Patents

Literature

47 results about "Statistical quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Statistical quality control is the observation of variables of a manufacturing process over time and the application of statistical analysis of those variables to define operating windows that yield lower defect products. This method is used primarily for manufacturing lines rather than chemical processing...

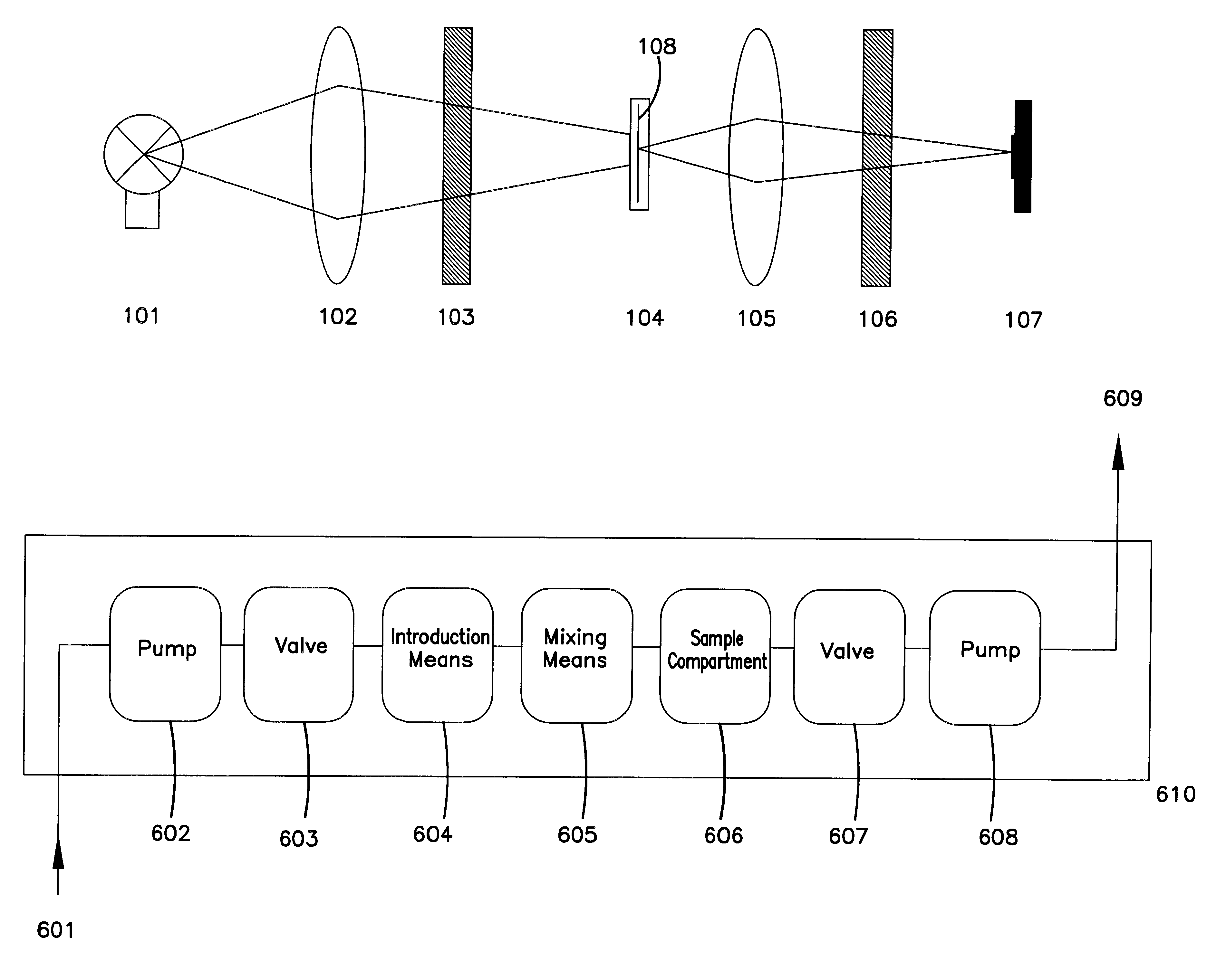

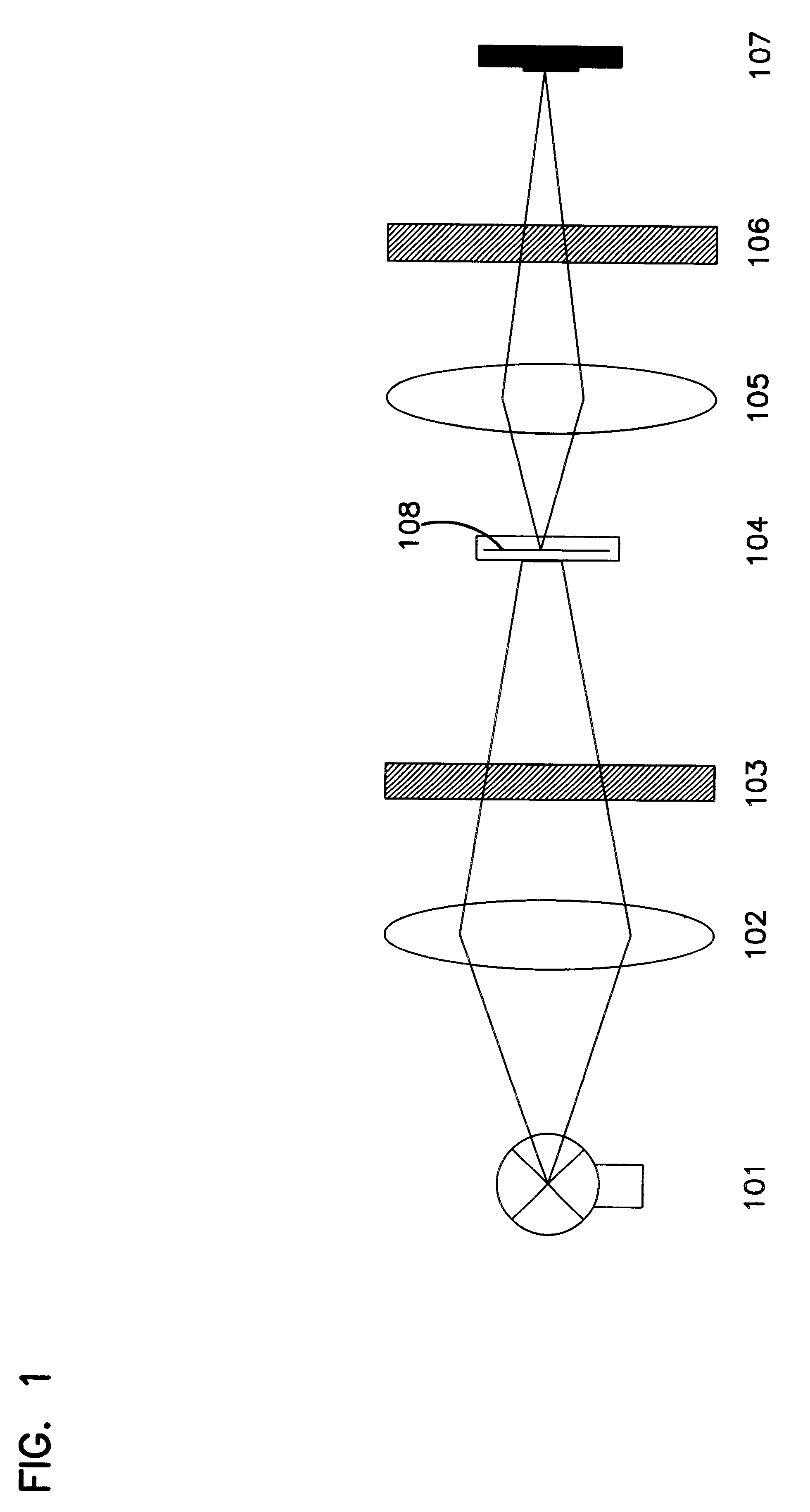

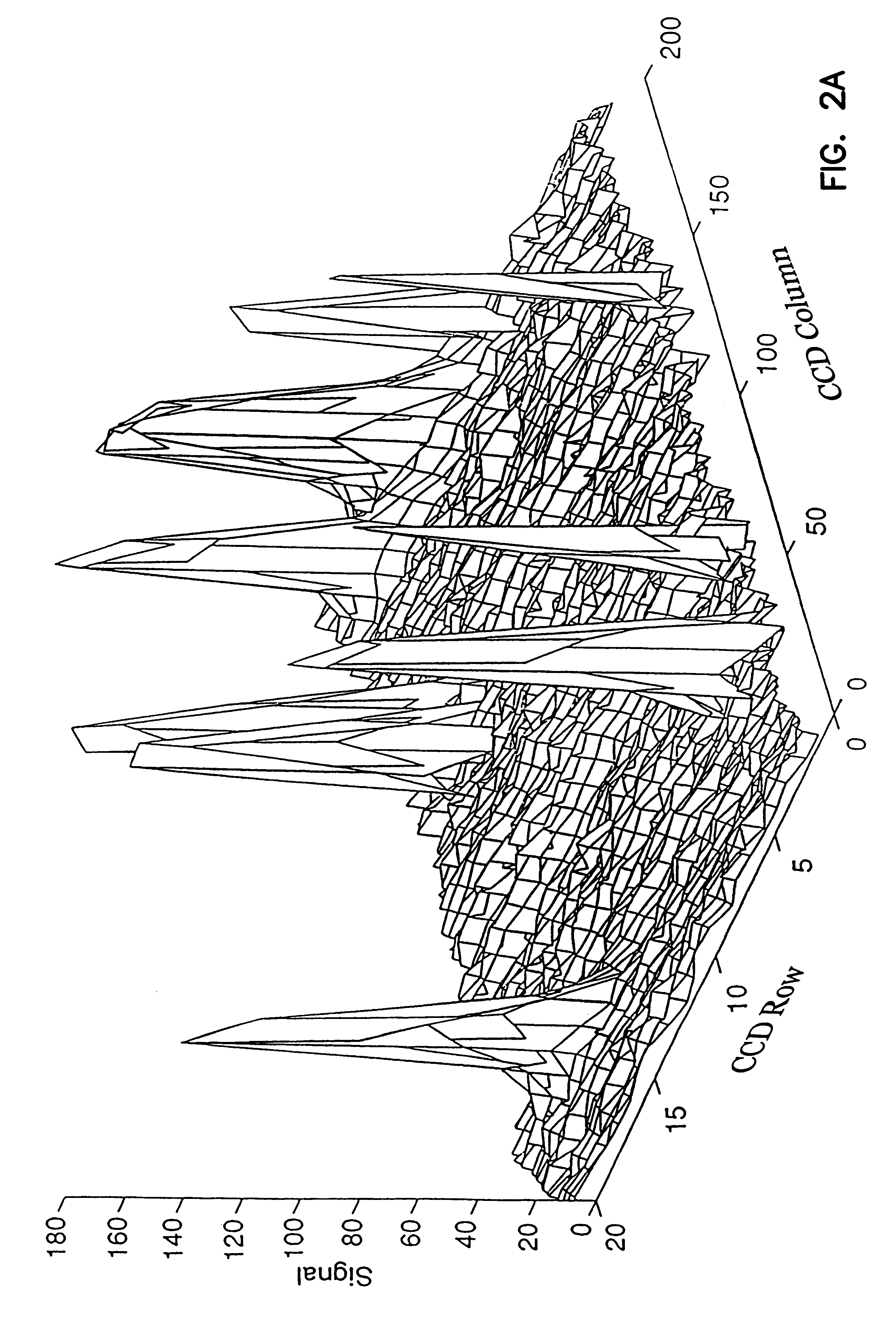

Method and a system for determination of particles in a liquid sample

InactiveUS6919960B2Simplified quantityEase of evaluationBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteStatistical quality

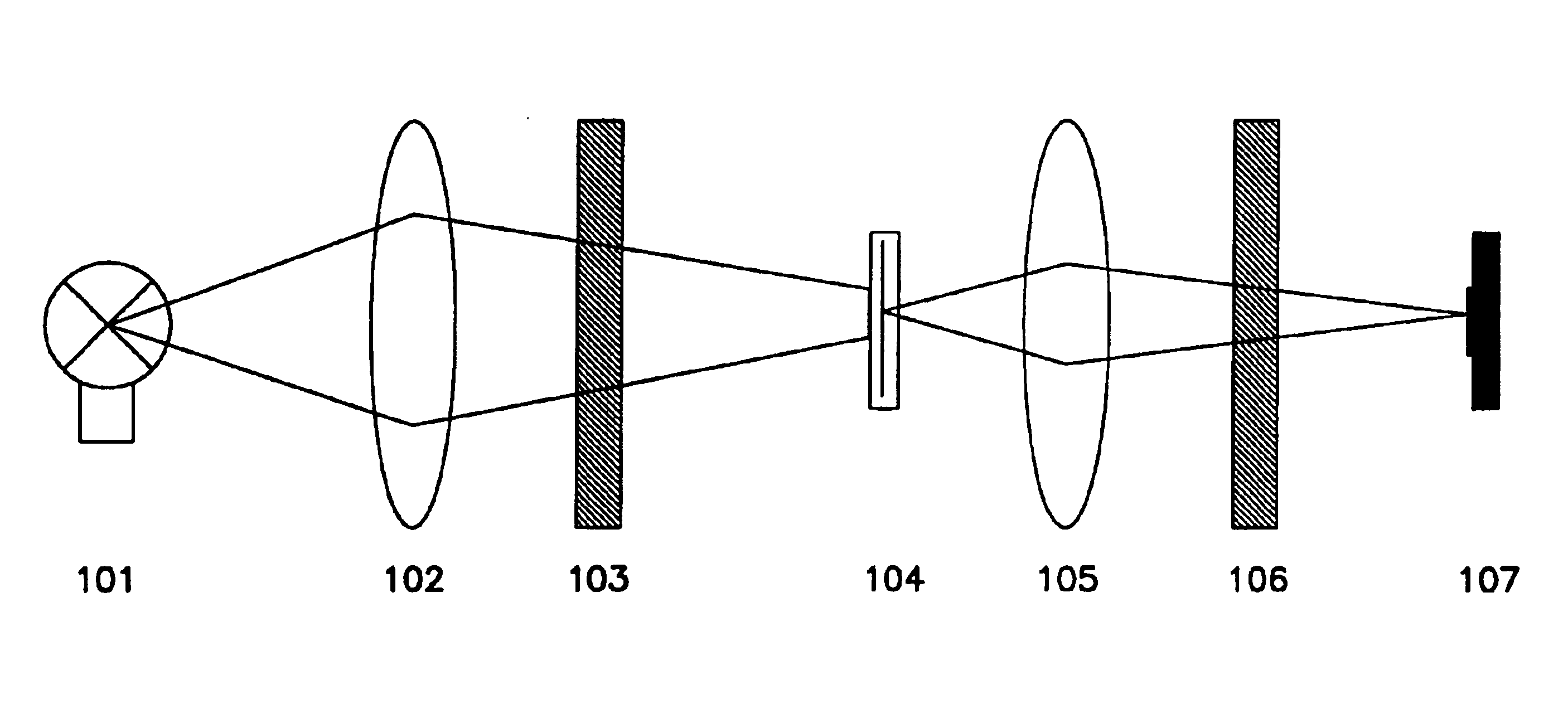

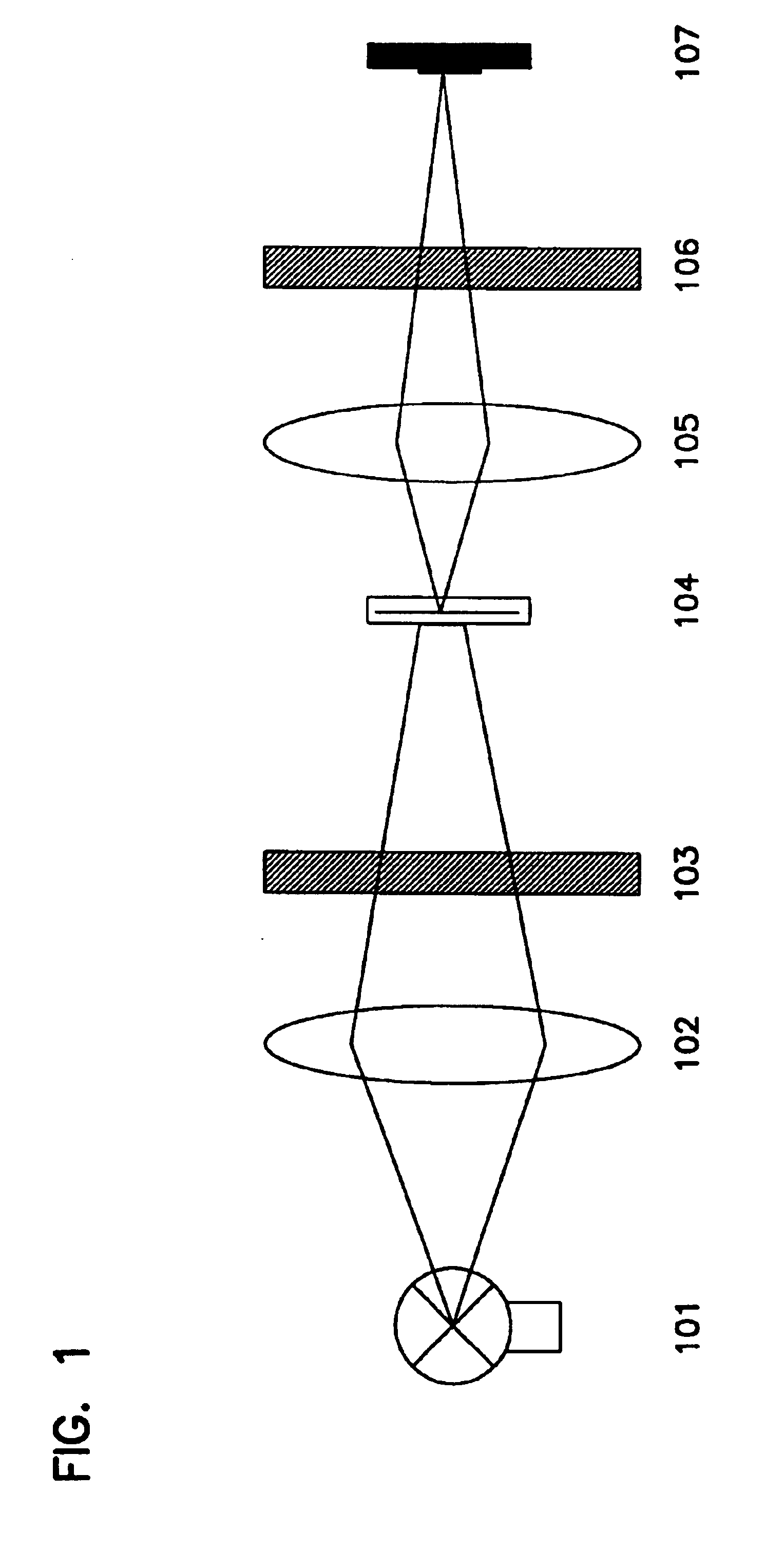

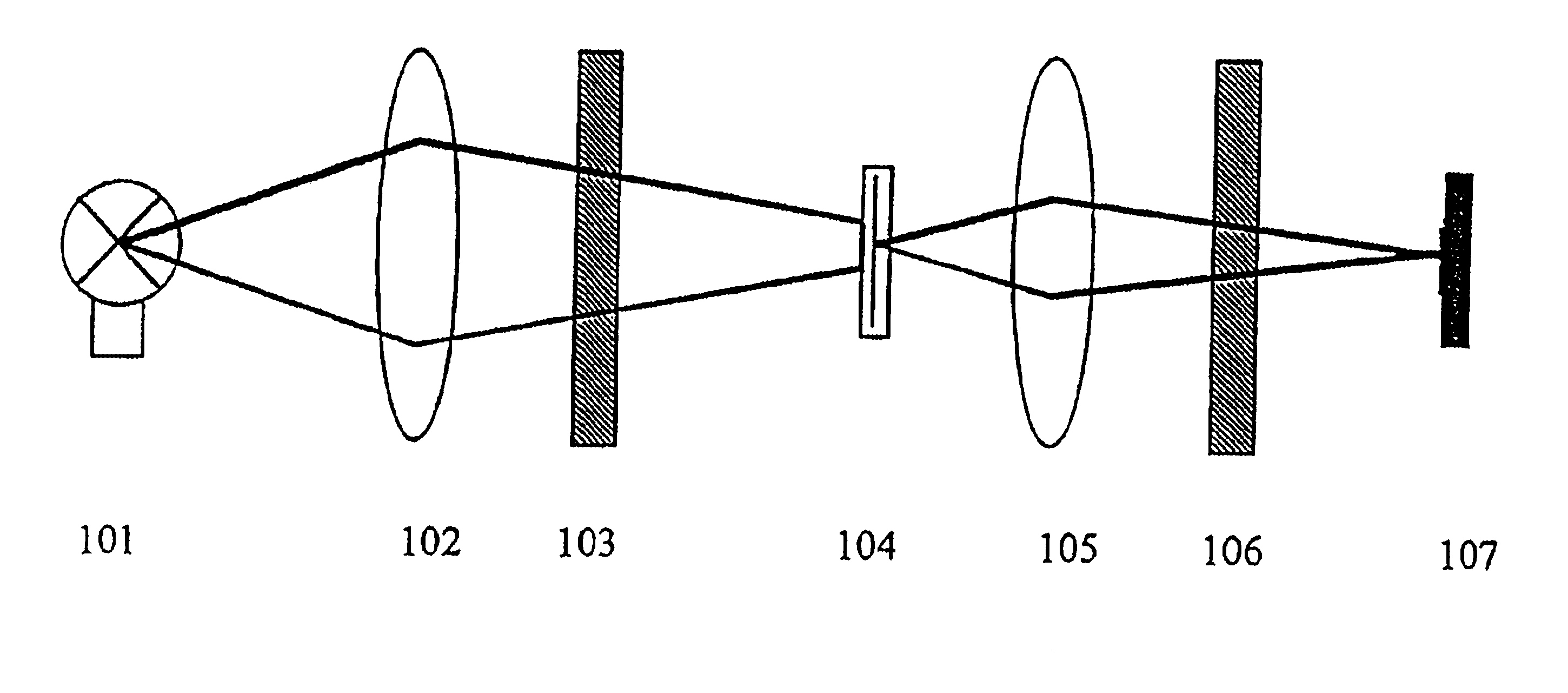

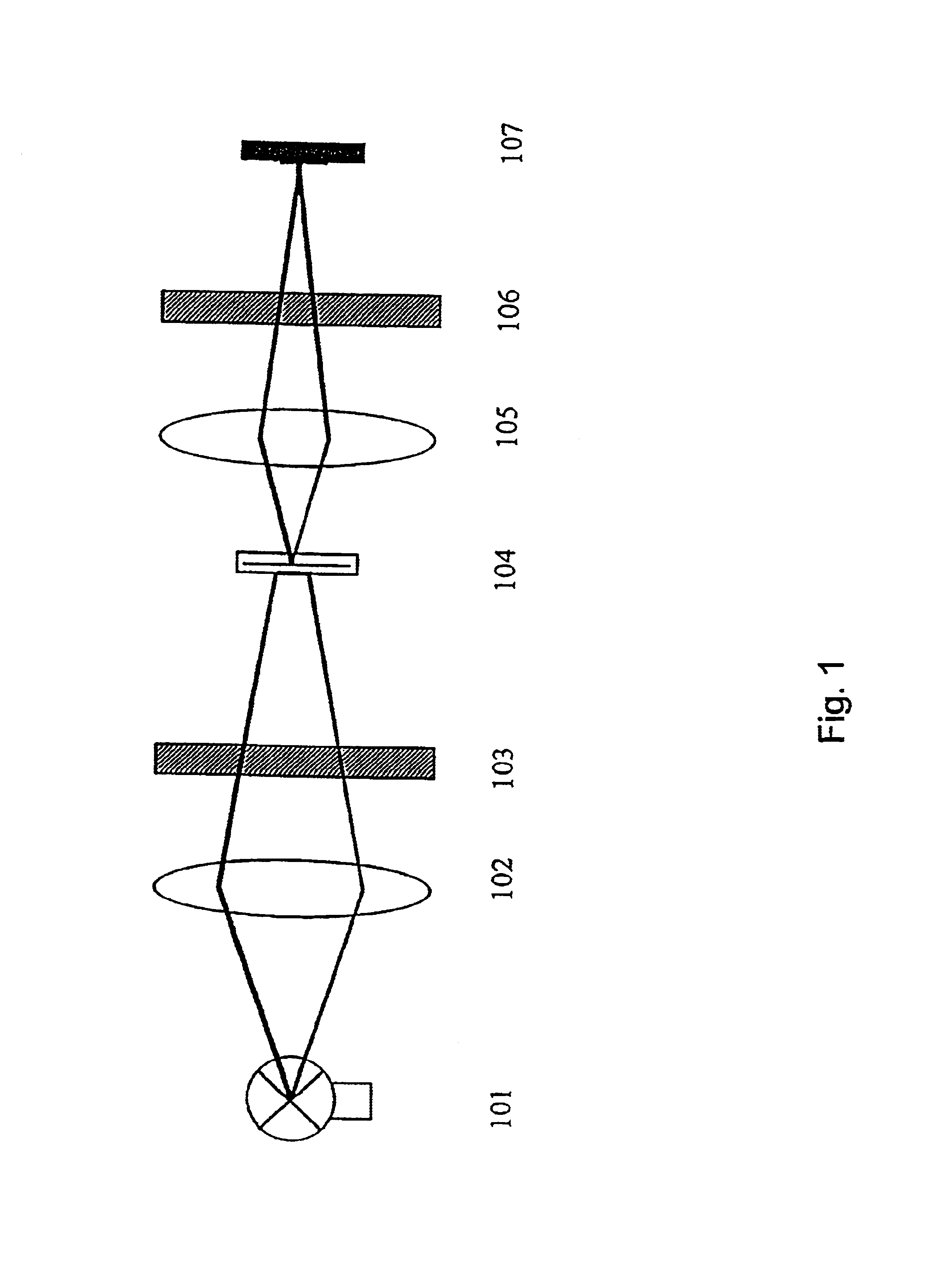

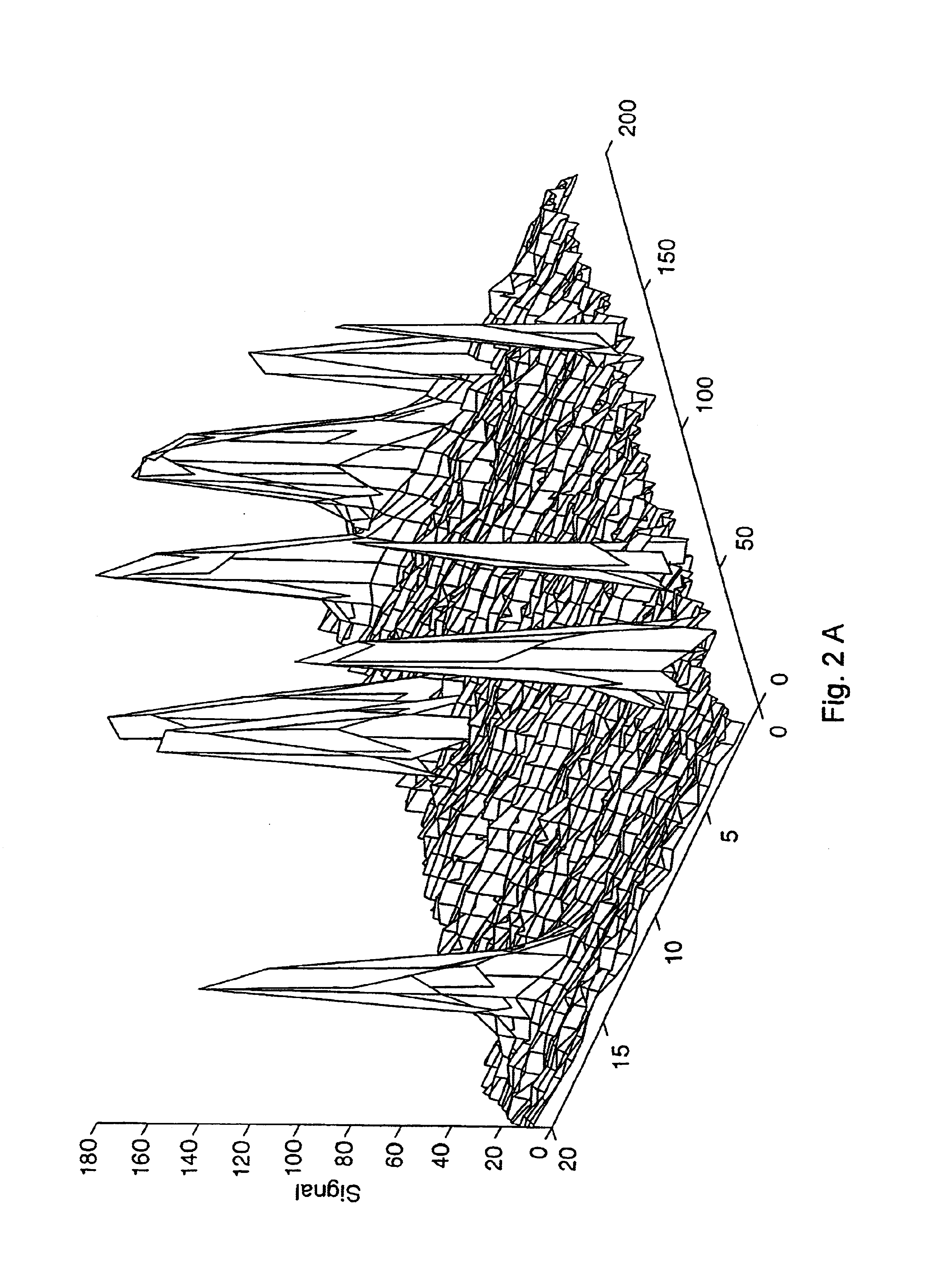

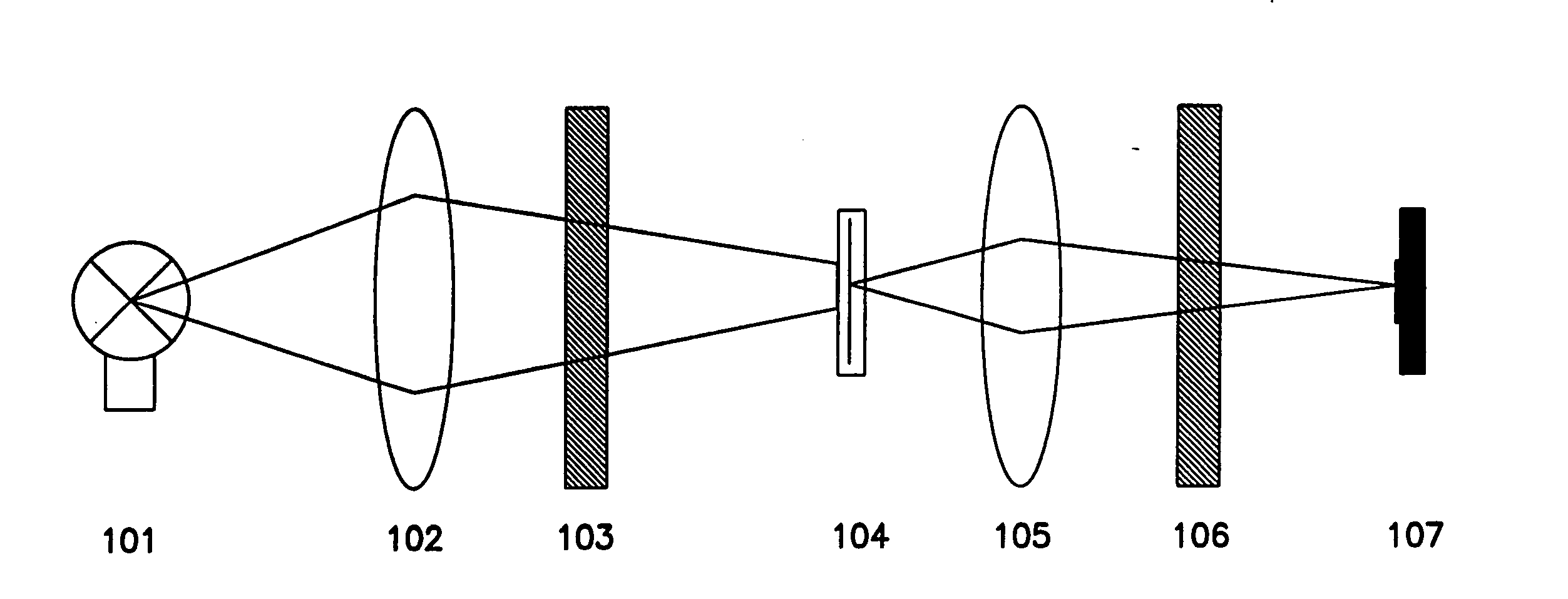

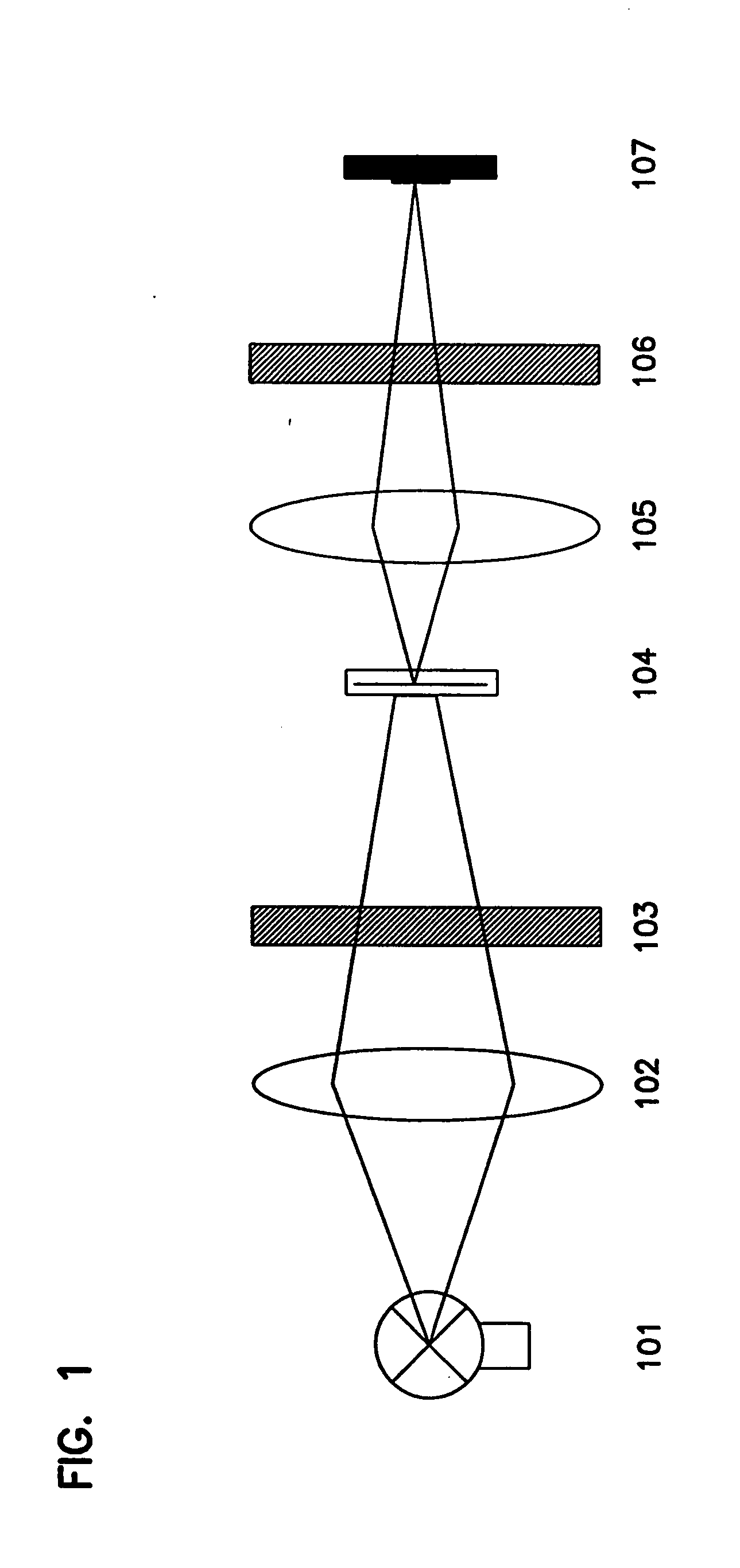

The present invention relates to a method for the assessment of quantity and quality parameters of biological particles in a liquid analyte material. The method comprises applying a volume of a liquid sample to an exposing domain from which exposing domain electromagnetic signals from the sample in the domain can pass to the exterior, and exposing, onto an array of active detection elements such as CCD-elements, a spatial representation of electromagnetic signals having passed from the domain, the representation being detectable as an intensity by individual active detection elements, under conditions permitting processing of the intensities detected by the array of detection elements during the exposure in such a manner that representations of electromagnetic signals from the biological particles are identified as distinct from representations of electromagnetic signals from background signals. The size of the volume of the liquid sample is sufficiently large to permit the assessment of the quantity and quality parameters to fulfill a predetermined requirement to the statistical quality of the assessment based on substantially one exposure.

