Patents

Literature

50results about How to "Improve twisting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-twist spinning method

The invention relates to a double-twist spinning method and belongs to the technical field of textile. The method adopts the follwing steps: a double-twist winding mechanism is arranged in front of adrawing system of a spinning machine, the double-twist winding mechanism consists of a double-twist structure and a winding mechanism, the winding mechanism is positioned in a yarn storage tank of thedouble-twist structure, a drawn fiber strip is output through a front roller nipper and then twisted to form a yarn, the yarn is warped by a guide wire, enters a yarn inlet pipe, a yarn running pipeand a yarn outlet pipe and runs to the tensioner, under the rotating action of a twisting disc with a rotating speed of n revolutions / min, the yarn running from the front roller nipper to the tensioner section obtains 2n twists per minute, under the action of the tensioner, the tension of the yarn is drawn out from the yarn outlet pipe, and then wound through the winding groove drum to form the drum yarn package. By adopting the method, the ring twisting and pipe winding mode of the ordinary spinning machine are changed, the double-twist spinning is adopted, thereby greatly improving the twisting efficiency, the spinning quality and the uniformity; by adopting a drum yarn winding mode, the spinning yarn package is increased, and the production efficiency is improved.

Owner:WUHAN TEXTILE UNIV

Kapok fiber pre-treating method

InactiveCN102182065AIncrease labor intensityImprove the mixing effectTextile treatment by spraying/projectingVegetal fibresPretreatment methodKapok fiber

The invention provides a kapok fiber pre-treating method. The method comprises the following steps of: spraying an auxiliary agent onto a raw material, namely kapok fibers; and then placing the kapok fibers in an environment of which the humidity is 55 to 60 percent and the temperature is 25 to 32 DEG C and balancing for 20 to 26 hours to obtain the pre-treated kapok fibers. The auxiliary agent comprises the following components in part by weight: 70 to 80 parts of water, 2 to 6 parts of silicone oil and 20 to 25 parts of crude oil. The spinning property of the kapok fibers can be obviously improved by treating the raw material, namely the kapok fibers, and then blending the kapok fibers and other fibers by the method; the labor intensity is reduced to a large extent; and the yield and the quality are approved by clients.

