Patents

Literature

163results about How to "Blanking evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

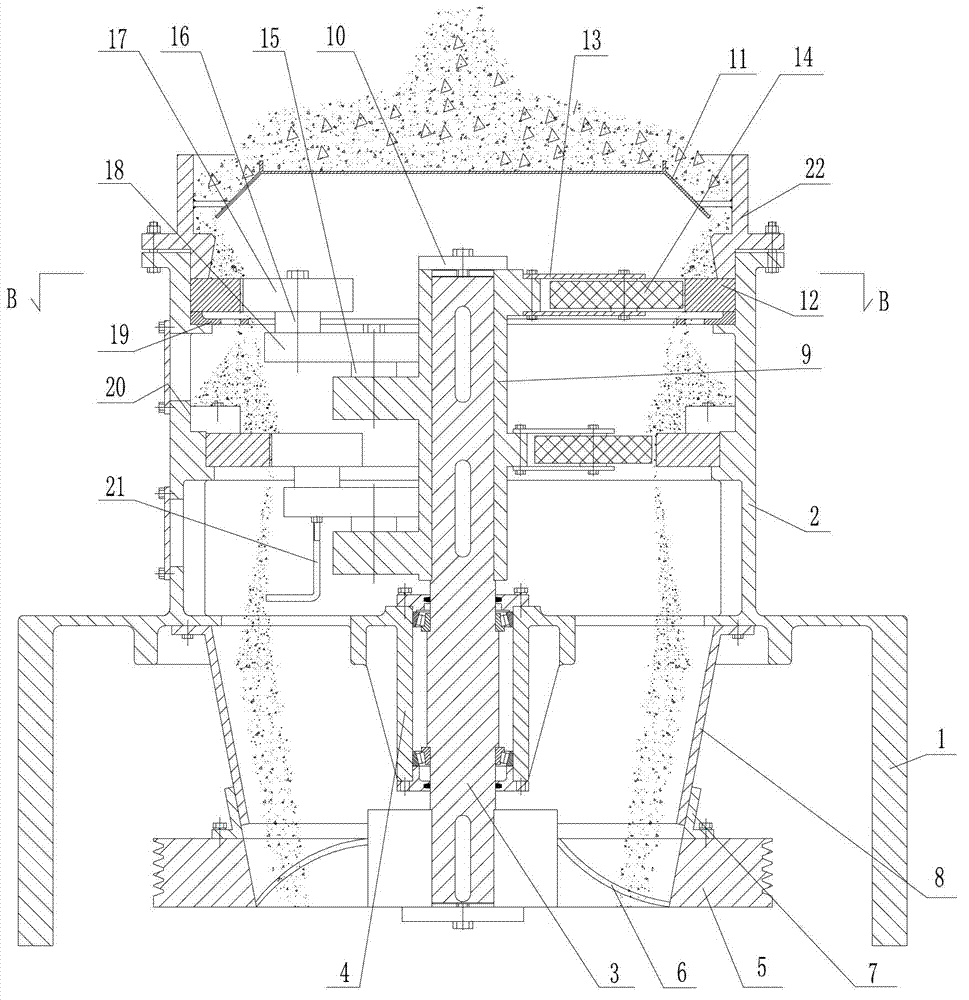

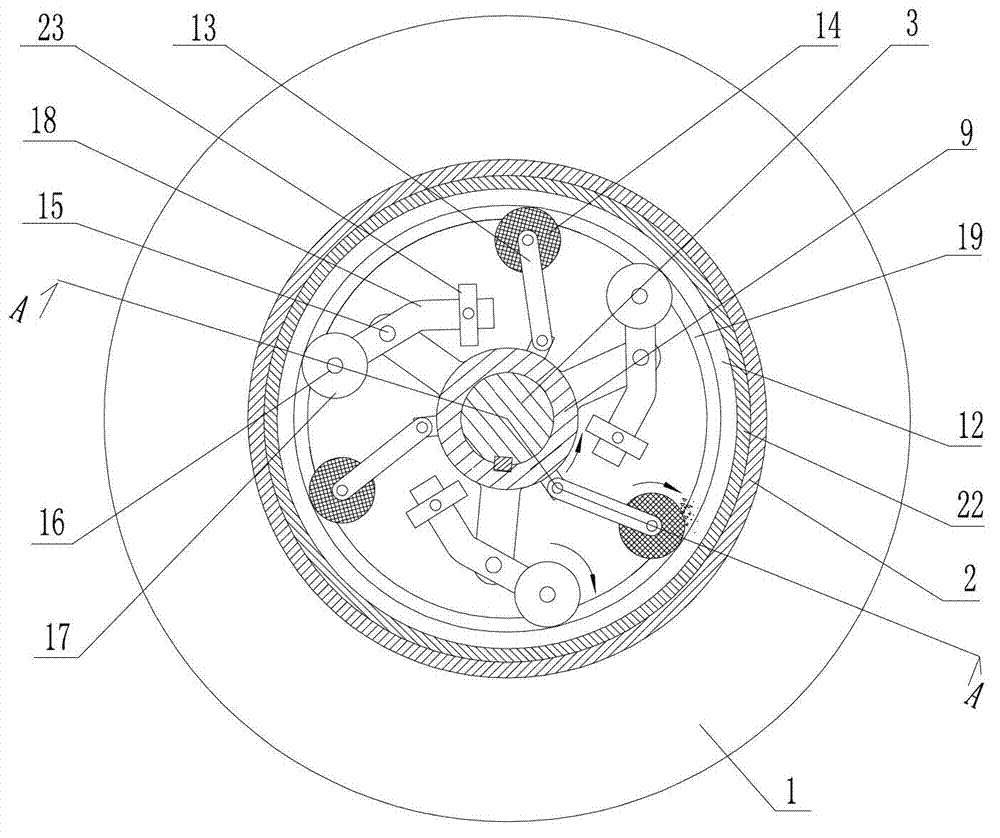

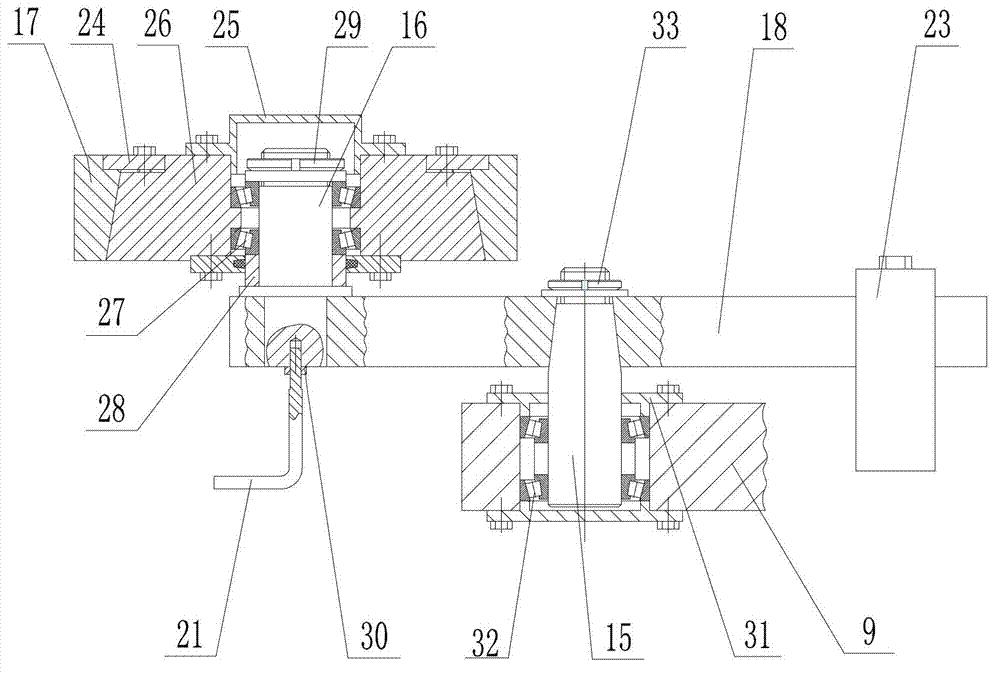

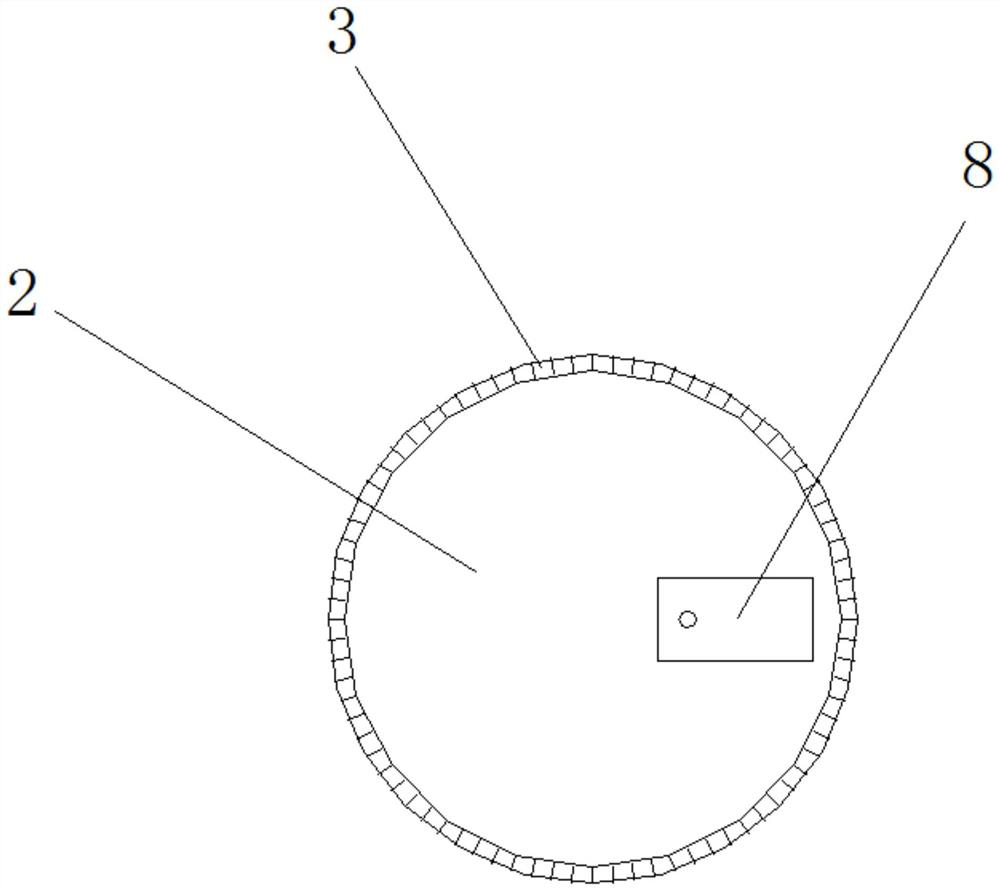

Flexible vertical grinder

The invention discloses a flexible vertical grinder. A hammer wheel powder-grinding device and a material sorting balance wheel device are mounted on a star-shaped support of a spindle. The flexible vertical grinder has the technical advantages that different grinding forces are applied by grinding bodies in different layers from top to bottom at a set rotation speed according to different specific surface areas of ground materials, a principle of 'more crushing and less grinding' is met, and the materials in different grades can be ground but are not over ground; a material bed is stable, the phenomenon that 'iron is ground by another iron' is avoided, and abrasion is reduced; the flexible vertical grinder not only can be used for dry grinding, but also can be used for wet grinding, the application range of the multilayer annular grinder is broadened, materials in a barrel are discharged smoothly, and the problem of 'middle distortion' is solved; crushing efficiency is greatly improved, and power consumption of the flexible vertical grinder is greatly reduced as compared with an existing multilayer annular grinder; the flexible vertical grinder is good in integral rigidity, stable in running and low in noise and is free of dust pollution; and the flexible vertical grinder is easy and convenient to maintain.

