Patents

Literature

260results about How to "Improve quality uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

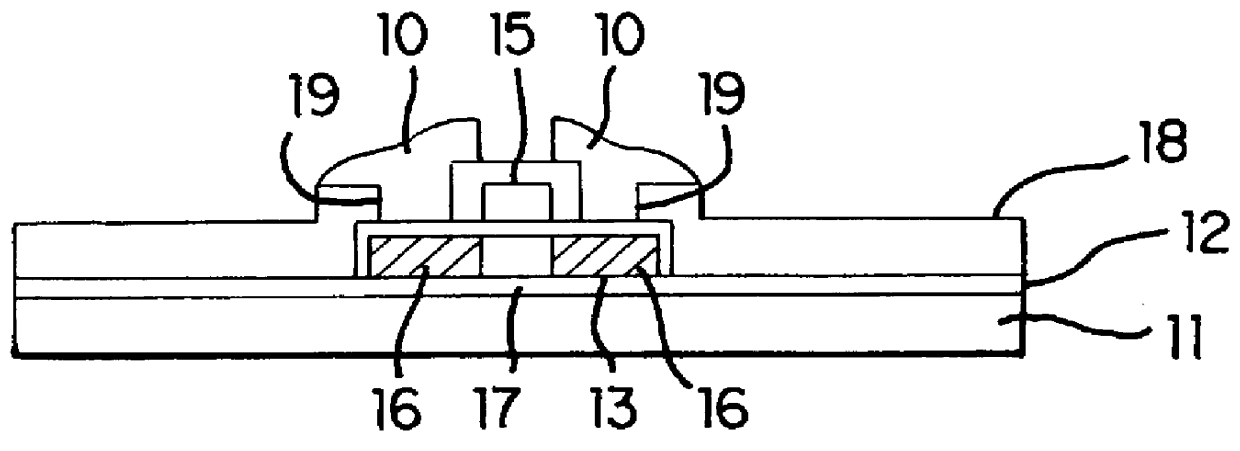

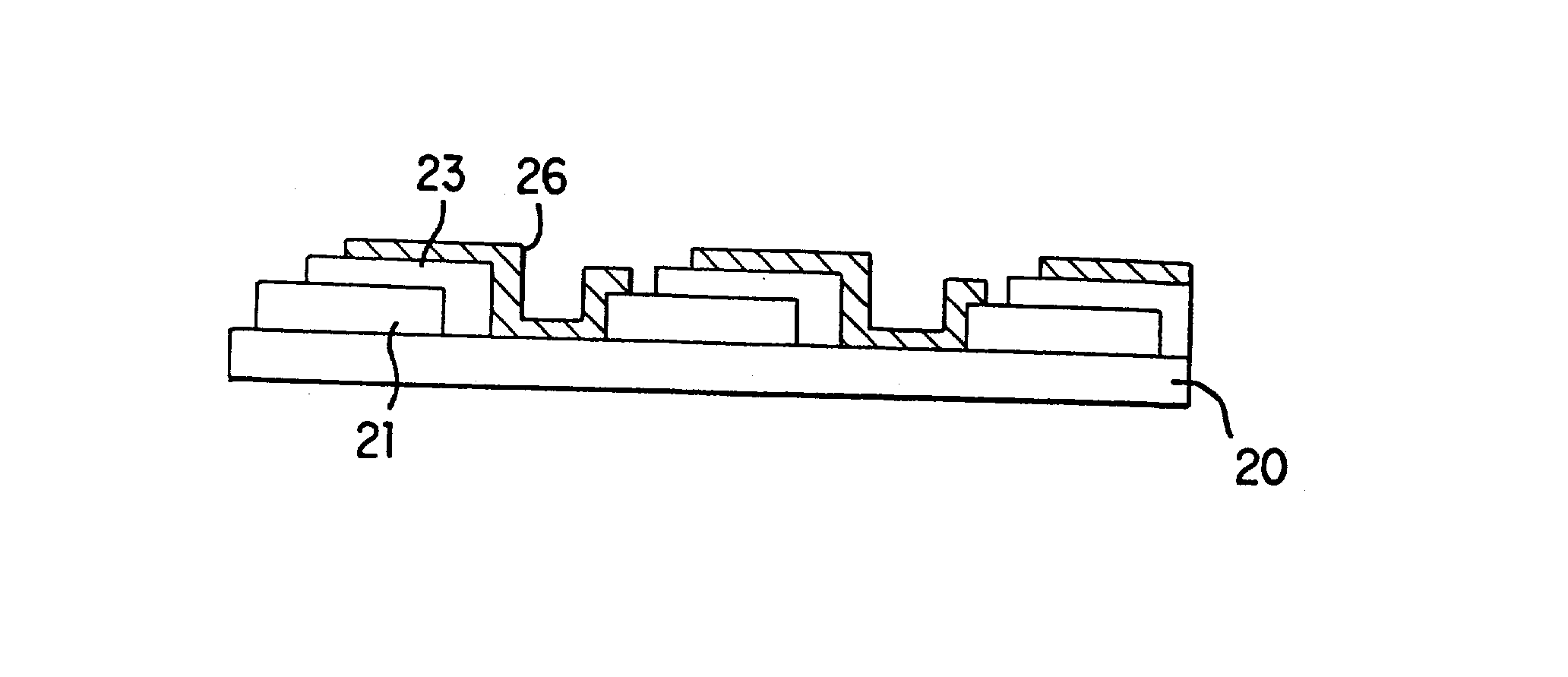

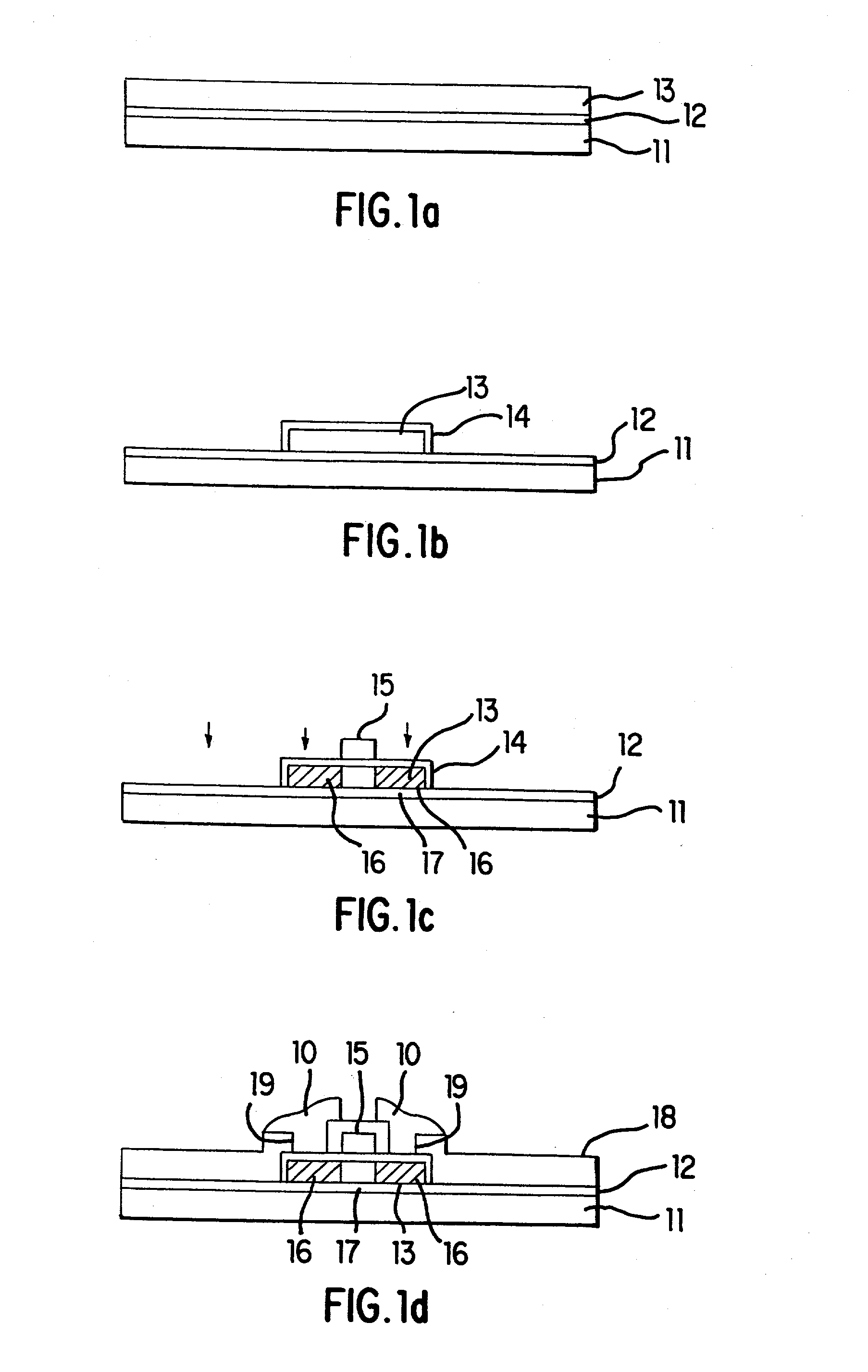

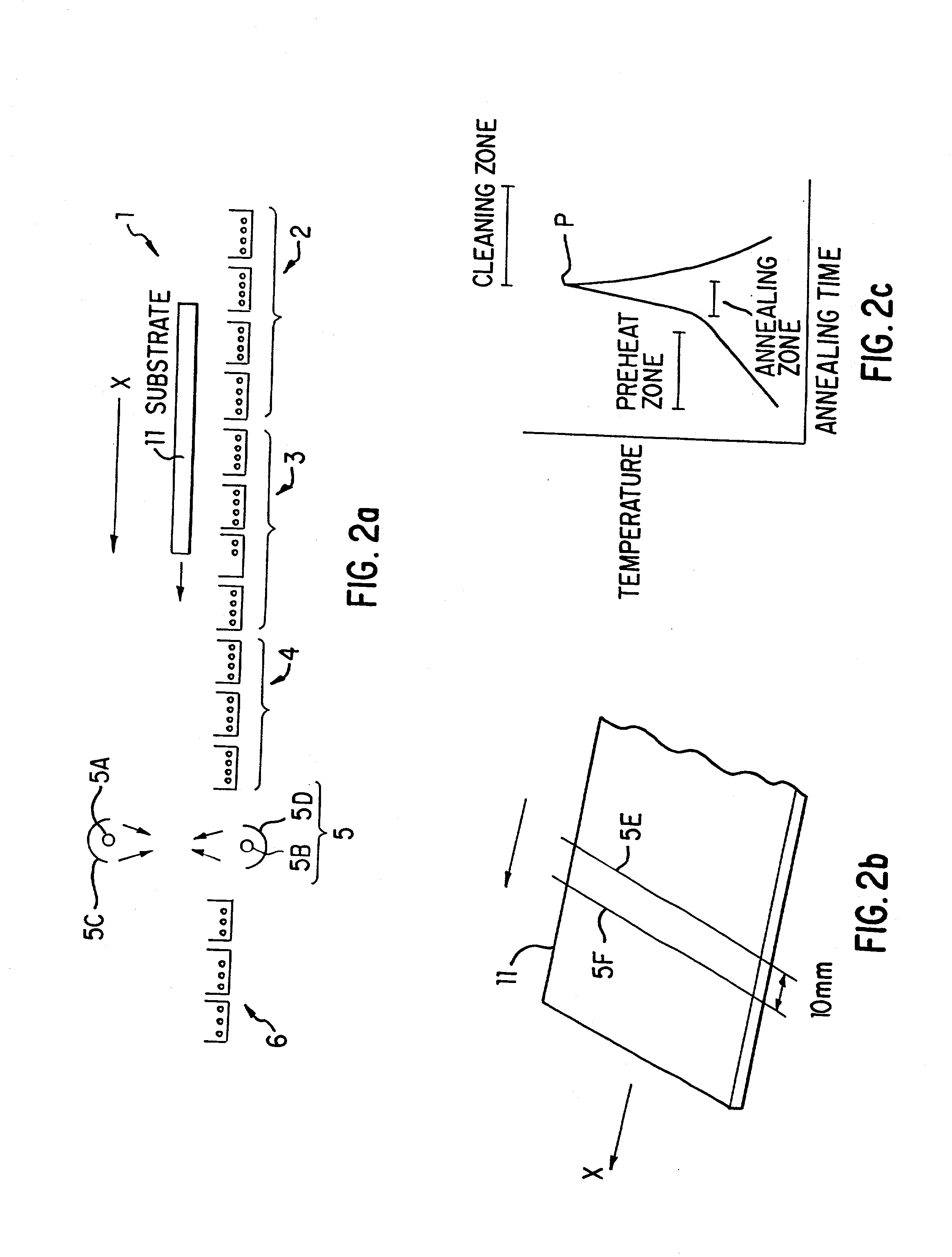

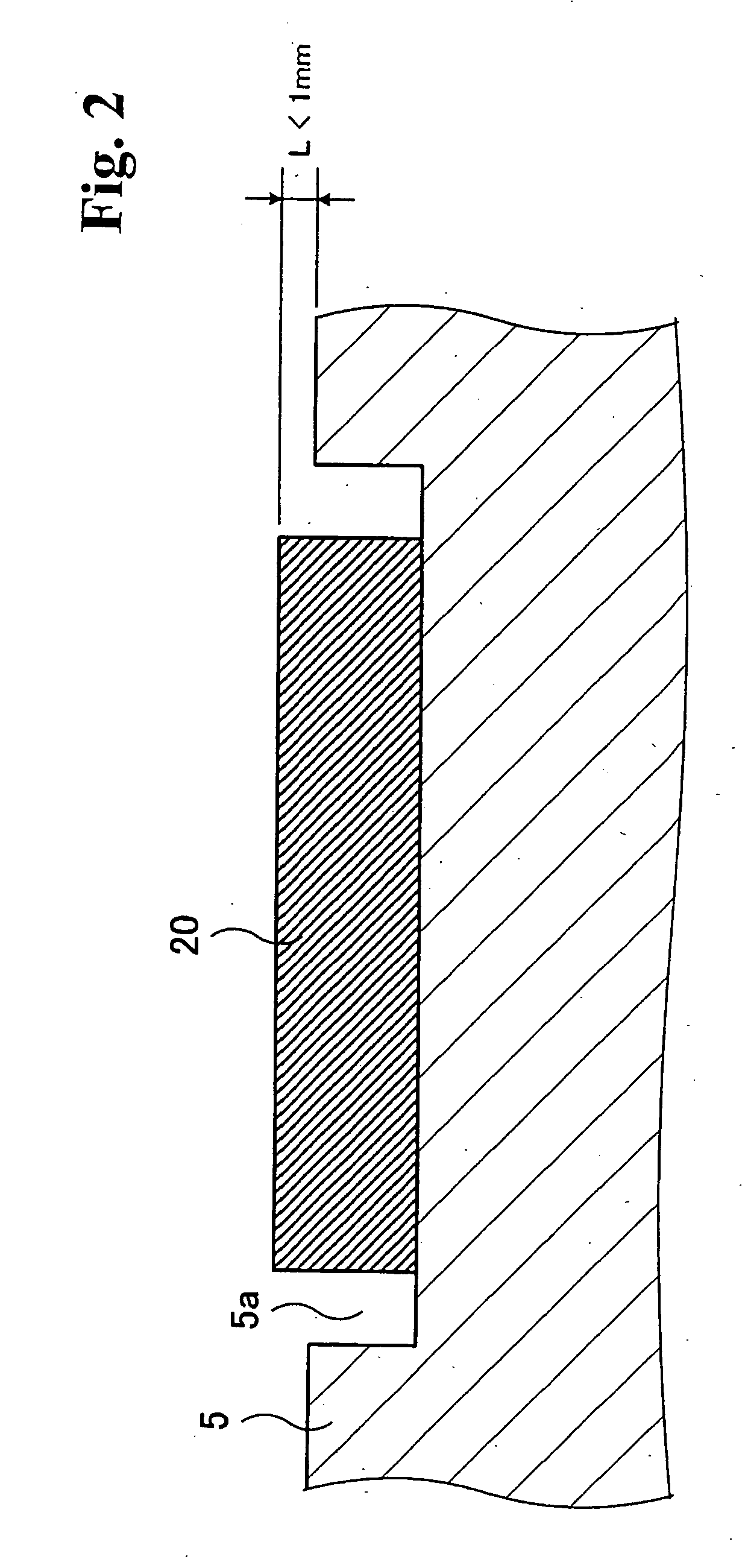

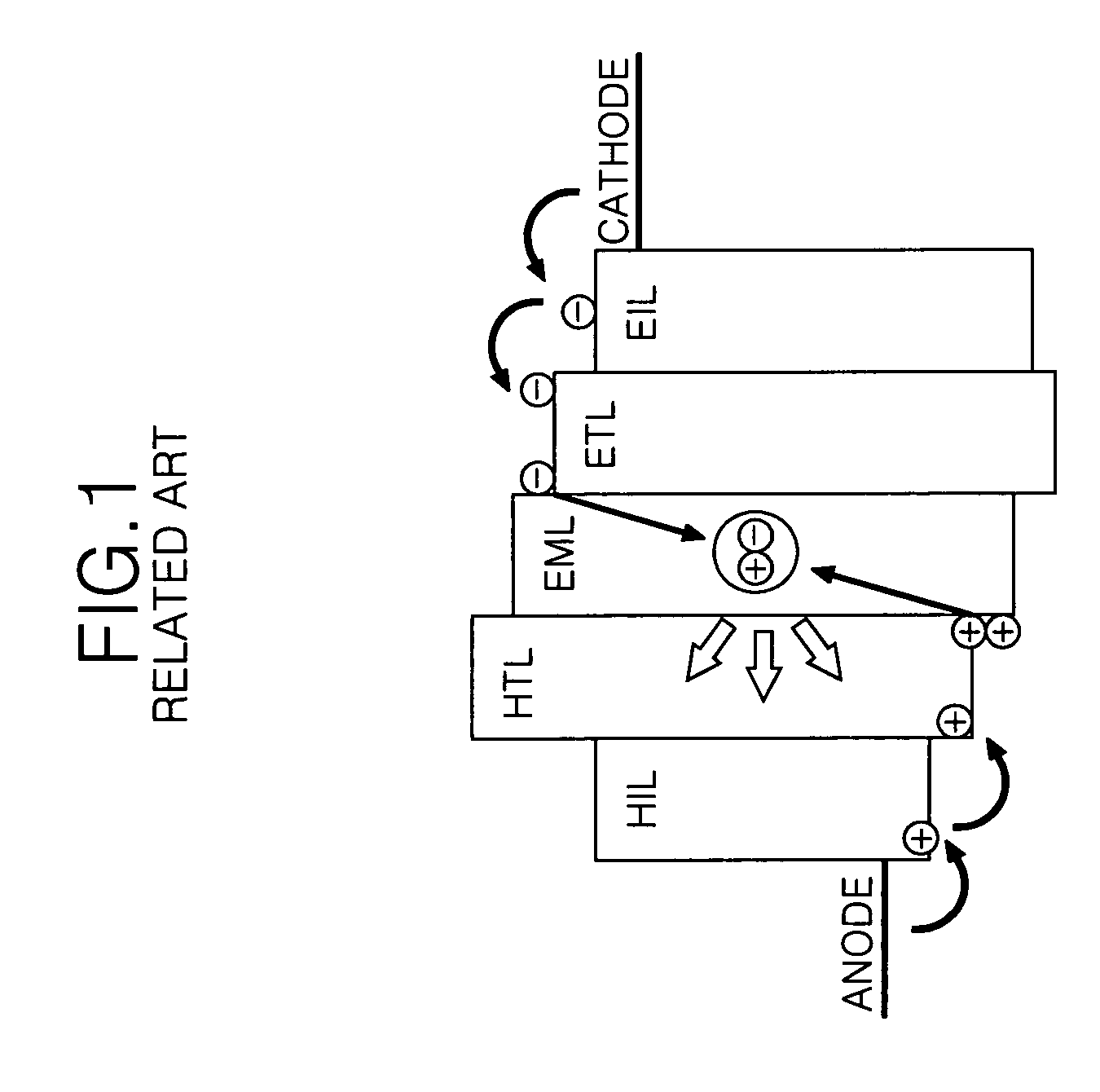

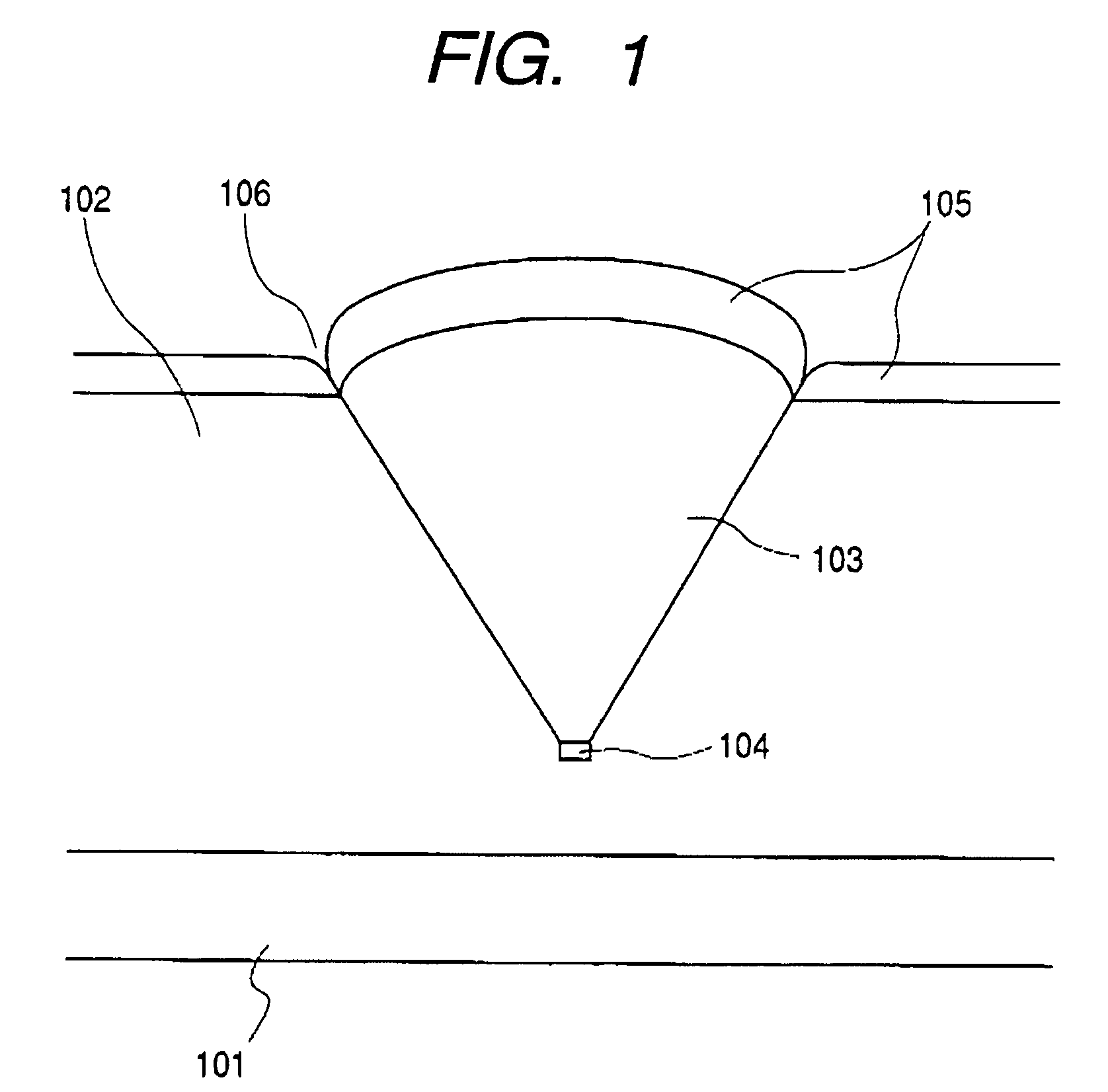

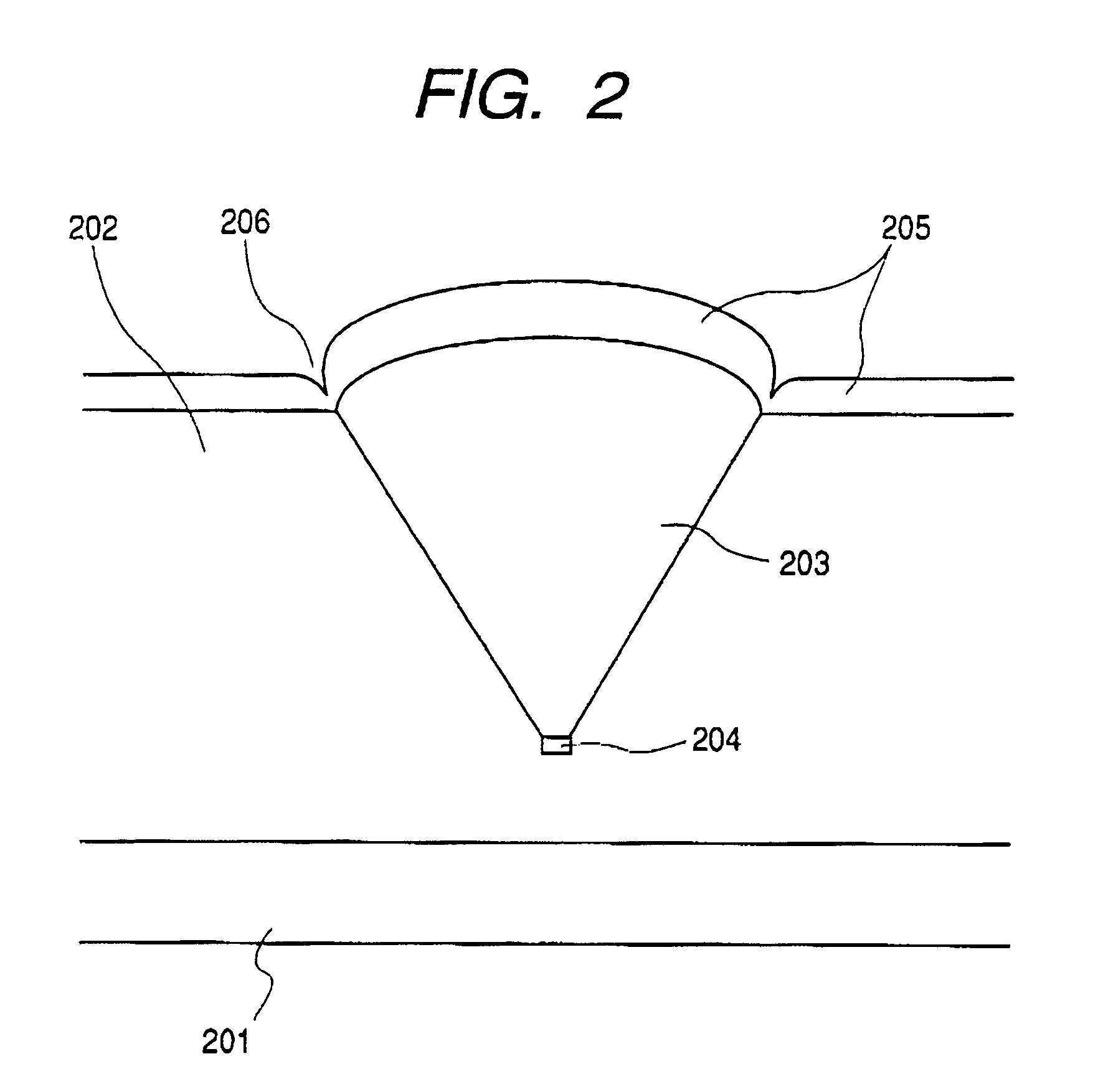

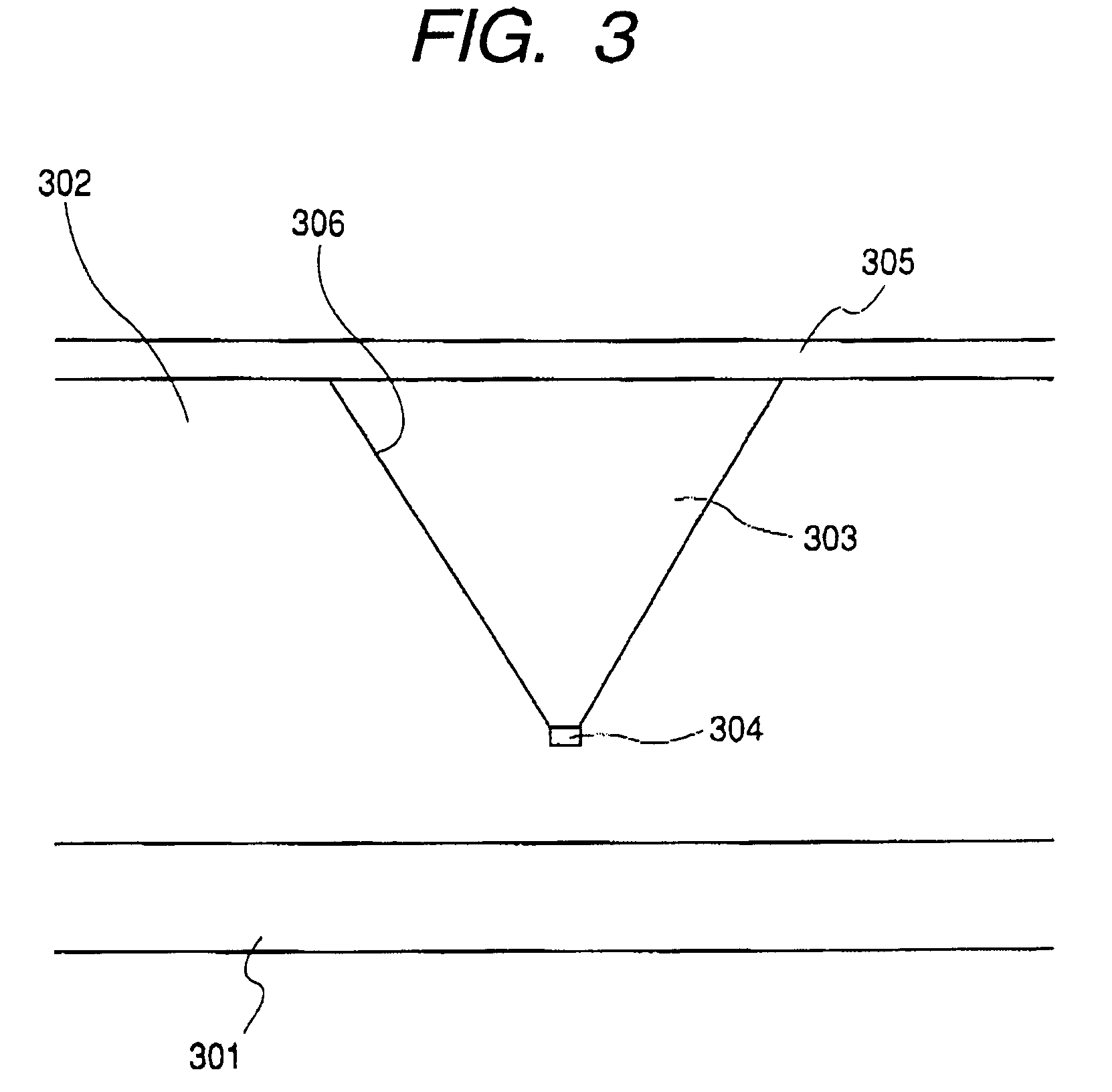

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS6066516AGreat fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

PCT No. PCT / JP96 / 01775 Sec. 371 Date Jan. 31, 1997 Sec. 102(e) Date Jan. 31, 1997 PCT Filed Jun. 26, 1996 PCT Pub. No. WO97 / 01863 PCT Pub. Date Jan. 16, 1997A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

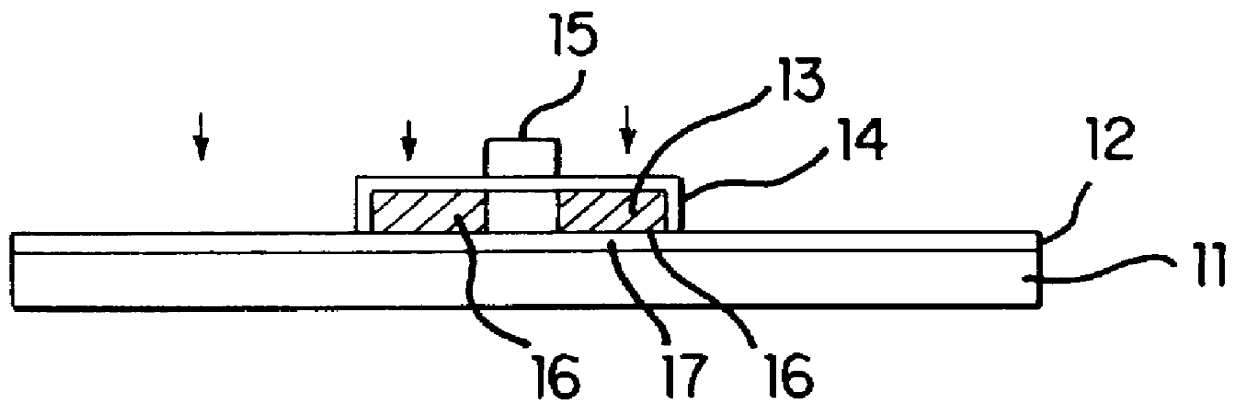

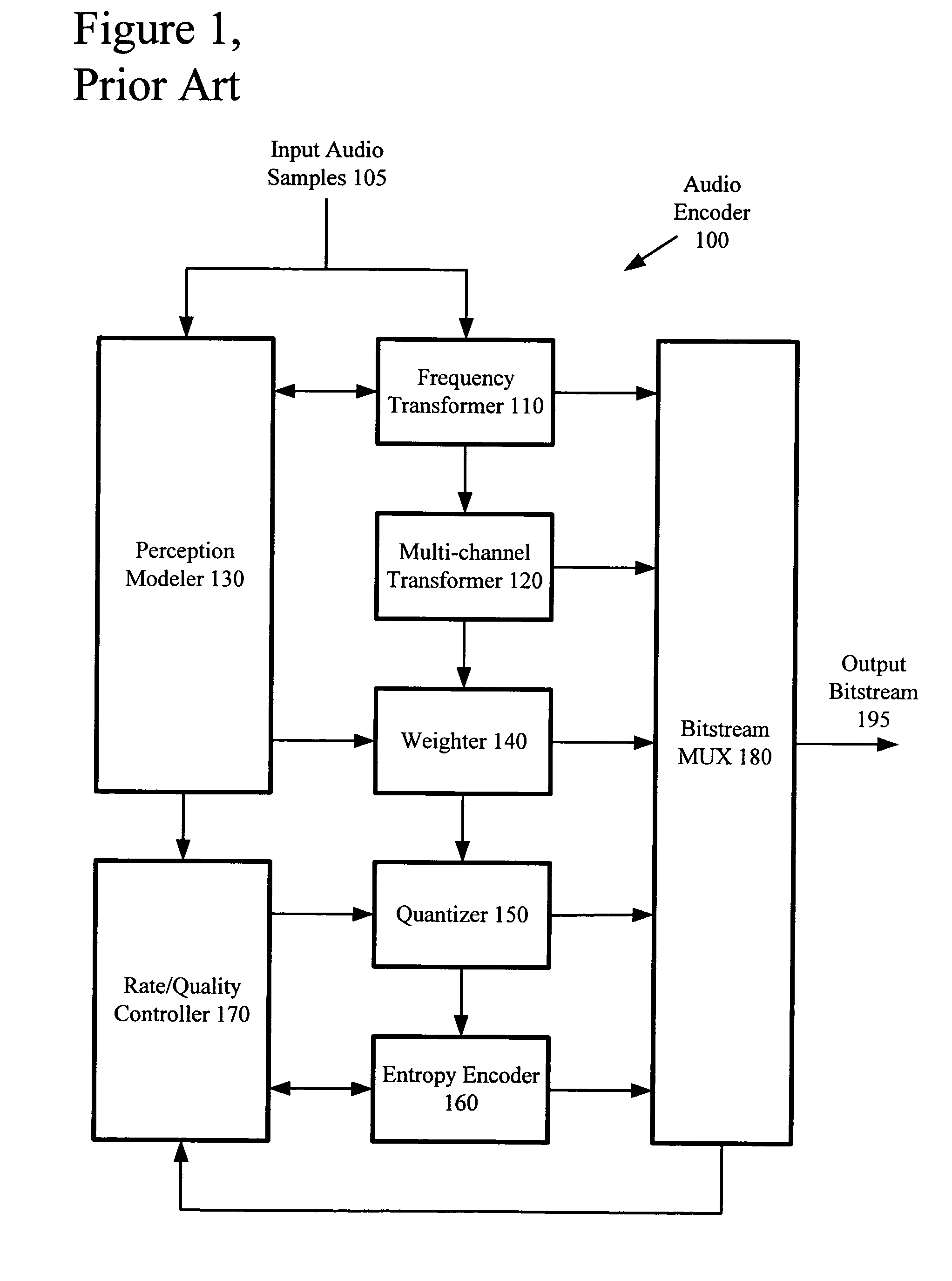

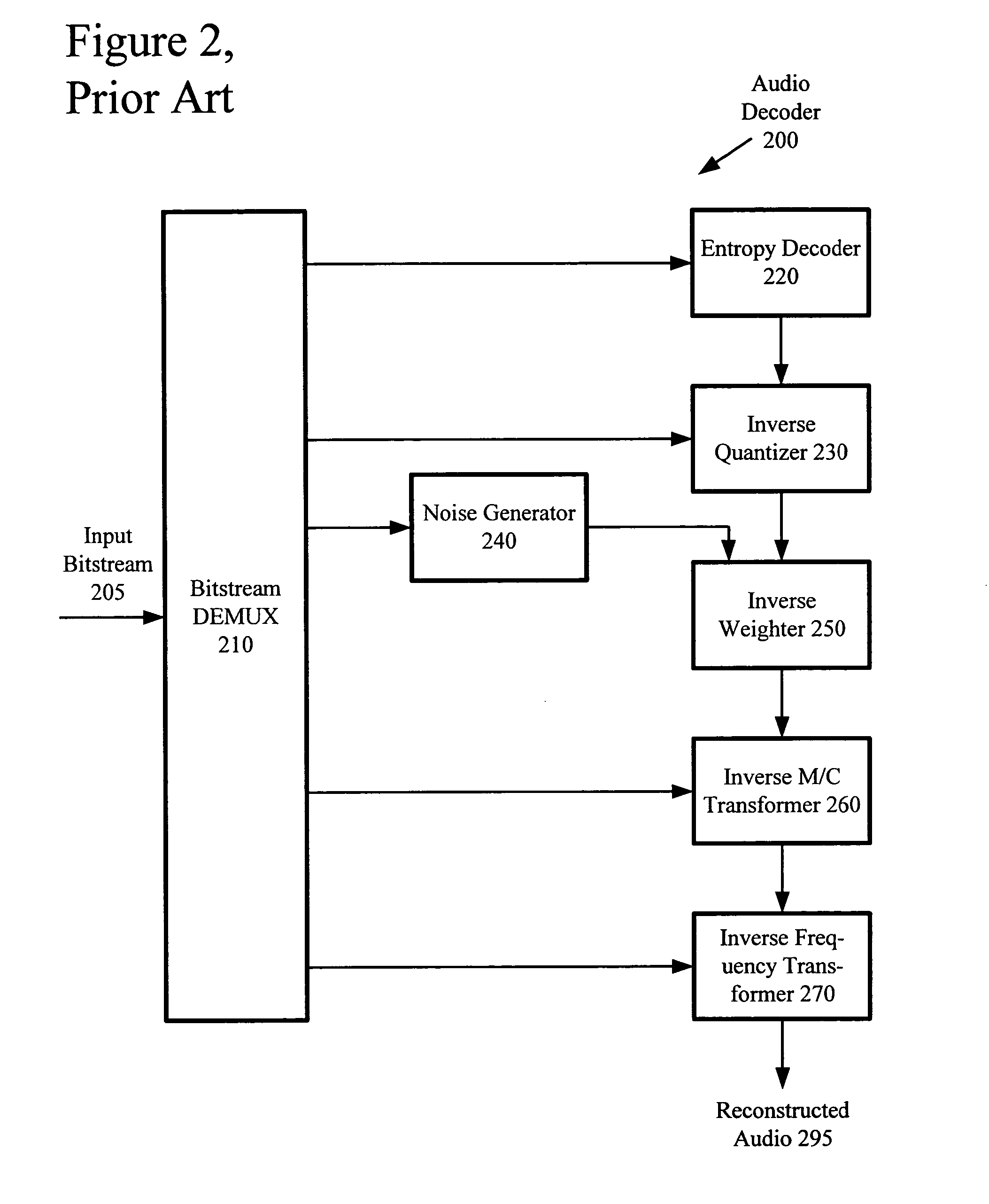

Multi-pass variable bitrate media encoding

InactiveUS20050015246A1Enhance listening experienceQuality improvementSpeech analysisFile sizeComputer science

An encoder uses multi-pass VBR control strategies to provide constant or relatively constant quality for VBR output while guaranteeing (within tolerance) either compressed file size or, equivalently, overall average bitrate. The control strategies include various techniques and tools, which can be used in combination or independently. For example, in a first pass, an audio encoder encodes a sequence of audio data partitioned into variable-size chunks. In a second pass, the encoder encodes the sequence according to control parameters to produce output of relatively constant quality. The encoder sets checkpoints in the second pass to adjust the control parameters and / or subsequent checkpoints. The encoder selectively considers a peak bitrate constraint to limit peak bitrate. The encoder stores auxiliary information from the first pass for use in the second pass, which increases the speed of the second pass. Finally, the encoder compares signatures for the input data to check consistency between passes.

