Real-time fluctuation concrete-quality management and control system and method

A quality fluctuation and control system technology, applied in the direction of material inspection products, instruments, data processing applications, etc., can solve the problems of affecting the concrete water-binder ratio, unable to give timely feedback, and low unit price of ready-mixed concrete, so as to facilitate continuous improvement and improvement , huge social and economic benefits, and the effect of improving the level of construction management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

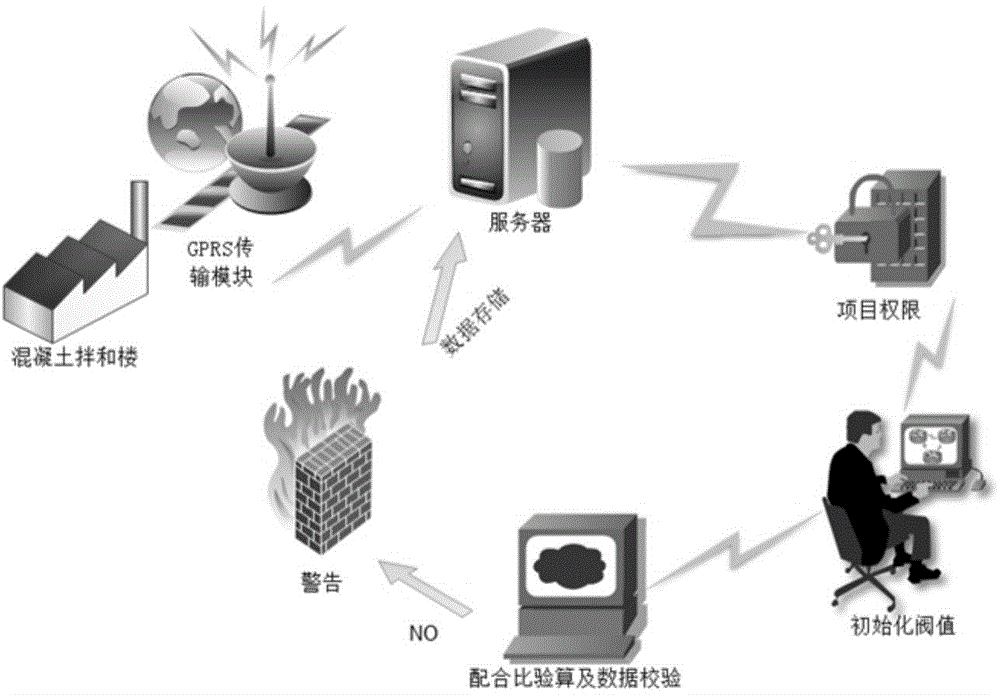

[0019] Such as figure 1 As shown, the concrete quality and its fluctuation control system of this embodiment, its working process is mainly that the server receives the real-time data of the concrete mixing plant through the GPRS transmission module, and the user with project authority transmits the initial value to the server by setting the initial value, and compares the data through the software Analysis and verification save unqualified data as warning data to the database of the server.

[0020] The concrete quality fluctuation real-time management and control system of this embodiment includes the hardware part for sending and receiving the real-time data of the concrete mixing plant, the hardware part processes the real-time data through the software part through the network signal, and calculates the result; Metering device, moisture content automatic measuring device and data transmission device, the data transmission device includes GPRS server, network system and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com