Owner:HUNAN ZHONGHONG HEAVY MACHINERY CO LTD

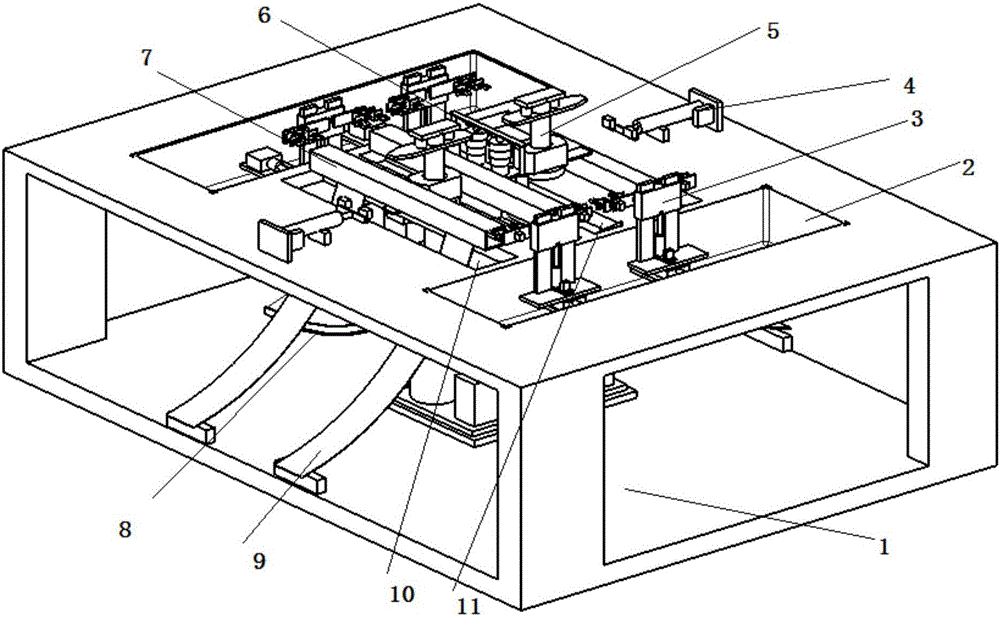

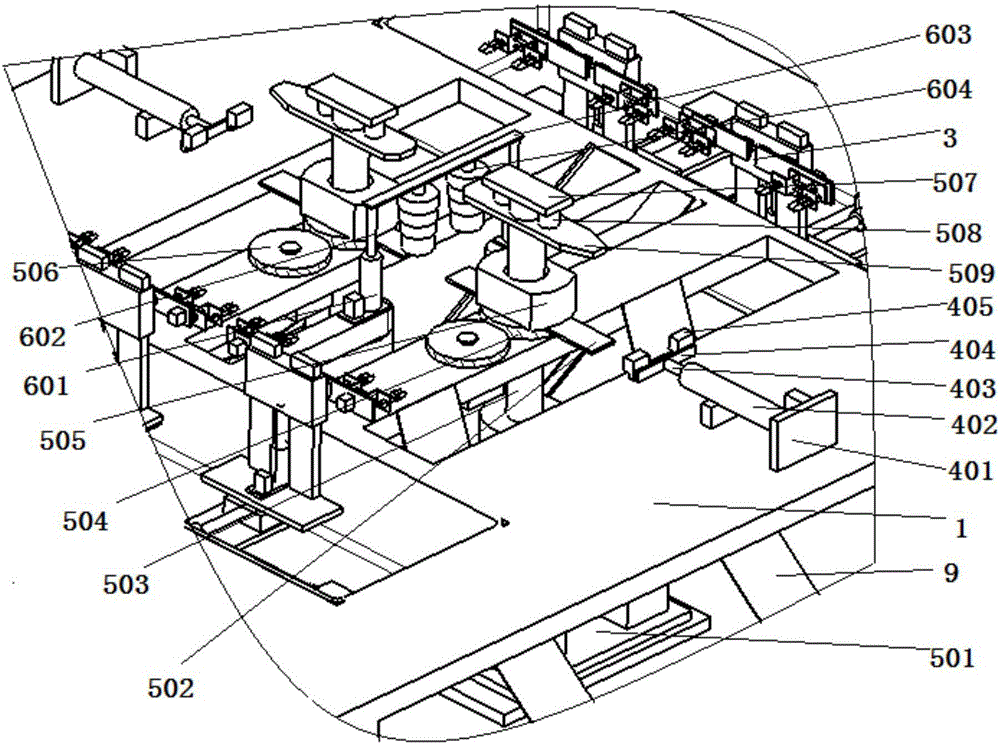

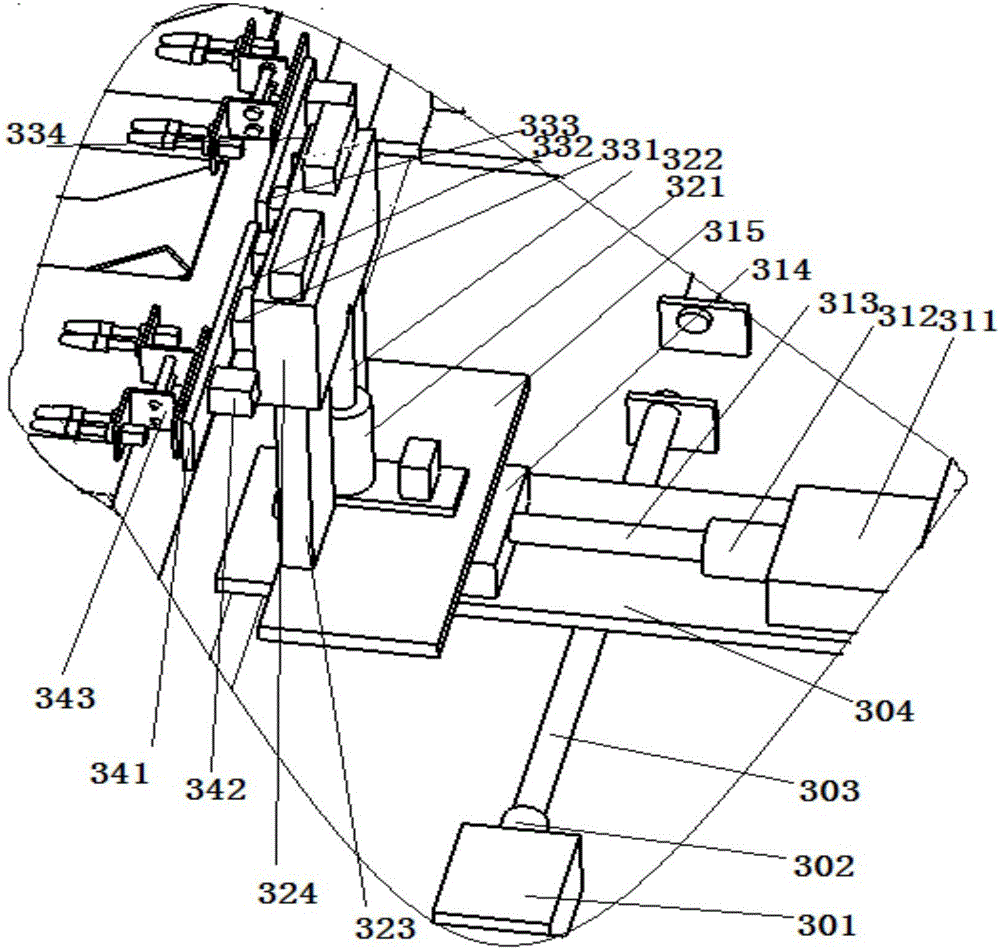

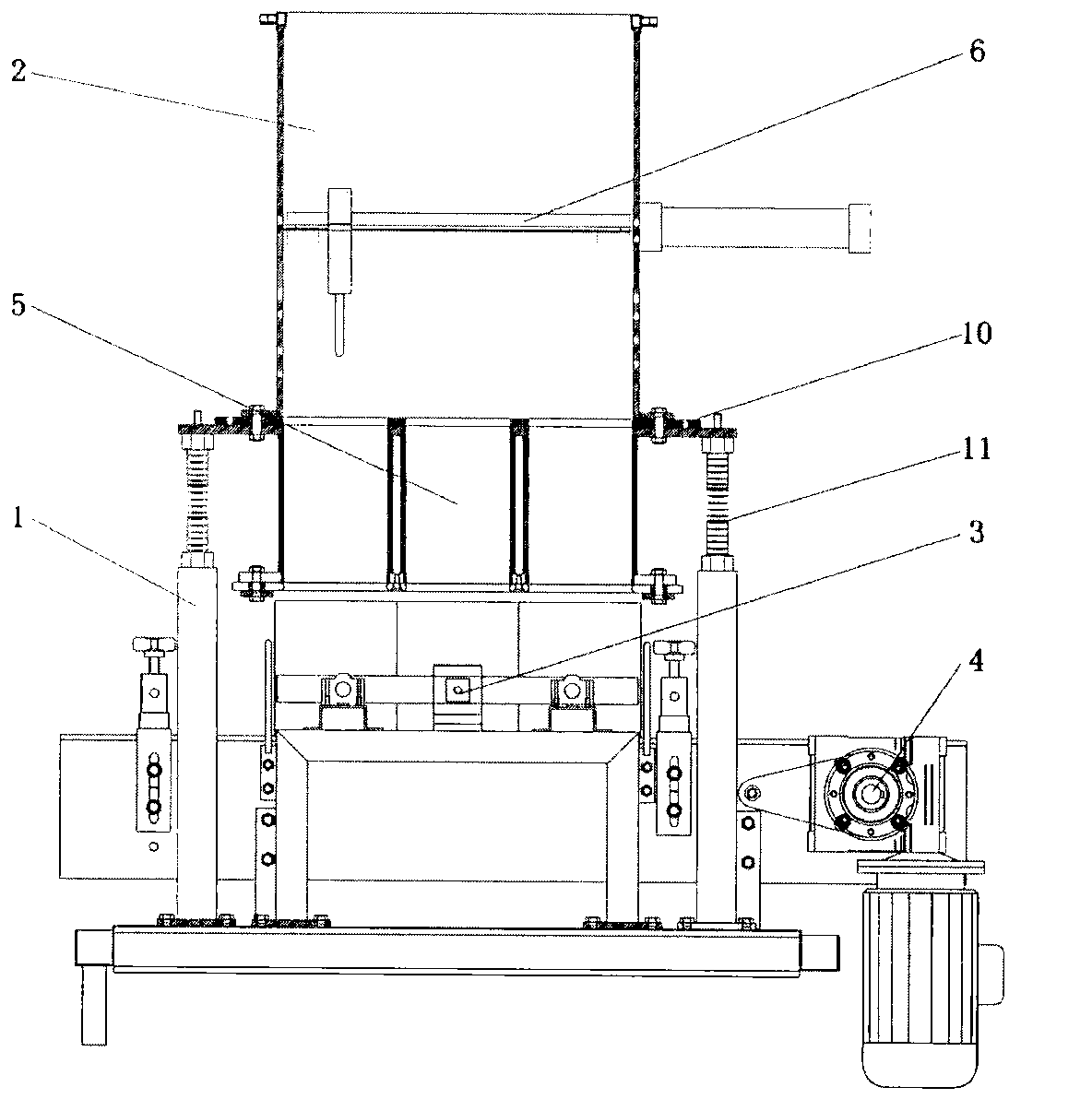

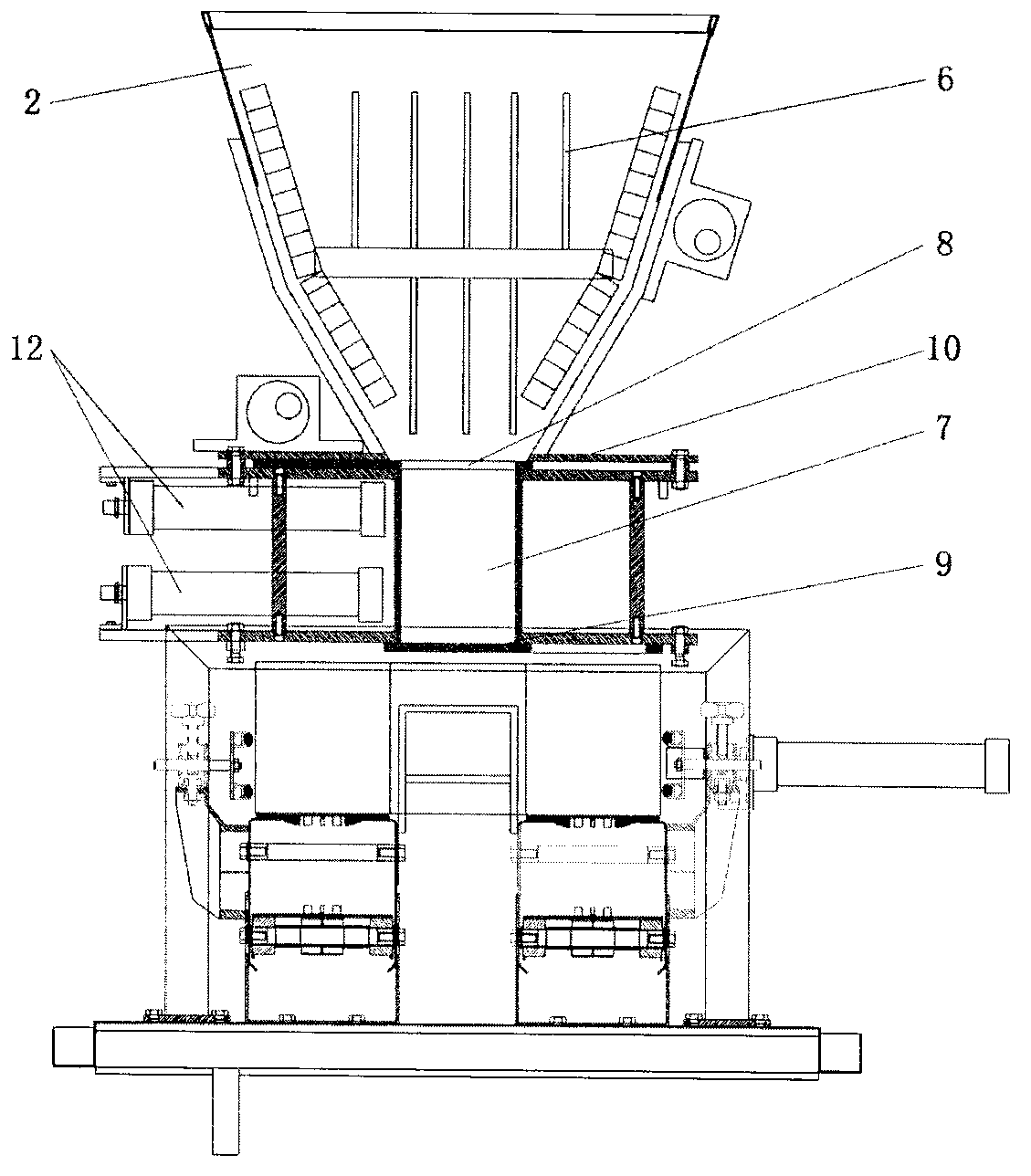

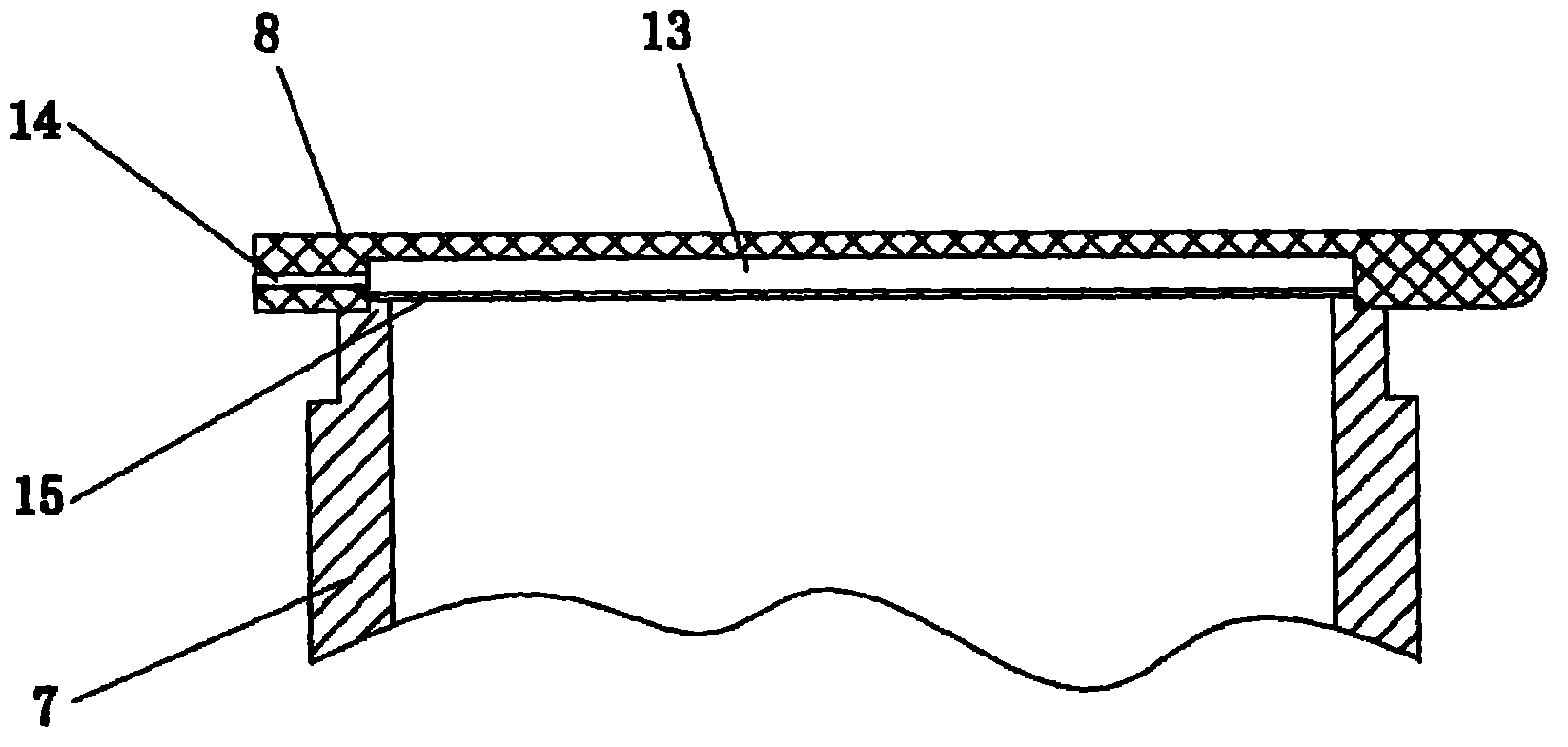

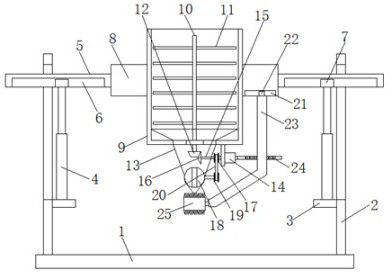

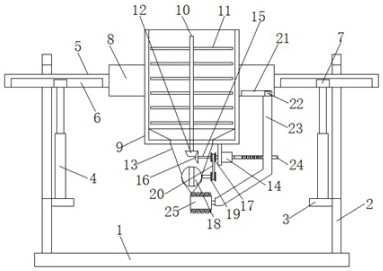

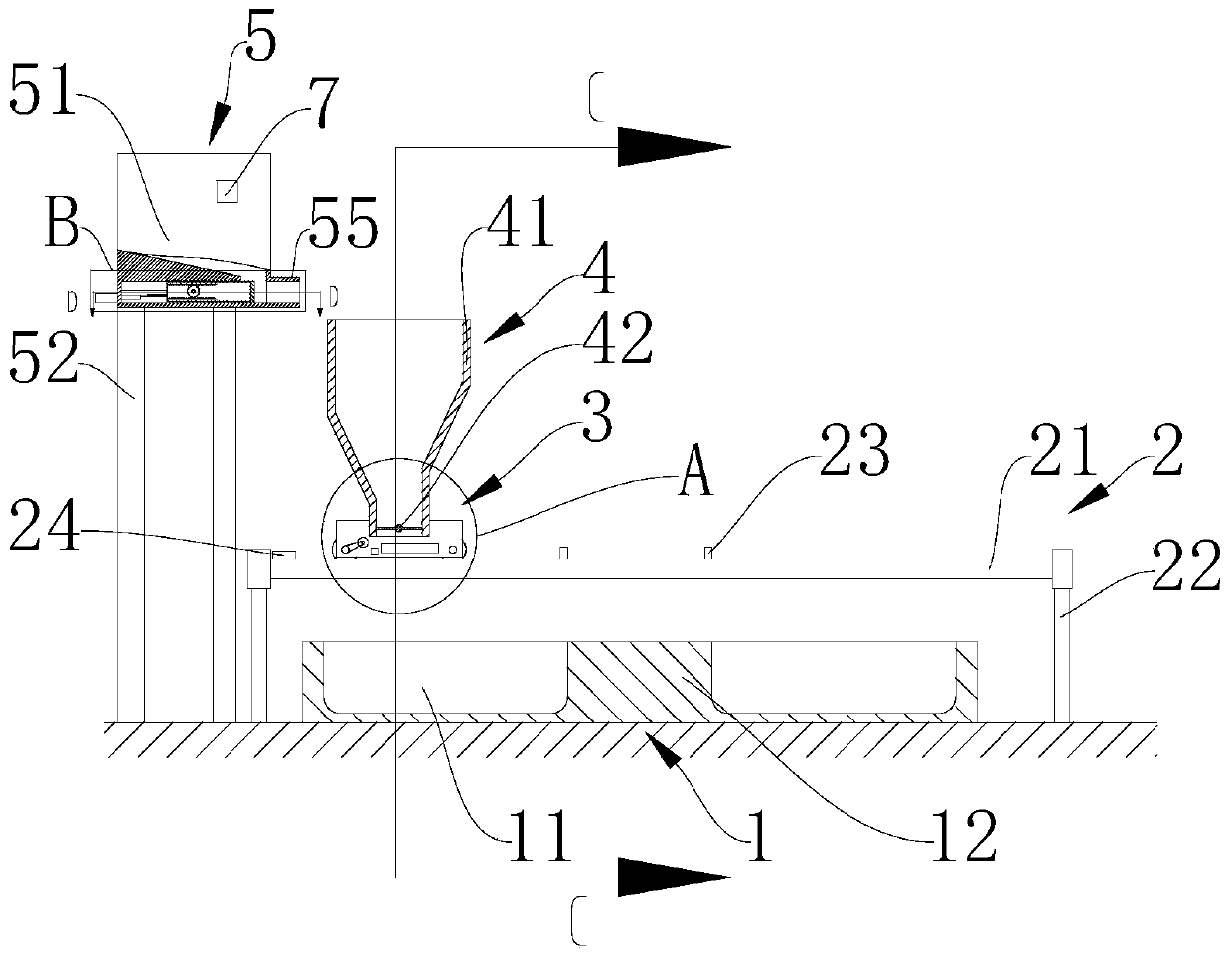

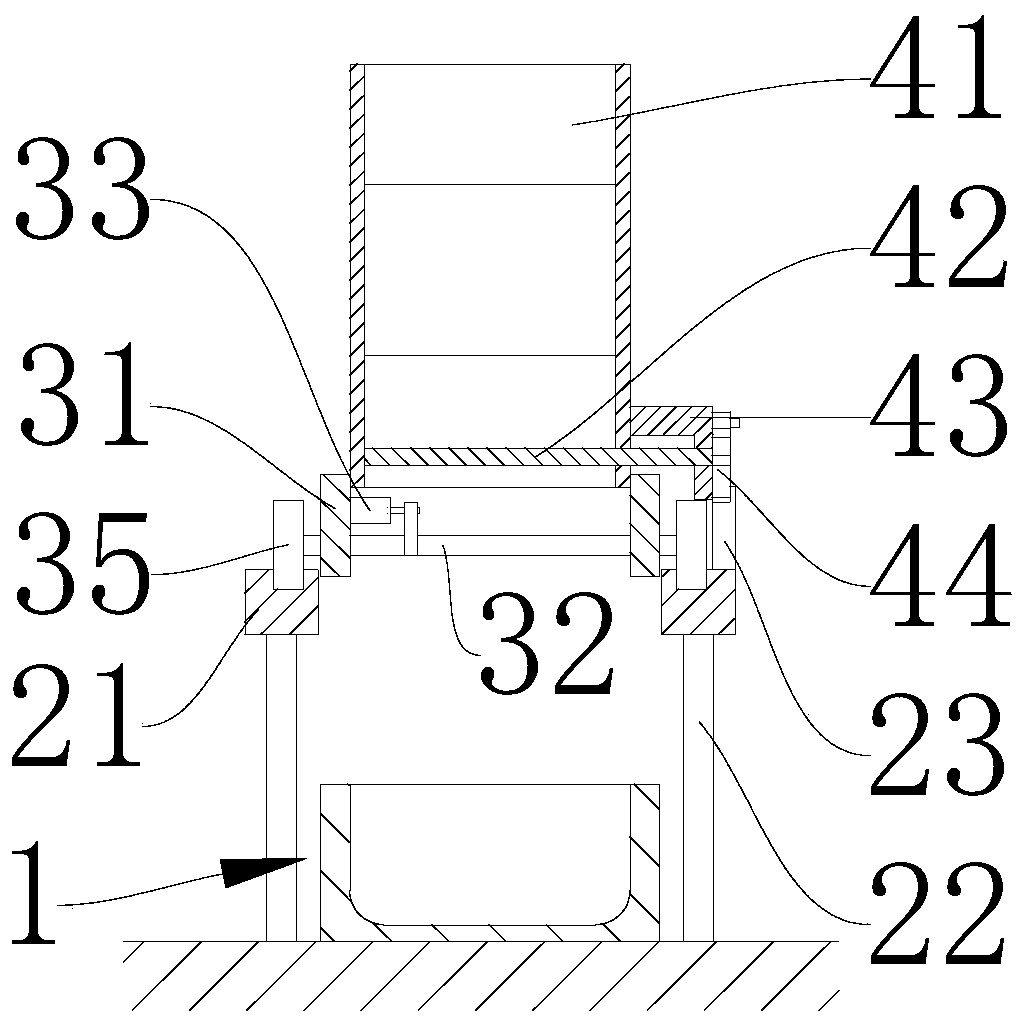

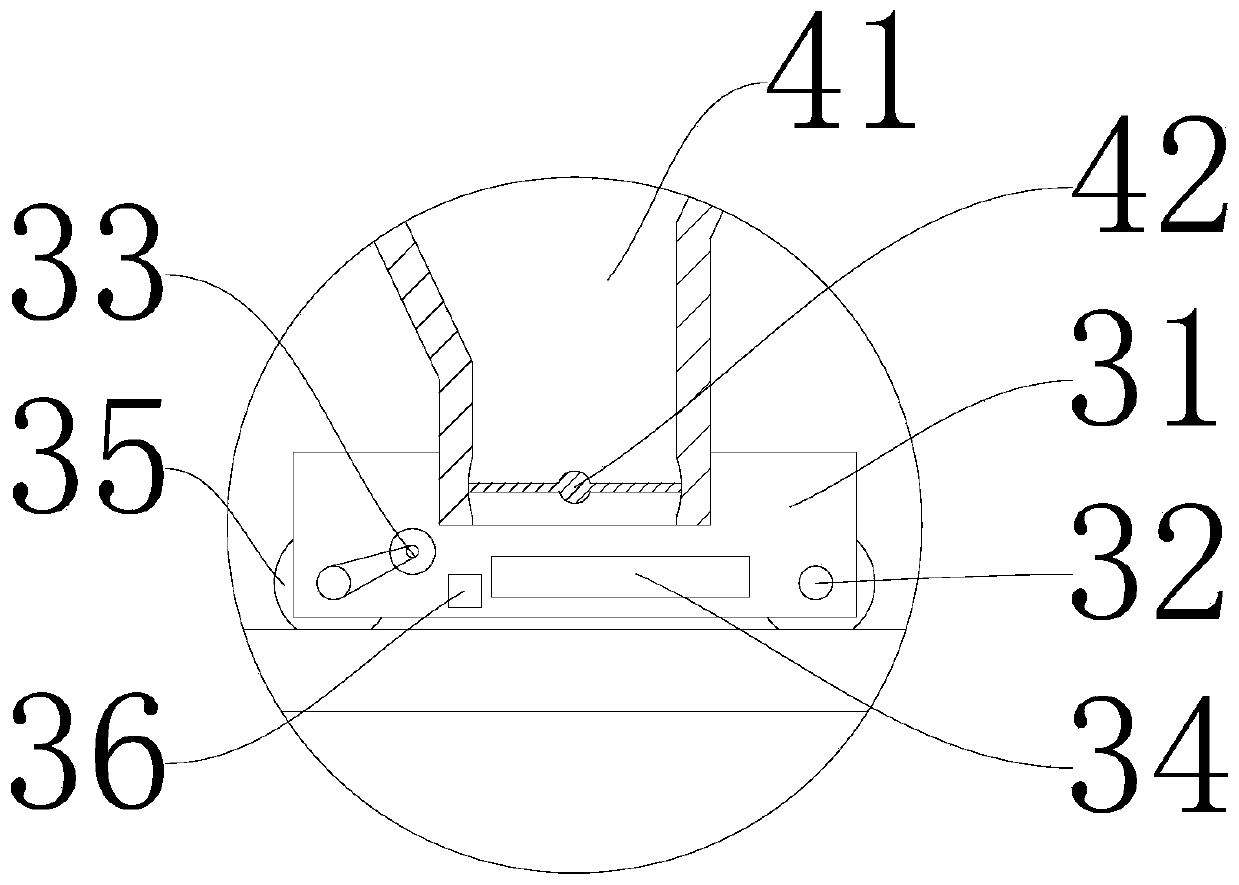

Machining equipment for square tubes

InactiveCN106624178AFully automatedImprove chamfer effectMetal working apparatusPositioning apparatusHydraulic cylinderEngineering

The invention provides machining equipment for square tubes. The machining equipment comprises a bracket and two clamping mechanisms arranged on the bracket. First positioning mechanisms are arranged on the two sides of the two clamping mechanisms. Chamfering mechanisms are arranged in grooves. First blanking holes and second blanking holes are formed in the bracket. A first blanking rail and a second blanking rail are arranged on the bracket. A second positioning mechanism is arranged between the two second blanking holes. The second positioning mechanism comprises first hydraulic cylinders which are arranged in a mirror manner. A through hole is formed in the position, between the two first hydraulic cylinders, of the bracket. A first support is fixedly arranged between first ejector rods of the two first hydraulic cylinders. At least two layered positioning blocks are fixedly arranged at the bottom of the first support. By means of the machining equipment for the square tubes, the square tubes can be machined in batches, inner chamfering and outer chamfering of the square tubes of various specifications can be conducted at the same time, automatic blanking and automatic discharging after machining is completed can be achieved, the degree of automation is high, the machining efficiency is improved, and the production cost is lowered.

Owner:天津福常科技有限公司

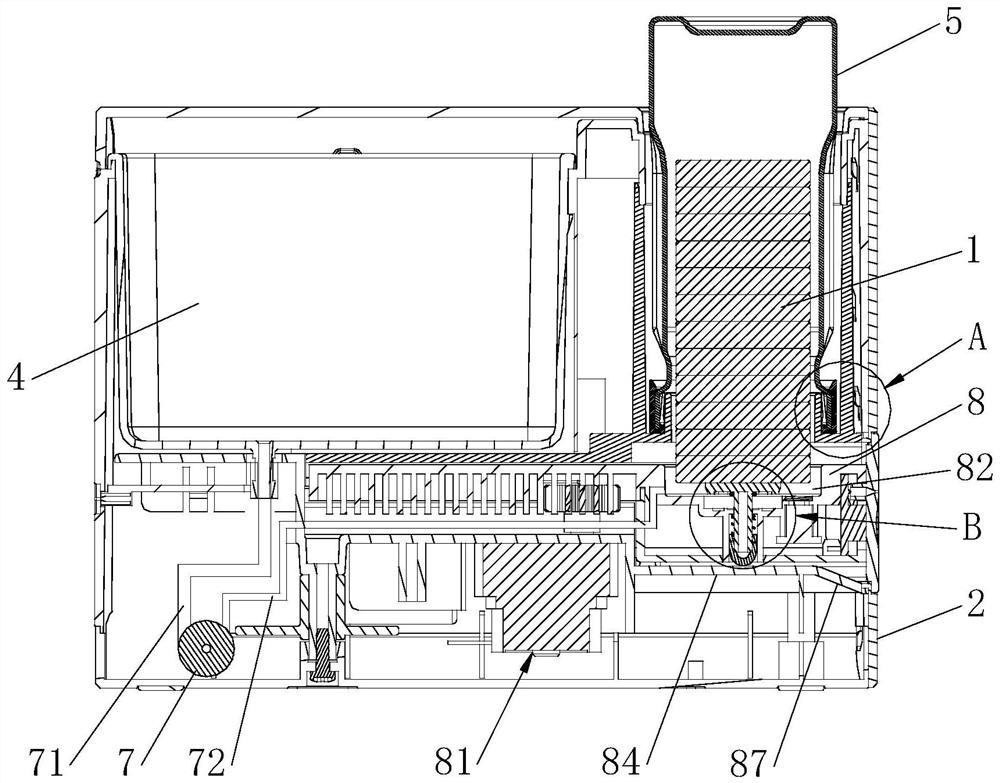

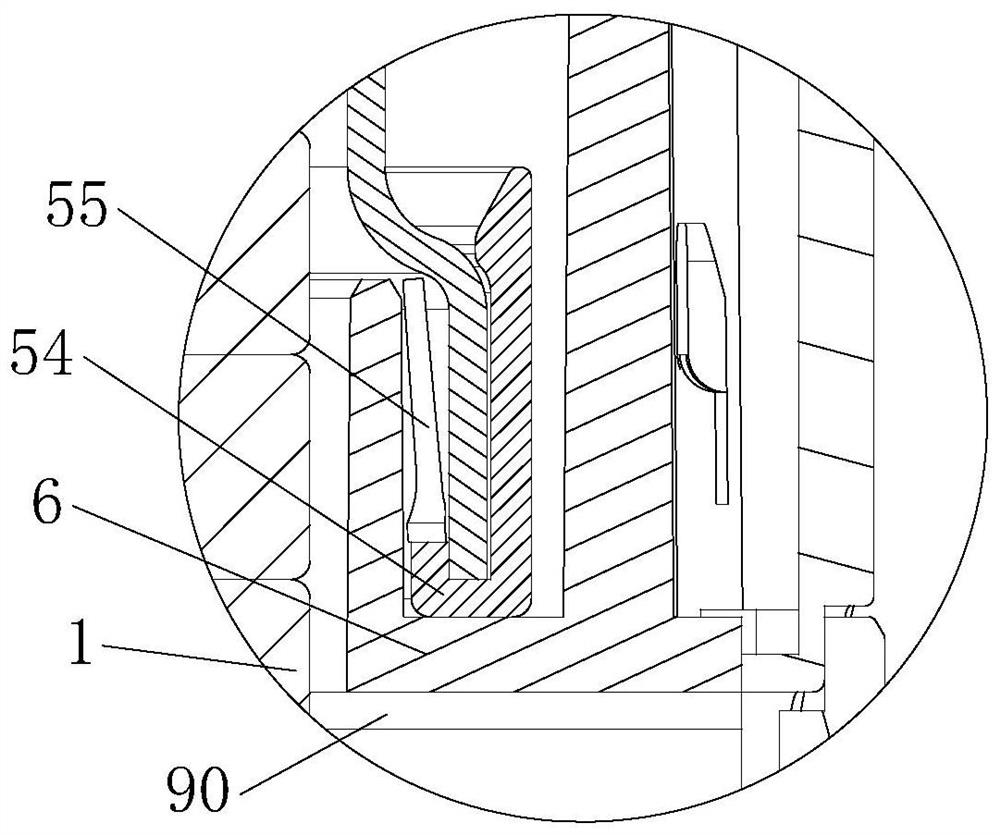

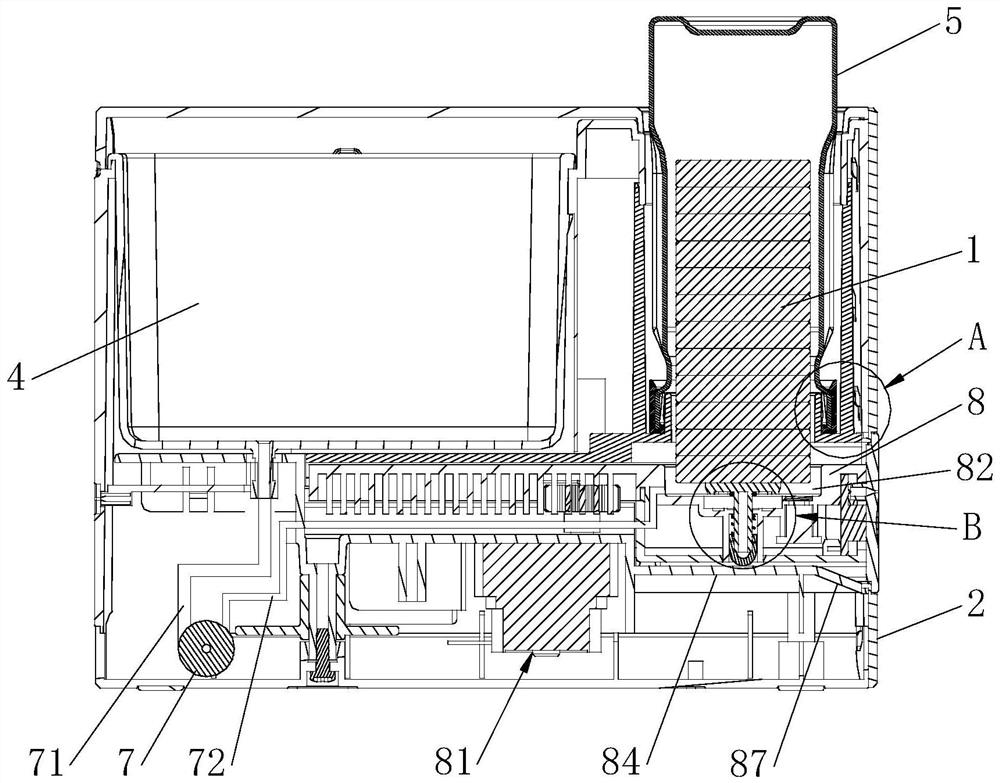

Instant wet tissue manufacturing device and method

InactiveCN112263171AGuaranteed immediacyEasy to useDomestic applicationsProcess engineeringIndustrial engineering

The invention relates to the technical field of wet tissues, in particular to an instant wet tissue manufacturing device and method. An instant wet tissue manufacturing device comprises a case, a control module, a storage module used for storing compressed tissue blocks to be soaked, a liquid storage module used for storing compressed tissue block soaking liquid, a soaking area used for soaking the compressed tissue blocks, and a liquid conveying module used for conveying the soaking liquid in the liquid storage module to the soaking area. The compressed towel block and the soaking liquid areseparately stored. The instant wet tissue manufacturing device is simple and reasonable in structure and suitable for daily use, the instantaneity of wet tissue production can be guaranteed, and the use effect of the produced wet tissue can be guaranteed.

Owner:FOSHAN NEWCURVE TECH CO LTD

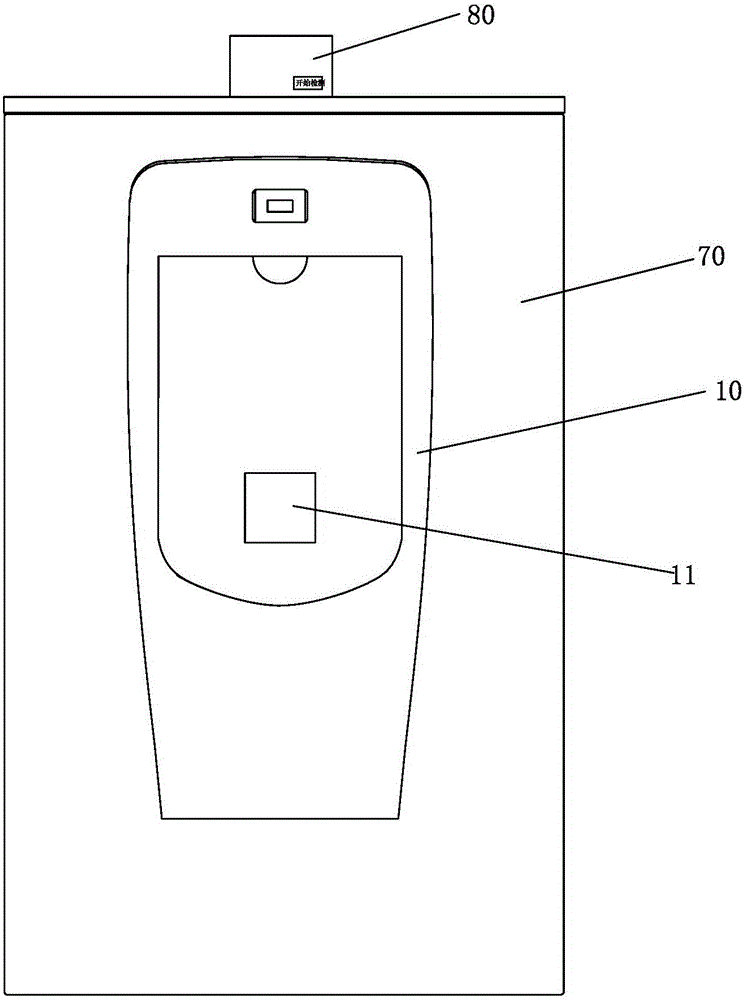

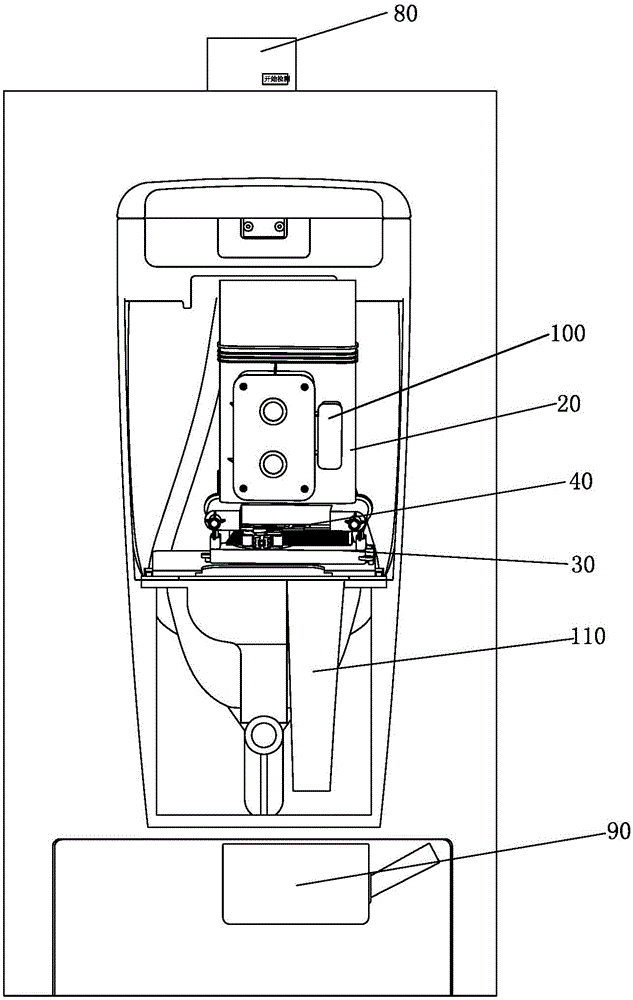

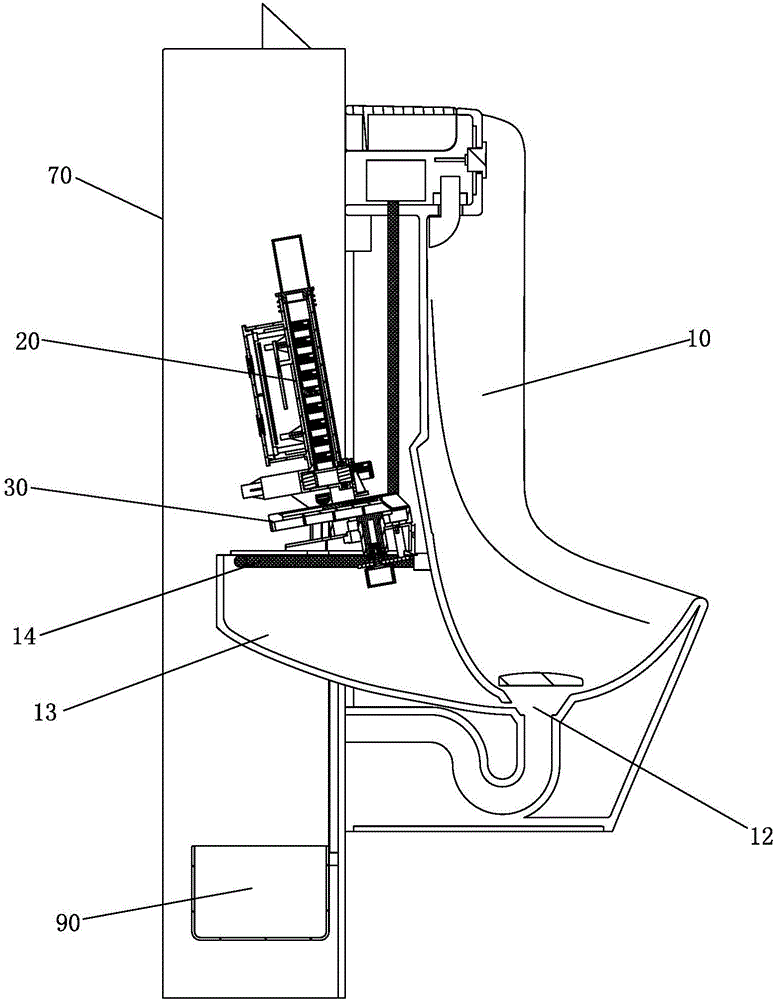

Urine detection device and method

ActiveCN106248920AHigh degree of automationImprove work efficiencyMaterial analysisComputer scienceTest strips

The invention discloses a urine detection device and method. The urine detection device comprises a urine detection assembly. The urine detection assembly comprises a feeding module, a conveying module and a data obtaining module, wherein the feeding module comprises a storage box, the storage box is provided with a plurality of test paper boxes, the test paper boxes contain urine detection test paper, the storage box is provided with a test paper box outlet, the conveying module drives the test paper boxes output from the outlet of the storage box to move so as to achieve urine sampling or urine detection data obtaining or discharging, and the data obtaining module is used for obtaining urine detection data of urine detection test paper soaked with urine in the test paper boxes. The device can automatically complete test paper box feeding, urine sampling, urine detection data obtaining, and is high in automation degree and working efficiency, more intelligent, low in overall cost, high in practicability and easier to popularize.

