Patents

Literature

395results about How to "Improve the efficiency of impurity removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clapboard adsorption device and method for removing boron impurities in chlorosilane system

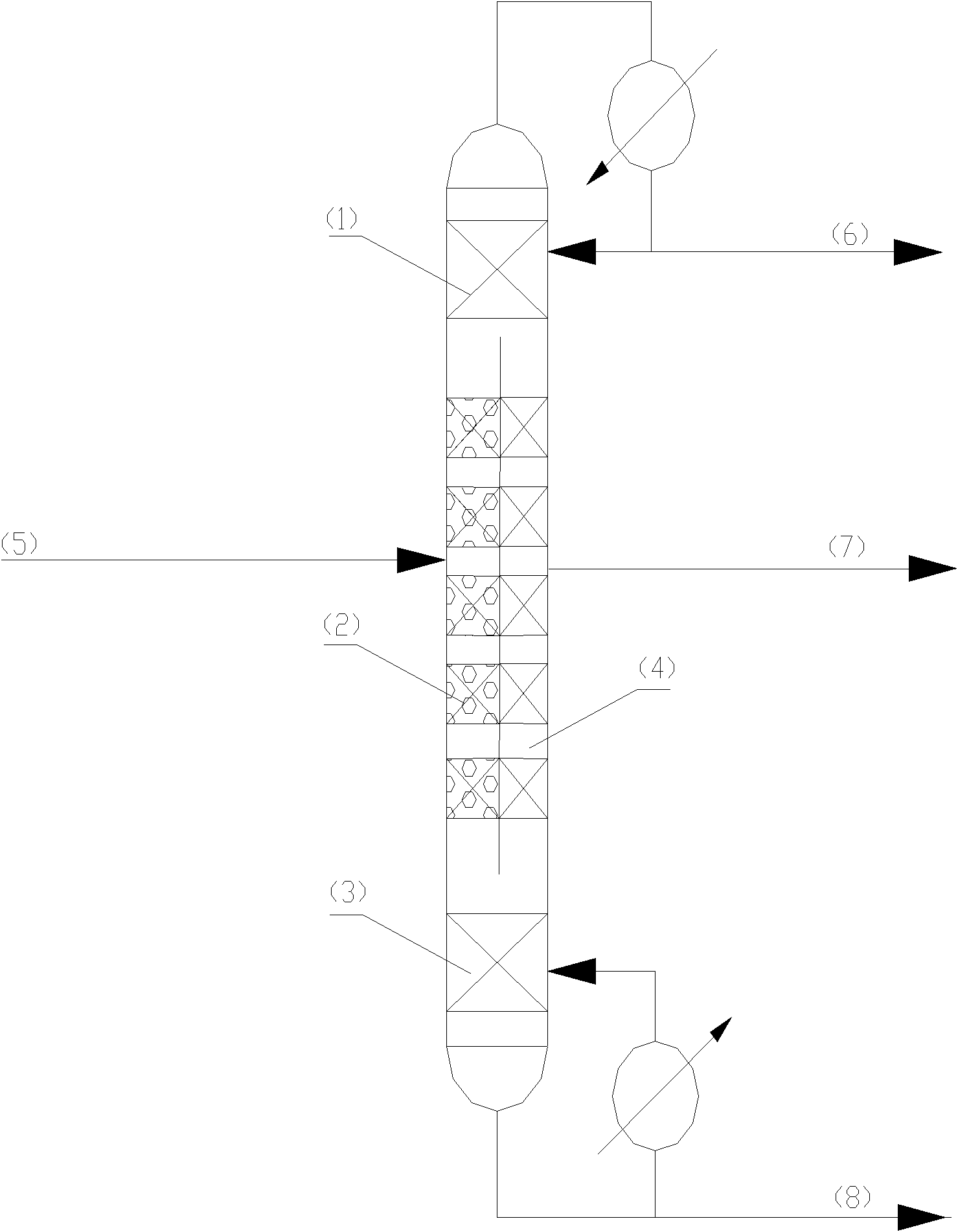

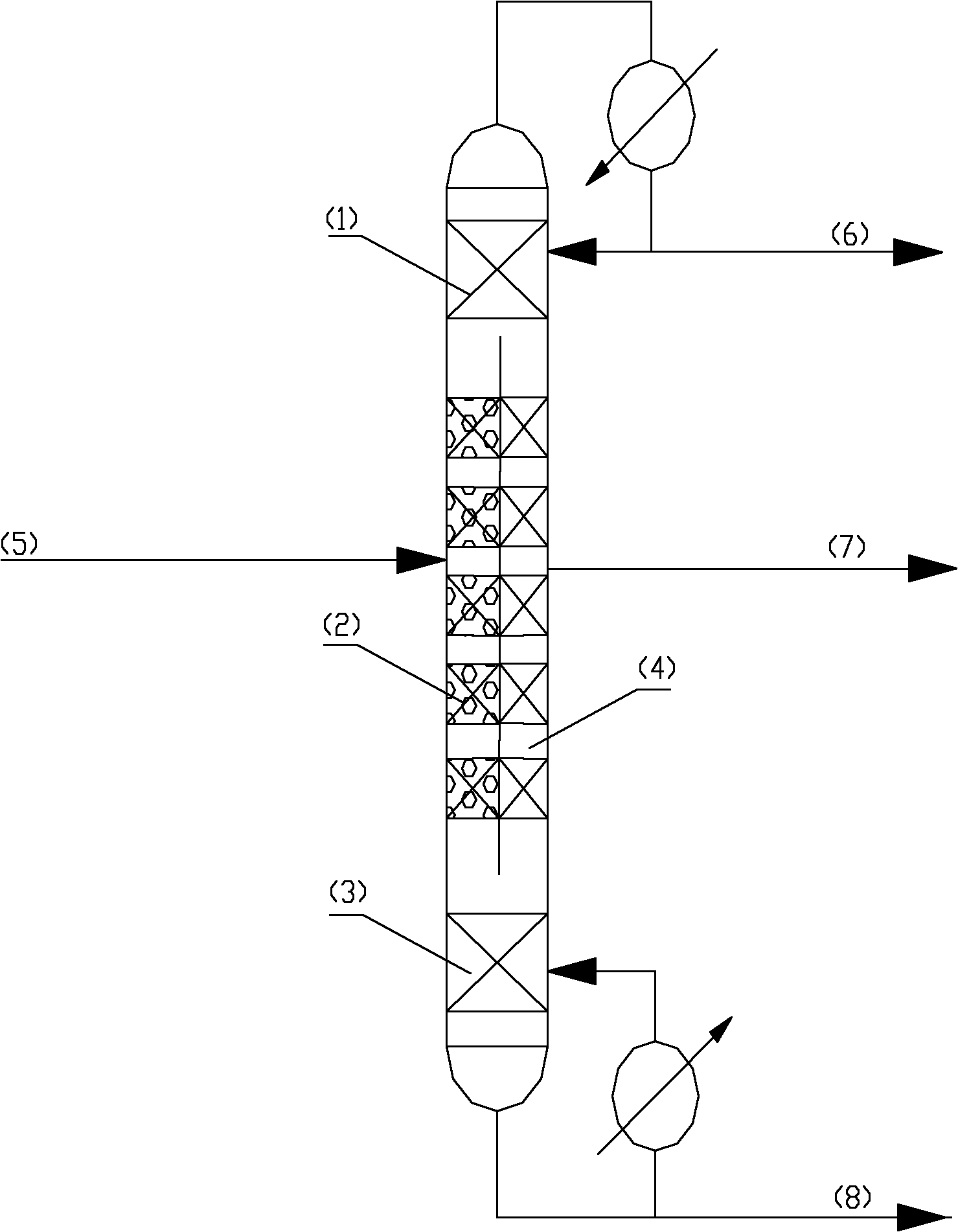

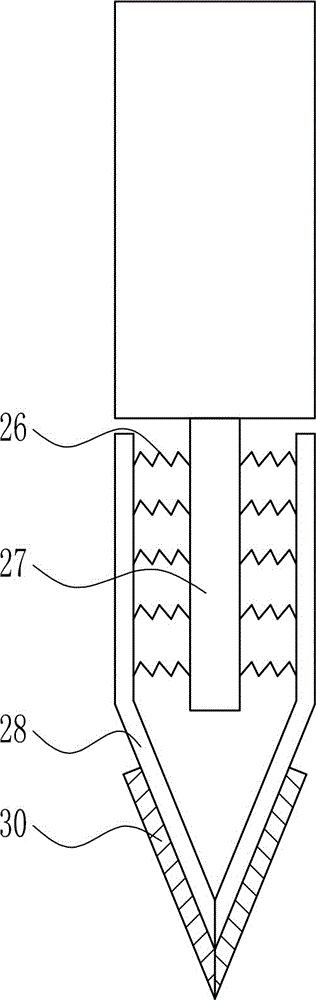

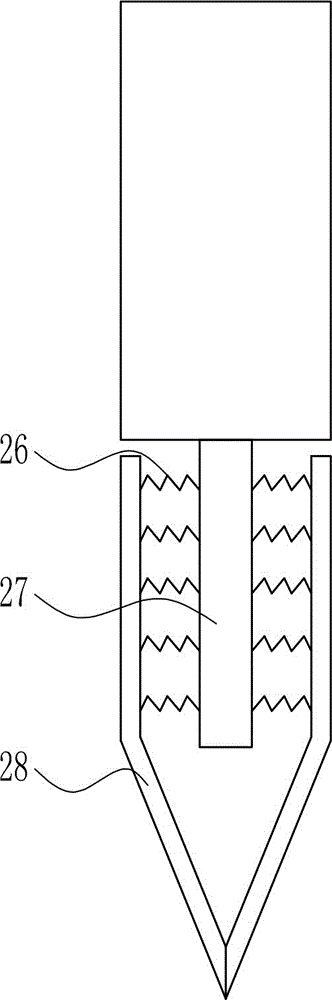

ActiveCN102058992ASimple processHigh purityDispersed particle separationHalogenated silanesSorbentTower

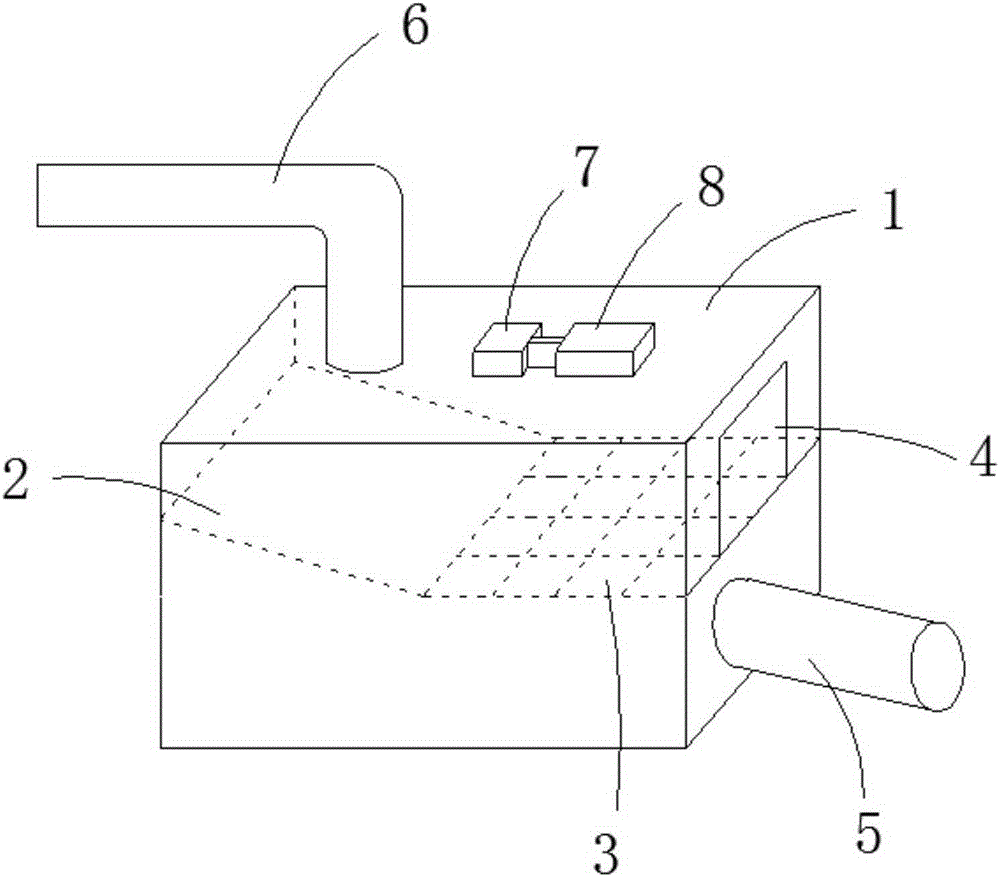

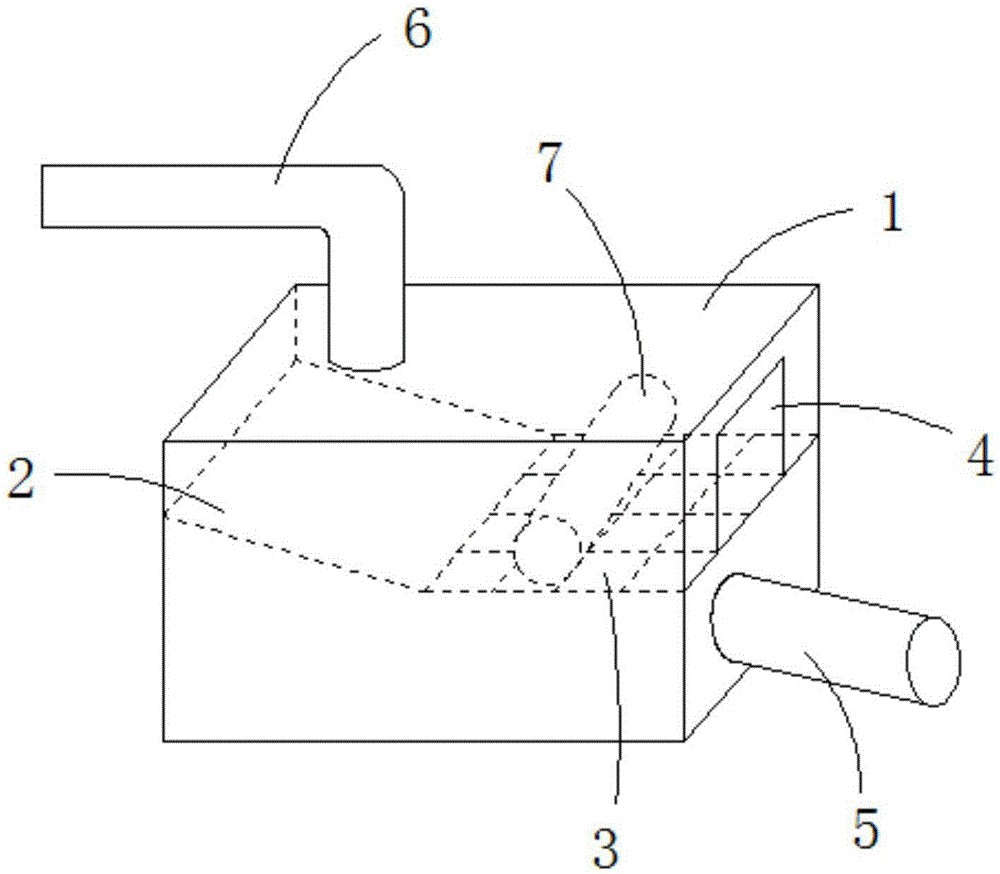

The invention relates to a clapboard adsorption device and method for removing boron impurities in a chlorosilane system. The device is divided into four areas by a clapboard which has the same height as a tower type adsorption section and is placed in the middle of the tower: a public rectifying section (1), a tower type adsorption section (2), a side withdrawing section (3) and a public stripping section (4), wherein an adsorbent is filled in the tower type adsorption section (2). A chlorosilane material (5) containing impurities of boron compounds is fed at the middle part of the tower type adsorption section, light components (6) are obtained from the tower top, the purified product trichlorosilane (7) is obtained from the side withdrawing section, heavy components (8) are obtained from the tower bottom, and the operation pressure of the tower is 300-500 KPa. Through the process, the removal rate of the boron impurities is 80%, and the energy consumption is reduced by 60-80%. Compared with the former boron removal process, the flow is greatly simplified, and the energy consumption and equipment expenses are remarkably reduced. Based on effective removal of boron, the key components are separated, the separated components enter corresponding units of polycrystalline silicon production respectively, and the production cost is reduced.

