Patents

Literature

289 results about "Abrasive machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

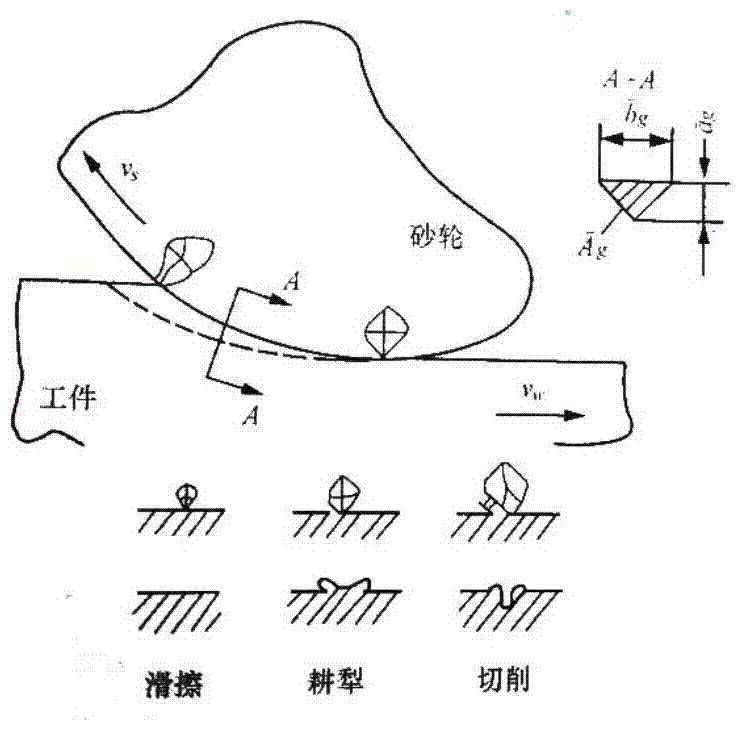

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles. Common examples include grinding, honing, and polishing.

Abrasive processing of hard and /or brittle materials

ActiveUS20090084042A1Slow feed ratePigmenting treatmentOther chemical processesManufacturing technologyTitanium carbide

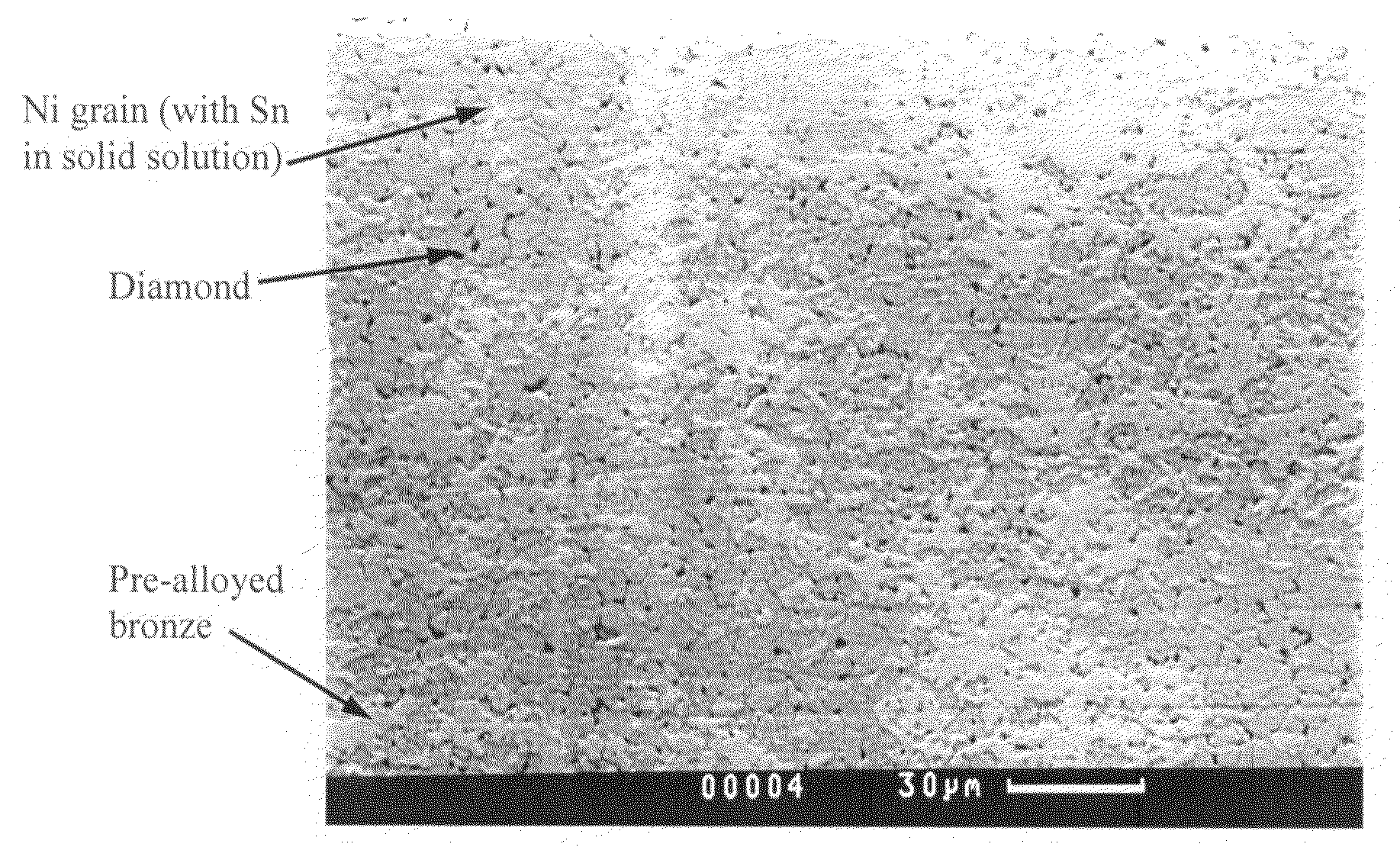

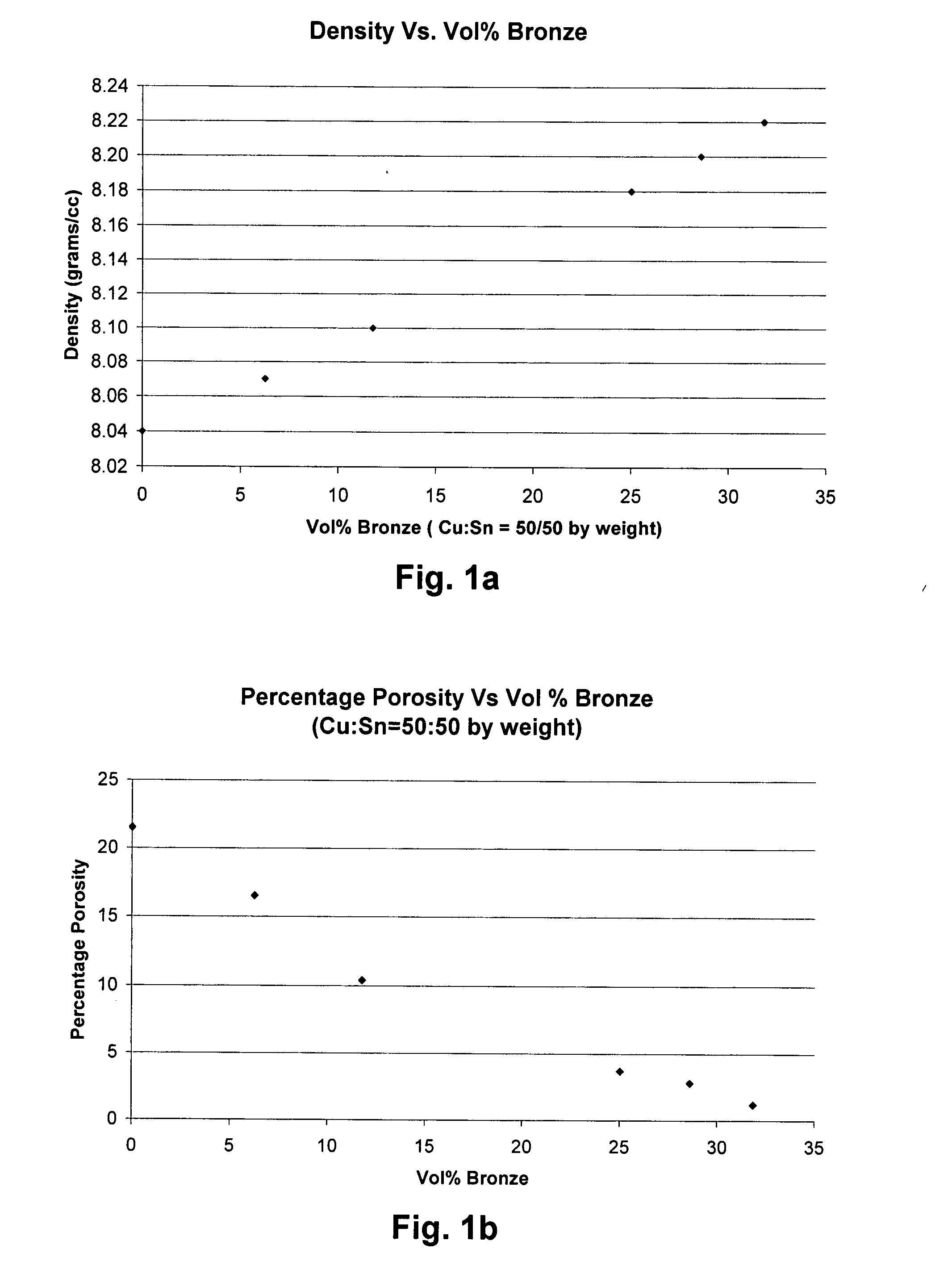

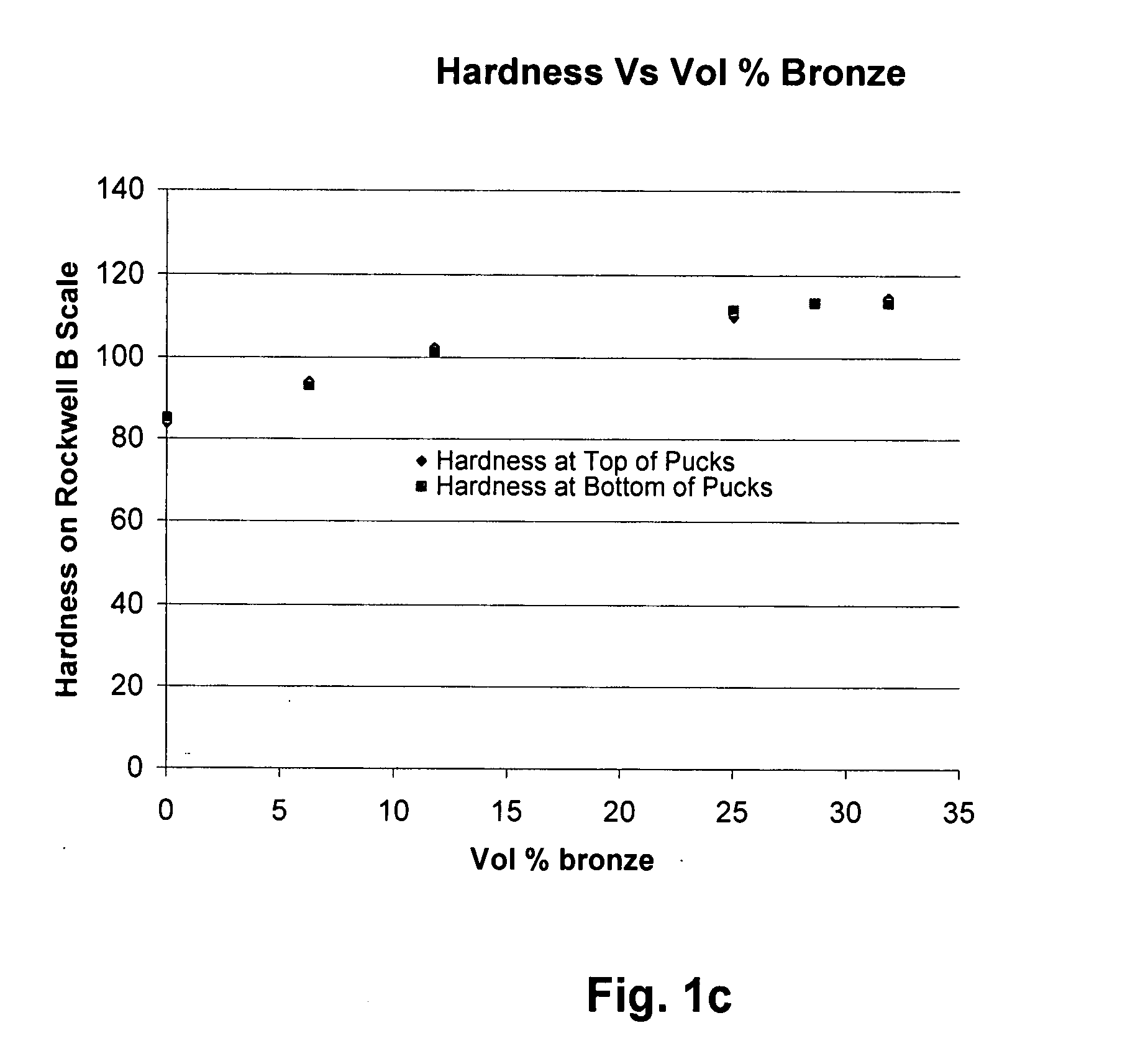

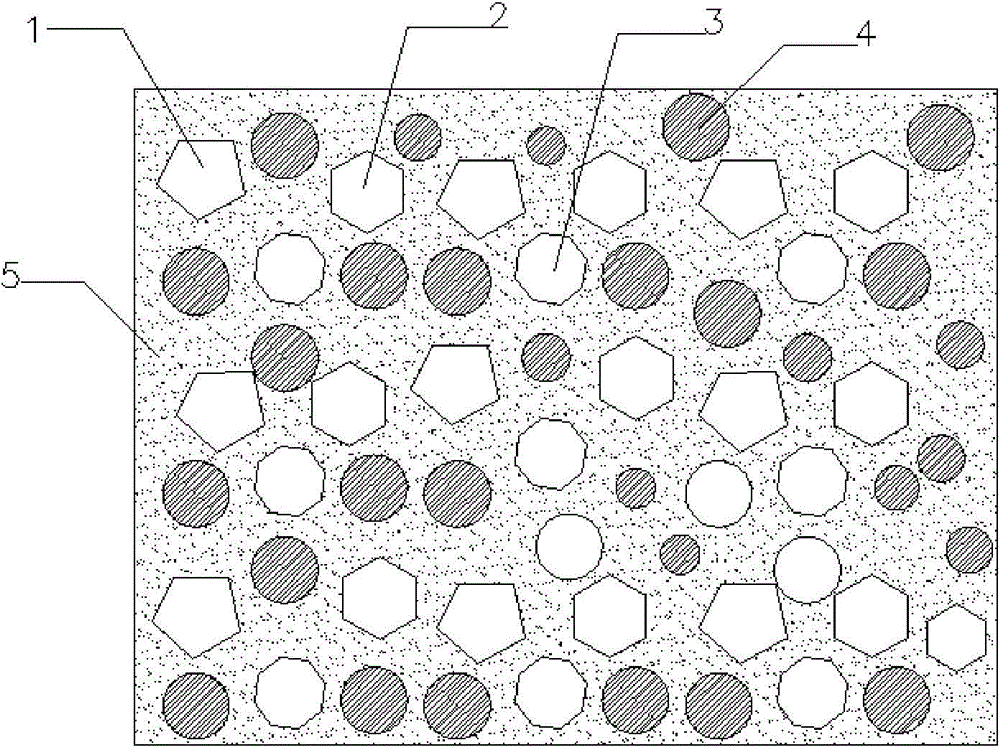

Abrasive articles possessing a highly open (porous) structure and uniform abrasive grit distribution are disclosed. The abrasive articles are fabricated using a metal matrix (e.g., fine nickel, tin, bronze and abrasives). The open structure is controlled with a porosity scheme, including interconnected porosity (e.g., formed by leaching of dispersoid), closed porosity (e.g., induced by adding a hollow micro-spheres and / or sacrificial pore-forming additives), and / or intrinsic porosity (e.g., controlled via matrix component selection to provide desired densification). In some cases, manufacturing process temperatures for achieving near full density of metal bond with fillers and abrasives, are below the melting point of the filler used, although sacrificial fillers may be used as well. The resulting abrasive articles are useful in high performance cutting and grinding operations, such as back-grinding silicon, alumina titanium carbide, and silicon carbide wafers to very fine surface finish values. Techniques of use and manufacture are also disclosed.

