Patents

Literature

48 results about "Leaf water content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

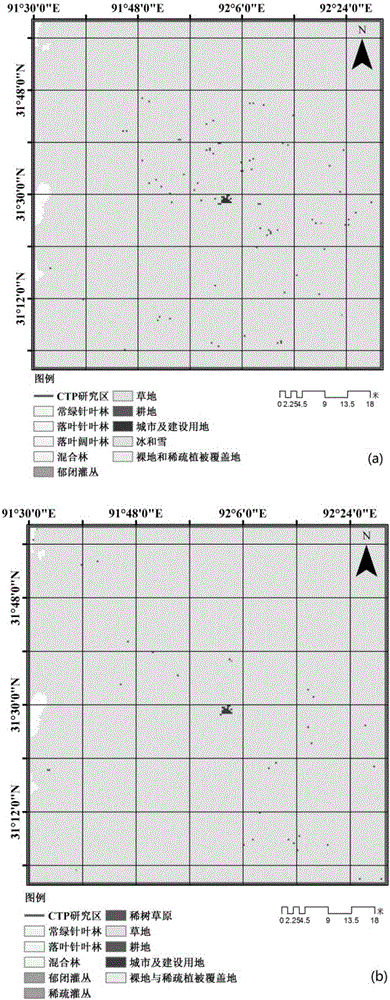

Agricultural drought monitoring method

InactiveCN101187630APrecise inversionEasy to operateScattering properties measurementsOptical detectionSensing dataAlbedo

