Coreless abrasive machining measurement and control system and corresponding coreless abrasive machining method

A centerless grinding, measurement and control system technology, used in grinding machine parts, grinding automatic control devices, metal processing equipment, etc., can solve the problems of complex control methods, reduce costs, improve anti-interference ability and measurement accuracy , the effect of improving data transmission rate and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

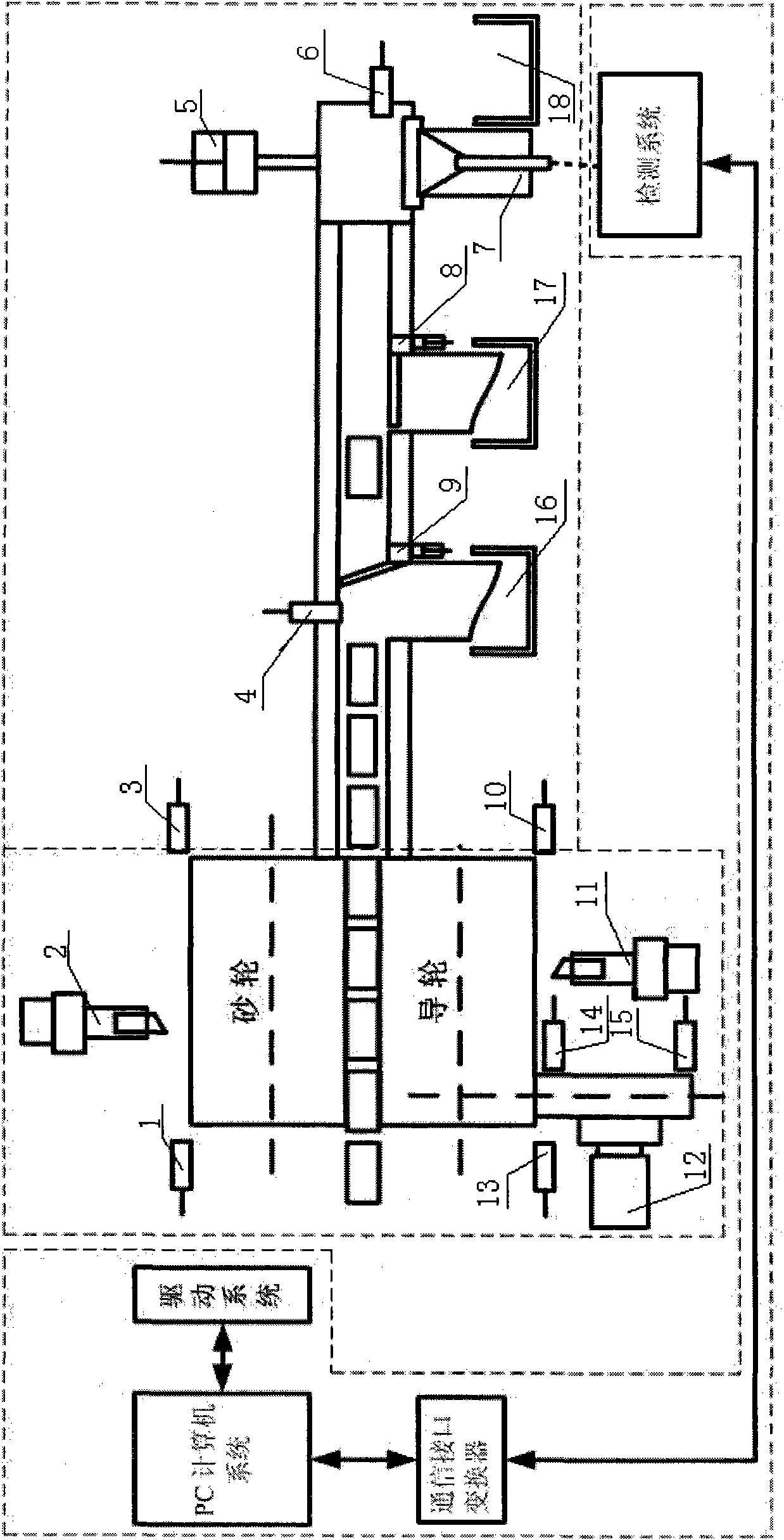

