Patents

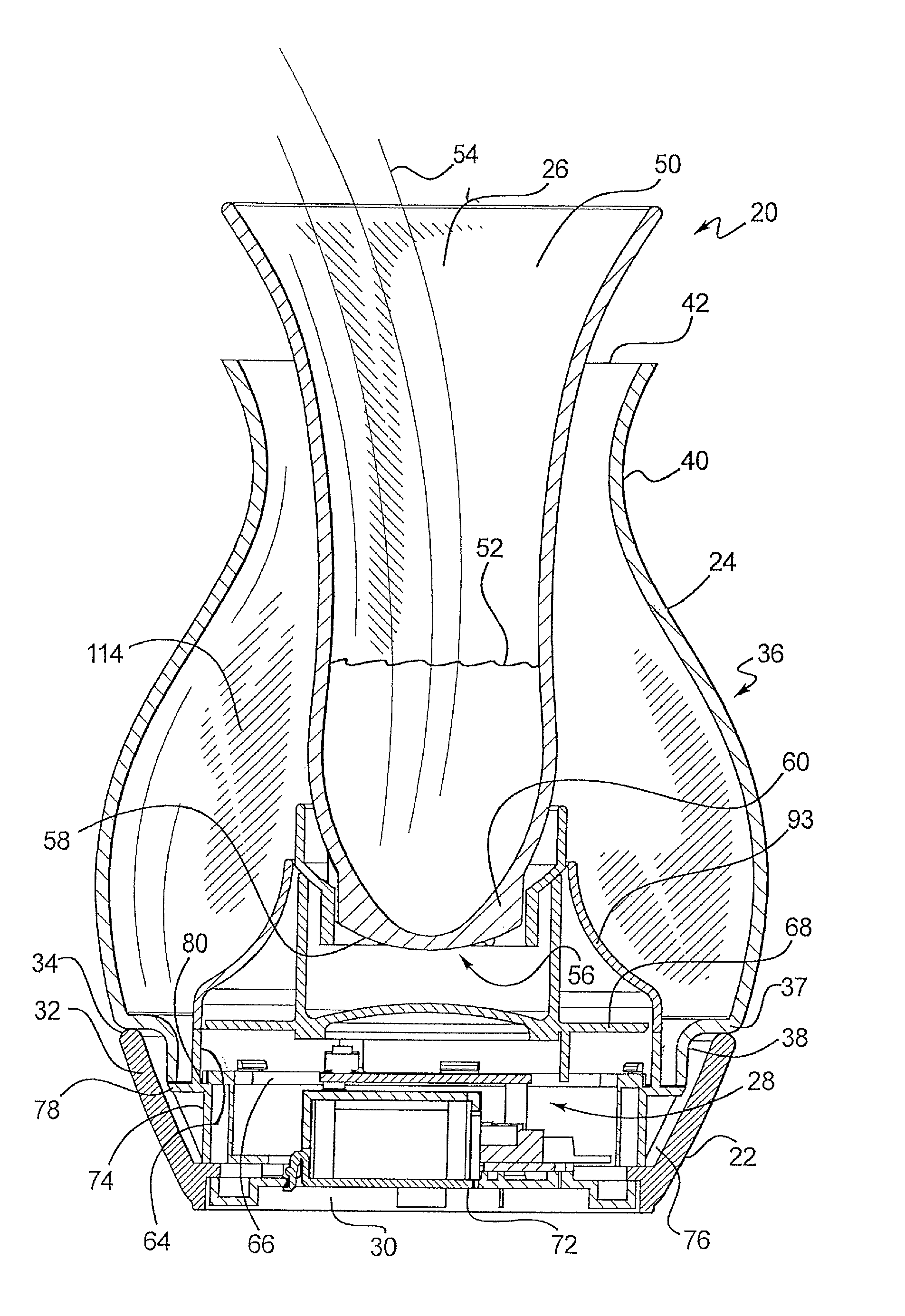

Literature

441 results about "Vase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

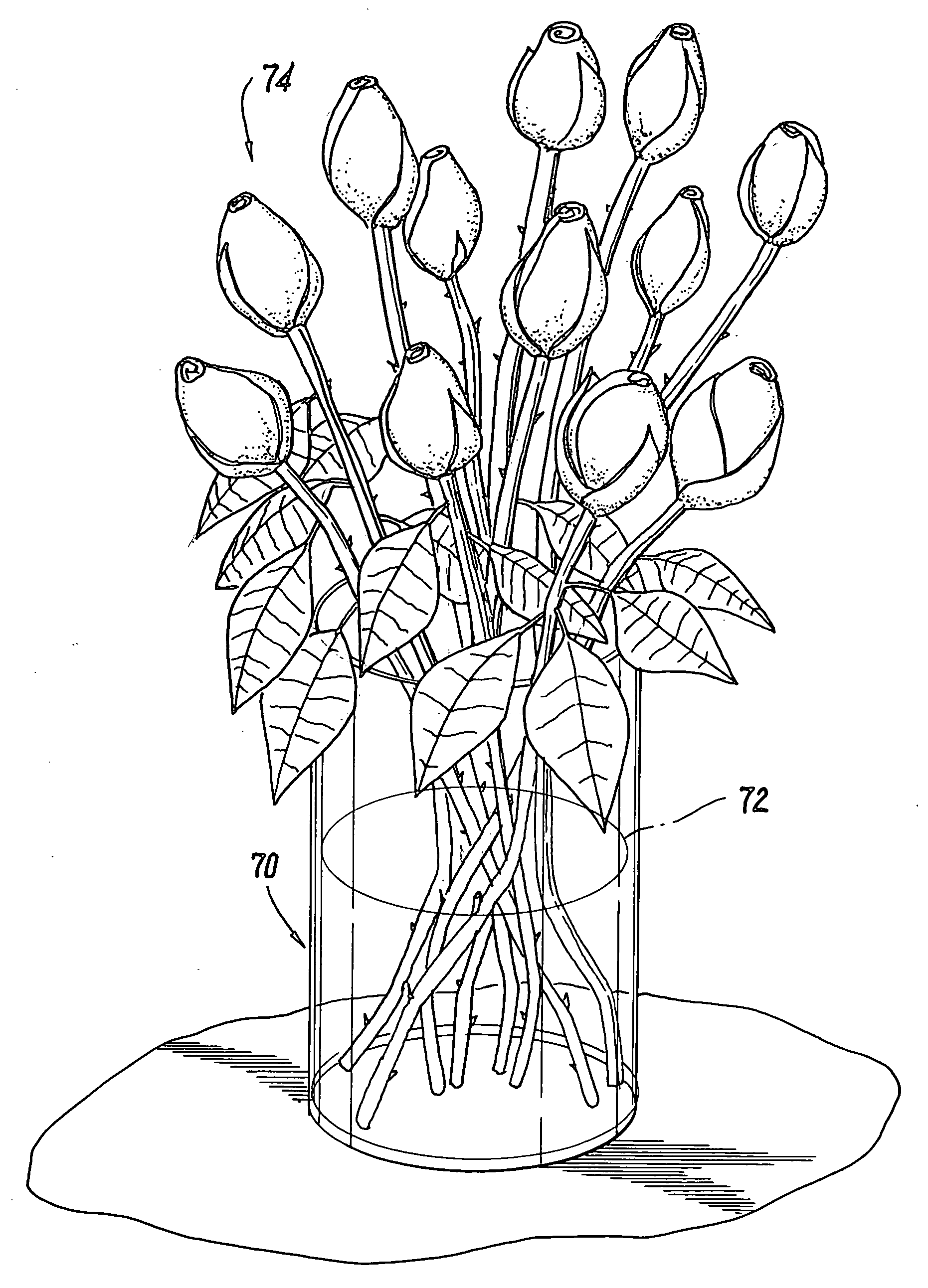

A vase (/ˈvɑːz/, /ˈveɪs/, or /ˈveɪz/) is an open container. It can be made from a number of materials, such as ceramics , glass, non-rusting metals, such as aluminium, brass, bronze, or stainless steel. Even wood has been used to make vases, either by using tree species that naturally resist rot, such as teak, or by applying a protective coating to conventional wood. Vases are often decorated, and they are often used to hold cut flowers. Vases come in different sizes to support whatever flower its holding or keeping in place.

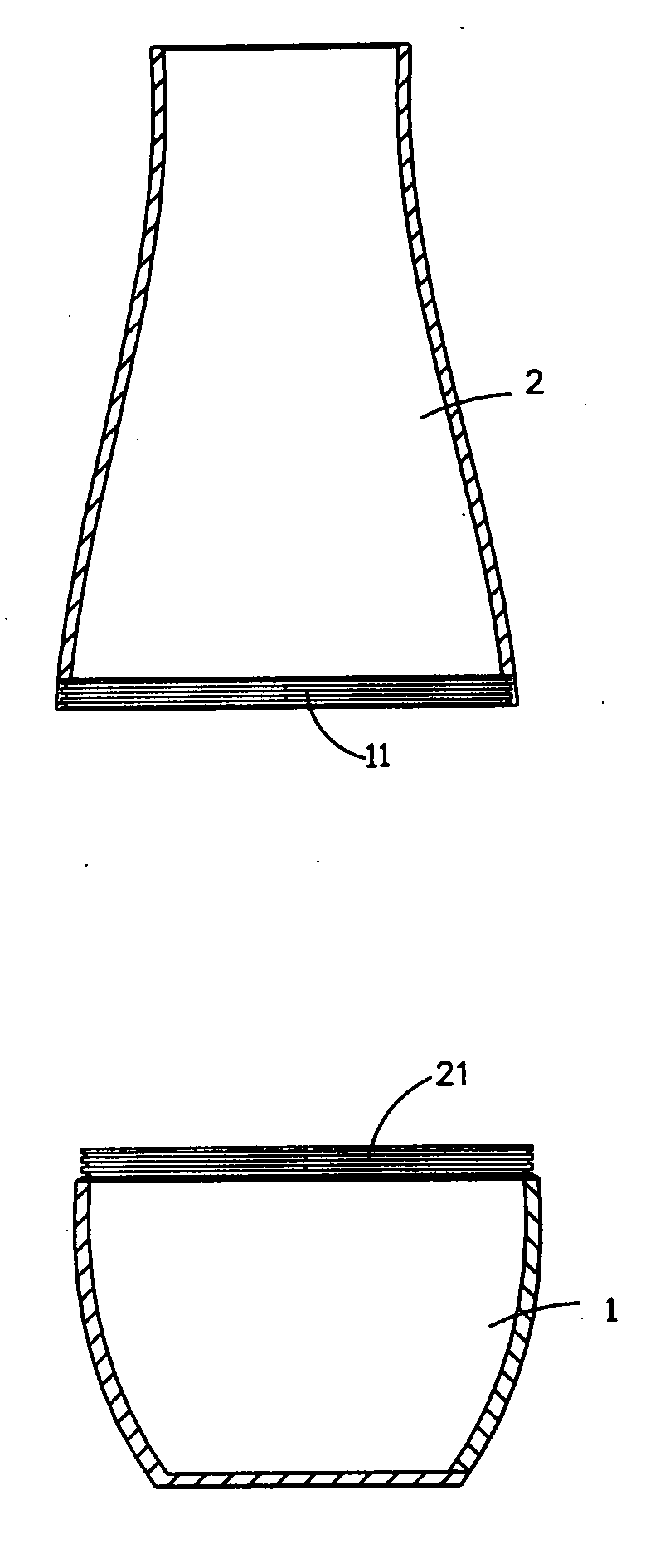

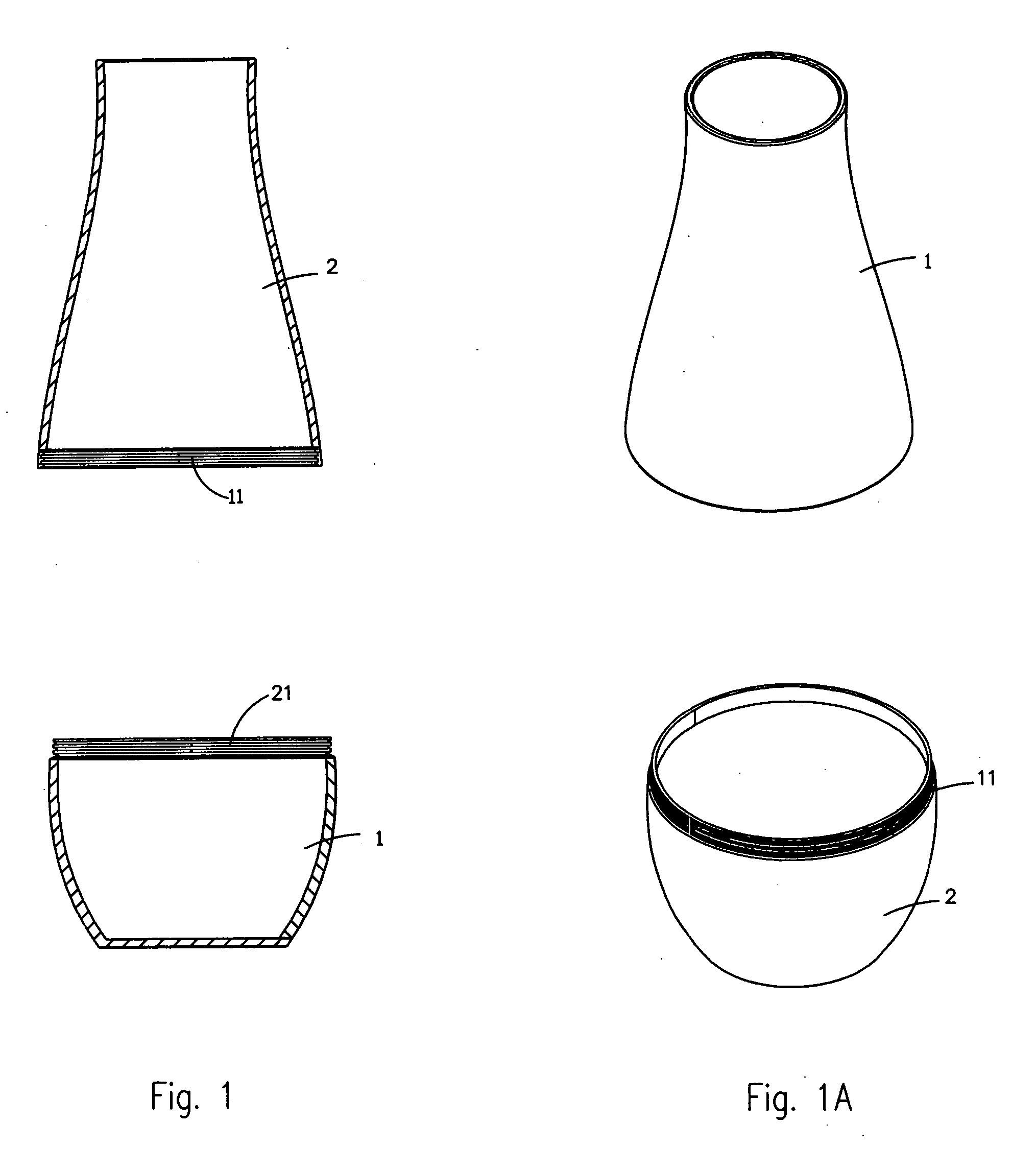

Datachable vase for separately filling water and retaining plants

A detachable vase for separately filling water and retaining plants comprises a lower water-filled bottle body for receiving water; and an upper side of the lower water-filled bottle body having a first connect unit; and an upper bottle body for receiving plants or flowers; the upper connect unit connected to the lower water-filled bottle body; a lower side of the upper bottle body having a second connect unit which can be engaged to the first connect unit. The upper bottle body includes at least two sub-bodies which are engageable to one another. The vase is divided into a first and a second bottle bodies. The lower water-filled bottle body is detachable from the upper bottle body. When it is desired to update the water in the vase, it is only necessary to detach the lower water-filled bottle body from the upper bottle body.

Owner:TING WEI WEN

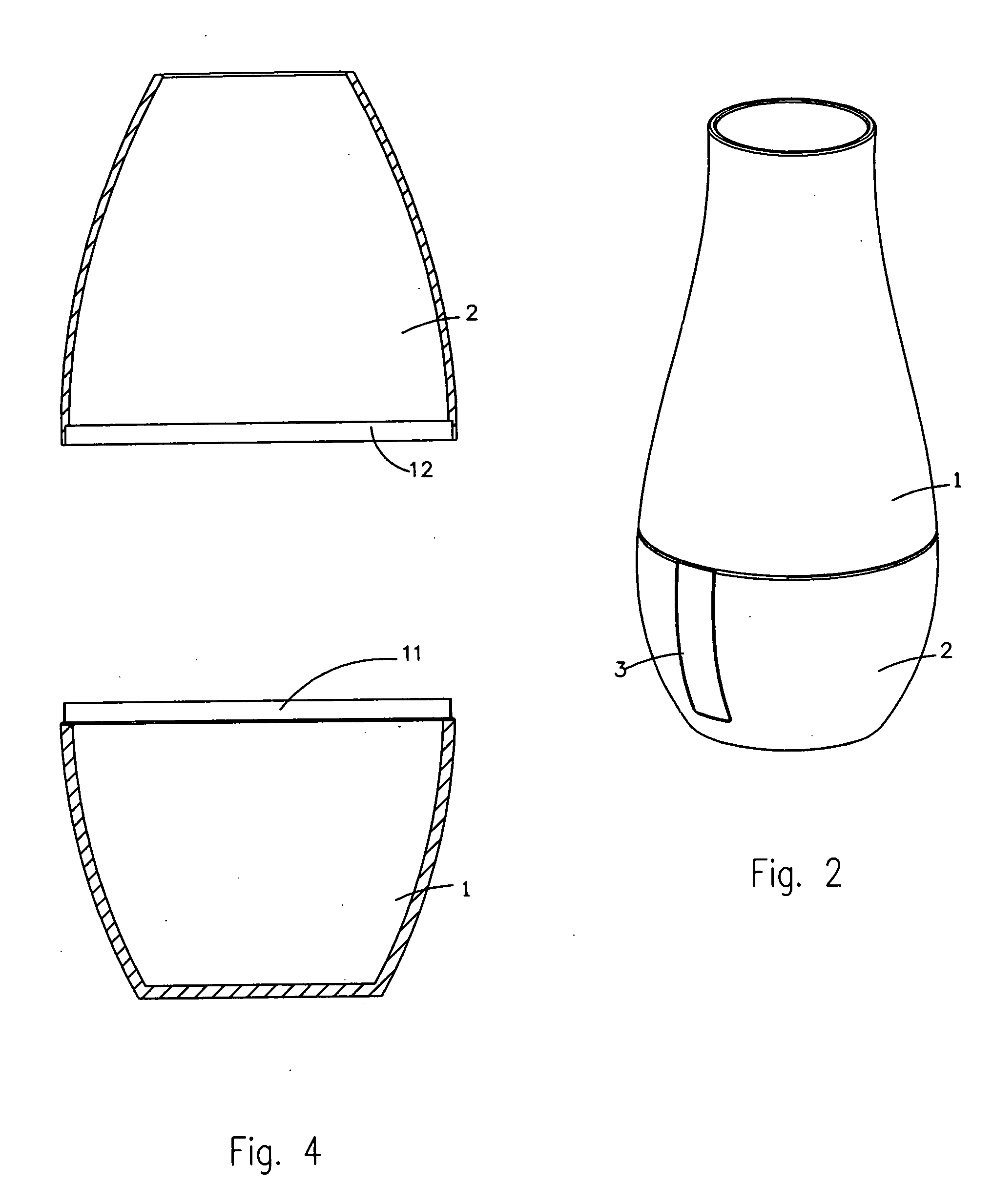

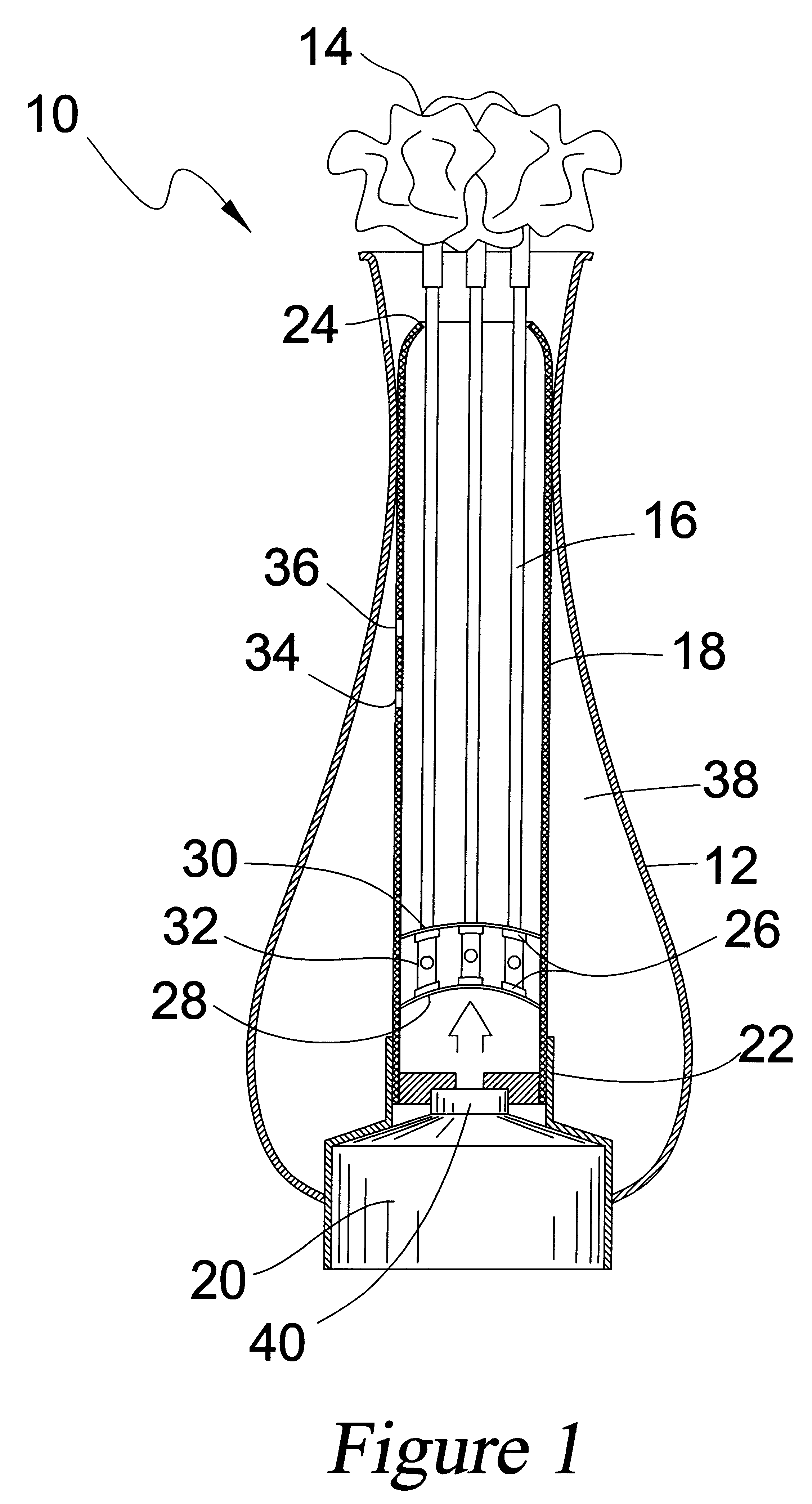

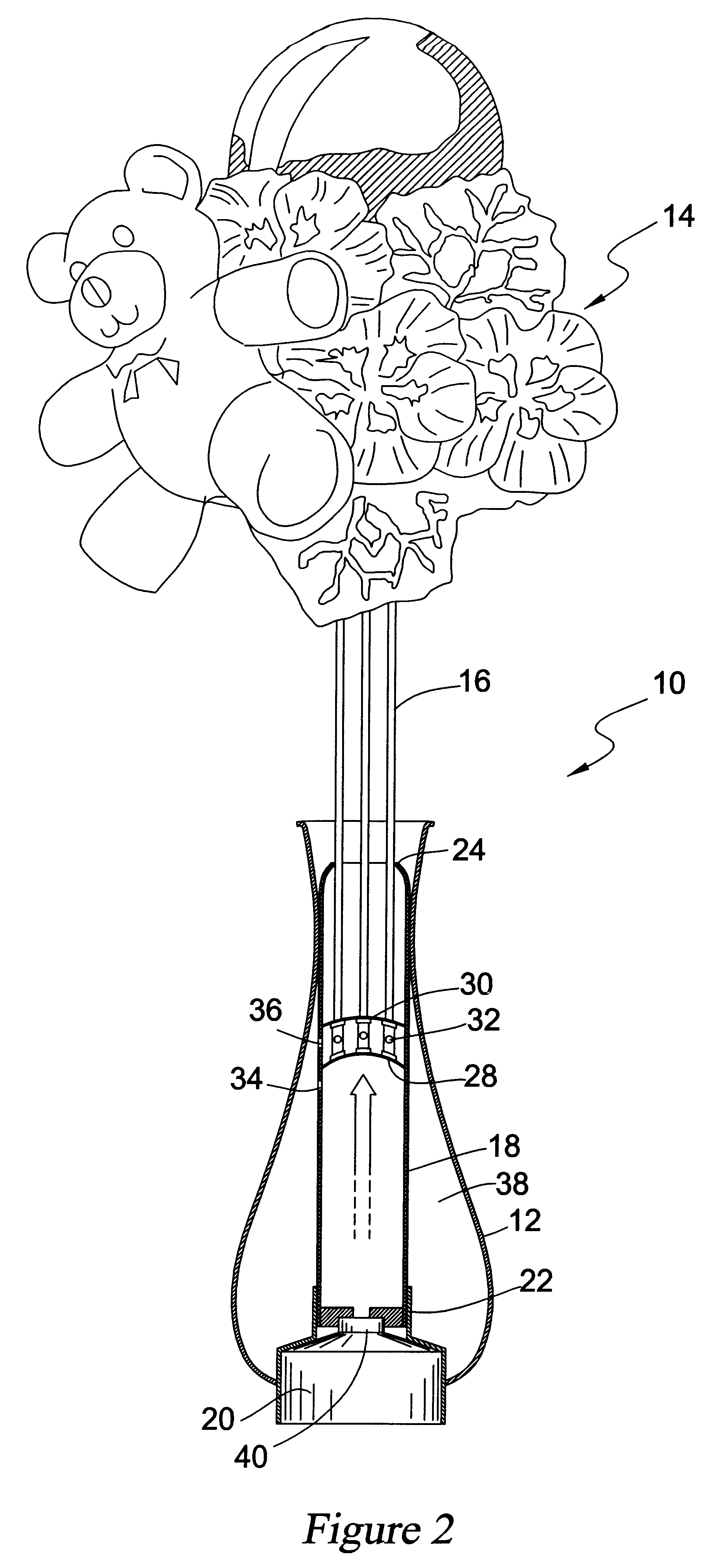

Inflatable balloon bouquet

The present invention discloses a flower vase containing an inflatable balloon bouquet. The flower vase contains a source of air for inflating the balloons positioned near the bottom of the vase being connected to an upwardly standing air cylinder whereby the balloon bouquet stems are pushed upwardly through the air cylinder somewhat as an internal combustion piston passing through its cylinder. Means are provided for transferring gas from the gas canister through apertures in the wall of the air cylinder and thereafter through apertures in the hollow stems of the balloons and thereafter into the balloons themselves so that the balloons become inflated.

Owner:WEIR STEVEN A

Methods to solidify cremation ash

Residual bones, and ashes from the cremation process of deceased humans and animals are turned into solid objects containing glass, ceramics, clay based materials, or composites such as organic polymer matrix, metal matrix, or inorganic cementaceous matrix, or combination of thereof. In another embodiment, ash is mixed with at least a liquid phase such as paint or coating, which upon dying or heating the mixture becomes solid. The final solid product can be made into any shapes or forms that the matrix can be made into without the addition of the ash. The final form of the product thereof can range from abstractive non-functional to geometrical shapes or functional forms such as containers, vases, or in the form of jewelry stones. Or painting, drawing, coating, and glazing. The objects can be made to contain almost all ash, such as in the case of ceramics or partially loaded with ash as is the case for glass and composites. In one other embodiment, the cremation residue either in a solid form or powdery form can be encapsulated in glass, ceramics, and various composites to form a heterogeneous product. The finished products can be marked with identification formats such as bar codes which make them possible to be traced electronically in a data base environment.