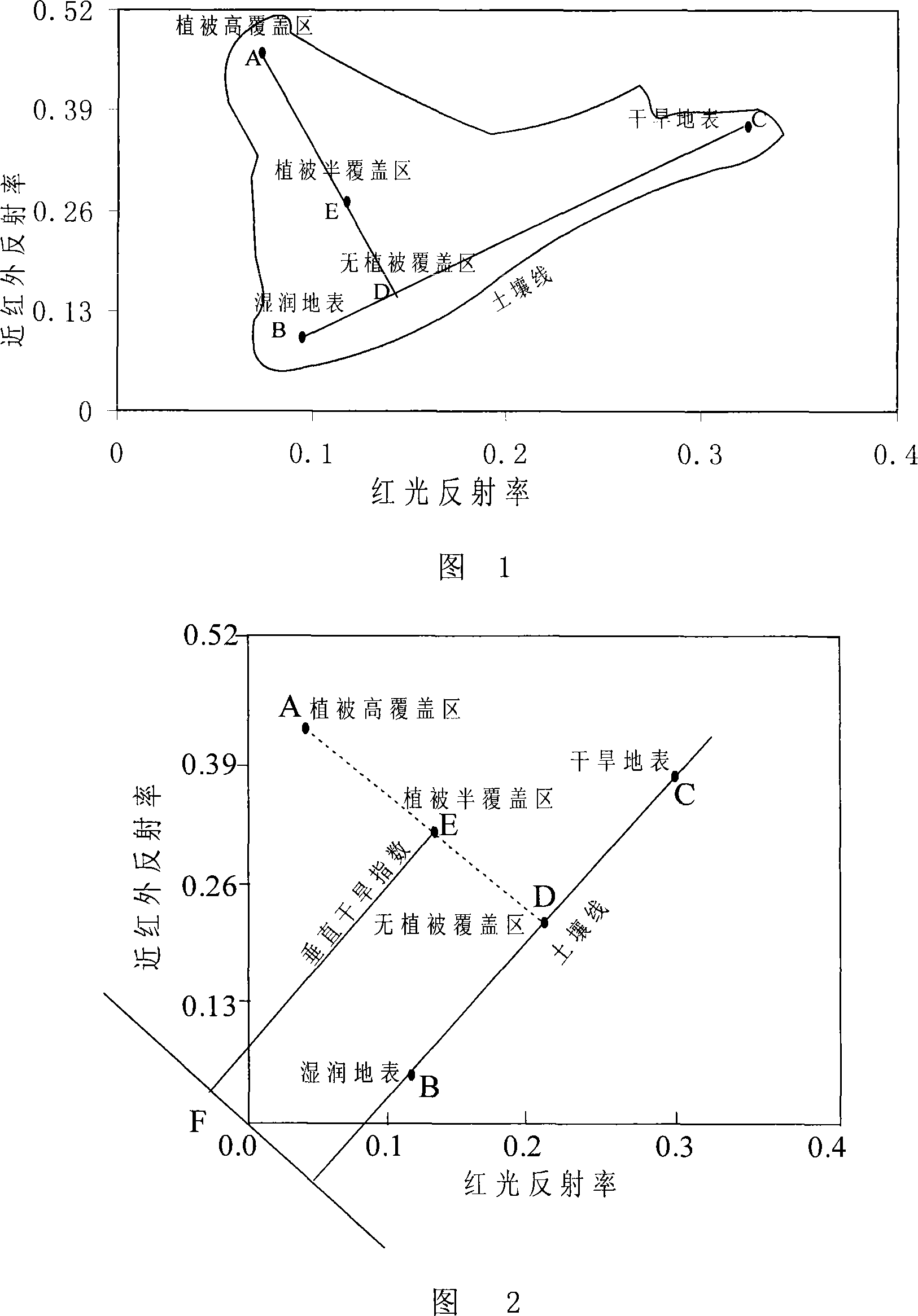

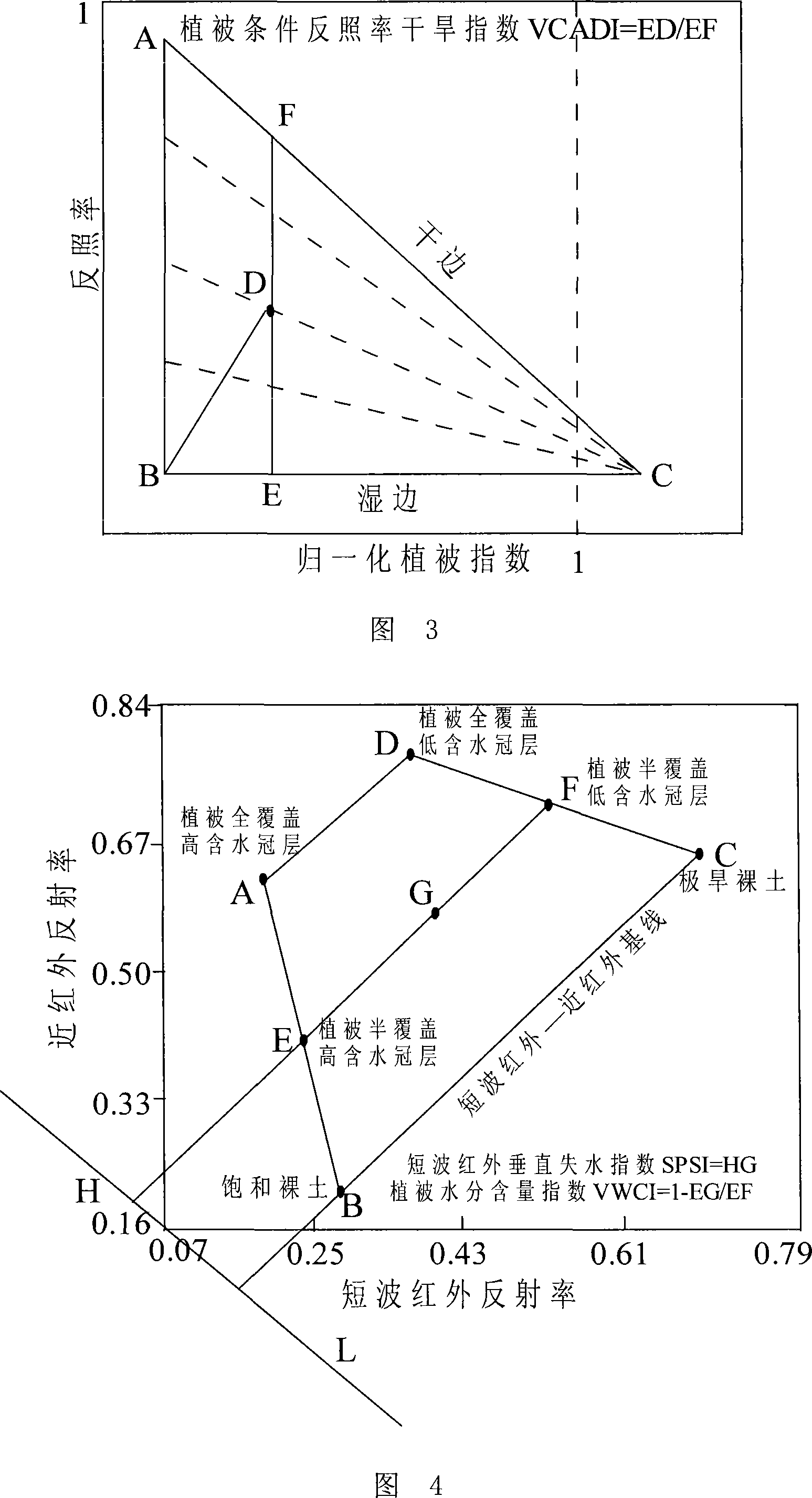

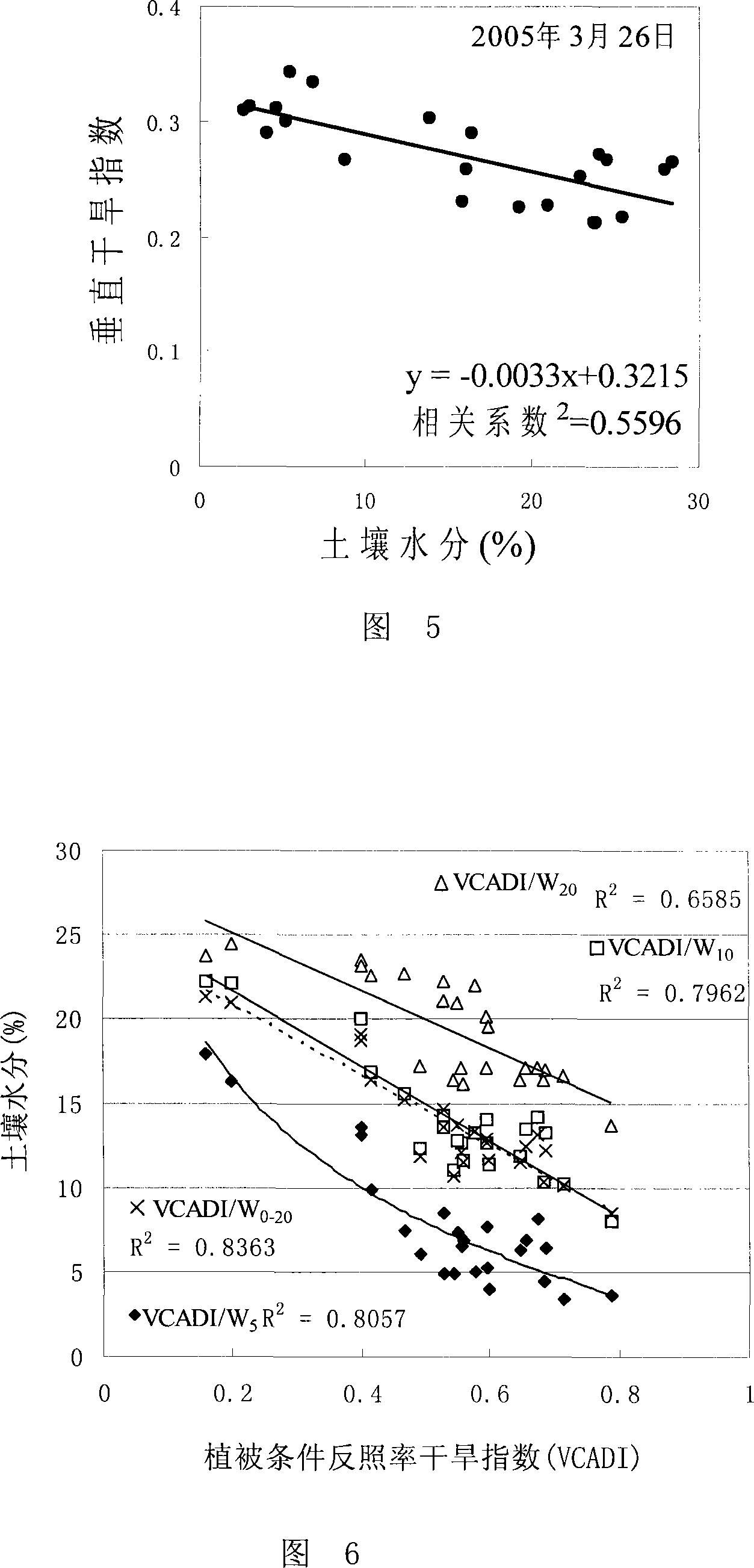

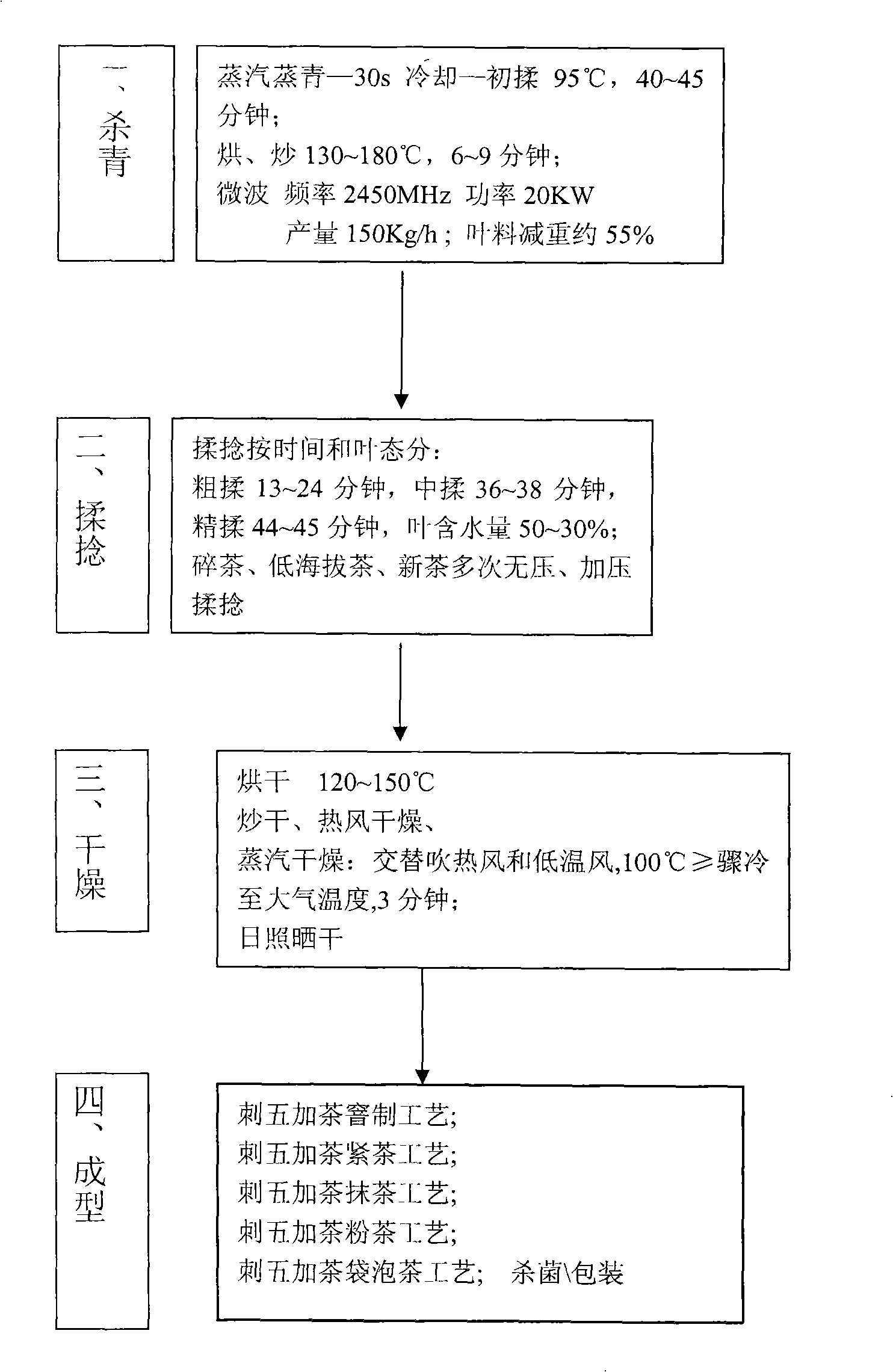

The invention discloses a method for monitoring farmland drought, which comprises obtaining soil or leaf water content of an observing point which is arranged on monitoring ground surface, building a functional relation between soil or leaf water content of the observing point and a corresponding index of characterized farmland drought condition, taking remote sensing data into the functional relation, and obtaining the soil or leaf water content of the monitoring ground surface, wherein the corresponding index of characterized ground surface drought condition is defined according to following methods: Firstly, the farmland ground surface whose vegetation coverage< =15% adopts a vertical drought index, secondly, the farmland ground surface whose vegetation coverage>15% and <= 65% adopts a vegetation conditions albedo drought index, and thirdly, the farmland ground surface whose vegetation coverage>65% to 100% adopts at least one of three following indexes: a short wave infrared vertical water loss index, a vegetation water content index, and a vegetation water deficit index. The ground surface drought monitoring method of the invention is applied for drought testing farmland ground surface with different vegetation coverage degrees.

Owner:PEKING UNIV

Radix acanthopanacis senticosi tea and its preparation technique

The invention relates to a tea product of Acanthopanax senticosus. Thetea product of Acanthopanax senticosus is made from fresh leaves of Acanthopanax senticosus, and is characterized in that the product is processed by the steps of enzyme deactivation, kneading, drying, shaping, grading and packaging. During the enzyme deactivation step, the temperature of steaming for enzyme deactivation is controlled in the range of 10-200 DEG C; the temperature of baking and parching for enzyme deactivation is controlled in the range of 130-180 DEG C; and the water content after enzyme deactivation is below 75%. The kneading step includes the following three stages: coarse kneading stage, medium kneading stage and fine kneading stage. The water content in Acanthopanax senticosus leaf after kneading step is below 12%. The drying treatment lasts 35-45 minutes and reduces the water content in Acanthopanax senticosus leaf down to 5% of the final product. The dried leaves of Acanthopanax senticosus are sequentially shaped, classified, test, sterilized and packaged in different specifications. The tea product of Acanthopanax senticosus is fragrant, mellow and green (green dried product, green tea liquid and green residue). The process method can retain the original color, fragrance and taste of natural Acanthopanax senticosus. The tea product of Acanthopanax senticosus is a new health product. Based on the combination of the conventional tea processing technique and new equipment, the invention retains the effective components in Acanthopanax senticosus leaf, accurately controls various parameters of the process, and utilizes the leaves unqualified for pharmacy to make high-quality tea product.

Owner:杨晓宇

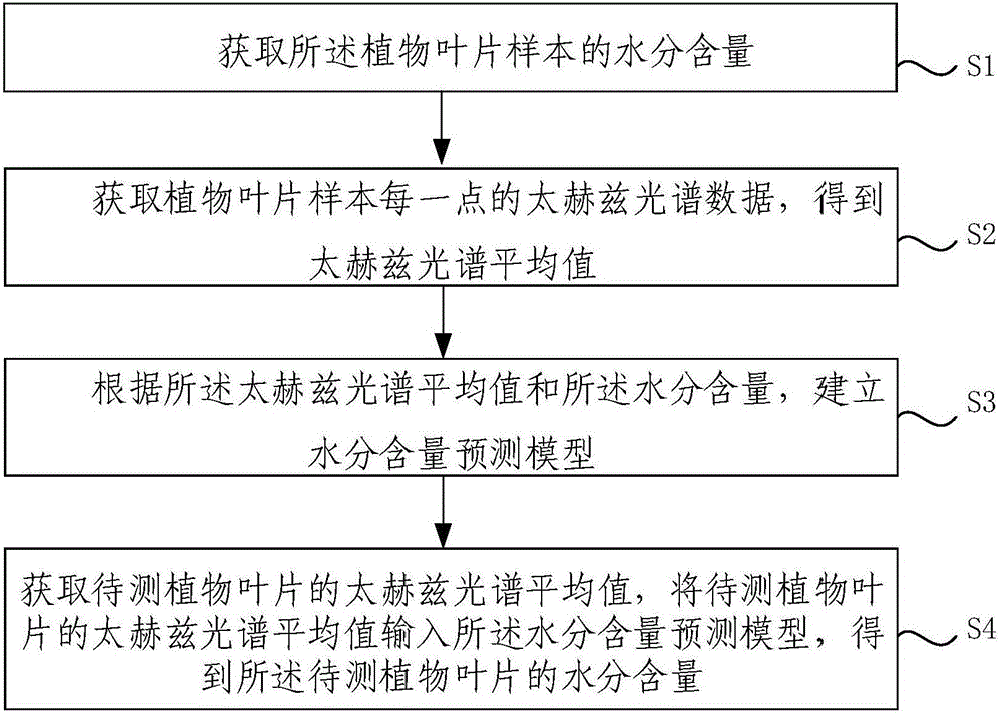

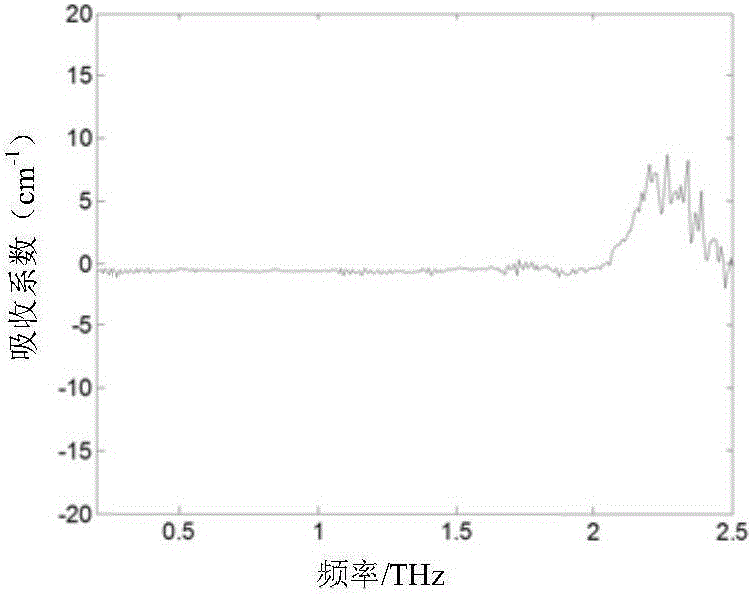

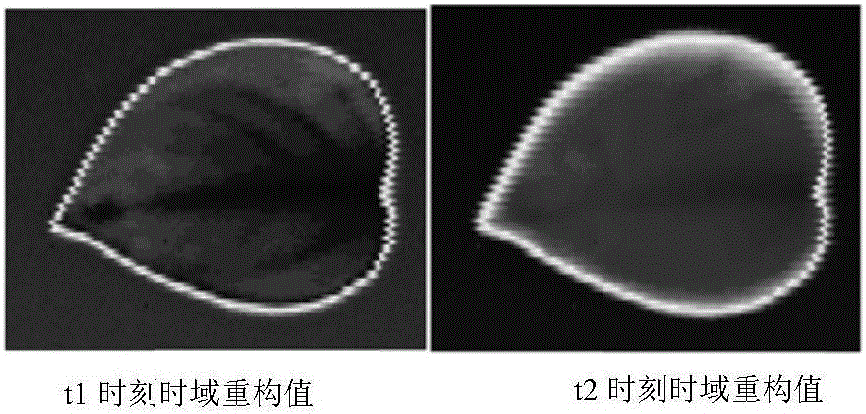

Terahertz wave based method and system for detecting water content of plant leaves

InactiveCN106018327ACause some damagesRealize dynamic non-destructive online detectionMaterial analysis by optical meansInvestigation of vegetal materialWater contentEnvironmental geology

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

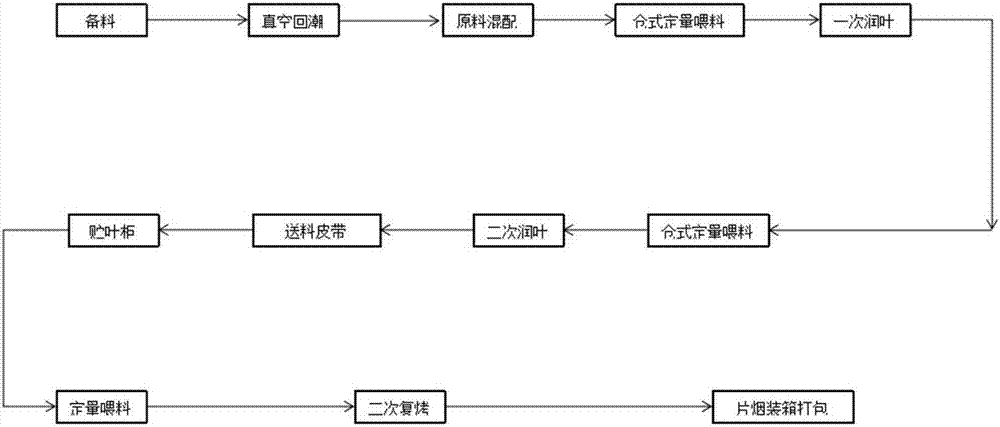

Treating process for Burley tobacco sheet

InactiveCN1457708APromote absorptionAbsorb evenlyTobacco preparationChemical compositionTime control

The improved Burley tobacco sheet treating process includes twice additions of liquid material before roasting, and increased Bruley leaf storing step and Bruley leaf moistening step between the twice additions. The liquid material adding amount of the first addition accounts for 50-67 % of total amount and results in Bruley tobacco leaf water content of 23-30 %; and the liquid material adding amount of the second addition accounts for 33-50 % of total amount and results in Bruley leaf water content of 30-35 %. The Bruley tobacco leaf storing step has time controlled in 0.5-3.0 hr, Bruley tobacco leaf moistening step is at 40-60 deg.c, and the second addition step has Burley tobacco sheet temperature increased to 60-100 deg.c. The present invention can make Burley tobacco sheet absorb liquid material homogeneously, increase the compatibility of its chemical components and raise its quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

