Method for manufacturing recombined integrated section by using wood in fast-growing forest

A technology of recombining and integrating profiles, applied in the direction of wood compression, wood processing appliances, manufacturing tools, etc., can solve the problems of easy occurrence of moth-eaten, loss, and inability to preserve texture well, and achieve tight and firm bonding and dimensional stability. Good, fast growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

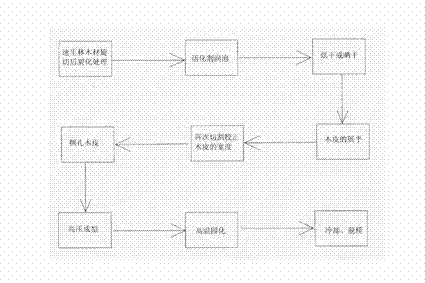

[0032] Use the following process to make recombined integrated profiles with fast-growing forests:

[0033] ① Cut the fast-growing forest wood into 3-5mm thick and equal-length peeled veneers, and perform high-temperature degreasing, sterilization, desugar, and destarch in the carbonization furnace to make the veneer uniform in color and soften the veneer;

[0034] ②Dry or sun-dry the above-mentioned rotary-cut veneer after high-temperature treatment in a high-temperature carbonization furnace, and then soak the dried or sun-dried veneer with a glue activator. The glue activator is activated according to the glue primer when used. Agent: dilute with water at a ratio of 1:2 to moisten the veneer;

[0035] ③ Dry or dry the veneer soaked with the glue activator in ②. The temperature of the drying room should not be higher than 60°C when drying, and the dry burning rate of the veneer can be out of the drying room when the dry burning rate reaches 12-15°C;

[0036] ④ Put the venee...

Embodiment 2

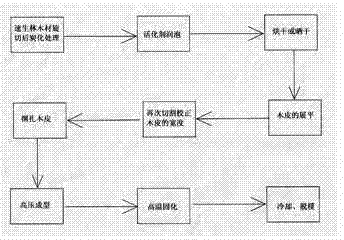

[0045] Use the following process to make recombined integrated profiles with fast-growing forests:

[0046] ① Cut the fast-growing forest wood into 3-5mm thick and equal-length peeled veneers, and perform high-temperature degreasing, sterilization, desugar, and destarch in the carbonization furnace to make the veneer uniform in color and soften the veneer;

[0047] ②Dry or sun-dry the above-mentioned rotary-cut veneer after high-temperature treatment in a high-temperature carbonization furnace, and then soak the dried or sun-dried veneer with a glue activator. The glue activator is activated according to the glue primer when used. Agent: dilute with water at a ratio of 1:2 to moisten the veneer;

[0048] ③ Dry or dry the veneer soaked with the glue activator in ②. The temperature of the drying room should not be higher than 60°C when drying, and the dry burning rate of the veneer can be out of the drying room when the dry burning rate reaches 12-15°C;

[0049] ④ Put the venee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com