Patents

Literature

119 results about "Manufactured form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

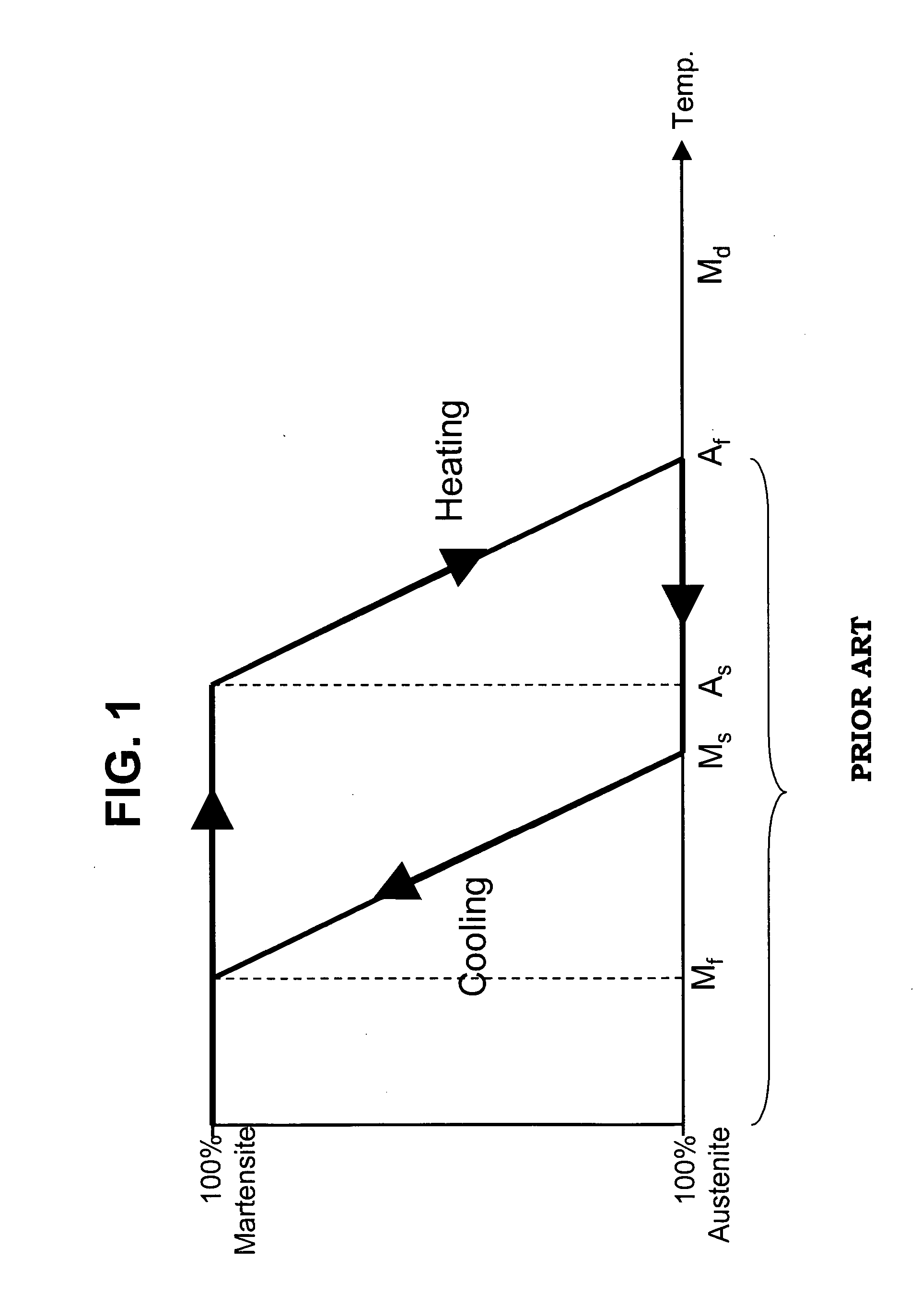

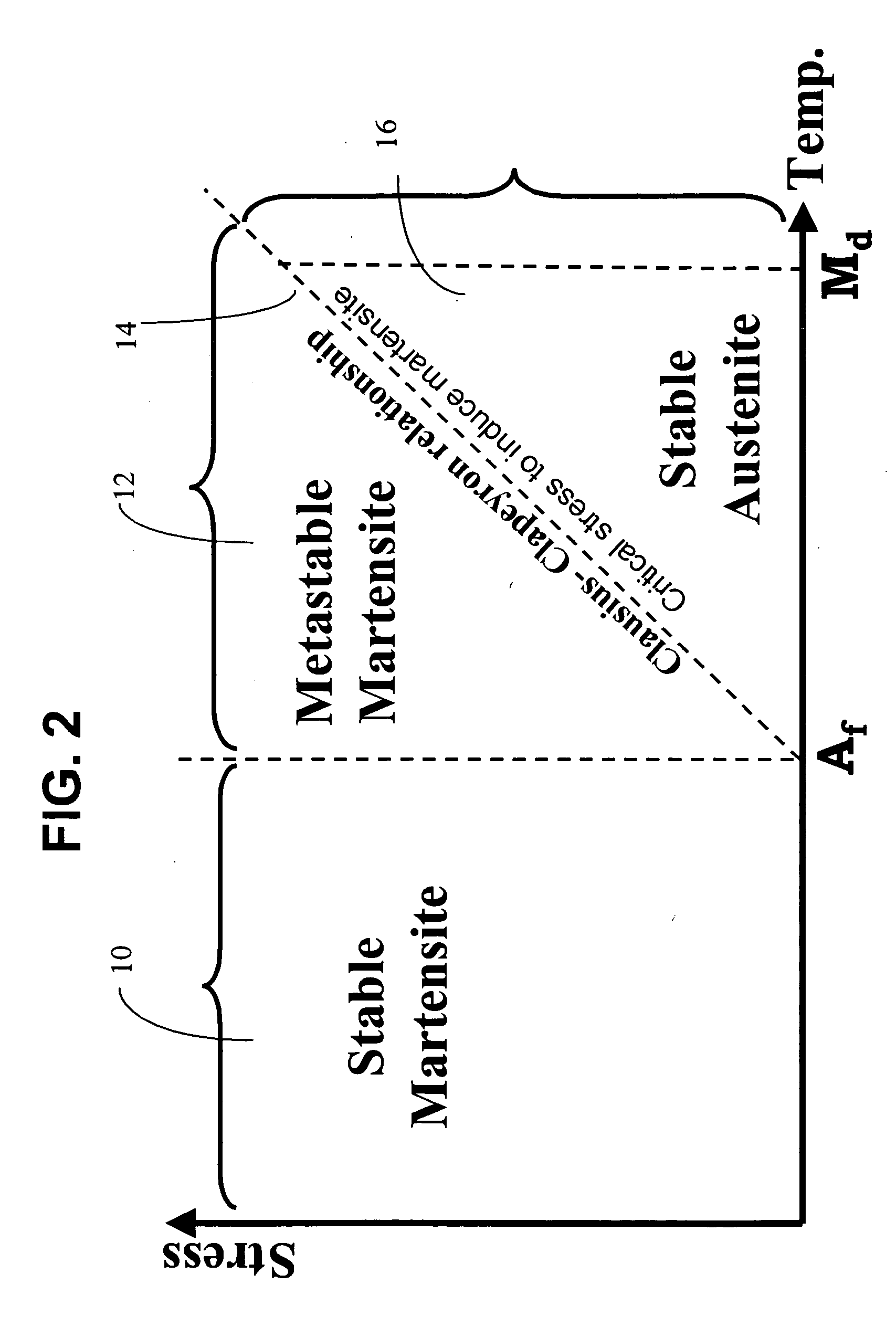

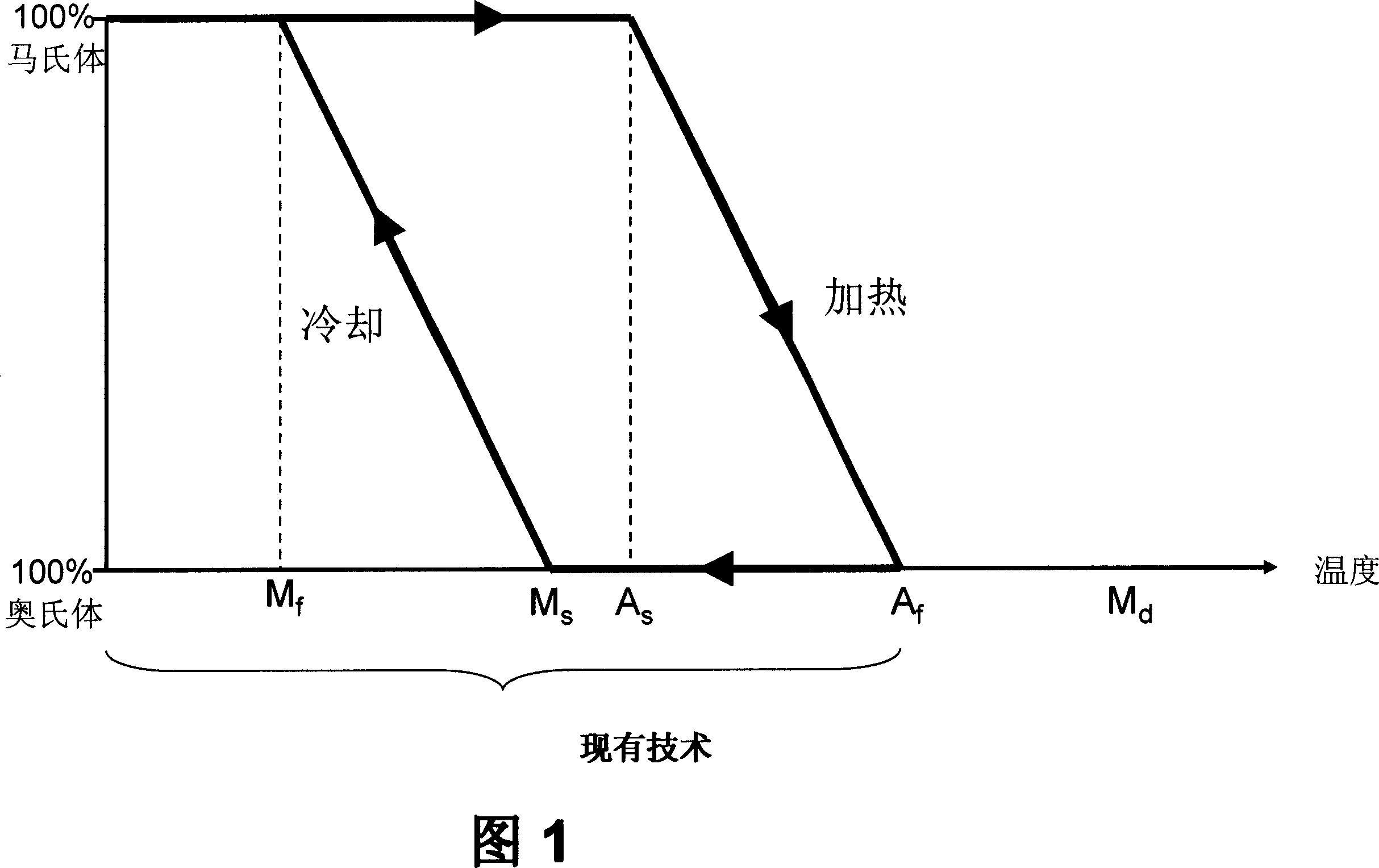

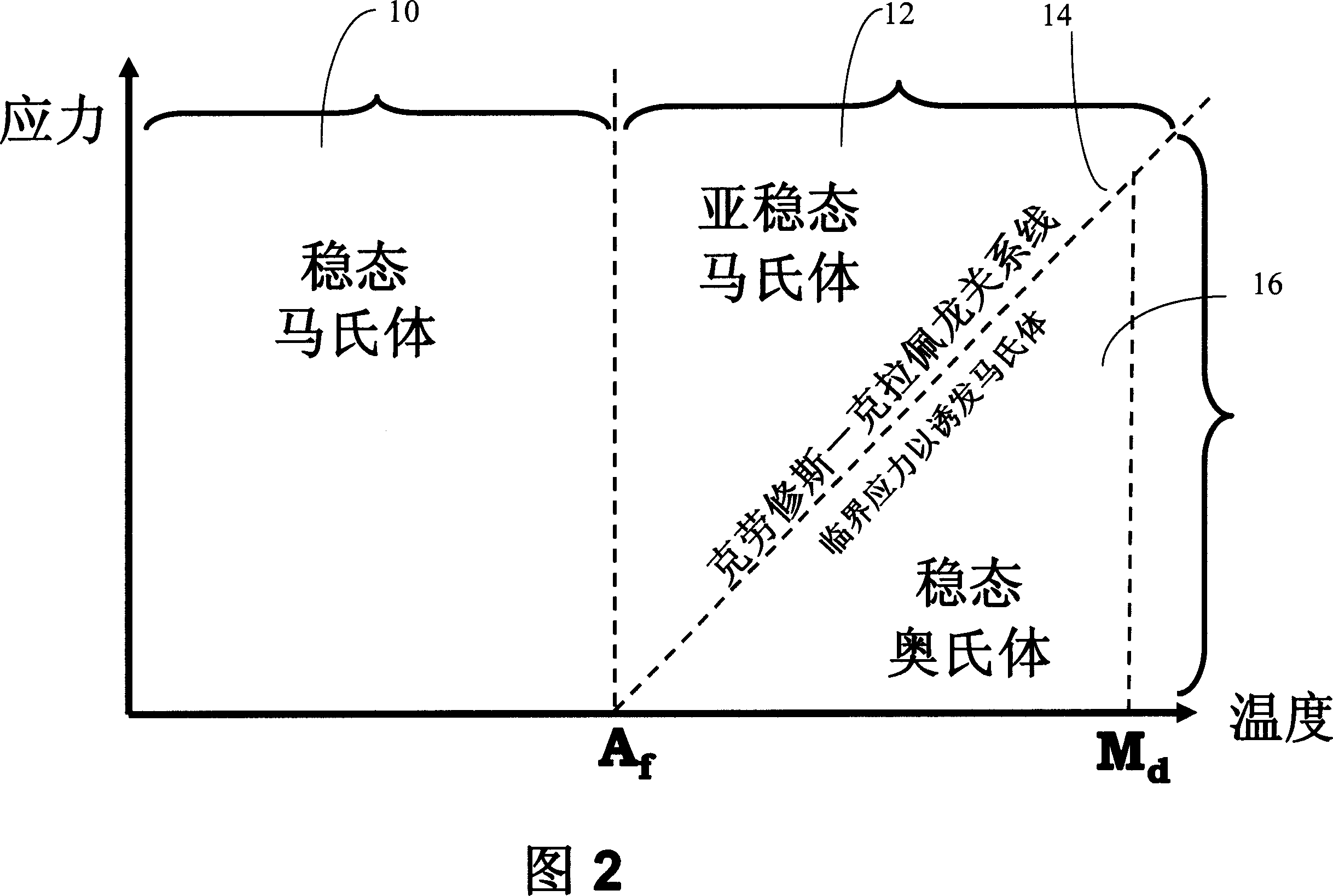

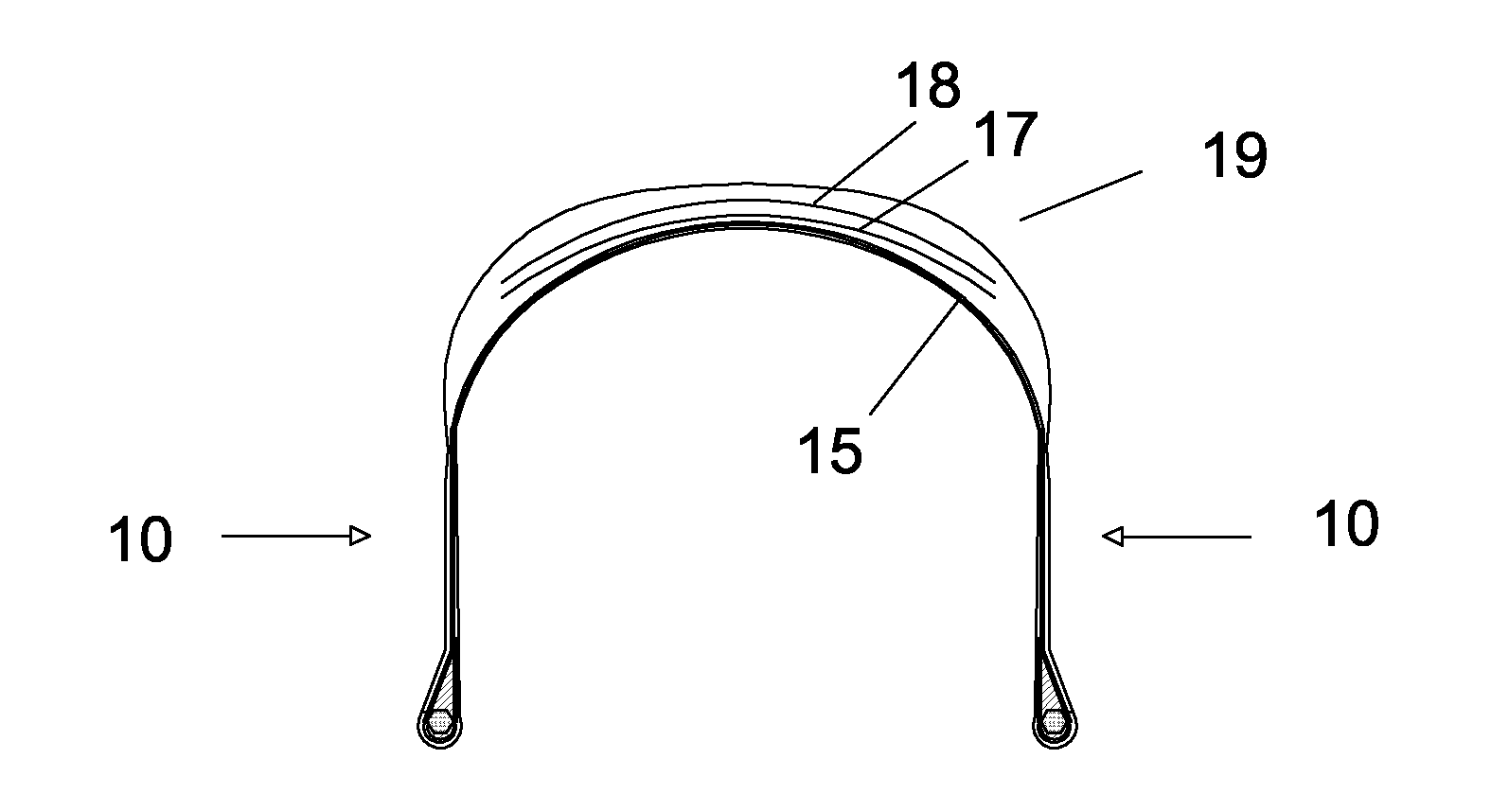

Medical devices formed from shape memory alloys displaying a stress-retained martensitic state and method for use thereof

InactiveUS20050043757A1Good body shapePromote recoverySuture equipmentsDental implantsManufactured formShape-memory alloy

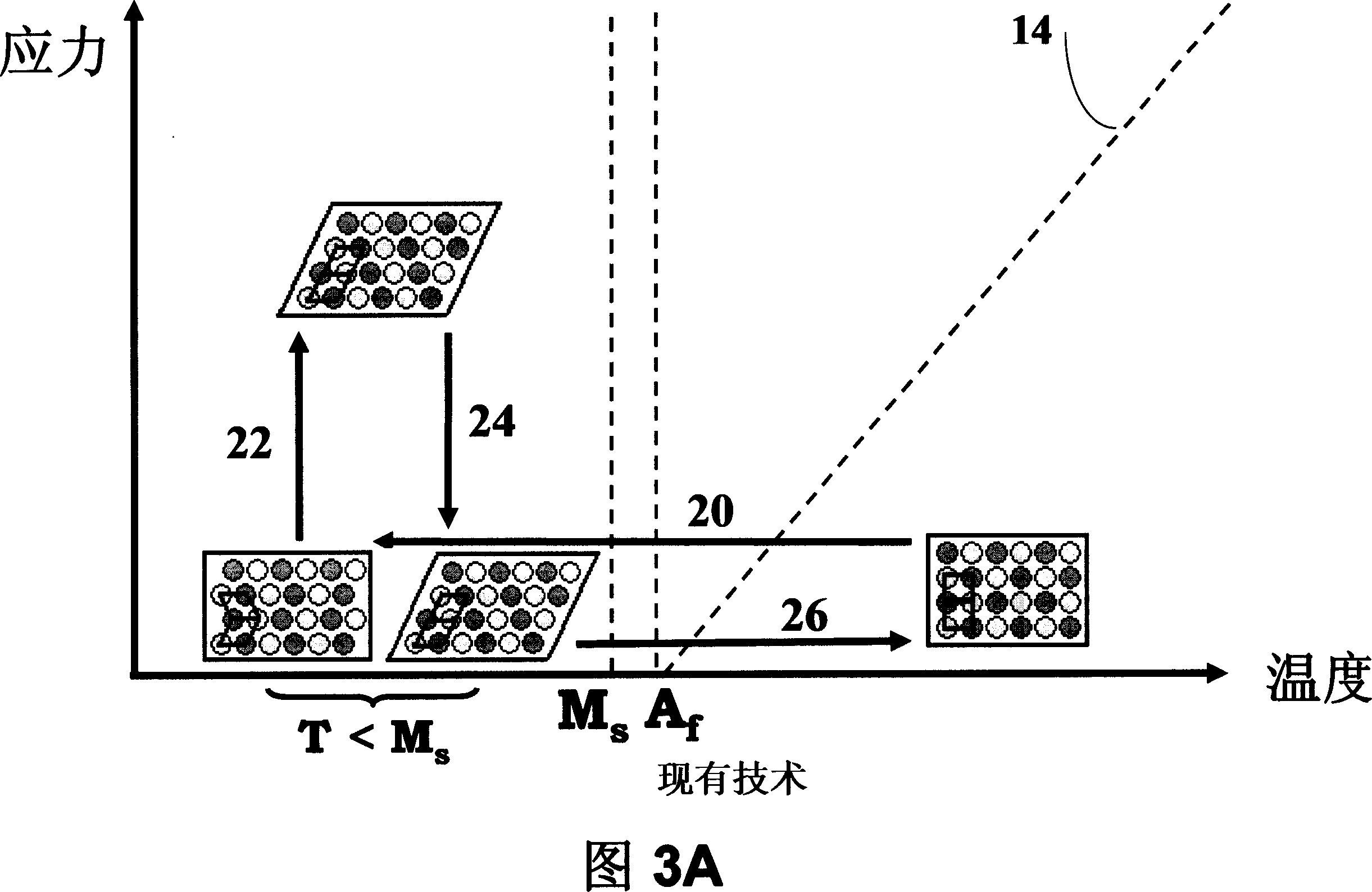

A method is disclosed for utilizing a deformable article of manufacture formed at least partly of a shape memory alloy. The method includes the steps of deforming the article from a first predetermined configuration to a second predetermined configuration while the shape memory alloy is, at least partially, in its stable martensitic state and at a first temperature. A resisting force is applied to the deformed article of manufacture using a restraining means and the article is heated from the first temperature to a second temperature in the presence of the resisting force. The stable martensitic state is transformed to a metastable stress-retained martensitic state. The resisting force is then removed allowing the alloy to transform to its austenitic state and the shape of the article to be restored substantially to its first configuration. Devices primarily medical devices operative by employing this method are also disclosed.