Owner:SHANGHAI HEYE TEXTILE +1

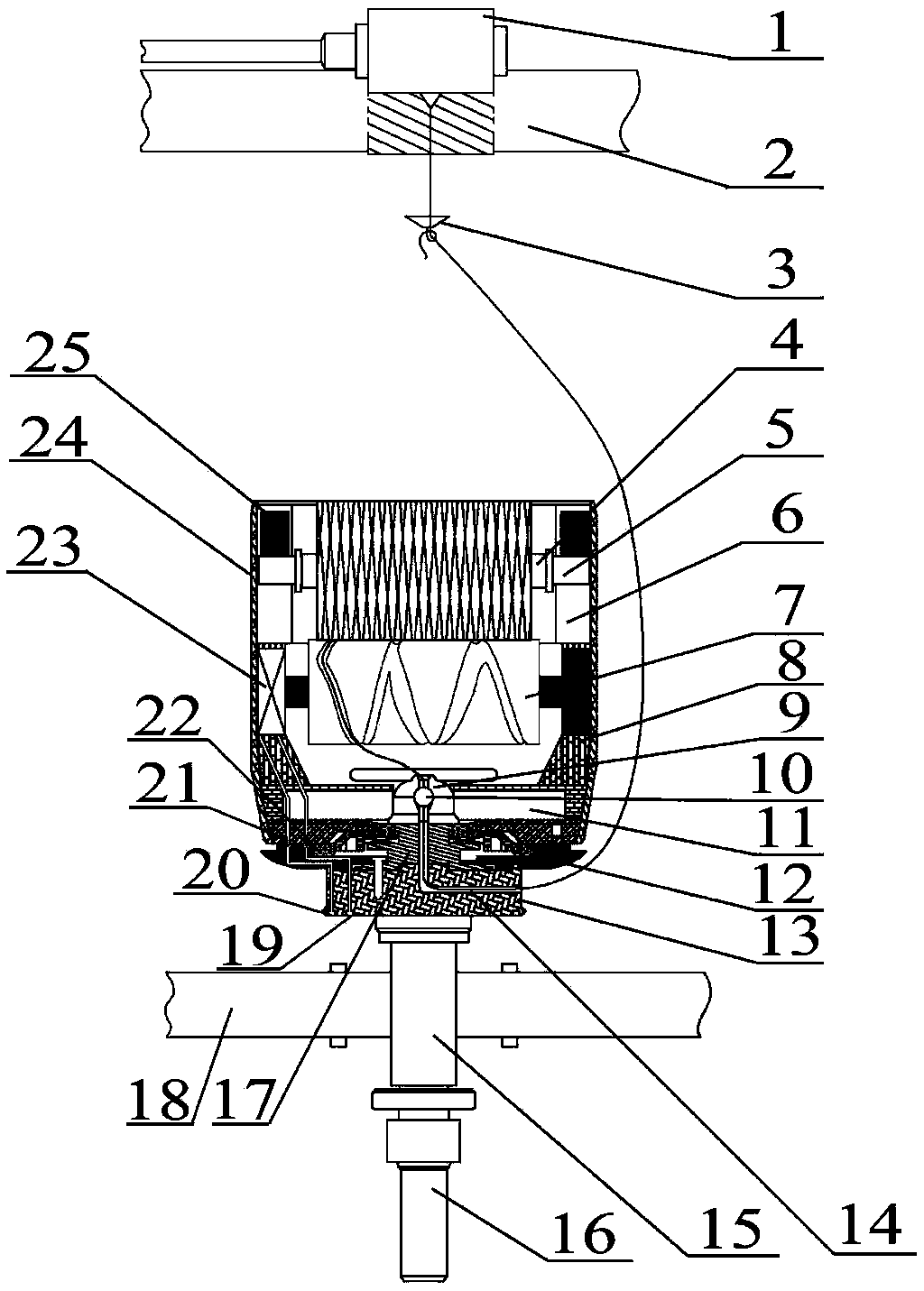

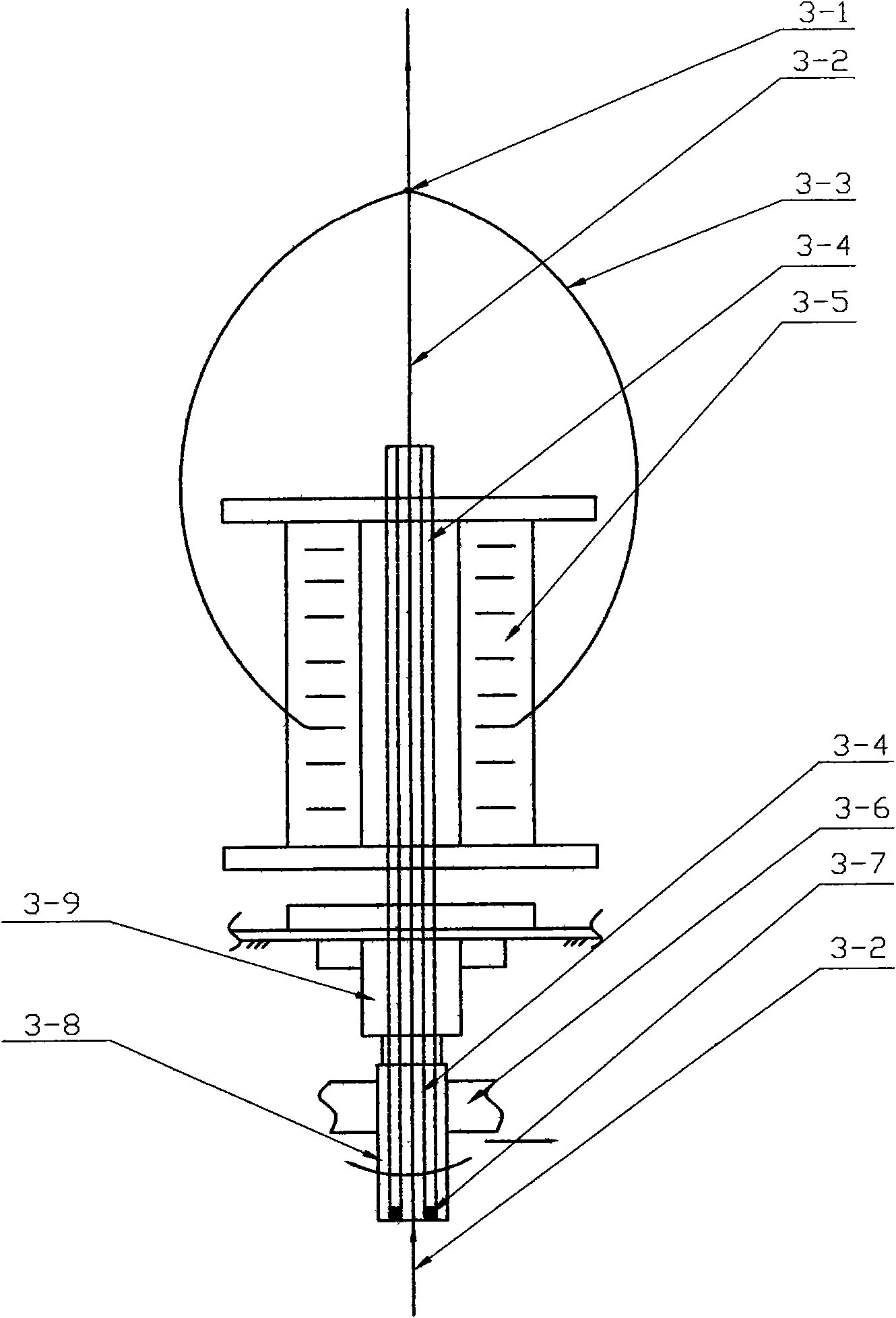

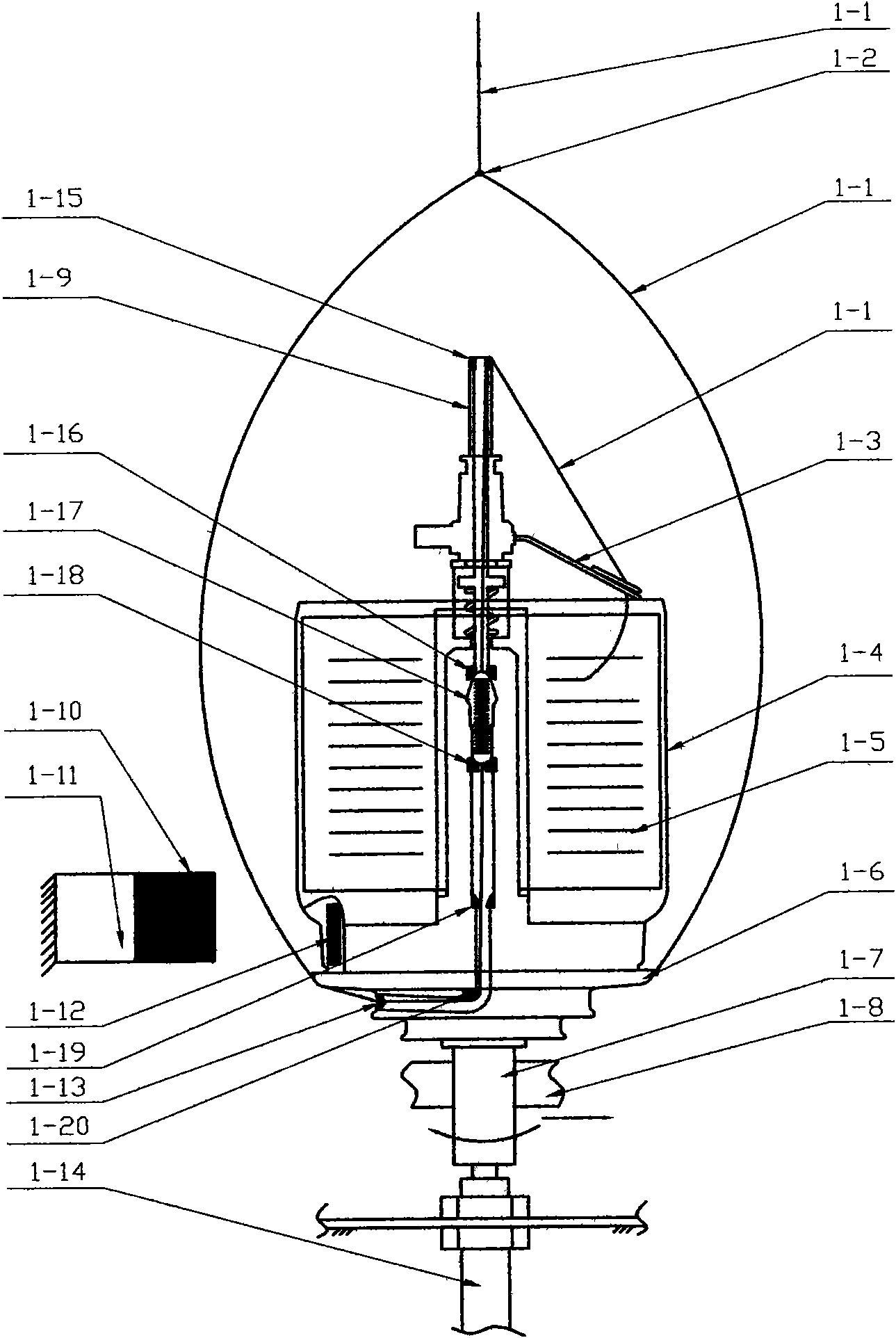

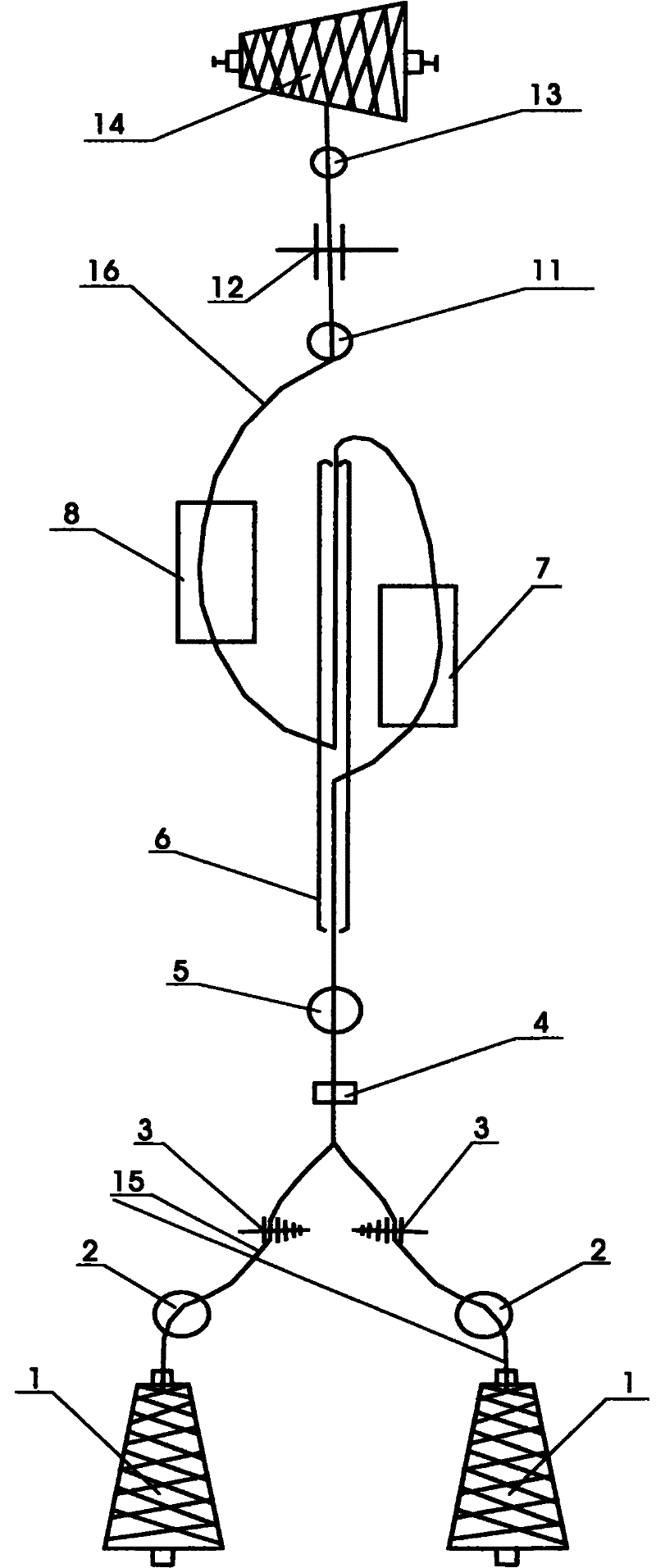

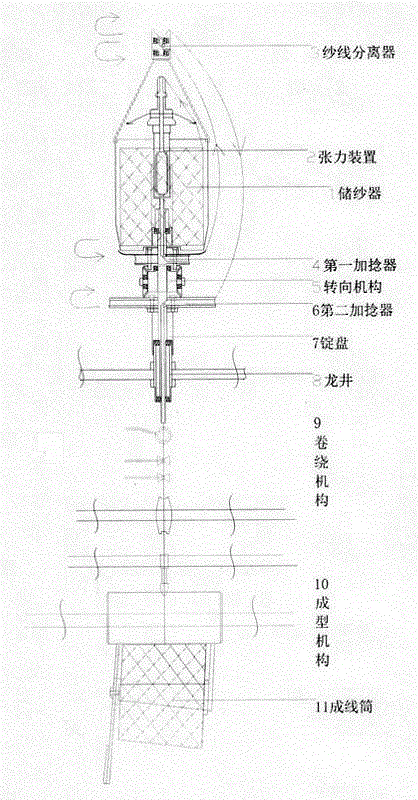

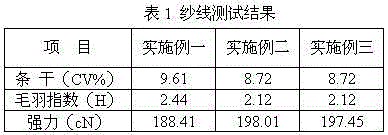

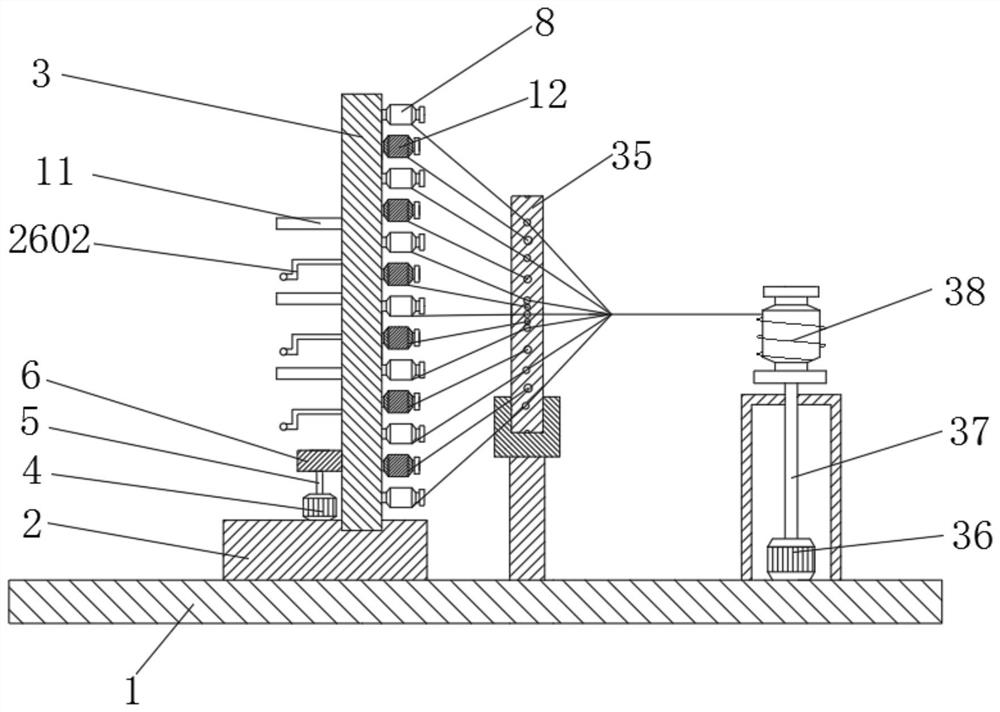

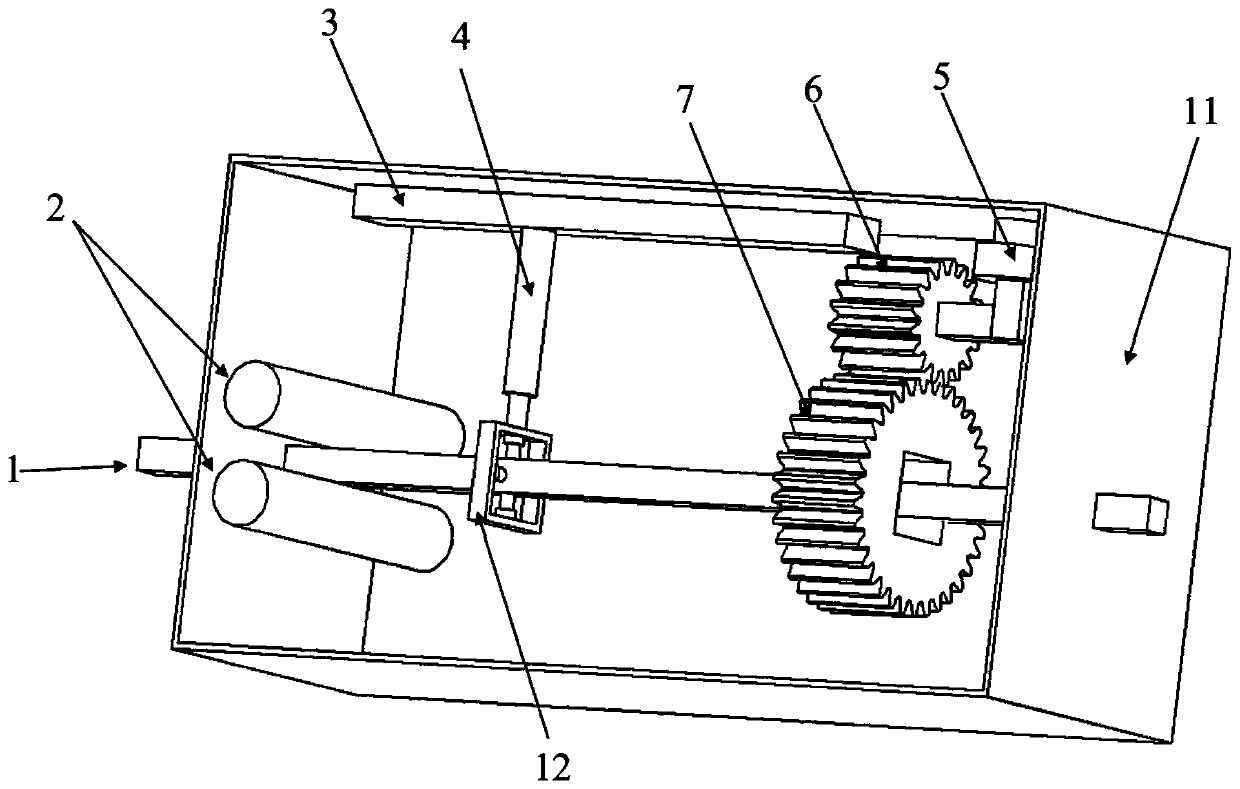

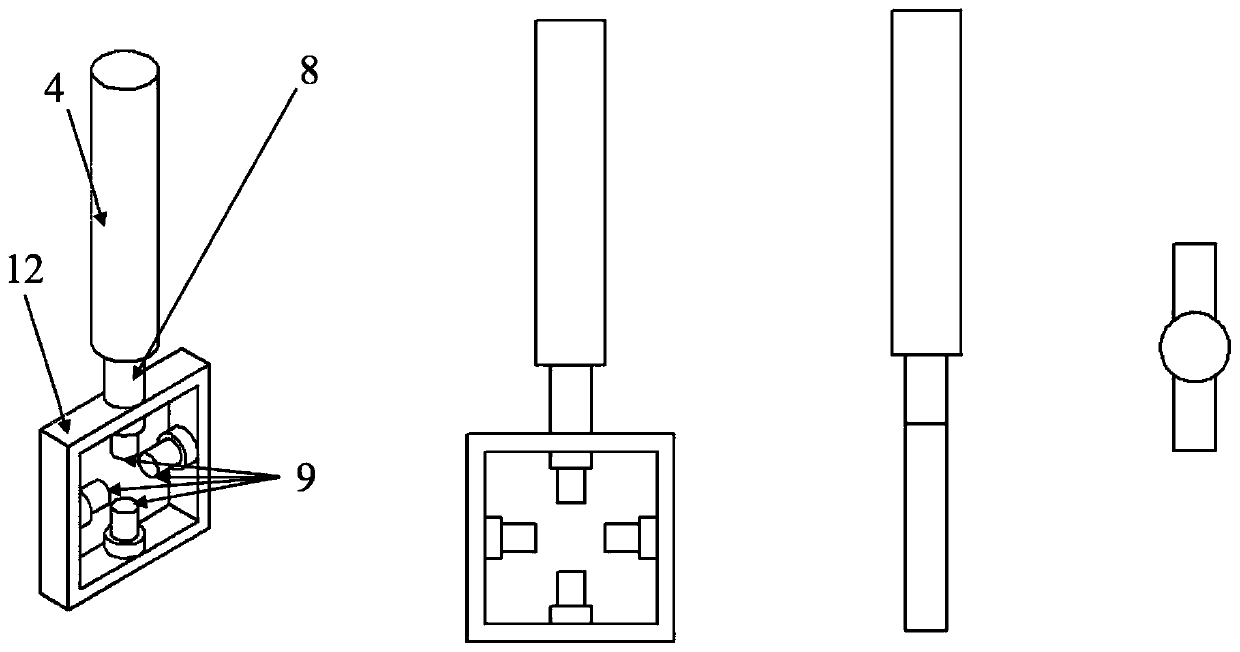

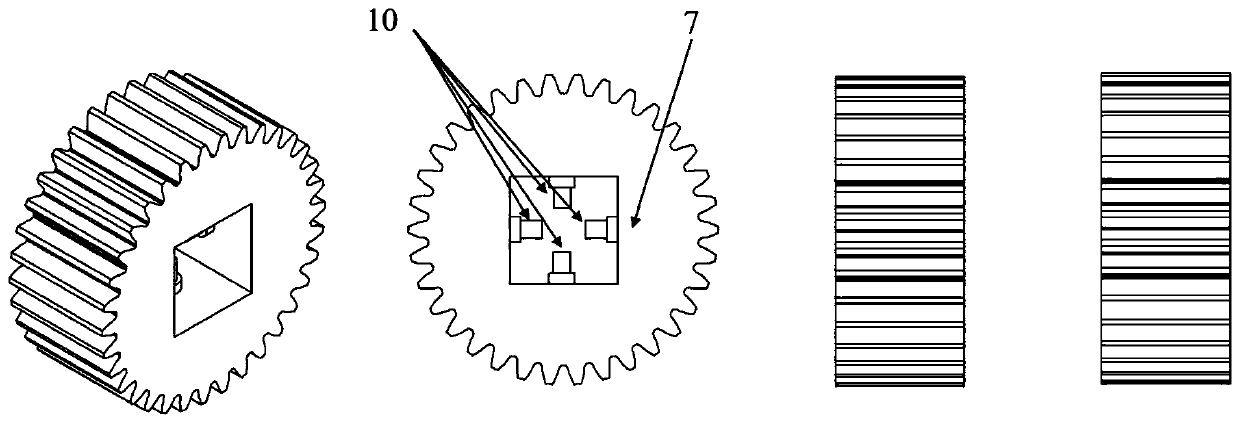

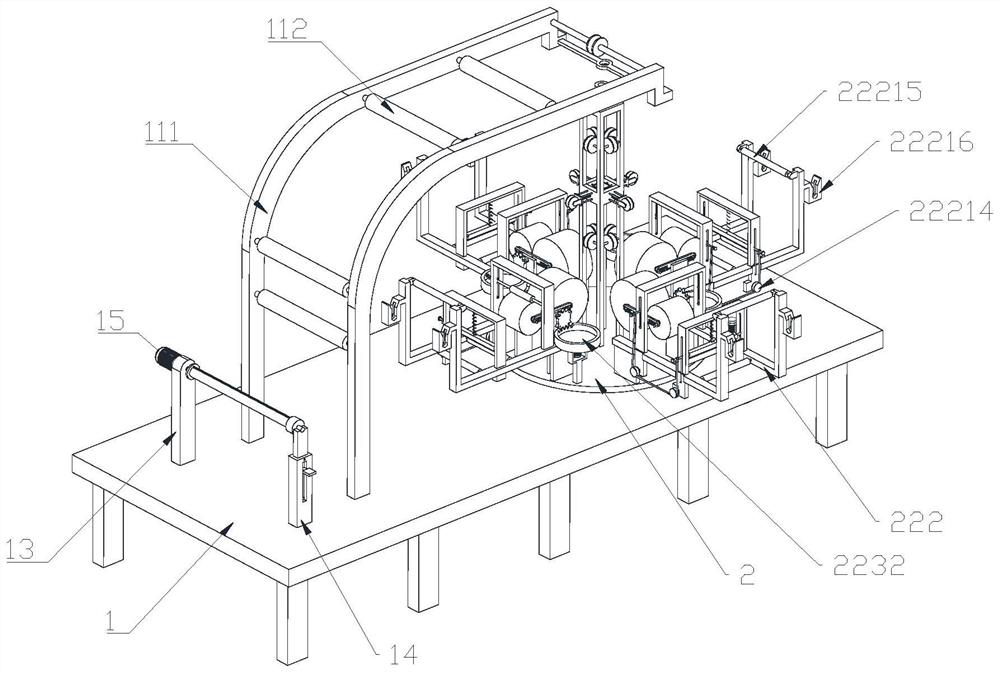

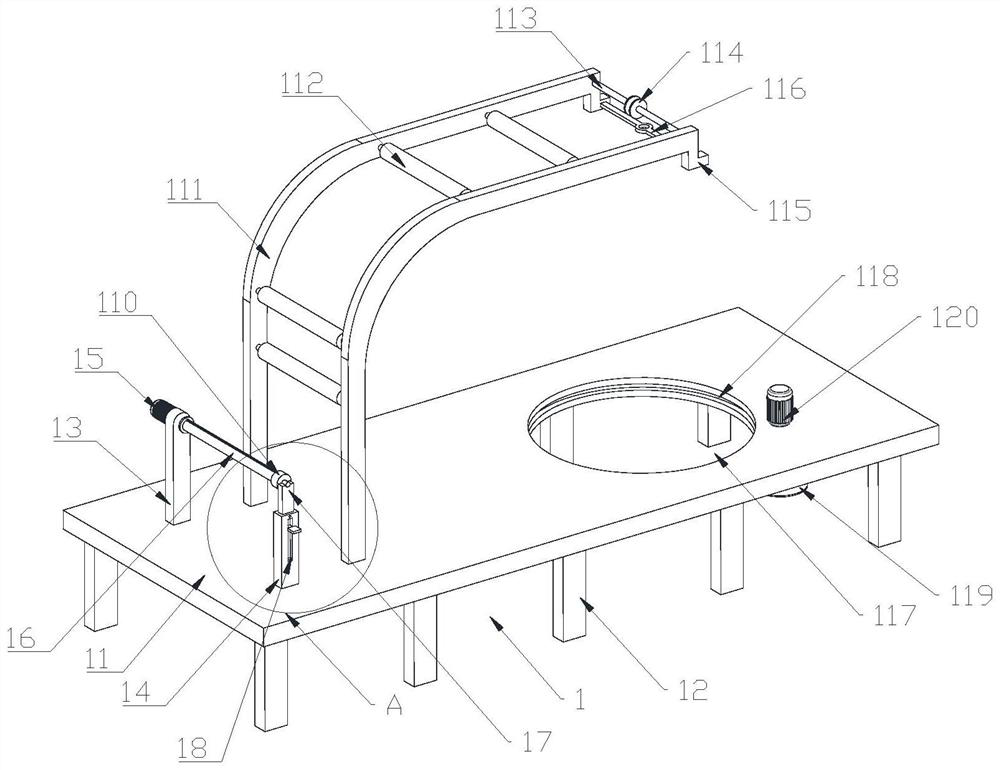

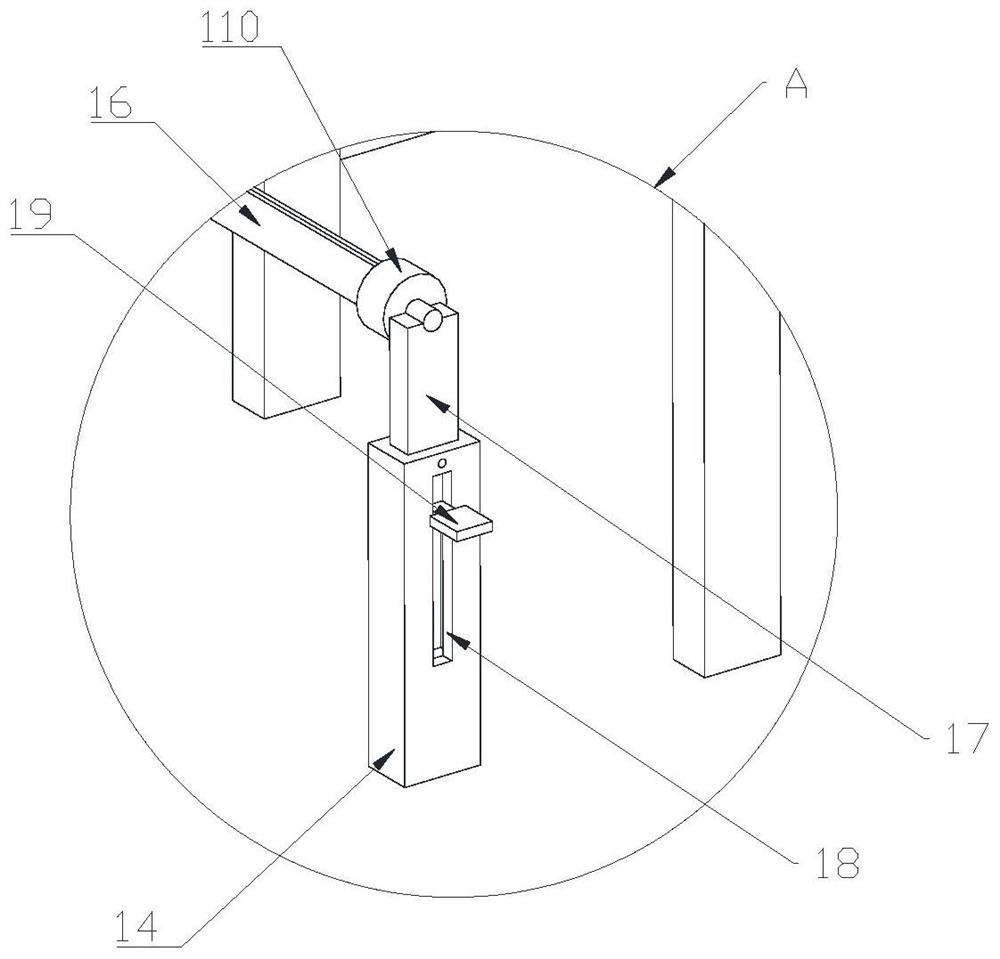

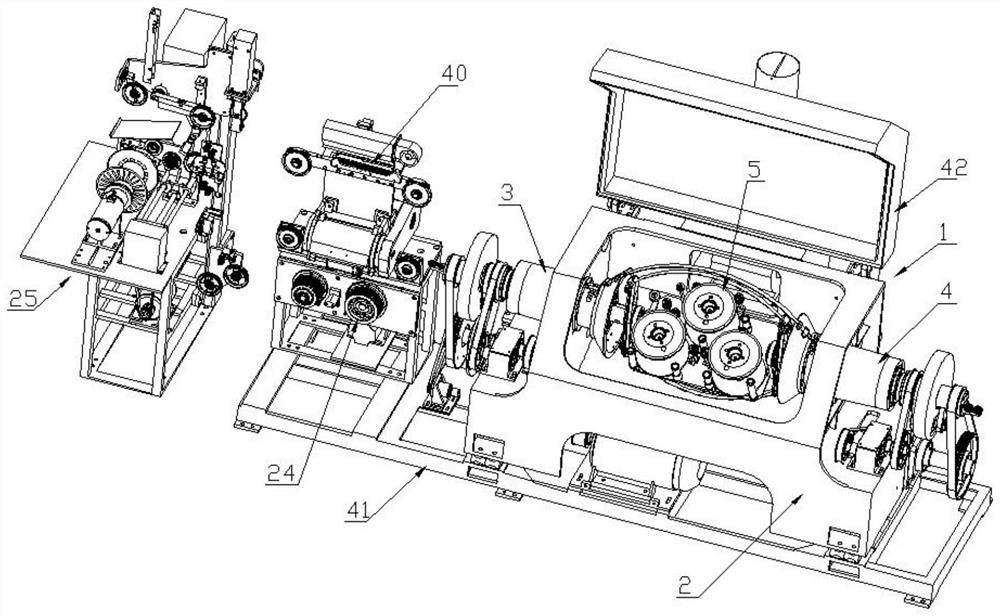

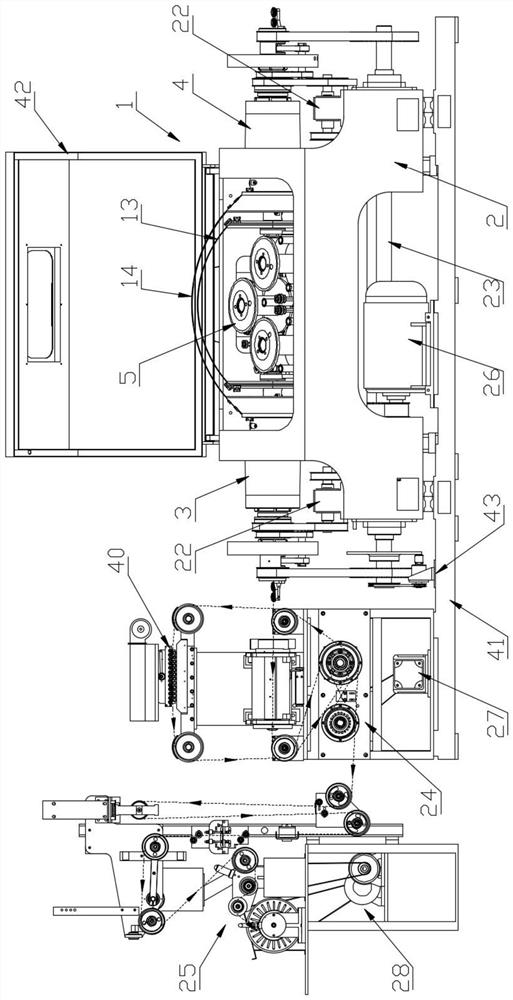

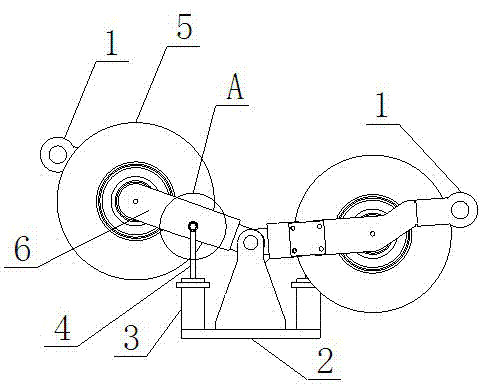

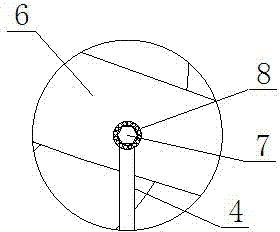

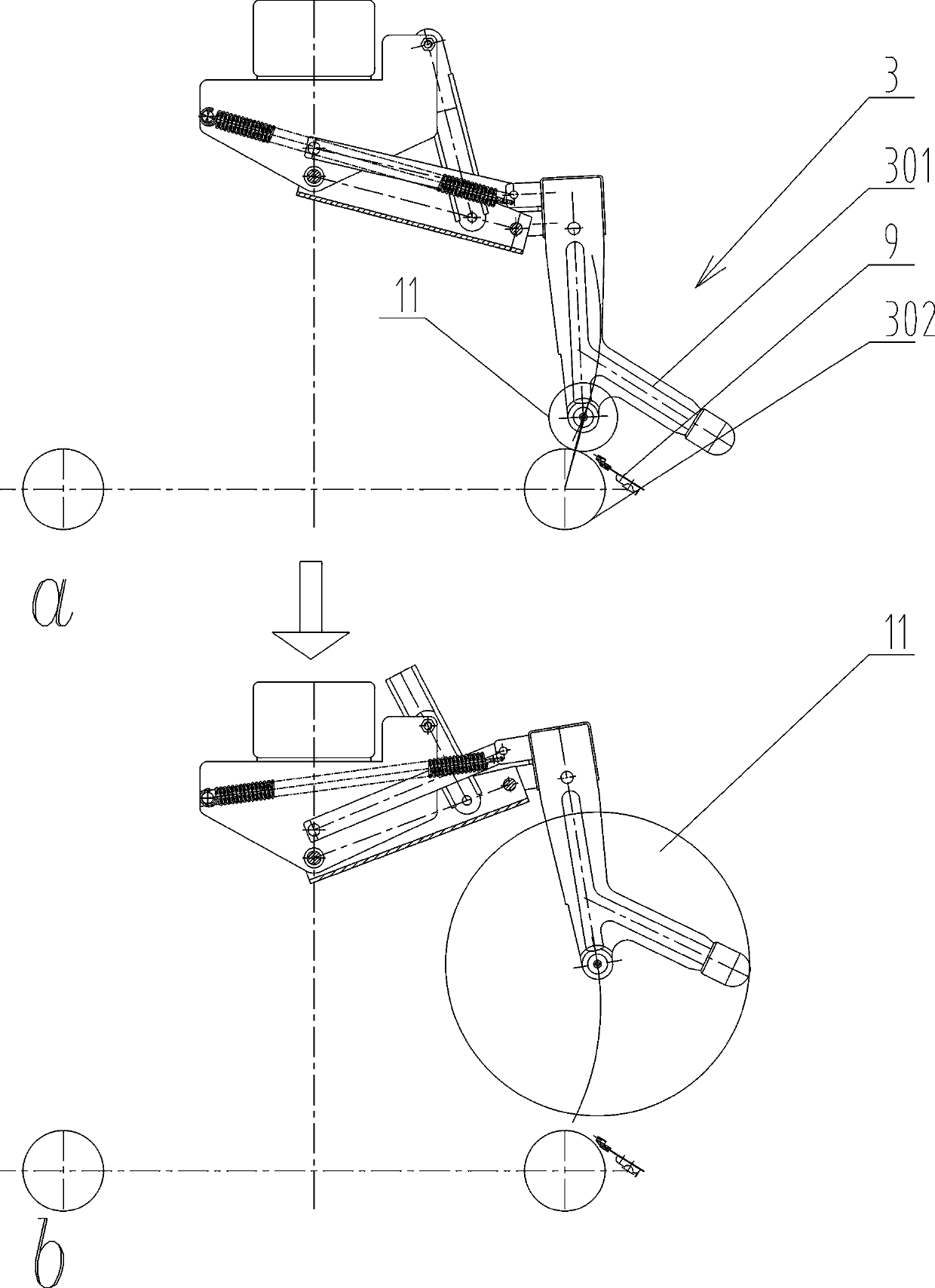

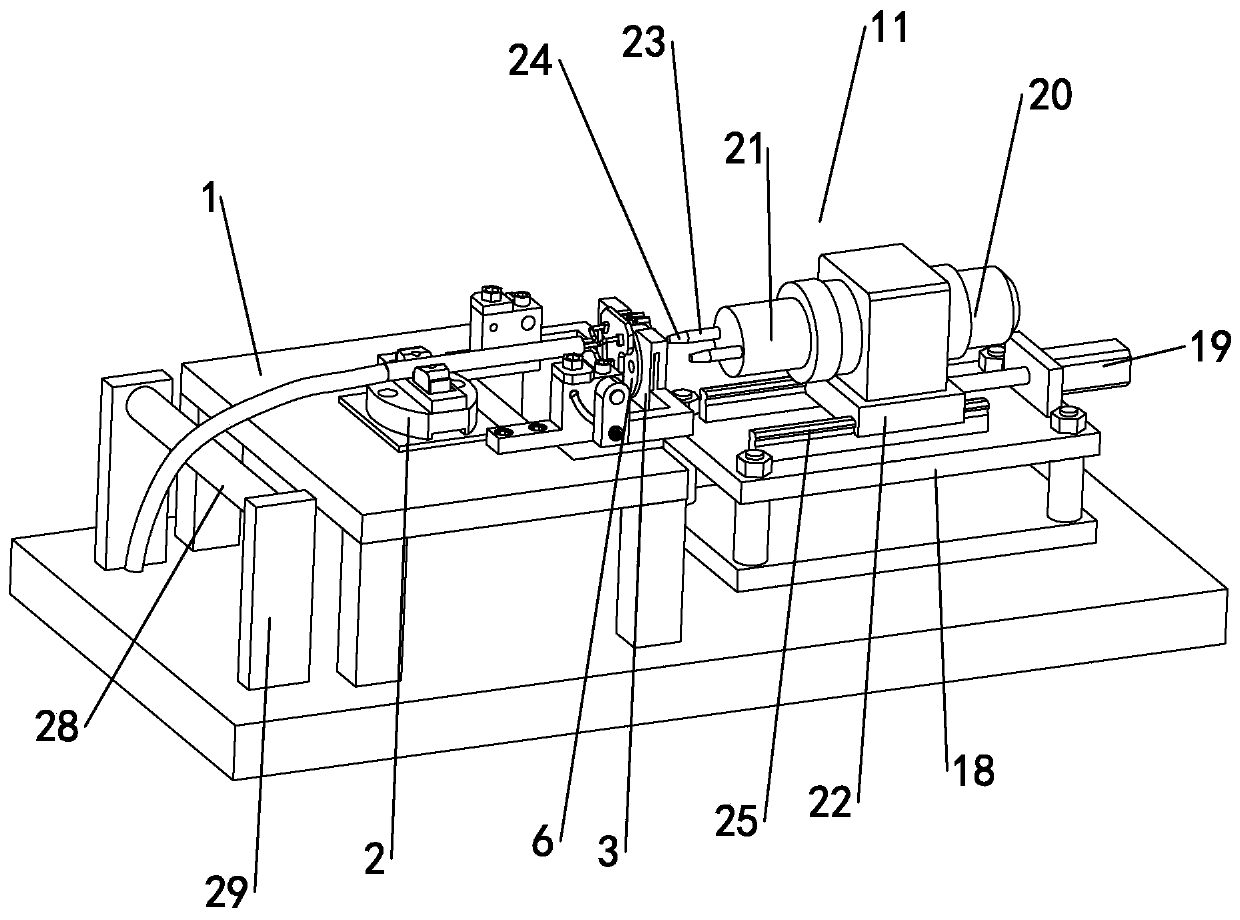

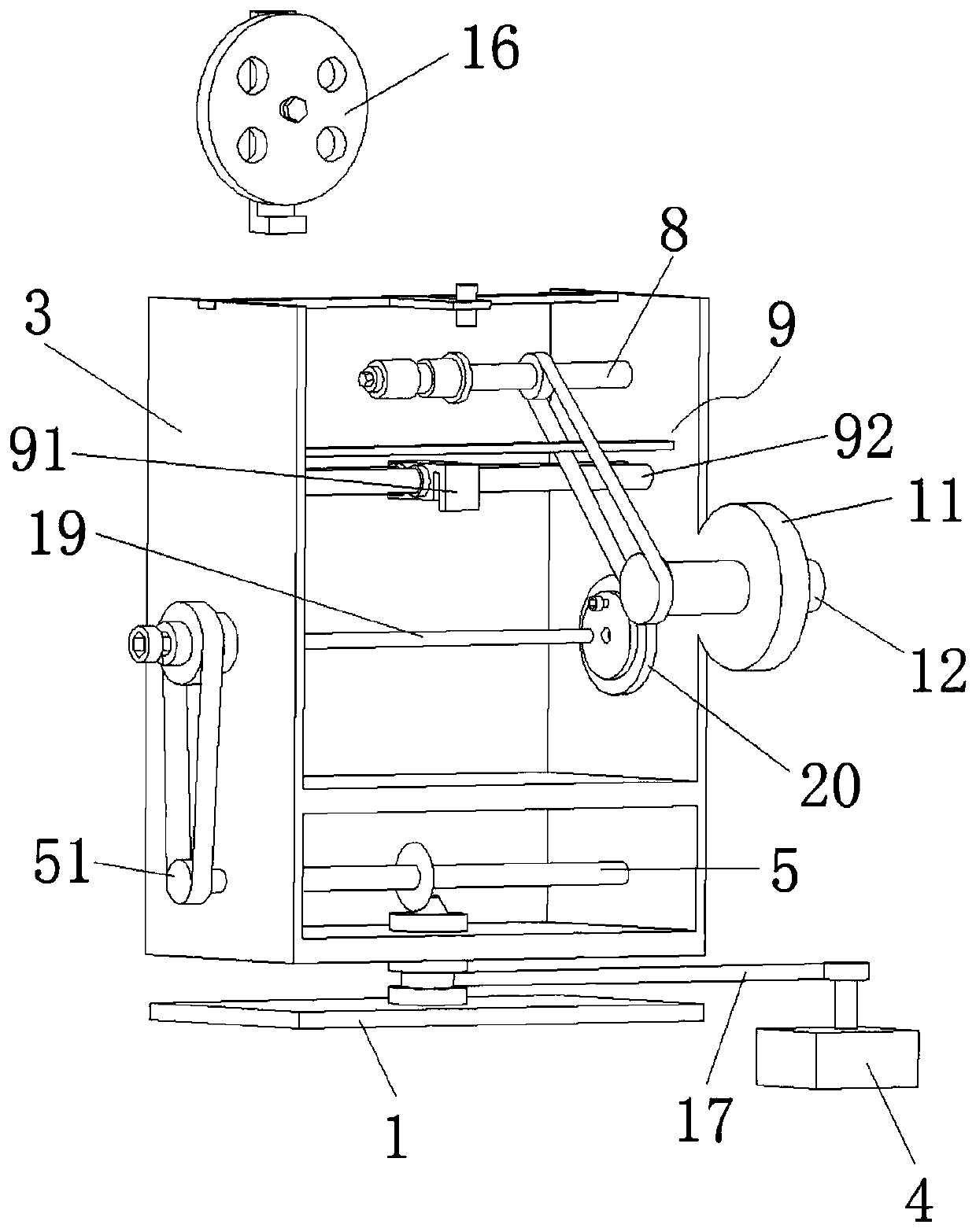

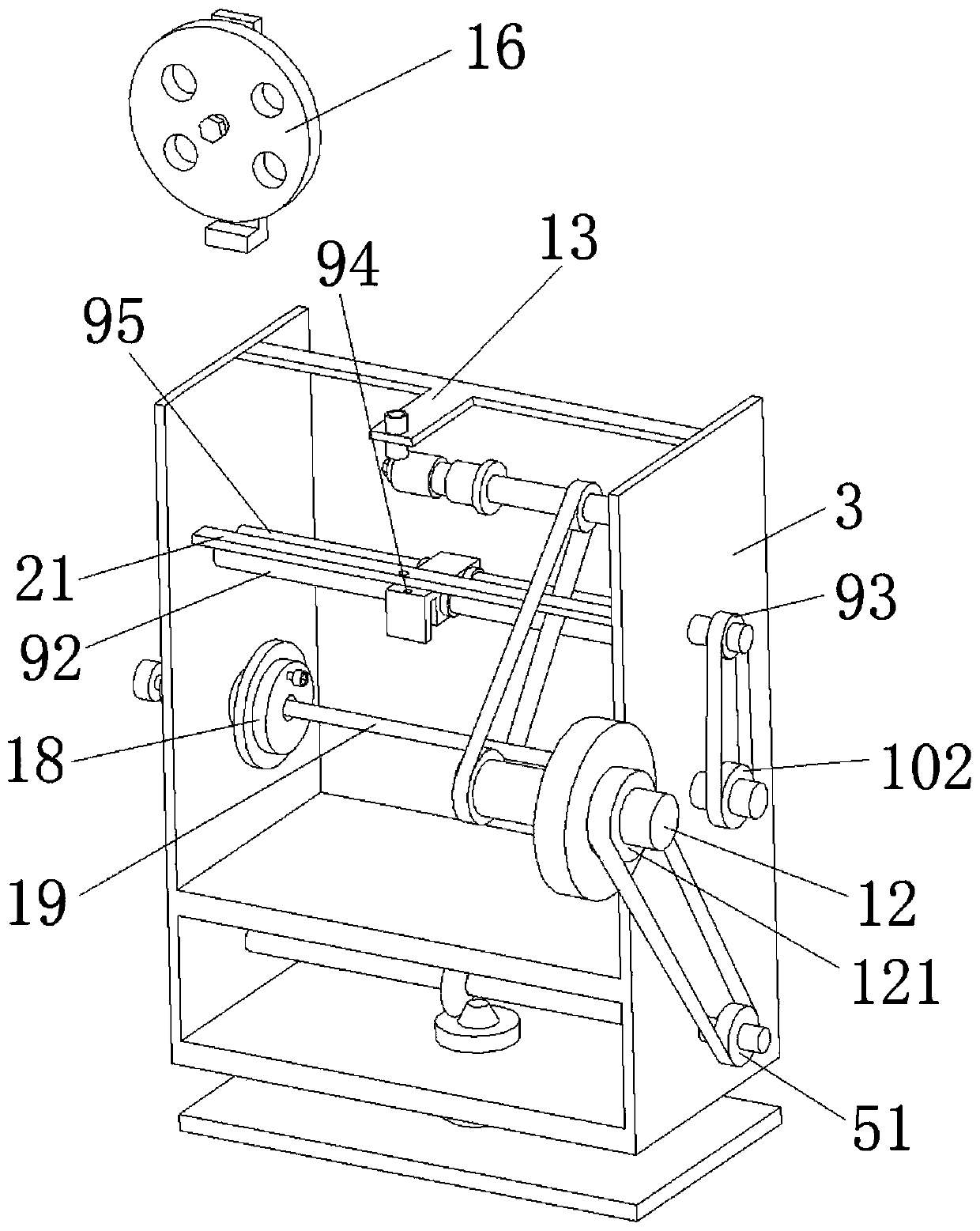

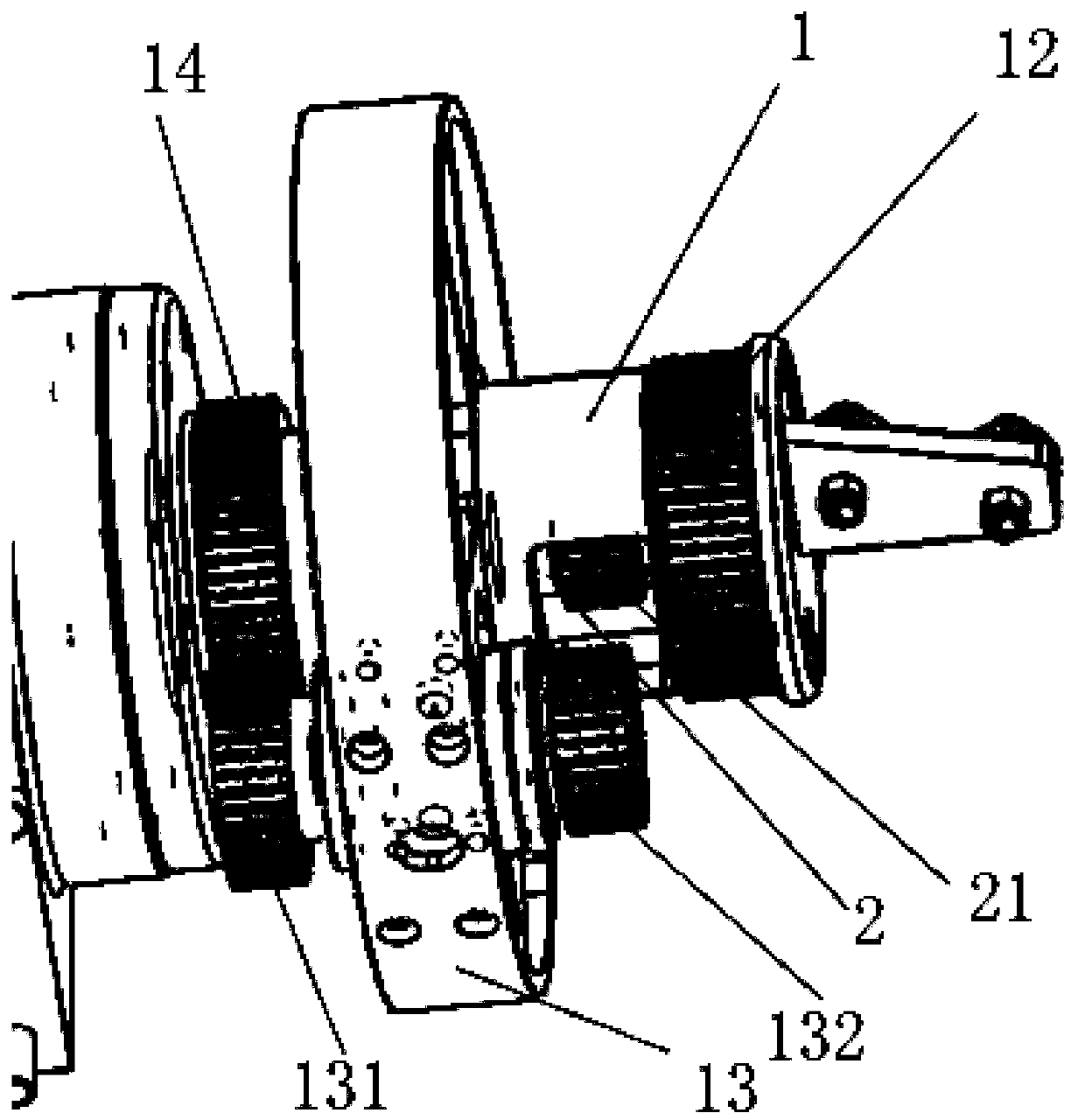

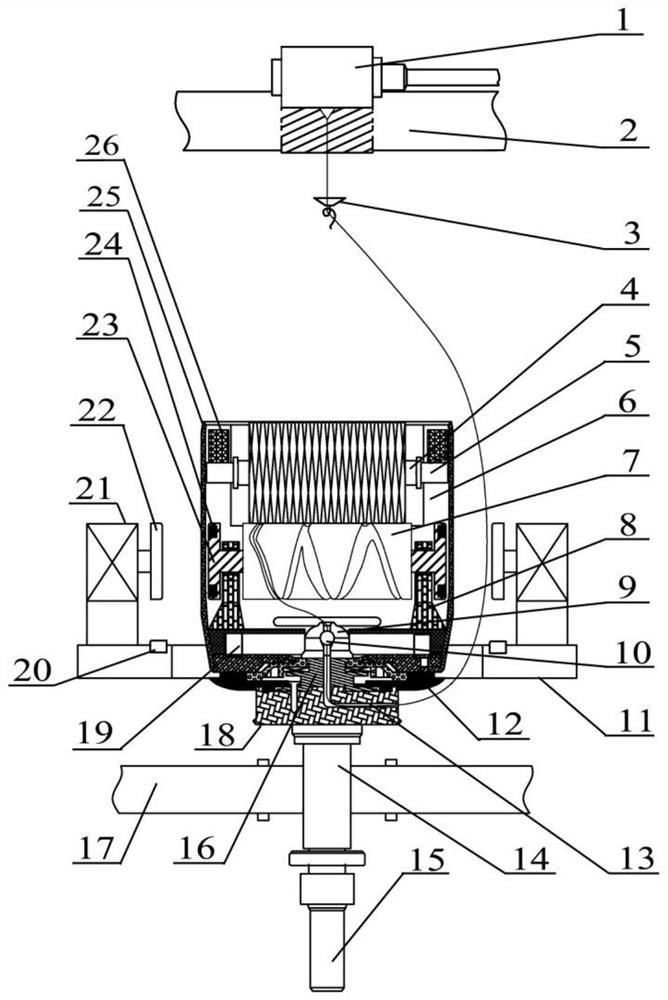

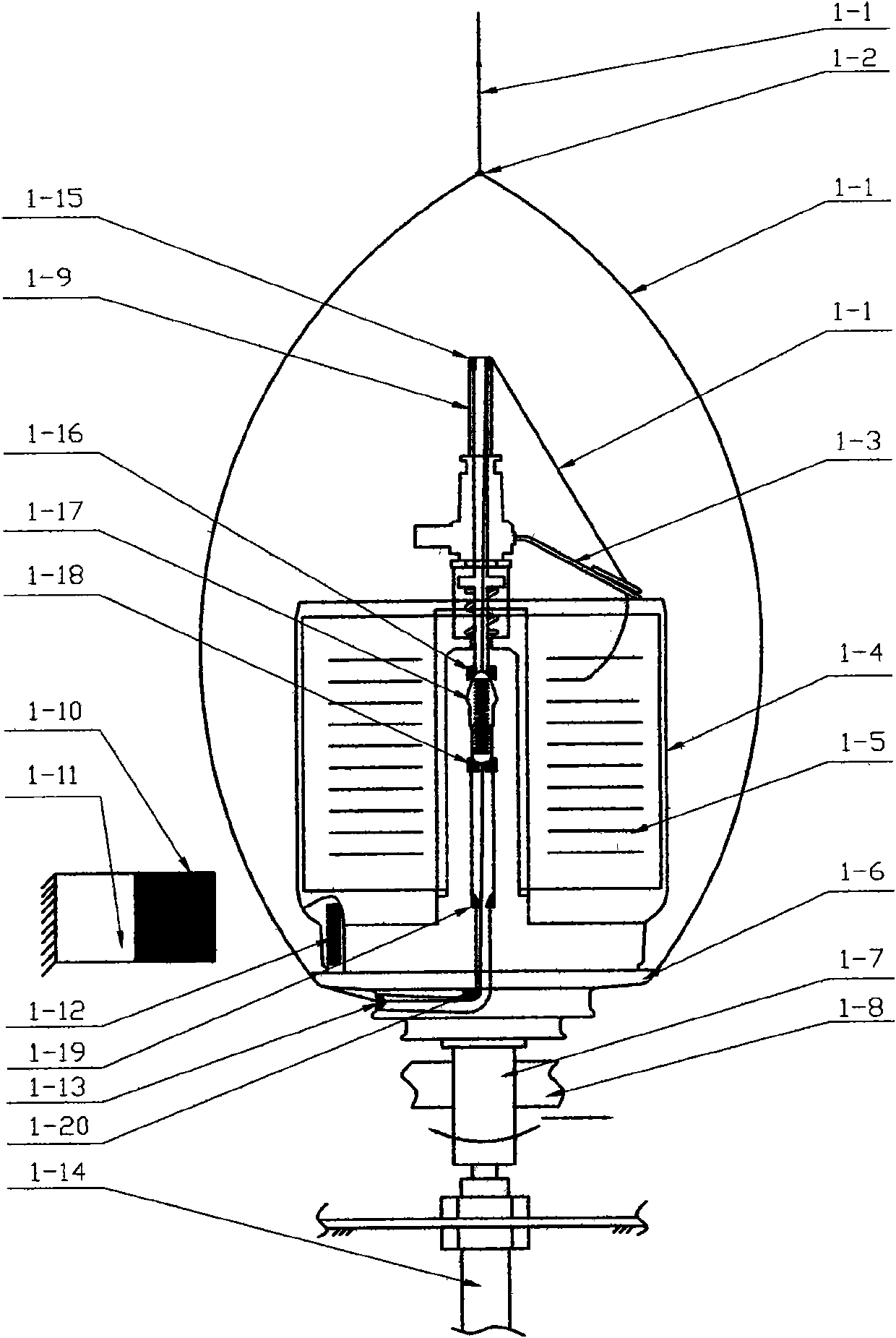

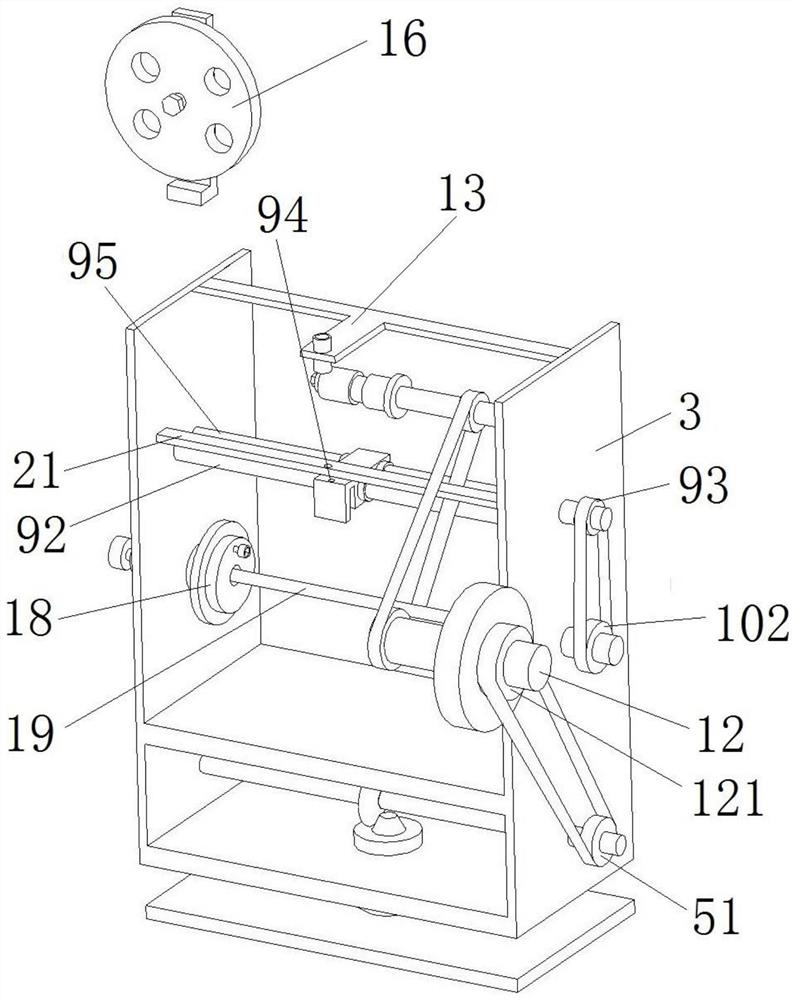

Two-for-one twisting type spinning frame

ActiveCN109554784AImprove twisting efficiencyDestroy qualityDrafting machinesContinuous wound-up machinesYarnWind component

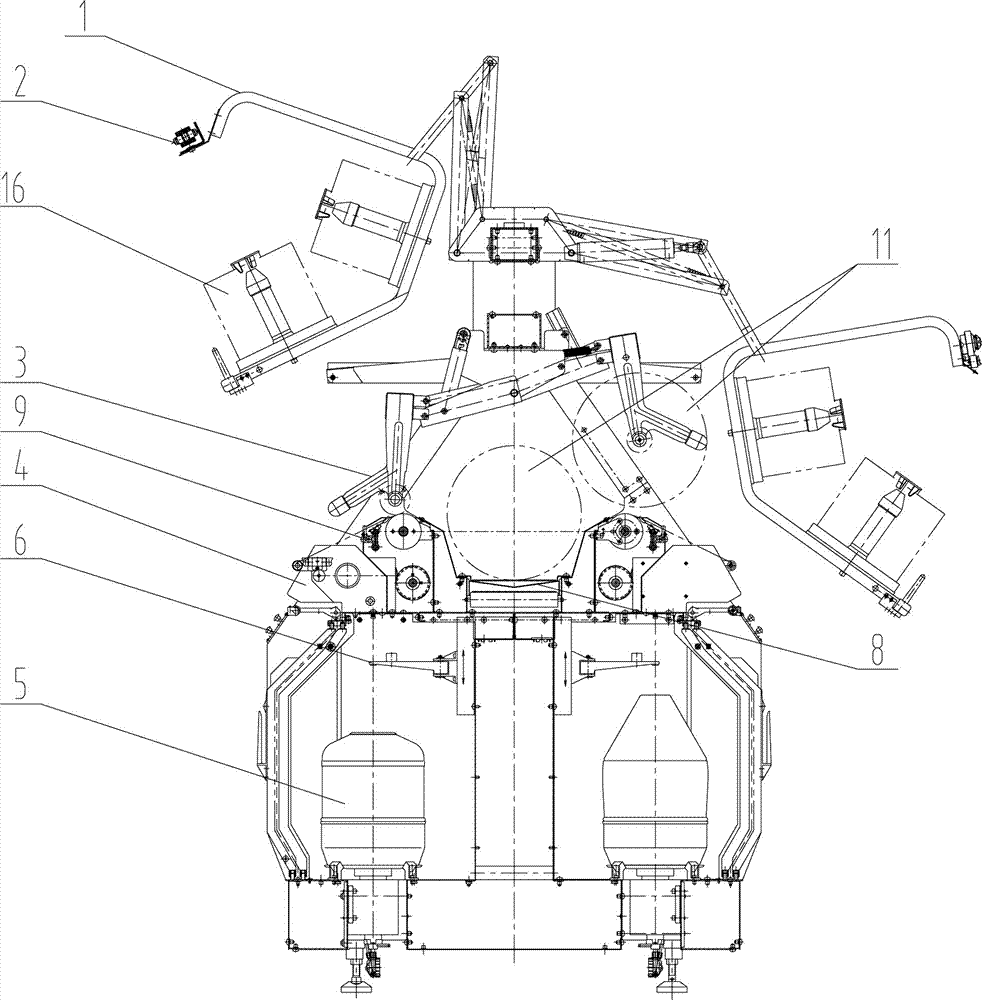

The invention relates to a two-for-one twisting type spinning frame, and belongs to the technical field of textile. The two-for-one twisting type spinning frame has the advantages that a twisting andspinning mechanism of an ordinary ring spinning frame is changed into a two-for-one twisting winding mechanism, the two-for-one twisting winding mechanism comprises a two-for-one twisting mechanism and a winding mechanism, a twisting disc can rotate by a circle for silver operated in zones from jaws of a front roller to a tension device, accordingly, two-twist two-for-one twisting effects can be realized for the silver, and the twisting efficiency can be improved; the winding mechanism is positioned in a yarn storage tank of the two-for-one twisting mechanism, twisting components and winding components are substantially separated from one another, twisting and winding can be separately individually controlled, the twisting and winding mechanism, by which twisting and winding can be simultaneously carried out and are constrained by each other, of the ordinary ring spinning frame is thoroughly changed, large-package spun yarns of cheese can be formed, the shortcomings of great winding balloon and tension difference of the traditional spinning frame mechanisms and high fluctuation of the quality of existing resultant yarns can be overcome, and accordingly the quality and the uniformity of resultant yarns can be improved; the two-for-one twisting type spinning frame is reasonable in structure and convenient to operate, and popularization can be facilitated.

Owner:WUHAN TEXTILE UNIV

Wire twisting device