Owner:SAINT GOBAIN ABRASIVES INC +1

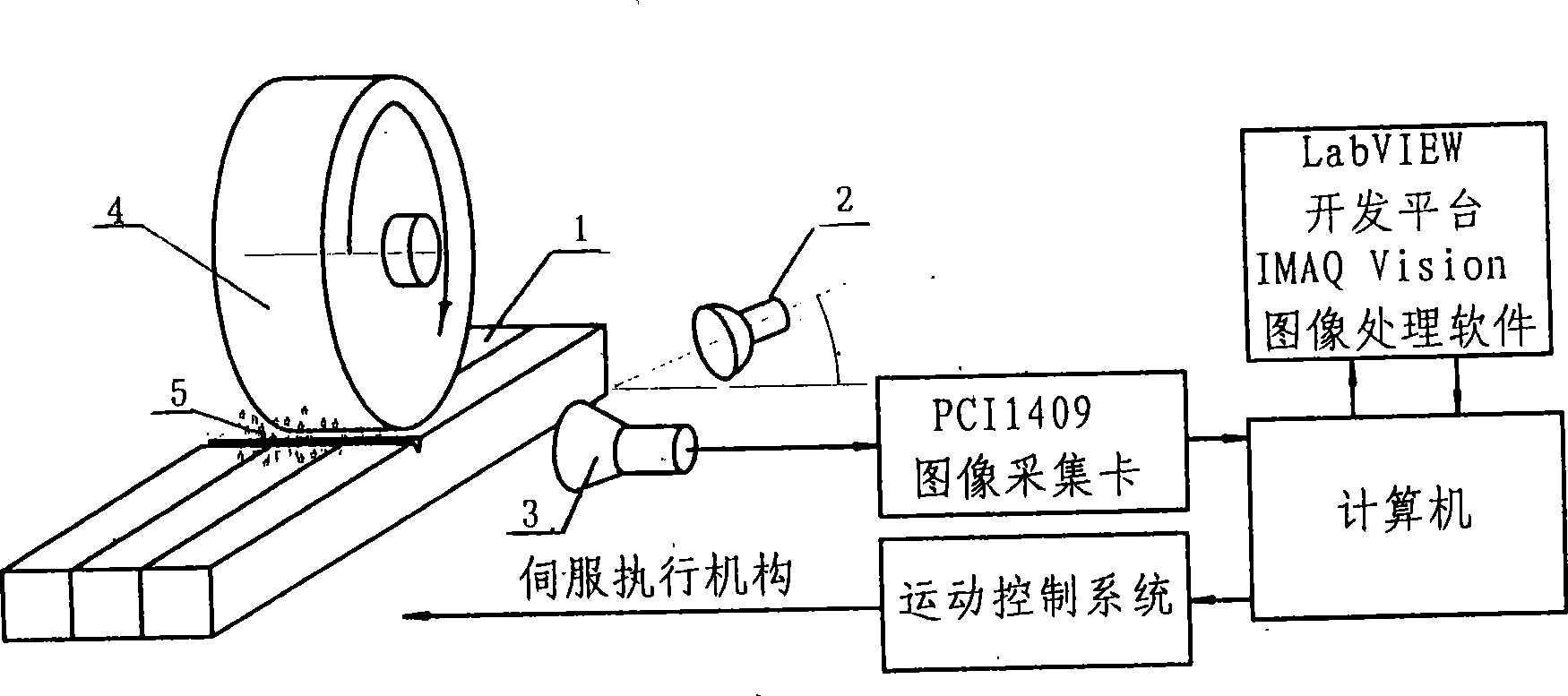

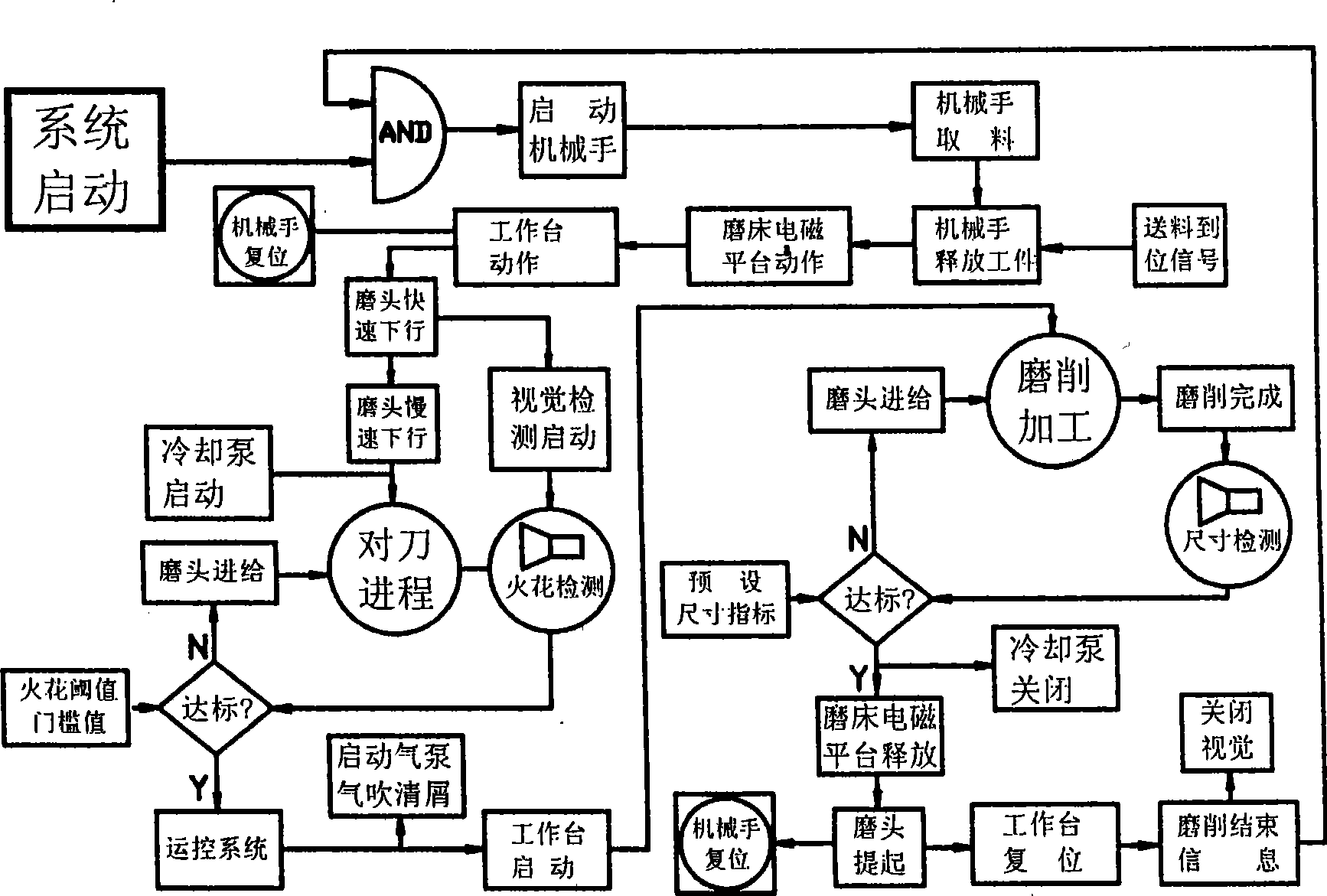

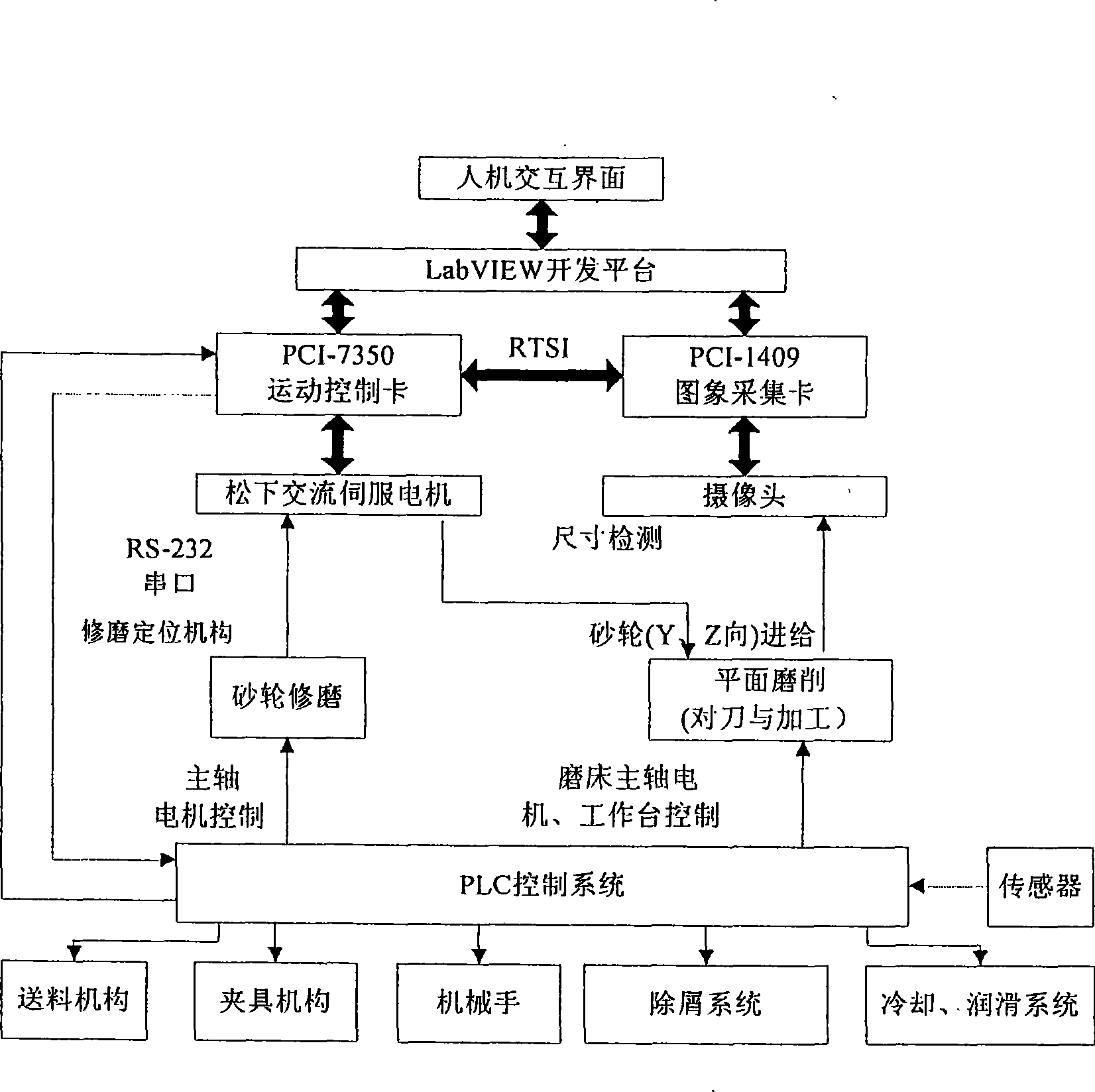

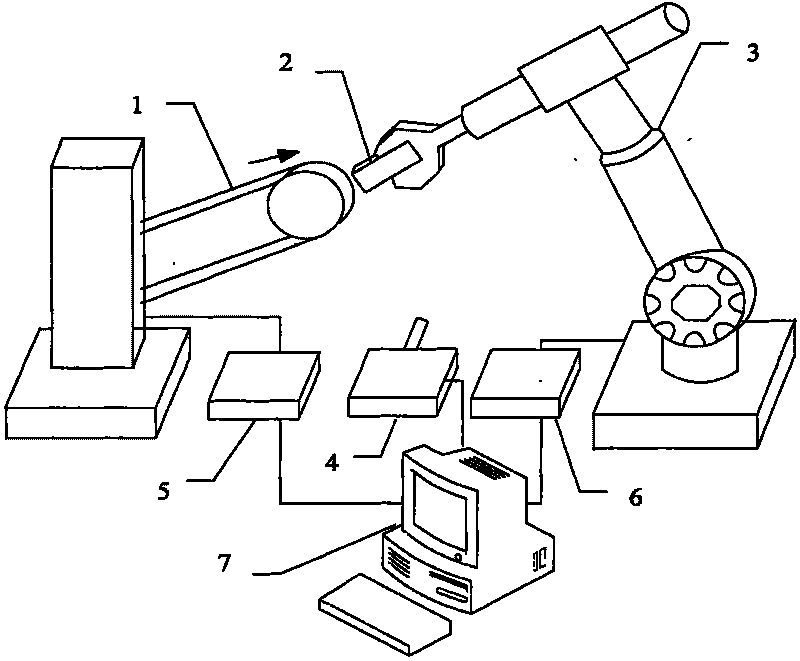

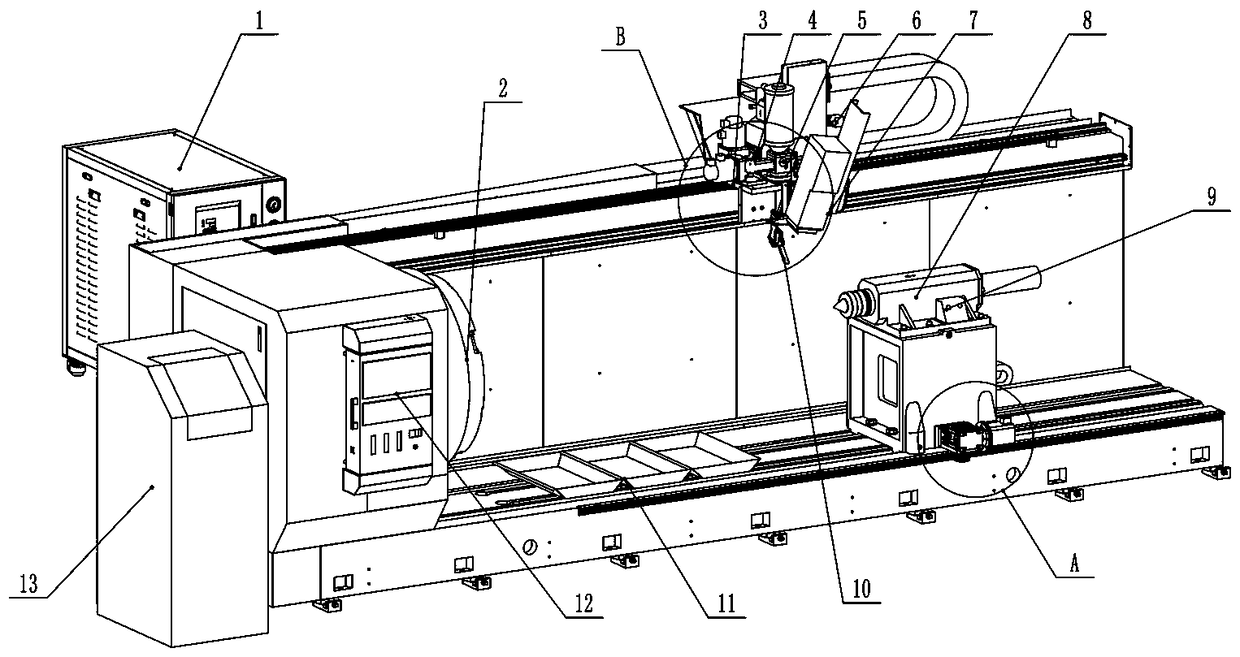

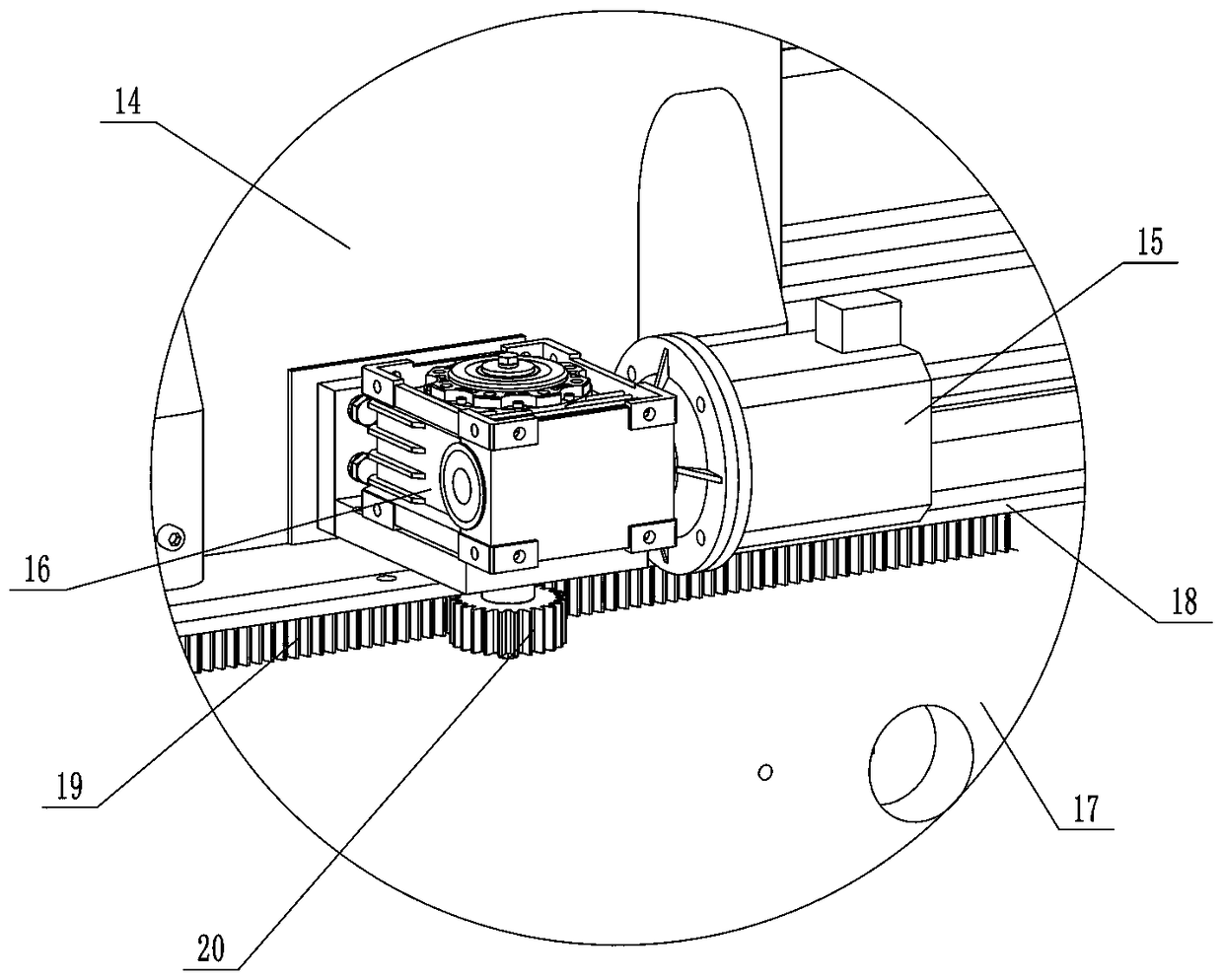

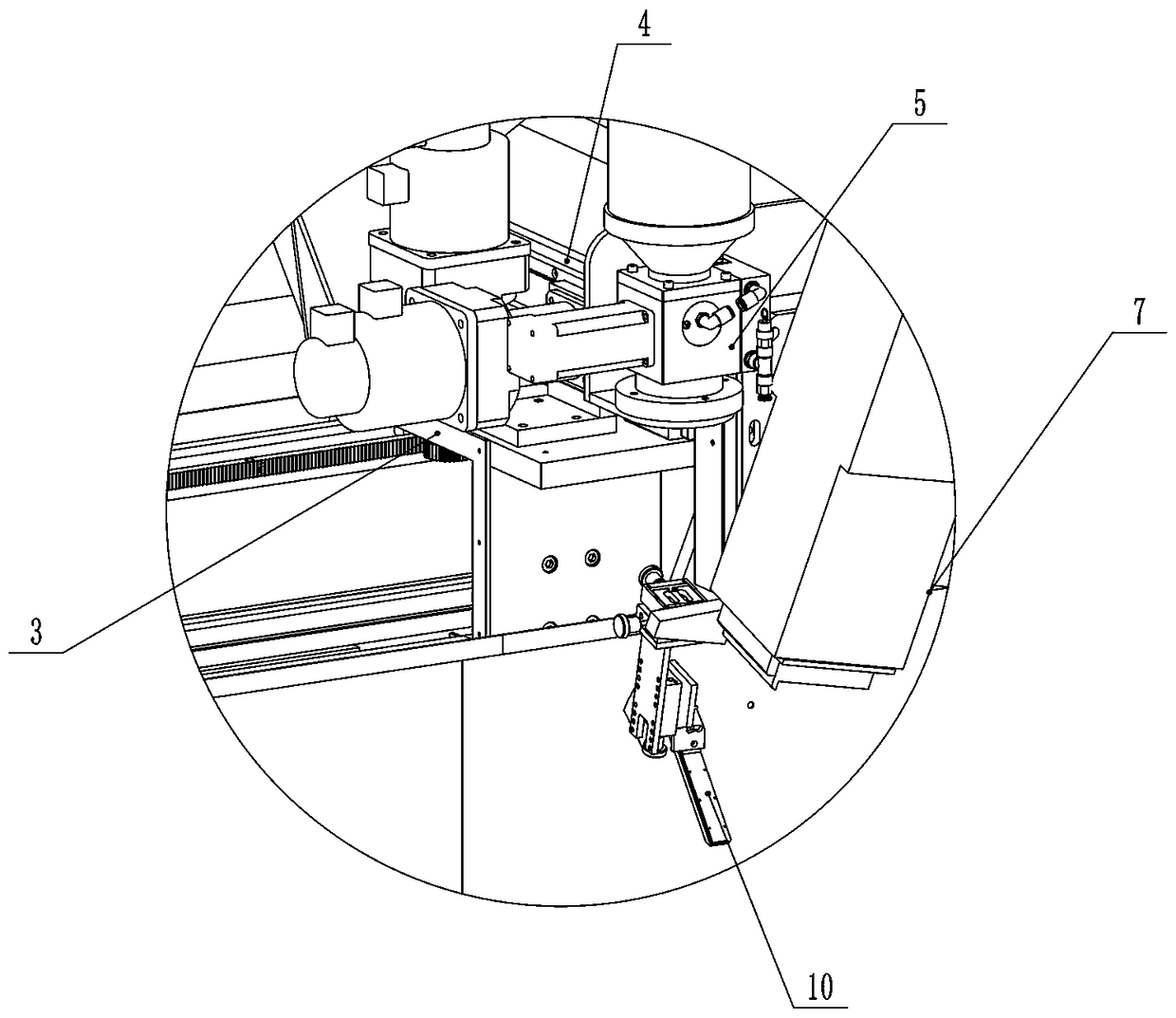

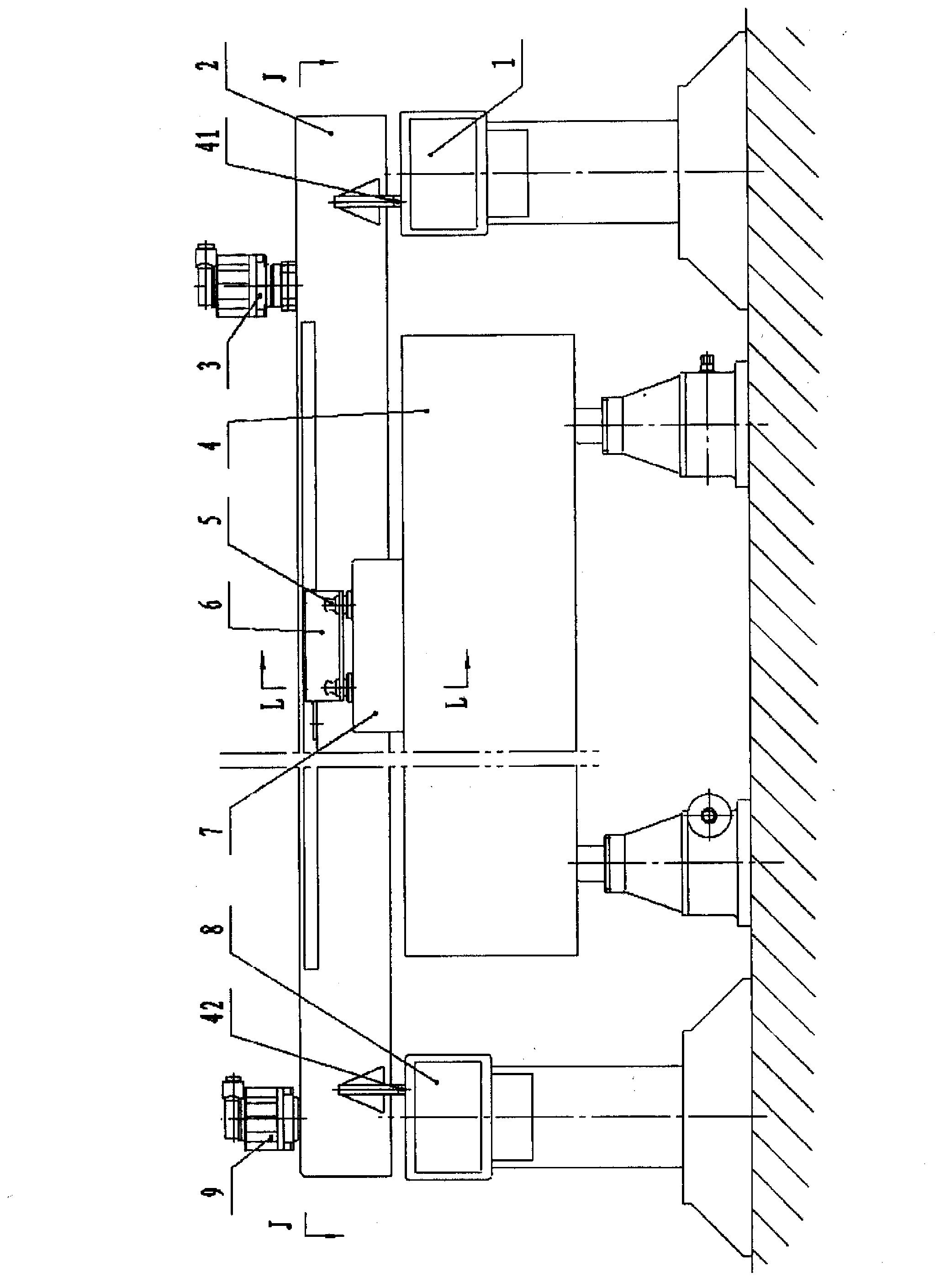

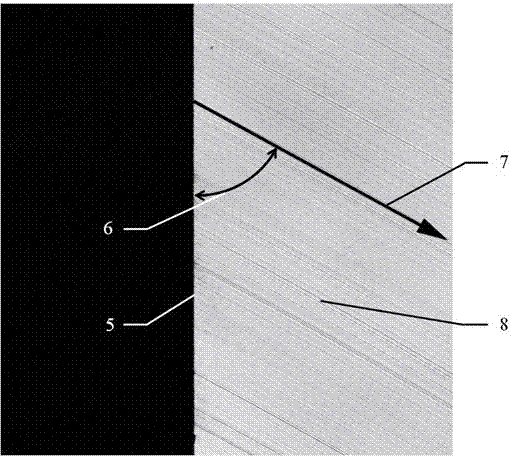

Spark identification tool-setting method and abrasive machining automatic system

The invention discloses a method for setting a tool through sparkle identification and an automatic system for grinding processing. The method and the system achieve the intelligent automatic control for the whole grinding process and accurately and reliably solve the problem of automatic tool setting, the problem of dimension compensation caused by the abrasion of a grinding wheel, and the problems of on-line dimension measurement and motion servo control in the grinding process. The method organically combines a vision technique, a PLC technique and a motion control technique, and provides a solution for solving the problems of tool setting, on-line dimension measurement and grinding wheel wear compensation by using the vision technique, and the problem of motion servo control by using the PLC technique and the motion control technique. The method makes use of the vision technique to automatically identify the operating condition contacted with a workpiece, and switch the operating condition to a grinding processing state instantly so as to solve the problem of automatic tool setting, thus the method can combine a plurality of mature correlation techniques to construct the automatic system which integrates detection and motion control. The method and the automatic system achieve the accurately automatic tool setting, solve the problems of the wear measurement and compensation of the grinding wheel, and open up a novel approach for fully automatic and intelligent control in the grinding process.

Owner:QIQIHAR HUAGONG MACHINE +1

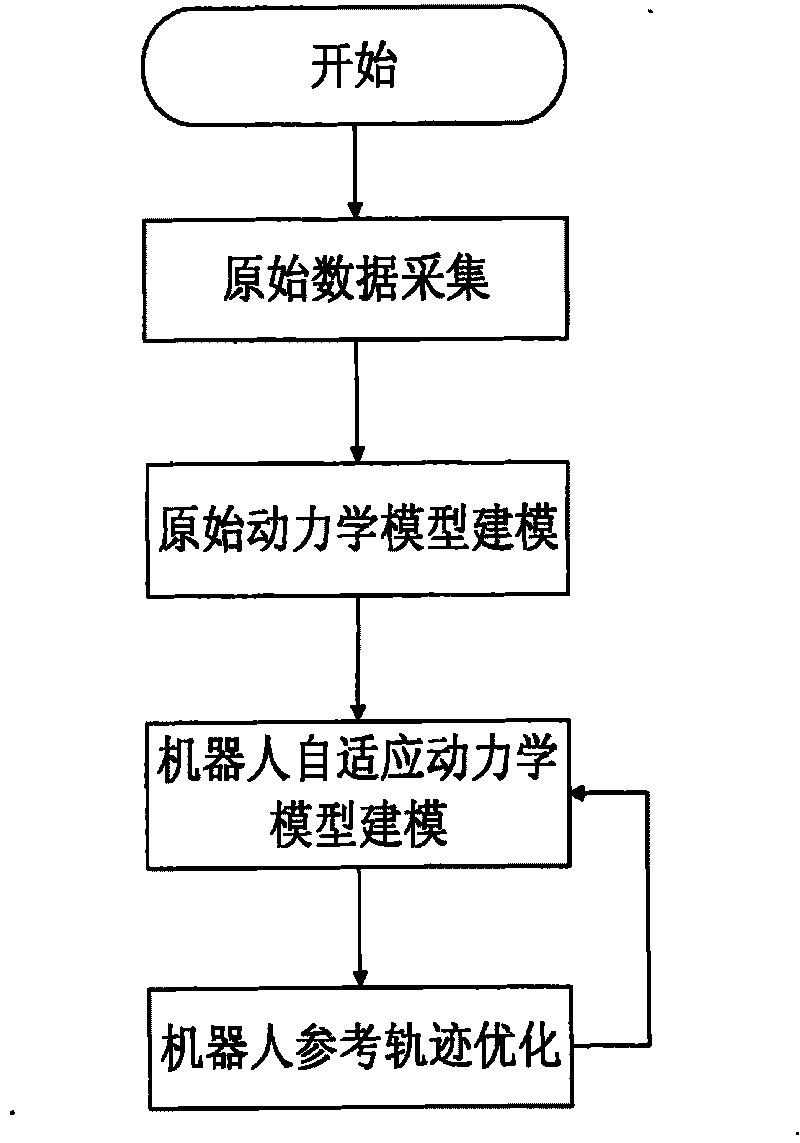

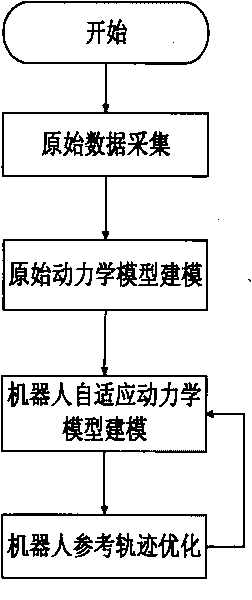

Machine learning-based robot grinding method

InactiveCN101738981AAvoid blindnessImprove adaptabilityNumerical controlLearning basedDynamic models

The invention relates to a machine learning-based robot grinding method, which belongs to the field of abrasive machining. The method comprises the following steps of: in each working stage of an abrasive belt, grinding workpieces made of different materials to obtain the contact force between the workpieces and a grinding wheel, the curvature and the grinding quantity of grinding surfaces of the workpieces, and the processing speed; modeling a dynamic model and initializing a self-adapting dynamic model set of a robot by using initial data and adopting a machine learning method; and according to an original dynamic model and measured data of the current working condition during grinding, establishing a self-adapting dynamic model of the current robot, and adding the self-adapting dynamic model to the self-adapting dynamic model set M of the robot. The machine learning-based robot grinding method can realize high-precision grinding, reduce the production cost and improve the processing efficiency.

Owner:TSINGHUA UNIV

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

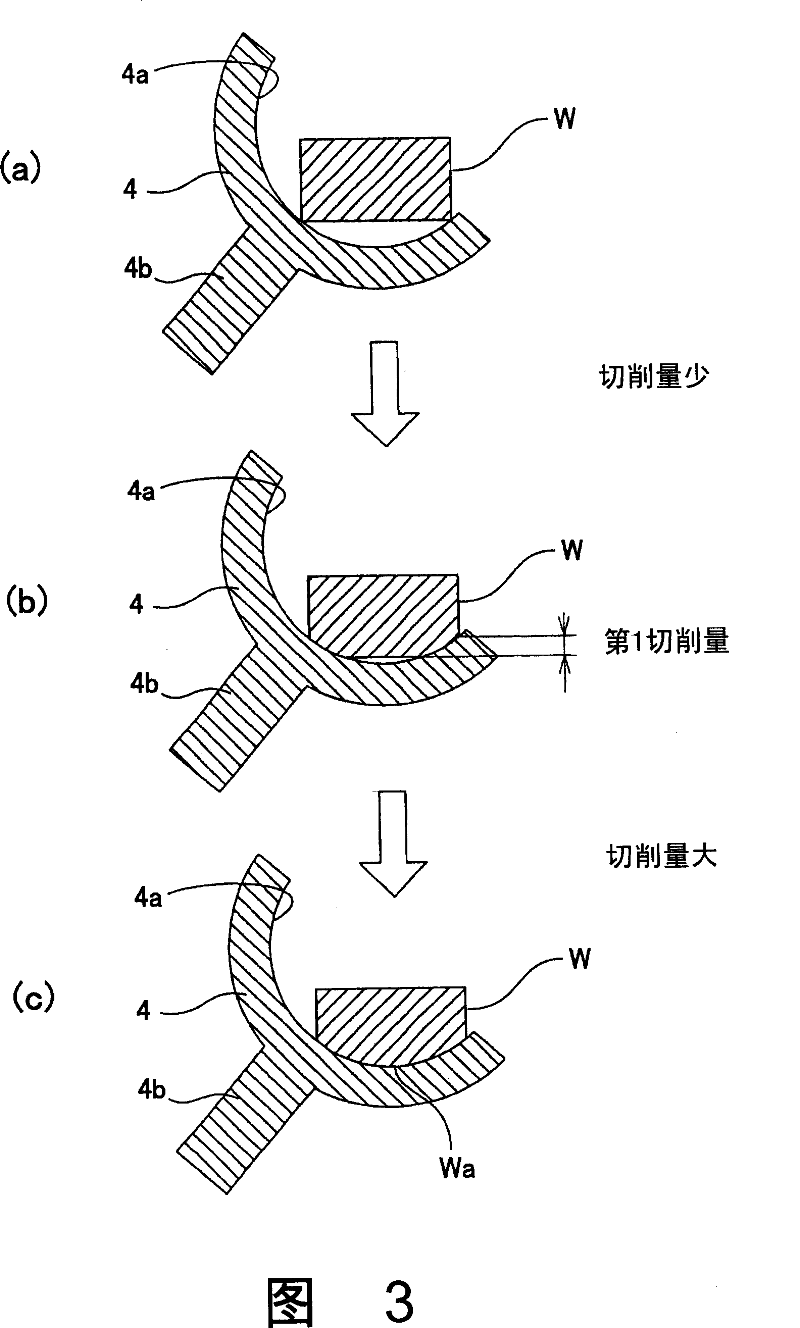

Prestress grinding method for revolved body workpiece

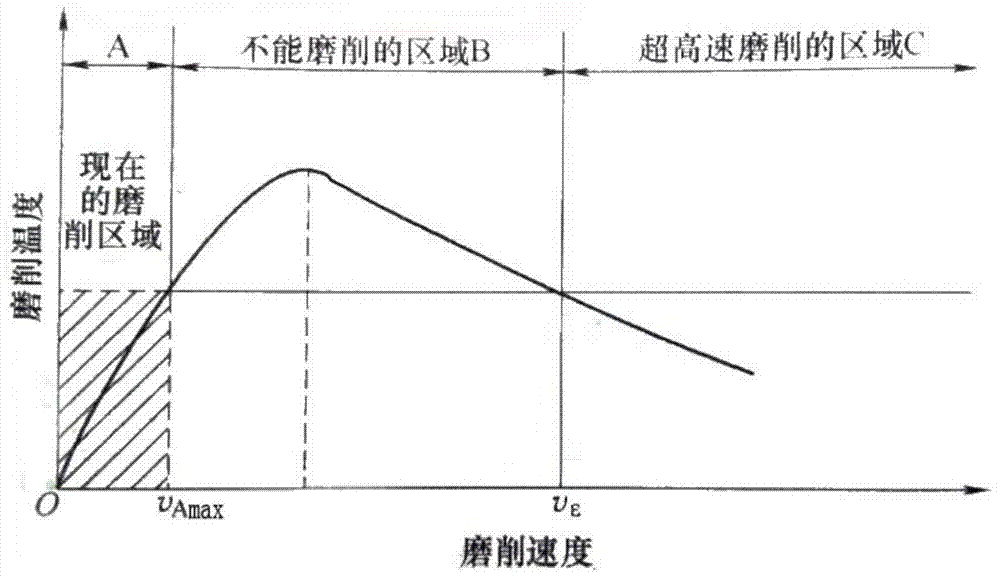

ActiveCN104759954ASimple structureStability is not affectedRevolution surface grinding machinesUltra high speedLow speed

The invention discloses a prestress grinding method for a revolved body workpiece. The method includes the following steps that (1) the workpiece to be machined is well clamped on a grinding machine; (2) tool setting operation is conducted, a grinding wheel and the workpiece are made to be in a low speed state first, the position of the grinding wheel is adjusted step by step, the linear speed of the grinding wheel is adjusted to be in an ultra high speed state of vs>=150 m / s after sparks just appear on the surface of the workpiece, and the rotating speed of the workpiece is adjusted to be in an ultra high speed centrifugal state; (3) abrasive machining is carried out according to a certain radial amount of feed; after machining is completed, the grinding wheel and the workpiece are separated first, and then the grinding wheel and the workpiece are decelerated to be zero. According to the prestress grinding method for the revolved body workpiece, there is no need to use a special force application mechanism to apply prestress to the workpiece, only the rotating speed of the workpiece in the machining process needs to be controlled, and residual compressive stress can be obtained on the surface of the workpiece after machining is completed; due to the fact that the rotating speed of the workpiece can be adjusted flexibly, different magnitudes of residual compressive stress can be obtained by controlling the rotating speed of the workpiece, so that the using requirements of different parts are met.

Owner:GUANGZHOU UNIVERSITY

Abrasive flow machining numerical simulation research method based on molecular dynamics

InactiveCN104657564AAchieve micromachiningImplementing Molecular Dynamics SimulationsSpecial data processing applicationsEnergy variationMachined surface

The invention relates to an abrasive flow machining numerical simulation research method based on molecular dynamics. According to the method, numerical simulation researches are carried out on a machining course by taking a single abrasive grain as a tool. Specifically, the method comprises the following steps: (1) carrying out abrasive flow machining course simulation researches on the basis of molecular dynamics; (2) establishing an abrasive micro-cutting molecular dynamic model; (3) discussing the influence of related parameters on energy change in the machining course and analyzing the quality of a machined surface; and (4) exploring the influence of abrasive machining on an abrasive crystal structure at a micro-scale. According to the method disclosed by the invention, by researching and analyzing a single-abrasive micro-cutting process in the abrasive flow machining course by virtue of a molecular dynamics method, atomic displacement in a Newtonian layer of a workpiece during the abrasive micro-cutting process can be calibrated; and the method can be used for achieving molecular dynamic simulation of abrasive grains and pointing out that bond angle of an abrasive grain can be changed in the course of machining the abrasive grains, so as to lay a theoretical foundation for the subsequent researches on the deformation of the abrasive crystal structure in the abrasive flow machining course.

