Patents

Literature

161results about How to "Increase usage ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing super absorbent resin by plant straw

The invention discloses a method for synthesizing super absorbent resin by plant straw and raw material selection. In the synthesizing process, the prepolymer of crylic acid and acrylamide serves as polymerized monomer, the saline alkali tolerance of the super absorbent resin is improved while improving water absorption. The invention chooses renewable plant straw with low cost and wide resource as a raw material, effectively solves the problem of processing plant straws, and has important environmental protection value and economic significance.

Owner:UNIV OF JINAN

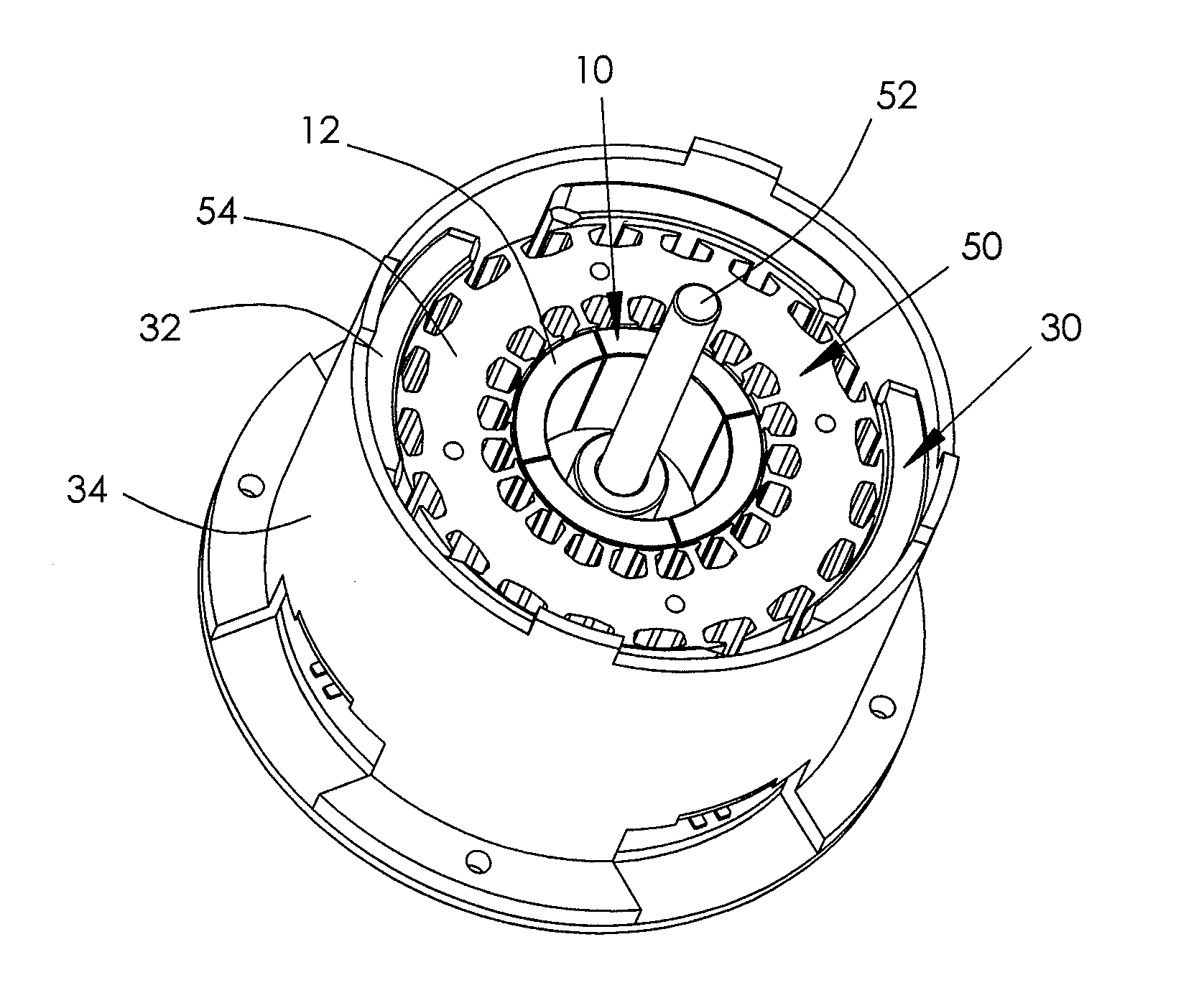

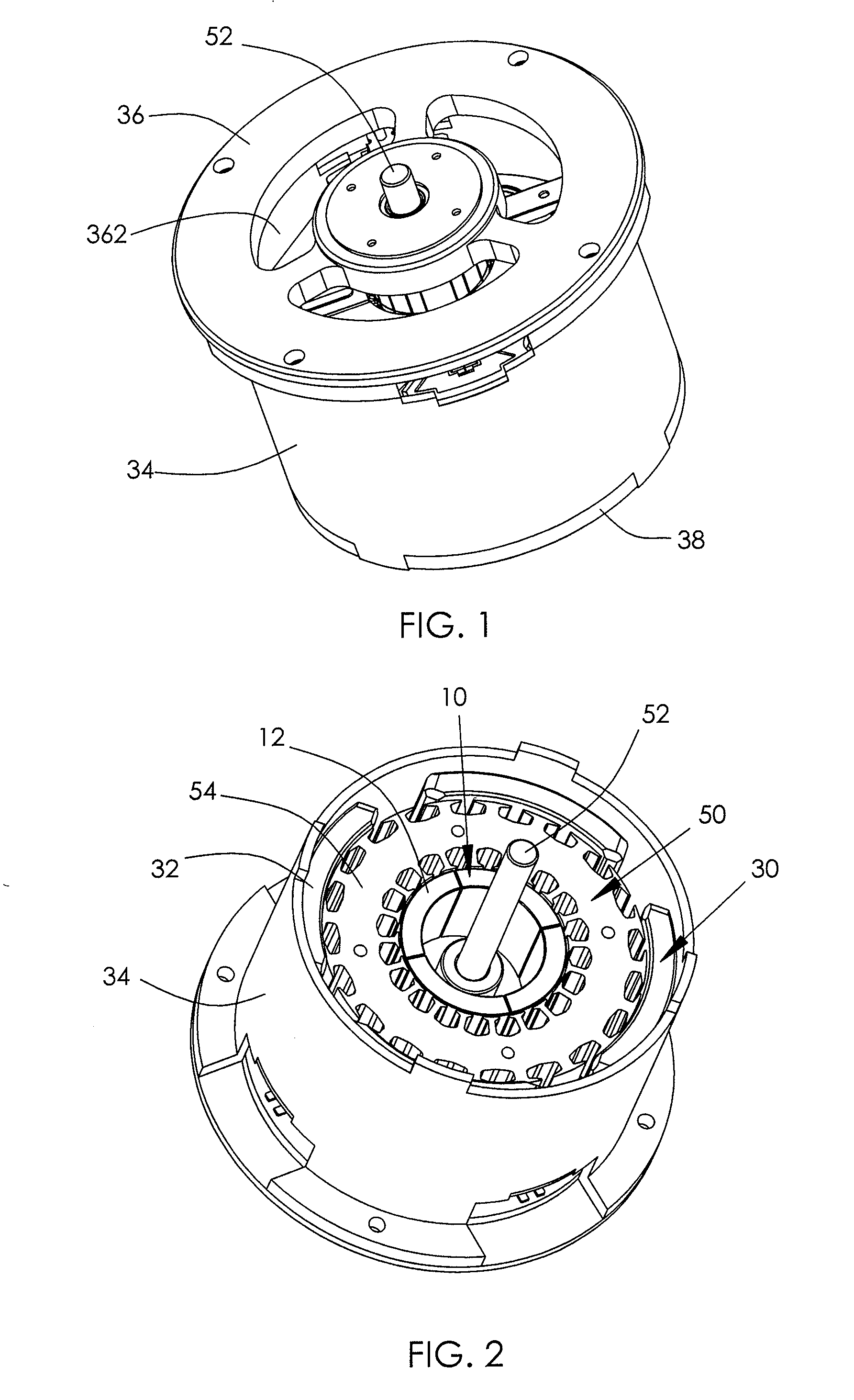

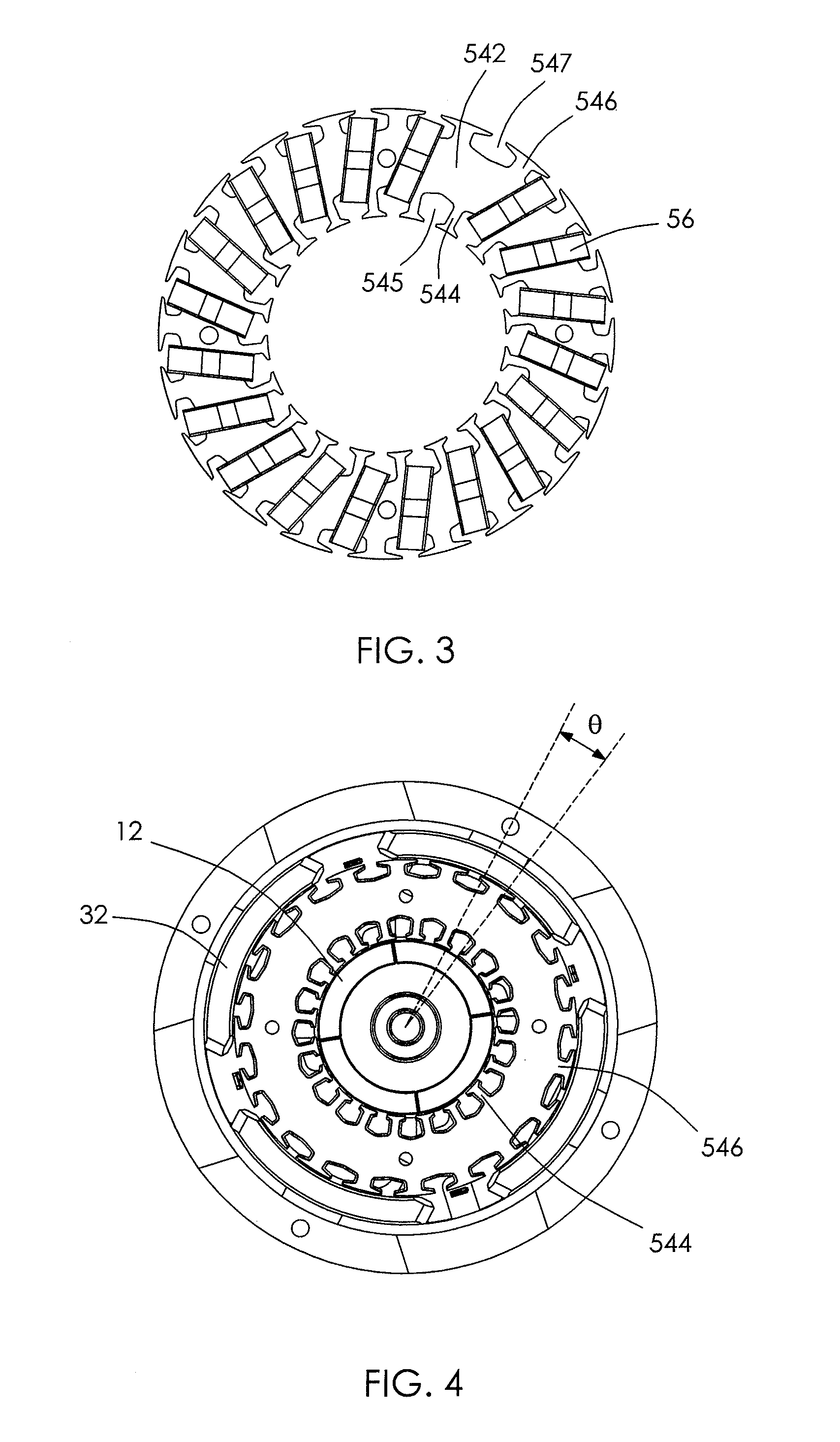

Electric motor

InactiveUS20120299405A1Reduce axial lengthIncrease usage ratioMagnetic circuit rotating partsDC commutatorStatorEngineering

An electric motor includes an inner stator including inner magnetic poles arranged circumferentially, an outer stator including outer magnets arranged circumferentially, and a rotor rotatably disposed between the inner and outer stators. The rotor includes a shaft, a rotor core fixed to the shaft and a winding wound on the rotor core. The rotor core includes a ring shaped yoke having a plurality of inner teeth extending inwardly and a plurality of outer teeth extending outwardly. The winding includes a plurality coils each including an inner side received in a corresponding inner slot formed between adjacent inner teeth and an outer side received in a corresponding outer slot formed between adjacent outer teeth.

