Patents

Literature

45results about How to "Solve the difficulty of blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

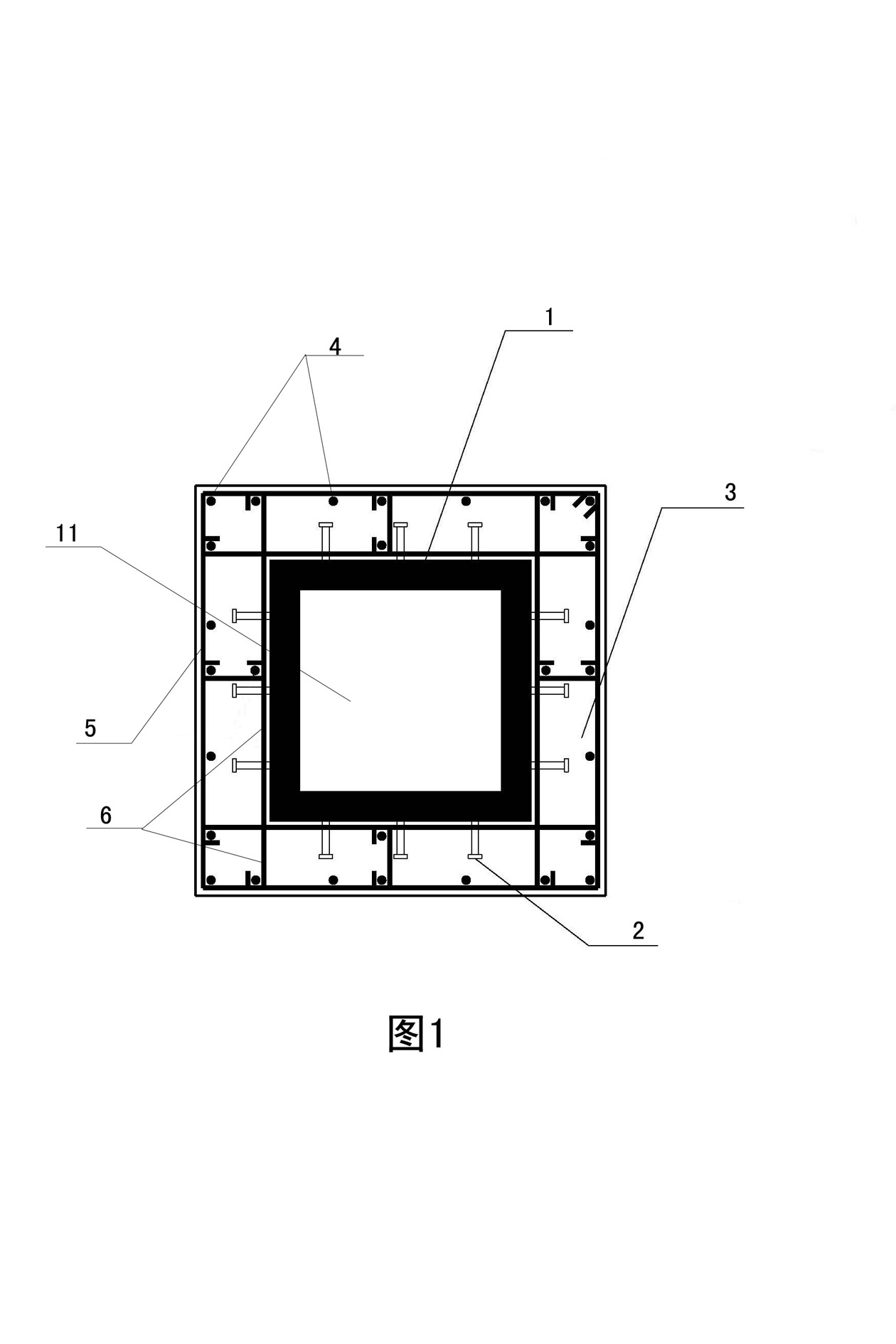

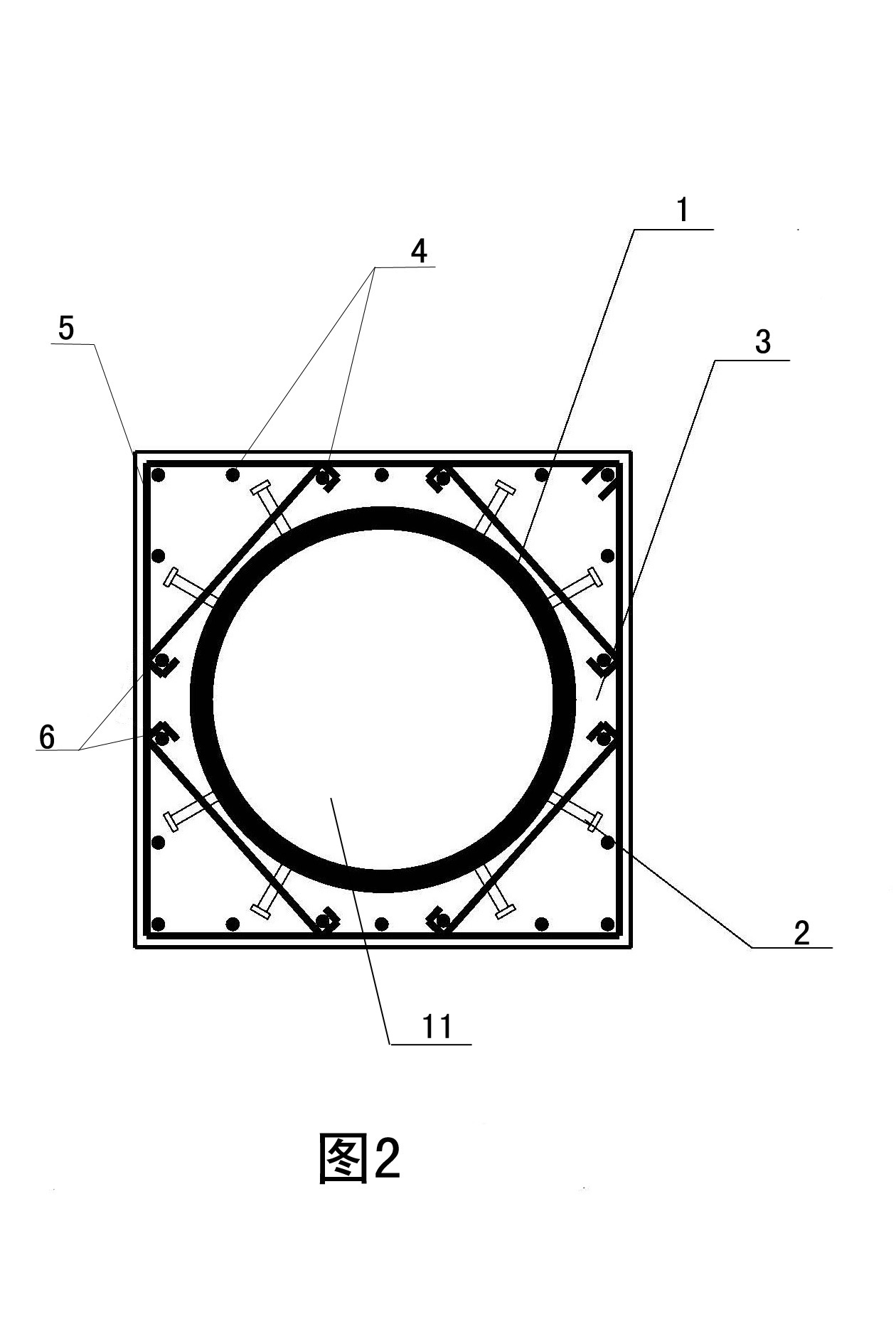

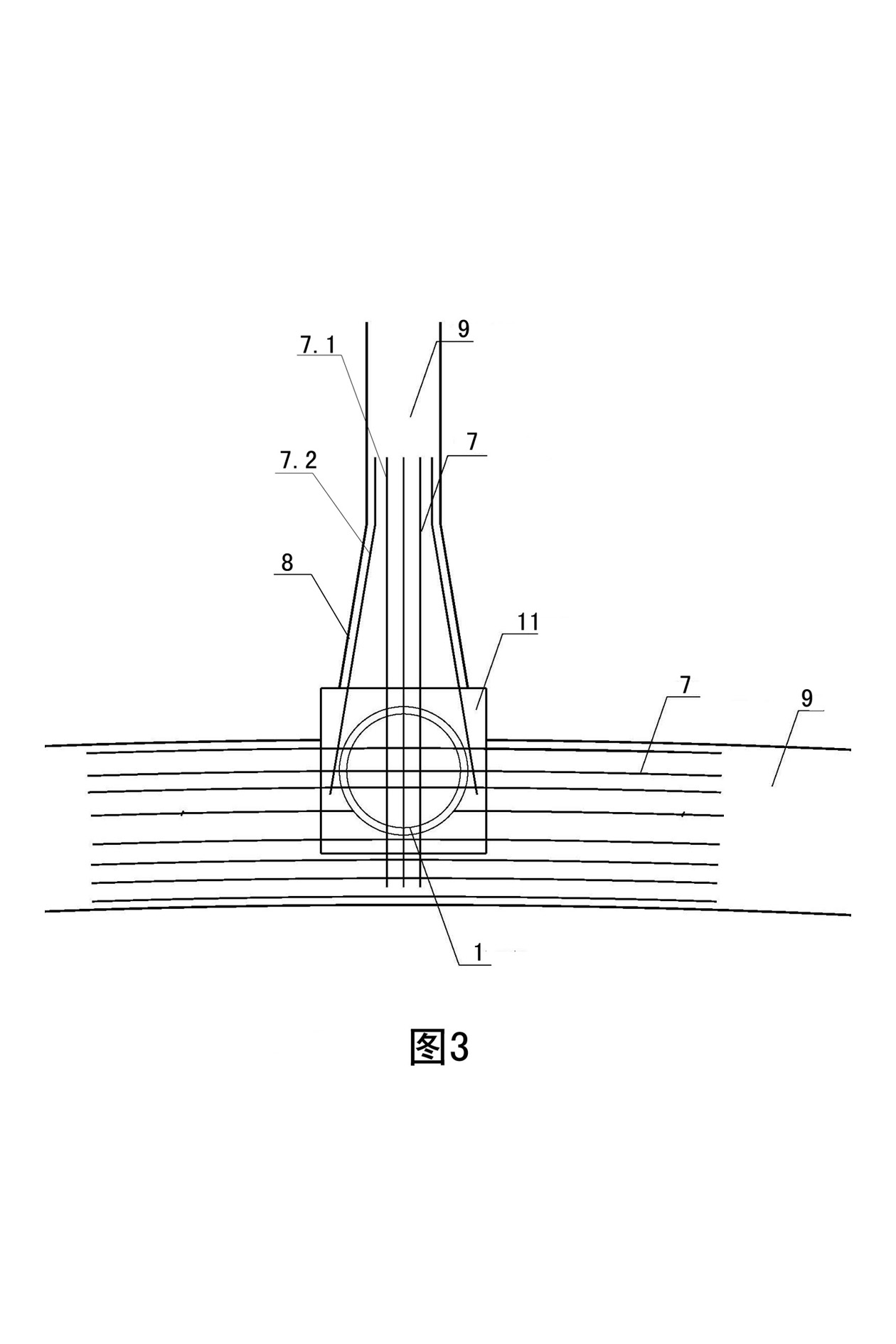

Strengthening concrete frame structure and construction method thereof

InactiveCN101845850AImprove fire performanceImprove mechanical performanceBuilding material handlingReinforced concreteSteel bar

The invention relates to a strengthening concrete frame structure. A frame column is formed by integrally pouring a stem steel rib and peripheral column reinforced concretes, wherein the concrete is poured inside the stem steel rib; studs which are vertical to the steel rib are arranged on the periphery of the stem steel rib; the stem steel rib is embedded in the column reinforced concrete structure; the reinforced steel bar in the column reinforced concrete structure comprises a stud, a column stirrup and a drag hook; the beam tendons at the upper part of a beam column joint are a main penetration tendon and a column winding tendon; when the upper column winding tendon passes by the stem steel rib in the frame column, the column winding tendon is bent outwards at a gradient of 1: 6; and when the upper main penetration tendon penetrates a reserved hole on the stem steel rib in the frame column, one end of a lower beam tendon is anchored in the column reinforced concrete structure or is bent upwards. The invention solves the problems that the reinforcing steel bar in the steel rib-concrete structure beam column joint areas is difficult to penetrate the stem steel rib, the concrete is inconvenient to pour and vibrate and the pouring effect is inferior. The structure of the invention can be widely applied to a long span high-rise frame structure.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

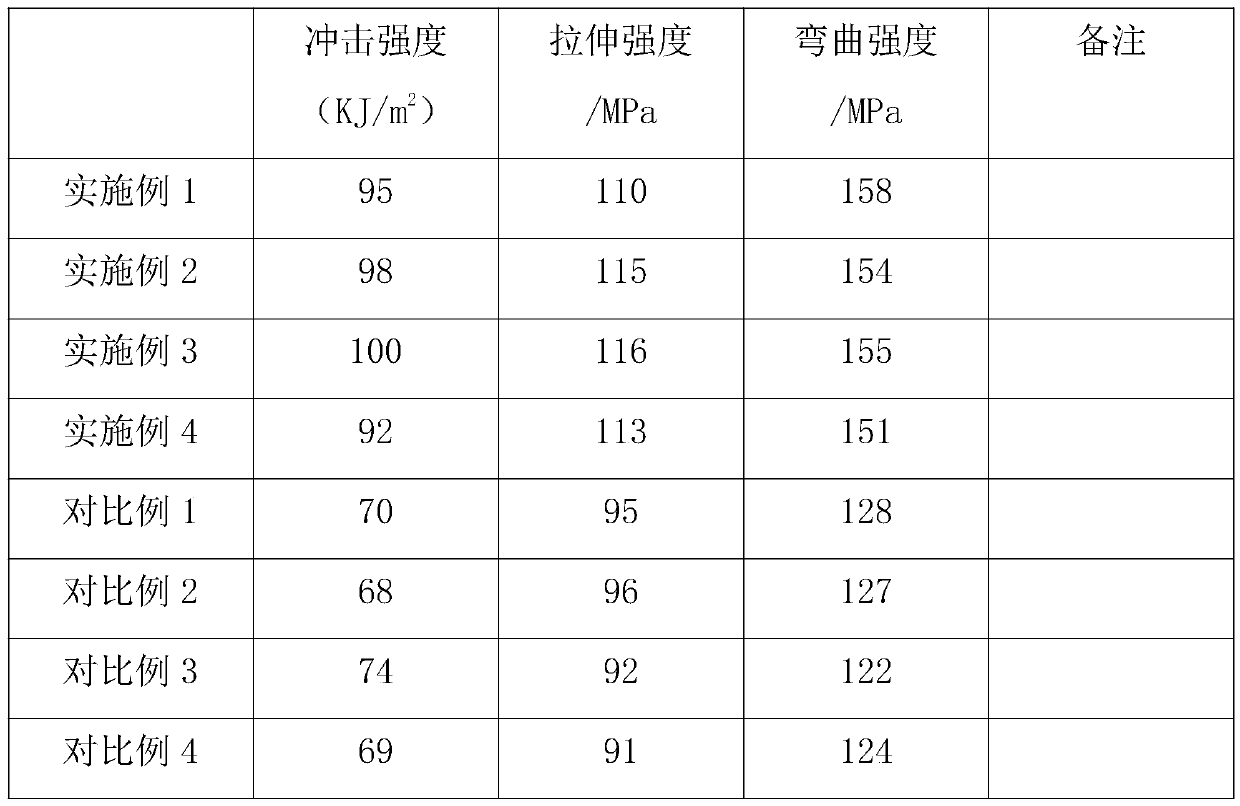

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

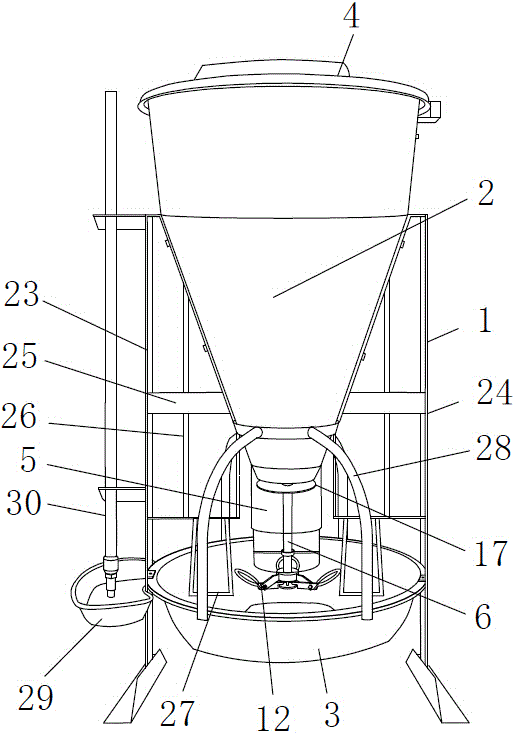

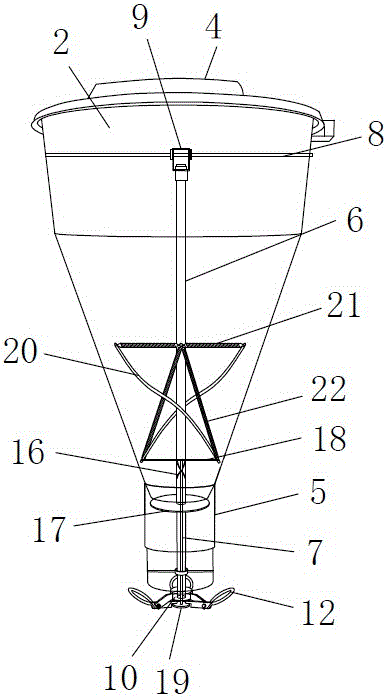

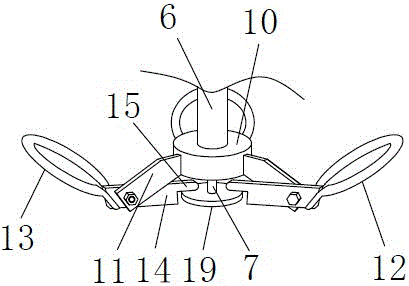

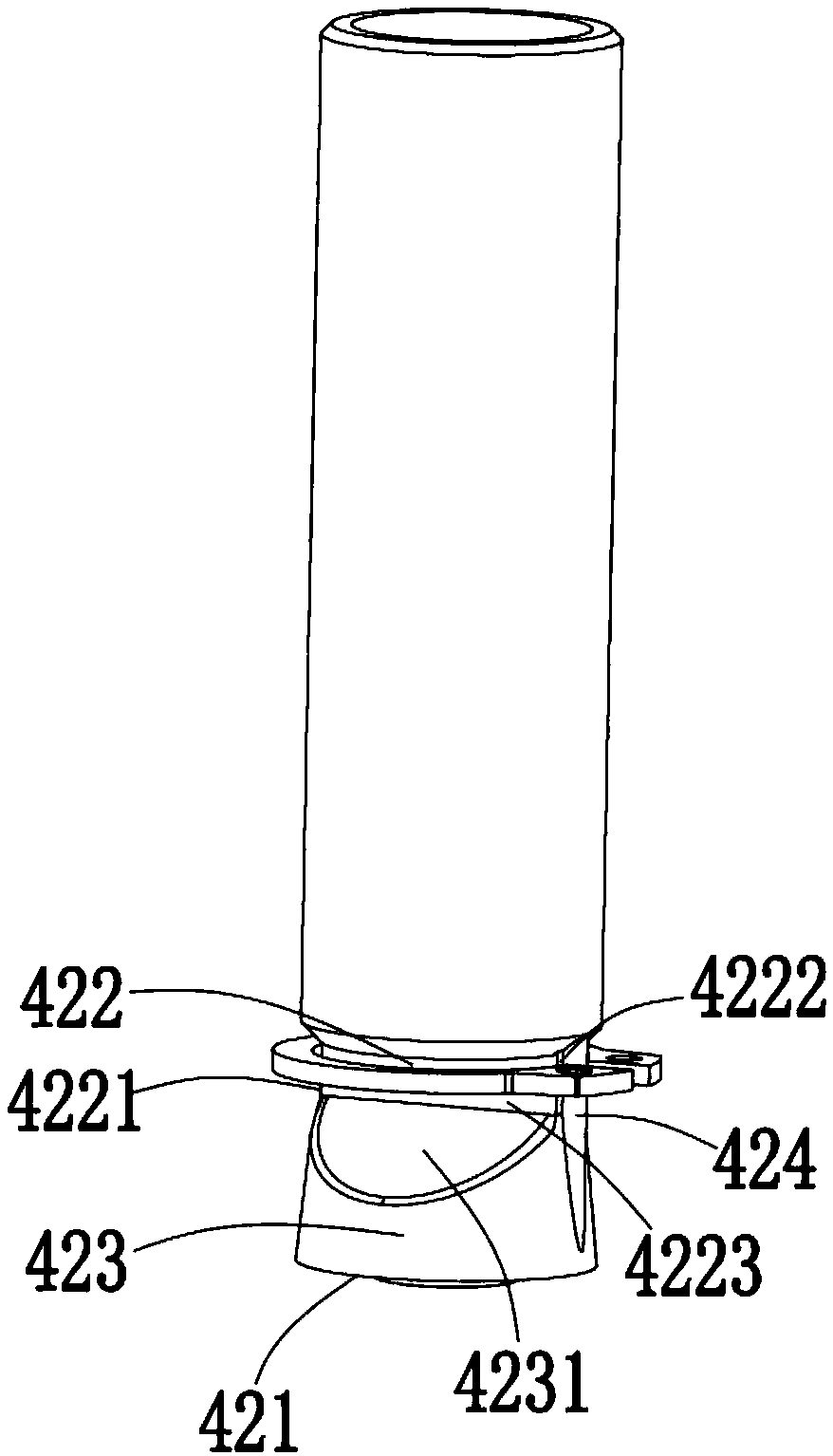

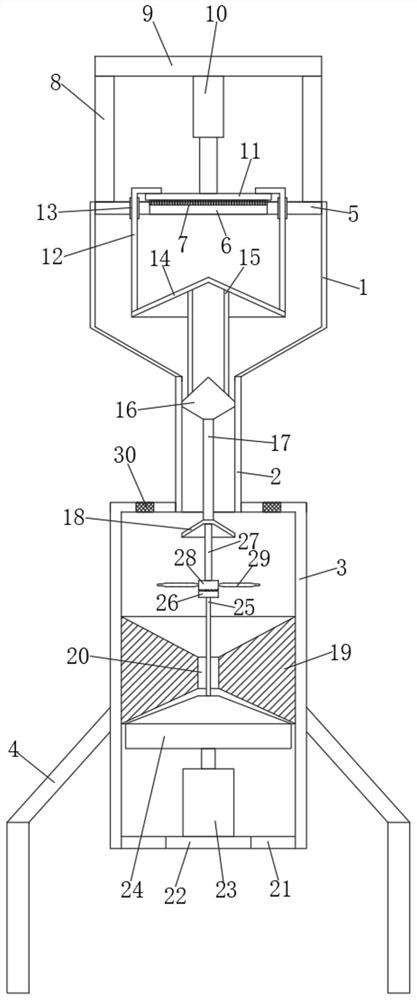

Pig anti-blocking powder feed feeder

InactiveCN105993995AAvoid pollutionReduce the cost of farmingAnimal watering devicesAnimal feeding devicesLivestockAnimal science