ActiveCN107359047ANo offsetNo slidingContact member manufacturingCoils manufactureClassical mechanicsConveyor belt

The invention relates to a wire twisting device, comprising a working platform and a conveyor belt arranged on the working platform, wherein the conveyor belt is used for transporting a conveying disk with a magnetic coil, and the magnetic coil has a plurality of terminals extending to both sides of the conveying disk. The wire twisting device comprises a fixed bracket fixed on the working platform, a wire pressing mechanism fixed on the fixed bracket and a wire twisting mechanism fixed on the working platform; the wire pressing mechanism is located above the conveying disk, and comprises a plurality of pressure bars, and the pressure bars are used for holding the terminals on both sides of the magnetic coil; the wire twisting mechanism comprises two wire twisting modules, and the two wire twisting modules are distributed on both sides of the conveyor belt respectively. Each wire twisting module comprises a plurality of clamps and a rotating module used for driving the rotation of the clamps; the clamps are used for clamping the terminals on both sides of the magnetic coil, and are driven by the rotating module to rotate, so as to achieve the purpose of twisting the terminals on both sides. By means of the wire twisting device, the technical problem of low efficiency when the terminals are twisted by hand is solved.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

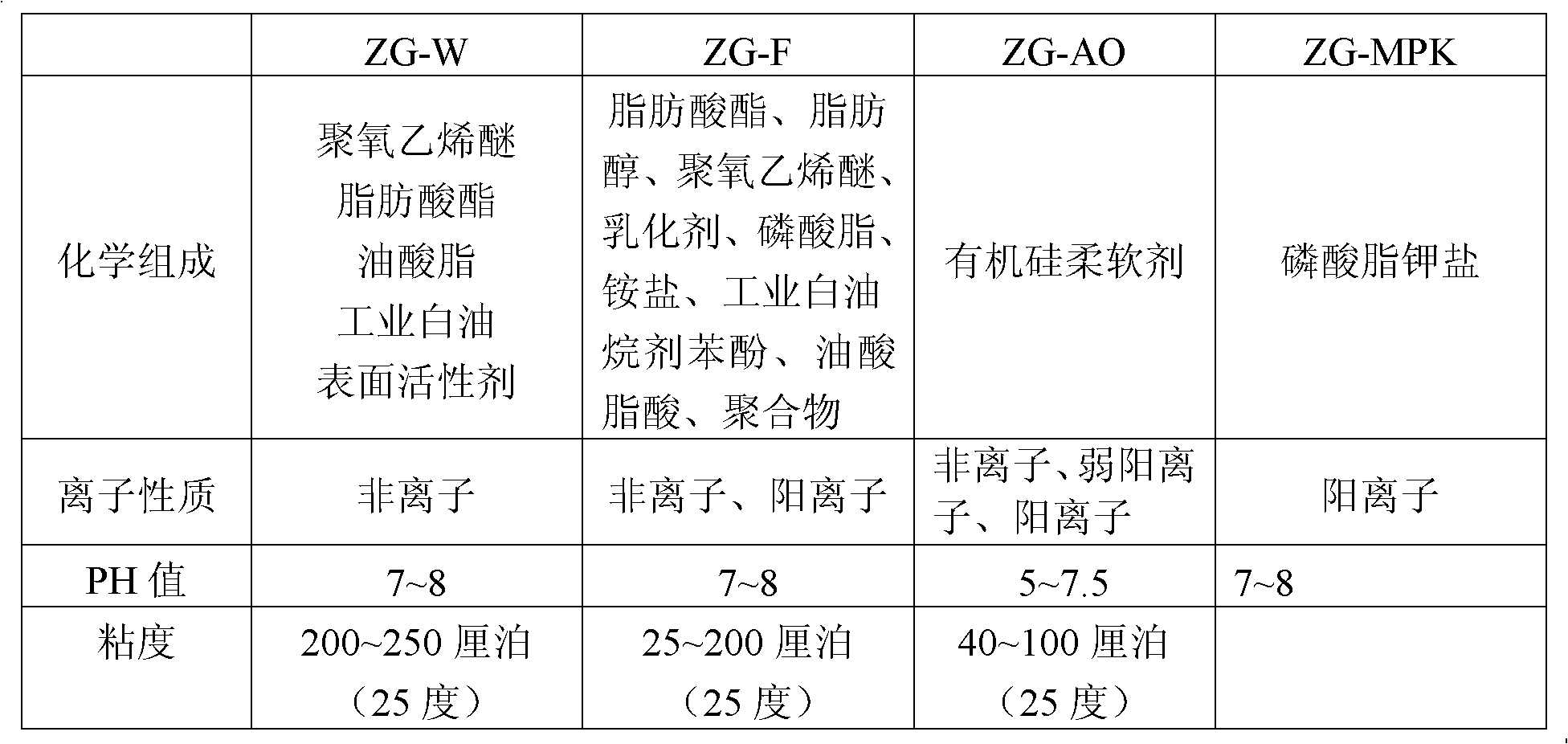

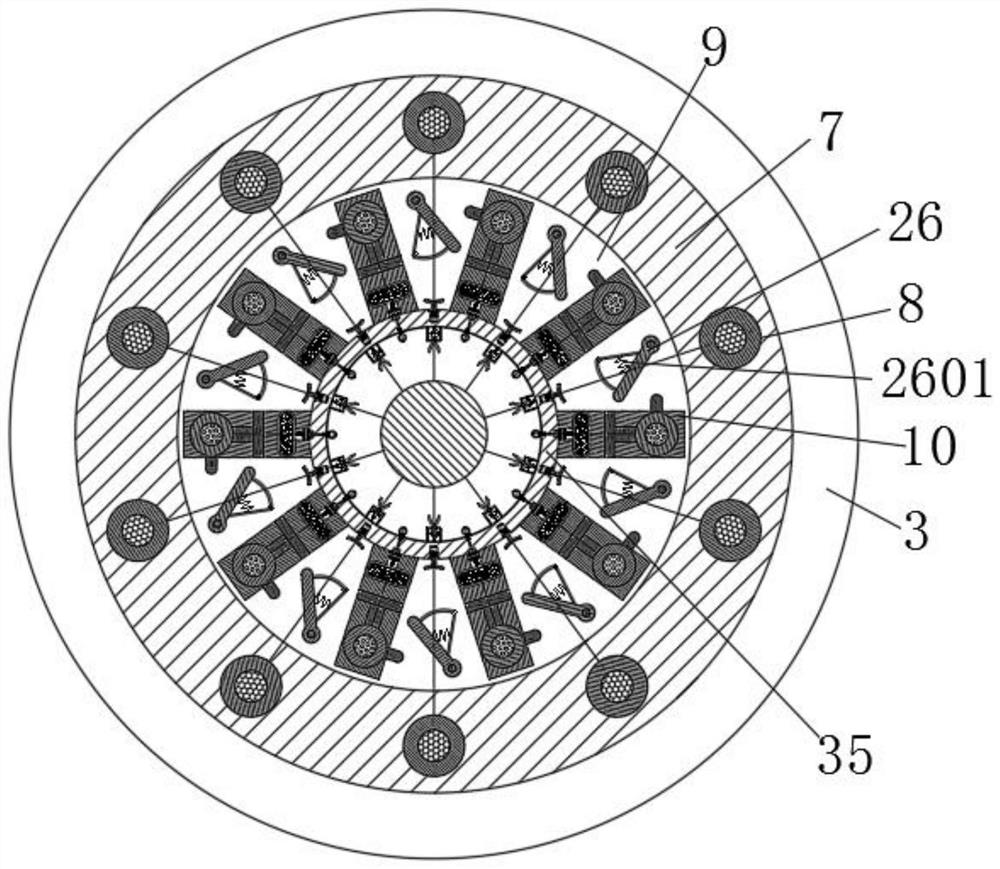

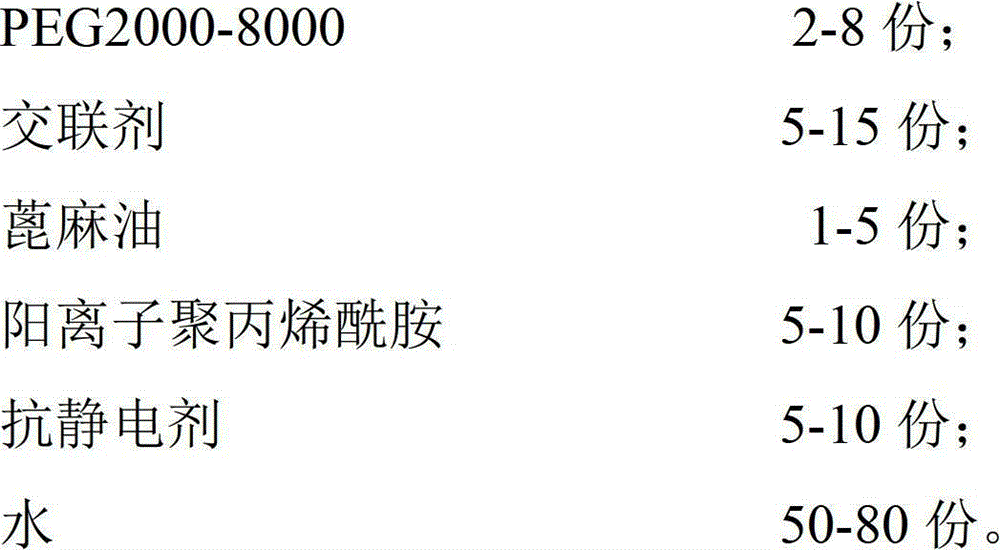

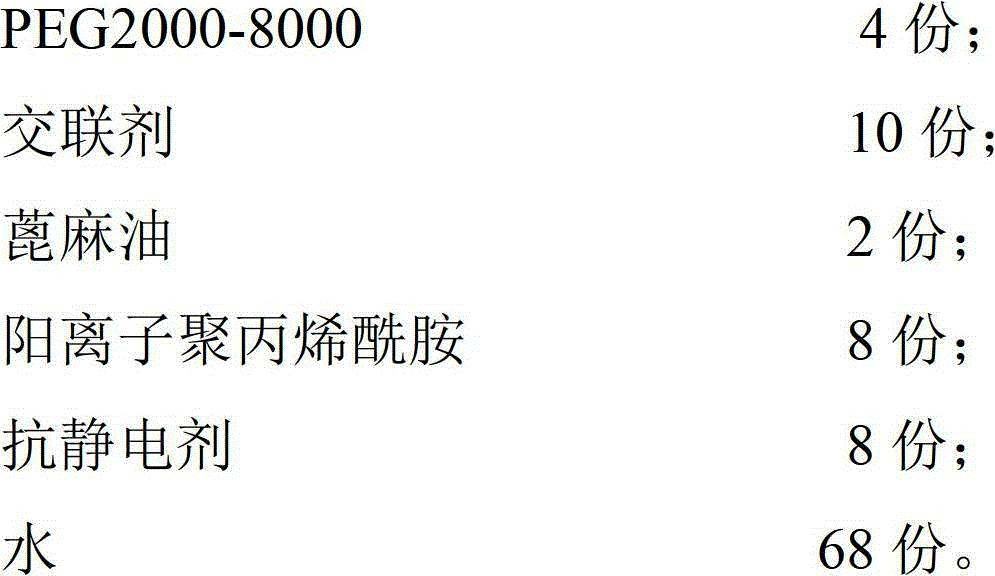

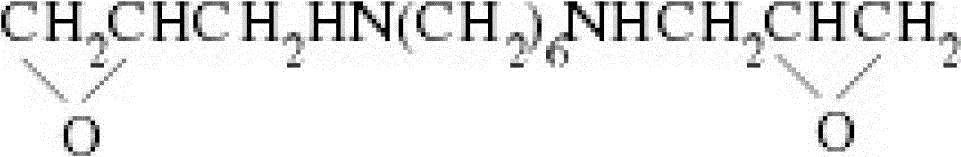

Kapok fiber pretreatment auxiliary agent and kapok fiber pretreatment method

InactiveCN103255621AImprove twisting efficiencyImproved roll stickingVegetal fibresYarnPretreatment method

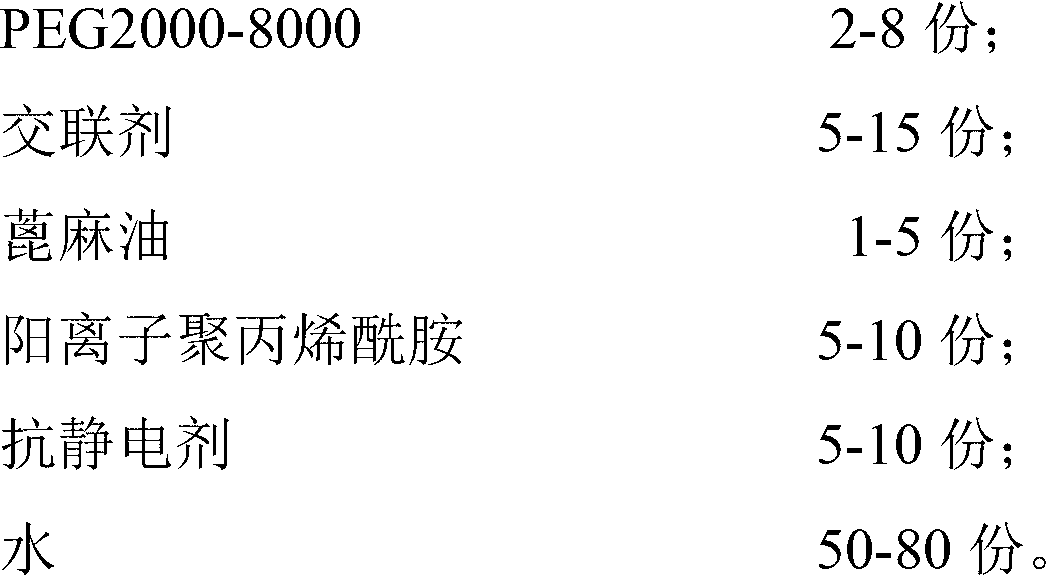

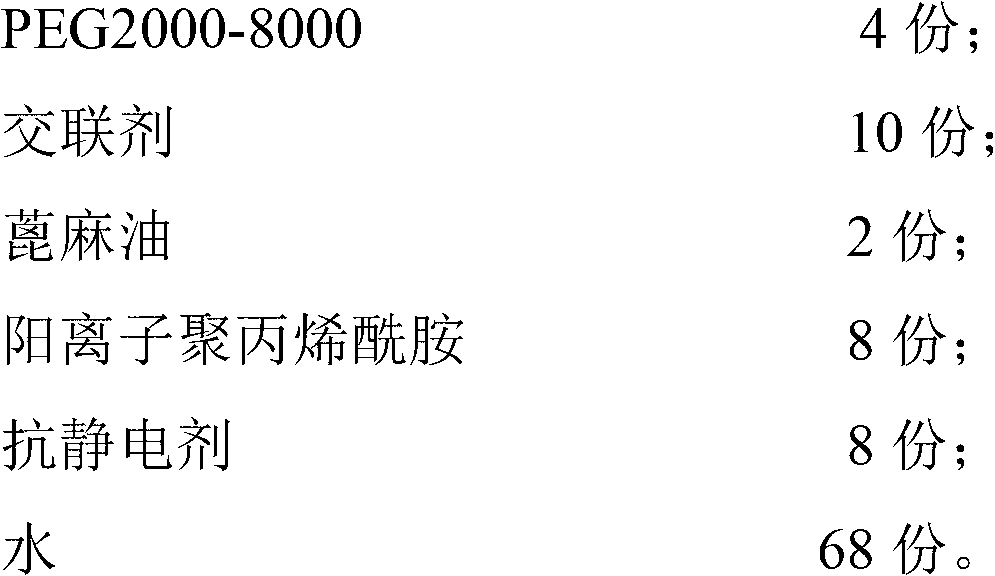

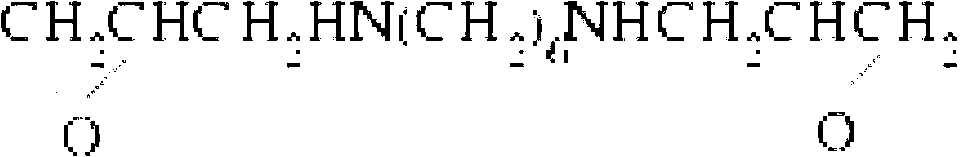

The invention discloses a kapok fiber pretreatment auxiliary agent and a kapok fiber pretreatment method. The kapok fiber pretreatment auxiliary agent comprises the following ingredients by weight: 2-8 parts of PEG 2000-8000; 5-15 parts of cross-linking agent; 1-5 parts of castor oil; 5-10 parts of cation polyacrylamide; 5-10 parts of antistatic agent; 50-80 parts of water. The kapok fiber pretreatment auxiliary agent is sprinkled on the kapok fiber, and is placed at room temperature for 6-24 hours, and the kapok fiber pretreatment method is completed. After the kapok fiber pretreatment is carried out by the kapok fiber pretreatment auxiliary agent of the present invention, the strip weight unevenness decreases by 18-25%, the hairiness index decreases by 55-65%, the single thread strength increased by 20-25%, the spun yarn twisting efficiency increases by 10-15%, and the roll banding case obviously improves.