Owner:TIANJIN UNIV

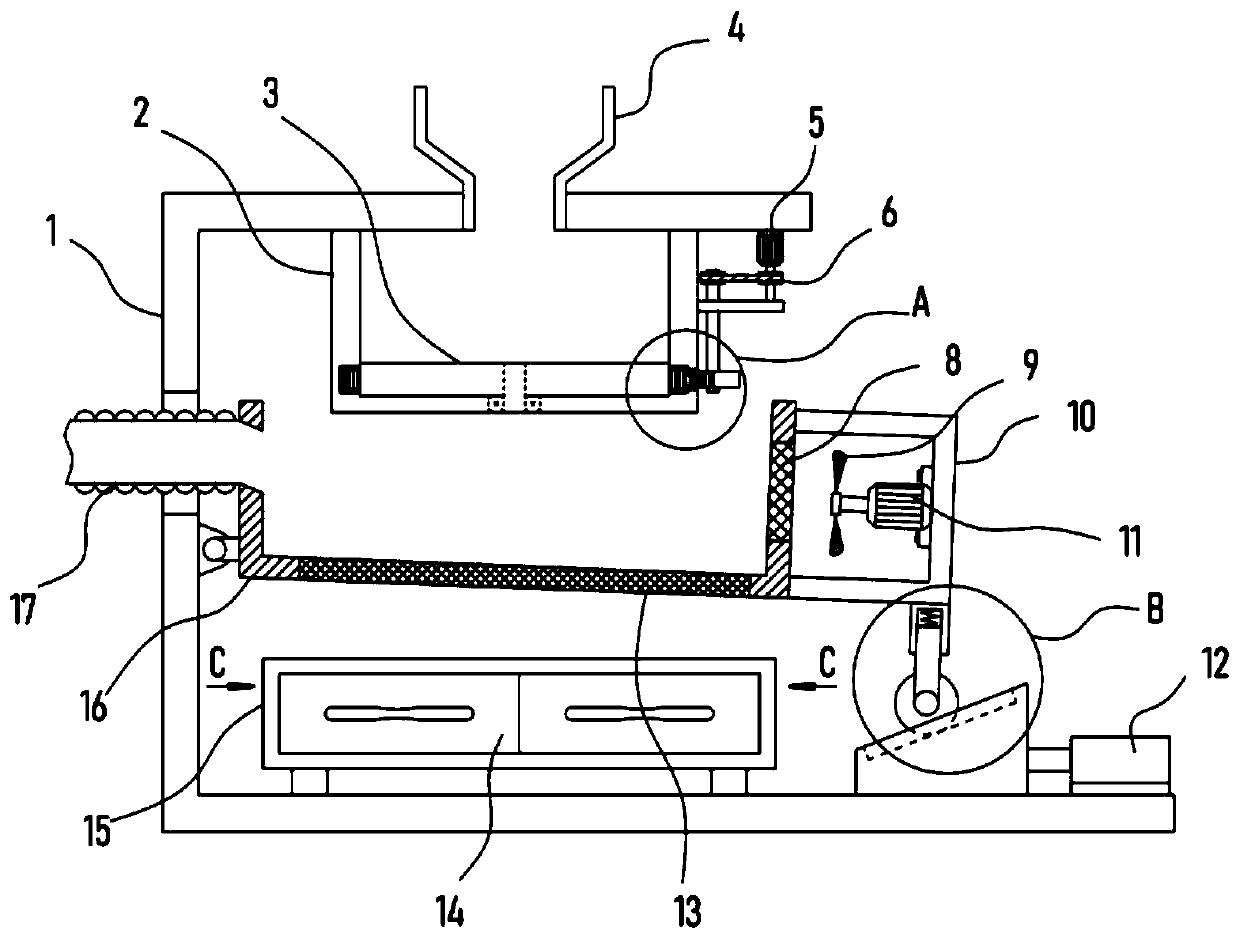

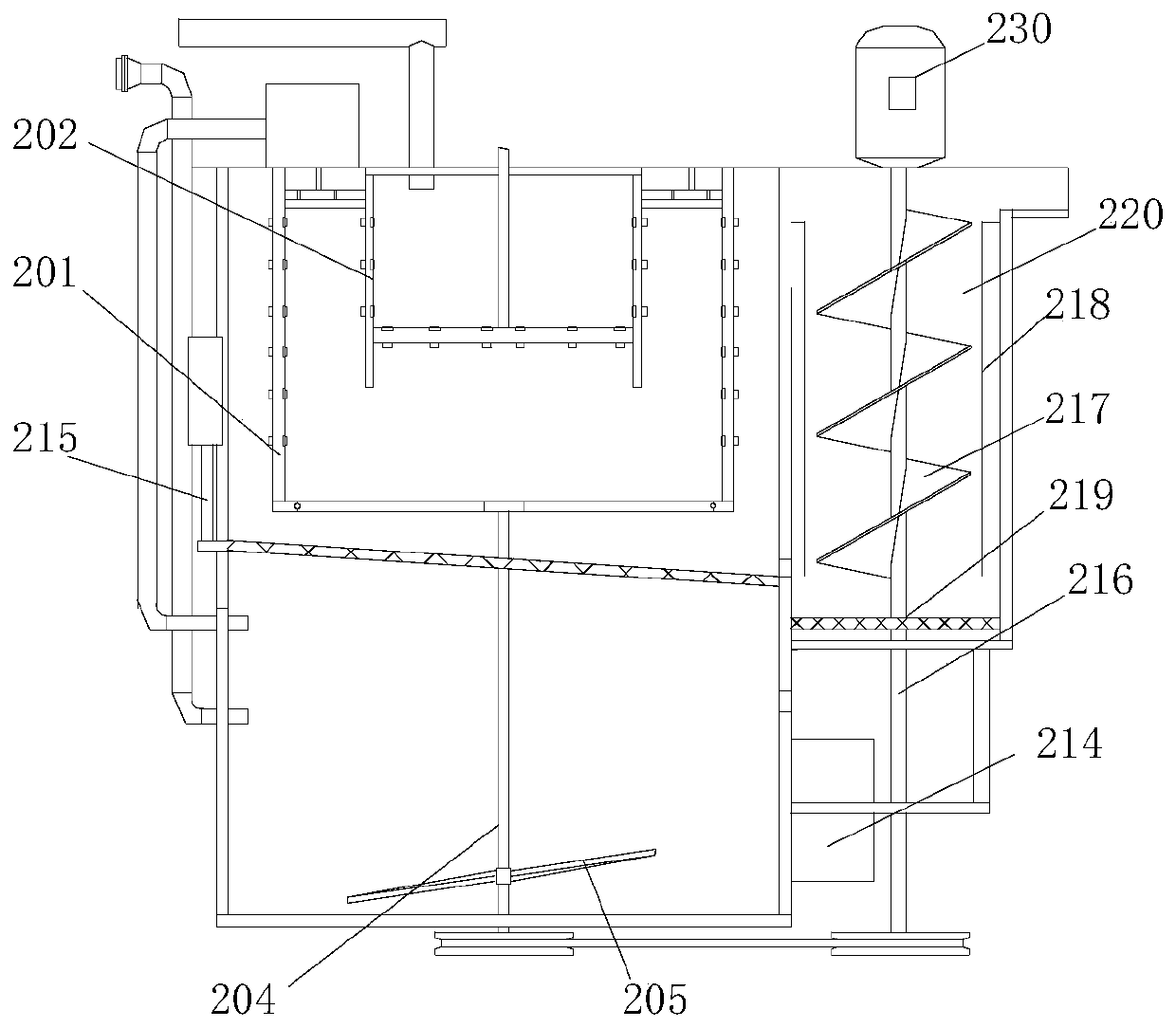

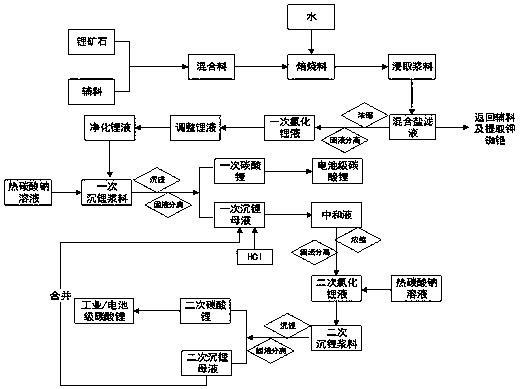

Building residual sandstone rapid filtering and impurity removing device

The invention relates to a filtering and impurity removing device, in particular to a building residual sandstone rapid filtering and impurity removing device. The invention aims at providing a building residual sandstone rapid filtering and impurity removing device with high impurity removing efficiency. In order to achieve the aim, the invention provides the building residual sandstone rapid filtering and impurity removing device which comprises a first strut, a first spring, a mounting base, first sliding blocks, a first sliding rail, electric wheels, a second sliding block, a first pulling rope, a second sliding rail, a mounting plate and the like. The first sliding blocks are arranged on the first sliding rail; a placement frame is arranged at the upper ends of the first sliding blocks; a filter screen is arranged in the placement frame; a second guide wheel and the first strut are arranged at the top of the first sliding rail. The building residual sandstone rapid filtering and impurity removing device disclosed by the invention achieves the effect of high impurity removing efficiency.

Owner:李长财

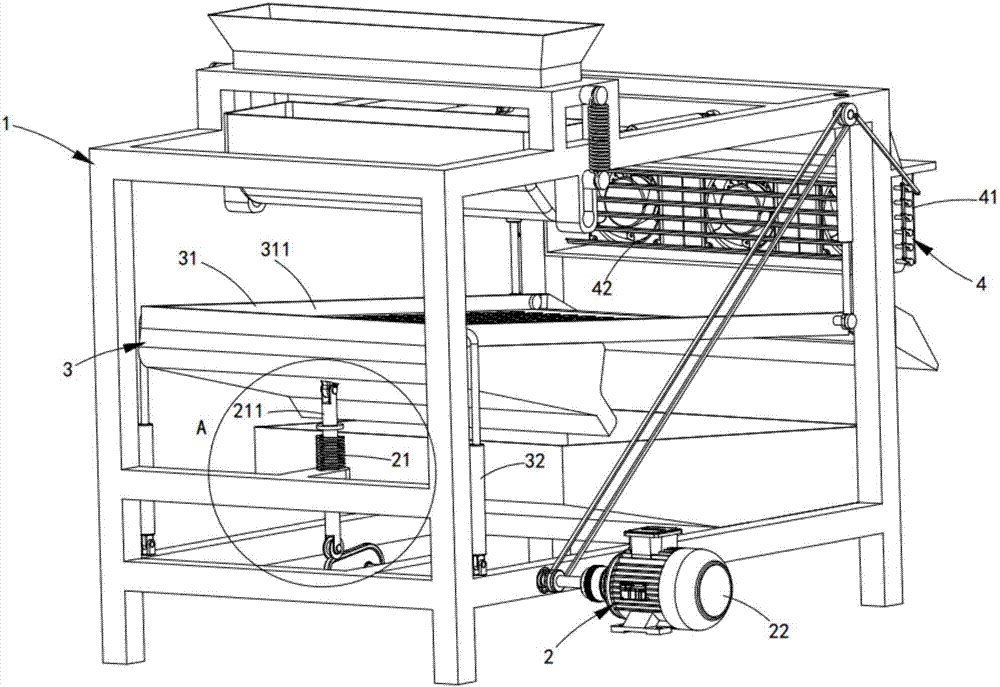

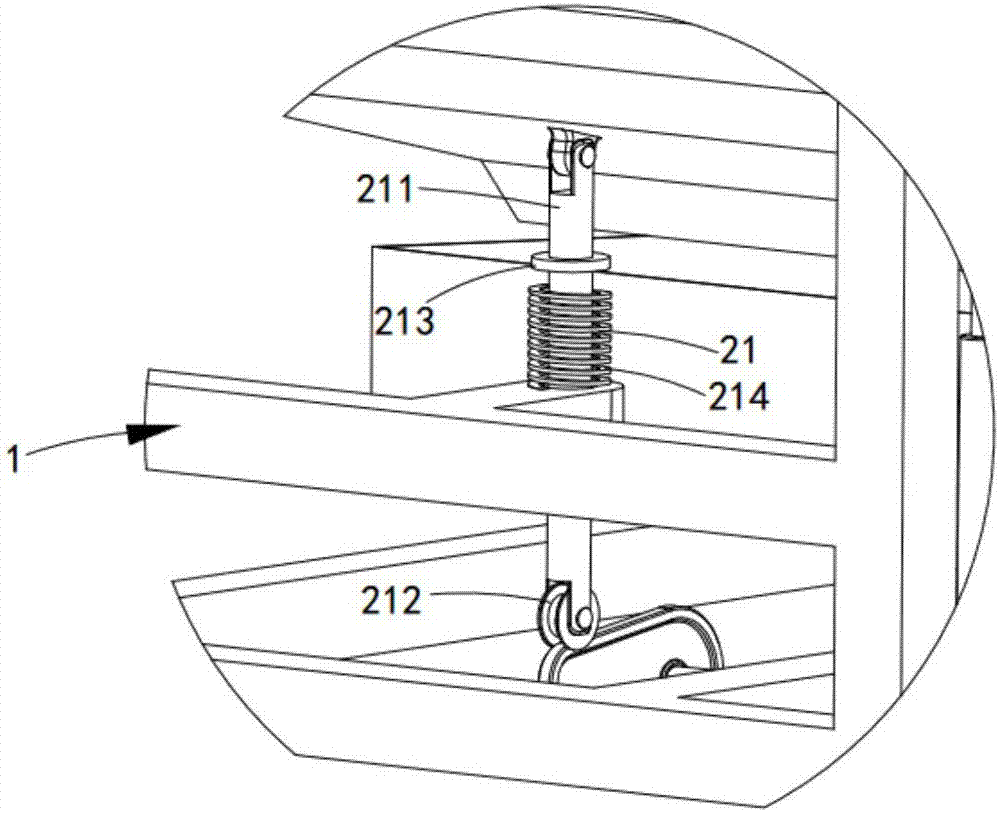

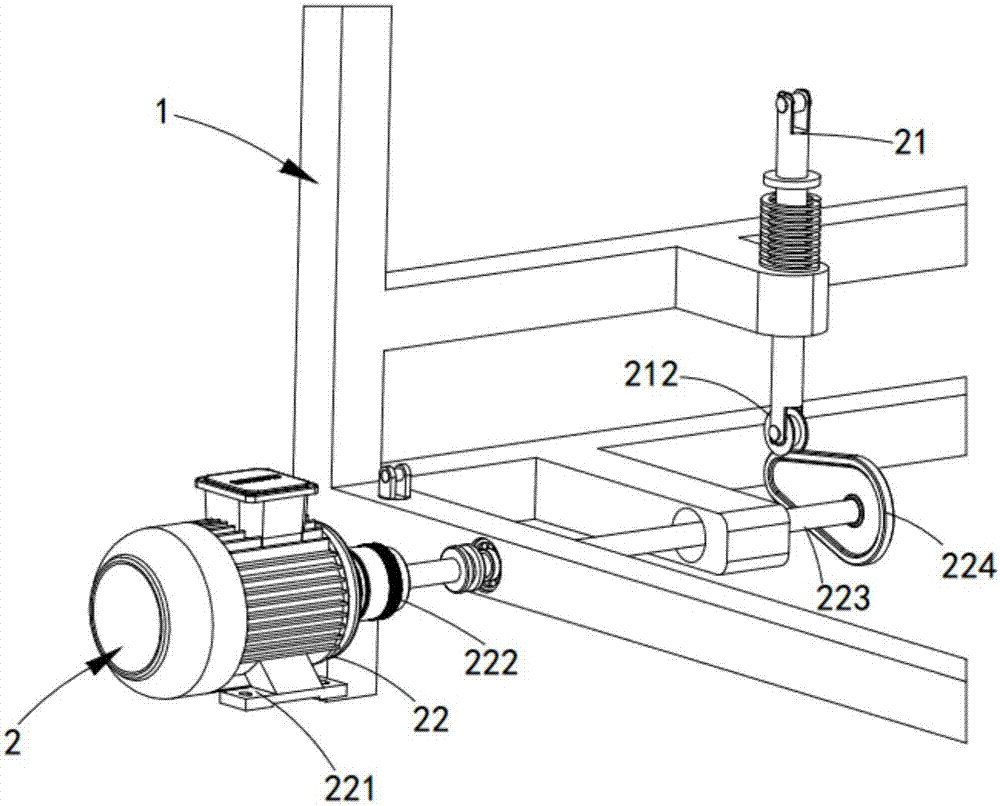

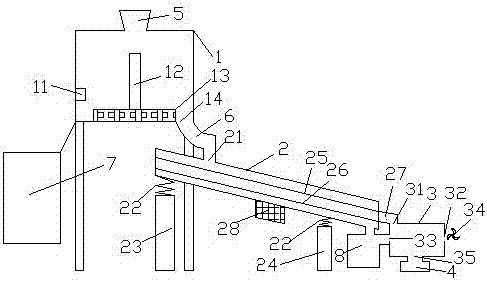

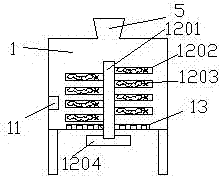

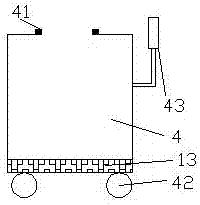

Small-size oscillation grain dehuller

InactiveCN106862081AImprove efficiencyAvoid rigid contactSievingGas current separationEngineeringImpurity

The invention discloses a small oscillating grain hulling machine, which comprises a frame, an oscillating mechanism, a screening mechanism and an air outlet mechanism. The air outlet component and the damper component drive the vibration component to run through the driving component. After the vibration component pushes the screening net in the screening component to a high place, the screening net drops rapidly by gravity, throws the grain on the screening net into the air, and is removed by the wind component. Light impurities such as chaff in the grain, and then the grain is returned to the screening net, and the granular impurities in the grain are screened and removed by the screening net. Repeat this process to completely remove the chaff impurities and granular impurities in the grain, and improve the screening efficiency.