Owner:CHEMOMETEC AS

Method and a system for determination of particles in a liquid sample

InactiveUS6710879B1Ease of evaluationRaise countOptical radiation measurementBioreactor/fermenter combinationsAnalyteStatistical quality

The present invention relates to a method for the assessment of quantity and quality parameters of biological particles in a liquid analyte material. The method comprises applying a volume of a liquid sample to an exposing domain from which exposing domain electromagnetic signals from the sample in the domain can pass to the exterior, and exposing, onto an array of active detection elements such as CCD-elements, a spatial representation of electromagnetic signals having passed from the domain, the representation being detectable as an intensity by individual active detection elements, under conditions permitting processing of the intensities detected by the array of detection elements during the exposure in such a manner that representations of electromagnetic signals from the biological particles are identified as distinct from representations of electromagnetic signals from background signals. The size of the volume of the liquid sample is sufficiently large to permit the assessment of the quantity and quality parameters to fullfil a predetermined requirement to the statistical quality of the assessment based on substantially one exposure.

Owner:CHEMOMETEC AS

Method and a system for determination of particles in a liquid sample

InactiveUS20050225766A1Simplified quantityEase of evaluationBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteStatistical quality

Owner:CHEMOMETEC AS

Systems and methods for digitally re-mastering or otherwise modifying motion pictures or other image sequences data

ActiveUS7856055B2Improve spatial resolutionExpands image frequency spectrumTelevision system detailsPicture reproducers using cathode ray tubesImage resolutionStatistical quality

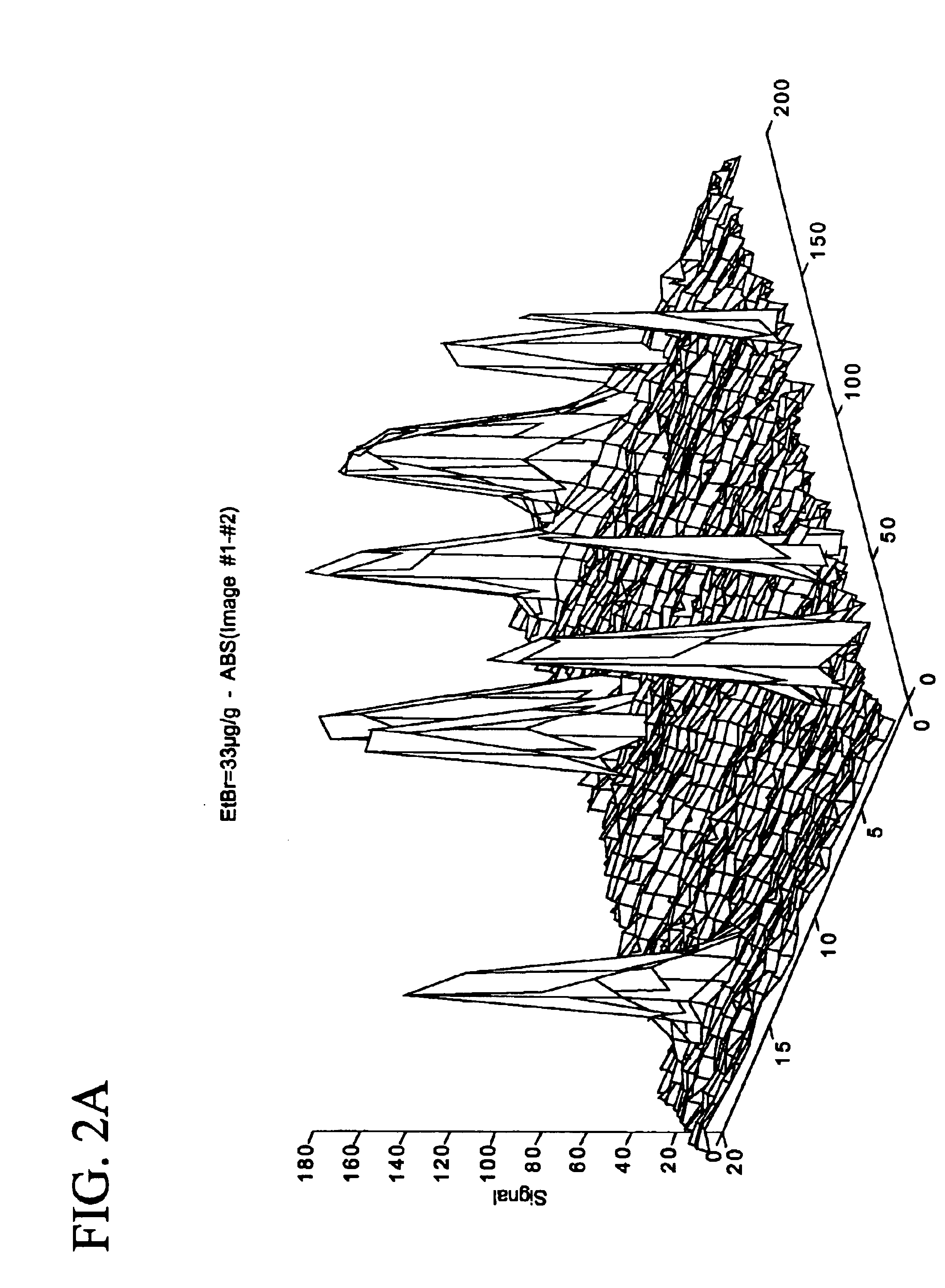

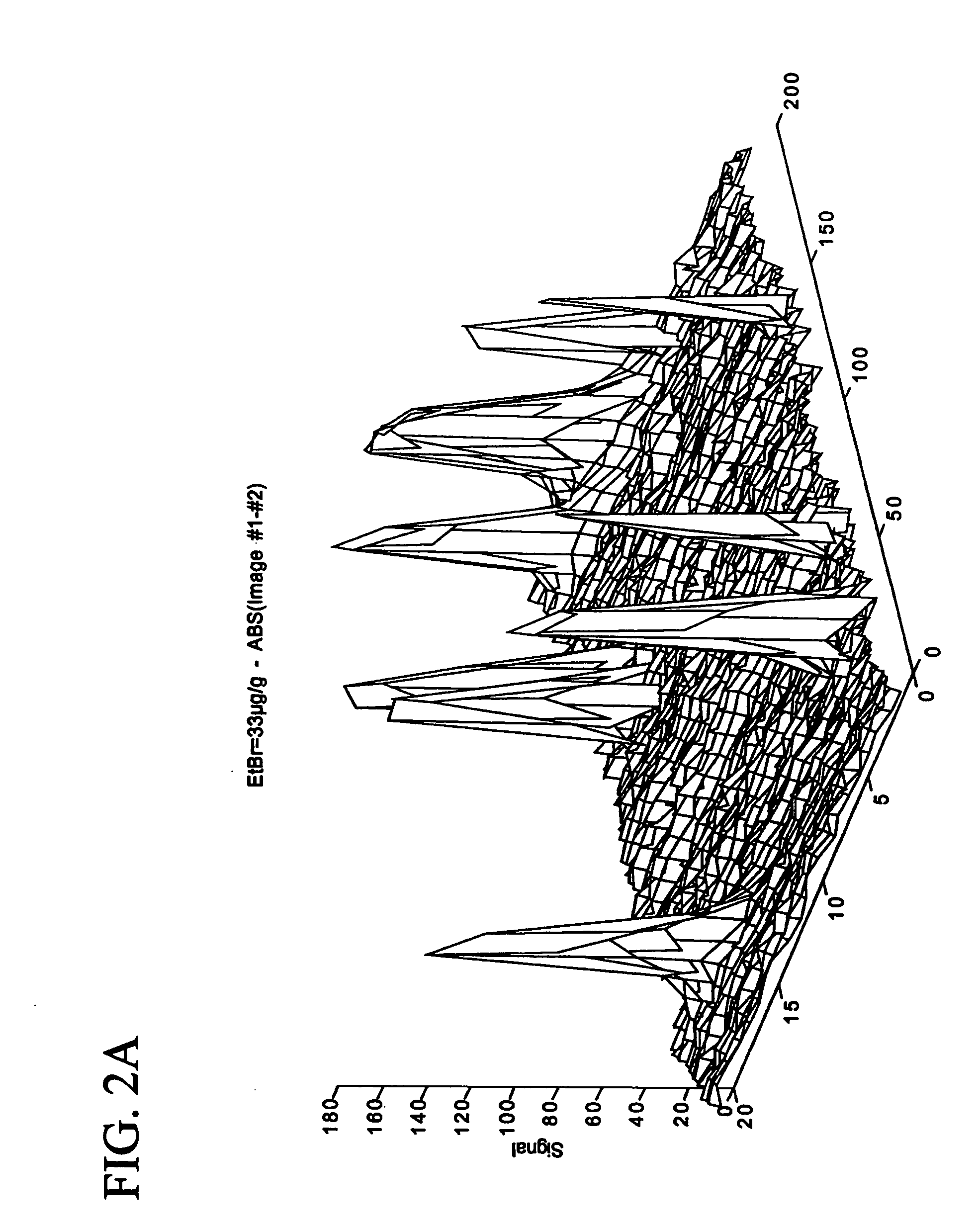

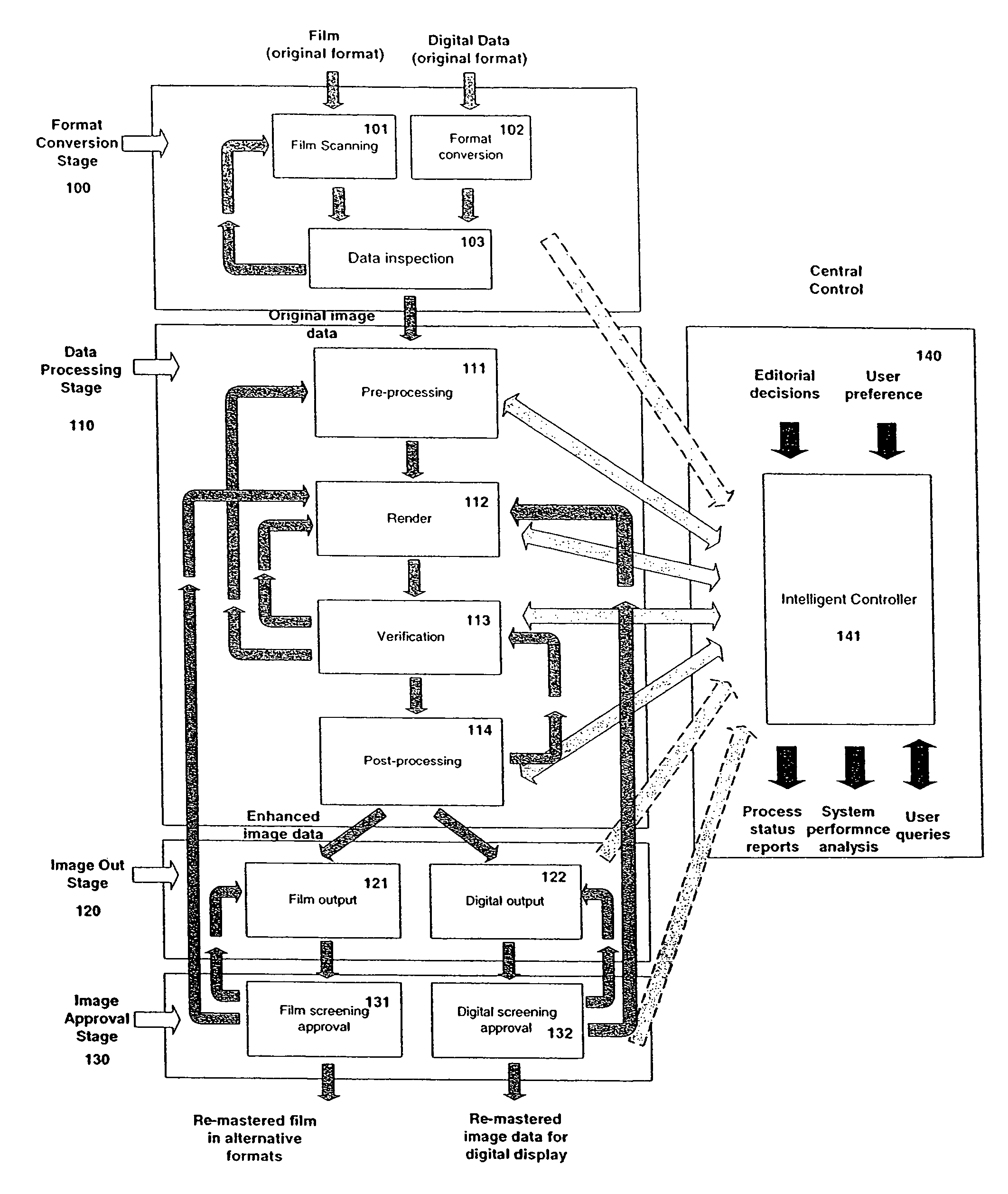

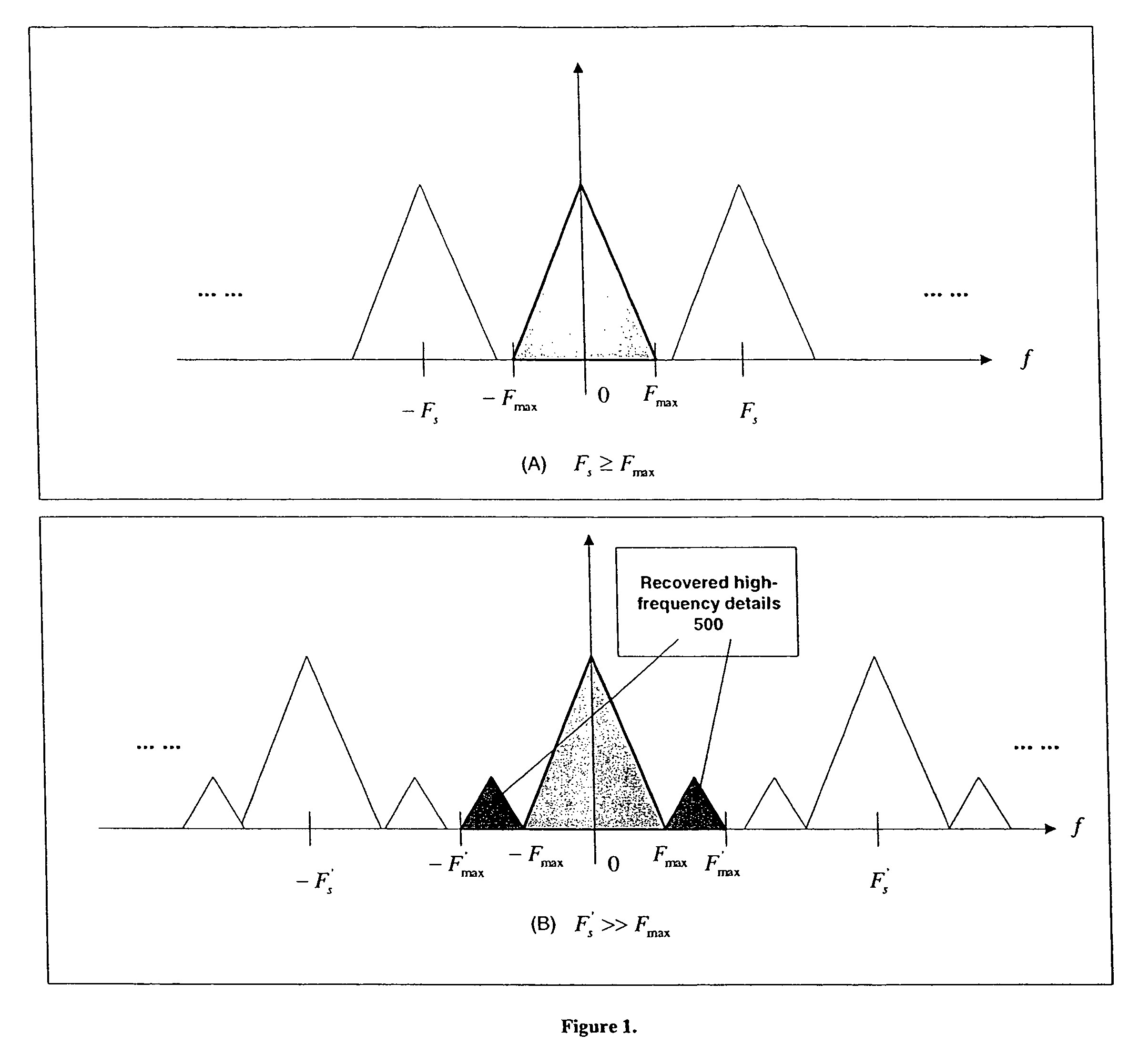

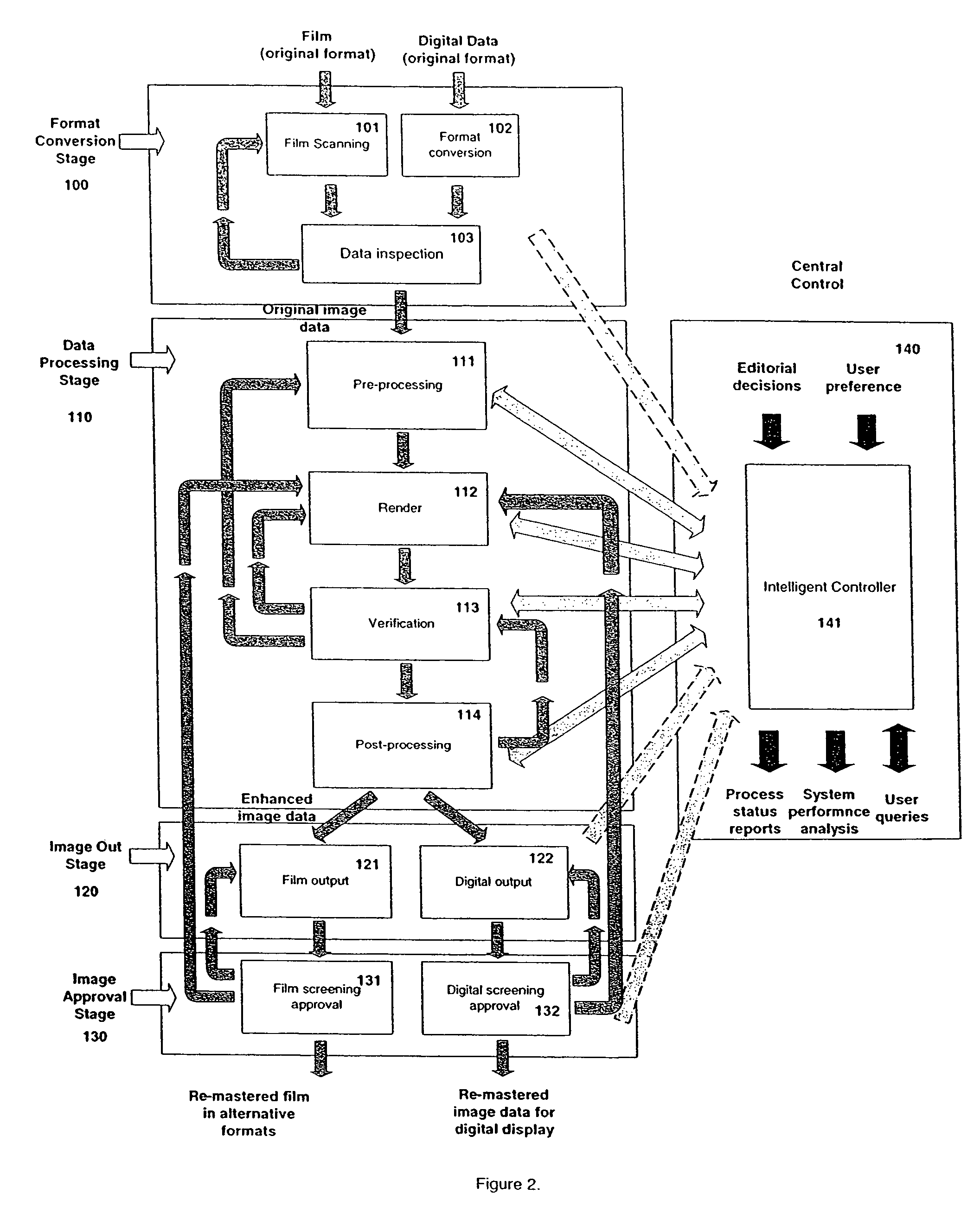

A process and methods of digital enhancement of motion pictures and other moving image sequences for the purpose of being exhibited in an alternative display format including a large format cinema are disclosed. The invention efficiently enhances image resolution and quality through a temporal filtering process and achieves high performance using automated or interactive statistical quality evaluation methods. A system specially designed for efficient temporal computing with a parallel and distributed computing configuration equipped with a variety of optimization schemes is also disclosed. The performance of the process and the system is optimized through an intelligent controller and is scalable to support any throughput requirements demanded for concurrent motion picture releases in the original format as well as in any alternative format.

Owner:IMAX CORP

Pattern recognizing method and apparatus

InactiveUS20060110029A1Improve detection accuracyFast and robust detectionCharacter and pattern recognitionFeature vectorPattern detection

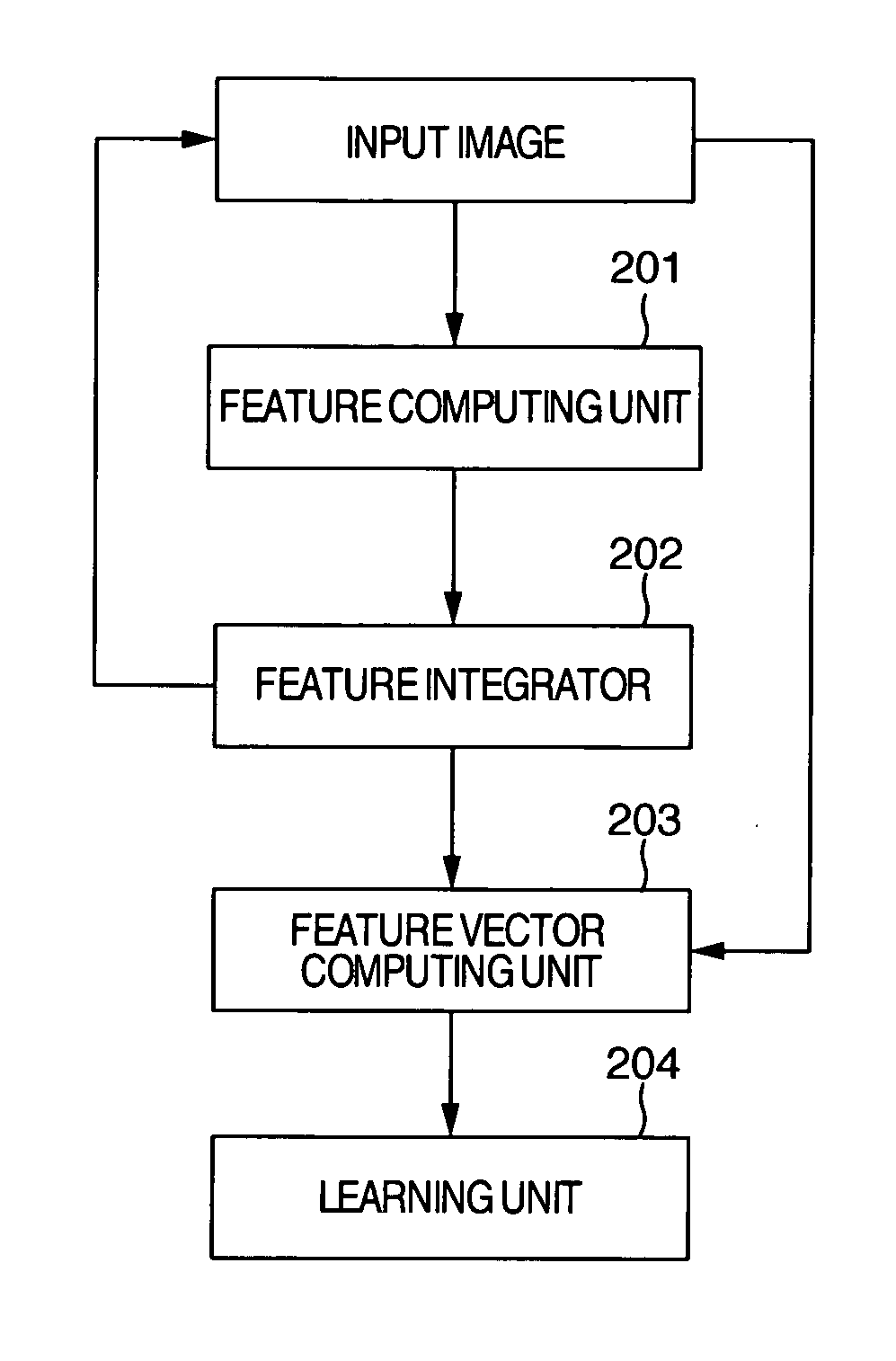

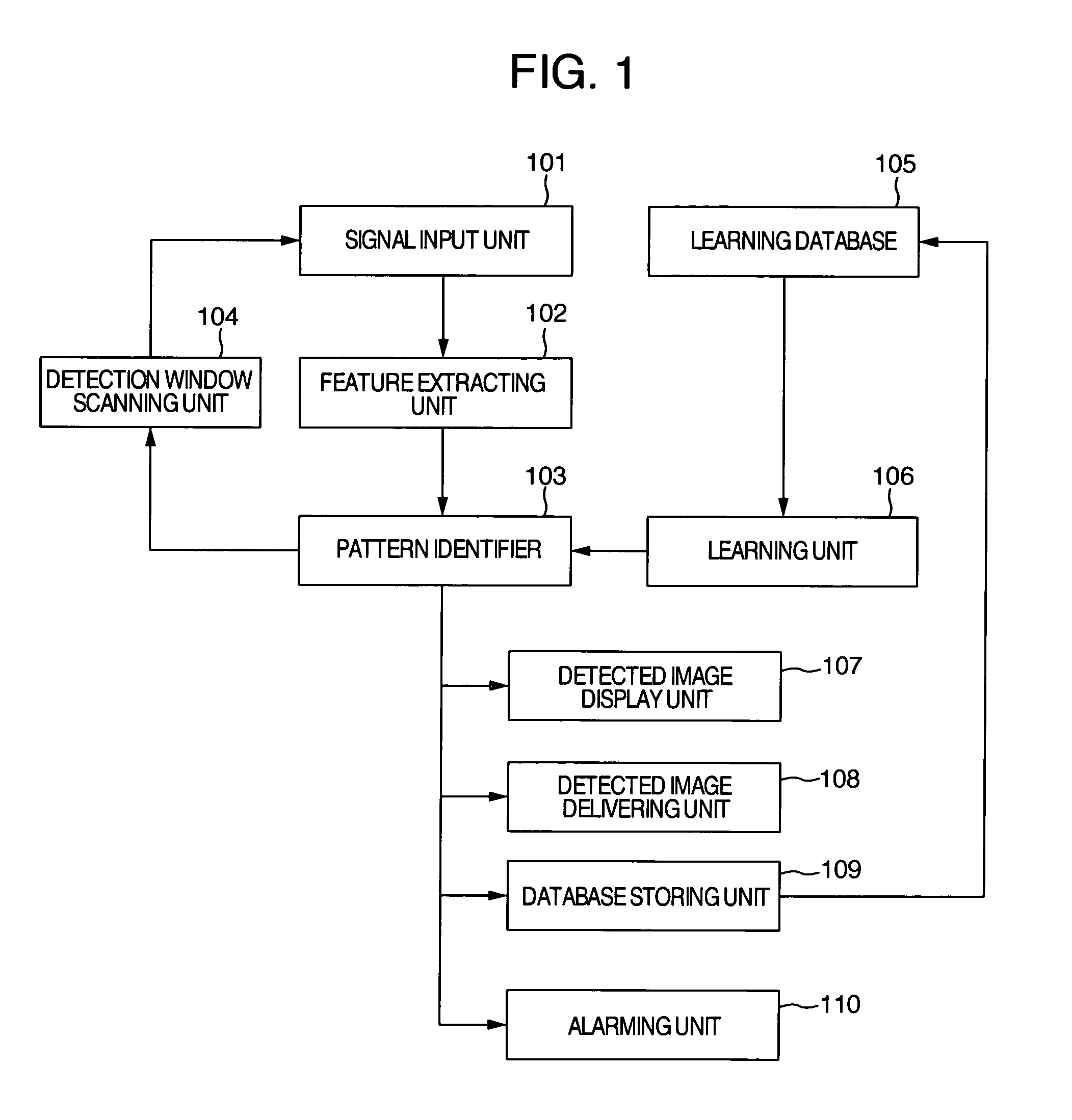

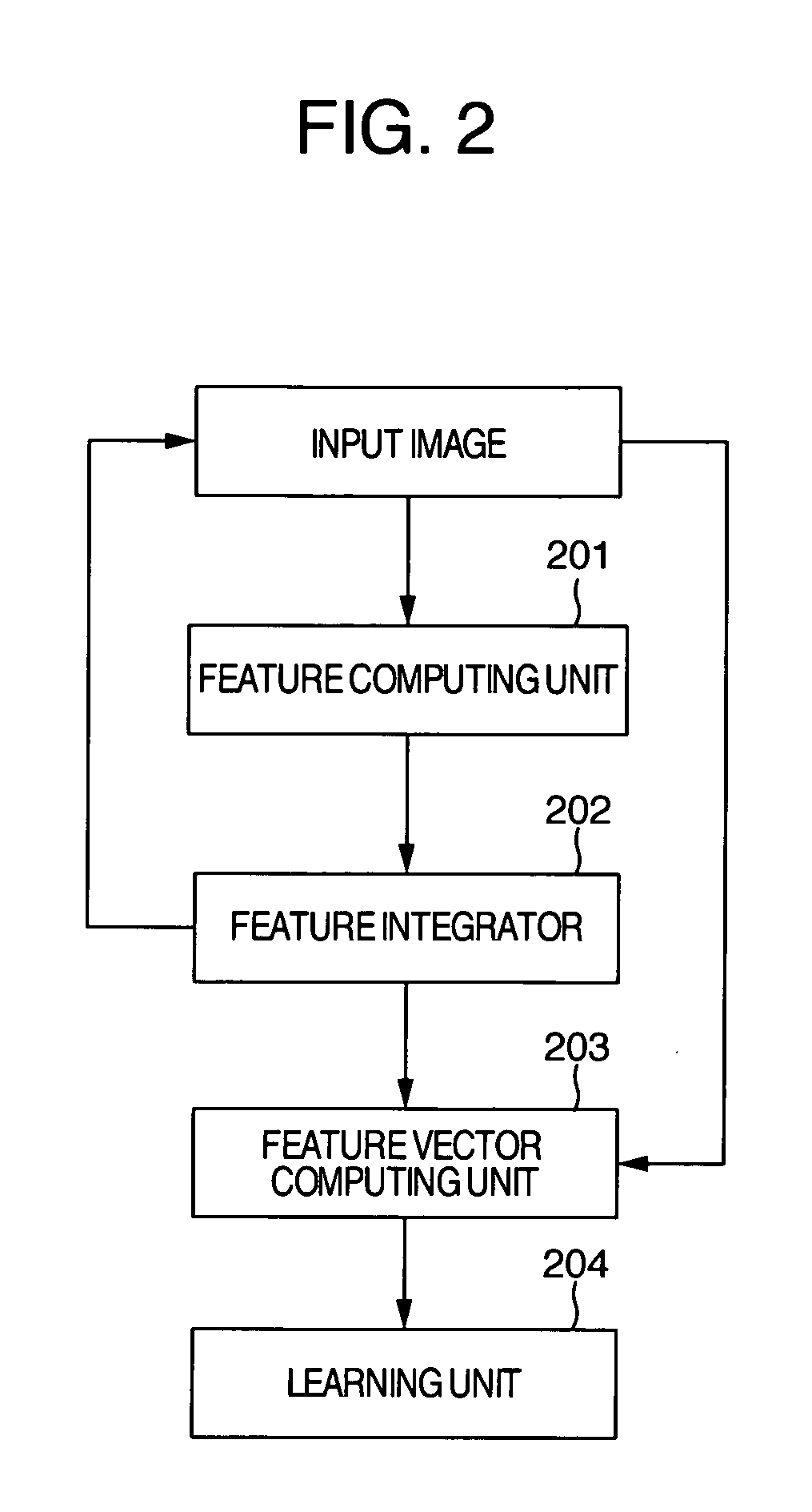

A pattern recognizing method and apparatus are arranged to detect one or more objects with its own individuality belonging to the same category, such as a vehicle or a human's face, by using incremental signs in a manner to correspond with an apparent change caused by the posture variation of the object. For achieving the pattern detection corresponding with the apparent change caused by the posture variation of the object, the statistic quality of the incremental signs is extracted from a database having image data of the objects. The learning of a feature vector composed by using the quality makes it possible to design the most approximate identifier for detecting a pattern.

