by It is composed of the ordinary concrete area 5 in the geology 10 below the surface line 9 and the ultra-high performance fiber concrete composite material area 4 connected thereto, and the space between the abutment and the flexible pile and the bank ground is filled with filling Soil 8, the filling is laid with a board 7, and the end of the board near the abutment is overlapped with the end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com