Patents

Literature

1339results about How to "Guarantee the quality of the project" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

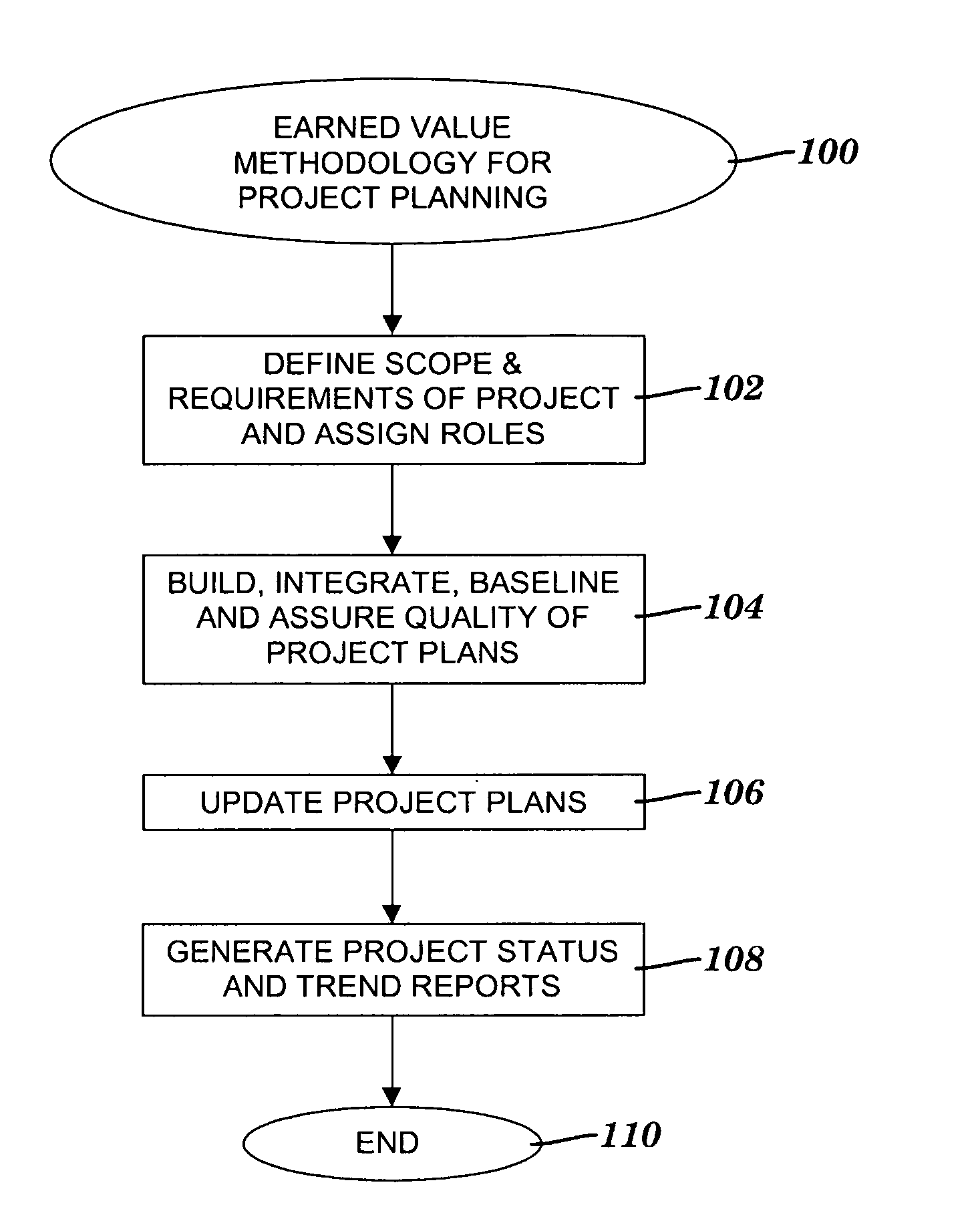

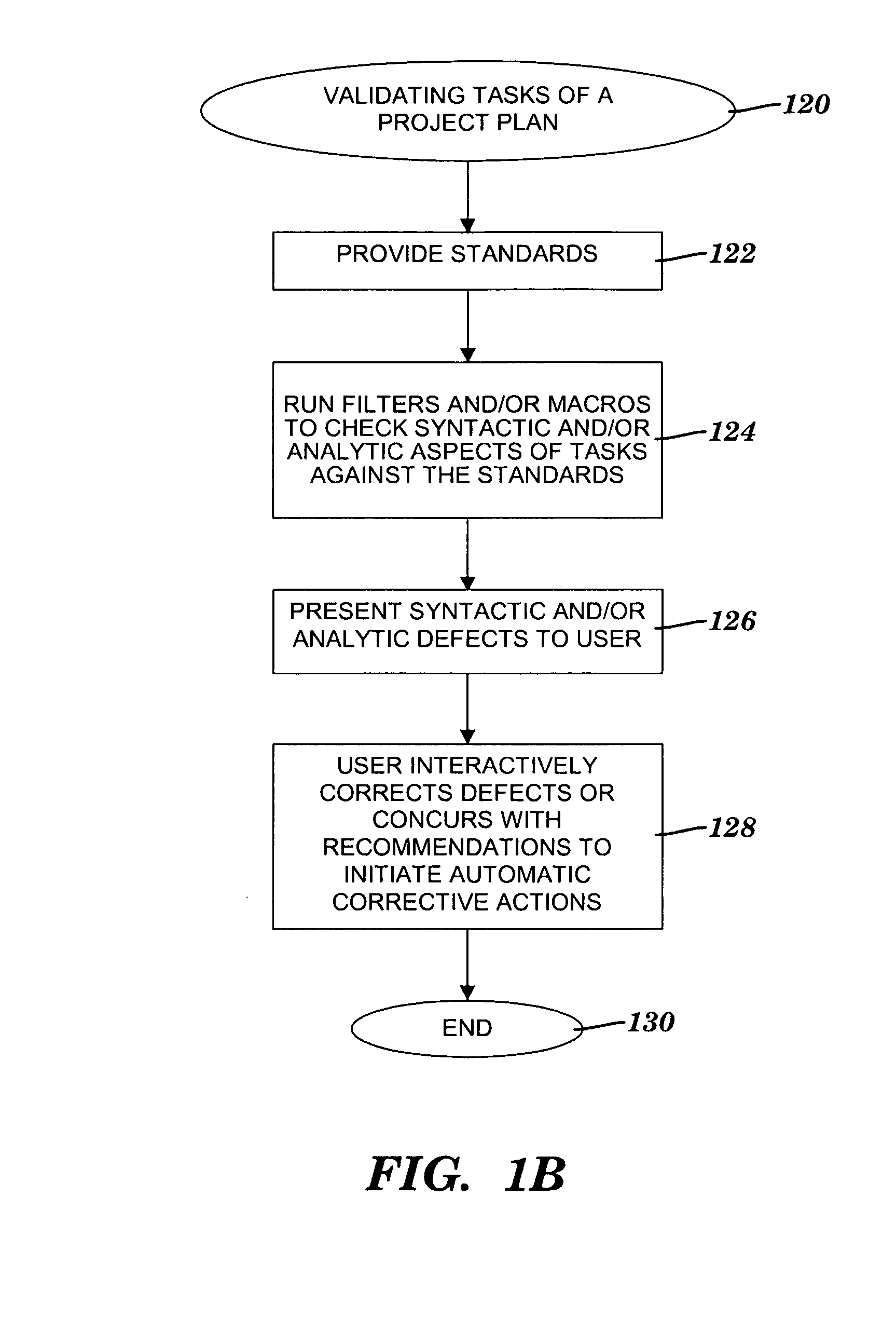

Method and system for validating a baseline

InactiveUS20080082956A1Quality assuranceGuarantee the quality of the projectOffice automationSpecific program execution arrangementsMethod valuesApplication software

A computer-implemented method and system for validating a baseline of a project. A computing application executes routines to automatically identify baseline errors associated with one or more tasks and generate exception reports to facilitate correction of the errors. The baseline errors are identified via determinations of whether (1) a task has no resources assigned, (2) resources are assigned to a summary task, (3) a task has an invalid earned value method value, (4) a task or milestone was not baselined, (5) a task's baseline start date was manually updated, (6) a task's baseline finish date was manually updated, (7) a task's baseline cost (BAC) was manually increased, (8) a task's BAC was manually decreased, and (9) a task's budgeted cost of work performed is not equal to the task's BAC.