Owner:MICROSOFT TECH LICENSING LLC

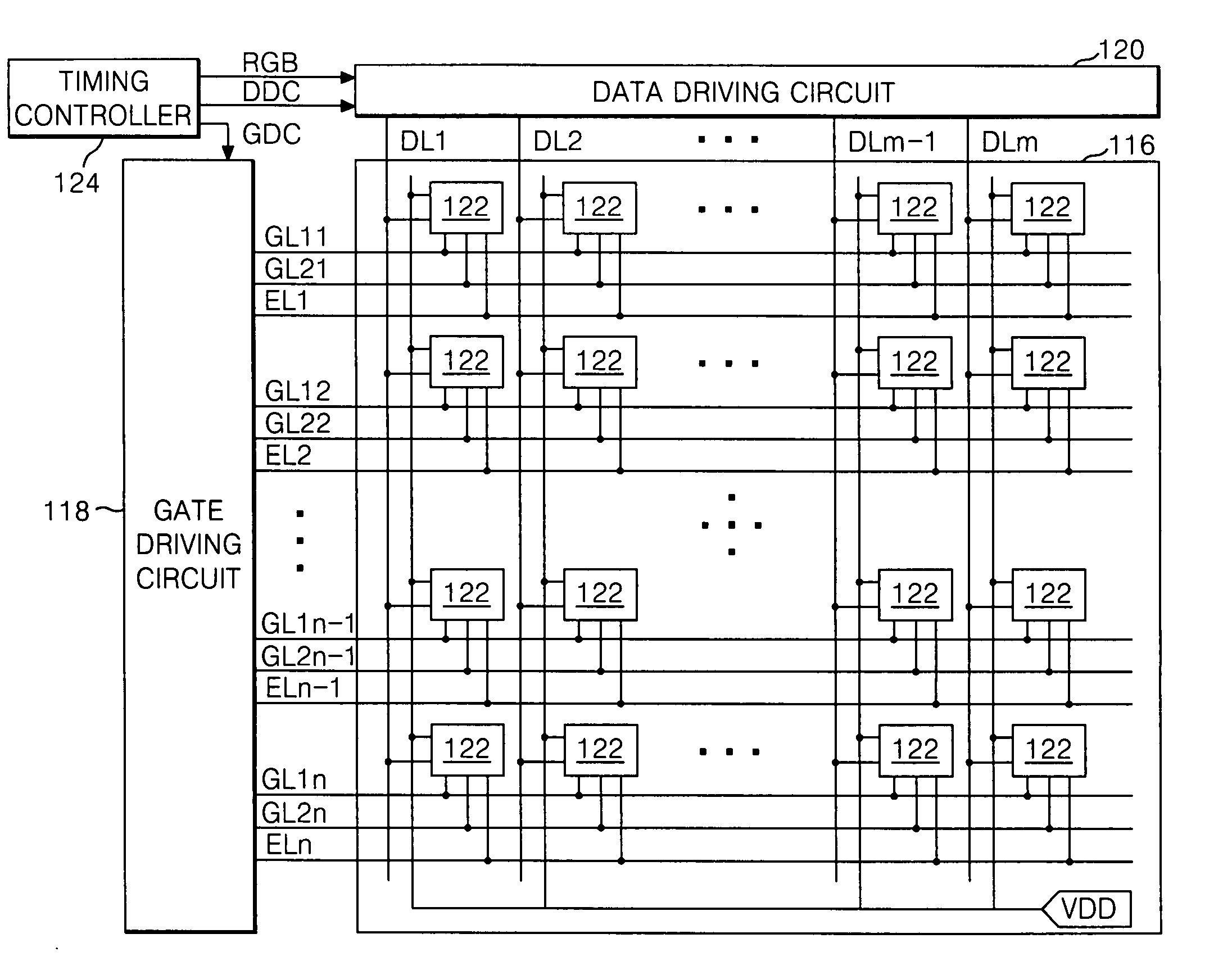

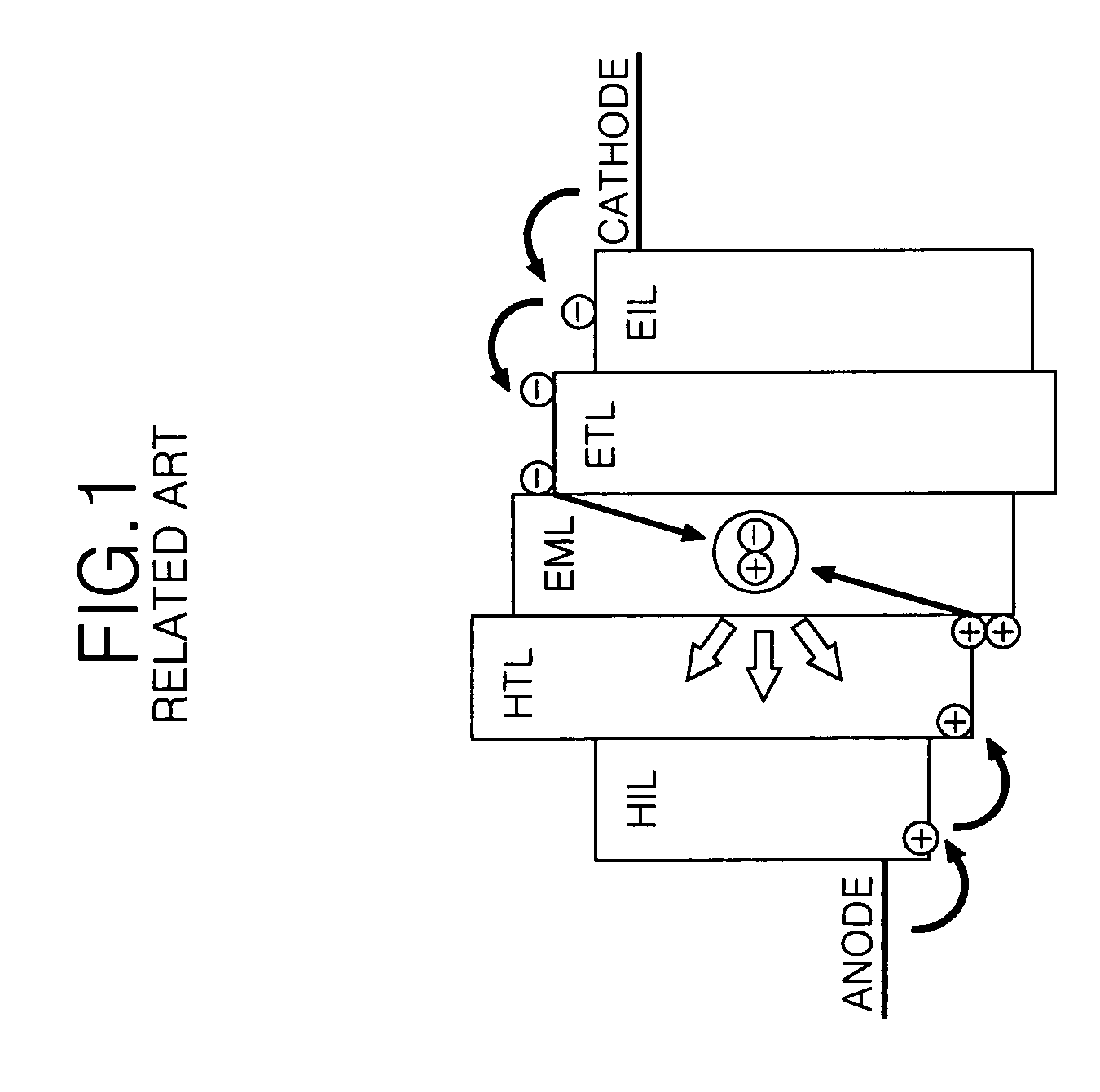

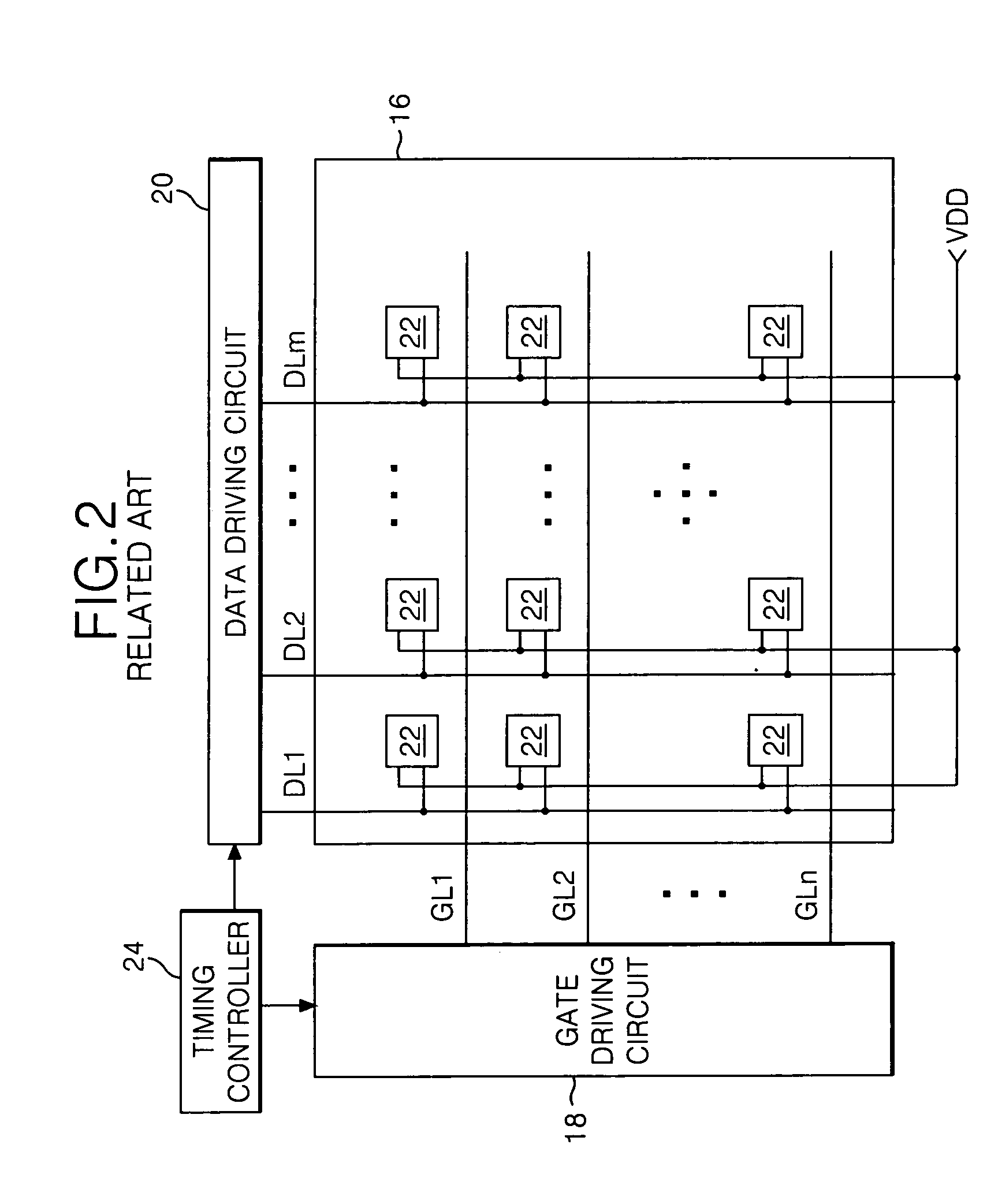

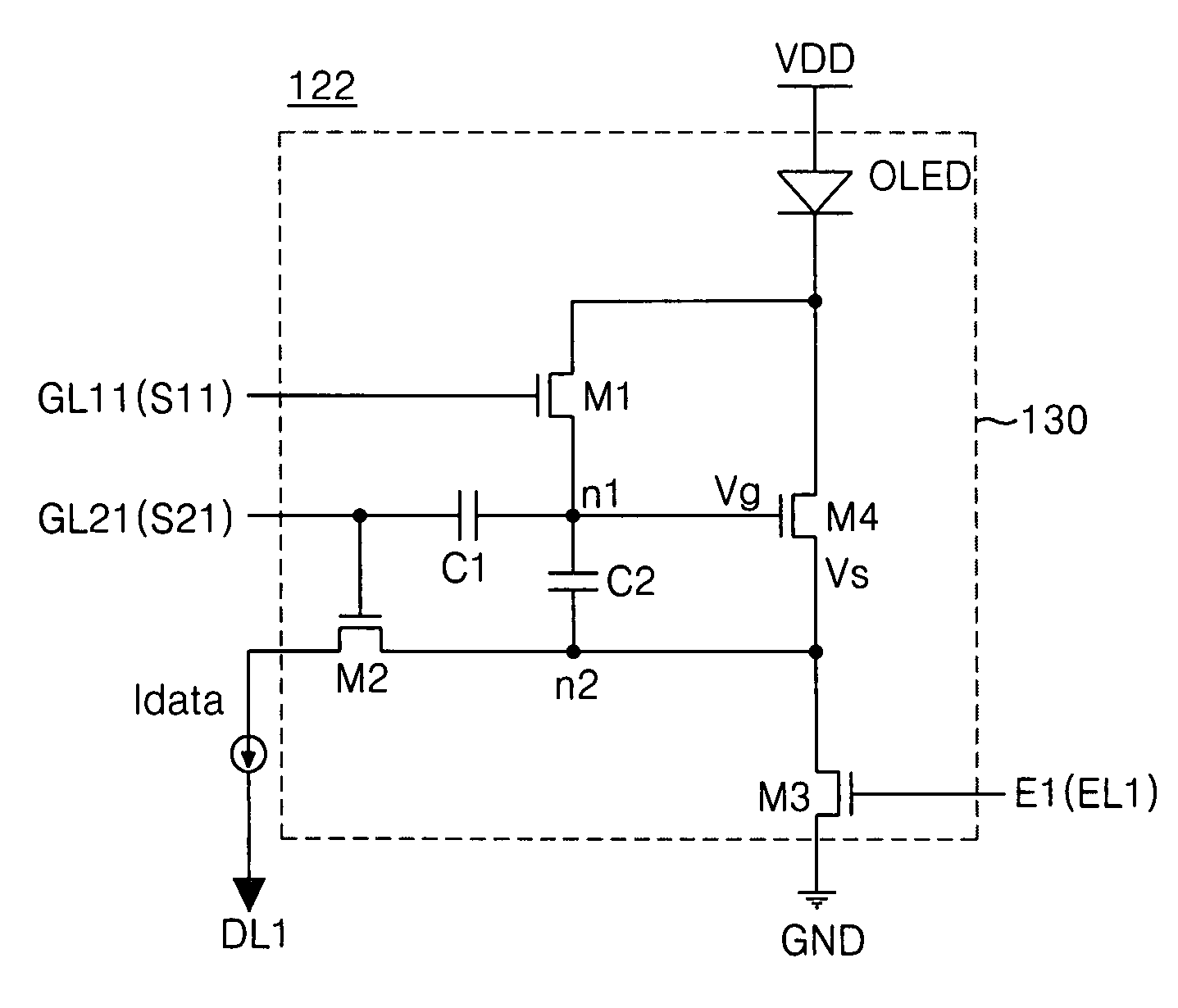

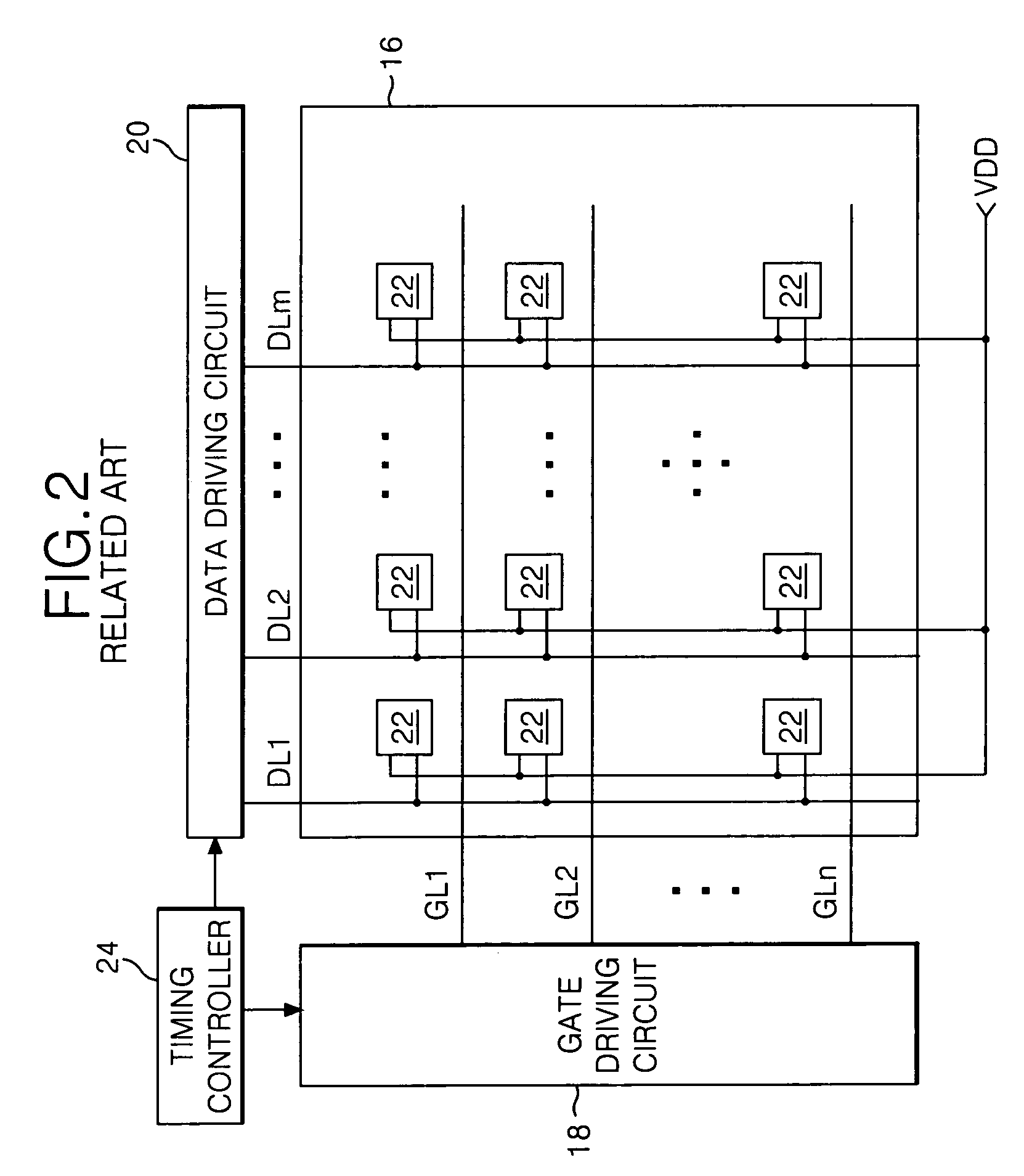

Organic light-emitting diode display device and driving method thereof

ActiveUS20080001857A1Reduce charging timeImprove quality uniformityElectrical apparatusElectroluminescent light sourcesData linesVoltage source

An organic light-emitting diode display device includes a data line, a first and second gate lines crossing the data line, an emission line crossing the data line, an organic light-emitting diode device having an anode electrode and a cathode electrode, a high-level potential driving voltage source for supplying a high-level potential driving voltage to the anode electrode, a first switch element for connecting a cathode electrode of the organic light-emitting diode device to a first node, a second switch element for connecting the data line to a second node, a third switch element for connecting the second node to a ground voltage source, a driving element for adjusting a current flowing between the cathode electrode of the organic light-emitting diode device and the first node in accordance with a voltage of the first node, a first capacitor connected between the second gate line and the first node, and a second capacitor connected between the first node and the second node.

Owner:LG DISPLAY CO LTD

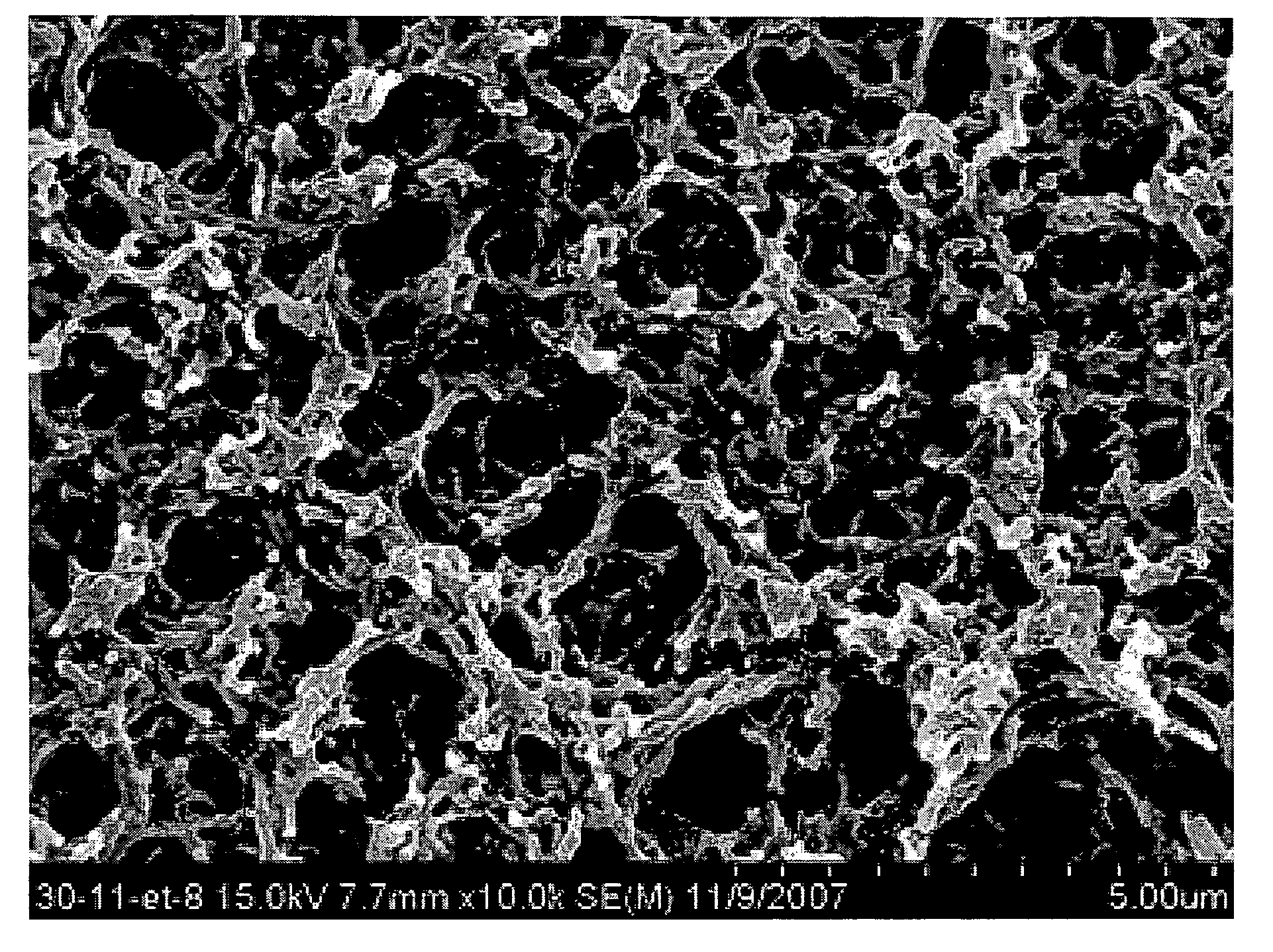

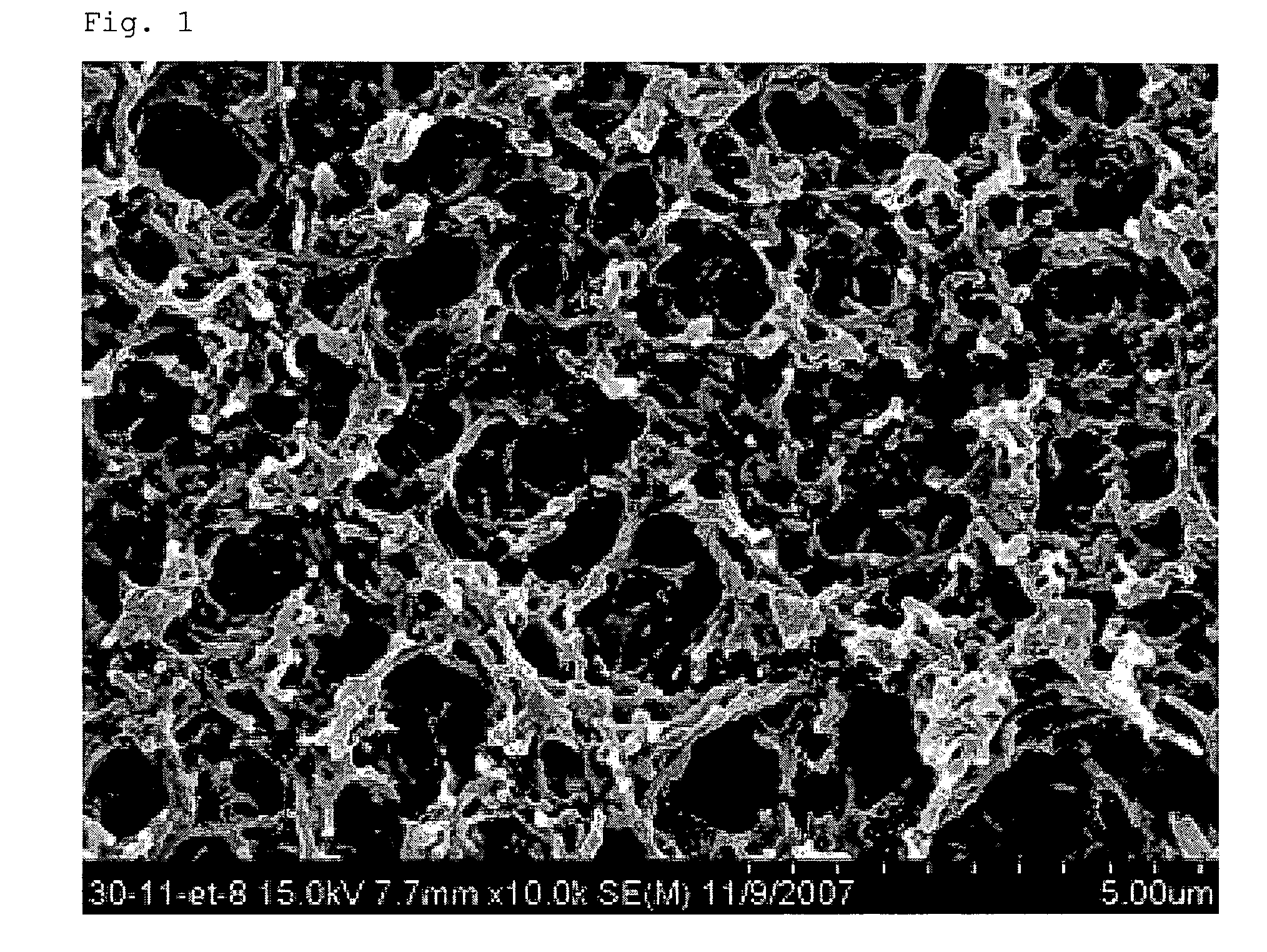

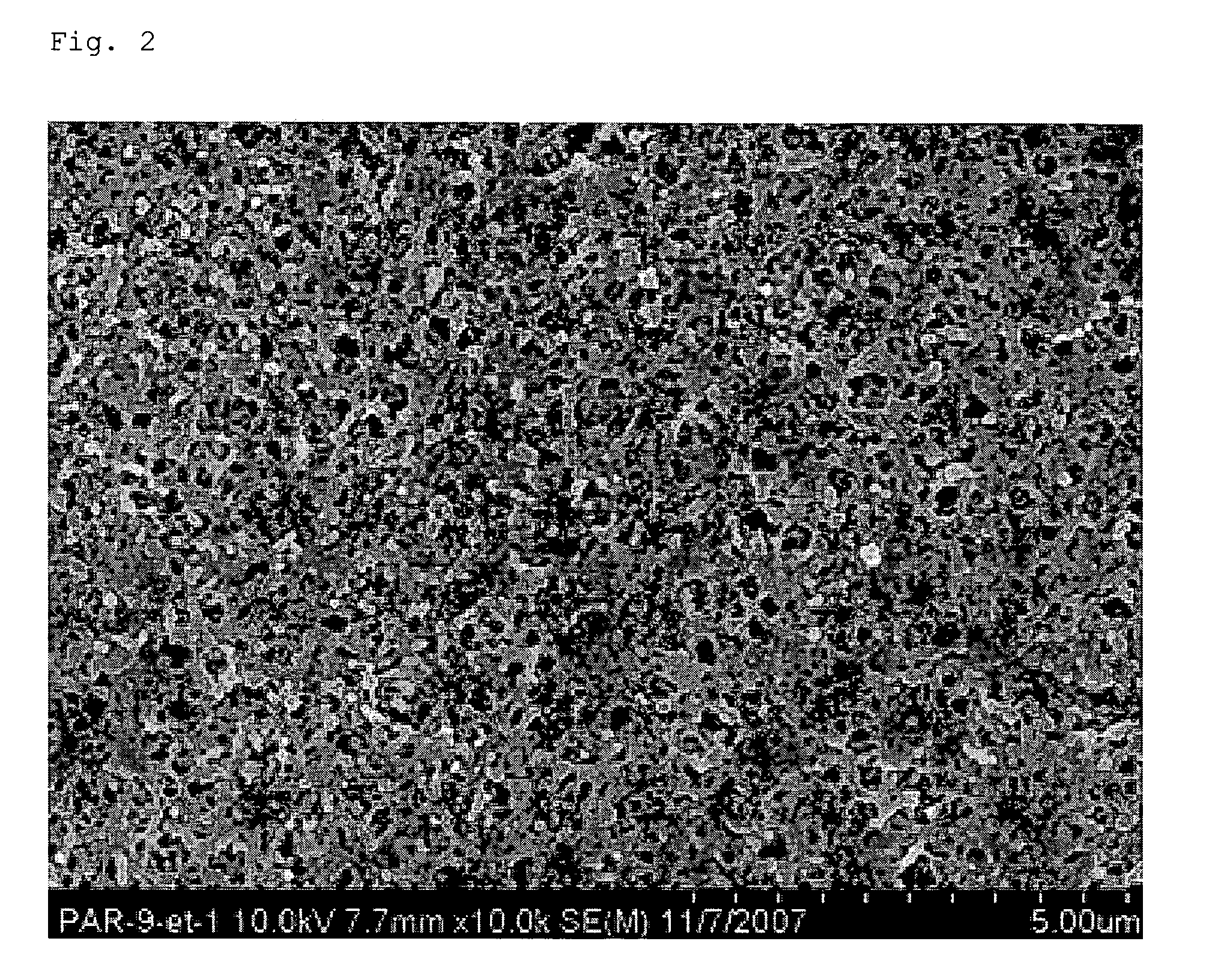

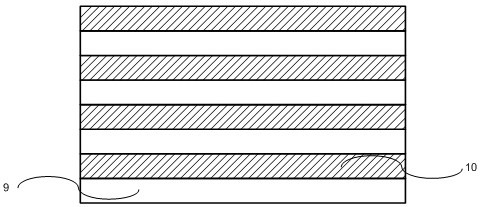

Method of manufacturing the microporous polyolefin composite film with a thermally stable layer at high temperature

InactiveUS20110033743A1Improve breathabilityLow shrinkageSemi-permeable membranesLi-accumulatorsPolyolefinPolymer science

Provided is a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, particularly, to a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, comprising preparing a polyolefin microporous film using a composition containing a polyolefin resin; coating a solution, in which a high heat-resistant resin is dissolved in a solvent, on one surface or both surfaces of the polyolefin microporous film; phase-separating the polyolefin microporous film coated with the solution by contacting with a nonsolvent after the coating; and drying the polyolefin microporous film so as to remove the solvent and nonsolvent remained after the phase-separating, and thus forming the thermally stable layer at high temperature.