Owner:HITACHI LTD

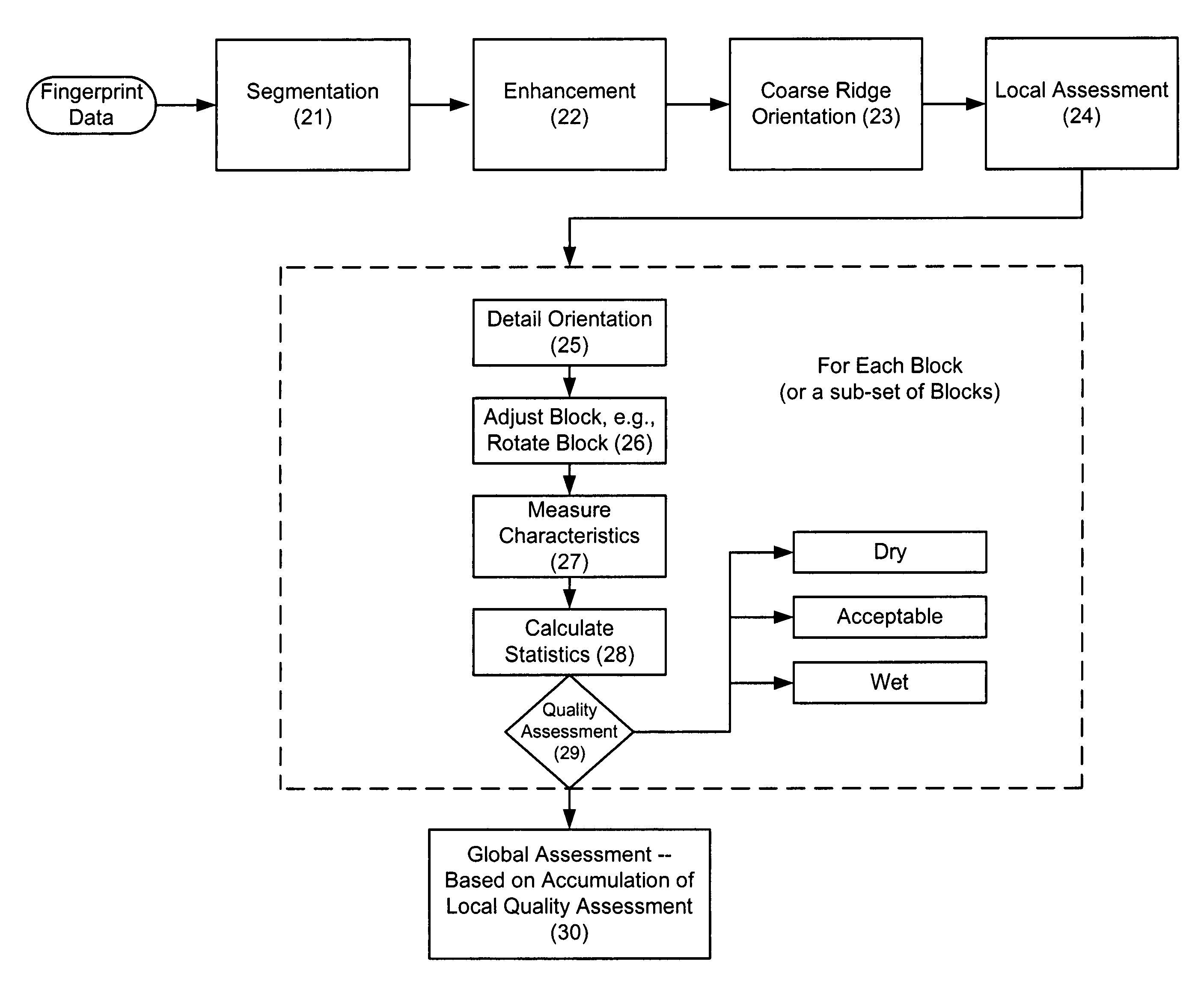

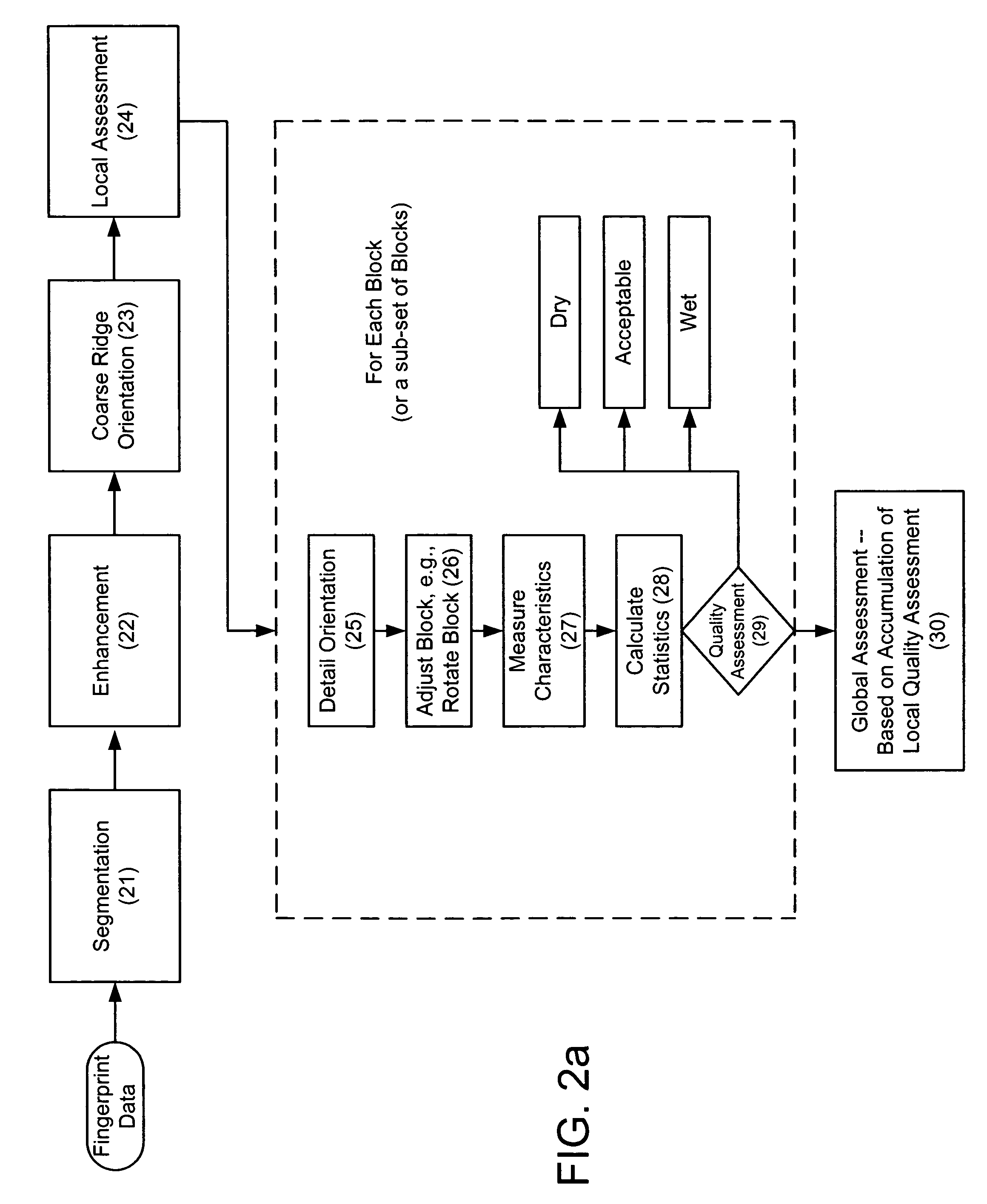

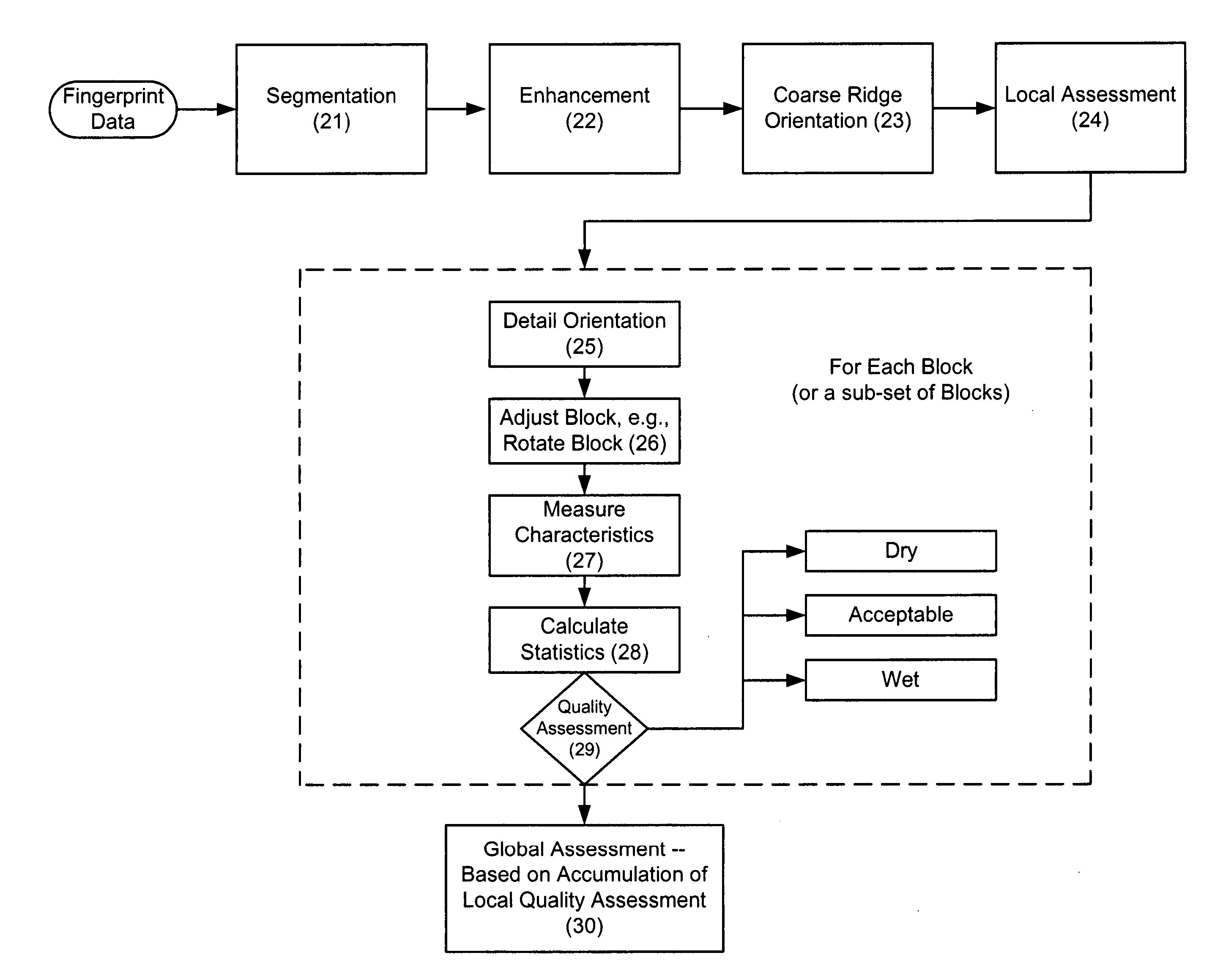

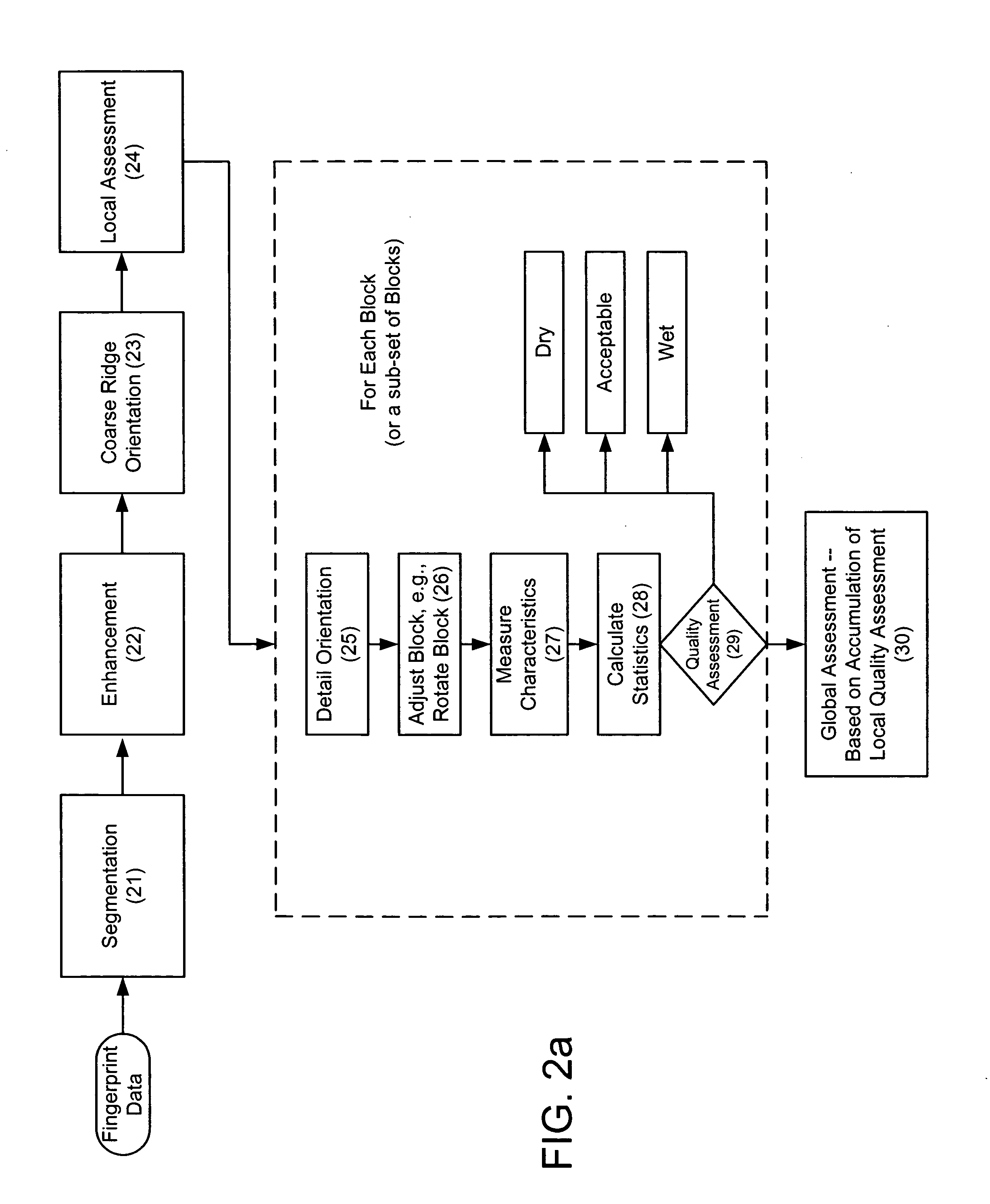

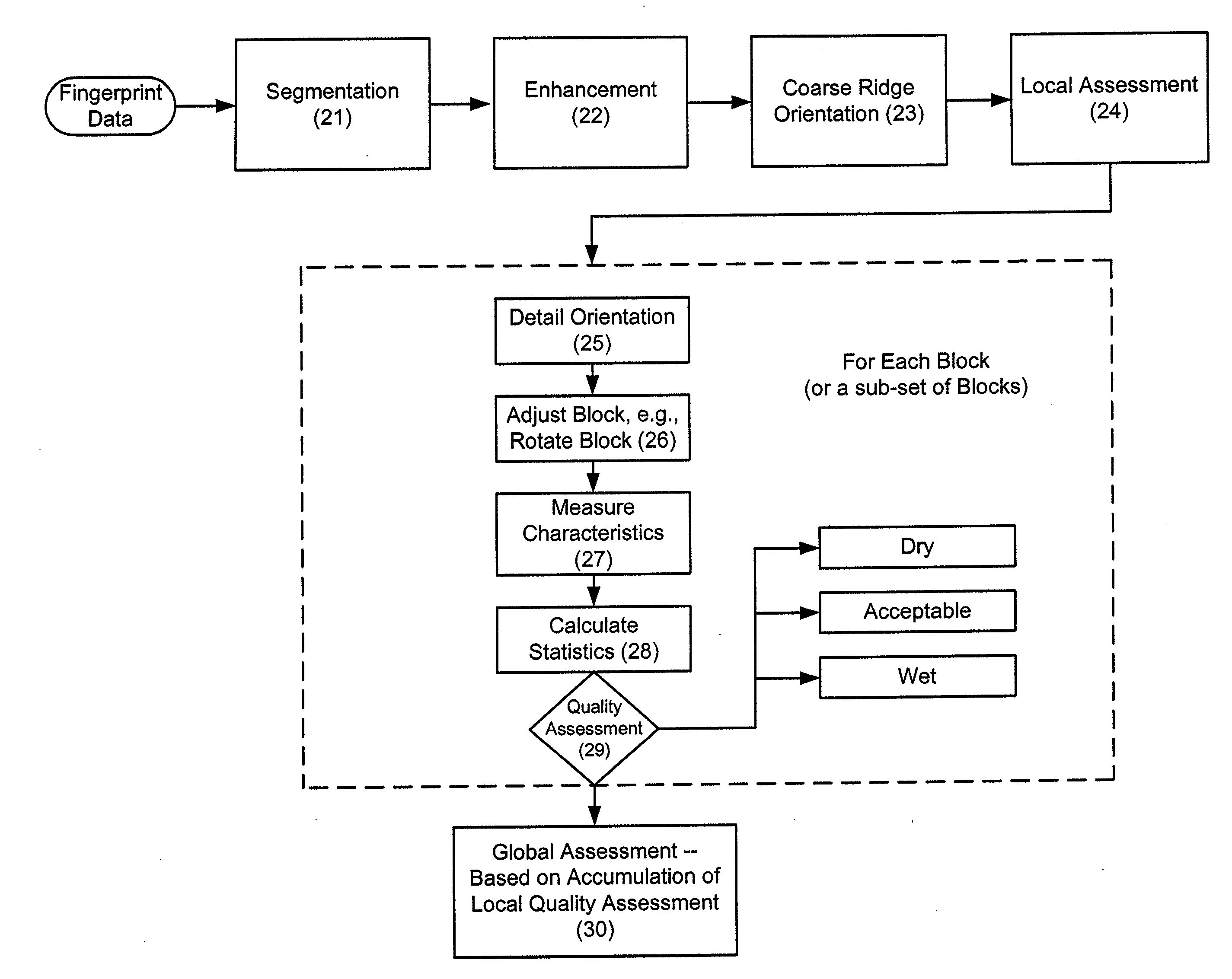

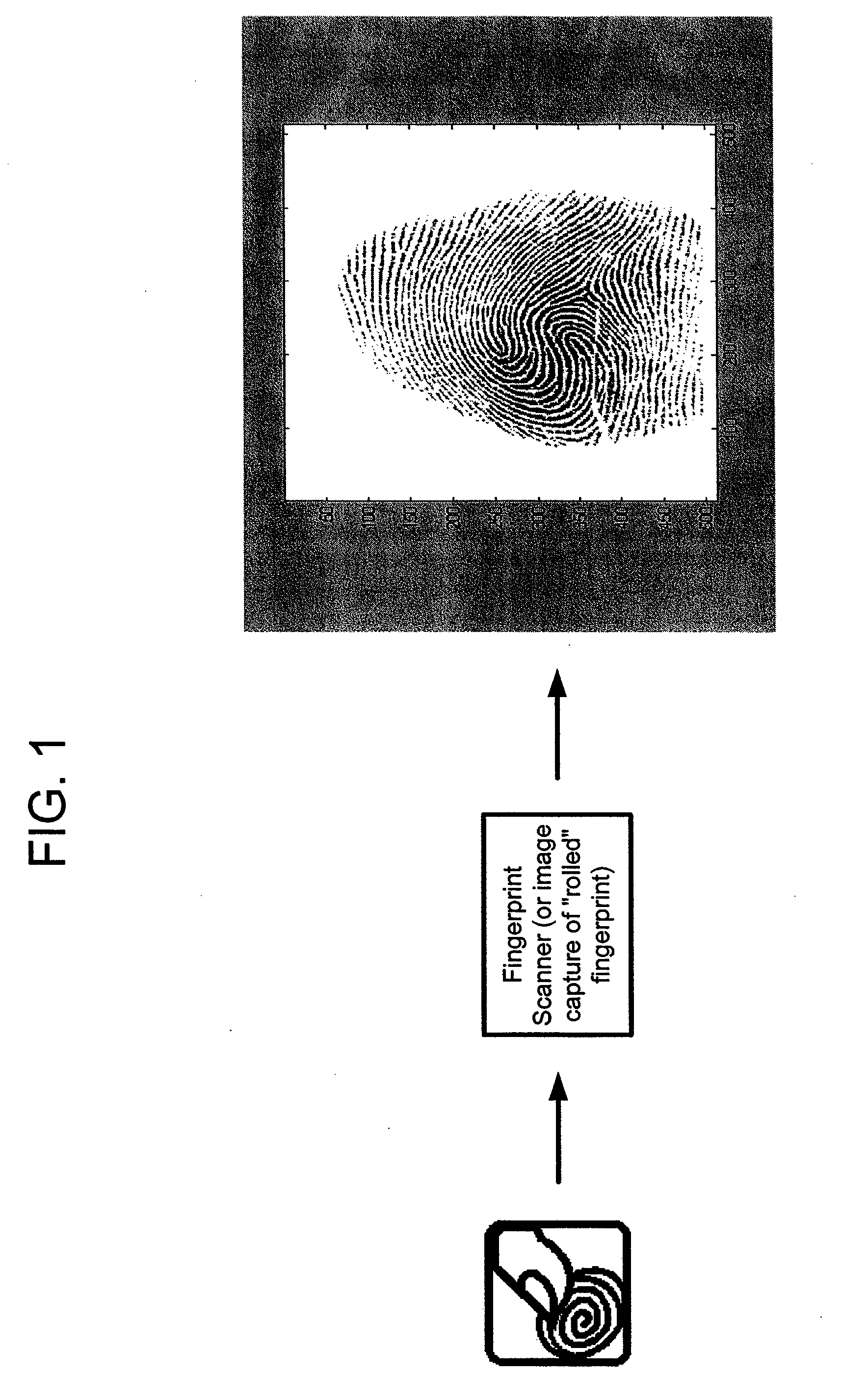

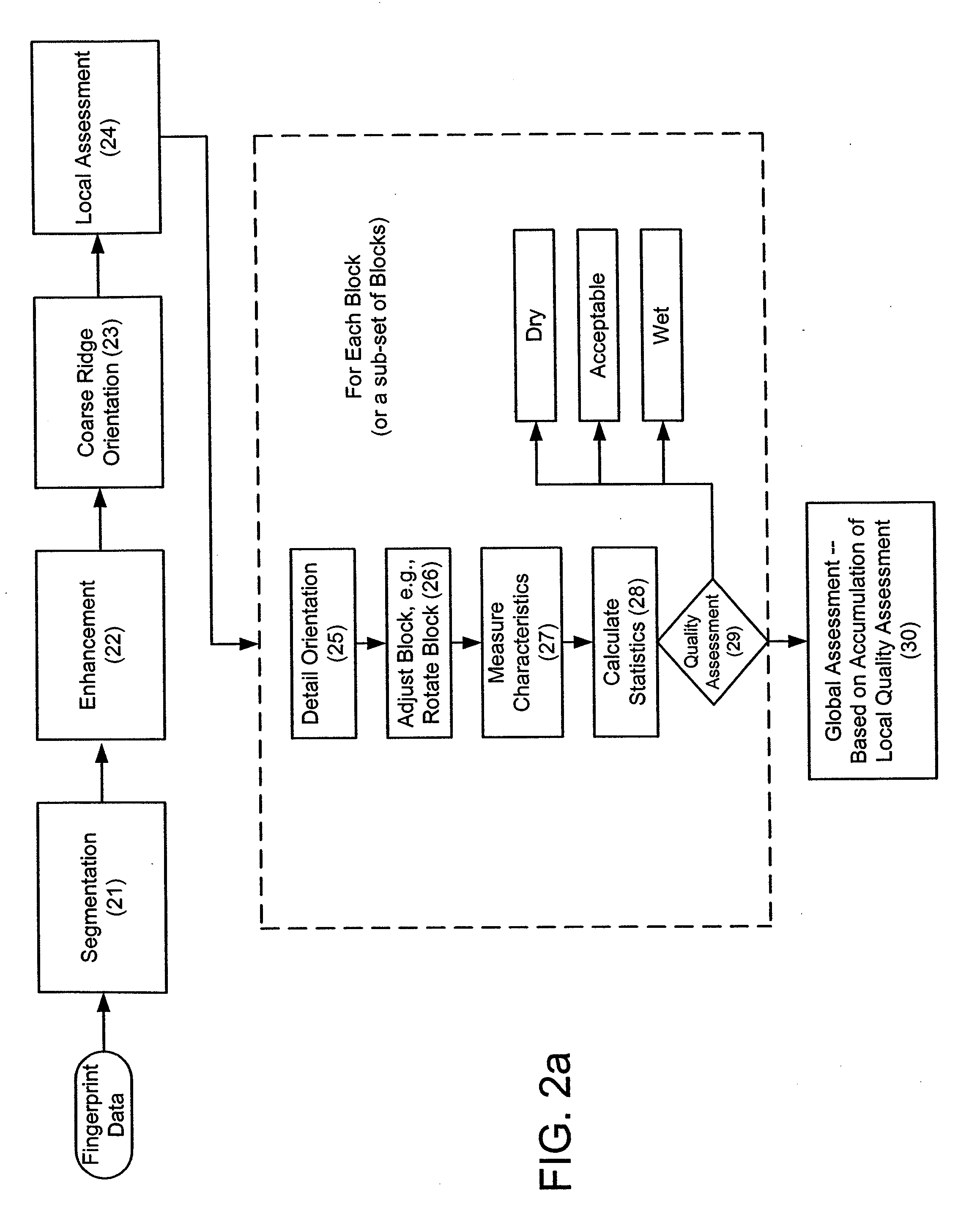

Statistical quality assessment of fingerprints

The present invention relates generally to human fingerprints. More specifically the present invention relates to assessing the quality of a fingerprint image. An assessment is made by analyzing characteristics of image sub-regions. For example, the characteristics may include statistics that are associated with a sub-region. If a sub-region is found to have unacceptable characteristics, it can be modified through a morphological operation to compensate for the unacceptable characteristics.

Owner:L 1 SECURE CREDENTIALING

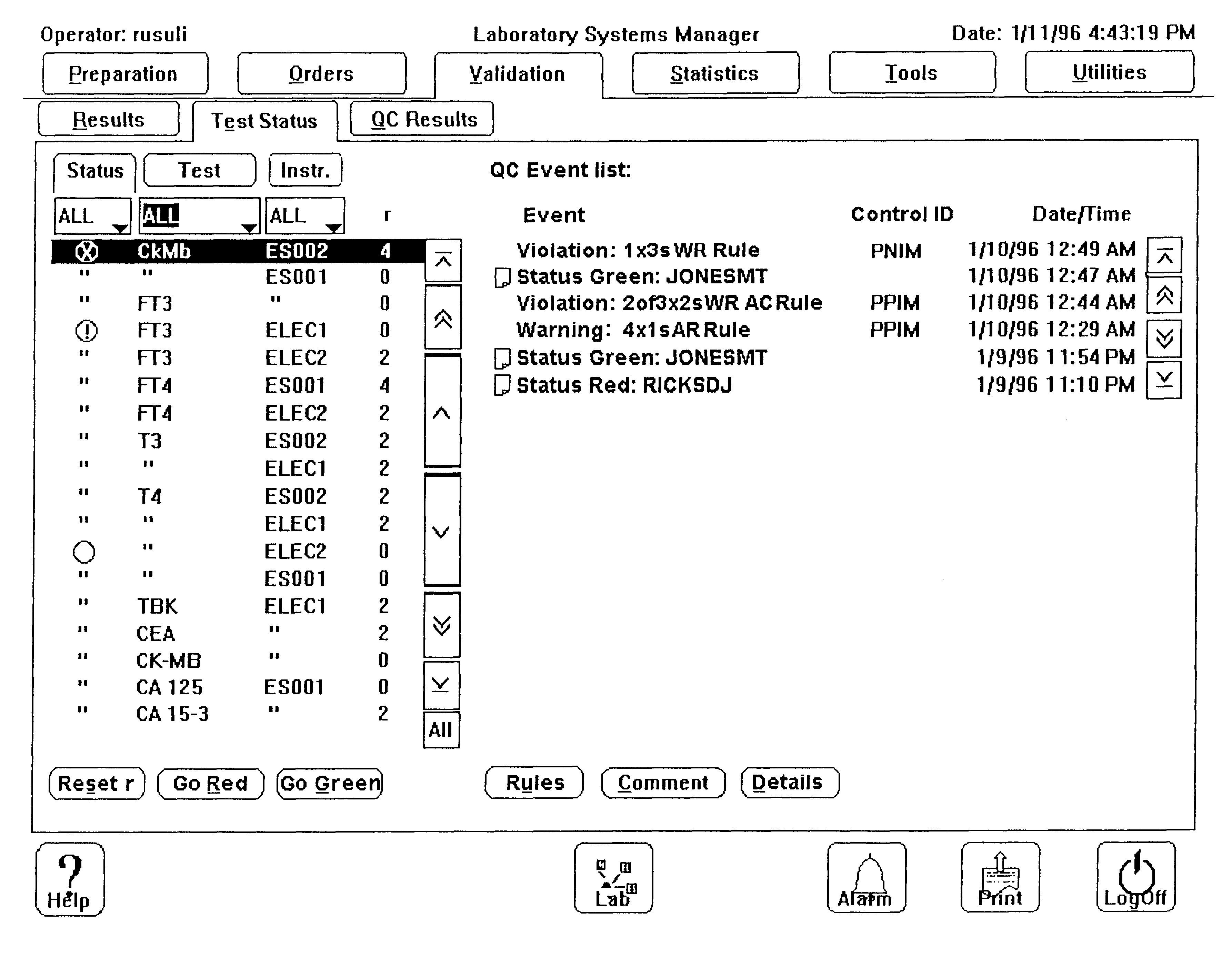

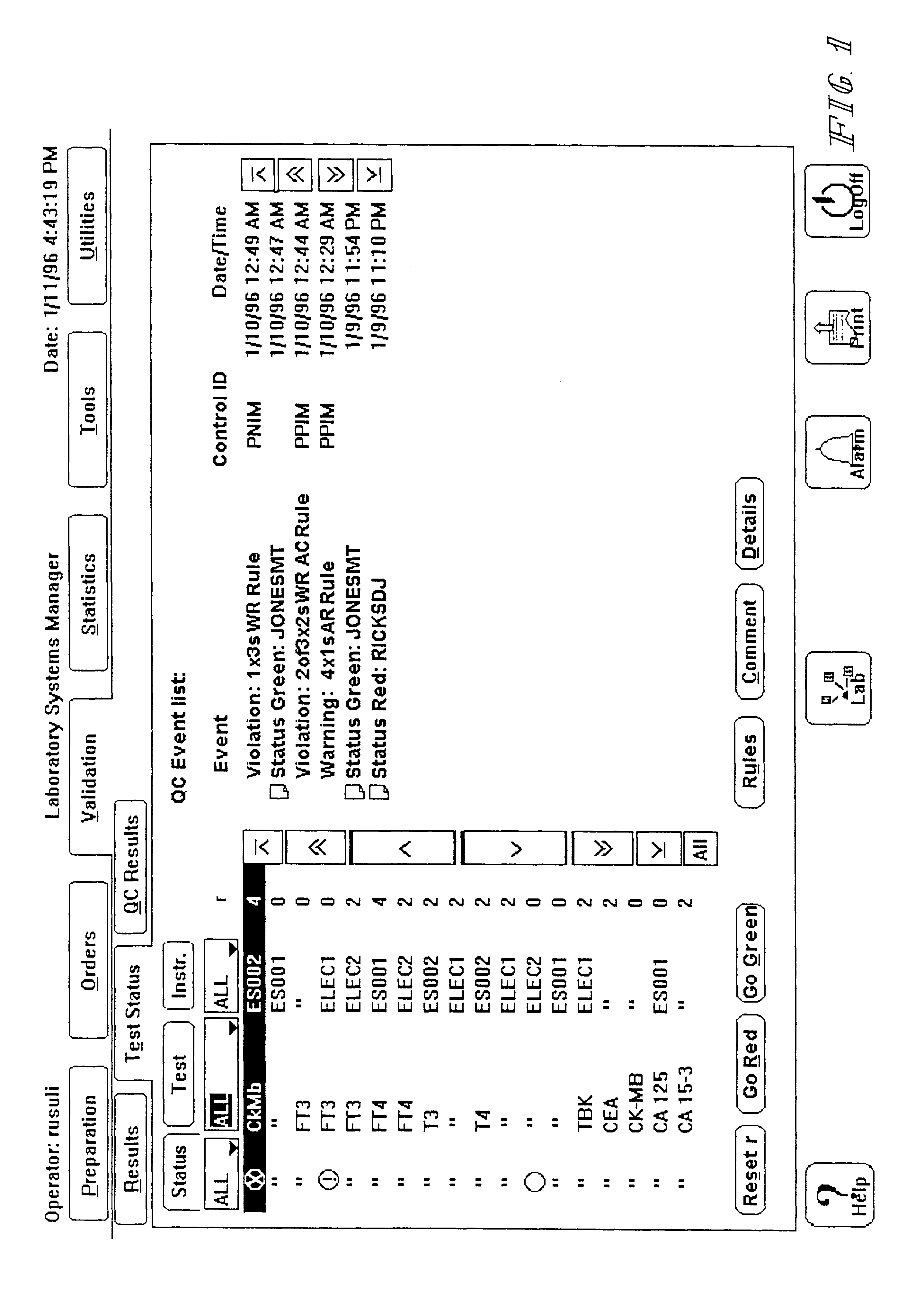

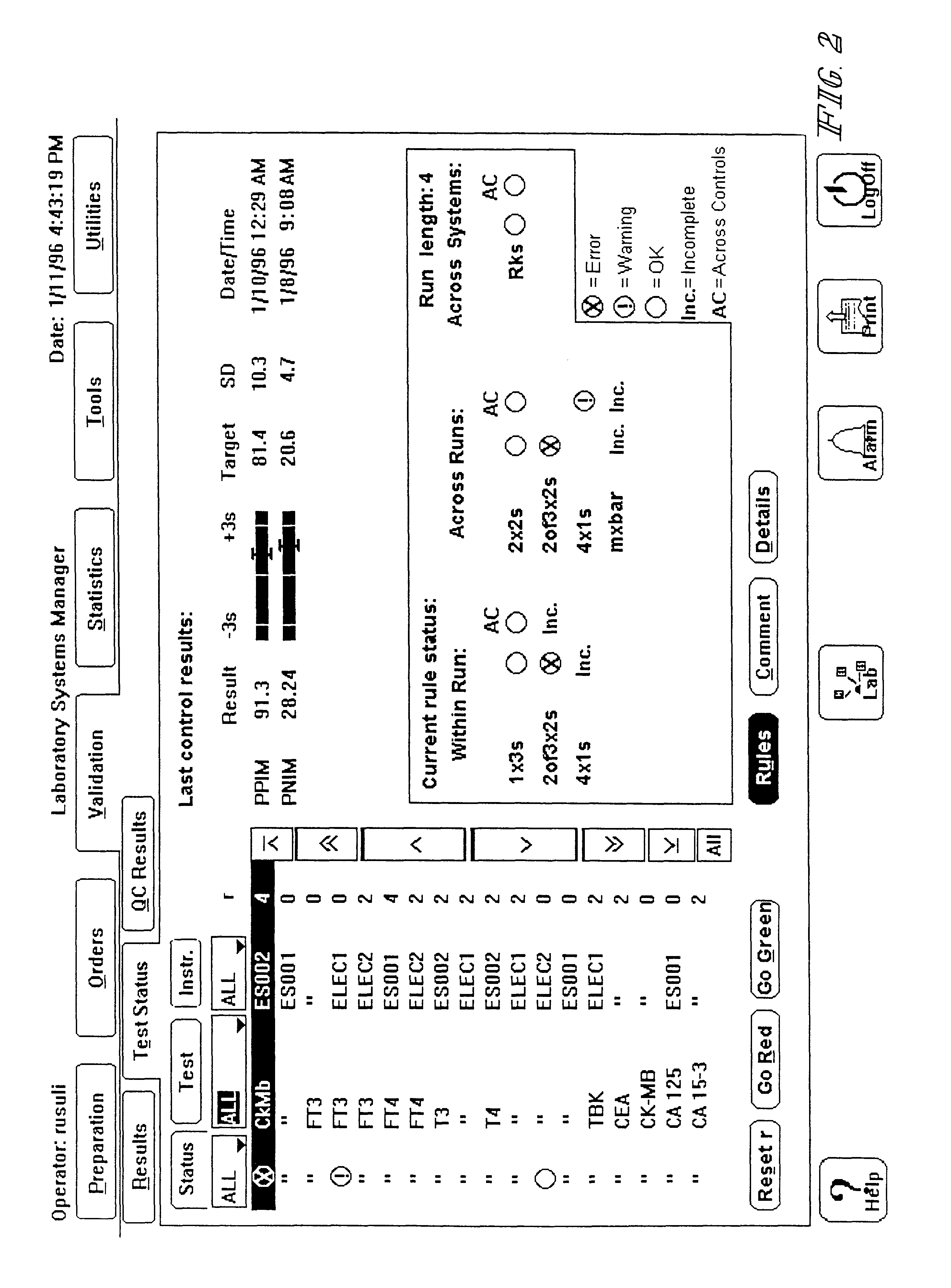

Multi-rule quality control method and apparatus

InactiveUS6269276B1Local control/monitoringComputer-assisted medical data acquisitionStatistical qualityQuality control

A method and apparatus for analyzing the results of determinations of the concentrations of medically significant components of control solutions comprise providing a programmable machine, executing on the machine a program which tests the results against a set of statistical quality control rules, and producing indications to an operator of the results of the tests. Illustratively, (a) laboratory analytical instrument(s) run(s) the control solutions interspersed among patient samples, the concentrations of medically significant components of which are determined by the laboratory instrument(s). The quality of the laboratory instrument's(s') process(es) for determining the concentrations of the medically significant components of the patient samples are monitored by testing the outcomes of the concentration determinations of the control solutions against the set of QC rules. The QC testing process is conducted as the concentrations of the medically significant components of the control solutions are determined, so that delays between the determination of the concentrations of the medically significant components of the patient samples and the determination of the state of control of the process(es) by which those concentrations are determined are minimized.

Owner:ROCHE DIAGNOSTICS GMBH

Acquisition and assessment of classically non-inferable information

InactiveUS20160062735A1Quality improvementIncrease the effective random number generation rateMathematical modelsDigital data information retrievalAlgorithmStatistical quality

Mind-enabled question answering (MEQA) systems (300, 340) and methods (400, 500) produce answers (313) that are not inferable from information available from private databases, online searching or other traditional sources. MEQA systems utilize information provided by using devices (200) and methods that are responsive to an influence of mind. Preferred embodiments of MEQA technology use a Bayesian Network to calculate the probability of an answer's correctness. MEQA systems and methods utilize high speed non-deterministic random number generators (NDRNGs). Preferred NDRNGs (202) achieve high statistical quality without randomness correction, which allows improved response of a mind-enabled device (200, 302).

Owner:PSIGENICS CORP

Method and a system for determination of somatic cells in milk

InactiveUS6731100B1Ease of evaluationResistance/reactance/impedenceScattering properties measurementsAnalyteStatistical quality

Assessment of the number of somatic cells in a liquid milk or milk product analyte material comprises arranging a volume of a liquid sample representing the analyte material in a sample compartment and allowing electromagnetic signals from the sample in the compartment to pass through and be exposed to the exterior. There is exposed onto an array of active detection elements, an at least one-dimensional spatial representation of electromagnetic signals from the sample. The representation is detectable as an intensity by individual active detection elements. Representations of electromagnetic signs from the somatic cells are identified. The size of the volume of the liquid sample is sufficiently large to permit the assessment of the number of somatic cells to fulfill a predetermined requirement to the statistically quality of the assessment based on substantially one exposure.

Owner:CHEMOMETEC AS

Statistical quality assessment of fingerprints

The present invention relates generally to human fingerprints. More specifically the present invention relates to assessing the quality of a fingerprint image. An assessment is made by analyzing characteristics of image sub-regions. For example, the characteristics may include statistics that are associated with a sub-region. If a sub-region is found to have unacceptable characteristics, it can be modified through a morphological operation to compensate for the unacceptable characteristics.