Owner:JOHNSON ELECTRIC INTERNATIONAL AG

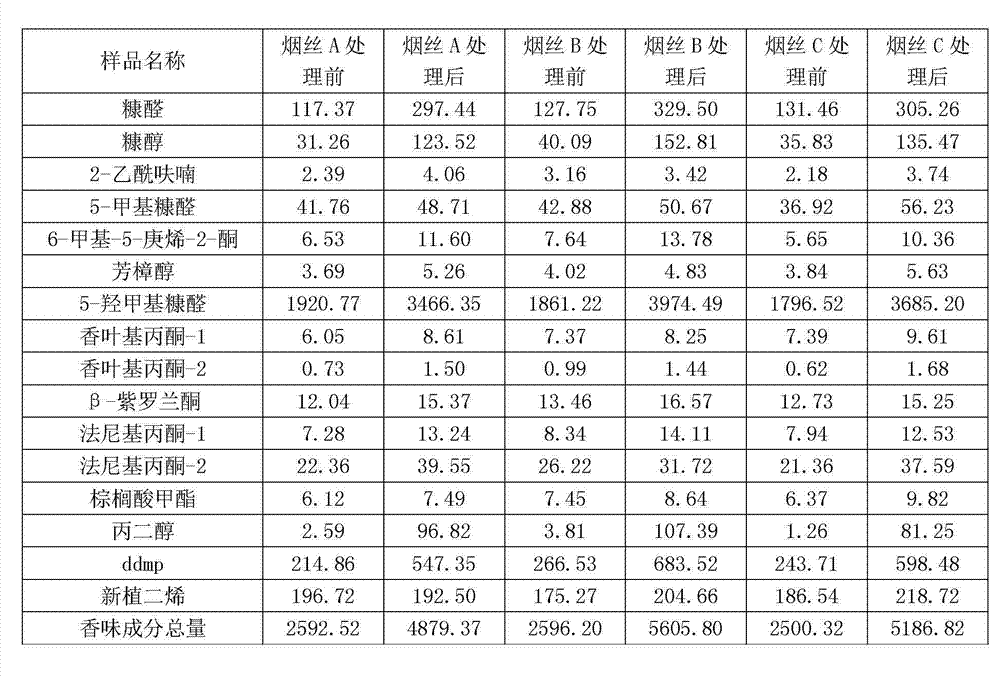

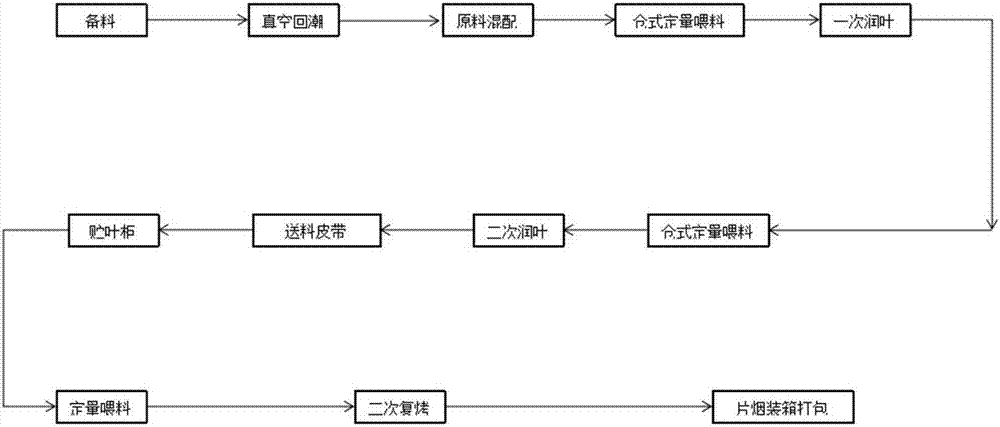

Processing method for increasing low-grade tobacco use value

A processing method for increasing low-grade tobacco use value includes the steps: moistening a tobacco group composed of low-grade tobacco to enable the water content to be 18-22%; storing for 1-24h, and entering a lining feeder to enable the tobacco water content to be 28-36%; using a burley tobacco curing machine to dry the tobacco under the conditions that the temperature is 70-1100 DEG C and the process flow is 1600kg / h to enable the water content of tobacco in a cooling area to be 4-7%, and entering a resurgence area to enable the tobacco water content to be 10-14%; entering a surface material feeder to enable the tobacco water content to be 18.5-21.5% after surface material feeding, storing for 1-4h, and shredding, wherein the tobacco water content is 17.5-20.5%; and drying the shredded tobacco through a sheet cut-tobacco dryer to enable the tobacco water content to be 12.5-13.5% after drying of cut tobacco. By means of the processing method, the use ratio of low-grade tobacco in third-grade and fourth-grade cigarettes can be evidently increased to be 8-20%, and cost of formula raw materials can be remarkably lowered.

Owner:CHINA TOBACCO ANHUI IND CO LTD

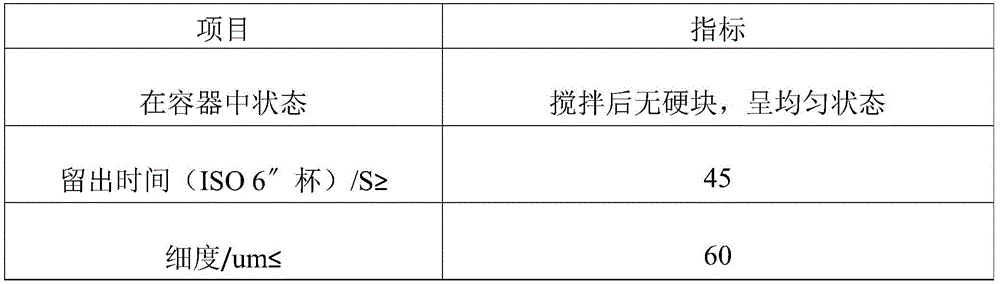

Water-based metal antirust paint and preparation method thereof

InactiveCN105602382AImprove densification performanceImprove shielding effectAnti-corrosive paintsWater basedEmulsion

The invention discloses water-based metal antirust paint. The water-based metal antirust paint is prepared from, by mass, 35-45 parts of pigment, 8-15 parts of filler, 8-15 parts of corrosion inhibitors, 10-20 parts of deionized water, 15-25 parts of silicone acrylic emulsion, 0.1-0.2 part of a dispersing agent, 0.1-0.2 part of a flatting agent, 2-5 parts of an adhesive force promoting agent, 1-3 parts of film-forming aiding agent, 0.1-0.3 part of surfactant OP-10, 0.1-0.2 part of a defoaming agent and 0.05-0.1 part of bacteriacide. The invention further discloses a preparation method of the water-based metal antirust paint. The water-based metal antirust paint solves the problems that water-based metal antirust paint used in the current market is poor in corrosion resistance and adhesive force, slow in drying, poor in early-stage water resistance and high in cost.

Owner:JINAN GUANGDA CASTING MATERIAL CO LTD

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

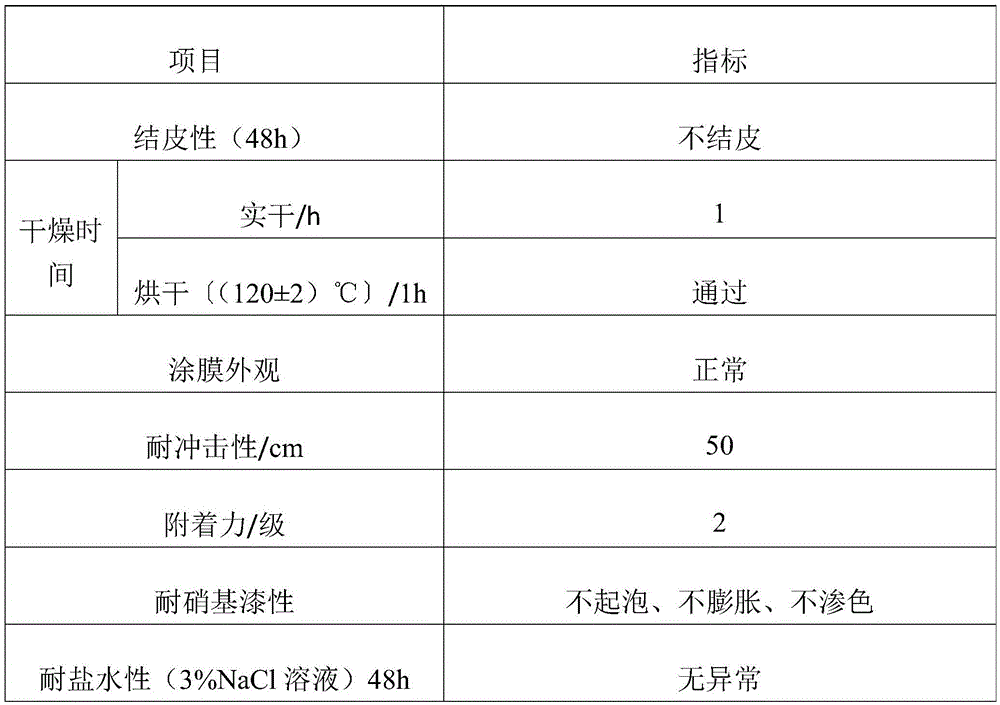

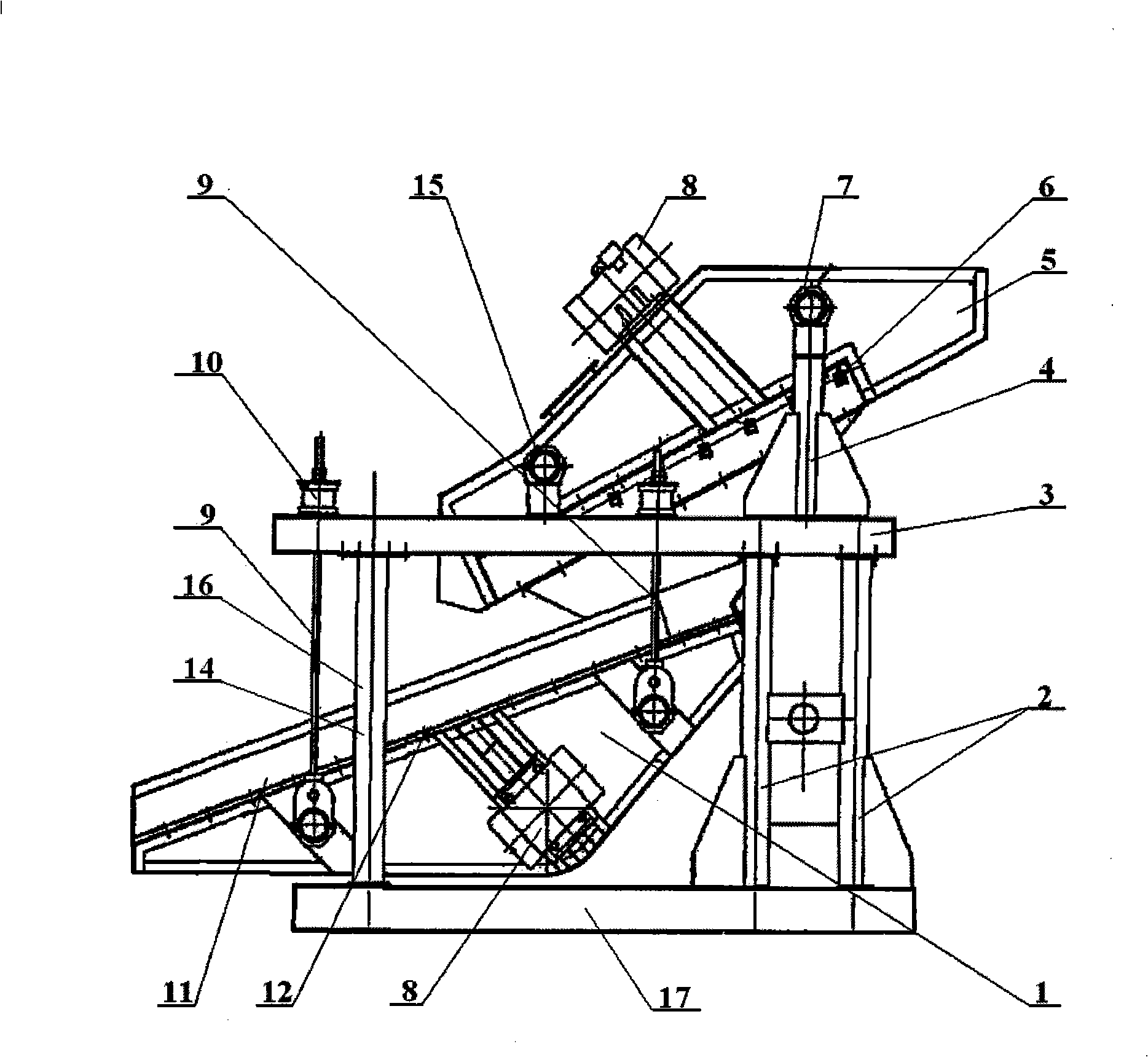

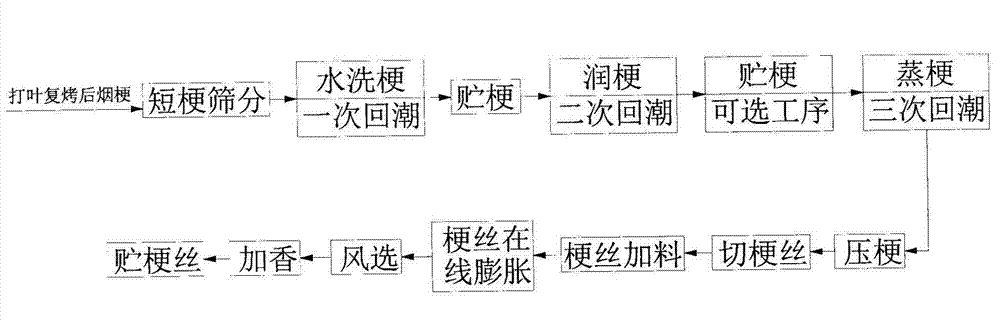

Process for processing filament-shaped stem and strip-shaped stem simultaneously

ActiveCN103960769AQuality improvementImprove quality uniformityTobacco preparationTobacco treatmentMicrowaveBiology

Provided is a process for processing a filament-shaped stem and a strip-shaped stem simultaneously. The process is characterized in that the first step of tobacco stem expansion, the second step of tobacco stem storage, the third step of tobacco stem separation and the fourth step of tobacco stem classification processing are included; in the first step of tobacco stem expansion, fed tobacco stems are expanded in a stem explosion mode or a microwave mode; in the second step of tobacco stem storage, the expanded tobacco stems are stored for 5 days to two years, so that the tobacco stems are structurally solidified; in the third step of tobacco stem separation, two types of the expanded tobacco stems obviously different in size are separated through tobacco stem separation equipment, one type of tobacco stem is thin expanded tobacco stems, the width or the diameter of each tobacco stem is smaller than 5 mm, and the other type of tobacco stem is thick expanded tobacco stems, and the width or diameter of each tobacco stem is larger than 5 mm; in the fourth step of tobacco stem classification processing, according to the characteristics of the thin expanded tobacco stems and the characteristics of the thick expanded tobacco stems, classification processing is carried out in the corresponding processing process, the thin expanded tobacco stems are processed to be filament-shaped stems and the thick expanded tobacco stems are processed to be strip-shaped stems.

