Process for processing filament-shaped stem and strip-shaped stem simultaneously

A processing technology and cut stem technology, which is applied in the preparation of tobacco, tobacco, food science, etc., can solve the problems of large size, difficult compaction, and large thickness of stem slices, and achieve quality uniformity and stability. The effect of improving the uniformity and improving the quality of the tobacco stem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

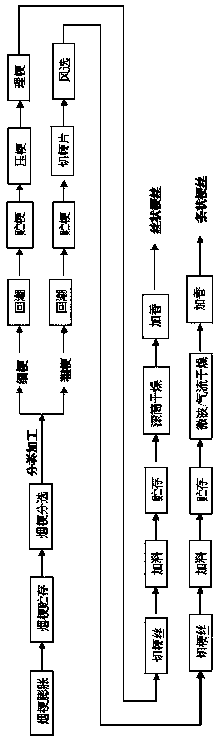

[0034] like figure 1 Shown, concrete technological process of the present invention and each working procedure concrete steps are as follows:

[0035] 1. Take the following steps:

[0036] Step 1, tobacco stem expansion: the raw tobacco stem is expanded by steam explosion or microwave;

[0037] Step 2, storage of tobacco stems: store the expanded tobacco stems for a certain period of time (15 days to two years) according to the origin, time, processing characteristics, and expansion effect of the original stems, so as to solidify the structure of the tobacco stems and facilitate the chemical composition of the tobacco stems. reactions and transformations;

[0038] Step 3, tobacco stem sorting: use tobacco stem sorting equipment to separate the two types of tobacco stems that have obvious differences in size after expansion, one is thinner expanded tobacco stems, and the width of the tobacco stem or the diameter of the tobacco stem is less than 5mm The first category is rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com