Owner:上海鼎乘生物科技有限公司 +1

Twisting method of ultra-fine nylon stretch yarn and device thereof

The invention discloses a twisting method of ultra-fine nylon stretch yarn and a device thereof, belonging to the technical field of textile. The invention utilizes a doubler winder with polyurethane fibre drawing to process the two-for-one twisting feeding tube of the ultra-fine nylon stretch yarn, and then utilizes a two-for-one twister spindle to twist the ultra-fine nylon stretch yarn. The invention utilizes one bout plus two turns of a two-for-one twisting spindle, which has the advantages of constant air ring, constant tension and big package, so that the twisting method of the invention improves production efficiency, effectively realizes myriametre knot-free yarn, improves the equality index of thrown silk degree of twist, and lowers energy consumption of yield per unit. The invention provides a new method and technical device for producing ultra-fine nylon stretch yarn with high efficiency, good quality and small energy consumption.

Owner:绍兴华裕纺机有限公司

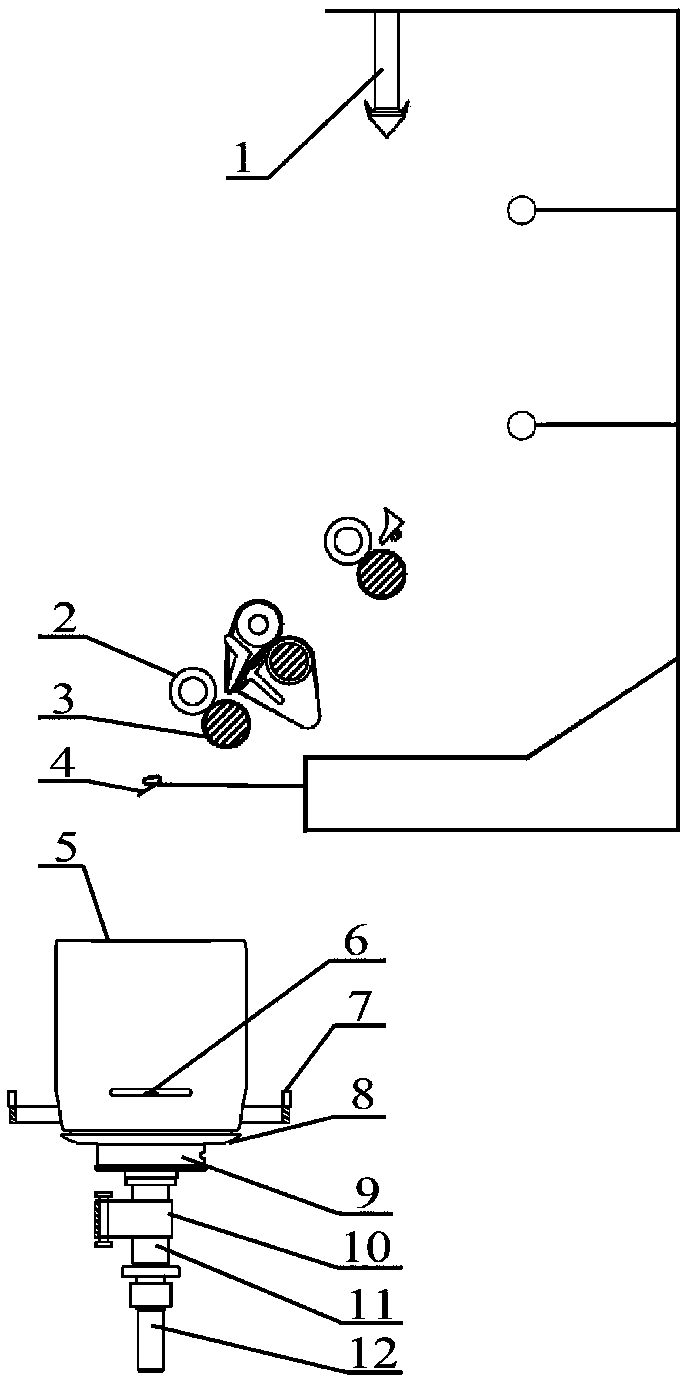

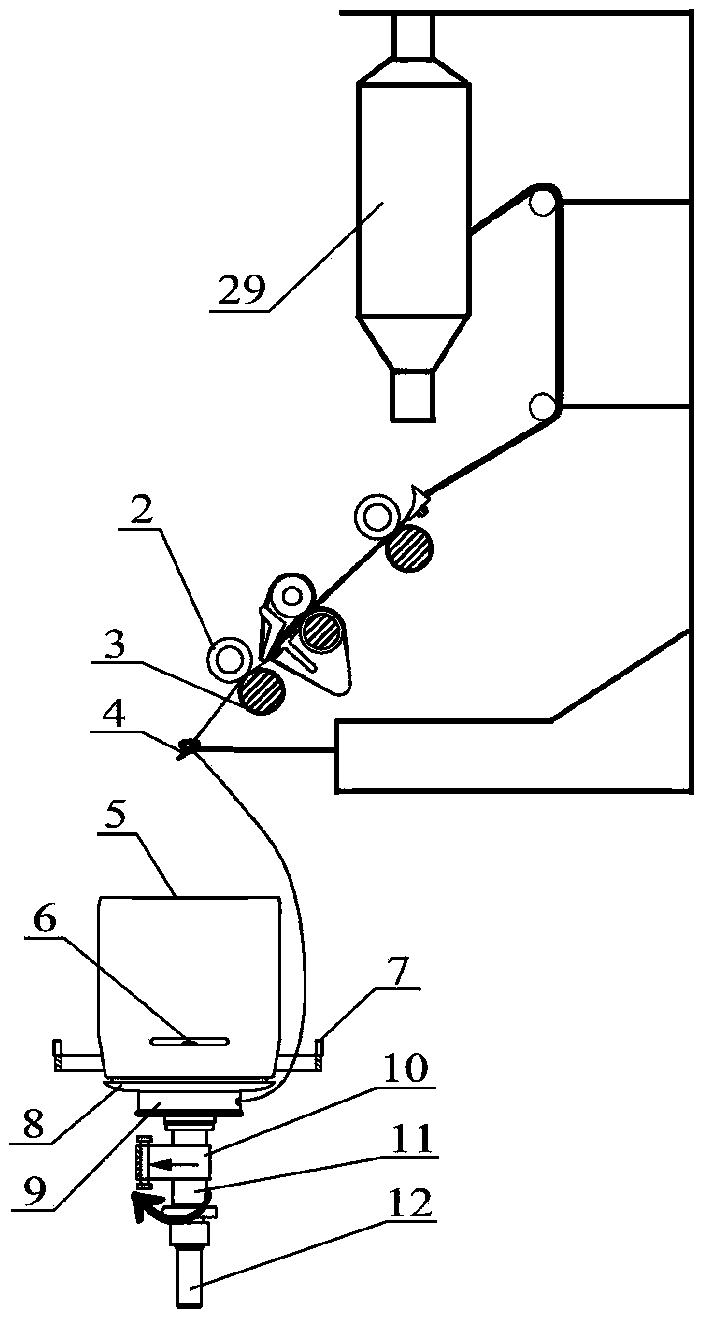

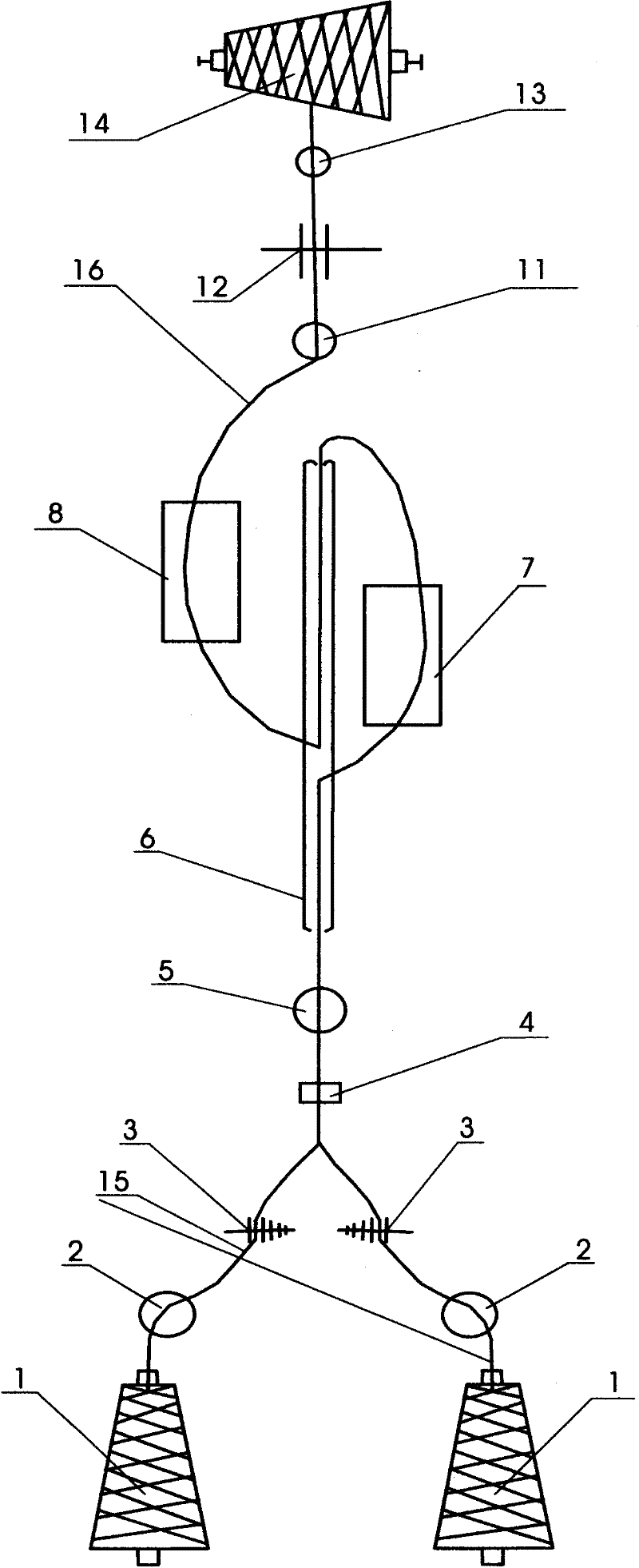

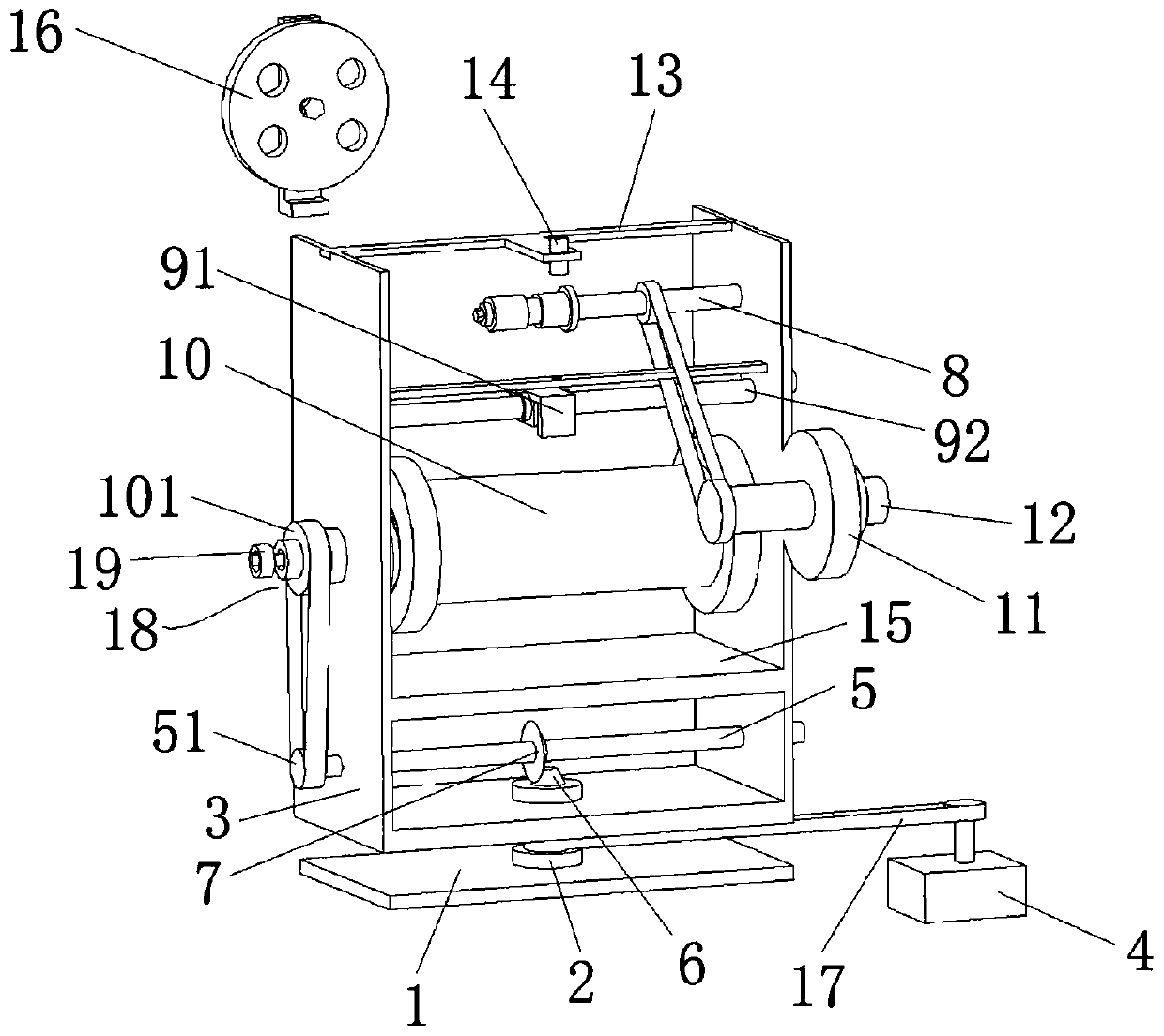

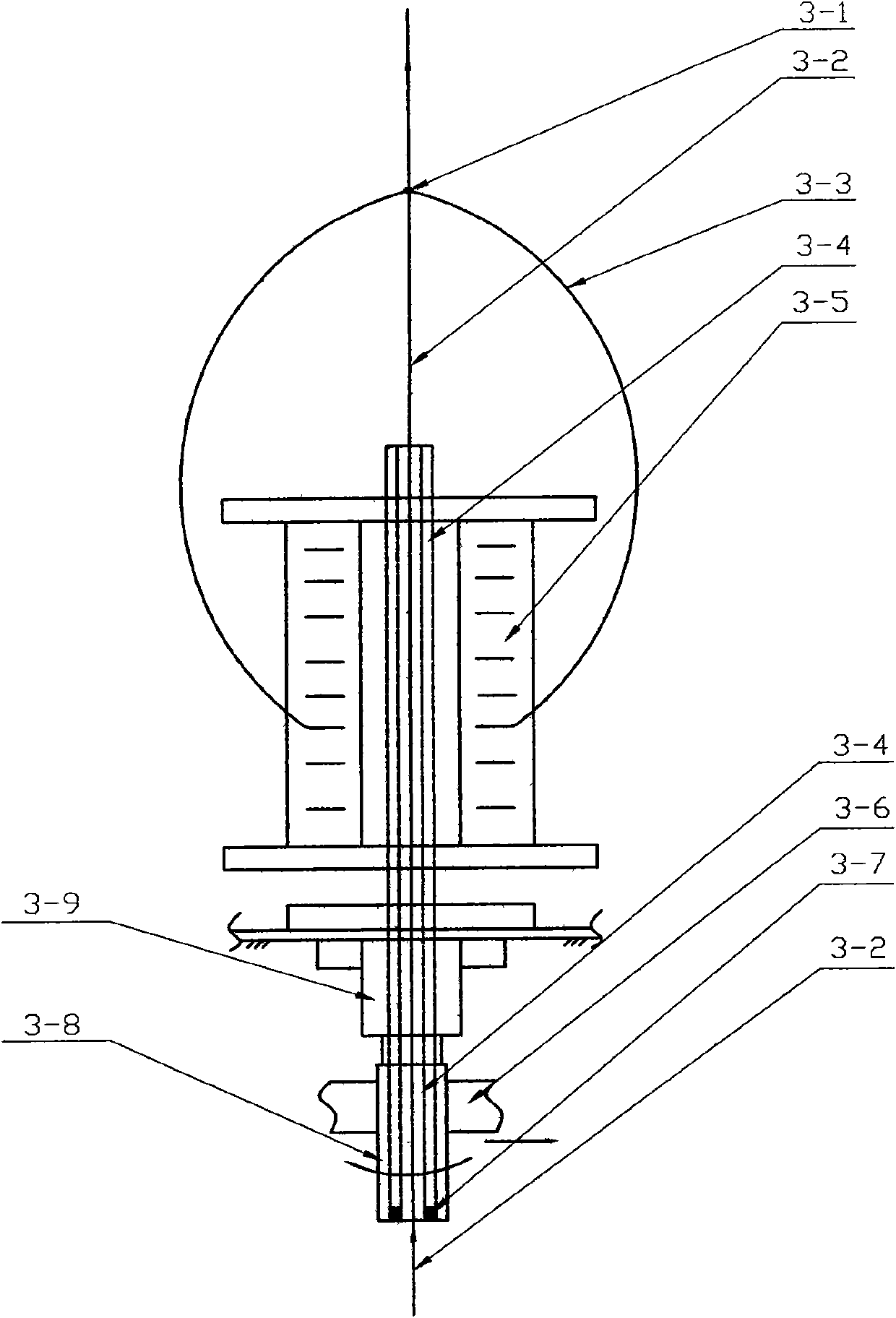

Hollow spindle twisting machine

The invention discloses a hollow spindle twisting machine. The machine mainly comprises a single wire bobbin holder (1), a primary yarn guiding device (2), a tension regulating device (3), a yarn breaking automatic stop device (4), a secondary yarn guiding device (5), a hollow spindle (6), a primary double-twisting device (7), a secondary double-twisting device (8), an internal air ring controller (9), an external air ring controller (10), a ternary yarn guiding device (11), a tension twist device (12), a superposition prevention yarn guiding device (13) and a braided wire winding device (14), wherein all the components are sequentially arranged on a frame to form a production line type sequence structure. In the invention, the hollow spindle twisting machine has a simple structure, high efficiency and a large package, is convenient to operate and makes bobbins changed at low frequency, so that a joint-free braided wire is realized, and the labor intensity of workers are reduced by one third while the quality is improved; and the hollow spindle twisting machine is widely applied to the fields of spinning, chemical fiber and silk double-twisting devices.