The invention belongs to the technical field of livestock breeding equipment and particularly relates to a pig anti-blocking powder feed feeder which comprises a hollow outer rod and an inner rod, wherein the outer rod passes through a discharge port, and a stirring rod fixing ring is arranged at the bottom; multiple stirring rod fixing rods are fixed on the stirring rod fixing ring; the bottom of the stirring rod fixing rod is articulated with a stirring rod; two spiral through holes are formed in the outer rod; a circular baffle is arranged on the outer rod; the circular baffle is positioned below a bottom opening of a barrel body and above the stirring rod fixing ring; the inner rod is arranged in the outer rod; a cross rod in slip connection with the spiral through holes is arranged at the top of the inner rod; a disk is arranged at the bottom of the inner rod and positioned below the stirring rod; a scraping plate is arranged at each of the two ends of the cross rod; and the scraping plate is fixedly connected with the upper part of the outer rod through a first spring and a second spring. According to the invention, the problem of difficulty in feeding of powder feed is effectively solved; and meanwhile, without external power, the feeding can be realized smoothly, and the breeding cost is reduced.

Owner:温岭市泽国绿丰生猪养殖场

Bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors and preparation method of bast fiber plate waste recycling-based short fiber-reinforced composite material

InactiveCN105504504ASolve the difficulty of blankingReduce reprocessingAntioxidantFiber-reinforced composite

The invention discloses a bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors. The bast fiber plate waste recycling-based short fiber-reinforced composite material is prepared from the following raw materials in parts by weight: 20-60 parts of crushed bast fiber plate materials, 100 parts of thermoplastic resin, 2-5 parts of an antioxidant, 1-3 parts of a light stabilizer, 2-5 parts of a lubricant and 0-10 parts of a flexibilizer. The bast fiber plate waste recycling-based short fiber-reinforced composite material has the beneficial effects that compared with the prior art, the bast fiber plate waste is recycled and changed into treasures; and the cost is reduced. The bast fiber plate is crushed and pelletized as a processing raw material for the short fiber-reinforced composite material, so that the problem that a bast fiber is difficult to feed is solved; the reprocessing technology of the bast fiber is reduced; the short fiber-reinforced composite material can be applied to the automotive interiors through an injection molding process; relatively complicated part injection molding manufacturing in the automobile industry can be further achieved; and the application situation that only the bast fiber plate is marketized in the field of the automotive interiors is also changed.

Owner:SHANGHAI PRET COMPOSITES

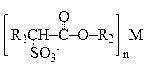

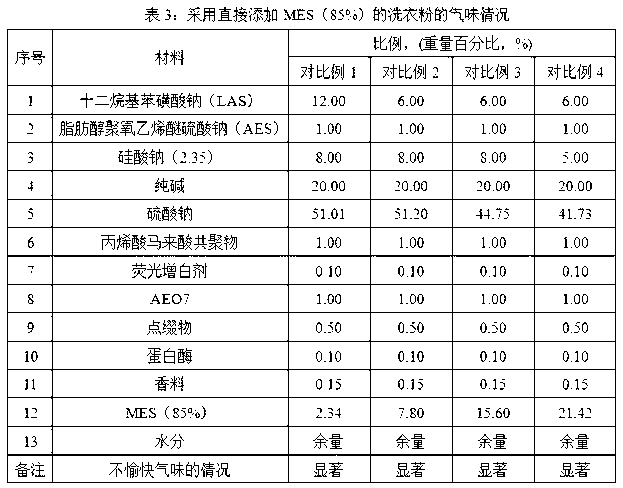

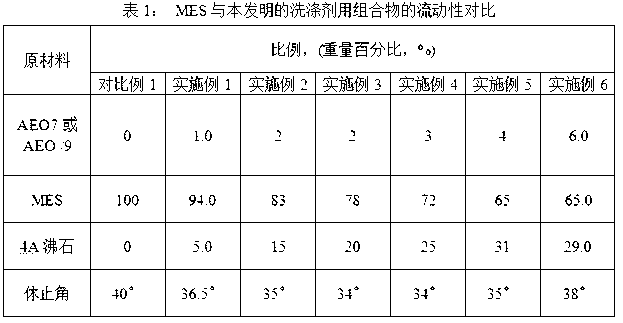

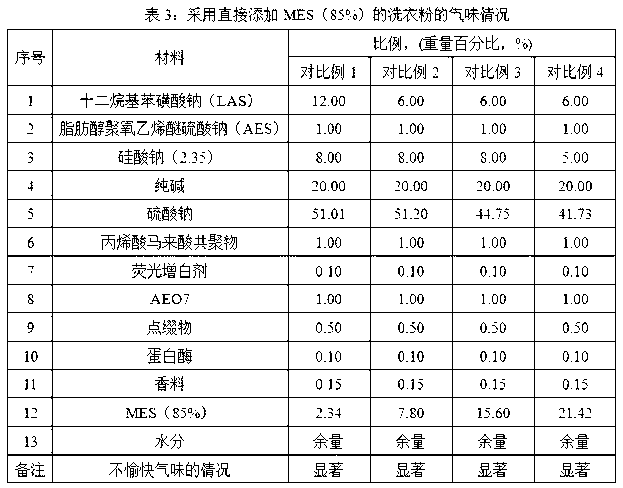

Preparation method of composition for alpha-sulfo-group fatty acid alkyl ester salt-containing detergent

ActiveCN102994258AChange mobilityImprove liquidityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentSurface-active agents

The invention discloses a preparation method of composition for alpha-sulfo-group fatty acid alkyl ester salt-containing detergent, and the preparation method comprises the following steps of: spraying a non-ionic surface active agent onto powdery alpha-sulfo-group fatty acid alkyl ester salt in the manner of spraying, spraying and stirring to be formed into a compound of the non-ionic surface active agent and the powdery alpha-sulfo-group fatty acid alkyl ester salt and formed into a layer of liquid non-ionic film-packed layer on a surface; and adding zeolite, and evenly mixing into the composition for detergent. The flowability of the composition for the detergent prepared by the method is obviously higher than that of the alpha-sulfo-group fatty acid alkyl ester salt per se, the detergent is hard to bond to be clustered, and is stable in property, the requirement of the stable discharge in a production technology can be met, and the generation of the bad smell when the alpha-sulfo-group fatty acid alkyl ester salt-containing powdery detergent is stored can be effectively restrained.

Owner:广州浪奇日用品有限公司

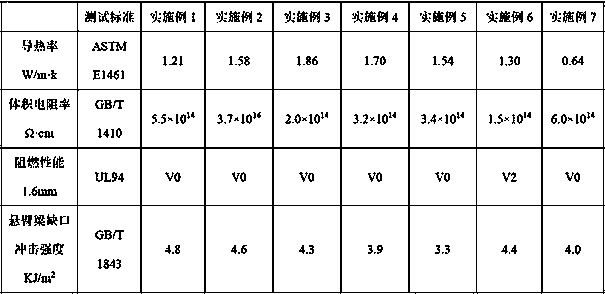

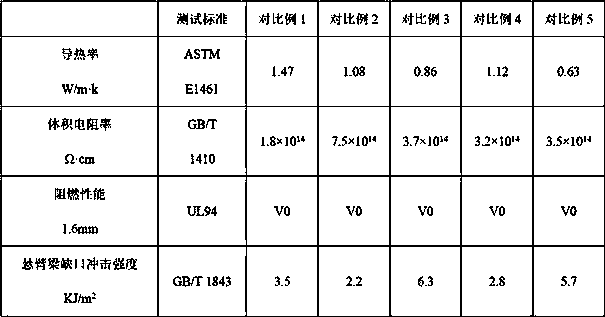

PPS (polyphenylene sulfide) composite material and preparation method thereof

ActiveCN104262965AReduce workplace contamination and human health threatsSolve the difficulty of blankingPolyamideMagnesium

The invention discloses a PPS (polyphenylene sulfide) composite material and a preparation method thereof. The PPS composite material is prepared by raw materials in percentage by weight as follows: 19%-49.5% of PPS, 50%-80% of heat conducting master batch taking PA (polyamide) 12 as a matrix and 0.5%-1.0% of a lubricating agent. According to the preparation method, the heat conducting master batch is firstly prepared by raw materials in percentage by weight as follows: 13%-19% of PA 12, 20%-65% of magnesium oxide with small particle size, 20%-65% of magnesium oxide with large particle size, 0.5%-1.0% of an antioxidant and 0.5%-1.0% of an lubricating agent; and the well prepared master batch, PPS and the lubricating agent are blended to prepare the PPS composite material. The PPS composite material prepared with the heat conducting master batch method is provided with high-filling heat conducting filler, has excellent processing property, impact strength and heat conduction property and is simple in process.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Composition for alpha-sulfo fatty acid alkyl ester salt-containing detergent, and application thereof

ActiveCN102994257AAvoid hydrolysisImprove liquidityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentSurface-active agents

The invention discloses a composition for alpha-sulfo fatty acid alkyl ester salt-containing detergent, and the composition is prepared from the following raw materials by weight percent: 1.0-6.0% of non-ionic surface active agent, 65.0-94.0% of powdered alpha-sulfo fatty acid alkyl ester salt and 5.0-34.0% of zeolite. The invention also discloses an application of the composition. The composition has good fluidity, can be used for remarkably improving the stability of products in the storage process when being applied to the detergent powder formulation, and effectively inhibiting the generation of unpleasant smell.

Owner:广州浪奇日用品有限公司

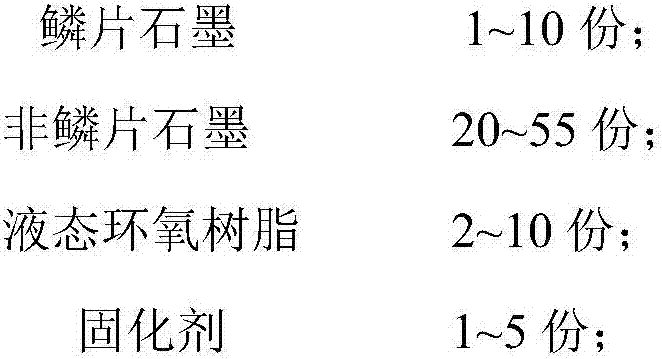

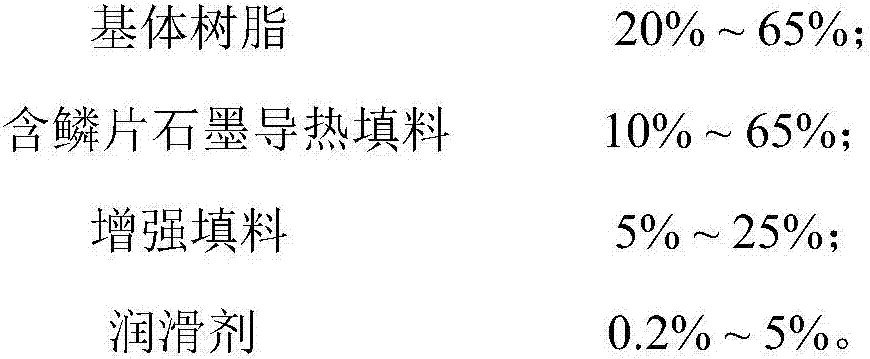

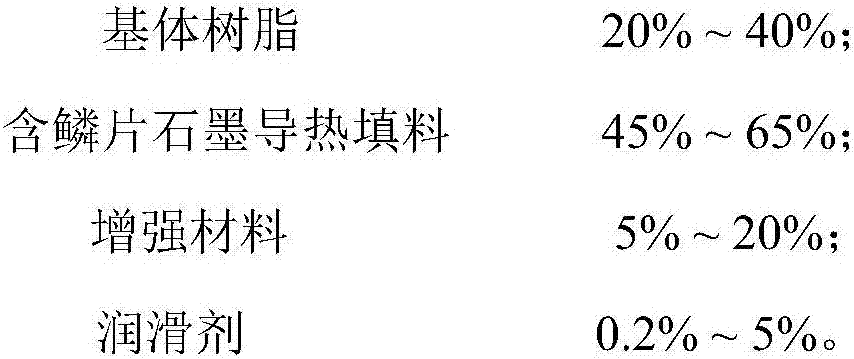

Heat-conducting filler containing crystalline flake graphite, and preparation method and application of heat-conducting filler

ActiveCN107011631AEasy extrusionSolve the difficulty of blankingHeat-exchange elementsParticulatesEpoxy

The invention relates to a heat-conducting filler containing crystalline flake graphite, a preparation method of the heat-conducting filler, and application of the heat-conducting filler to preparation of a high heat-conducting composite material, and belongs to the field of high molecular material modification and heat-radiation material utilization. The heat-conducting filler is granular lump paste comprising the following components in parts by weight: 1-10 parts of 1-100 (mu)m crystalline flake graphite, 20-55 parts of 100-500 (mu)m non-crystalline flake graphite, 2-10 parts of liquid epoxy resin and 1-5 parts of curing agent. According to the heat-conducting filler of the high heat-conducting composite material and the preparation method of the heat-conducting filler, the heat-conducting filler containing the crystalline flake graphite is processed into a granule, so that blanking is easy in use; no breakage problem exists during extrusion production at high filling capacity; the production efficiency of the heat-conducting composite material is improved; application scope of the heat-conducting filler containing the crystalline flake graphite is widened. The high heat-conducting composite material widens application of heat-conducting plastic in components with higher heat-radiation requirements in the fields of heat radiators, electric products, automobiles, LED illumination and the like.

Owner:BENSONG ENG PLASTICS HANGZHOU

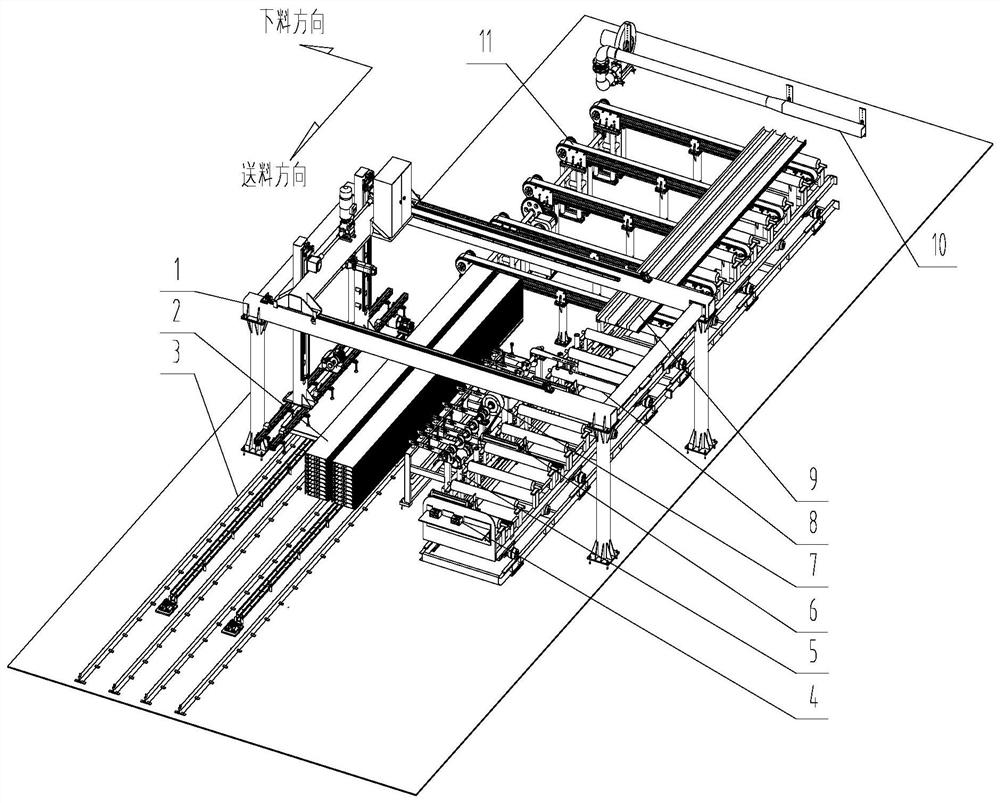

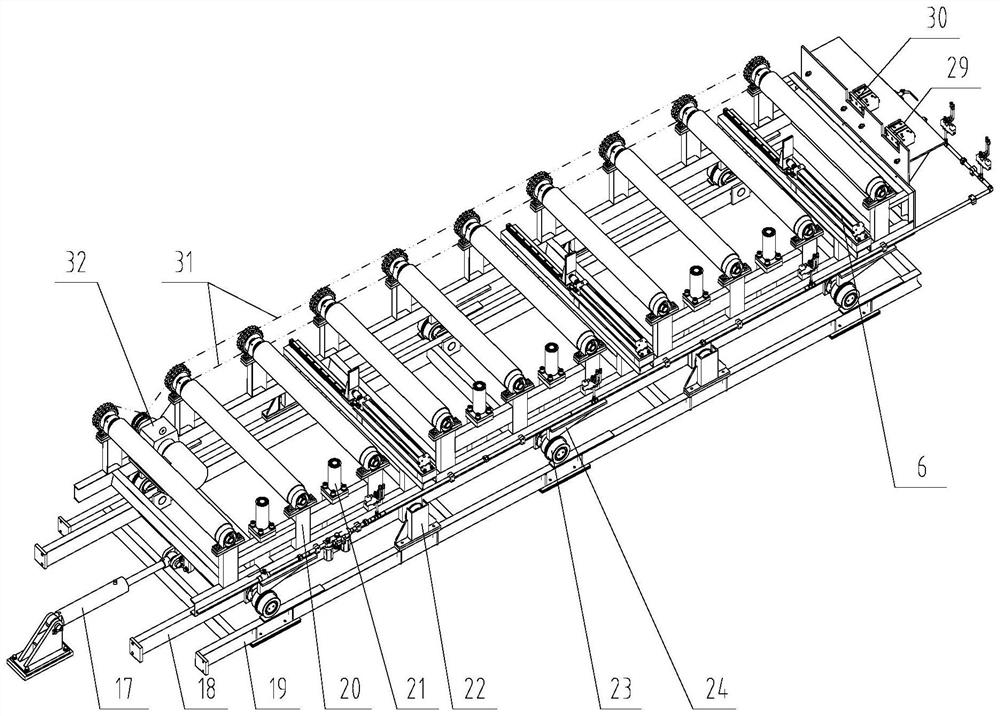

Automatic stacking device for aluminum profile finished products

InactiveCN112390018ARealize upside-down interspersed stackingSave stack spaceStacking articlesRobot handControl system

The invention relates to an automatic stacking device for aluminum profile finished products, and belongs to the technical field of mechanical equipment. The automatic stacking device comprises a control system, a conveying device, a mechanical arm, a material conveying device and a material turning device, wherein the conveying device, the mechanical arm, the material conveying device and the material turning device are connected with the control system. The conveying device is arranged on one side of a discharging port of a finished product saw so as to convey sawn profiles. The material conveying device is located at the end, away from the finished product saw, of the conveying device and is parallel to the conveying device. The mechanical arm comprises a portal frame stretching acrossthe conveying device and the material conveying device and a mechanical arm body arranged on the portal frame. The material turning device is arranged between the material conveying device and the conveying device and can grab and turn over profiles located on the conveying device. The mechanical arm body can grab profiles located on the conveying device and the material turning device according to the manner set by the control system and place the profiles onto the material conveying device so as to complete stacking of the profiles. Through cooperation of the mechanical arm and the materialturning device, inverted alternate stacking of irregular-section profiles is achieved, and the stacking space is greatly reduced.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