Owner:CHANGCHUN UNIV OF SCI & TECH

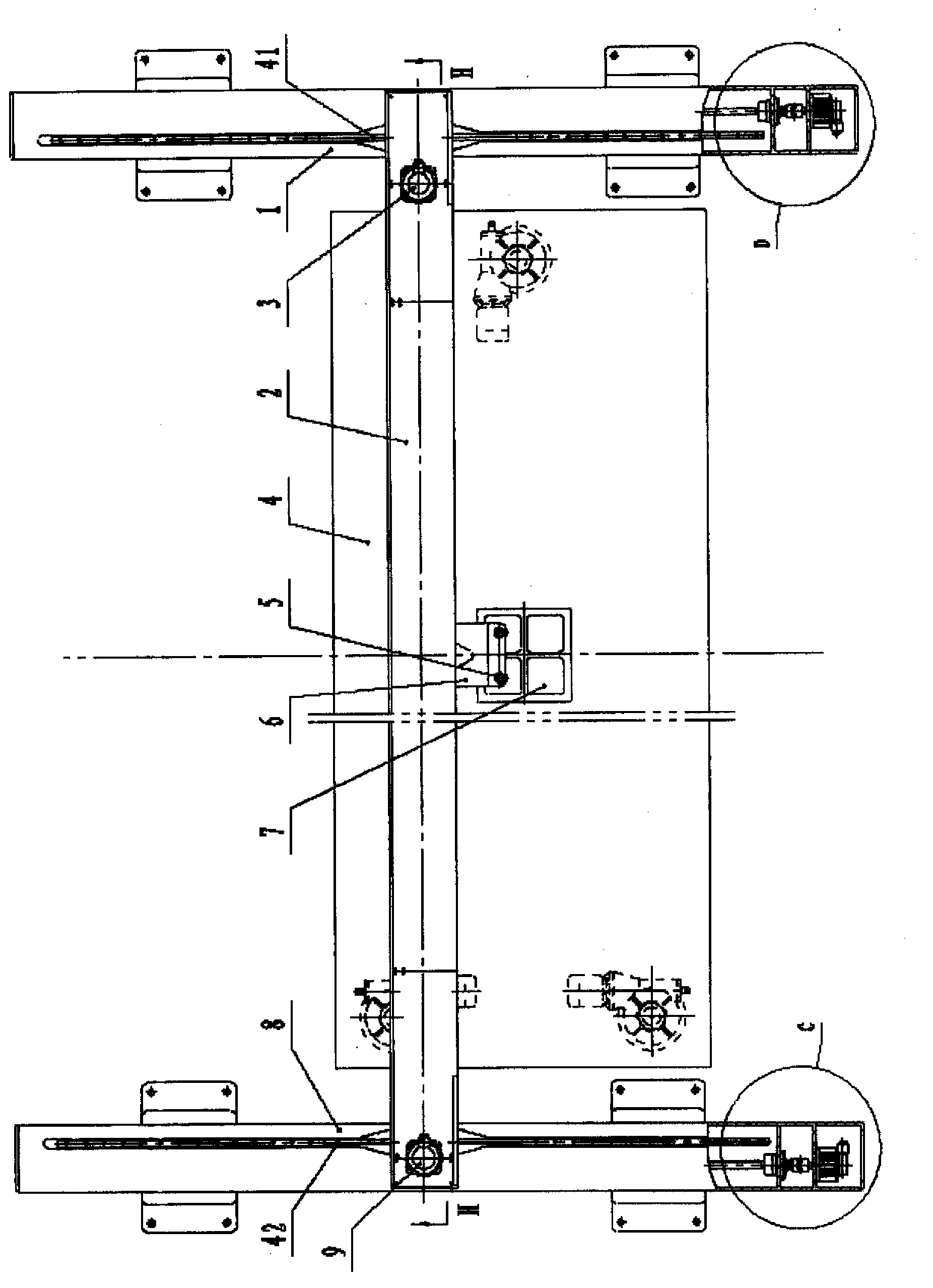

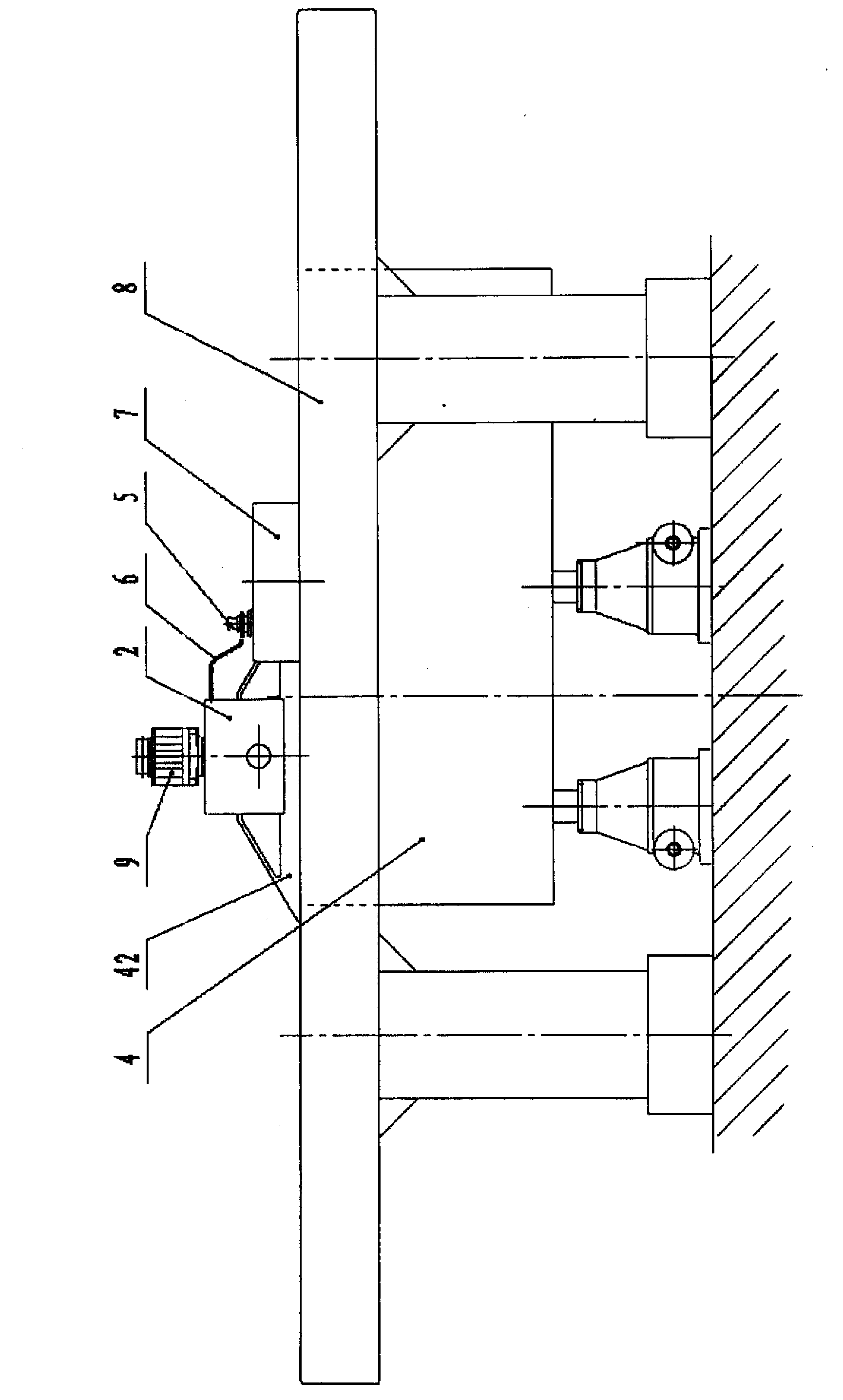

Numerical control rubbing type grinding machine tool

InactiveCN103252709AAchieve sliding grindingRealize kneading grindingLapping machinesBridge typeEngineering

The invention discloses a numerical control rubbing type grinding machine tool. A left support, a right support and a cross beam constitute a bridge type frame structure, the cross beam can move along the left support and the right support forwards and backwards, and a sliding box arranged on the cross beam can move along a guide rail of the cross beam leftwards and rightwards. The sliding box can additionally output winding translational-motion power, and the sliding box is connected with a grinding board and drives the grinding board to move. All kinds of movement are controlled by a numerical control system, the grinding board can move along various tracks freely and can simulate manual rubbing type actions, manual grinding work can be completely replaced, and a plane abrasive machining process can be leapt forward to mechanization, automation and numerical control in one step.

Owner:孟凡朔

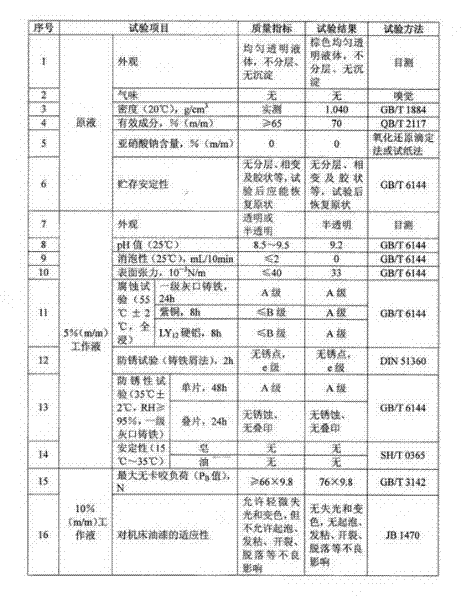

Environmental-friendly micro emulsion cutting fluid

InactiveCN102533418AImprove the lubrication effectEasy to cleanLubricant compositionPhosphoric Acid EstersChemical industry

The invention relates to an environmental-friendly micro emulsion cutting fluid, which belongs to the field of chemical industry. The invention aims to provide the environmental-friendly micro emulsion cutting fluid, which not only is capable of protecting the environment but also is capable of performing cooling and lubrication actions in the metal cutting abrasive machining process. The environmental-friendly micro emulsion cutting fluid comprises 10# industrial white oil, sodium petroleum sulfonate, oleic acid, triethanolamine, alkylphenol polyoxyethylene OP-10, alkyl alcohol amido phosphate ester 6503, an antirusting agent monomer, tetradecyl alcohol or stearyl alcohol, benzotriazole, sodium tetraborate, sodium carbonate, triazine compound / benzisothiazolinone bactericide (NEUF652), a defoaming agent MS-455 and water. The environmental-friendly micro emulsion cutting fluid not only has the advantages of good lubricity of an emulsion-type cutting fluid and strong cleaning capacity of synthetic cutting fluid but also is capable of overcoming the defects that the emulsion-type cutting fluid is easy to go bad and stink and has a short service life and the synthetic cutting fluid has poorer lubricating property, and has the characteristics of good lubricity, strong cooling and cleaning capacity, long service life and the like.

Owner:FAW GROUP

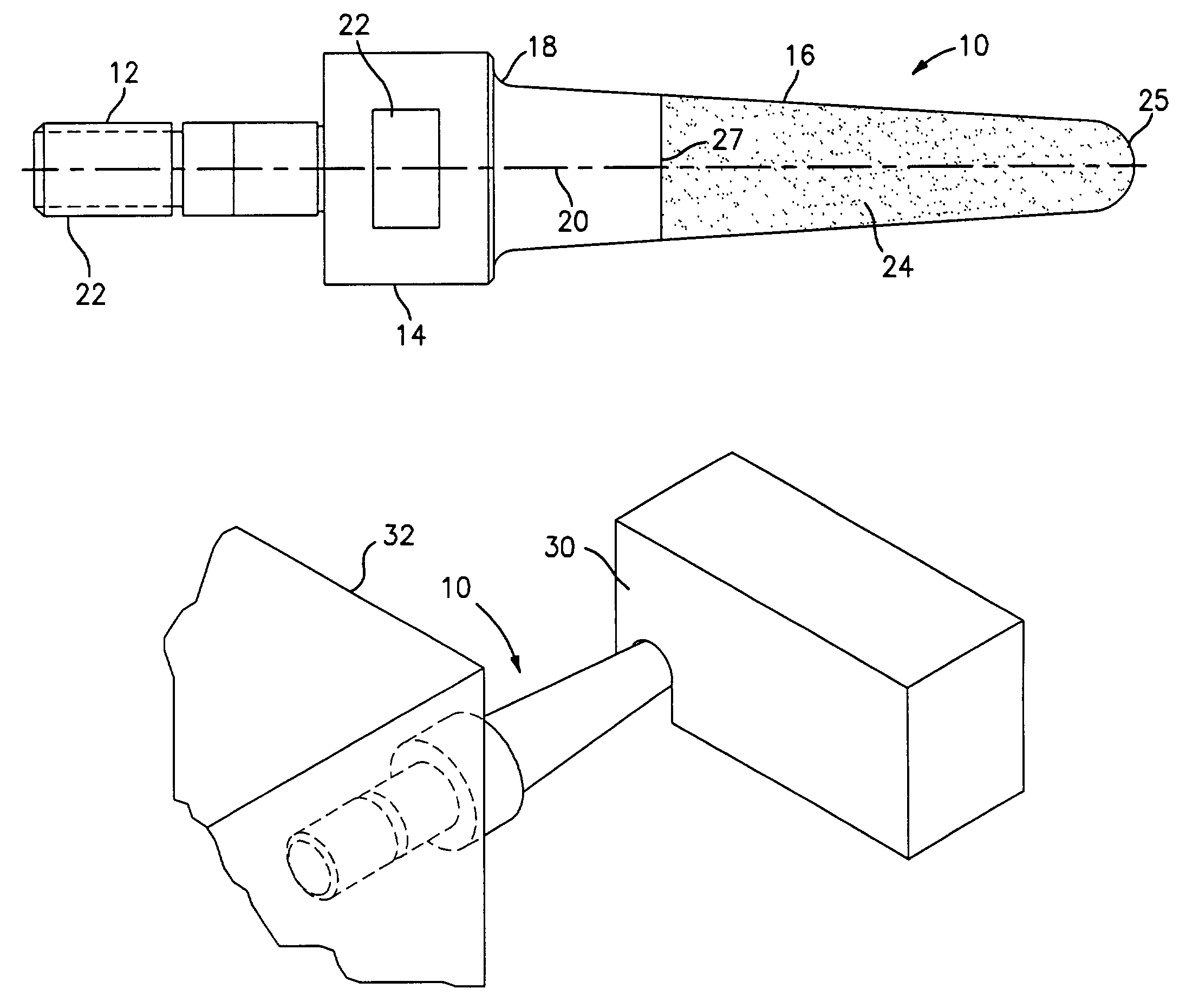

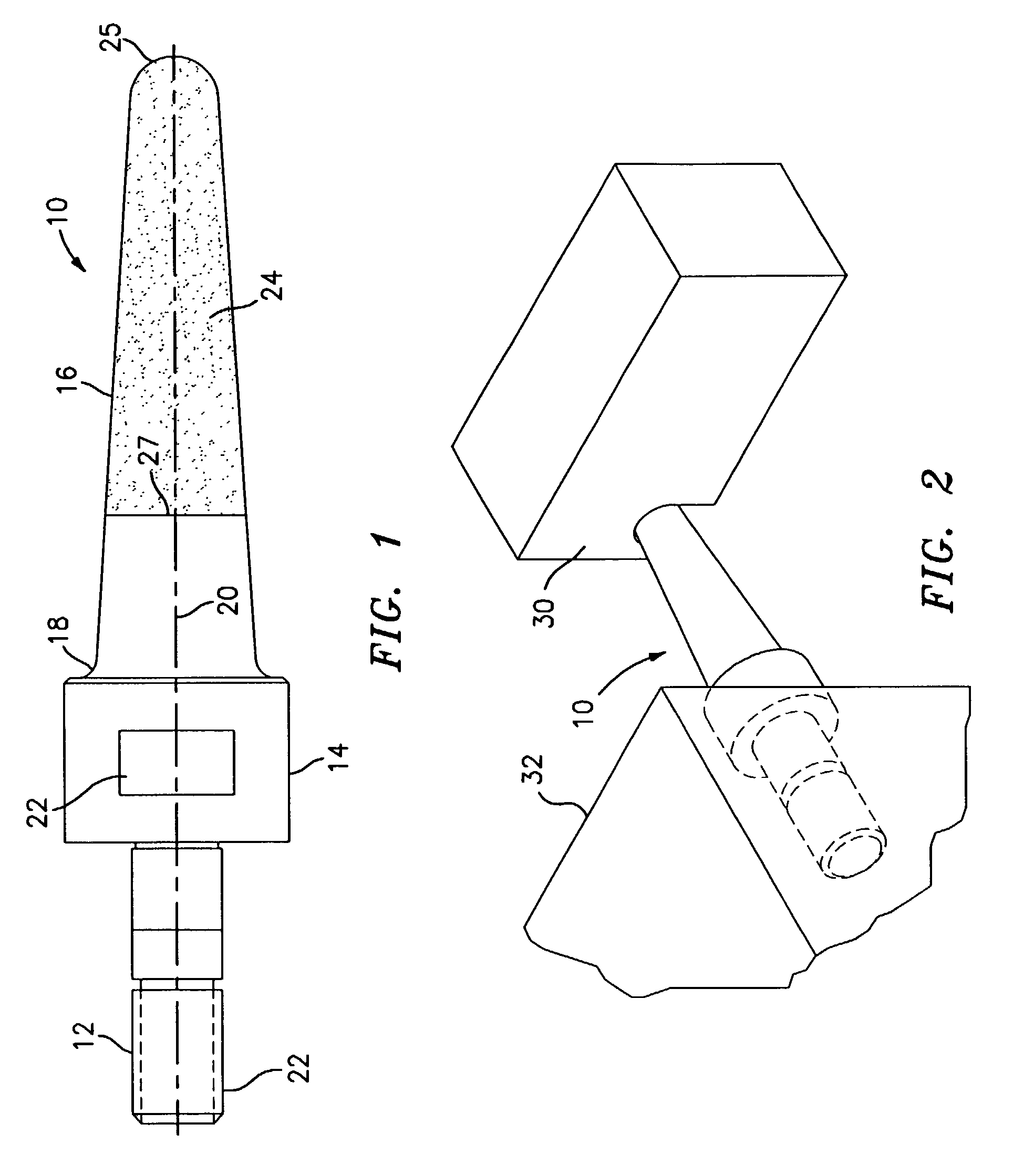

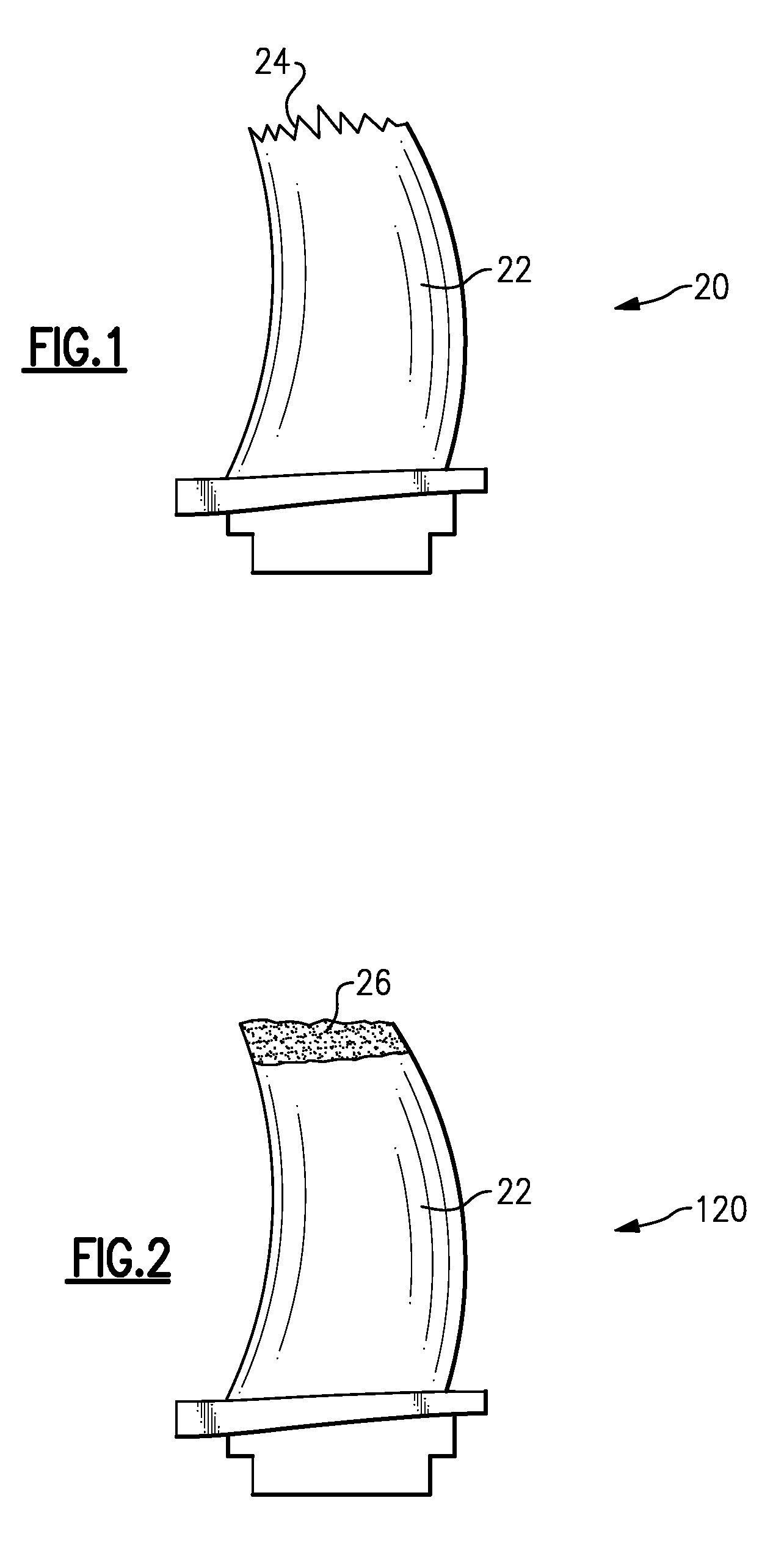

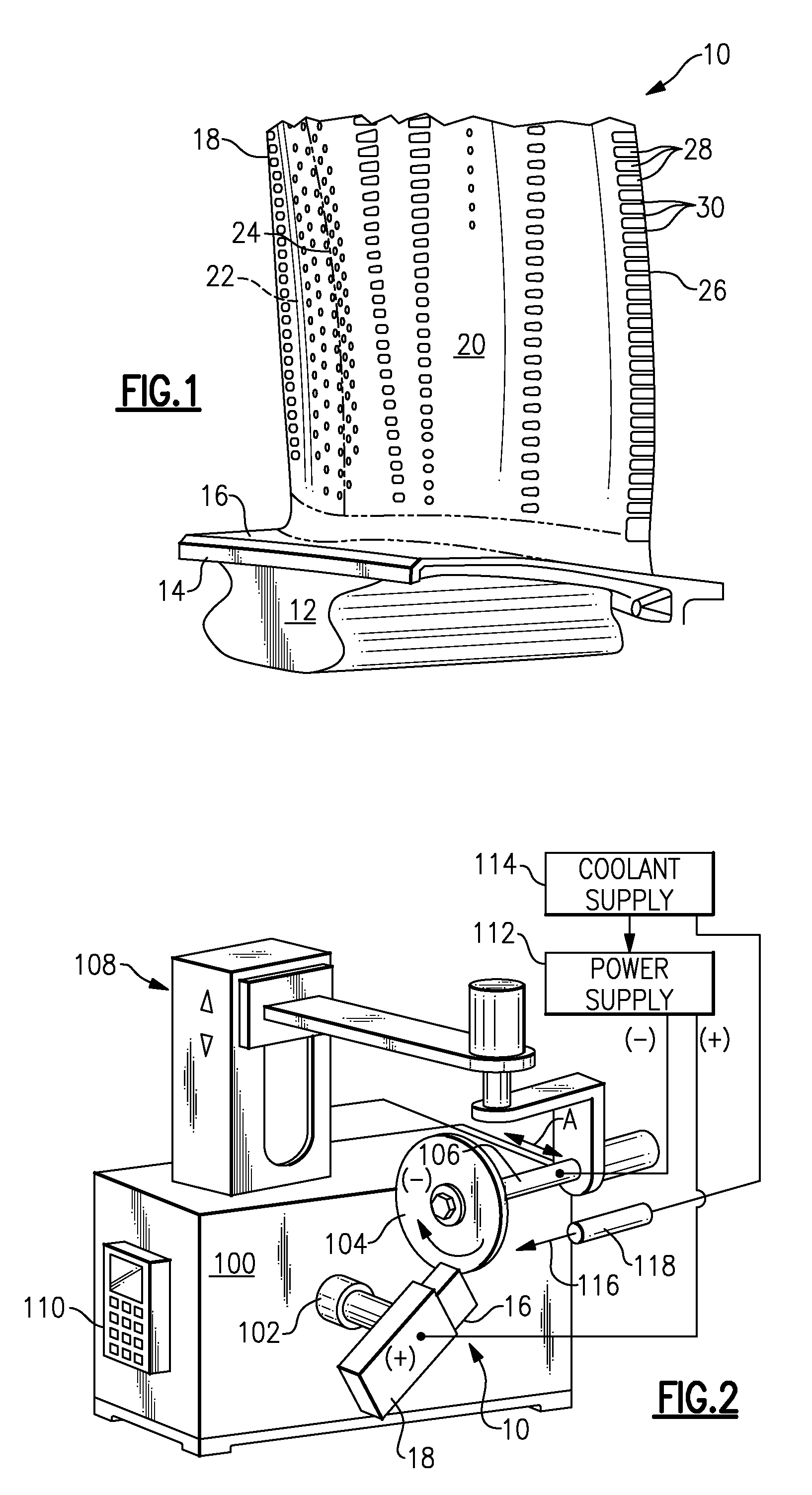

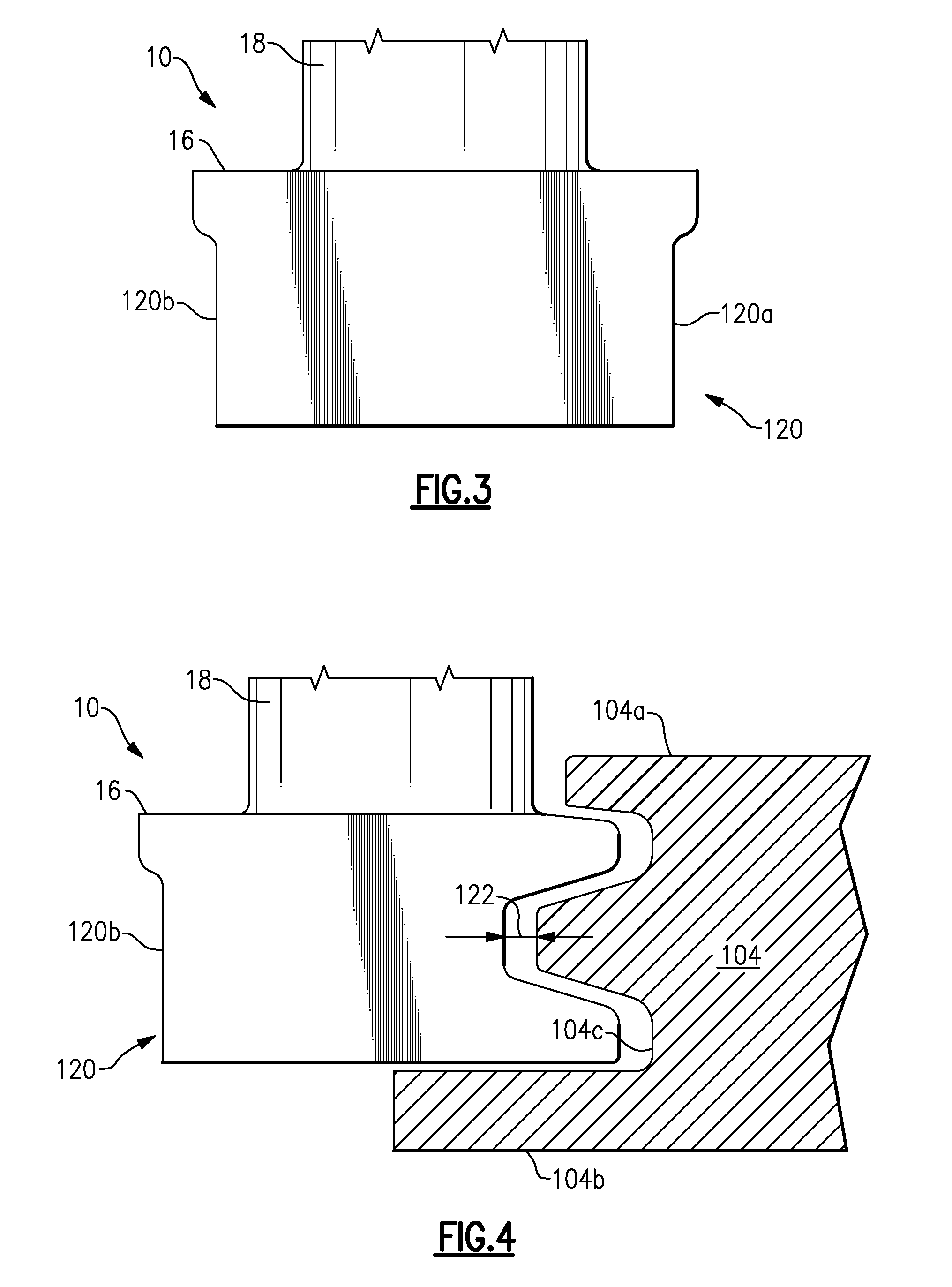

Flank superabrasive machining

ActiveUS7101263B2Reduce loadLess timeRevolution surface grinding machinesBonded abrasive wheelsBoron nitrideAbrasive machining

The present invention relates to a quill to be used to superabrasively machine complex shapes, such as airfoil shapes, into a substrate. The quill has a shaft portion, an enlarged head portion adjacent the shaft portion, and a tapered grinding portion adjacent the enlarged head portion. The tapered grinding portion has a layer of grit material selected from the group consisting of diamonds and cubic boron nitride thereon. In a preferred embodiment, the quill is a vitrified or plated cubic boron nitride quill on the grinding portion. A method of using the tool is also disclosed.