Owner:HOJAJI HAMID

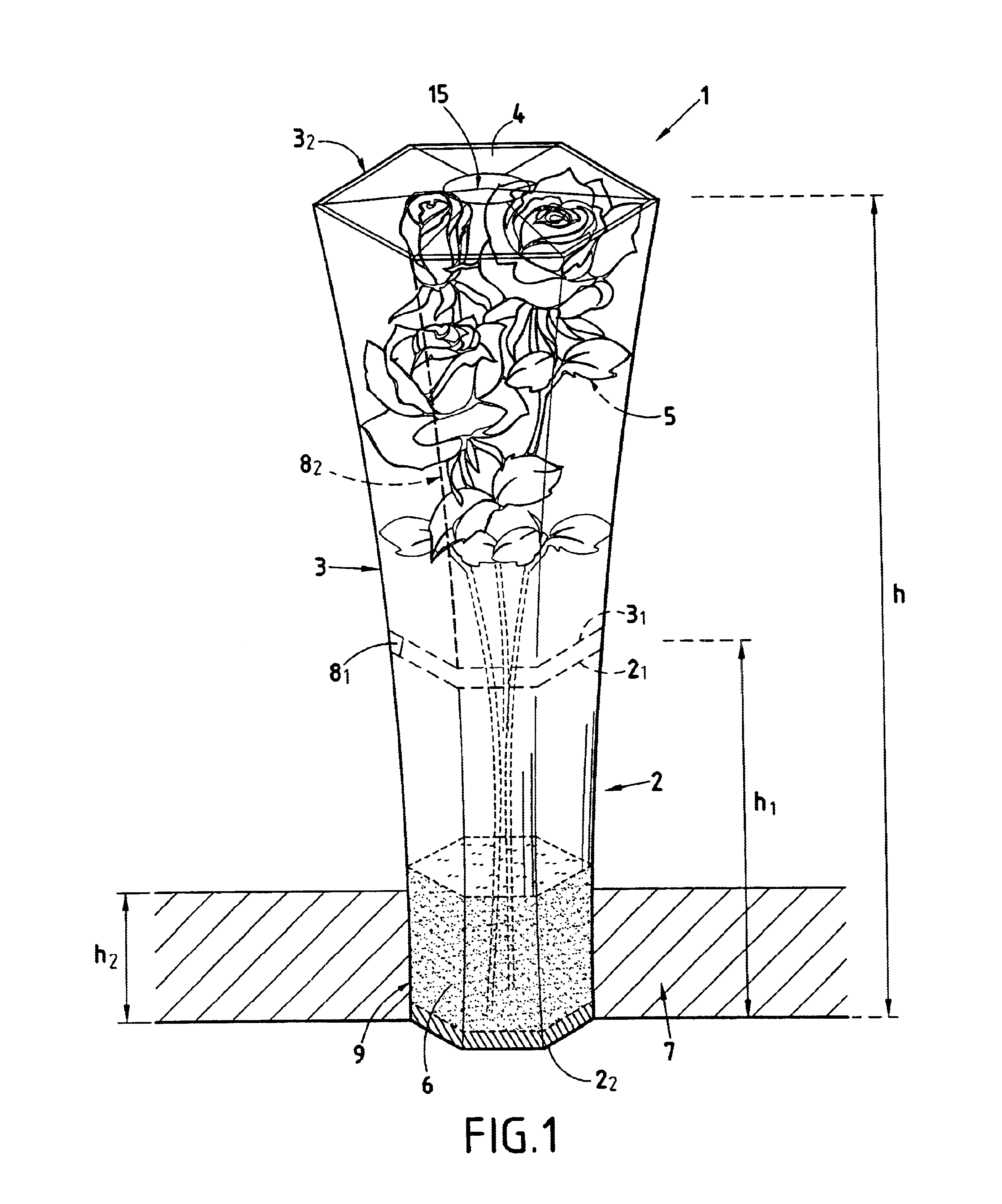

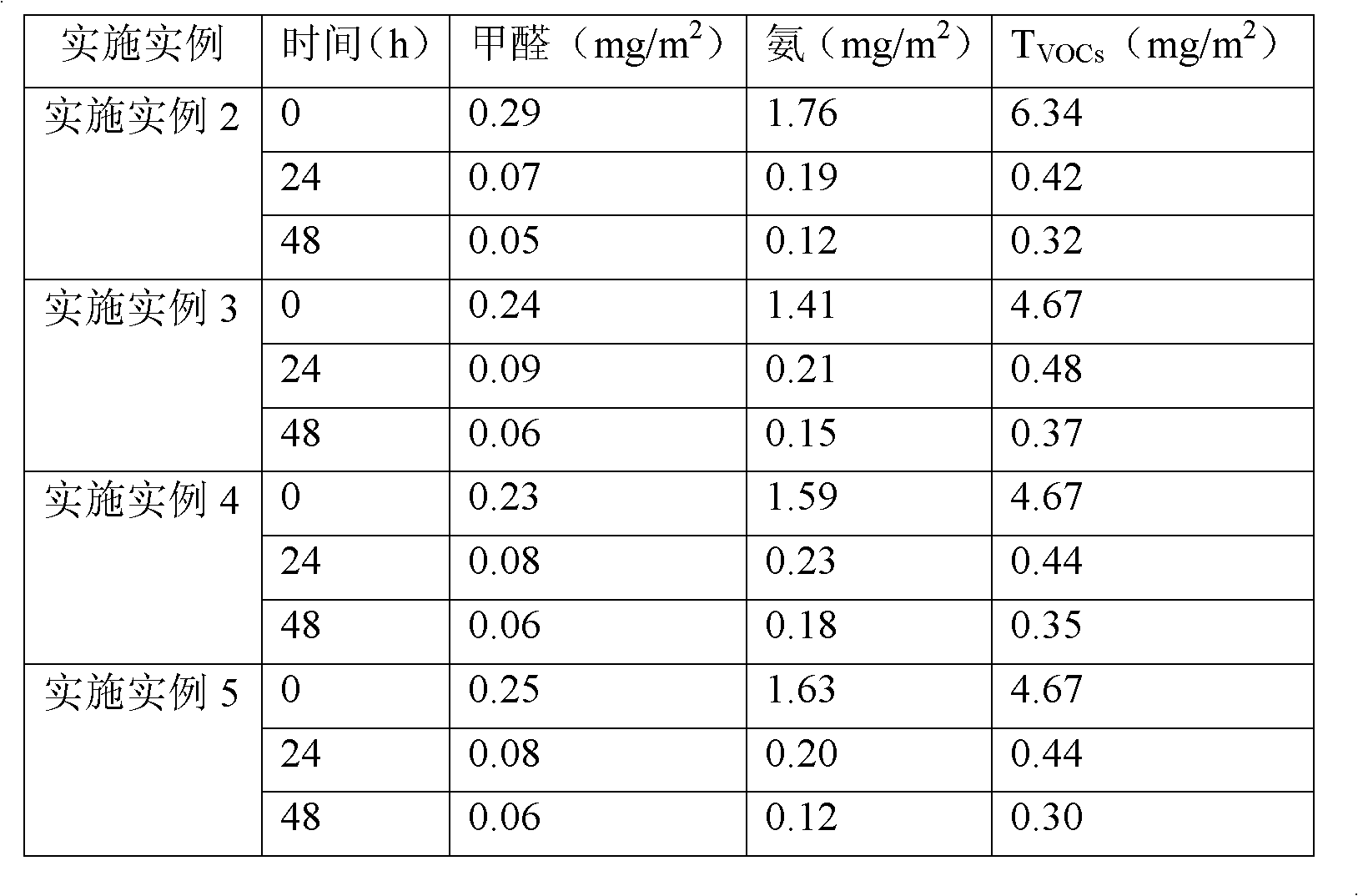

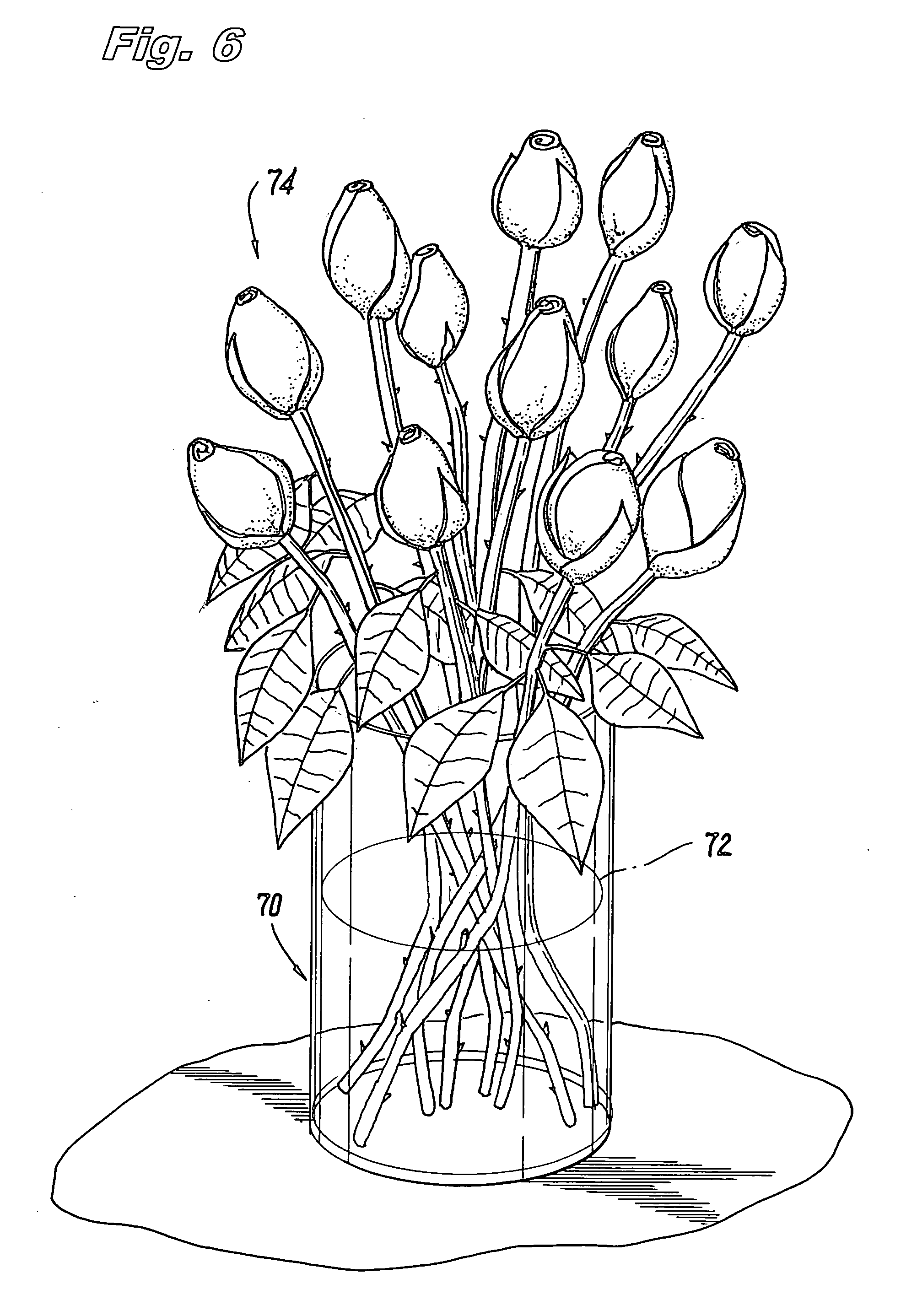

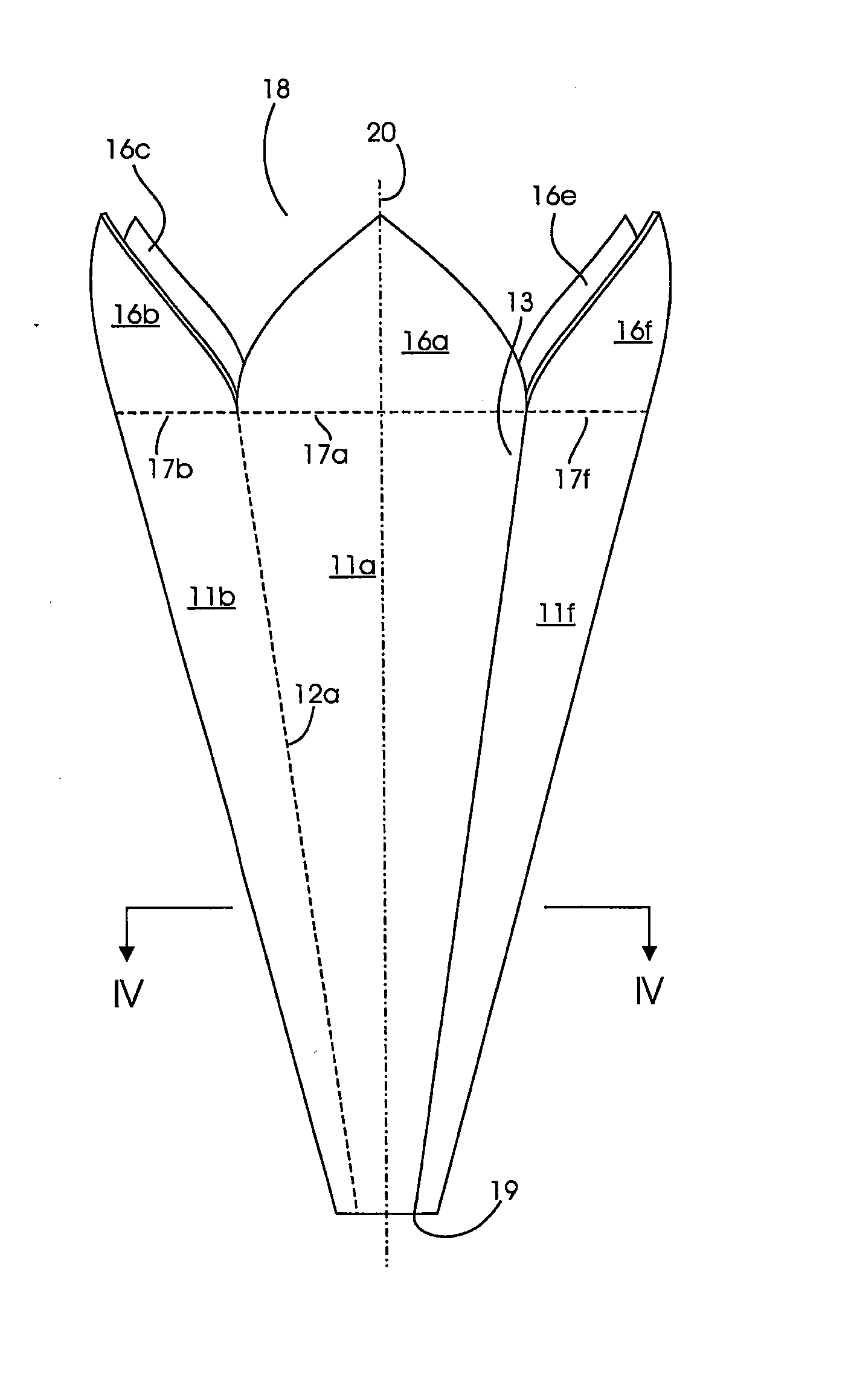

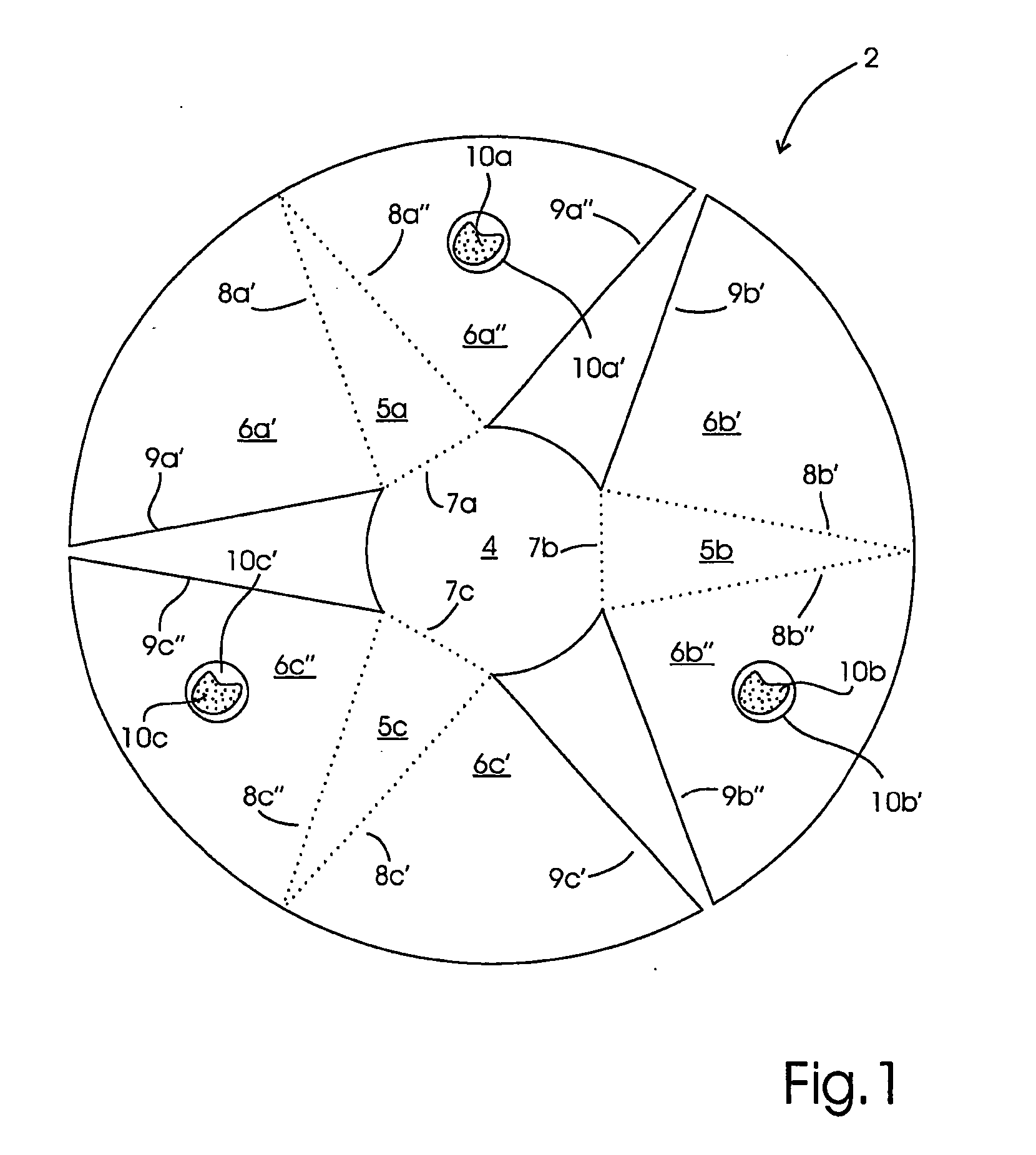

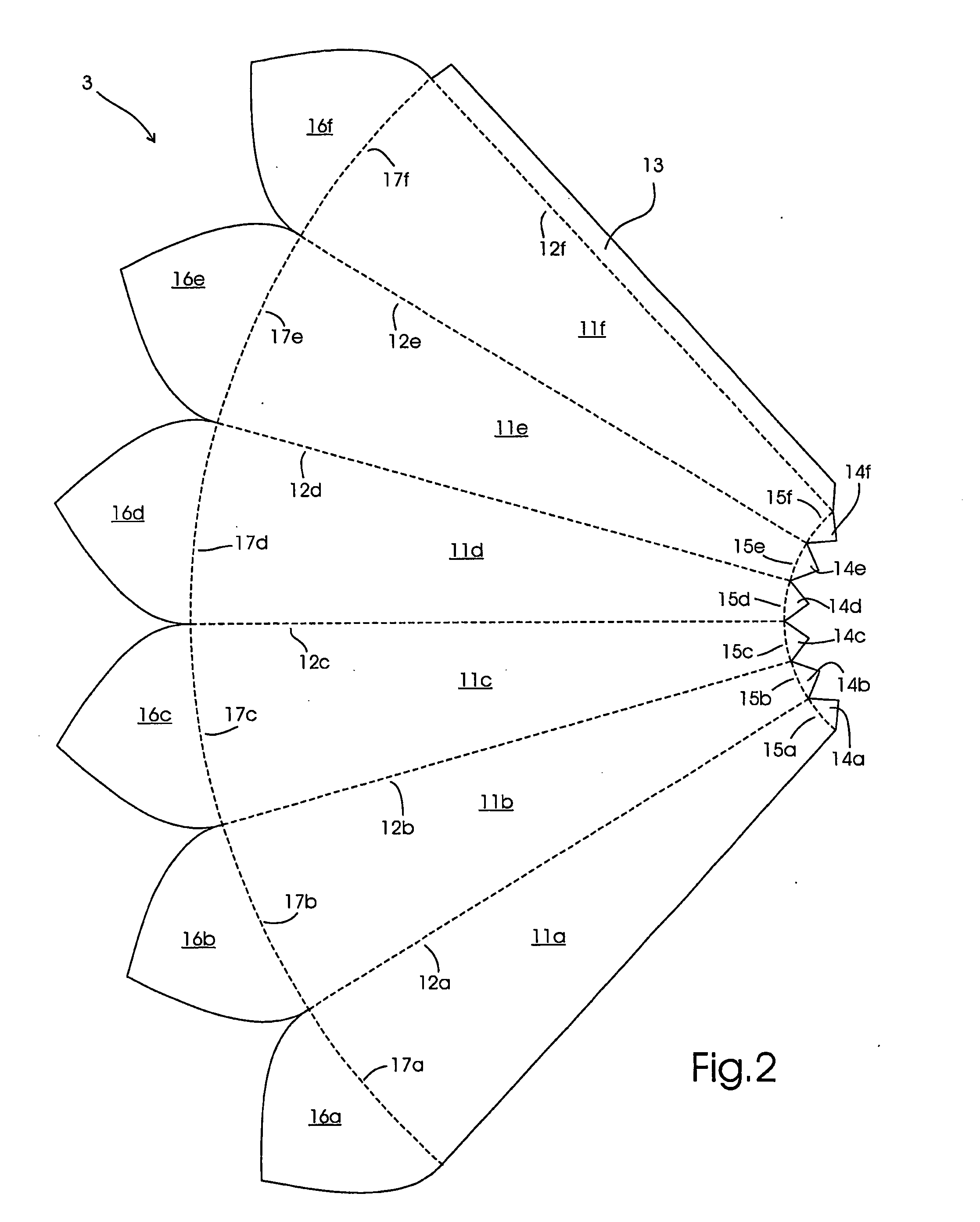

Package for transporting and displaying bunches of fresh cut flowers

InactiveUS6672002B1Increase spaceFlat shapeLiving organism packagingFloral handlingBiological bodyCut flowers

The technical field of the invention is that of making receptacles, packages, or parcels for living organisms or materials that are sensitive to changes in atmospheric conditions or surroundings, such as cut flowers. The lower portion (31) of a funnel-shaped shell overlies and matches the shape of a top portion (21) of a vase (2) which has the same funnel shape as the lower portion of the shell.

Owner:GUMPPER MARIE

Preparation method and applications of aqueous polyurethane emulsion

The invention discloses a preparation method and applications of an aqueous polyurethane emulsion. The aqueous polyurethane emulsion is mainly composed of the following components in parts by weight: 50 to 100 parts of composite polyol with a carbonate structure and an ether structure, 0.05 to 0.2 part of catalyst, 10 to 80 parts of isocyanate, 1 to 12 parts of crosslinking agent, 2 to 10 parts of hydrophilic chain extender, 0 to 15 parts of non-hydrophilic chain extender, 30 to 100 parts of acetone, 1 to 12 parts of neutralizer, 150 to 400 parts of deionized water, 0 to 25 parts of filling materials, 0 to 30 parts of pigment, and 0 to 15 parts of auxiliary agents. The hard paint has the characteristics of low film-forming temperature (0 DEG C or more), quick drying, strong adhesive force, scratch resistance, and impact resistance, has a pencil hardness of 2H, can be used to paint materials such as metal, woodware, glass, plastic, leather, and the like, and has the advantages of wide application range, high performance-cost ratio, and vase market prospect.

Owner:JIANGSU ZHONGKE JINLONG CHEM

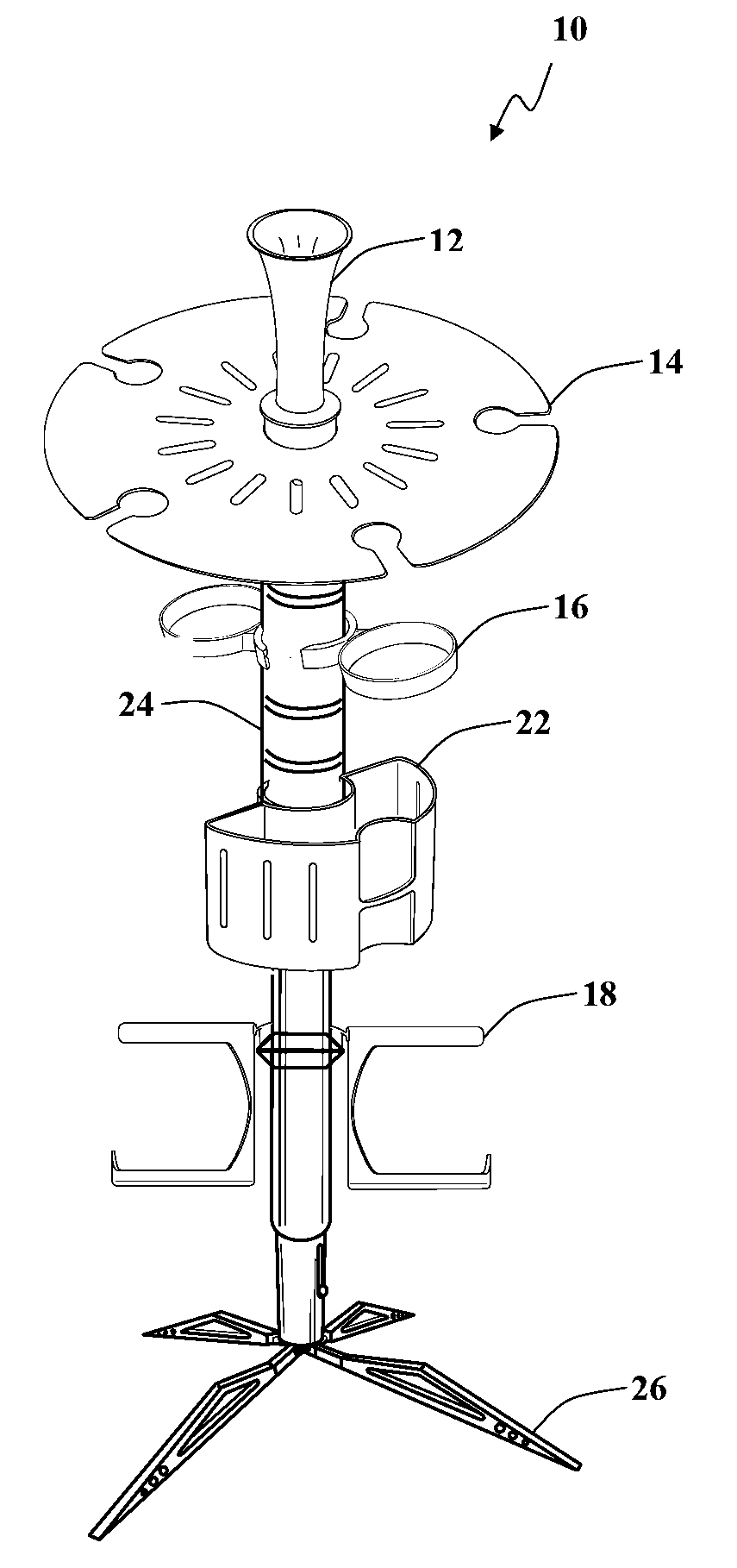

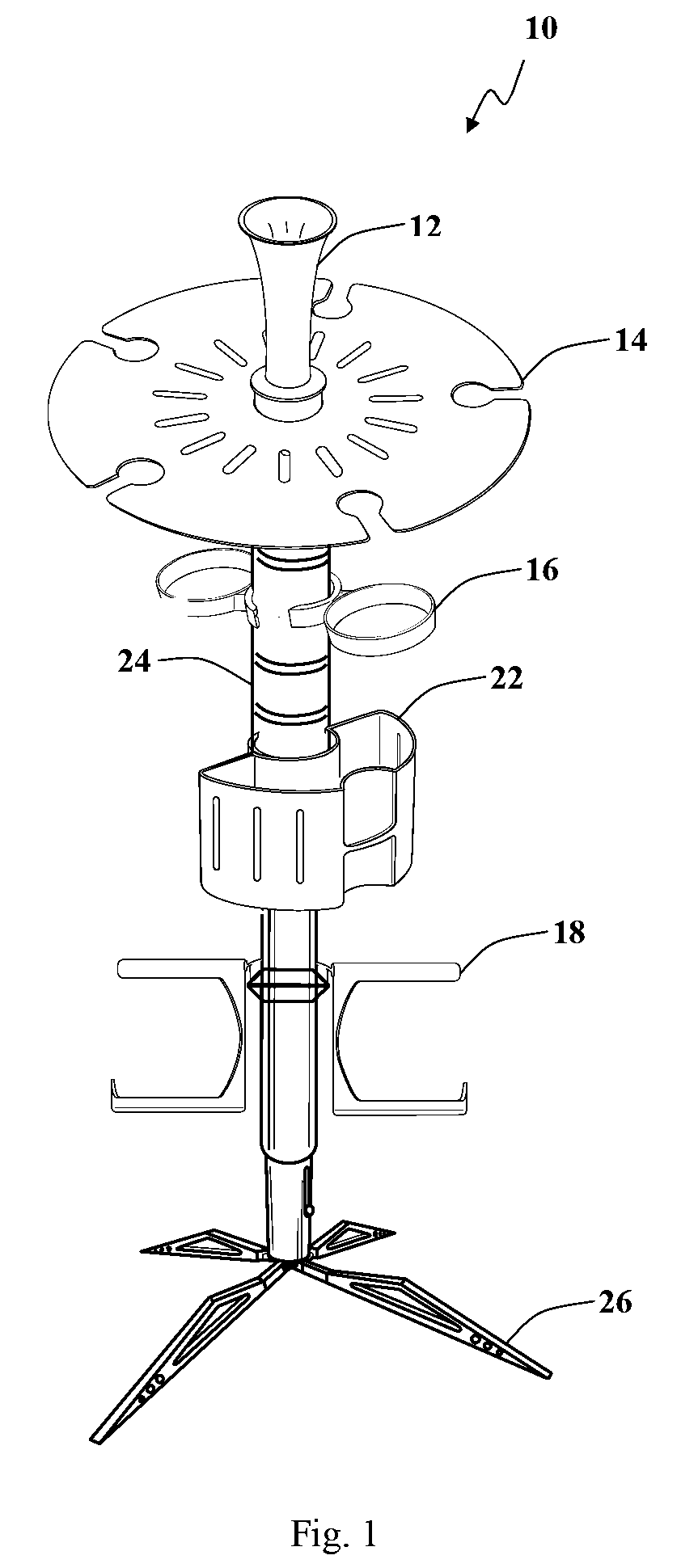

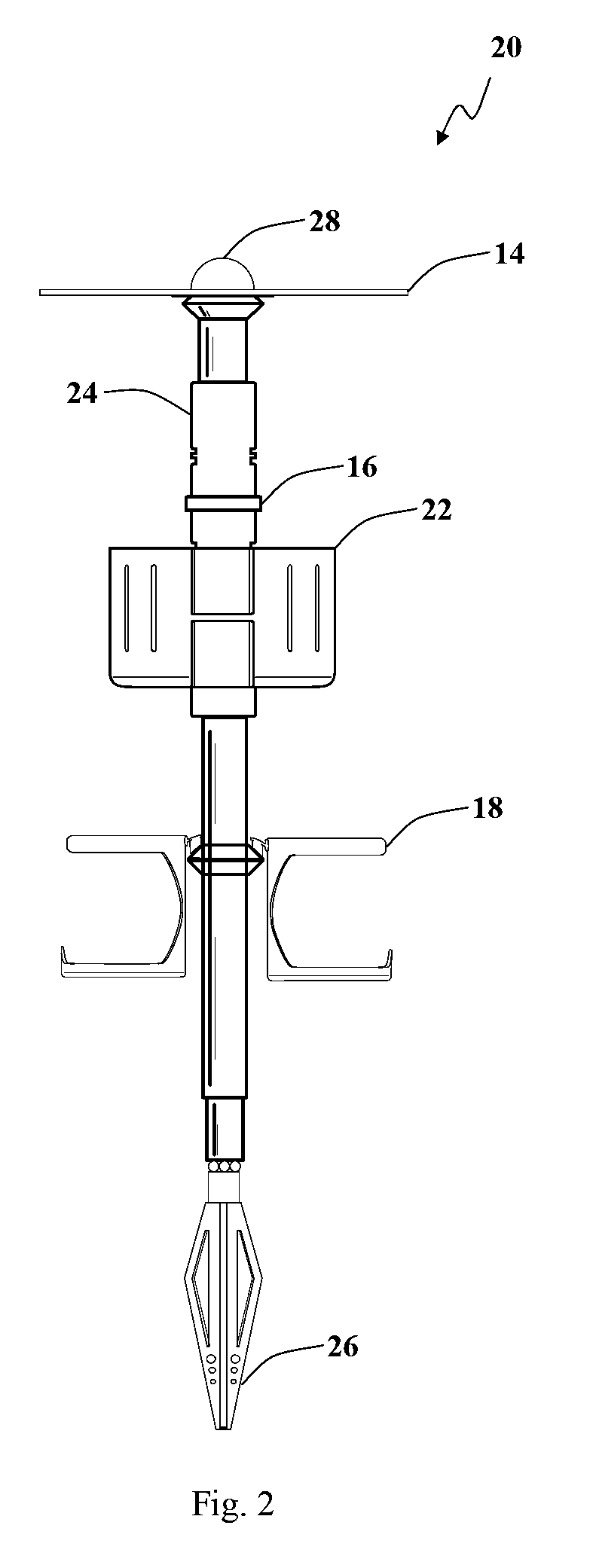

Portable drink stand

The present invention is a portable stand that generally comprises of an upper telescopic pipe, a lower telescopic pipe that is movably inserted into the upper telescopic pipe to form a longitudinal shaft, a plurality of expandable legs at the bottom of the longitudinal shaft with a leaf spring mechanism, a round plate holder, a bottle holder, a v-shaped plate holder, a flower vase, umbrella stand, a box for magnetic compass or LED light, a knickknack pouch and a beverage holder. The longitudinal shaft of the portable stand is adjusted for a desired height. A controller knob is slid up and down, to fold and expand the expandable legs at the bottom of the longitudinal shaft to a desired angle. Various attachments are attached onto the longitudinal shaft depending on the need.

