Medical devices formed from shape memory alloys displaying a stress-retained martensitic state and method for use thereof

A technology of memory alloy and martensite, applied in application, prosthesis, staple, etc., can solve problems such as complex function and positioning, difficult operation, damage to human tissue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

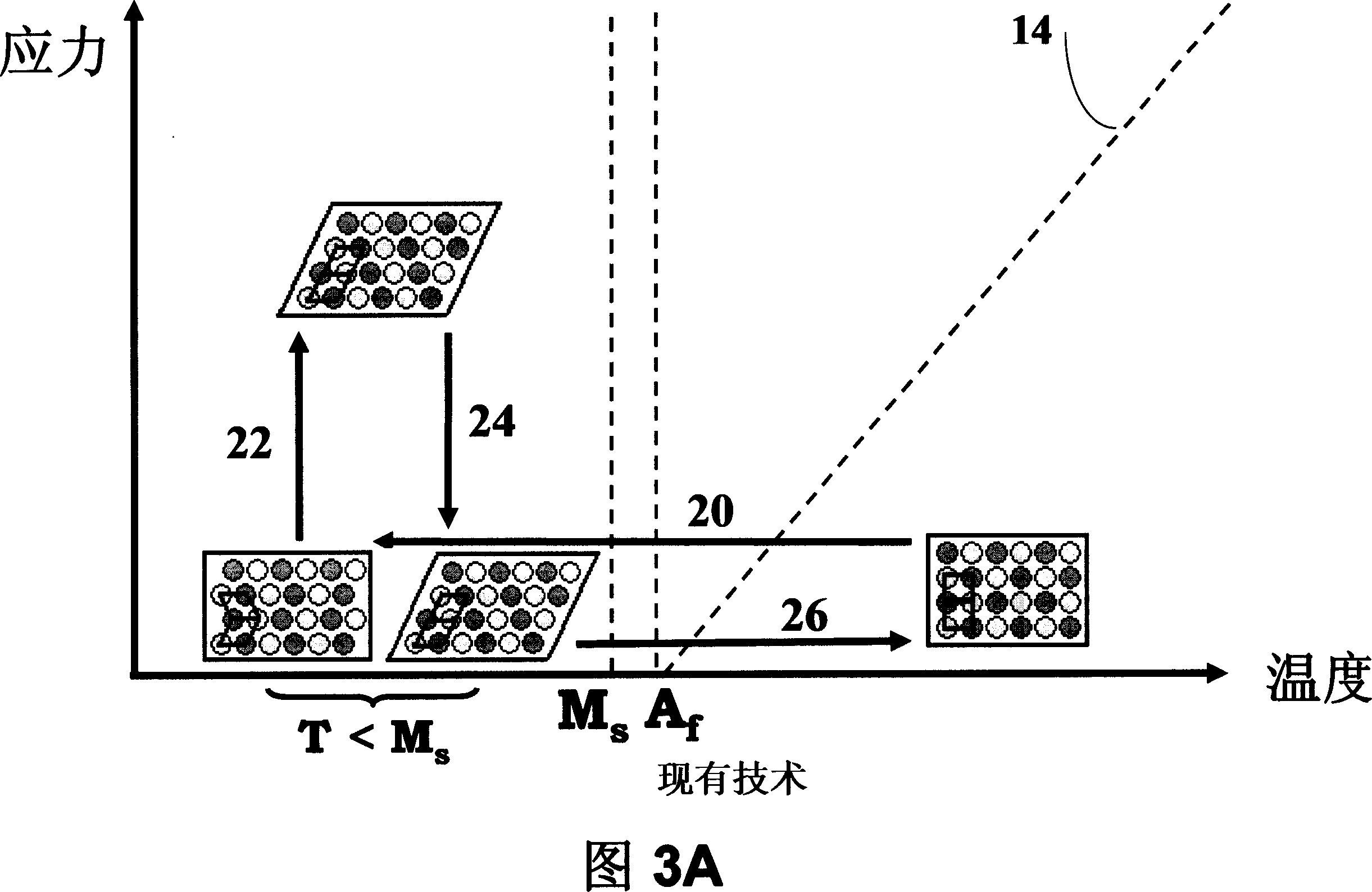

[0099] Among other things, the present invention generally teaches a method of using a device, particularly a medical device, at least a portion of which is made of a shape memory alloy. The effect used by this method is referred to herein as the superelastic-plastic (SEP) effect. The operable phase corresponding to this effect is referred to herein as stress retained martensite (SRM). As can be clearly understood from the following description, medical devices applying SEP effects based on SRM, for example, have a higher Obvious advantages. The SEP effect (and the SRM on which it is based) applied to medical devices, and the method of exploiting this effect for SMA devices, are the basis of the invention described below.

[0100] Referring now to FIG. 6, superelastic plasticity (SEP) is applied to devices such as bone nails, bone anchors, expandable bone fixators, brackets, or anastomotic clips. The SEP effect used by the method according to the invention represents a defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com