Owner:RAYTHEON TECH CORP

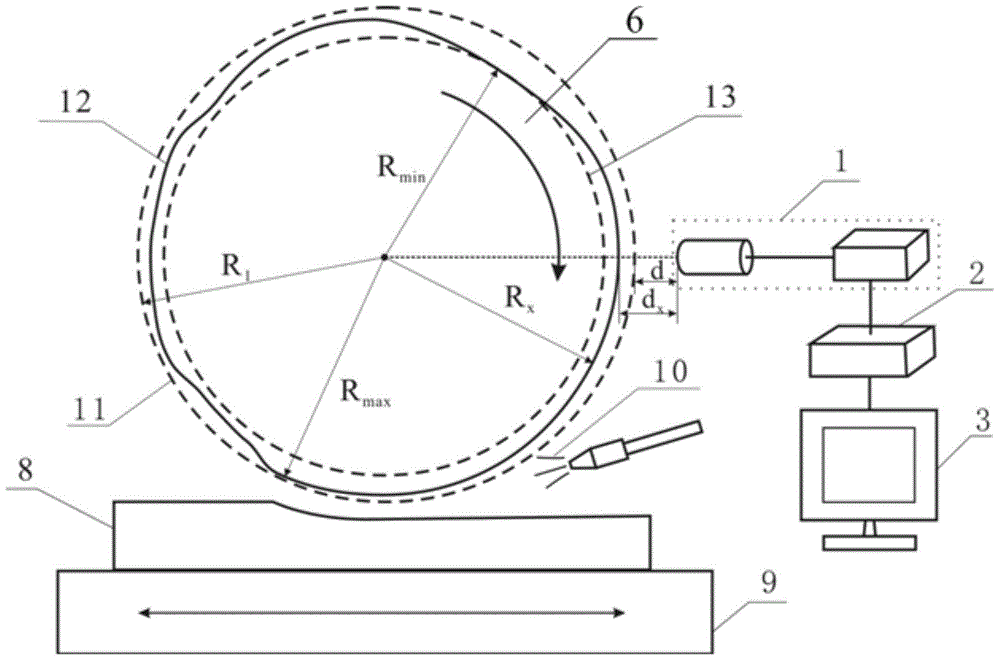

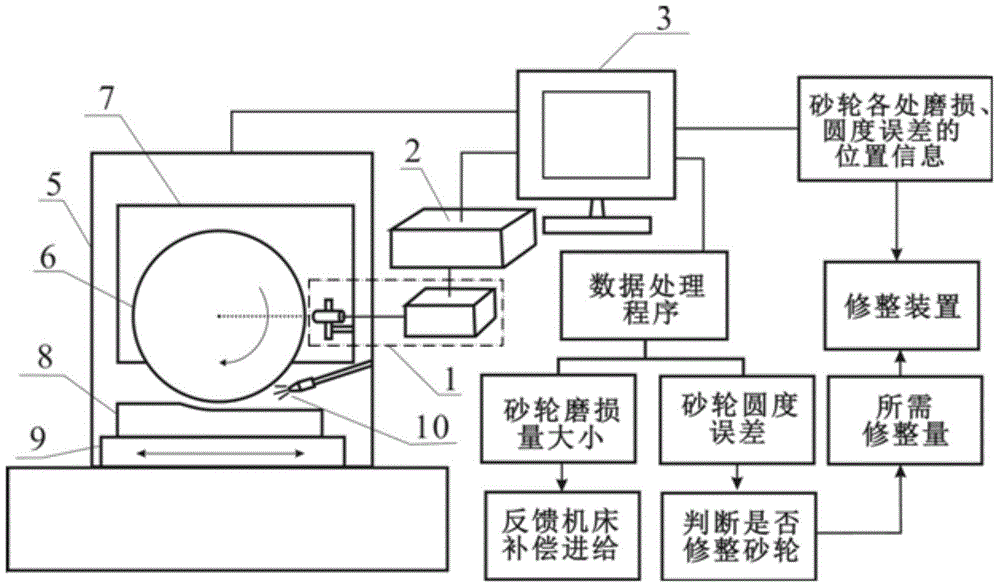

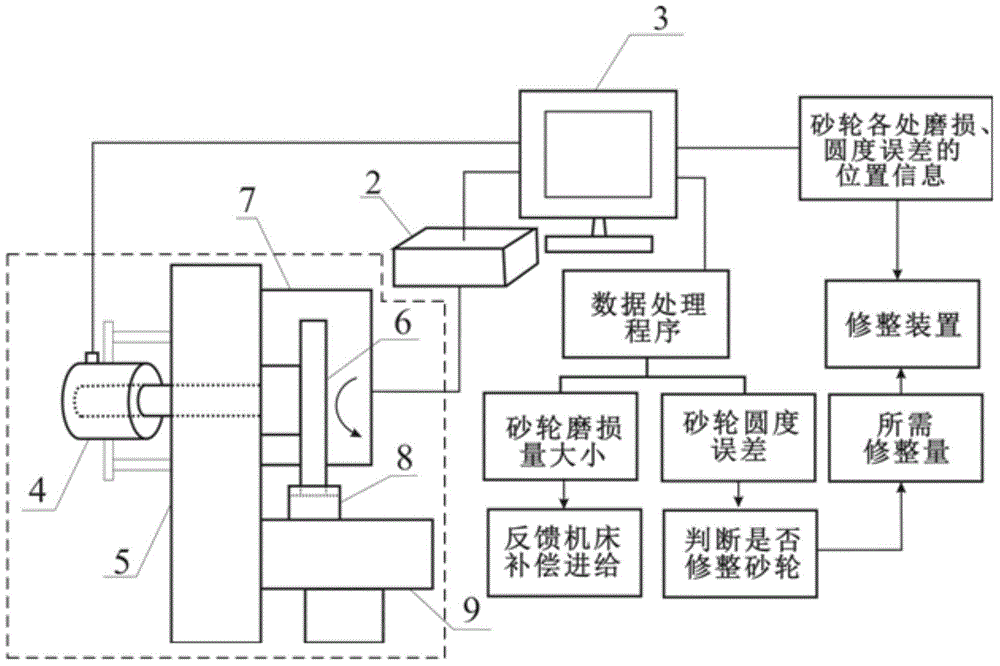

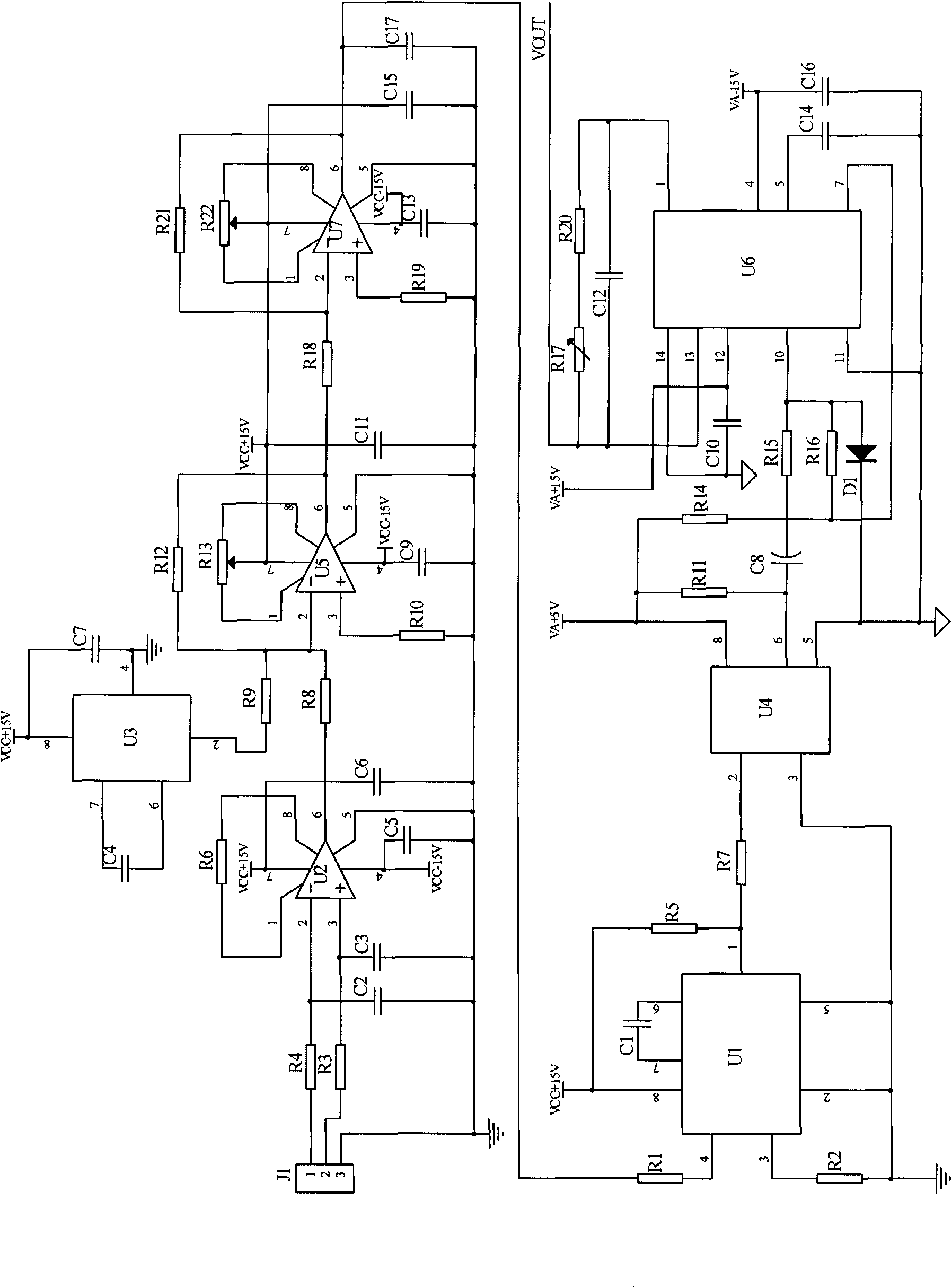

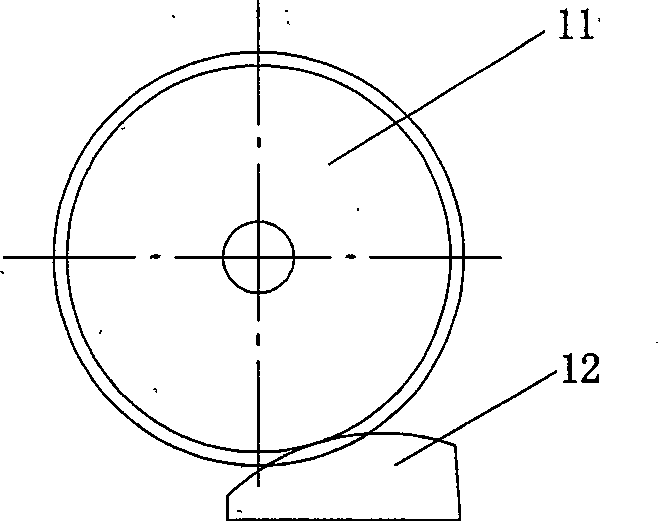

Non-contact online detection method for circular degree error and abrasion loss of metal based abrasion wheel and device for achieving method

ActiveCN105234820AHigh sensitivityImprove detection accuracyGrinding feed controlElectricityWheel wear

The invention discloses a non-contact online detection method for the circular degree error and the abrasion loss of a metal based abrasion wheel and a device for achieving the method and relates to the online detection technology of the circular degree error of the metal based abrasion wheel and the abrasion loss of a abrasion wheel of the abrasive machining field. The problem that the application range of an existing method for measuring the circular degree error of the metal based abrasion wheel and the abrasion loss of the abrasion wheel is narrow is solved. According to the scheme, the position of an eddy current sensor is fixed, the distance between a measuring head of the eddy current sensor and the surface of the metal based abrasion wheel is detected online through the eddy current sensor, and the change conditions of the radius of the abrasion wheel in different positions are obtained through calculation, so that a circular degree error curve for the metal based abrasion wheel to rotate one circle is obtained. The abrasion loss of different positions of the surface of the metal based abrasion wheel is obtained through calculation by comparing the changes of the radius of corresponding positions after a period of grinding time. The non-contact online detection method for the circular degree error and the abrasion loss of the metal based abrasion wheel and the device for achieving the method are capable of detecting the abrasion loss of the metal based abrasion wheel and the circular degree error of the abrasion wheel in the grinding process in a non-contact mode in real time; the detection precision is high and the application range is broad.

Owner:HARBIN INST OF TECH

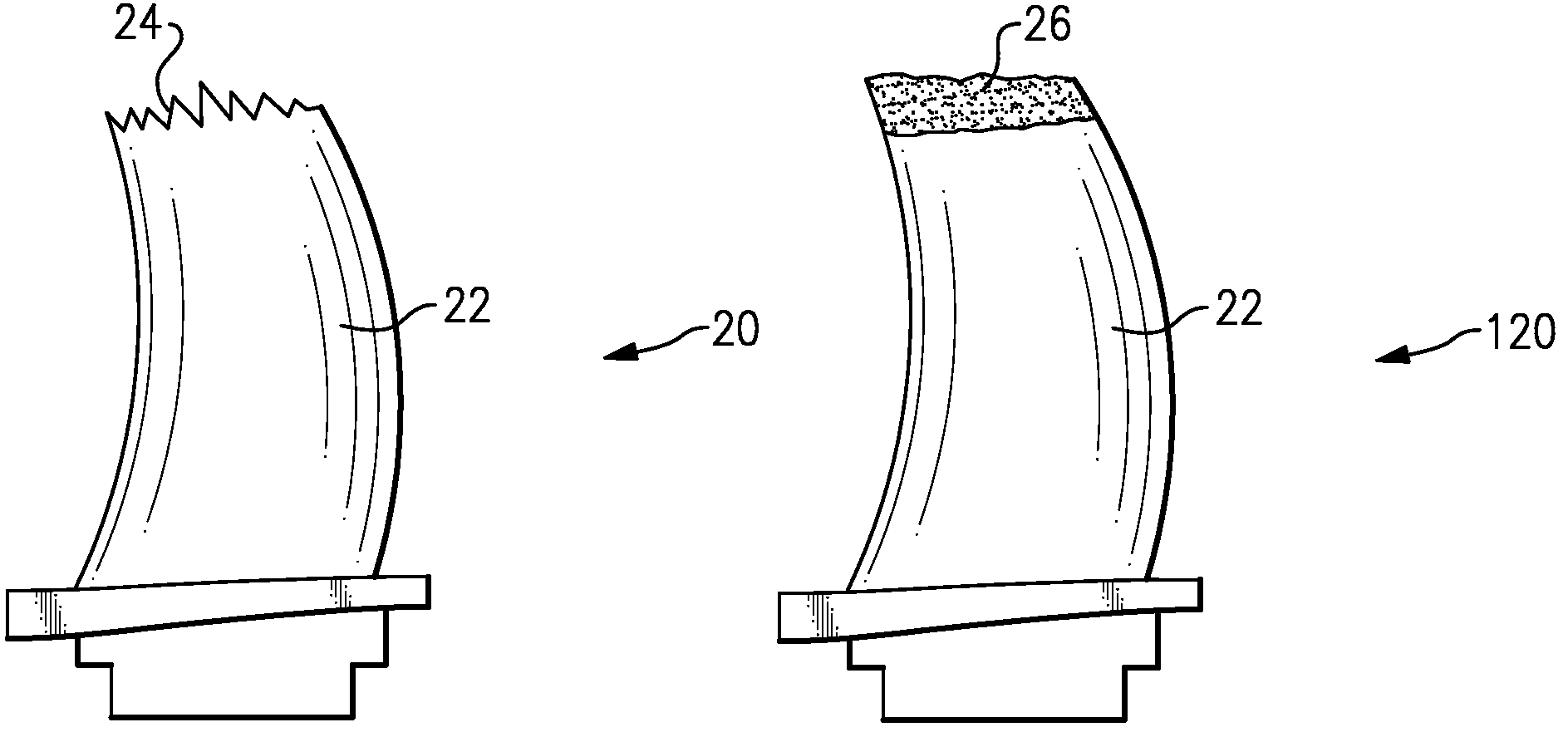

Method for restoring airfoil tip contour

ActiveUS7836594B2Small radius of curvatureBlade accessoriesMachines/enginesPulp and paper industryKnife blades

Owner:RTX CORP

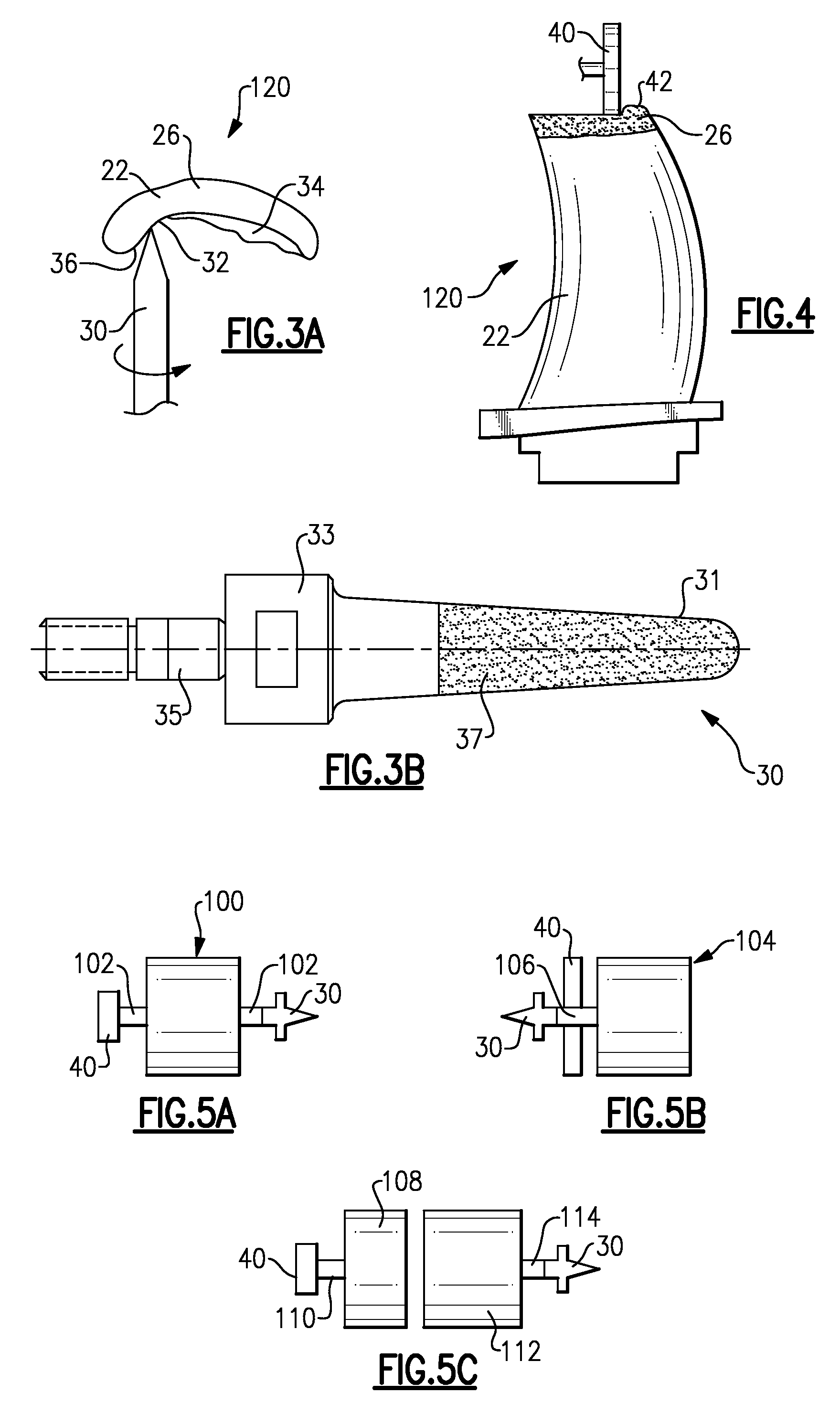

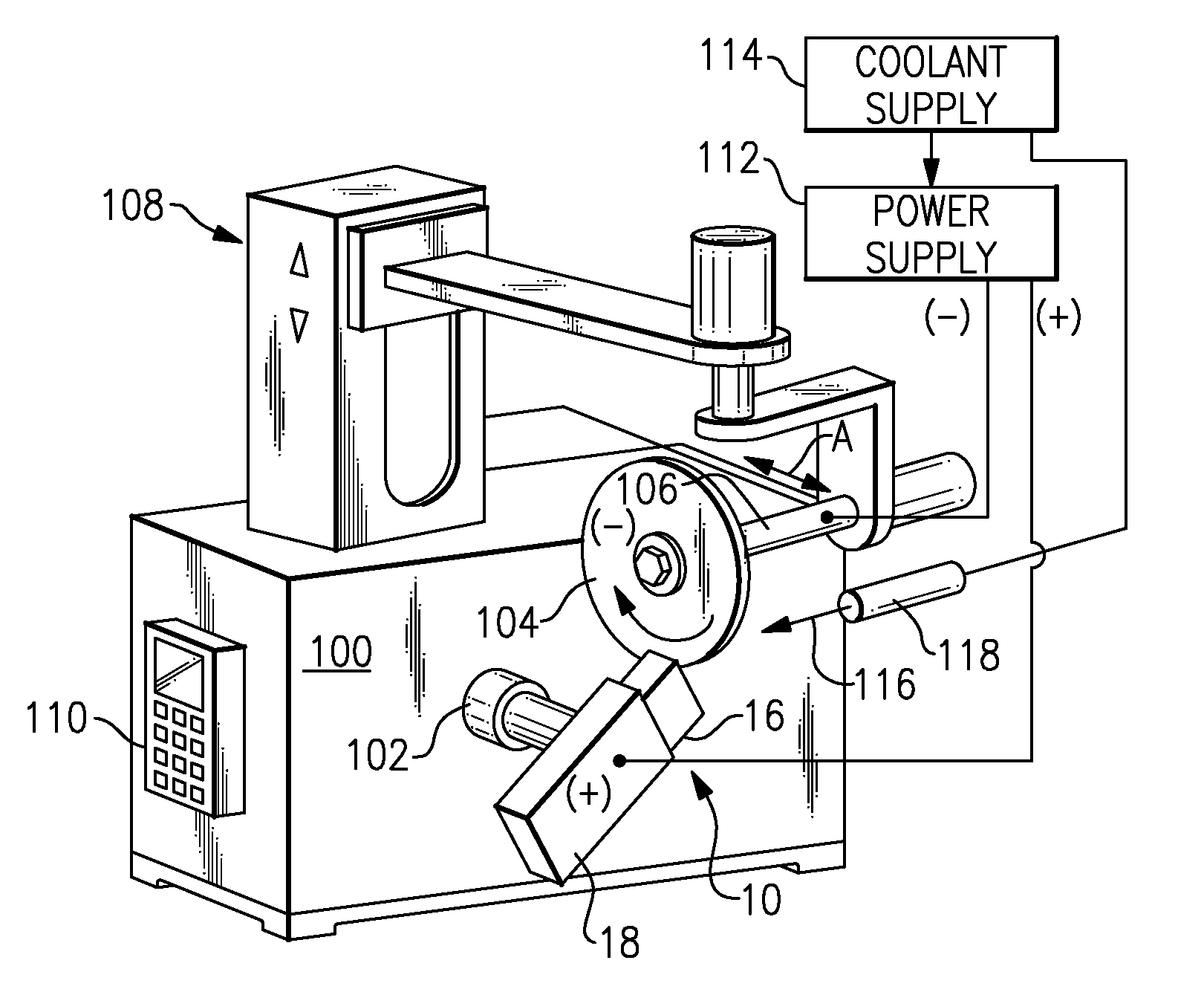

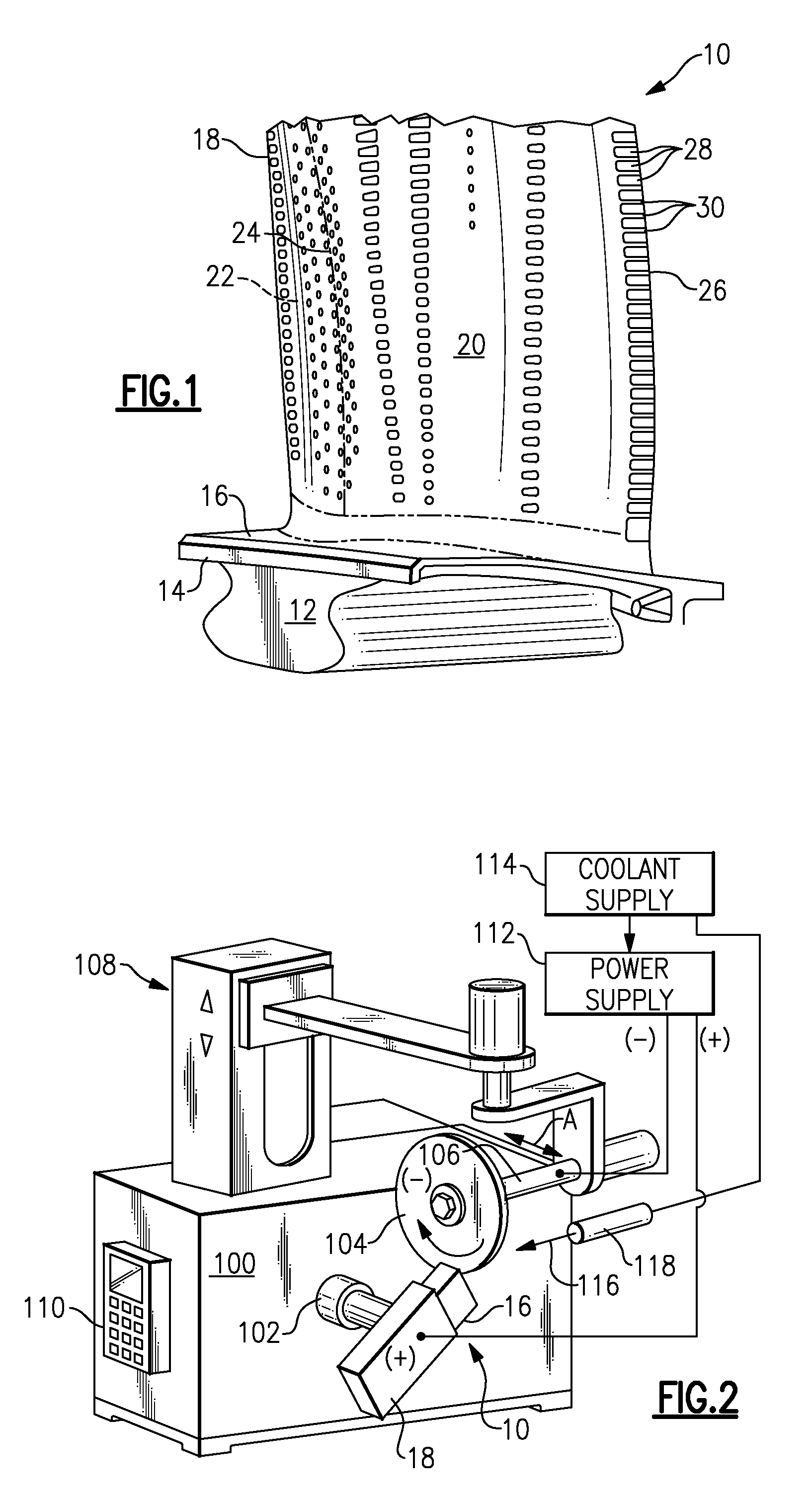

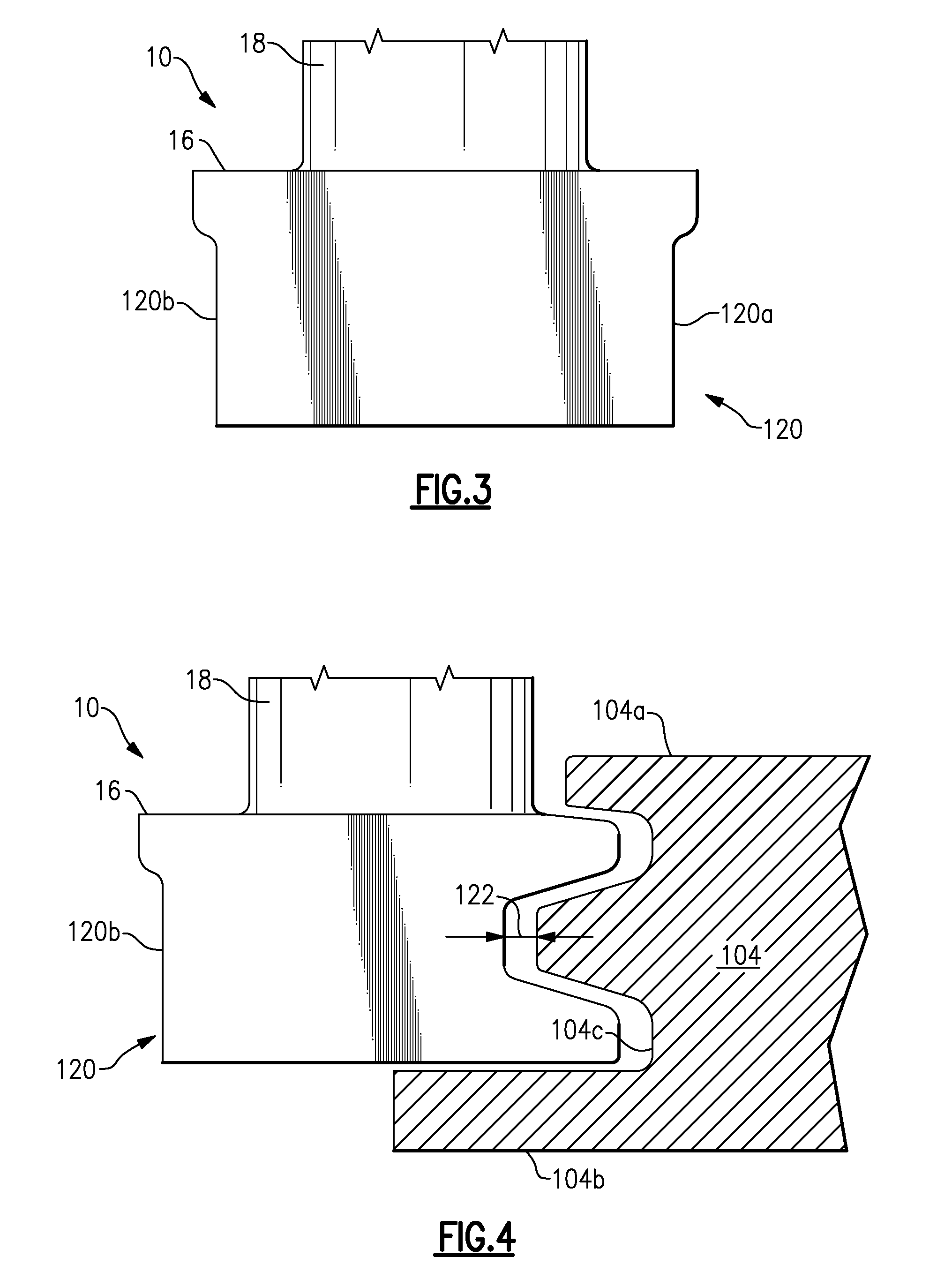

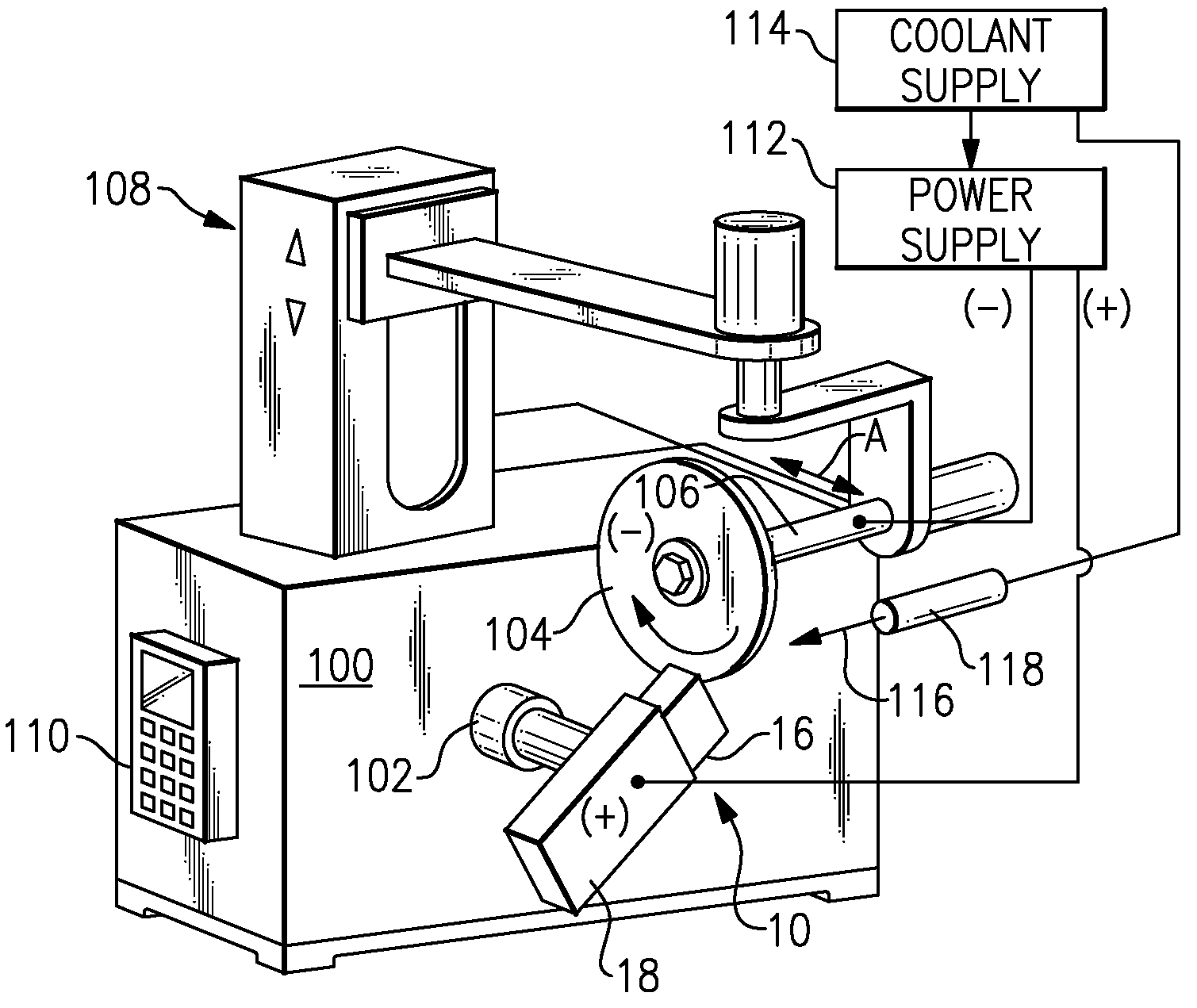

Apparatus and method for hybrid machining a workpiece

An apparatus and method for hybrid machining a workpiece is disclosed. The apparatus includes a mandrel for supporting the workpiece adjacent a cutter mounted on an arbor. A workpiece is powered as an anode and the cutter is powered as a cathode, and a cutting fluid or coolant is circulated therebetween. The cutter is made of a conductive material and a non-conductive abrasive material to maximize the amount of material removed from the workpiece. The coolant includes one or more additives to enhance the electrical discharge between the cutter and the workpiece. The cutter is moved relative to the workpiece to remove material from the workpiece at a predetermined depth of cut using an enhanced high-speed electro-erosion (HSEE) process in which both HSEE and abrasive machining processes are used. The workpiece may then be finish machined to a final shape of the titanium article, such as a dovetail of a turbine blade.