Owner:奥林精密机械科技(长兴)有限公司

Preparation process for high-strength high-conductivity micro copper wire

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

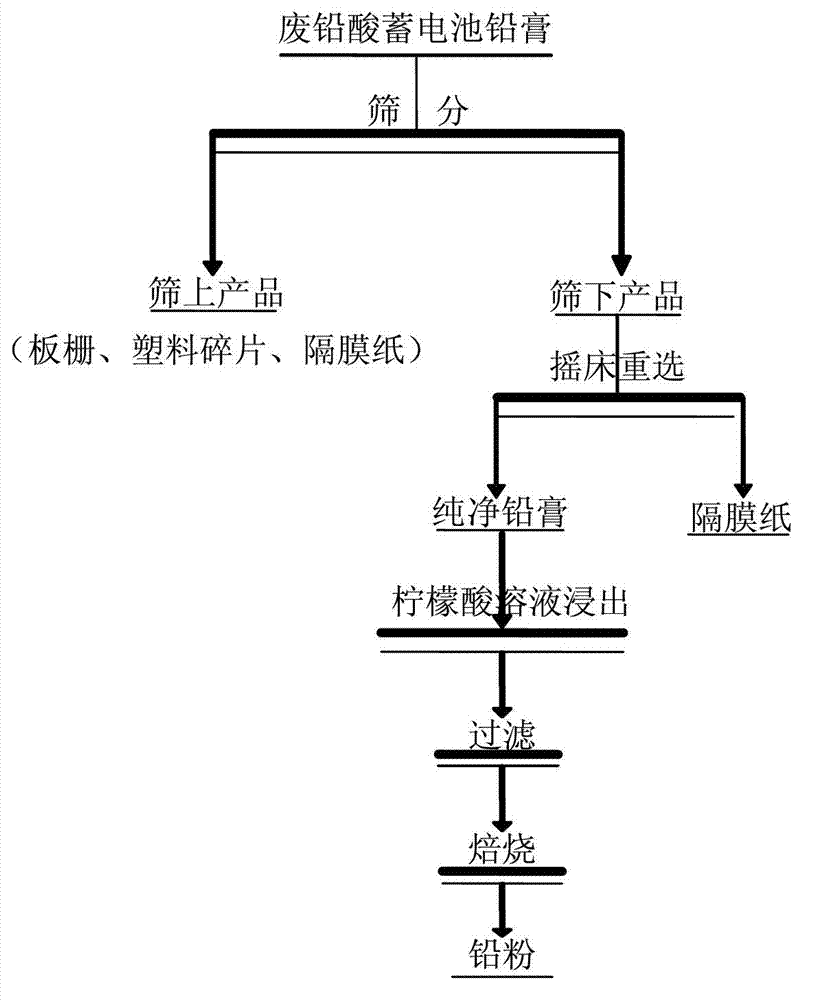

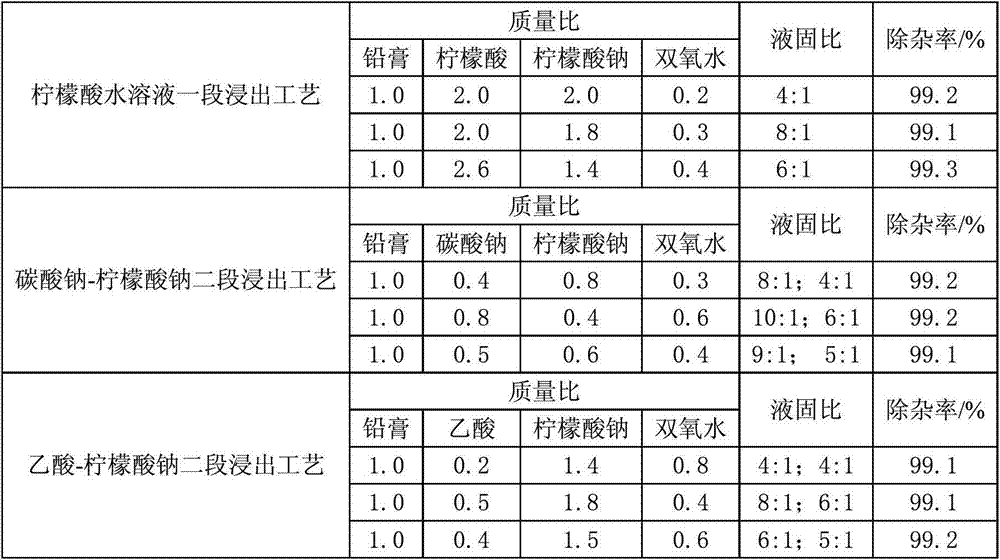

Pretreatment method for lead plaster of waste lead-acid accumulators

ActiveCN103050745AAchieve separationLess investmentWaste accumulators reclaimingBattery recyclingAcetic acidPretreatment method

The invention belongs to the field of utilizing waste lead-acid accumulators to produce secondary lead, and relates to a novel pretreatment method for lead plaster of the waste lead-acid accumulators. The pretreatment method comprises the steps that after the waste lead-acid accumulators are crushed and subjected to preliminary separation, waste lead plaster is obtained; wet sieving or dry sieving is conducted on the waste lead plaster by a 0.85mm-0.106mm sieve; plate grid and plastic fragment products are obtained; table reconcentration is conducted on undersize products; diaphragm paper products and pure lead plaster are obtained; the plate grid and plastic fragment products and the diaphragm paper products can enter a fire smelting system; the pure lead plaster is treated by a citric acid aqueous solution or sodium carbonate or a new acetic acid leaching technology; and lead powder is obtained, and can be used for preparing the lead-acid accumulators directly. The pretreatment method for the lead plaster of the waste lead-acid accumulators is simple in technological equipment, low in investment, low in cost, high in impurity removal rate, clean, highly-efficient and energy-saving.

Owner:HUAZHONG UNIV OF SCI & TECH +1

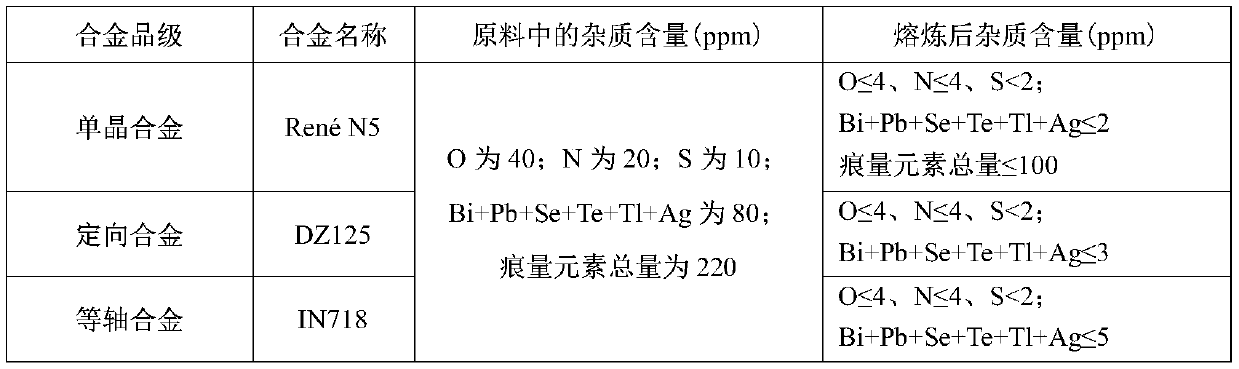

Pure purification smelting method used for nickel-based high-temperature alloy master alloy

The invention relates to a pure purification smelting method of an alloy, in particular to a pure purification smelting method for a nickel-based high-temperature alloy master alloy, and belongs to the technical field of metal smelting. According to the method, pure purification smelting of a master alloy is completed through material distributing and alloy melting, primary refining, alloying andsecondary refining, microalloying controlling and casting. The method has the advantages that the purity of vacuum melting can be effectively improved, the element segregation can be improved, and a nickel-based high-temperature alloy prepared by the method has the advantages that the purity is high, the segregation is low, the quality is remarkably higher than that of an alloy prepared through the existing technology and method, the quality of the nickel-based high-temperature alloy is improved, and the application field is expanded; nickel-based high-temperature alloys with different gradesand marks smelted by adopting the method has good effects; vacuum induction furnaces with the furnace types of 250 kg-grade and 1.5 ton-grade are adopted; and compared with an alloy before smelting and prepared through other technologies and methods, the alloy is remarkably improved in purity and uniformity.

Owner:METALINK SPECIAL ALLOYS CORP

Production process for preparing high-purity quartz powder from quartzite

InactiveCN104556047ALoose structureGuaranteed structural porositySilicon compoundsStrong acidsMetal impurities

The invention discloses a production process for preparing high-purity quartz powder from quartzite. The production process comprises the following steps: 1) soaking; 2) smashing; 3) calcining; 4) water quenching; 5) grinding; 6) magnetic separation; 7) elestrostatic separation; 8) acid pickling; 9) cleaning by deionized water; 10) drying. According to the production process, the contamination particles are eluted via gradient acidity distribution; before the smashing, strong acid is used for soaking so as to remove the impurities on the surface of the quartzite; during the water quenching, medium / strong acid is used for removing the metal impurities wrapped in the quartzite; during the grinding, in order to protect the equipment from erosion, medium / weak acid is used for removing the impurities during the grinding, and a ball grinding mill is utilized to increase the contact probability and contact area between the acid liquor and the impurities so as to increase the impurity removal efficiency; during the final acid pickling, weak acid is used for further removing a small quantity of residual contamination particles which are not reacted completely; the afterheat generated during the calcination is collected and used for the final drying, so that the energy consumption is reduced and the production cost of the enterprise is decreased.

Owner:新沂市永恒熔融石英有限公司

Method for preparing filler-level silicon micropowder by using waste quartz crucibles as raw materials

InactiveCN103613103AWide variety of sourcesMeet the requirements of filler useSilicaNatural resourceResource depletion

The invention relates to a method for preparing filler-level silicon micropowder by using waste quartz crucibles as raw materials. Aiming at the problems that the quartz crucible waste products have great stock at present and high-quality silicon natural resources are scarce increasingly, the invention provides a method for preparing silicon micropowder which is suitable for serving as fillers and has high purity, wide particle size distribution and low electric conductivity by using waste quartz crucibles as raw materials through the technical treatment of ultrasonic washing, crushing, levigating and acid washing, flotation, magnetic separation, flashing and drying, electric separation and the like. By adopting the method, the problem about resource exhaustion of high-purity quartz mine and the problem about comprehensive utilization of waste quartz crucibles of photovoltaic enterprises and crucible preparation enterprises are relieved to a certain degree.

Owner:南京工业大学东海先进硅基材料研究院 +1

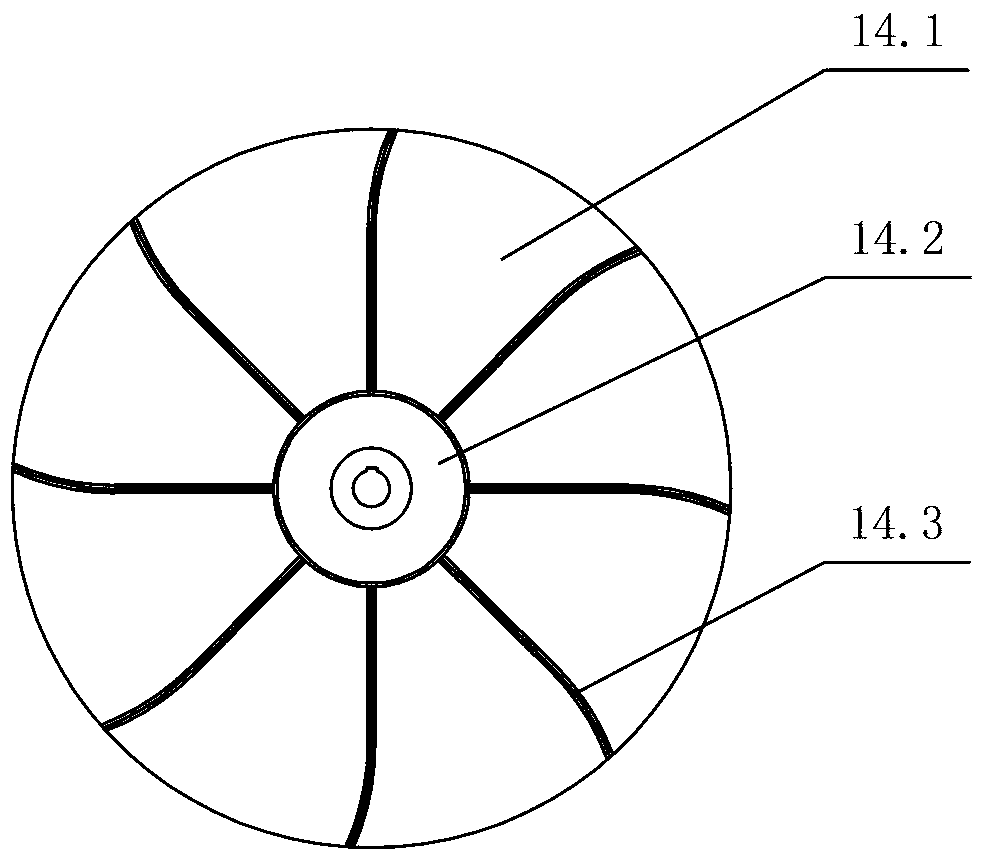

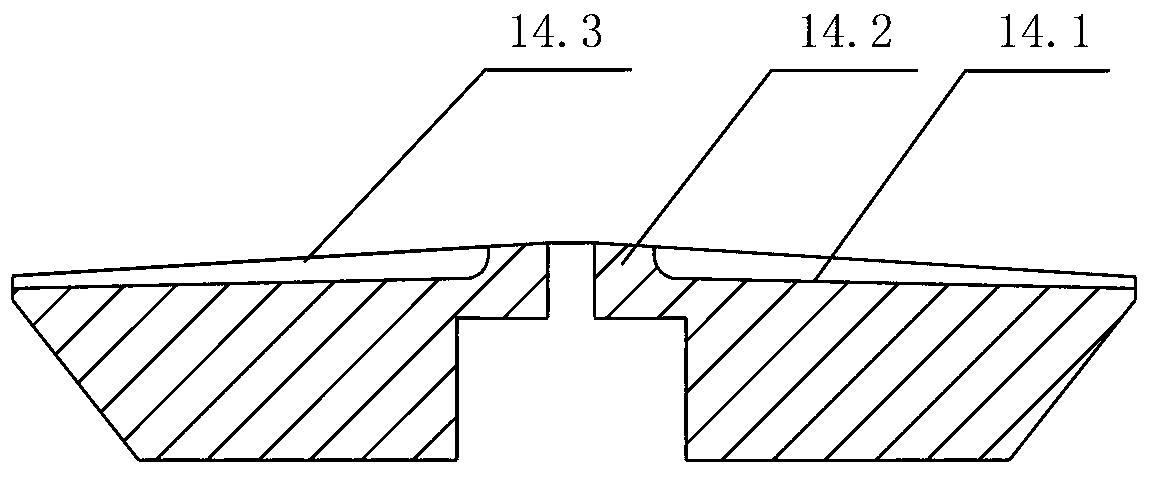

Rapeseed screening and impurity removal device for production of rapeseed oil

InactiveCN109772706ARealize decentralized feedingEasy to separateSievingGas current separationOil processingFixed frame

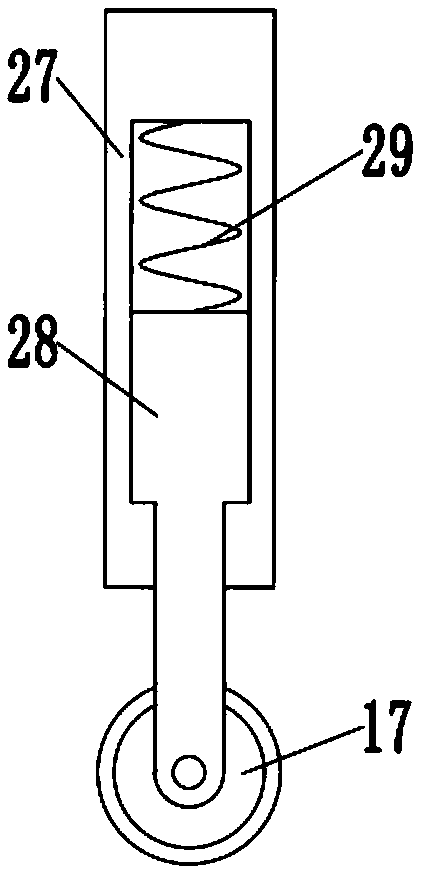

The invention discloses a rapeseed screening and impurity removal device for production of rapeseed oil and relates to the technical field of rapeseed oil processing. The device comprises a supportingframe, wherein a screening groove is hinged to the supporting frame; a screening plate is embedded in the bottom of the screening groove; a material separation barrel fixed at the top in the supporting frame is arranged above the screening groove; a limiting sleeve is fixed at the bottom of a fixed frame; a sliding column is mounted in the limiting sleeve; a wedge block abutted against the a guiding roller is slidably mounted on the supporting frame; and a collecting groove fixed on the supporting frame is arranged below the screening groove. According to the invention, through the transmission cooperation of the arranged wedge block and the guiding roller, the vibration of the screening groove together with the screening plate is achieved and thus separation of rapeseeds and impurities is facilitated; arranged fan blades rotate and blow air towards the interior of the screening groove, so that light impurities mixed in the rapeseeds are blown away and the separation effect of the rapeseeds and impurities is better; and arc holes formed in a discharging disc are staggered with disperse radial holes formed in the material separation barrel intermittently and repeatedly, so that excessive concentrated screening of the rapeseeds is avoided and the impurity removal efficiency is improved greatly.

Owner:安庆市汇智科技咨询服务有限公司

Zinc and cobalt separation method

ActiveCN106119560AHigh recovery rateAchieve primary separationProcess efficiency improvementSlagNinetieth percentile

The invention provides a zinc and cobalt separation method. The zinc and cobalt separation method specifically includes the steps that 1, most metal in slag with high content of zinc and cobalt enters leaching solutions in a leaching mode, the leaching rate reaches 95% of above, and the metal recovery rate is high; 2, iron, copper and cadmium are removed in a combined mode, the purification process is simplified, the content of the iron, the copper and the cadmium in the solutions can be lowered to 5 mg / L or below, and the purification efficiency is high; 3, preliminary separation of the zinc and the cobalt is realized, the technology is simple, and the operation is easy; and 4, residual zinc is further removed, and complete separation of the zinc and the cobalt is realized. According to the method, the technology is simple, separation of the zinc and the cobalt is complete, the consumption is small, the production cost is low, and the recovery rate of the zinc and the cobalt in materials containing the zinc and the cobalt can reach 90% or above.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Device for efficiently removing impurities in feed

InactiveCN107413643AEasy to cleanAvoid pollutionSievingGas current separationAir separationDrive motor

The invention discloses a high-efficiency feed impurity removal device, which comprises a body, a driving motor and a rotating motor; a screen box is arranged on the upper part of the body, and an inward plate is fixedly connected to the side wall of the screen box; a screen plate is arranged at the bottom of the screen box The sieve plate is connected to the body through a spring; a fan is provided under the sieve plate, and the fan communicates with the inner cavity of the body; the left side wall of the body is provided with a baffle at the corresponding position of the fan; A dust bag is provided; an iron removal plate is provided in the body; a door panel is hinged on the right side of the body. The present invention is equipped with shaking sieve box, winnowing dust removal and iron removal plate to clean and remove dust, large particles and iron filings in the feed, and has better effect of removing impurities; the present invention is provided with dust removal bag and collection The crumb bag efficiently cleans up impurities, improves the efficiency of removing impurities, and avoids polluting the environment at the same time.

