Patents

Literature

558 results about "Fibre cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibre cement is a composite building and construction material, used mainly in roofing and facade products because of its strength and durability. One common use is in fiber cement siding on buildings.

Composite building material

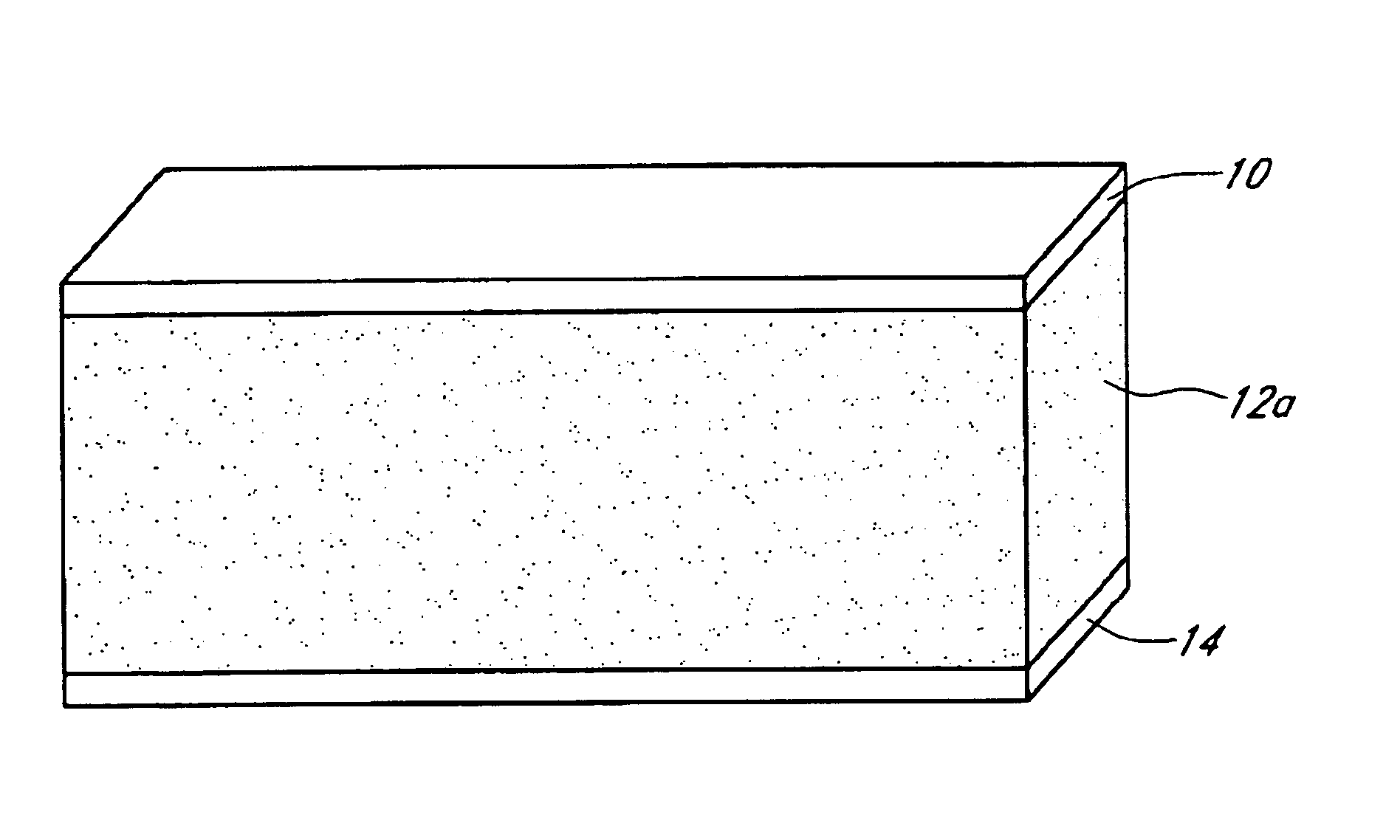

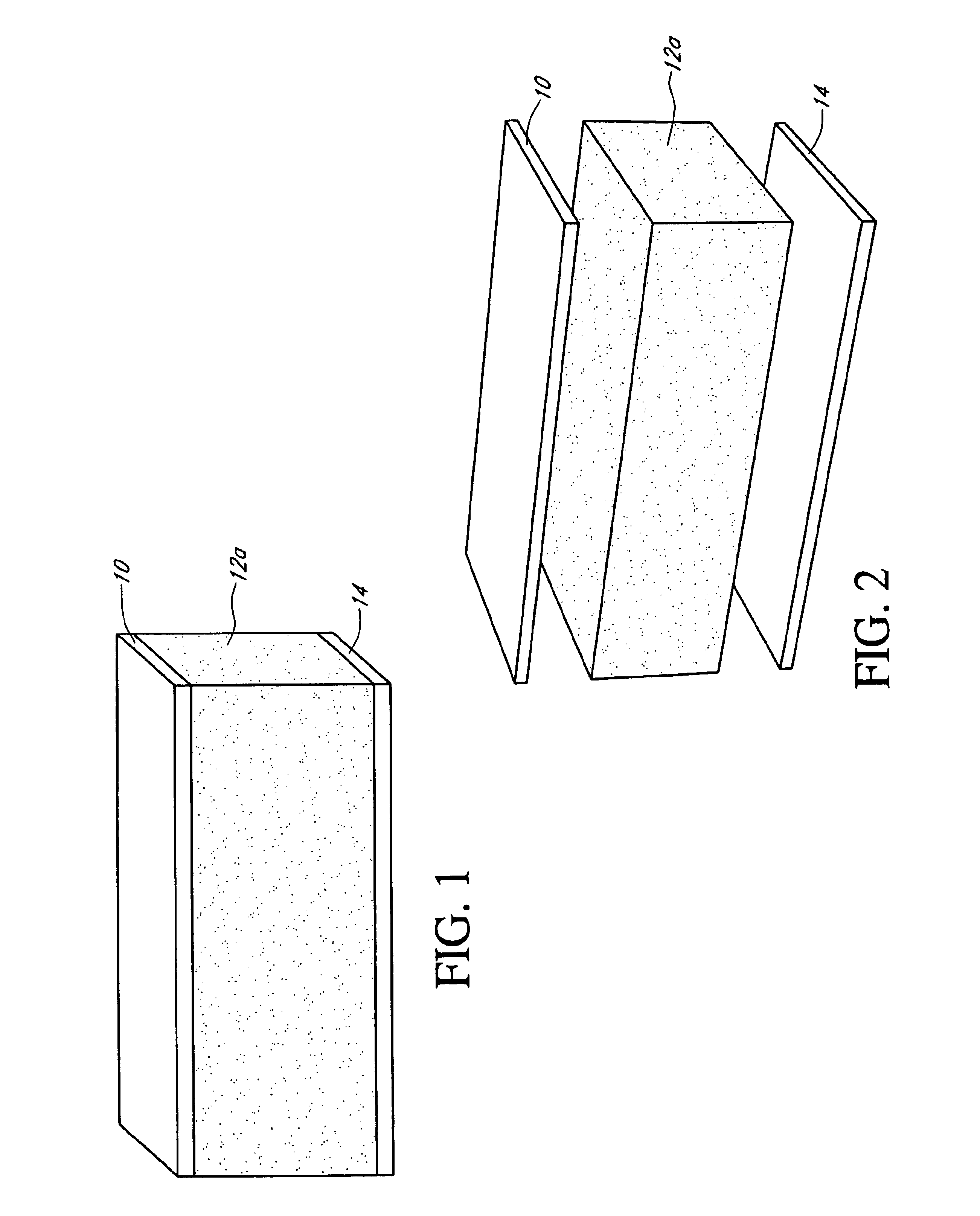

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

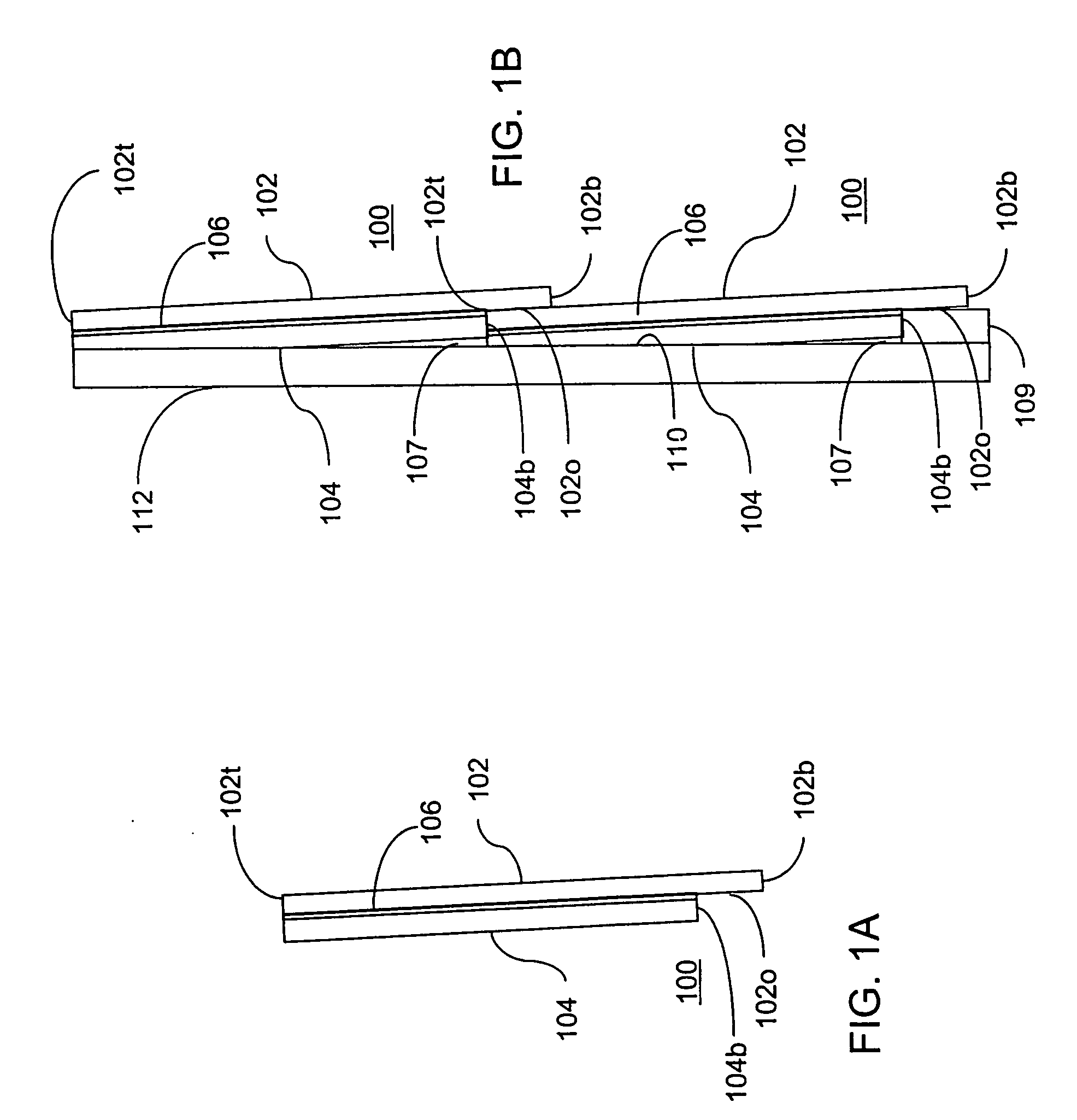

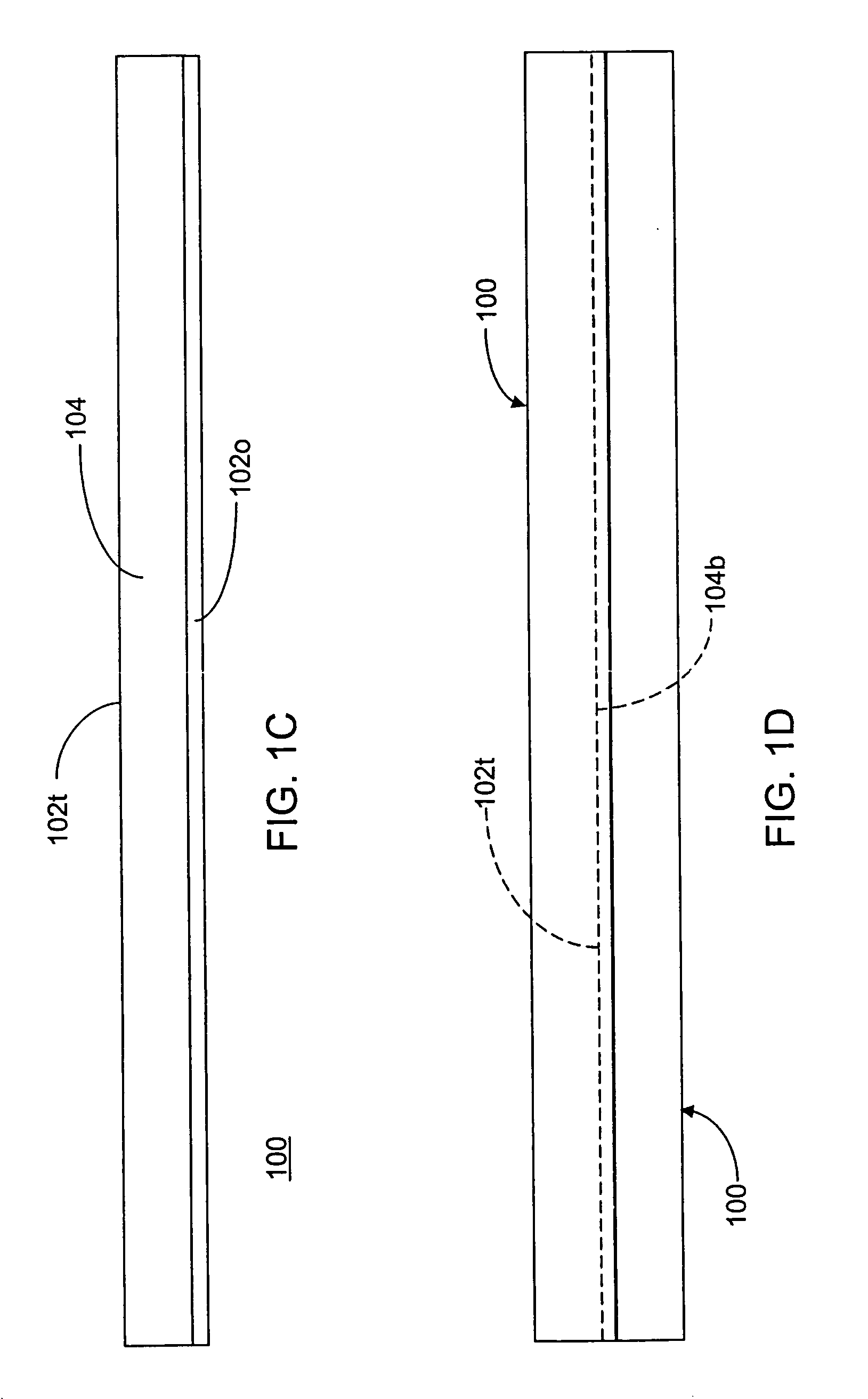

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

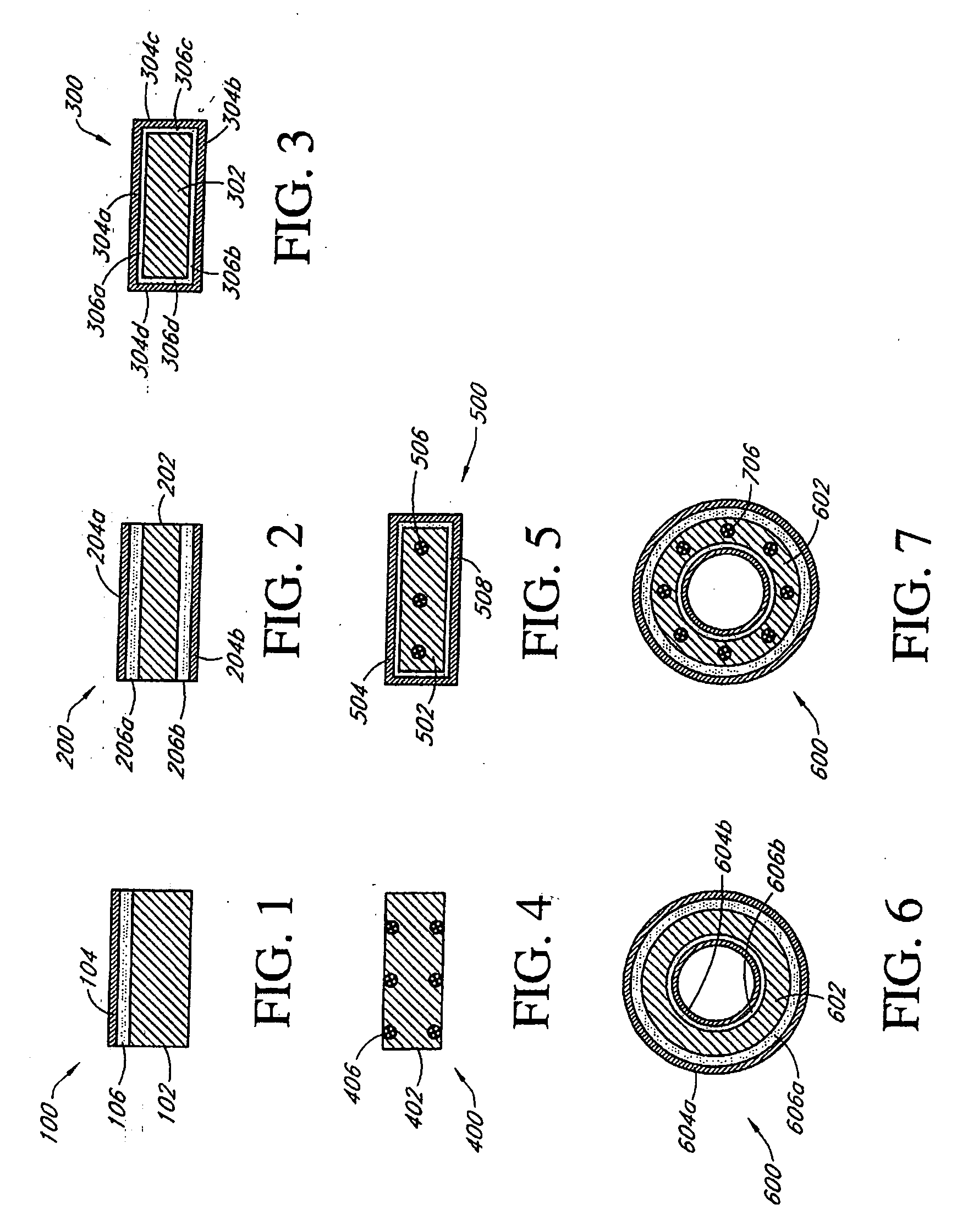

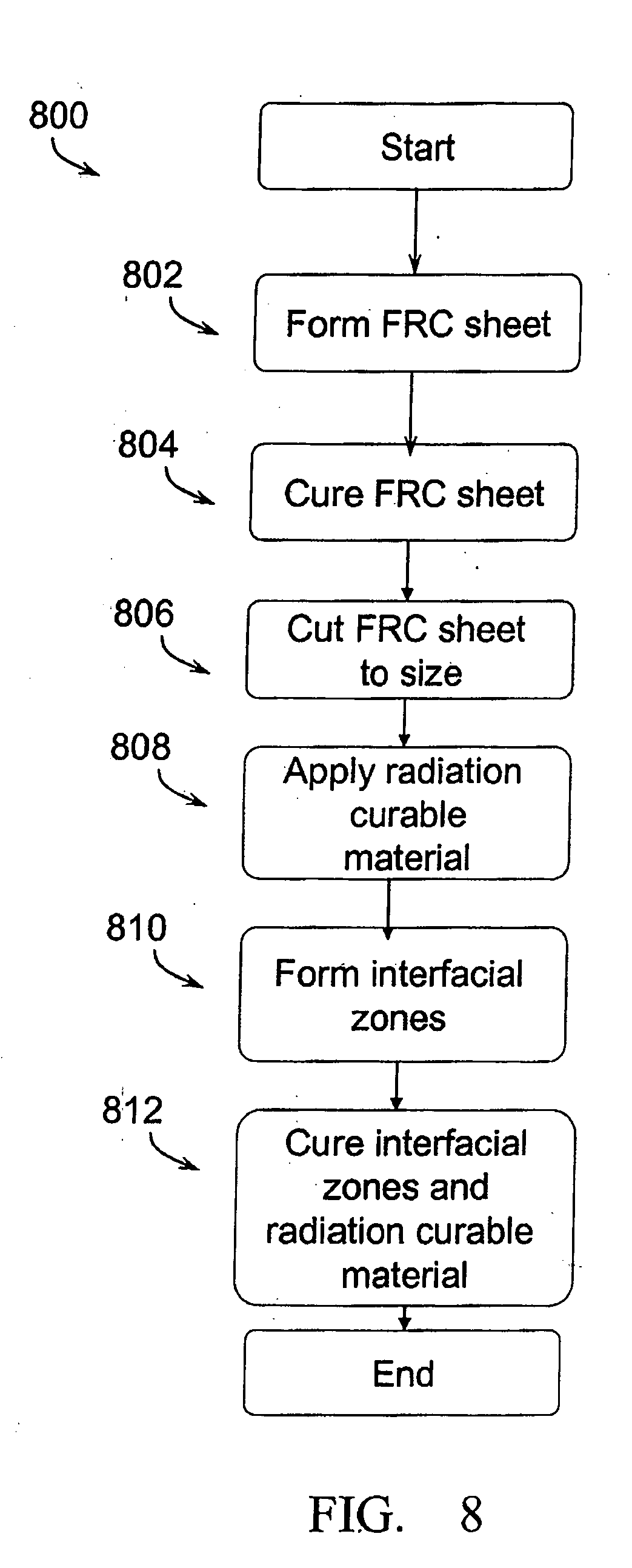

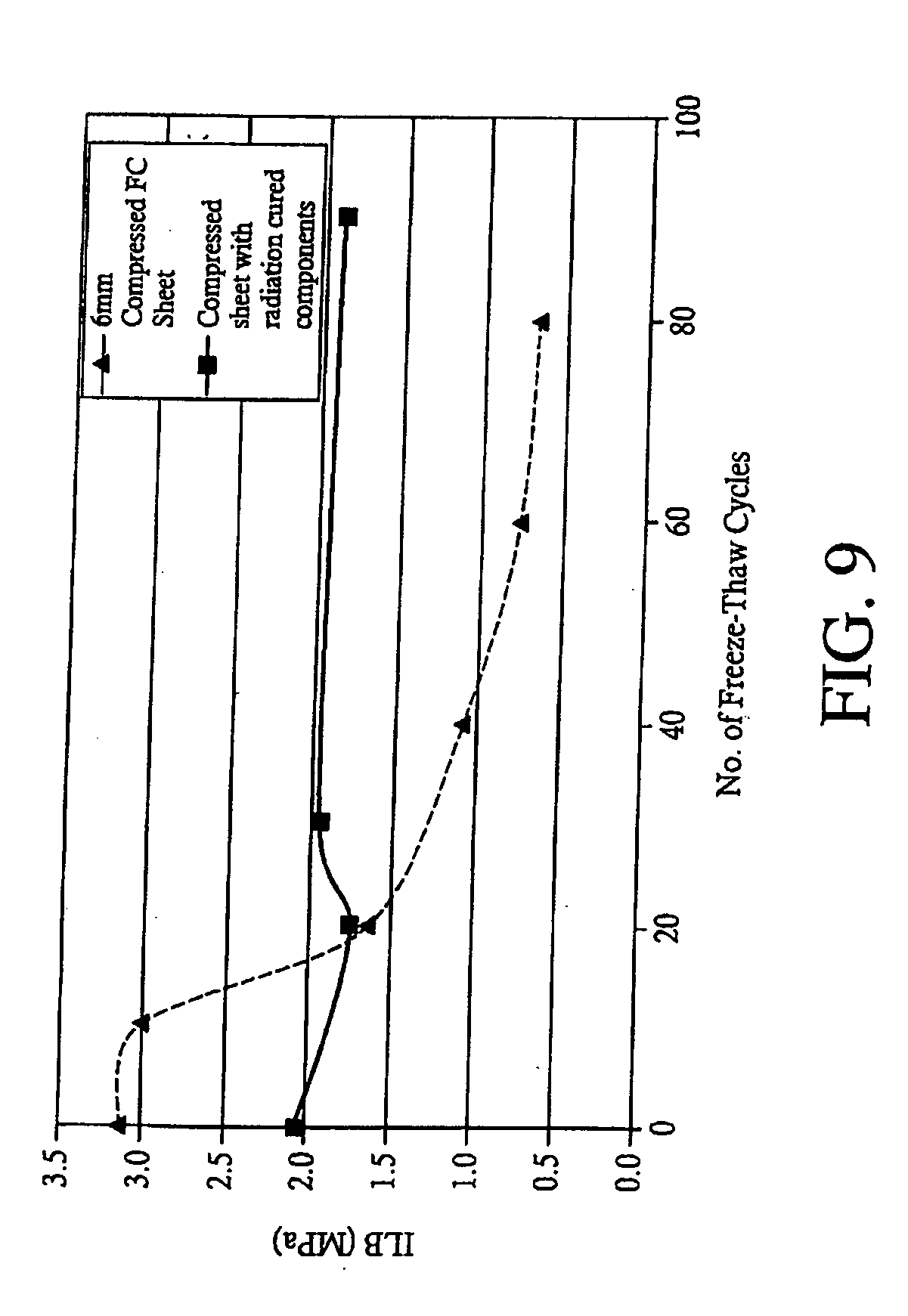

Composite fiber cement article with radiation curable component

ActiveUS20050208285A1Increased durabilityImprove adhesionConstruction materialSolid waste managementFibre cementRadiation

A composite building article is configured with one or more subsurface interfacial zones provided to improve the durability of the article. Each subsurface interfacial zone is made of a matrix of fiber cement and radiation curable material. The radiation curable material forms an interlocking network with the fiber cement to provide a interfacial zone against ingress of environmental agents that can degrade the article. The number, configuration and distribution of the subsurface interfacial zones can vary dependent on the desired characteristics of the final product. The subsurface interfacial zones also improves the adhesion between exterior coatings and the substrate as the interfacial zones can be integrally formed with the substrate as well as exterior coating layer.