Owner:GENERAL ELECTRIC CO

Fully-synthetic water-based anti-rust complex agent, and evaluation method and application thereof

ActiveCN108774574AEasy to prepareLow priceLubricant compositionMaterial analysisWater basedOrganic base

The invention provides a fully-synthetic water-based anti-rust complex agent, and an evaluation method and application thereof. The fully-synthetic water-based anti-rust complex agent comprises, by weight, 5-20 parts of an organic anti-rust agent, 0.2-8 parts of an inorganic anti-rust agent, 5-25 parts of an organic base and 0.005-5 parts of a lubricating anti-rust aid, with the balance being water. The fully-synthetic water-based anti-rust complex agent of the invention is green and environment-friendly, has excellent rust prevention performance, and can be used for inter-process rust prevention of ferrous metals; at the same time, the complex agent has lubricating and anti-wear properties and can be used for abrasive machining of ferrous metals.

Owner:超滑科技(佛山)有限责任公司

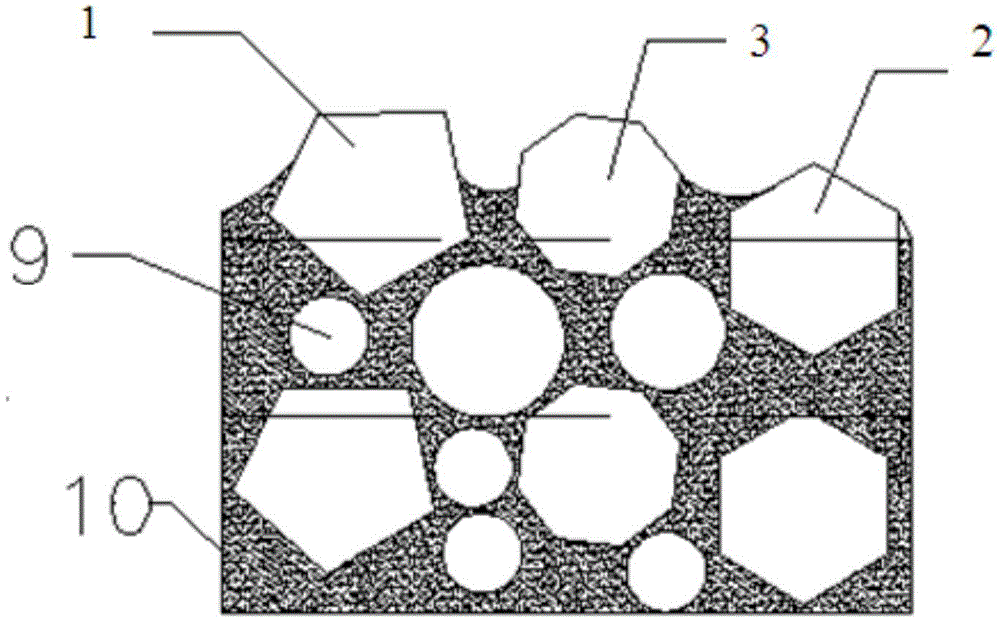

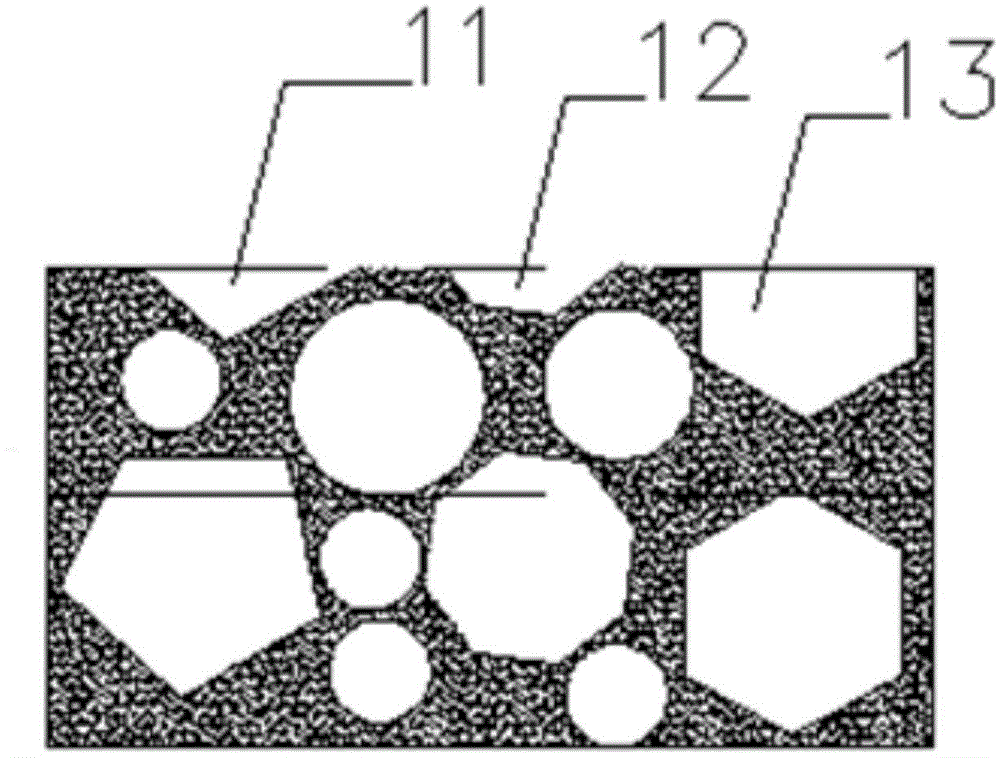

Three-dimensional cooperative distribution method for various grinding materials for preparing superhard tool

The invention discloses a three-dimensional cooperative distribution method for various grinding materials for preparing a superhard tool, and belongs to the field of superhard grinding material tool manufacturing. The distribution method comprises the following steps that grinding material parameters are determined according to processing requirements, wherein the grinding materials comprise major grinding materials in charge of major processing effects and auxiliary grinding materials achieving auxiliary effects, and the granularity of the major grinding materials is generally greater than that of the auxiliary grinding materials; various kinds of grinding materials determined in the former step are uniformly mixed according to the required proportion or are sequentially distributed in the sequence according to the granularity; according to the method for preparing the tool, material mixing agents are added, various kinds of mixed grinding materials are proportionally and uniformly mixed with brazing materials and pore creating materials, and the mixture is poured into a mold and is pressed into a blank; bonding agents can also be brushed and coated on the surface of a substrate, then, various grinding materials which are uniformly mixed are cooperatively distributed on the surface of the substrate in the sequence according to the granularity size, and then, the brazing materials are added. The method provided by the invention has the advantages that the processing adaptability of the grinding materials is good, the efficiency is high, the continuous processing capability is high, the performance is excellent, and the processing stability is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

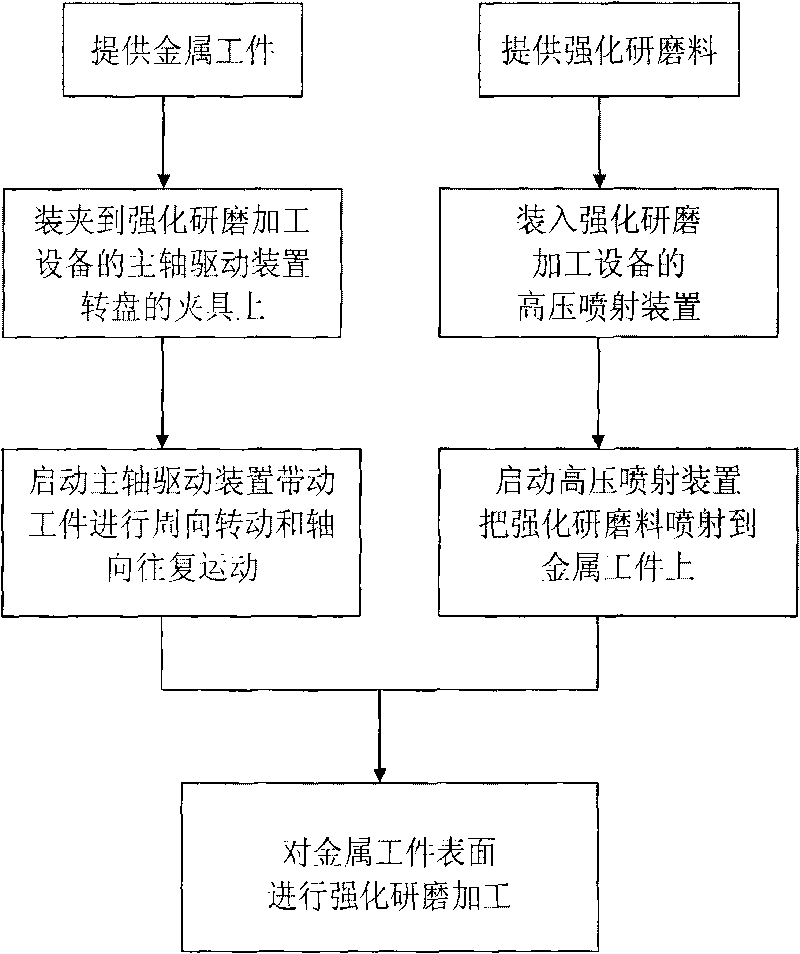

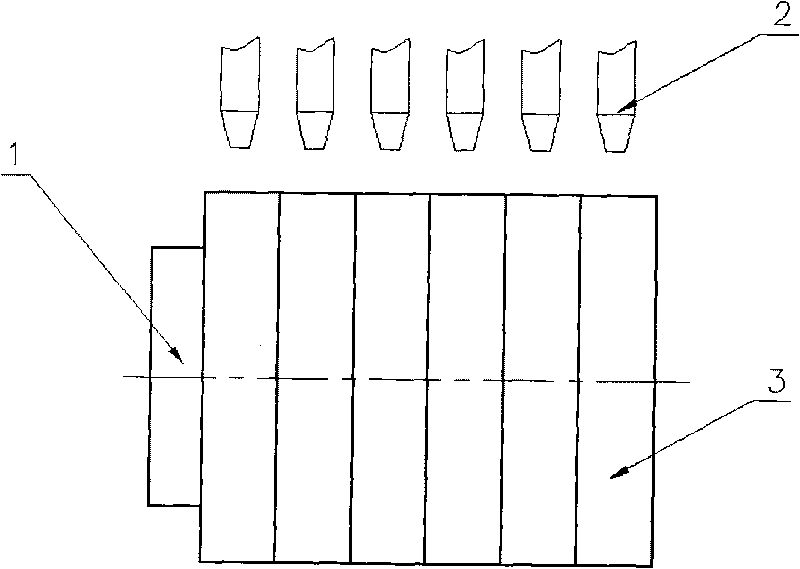

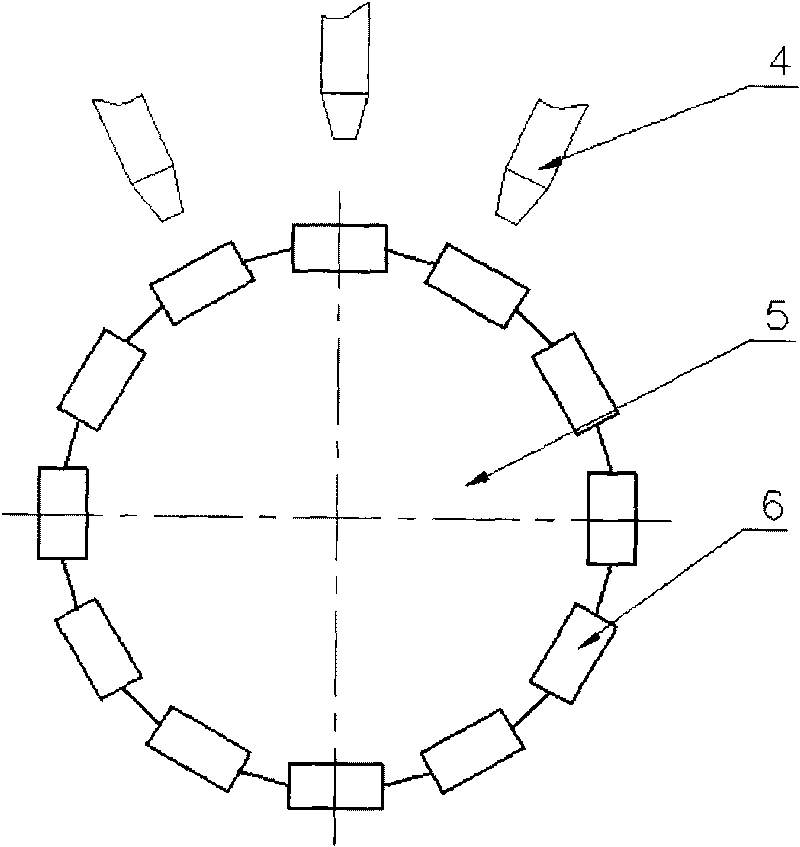

Intensified abrasive machining method for mechanical surface

InactiveCN101733707AUniform micro cuttingTo achieve the effect of surface grindingMachine partsMetal machining

The invention discloses an intensified abrasive machining method for a mechanical surface. The method comprises the following steps of: (1) providing a metal workpiece and clamping the metal workpiece on a fixture of a turnplate of a spindle driving device of intensified abrasive machining equipment; (2) providing intensified abrasive and loading the intensified abrasive to a high pressure injection device of the intensified abrasive machining equipment; and (3) injecting the intensified abrasive onto the surface of the rotating metal workpiece through the high pressure injection device of the intensified abrasive machining equipment to perform intensified abrasive machining. When the method is used to process mechanical parts, the method enhances the surface hardness of a metal machined part, effectively improves the surface quality and prolongs the fatigue life.