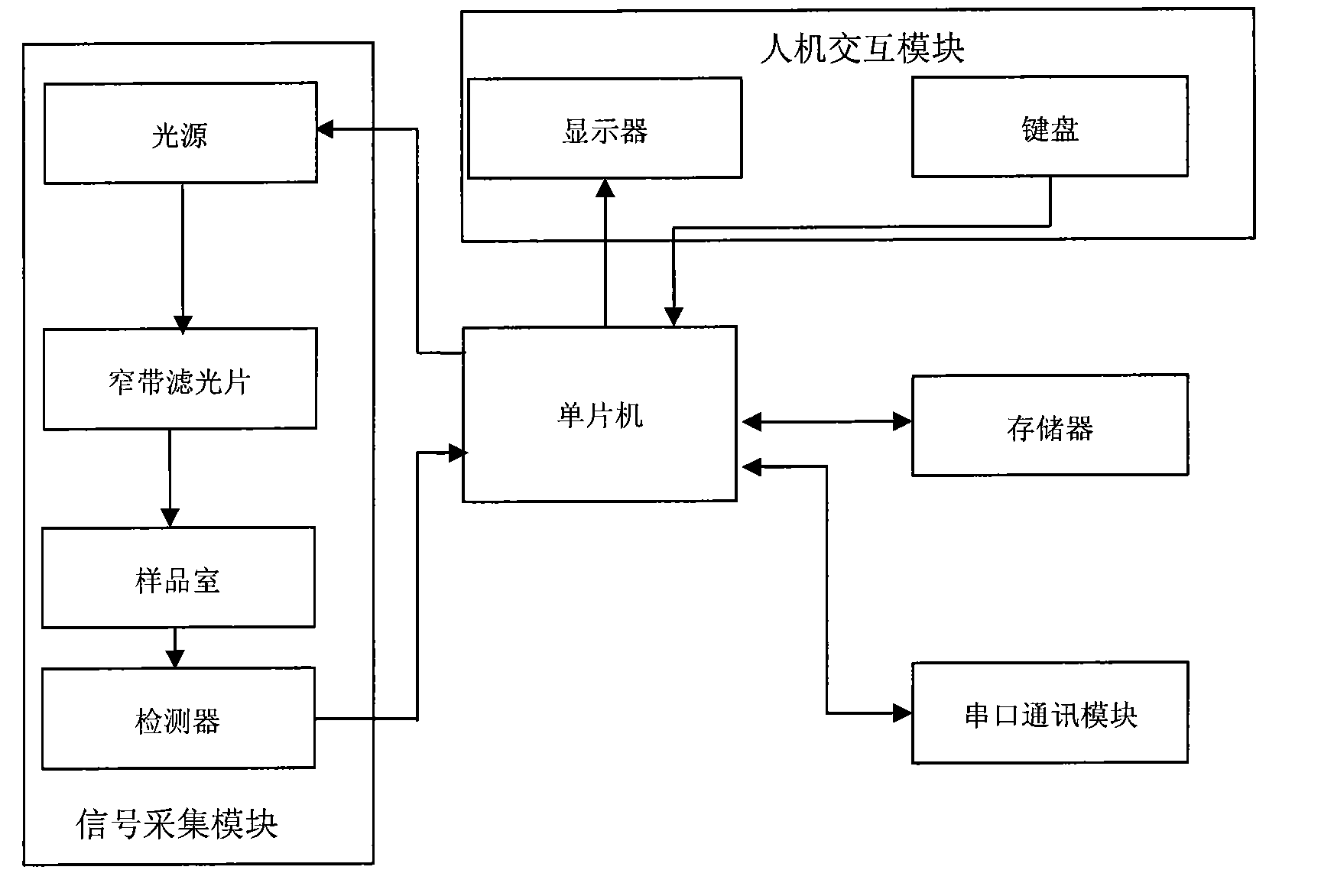

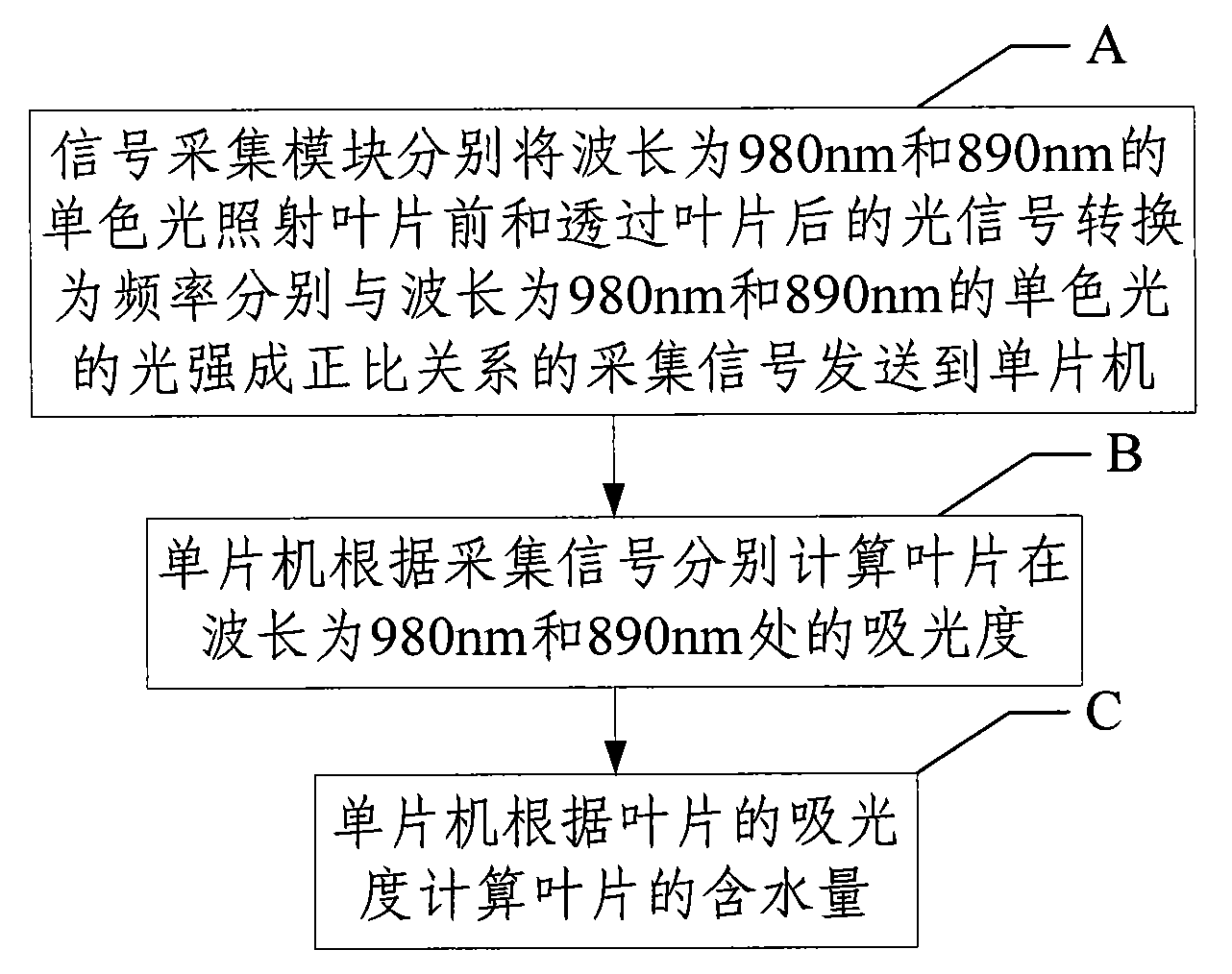

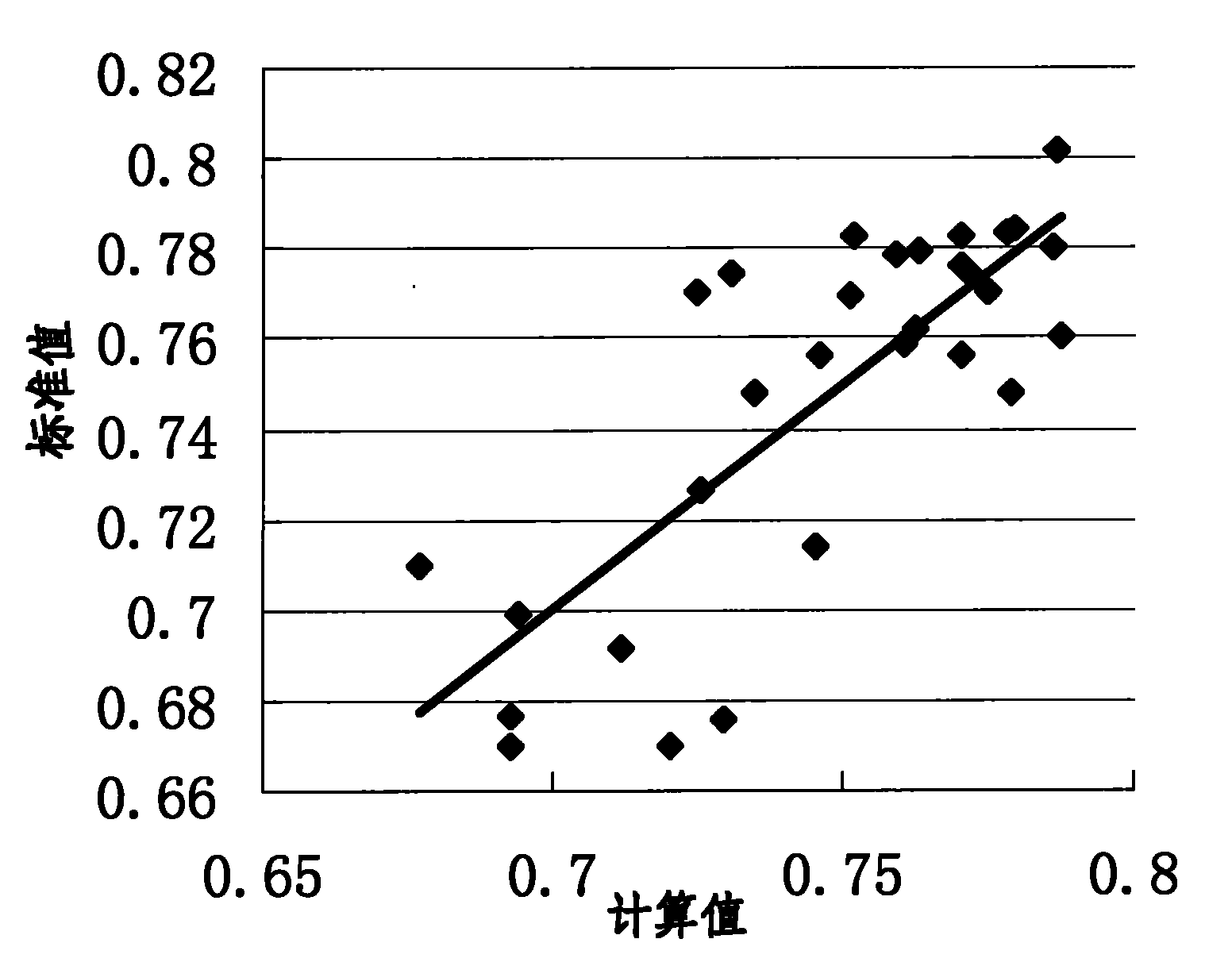

Transmission-type nondestructive measuring device and method of water content of plant leaves

InactiveCN101975759ANon-destructive testingReduce volumeColor/spectral properties measurementsMicrocontrollerMathematical model

The invention discloses a transmission-type nondestructive measuring device and a method of water content of plant leaves. The device comprises a singlechip, a signal acquisition module connected with the singlechip, a man-machine interaction module, a memorizer and a serial communication module. In the invention, the transmission-type nondestructive measuring device of water content of the plant leaves consisting of the singlechip and an optical frequency converter is used to measure the absorbance of the plant leaves respectively at the water content absorption feature wavelength of the leaves of 980 nm and the reference wavelength of 890 nm based on the transmission method and a near-infrared LED light source, and the water content of the plant leaves is measured in a nondestructive mode through the quantitative relation of the water content of the plant leaves and the absorbance by using the mathematical model which is established through the least square method. The device has the characteristics of small volume, light weight, convenient carrying, fast and nondestructive measurement of the water content of the plant leaves.

Owner:CHINA AGRI UNIV

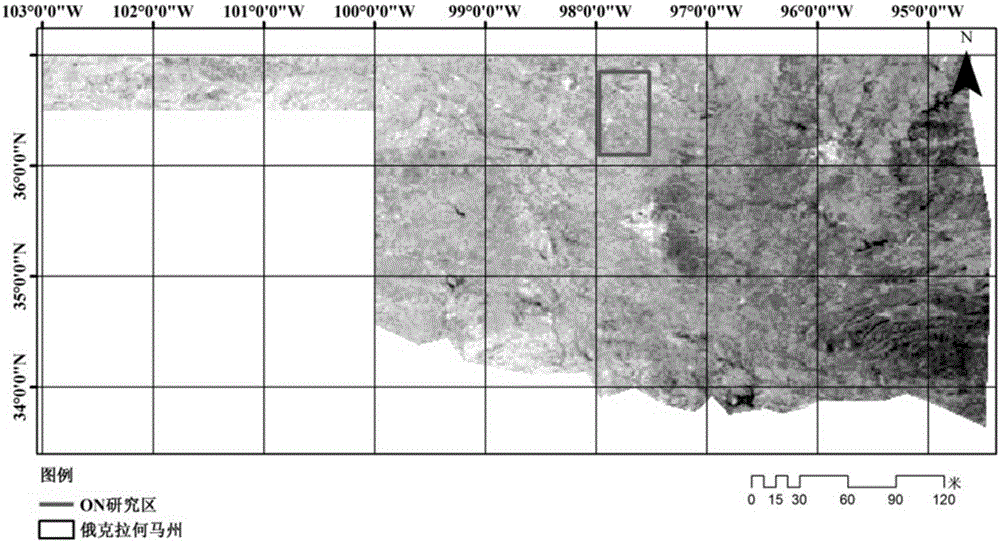

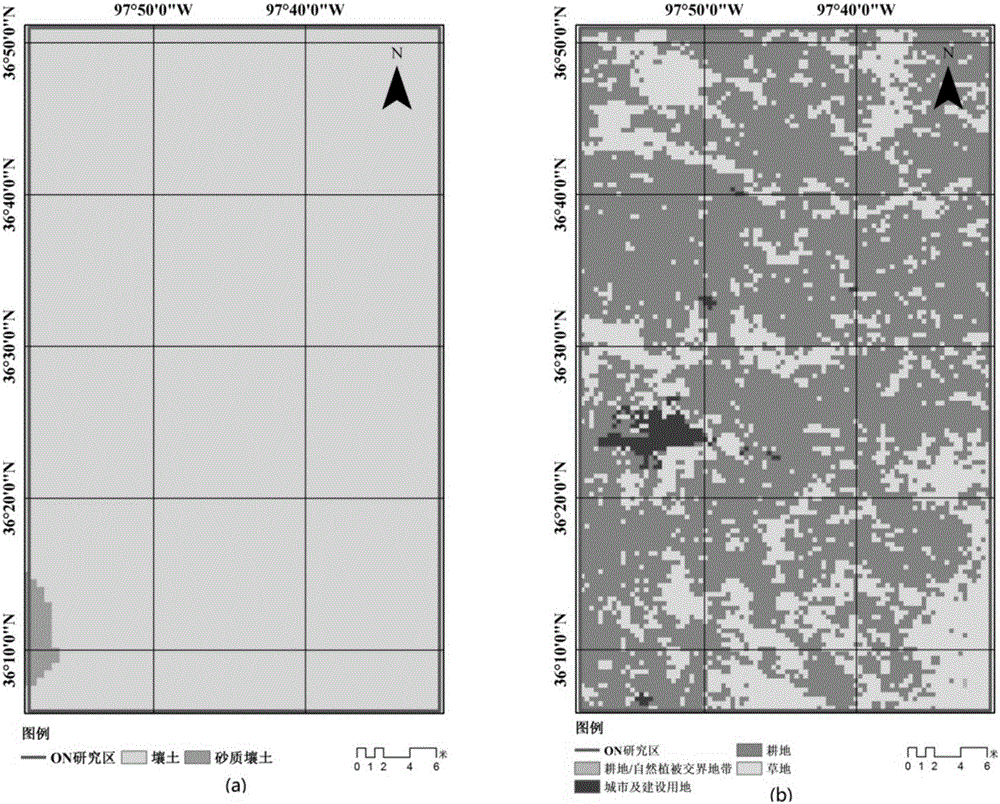

Remote sensing inversion method for soil moisture based on improved two-channel algorithm

The invention relates to a remote sensing inversion method for soil moisture based on an improved two-channel algorithm. According to the remote sensing inversion method, a calculation method for the water content of a Jackson vegetation in a two-channel algorithm is improved, the content of caulome of the vegetation is calculated by virtue of a Chan method based on the calculation of the leaf water content of the vegetation, then a vegetation effect is corrected, and the improved two-channel algorithm is disclosed for the first time. Soil moisture on the surface layer of a research area is inverted by virtue of brightness temperature data of an AMSR-E10.65GHZ dual-polarization channel, VWC is used and calculated, then the vegetation effect is corrected, and the inversion precision of the soil moisture is improved, so that the precision higher than that of the two-channel algorithm is realized.