Owner:MEDDERS NEIL +1

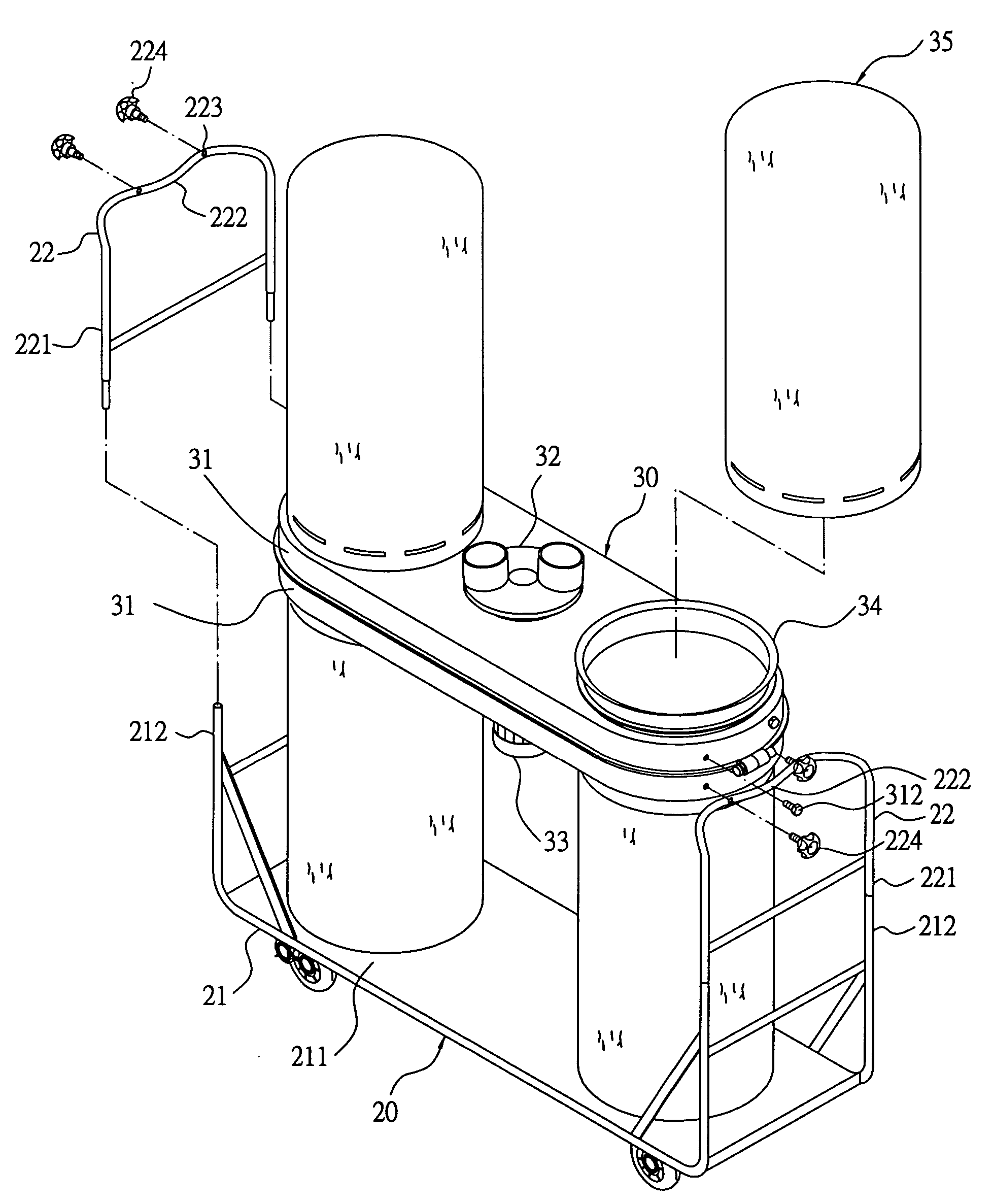

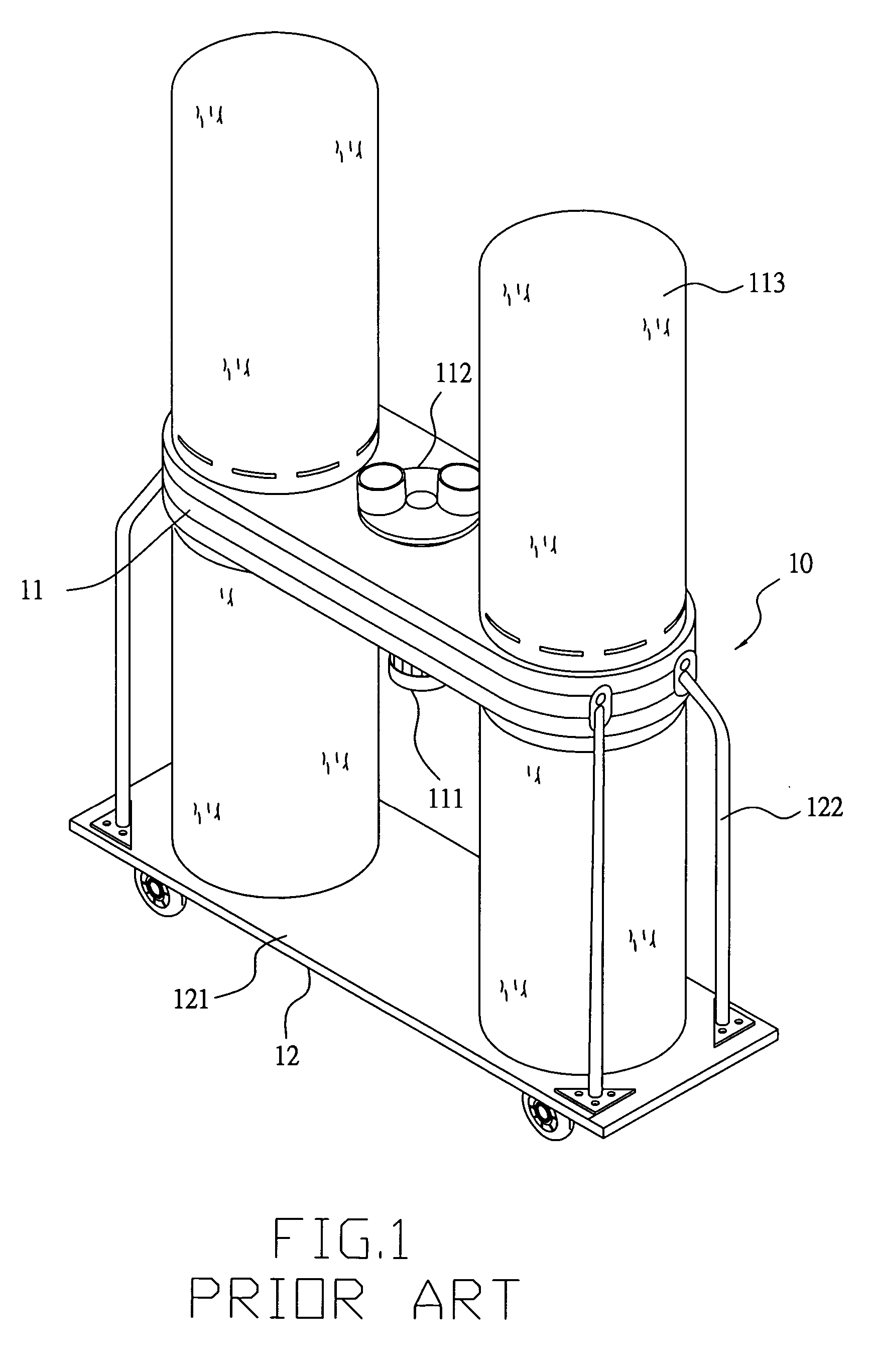

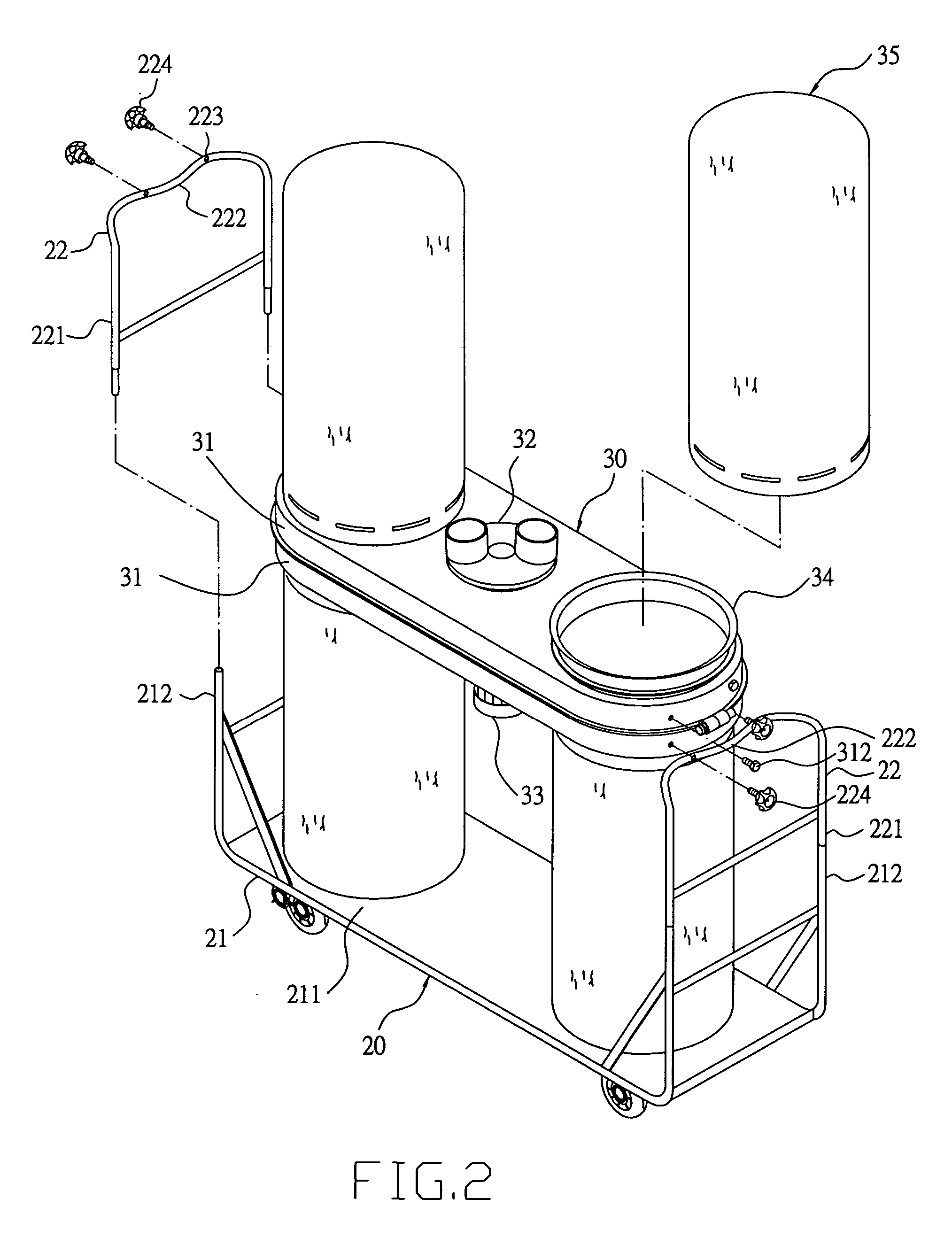

Dust collector with an invertible wind exhausting case

InactiveUS7217307B2Avoiding improper dust sucking effect of suckingEasiness and fastnessCombination devicesAuxillary pretreatmentEngineeringTruck

Owner:SAN FORD MACHINERY

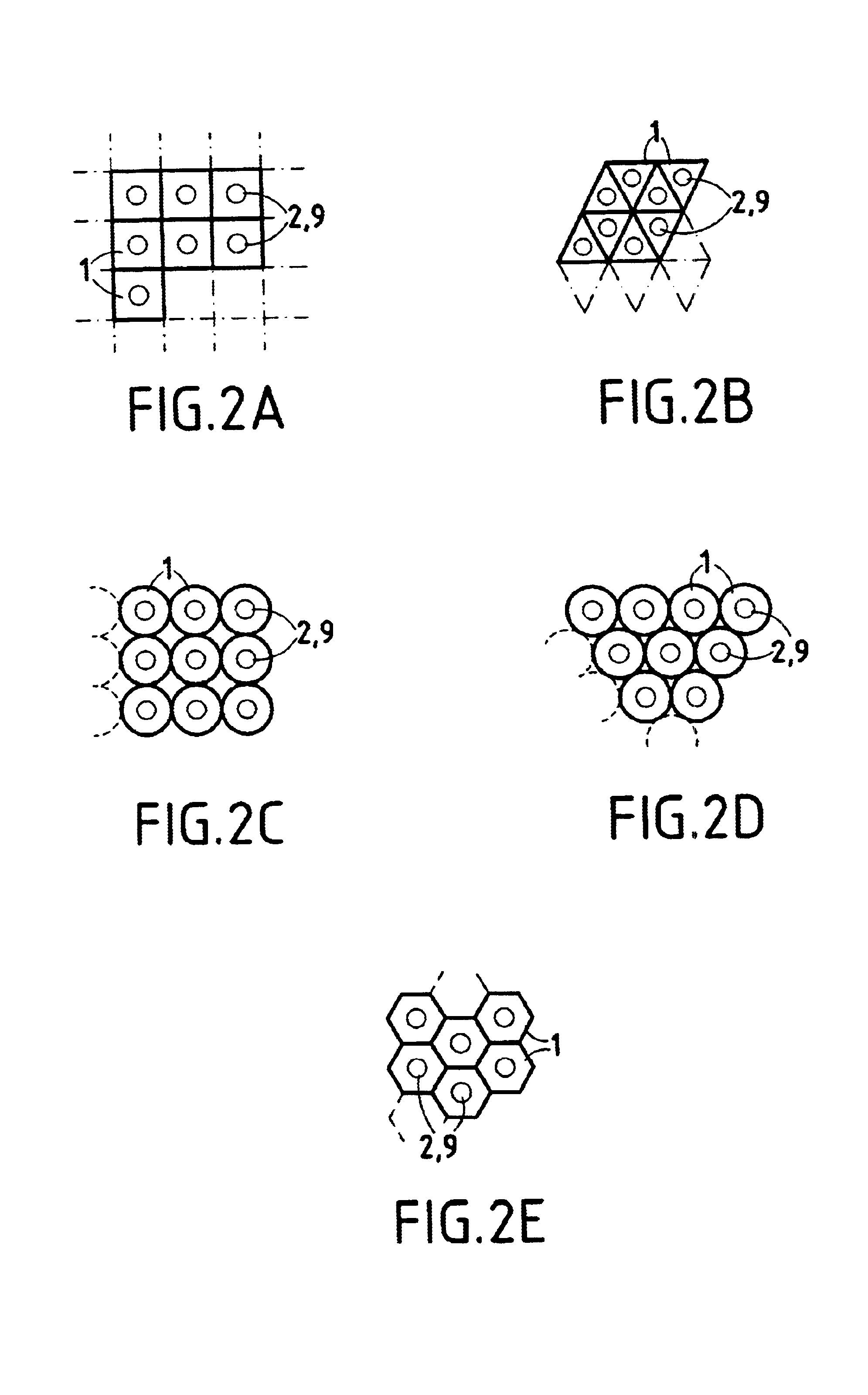

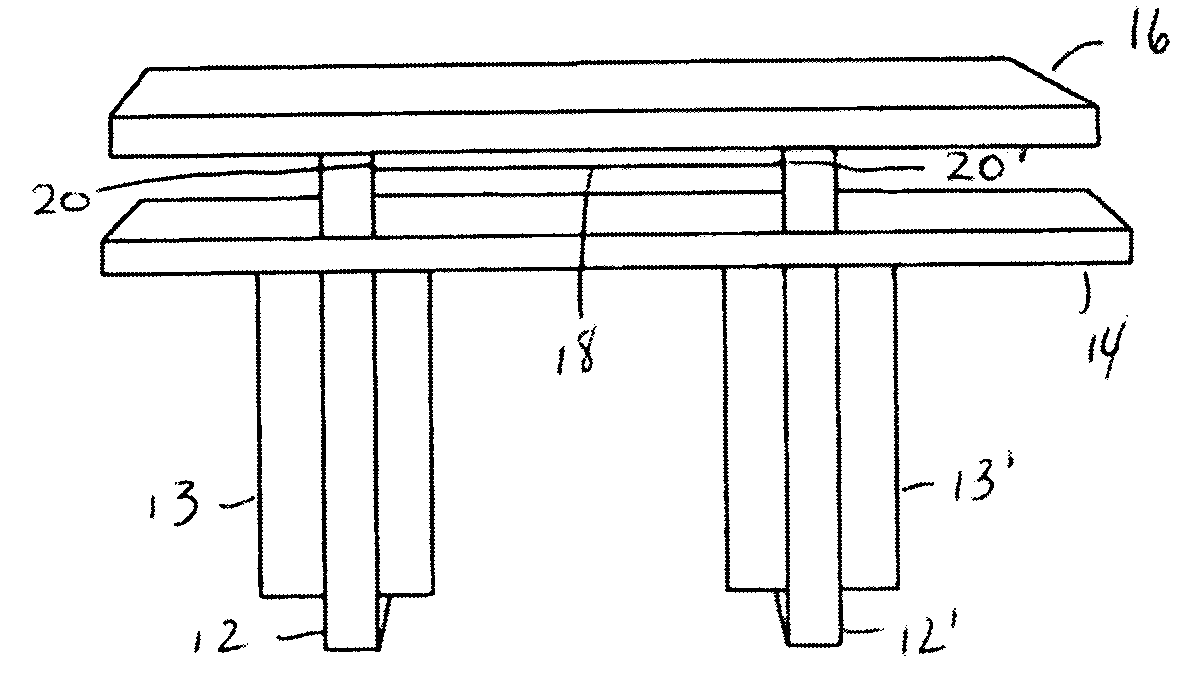

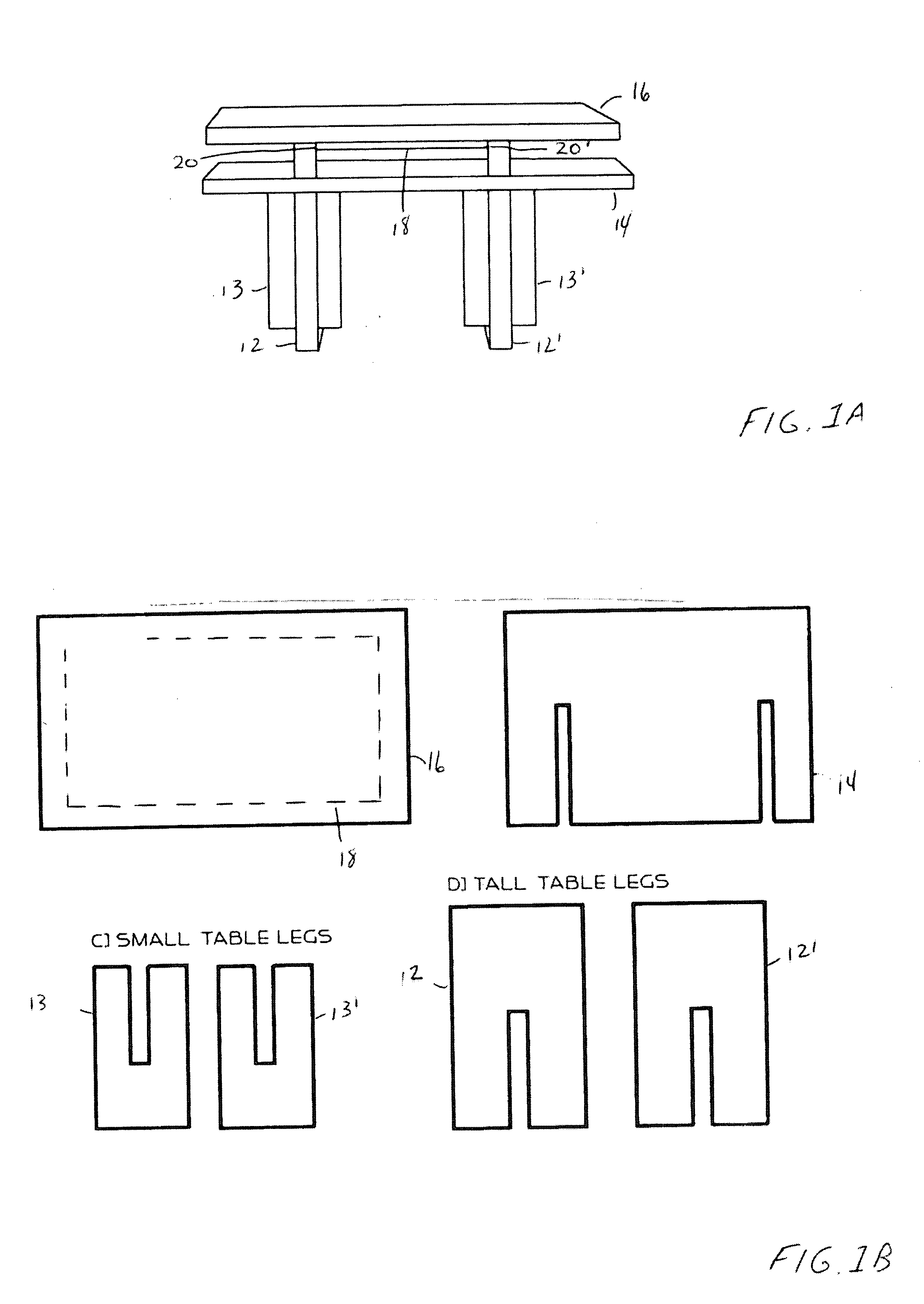

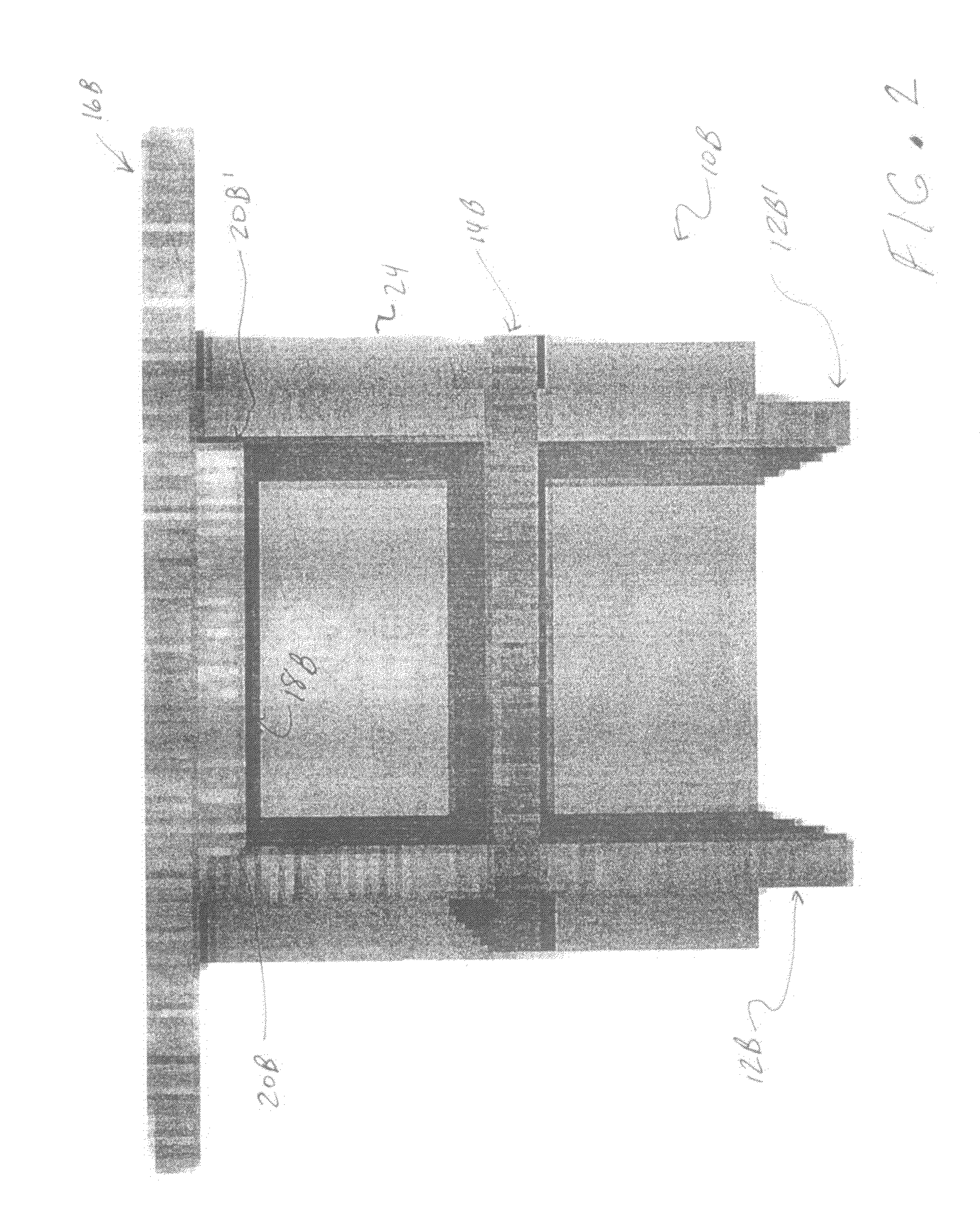

Furniture, home decor, and other items of manufacture formed of cellular material

InactiveUS20080237319A1Improve rigidityImprove structural strengthFurniture joining partsDismountable chairsManufactured formCardboard

Articles of furniture and home décor formed of a single panel of unfinished honeycomb cardboard cut in a compressed state along a first plane to have a predefined shape and expanded along a second plane; and fixing means for fixing the cut honeycomb cardboard in an expanded state. In preferred embodiments, the compressed honeycomb cardboard may be cut in the first plane to have the profile of a sofa, a chair, a table, a vase, or a tray, such that when the honeycomb cardboard is expanded it takes on a three-dimensional form thereof.