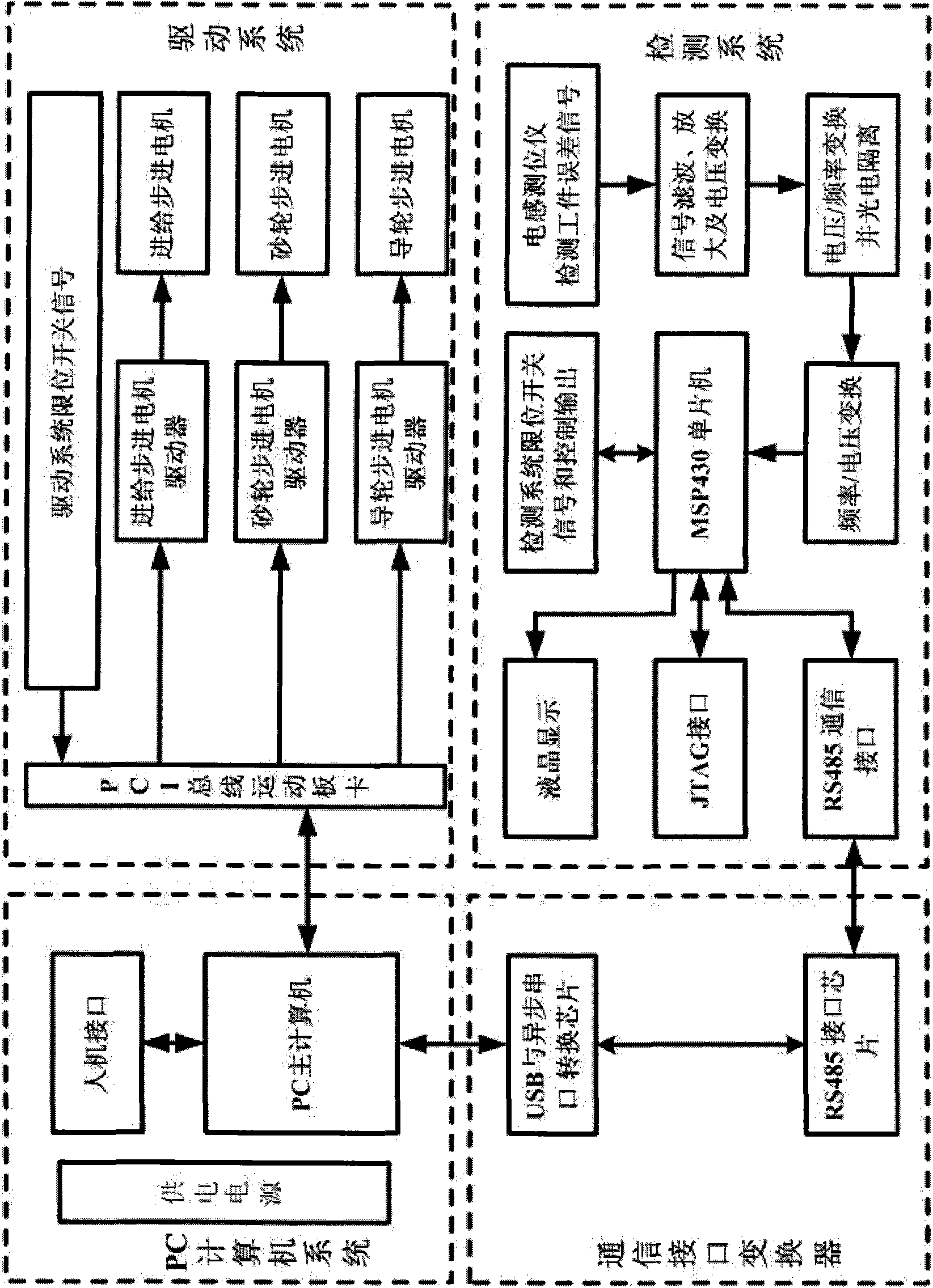

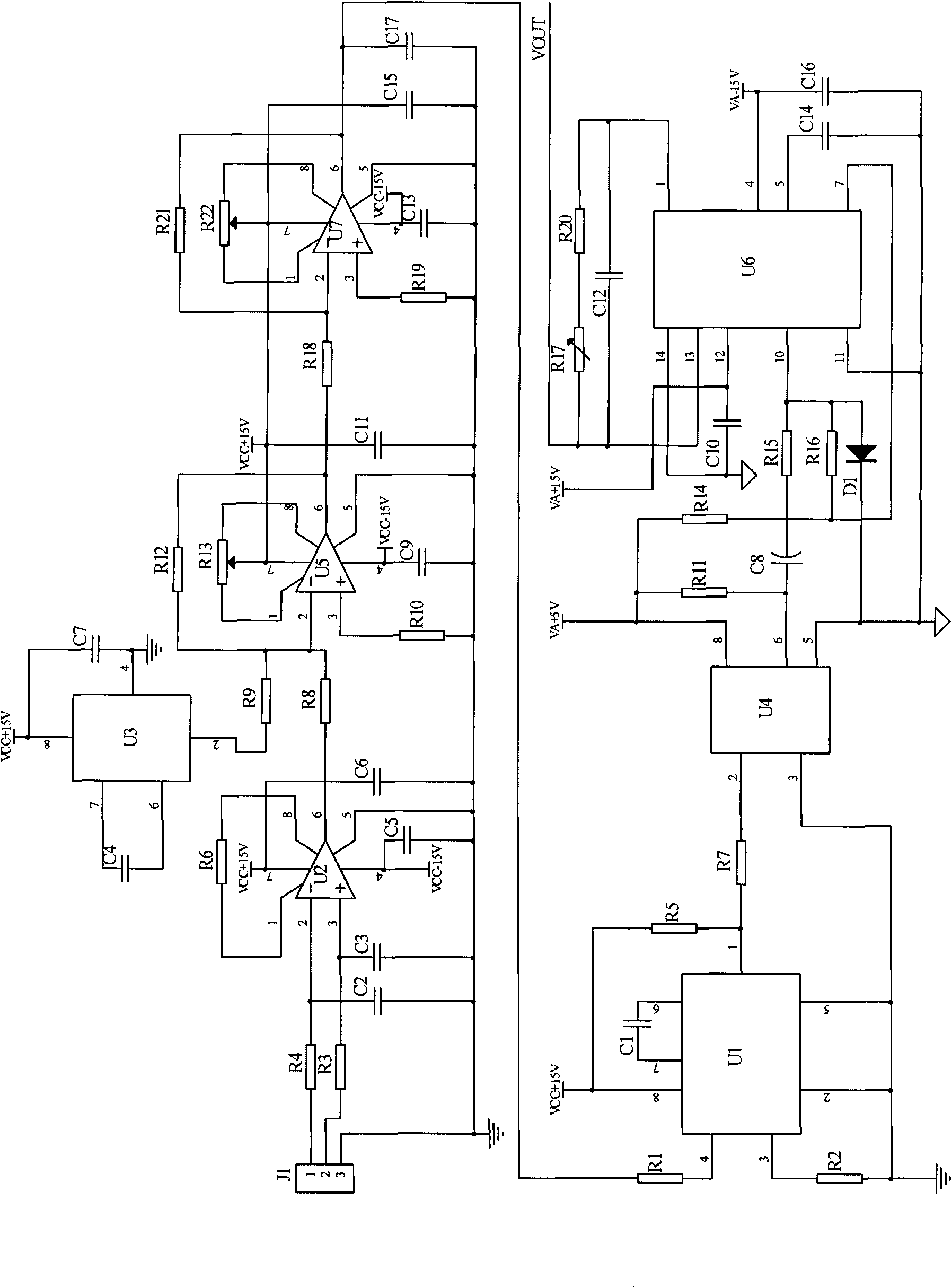

[0033] combine figure 1 To illustrate the centerless grinding machine installed with the centerless grinding measurement and control system, based on the grinding process, combined with the fact that the error of the centerless grinding workpiece is mainly caused by the wear of the grinding wheel and the guide wheel, according to the control process The centerless grinding machine installed with the centerless grinding processing error measurement and control system is divided into three areas: the feeding area, the centerless grinding processing area and the detection area. The feeding area can be fed manually or automatically. Here, it is considered as manual feeding. According to During the control process, the main computer system sends out an alarm instruction to stop feeding and an alarm instruction to release whether to carry out material feeding; the centerless grinding processing area includes the set grinding wheel dresser 2 and its pair of limit switches 10, 13, guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com