Owner:NITI SURGICAL SOLUTIONS

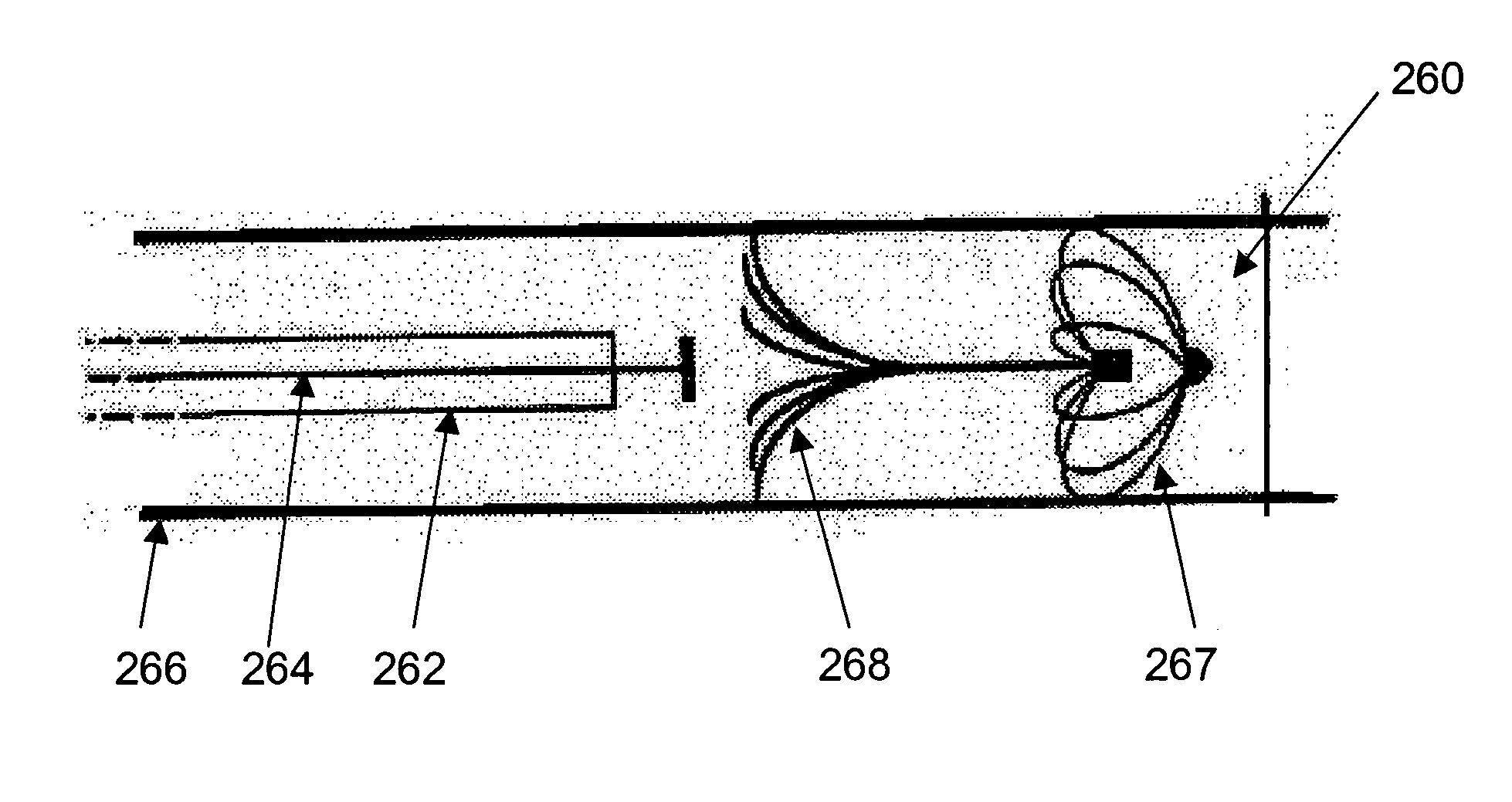

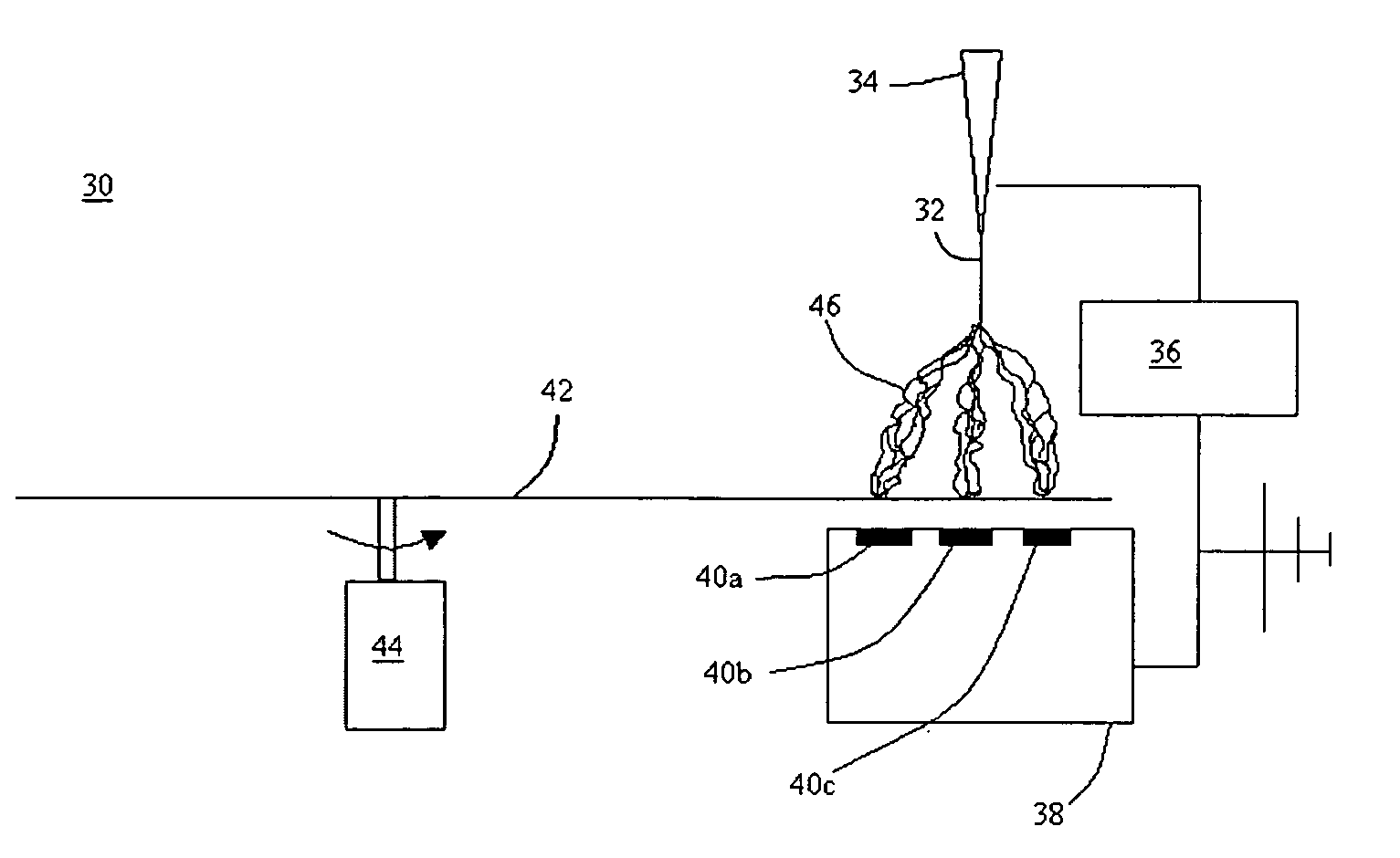

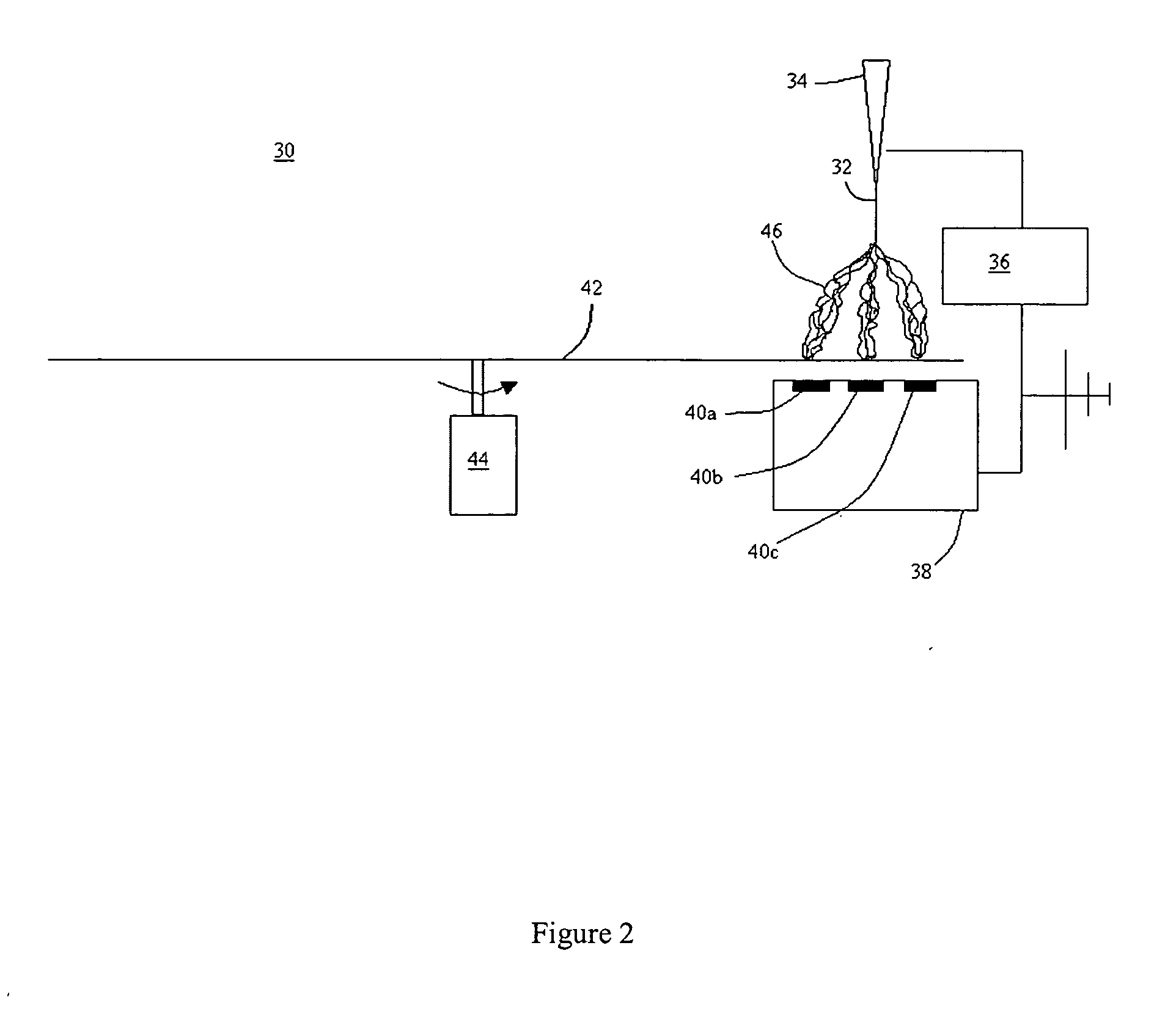

Patterned electrospinning

A polymer is directed from a source electrode into an electric field that drives the formation of electrospun fibers that are deposited onto a collecting surface to thereby form a patterned polymer structure. The collecting surface can be a counterelectrode or a collecting surface that is between the source electrode and a counterelectrode. Apparatus employed to conduct the method include an electrospinning source that directs polymer into an electric field formed by source and counterelectrodes. A collecting surface, such as the counterelectrode or a surface interposed between the source and counterelectrodes, collects electrospun fibers. Articles of manufacture formed by the method of apparatus include, for example, a structure of patterned electrospun fibers comprising multiple aggregations of polymeric electrospun fibers.

Owner:PHYSICAL SCI

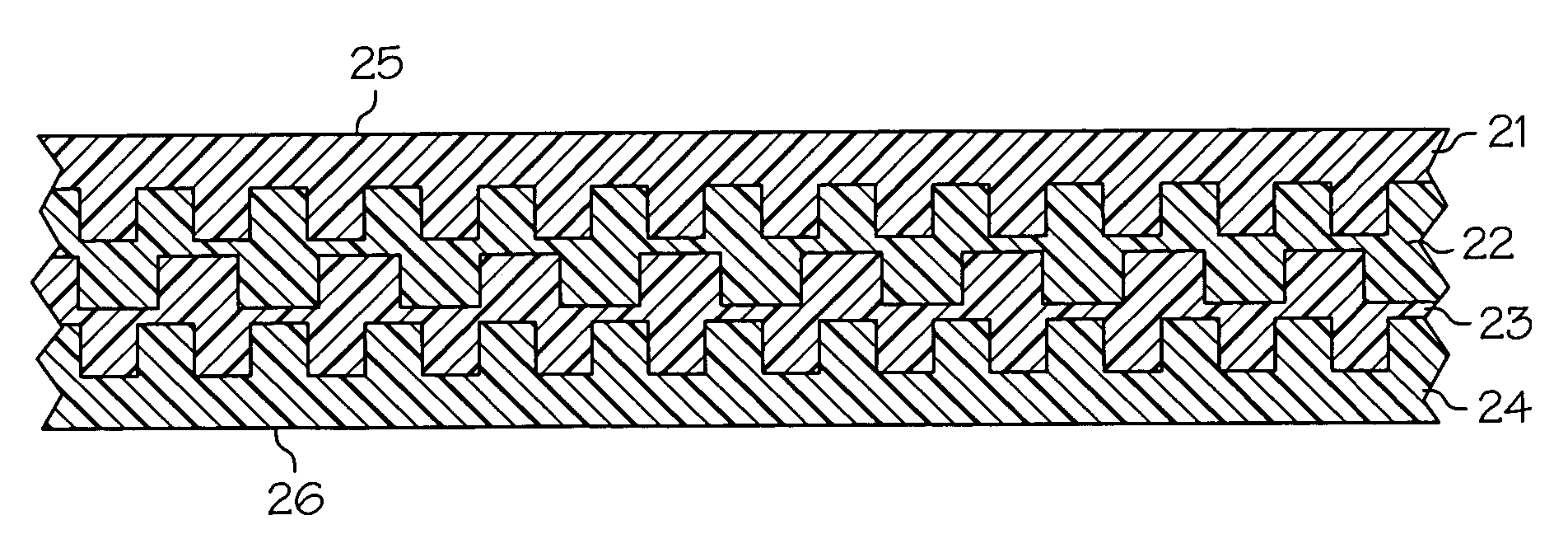

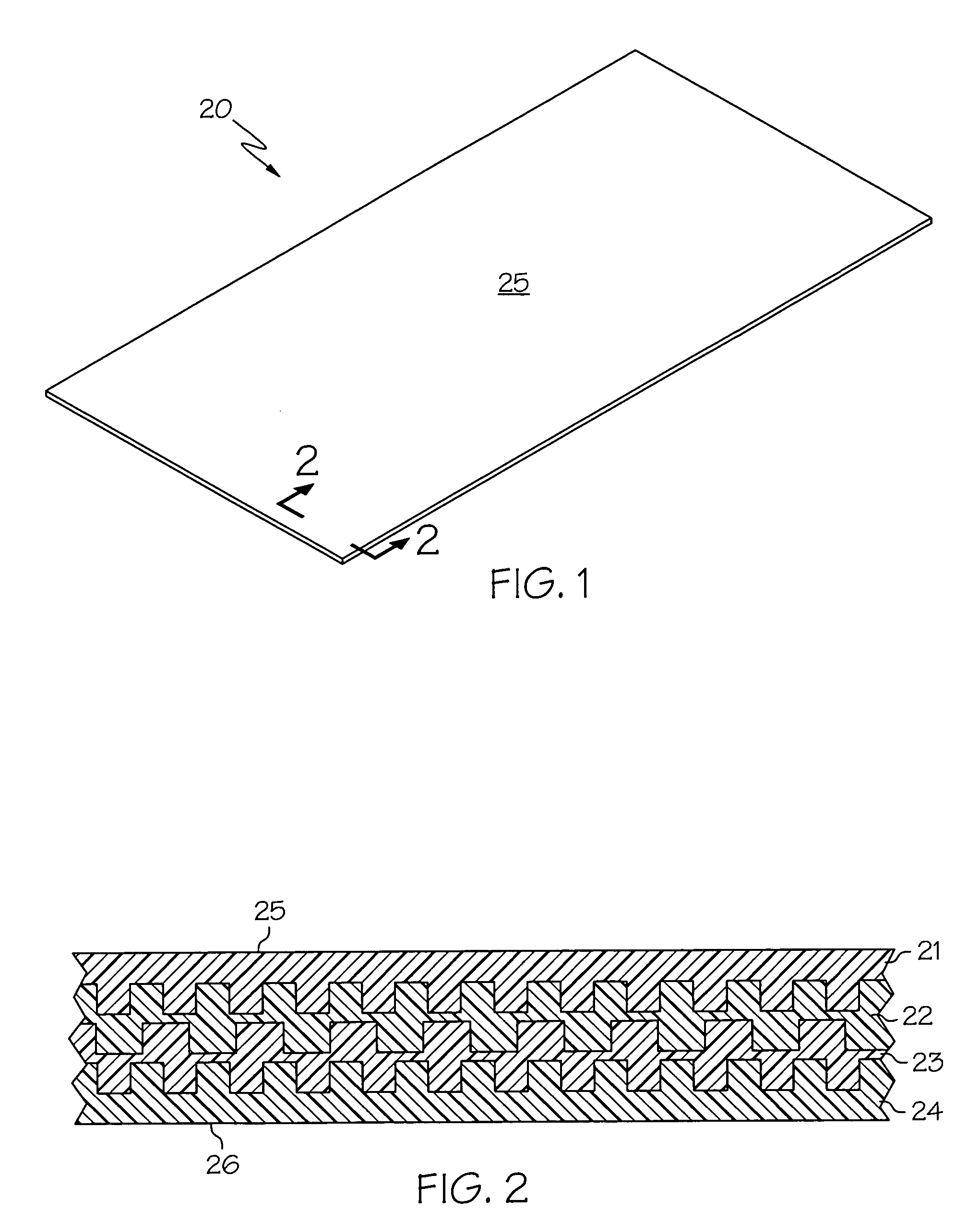

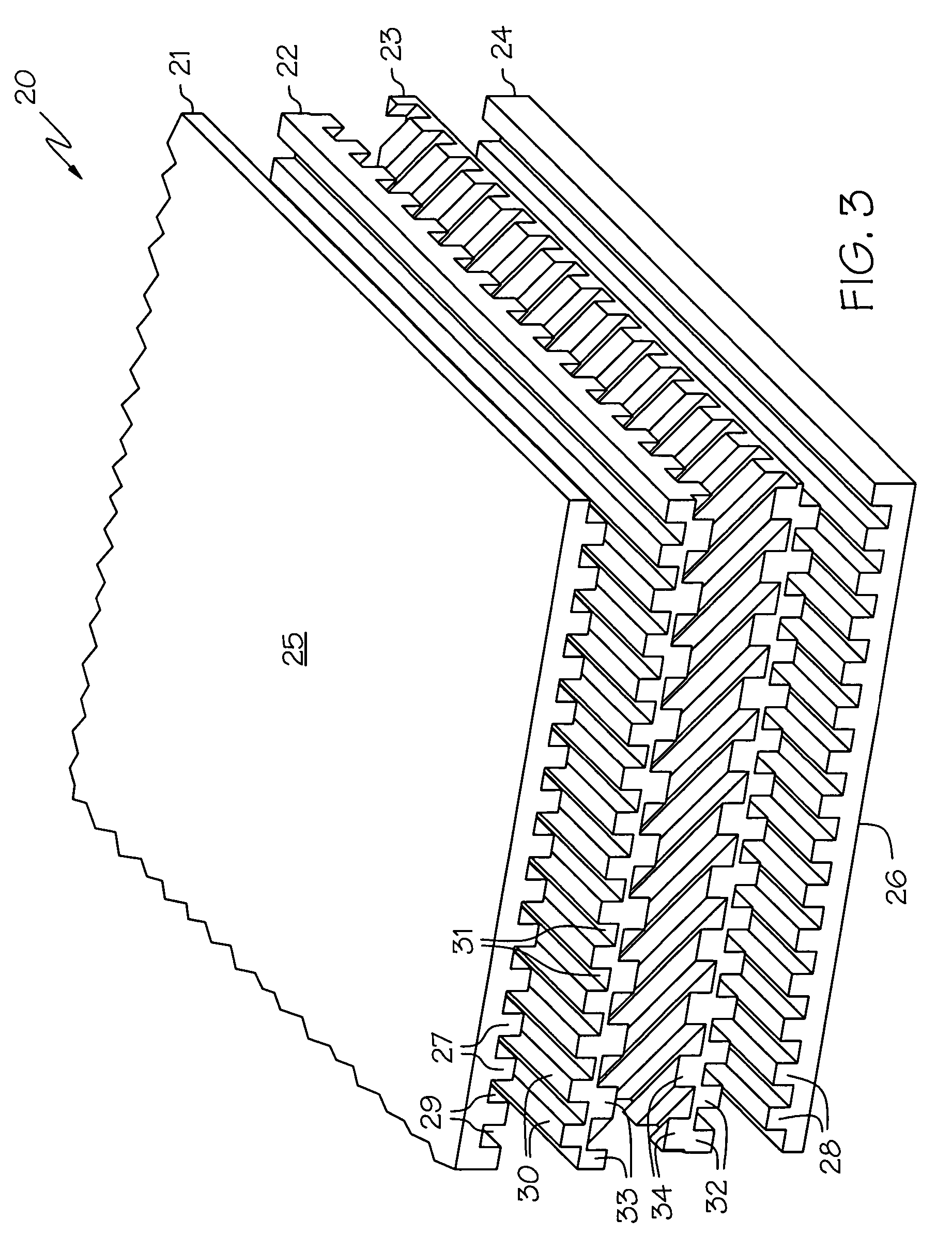

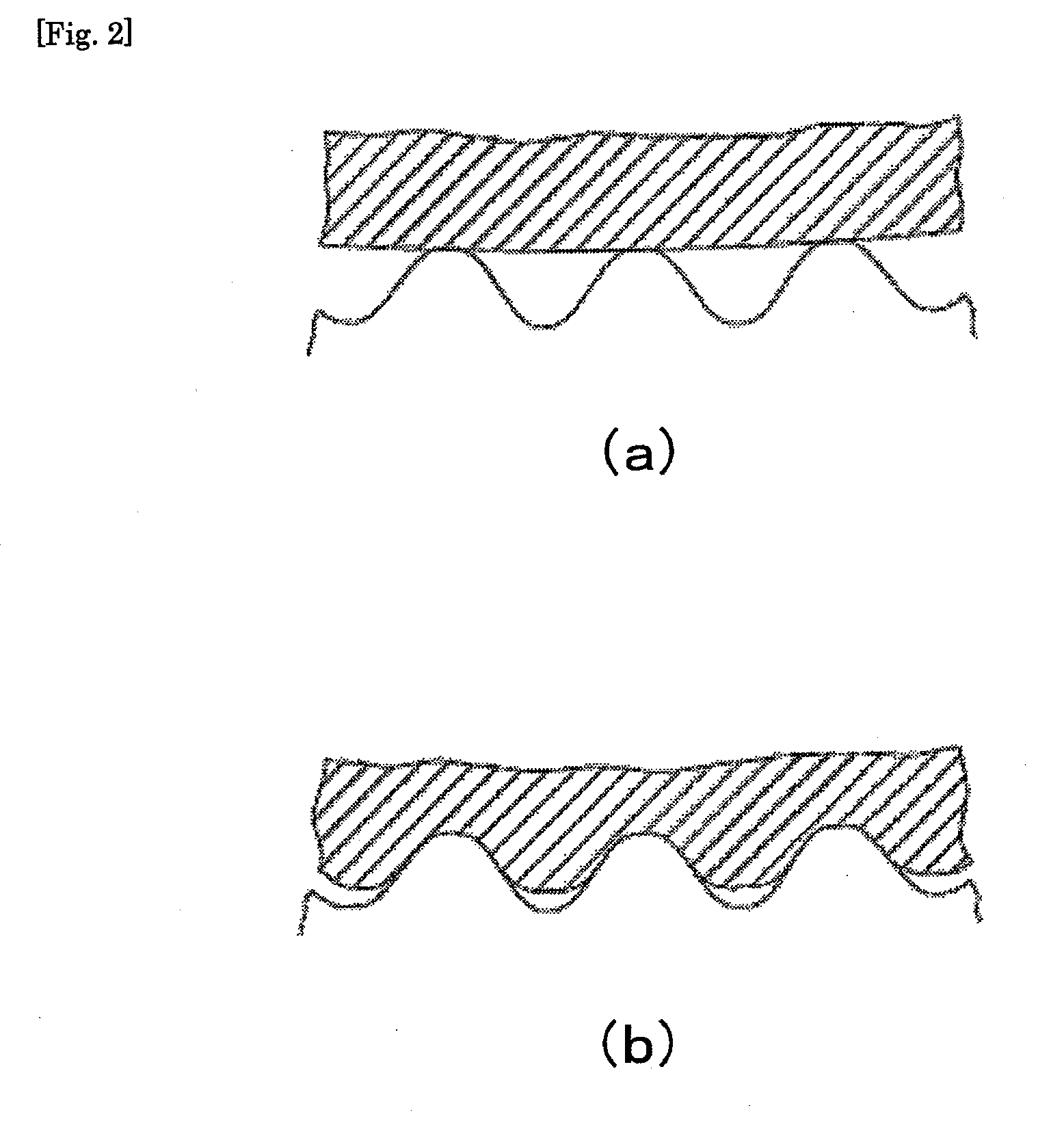

Composite articles formed from sheets having interconnecting ridges

ActiveUS7090911B2Increased strength and rigidityIncrease surface areaSynthetic resin layered productsLoad-supporting elementsManufactured formEngineering

A composite article of manufacture formed from at least three sheets of material laminated to one another. At least one surface of each of the sheets has a plurality of spaced-apart ridges which extend in a predetermined direction along the surface, and each of the pluralities of ridges is arranged so as to nest between a plurality of ridges on an adjacent sheet.

Owner:LASCELLES GARY

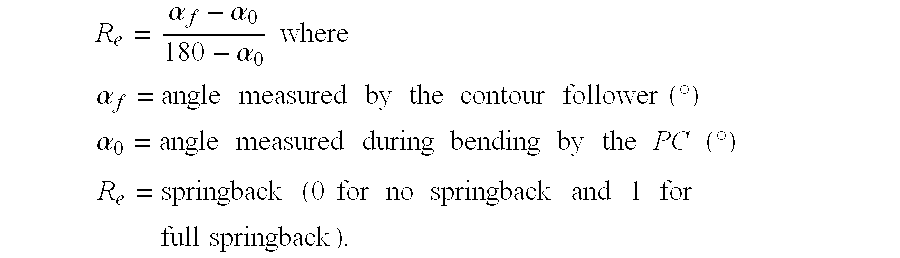

Method of manufacturing formed pieces of type 2024 aluminum alloy

InactiveUS20030140990A1Improve corrosion resistanceMetal rolling arrangementsManufactured formSolution treatment

This invention relates to a method of manufacturing highly worked pieces of AlCuMg alloy, comprising the steps of: a) casting a plate composed of (weight per cent): Cu: 3.8-4.5 Mg: 1.2-1.5 Mn: 0.3-0.5 Si<0.25 Fe<0.20 Zn<0.20 Cr<0.10 Zr<0.10 Ti<0.10, b) possibly homogenizing at a temperature between 460 and 510° C. for 2 to 12 hrs, and preferably at a temperature between 470 and 500° C. for a duration for 3 to 6 hrs, c) hot rolling at an input temperature between 430 and 470° C., and preferably between 440 and 460° C., d) cutting out sheets, e) forming in one or several processes, such as stretch forming, drawing, flow spinning, or bending, f) solution treating between 480 and 500° C., for a duration between 5 min and 1 hr, g) quenching, wherein forming can take place before and after solution treatment and quenching. The invention is applicable in particular for manufacturing aircraft fuselage panels.

Owner:PECHINEY RHENALU

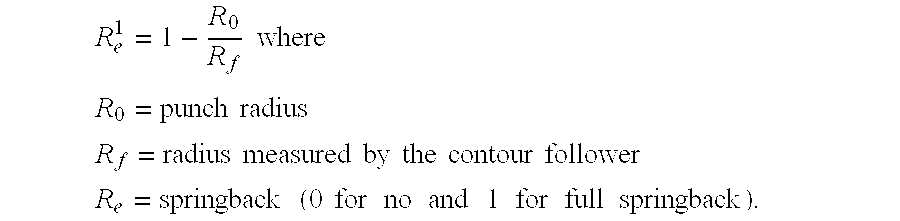

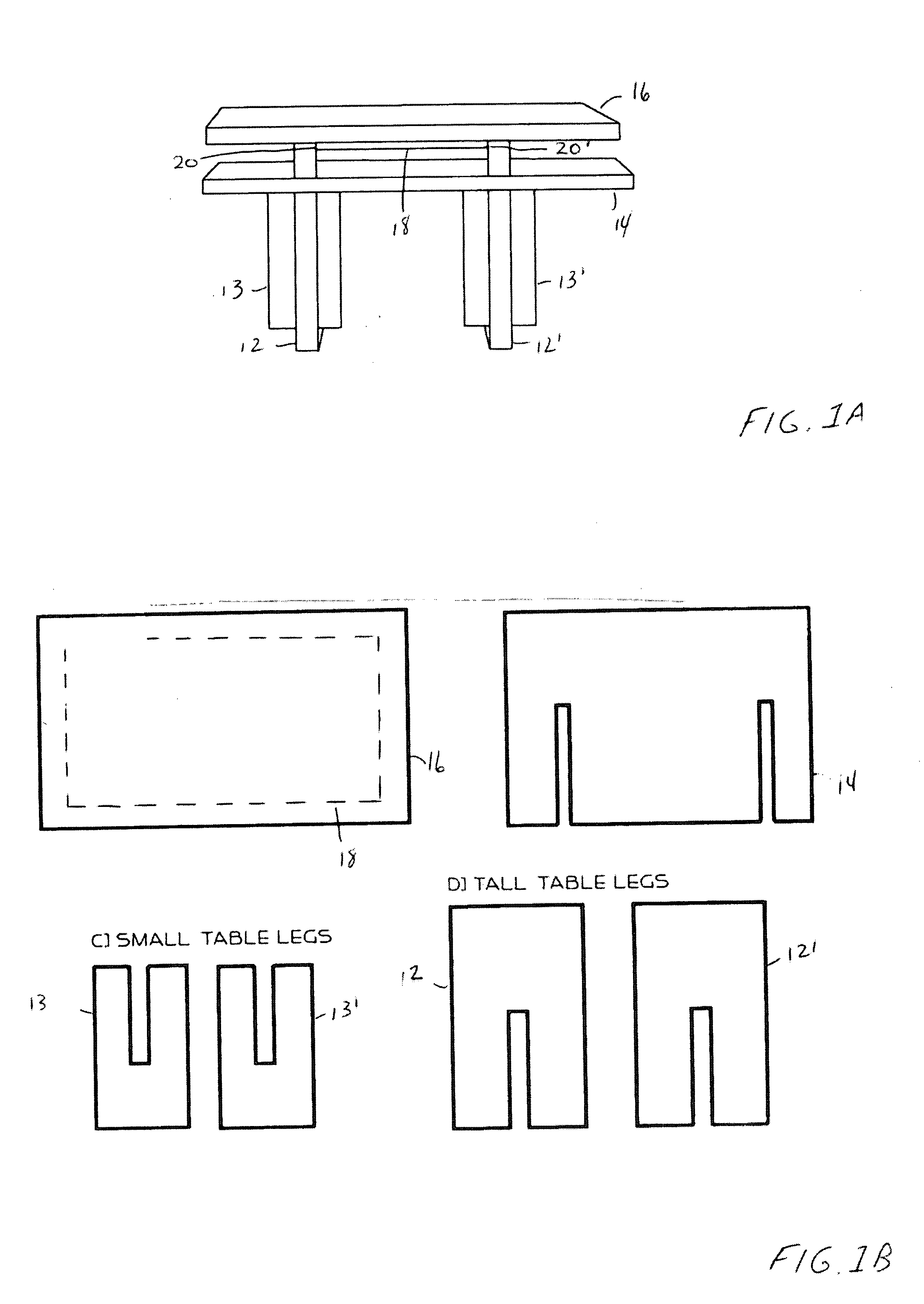

Furniture, home decor, and other items of manufacture formed of cellular material

InactiveUS20080237319A1Improve rigidityImprove structural strengthFurniture joining partsDismountable chairsManufactured formCardboard

Articles of furniture and home décor formed of a single panel of unfinished honeycomb cardboard cut in a compressed state along a first plane to have a predefined shape and expanded along a second plane; and fixing means for fixing the cut honeycomb cardboard in an expanded state. In preferred embodiments, the compressed honeycomb cardboard may be cut in the first plane to have the profile of a sofa, a chair, a table, a vase, or a tray, such that when the honeycomb cardboard is expanded it takes on a three-dimensional form thereof.