Owner:HENSEY CATHY +1

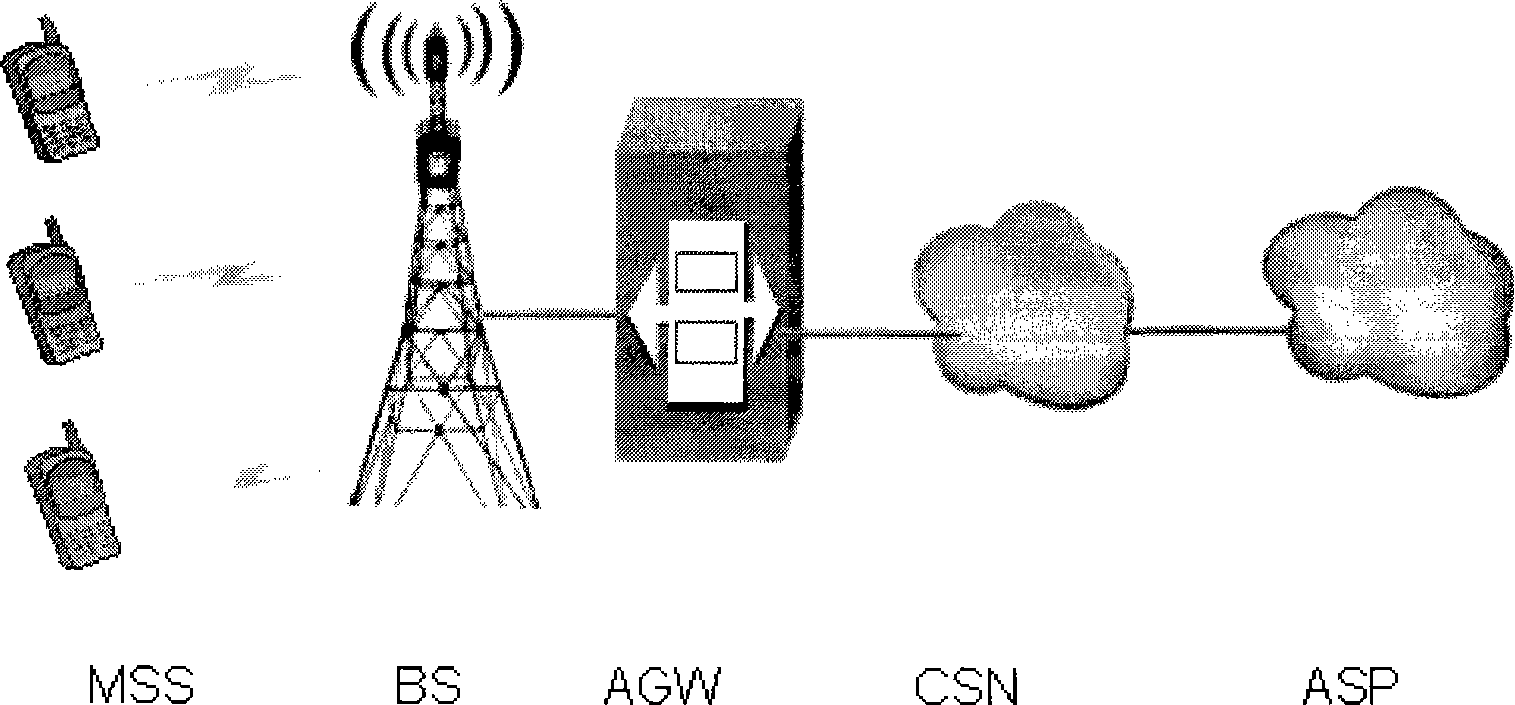

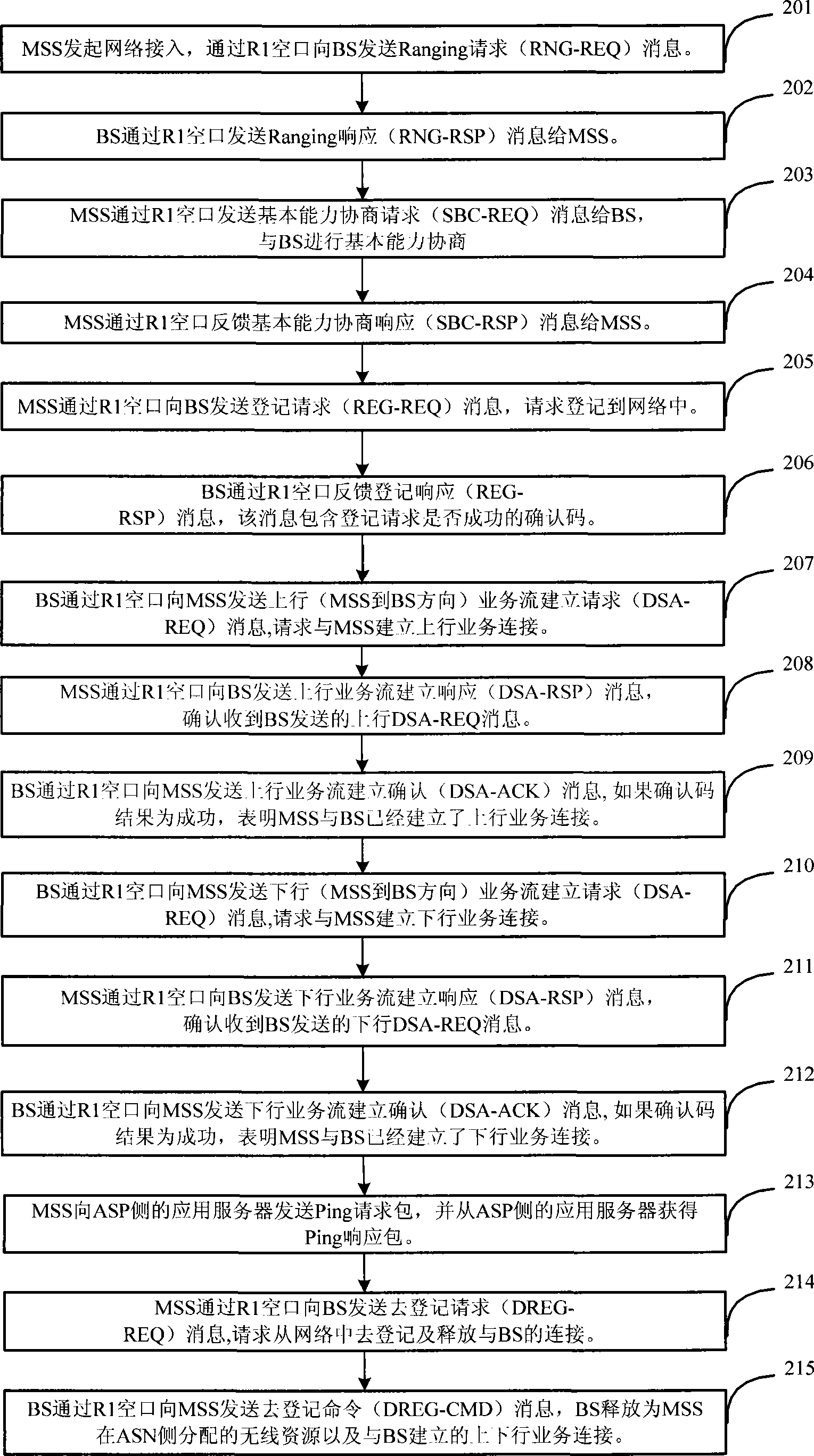

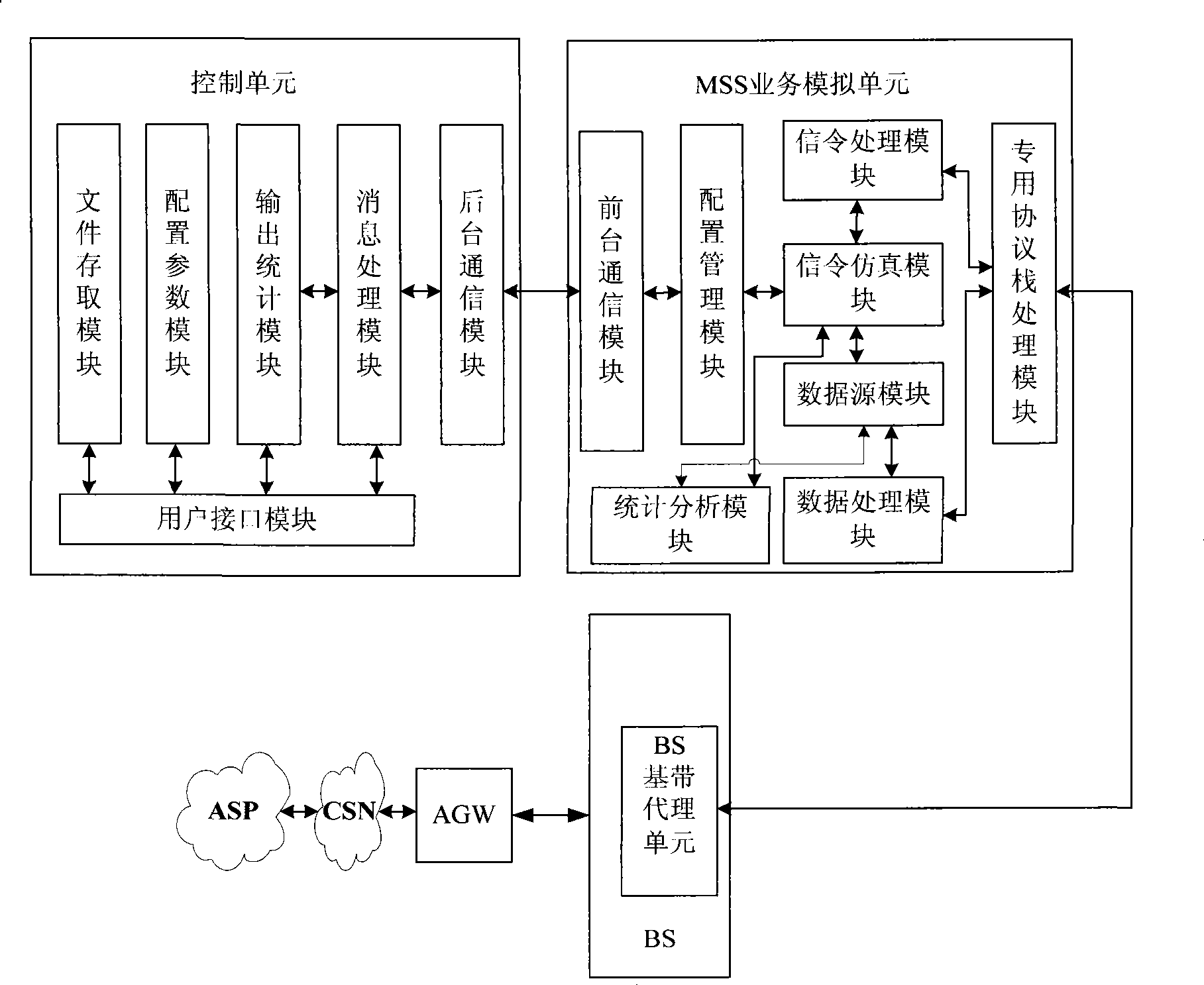

Large traffic simulation test system and method

InactiveCN101389107AReduce testing costsSatisfies many-to-one configurationSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsTest efficiencyTraffic simulation

The invention discloses a vase telephone call simulating test system, comprising a control unit, an MSS service simulating unit for customer mobile terminal, wherein the control unit is used for controlling and communicating with the MSS service simulating unit, and controlling message transmission to the MSS service simulating unit; moreover, the control unit further receives test result from the MSS service simulating unit, and outputs the test result; the MSS service simulating unit is used for receiving the control message, simulating communication between the real MSS and the tested base station BS, and receiving feedback test data. The MSS service simulating unit carries out statistic and analysis to the test data and obtains test result, and sends to the control unit. The invention further discloses a vase telephone call simulating test method. The inventive scheme substitutes expensive test devices, saves test cost, realizes satisfying call requirement in performance test of vase telephone call test by simple method, improves efficiency of test.

Owner:ZTE CORP

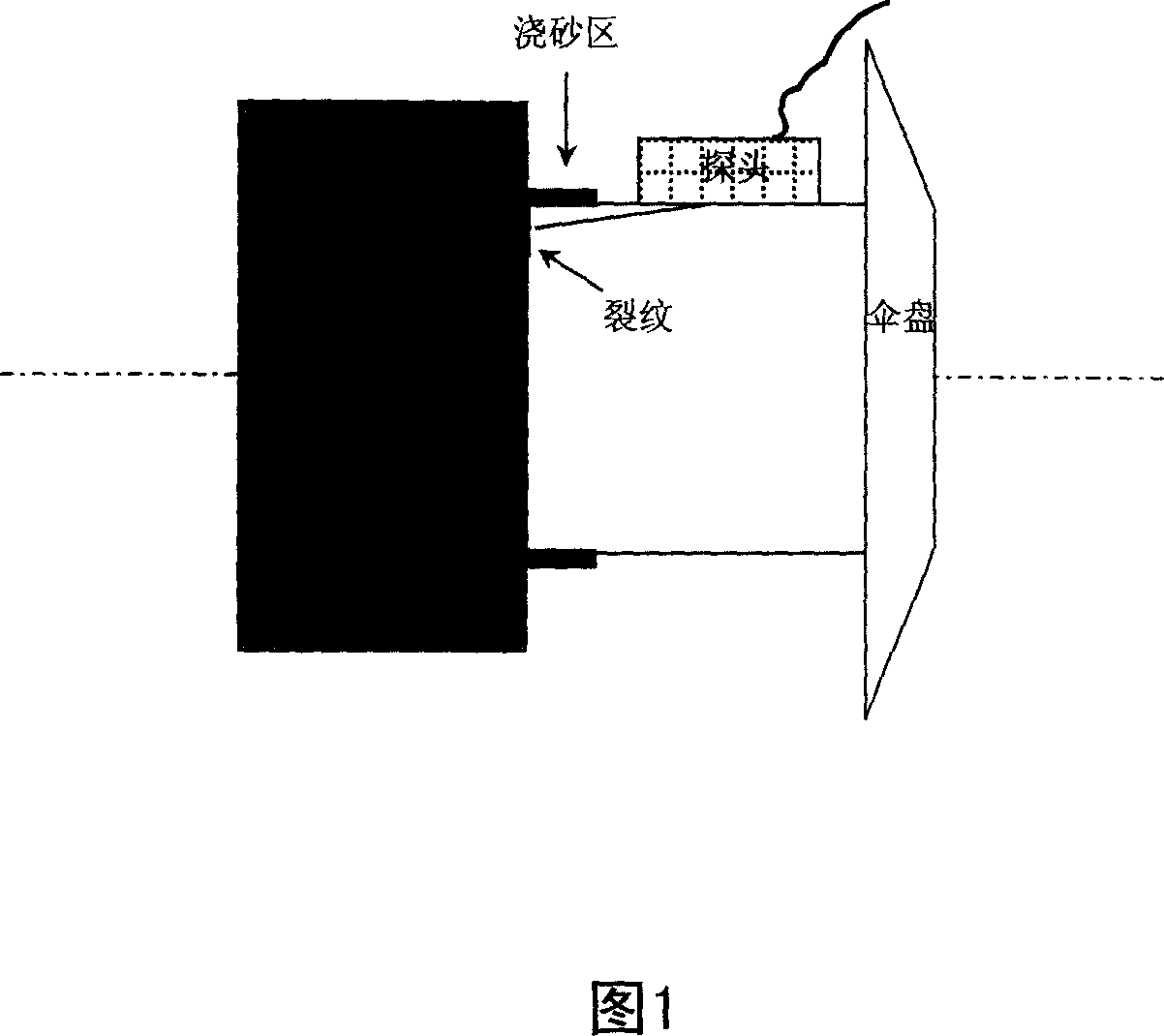

Supersonic crack detecting method of pillar porcelain insulator and probe thereof

ActiveCN1948962ASmall attenuationHigh reflection amplitudeAnalysing solids using sonic/ultrasonic/infrasonic wavesReflected wavesTransverse wave

The invention discloses brace porcelain insulator ultrasonic flaw detection method. It includes the following steps: emitting SH wave to detected surface; using transversal wave couplant for the probe and the detected surface; using the probe to check the detected surface; using porcelain insulator test piece to adjust probe reference sensitivity and checking sensitivity; detecting the reflection wave of the detected surface, recording the one which reaches defect setting value as defect signal; measuring the defect length; judging the work piece recorded with defect signal as waste. The invention also discloses the defect detecting probe of which emitted ultrasonic is SH type transverse wave. The method has high sensitivity, reliability, and large detecting range. Meanwhile the special probe has little size which can ensure detecting sensitivity and increase porcelain vase retrievable rate at the same time.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +2

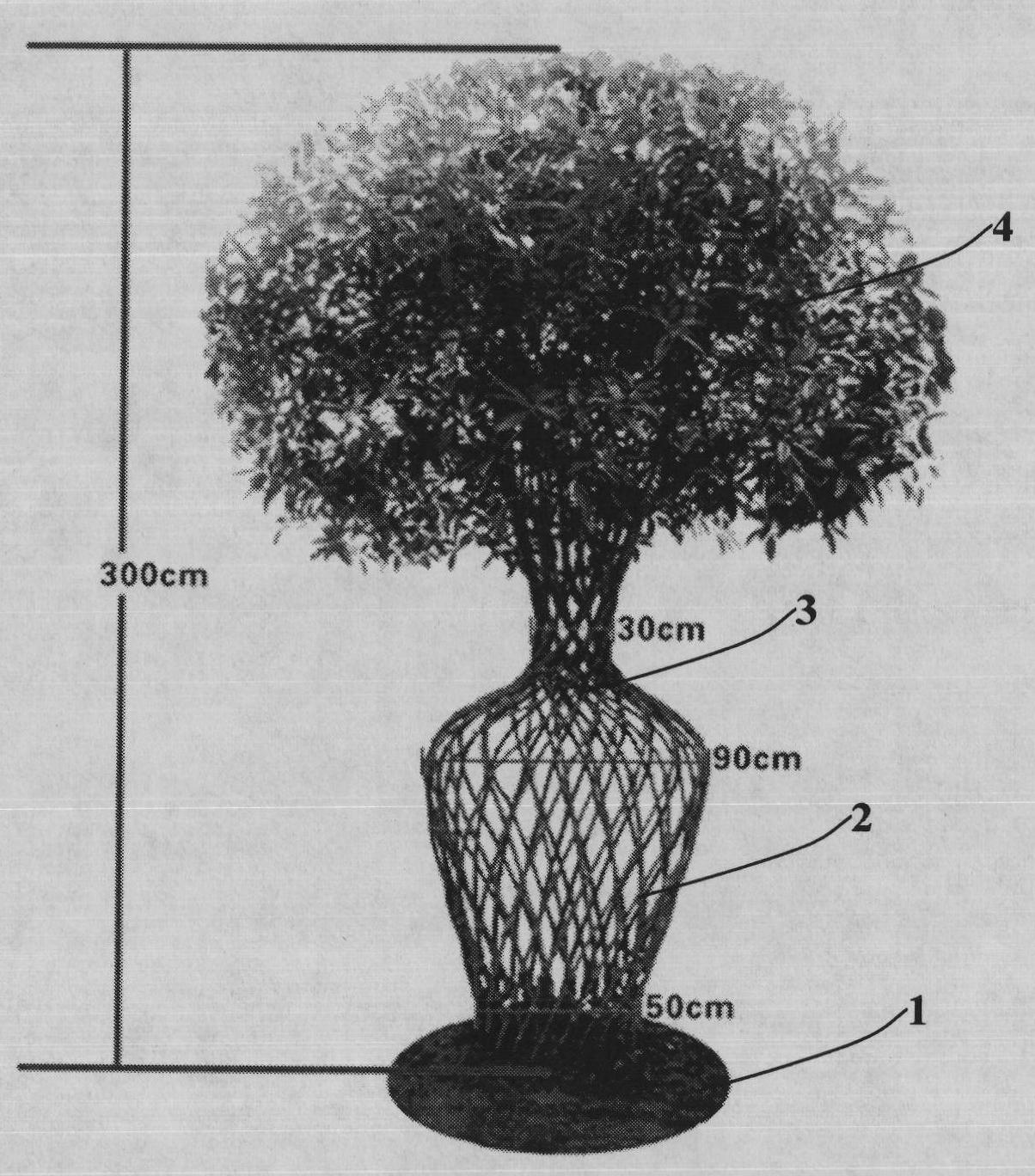

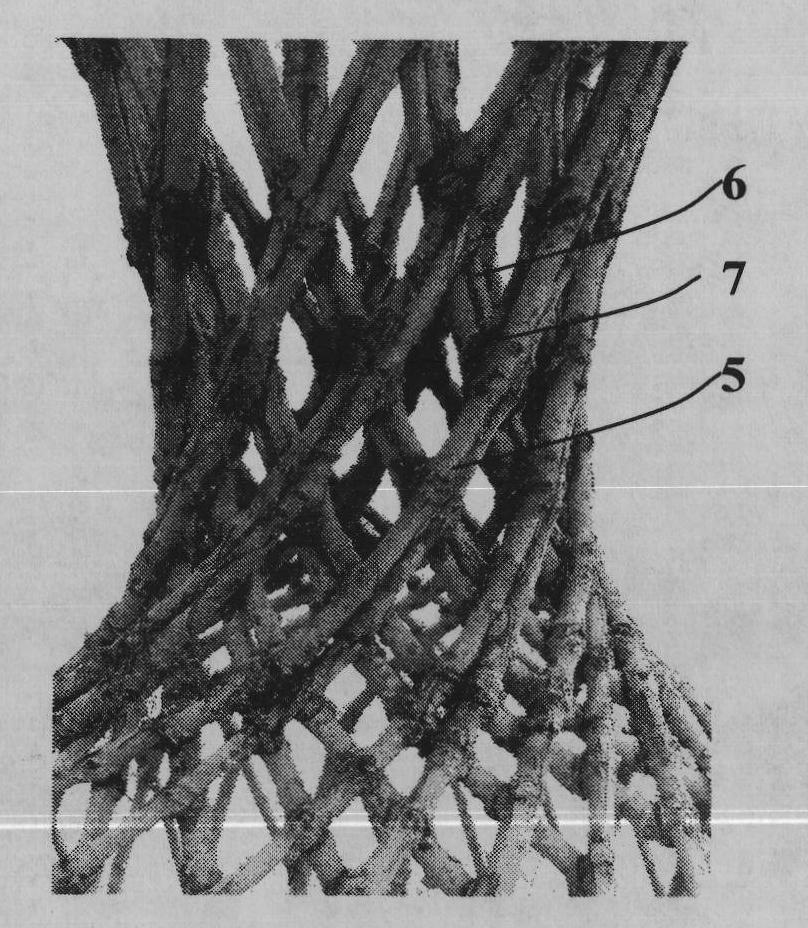

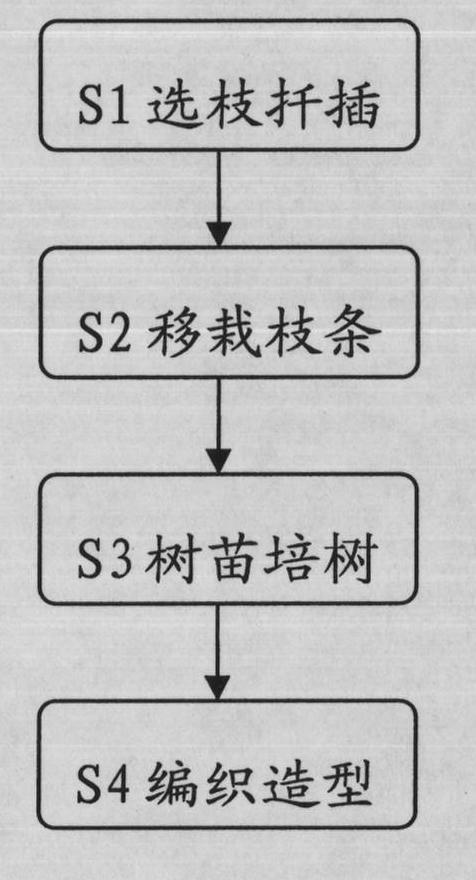

Production method of sweet osmanthus tree vase

The invention relates to a production method of a sweet osmanthus tree vase, comprising the following steps: S1, branch selection and cottage; S2, branches transplanting: selecting flourishing and strong sweet osmanthus tree seedlings, and then carrying out determination and planting on the seeldings; S3, seedling cultivation; S4, knitting and modeling: selecting seedlings with the same height and size from the cultured sweet osmanthus tree seedlings, ensuring multiple strains of the sweet osmanthus tree seedlings to be distributed and arranged according to circumference with a certain number so as to form a cluster of the sweet osmanthus trees, managing and cultivating the cluster of the sweet osmanthus trees to let the sweet osmanthus tree seedlings grow and survive; and after the sweet osmanthus tree grows and survives, knitting and modeling the setting mould of the sweet osmanthus tree to enable the branches of a plurality of the sweet osmanthus tree seedlings to be curved and enveloped into a vase structure, and carrying out manual treatment on the trunk crossing section of the sweet osmanthus tree to ensure the natural growth and coalescence of the trunks so as to be connected together. The invention has the beneficial effects of enabling the joint of the sweet osmanthus tree to naturally heal and grow into a whole, thus the sweet osmanthus tree vase formed in the way is firmer.

Owner:成都孙氏桂花园艺有限公司

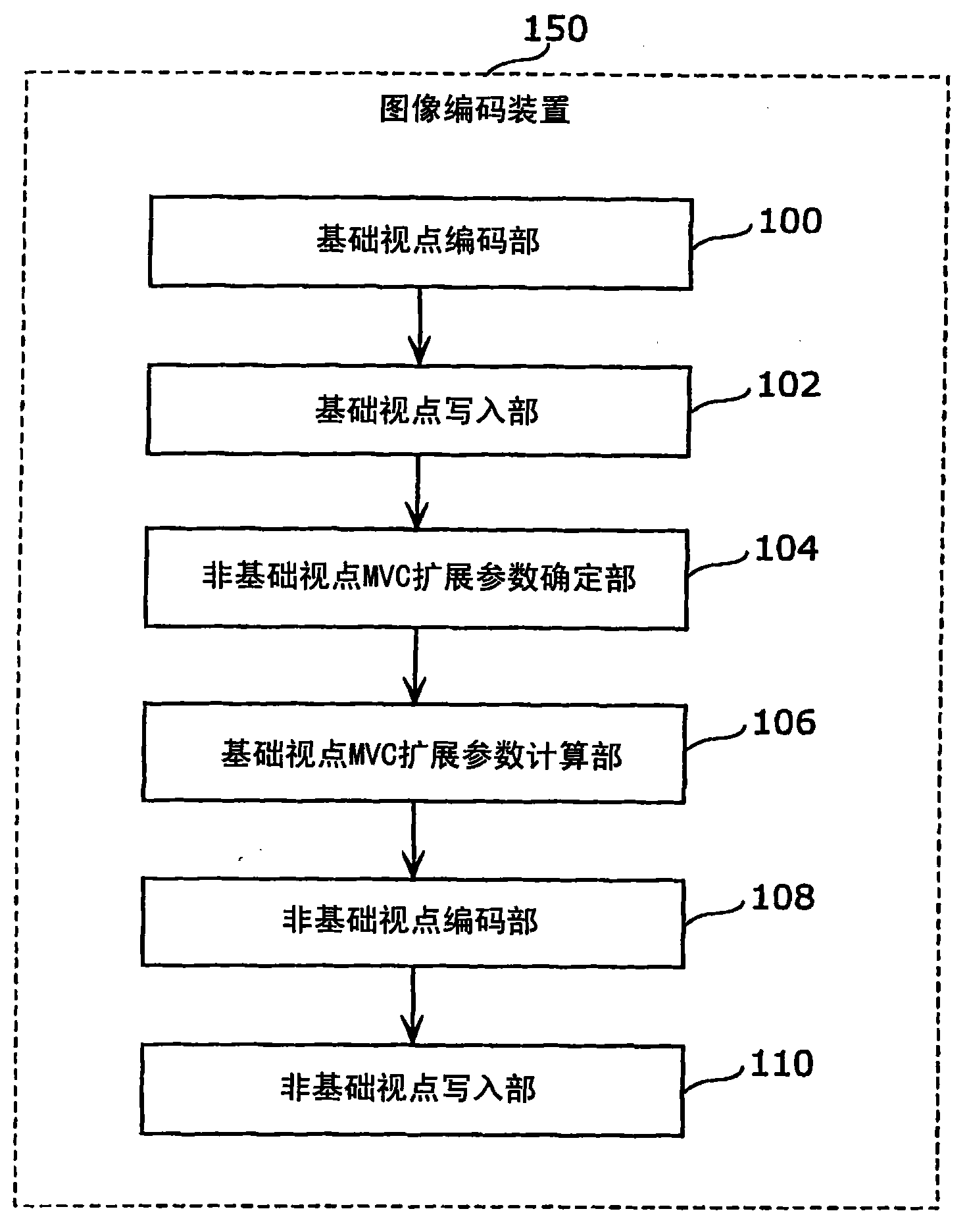

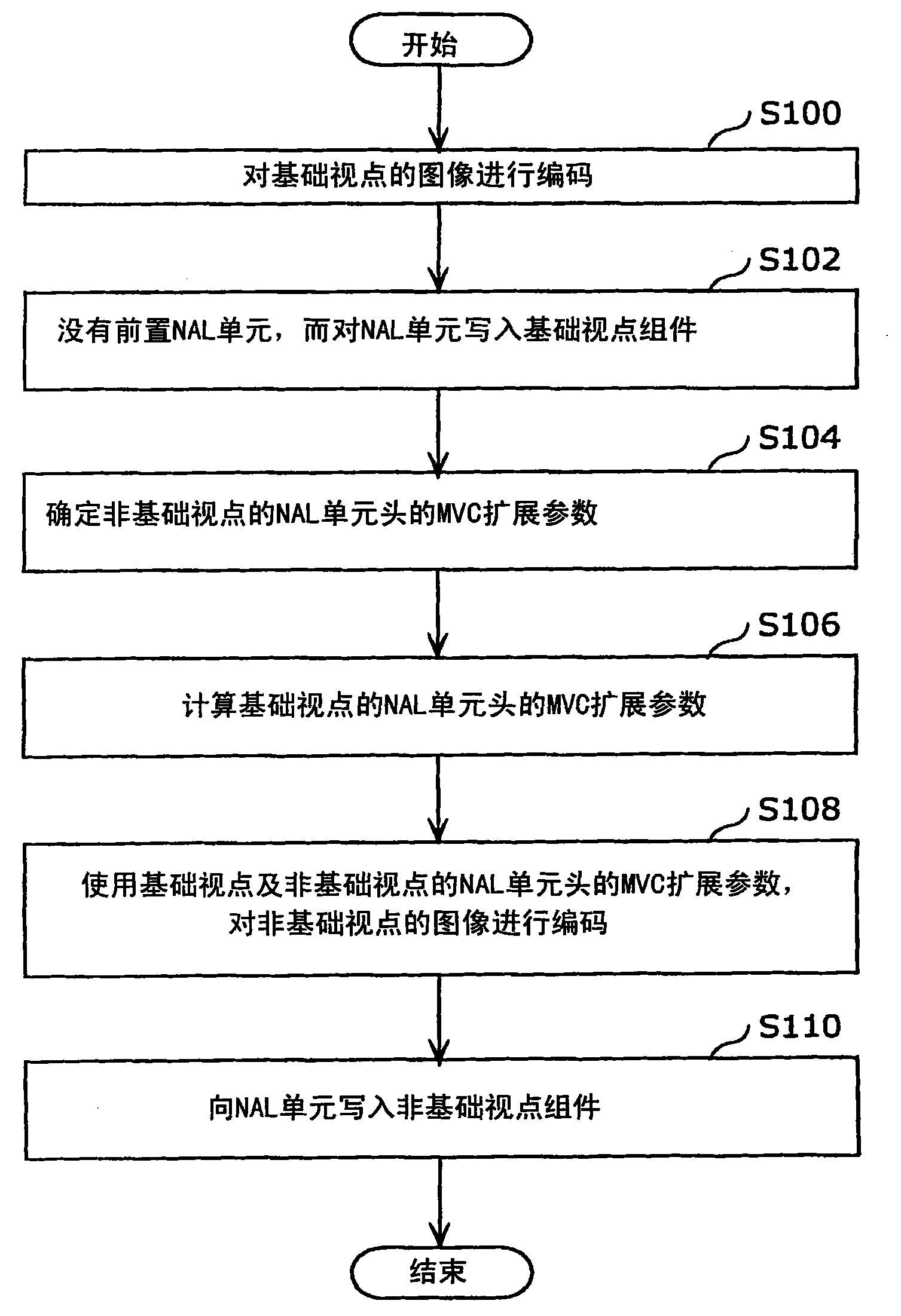

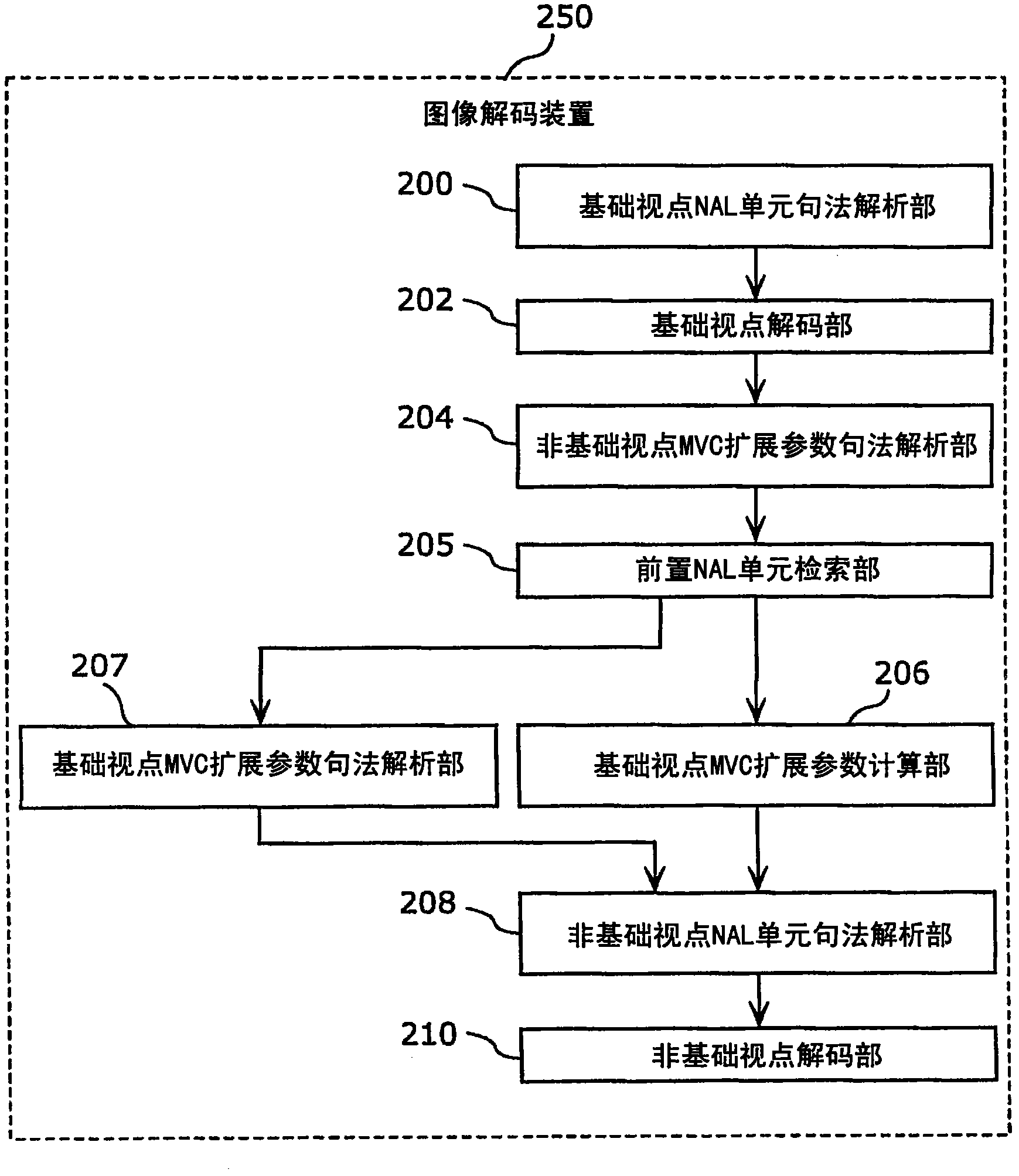

Image decoding method, image coding method, image decoding device, and image coding device

ActiveCN101981936AEasy to addTelevision systemsDigital video signal modificationDecoding methodsImage code

Disclosed is an image decoding method for decoding a multiview video even if any prefix NAL unit is not used. According to the image decoding method, an NAL unit of the base view is parsed (S200), the image of the base view is decoded (S202), the MVC extension parameter of a non-base view is parsed (S204), whether or not there is any prefix NAL unit of the base view is checked (S205), the MVC extension parameter of the vase view is calculated if there is no prefix NAL unit (S206), the MVC extension parameter of the base view is parsed if there is a prefix NAL unit (S207), the NAL unit of the non-base view is parsed (S208), and the image of the non-base view is decoded using the MVC extension parameter of the base view and MVC extension parameter of the non-base view (S210).