Owner:SK INNOVATION CO LTD

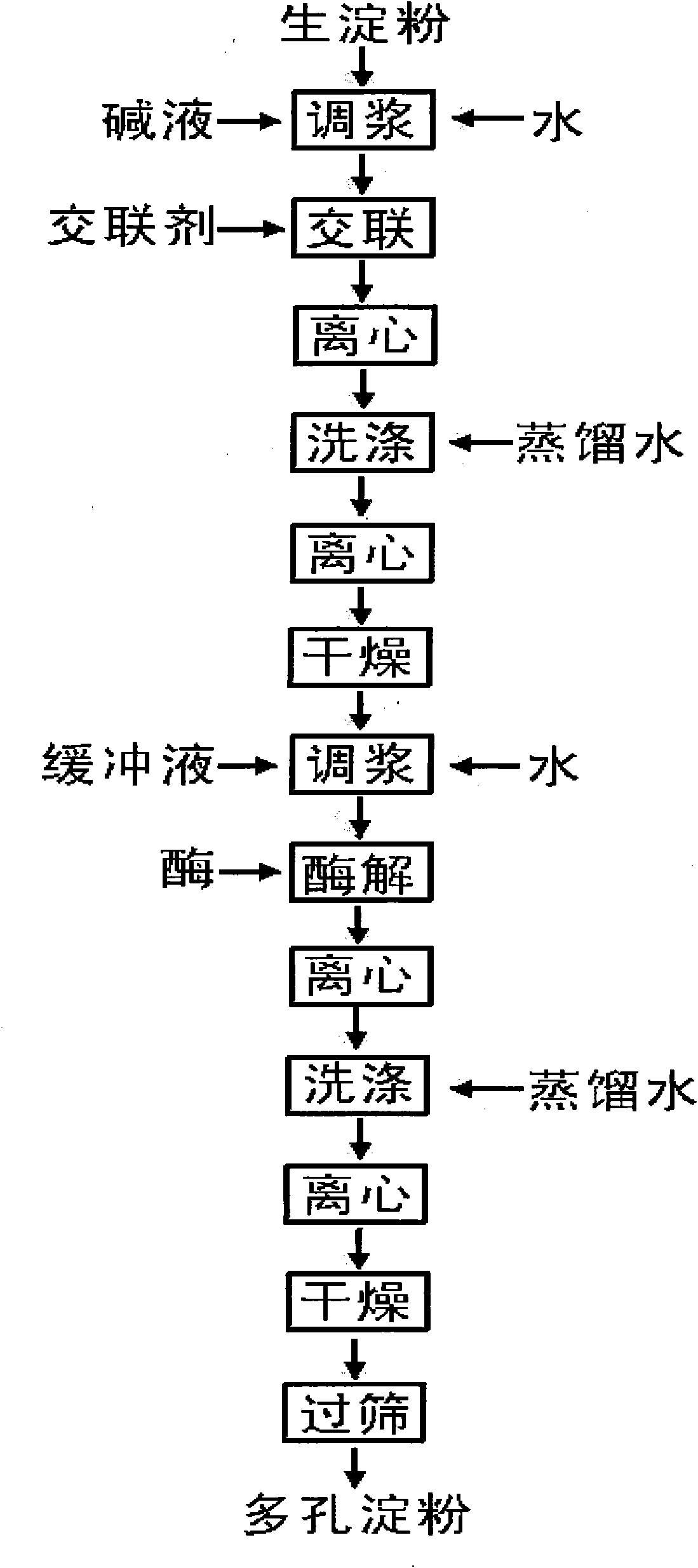

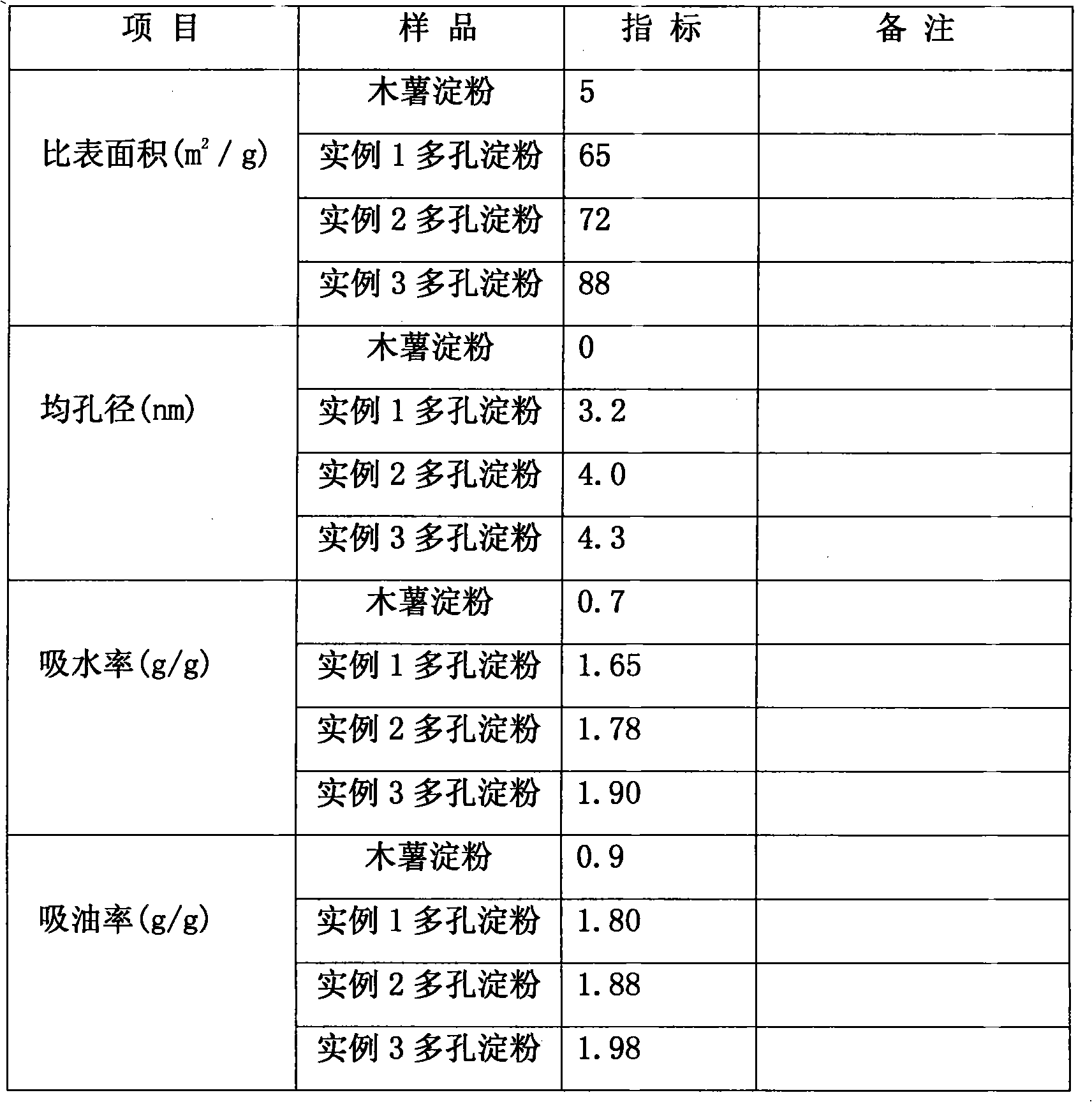

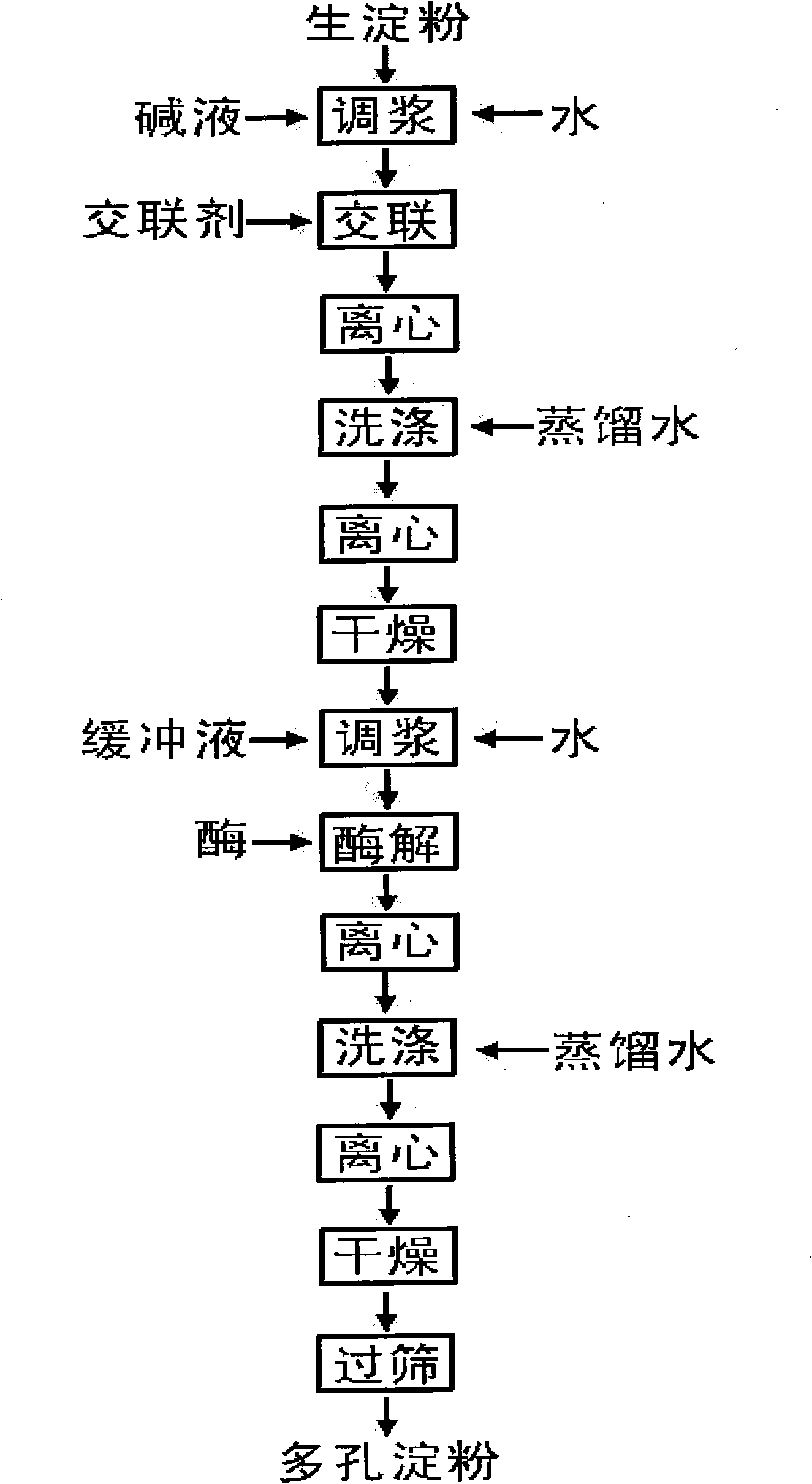

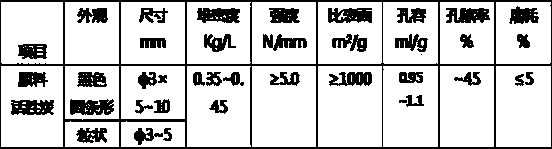

Method for preparing crosslinked porous cassavastarch

InactiveCN101979638AGood for cross-linking reactionIncrease the degree of cross-linkingFermentationMolecular networkChemistry

The invention discloses a method for preparing crosslinked porous cassavastarch, which is to regulate the concentration of cassavastarch suspension to a diluter range from 20 to 34.8 weight percent for facilitating cross-linking reaction, achieving high degree of crosslinking and ensuring the quality uniformity of the crosslinked starch and creating a favorable condition for subsequent enzymolysis. The prepared crosslinked porous cassavastarch has a compact molecular shell structure, is stable in structure, enzymolysis resistant, chemically stable, free from collapse, safe, nontoxic, biodegradable and widely applicable and allows the size of the aperture of the molecular network to be adjusted by processes. In the preparation method, the production process is simple, the raw material cassavastarch is rich, cheap and readily available, the production cost is low, the production scale can be adjusted flexibly and the adaptability is high. The method is applicable to common fine starch manufacturers, chemically modified starch manufactures and common food, medicine, industrial, farm chemical, pesticide manufacturers and other manufacturers.

Owner:南宁创新科技医药技术有限公司

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and a method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS20020146868A1Great fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

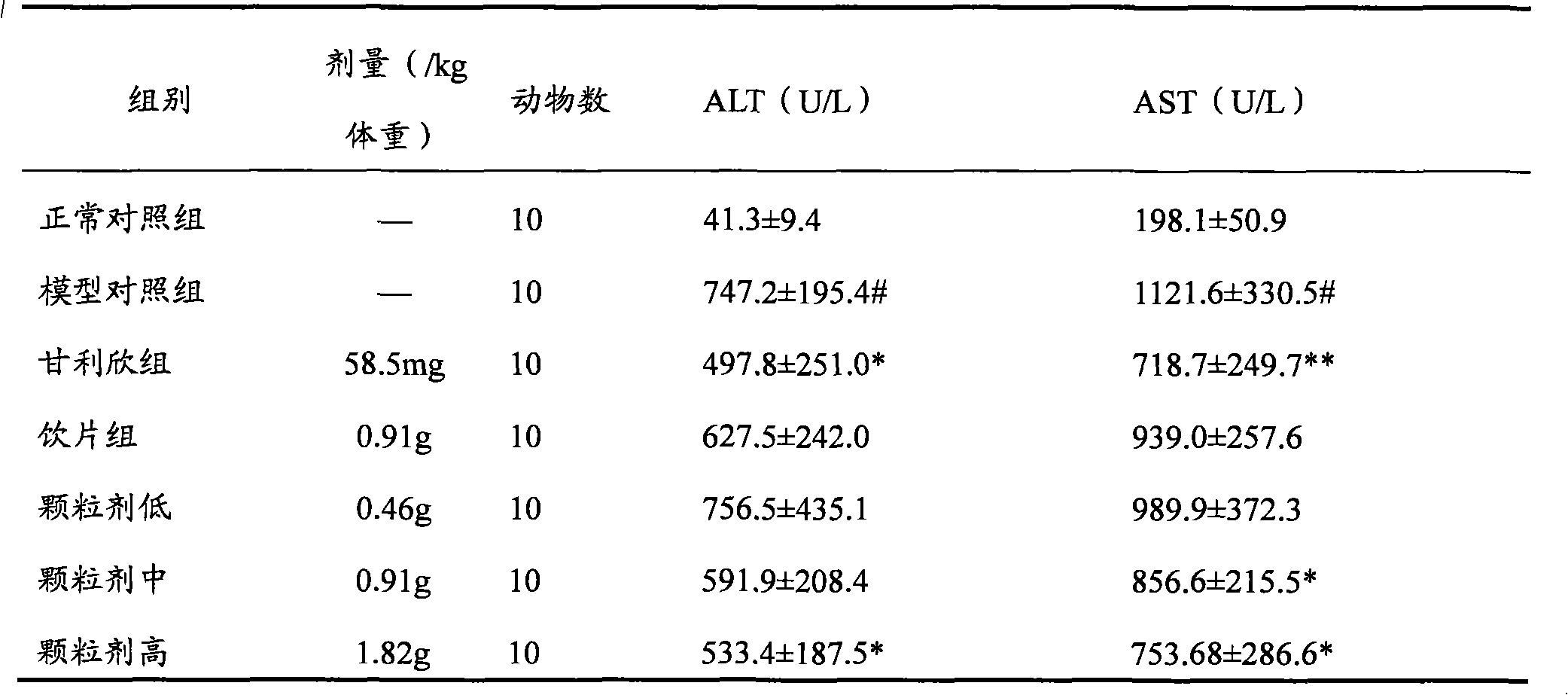

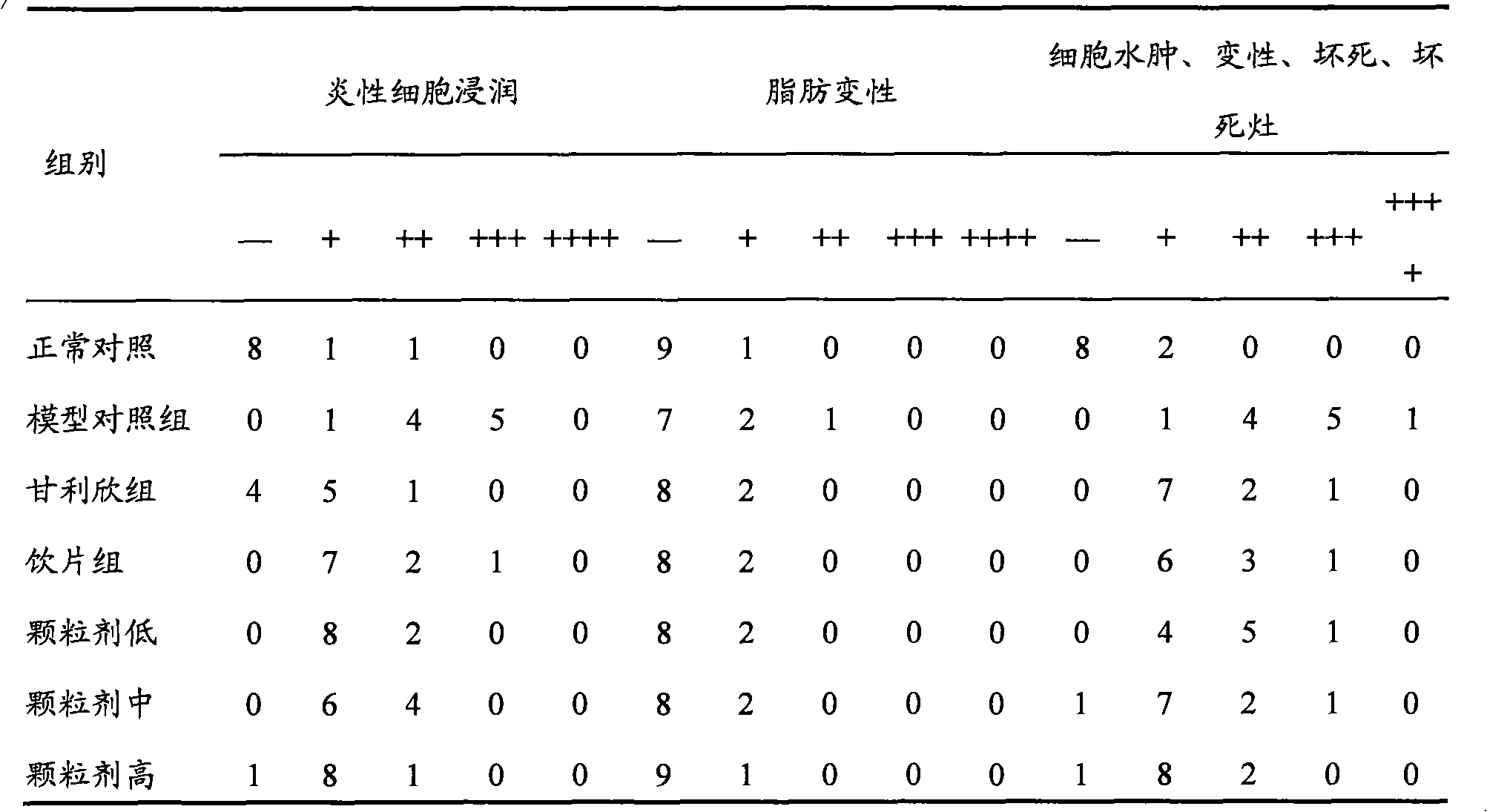

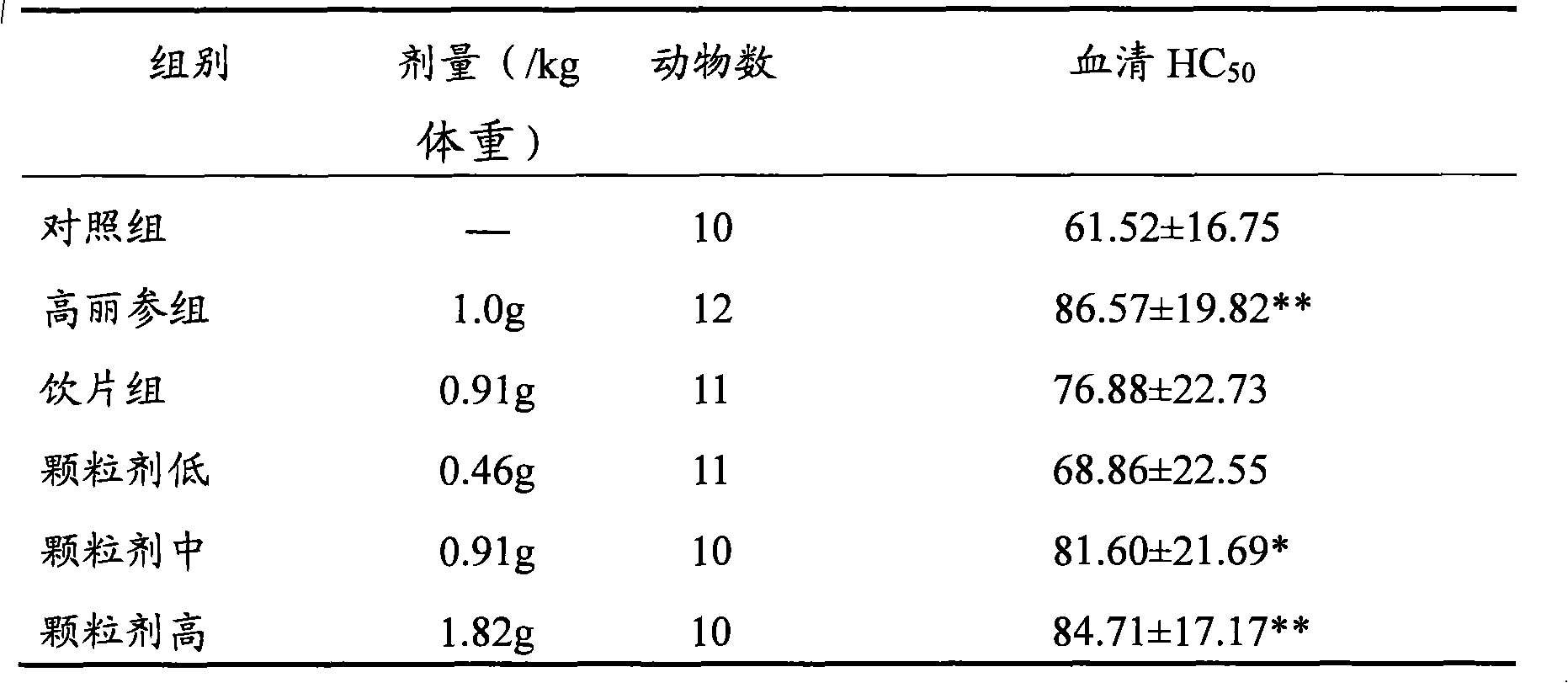

Chinese medicinal composition granules and preparation method thereof

ActiveCN101850066AGood effectSafe to takeAntinoxious agentsGranular deliveryDiseaseSalvia miltiorrhiza

The invention relates to Chinese medicinal composition granules and a preparation method thereof. The Chinese medicinal composition granules comprise the following ruptured powder in part by weight: 3 to 18 parts of American ginseng ruptured powder, 1 to 24 parts of pseudo-ginseng ruptured powder, 6 to 36 parts of dendrobium ruptured powder, and 9 to 45 parts of root of red-rooted salvia ruptured powder, wherein the granularity D90 of the ruptured powder is between 5 and 75 mu m. The invention also provides a method for preparing the Chinese medicinal composition granules. The method comprises the following steps of: uniformly mixing the American ginseng ruptured powder, pseudo-ginseng ruptured powder, dendrobium ruptured powder, and root of red-rooted salvia ruptured powder of which the D90 is between 5 and 75 mu m; preparing a soft material by adopting aqueous ethanol at the concentration of over 20 vol percent; and after granulating by using a granulator with 10 to 30 meshes, drying and finishing the granules to obtain the Chinese medicinal composition granules. The Chinese medicinal composition granules are applied to preventing and regulating human cardiac-cerebral vascular system diseases and sub-health state such as weak immunity and fatigability, have the obvious advantages of high medical effect, high quality uniformity, convenient carrying and administration, safety, reliability, and the like, and can meet the requirement on modern fast-paced lifestyle.

Owner:ZHONGSHAN ZHONGZHI PHARMA GRP +1

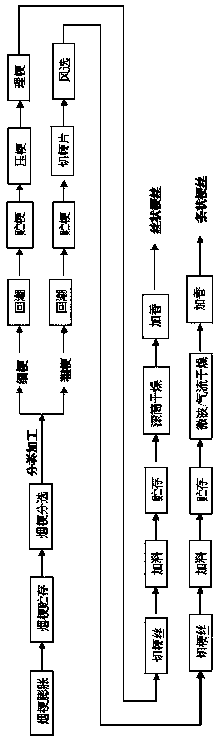

Process for processing filament-shaped stem and strip-shaped stem simultaneously

ActiveCN103960769AQuality improvementImprove quality uniformityTobacco preparationTobacco treatmentMicrowaveBiology

Provided is a process for processing a filament-shaped stem and a strip-shaped stem simultaneously. The process is characterized in that the first step of tobacco stem expansion, the second step of tobacco stem storage, the third step of tobacco stem separation and the fourth step of tobacco stem classification processing are included; in the first step of tobacco stem expansion, fed tobacco stems are expanded in a stem explosion mode or a microwave mode; in the second step of tobacco stem storage, the expanded tobacco stems are stored for 5 days to two years, so that the tobacco stems are structurally solidified; in the third step of tobacco stem separation, two types of the expanded tobacco stems obviously different in size are separated through tobacco stem separation equipment, one type of tobacco stem is thin expanded tobacco stems, the width or the diameter of each tobacco stem is smaller than 5 mm, and the other type of tobacco stem is thick expanded tobacco stems, and the width or diameter of each tobacco stem is larger than 5 mm; in the fourth step of tobacco stem classification processing, according to the characteristics of the thin expanded tobacco stems and the characteristics of the thick expanded tobacco stems, classification processing is carried out in the corresponding processing process, the thin expanded tobacco stems are processed to be filament-shaped stems and the thick expanded tobacco stems are processed to be strip-shaped stems.

Owner:CHINA TOBACCO HENAN IND

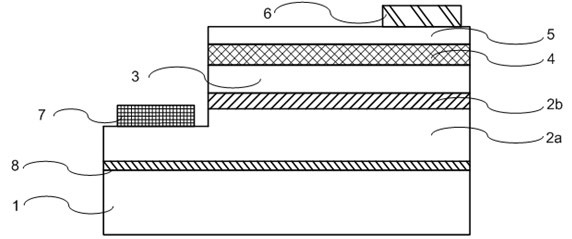

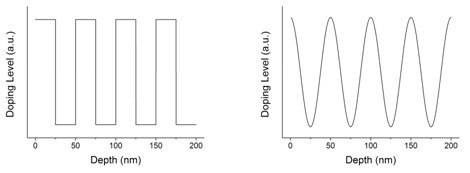

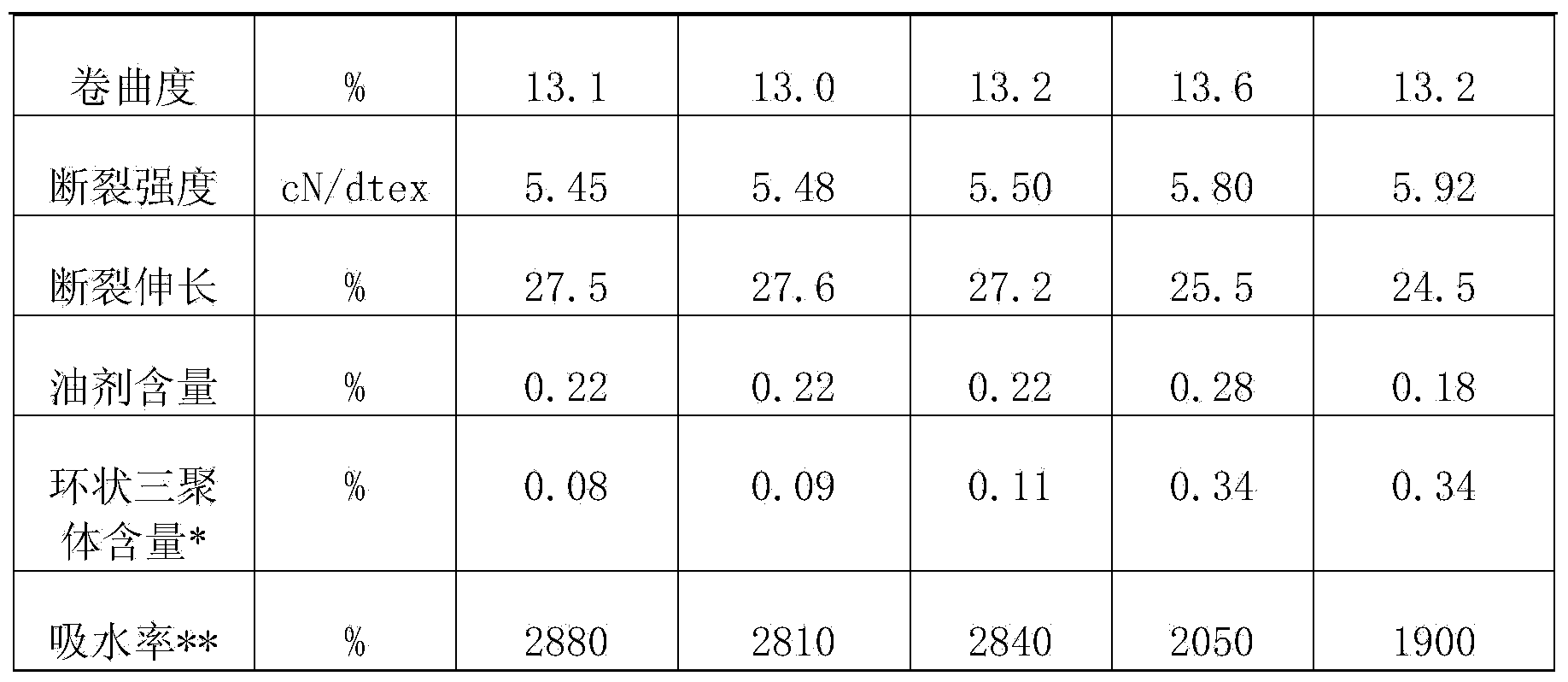

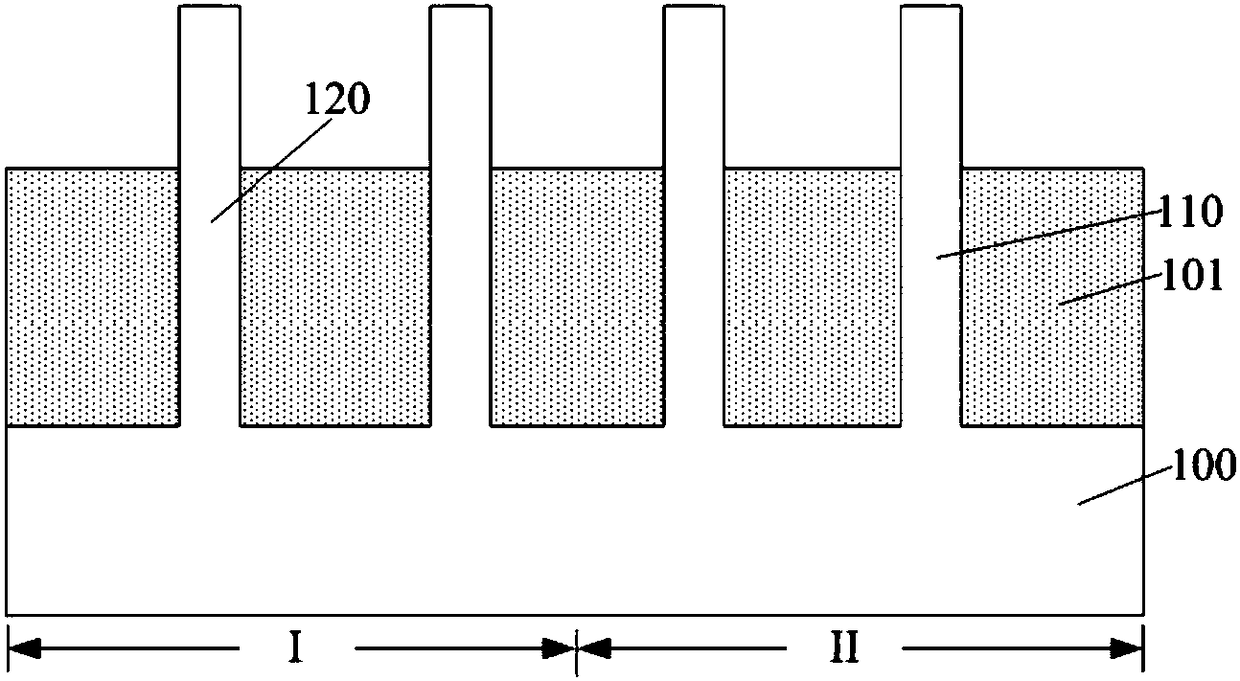

III-group nitride light-emitting diode (LED) and manufacturing method thereof

ActiveCN102185062AIncreased longitudinal resistivityImprove crystal qualitySemiconductor devicesNitrideLight-emitting diode

The invention discloses a III-group nitride light-emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate and a semiconductor epitaxial laminate which is laminated on the substrate, wherein the semiconductor epitaxial laminate sequentially comprises an N type layer, a luminescent layer and a P type layer from top to bottom. The LED is characterized in that: an N type layer table face is formed in the N type layer by etching a part of the semiconductor epitaxial laminate; an N type electrode is arranged on the N type layer table face; a P type electrode is arranged on the upper surface of the un-etched part of the P type layer; the N type layer also comprises a uniformly doped layer of which the doping concentration is consistent and a modulation doped layer of which the doping concentration is changeable; and the modulation doped layer is arranged between the uniformly doped layer and the luminescent layer. A doped mode of the modulation doped layer is gradual transition doping which connects uniformly doped layer and the luminescent layer of which the doping concentration is consistent. The concentration change trend is decrease progressively change from the uniformly doped layer to the luminescent layer. By the LED and the manufacturing method, the crystal quality and the luminance uniformity can be obviously improved, and the lighting effect is improved.

