Patents

Literature

73 results about "Total quality management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total quality management (TQM) consists of organization-wide efforts to "install and make permanent climate where employees continuously improve their ability to provide on demand products and services that customers will find of particular value." "Total" emphasizes that departments in addition to production (for example sales and marketing, accounting and finance, engineering and design) are obligated to improve their operations; "management" emphasizes that executives are obligated to actively manage quality through funding, training, staffing, and goal setting. While there is no widely agreed-upon approach, TQM efforts typically draw heavily on the previously developed tools and techniques of quality control. TQM enjoyed widespread attention during the late 1980s and early 1990s before being overshadowed by ISO 9000, Lean manufacturing, and Six Sigma.

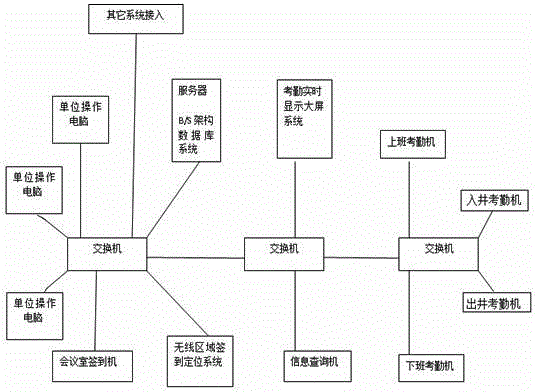

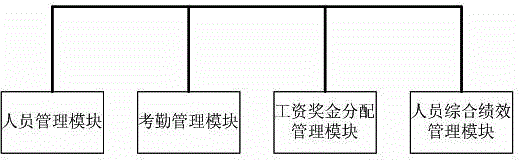

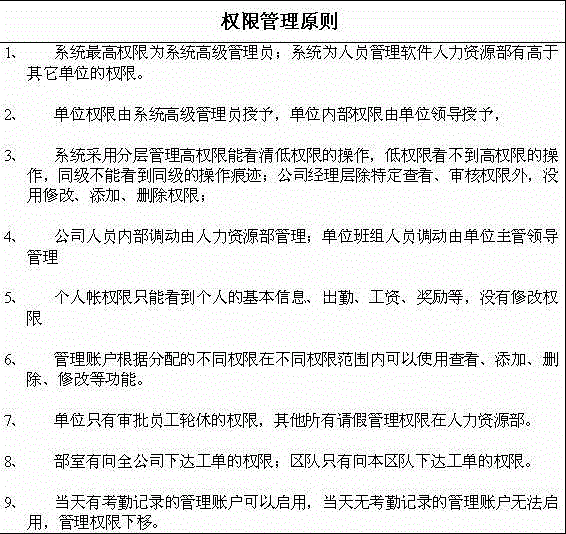

Personnel information comprehensive management system

InactiveCN104636889AGuarantee justiceEqual protectionResourcesTotal quality managementManagement environment

The invention discloses a personnel information comprehensive management system. The system comprises a personnel management module, an attendance management module, a salary and bonus distribution management module and a personnel comprehensive achievement management module. A management system is a basis of an enterprise, and execution power is guarantee for development of the enterprise. The enterprise is not in lack of the system but in lack of the execution of the system; the system is quantized by using an informationalized technical means and the execution is measured by using tracing supervision, the measuring result is related to personal interest; the system is a means for carrying out the system powerfully. Total factor management of personnel can be realized through the system; the enterprise management is both rigid and flexible and is performed well through the rigidness of computer management and the flexibility of manual management of the personnel information comprehensive management system, the national laws and regulations and the system of the enterprise are effectively implemented, the power of a manager is supervised, the personnel can work in a good management environment of the enterprise, finally healthy, harmonious and positive development of the enterprise is realized, employee benefit, the efficiency of the enterprise is increased, and the nation is stable.

Owner:刘升 +1

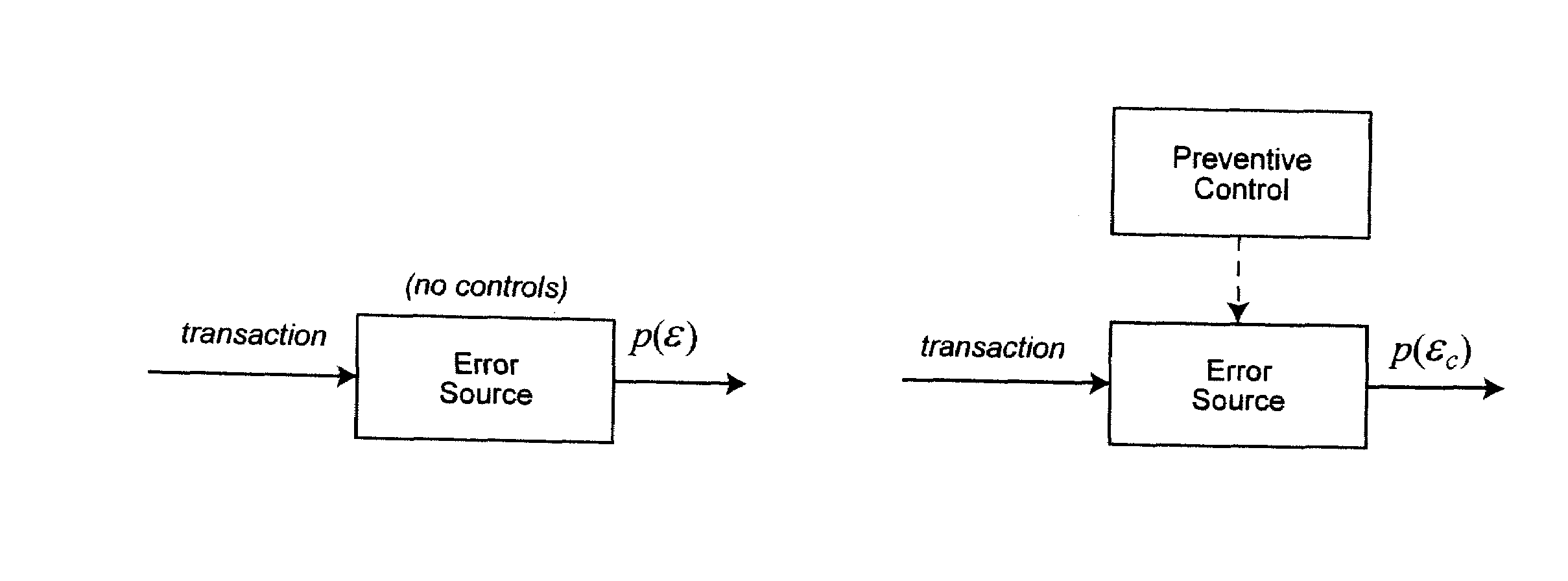

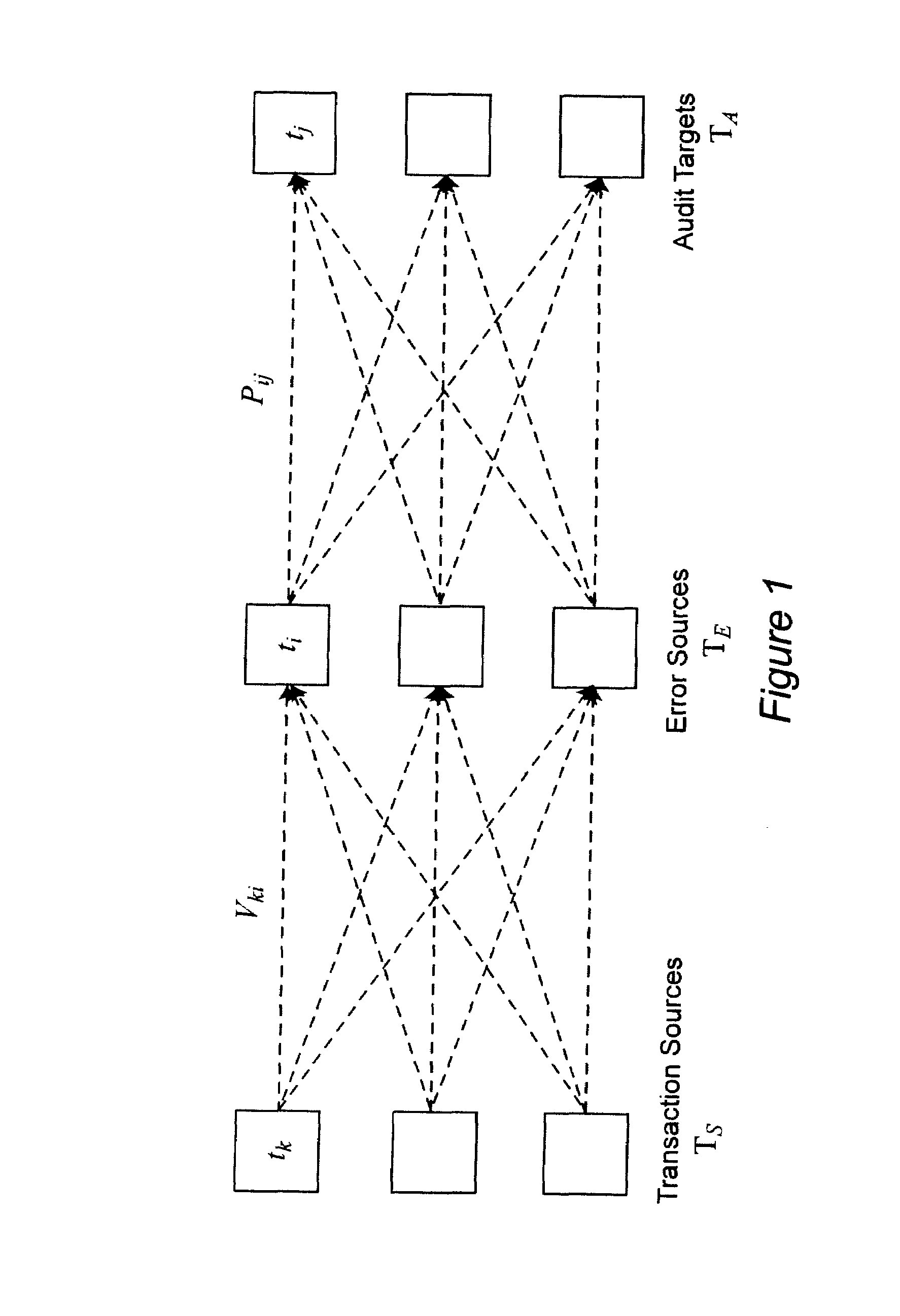

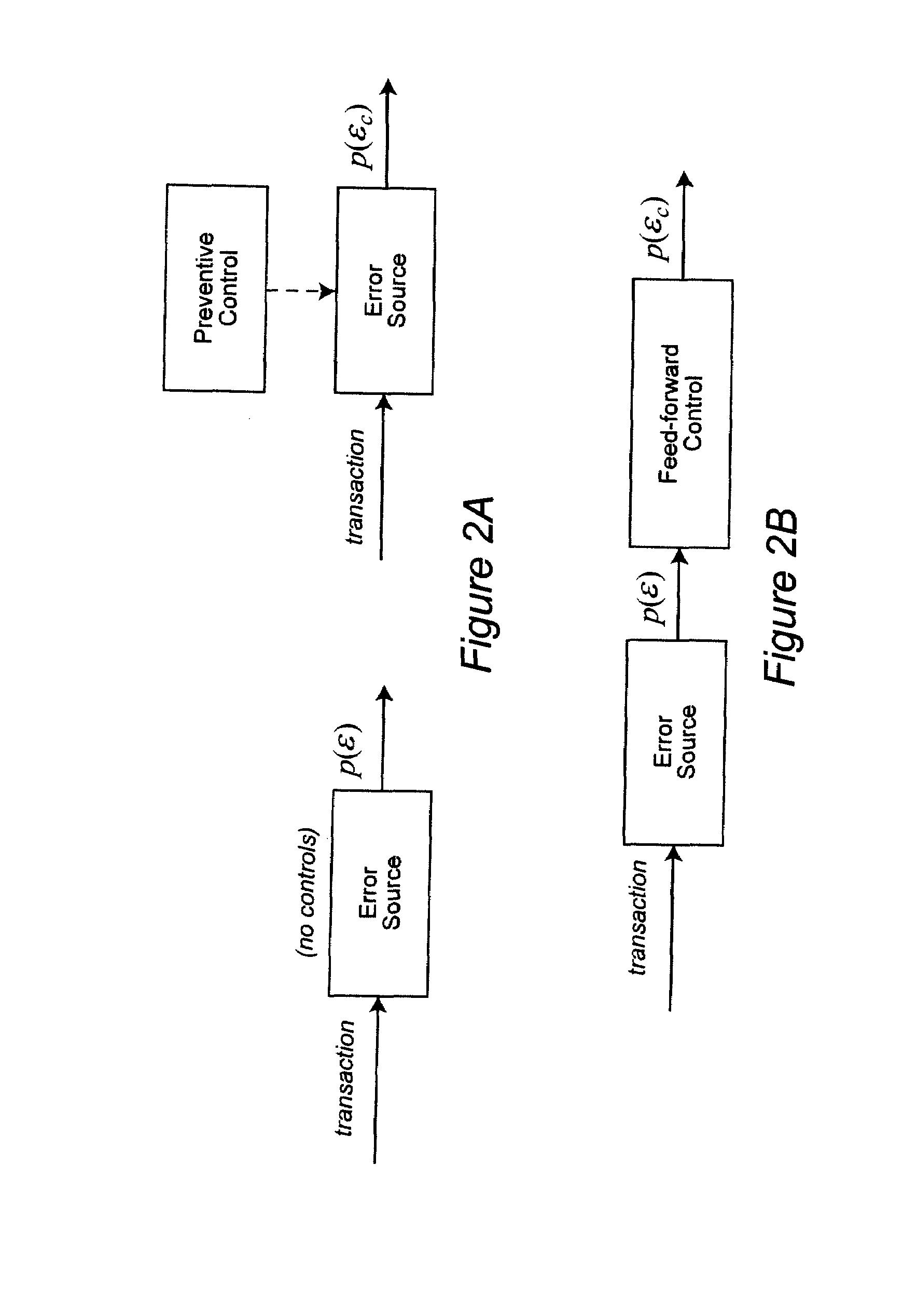

Data quality management using business process modeling

InactiveUS20080195440A1Impacts the overall quality of sales data.Low costResourcesComplex mathematical operationsDashboardInformation processing

A business process modeling framework is used for data quality analysis. The modeling framework represents the sources of transactions entering the information processing system, the various tasks within the process that manipulate or transform these transactions, and the data repositories in which the transactions are stored or aggregated. A subset of these tasks is associated as the potential error introduction sources, and the rate and magnitude of various error classes at each such task are probabilistically modeled. This model can be used to predict how changes in transactions volumes and business processes impact data quality at the aggregate level in the data repositories. The model can also account for the presence of error correcting controls and assess how the placement and effectiveness of these controls alter the propagation and aggregation of errors. Optimization techniques are used for the placement of error correcting controls that meet target quality requirements while minimizing the cost of operating these controls. This analysis also contributes to the development of business “dashboards” that allow decision-makers to monitor and react to key performance indicators (KPIs) based on aggregation of the transactions being processed. Data quality estimation in real time provides the accuracy of these KPIs (in terms of the probability that a KPI is above or below a given value), which may condition the action undertaken by the decision-maker.

Owner:DOORDASH INC

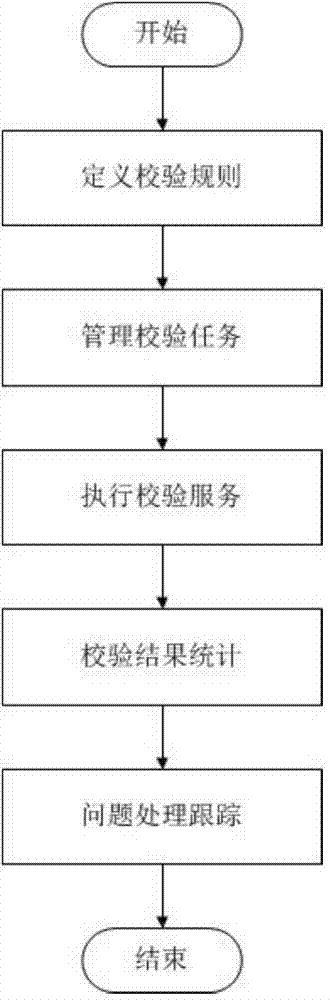

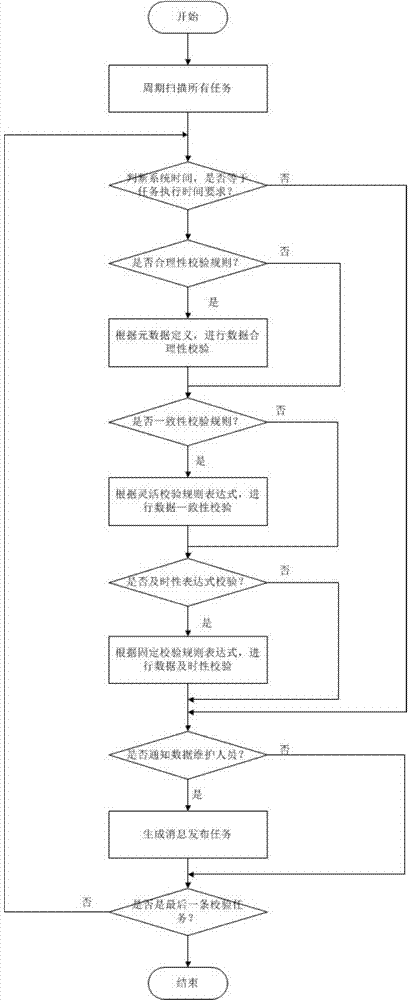

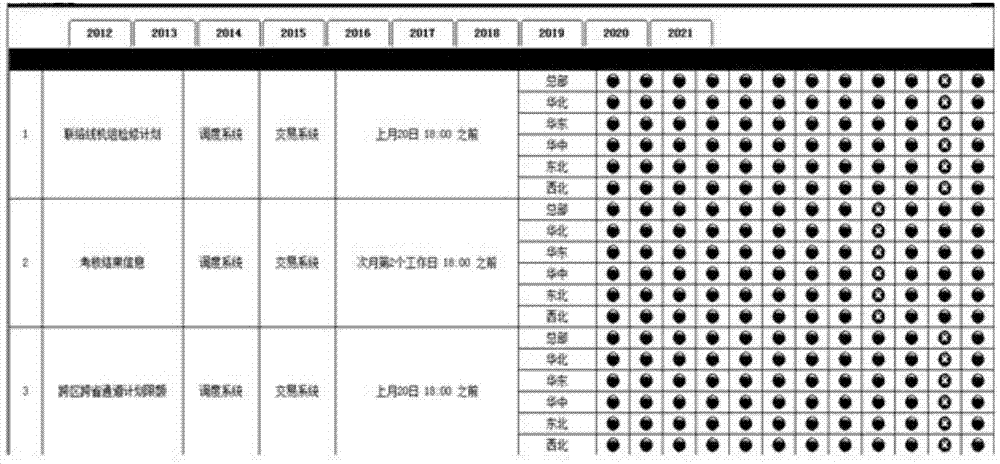

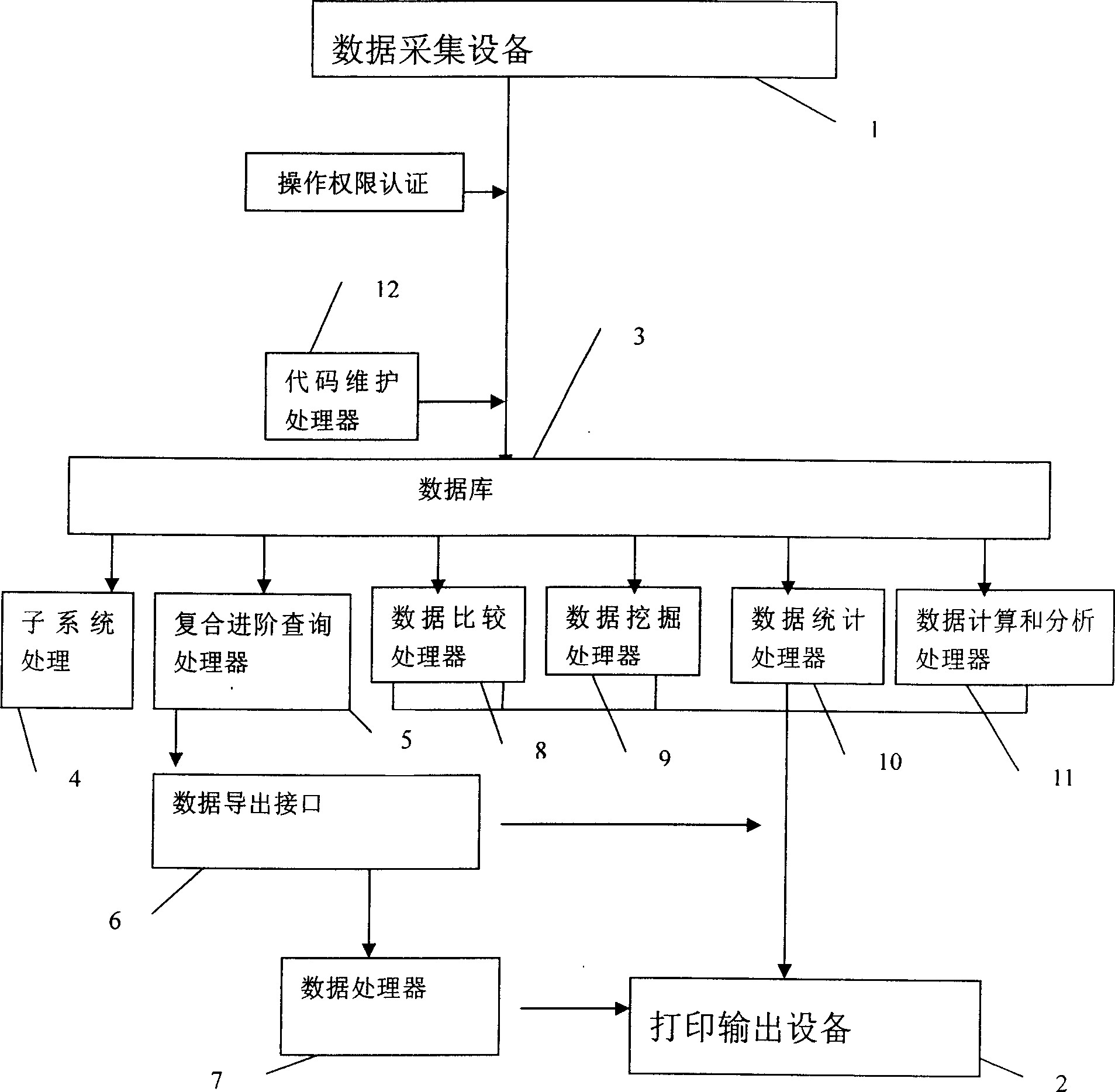

Quality management and control method for electricity transaction data warehouses and management and control system thereof

InactiveCN104766151ARealize timely releaseImplement trackingOffice automationResourcesData setData warehouse

The invention relates to a quality management and control method for electricity transaction data warehouses and a management and control system thereof. The method comprises the following steps: defining checking metadata and checking rules; setting checking tasks; performing checking service; releasing a data checking result; and handling and tracking quality problems. According to the technical scheme of the invention, the rationality, consistency, integrality and timeliness of data are judged by aiming at a data set and through flexible definition of the checking rules, statistical and historical trend analysis is made on four management and control indicators, and a problem handling and tracking feedback mechanism is designed to facilitate quality control measure formulation by management personnel. After implementation, the system, as an important part of an electricity market data warehouse, provides a data quality guarantee for advanced analysis and mining application of the market.

Owner:STATE GRID CORP OF CHINA +4

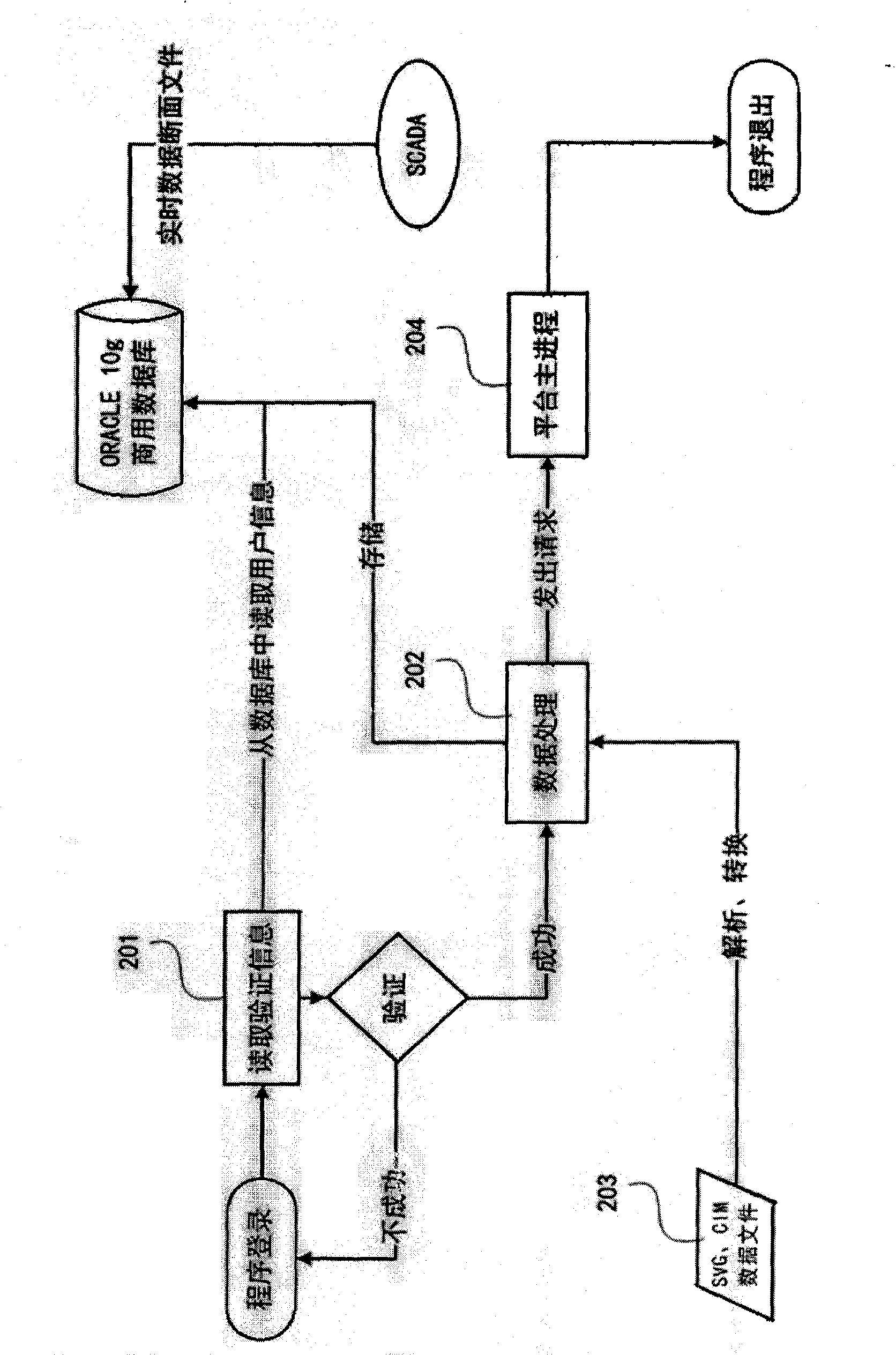

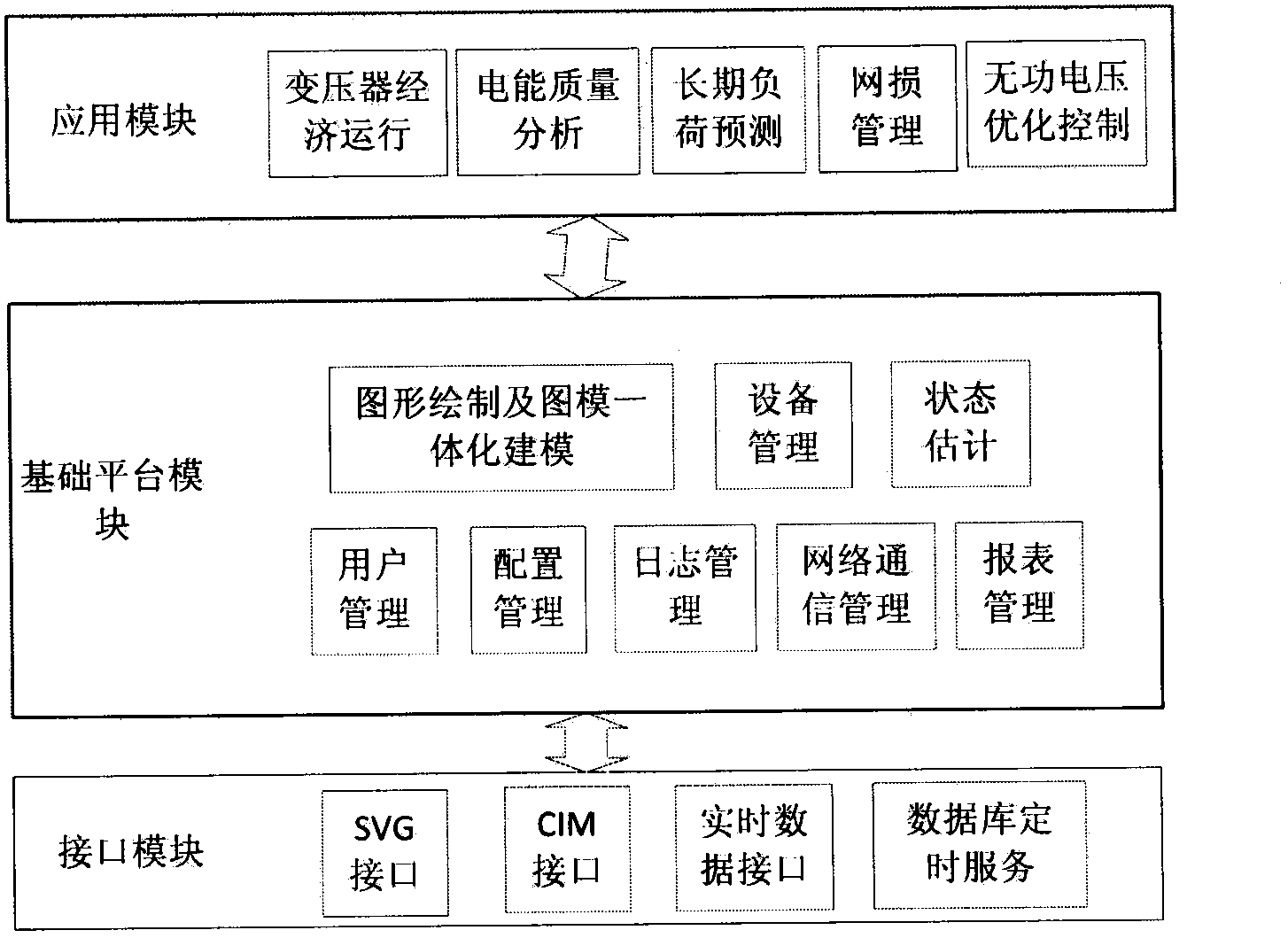

Regional power grid economic operation and energy saving total management system

InactiveCN103514501AImprove efficiencyIncrease power levelTechnology managementResourcesPower qualitySimulation

The invention relates to a regional power grid economic operation and energy saving total management system which comprises three layers of structures. The bottom layer is an interface module, the middle layer is a foundation platform module, and a high-level layer is a function application layer. The interface module achieves image equipment and topological data reading to the system and a database timed task function. The middle layer supports power grid visualization graphic modeling and universal tool service functions. The high-level layer achieves a complete set of regional power grid economic operation analysis and energy saving total management functions and an auxiliary-implemented working process. The system mainly has five application functions, namely long-term load prediction, transformer economic operation, power quality analyzing, transmission loss managing and reactive voltage optimal controlling.