Owner:IBM CORP

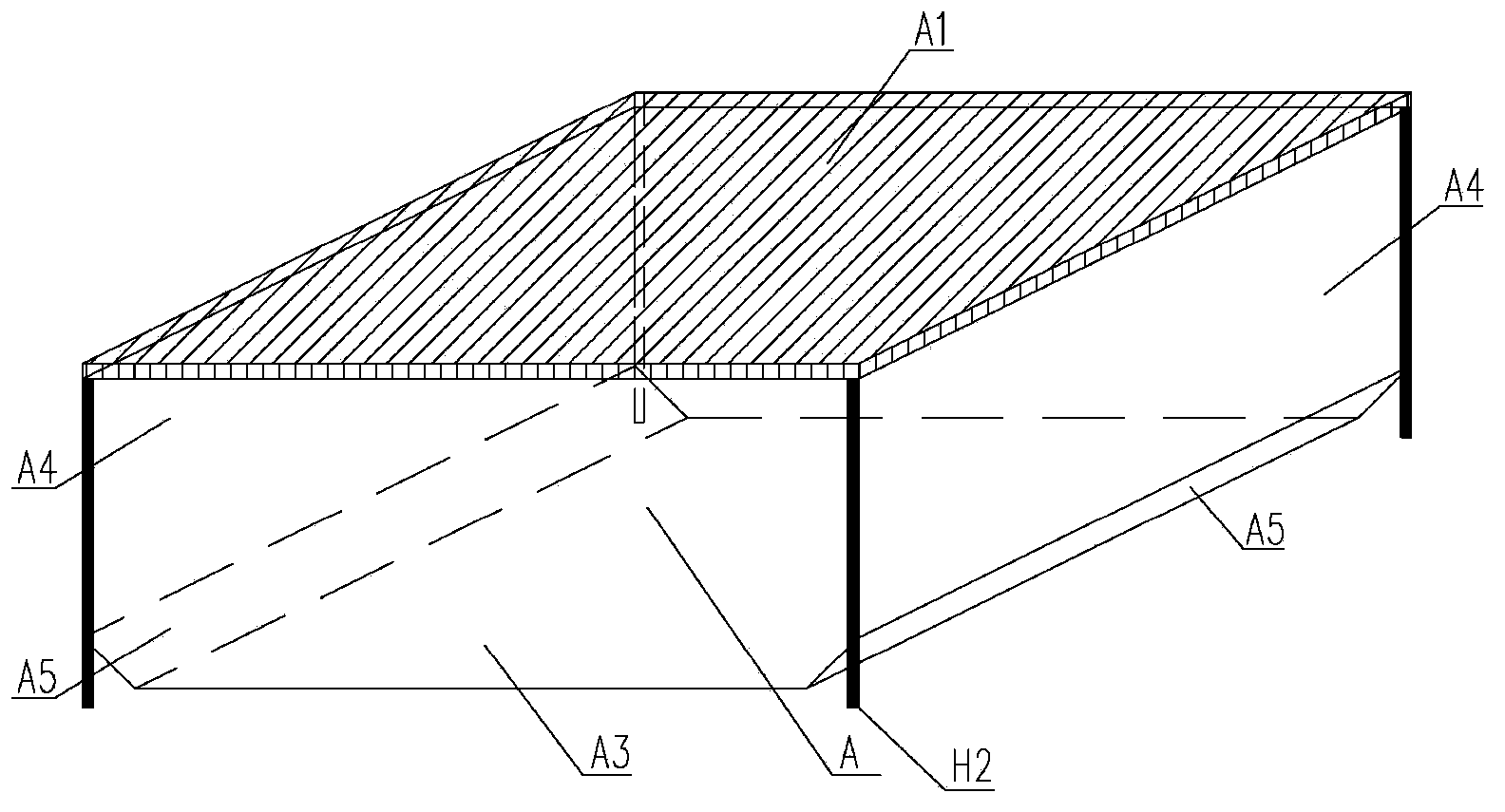

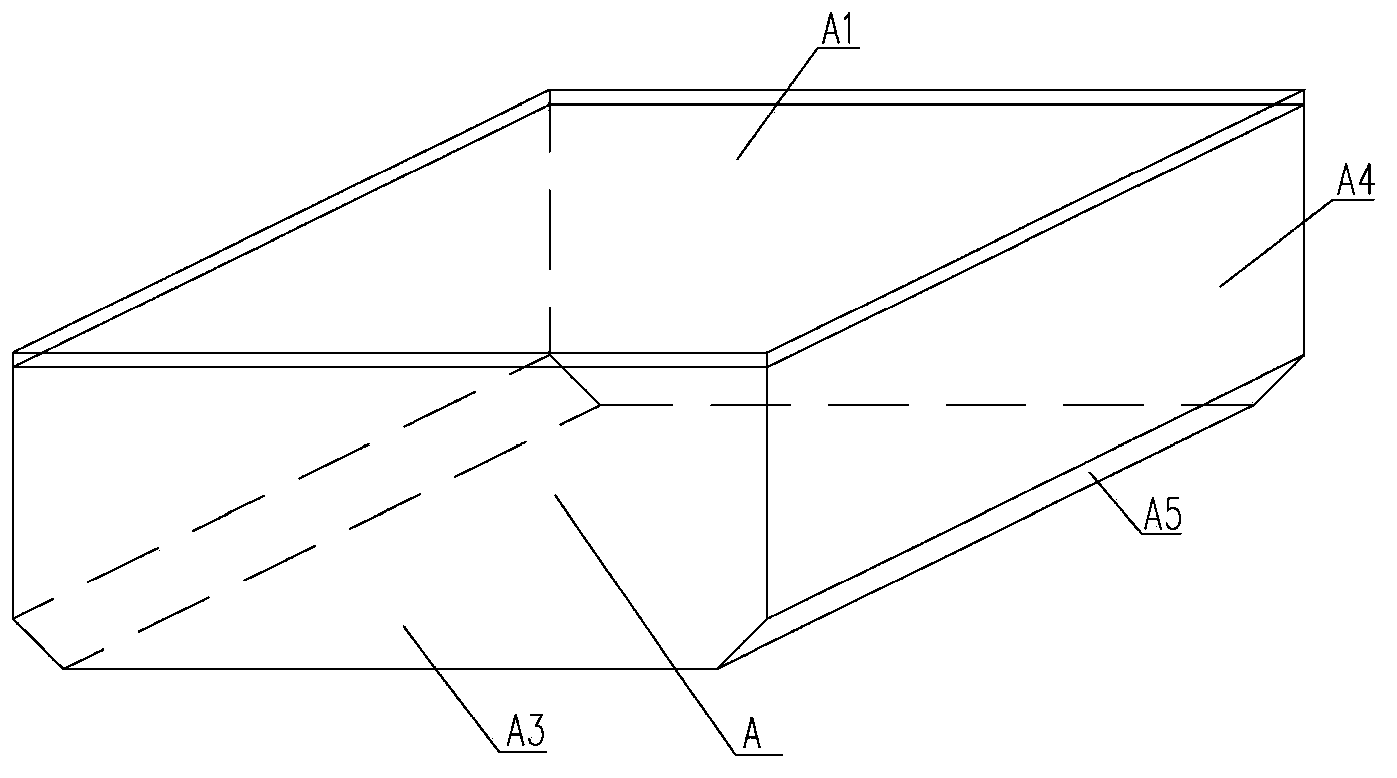

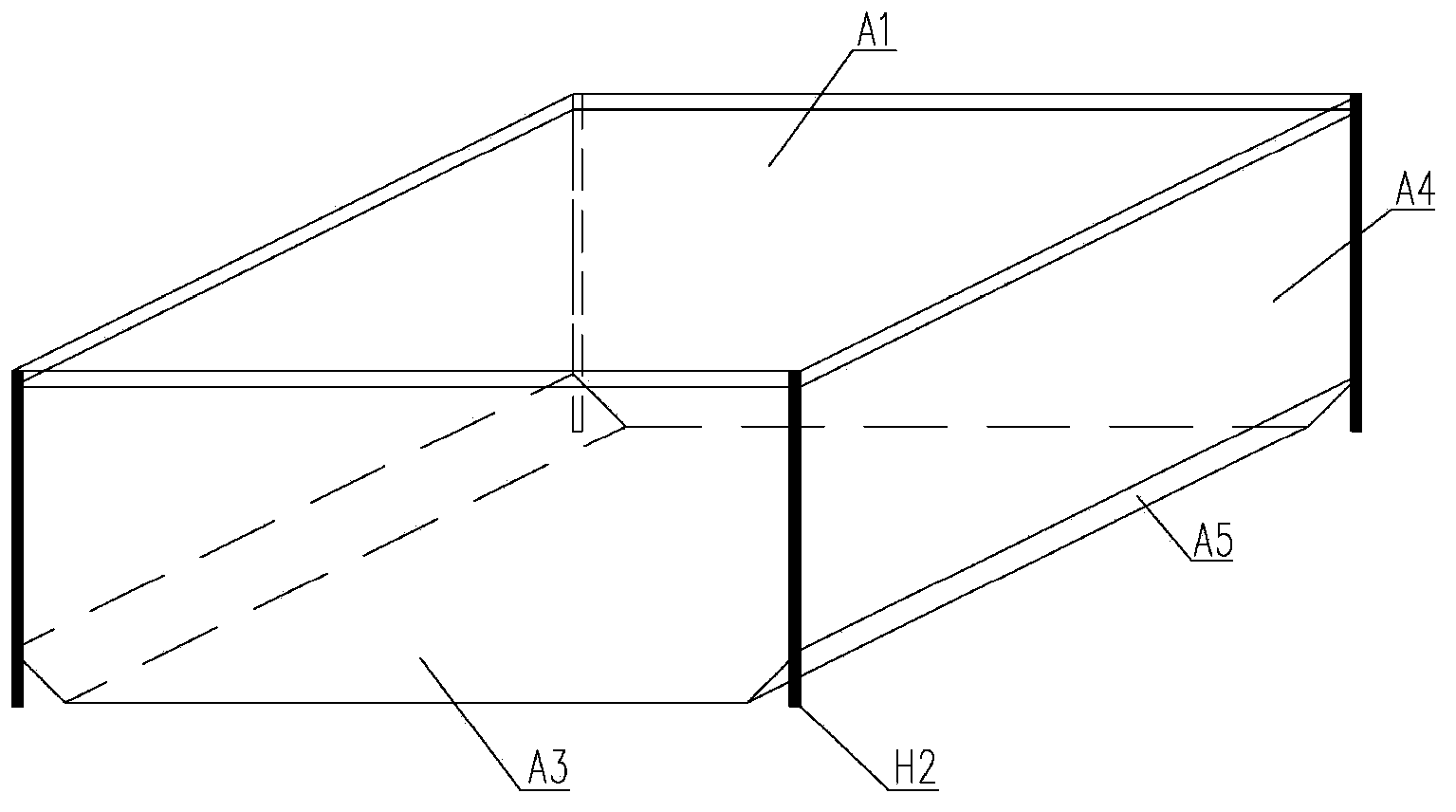

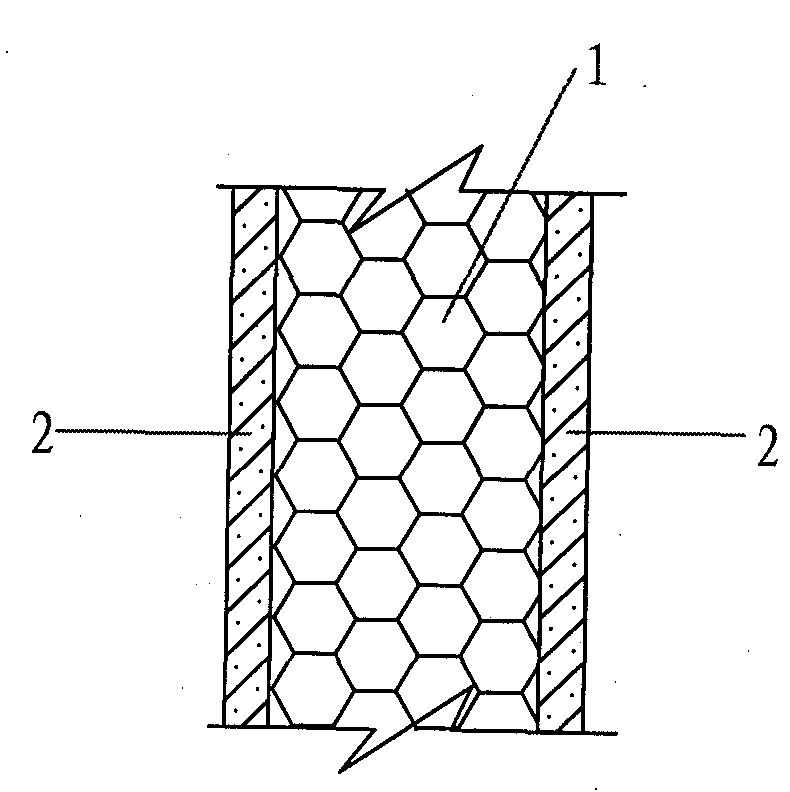

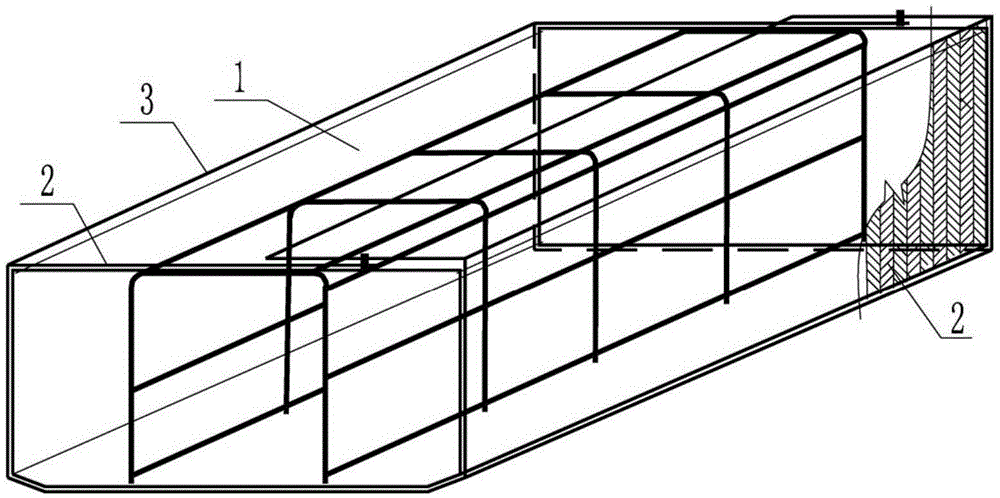

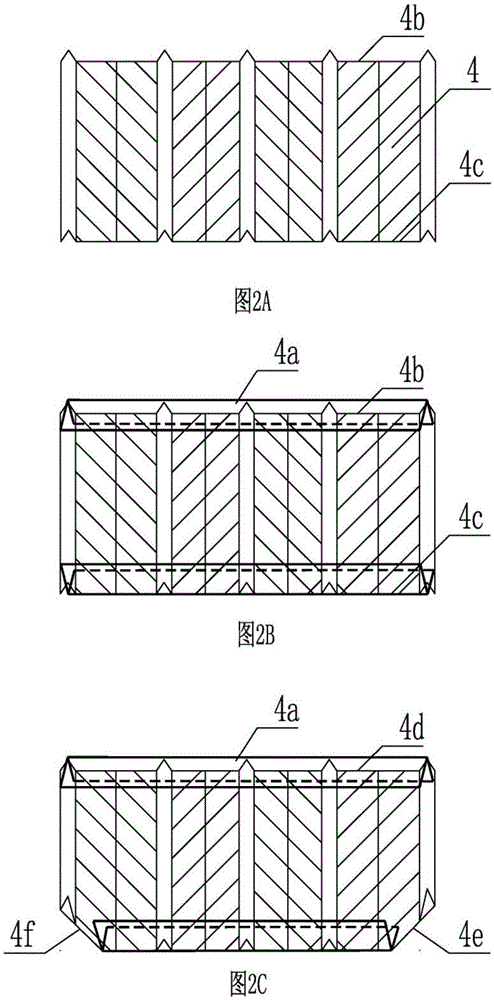

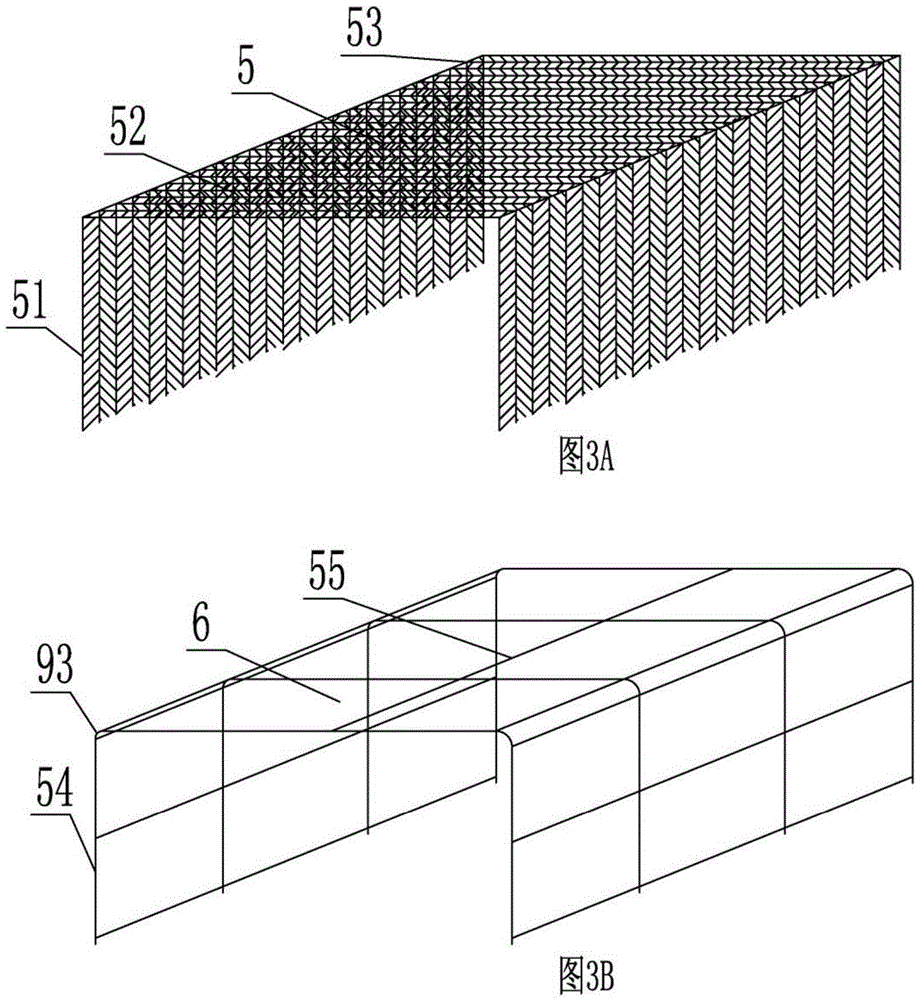

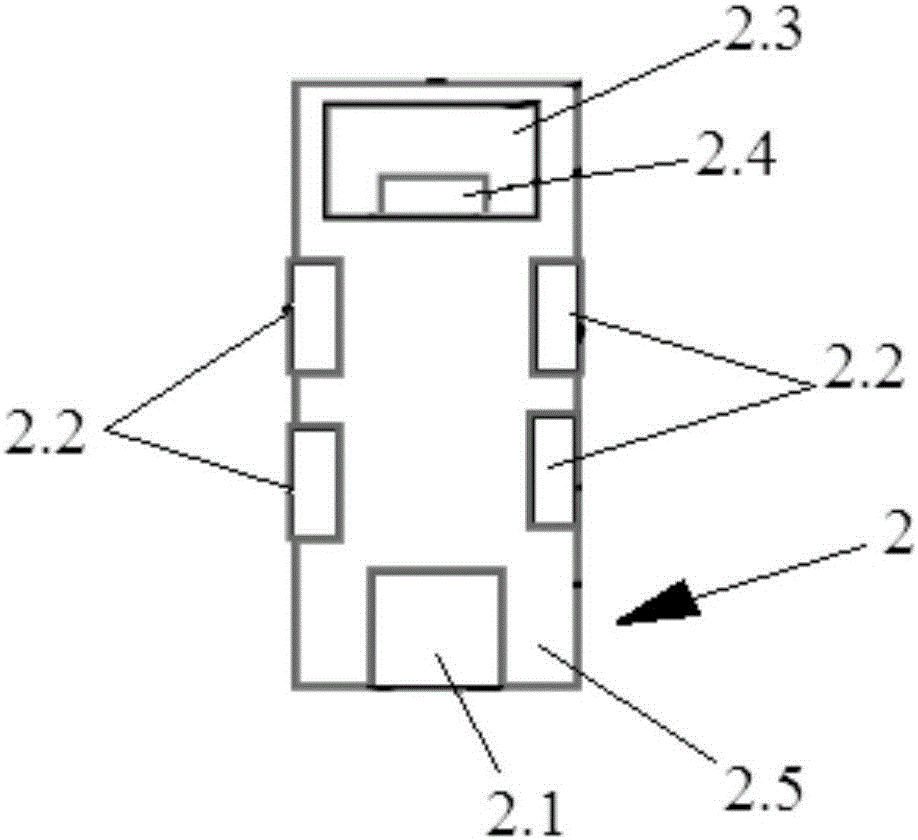

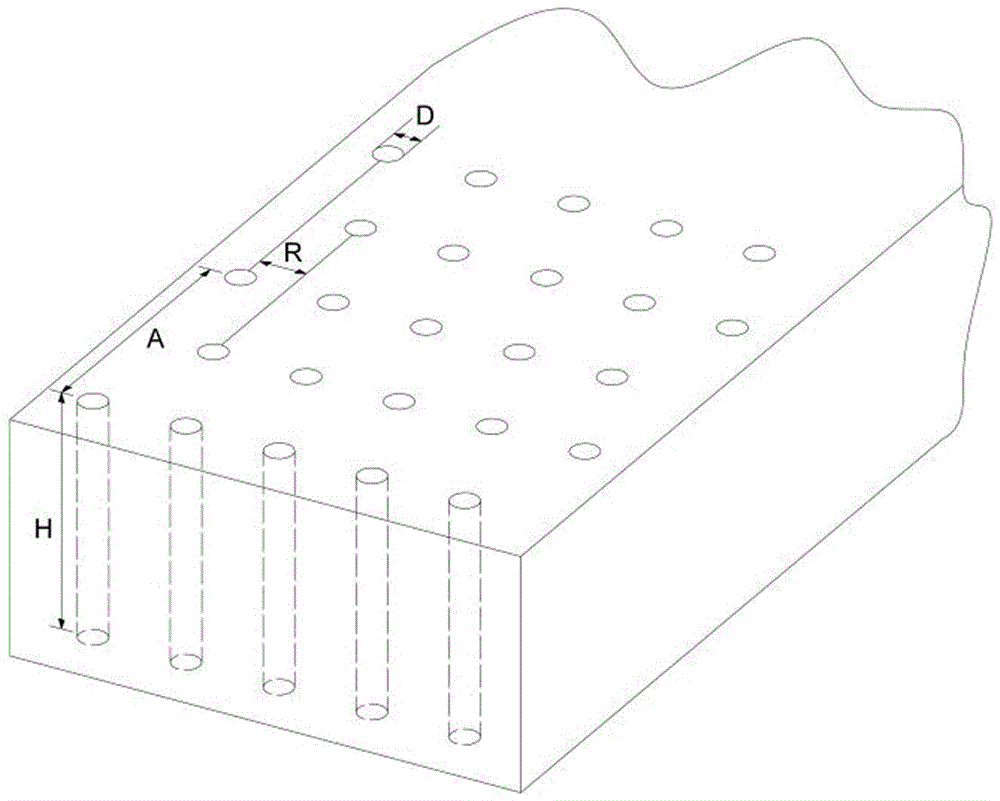

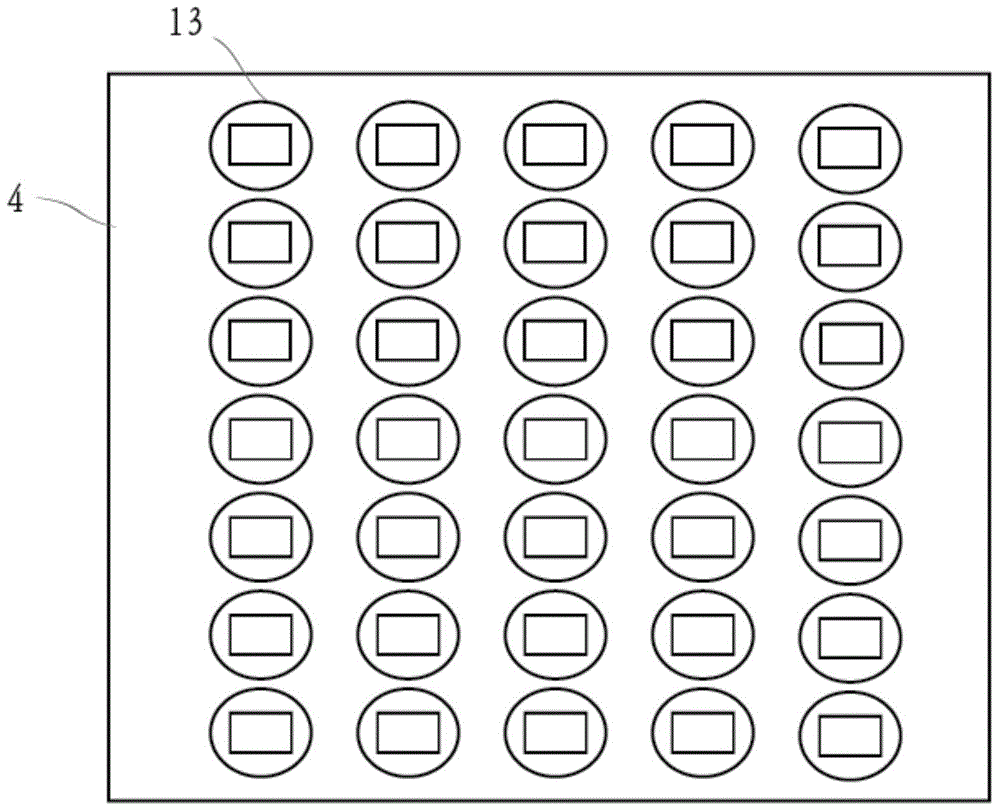

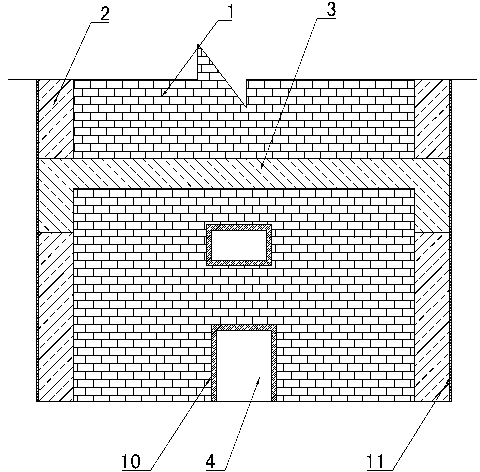

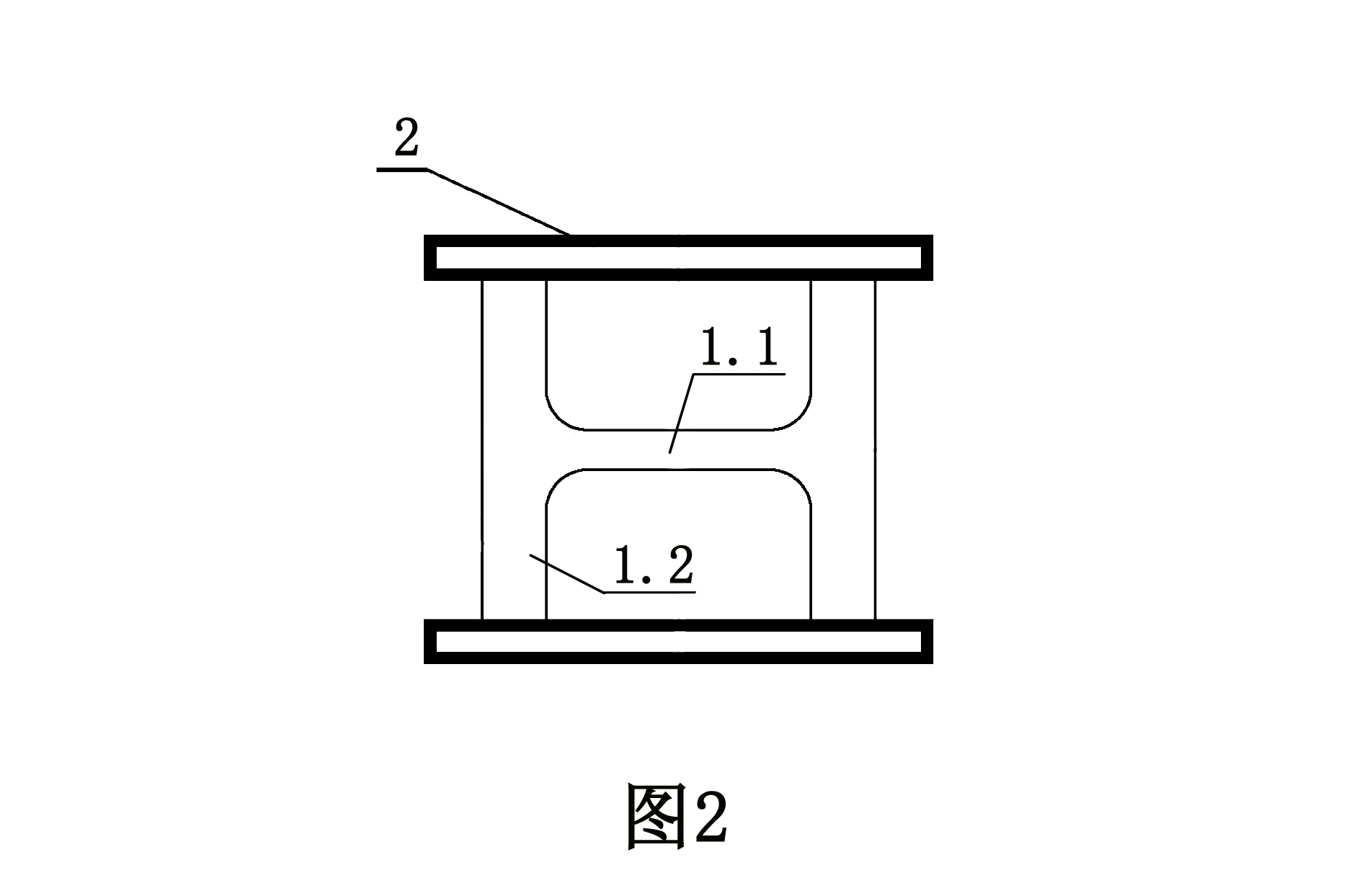

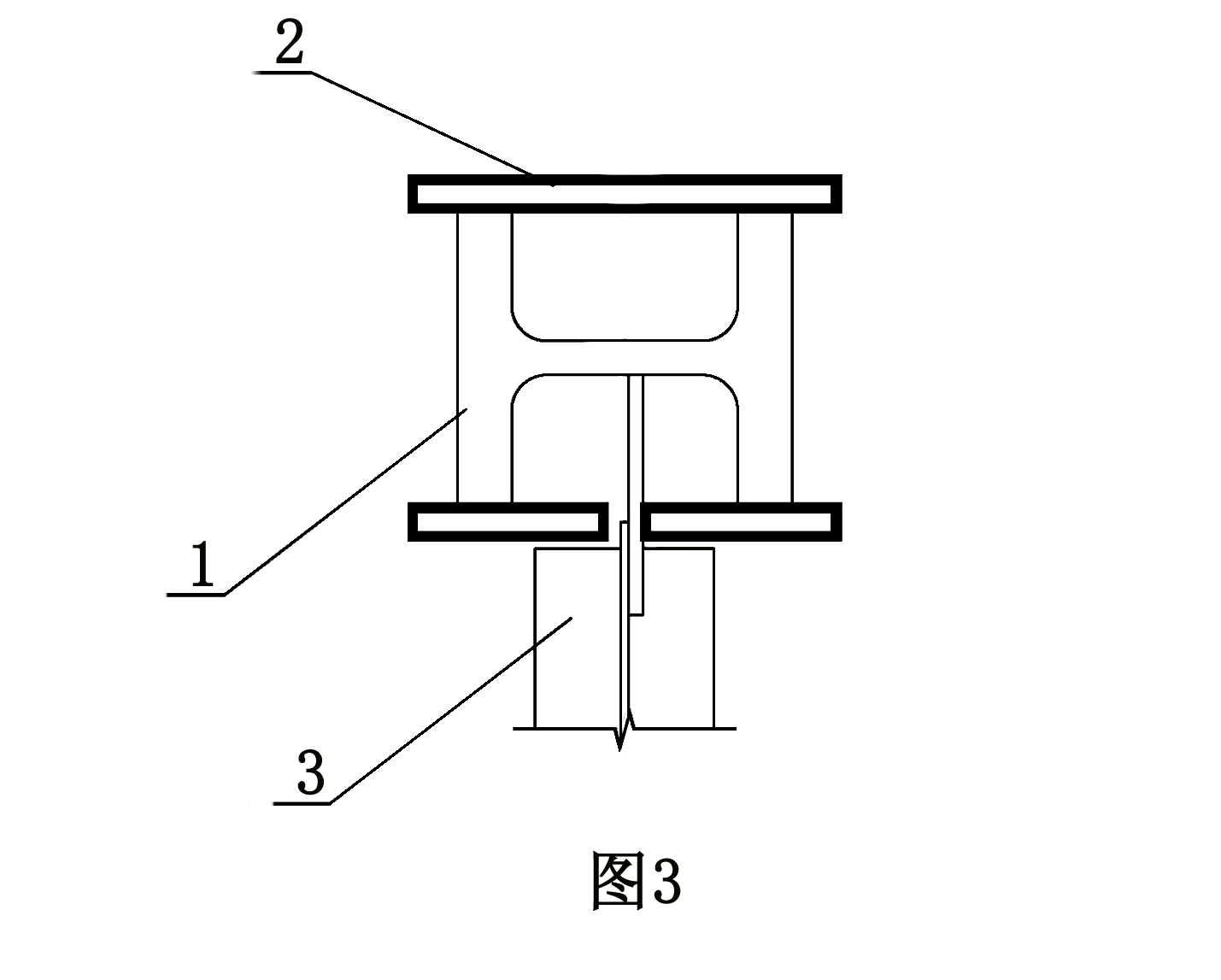

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

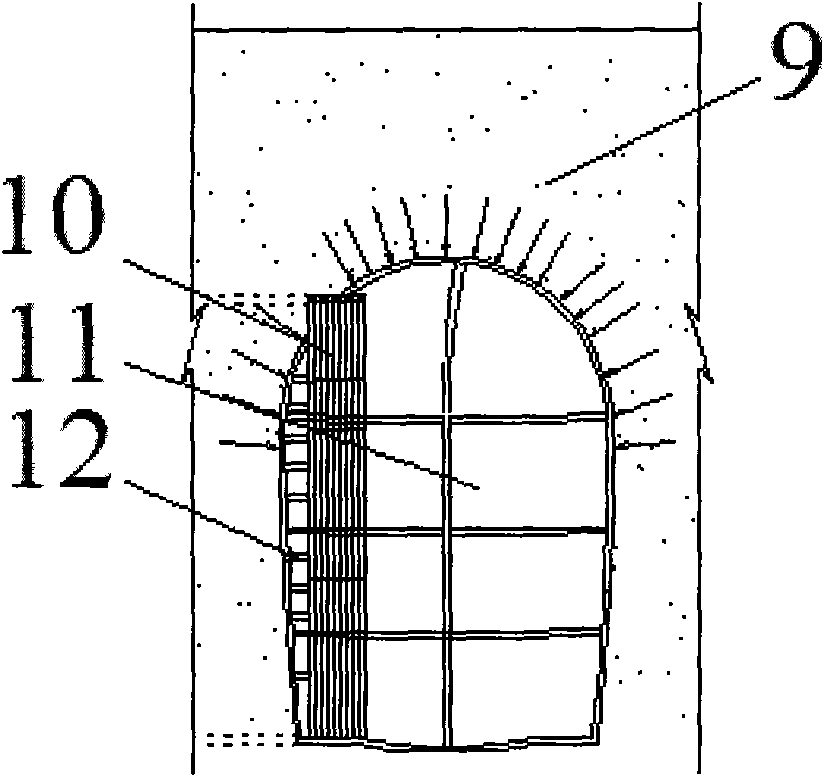

Method for tunneling construction of main structure of underground station

ActiveCN101864959AEffectively control land subsidenceAvoid unfavorable stress statesUnderground chambersTunnel liningSoil massEngineering

The invention discloses a method for tunneling construction of a main structure of an underground station. In the method, the air shaft and air duct are excavated at first for the station and are then used as construction channels for excavation of the main structure of the station. The method for tunneling construction of the main structure of the station comprises the following steps: forming a reinforcing ring at the air duct port with a composite initial support; excavating the soil mass of a middle hole according to a certain sequence; constructing the internal structure of the middle hole; excavating the soil mass of a side hole; and constructing the internal structure of the side hole. The scheme can realize the smooth force transfer in the excavation of the soil mass, the initial support and the construction of permanent structures, avoid excessive adverse force-bearing states during the construction of the permanent structures, facilitate the construction, enhance the construction safety and construction efficiency, improve working conditions and ensure the quality of the project.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

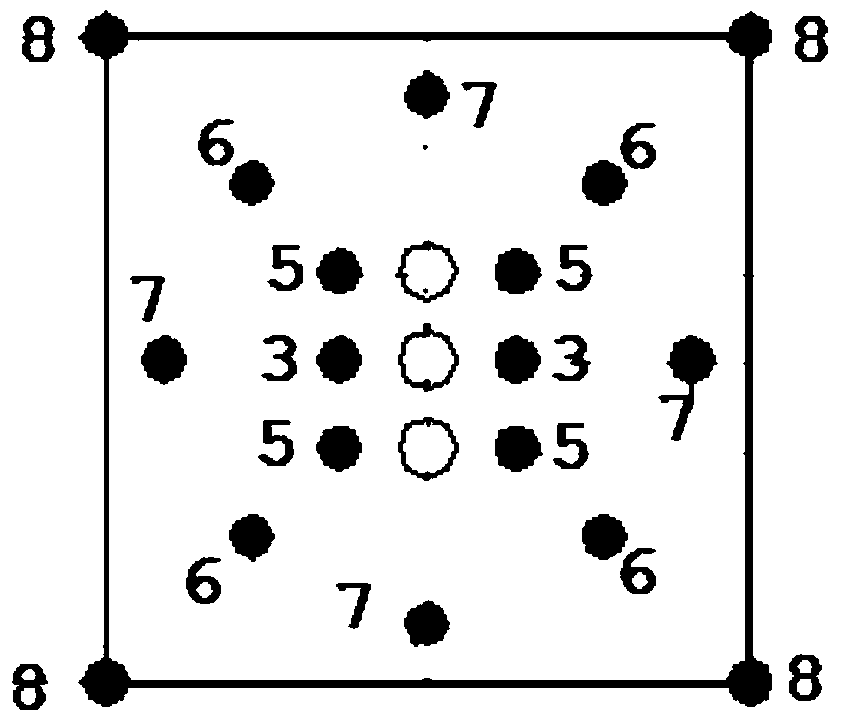

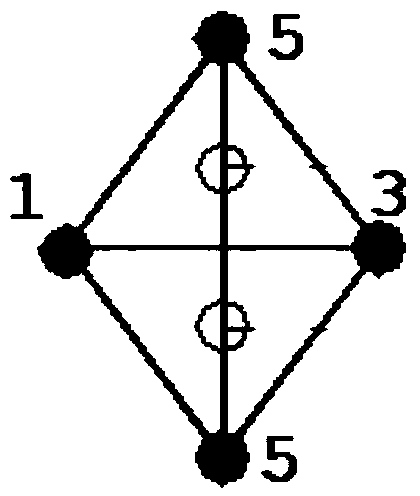

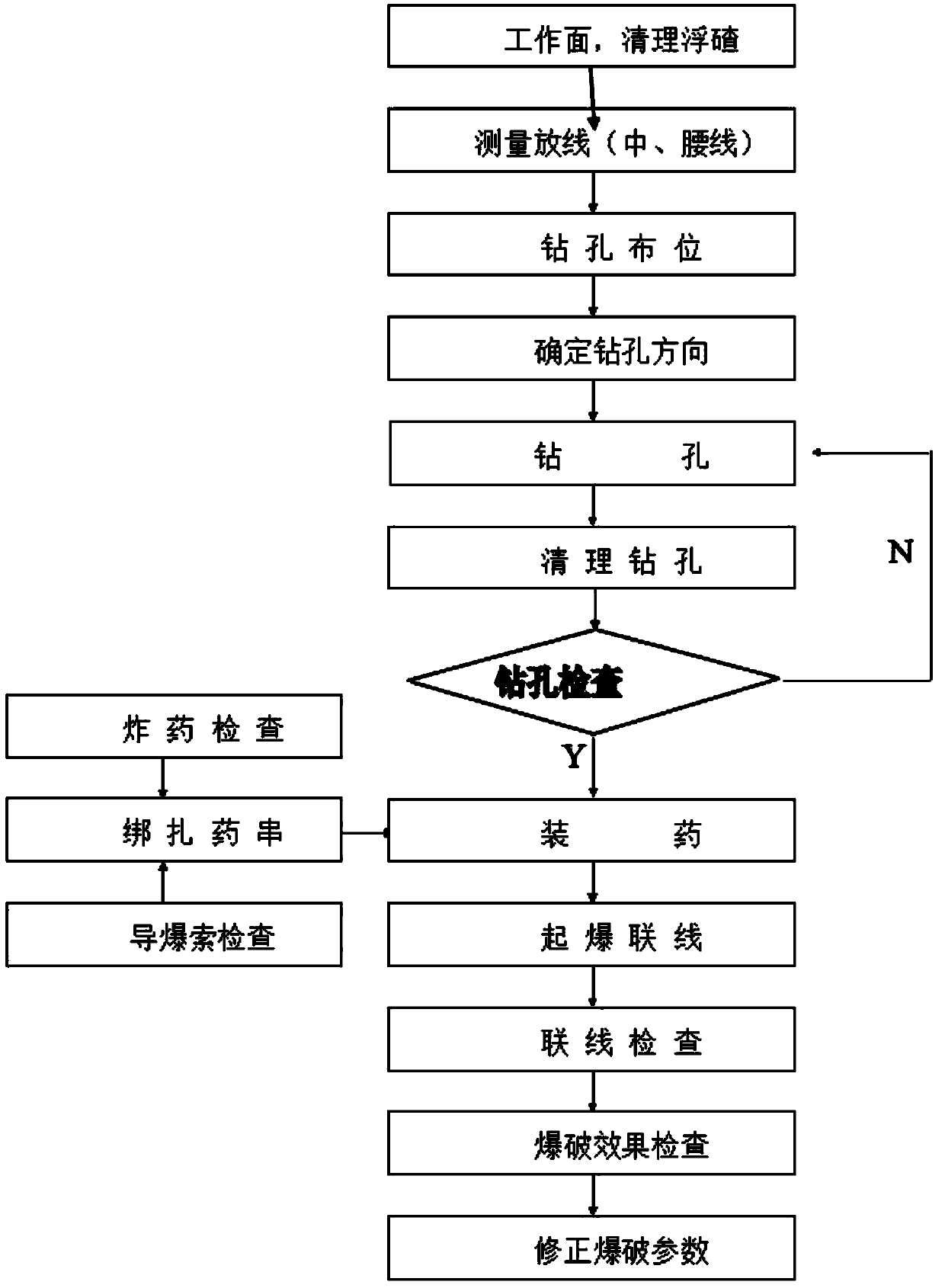

Construction method of three parallel metro tunnels with ultra-small clear distance