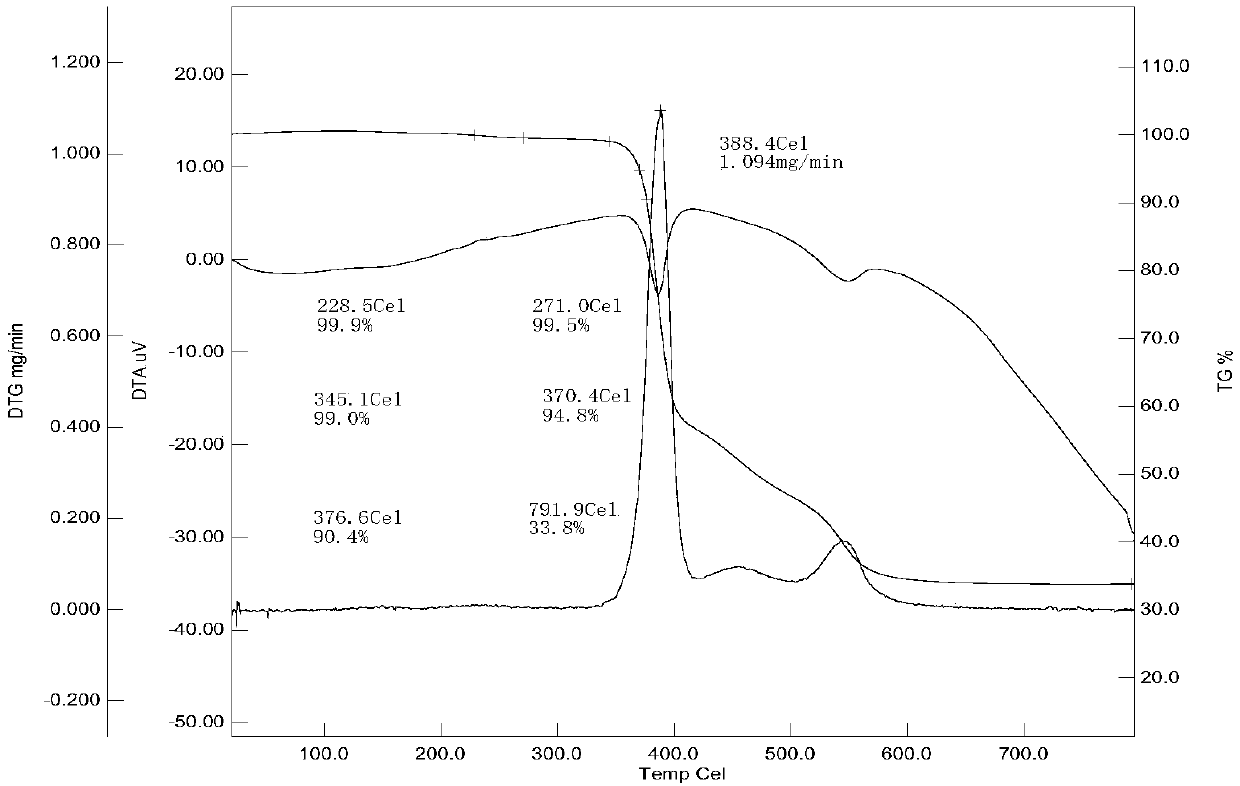

Preparation and application methods of small-grain-size polyimide powder

The invention provides a preparation method of a small-grain-size polyimide powder. The preparation method of the small-grain-size polyimide powder comprises the following steps of dissolving diamineinto organic solvent, then adding in dianhydride for reaction for 3-7 hours, then adding in water separating agent, increasing the temperature to 140-160 DEG C, inletting and mixing in inert gas for dewatering for 6-12 hours, cooling down to 70-90 DEG C, pouring the hot reaction liquid into separated solution, cooling down to 0-35 DEG C for crystallization, and performing filtering and drying to obtain the small-grain-size polyimide powder. The preparation method of the small-grain-size polyimide powder has the advantage that the fine powder is directly obtained after reaction is completed, sothat crushing and screening can be saved, granularity can be uniform, production devices can be simplified, the problem of feeding difficulty during processing can be solved, and industrial values can be achieved. The prepared small-grain-size polyimide powder can be fed into a double-screw extruder for extrusion pelletizing to obtain polyimide granules, which are then injection-molded into standard mechanical testing sample bars for standard mechanical testing, thereby improving the overall mechanical performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Preparation and application of granular aluminum alkyl hypophosphite

InactiveCN107652321AImprove flame retardant performanceEasy to recycleGroup 5/15 element organic compoundsElastomerPolyester

The invention discloses a preparation method and application of a granular aluminum alkyl hypophosphite, and the preparation method is as follows: radical initiator catalyzed addition reaction in an organic solvent as a solvent of hypophosphorous acid and an alcohol as raw materials for synthesis of alkyl phosphinic acid, and double decomposition reaction of the alkyl phosphinic acid with an aluminum salt in the presence of an organic solvent to obtain the granular aluminum alkyl hypophosphite. The granular aluminum alkyl hypophosphite is applied to flame retardance of polyamide, polyester, thermosetting plastics and elastomers such as PA6, PA66, PBT, PET, PU and EVA, and shows excellent flame retardancy. The granular aluminum alkyl hypophosphite can solve the problems of material discharging difficulty and lot of dust in the processing process, the alcohol replaces an olefin as a raw material, reaction yield and safety coefficient are high, byproducts are few, because the organic solvent and water are immiscible, the difficulty of post separation is reduced, and solvent recovery is easier.

Owner:JINAN TAIXING FINE CHEM

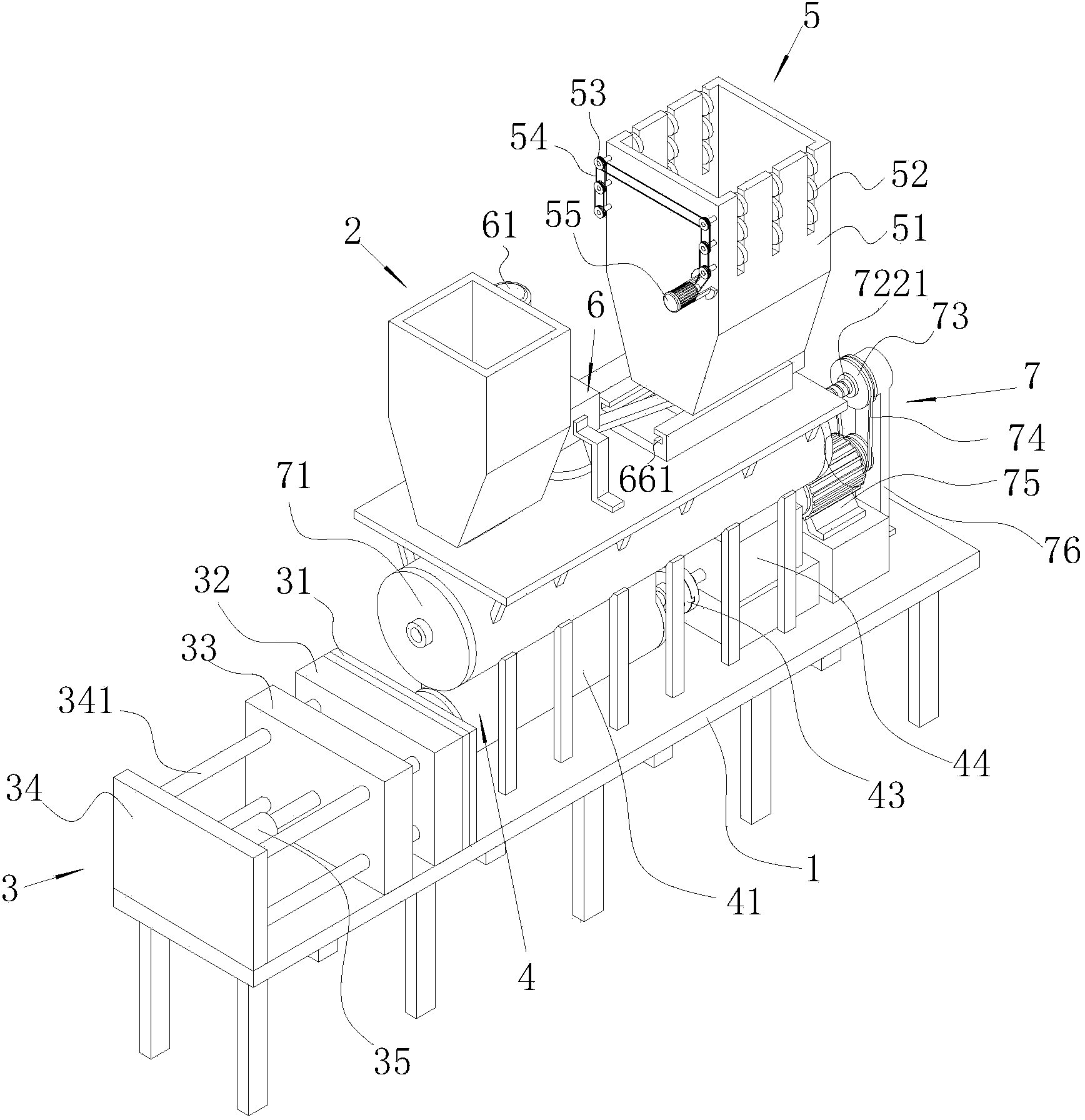

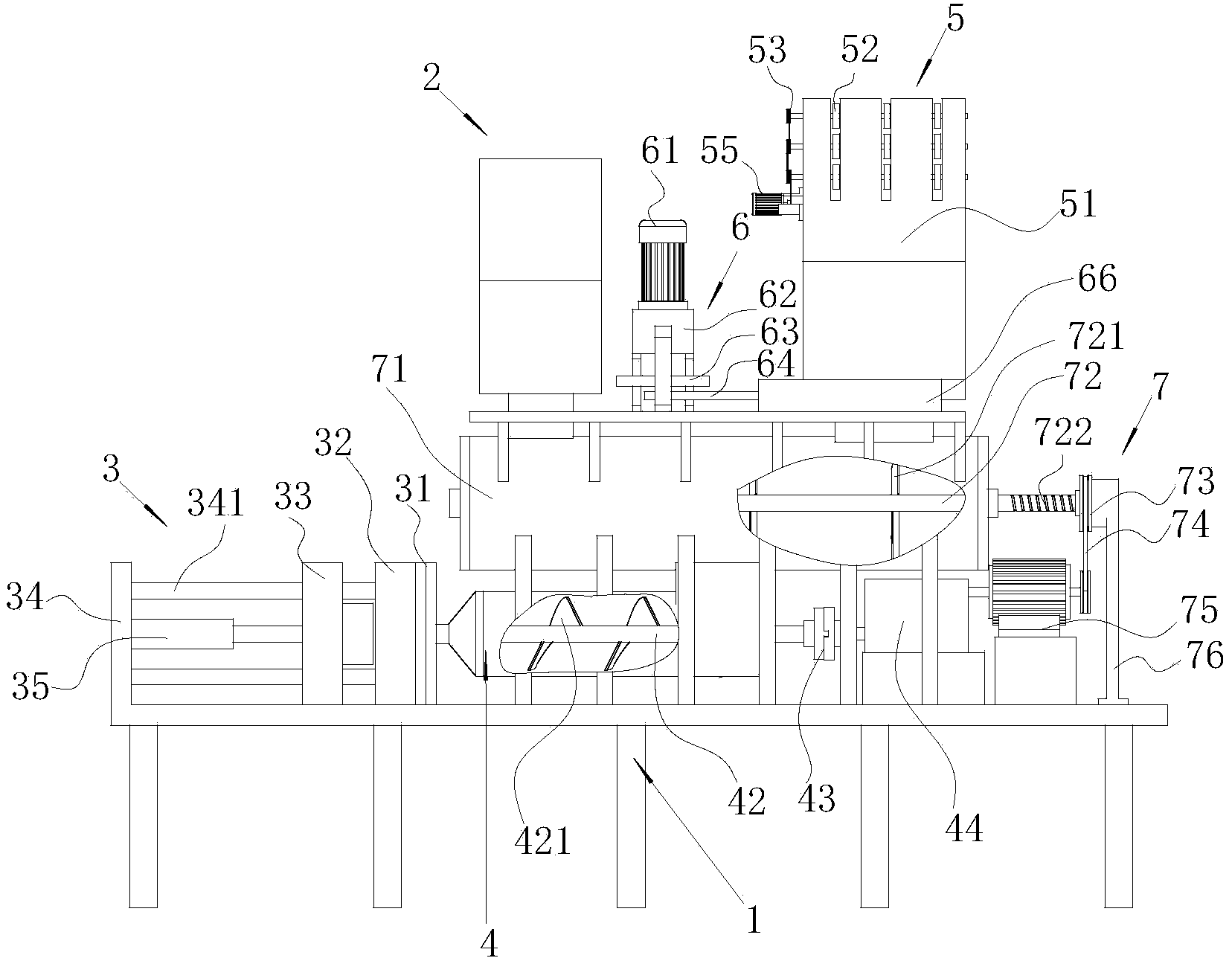

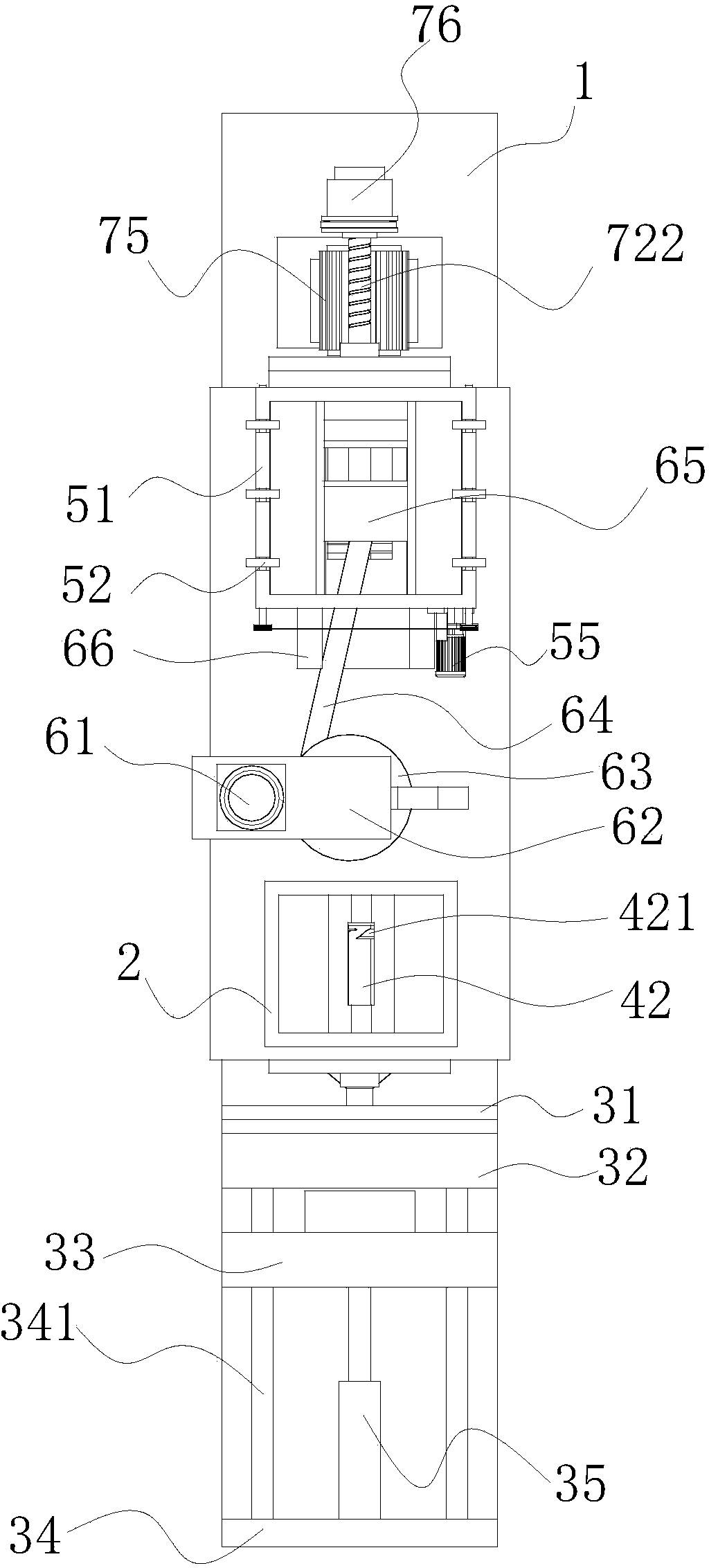

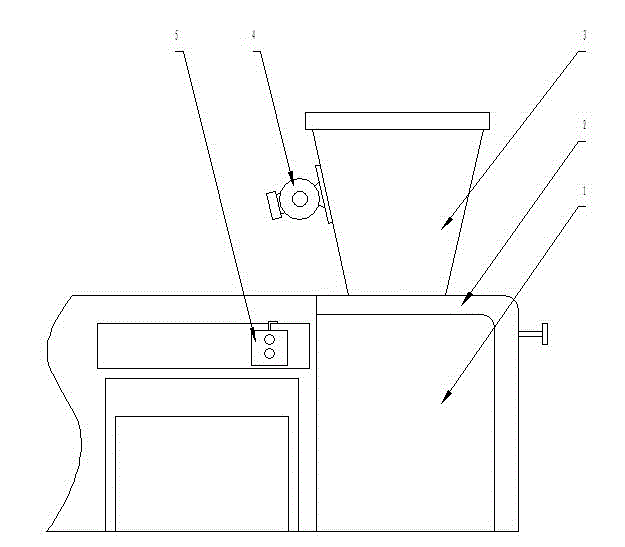

Energy-saving waste scrap iron and waste plastic mixer

ActiveCN104070049ARealize the function of cutting and crushingAchieve hybridSolid waste disposalElectricityMixed materials

The invention relates to an energy-saving waste scrap iron and waste plastic mixer. The energy-saving waste scrap iron and waste plastic mixer comprises a rack, a fusion box, a forming device, a spiral conveying device, a discharging and conveying device, a cutting and smashing device and a stirring and mixing device, wherein the discharging and conveying device consists of a discharging hopper, friction wheel sets, belt wheels I, upper belts and a motor A; the friction wheel sets are installed on the upper end of the discharging hopper; the cutting and smashing device consists of a motor B, a transmission, an eccentric wheel, a connecting rod, a cutter bit and a cutting base, wherein two sides of the cutting base are symmetrically provided with chutes; the stirring and mixing device consists of a mixing cavity, a first rotary shaft, a belt wheel II, a lower belt, a dual-output motor and a fixing base, wherein the left end of a first rotary shaft is provided with a stirring blade, and the right end of the first rotary shaft is fixedly connected with a screw rod; the screw rod is provided with a drive base. According to the mixer, the problems of difficulty in preparation of mixed materials of waste scrap iron and waste plastics, low material binding rate, difficulty in forming and the like.