Owner:QINHUANGDAO POWER SUPPLY COMPANY OF STATE GRID JIBEI ELECTRIC POWER COMPANY +1

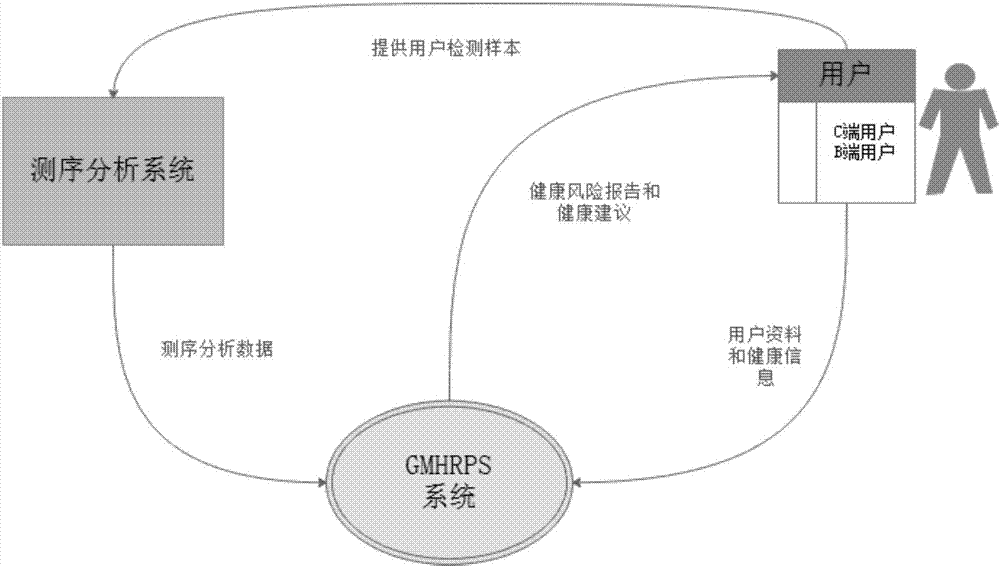

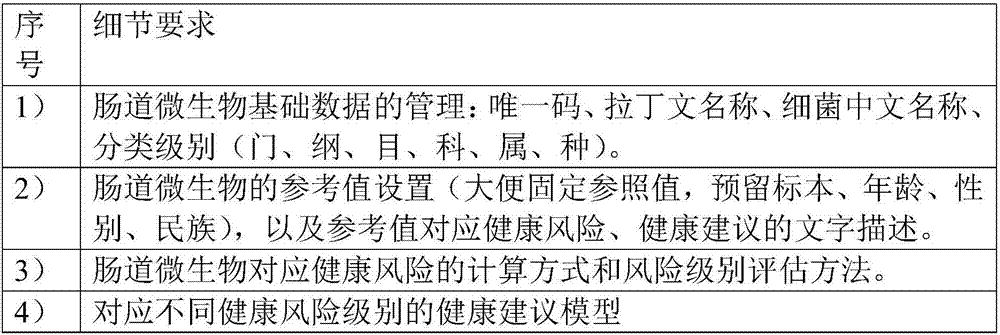

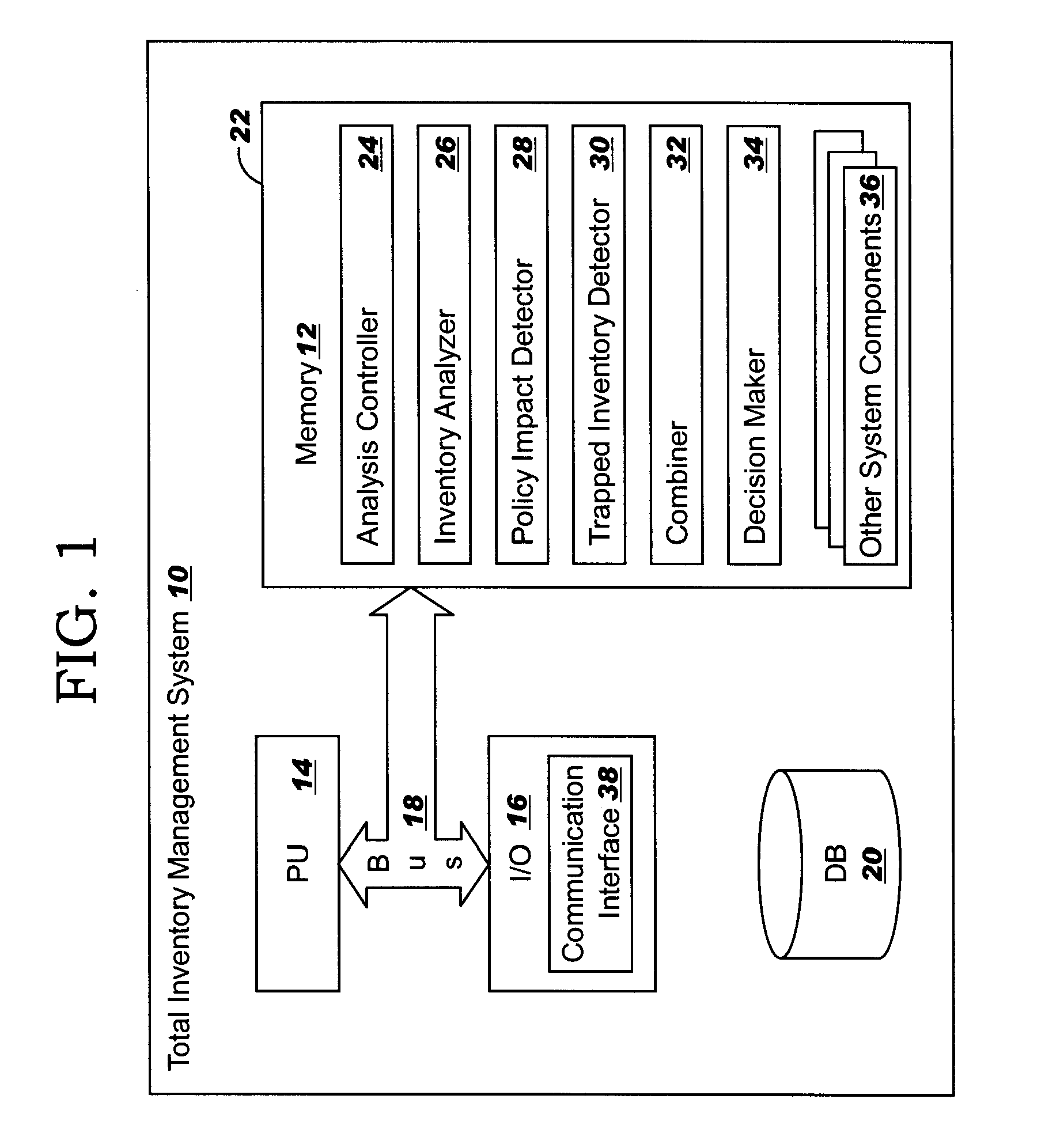

Enteric microorganism-based health risk prediction system

PendingCN107506582AManagement scienceStandardized managementSequence analysisSpecial data processing applicationsInformatizationHuman body

Owner:周礼红

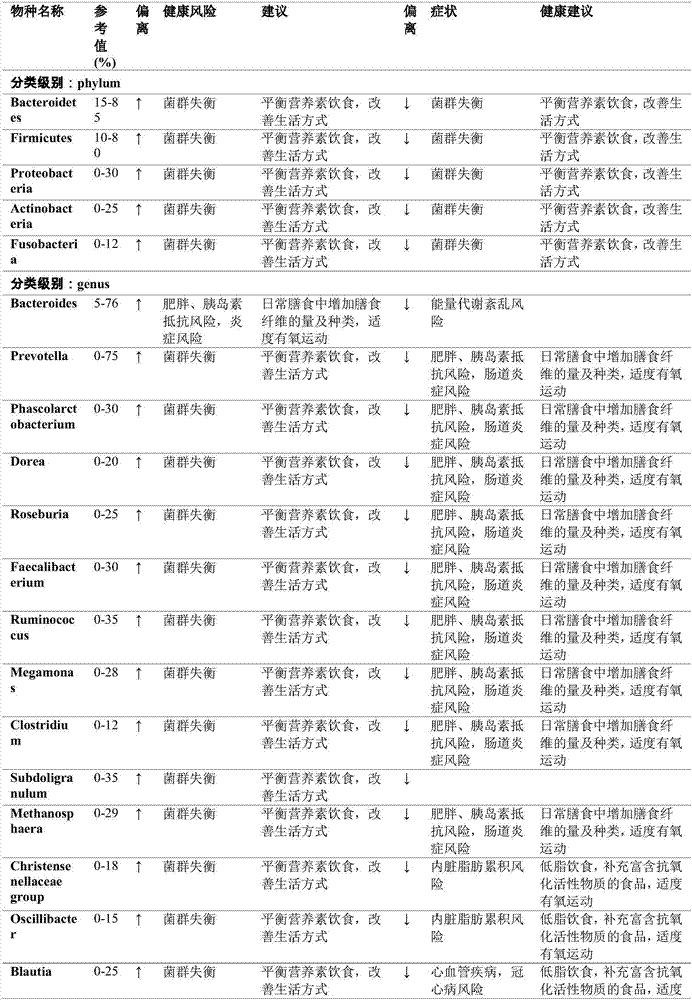

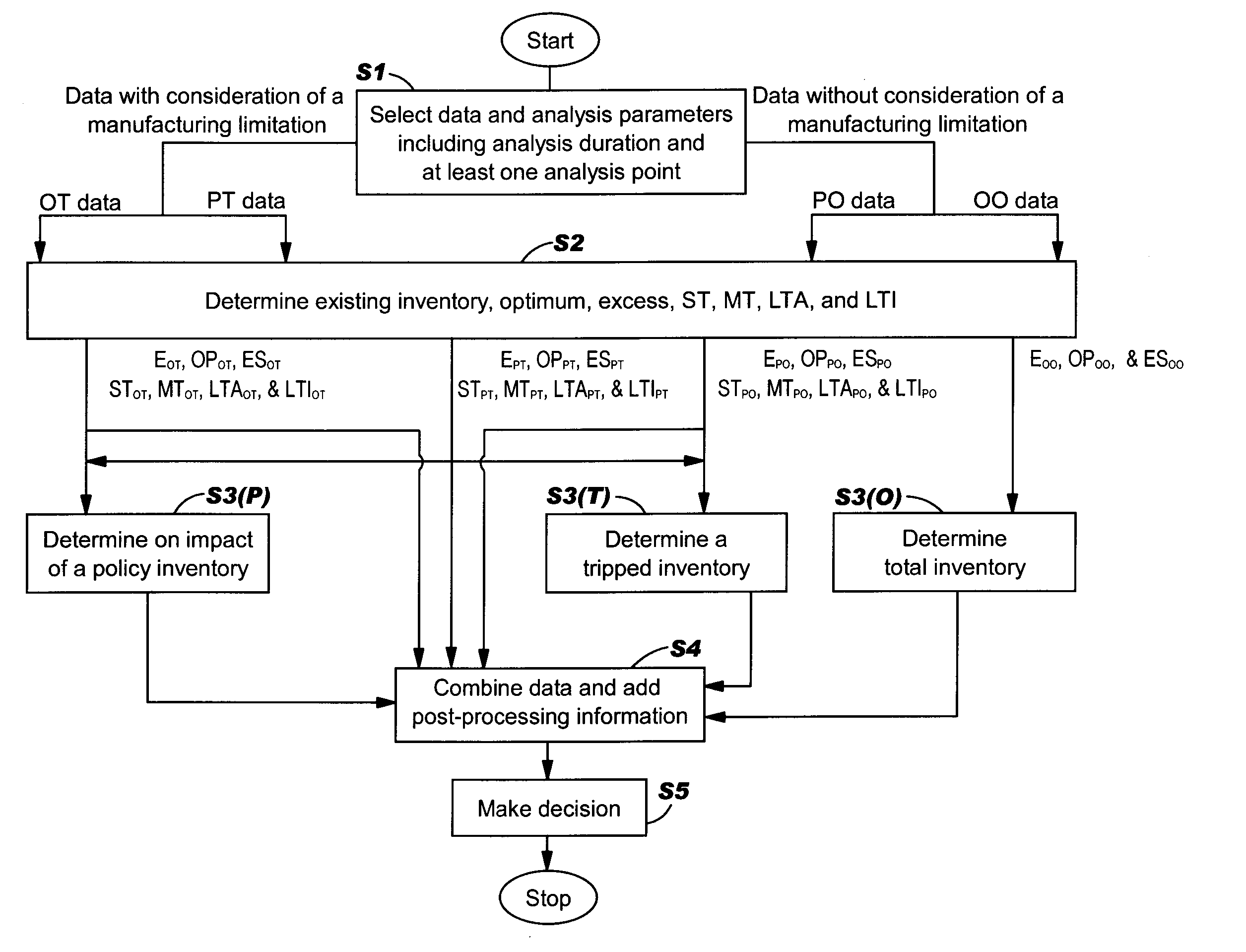

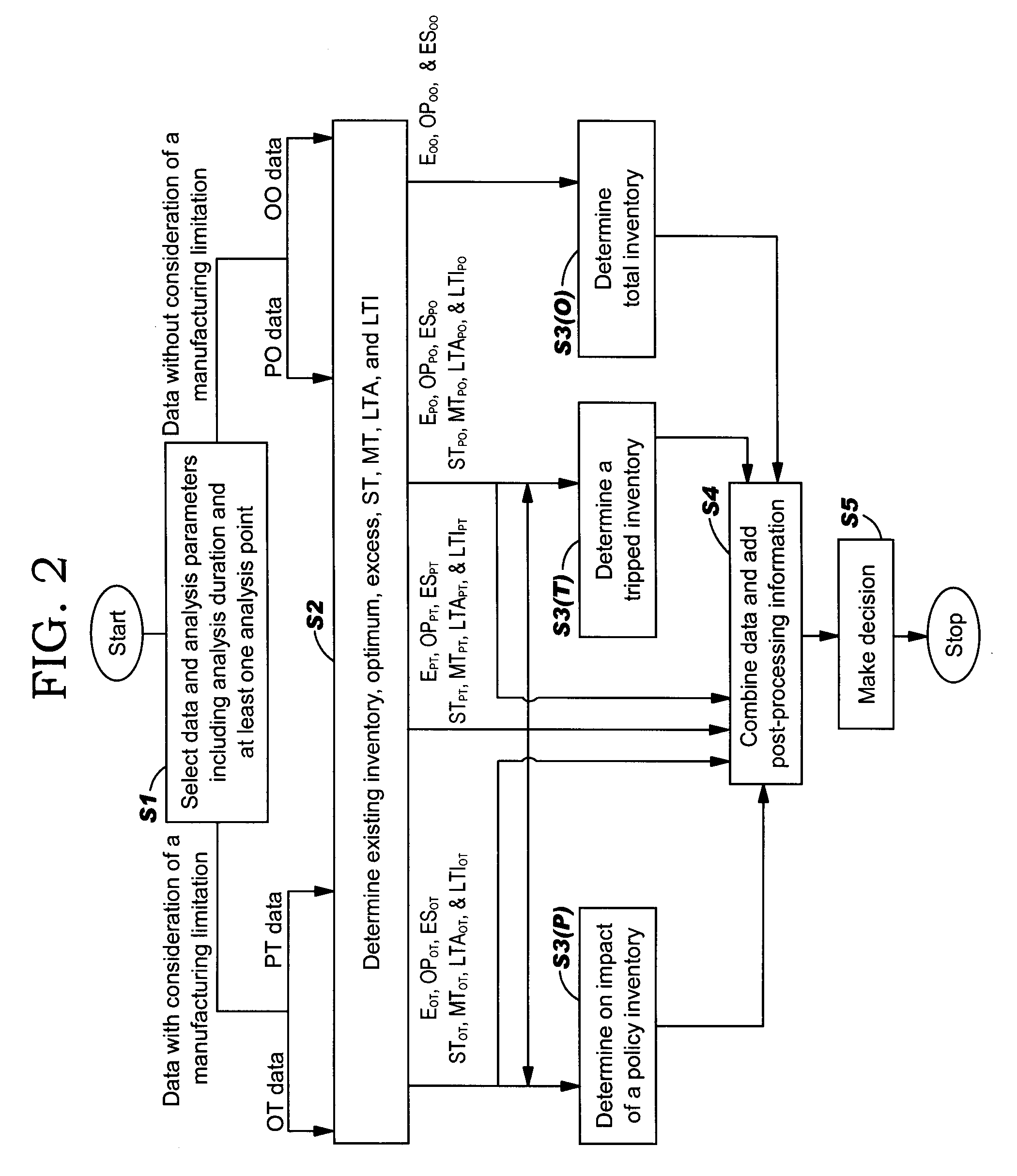

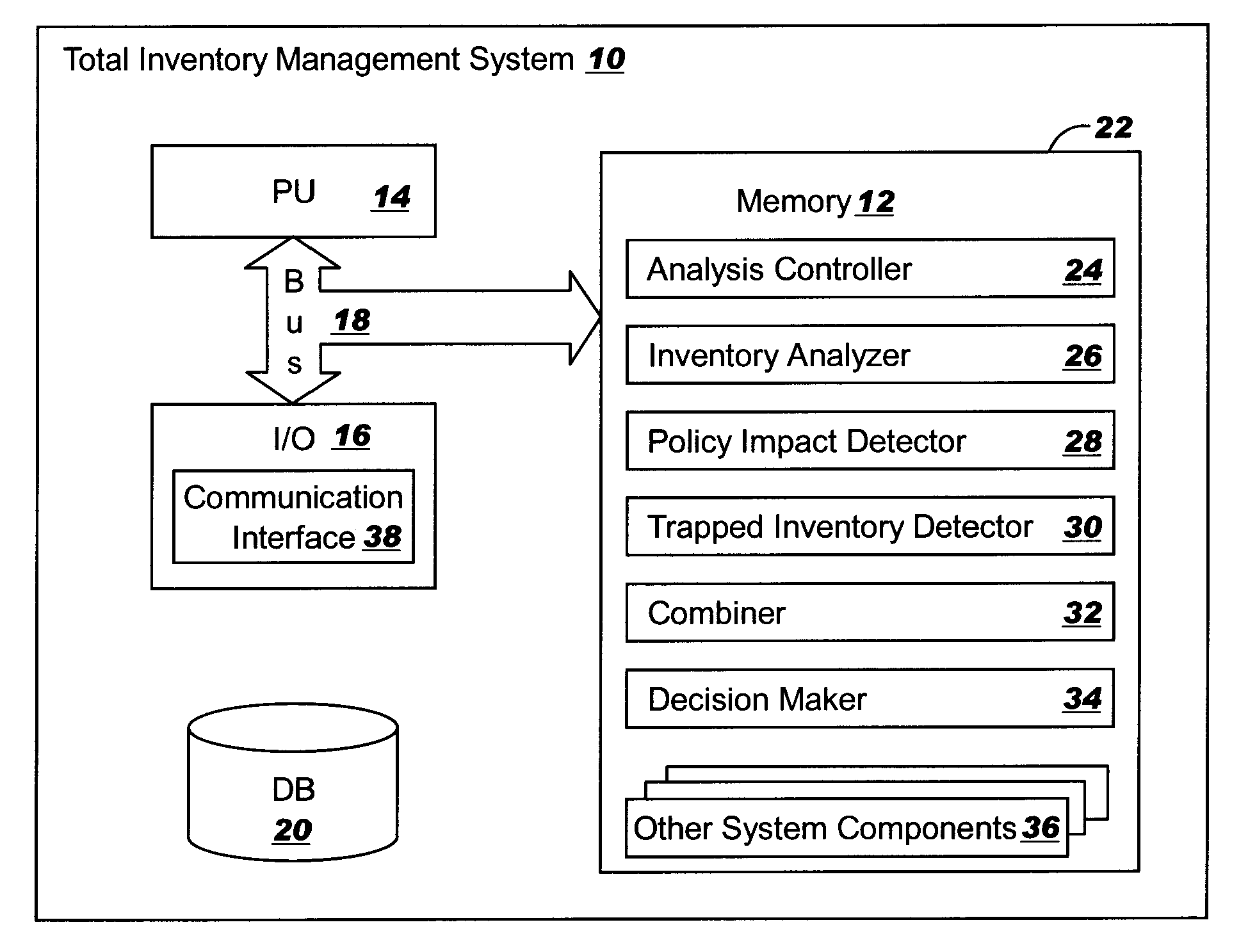

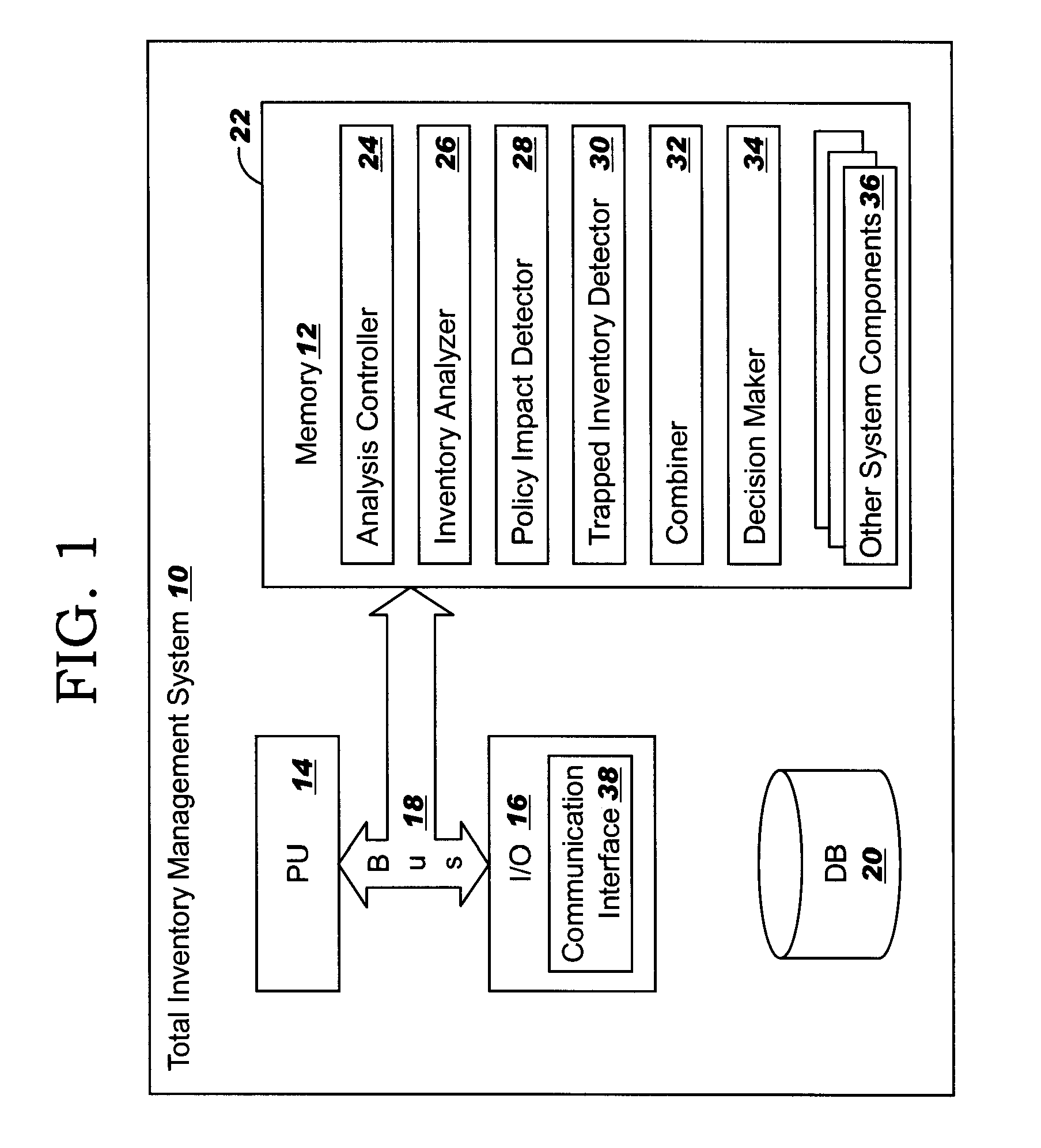

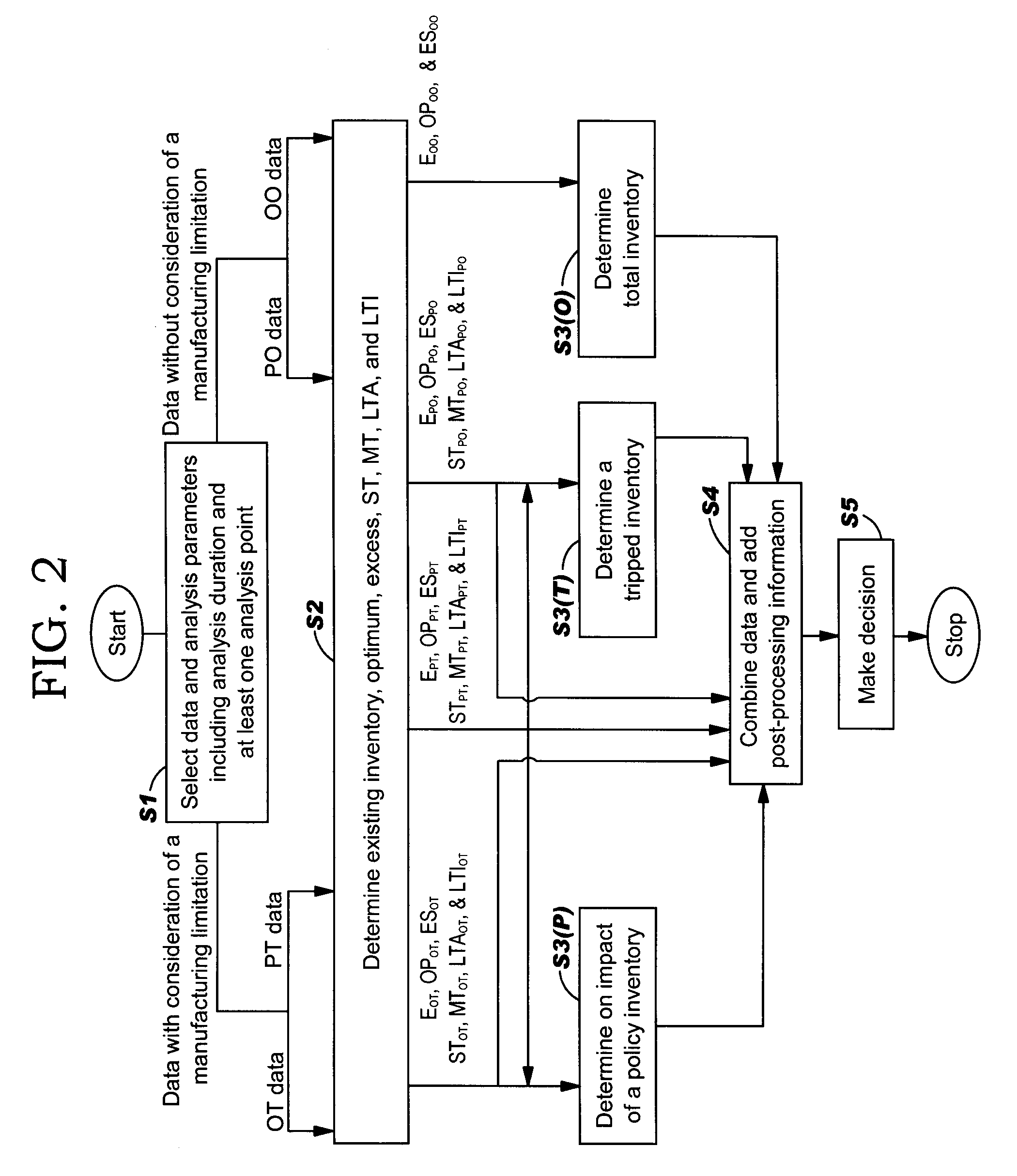

Total inventory management

A method, system and program product to manage total inventory. Existing inventory, optimum inventory, excess inventory and inventory consumption are calculated according to different sets of data regarding whether one is considering a policy inventory and / or a manufacturing limitation. Results of the calculations with different sets of data are compared to determine an impact of the policy inventory and an inventory trapped in manufacturing. This invention has application in the microelectronics industry as well as other industries.