InactiveCN104196537AAdvanced and reasonable construction methodsEfficient construction methodsTunnelsSocial benefitsEconomic benefits

The invention discloses a construction method of three parallel metro tunnels with an ultra-small clear distance. The method includes a tunnel portal and open-cut tunnel construction method, a barrel digging method, an explosion method, an advanced small pipe construction method, a steel mesh hanging method, a vertical steel frame erecting method, a combined anchor rod construction method, a primary lining supporting construction method, a tunnel waterproof construction method, a secondary tunnel lining construction method, a pouring method, a geological advanced forecast method and a monitoring and measuring method. Compared with the prior art, the construction method is advanced, reasonable, efficient and concise; on the basis that stability of surrounding rocks, constructed tunnels and surrounding buildings and safety of construction personnel in a construction area are guaranteed, engineering quality is guaranteed, construction cost is effectively lowered, the constriction time is shortened, and social benefits and economic benefits of enterprises are remarkable.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR

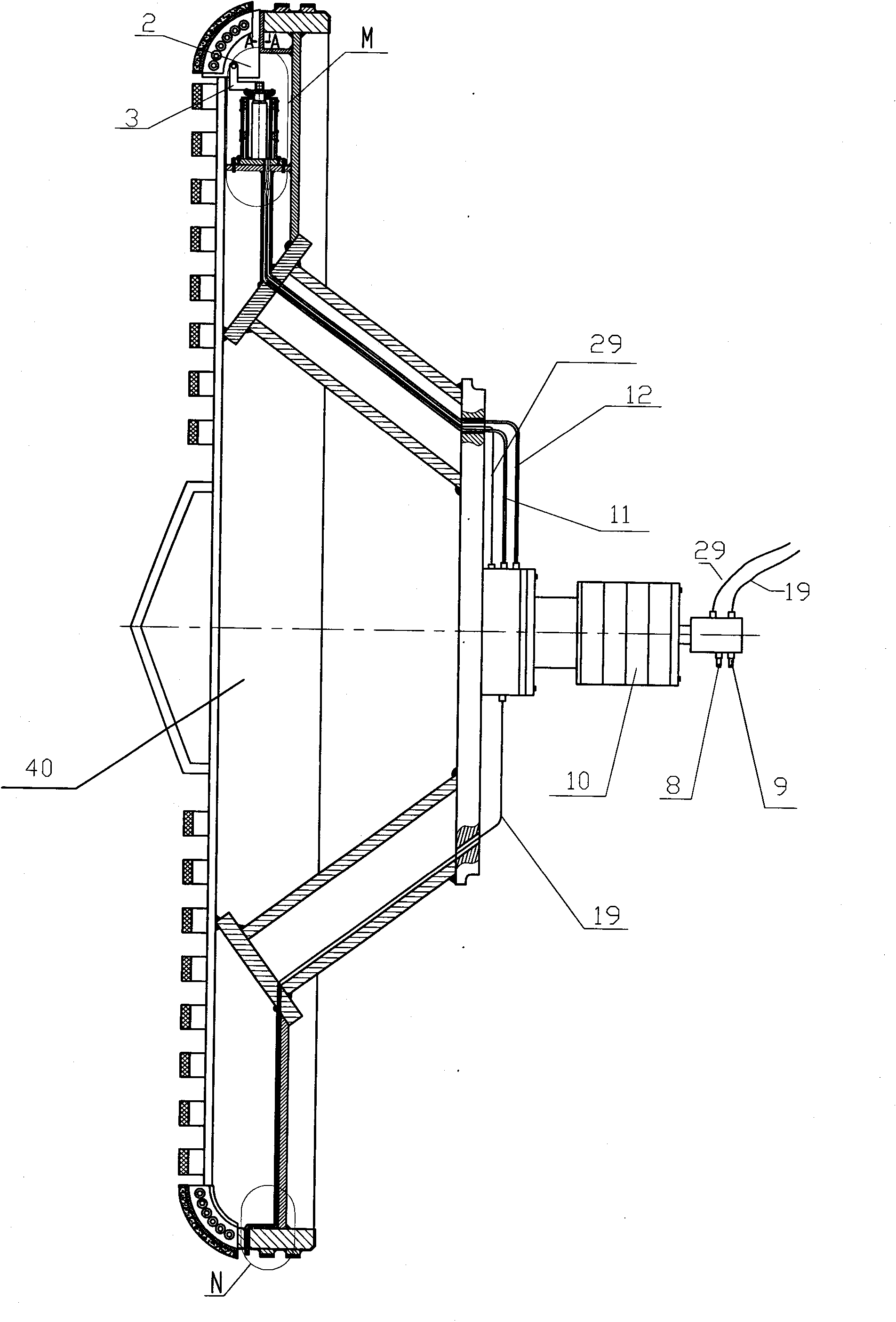

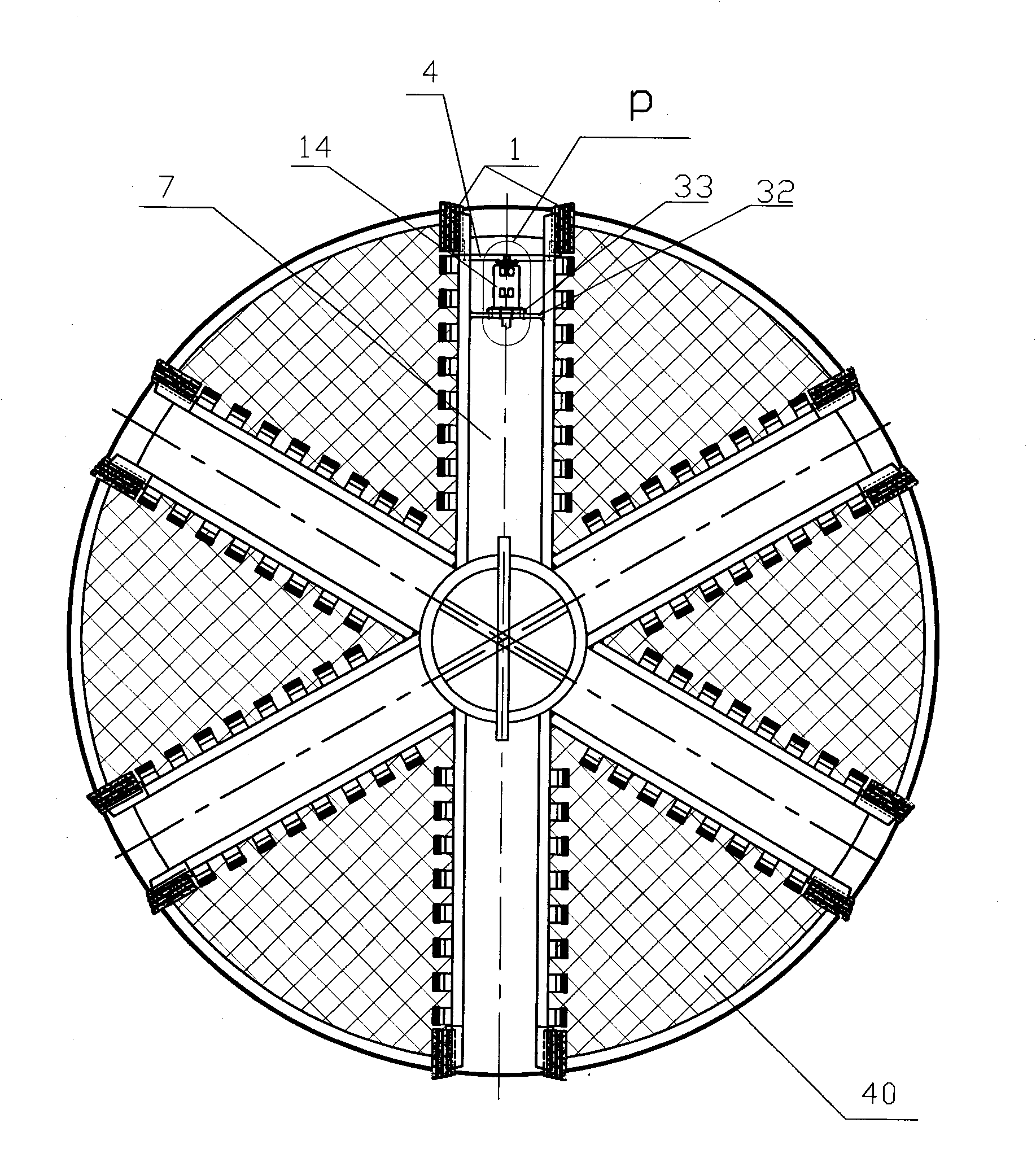

Cutting device with small-range diameter-variable function of soft rock shield machine

A cutting device with of small-range diameter-variable function of a soft rock shield machine comprises a cutter head, a cutter mounted on the cutter head, a side scraper telescoping mechanism, a hydraulic control device and a wearing limit detecting device, wherein two sides of end parts of at least one slag outlet groove of the cutter head are provided with a scraper respectively; the two side scrapers are left-and-right symmetrical according to the radial centerline of the slag outlet groove and are connected with a telescoping mechanism; the telescoping mechanism is mounted in the slag outlet groove of the cutter head and is driven by a driving cylinder in the hydraulic control device; a displacement sensor is arranged in the driving cylinder; and a wearing limit detecting head of the wearing limit detecting device is arranged on a sleeve protruding along the radius of the cutter head. Compared with the existing cutting device, the cutting device can adjust cutting diameter in a certain range, therefore, the cutting device can improve working efficiency, confirm cutting quality and confirm operator safety.

Owner:CREG TUNNEL BORING MFG CO LTD

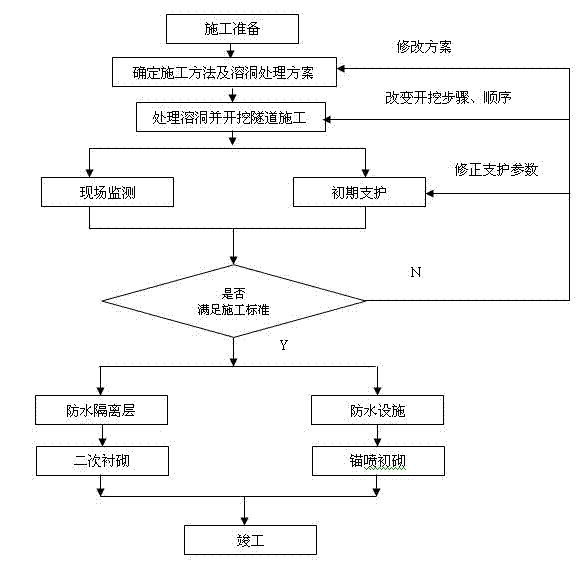

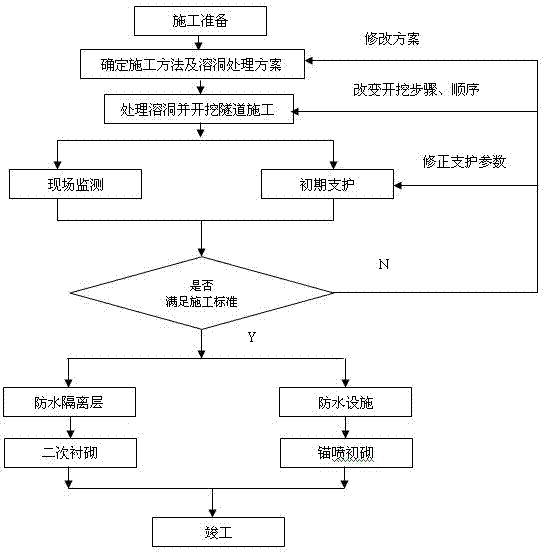

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

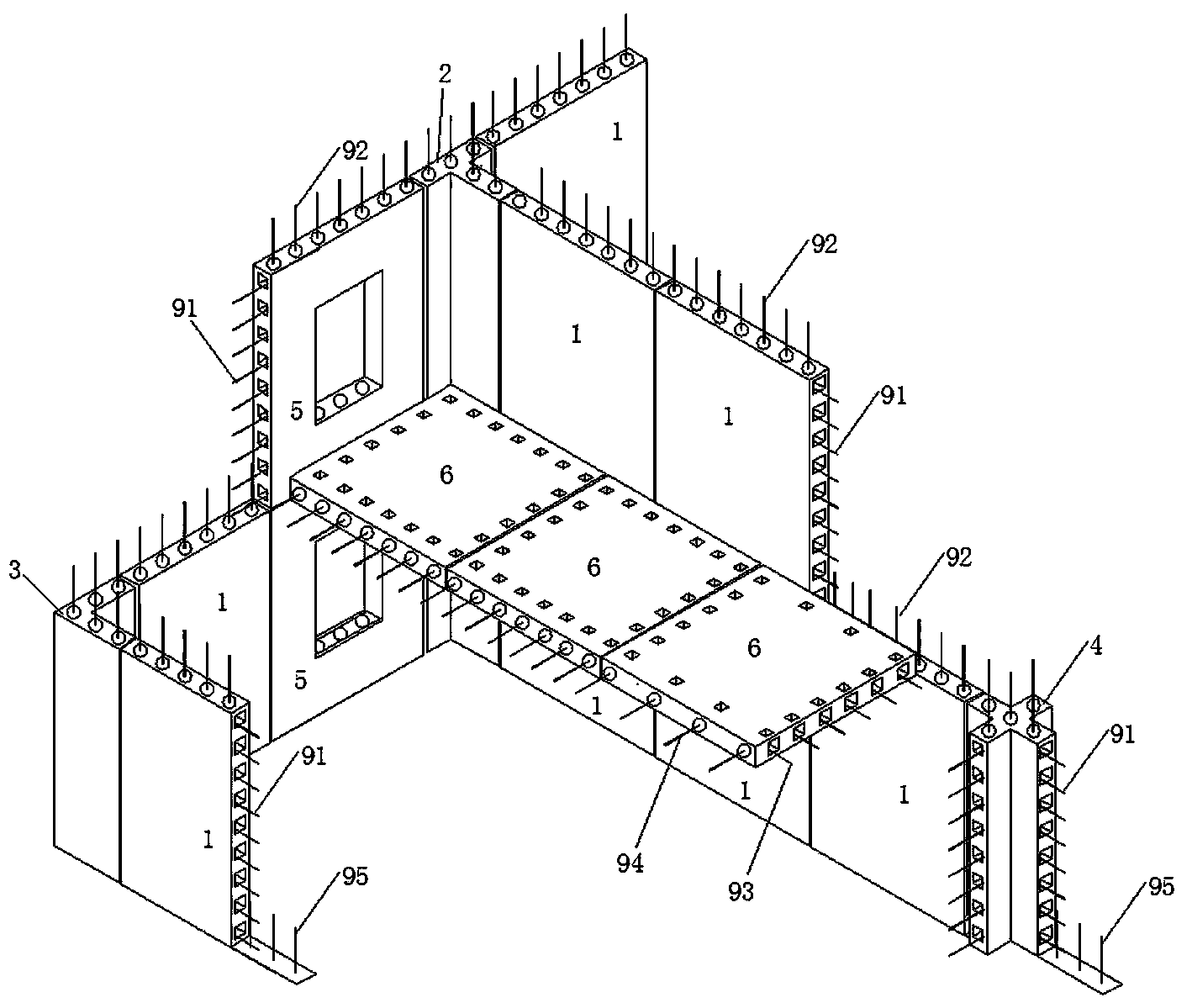

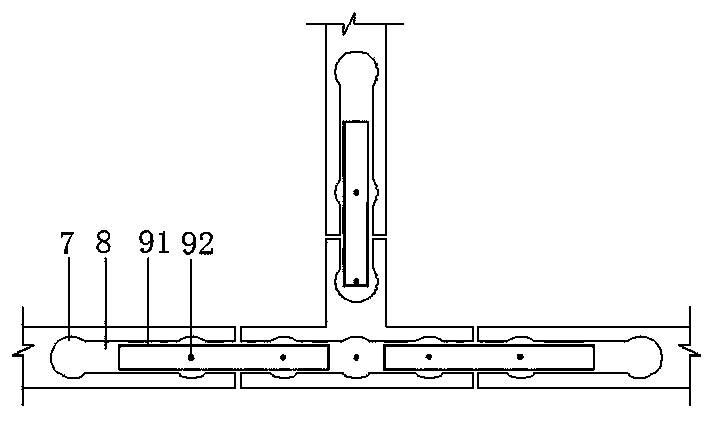

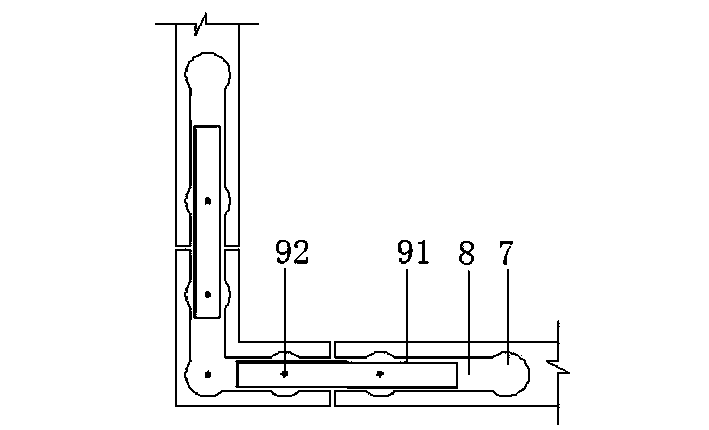

Assembly integral shear wall building structure and building method

ActiveCN103669559AImprove the level of industrializationIncrease productivityWallsBuilding material handlingRebarHigh rise

The invention relates to an assembly integral shear wall building structure and a building method and belongs to the field of buildings and construction technologies of the buildings. The shear wall building structure is formed by connecting prefabricated concrete hollow components through steel bars and cast-in-place concrete, wherein the prefabricated concrete hollow components include prefabricated wall body components, floor board components, T-shaped wall pillar components, L-shaped wall pillar components, cross-shaped wall pillar components and wall body components with holes. Multiple parallel lengthwise through holes are formed in the prefabricated hollow components in the length direction and multiple parallel transverse non-through holes communicated with the lengthwise through holes are formed in the prefabricated hollow components in the width direction. Horizontal anchor connection steel bars inserted into the transverse holes are arranged among the different prefabricated components. Lengthwise anchor connection steel bars are arranged in the lengthwise holes, wherein one end of each lengthwise anchor connection steel bar protrudes out of the surface of the corresponding prefabricated component by a certain length. The concrete is filled into the lengthwise holes and the transverse holes to form a layer of structural unit or a single-layer building structure. Multiple structure units are connected to form a multiple-layer or high-rise assembly integrated shear wall structure. The assembly integral shear wall building structure and the building method can be applied to the multiple-layer or high-rise shear wall building structures and frame-shear wall building structures. Thus, the industrial level of the building structures can be improved, stress performance can be improved and resources are saved.