Owner:L 1 SECURE CREDENTIALING

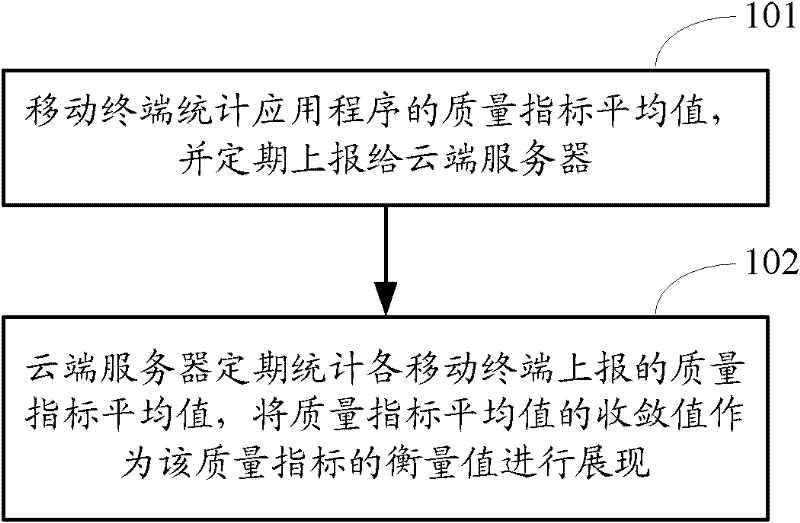

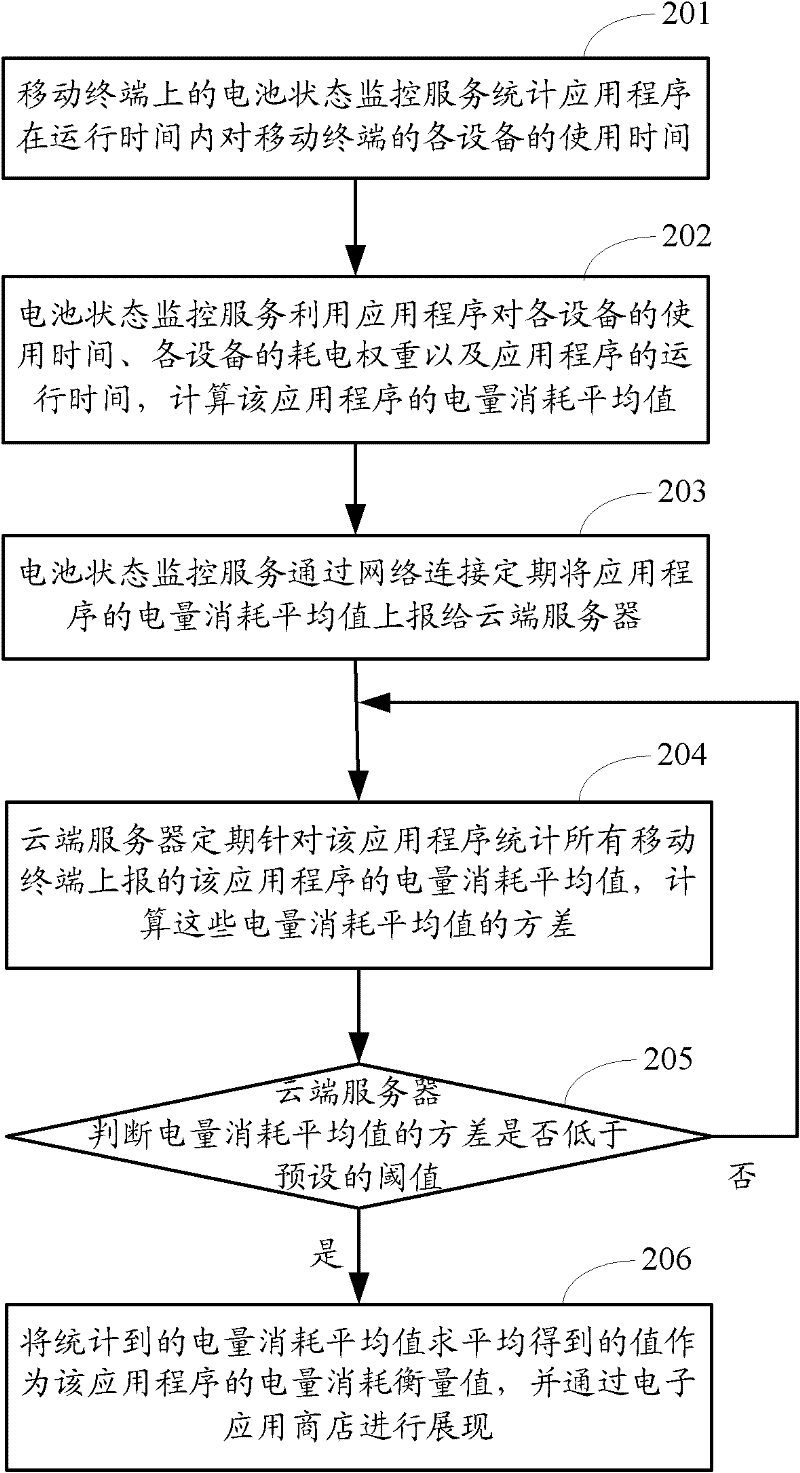

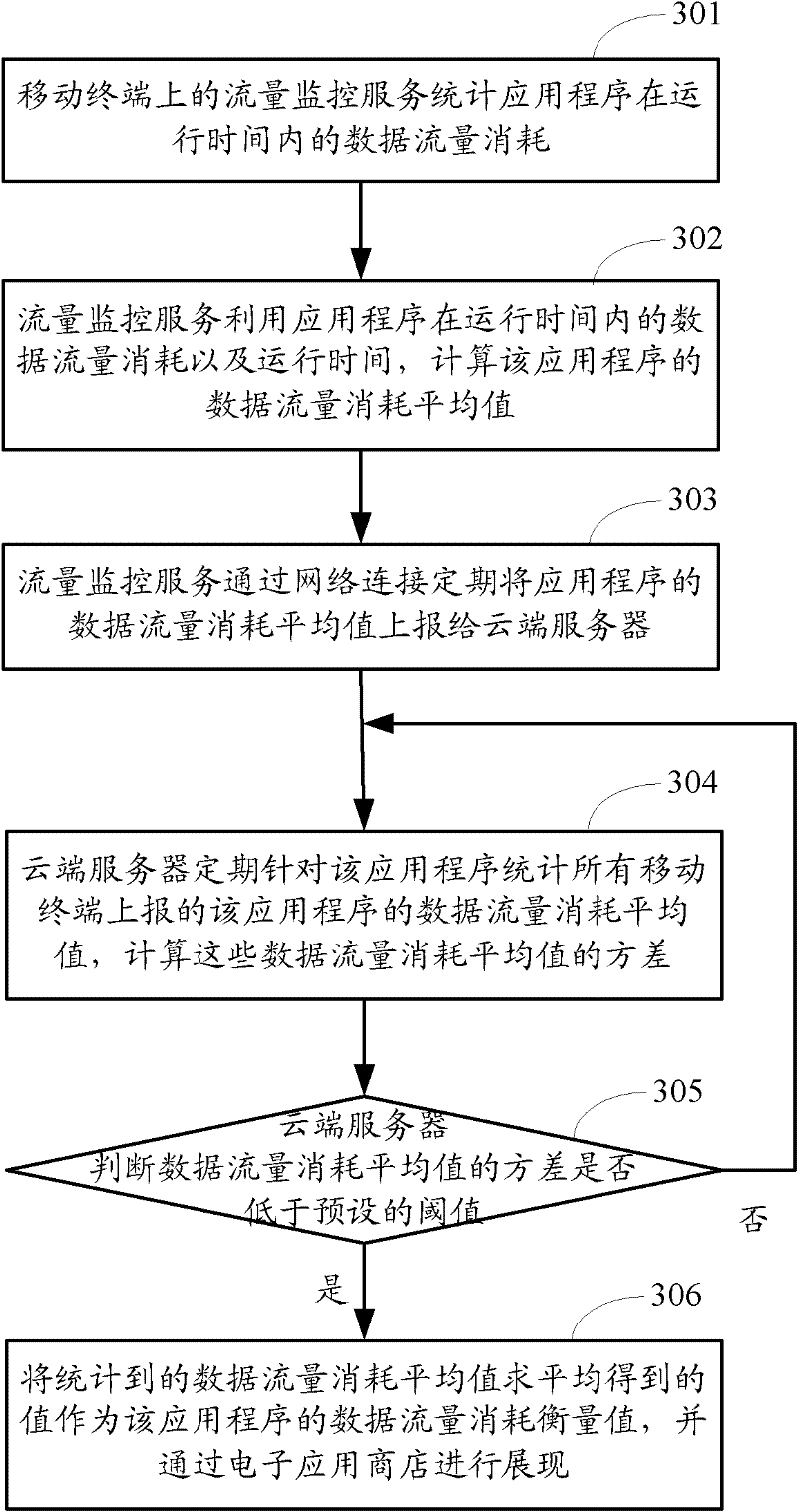

A method and system for determining the quality of an application program

InactiveCN102298542AQuality reflectionAvoid performanceError detection/correctionStatistical qualityResource consumption

The present invention provides a method and system for determining the quality of an application program, wherein the method includes: the mobile terminal counts the average value of the quality index of the application program, and regularly reports it to a cloud server; The average value of the quality index of the application program, the convergence value of the average value of the quality index is displayed as the measured value of the quality index of the application program. The measurement value of the quality index of the application program obtained by the present invention is based on the convergence value of the average value reported by a large number of mobile terminals, which reflects the general quality state of the application program, can accurately reflect the quality of the application program, and provides users with a better It is used as a reference to avoid the poor impact on the performance or resource occupation of the mobile terminal caused by the application program downloaded by the user with poor quality.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

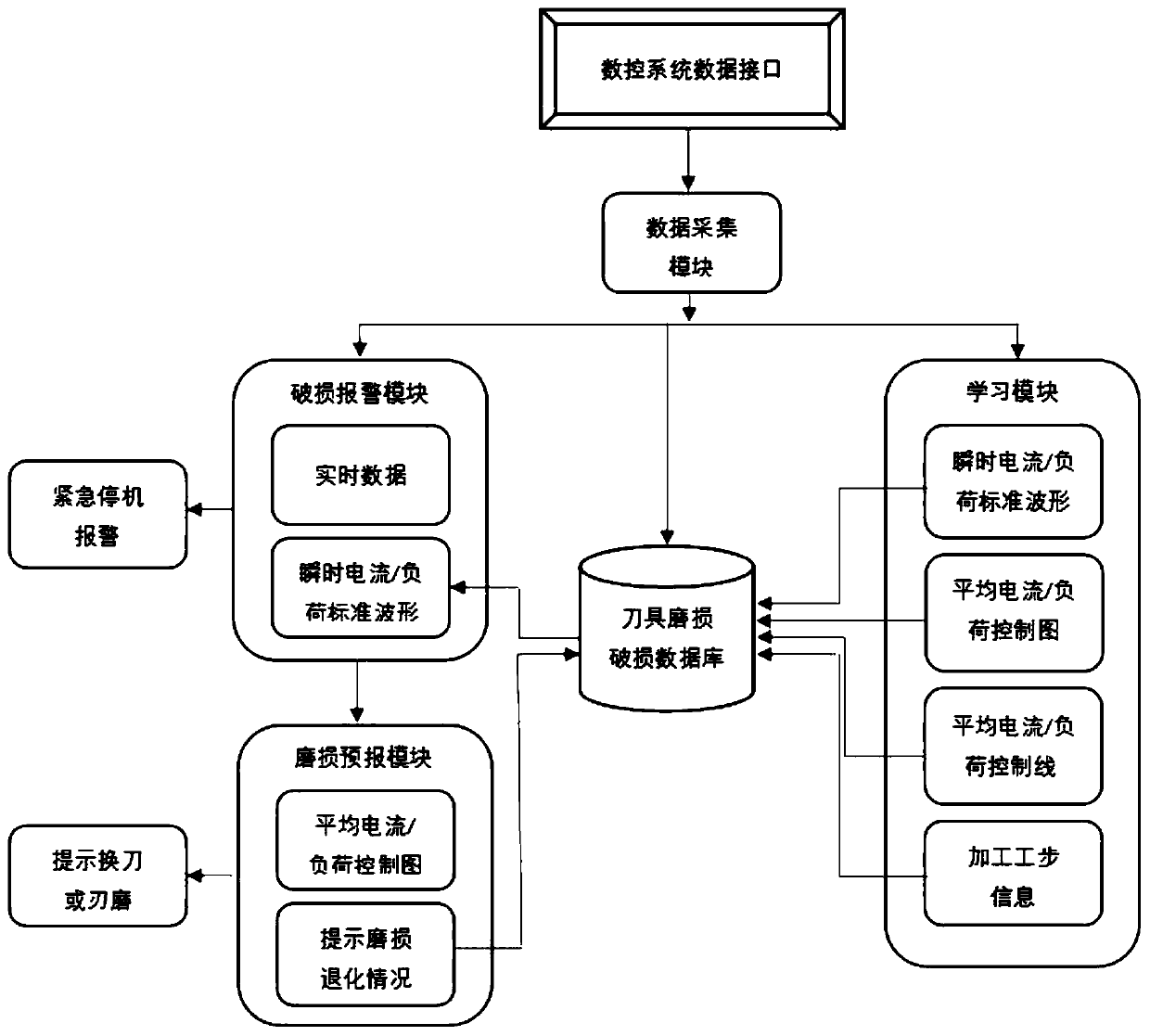

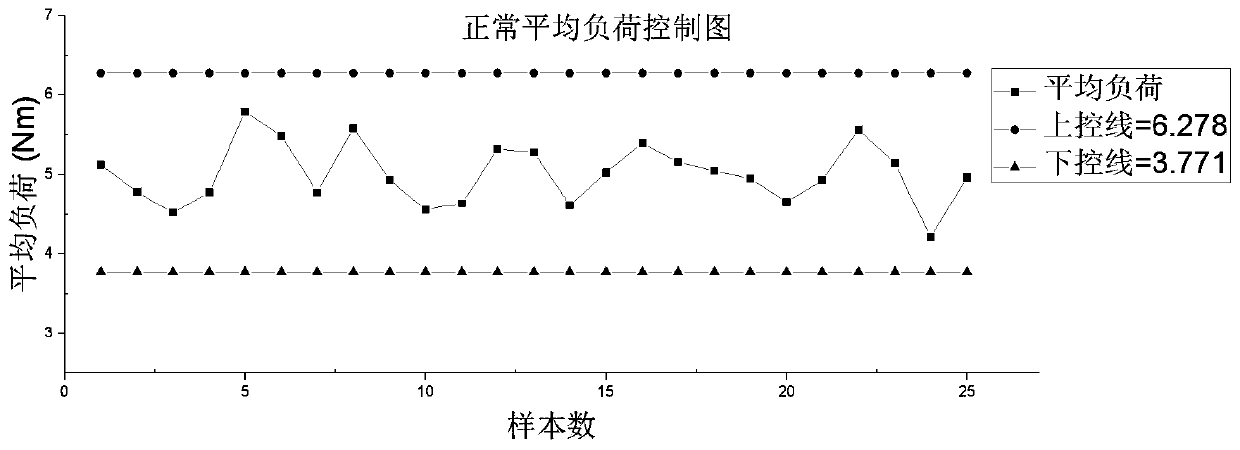

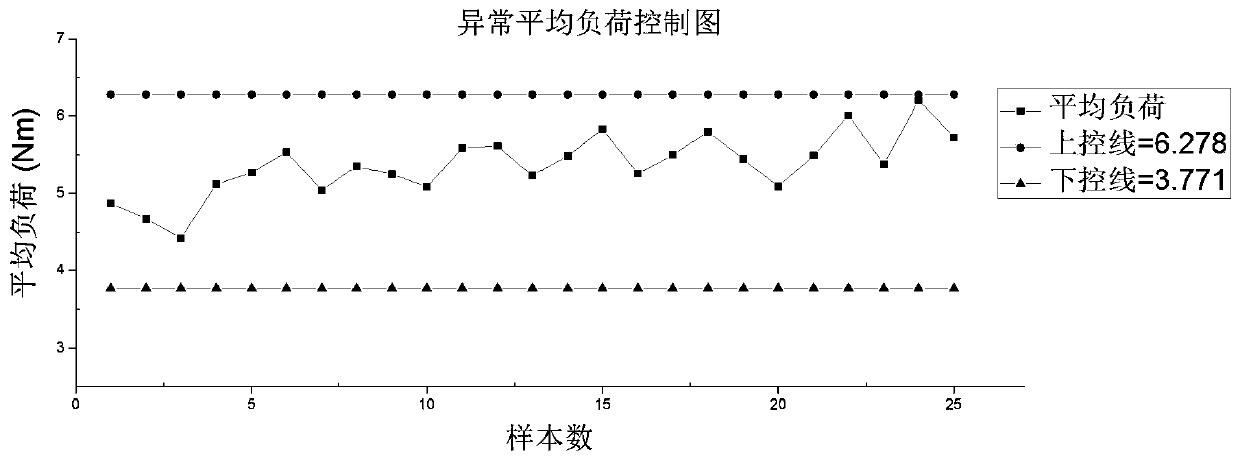

On-line monitoring method for cutter abrasion damage based on main shaft driving current and working step.

ActiveCN109909804ARealize breakage alarmExtended service lifeMeasurement/indication equipmentsAverage currentControl line

The invention discloses an on-line monitoring method for cutter abrasion damage based on main shaft driving current and working step. The method is made by the following steps that realizing communication with a numerical control system to obtain machining working step information, meanwhile, the driving current and the load of the main shaft are monitored, and on the basis of a normal cutter andabrasion damage cutter cutting torque difference analysis and statistical quality control principle. Control graph for drawing average current / load required by each working step processing, a control graph control line is reasonably formulated, the abrasion state of each working step is judged, and a tool changing or cutter edge grinding rule is formulated. According to the variation of instantaneous main shaft current or instantaneous load with the deviation from the instantaneous current / load in normal machining in each working step of machining, the cutter breakage is determined, the alarm signal is sent to inform the numerical control system to emergency shutdown so as to avoid the serious consequences of damaging the workpiece and the machine tool. According to the method, on onehand, the part rejection rate and the machine tool fault rate can be reduced, on the other hand, the service life of the cutter can be prolonged to the maximum extent, and the use cost of a plant cutter is reduced.

Owner:BEIJING UNIV OF TECH +1

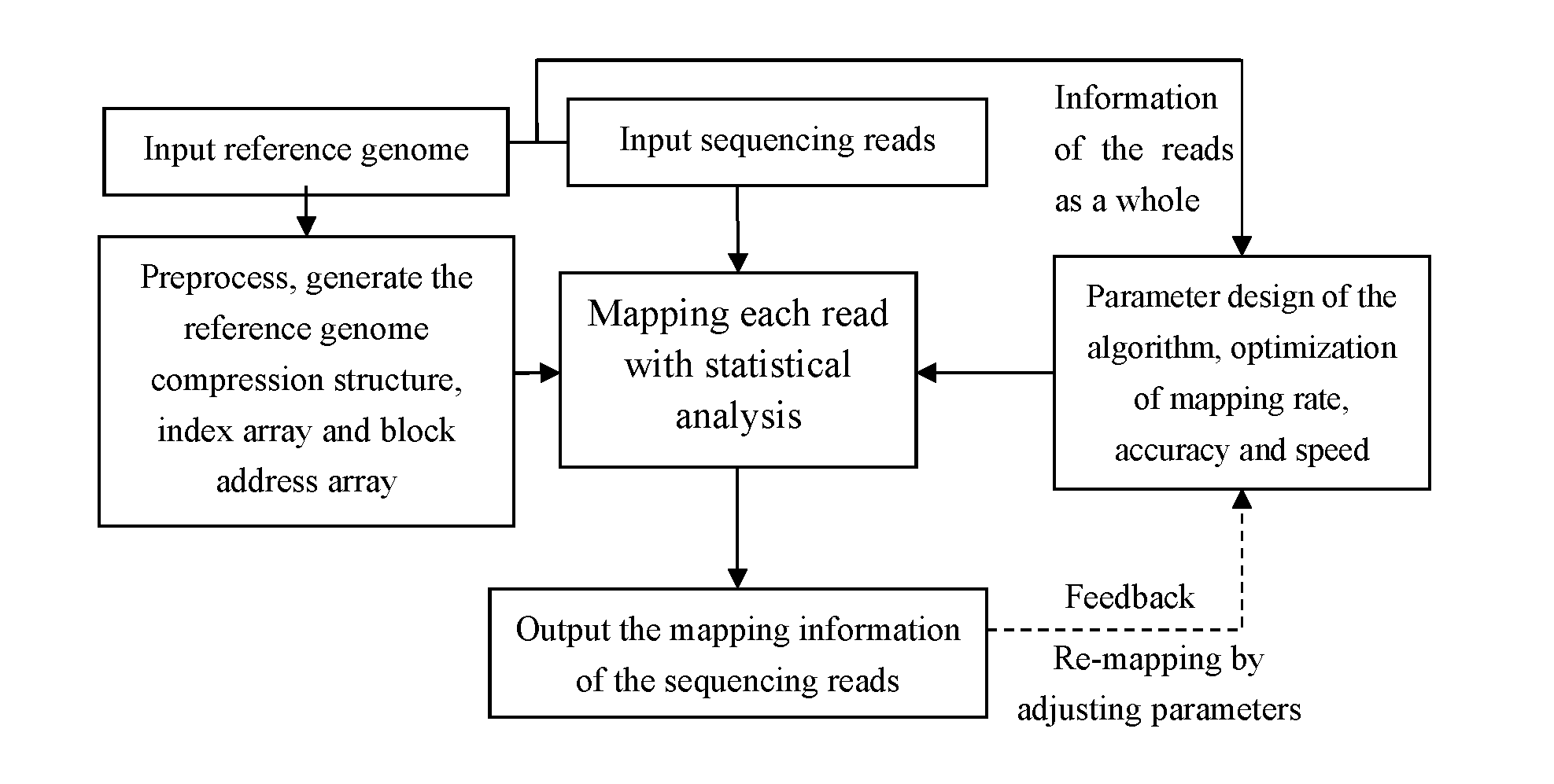

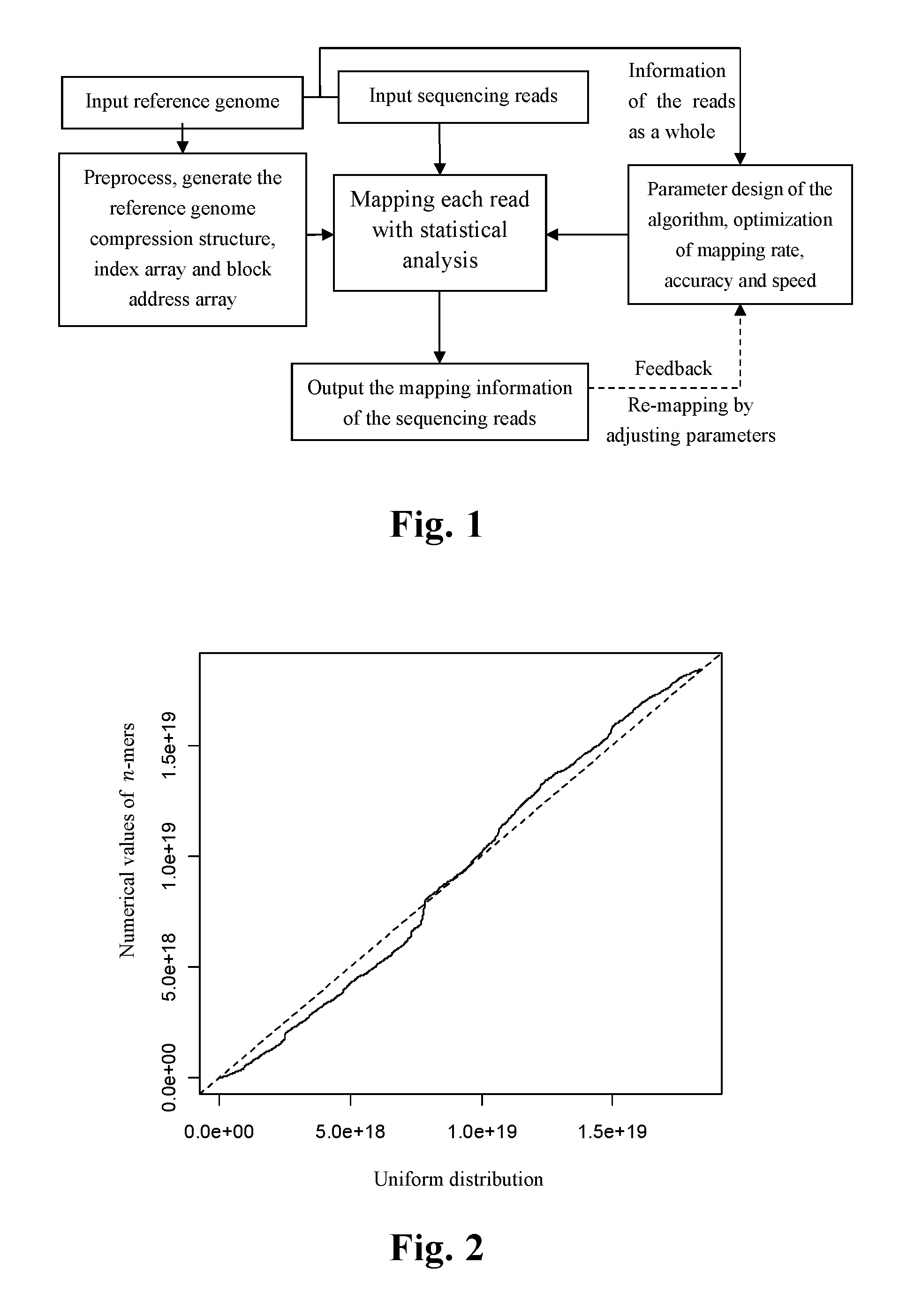

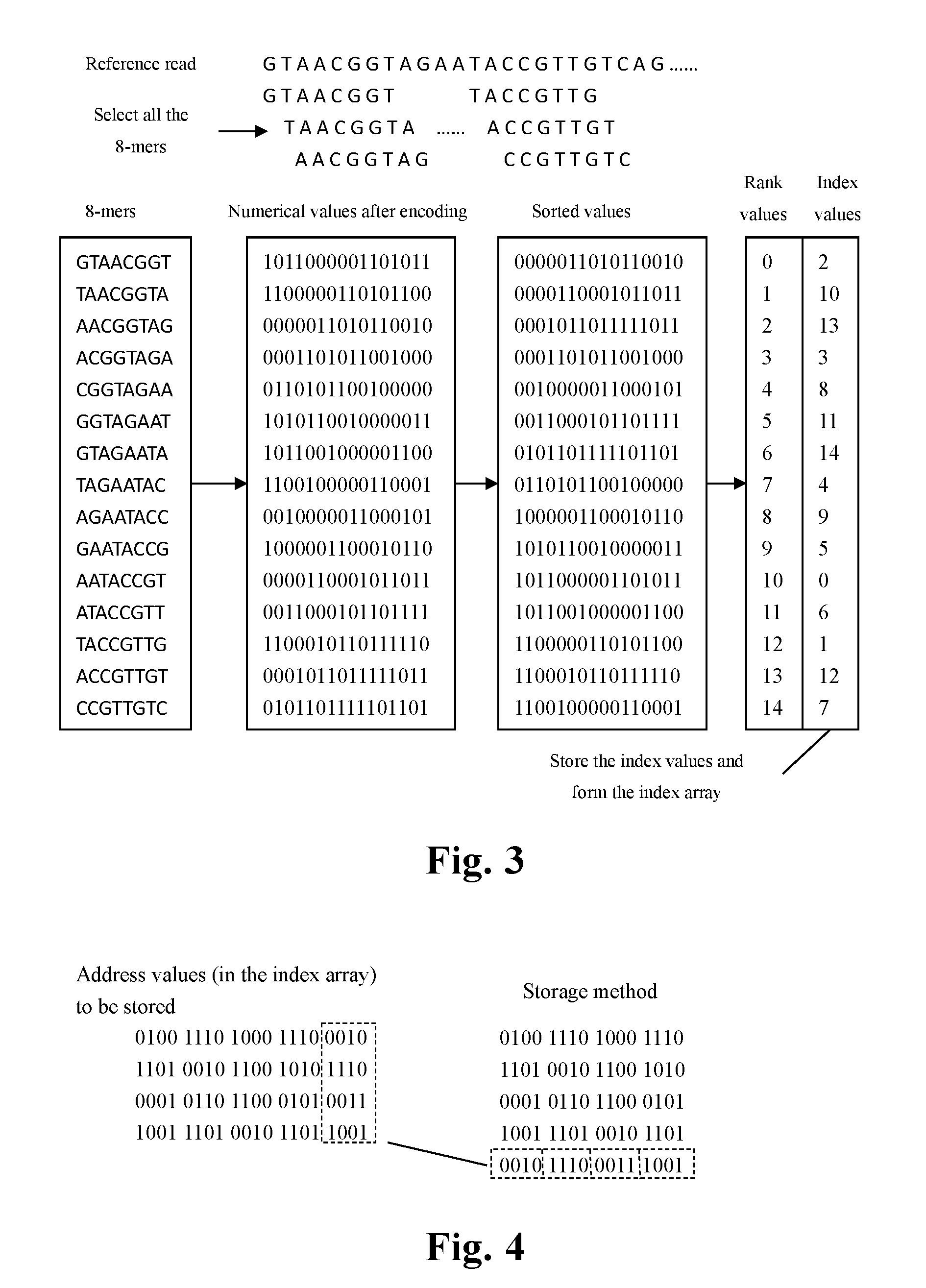

Method and system of mapping sequencing reads

InactiveUS20160259886A1Improve mapping speedImprove throughputDigital data information retrievalSequence analysisStatistical qualityMatch function

A method and a parallel-computing system of mapping sequencing reads is provided. The method preprocesses a reference genome to construct a compression structure of the reference genome, an index array and a block address array; the index array stores the index values of all sorted subsequences on the reference genome; the block address array stores the positions of a portion of the elements in the index array; the parameters involved in the mapping method are selected based on the statistical characteristics of the reference genome, the statistical quality information of sequencing reads and the polymorphism rates of the target species from which the sequencing reads are generated. Based on the structures constructed in the preprocessing stage, each sequencing read is mapped to the reference genome by anchoring on the genome by a certain single perfect match prefix seed, alignment extension based on the auto-match function method, and statistical assessment.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