Owner:BEIJING NORMAL UNIVERSITY

Method for processing summer tea leaves into black tea

InactiveCN107691673AEasy to shapeImprove oxidation effectPre-extraction tea treatmentClimate change adaptationCooking & bakingBlack tea

The invention relates to the technical field of processing of tea leaves and particularly relates to a method for processing summer tea leaves into black tea. The method provided by the invention mainly comprises the following steps: a, withering: picking fresh tea leaves at April to August every year, spreading the picked fresh tea leaves, and performing withering until the moisture content of the leaves is 24-36% to obtain withered tea leaves; b, wetting again: performing stacking, and covering wet cotton cloth on the surfaces of the stacked tea leaves for wetting again; c, rolling: taking back the wet tea leaves, and rolling the wet tea leaves by adopting a stone mill in a pressurization mode thrice; d, fermentation: adjusting the moisture content of the rolled tea leaves to be 65-75%,performing fermentation for 2-6 hours, stirring the tea leaves once every 1-2 hours, and keeping the temperature of the tea leaves to be not higher than 40 DEG C to obtain fermented tea leaves; and e,baking and drying for three times: baking the fermented tea leaves three times, taking out the tea leaves and cooling the tea leaves to room temperature at the interval between two times of baking, and finally obtaining the finished product of the black tea, wherein the parameters and times are different in baking each time. The processing procedure is performed according to the characteristics of summer black tea, so that the fragrance of the tea can be effectively improved, the bitter and astringent taste of the tea can be reduced, and the tea liquor color can be deepened.

Owner:覃光华

Substitutional tea of elderberry leaf and preparation method thereof

The invention provides a substitutional tea of an elderberry leaf, which has a health-care function and is convenient to take, and a preparation method of the substitutional tea. The method comprises the following steps of airing until the moisture content of the leaf is 68-70% after cleaning picked elderberry leaf; putting into a water-removing machine to remove moisture, wherein the water-removing temperature is 150-250 DEG C, airing and cooling after removing moisture, drying in a dryer until the moisture content of the leaf is 5-9% after rolling, wherein the drying temperature is 80-120 DEG C, and preparing the substitutional tea of the elderberry leaf in inspecting and packaging manners. The substitutional tea of the elderberry leaf disclosed by the invention is convenient to take, not only can improve the patient conditions of diabetes mellitus, dyslipidemia and hypertensive patients, but also can be used as a green health food to increase the health of healthy population. Thus, multiple effects of increasing the bone mineral density, enhancing the immunity, antioxidation and the like are achieved.

Owner:山西琪尔康翅果生物制品有限公司

Transpiration regulator for planting stocks in hilly lands and preparation method of transpiration regulator

ActiveCN102557832ASolve the problem of water shortage and droughtImprove survival rateFertilizer mixturesSodium bisulfateChlorophyllin

The invention discloses a transpiration regulator for planting stocks in hilly lands. The transpiration regulator comprises the following raw materials by weight in 1 L of water: 50 to 150 mg of fulvic acid, 50 to 100 mg of sodium thiosulfate, 50 to 100 mg of sodium bisulfite, 50 to 80 mg of para-aminosalicylic acid, 200 to 300 mg of nitrogen, phosphorus and potassium compound fertilizer, 200 to 400 mg of trace elements, and 50 to 100 mg of citric acid. The transpiration regulator for planting stocks in hilly lands can effectively solve the problem that the planting stocks in the hilly lands are lack of water and dry, can promote the growth of root systems of the planting stocks in the hilly lands, improves the survival rate of planting stock transplantation, effectively decreases the opening degree of air holes of the planting stocks in the small hilly lands, inhibits transpiration, improves the water content of leaves, improves the content of free proline and the content of chlorophyl, and greatly improves the survival rate and the drought resistance of transplanted planting stocks. The invention further discloses a preparation method of the transpiration regulator for planting stocks in hilly lands.

Owner:HUAYUAN LANDSCAPE ARCHITECTURE CO LTD

Wicker processing method for wickerwork manufacturing

InactiveCN107379166ADamaged will notIncrease moisture contentWood treatment detailsReed/straw treatmentDiseaseCelsius Degree

The invention discloses a wicker processing method for wickerwork manufacturing. The wicker processing method comprises the following steps that (1) wickers which are uniform in thickness, no diseases and insect pests, non-bifurcate and good in smoothness are harvested, the wickers are paved horizontally and sun-cured, and until the leaf water content is less than 3%, leaves are removed; (2) the wickers without the leaves are washed cleanly by using clear water and then placed in a pretreatment liquid of 50 degrees celsius to be soaked for 20 minutes, willowpelts are stripped after the soaked wickers are taken out, and the wickers are washed cleanly; (3) the wickers after being processed in the step (2) are dried by using hot wind until the wicker water content is less than 30%; (4) the wickers are soaked for four hours by using a softening fluid again, then washed cleanly and dried by using the hot wind until the wicker water content is less than 20%; and (5) the wickers are fumigated for half hour by using steam, the temperature is naturally lowered to normal temperature after the wickers are taken out, and the wickers can be directly used for wickerwork. The wicker processing method is simple, the wickers can be softened before weaving, the weaving difficulty is reduced, wicker fracture is prevented in the weaving process, the quality of products is high, and the processed wickers have mould-proof and insect-proof functions.

Owner:阜南县铭钰柳木工艺品有限公司

White tea processing method

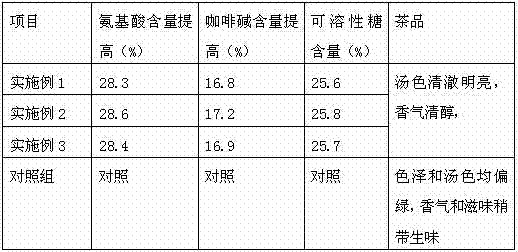

The invention relates to the technical field of white tea deep processing, and discloses a white tea processing method. The withering is divided into three phase. After the first phase, liquid cellulase is evenly sprayed on withered leaves. Cellulase acts on fresh tea and improves the permeability of cell walls. The combination of enzymes and substrate is promoted and the substance conversion is also promoted. The contents of water extract, soluble sugar, and free amino acids in tea are increased, and thus the tea quality is improved. In the second withering phase, a vitamin C solution is evenly sprayed on the surface of withered leaves, the activity of polyphenol oxidase is maintained, the color and aroma of white tea are protected; the crispy tea becomes soft, then the soft tea becomes hard along with the change of the water content; after the tea is wetted, the tea becomes soft again, shaping becomes easier; and the processing method obviously increases the contents of amino acid, caffeine, and soluble sugar in white tea.

Owner:ANHUI SHANGHANGSHAN TEA

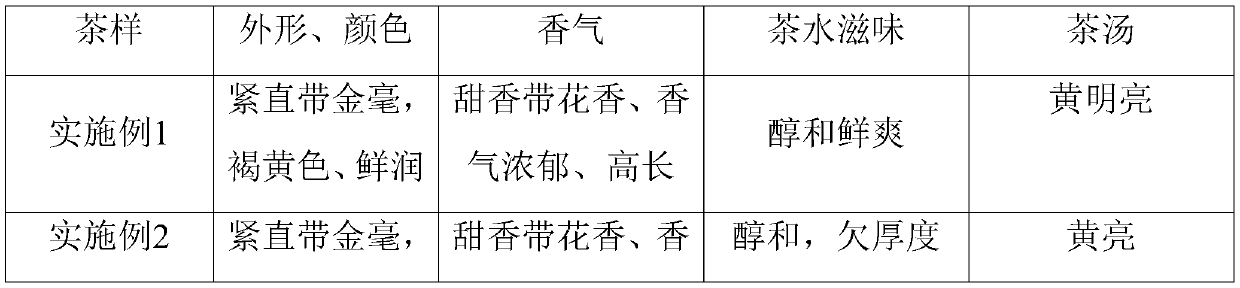

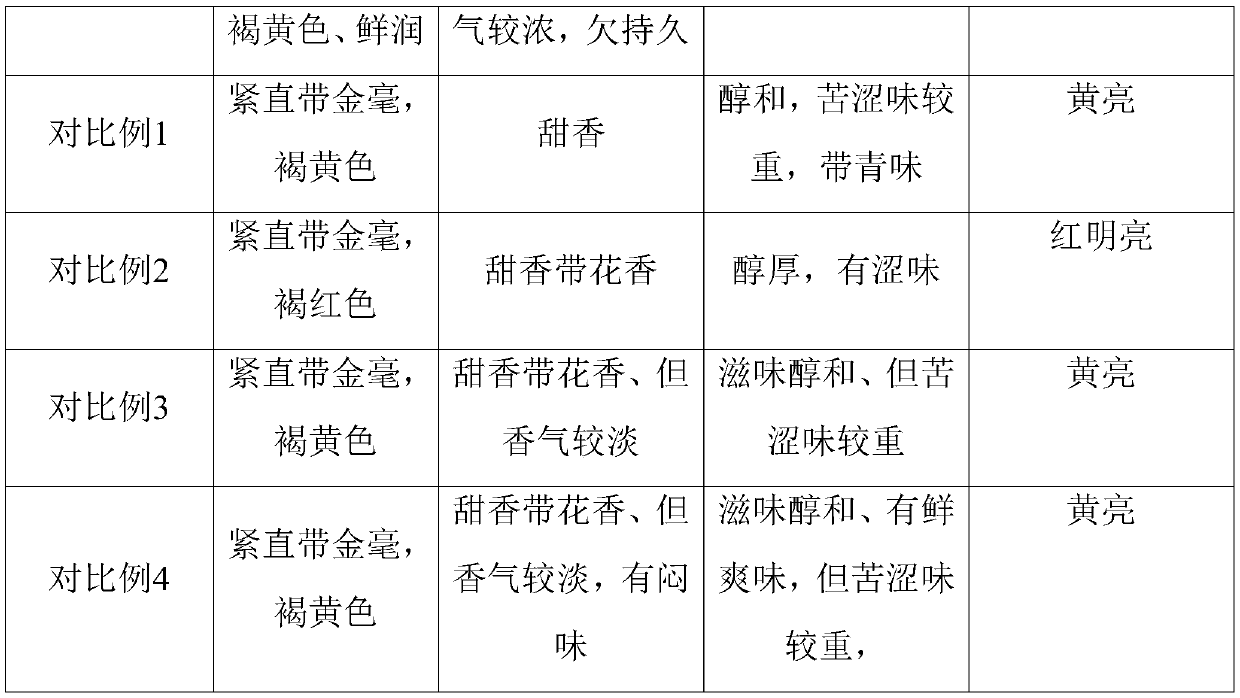

Large-leaf yellow tea and efficient preparation method thereof

ActiveCN109938119APromote conversionAvoid rednessPre-extraction tea treatmentClimate change adaptationShootTwo step

The invention provides a preparation method of a large-leaf yellow tea. The preparation method comprises the following steps of (1) picking, wherein tea shoots of a large-leaf yellow tea tree are picked; (2) sunning, wherein sunning is carried out in the sunshine condition; (3) withering, wherein indoor spreading out is carried out, natural withering is carried out until the leaf water content is60-68%; (4) water removing and rolling; (5) heaping for yellowing, wherein heaping for yellowing is divided into two steps, the first step comprises low-temperature heaping for yellowing and fermentation, and the second step comprises dry heaping; (6) drying. The yellow tea which has sweet aroma with flower fragrance, is golden yellow, fresh and moist, and strong, mellow, fresh and brisk in taste,and has canary yellow and bright leaf bottoms is prepared through the method.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI +1

Industrial method for improving applicability of senior tobacco leaves through module group secondary rebaking

The invention provides an industrial method for improving applicability of senior tobacco leaves through module group secondary rebaking. Senior stock tobacco leaves are subjected to function module grouping, grouping adopts a Schmuck value as a main reference condition, the tobacco leaves with a Schmuck value of 2.8-3.6 are A module Schmuck tobacco leaves with high applicability, the tobacco leaves with a Schmuck value of 2.3-2.8 are B module Schmuck tobacco leaves with medium applicability, and the tobacco leaves with a Schmuck value of 2.3 or below are C module Schmuck tobacco leaves with low applicability; through the grouped function modules, the tobacco leaves are subjected to feed preparation according to a tobacco leaf formula, and are sent to a leaf storage cabinet through vacuum wetting and primary conditioning till the leaf water content is 15%-18% and through secondary conditioning till the leaf water content is 17%-20%, the tobacco leaves in the leaf storage cabinet are subjected top leaf secondary rebaking, a second area temperature key in rebaking is controlled at 70-88 DEG C, temperatures in a first area, a third area and a fourth area are matched and adjusted according to the temperature in the second area, rebaking is completed, and the tobacco leaves are packed in boxes for standby use. According to the industrial method for improving the applicability of the senior tobacco leaves through module group secondary rebaking, the senior stock tobacco leaves can be massively utilized, the stock and the raw material cost are saved, and the tobacco quality is not lowered when the method is applied to a tobacco formula.