Owner:YANCHENG CIVIL MACHINERY CO LTD

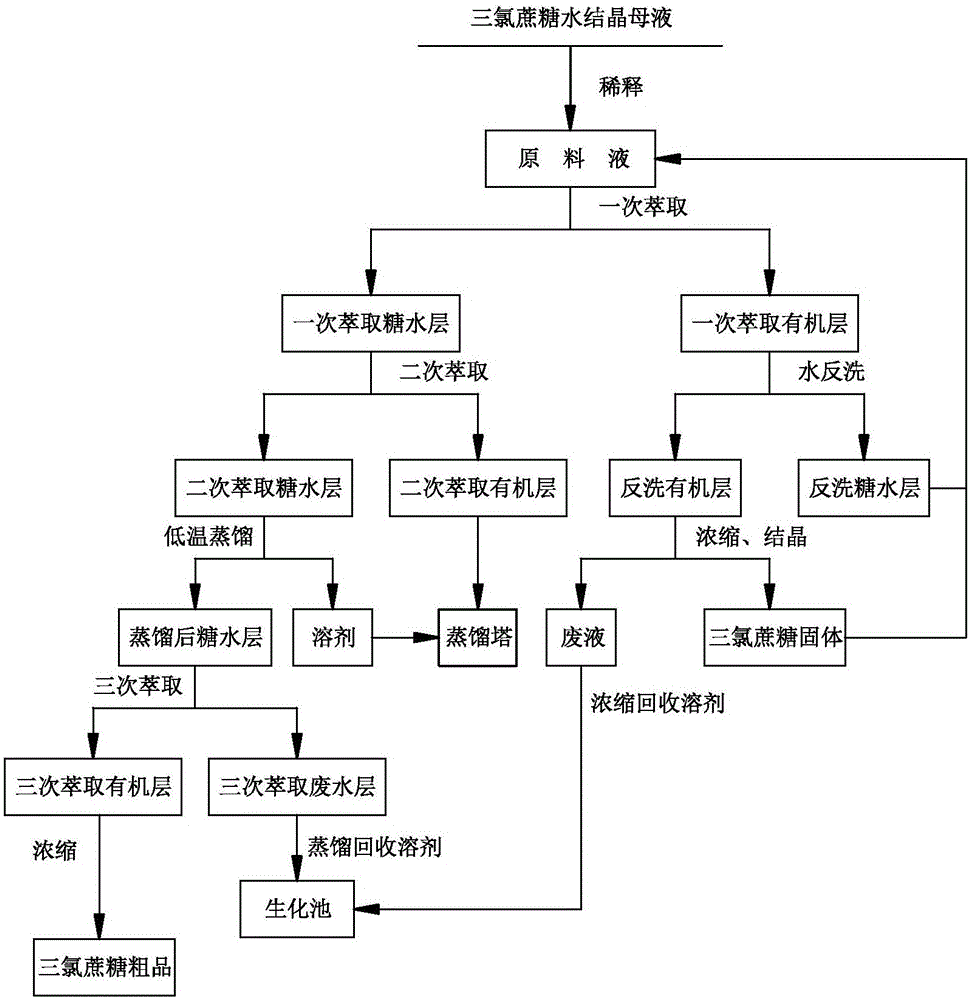

Method for purification treatment of sucralose water crystallization mother liquor

ActiveCN106674292AResidue reductionHigh puritySugar derivativesSugar derivatives preparationWastewaterSolvent

The invention discloses a method for purification treatment of sucralose water crystallization mother liquor. According to the method, not only can residues of an impurity removing solvent in a sugar water layer be reduced, but also removes low-polarity and high-polarity impurities in the sucralose water crystallization mother liquor can be removed by virtue of stepwise extraction, so that the purity of a sucralose crude product obtained after impurity removal is greatly improved; and meanwhile, according to the technological process of the purification treatment of the method disclosed by the invention, the recovery rate of sucralose can be effectively increased, and losses and wastewater discharge amount can be reduced, and the technological process is suitable for industrial actual production.

Owner:TECHNO (FUJIAN) FOOD INGREDIENTS CO LTD

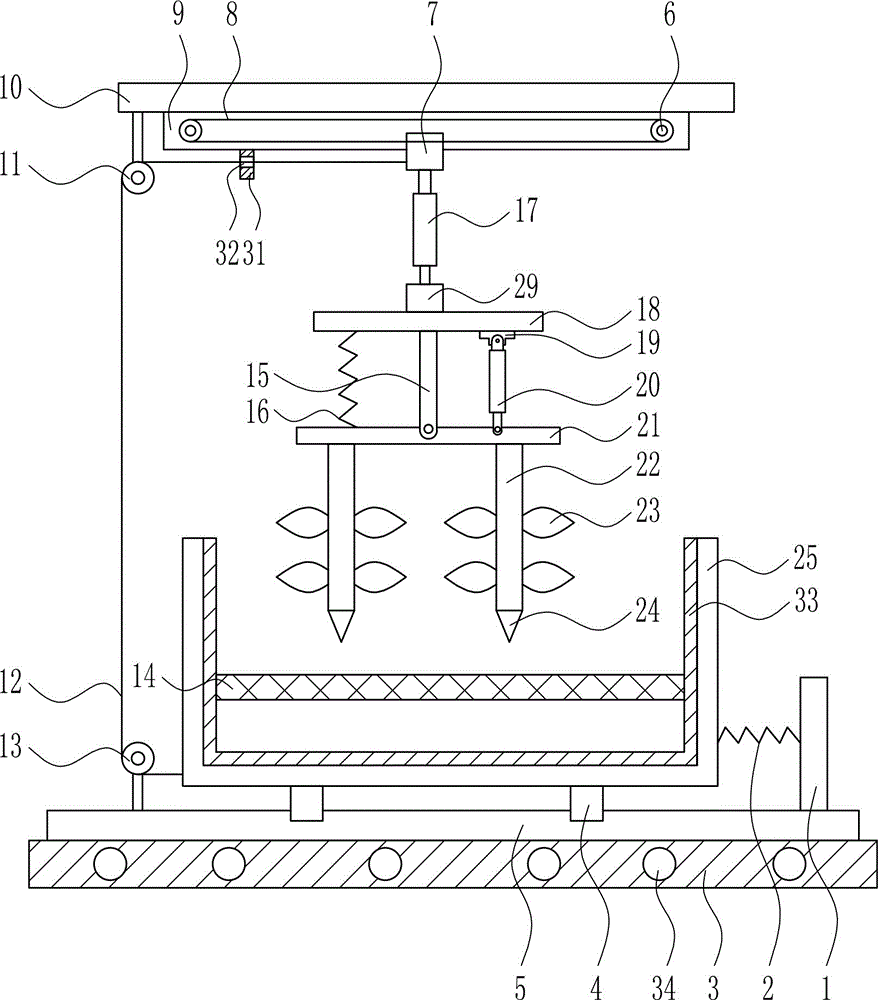

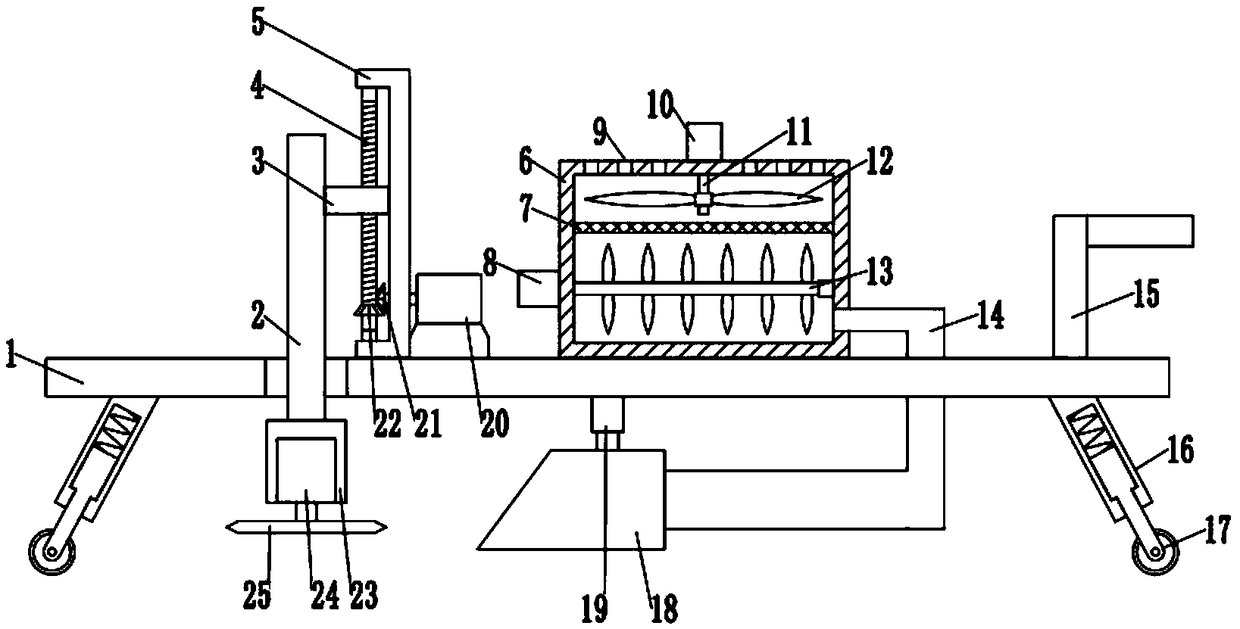

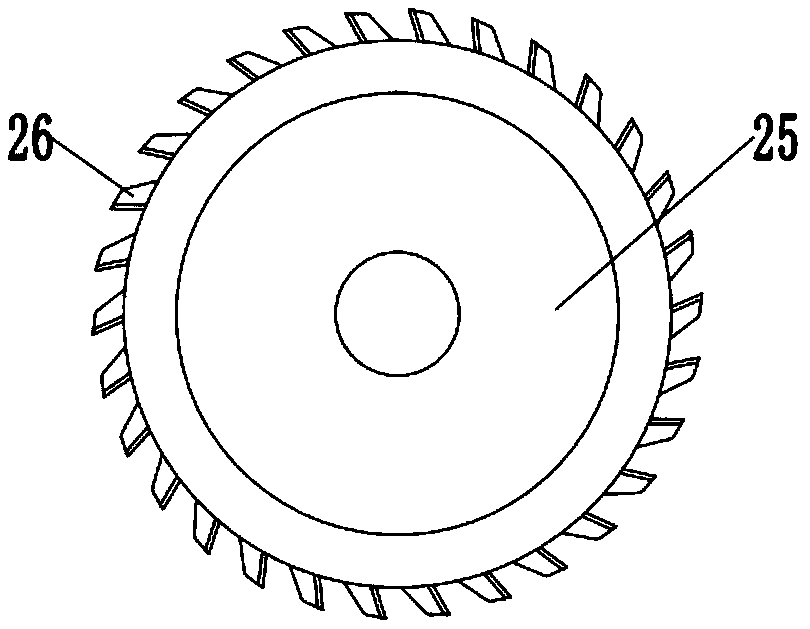

Agricultural weeding device with breaking function

InactiveCN108770469AEasy to moveImprove the efficiency of impurity removalMowersAgricultural engineeringWeed

The invention discloses an agricultural weeding device with breaking function, wherein the agricultural weeding device comprises a pedestal and a crushing case; a frame is fixedly mounted on an upperleft side of the pedestal; a screw is rotationally mounted inside the frame; a thread sleeve is threaded to the screw; the thread sleeve is slidingly connected to the frame; a lifting frame is slidingly mounted, at the left side of the frame, on the pedestal; the lifting frame is fixedly connected with the thread sleeve; a motor cover is fixedly mounted on a bottom of the lifting frame, and a fourth motor is fixedly mounted inside the motor cover; an output end of the fourth motor is fixedly connected with a cutting blade; the crushing case is fixedly mounted on the pedestal; a collecting hopper is disposed on a lower side of the pedestal, and a discharge port of the collecting hopper is connected with an interior of the crushing case through an air inlet pipe. The invention performs weeding according to the height of weeds, and pulverizes the absorbed weeds after cutting, and discharges the crushed weeds to improve the efficiency of removing impurities.

Owner:牛瑞志

Mineral separation feeding box with material crushing function

The invention relates to a mineral separation feeding box with the material crushing function. The mineral separation feeding box comprises a material box, a buffer board, a screen, an impurity removing door and a discharging pipe. The buffer board is obliquely arranged in the middle in the material box and located below a discharging port of an ore pulp pipe. The screen is horizontally arranged in the middle in the material box and jointed with the buffer board. The impurity removing door is arranged at the portion, away from one side of the buffer board, of the screen, on the side wall of the material box. The discharging pipe is arranged below the impurity removing door and communicated with the bottom in the material box. An ultrasonic generator for emitting ultrasonic waves towards the screen is arranged at the upper end of the material box. Compared with the prior art, large ores in ore pulp can be smashed, the screen is prevented from being blocked, and the impurity removing efficiency is high.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

Kapok fiber pre-treating method

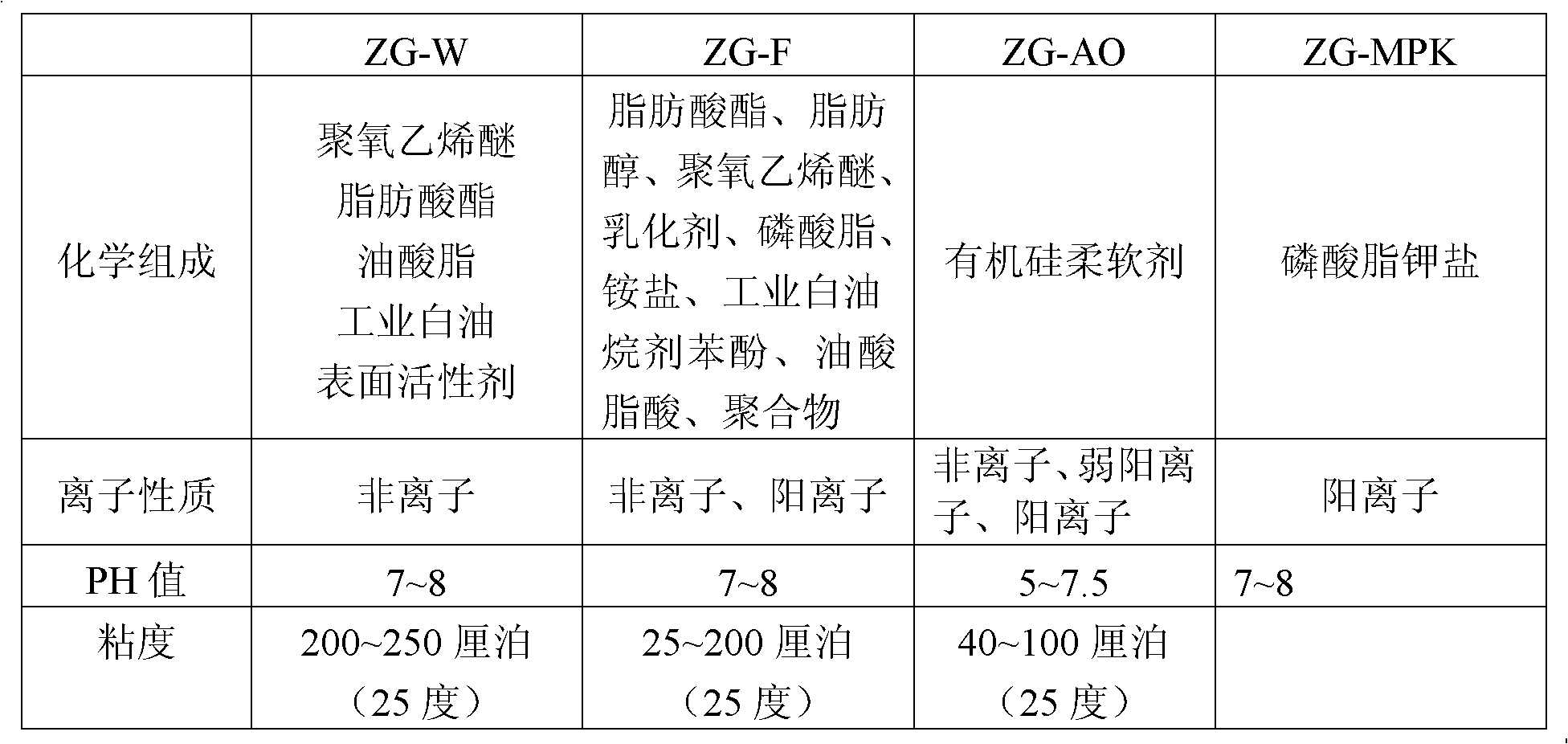

InactiveCN102182065AIncrease labor intensityImprove the mixing effectTextile treatment by spraying/projectingVegetal fibresPretreatment methodKapok fiber

The invention provides a kapok fiber pre-treating method. The method comprises the following steps of: spraying an auxiliary agent onto a raw material, namely kapok fibers; and then placing the kapok fibers in an environment of which the humidity is 55 to 60 percent and the temperature is 25 to 32 DEG C and balancing for 20 to 26 hours to obtain the pre-treated kapok fibers. The auxiliary agent comprises the following components in part by weight: 70 to 80 parts of water, 2 to 6 parts of silicone oil and 20 to 25 parts of crude oil. The spinning property of the kapok fibers can be obviously improved by treating the raw material, namely the kapok fibers, and then blending the kapok fibers and other fibers by the method; the labor intensity is reduced to a large extent; and the yield and the quality are approved by clients.