Owner:初明进

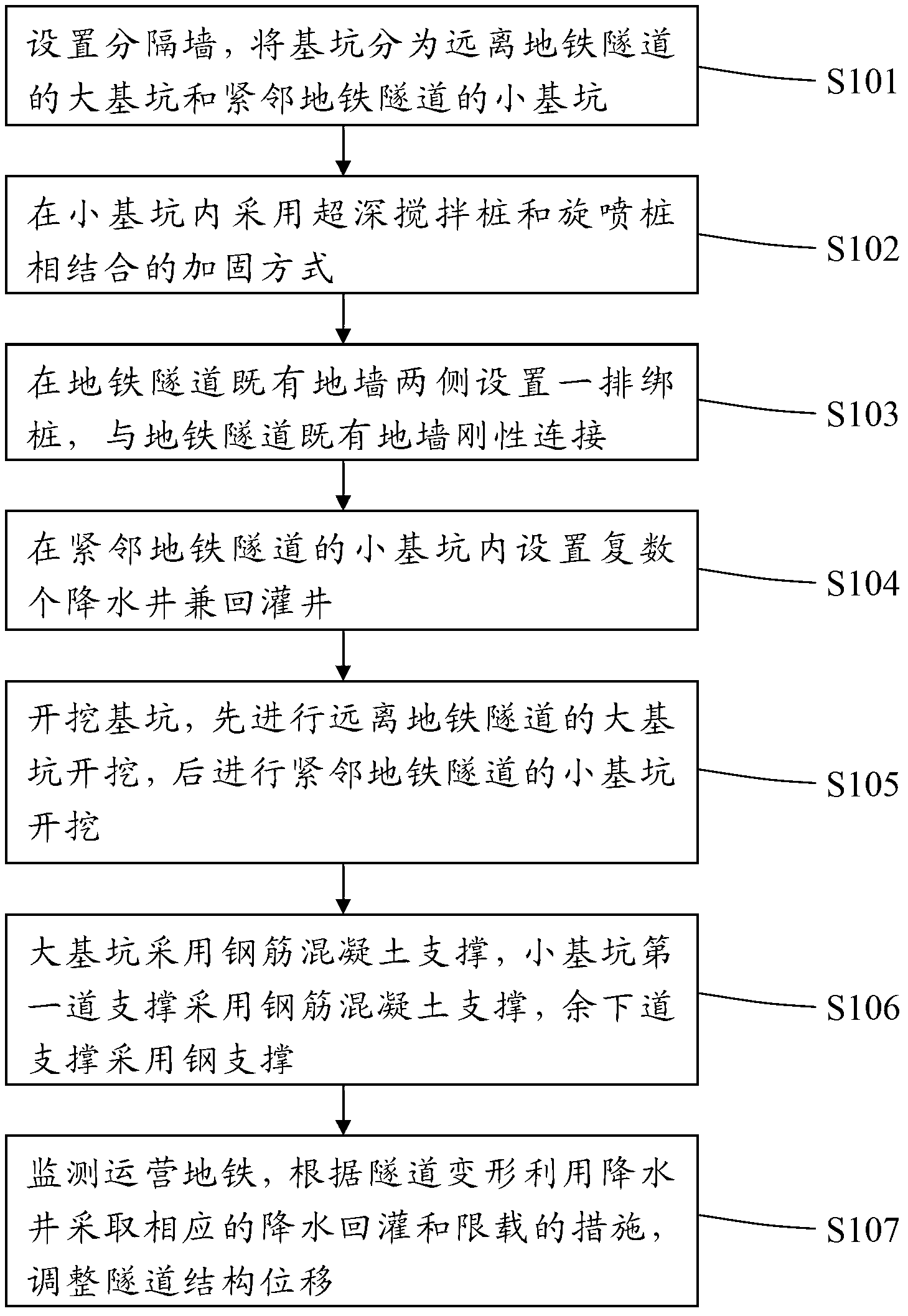

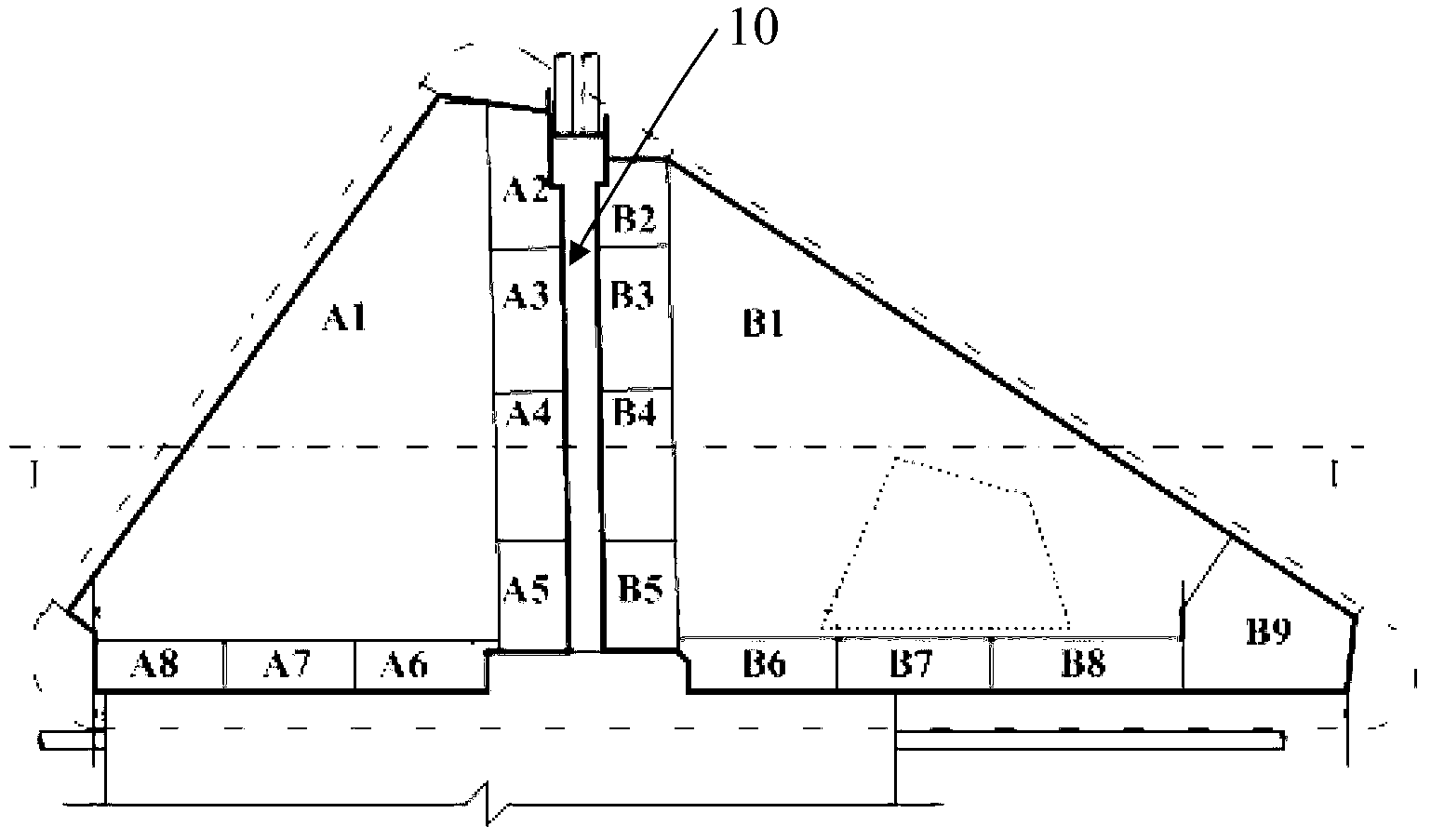

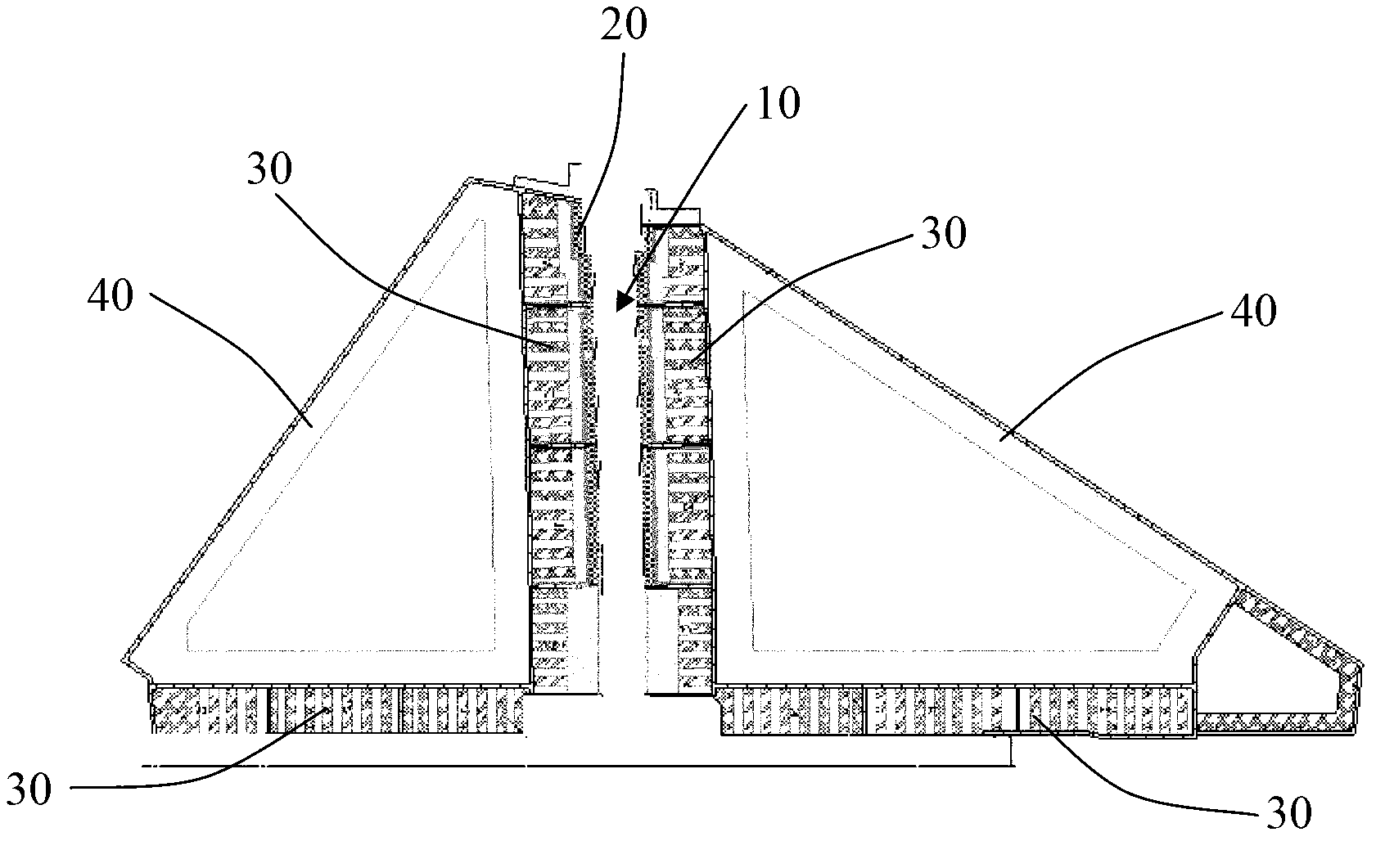

Excavation method for deep and big foundation pit in long-distance crossing field for shallow-buried subway

The invention discloses an excavation method for a deep and big foundation pit in a long-distance crossing field for a shallow-buried subway. The excavation method includes a first step of arranging separating walls, and dividing the foundation pit into a big foundation pit away from a subway tunnel and a small foundation pit adjacent to the subway tunnel, a second step of adopting a reinforcing mode that super-deep stirring piles are combined with chemical churning piles in the small foundation pile, a third step of arranging a row of tying piles on two sides of existing ground walls of the subway tunnel and enabling the tying piles to be in rigid connection with the existing ground walls of the subway tunnel, a fourth step of arranging a plurality of precipitation wells which also serve as recharge wells in the small foundation pit, a fifth step of excavating the foundation pits, firstly excavating the big foundation pit and then excavating the small foundation pit, a sixth step of using reinforced concrete to support the big foundation pit, using the reinforced concrete to support a first support of the small foundation pit, and using steel to support the rest of the supports, and a seventh step of monitoring the operation of the subway tunnel, and using the precipitation wells to take corresponding precipitation recharge and load limiting measures according to tunnel deformation. The excavation method greatly reduces upheaval and deformation of the foundation pits, and severely controls the deformation on the periphery caused by excavation of the foundation pits.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

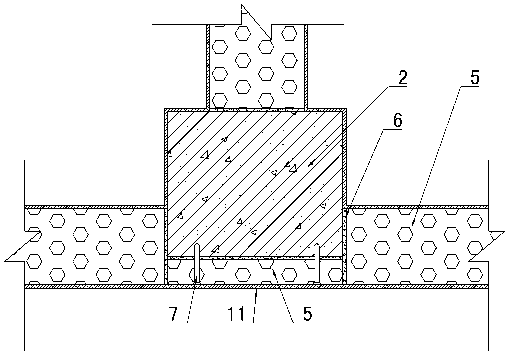

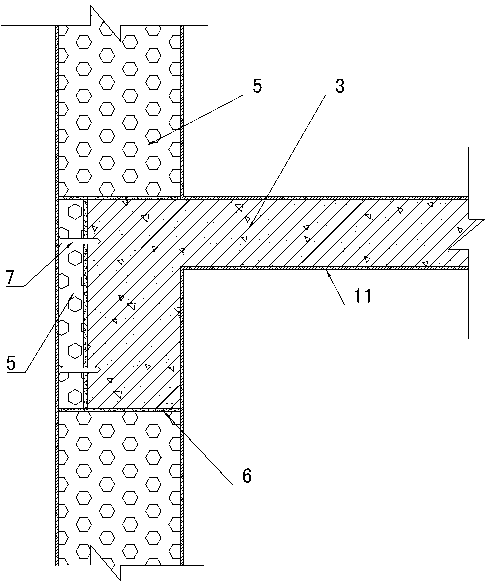

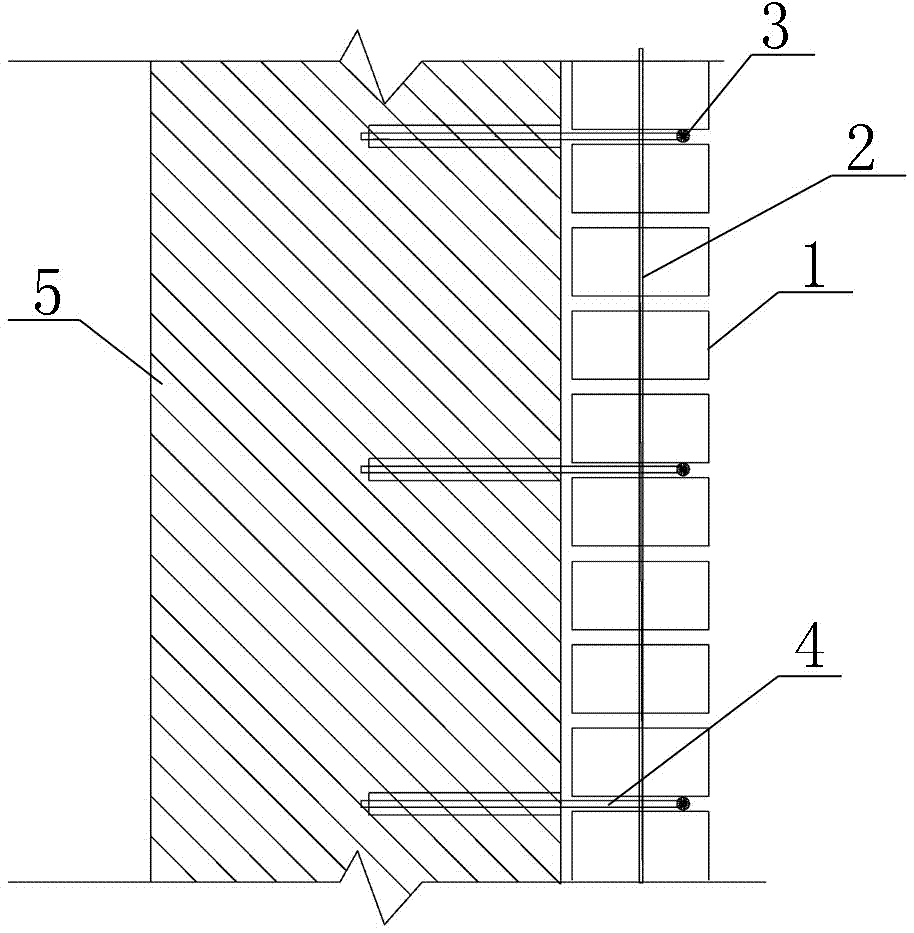

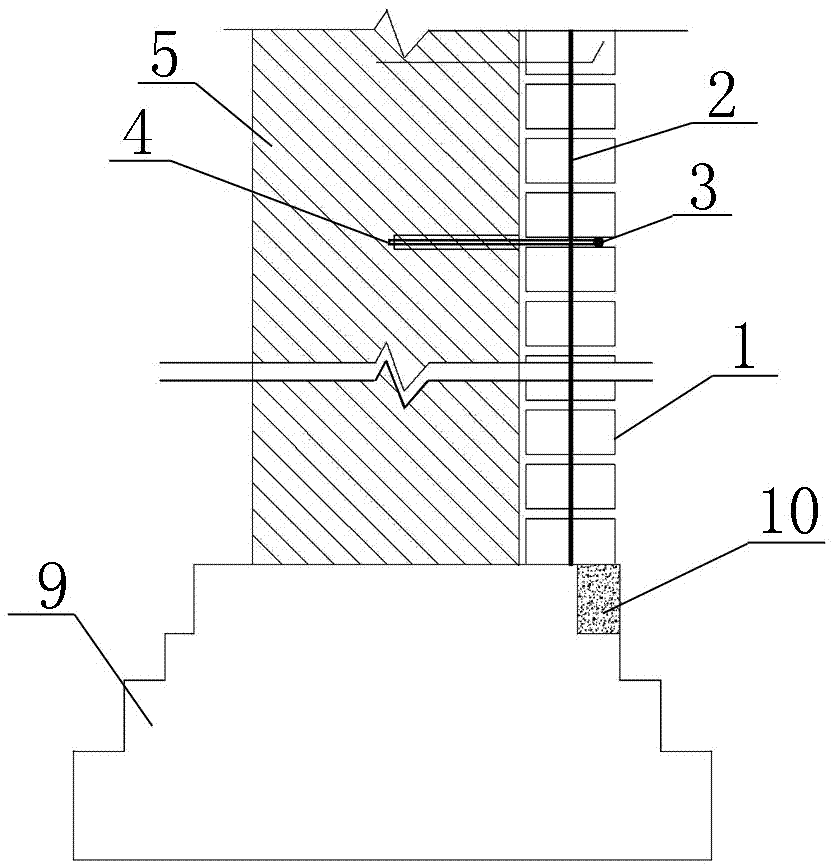

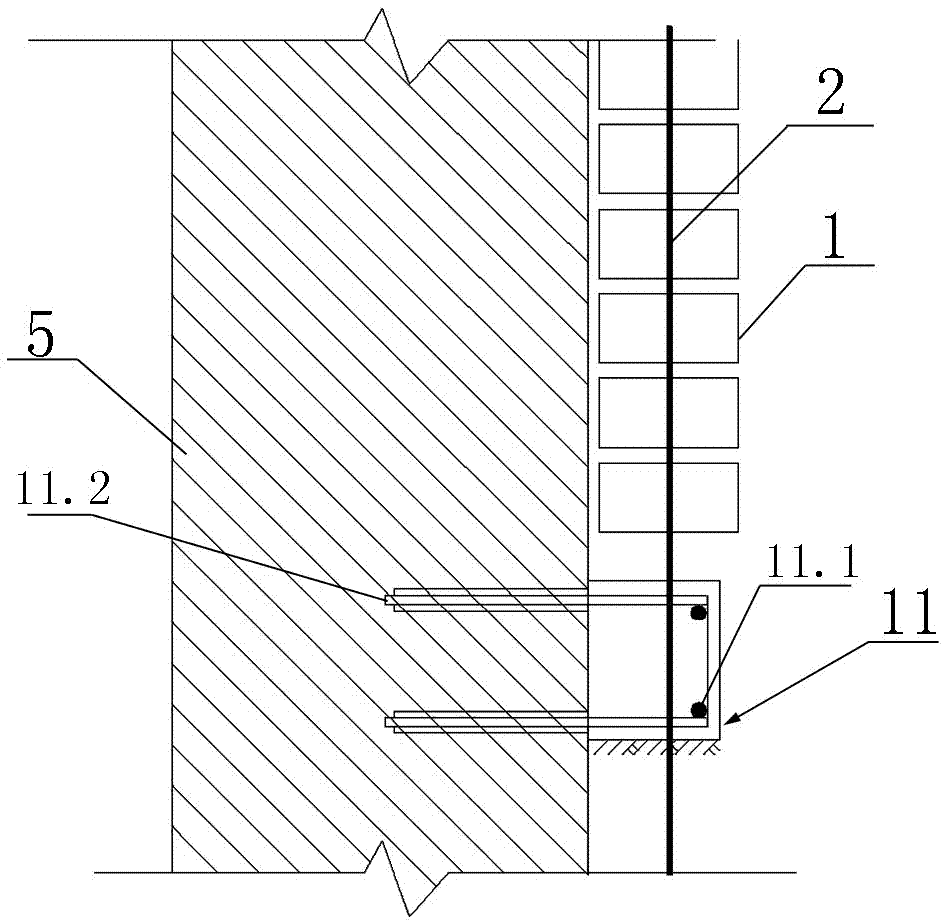

Composite heat preserving template and building main body integrated construction heat preserving system

InactiveCN101775862AFacilitate engineering qualityEasy to guaranteeWallsHeat proofingArchitectural engineeringBuilding construction

The invention discloses a composite heat preserving template and building main body integrated construction heat preserving system. The making of a composite heat preserving template substituted template by outer heat preservation and concrete pouring are carried out simultaneously so that a heat preserving layer and a concrete structure are simultaneously finished; a composite heat preserving template is not only the heat preserving layer, but also plays a role of the template, thereby saving a plurality of outer wall templates; in the outer heat preservation of the building part, the composite heat preserving template is supported outside a building body, a certain gap is retained between the building body and the composite heat preserving template during building and poured by mortar; after the building body is finished, the heat preservation of the part is also finished; and thus the building body and the composite heat preserving template form a heat preserving system in which the composite heat preserving template and building main body are constructed integrally. The technical scheme of the invention simultaneously finishes the outer heat preservation of the building and the building main body engineering, greatly saves the construction period and cost, thoroughly solves the problems of firmness and durability of connection between the heat preserving layer and the main body as well as flatness and perpendicularity of the heat preserving layer and ensures the engineering quality.

Owner:王新强

Construction method for subway contact passage

The invention provides a construction method for a subway contact passage suitable for a very thick Cenozoic stratum region with low heat conductivity and strong heat insulation effect. The method comprises five stages, namely construction preparation, construction of freezing holes, freezing, digging and supporting of the passage and a water collecting well and slurry filling in the back of a wall. The method specifically comprises the following steps of: performing the construction preparation, then forming the freezing holes under the condition that the thickness of a frozen soil curtain is ensured, adding short-range freezing holes on the upper parts of the bell mouths of the freezing holes, and detaching reserved steel pipe sheets at the opening of the passage by adopting a secondary hole forming technology; performing positive freezing after a freezing system runs normally, and making the freezing system perform maintenance freezing after the frozen soil curtain meets the design requirement; after the procedures are finished, performing the digging and supporting stage of the passage and the water collecting well; and pre-burying slurry pipes and filling slurry. By the construction method, the construction difficulty is reduced, the safety and the reliability of engineering are improved, the construction period is shortened, the construction efficiency is improved, and the quality of the engineering is ensured.

Owner:TIANJIN URBAN CONSTR TUNNEL

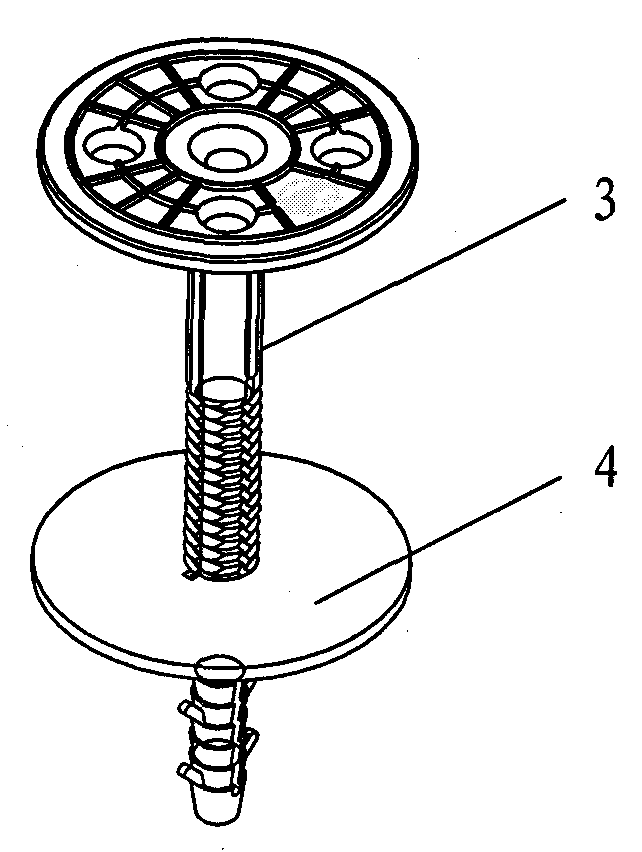

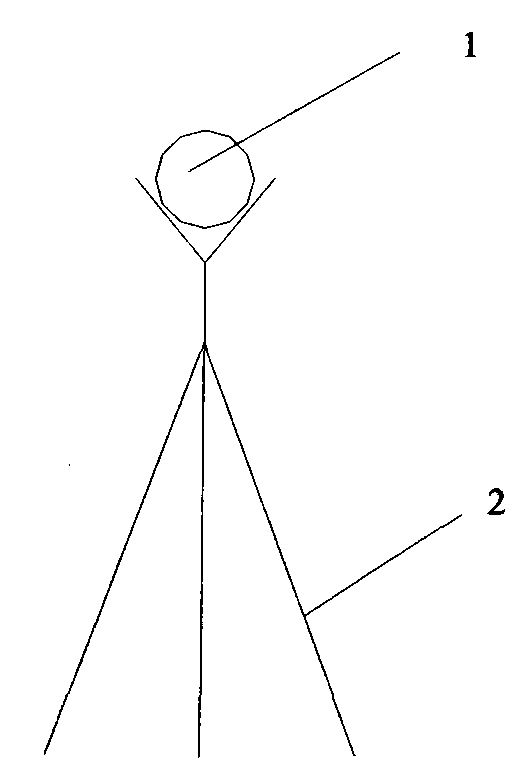

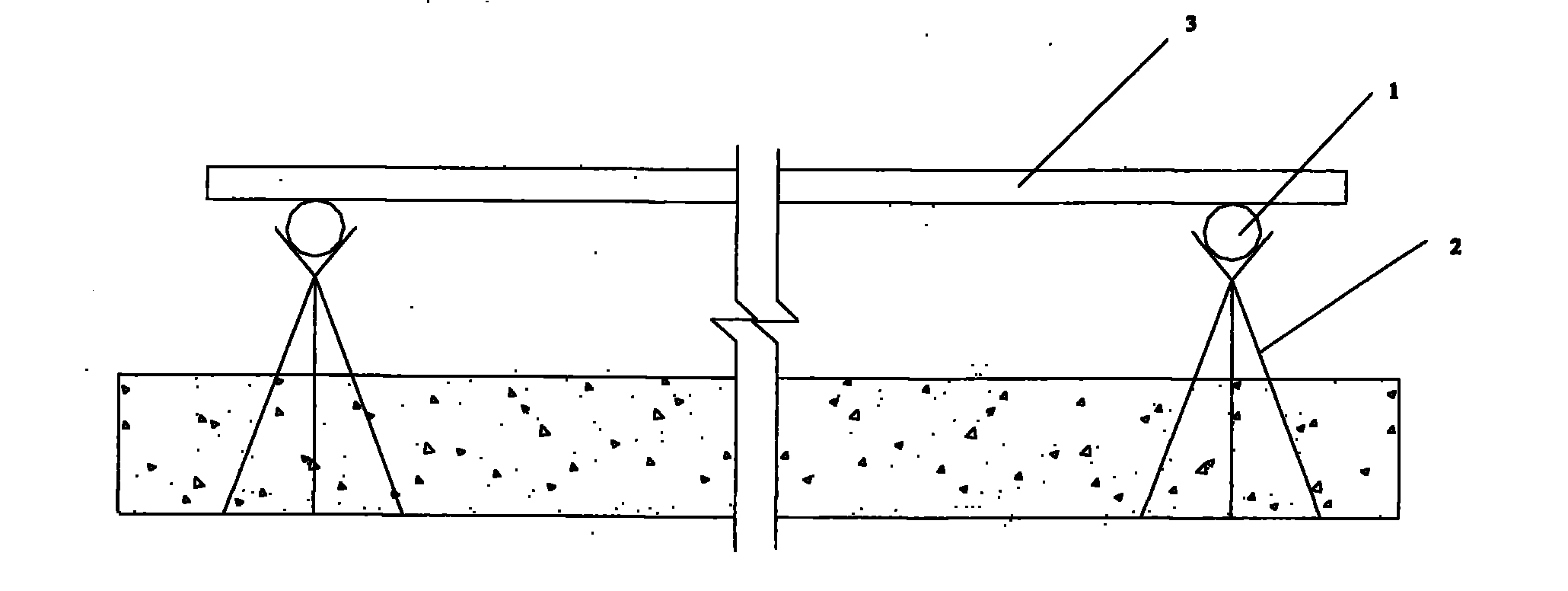

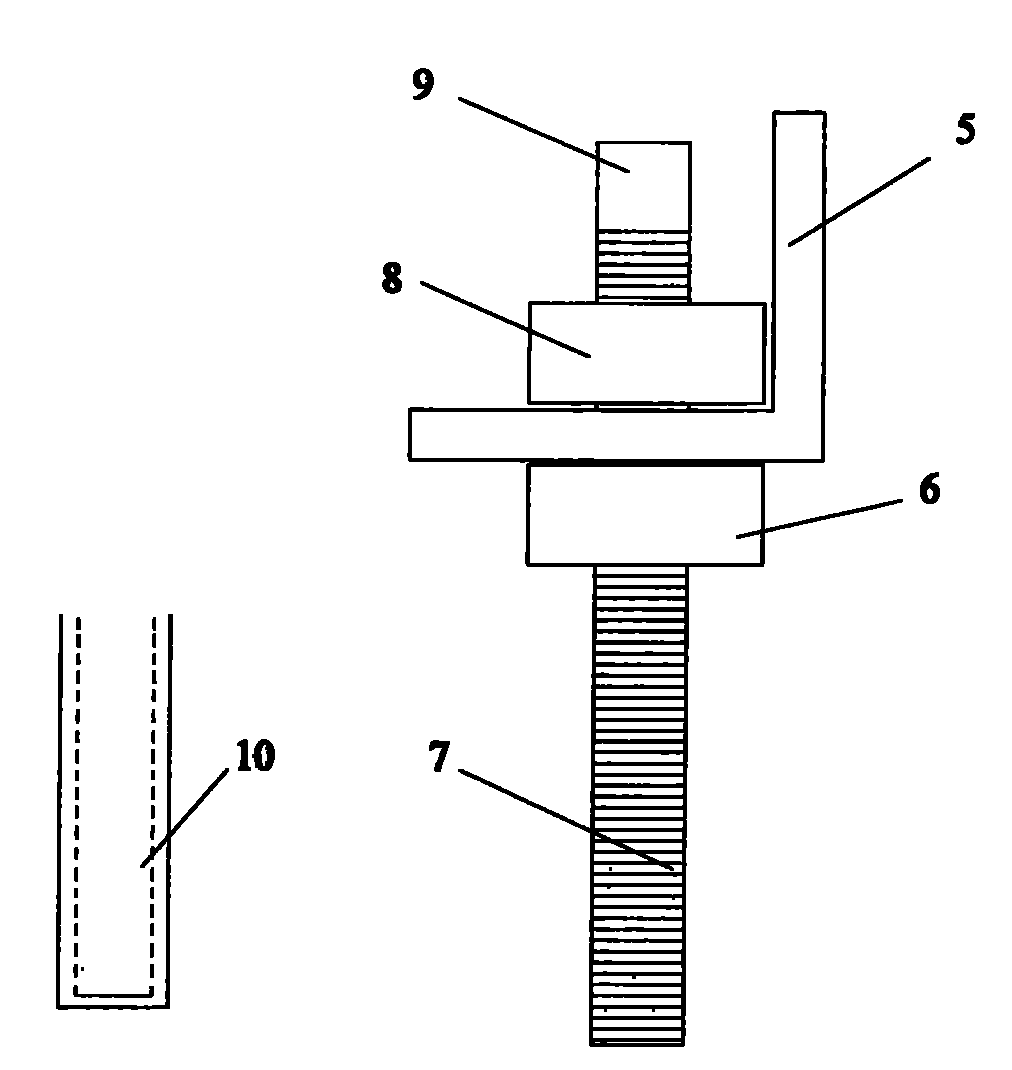

Adjustable leveling guide rail and leveling method thereof

InactiveCN101775905AHigh leveling accuracyReduce weightBuilding material handlingClean environmentEngineering

The invention provides an adjustable leveling guide rail. The adjustable leveling guide rail comprises a guide rail beam and a plurality of supporting pieces, wherein each supporting piece comprises a screw rod and a nut; the screw rod is connected with the guide rail beam through the nut; the end part of the screw rod is provided with a fixing block which is hexagonal, tetragonal or triangular; the fixing block is connected with the screw rod in an integral molding mode or the fixing block is detachably connected with the screw rod; and the supporting piece also comprises a positioning piece connected with the screw rod in a fitting mode. The invention also provides a leveling method for realizing the leveling guide rail, namely, the levelness of the leveling guide rail is adjusted by rotating a leveling nut and a positioning nut. In a construction process, instant leveling is realized by clamping the fixing block, fixing the screw rod and adjusting the levelness of the guide rail by screwing the positioning nut and the adjusting nut respectively. The adjustable leveling guide rail has high leveling accuracy, can realize instant leveling in the construction process and has the advantages of low cost, convenient detachment, easy construction, clean environment, green construction and the like.

