Method for pre-mixing high-ductility cement-based composite material

A composite material, high ductility technology, applied in the direction of climate change adaptation, etc., can solve problems such as uneven dispersion, achieve the effect of ensuring dispersion, solving agglomeration, and ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

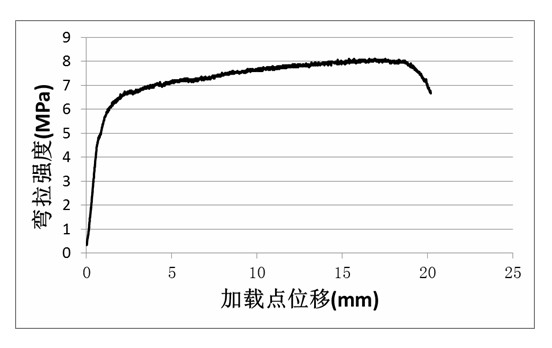

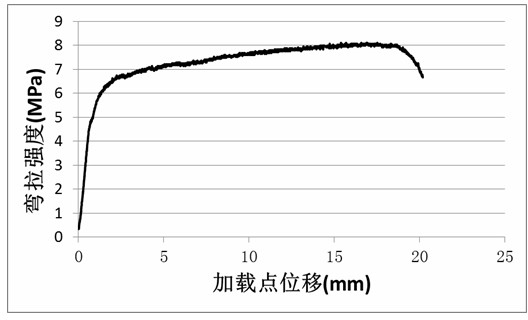

Examples

specific example

[0025] Step 1: In the large mixing station / building / machine, first add cement, fly ash, quartz sand and powdered superplasticizer, and mix it at low speed for 10-15 minutes, then add fiber and in high speed. Stir for 10 to 15 minutes to make the components mix evenly to make a high ductility fiber-reinforced cement-based composite material ECC dry material mixture;

[0026] Step 2: Use a concrete mixer truck to transport the pre-mixed and uniform ECC dry material mixture to the construction site, or transport the packaged ready-mix ECC dry material mixture to the construction site by truck, and load it into the small mixer on site. Finally add an appropriate amount of water and stir evenly,

[0027] Step 3: Add water to the mixing truck at the construction site, and then mix the mixing bucket of the truck with a rotation speed of 18 r / min; or pour the ECC cement material that is basically evenly mixed after adding water into the construction site In the mixer, a second intensive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com