Owner:JAMES HARDIE TECH LTD

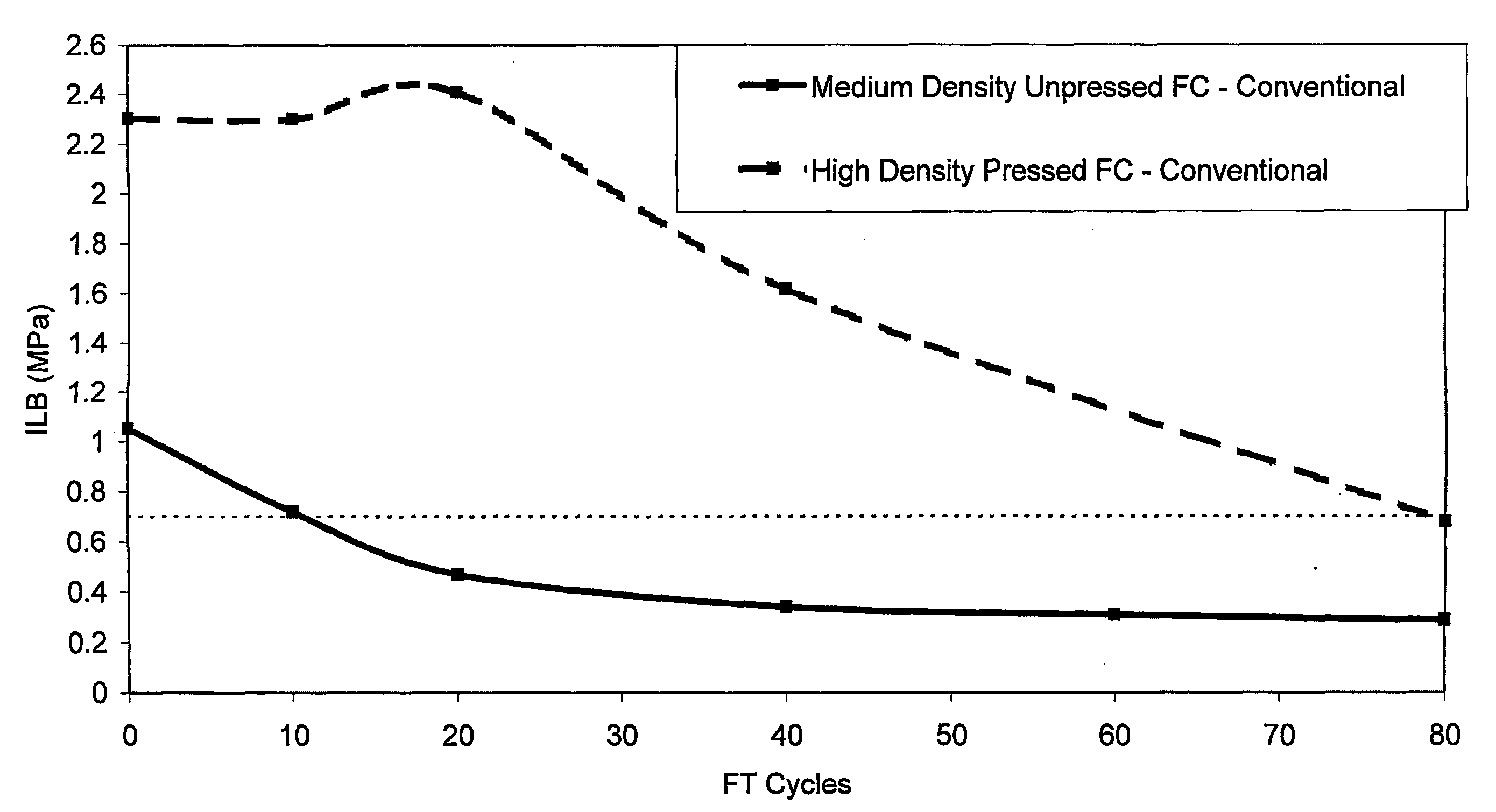

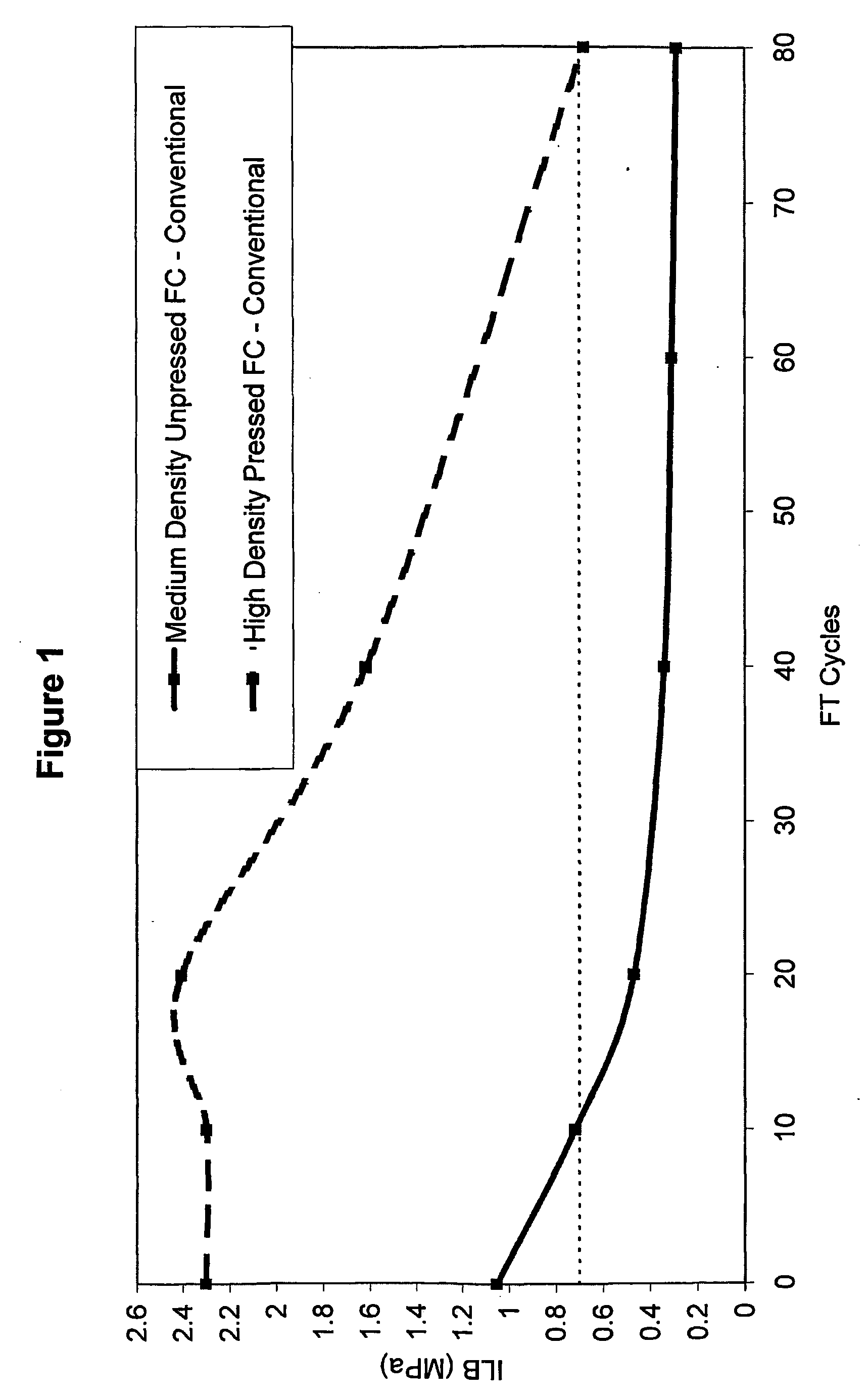

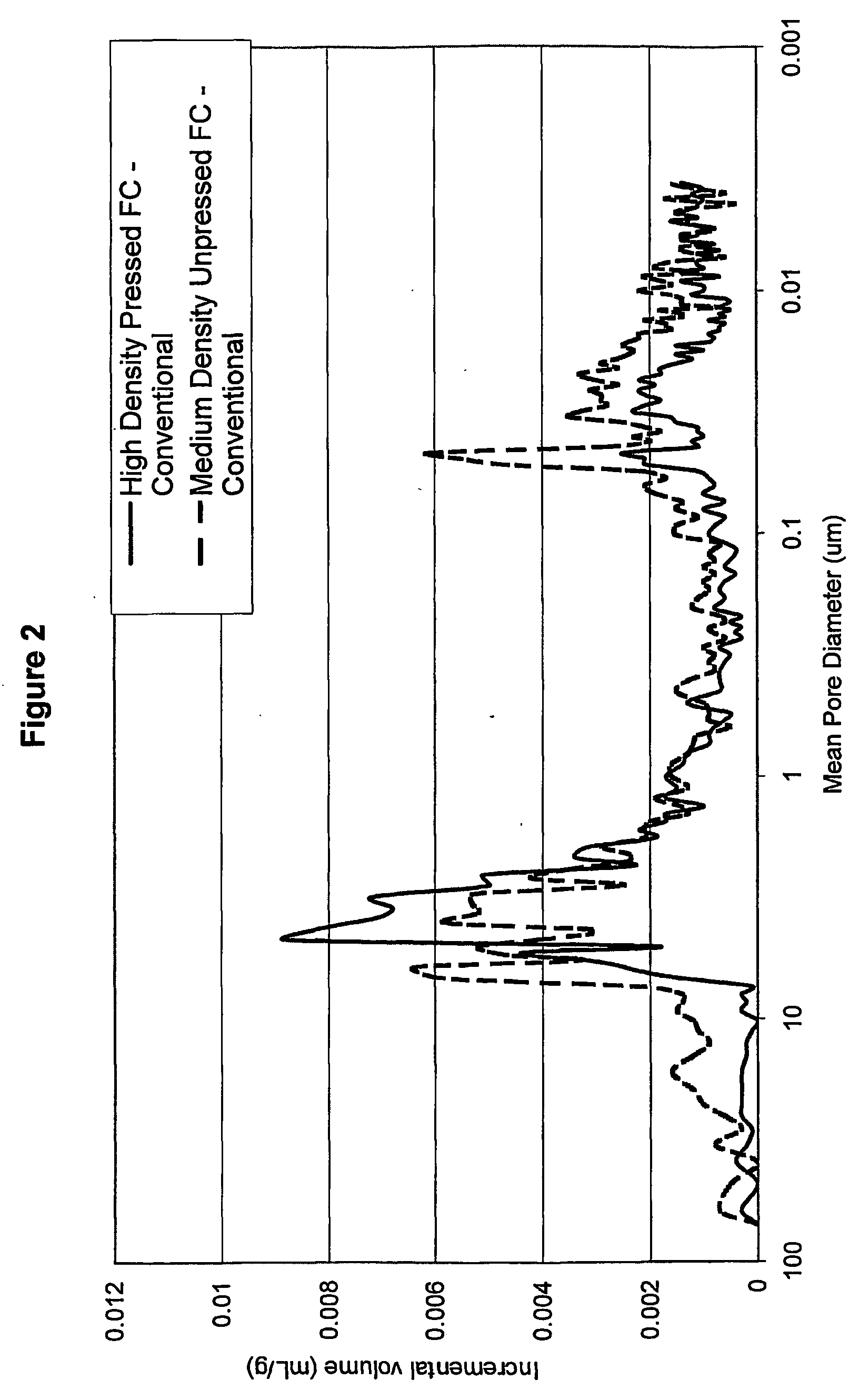

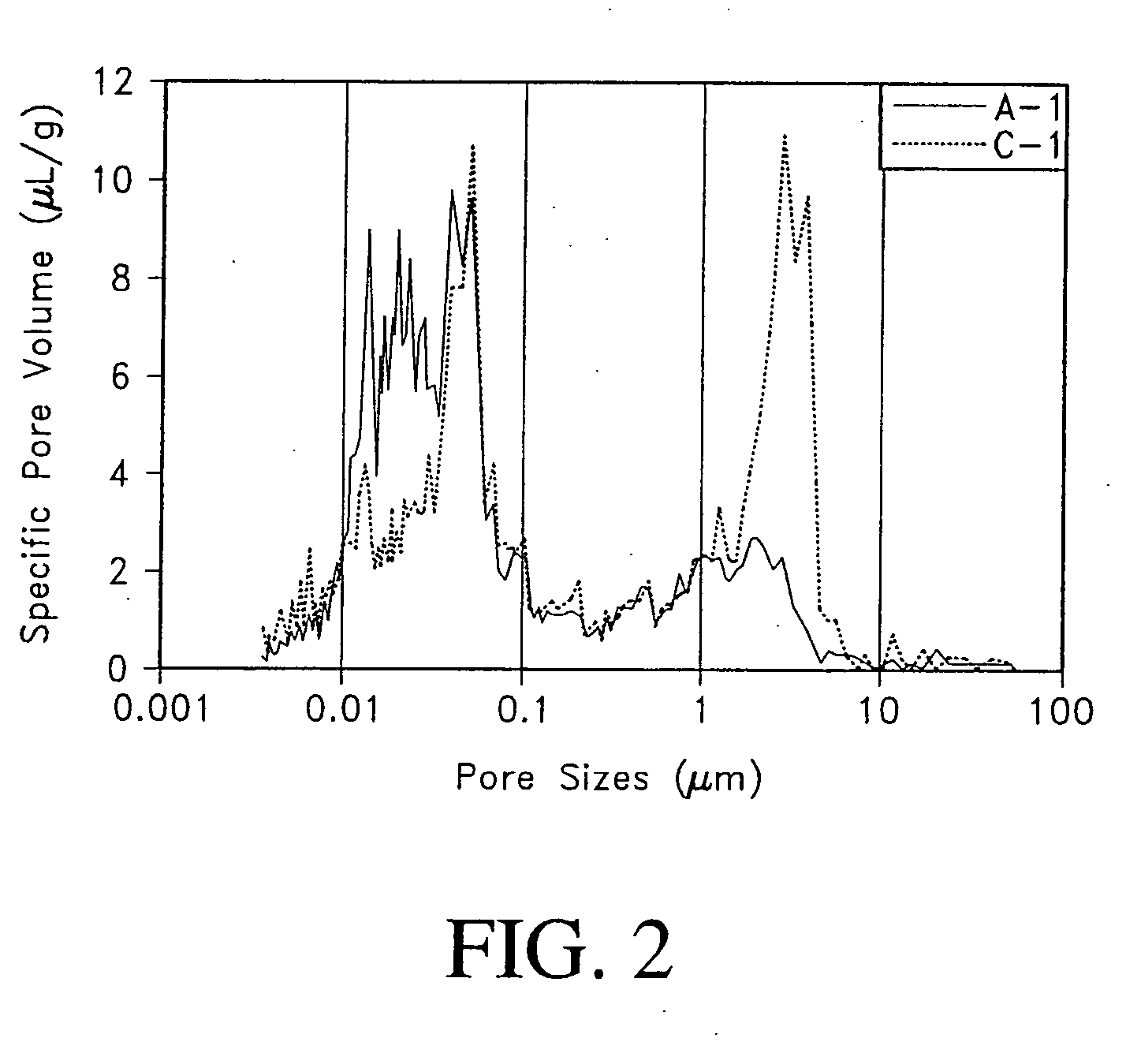

Durable medium-density fibre cement composite

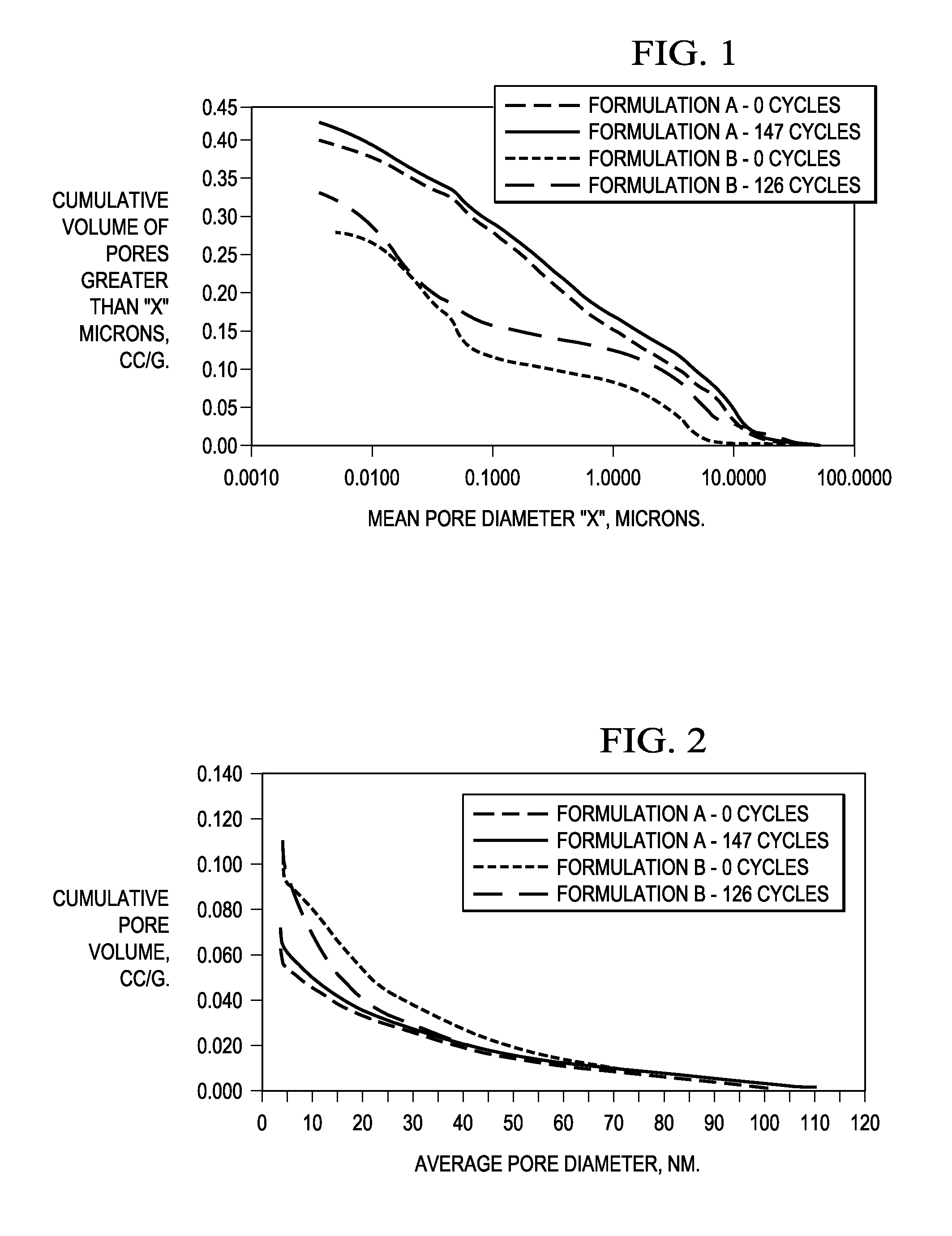

ActiveUS20060288909A1Simple materialIncreased durabilitySolid waste managementCeramic shaping apparatusHigh densityCement composites

A cementitious product and method of modifying the properties of a low or medium density FRC product by providing a predetermined pore size distribution. The pore size distribution is obtained such that in critical zones of the distribution, the pore volume is substantially equivalent to or less than the pore volume in a respective critical zone of a conventional high density FRC product. The resultant material provides improved properties over conventional medium density FRC products, in particular improved freeze / thaw durability and / or improved workability.

