Kapok fiber pre-treating method

A kapok fiber and pretreatment technology, which is applied in fiber treatment, plant fiber, spray/jet textile material treatment, etc., can solve the problems of kapok fiber being susceptible to moisture, affecting the smooth progress of the spinning process, and easy fiber adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

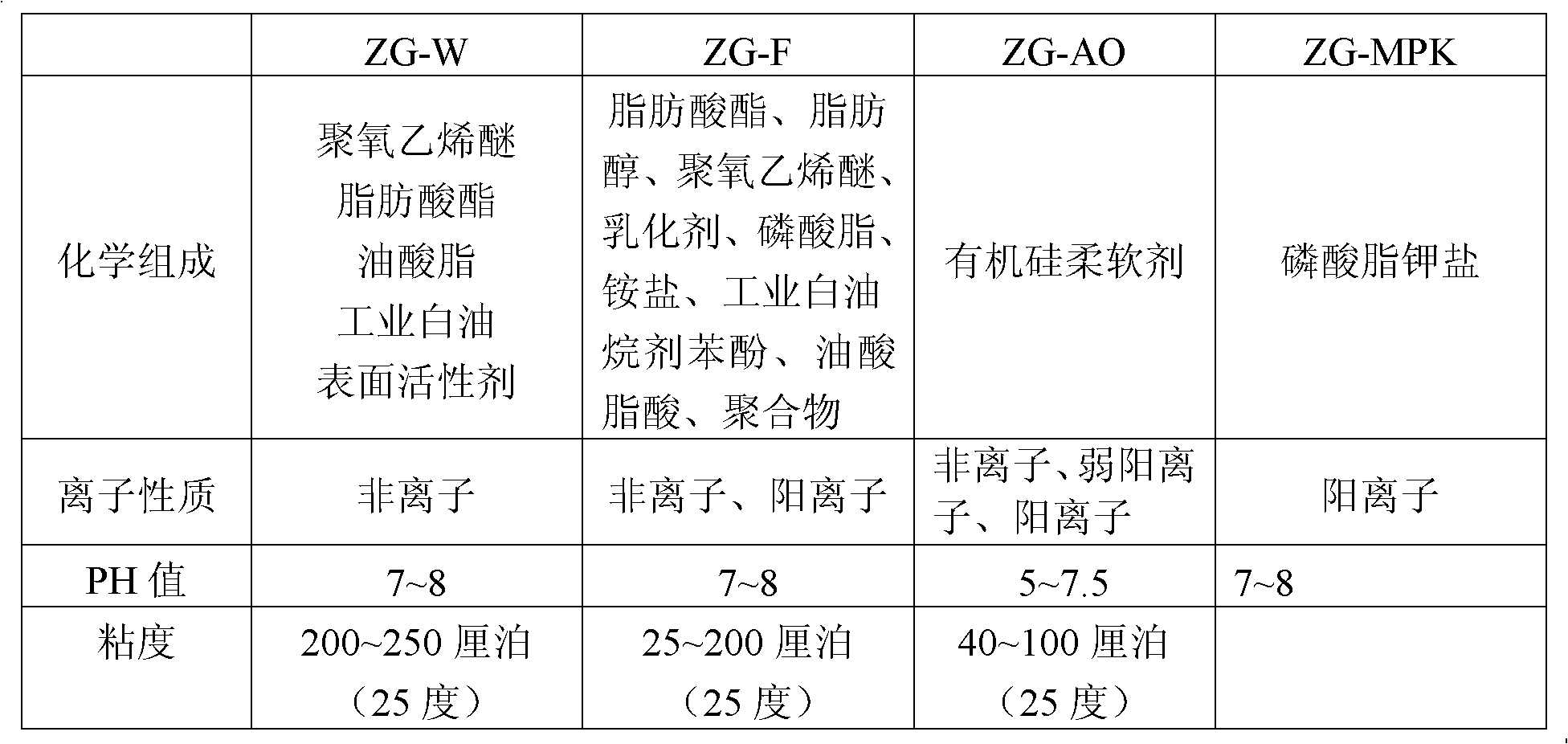

[0027] In Example 1, the silicone oil is the product of Shanghai Fangxin Technology Development Co., Ltd., the brand is ZG-AO; and the crude oil is the product of Shanghai Fangxin Technology Development Co., Ltd., the brand is ZG-W.

Embodiment 2

[0028] In Example 2, the crude oil is the product of Shanghai Fangxin Technology Development Co., Ltd., whose brand is ZG-MPK.

Embodiment 3

[0029] In Example 3, the crude oil is made of ZG-AO product of Shanghai Fangxin Technology Development Co., Ltd.

[0030] The specifications of kapok: the fiber length is 17-20mm short, of which 90% are below 17mm.

[0031] Example 1

[0032] Auxiliary formula:

[0033] 78 parts of water

[0034] Silicone oil 5 parts

[0035] and crude oil 24 parts

[0036] The components are mixed and then stirred to obtain the auxiliaries.

[0037] Spray the above-mentioned additives on the raw kapok fiber, the weight dosage is 10% of the raw kapok fiber, and then place it in an environment with a humidity of 55% and a temperature of 25°C, and balance for 23 hours to obtain the pretreated kapok fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com