Owner:HENSEY CATHY +1

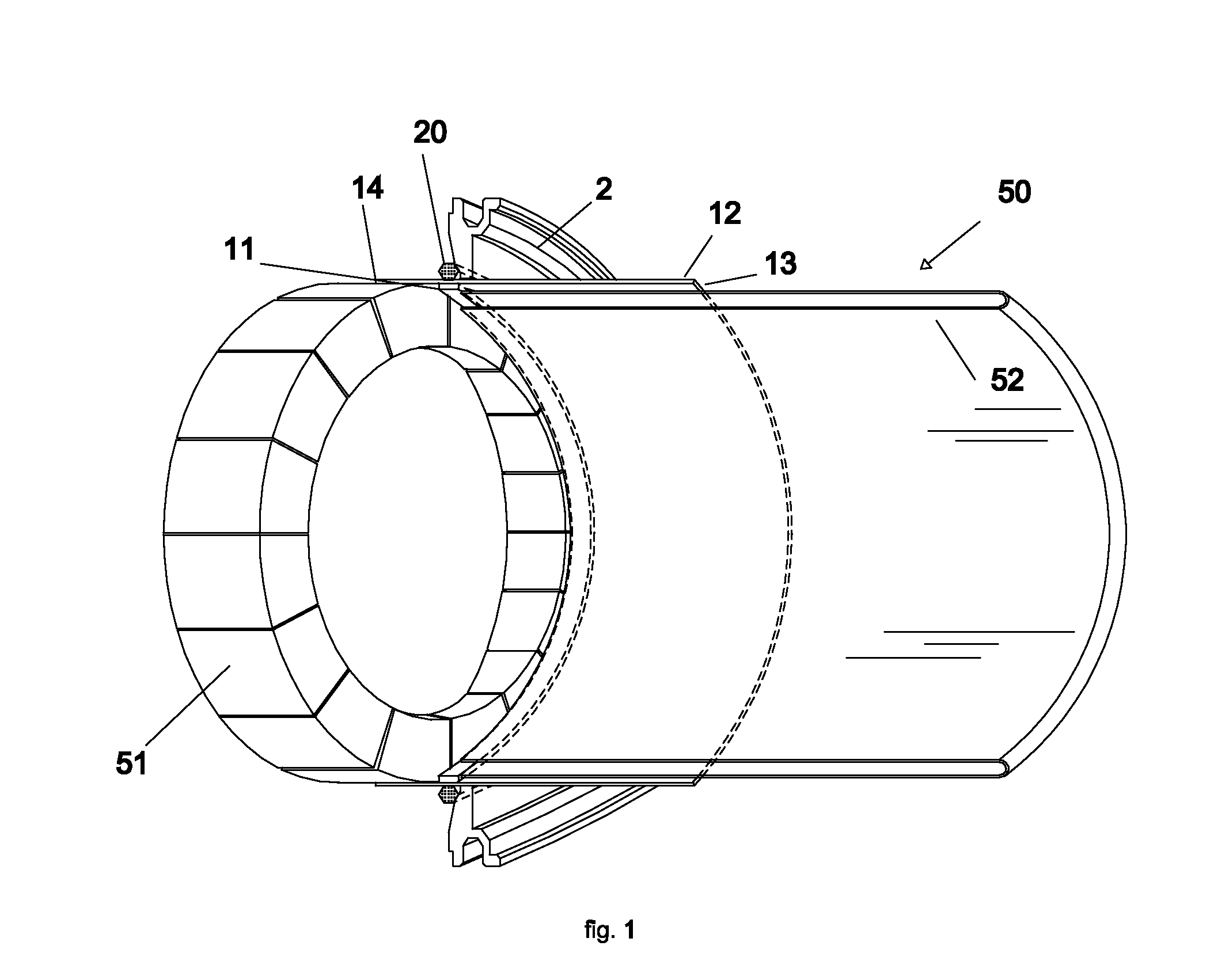

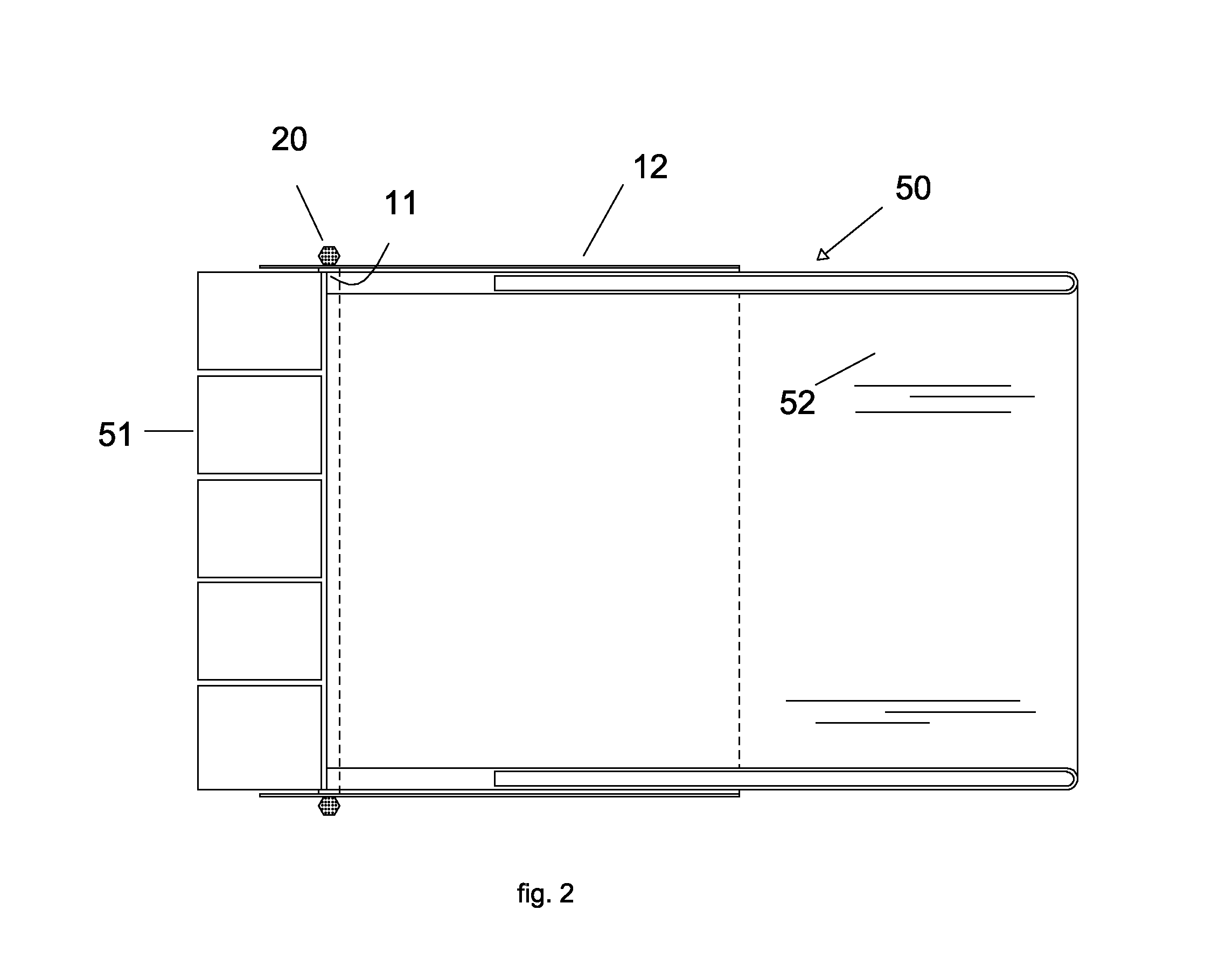

Decorative outer wrap subassembly and method of fabrication

InactiveUS20070137413A1Gap is minimalControlling membersMechanical apparatusManufactured formBiomedical engineering

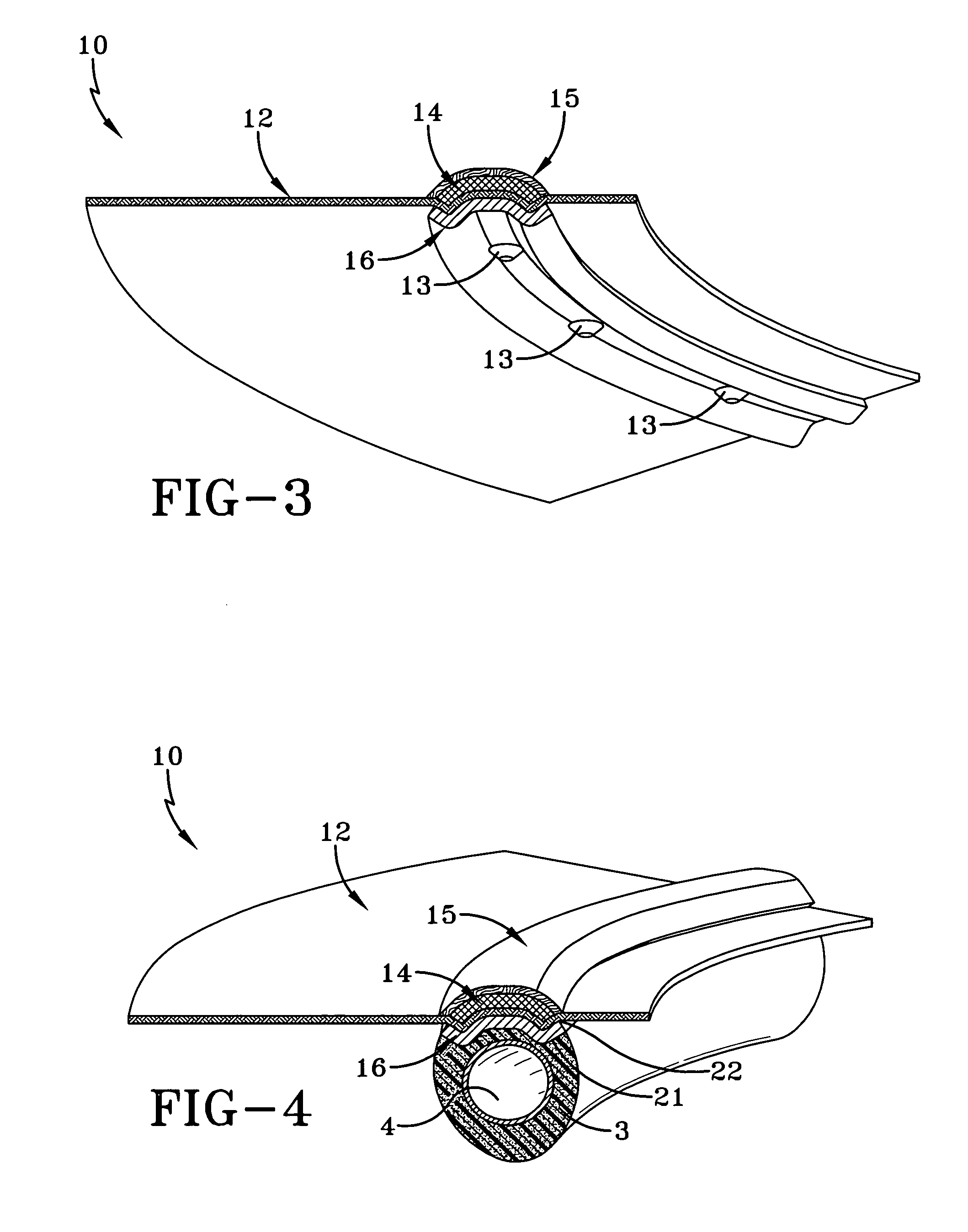

An intermediate article of manufacture forming an outer wrap subassembly having a leather, simulated leather or leather equivalent pliable component and one or more decorative components adhered to or otherwise attached to said leather, simulated leather or leather equivalent pliable component and one or more securing components is disclosed. The one or more securing components adheres or attaches the one or more decorative components to form the subassembly. The subassembly creates a unique attachment capability such that the crevice formed between the leather and the decorative component is maintained at a minimal gap and the radius of curvature of the leather component when assembled to the underlying article to form the final assembly has a radius of curvature of less than 2 mm, preferably 1.5 mm or less.

Owner:KEY SAFETY SYST

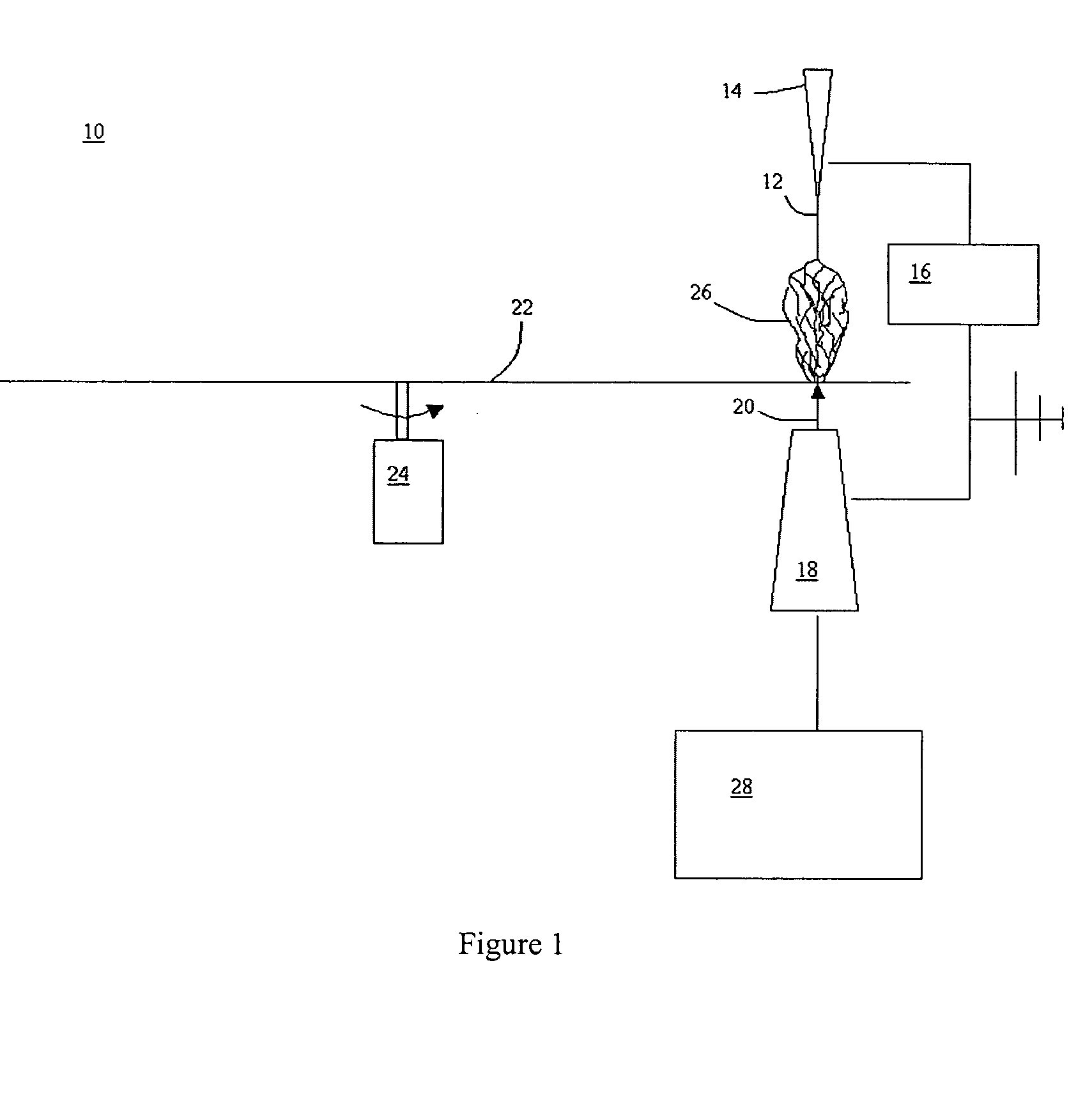

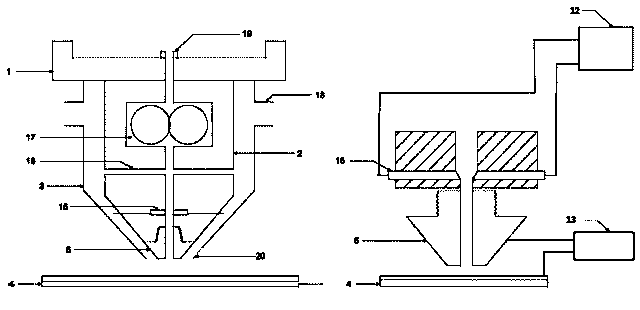

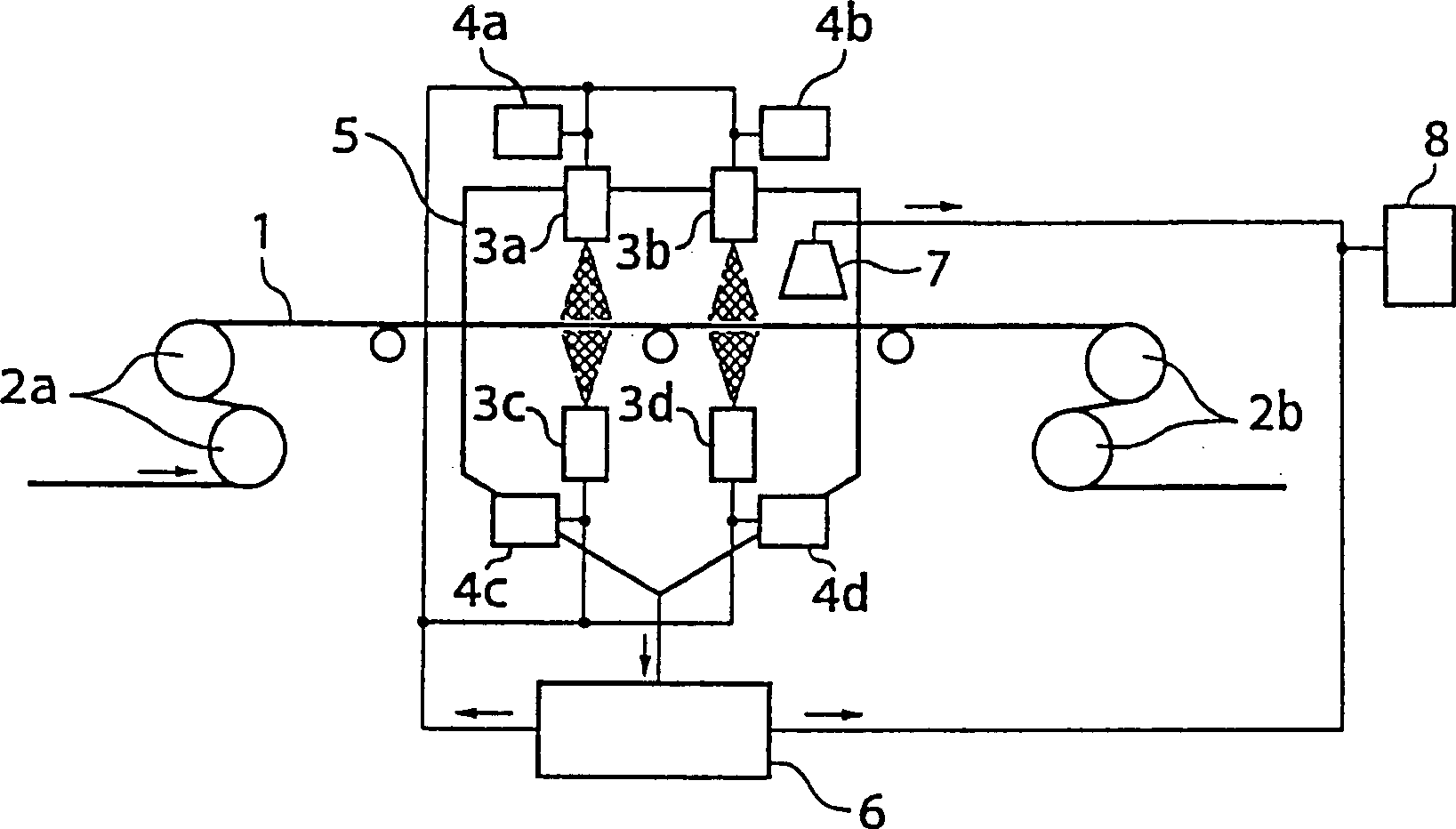

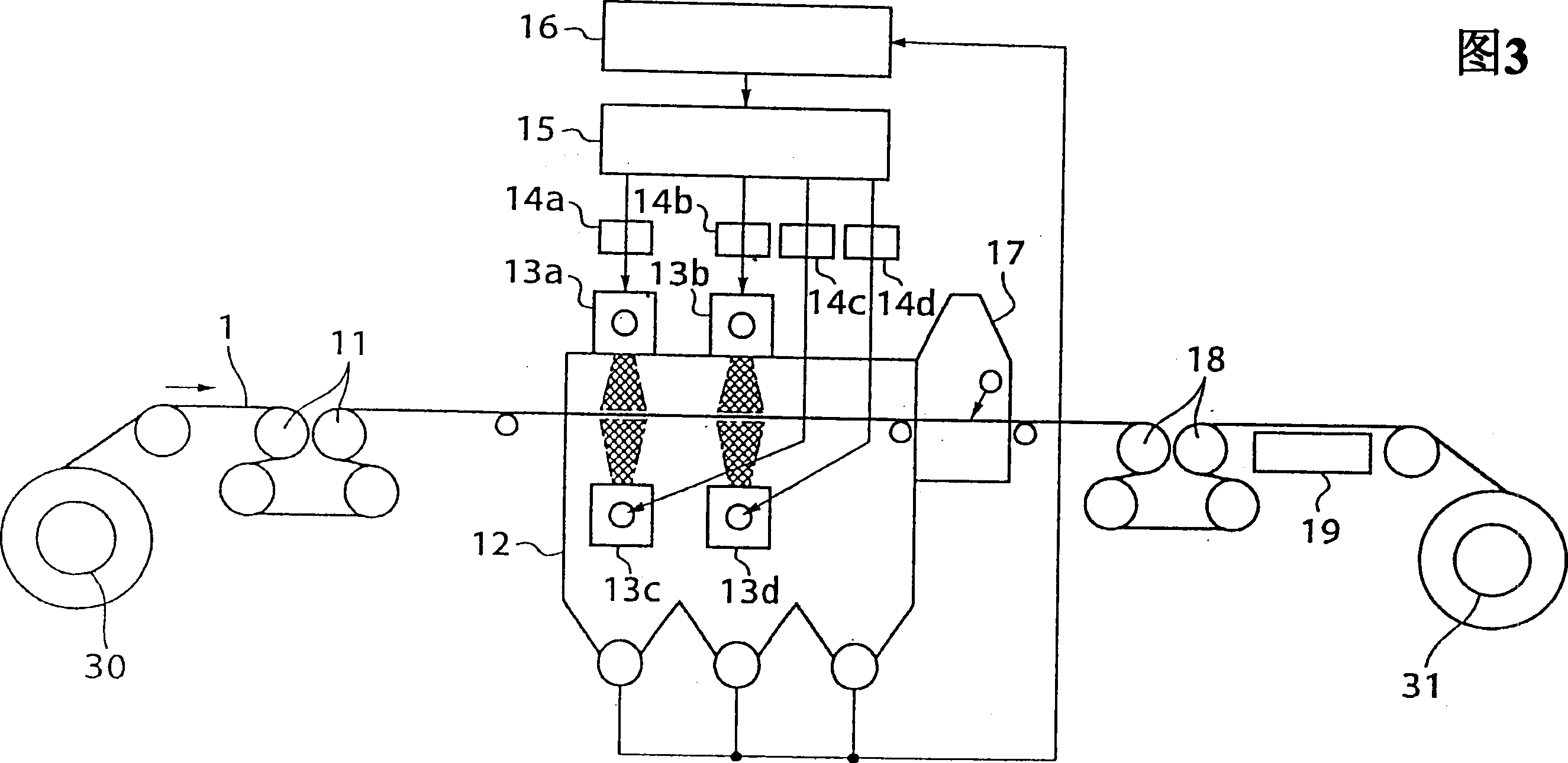

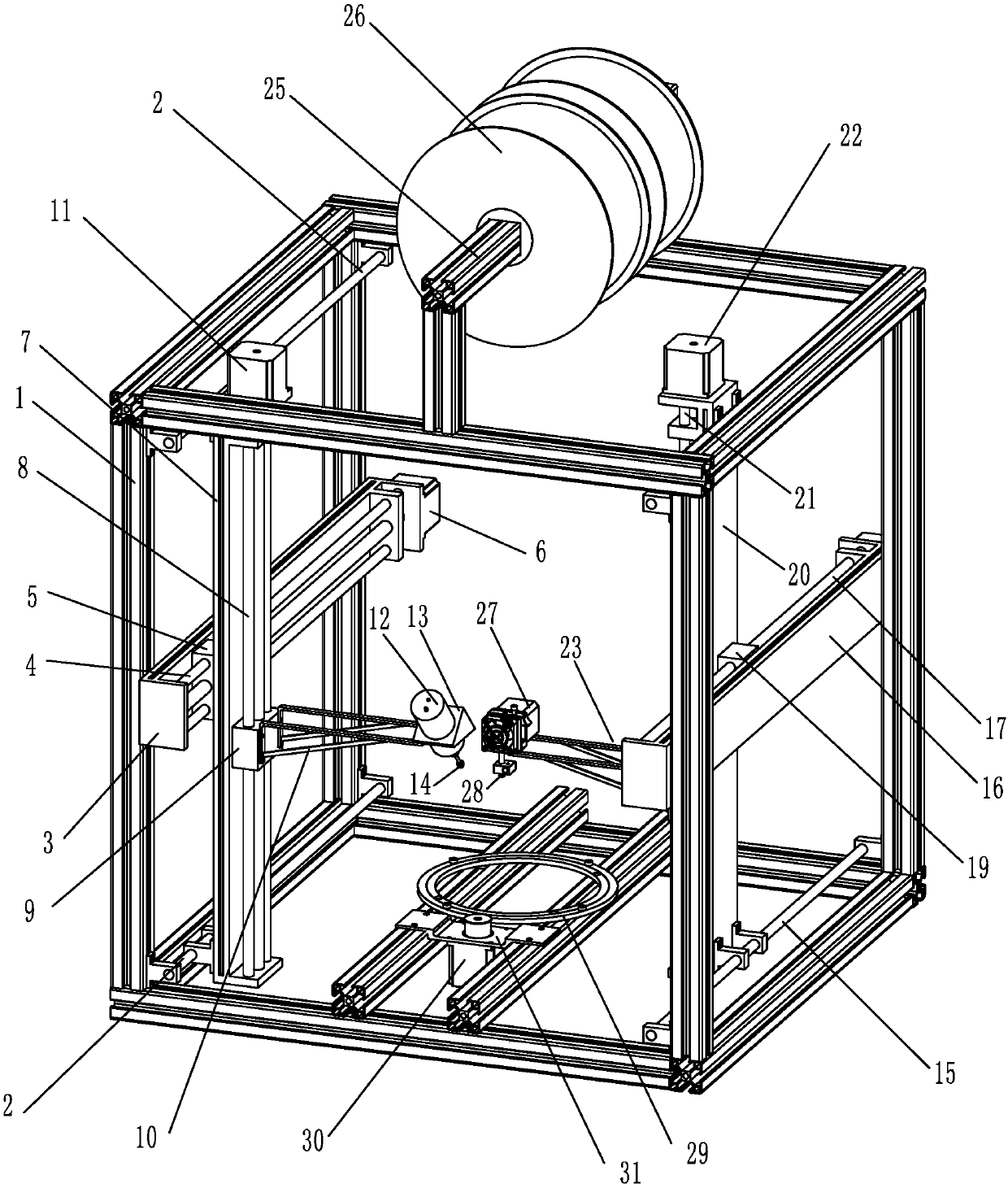

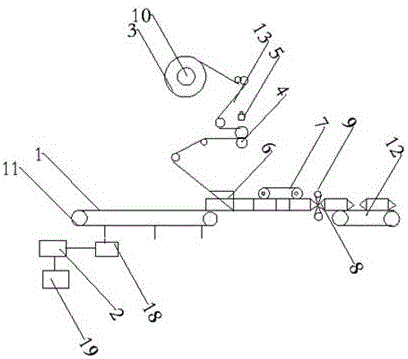

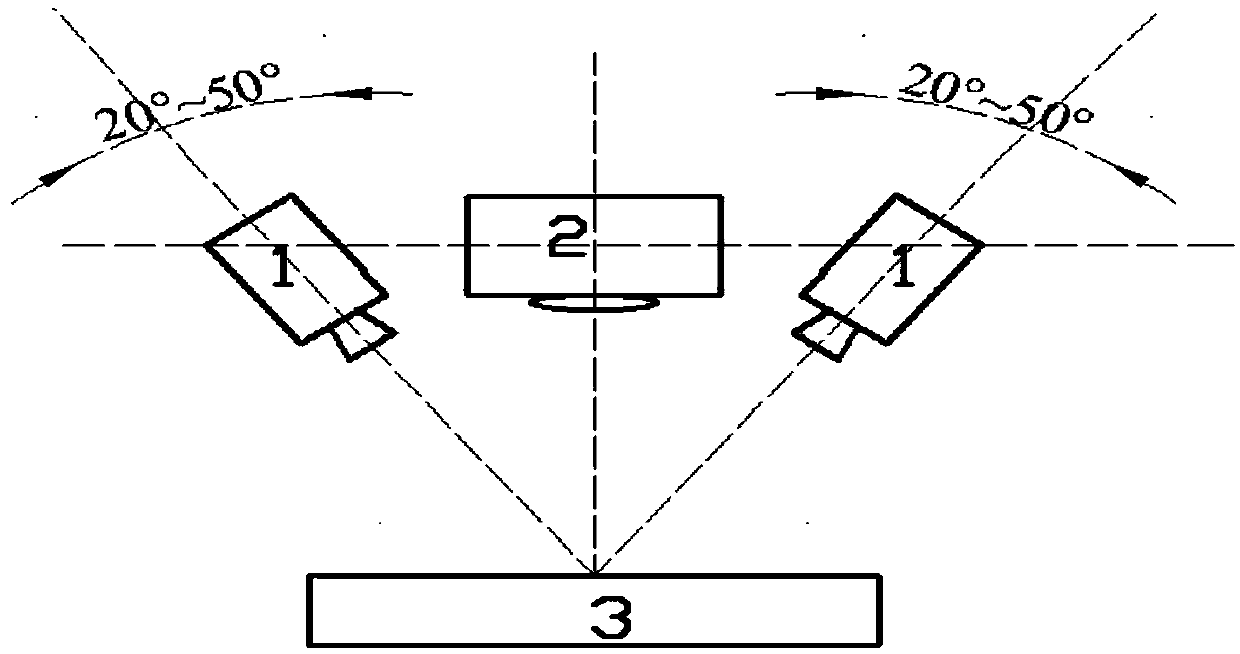

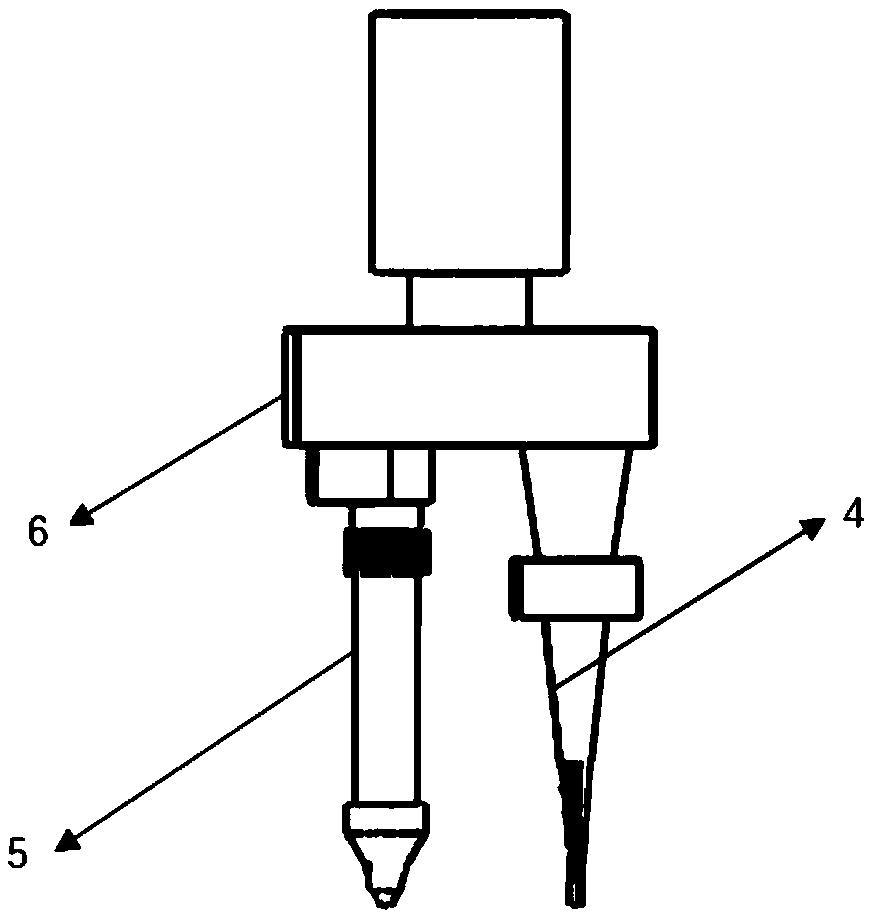

Resistance type double-melting stacking three-dimensional metal member manufacturing forming system

InactiveCN104001918ALow costReduce manufacturing costManufactured formElectrical resistance and conductance

The invention relates to a resistance type double-melting stacking three-dimensional metal member manufacturing forming system and discloses a metal part fast three-dimensional forming system. A resistor is utilized to heat materials, and a secondary re-melting method is adopted to quickly manufacture metal parts. The system is composed of a melting forming system, a material release system, a cooling and antioxidant conveying system and a high-power power supply. The system solves the problem that the existing three-dimensional part manufacturing system is high in cost, low in manufactured part density and poor in quality.