Owner:JOMOO KITCHEN & BATHROOM

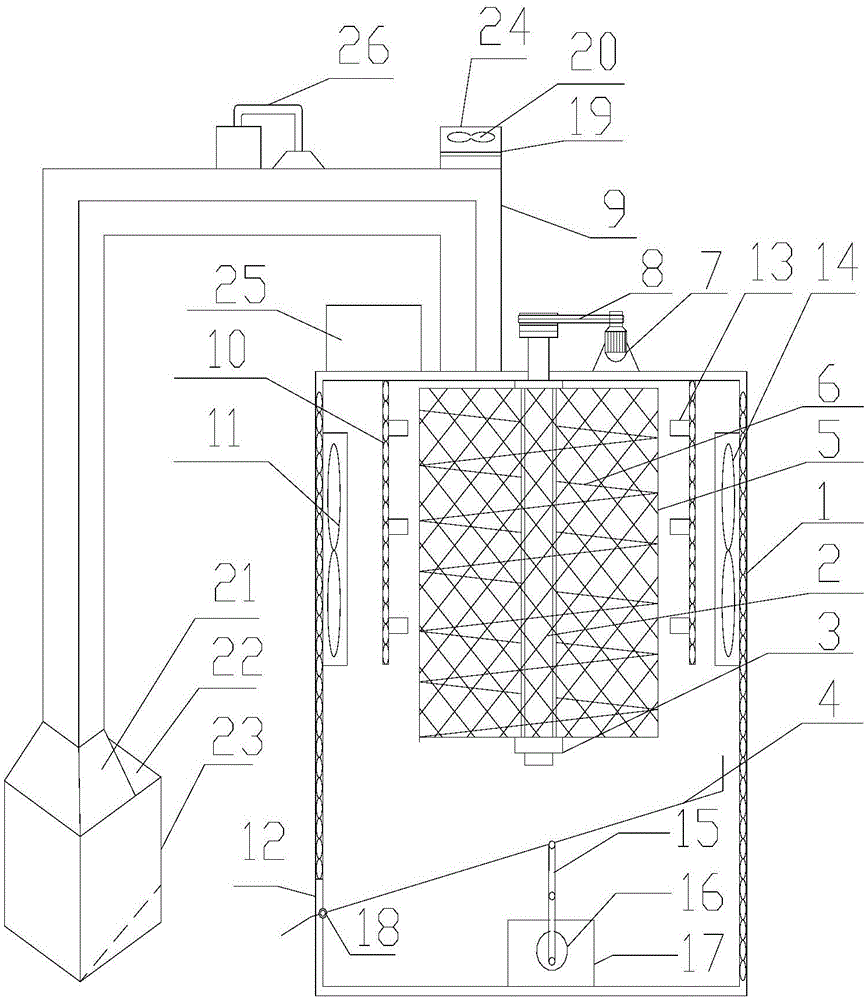

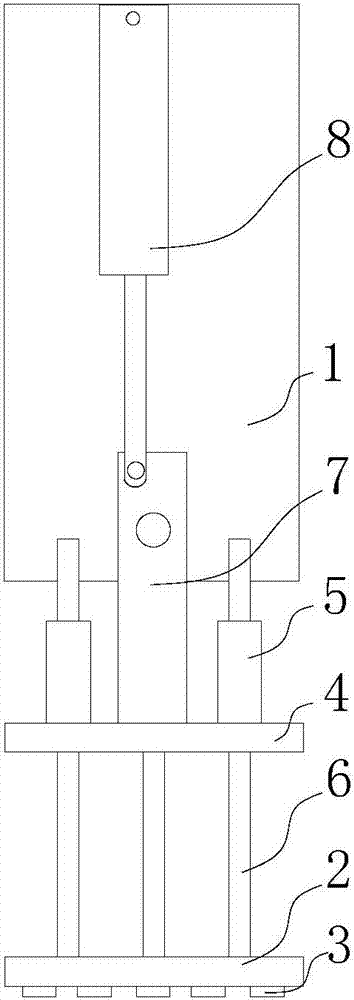

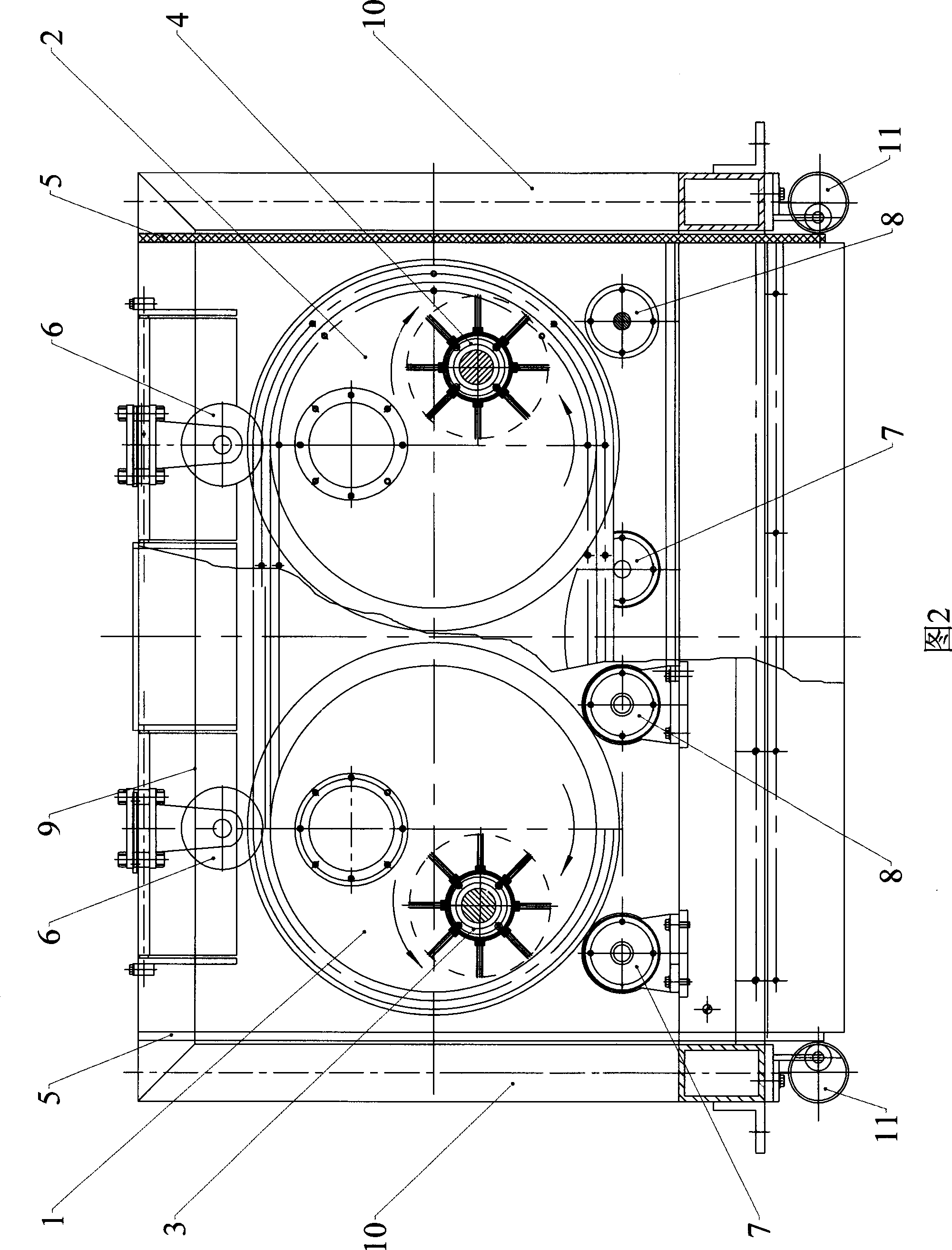

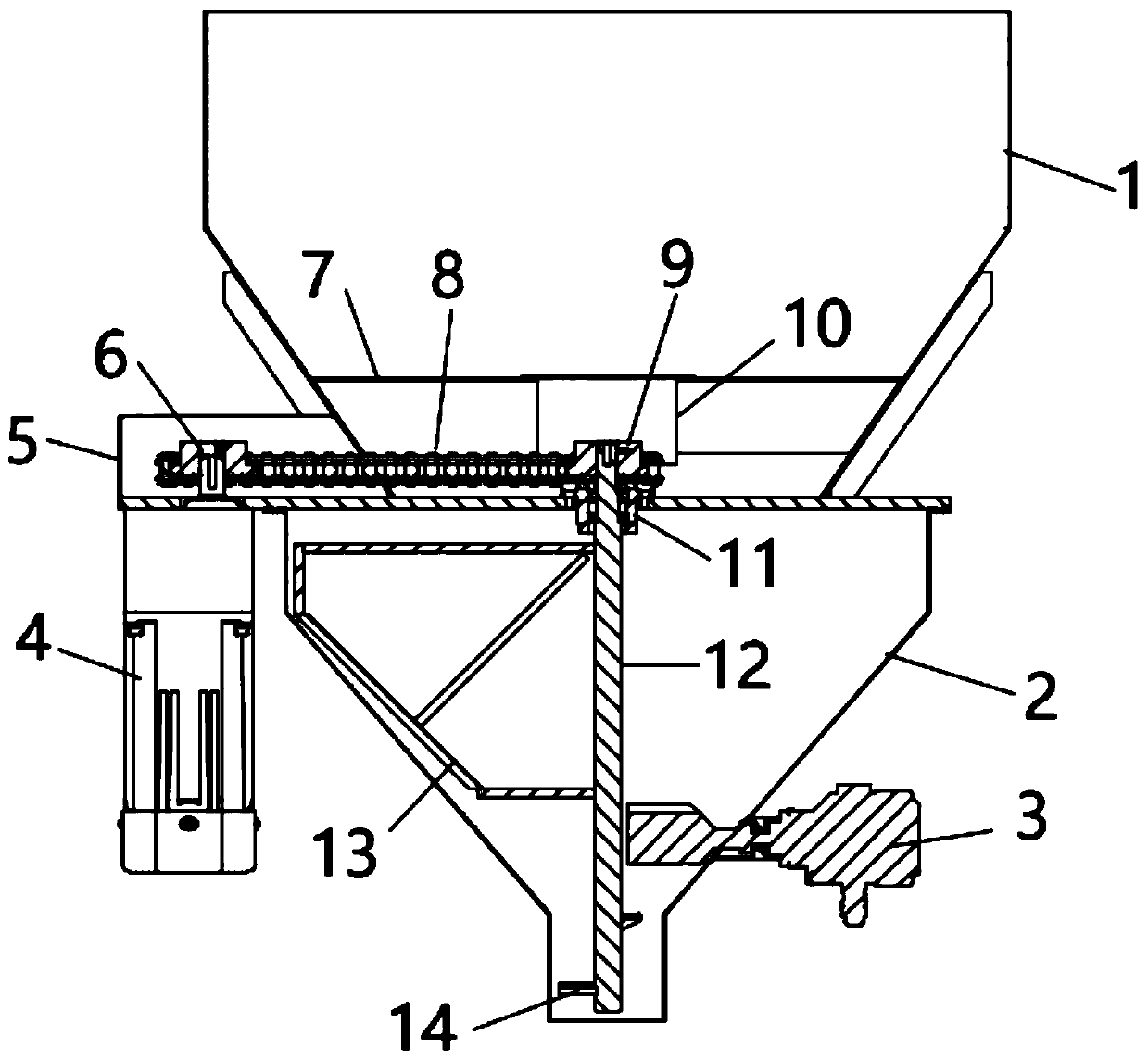

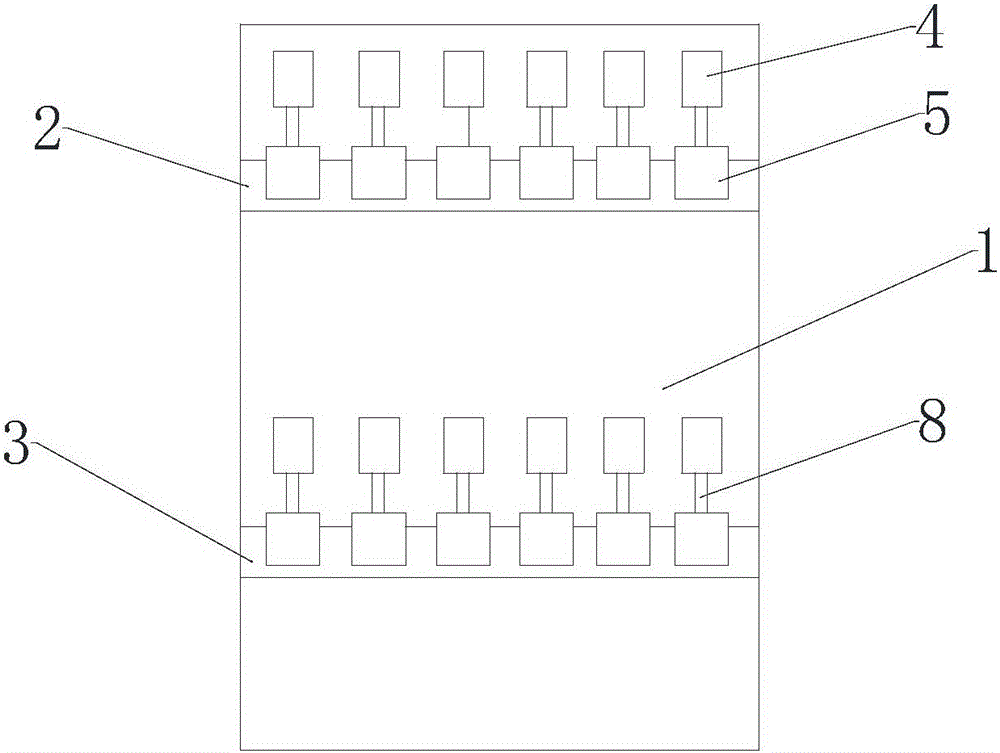

Vertical full-automatic capsule drying device

ActiveCN105157392AImprove drying efficiencySmooth blankingDrying chambers/containersDrying solid materialsEngineeringDust collector

The invention discloses a vertical full-automatic capsule drying device. The vertical full-automatic capsule drying device comprises a box body, a rotating shaft, a drying barrel mounting clamping ring, a discharging plate, a drying barrel, a spiral guiding plate, a rotating shaft motor, a conveying belt, a feeding pipe, infrared device fixing plates, a fan, a discharging outlet, infrared generating devices, an exhaust fan, a connecting rod, an eccentric wheel, a motor, a hinge, a filter screen, a powerful negative pressure fan, a feeding inlet, a charging hole, a storage box, a negative pressure fan storage box, a negative pressure fan controlling device and a dust collector. According to the vertical full-automatic capsule drying device, the principle of infrared heating drying and the meshed drying barrel with the two ends open are adopted, and therefore the phenomena that capsules are deformed, melted, adhered and partially hardened due to uneven heating are effectively avoided; the dust collector is mounted on the feeding pipe, so that dust removing of the capsules is achieved while the capsules are dried.

Owner:浙江宏辉胶丸有限公司

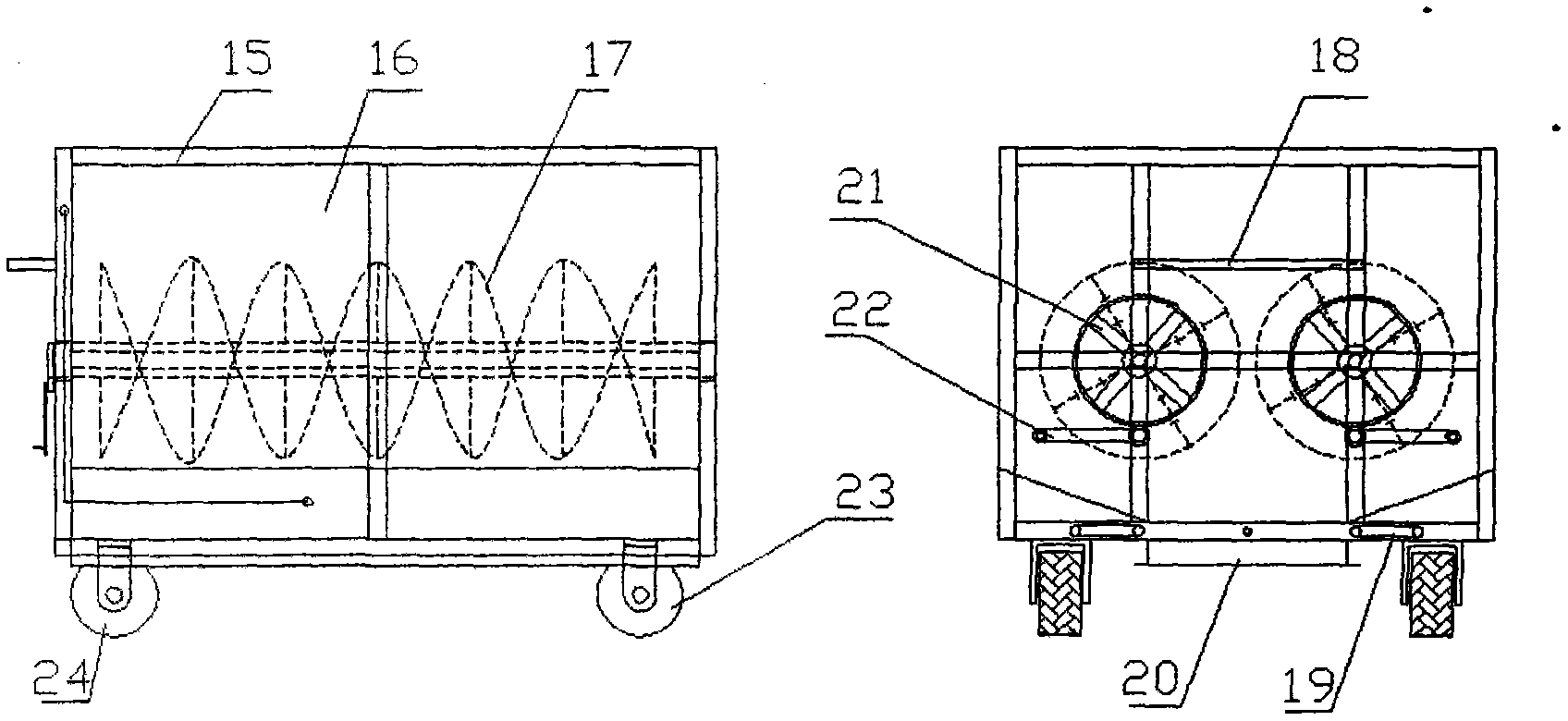

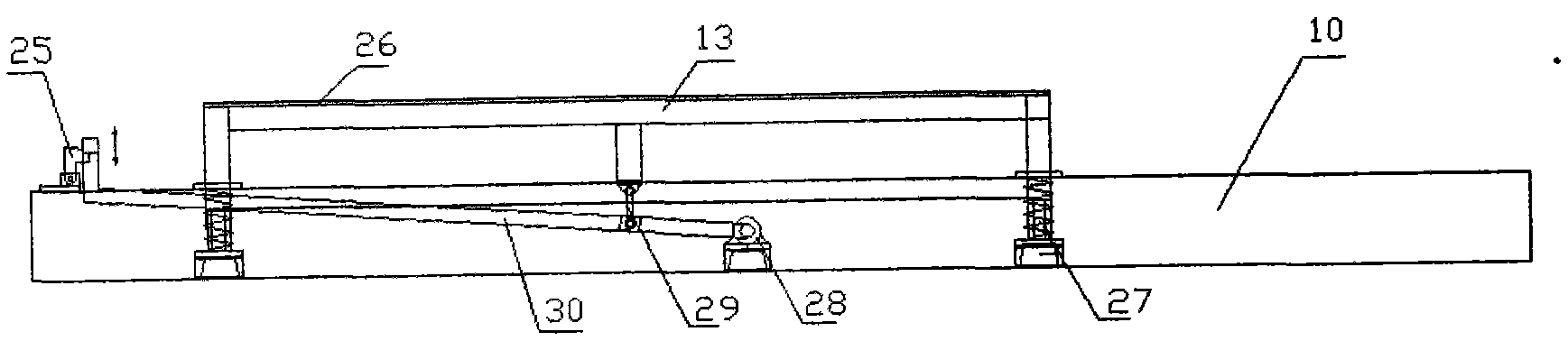

Convenient energy-saving static OAR (Organics Aerobic oxidation Resources) treatment device

ActiveCN104016746AIncrease profitSolve shipping problemsClimate change adaptationEnergy inputCartWater pipe

The invention provides a convenient energy-saving static OAR (Organics Aerobic oxidation Resources) treatment device, belonging to the field of the technical equipment for solid waste organics resource utilization. The device is composed of a transfer fermentation cart, a base, an aeration system, a heat preservation chamber, a solar power generation system, a control system, a spraying system, an exhaust system and a filtrate pipe. The transfer fermentation cart is a movable part; after the transfer fermentation cart is loaded with materials, the transfer fermentation cart is pushed into the heat preservation chamber; the heat preservation chamber is connected with the base; the aeration system is powered by the solar power generation system; the solar power generation system is mounted on a cross beam of two upright columns; the control system comprises a temperature sensor, an overall control cabinet and the like; the temperature sensor is mounted on a side part of the transfer fermentation cart, and the overall control cabinet is mounted on the side surfaces of the upright columns; the spraying system is connected with a tap water pipe and is capable of adjusting the moisture content of materials; the exhaust system is mounted at the top of the heat preservation chamber so as to discharge stink generated in the fermentation process. The device is simple in structure, low in energy consumption, high in efficiency, simple and convenient to operate, and suitable for treating solid waste organics.