Owner:GUANGZHOU UNIVERSITY

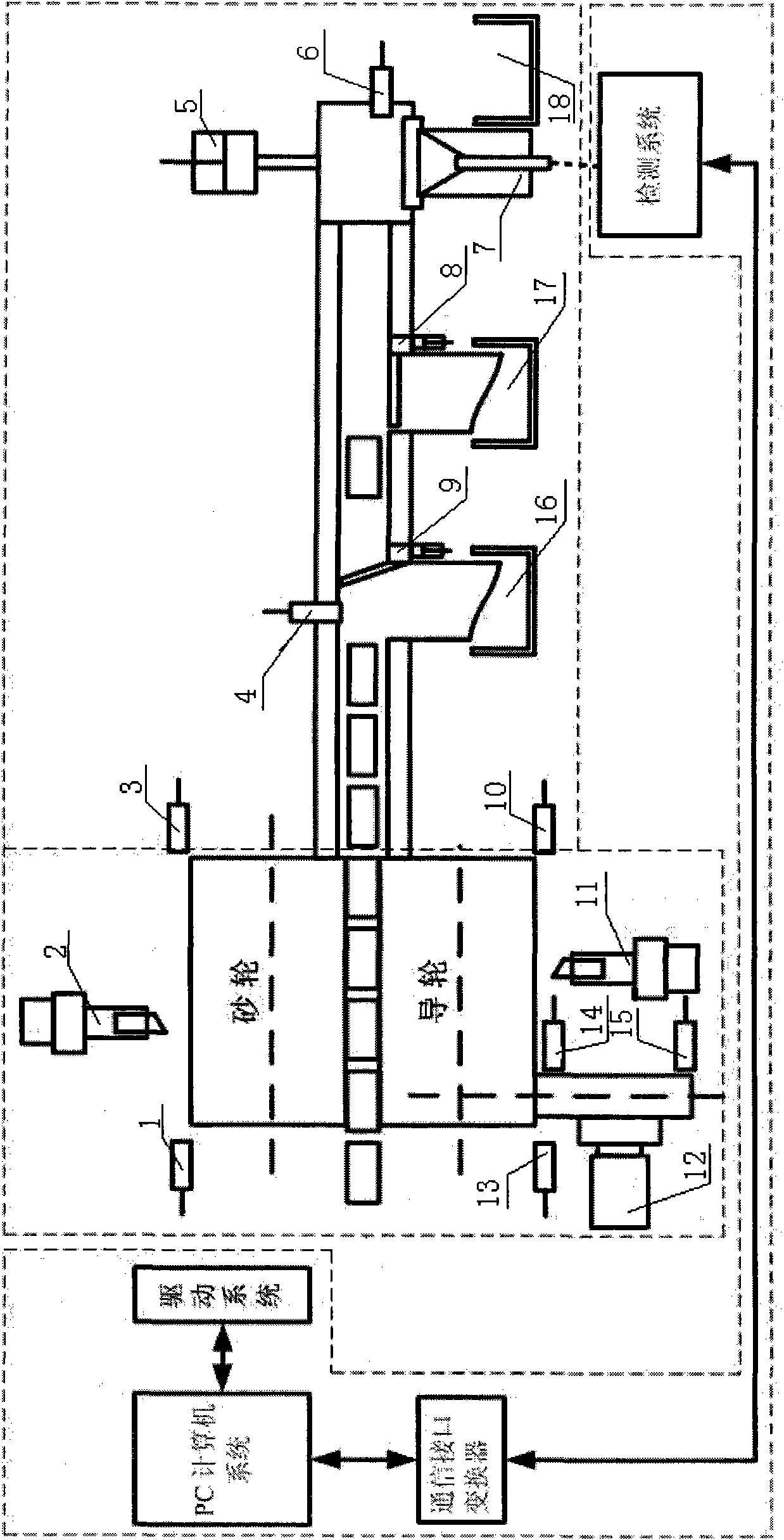

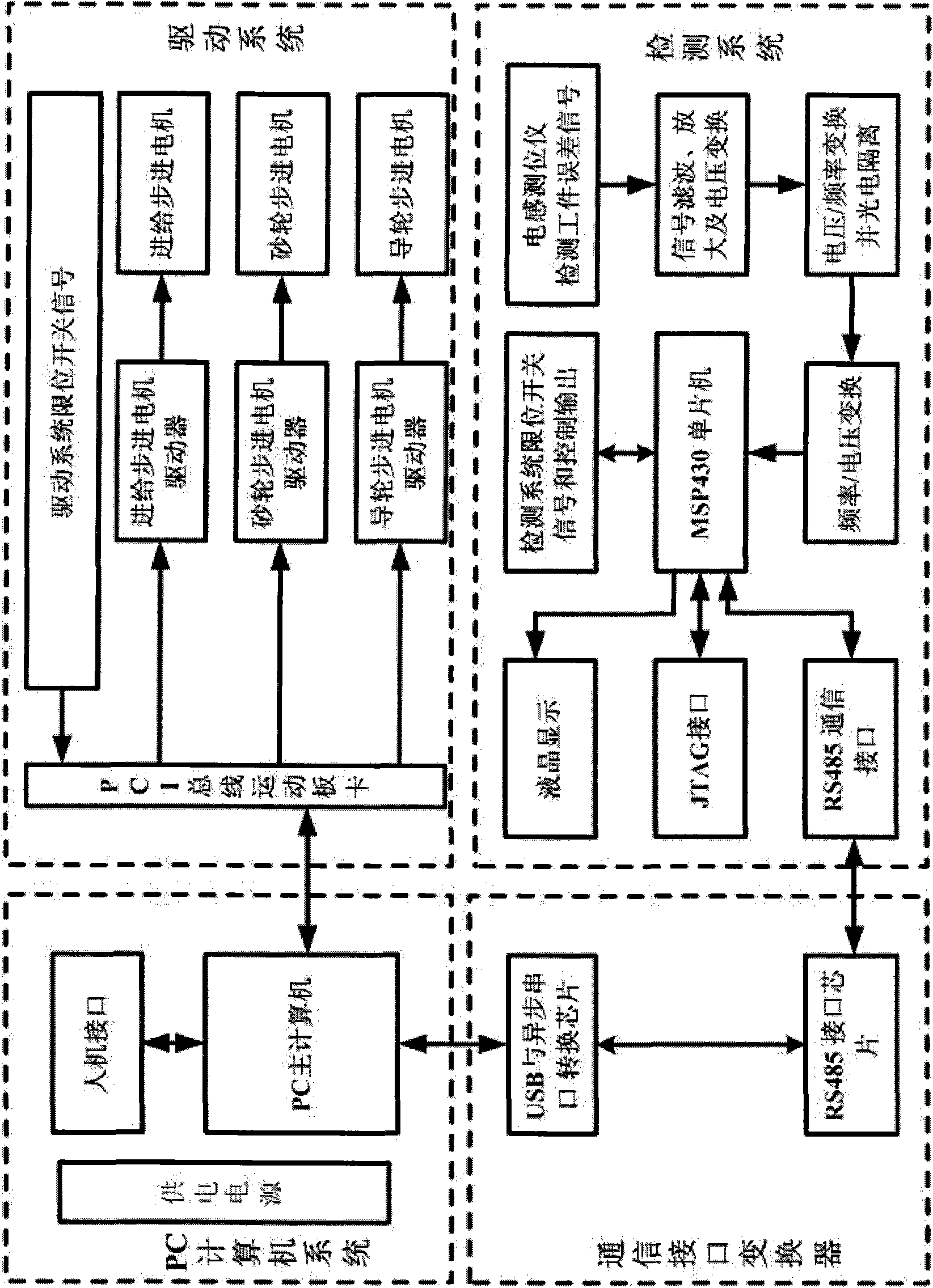

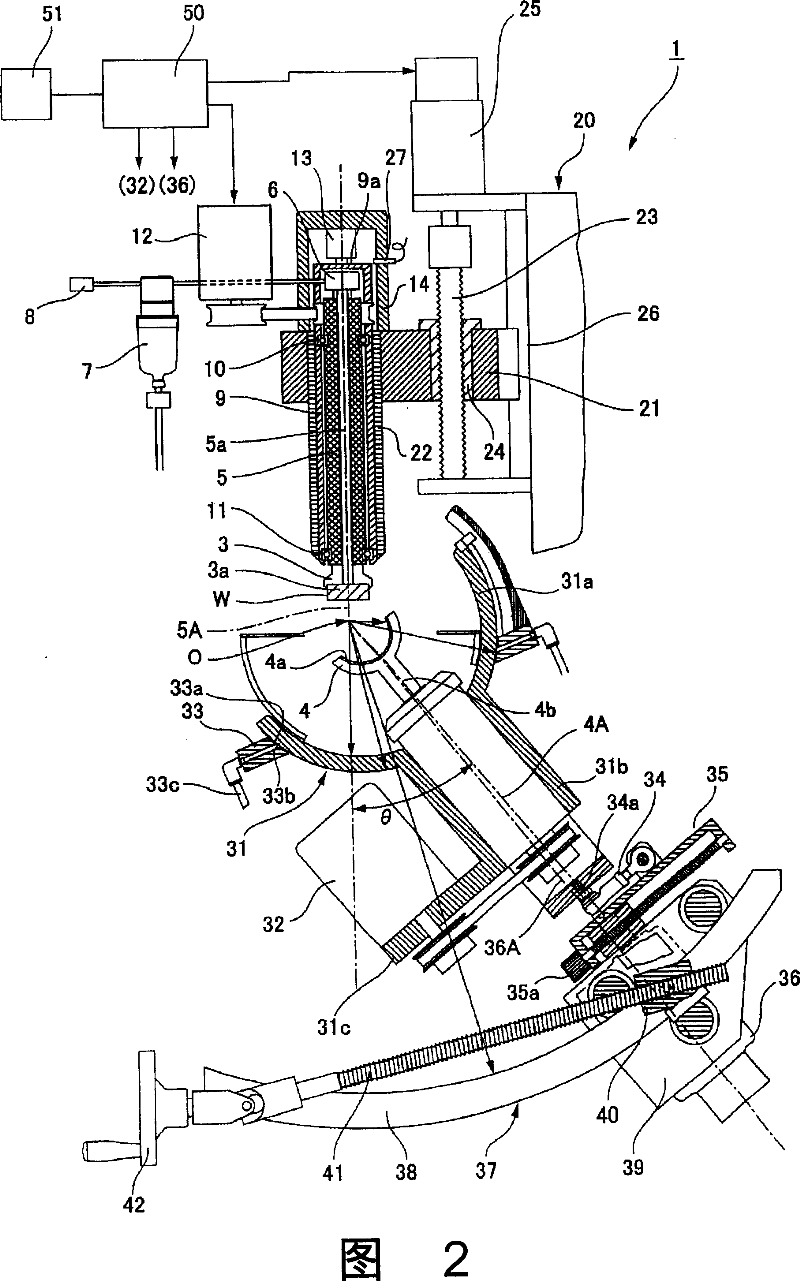

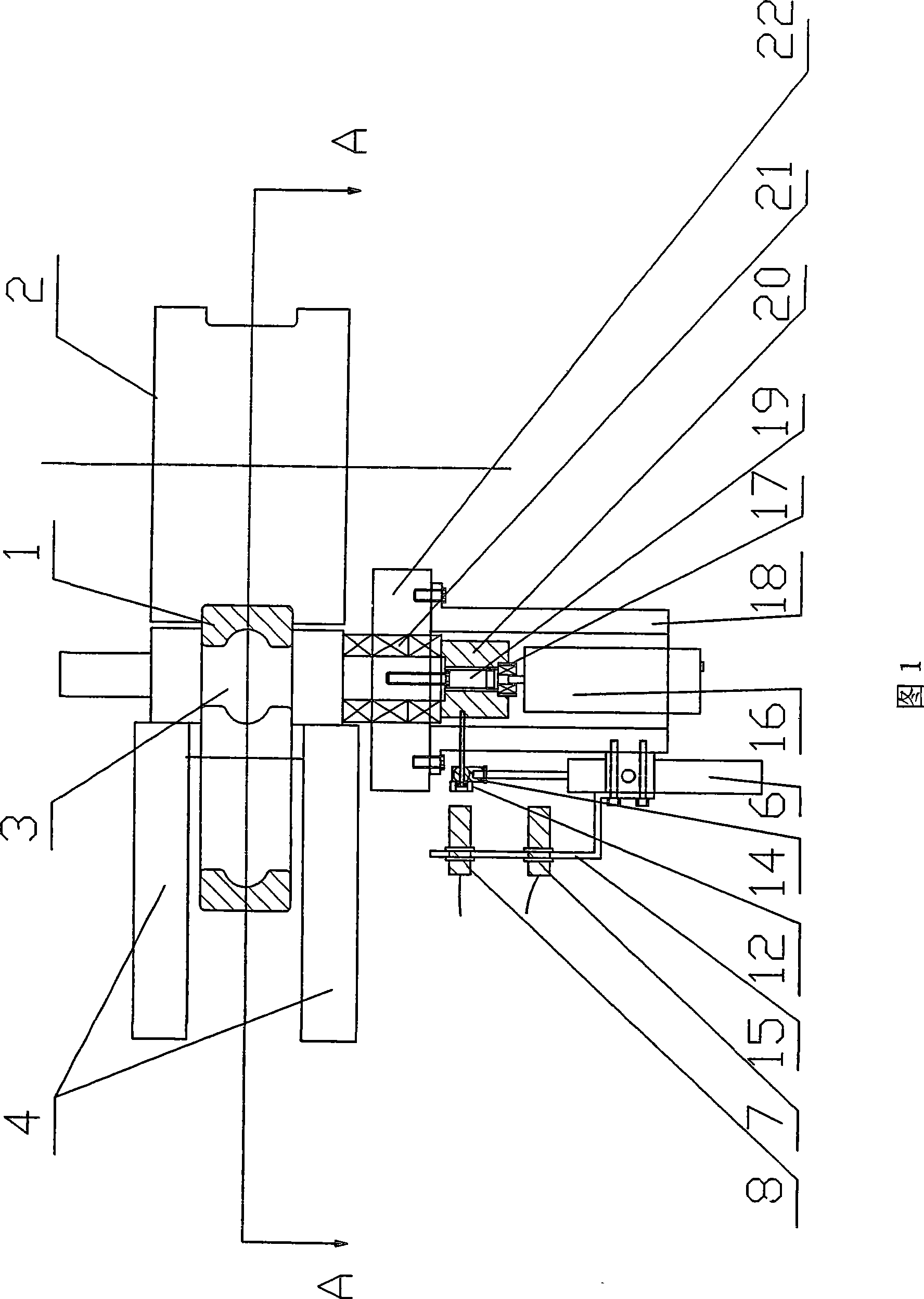

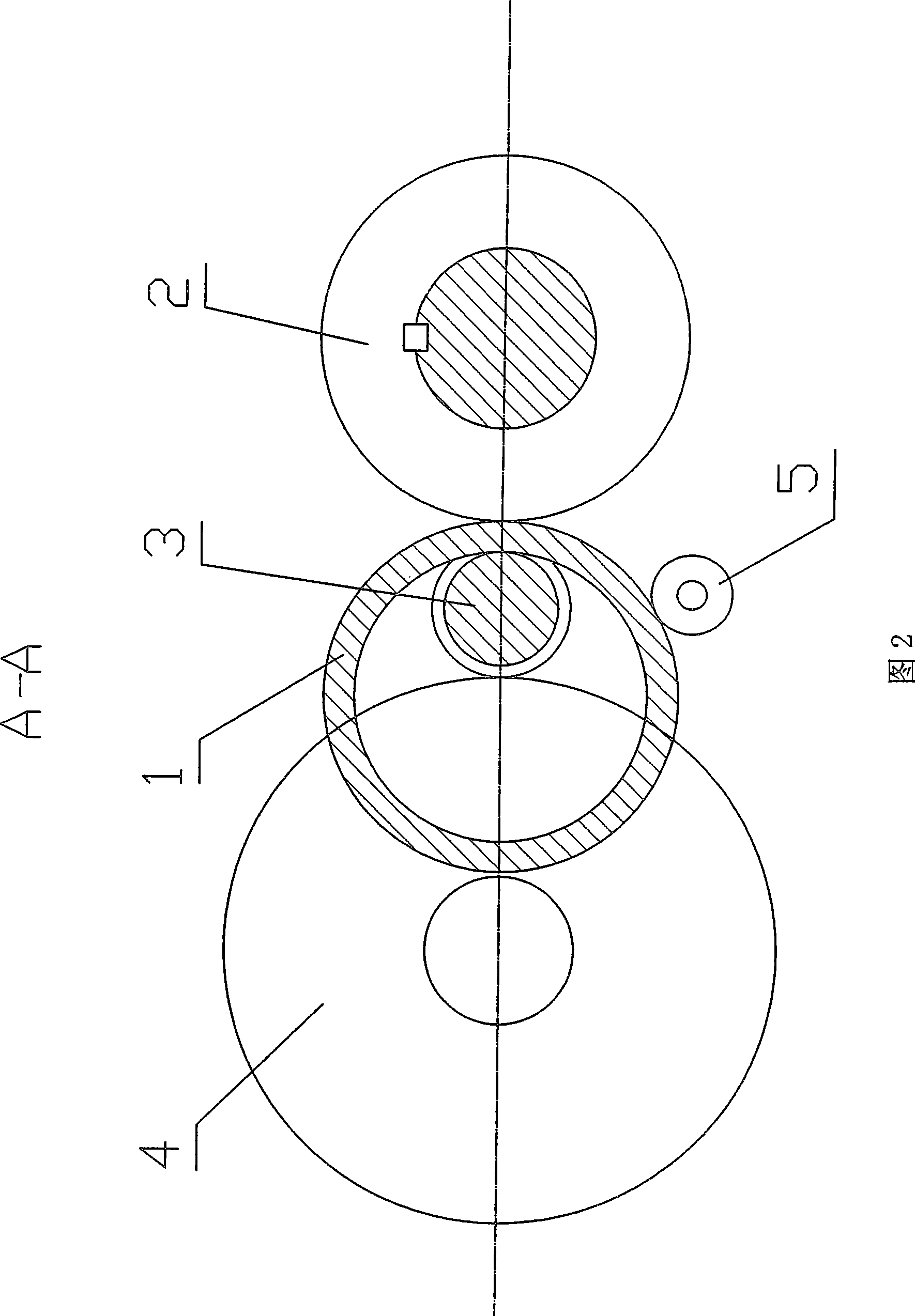

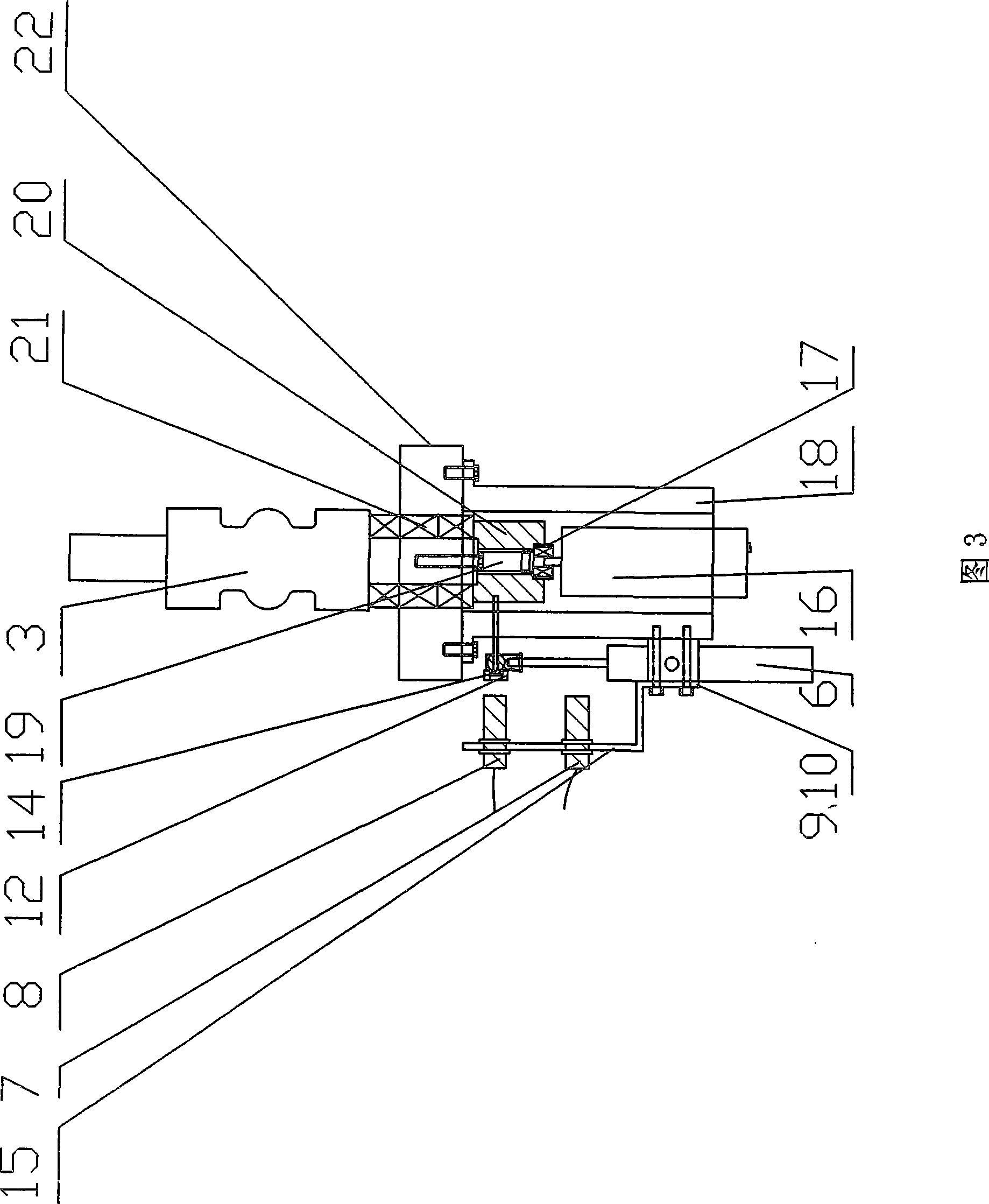

Coreless abrasive machining measurement and control system and corresponding coreless abrasive machining method

InactiveCN101559578AEasy to transformEasy to adjustGrinding feed controlUsing electrical meansCommunication interfaceControl system

The invention relates to a coreless abrasive machining measurement and control system and a corresponding coreless abrasive machining method. Combining with the fact that the coreless abrasive machining workpiece errors are mainly caused by the abrasion of a grinding wheel and a guide wheel, the coreless abrasive machining method samples and processes error signals through a workpiece error detection system in a coreless abrasive machining system, and sends the error signals to a PC computer system through a communication interface converter, and the PC computer system calculates the adjustedquantity and outputs signals to control a grinding wheel finisher, a guide wheel finisher and a feed mechanism driving system so as to achieve the finishing of the grinding wheel and the guide wheel and the adjustment of the feed mechanism. The measurement and control system and the method are mainly used for solving the problems that the prior system and the implement method thereof have a complex control method and are designed integrally.

Owner:HENAN UNIV OF SCI & TECH

Apparatus and method for hybrid machining a workpiece

An apparatus and method for hybrid machining a workpiece is disclosed. The apparatus includes a mandrel for supporting the workpiece adjacent a cutter mounted on an arbor. A workpiece is powered as an anode and the cutter is powered as a cathode, and a cutting fluid or coolant is circulated therebetween. The cutter is made of a conductive material and a non-conductive abrasive material to maximize the amount of material removed from the workpiece. The coolant includes one or more additives to enhance the electrical discharge between the cutter and the workpiece. The cutter is moved relative to the workpiece to remove material from the workpiece at a predetermined depth of cut using an enhanced high-speed electro-erosion (HSEE) process in which both HSEE and abrasive machining processes are used. The workpiece may then be finish machined to a final shape of the titanium article, such as a dovetail of a turbine blade.

Owner:GENERAL ELECTRIC CO

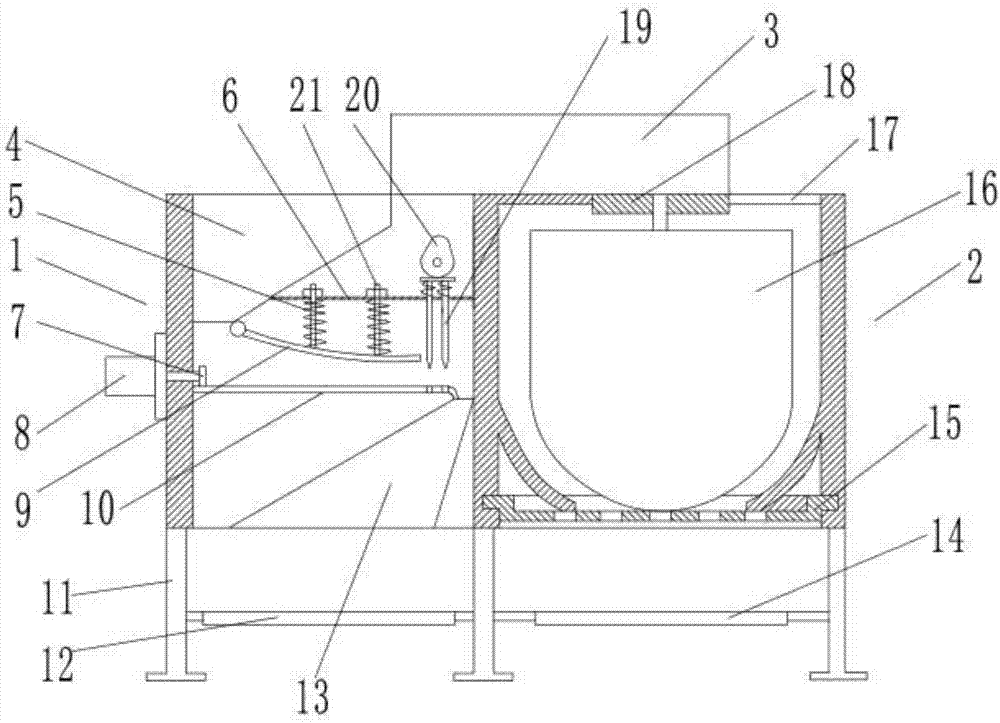

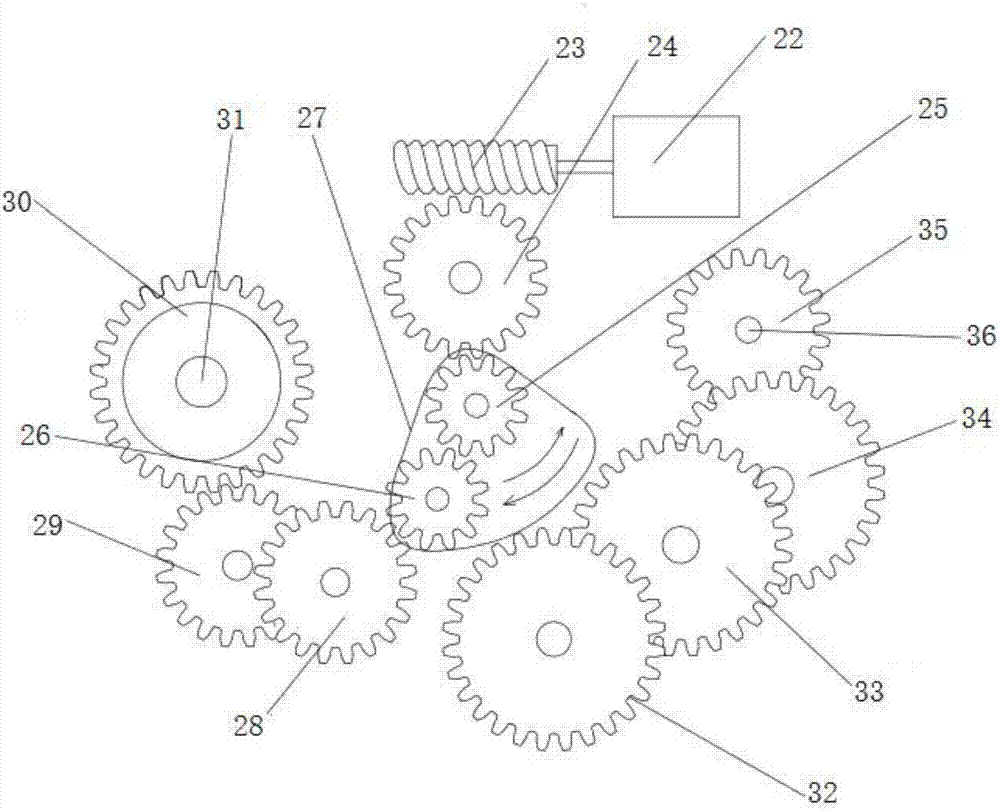

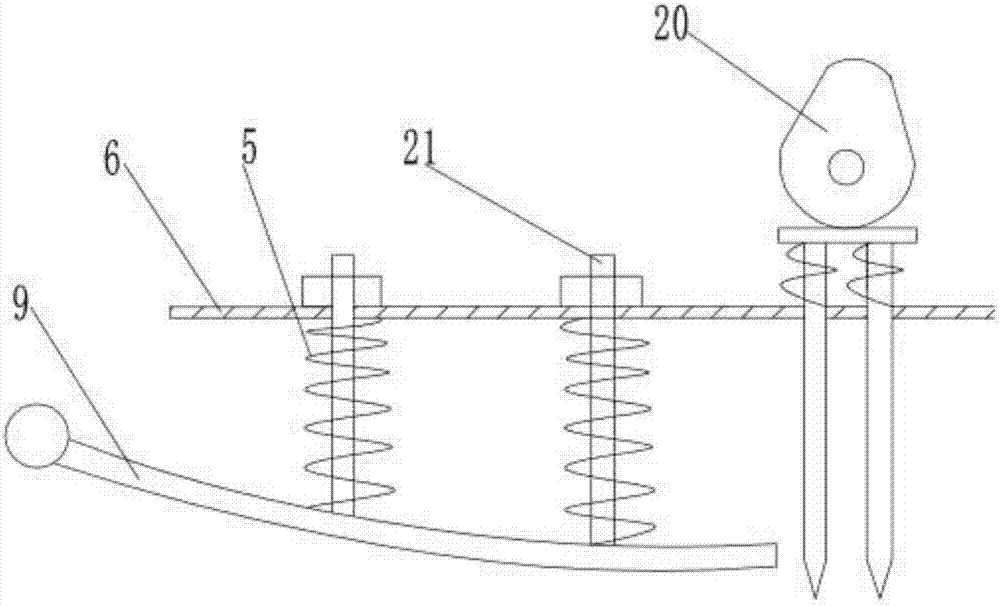

Single-power cutting and grinding double-purpose traditional Chinese medicine processing device

The invention discloses a single-power cutting and grinding dual-purpose traditional Chinese medicine processing device, which includes a cutting machine box for cutting medicinal materials, a grinding machine box for grinding medicinal materials, and a power output box. Both the cutting machine box and the grinding machine box pass through multiple The base of the column is installed on the ground, and the power output box is fixed on the top position of the cutting machine box and the grinding machine box. The beneficial effect of the present invention is: the rotation of the motor-driven cam or the grinding column can be realized through the positive and negative rotation of the motor in the power output box, Realize the cutting or grinding action, the cutting machine box and the grinding machine box are both driven by the same motor, which saves energy and can greatly improve the processing efficiency of Chinese medicinal materials.

Owner:惠安益源信息技术咨询有限公司

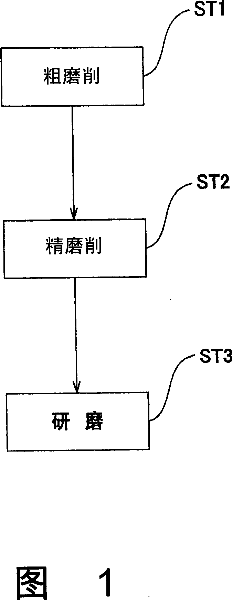

Turntable bearing machining technique

The invention discloses a turntable bearing machining technique. The turntable bearing machining technique includes the following processes: 1) checking a forge piece blank; 2) performing lathe work machining; 3) performing heat treatment, 3.1) performing quenching on a surface of a ball track: performing medium-frequency quenching on the surface of the ball track, wherein the hardness is not less than 55 HRC, the depth of a hardened layer is not less than 4 mm, and the width of a soft zone is less than 50 mm; 3.2) performing tempering after heating: performing medium-frequency quenching on an inner ring and an outer ring of a bearing at the temperature of 200 DEG C for 48 hours, and then performing discharge to ensure the situation that internal stress vanishes; 4) performing rolling and milling machining, 4.1) performing hobbing on a turntable bearing with inner and outer teeth before abrasive machining, wherein the accuracy class should reach over 8 class; 5) performing hole drilling; 6) performing abrasive machining, 6.1) performing coarse grinding, wherein a medium-corundum resin wheel with the soft-three-granularity of 36 is adopted to perform grinding, the linear velocity is controlled to be 1500 revolutions / minute to prevent the ball track form burn, and the maximum grinding depth is not greater than 1 mm; and 6.2) performing accurate grinding, wherein a resin wheel with the granularity of 46 or 60 is adopted to perform grinding, and the grinding amount is less than that of coarse grinding machining.

Owner:CHONGQING HUANDE TECH CO LTD

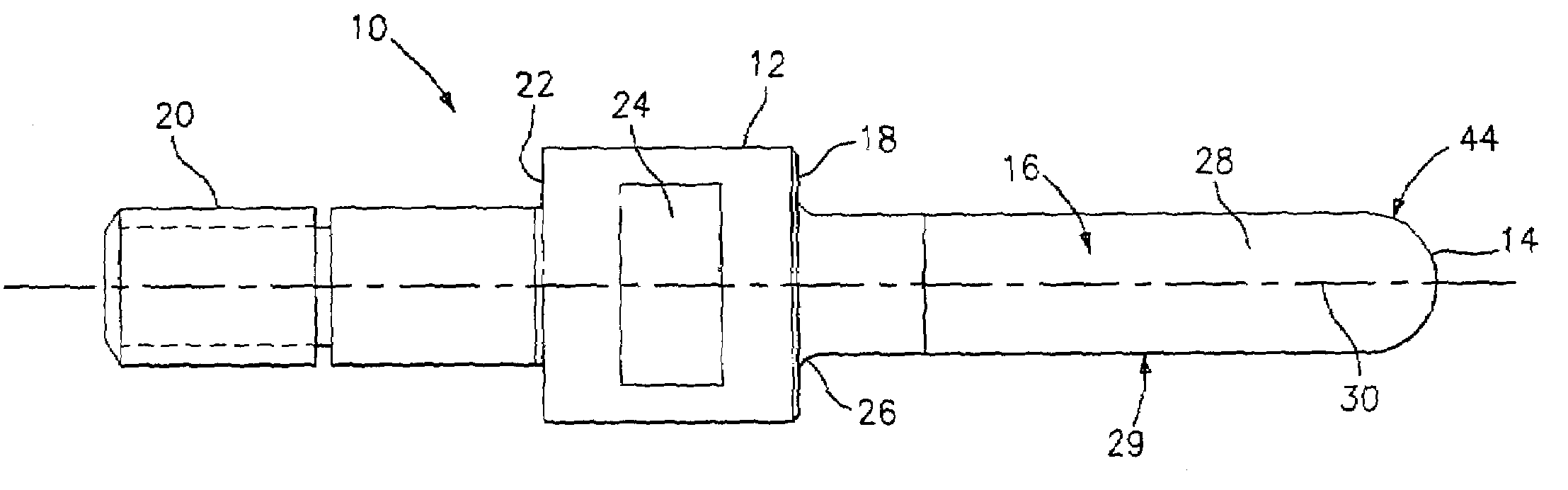

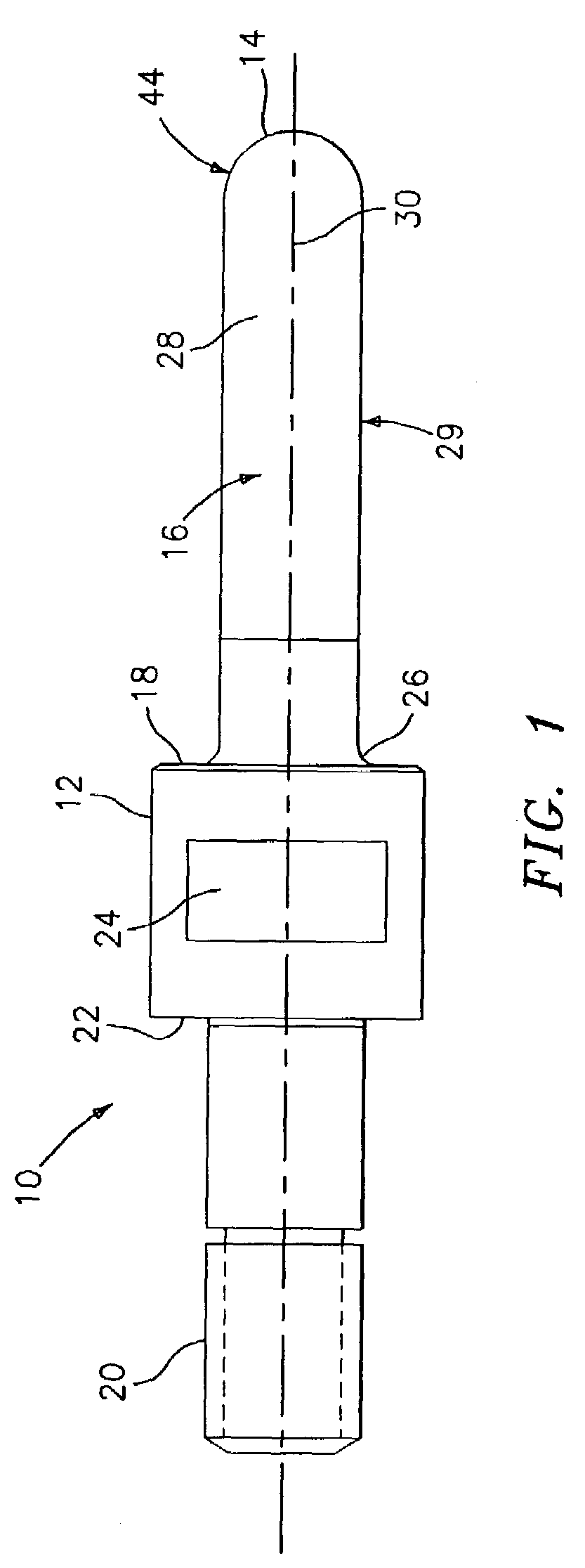

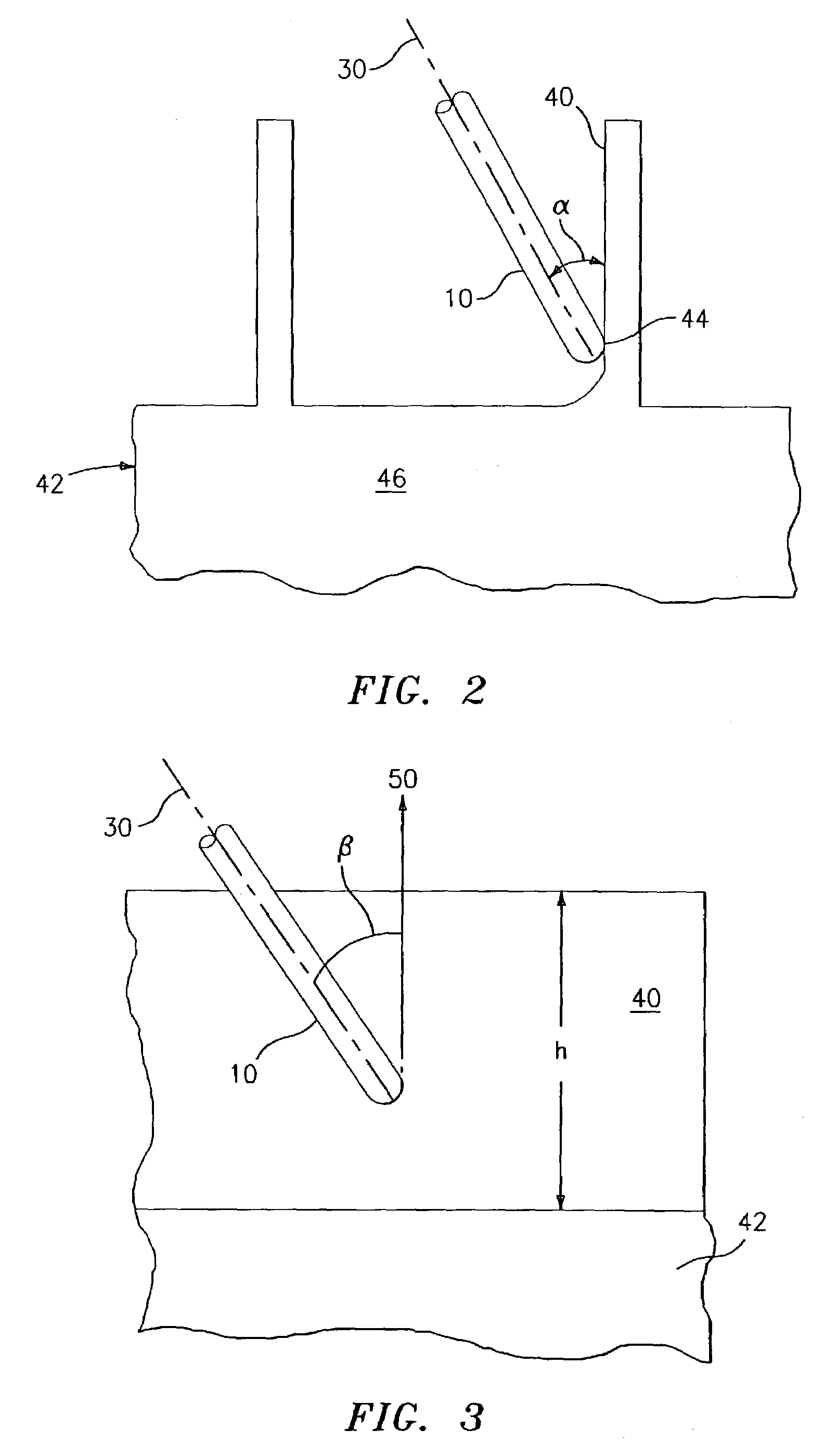

Point superabrasive machining of nickel alloys

ActiveUS7144307B2Edge grinding machinesRevolution surface grinding machinesNickel alloyPoint contact

A process for point superabrasive machining of a nickel based material comprising the steps of providing a tool having a grinding surface coated with a superabrasive material, orienting the tool relative to a surface of the nickel based material to be machined so that there is point contact between the surface to be machined and the grinding surface, and forming a part by removing material at the point contract by rotating the tool. The tool comprises an enlarged portion, a tip portion, and a first shaft portion extending from the enlarged portion to the tip portion, the first shaft portion and the tip portion being coated with an abrasive material, and the first shaft portion having a constant diameter.