Owner:JAMES HARDIE TECH LTD

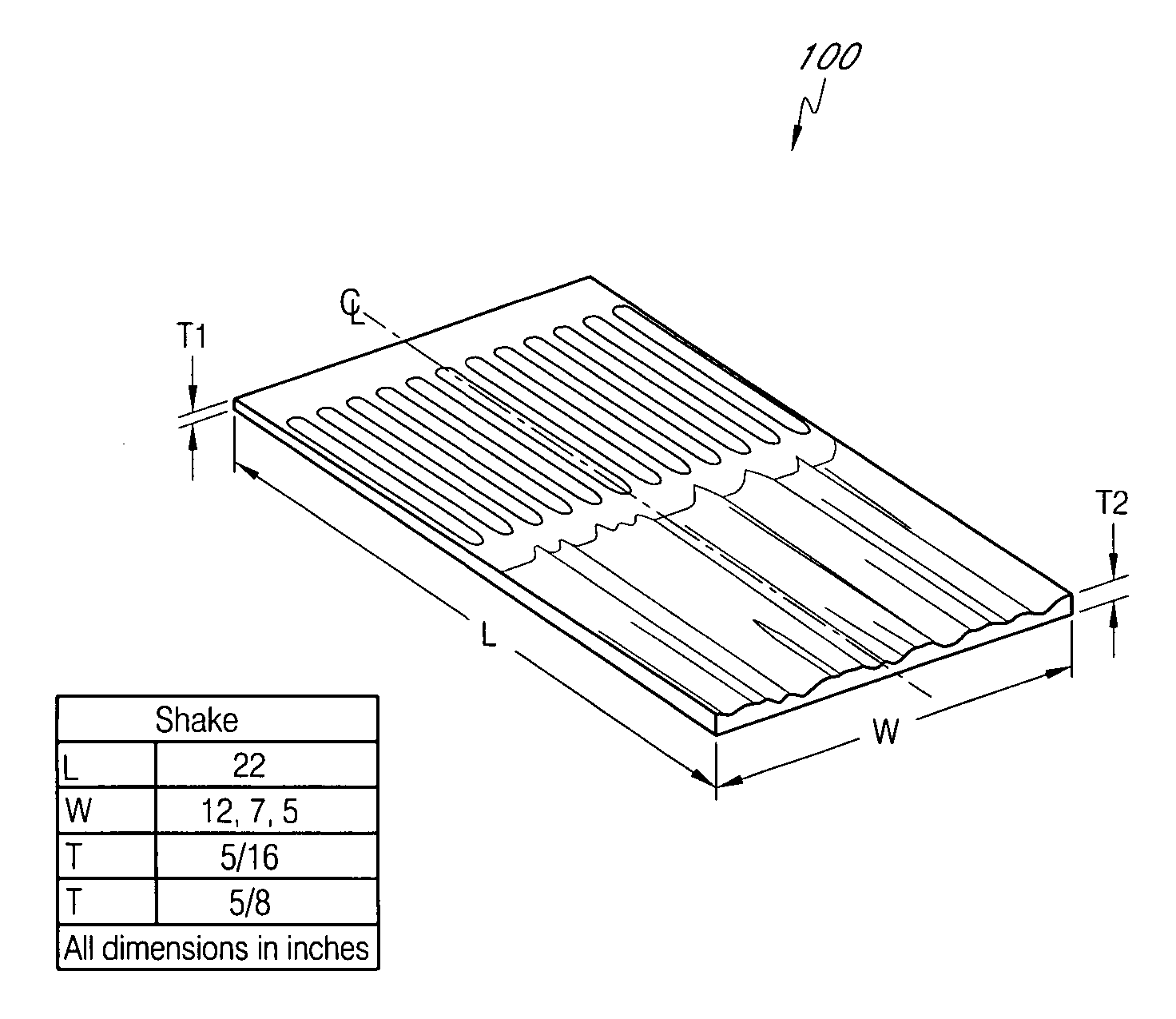

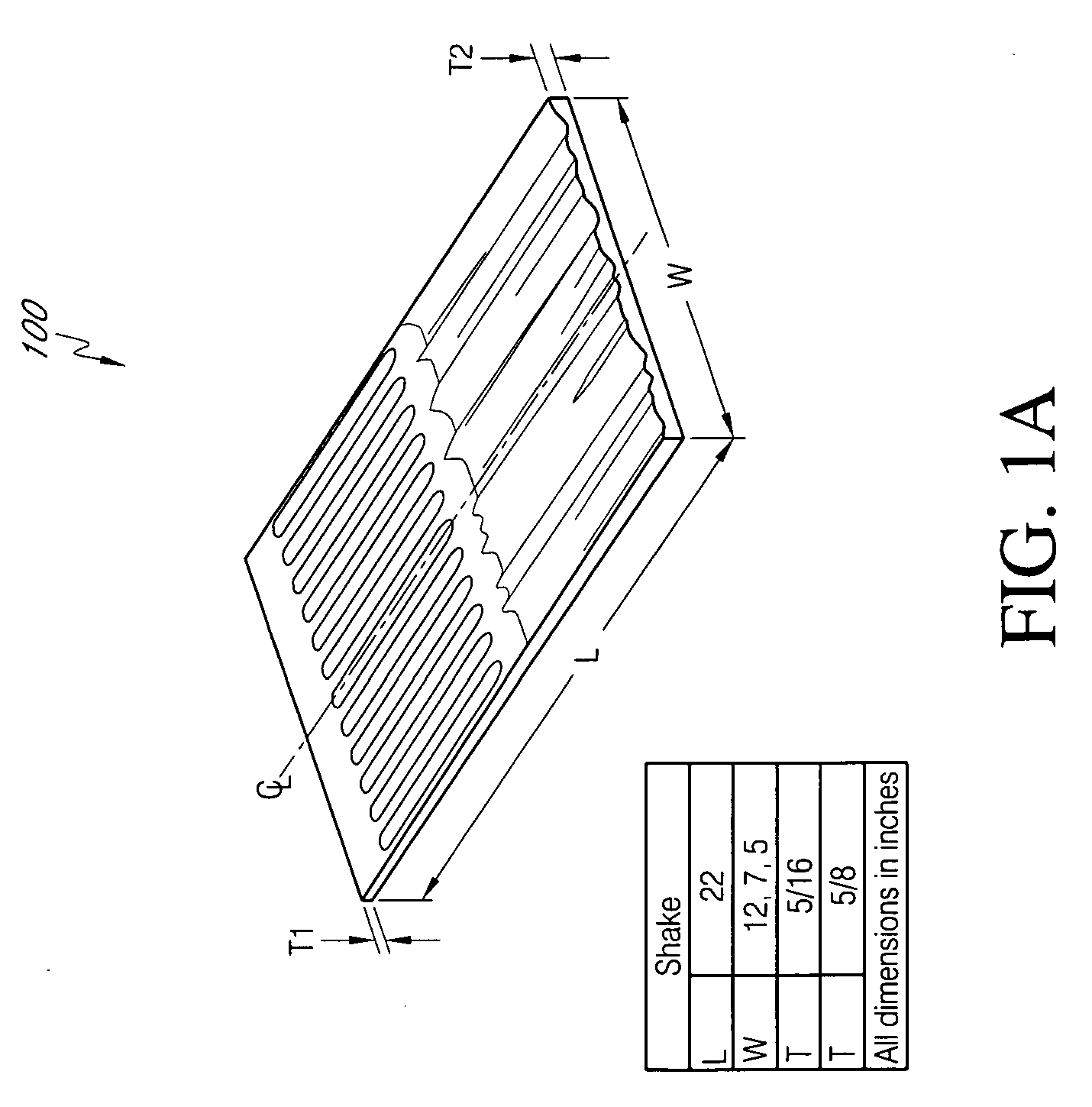

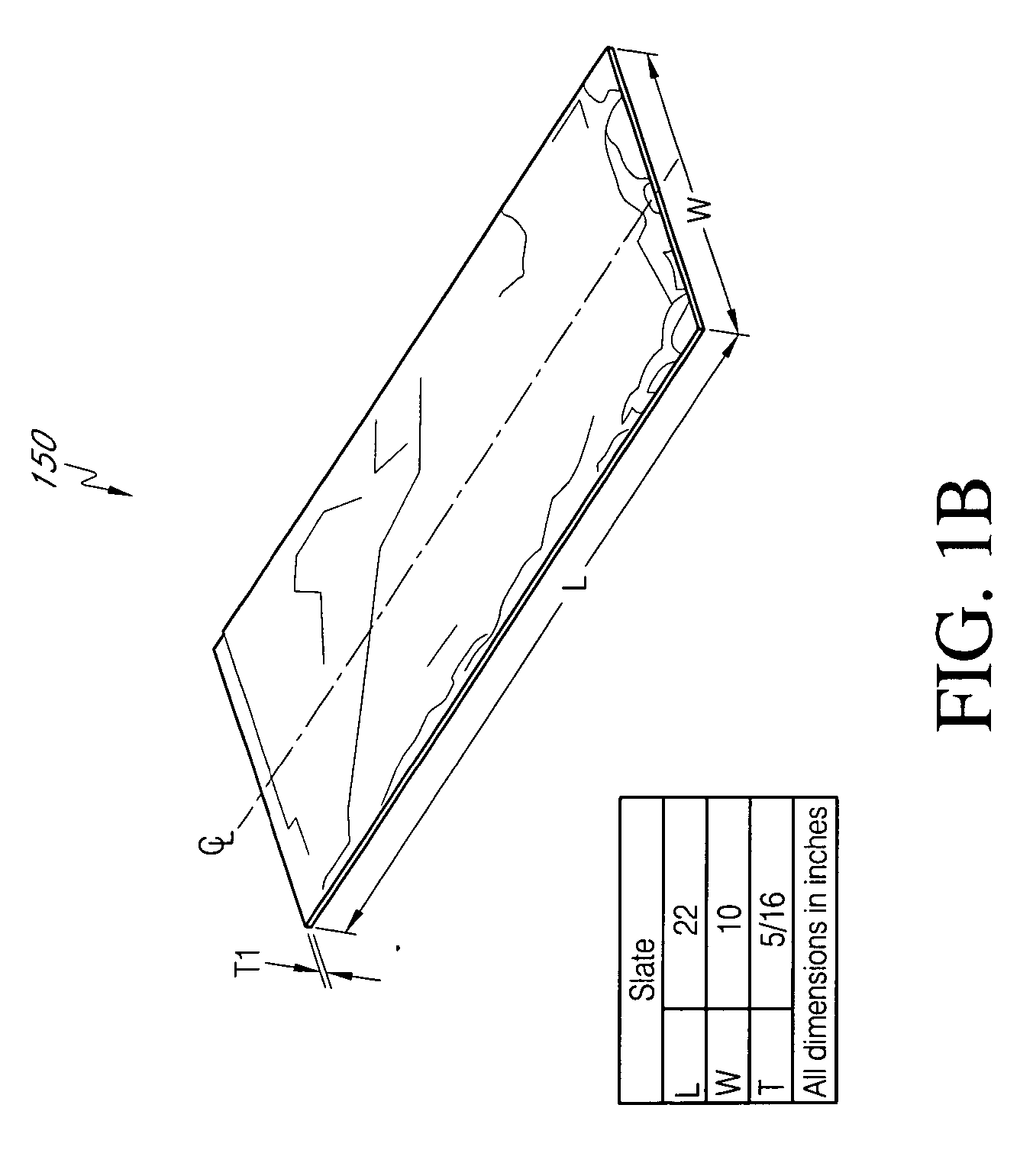

Durable building article and method of making same

InactiveUS20050284339A1Induced crackingRoof covering using tiles/slatesNatural patternsPolymer scienceViscosity

A durable, nailable, lightweight and fire resistant fiber cement article that can be a cost-effective substitute for conventional building materials is provided. The fiber cement article can be profiled to resemble a roofing article such as a wood shake or slate. The fiber cement article incorporates a hydrophobe and a viscosity enhancing agent that are each selected to control the rate of hydration of the binder. The fiber cement article is durable, is walkable and nailable without cracking during installation and maintains walkablilty after exposure in service.