Owner:CHINA TOBACCO HENAN IND

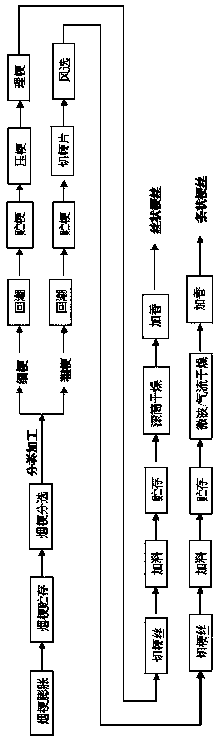

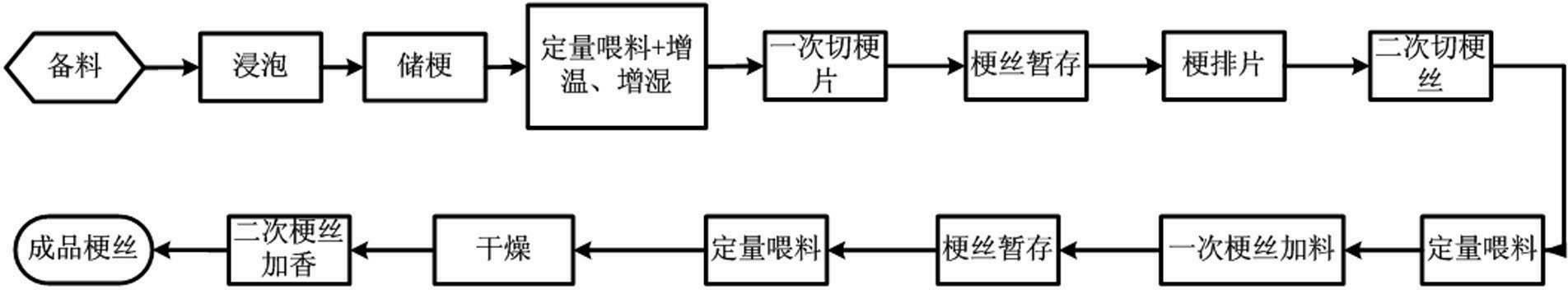

Technology for treating expanded stems

The invention discloses a technology for treating expanded stems, belongs to the technical field of shred making of tobacco, and in particular relates to the technical field of shred making with tobacco stems. The technology comprises the following steps of: soaking the tobacco stems, storing the stems, quantitatively feeding, heating and humidifying, slicing the stems for the first time, temporarily storing the stem slices, discharging the stem slices, cutting the stems into shreds for the second time, quantitatively feeding, adding the primary stem shreds, storing the stem shreds, quantitatively feeding, drying, and performing secondary flavoring, thus obtaining a stem shred finished product. The obtained product has the advantages of good bulkiness, low breaking rate, low production cost, pure aroma, high filling value, light wood mixed gas, comfortable mouthfeel, soft smoke, capability of reducing tar of cigarettes and good compatibility with the tobacco shreds.

Owner:HONGTA TOBACCO GRP

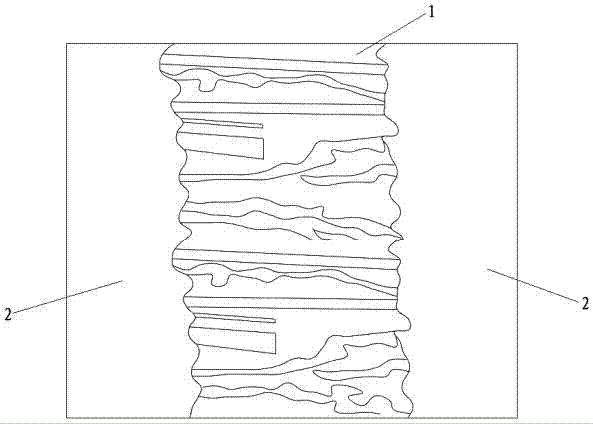

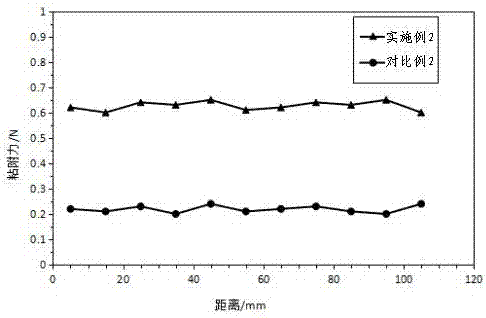

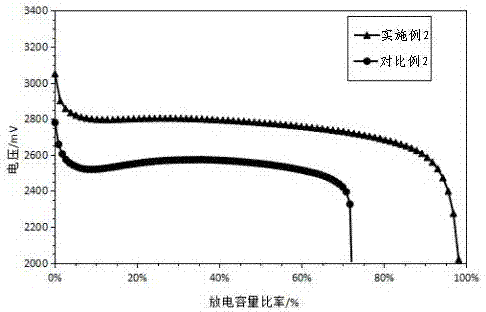

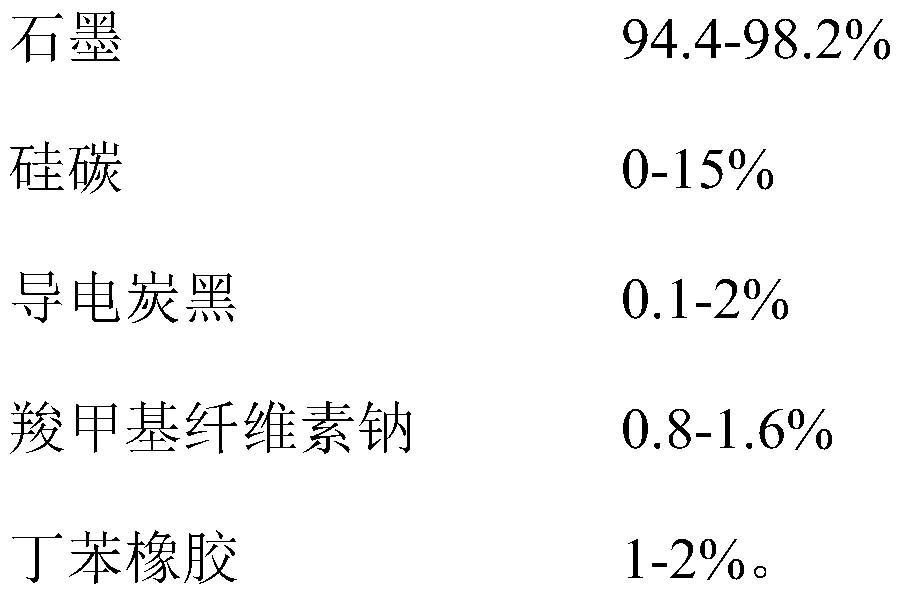

Lithium ion battery positive electrode plate and manufacturing method thereof

PendingCN107394209AImprove conductivityIncrease contact areaElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceMicrometer

The invention provides a lithium ion battery positive electrode plate and a manufacturing method thereof. The lithium ion battery positive electrode plate comprises porous current collector aluminum foil and positive electrode material layers, through holes and non-through holes are distributed on the porous current collector aluminum foil, and the two sides of the porous current collector aluminum foil are coated with the positive electrode material layers. The manufacturing method of the lithium ion battery positive electrode plate comprises the following steps that 1, current collector aluminum foil with the thickness of 10-50 micrometers is taken, and the surface of the current collector aluminum foil is subjected to a direct-current etching process; 2, the current collector aluminum foil processed through the step 1 is subjected to a chemical etching process with oxidative acid, and then the porous current collector aluminum foil can be obtained; 3, the two side faces of the porous current collector aluminum foil are coated with the positive electrode material layers, and then drying is conducted; and 4, rolling compaction is conducted to obtain the positive electrode plate of a lithium ion battery. According to the lithium ion battery positive electrode plate, by adopting the porous current collector aluminum foil, the adhesive power between a current collector and active material particles is effectively improved, the contact resistance is reduced, the active material coating amount is increased, the space ratio of the current collector is decreased, and the usability of the lithium ion battery is improved.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Desulphurization hot-metal bottle edge steel fibre enhanced fire resistant castable refractory

The invention discloses a steel fiber reinforced refractory castable for the edge of a desulfurization hot metal tank, which is made from the following raw materials with the weight percentages: 55-75% of a reclaimed material of a working lining of a desulfurization spray gun refractory material, 10-20% of high-alumina clinker, 5-10% of alumina cement, 3-7% of silica micropowder, 1-3% of reclaimed aluminum silicate fiber, 2-4% of reclaimed refractory steel fiber, 1-3% of Portland cement, 0.1-0.3% of sodium tripolyphosphate and 0.05-0.15% of calcium lignosulphonate. In the invention, the waste refractory working lining material decomposed by the desulfurization spray gun is taken as the resource of the main raw material of the castable, and finally the steel fiber reinforced refractory castable for the edge of the desulfurization hot metal tank with low cost, convenient preparation and simple use and with the reclaimed material of the waste refractory material as the main raw material is obtained, which greatly improves the integrated overall performance and anti-mechanical damage performance of the working lining of the tank edge.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Method for improving strength of pellets

ActiveCN103451416ARaise the firing temperatureImprove crystal bridge connectionSodium BentoniteReduction treatment

The invention provides a method for improving the strength of pellets. The method comprises the following steps: respectively and independently mixing magnetite concentrates and non-magnetite concentrates with externally matched bentonite uniformly; pelletizing, wherein pellets comprise not less than 20% of magnetite concentrates and not more than 80% of non-magnetite concentrates, and in the pelletizing process, the magnetite concentrates added for the first time account for 40-80% of total addition of the magnetite concentrates, the mixture of the non-magnetite concentrates and bentonite is added for the second time, the remaining magnetite concentrates are added for the third time, and 1.3-1.5wt% of bentonite is added in the pelletizing process to serve as a binder; carrying out pressure increase and reduction treatment on the pellets. The method has the beneficial effects that the calcination temperatures of ores at the middle layer and crystal bridge connection between the pellets can be improved, the content and existing state of water in the pellets can be changed, the preheating and drying time can be shortened, the preheating and drying temperatures can be reduced, the burst properties of the pellets can be reduced, the strength of the pellets can be improved, the use proportions of hematite, limonite and siderite in the pellets can be increased, and the production cost of the pellets can be lowered.

Owner:ANGANG STEEL CO LTD

WPU (Water-soluble Polyurethane) coating applied to powder-free PVC (Poly Vinyl Chloride) glove and preparation method thereof

ActiveCN102807810ANo self-adhesionImprove smoothnessPolyurea/polyurethane coatingsEmulsionWater soluble

The invention provides a WPU (Water-soluble Polyurethane) coating applied to a powder-free PVC (Poly Vinyl Chloride) glove. The WPU coating is prepared from the following components in percentage by weight: 15-30 percent of an aqueous polyurethane emulsion, 2-5 percent of flatting silica, 5-10 percent of a substrate wetting agent, 5-10 percent of a thickener, 2-3 percent of a slipping agent and 50-70 percent of deionized water, wherein the sum of the weight percentage of each component is 100 percent. The invention further provides a method for preparing the WPU coating applied to the powder-free PVC glove.

Owner:优美特(北京)环境材料科技股份公司

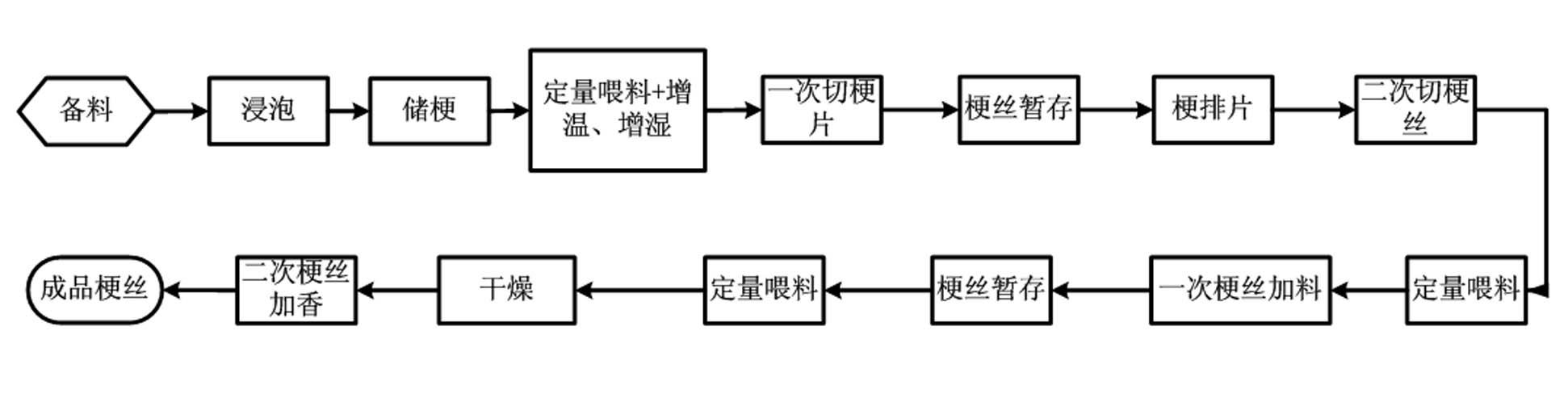

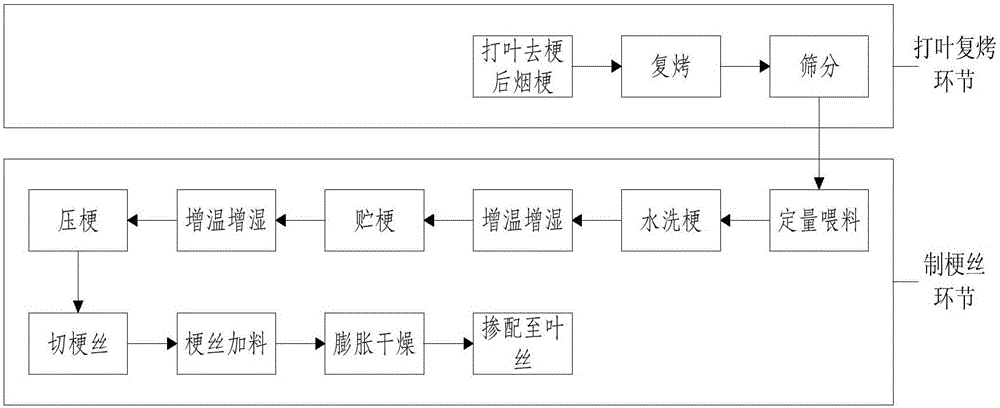

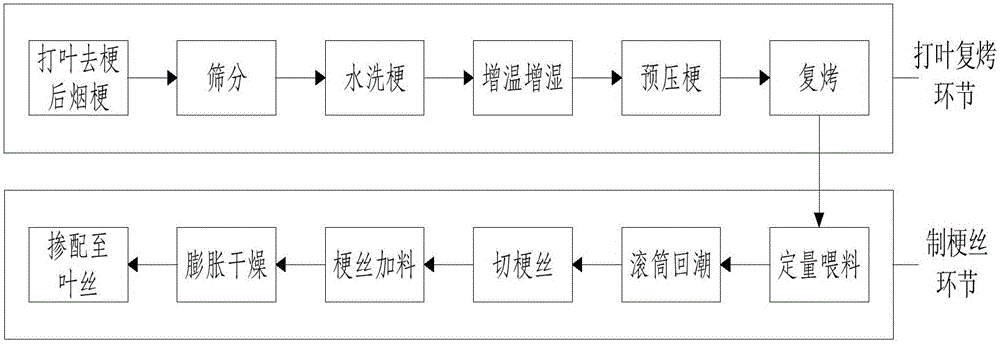

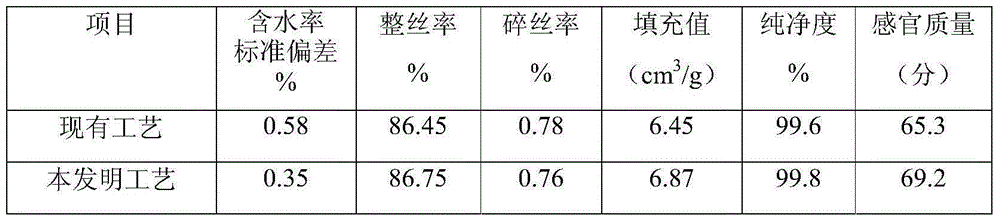

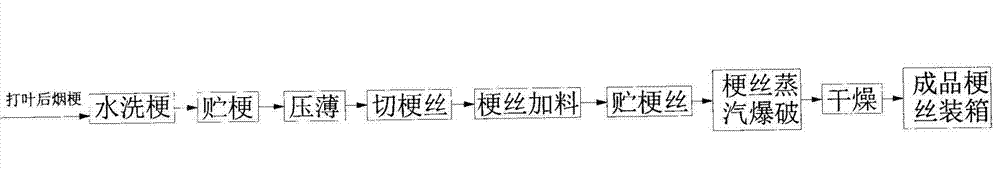

Processing method for pre-pressing threshed and re-dried tobacco stems and producing cut stems