Owner:CHINA TOBACCO JIANGXI IND CO LTD +1

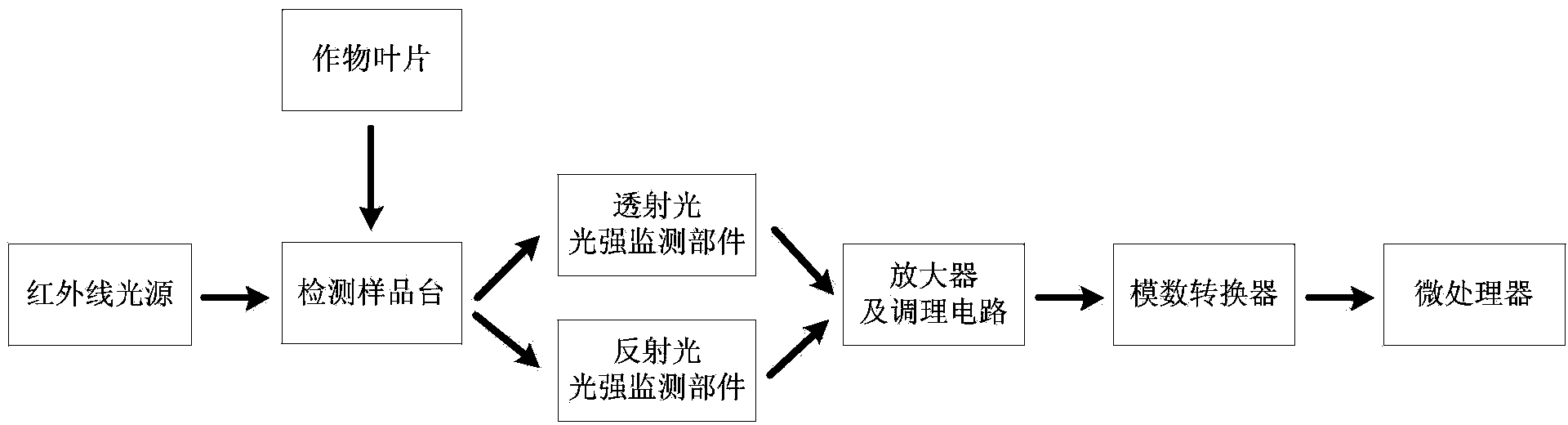

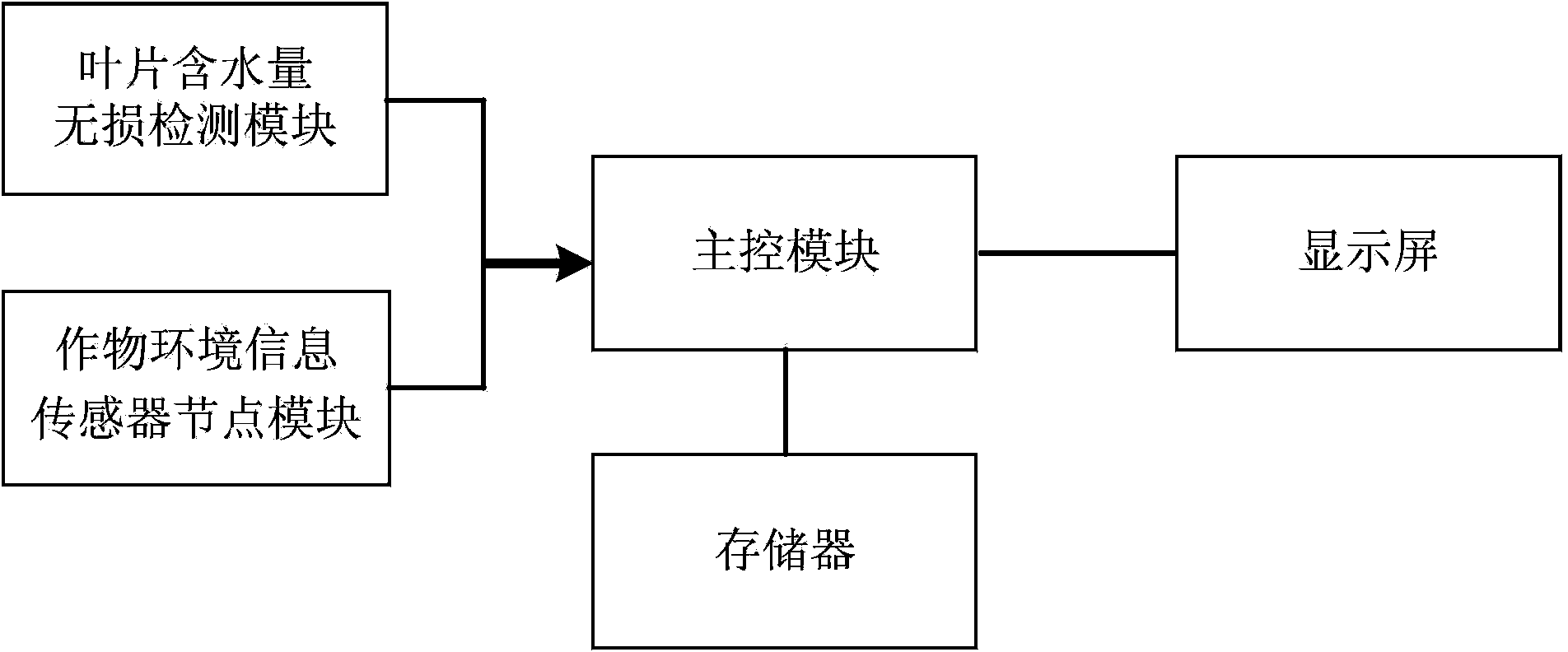

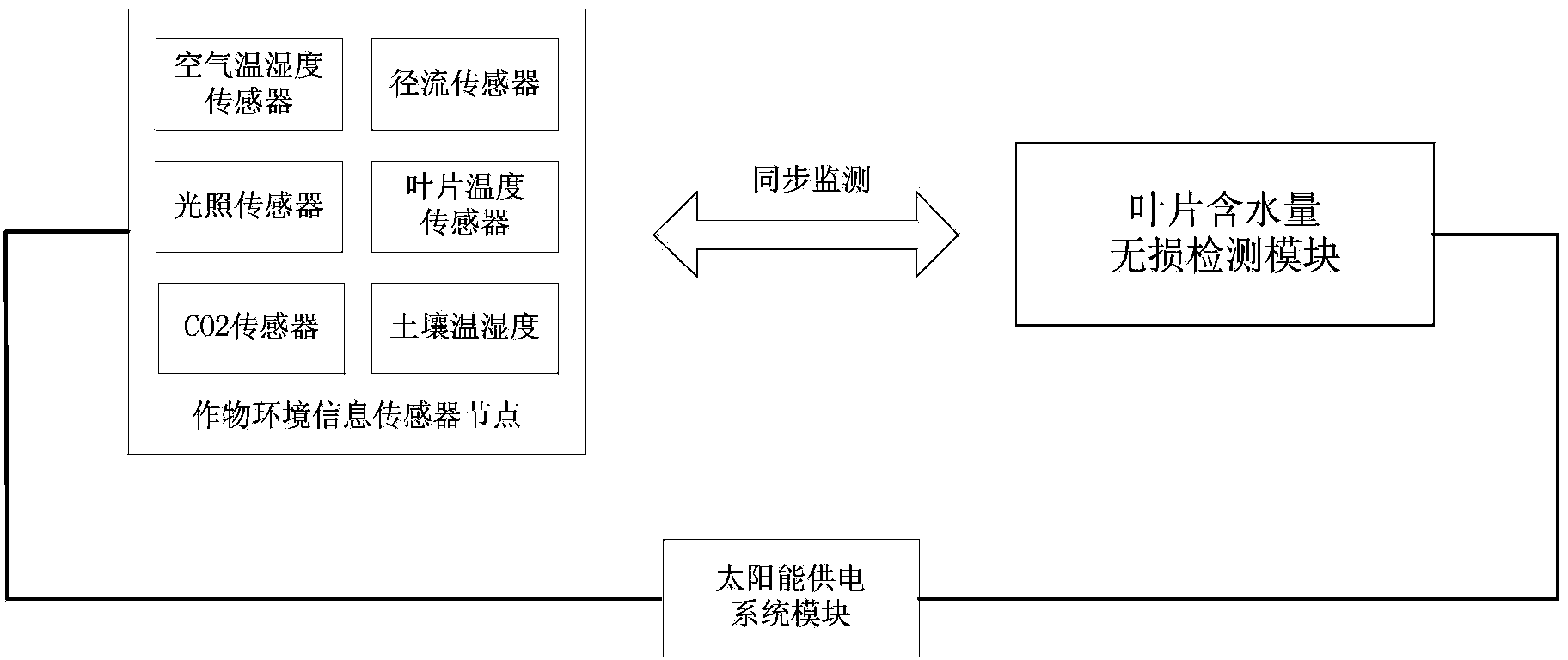

System for monitoring physiological water in crop leaves

InactiveCN104374732AReal-time non-destructive testing of moisture contentReduce volumeMaterial analysis by optical meansInfraredUltimate tensile strength

The invention relates to the technical field of nondestructive monitoring of physiological information of crops, and discloses a system for monitoring physiological water in crop leaves. The system comprises a nondestructive leaf water content detection module, wherein the nondestructive leaf water content detection module comprises an infrared light source emitter, a detection sample table and a transmitted / reflected light intensity detection component; the detection sample table is made of transparent glass; a narrow-band filter is arranged on the surface of the sample table; infrareds emitted by the infrared light source emitter are projected on a sample; the transmitted / reflected light intensity detection component is respectively used for detecting the intensity of transmitted / reflected light of the infrareds transmitted / reflected by the sample. The system disclosed by the invention can be used for quickly and accurately acquiring water condition information of the crops, is easy to operate, can realize the nondestructive detection and has the advantages of being small in size, high in sensitivity and quick to response.

Owner:AGRI INFORMATION INST OF CAS

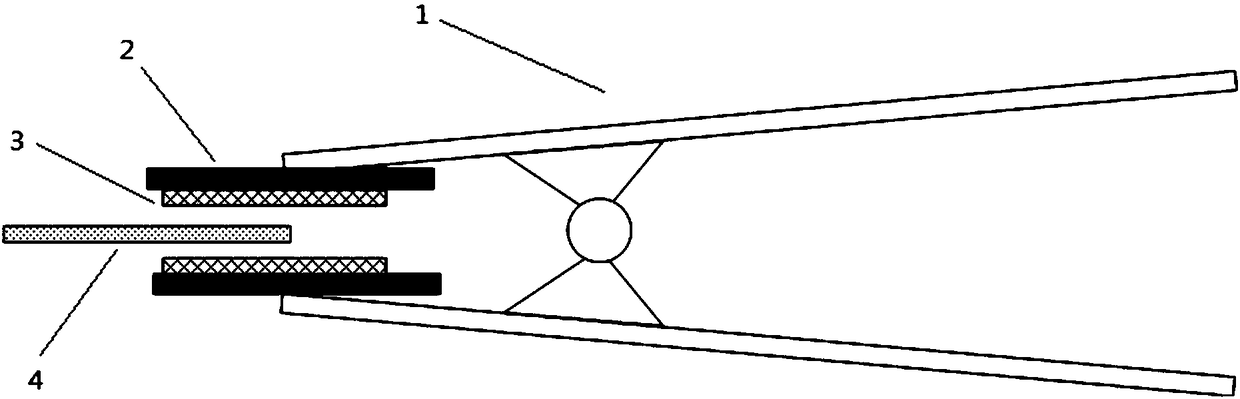

Capacitive sensor for detecting plant leaf water content and measuring device formed by sensors

InactiveCN108459058AReduce the clamping areaNot easy to damageMaterial capacitanceMeasurement deviceParallel plate

The invention discloses a capacitive sensor for detecting a plant leaf water content. The sensor comprises a light measuring clamp, two substrates and two parallel plate electrodes, wherein the lightmeasuring clamp comprises an upper clamp body and a lower clamp body, the two substrates are fixed to the upper clamp body and the lower clamp body of the light measuring clamp, the two parallel plateelectrodes are respectively fixed to the two substrates, the substrates are insulator thin plates, and the parallel plate electrodes are conductive foam. The parallel plate electrodes in the capacitive sensor disclosed by the invention can well transmit clamping force of a plastic clamp to a leaf, the leaf can be attached to the parallel plate electrodes, and the leaf is not prone to being damaged. A measuring device disclosed by the invention is composed of a plurality of the capacitive sensors which are in parallel connection; thus, the clamping size of one single sensor can be reduced, leaf veins are prevented from being clamped, measuring errors are reduced, and leaf water content measuring accuracy is improved.

Owner:浙江省中药研究所有限公司

Paper mulberry tea processing technology

The invention discloses a paper mulberry tea processing technology which includes the steps: (1) raw material collection; (2) slicing: cutting drained leaves into square fragments; (3) mixing: uniformly mixing 80% of paper mulberry fresh leaves with 20% of white mulberry fresh leaves; (4) fixation; (5) cooling: taking out, spreading and cooling tea leaves; (6) rolling: rolling the tea leaves taken out; (7) tea frying: pouring the rolled tea leaves into a boiler for stir-frying; (8) shaping: rolling the stir-fried tea leaves again into strips; (9) baking: baking the tea leaves rolled into the strips; (10) roasting: roasting the tea leaves for 15 minutes at the temperature of 75-95 DEG C and enabling the water content of the tea leaves to reach 10-12% until the tea leaves can be twisted and broken with hands. Compared with the prior art, the paper mulberry tea processing technology has the advantages that paper mulberry tea is alkaline tea, the acidity and alkalinity of the body of a user can be adjusted when the user drinks the tea for a long time, human health is more facilitated, and the tea has the functions of clearing heat, cooling blood, removing dampness, killing pests and the like.