Owner:JAMES HARDIE INT FINANCE BV

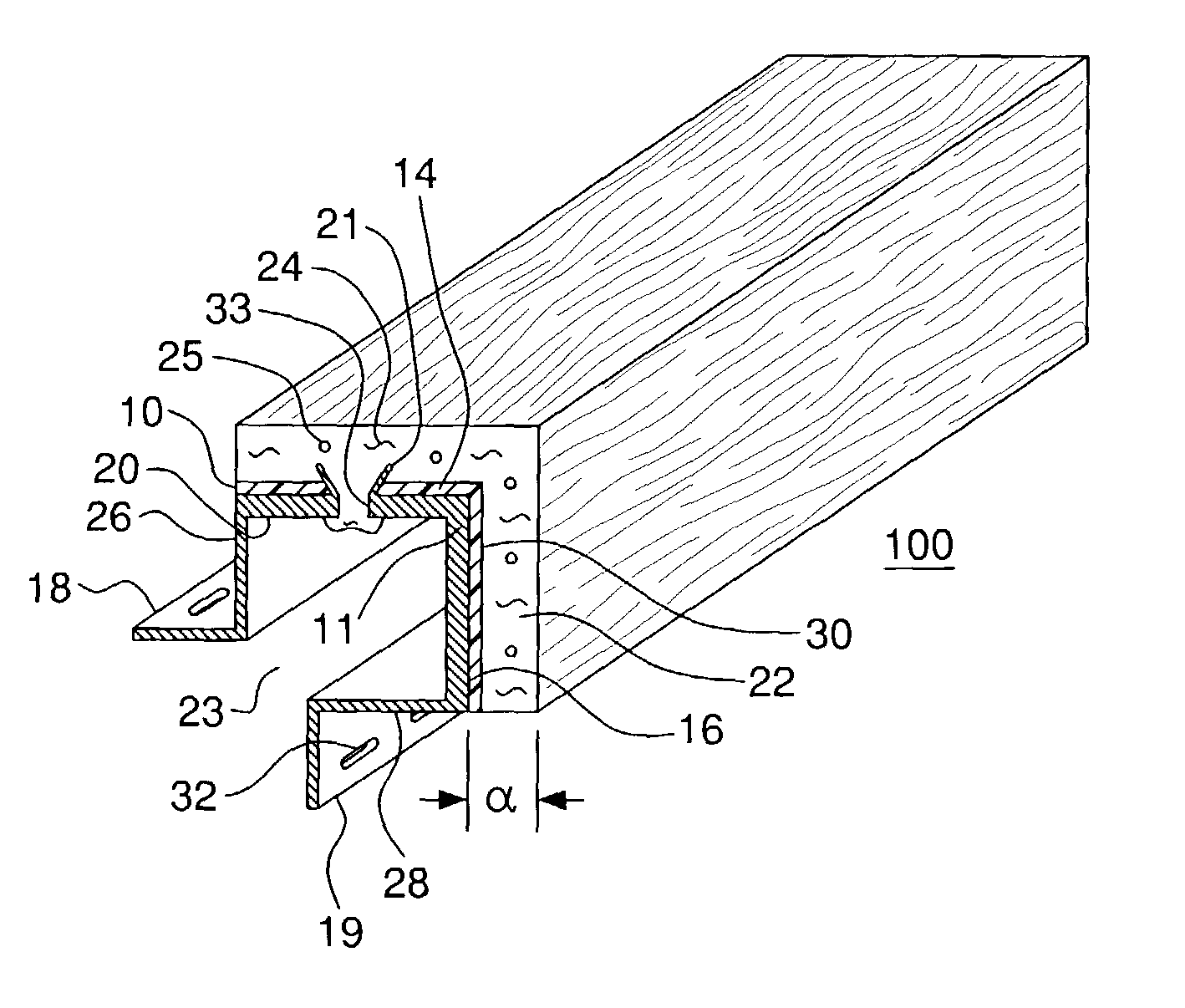

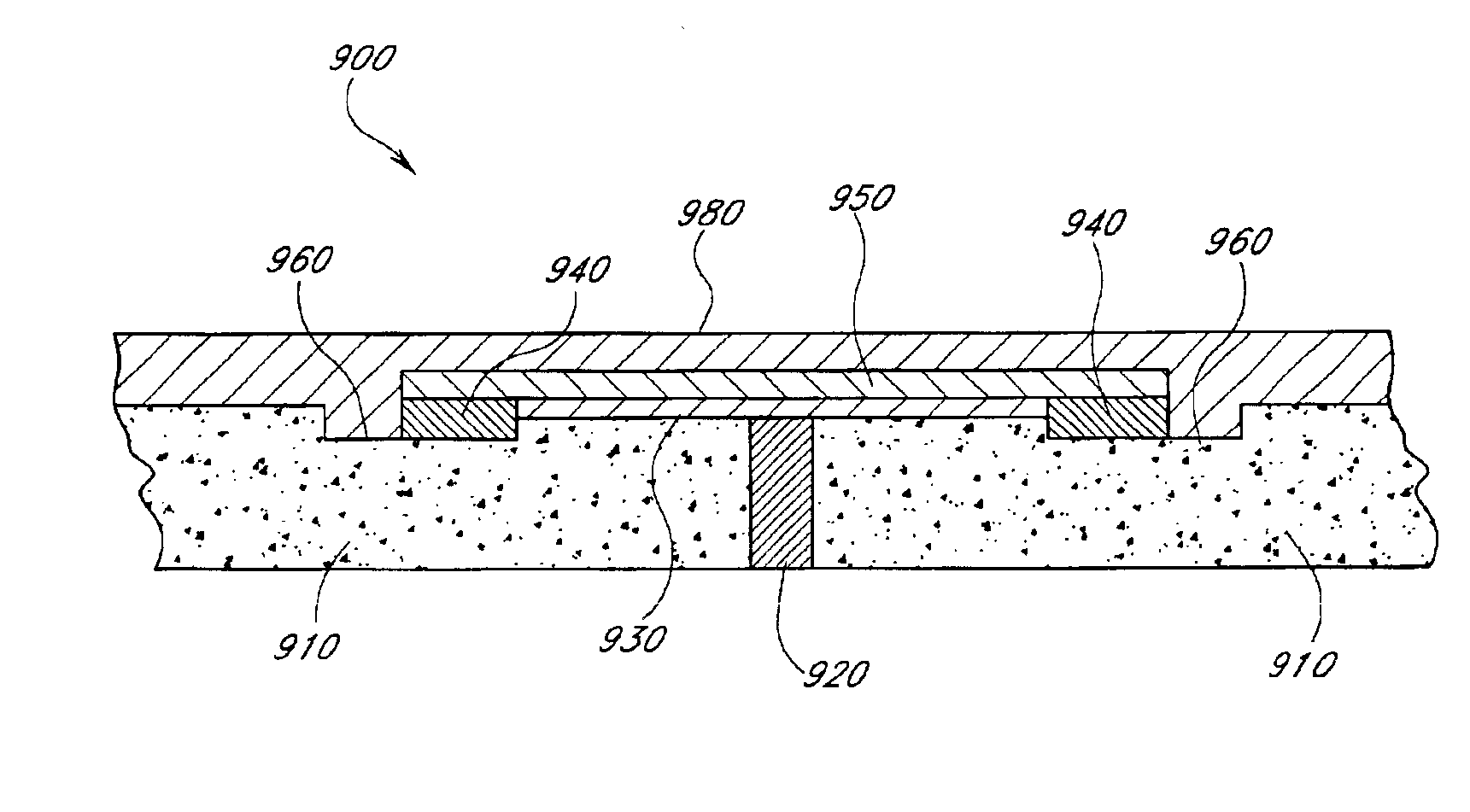

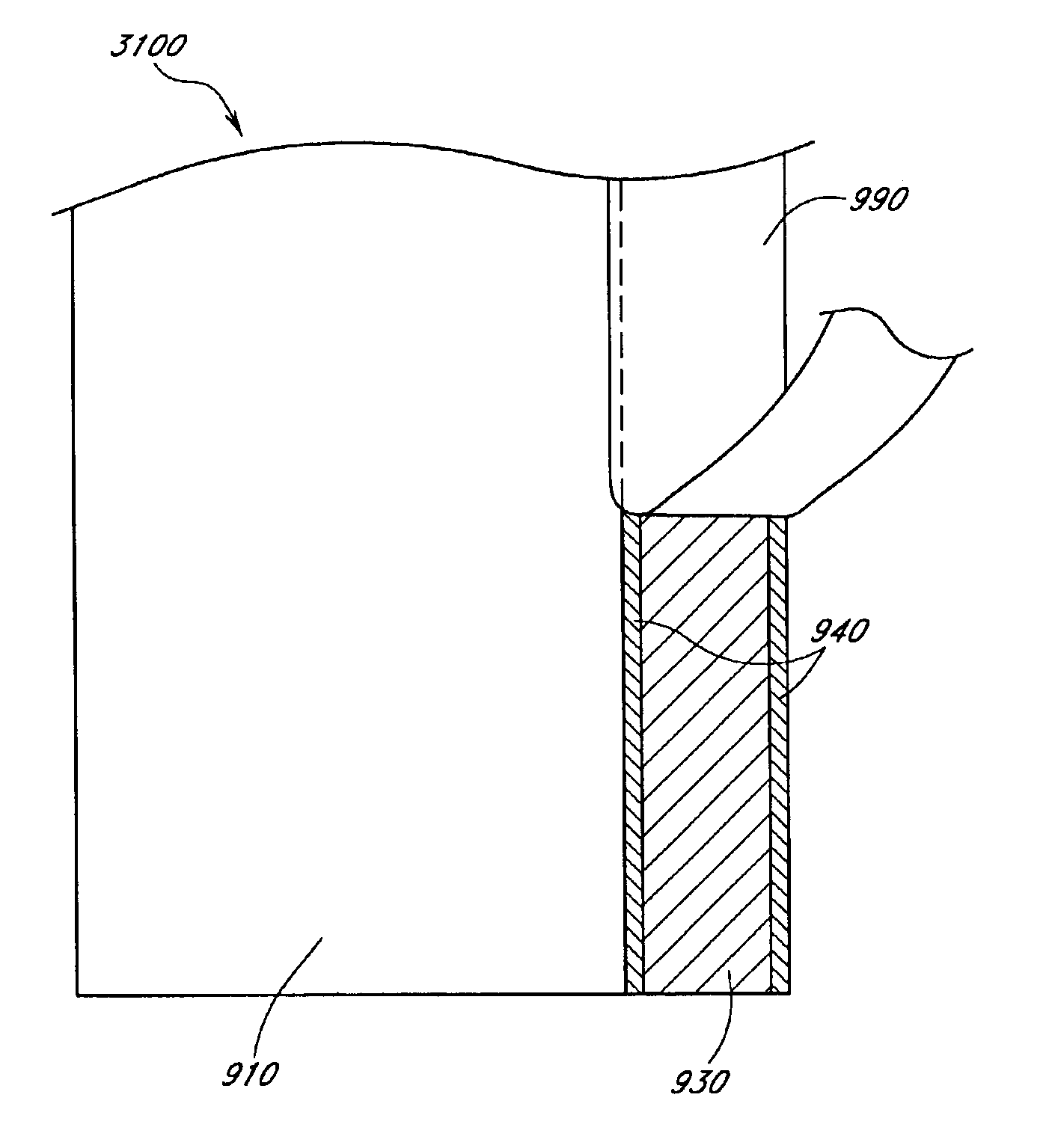

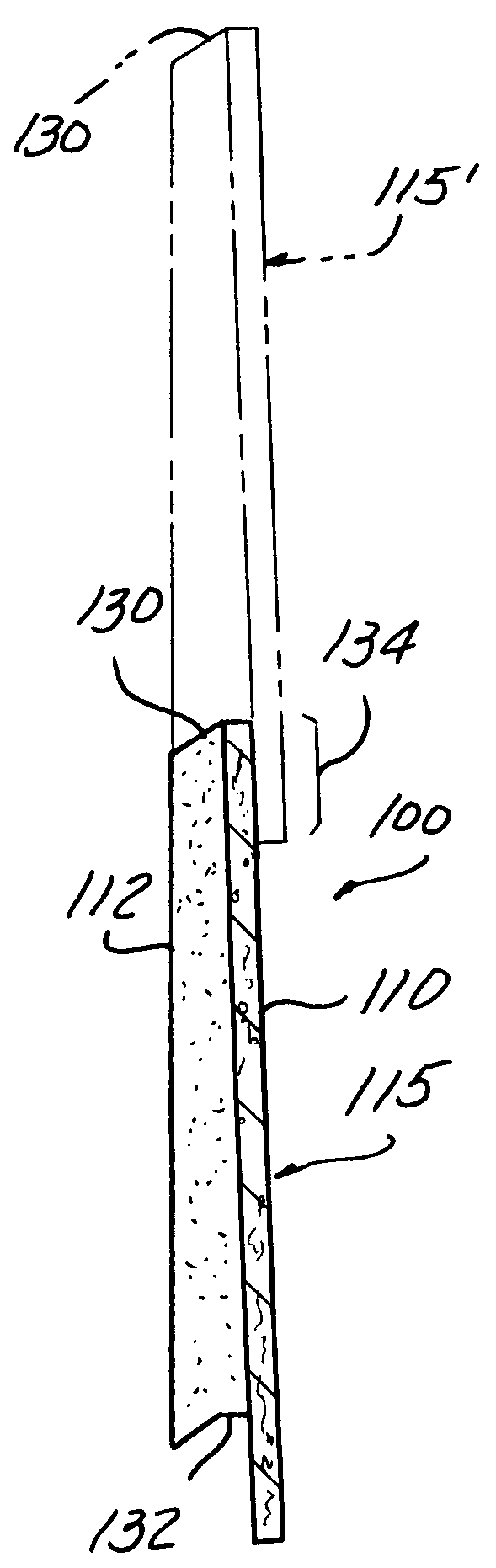

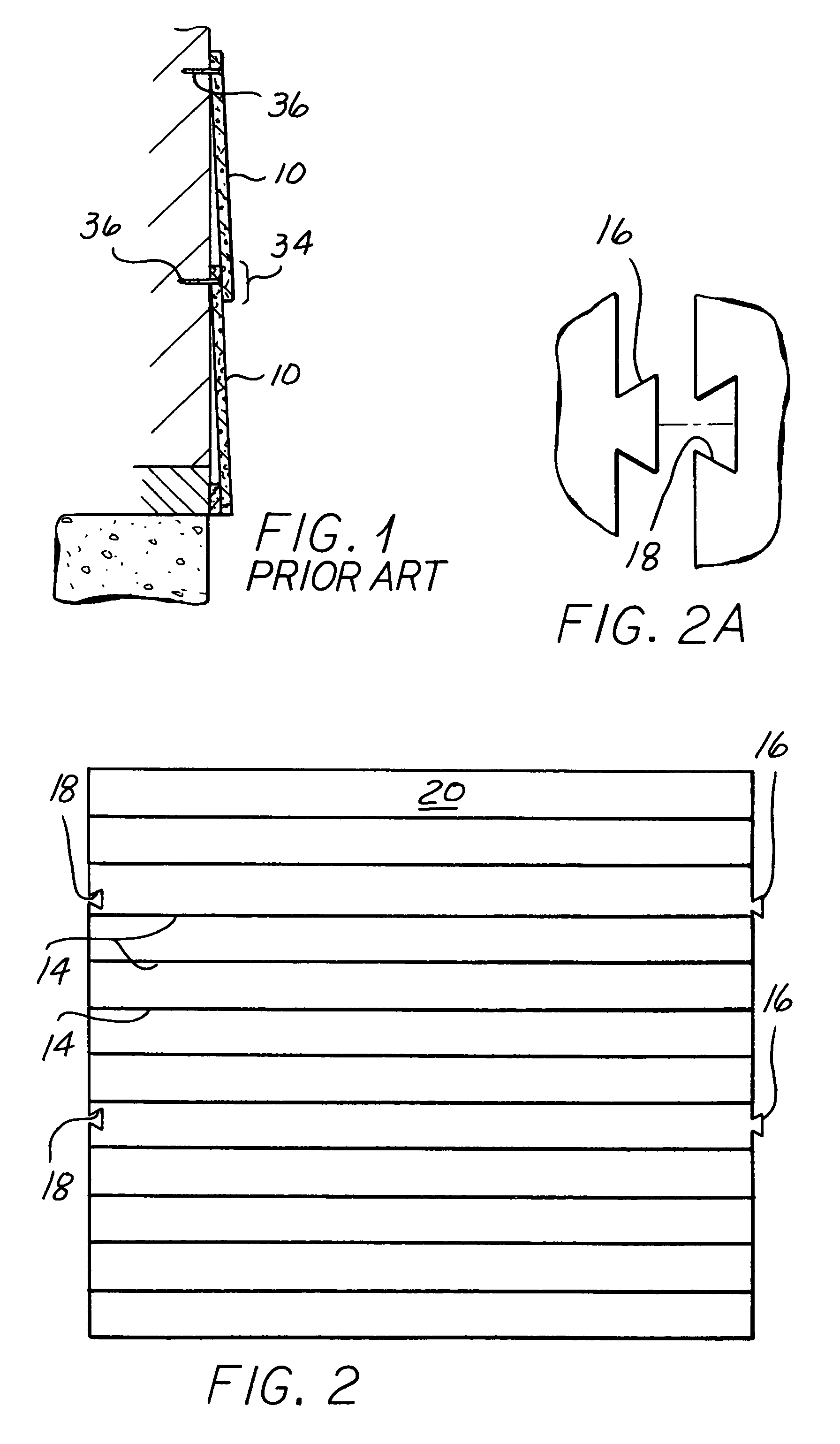

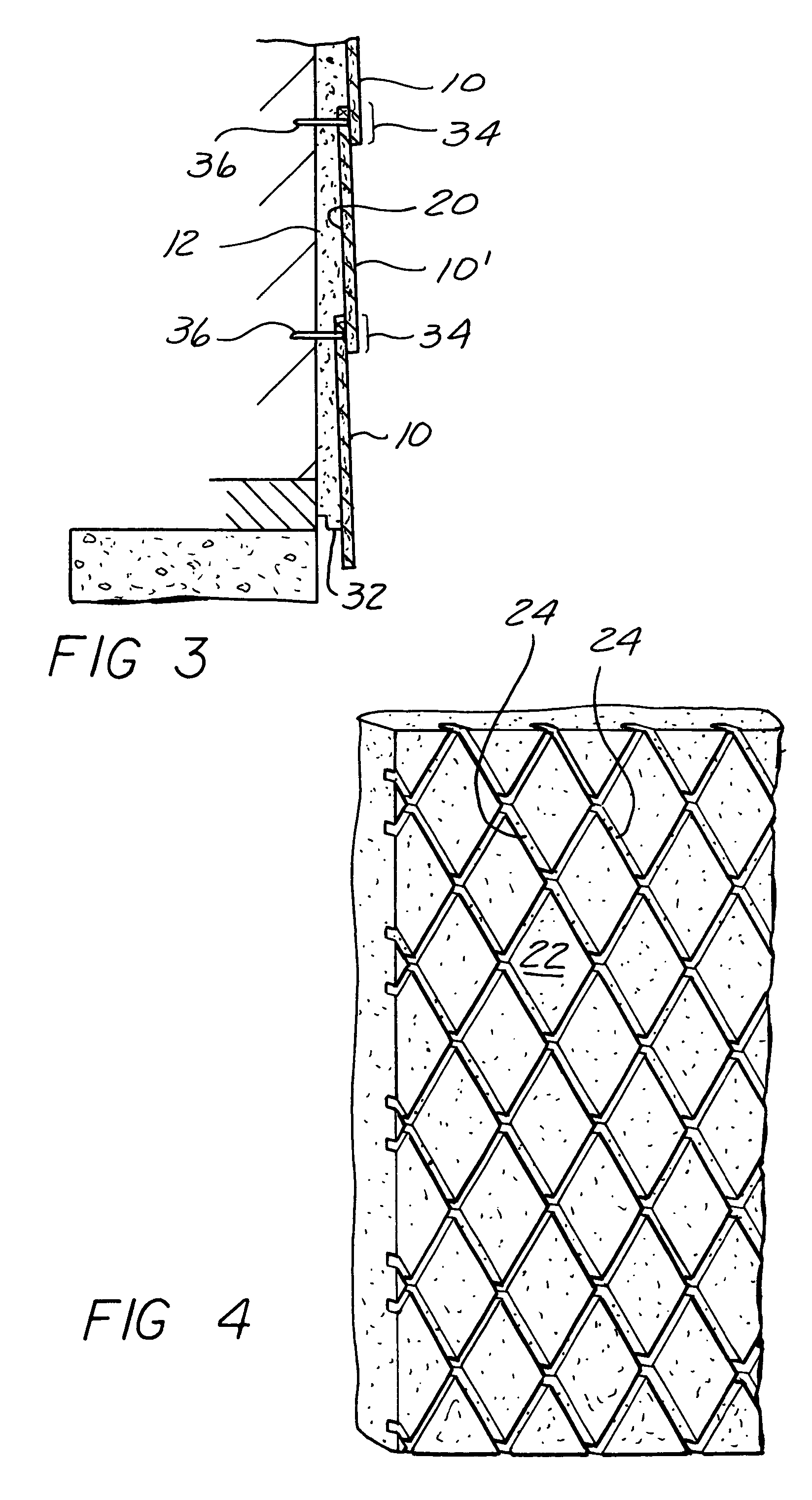

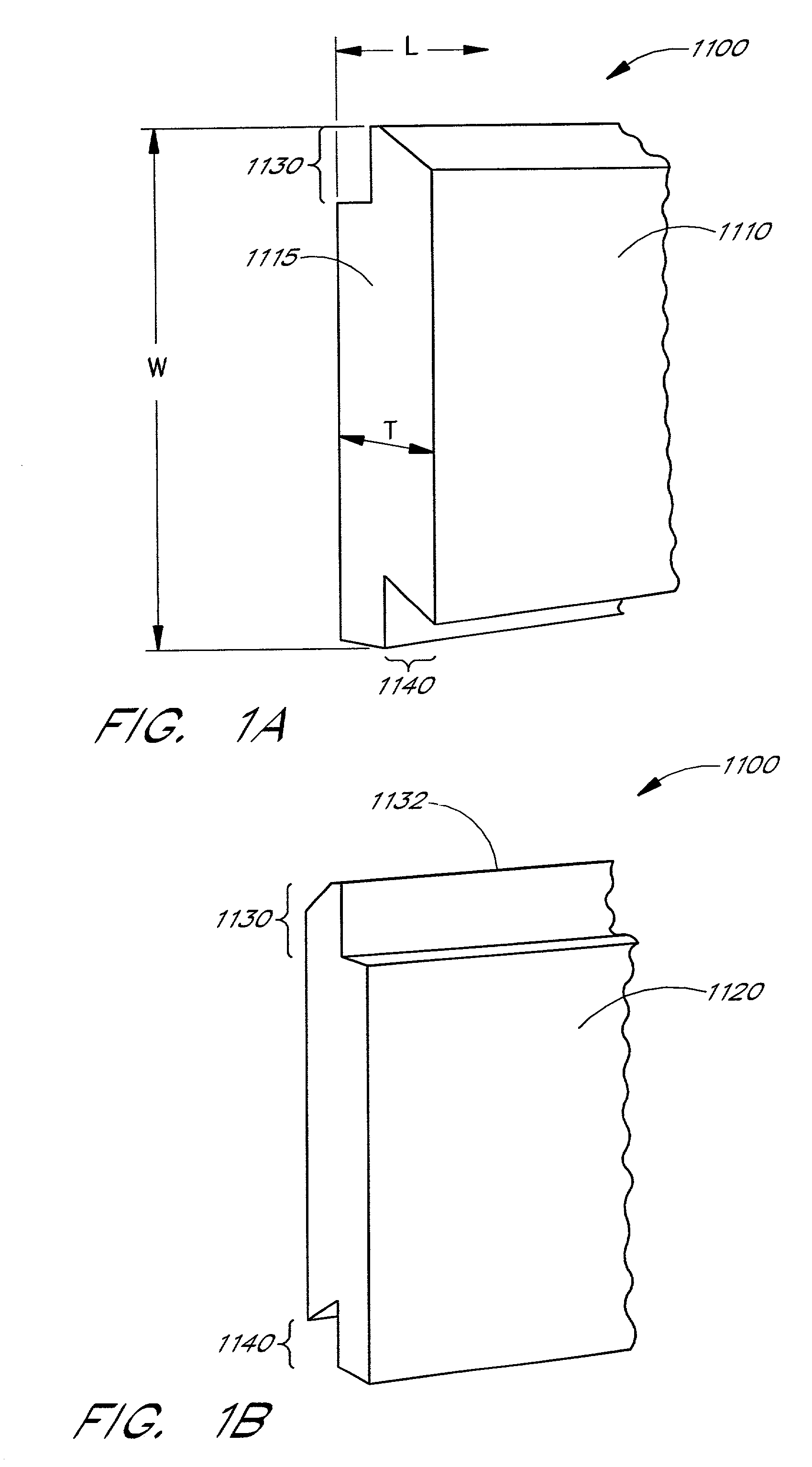

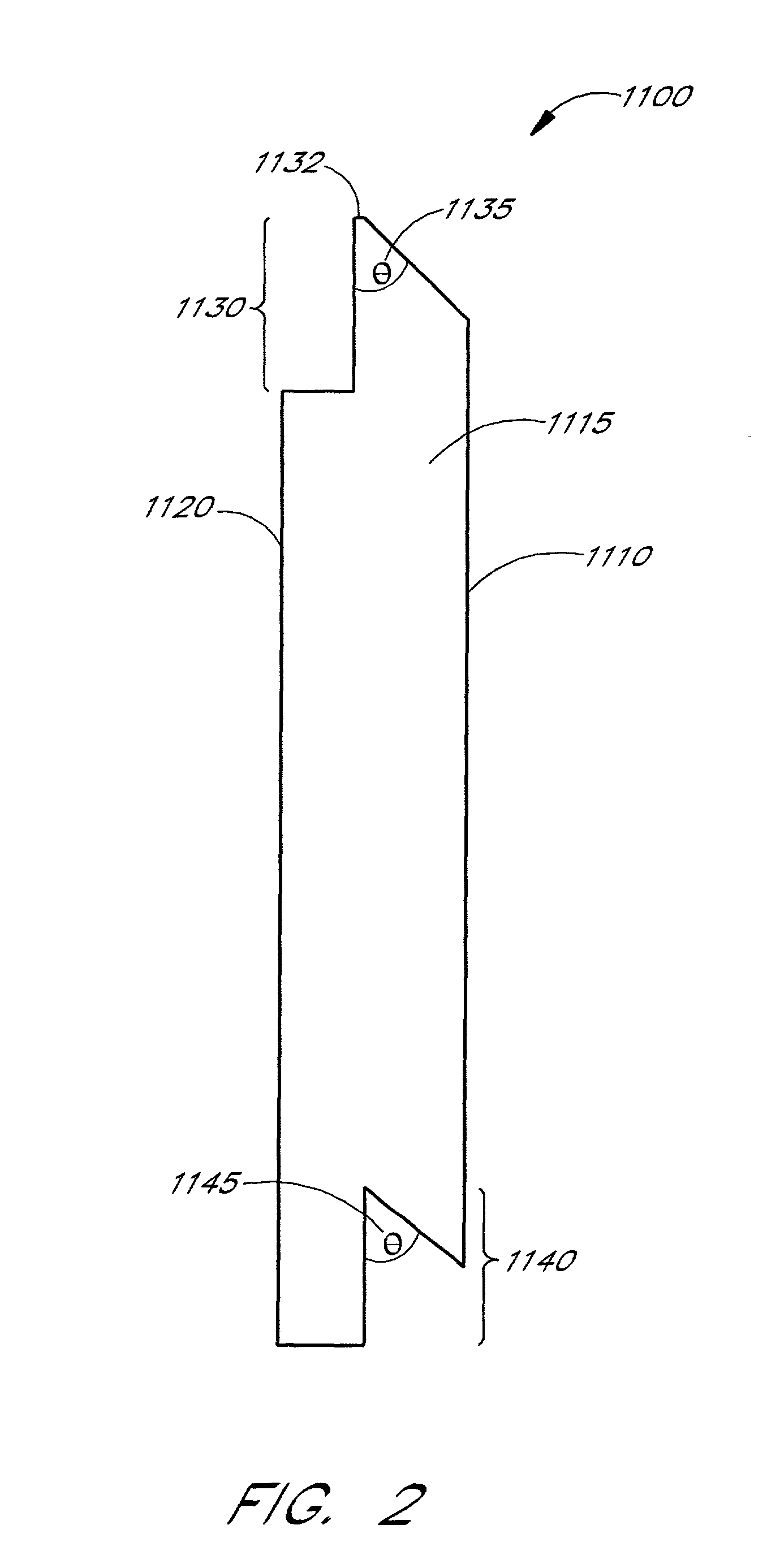

Cementitious exterior sheathing product with rigid support member

InactiveUS7028436B2Reduce thicknessEasy to carryConstruction materialRoof covering using tiles/slatesAdhesive bondingFlange

Cementitious exterior sheathing products are provided which include a rigid support member affixed to a cementitious layer. The rigid support member includes at least one nailing flange disposed along one of its lateral sides for allowing the sheathing product to be affixed to an exterior wall of a building. Preferred mechanical and adhesive bonding techniques are suggested for combining the cementitious layer and rigid support member together to form an integrated product. Such products are lighter in weight and are more crack resistant than currently available fiber cement trim boards.

Owner:PLYCEM USA

Foam backed fiber cement

A product comprises a fiber cement substrate, and a porous, closed cell foam joined to a substantial portion of a major surface of the fiber cement substrate.

Owner:PLYCEM USA

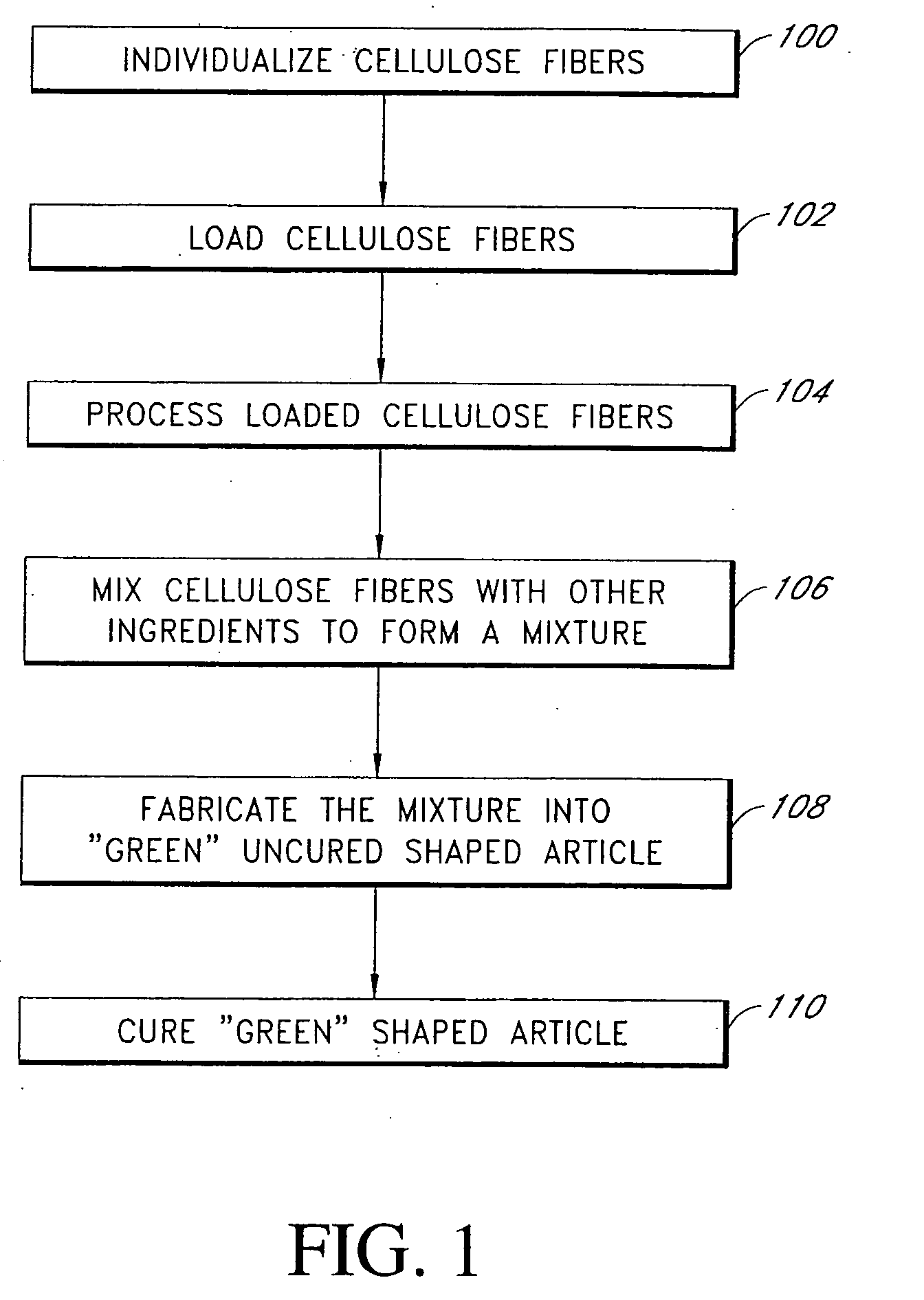

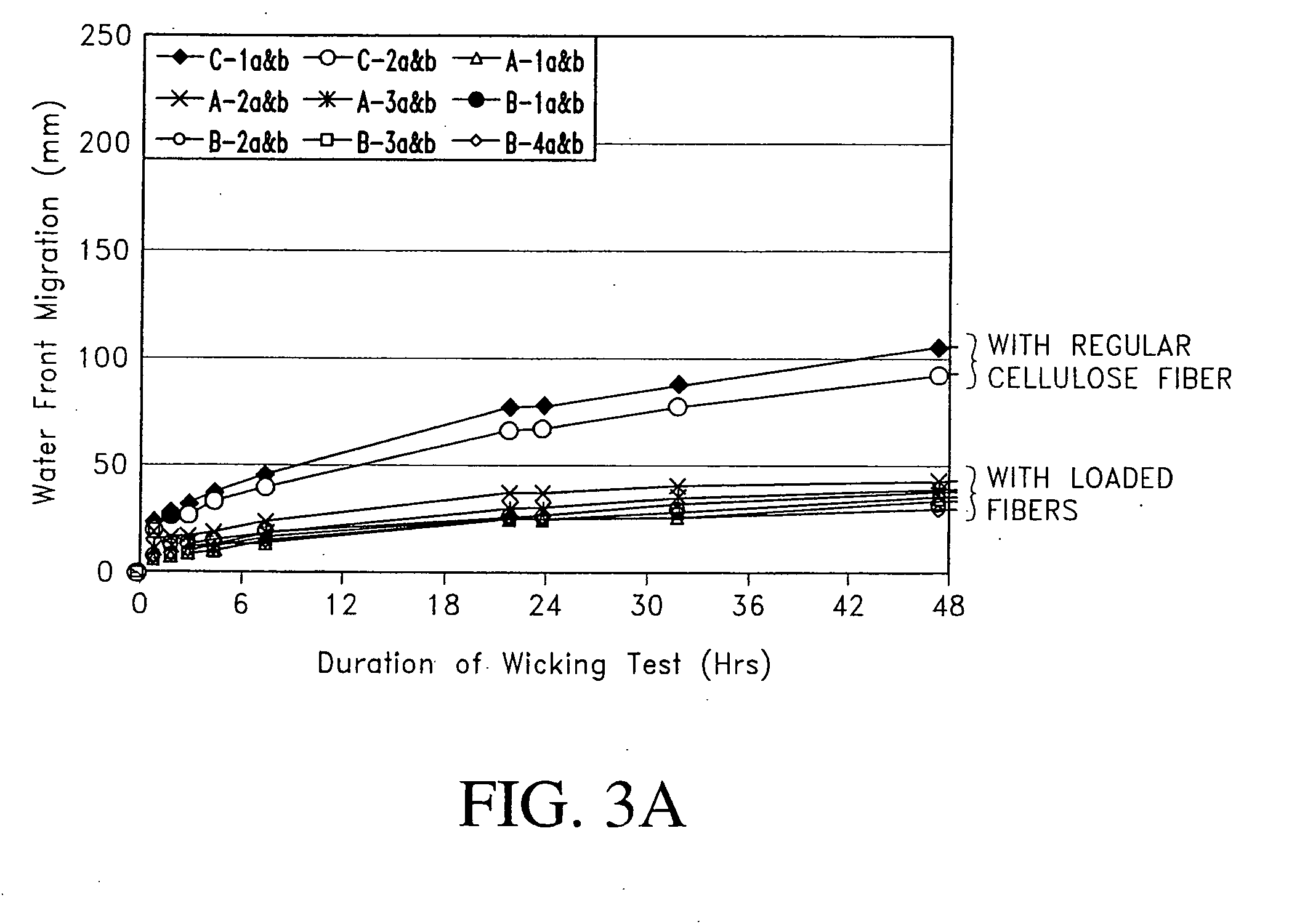

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

Panelized wall system utilizing trough-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with trough-edge building panels. The trough-edge building panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE TECH LTD