Owner:LINKEDIN

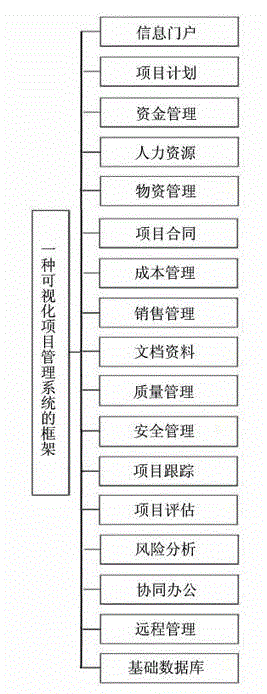

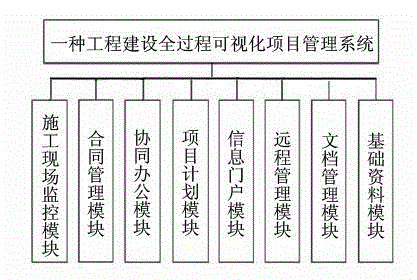

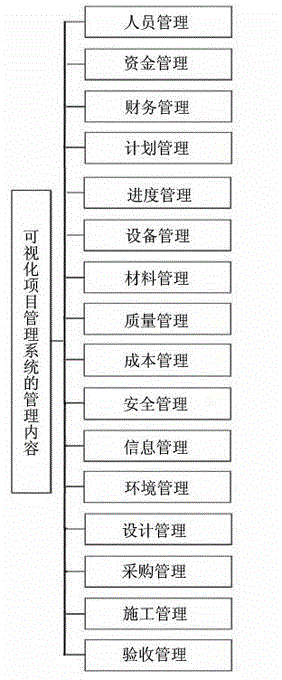

Whole process visual project management system for engineering construction

InactiveCN104573892ASimple and fast operationEfficient use ofResourcesSite monitoringTotal quality management

A whole process visual project management system for engineering construction is based on a webpage display interface and mainly comprises a construction site monitoring module, a contract management module, a cooperative office module, a project plan module, an information portal module, a remote management module, a document management module and a basic data module. The project construction implementation process comprises project document management, contract reminding and real-time monitoring of construction sites. The system is based on the humanized visual graph interface, management staff can conveniently check and analyze comprehensive conditions of projects, including data in the aspects of collection, costs, contracts and the like, and all levels of early warning mechanisms are assisted, so that whole process tracking management of the projects is completed, comprehensive requirements of the society, the government, developers, builders and consumers are met, high technology competition, low cost competition and high quality management are realized, the development and change of the construction market are accurately mastered, and the system has the broad application prospect.

Owner:王丽华

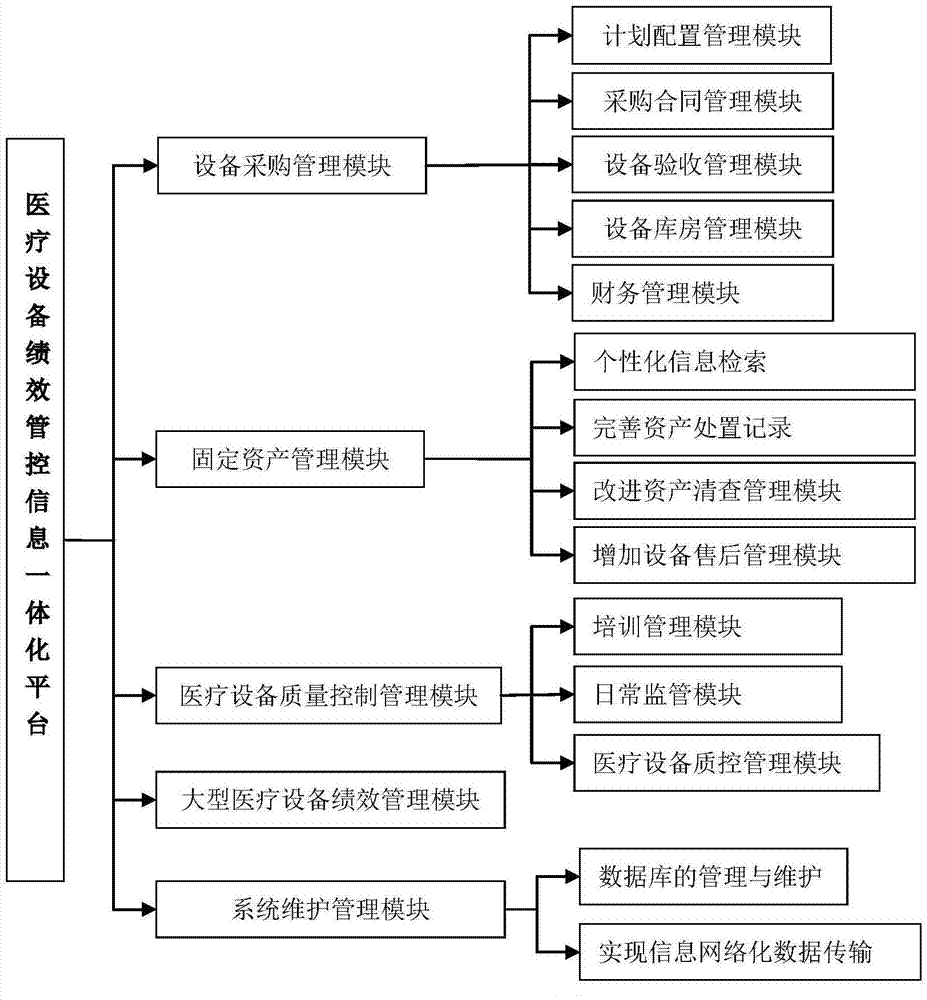

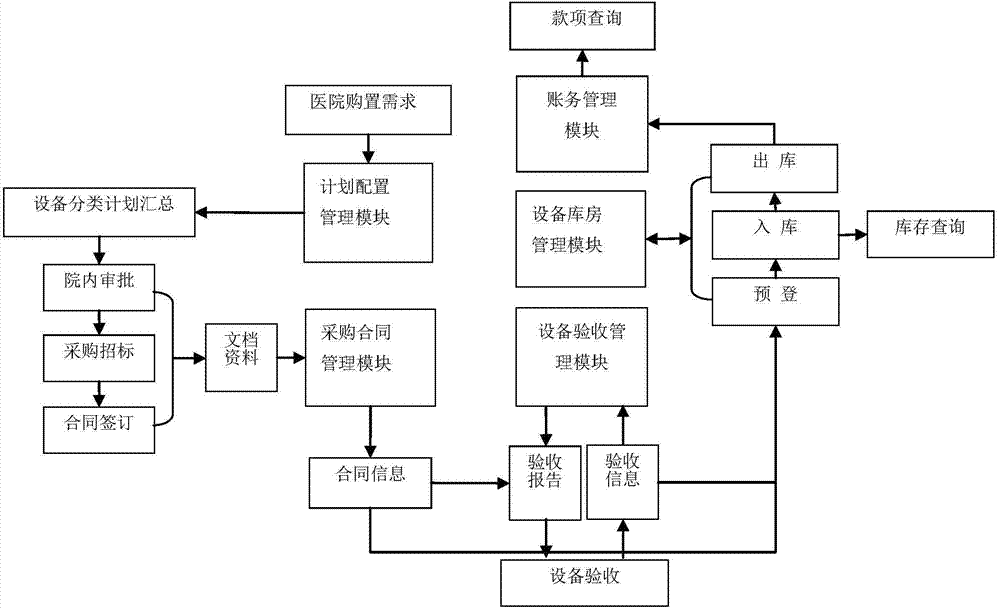

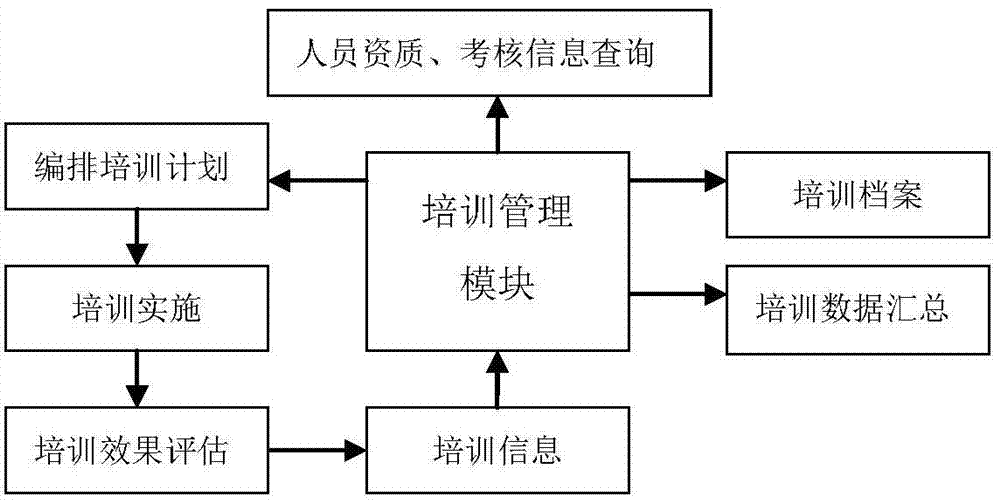

Medical facility performance management and control information integrated platform

InactiveCN104732336AQuality improvementGuaranteed uptimeResourcesMedical equipmentSystem maintenance

The invention discloses a medical facility performance management and control information integrated platform. The medical facility performance management and control information integrated platform comprises a facility purchasing management module, a fixed asset information management module, a medical facility quality control and management module, a large-medical-facility performance management module and a system maintenance management module. By means of the medical facility performance management and control information integrated platform, a digitized and informationized data exchange platform is provided for quality control over and quality management on medical facilities, the management functions of different departments are fused, the summarized information of the facilities in the whole service life is provided, and the information extracting and contact strength of managers is improved. The medical facility performance management and control information integrated platform has the advantages that related permission of management departments is set according to the management content and the management requirements of the facilities in different stages of the full service life and different aspects, the different management functions and the different analysis inquiry functions are achieved, the effect of information sharing is sufficiently developed, paths are unified, repeated working doing or information non-correspondence is avoided, the inquiring work efficiency is improved, and data foundations are provided for decision makers.

Owner:JILIN UNIV FIRST HOSPITAL

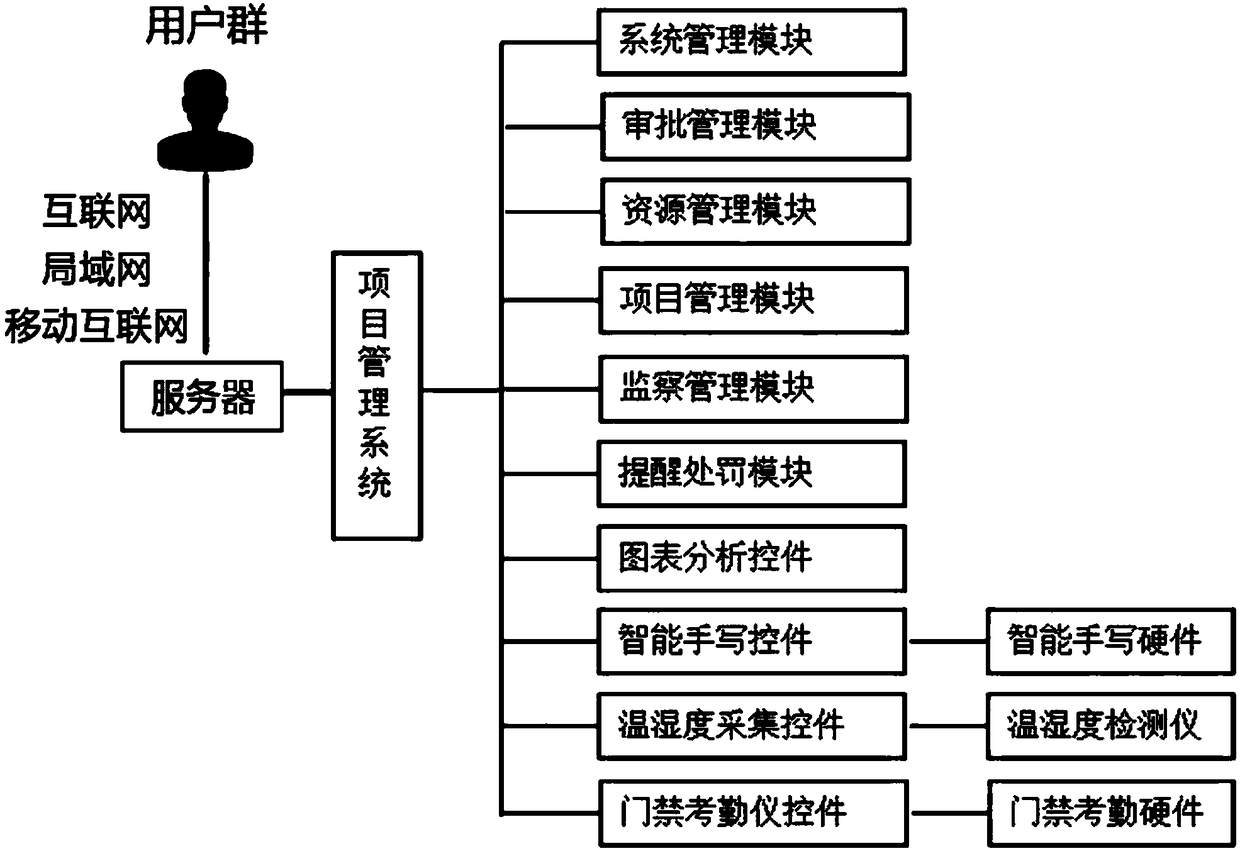

Intelligent project management system

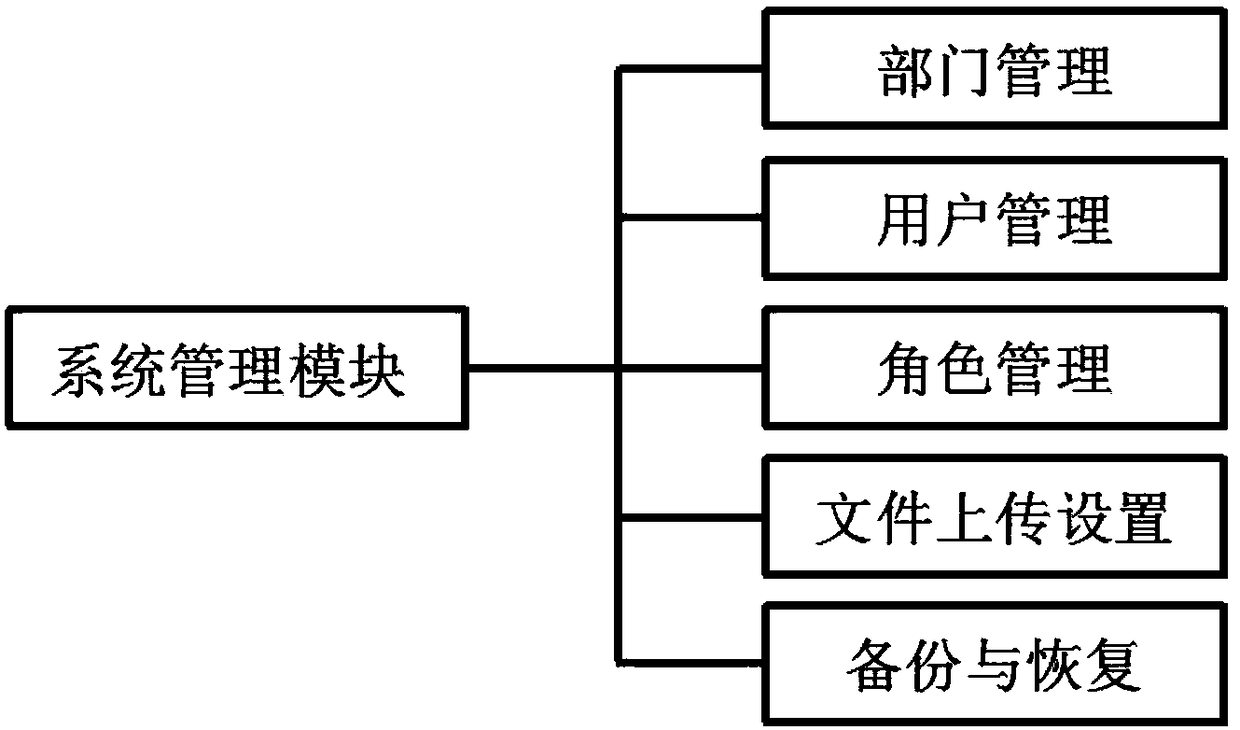

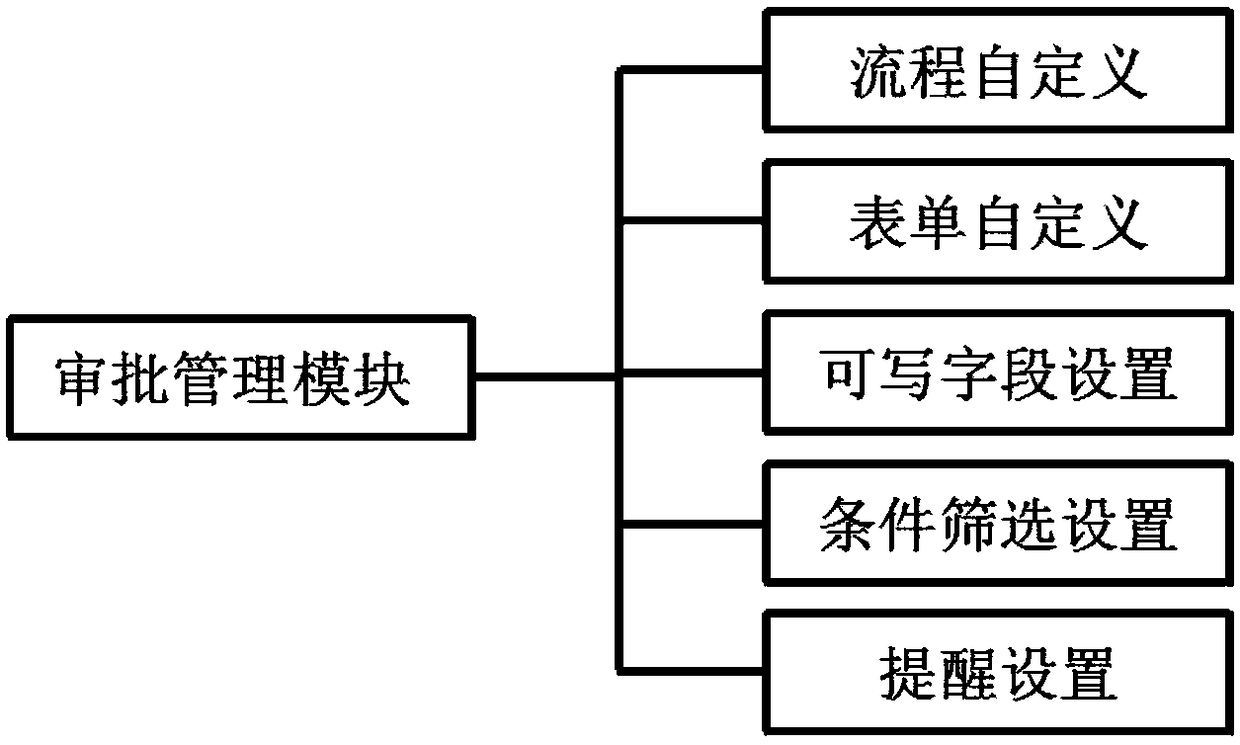

The invention relates to an intelligent project management system, which comprises a project management module, a system management module, an approval management module, a resource management module,a supervision management module and a reminding and punishment module. The system has a chart statistics function, realizes objective management, plan management, summary management, evaluation management and quality management and the like of the whole process of the project, and can carry out integrated deployment management on personnel, equipment, materials and fund resources, thereby improving resource utilization rate; the system has a timeout automatic penalty function and integrates intelligent pressure-sensitive original handwriting hardware; when paper is signed or paper records arewritten, original handwriting electronic data is kept synchronously; the system integrates access control and attendance hardware and a temperature and humidity detector, and has a supervisory and management function, thereby preventing the submitted data from being tampered and deleted and ensuring originality and integrity of the data; the system wholly plays the function of risk control and cost control, thereby improving efficiency and project success rate; and the system is especially suitable for research and development and project management in the medical field.

Owner:黄玉新

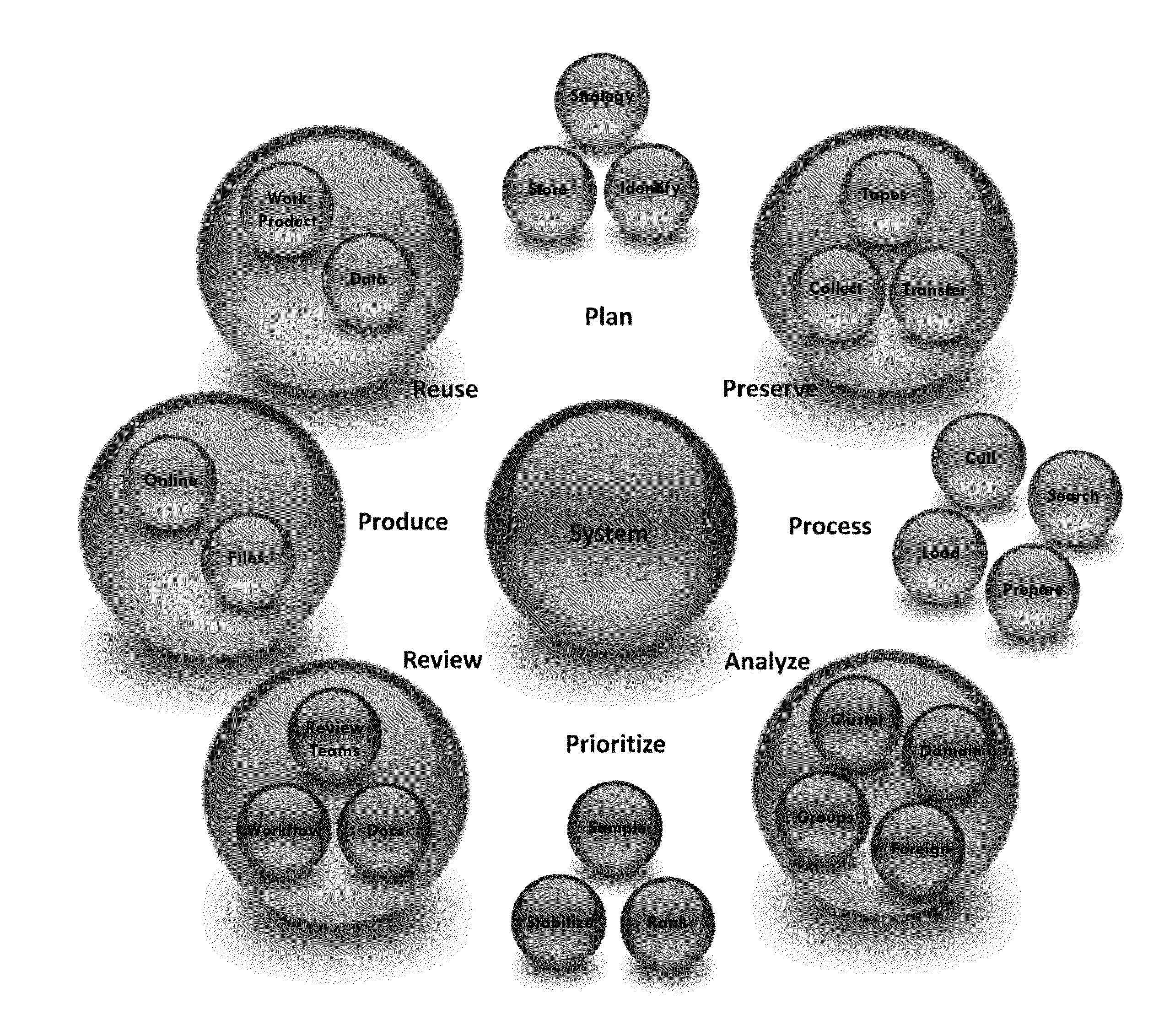

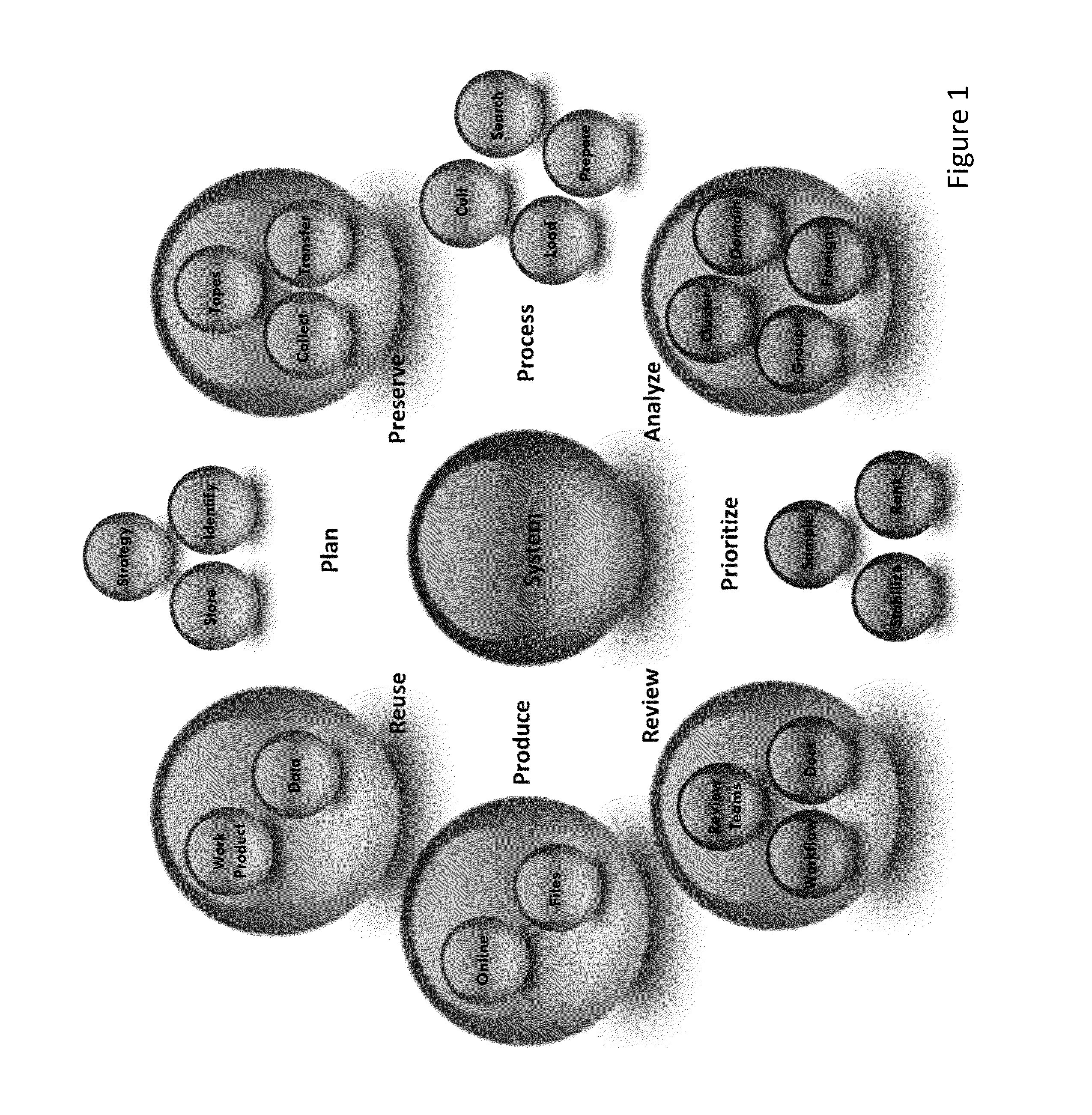

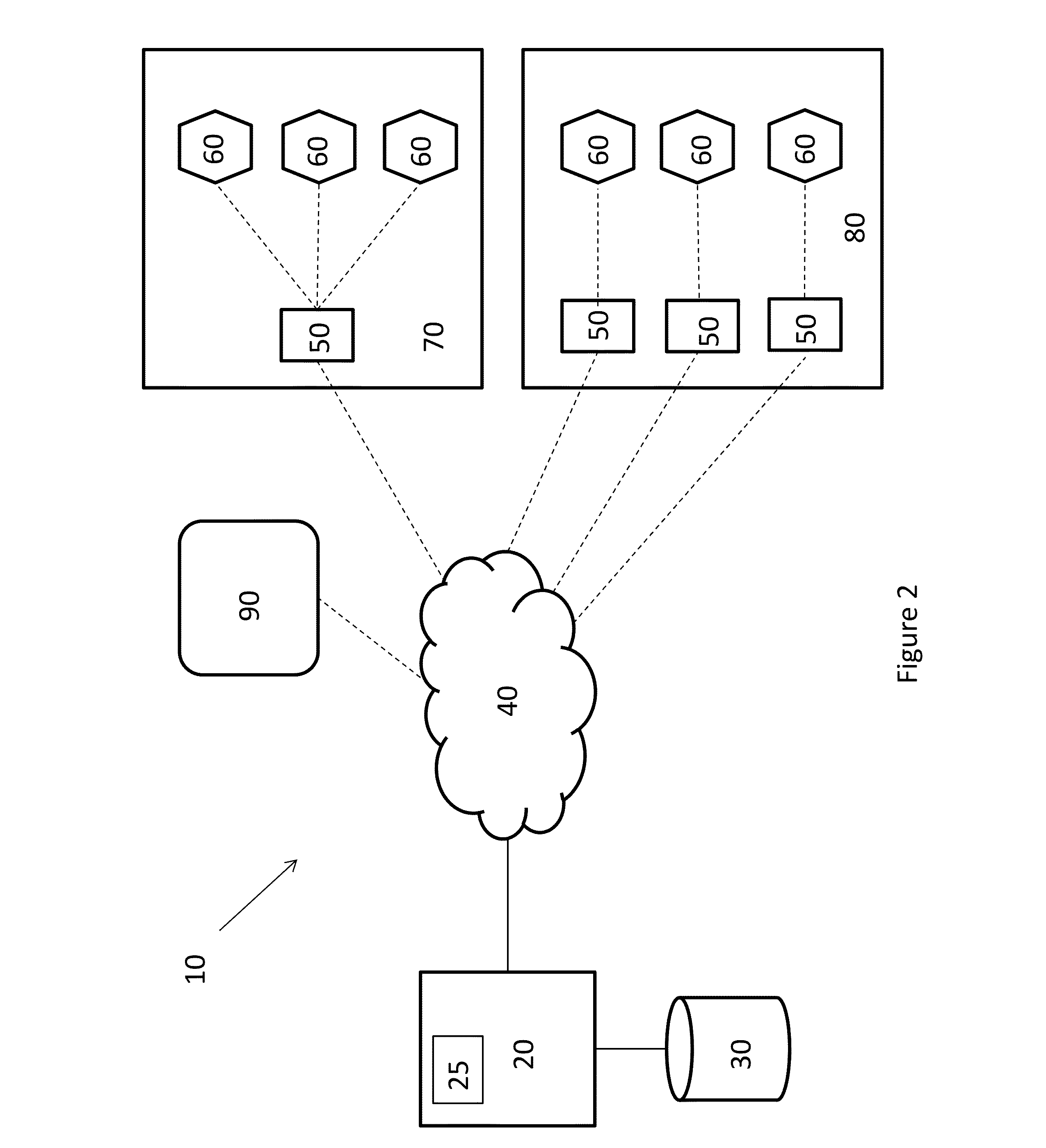

System and Method of Reviewing and Producing Documents

A system and method of providing comprehensive document review, production and reporting is described. The system and method provide a total quality management approach to a document review matter that not only controls costs but increases defensibility of the overall process, thereby reducing risk. The system utilizes unique review and performance metrics, increases quality control, and enhances physical and data security mechanisms. The system of the present invention can be implemented with any document review software or hosted platform desired for use by a customer.