InactiveCN105077563AGood hygroscopicityImprove preprocessing effectTobacco treatmentPulp and paper industryMoisture

The invention discloses a processing method for pre-pressing threshed and re-dried tobacco stems and producing cut stems, and belongs to the technical field of tobacco processing. The processing method comprises the following steps: sieving tobacco stems obtained by threshing tobacco leaves, washing the stems with water, increasing temperature and humidity, pre-pressing the stems, re-drying, quantitatively feeding, regaining moisture by virtue of a roller-type moisture regaining machine, cutting the tobacco stems so as to obtain cut stems, charging the cut stems, and expanding and drying so as to obtain the cut stems. The processing method disclosed by the invention can be used for simplifying a cut stem production technological flow, shortening cut stem production processing time and reducing energy consumption; in the process of producing the cut stems, an effect of preprocessing the tobacco stems is good and the obtained cut stems are uniform in quality; the moisture content stability and the filling performance of the cut stems are increased, and the purity and the sensory quality of the cut stems are slightly improved, so that a purpose of increasing the using proportion of the cut stems in a cigarette formula is improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Preparation method of blast furnace sludge pre-reduced pellet

ActiveCN103451421AImproved metallurgical propertiesLow firing temperatureBlast furnace detailsSludgeDolomite

The invention provides a preparation method of a blast furnace sludge pre-reduced pellet. The blast furnace sludge pre-reduced pellet is prepared from the following raw materials in percentage by mass: 10-30% of blast furnace sludge, 3.5-10% of SiC powder, 60-85% of iron ore concentrate and 1.2-1.5% of bentonite. The preparation method comprises the following steps: uniformly mixing 20-30% of the total dosage of the bentonite with the blast furnace sludge and the SiC powder, respectively, and uniformly mixing the iron ore concentrate with 70-80% of the total dosage of the bentonite to prepare a mixture; in a pellet preparation process, firstly, preparing the mixture of the blast furnace sludge, the SiC powder and the bentonite to a pellet core; then, adding the mixture of the iron ore concentrate and the bentonite to continue the pellet preparation process; and wrapping a layer of dolomite accounting for 0.5-1.5% of the total mass of the raw materials on the formed pellet, and preparing the pre-reduced pellet according to a conventional production process. By adopting the preparation method provided by the invention, a large amount of blast furnace waste can be consumed, the roasting temperature of the pellet is reduced, the utilization proportion of non-magnetite concentrate is increased, and the finished product pellet is non-adhesive, good in metallurgical performance and beneficial to improving the blast furnace efficiency and reducing the coke ratio of a blast furnace.

Owner:ANGANG STEEL CO LTD

Method for preparing drug-carrying polyester polymer/biological ceramic bone repairing scaffold through low-temperature 3D printing technology as well as product and application thereof

InactiveCN109395159AGood dispersionIncrease usage ratioAdditive manufacturing apparatusInksPolyesterFreeze-drying

The invention relates to a method for preparing a polyester polymer / nano-biological ceramic bone repairing scaffold through a low-temperature 3D printing technology as well as a product and application thereof. The method comprises the following steps: using physical property of a polar solvent hexafluoroisopropanol, taking a hexafluoroisopropanol solution mixed with drug, polyester polymer and biological ceramic as 3D printing ink, printing till a product is solidified and molded on a low-temperature platform, then carrying out freeze-drying, heating and volatilizing to remove the solvent, soas to complete preparation of an artificial bone repairing scaffold. The preparation method provided by the invention is simple and practicable, provides a new method for clinical individualized treatment on massive bone defects, and has extensive clinical application prospects.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

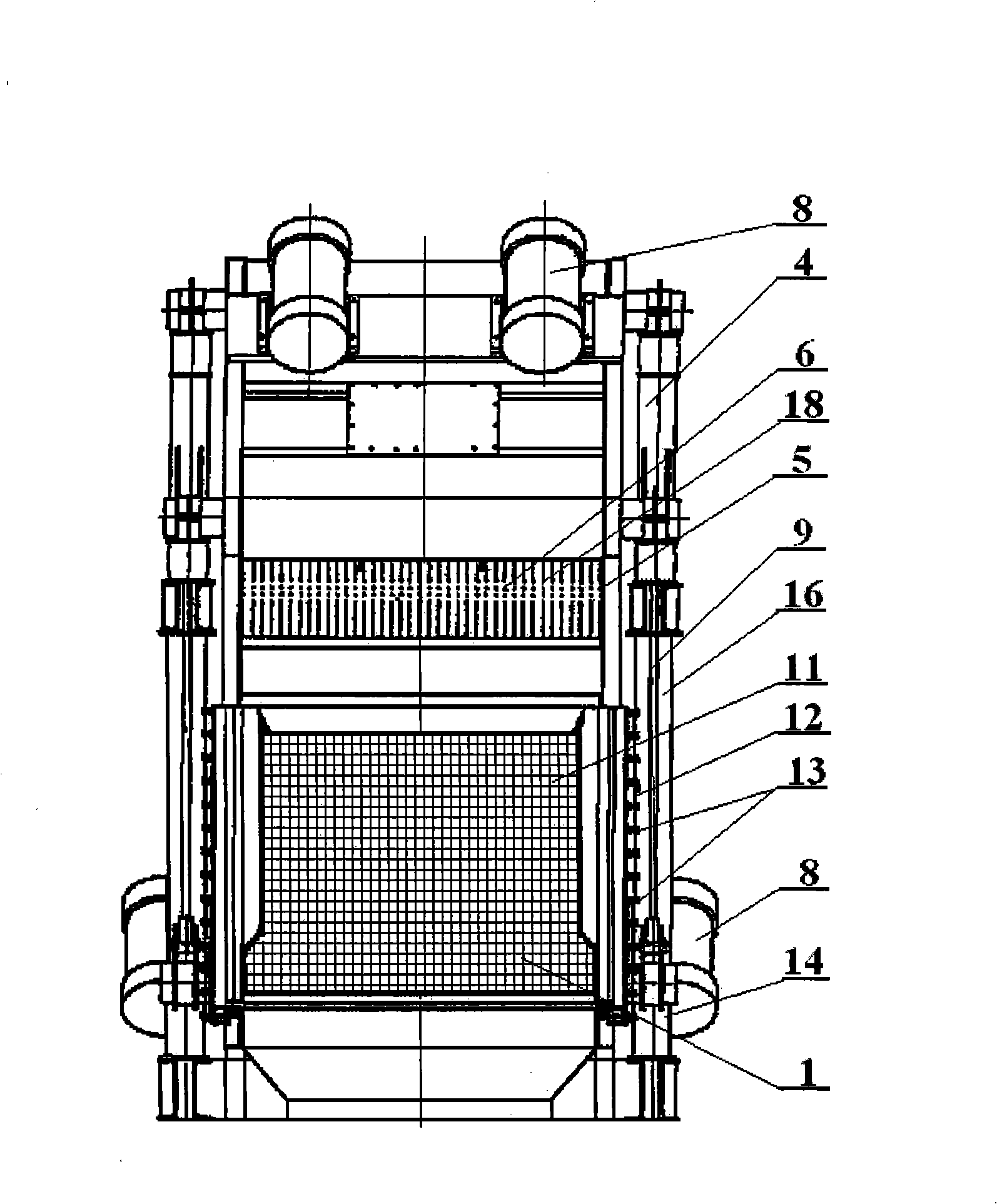

Combination vibration sieve

The invention discloses a combined vibration sieve, wherein a coarse sieve surface (6) of a coarse vibration sieve (5) is a sieve mesh formed by a plurality of suspended self-cleaning elastic coarse sieve bars (18) which are uniformly spaced at a certain distance and in a mounting direction oblique upwards or downwards to the coarse sieve surface (6). By adopting the technical proposal, the combined vibration sieve has reasonable structure and high safety and reliability, solves the problems of low screening efficiency and poor screening quality in the prior art, improves the efficiency of screening lump ores, particularly the lump ores with a high water content, minimizes the dust content of screened lump ores and the proportion of lump ores in the powdered ores after screening, further meets the requirements for lump ores in blast furnace production, increases the utilization coefficient of the blast furnace and reduces the production costs.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for improving tobacco leaf quality on upper part of flue-cured tobacco by applying steam explosion technology

InactiveCN101897473AReduce total phytoalkaloid contentLess irritatingTobacco treatmentSteam pressureIrritation

The method discloses a method for improving tobacco leaf quality on an upper part of flue-cured tobacco by applying steam explosion technology, and relates to the technical field of tobacco processing. The method comprises the following steps of: performing steam explosion on the upper tobacco leaf of flue-cured tobacco, wherein the working medium for steam explosion is saturated steam, the steam explosion time is less than 0.01 second, the steam pressure is between 0.4 and 0.8 MPa, and the pressure preserving time is between 10 and 60 seconds; drying the upper tobacco leaf subjected to steam explosion, and reducing the moisture to 10-25 percent; and making the dried upper tobacco leaf enter a shredding and expanding process, and using the upper tobacco leaf in a cigarette formula. The method for improving the tobacco leaf quality effectively reduces the total plant alkaloid content in the tobacco leaf on the upper part of flue-cured tobacco, increases the content of reducing sugar, lightens the irritation and strength of the upper tobacco leaf, increases the aroma, effectively improves the combustibility of the tobacco leaf, makes the ratio of the upper tobacco leaf of the flue-cured tobacco to the cigarette formula increased from 10 percent to 15 percent, and effectively improves the utilization rate of the tobacco leaf on the upper part.

Owner:CHINA TOBACCO CHUANYU IND

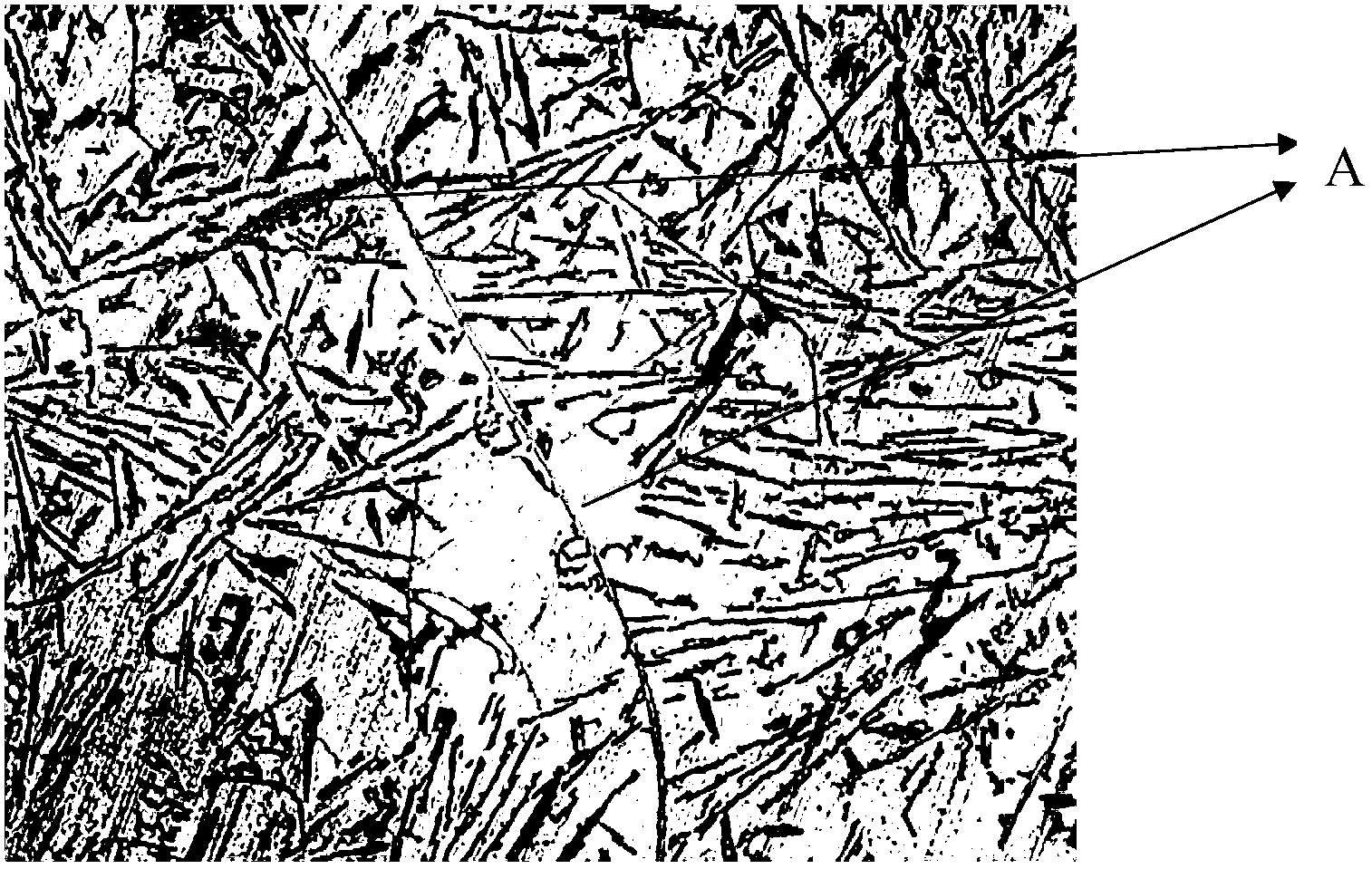

Novel secondary aluminum modifying refiner and method for smelting secondary aluminum by utilizing refiner

ActiveCN103173643AImprove organizational structureIncrease usage ratioProcess efficiency improvementSlagIngot

The invention relates to a novel secondary aluminum modifying refiner and a method for smelting secondary aluminum by utilizing the refiner. The method for producing the secondary alumium by utilizing the refiner specifically comprises the following steps: putting weighed industrial pure aluminum, industrial silicon and waste aluminum into a constant-temperature preheating drying furnace of 250 DEG C to dry for 2-3 hours; conveying dried raw materials into a melting furnace, and removing gas and slag after complete melting; adding 0.3wt%-0.5wt% of novel secondary aluminum modifying refiner when the temperature reaches 730-750 DEG C, fully stirring and standing, detecting and regulating the components; and (5) casting ingots when the temperature is 680-720 DEG C to prepare the secondary aluminum. The novel modifying refiner provided by the invention not only can effectively control the content of impurity elements but also can fully utilize interaction effect between the elements to realize the benefits of the impurity elements, thereby greatly reducing the relegation and regeneration cost and improving the quality and performance of the regenerated products.