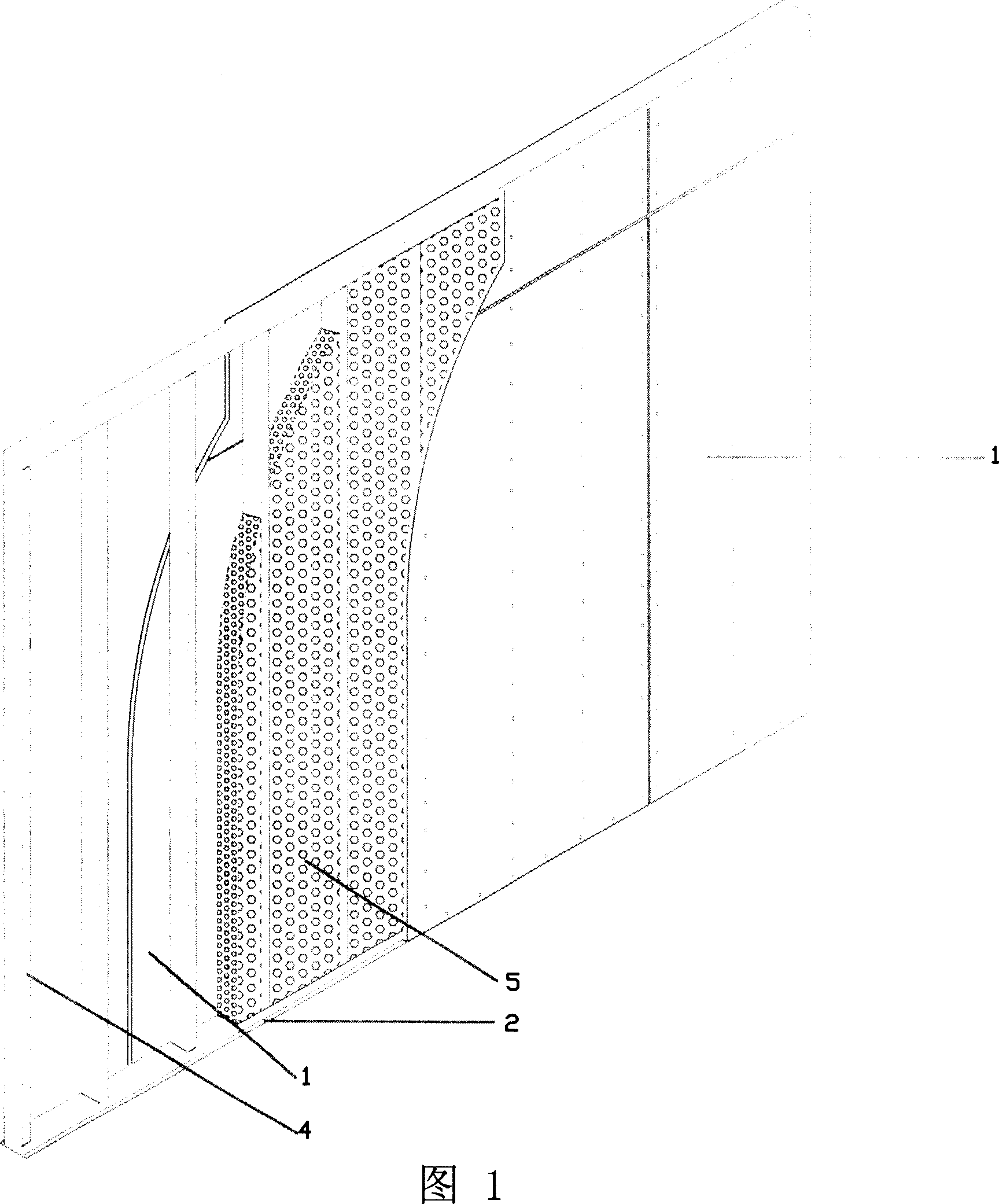

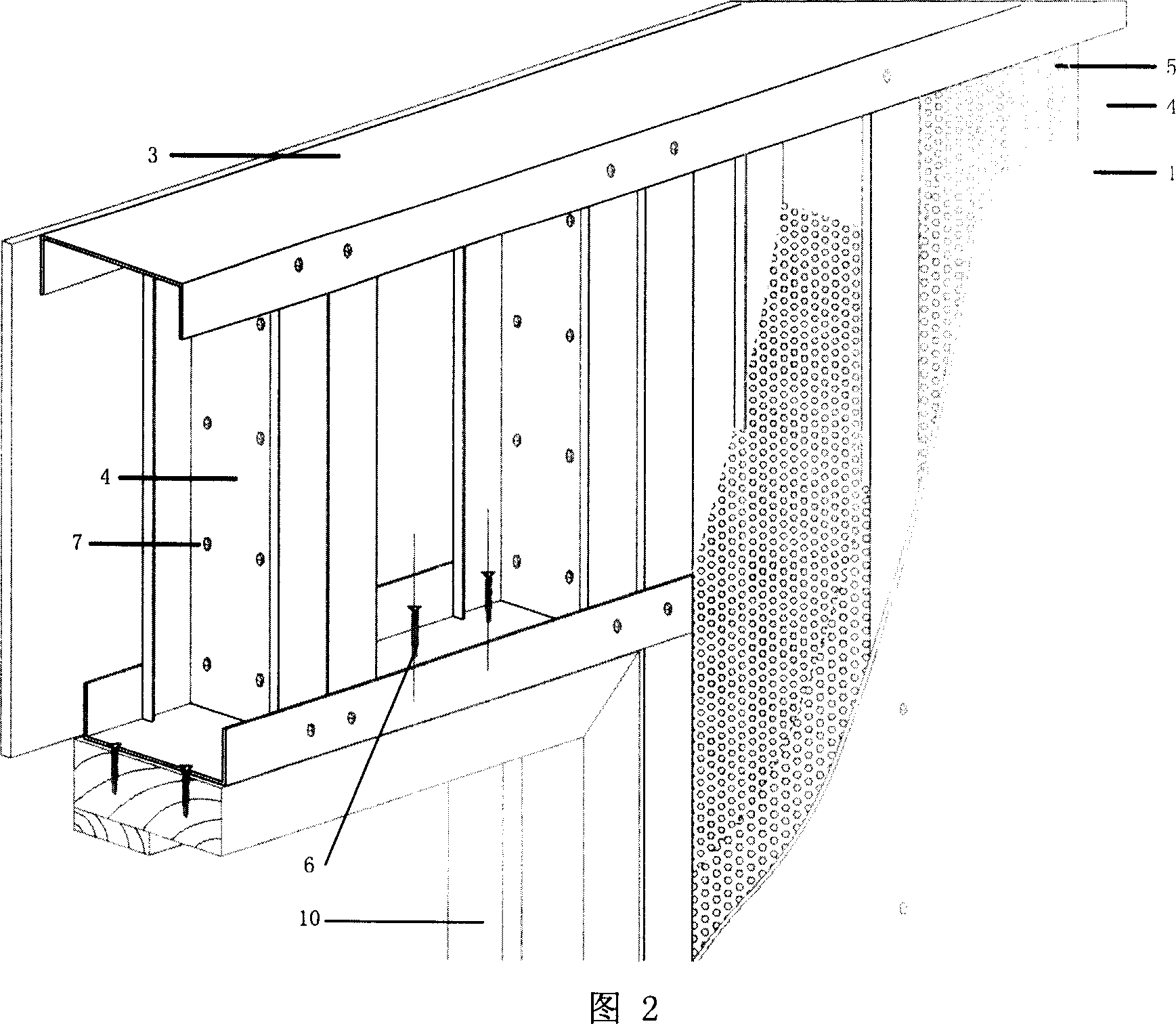

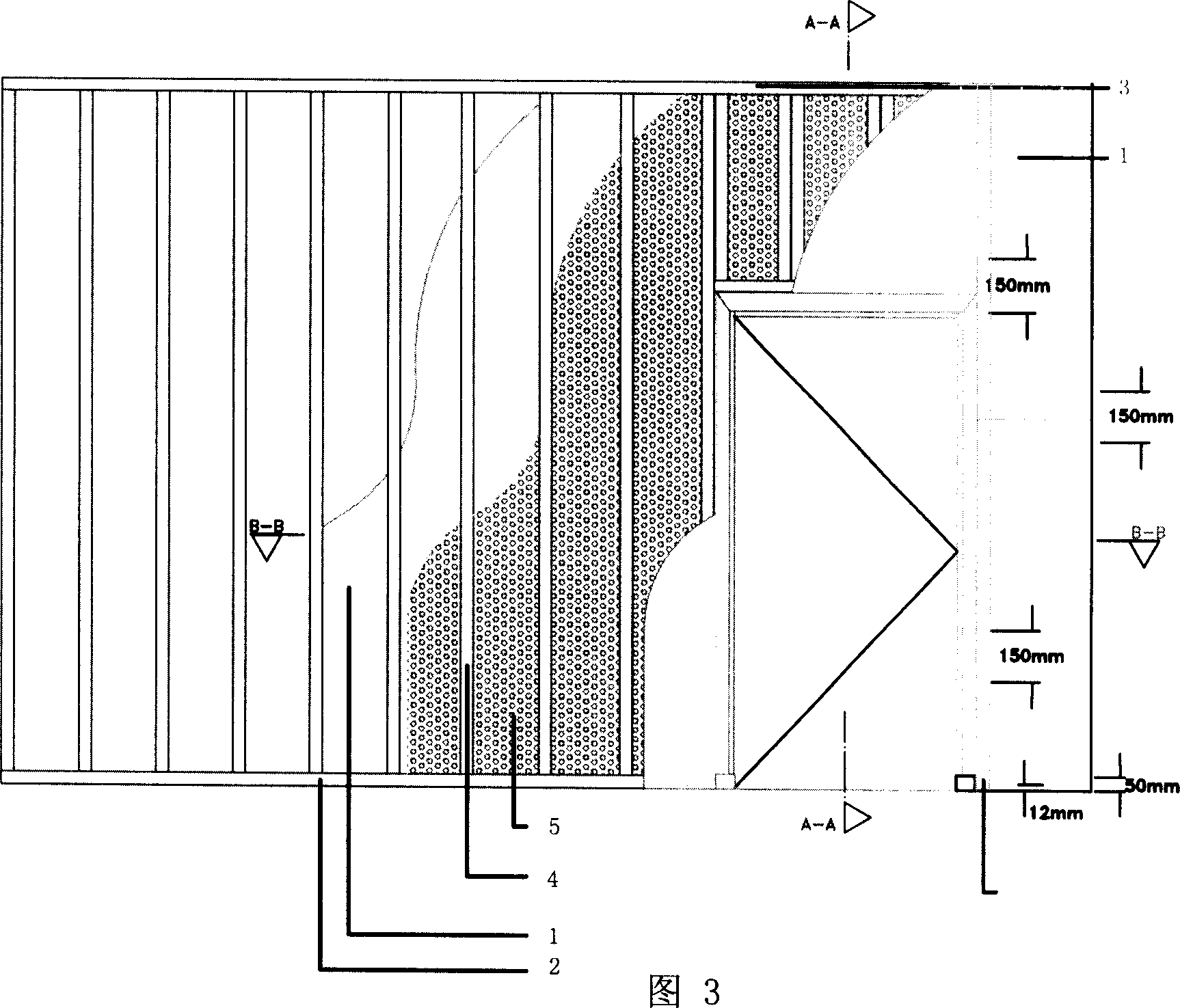

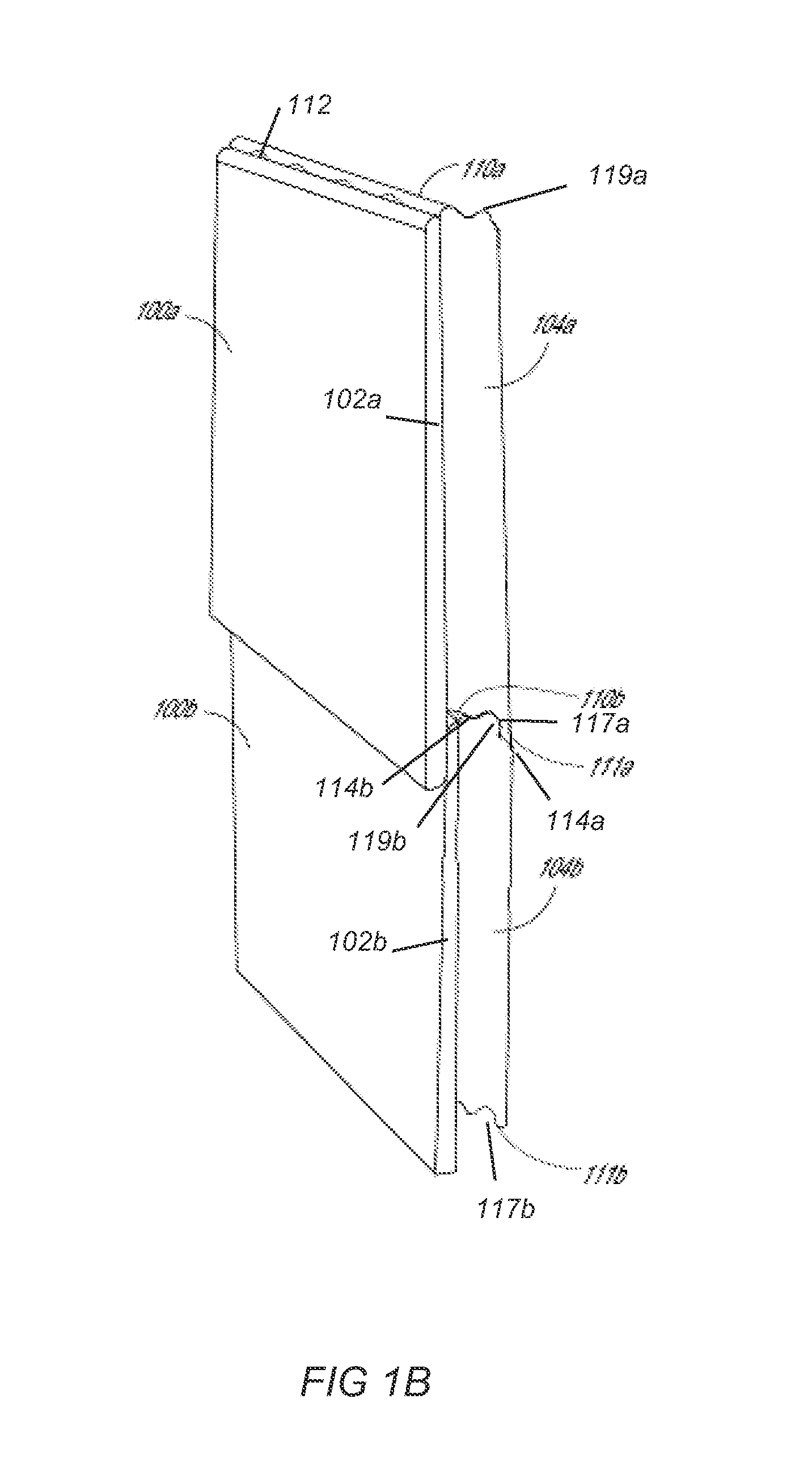

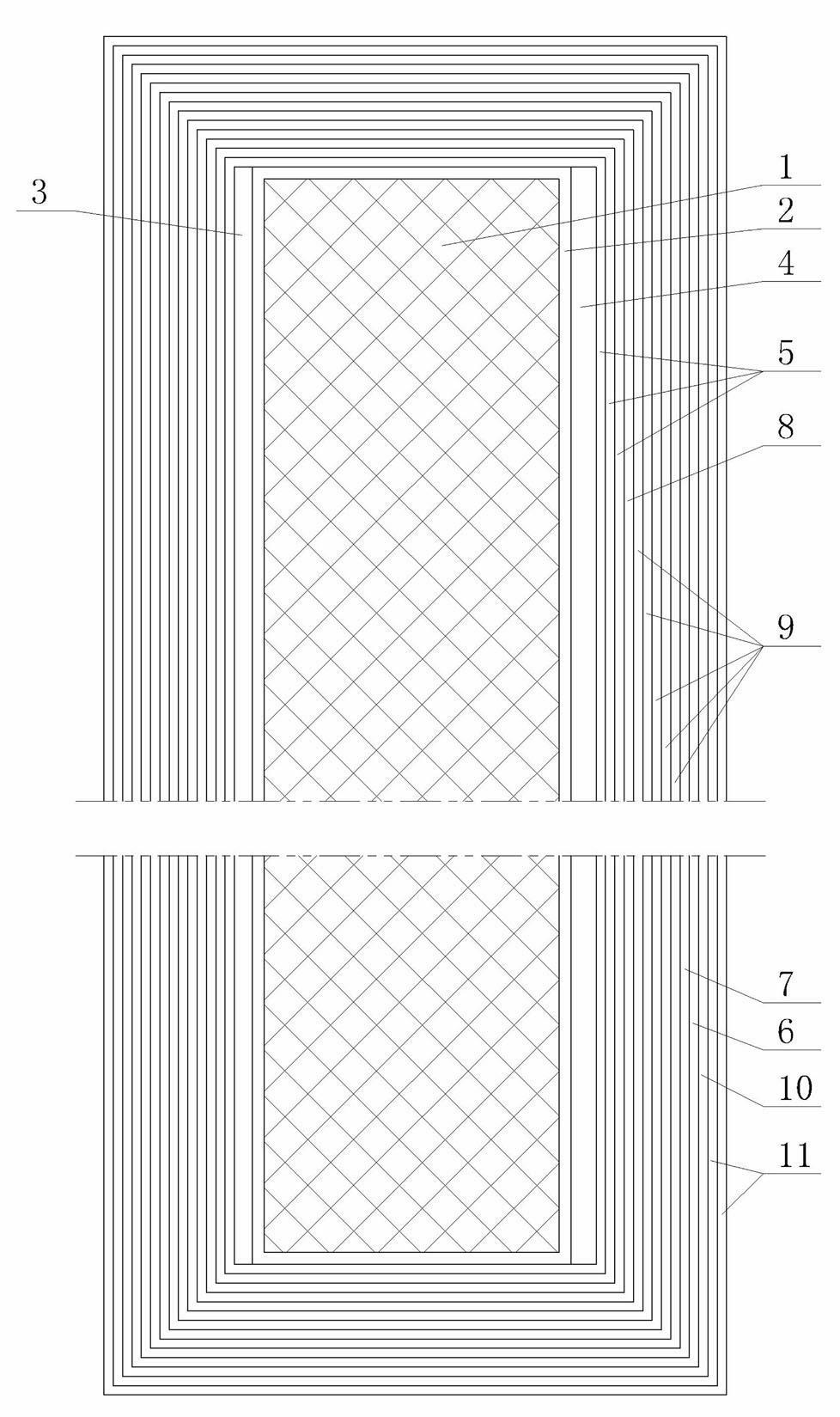

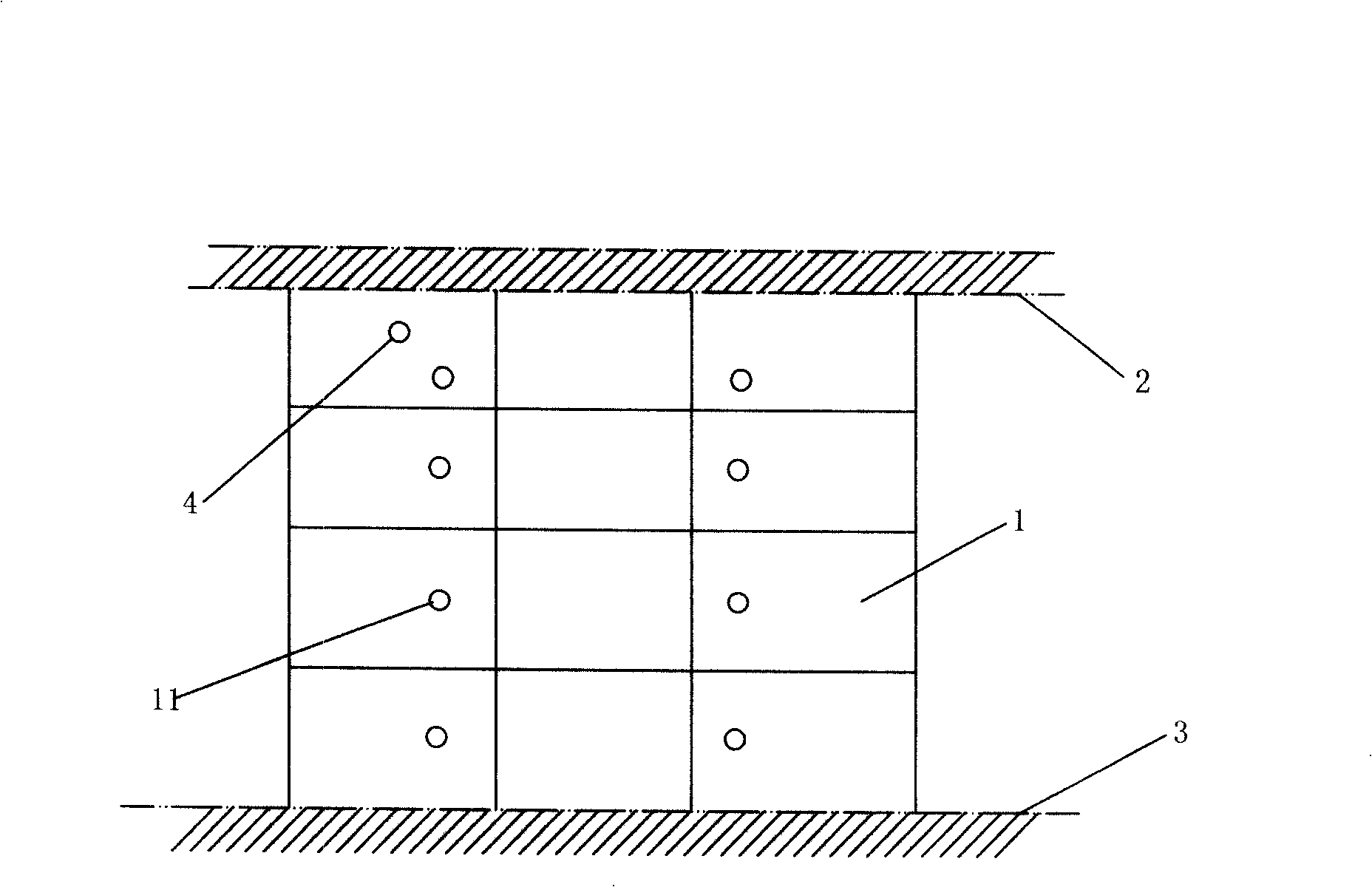

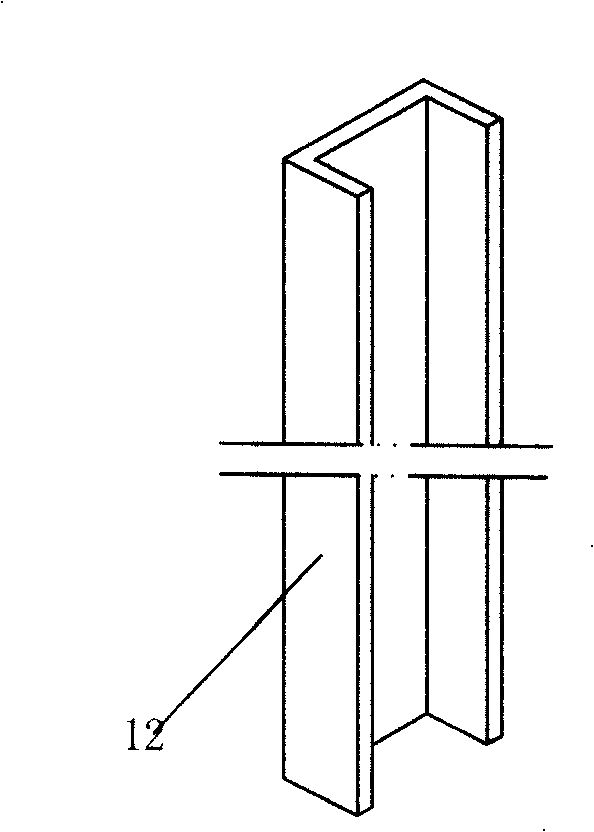

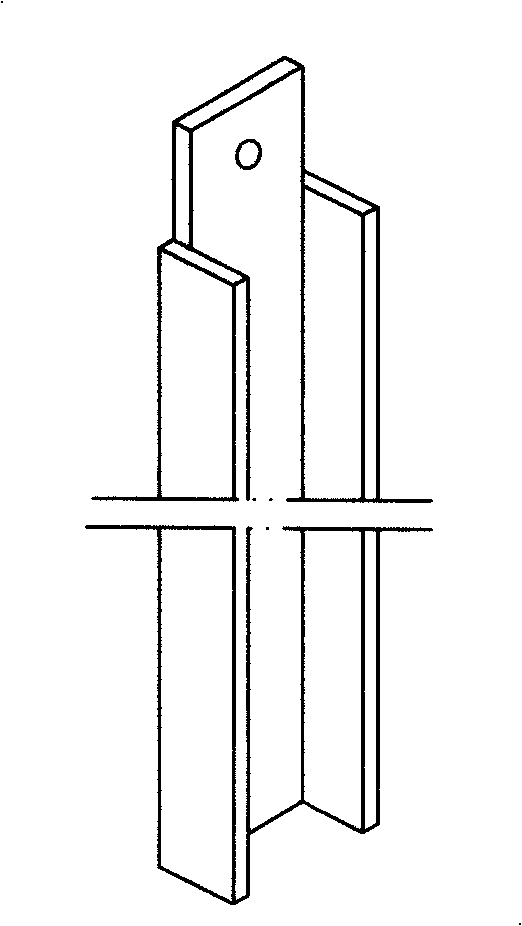

Fiver cement board grouting wall and construction method therefor

The invention discloses a lightweight nonbearing grouting wall and its construction method for inner walls of buildings, comprising a lightgage steel joist or C-shaped steel as a framework, two fiber cements covered on two sides, a hollow space within lightweight grouting materials by special equipment, and a skin layer decorated and dealt directly. The wall has a simple structure for easy construction and a light weight thereby reducing the cost of entire structure and improving the fireproof property up to 2.5 hours or more and the sound insulation property as 40dB, therefore the invention is an inner wall construction with higher utility and economic profit.

Owner:杨建平

Panelized wall system utilizing adhesive-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with adhesive-edge building panels. The adhesive-edge building panels are preferably fiber cement. The front surface of each panel has an adhesive preapplied to an edge of the panel. Panels are fastened to a frame with the adhesive-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape adhere to the adhesive-edges of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE INT FINANCE BV

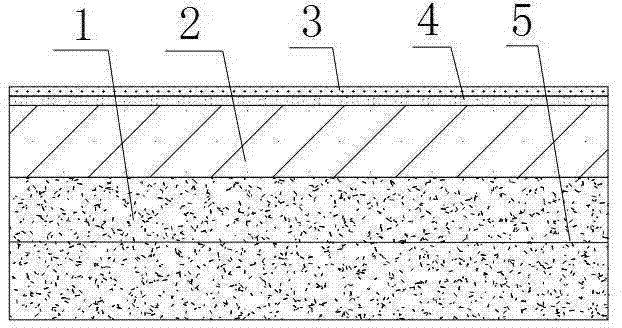

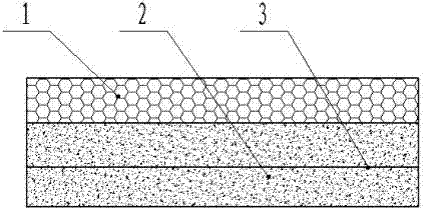

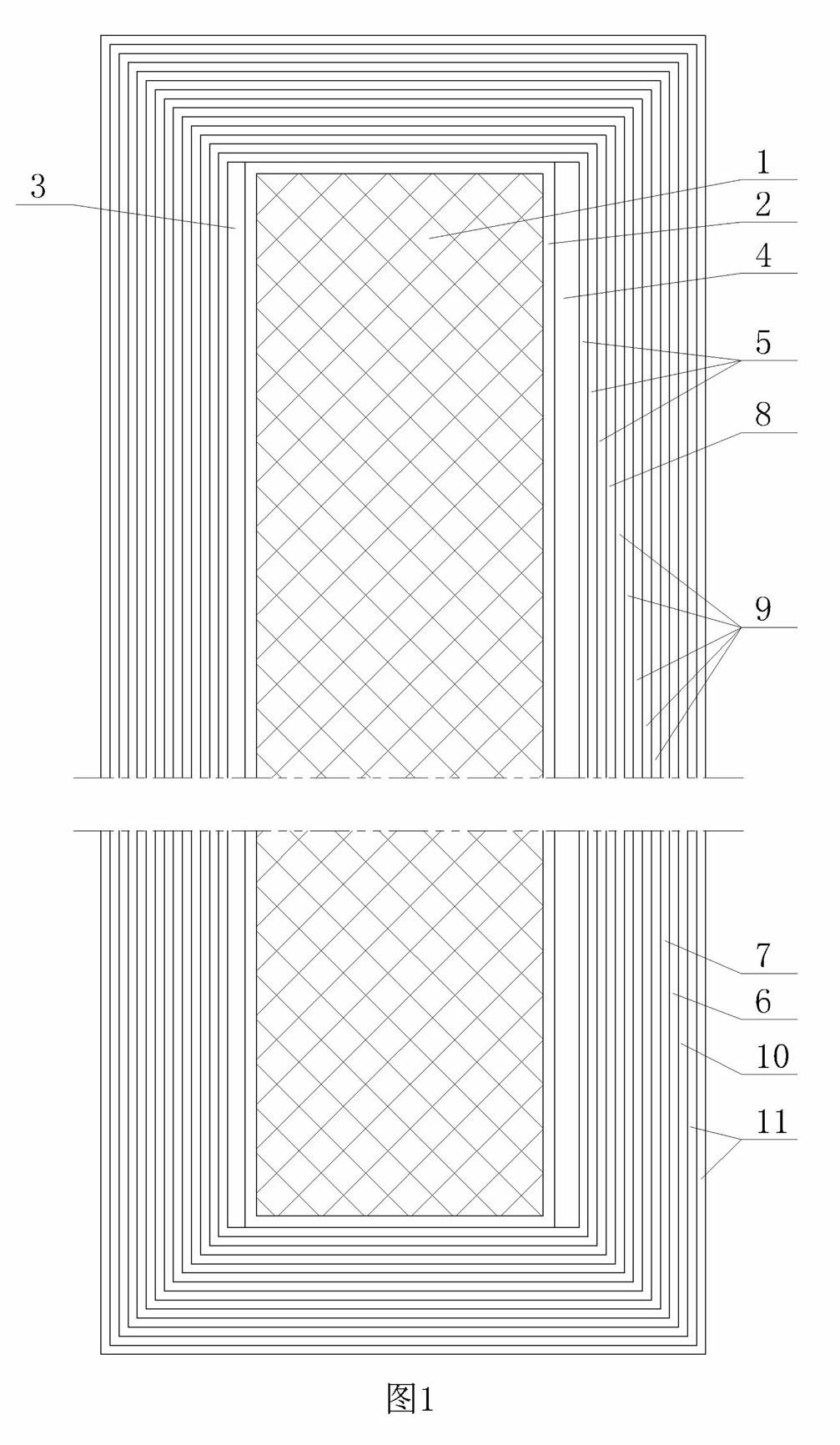

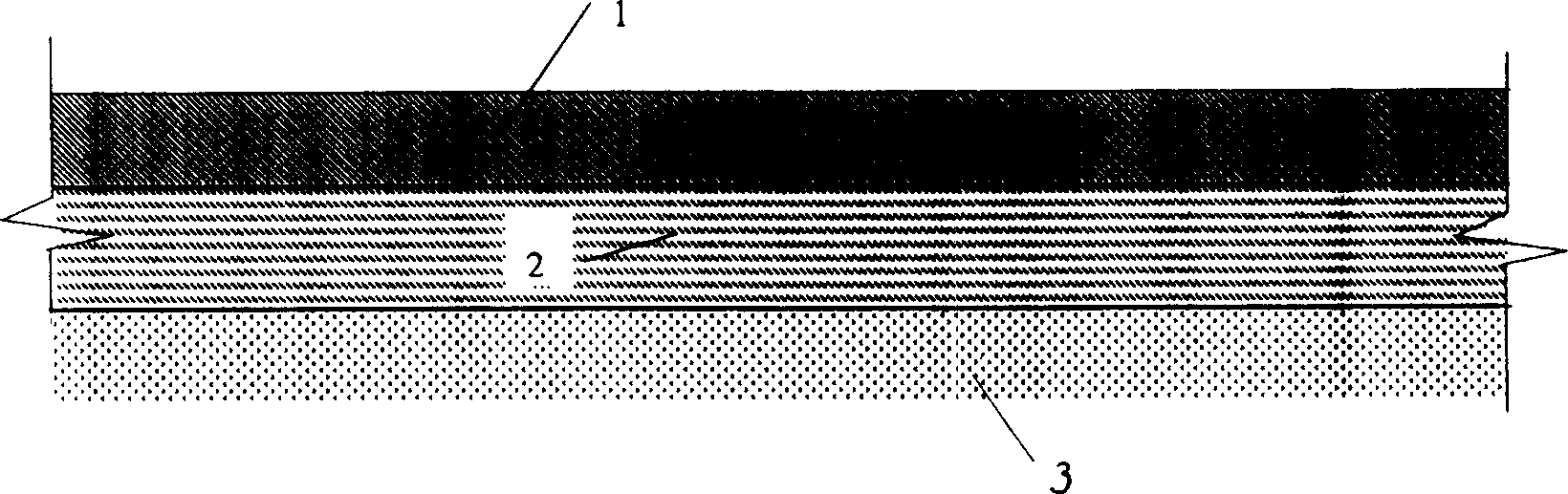

Nano self-cleaning fiber reinforced cement product and production method for same