Owner:TONGLING TONGFEI TECH

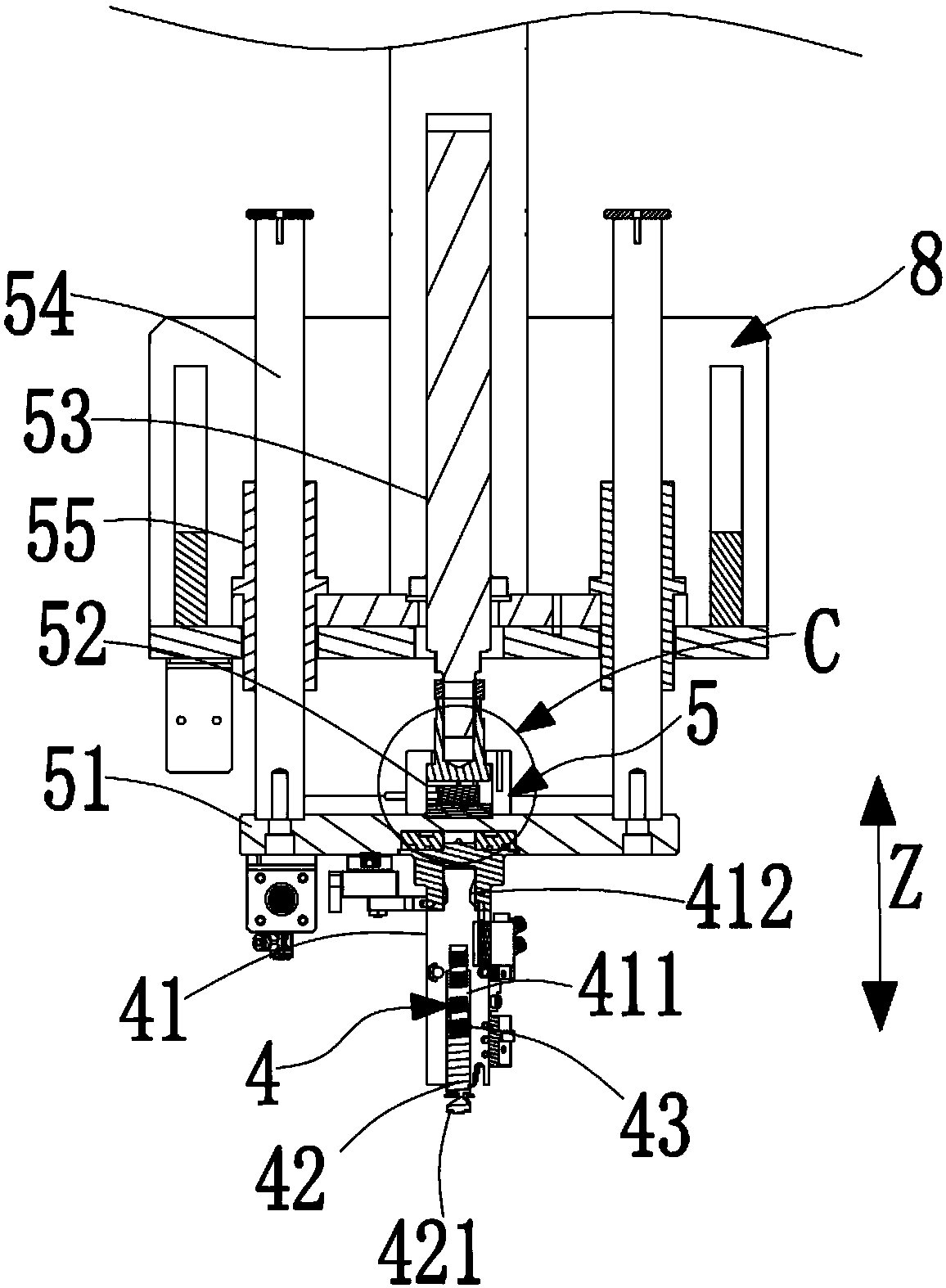

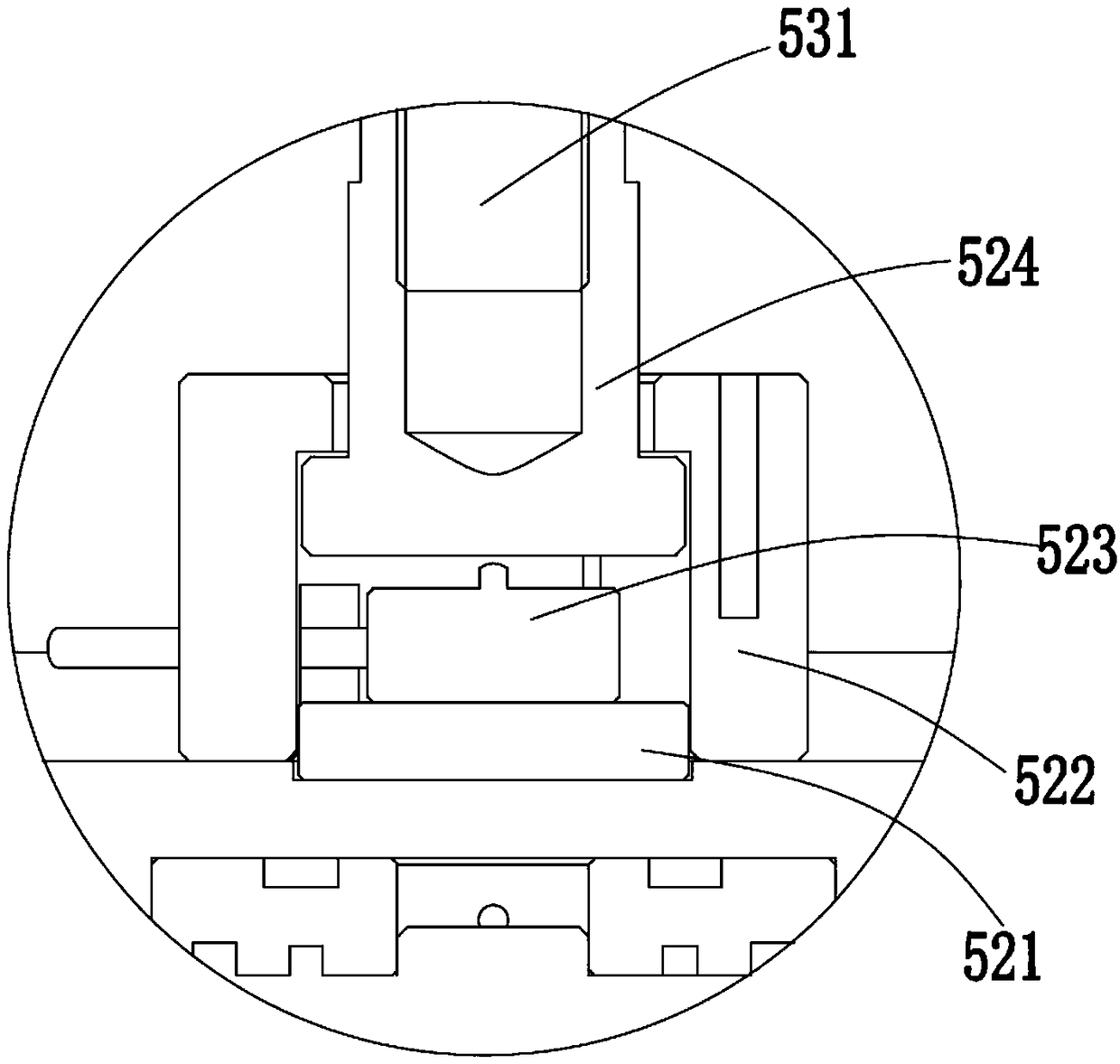

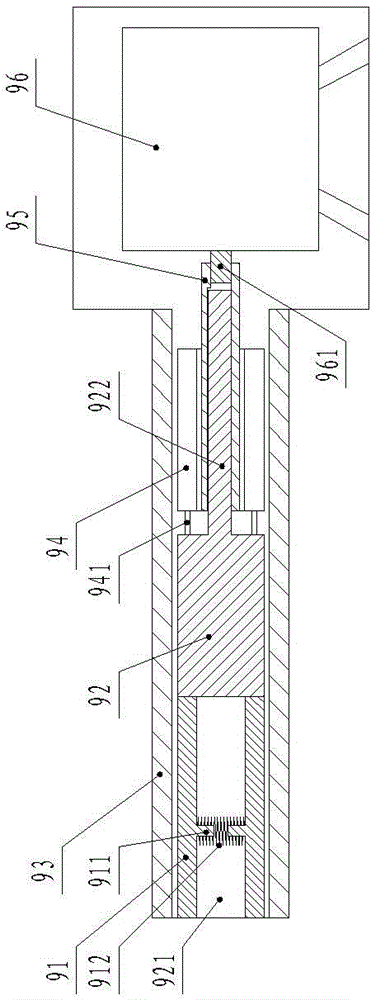

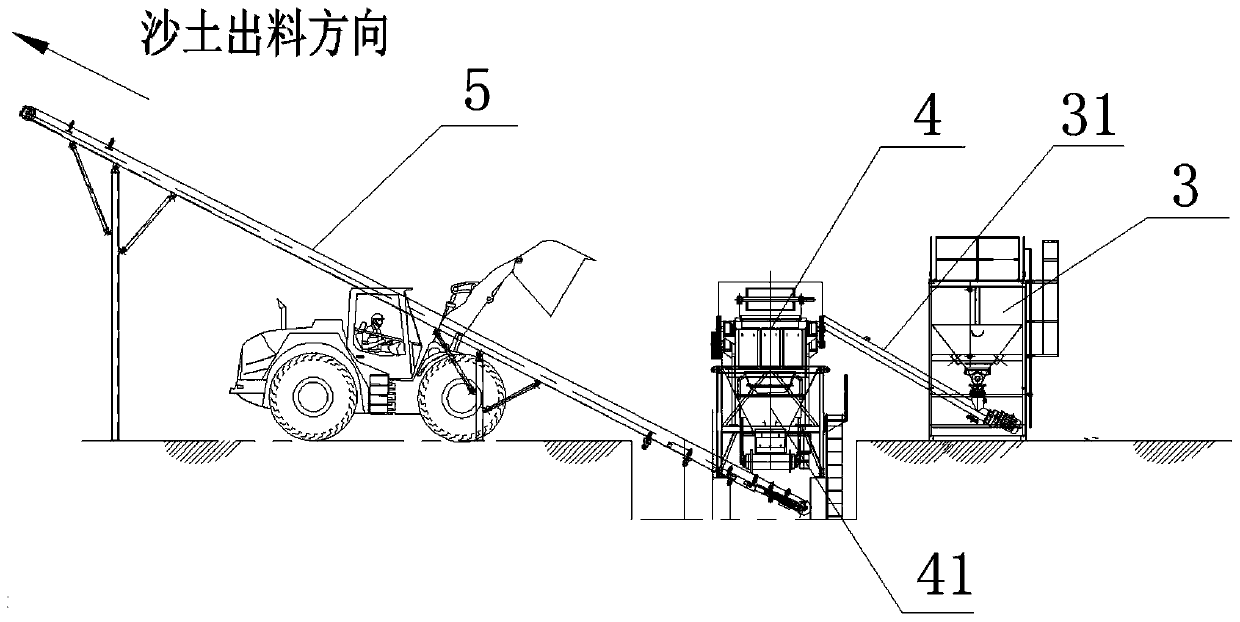

Elastic ring pressing machine, elastic ring and shaft assembling machine and machining method thereof

The invention discloses an elastic ring pressing machine, an elastic ring and shaft assembling machine and a machining method thereof. The elastic ring pressing machine comprises a pressing head and adriving device for driving reciprocating moving. The pressing head comprises a pressing sleeve and a material rod. The material rod is arranged in a guiding groove, extending in the axial direction,in the pressing head in a floating mode. In a normal state, the lower end of the material rod is located outside the guiding groove and can be connected with an elastic ring in a clamped mode, the limiting face of the tail end of the material rod is a profiling face which is the same as the shaft top face in shape, and the area of the limiting face is not less than the area of the shaft top face.The elastic ring pressing machine is ingenious in design, the elastic ring on the material rod can be separated from the material rod through the pressing sleeve, and during separating, through arrangement of the limiting face, the elastic ring and a rotor shaft are matched in outer diameter after the elastic ring is fully expanded; and during subsequent assembling, the elastic ring enters the rotor shaft successfully through the cohesive relation of the material rod and the rotor shaft, thus the elastic ring and the rotor shaft are assembled rapidly and accurately, the automation degree is high, and the efficiency is greatly improved.

Owner:KUNSHAN JIEYUN INTELLIGENT EQUIP CO LTD

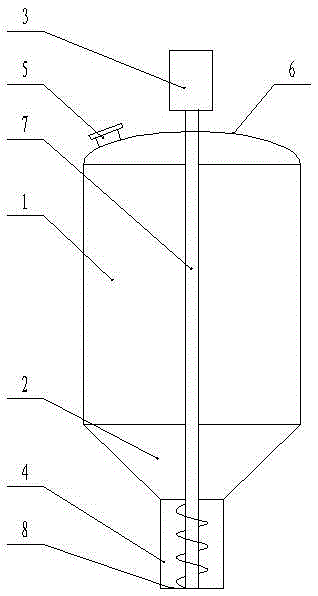

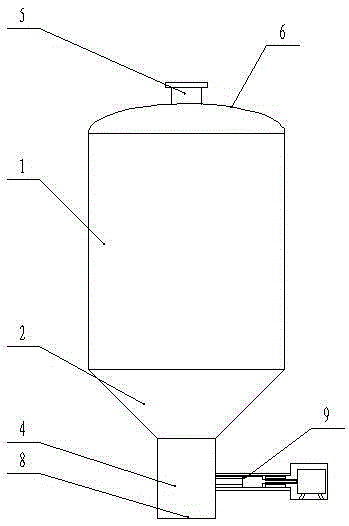

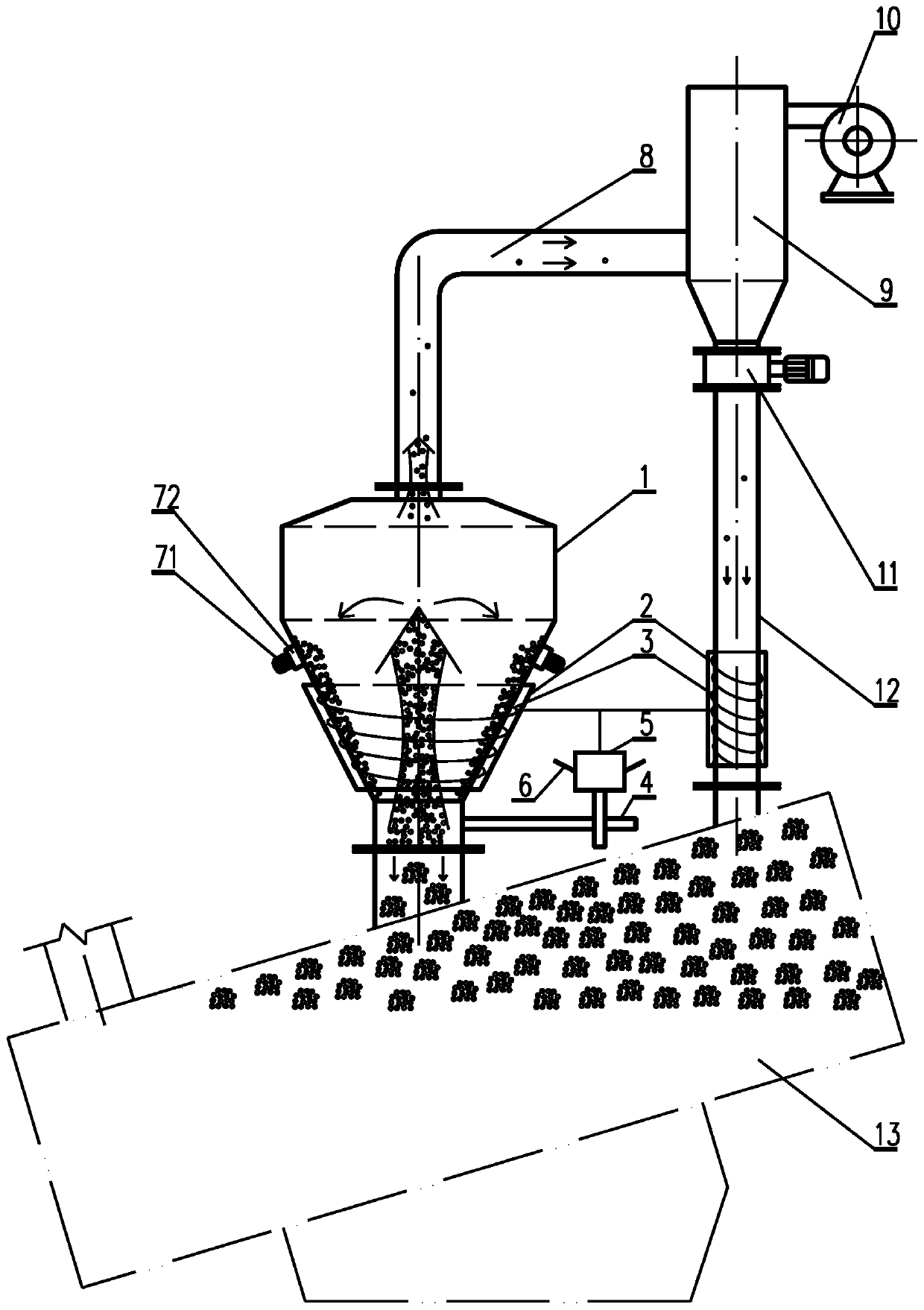

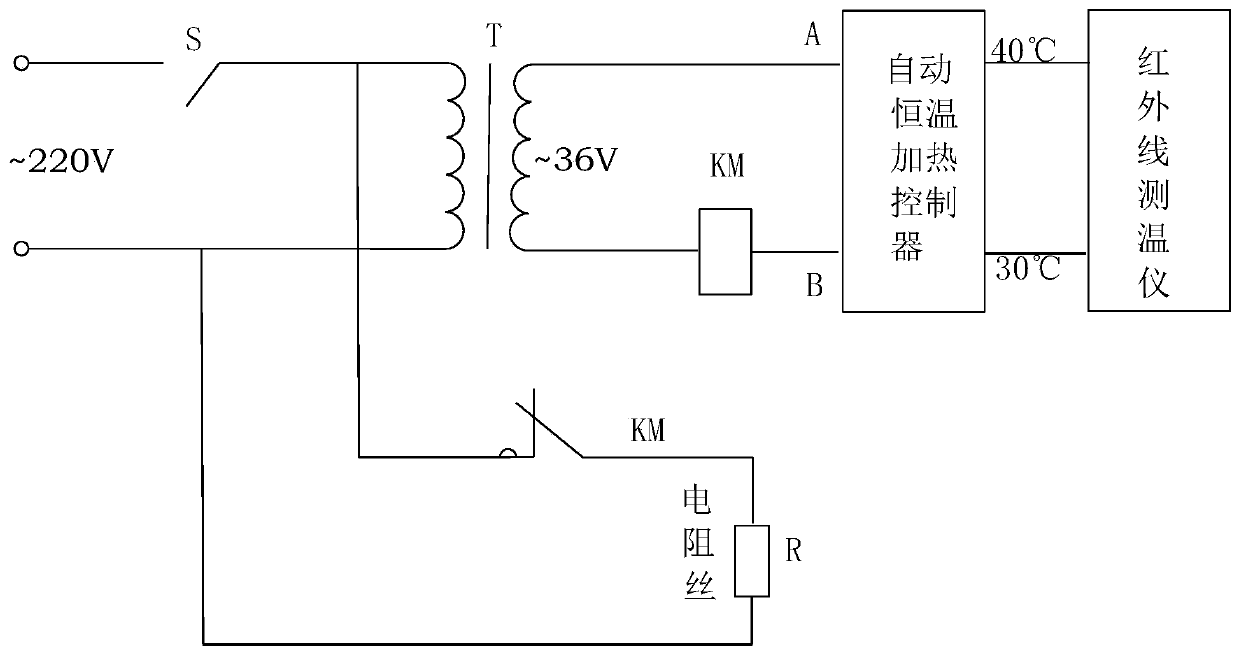

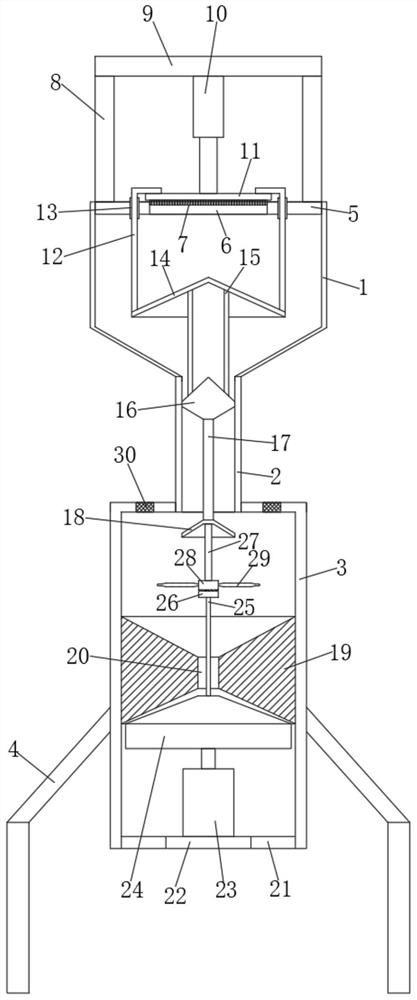

Microwave drying device for chemical pigment production

InactiveCN102620544ASimple structureSolve the difficulty of blankingDrying solid materialsMicrowaveProcess engineering

The invention relates to chemical equipment, in particular to a microwave drying device for chemical pigment production. The microwave drying device comprises a microwave dryer, a paste feeding hopper is arranged on a conveyor belt of the microwave dryer, and a vibrator is arranged on the side wall of the paste feeding hopper. A control device for controlling turn-on and turn-off of the vibrator is arranged on the microwave dryer. The microwave drying device for chemical pigment production is simple and practical in structure, can effectively solve the problem that paste is difficult to feed, and benefits to improving the production quality, and the paste uniformly falls down,.