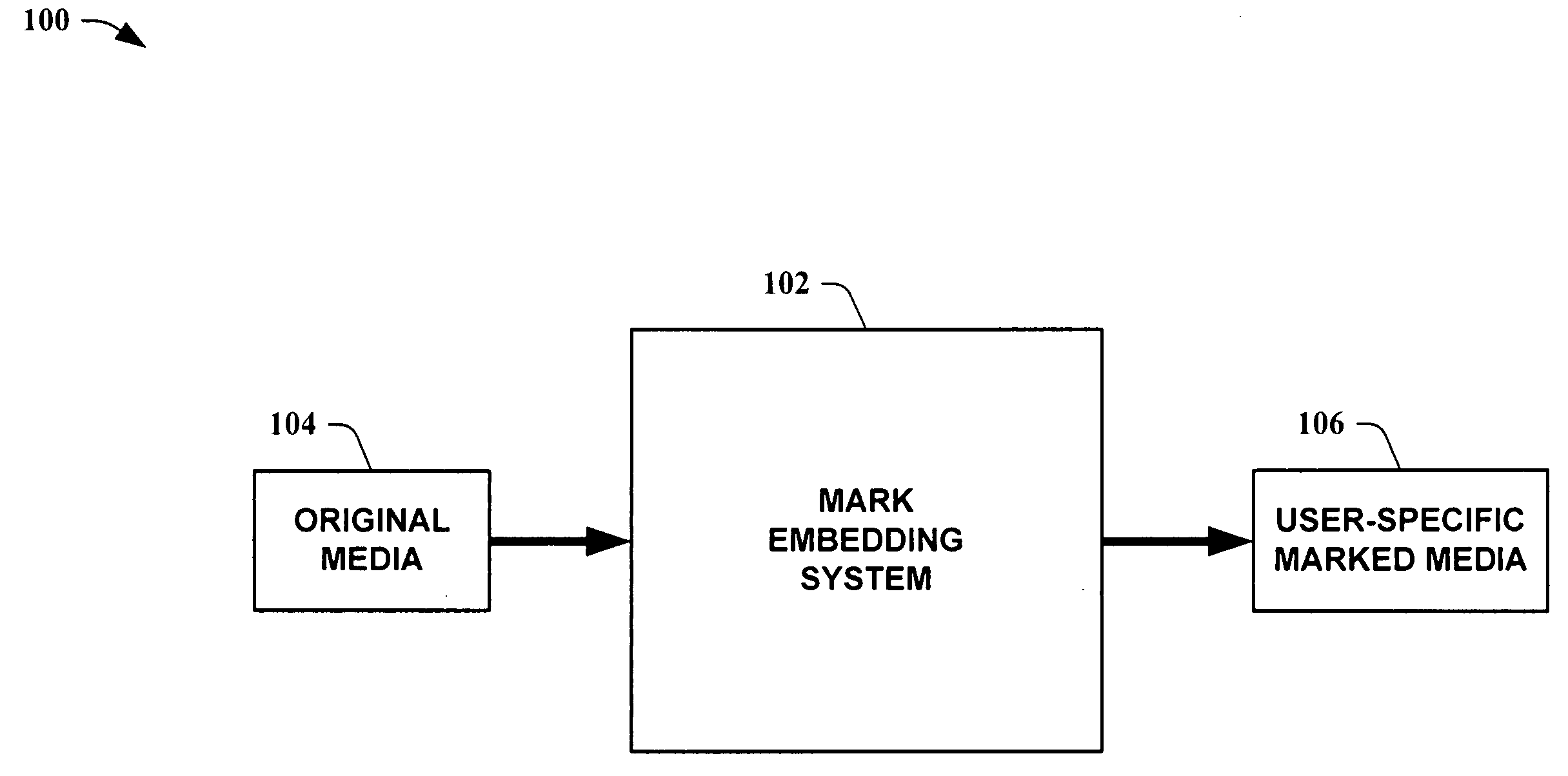

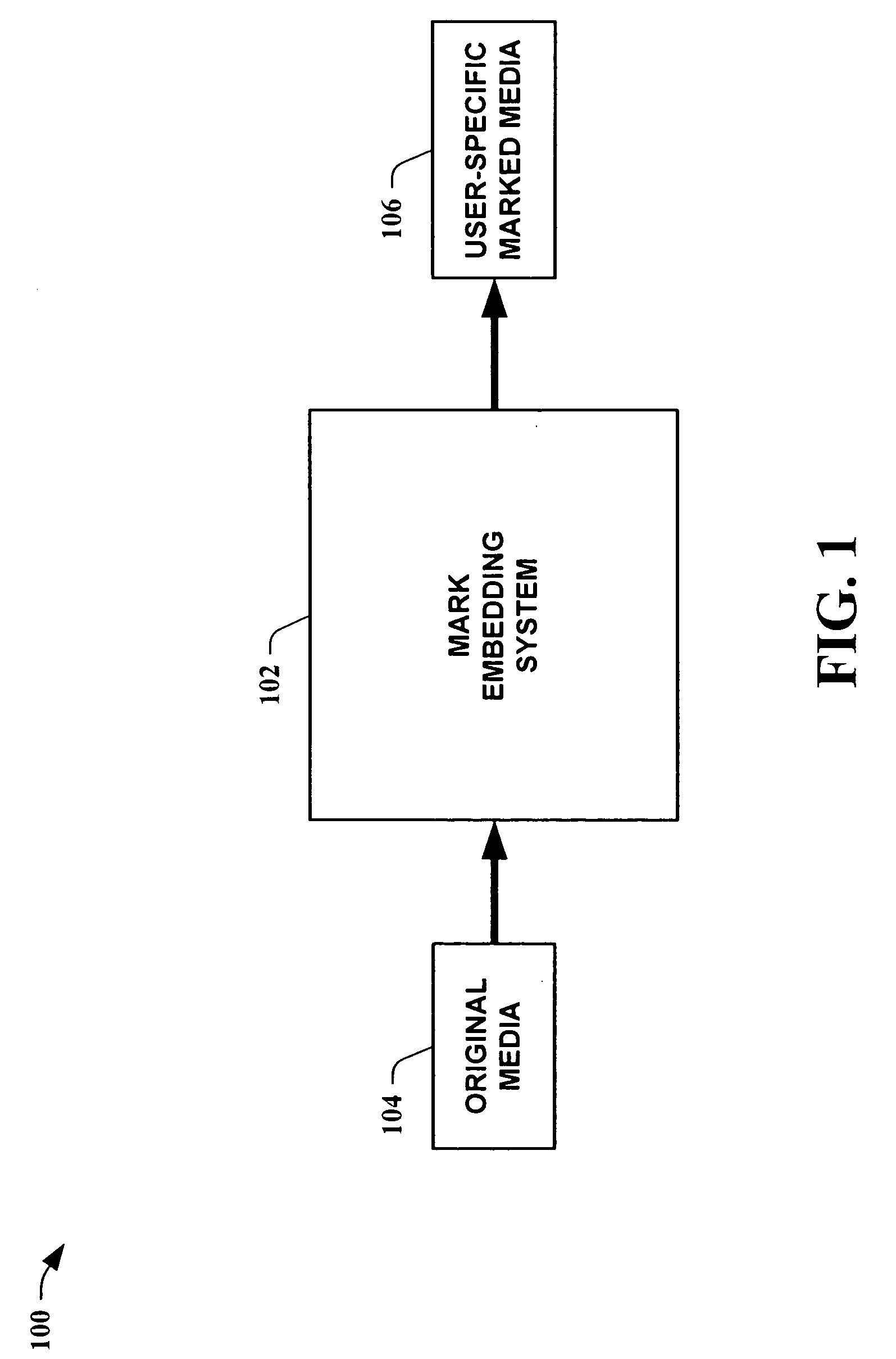

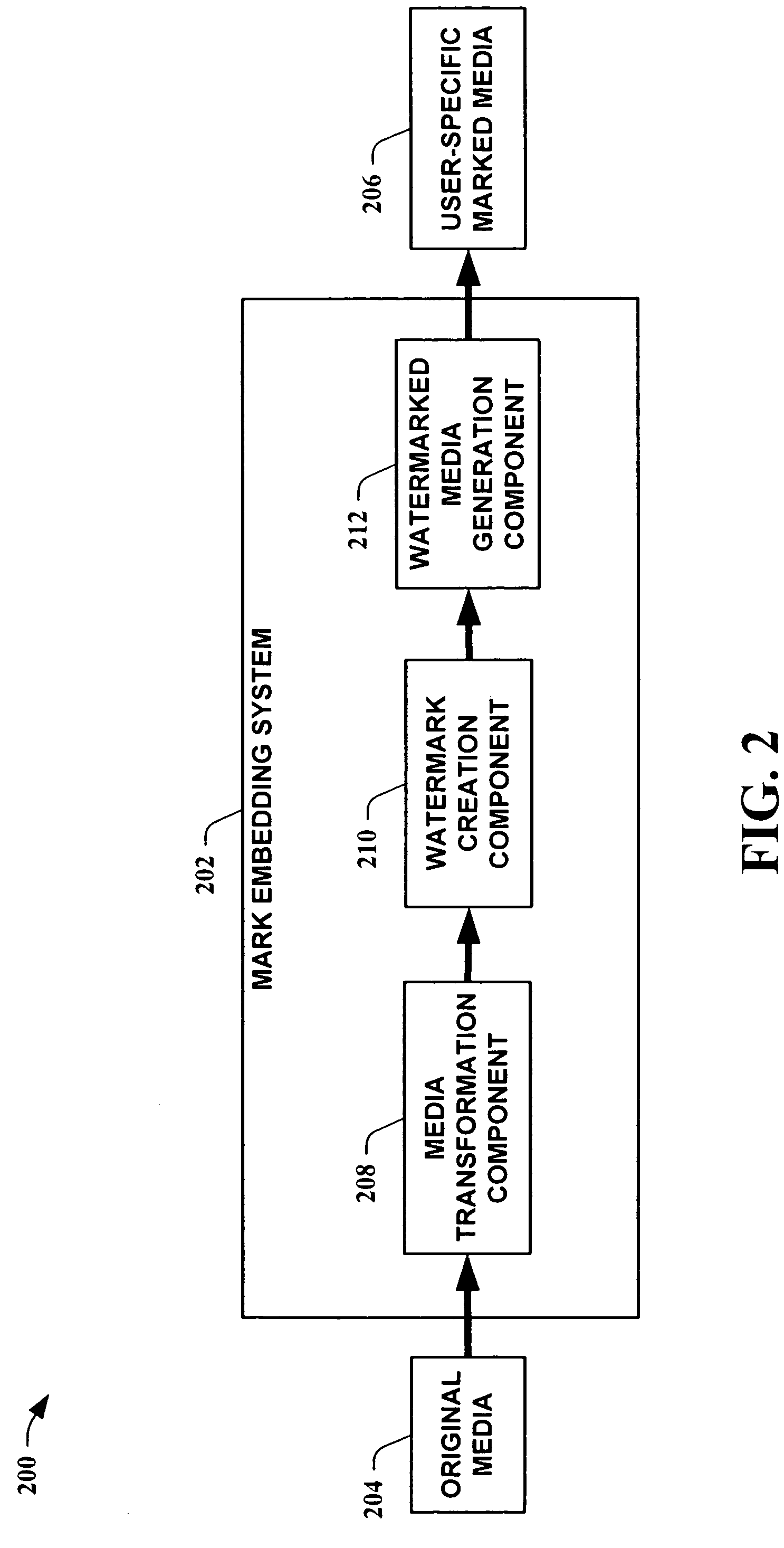

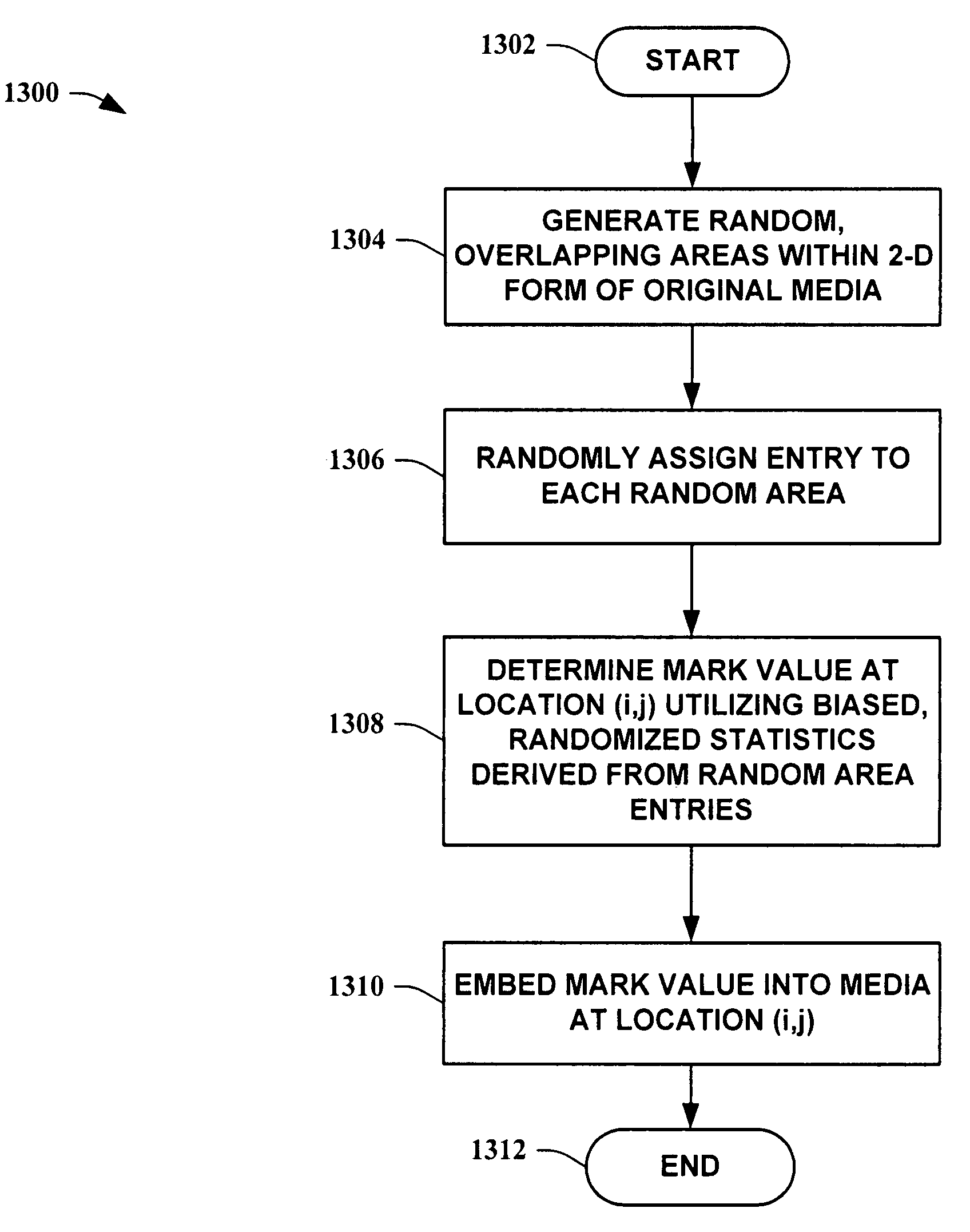

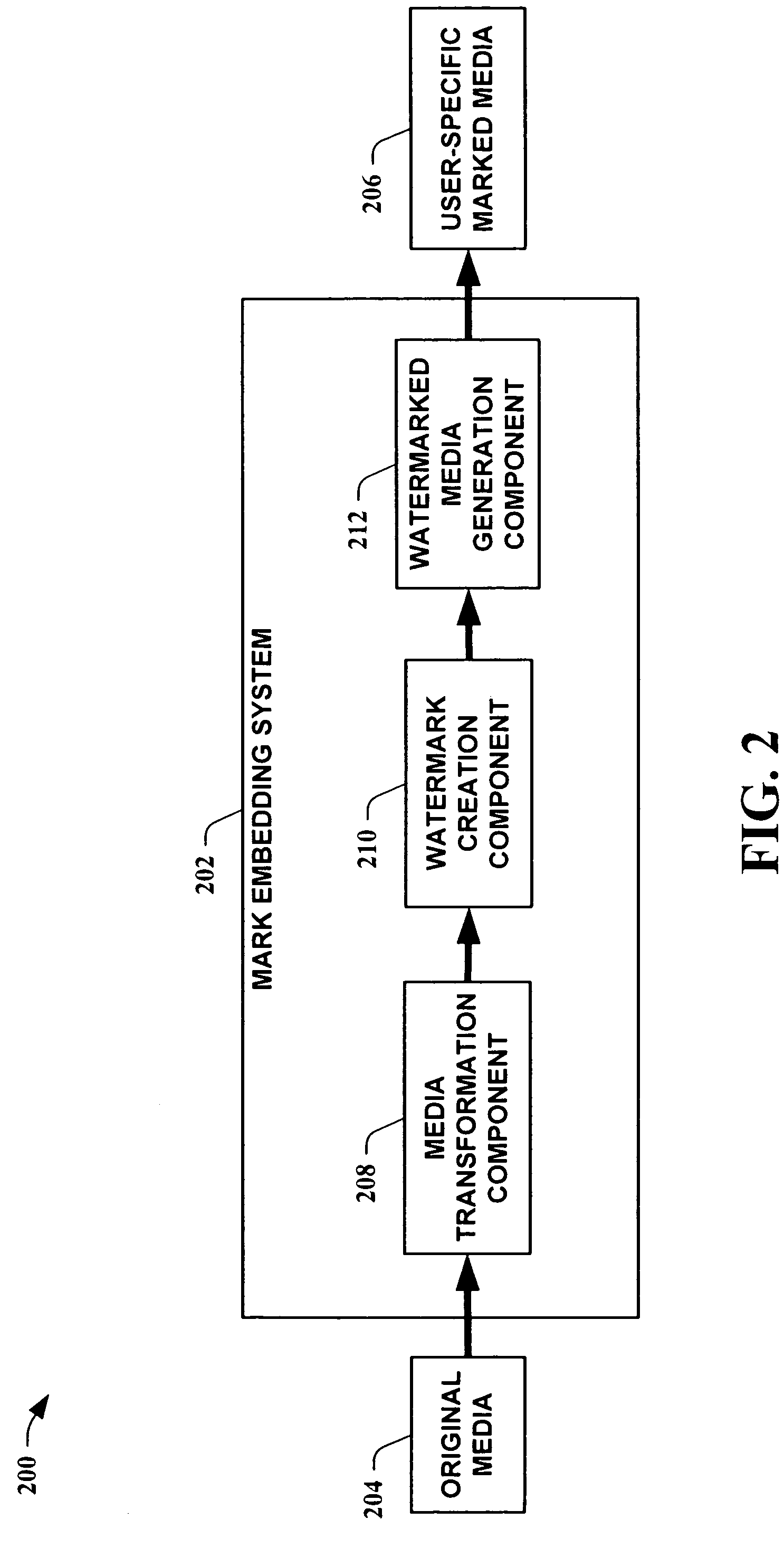

Media watermarking by biasing randomized statistics

InactiveUS20050175179A1User identity/authority verificationSpeech analysisPattern recognitionStatistical correlation

The present invention leverages randomly generated areas with random attributes from two-dimensional media forms to embed information relating to a media's ownership and / or distribution source. This provides a means to establish a media's source despite attacks. By providing embedded user-unique identification, media can enable detection for identifying the source of copied media without the embedded information substantially interfering with the intended purpose of the media itself. In one instance of the present invention, media is transformed into a two-dimensional media form with randomly generated areas having a subset of overlapping areas. User-unique keys are then utilized to determine attributes for each of the areas. This permits creation of statistically unique locations for each user key. The statistical qualities are biased and utilized to determine a logarithmic magnitude watermark value to embed in the media at that location. Detection is performed by utilizing a statistical correlation method to determine a user.

Owner:MICROSOFT TECH LICENSING LLC

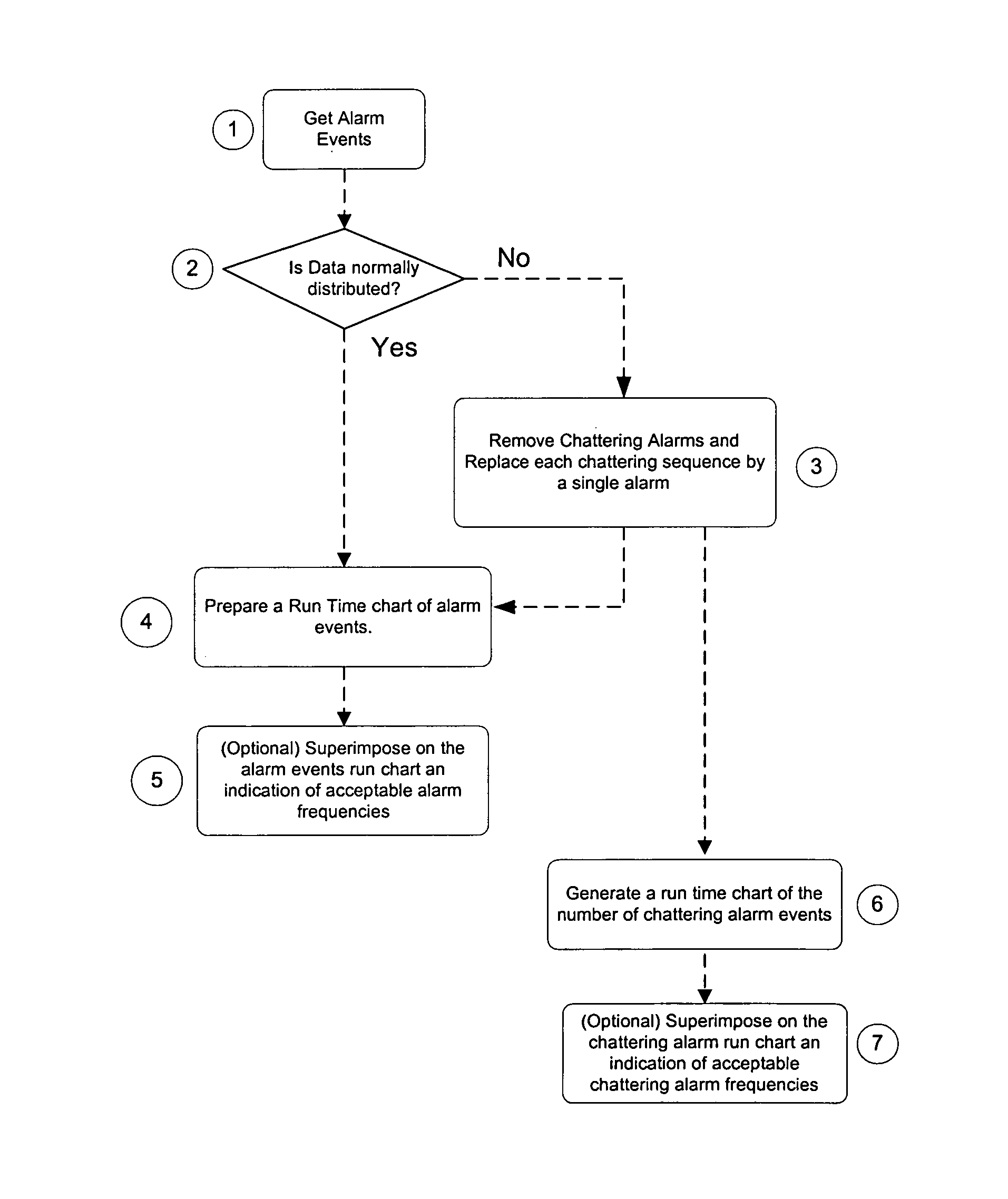

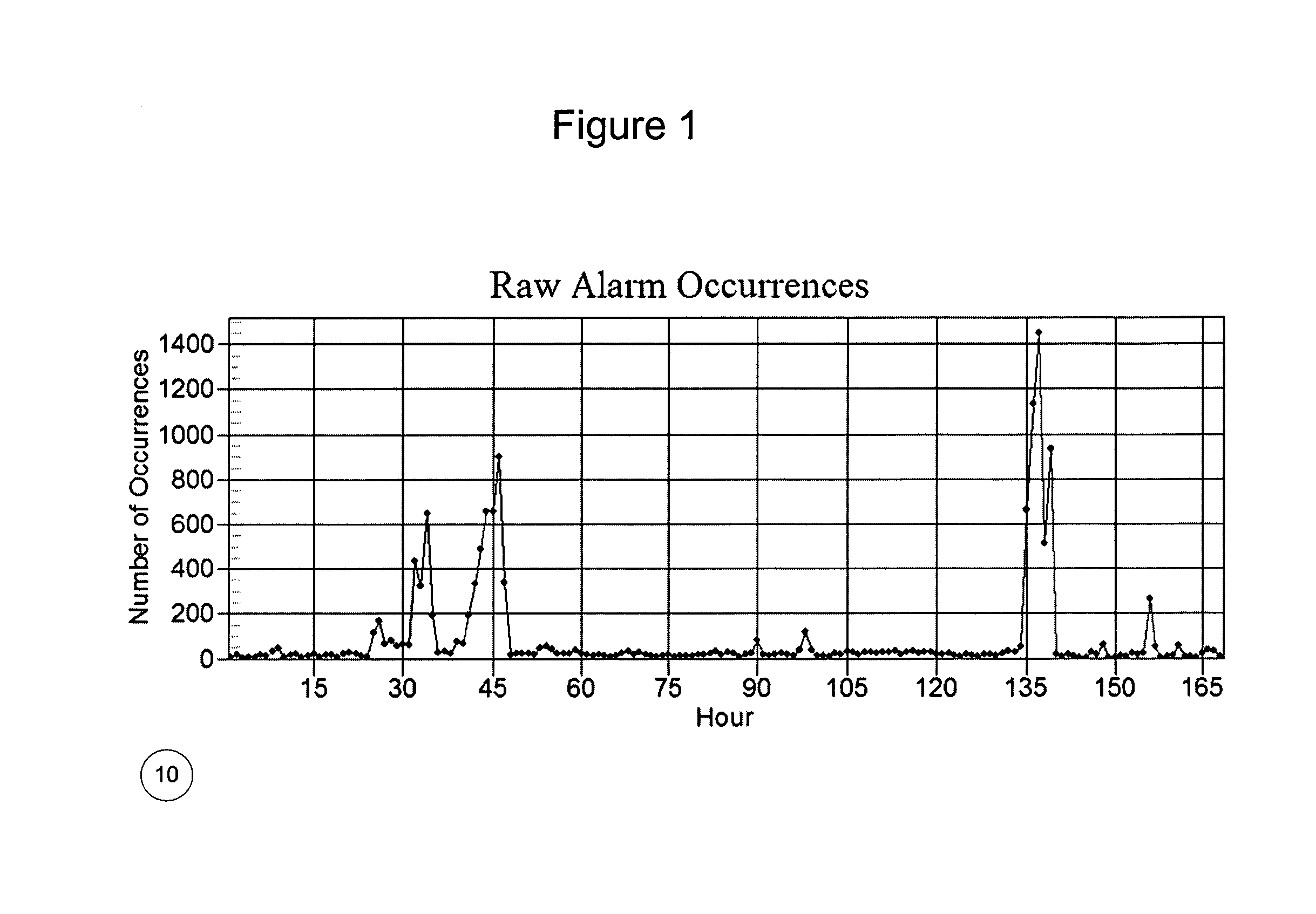

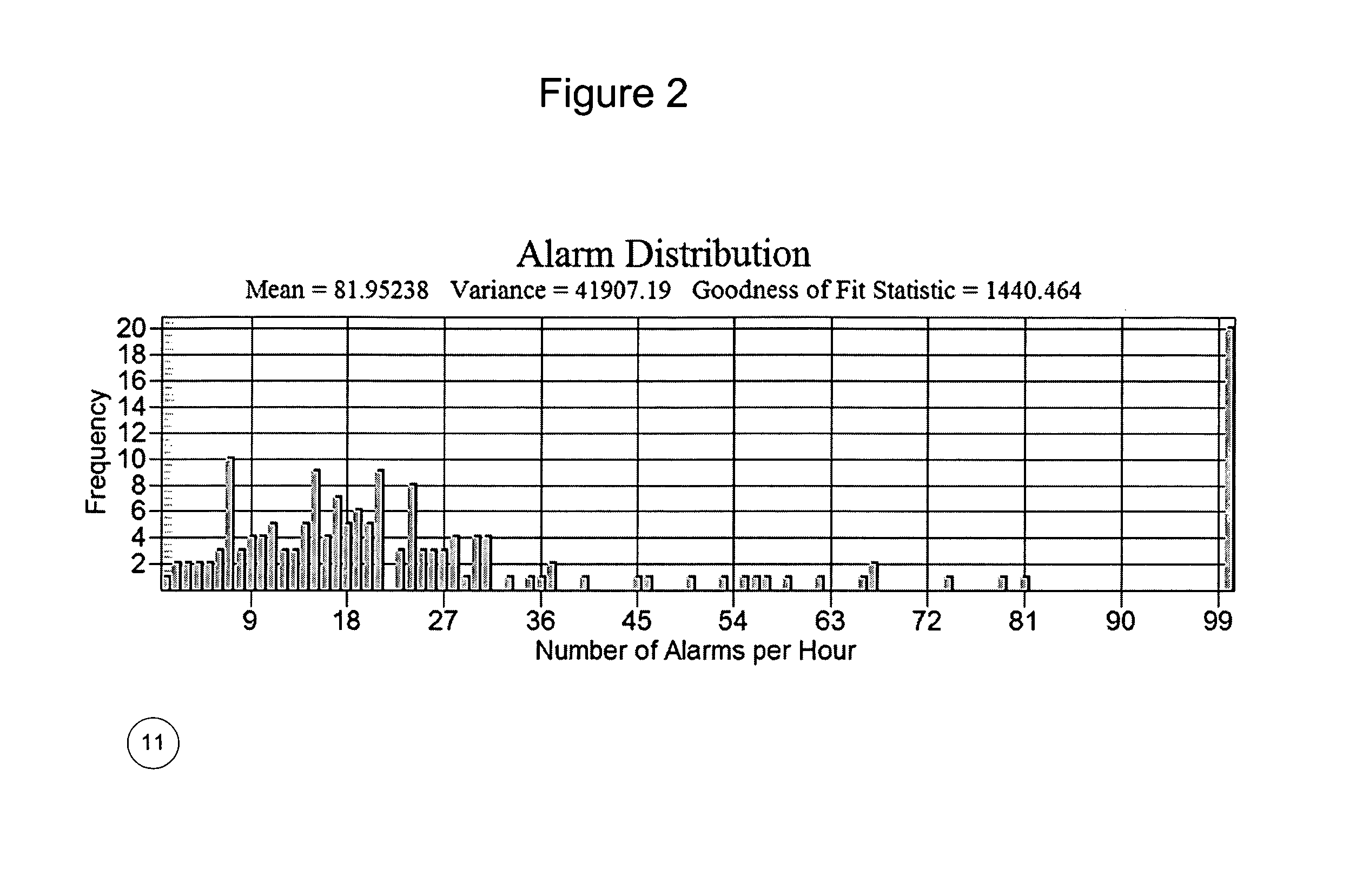

Statistical quality control of alarm occurrences

InactiveUS7289935B1Accurately reflectEfficiently indicatedTime indicationSynchronous motors for clocksData setStatistical quality

A method for evaluating an alarm system for continuous or semi-continuous processes that gives an indication of the actual loading on the operator. A transformations is applied to a data set consisting of alarms and associated times, resulting in the data being much more amenable to common techniques of statistical quality control. The technique requires only a history of alarm events, and the transformation has a strong intuitive appeal.

Owner:HUGO ALAN J

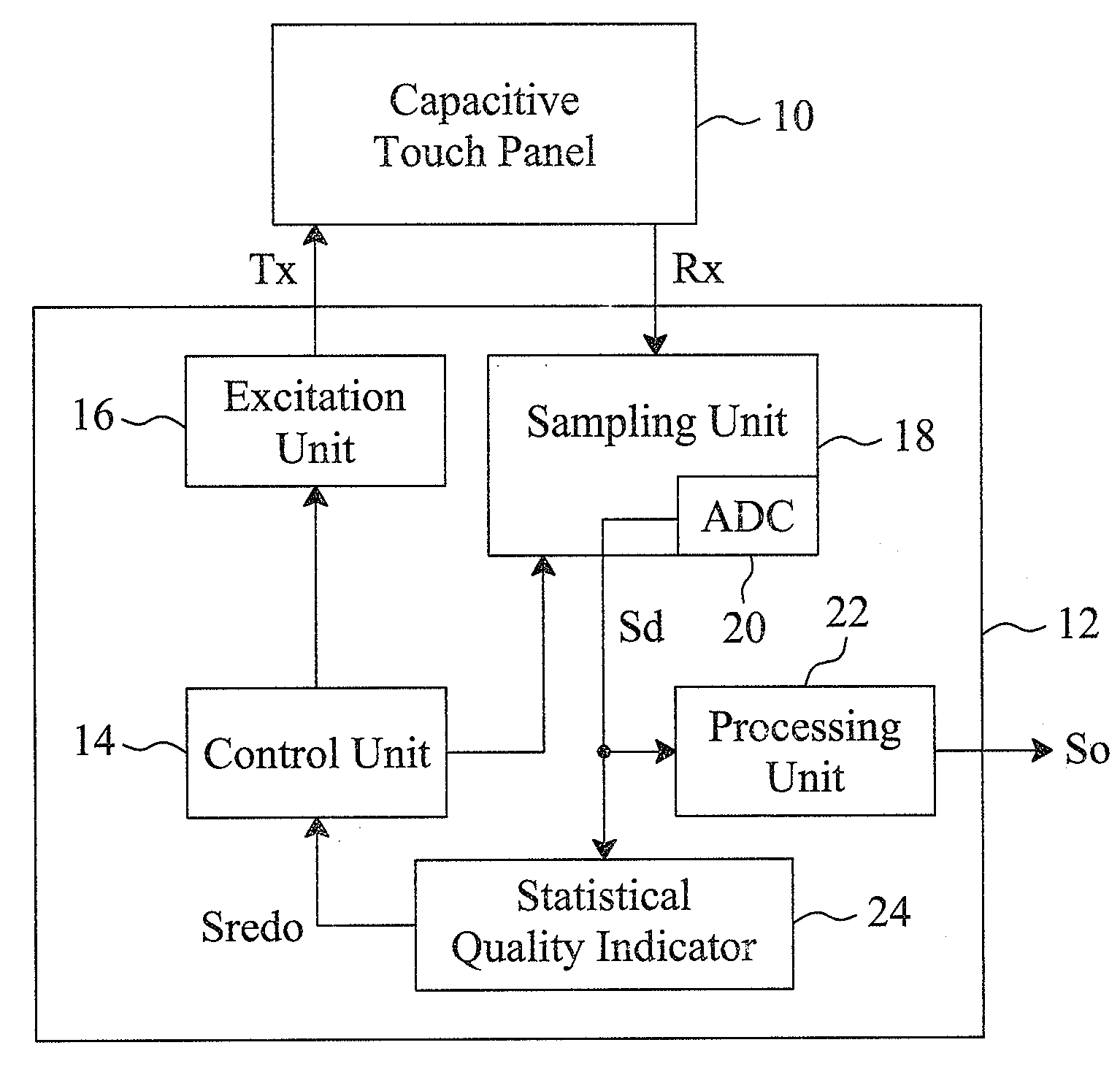

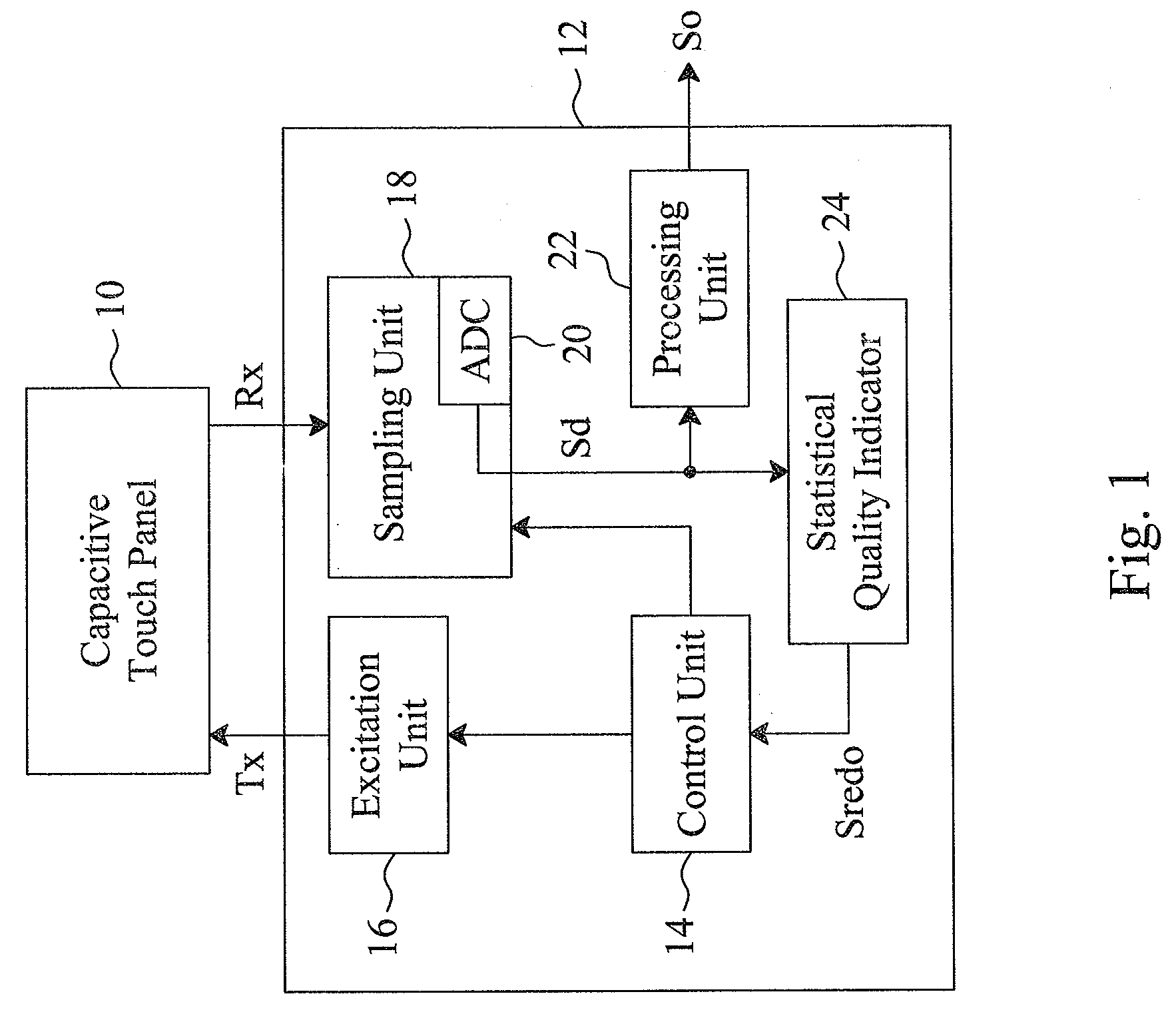

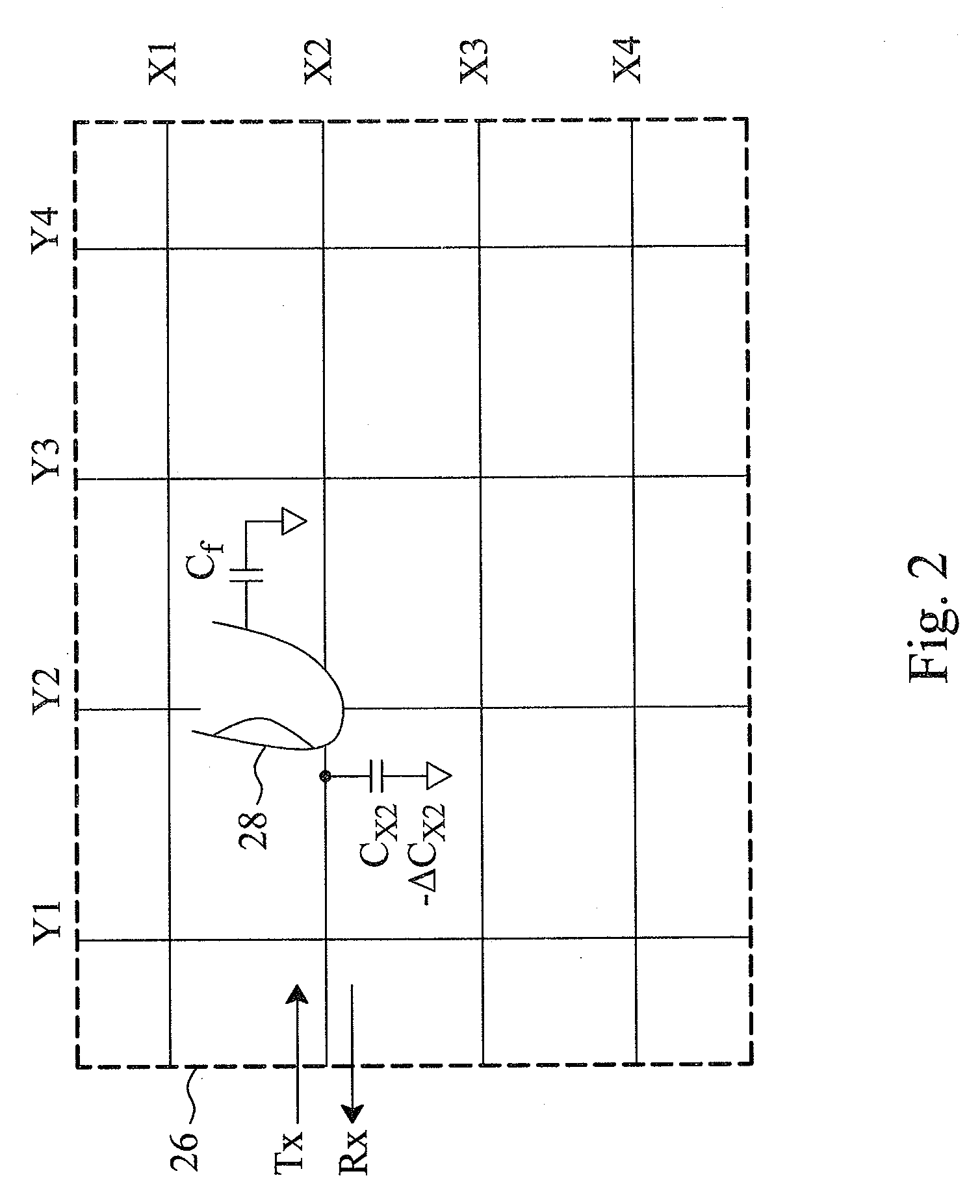

Statistical analyzing method and statistical quality indicator for reliability improvement of a capacitive touch device

InactiveUS20130249852A1Improve sensing qualityInput/output processes for data processingStatistical analysisStatistical quality

For a capacitive touch device having a capacitive touch sensor to be sensed to generate sensed values, a sensing apparatus and method statistically analyze the sensed values generated in a certain time period to evaluate the sensing quality thereof, discard the poor reliable sensed values, and re-sense the capacitive touch sensor to generate new sensed values, by which the resultant output signal will have improved reliability.