Owner:杭州易夫禾科技有限公司

Method for manufacturing formed plate by utilizing papermaking wastes

InactiveCN101733809AUniform compositionReduce energy consumptionSolid waste managementDomestic articlesSludgePapermaking

The invention relates to a method for manufacturing a formed plate by utilizing papermaking wastes, comprising the following steps of: A. preparing cut-off dust-removing material residues, slurry residues, papermaking sludge and boil flue gas-desulphurizing gypsum by weight part, uniformly mixing, drying and then pulverizing into a powdery mixed raw material; B. preparing the powdery mixed raw material, a magnesium lignosulfonate solution or a calcium lignosulphonate solution and plant straw particles by weight part, and uniformly mixing to obtain a basic raw material of the plate; and C. placing the basic raw material of the plate in a forming mould and implanting a strip-shaped skeleton or a grid-shaped skeleton, slicking, demoulding after forming the basic raw material of the plate by the compression of a press machine, and then sizing and drying to obtain the product of the formed plate. The method comprehensively utilizes a plurality of papermaking wastes and has the advantages of simple technology, low production cost, good quality, no three-waste discharge and no environmental pollution, and the manufactured formed plate has the advantages of high adhesive strength, high mechanical properties comprising compression resistance, tensile resistance, bending resistance, impact resistance and the like, good processing performance and wide application range.

Owner:刘保军

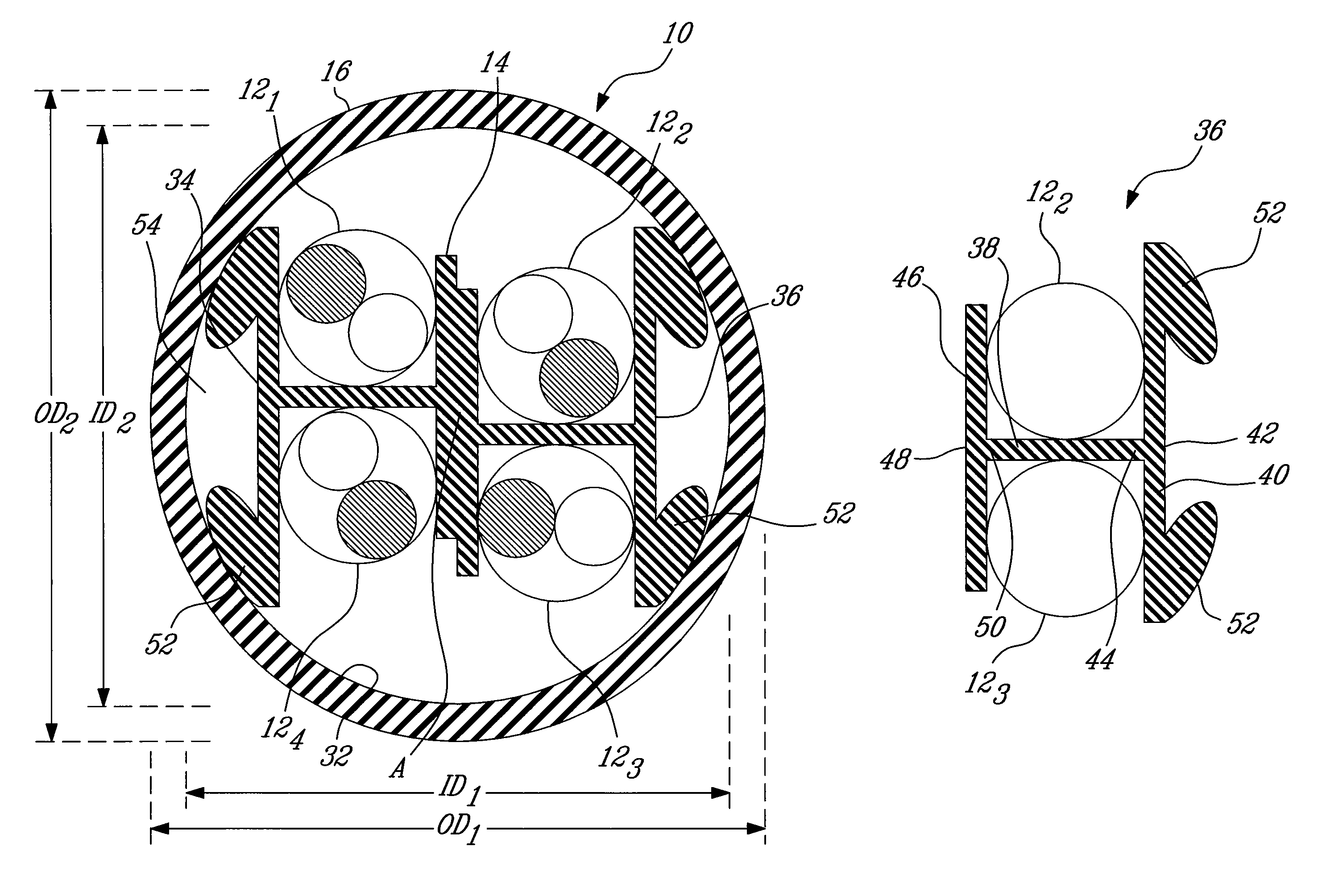

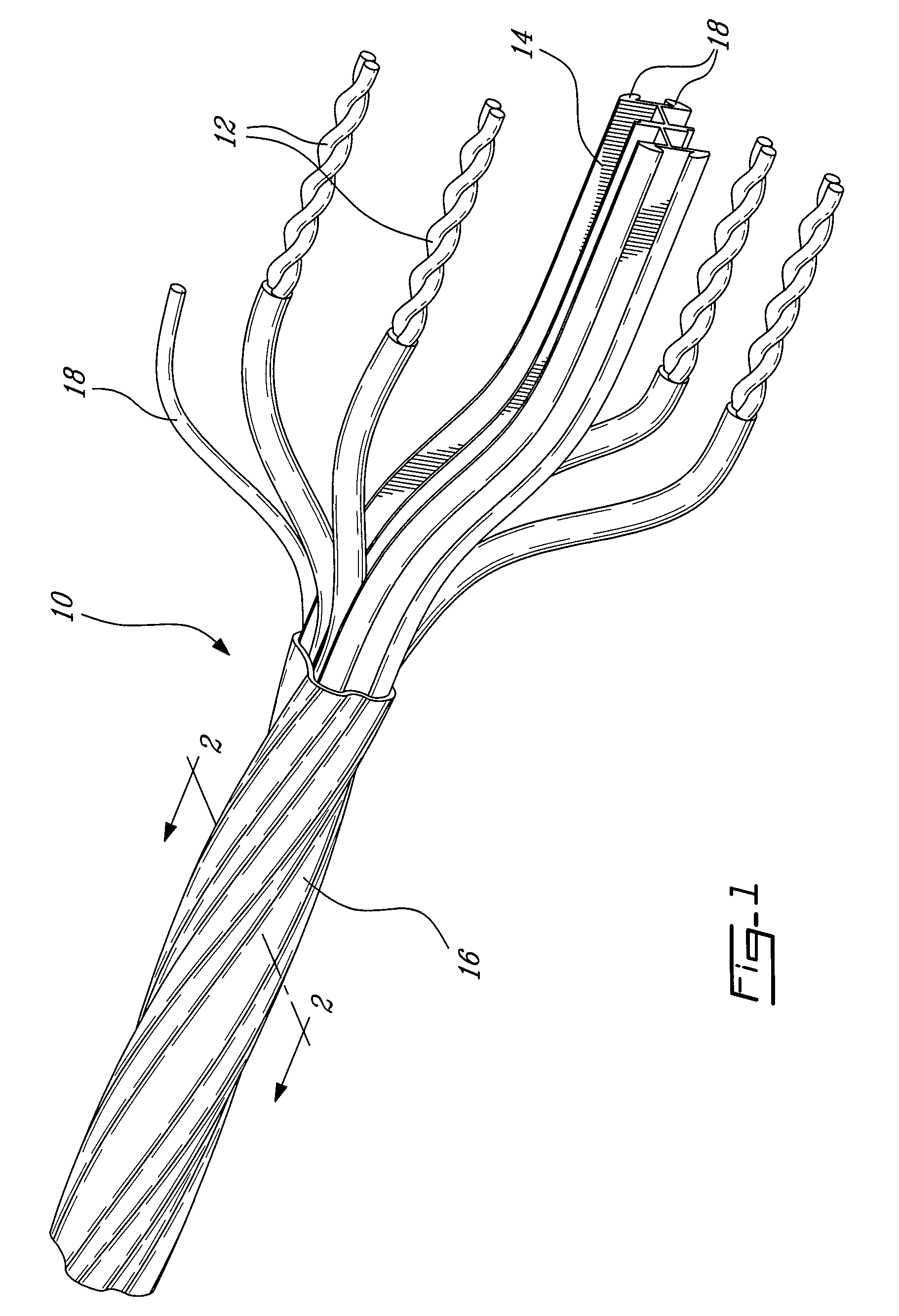

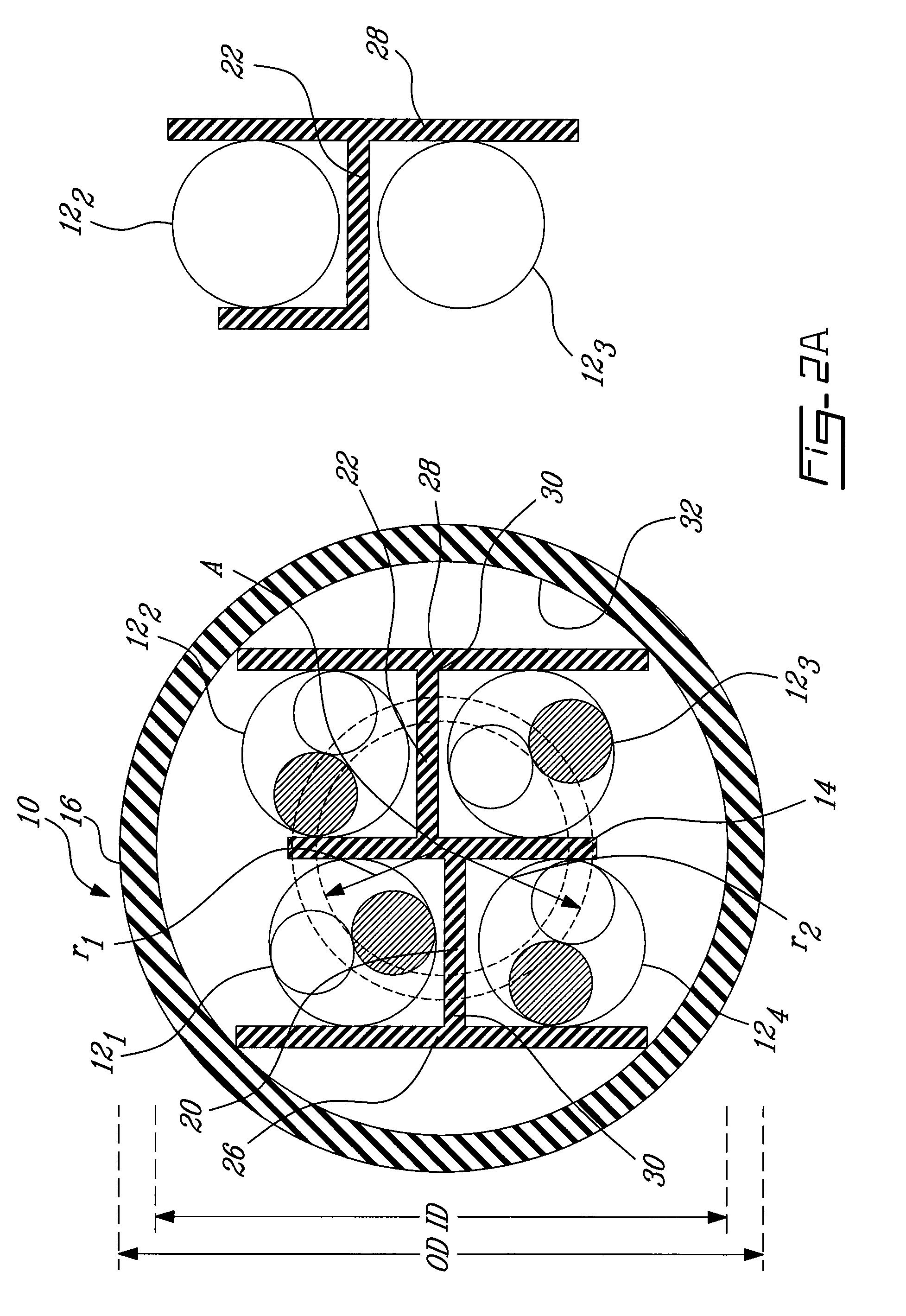

Web for separating conductors in a communication cable

A telecommunications cable having a cable jacket defining an elongate cable core, a conductor assembly comprising four twisted pairs of conductors disposed along the core and parallel elongate distensions formed on an inner surface of the cable jacket. The distensions are spaced about an inner surface of the cable jacket and prevent the conductor assembly from coming into contact with the inner surface. The distensions can be the result of a series of filler elements placed between the cable jacket and the cable core and which wind helicoidally along and about the cable core. A separator spline has first and second elongate dividing strips having a substantially H shaped cross section and arranged side by side. The spline twists helicoidally along its length. The separator spline and the insulation surrounding the twisted pairs of conductors can be manufactured form a material having the same dielectric constant.

Owner:BELDEN INC

Zinc-plated steel sheet and method for preparation thereof, and method for manufacturing formed article by press working

The method for manufacturing galvanized steel sheet has a step of adjusting the surface texture thereof by blasting solid particles against the surface thereof. The surface texture is defined by at least one parameter selected from the group of parameters consisting of mean roughness Ra on the surface of steel sheet, peak count PPI on the surface of steel sheet, and filtered centerline waviness Wca on the surface of steel sheet. The galvanized steel sheet has a surface in dimple-pattern texture.

Owner:JFE STEEL CORP

Laser additive manufacturing forming method of titanium alloy thin-walled component

InactiveCN106513675AHigh scrap rateCasting quality is not easy to controlAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufactured form

The invention relates to a laser additive manufacturing forming method of a titanium alloy thin-walled component, in particular to a preparing method of a multi-branch thin-walled titanium alloy structure and belongs to the technical field of titanium alloy structural machining and molding. The preparing method is the structural preparing method based on a selective laser melting forming and laser cladding technology. According to the thin wall, the titanium alloy structure with the thickness of the titanium alloy not larger than 5mm and particularly the wall thickness ranging from 2 mm to 4 mm is formed. The titanium alloy complex thin-walled component obtained through the method has the 4mm wall thickness, and the 0.1mm / 100mm size precision, and the manufacturing period is shortened by 50%.