Owner:程国民

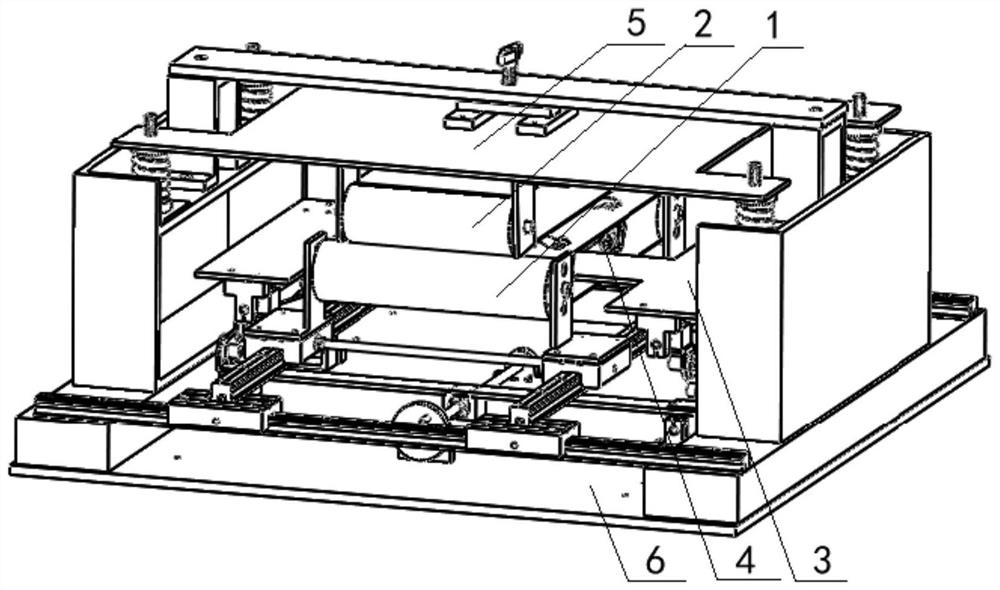

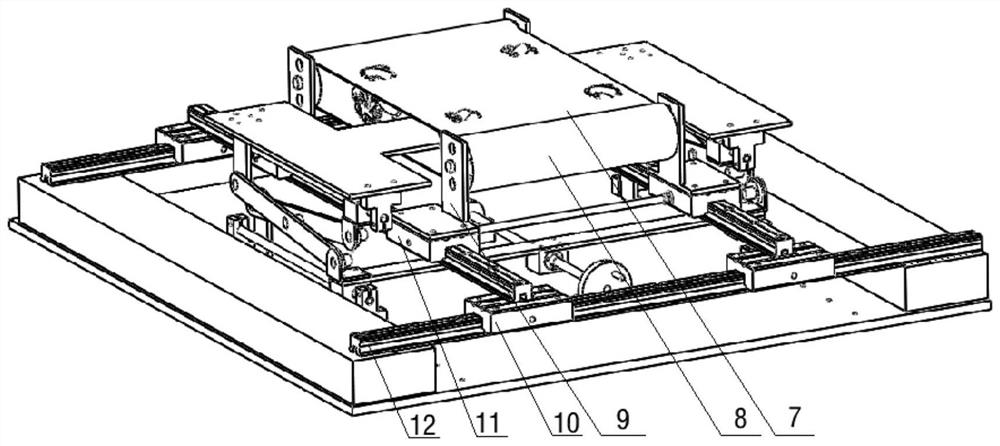

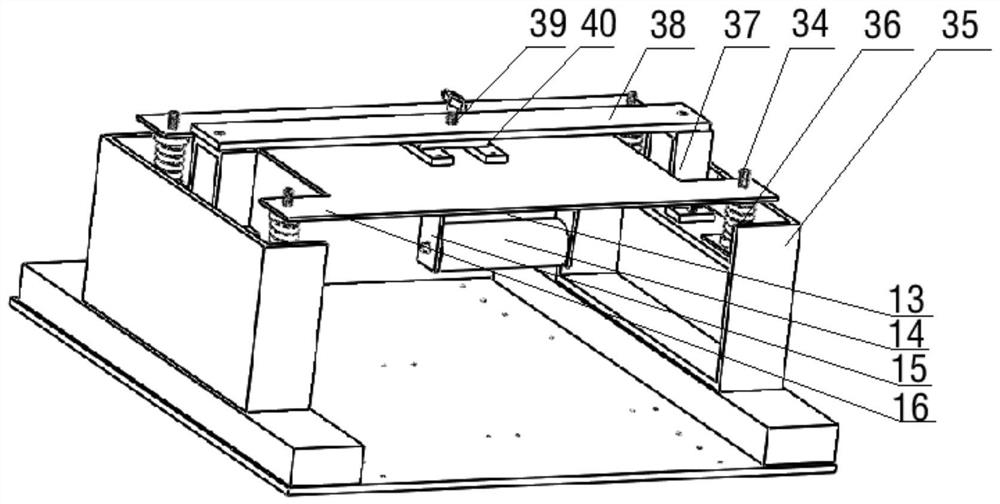

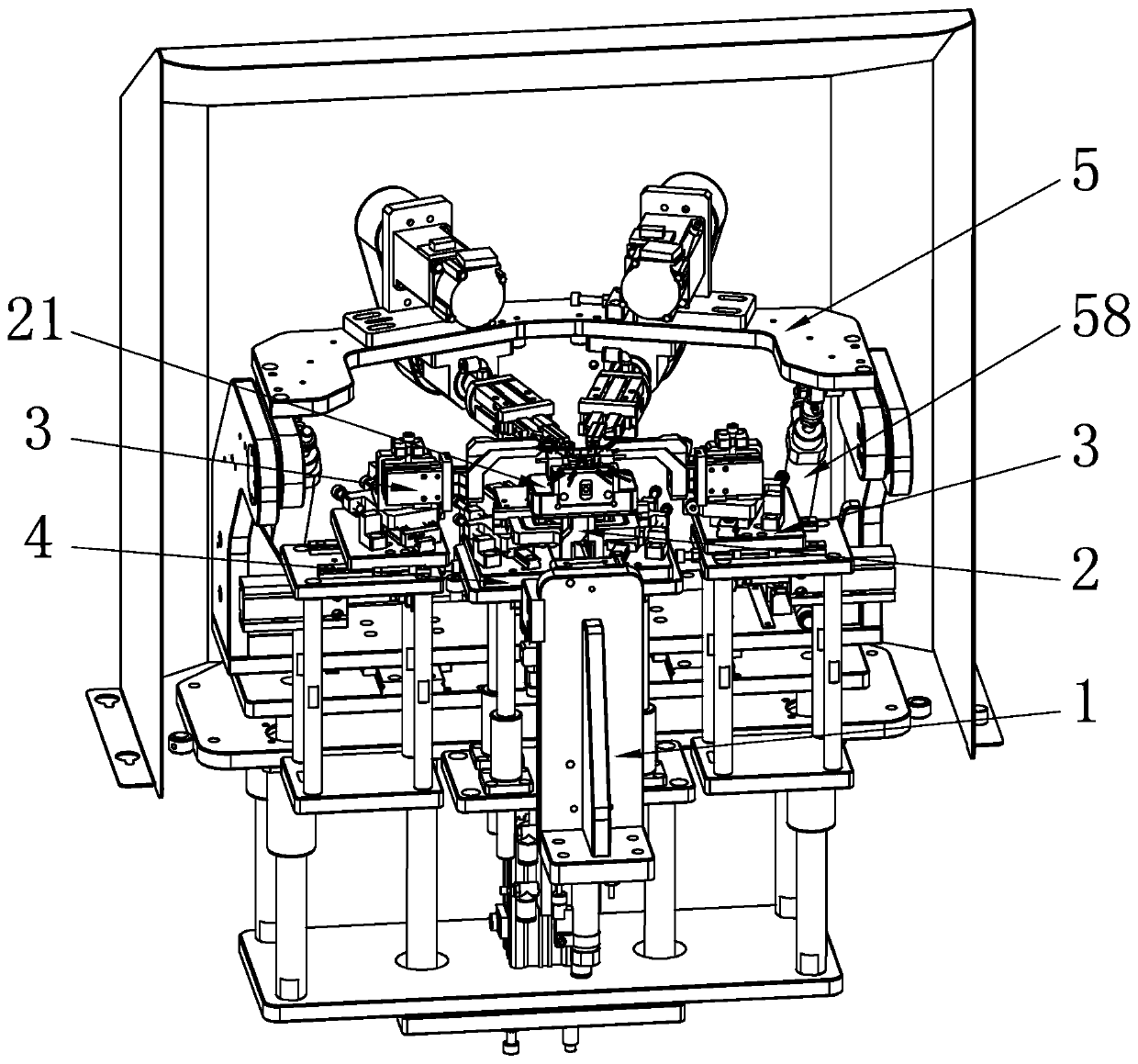

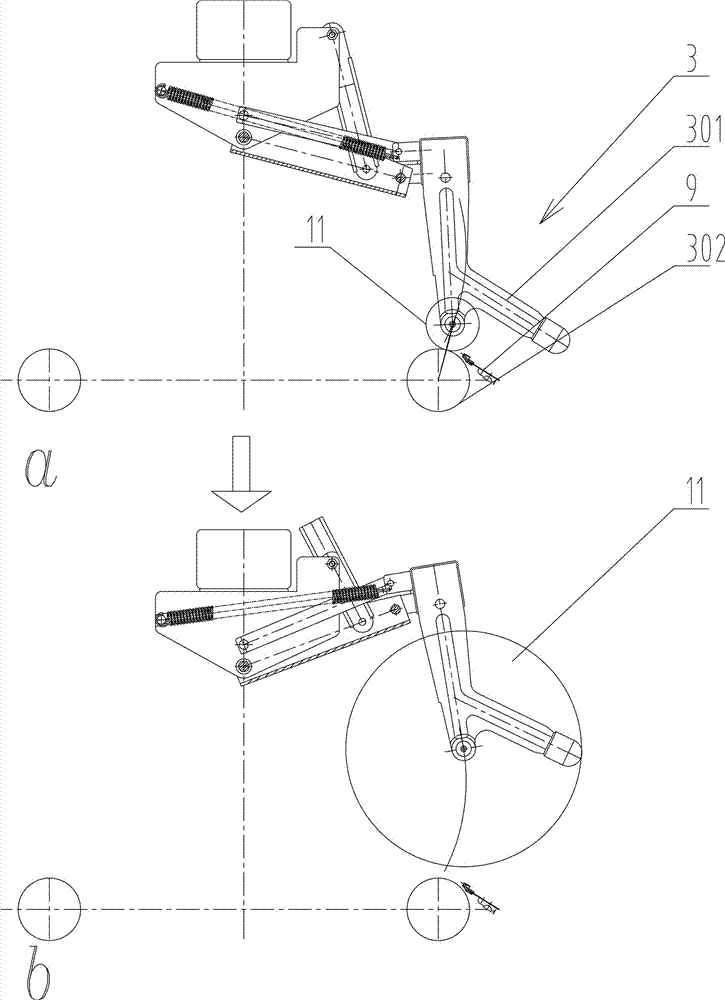

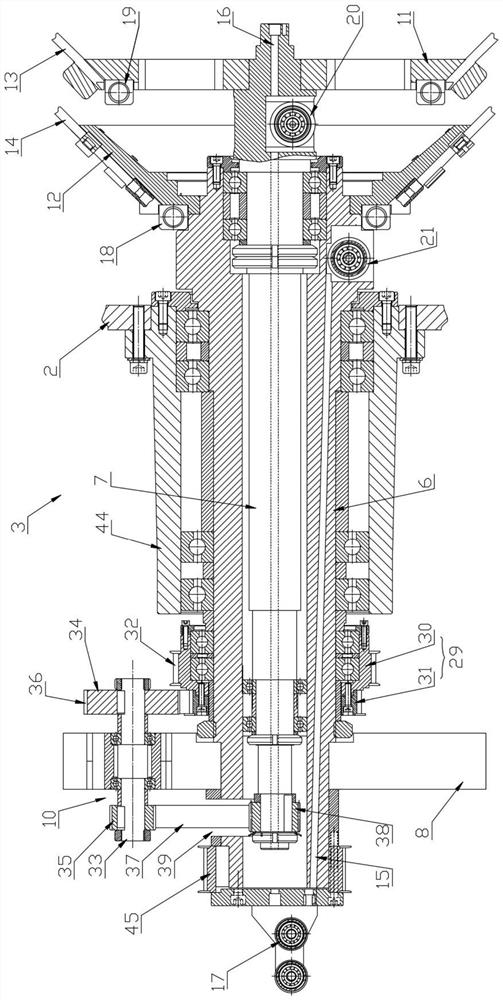

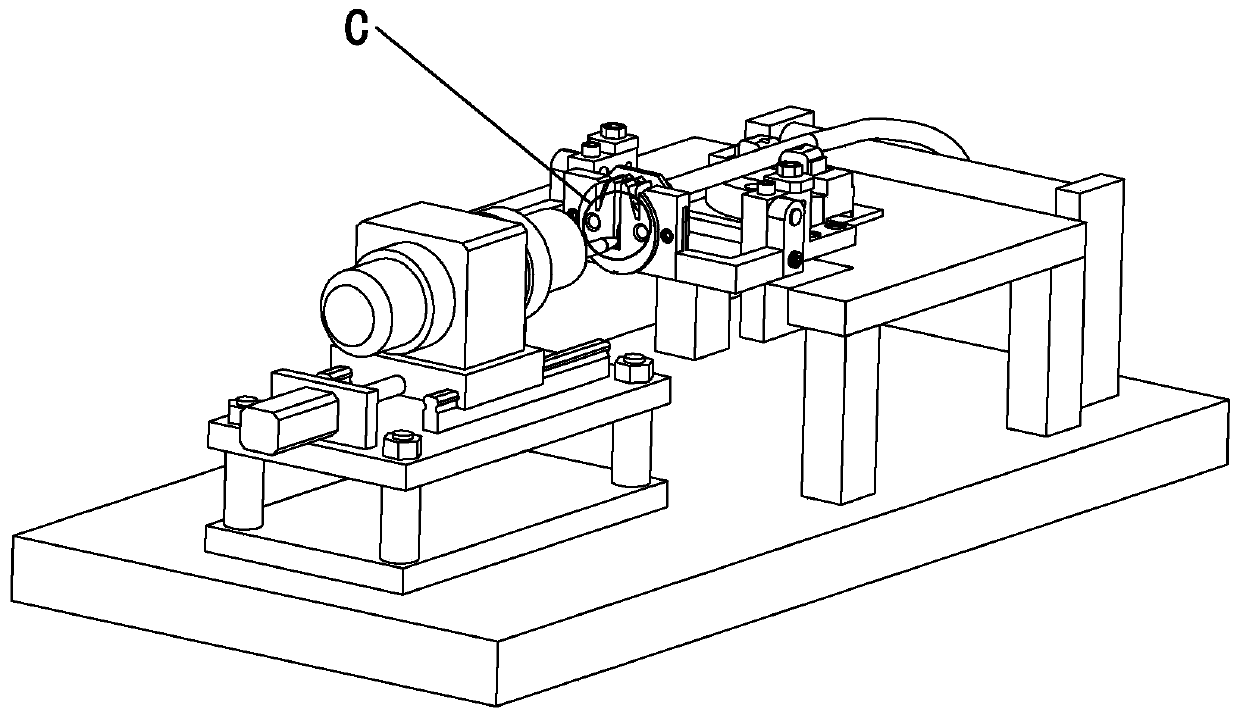

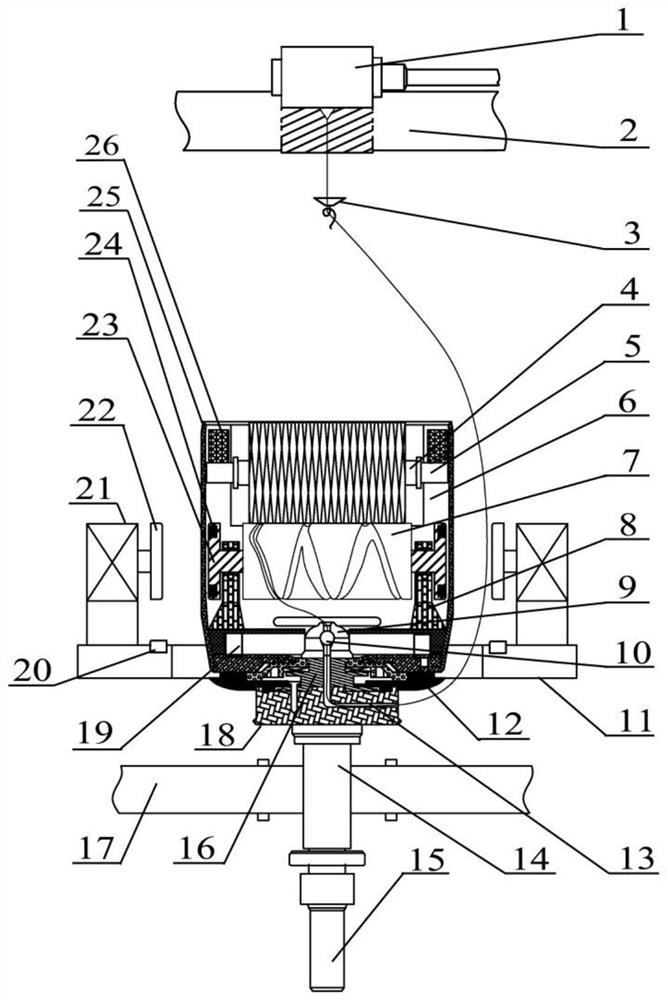

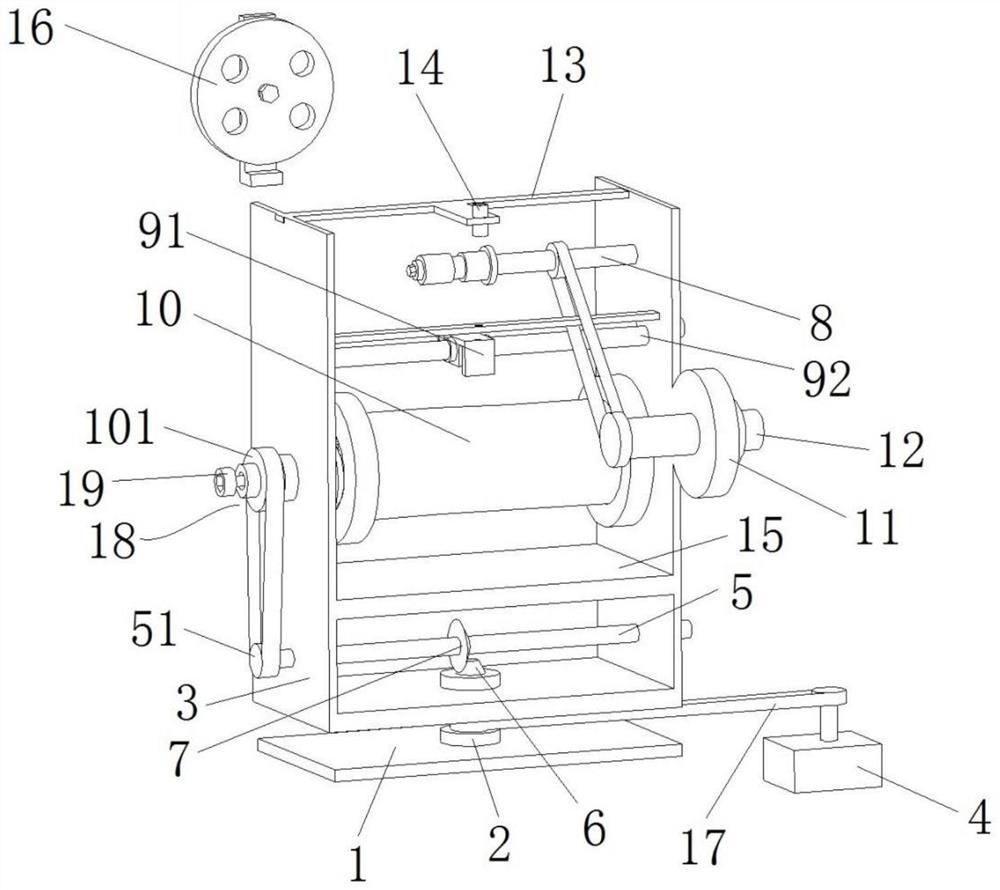

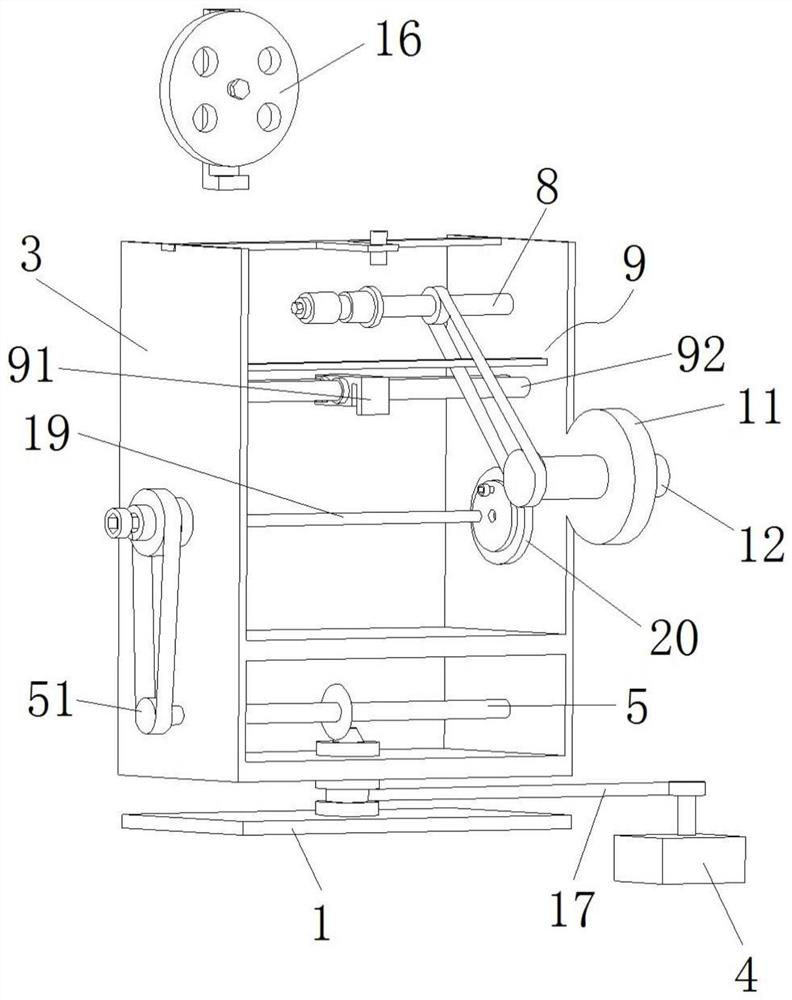

Vascular interventional instrument twisting device and method

ActiveCN113974787AAdjust clamping forceEffective Twisting ForceSurgical needlesFilament handlingControl engineeringStructural engineering

The invention relates to the technical field of surgical robots, and provides a blood vessel interventional instrument twisting device and method. The blood vessel interventional instrument twisting device comprises a supporting table on which two parallel first guide rails are arranged; a driving wire feeding mechanism which comprises a first support assembly, a driving conveying belt and a driving carrier roller belt wheel, the first support assembly being arranged on the first guide rail in a sliding mode, and the driving conveying belt being matched with the driving carrier roller belt wheel in a tensioning mode; a pressing mechanism which comprises a second support assembly, an adjusting assembly and a pressing plate; a driven wire feeding mechanism which comprises a driven conveying belt and a driven carrier roller belt wheel. The gap between the driven conveying belt and the driving conveying belt is adjusted through an adjusting assembly to adjust the clamping force on a guide wire, so that the slipping phenomenon in the twisting process is prevented, relative movement between the driving conveying belt and the driven conveying belt is guaranteed, effective twisting force is generated on the guide wire, and the twisting efficiency, the operation efficiency and the safety are improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