Owner:SHANGHAI HEYE TEXTILE +1

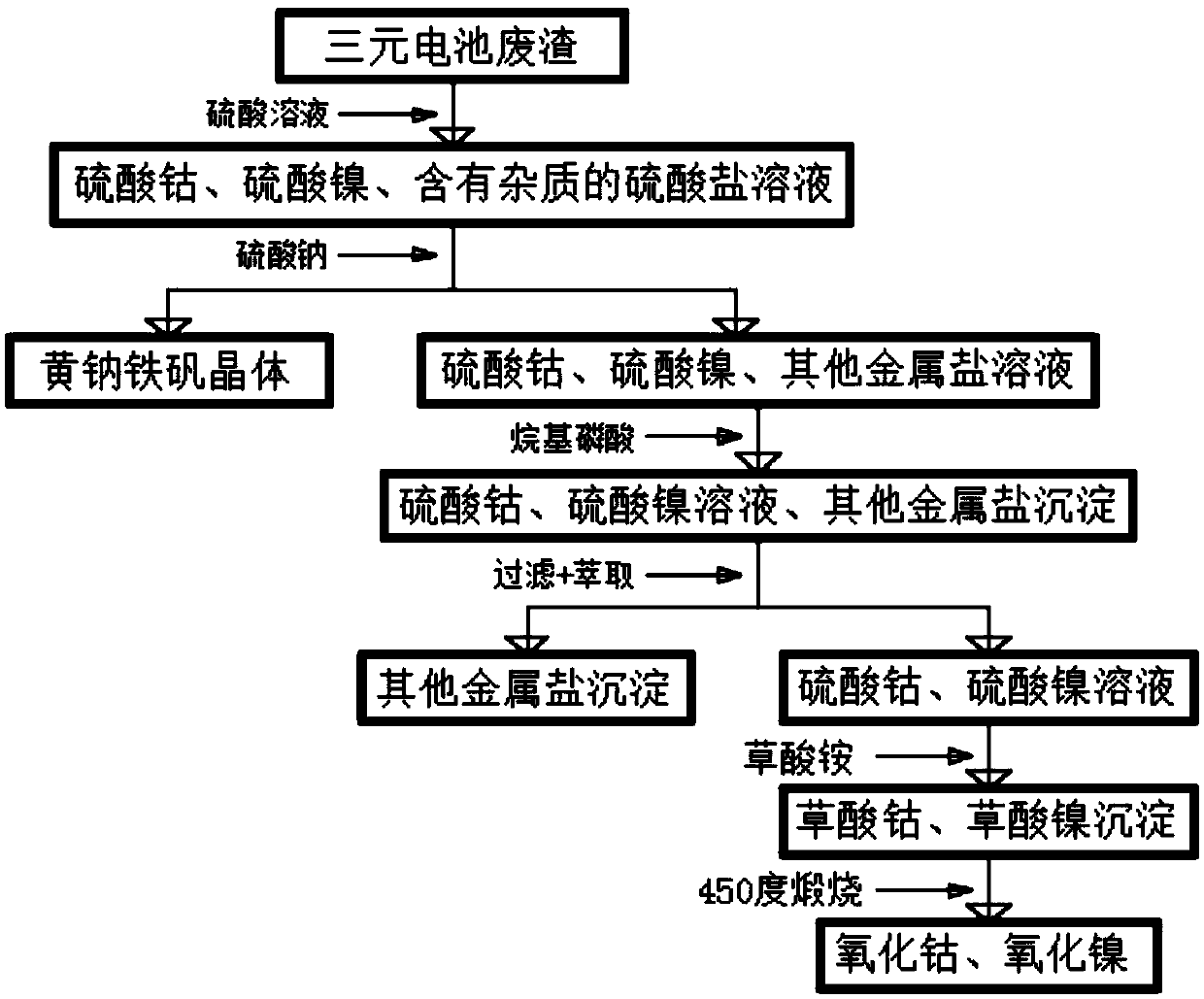

Cobalt and nickel purifying method based on waste battery metal recovery technology

InactiveCN109536724AHigh impurity removal rateImprove the efficiency of impurity removalProcess control/regulationChemical/physical/physico-chemical stationary reactorsFeedback effectMetal impurities

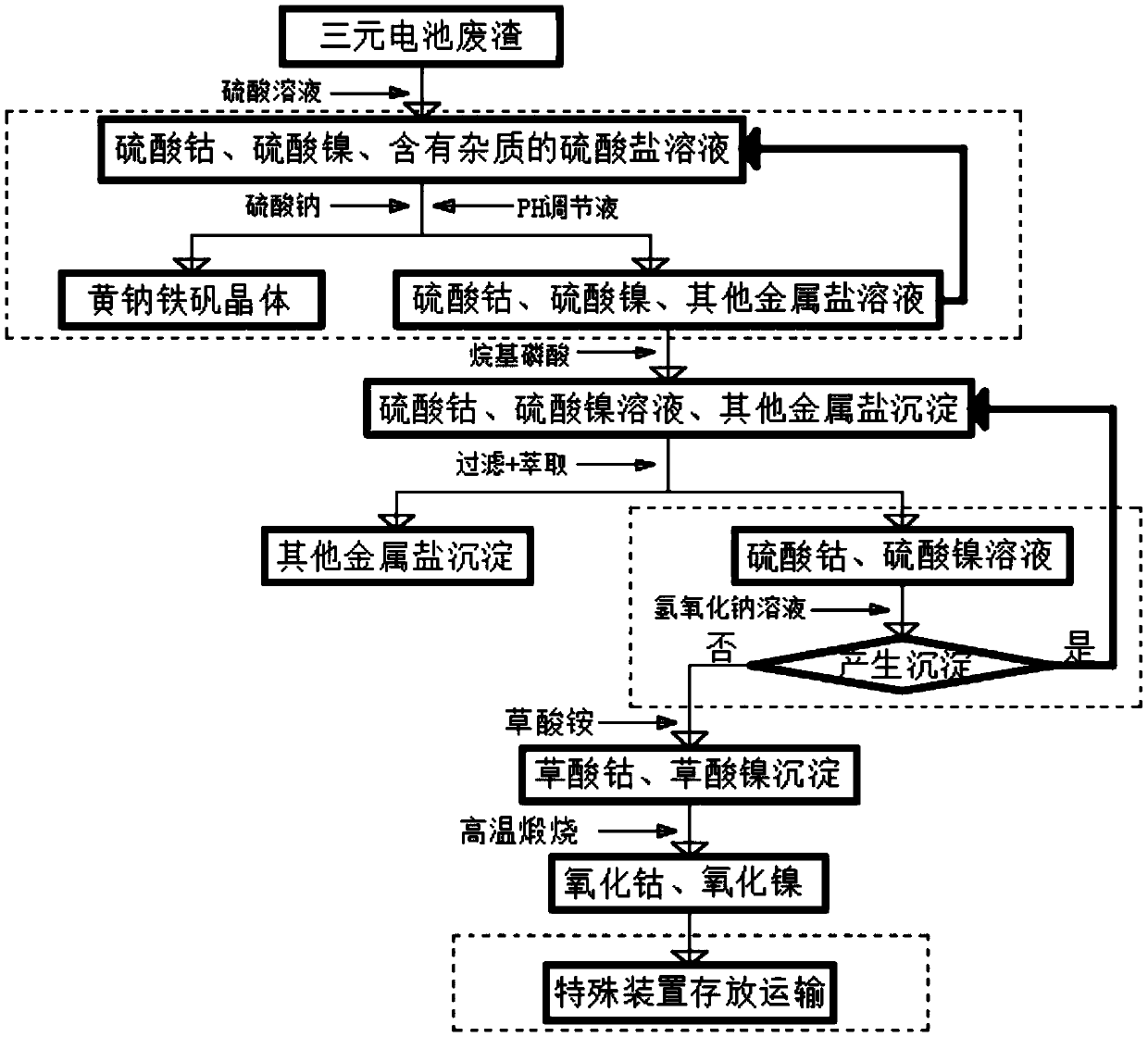

The invention discloses a cobalt and nickel purifying method based on a waste battery metal recovery technology, and belongs to the field of waste battery recovery. The cobalt and nickel purifying method based on the waste battery metal recovery technology comprises the step of recovery of ternary battery waste residues, the original waste battery metal recovery technology is improved, on the onehand, the impurity removal rate for iron ions can be higher than an impurity removal technology for the iron ions in the prior art, meanwhile, the impurity removal efficiency for the iron ions can beimproved, the recovery purity of cobalt and nickel is increased, the progress of the whole technology is accelerated, and the recovery efficiency is improved; on the other hand, compared with the prior art, the method has the advantages that detection of metal impurities in a solution after impurity removal operation is increased, the reaction phenomenon produced in the solution has the feedback effect, impurities can be removed more thoroughly, and the recovery purity of the metal cobalt and the metal nickel is further improved.

Owner:南通北新新能科技股份有限公司

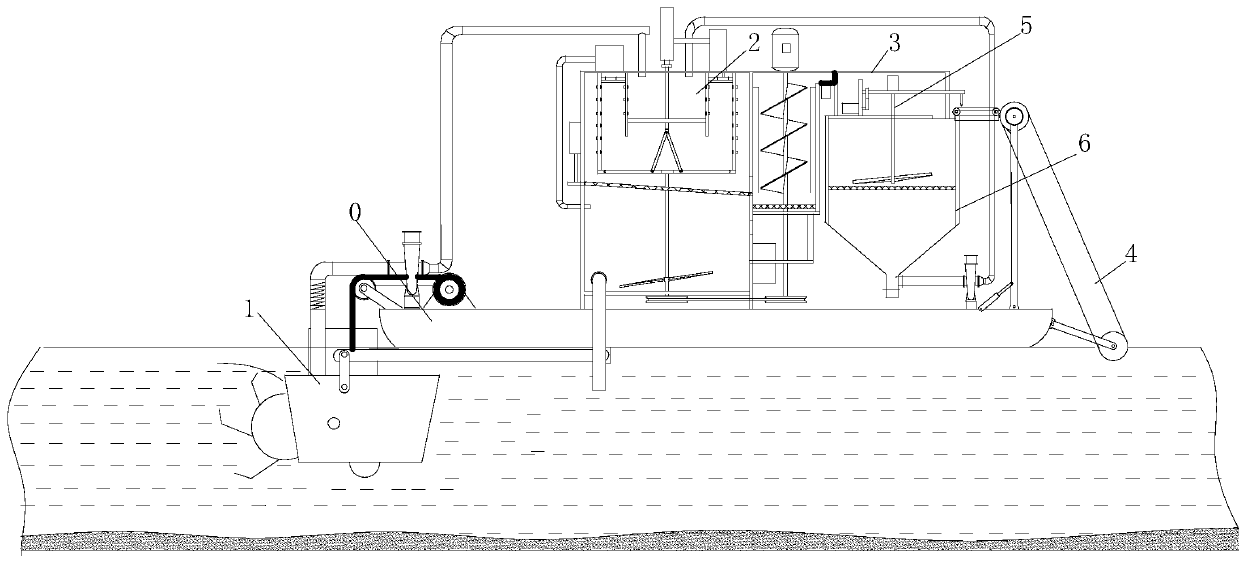

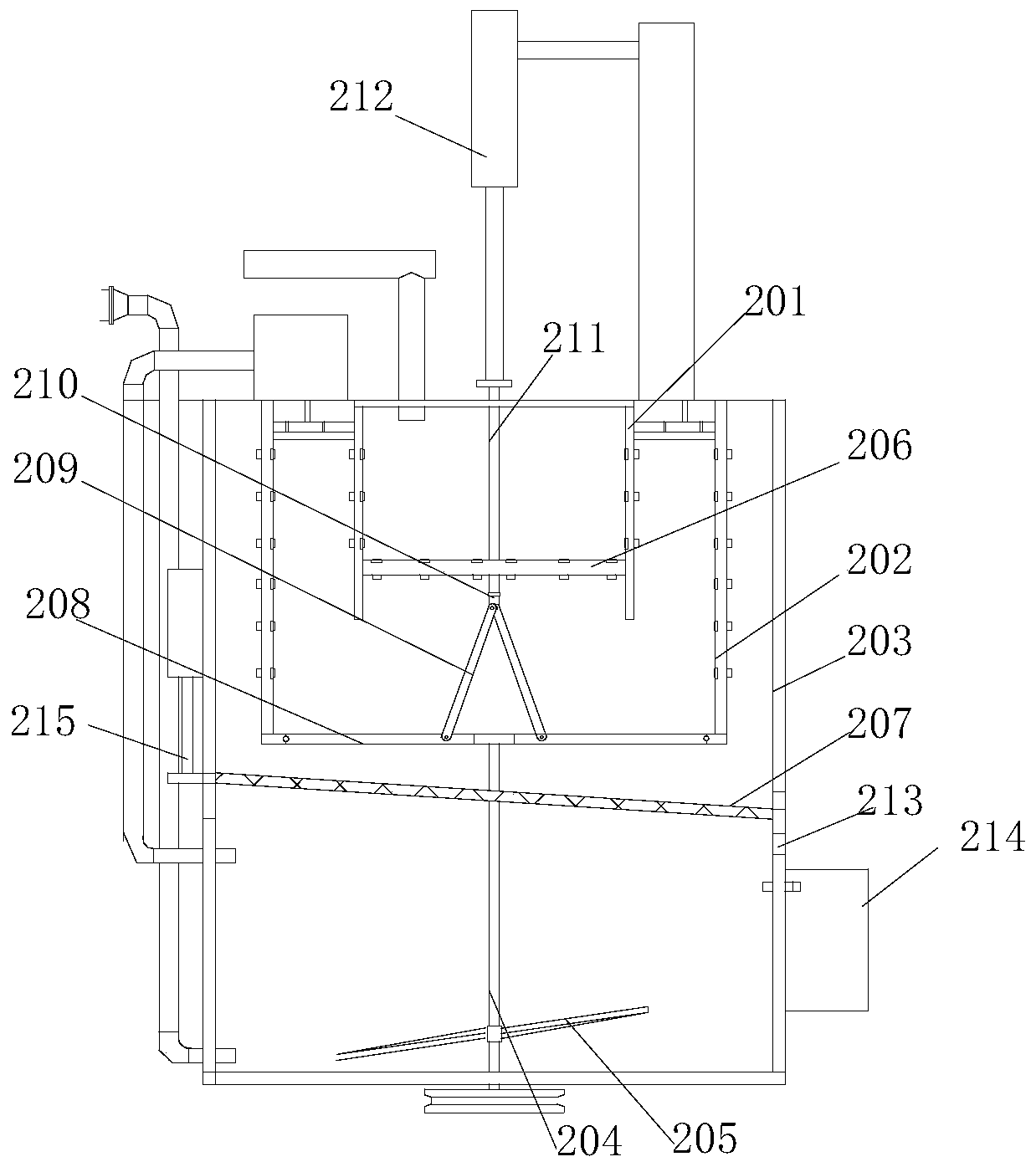

Environment-friendly dirt removing system

ActiveCN109944286ASmall space requirementReduce manufacturing costMechanical machines/dredgersEngineeringControl valves

The invention relates to an environment-friendly dirt removing system. A dirt removing device comprises a dirt removing unit, a dirt separation unit and a dirt collecting box, wherein the dirt separation unit comprises an outer box body, a first inner box body and a second inner box body; a waterweed removing device comprises a pulling unit, a cutting unit, a crushing unit and a waterweed collecting box; two discharge ports of the waterweed collecting box are both closed by control valves; one discharge port extends into the first inner box body through a waterweed pipe; and a waterweed material pump is arranged on the waterweed pipe. According to the system, the functions of dirt removing and waterweed removing are integrated, and the two operations can be carried out simultaneously, thus, the system is suitable for river channel treatment operations in various environments with high working efficiency. The waterweed removing device can fully utilize the dirt separation unit of the dirt removing system device, so that the dirt separation unit can not only separate the dirt but also dehydrate the waterweed. Due to the fact that a device for dehydrating the waterweed is not needed to be additionally designed as well as no space of a ship body needs to be occupied, the technical effects of saving the manufacturing cost of the device and reducing the space requirement for the shipbody are achieved.