Owner:RAYTHEON TECH CORP

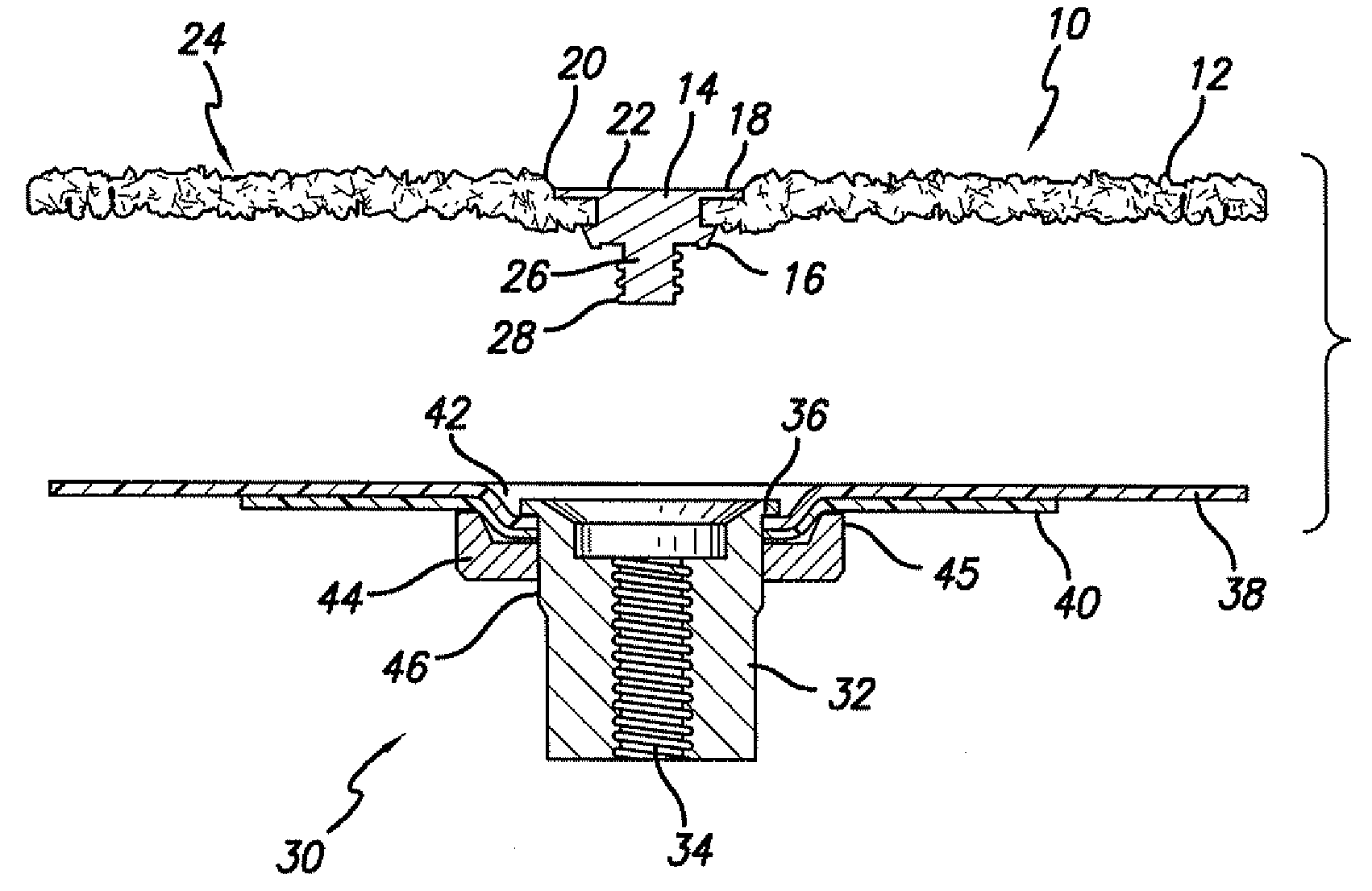

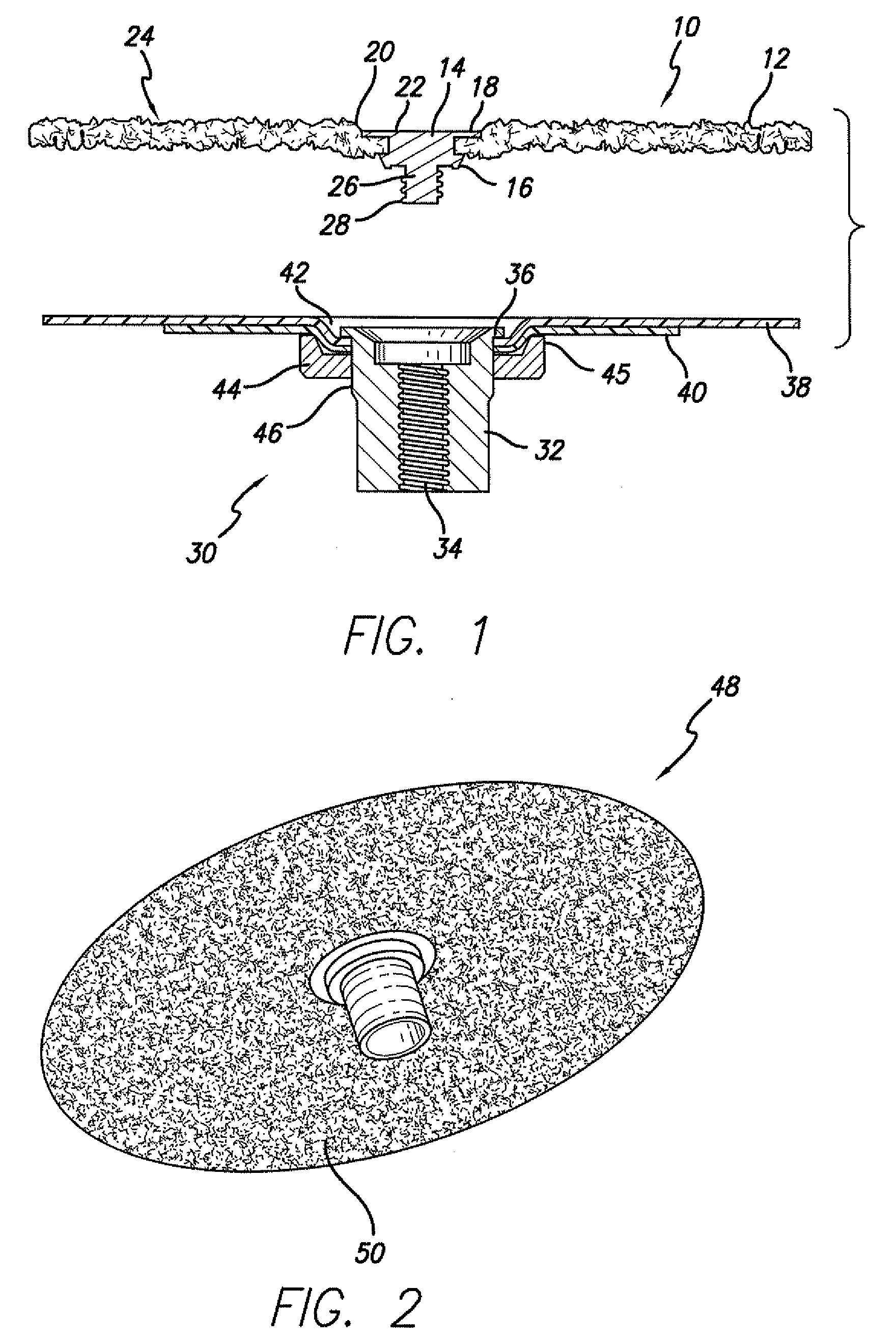

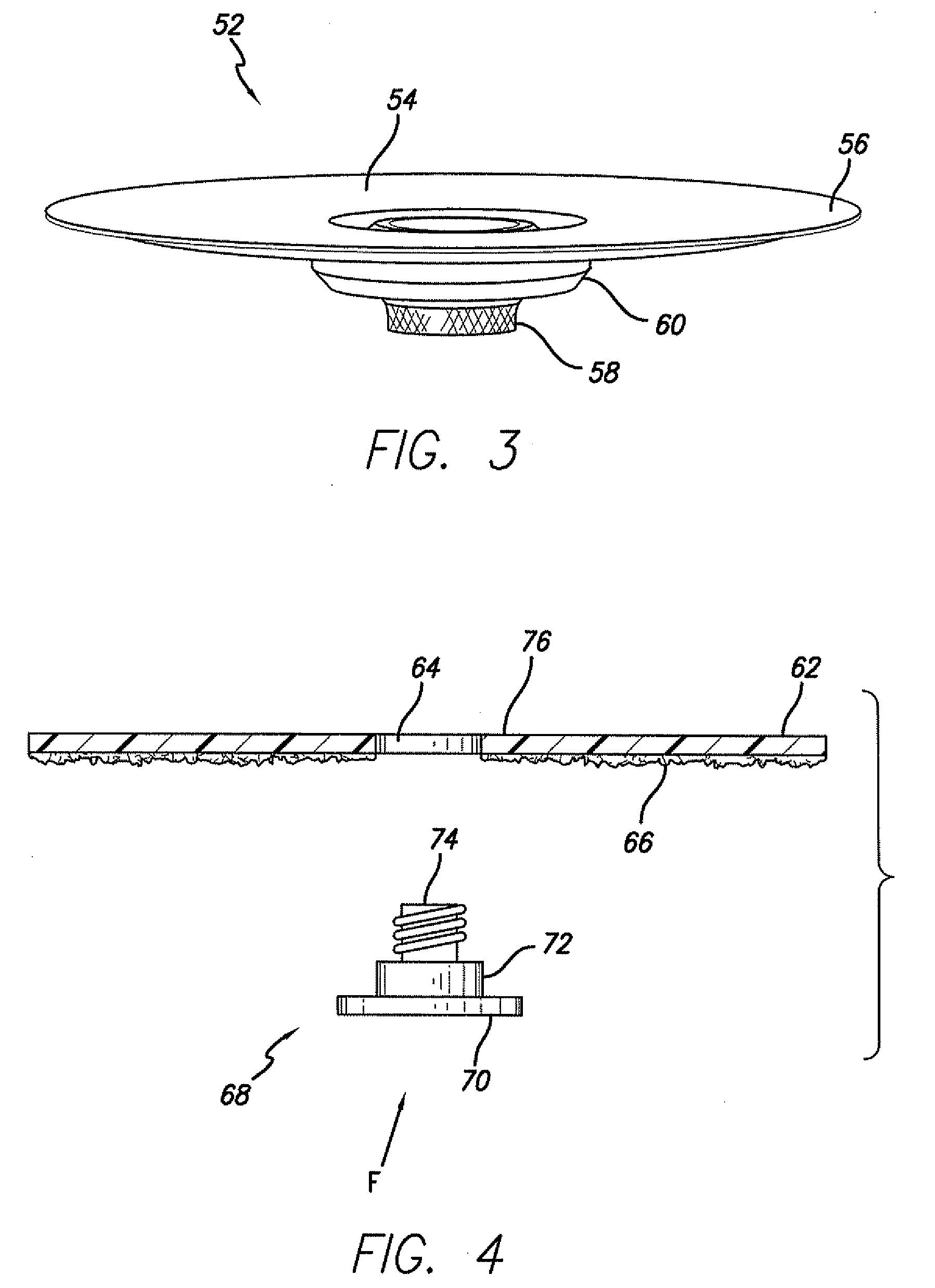

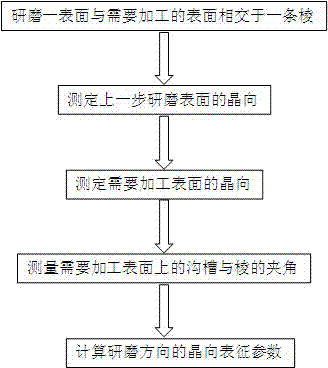

Expendable unitary quick mount abrasive discs and support pad therefor

InactiveUS20090104862A1Grinding wheel securing apparatusRevolution surface grinding machinesEngineeringScrew thread

The combination of an abrasive finishing device and a support member therefor. The support member includes a body having a threaded central opening with a flange at one end thereof. A fastening member having a threaded shaft and flange is permanently affixed to the abrasive finishing article by a resiliently deformable retainer press fitted over the threads on the shaft in such a manner that the flange on the fastening member is disposed entirely below the working surface of the abrasive finishing device. The retainer is a washer shaped member having an inner diameter which is less than the outer diameter of the threaded shaft on the fastening member and grips the thread on the shaft.

Owner:MACKAY JOSEPH HARTLEY

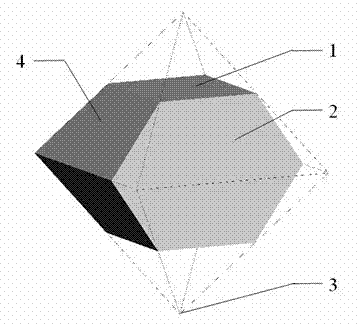

Method for confirming grinding crystal orientation of diamond

ActiveCN103616394AMaterial analysis using wave/particle radiationMaterial analysis by optical meansCrystal orientationLaser scanning

The invention relates to a method for conforming grinding crystal orientation of a diamond, belonging to the technical field of ultra-precise machining. The method comprises the steps of (1) grinding a single crystal diamond so as to obtain an abrasive surface, wherein the abrasive surface and a crystal face to be ground intersect so as to form a ridge; (2) measuring the index of the crystal surface of the obtained abrasive surface; (3) measuring the index of the crystal surface of the surface to be ground; (4) measuring the included angle between a groove left in the surface to be processed due to processing and the ridge formed in step (1); (5) calculating according to the data measured from step (2) to step (4) so as to obtain the specific crystal orientation index or direction in the grinding direction. According to the method, the abrasive surface provided in advance and the surface to be ground form the ridge which is taken as the reference crystal orientation, in subsequent abrasive machining, characterization parameters of the specific grinding direction can be measured by a laser scanning confocal microscope only by marking initial crystal orientation on the crystal surface, and the space placing position and placing gesture of the diamond workpiece do not need to be recorded, so that the method is convenient and rapid.

Owner:HARBIN INST OF TECH

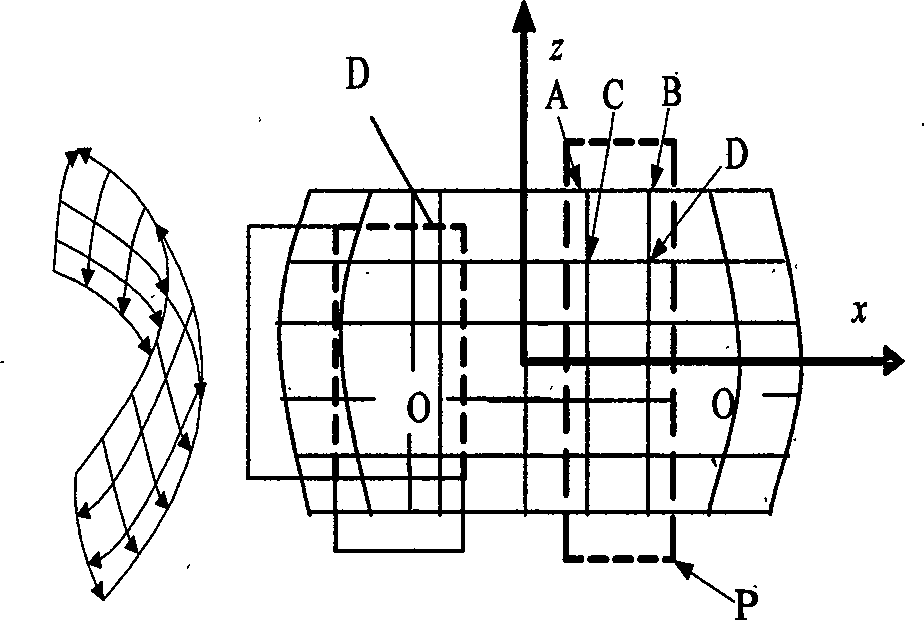

Abrasive machining method for cuneiform aspheric surface

InactiveCN101428399AImprove machining accuracyHigh precisionGrinding feed controlLensNumerical controlGrating

The invention discloses a method for grinding a wedge-shaped aspheric surface, relates to an aspheric surface process and provides the method for grinding the wedge-shaped aspheric surface. The method is characterized in that a circular arc diamond emery wheel is selected as the processing tool; according to the characteristic of the machine tool for realizing the three-axis linkage, the method adopts the processing way of fixing work pieces and three-axis linkage of the tool; installation and position of the work pieces; division of the numerical controlling interpolation points; and the track planning and design of the numerical controlling process. The adaptability of the processing tool for the work pieces is analyzed, and the processing is performed by adopting the circular arc diamond emery wheel; the adaptability of the processing and detection means is analyzed, and the method adopts the processing way of fixing the work pieces and three-linear axis linkage of the tool; the shape types of the work pieces are analyzed, the method poses the surface points measuring and processing track planning method suitable for processing the wedge-shaped aspheric surface, which includes the methods such as the linear optical grating type processing, the oblique line envelope processing and the like. The method has the advantages of convenience, stability, high precision and the like, therefore, the method is suitable for popularization and application.

Owner:XIAMEN UNIV

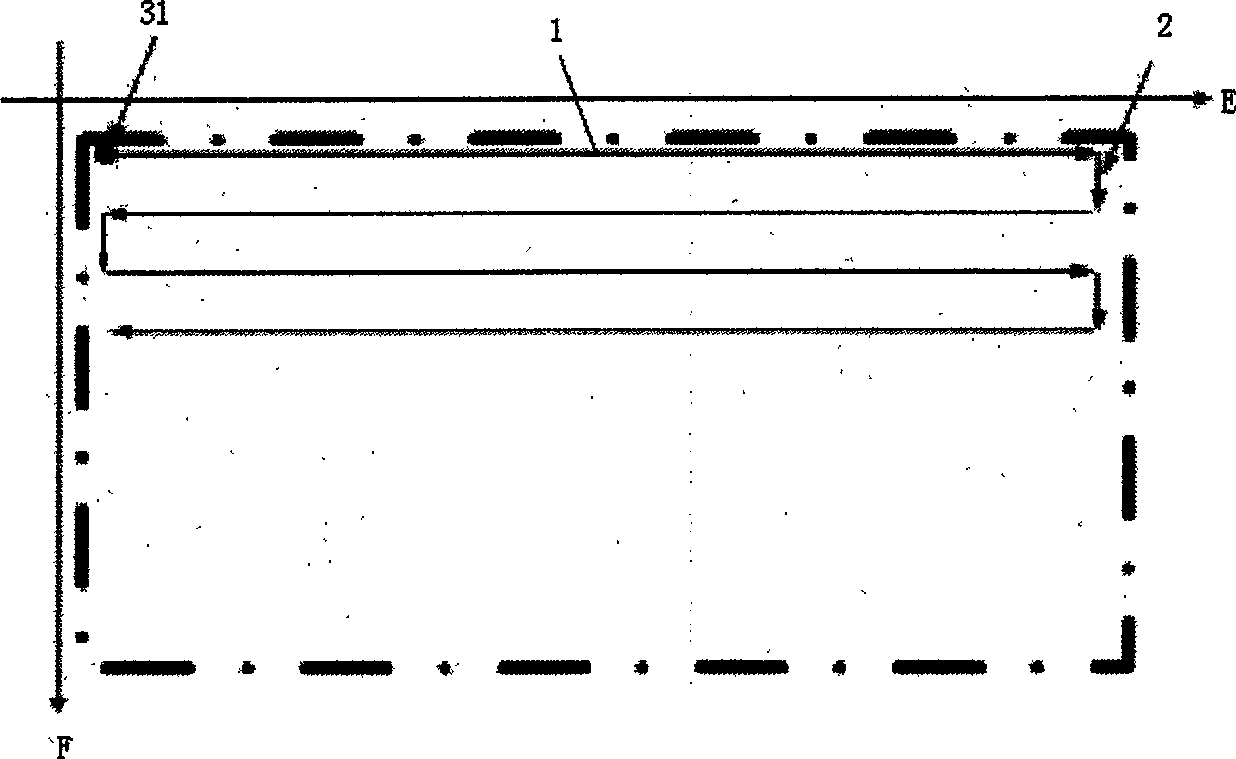

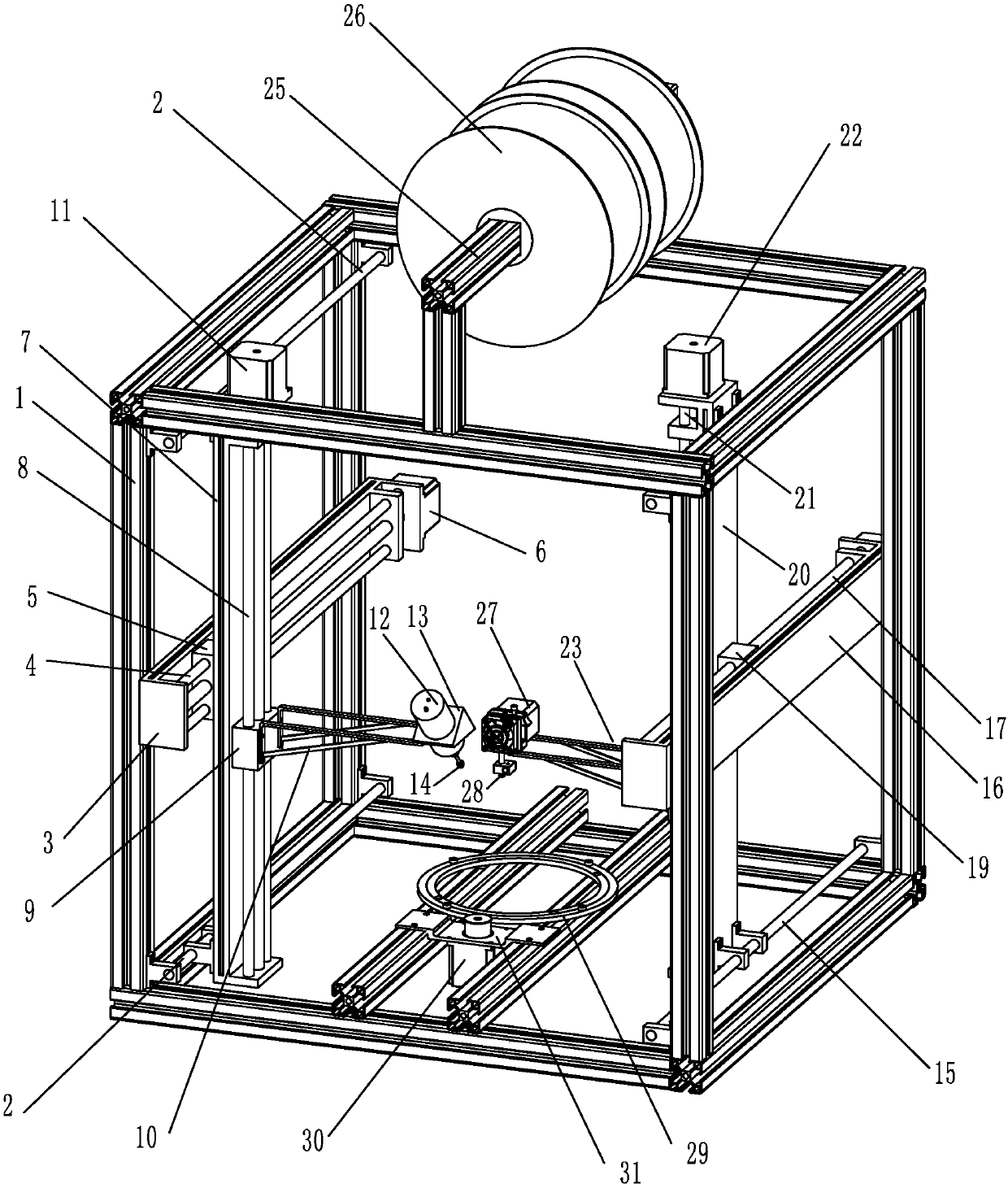

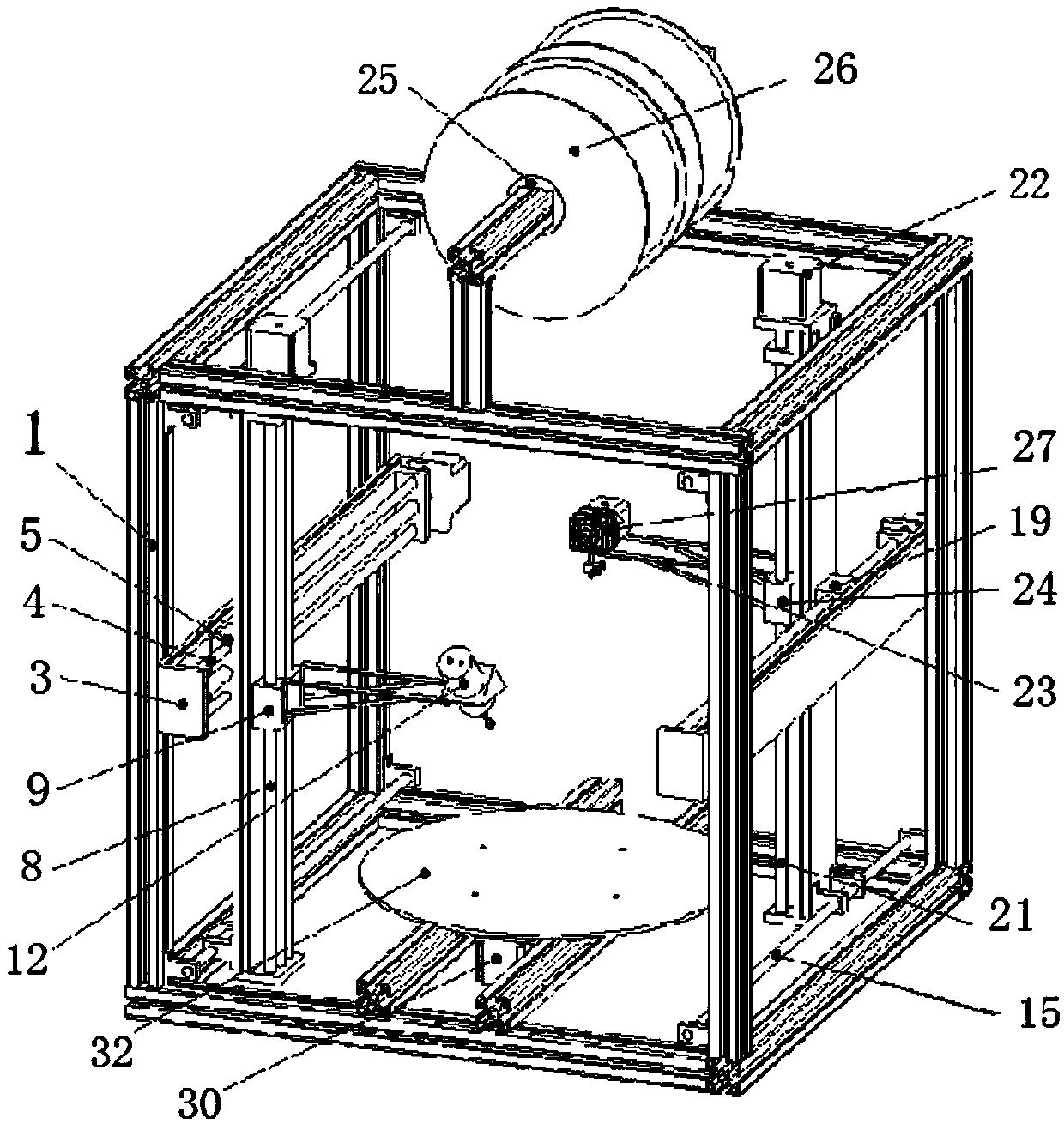

Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

PendingCN107672162AImprove flexibilityShorten the timeEdge grinding machinesAdditive manufacturing apparatusWear particleSurface roughness

The invention discloses a table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function, and relates to table top material increasing and decreasing wood-plastic composite 3D printers. In order to solve the problem that the shape accuracy, dimensional accuracy, surface quality and the like of parts are both limited by the single-layer printingthickness and plane printing accuracy in an existing 3D printing layer-by-layer stacking manufacturing mode, the table top material increasing and decreasing wood-plastic composite 3D printer comprises a rectangular frame (1) and further comprises a material decreasing assembly, a material increasing assembly and a material increasing and decreasing working platform. The material increasing and decreasing working platform is installed at the lower end of the rectangular frame (1) in a rotating mode. The material decreasing assembly and the material increasing assembly are installed on the rectangular frame (1). According to the table top material increasing and decreasing wood-plastic composite 3D printer, the wood-plastic composite is used as a manufacturing raw material to be stacked layer by layer, so that the material increase manufacturing technology is implemented; and a grinding wheel serves as a cutter in abrasive machining, and grinding wheel abrasive particles serve as cutting blades so that the size and shape accuracy and surface roughness needs required can be met. The table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function is used for wood-plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

Production process flow of automotive steering linkage joint assembly

InactiveCN102900754AQuality improvementImprove work efficiencyPivotal connectionsEngineeringHeat treated

The invention relates to the field of automotive parts, and specifically relates to a production process flow of an automotive steering linkage joint assembly. The process flow comprises the steps that: 1.1, raw materials used for producing a joint and a ball pin are prepared; 1.2, the raw materials are subjected to processes such as machining, milling, planning, and clamping, such that rough blanks of the joint and the ball pin are obtained; 1.3, the rough blanks are subjected to a heat treatment; 1.4, the treated rough blanks are subjected to abrasive machining; 1.5, ultrasonic flaw detection is carried out; 1.6, the joint and the ball pin obtained after processing and flaw detection are tested; and 1.7, a finished product is assembled by using the joint, the ball pin, and other automotive steering linkage joint assembly parts. With the process flow provided by the invention, working efficiency is greatly improved, and qualities of the joint and the ball pin are greatly improved.