Owner:PANASONIC CORP

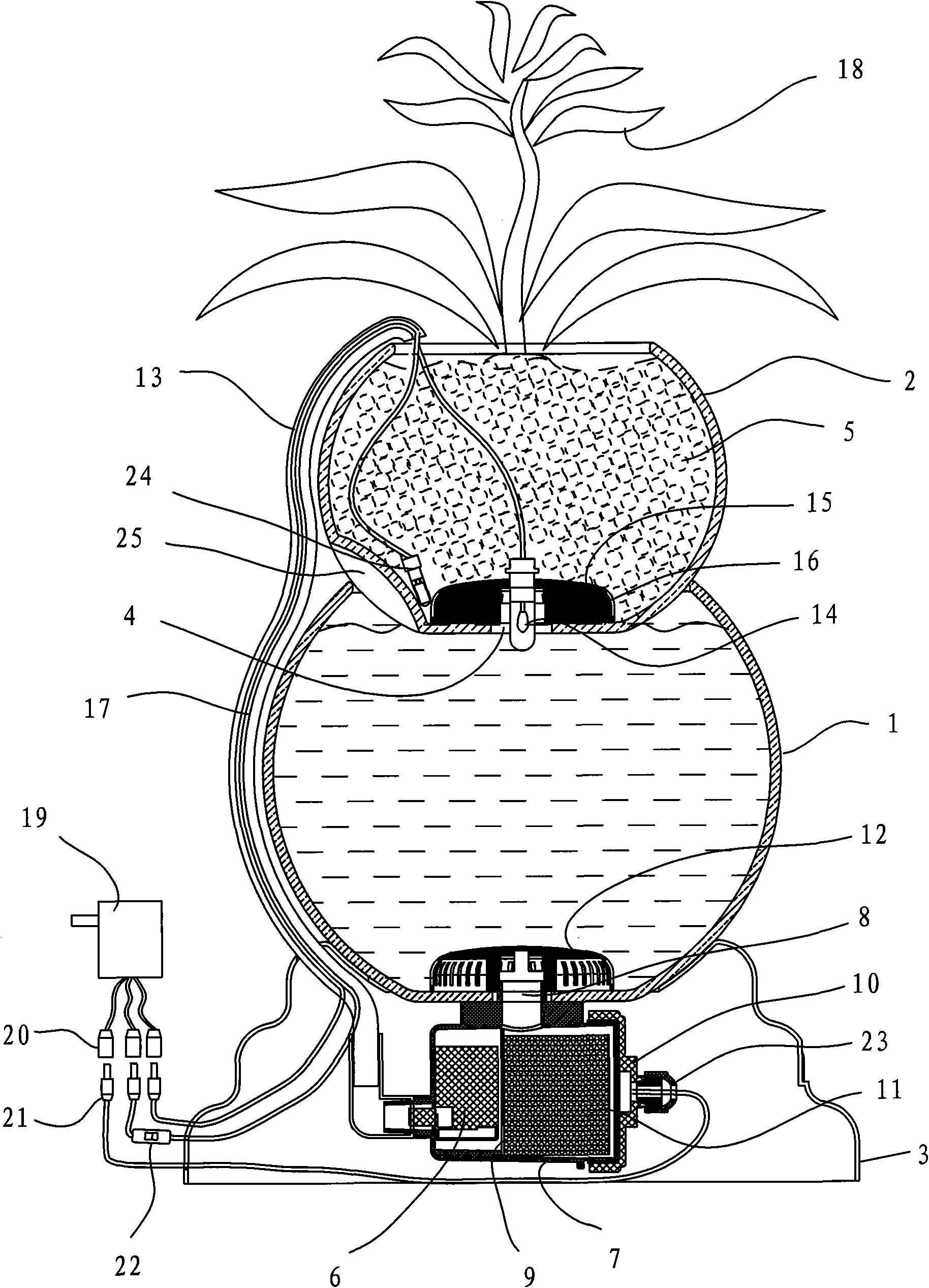

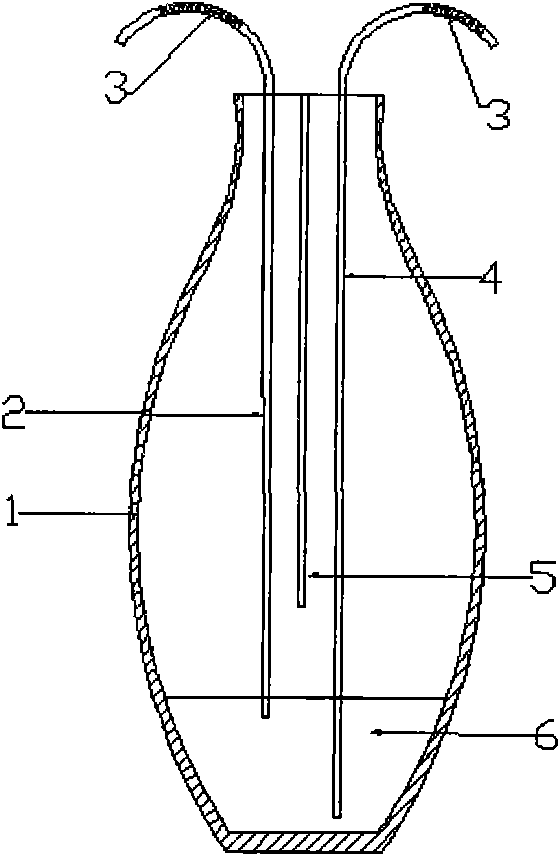

Vase fish tank

InactiveCN101558751AGood choice varietyStrong perceptionPisciculture and aquariaAgriculture gas emission reductionEngineeringCirculating pump

The invention discloses a vase fish tank which comprises a fish tank and a vase, wherein the vase is arranged above the fish tank, the bottom of the vase is provided with a through hole communicated with an inner cavity of the fish tank, the inner part of the vase is provided with ice soilless nutrient body, the fish tank is arranged on a fish tank base internally provided with a circulating water pump, the bottom of the fish tank is provided with a water outlet communicated with the inner cavity of the fish tank and the circulating pump, and an outlet pipe of the circulating pump extends outside an opening of the vase from the outside of the vase. The vase and the fish tank can be placed in an overlapping way, i.e. plant landscape is arranged in the vase and water landscape is arranged in the fish tank, therefore, the vase fish tank can be used for planting various plants including land plant so as to have good selection variety; solid material produced by the water plant can be used as nutrient source of the plant, so the vase fish tank is easy to build and maintain natural balance, and has strong ornamentation effect because of strong integral sight and special model.

Owner:GUANGDONG ZHENHUA ELECTRICAL APPLIANCE CO LTD

Production technology for rattan-woven wood bottom vase

InactiveCN105904552AImprove corrosion resistanceImprove antioxidant capacityWood treatment detailsCane mechanical workingUltravioletOxidation resistant

The invention provides a production technology for a rattan-woven wood bottom vase. The production technology comprises the following steps that fresh willows are selected and processed into a circular or rectangular wood board, and then the wood board is immersed for 1-2 h through preservative liquid; freshly-cut rattan is naturally aired and dried, the interior of a pressure tank is pressurized through mixed gas of nitrogen and carbon dioxide, and the interior of the pressure tank continues to be pressurized to 0.15 MPa-0.2 MPa through hot steam; the processed wood board and the processed rattan are input into a drier to be dried, and the rattan is utilized for being woven on the wood board to form the vase; distilled water is sprayed to the vase for wetting, and drying is conducted again through the drier. According to the production technology, the corrosion resistance and oxidation resistance of the vase are greatly improved, planting soil can be placed in the vase and used for planting flowers, and the vase cannot be decomposed by humus bacteria. The vase manufactured through the production technology is particularly suitable for being used near the equator, and the vase can bear long-time and continuous high-temperature scorching in the open and resist the high-intensity ultraviolet irradiation.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

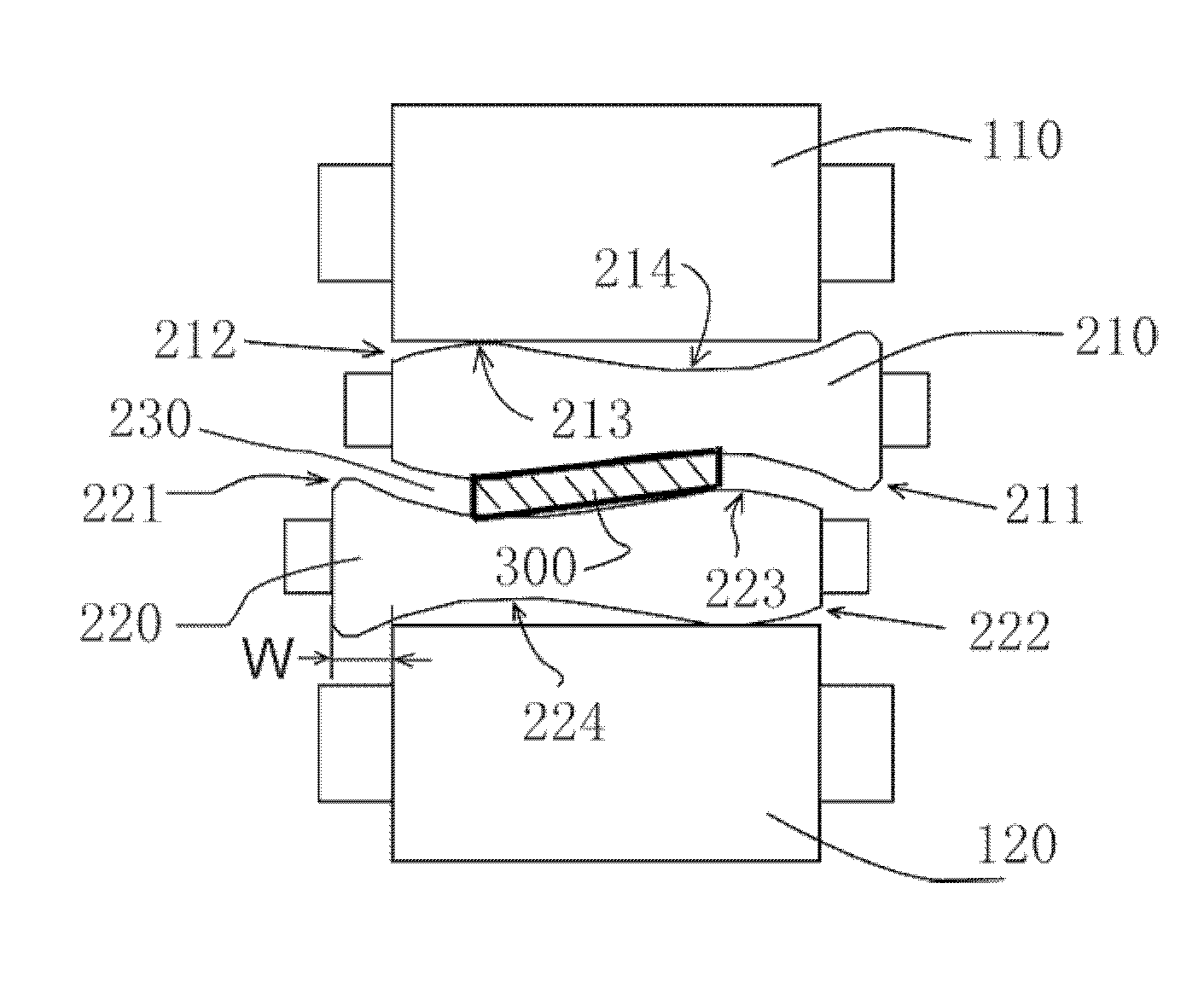

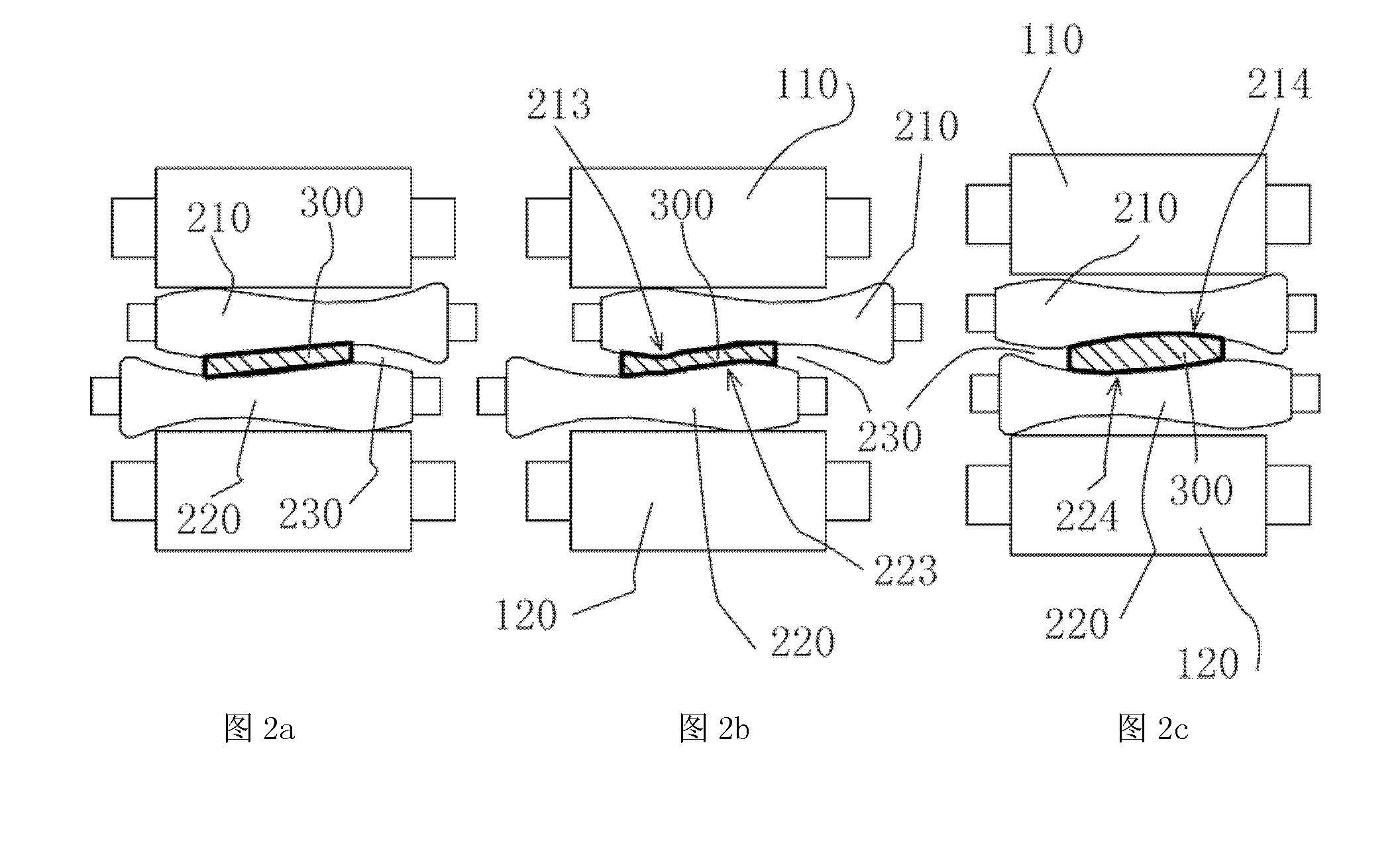

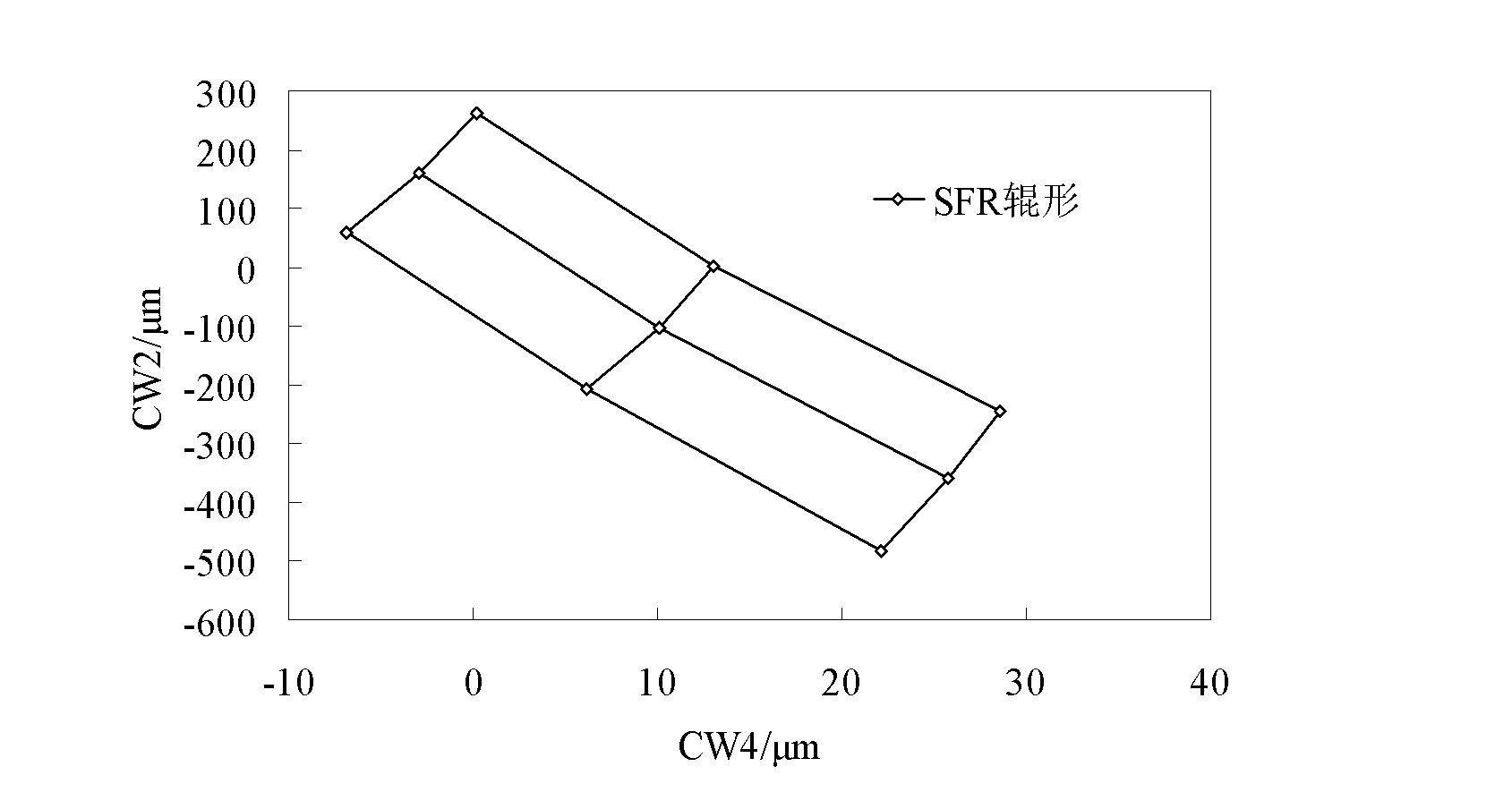

Edge wave control method aiming at high-strength steel and work rollers thereof

InactiveCN103203370AIncrease lateral stiffnessRealize edge wave control problemRollsMetal rolling arrangementsEngineeringContact line

The invention relates to an edge wave control method aiming at high-strength steel and work rollers thereof. The method comprises the steps of (a) machining and maintaining a continuously changed axisymmetric roll-shaped curved face at the circumferential face of each work roller, and (b) enabling the no-load roller seam between the upper and lower rollers to be continuously changed to negative convexity from zero convexity, and the length of the contact line between the upper and lower work rollers and an adjacent support roller to be reduced when the upper and lower rollers in antisymmetry arrangement are oppositely shifted along the axial direction, wherein the roller shapes of the work rollers are approximately axisymmetric vase-shaped, and the roller curves of the vase-shaped work rollers at least comprise a section of continuous waved curve consisting of a group of crests and troughs. According to the method and the work rollers thereof, both the no-load roller seam shape and the inter-roller contact line length are changed during the process that the upper and lower rollers are oppositely shifted along the axial direction, thus increasing the transverse rigidity of a rolling mill by roller shifting, achieving higher convexity control capacity and realizing the control over the edge wave during the panel-strip rolling.

Owner:BAOSHAN IRON & STEEL CO LTD +1

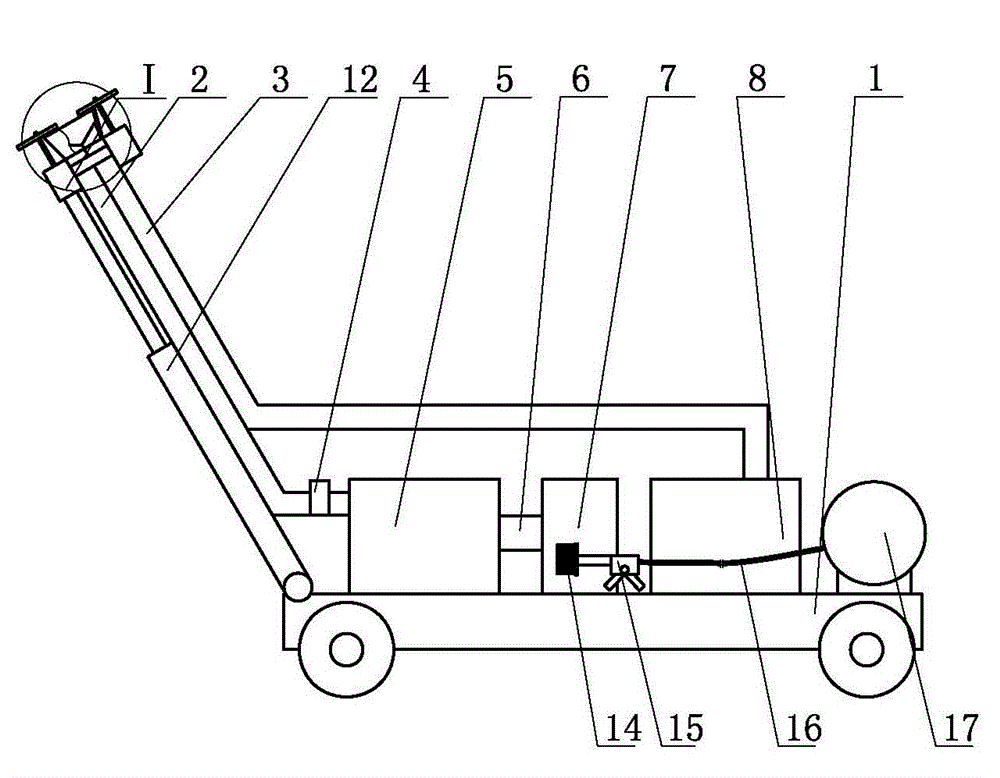

Special tool for electrically cleaning support vase

ActiveCN104148336AIce meltingMelting fastCleaning using toolsCleaning using gasesGas compressorAir compressor

A special tool for electrically cleaning a support vase comprises a trolley, wherein a telescopic rod is arranged on the trolley; an air compressor and a hot-air blower are arranged on the surface of the trolley; an air outlet of the air compressor is connected with an air guide pipe, and an air outlet of the hot-air blower is connected with a hot air pipe; clamps are arranged at the end parts of the hot air pipe and the air guide pipe; motors are arranged on the outsides of the clamps; the output shafts of the motors are connected with a rotary table provided with a brush; the rotary table is located on one side of the end part of the hot air pipe; the clamps are fixed at the end part of the telescopic rod. According to the special tool for electrically cleaning the support vase, the hot air pipe and the hot air guide pipe are added on the basis of original electric snow removal equipment, when a freezing phenomenon occurs to accumulated snow on the electric equipment, the hot-air blower brings hot air to the accumulated snow position, so that ice blocks in the accumulated snow area can be melted rapidly, and accordingly, the accumulated snow on the electric equipment is cleared rapidly.

Owner:STATE GRID CORP OF CHINA +1

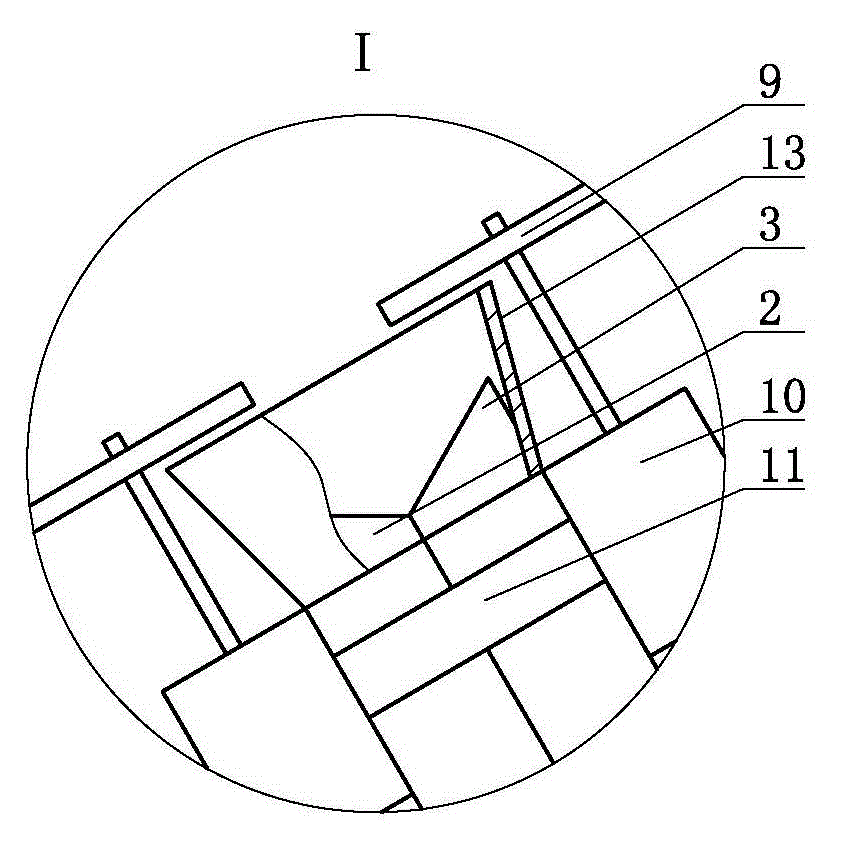

Method for preparing efficient air purification material

InactiveCN102580703AEasy to dissociate and disperseImprove adsorption capacityOther chemical processesAluminium silicatesDiseaseClay minerals

The invention discloses a method for preparing an efficient air purification material. Clay mineral fibers using silicon and magnesium as main components are used as a raw material, and the method comprises the following steps of: activating carbonates and oxides among dissolved fiber granules by adopting semi-dry acid so that fiber bundles are easily dissociated and dispersed by a mechanical force, and dredging structural micropores of mineral fiber crystal so that the specific surface area of the mineral is greatly enlarged; adding a surfactant to increase the adsorption capability of mineral powder on formaldehyde, ammonia and other volatile organic pollutant molecules; and granulating, forming pores, roasting at a low temperature to set the shape of the product, and thus obtaining the efficient indoor air purification material. The material is placed in hollow and porous indoor ornaments of different types such as vases, flowerpots, or textile packages and the like, so that the environment is beautified, the concentration of indoor pollutants such as formaldehyde, ammonia and other harmful gases can be reduced, and the aims of purifying the indoor air, preventing decoration diseases and improving the health level of residents are fulfilled.