Owner:BEIJING SATELLITE MFG FACTORY

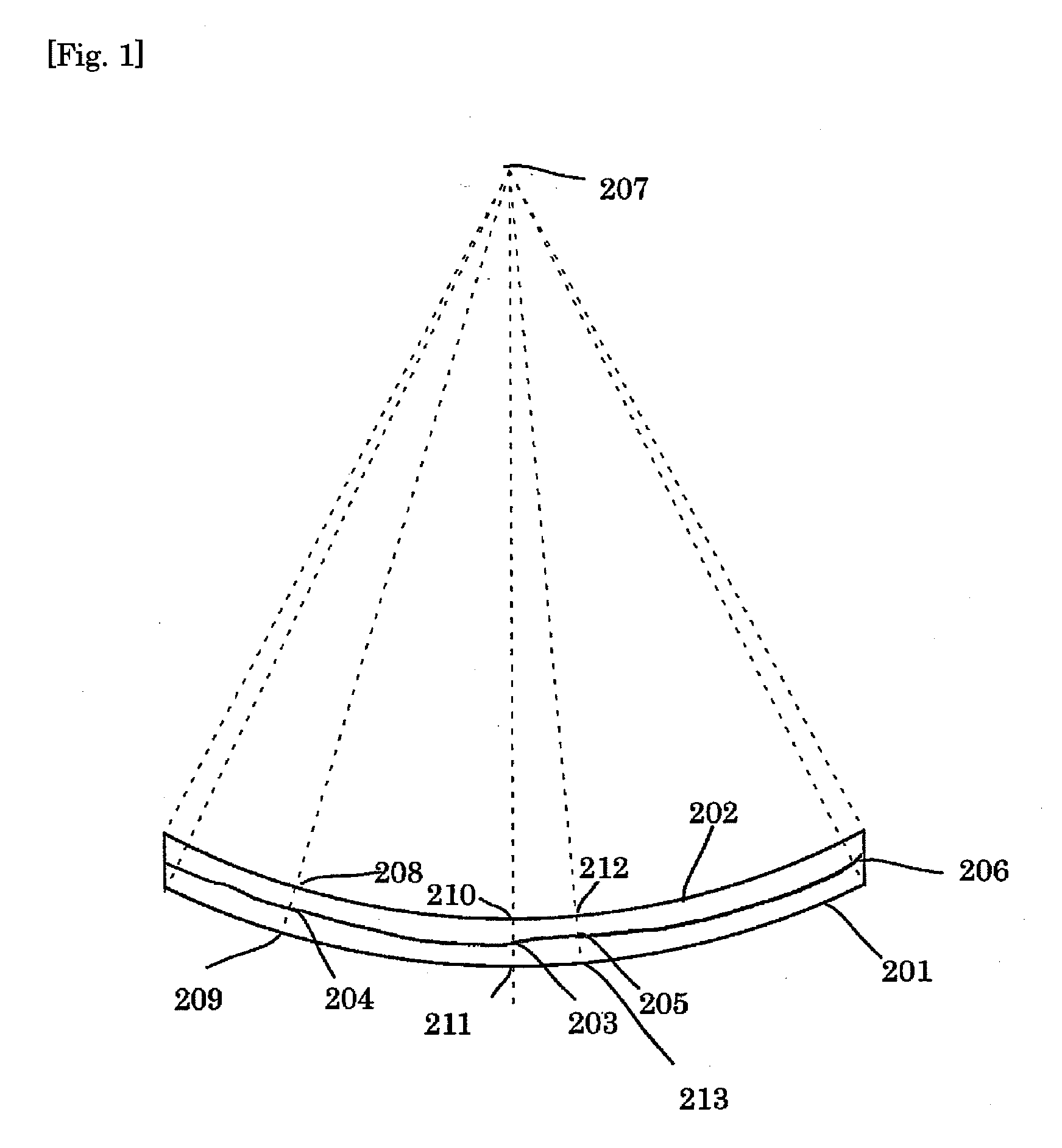

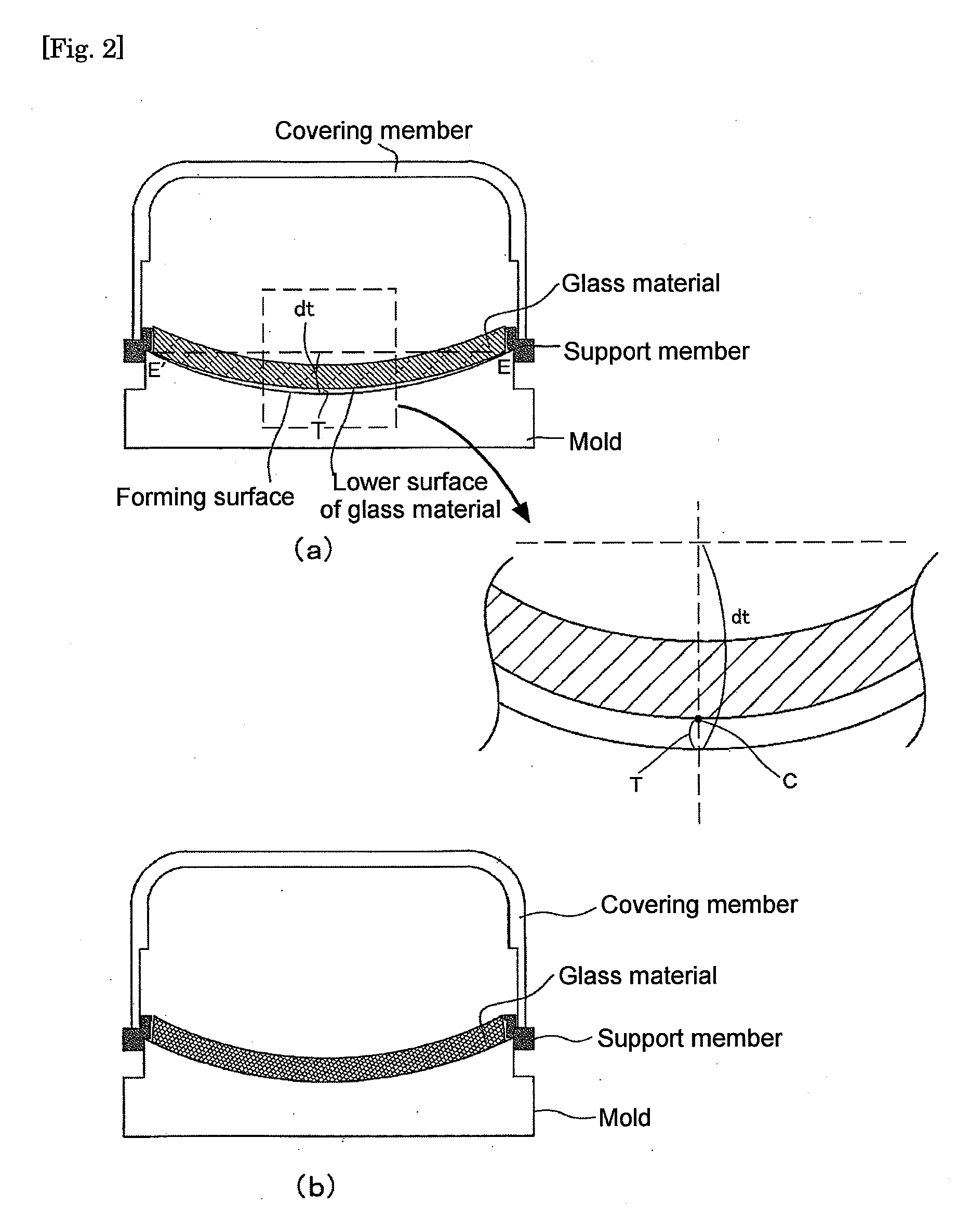

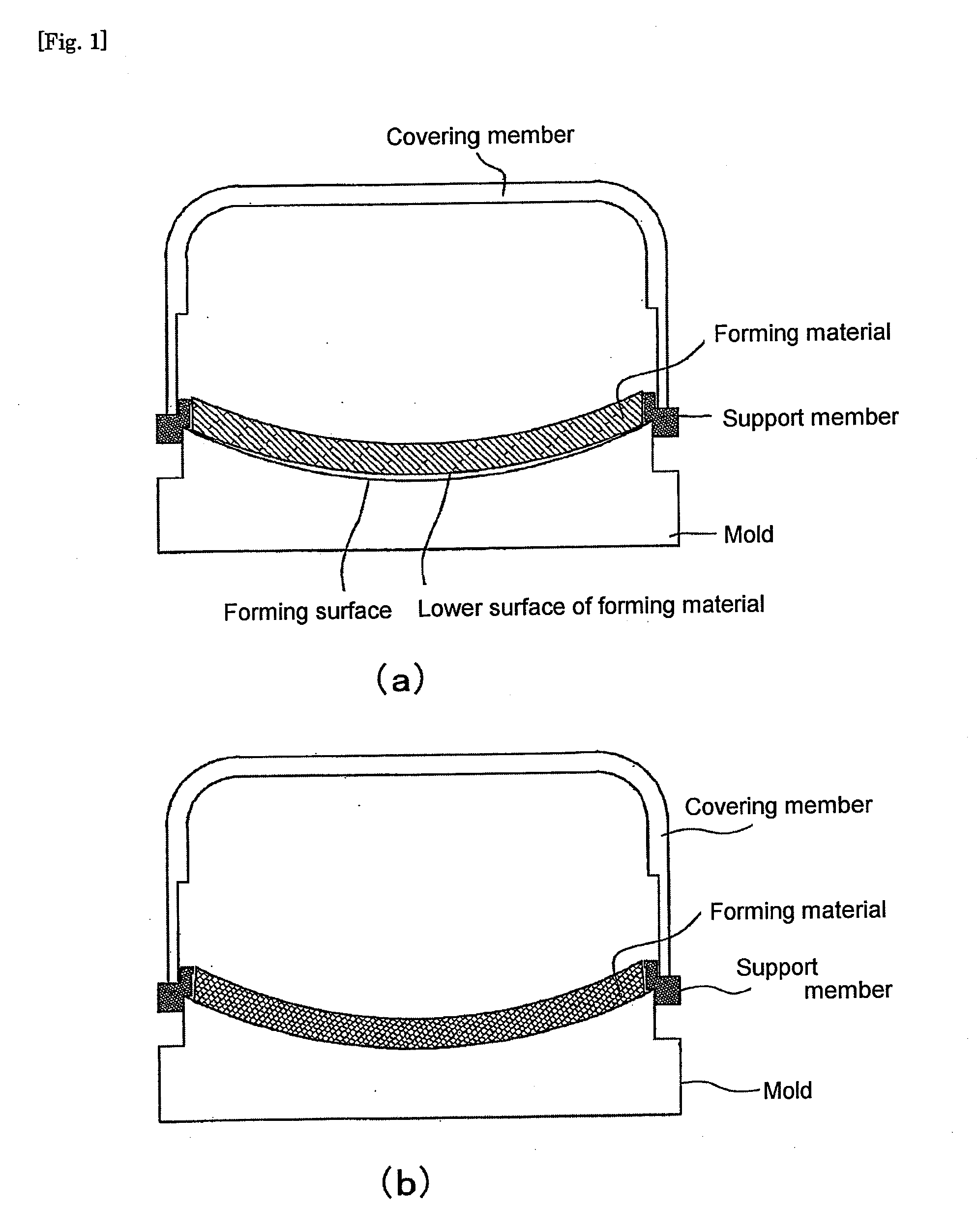

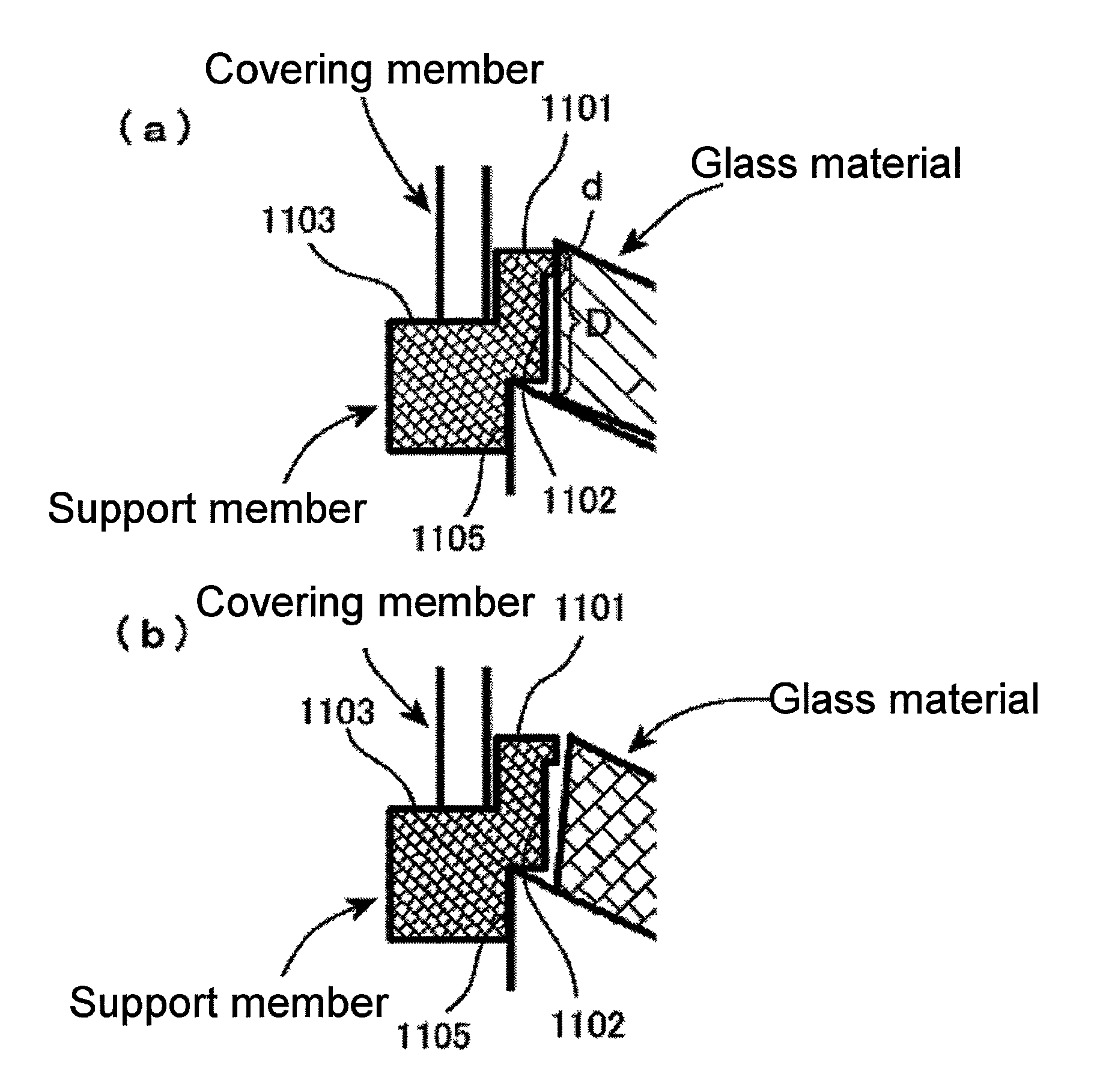

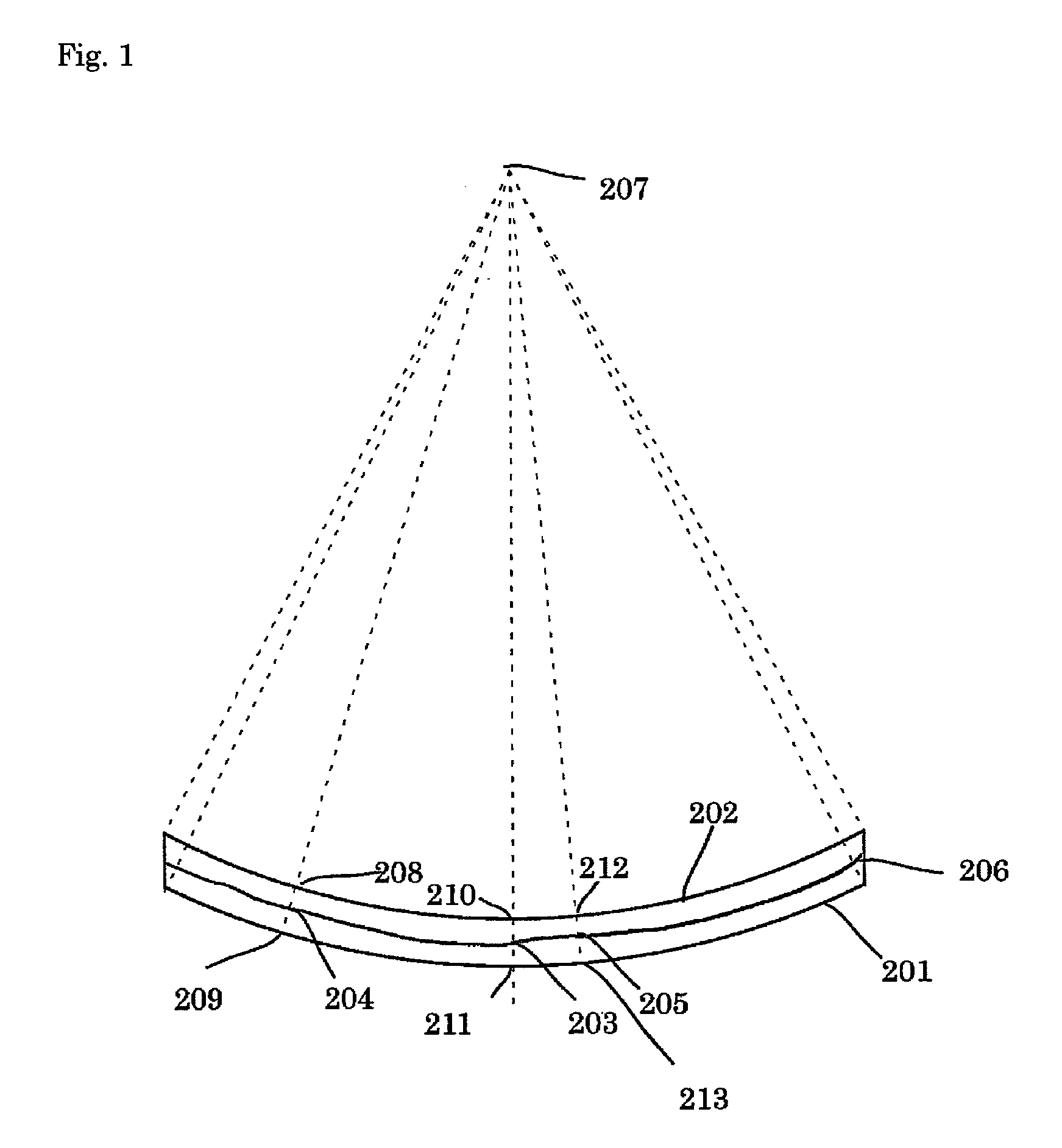

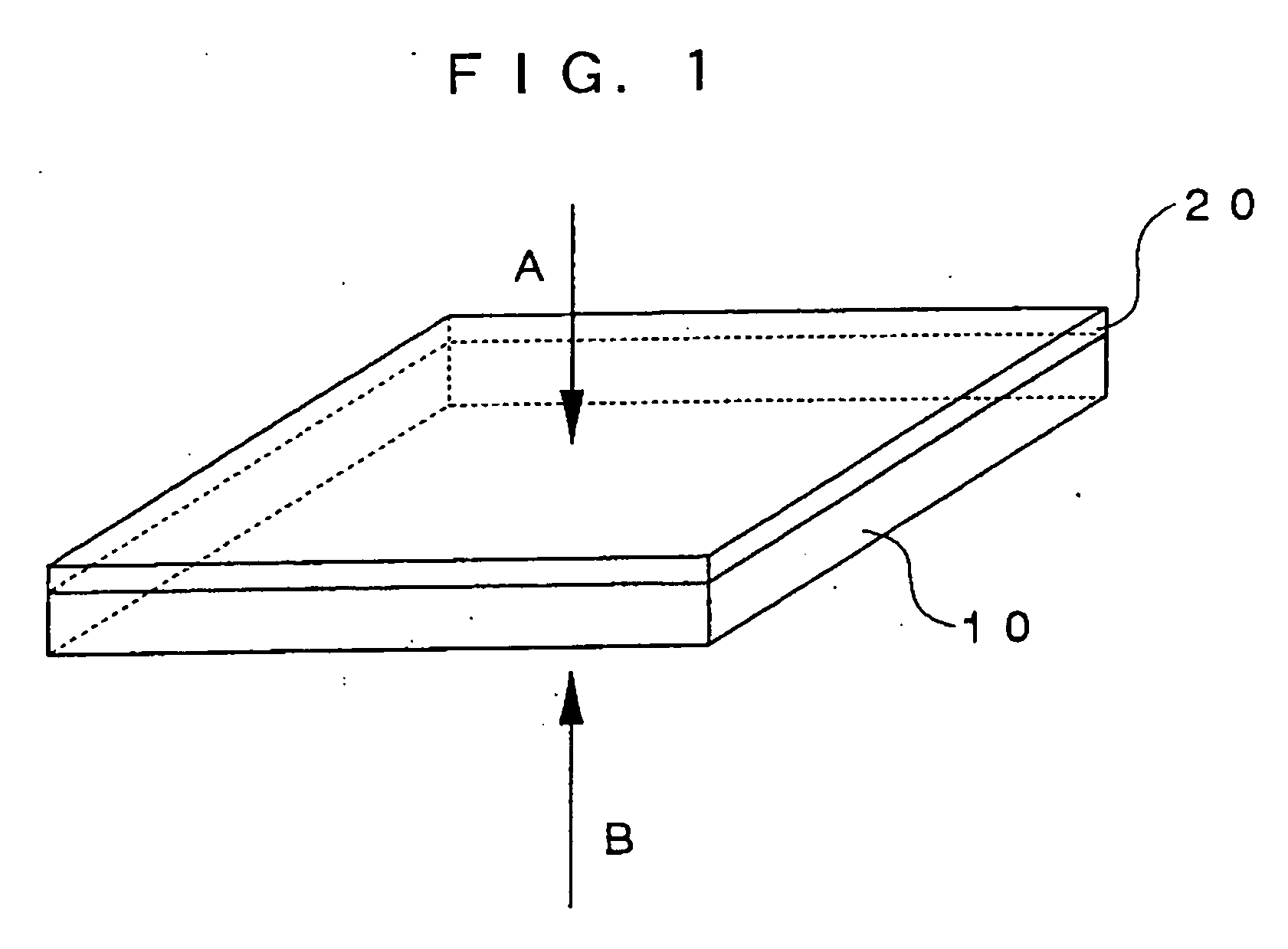

Method of Manufacturing Formed Article, Glass Material, and Method of Determining Shape of Glass Material and Mold

ActiveUS20090108477A1Improve accuracyEasy and simple determinationConfectioneryOptical articlesManufactured formHeat flow

The present invention relates to a method of manufacturing a formed article comprising forming an upper surface of a glass material that has been positioned on a forming surface of a mold to obtain the formed article by heating the glass material to a temperature permitting deformation to bring a lower surface of the glass material into tight contact with the forming surface. Glass having upper and lower surfaces being spherical in shape is employed as the glass material, a mold having a forming surface being a free-form surface other than a spherical surface is employed as the mold, the upper surface of the glass material is formed into a roughly offset surface relative to the forming surface of the mold. The present invention permits the manufacturing of formed articles of desired shape with high precision by hot sag molding method. The present invention also permits the easy and simple determination of the surface shapes of molds and glass materials employed in hot sag molding method.

Owner:HOYA CORP

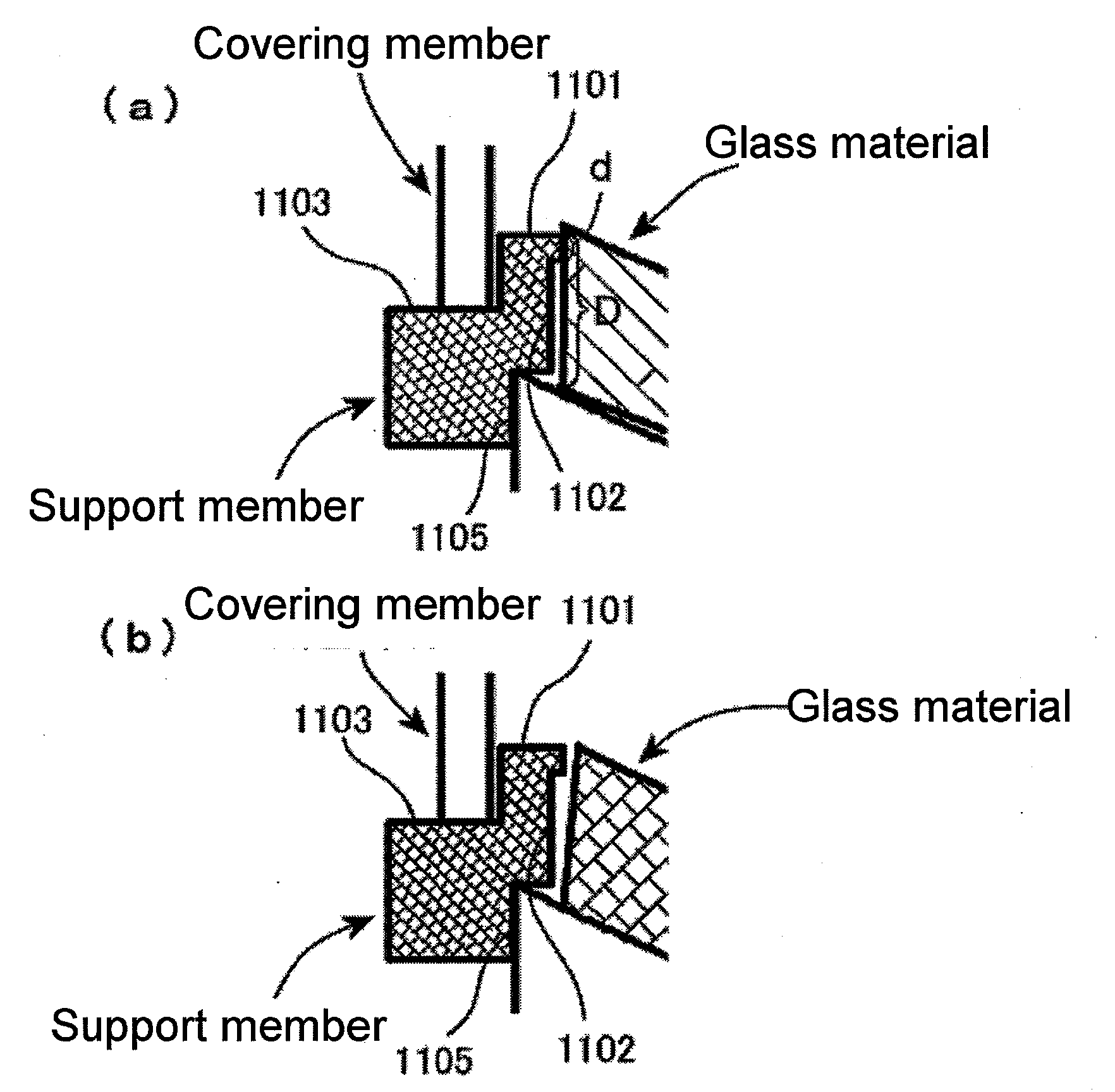

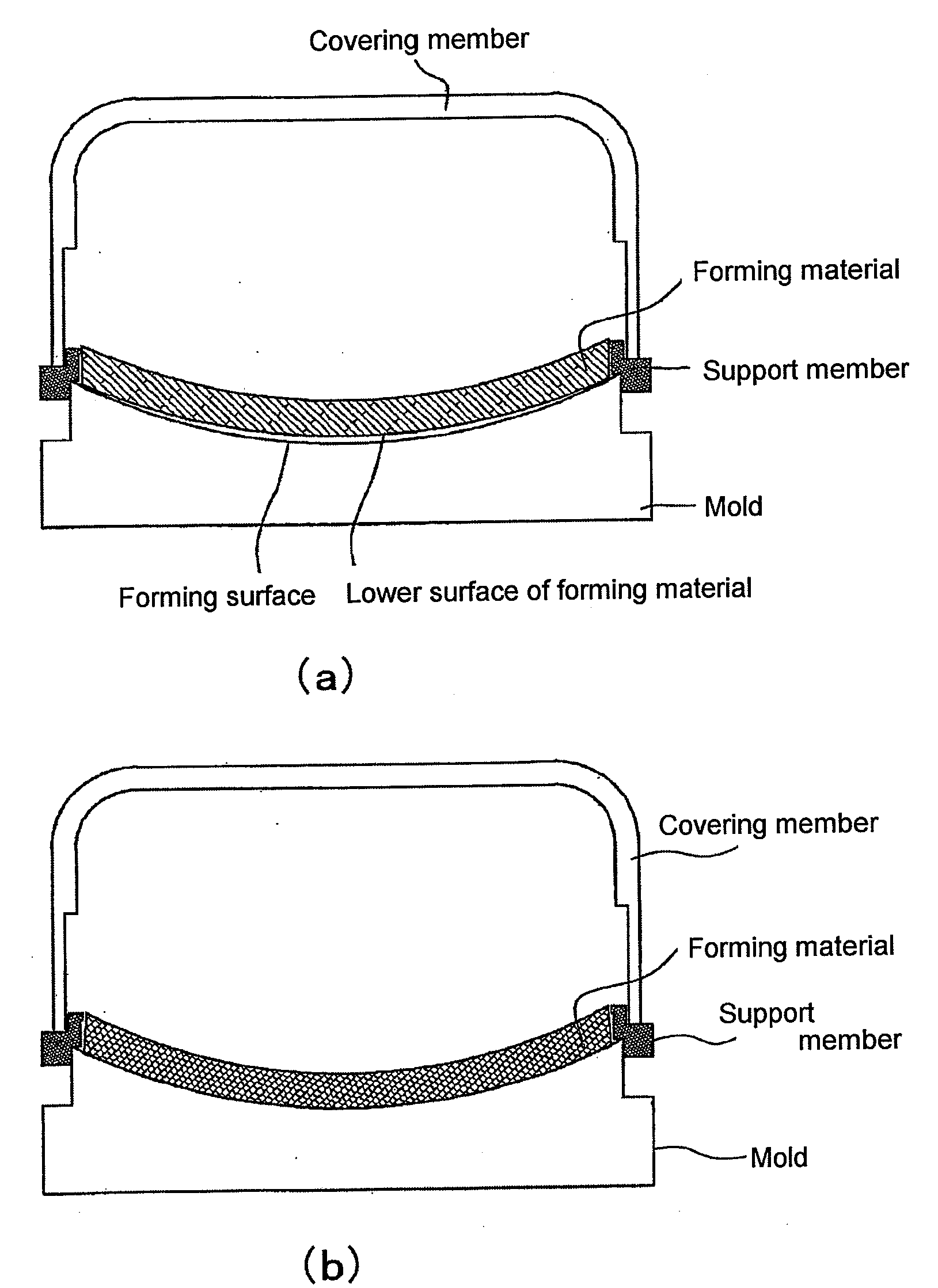

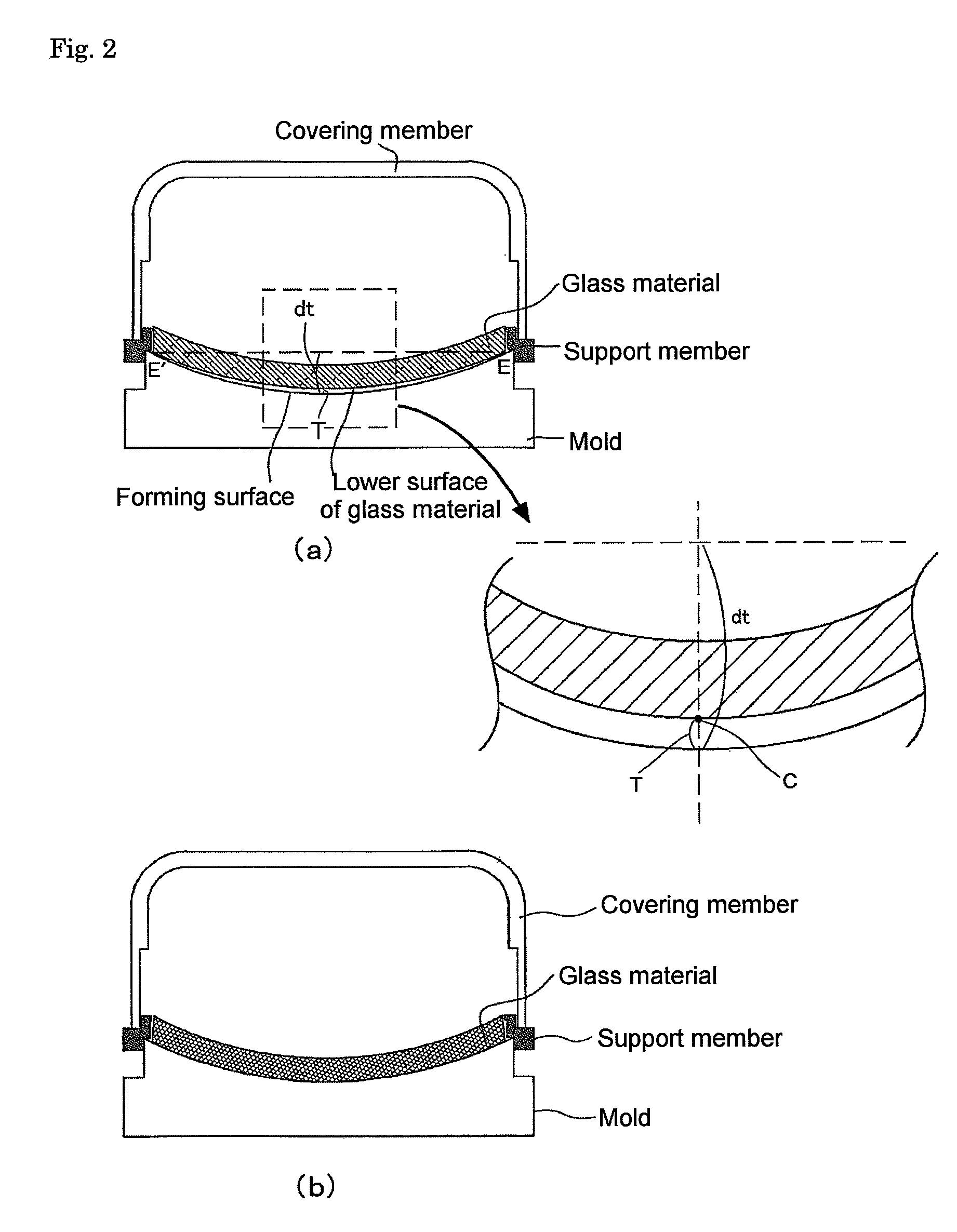

Method of manufacturing formed article, covering member, and forming apparatus comprising the same

InactiveUS20090289380A1Improve accuracyRemove distortionMelt-holding vesselsOptical articlesForeign matterBiomedical engineering

The present invention relates to a method of manufacturing a formed article forming an upper surface of a forming material comprised of a thermosoftening substance into a desired shape by positioning the forming material on a forming surface of a mold and heating the forming material to a temperature permitting deformation to bring a lower surface of the forming material into tight contact with the forming surface. The forming is conducted while an exposed portion on the forming surface side of the mold upon which the forming material has been positioned is covered with a covering member. The present invention further relates to a covering member and a forming apparatus. According to the present invention, formed articles with a desired shape can be formed with high accuracy by preventing the contamination of upper surface of forming materials by foreign matter during forming.

Owner:HOYA CORP

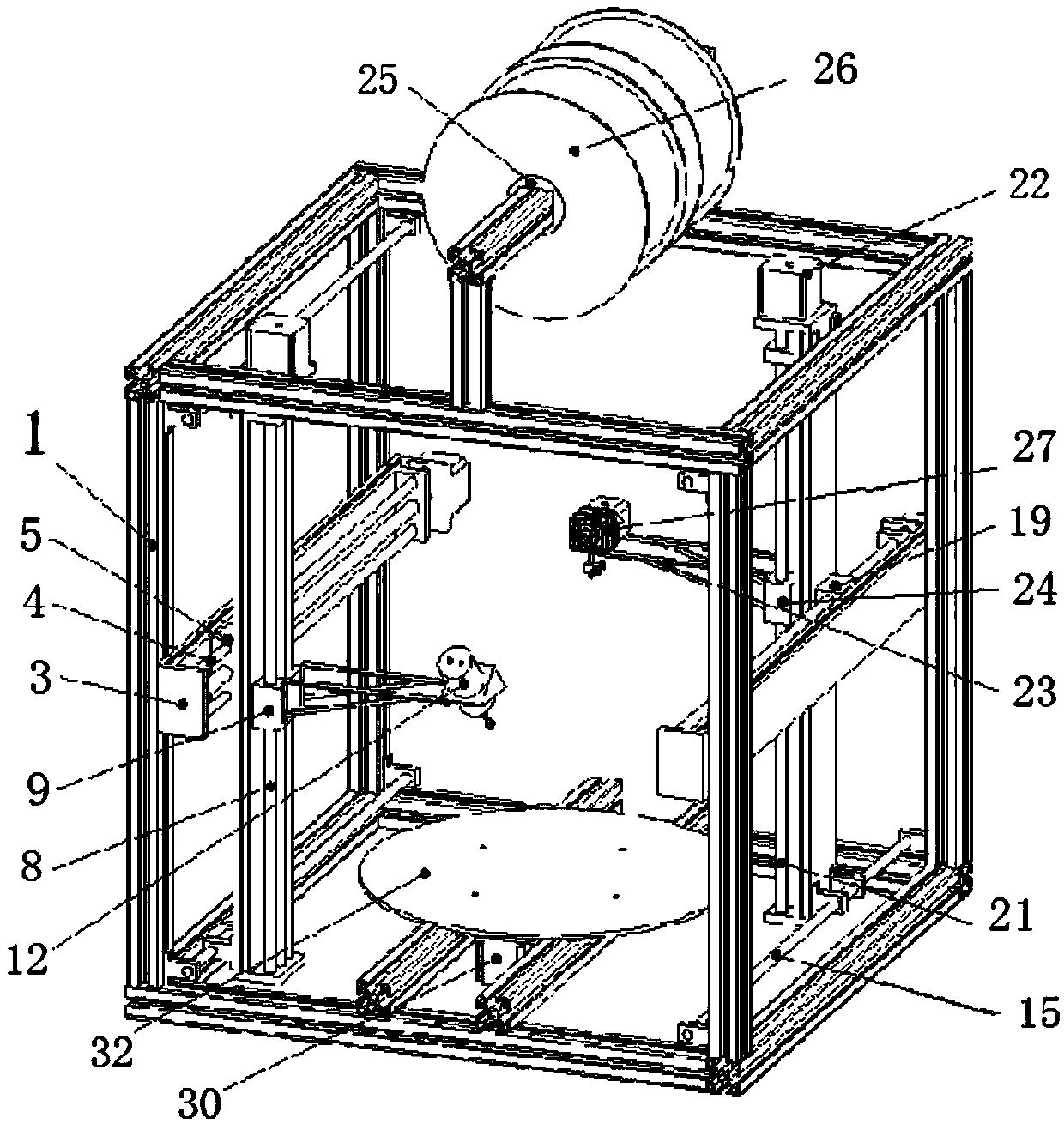

Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

PendingCN107672162AImprove flexibilityShorten the timeEdge grinding machinesAdditive manufacturing apparatusWear particleSurface roughness

The invention discloses a table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function, and relates to table top material increasing and decreasing wood-plastic composite 3D printers. In order to solve the problem that the shape accuracy, dimensional accuracy, surface quality and the like of parts are both limited by the single-layer printingthickness and plane printing accuracy in an existing 3D printing layer-by-layer stacking manufacturing mode, the table top material increasing and decreasing wood-plastic composite 3D printer comprises a rectangular frame (1) and further comprises a material decreasing assembly, a material increasing assembly and a material increasing and decreasing working platform. The material increasing and decreasing working platform is installed at the lower end of the rectangular frame (1) in a rotating mode. The material decreasing assembly and the material increasing assembly are installed on the rectangular frame (1). According to the table top material increasing and decreasing wood-plastic composite 3D printer, the wood-plastic composite is used as a manufacturing raw material to be stacked layer by layer, so that the material increase manufacturing technology is implemented; and a grinding wheel serves as a cutter in abrasive machining, and grinding wheel abrasive particles serve as cutting blades so that the size and shape accuracy and surface roughness needs required can be met. The table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function is used for wood-plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