Owner:SUN YAT SEN UNIV

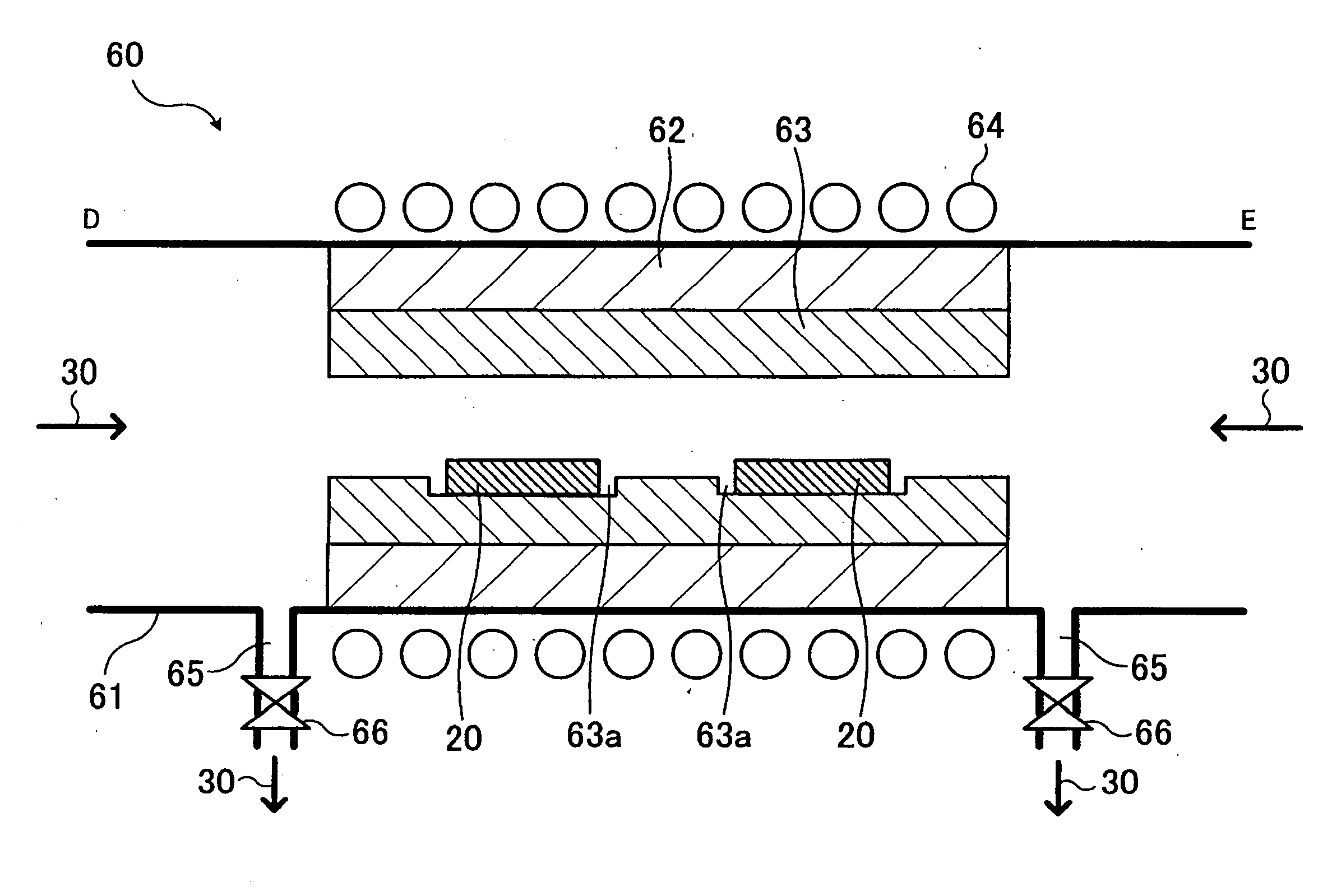

Epitaxial film deposition system and epitaxial film formation method

InactiveUS20060252243A1Improve film thickness uniformityImprove quality uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesPyrometerEngineering

An epitaxial film deposition system includes a reactor, a susceptor, a wafer heating unit, a reactant gas supply orifice, and an aperture for venting the reactant gas. The reactant gas is supplied to a reactor region between the susceptor and a graphite plate so as to circulate in layered flow in a direction along the reactor inner wall in the planar direction of a mounted SiC wafer. The temperature of the wafer is controlled by a high frequency coil and halogen lamps based on temperatures detected by a pyrometer. By circulating the reactant gas over the surface of the stationary wafer, it is possible to form, under various process conditions, an SiC epitaxial film having good film quality and good uniformity of film thickness, without providing any wafer rotation mechanism.

Owner:FUJI ELECTRIC HLDG CO LTD

Wood pulp nitrocotton production method

The invention belongs to the technical field of nitrocotton production methods, and in particular relates to a wood pulp nitrocotton production method. In the method, wood pulp is used as a raw material, the energy consumption in production is low, the production efficiency is high and the chroma of the product is low. The wood pulp nitrocotton production method comprises the following steps of: nitrifying wood, wherein mixed acid is a mixture of nitric acid, sulfuric acid and water, and the mixed acid comprises 20 to 55 mass percent of nitric acid, 10 to 18 mass percent of water and the balance of sulfuric acid; centrifugally driving acid to obtain acid wood pulp nitrocotton; boiling and washing the acid wood pulp nitrocotton; adding water to regulate the initial acidity to be 0.5-10g / l,and controlling the boiling and washing temperature to be 101-150DEG C; dehydrating; and driving water. The wastewater emission in the refined cotton production process is reduced, environmental pollution is lightened, and the aims of saving energy and reducing emission can be fulfilled.

Owner:SICHUAN NITROCELLULOSE CORP

Solid expandable compositions

Solid expandable compositions useful for the manufacture of cavity filler inserts and the like are obtained by combining at least one anhydride- functionalized thermoplastic, at least one amine-functionalized latent curing agent, and at least one latent blowing agent. Such compositions may be formulated so as to provide a highly expanded foam upon heating to activate the blowing agent, wherein the foam is resistant to sagging and tolerant of overbaking conditions.

Owner:HENKEL KGAA +1

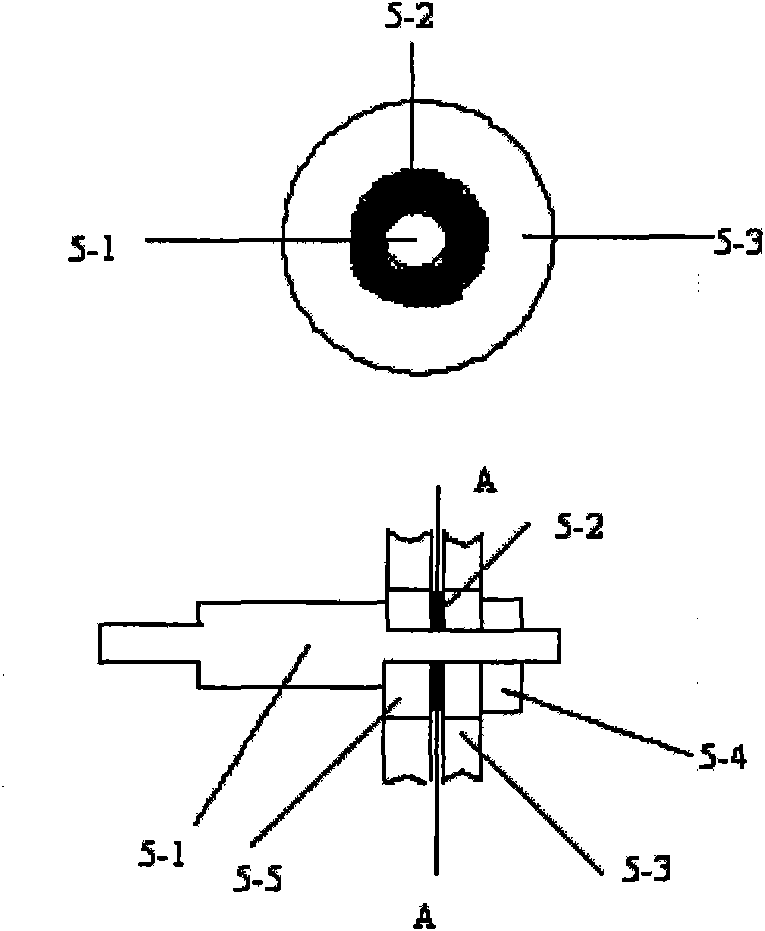

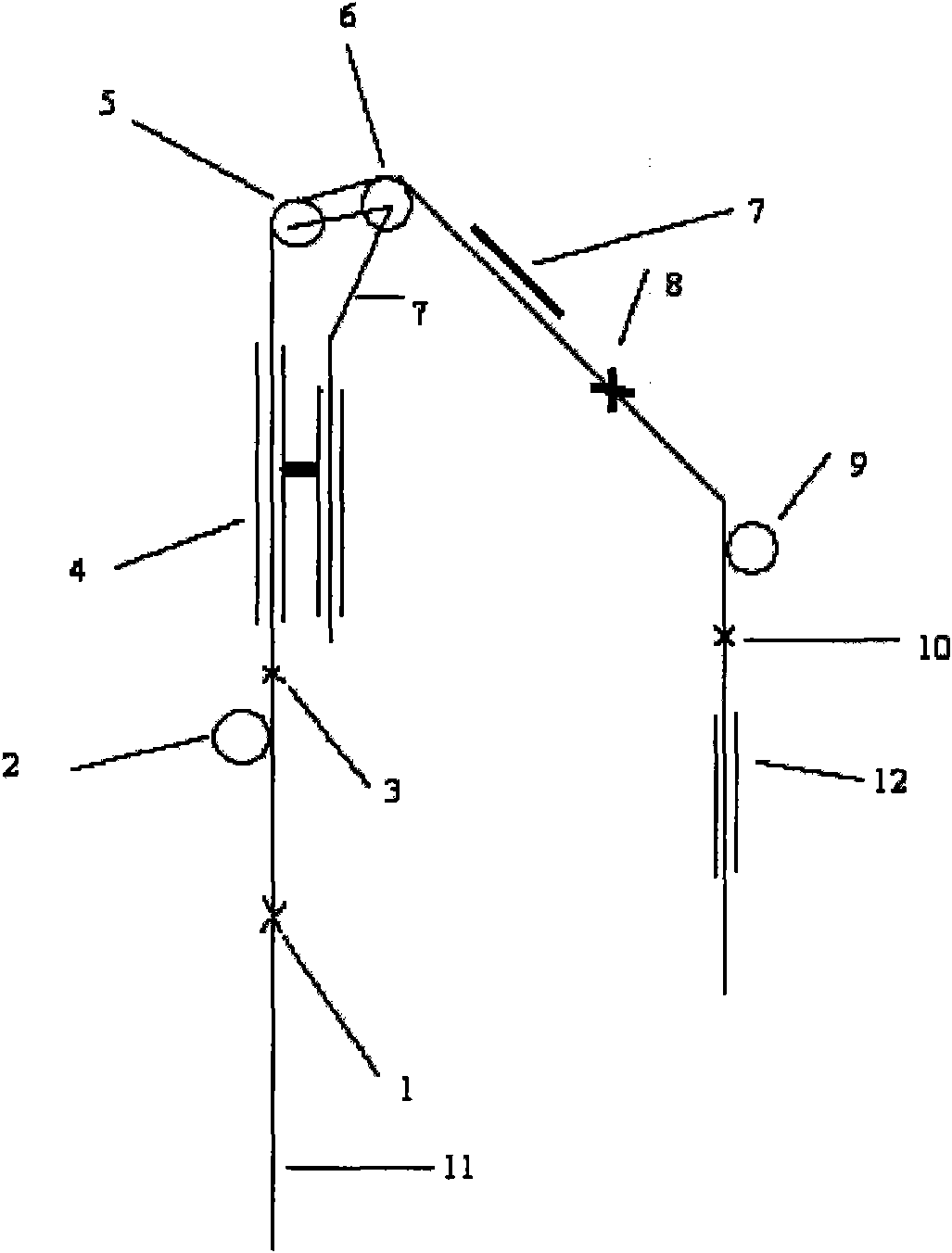

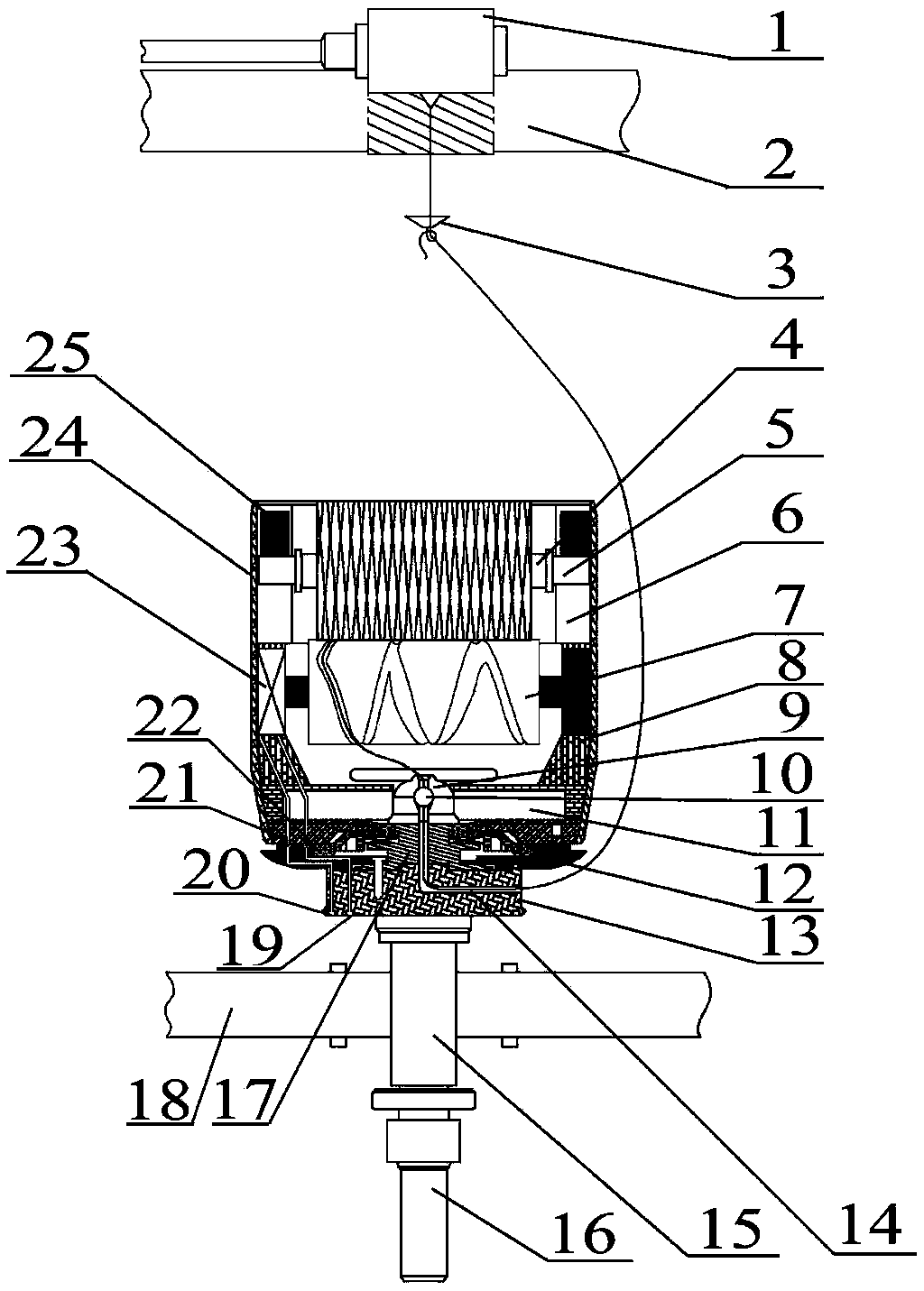

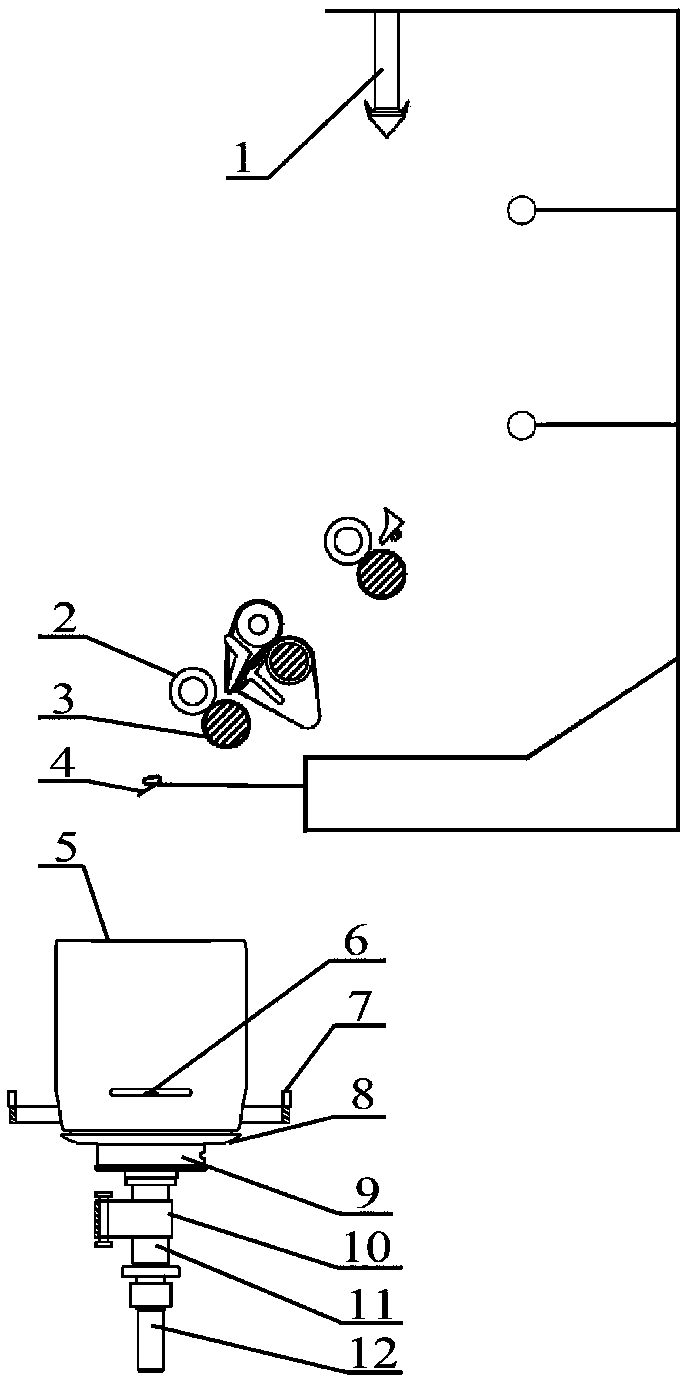

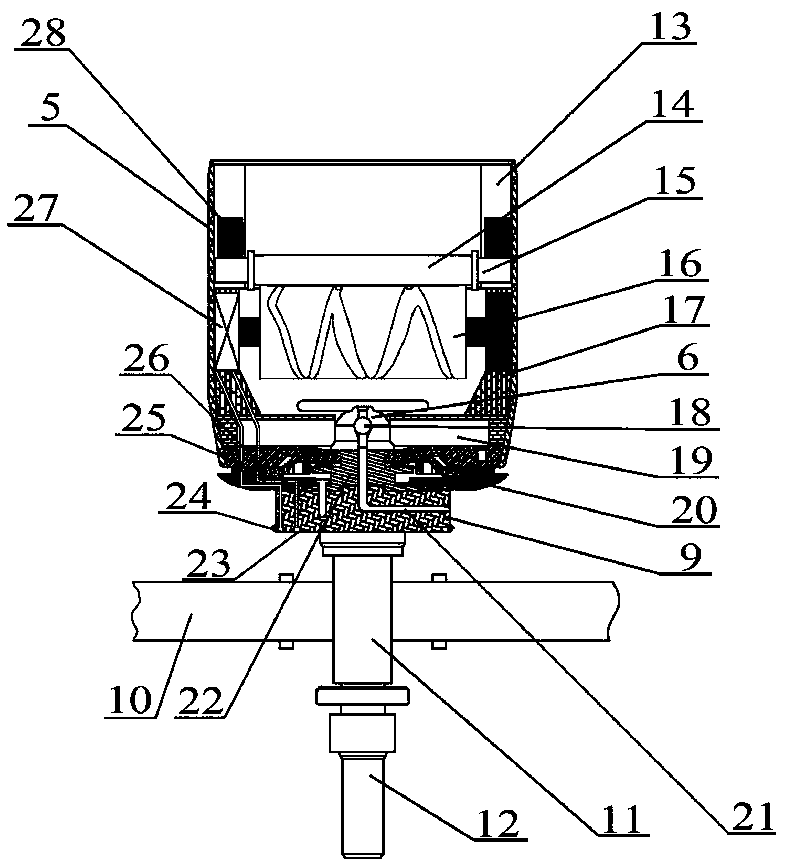

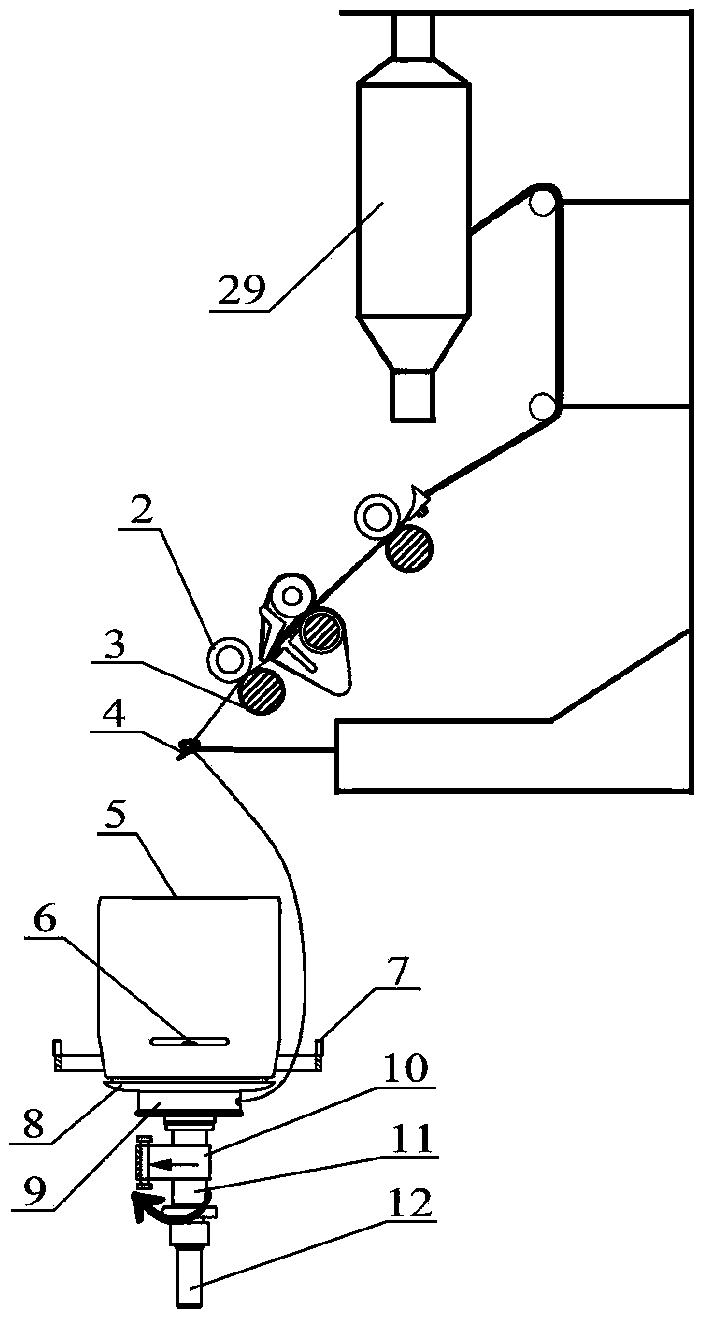

Method for manufacturing superfine denier modified terylene torque-less false twist textured yarn and special thread guide

The invention relates to a method for manufacturing a superfine denier modified terylene torque-less false twist textured yarn and a special thread guide. The invention aims to solve the technical problem of providing a special thread guide and a manufacturing method using the thread guide. The thread guide comprises two thread rollers (5-3) on the thread guide shaft (5-1), wherein the two thread rollers can rotate independently, and a gap is reserved between the two thread rollers. The manufacturing method comprises the following steps that: two threads (11) get into a front thread-separation thread guide (1) of a first roller along the respective thread path; then the threads pass through a roller (2), a first hot box inlet thread guide (3), a first hot box (4), a special double-thread free-rotation thread guide (5), a special turning double-thread free-rotation thread guide (6), a cooling plate (7), a false twister (8), a second roller (9) and a network nozzle (10) in turn for stranding; and then the threads get into a second hot box (12) to perform heat shaping and obtain the product.

