Strengthening concrete frame structure and construction method thereof

A frame structure, concrete technology, applied in the direction of building structure, construction, building materials processing, etc., to achieve the effect of improving the construction progress, speeding up the construction speed, and solving the problem of steel bar binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

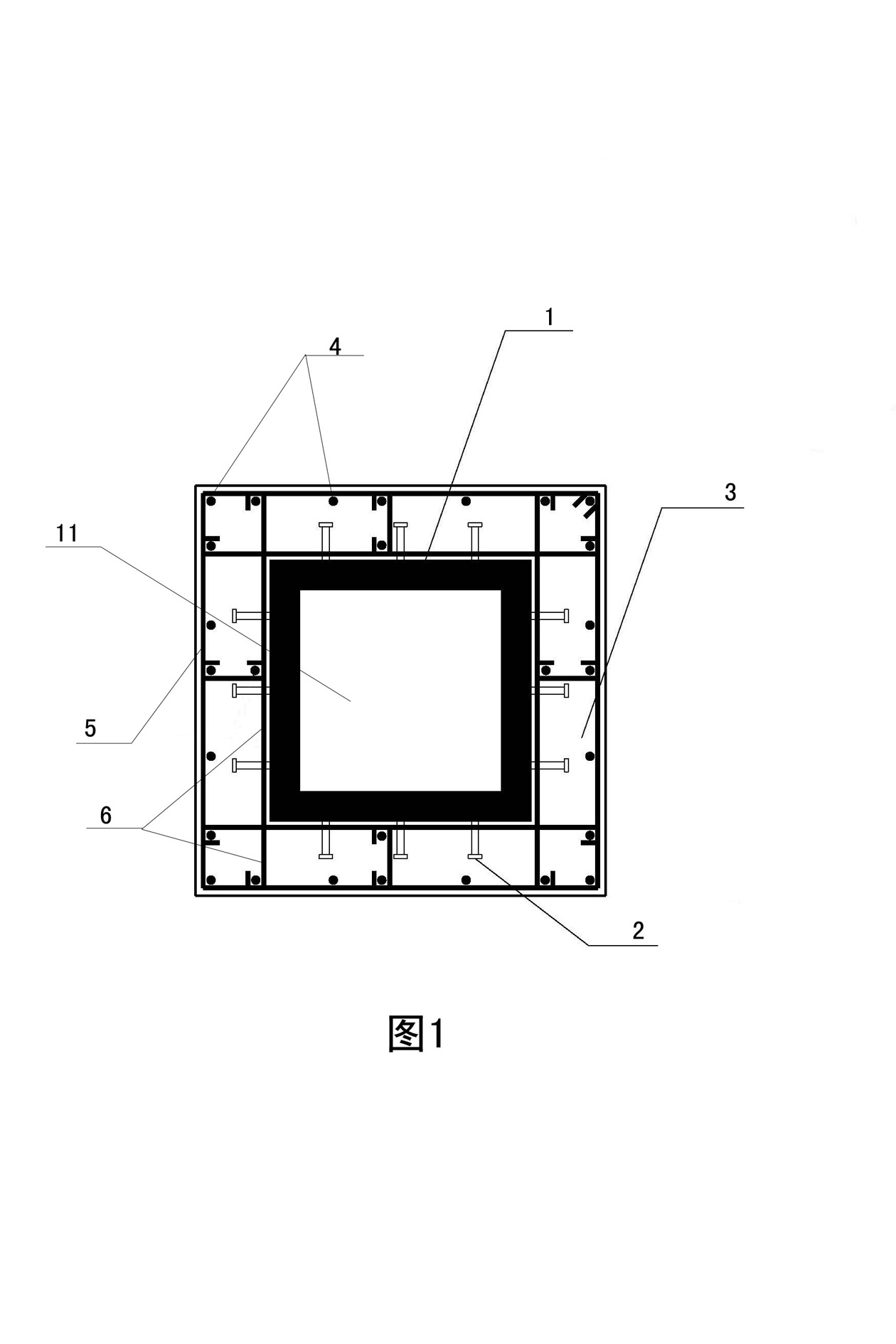

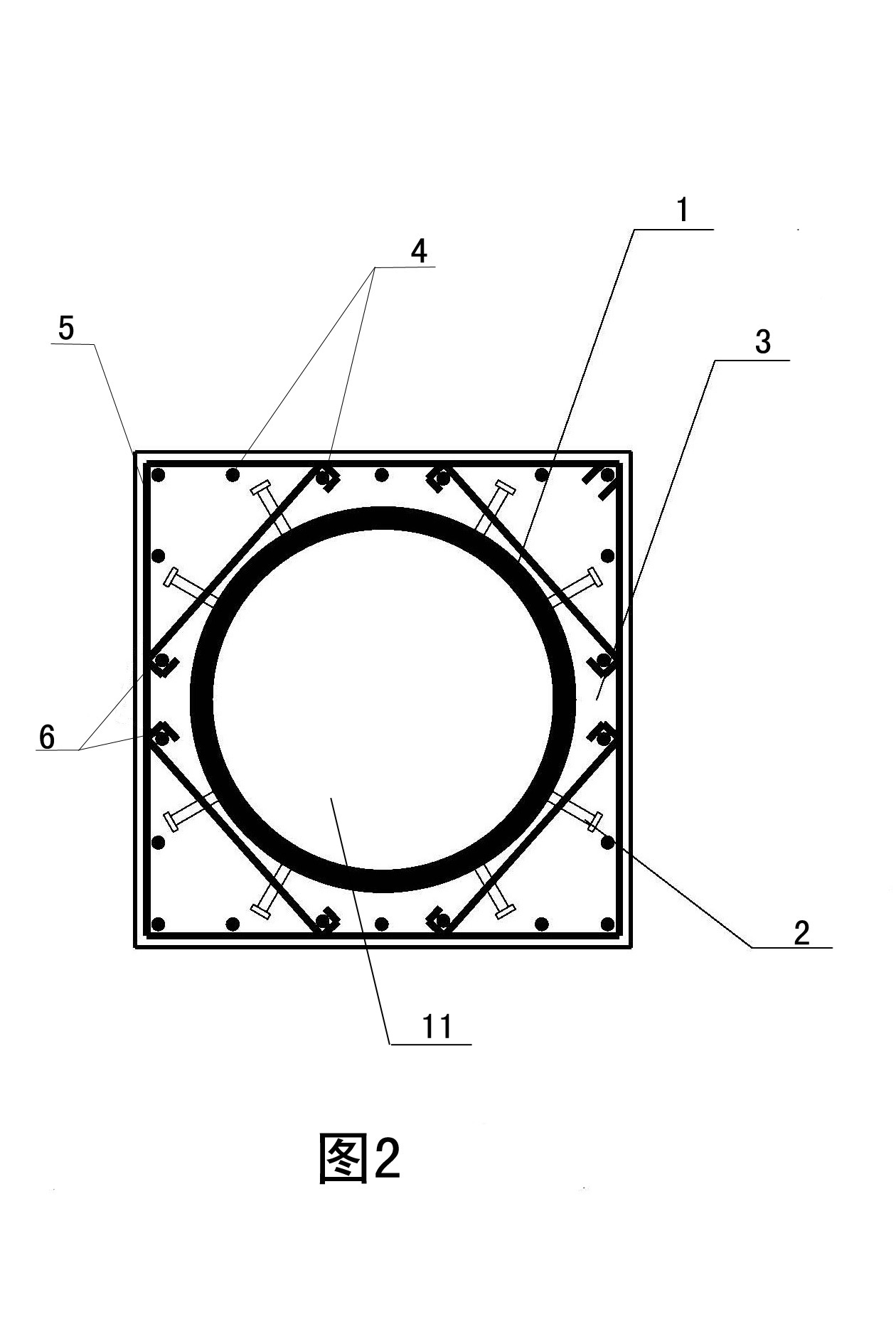

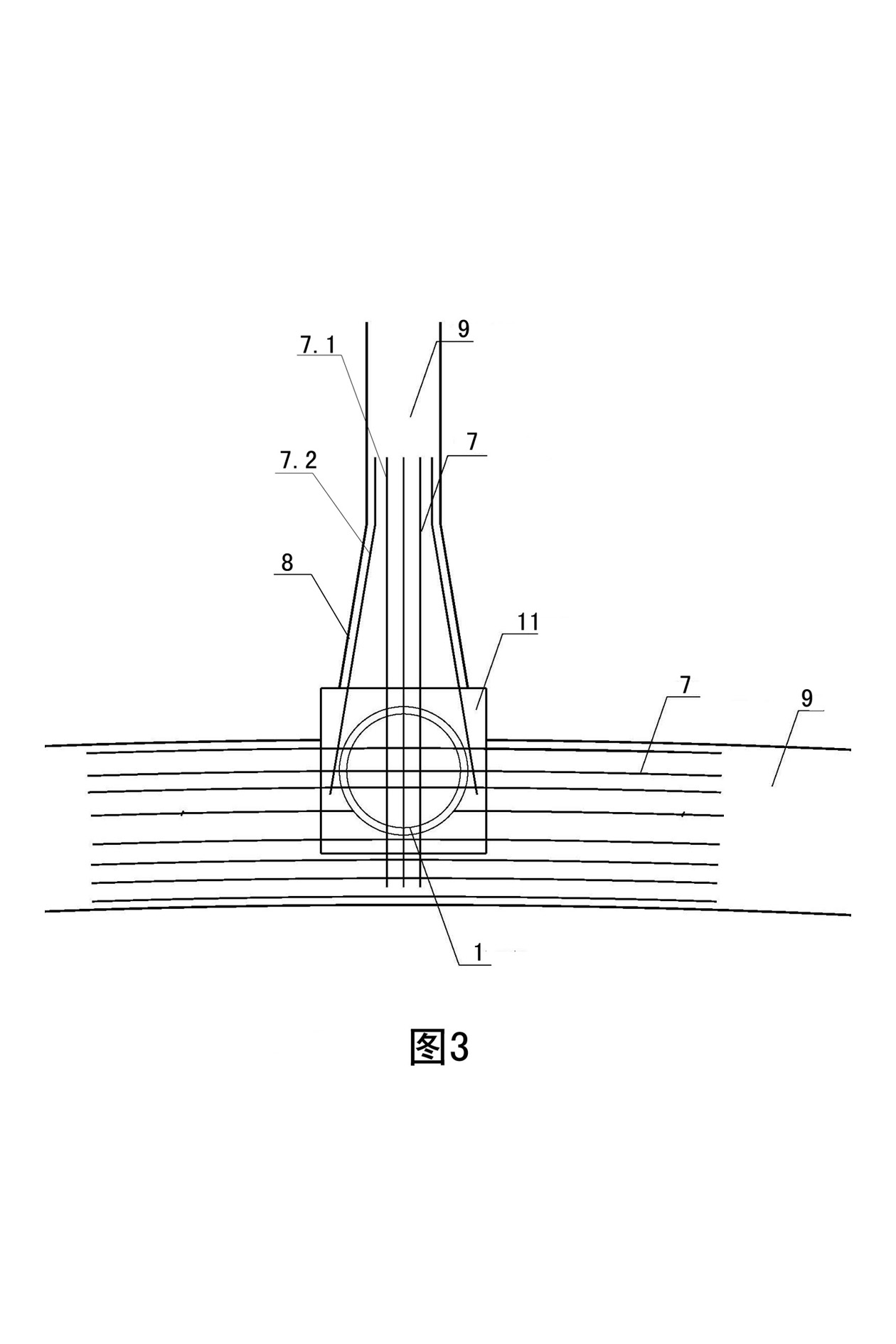

[0040] Examples see Figure 1 ~ Figure 6 As shown, the B1 layer of a certain project is a structural transfer layer, and a rigid concrete frame structure is adopted. It is composed of frame columns and frame beams 9. The frame beams 9 are reinforced concrete beams. The steel bars include beam main reinforcement 7 and beam stirrups. 7 includes long ribs and non-long ribs. The frame beam 9 is connected to the side or top of the frame column. The frame beam 9 is provided with a floor slab. The floor slab and the frame beam 9 are cast as a whole. The frame column is made of core column steel. It is integrated with the surrounding column reinforced concrete structure. The core column steel frame 1 is filled with concrete, and the core column steel frame 1 is covered with studs 2 perpendicular to the surface of the steel frame, and is embedded in the column reinforcement through the studs 2. In the concrete structure 3; the reinforcing bars of the column reinforced concrete structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com