Owner:HAOHE ENG & CONSTR

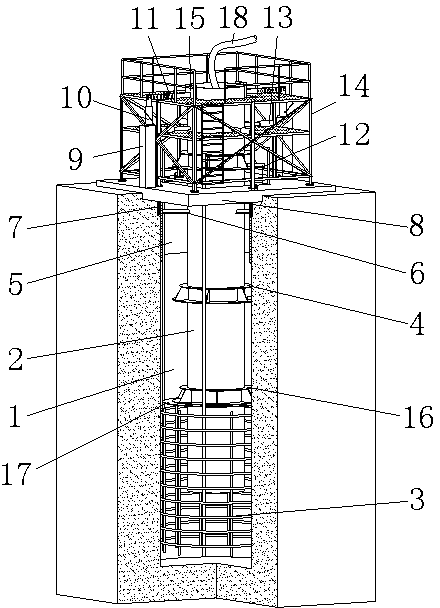

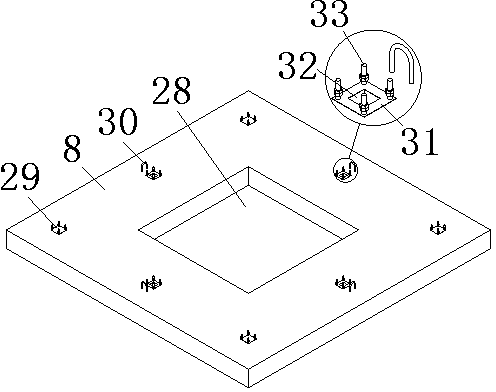

Construction method and structure for mounting reverse-construction steel pipe column in rotary drilled pile hole

The invention discloses a construction method and structure for mounting a reverse-construction steel pipe column in a rotary drilled pile hole. The construction method comprises the steps as follows: 1, drilling the pile hole; 2, mounting a reinforced concrete bearing platform; 3, hoisting a pile foundation reinforcement cage; 4, hoisting the steel pipe column; 5, mounting a concrete pouring platform; 6, cleaning the pile hole; 7, adjusting the elevation, the center position and the perpendicularity of the steel pipe column; 8, completing pouring of concrete in a pile foundation and the steel pipe column. The method is simple and practical, the construction period can be shortened, the project cost can be reduced, and the problem that the construction period is longer due to the fact that the pile foundation and the steel pipe column are constructed separately is solved. By the aid of the construction method and structure, the construction period is shortened while the project quality is guaranteed. The construction method and structure have the good social benefit and the good economic benefit. According to the construction method and structure, the high-efficiency construction requirement is met, the construction cost is saved, the project cost is reduced, the problem of continuous construction of rotary drilling and the steel pipe column in basement reverse construction is effectively solved, and the construction method and structure have the wide practicability and the popularization performance.

Owner:CHINA CONSTR FOURTH ENG DIV

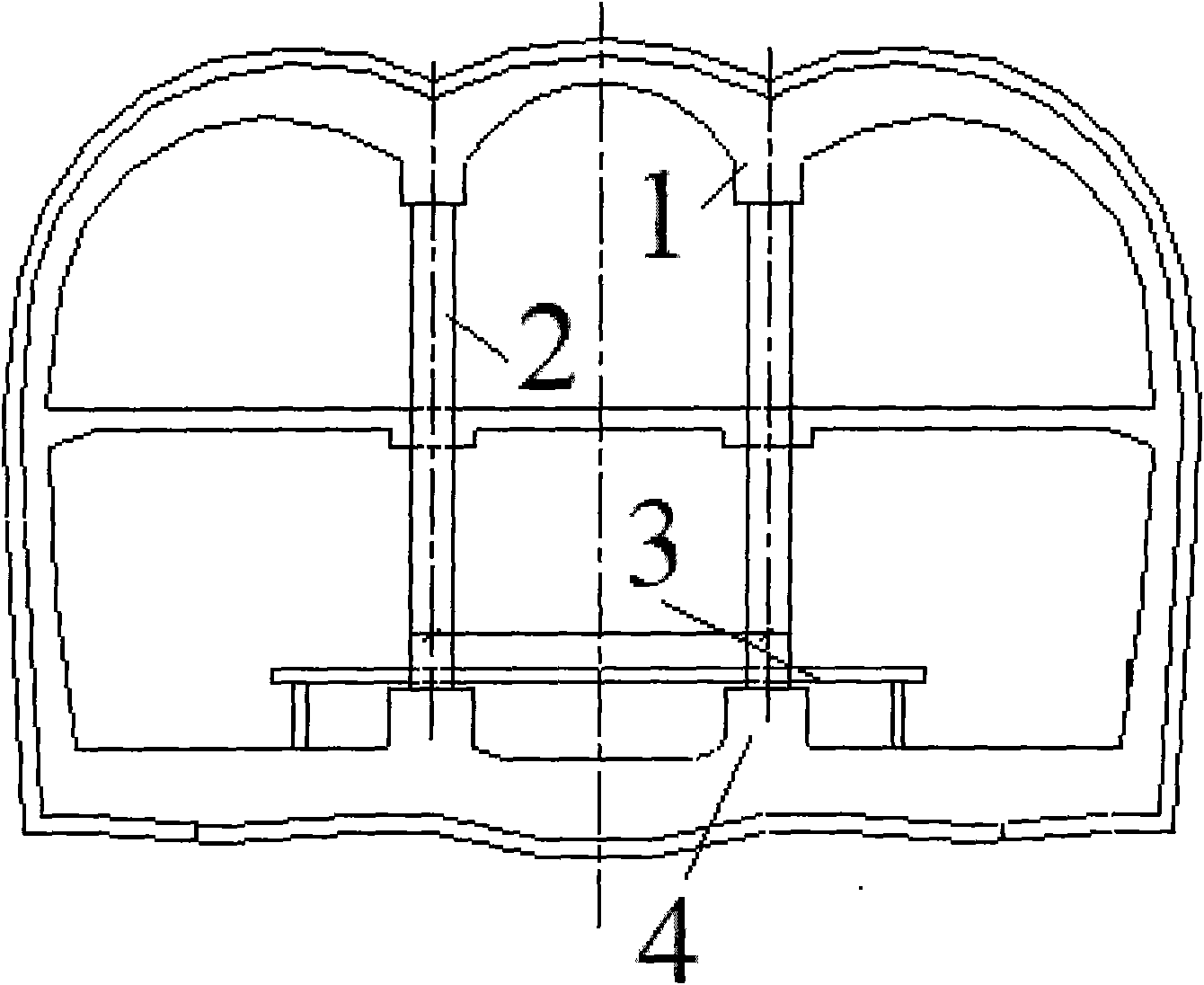

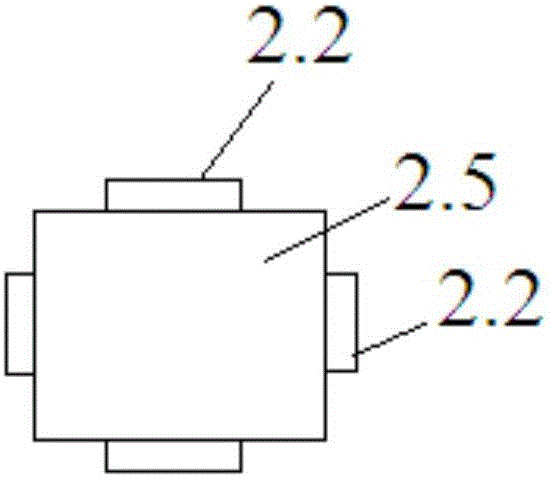

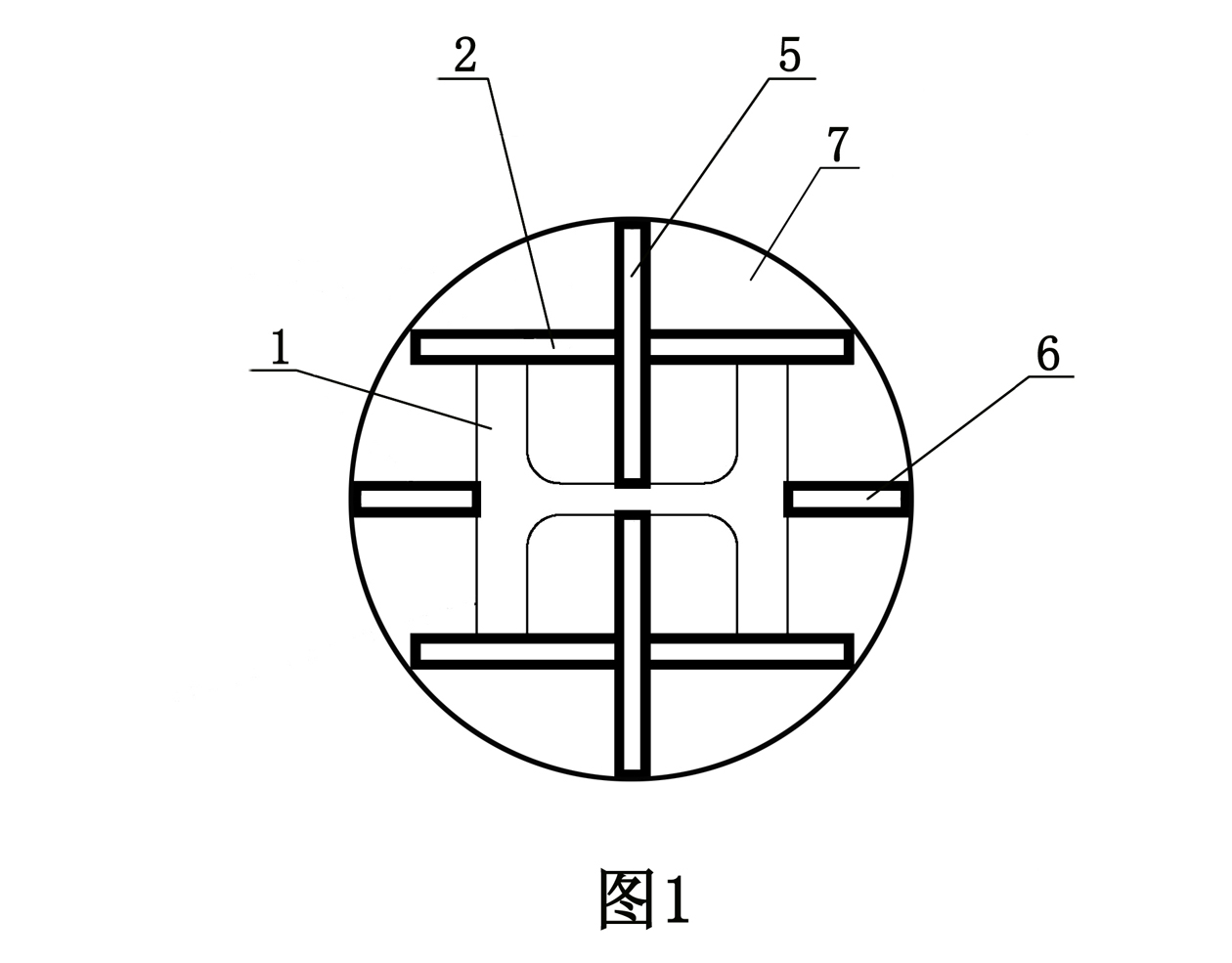

Ribbed steel engraved mesh for cast-in-place cavity floor

InactiveCN105421663AInhibitionFast productionFloorsBuilding reinforcementsSheet steelMetallic materials

The invention provides a ribbed steel engraved mesh for a cast-in-place cavity floor. The ribbed steel engraved mesh is composed of an engraved mesh, a supporting mesh and an engraved end mesh; the engraved mesh, the supporting mesh and the engraved end mesh all are made of a pure metal material; the engraved mesh forms a periphery of the ribbed steel engraved mesh; the engraved end mesh closes the ribbed steel engraved mesh and the supporting engraved mesh to form an engraved end section shape of the ribbed steel engraved mesh; the supporting mesh controls a height of an internal space of the ribbed steel engraved mesh; the engraved mesh and the engraved end mesh are fabricated from steel mesh bodies, and each steel mesh body comprises steel sheet dilated mesh holes, a V-shaped rib and a steering connecting piece; the dilated mesh holes on two sides of the steering connecting pieces are not in the same direction; the V-shaped rib is greater than 6mm high; at least four measuring fixed marks are formed by pressing on the V-shaped rib of the steel mesh body of the engraved mesh in a vertical direction; and the supporting mesh is a steel mesh body or a reinforcing mesh body; the ribbed steel engraved mesh is used for casting the cavity floor, and the ribbed steel engraved mesh is directly buried in concrete cast in place at edges of a cavity to achieve a suppression effect on temperature cracks of the floor.