Owner:天津市雷升科技有限公司

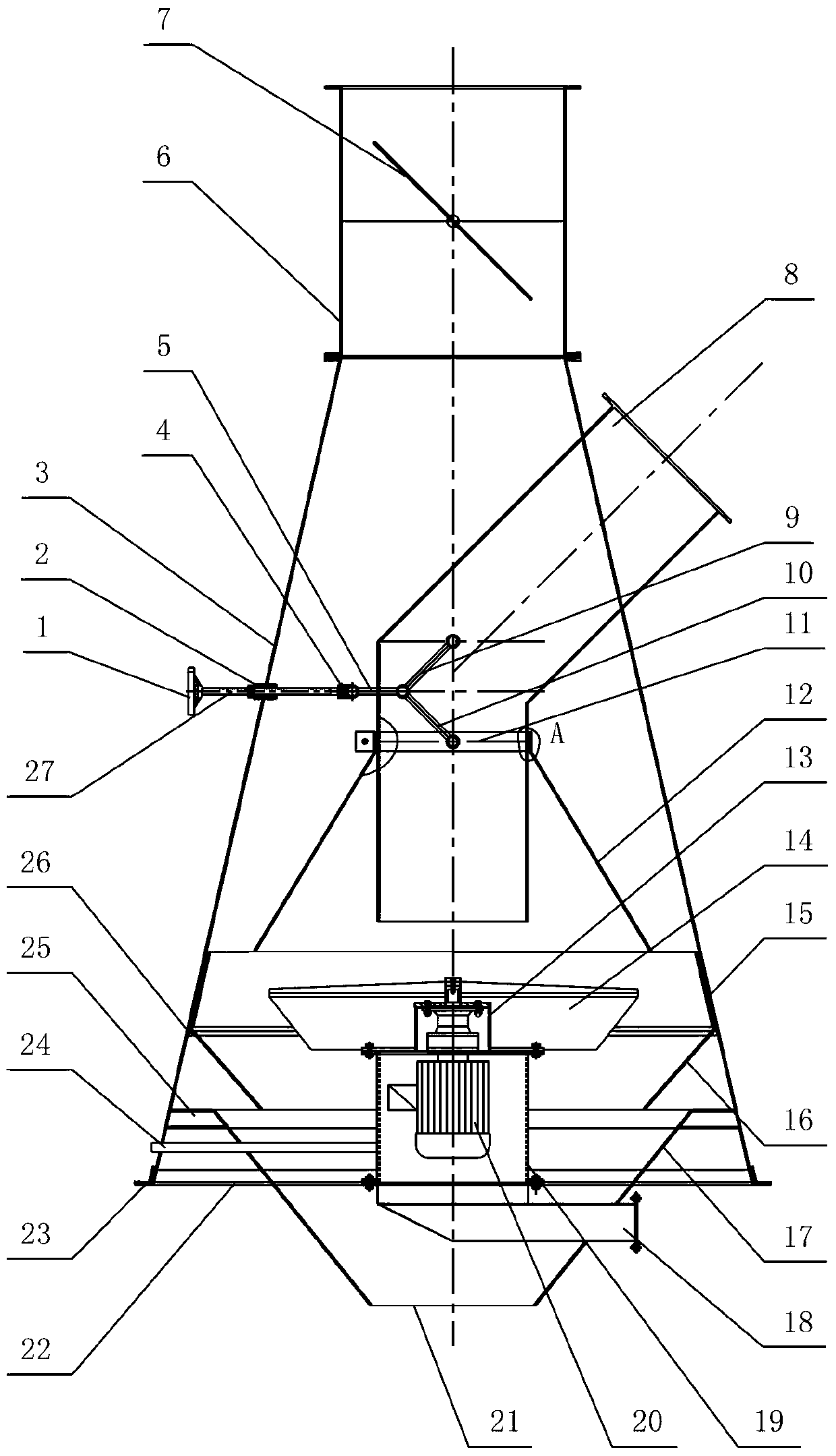

Rotary type grain separating device

ActiveCN103341445AConvenient and smooth flowReduce falling speedGas current separationEngineeringResidence time

The invention relates to a grain separating device, in particular to a grain winnowing separating device and belongs to the field of grain machinery. The rotary type grain separating device comprises a shell body, a rotary disc and a discharging tube. The rotary disc is arranged in the shell body; the discharging tube is arranged above the rotary disc; a motor is connected with the axial position of the rotary disc; a material collecting structure is arranged above the rotary disc; a winnowing region is formed among the rotary disc, the shell body and the material collecting structure; the opening portion of the shell body is connected with a wind power device. The rotary type grain separating device is reasonable in structure, small in size and occupied space, convenient to transport and suitable for application of a peasant household and small-sized operation. Grain is evenly distributed in the winnowing region, the residence time of the grain in the winnowing region is improved, the impurity removing efficiency is greatly improved, and the impurity removing efficiency is improved to 85% from 70%.