Owner:吕晓萍

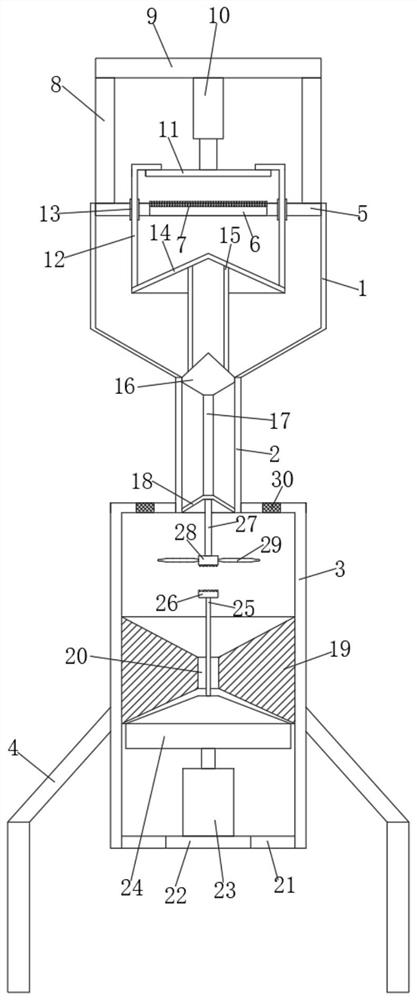

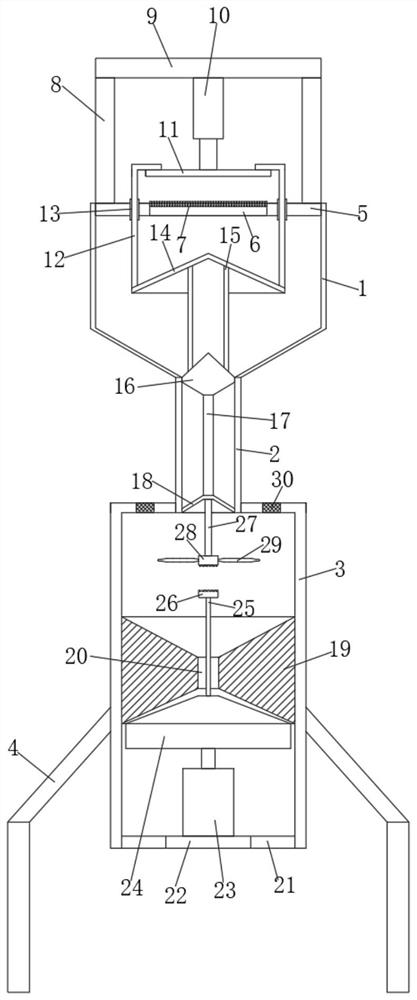

Traditional Chinese medicine medicinal material grinding equipment for quantitatively conveying materials

InactiveCN111686852AImprove work efficiencyReduce mistakesGrain treatmentsMetal working apparatusMedicinal herbsProcess engineering

The invention discloses traditional Chinese medicine medicinal material grinding equipment for quantitatively conveying materials. The equipment comprises a hopper, a conveying pipe and a grinding cylinder. The hopper is fixedly connected to the top end of the conveying pipe. The grinding cylinder is fixedly connected to the bottom end of the hopper. Four supporting columns are fixedly connected to the outer side wall of the grinding cylinder symmetrically. A supporting plate is fixedly connected to the inner side wall of the hopper. According to the equipment, medicinal materials can be conveyed into the grinding cylinder from the hopper quantitatively in batches for grinding, the medicinal materials are cut into small pieces in advance, therefore the error of quantitative conveying is reduced remarkably, follow-up grinding is carried out beneficially, and the working efficiency of grinding is improved remarkably. Meanwhile, the phenomenon that due to the fact that the medicinal materials are too large, blocking occurs in the conveying and grinding process is avoided, and by means of the operation manner of carrying out grinding quantitatively in batches, the problems that for fine grinding, needed time is long, a large number of materials are piled up in the grinding cylinder, and blocking is caused can be effectively solved.

Owner:王静业

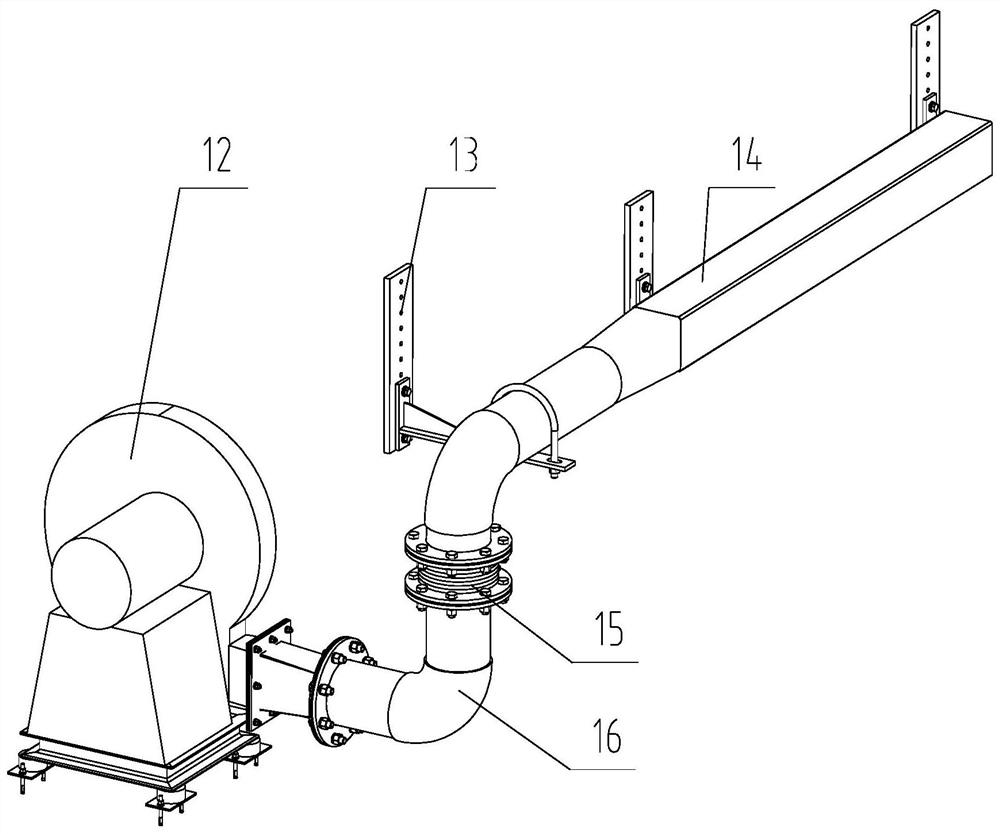

Novel garbage incinerator

The invention relates to technical field of garbage incinerators, in particular to a novel garbage incinerator. The novel garbage incinerator comprises an incinerator body, a feeding device, a deslagging device, a garbage sorting device, a blower, a flue, a chimney and a garbage conveying device. The feeding device is located on the right side of the incinerator body. The deslagging device is located at the bottom of the incinerator body. The garbage sorting device is located on the right side of the feeding device. The garbage conveying device is arranged between the garbage sorting device and the feeding device. The tail end of an outlet of the blower is located in the interior of the incinerator body and disposed below the feeding device. The flue is connected with the top of the incinerator body and the feeding device. The chimney is connected with the feeding device. The novel garbage incinerator has following beneficial effects: the novel garbage incinerator garbage is capable of fully combusting garbage, depositing dust of flue gas and secondarily combusting incomplete combustion material in flue gas, thereby effectively reducing emission of hazardous substances including dioxins and the like; the enclosed deslagging device is capable of decreasing heat loss of deslagging; and utilization rate of energy is improved.

Owner:安徽省安庆市皖清环保科技有限公司

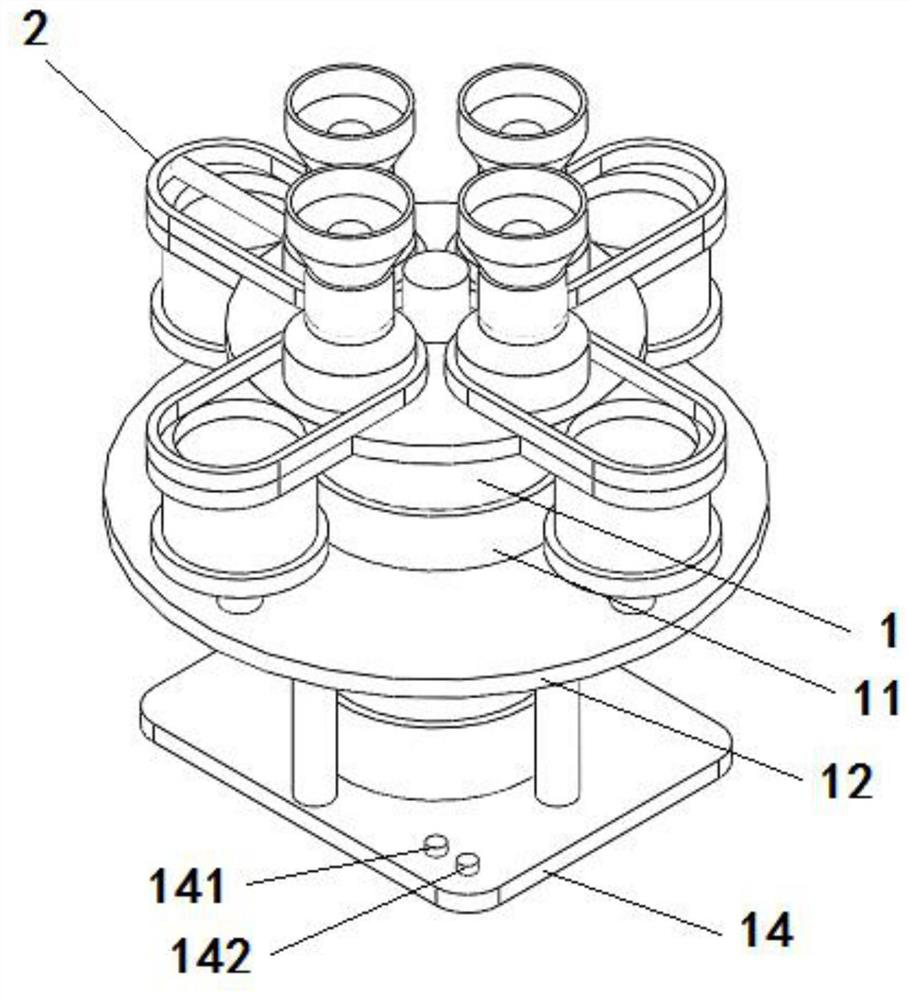

Agricultural fertilizer mixing device

InactiveCN111686599AEasy to put inSolve the difficulty of blankingTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention discloses an agricultural fertilizer mixing device which comprises a mixing tank and feeding mechanisms uniformly distributed on the edge of the top surface of the mixing tank in the circumferential direction, and a first mounting ring is fixedly mounted on the outer surface of the mixing tank. Through the arrangement of the multiple feeding mechanisms, various fertilizers can be conveniently fed into the mixing tank through the feeding device, stirred and uniformly mixed through a stirring paddle and then moved into a collecting tank to be used; by arranging the stirring mechanism, when the fertilizers are fed into a middle connecting cylinder, the situation that the fertilizers are accumulated on the top face of a second supporting disc and consequently discharging is difficult can be effectively prevented; by arranging a filtration mechanism, caked fertilizers can be effectively blocked to the top surface of the second supporting disc; after discharging is completed, the caked fertilizer is moved into a recycling barrel through a material recycling mechanism, scattered and then put into the feeding mechanisms to be mixed, and thus the situation that after the cakedand uneven fertilizer is mixed with other fertilizers, fertilization is uneven is prevented.

Owner:泉州市泉港区竞丰工业设计服务中心

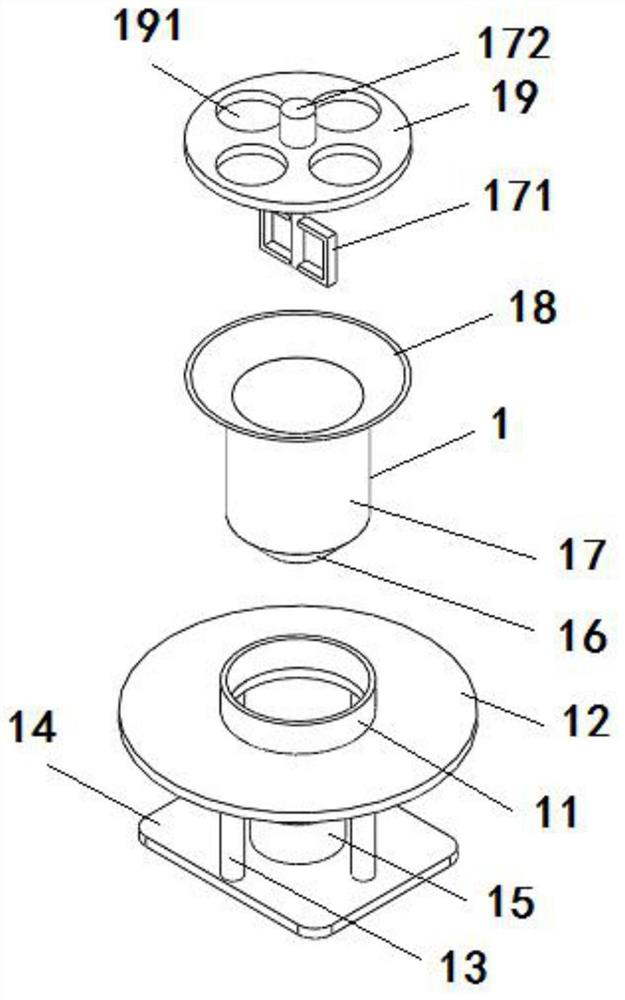

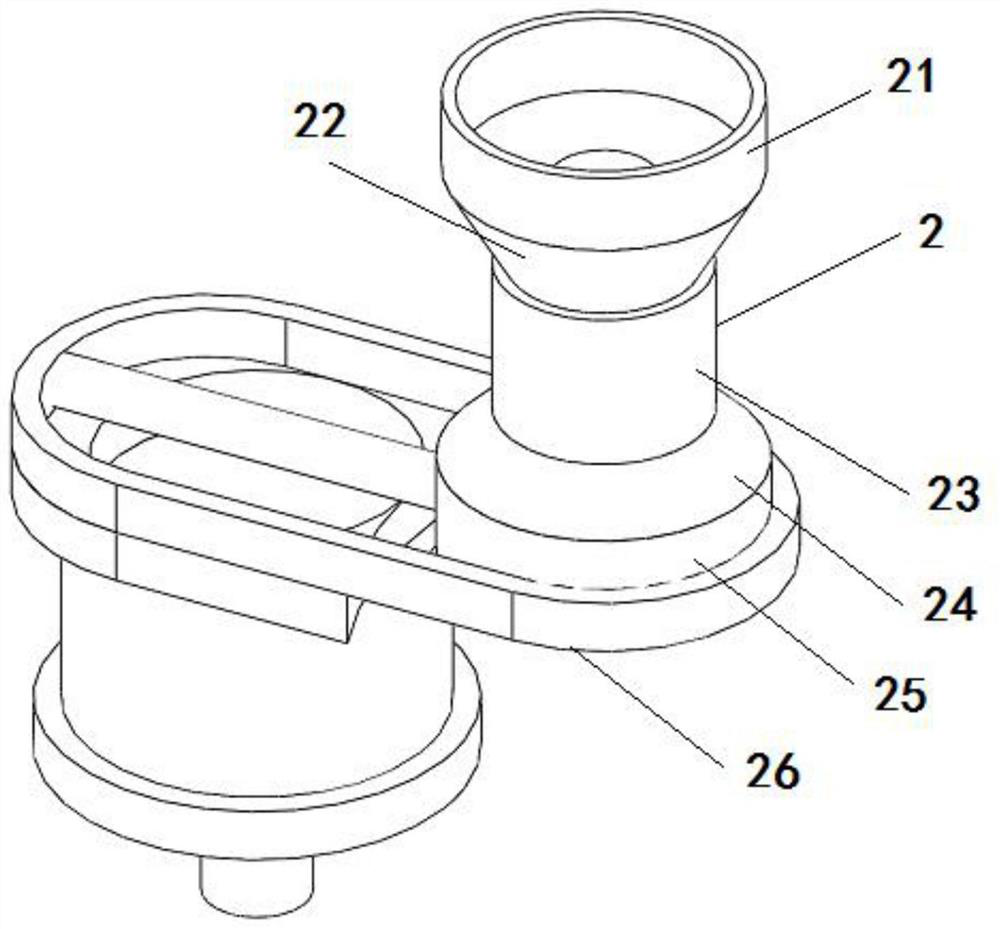

Feeding funnel device of tablet press

The invention belongs to the field of medical equipment and in particular relates to a feeding device of a tablet press. The feeding device comprises a motor, a threaded rod, a first hopper and a second hopper; an end cover is arranged on the first hopper; a feeding hole is formed in the end cover; the second hopper is an inverted cone-shaped transition hopper arranged under the first hopper; a feed pipe is connected to a lower portion of the second hopper; a lower discharge hole of the feed pipe is connected with the tablet press; a tail end of the threaded rod penetrates through an end cover to be connected with a motor arranged on the end cover; a lower end of the threaded rod is flush with the lower discharge hole; moreover, an axis of the threaded rod is coincident with axes of the first hopper, the second hopper and the feed pipe; at least one section, located within the feed pipe, of the threaded rod is provided with threads for stirring materials passing through the feed pipe. The invention provides a feeding funnel device of the tablet press, so that a powdery material goes into the tablet press uniformly, and therefore, the problem of difficulty in feeding is solved thoroughly.

Owner:LINFEN BAOZHU PHARMA

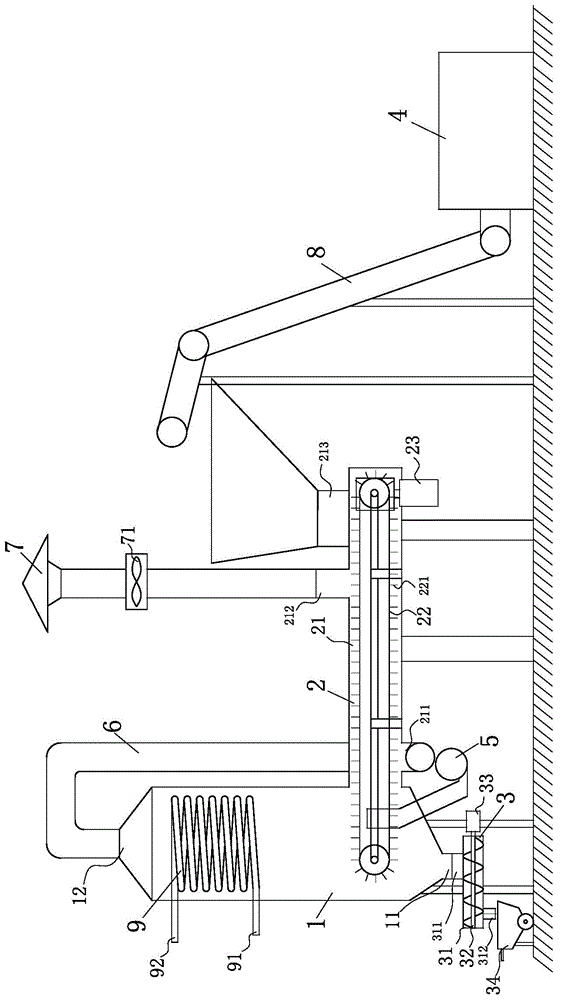

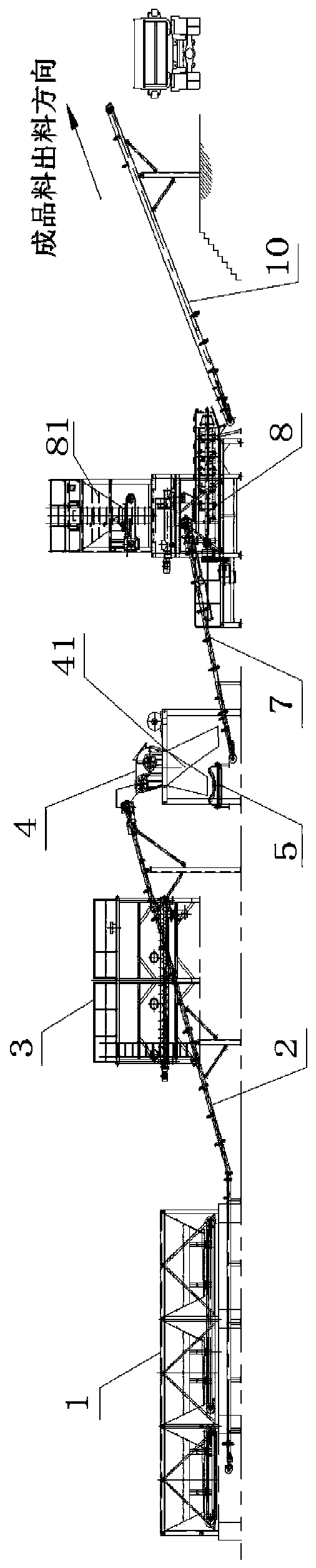

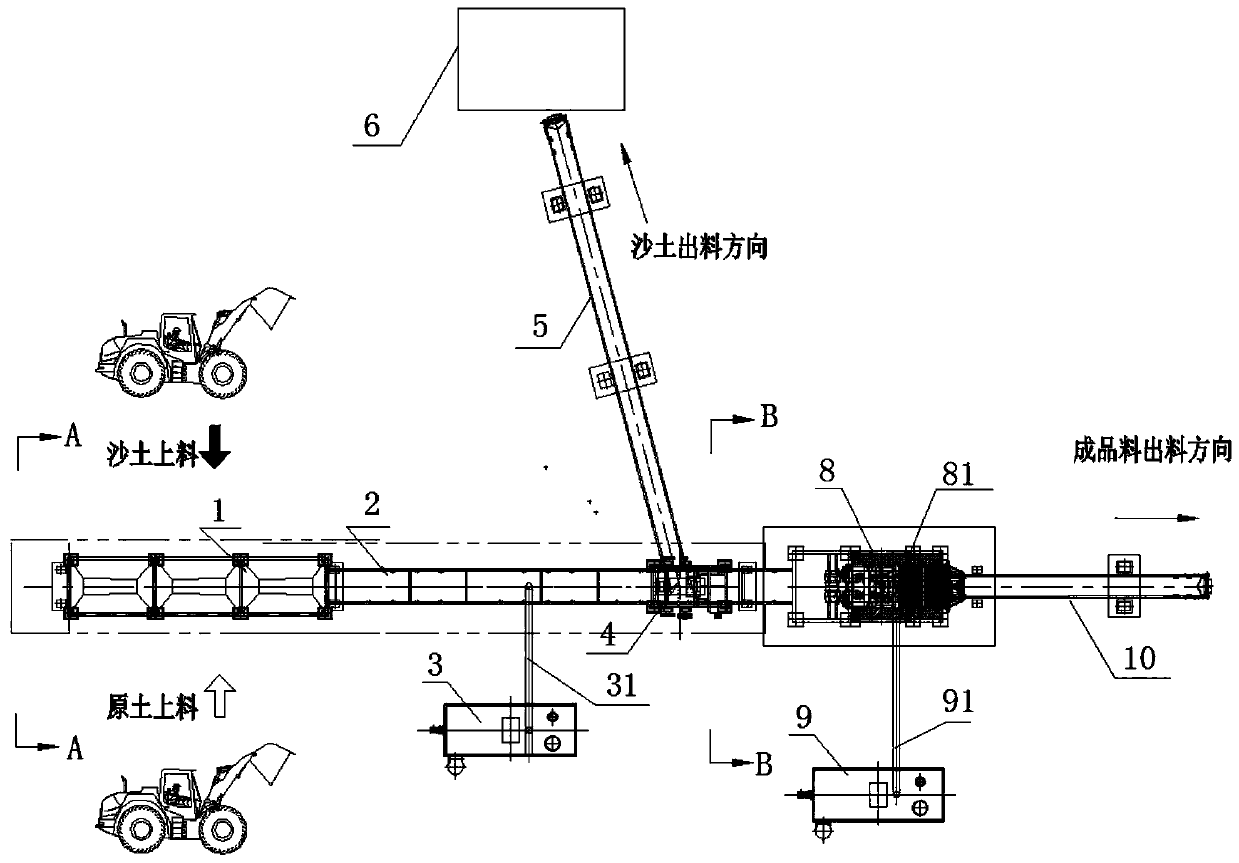

Solidified soil plant mixing treatment method and equipment thereof

The invention relates to a solidified soil mixing method and equipment in highway construction and particularly relates to a solidified soil plant-mixing treatment method and equipment thereof. The method is characterized in that: raw soil is stored in a feeding hopper, after the raw soil is discharged in the feeding hopper, the raw soil is conveyed to a crusher through a first conveying belt, meanwhile, a lime powder bin conveys lime powder to the first conveying belt through a first spiral conveyor, the raw soil is covered with the lime powder, and the lime powder and the raw soil are conveyed into the crusher together; after the crusher performs preliminary crushing treatment and mixing on the mixture of the original soil and the lime powder, the crusher discharges the mixed sandy soilof the original soil and the lime powder to a second conveying belt through a distributor; and the second conveying belt conveys the mixed sandy soil to a soil covering field for soil covering treatment for 48 hours or longer, thus sanding original soil; and when the transport cart transports the sandy soil into the feeding hopper for discharging, the sandy soil is more uniform and smooth, and thesandy soil is easier to crush during crushing treatment.