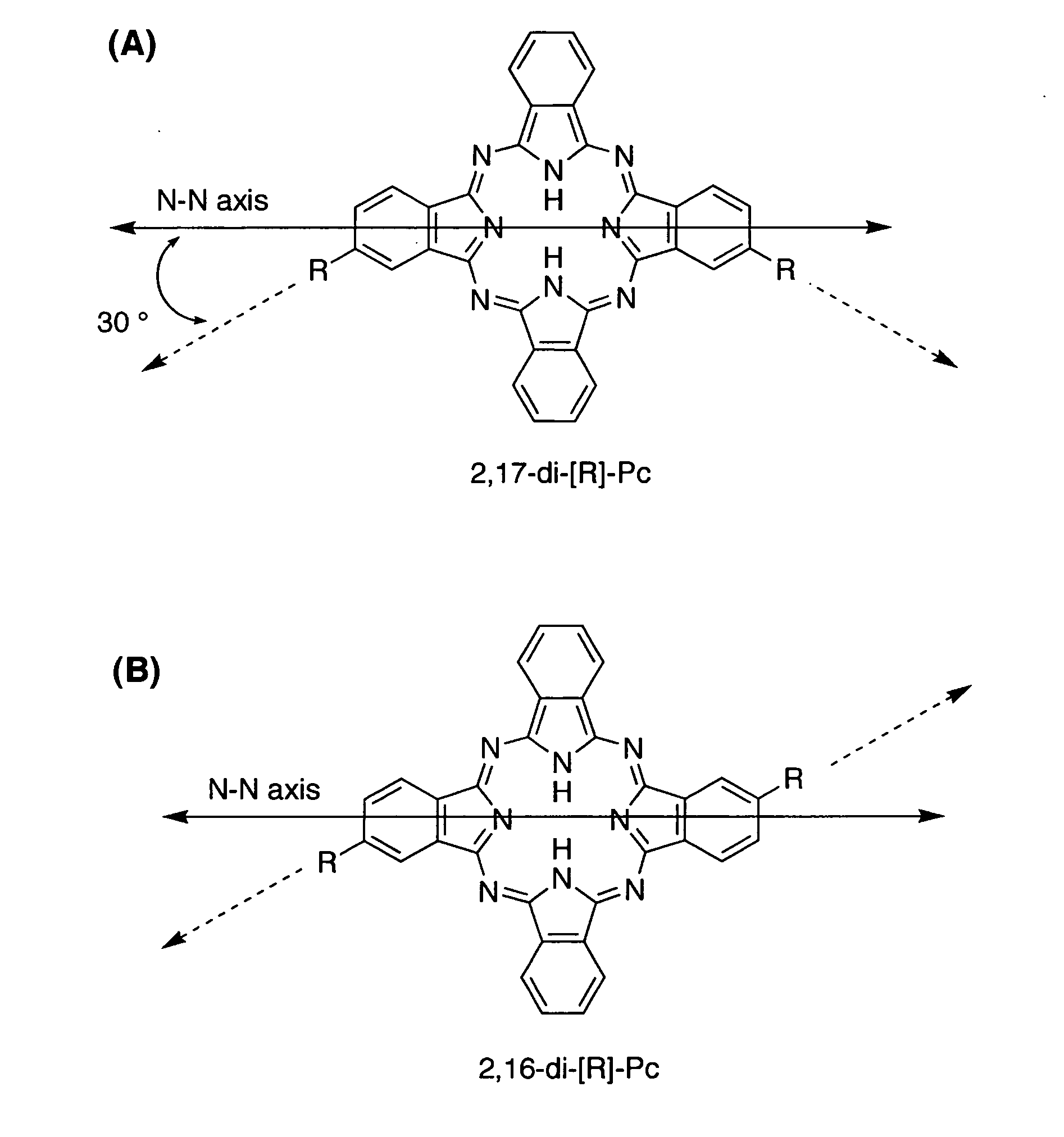

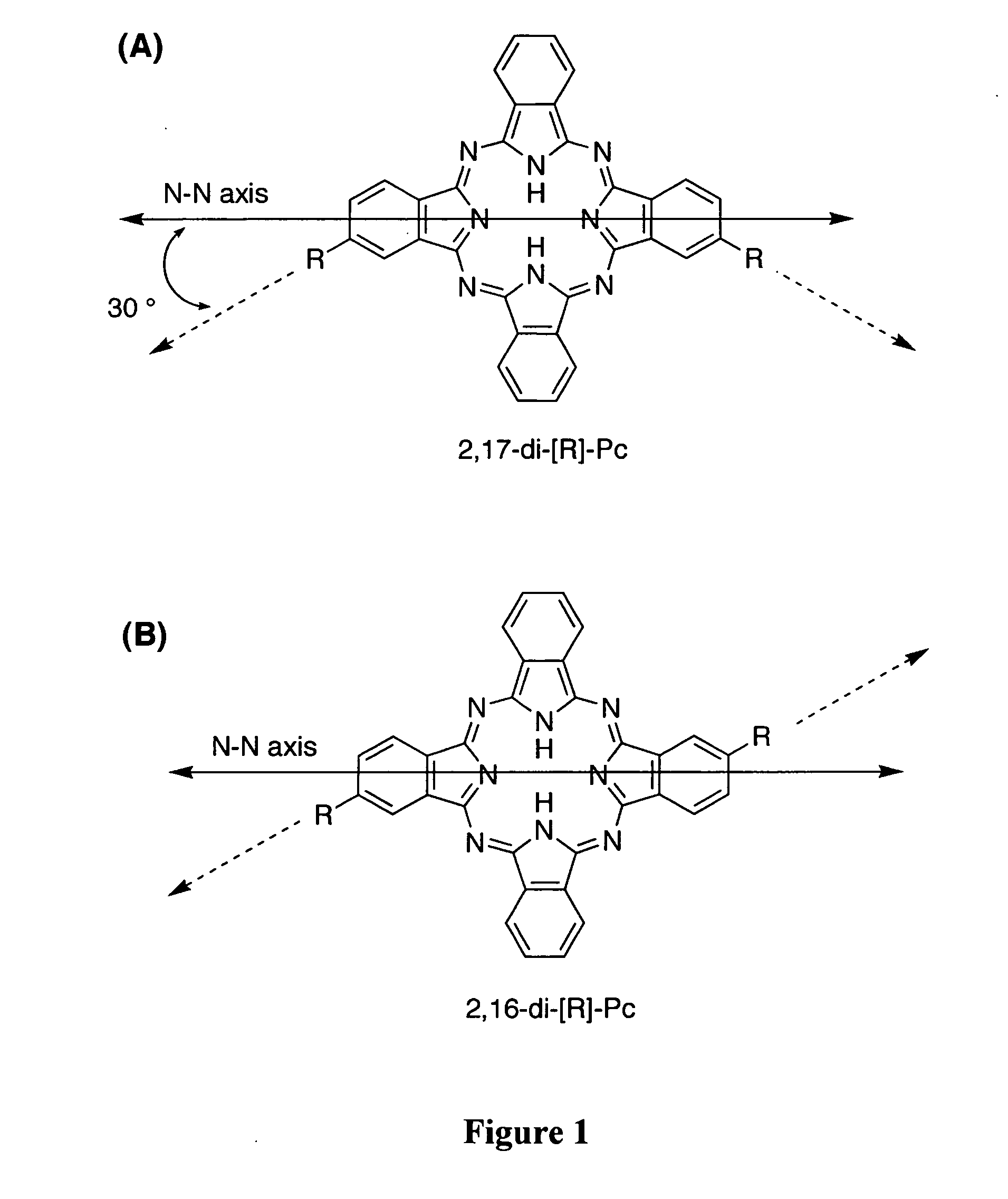

Substituted benzazoloporphyrazines for polymerization and surface attachment and articles formed therefrom

The present invention provides an article of manufacture formed from a substrate and a benzazoloporphyrazine bound to the substrate. The article may take a variety of different forms and may be for example an electrochromic display, a molecular capacitor, a battery, a solar cell, or a molecular memory device. Methods of making such articles, along with compounds, methods and intermediates useful for making such benzazoloporphyrazines, are also described.

Owner:NORTH CAROLINA STATE UNIV

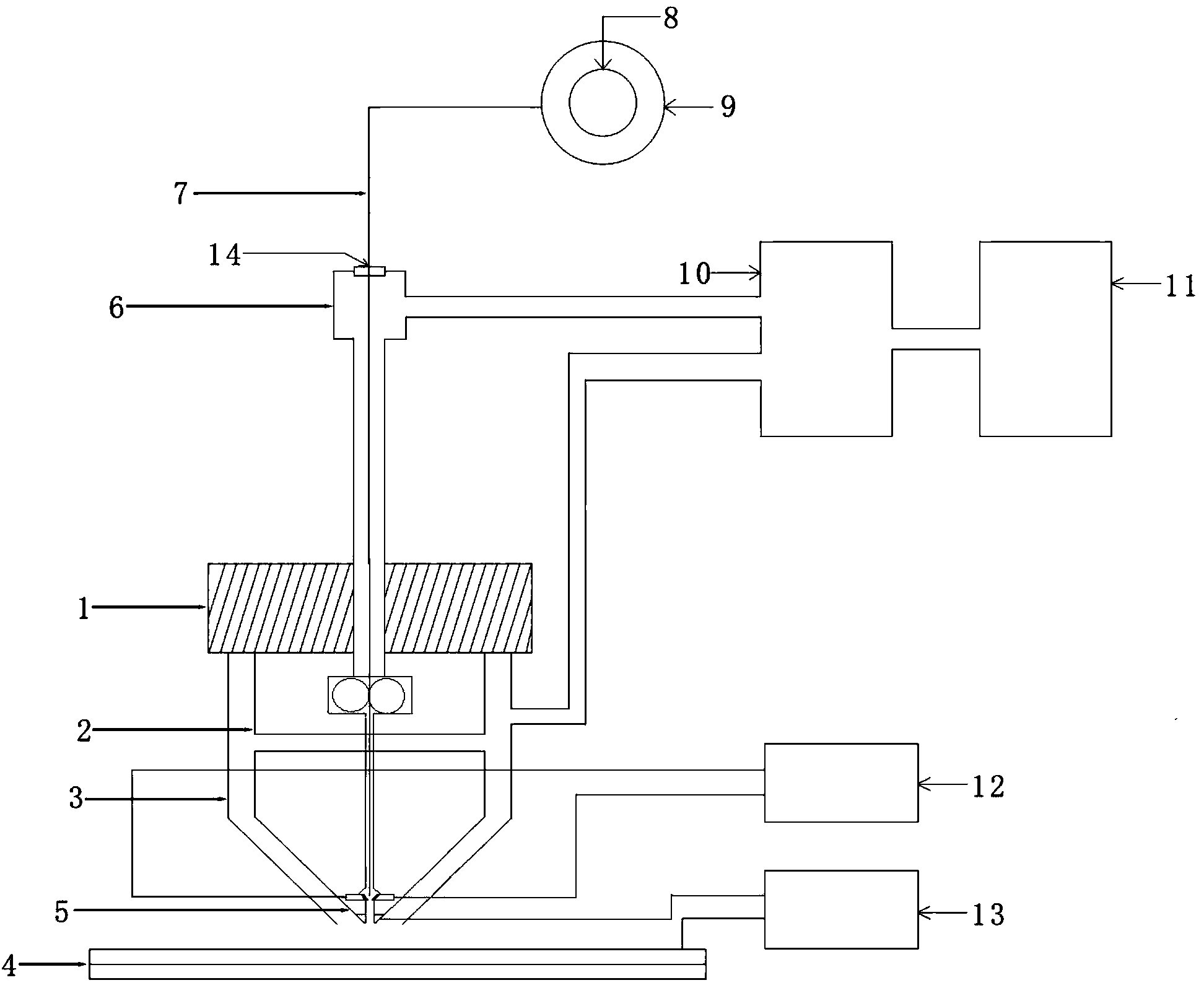

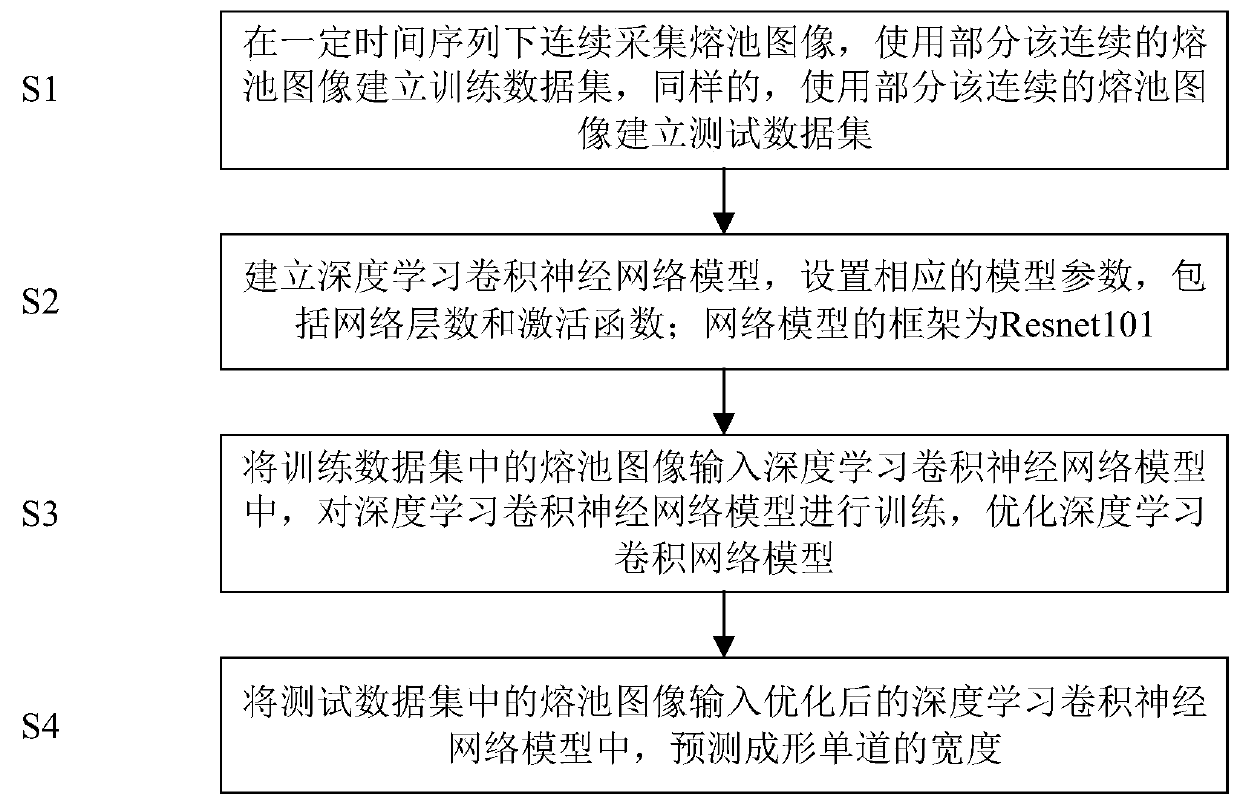

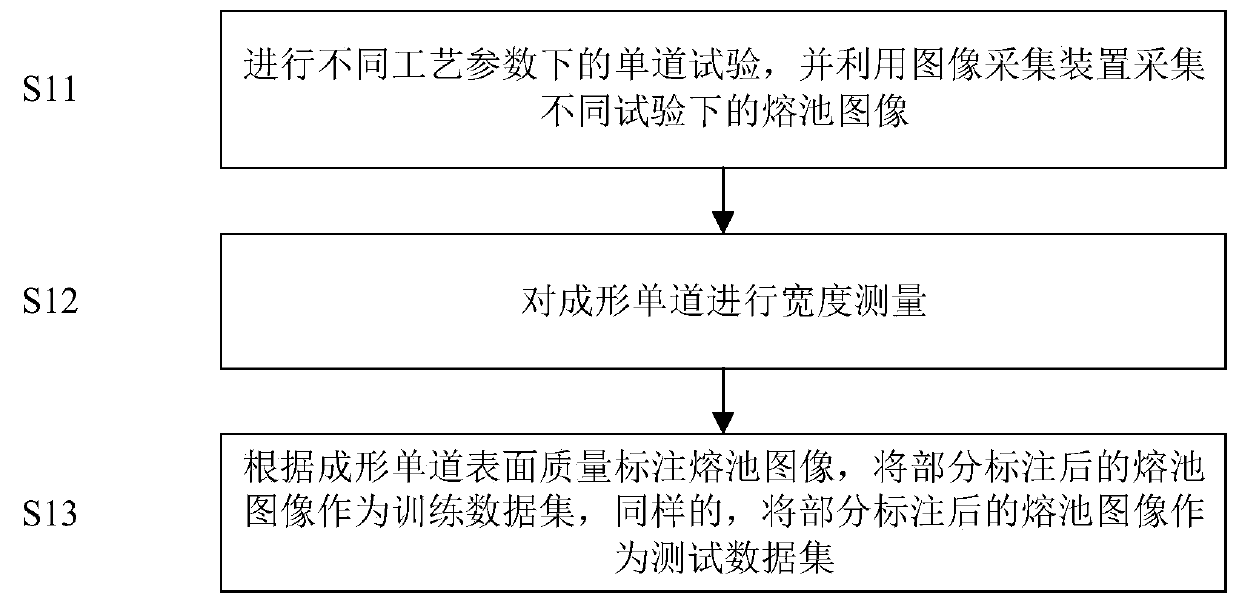

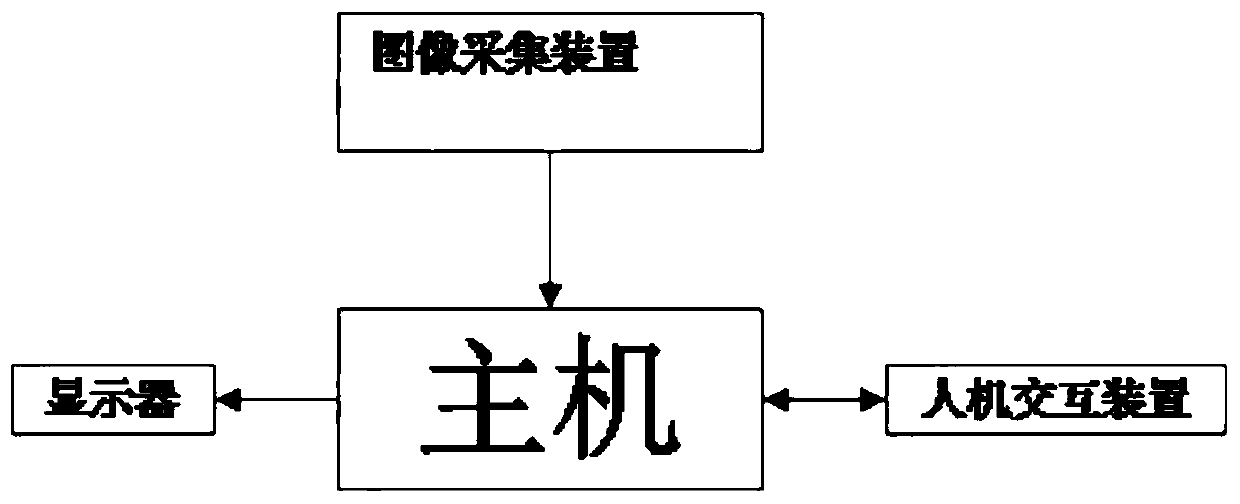

Metal additive manufacturing forming size real-time prediction method based on deep learning

ActiveCN110490867AImprove training efficiencyHigh precisionImage enhancementImage analysisPredictive methodsDisplay device

The invention discloses a laser metal additive manufacturing forming precision prediction system based on deep learning, which comprises a printing workbench, an image acquisition device, a man-machine interaction device, a display and a host. The image acquisition device, the man-machine interaction device and the display are electrically connected with the host. Molten pool images and temperature images are continuously collected in a certain time sequence; firstly, normalization processing is carried out on an effective molten pool image and an effective temperature image; the parameters ofthe picture size and the pixel size of the molten pool image are kept consistent, other irrelevant features are eliminated during training of the deep learning convolutional neural network model, only key features are trained, and the method has the advantage that the training efficiency of the deep learning convolutional neural network model is improved; and the deep learning convolutional neural network model is adopted to predict the single-channel forming width, so that the precision of parameters can be effectively improved.