Owner:SHAOXING UNIVERSITY

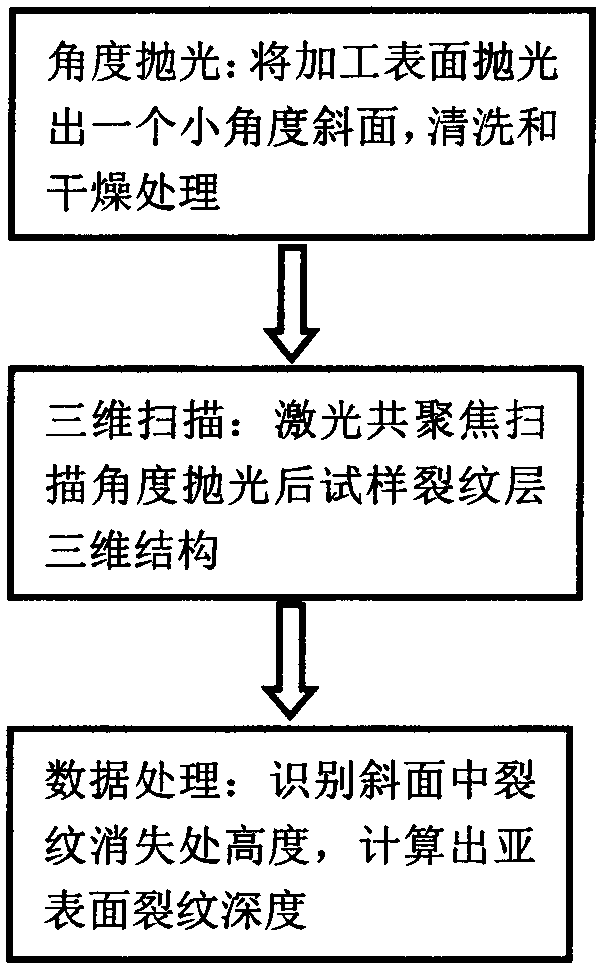

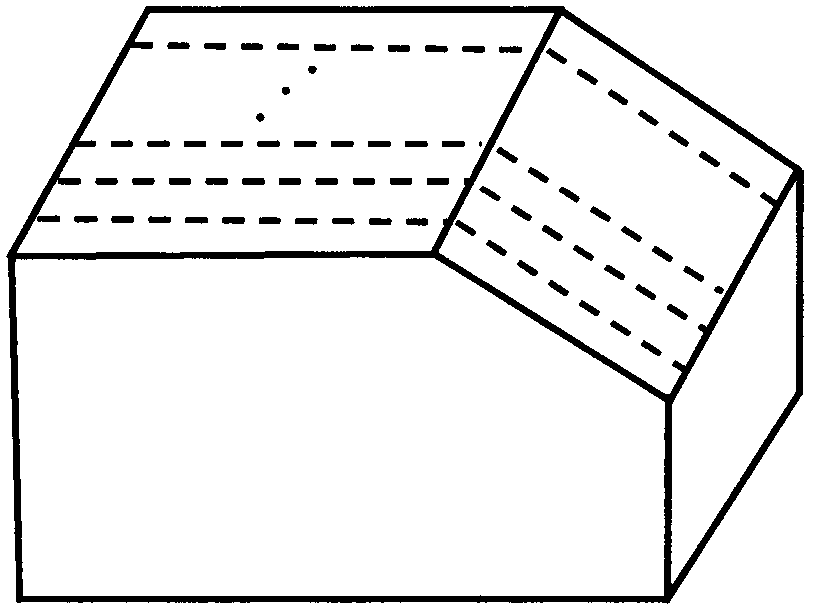

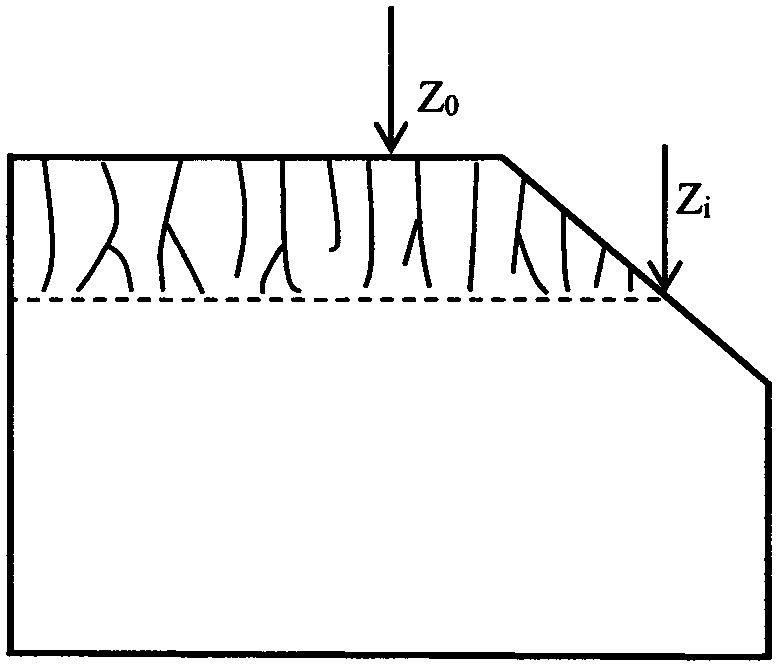

Method for detecting depth of subsurface crack of optical material

InactiveCN107037059AImprove detection efficiencyAvoid factors that interfere with detection accuracyPreparing sample for investigationOptically investigating flaws/contaminationTwo-dimensional graphData treatment

The invention discloses a method for detecting depth of a subsurface crack of an optical material. The method comprises the following steps: polishing one small-angle inclined plane on a sample surface subjected to abrasive machining by adopting an angle method, and corroding the sample surface and the inclined plane by utilizing a specific etching liquid, thereby guaranteeing that a surface polishing deposited layer is removed; carrying out three-dimensional scanning on a sample subjected to angle polishing by utilizing a laser confocal microscopy, and obtaining a three-dimensional chromatography structure of a crack layer of the sample; and converting the three-dimensional structure of the crack layer into a two-dimensional graph, carrying out data processing, and finally obtaining the depth of the subsurface crack of the to-be-detected material. The method disclosed by the invention overcomes the defects of an existing angle polishing method used for detecting the depth of the subsurface crack by utilizing a laser confocal microtechnique and is efficient, high in precision and portable when being used for detecting the depth of the subsurface crack of the optical material.

Owner:ZHEJIANG NORMAL UNIVERSITY

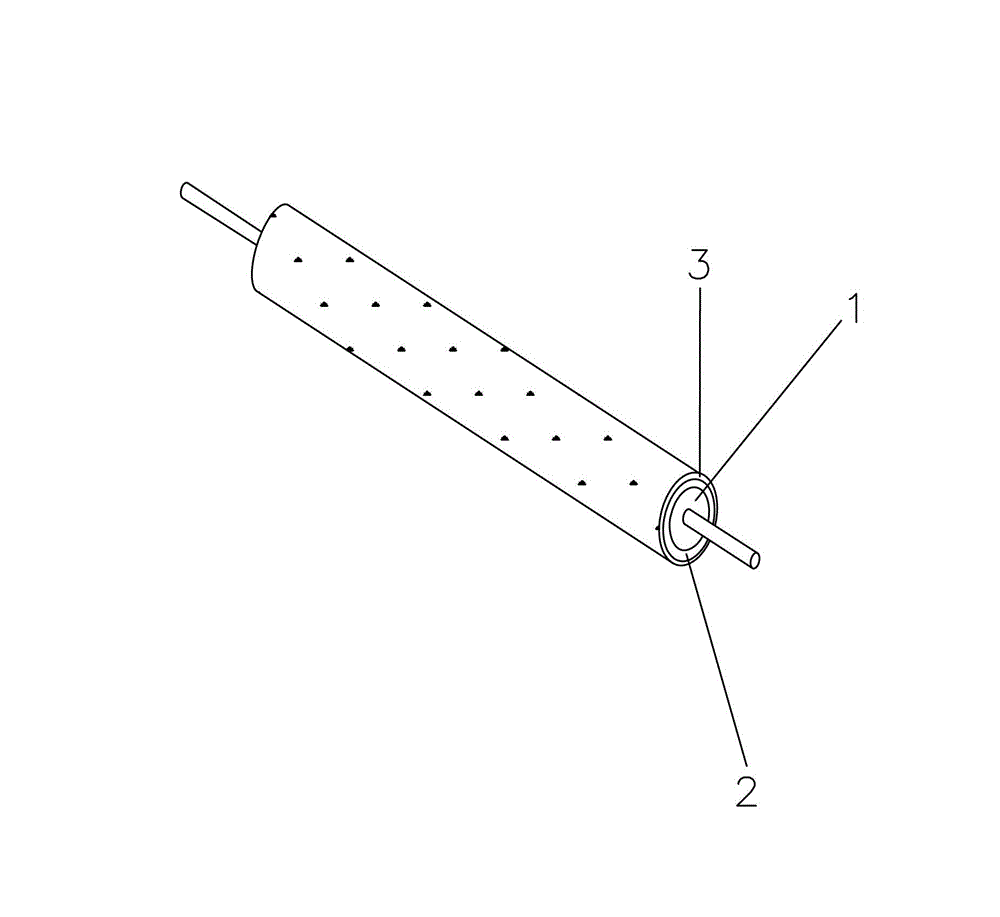

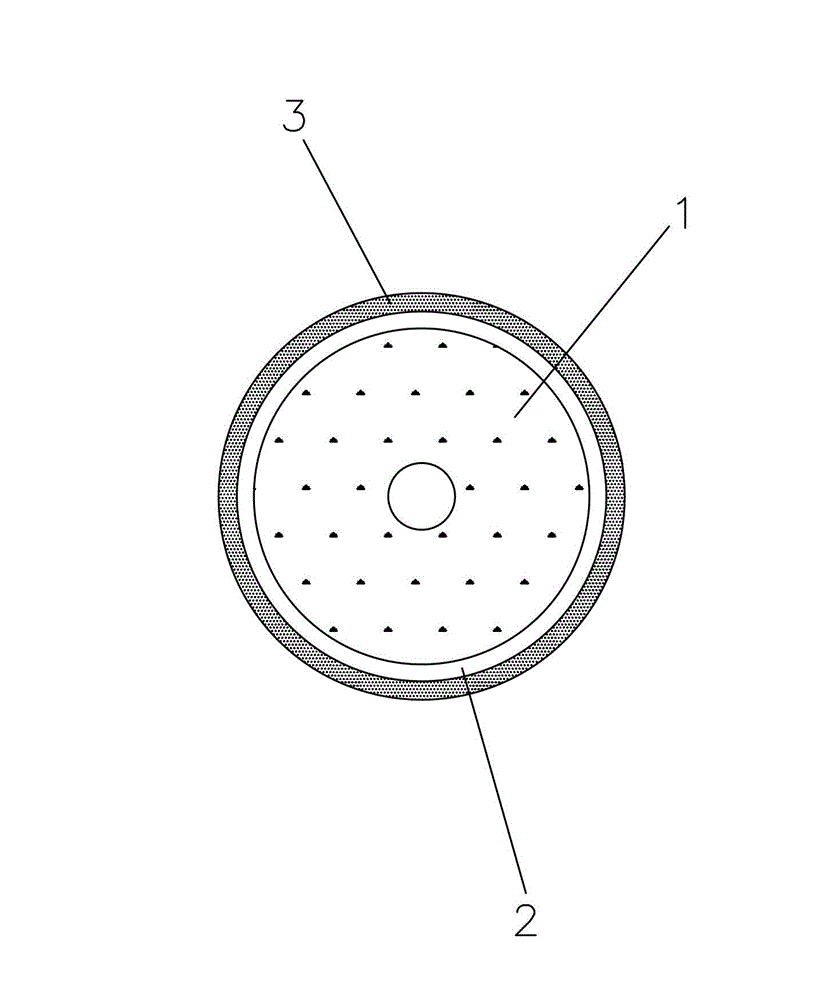

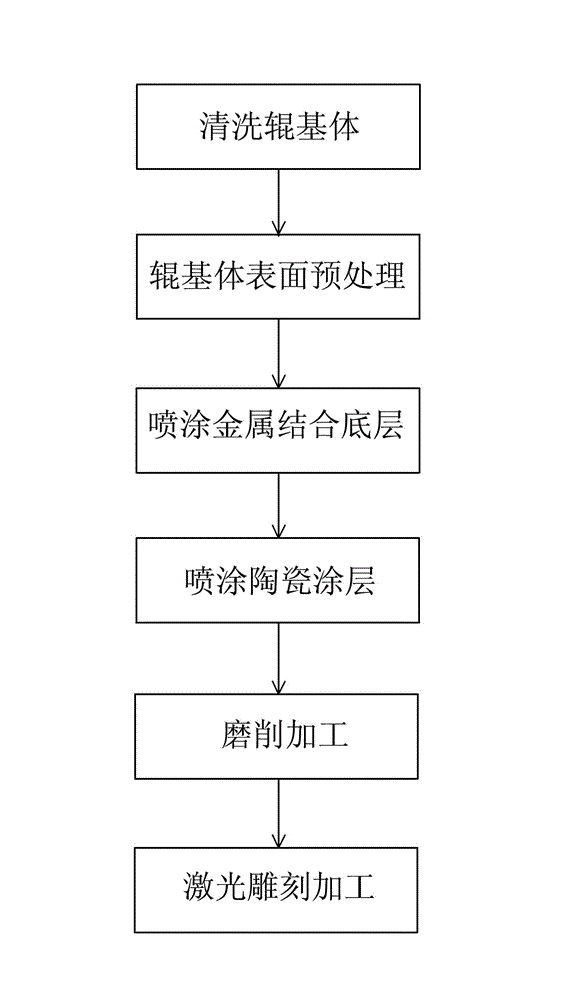

Laser engraved ceramic coating anilox roller and production method thereof

InactiveCN104002552AImprove printing accuracyHigh densityCeramic layered productsPrinting press partsCeramic coatingSpray coating

The invention discloses a laser engraved ceramic coating anilox roller and a production method thereof. The laser engraved ceramic coating anilox roller comprises a roller body, a transition layer and a working layer; the transition layer is a metal combined bottom layer, and the working layer is a ceramic coating layer; the transition layer is fixed onto the roller surface of the roller body, and the ceramic coating layer is fixed to the transition layer. The production method includes the steps of roller body cleaning, roller body surface pretreatment, metal combined bottom layer spray coating, ceramic working layer spray coating, spray coated ceramic working layer abrasive machining and ceramic working layer laser engraving machining. The laser engraved ceramic coating anilox roller has the advantages of long service life and high printing accuracy. The production method is fewer in process steps and not demanding in production conditions, can ensure the technical effect of the ceramic anilox roller, and is applicable to industrial batch production.

Owner:SUZHOU ZHISHUN SURFACE TECH

Grinding processing method for optical spherical lens

InactiveCN101041230ARationalizeProcessing time shortenedOptical surface grinding machinesGrinding drivesConcentration ratioMetallurgy

The invention relates to a grinding processing method for optical spherical lens, in which the fine grinding procedure can be used as single procedure to perform rough grinding. The rough grinding for optical spherical lens is performed at the following condition: 1) grinding disc of nucellus swing type performing the rough grinding of the said lens sheet; 2) using diamond tool of #300-#600 (average size : 60 mu m-30 mu m) and more than 50 of concentration ratio as rough grinding tool disc; setting the rotating speed of the said rough grinding tool disc as 2500rpm-3000rpm. Thus, the allowance of the next fine grinding procedure is about below 20 mu m, which can improve the surface roughness and sphere precision of the said rough grinding procedure. The fine grinding is single grinding procedure, which can realize the shortening of the abrasive machining time of the spherical lens and rationalization of the process management.

Owner:HARUCHIKA

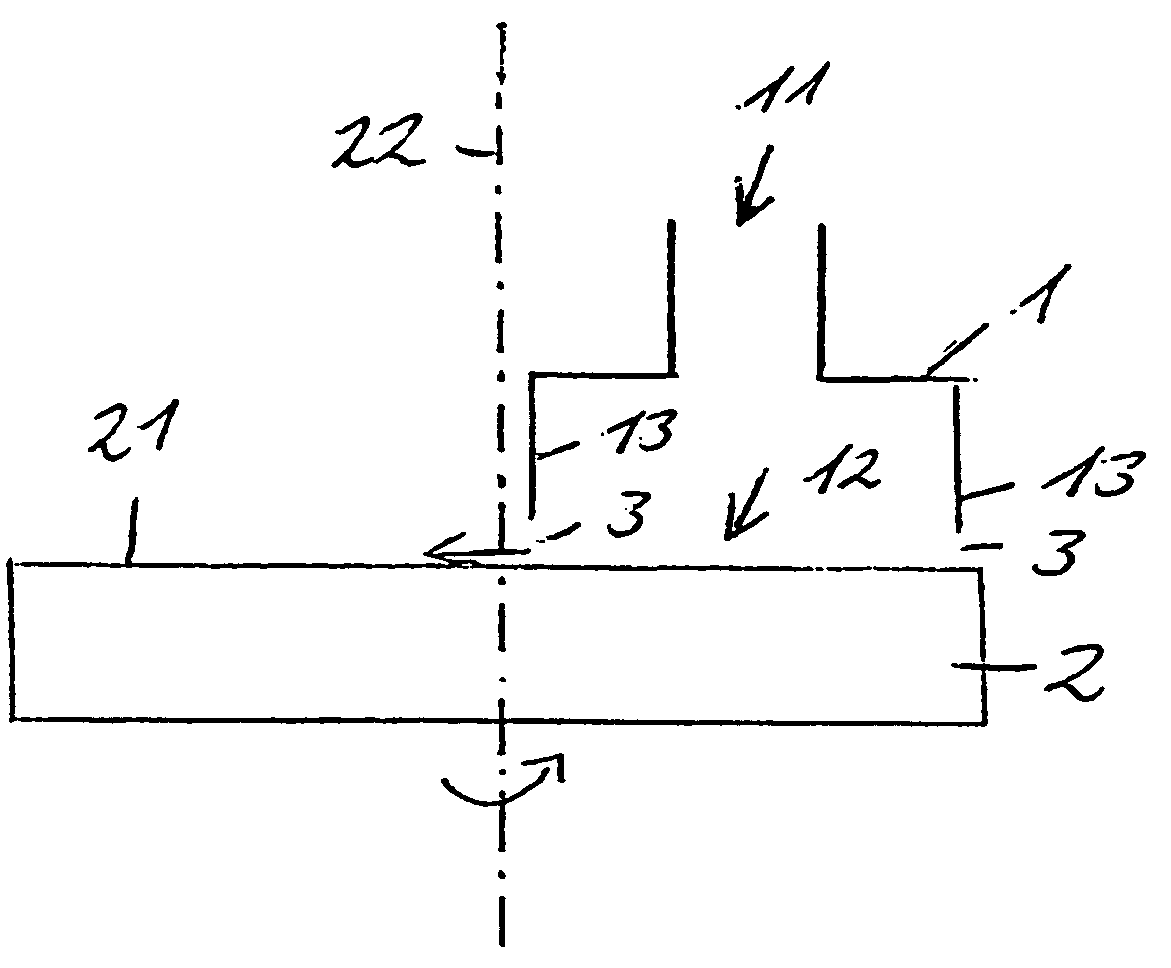

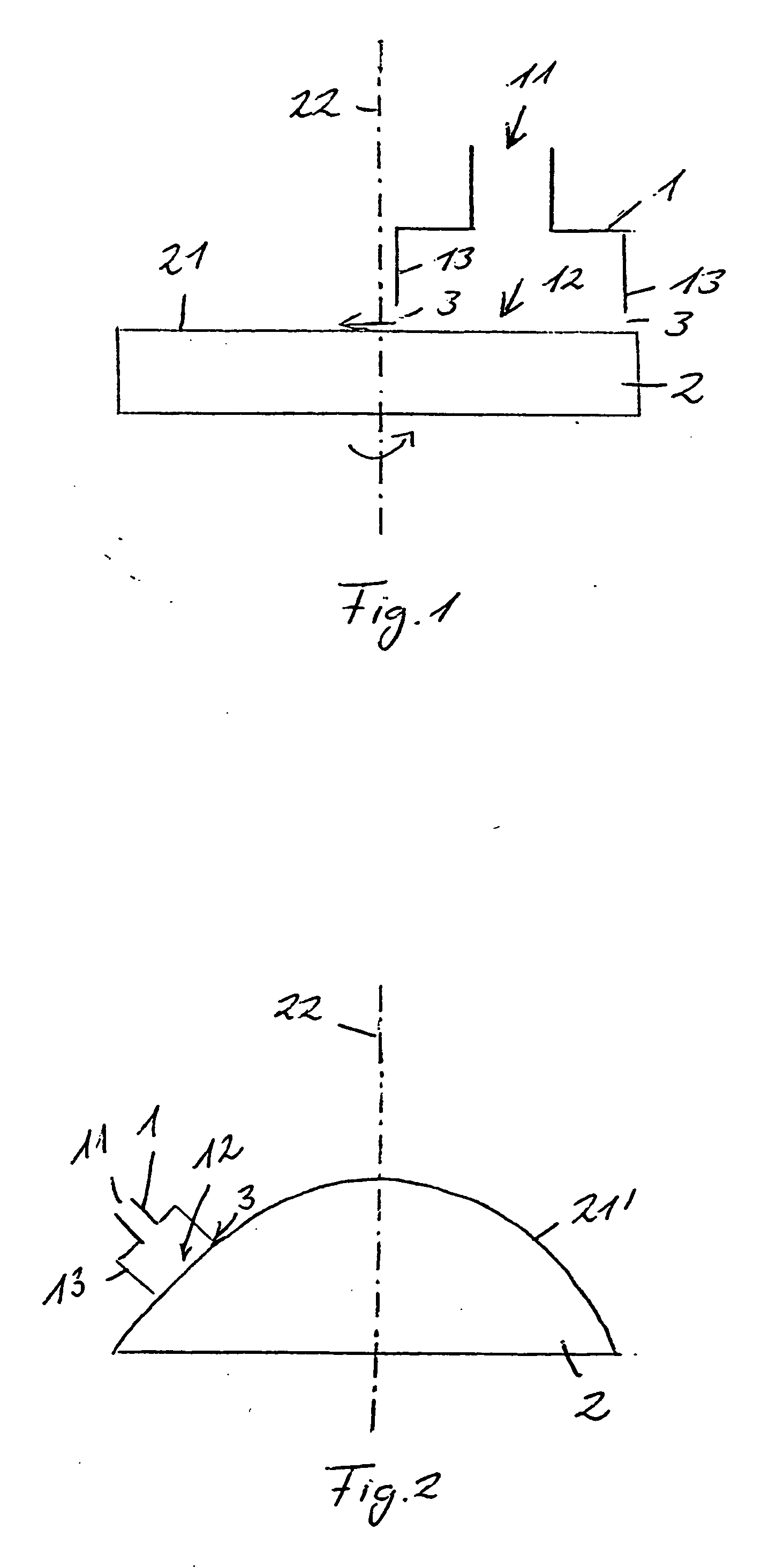

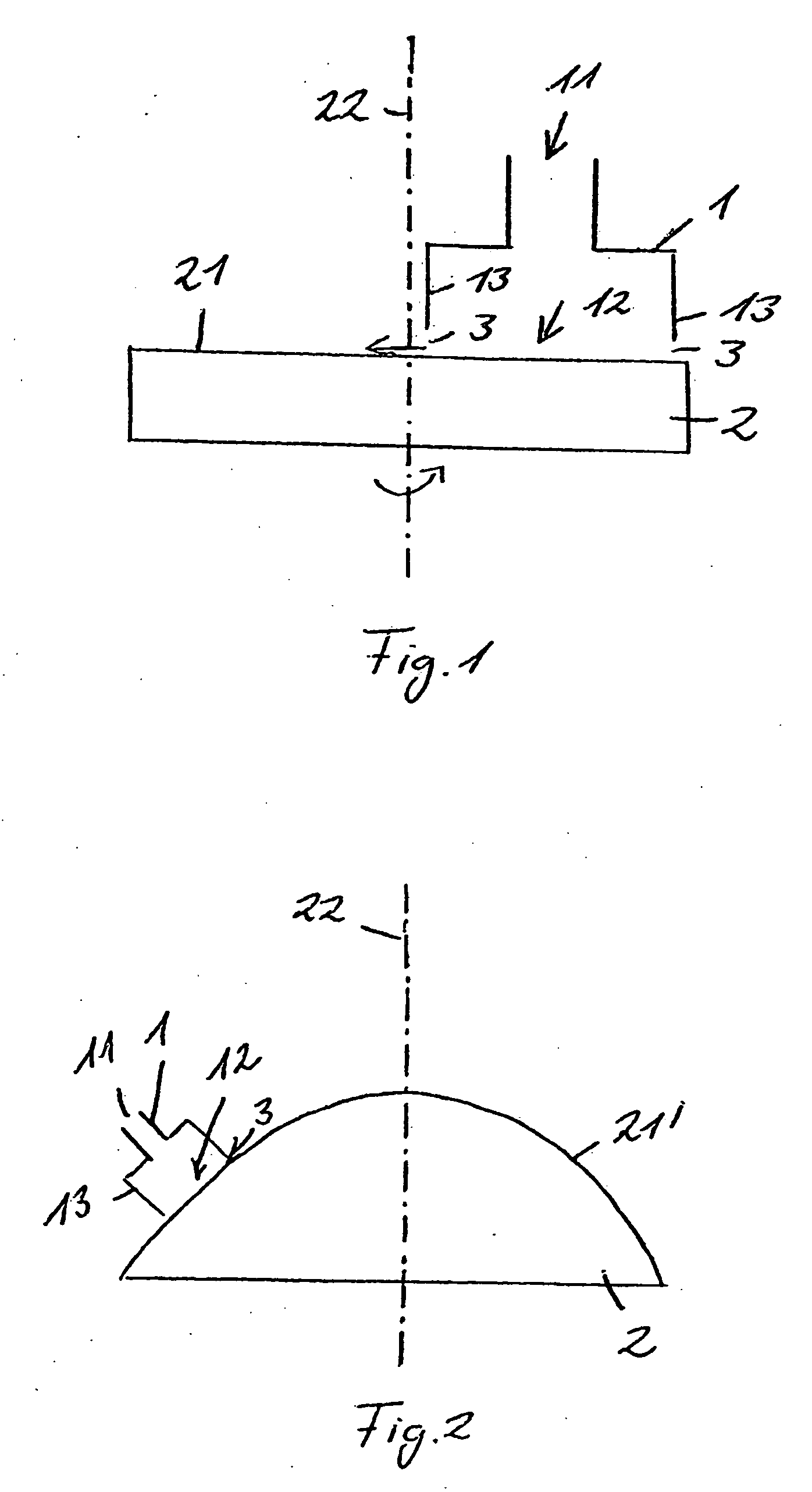

Device for the abrasive machining of surfaces of elements and in particular optical elements or workpieces

A device for abrasive machining of surfaces of components, comprising a tool (1) having an inlet (11) and an outlet (12); a supply unit for conveying to the inlet (11) a liquid in which abrasive agents are dissolved and which emerges from the outlet (12); and a positioning means which guides the tool across a surface to be machined and simultaneously positions the tool in such manner that the outlet faces the surface to be machined, an area of an annular gap (3) defined by boundary walls (13) of the outlet (12) and the surface (2) to be machined being smaller than a cross-sectional area of the inlet (11).

Owner:FAHNLE OLIVER

Mandrel power mechanism for cold rolling machine

InactiveCN101433916AReduce wearExtended service lifeRolling mill drivesMetal rolling arrangementsControl systemEngineering

The invention relates to a mandrel power unit for a cold roller, which is provided with a rolling wheel, a supporting wheel, a core roll which is arranged between the rolling wheel and the supporting wheel, and a control system of the core roll. The mandrel power unit is characterized in that the core roll is provided with a driving rotary power unit, and the unit consists of a hydraulic oil cylinder, a motor, a position detecting device and a connecting body which are integrated into a whole and used for driving the core roll and the supporting wheel. The mandrel power unit for the cold roller not only improves the service life of the core roll but also solves the problem of scrape of the furrow bottom of a bearing ring, improves the finish degree of the processed curved surface of cold-rolling pieces, reduces the production time of abrasive machining, and greatly improves the price performance ratio of the cold roller.

Owner:金凯岷 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com