Owner:张国强 +1

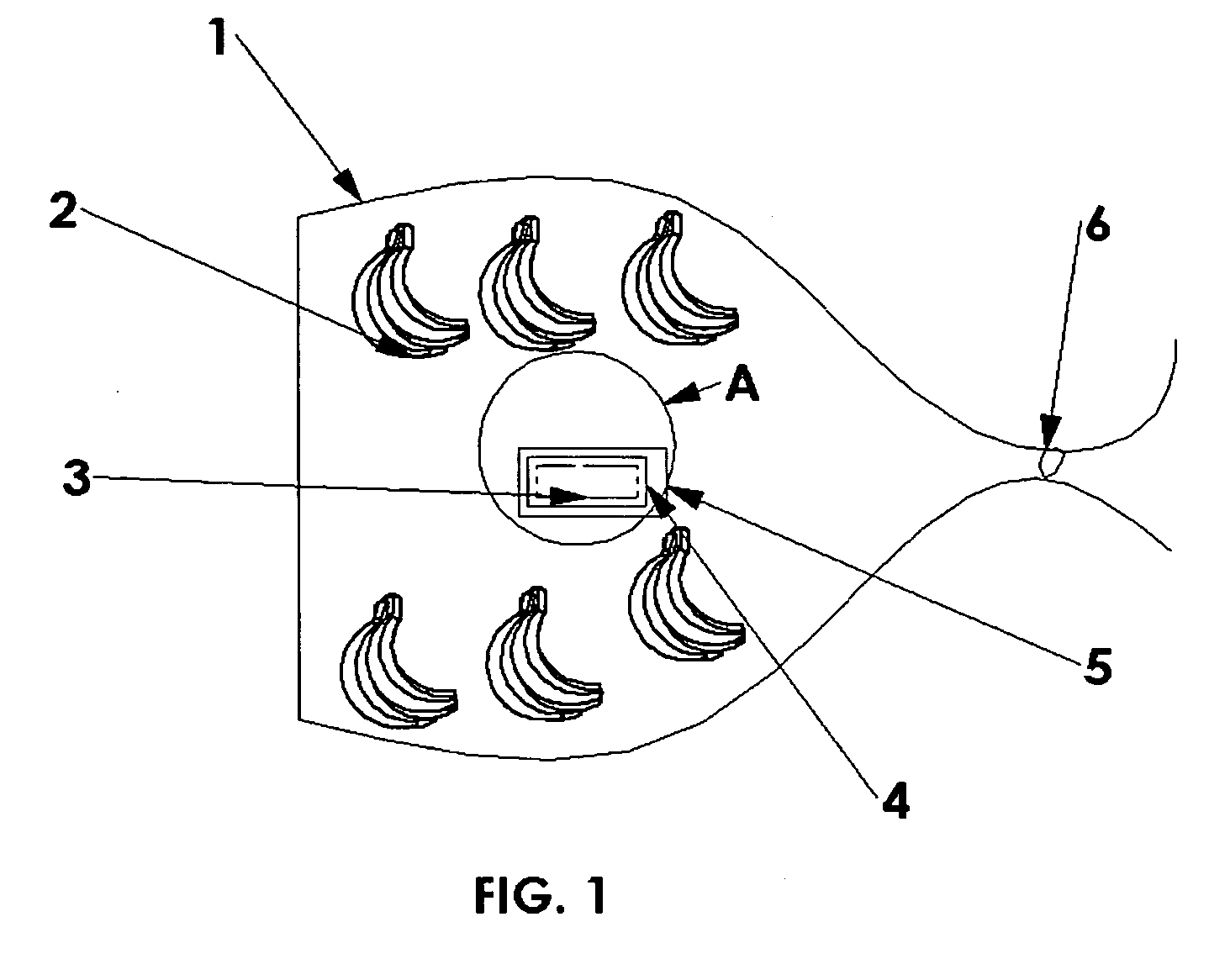

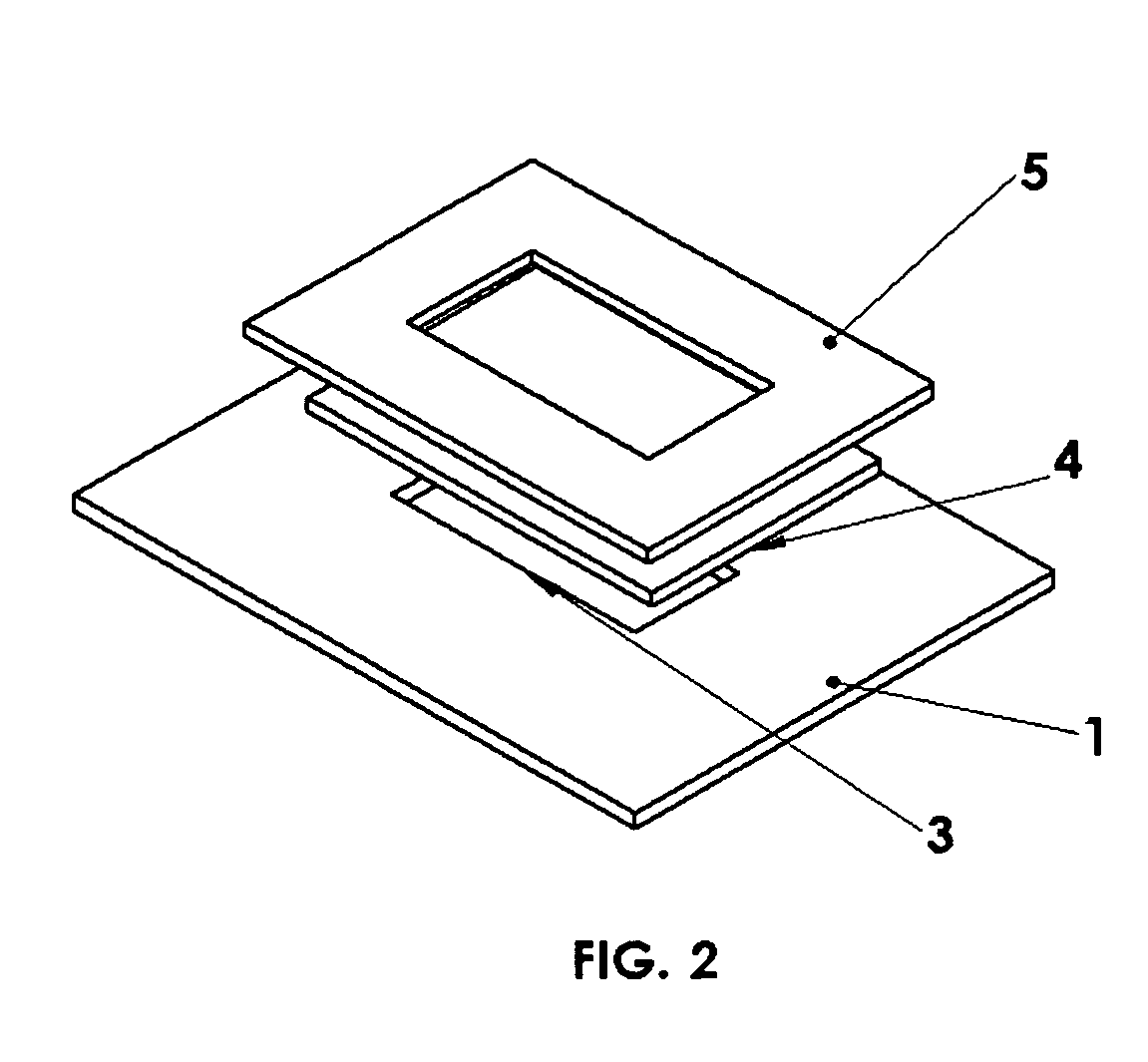

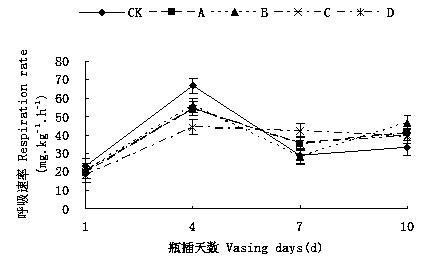

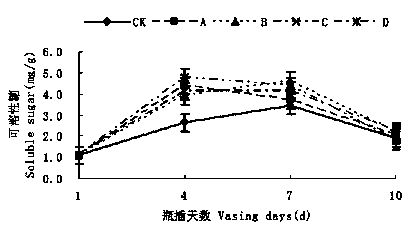

Gas permeable non-woven fabric based film for extending the shelf life of fresh fruits & vegetables and vase life of fresh cut flowers

ActiveUS20090239432A1Extends its shelf/vase lifeHigh permeable polymerSynthetic resin layered productsBagsEngineeringMetabolic heat

Packaging using Gas Permeable Non-Woven Fabric based Film extends the shelf life of various fresh fruits and vegetables and vase life of fresh cut flowers by changing the atmosphere in which these living products are stored and respires. The high oxygen and carbon dioxide permeability of the Gas Permeable Non-Woven Fabric based Film establishes an ideal atmosphere for the specific perishable item, and therefore extends its shelf life. The establishment of lower oxygen and carbon dioxide atmospheres inside packages using Gas Permeable Non-Woven Fabric based film, also leads to reduction in the respiration rate of the perishable items. The reduction in the respiration rate prevents loss of moisture, production of metabolic heat, and yellowing, browning, reduction in production levels of ethylene. Thus the created atmosphere is able to extend shelf life, maintain high quality and preserve nutrients of fresh produce items by naturally regulating respiration of said produce / flower.

Owner:CHANDRA SHUBHAM

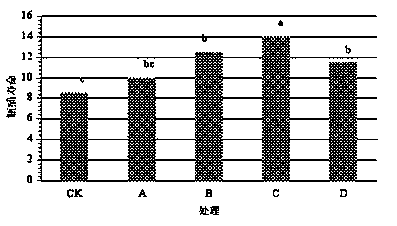

Cut flower preservative and application thereof

The invention discloses a cut flower preservative, which contains the following components: sucrose with the final concentration between 30 and 50 g / L, 6-benzylamino adenine with the final concentration between 8 and 12 mg / L, and Triton with the final concentration between 2 and 6 mL / L, wherein pH is between 5.5 and 6.0. The cut flower preservative has the advantages of maintaining the quality of cut peach flowers, preventing the propagation of microorganisms, prolonging the vase lifespan of the peach flowers by about 1 to 4 days, improving the ornamental quality of the peach flowers and ensuring that petals are plumper and bright in color.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

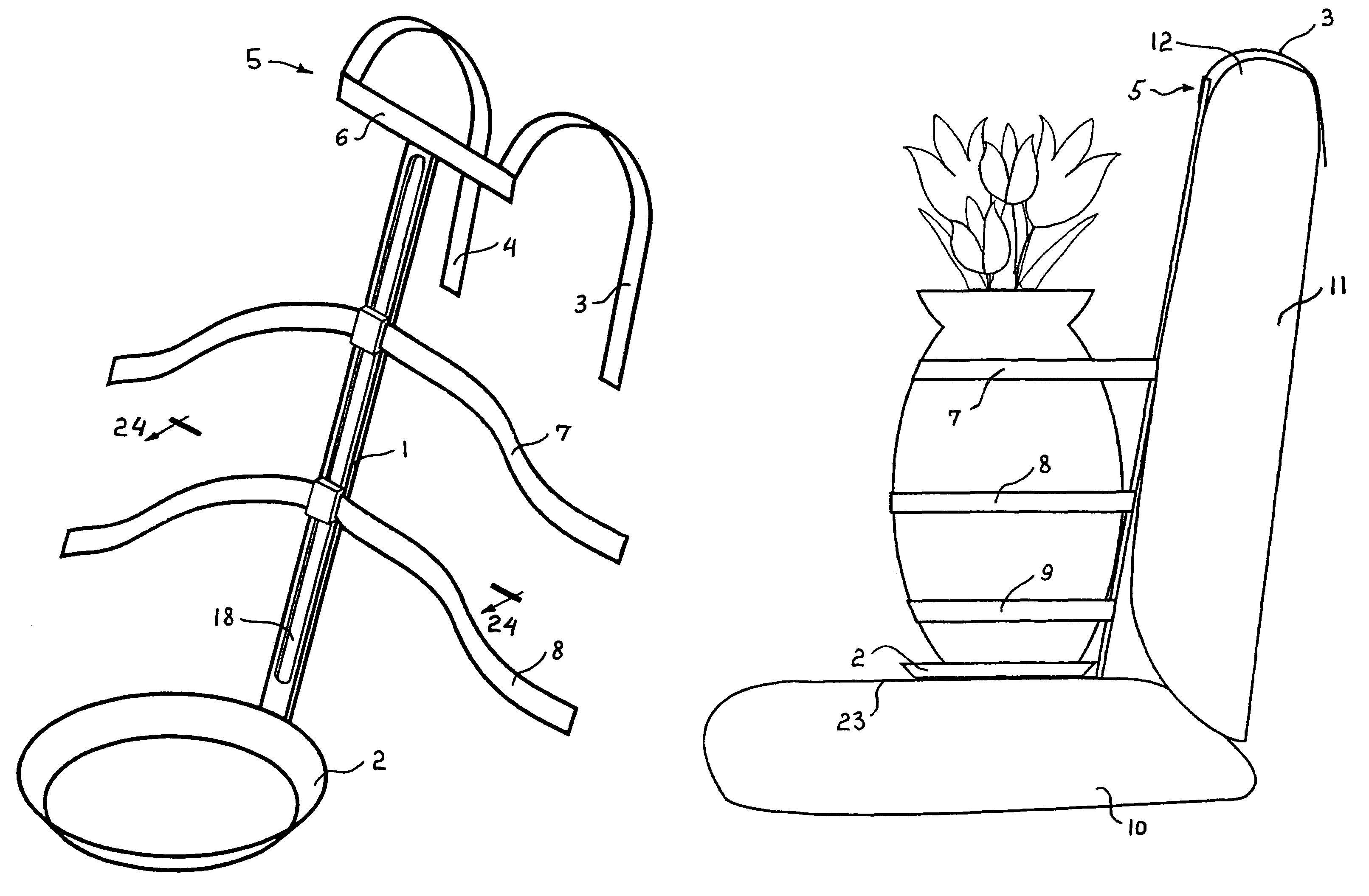

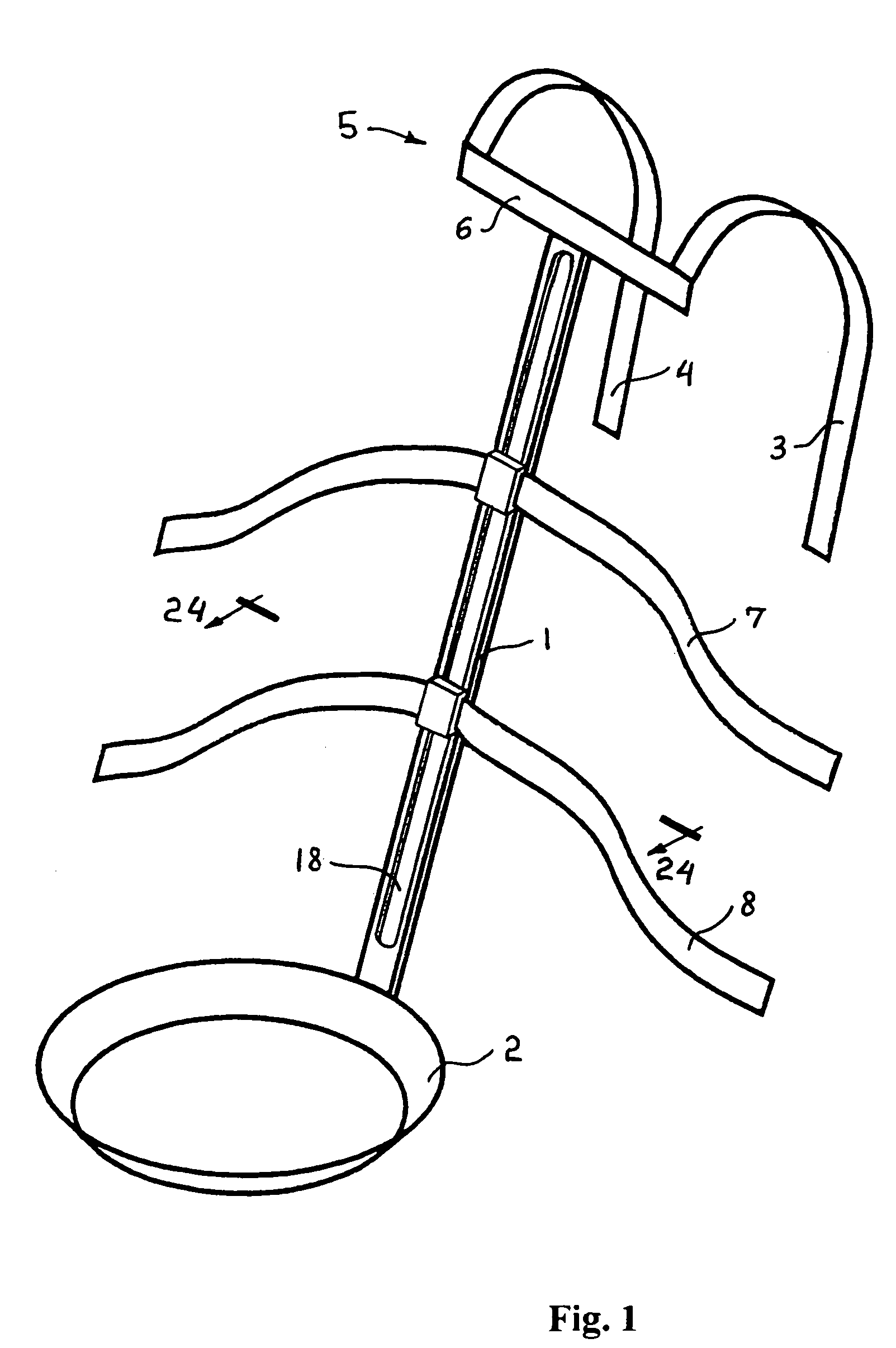

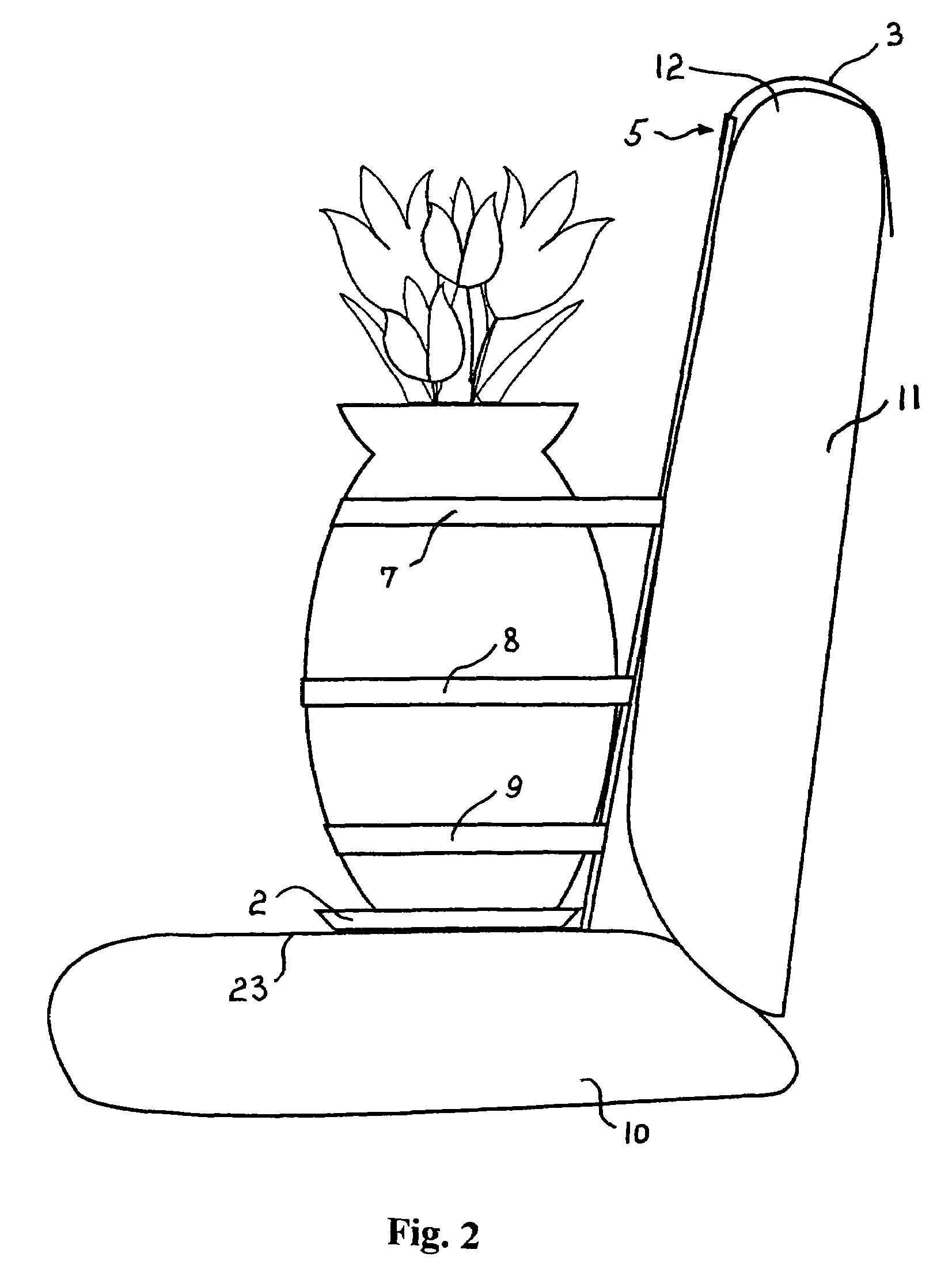

Floral container holder for vehicle

The improved floral container holder for vehicle is intended to provide the secure delivery of floral container, for example, such as vase with the flower, in upright position. The improved flower container holder comprises a lower portion connected to a main portion, which is by an upper connector coupled with the upper portion including the first and second supporting hooks appropriately coupled with the main portion. Also, the improved floral container holder comprises at least one of a plurality of supporting straps, each of which is by an appropriate strap connector coupled with the main portion.

