Microwave drying device for chemical pigment production

A technology of microwave drying and microwave drying machine, which is used in drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of difficulty in blanking, affecting work efficiency, unevenness, etc. Uniform material, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

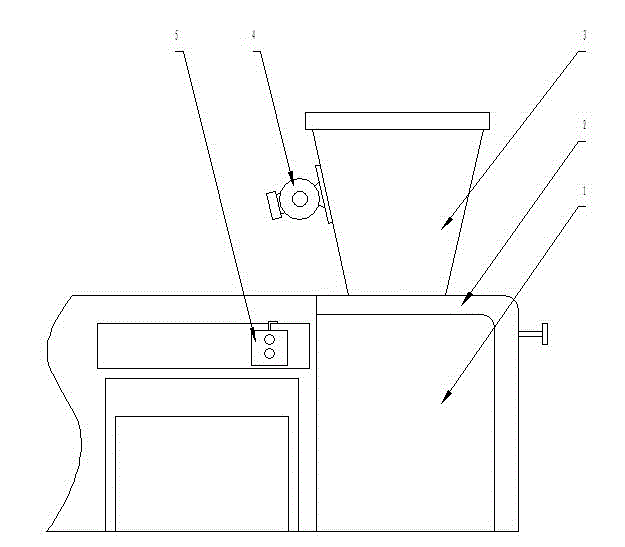

[0010] Such as figure 1 Shown, a kind of microwave drying device that is used for the production of chemical pigment of the present invention, it comprises microwave drier 1, and slurry feeding hopper 3 is installed on the conveyer belt 2 of microwave drying machine 1, and slurry feeding hopper 3 side walls are installed with vibrator4. The microwave dryer 1 is equipped with a control device 5 for controlling the switch of the vibrator 4 .

[0011] During operation, open the control device 5 to start the vibrator 4, add the slurry from the slurry hopper 3 with the vibrator 4, and through the vibration of the vibrator 4 to the wall of the hopper, the slurry can be smoothly fed from the slurry hopper 3 Fall onto the conveyor belt 2 and enter the microwave drying device 1 for drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com