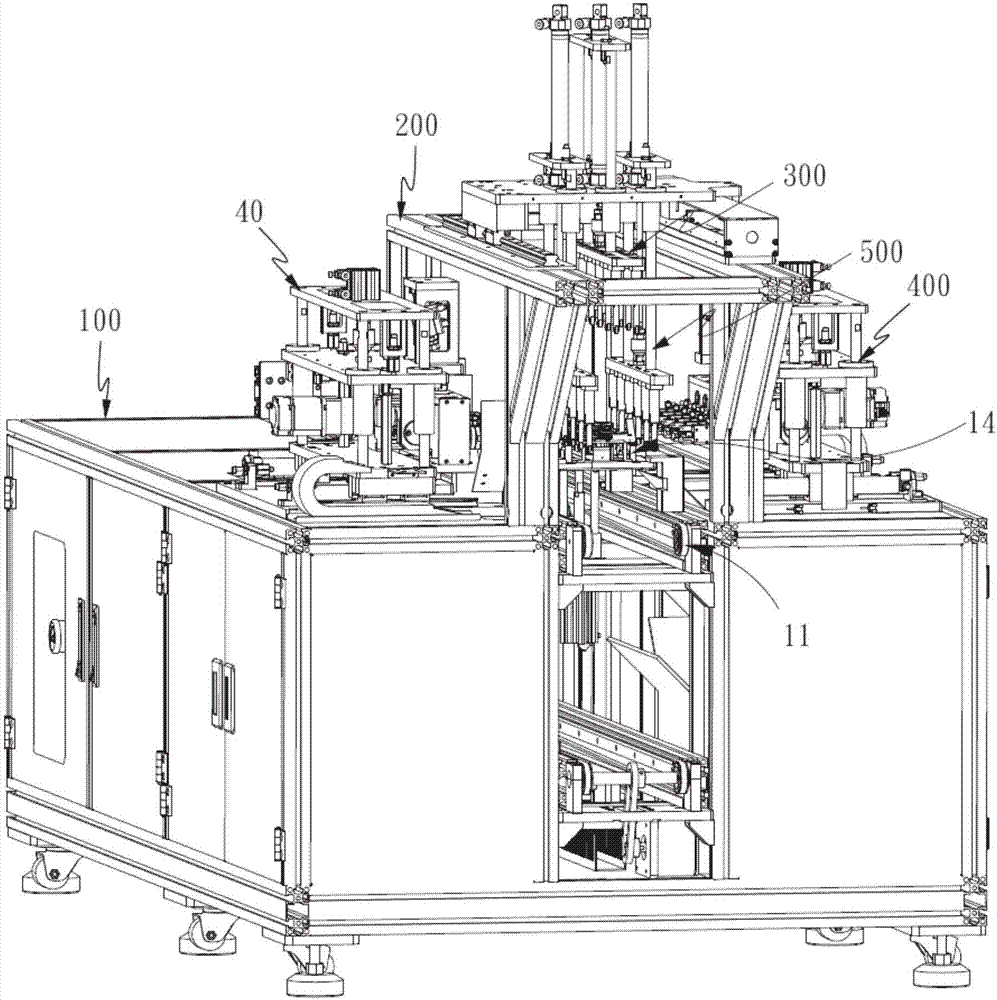

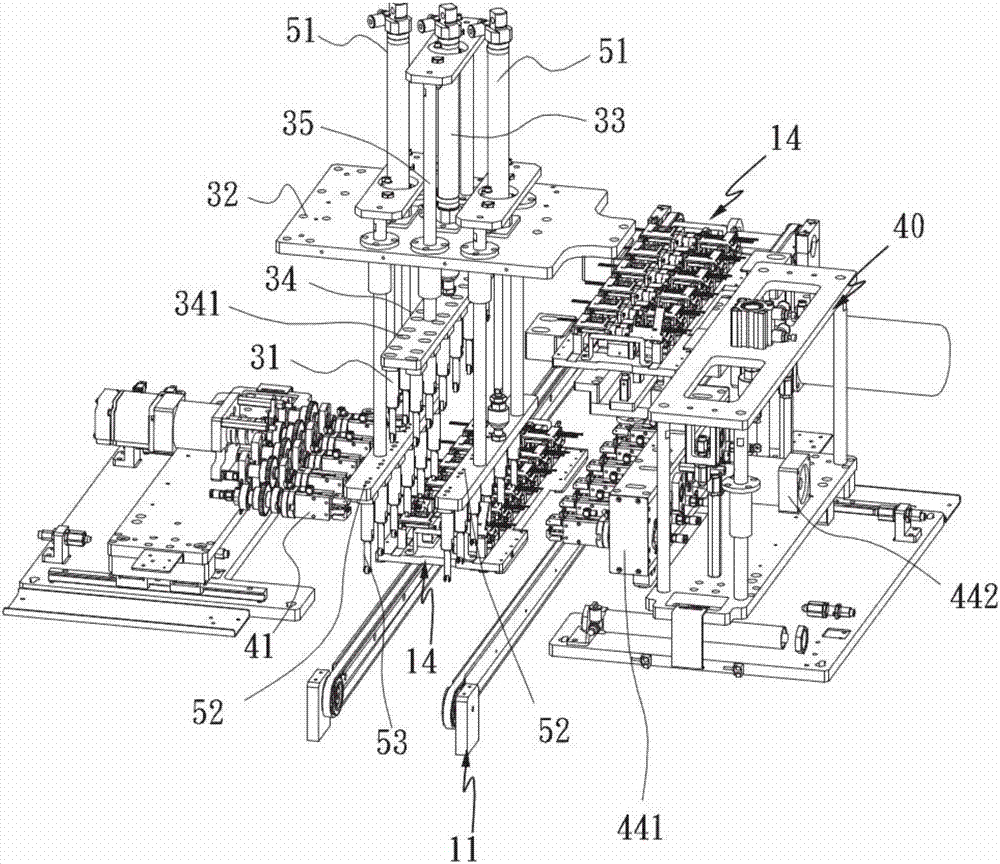

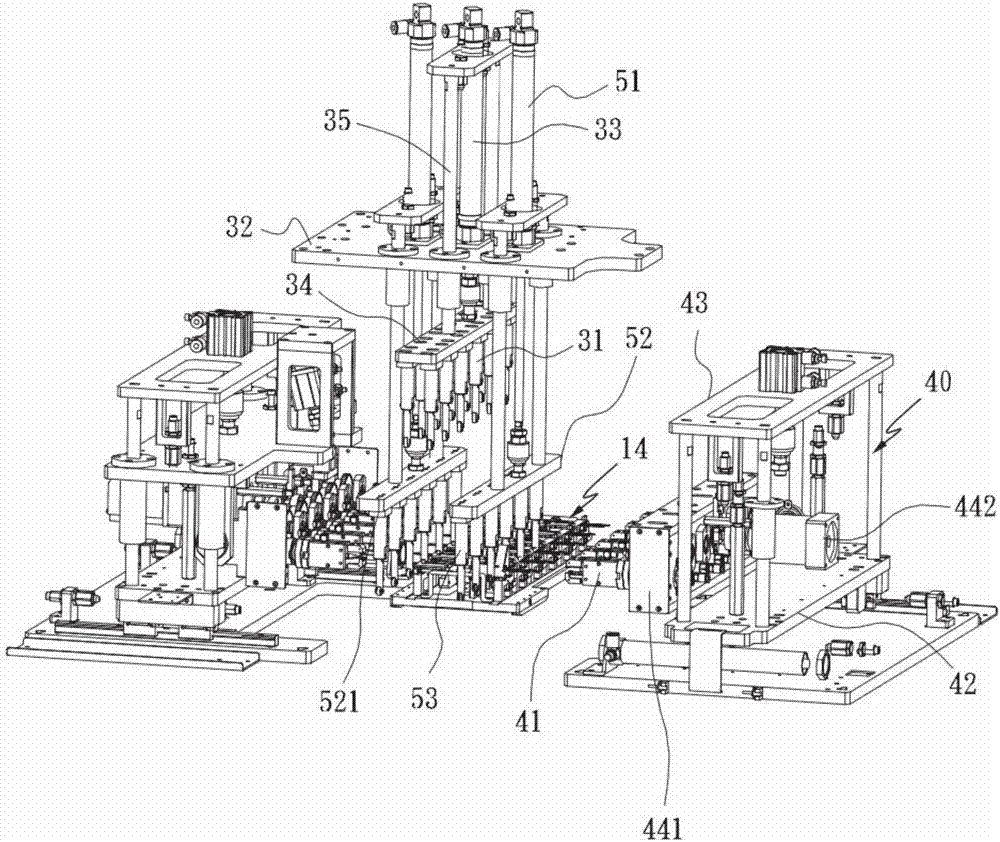

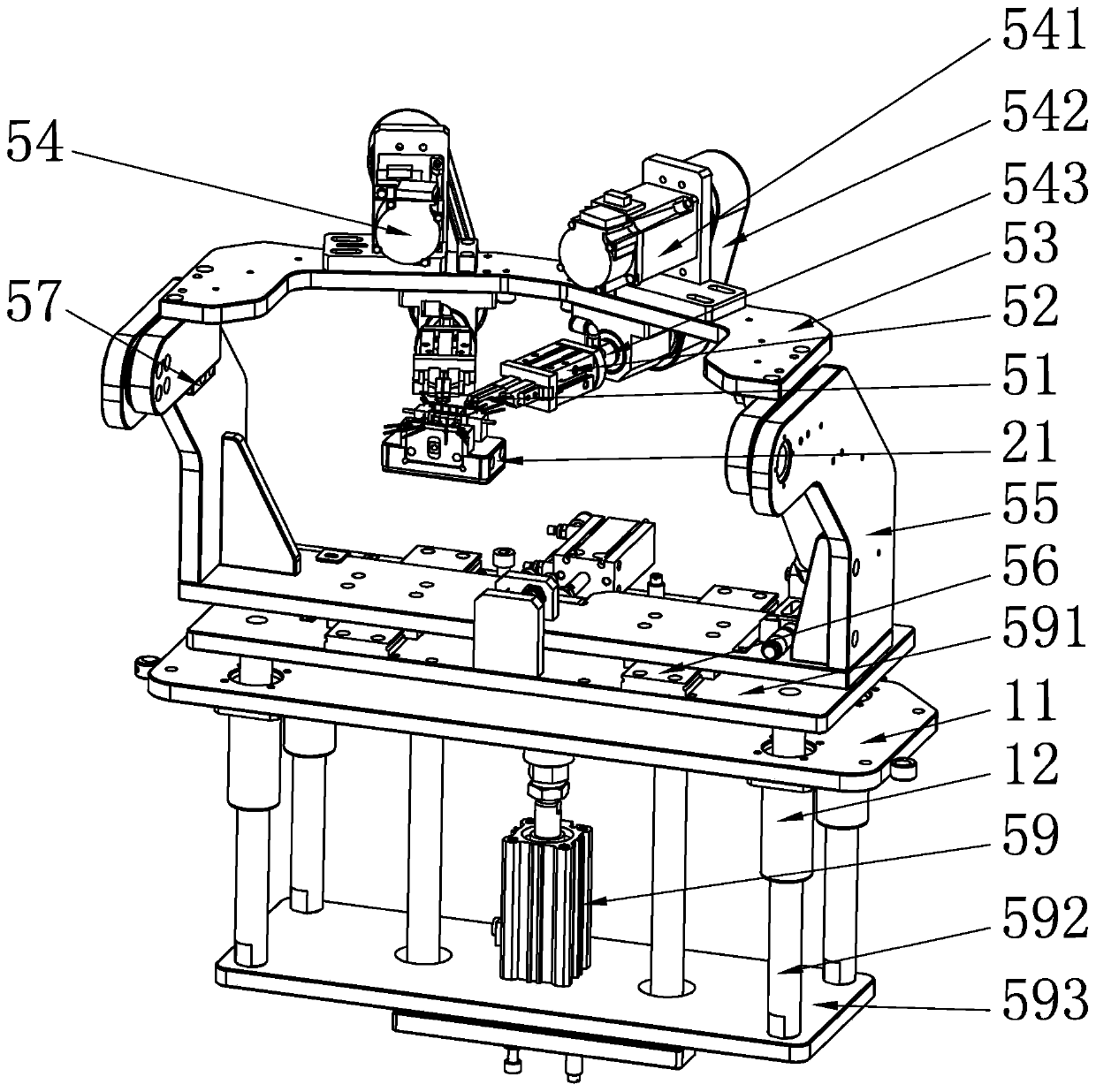

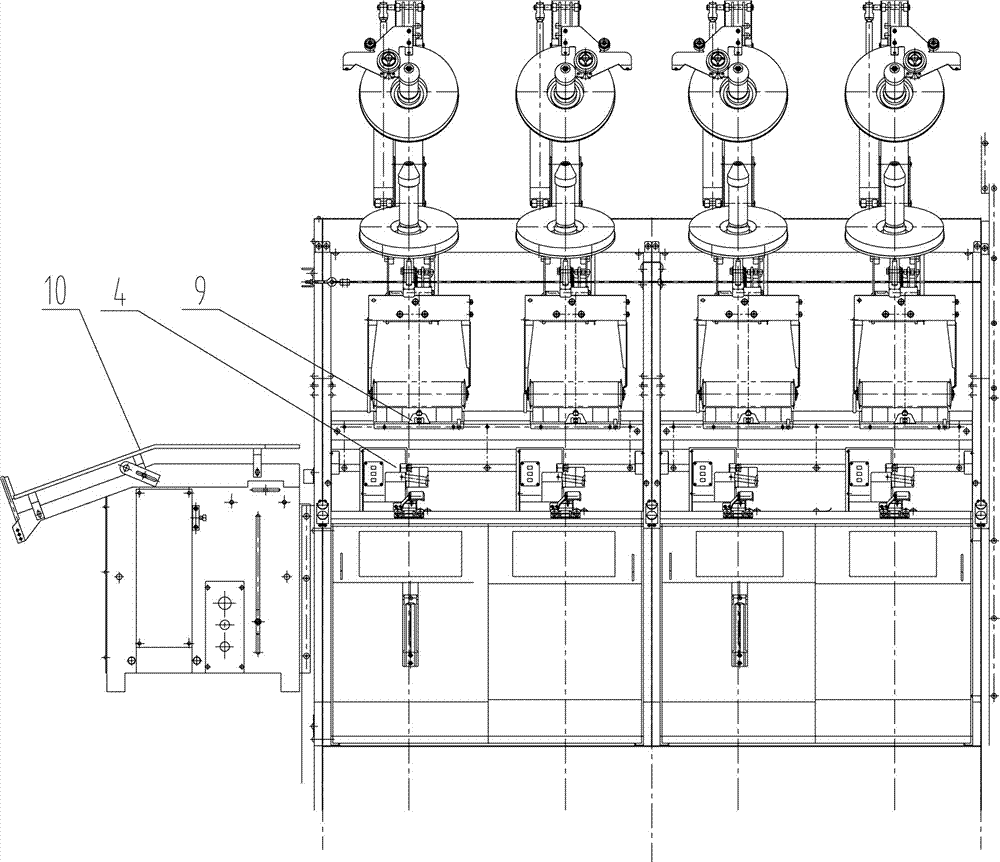

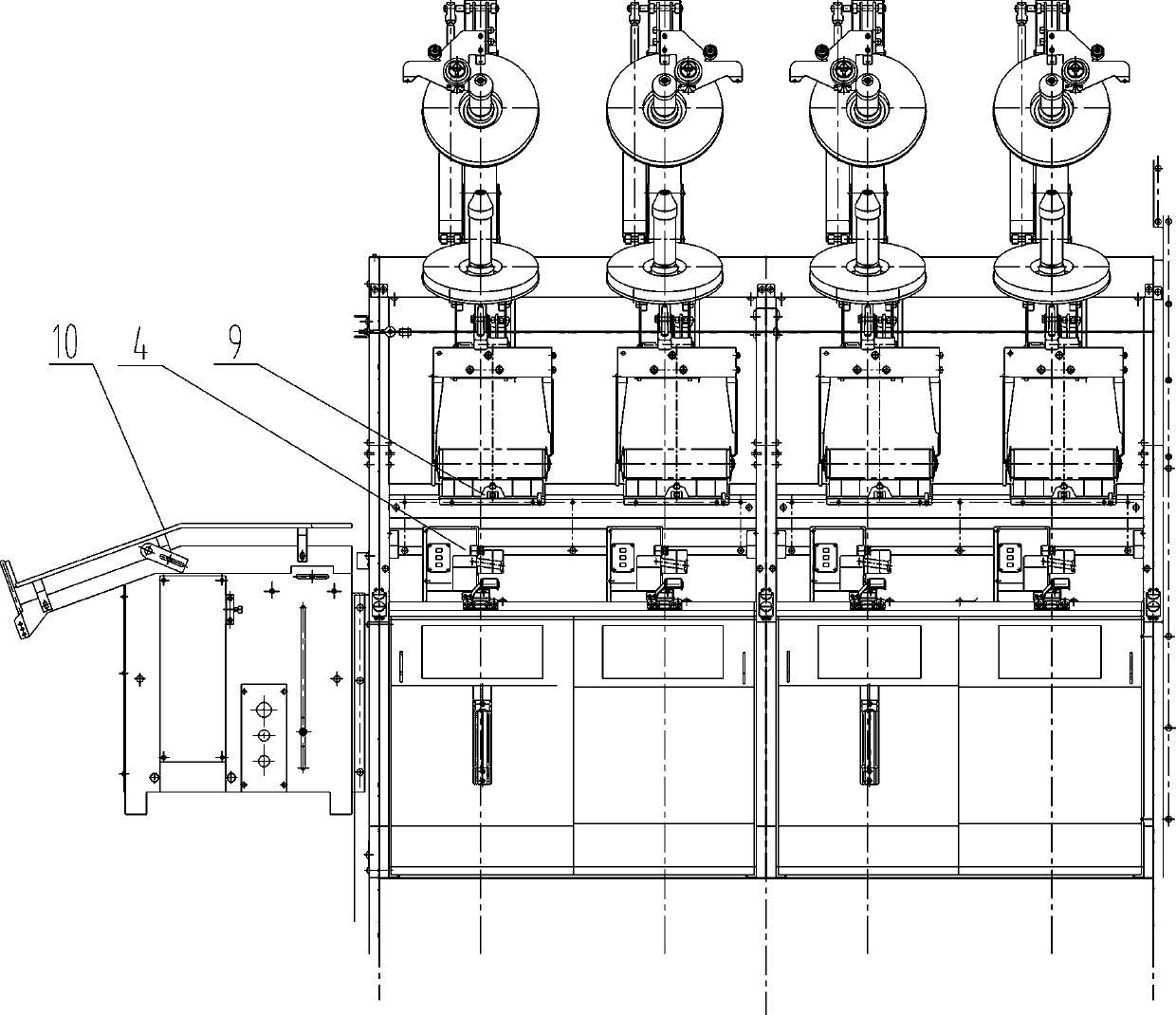

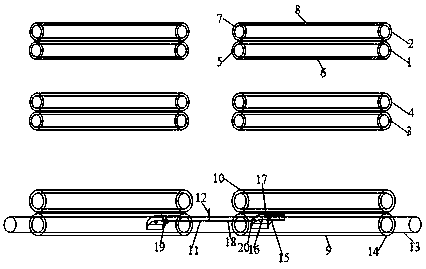

Inductor wire twisting mechanism and device

The invention relates to the technical field of inductor manufacturing, and discloses an inductor wire twisting mechanism. The mechanism comprises a frame, a positioning component, a cable managementjaw, a branching jaw and a twisting jaw, wherein the positioning component, the cable management jaw, the branching jaw and the twisting jaw are arranged on the frame. The positioning component can position a jig. The cable management jaw, the branching jaw and the twisting jaw are all located on the same side of the jig. The cable management jaw, the branching jaw and the twisting jaw can move toward or away from the jig. The wire management jaw can be clamped or stretched vertically. The branching jaw can be clamped or stretched horizontally. The twisting jaw can be rotated. The invention further discloses an inductor wire twisting device. The device comprises a main frame, a conveying mechanism arranged on the main frame, a number of feeding mechanisms which are sequentially arranged along the side of the conveying mechanism, a number of inductor wire twisting mechanisms and a blanking mechanism. The feeding mechanisms take the jig on which a wire package is placed to the conveyingmechanism. The inductor wire twisting mechanism twists multiple strands on the wire package. The blanking mechanism takes and transfers the jig on the conveying mechanism. The device has the advantages of high efficiency and high consistency.

Owner:珠海林顺机电有限公司

Quadruple-twisting machine

InactiveCN105401267AImprove twisting efficiencyReduce energy costsContinuous wound-up machinesEngineeringMechanical engineering

The invention provides a quadruple-twisting machine, and the machine is a novel twisting machine which can be widely applied in industries of weaving, chemical fibers, and silk, etc. In the past, a twisting machine is mostly used in a twisting technology, that is, a spindle rotates for 360 DEG to increase to twisting rounds for a yarn. Limitations of the twisting machine are high power consumption per unit output, and more time consumption and more labor usage. The quadruple-twisting machine is exploration aimed at the limitations of the conventional technology, conventional design of one-spindle one-twister is changed into one-spindle two-twister, so as to realize to add four twisting rounds for a yarn by 360 DEG rotation of the spindle. Key technology to realize the quadruple-twisting machine is to design an inversion mechanism between the two twisters, to make the two twisters rotate in reverse directions. Therefore, the quadruple-twisting machine can improve twisting efficiency in a multiplied manner, so as to reduce energy consumption cost, time cost, and labor cost per unit output in a multiplied manner.

Owner:程国民

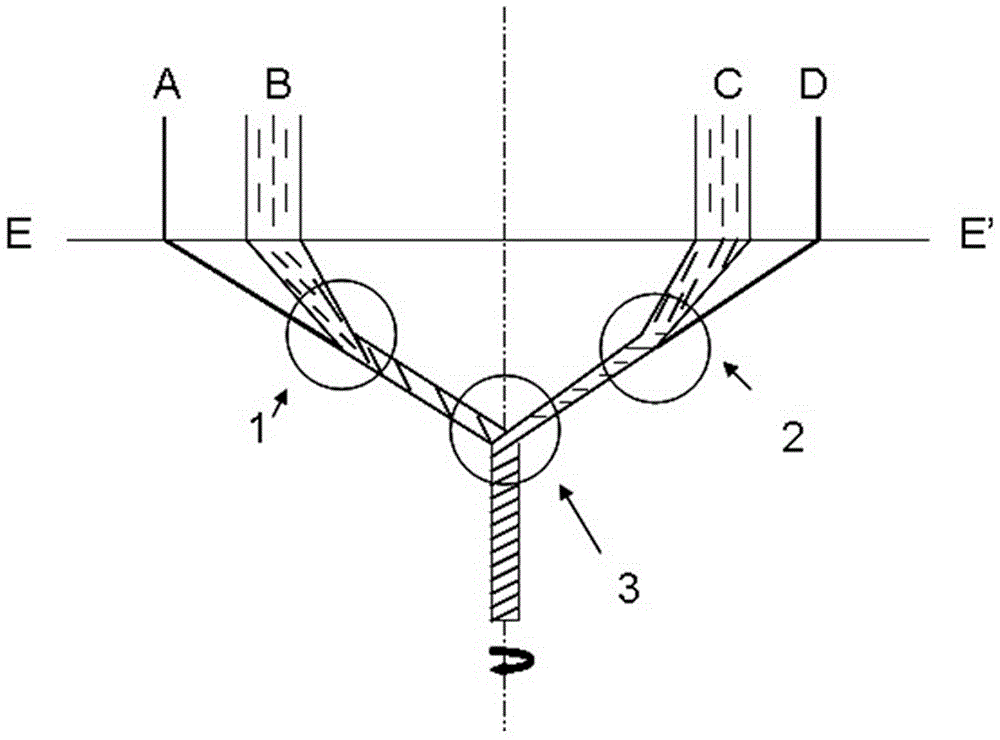

Spinning method for high-count high-quality embedded compact spun yarn

The invention provides a spinning method for high-count high-quality embedded compact spun yarn. Filament yarn and short fiber rough yarn can be spun, the quantity of harmful hairiness can be effectively reduced, and the resultant yarn quality can be improved. The spinning method includes the following steps that two pieces of short fiber rough yarn are placed in the middle, two pieces of filament yarn are distributed at the two sides of the short fiber rough yarn respectively, the four pieces of yarn are divided into two groups, and each group comprises one piece of short fiber rough yarn and one piece of filament yarn; when the four pieces of yarn pass through a horizontal line of a front jaw of a drawing roller, downward air negative pressure is added below a twisting trigonum plane in the opposite direction; one pair of filament yarn and short fiber rough yarn are twisted in a first twisting trigonum, and the other pair of short fiber rough yarn and filament yarn are twisted in a second twisting trigonum; the semi-finished product yarn after being twisted in the first twisting trigonum and the second twisting trigonum enters a third twisting trigonum and is twisted through a steel collar bead ring. The air negative pressure ranges from 0.15 Mpa to 0.3 Mpa.

Owner:ANHUI HUAMAO TEXTILE

Yarn twisting number adjusting mechanism for textile machinery

ActiveCN111876860AIncrease the number of twisted threadsRoot adjustmentTextiles and paperYarnEngineering

The invention relates to the technical field of textile processing, and discloses a yarn twisting number adjusting mechanism for textile machinery. The mechanism comprises a floor, the upper side of the floor is connected with a first fixed block, the left side of a second moving rod is connected with a third metal block, and the left side of the third metal block is provided with a fourth metal block; and an electric push rod is arranged at the left side of the fourth metal block, a first connecting rod is rotatably connected to the left side of the electric push rod, and the left side of thefirst connecting rod is rotatably connected with a shear. According to the yarn twisting number adjusting mechanism for the textile machinery, an air pump blows yarn in a yarn storage chamber to penetrate through a yarn penetrating hole in a yarn clamp to move outwards, so that the yarn and the yarn which is being twisted are wound together, the twisting number is increased, and when the twistingnumber needs to be decreased, the electric push rod is started to conduct rod retracting action, so that the shear is driven to be closed for yarn shearing, and by means of the structure, the effectsthat the number of twisted yarn can be adjusted, the yarn twisting efficiency is high, and the equipment cost is reduced are achieved.

Owner:江西宏盛纺织科技有限公司

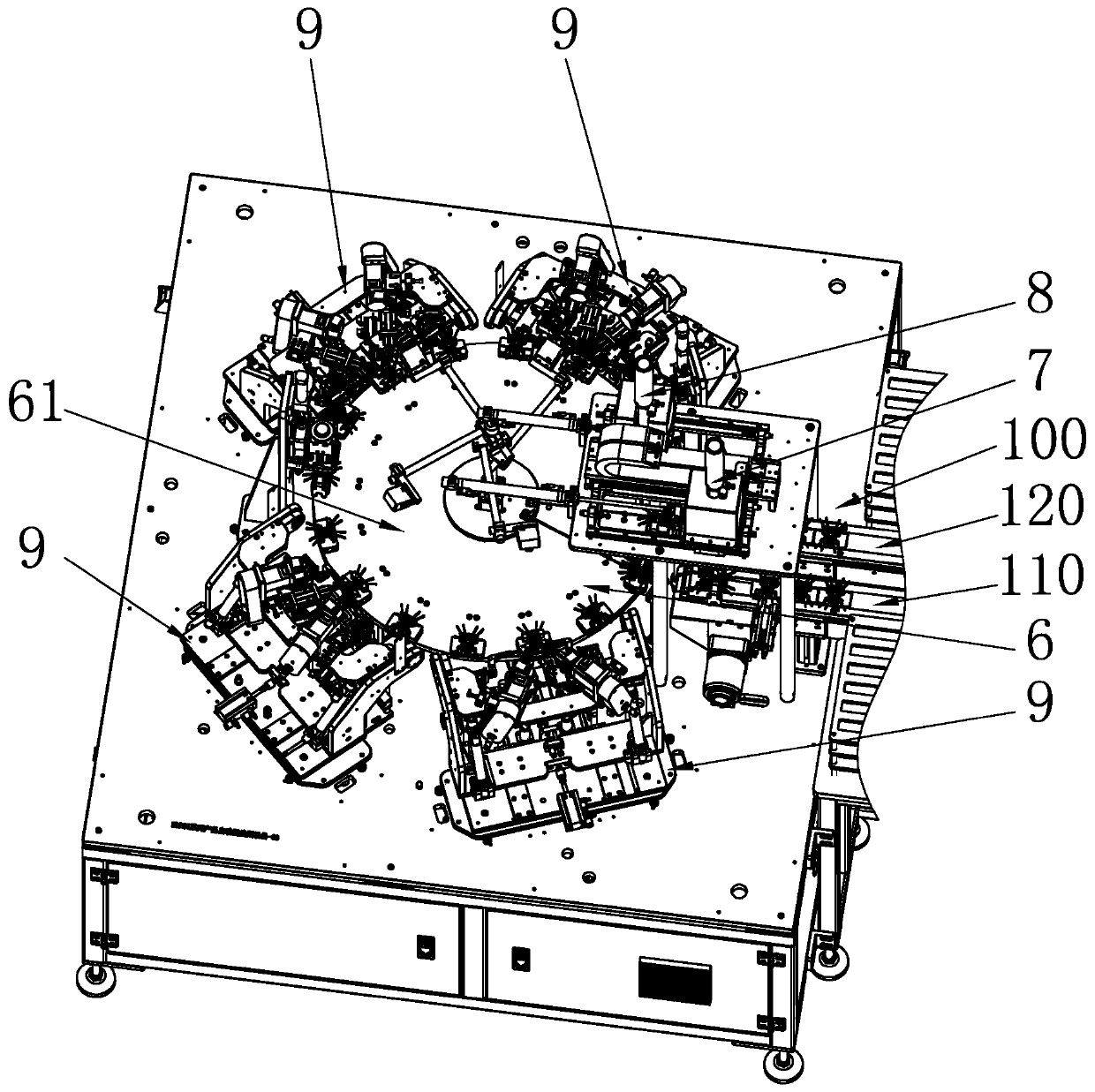

Carpet yarn twister

ActiveCN107299422AImprove twisting efficiencyIncrease speedContinuous wound-up machinesYarnYarnState of art

The invention provides a carpet yarn twister, and relates to the field of textile machinery. The carpet yarn twister comprises a rack, a yarn frame device, an electric spindle device, an overfeeding device and a winding device, in the electric spindle device, a hollow spindle rod is fixedly connected with a motor, the motor drives the hollow spindle rod to rotate, and a twisting disc and a yarn storage disc are fixedly connected with the hollow spindle rod, and rotate with the hollow spindle rod; the yarn storage disc is provided with a yarn discharge hole communicated with a yarn channel inside the hollow spindle rod; a spindle jar used for accommodating an internal yarn winding package is connected with the hollow spindle rod through a spindle rod bearing, and the yarn jar is fixed. By means of the scheme that the motor directly drives a spindle, the scheme in the prior art of drive through a spindle tape is replaced, the spindle can obtain a higher rotation speed, the rotation speed is increased from 4,000-6,000 rpm currently to 7,000-1,0000 rpm, and the twisting efficiency of carpet yarn is improved.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