Owner:STEPANOVA IRINA

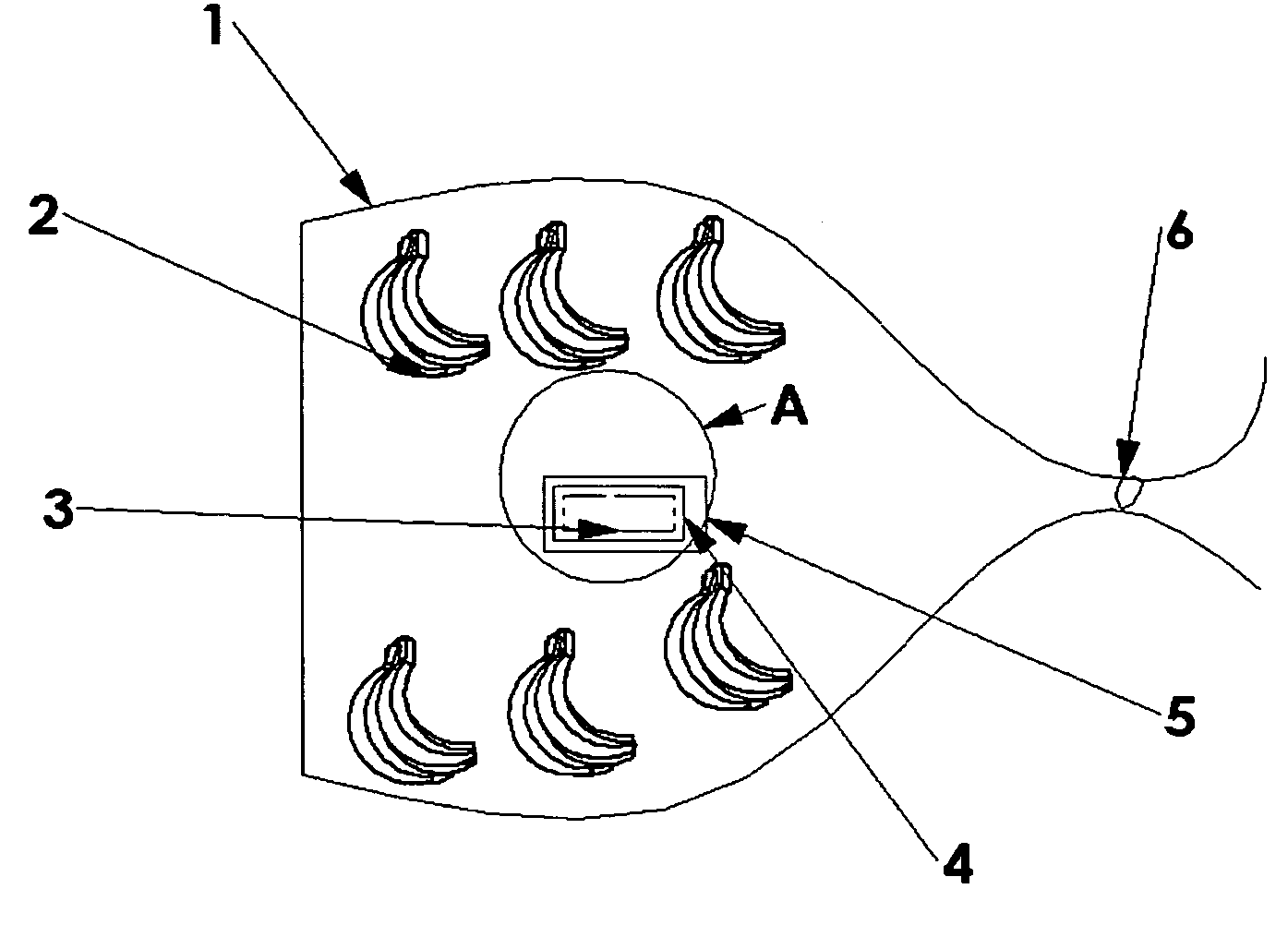

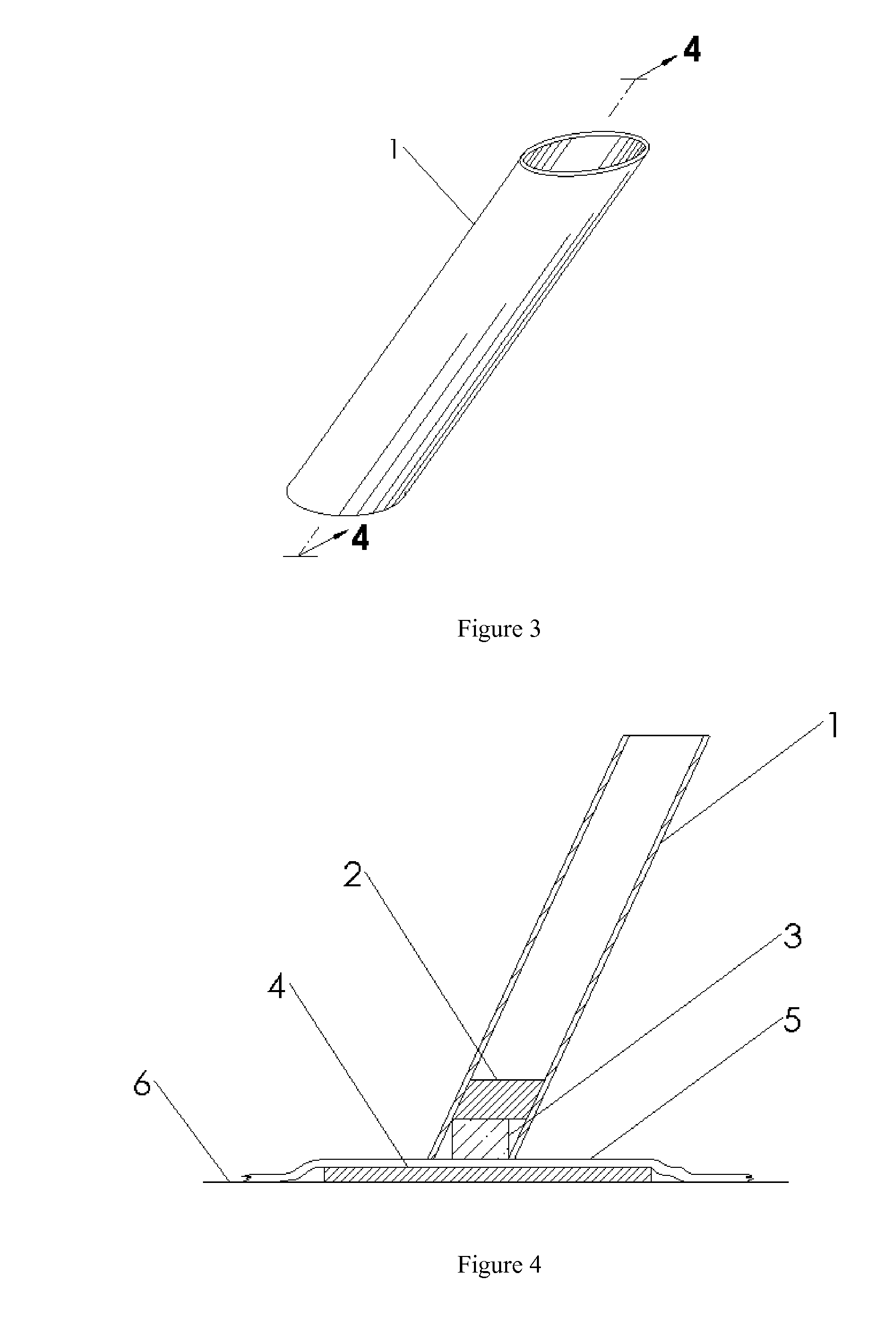

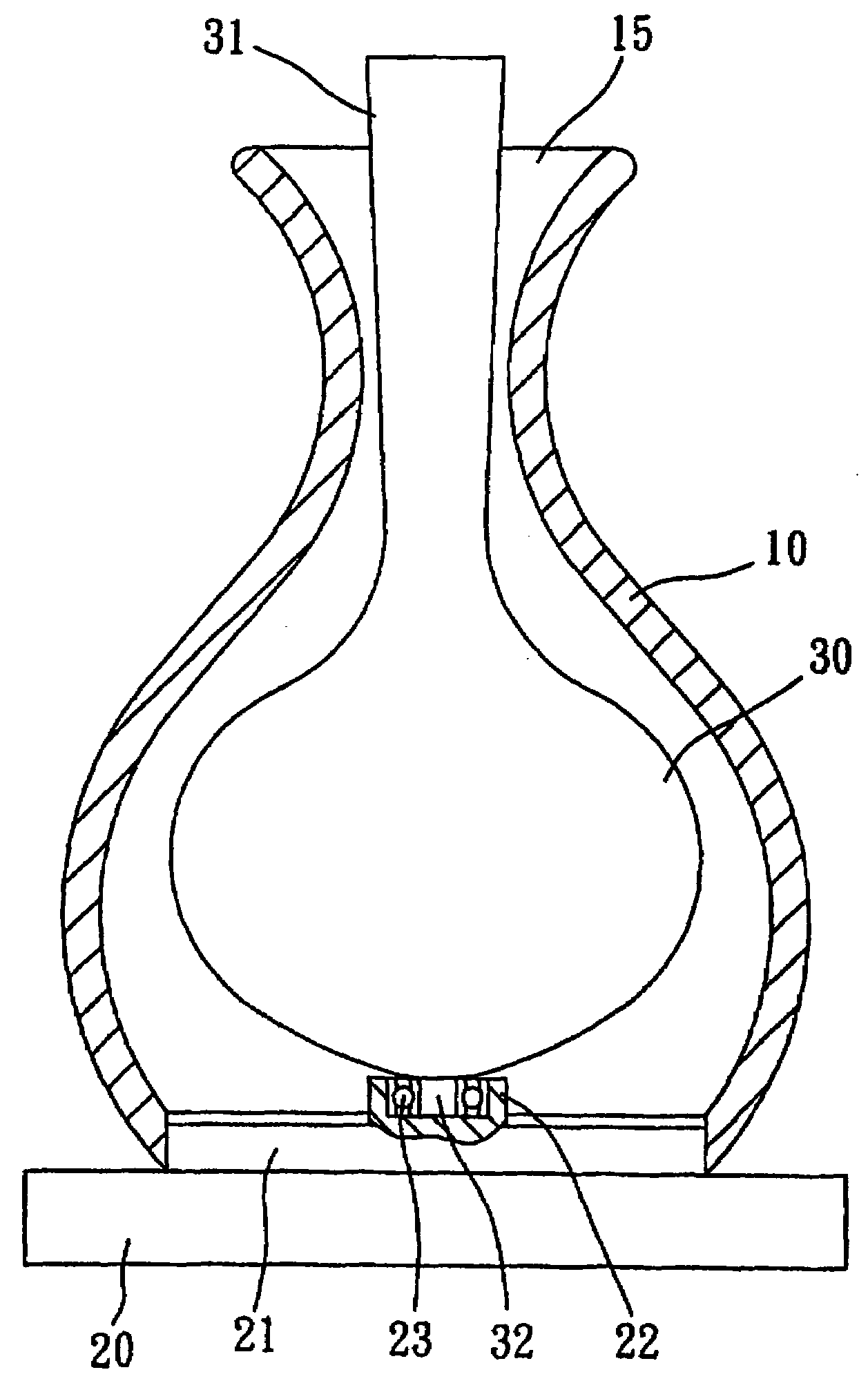

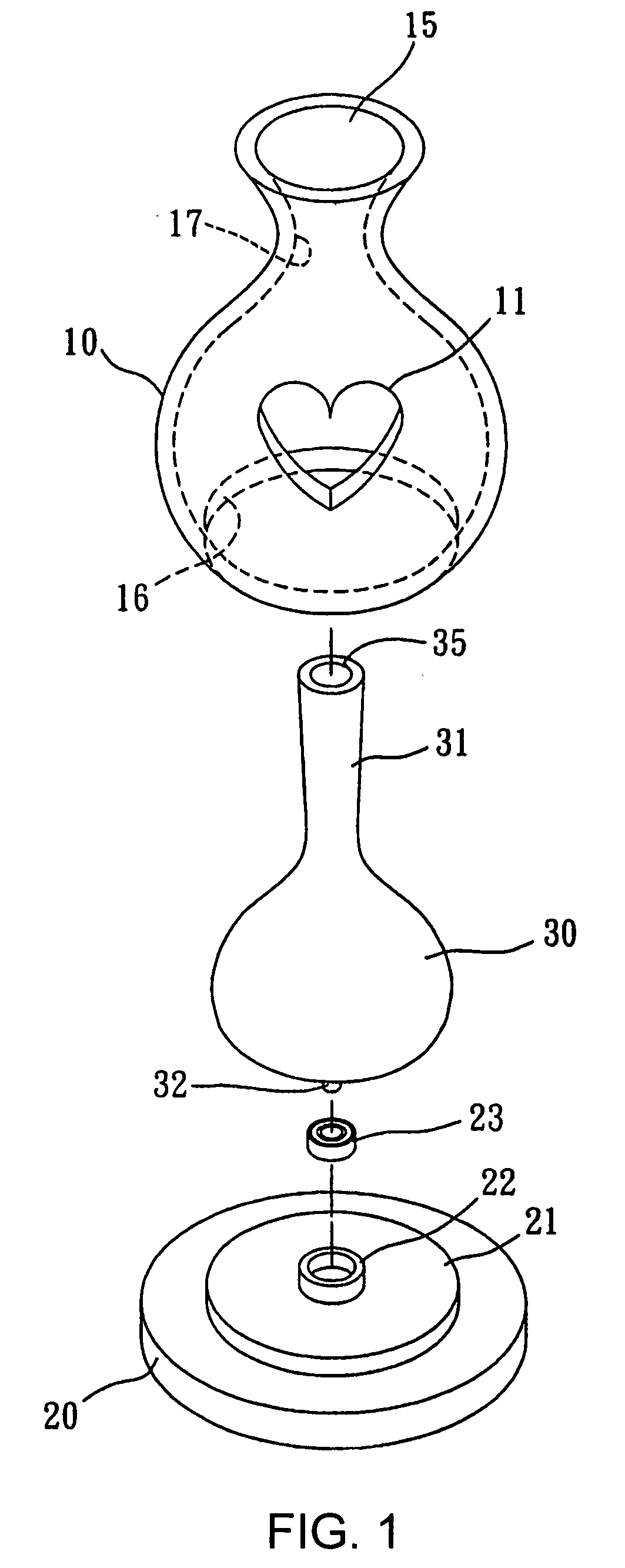

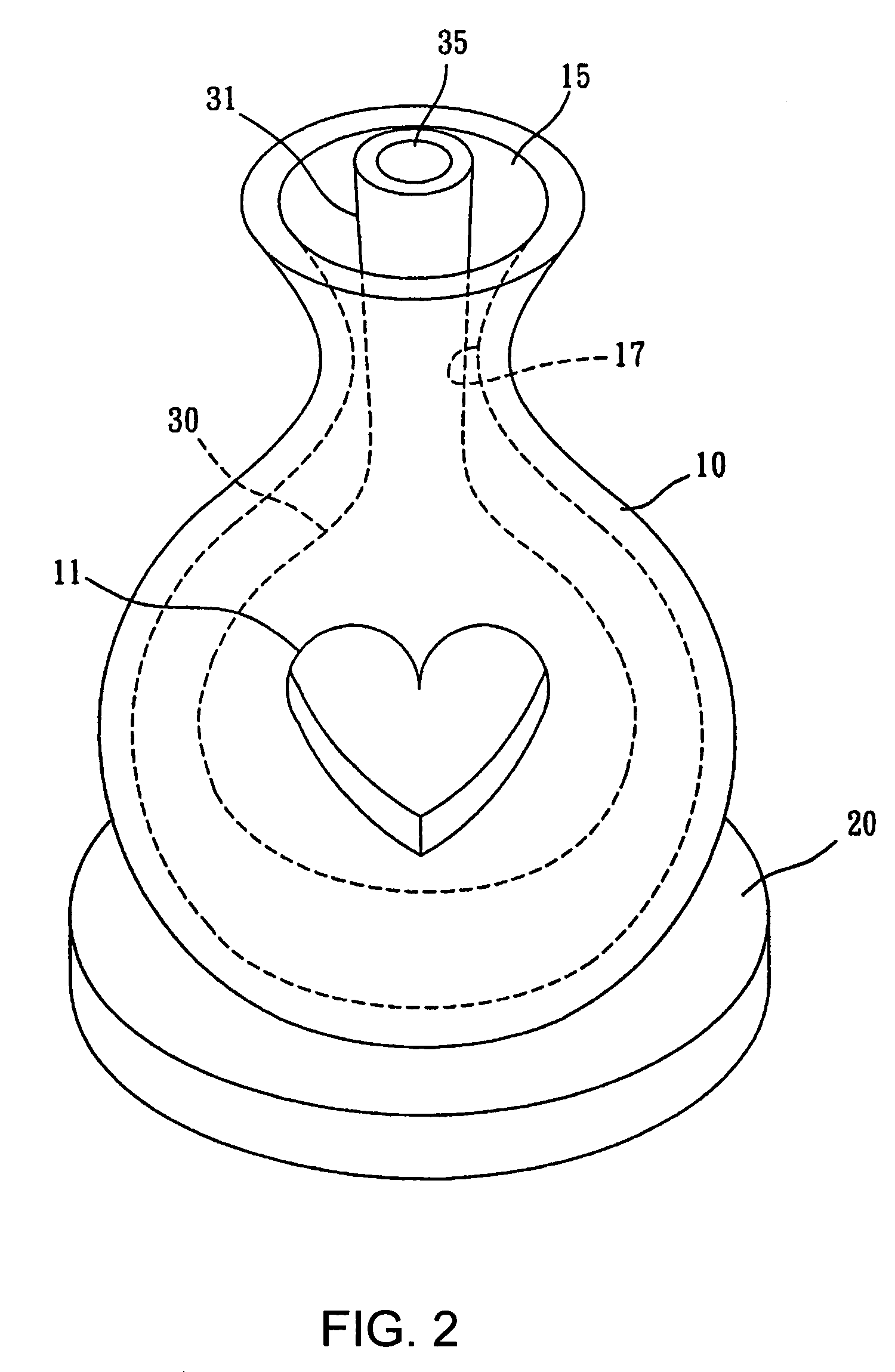

Inherently Unstable Vase Container with Attached Magnet

InactiveUS20120261281A1Useful displayWriting connectorsWriting accessoriesEngineeringMetallic Object

One embodiment of an inherently unstable vase with a magnet (3) attached to the base of the vase container (1). One pole of the magnet (3) allows the vase to be magnetically attracted to any metal object, including a ferrous metal base (4) plate. A ferrous block (2) near the opposite magnet pole augments the force provided by the magnet. The center of gravity of the vase would not allow the vase to remain upright without the use of the magnetic forces. A non-ferrous material can be placed between the vase magnet (3) and base (4), hiding the method by which the inherently unstable vase remains upright. Vases can be magnetically attached to one another, creating multi-tier vase arrangements. Magnetic forces allow the vases to be easily arranged and reconfigured to the desired angle, height, and shape. Also, the magnetic forces inhibit the vase from toppling due to perturbations.

Owner:MORGAN JONATHAN MARK

Method for cultivating live glossy ganoderma vase landscape

InactiveCN101584284AAvoid the problem of easy infection caused by transplantingAvoid problems that predispose you to infectionSpecial ornamental structuresHorticultureNutritionEngineering

The invention discloses a method for cultivating live glossy ganoderma vase landscape, which is characterized by comprising the following steps: filling proper amount of porous filler at the bottom in a vase, implanting a temperature-resistant drainage tube and an air duct with built-in filter material, and putting one end of the drainage tube and one end of the air duct at the opening of the vase, positioning the other end of the drainage tube at the bottom of the vase, positioning the other end of the air duct on the slightly lower part of the upper surface of the porous filler, filling a cultivation material into the opening of the vase, pricking one deep strain inoculation hole in the center of the cultivation material, inoculating liquid strain into the strain inoculation hole after sealing, sterilization and cooling, and switching into cultivation management; and regulating the growth conditions required by glossy ganoderma cultivation by adjusting temperature, humidity, illuminance and the like of environment and adding moisture or nutrient fluid in time through the drainage tube to meet the requirement of moisture and nutrition of the cultivation material at different growth stages. The method effectively solves the problems of regulating moisture, nutrient element, oxygen content and the like of glossy ganoderma mycelium and fruiting body at different growth stages, and is easy to operate, and the products are tufted and multibranched and have various shapes and natural beauty.

Owner:JIANGSU UNIV OF SCI & TECH

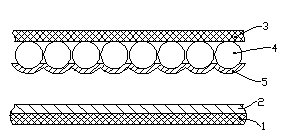

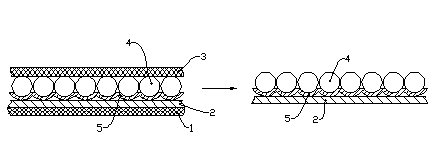

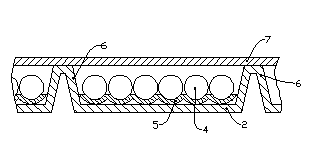

Manufacturing method of high-strength type reflection film

InactiveCN103105637ASimple preparation processFlat coatingLaminationLamination apparatusSizingMaterials science

The invention relates to a manufacturing method of a high-strength type reflection film. The manufacturing method of the high-strength type reflection film includes the following steps: step a, a bonding layer is coated on the surface of a first vase material; step b, a bead establishing layer is formed on the surface of a second base material with pressure-sensitive adhesive, and a reflection layer is plated on the surface of the outer side of glass beads of the bead establishing layer; step c, a light reflecting layer formed by the bonding layer, the reflection layer and the glass beads is formed; step d, embossing is carried out on the back face of the bonding layer through a hot-press embossing roller, and therefore partial of the bonding layer is pressed to form square protruded ribs, and transparent surface material is connected with tops of the protruded ribs; step e, after the bonding layer is embossed, a supporting layer is sprayed on the back of the bonding layer so as to form a plane; and step f, the pressure-sensitive adhesive is evenly coated on the back of the supporting layer, and release materials are covered on the pressure-sensitive adhesive. According to the manufacturing method of the high-strength type reflection film, the smooth supporting layer can be acquired, coating of the pressure-sensitive adhesive can be smooth and uniform, bonding effect is good, and sizing material can be saved.

Owner:JIANGSU TST NEW MATERIALS SCI & TECH

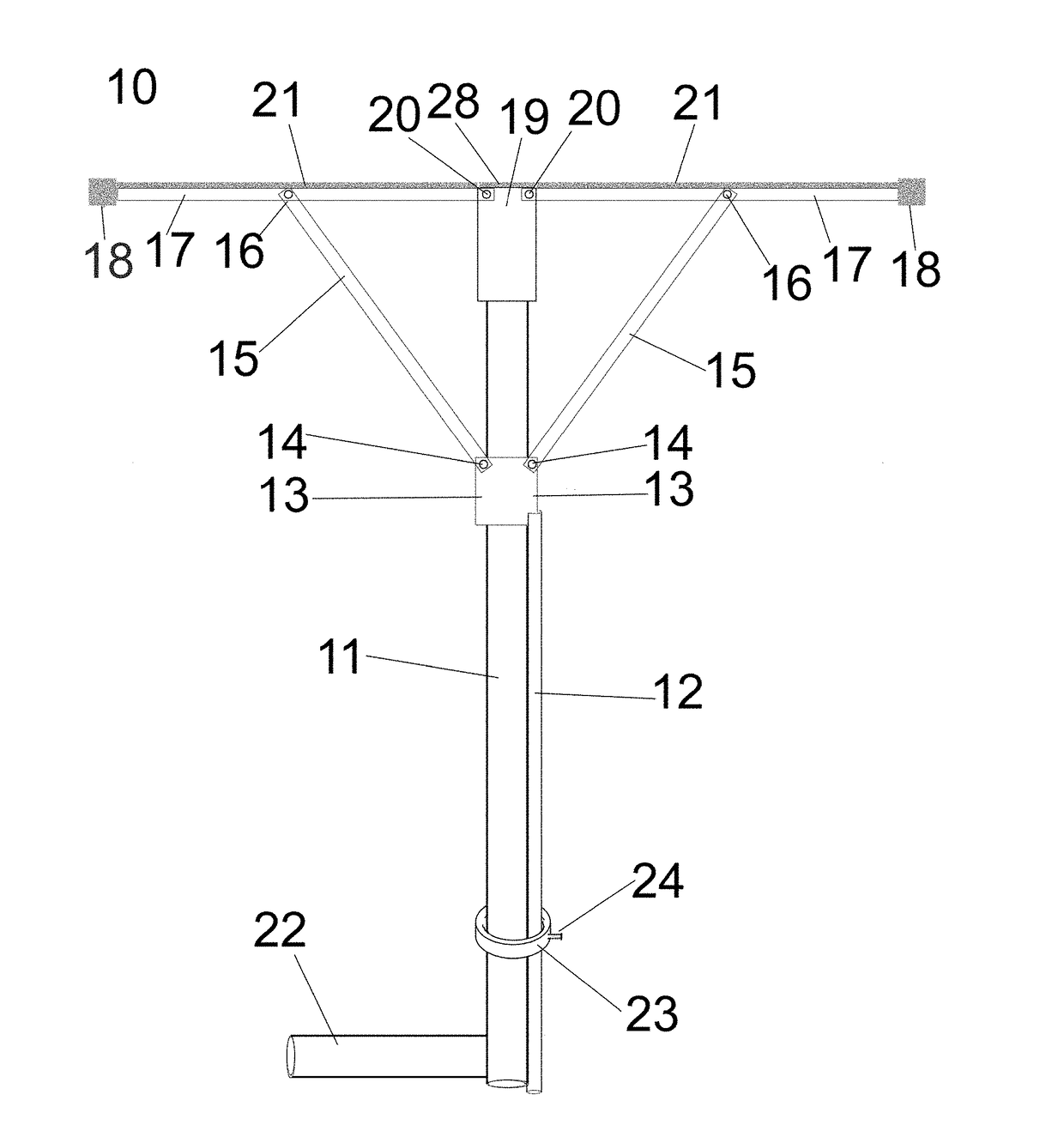

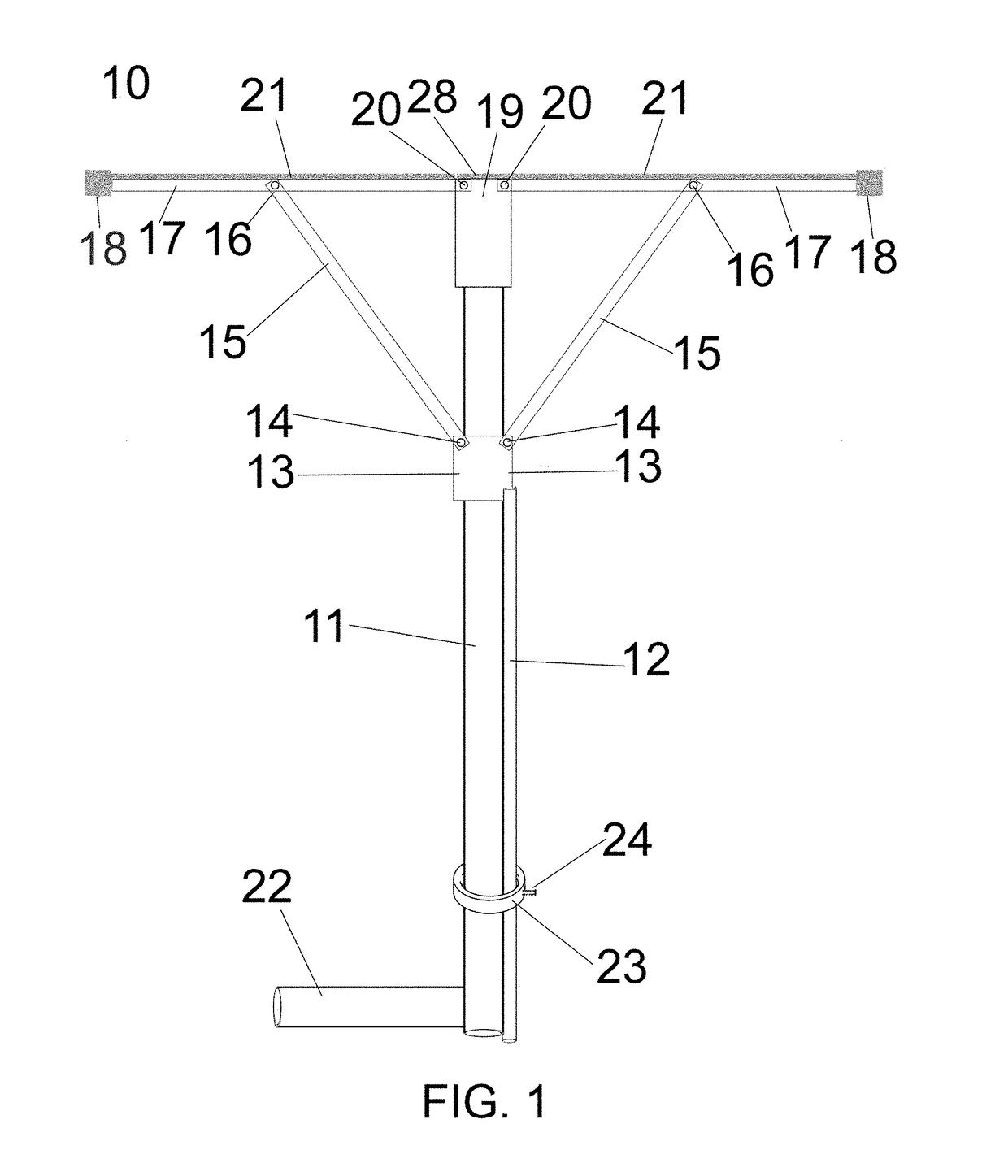

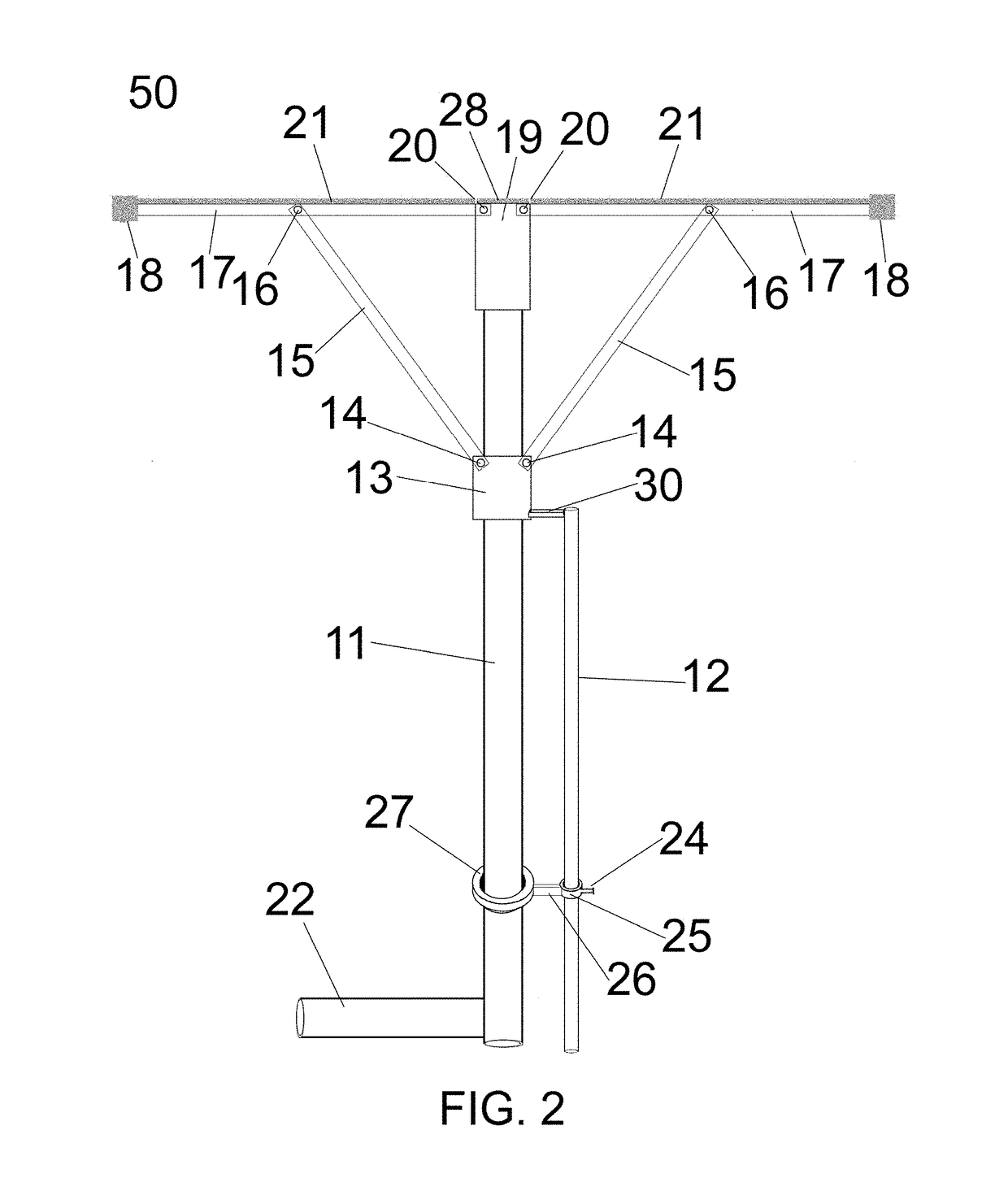

Cleaning Device

InactiveUS20170368582A1Significant retractionBrush bodiesHollow article cleaningBottleBiomedical engineering

A cleaning device for cleaning inner surfaces of an object such as a bottle or vase. A device includes a shaft, a slidably coupled runner, a hub, arms pivotally coupled to the hub, stretchers, cleaning heads attached to the tips of the arms, and arm rod coupled to the runner. The arms can include wiping material along their length. When retracted, the device can be inserted into an object. Pushing on the rod leads to extension of the arms. The extended arms can be held in place by a securing means such as a set screw. The device can then be moved rotationally, translationally or both relative to the object. The securing means can then be released, and the arms can be retracted by pulling the rod. The device can be removed from the object, and the cleaning heads can be removed.

Owner:ZACKSON TRACY LYNN +1

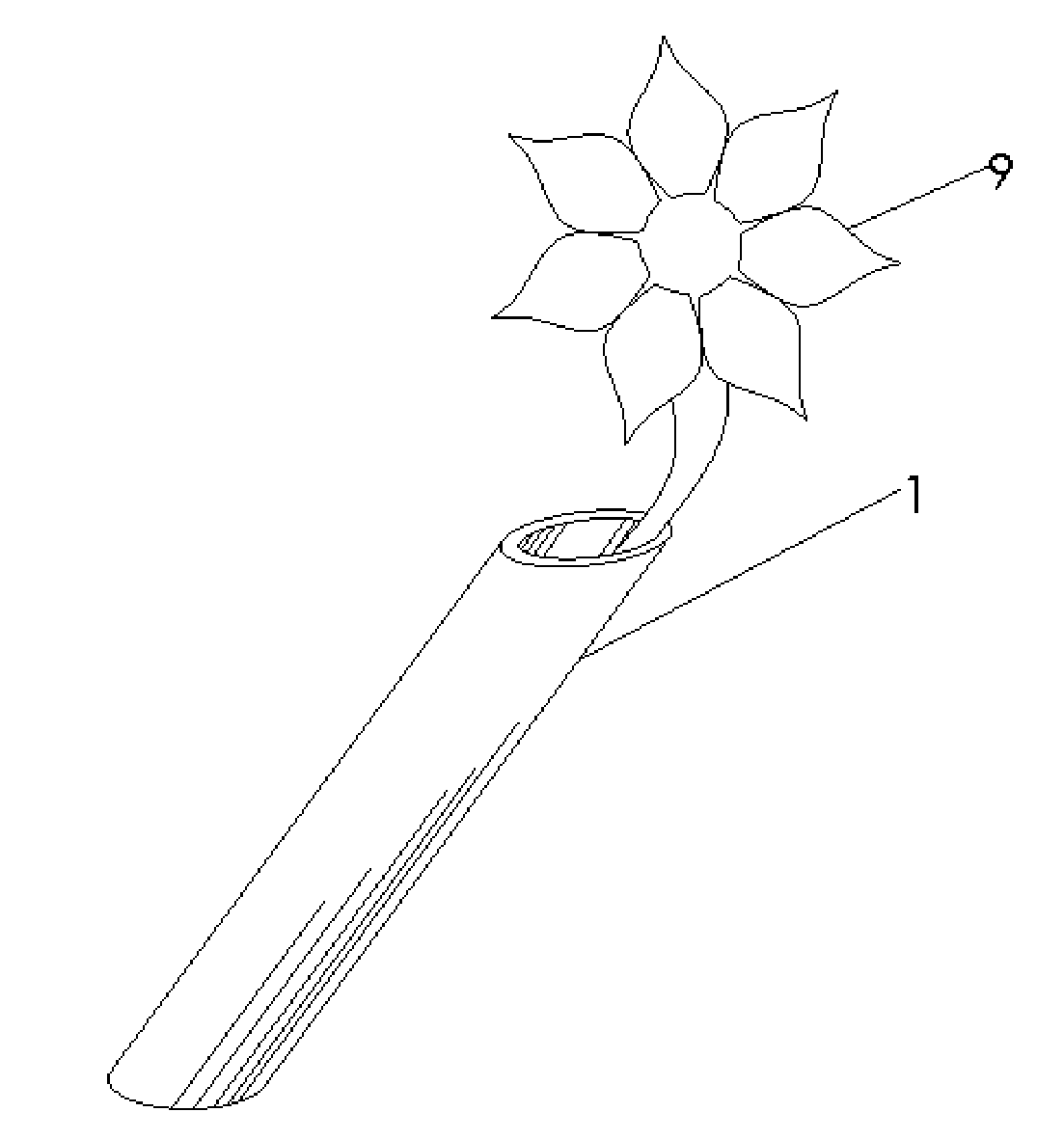

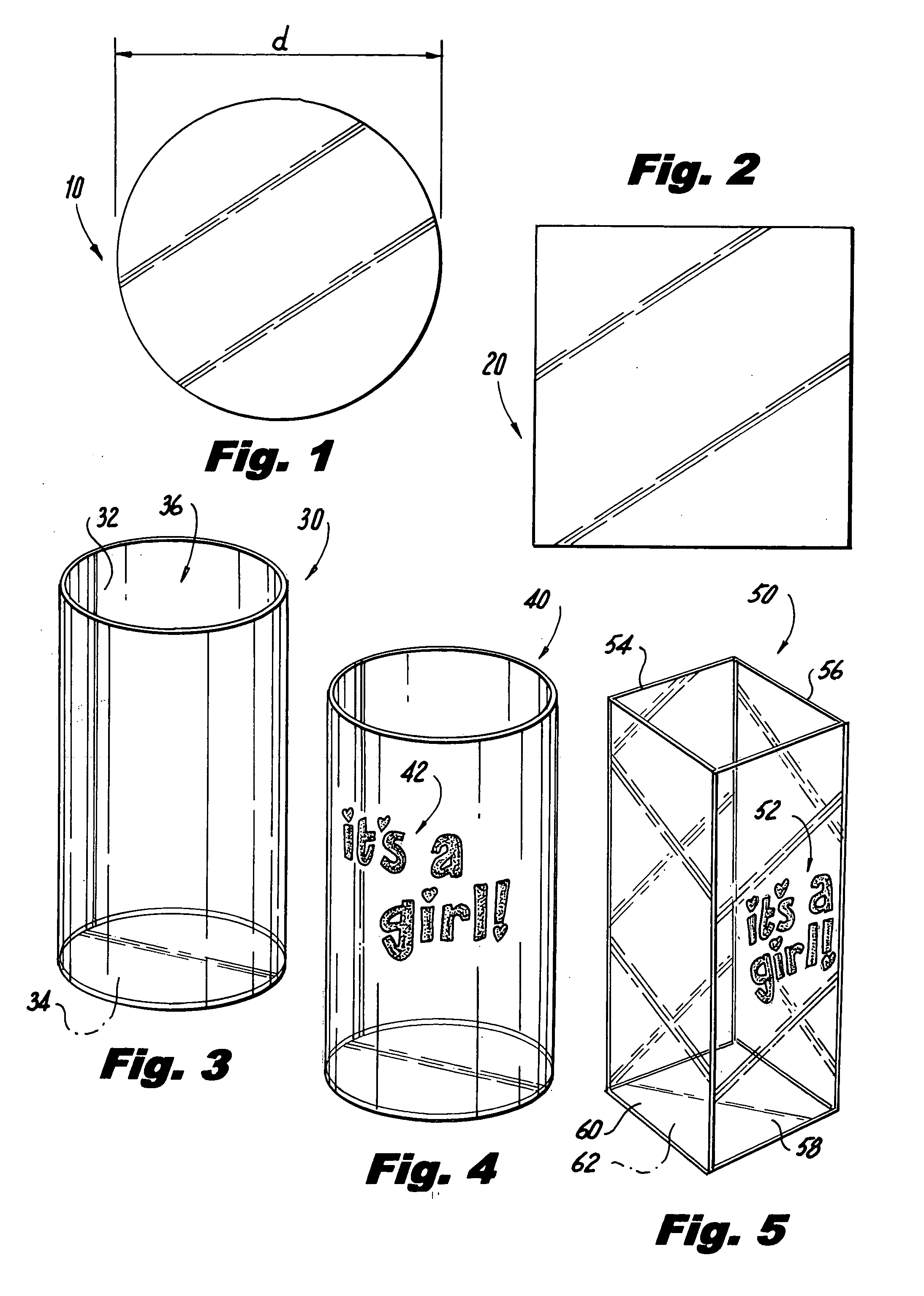

Space saving vase

InactiveUS20070289212A1Easy to cleanImprove lateral stabilityFlower vasesCultivating equipmentsEngineeringVase

A vase made of a material that can be folded up and stored when not in use and when in use filled with water and able to hold flowers.