Owner:北京圣海林生态环境科技股份有限公司 +2

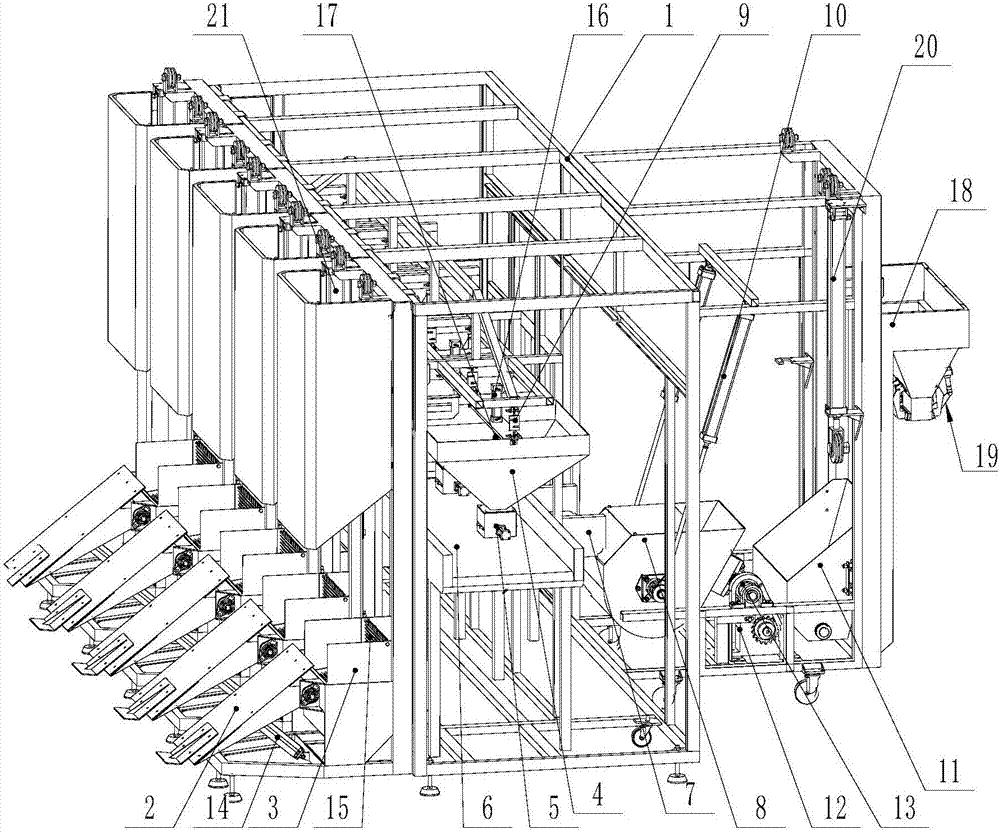

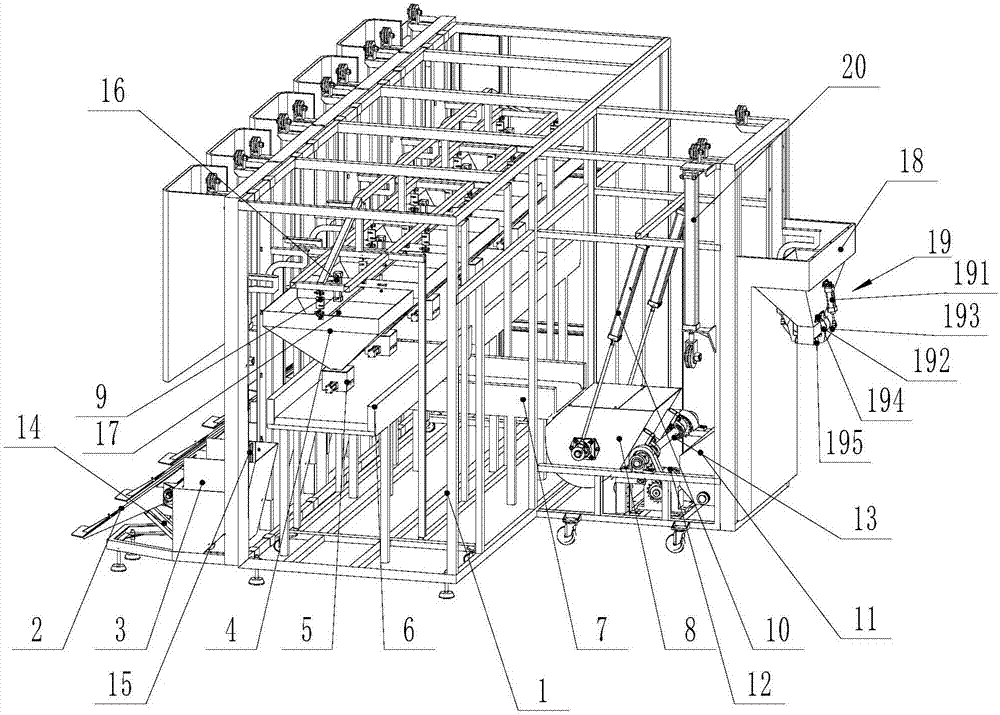

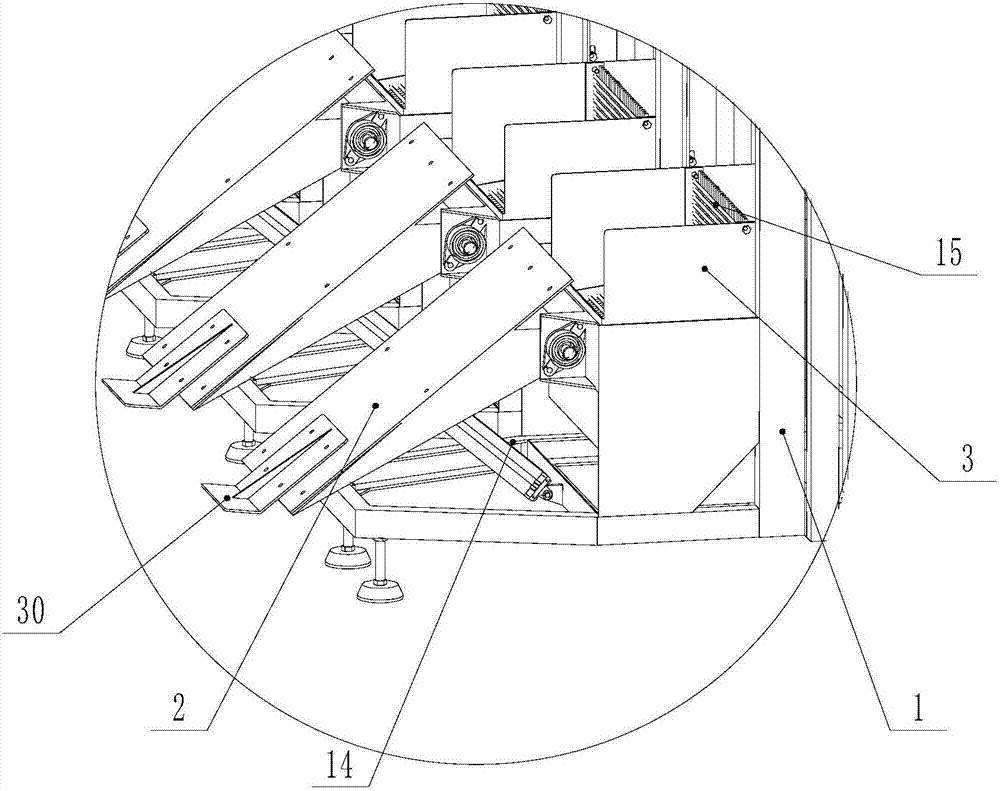

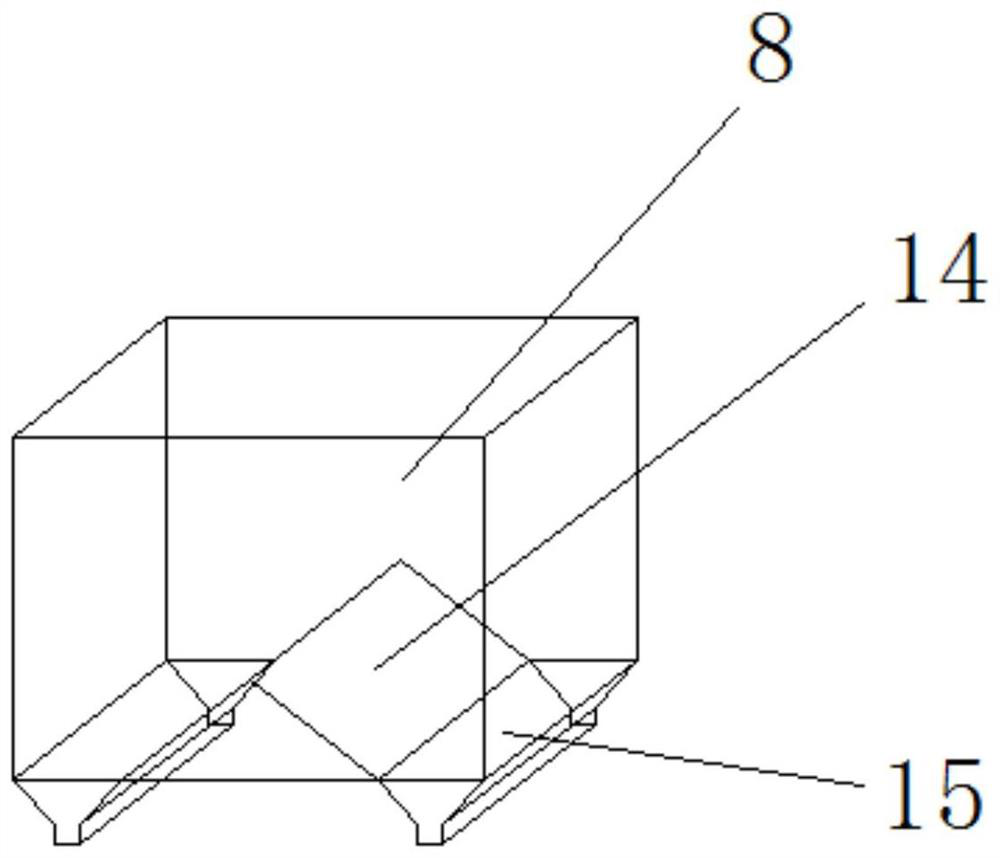

Automatic fertilizer allocation machine and fertilizer allocation method

InactiveCN106964276AImplement automatic configurationImplement baggingRotary stirring mixersTransportation and packagingAgricultural engineeringEngineering

The invention discloses an automatic fertilizer allocation machine and a fertilizer allocation method. The fertilizer allocation machine comprises a rack and at least two feed lifting turnover devices, wherein weighing devices are used for receiving fertilizers which are turned over and dumped by the corresponding feed lifting turnover devices; the weighed fertilizers are conveyed to a stirring transfer device by a belt conveying device, stirred, turned over and dumped to a discharge hopper; and then the discharge hopper is lifted and turned over into a bagging device for bagging. According to the automatic fertilizer allocation machine and the fertilizer allocation method, various fertilizers can be automatically weighed, stirred and bagged, so that the fertilizer allocation efficiency is improved; the fertilizer allocation stability is higher; and the labor intensity of a worker is reduced.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

