Rotary type grain separating device

A rotary, grain-based technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of reducing production, crushing materials, affecting the effect of impurity removal, etc., and achieves a simple overall structure , Slow down the falling speed and take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

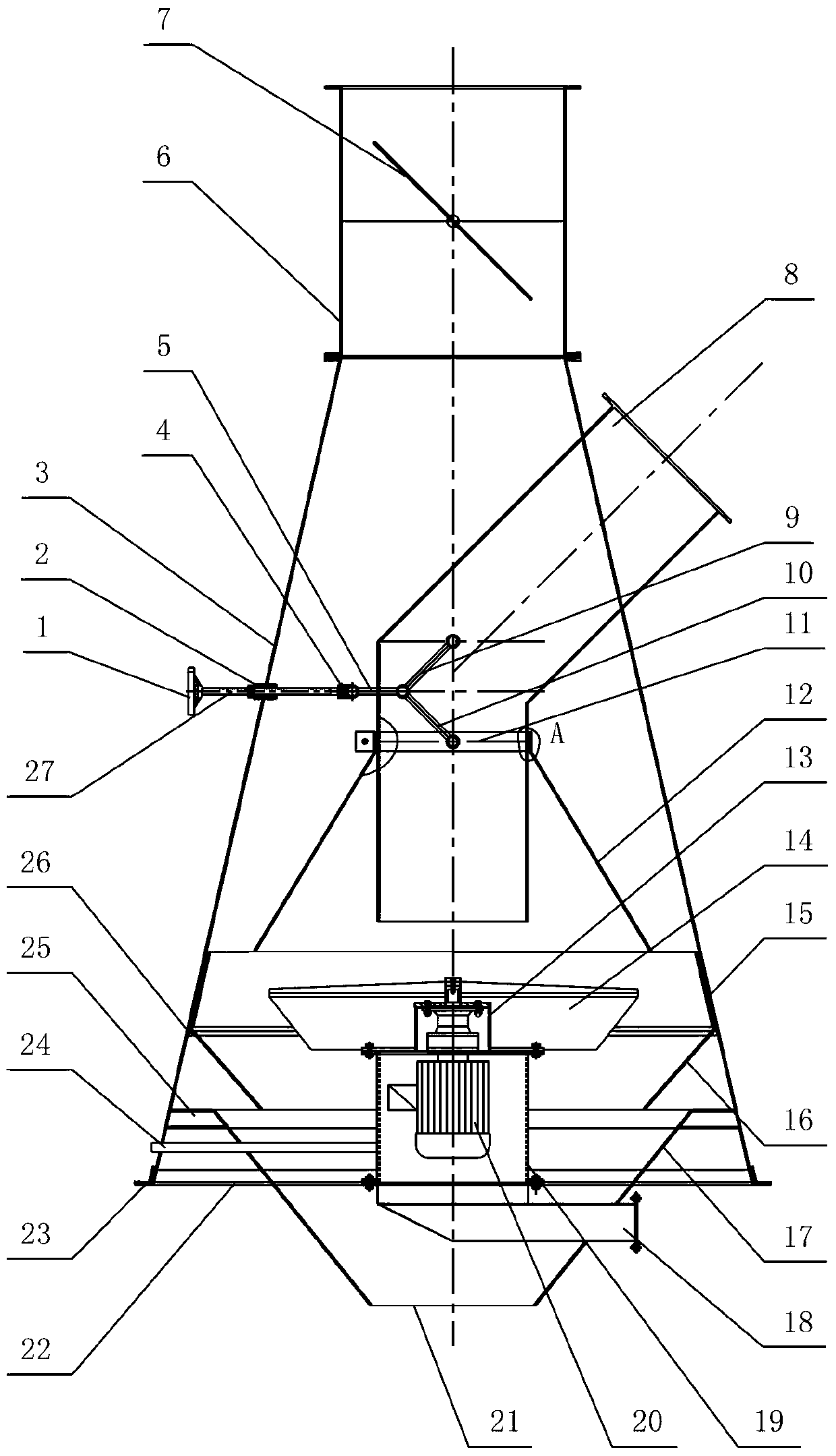

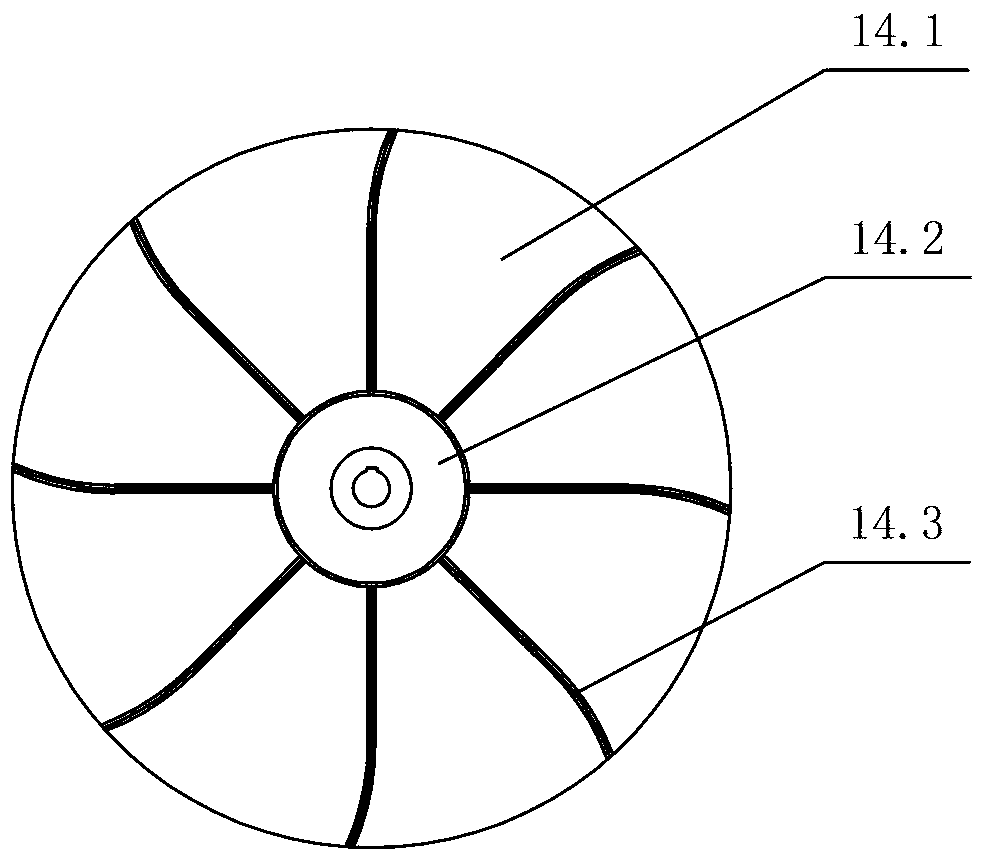

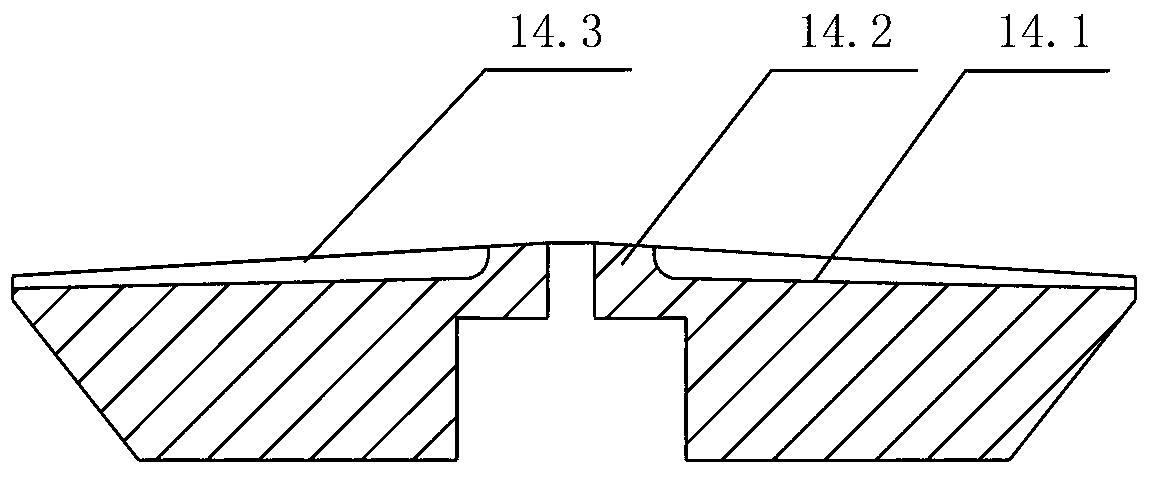

[0035] Examples of the present invention Figure 1~4 and Figure 6 , Figure 7 As shown, it includes a housing 3, a rotating disk 14, and a feeding pipe 8. The rotating disk 14 is arranged in the housing 3, and the feeding pipe 8 is fixed on the housing 3. The feeding pipe includes an oblique end of 45 and a vertical The oblique end is that the grain can flow into the housing by itself. The outlet of the feeding pipe is set directly above the rotating disk 14. The middle part of the rotating disk 14 is higher than the edge. The rotating disk 14 is an upwardly inclined curve from the edge to the middle, and the middle is A circular protrusion 14.2, fan blade 14.3 is arranged on the rotating disk 14, and the fan blade 14.3 is distributed on the disk surface 14.1 of the rotating disk 14 in a divergent shape, the circular protrusion 14.2 is fixedly connected with one end of the fan blade 14.3, and the other end of the fan blade 14.3 Extending to the edge of the rotating disk 14,...

Embodiment 2

[0042] This example Figure 5 As shown, the second collecting hopper 17 is connected to the casing 3 through four symmetrically arranged strip plates 28, so that the external natural wind can smoothly enter the casing.

Embodiment 3

[0044] This example Figure 8 As shown, one end of the adapter 4 is hinged with the middle rod, and the other end is provided with a blind hole for the insertion of the adjusting connecting rod 27. There is a side hole on the side of the blind hole, and a bolt is screwed into the side hole, and the bolt is connected to the insertion end of the adjusting connecting rod. A retaining ring is arranged between, and the retaining ring is stuck in the groove of the insertion end of the adjusting connecting rod 27. The adjusting connecting rod 27 and the adapter 4 are axially fixed and clamped by the retaining ring, and the adjusting connecting rod 27 can rotate around the axis at the same time.

[0045] work process:

[0046] When working, the motor 20 drives the rotating disk 14 to rotate, and the grain enters the rotating disk 14 through the feeding pipe 8, and is evenly distributed to the winnowing area under the drive of the rotating disk 14. 17. The joint of the shell 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com