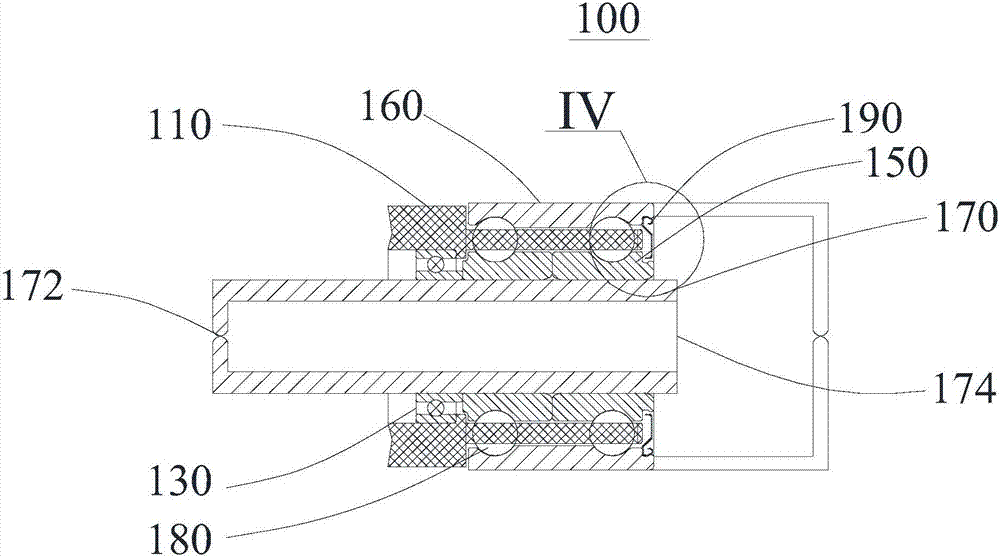

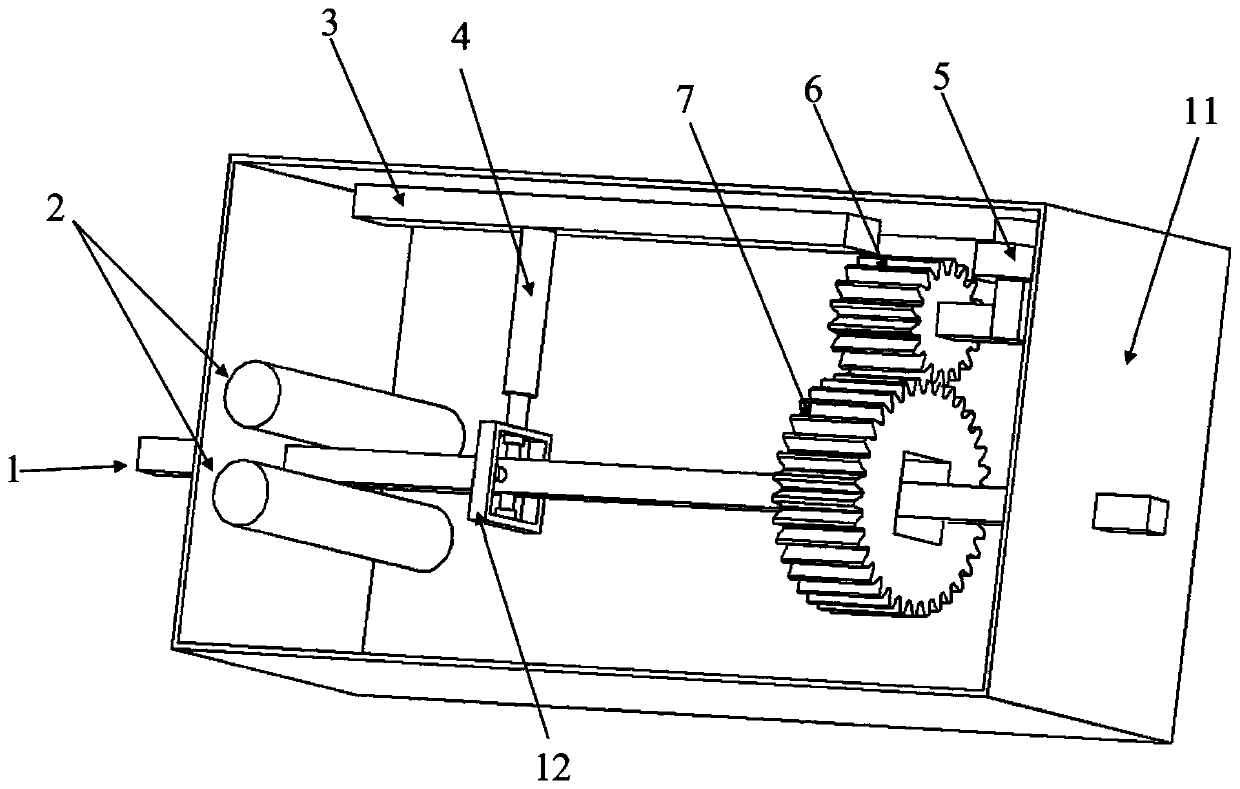

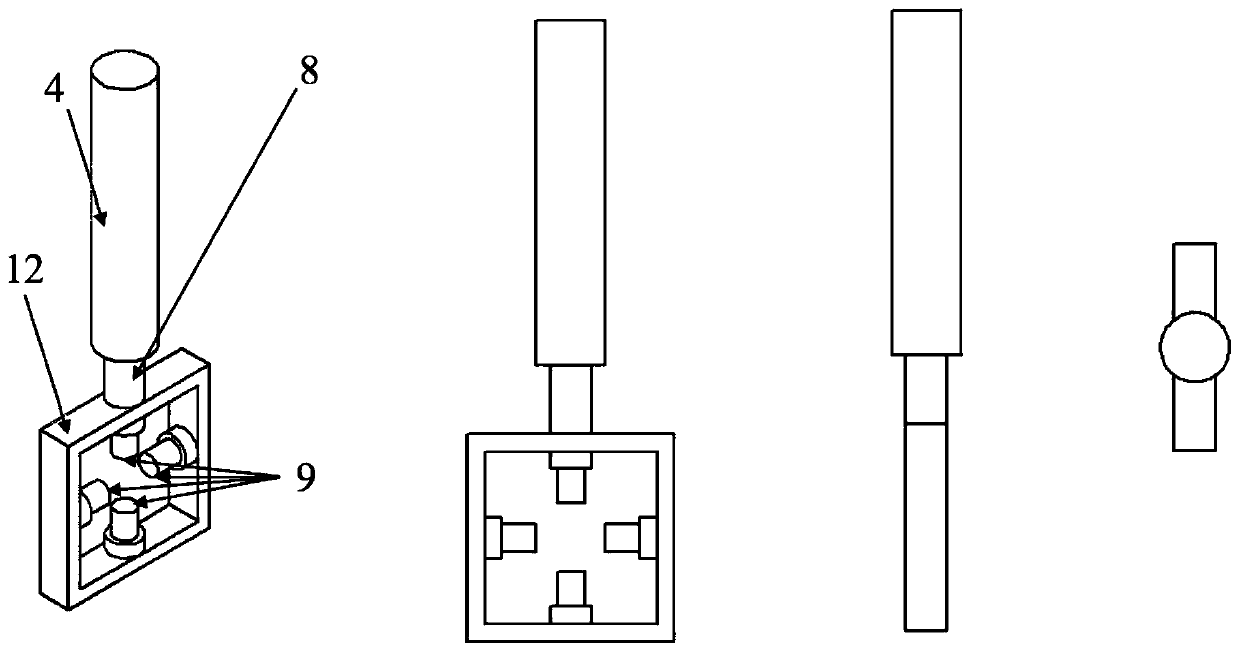

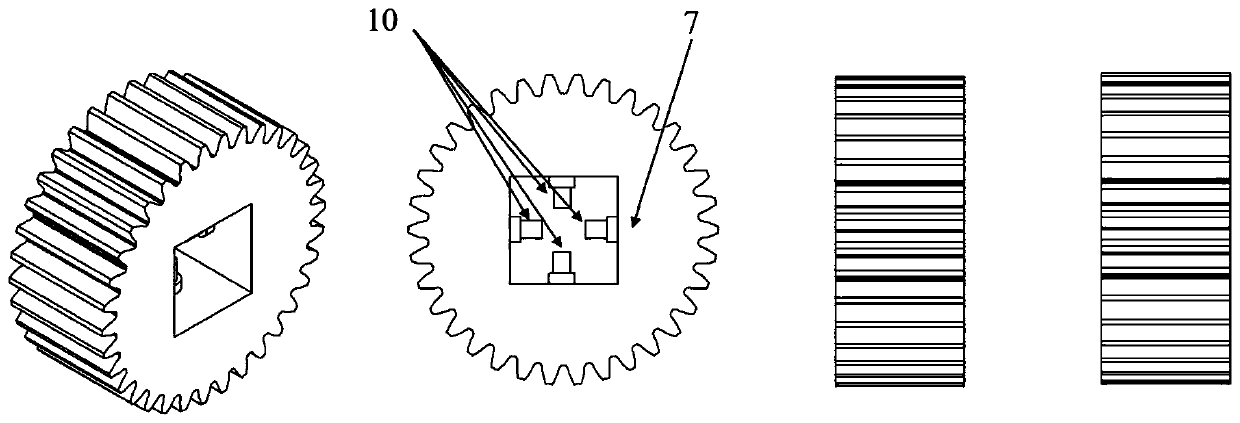

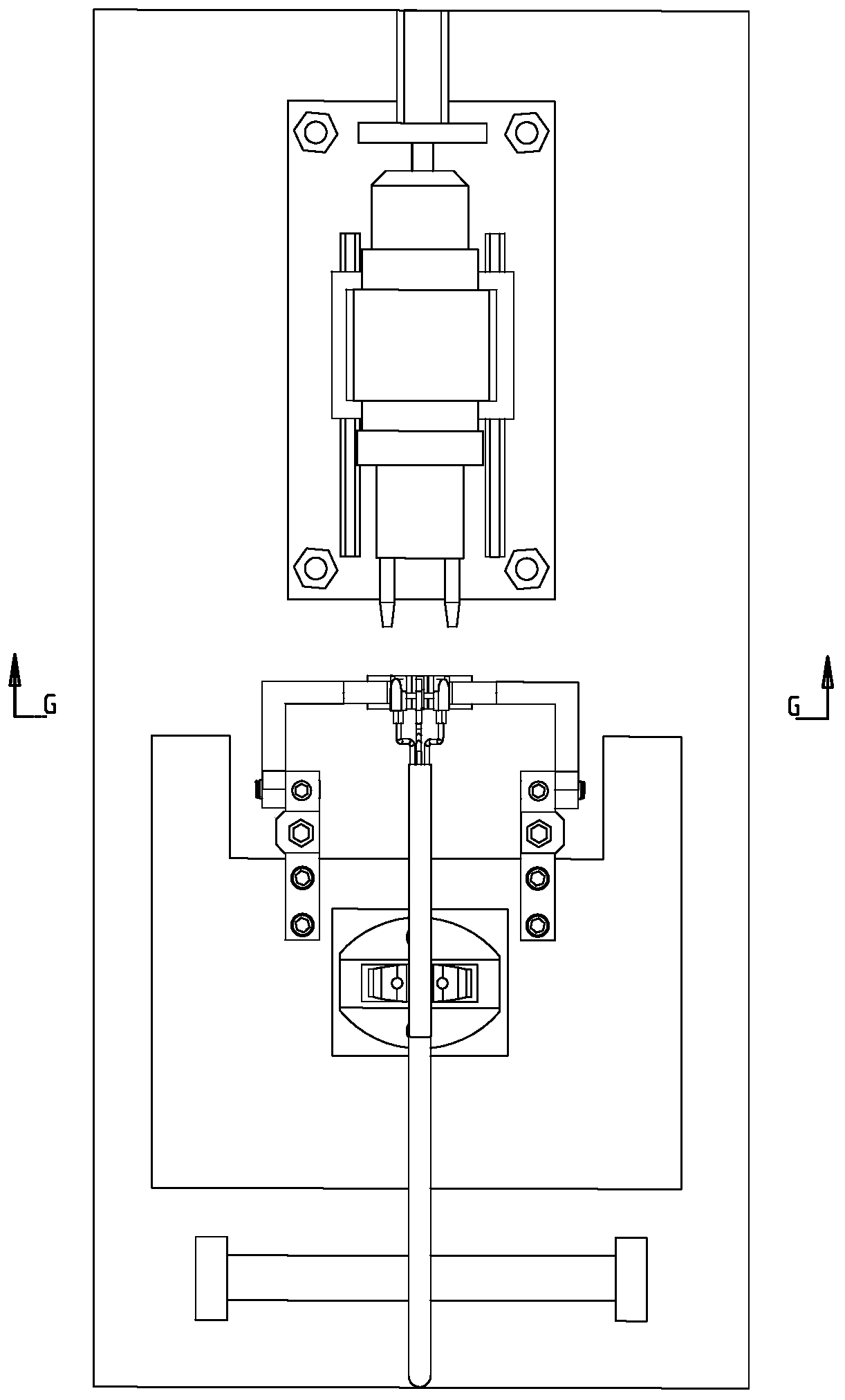

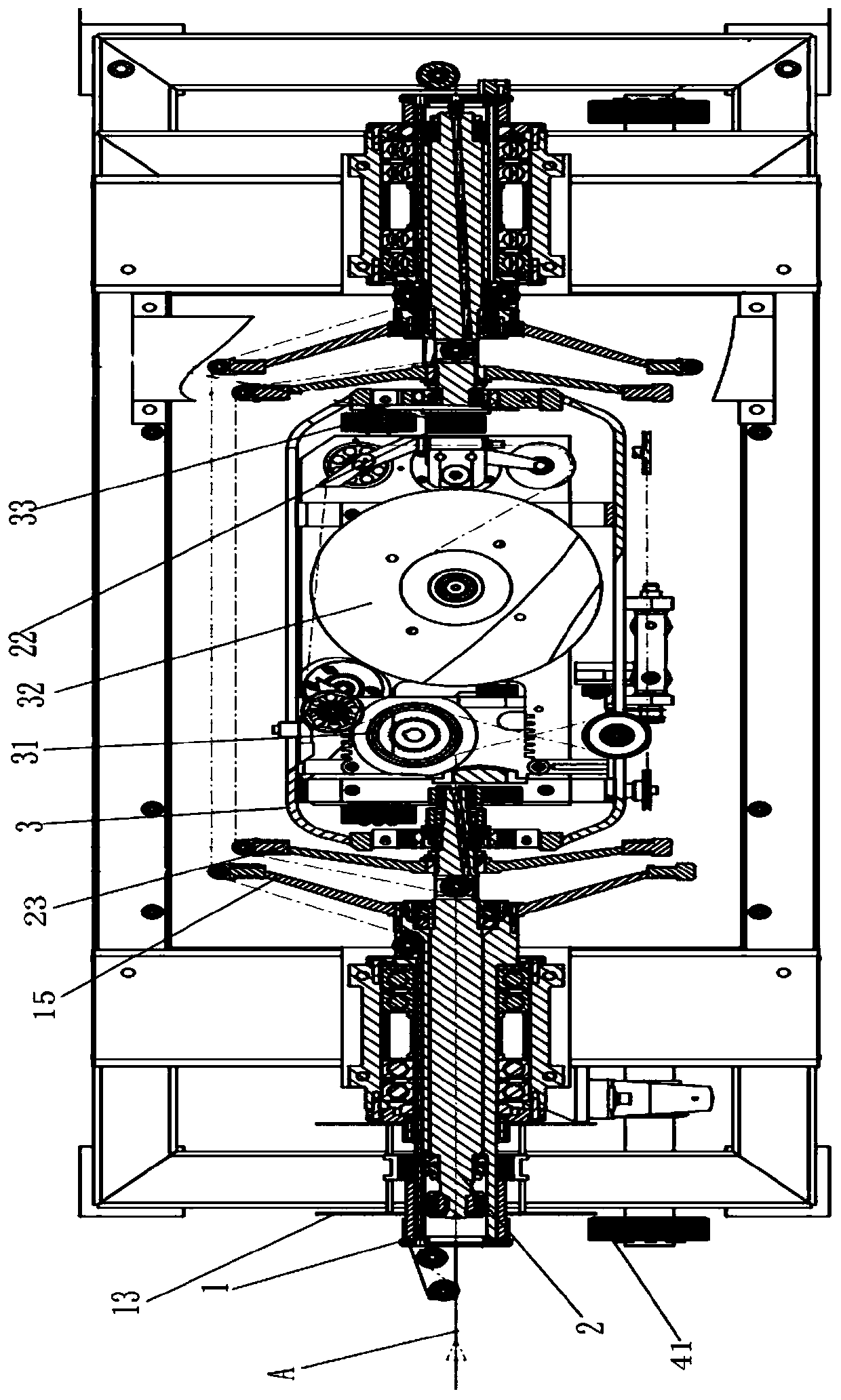

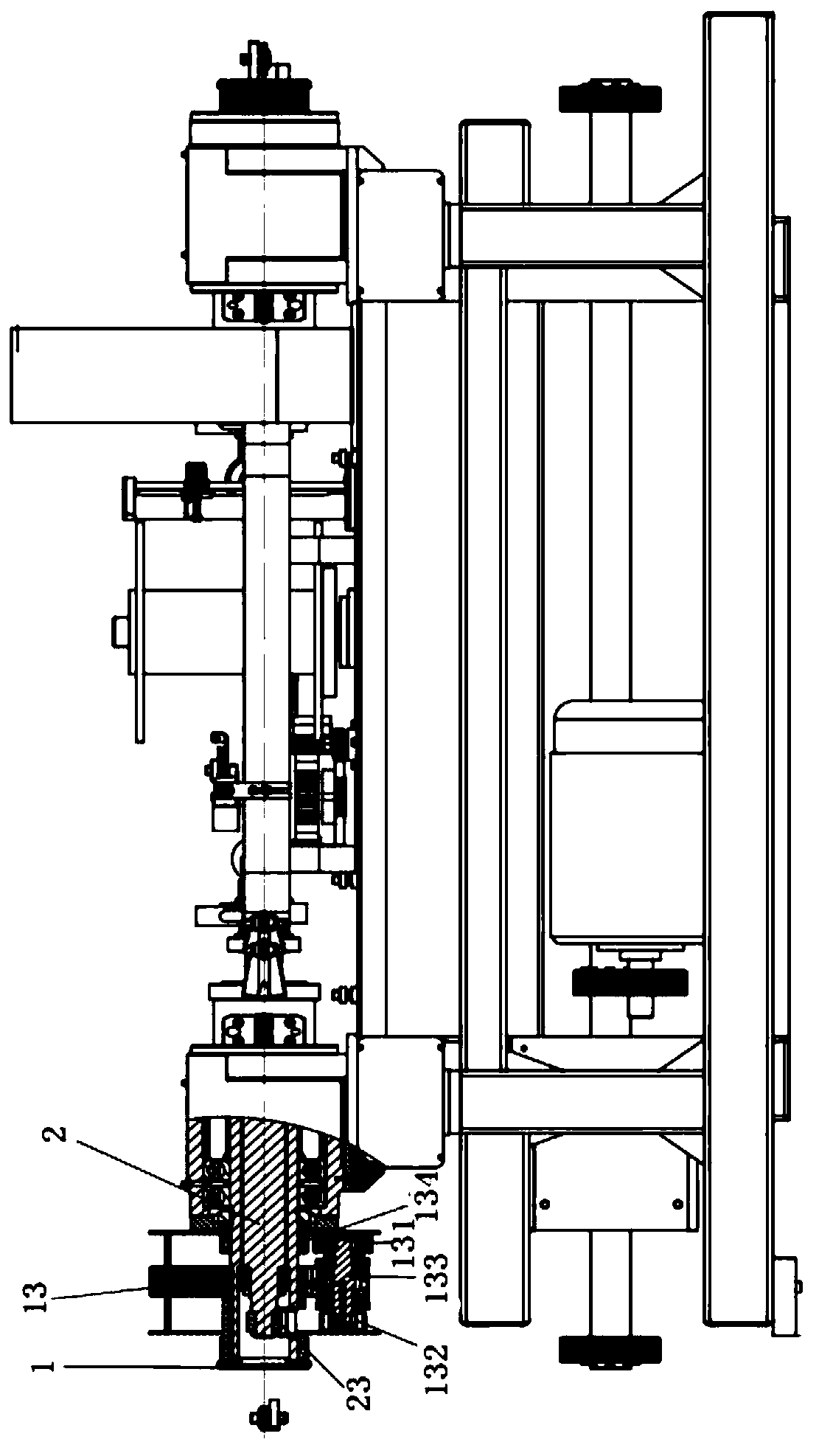

High-temperature superconducting stacked wire twisting device and operating method thereof

ActiveCN110010300AImprove twisting efficiencyUniform lay length distributionSuperconductors/hyperconductorsSuperconductor devicesEngineeringHigh temperature superconducting

The invention relates to a high-temperature superconducting stacked wire twisting device and an operating method thereof. The device comprises a case, a fixing mechanism and a twisting mechanism, wherein the case is of a hollow structure; the fixing mechanism is arranged in the case; the twisting mechanism is arranged in the case; and a stacked wire respectively passes through the fixing mechanismand the twisting mechanism. Compared with the prior art, the device has the beneficial effect of being capable of achieving the twisting of the superconducting stacked wire. Compared with the conventional manual twisting, the device not only improves the twisting efficiency, but also is more uniform in distribution of the twisting pitch of the twisted stacked wire.

Owner:SHANGHAI JIAO TONG UNIV

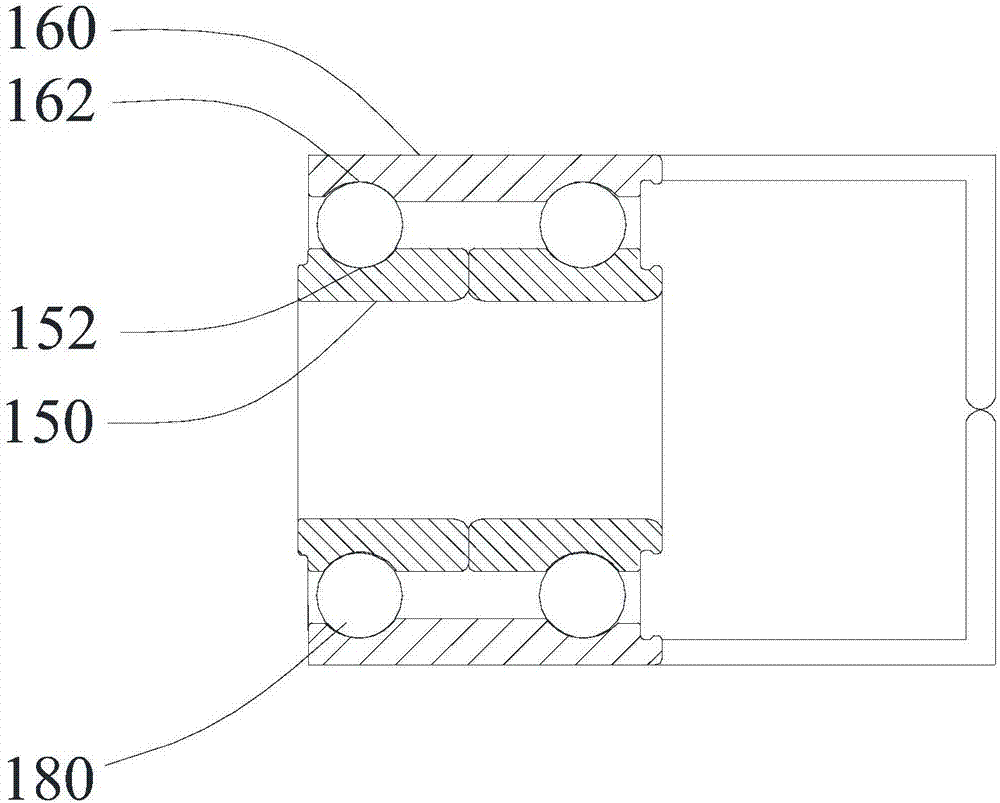

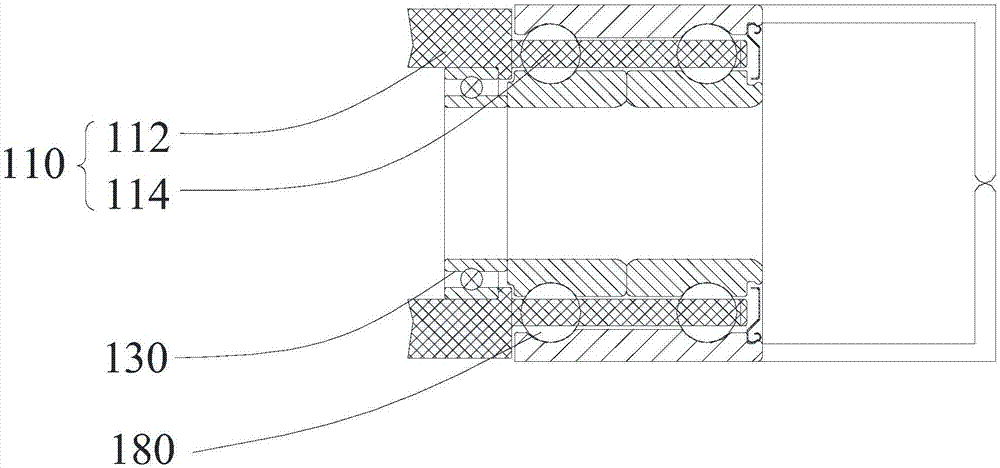

Wire twisting bearing and wire twisting machine

PendingCN107131206AIncrease speedImprove twisting efficiencyTextile treatmentShaftsMechanical engineeringCenter of mass

The invention provides a wire twisting bearing and a wire twisting machine, and relates to the field of wire production equipment. The wire twisting bearing is mounted on the wire twisting machine; the wire twisting bearing comprises a cage, a support bearing, an outer ring, an inner ring, a shaft tube and a rolling body; the inner ring sleeves one end of the shaft tube, and is fixedly connected with the shaft tube; the support bearing sleeves the shaft tube; the inner ring and the outer ring are rotationally connected through the rolling body; the rolling body is connected with the cage, and the cage is positioned, so that the centroid of the rolling body is fixed relative to the cage, and the cage is fixedly connected with a base; and when the outer ring rotates, the inner ring is driven to rotate by transmission of the rolling body. Compared with a traditional conventional bearing, the inner ring and the outer ring can relatively rotate in opposite rotating directions, so that the relative rotating speeds of the outer ring and the inner ring are greatly accelerated; and for the wire twisting operation, under the condition of the same power input, the wire twisting efficiency is greatly improved.

Owner:新昌县城南东明轴承厂

Chemical fiber yarn twisting device and using method thereof

The invention discloses a chemical fiber yarn twisting device and a using method thereof.The chemical fiber yarn twisting device comprises a device body, a winding assembly is arranged on the device body, the winding assembly comprises a mounting plate, a yarn conveying assembly is arranged on the mounting plate, a twisting assembly is arranged in the middle of the mounting plate, and the yarn conveying assembly comprises a first yarn conveying support and a second yarn conveying support; an incomplete gear is arranged at the side end of the first wire conveying support. According to the invention, one wire conveying rotating shaft is used for paying off, the other wire conveying rotating shaft is used for winding, and the maximum radial size of the wire conveying rotating shafts is a fixed value, so that the wire conveying rotating shafts can only wind silk threads in a certain length range in sequence, and coiled silk threads with a certain specification can be directly produced; the yarn conveying rotating shaft is directly rotated by 180 degrees, and the position of the yarn conveying rotating shaft is changed, so that the device can take up and pay off the silk yarn all the time, and the twisting efficiency of the device is improved; the guide wheel of the elastic assembly ensures that the silk thread is always in a tight state in the twisting process, and ensures that the twist of the twisted rope reaches the quality standard.

Owner:浙江伊兰文科技股份有限公司

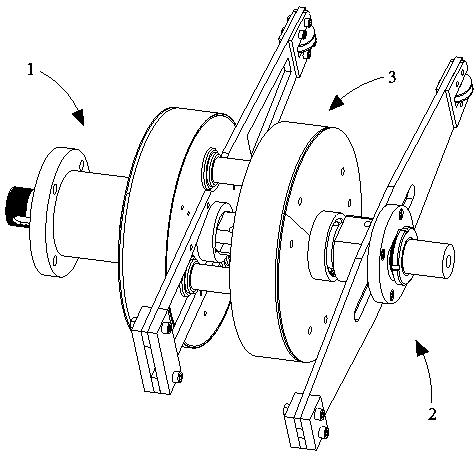

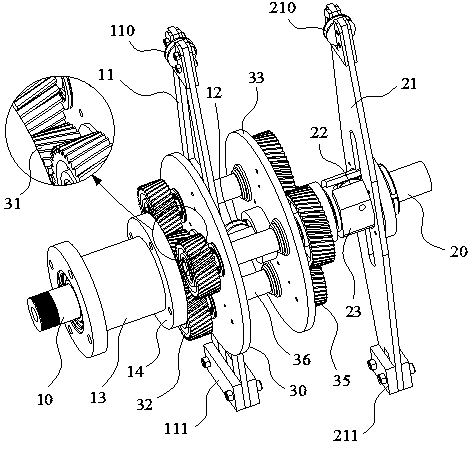

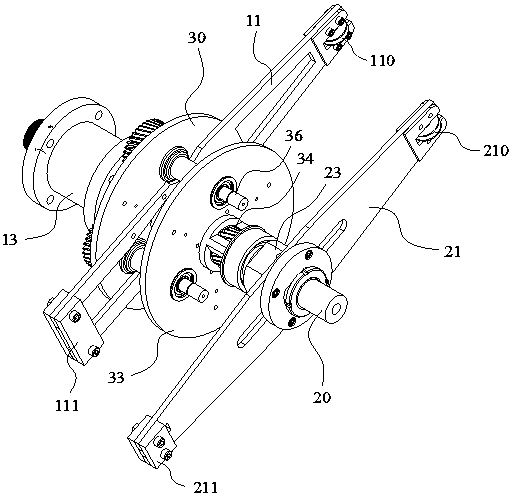

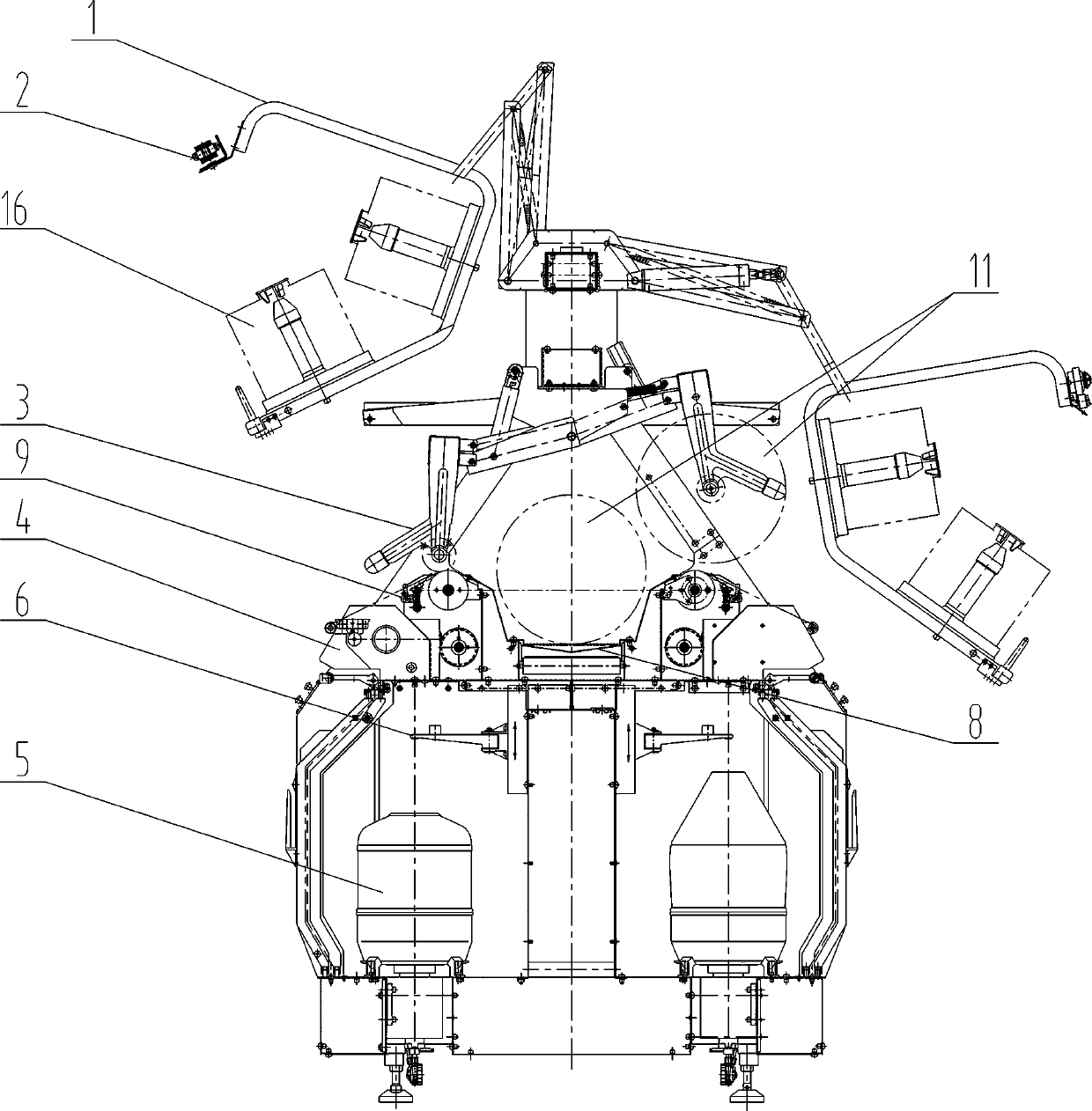

Double twisting mechanism and working method thereof, and double twisting device

The invention relates to a double twisting mechanism and a working method thereof, and a double twisting device. The double twisting mechanism comprises a first twisting sub mechanism and a second twisting sub mechanism. The first and second twisting sub mechanisms are used for twisting a plurality of raw material yarns successively in rotation directions being opposite to each other. According tothe double twisting mechanism, the two twisting sub mechanisms including the first twisting sub mechanism and the second twisting sub mechanism are arranged and twist the plurality of raw material yarns successively in rotation directions being opposite to each other, so that the twisting efficiency is improved effectively and thus the rope making efficiency is increased effectively. In addition,the double twisting mechanism is designed ingeniously; and the first twisting sub mechanism and the second twisting sub mechanism carry out transmission connection by using a transmission sub mechanism with a planetary transmission mechanism. Because the transmission sub mechanism occupies small space and has high transmission stability, so that the reliability of the twisting action is enhancedand thus the high twisting efficiency and the good twisting quality are ensured.