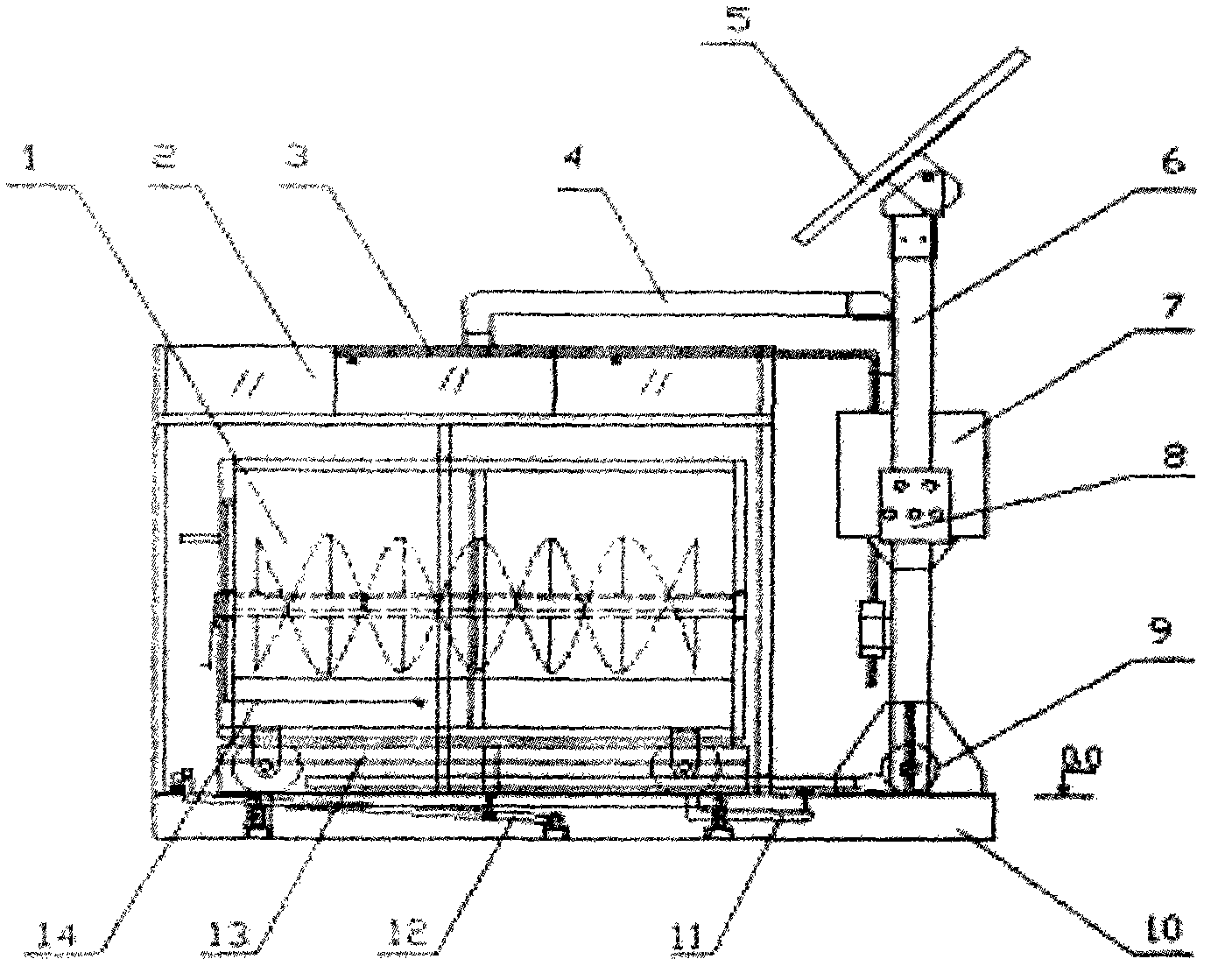

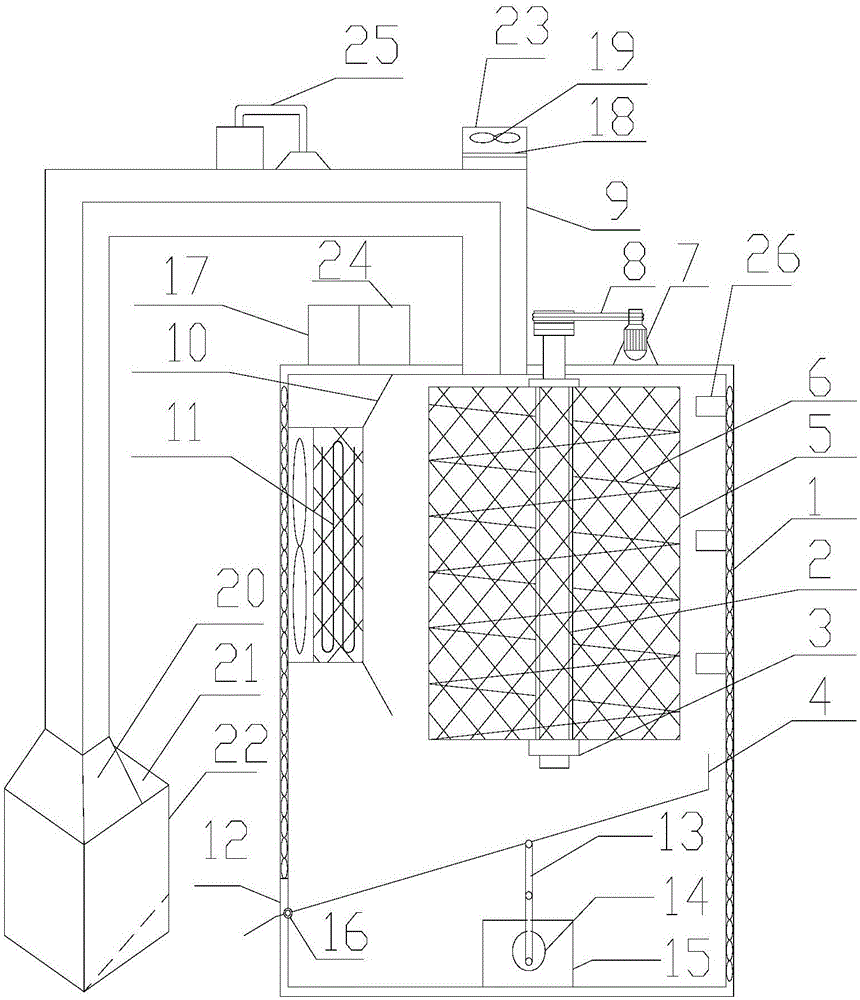

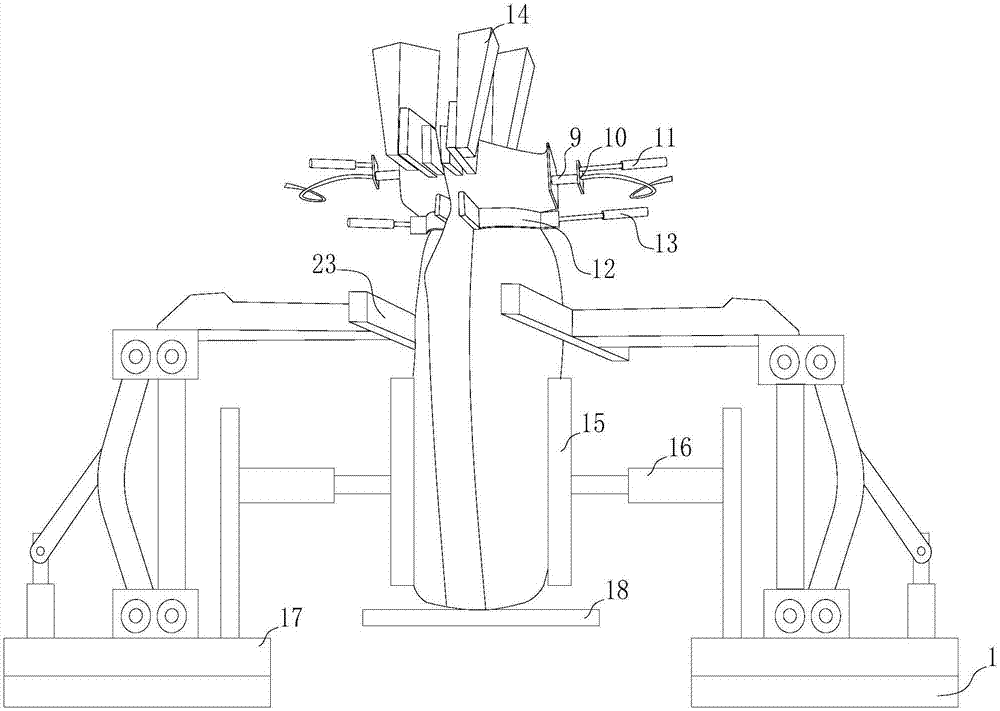

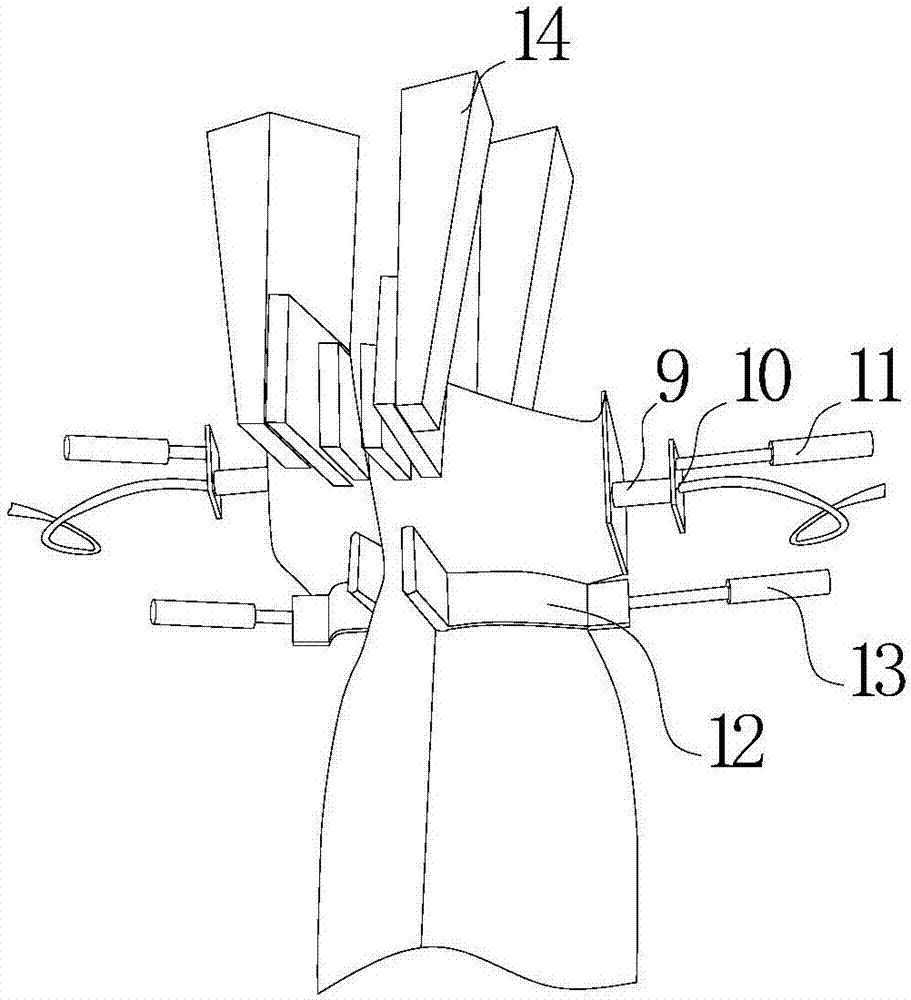

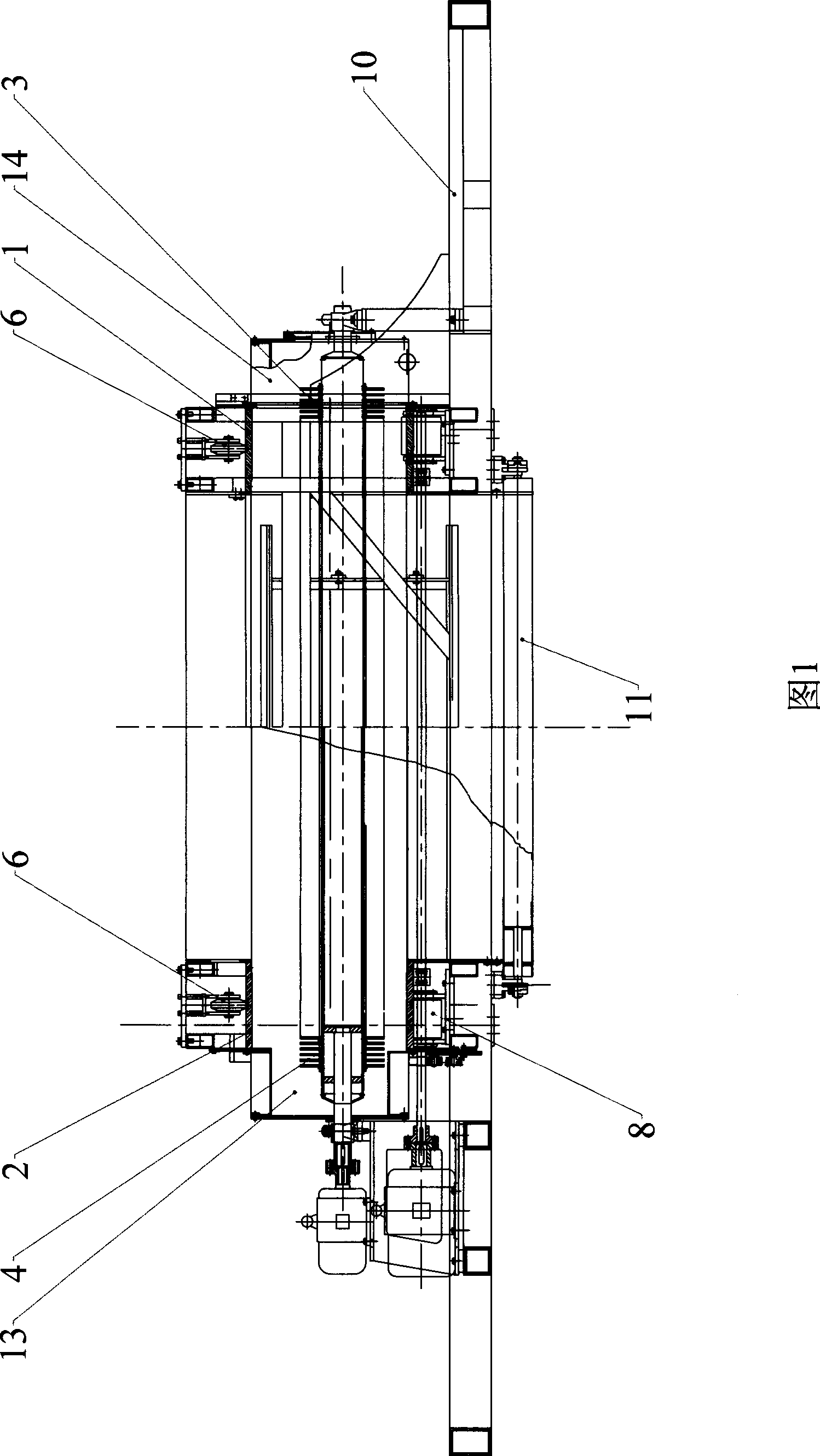

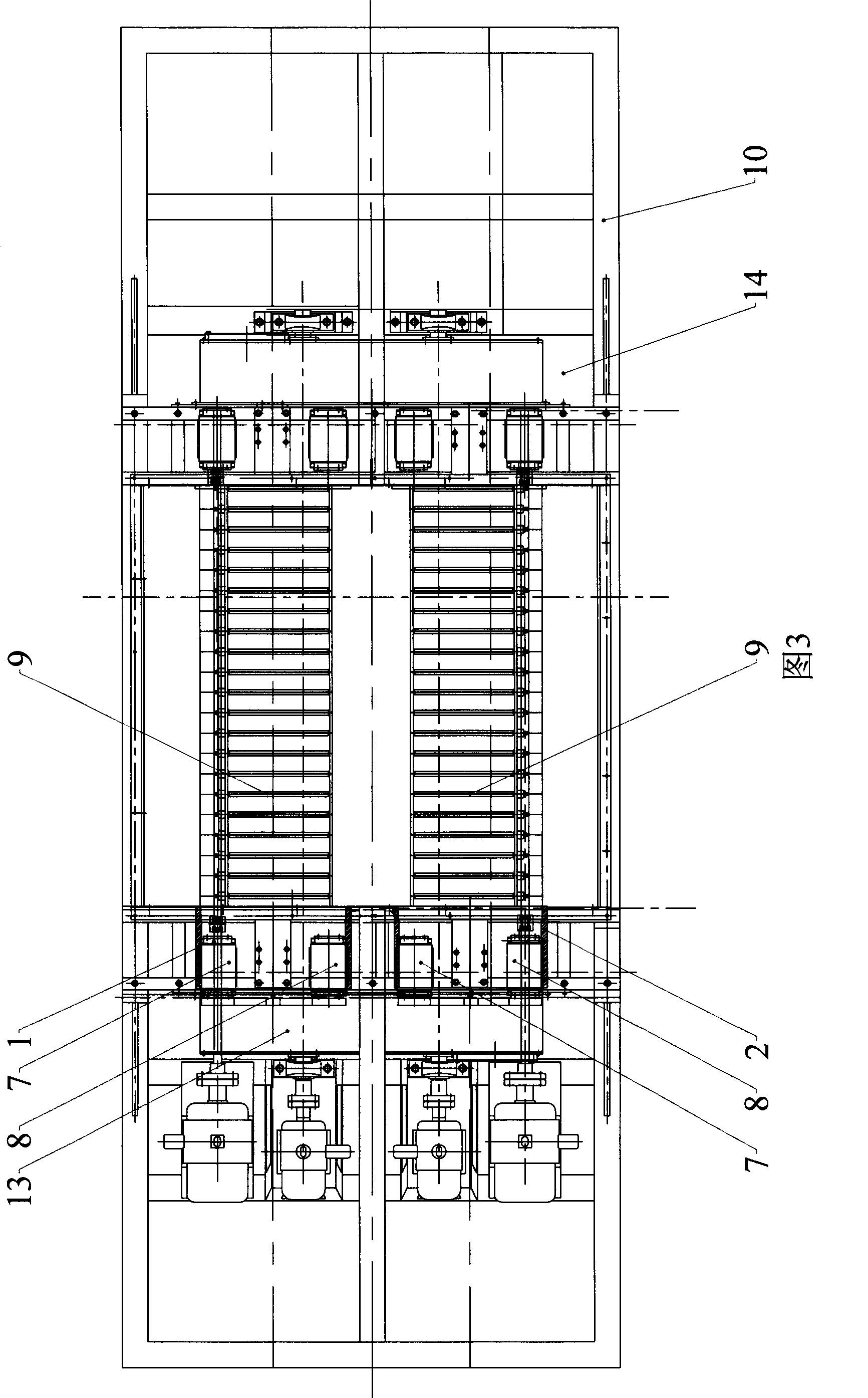

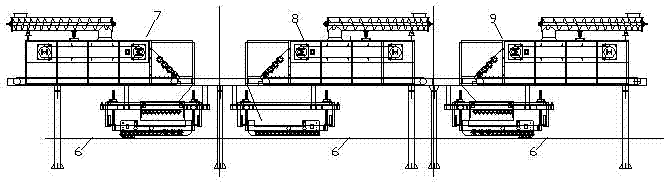

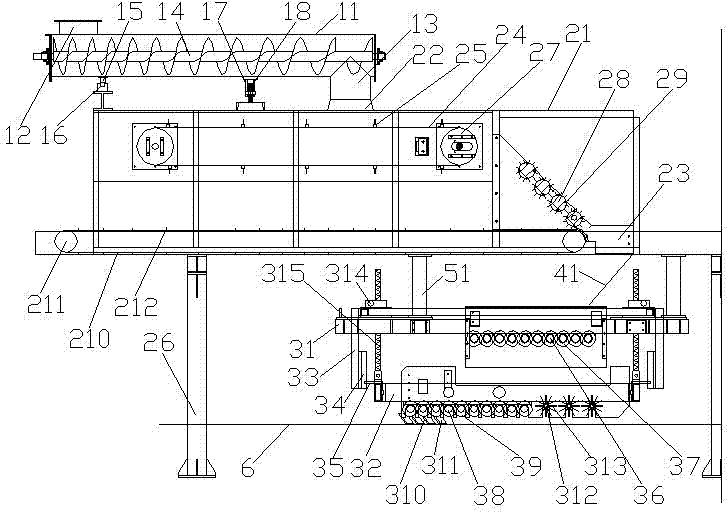

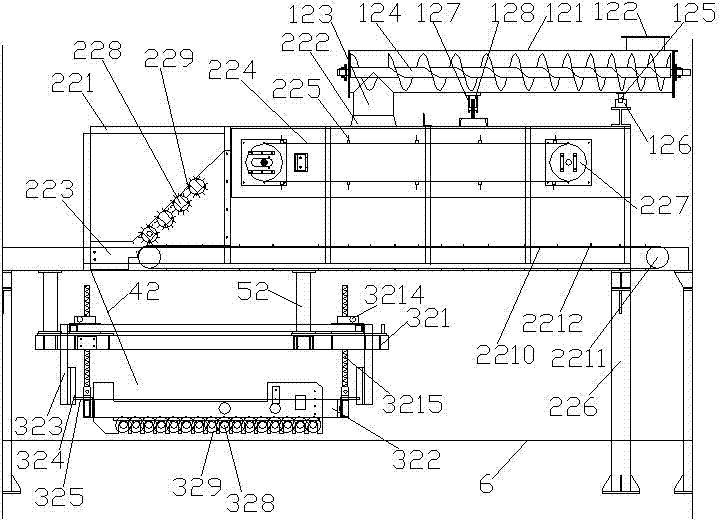

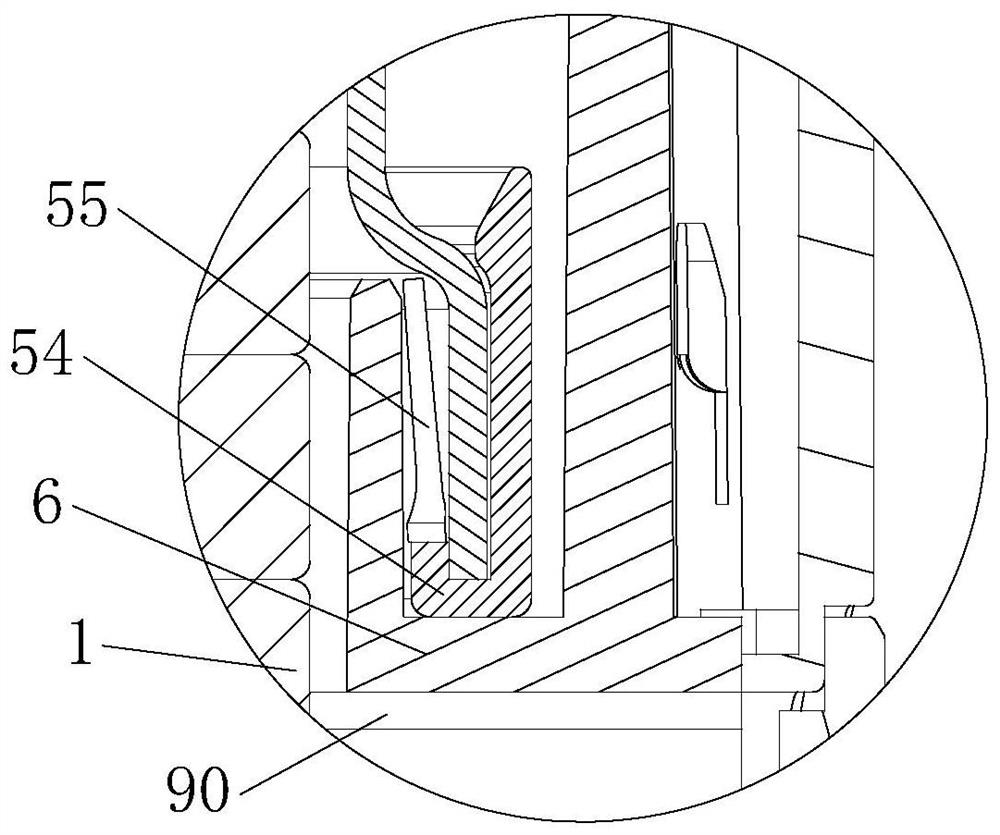

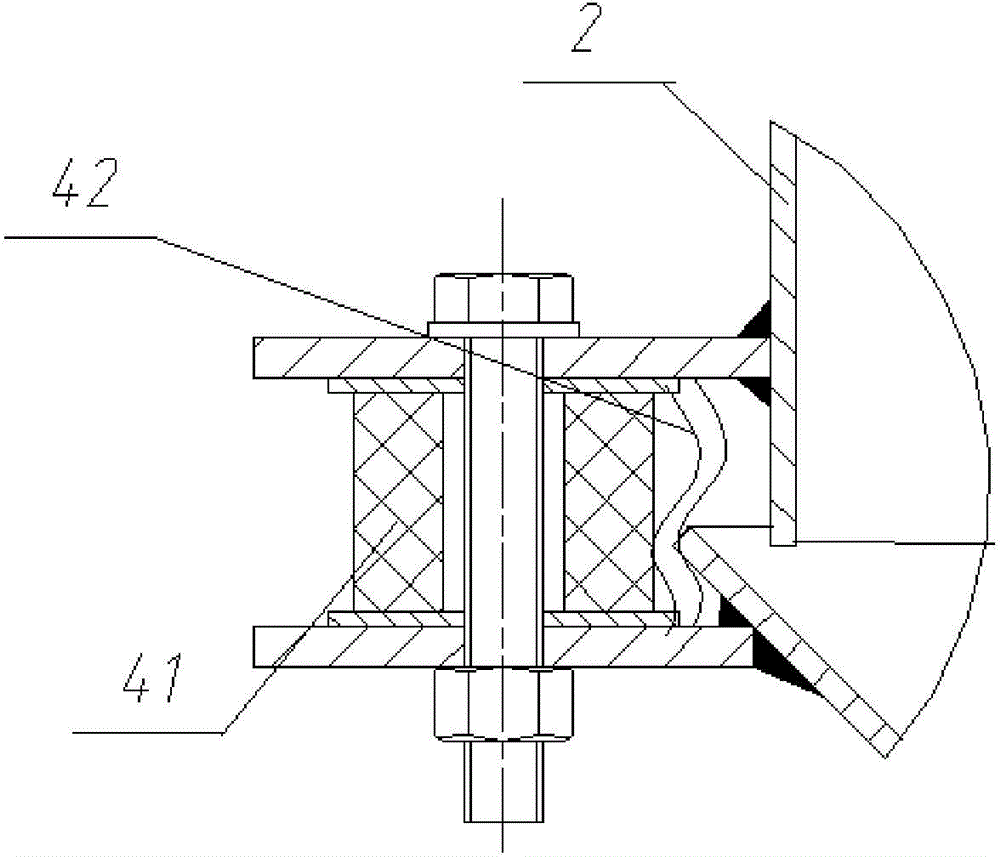

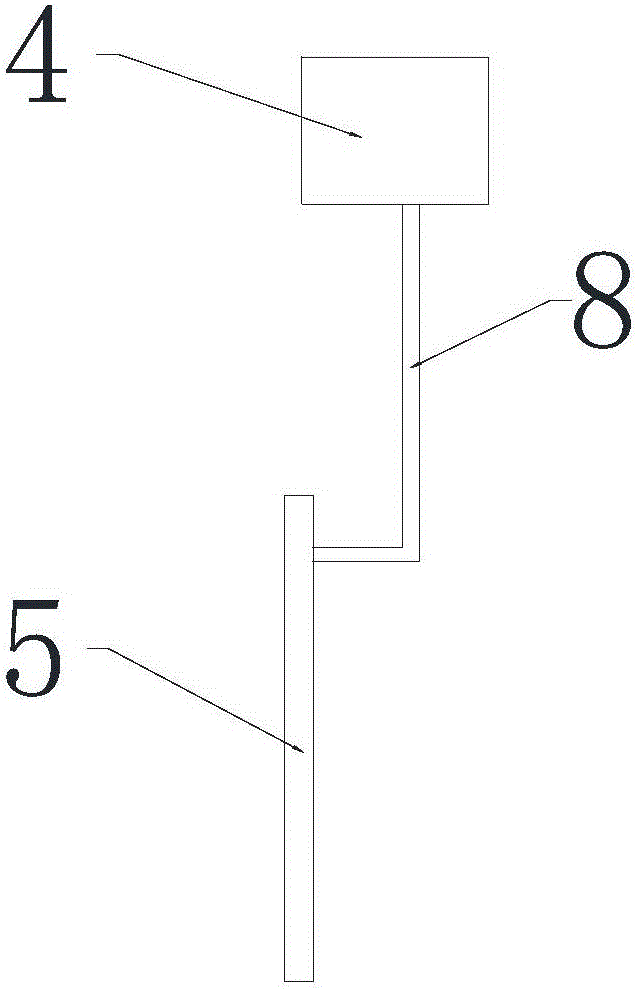

Full-automatic screw type capsule drying machine

ActiveCN105091543AHomogenization and rapid dryingBlanking evenlyDrying gas arrangementsDrying solid materialsInductorEngineering

The invention discloses a full-automatic screw type capsule drying machine which comprises a box body, a rotating shaft, a drying cylinder installation clamping ring, a discharging plate, a drying cylinder, a spiral guiding plate, a rotating shaft motor, a conveyor belt, a feeding pipe, an air flue expansion board, an electric heating fan, a discharging opening, a connecting rod, an eccentric wheel, a motor, a hinge, a negative pressure fan control device, a filter net, a strong negative pressure fan, a feeding opening, a charging opening, a storage box, a negative pressure fan placement box, an electric heating fan control device, a dust remover and a temperature inductor. The manner that the two ends of the net-shaped drying cylinder are opened and the mesh screw guiding plate is additionally arranged inside the mesh drying cylinder is adopted, so that the capsule drying efficiency is greatly improved, and then the phenomena that due to the fact that heating is uneven, capsule deformation, melting and adhesion are caused and partial capsules are hardened are effectively avoided. According to the full-automatic screw type capsule drying machine, the dust remover is installed on the feeding pipe, so that dust removal is performed on the capsules while the capsules are dried.

Owner:浙江宏辉胶丸有限公司

Ultrafine powder packaging machine

The invention relates to an ultrafine powder packaging machine. The ultrafine powder packaging machine comprises a film delivery system, a packaging system and a bag holding system sequentially from front to back according to the sequence of a technical process, and the film delivery system, the packaging system and the bag holding system are arranged on a machine frame. The film delivery system comprises a film sucking mechanism and a turning mechanism. The packaging system comprises a flaring mechanism, a clamping mechanism and a feeding mechanism. The feeding mechanism comprises an inner barrel and an outer barrel, and the inner barrel and the outer barrel are fixedly connected and can move vertically relative to the machine frame. An exhaust pipe is arranged on the outer side of the outer barrel and can move vertically relative to a sealing ring. A filter element for filtering ultrafine powder is arranged in the exhaust pipe. The exhaust pipe communicates with an exhaust fan outside. The clamping mechanism is used for enabling a plastic film to be partially pasted to the outer barrel. The bag holding system comprises a bag holding mechanism. The ultrafine powder packaging machine provided by the invention can package powdery materials, manual feeding and discharging are not needed, the degree of automation is high, the processing efficiency is high, and no dust flies in the packaging process.

Owner:合肥正远智能包装科技有限公司

Shaper for dust-free paper production line

InactiveCN101362357AImprove adjustabilityNo partial stackingWood working apparatusDomestic articlesFiberProduction line

Owner:JIEYANG JIEXIN PAPER IND

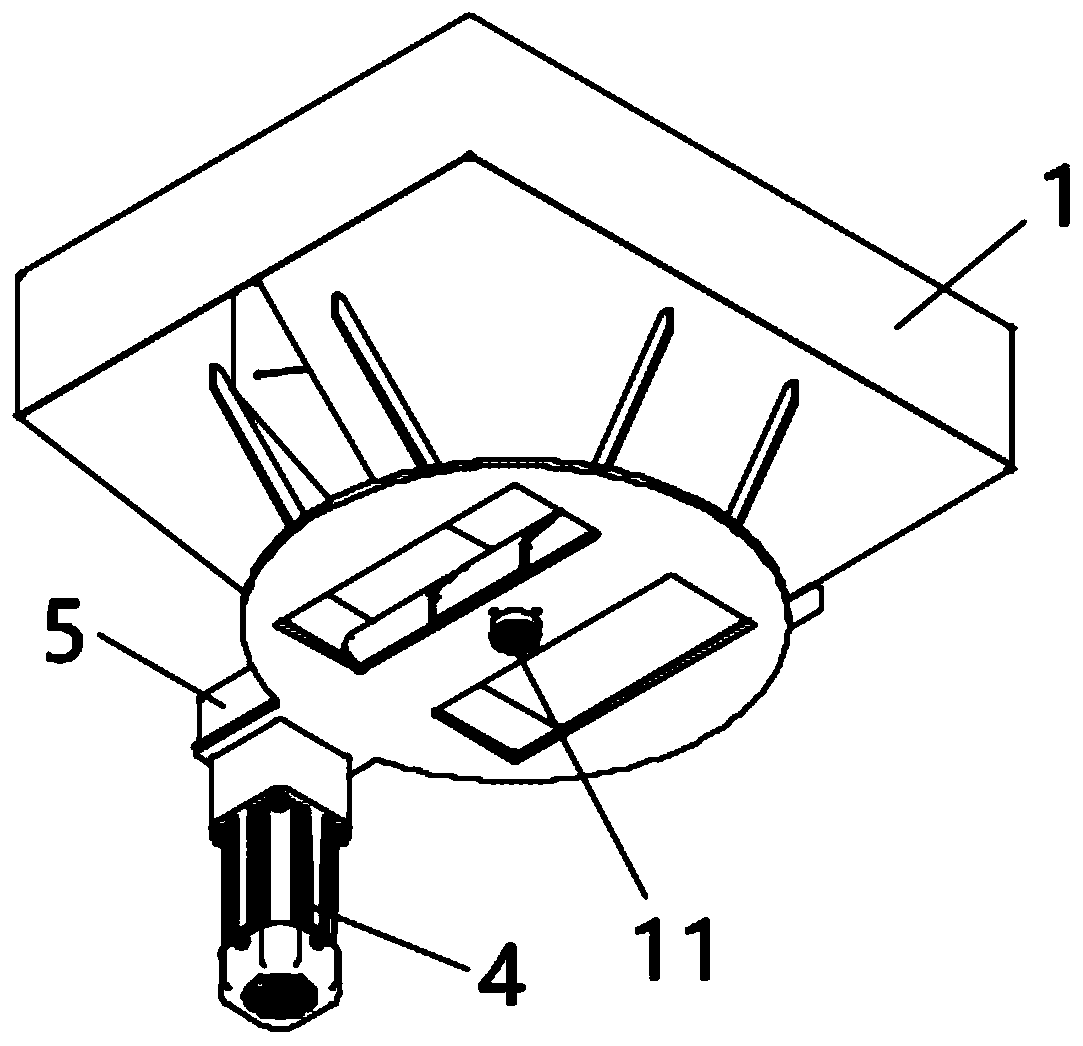

Uniform-discharging fertilizing machine

InactiveCN108419495ABlanking evenlySolve the problem of uneven blankingFertiliser distributersMotor driveFertilizer

The invention provides a uniform-discharging fertilizing machine which comprises a first working bin, a second working bin, a third working bin and a screen. A first supporting plate is welded on theleft side of the second working bin, a motor is fixedly mounted at the top of the first supporting plate, a first bevel gear is fixedly mounted on the rotating shaft of the motor, a first rotating block is welded at the bottom of the first supporting plate, a transmission rod is rotatably connected inside the first rotating block, and the top of the transmission rod sequentially penetrates the topof the first rotating block and the bottom and the top of the first supporting plate and is fixedly mounted with a second bevel gear. Compared with the prior art, the uniform-discharging fertilizingmachine has the advantages that when the machine is in use, fertilizers are put into the second working bin first, then the motor is started, the rotating shaft of the motor drives a second connectionrod to rotate, the second connection rod stirs and mixes different fertilizers in the second working bin and breaks up some caked fertilizers, and a cylinder is started after mixing of the fertilizers in the second working bin is completed.

Owner:刘烨

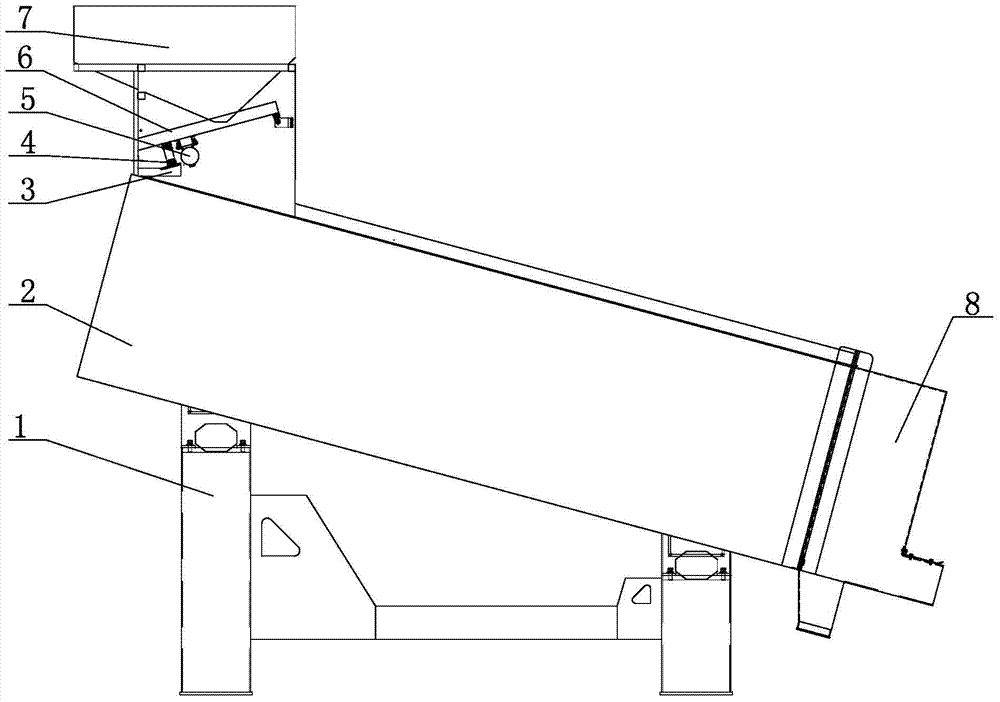

Automatic feeding device of grain cleaning sieve

The invention relates to an automatic feeding device of a grain cleaning device, and belongs to the field of grain cleaning equipment. The automatic feeding device of the grain cleaning device comprises a rack, a sieve body, a feeding box and a discharging box and is characterized in that a downward-inclining vibration plate is arranged below an outlet of the feeding box, and the vibration motor is arranged at the bottom of the vibration plate; the top end of the vibration plate is hinged to the inner wall of the rack, and the lower end of the vibration plate is a discharging end; and a vibration spring is connected to the bottom of the discharging end, and is mounted on the rack through a support. The automatic feeding device is simple and reasonable in structure, and grains fall in the vibration below the feeding box from the feeding box; through the vibration plate, the defined amount of materials can be evenly fed in the sieve body to be cleaned and sieved, and the vibration amplitude and the vibration frequency of the vibration plate can be controlled by adjusting the vibration motor, so that the needed grain feeding effect is achieved; and material falling is even, the material falling speed and the feeding amount are controllable, and the automation level is high.

Owner:SHANDONG YIKAI STORAGE ENG

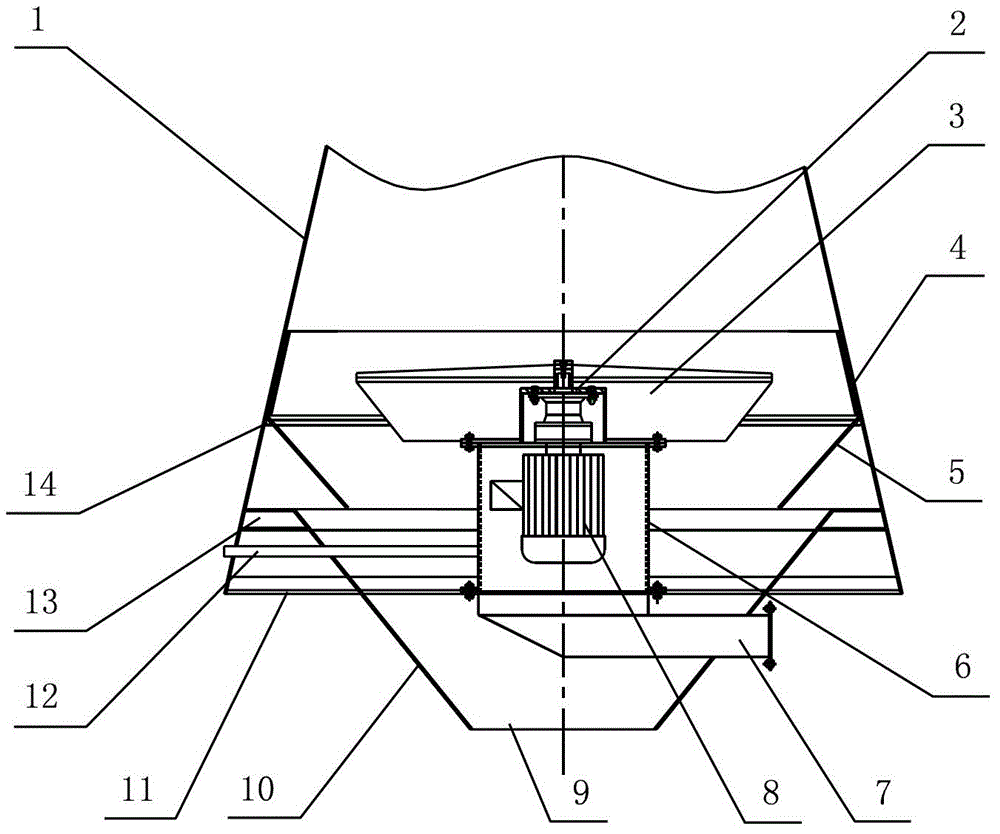

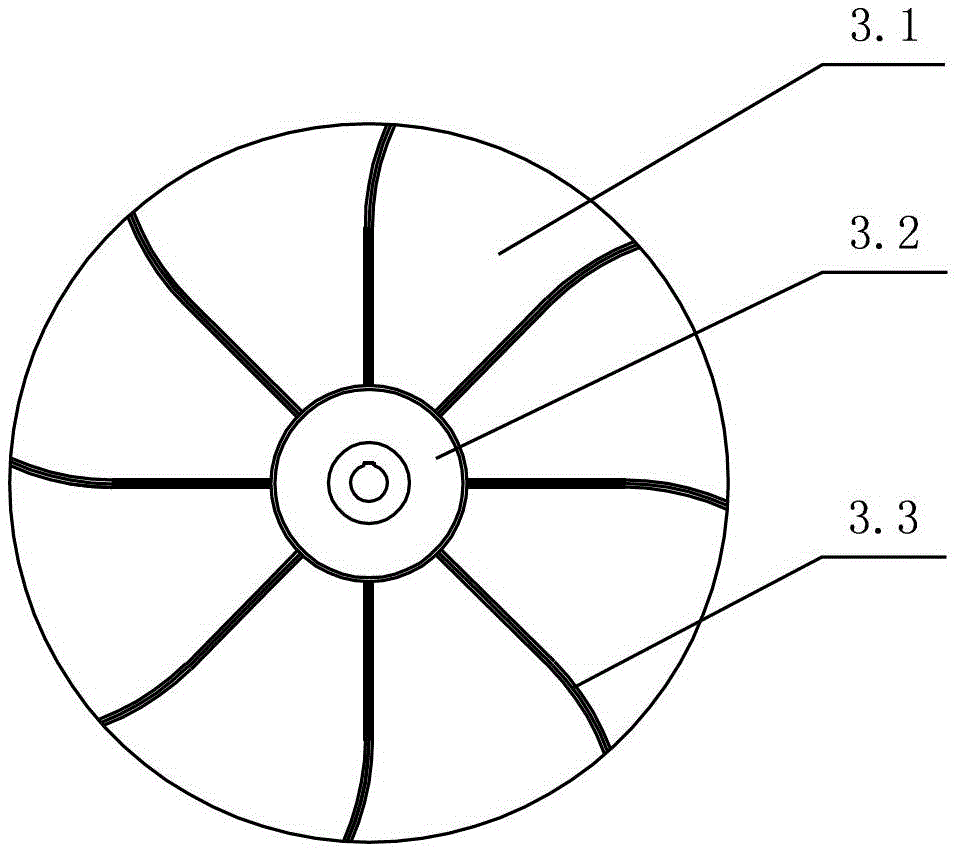

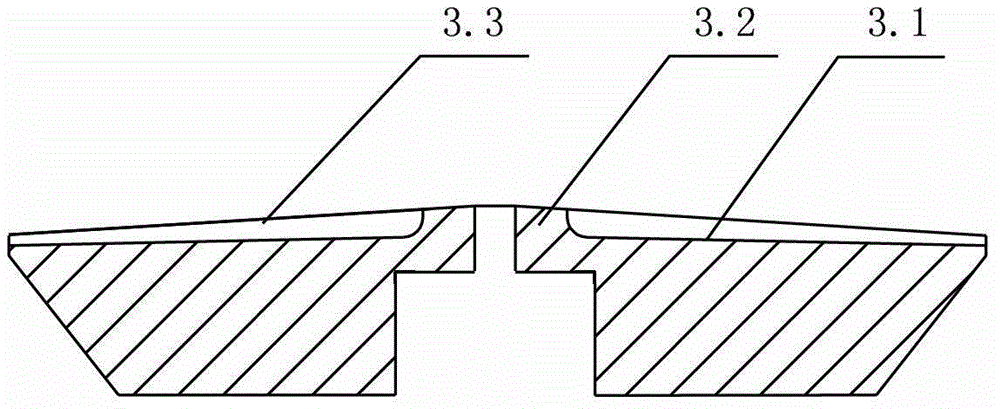

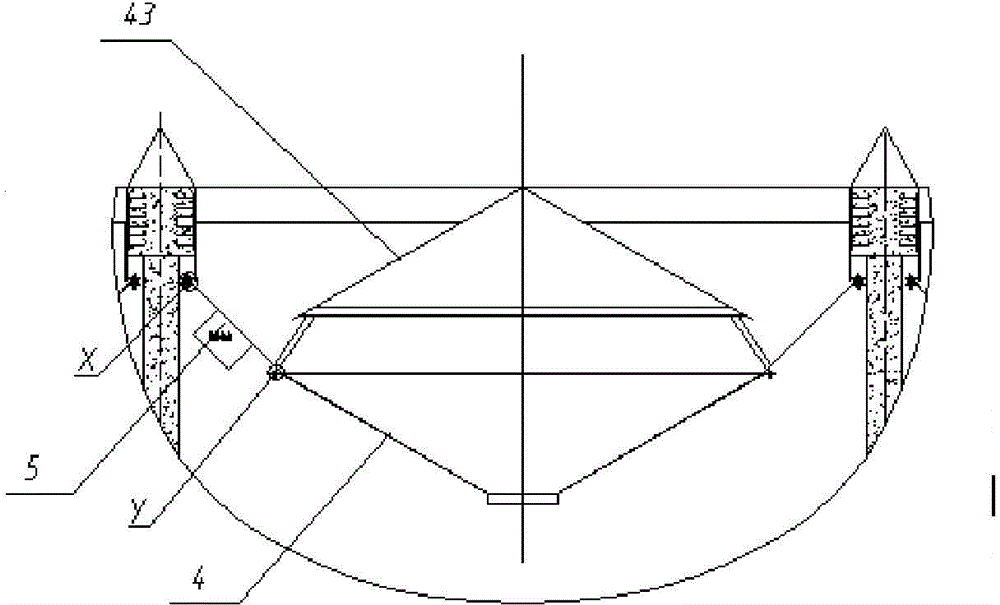

Cereal homogenizing and collecting device

ActiveCN103331263ABlanking evenlyGood wind separation and impurity removal effectGas current separationResidence timeWinnowing

The invention relates to a cereal homogenizing and collecting device applied to a cereal winnowing machine, and belongs to the field of grain machinery. The device comprises a shell and a rotary disc, wherein the rotary disc is arranged in the shell, and the middle part of the rotary disc is higher than the edge. The rotary disc is an upward inclined curve from the edge to the middle part. The rotary disc is provided with fan blades which are scattered and distributed on the upper surface of the rotary disc. A motor is connected to the axis of the rotary disc, and a cereal collecting structure is arranged below the rotary disc. According to the device provided by the invention, cereals are uniformly distributed in a winnowing area, so that the residence time of cereals in the winnowing area is prolonged and the edulcorating efficiency is greatly improved, and the edulcorating rate is improved to 85% from original 70%. The cereals uniformly enter into a cereal colleting funnel to avoid blocking, so that the edulcorating system operates smoothly. The cereals are collided with the shell flexibly to prevent cereal particles from being crushed or cracked due to impact, so that the cereal winnowing output is improved.