Owner:天津新立中合金集团有限公司

Tobacco stem cutting process by threshed tobacco stems

InactiveCN102783705AImprove qualityImprove blending uniformityTobacco treatmentIndustrial engineeringCigarette smoke

The invention discloses a tobacco stem cutting process by threshed tobacco stems. The process is characterized in comprising the following technical steps: washing stem, storing stem, thinning, cutting stem, carrying out steam explosion for cut stem, drying and so on. The process has the advantages that color and shape of the cut stem processed by the technical method are close to that of the cut tobacco; the breakage rate in the cut stem process is low; the blending uniformity is improved; when smoked, the tobacco is free from harmful wood flavor; the cigarette smoke is harmonized; the comfort of the tobacco is improved; the cut stem is strong in filling capability; and the internal quality of the cigarette is further improved. The power consumption of the corresponding tobacco stem processing enterprise can be reduced. At present, a threshing redrying factory usually stores a lot of tobacco stems, so that the direct stem cutting process provides a new method for comprehensive utilization of the tobacco stems for the redrying factory, and provides a technical economic scheme for forward leading the stem cutting process of a cigarette factory to the redrying factory.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

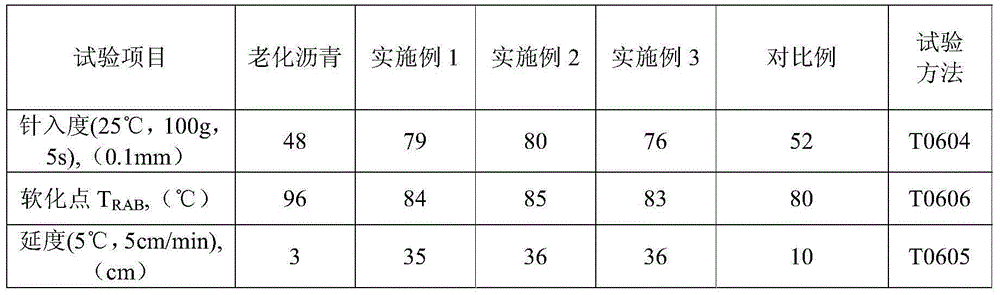

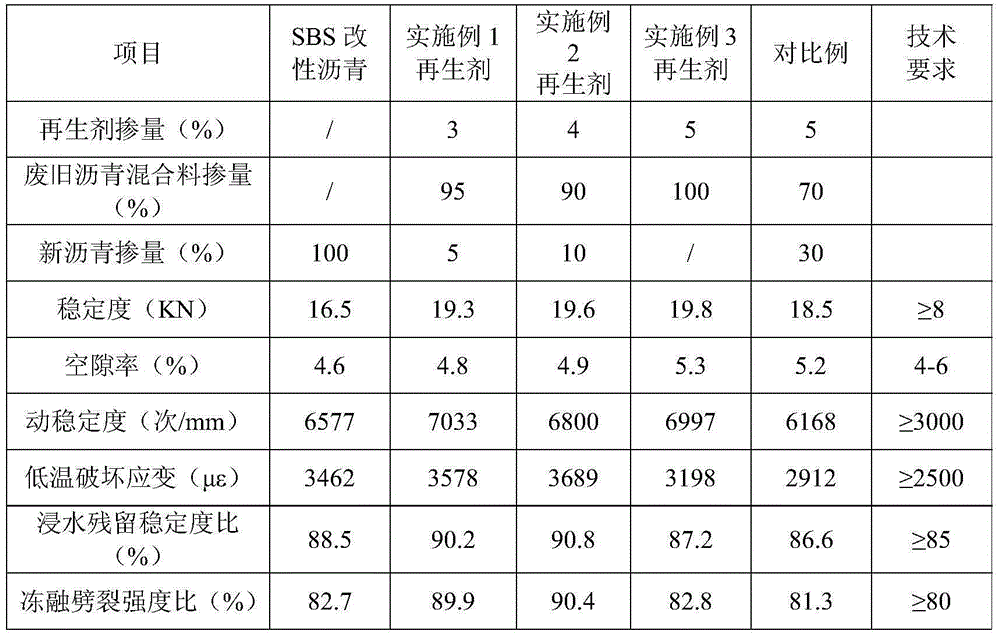

Reaction type asphalt regenerating agent and preparation method thereof

The invention relates to a reaction type asphalt regenerating agent and a preparation method thereof. The preparation method comprises the following steps: adding petroleum asphalt, maleic anhydride and a Diels-Alder addition reaction catalyst into a reaction container, heating to 160-180 DEG C to carry out addition reaction for 8-12 hours, cooling a system to 70-80 DEG C, adding a polyurethane prepolymer and a chain extender, and continuing the thermal insulation reaction for 8-10 hours, then adding a fatty acid amide serving as a viscosity reducer, nonylphenol polyoxyethylene ether serving as a penetrating agent and an anti-aging agent, and mechanically stirring at 80-90 DEG C for 2-4 hours until the mixture is uniformly stirred, so as to obtain the reaction type asphalt regenerating agent. The reaction type asphalt regenerating agent provided by the invention is relatively low in viscosity, does not need to be heated in use, is convenient to construct, has a good restoration effect to the ductility of aged asphalt and can meet the performance requirement of unused asphalt; and furthermore, the use ratio of regenerated materials can be increased, and the water damage resistance of a prepared regenerated asphalt mixture is superior to that of a general regenerating agent.

Owner:HAISO TECH

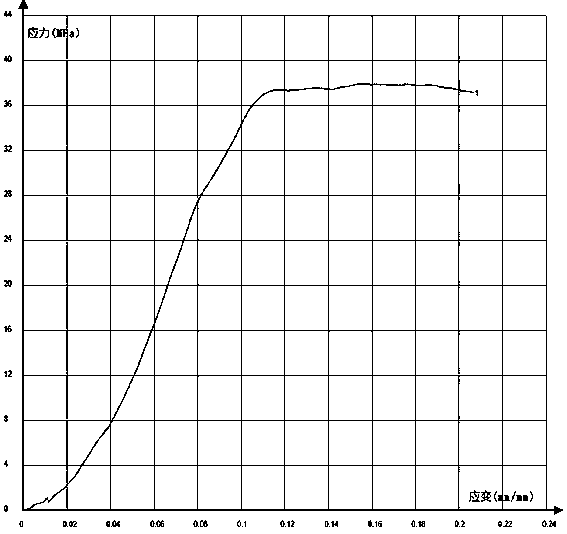

Low-carbon, low-silicon, cold-rolled and hot-galvanized dual-phase steel for extra-deep drawing and preparation method thereof

InactiveCN104233093AImprove hardenabilityGuaranteed hot-dip galvanizing performanceChemical compositionMo element

The invention relates to low-carbon, low-silicon, cold-rolled and hot-galvanized dual-phase steel for extra-deep drawing and a preparation method thereof. The dual-phase steel comprises chemical components in percentages by mass as follows: 0.035%-0.045% of C, 0.03%-0.05% of Si, 1.3%-1.75% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, smaller than or equal to 0.075% of Al, 0.5%-0.68% of Cr, 0.35%-0.5% of Mo and the balance of Fe and unavoidable impurities, wherein the content of P, S and Al is not 0, texture in the {111} / / RD direction in microstructures of the dual-phase steel occupies more than 90 vol.%, the main microstructures adopt ferrite and martensite structures, the tension strength of the dual-phase steel ranges from 485-600 MPa, the elongation is higher than or equal to 32%, and an r value is 2-2.2. The dual-phase steel is matched with the corresponding preparation method. By means of the invention, certain quantity of Cr and Mo elements are added into the low-carbon dual-phase steel, a texture pre-treatment process is adopted, so that the deep drawability of a material is improved remarkably under certain strength condition, and the hot galvanizing performance of the material is improved sufficiently.

Owner:朱忠良

Processing method of high-grade tobacco expansion shreds

InactiveCN103005663AGood colorImprove whole yarn rateTobacco preparationFluidized bed dryingCO2 content

The invention discloses a processing method of high-grade tobacco expansion shreds. The method comprises the following steps of A, dampening cut tobacco shreds through a CO2 expansion line until the moisture content is 20 to 25 percent; B, dipping the cut tobacco shreds in a CO2 dipping tank, wherein the dipping time is 10 to 80 seconds, the CO2 draining time is 120 to 350 seconds, and the CO2 content in the dipped tobacco shreds is 2 to 6 percent; C, drying and expanding the tobacco shreds in a fluidized bed, wherein the process flow rate of the fluidized bed is 2,500kg / h, the temperature of the first area is 100 to 1,400 DEG C, the temperature of the second area and the third area is normal temperature, the steam flow is 600 to 900kg / h, and the moisture content of the dried and expanded tobacco shreds is 12.5 to 13.0 percent; and D, adding a characteristic aroma into the shreds by using an aroma adding machine. The expansion shreds manufactured by the process are relatively good in color and luster, lemon yellow and high in expansion shred finishing rate, the fill value is slightly lower than that of the expansion shreds manufactured in the prior art, the internal quality is obviously improved, and volatile and semi-volatile aromatic component loss is low.

Owner:CHINA TOBACCO ANHUI IND CO LTD

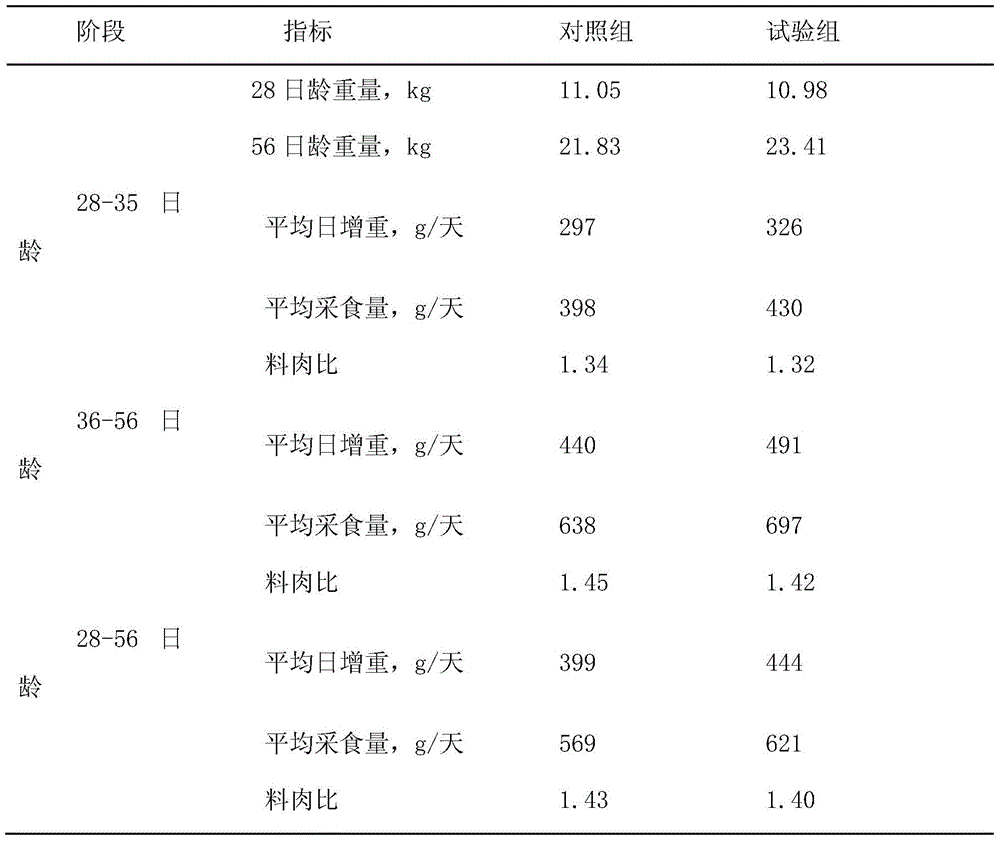

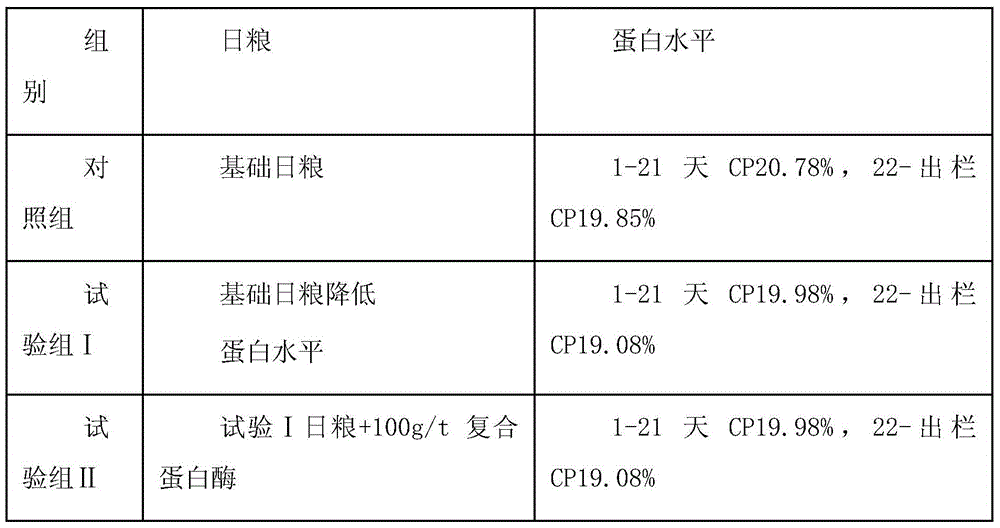

Compound protease as well as production method and applications thereof

InactiveCN105779423AIncrease enzyme activityThe fermentation process is simpleHydrolasesMicroorganism based processesAlkaline proteaseNeutral protease

The invention belongs to the technical field of enzyme preparations, and in particular relates to a compound protease as well as a production method and applications of the compound protease. The compound protease is prepared from the following components in parts by weight: 1-7 parts of alkaline protease, 2-5 parts of acid protease, and 1-4 parts of neutral protease. The gene engineering technology is adopted in the project, the improved bacillus licheniformis containing alkaline protease genes is obtained, the step-by-step scale-up fermentation test is carried out, the fermentation and the aftertreatment technologies are optimized, the preparation improvement is developed, and the follow-up application and development are carried out.