Owner:ZHEJIANG HENGYI GRP CO LTD +3

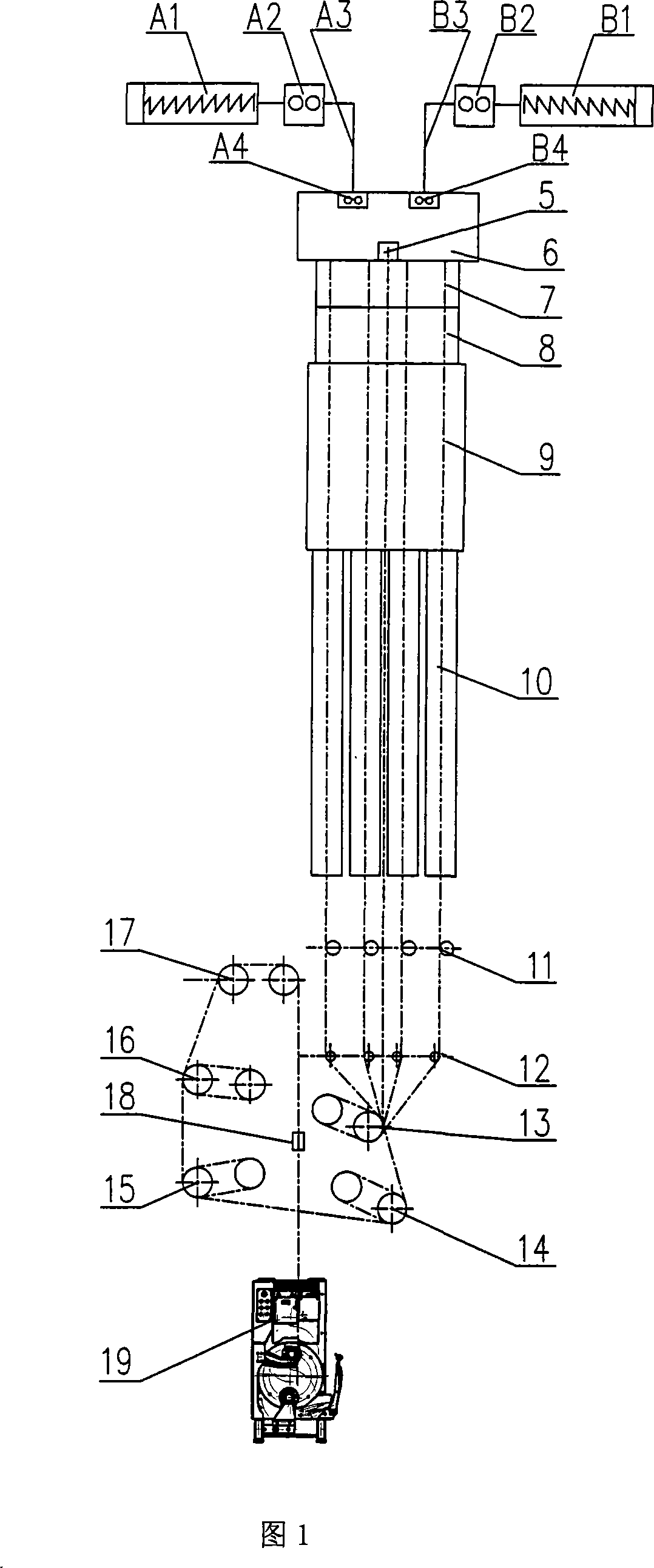

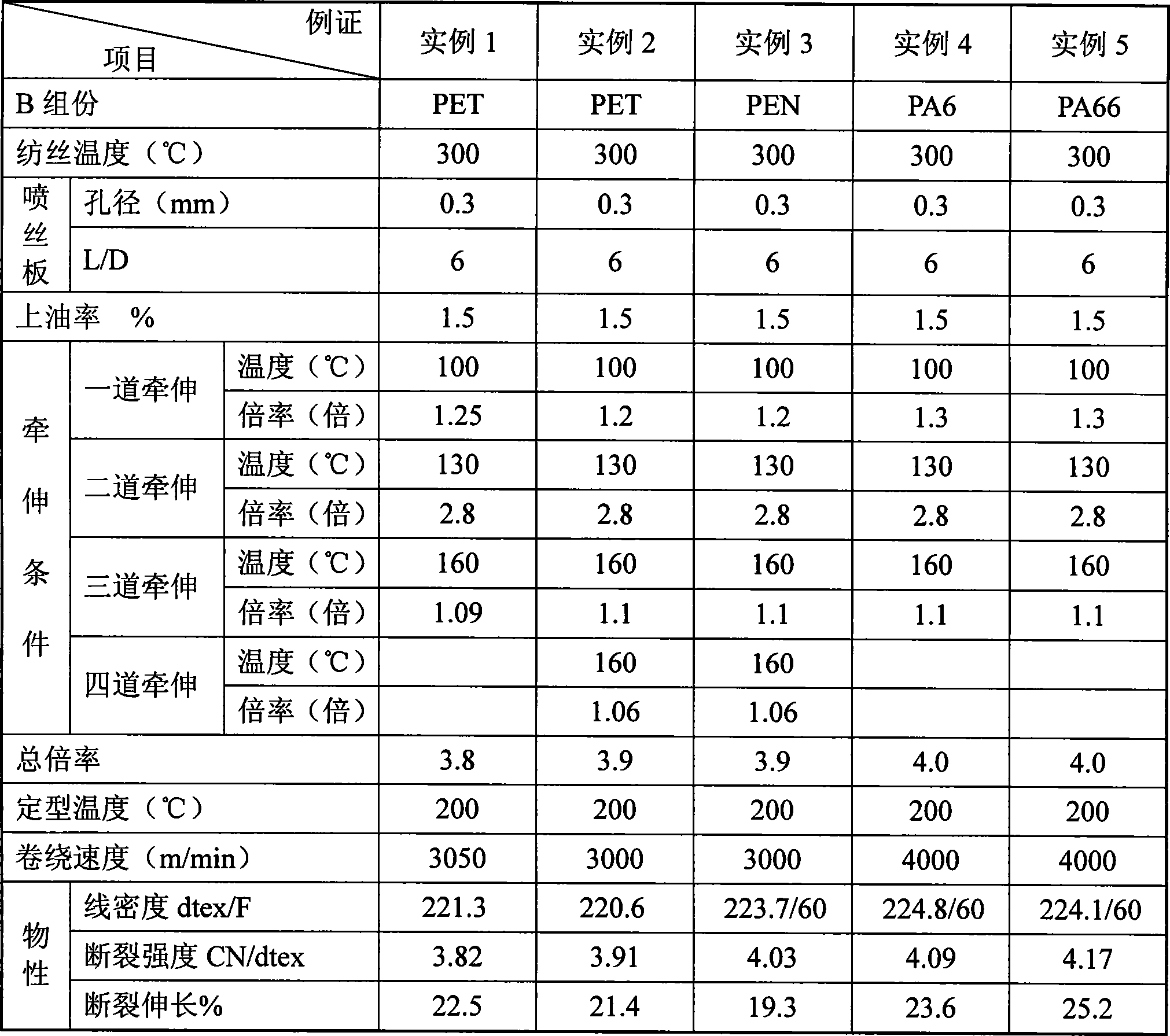

Polyphenylene sulfide composite filament one-step method complete plant and production method

InactiveCN101200817AStable production processEasy to manageFilament/thread formingConjugated synthetic polymer artificial filamentsChemistrySkin core

The invention relates to one-step complete sets of equipment and a production method of polyphenylene sulfide composite filament. Linear polyphenylene sulfide (PPS) is taken as cortex and polyester ethylene terephthalate (PET) or polyester ethylene-acid naphthalene (PEN) or polycaprolactum (PA6) or polyhexamethylene adipamide (PA66) is taken as a skin-core structure of a core layer in the polyphenylene sulfide composite filament. The composite filament one-step complete sets of equipment and the production method are adopted to produce polyphenylene sulfide composite filament. The complete sets of equipment and the production method include a spinning draft winding combination machine and a polyphenylene sulfide composite spinning preparation method. The polyphenylene sulfide composite filament is cheap with high quality. Compared with single component polyphenylene sulfide filament, the raw material cost can be reduced by more than 30-40 percent. The fiber which is used as filtering material can be widely applied to environmental protection industry.

Owner:SINOSELEN HI TECH

Double-twist spinning method

The invention relates to a double-twist spinning method and belongs to the technical field of textile. The method adopts the follwing steps: a double-twist winding mechanism is arranged in front of adrawing system of a spinning machine, the double-twist winding mechanism consists of a double-twist structure and a winding mechanism, the winding mechanism is positioned in a yarn storage tank of thedouble-twist structure, a drawn fiber strip is output through a front roller nipper and then twisted to form a yarn, the yarn is warped by a guide wire, enters a yarn inlet pipe, a yarn running pipeand a yarn outlet pipe and runs to the tensioner, under the rotating action of a twisting disc with a rotating speed of n revolutions / min, the yarn running from the front roller nipper to the tensioner section obtains 2n twists per minute, under the action of the tensioner, the tension of the yarn is drawn out from the yarn outlet pipe, and then wound through the winding groove drum to form the drum yarn package. By adopting the method, the ring twisting and pipe winding mode of the ordinary spinning machine are changed, the double-twist spinning is adopted, thereby greatly improving the twisting efficiency, the spinning quality and the uniformity; by adopting a drum yarn winding mode, the spinning yarn package is increased, and the production efficiency is improved.

Owner:WUHAN TEXTILE UNIV

Organic light-emitting diode display device and driving method thereof

ActiveUS7889160B2Shorten charging timeImprove quality uniformityElectrical apparatusElectroluminescent light sourcesDisplay deviceEngineering

An organic light-emitting diode display device includes a data line, a first and second gate lines crossing the data line, an emission line crossing the data line, an organic light-emitting diode device having an anode electrode and a cathode electrode, a high-level potential driving voltage source for supplying a high-level potential driving voltage to the anode electrode, a first switch element for connecting a cathode electrode of the organic light-emitting diode device to a first node, a second switch element for connecting the data line to a second node, a third switch element for connecting the second node to a ground voltage source, a driving element for adjusting a current flowing between the cathode electrode of the organic light-emitting diode device and the first node in accordance with a voltage of the first node, a first capacitor connected between the second gate line and the first node, and a second capacitor connected between the first node and the second node.

Owner:LG DISPLAY CO LTD

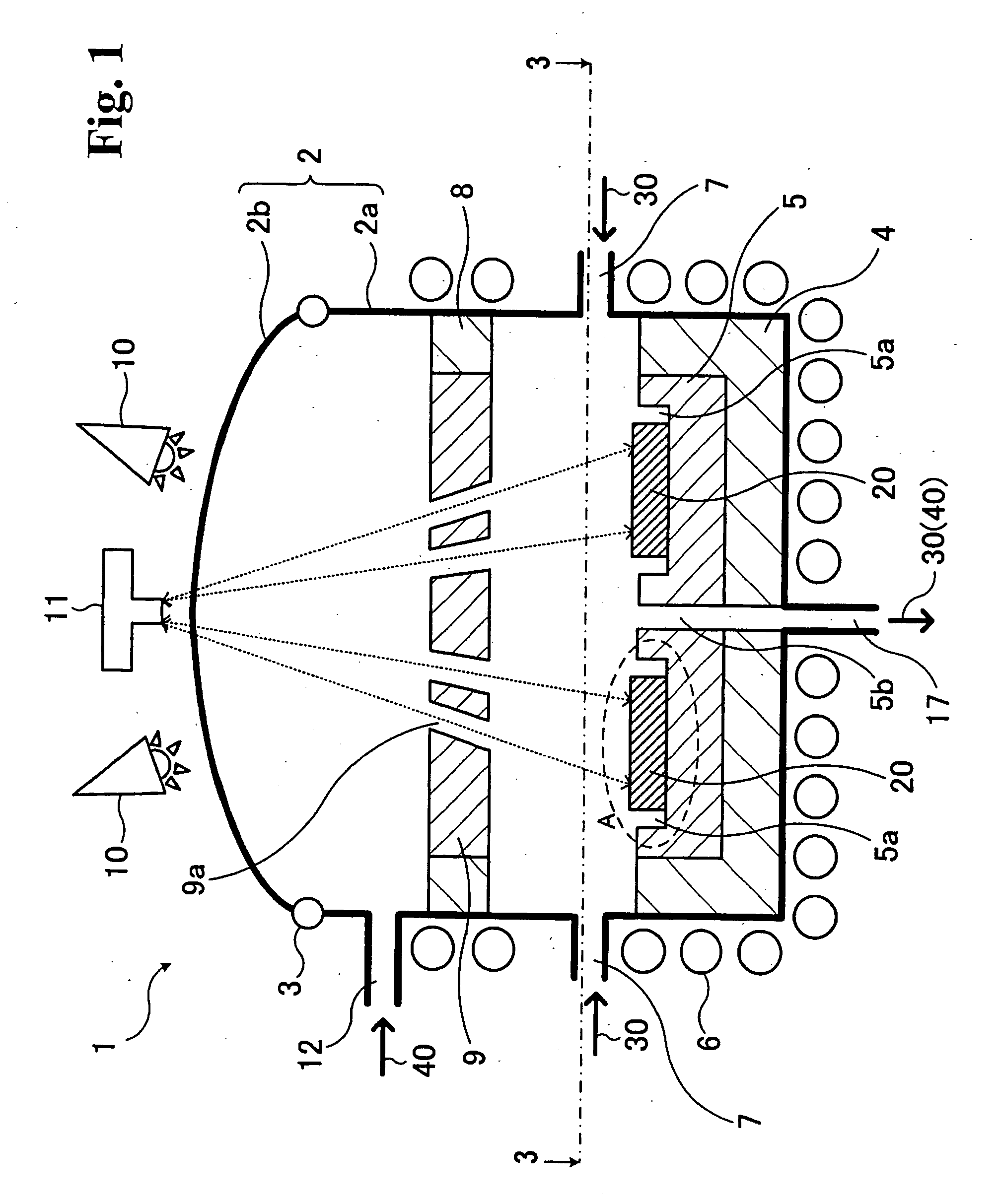

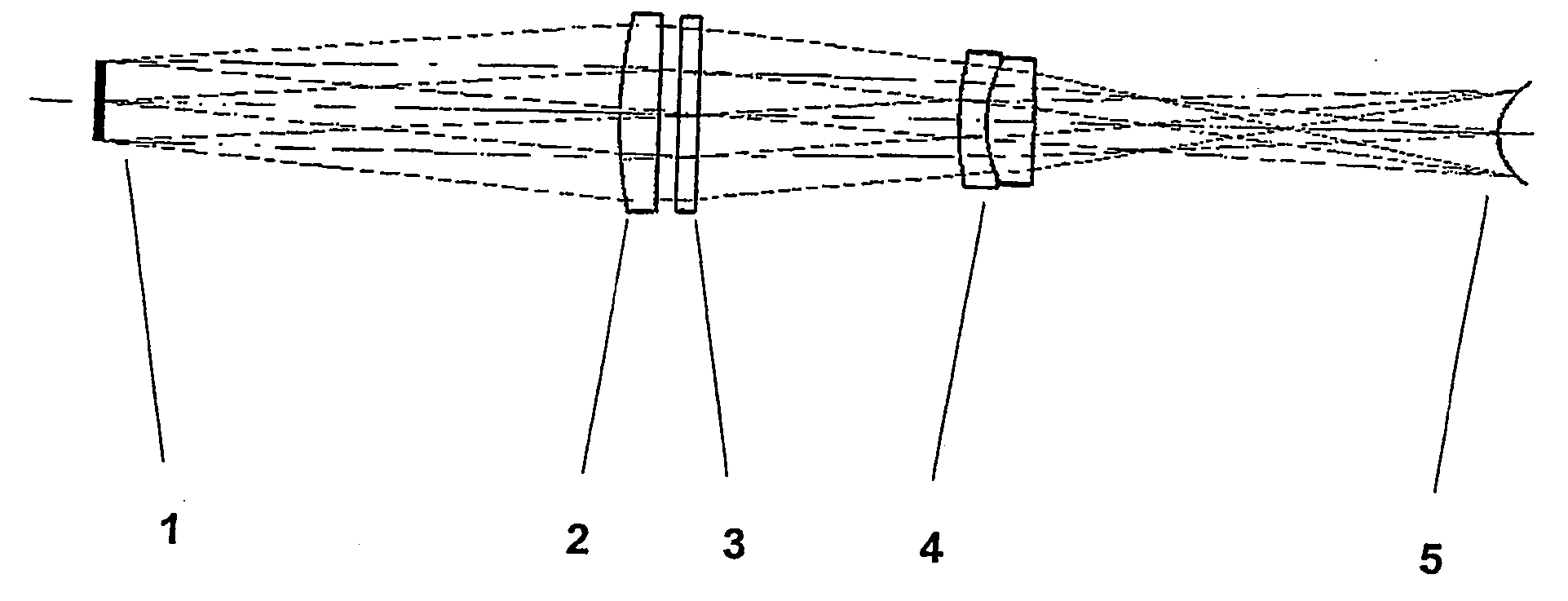

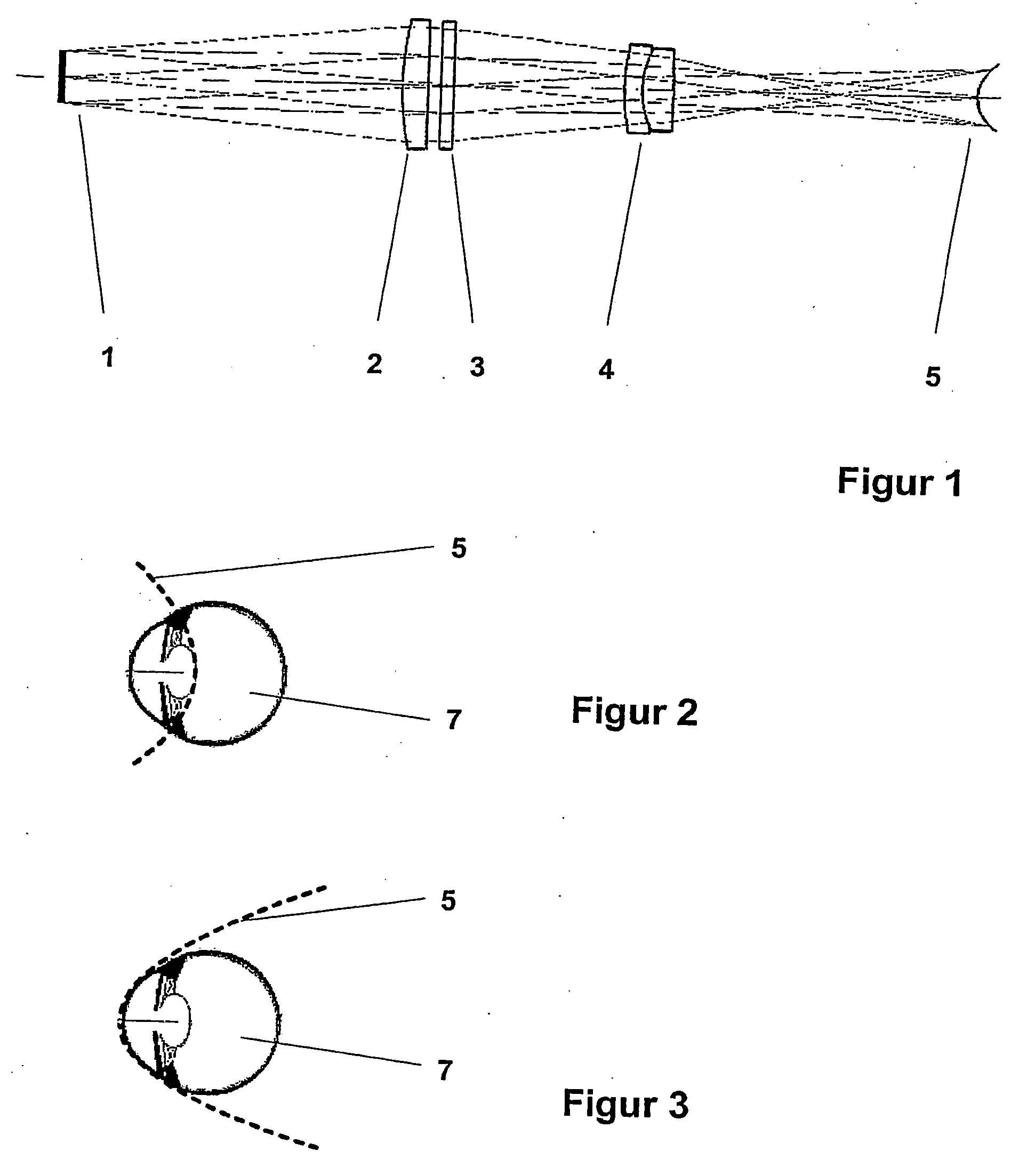

Arrangement for improving the image field in ophthalmological appliances

InactiveUS20060170867A1Improve quality uniformityEnhance the imageLaser surgeryOthalmoscopesSurgical microscopeImaging quality

The present invention is directed to an arrangement by which the image field of the illumination components and irradiation components of ophthalmic instruments for diagnosis and therapy is improved. In the arrangement according to the invention, one or more diffractive optical elements is / are arranged additionally in the illumination beam path for deliberate shaping of the image plane in the eye to be irradiated. These diffractive optical elements can be located on the surface of other optical elements, swiveled into the illumination beam path, and their wavelength changed by filters. The image plane can be adapted to the spherical contour of the eye so that the projected characters and structures have a uniformly high image quality in the center and in the edge area of the eye. The present invention is applicable for variable illumination for diagnosis and treatment of the eye, in particular for irradiation of the eye lens and other parts of the eye such as the cornea or retina. The arrangement can be used in a great variety of ophthalmic instruments such as fundus cameras, slit lamps, laser scanners, OPMI instruments or surgical microscopes.

Owner:CARL ZEISS MEDITEC AG

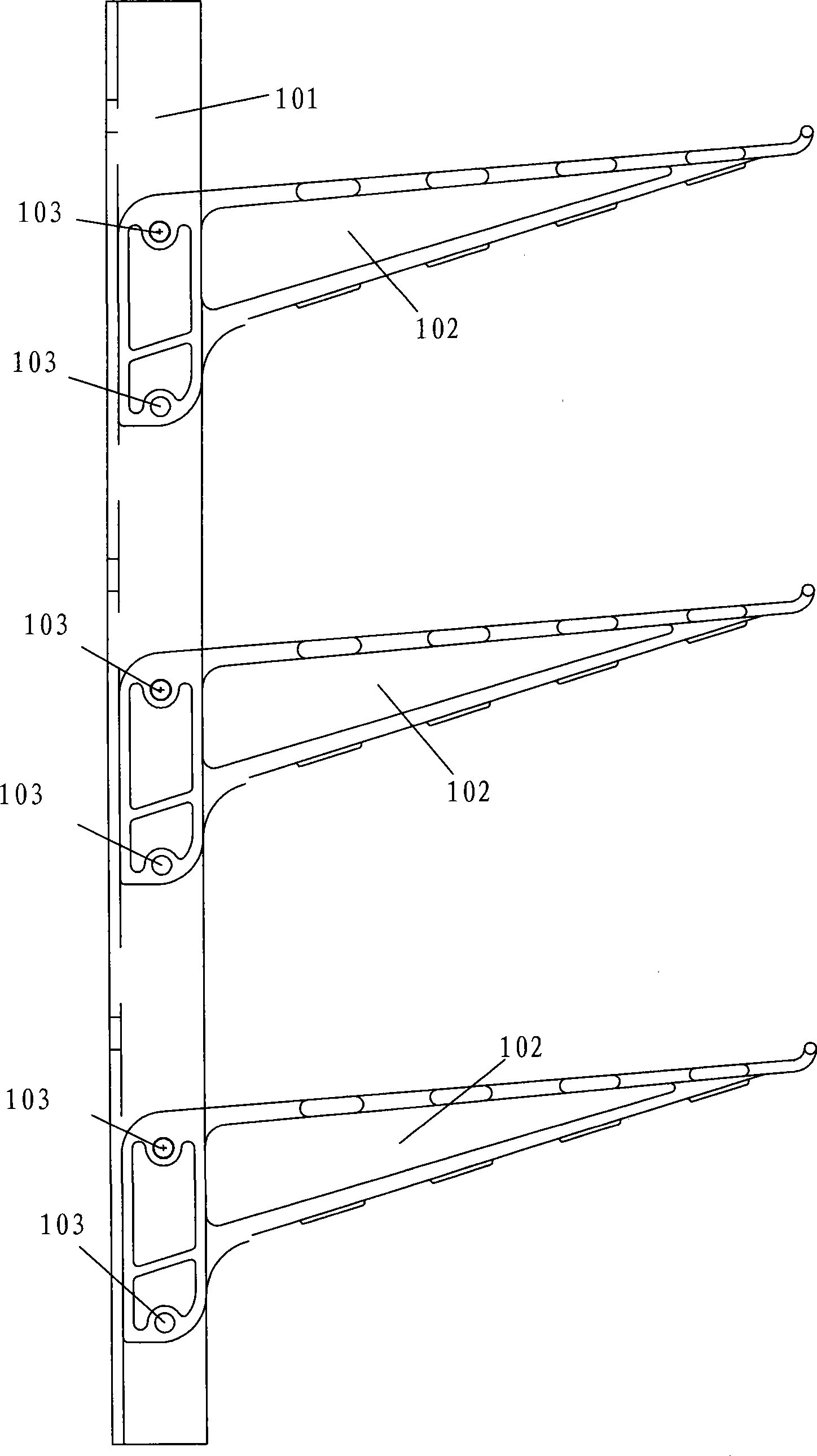

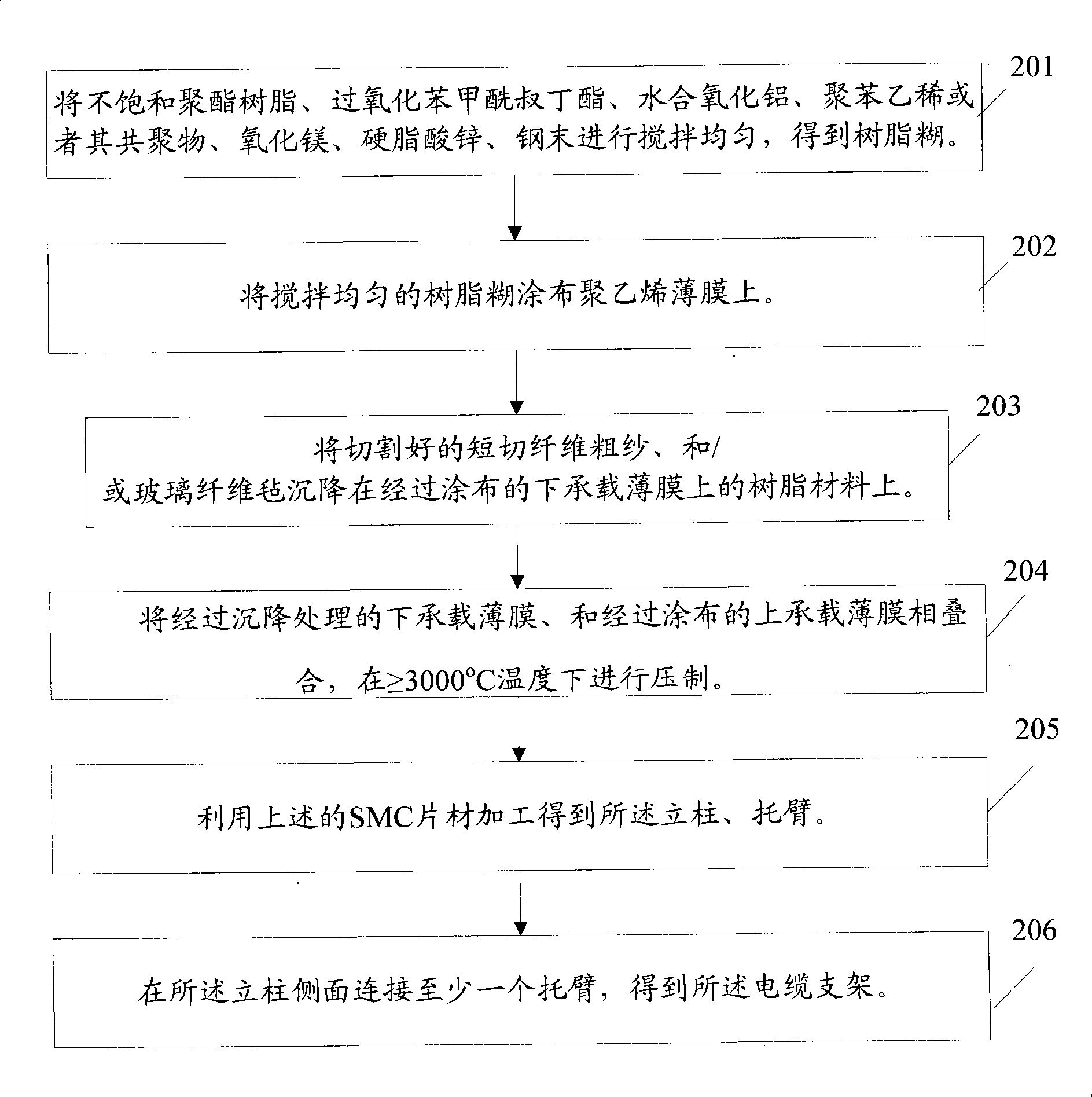

Assembled high molecule composite material cable stand and manufacture method thereof

The invention discloses an assembly-typed polymer composite material cable bracket and a preparation method thereof, and relates to the field of electric material. The cable bracket comprises a vertical column 101; the side surface of the vertical column 101 is connected with at least a supporting arm 102; the vertical column 101 and the supporting arm 102 are respectively made of piece-shaped molding material mixed by steel powder. The assembly-typed polymer composite material cable bracket can resist corrosion, resist oxidation and has smooth surface.

