Additive manufacturing forming cylinder drive mechanism, forming cylinder and additive manufacturing equipment

A driving mechanism and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problem of limited forming height of forming equipment, achieve force optimization, improve stability, and increase forming height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

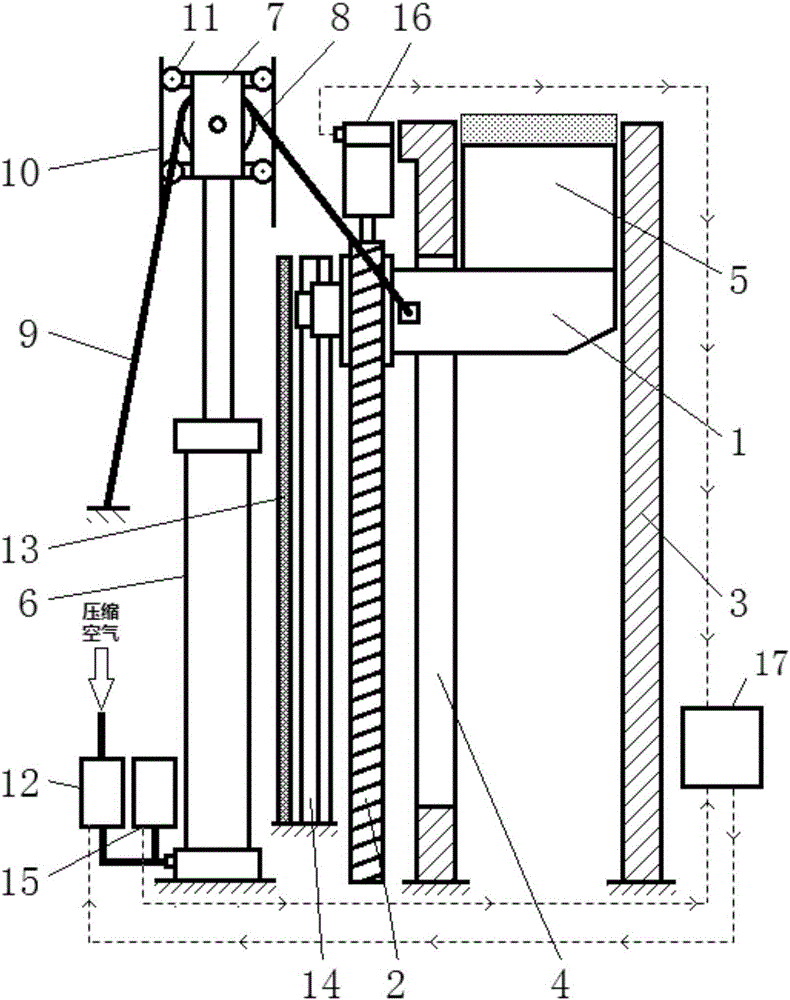

[0023] The additive manufacturing forming cylinder driving system of the present invention includes a cantilever lifting system and a dynamic compensation system.

[0024] In a structure of the drive system, the cantilever lifting system includes a cantilever 1 and a screw drive mechanism 2, such as figure 1 As shown, one end of the cantilever 1 is installed on the screw drive mechanism 2 , and the other free end is used to fix the base plate 5 . The screw driving mechanism 2 drives the cantilever 1 to feed up and down, and drives the base plate 5 to lift. One side of the screw drive mechanism 2 is provided with a slider slide rail mechanism 14, which is connected with the cantilever 1, and assists the cantilever 1 to move up and down to ensure that the cantilever 1 moves up and down in the vertical direction. A force sensor is arranged on the upper surface of the cantilever 1 for measuring and feeding back the downward load force on the cantilever.

[0025] The dynamic comp...

Embodiment 2

[0029] In another structure of the drive system, the structure of the cantilever lifting system is the same as in Embodiment 1, the difference is that no force sensor is set on the cantilever 1, and the cantilever lowering height or Servo motor torque, and height data or torque data are fed back to the controller 17 of the driving system, and the downward load force that cantilever is subjected to under this height or torque is obtained by calculation, and then the inlet air pressure of the air pressure regulator 12 is adjusted to make it The upward compensating force is balanced by the downward load on the cantilever. The structure of the dynamic compensation system is the same as in Embodiment 1, the difference is that the movable pulley system is composed of a sprocket, a chain and a sprocket support structure.

Embodiment 3

[0031] In another structure of the drive system, the structure of the cantilever lifting system is the same as in Embodiment 1, the difference is that no force sensor is set on the cantilever 1, and a height measuring device is set on the screw drive mechanism 2 to measure and feed back the cantilever drop. As far as the controller 17 of the drive system is concerned, a grating scale 13 is provided on one side of the screw drive mechanism. The structure of the dynamic compensation system is the same as in Embodiment 1.

[0032] The working process of the above-mentioned additive manufacturing forming cylinder driving mechanism is as follows: on the one hand, the screw driving mechanism 2 drives the cantilever 1 to feed up and down, and drives the substrate 5 to move up and down. The cantilever lifting system is used to replace the piston drive mechanism, so that the height of the additive manufacturing equipment can be greatly increased under the condition of limited height. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com