Owner:ELAN MICROELECTRONICS CORPORATION

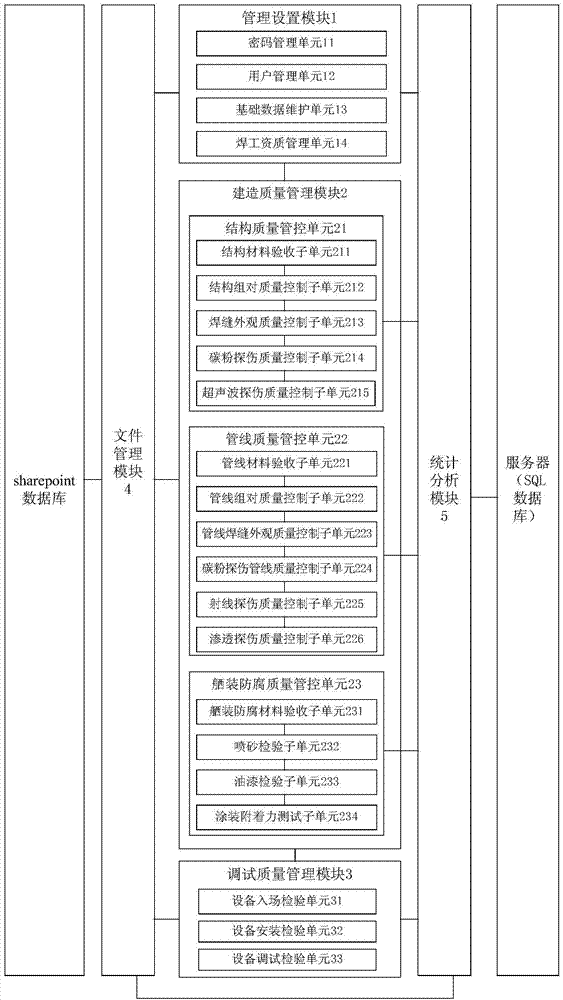

Oceanographic engineering quality control information system

InactiveCN104751296AQuick customizationImprove quality management efficiencyResourcesICT adaptationStatistical analysisTotal quality management

The invention relates to the field of offshore oil engineering and provides an oceanographic engineering quality control information system. The oceanographic engineering quality control information system comprises a management setting module, a construction quality managing module, a debugging quality managing module, a file managing module and a statistical analyzing module, wherein the management setting module is used for setting a user login password and authorities of a user, setting essential data and preserving welder qualifications; the construction quality managing module is used for determining construction quality acceptance when monitors that information input by a general contractor is examined and approved by an owner party and a third party; the debugging quality managing module is used for acquiring the information input by the general contractor and recording left problems for subsequent elimination; the file managing module is used for uploading, checking and downloading item information; and the statistical analyzing module is used for extracting various data input in the earlier stages according to a user command and giving an analysis result. The oceanographic engineering quality control information system is capable of finishing daily quality inspection work, performing real-time quality information statistics, collecting the statistical information and generating weekly reports and monthly reports needed in working automatically, and the aid of the oceanographic engineering quality control information system, traditional paper file transmission can be replaced to achieve automatic real-time data statistics, so that efficiency in quality management is improved greatly.

Owner:CHINA NAT OFFSHORE OIL CORP +1

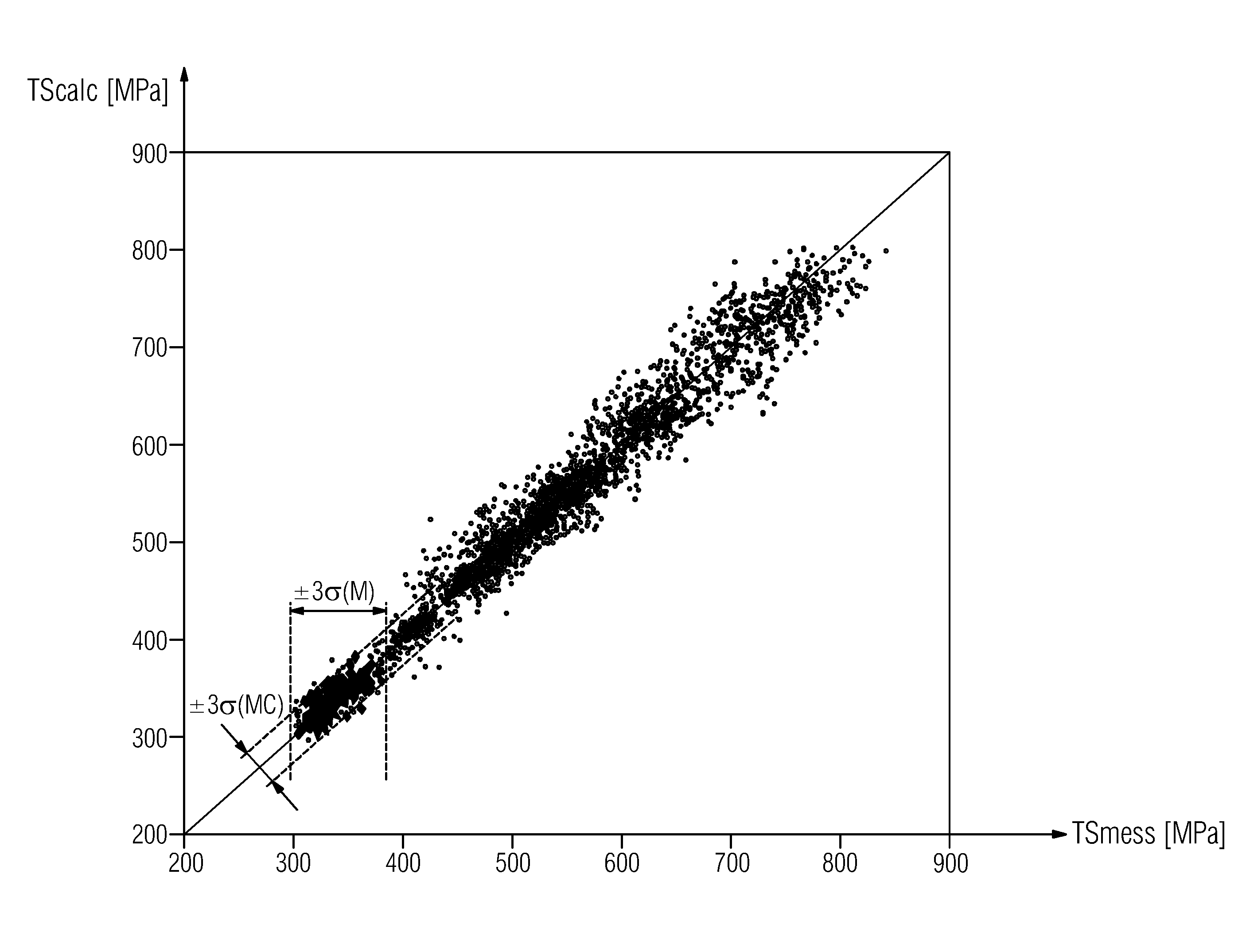

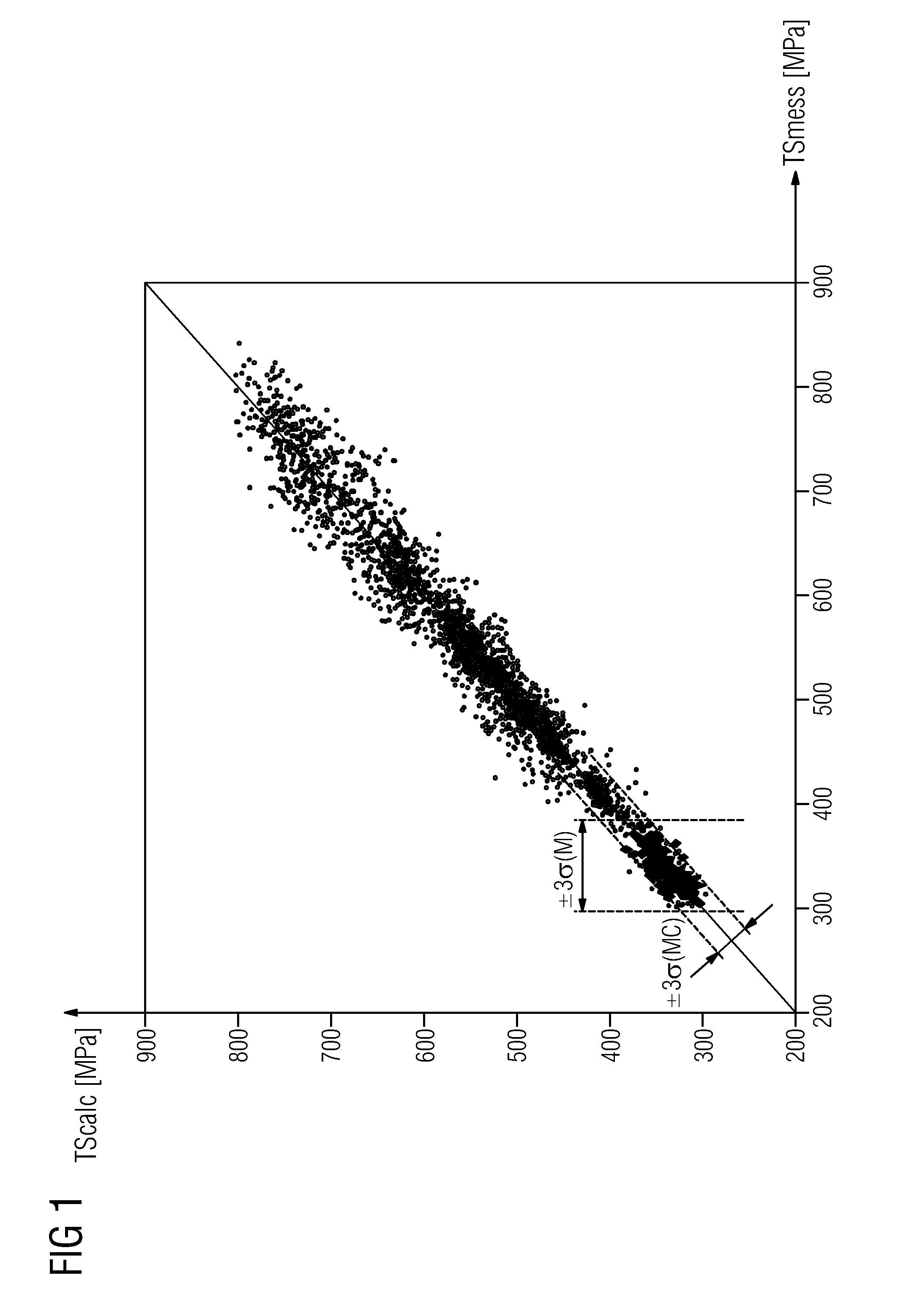

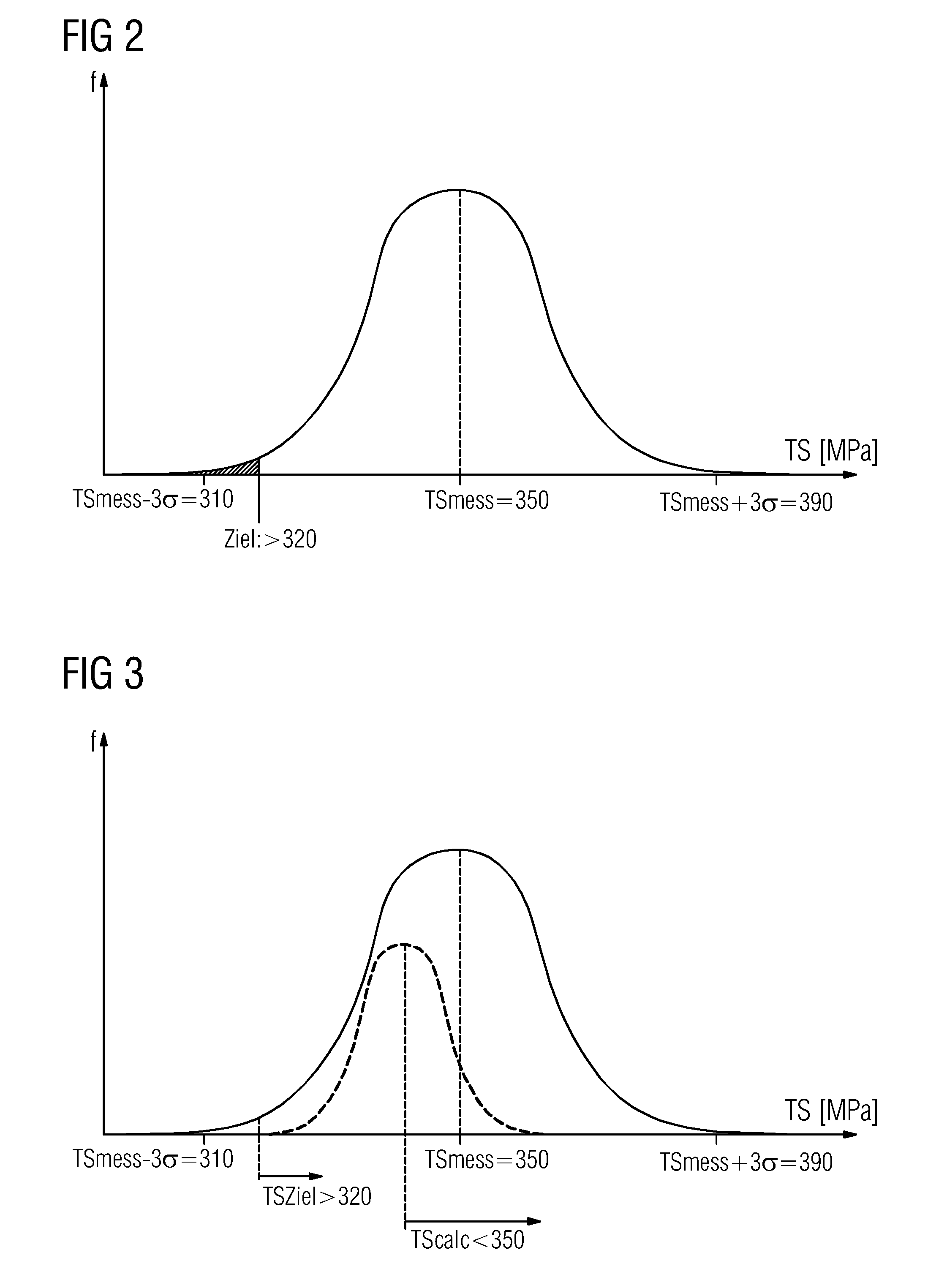

Method for statistical quality assurance in an examination of steel products within a steel class

InactiveUS20140005981A1Reduce transmissionQuickly and easily determineDigital computer detailsMaterial strength using tensile/compressive forcesStatistical qualityComputer-aided

A method for statistical quality assurance in an examination of steel products within a steel class is provided. Initially measurement samples are taken to determine at least one mechanical property. In addition to the measurement results, computed results of a computer-aided model for calculating the mechanical property of the respective steel product are used. Taking into account the statistical deviation between the measured results and the computed results, a statement is made as to whether the steel products have a specified probability of achieving a target value for the mechanical property.

Owner:SIEMENS AG

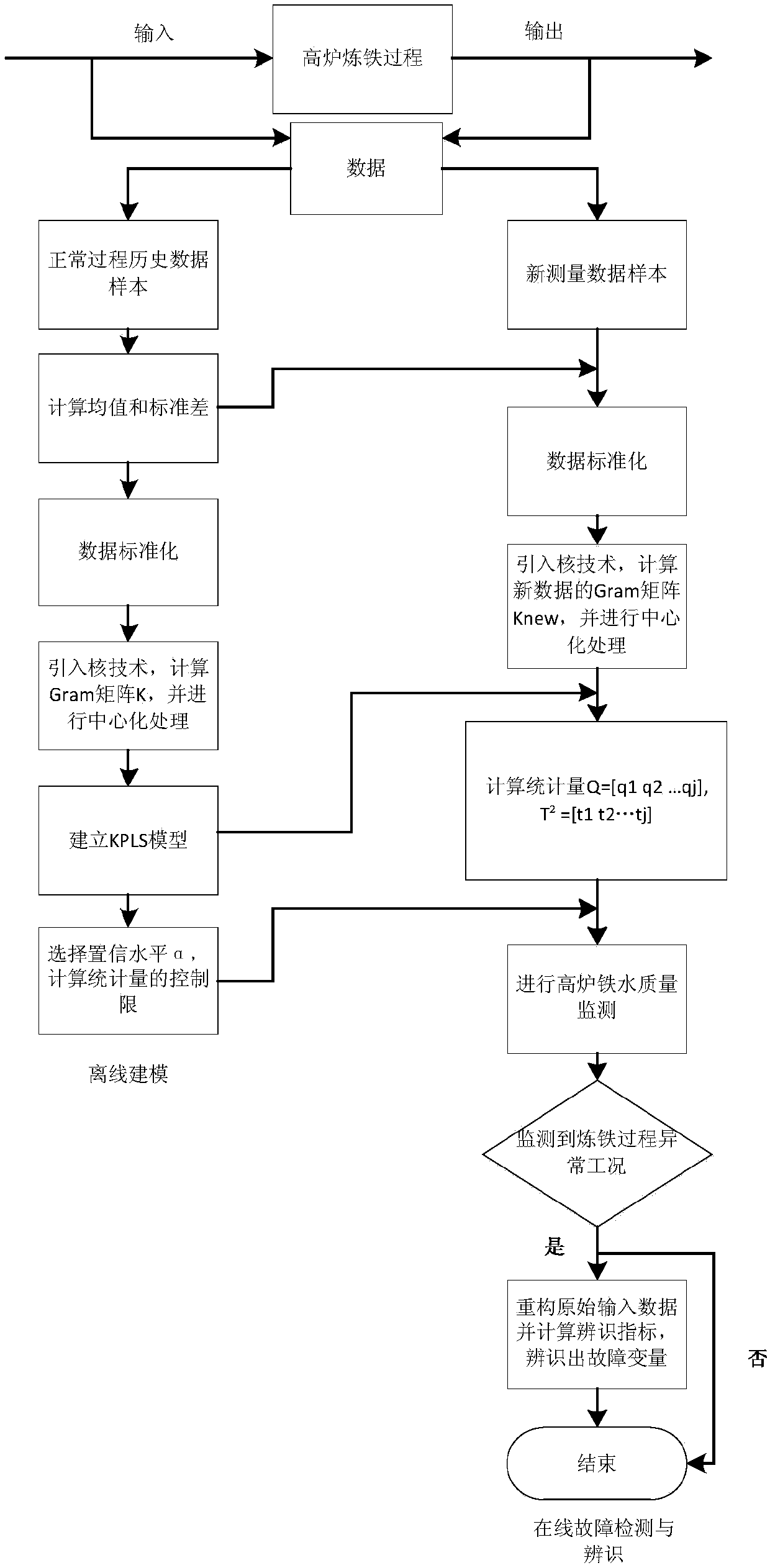

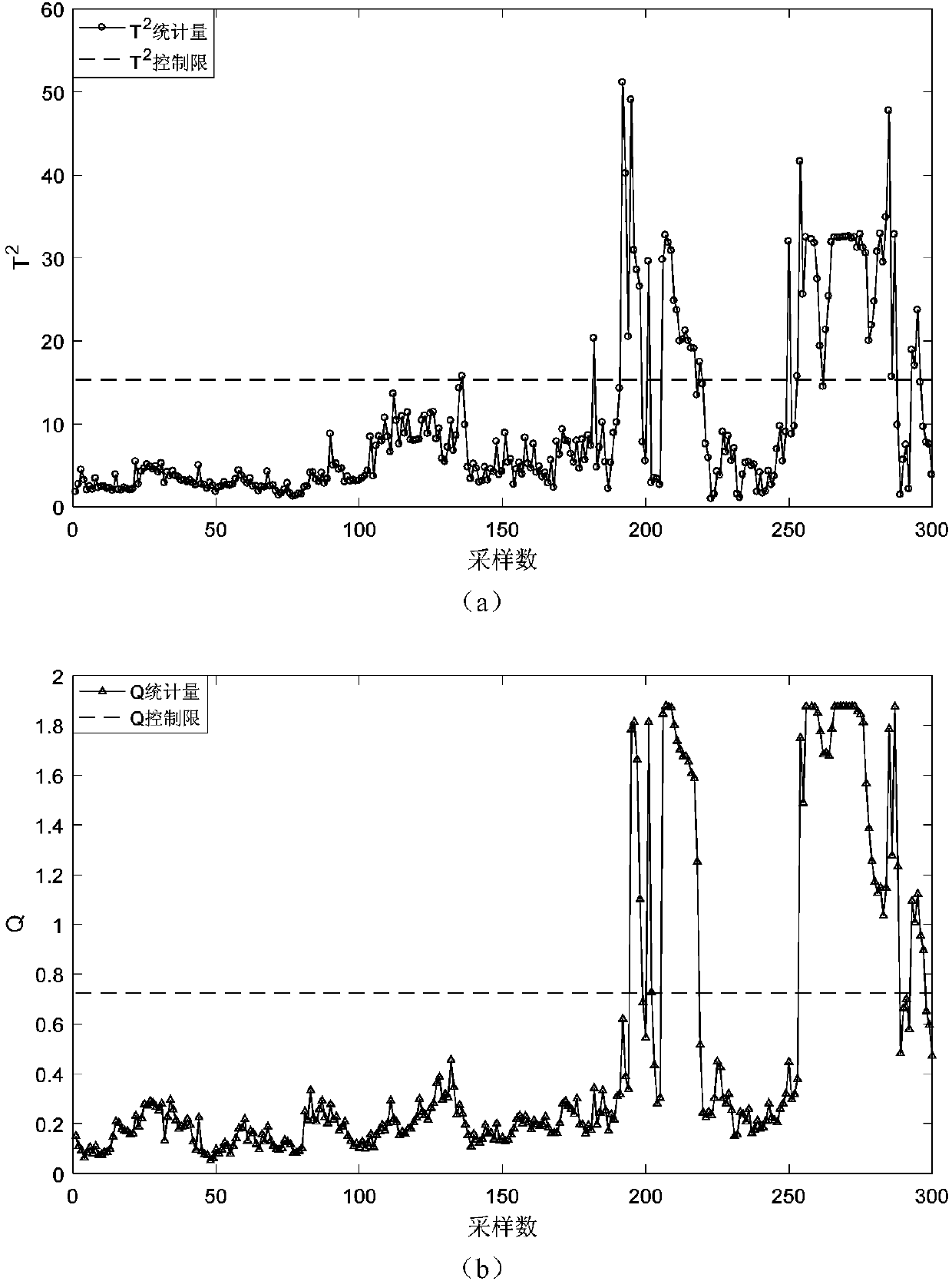

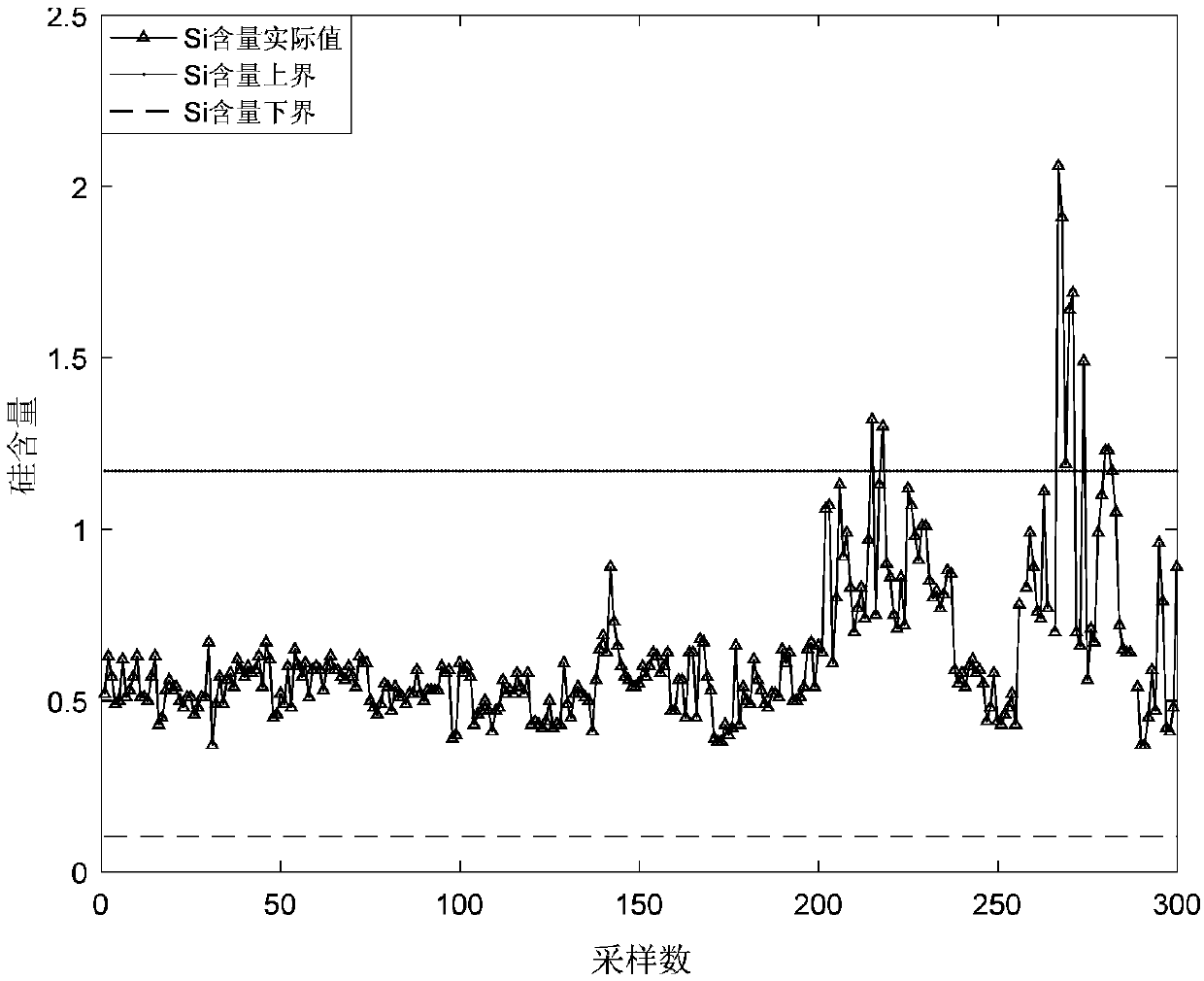

A blast furnace molten iron quality monitoring method based on KPLS robustness reconstruction error

ActiveCN107463093ASolve the problem of fault identification in quality monitoringSolve the problem of fault identificationAdaptive controlHigh dimensionalData Matrix

The invention provides a blast furnace molten iron quality monitoring method based on KPLS robustness reconstruction error. The method comprises the steps of collecting blast furnace operating parameters and molten iron quality variables at the same moment; selecting a training set and standardizing the same; mapping input data in the training set into a high-dimensional feature space to obtain a Gram matrix K and performing centralization processing; acquiring new blast furnace operating parameter and molten iron quality variable samples including abnormal working conditions as a testing set and performing standardization processing; mapping an input data matrix in the testing set in to the high-dimensional feature space to obtain a Gram matrix and performing centralization processing; building a partial least square model to describe the high-dimensional feature space and an output data matrix; checking whether a blast furnace iron making process is abnormal by using a T2 statistical quality and a Q statistical quality; calculating a reconstruction value of original process variable data and identifying process variables causing abnormal working conditions of the blast furnace. The method can accurately identify faults in blast furnace molten iron quality monitoring and improve molten iron quality monitoring performance, thus guaranteeing blast furnace molten iron quality.

Owner:NORTHEASTERN UNIV

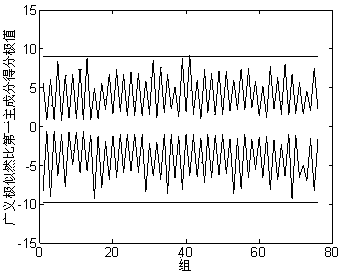

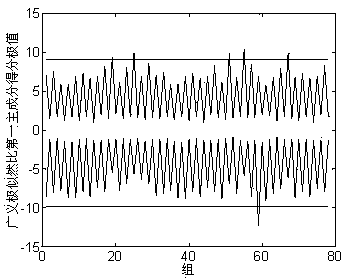

Method for node rigidity prediction based on vibration measurement

ActiveCN103971018AQuickly Predict StiffnessSpecial data processing applicationsElement modelPrincipal component analysis

The invention relates to a method for node rigidity prediction based on vibration measurement. The method is characterized by comprising the steps of first establishing a node model (a finite element model or a test model), utilizing the model to enable a first principal component score extreme value obtained through generalized likelihood ratio principal component analysis to serve as a control index, and establishing a relation curve of the proportion of the control index exceeding the upper limit and the lower limit and node rigidity under different damage working conditions in a statistical quality control chart; in actual engineering, measuring vibration response of a node, and calculating the proportion of the control index exceeding the upper limit and the lower limit in the statistical quality control chart according to the response; and finally substituting the proportion of the control index exceeding the upper limit and the lower limit into the relation curve to predict the node rigidity. According to the method, the node rigidity can be rapidly and effectively predicted without needing other data, only acceleration response of a structure needs collecting, and the method can be used for structural ageing and after-calamity rapid prediction.

Owner:FUZHOU UNIV

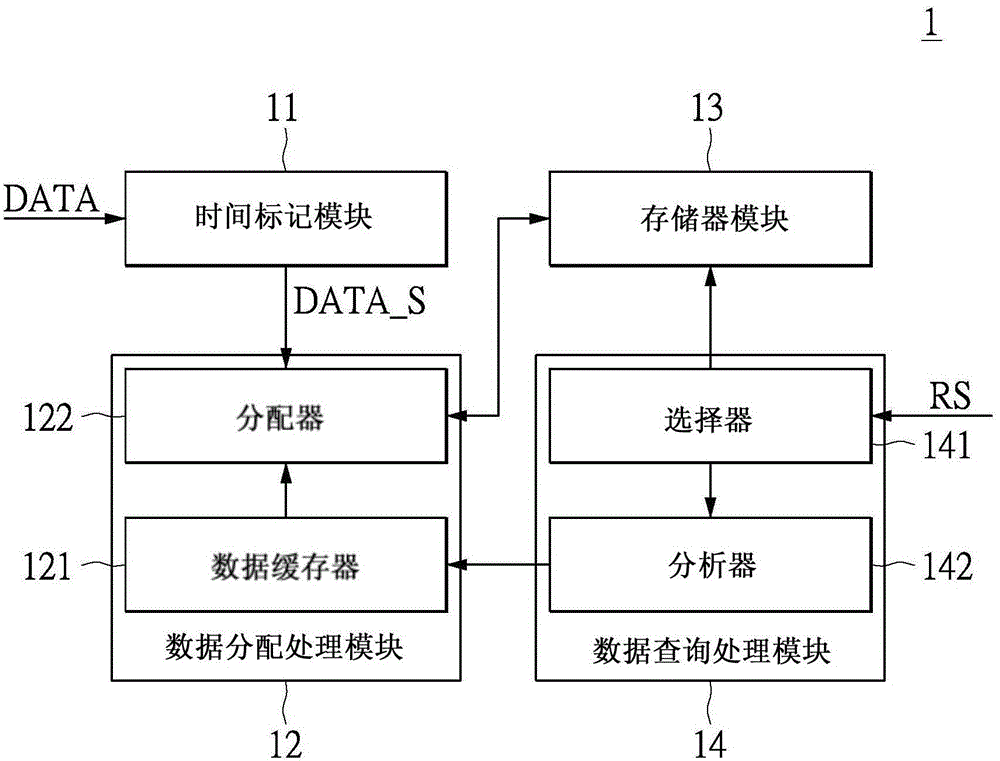

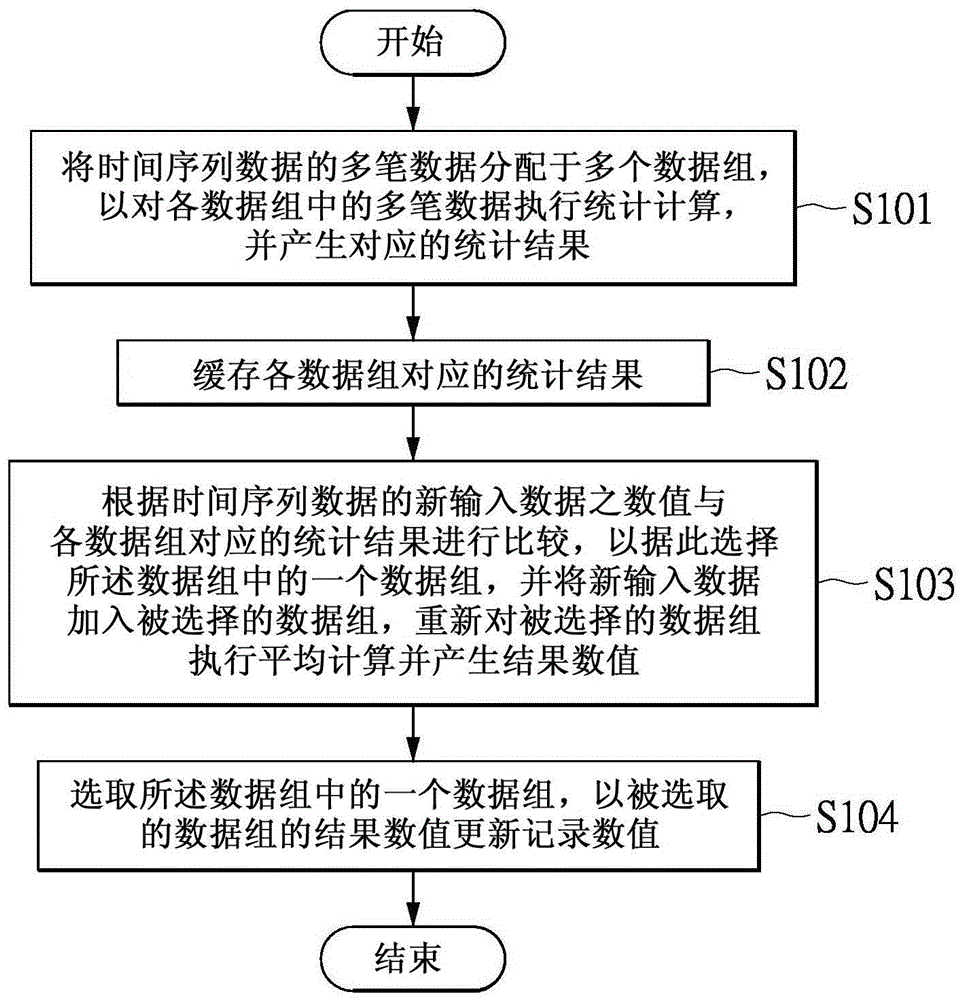

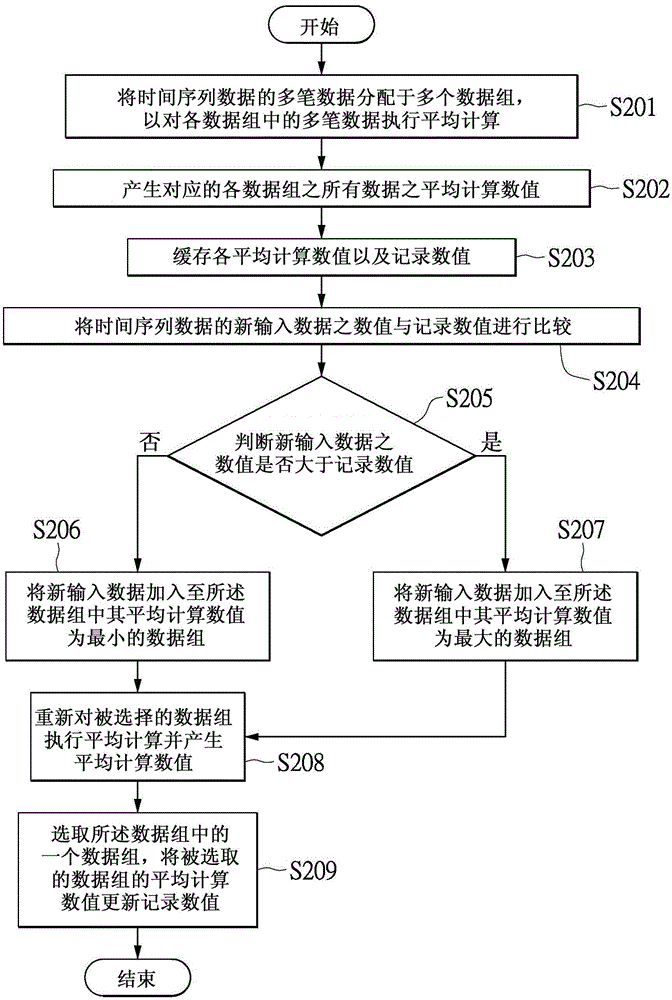

Method for processing time series and system thereof

InactiveCN105608096AGuarantee the amount of calculationStable response timeSpecial data processing applicationsStatistical qualityData mining