Owner:山东聚阳智能装备有限公司

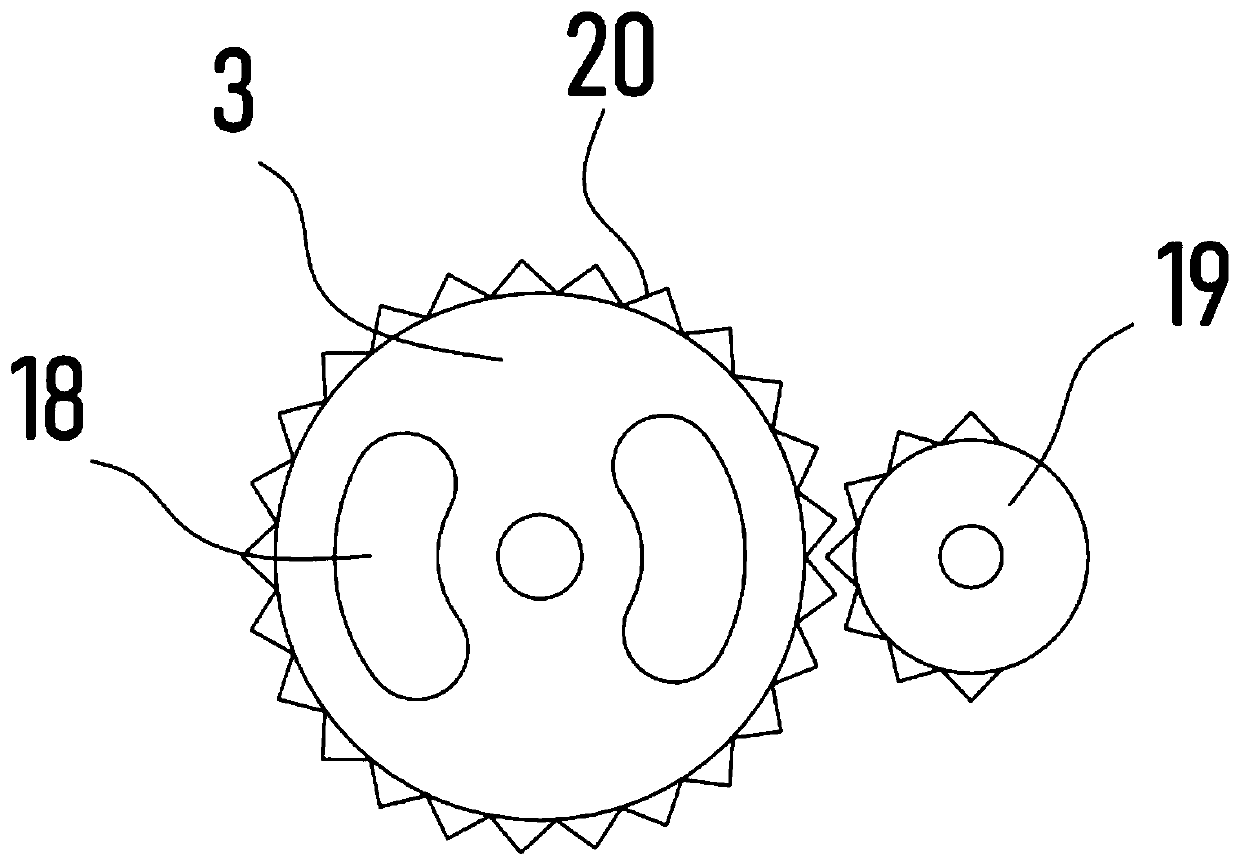

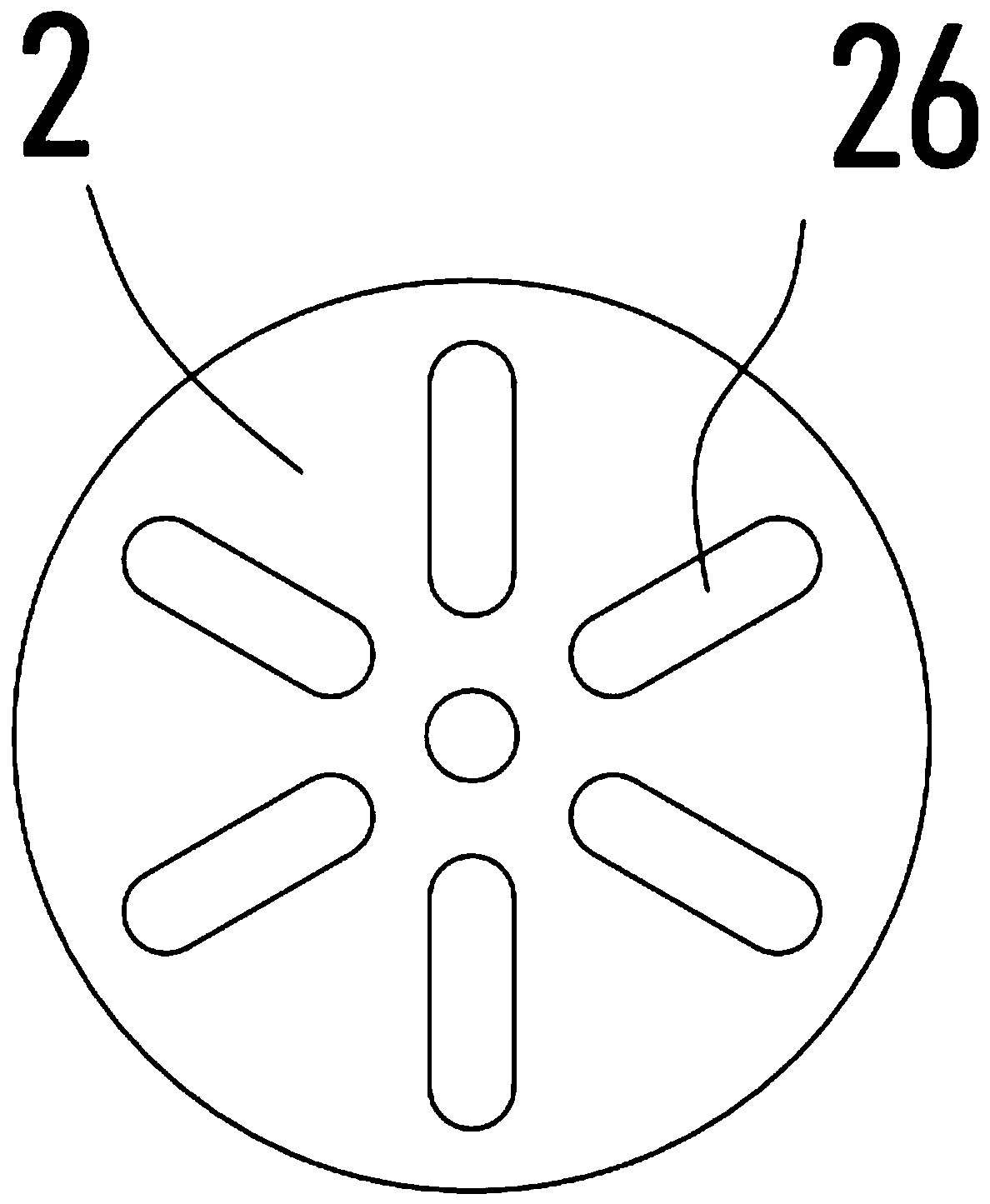

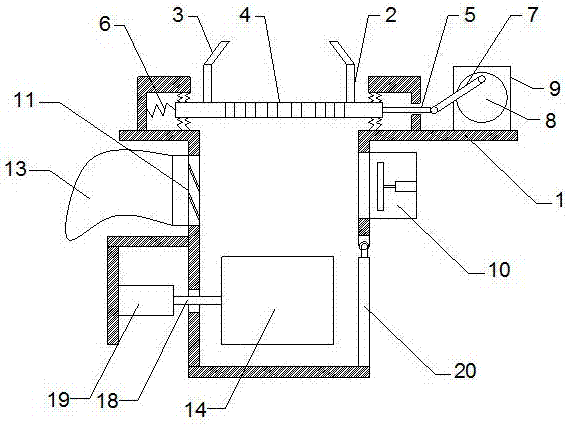

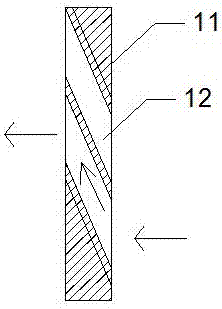

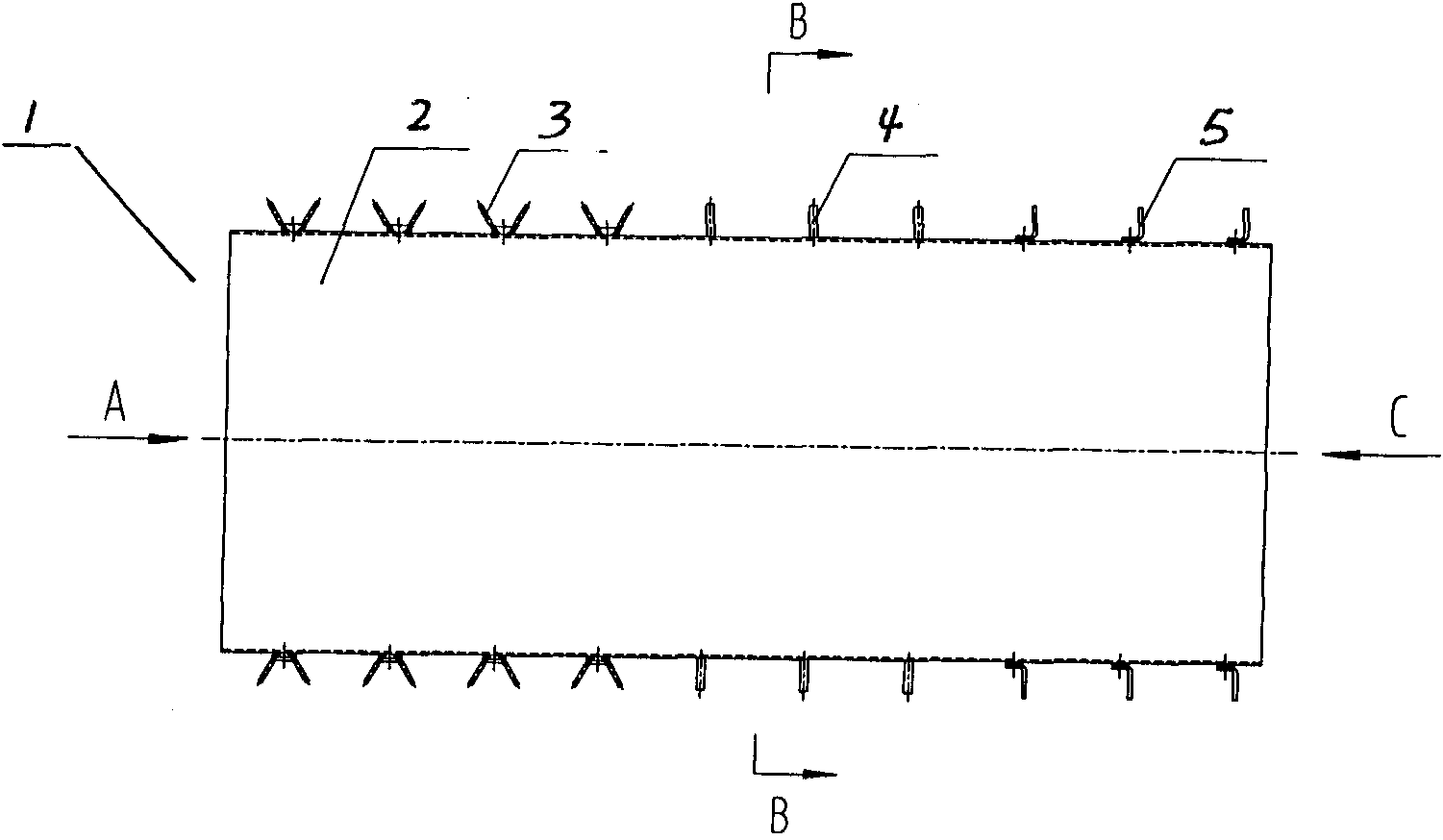

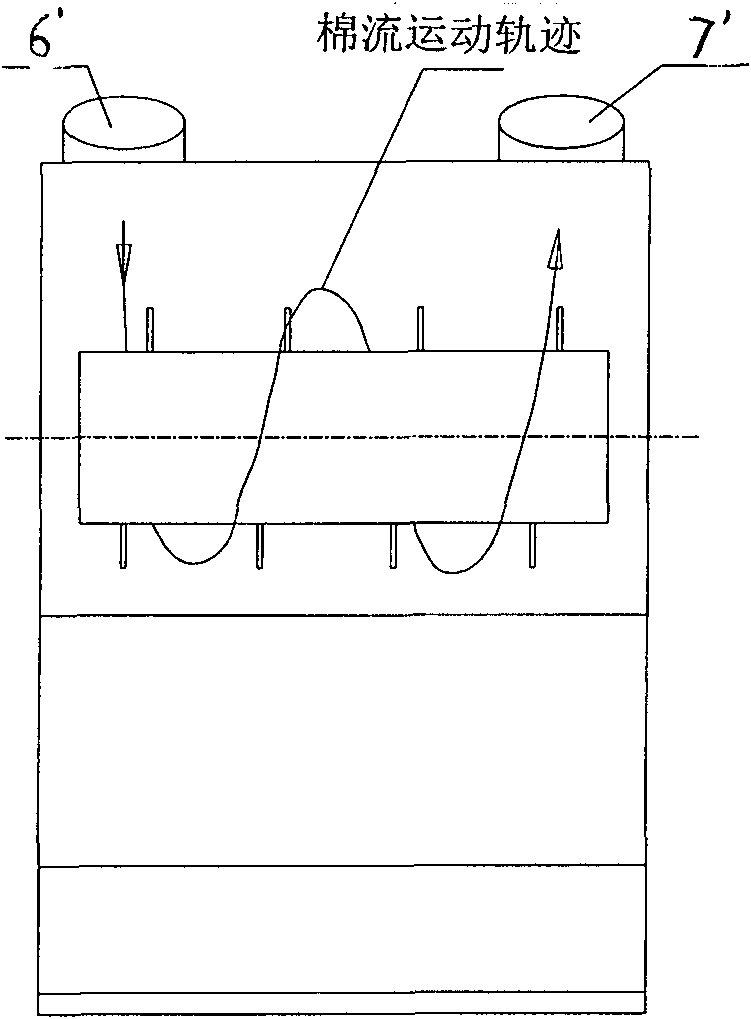

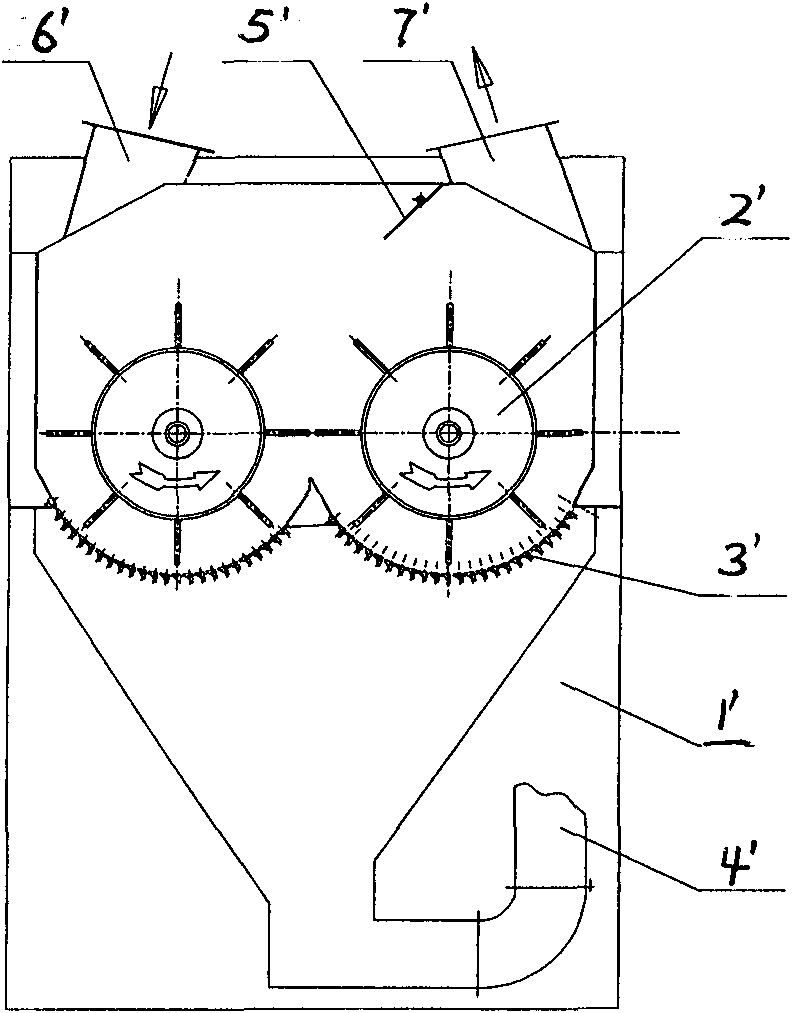

Opening and cleaning method for axial flow opener for opening picking or blowing carding process and special composite beater device thereof

ActiveCN101812745AMeet free strikeSatisfy the weak first and then the strongFibre cleaning/opening by toothed membersFibre cleaning/opening machinesState of artFiber

The invention provides an opening and cleaning method for an axial flow opener for opening picking or blowing carding process, and a special composite beater device. The method comprises the step that a cotton block to be opened makes spiral movement along beaters under common action of the beaters and air flow after the cotton block to be opened is fed into a beater chamber. The method is characterized in that the cotton block is subjected to opening and cleaning in different beating modes in turns when the cotton block makes spiral movement from a cotton inlet to a cotton outlet. The special composite beater device comprises beater cylinders, and is characterized in that the beater cylinders are provided with a blade region, a bar-shaped brad region and a V-shaped brad region in sequence from the inlet end to the outlet end. A reducing mode that the beater outer diameter is reduced from the inlet to the outlet in turns is adopted, so distances between beaters and grid bars are increased from the inlet to the outlet in turns to adapt to the condition that the cotton block is gradually opened and expanded in the forwarding process. The method has reasonable opening mode, high cleaning efficiency and fiber destruction prevention, and achieves the effect of developing strong points and avoiding weak points compared with the prior art.

Owner:CHTC HEAVY IND +1

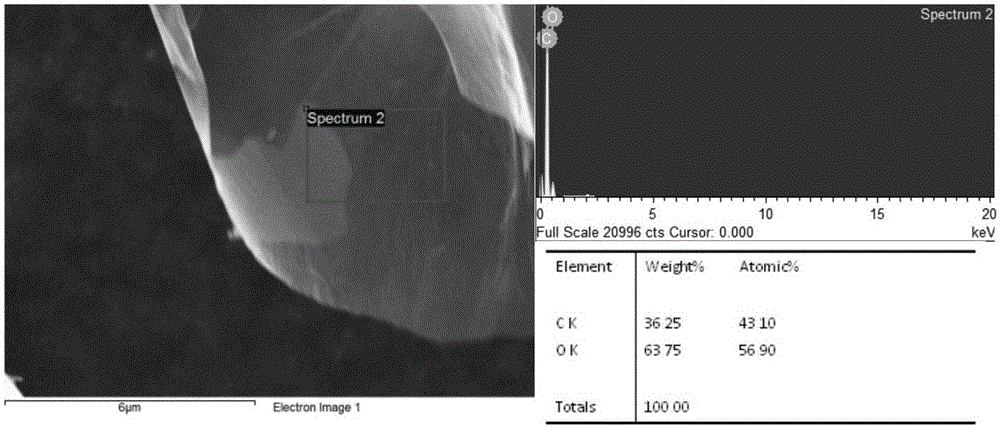

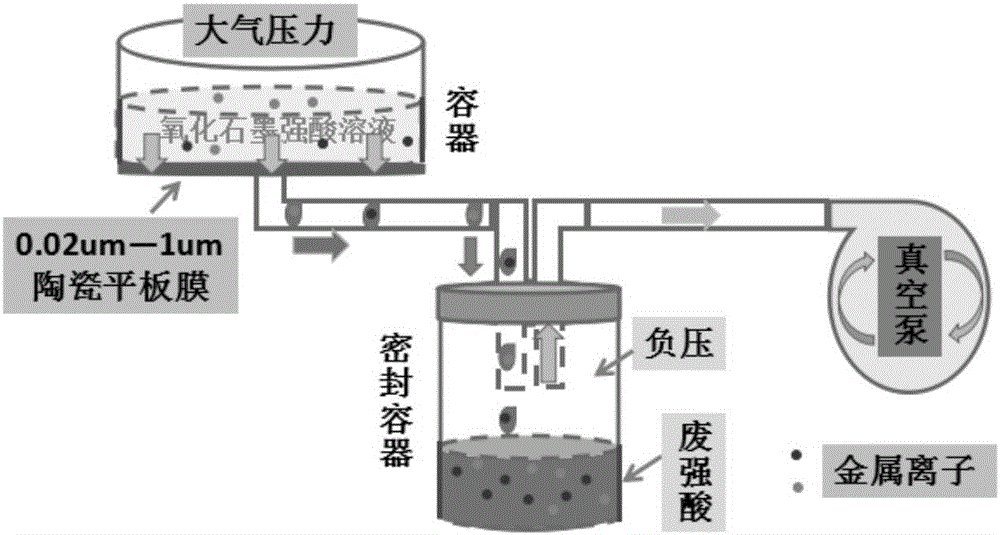

Separating and impurity-removing method for graphene oxide

The invention discloses a separating and impurity-removing method for graphene oxide. Vacuum filtration, cross flow filtration and a ceramic membrane are combined, rapid recycling of waste high acid of graphite oxide reaction liquid and efficient and low-cost removing of metal ion impurities in a graphite oxide solution are achieved, discharging of waste acid wastewater is reduced, the efficiency of preparing high-purity graphene oxide products is improved, and the separating and impurity-removing method is suitable for preparing small-scale high-purity graphene oxide products of scientific-research units and university laboratories, and is also suitable for preparing graphene oxide and grapheme products in an industrialization and large-scale mode.

Owner:SANDA FILM SCI & TECH XIAMEN

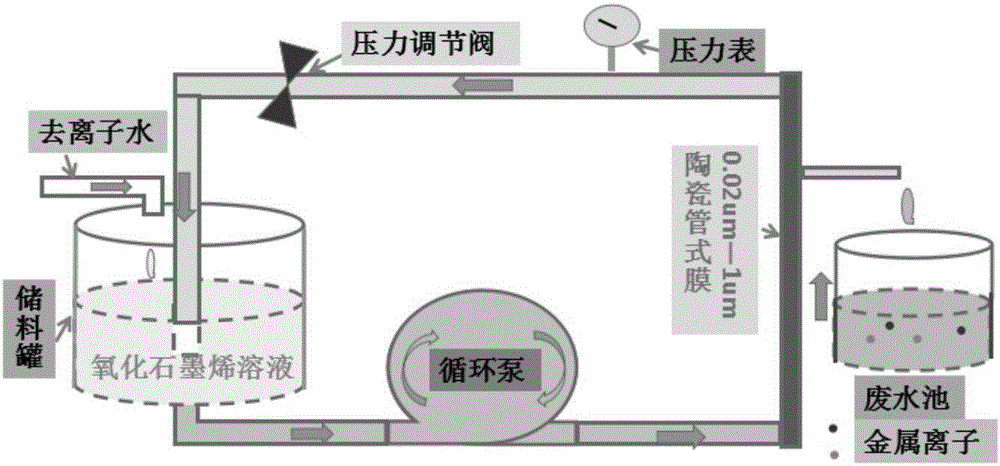

Method for extracting lithium salt from lithium ore

The invention discloses a method for extracting lithium salt from lithium ore. The method comprises the steps as follows: performing material mixing, roasting, water extraction, concentration, separation of sodium, potassium, rubidium and cesium, purification and impurity removal, lithium precipitation, washing, drying and fine grinding to obtain battery-grade lithium carbonate; performing neutralization, concentration, separation of sodium, potassium, rubidium and cesium, washing and drying on primary lithium precipitation mother liquor to obtain industrial-grade or battery-grade lithium carbonate; returning obtained secondary mother liquor to be mixed with the primary lithium precipitation mother liquor to form a closed loop. The method has better leaching effects on various content of lithium, sodium, potassium, rubidium and cesium in lithium ore, the lithium leaching rate in spodumene reaches 99%, and the leaching rates of rubidium and cesium in lepidolite are larger than 99%; recovery rate of lithium later is larger than 97% and the total yield of lithium is larger than 91%. Byproducts can be reused, and the method is environmentally friendly due to the fact that fluorine is fixed in slag, adopts a short technological process, is low in cost and has good industrial promotion value.

Owner:CHANGSHA YUANPENG CHEM TECH

Novel production process for extracting soy isoflavones aglycones

The invention relates to a novel production process for extracting soy isoflavones aglycones. The production process in the invention comprises the following steps of: smashing soy embryos or soy bean meal which serves as a raw material, extracting required ingredients, concentrating, removing proteins, performing column absorption and analysis, concentrating for the second time, performing enzymolysis, extracting a solvent, concentrating for the third time, freeze drying and obtaining the soy isoflavones aglycones. The novel production process for extracting the soy isoflavones aglycones is convenient to operate, high in repeatability and yield and suitable for industrial production; the enzymolysis method is adopted for converting the aglycones, so that the conversion rate is high and the process avoids using poison andharmful solvents; and electrolyte is used for settling the proteins, so that impurity removal is efficient and quick.

Owner:XUZHOU JIYUAN PHARMA

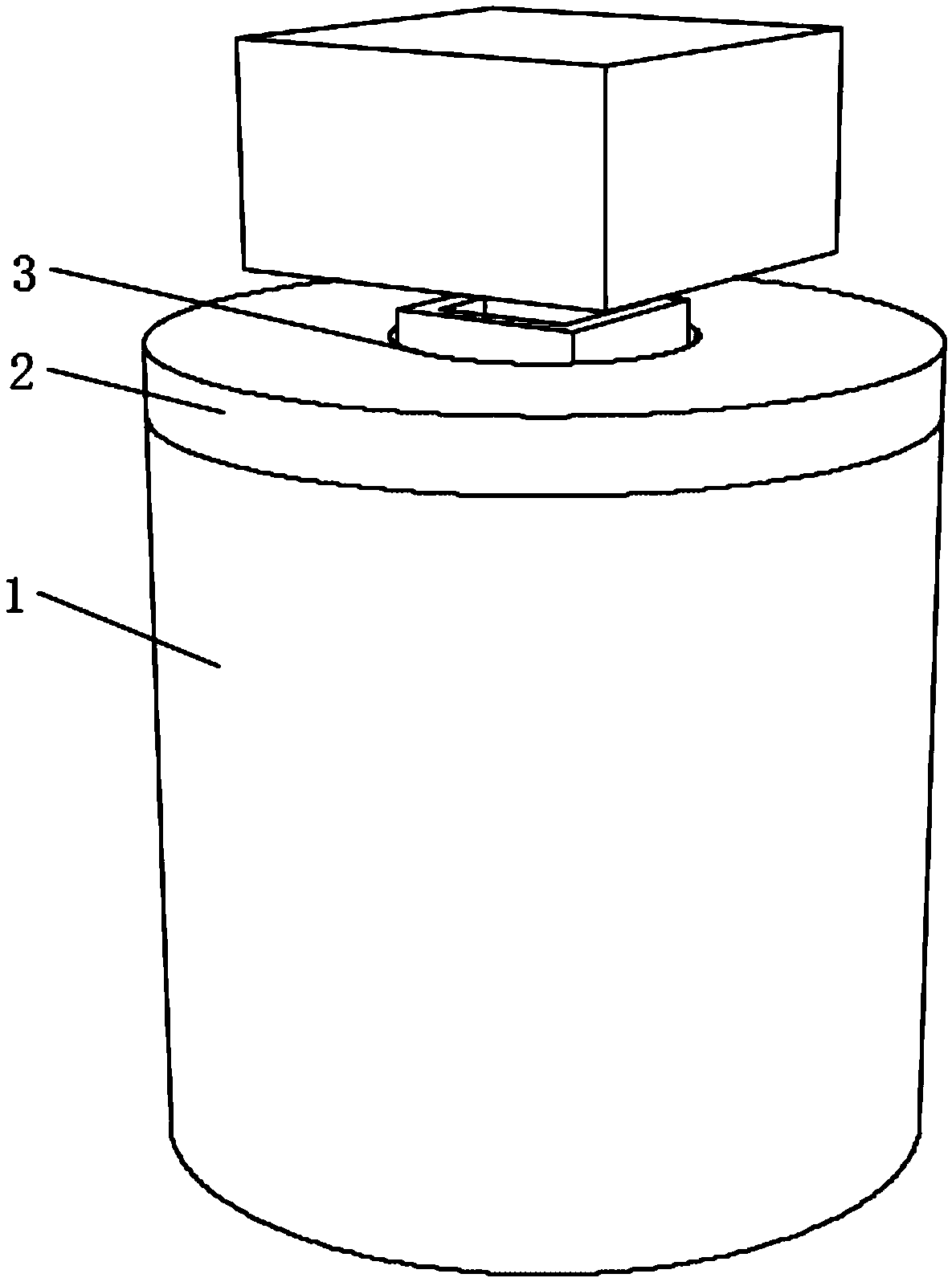

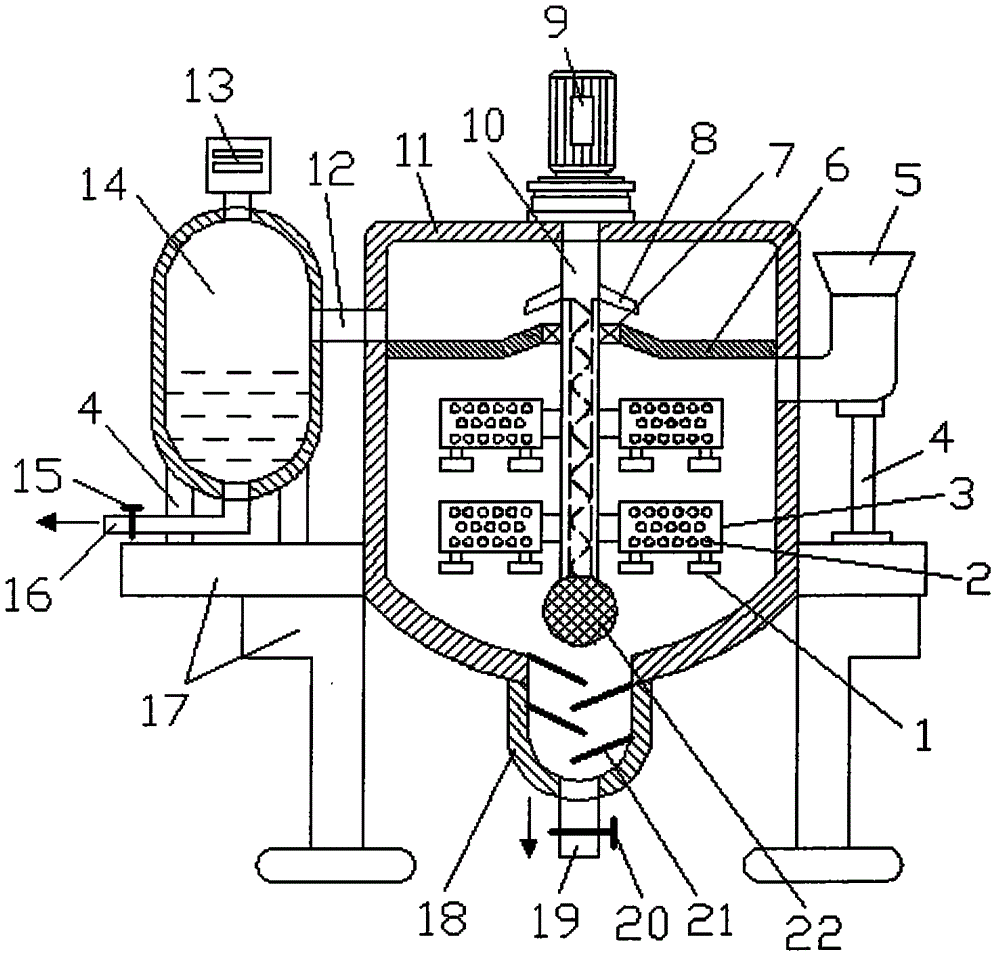

Honey stirring purification device

ActiveCN104857772AImprove qualityImprove the efficiency of impurity removalFiltration circuitsFood preparationAgricultural engineeringSelf-absorption

The invention discloses a honey stirring purification device which comprises a stirring tank, wherein a honey discharge hopper is arranged at the top of a hollow pipe of a stirring shaft in the stirring tank in a communicating manner; a drainage plate is fixed on the stirring shaft on the lower side of the honey discharge hopper via a bearing; a first stirrer and a second stirrer are fixed on the left side and the right side of the stirring shaft on the lower side of the drainage plate; a filter bulb is arranged at the bottom end of the stirring shaft; the top of the stirring tank is connected with a motor via a speed changer at the top end of the stirring shaft; a sediment tank is arranged in the middle of the bottom of the stirring tank in a communicating manner; and the upper side of the drainage plate is connected with a honey tank via a communicating pipe on the left side of the stirring tank. The device is compact in structure, small in floor area, better in honey quality and high in purification efficiency, and purifies honey via self-absorption and drainage.