Owner:王子成

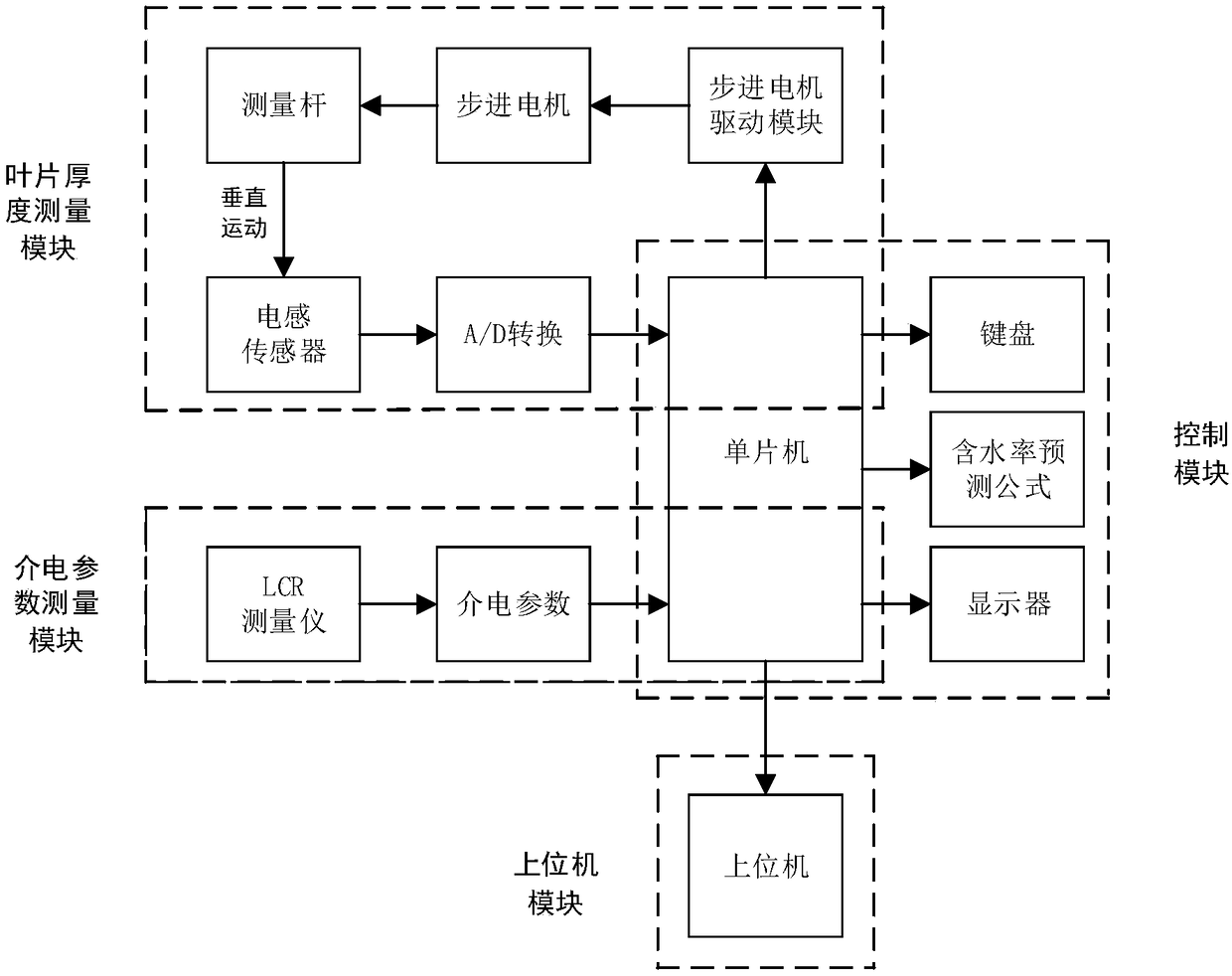

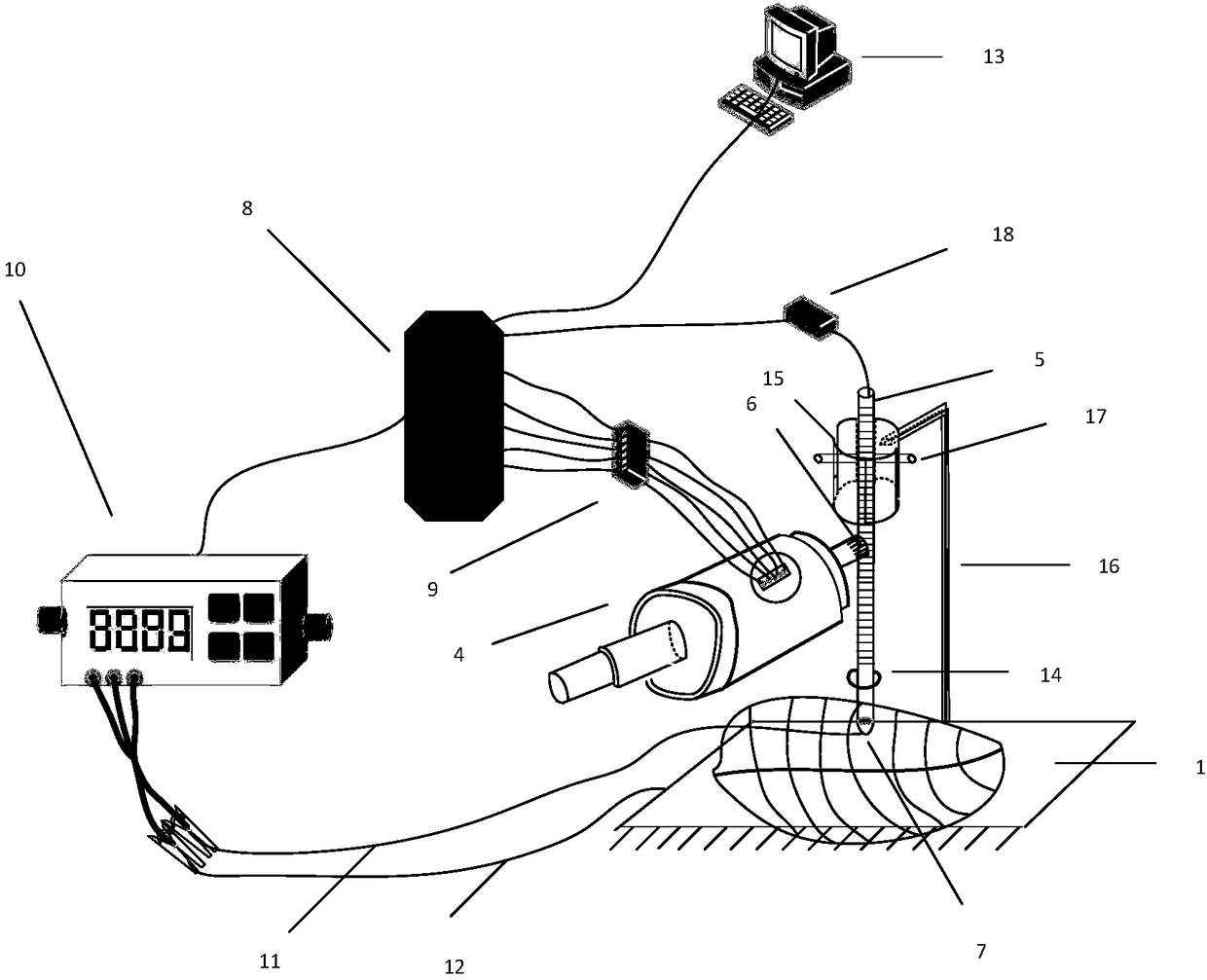

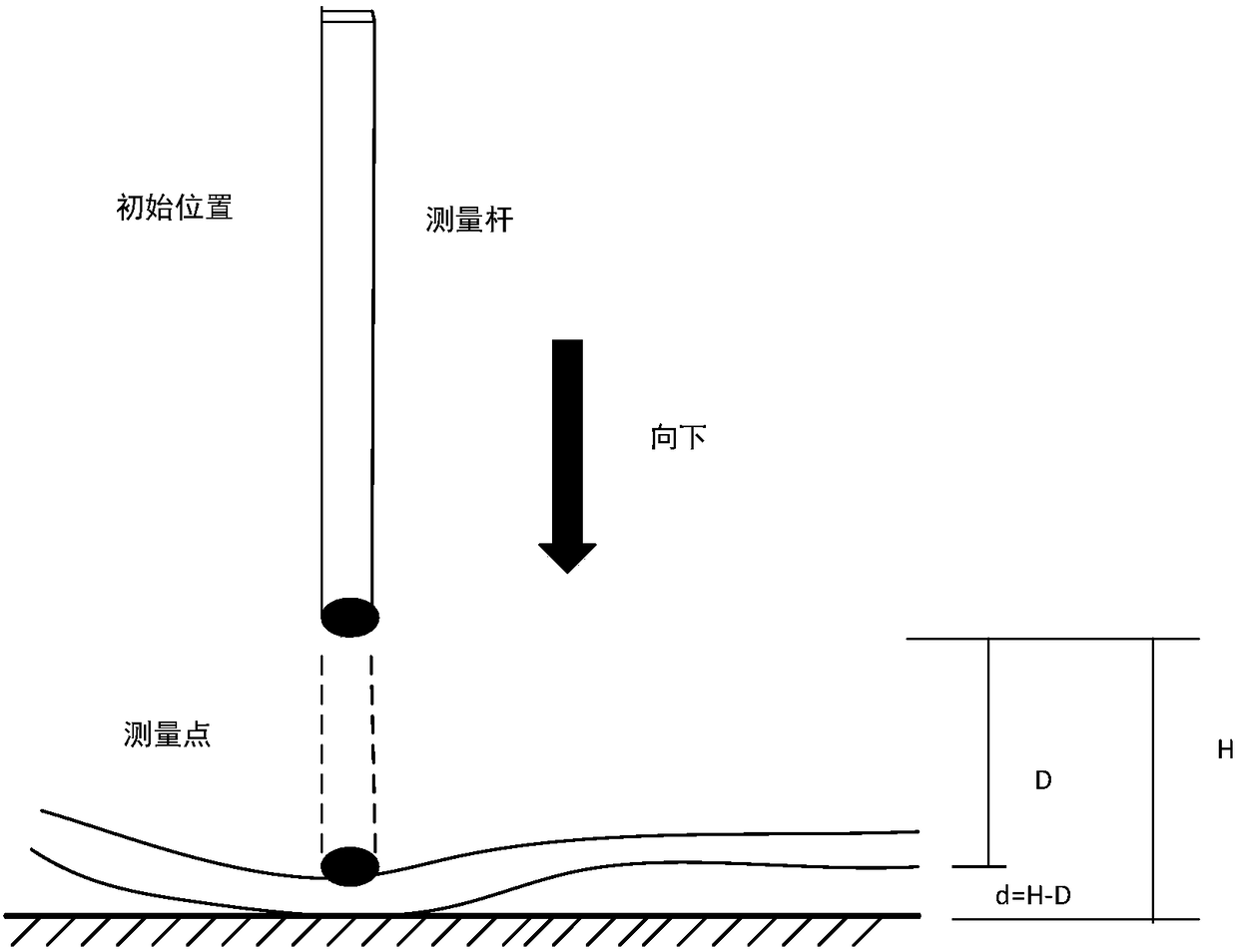

Plant leaf water content measuring device and method

ActiveCN108375606AGuaranteed not to leave the bodyAccurate measurementMaterial capacitanceElectricityStopped work

The invention discloses a plant leaf water content measuring device and method. The device mainly comprises a leaf placement platform, a leaf thickness measuring module, a dielectric parameter measuring module, a control module and an upper computer module. The leaf thickness measuring module comprises a measuring rod and a differential type inductive transducer mounted at the bottom end of the mounting rod. When a probe descends and contacts with the surface of a leaf, a deformation signal of the transducer is transmitted to a single chip microcomputer after A / D conversion, the single chip microcomputer controls a stepping motor to stop working and calculates descending displacement of the probe, and thickness d of the leaf can be calculated according to an initial position of the probe and the descending displacement; then the dielectric parameter measuring module starts to work to measure dielectric parameter epsilon' of the leaf, and the single chip microcomputer combines the thickness d of the leaf and the dielectric parameter epsilon' of the leaf, utilizes an algorithm to predict water content of the plant leaf and can transmit a result to an upper computer for display, storage, analysis and application expanding. The plant leaf water content measuring device and method are suitable for quick, nondestructive and accurate detection of plant leaf water content.

Owner:JIANGSU UNIV

Comprehensive evaluation method for waterlogging tolerance of plants

ActiveCN112840886AMeet the task requirements of screening waterlogging-tolerant plantsCultivating equipmentsHorticulture methodsChlorophyllLeaf water content

The invention relates to a comprehensive evaluation method for waterlogging tolerance of plants. The method is characterized in that the following evaluation system is adopted to comprehensively evaluate the waterlogging tolerance of the plants, and the evaluation indexes of the evaluation system include at least one of the following indexes of (1) chlorophyll photosynthetic fluorescence potential; (2) leaf SPAD; (3) leaf water content; (4) specific leaf area; (5) leaf preservation rate; (6) post-recovery survival rate; (7) post-recovery viewing effect; (8) post-overwintering survival rate; and (10) post-overwintering viewing effect. According to the method, the evaluation period of the comprehensive evaluation system is short, and the waterlogging tolerance of various plants can be accurately and effectively evaluated.