Owner:NETMATRIX INC

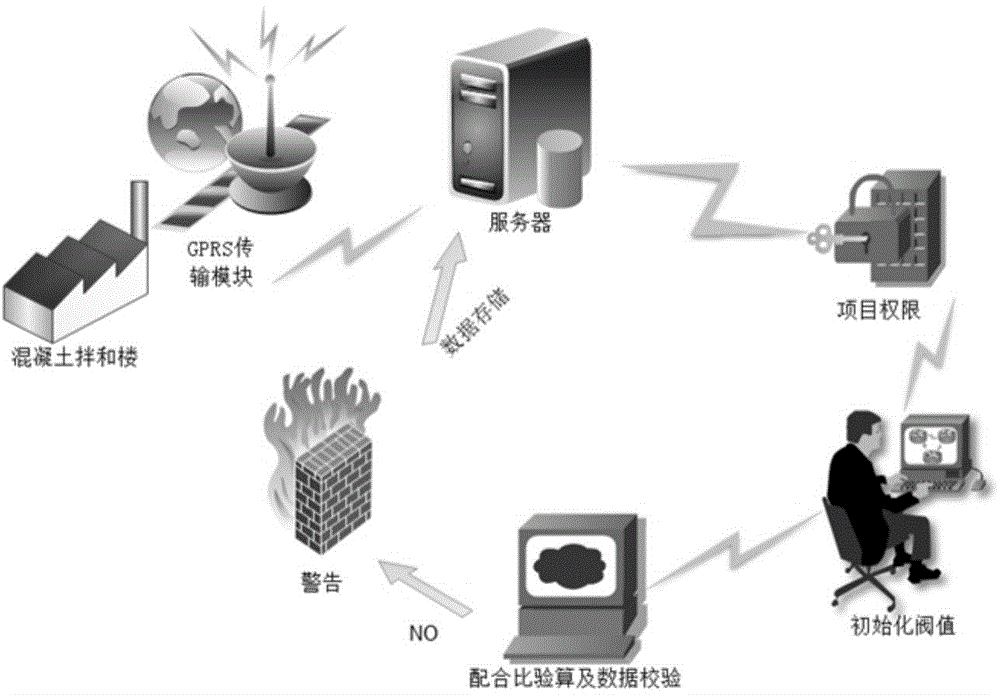

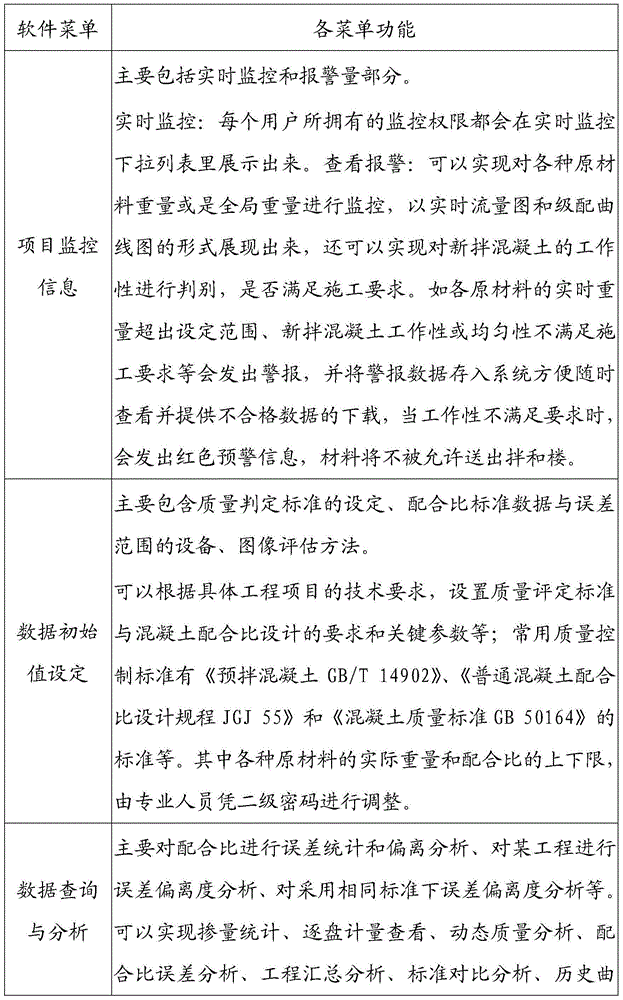

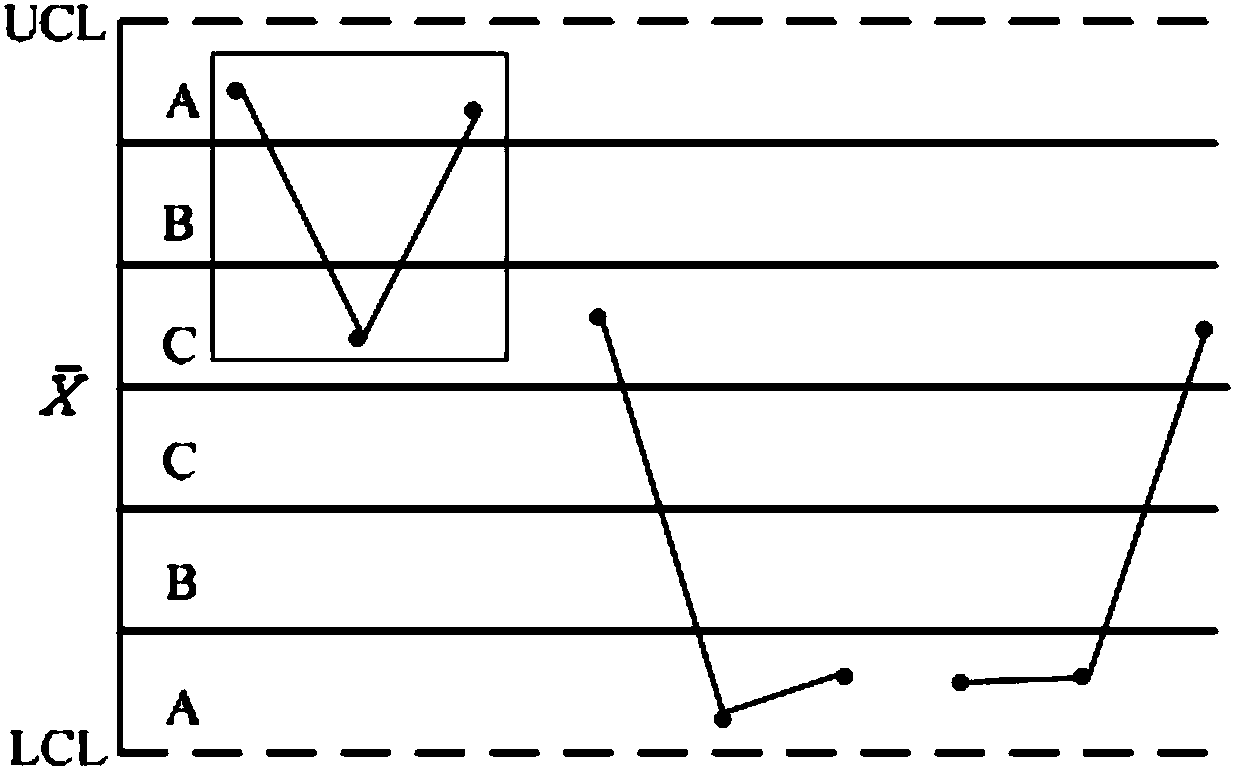

Real-time fluctuation concrete-quality management and control system and method

InactiveCN104573932ARealize real-time monitoringImprove construction management levelMaterial testing goodsResourcesContinual improvement processTotal quality management

The invention relates to a real-time fluctuation concrete-quality management and control system and method, and belongs to the technical field of engineering construction. Through the adoption of the real-time fluctuation concrete-quality management and control system and method provided by the invention, the real-time monitoring of concrete quality is realized, various data during monitoring is acquired in real time, and the feedback of the data is sent out in time so as to achieve the purposes of management and control, and the improvement of the management level of concrete engineering construction; effective quality precontrol is performed on cement concrete before production use, the mix proportion which does not satisfy construction requirements and quality control standard requirements is not allowed to be used for mixing; feedback information is accurately acquired in events in time, and the processes of production and construction are managed in real time; the data of the overall process is combined and analyzed after the events, and the analysis of the data is favorable to continuous improvement and enhancement; requirements for overall quality management are really met, and cheating on workmanship and materials is effectively avoided, so that the engineering quality is guaranteed, and huge social and economic benefits are achieved.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD +1

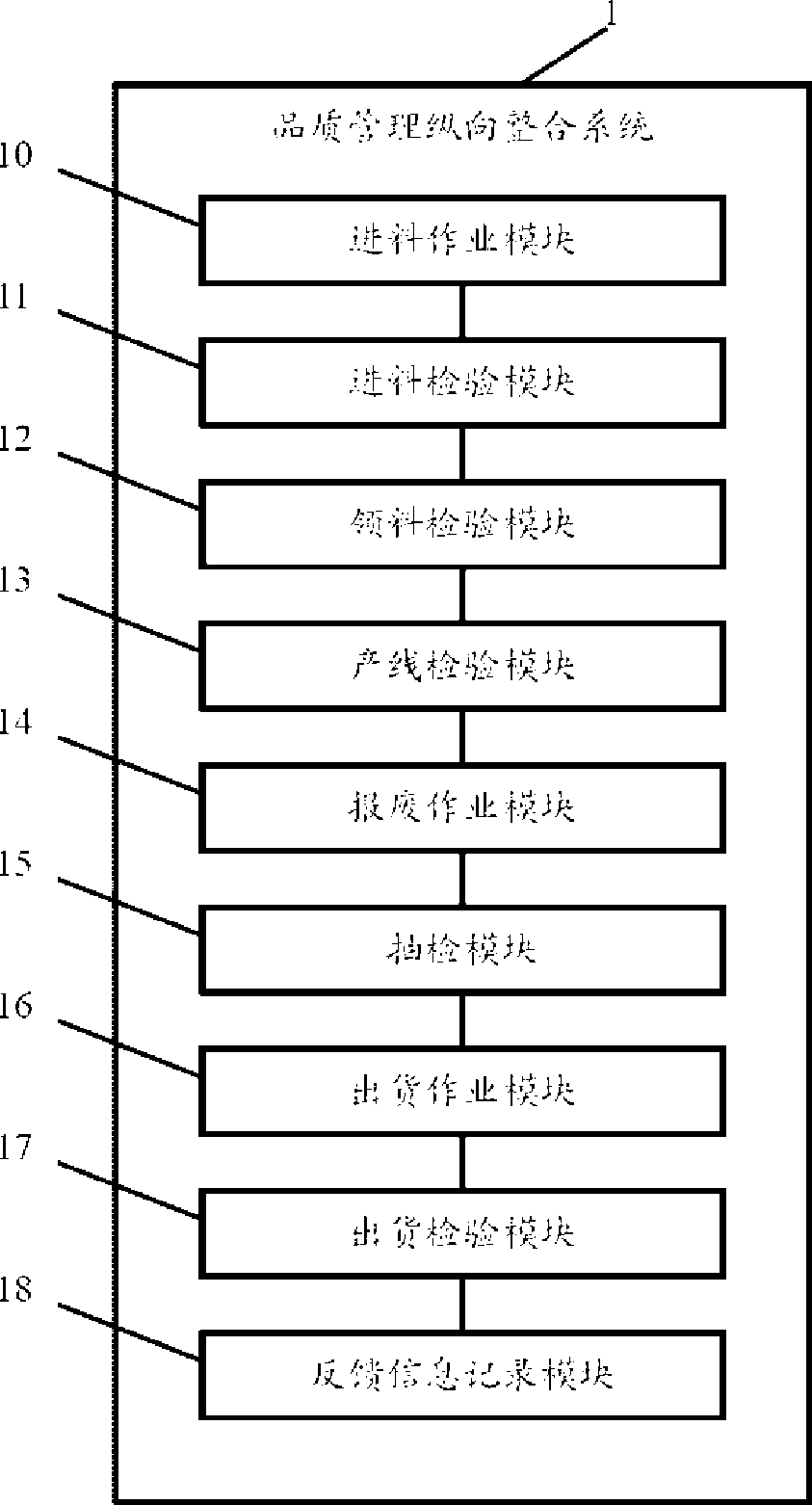

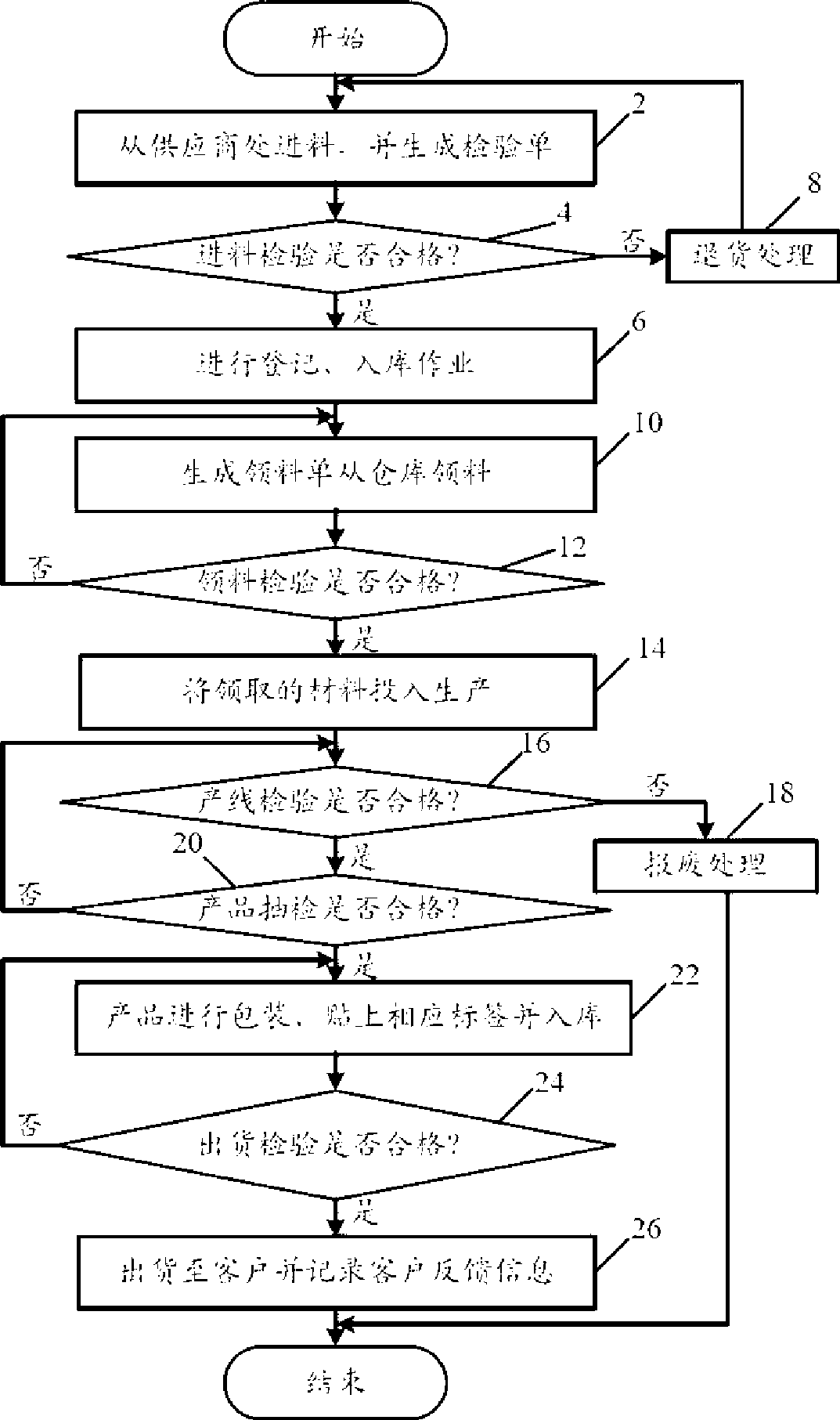

Longitudinal integration system and method for quality management

A vertical integration system for quality management comprises a feeding operation module used for purchasing raw material from a supplier according to an order bill and generating a relevant inspection sheet on each type of raw material; a feeding inspection module used for feeding inspection for the raw material purchased; an alloting material inspection module used for generating a material registration for collecting relevant raw material from a storehouse according to manufacturing demands and for alloting material inspection for the raw material collected; a production line inspection module used for inspecting product quality generated in the production line; a sampling inspection module used for sampling and inspecting qualified products inspected in the production line; a delivery operation module used for delivery operation for qualified products sampled and inspected; and a delivery inspection module used for delivery inspection for products packaged in the storehouse before delivery and for delivery processing for qualified products inspected before delivery.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

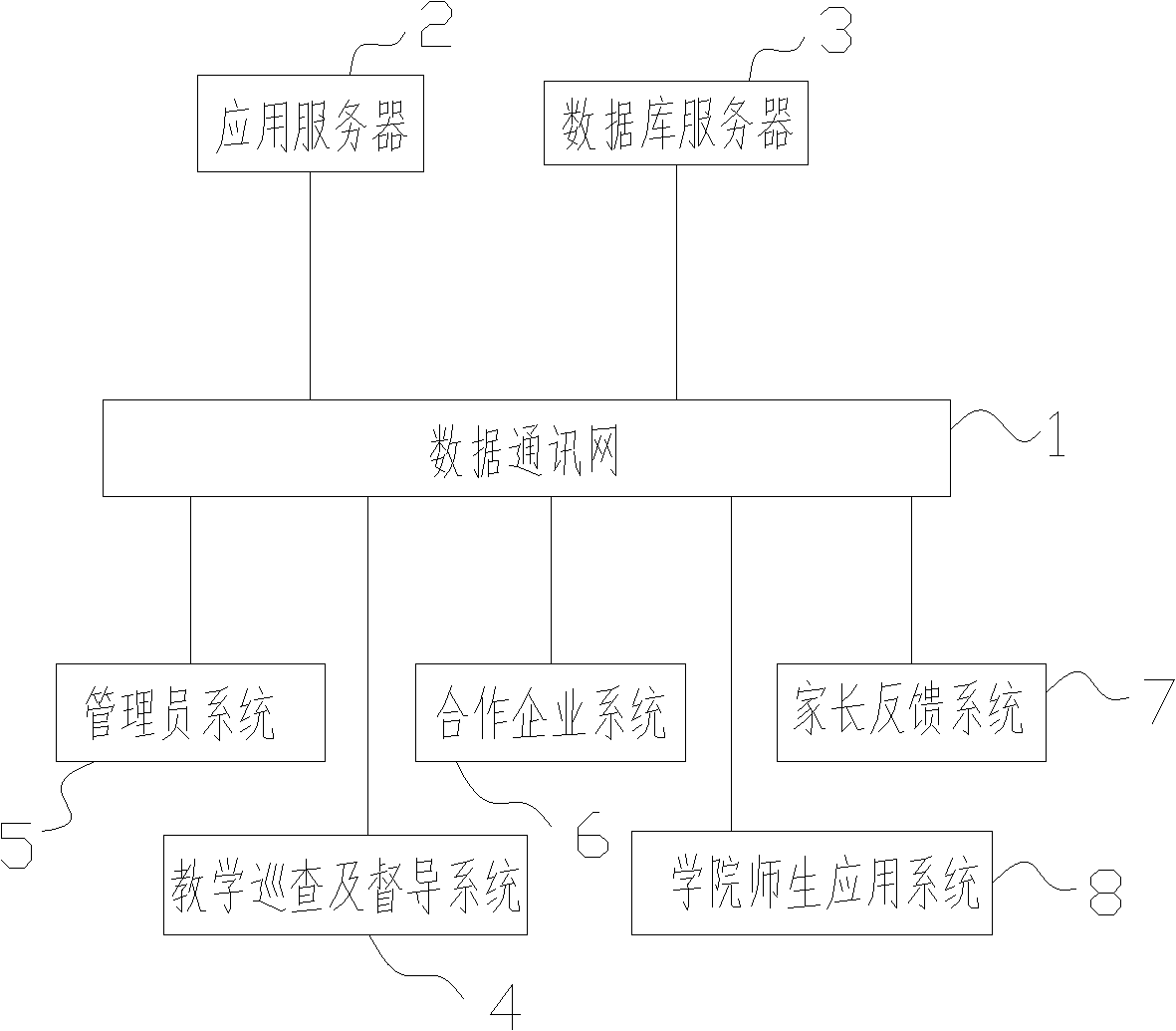

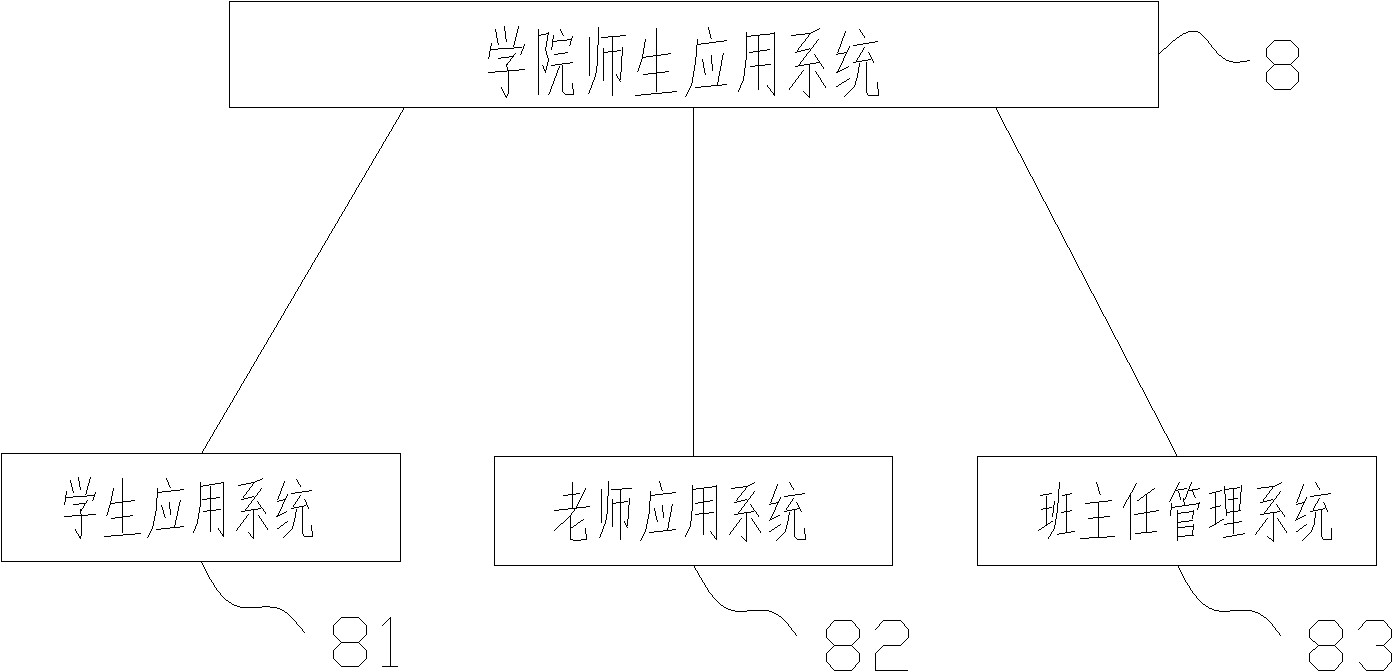

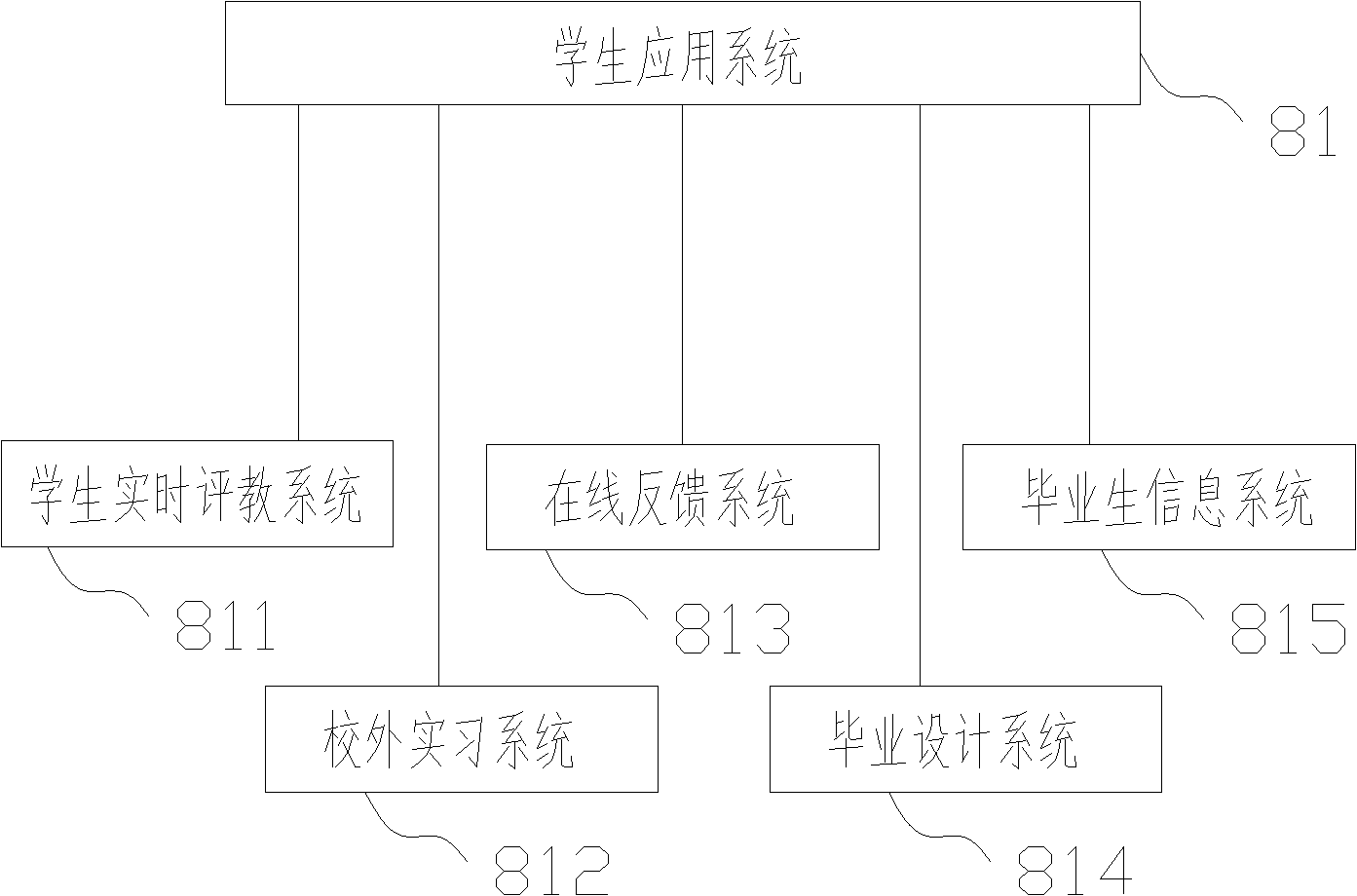

Intercollege application teaching quality management system at university

InactiveCN102663551AImprove work efficiencyEnhanced interactionResourcesApplication serverDatabase server

The invention discloses an intercollege application teaching quality management system at a university. A teaching inspection and supervision system, an administrator system, a cooperative enterprise system, a parent feedback system, and a college teacher and student application system are connected with an application server and a database server through a data communication network. The system has the following advantages: the work efficiency of teaching participants is raised, interactive communication between a teacher and a student is enhanced, separate design is carried out for different roles of staffs, requirements of the different roles of teaching staffs and students can be satisfied to the max, and the completion of a teaching task, student internship, inauguration and the like is assisted; according to the arrangement of the administrator system, the whole system can clearly define the authority of system use personnel, and reasonability and safety of system data in use are ensured; teaching is assessed; the teaching inspection and supervision system greatly improves the efficiency of teaching assessment in teaching and can reflect the problems existing in the teaching scientifically, simply, and timely.