Owner:山东聚阳智能装备有限公司

Directional straw spreading machine

InactiveCN102514074ANice appearanceHigh strengthWood working apparatusDomestic articlesFailure rateAgricultural engineering

The invention discloses a directional straw spreading machine, which comprises a first spreading head, a second spreading head and a third spreading which are sequentially adjacent and parallel. A conveying belt is arranged below the first spreading head, the second spreading head and the third spreading. Elongated materials falling through the first spreading head and the third spreading head form the upper surface and the lower surface of a composite plate, directionality is high, materials falling from the second spreading head are small and form an inner layer of the composite plate, and the directional straw spreading machine is simple in structure and low in failure rate. The composite plate pressed by the method is attractive in appearance, high in strength, fine in quality and high in yield in unit time.

Owner:SANMENXIA YIXING HARD BOARD EQUIP

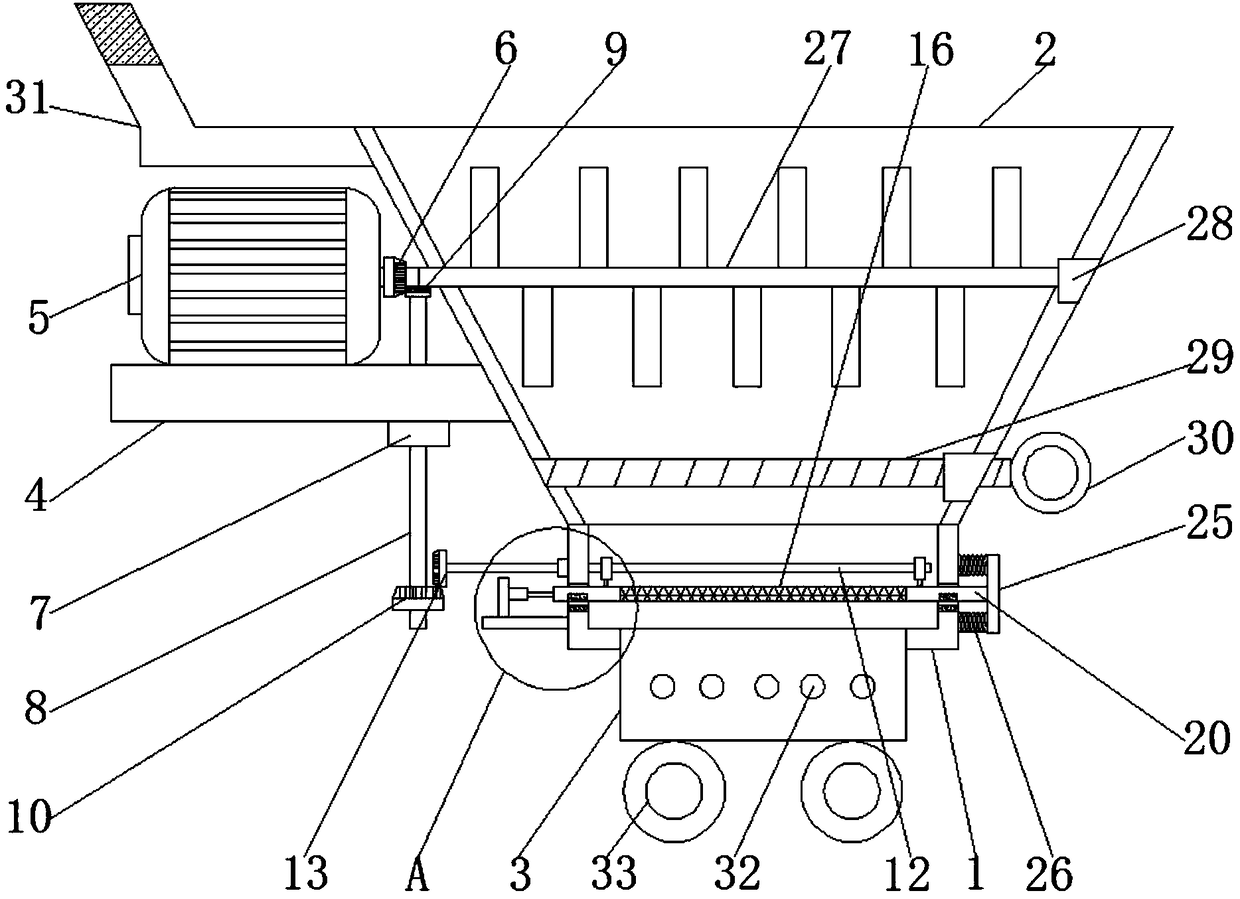

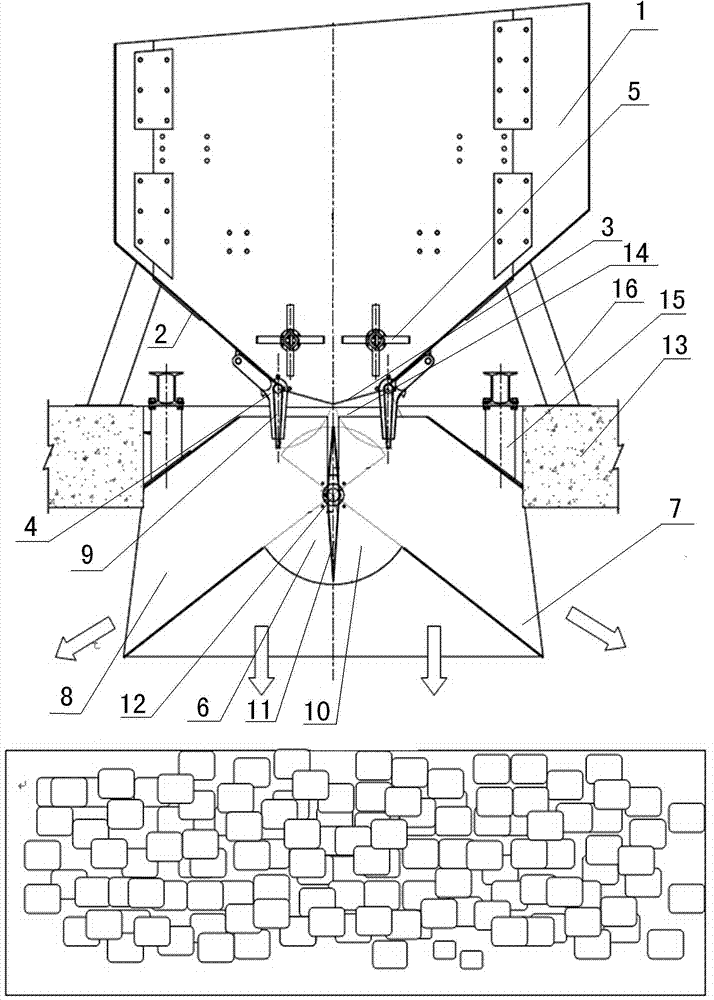

Deeply-dehydrated sludge homogenizing discharge device for sewage plant plate-frame machines

The invention discloses a deeply-dehydrated sludge homogenizing discharge device for sewage plant plate-frame machines. Hopper walls distributed on the inner side obliquely are formed on two sides of the lower end a feeding hopper, a discharge opening is formed between the lower ends of the hopper walls on two sides, an opening and closing valve is arranged at the discharge opening and composed of a left valve plate and a right valve plate in symmetrical distribution, a group of cross stirring rollers is arranged in the feeding hopper and above the discharge opening, a chute feeding mechanism is arranged below the discharge opening, a front chute and a rear chute are formed on the outer sides of the two sides of the chute feeding mechanism obliquely, a vertical chute is formed the middle of the chute feeding mechanism downwardly, a distribution guide plate is arranged over the vertical chute, a rotating shaft is arranged at the valve plate center of the distribution guide plate, and the valve plates rotate by taking the rotating shaft as a center pivot. By the homogenizing discharge device, falling is uniform during sludge discharge; compared with the existing discharging technique, the homogenizing discharge device has the advantages that transport capacity of transporting cars is increased by more than 90%, sludge clods fall on the ground rarely during discharging, and manpower and human resources are saved.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

Punching device

InactiveCN105234283AHigh scrap drop rateThe device is easy to operateShaping toolsStripping-off devicesEngineeringHigh pressure

The invention relates to a punching device which is simple and convenient to operate, low punching waste drop rate and low in production cost. The punching device comprises a convex die, a concave die and a discharging plate, wherein an air channel is formed in the side surface of the discharging plate; a vent groove is formed in a punching cutting edge of the convex die; high-pressure of the air channel flows into the vent groove of the punching cutting edge of the convex die and is guided by the vent groove to be discharged by a through hole of the concave die during operation of punching; when the high-pressure air is discharged, the punched waste is pushed to drop smoothly. The punching device is high in waste drop rate, simple and convenient to operate and low in production cost.

Owner:XIAMEN YONGHONG TECH

Instant wet tissue manufacturing device and method

InactiveCN111887756AGuaranteed immediacyEasy to useLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor article treatmentProcess engineeringIndustrial engineering

The invention belong to the technical field of wet tissues, and relates to an instant wet tissue manufacturing device and method. The instant wet tissue manufacturing device comprises a case, a control module, a storage module used for storing compressed tissue blocks to be soaked, a liquid storage module used for storing compressed tissue block soaking liquid, a soaking area used for soaking thecompressed tissue blocks, and a liquid conveying module used for conveying the soaking liquid in the liquid storage module to a soaking area; the compressed tissue blocks and the soaking liquid are stored separately. The instant wet tissue manufacturing device is simple and reasonable in structure and suitable for daily use; the instantaneity of wet tissue production can be guaranteed; and the useeffect of produced wet tissues can be guaranteed.