Owner:重庆杰友电气材料有限公司

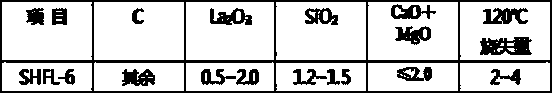

Special activated carbon for adsorption separation of chlorine gas and oxygen

ActiveCN103752270AImprove adsorption capacityImprove adsorption and separation efficiencyChlorine/hydrogen-chloride purificationOther chemical processesActivated carbonPhysical chemistry

The invention discloses special activated carbon for adsorption separation of chlorine gas and oxygen. A product is prepared from activated carbon by the processes of dipping, drying and baking for decomposing in sequence. The special activated carbon has the physical properties that the bulk density is 0.40-0.45 kg / L, the strength is greater than or equal to 5.5N / mm, the specific surface is greater than or equal to 900m<2> / g, the pore volume is 0.9-1.0 ml / g, and the abrasion is smaller than or equal to 5%. By virtue of the special activated carbon, the related application performance such as the adsorption and separation efficiency and stability, the compression strength and the abrasion resistance quality uniformity of the chlorine gas and the oxygen are improved, and not only is the purity of the products, namely the chlorine gas and the oxygen, is improved, but also the safe and stable operation of an industrial device is facilitated.

Owner:FININGS CO LTD

Method of manufacturing the microporous polyolefin composite film with a thermally stable layer at high temperature

InactiveCN102017233AImprove stabilityImprove permeabilitySemi-permeable membranesLi-accumulatorsNon solventPolymer science

Provided is a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, particularly, to a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, comprising preparing a polyolefin microporous film using a composition containing a polyolefin resin; coating a solution, in which a high heat-resistant resin is dissolved in a solvent, on one surface or both surfaces of the polyolefin microporous film; phase-separating the polyolefin microporous film coated with the solution by contacting with a nonsolvent after the coating; and drying the polyolefin microporous film so as to remove the solvent and nonsolvent remained after the phase-separating, and thus forming the thermally stable layer at high temperature.

Owner:SK INNOVATION CO LTD

Process for producing electrophotographic photosensitive member, and electrophotographic photosensitive member and electrophotographic apparatus making use of the same

InactiveUS7033717B2Improve image qualityEasy to handleElectrographic process apparatusAbnormal growthsHigh frequency power

An electrophotographic photosensitive member production process is provided having the steps of placing a cylindrical substrate having a conductive surface in a first film-forming chamber, and decomposing a source gas with high-frequency power to deposit on the cylindrical substrate a first layer formed of a non-single-crystal material, taking out of the first film-forming chamber the cylindrical substrate with the first layer deposited thereon, and placing the cylindrical substrate with the first layer deposited thereon in a second film-forming chamber, and decomposing a source gas with a high-frequency power to deposit on the first layer a second layer having an upper-part blocking layer formed of a non-single-crystal material. Even where abnormal growth portions called spherical protuberances are present on the photosensitive member surface, they can be made not to appear on images, and image defects can vastly be remedied.

Owner:CANON KK

Preparation method of healthy type low temperature hot melt adhesive

ActiveCN105400479AActivate moistureImprove the surrounding environmentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMetallurgyMaterials science

The invention relates to a preparation method of a healthy type low temperature hot melt adhesive, which comprises the following components by weight: 45-60 parts of TPU hot melt adhesive resin, 10-20 parts of PETG, 25-30 parts of a negative ion / bamboo-based activated carbon composite material, and 3-5 parts of a compatilizer. The method includes: (1) putting the raw materials into a material storage mechanism respectively to remove metals by high strong magnetism; (2) conveying the raw materials into a material cylinder to conduct complete stirring for 30-45min to an even state; and (3) subjecting the well mixed raw materials to secondary metal removal by strong magnetism, then conveying the treated raw materials to the feed hopper of a tape casting extruder, conducting constant speed feeding to a screw machine by a metering feed mechanism according to a preset quantity, carrying out 130-150DEG C high temperature melt mixing evenly by the screw machine to perform tape casting into a sheet, and then conducting cold pressing shaping. The healthy type low temperature hot melt adhesive provided by the invention contains organic bentonite, can significantly improve the quality homogeneity and breathability homogeneity of low temperature hot melt adhesive, and has greatly improved breathability and high quality.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

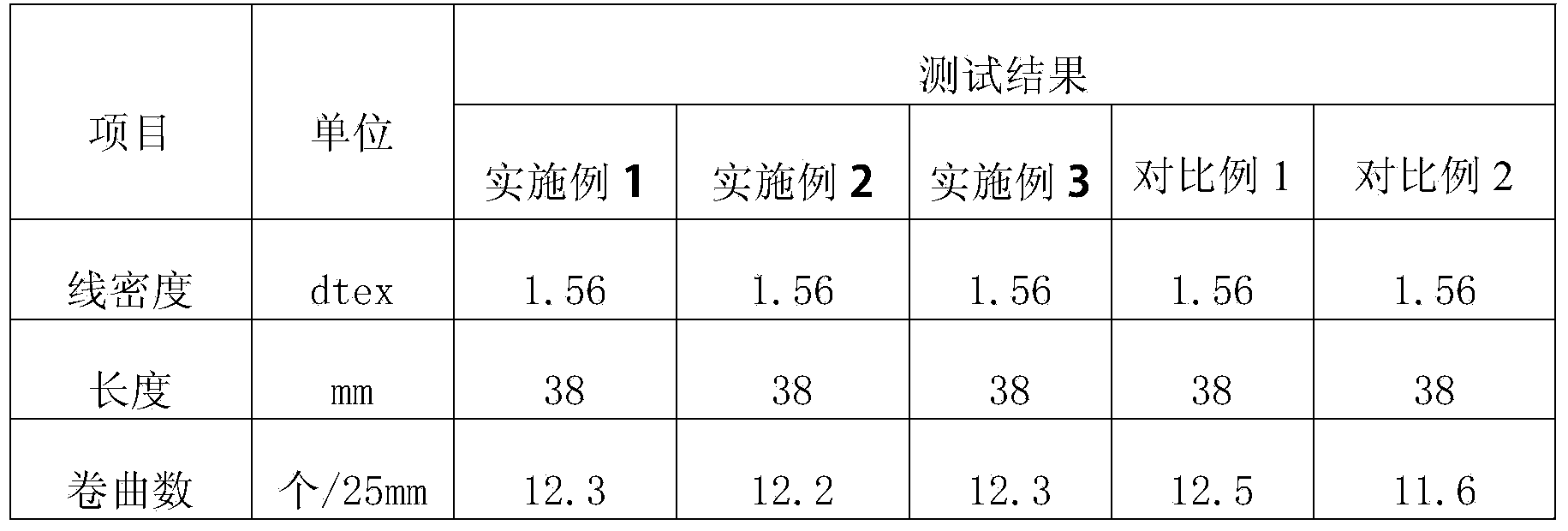

Manufacturing method of hydrophilic polyester short fibers for directly spinning spun-laced non-woven fabric

ActiveCN104328531AImprove quality uniformityImprove hydrophilicityFibre typesMelt spinning methodsPolyesterChemistry

The invention provides a manufacturing method of hydrophilic polyester short fibers for directly spinning a spun-laced non-woven fabric. The manufacturing method comprises the following steps: carrying out esterification on polyester slurry, carrying out pre-condensation polymerization, carrying out final condensation polymerization, spinning and carrying out after-finishing. In a pre-condensation polymerization process, comonomer polyethylene glycol PEG is added, the molecular weight of the added PEG is 1500-2000, and the adding amount is 0.5wt%-1.0wt% of a polyester melt. The temperature of the melt obtained by the final condensation polymerization is controlled to be lower than 290 DEG C, so that the quantity of generated annular tripolymers is reduced and the spun-laced processing efficiency of the fibers is improved. A hydrophilic modifier is added in an online polyester synthetic process and the polyester melt is directly used for spinning; the production cost is lower compared with the production cost of chip spinning, the quality uniformity of the short fibers is improved by 50% and the hydrophilic effect is obvious; eight paths of surface treatment are carried out, so that the distribution of a fiber surface finishing agent is uniform and the attaching firmness is improved; the fiber surface hydrophilic effect is improved in a spun-laced processing process; and the polyester PET short fibers can be used for completely replacing mucilage glue short fibers to be used as production raw materials of the non-woven fabric, so that the whole cost of the non-woven fabric is reduced.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

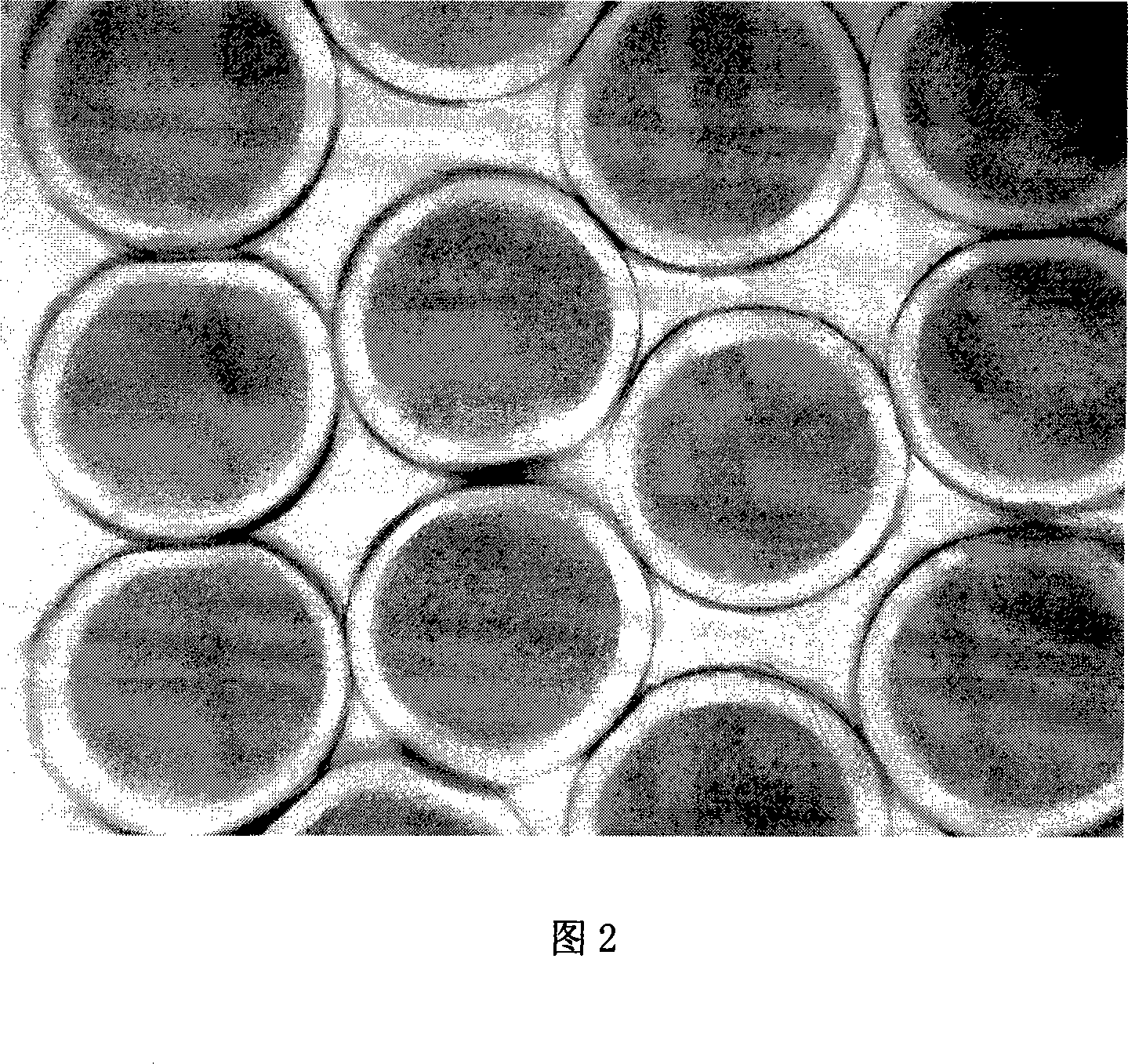

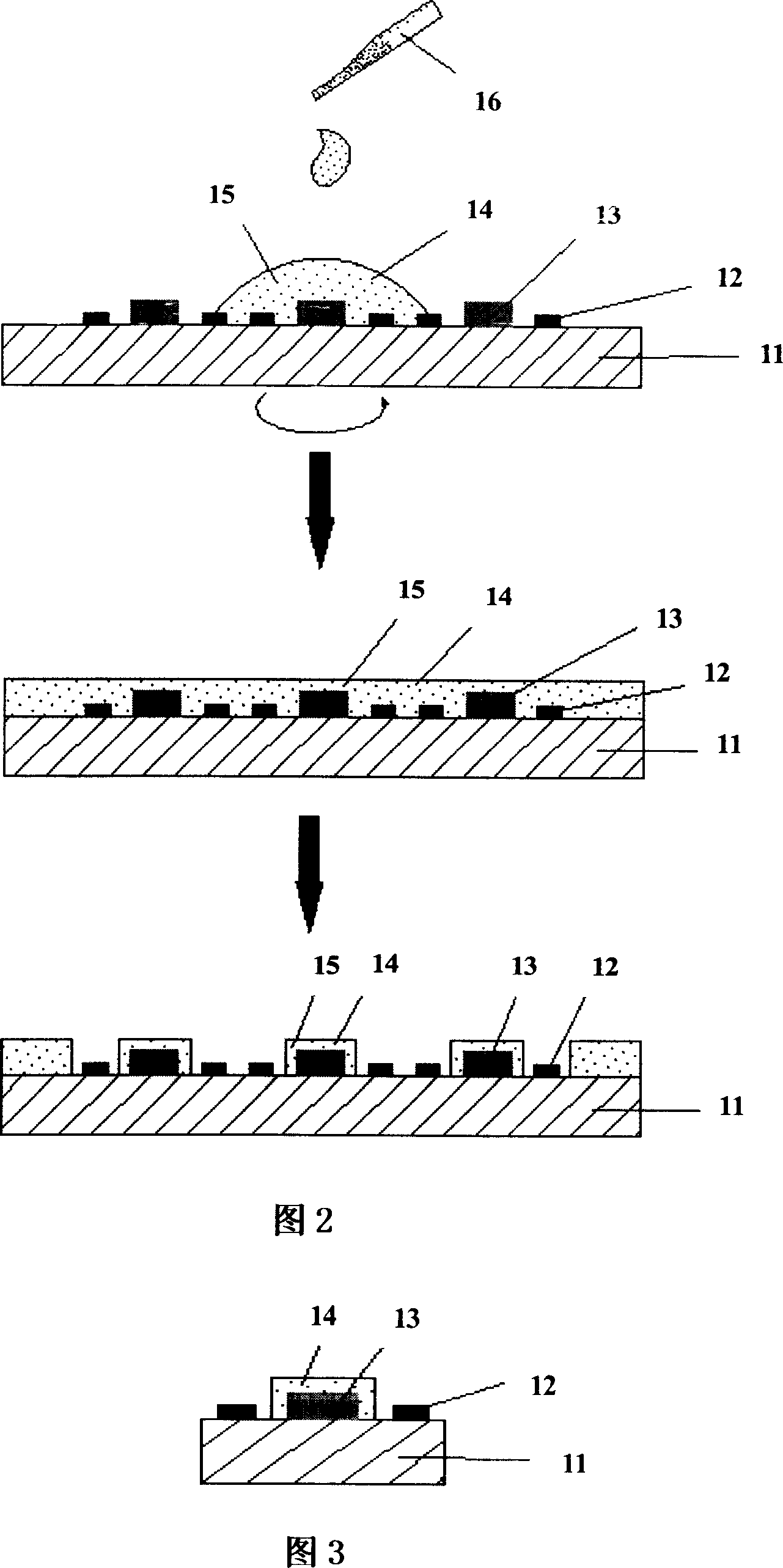

Method for encapsulating LED with rotary glue and optical etching technology

ActiveCN101123285AImprove quality uniformityImprove uniformity of light emissionSemiconductor/solid-state device manufacturingSemiconductor devicesLithographic artistLithography process

A packaging method of white LED by rotating glue and lithography process mainly comprises a monochromatic LED chip, a lead wire, a phosphor glue layer and a chip substrate. The invention is characterized in that the phosphor glue layer is fabricated by the rotating glue process for forming the phosphor glue layer on the surface of the chip substrate, then the packaging of white LED is completed by lithography, developing, solidification and cutting processes. The invention has the advantages that the packaging method of LED by the rotating glue and lithography process can accurately control the thickness of the phosphor glue layer on the chip surface, promote the light quality and uniformity of luminescence from white LED after packaging, and promote the production efficiency of packaging.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

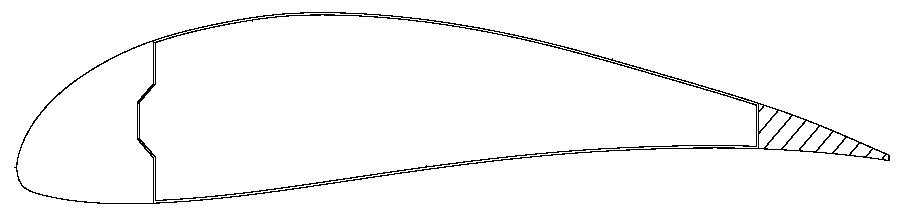

Technology forming method of small and medium-sized unmanned aerial vehicle composite material outer wing

ActiveCN110193955AImprove shock absorptionImprove resistance to damageInternal combustion piston enginesSilicon rubberFront edge

The invention relates to a technology forming method of a small and medium-sized unmanned aerial vehicle composite material outer wing. The method comprises the following steps of forming mold manufacturing, front edge silicon rubber core mold manufacturing, film bag body manufacturing, outer wing front edge manufacturing, and outer wing main body manufacturing; after surface treatment is correspondingly carried out on bonding areas corresponding to the outer wing front edge and a main body front beam surface, and structure double-sided adhesive tapes with the same shape as that of the bondingareas are tore to remove isolation paper on one sides, the adhesive surfaces are adhered to the bonding areas of the outer wing front edge, then solating films on the other sides of the structural adhesive tapes are tore, and the outer wing front edge is horizontally embedded into a boss of the corresponding position of the outer wing main body through a positioning groove at the left end of theouter wing front edge so as to obtain a composite material integral structure outer wing product. According to the technology forming method, the problem of limitation of multiple curing forming, andthe uniformity of the product quality and the thickness are improved.

Owner:XIAN AISHENG TECH GRP +1

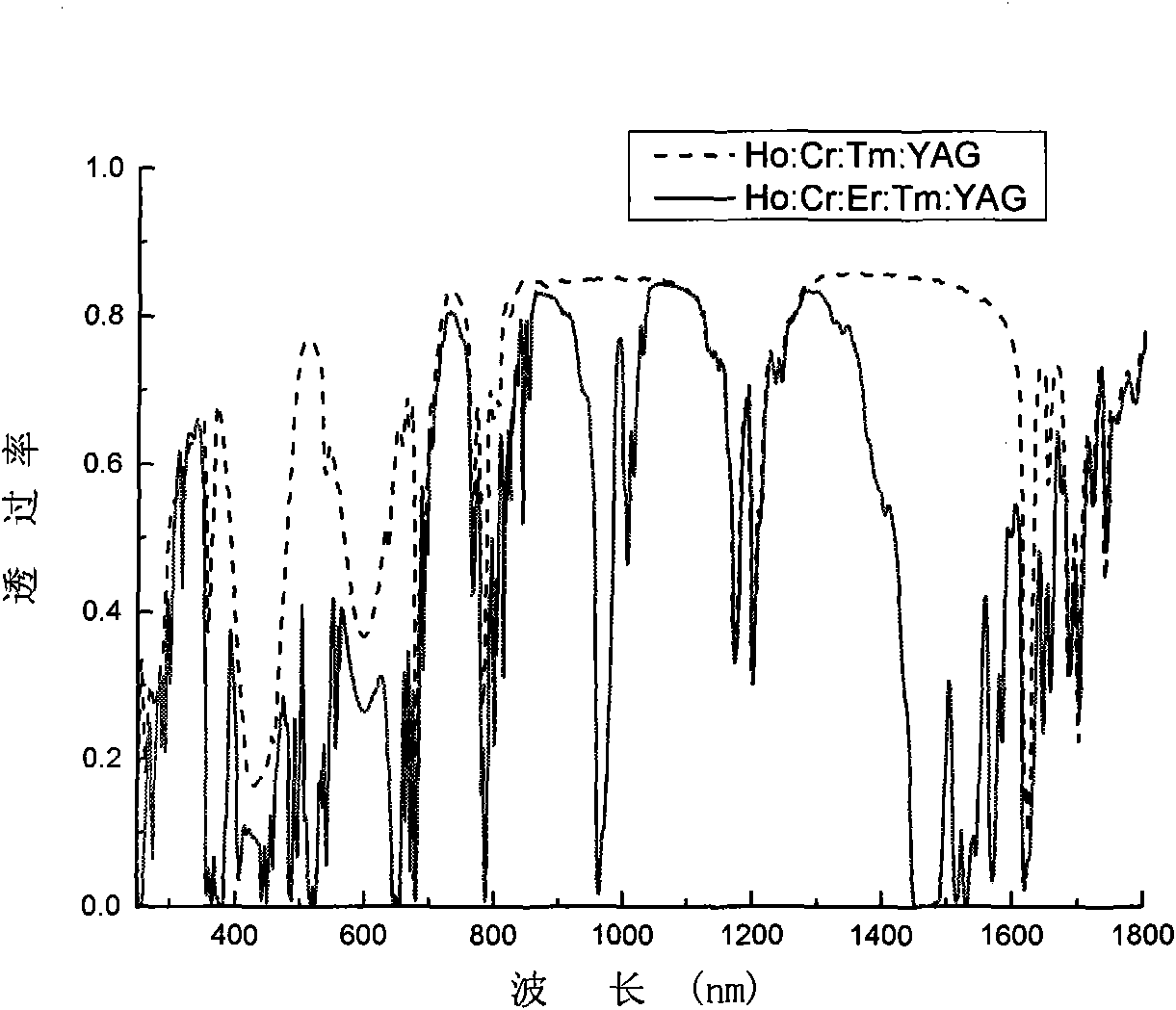

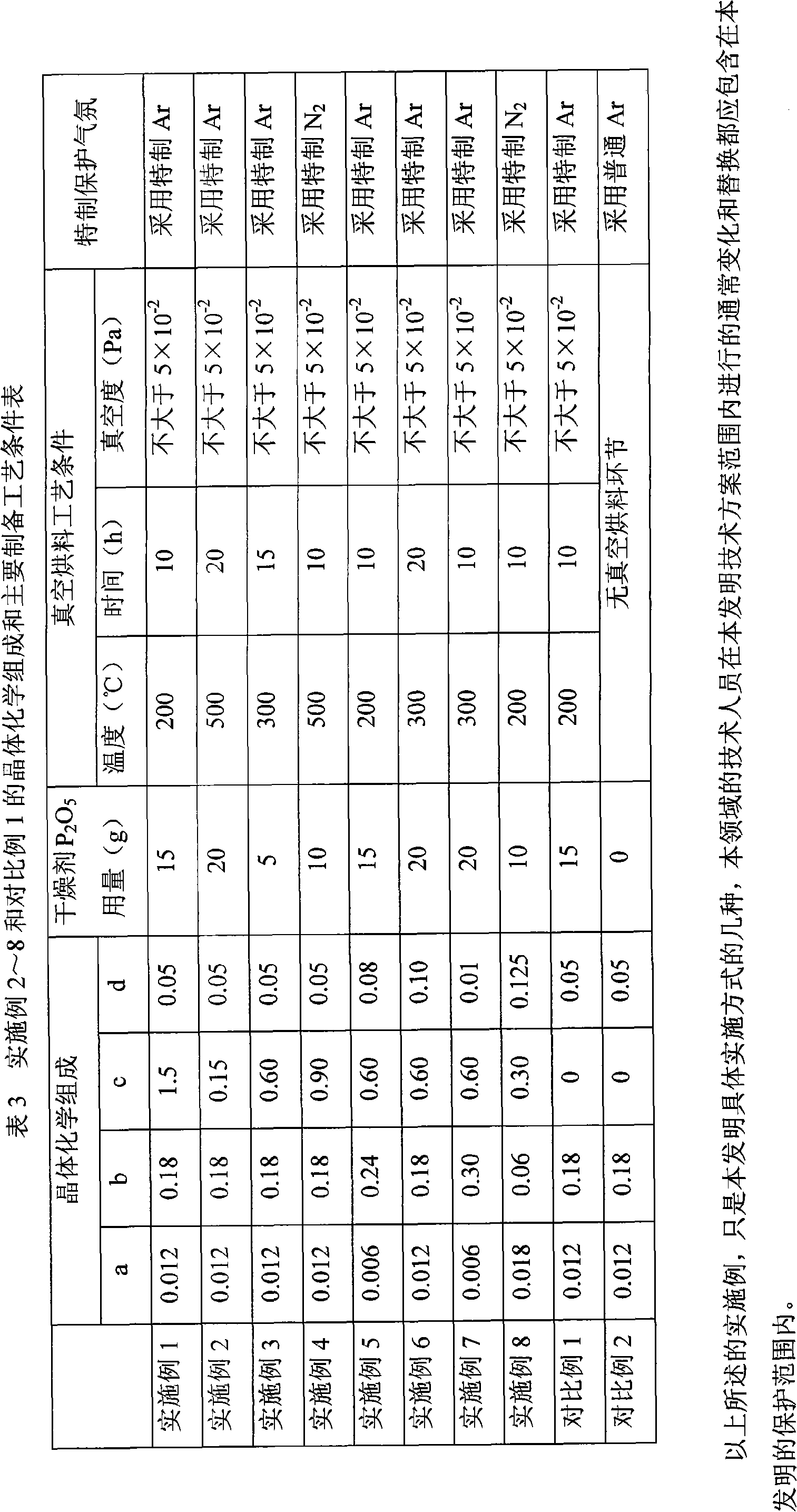

Laser crystals doped with holmium, chromium, erbium, thulium and yttrium aluminum garnet, and preparation method thereof

ActiveCN101560696AImprove Absorption and UtilizationImproved optical quality and optical uniformityPolycrystalline material growthBy pulling from meltWater contentMuffle furnace

The invention discloses Ho:Cr:Er:Tm:YAG-doped laser crystals and a preparation method thereof. The chemical composition of the laser crystal is Ho[a]Tm[b]Er[c]Y[3-a-b-c]Cr[d]Al[5-d]O[12], wherein a is more than 0.003, and less than or equal to 0.018; b is more than or equal to 0.06, and less than or equal to 0.30, c is more than 0, and less than or equal to 1.5; and d is more than 0, and less than or equal to 0.25. The method for preparing the Ho:Cr:Er:Tm:YAG-doped laser crystals comprises the following steps: (1) placing desiccant in a crystal growth furnace to absorb moisture in an atmosphere in the furnace; (2) vacuumizing the crystal growth furnace and performing continuous baking for 8 to 12 hours at a temperature of between 200 and 500 DEG C when the pressure in the furnace is not greater than 5*10 Pa so as to remove the moisture in the furnace; (3) filling the furnace with argon gas or nitrogen of which the water content is not higher than 1.5 ppm; and (4) treating Ho:Cr:Er:Tm:YAG-doped crystals grown in an inert atmosphere in a muffle furnace for 15 to 20 hours at a high temperature of 1,300 DEG C. The preparation method can further improve the rate of Ho-doped crystals in absorbing and utilizing flashlamp pumped energy, and has the advantages of improving the optical quality and optical homogeneity of the crystals, reducing the thermal effect of pumping, reducing laser loss, reducing pumping threshold and improving laser efficiency.