Owner:JINHUA ZHENGYUAN COMP ENG

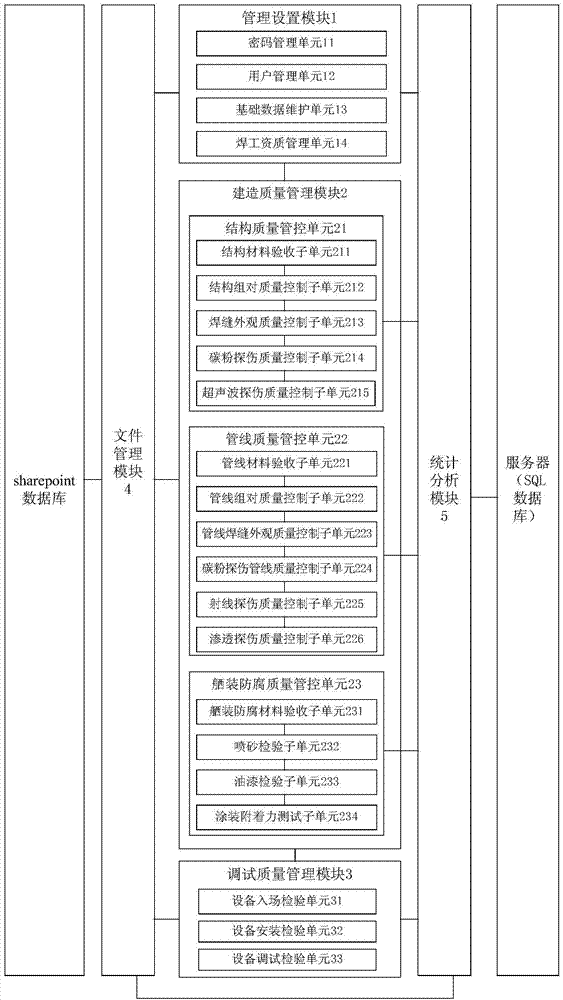

Oceanographic engineering quality control information system

InactiveCN104751296AQuick customizationImprove quality management efficiencyResourcesICT adaptationStatistical analysisTotal quality management

The invention relates to the field of offshore oil engineering and provides an oceanographic engineering quality control information system. The oceanographic engineering quality control information system comprises a management setting module, a construction quality managing module, a debugging quality managing module, a file managing module and a statistical analyzing module, wherein the management setting module is used for setting a user login password and authorities of a user, setting essential data and preserving welder qualifications; the construction quality managing module is used for determining construction quality acceptance when monitors that information input by a general contractor is examined and approved by an owner party and a third party; the debugging quality managing module is used for acquiring the information input by the general contractor and recording left problems for subsequent elimination; the file managing module is used for uploading, checking and downloading item information; and the statistical analyzing module is used for extracting various data input in the earlier stages according to a user command and giving an analysis result. The oceanographic engineering quality control information system is capable of finishing daily quality inspection work, performing real-time quality information statistics, collecting the statistical information and generating weekly reports and monthly reports needed in working automatically, and the aid of the oceanographic engineering quality control information system, traditional paper file transmission can be replaced to achieve automatic real-time data statistics, so that efficiency in quality management is improved greatly.

Owner:CHINA NAT OFFSHORE OIL CORP +1

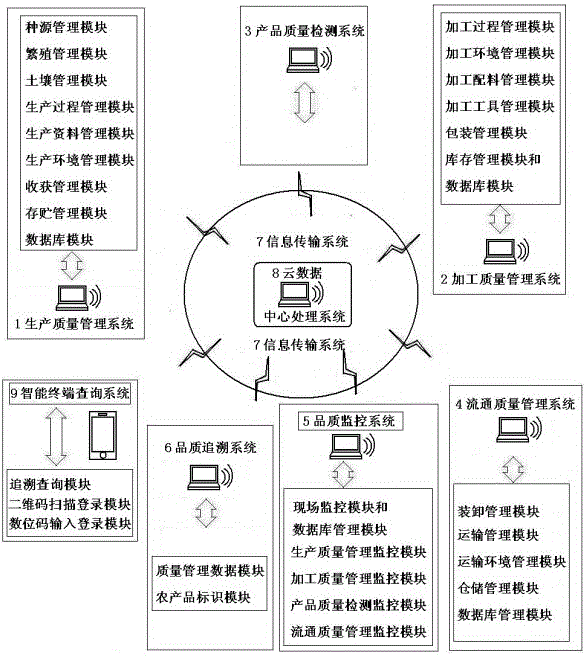

Cloud control intelligent e-commerce agricultural product quality guarantee system

InactiveCN105931062AQuality assuranceEffectively grasp the quality statusCommerceThe InternetTotal quality management

The invention provides a cloud control intelligent e-commerce agricultural product quality guarantee system comprising quality management of crop products and animal husbandry products. The cloud control intelligent e-commerce agricultural product quality guarantee system is characterized by comprising a production quality management system, a processing quality management system, a product quality detection system, a circulation quality management system, a quality monitoring system, a quality tracing system, an information transmission system, a cloud data center processing system and an intelligent terminal inquiring system. The production quality management system, the processing quality management system, the product quality detection system, the circulation quality management system, the quality monitoring system, the quality tracing system and the intelligent terminal inquiring system are connected with the cloud data center processing system through the information transmission system. The beneficial effects of the cloud control intelligent e-commerce agricultural product quality guarantee system are that quality management and monitoring are performed on the planting, processing, transport and terminal using or eating links of agricultural products on the basis of the internet of things so that the quality problem in the production and circulation process can be effectively prevented under the effect of the monitoring system, the tracing system and the mobile phone inquiring system, and the quality of the agricultural products can be guaranteed.

Owner:秀山云智科贸有限公司

Tobacco leaf quality management system and method

ActiveCN1744115AIncrease aromaIncrease the amount of aromaResourcesEcological environmentQuality assurance

Through a database, statistical analysis is carried out for information related to quality of tobacco leaves. Each index of tobacco leaves can be obtained expediently. Thus, the method is in favor of making correct evaluation for quality, raising work efficiency and strengthening information circulation among producing areas. Through analyzing environment, diversified tastes of products of tobacco, the invention raises quality and quantity of fragrance and industrial usability correctly and effectively so as to provide quality assurance and data support for research and development of product.

Owner:CHINA TOBACCO SHANDONG IND

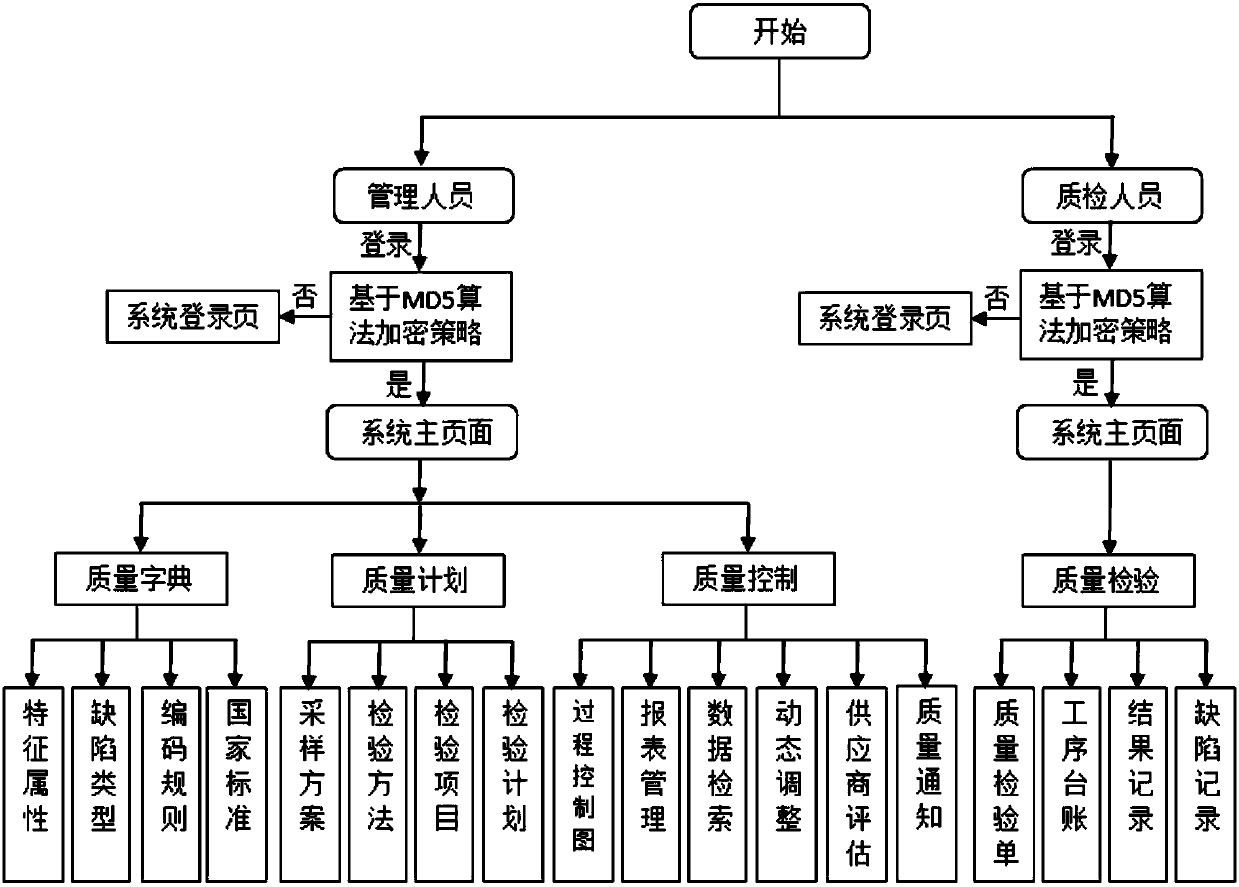

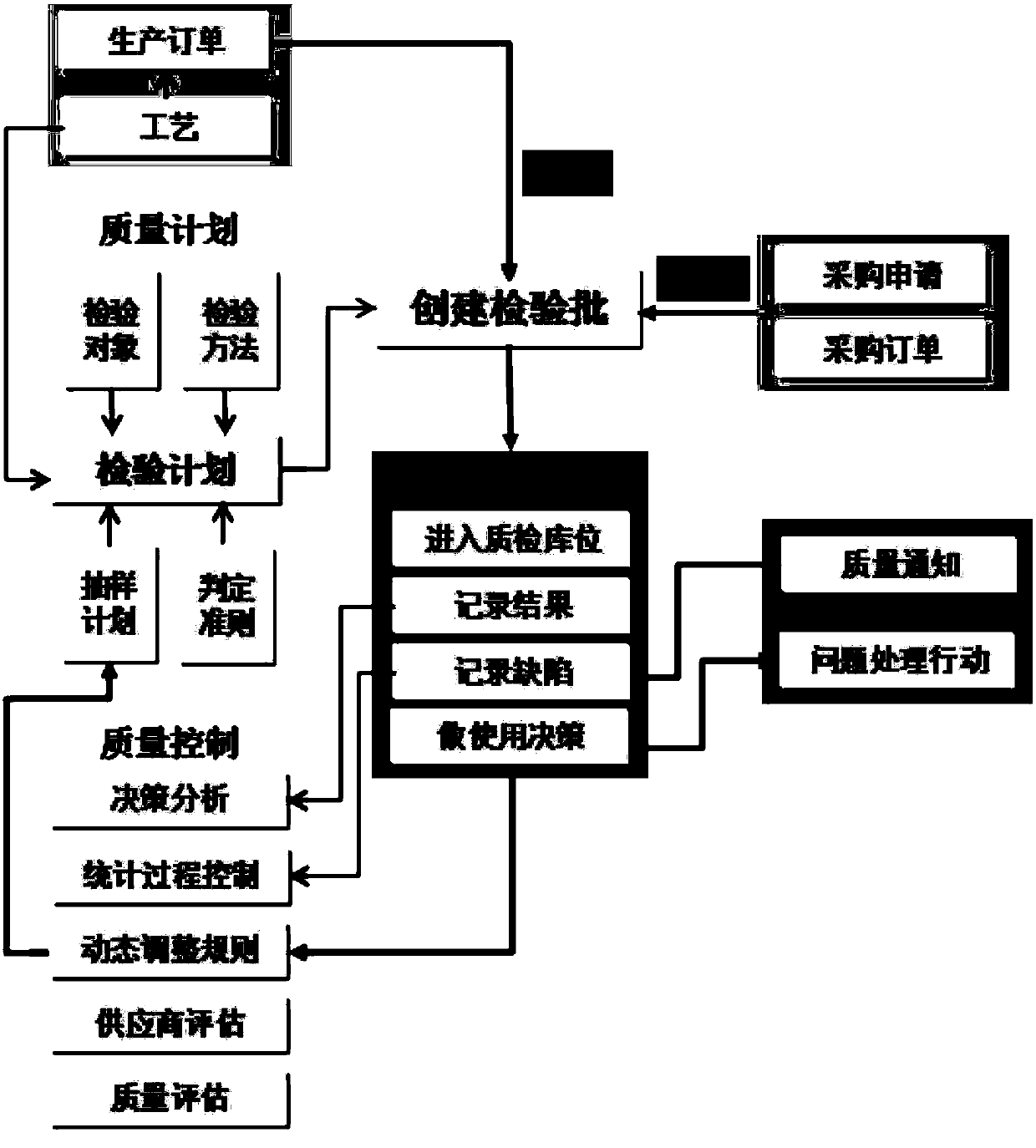

Quality management system for finished automobile production and manufacturing

InactiveCN108090675AEnsure transmission securityEncryption apparatus with shift registers/memoriesResourcesObject basedTotal quality management

The invention discloses a quality management system for finished automobile production and manufacturing. The system is composed of a quality dictionary module, a quality planning module, a quality inspection module, and a quality control module. The quality dictionary module is used for carrying out quantification processing on characteristic attributes, defect types, coding rules of different batches, and national standards of inspection items during a production and manufacturing process and constructing essential data by using an integrated and standardized description as criteria for later-period inspection. The quality planning module is used for creating targeted inspection plans based on business demands and inspection objects. The quality inspection module is used for applying designated inspection plans to specific inspection objects based on inspection plans created in the quality planning, collecting quality data and synchronizing the data to a server side to complete product quality inspection. The quality control module is used for completing inspection on the specific inspection objects in quality inspection and realizing quality control on the same batches of inspection objects with the same batch number prefix positions.

Owner:BEIJING UNIV OF TECH

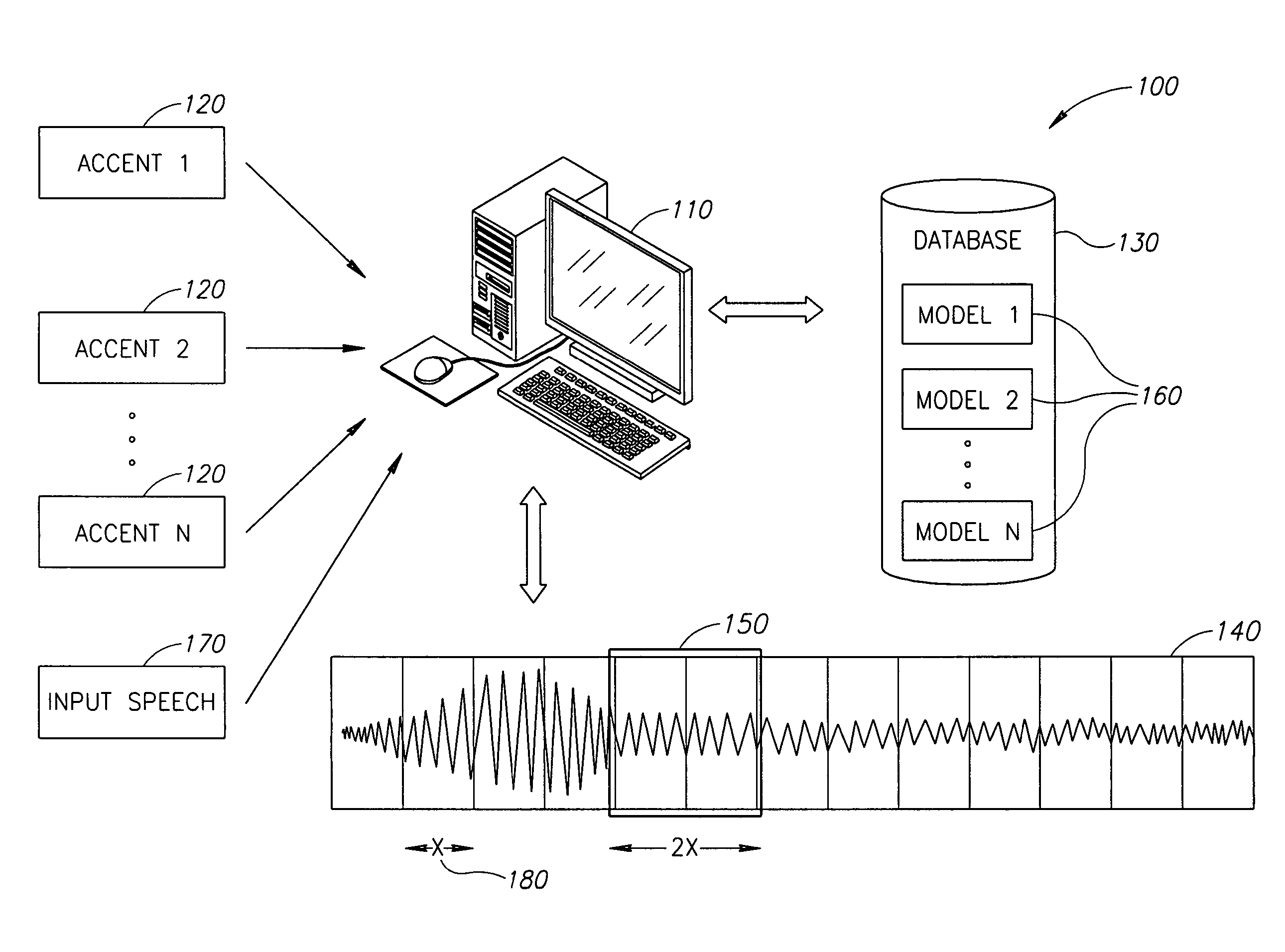

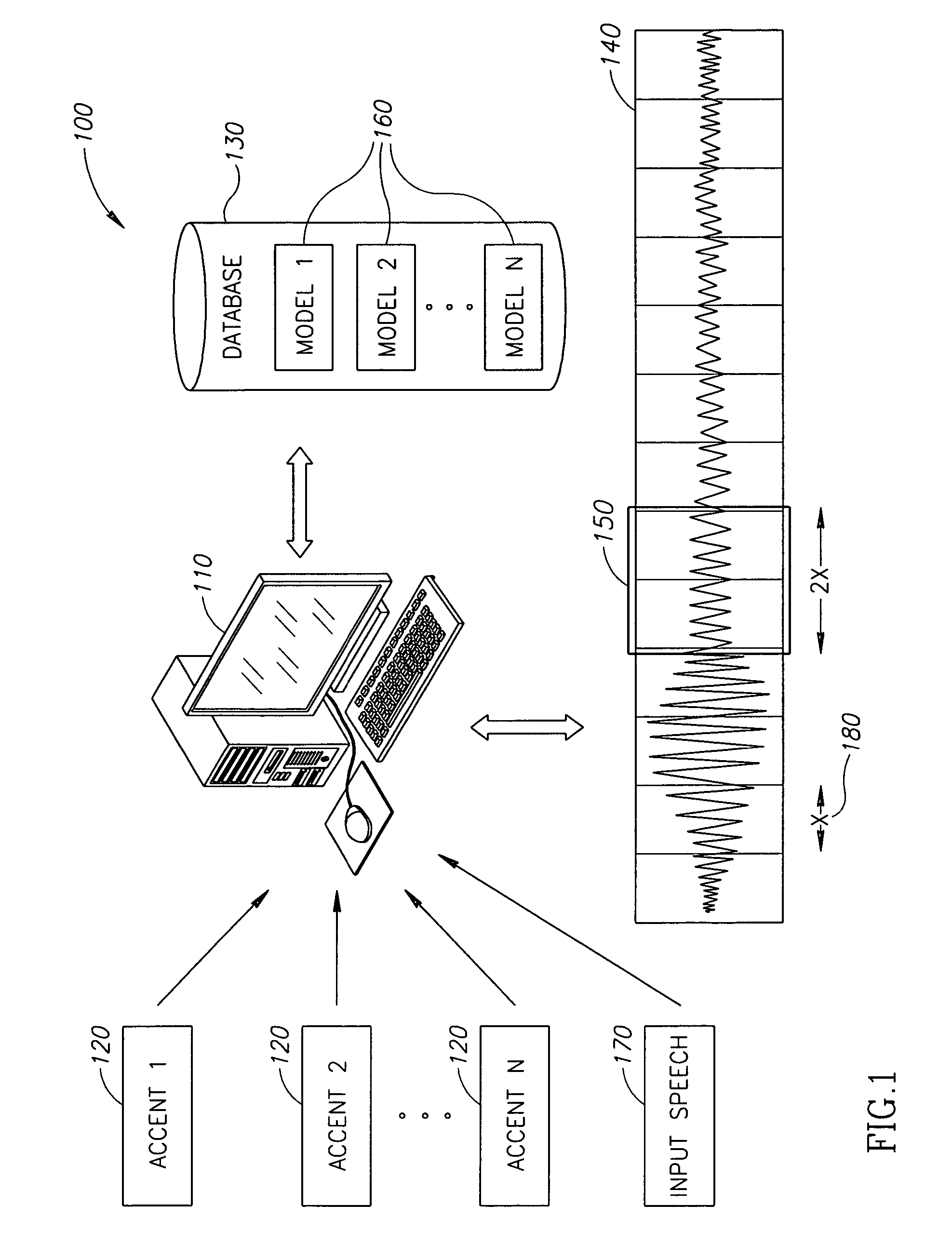

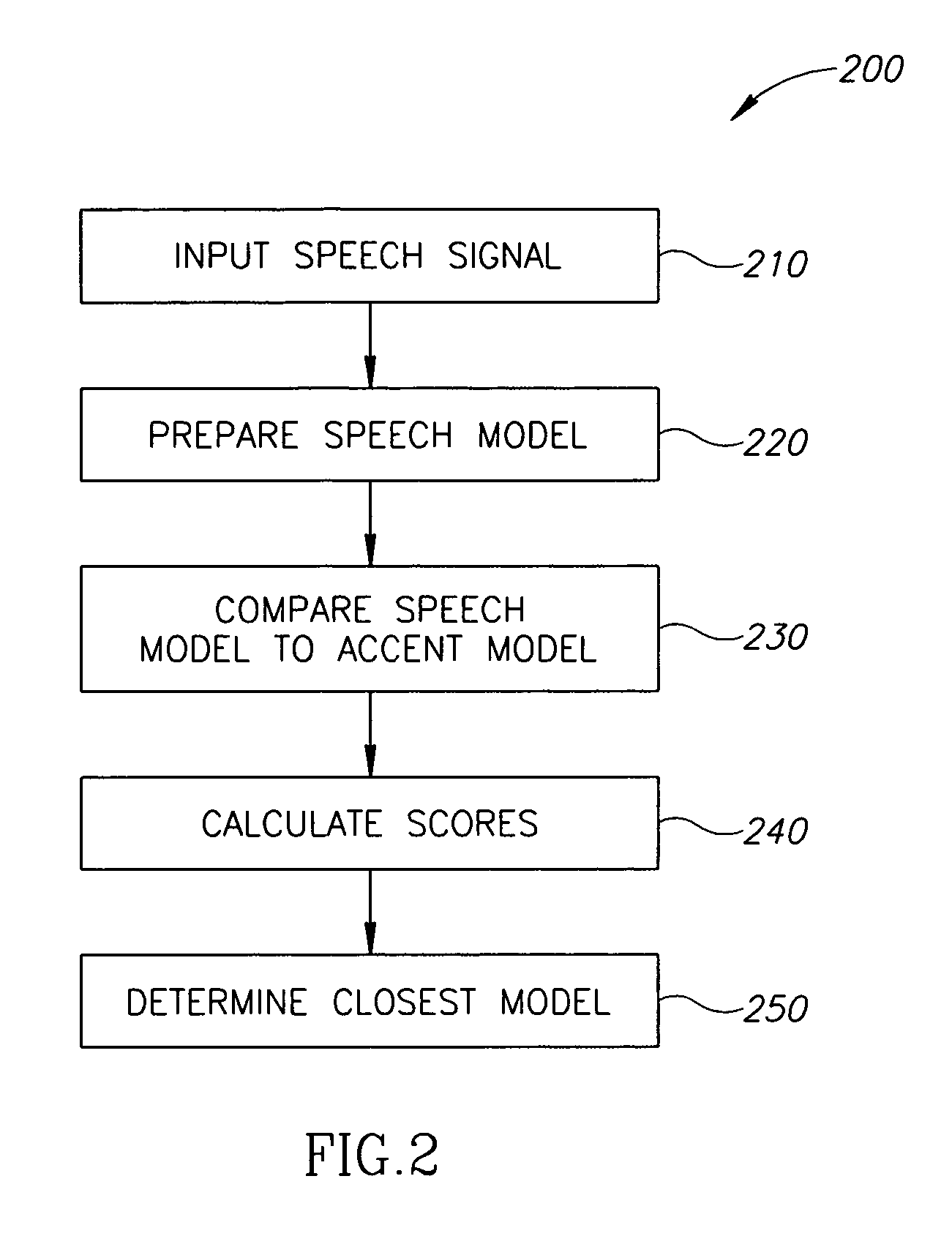

Automatic speech analysis

ActiveUS8725518B2Natural language data processingSpeech recognitionTotal quality managementAutomatic speech

A system for providing automatic quality management regarding a level of conformity to a specific accent, including, a recording system, a statistical model database with statistical models representing speech data of different levels of conformity to a specific accent, a speech analysis system, a quality management system. Wherein the recording system is adapted to record one or more samples of a speakers speech and provide it to the speech analysis system for analysis, and wherein the speech analysis system is adapted to provide a score of the speakers speech samples to the quality management system by analyzing the recorded speech samples relative to the statistical models in the statistical model database.