Owner:JINANBESTZYME BIO ENG CO LTD

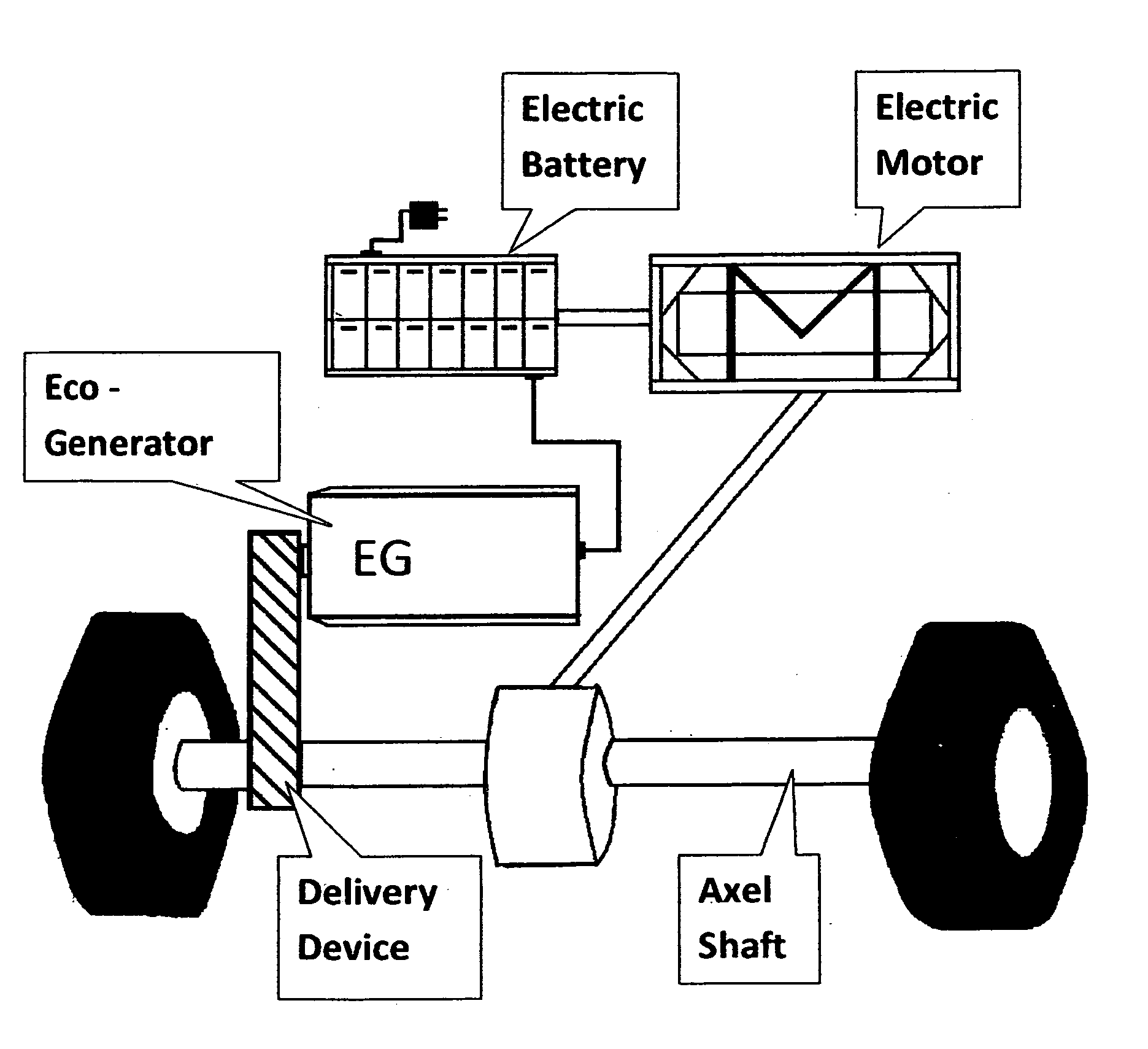

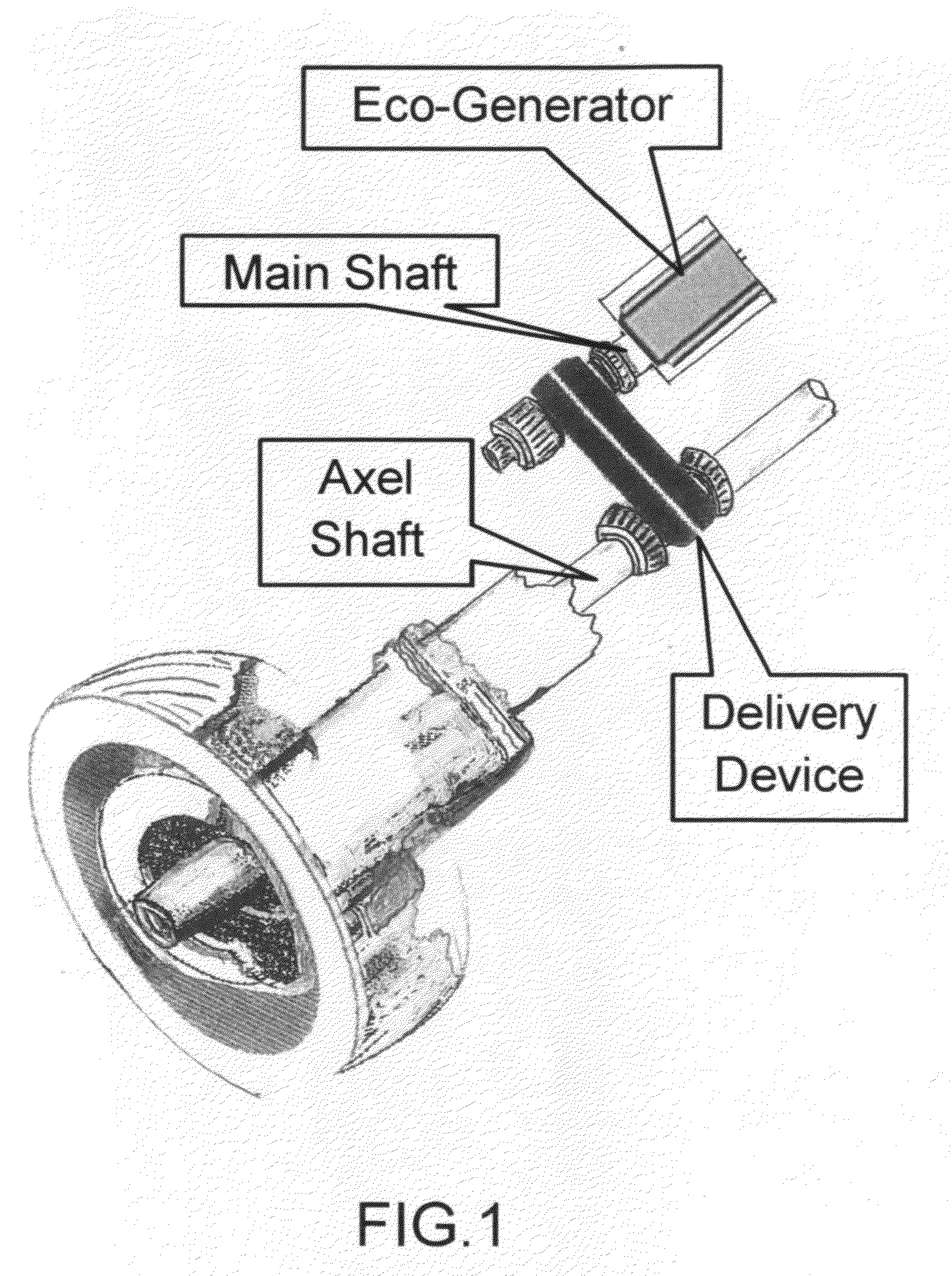

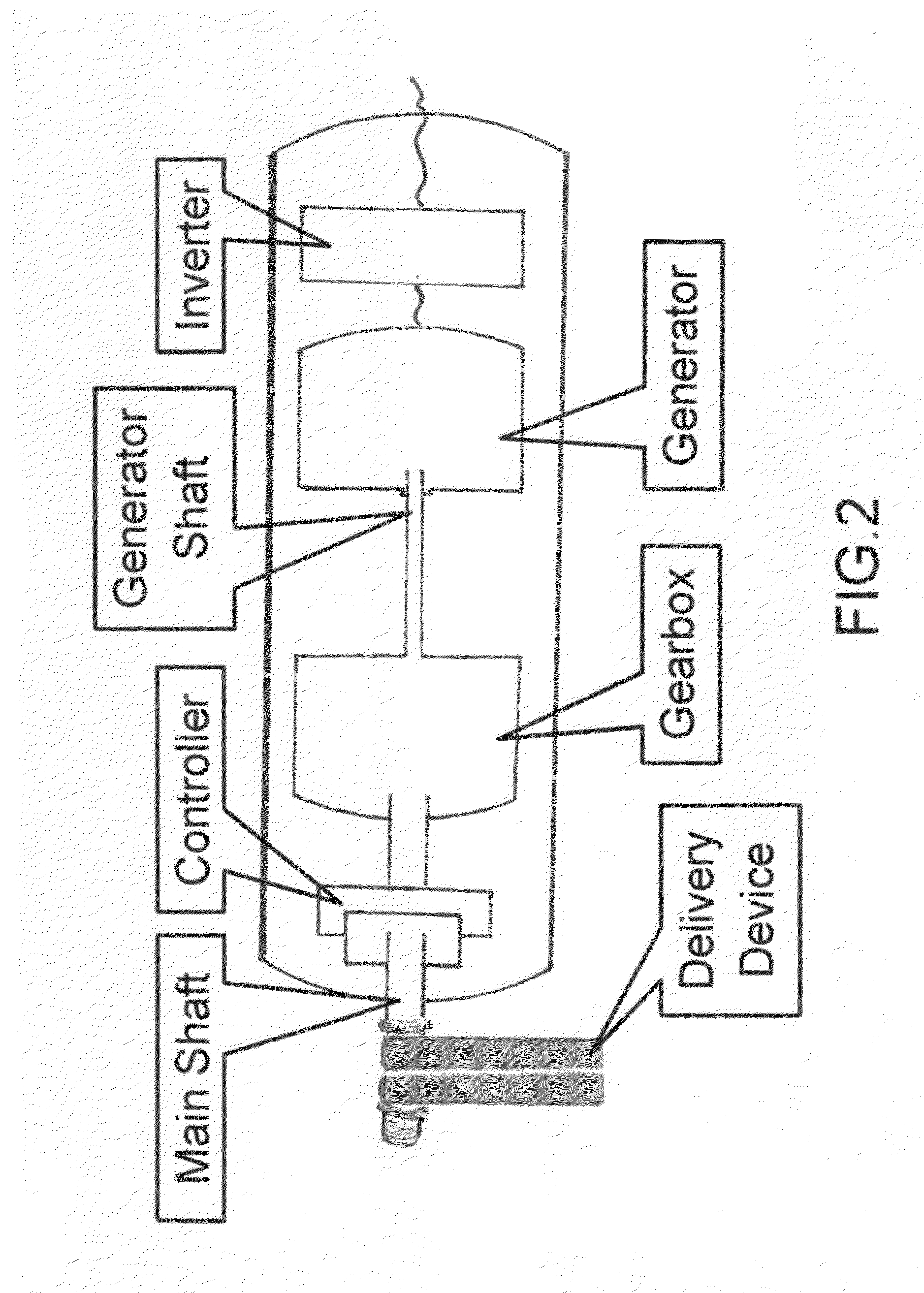

Method for internally generating electric energy in electric vehicles

InactiveUS20130154363A1Increase usage ratioIncrease usageAuxillary drivesElectric devicesElectrical batteryAutomotive engineering

Disclosed is a method to create an extra electric energy source to power electric batteries while the electric vehicle is in motion. This electric energy source is generated from a separate internally installed component (a specially designed “Eco-Generator”). This component converts the axel shaft rotational energy through a delivery device.

Owner:LIM JAE HYUN

Modifier as well as preparation method and applications thereof

InactiveCN101831131BEfficient recyclingIncrease usage ratioCable installations on groundElastomerPolymer science

Owner:PUTIAN HENGTONG COMM EQUIP

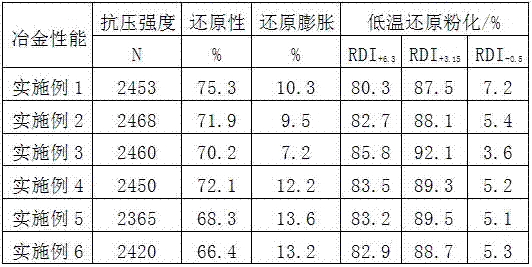

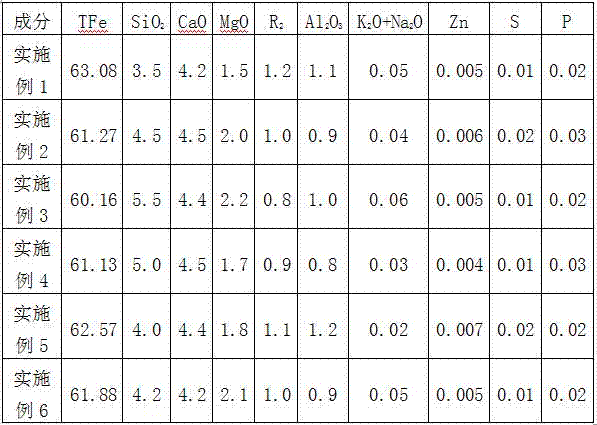

High-silica magnesian fluxed pellet for blast furnace and production method of high-silica magnesian fluxed pellet

InactiveCN106987705AIncrease usage ratioHigh silicon contentBlast furnace detailsAlkalinityHigh silica

The invention discloses a high-silica magnesian fluxed pellet for a blast furnace and a production method of the high-silica magnesian fluxed pellet. The high-silica magnesian fluxed pellet comprises, by mass fraction, 3.5%-5.5% of SiO2, 1.5%-2.2% of MgO, 0.8%-1.2% of basicity, not larger than 1.5% of Al2O3, not larger than 0.1% of K2O and Na2O, not larger than 0.02% of Zn, not larger than 0.05% of S and not larger than 0.07% of P. The silica content of the pellet is high, the pellet can be produced through high-silica iron fine powder, the using proportion of the pellet in the blast furnace is improved, meanwhile, the using scope of the iron fine powder is enlarged, and the using proportion of the iron fine powder inland is improved. By means of the method, the high-silica iron fine powder can be used for producing the magnesian fluxed pellet, the production cost is reduced, meanwhile, the pellet qualified in quality can be obtained, and requirement of the blast furnace for using the high proportion of pellet is met; and by means of the method, the scope of the iron fine powder used for producing the magnesian fluxed pellet can be expanded, and the using amount of the high-silica iron fine powder inland can be particularly improved. The method has the beneficial effects of being low in production cost, simple in process and excellent in product performance.