Owner:王本淼 +2

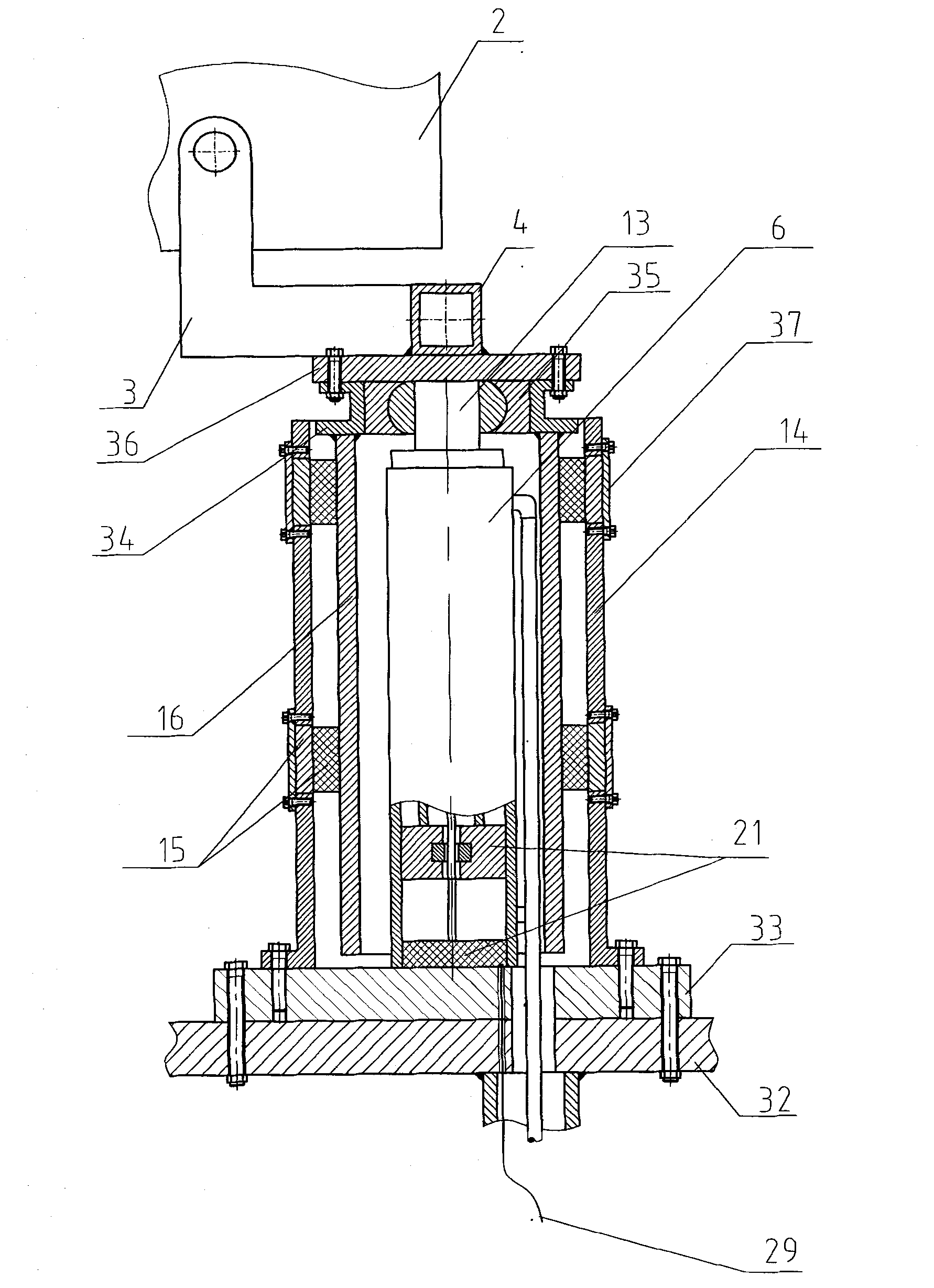

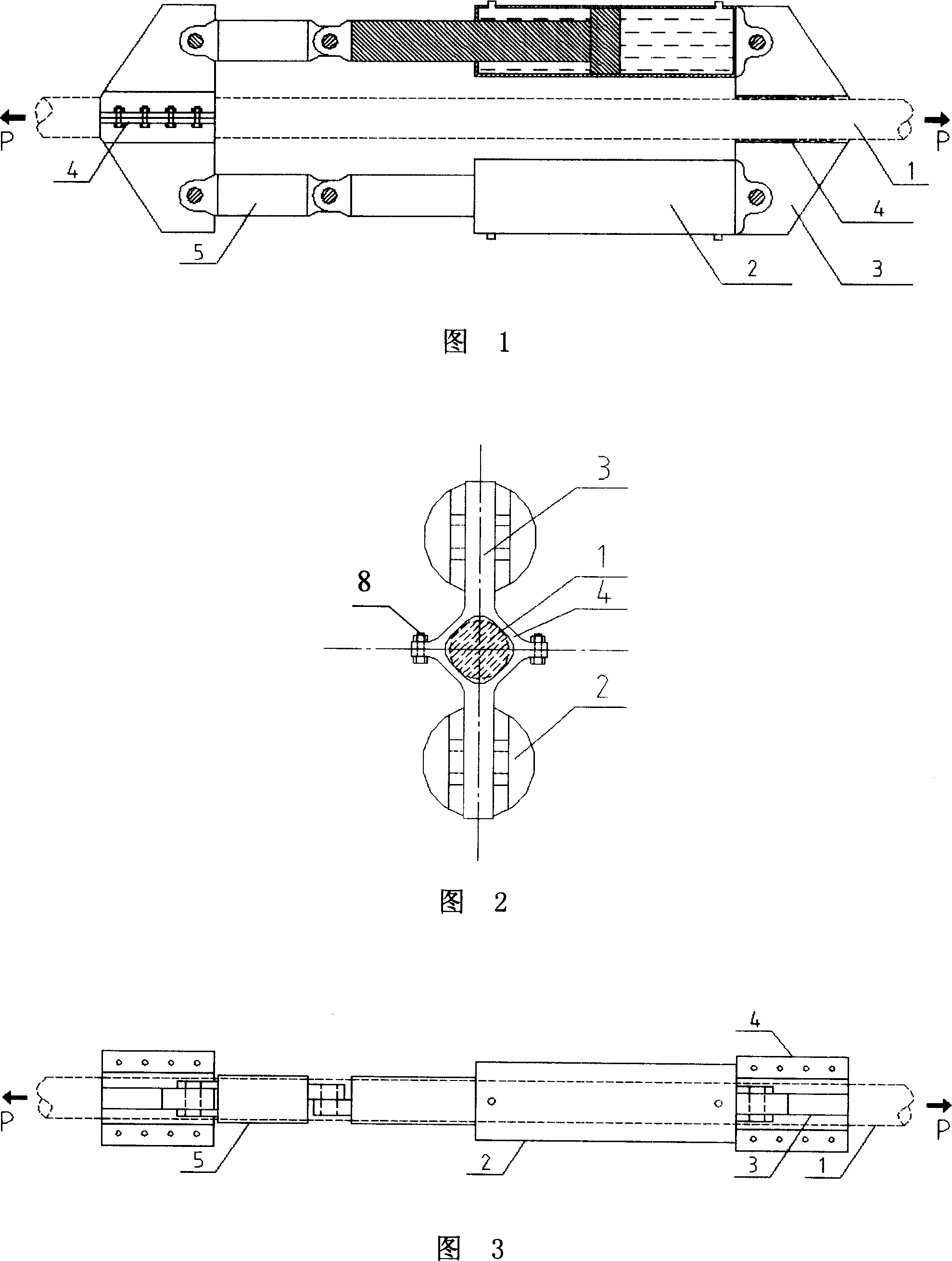

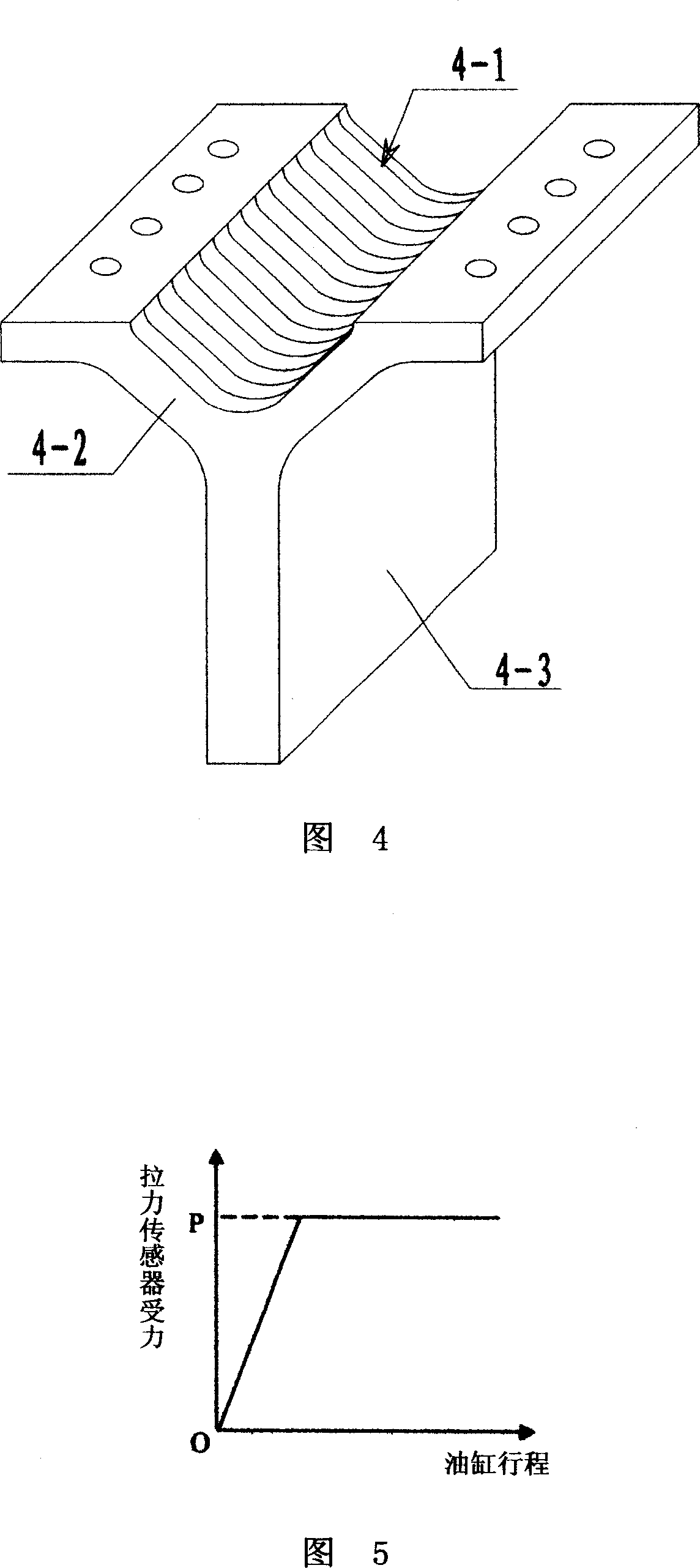

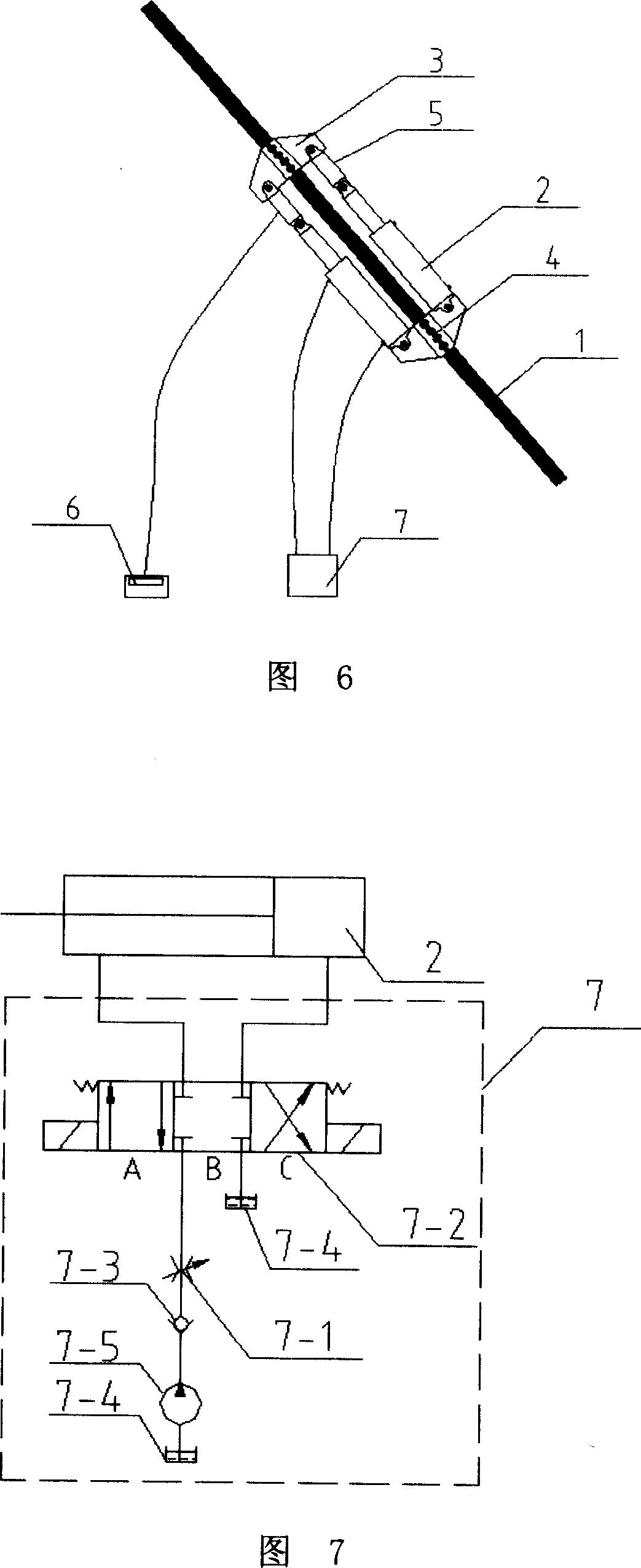

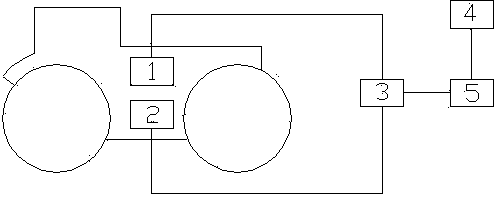

Steel cable stretching force detecting apparatus

InactiveCN101013056AEasy to useGuarantee the quality of the projectForce measurement using piezo-electric devicesTension measurementHydraulic cylinderPull force

The invention discloses a steel cable pull force detection device, the device being a symmetric mutual articulated four rods frame structure, in which the two rods respectively form a cable clamp (4); both side rods respectively serially comprise a pull force sensor (5) and a hydraulic cylinder (2). The cable pull detection device of the invention can be used for detecting the tilted-stay bridge, the suspending-cable bridge, and the tied rod arch, and it uses the cable carrying the actual steel cable carrying pull force in the project, providing the technical means to protect the project quality. The steel cable pull force detection device of the invention has no assumption and conversion, and it can directly detect the steel cable carrying pull force.

Owner:GUANGZHOU UNIVERSITY

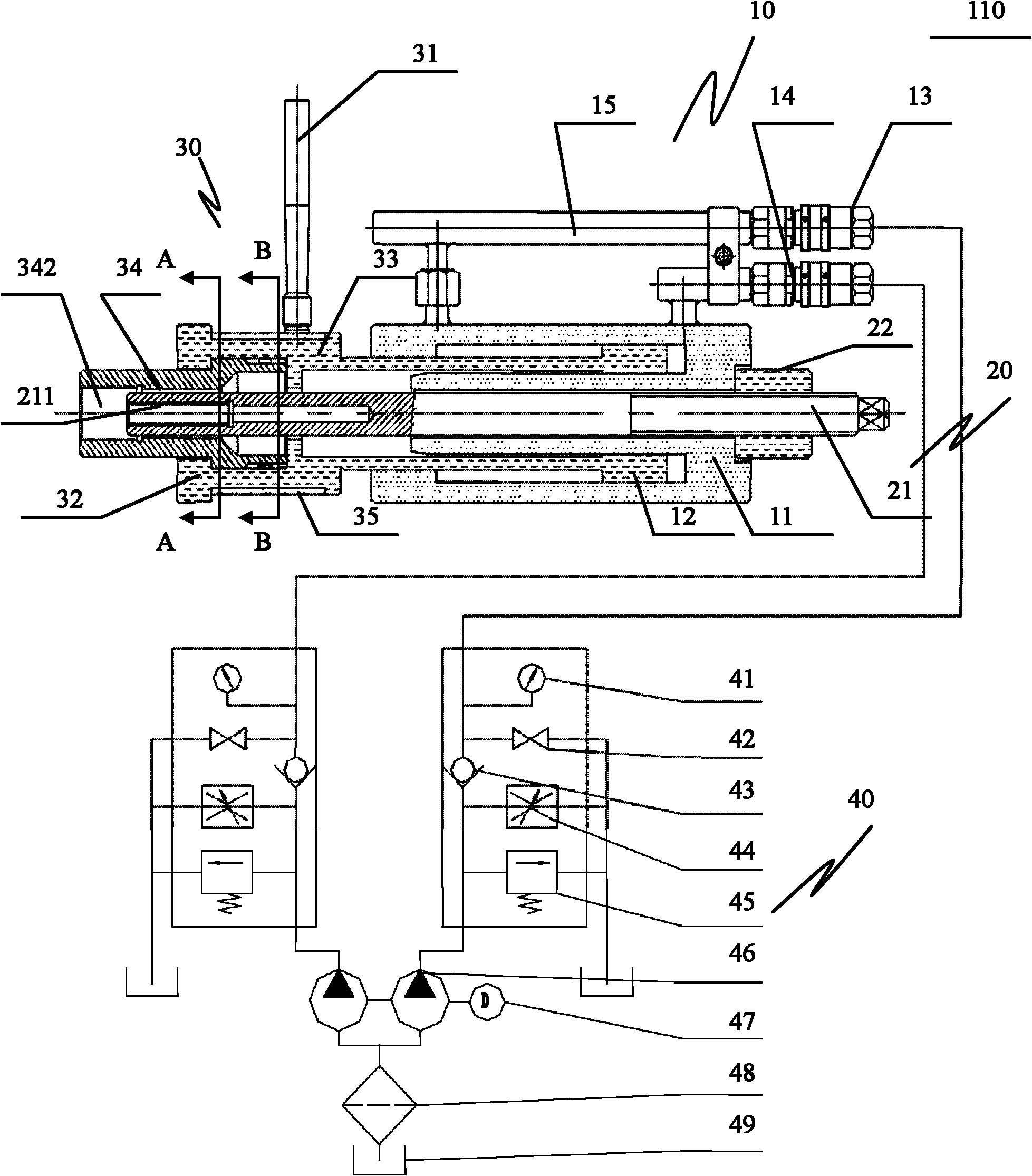

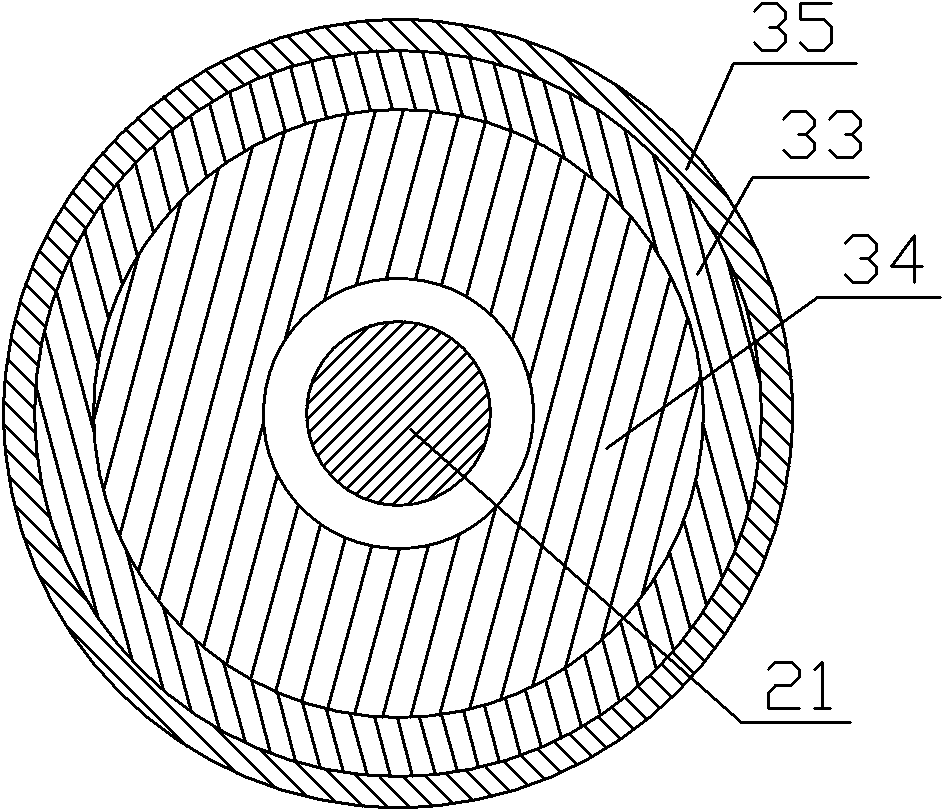

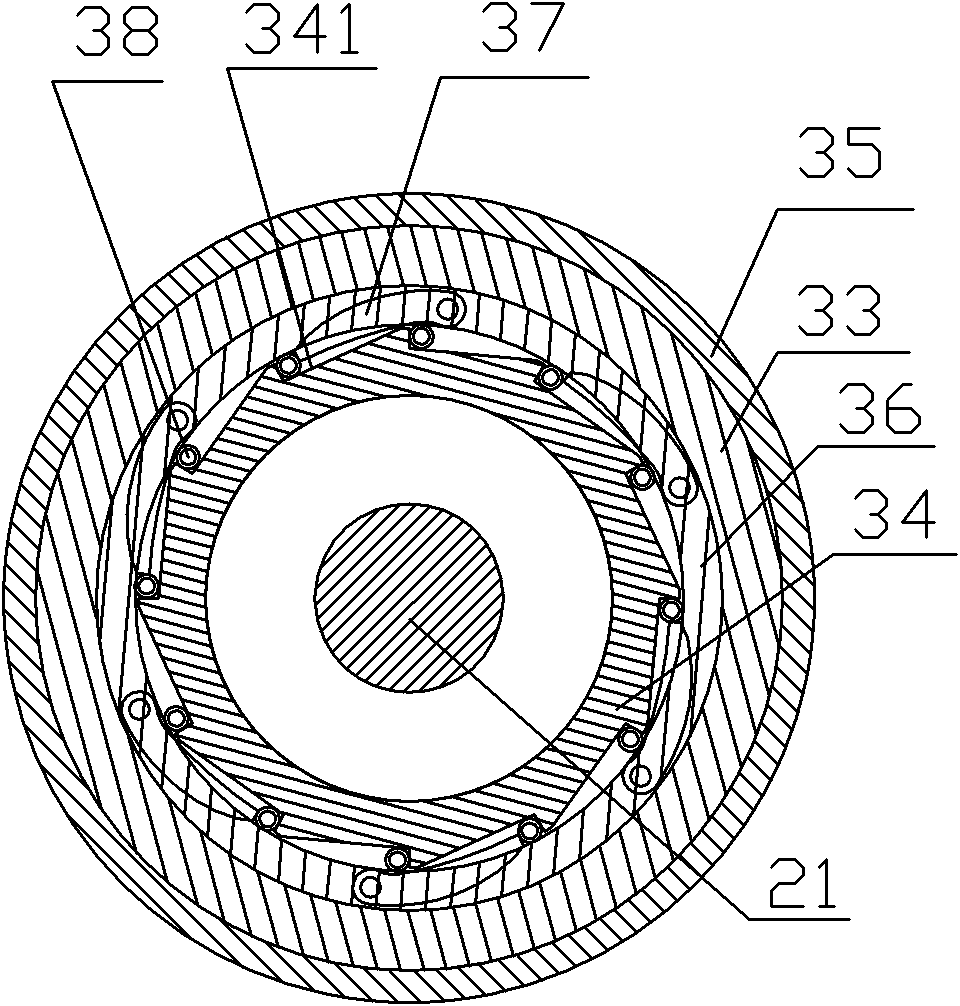

Prestress rib tensioning equipment, system and method and concrete continuous box girder

ActiveCN102182146AGuarantee the quality of the projectSimplify construction stepsBridge erection/assemblyBuilding material handlingPre stressLocking mechanism

The invention relates to prestress rib tensioning equipment, system and method and a concrete continuous box girder. A prestress rib is tensioned by using the tensioning equipment comprising a jack, a tensioning mechanism and a locking mechanism; the tensioning mechanism comprises a tensioning rod and a pressure-bearing member; the tensioning rod penetrates through a cylinder body of the jack and a rotating sleeve of the locking mechanism; one end of the tensioning rod is provided with a connecting part for being connected with the prestress rib, and the connecting part is positioned in the rotating sleeve; and the pressure-bearing member is arranged at the other end of the tensioning rod and abutted against the cylinder body. The invention realizes tensioning and anchoring by connecting the tensioning rod with the prestress rib and combining the jack and the locking mechanism, can realize tensioning and anchoring by one-step tensioning process, is convenient for the prestress application, simplifies the construction procedure of a railway bridge culvert and ensures the engineering quality.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

BIM technology-based curtain wall mounting design method

InactiveCN108460189AEliminate biasImprove installation accuracyGeometric CADDesign optimisation/simulationPoint cloudEngineering

The invention discloses a BIM technology-based curtain wall mounting design method. The method comprises the following steps of (1) importing a two-dimensional drawing of a curtain wall to BIM software Revit, and building three-dimensional models of to-be-mounted curtain wall unit members according to modeling specifications; (2) exporting detail drawings according to the three-dimensional modelsof the to-be-mounted curtain wall unit members, and performing processing production according to the detail drawings of the curtain wall unit members by a factory; (3) building three-dimensional point cloud models of the curtain wall unit members by utilizing fixed point cloud information; (4) adjusting information of the curtain wall unit members by using a processing device; and (5) simulatingwhole pre-mounting of the curtain wall in the Revit according to the three-dimensional point cloud models of the curtain wall unit members meeting specification requirements, and according to a pre-mounting process, performing entity member mounting. The BIM technology-based curtain wall mounting design method solves the problems of high field mounting difficulty, low mounting efficiency and low precision of the curtain wall.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

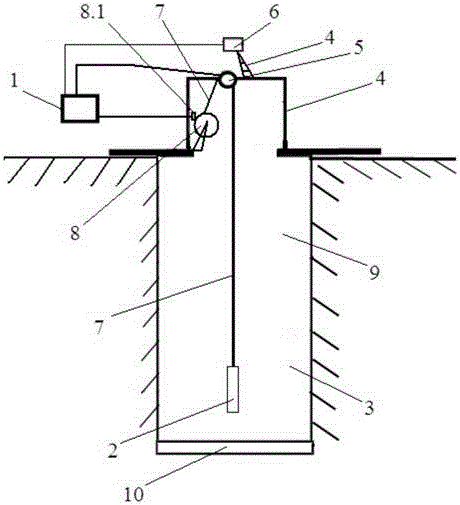

Bored pile pore-forming quality detecting device and method

ActiveCN106545329AImprove quality assuranceComprehensive detection functionSurveyMeasurement devicesEngineeringPore diameter

The invention relates to a bored pile pore-forming quality detecting device. A fluid density signal input interface, an ultrasonic communication interface and a three-dimensional posture interface of a pore-forming detecting host of the bored pile pore-forming quality detecting device are sequentially connected with a fluid density sensor, an ultrasonic launching and receiving sensor and a three-dimensional posture sensor through cable transfer nodes of a take-up and pay-off spool and a cable bus. The cable bus is wound around the take-up and pay-off spool and controlled to be taken up and paid off by the take-up and pay-off spool, the cable bus is taken up and paid off on a depth counting pulley, the depth counting pulley records the take-up and pay-off length of the cable bus, and the depth feedback signal output end of the depth counting pulley is connected with the pore-forming detecting host. A GPS sensor is located over a probe, and the signal output end of the GPS sensor is connected with the GPS signal input end of the pore-forming detecting host. The bored pile pore-forming quality detecting device can detect parameters such as pore diameters, pore depths, perpendicularities, whole-pore mud densities, dreg thicknesses, boring inclination directions and pore opening coordinates of bored pile formed pores, and the bored pile pore-forming quality reliability is ensured.

Owner:WUHAN CHANGSHENG ENG EXPLORATION TECH DEV CO LTD +1

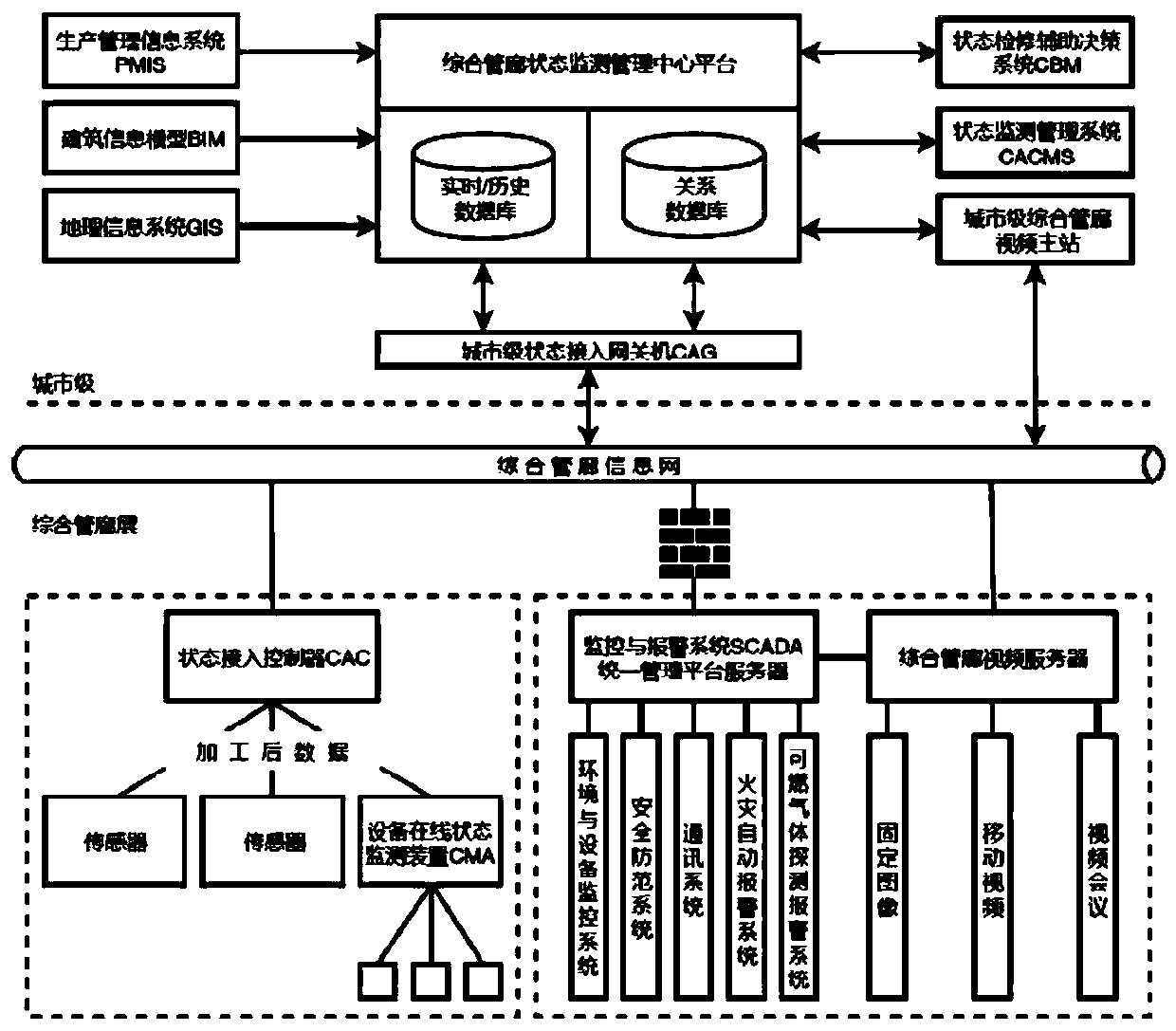

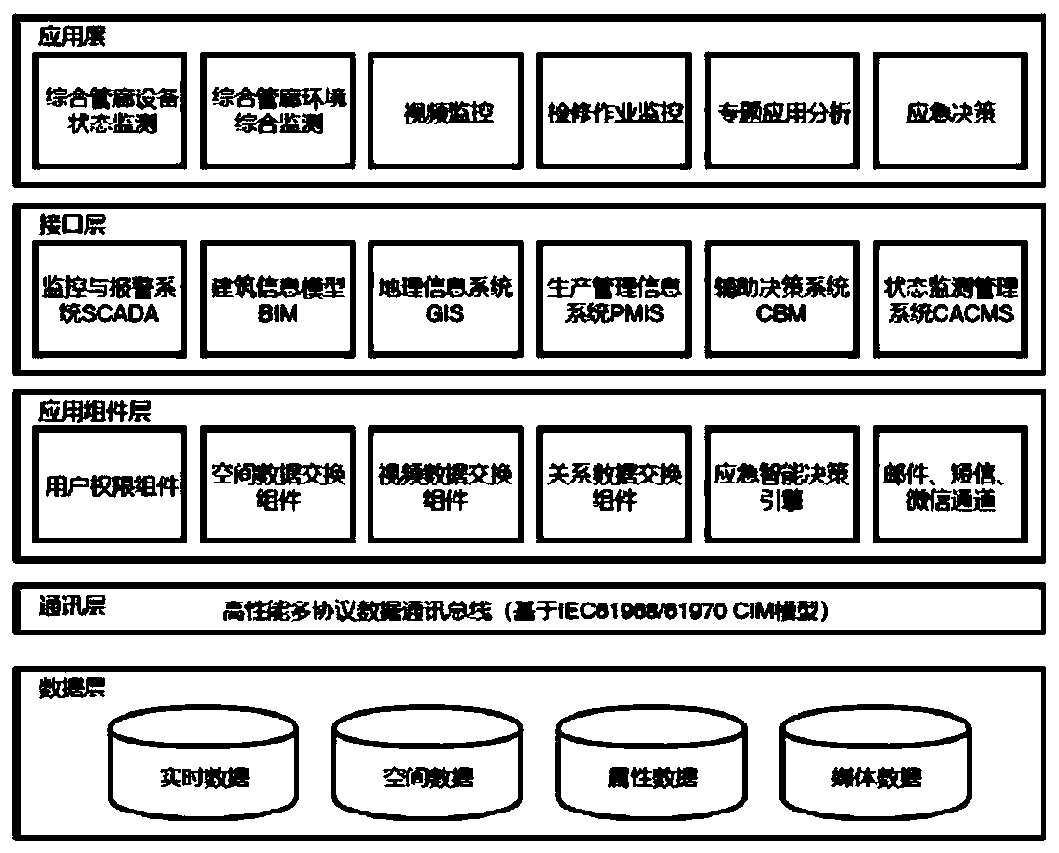

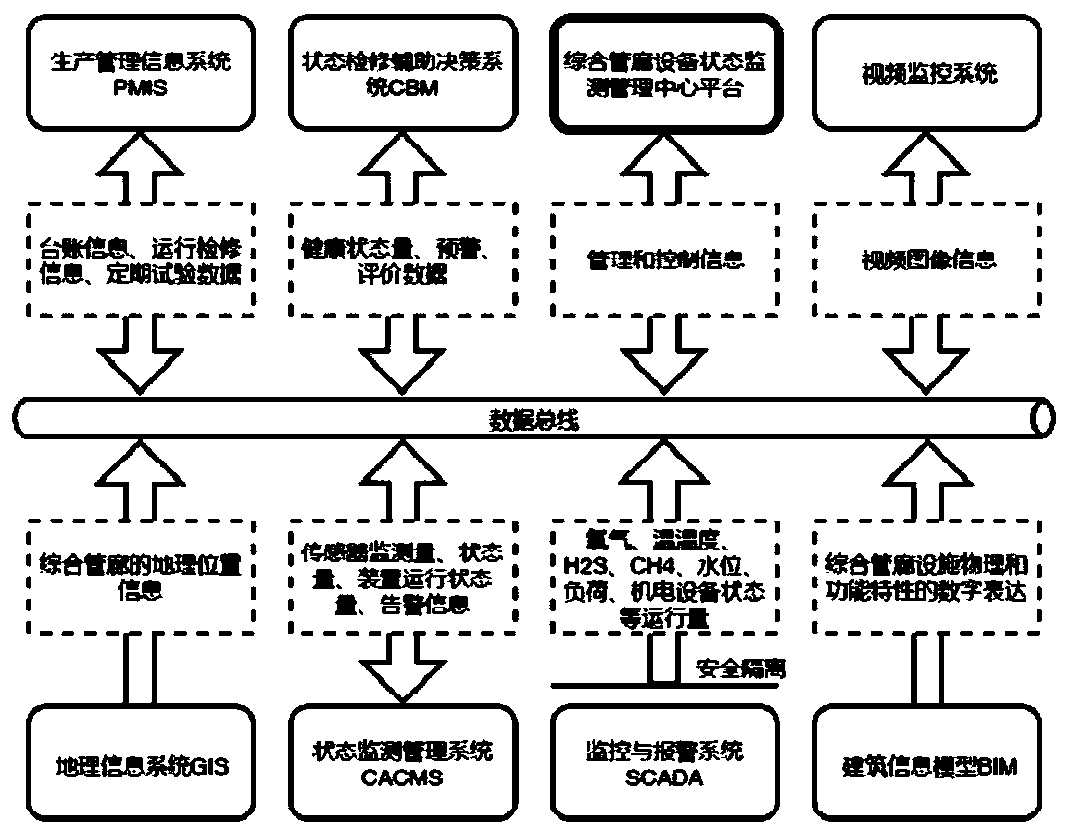

Comprehensive pipe gallery equipment state monitoring and management system

PendingCN110428135AComprehensive and timely information serviceImprove operational efficiencyRegistering/indicating working of machinesHardware monitoringTime informationData warehouse