A method for processing time series is disclosed. In the method, the time series is distributed into a plurality of indexes. A statistical method is applied to the data in each index for generating corresponding statistical result. The statistical result is the value with respect to the every index, and also the record with respect to the indexes in the time series. The statistical result for the every index is temporarily buffered. After that, a new input time series is compared with the statistical result for every index so as to select one of the indexes. The new input data is therefore inserted to the selected index. The statistical method is then applied to this selected index again. A new statistical result is generated. The record is updated as referring to the selected index and the new corresponding statistical result.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

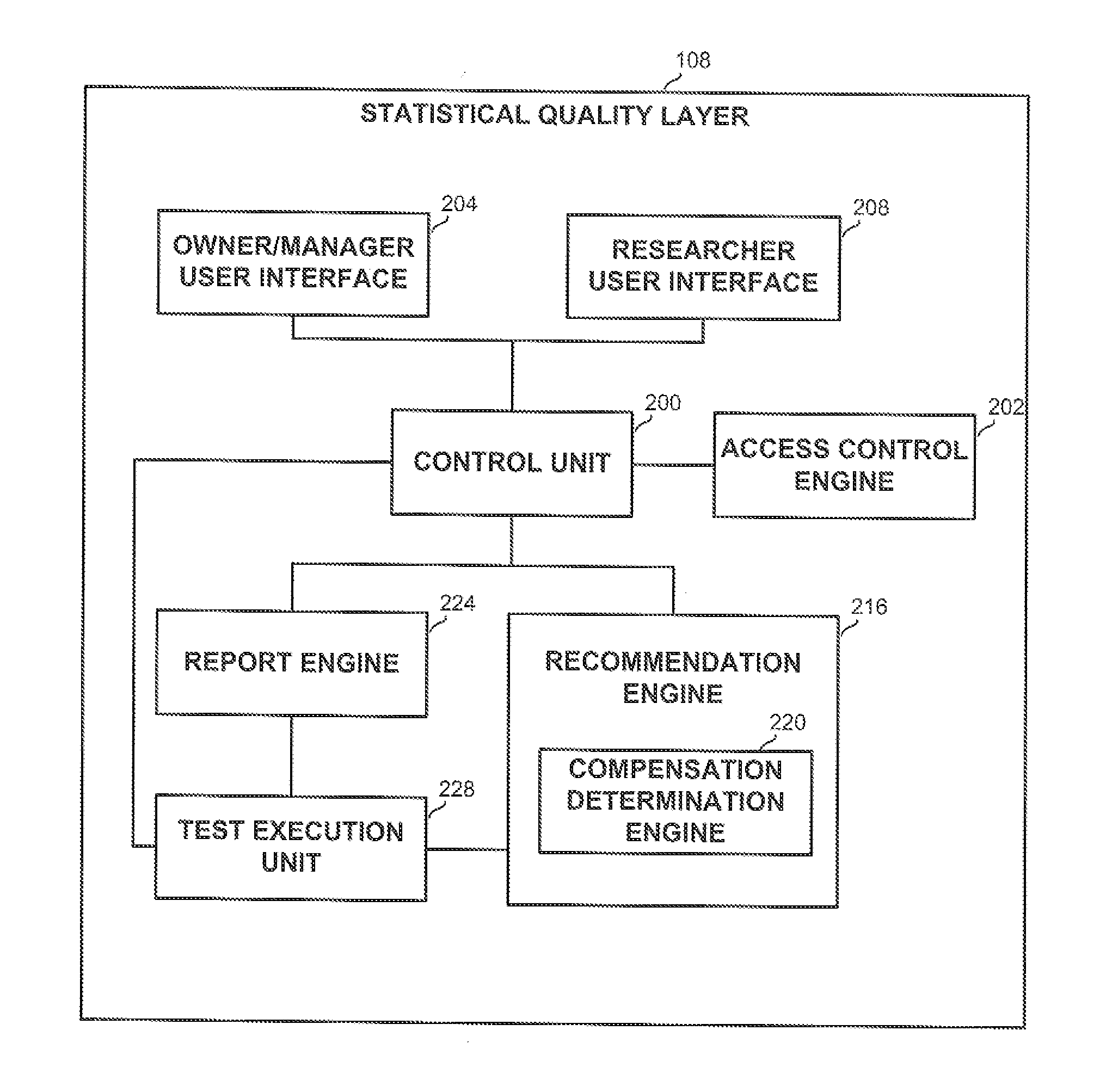

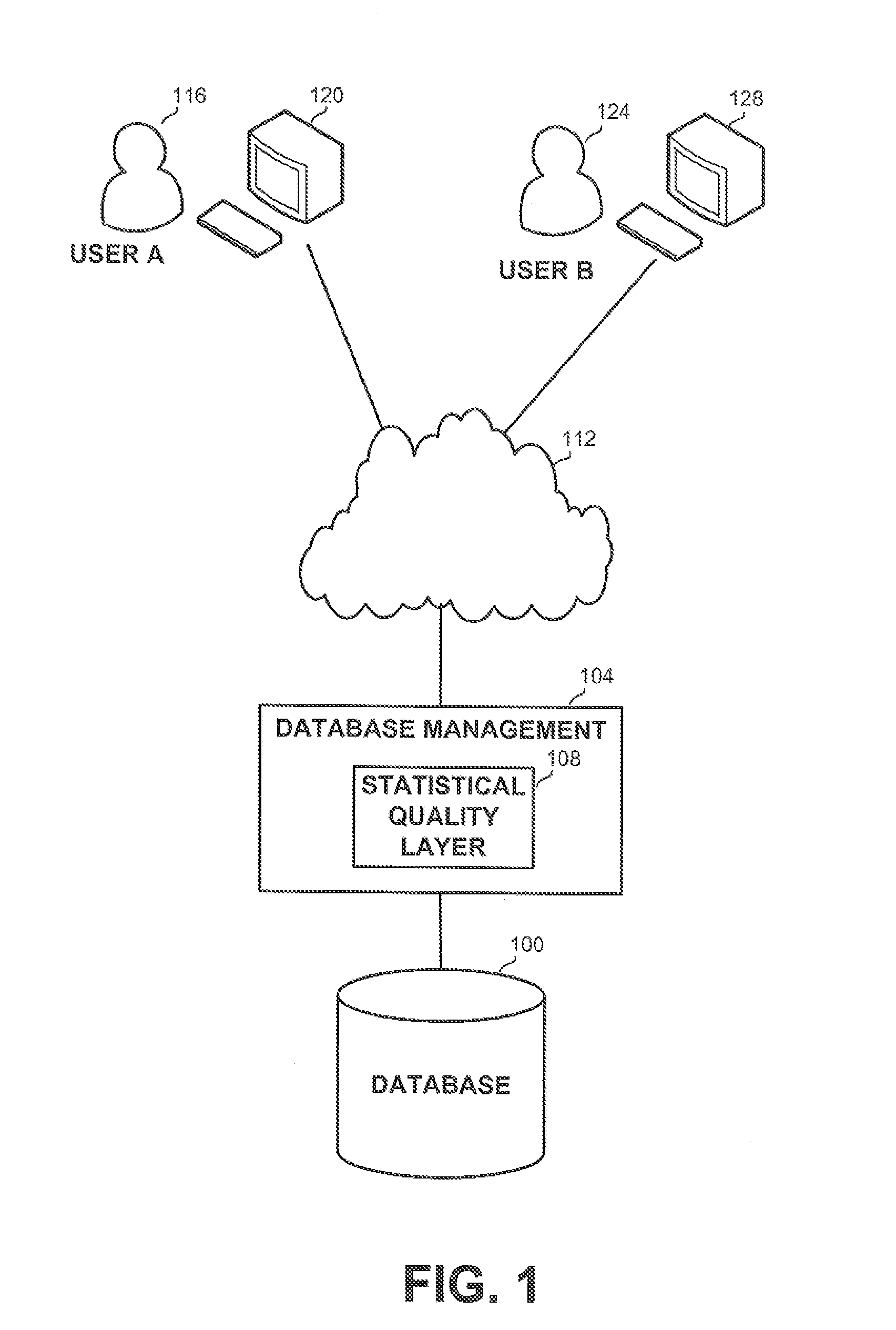

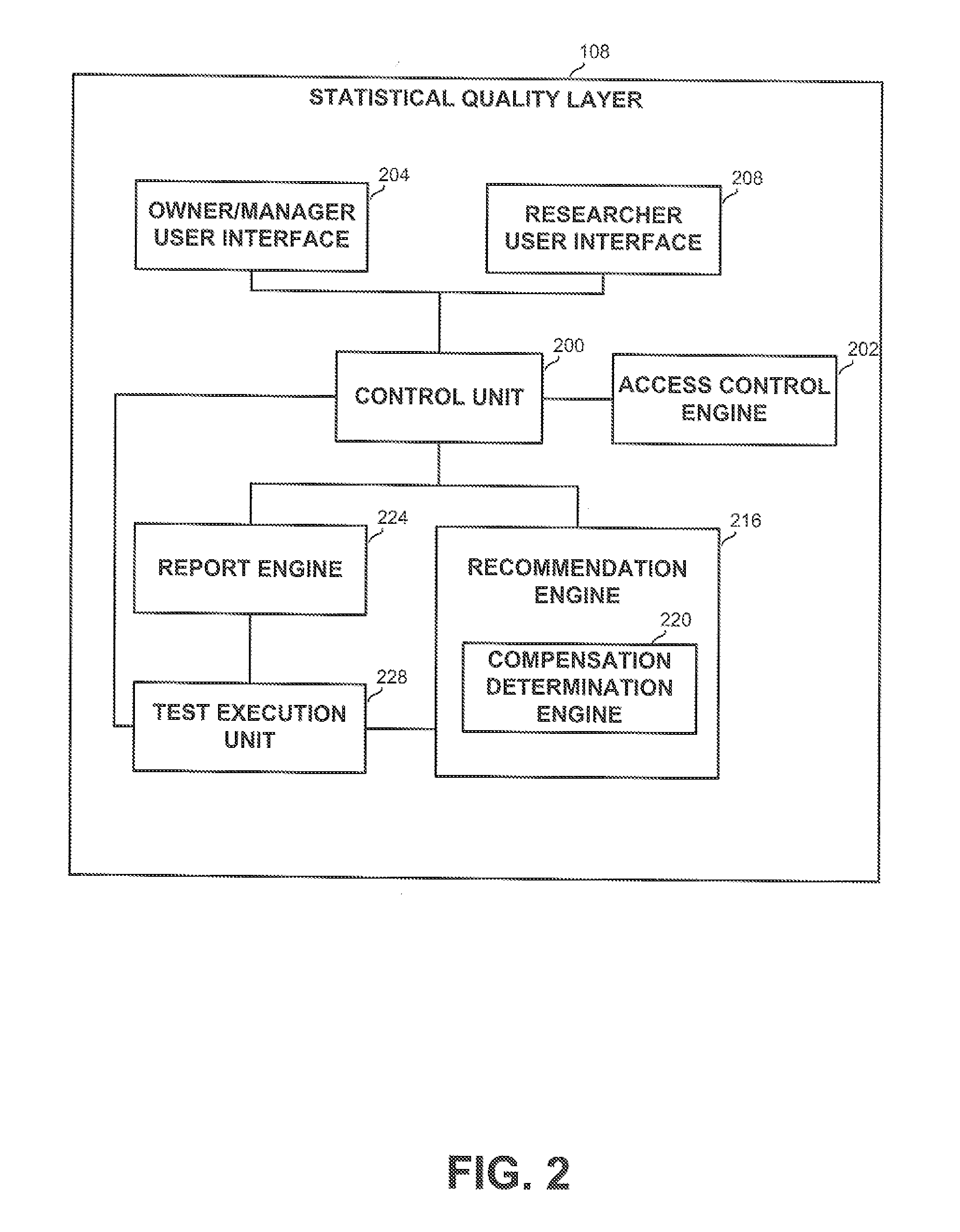

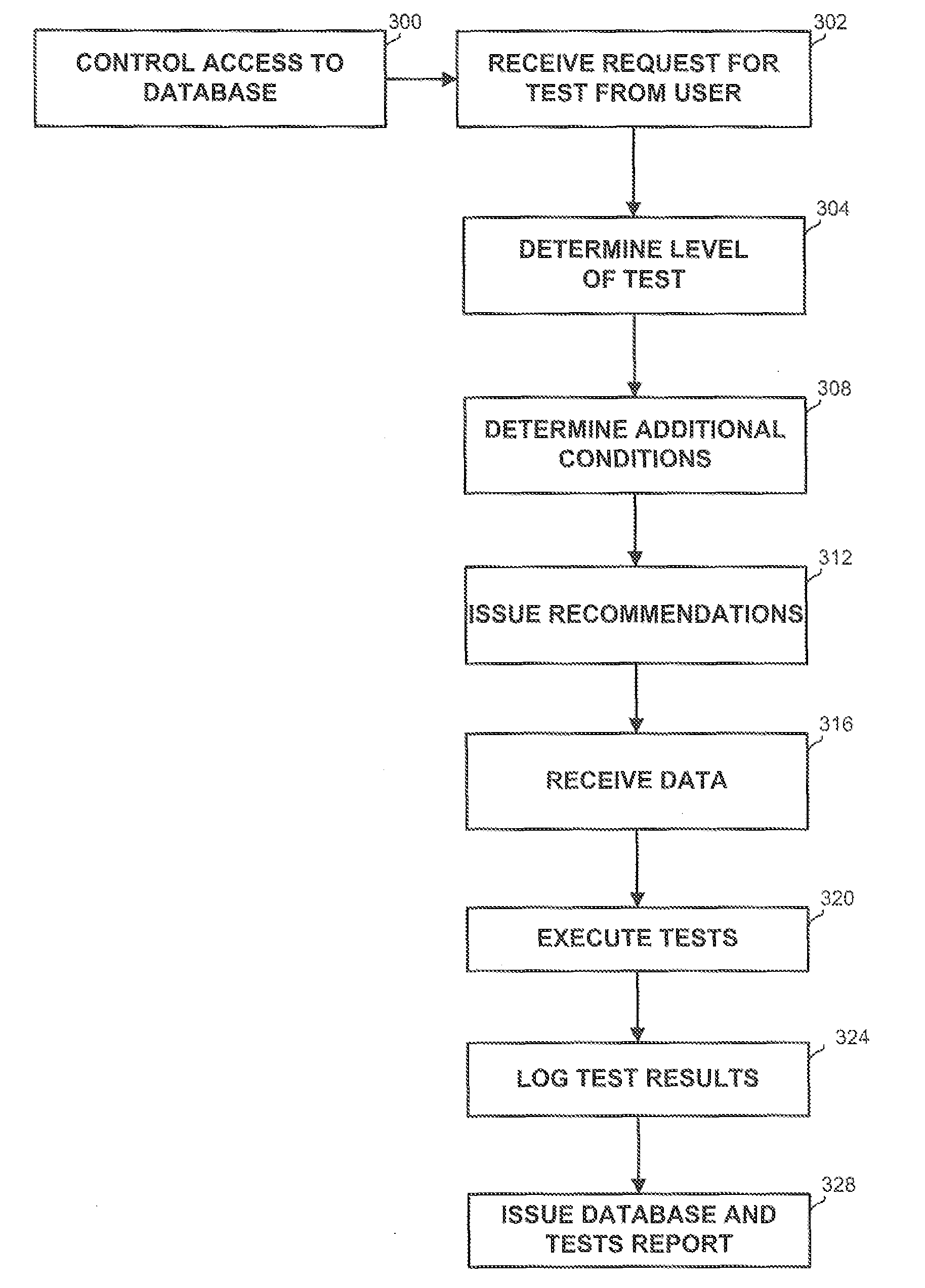

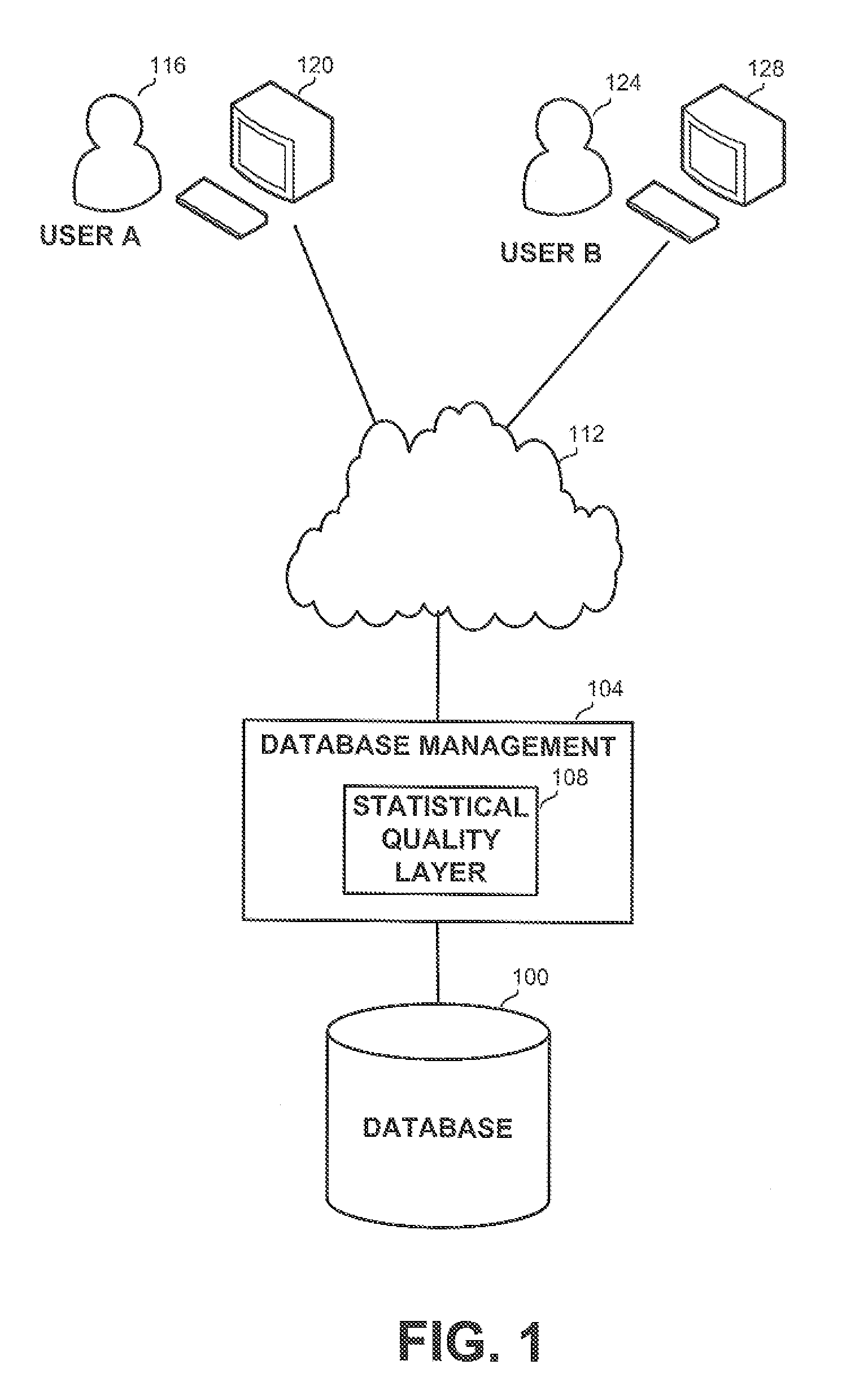

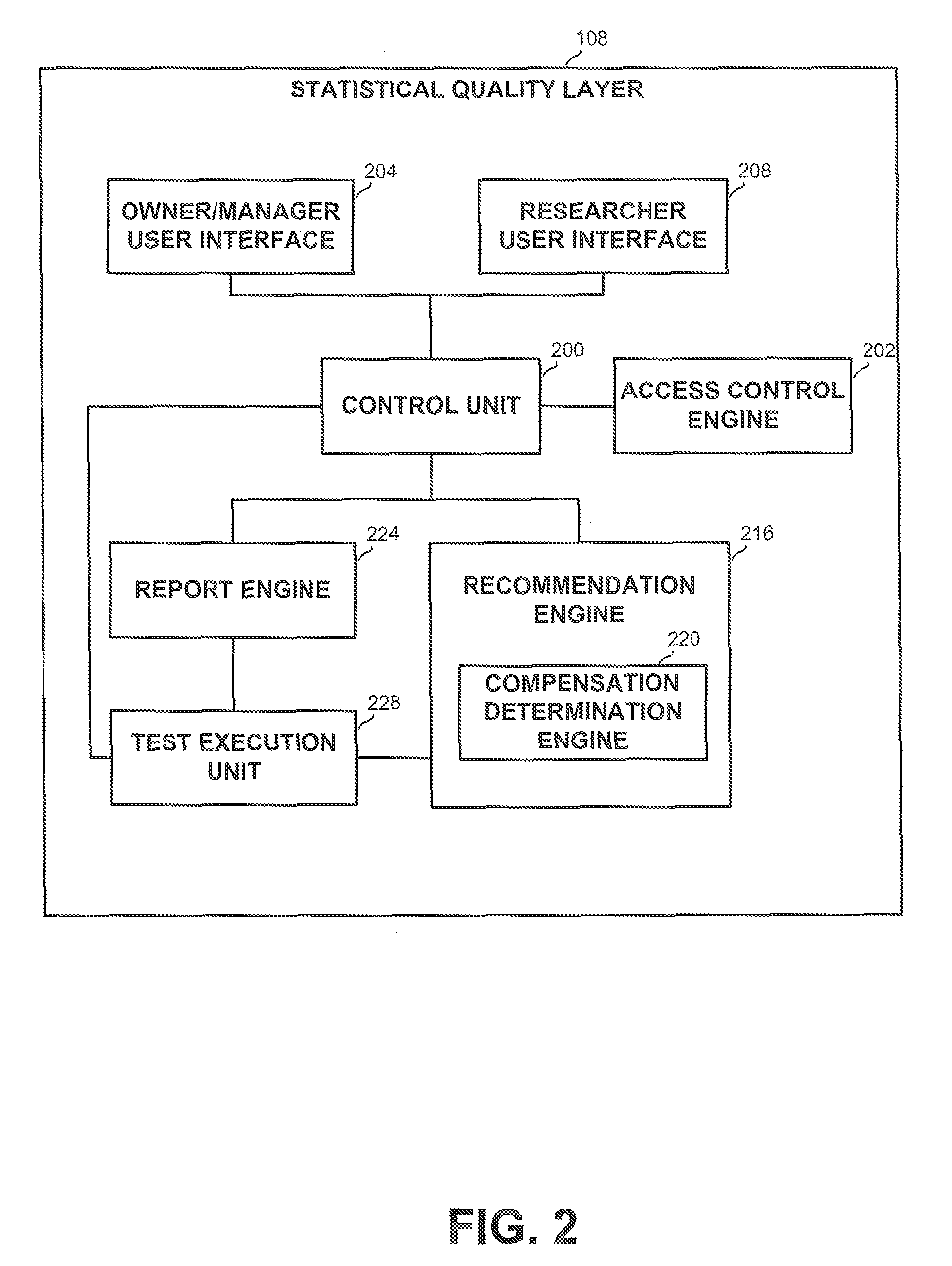

Statistical quality monitoring and enhancement

InactiveUS20110145291A1Reduce in quantityDigital data information retrievalDigital data processing detailsStatistical qualityConfidence metric

A method and computer system for monitoring and controlling the quality of tests performed upon a database. A statistical quality layer is provided, which for each new test to be executed on the database, provides recommendations as to a confidence level to be applied to the test and to a number of additional data records to be added to the database in order to maintain the total expected number of type-I errors of tests performed upon the database. The method and computer system further provide access control of users to the database.

Owner:SERVICENOW INC

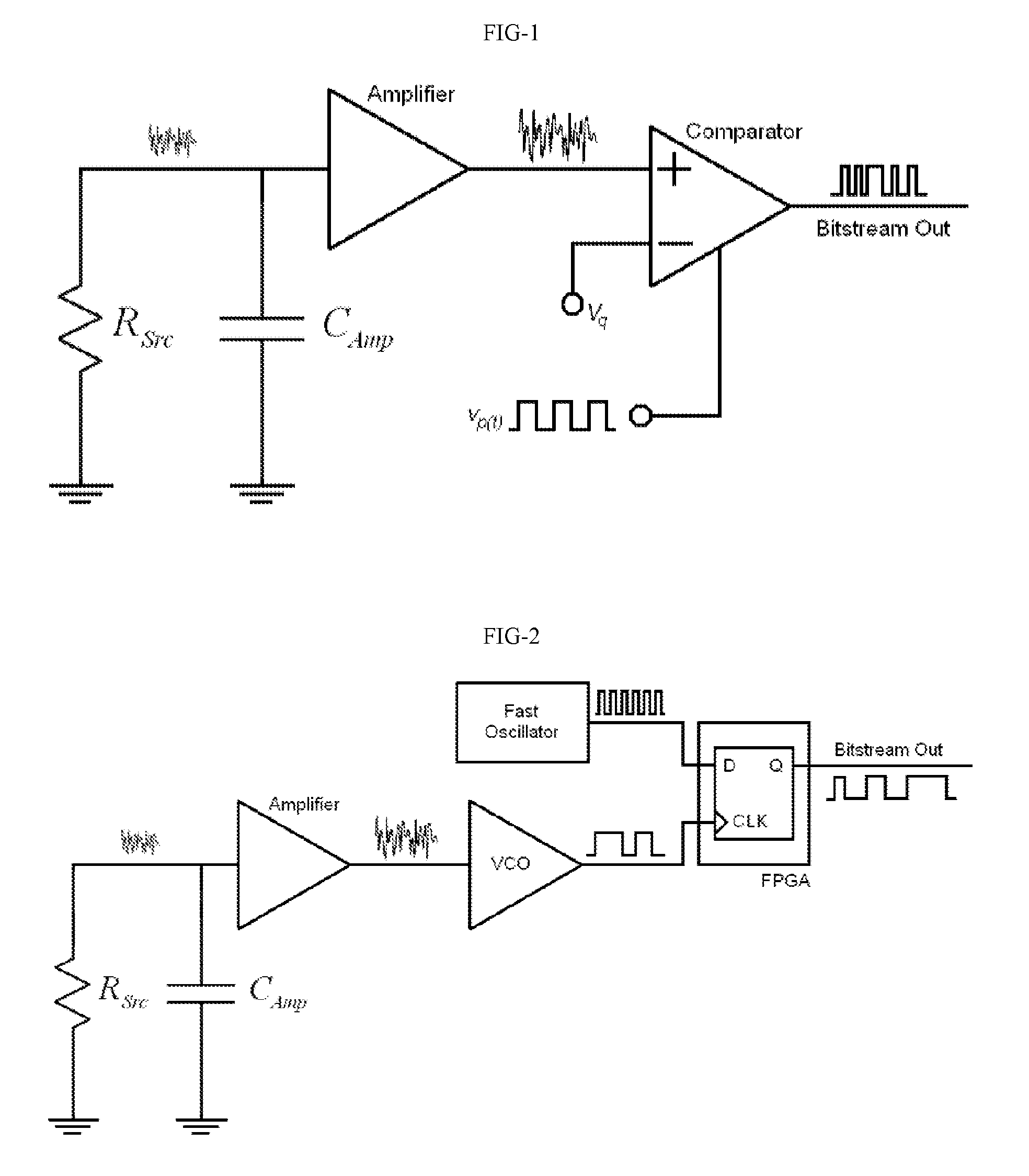

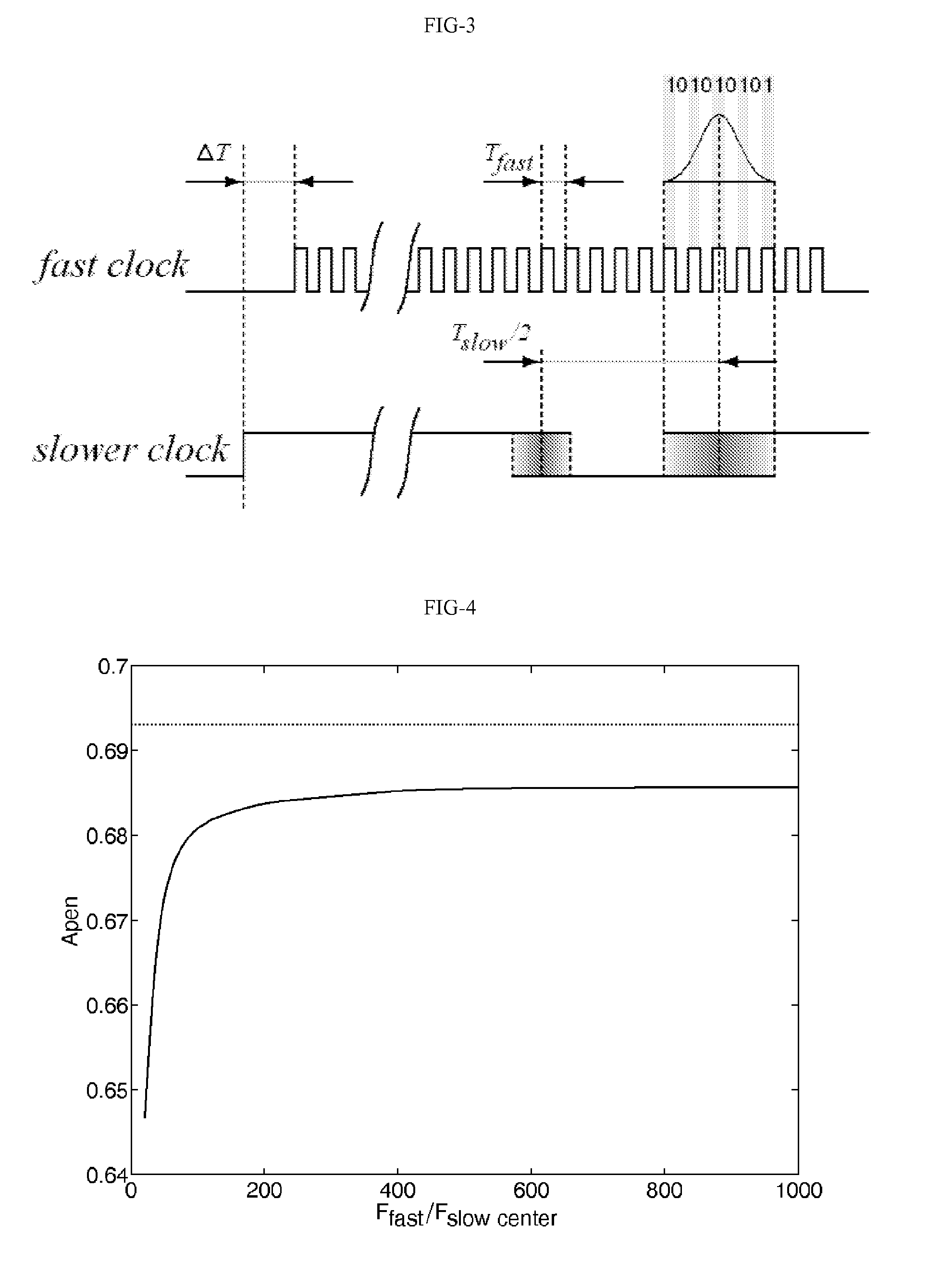

Method and hardware for generating random numbers using dual oscillator architecture and continuous-time chaos

ActiveUS8612501B2Improve throughput speedQuality improvementRandom number generatorsSecuring communication by chaotic signalsStatistical qualityNumber generator

Novel random number generation methods and novel random number generators based on continuous-time chaotic oscillators with dual oscillator architecture are presented. Numerical and experimental results not only verify the feasibility of the proposed circuits, but also encourage their use as a high-performance IC TRNG. In comparison with RNG's based on discrete-time chaotic maps, amplification of a noise source and jittered oscillator sampling, which are advantageous in the sense that true random behavior can be mathematically proven thanks to an analytical model that has been developed, it is seen that RNG's based on continuous-time' chaotic oscillators can offer much higher and constant data rated without post-processing. The proposed innovation increases the throughput, maximizes the statistical quality of the output sequence and is robust against external interference, parameter variations and attacks aimed to force throughout. The proposed circuits can be integrated on today process at GHz range.