Owner:枣庄科顺数码有限公司

Beneficiation impurity removal feed box

InactiveCN105233980ACleanup implementationAvoid cloggingSievingScreeningPulp and paper industryImpurity

The invention relates to a beneficiation impurity removal feed box which comprises a material box, a buffer plate, a screen, an impurity removal door and a discharging pipe. The top of the material box is communicated with a discharging opening of a pulp pipeline. The buffer plate is obliquely arranged in the middle in the material box and located below the discharging opening of the pulp pipeline. The screen is horizontally arranged in the middle in the material box. The screen is connected with the buffer plate. The impurity removal door is arranged on the side wall, on the side, far away from the buffer plate, of the screen, of the material box. The discharging pipe is arranged below the impurity removal door and communicated with the bottom of the material box. A roller capable of axially rolling is arranged at the upper end of the screen. Compared with the prior art, impurity removal can be carried out on pulp, impurity removal efficiency is high, and impurity blocking is avoided.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

Method of eliminating potassium impurity from molybdenum powder

The method of eliminating potassium impurity from molybdenum powder includes the following steps: the first hydrogen reduction of ammonium molybdate to produce molybdenum dioxide, sieving and the secondary hydrogen reduction to produce molybdenum powder; water washing or acid pickling molybdenum powder, solid-liquid separation, stoving and sieving to obtain the molybdenum powder product. One third hydrogen reduction step may be also added after stoving. The technological process is simple and has obvious effect of eliminate potassium impurity.

Owner:JIANGSU DONGTAI FENGFENG TUNGSTEN & MOLYBDENUM MATERIAL

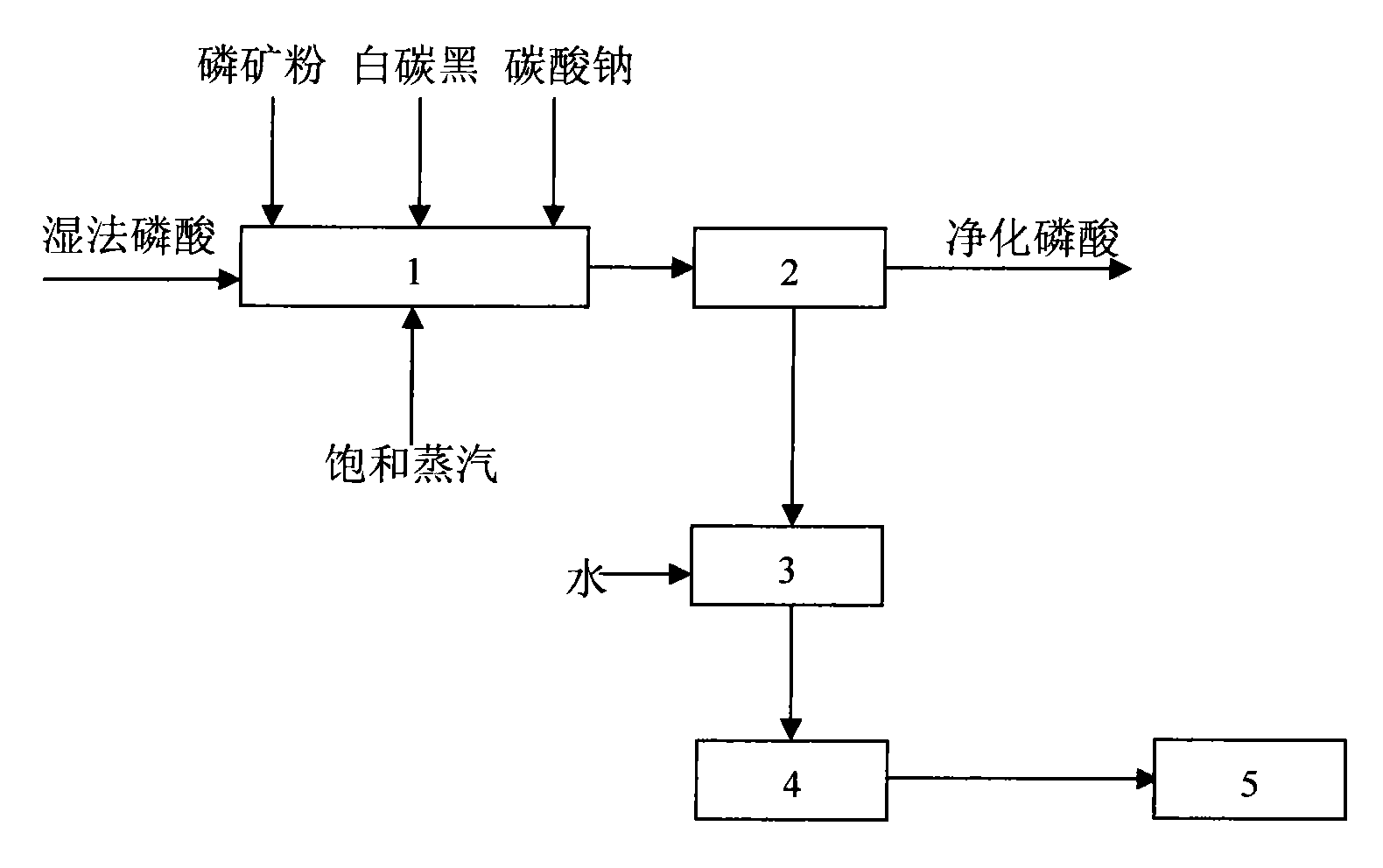

Purification treatment method of wet-process phosphoric acid

InactiveCN101602498AHigh quality phosphoric acidRaw materials are easy to getPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a purification treatment method of wet-process phosphoric acid, which comprises the following steps: firstly analyzing contents of fluorine and sulfur trioxide in the wet-process phosphoric acid; secondly adding the wet-process phosphoric acid to a reactive tank; according to the analytical data, calculating and taking white carbon black and sodium carbonate in the quantity of defluorination; calculating and taking powdered rock phosphate in the quantity of desulfurization; respectively throwing the white carbon black, the sodium carbonate and the powdered rock phosphate in a solid phase into the purification reactive tank and stirring; thirdly leading saturated vapour into the purification reactive tank; controlling the reaction temperature and the time of materials; obtaining reactive materials; fourthly using a pump to send the reactive materials into a groove of a plate and frame filter press; directly using filter liquor which is purified wet-process phosphoric acid after filter pressing to produce feed-grade calcium biphosphate; fifthly placing filter cakes after filter pressing into a surge tank; adding clear water to prepare the filter cakes into slurry; using the pump to send the slurry into an extraction tank; and recovering residual phosphorus. The invention has the advantages of high impurity removal efficiency, small phosphorus loss, easy obtainment of impurity removing agents, low cost and easy operation control; moreover, purified wet-process phosphoric acid can be directly used for producing feed-grade calcium biphosphate.

Owner:云南新龙矿物质饲料有限公司

Method for recovering carbon from aluminum electrolysis waste cathodes

ActiveCN110407190AImprove the effect of impurity removalEfficient recyclingCarbon preparation/purificationElectrolysisSlag

The invention discloses a method for recovering carbon from aluminum electrolysis waste cathodes, and the method comprises the following steps: step 1, crushing waste cathode carbon blocks of an aluminum electrolysis cell to obtain spare particles; (2) uniformly mixing the spare particles obtained in the step (1) with a solid alkali, adding deionized water, standing, and evaporating to remove moisture to obtain a mixture; step 3, heating the mixture obtained in the step 2 to 320-700 DEG C in a protective atmosphere, keeping the temperature for 0.5-4h, cooling, washing with water to neutrality,filtering and drying to obtain alkali slag; and step 4, adding the alkali slag obtained in the step 3 into a mixed solution of an acid and sodium fluoride for leaching, filtering after the leaching,and washing with water to neutrality to obtain carbon powder. The method realizes high-efficiency recovery of carbon components in the waste cathode carbon blocks, and the purity of the obtained carbon powder is not less than 99.0%.

Owner:CENT SOUTH UNIV

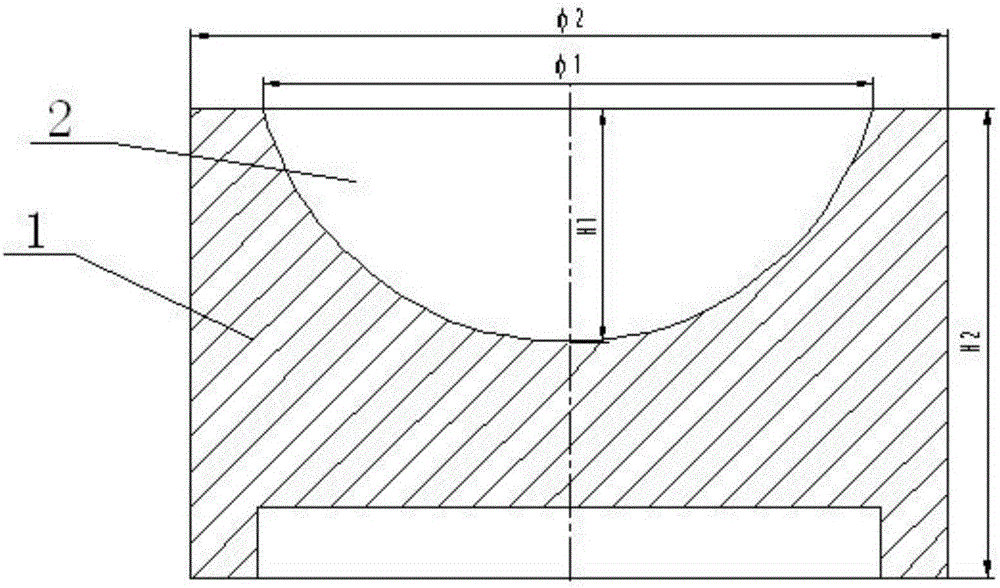

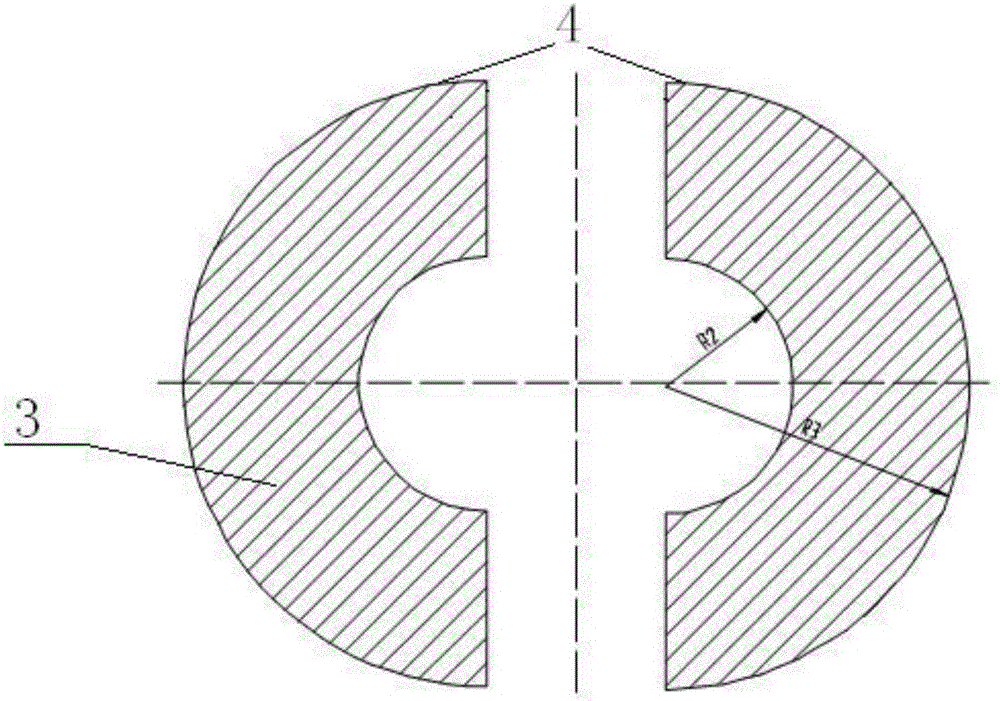

Device and method for removing impurity in uranium metal effectively

The invention discloses a device and method for removing impurity in uranium metal effectively. The device includes an electron-beam melting furnace and a melting crucible, wherein the melting crucible is disposed in a furnace chamber of the electron-beam melting furnace. The melting crucible includes a water cooled copper crucible and a graphite ring sleeved surrounding the water cooled copper crucible, wherein the water cooled copper crucible has a hemispherical smelting chamber. The method uses the device for removing impurity in uranium metal effectively, and includes a plurality of steps such as charging furnace, preforming preheating, preforming smelting, and discharging furnace. Finally, the uranium ingot with low impurity is prepared.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Wheat impurity-removing device

InactiveCN107047757ASimple structureReduce labor intensitySievingGas current separationMoisture sensorMechanical engineering

The invention discloses a wheat impurity-removing device. The wheat impurity-removing device comprises a drying chamber, a vibration screening device, a wind-selecting mechanism and a wheat collecting device, the drying chamber is located above the vibration screening device, the wind-selecting mechanism is located below the vibration screening device, the wheat collecting device is located below the wind-selecting mechanism, wheat enters the drying chamber from a feeding hopper, when a pressure sensor at the bottom of the drying chamber detects that the weight of the wheat in the drying chamber exceeds a specified value, addition of the wheat is stopped, a drying device is started to dry the wheat, when a humidity sensor detects that the humidity of the wheat meets requirements, the drying chamber opens a drying chamber discharging opening, the wheat enters the vibration screening device, a vibration motor drives the vibration screening device to vibrate, after impurities are removed by the vibration screening device, the wheat enters the wind-selecting mechanism, and awn of wheat and other light-weight impurities are removed. The wheat impurity-removing device is simple in structure and wide in application range, can automatically remove the impurities of the wheat and drying the wheat, and has the advantages of being high in impurity-removing efficiency and drying speed.

Owner:河南颇文商贸有限公司

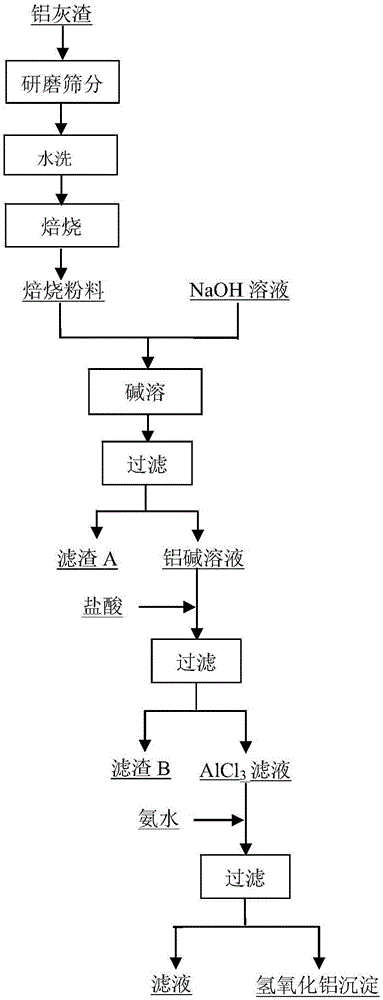

Method for removing impurities from aluminum ash

InactiveCN106745128AImprove the efficiency of impurity removalEfficient removalAluminium compoundsAluminium hydroxideDissolution

The invention discloses a method for removing impurities from aluminum ash and belongs to the technical field of compound impurity removal and industrial waste recycling. The method comprises the following steps: grinding, sieving and water-washing the aluminum ash, roasting to obtain roasted powder, and performing alkali dissolution on the roasted powder by using a NaOH solution to obtain an aluminum alkali solution; adding the aluminum alkali solution into diluted hydrochloric acid until the precipitation capacity of the solution is not changed any more, and performing solid-liquid separation to obtain AlCl3 filtrate; and introducing ammonia water into the AlCl3 filtrate, and filtering to obtain aluminium hydroxide precipitate to finally fulfill the aim of removing impurities from the aluminum ash. According to the method, processes of waster washing, roasting, alkali solution, acid treatment and the like are adopted, the impurities can be effectively removed, pure aluminum hydroxide precipitate is obtained, and high-purity raw materials are provided for subsequent preparation of aluminum oxide and other aluminum-containing products, so that the aluminum ash is completely utilized, and the method has the advantages of wide raw material source, low environmental pollution, low material consumption and energy consumption, low cost and the like, and is suitable for industrialized production.

Owner:NORTHWEST A & F UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com