Owner:FOSHAN NEWCURVE TECH CO LTD

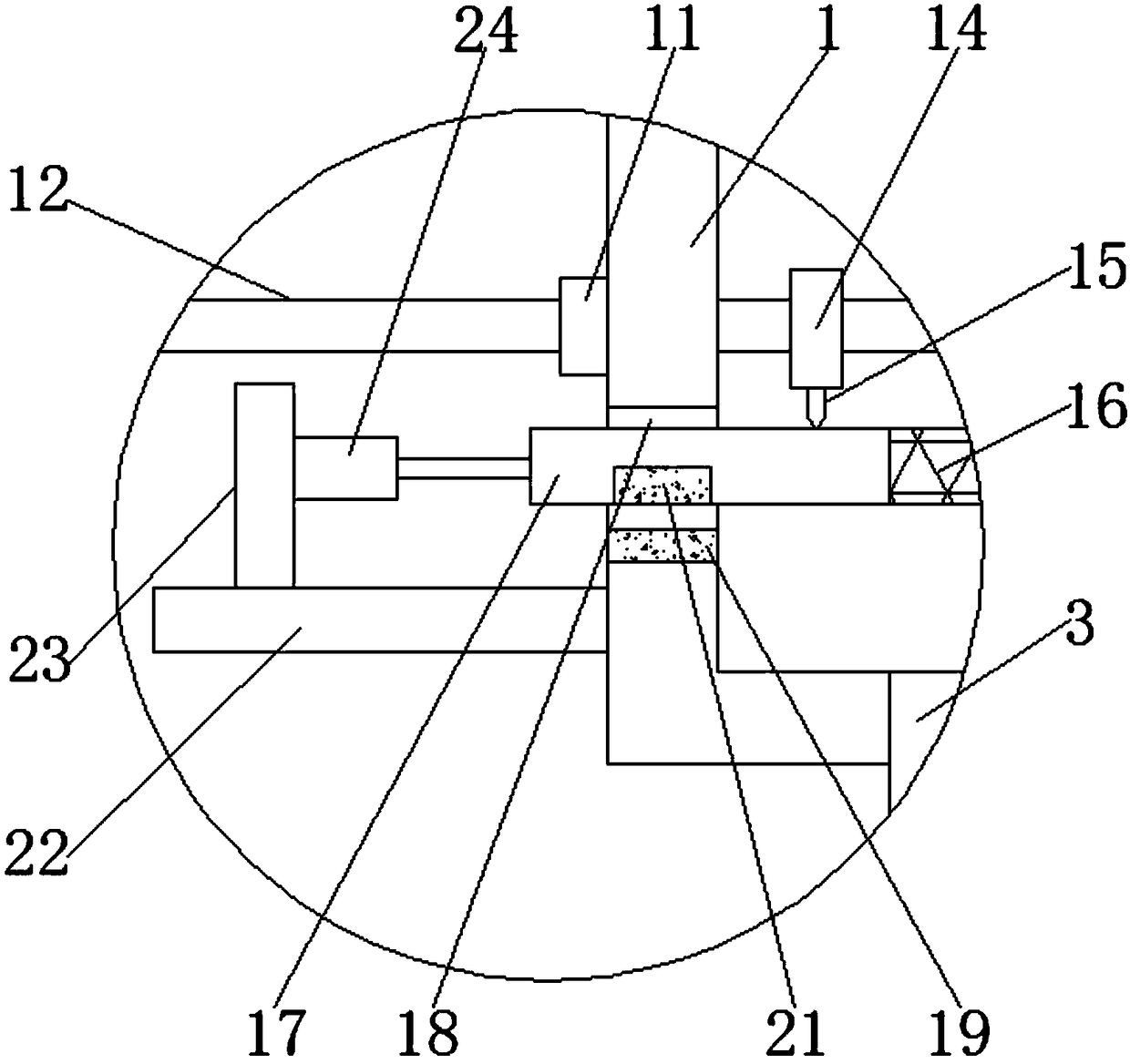

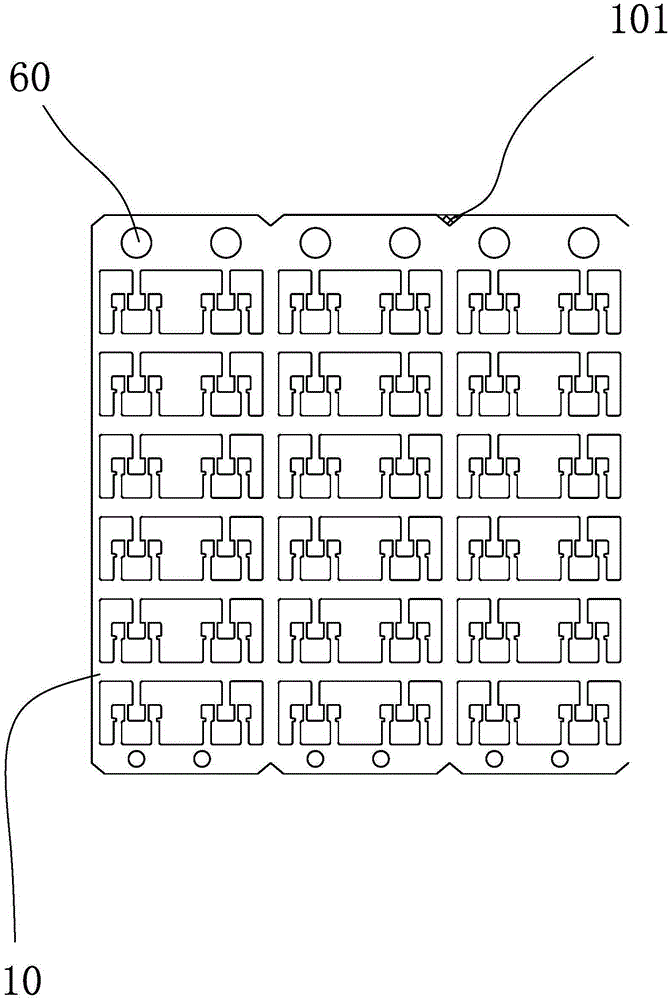

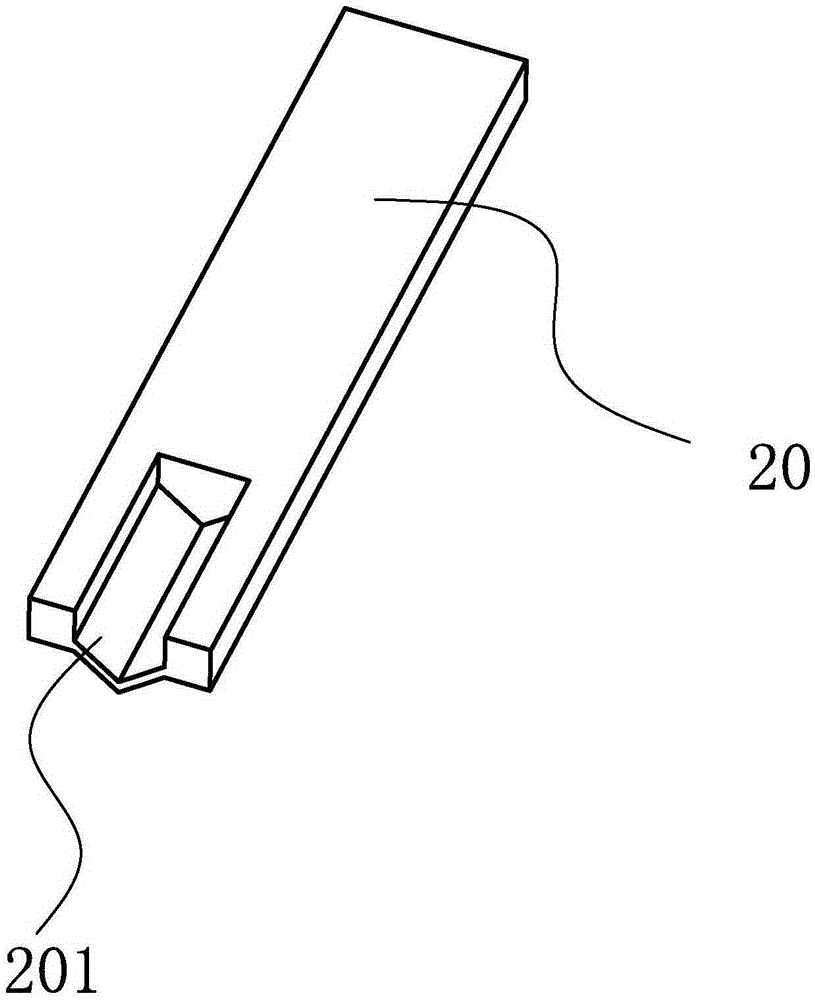

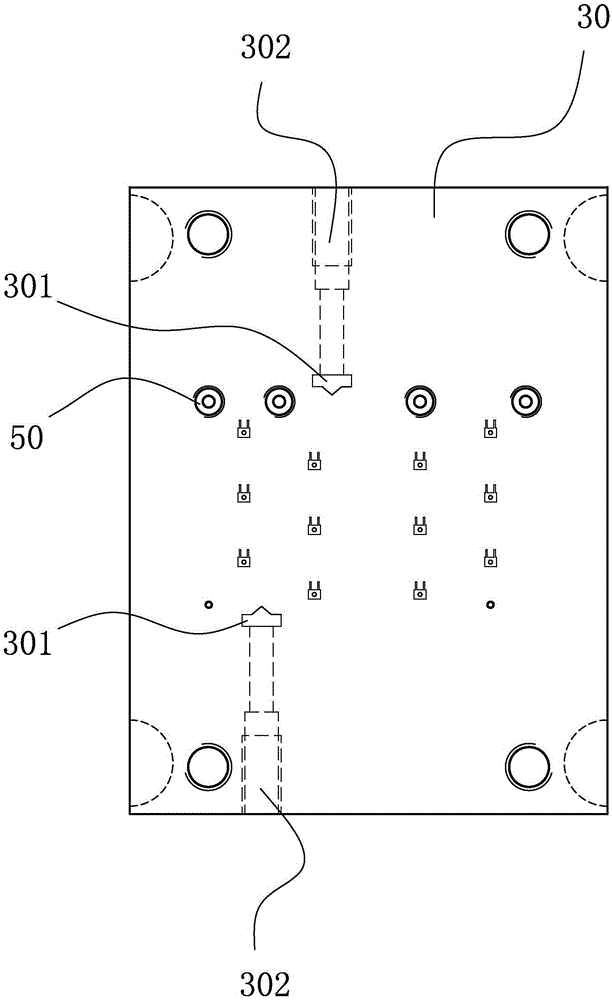

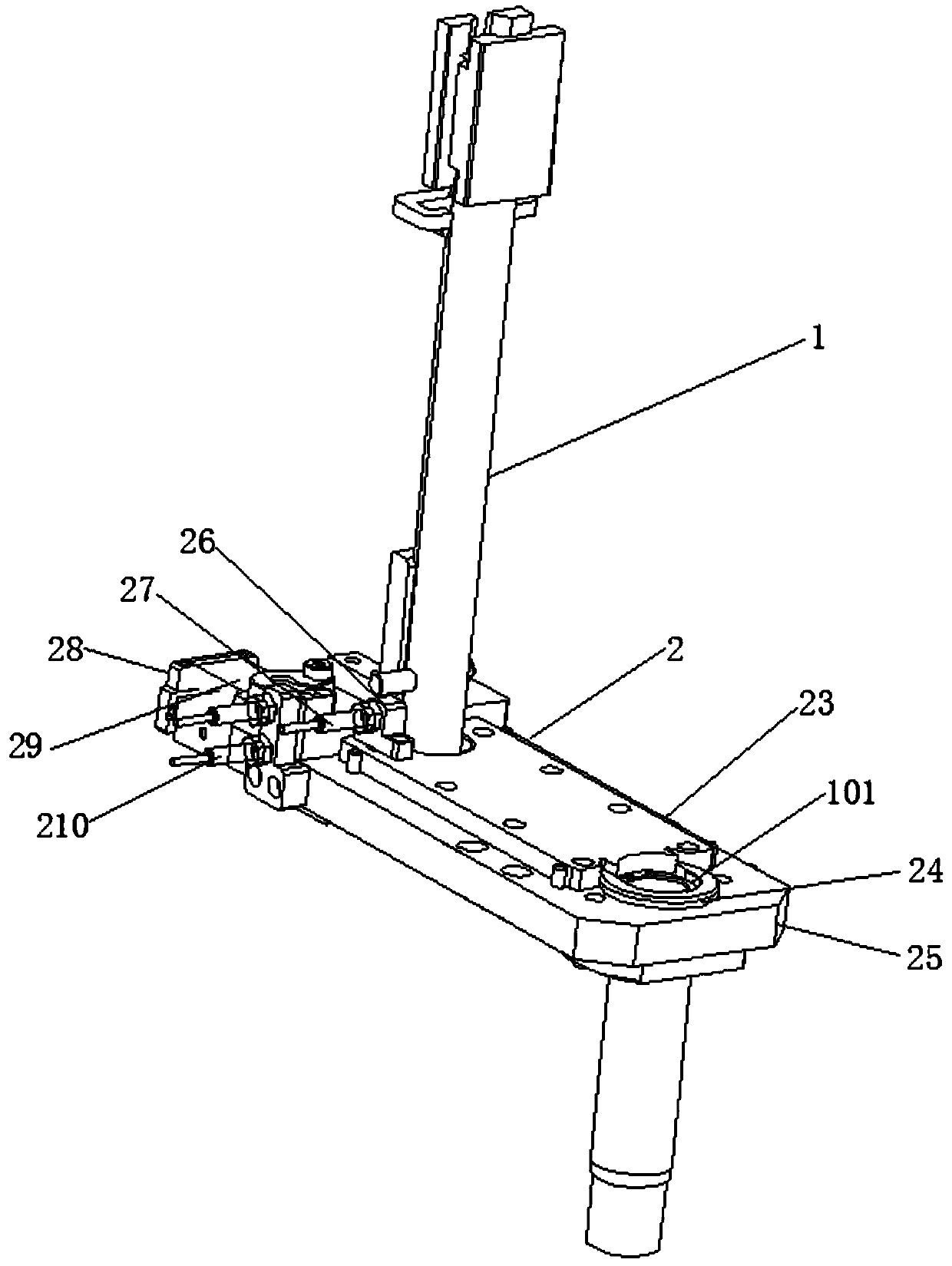

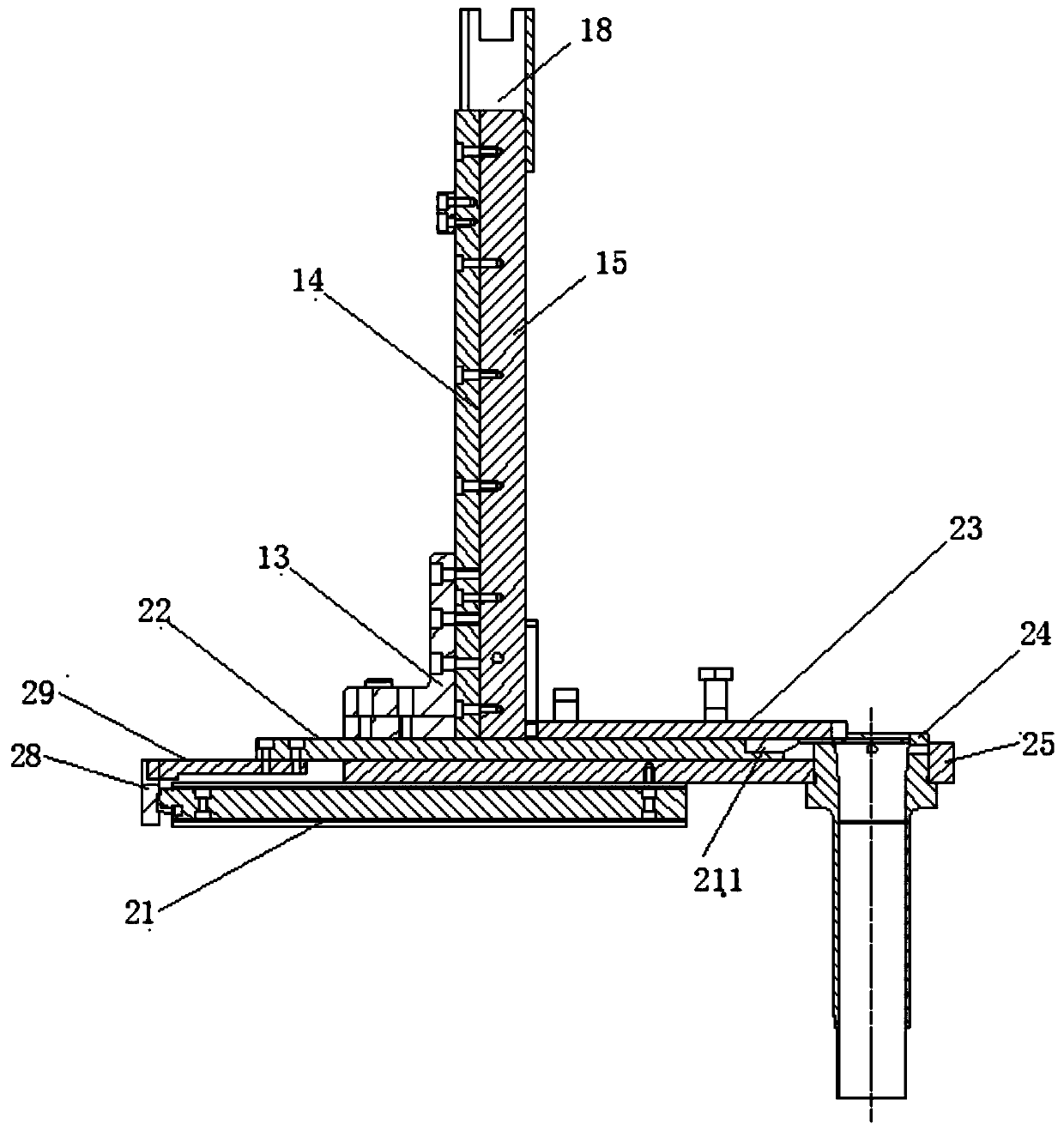

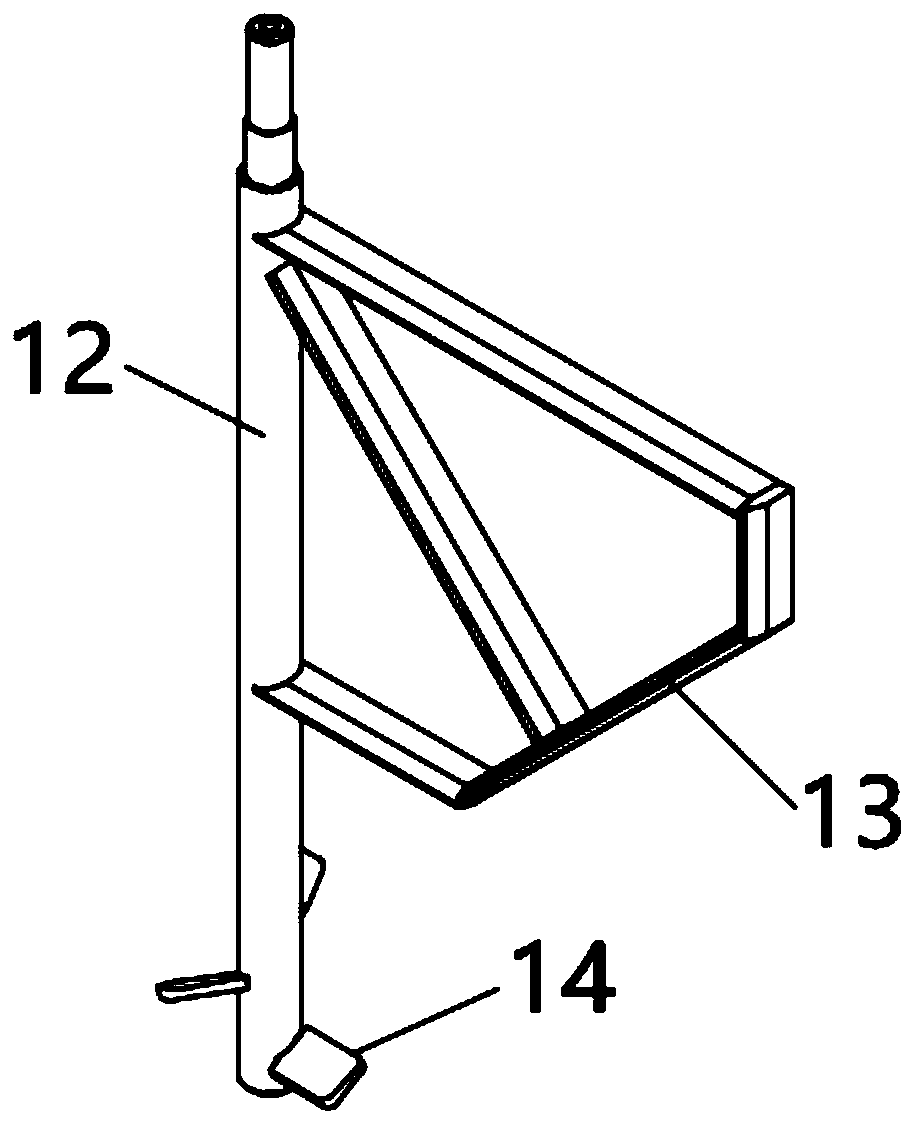

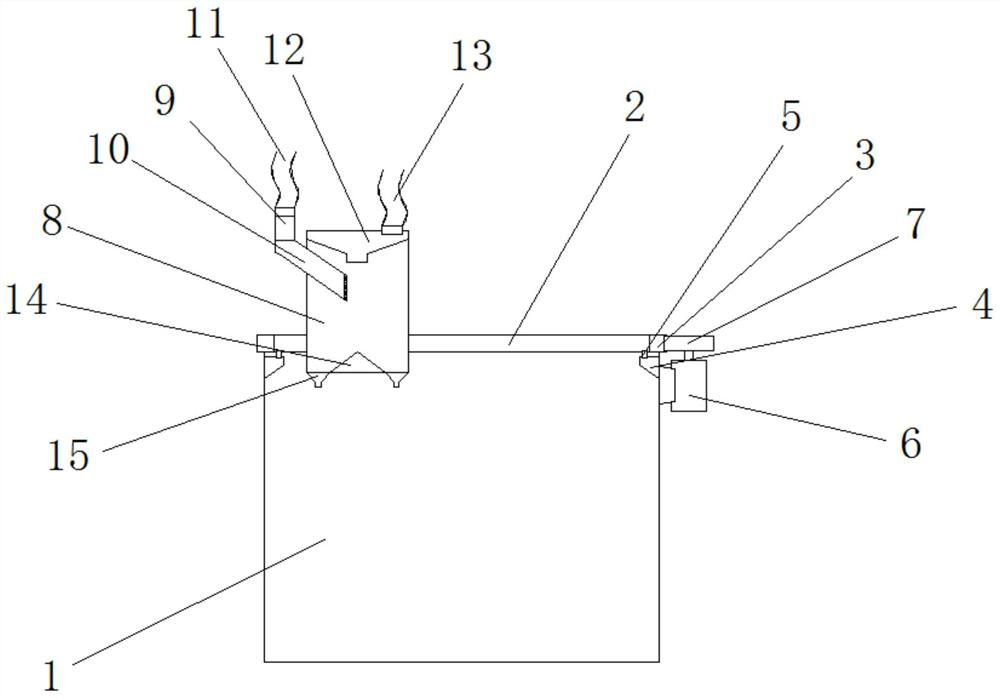

Automatic feeding and pressing equipment for elastic retainer ring for holes

PendingCN110371619AAchieving correct press fitRealize automatic interval feedingConveyorsDe-stacking articlesEngineeringCalipers

The invention discloses automatic feeding and pressing equipment for an elastic retainer ring for holes. The automatic feeding and pressing equipment comprises a material tower assembly, an air cylinder feeding assembly and a floating pressure head assembly, wherein the material tower assembly comprises a material tower which is vertically arranged and is connected with a positioning key strip onthe side surface, the elastic retainer ring is nested in the material tower in a sliding mode and is matched with the positioning key strip, the air cylinder feeding assembly comprises a base with a material channel, a guide sleeve connected with the tail end of the material channel and a material pushing plate for pushing the elastic retainer ring falling from the material tower to the guide sleeve along the material channel, the material pushing plate is driven by an air cylinder, the floating pressure head assembly comprises a pressing rod sleeve with an inner hole, a connecting rod is connected to the upper part of the pressing rod sleeve, a self-adjusting spring and a sliding sleeve are arranged in the pressing rod sleeve, a connecting screw is connected between the connecting rod andthe sliding sleeve, the self-adjusting spring sleeves the connecting screw and the upper end of the self-adjusting spring is connected with the connecting rod, and the lower end of the self-adjustingspring is connected with the sliding sleeve. According to the automatic feeding and pressing equipment, automatic interval feeding can be realized and correct press fitting of the elastic retainer rings for caliper holes can be realized.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Positive displacement quantitative filling machine for sliced mushroom

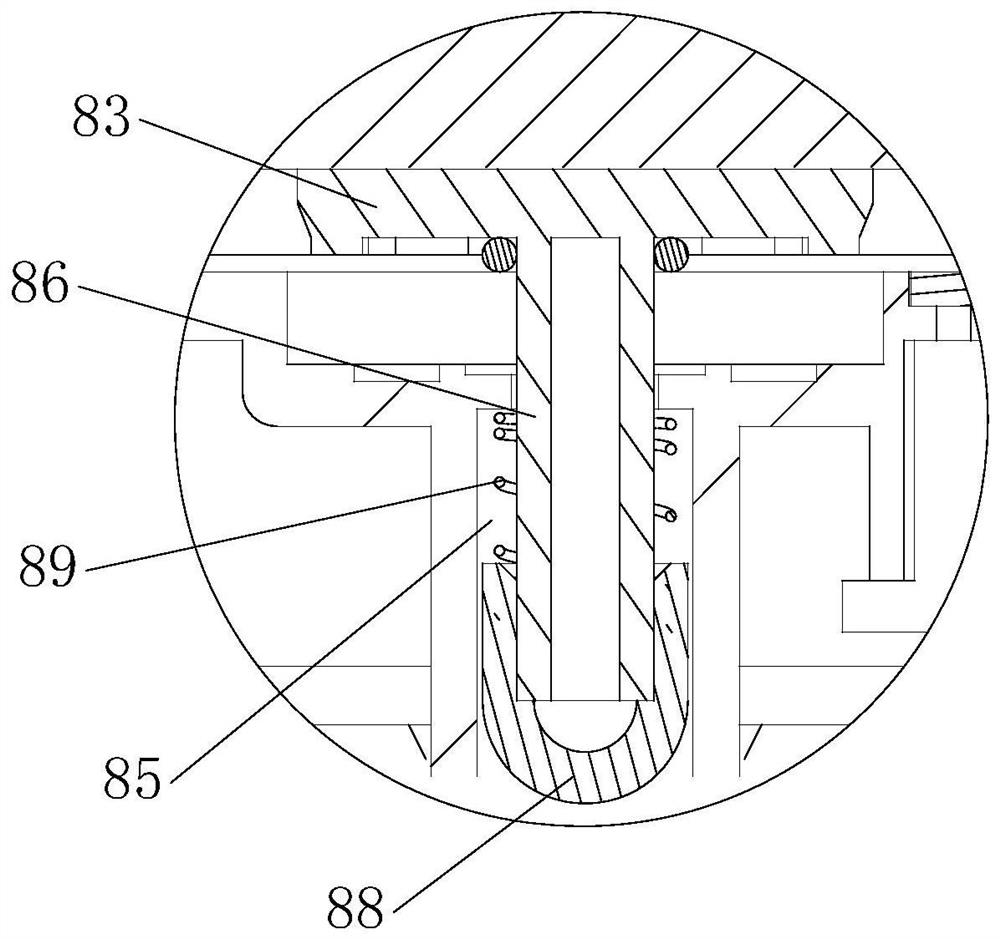

InactiveCN103274068ADestruction of Mutual StickinessDestruction of adsorptionLiquid materialEngineeringUltimate tensile strength

The invention discloses a positive displacement quantitative filling machine for sliced mushroom. The machine comprises a support, a material box, a quantitative filling device with a quantitative cup and a raking device. A support plate is installed on the support, the quantitative filling device is installed on the support plate, the support plate is connected with a spring seat, and the raking device is provided with a scraping plate used for rubbing the wall face of the material box. The quantitative filling device is provided with a vibrator, and an air blowing port is arranged on the lateral wall of the quantitative cup. By means of effective combination of five special functions including vibrating, raking, wall scraping, air blowing and the flexible quantitative cup, physical characteristics affecting smooth quantitative filling of materials are removed, the materials can flow smoothly to enter the quantitative cup and enter a product container finally, accurate quantification meeting product specification requirements is achieved, production efficiency is improved, product quality is ensured, labor intensity is greatly reduced, and production cost is reduced.

Owner:何立荣 +1

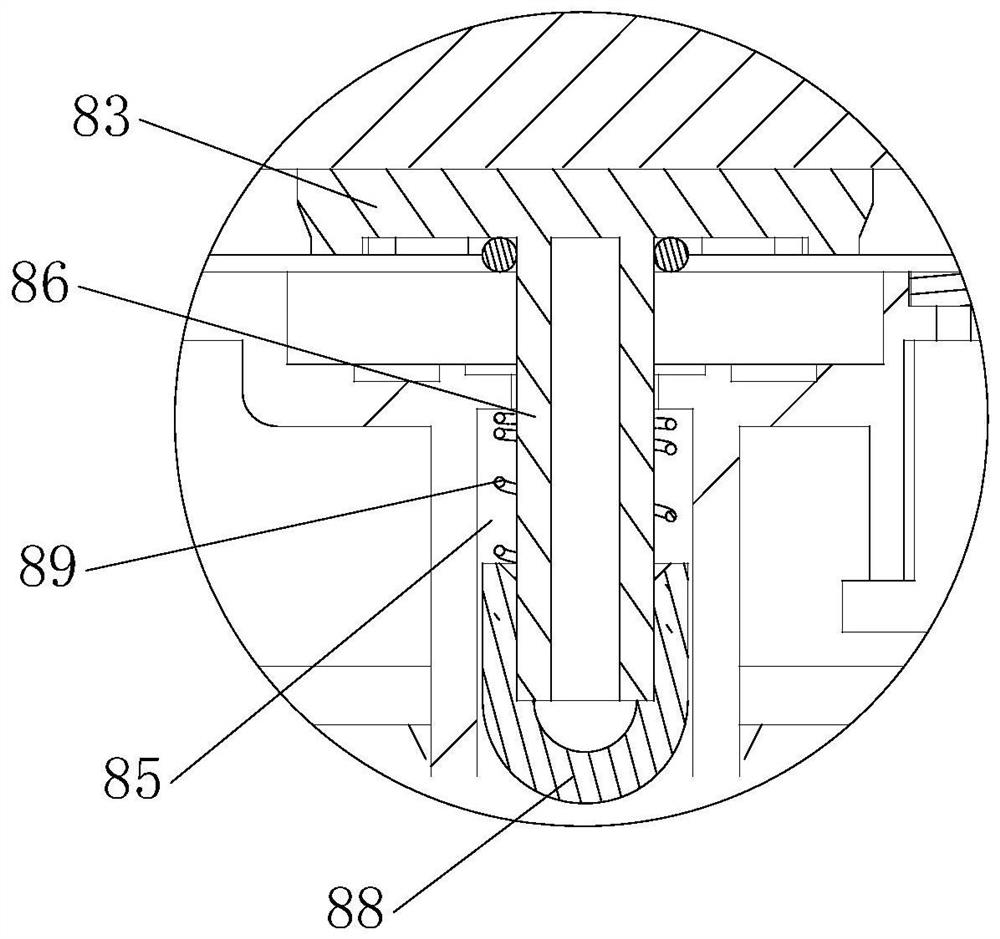

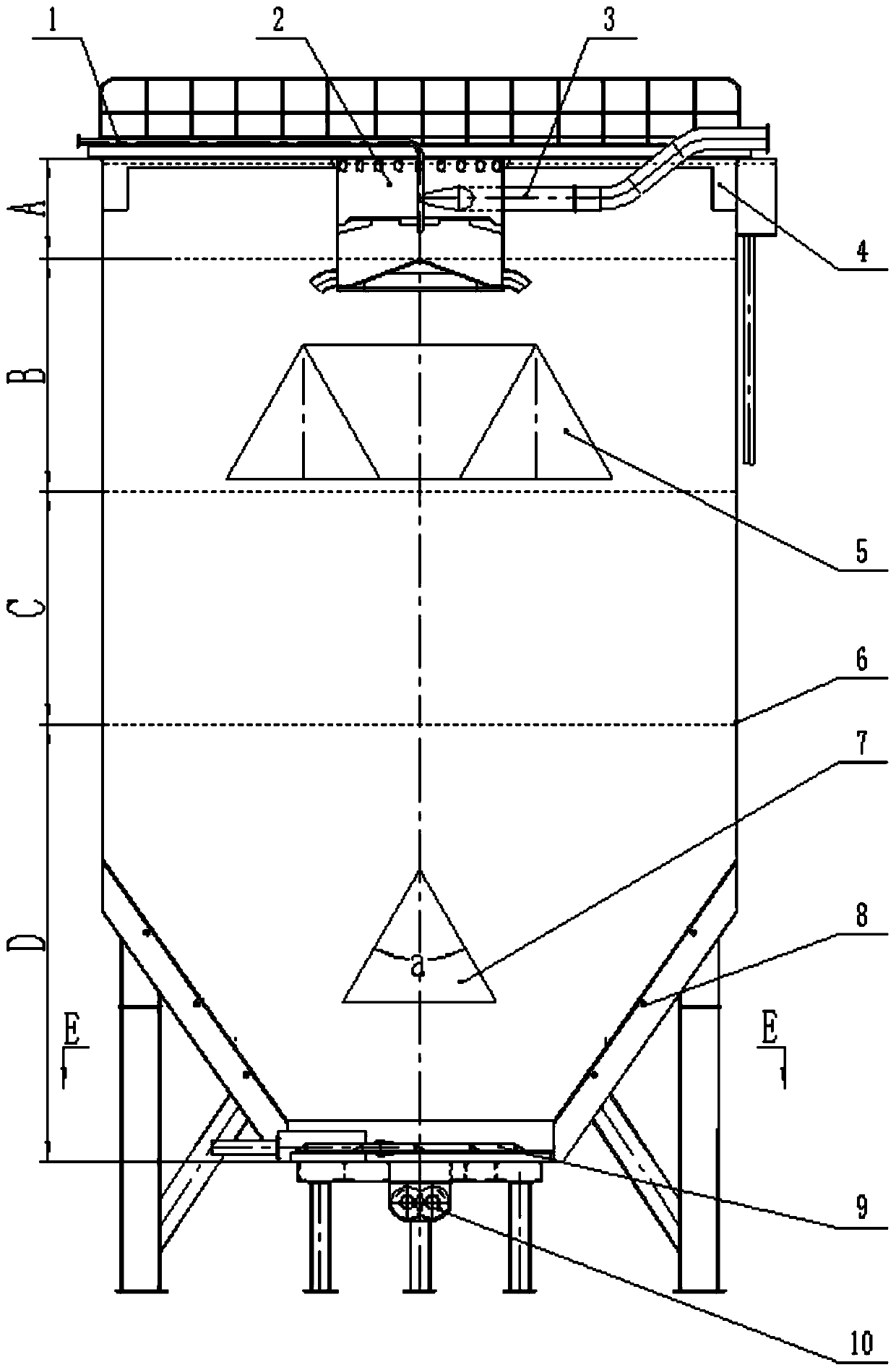

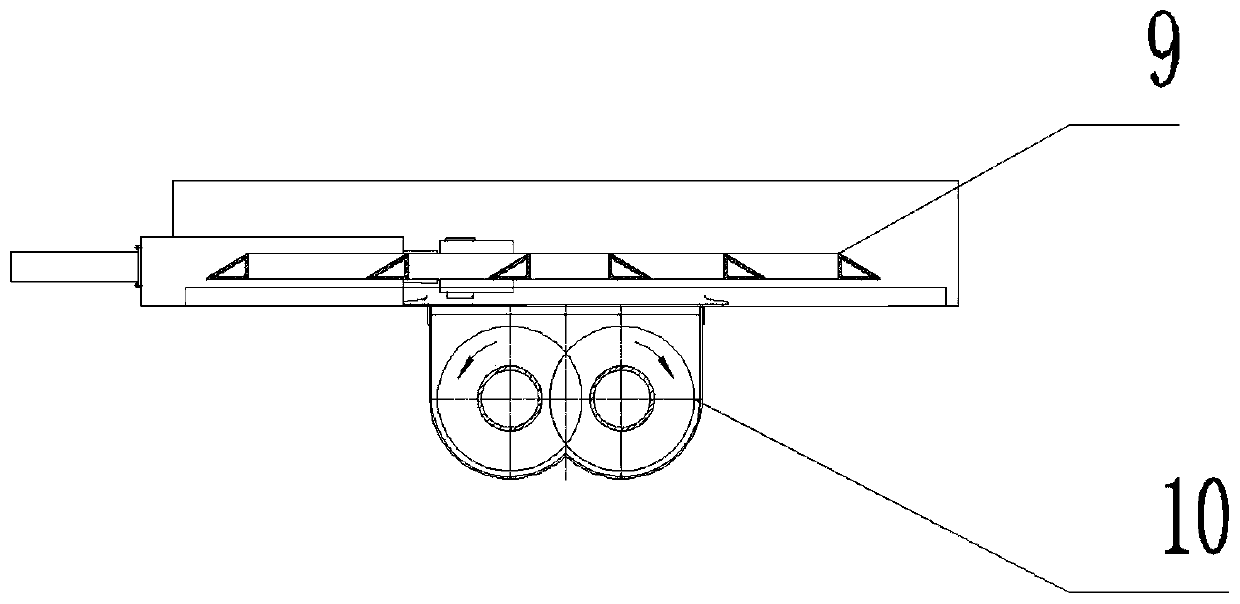

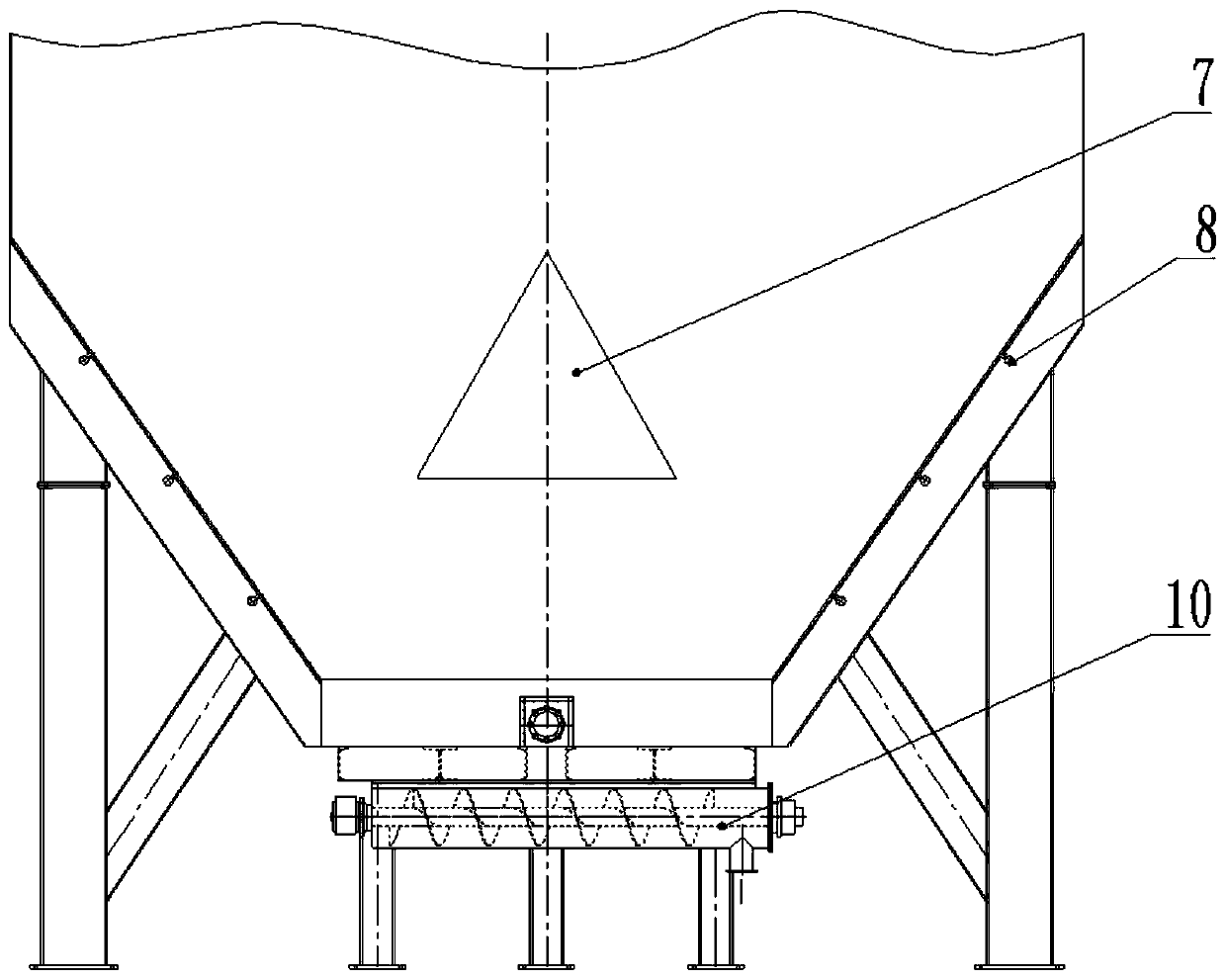

Rake-free separation tailing thickening sand bin

PendingCN110152359ACan't play the role of deliverySmooth dischargeSettling tanks feed/dischargeCentrifugal force sediment separationFlocculationHigh concentration

The invention relates to a rake-free separation tailing thickening sand bin, and aims to solve the problems that tailing concentration equipment in the prior art is complex in structure, low in sand discharging concentration and unsmooth in discharging. The rake-free separation tailing thickening sand bin comprises a sand bin body, a flocculation feeding tube, a center feeding barrel with a middleseparation plate, a tailing feeding tube, an overflow groove, an annular sedimentation cone, a sliding frame fluidization device and a double-screw discharging device. Through design of the structure, flow field variation of a material flow in the sand bin is changed, and the flocculation agglomeration speed of fine particle tailings is accelerated; and meanwhile, a mechanical sliding frame fluidization sand-discharging technology is adopted, so that smooth sand discharging under a condition of highest underflow concentration is realized. The rake-free separation tailing thickening sand bin has the outstanding advantages of small size, simple structure, low manufacturing cost, high concentration efficiency, high underflow concentration and the like.

Owner:北京金诚信矿山技术研究院有限公司

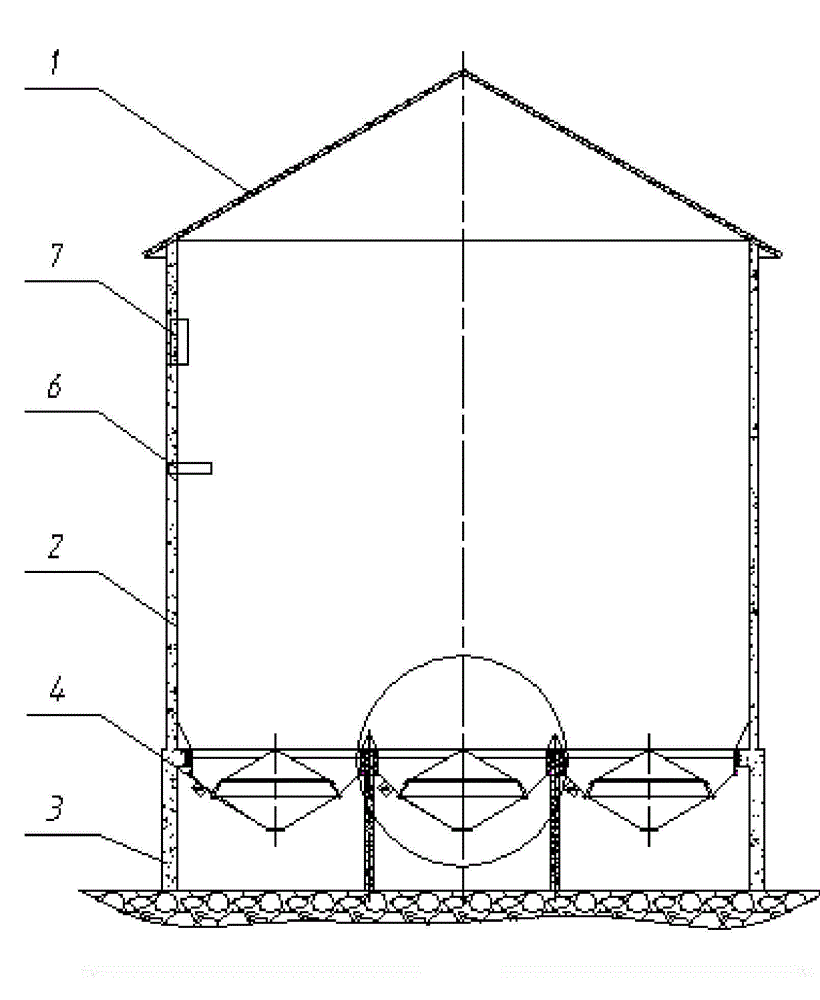

Multi-bucket vibratory discharge silo and layered discharge method thereof

ActiveCN102975988AGuaranteed freshEnsure safetyLarge containersElectric machineStructural engineering

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

Stock bin device

InactiveCN111196509AEasy blankingFast blankingLarge containersLoading/unloadingStructural engineeringMechanical engineering

The invention relates to the technical field of production machining, in particular to a stock bin device. The device comprises a loading hopper, an unloading hoper, and a stirring assembly, the loading hopper is located above the unloading hopper, after the loading hopper carries materials, the unloading hopper is used for falling, the stirring assembly is located between the loading hopper and the unloading hopper and achieves the arch breaking function, through combined use of the loading hopper and the unloading hopper, blocky materials can be avoided, the materials can more easily fall down, in addition, the stirring assembly is mounted between the loading hopper and the unloading hopper, the material in the unloading hopper can be further assisted to rapidly and smoothly fall out, the possibility of material arching can be reduced, and work efficiency can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Gluing device for kraft box paperboard production

InactiveCN111992415ASolve manual glue brushingPrevent solidificationLiquid surface applicatorsRotary stirring mixersPaperboardAdhesive glue

The invention discloses a gluing device for kraft box paperboard production, and relates to the technical field of kraft box paperboard production. The gluing device aims at solving the problems thatmanual glue brushing is low in efficiency and cannot ensure the uniformity of glue brushing during existing paperboard gluing, and the viscosity of glue is influenced due to the fact that the bottom of the glue is easy to solidify after standing for a long time. According to the gluing device disclosed by the scheme, the gluing device comprises a bottom plate, supporting plates are fixedly connected to the two sides of the top of the bottom plate, lifting mechanisms are arranged on the sides, close to each other, of the two supporting plates, a glue box is arranged on the sides, close to eachother, of the two lifting mechanisms, a stirring mechanism is rotationally connected to the interior of the glue box, an intermittent discharging mechanism is fixedly connected to the bottom of the glue box, and a movable wiping mechanism is arranged below the intermittent discharging mechanism. According to the gluing device, the position of a brush roller can be conveniently adjusted, moreover,uniform blanking on the surface of the brush roller is facilitated, uniform smearing of the glue is facilitated, moreover, the glue can be synchronously stirred, and the glue is prevented from being solidified.