Owner:NICE LTD

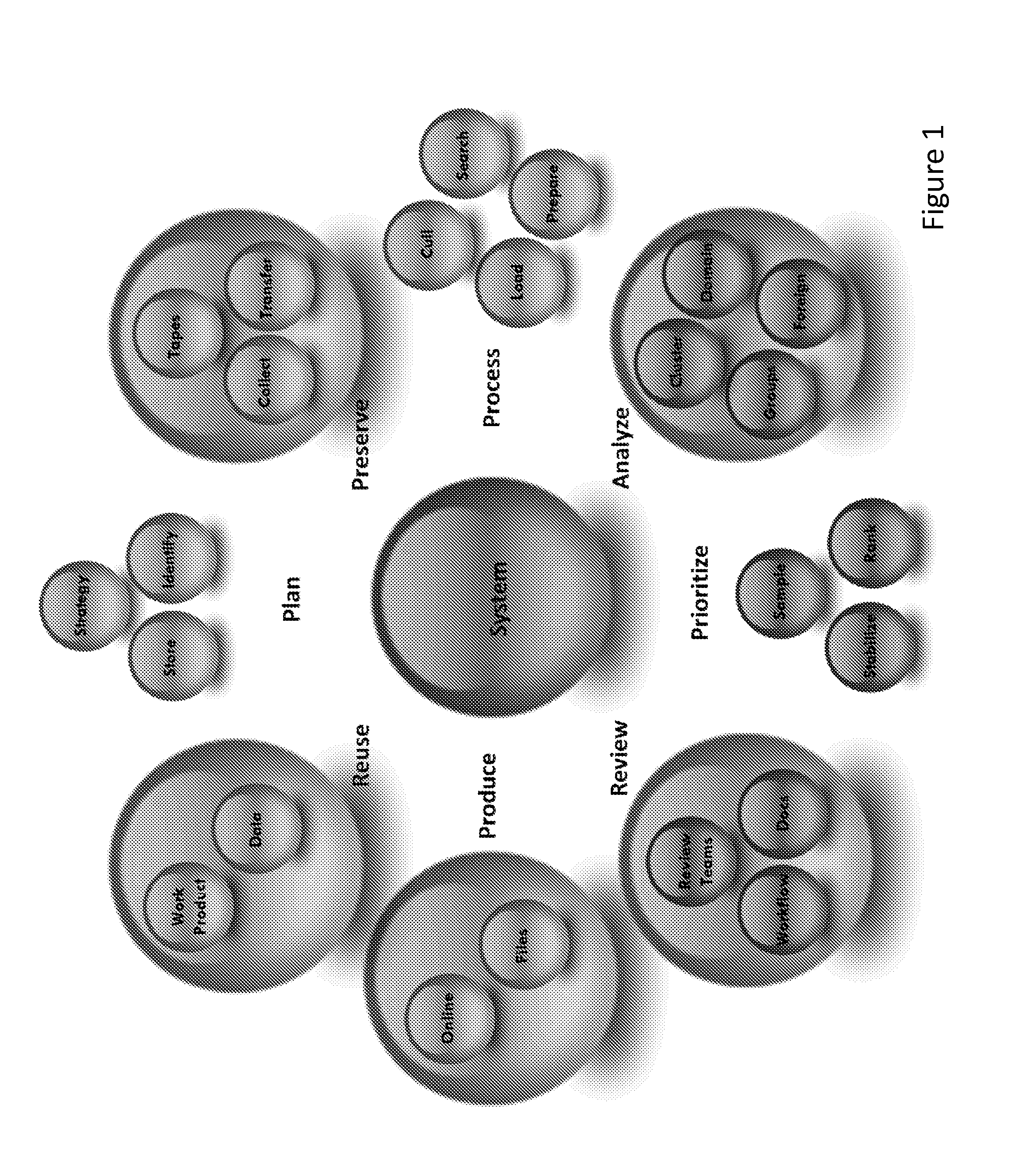

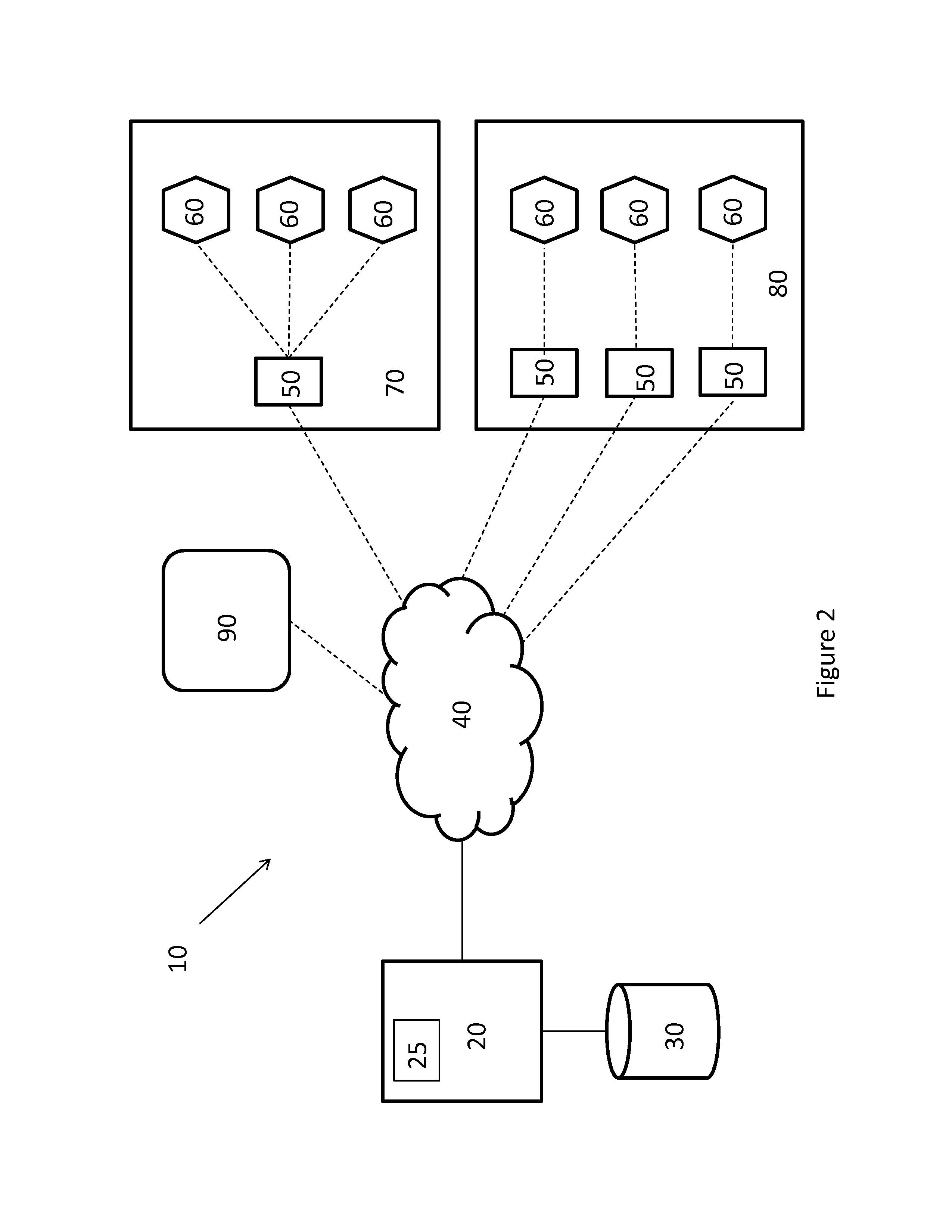

System and method of reviewing and producing documents

ActiveUS8560378B1Track performanceMultiprogramming arrangementsQuality controlTotal quality management

A system and method of providing comprehensive document review, production and reporting is described. The system and method provide a total quality management approach to a document review matter that not only controls costs but increases defensibility of the overall process, thereby reducing risk. The system utilizes unique review and performance metrics, increases quality control, and enhances physical and data security mechanisms. The system of the present invention can be implemented with any document review software or hosted platform desired for use by a customer.

Owner:NETMATRIX INC

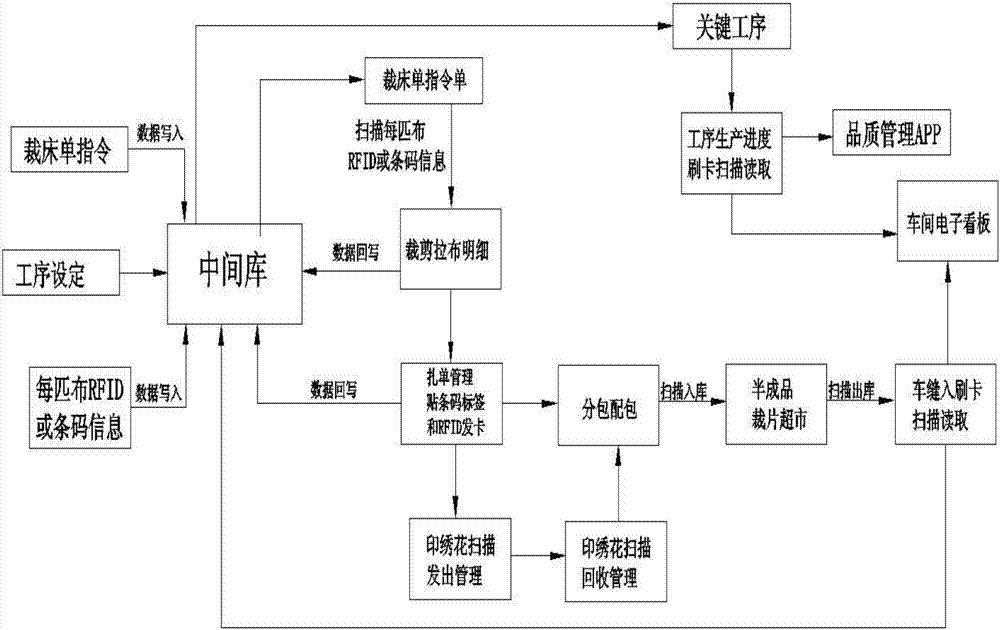

Quality management method for production workshop

InactiveCN106919155AMeet production development requirementsClear processCo-operative working arrangementsTotal factory controlData displayDisplay board

The invention relates to a quality management method for a production workshop, which comprises the steps of writing a bed sheet clipping instruction, RFID or barcode information of each piece of cloth and related data of working procedure setting into a middle database, wherein the middle database generates a bed sheet clipping instruction sheet and captures key working procedures in working procedure setting; scanning an RFID or barcode tag of each piece of cloth to be clipped and then automatically generating cloth clipping and pulling details; then performing bed sheet bundling management on clipped pieces, attaching barcode tags and performing RFID card distribution; performing package sorting and distributing on the clipped pieces after bed sheet bundling management, scanning and delivering the clipped pieces to a semi-finished product clipped piece supermarket, and then scanning and delivering the semi-finished product clipped pieces out of the supermarket; performing sewing inlet card-swiping scanning and reading on the semi-finished product clipped pieces which are scanned and delivered out of the supermarket, and carrying out data display through a workshop electronic display board; and performing working procedure production progress card-swiping scanning and reading on key working procedures at the same time, and sending the key working procedures to a quality management APP to perform quality management. The quality management method improves the overall production efficiency of enterprises, saves the labor and paper, and ensures the quality of products.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

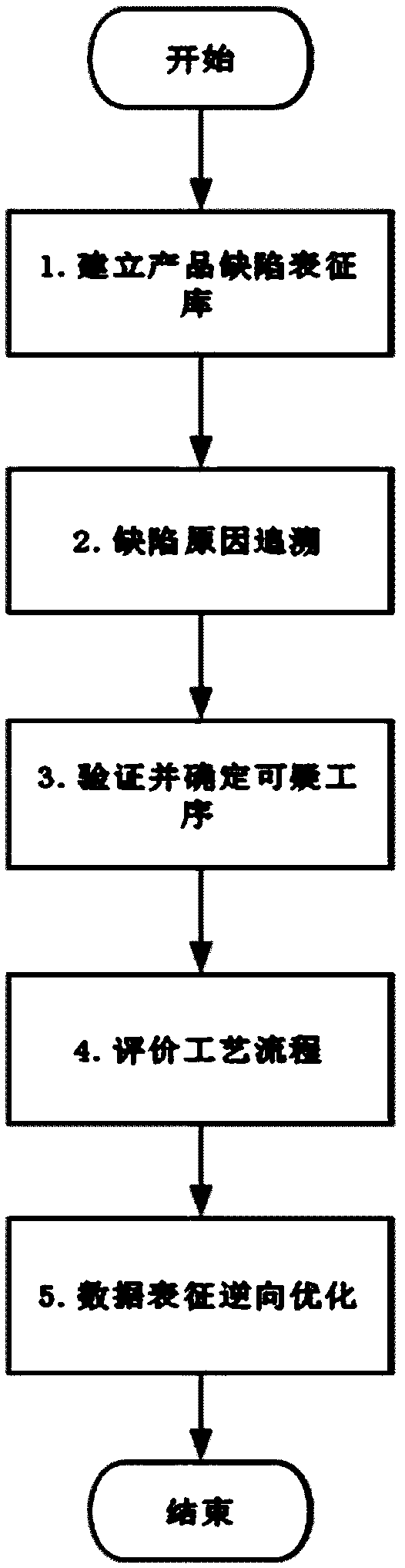

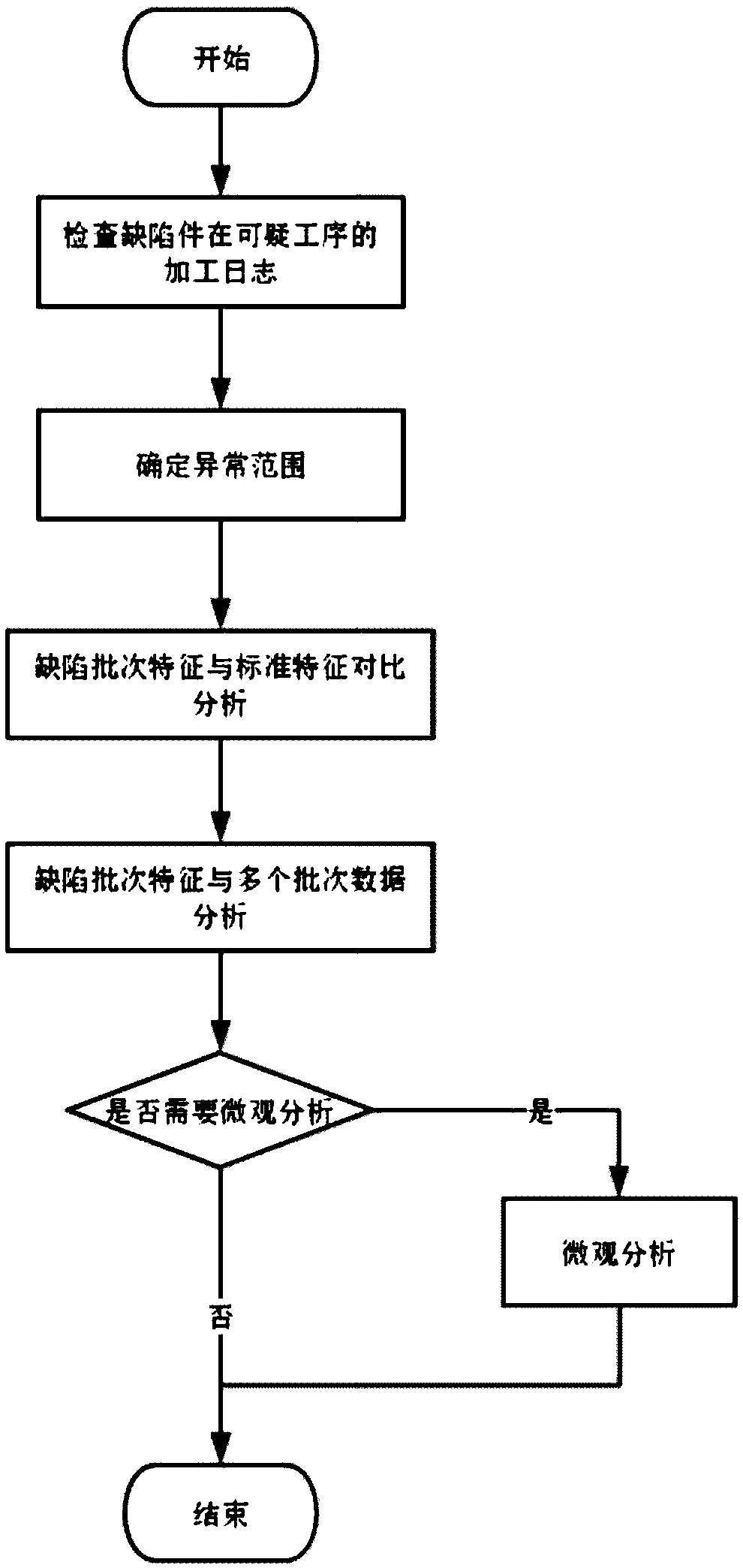

Quality traceability analysis method of whole process product based on process rules and big data

ActiveCN109146279APrevent leakageImprove analysis efficiencyDigital data information retrievalResourcesProduct baseTotal quality management

The invention belongs to the technical field of product quality management and control, and particularly discloses a whole-process product quality traceability analysis method based on process rules and big data. The method mainly comprises the following steps: establishing product defect characterization database, process flow monitoring, process evaluation, product quality evaluation, querying product defect characterization database, and reverse optimization of data characterization. The invention uses overall inspection instead of sampling inspection to improve the effectiveness of evaluation and avoid unqualified products leaking to users. Effectively support the follow-up product improvement and development, rule optimization, dynamic design adjustment, spare parts matching optimization, optimization sampling and other work.

Owner:TONGJI UNIV

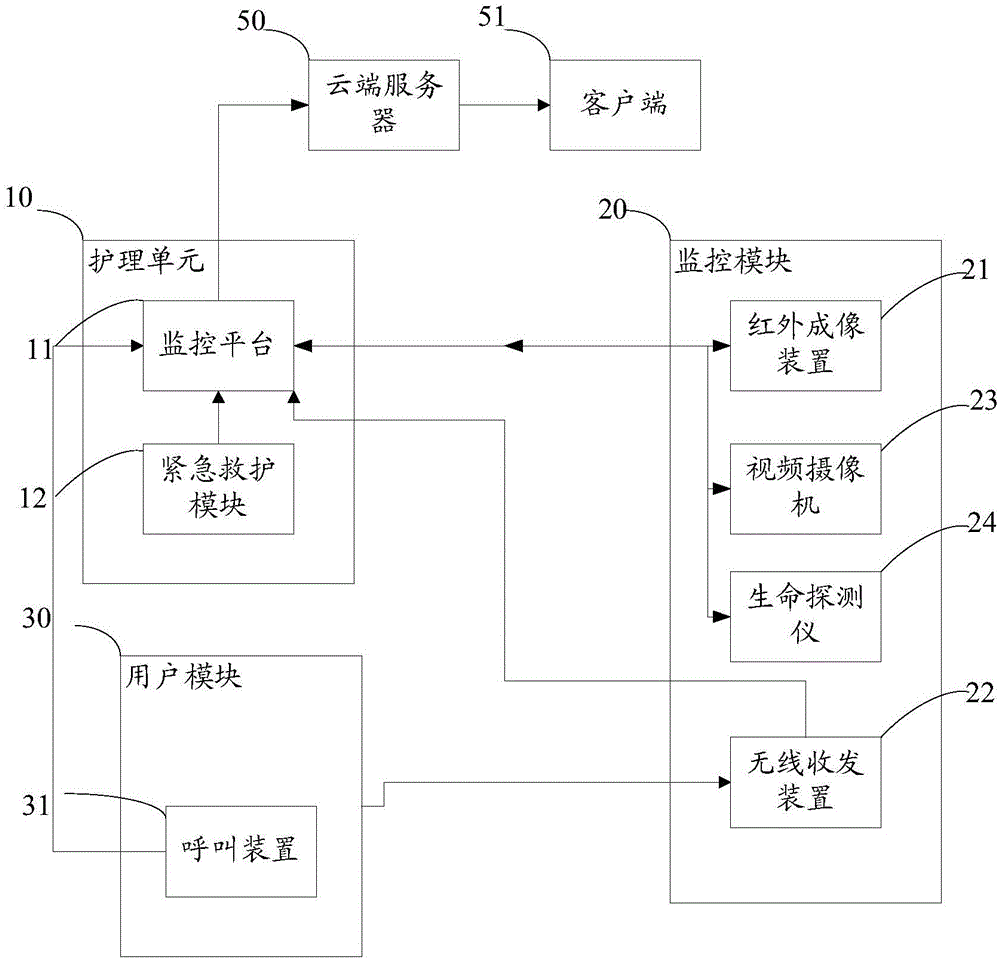

Total management system and management method of apartment for the aged

InactiveCN105007463AMaster the basic situation in real timeAvoid disturbanceClosed circuit television systemsDiagnostic recording/measuringOlder peopleComputer module

The invention belongs to the apartment total management field, in particular to an intelligent management system of an apartment for the aged and a method. The method provides a total management system of the apartment for the aged. An intelligent people-oriented service management system is built through a join combination among a nursing unit, a monitoring module and a user module; an infrared imaging device is selected as one part of the monitoring module, which considered from the old man's privacy; the nurse just can know the status of the old man via the infrared imaging mode in non-emergency situations and can open a video camera to know the situation when the old man uses a calling device. The management system can real-time master the basic situation of the old man in the room and avoid the disturbance to the old man because of more care via the connection among the nursing unit, the monitoring module and the user module. The connection between a cloud server and a client can ensure that the relatives of the old man can real-time understand the dynamic state of the old man via data or pictures or videos.

Owner:盛玉伟

Total inventory management

A method, system and program product to manage total inventory. Existing inventory, optimum inventory, excess inventory and inventory consumption are calculated according to different sets of data regarding whether one is considering a policy inventory and / or a manufacturing limitation. Results of the calculations with different sets of data are compared to determine an impact of the policy inventory and an inventory trapped in manufacturing. This invention has application in the microelectronics industry as well as other industries.

Owner:LINKEDIN

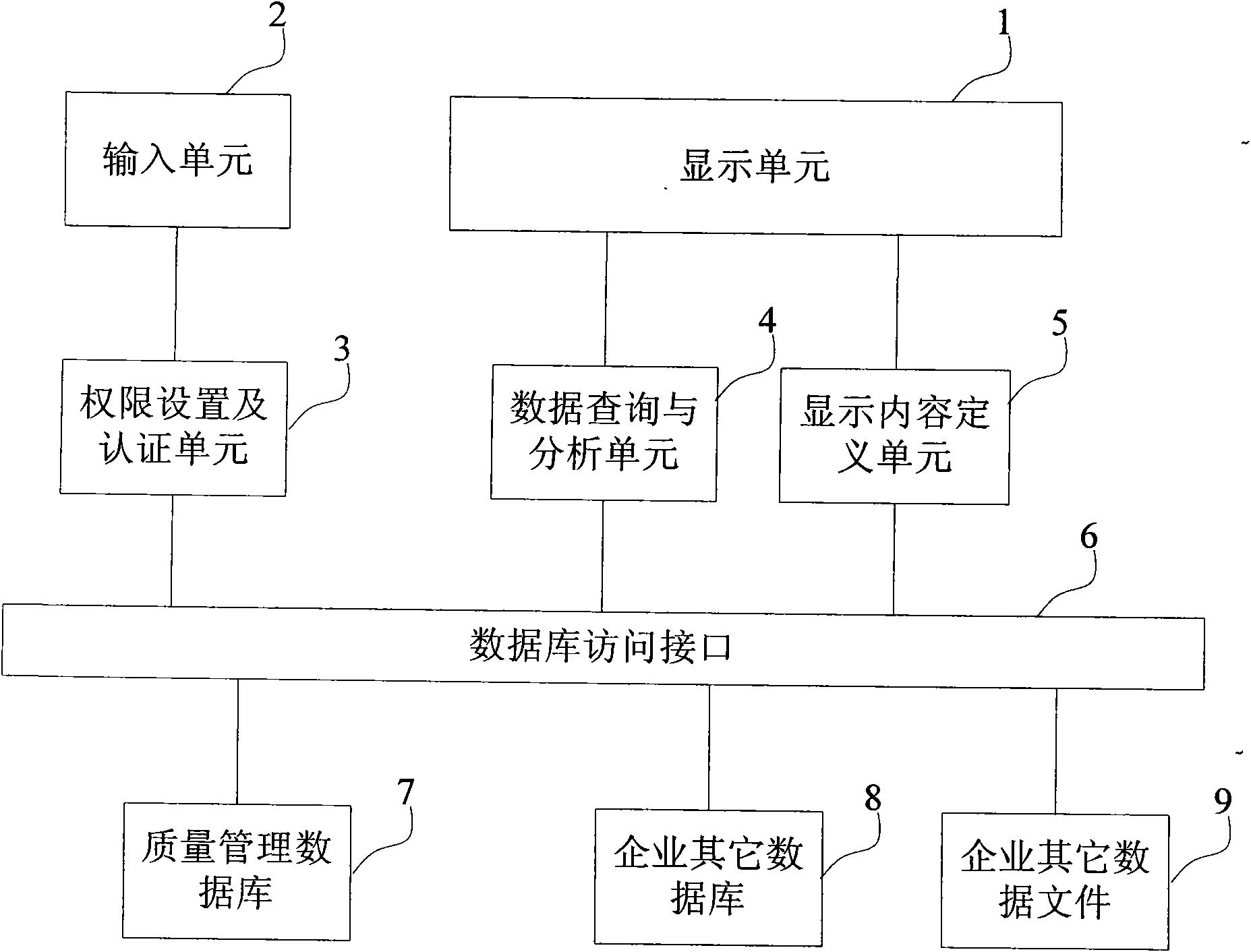

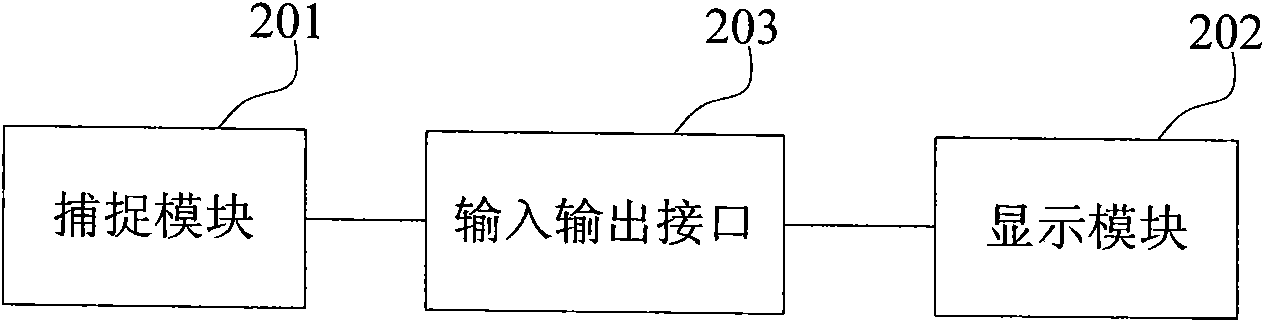

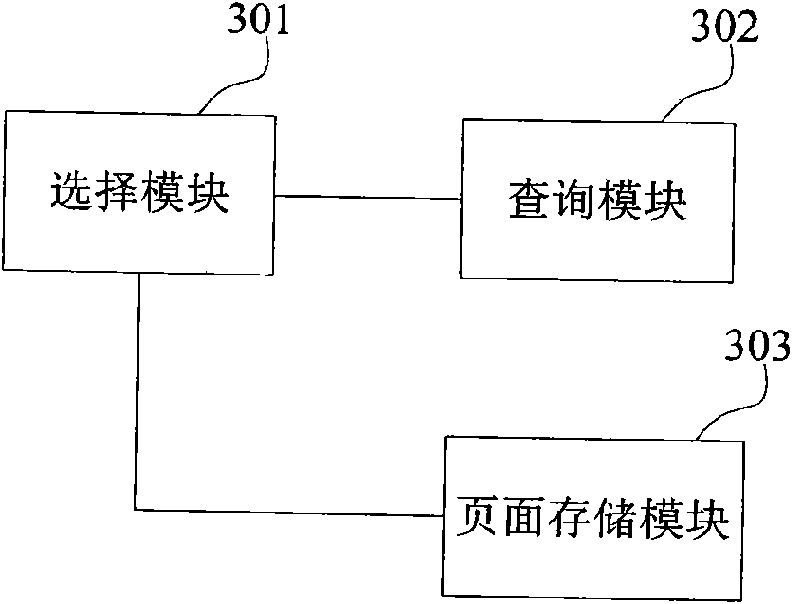

System and method for displaying quality management

The invention provides a system and a method for displaying quality management. In order to solve the problems that in the prior art, data of quality management is not real-time enough and the control of a certain working position and personnel in an enterprise cannot be realized, the invention provides the method for displaying the quality management, which comprises that: a user operation parameter is acquired in a quality management page; according to the operation parameter, a display parameter and corresponding inquiry instruction are matched; according to the display parameter, a current user operation window is zoomed or reduced; according to an inquiry result, quality monitoring data is displayed in the window; whether abnormal quality monitoring data occurs in a quality management database is judged in real time; and if the abnormal quality monitoring data occurs, a prompt message is displayed in a display unit in real time. The system and the method have the advantages that: when a certain quality link has a quality problem, a corresponding red alarming message glitters in a window corresponding to a page; and detailed quality information can be gradually zoomed and viewed through the positioning of the window.

