Cereal homogenizing and collecting device

A technology of agglomeration device and grain, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Impact force, guaranteed operation, avoid crushing or cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

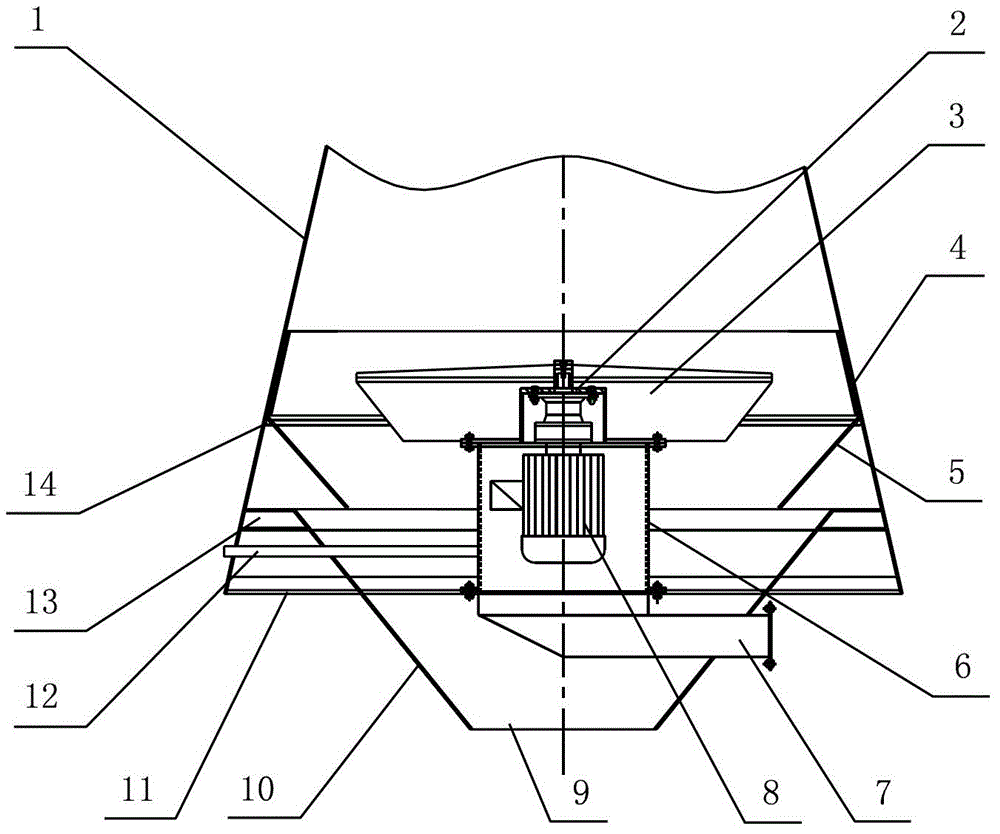

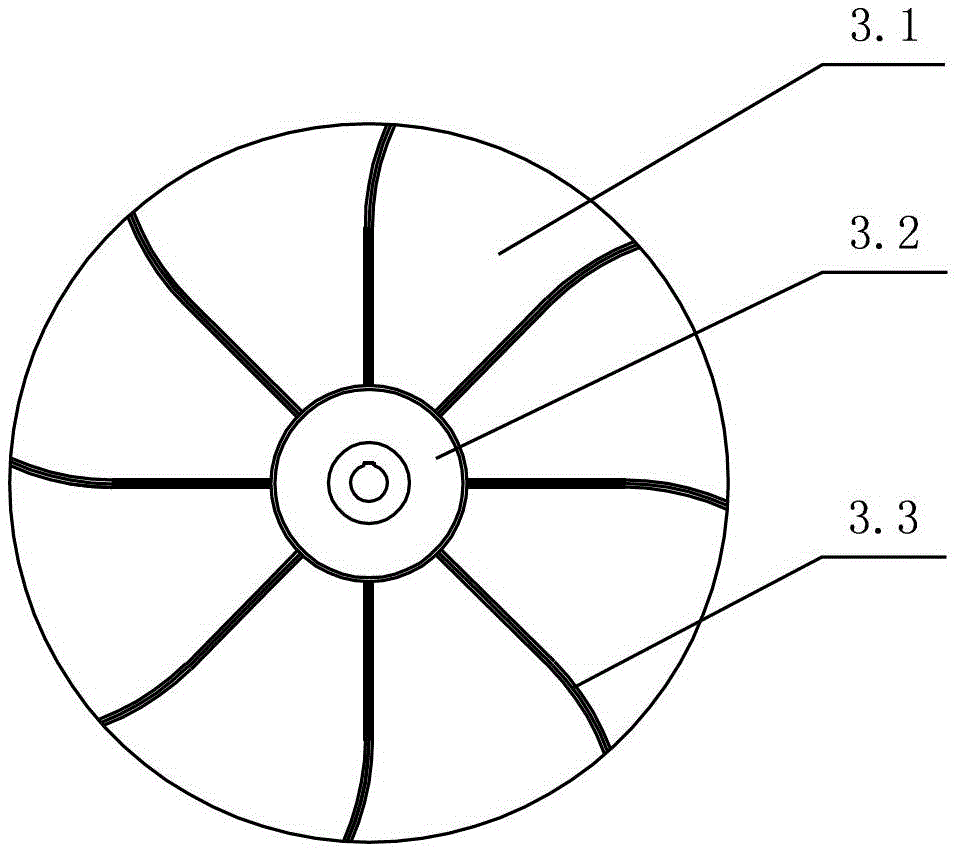

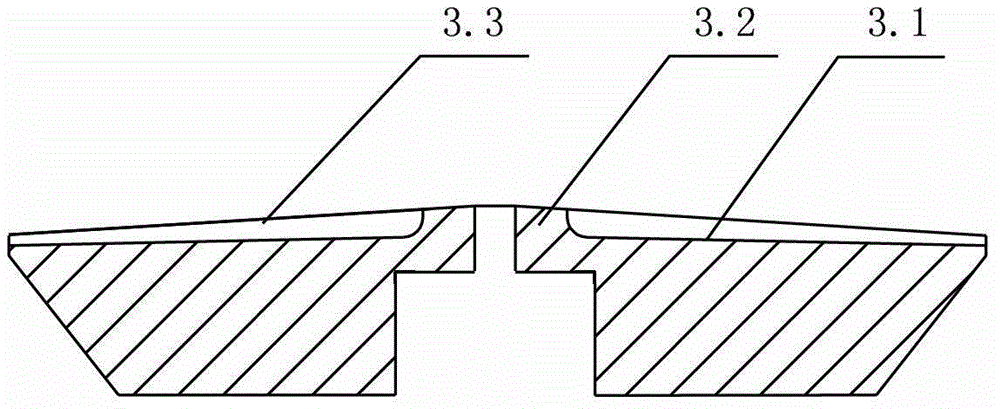

[0030] Examples of the present invention Figure 1~4 As shown, the rotating disk 3 is included, and the rotating disk 3 is arranged in the housing 1. The middle part of the rotating disk 3 is higher than the edge, and there is a circular protrusion 3.2 in the middle, and the bottom of the rotating disk 3 is a circular protrusion 3.2 from the edge to the middle. An upwardly inclined curve, the upper surface of the circular protrusion 3.2 is an inclined downward curve from the center to the edge, the fan blade 3.3 is arranged on the rotating disk 3, the circular protrusion 3.2 is fixedly connected with one end of the fan blade 3.3, and the outer edge is aligned Flat, the other end of the fan blade 3.3 extends to the edge of the rotating disk 3, the fan blade 3.3 is distributed on the upper surface of the rotating disk 3 in a divergent shape, and the fan blade 3.3 is a curved section from the middle of the rotating disk 3 to the edge of the rotating disk 3 in the same direction, ...

Embodiment 2

[0032] Such as Figure 5 As shown, the second collecting hopper 10 is connected to the housing 1 through the strip plates 15 arranged at intervals, and four strip plates can be arranged symmetrically, which can not only provide support for the second collecting hopper 10, but also ensure the smoothness of the winnowing channel .

Embodiment 3

[0034] Such as Figure 6 As shown, embodiment 1 is applied to a small winnowing machine. A feeding pipe 17 is arranged directly above the rotating disk 3. The feeding pipe is fixed on the housing 1. The upper end of the housing 1 is provided with an air suction port. The air suction port 16 is connected to an exhaust fan or light Miscellaneous processing equipment provides wind power for winnowing. The lower end of the shell 1 is fixed with a ring-shaped reinforcing plate 18 to stabilize the support of the shell. The feeding port is connected to the next process equipment.

[0035] work process:

[0036]Under the action of the suction fan at the air suction port 16 or the light miscellaneous treatment equipment, the air in the casing 1 flows upwards, and the outside air enters the casing through the air inlet and the discharge port at the connection between the second collecting hopper 10 and the casing 1. Inside the body, it enters the winnowing area formed by the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com