InactiveCN102518275AReduced contentSolve the problem of efflorescence affecting the effect of the functional layerCovering/liningsDispersed particle separationPhoto catalysisAir purification

The invention relates to a nano self-cleaning fiber reinforced cement product and a production method for the same, which particularly aim to realize photocatalysis antifouling self-cleaning and air purification functions on a traditional fiber cement product by means of coating. The product is mainly applied to building roofs, building curtain walls, wall decoration, municipal traffic engineering construction and modification works, and comprises a fiber reinforced cement structural layer, a fiber reinforced cement decorative finish layer, a nano isolation layer and a photocatalysis layer, wherein the fiber reinforced cement decorative finish layer is composited on the fiber reinforced cement structural layer, the nano isolation layer is composited between the fiber reinforced cement decorative finish layer and the photocatalysis layer, and the fiber reinforced cement structural layer and the fiber reinforced cement decorative finish layer are composited to mold in a mould with a modeling. Net-shaped reinforced materials are laid in the fiber reinforced cement structural layer.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

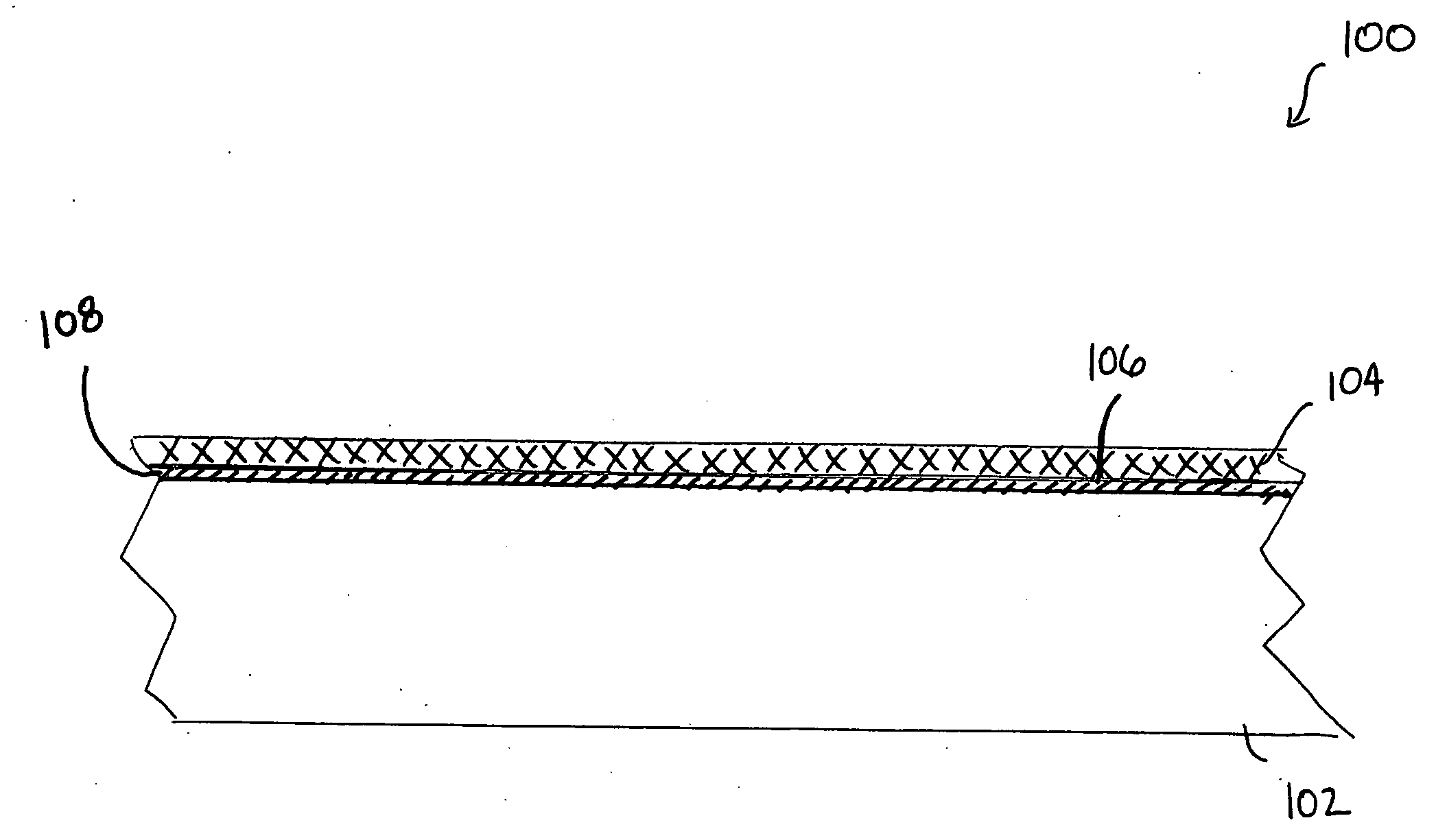

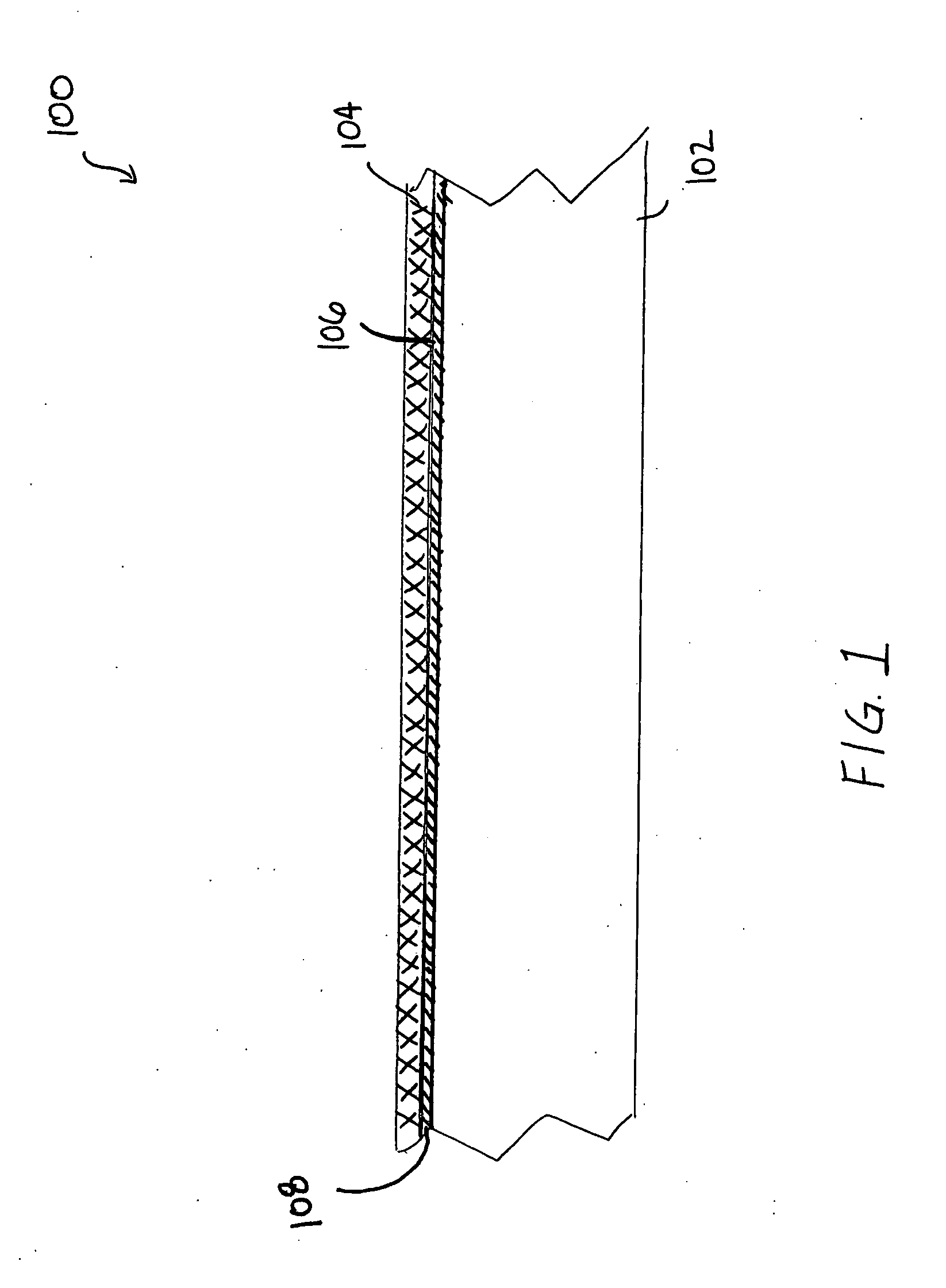

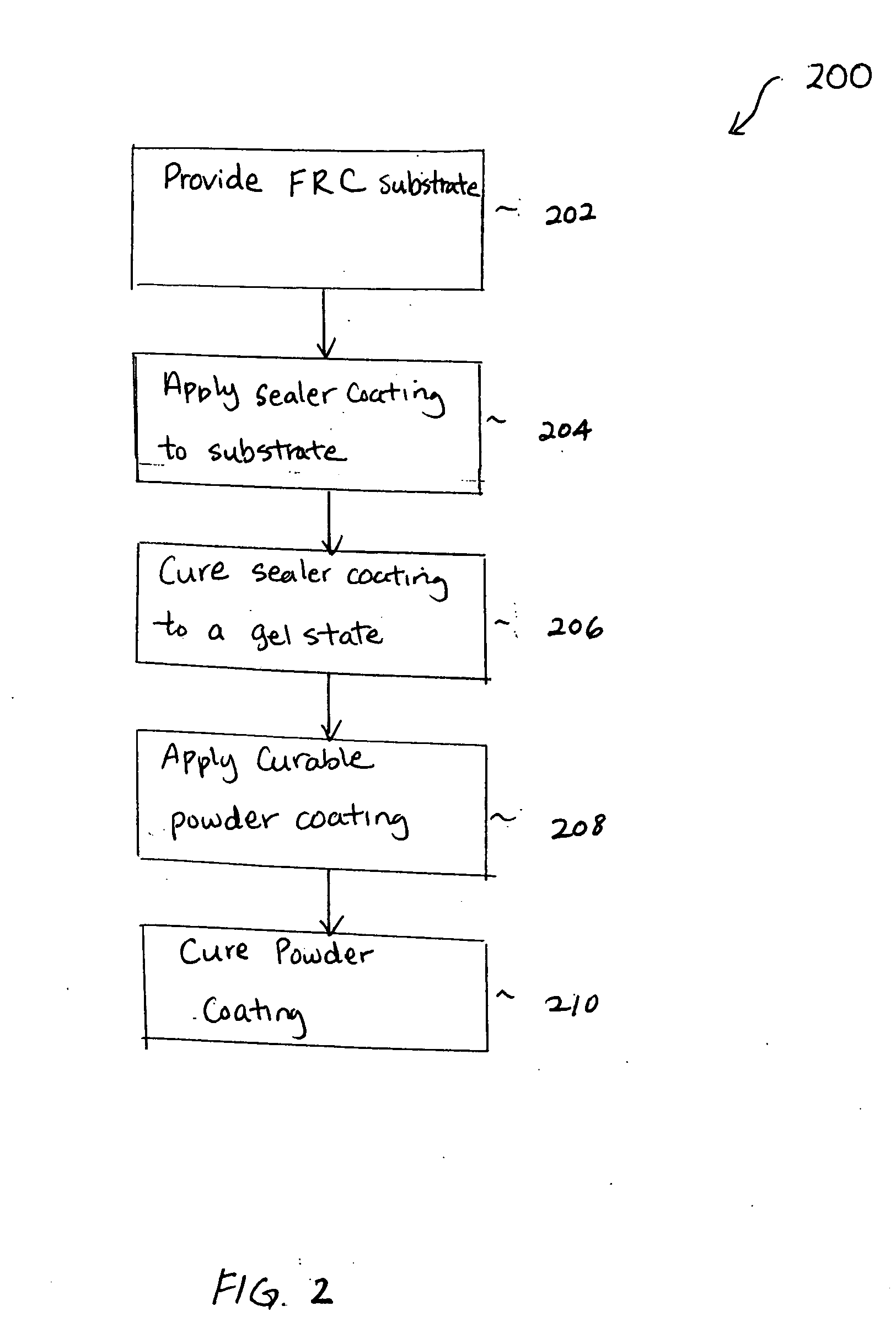

Composite cement article incorporating a powder coating and methods of making same

A cementitious composite article incorporating a powder coating on at least one surface is provided. The composite article includes a surface treatment adapted to facilitate application of the powder coating onto the article. The surface treatment can include modifications to surface porosity, surface, and / or application of a sealer to the surface so as to make the cementitious surface more conducive to powder coating. One method of manufacturing the cementitious composite article includes first applying a sealer coating to a surface of a fiber cement substrate, partially curing the substrate to a gel-like state, applying a powder coating to the article, processing the article to a curing device in which the powder coating and sealer coating are co-cured to form a hardened film.

Owner:JAMES HARDIE TECH LTD

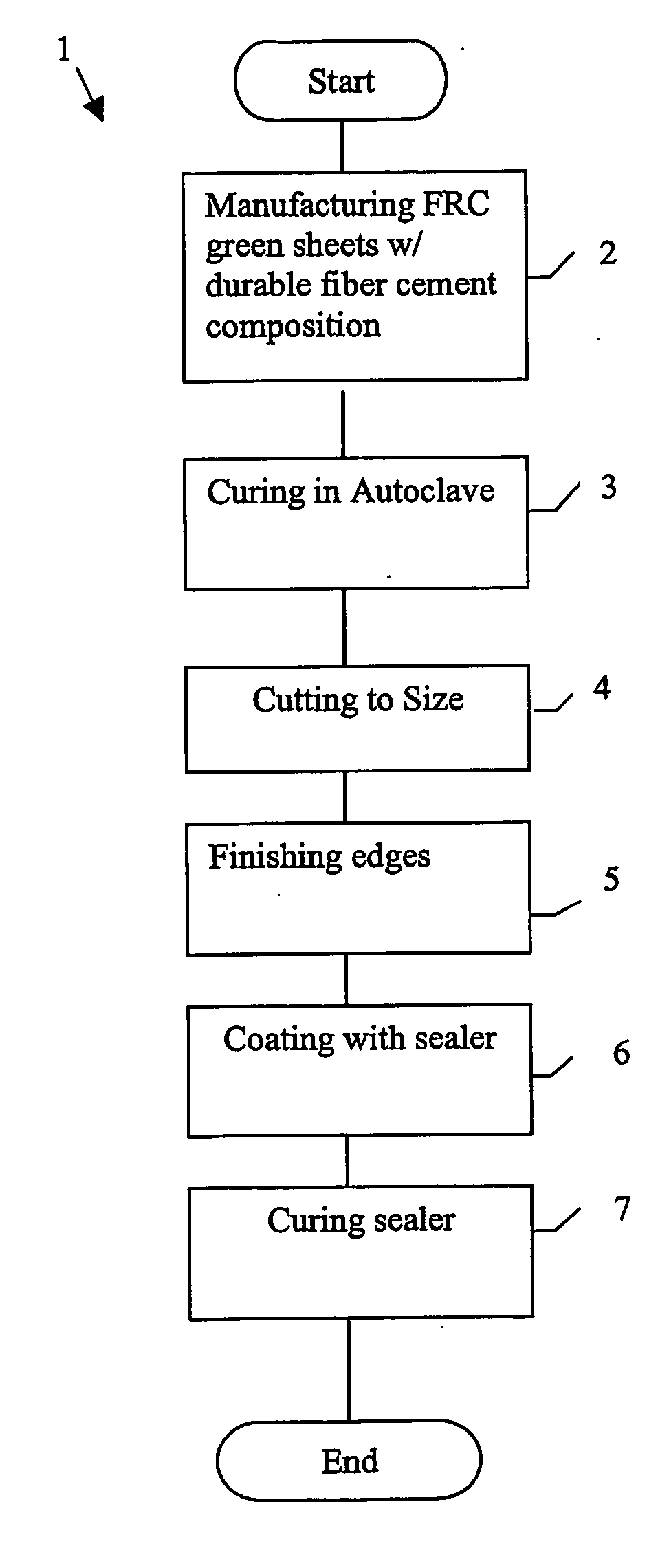

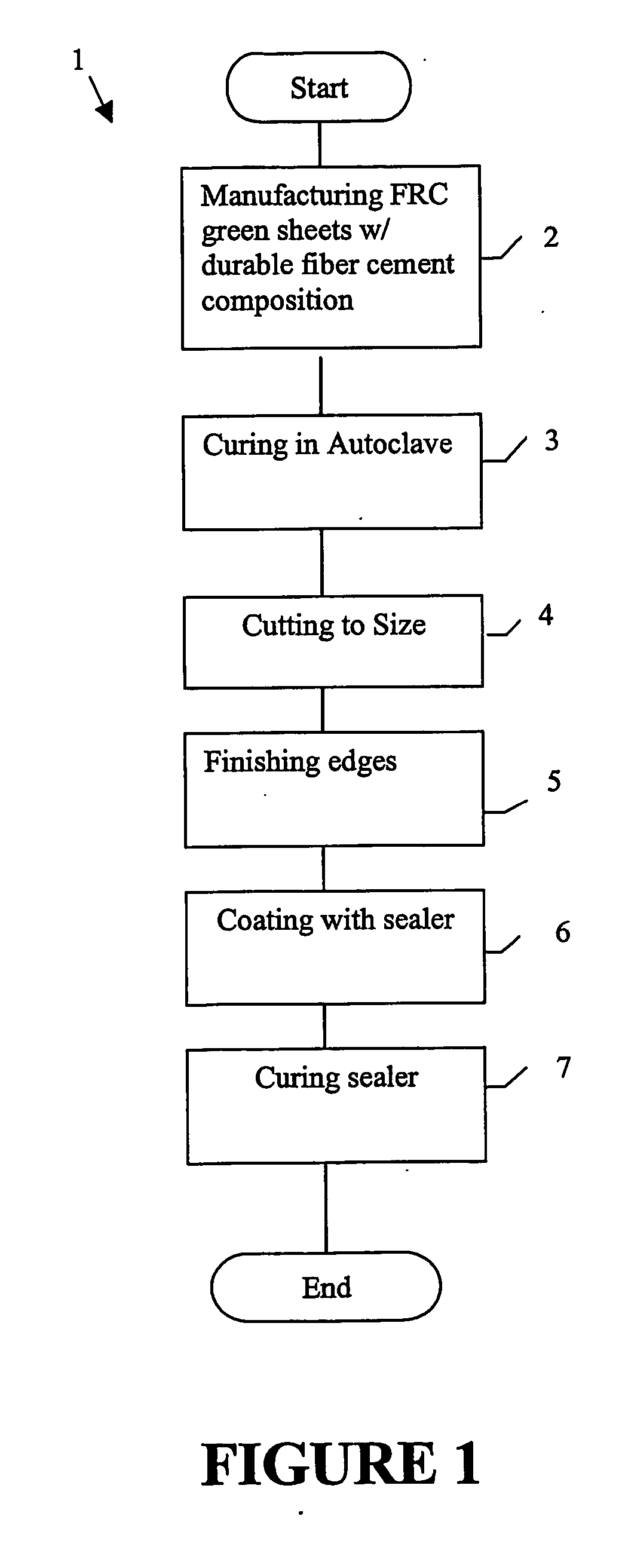

Durable high performance fibre cement product and method on manufacture

InactiveUS20060182946A1Reduction tendencyReducing eliminating transportSolid waste managementSynthetic resin layered productsPorositySilicon dioxide

An engineered fibre reinforced cement product including a first major surface to which a carbonation reducing sealer is applied and a second generally opposing major surface to which a carbonation reducing sealer is applied, so as to reduce propensity for differential carbonation in the product. A method of manufacturing a durable fibre reinforced cement product, said method comprising steps of: (e) mixing a wet fibre reinforced cement formulation; (f) forming from said formulation a green product defining first and second generally opposing major surfaces; (g) curing the green product to form a cured product; and (h) applying a carbonation reducing sealer to said first and second major surfaces, so as to reduce propensity for differential carbonation in the product. An engineered fibre reinforced cement product including a first major surface with a reduced propensity to differential carbonation, wherein the product has a cement to silica ratio of between 0.29 and around 0.51 and a porosity of between 25% and around 45%.