Owner:亿维讯软件(北京)有限公司

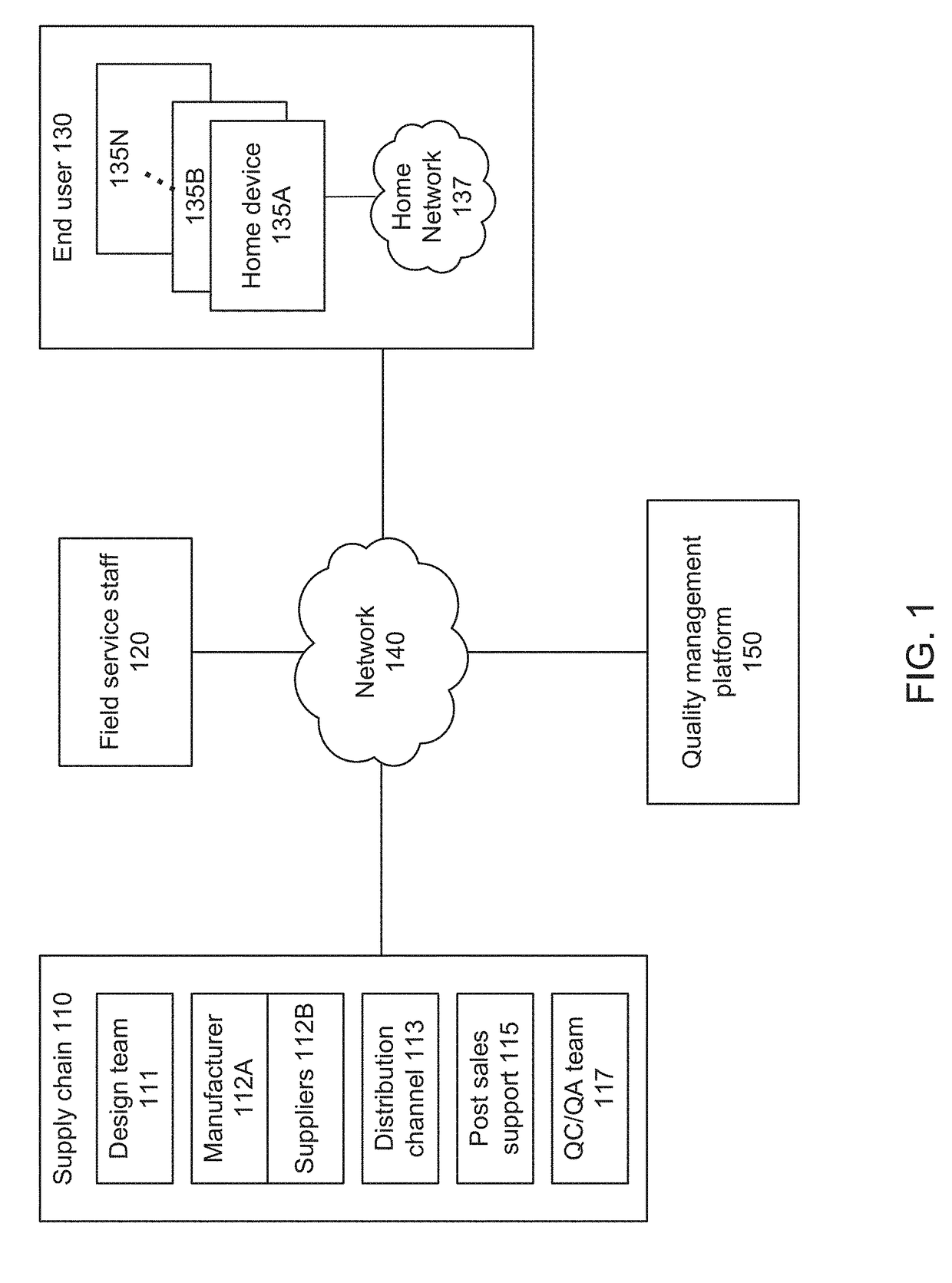

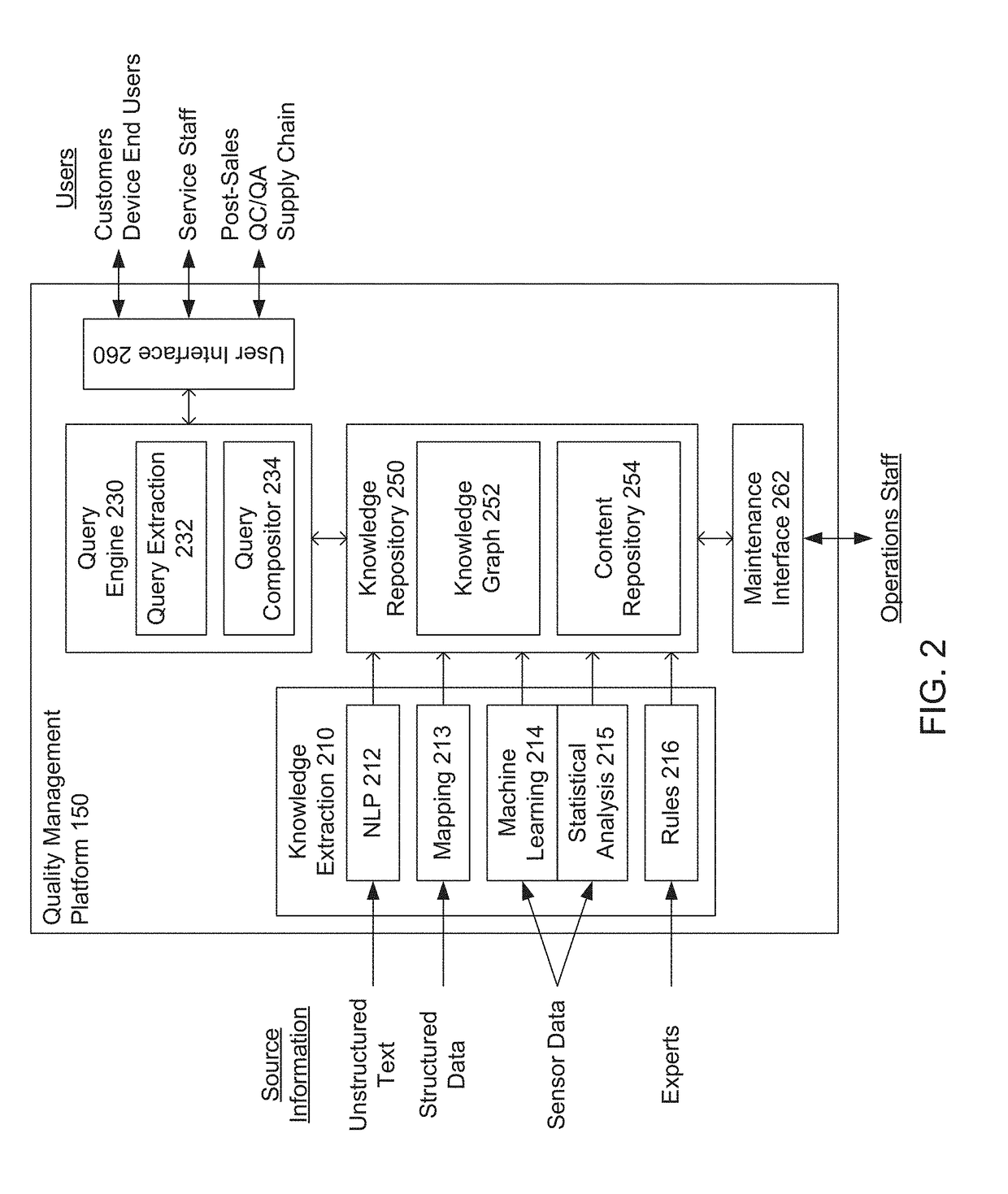

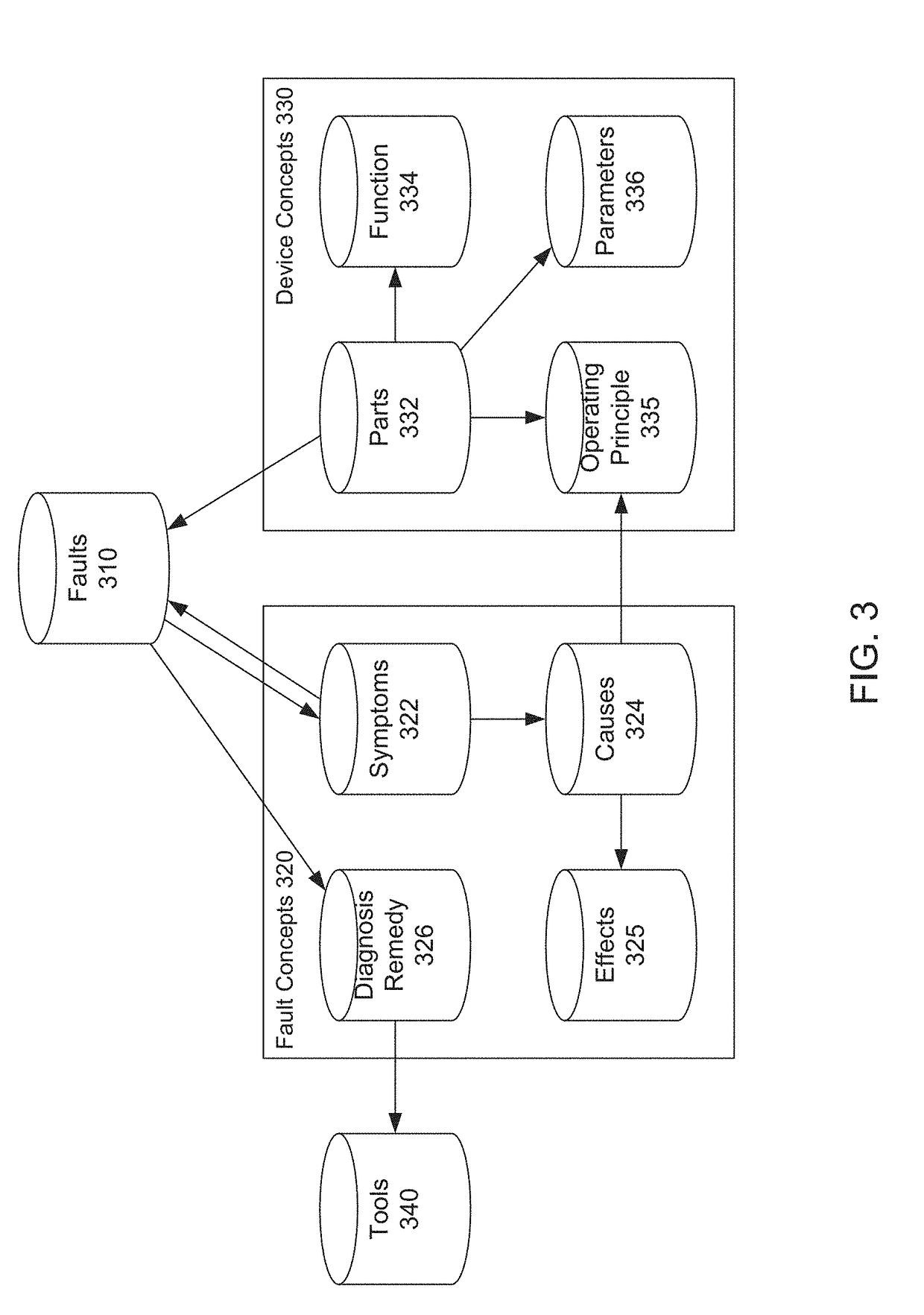

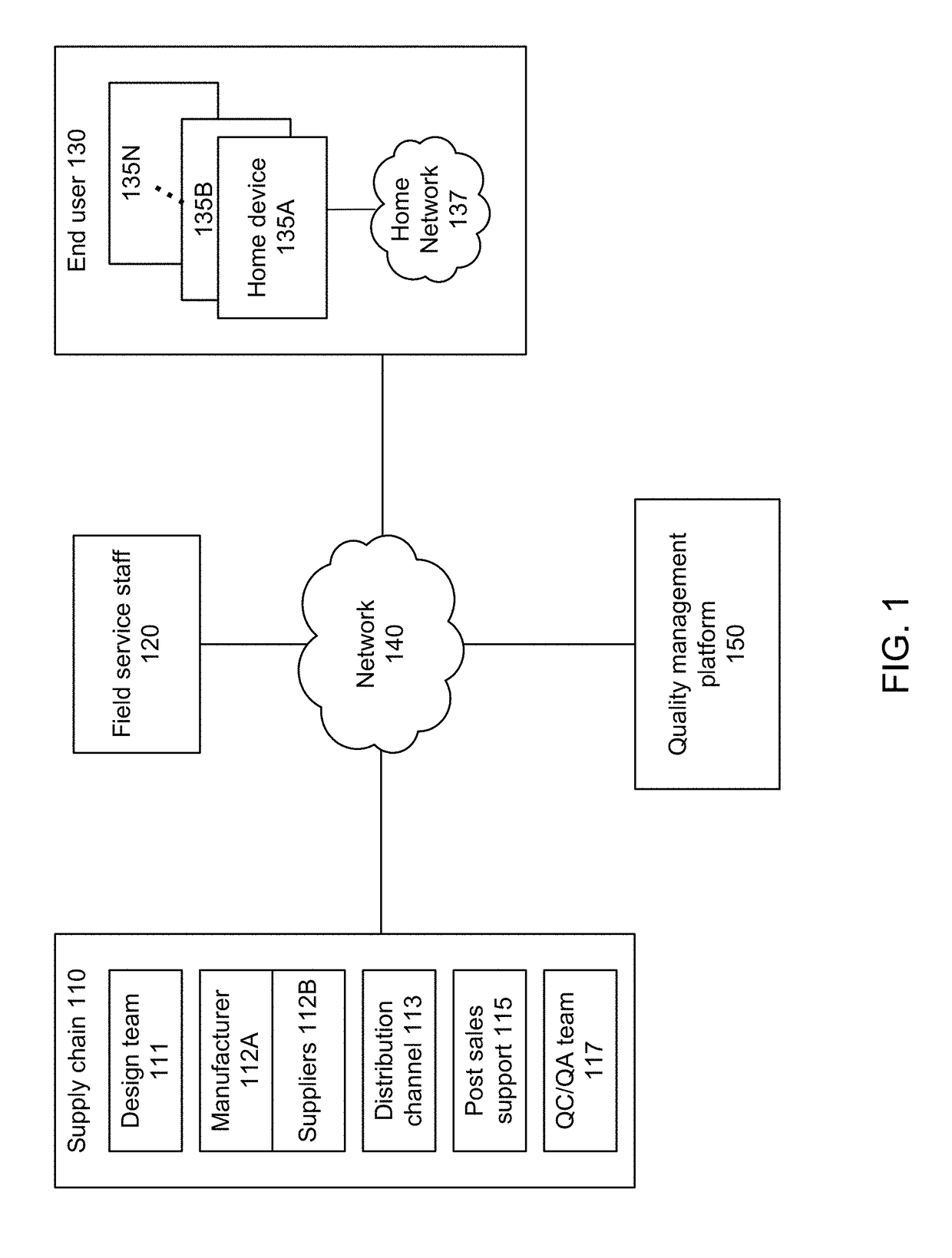

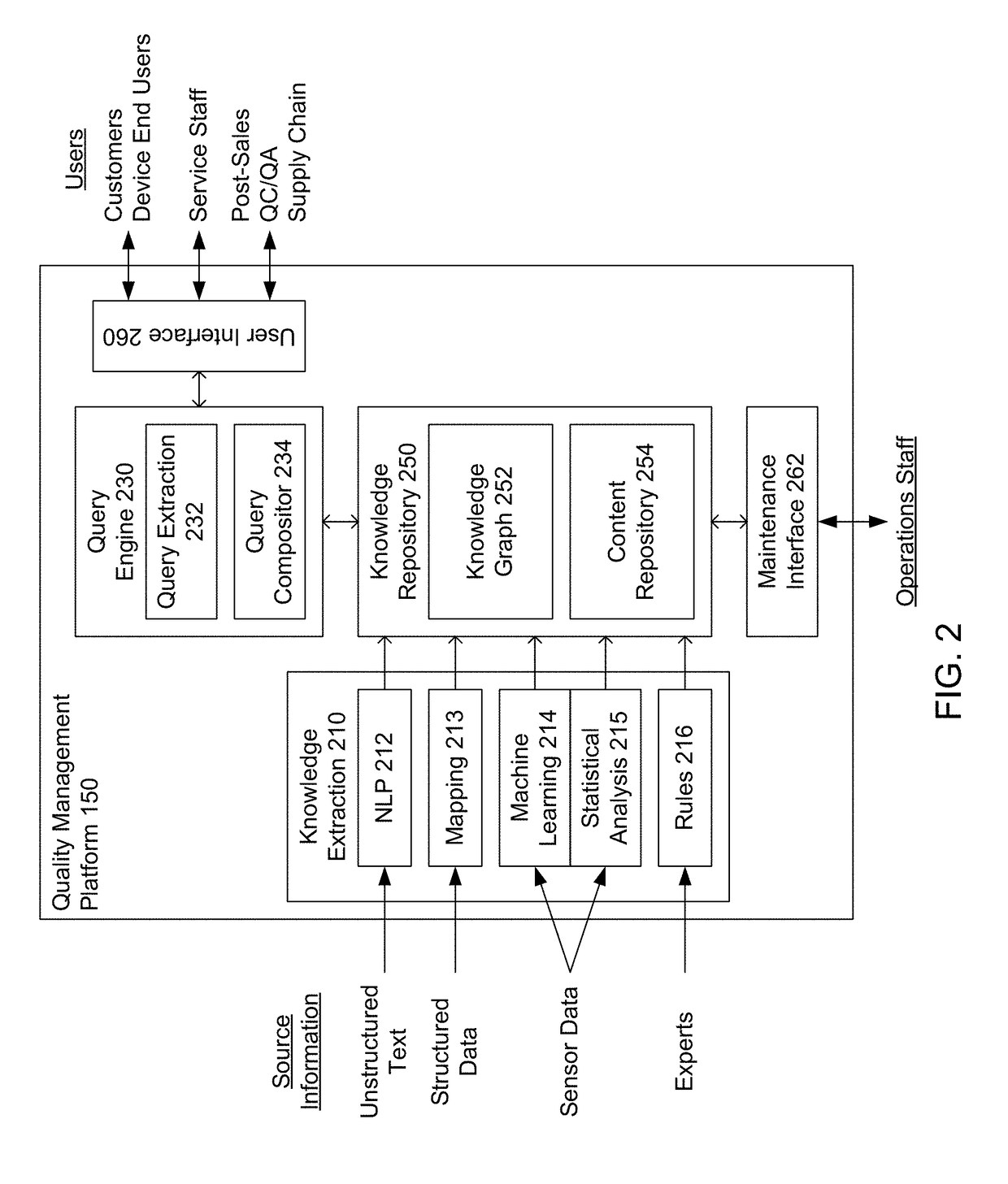

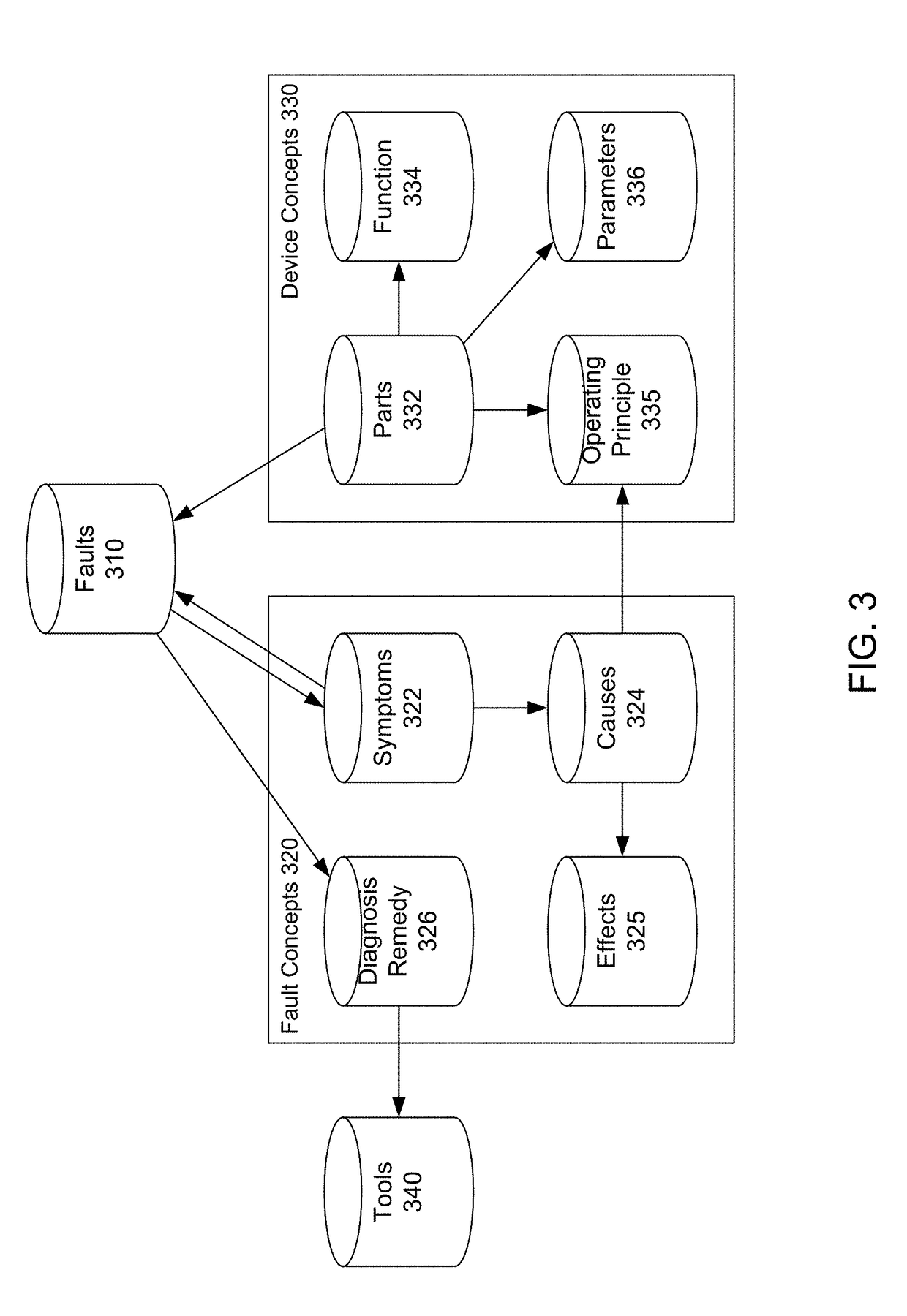

Computer-based platform for quality management of home devices, including knowledge extraction

ActiveUS20190020497A1Overcome limitationsSemantic analysisKnowledge representationComputerized systemKnowledge extraction

A quality management platform for home devices is implemented on a computer system and comprises a knowledge repository and a query engine. The knowledge repository includes a knowledge graph of nodes connected by edges. The nodes represent concepts relating to home devices and their operation and faults, and the edges represent relations between the concepts. The query engine receives requests relating to home devices, queries the knowledge graph based on the requests, and returns responses based on the query results.

Owner:MIDEA AMERICA CORP

Computer-based platform for quality management of home devices

ActiveUS20190018883A1Overcome limitationsSemantic analysisKnowledge representationComputerized systemKnowledge graph

A quality management platform for home devices is implemented on a computer system and comprises a knowledge repository and a query engine. The knowledge repository includes a knowledge graph of nodes connected by edges. The nodes represent concepts relating to home devices and their operation and faults, and the edges represent relations between the concepts. The query engine receives requests relating to home devices, queries the knowledge graph based on the requests, and returns responses based on the query results.

Owner:MIDEA AMERICA CORP

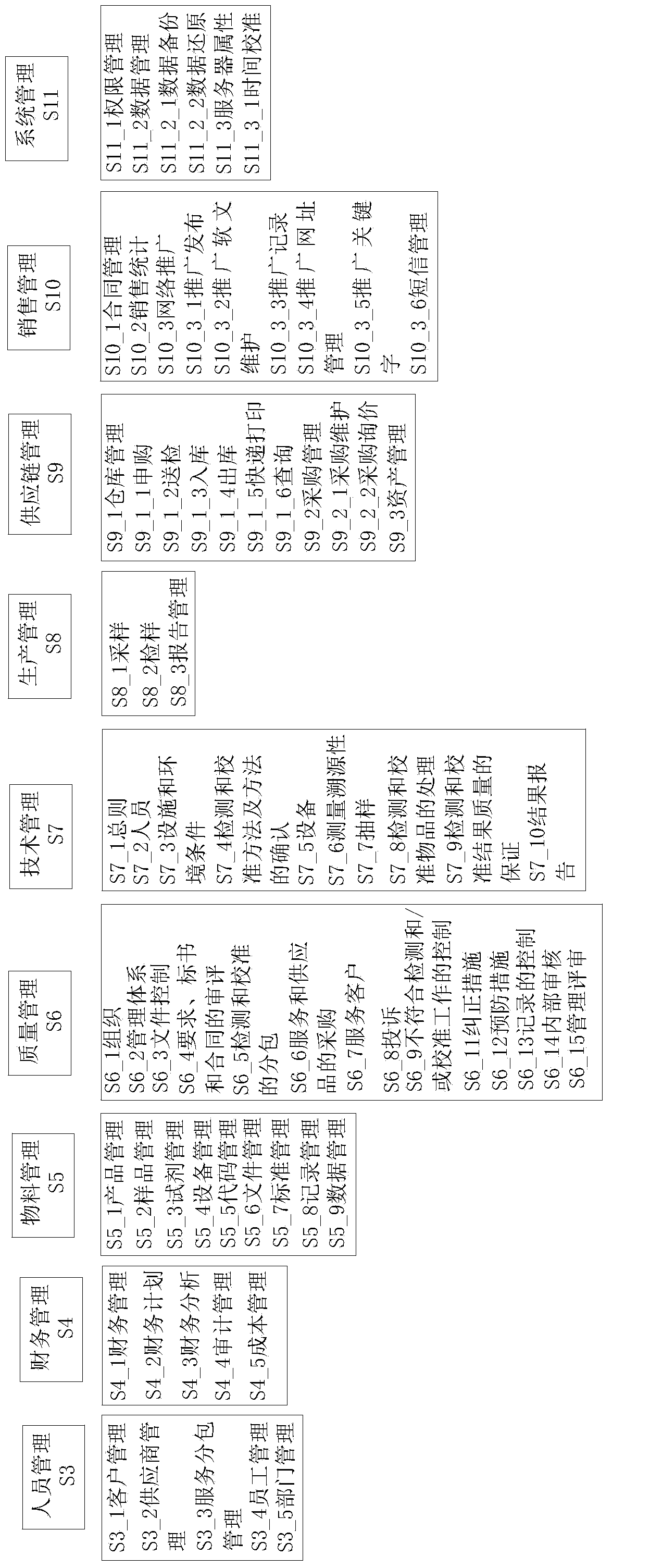

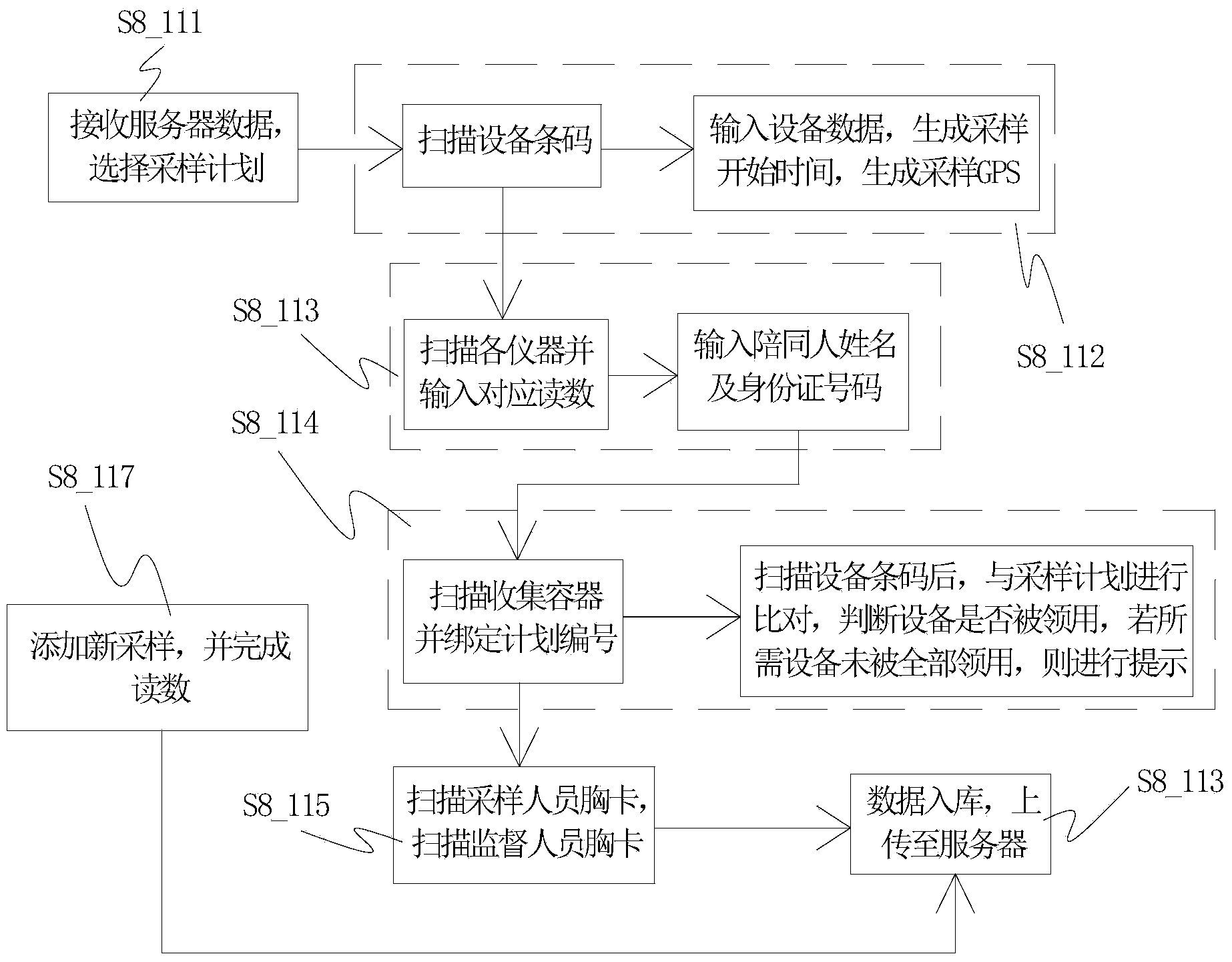

Testing organization ERP management method

InactiveCN104008450AImprove accuracyControl real-timeResourcesSystems managementTotal quality management

The invention provides a testing organization ERP management method. The testing organization ERP management method comprises the following steps of (S1) operational order receiving, (S2) operational order type judgment, (S3) personnel management, (S4) financial management, (S5) material management, (S6) quality management, (S7) technological management, (S8) production management, (S9) supply chain management, (S10) marketing management and (S11) system management. According to the testing organization ERP management method, the accuracy and instantaneity of data can be effectively ensured, and the disorder and the loss of the data can be avoided.