The invention discloses a comprehensive pipe gallery equipment state monitoring and management system which is characterized by comprising a comprehensive pipe gallery layer system and a city-level system. According to the invention, a real-time database, a data warehouse and an intelligent platform tool are used as key technical means; a centralized and unified integration and sharing platform isprovided for various real-time information and production management information; a comprehensive pipe gallery equipment state unified centralized monitoring system is established; real-time information and business information based on manual work are effectively collected, converted, integrated, loaded and displayed, and more comprehensive and timely information services are better provided forvarious business fields such as comprehensive pipe gallery production operation commanding, emergency disposal, gallery entry professional pipeline operation management and state maintenance.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

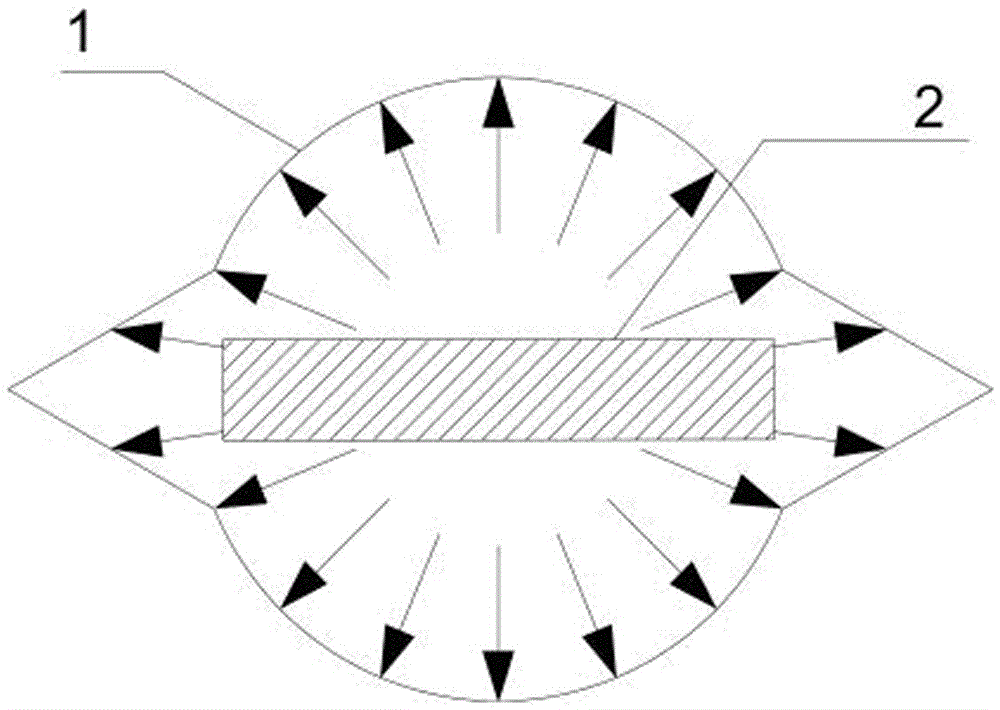

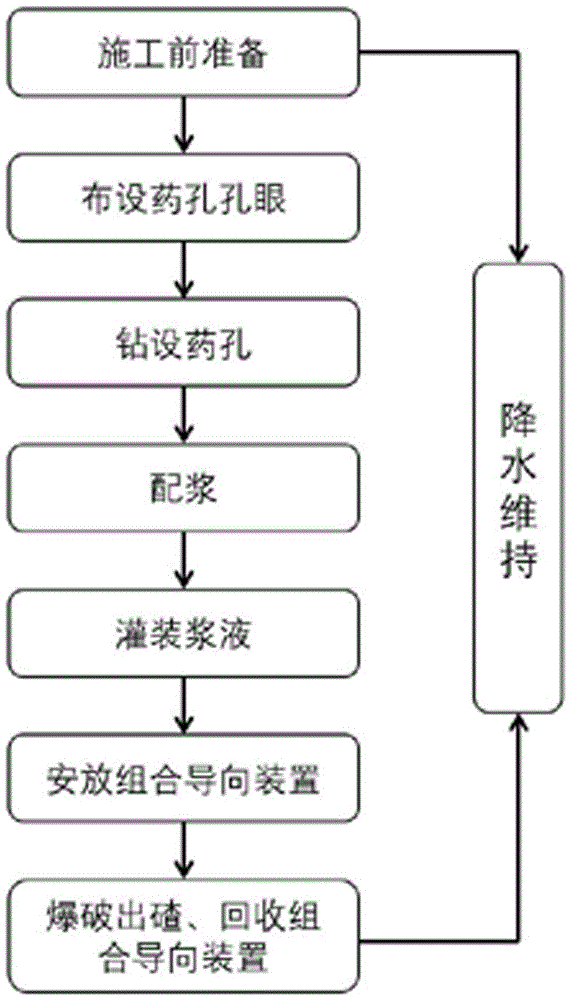

Directional static blasting construction method for foundation pit stratum and combined guiding device for directional static blasting construction method

The invention discloses a directional static blasting construction method for a foundation pit stratum and a combined guiding device for the directional static blasting construction method. The directional static blasting construction method for the foundation pit stratum comprises the first step of field testing, the second step of chemical hole opening arranging, the third step of chemical hole drilling, the fourth step of grout preparing, the fifth step of grout filling, the sixth step of combined guiding device arranging, the seventh step of blasting, slag discharging and combined guiding device recycling and the eighth step of dewatering maintaining. The combined guiding device for directional static blasting is formed by combining long-strip steel sheets and a metal square pipe with guiding square holes for the long-strip steel sheets to penetrate. The long-strip guiding steel sheets are placed in static blasting chemical holes, and consequently penetrating main cracks are generated by a rock mass in the width direction of the long-strip steel sheets. Meanwhile, compared with a conventional static blasting method, the distance of the chemical holes is increased by 1.3-1.5 times in the method, the effect of directional rock mass fracturing is achieved, and meanwhile the blasting efficiency is improved.

Owner:湖南航天建筑工程有限公司

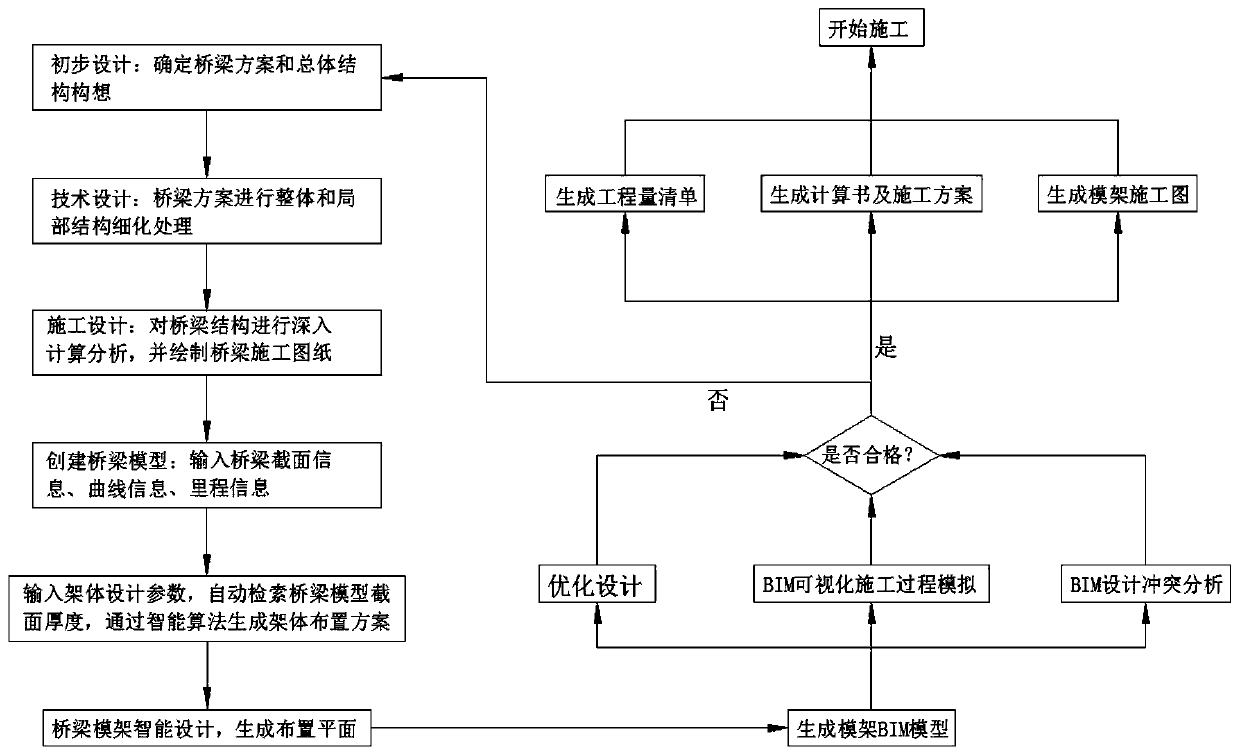

Bridge formwork intelligent design method based on BIM

ActiveCN109753753AImprove design efficiencyImprove accuracySpecial data processing applicationsIntelligent designShop drawing

The invention discloses a bridge formwork intelligent design method based on BIM, and belongs to the field of BIM bridges, and comprises the following steps: 1) preliminary design: determining a bridge scheme and overall structure concepts, such as arrangement of a bridge plane, a vertical surface and a cross section, by professionals; and 2) technical design: carrying out integral and local structure refinement processing on the bridge scheme determined in the preliminary design. The bridge formwork intelligent design method provided by the invention has a powerful rapid modeling function. Abridge three-dimensional model can be quickly created according to a CAD construction drawing. The problem that traditional two-dimensional design expression is not perfect, visual and clear is solved, through design conflict analysis, possible problems in the bridge construction process are found in advance and solved in advance, the traditional management thought is changed, namely, passive management of a waiting problem is converted into active management of an active discovery problem, and the working efficiency is improved.

Owner:广东星层建筑科技股份有限公司

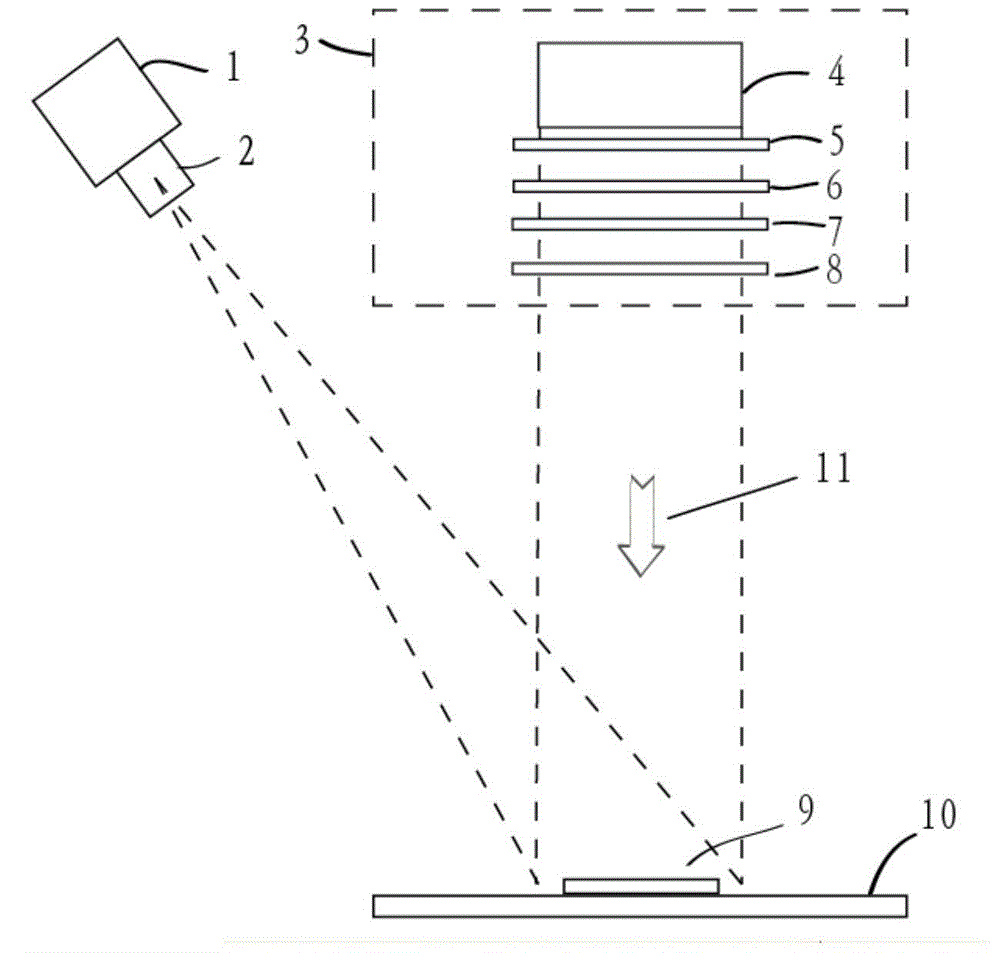

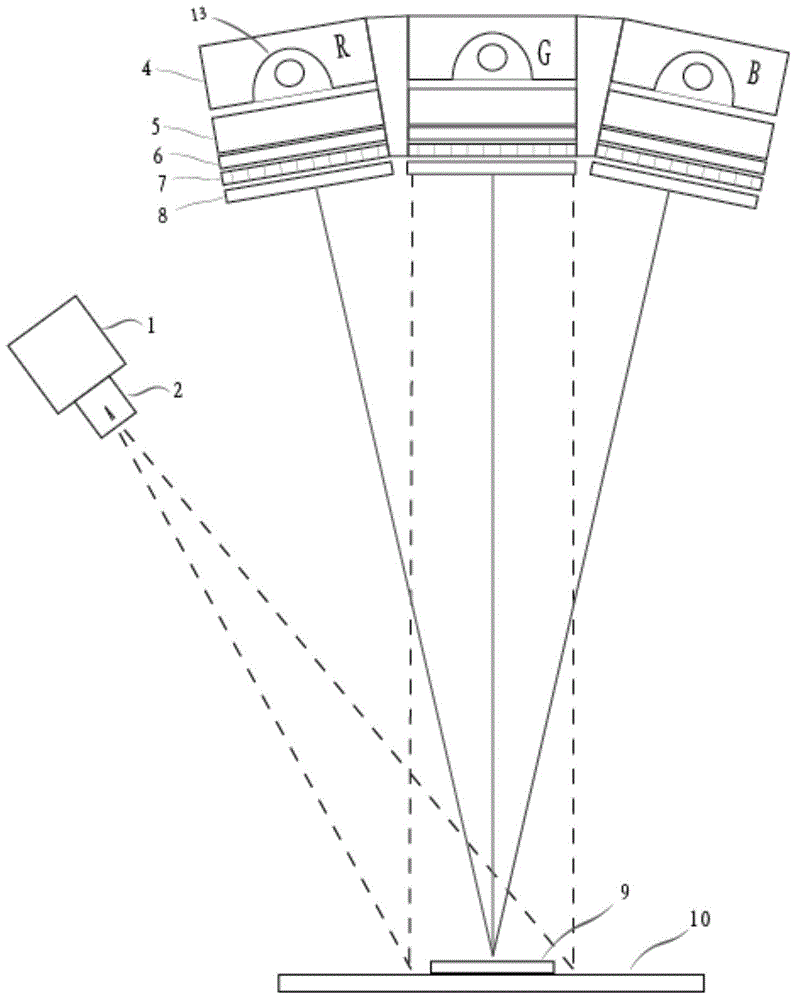

Online three-dimensional detection device based on RGB structured light

InactiveCN104568963AGuarantee the quality of the projectLow costOptically investigating flaws/contaminationImaging processingComputer science

The invention discloses an online three-dimensional detection device based on RGB structured light. The online three-dimensional detection device comprises a to-be-detected object, an RGB structured light source, a shooting module and an image processing module, wherein the RGB structured light source comprises multiple LED light source modules; each LED light source module sequentially comprises an LED chip array, a light path alignment part, a color filter, a diffraction grating and a focusing lens; and the shooting module is connected with the image processing module. According to the detection device disclosed by the invention, a series of sampling problems caused by asynchrony between projecting and shooting in the image acquisition process can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

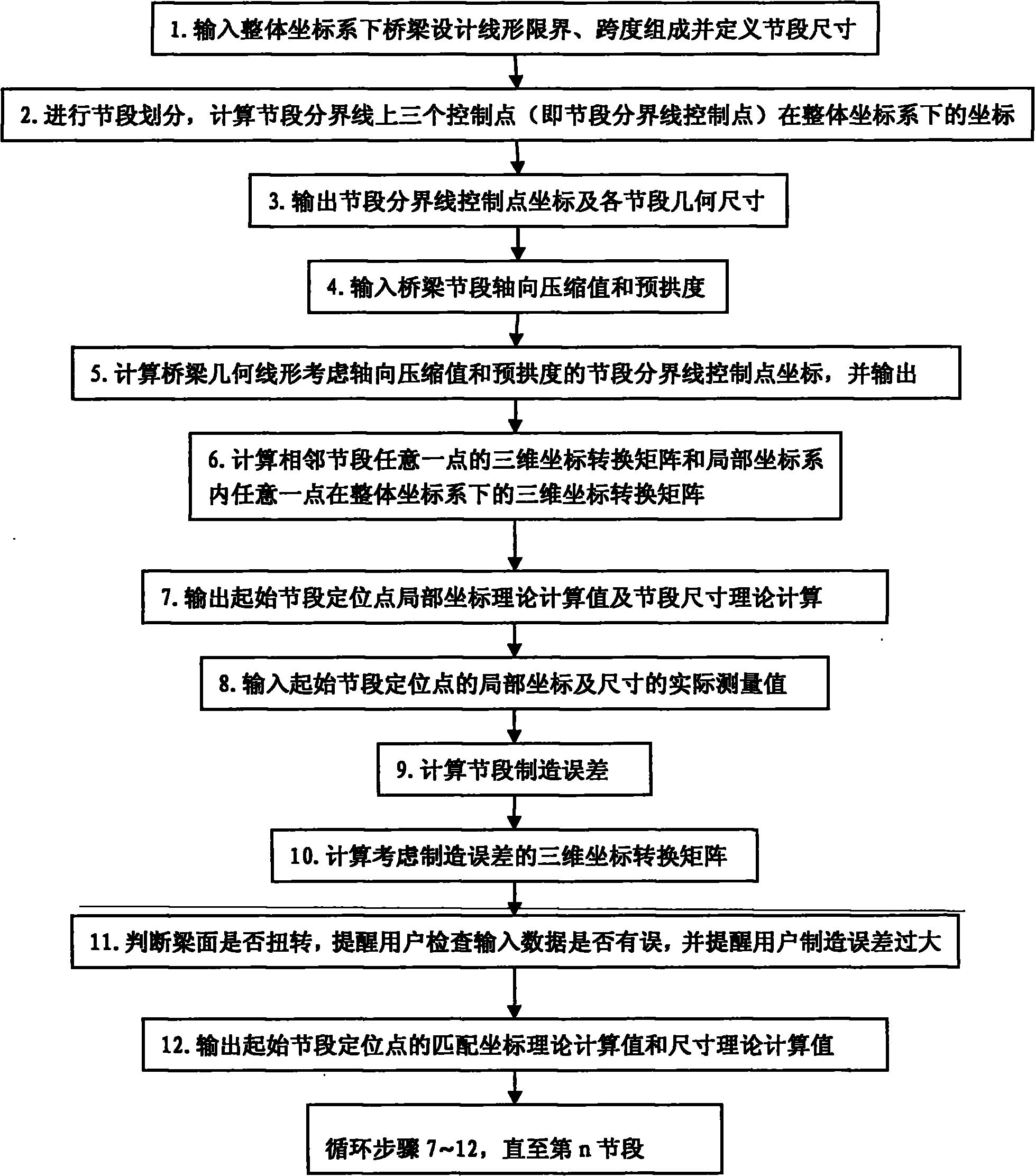

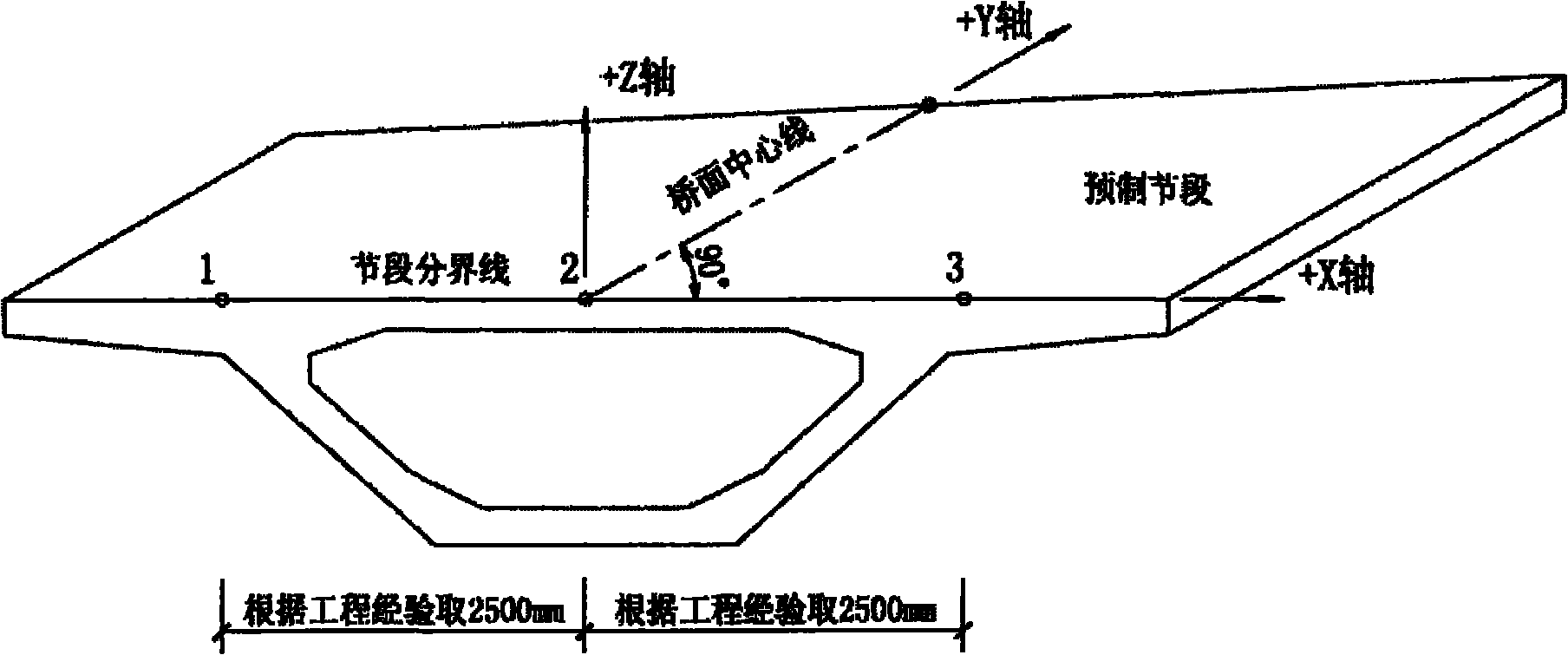

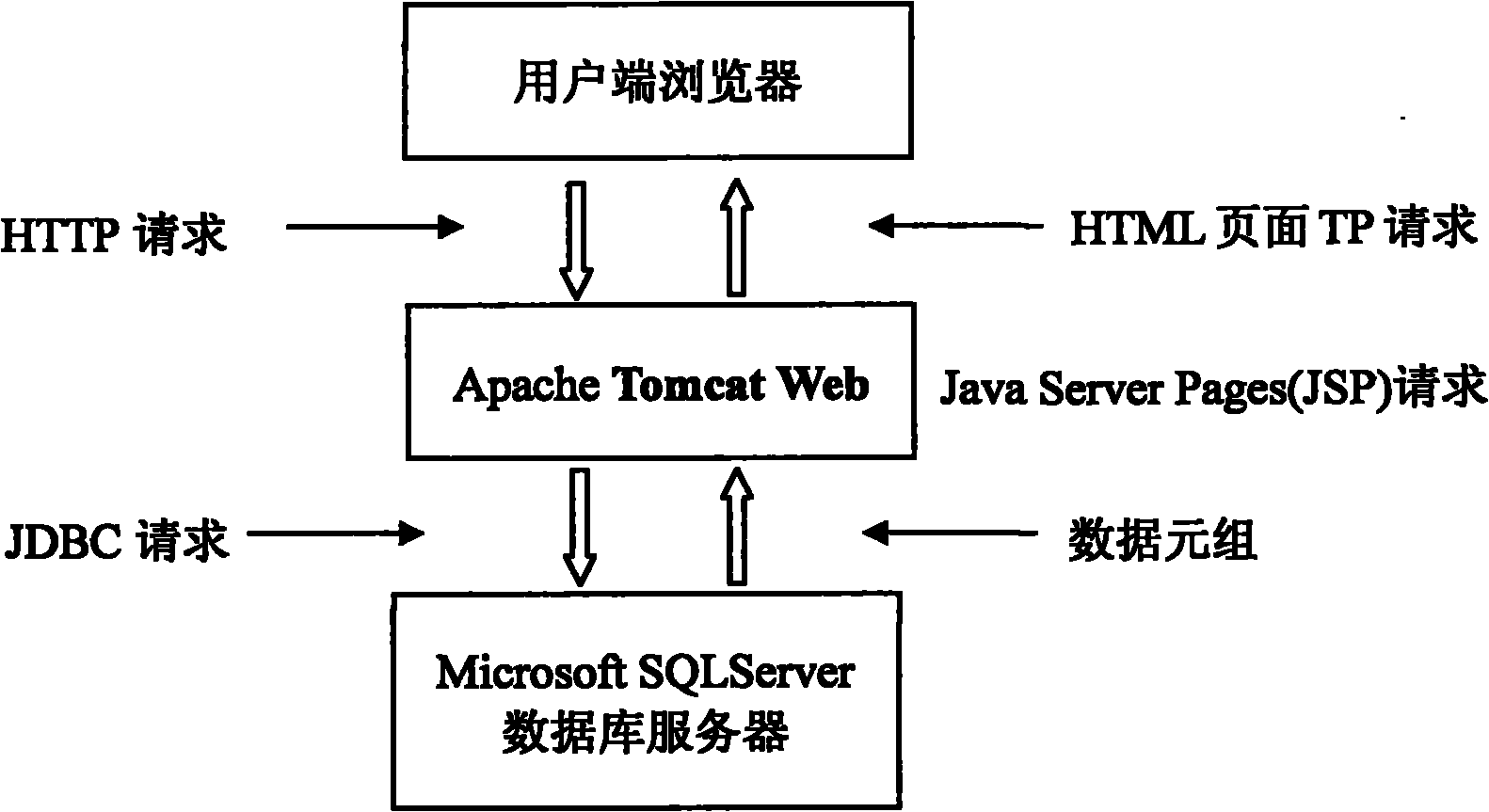

Three-dimensional numerical control method for bridge section precasting technology