Owner:BEIJING INST OF LANDSCAPE ARCHITECTURE

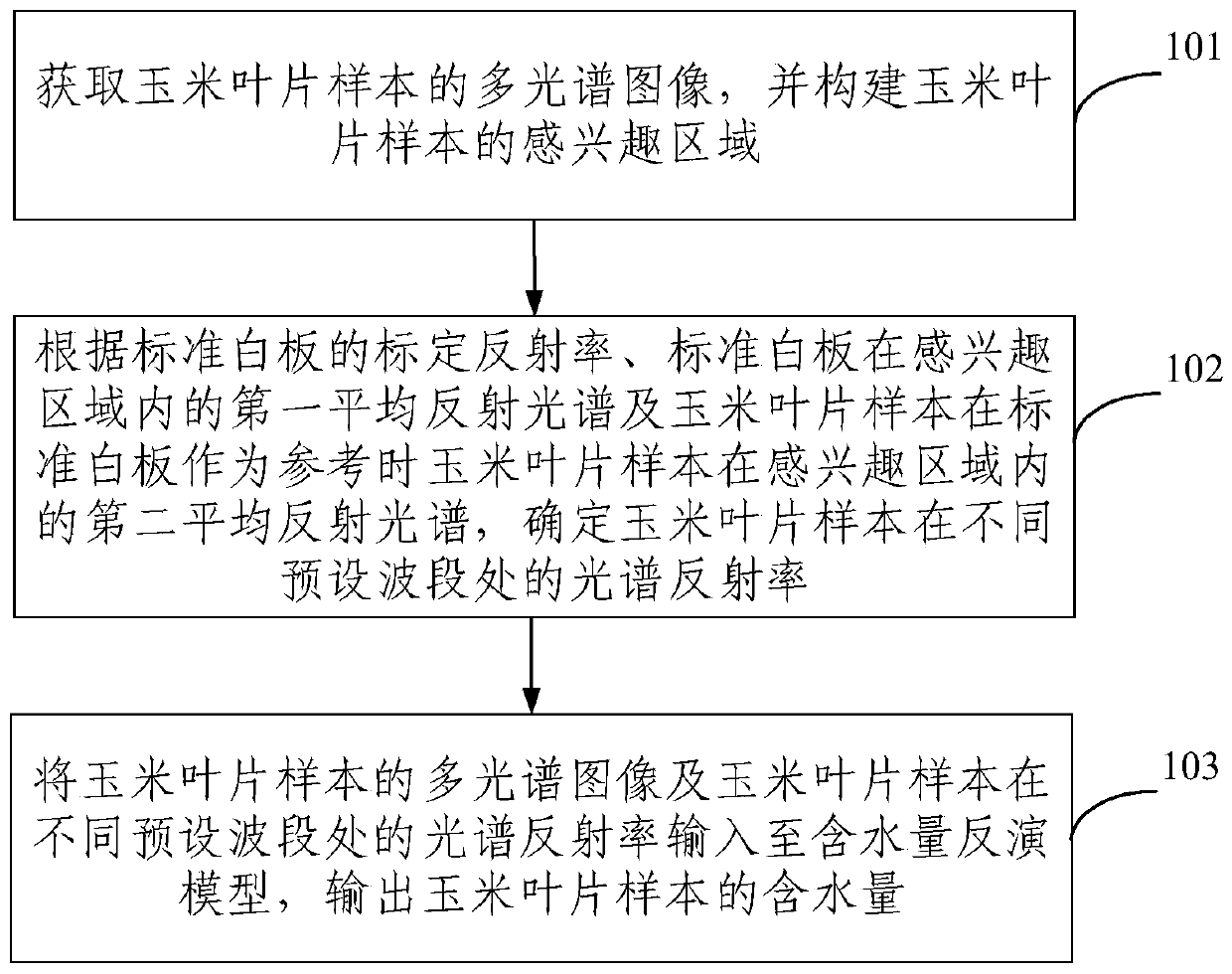

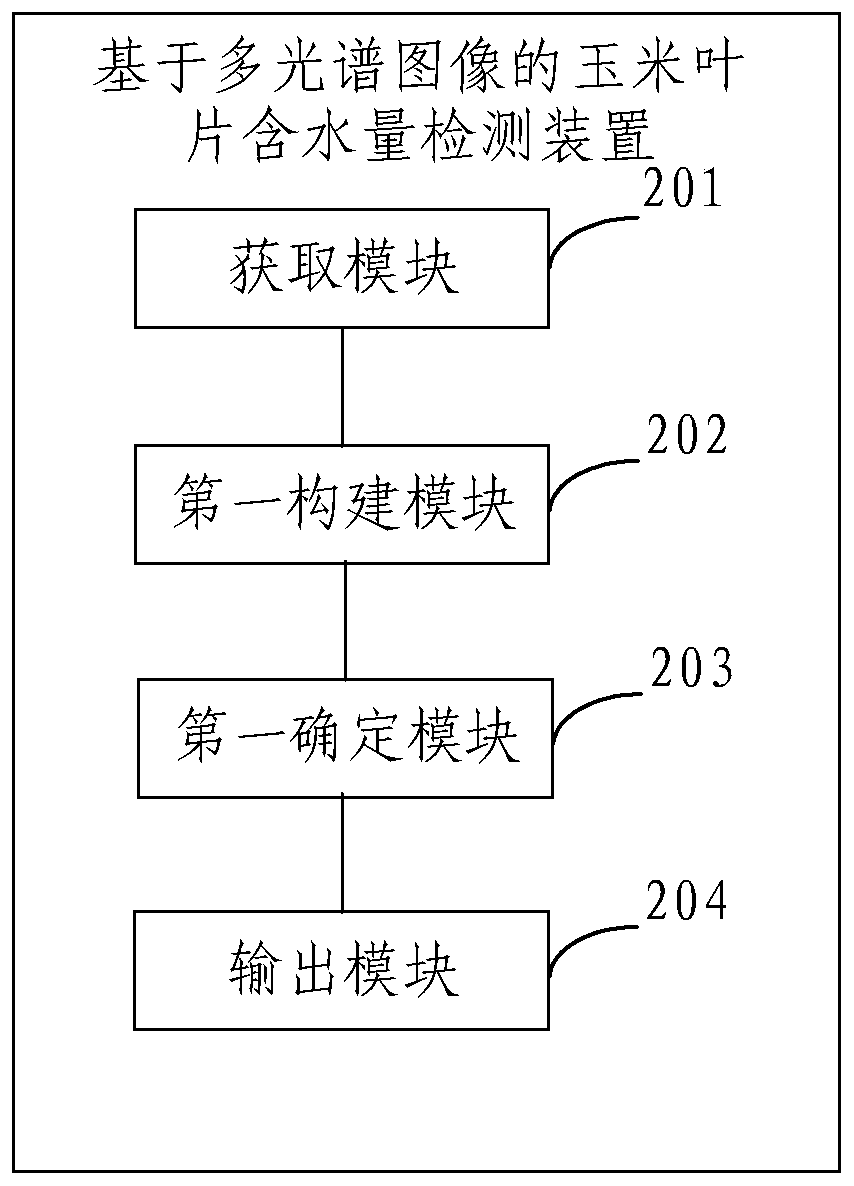

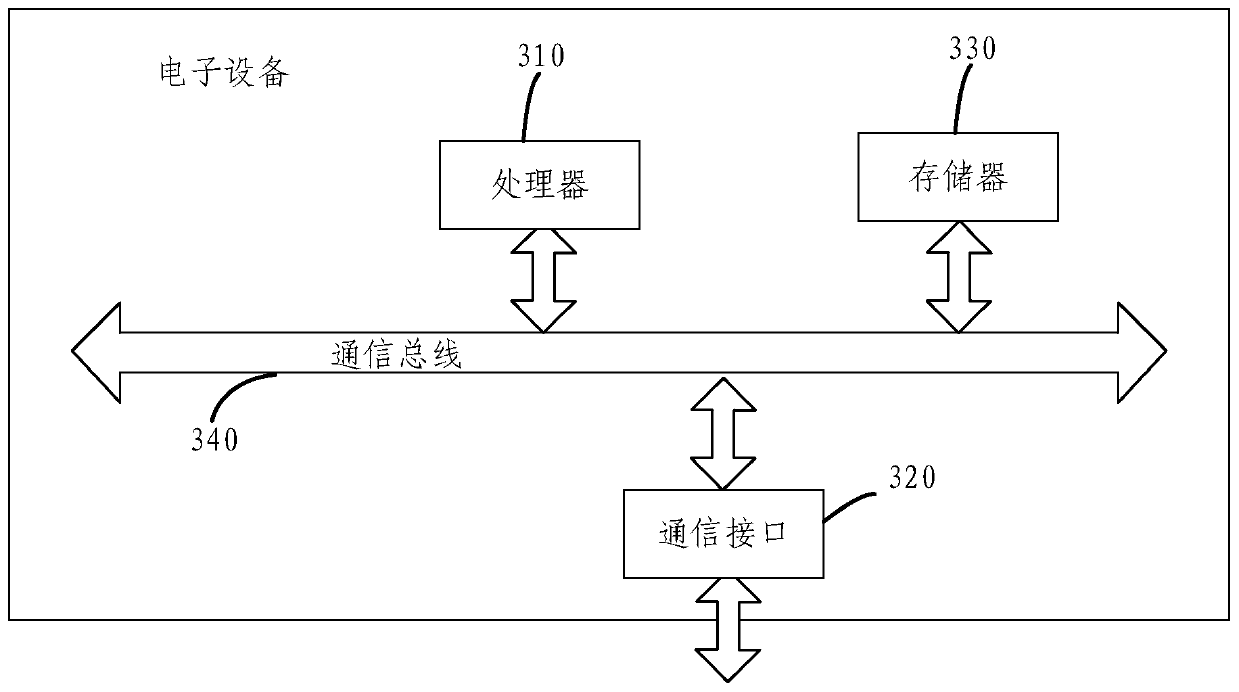

Corn leaf water content detection method and device based on multi-spectral image

InactiveCN109916836AWon't hurtEfficient measurementColor/spectral properties measurementsWhiteboardMultispectral image

The embodiment of the invention provides a corn leaf water content detection method and device based on a multi-spectral image and belongs to the multispectral technology application field. The methodcomprises the following steps of acquiring the multi-spectral image of a corn leaf sample and constructing an area of interest of the corn leaf sample; determining spectral reflectivity of the cornleaf sample at different preset wave bands according to calibration reflectivity of a standard whiteboard, a first average reflection spectrum of the standard whiteboard in the area of interest, and asecond average reflection spectrum of the corn leaf sample in the area of interest when the corn leaf sample uses the standard whiteboard as a reference; and inputting the multi-spectral image of thecorn leaf sample and the spectral reflectivity of the corn leaf sample at the different preset wave bands to a water content inversion model, and outputting the water content of the corn leaf sample.Since a leaf water content is not measured by a machine on the spot, a measurement process is relatively efficient, leaf tissues are not damaged, and applicability is wide.

Owner:CHINA AGRI UNIV

Manufacturing method of wicker plaiting vase

InactiveCN107259896AImprove softening effectStrong toughnessFlower vasesSurface moistureRoom temperature

The invention discloses a manufacturing method of a wicker plaiting vase. The method comprises the following steps of (1) harvesting wickers; flatly spreading and drying the wickers until the leaf water content is lower than 3 percent; and removing leaves; (2) cleaning the leaf removal wickers by clean water to remove impurities; then, putting the wickers into pretreatment liquid being 70 DEG C to be soaked for 1 hour; taking out the wickers; then, peeling the wicker peels; and cleanly washing the wickers; (3) flatly spreading and drying the wickers treated in the step (2) until the wicker water content is lower than 25 percent; then, soaking the wickers by purpose made floral liquid for 4 hours; then, cleanly washing the wickers; (4) taking out the cleanly washed wickers; drying the wickers by hot air being 50 DEG C until the water content is between 20 percent and 30 percent; then, putting the wickers into the purpose made floral liquid to be soaked for 2 hours; and then, cleanly washing the wickers; (5) drying the surface moisture on the wickers; putting the wickers into a freezer for fast lowering the temperature to 0 DEG C; then, taking out the wickers; and naturally recovering the wickers to the room temperature; and (6) plaiting the wickers treated by the steps into the vase; then, coating colorful paint onto the vase; drying the paint; and obtaining a finished product.

Owner:阜南县铭钰柳木工艺品有限公司

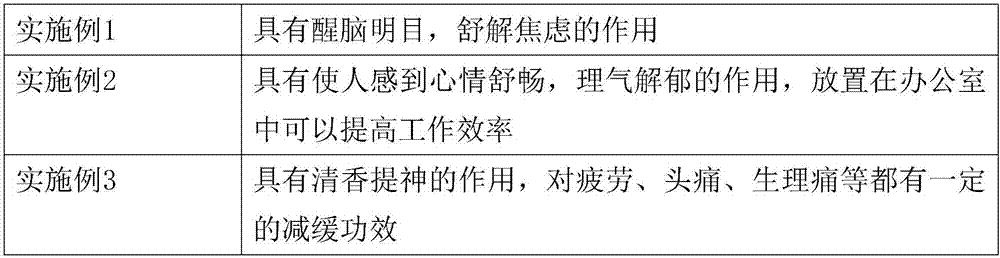

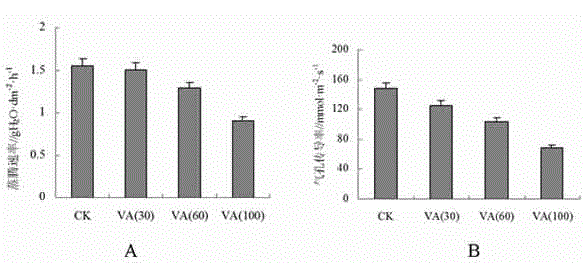

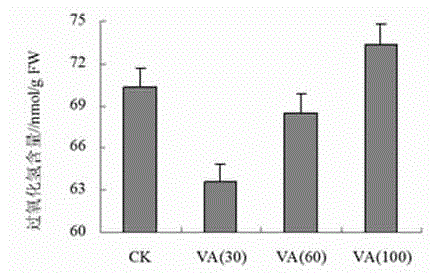

Application of vanadate to improvement of soil cultivated plant drought resistant stress

InactiveCN104542033AEasy to useImprove drought resistanceSeed and root treatmentHorticulture methodsPump activityTranspiration

The invention discloses an application of vanadate to improvement of soil cultivated plant drought resistant stress. In the use process, a vanadate solution with the concentration being 30 to 100mu mol / L is used for treating potted broad beans, water treatment is used as the blank control, after one day and three days after the treatment, the growth condition of the plants is observed, and various physiological indexes of the plants are measured. Experimental results show that through comparison with control, after vanadate treatment, the pore conductivity, the transpiration rate, the H<+>- pump activity and plasma membrane H<+>- ATPase activity of the plants and the H2O2 content are improved, and the water content of leaves is increased, and the physiological activities of the plants are favorably weakened through changes, so that the whole water content of the plants is enabled to be in a relatively stable level. Experimental results show that vanadate has an application prospects in the aspect of improving the drought resistant stress capability of soil cultivated plants.

Owner:KUNMING UNIV OF SCI & TECH

Tea-preparing method of oolong tea

InactiveCN107509825AImprove qualityImprove economyPre-extraction tea treatmentClimate change adaptationTemperature controlBud

The invention discloses a tea-preparing method of oolong tea. The method includes the following steps: (1) plucking fresh buds each of which has two leaves; (2) performing withering to control fresh leaf weight reduction within 3%-4%; (3) performing rocking at a temperature of 20 DEG C to 25 DEG C; (4) performing deactivation of enzymes to control leaf water content within 36%-46%; (5) after enzyme deactivation, wrapping the enzyme-deactivated leaves with cloth, performing rolling for 3 times and performing standing for 5-6h; (6) controlling the final water content of dried leaves within 8%-10%; (7) performing aroma increasing, performing tedding to cool the aroma-increased leaves when the tea leaf water content is 5% and performing storage; and (8) performing vacuum packaging in time on the dried tea leaves and performing low-temperature storage. The new oolong tea processing technology provided by the invention can be realized in tea factories which meet the requirements of green tea processing without the need of purchasing new tea-preparing equipment. According to the invention, through creating the new oolong tea processing technology, the defects of poor tea quality and low added economic value of traditional oolong tea varieties are improved; the quality of the prepared tea is stable and the rate of high quality products is high; labor intensity is low and the technology is easy to master; and the method has a broad promotion prospect.

Owner:江苏大敬茶业有限公司

Manufacturing method for mosquito repellent wickerwork deck chair

InactiveCN107414994AImprove softening effectStrong toughnessWood treatment detailsCane mechanical workingAfter treatmentPulp and paper industry

The invention discloses a manufacturing method for a mosquito repellent wickerwork deck chair. The manufacturing method comprises the following steps that firstly, wicker uniform in thickness and good in tenacity and willow hard in woodiness and free of insect damage are selected as raw materials; secondly, the willow is immersed in saline water, then the veneer is peeled off, a wood rod shape is formed through machining, the surface is ground after airing and coated with an antiseptic coating, and after the coating is aired, a deck chair frame is formed through splicing to be used later; thirdly, the wicker is flatly laid and aired till when the leaf water content is smaller than 3%, leaves are removed; fourthly, the willow without the leaves is thoroughly cleaned and then placed in pre-treating liquid to be immersed for two hours, the willow peel is peeled off after the willow is taken out, and thorough cleaning is conducted; fifthly, the willow obtained after treatment in the fourth step is dried through hot air; sixthly, the dried willow is immersed in a mosquito repellent agent for four hours, then thorough cleaning is conducted, and draining off is conducted; seventhly, the willow obtained after treatment in the sixth step and the deck chair frame manufactured in the second step are woven into the deck chair; and eighthly, the deck chair is dried through hot air, then natural cooling is conducted to the normal temperature, and a finished product is obtained.

Owner:阜南县铭钰柳木工艺品有限公司

NM material rising-resisting agent

The present invention provides an anti-transpirant developed by adopting NM material and PAL material. Said natural NM material contains lots of fulvic acid, the PAL material has stronger adsorbability and suspension property. The purified fulvic acid and PAL material powder body can be prepared into preparation form, and can be sprayed on the plant foliage and formed into film so as to reduce plant stem and leaf water content transpiration.

Owner:GANSU KAIXI ECOLOGICAL ENVIRONMENTAL ENG

Wicker softening treatment method

InactiveCN107379186ADamaged will notIncrease moisture contentWood treatment detailsCane mechanical workingImpurityLeaf water content

The invention discloses a wicker softening treatment method. The wicker softening treatment method comprises the following steps that (1) wickers with uniform thickness are collected, tiled and dried for 2-3 days till leaves are dry and the water content of the leaves is less than 3%, the dried leaves are removed; (2) the wickers with the leaves removed are washed with clear water to remove impurities, and then the wickers are put into a pretreatment liquid of 50-80 DEG Cand soaked for 40 minutes, wicker skins are removed after the wickers are taken out, the wickers are washed with clear water for backup use; (3) the treated wickers in the step (2) are dried with hot air until the water content of the wickers is less than 30%; and (4) the wickers are then soaked in a softening solution for 4 hours, and then the wickers are washed and dried with hot air until the water content of the wickers is less than 40%. The wicker softening treatment method is simple, the wickers can be softened before weaving, the difficulty of weaving is reduced, cracking or breaking of the wickers during the weaving process is prevented, and the quality of products is improved.

