Construction method of reinforcing large-span concrete structure with prestressed carbon fiber sheet

A technology for concrete structures and carbon fiber sheets, which is applied in the processing of building materials, bridge materials, building structures, etc., can solve the problem of lack of stereotyped and reliable tensioning equipment, difficult to achieve practical engineering applications, and complex tensioning construction processes. problems, to achieve the effect of short installation and tensioning time, sufficient force, and improved coordination and deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

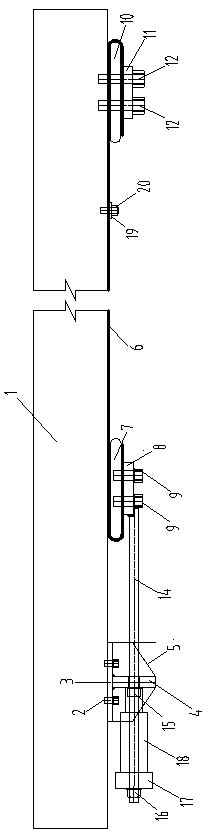

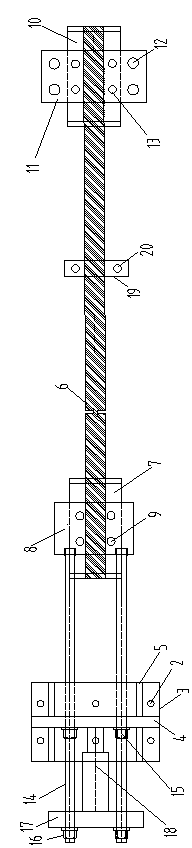

[0034] Such as figure 1 and figure 2 As shown, the prestressed carbon fiber sheet of the present invention reinforces the tension anchorage device of the large-span concrete structure, including the fixed part of the tension sheet, the movable part of the tension sheet, the fixed part of the tension force, the tension force part and the carbon fiber Tensile sheet material 6 made of material, the two ends of the tensioned sheet material 6 are respectively connected with the fixed part of the tensioned sheet material and the movable part of the tensioned sheet material, and the fixed part of the tensioned sheet material and the movable part of the tensioned sheet material are respectively set At both ends of the same side of the long-span concrete structure 1, one side of the tension sheet 6 is in contact with the side of the long-span concrete structure 1, the tension power part is arranged on the tension power fixed part, and the tension power part is connected with the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com