Owner:镇江路机重工科技有限公司

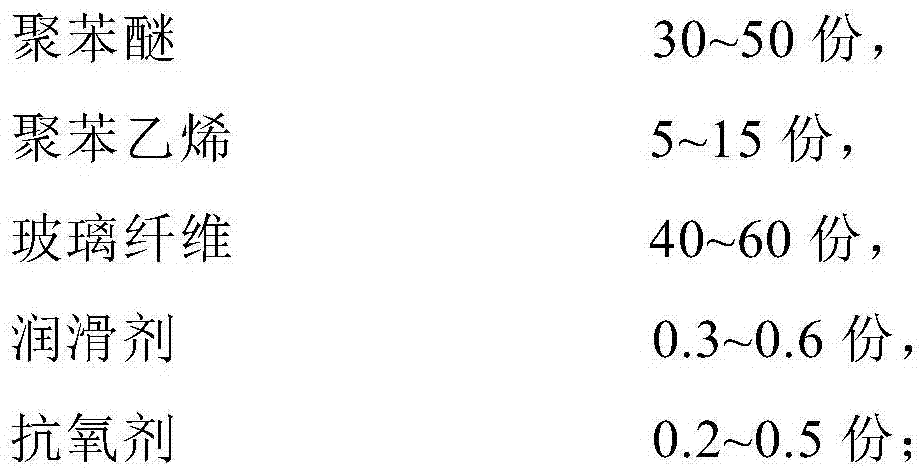

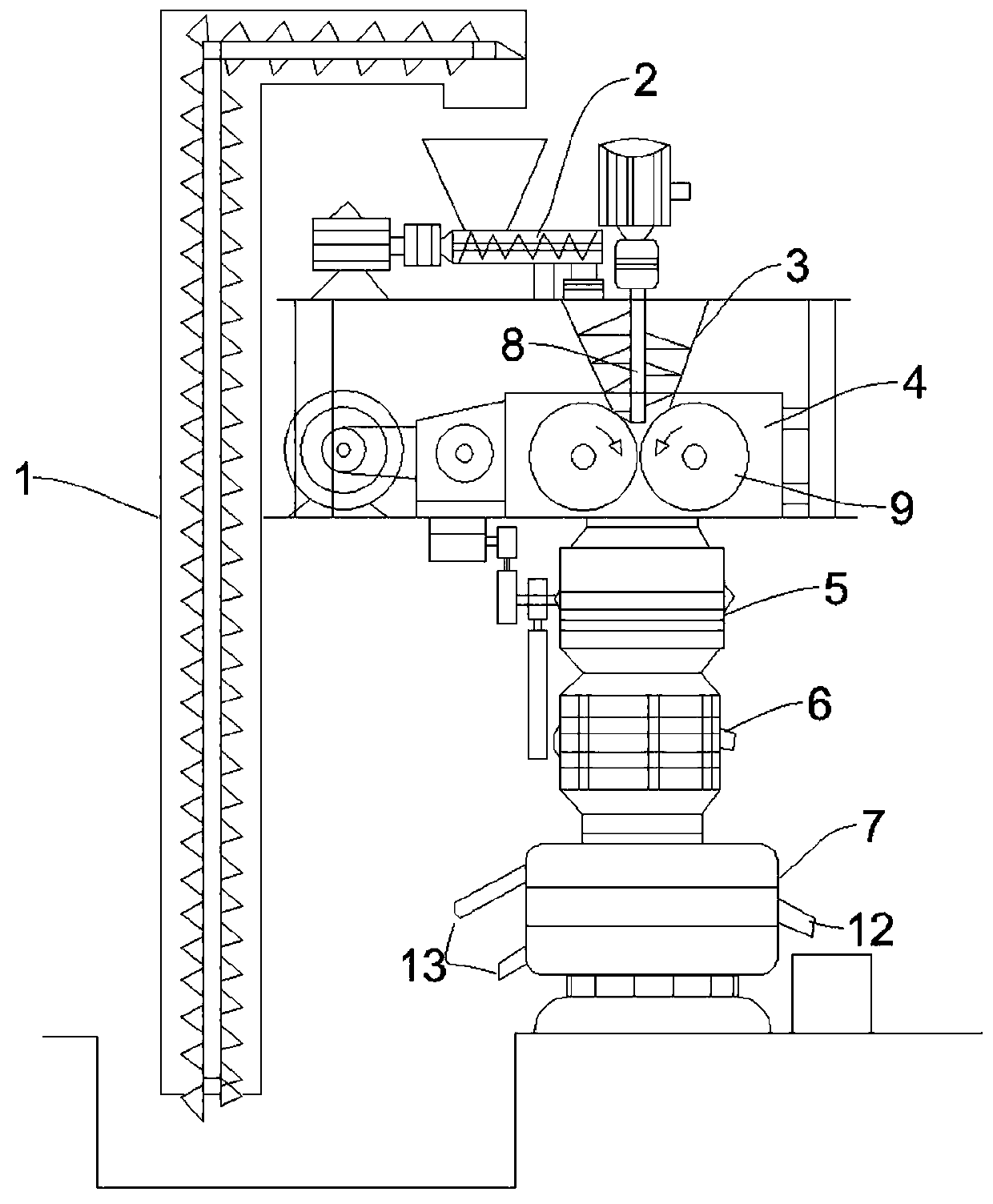

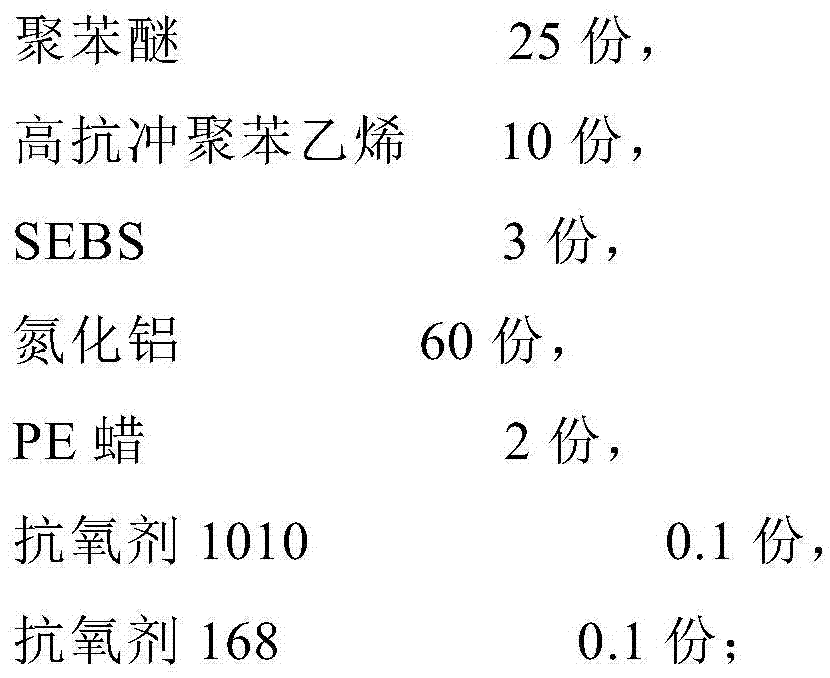

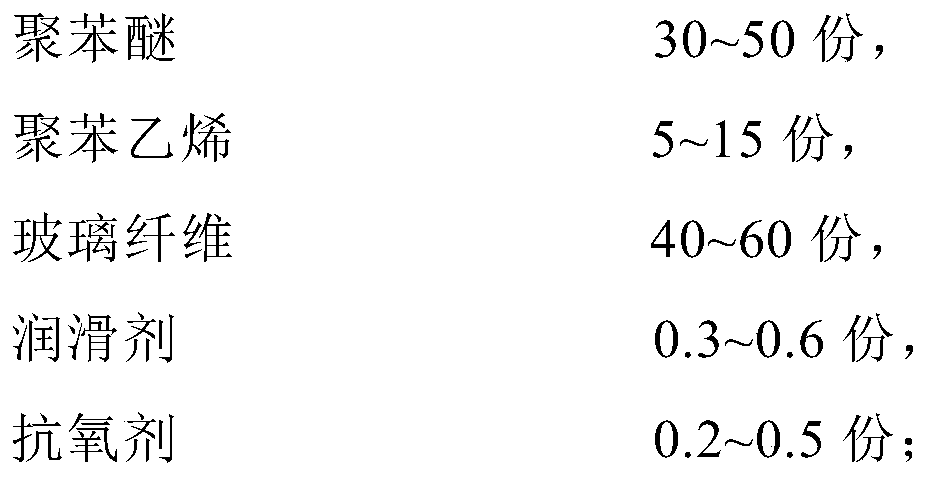

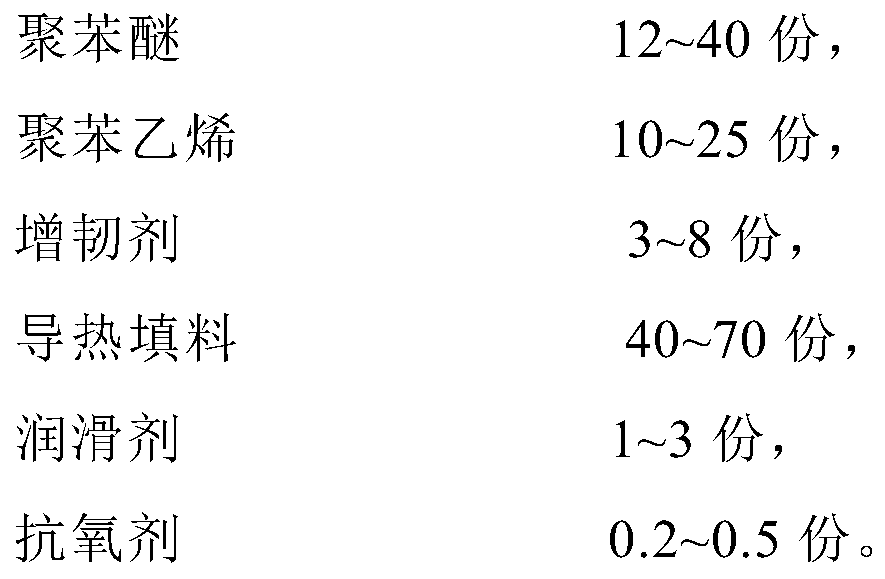

High-strength,high-thermal-conductivity and modified polyphenyl ether material and preparation method thereof

The invention relates to a high-strength, high-thermal-conductivity and modified polyphenyl ether material and a preparation method thereof. The polyphenyl ether material is formed by mixing an enhanced modified material and a thermal conductive modified material; the enhanced modified material is prepared from, by weight, 30-50 parts of polyphenyl ether, 5-15 parts of polystyrene, 40-60 parts of glass fibers, 0.3-0.6 part of lubricant and 0.2-0.5 part of antioxidant; the heat-conducting modified material is prepared from, by weight, 12-40 parts of polyphenyl ether, 10-25 parts of polystyrene, 3-8 parts of toughening agent, 40-70 parts of thermal conductive filler, 1-3 parts of lubricant and 0.2-0.5 part of antioxidant. The polyphenyl ether material is prepared by firstly preparing the enhanced modified material and the thermal conductive modified material respectively and then mixing the enhanced modified material and the thermal conductive modified material in batch according to a certain proportion. Compared with the prior art, the polyphenyl ether material has the advantages of being large in mechanical strength, excellent in thermal conductivity, good in processability and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