ActiveCN101942805AReduce manufacturing errorsReduce Prefabrication DeviationsBridge erection/assemblyNumerical controlAxial compression

The invention discloses a three-dimensional numerical control method for a bridge section precasting technology, which comprises the following steps: dividing the bridge into sections; calculating the global coordinates of the section boundary control point and the geometric dimensions of each section; inputting the axial compression value and camber of the sections, correcting the global coordinates of the section boundary control point, and calculating new coordinates; calculating the three-dimensional coordinate transition matrix of any point of the adjacent sections; calculating manufacturing errors of the sections and adjustment quantities of the adjacent sections in six directions; calculating the three-dimensional coordinate transition matrix of any point of the adjacent sections after considering the section manufacturing errors; judging whether the beam surface is twisted according to the manufacturing errors of the sections; and according to the three-dimensional coordinate transition matrix of any point of the adjacent sections after considering the section manufacturing errors, outputting the theoretical calculation values of the matching coordinates of the initial section locating point, and the theoretical calculation values of the section dimensions. The invention realizes three-dimensional control on the geometric line shapes of the bridge sections, and reduces the manufacturing errors caused by the separate control on plane and facade line shapes.

Owner:瀚阳国际工程咨询有限公司

Preparation method of esters retarding polycarboxylic acid slump retaining agent

The invention discloses a preparation method of an esters retarding polycarbocylic acid slump retaining agent. The method comprises the following steps that 1, unsaturated carboxylic acid and / or anhydride, alkoxy poly alkylene glycol, hydroxy ethidene diphosphonic acid and / or 2-hydroxyphosphonoacetic acid and polymerization inhibitor are mixed, under the protection of nitrogen, the temperature is increased to range from 40 DEG C to 60 DEG C, a catalyst is added, the temperature is increased to 100-140 DEG C, thermal reaction is conducted for 0.5-3 h, water is removed during the reaction, after reaction is finished, the temperature is cooled to room temperature, and a first mixture is obtained; 2, the first mixture and unsaturated carboxylic acid hydroxyl esters are mixed, and a comonomer mixture solution is obtained; 3, the comonomer mixture solution, an initiator aqueous solution and a molecular weight regulator aqueous solution are dropped in water to conduct reaction, and a copolymer product is obtained; 4, pH of the copolymer product is adjusted to 5-7 through alkali, and the esters retarding polycarbocylic acid slump retaining agent is obtained. According to the preparation method of the esters retarding polycarbocylic acid slump retaining agent, a structure of the hydroxy ethidene diphosphonic acid and / or the 2-hydroxyphosphonoacetic acid is introduced into the esters polycarbocylic acid slump retaining agent, and a finally obtained product has the effects of retardation and slump retaining.

Owner:KZJ NEW MATERIALS GROUP CO LTD

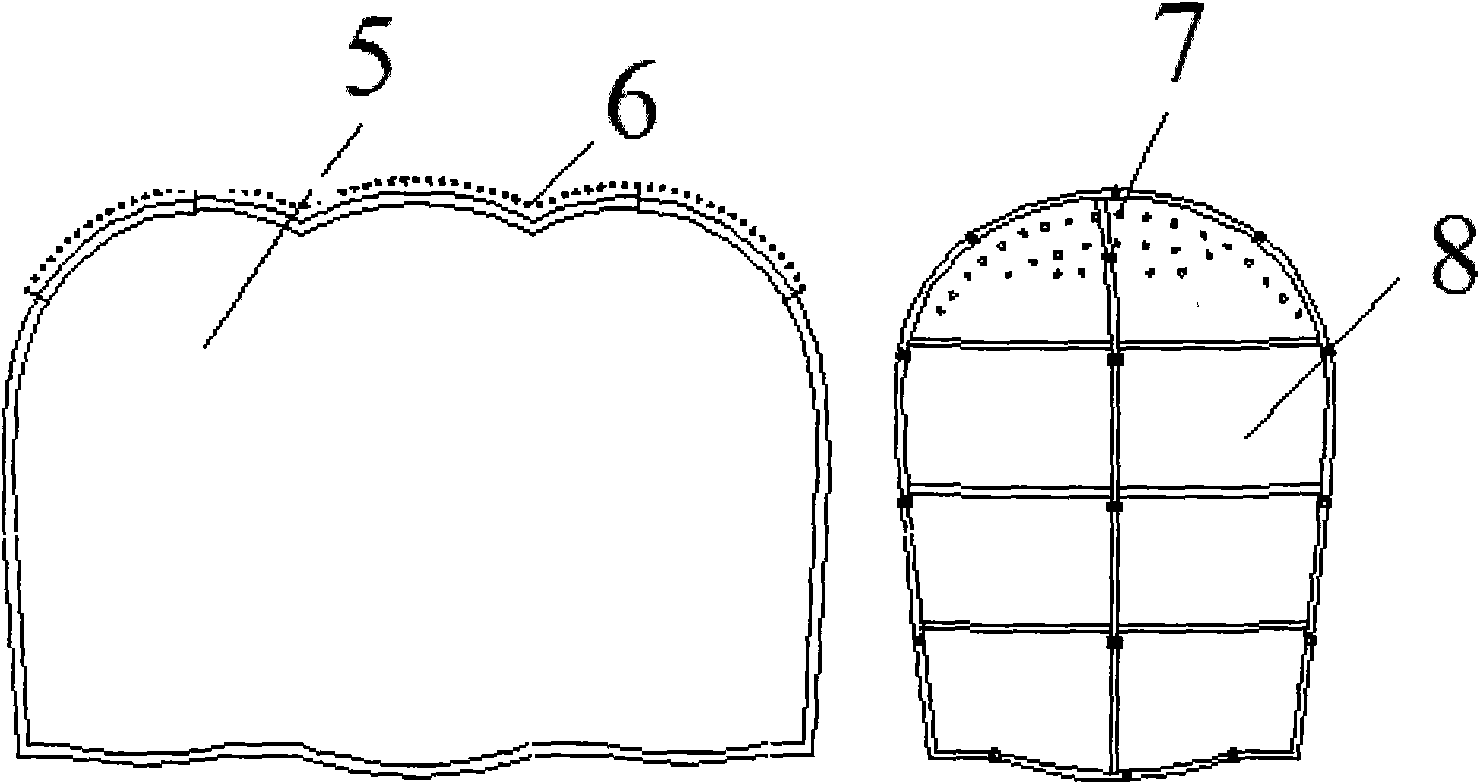

Low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and construction method

InactiveCN103074936ASimple structure designSolve thermal insulationWallsClimate change adaptationThermal insulationThin layer

The invention discloses a low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and a construction method, and belongs to the field of construction energy saving and structure integration. The system is characterized in that a wall body (1) is built by AAC building blocks (5) of which the density grade is B03-B05 grade; two adjacent AAC building blocks (5) are bonded by a building block binder layer (6); and one layer of stacked AAC building blocks (5) are built on the outer side surface of each column body (2). The construction method for the low-density AAC precise-masonry self-thermal insulation system mainly comprises the following steps of: stirring the building block binder layer (6); building the AAC building blocks (5); bonding an L-shaped bonding piece (8); and plastering thin-layer plaster mortar (11). According to the low-density AAC precise-masonry self-thermal insulation system and the construction method, the thermal insulation, fire prevention and energy saving requirements of a building can be satisfied without a composite thermal insulation layer, and construction working procedures are reduced, thereby being favorable for the engineering construction quality and shortening the days for construction.

Owner:山东高阳建材有限公司

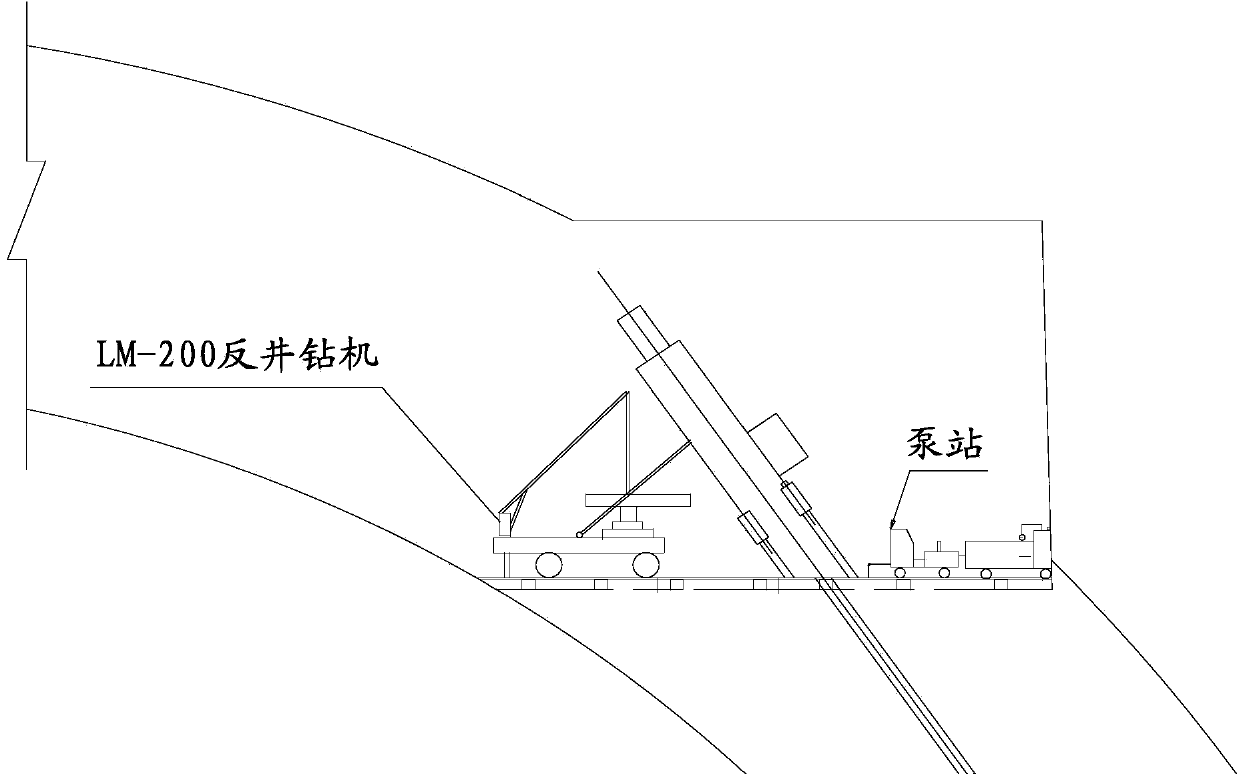

Method for carrying out construction in vertical shaft or inclined shaft through raise boring machine

InactiveCN104196442ASpeed up the construction progressGuarantee the quality of the projectDirectional drillingWork periodDrill bit

The invention relates to a method for carrying out construction in a vertical shaft or an inclined shaft through a raise boring machine. The construction method comprises the steps that the raise boring machine is used for downwards drilling a guide hole with the diameter of 216 mm in an upper horizontal plane excavation expanding area of an upper curved section in the axis direction of the inclined shaft, a drill bit of phi216 mm is replaced with an excavation expanding tool disc of phi1,400 mm on a lower curved section after the guide hole is formed, and then a slip slug pilot shaft with the diameter phi of 1,400 mm is formed in a counter pull excavation expanding mode from top to bottom. According to the method for carrying out construction in the vertical shaft or the inclined shaft through the raise boring machine, construction and shaft guide are carried out by the raise boring machine in the hydropower project, and safety accidents are avoided in the construction process. Excavation and supporting of the vertical shaft and the slow inclined shaft are smoothly completed during the joint work period, the investment of personnel and equipment is reduced, the construction schedule is accelerated, meanwhile, project quality is guaranteed, and economic benefits are increased for the project. The experience measures for controlling angle deviation in the construction process of the vertical shaft and the slow inclined shaft are grasped, and reference is provided for controlling hole direction deviation through the raise boring machine in the construction process of the vertical shaft and the slow inclined shaft later.

Owner:SINOHYDRO BUREAU 11 CO LTD

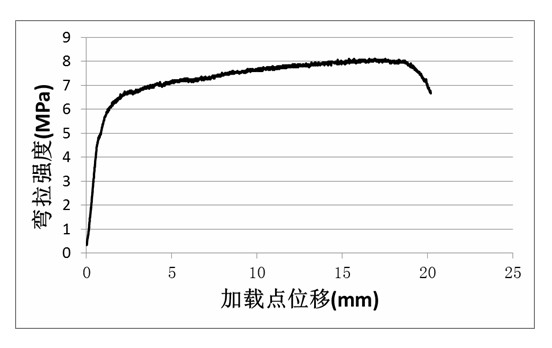

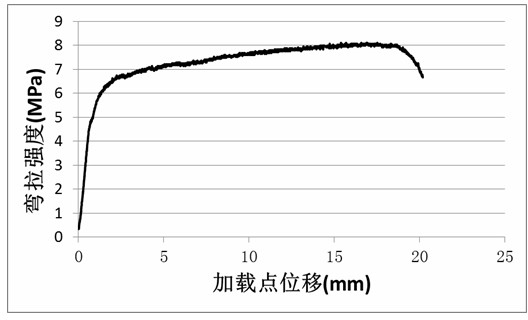

Method for pre-mixing high-ductility cement-based composite material

InactiveCN102603234ASolve into a groupSimplify the construction processClimate change adaptationCement slurryCement based composites

The invention provides a method for pre-mixing a high-ductility cement-based composite material. The method technically includes steps: firstly, adding cement, fly ash, quartz sand and powdery high-efficiency water reducer into a large-sized mixing station / plant / machine at first, and leading the various components to be uniformly mixed; secondly, conveying ECC (engineering cementitious composites) dry mixture which is uniformly pre-mixed by a concrete mixing vehicle to a construction field, loading the ECC dry mixture into a small-sized mixing machine in the field and finally adding a proper quantity of water to uniformly mix the mixture; thirdly, adding a certain quantity of water into the mixing vehicle in the construction field, and then leading a mixing barrel of the mixing vehicle tomix the mixture at the rotation speed of 18r / min; and fourthly, stopping mixing when the expansion radius of fiber cement slurry reaches 20mm at least under jumping table fluidity experimental conditions, and carrying out construction. By the aid of the method, fibers are finally uniformly dispersed in the cement slurry, the problem of fiber balling is avoided, and accordingly high performances of the high-ductility cement-based composite material are guaranteed.

Owner:SOUTHEAST UNIV

Steel frame reinforced column and reinforcing method thereof

InactiveCN101839074AReasonable structural stressImprove structural bearing capacityStrutsBuilding repairsSheet steelSteel frame

The invention relates to a steel frame reinforced column and a reinforcing method thereof. The steel frame reinforced column is characterized in that sealing reinforcing steel plates are welded between two flanges at two sides of an H-shaped steel frame column along the overall length of the column, are arranged in pair at two side openings of the H-shaped steel frame column and are welded with two flanges at the opening of the H-shaped steel frame column, and two sealing reinforcing steel plates adjacent up and down are mutually welded. In the invention, the reinforcing steel plates are prefabricated into parts in advance, are directly hoisted to the position during construction, pass through the steel column in over length along the direction of a weak shaft of the H-shaped steel frame column and are welded in pair, thereby enabling the structure stress of the steel reinforced column to be more reasonable and the structural bearing of an original building to be enlarged and satisfying the structural bearing stress requirement. By adopting the construction method of the invention, the original structure can be used for reinforcing the frame steel column of the original steel structure without being disassembled, thereby not influencing the normal work in the original building. All the reinforcing steel plates can be precast in factories, thereby not only shortening the time limit for a project and reducing the construction cost but also ensuring project quality and satisfying the requirement of building extension.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

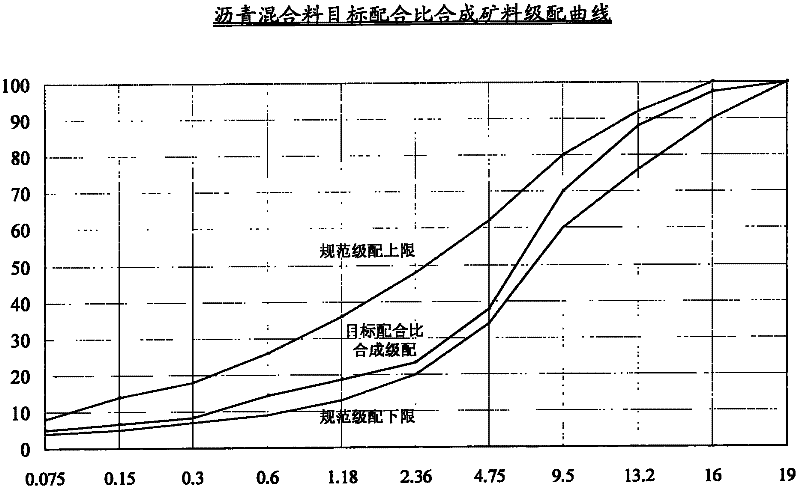

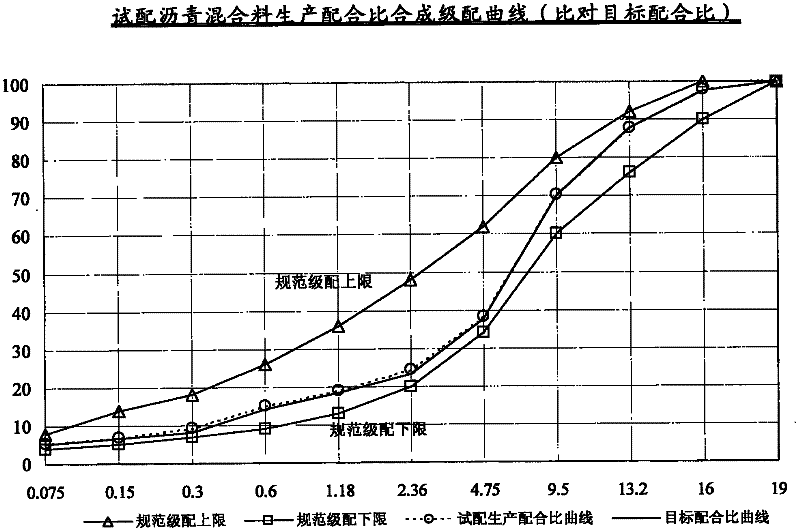

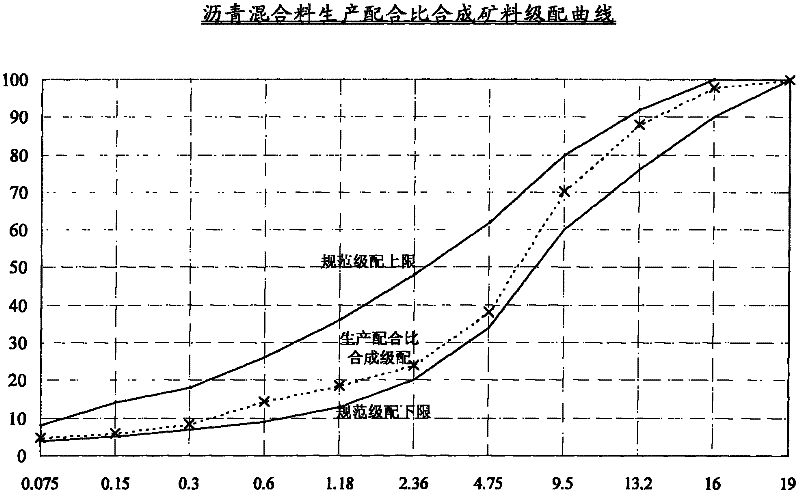

Method for mix design of hot-mix asphalt mixture produced with intermittent mixer

ActiveCN102173655AClose to practical applicationAvoid overflow and other material phenomenaRoads maintainenceEngineeringMix proportion

The invention relates to a method for mix design of a hot-mix asphalt mixture produced with an intermittent mixer and is characterized in that: the process mix design method comprises the following steps of: mineral mix design, Marshall test, determination of optimal asphalt dosage or oil-stone ratio, mix design test, correction of optimal asphalt dosage or oil-stone ratio and determination of final process mixing proportions of minerals. The step of mineral mix design comprises the procedures of determining initial proportions and designing mineral mixing proportions. The mix design method provided by the invention maintains consistency between process mix design and target mix design, and achieves quantization and visualization of the comparison between process mix design and target mix design. The mix design method effectively prevents the problem of material overflow, reduces loss, increases the running efficiency of equipment, reduces the consumptions of asphalt and mineral powder, ensures the construction quality and reduces the construction cost.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Method and device for continuously detecting compactness of asphalt concrete pavement

The invention relates to a method and a device for continuously detecting the compactness of an asphalt concrete pavement. According to the invention, continuous detection and real-time processing is carried out on pavement temperature and the vibration frequency of a road roller through a special device and dynamically, efficiently and accurately reflect the processing effect of the road roller on a pavement. The method and the device which are disclosed by the invention can be used for continuously detecting the compactness of the pavement in real time in a construction process, is high in timeliness, ensures the engineering quality by conveniently discovering problems in time and has the advantages of good compatibility and low system building cost without special demand on a hardware condition.

Owner:CHONGQING JIAOTONG UNIVERSITY

Existing building exterior wall reconstruction structure and construction method

The invention discloses an existing building exterior wall reconstruction structure and a construction method. The existing building exterior wall reconstruction structure comprises a newly-built wallbody, vertical reinforcing steel bars, horizontal reinforcing steel bars and tie bars, wherein the newly-built wall body is tightly attached to the outer side face of an existing building wall body,and is built with porous bricks; pores of upper-layer porous bricks and lower-layer porous bricks of the newly-built wall body are vertically formed correspondingly; one group of horizontal reinforcing steel bars is arranged at intervals along the outer side face of the existing building wall body; the vertical reinforcing steel bars are inserted into the pores of the porous bricks in the full length; one group of horizontal reinforcing steel bars is arranged at intervals along a vertical direction; the horizontal reinforcing steel bars are arranged in mortar joints of two adjacent layers of porous bricks; the two ends of the horizontal reinforcing steel bars are fixedly connected with the vertical reinforcing steel bars on a corresponding side; the tie bars are horizontally arranged between the existing building wall body and the newly-built wall body. The existing building exterior wall reconstruction structure and the construction method provided by the invention have the advantagesthat the technical problems of difficulty in reconstructing and upgrading the existing wall body and recovering the original appearance, incapability of making the building reach designed service life and resource waste are solved.

Owner:BUCG THE EIGHTH CONSTR DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com