Owner:BROADWAY KLEER GUARD CORP

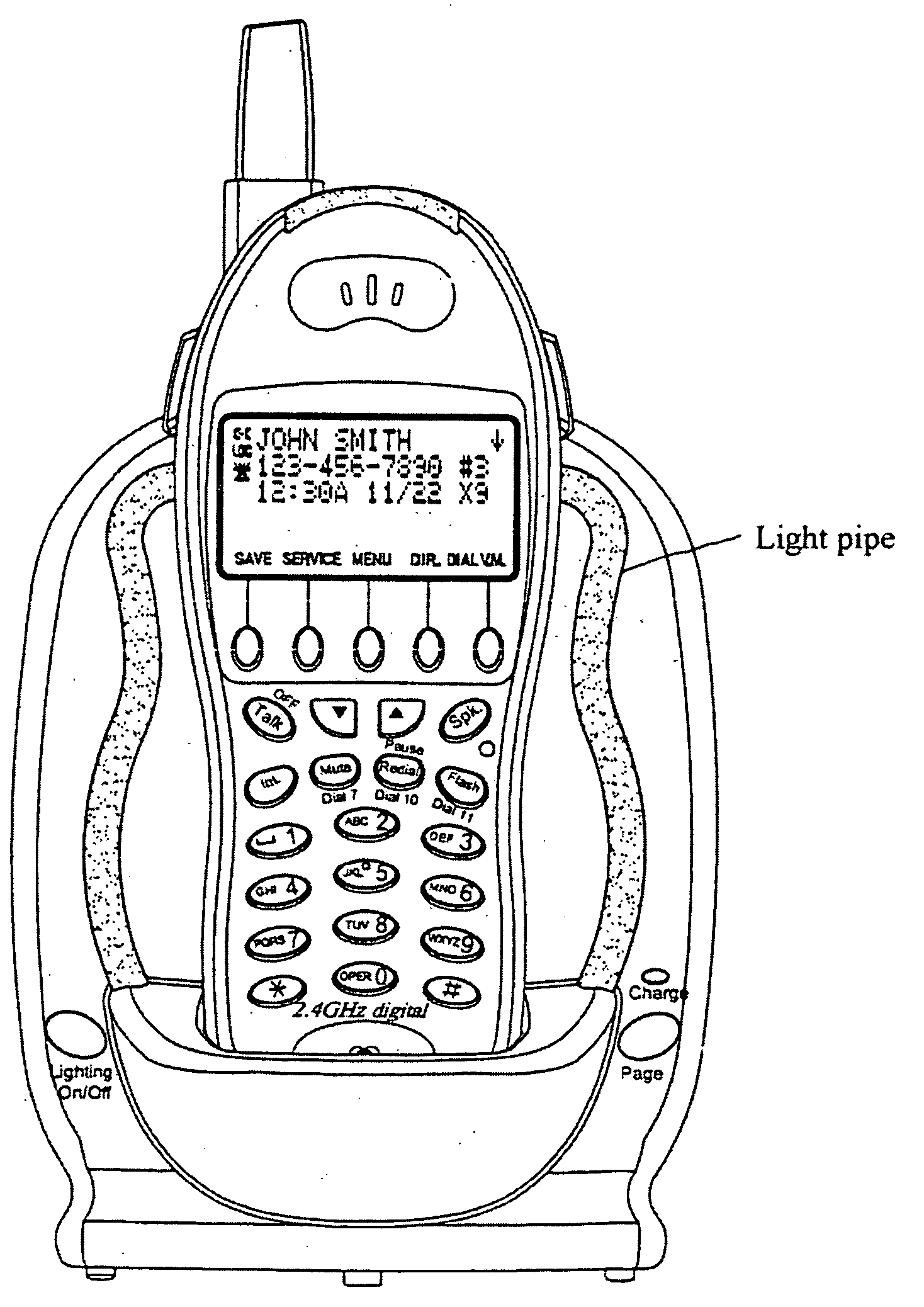

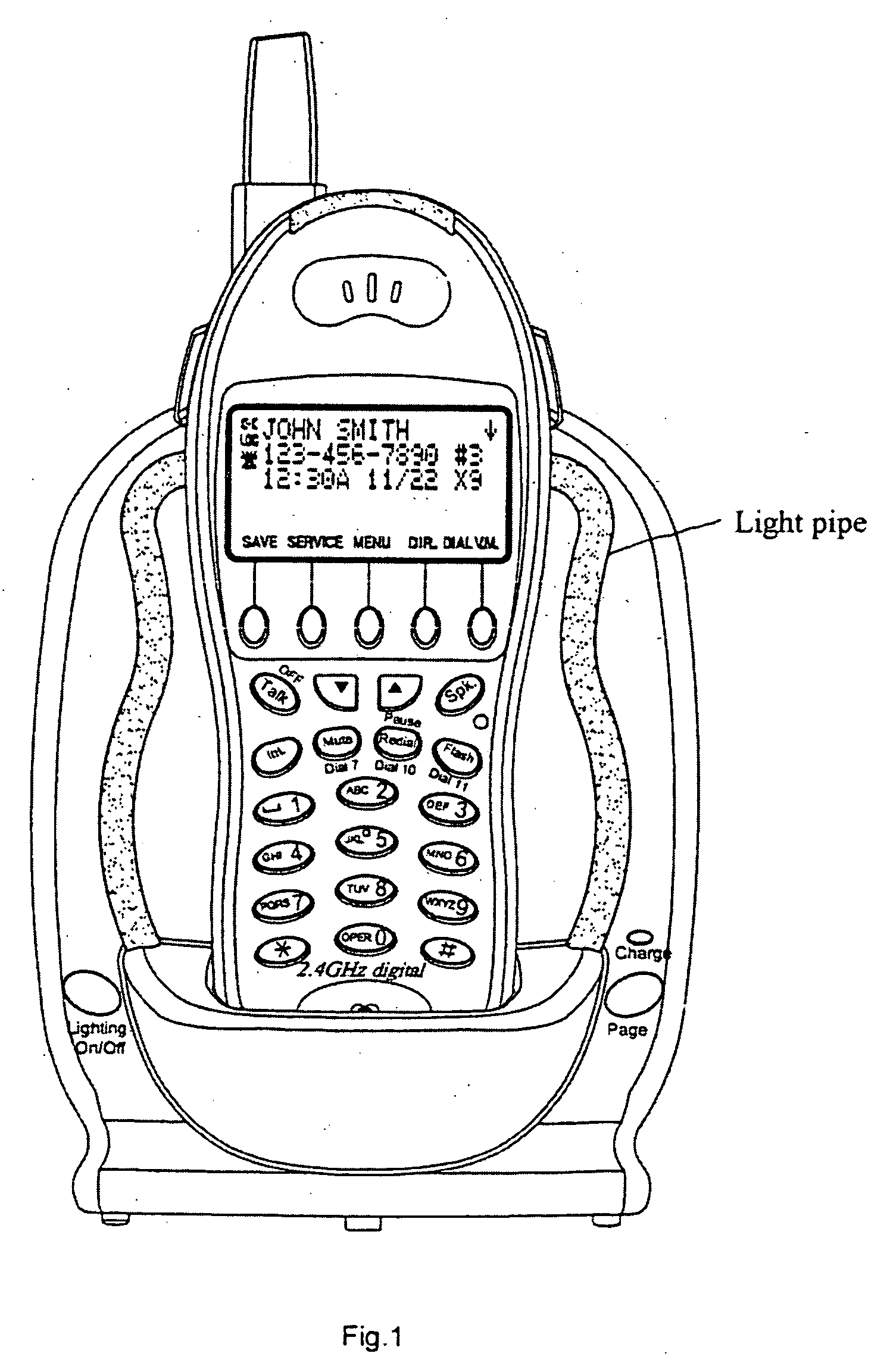

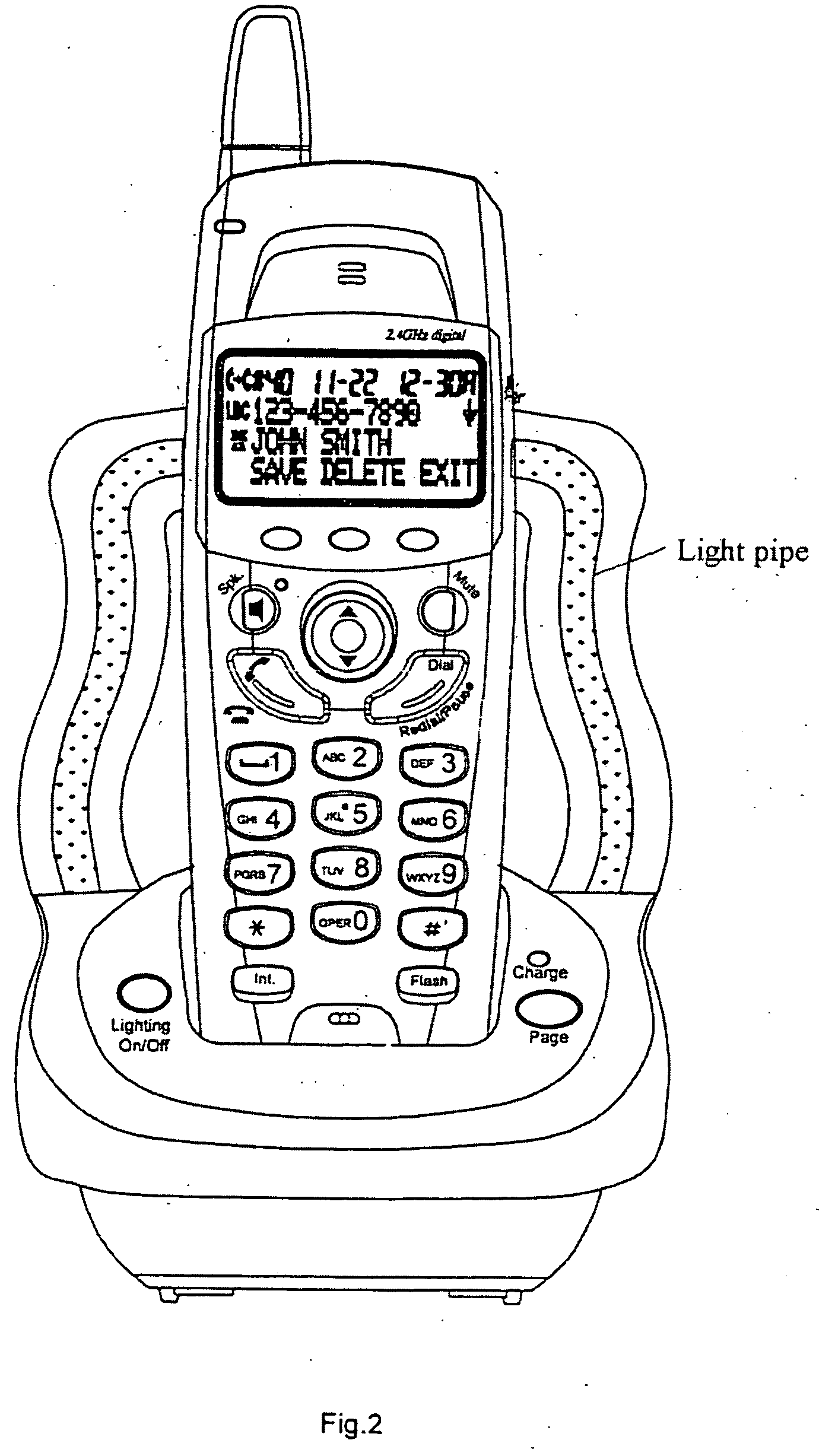

Telephone device with ornamental lighting

InactiveUS20060209559A1Current supply arrangementsCalling susbscriber number recording/indicationEffect lightEngineering

Various ornamental lighting for a telephone device or telephone add-on device, which consists of an LED as a light emitting source and light conductor material for forming various attractive ornamental lighting, such as the shape of a light emitting vase, a light emitting ring, light emitting strips with light emitting pearl, etc., for the devices. The ornamental lighting can be further combined with functional indicators of the device.

Owner:LIM BOON CHEN

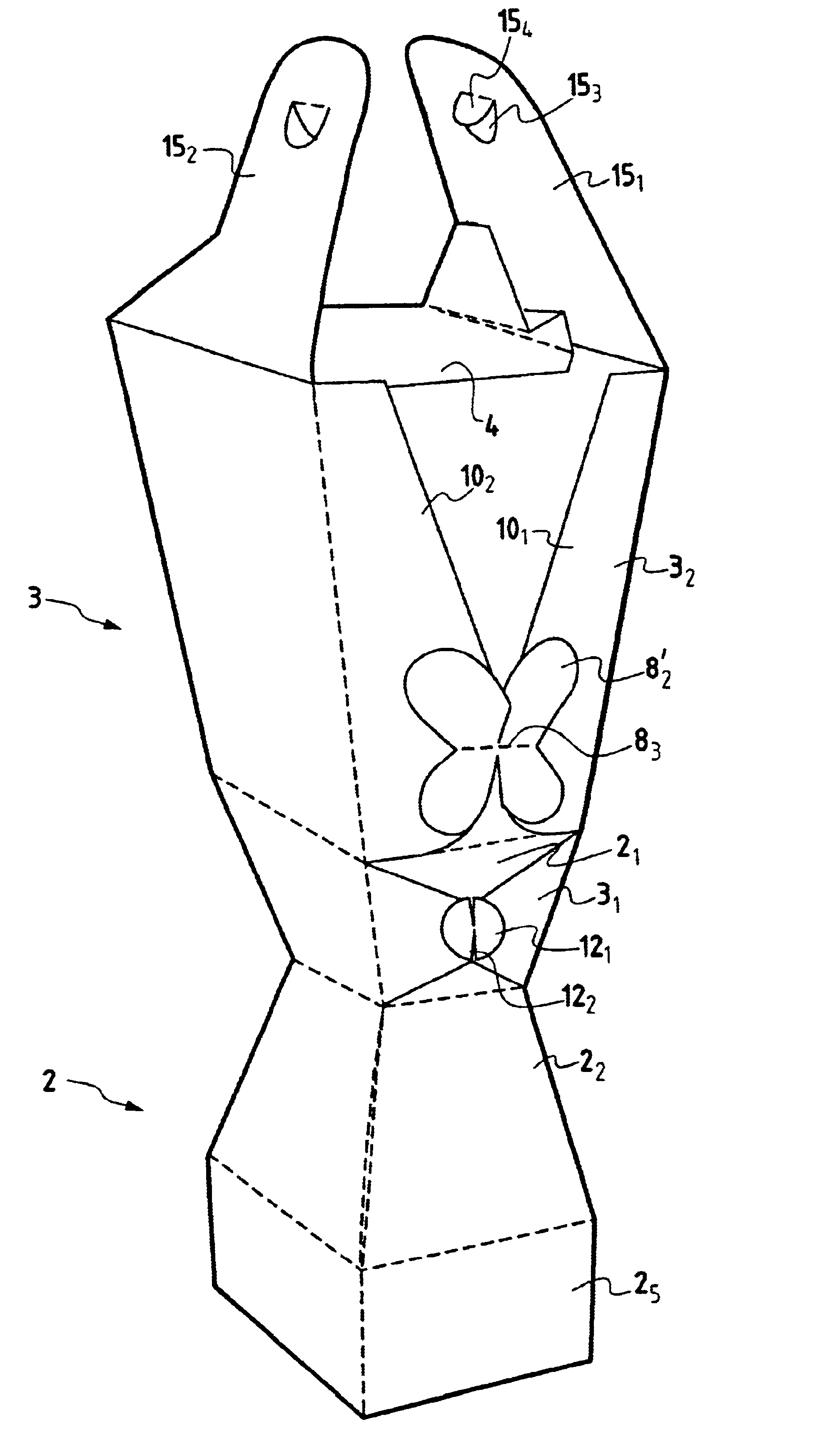

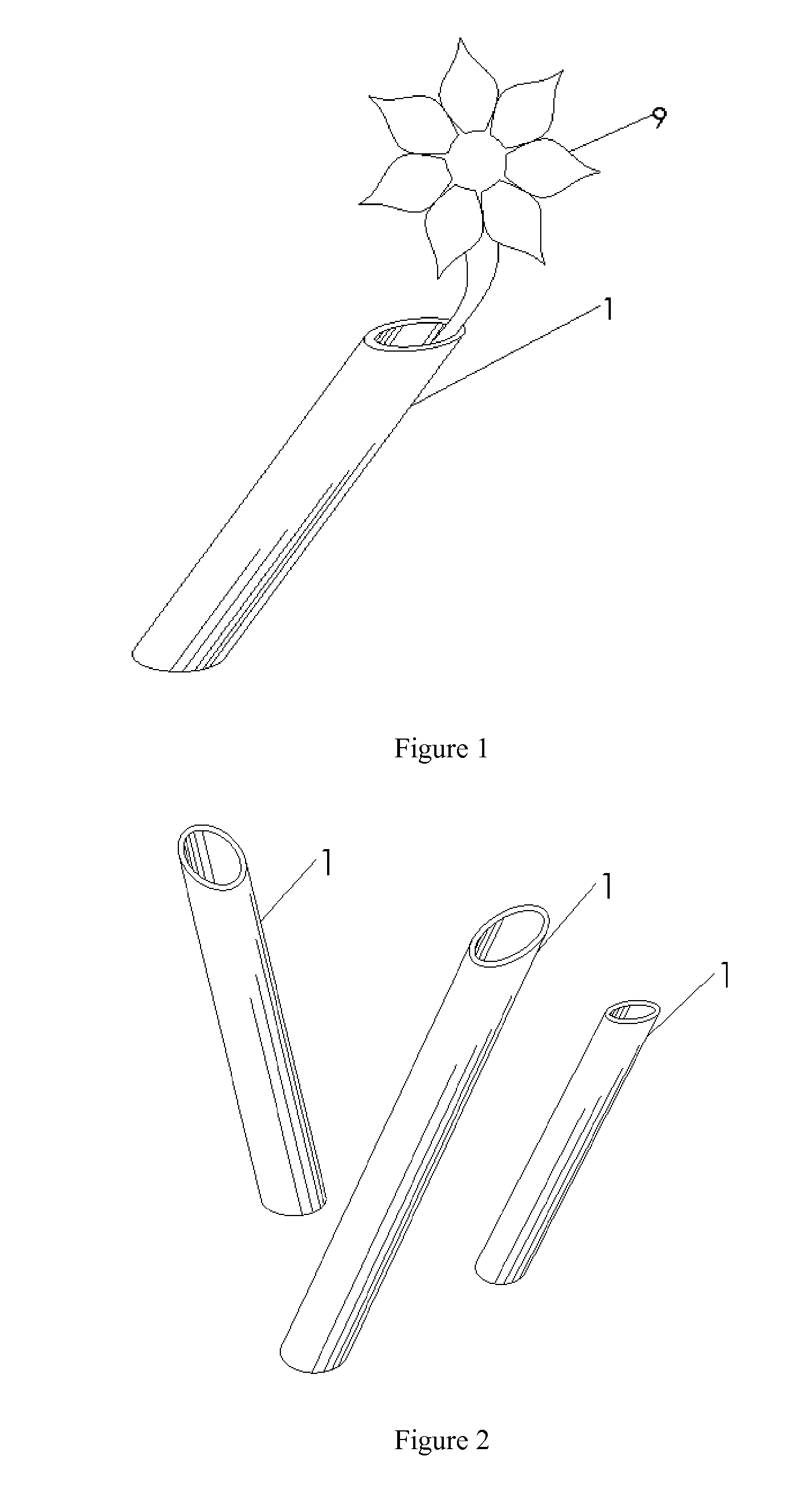

Vase

InactiveUS20050144841A1Easy and inexpensive to manufactureSpace minimizationFloral handlingFlower vasesVaseSurface plate

A vase made of a thin foldable material and having a wall, an upper opening and a lower bottom, provided with a foot, with the vase being formed by a first plane unfolding by folding along fold lines, with the first plane unfolding designed with a central panel having essentially the same configuration as the bottom of the vase and defined by a first set of fold lines, a number of radial panels defined by a second set of fold lines and extending outwardly from the first fold lines, and a number of edge panels issuing from the second fold lines. The vase has a bottom formed by folding the bottom panels along the fold lines. The bottom is, by gluing, joined to a central panel of the first plane unfolding to secure the foot on the vase. The foot parts are provided by the radial panels and the edge panels folded up around the side panels or third fold lines of the vase. The vase is especially applicable as packaging during transport of a flower bouquet.

Owner:HJORTH BIRGIT

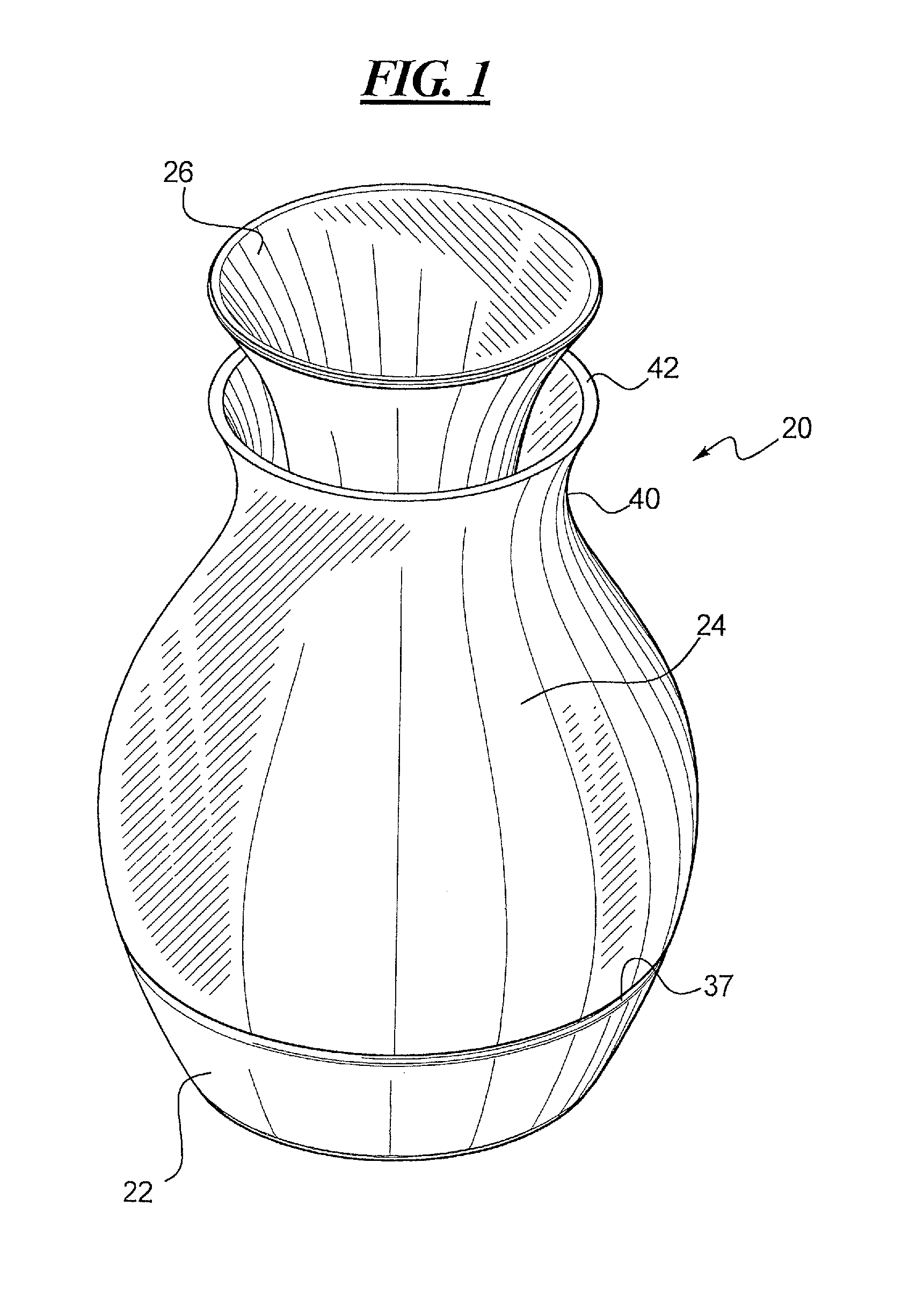

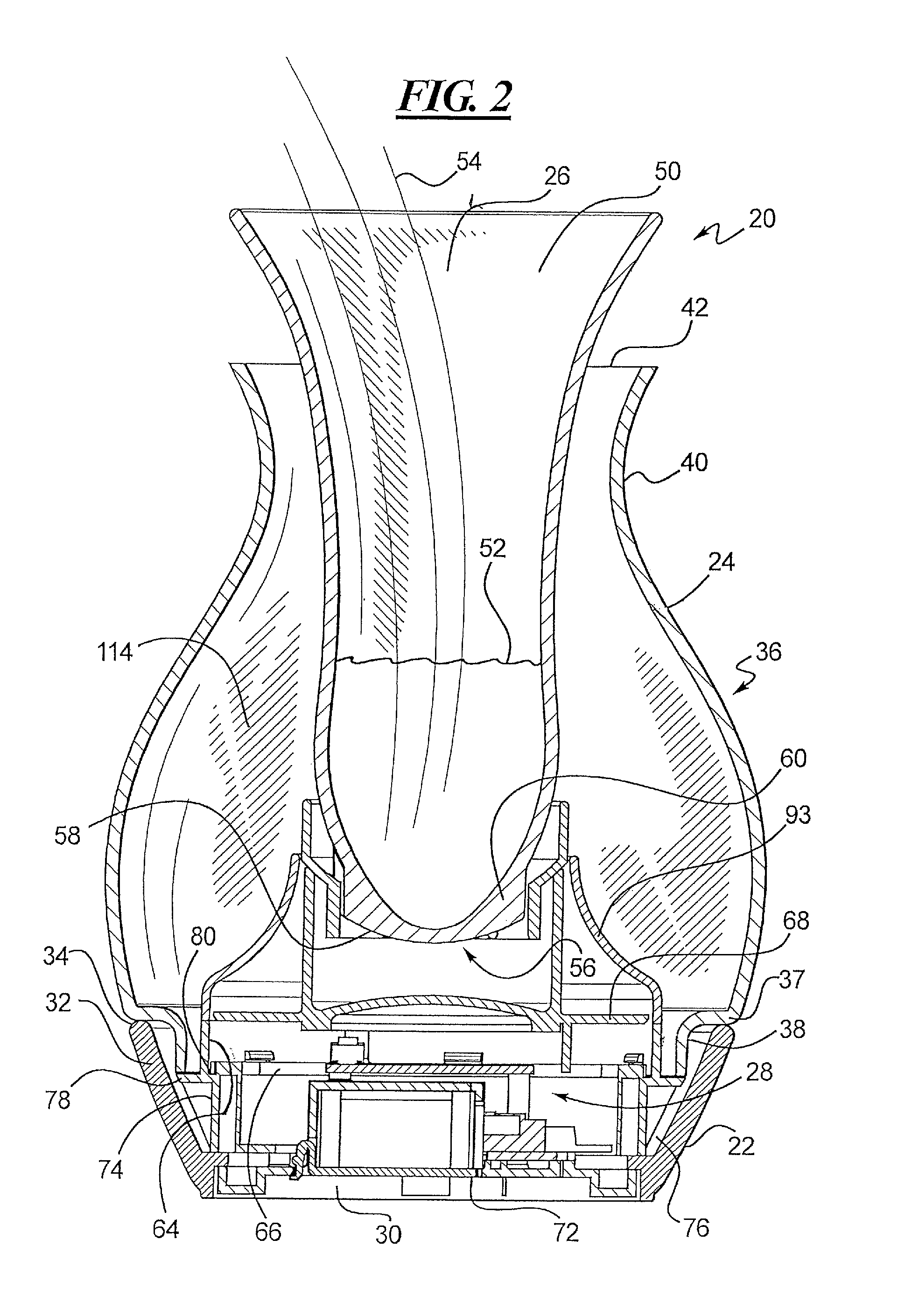

Multi-sensory product combining reeds, volatile actives diffusion, form-within-a-form construction, and light show capabilities

A multi-sensory product able to disperse chemical actives using reeds or other wicks, as well as providing a light show is disclosed. The product includes a form-within-a-form design wherein the inner form or vase is able to store the chemical actives, as well as mount the reeds or other wicks. The outer vase complements the aesthetics of the inner vase while at the same time concealing the electronics of the device. The electronics of the device can include a power source, as well as a circuit board for driving LEDs mounted thereon. The LEDs can generate a light show which can be refracted and diffused through the glass or polymer material forming the inner and outer vases thereby creating an aesthetically pleasing and multi-sensory experience through the use of the product.

Owner:SC JOHNSON & SON INC

Vase preservative for eustoma grandiflorum cut flowers

InactiveCN103621496AReduce dehydrationDecrease breathing rateDead plant preservationCut flowersSucrose

The invention relates to a vase preservative for eustoma grandiflorum cut flowers, and belongs to the technical field of preservation of fresh cut flowers. The vase preservative is technological characterized by comprising the following components in percentage by weight: 3 percent of sugar cane, 0.04 percent of calcium chloride (CaCl2), 0.03 percent of 8-hydroxyquinolinium citrate (8-HQC), 0.2 percent of citric acid and the balance of water. The preservative has the characteristics of low production cost, easiness and convenience in preparation, no pollution, good vase preservation effect on the eustoma grandiflorum cut flowers, and the like.

Owner:师进霖

Vase with rotatable inner container

A vase in one embodiment includes an outer shell comprising open top and bottom ends and at least one opening on the surface; a base comprising a projecting member on the top with the bottom end of the outer shell being securely put thereon, an annular flange on the top of the projecting member, and an annular bearing releasably fastened in the flange; and an inner container disposed in the outer shell and comprising an upper member projecting out of the top end of the outer shell, a central shaft projecting downward from the underside to be rotatably disposed in the bearing, and at least one pattern on the outer surface. The inner container is adapted to rotate about the outer shell by rotating the upper member.

Owner:CHOU YUNG MING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com