Owner:JAMES HARDIE TECH LTD

Anti-cracking low-shrinkage-deformation fiber-cement product and production method thereof

InactiveCN102785423AIncreased durabilityExtended service lifeWater-setting substance layered productEngineeringUltimate tensile strength

The invention relates to an anti-cracking low-shrinkage-deformation fiber-cement product and a production method thereof. Concretely, a novel fiber-reinforced cement product with an excellent anti-cracking function and low shrinkage deformation is realized through an ultra-short fiber, low-elasticity-modulus short fiber and high-elasticity-modulus long-fiber composite reinforced-cement base material by simultaneously adopting high-efficiency additives (a high-efficiency water-reducing agent, a thickening agent, an expanding agent and the like). The product comprises a flexible anti-cracking surface layer and a fiber-reinforced cement structural layer, has a simple and resaonable structure, is convenient and easy in production construction and can be applied to projects, such as building external-wall decorative enclosure, indoor engineering construction as well as roads, bridges and the like with higher requirements on the strength and the durability of the cement base material.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

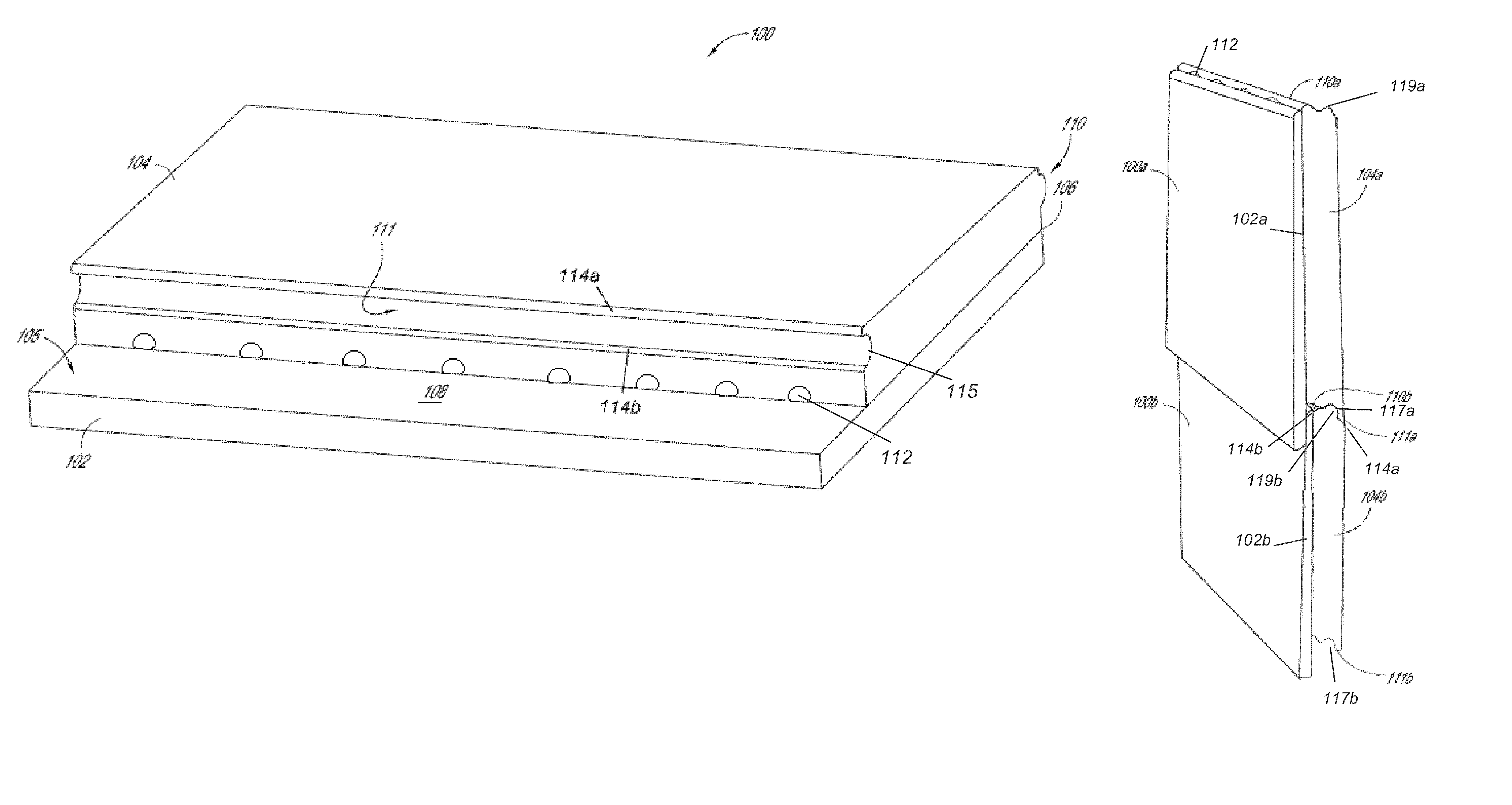

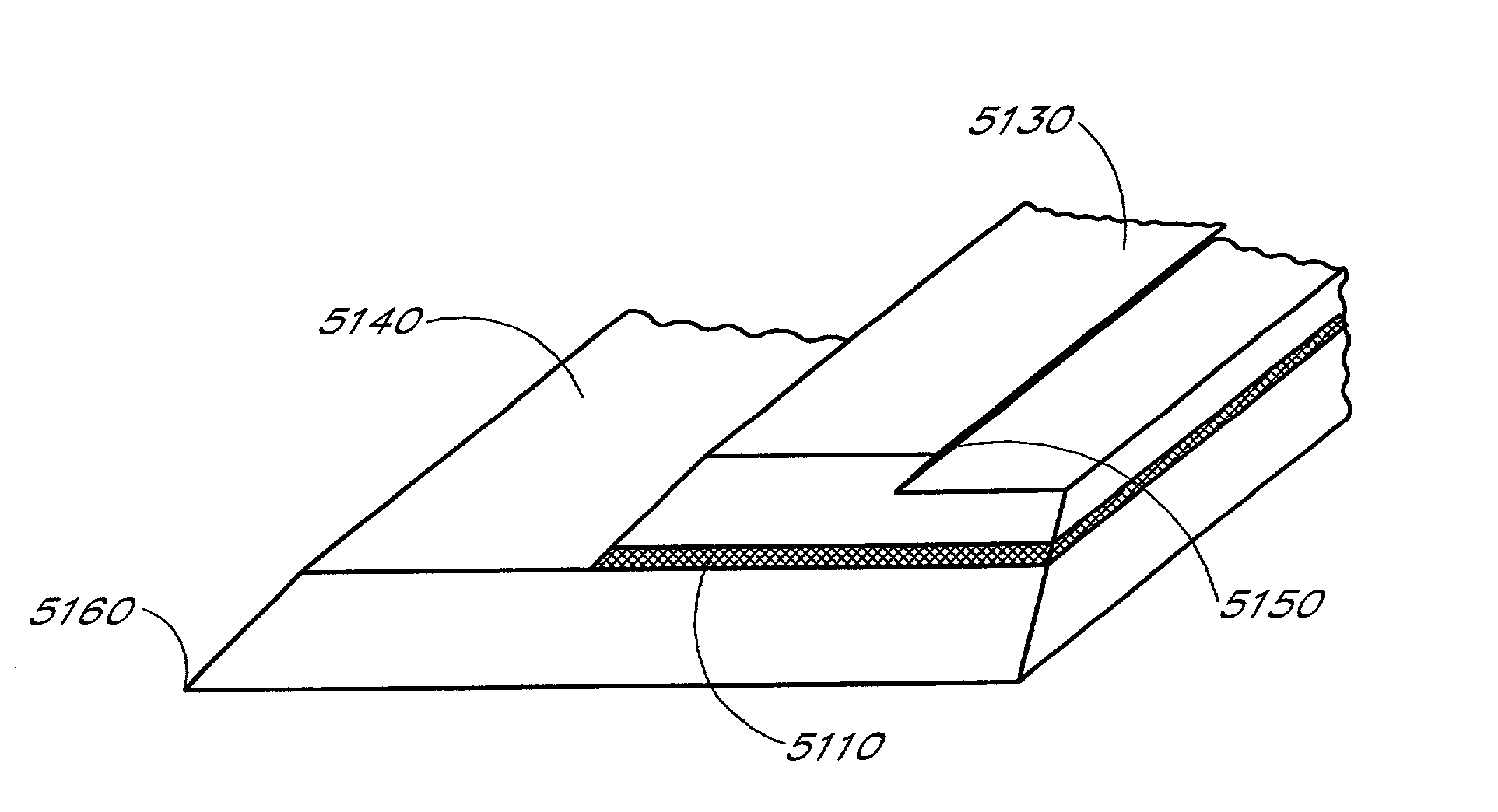

Integrated fiber cement and foam as insulated cladding with enhancements

ActiveUS20150047281A1Improve insulation performanceReduce the time required for installationConstruction materialCovering/liningsThermal energyMaterials science

An integrated fiber cement and foam cladding system is provided that incorporates foam or similar light weight material to improve the insulation capacity of the cladding system. The system includes at least a fiber cement layer and a foam layer disposed on the backside of the fiber cement layer. The system improves the R-value of the building, a measure of the building's resistance to transferring heat or thermal energy.

Owner:JAMES HARDIE TECH LTD

Insulating Wall Panel System

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

Hollow partition slab made of broken straw and cement and its preparing process

A hollow partition lath made of stalk fibre cement used in the enclosure wall and internal partition of building contains strew or stalk fibres (10-18 wt.%), active filler (20-30), cement (45-55), chemical additive (5-8), water-reducing agent (0.2-0.5) and alkali-resistant glass fibres (0.5-1). Its advantages are high hollow rate (more than 55%), good bending strength, durability and weatherability, and low cost and shrinkage.

Owner:黄华大

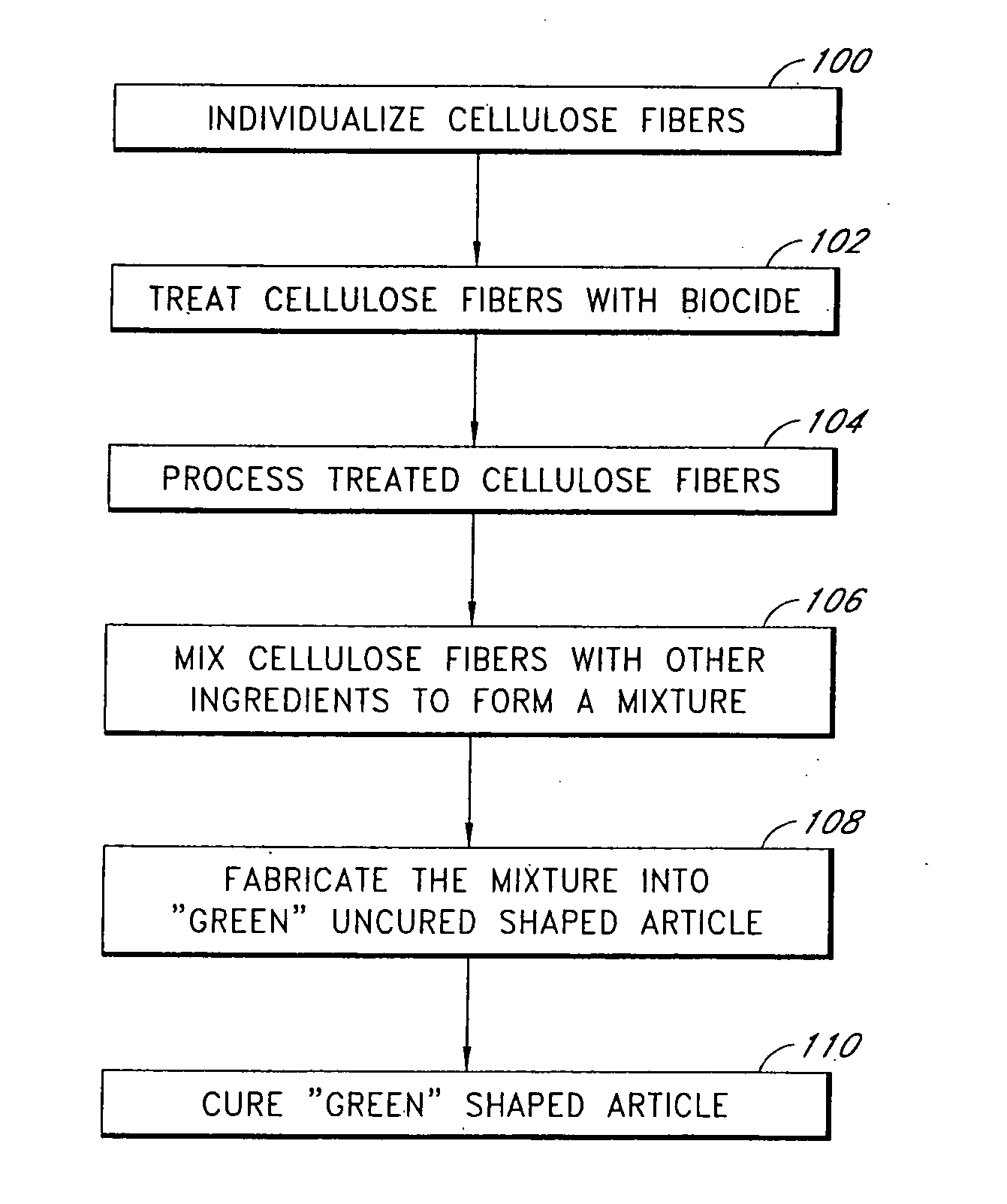

Fiber cement composite material using biocide treated durable cellulose fibers

InactiveUS20050016423A1Increased durabilityImproves rot resistanceFireproof paintsAntifouling/underwater paintsBiotechnologyHydration reaction

A fiber cement composite material providing improved rot resistance and durability, the composite material incorporating biocide treated fibrous pulps to resist microorganism attacks. The biocide treated fibers have biocides attached to inner and outer surfaces of individualized fibers to protect the fibers from fungi, bacteria, mold and algae attacks. The biocides selected have strong affinity to cellulose and do not interfere with cement hydration reactions. This invention also discloses the formulation, the method of manufacturing and the final fiber cement products using the biocide treated fibers.

Owner:JAMES HARDIE TECH LTD +1

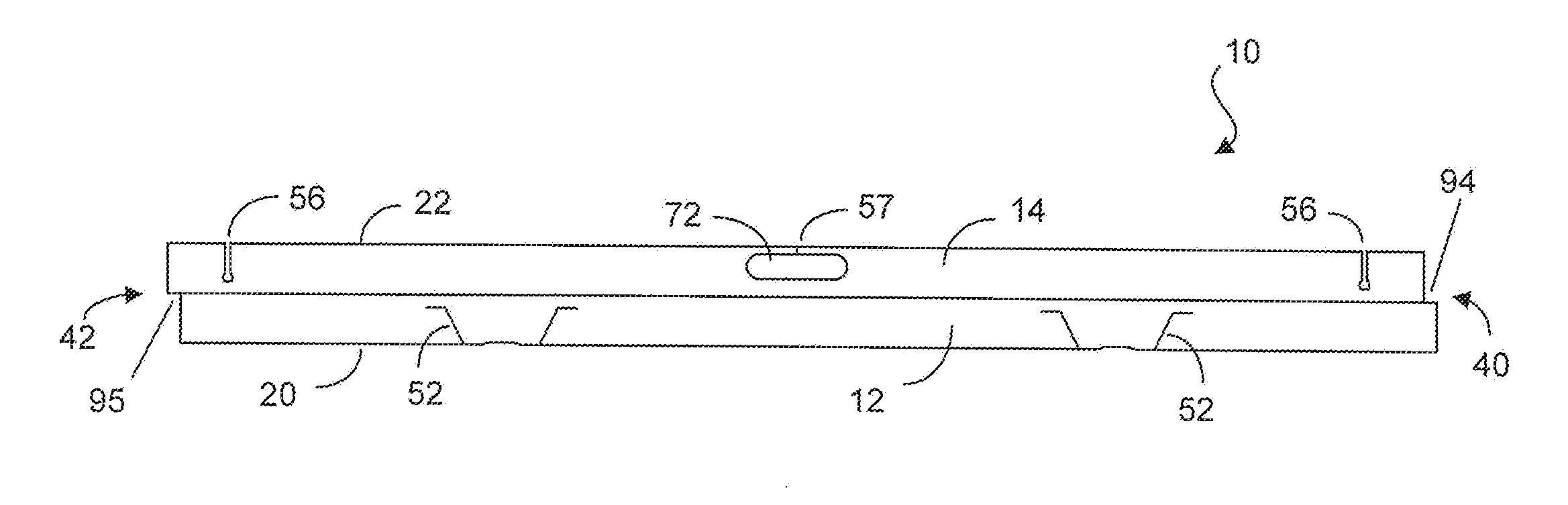

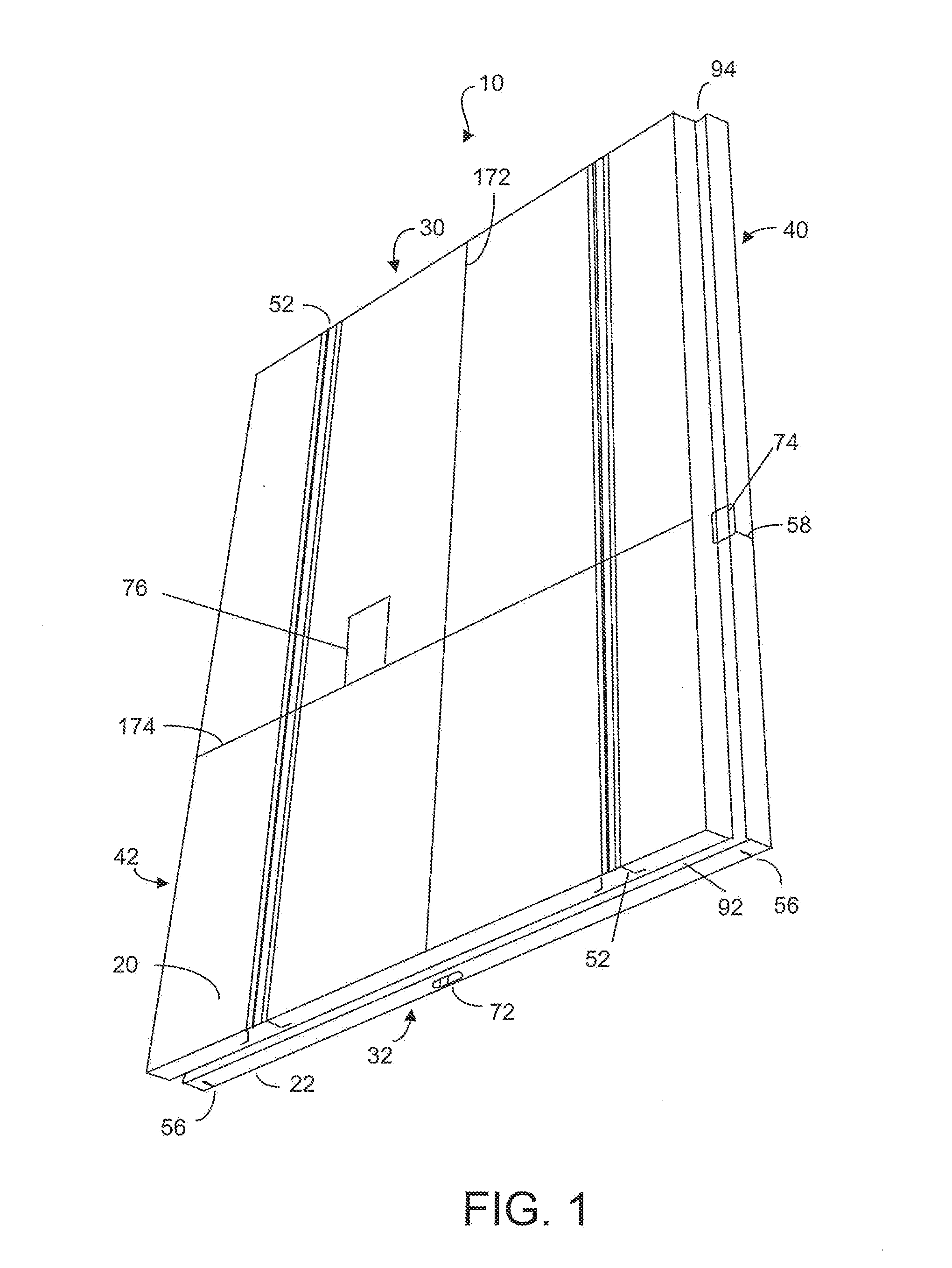

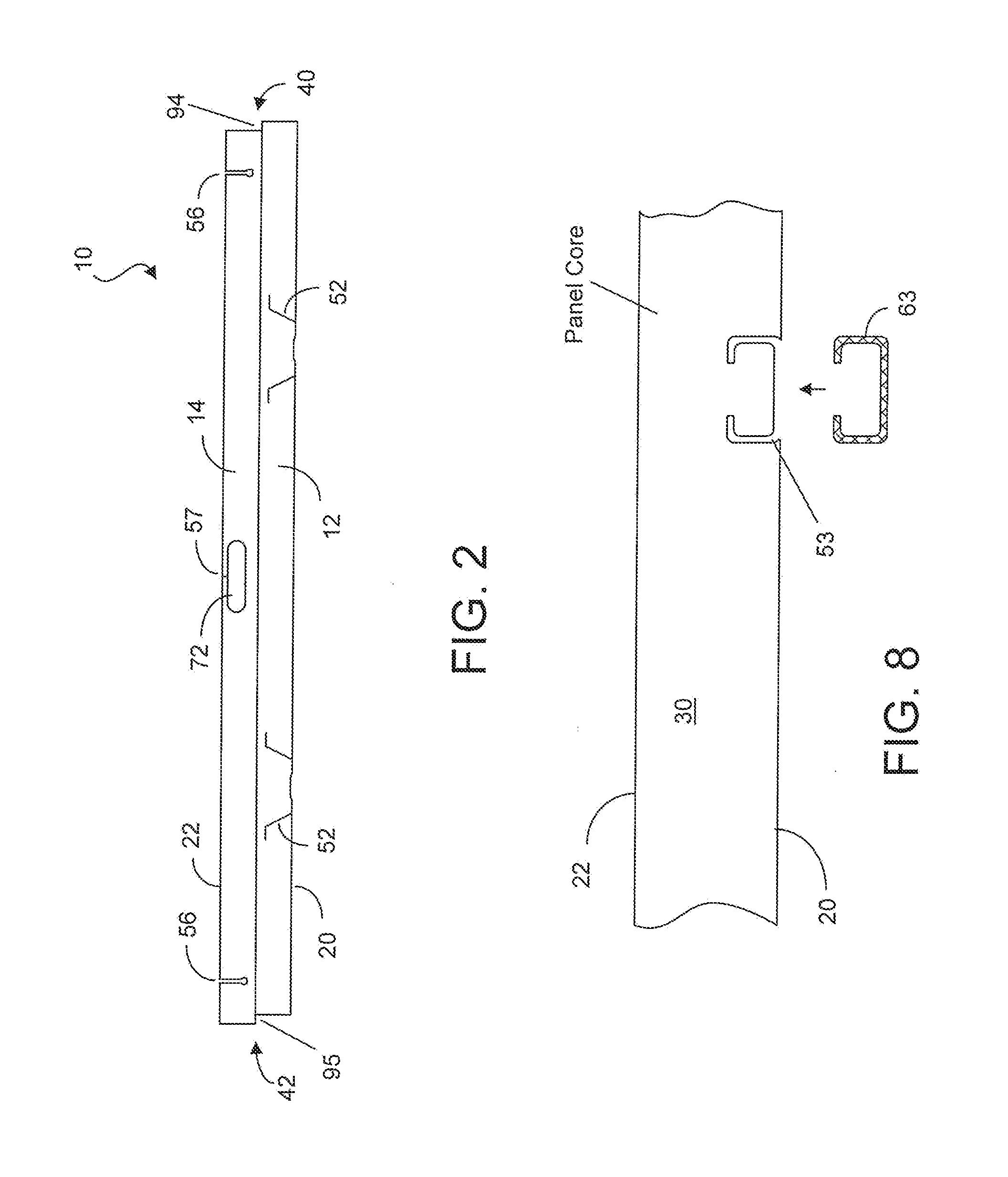

Insulated fiber cement siding

ActiveUS7762040B2Eliminates meticulous measuring of overlapRoof covering using tiles/slatesCovering/liningsVertical edgeReference line

A method for installing siding panels to a building includes providing a foam backing board having alignment ribs on a front surface and a drainage grid on a back surface and then establishing a reference line at a lower end of the building for aligning a lower edge of a first backing board and tacking thereon. Tabs and slots along vertical edges of the foam backing board align and secure adjacent backing boards to each other. A siding panel is butted against one of the lower alignment ribs and secured thereto. Another siding panel is butted against and secured to an adjacent alignment rib to form a shadow line between the adjacent siding panels on the building.

Owner:PROGRESSIVE FOAM TECH

Cementitious exterior sheathing product with rigid support member

InactiveUS20060010800A1Reduce thicknessEasy to carryCeilingsRoof covering using tiles/slatesEngineeringAdhesive bonding

Cementitious exterior sheathing products are provided which include a rigid support member affixed to a cementitious layer. The rigid support member includes at least one nailing flange disposed along one of its lateral sides for allowing the sheathing product to be affixed to an exterior wall of a building. Preferred mechanical and adhesive bonding techniques are suggested for combining the cementitious layer and rigid support member together to form an integrated product. Such products are lighter in weight and are more crack resistant than currently available fiber cement trim boards.

Owner:PLYCEM USA

Stones-like laminates

InactiveUS20050055931A1Reduce manufacturing costSimulating appearanceCeilingsCovering/liningsCement boardOragene

The present invention provides a laminate which has a stone-like appearance comprising a fiber cement board. The cement board layer can be embossed and / or engraved and / or painted to give the impression of colors and depths. Organic polymer composition which includes inorganic filler is included in the laminate.