Owner:TANGSHAN IRON & STEEL GROUP +1

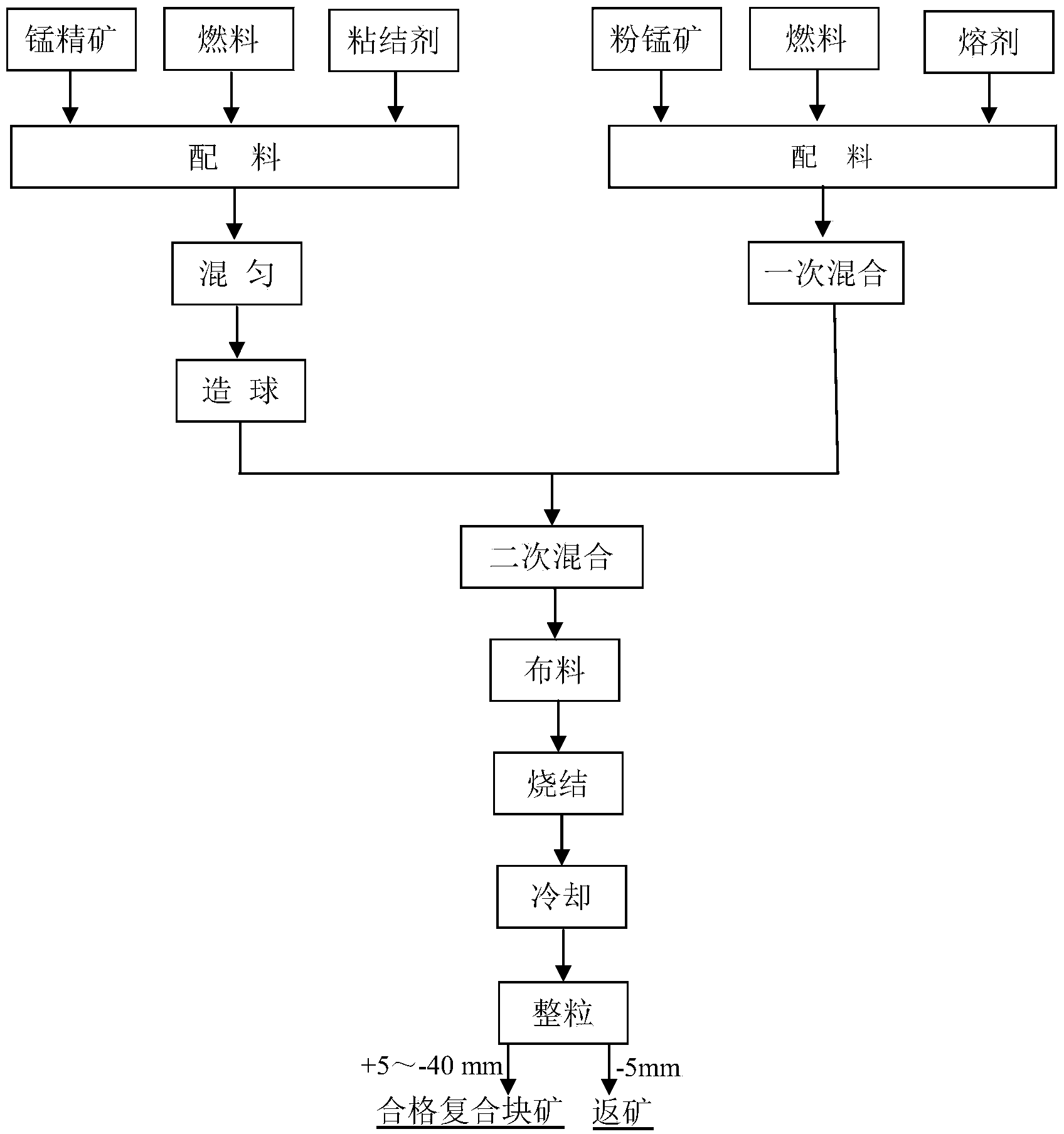

Composite manganese smelting furnace charge preparation process capable of realizing comprehensive utilization of manganese ore

The invention discloses a composite manganese smelting furnace charge preparation process capable of realizing comprehensive utilization of manganese ore. The composite manganese smelting furnace charge preparation process comprises the following steps: mixing fine-fraction manganic concentrate, an adhesive and fuel with water and preparing a mixture A obtained after mixing into a pellet material on a pelletizer; additionally taking manganese ore powder, flux and fuel, adding water to carry out blending and carrying out primary mixing in a mixer to obtain a mixture B; uniformly mixing the prepared pellet material and the mixture B again in the mixer, placing an obtained mixture on a sintering machine after uniform mixing for material distribution, ignition and sintering and after cooling, carrying out crushing and screening to obtain the composite manganese smelting furnace charge that the acid pellet is embedded into high basicity sinter. The process disclosed by the invention is simple, and low in cost, can greatly improve gas permeability of a sintered material layer, improves the utilization level of the fine-fraction manganic concentrate and increases a vertical sintering speed and a utilization coefficient.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

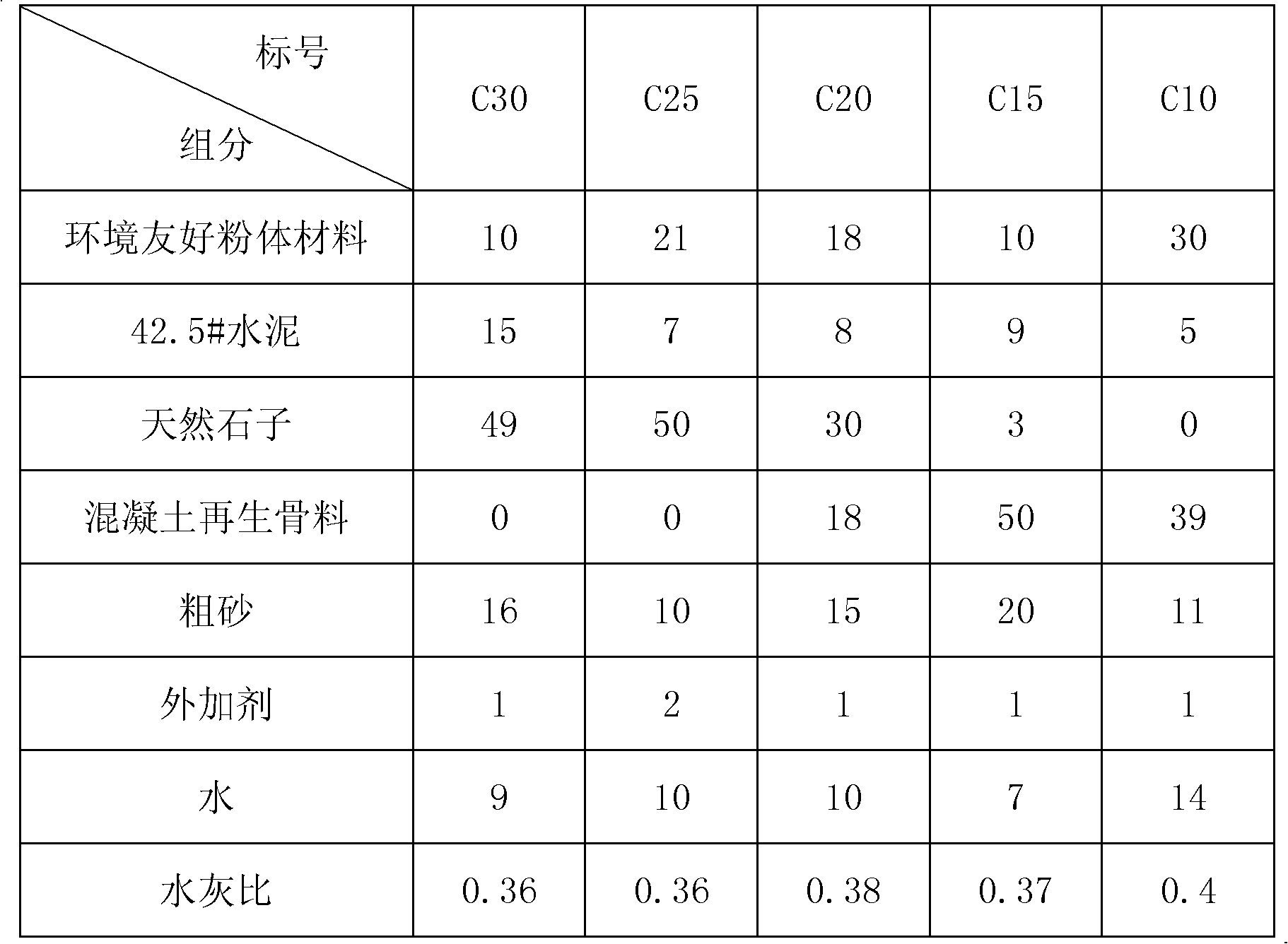

Environmentally-friendly green concrete

ActiveCN103183489AReduce dosagePlay a stimulating roleSolid waste managementAcid–base reactionUltimate tensile strength

The invention discloses an environmentally-friendly green concrete. The green concrete is prepared from the following material components in ratio by weight: 10-30% of an environmentally-friendly powder material, 5-15% of cement, 0-50% of natural stone, 0-50% of concrete recycled aggregate, 10-20% of coarse sand, and 1-2% of additives. The environmentally-friendly green concrete disclosed by the invention uses the building recycled environmentally-friendly powder material with a certain activity and capable of replacing a part of cement, thus saving cost, improving peaceability, reducing the phenomena of bleeding and separation, and improving the performance of the concrete; and the environmentally-friendly green concrete has the functions of delaying coagulation, reducing water, enhancing compactness and later-stage strength, reducing hydration heat, suppressing sun-crack and shrink, and improving acid-base reaction resisting capacity.

Owner:上海德滨环保科技有限公司

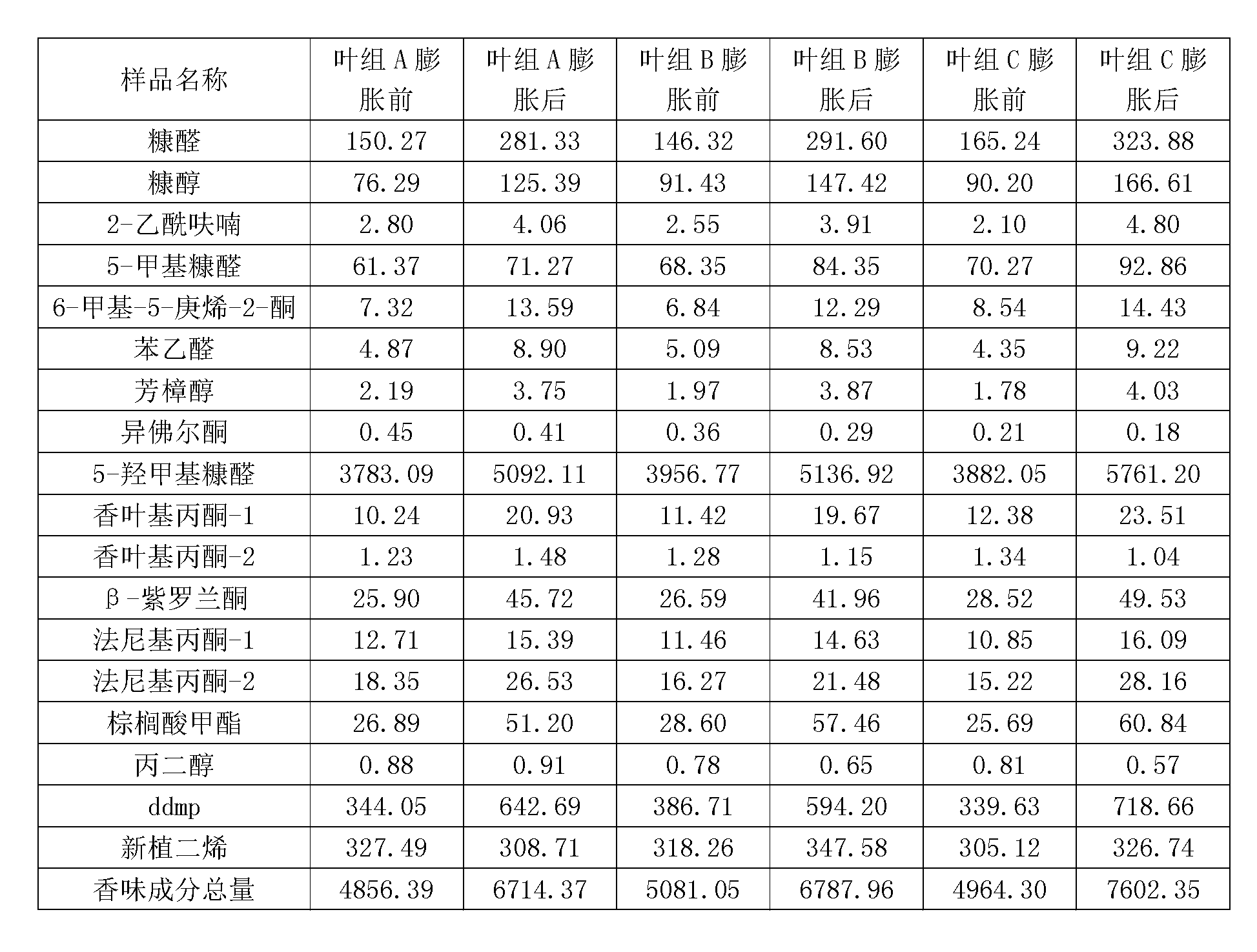

Industrial method for improving applicability of senior tobacco leaves through module group secondary rebaking

The invention provides an industrial method for improving applicability of senior tobacco leaves through module group secondary rebaking. Senior stock tobacco leaves are subjected to function module grouping, grouping adopts a Schmuck value as a main reference condition, the tobacco leaves with a Schmuck value of 2.8-3.6 are A module Schmuck tobacco leaves with high applicability, the tobacco leaves with a Schmuck value of 2.3-2.8 are B module Schmuck tobacco leaves with medium applicability, and the tobacco leaves with a Schmuck value of 2.3 or below are C module Schmuck tobacco leaves with low applicability; through the grouped function modules, the tobacco leaves are subjected to feed preparation according to a tobacco leaf formula, and are sent to a leaf storage cabinet through vacuum wetting and primary conditioning till the leaf water content is 15%-18% and through secondary conditioning till the leaf water content is 17%-20%, the tobacco leaves in the leaf storage cabinet are subjected top leaf secondary rebaking, a second area temperature key in rebaking is controlled at 70-88 DEG C, temperatures in a first area, a third area and a fourth area are matched and adjusted according to the temperature in the second area, rebaking is completed, and the tobacco leaves are packed in boxes for standby use. According to the industrial method for improving the applicability of the senior tobacco leaves through module group secondary rebaking, the senior stock tobacco leaves can be massively utilized, the stock and the raw material cost are saved, and the tobacco quality is not lowered when the method is applied to a tobacco formula.