Owner:濉溪县国光纸业有限责任公司

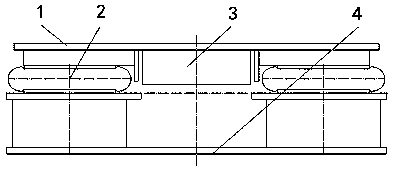

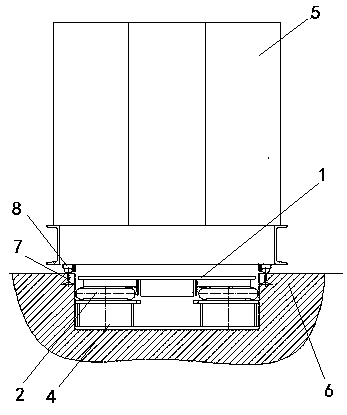

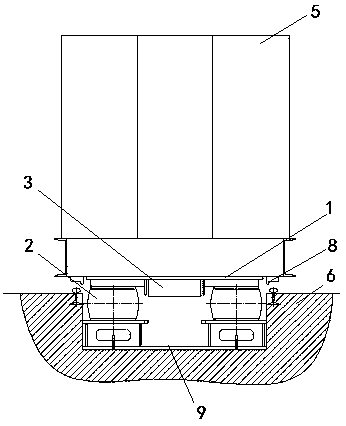

Vibrating device for precast concrete stairs

The invention provides a vibrating device for precast concrete stairs. The vibrating device for the precast concrete stairs is applicable to stair dies. The device comprises at least one vibrating unit assembly, wherein the vibrating unit assembly comprises a lifting part and a vibrating part; the lifting part comprises a vibrating pedestal, vibration absorbing air bags which are arranged at the left side and the right side of the vibrating pedestal, and an air compressor; the vibration absorbing air bags are correspondingly connected to the air compressor through pneumatic hoses; the vibrating part comprises a vibrating table board and a vibrating motor; the vibrating motor is mounted on the lower end surface of the vibrating table board; the upper ends of the vibration absorbing air bagsare connected to the vibrating table board through bolts, and the lower ends of the vibration absorbing air bags are connected to the vibrating pedestal through bolts. The device is simple in structure, and reasonable in design; concrete can be smoothly charged, and air in the concrete can be effectively exhausted, so that the strength of formed precast stair components can be ensured. The deviceis good in vibrating effect, and small in noise; the working intensity of workers can be effectively reduced; the working efficiency is improved; the massive production is conveniently carried out; and the device is worthy of popularization.

Owner:济南恒基信息科技有限公司

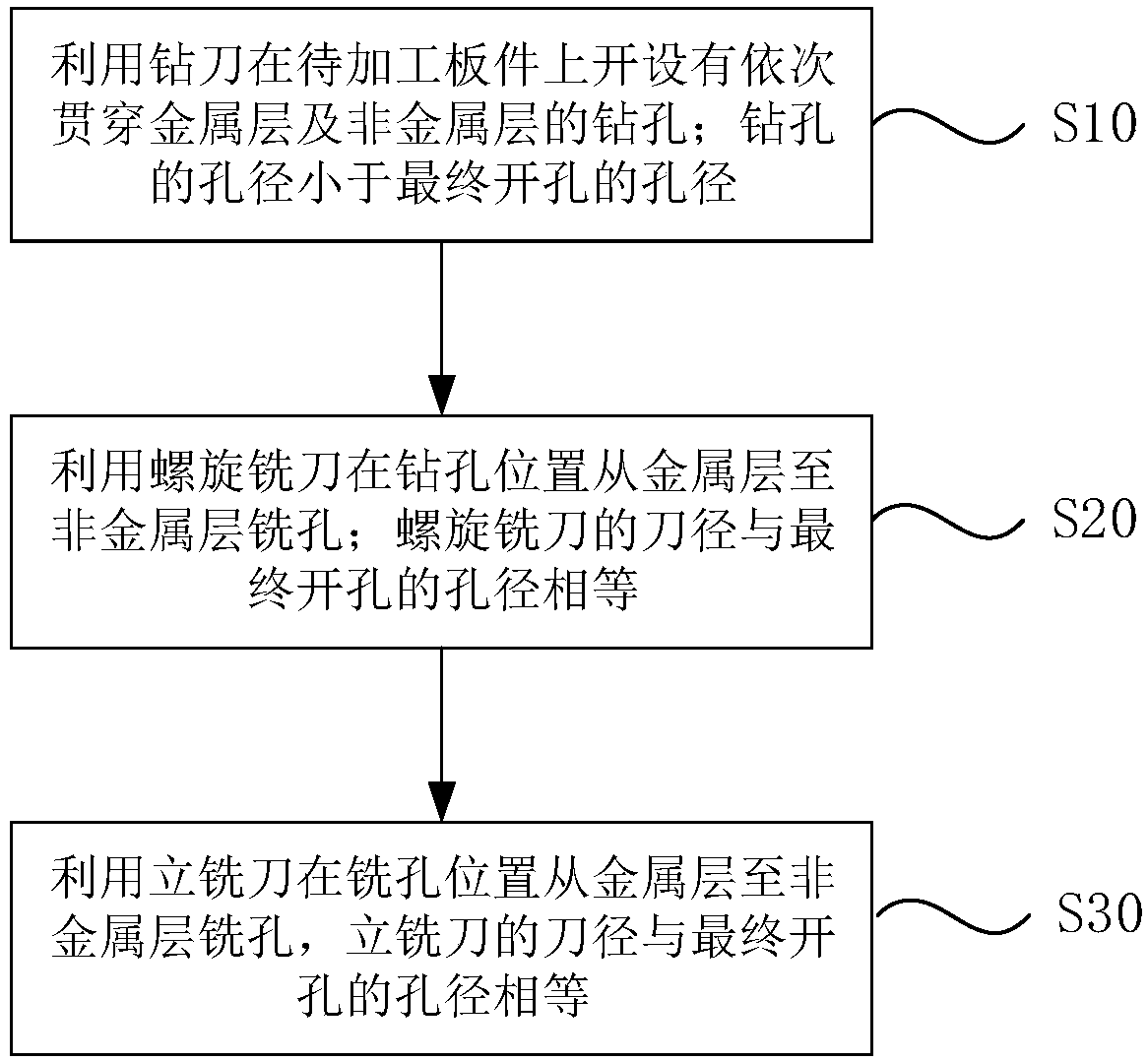

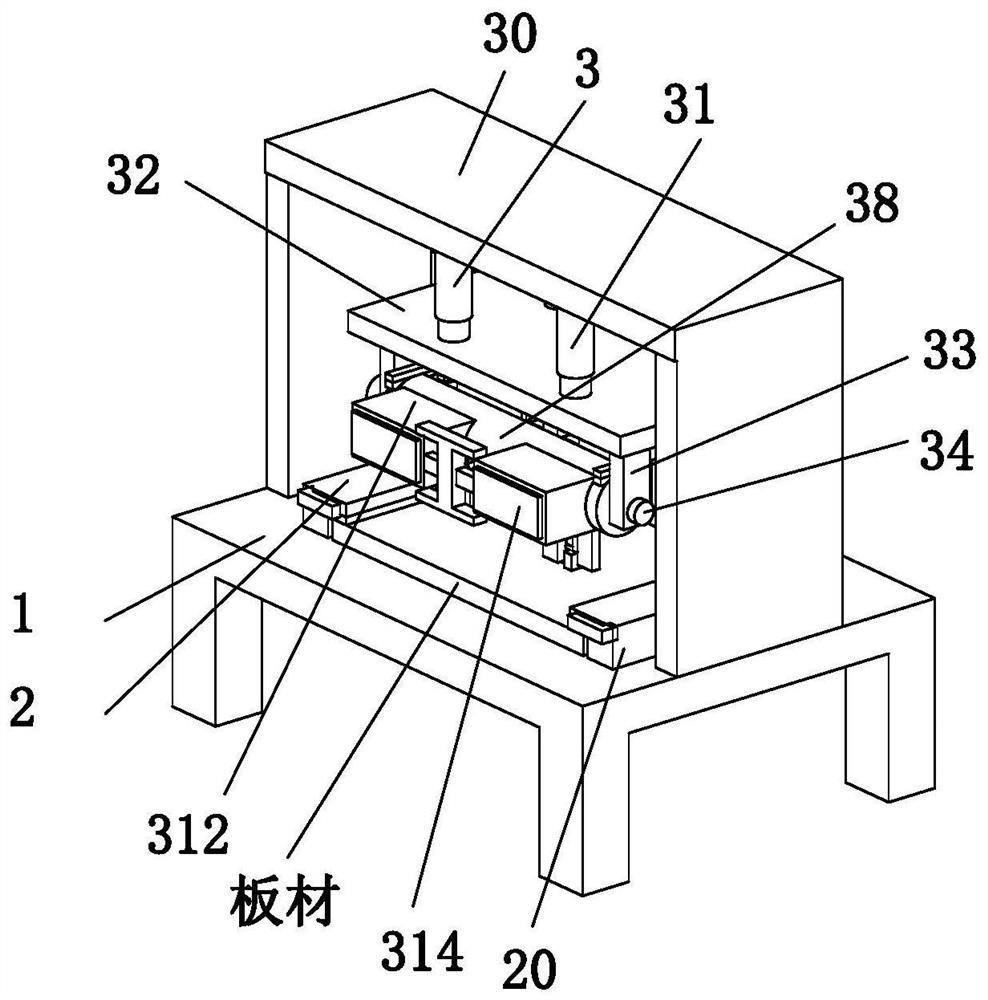

Machining method for plate perforating

ActiveCN108145376AQuality assuranceBlanking evenlyOther manufacturing equipments/toolsMilling cutterEngineering

The invention relates to a machining method for plate perforating. A plate includes metal layers and non-metal layers which are arranged layers upon layers, and the machining method includes the stepsthat (1) drill holes which can sequentially penetrate through the metal layers and the non-metal layers are formed in to-be-machined plates through a drilling tool; the hole diameter of the drill holes is less than that of a final hole; (2) a drilling hole position is subjected to hole milling from the metal layers to the non-metal layers through a spiral milling cutter; the cutter diameter of the spiral milling cutter is equal to the hole diameter of the final hole; and (3) a hole milling position is subjected to hole milling from the metal layers to the non-metal layers through an end mill,and the diameter of the end mill is equal to the hole diameter of the final perforating. According to the machining method for the plate perforating, machined hole walls and hole bottoms do not haveburrs, and machined holes are high in quality, thereby ensuring the plate quality.

Owner:GUANGDONG EVERWIN PRECISION TECH

Feeding device for animal husbandry

InactiveCN111296309ABlanking evenlyClimate change adaptationAnimal feeding devicesAnimal scienceElectric machinery

The invention discloses a feeding device for an animal husbandry and belongs to the field of breeding equipment for the animal husbandry. A feed trough comprises a feeding area and a partition area, poking blocks are detachably connected to the outer side of one sliding groove; walking wheels are in rolling connected with limiting grooves, and a motor is in drive connection with connecting rods; an opening and closing turning plate is rotationally connected to an outlet of a hopper body, a poking piece is fixedly connected to one end of the opening and closing turning plate, positioning beadsand positioning holes are matched for positioning, and the poking blocks and the poking piece are matched for poking. When the feeding device walks above the feeding area, the opening and closing turning plate is opened, a dropping hopper uniformly drops feed in the feeding area; when the feeding device advances to the upper side of the partition area, the poking blocks poke the poking piece to drive the opening and closing turning plate to rotate by 90 degrees, the positioning beads and the positioning holes are matched for positioning, the opening and closing turning plate closes a discharging port of the dropping hopper; and when the feeding device walks to the upper side of the next feeding area, the poking blocks poke the poking piece, the discharging port of the dropping hopper is opened to uniformly drop feed.

Owner:张仲萍 +2

Rotating disc type grain discharging and storing device

InactiveCN111661572AAvoid local accumulationEasy to suck outThrowing machinesCleaning using gasesGear wheelElectric machinery

The invention discloses a rotating disc type grain discharging and storing device. The rotating disc type grain discharging and storing device comprises a material bin, the material bin is arranged tobe in a barrel shape, an annular rail is fixedly installed at the top of an inner cavity of the material bin, a rotating disc is rotationally connected to the top of the annular rail, a gear ring isfixedly connected to the outer side of the rotating disc, a motor is fixedly installed on the side wall of the top of the material bin, the top of the motor is fixedly connected with a gear, the gearmeshes with the gear ring, a discharging bin is fixedly installed at the edge position of the rotating disc, a discharging hopper is fixedly installed at the bottom of the discharging bin, and the discharging hopper is located on the lower side of the rotating disc. According to the rotating disc type grain discharging and storing device, the structure is simple, convenience and practicality are achieved, the technical effect of uniform discharging can be achieved, the situation that storage is affected due to the fact that grains are locally accumulated in a stock bin is avoided, and dust mixed in the grains can be removed in the discharging process.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

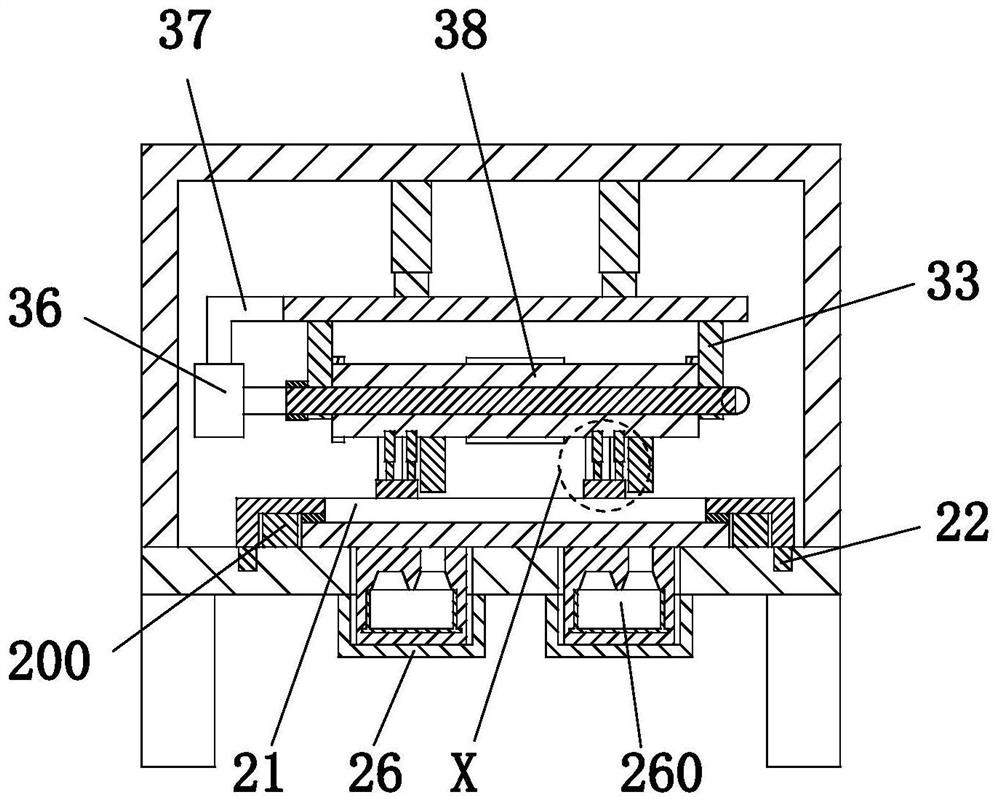

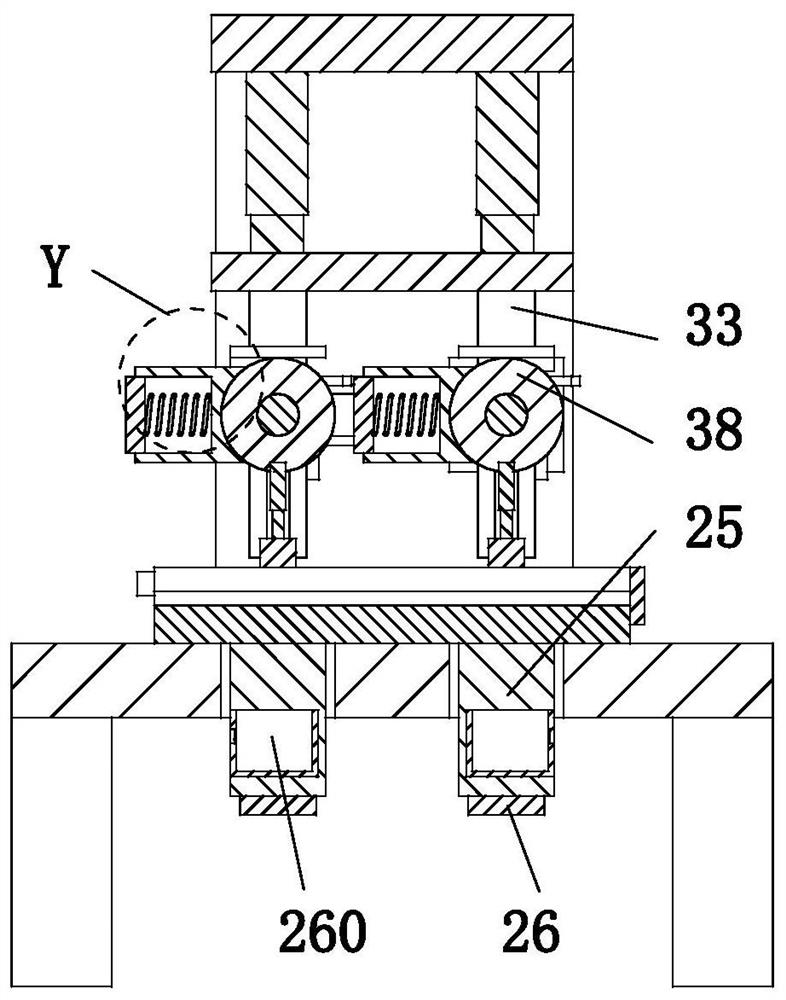

Multi-stage machining and forming equipment for curtain wall connecting piece

InactiveCN111804808AOmni-directional limit operationSimplify processing and forming stepsPerforating toolsMetal-working feeding devicesPunchingMachining

The invention relates to multi-stage machining and forming equipment for a curtain wall connecting piece. The equipment comprises a workbench, a clamping mechanism and a blanking mechanism, wherein the clamping mechanism is arranged in the middle of the upper end of the workbench, and the blanking mechanism is arranged above the clamping mechanism. The design concept of a continuous punching and cutting integrated combined structure is adopted for multi-stage machining and forming of the curtain wall connecting piece, machining and forming steps are simplified, and the machining and forming efficiency is improved; a plurality of structures with pressing effects are arranged for punching and cutting plates, so that the purpose of improving punching and cutting quality is achieved; and meanwhile, the equipment can perform omnibearing limiting operation on the plates, and a centralized storage structure is arranged for punching wastes.

Owner:浙江研基科技有限公司

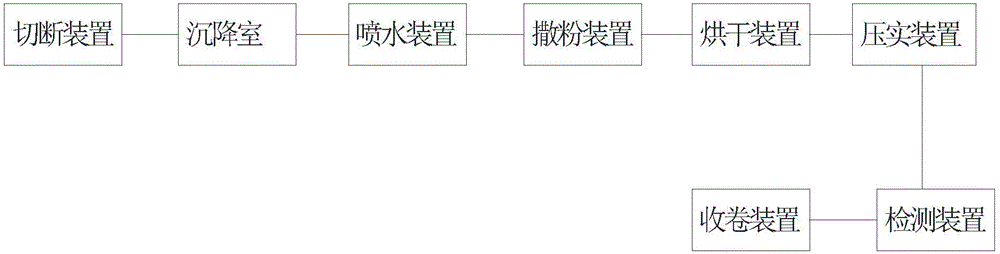

System for producing glass fiber chopped strand mats

The invention discloses a system for producing glass fiber chopped strand mats. A plurality of air doors are arranged on an air inlet of a settling chamber, two sets of symmetrically-designed laser sensors are arranged at a detecting device part to be used for detecting the thickness of the chopped strand mats, the detecting result is transmitted to an upper computer through a single-chip microcomputer, the upper computer processes the detecting result, and feeds the processed result back to a control unit, the control unit controls corresponding electric cylinders to drive the corresponding air doors to perform corresponding actions, timely adjusting of openings in the portions, corresponding to the air inlet, of the air doors is achieved accordingly, the chopped strand mats is even in falling, and it is avoided that more resources are wasted; in addition, partition plates are arranged in the settling chamber, the cross sections of the upper ends of the partition plates are triangular, the number of the partition plates can be set according to the production requirement, grooves are formed in the two sides of the lower ends of the partition plates, a plurality of double-rough-selvedge chopped strand mats can be once formed in the settling chamber, and the rough selvedges on the two sides of the chopped strand mats are relatively uniform in thickness.

Owner:嘉兴市宏宇新材料股份有限公司

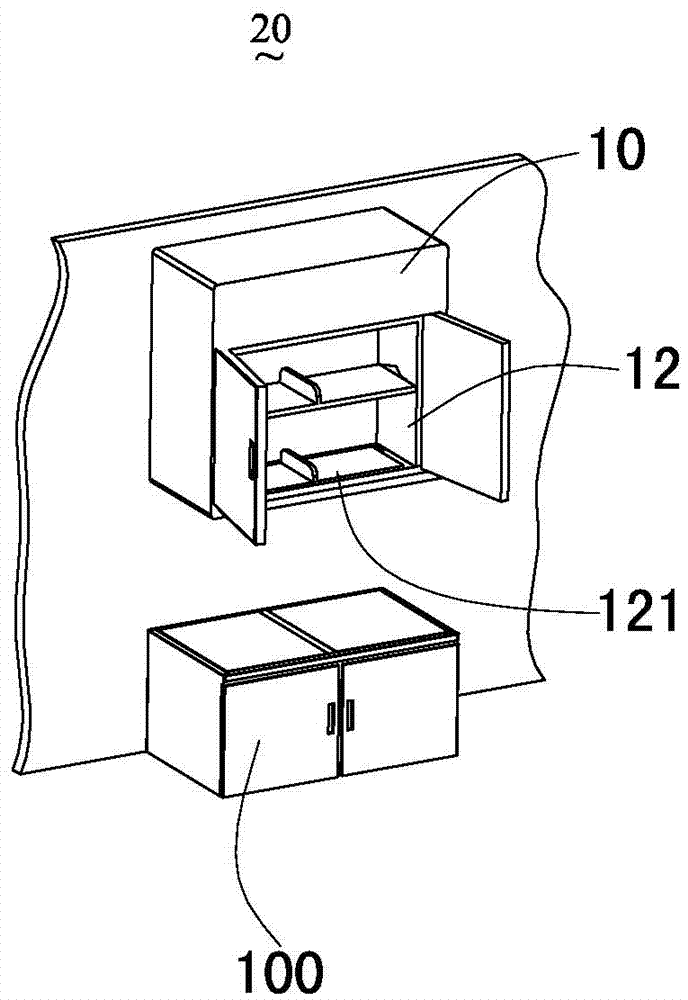

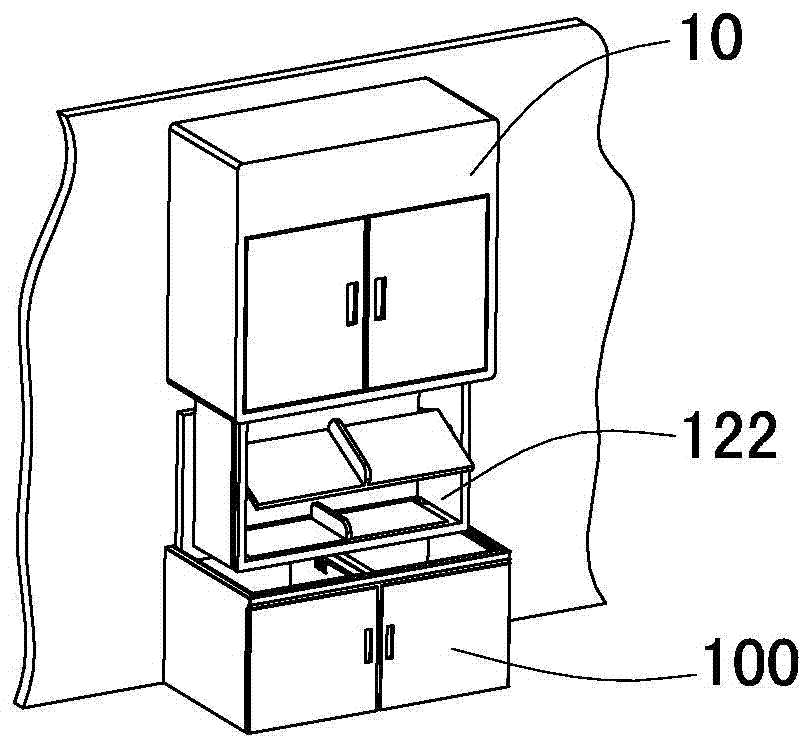

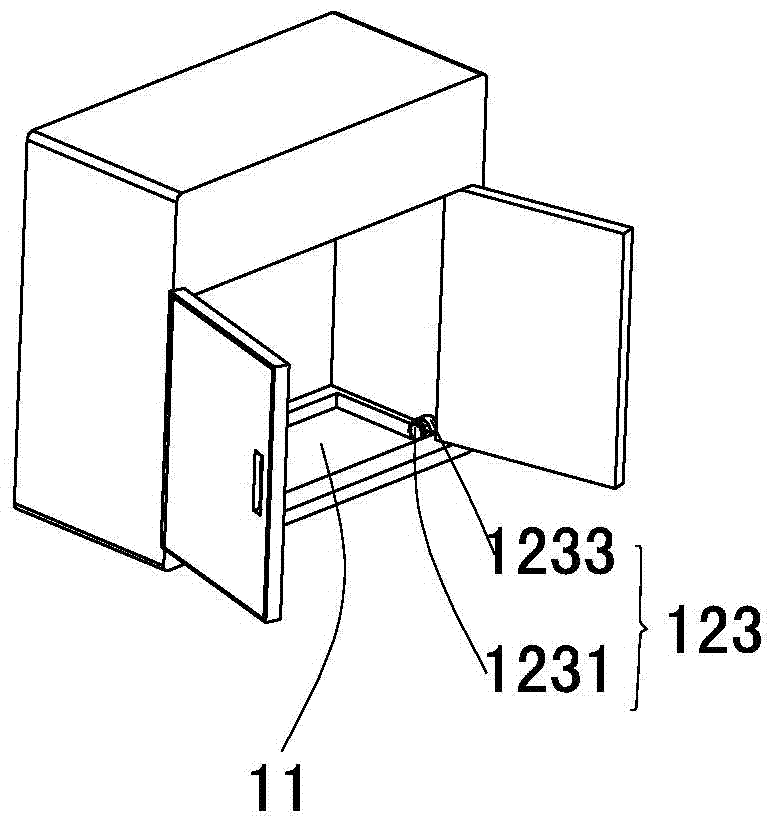

Intelligent refrigerator

InactiveCN107421189AImprove experienceImprove life experienceLighting and heating apparatusDomestic refrigeratorsRefrigerator carEngineering

The invention relates to an intelligent refrigerator. The intelligent refrigerator comprises a control unit, and is provided with an opening communicating with the exterior, and an automatic discharging device is arranged in the refrigerator, and comprises a panel for sealing the opening, a containing frame used for containing food materials, and a first drive part used for driving the containing frame to move and opening the opening. The panel is fixed to the containing frame, the first drive part is in electric signal connection with the control unit, and the automatic discharging device conveys the food materials to the exterior of the refrigerator from the opening. Compared with the prior art, the food materials can be automatically taken out of the refrigerator, discharging through one-key starting can be achieved, people can take the food materials without opening a refrigerator door, the user experience can be greatly improved, rapid and convenient life experience is brought to a user, in addition, in cooperation with a water groove, that is, the food materials fall in the water groove automatically, automatic cleaning is carried out, people can operate the refrigerator at home or outside, and after people go home, the food materials capable of being directly cooked are presented to the user.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com