Owner:阜南县铭钰柳木工艺品有限公司

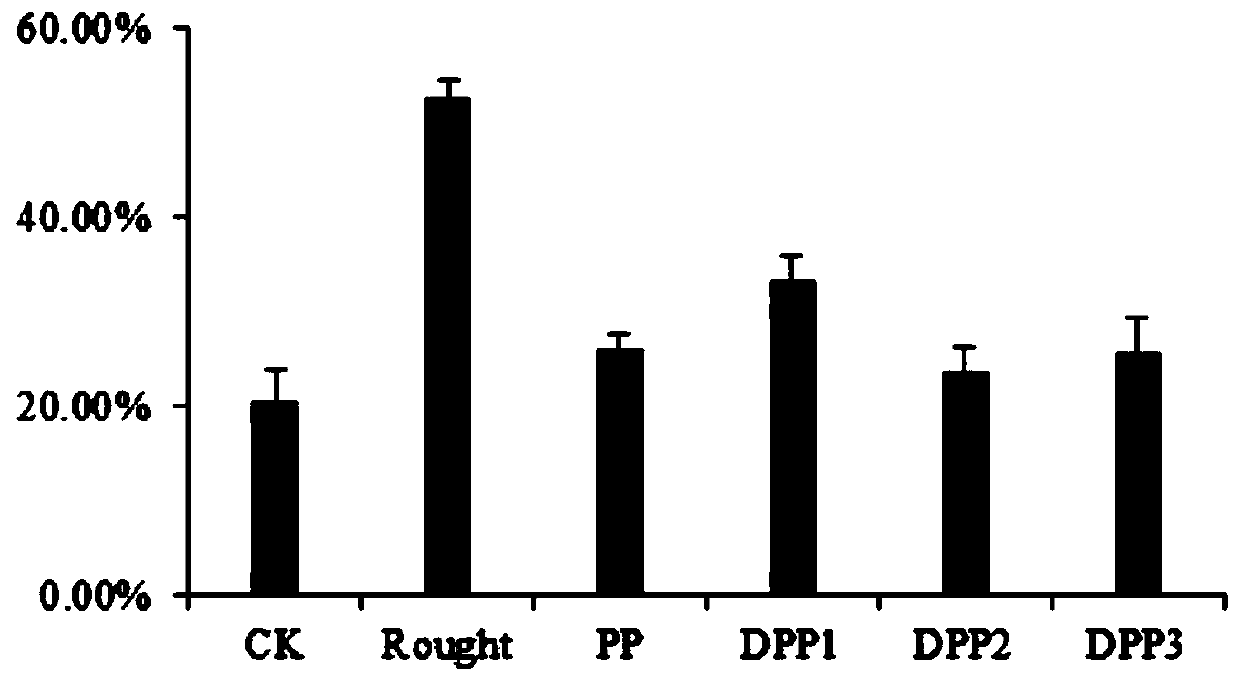

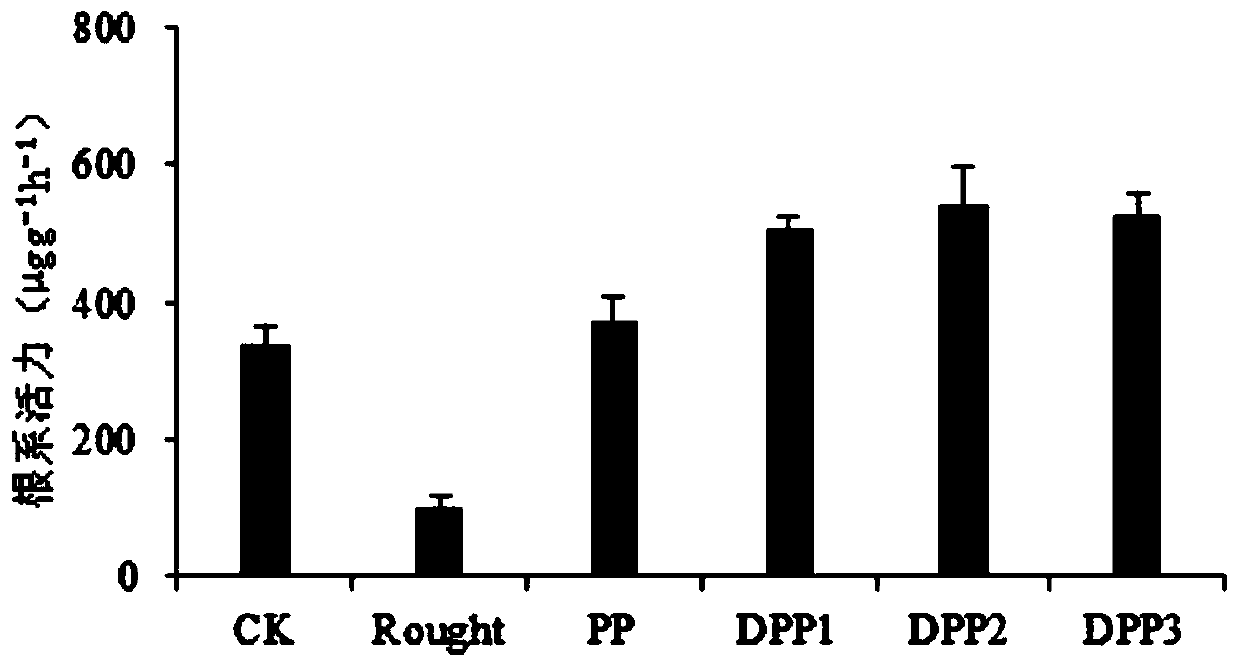

Application of porphyra polysaccharide in improving drought-resisting property of plant

ActiveCN109757247AImprove antioxidant enzyme activityEnsure normal growth and developmentBiocidePlant growth regulatorsGrowth plantPlant cell

The invention provides application of porphyra polysaccharide in improving drought-resisting property of a plant and belongs to the technical field of plant growth regulation. According to the application, the porphyra polysaccharide can regulate the osmotic pressure of plant cells under drought stress, so that the leaf water content is guaranteed. The porphyra polysaccharide also can improve theactivity of antioxidase in the plant and alleviate peroxidation of a plasma membrane caused by drought stress, so that the comprehensive resistance of the plant to drought stress is further improved,and normal growth and development of the plant are guaranteed. The application adopts laver as a raw material, the sources are rich, the cost is low and environmental protection is achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Eucommia ulmoides health preserving tobacco and preparation method thereof

InactiveCN110250563AGreat tasteNo side effectsTobacco treatmentCigar manufactureChemical compositionNatural product

The invention relates to the field of eucommia ulmoides health care tobaccos, in particular to a eucommia ulmoides health preserving tobacco and a preparation method thereof. Wild plant essence, licorice extracts, honeysuckle extracts and ginseng essential oil are prepared into a liquid material to be added into tobacco shreds of eucommia ulmoides leaves, and then rolled into cigarettes. In the preparation process, while the eucommia ulmoides leaves are dried by hot air, chemical components in the eucommia ulmoides leaves are well kept in the leaves, the eucommia ulmoides leaves turn yellow integrallyand are dried to reduce the water content and the loss of nutrients, and storage and transportation are easy; by separating lamina and veins, the lamina is cut into shreds to enable the tobacco shreds to be an optimal state, and the water content of the lamina is controlled to ensure the composition of natural products, meanwhile softness and flammability are enhanced, and the taste in the use process is enhanced; and by cold air drying, the water content of the tobacco shreds is further reduced while the mixture of the liquid material and the tobacco shreds is ensured, and while flavoring is carried out, the quality of tobacco is ensured.

Owner:伟润诚生物科技(北京)集团有限公司

Green tea processing method

InactiveCN109892419AImprove stabilityGood curling effectPre-extraction tea treatmentMicrowaveTime control

The invention discloses a green tea processing method. The method comprises the following steps of: a, spreading green tea: naturally spreading the green tea to cool naturally, and reducing the watercontent of the green tea to 60-65 % to obtain a product A; b, de-enzyming: putting the product A into a de-enzyming machine for de-enzyming, wherein the feeding amount of the product A is controlled to be 80-100 kg / h during de-enzyming; controlling the feeding port temperature of the de-enzyming machine to be 300-320 DEG C, controlling the discharging port temperature to be 280-290 DEG C, and obtaining a product B after de-enzyming; c, primarily kneading: putting the product B into a kneading machine for primarily kneading for 8-10 min, and obtaining a product C; d, drying and dehydration: drying the product C at 90-100 DEG C and reducing the water content of leaves to 35-40 %, and obtaining a product D; e, rekneading: putting the product D in a tea kneading machine and twisting for 15-20min to obtain a product E; f, drying: drying the product E in a continuous microwave dryer, reducing the water content of leaves to 3-5 %, screening out crushed leaves to obtain the green tea. The green tea processing method has the advantages of stable production quality, sweet taste of the product, good sweet returning characteristic, strong fragrance and beautiful tea shape of the product.

Owner:都匀市毛尖镇高原布依茶业有限责任公司 +1

Nursery stock growth regulator and preparation method thereof

InactiveCN106631370ASolve the problem of water shortage and droughtImprove survival rateBioloigcal waste fertilisersPotassium fertilisersBiologyNaphthylacetic acid

The invention discloses a nursery stock growth regulator and a preparation method thereof. The nursery stock growth regulator is prepared from, by weight, 16-25 parts of zinc sulfate, 6-11 parts of naphthylacetic acid, 7-11 parts of chlormequat chloride, 3-5 parts of abscisic acid, 4-7 parts of potassium sulfate, 2-6 parts of brassinolide, 15-21 parts of plant straw, 7-12 parts of potassium butanoate, 6-12 parts of potassium sorbate, 1-4 parts of rooting agent and 3-8 parts of rooting powder. The effective formula of the zinc sulfate, the naphthylacetic acid, the chlormequat chloride, the abscisic acid, the potassium sulfate, the brassinolide, the plant straw, the potassium butanoate, the potassium sorbate, the rooting agent and the rooting powder is adopted, the problem of water shortage and drought of nursery stocks is solved, root system growth is promoted, the survival rate of transplanted nursery stocks is improved, the pore opening degree of the nursery stocks is effectively decreased, the transpiration is inhibited, the water content of leaves is increased, the free amino acid content is increased, the chlorophyll content is increased, and the survival rate and drought resistance of transplanted nursery stocks is greatly improved.

Owner:芜湖国苑苗木服务有限公司

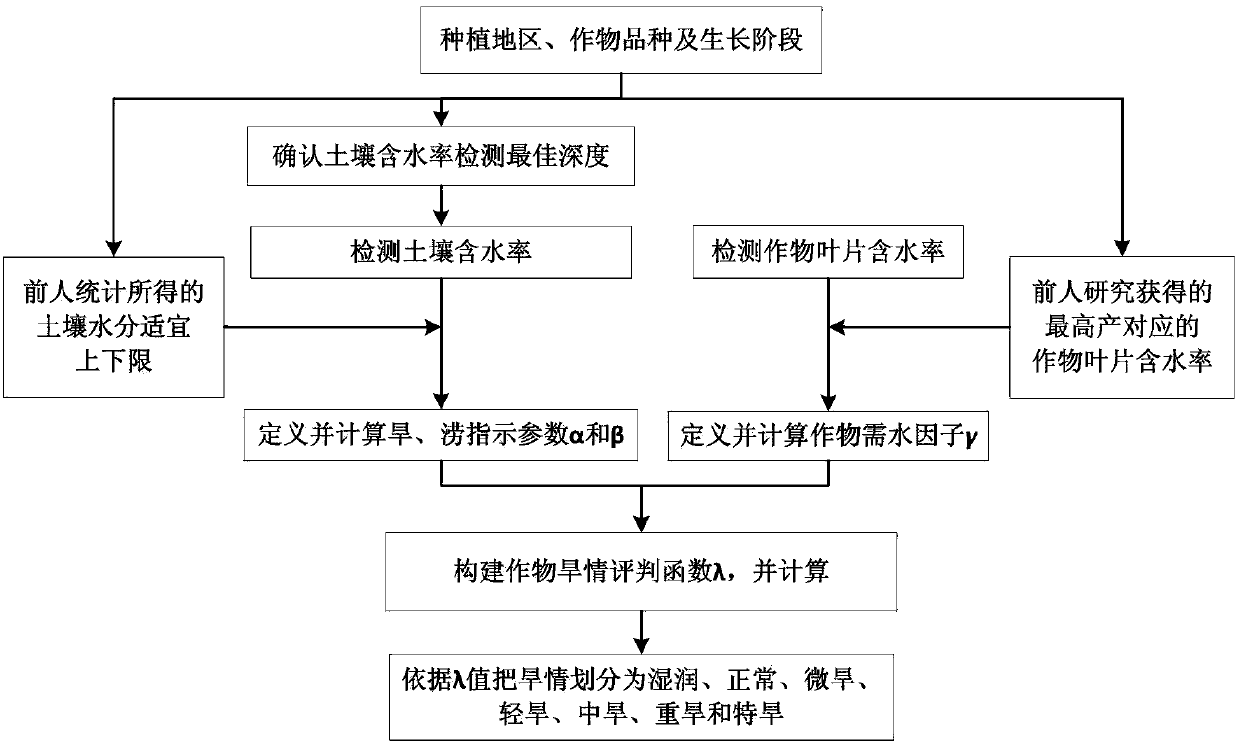

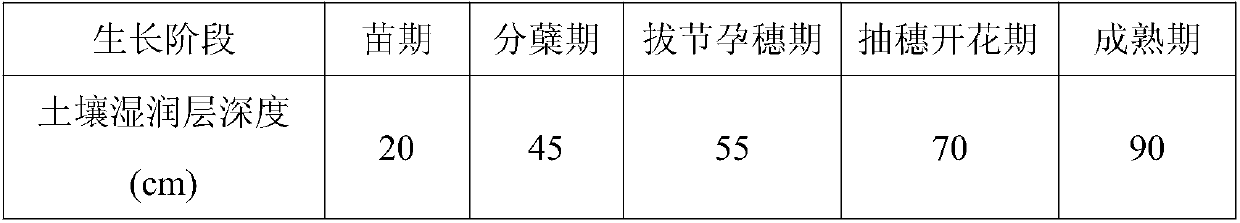

Field crop drought judgment method

InactiveCN107657541ADiscriminant realizationAccurate discriminationData processing applicationsClimate change adaptationField cropWater requirement

The invention discloses a field crop drought judgment method, which comprises the steps of 1 determining the depth of a soil moist layer and detecting the soil moisture content; 2 acquiring a droughtindicating parameter and a waterlogging indicating parameter; 3 acquiring a crop water requirement factor; 4 building a drought judgment function; and 5 acquiring a drought condition of the field cropin the planting area according to a value of the drought judgment function. The field crop drought judgment method comprehensively integrates influences imposed on drought judgment by crop information, the soil moisture content and the crop leaf water content so as to enable the judgment result to be more reasonable and more accurate.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com