Owner:SICHUAN UNIV

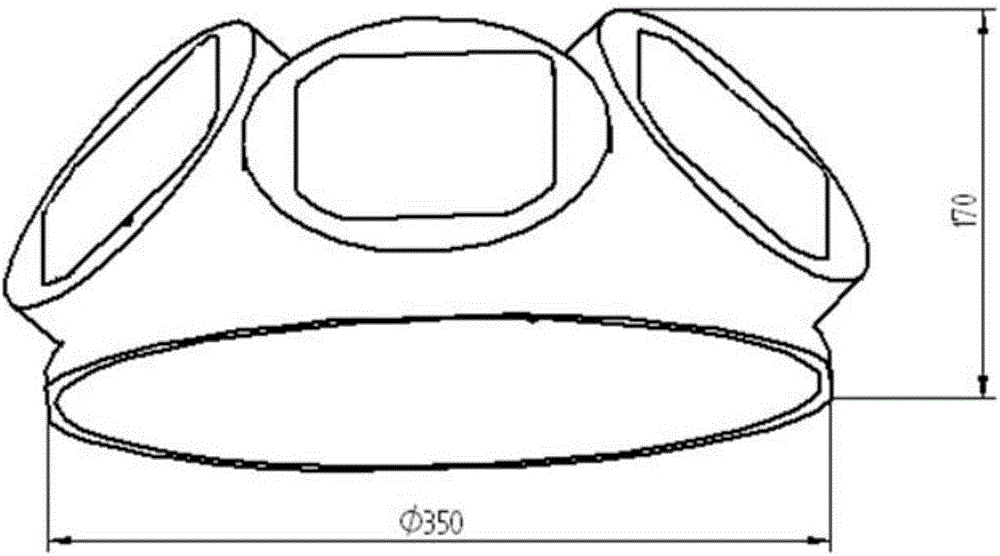

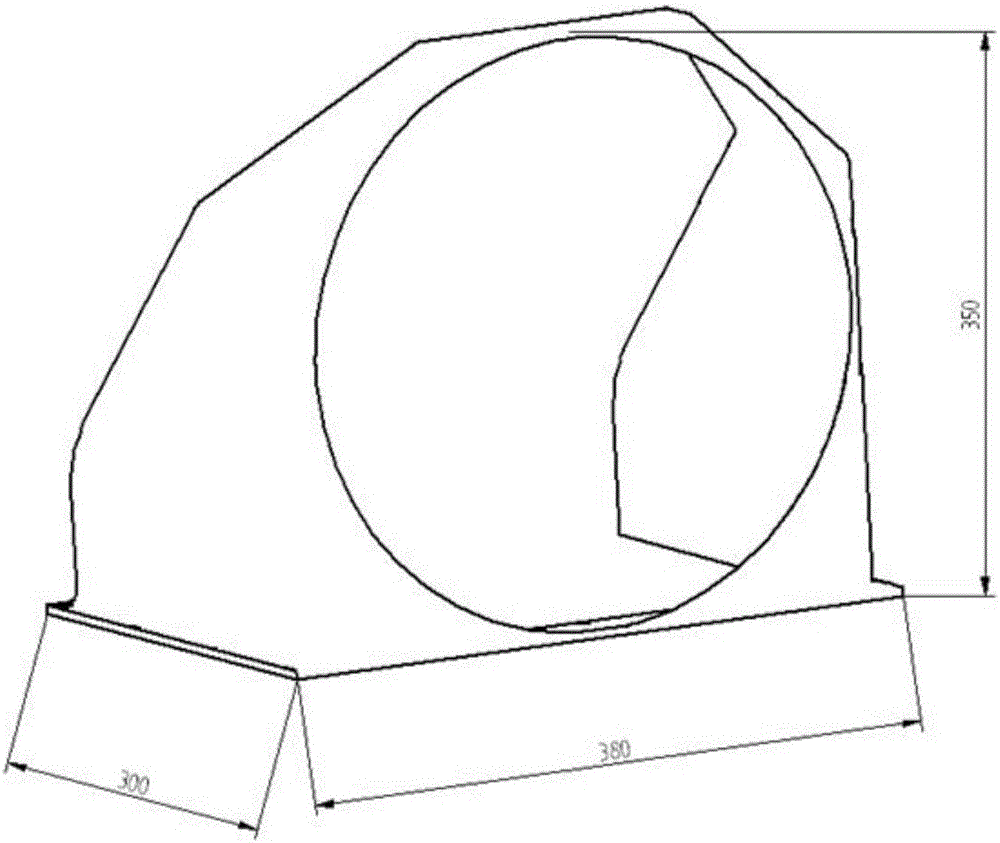

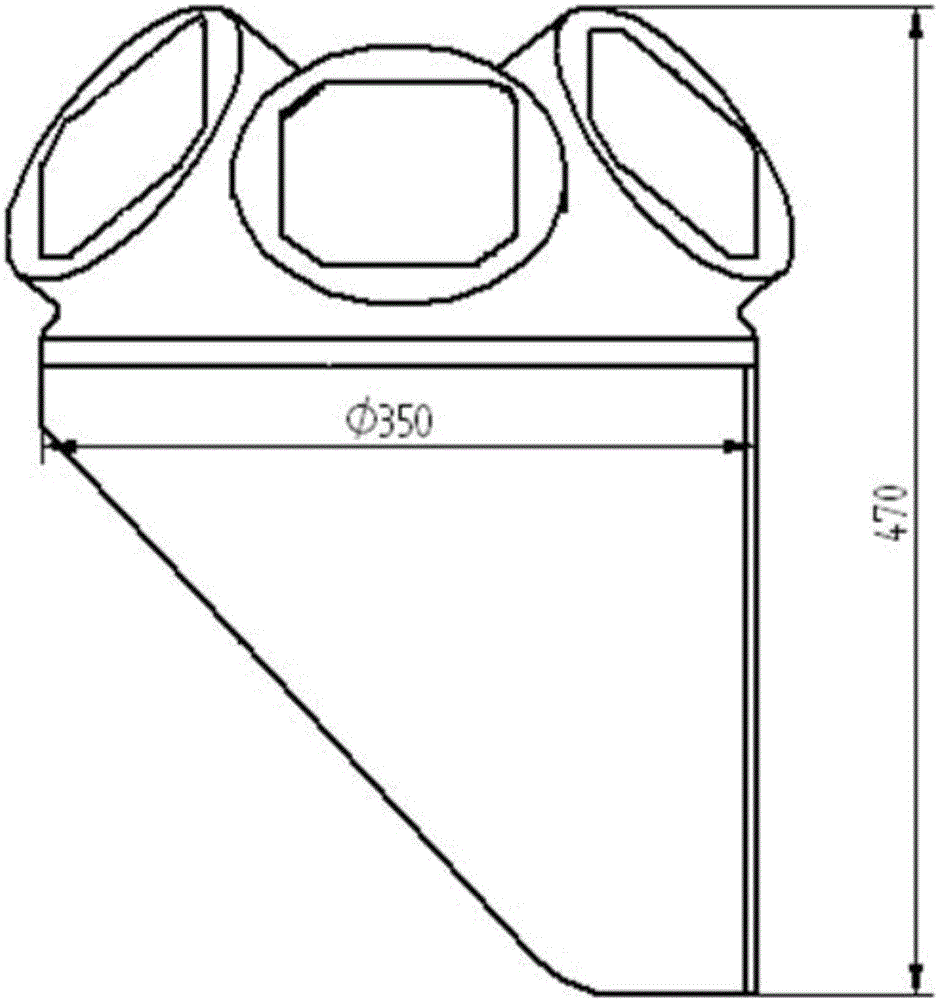

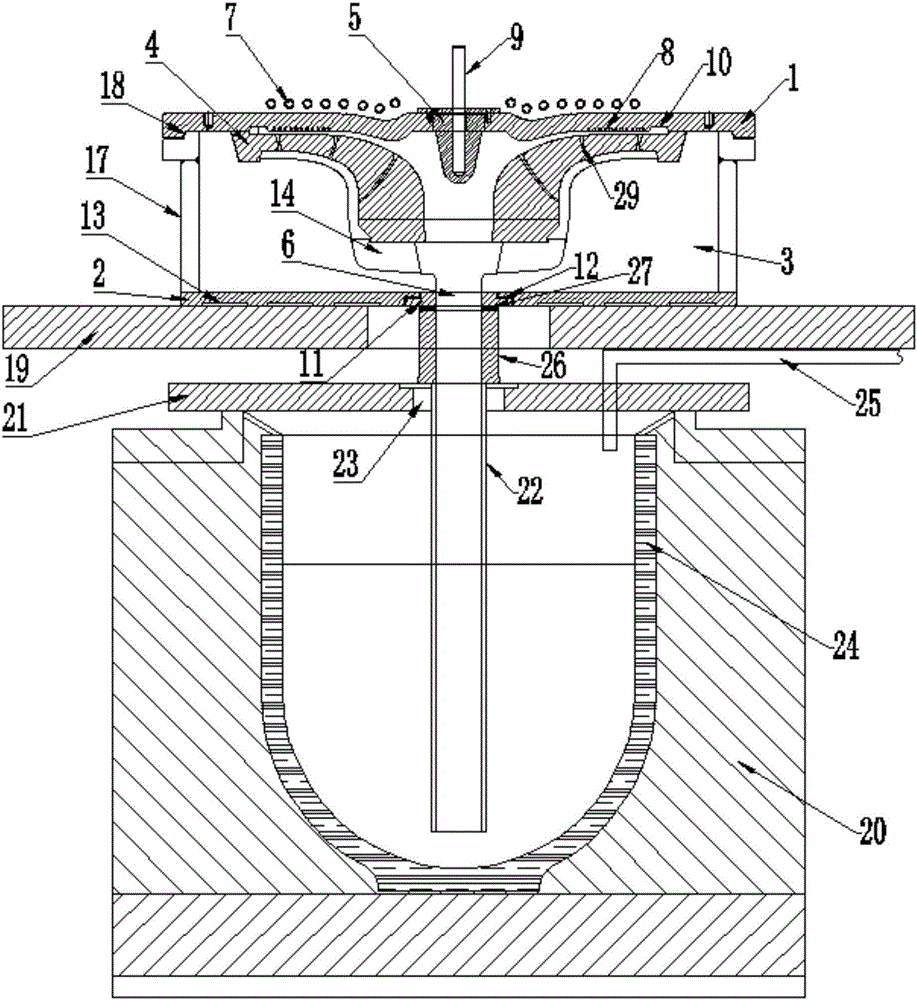

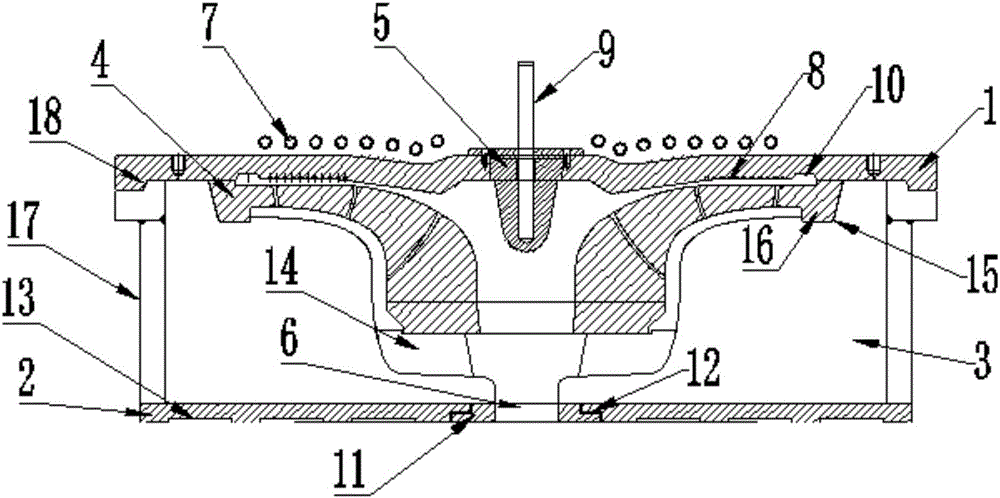

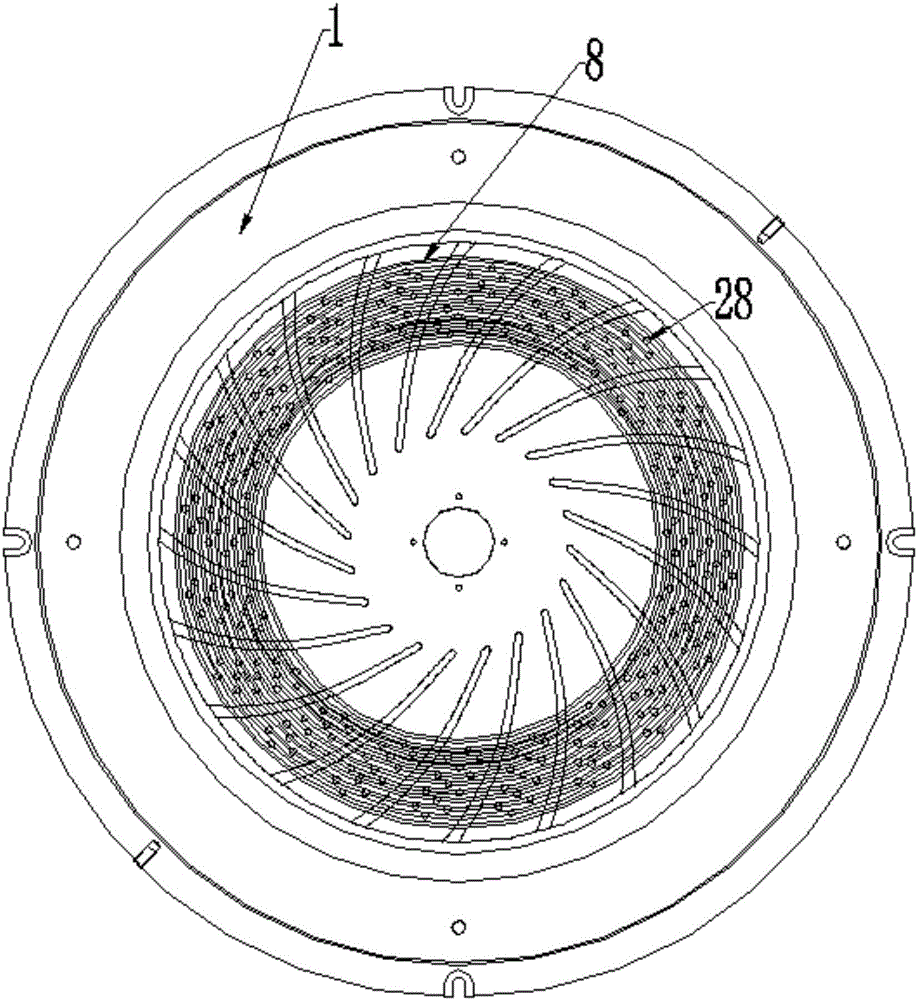

Low-pressure casting method, cooling control process and exhaust system of large impeller

The invention discloses a low-pressure casting method, a cooling control process and an exhaust system of a large impeller. The low-pressure casting method comprises the steps that a manufactured forming element and a manufactured mold core are dried, and a low-pressure casting mold of the impeller is preheated; a casting material is put in a casting device, heating and smelting are carried out to form a casting solution, and slag removal is carried out on the casting solution when the casting solution reaches the set temperature; the casting mold of the impeller is assembled, and the casting mold of the impeller and the casting device are connected to form an impeller casting system; the low-pressure casting device is subjected to low-pressure mold filling along a set pressure curve; after mold filling is finished, the low-pressure casting mold of the impeller is cooled; and after the temperature of the low-pressure casting mold of the impeller is reduced to the set temperature, the impeller is taken out to be cleaned. In the casting process, the pressure and the speed are adjusted, and therefore short run can be reduced; aluminum liquid oxidization can be controlled by adjusting the aluminum liquid temperature; and shrinkage porosity can be reduced by adjusting the cooling process.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

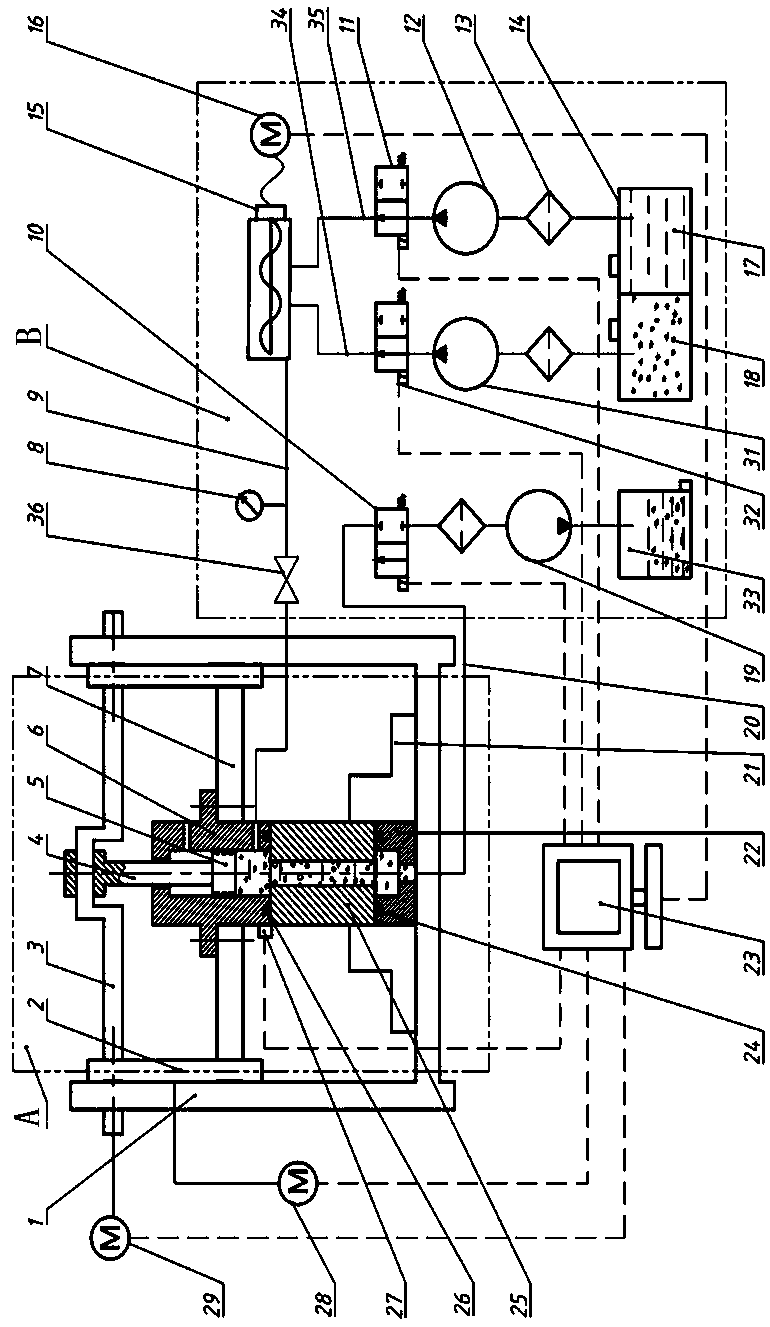

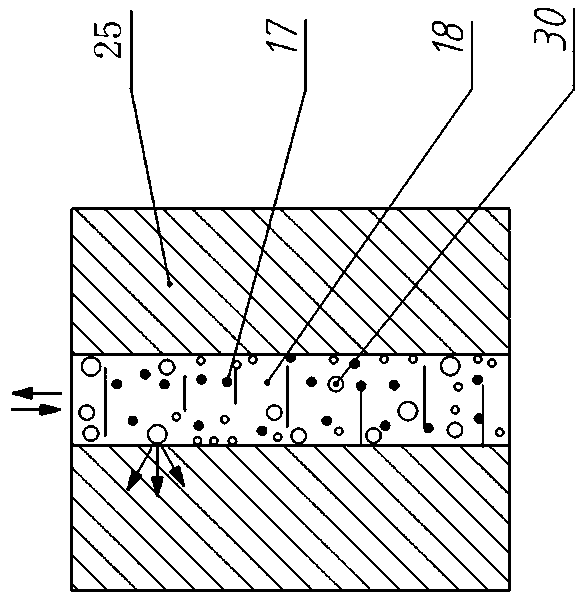

Additive manufacturing forming inner hole surface polishing and strengthening integrated machining system and method

The invention discloses a workpiece inner hole surface polishing and strengthening integrated machining system and a method adopting additive manufacturing forming. The system comprises a workbench, an cavitation generation system, a liquid supply circulation system and a controller, the volume alternating mode is adopted to change the volume of liquid in an inner hole of the additive manufacturing forming workpiece to be changed by virtue of the rapid reciprocating motion of a piston, so that the pressure is changed, a hollow bubble group is formed at the inner part of the liquid and an innersurface of the inner hole, and the hollow bubble group is killed along with further compression, so that shock waves and high-speed water jet flows are generated in the liquid medium; a nano-colloidin the inner hole makes full contact with the inner surface of the hole, ultra-fine polishing of the inner surface of the hole is realized, the shock waves and the high-speed water jet flows on an inner wall of the hole, so that a certain amount of plastic deformation is generated on the inner wall of the inner hole, and the reinforcing of the inner surface of the inner hole is realized. The cavitation technology and the nano colloid polishing technology are organically combined, the fatigue life and the surface smoothness of the inner surface of the inner hole are remarkably prolonged, and the requirements on the ultra-smooth surface are reaches.

Owner:JIANGSU UNIV

Method of manufacturing formed article, glass material, and method of determining shape of glass material and mold

The present invention relates to a method of manufacturing a formed article comprising forming an upper surface of a glass material that has been positioned on a forming surface of a mold to obtain the formed article by heating the glass material to a temperature permitting deformation to bring a lower surface of the glass material into tight contact with the forming surface. Glass having upper and lower surfaces being spherical in shape is employed as the glass material, a mold having a forming surface being a free-form surface other than a spherical surface is employed as the mold, the upper surface of the glass material is formed into a roughly offset surface relative to the forming surface of the mold. The present invention permits the manufacturing of formed articles of desired shape with high precision by hot sag molding method. The present invention also permits the easy and simple determination of the surface shapes of molds and glass materials employed in hot sag molding method.

Owner:HOYA CORP

Medical devices formed from shape memory alloys displaying a stress-retained martensitic state and method for use thereof

A method is disclosed for utilizing a deformable article of manufacture formed at least partly of a shape memory alloy. The method includes the steps of deforming the article from a first predetermined configuration to a second predetermined configuration while the shape memory alloy is, at least partially, in its stable martensitic state and at a first temperature. A resisting force is applied to the deformed article of manufacture using a restraining means and the article is heated from the first temperature to a second temperature in the presence of the resisting force. The stable martensitic state is transformed to a metastable stress-retained martensitic state. The resisting force is then removed allowing the alloy to transform to its austenitic state and the shape of the article to be restored substantially to its first configuration. Devices primarily medical devices operative by employing this method are also disclosed.

Owner:NITI MEDICAL TECH

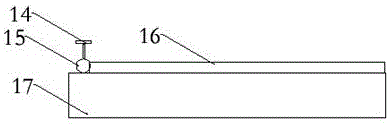

Full-automatic plastic-package packaging robot based on PLC

InactiveCN105711896ASimple structureEasy to operateWrapping material feeding apparatusWrapper twisting/gatheringManufactured formTransmission belt

The invention discloses a full-automatic plastic-package packaging robot based on a PLC. The full-automatic plastic-package packaging robot based on the PLC comprises a material conveying module and a film conveying shaft. The material conveying module is composed of chain wheels, a tensioning device, a conveying chain, a push rod and a guide rail. The push rod is located on the conveying chain and is connected with the conveying chain together in a hinged manner. The conveying chain is wound around a feeding shaft. The guide rail is fixed to a conveying table through screws. The width of the guide rail can be adjusted through a screw groove for different packaging widths. A packaging film is wound around the film conveying shaft. The packaging film is connected with a film pulling driving roller through a traction conveying device. A film shaft color code detector is arranged above the film pulling driving roller. The packaging film is connected to a bag manufacturing forming device through the film pulling driving roller. An object wrapped by the bag manufacturing forming device is flatly pressed through a pressing and conveying brush and is then sent to an end seal cutting mechanism. A flying shear end seal shaft connected to the end seal cutting mechanism is used for cutting off the packaging film obtained after plastic package, and a packaged finished product is conveyed offline through a finished product output transmission belt.

Owner:王凯盛

Sheet for forming process and method for manufacturing the same, image forming method, method for manufacturing forming processed product and the forming processed product

InactiveUS20060035065A1High resolutionQuality improvementLamination ancillary operationsDecorative surface effectsManufactured formSurface resistivity

A sheet for forming process including a base material and at least one functional layer provided on a surface of the base material, wherein the functional layer has, at the outermost surface thereof, a surface resistivity of 1.0×108 to 1.0×1013 Ω / □, and a surface of the base material, on which surface the functional layer is provided, contains at least one selected from polycarbonate resins and polyarylate resins; a method for manufacturing the sheet for forming process, an image forming method, a method for manufacturing a forming processed product using the sheet for forming process, and the forming processed product.

Owner:FUJIFILM BUSINESS INNOVATION CORP

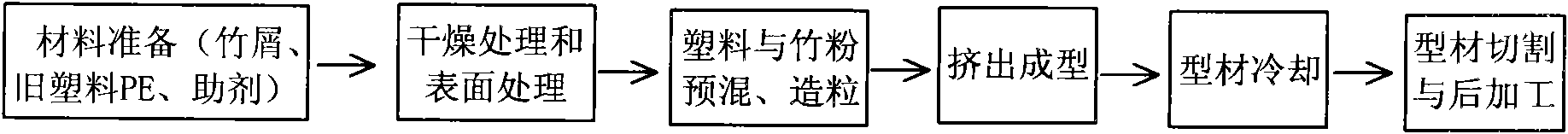

Bamboo scrap and waste plastic PE composite outdoor building material and application thereof

The invention discloses a bamboo scrap and waste plastic PE composite outdoor building material, which is manufactured and formed by mixing 65 weight percent of bamboo scrap, 30 weight percent of waste plastic PE and 5 weight percent of auxiliary agent; and the manufacture forming process after the mixing comprises drying treatment, surface treatment, premixing, granulation, extrusion forming, cooling and cutting. The building material can be prepared into plates, vertical strips of which the shape of the section is a solid rectangle, hollow upright posts, polygonal sections of which the planes are provided with holes and the peripheries are provided with sawtooth and matching semicircular grooves, and the like. The building material has low cost, wide application, and particularly has excellent humidity resistance and moth resistance, so the building material is most suitable to be used as the outdoor building material, realizes resource of waste, and solves the problem of environmental pollution caused by white plastics.

Owner:贵州新锦竹木制品有限公司

Nickel-Chromium-Iron-Molybdenum Corrosion Resistant Alloy and Article of Manufacture and Method of Manufacturing Thereof

A solid-solution nickel-based alloy for use in sour gas and oil environments, including, in percent by weight: chromium: min. of 21.0 and max. of 24.0%; iron: min. of 17.0 and max. of 21.0%; molybdenum: min. of 6.5 and max. of 8.0%; copper: min. of 1.0 and max. of 2.5%; tungsten: min. of 0.1 and max. of 1.5%; sol. nitrogen: min. of 0.08 and max. of 0.20%; manganese: max. of 4.0%; silicon: max. of 1.0%; carbon: max of. 0.015%; aluminum: max of 0.5%; and a total amount of niobium, titanium, vanadium, tantalum, and zirconium: max of 0.45%; the balance being nickel and incidental impurities, along with a method of manufacturing an article from the alloy, and an article of manufacture formed from the alloy.

Owner:HUNTINGTON ALLOYS CORP (US)

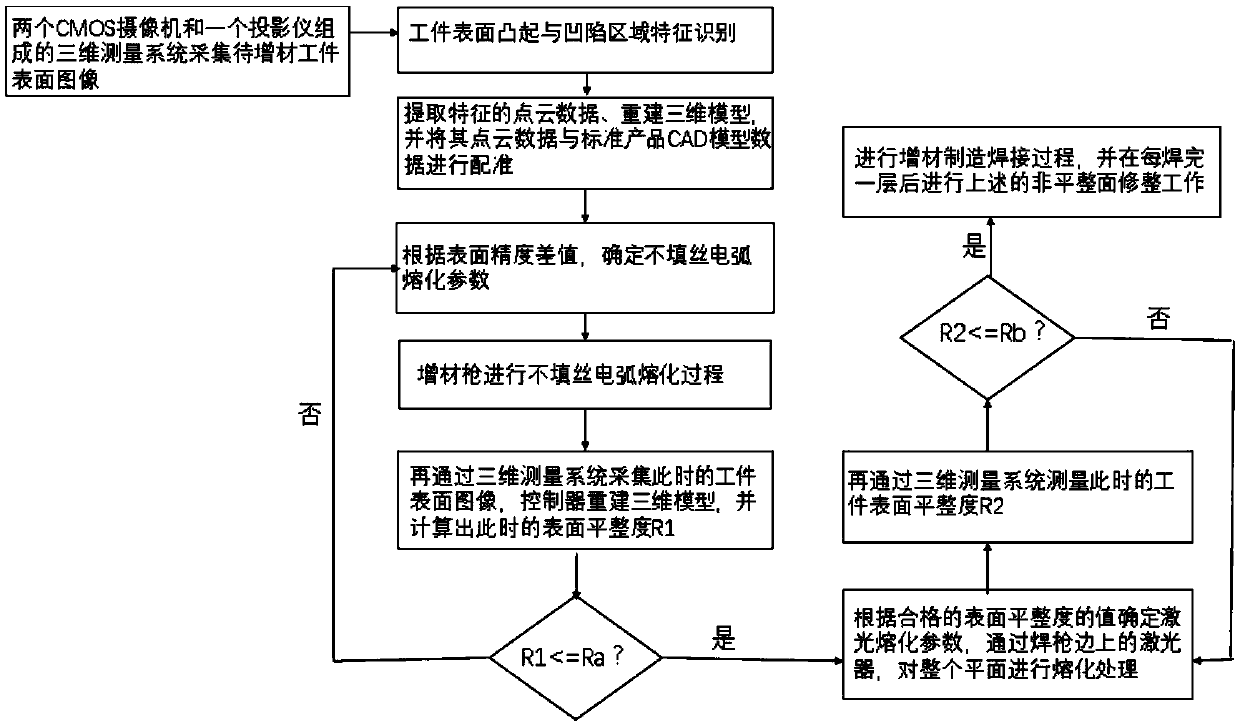

Non-leveling surface autonomous identification robot additive manufacturing forming precision control method

ActiveCN109648202AImprove surface accuracyQuality improvementLaser beam welding apparatusThree dimensional measurementVisual perception

The invention discloses a non-leveling surface autonomous identification robot additive manufacturing forming precision control method. A CMOS camera and a projector form a three-dimensional measuringsystem, the surface image of a workpiece is collected, the binocular vision based on structured light is combined, the characteristic data of the surface of the workpiece are extracted, and a controller is used for reconstructing a three-dimensional model and determining electric arc melting parameters; flat-peak valley filling operation of non-filler wire melting is carried out in a protective atmosphere by utilizing a TIG welding gun; the corresponding energy is set according to the measured value of the surface flatness, and a laser heat source is used for carrying out laser melting treatment on the surface through the laser; and the actual surface flatness is detected, and the actual surface flatness is compared with the standard surface flatness, if not, the process is repeated untilthe process is qualified. According to the non-leveling surface autonomous identification robot additive manufacturing forming precision control method, the surface precision of an arc additive partcan be effectively improved, welding quality and stability are guaranteed, and therefore the quality of the arc additive forming part can be effectively improved.

Owner:NANJING UNIV OF SCI & TECH

Method for manufacturing recombined integrated section by using wood in fast-growing forest

InactiveCN102310442AFast growthShort rotation periodWood compressionWood charring/burningManufactured formVolumetric Mass Density

The invention provides a method for manufacturing a recombined integrated section by using wood in fast-growing forest, which comprises the following steps of: rotatably cutting the wood in the fast-growing forest according to the requirement; carrying out carbonizing treatment, degreasing, desugarization and color on the rotatably-cut wood bark and drying; and softening the wood bark by soaking in a glue-leading activating agent, drying, flattening, binding, filling into a die, then forming at high temperature and curing at high temperature. According to the method disclosed by the invention, the wood in the fast-growing forest is used as a raw material and is subjected to rotary cutting and flattening and then is recombined into the integrated section. The method is simple; the density is uniform and easily controlled; the wood can be fully utilized so as to reduce waste; the manufactured formed section has no damage to wood grains and has the advantages of attractiveness, firmness, mildew resistance, worm damage resistance, high strength, favorable size stability, no cracking or deforming; and not any substances harmful to the body are added in the manufacturing process, and thus environment friendliness is achieved.

Owner:中宇创业联合控股有限公司

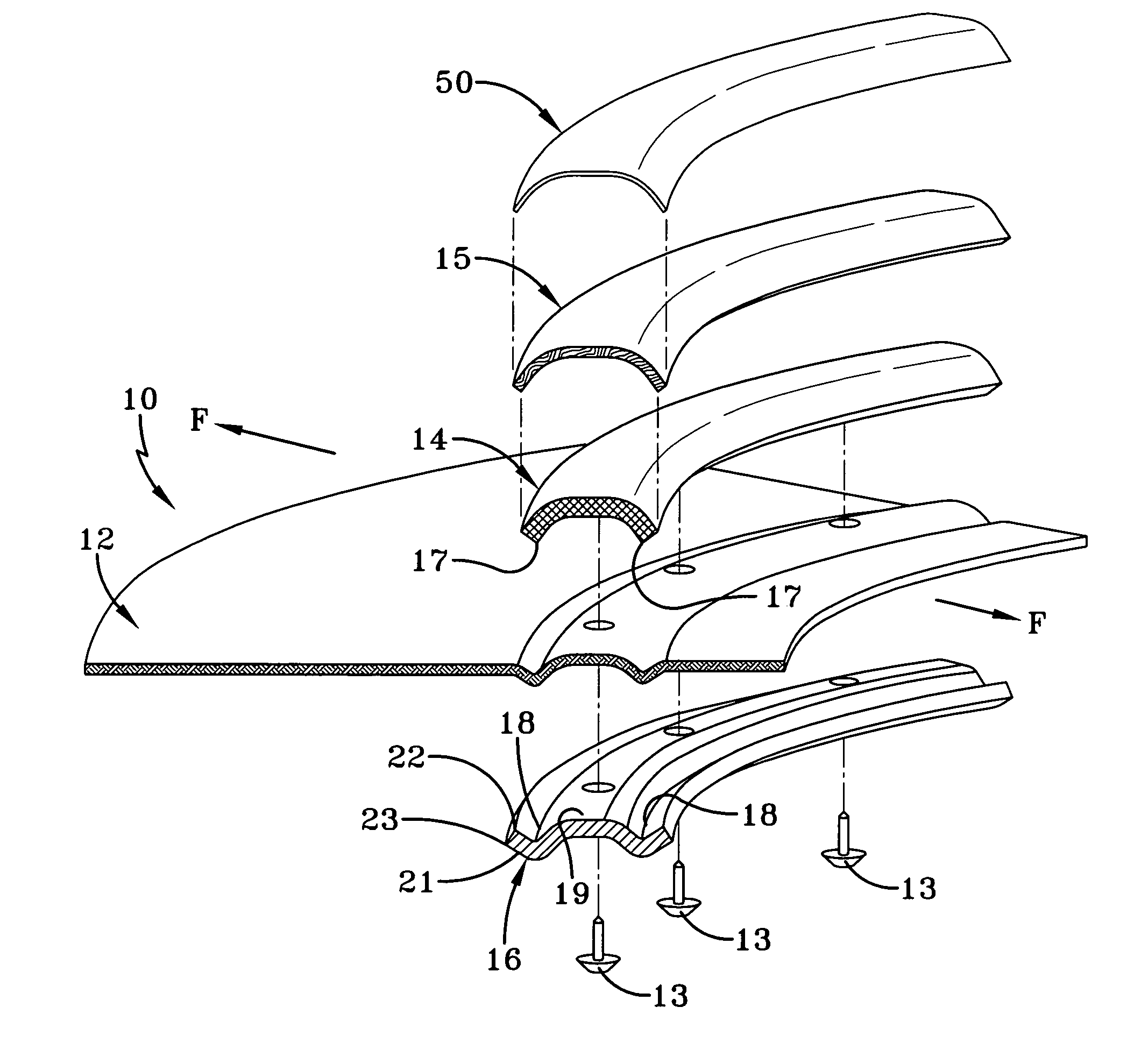

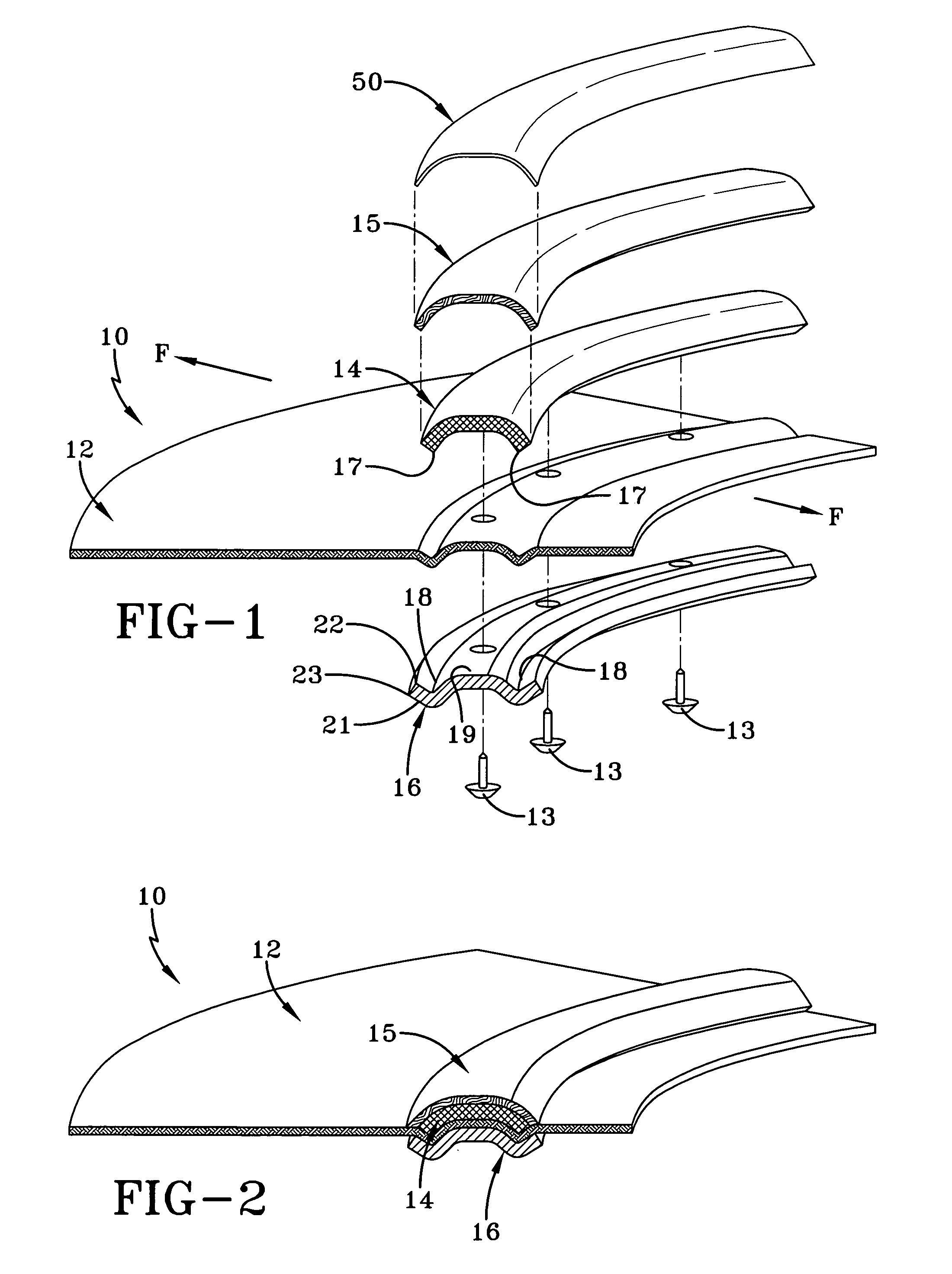

Split ply tires and bead area monocomponents

An intermediate article of manufacture formed as a first stage bead area subassembly for a split ply pneumatic tire carcass is disclosed. The bead area subassembly has an annular bead core; a bead apex; a ply strip; and preferably a sidewall affixed to the ply strip. The subassembly is formed into a disk-shaped bead area monocomponent. The ply strip is wrapped about the bead core and the apex to form a ply turnup and both the ply strip and the ply turnup extend radially outwardly from the bead core. The bead area subassembly when formed into the disk-shaped bead area monocomponent is placed on an annular holder device. The combination of the bead area monocomponent on the holder device can be stacked for storage and latter assembly into a split ply carcass. Preferably, the ply turnup can be oriented extending inside or axially inward of the bead core on final assembly to form a split ply tire having axially inside turnups. In the preferred embodiment the ply strip is reinforced by radially extending ply cords.