Owner:广州雅皓检测科技有限公司

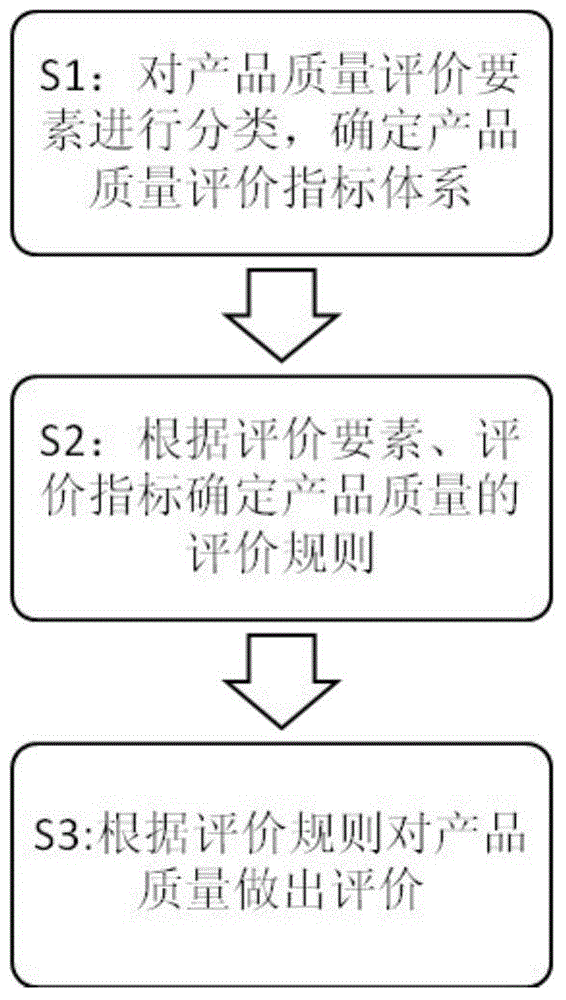

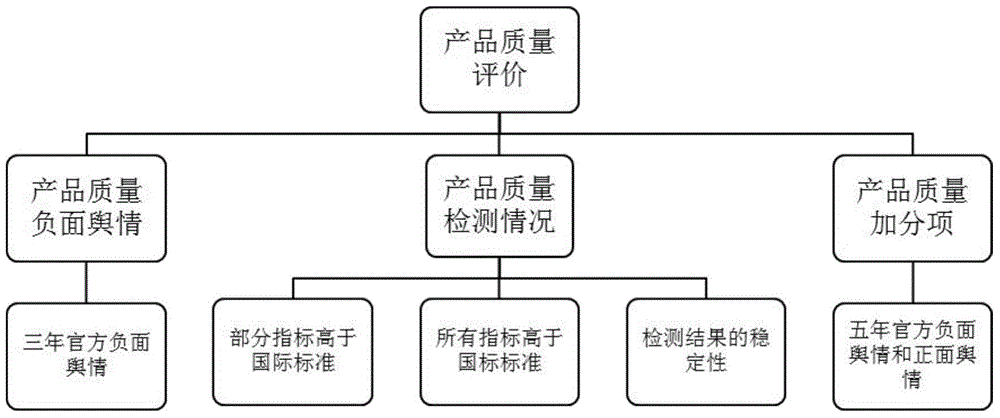

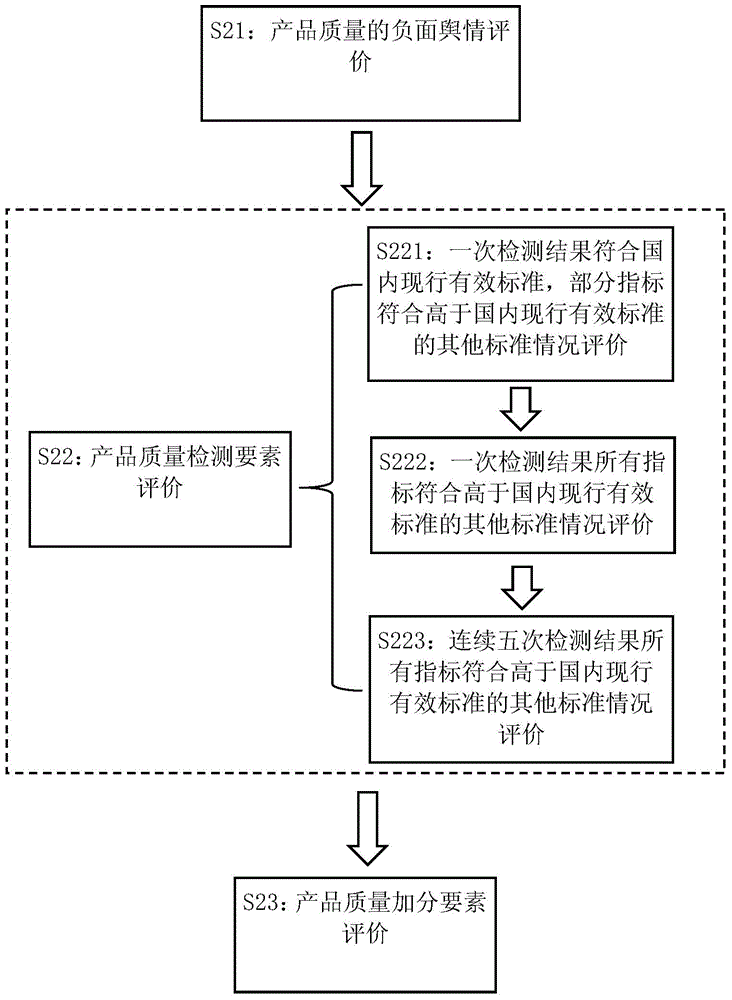

Product quality evaluation method

A product quality evaluation method includes classifying evaluative factors of product quality to build a system of evaluative factors; determining evaluative rules of product quality according to the evaluative factors of product and evaluative indexes of product quality; finally evaluating the product quality according to the determined evaluative rules. The method has the advantages that multilayer multi-index comprehensive evaluation can be provided for product quality, and evaluation results can support quality management for producers and also guide consumption selections for consumers.

Owner:云南同创检测技术股份有限公司

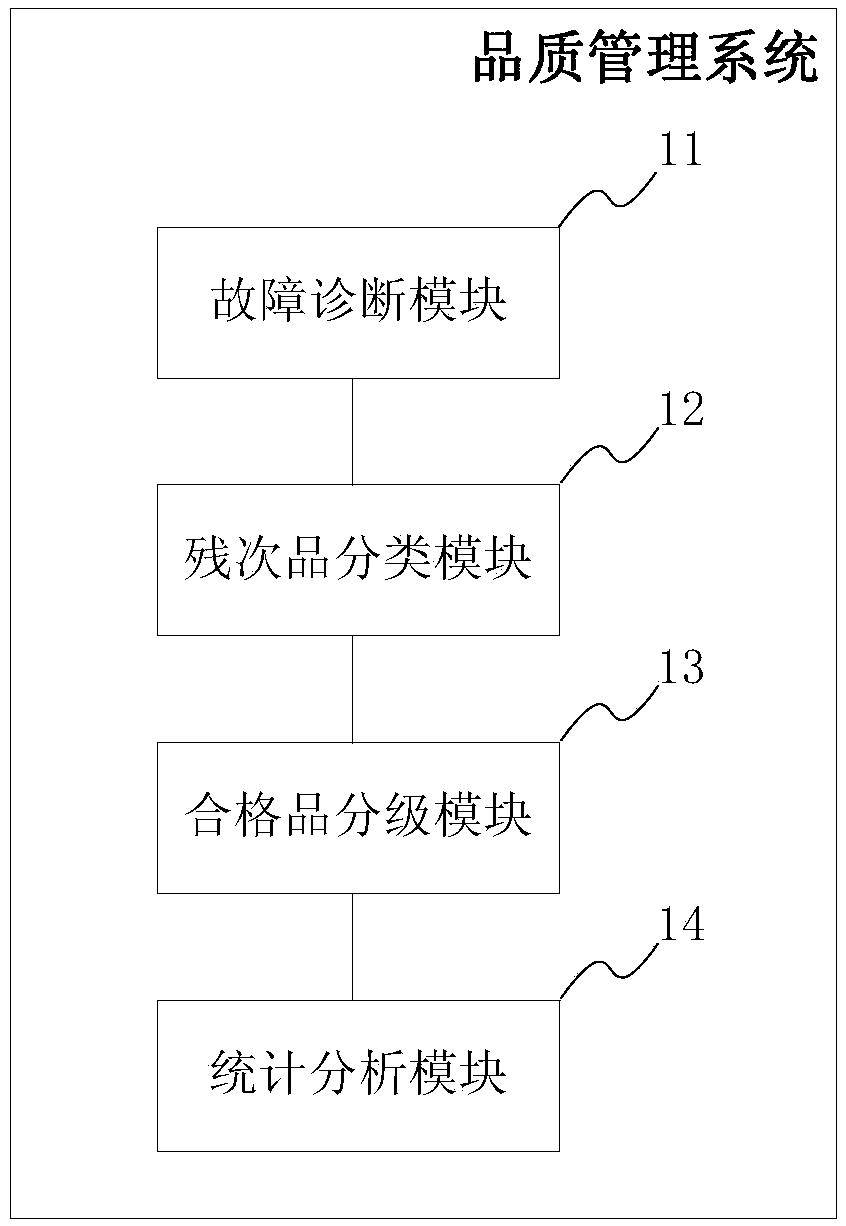

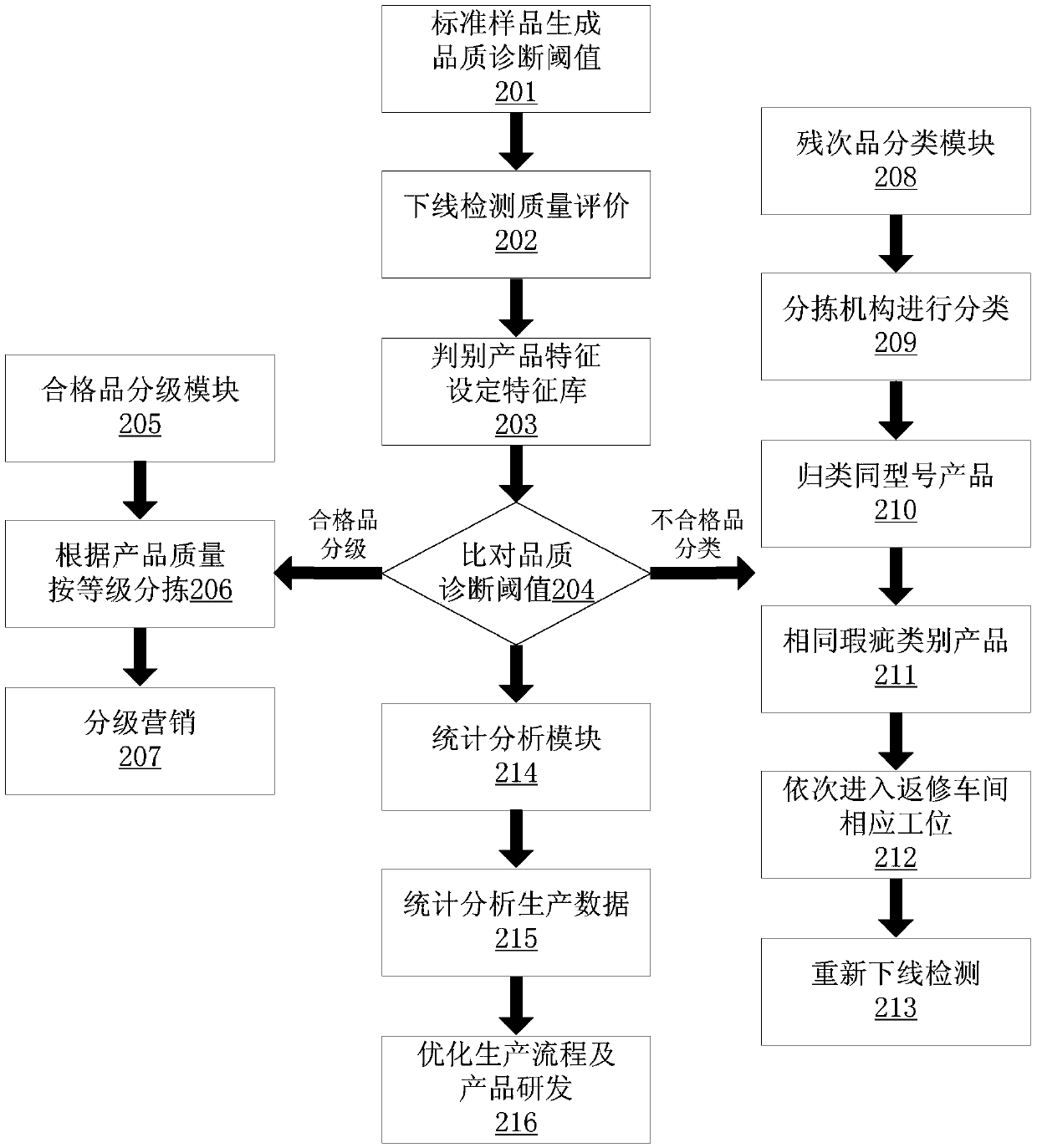

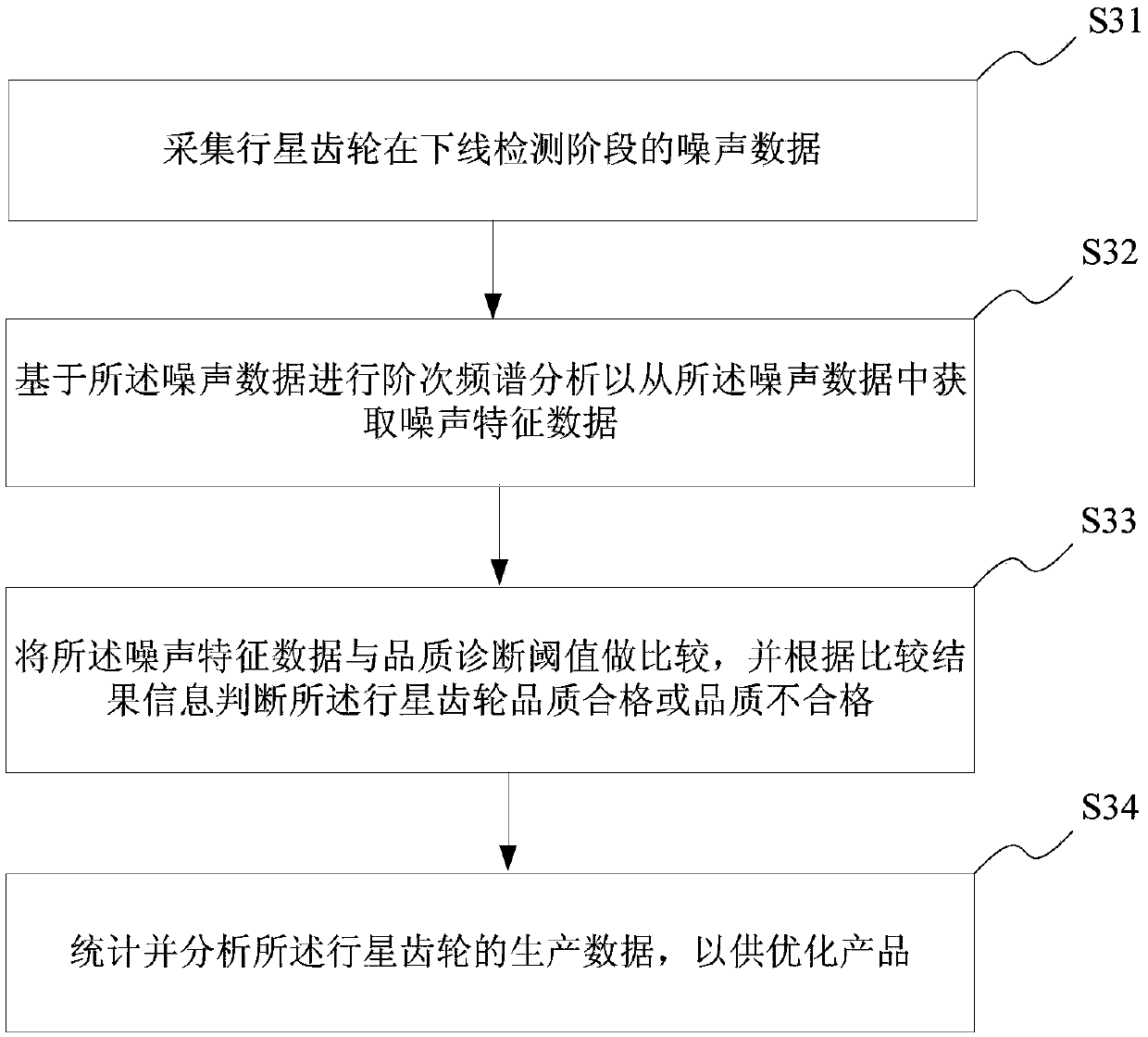

Quality management system and method suitable for planetary gear, terminal and storage medium

PendingCN109685253ARealize hierarchical managementAchieve marketingForecastingResourcesTotal quality managementReliability engineering

The invention provides a quality management system suitable for a planetary gear. Method, terminal and storage medium, The system comprises: the fault diagnosis module is used for collecting noise data of the planetary gear in an offline detection stage, performing order frequency spectrum analysis based on the noise data to obtain noise characteristic data from the noise data, comparing the noisecharacteristic data with a quality diagnosis threshold value, and judging whether the quality of the planetary gear is qualified or not according to comparison result information; The defective product classification module is used for classifying the planet gears with unqualified quality according to flaw types; And the qualified product grading module is used for grading the qualified planetarygears according to the quality grade. According to the invention, whether the product is qualified or not is judged, quality grading processing is carried out on the qualified product, and graded management and marketing are carried out on the qualified product; And the defective goods are classified according to the defect types, and different types of defective goods are put into correspondingrepair stations, so that the repair efficiency and the repair success rate are greatly improved.

Owner:上海睿深电子科技有限公司

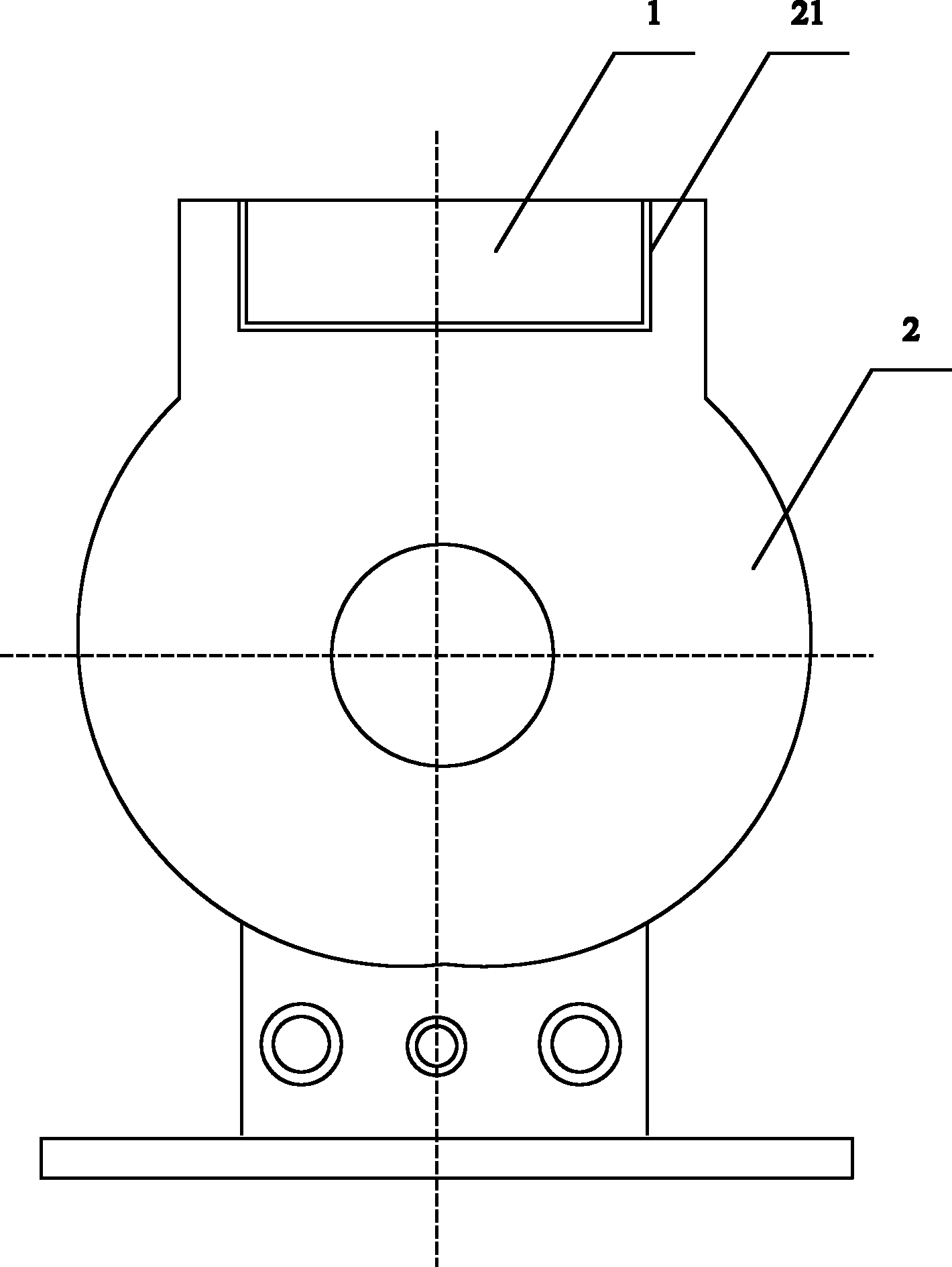

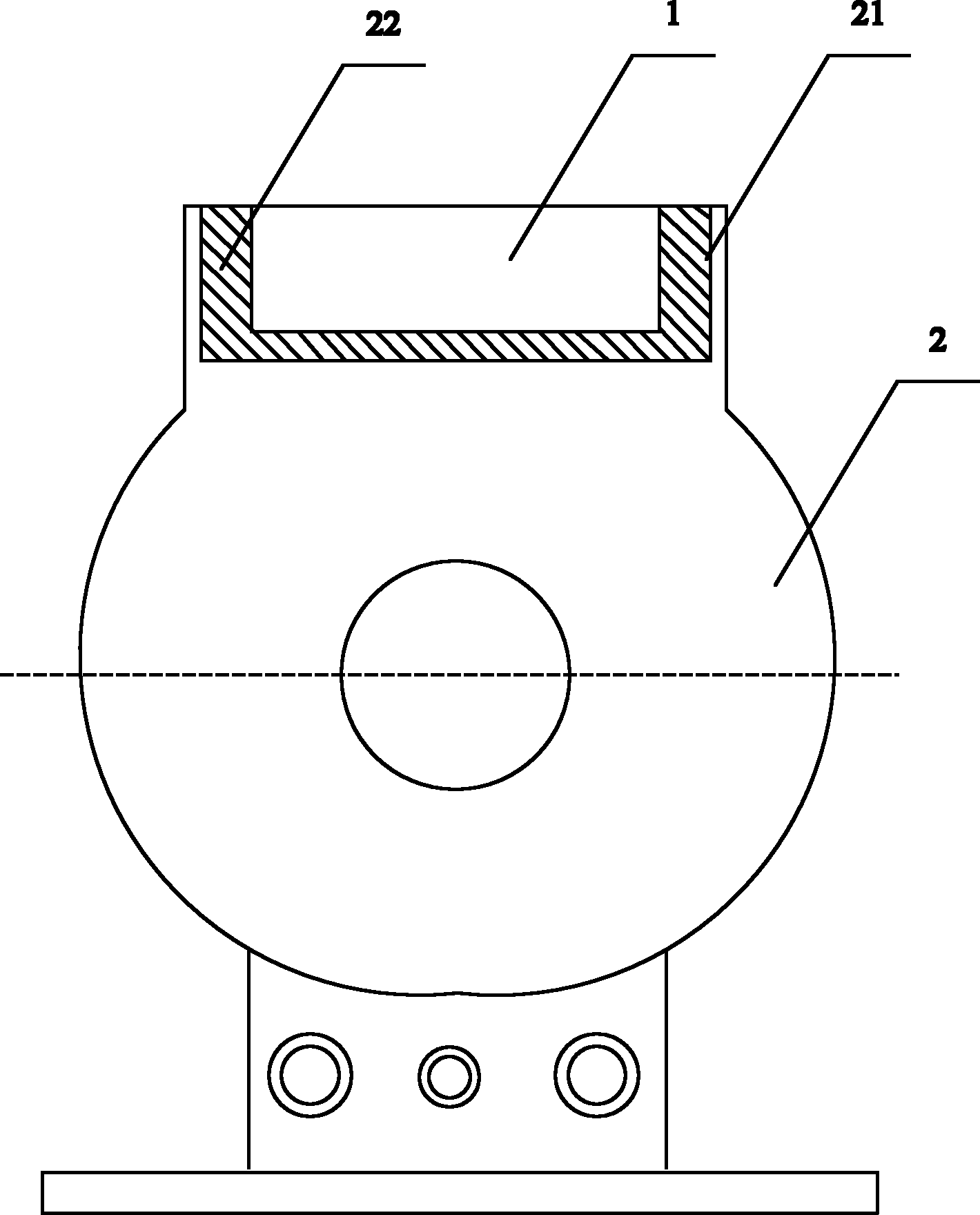

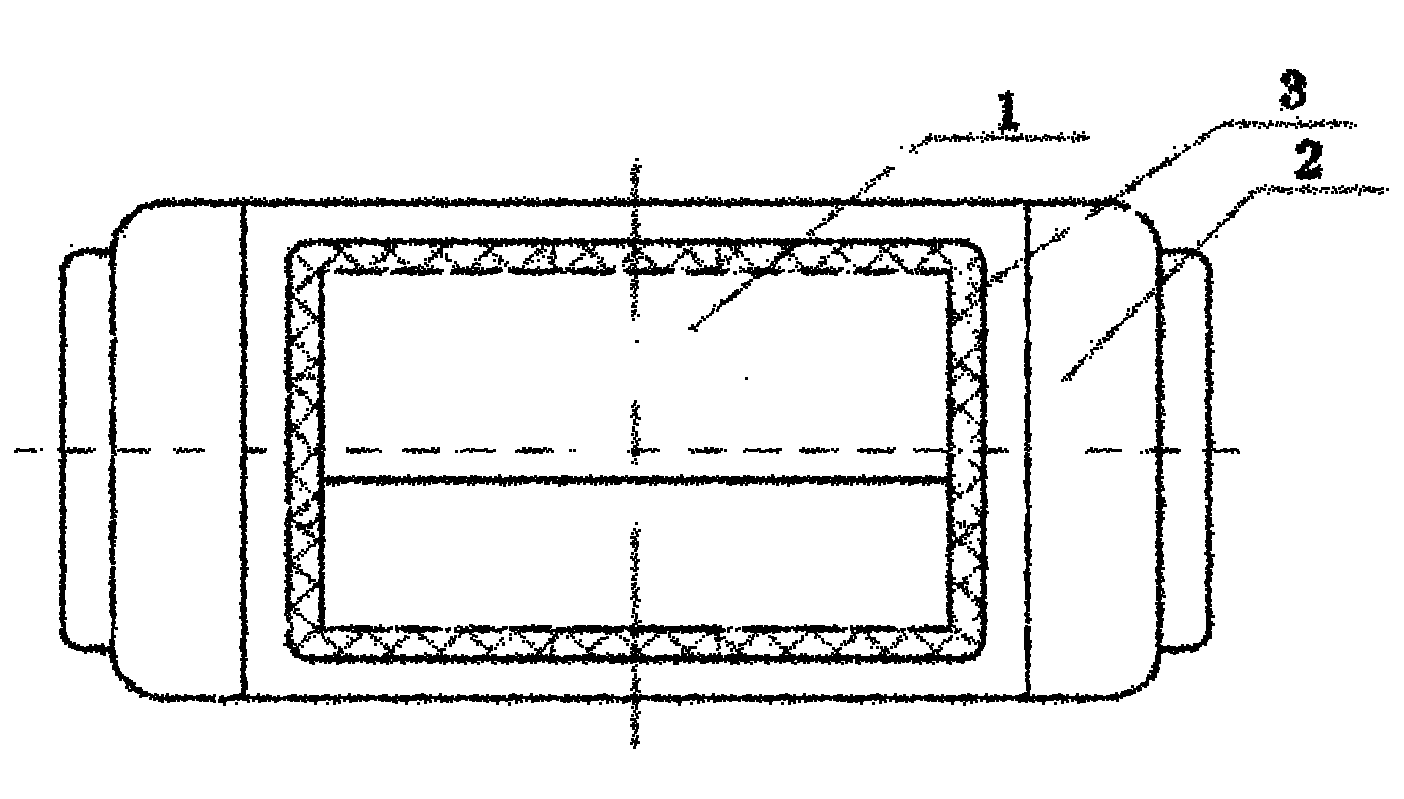

Mutual inductor device

ActiveCN102163297AWon't fall offNot easy to damageRecord carriers used with machinesLife qualityWhole body

The invention discloses a mutual inductor device. The device comprises a mutual inductor and an electronic label, wherein a slot is formed on the body of the mutual inductor; the electronic label is fixed in the slot; and the parameter information of the mutual inductor is stored in the electronic label. In the mutual inductor device, the electronic label is fixed with the mutual inductor to forma whole body, so that the electronic label cannot fall, is difficult to damage and cannot be replaced; the electronic label into which the parameter information of the mutual inductor is written has uniqueness, so that the identity of the mutual inductor can be effectively identified in the overall life cycle of the mutual inductor, and the execution of full-life quality management on products isfacilitated; the manual associated operation of the parameter information of the mutual inductor is not required, so that system faults due to manual operation errors in the process of delivering or warehousing stocks; and the electronic label has automatic scanning and quantity reading functions, so that the working intensity of workers can be reduced in the process of making an asset inventory.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com