Owner:长汀雷生科技有限责任公司

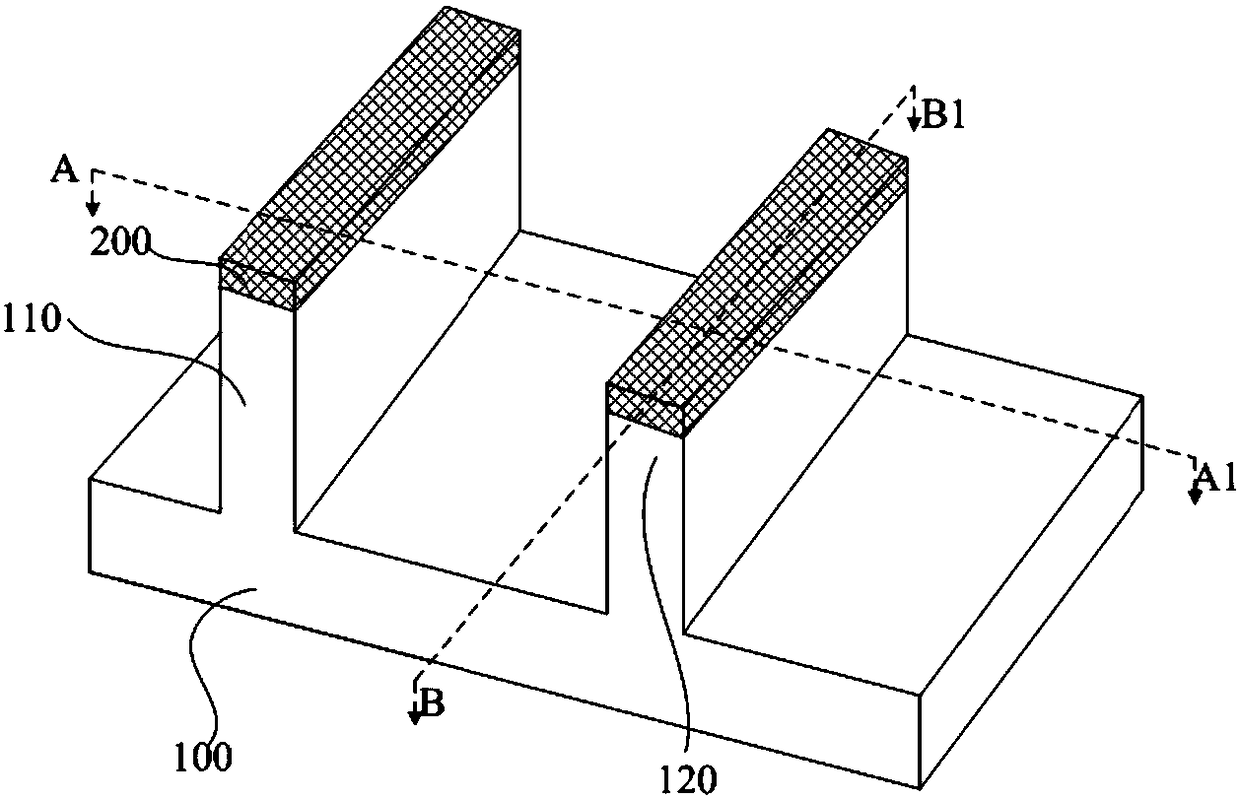

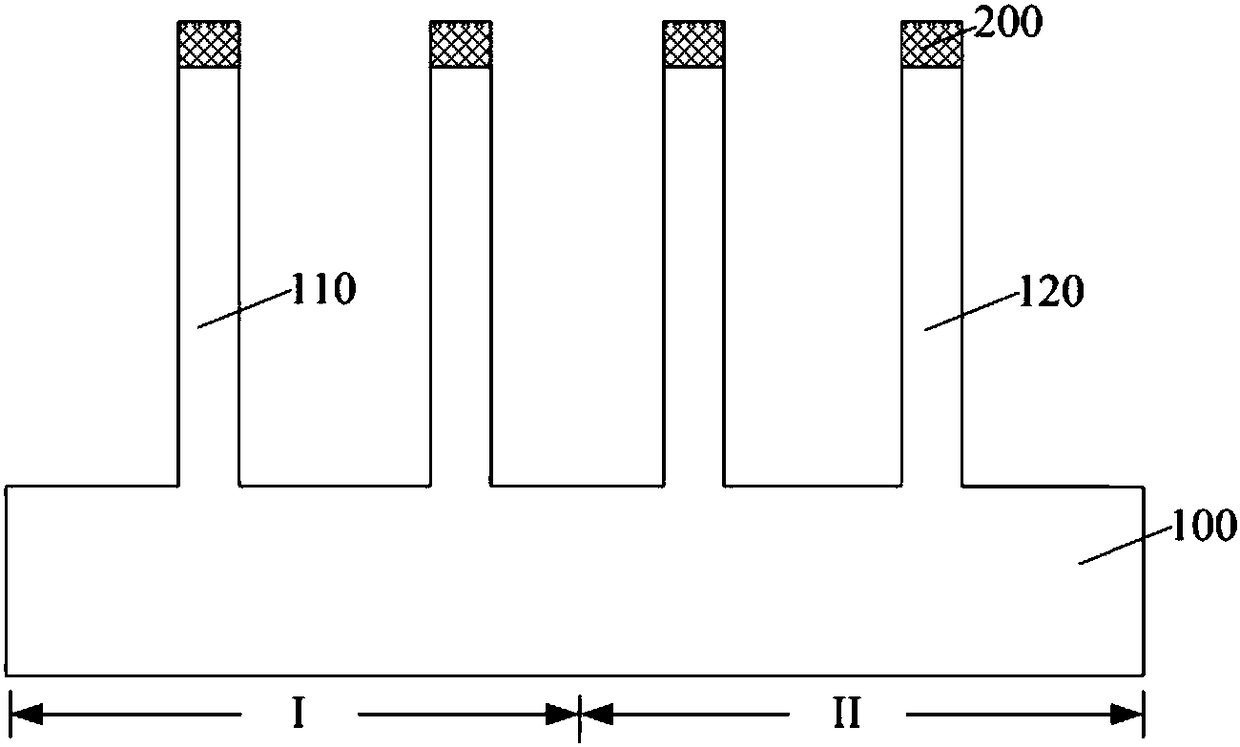

Semiconductor structure and formation method thereof

ActiveCN108257917AImproved formation quality and quality uniformityReduced body leakage currentTransistorSolid-state devicesRe crystallizationEngineering

Disclosed are a semiconductor structure and a formation method thereof. The formation method comprises the steps of forming a base, wherein the base comprises a substrate, a gate structure positionedon the substrate, source and drain doped regions positioned in the base on the two sides of the gate structure, and an interlayer dielectric layer positioned on the base and for covering the top of the gate structure; forming a first contact opening for exposing the source and drain doped regions in the interlayer dielectric layer on the two sides of the gate structure; performing pre-amorphization processing on the source and drain doped regions exposed from the first contact opening to form an amorphous layer; performing re-crystallization processing on a part of the amorphous layer close tothe source and drain doped regions; forming a metal silicide layer at the bottom of the first contact opening; and forming a first contact hole inserting plug in the first contact opening. Through re-crystallization processing, the defect at the end of range which is subjected to pre-amorphization processing is repaired, so that the quality of the metal silicide layer and quality consistency areimproved; and in addition, the problem of conduction between the source and drain doped regions and a bulk region can be avoided, and bulk leakage can be lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Two-for-one twisting type spinning frame

ActiveCN109554784AImprove twisting efficiencyDestroy qualityDrafting machinesContinuous wound-up machinesYarnWind component

The invention relates to a two-for-one twisting type spinning frame, and belongs to the technical field of textile. The two-for-one twisting type spinning frame has the advantages that a twisting andspinning mechanism of an ordinary ring spinning frame is changed into a two-for-one twisting winding mechanism, the two-for-one twisting winding mechanism comprises a two-for-one twisting mechanism and a winding mechanism, a twisting disc can rotate by a circle for silver operated in zones from jaws of a front roller to a tension device, accordingly, two-twist two-for-one twisting effects can be realized for the silver, and the twisting efficiency can be improved; the winding mechanism is positioned in a yarn storage tank of the two-for-one twisting mechanism, twisting components and winding components are substantially separated from one another, twisting and winding can be separately individually controlled, the twisting and winding mechanism, by which twisting and winding can be simultaneously carried out and are constrained by each other, of the ordinary ring spinning frame is thoroughly changed, large-package spun yarns of cheese can be formed, the shortcomings of great winding balloon and tension difference of the traditional spinning frame mechanisms and high fluctuation of the quality of existing resultant yarns can be overcome, and accordingly the quality and the uniformity of resultant yarns can be improved; the two-for-one twisting type spinning frame is reasonable in structure and convenient to operate, and popularization can be facilitated.

Owner:WUHAN TEXTILE UNIV

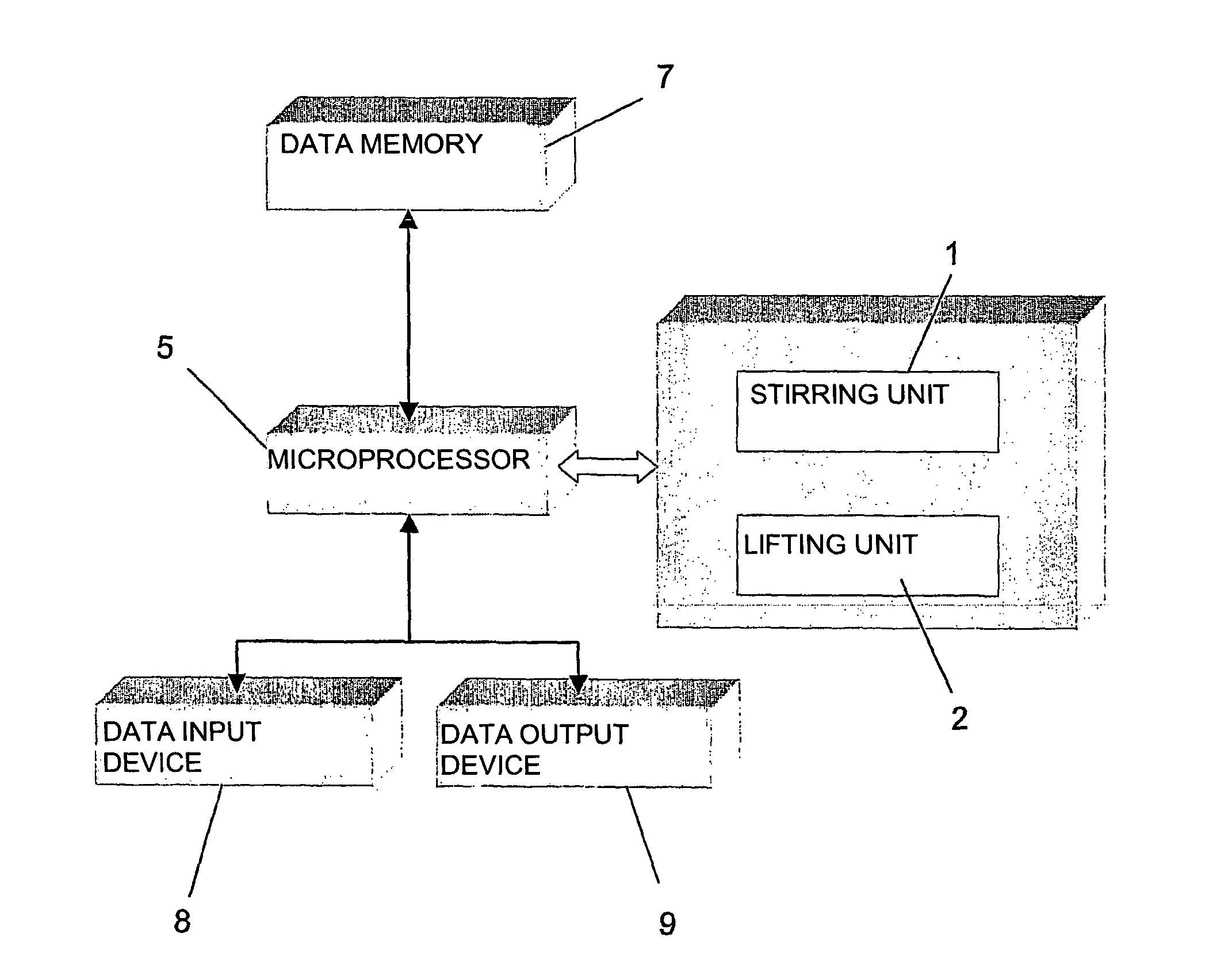

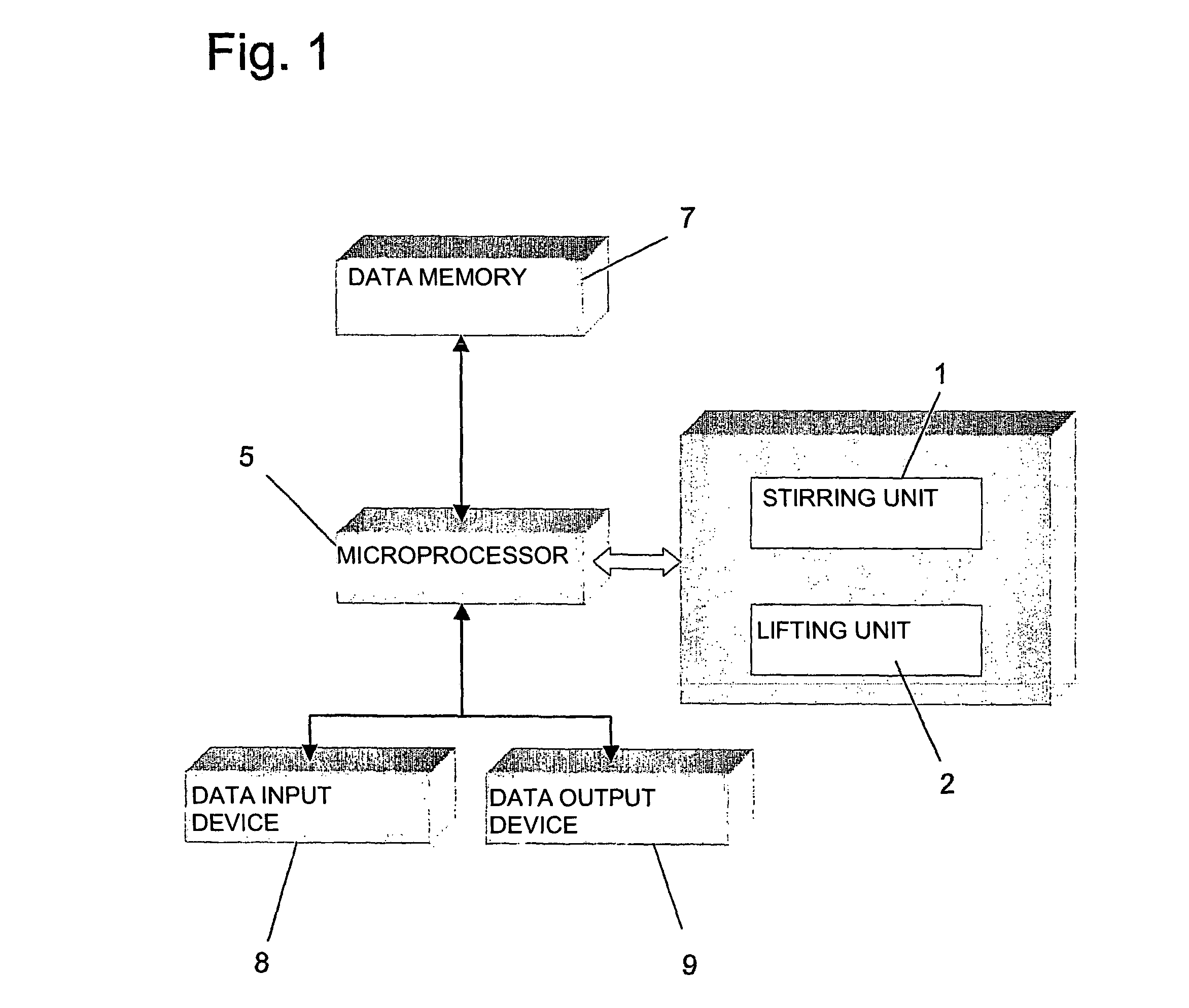

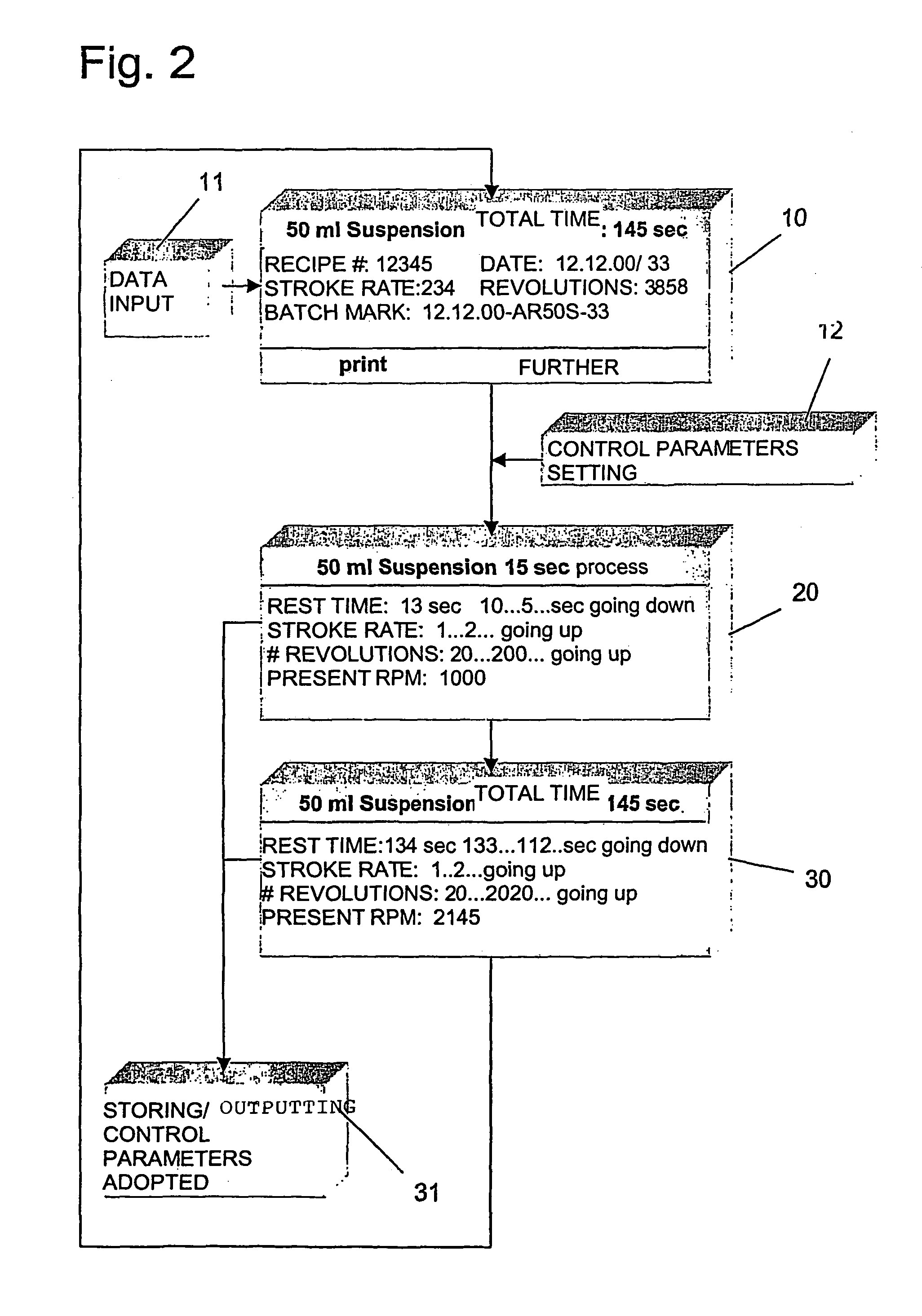

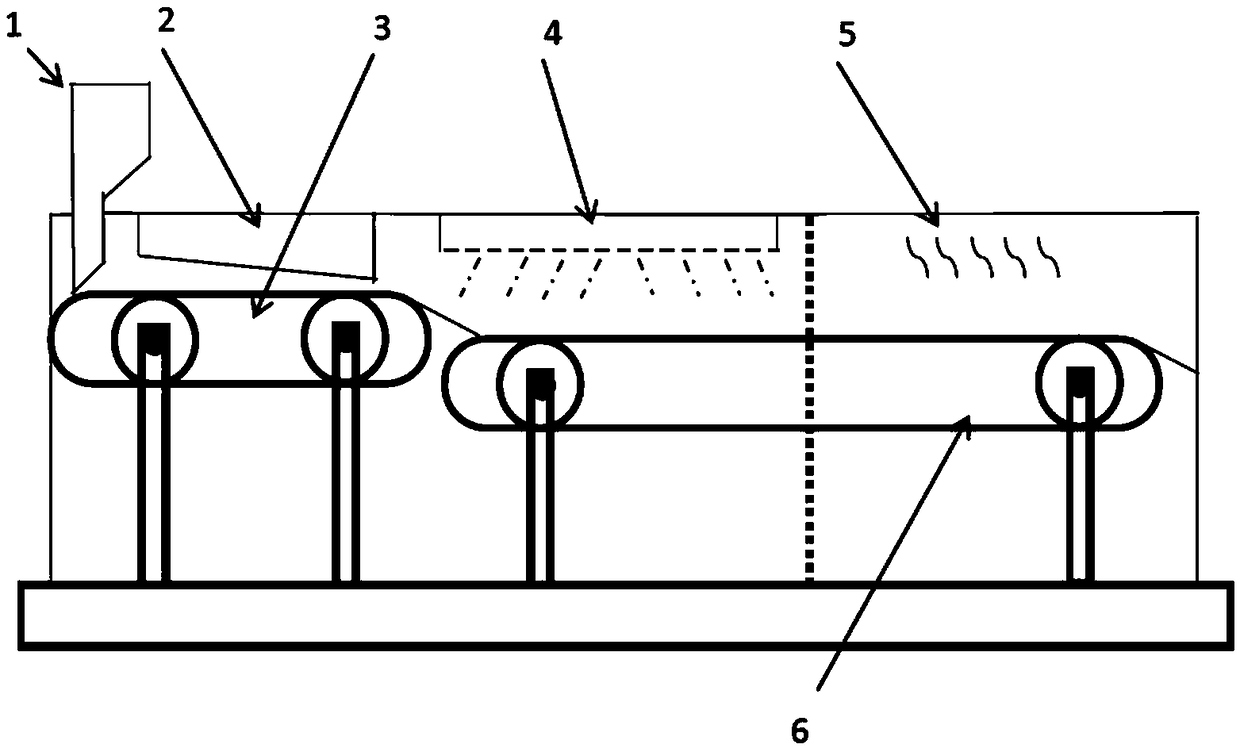

Program controlled stirrer and method for the operation thereof

InactiveUS7751934B2Minimize the differenceImprove efficiencySampled-variable control systemsOther chemical processesPower flowEngineering

The invention relates to a program controlled stirrer for producing pharmaceutical or cosmetic recipes, comprising a stirring unit which consists of a stirring tool which engages with a mixing receptacle. According to the invention, the stirring unit is coupled to a micro-processor which determines the length of stirring time and stirring speed at the stirring unit in a program-controlled manner. The micro-processor executes a data-processing program with the following steps: input of variable data; input of constant data; determination of the length of stirring time and stirring speed in order to produce the desired amount of the recipe by combining the variable and constant data; conversion of the determined length of stirring time and stirring speed into corresponding first current or voltage values; control of the stirring unit with said first current or voltage values. Preferably, the size of the receptacle is inputted as variable data, whereby the data-processing program calculates the number of necessary rotations of the stirring tool using the constant data stored in the data memory, then controls the stirring unit correspondingly.

Owner:KONIETZKO ALBRECHT

Method for extracting latex

The invention discloses a method for rapidly extracting latex. A rapid latex extraction device is composed of a positive and negative plate, a cleaning device and a drying device. A positive electrodeis composed of a conveying device with a surface where a conducting material is attached, and a negative electrode is composed of a conductive electrode plate. The latex is led into the rapid latex extraction device from a latex inlet, the distance of the positive and negative plate is adjusted to make the positive electrode and the negative electrode contact with the latex, a direct current voltage is adjusted, a thin film rubber piece is gathered on the conveying device serving as the positive electrode and is conveyed through the conveying device to the cleaning device to be cleaned, and the thin film rubber piece is dried and packaged to obtain a finished rubber. The method is simple in process, the obtained rubber performance is excellent, rubber ingredients are reserved completely,no flocculation process occurs, and the method is green and environmentally friendly and reduces cost. Man-made influence factors of the process are fewer, continuous production can be achieved, the product quality is stable, and industrialized research is easy.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com