Owner:THE GOODYEAR TIRE & RUBBER CO

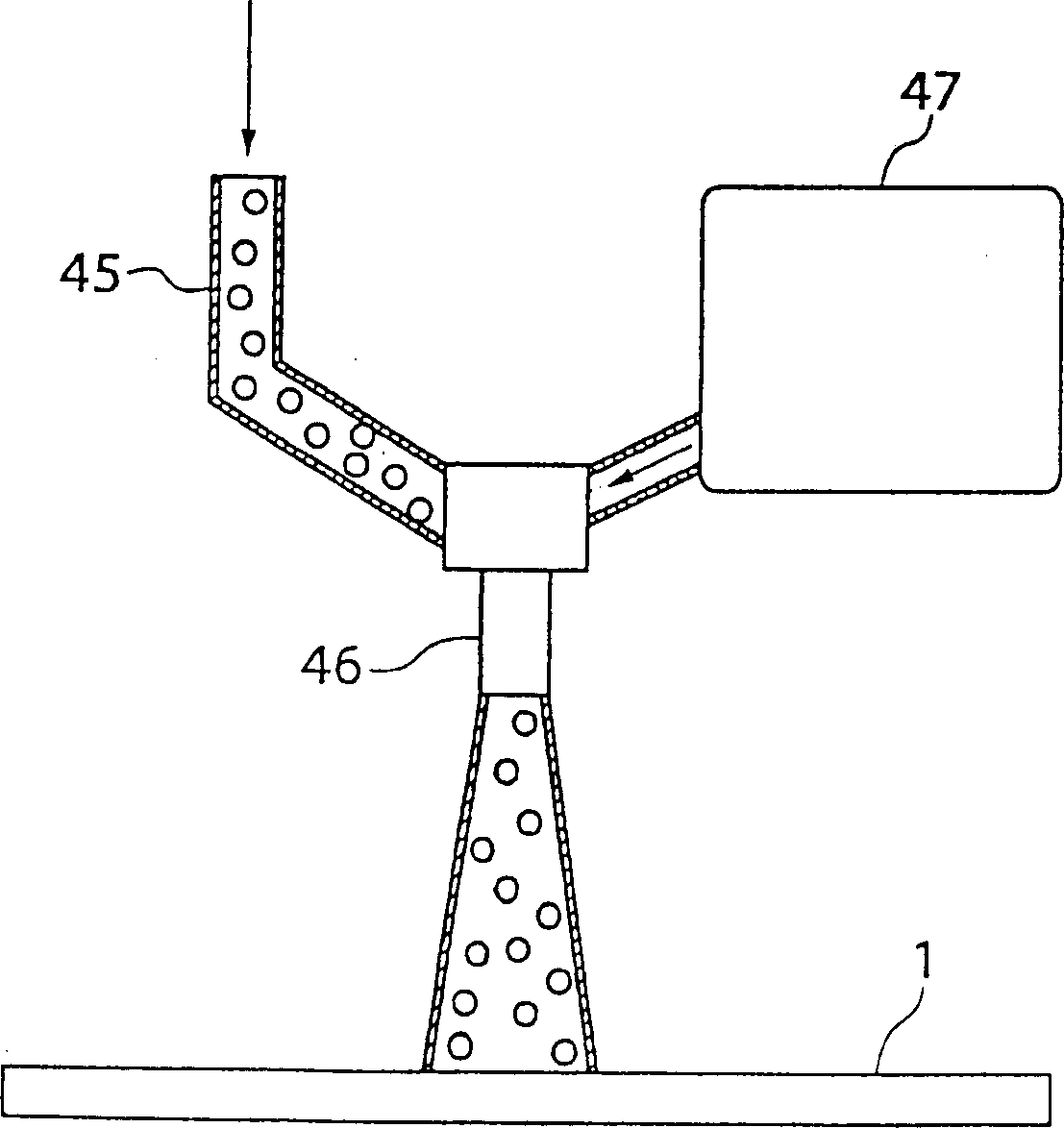

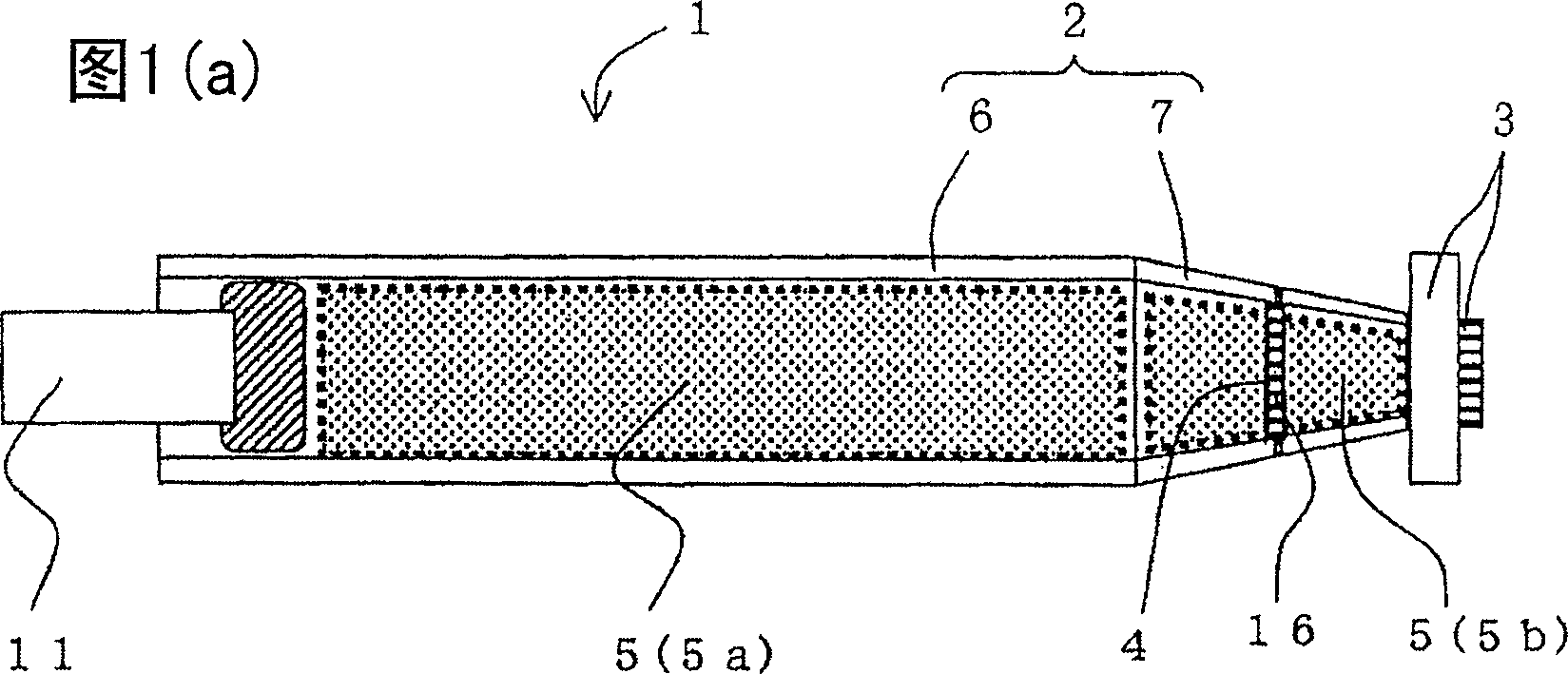

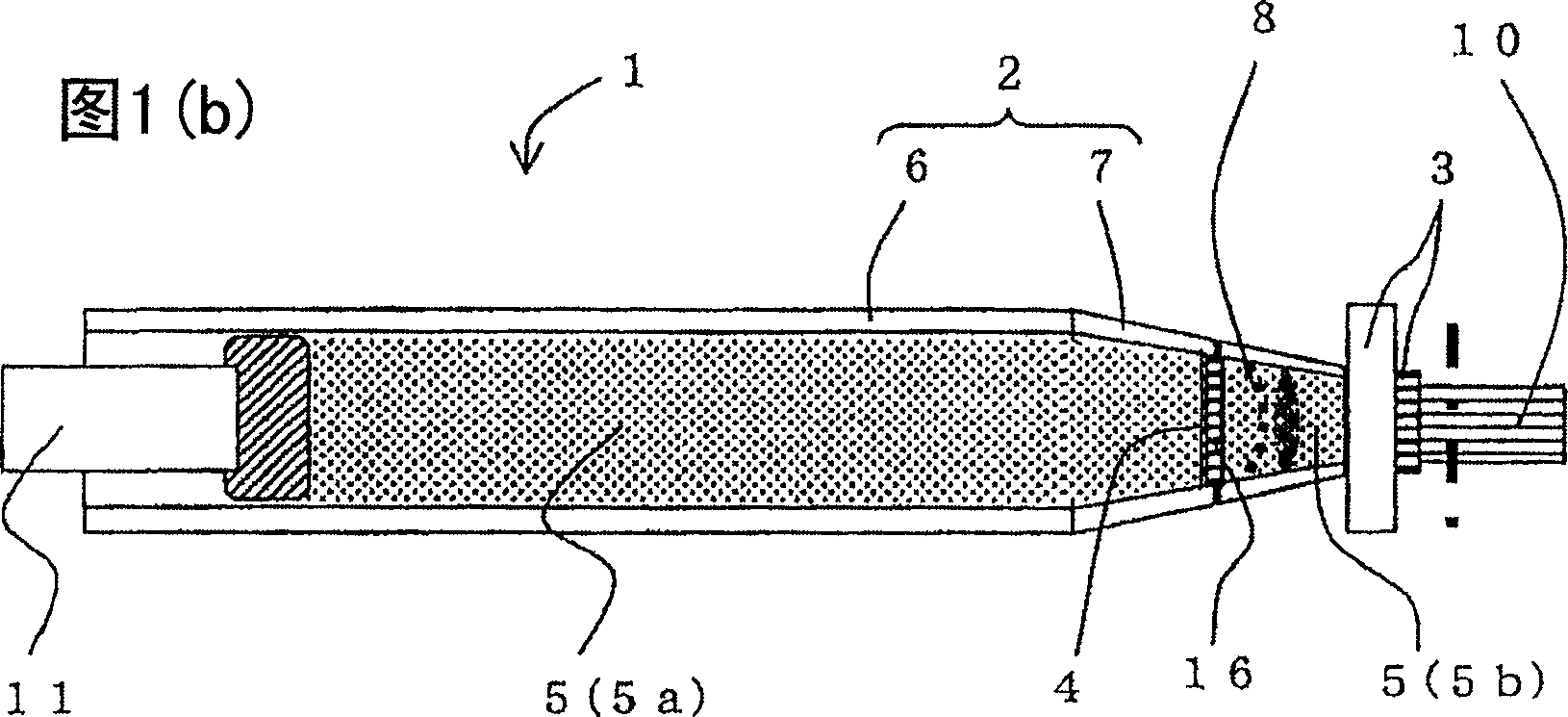

Method for manufacturing formed honeycomb structure

InactiveCN1833845AEasy to useReduce the impact of formingDispersed particle filtrationCeramic shaping apparatusForeign matterManufactured form

A method for manufacturing a formed honeycomb structure in an efficient manner which comprises the steps of: charging a material for forming a honeycomb structure 5 into a passage for preform material for a honeycomb structure whose one end portion is provided with die 3 for forming a formed honeycomb structure; and extruding the charged preform material for a honeycomb structure 5 from the die 3 to form a formed honeycomb structure 10 while passing it through the passage, wherein a screen 4 for filtering foreign matters included in the preform material for a honeycomb structure 5 is disposed in the vicinity of the die 3 , and wherein an operation for reduction of frictional resistances between an inner face of the passage for preform material for a honeycomb structure and the preform material for a honeycomb structure 5 which passes the passage is employed.

Owner:NGK INSULATORS LTD

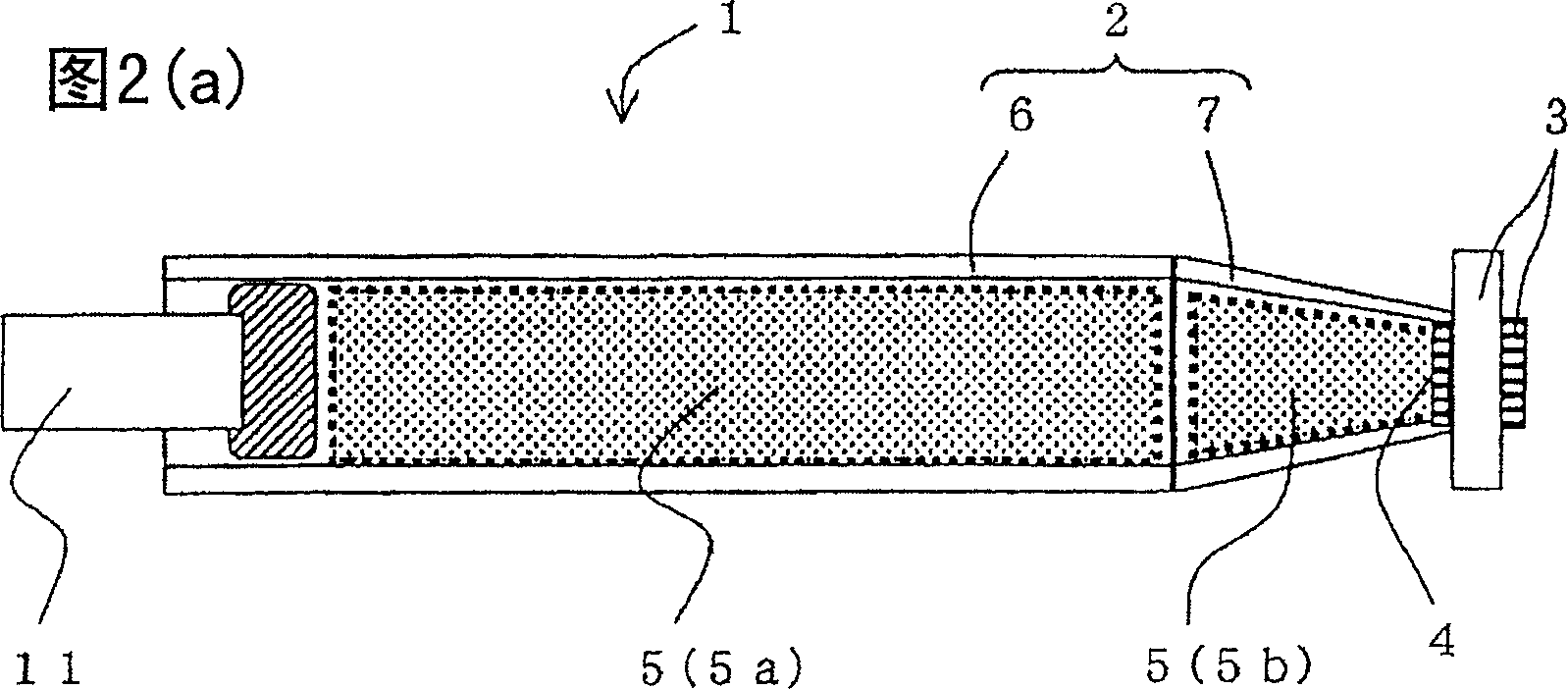

Additive manufacturing forming cylinder drive mechanism, forming cylinder and additive manufacturing equipment

ActiveCN106312063AImprove stabilityImprove the forceAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formEngineering

The invention discloses an additive manufacturing forming cylinder drive mechanism which comprises a cantilever lifting system and a dynamic compensation system. The cantilever lifting system comprises a cantilever and a cantilever drive mechanism. The cantilever comprises an installation end installed on the cantilever drive mechanism and a free end used for fixing a base plate. The cantilever drive mechanism drives the cantilever to conduct vertical feeding. The dynamic compensation system is connected with the cantilever and provides upward compensation force for the cantilever. The invention further discloses a forming cylinder with the drive mechanism and additive manufacturing equipment. According to the forming cylinder drive mechanism, the cantilever drive mechanism is used for replacing a piston drive mechanism so that the forming height of the additive manufacturing equipment can be greatly increased under the condition of the limited height; and meanwhile, the upward compensation force is provided for the cantilever in the descending process through the arranged dynamic compensation system, stress of the cantilever in the descending process is optimized, and the stability of the forming cylinder drive mechanism is improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

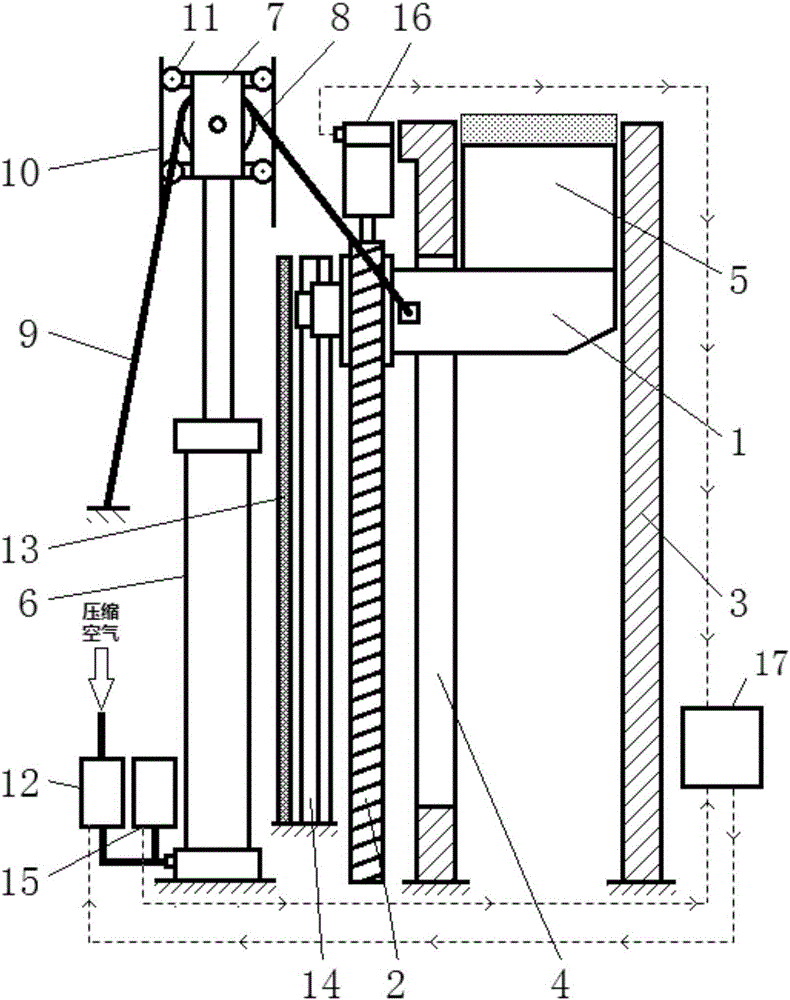

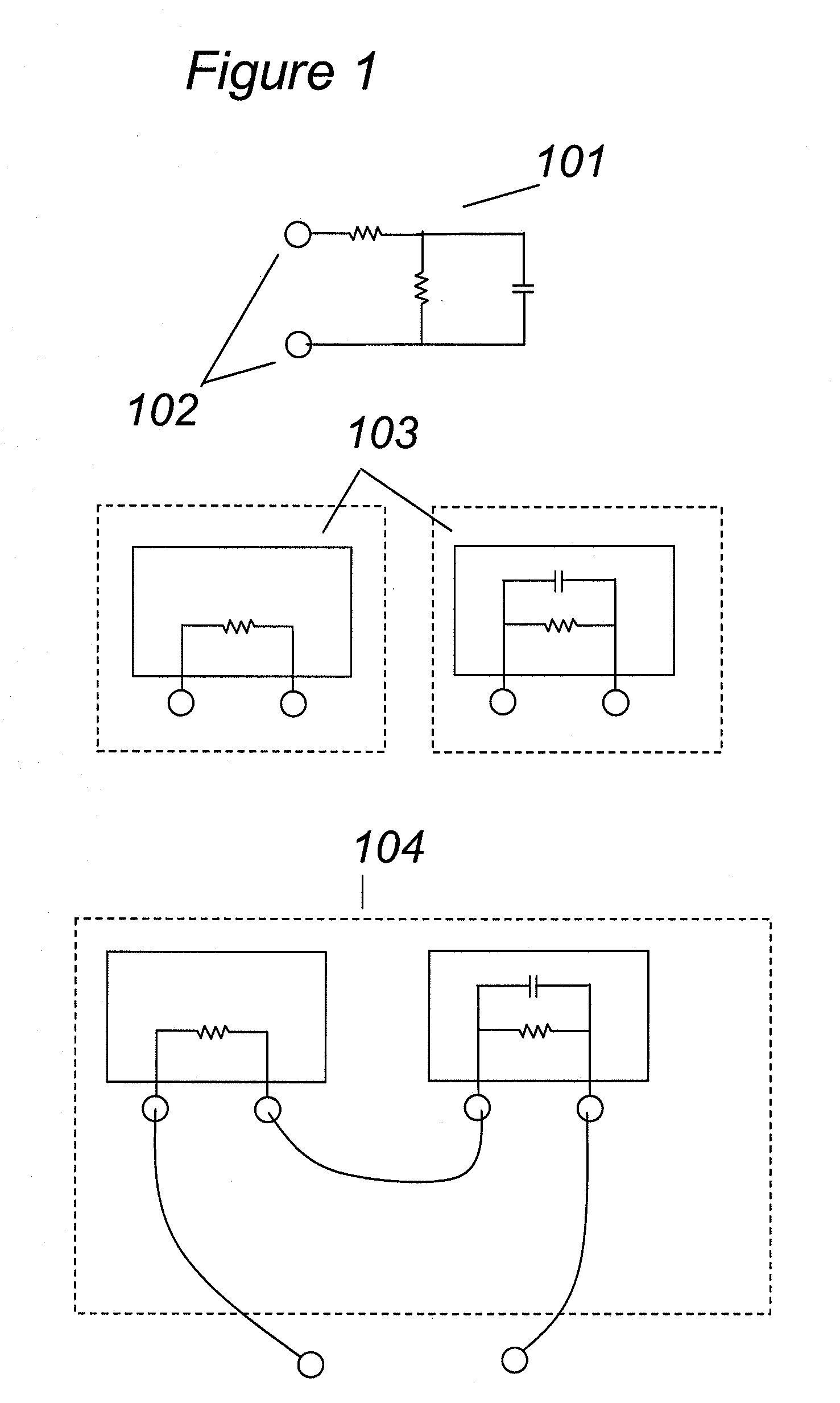

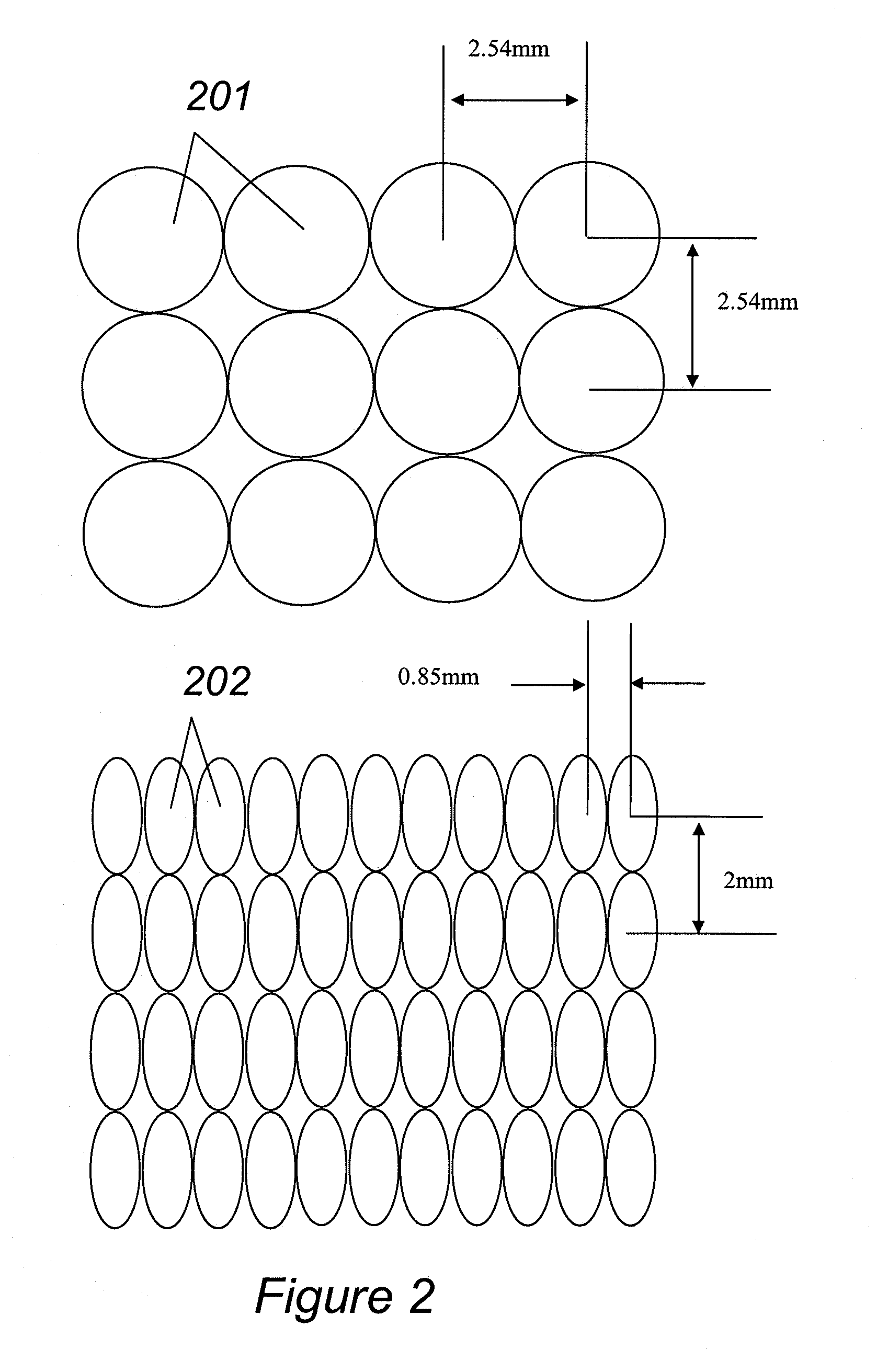

Modular prototyping of a circuit for manufacturing

Owner:CASKA JAMES PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com