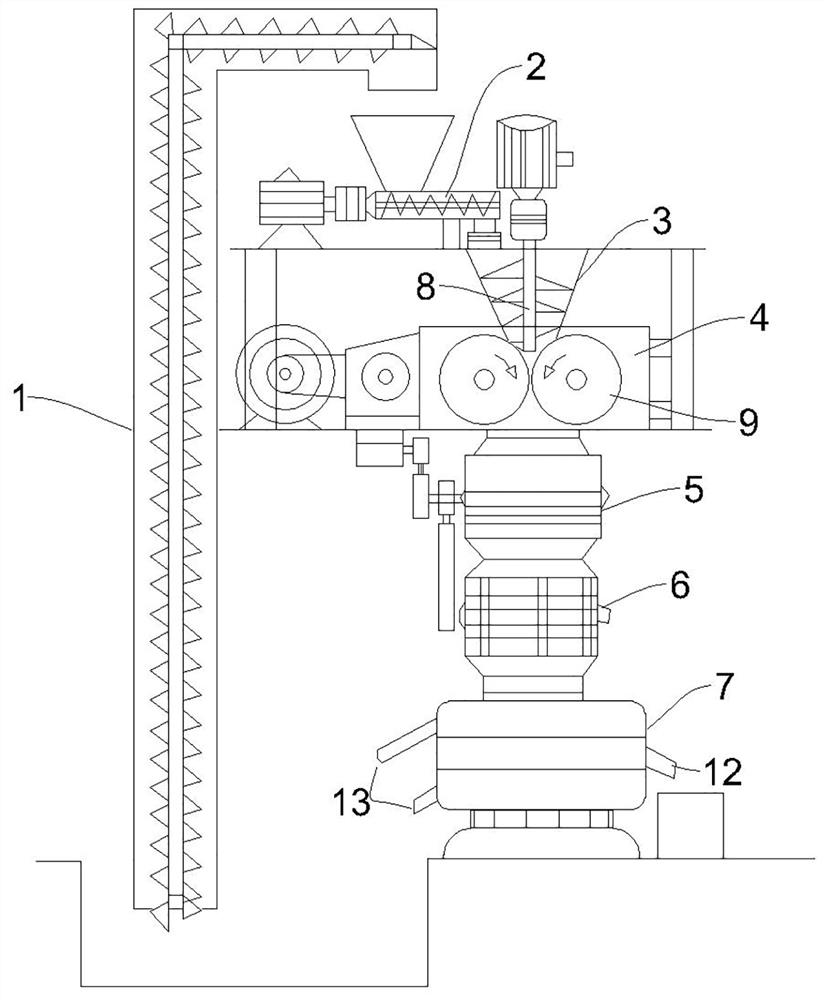

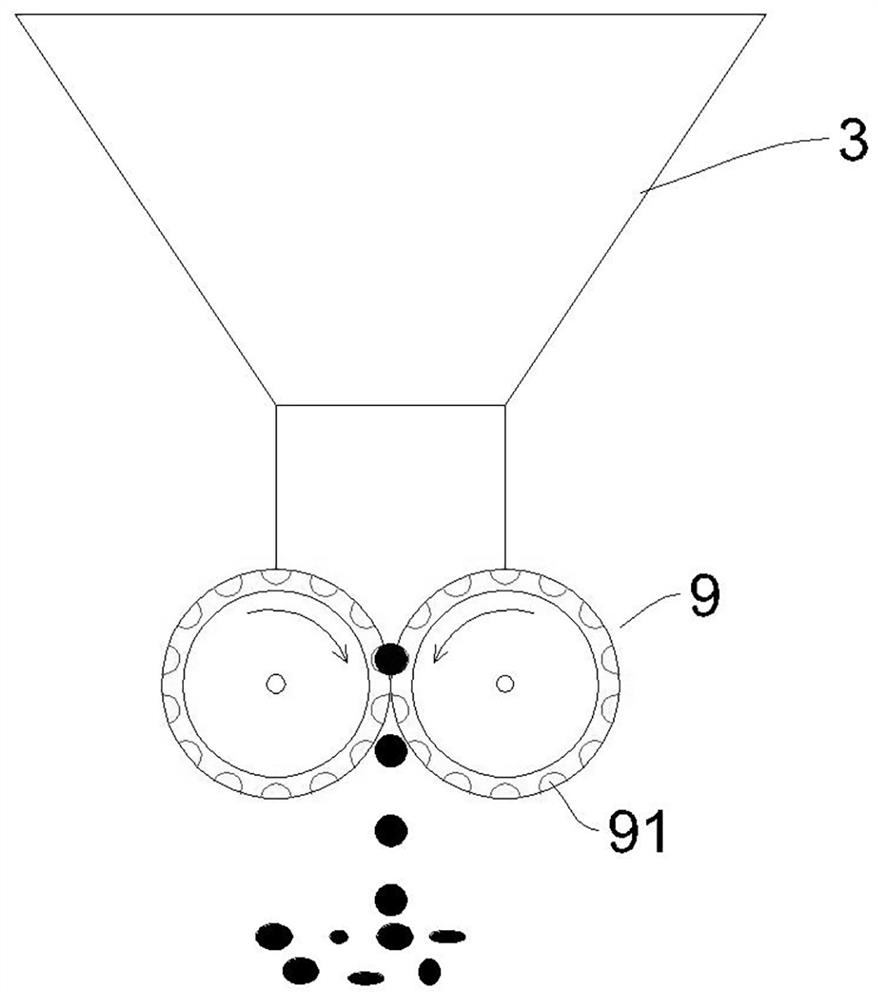

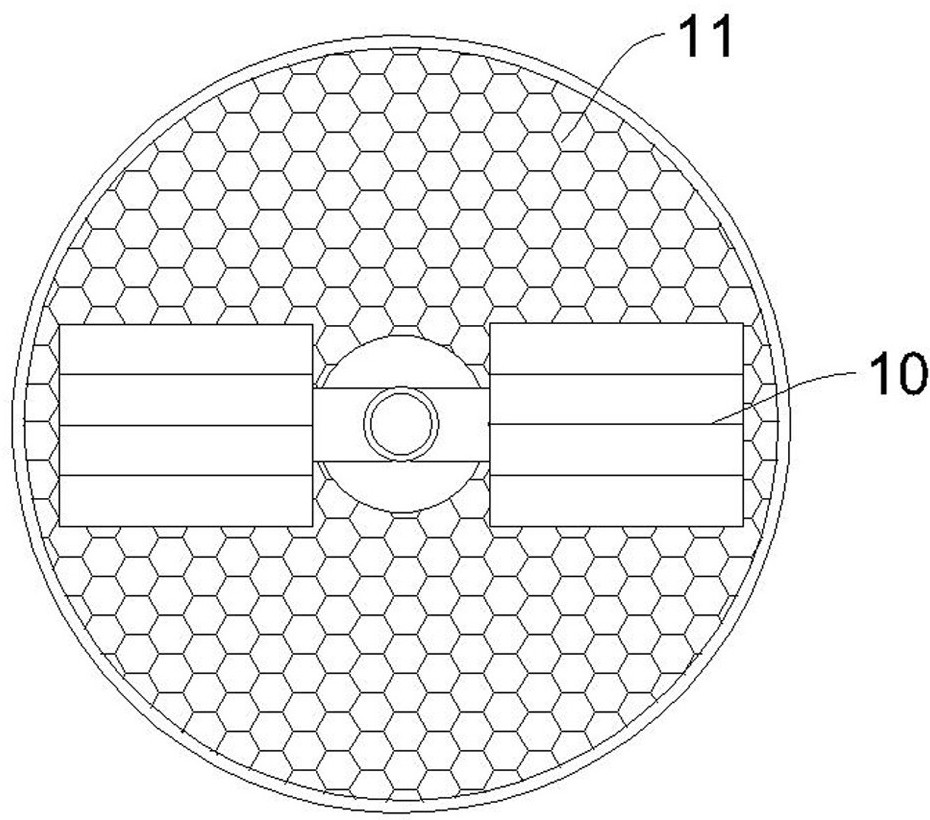

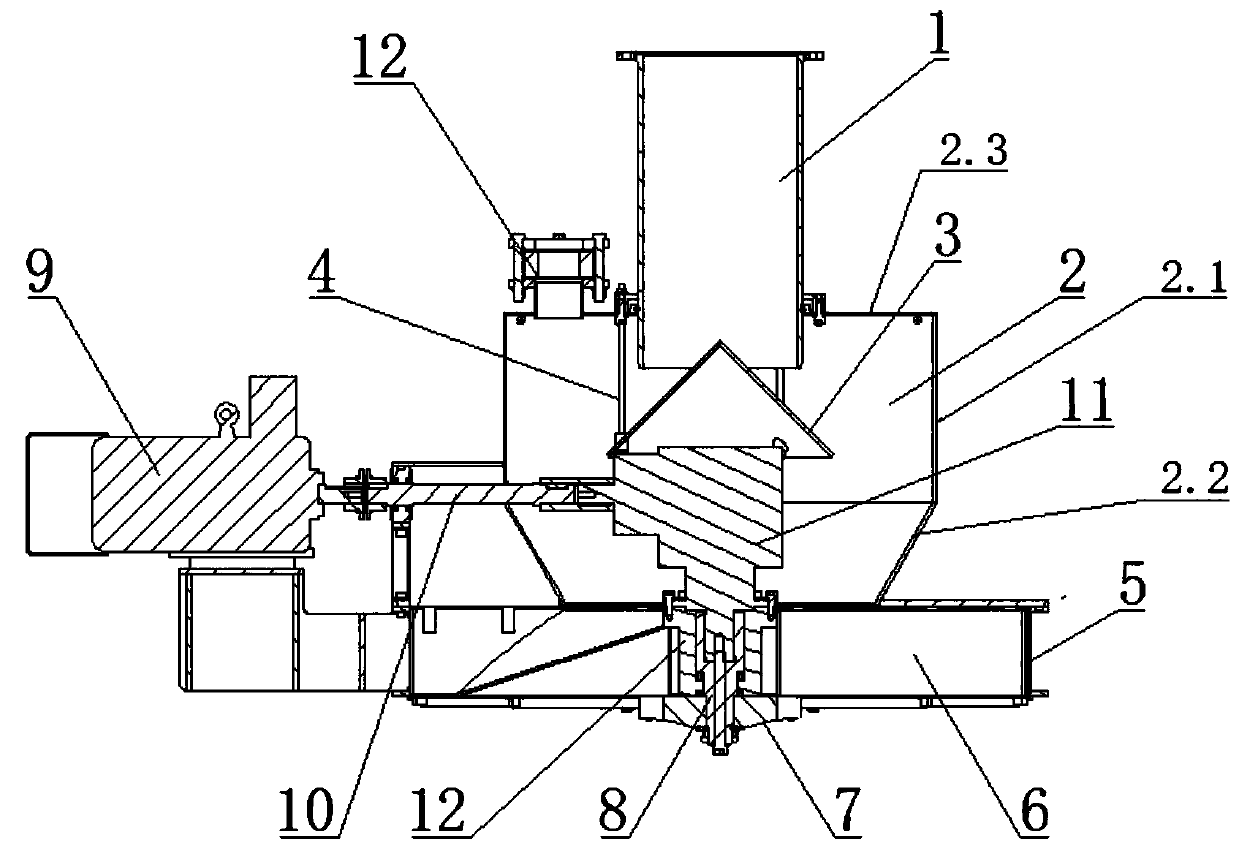

Production method of polyurethane foam powder solid waste particles

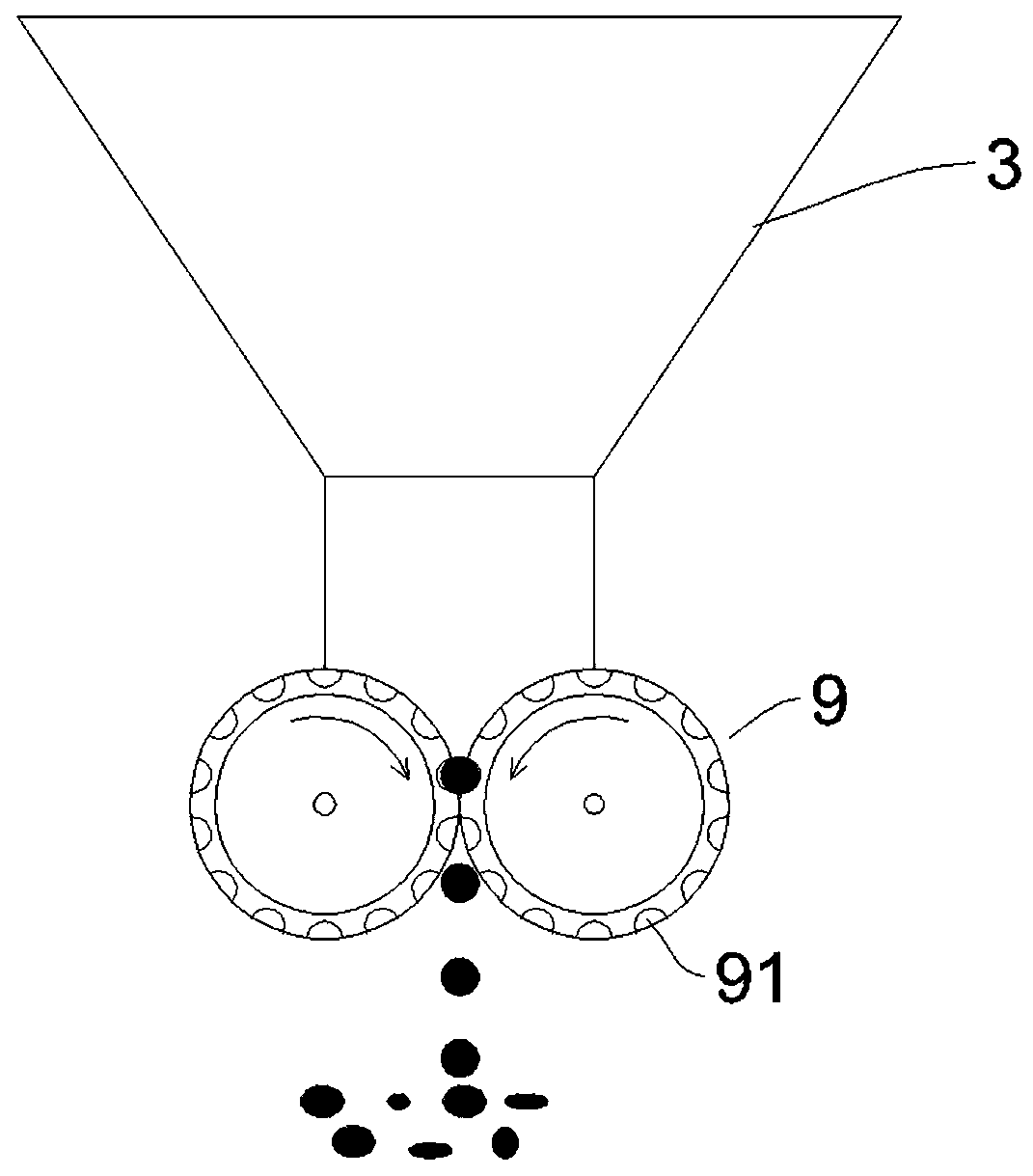

The invention belongs to the technical field of polyurethane solid waste recycling, and particularly discloses a production method of polyurethane foam powder solid waste particles. The method comprises the steps of mixing, compressing, double-roller shaping, compressing roller granulating and sorting; and in the whole process, compressing is carried out for four times, and the bonding strength among polyurethane foam powder is improved through addition of an adhesive so that the size of polyurethane foam powder solid waste can be reduced by 15 times or above, and the particles are good in compactness and uniform in size. According to the method, the transportation cost and the storage cost of the polyurethane foam powder solid waste can be greatly reduced, the polyurethane foam powder solid waste can be conveniently added into the production of boards such as wood-plastic floors and the like, the generation of dust is effectively reduced, and the occurrence of fire disasters is avoided; and meanwhile, the reutilization of waste resources is well realized, and the manufacturing cost of the boards is reduced.

Owner:ANHUI SENTAI WPC GRP CO LTD

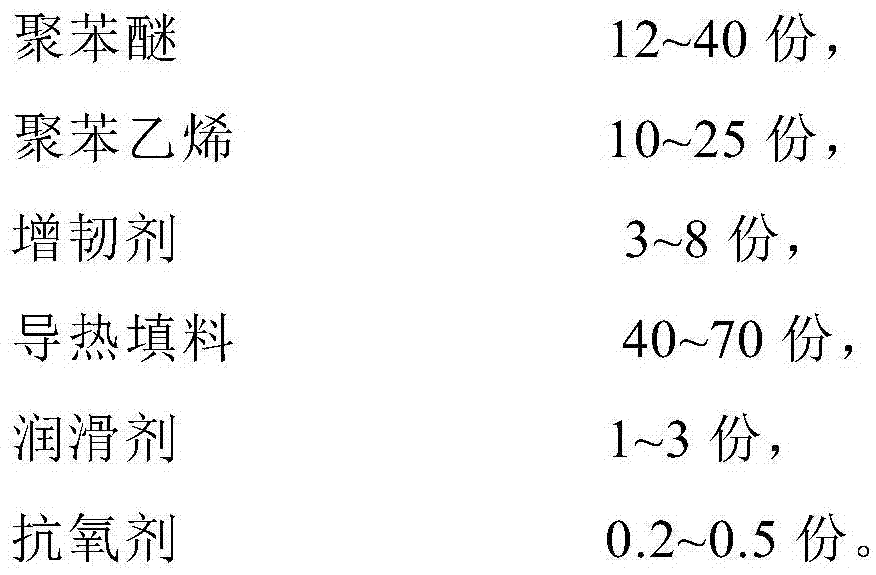

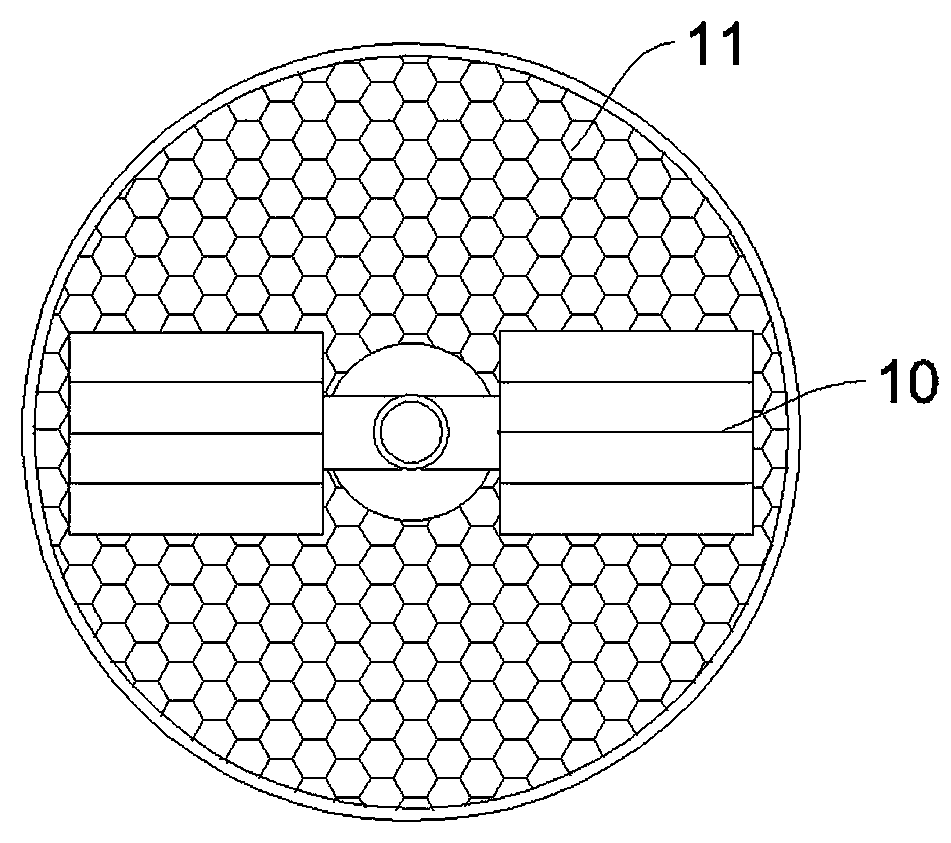

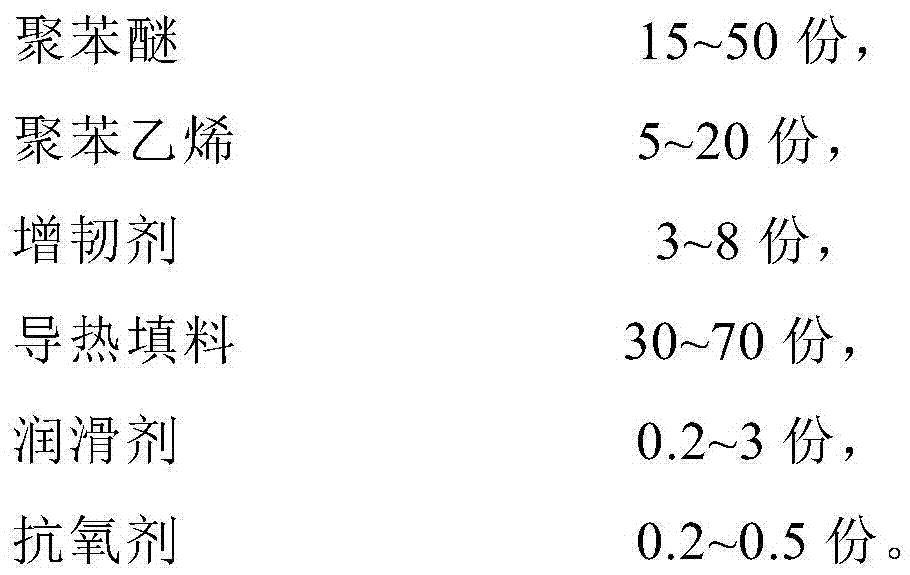

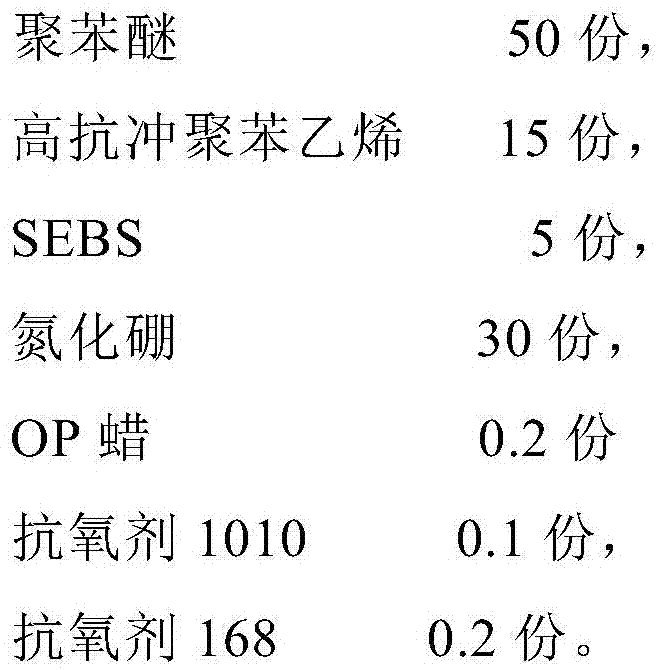

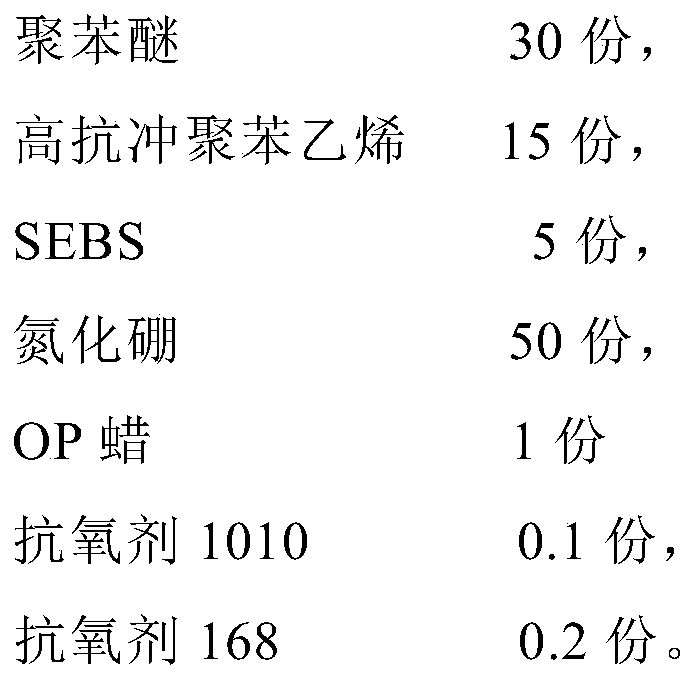

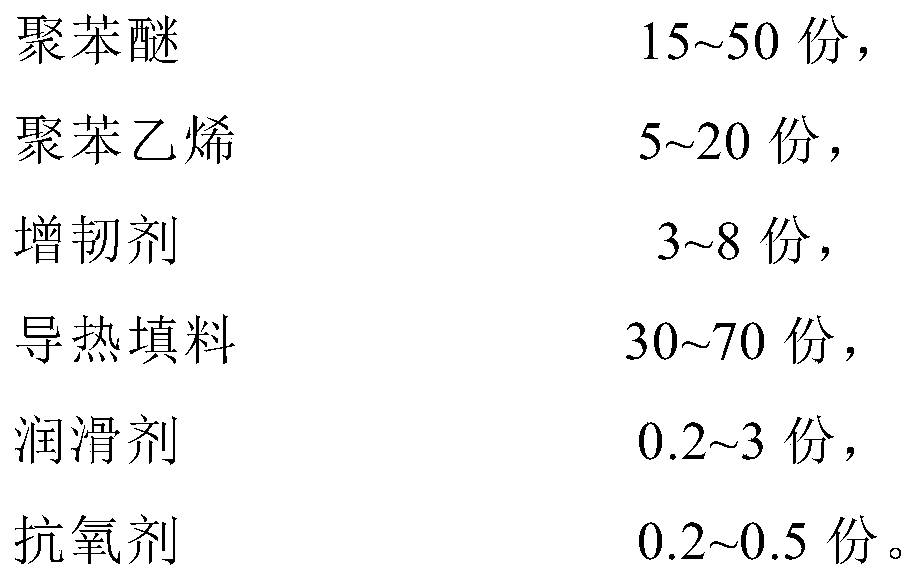

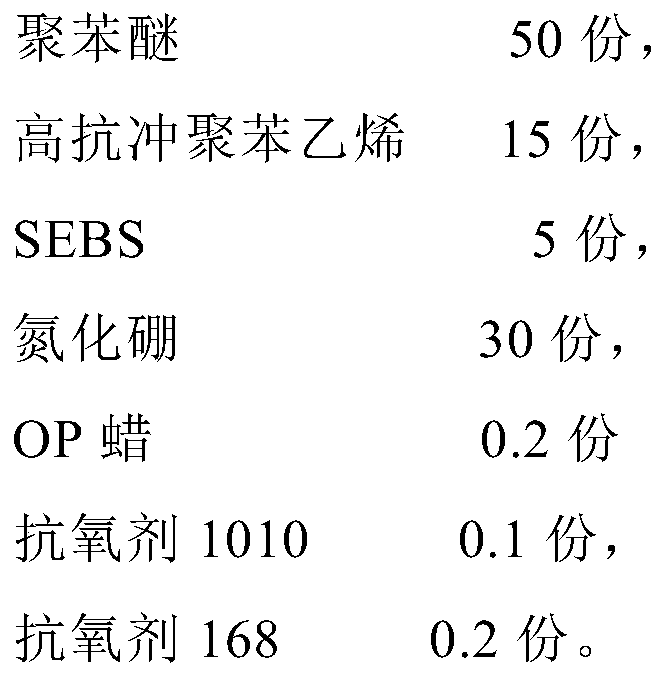

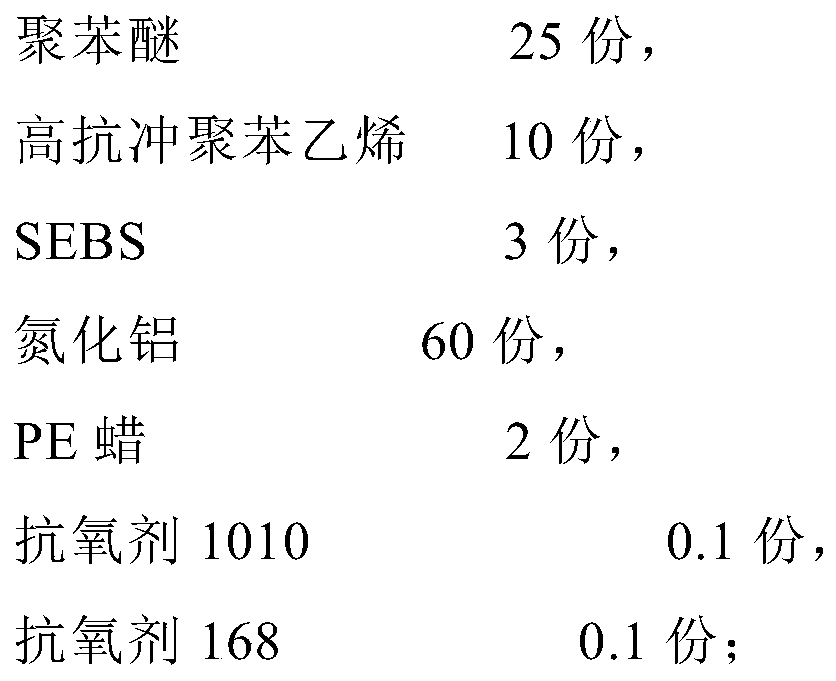

High-thermal-conductivity modified polyphenyl ether material and preparation method thereof