Owner:常州市万兴自控设备有限公司

A high-efficiency two-for-one twister

ActiveCN111705383BRealize the function of doubling the lay lengthRigid and stableDrafting machinesContinuous wound-up machinesRotational axisEngineering

The invention provides a high-efficiency two-for-one twisting ply machine, including a ply twister, the ply ply machine includes a fuselage support and a left spindle device and a right spindle device symmetrically installed on the fuselage support; the left spindle device includes a hollow outer spindle and an inner core The shaft and the rotating bearing seat fixed on the outer main shaft, the inner mandrel shaft is rotatably fitted in the outer main shaft; the outer main shaft is rotatably equipped with a central reversing assembly, and the rotating bearing seat is eccentrically equipped with a speed change transmission mechanism, which is respectively connected to the inner mandrel shaft and Center reversing assembly. The inner mandrel shaft of the present invention is set in the outer main shaft, and the overall structure is compact, and at the same time, the overall rigidity of the inner mandrel shaft and the outer main shaft is more stable; the power is realized through the rotating bearing seat, the central reversing assembly, the speed change transmission mechanism, and the reversing gear box Commutation; through the servo motor and encoder, the traction speed can be controlled steplessly, and the purpose of arbitrary lay length control can be achieved. The overall production efficiency is high and the versatility is strong.

Owner:宁波市祥宇机械有限公司

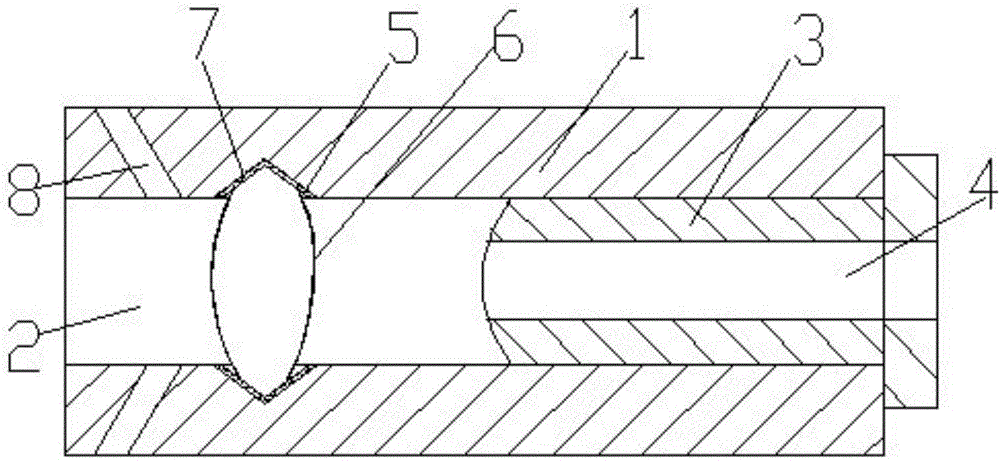

Vortex tube for spinning machine

InactiveCN104451975AIncrease speedImprove carrying capacityContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

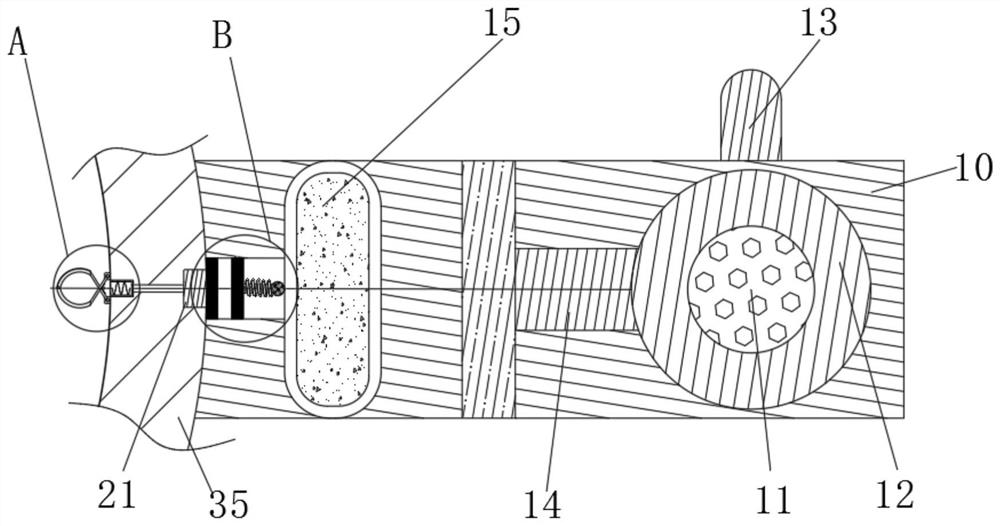

The invention discloses a vortex tube for a spinning machine. The vortex tube comprises a tube body with an inner cavity, a plug is arranged at one end of the tube body and provided with a yarn guide hole in communication with the inner cavity, a V-shaped groove structure is arranged on a circle of the wall of the inner cavity, a fiber ring is arranged in the V-shaped groove structure, flannelette structures are arranged at the joints between the V-shaped groove structure and the fiber ring, and a tilting air supplement hole is formed in the wall, close to the end opposite to the end where the plug is arranged, of the inner cavity. According to the scheme, the tilting air supplement hole is formed in the wall of the inner cavity of the tube body, so effective air flow in the tube body can be increased, the capacity to bear the fiber ring is enhanced, the rotation speed of the fiber ring is increased, and therefore twisting efficiency is improved, energy consumption is reduced, the structural design of the flannelette structures reduces friction of the fiber ring and prolongs the service life of the fiber ring, and spinning quality and spinning efficiency are improved.

Owner:SUZHOU CITY WUZHONG DISTRICT GUOXIANG XUYU WOOLENSWEATER PROCESSING PLANT

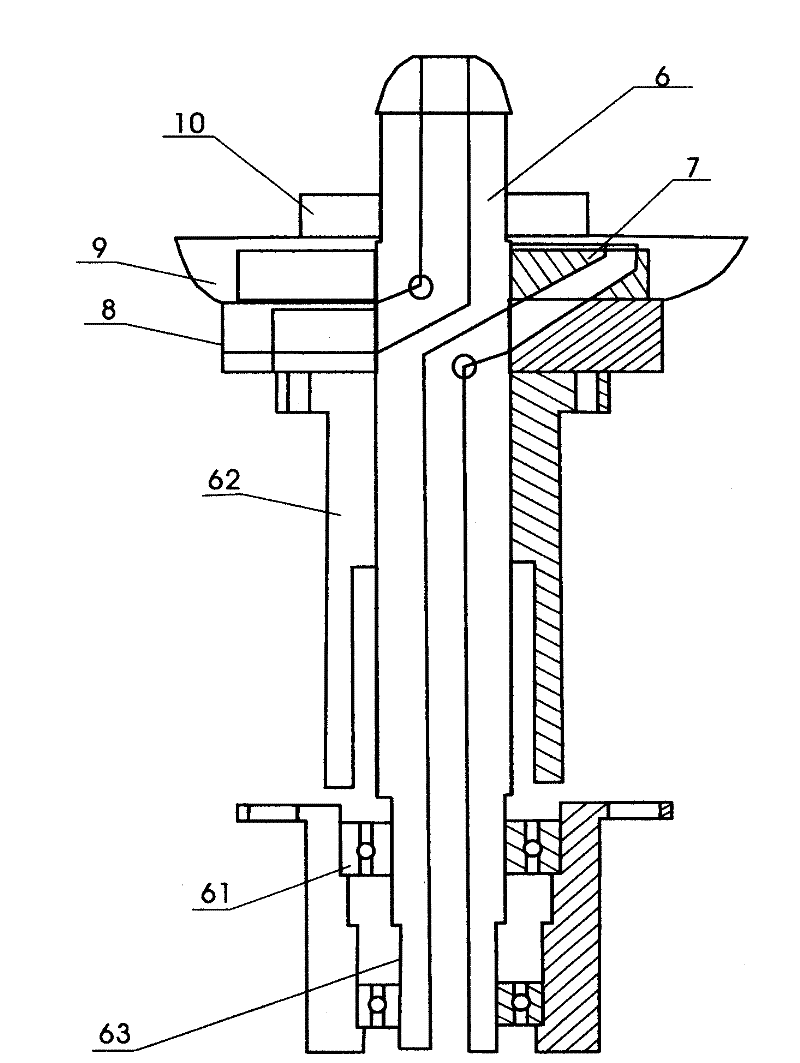

Pneumatic cradle for two-for-one twister

InactiveCN103668587AReasonable structural designEasy to liftDrafting machinesEngineeringMechanical engineering

The invention relates to a pneumatic cradle for a two-for-one twister, and belongs to the field of textile devices. The cradle comprises a cradle handle, a fixed base, an air cylinder, an ejector rod, an aluminum tube, an aluminum tube fixing plate, a screw and a bearing. The air cylinder is fixed to the fixed base. The screw is fixed to the aluminum tube fixing plate and sleeved with the bearing. The bearing can rotate around the screw. The upper end of the ejector rod is fixedly connected with the bearing. According to the pneumatic cradle for the two-for-one twister, due to the fact that the air cylinder is added to the cradle, the aluminum tube can be conveniently lifted up or placed down, the twisting efficiency is improved, and the problems that a traditional cradle is loose in structure, complex in operation and poor in locking function stability are solved. The pneumatic cradle is reasonable in structural design, stable and firm in locking function and suitable for being popularized and used.

Owner:吴江金名来丝绸进出口有限公司

Carpet yarn twisting machine

ActiveCN107299422BImprove twisting efficiencyIncrease speedContinuous wound-up machinesYarnYarnPhysics

Owner:YICHANG JINGWEI TEXTILE MACHINERY

High temperature superconducting stacked wire twisting device and its working method

ActiveCN110010300BAchieve twistingUniform lay length distributionSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingStructural engineering

The invention relates to a high-temperature superconducting stacked wire twisting device and an operating method thereof. The device comprises a case, a fixing mechanism and a twisting mechanism, wherein the case is of a hollow structure; the fixing mechanism is arranged in the case; the twisting mechanism is arranged in the case; and a stacked wire respectively passes through the fixing mechanismand the twisting mechanism. Compared with the prior art, the device has the beneficial effect of being capable of achieving the twisting of the superconducting stacked wire. Compared with the conventional manual twisting, the device not only improves the twisting efficiency, but also is more uniform in distribution of the twisting pitch of the twisted stacked wire.

Owner:SHANGHAI JIAOTONG UNIV

Wire twisting mechanism for rotating power plug part by 180 degrees

InactiveCN111193164AImprove twisting efficiencyEasy injection moldingContact member assembly/disassemblyStructural engineeringPower cord

Owner:浙江海宁普赛自动化科技有限公司

Graphite fiber band stranding system

ActiveCN110373923AImprove twisting efficiencyHigh strengthRope making machinesCable/conductor manufactureEngineeringFiber

The invention relates to the technical field of graphite fiber band processing equipment, in particular to a graphite fiber band stranding system. The graphite fiber band stranding system comprises astranding machine and a material plate located above the stranding machine, wherein the stranding machine comprises a base, a central shaft and a main body support; an opening for allowing a graphitefiber thread to penetrate from top to bottom is formed in the upper end of the main body support; a driving mechanism can drive the main body support to rotate; a driving shaft is arranged on the mainbody support and can rotate around own axis; the upper end of the central shaft extends into the main body support, and a central shaft bevel gear is mounted at the upper end; a driving shaft bevel gear meshed with the central shaft bevel gear is arranged on the driving shaft; a winding bar is arranged on the main body support; when rotating with the main body support, the winding bar can twist graphite fiber bands which are discharged from the material plate and extend from top to bottom into graphite fiber threads; a winding reel is used for winding and collecting the graphite fiber lines passing the winding bar; the driving shaft is in transmission connection with the winding reel to drive the winding reel to wind and collect the graphite fiber lines.

Owner:XUCHANG SIDA ELECTRIC POWER EQUIP

Novel stranding machine

PendingCN111593439AImprove twisting efficiencyReduce energy consumptionContinuous wound-up machinesElectric machineryStructural engineering

The invention provides a novel stranding machine. The novel stranding machine comprises a main machine frame, a motor, a transmission device, a pair of main shafts oppositely arranged along a same axis, a cradle frame fixed between the two main shafts, a paying-off device and a taking-up device. The novel stranding machine is characterized in that the main shafts include an inner shaft and an outer shaft which are arranged coaxially, and a reversing device is disposed on the main shaft at one end; the reversing device comprises a rotary disk fixed to the outer shaft, and a first intermediate wheel and a second intermediate wheel which are in pair and are coaxial with each other are arranged on the rotary disk; the first intermediate wheel is in flexible transmission with a first transmission wheel fixed to an outer shaft shell, and the second intermediate wheel is in flexible transmission with a second transmission wheel fixed to the inner shaft; the ends of the outer shaft and the inner shaft are connected with independent flywheel disks and wire wheels; and hollow holes allowing a wire to pass through are formed in the outer shaft and the inner shaft. Compared with an existing stranding machine, the novel stranding machine can improve the stranding efficiency by one time under the same rotation speed condition; and the same stranding efficiency can be achieved under the condition that the rotation speed of the main shafts is decreased by one time, and energy consumption is reduced.

Owner:株洲宏远机械制造有限责任公司

Kapok fiber pretreatment auxiliary agent and kapok fiber pretreatment method

InactiveCN103255621BImprove twisting efficiencyImproved roll stickingVegetal fibresYarnPretreatment method

The invention discloses a kapok fiber pretreatment auxiliary agent and a kapok fiber pretreatment method. The kapok fiber pretreatment auxiliary agent comprises the following ingredients by weight: 2-8 parts of PEG 2000-8000; 5-15 parts of cross-linking agent; 1-5 parts of castor oil; 5-10 parts of cation polyacrylamide; 5-10 parts of antistatic agent; 50-80 parts of water. The kapok fiber pretreatment auxiliary agent is sprinkled on the kapok fiber, and is placed at room temperature for 6-24 hours, and the kapok fiber pretreatment method is completed. After the kapok fiber pretreatment is carried out by the kapok fiber pretreatment auxiliary agent of the present invention, the strip weight unevenness decreases by 18-25%, the hairiness index decreases by 55-65%, the single thread strength increased by 20-25%, the spun yarn twisting efficiency increases by 10-15%, and the roll banding case obviously improves.

Owner:上海鼎乘生物科技有限公司 +1

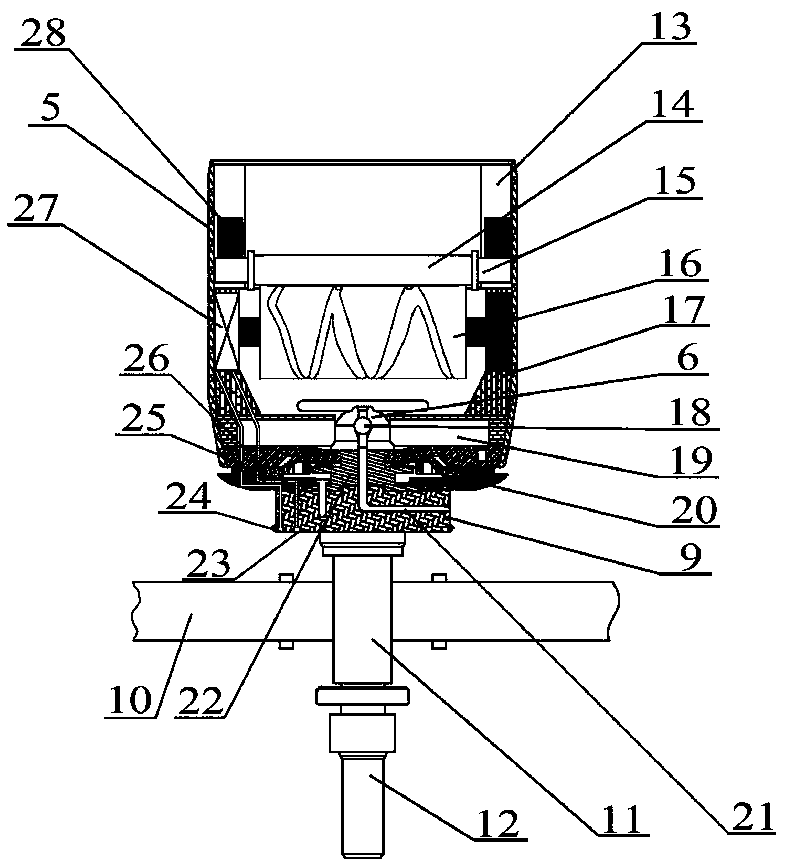

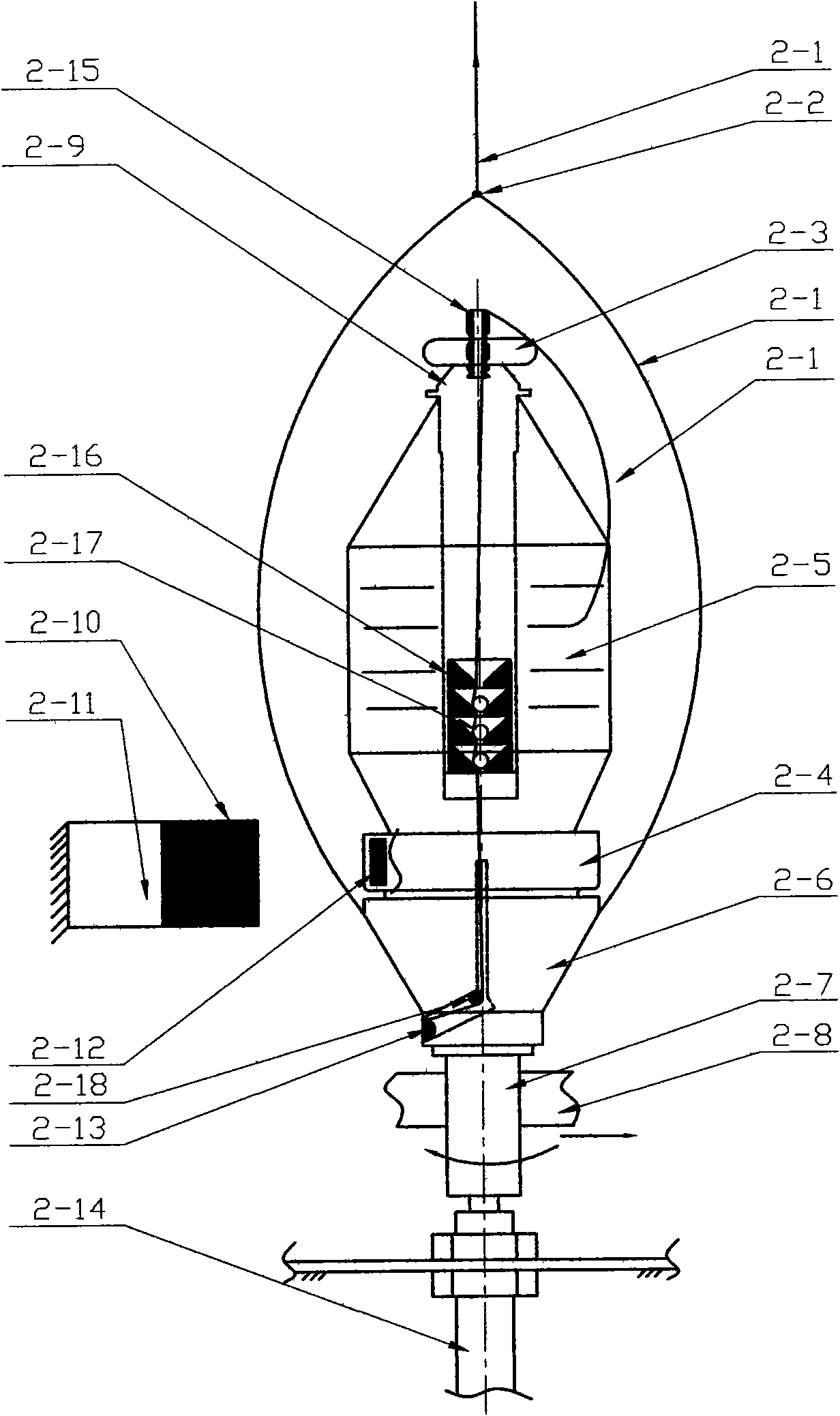

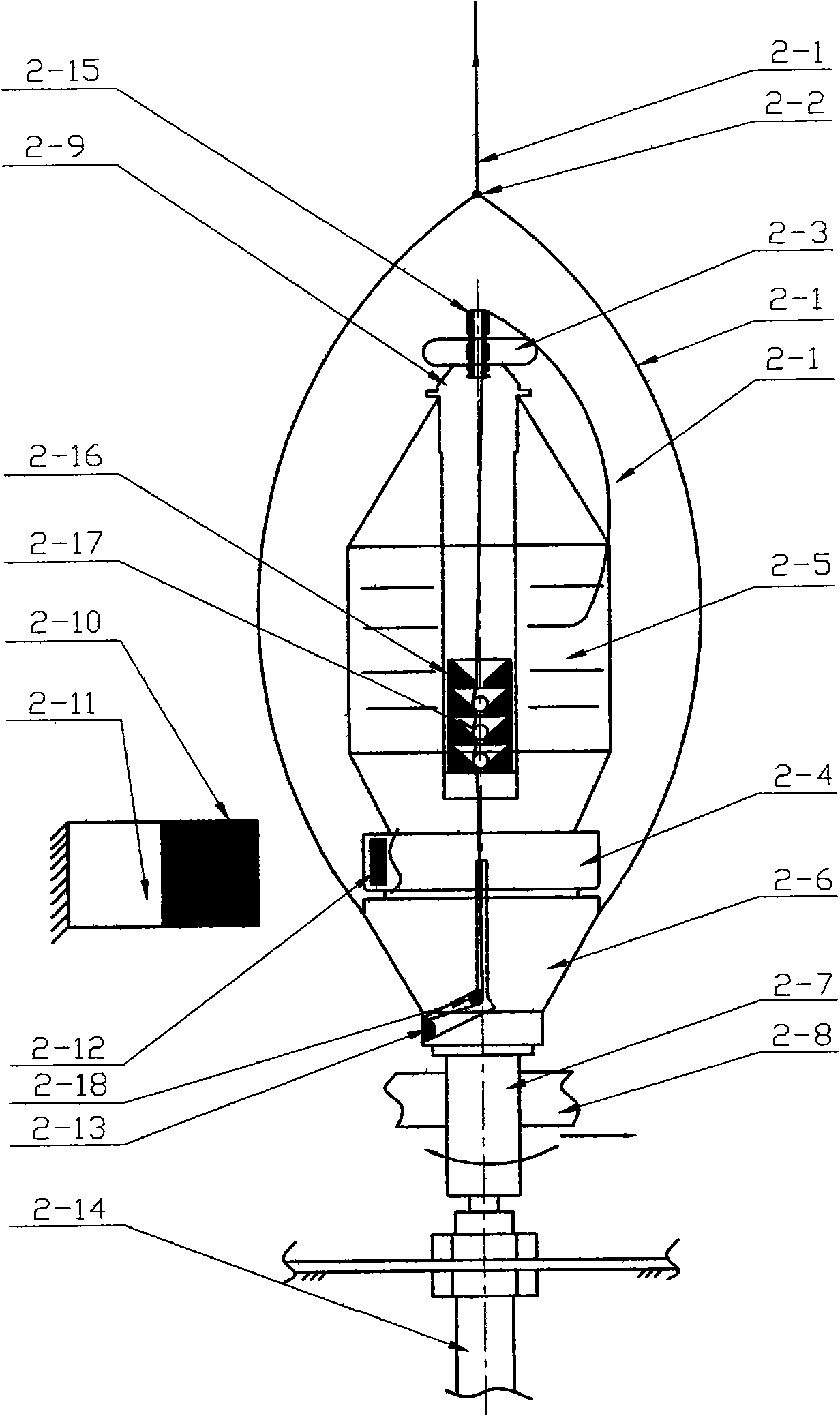

A magnetic winding type two-for-one twist spinning method

ActiveCN112410945BChange the winding methodImprove twisting efficiencyContinuous wound-up machinesYarnFiber

The invention relates to a magnetic winding type two-for-one twist spinning method, which belongs to the technical field of textiles. In the present invention, a two-for-one twisting mechanism consisting of a two-for-one twisting mechanism and a magnetic force winding mechanism is arranged in front of the drafting system of the spinning frame. The upper part is inlaid with permanent magnets evenly arranged along the circumferential direction. The active turntable drives the driven turntable to rotate with the help of magnetic force. The yarn sliver, through the yarn guide hook, enters the yarn inlet pipe and the yarn running channel in sequence, and after being drawn out from the yarn outlet pipe by the tensioner, it is wound into a bobbin package under the winding action of the magnetic winding mechanism. The present invention changes the winding spinning method of the existing two-for-one twist spinning with a built-in electric mechanism, solves the problem of low and unsustainable winding spinning speed of the built-in electric mechanism, and realizes high-speed and long-lasting large-package two-for-one twist spinning production .

Owner:WUHAN TEXTILE UNIV

Drafting double condensed spinning device and spinning method

InactiveCN110129928AAchieving centralized extraction and draftingImprove performanceDrafting machinesFiberYarn

The invention provides a drafting double condensed spinning device and spinning method. Front rollers of a drafting system adopt big rollers of hollow structures, uniformly arranged slots or holes areformed in the surfaces of the rollers, hollow air suction plug-ins fixed on the inner walls in a close attachment structure are arranged in the hollow structures of the rollers, air suction ports which are formed in a front-rear manner and located at the front parts and the rear parts of the pressing contact points of front rollers and front rubber rolls respectively are formed in the upper surfaces of the air suction plug-ins, so that fiber strands output by middle rollers are clustered under the negative pressure in the rear air suction ports, fiber at the front rollers change speed in a concentrated manner, the concentrated suction and drafting function on fiber in a front drafting area is realized, the evenness and strength of the yarn are improved substantially, condensing of the fiber strands output by the front rollers under the negative pressure in the front air suction port is realized, fiber strand compacting before twisting is realized, the overall twisting efficiency of the fiber strands is improved, the probability that fiber tips extend out of the yarn is reduced, and hairiness of the yarn is substantially reduced.

Owner:合肥经新科技有限公司

Twisting device of ultra-fine nylon stretch yarn

The invention discloses a twisting method of ultra-fine nylon stretch yarn and a device thereof, belonging to the technical field of textile. The invention utilizes a doubler winder with polyurethane fibre drawing to process the two-for-one twisting feeding tube of the ultra-fine nylon stretch yarn, and then utilizes a two-for-one twister spindle to twist the ultra-fine nylon stretch yarn. The invention utilizes one bout plus two turns of a two-for-one twisting spindle, which has the advantages of constant air ring, constant tension and big package, so that the twisting method of the invention improves production efficiency, effectively realizes myriametre knot-free yarn, improves the equality index of thrown silk degree of twist, and lowers energy consumption of yield per unit. The invention provides a new method and technical device for producing ultra-fine nylon stretch yarn with high efficiency, good quality and small energy consumption.

Owner:绍兴华裕纺机有限公司

A graphite fiber tape stranding system

ActiveCN110373923BImprove twisting efficiencyHigh strengthRope making machinesCable/conductor manufactureFiberGear wheel

The invention relates to the technical field of graphite fiber ribbon processing equipment, in particular to a graphite fiber ribbon strand-making system. The graphite fiber tape strand-making system includes a strand-making machine and a material tray located above the strand-making machine. The strand-making machine includes a base, a central shaft, and a main body bracket. The upper end of the main body bracket has an opening for the graphite fiber thread to penetrate from top to bottom; The driving mechanism can drive the main body bracket to rotate; the driving shaft is set on the main body bracket so that it can rotate around its own axis; the upper end of the central shaft extends into the main body bracket, and the upper end is equipped with a central shaft bevel gear. The drive shaft is conical gear meshed with gears; the winding rod is set on the main body support, and when the winding rod revolves with the main support, it can twist the graphite fiber tape released from the material tray and extend from top to bottom to form a graphite fiber line; The take-up wheel is used for winding and collecting the graphite fiber thread passing through the winding rod; the driving shaft is connected with the take-up wheel transmission to drive the take-up wheel to wind and collect the graphite fiber line.

Owner:XUCHANG SIDA ELECTRIC POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com