Buffer type conveyor line

A buffer conveyor line and buffer plate technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems affecting the quality of steel balls leaving the factory and the collision of collecting grooves, so as to achieve a wide range of use, reduce rolling speed, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

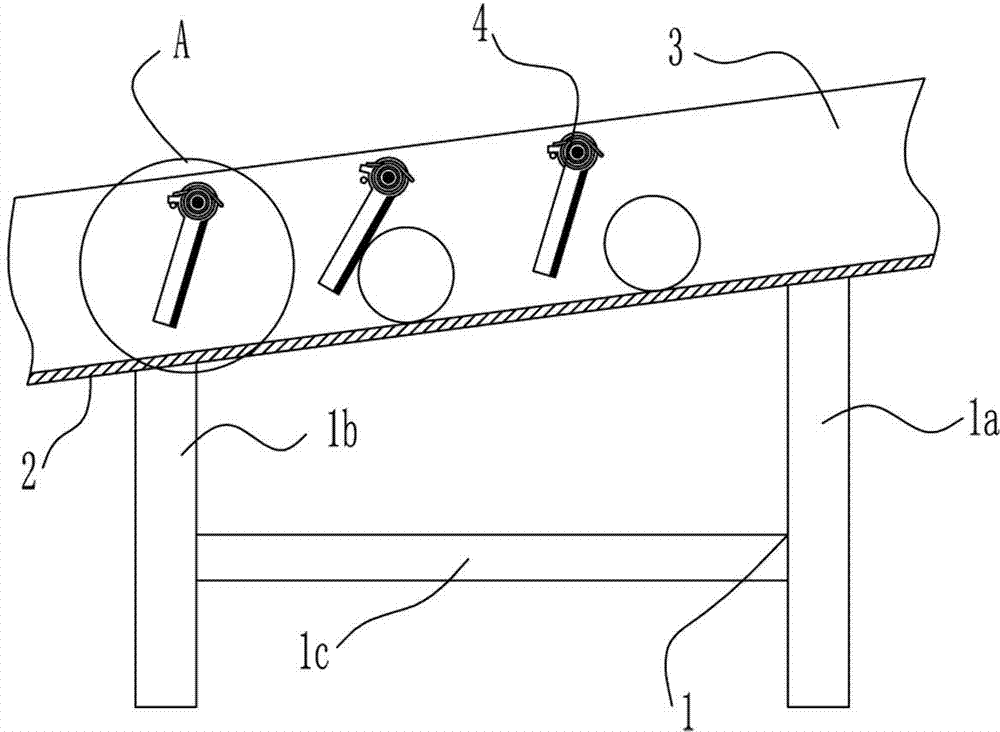

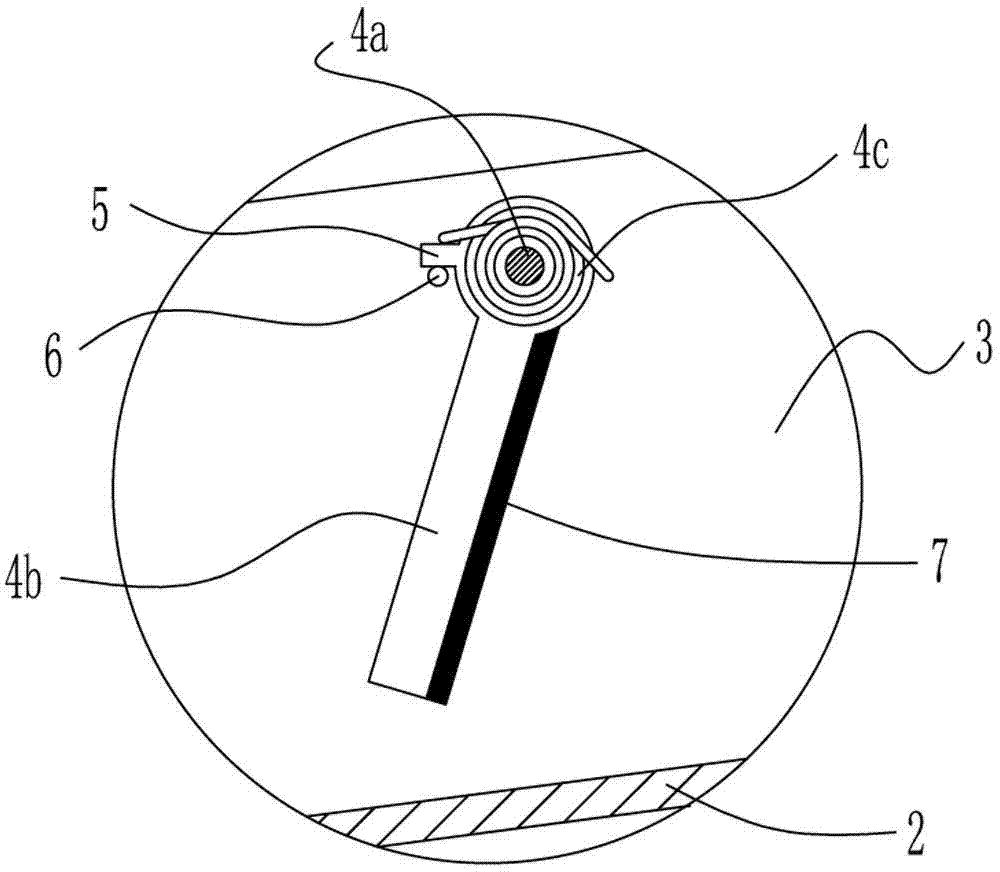

[0013] Such as figure 1 , figure 2 As shown, a buffer conveyor line according to the embodiment of the present invention mainly includes a bracket 1 and an inclined track located above the bracket 1. The inclined track includes a guide rail 2 and two identical baffles 3 fixed above the guide rail 2. Two baffles 3 are symmetrically fixed on both sides of the guide rail 2, and a plurality of identical buffer devices 4 are arranged between the two baffles 3, and the plurality of buffer devices 4 are located on the same straight line and evenly arranged along the inclination direction of the guide rail 2 Each buffer device 4 includes a rotating shaft 4a, a buffer plate 4b and a torsion spring 4c, the two ends of the rotating shaft 4a are respectively fixed on the two baffle plates 3, the buffer plate 4b is hinged with the rotating shaft 4a, and the torsion spring 4c is located between the buffer plate 4b and the rotating shaft 4a At the hinge, the buffer plate 4b is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com