Owner:CHINA TOBACCO JIANGXI IND CO LTD +1

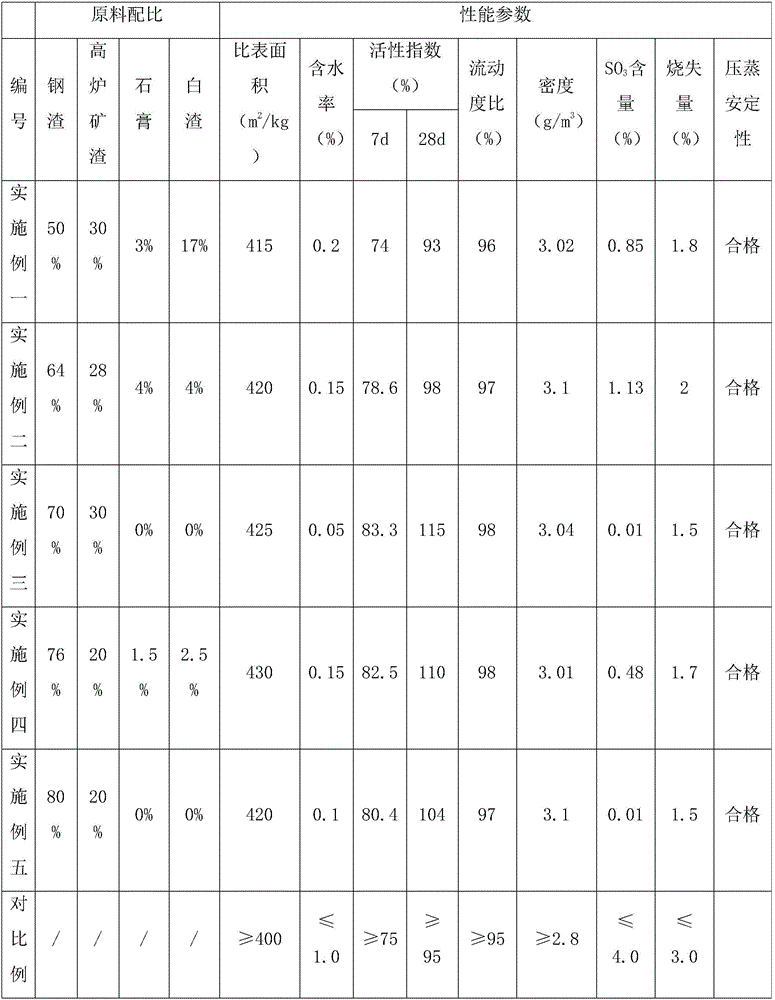

High-strength double-doped mineral powder

InactiveCN106747150AImprove wear resistanceImprove corrosion resistanceSolid waste managementElectric arc furnaceSlag

The invention discloses high-strength double-doped mineral powder and belongs to the technical field of metallurgical environmental protection. The high-strength double-doped mineral powder is prepared from the ingredients in percentage by weight: 50% to 80% of steel slag, 20% to 40% of blast-furnace slag powder, 0% to 3% of gypsum powder and 0% to 17% of white slag, wherein the double-doped mineral powder has the density of 3.0g / cm<3> to 3.1g / cm<3>, the moisture content of not higher than 1%, the free CaO content of lower than 3%, the fluidity ratio of not lower than 97%, the activity index of not lower than 75%, the specific surface area of not smaller than 400m<2> / kg, the SO3 content of not higher than 4% and the ignition loss of 1.5% to 20%; the slag powder is commercially-available slag powder which is in line with national standards GB / T18046-2008; the steel slag is steel slag of a converter or electric furnace; and the white slag is slag, which is formed through carrying out diffusive deoxidation by taking carbon powder and ferro-silicon powder as reducers during the reduction-period operation of arc-furnace steelmaking. The high-strength double-doped mineral powder disclosed by the invention is mainly prepared from the steel slag and the blast-furnace slag powder, and the steel slag and the blast-furnace slag powder complement each other in properties through combination, so that the later strength of concrete can be effectively improved, the heat of hydration is reduced, and the slump loss is reduced; and the improvement on the working performance of the concrete is much higher than that resulting from purely using blast-furnace slag or the steel slag.

Owner:重庆市富环建筑材料有限责任公司

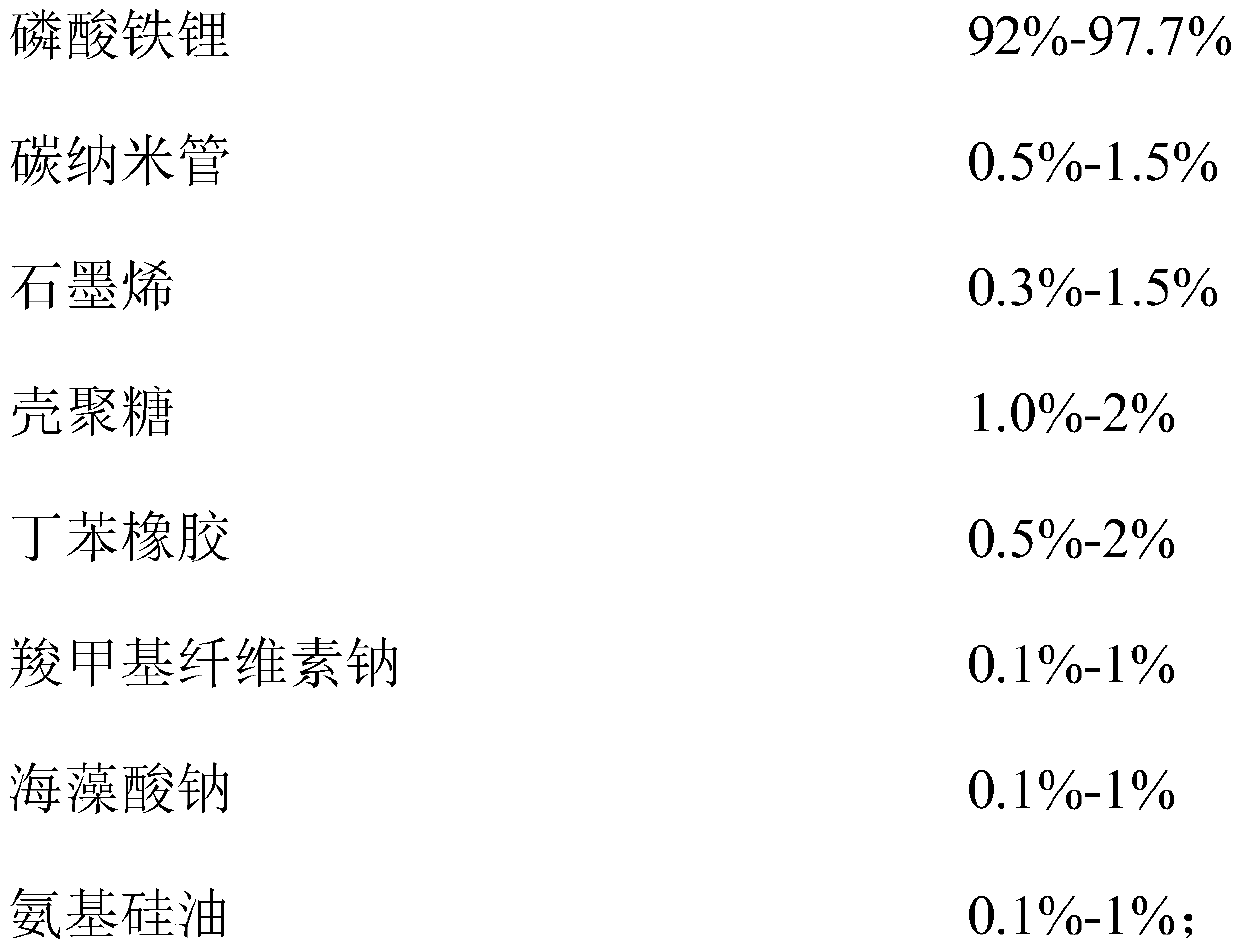

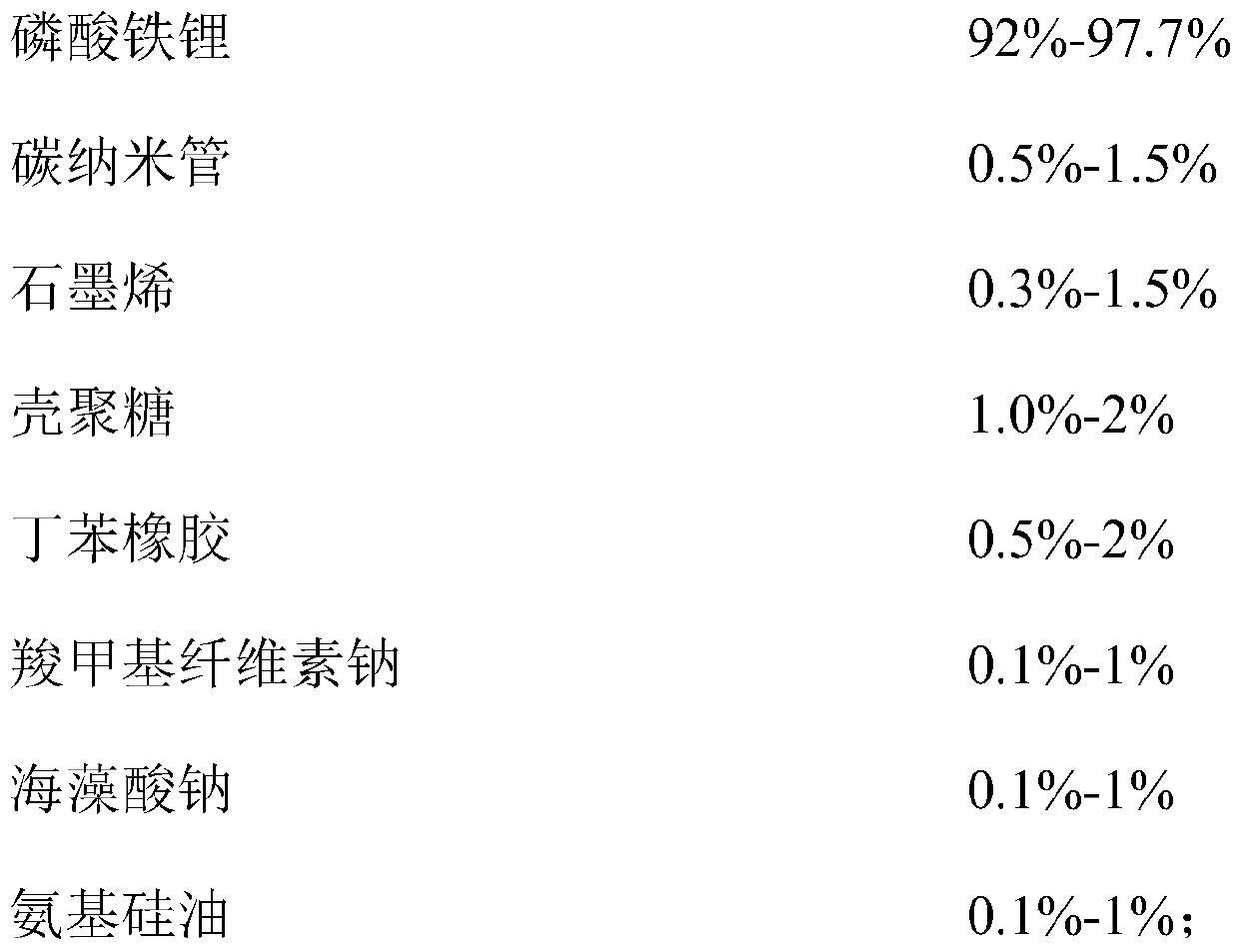

Lithium iron phosphate positive plate and environment-friendly low-temperature-resistant lithium battery comprising same

InactiveCN111261835AIncrease capacityAvoid secondary reunionsSecondary cellsPositive electrodesElectrical batteryButadiene-styrene rubber

The invention discloses a lithium iron phosphate positive plate. The lithium iron phosphate positive plate comprises an aluminum foil and water-based positive slurry which coats the aluminum foil; thewater-based positive slurry comprises lithium iron phosphate, carbon nanotubes, graphene, chitosan, butadiene styrene rubber, sodium carboxymethyl cellulose, sodium alginate and amino silicone oil; and the particle size of the lithium iron phosphate is 4-10 microns. According to the lithium iron phosphate positive plate of the invention, a positive electrode active substance with large particle size and small specific surface area is adopted, so that the low-temperature performance of the lithium iron phosphate positive plate is good; the environment-friendly water-based positive electrode slurry is adopted, so that the positive electrode plate is environment-friendly, non-toxic, good in processing environment adaptability and stable in processing performance, and the obtained positive electrode plate is high in compaction density, high in specific energy and excellent in low-temperature property. The invention further discloses an environment-friendly low-temperature-resistant lithium battery which comprises the lithium iron phosphate positive plate and is combined with a negative plate with high cost performance, large capacity and high activity, and the obtained lithium iron phosphate battery is good in safety performance, high in energy density, excellent in low-temperature performance, stable in processing performance, free of pollution in the production process and low in battery cost.

Owner:广西卓能新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com