Owner:TUBITAK

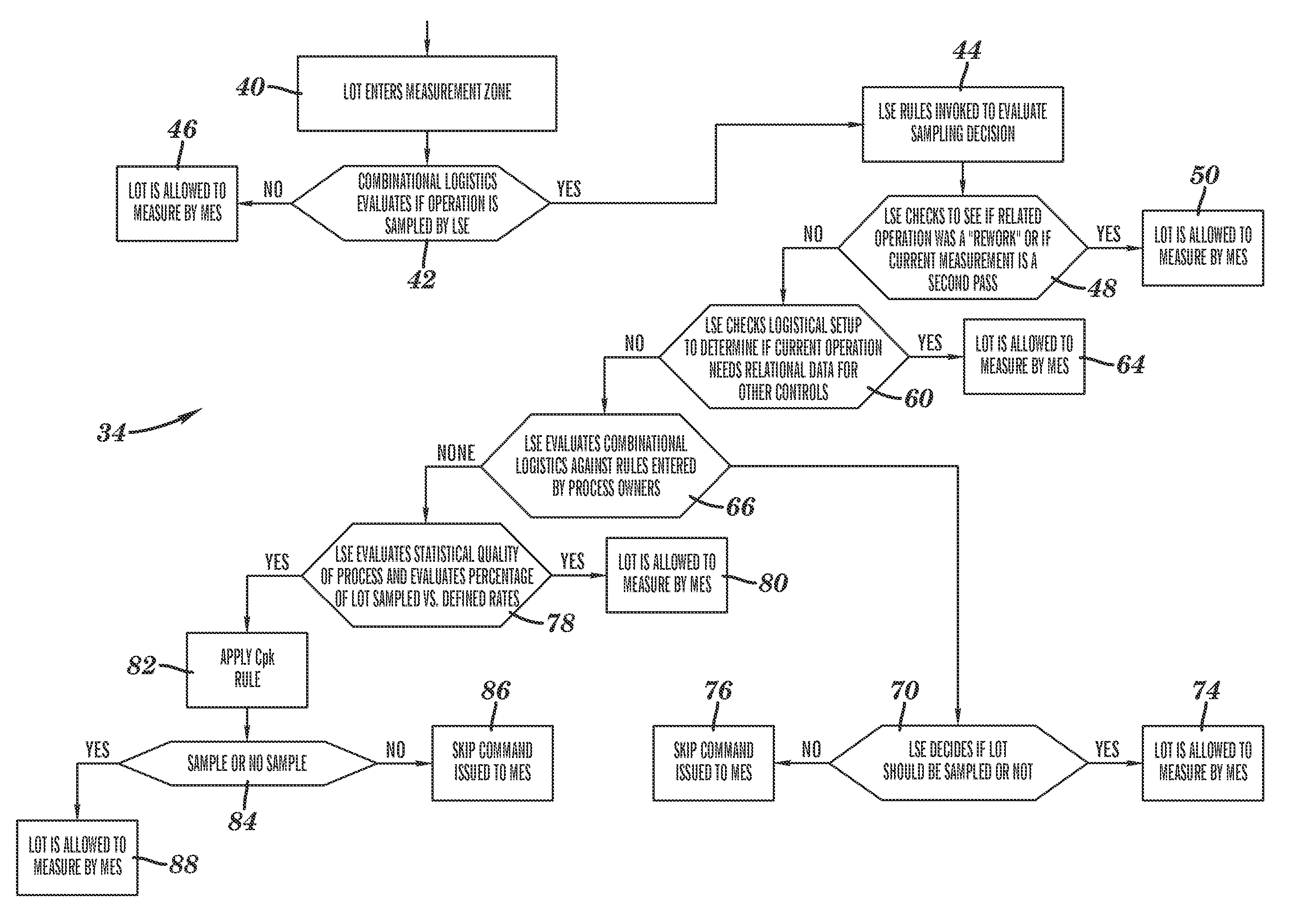

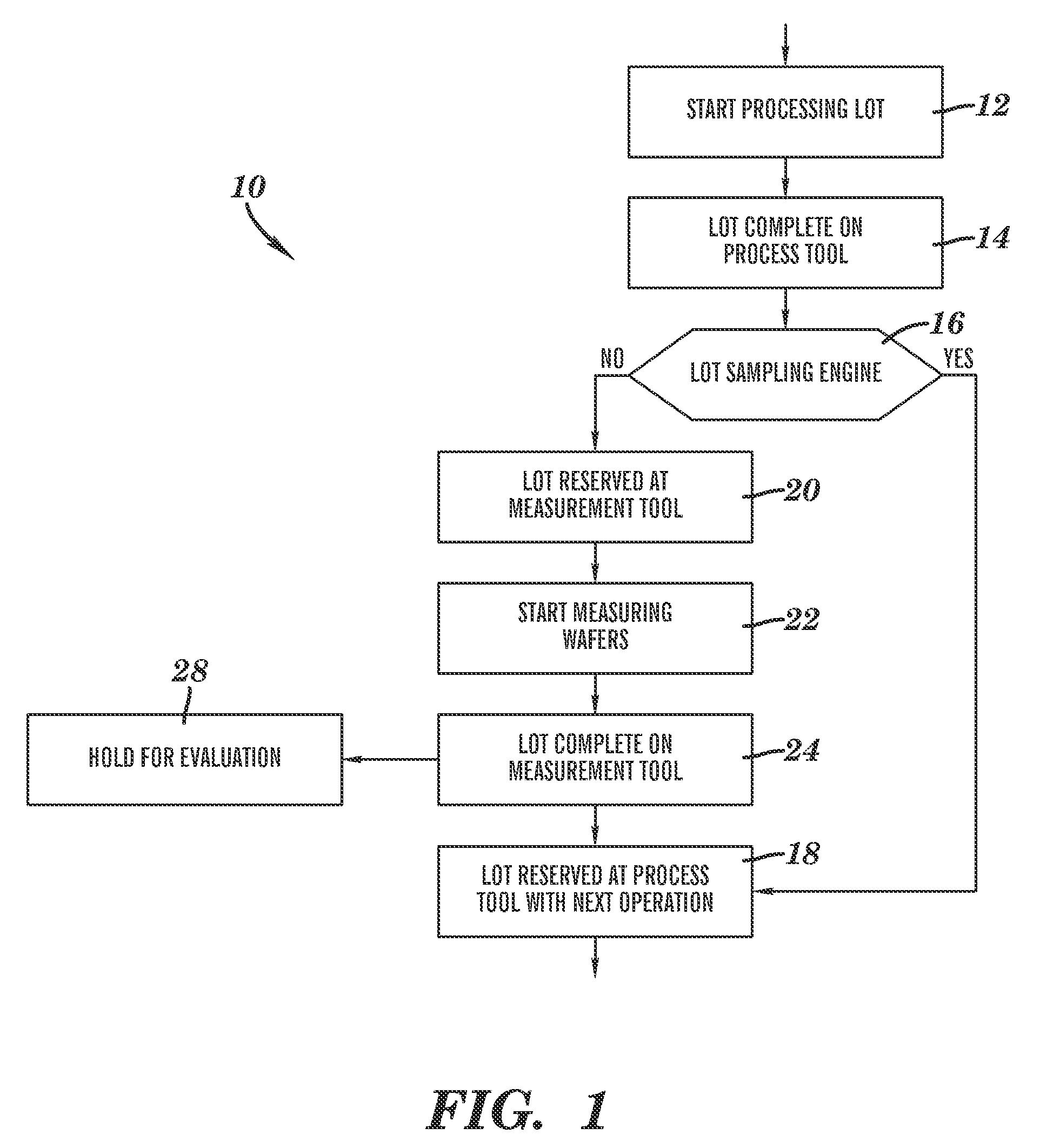

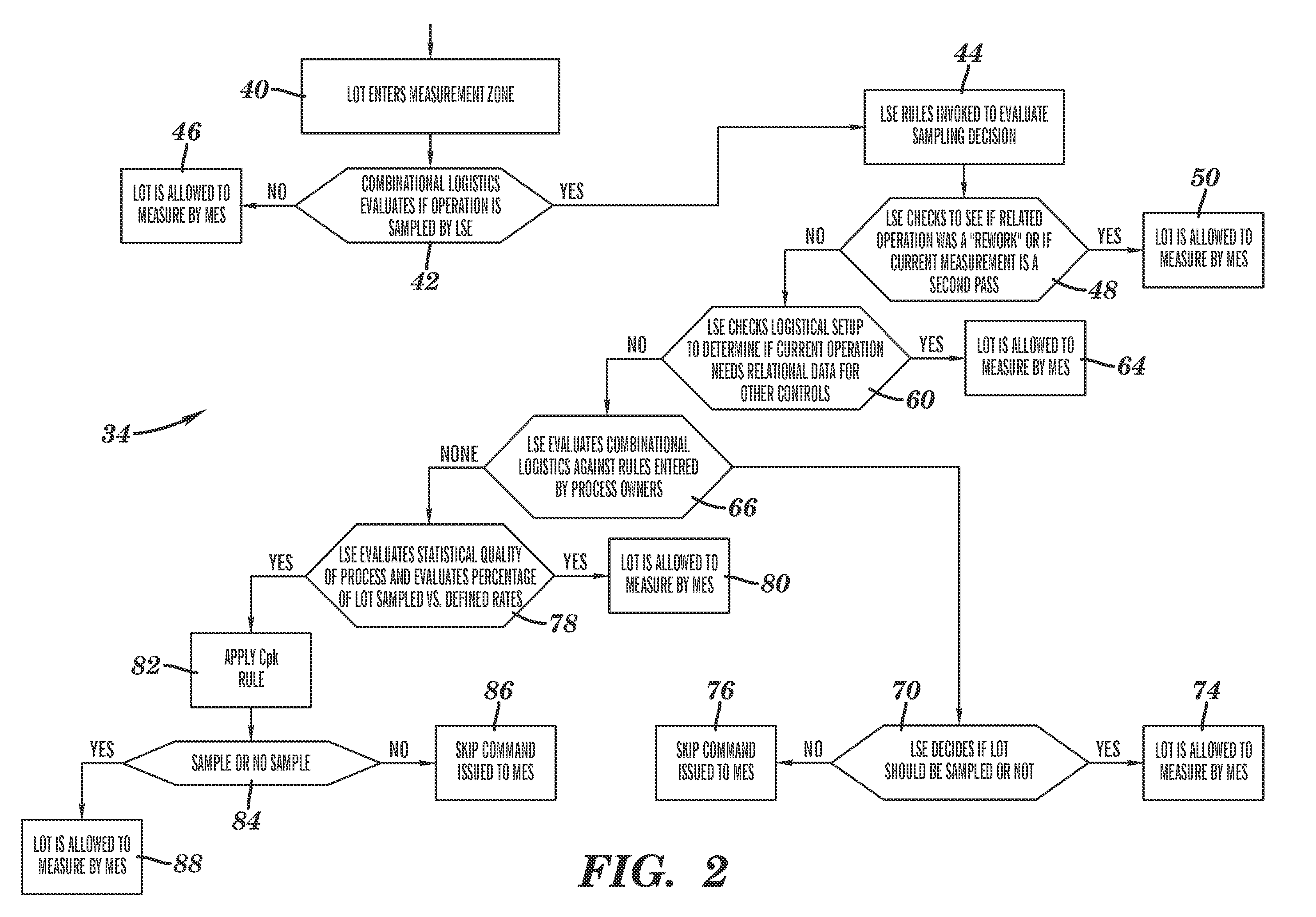

Method of performing measurement sampling of lots in a manufacturing process

InactiveUS20090234485A1Optimizes non-value added stepReduce manufacturing costProgramme controlTotal factory controlLogistics managementStatistical quality

Owner:IBM CORP

Statistical quality monitoring and enhancement

InactiveUS8140476B2Digital data information retrievalDigital data processing detailsStatistical qualityTest quality

A method and computer system for monitoring and controlling the quality of tests performed upon a database. A statistical quality layer is provided, which for each new test to be executed on the database, provides recommendations as to a confidence level to be applied to the test and to a number of additional data records to be added to the database in order to maintain the total expected number of type-I errors of tests performed upon the database. The method and computer system further provide access control of users to the database.

Owner:SERVICENOW INC

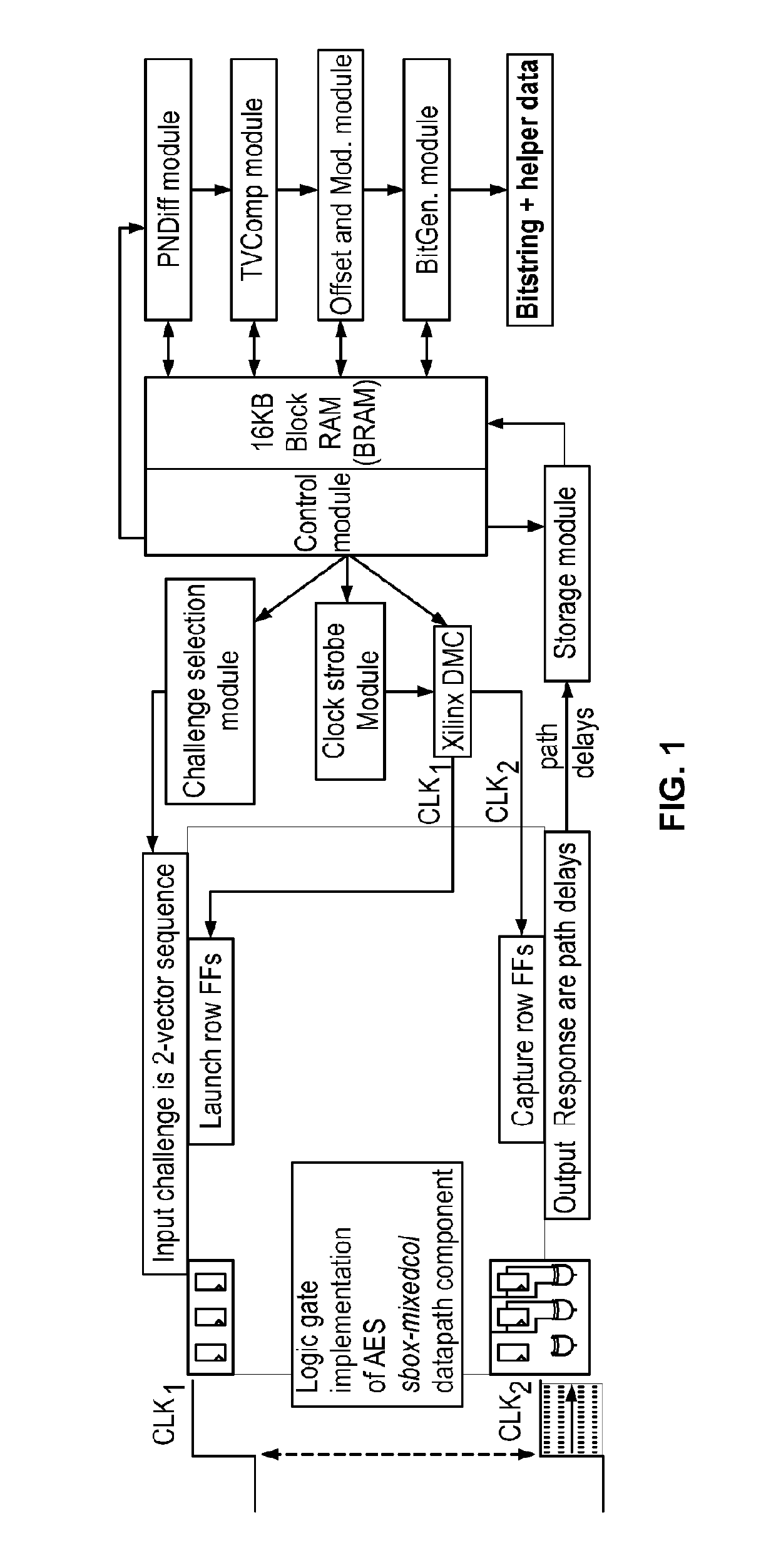

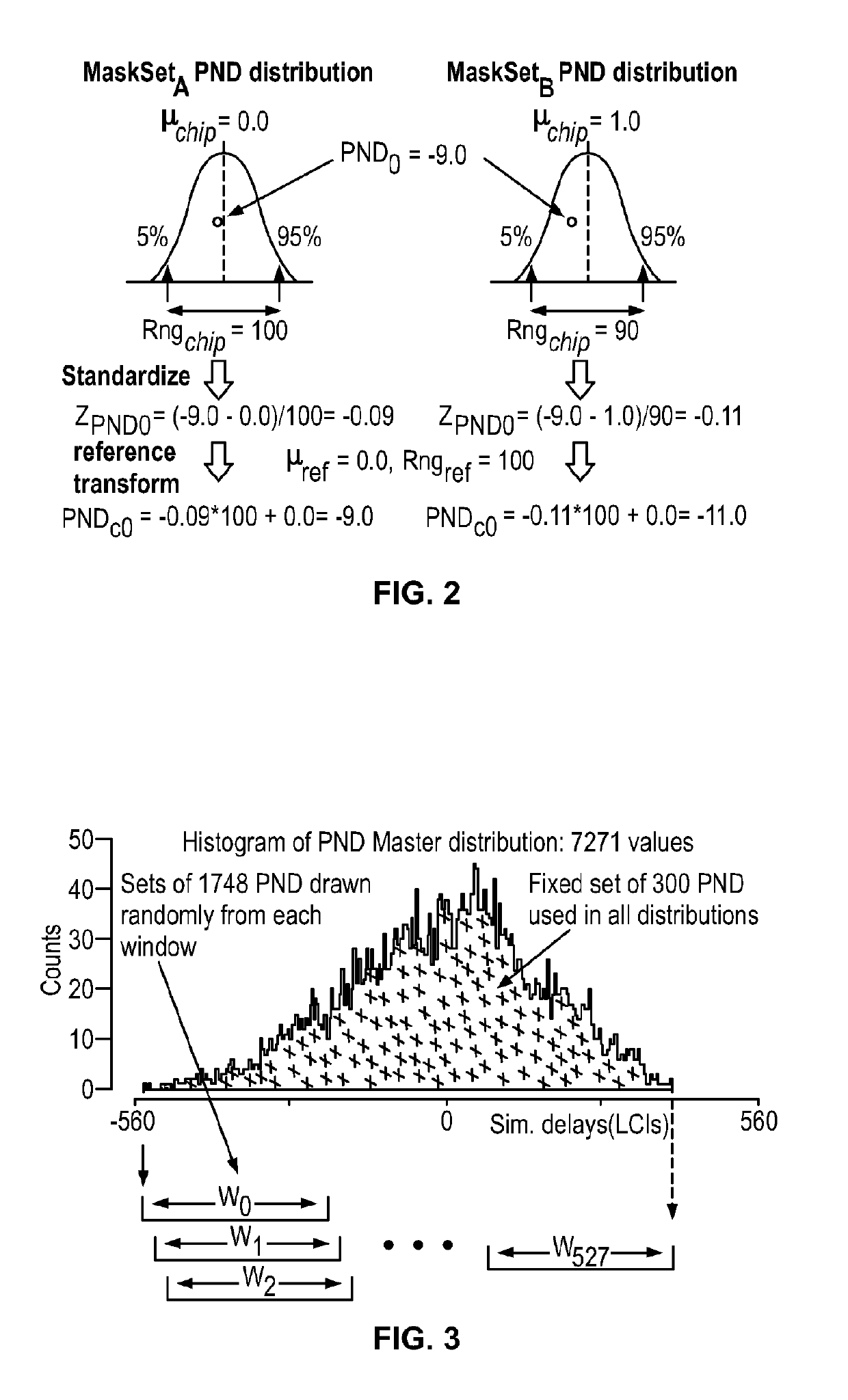

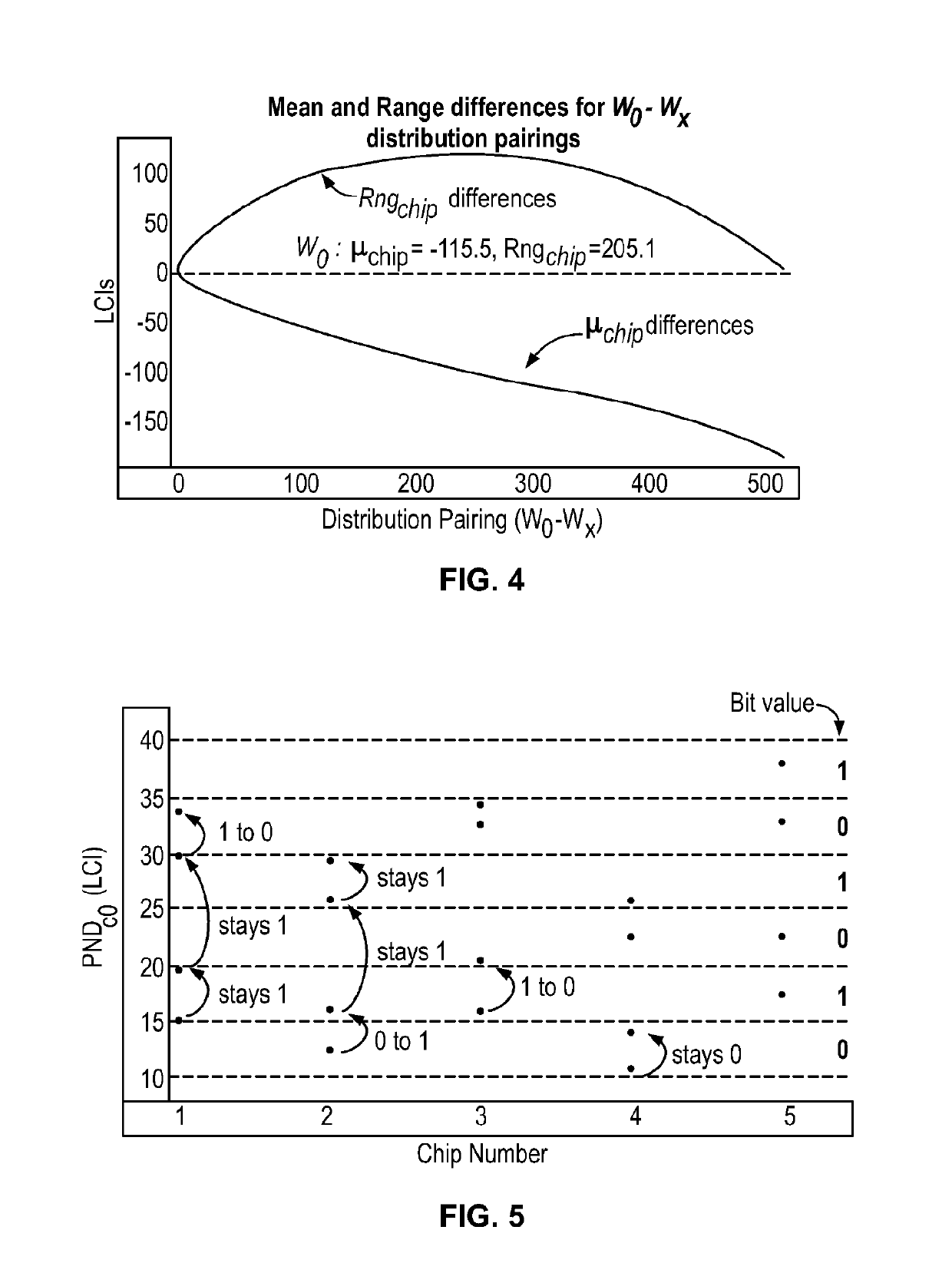

System and methods for entropy and statistical quality metrics in physical unclonable function generated bitstrings

ActiveUS20190268170A1Increase diversityIncrease unpredictabilityUser identity/authority verificationDigital data authenticationStatistical qualityPhysical unclonable function

The Distribution Effect is proposed for the HELP PUF that is based on purposely introducing biases in the mean and range parameters of path delay distributions to enhance entropy. The biased distributions are then used in the bitstring construction process to introduce differences in the bit values associated with path delays that would normally remain fixed. Offsets are computed to fine tune a token's digitized path delays as a means of maximizing entropy and reproducibility in the generated bitstrings: a first population-based offset method computes median values using data from multiple tokens (i.e., the population) and a second chip-specific technique is proposed which fine tunes path delays using enrollment data from the authenticating token.

Owner:UNM RAINFOREST INNOVATIONS

Statistical Quality Assessment of Fingerprints

The present invention relates generally to human fingerprints. More specifically the present invention relates to assessing the quality of a fingerprint image. An assessment is made by analyzing characteristics of image sub-regions. For example, the characteristics may include statistics that are associated with a sub-region. If a sub-region is found to have unacceptable characteristics, it can be modified through a morphological operation to compensate for the unacceptable characteristics.

Owner:L 1 SECURE CREDENTIALING

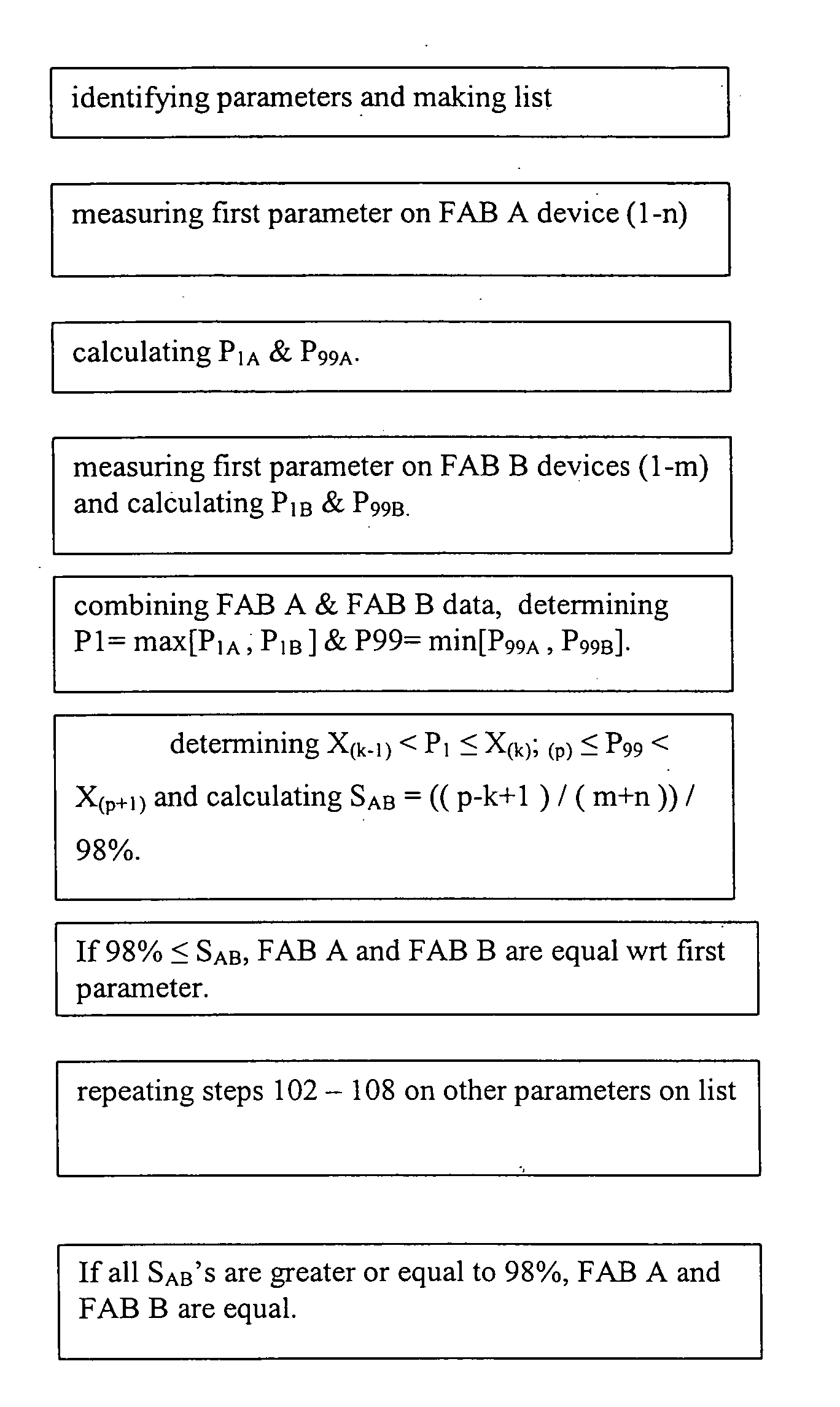

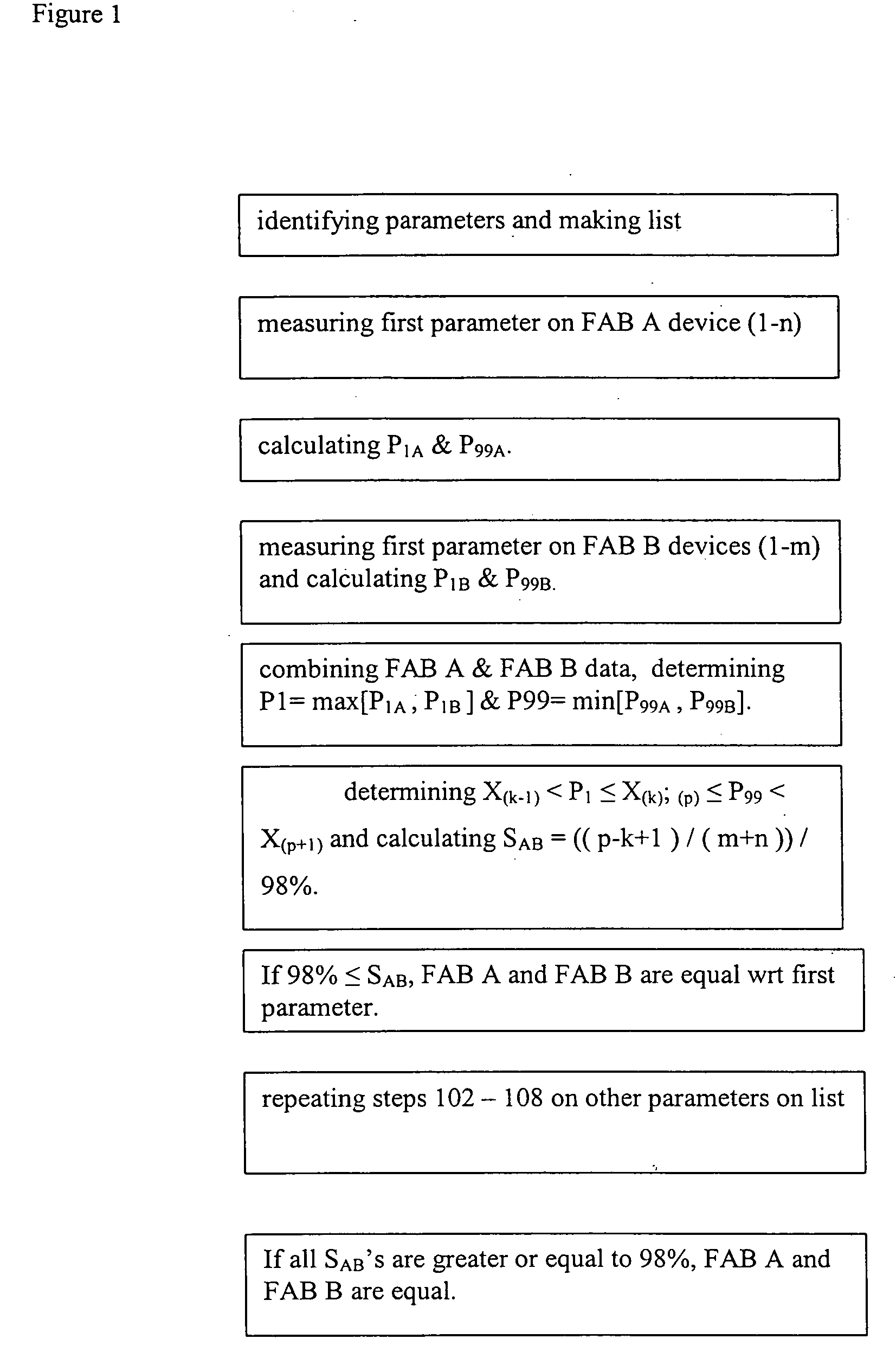

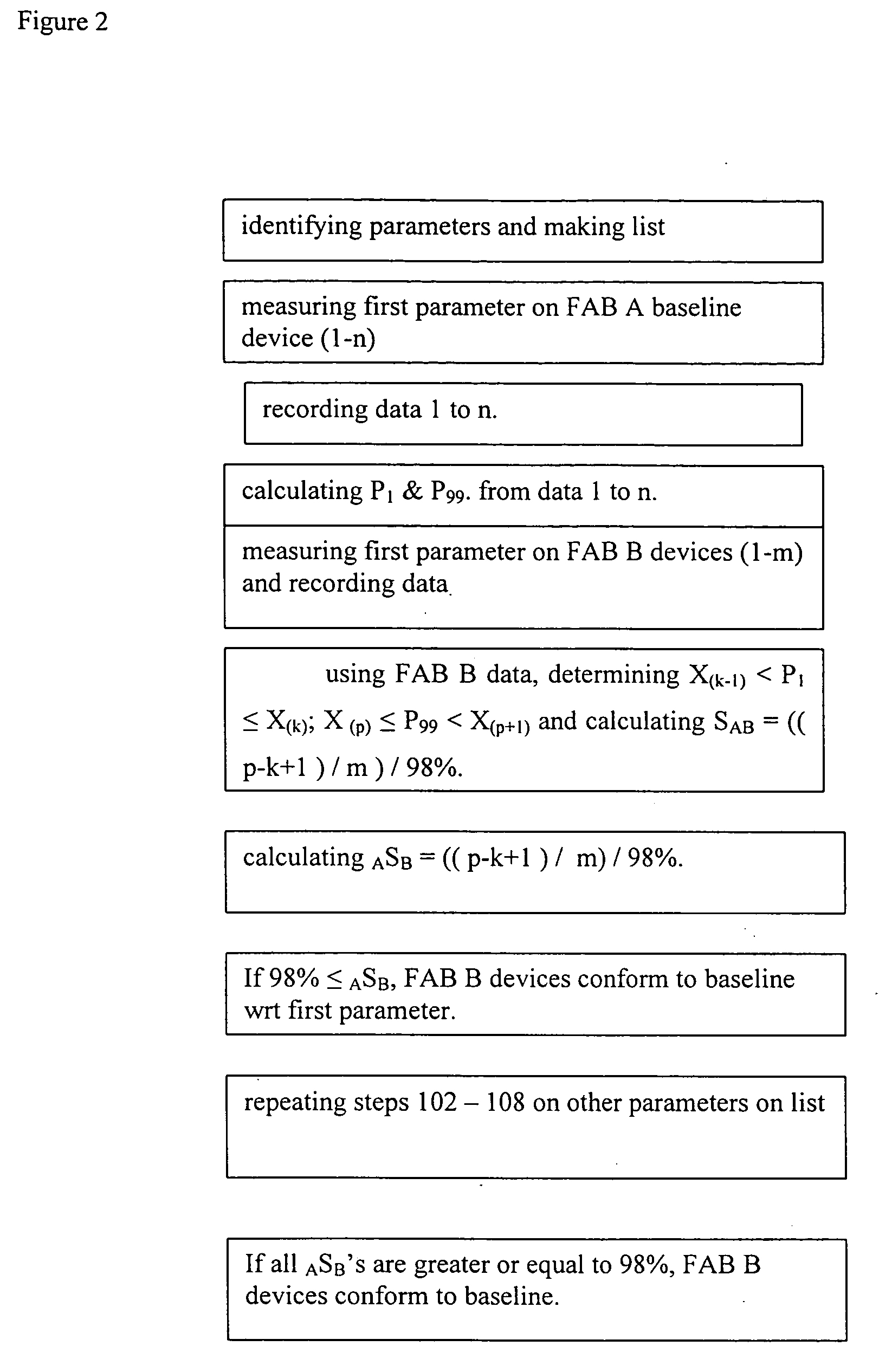

Method for determining the equivalency index of products and processes

ActiveUS20050142670A1Semiconductor/solid-state device manufacturingStructural/machines measurementStatistical qualityQuality control

A method is disclosed wherewith a person skilled in the art of statistical quality control may use to determine whether a process or a product is statically equivalent to another of known quality, or conforms to a desired known quality. The method may also be used to determine whether multiplicities of products or processes are statistically equivalent to one another. The method makes the determination based calculating an equivalency index that is associated with the measured parametric data, the population ratio of data points within a set of parametric limits.

Owner:TEXAS INSTR INC

Media watermarking by biasing randomized statistics

InactiveUS7539870B2User identity/authority verificationSpeech analysisPattern recognitionStatistical correlation

The present invention leverages randomly generated areas with random attributes from two-dimensional media forms to embed information relating to a media's ownership and / or distribution source. This provides a means to establish a media's source despite attacks. By providing embedded user-unique identification, media can enable detection for identifying the source of copied media without the embedded information substantially interfering with the intended purpose of the media itself. In one instance of the present invention, media is transformed into a two-dimensional media form with randomly generated areas having a subset of overlapping areas. User-unique keys are then utilized to determine attributes for each of the areas. This permits creation of statistically unique locations for each user key. The statistical qualities are biased and utilized to determine a logarithmic magnitude watermark value to embed in the media at that location. Detection is performed by utilizing a statistical correlation method to determine a user.

Owner:MICROSOFT TECH LICENSING LLC

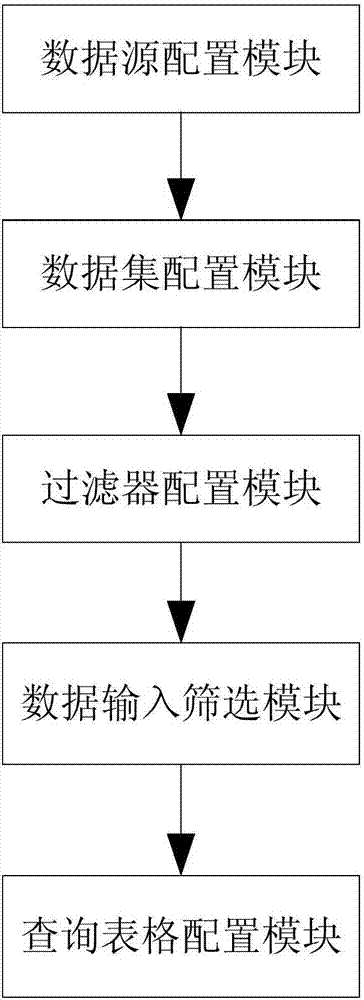

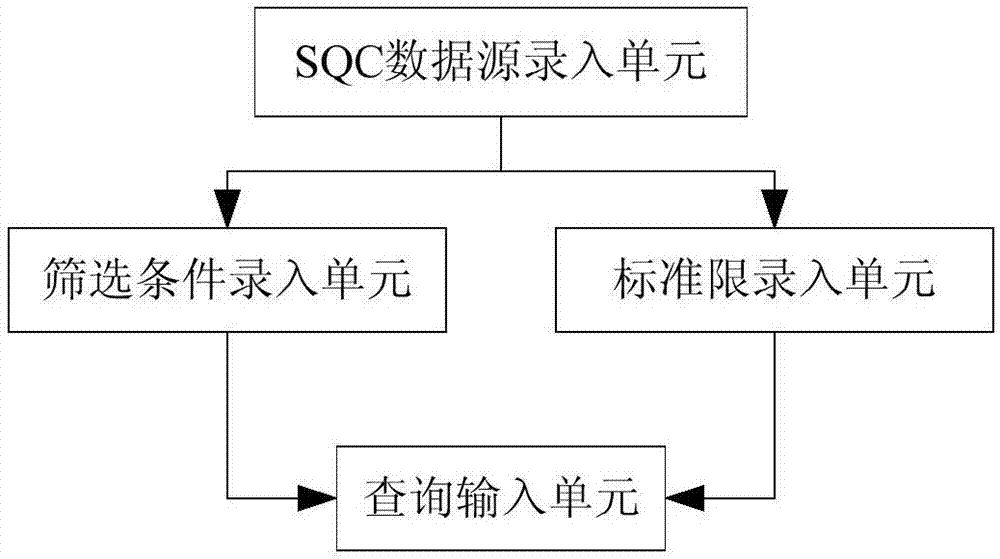

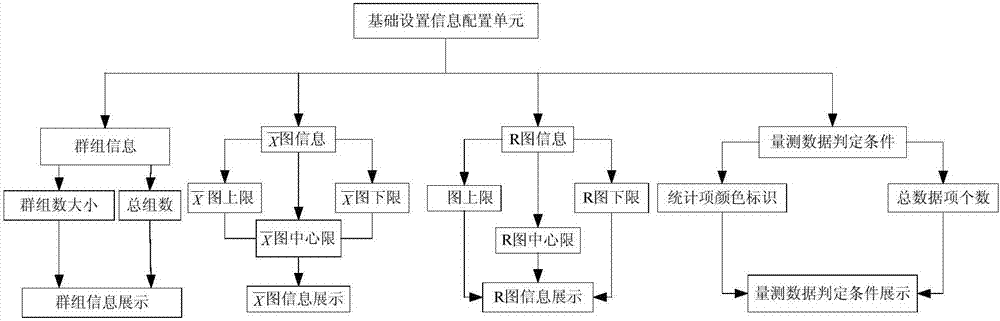

Statistical quality control system based on LIMS (Laboratory Information Management System)

The invention provides a statistical quality control system based on LIMS (Laboratory Information Management System). The system comprises a data source configuration module, used for specifying an SQC (Statistical Quality Control) data source to be queried; a data set configuration module, used for building a data set body including preset parameters based on the SQC data source; a filter configuration module, used for generating query conditions based on the preset parameters and configuring query condition control types and dependencies to generate a filter; a data input sieving module, used for configuring sieving conditions to sieve the input SQC data source; and a query form configuration module, used for configuring SQC statistical information query forms based on the sieving conditions and the selected filter. The system of the invention is capable of realizing index statistics required in SQC.

Owner:石化盈科信息技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com