ActiveCN106928690AImprove thermal conductivityReduce surface frictionThermal conductivityAntioxidant

The invention relates to a high-thermal-conductivity modified polyphenyl ether material and a preparation method thereof. The polyphenyl ether material is prepared from, by weight, 5-50 parts of polyphenyl ether, 5-20 parts of polystyrene, 3-8 parts of toughening agent, 30-70 parts of thermal conductive filler, 0.2-3 parts of lubricant and 0.2-0.5 part of antioxidant. The polyphenyl ether material is prepared in the steps that 1, the thermal conductive filler and the lubricant are weighed and pre-mixed to obtain pre-mixed thermal conductive filler; 2, polyphenyl ether, polystyrene, the toughening agent and the antioxidant are weighed and mixed evenly with the pre-mixed thermal conductive filler to obtain a mixture; 3, the mixture is added in a screw extruder and subjected to melting, extruding, strip molding and cutting into particles to obtain the target product. Compared with the prior art, the polyphenyl ether material has the advantages of being good in processability, excellent in thermal conductivity, high in production efficiency and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A special halogen-free flame-retardant masterbatch for nylon and its preparation method

The invention discloses a special halogen-free flame-retardant master batch for nylon, which is prepared from the following raw materials in percentage by weight: 20-48% of PA6 resin, 50-70% of nitrogen flame retardant, 0.4-2.0% of main antioxidant, 0.6-3.0% of auxiliary antioxidant, 0.8-3.0% of external lubricant and 0.2-2.0% of internal lubricant. The master batch solves the problem of difficulty in baiting or nonuniformity in feeding caused by the characteristics of the MCA (melamine cyanurate) flame retardant when the MCA flame retardant is used for preparing the flame-retardant nylon material, has the characteristics of favorable dispersibility, favorable flame retardancy, no toxicity, environmental protection, high safety and reliability and the like, and is convenient to use. The invention also discloses a preparation method of the special halogen-free flame-retardant master batch for nylon. The method adopts a direct-cutting underwater granulation technique, so that the high-concentration flame-retardant master batch is implemented, thereby reducing the master batch consumption in the subsequent processing process, and lowering the influence of the carrier in the specific material.

Owner:GUANGDONG JUSHI CHEM CO LTD

Pressure- relief material returning treatment device and method

PendingCN110756112AReduce labor intensityImprove working environmentTransportation and packagingMixer accessoriesDust controlRefractory

The invention relates to the technical field of refractory material mixing, in particular to a pressure- relief material returning treatment device and method when refractory materials with various particle sizes are unloaded into a mixing machine. The device comprises an expansion bin, a resistance wire, an anti-blocking device, a bag-type dust collector and an induced draft fan, the expansion bin is arranged above a mixing device, the bottom is connected with a dust removal port of the mixing device, the top is connected with the bag-type dust collector through a dust removal pipeline, and the anti-blocking device is arranged on the outer side of the middle bin wall; the induced draft fan is connected with the bag-type dust collector, and the bottom of the bag-type dust collector is connected with the mixing device through a material returning pipeline; a resistance wire is wound on the outer side of the lower bin wall of the expansion bin and the outer side of the lower part of thereturn pipeline. The refractory material powder can be automatically recycled and returned to the mixing device, so that the recycling of raw materials is realized; meanwhile, the labor intensity of workers is reduced; dust pollution during transferring is avoided, and the working environment of refractory material production is improved; the proportioning precision of all the raw materials in pugis improved, and the structure and performance of the product are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

A traditional Chinese medicinal material grinding equipment for quantitatively conveying materials

InactiveCN111686852BImprove work efficiencyReduce mistakesGrain treatmentsMetal working apparatusMedicinal herbsProcess engineering

Owner:王静业

A kind of modified polyphenylene ether material with high strength and high thermal conductivity and preparation method thereof

The invention relates to a high-strength, high-thermal-conductivity and modified polyphenyl ether material and a preparation method thereof. The polyphenyl ether material is formed by mixing an enhanced modified material and a thermal conductive modified material; the enhanced modified material is prepared from, by weight, 30-50 parts of polyphenyl ether, 5-15 parts of polystyrene, 40-60 parts of glass fibers, 0.3-0.6 part of lubricant and 0.2-0.5 part of antioxidant; the heat-conducting modified material is prepared from, by weight, 12-40 parts of polyphenyl ether, 10-25 parts of polystyrene, 3-8 parts of toughening agent, 40-70 parts of thermal conductive filler, 1-3 parts of lubricant and 0.2-0.5 part of antioxidant. The polyphenyl ether material is prepared by firstly preparing the enhanced modified material and the thermal conductive modified material respectively and then mixing the enhanced modified material and the thermal conductive modified material in batch according to a certain proportion. Compared with the prior art, the polyphenyl ether material has the advantages of being large in mechanical strength, excellent in thermal conductivity, good in processability and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A modified polyphenylene ether material with high thermal conductivity and its preparation method

The invention relates to a high-thermal-conductivity modified polyphenyl ether material and a preparation method thereof. The polyphenyl ether material is prepared from, by weight, 5-50 parts of polyphenyl ether, 5-20 parts of polystyrene, 3-8 parts of toughening agent, 30-70 parts of thermal conductive filler, 0.2-3 parts of lubricant and 0.2-0.5 part of antioxidant. The polyphenyl ether material is prepared in the steps that 1, the thermal conductive filler and the lubricant are weighed and pre-mixed to obtain pre-mixed thermal conductive filler; 2, polyphenyl ether, polystyrene, the toughening agent and the antioxidant are weighed and mixed evenly with the pre-mixed thermal conductive filler to obtain a mixture; 3, the mixture is added in a screw extruder and subjected to melting, extruding, strip molding and cutting into particles to obtain the target product. Compared with the prior art, the polyphenyl ether material has the advantages of being good in processability, excellent in thermal conductivity, high in production efficiency and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A kind of production method of polyurethane foam powder solid waste particles

The invention belongs to the technical field of polyurethane solid waste recycling and specifically discloses a production method of solid waste particles of polyurethane foam powder, including the steps of mixing, compressing, counter-roll shaping, pressing roll granulation and sorting. The whole process goes through Four times of compression, and by adding adhesives to improve the bonding strength between polyurethane foam powder, can reduce the volume of solid waste of polyurethane foam powder by more than 15 times, and the particles have good compactness and uniform size. The invention can greatly reduce the transportation cost and storage cost of solid waste of polyurethane foam powder, and can be conveniently added to the production of boards such as wood-plastic flooring, effectively reducing the generation of dust, avoiding the occurrence of fire, and at the same time, it is well realized The reuse of waste resources reduces the production cost of panels.

Owner:ANHUI SENTAI WPC GRP CO LTD

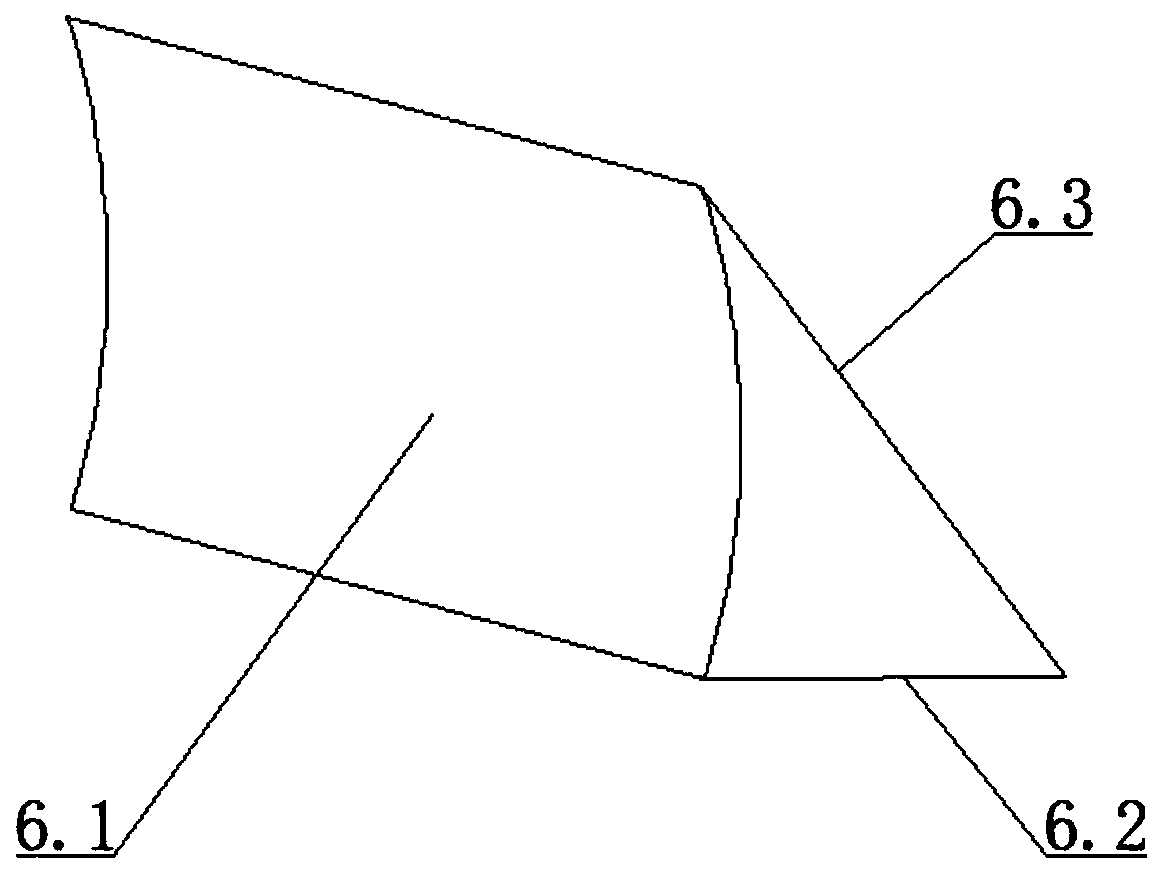

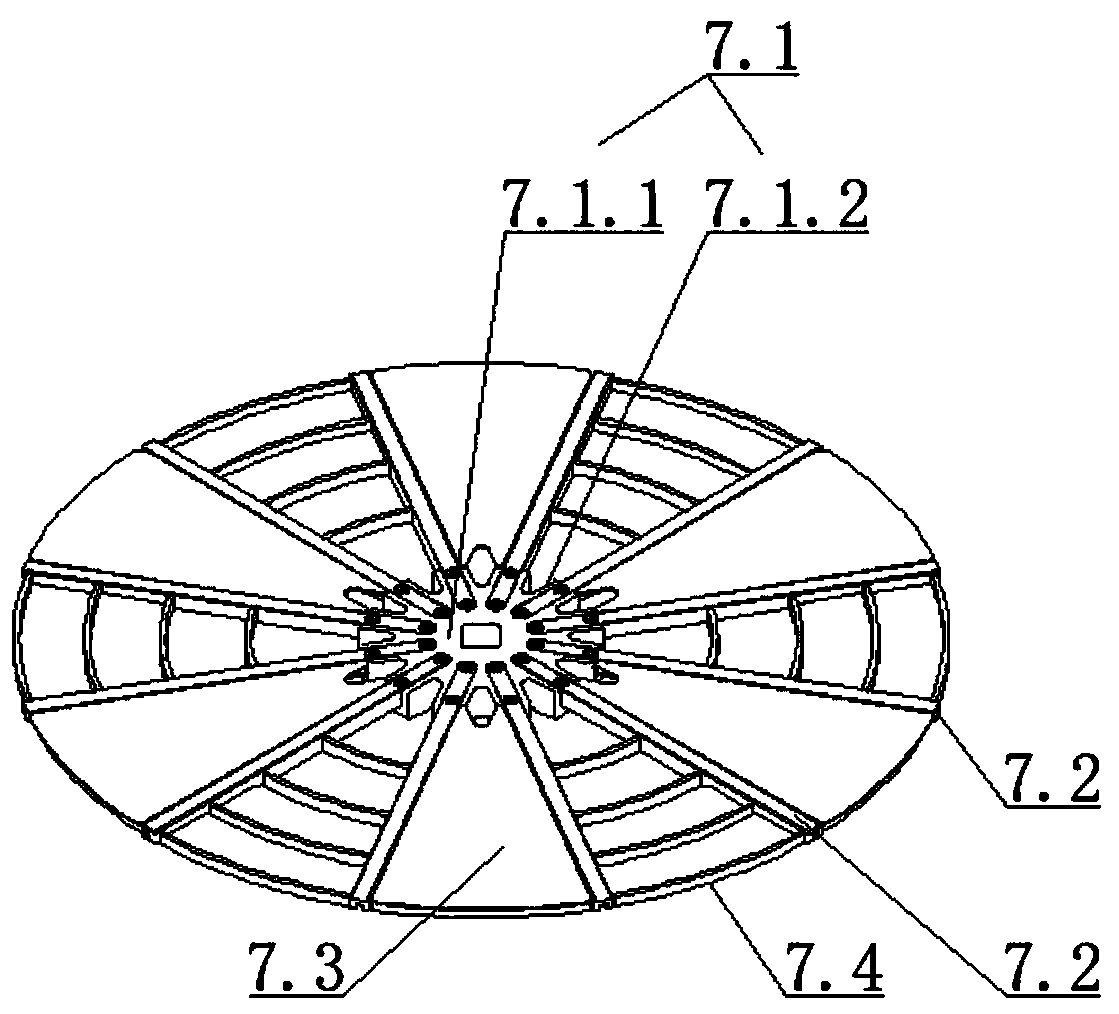

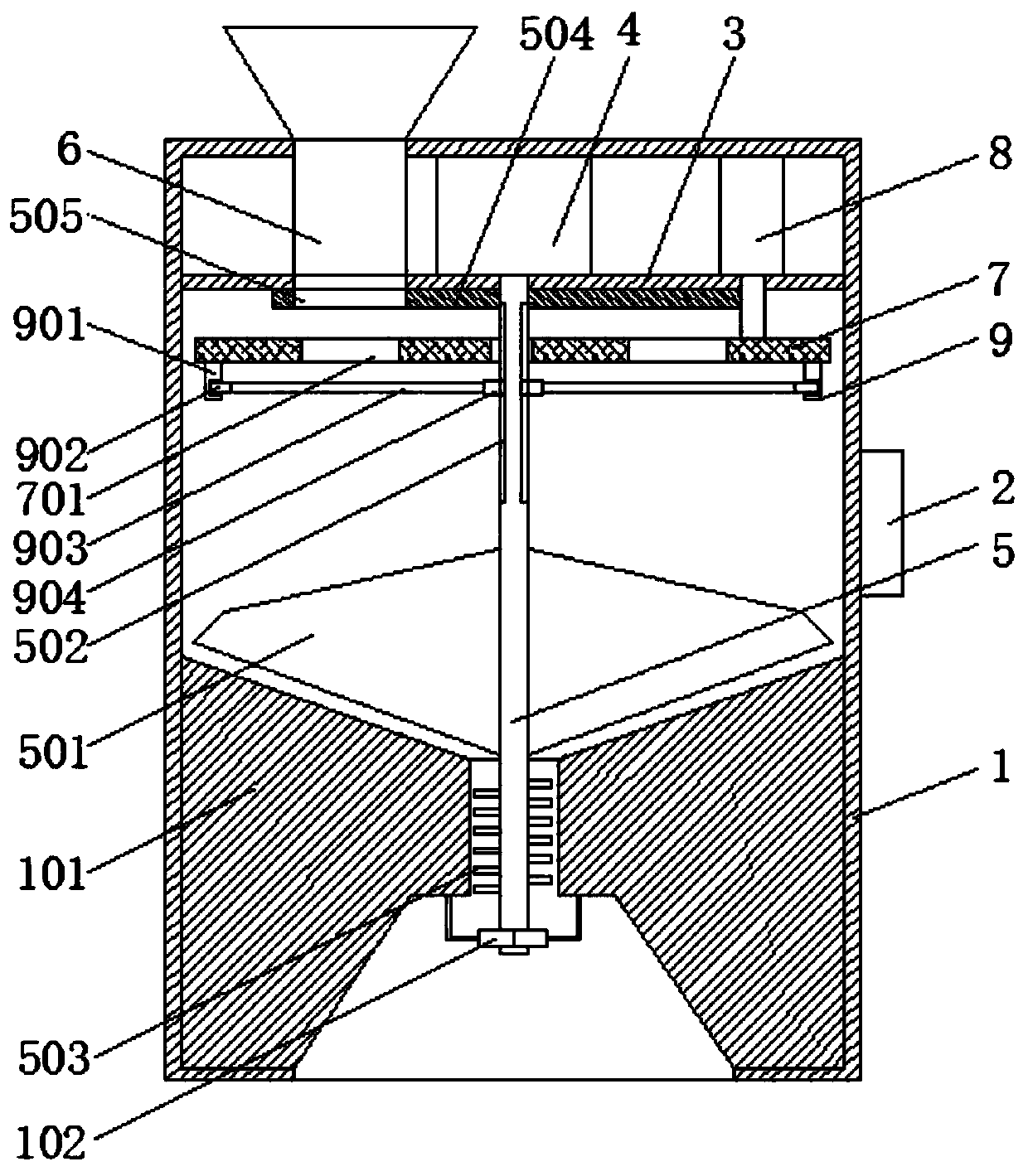

Feeding equipment for solid waste disposal equipment

PendingCN110397938ASolve the difficulty of blankingAvoid harmIncinerator apparatusDrive shaftMouth shape

The invention relates to feeding equipment for solid waste disposal equipment. The feeding equipment comprises a charging bin; the charging bin comprises an annular mounting top plate, a cylindrical upper bin body and a horn-mouth-shaped diversion bin body; the mounting top plate is provided with a feeding pipe; a cone body is mounted in the charging bin through a plurality of suspension rods andlocated below the feeding pipe; a cutting cutter head is mounted at the end of a transmission shaft and located on the outer side of a distribution bin, and comprises a flange; a plurality of supportrods are uniformly mounted on the outer side of the flange; fan-shaped baffles and curved connecting strip plates are alternately mounted in the intervals between every two adjacent support rods; theouter wall of a shaft sleeve is provided with a plurality of cutting chassis; the shaft sleeve and the cutting chassis are located in the distribution bin; each cutting chassis is of a triangular-shaped structure composed of a curved plate, a fan-shaped bottom plate and an inclined plate; and the fan-shaped bottom plates and the fan-shaped baffles have the same opening angle and the same radius. Through the feeding equipment, solid waste uniformly falls in the most efficient area of a reaction chamber, uniform feeding of viscous materials can be ensured, and the feeding efficiency is improved.

Owner:普霖环境科技有限公司

A high-efficiency traditional Chinese medicine grinding equipment for traditional Chinese medicine

ActiveCN107684962BSimple structurePrevent backflowCocoaGrain treatmentsWhole bodyTraditional medicine

The invention discloses efficient traditional Chinese medicine grinding equipment for a traditional Chinese medicine department. The efficient traditional Chinese medicine grinding equipment comprisesa shell body, wherein a control switch is mounted on the outer side face of the shell body. The efficient traditional Chinese medicine grinding equipment for the traditional Chinese medicine department is simple in structure; Chinese herbal medicines are processed and cut through a manner of firstly cutting and then grinding, so that tubers of the Chinese herbal medicines are further reduced andcan effectively fall into the lower side of a grinding disc, difficult blanking is avoided and the smoothness of a whole body is improved; a material pressing plate can move along the vertical direction and is matched with a separation plate to form a squeezes force, so that the Chinese herbal medicines can fall down from a through hole and are in effective contact with a rotary blade; a shieldingplate is arranged so that a condition that the Chinese herbal medicines are reflowed back into a feeding hopper when the material pressing plate squeezes is avoided; the chopped Chinese herbal medicines are ground and crushed by matching the grinding disc with a lining platform, so that the granularity of the Chinese herbal medicines is reduced; the discharging speed is controlled by a thread plate so that the Chinese herbal medicines stay for enough time between the grinding disc and the lining platform; a polishing path, which is longitudinally arranged, is convenient for discharging.

Owner:王国栋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com