Owner:ROCHETTE MICHEL

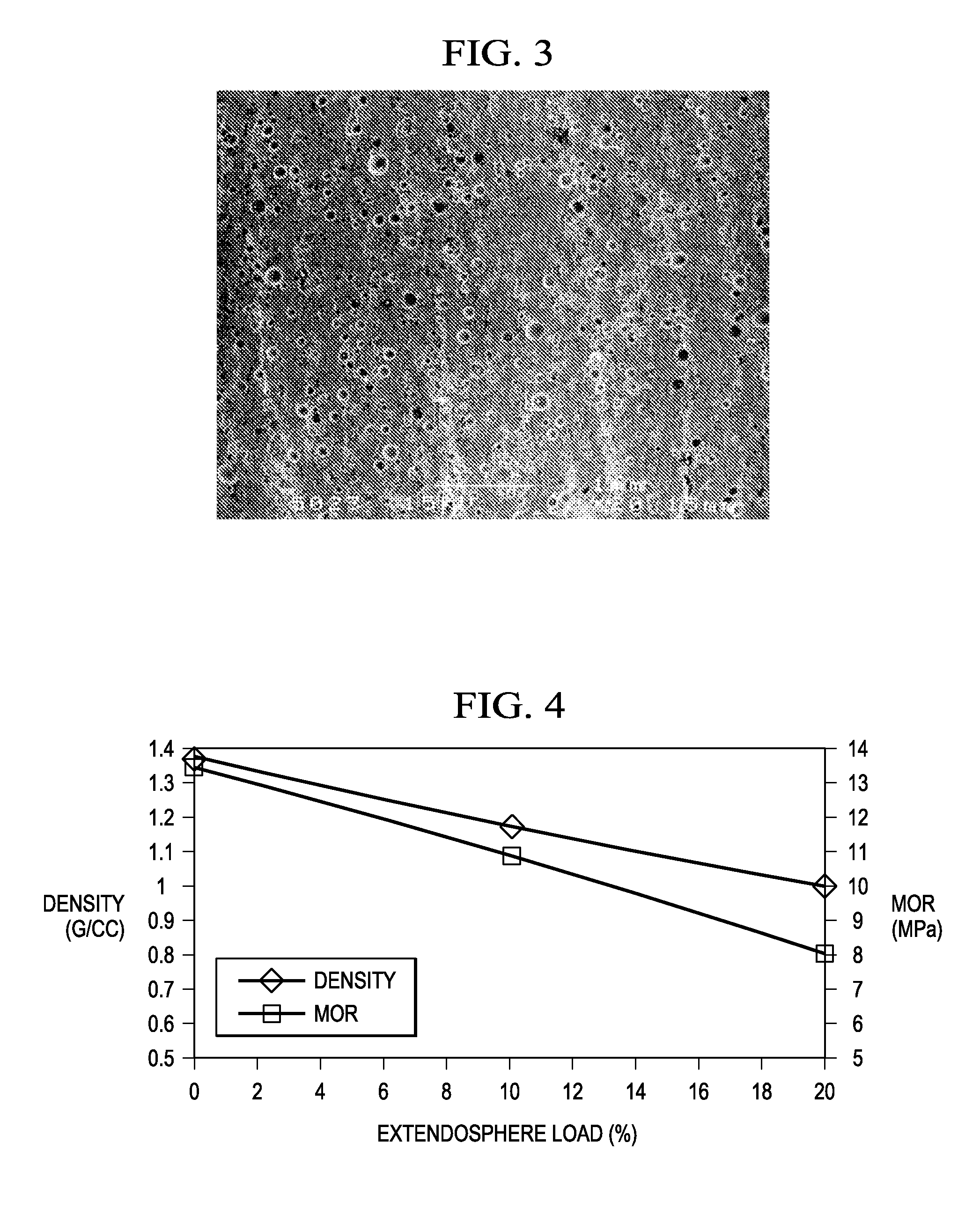

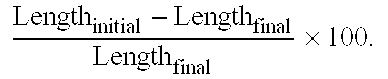

Fiber Cement Building Materials With Low Density Additives

InactiveUS20080203365A1Low densityImprove workabilityConstruction materialSolid waste managementFreeze thawingMicrosphere

This invention relates to a formulation with the addition of low density additives of volcanic ash, hollow ceramic microspheres or a combination of microspheres and volcanic ash or other low density additives into cementitious cellulose fiber reinforced building materials. This formulation is advantageously lightweight or low density compared as compared to current fiber cement products without the increased moisture expansion and freeze-thaw degradation usually associated with the addition of lightweight inorganic materials to fiber cement mixes. The low density additives also give the material improved thermal dimensional stability.

Owner:JAMES HARDIE TECH LTD

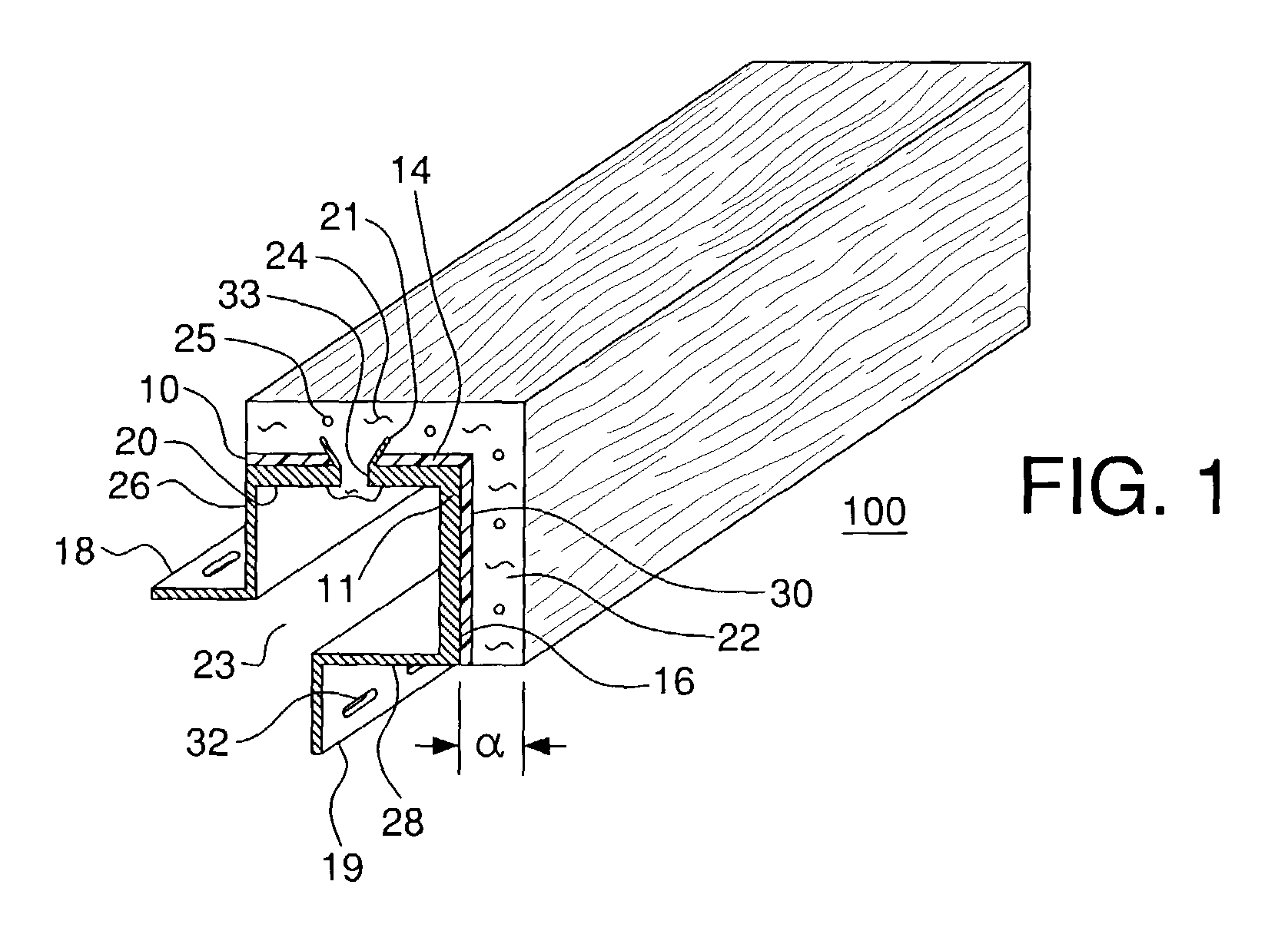

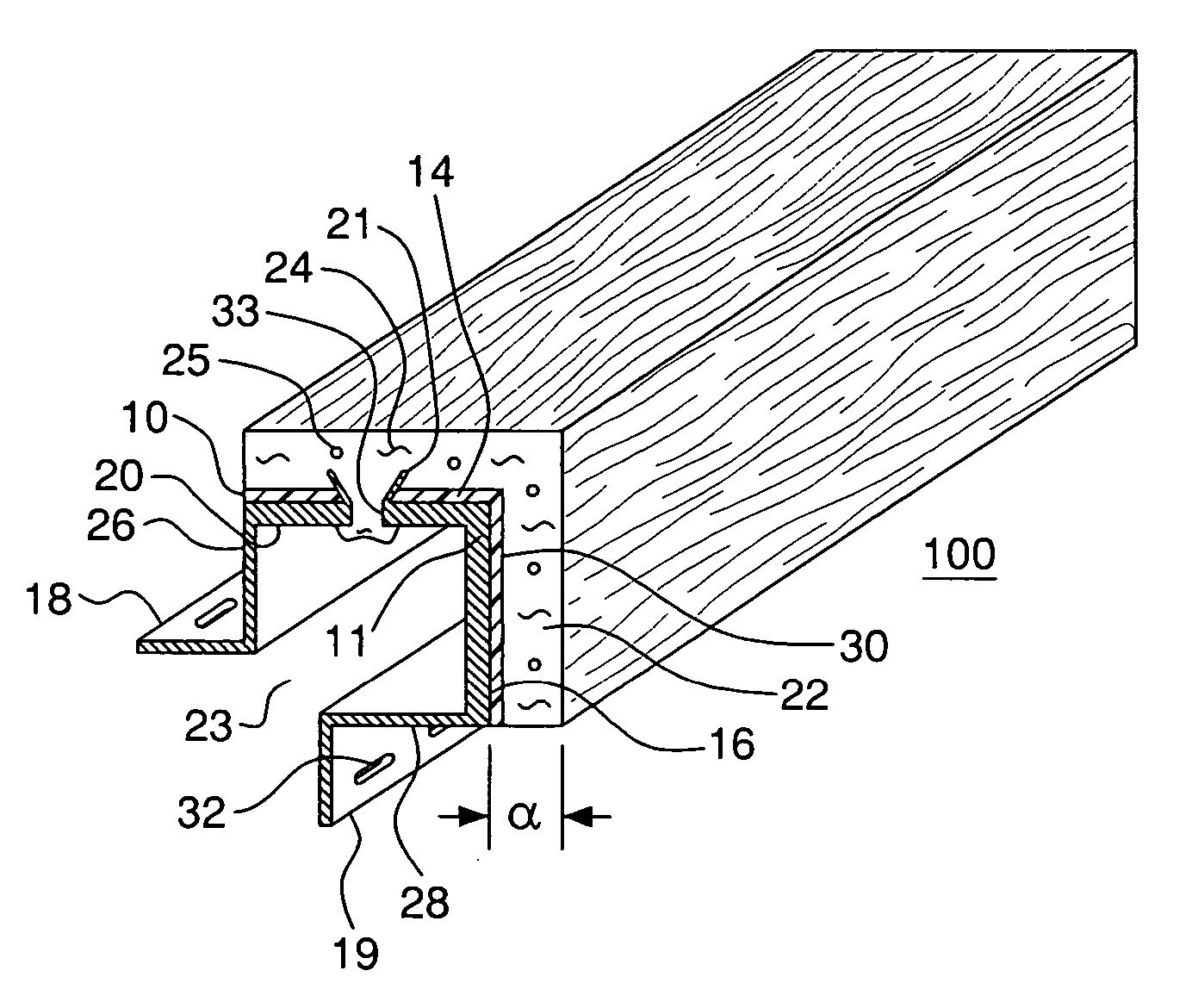

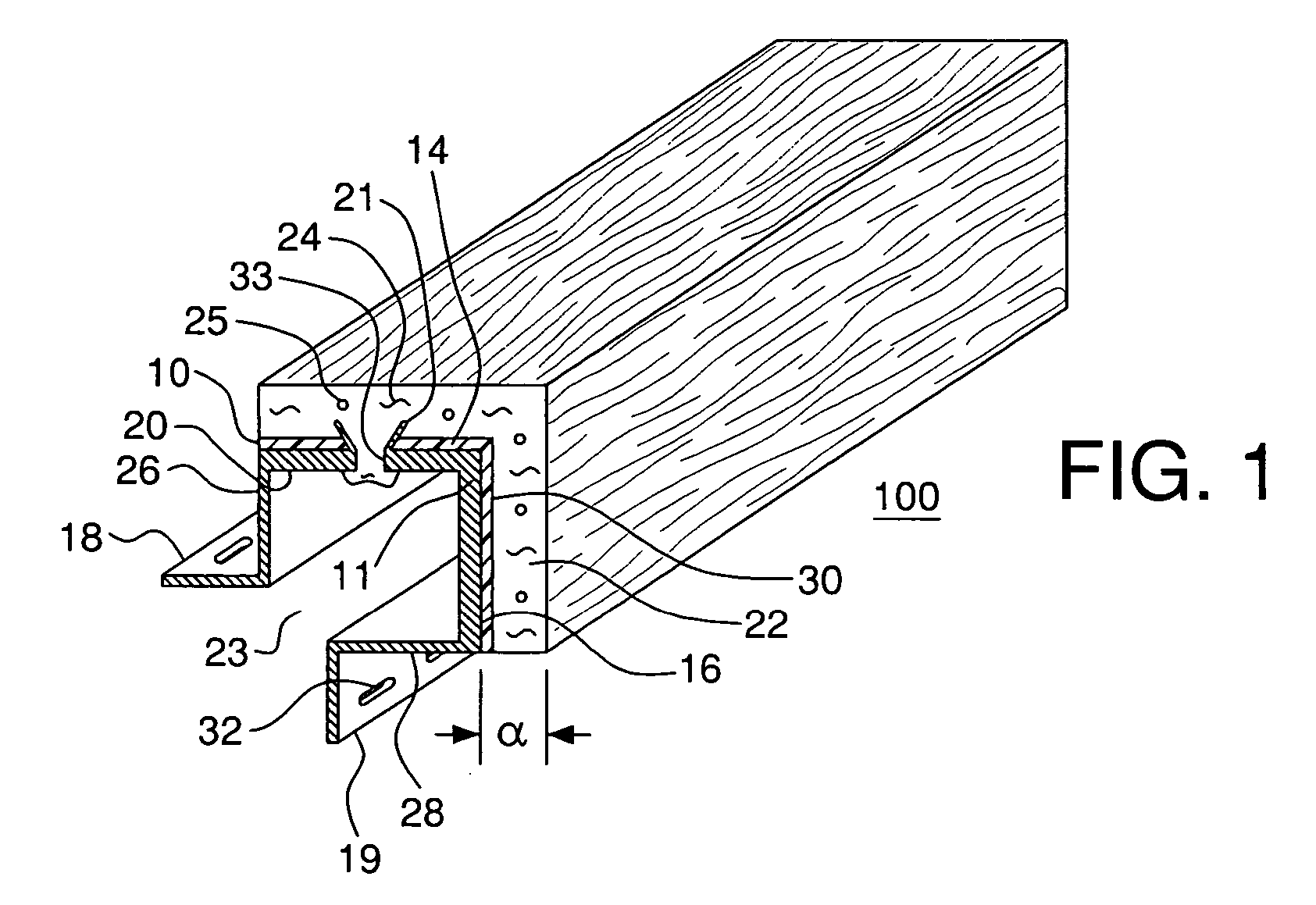

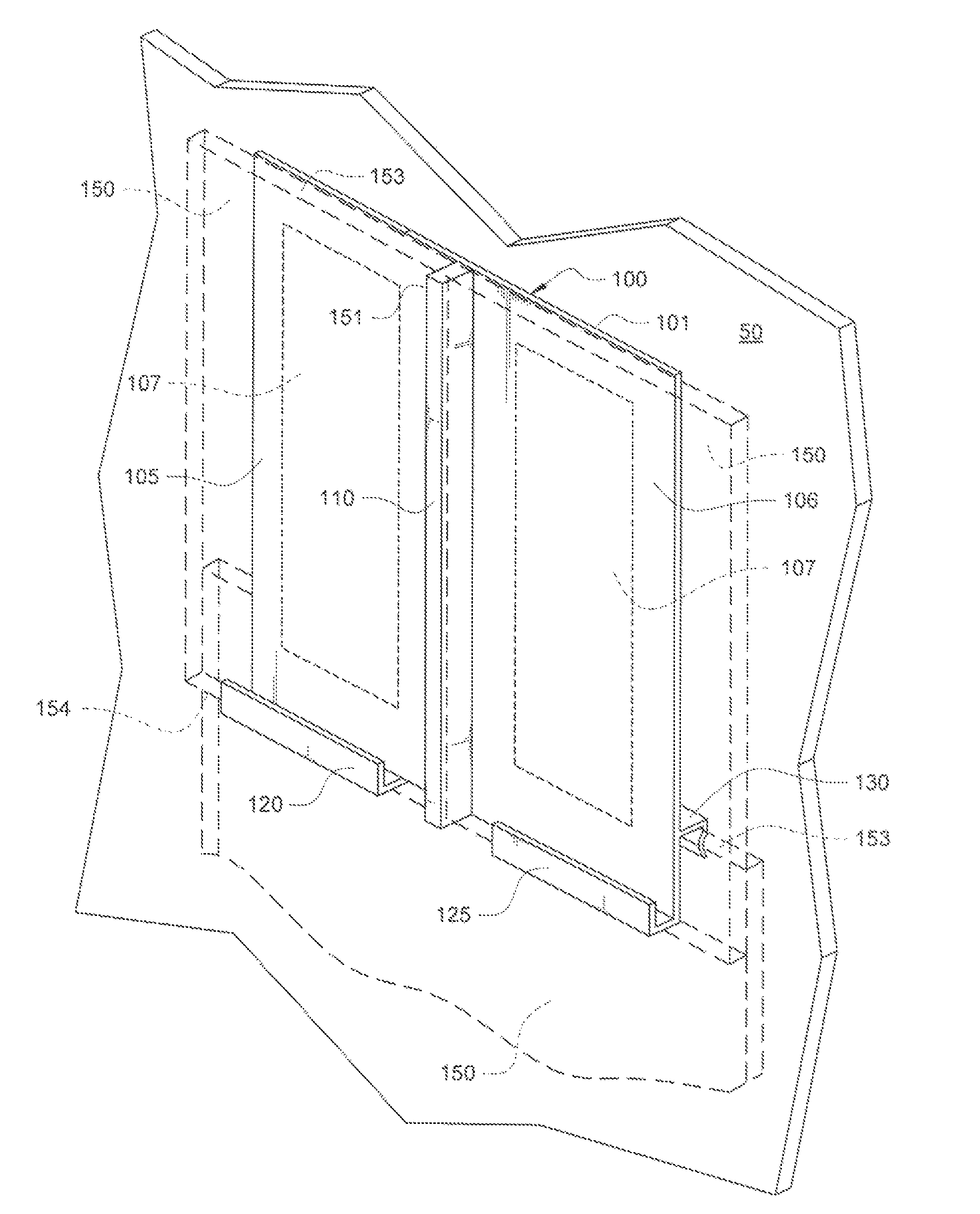

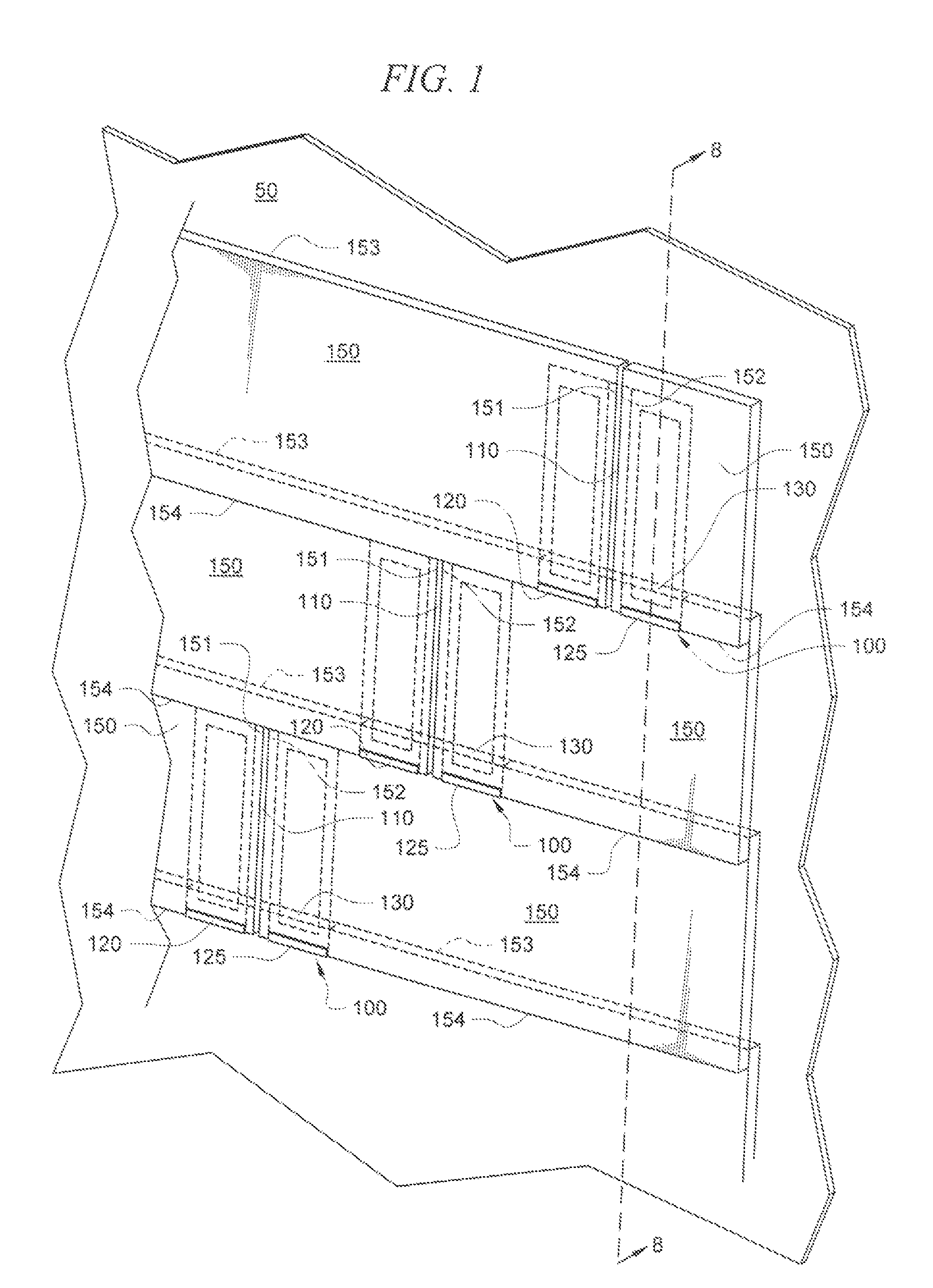

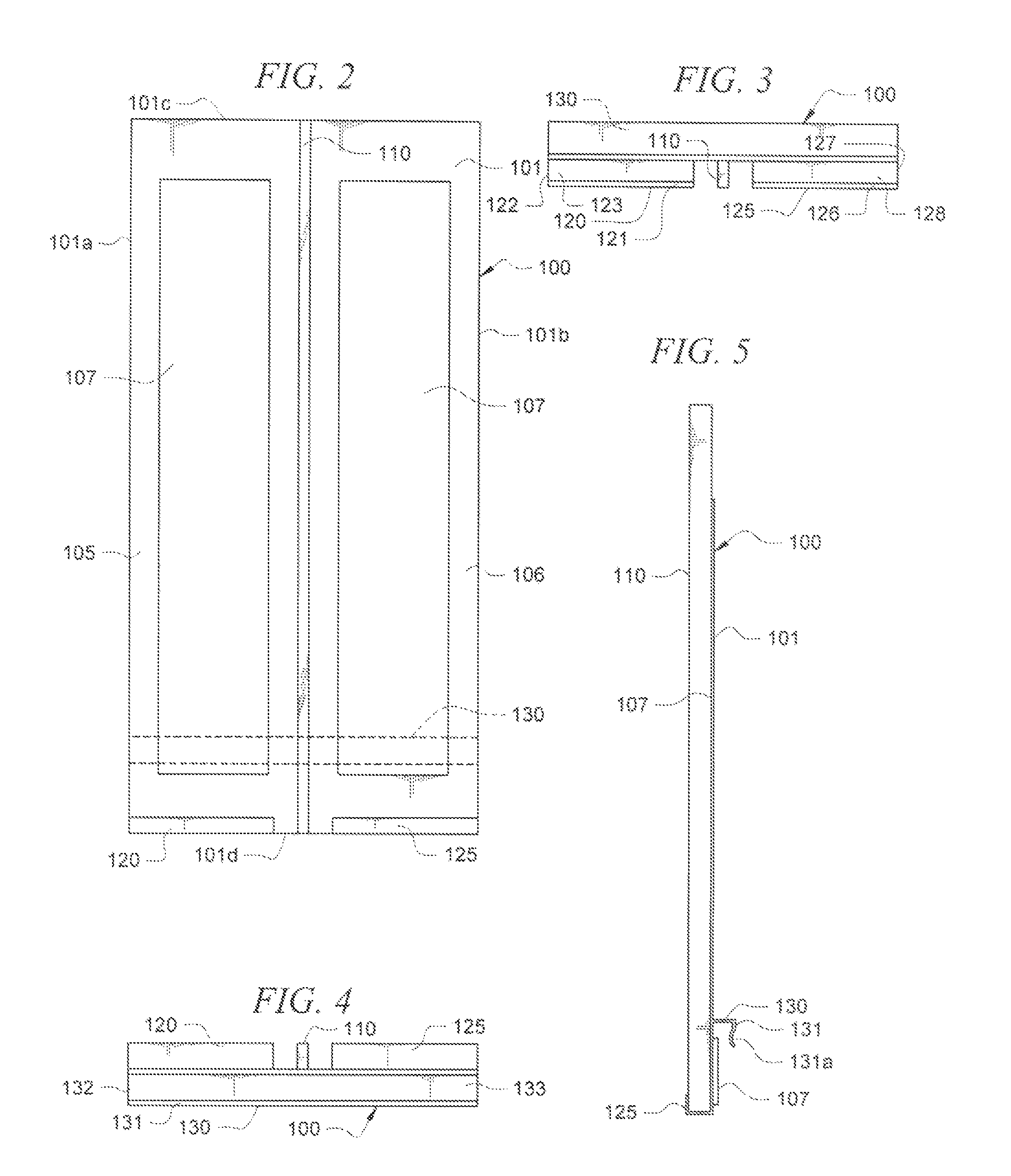

Apparatus for Aiding in the Installation and Sealing of Siding

InactiveUS20080209834A1Eliminate unsightly appearanceRoof covering using tiles/slatesCovering/liningsCement compositesEngineering

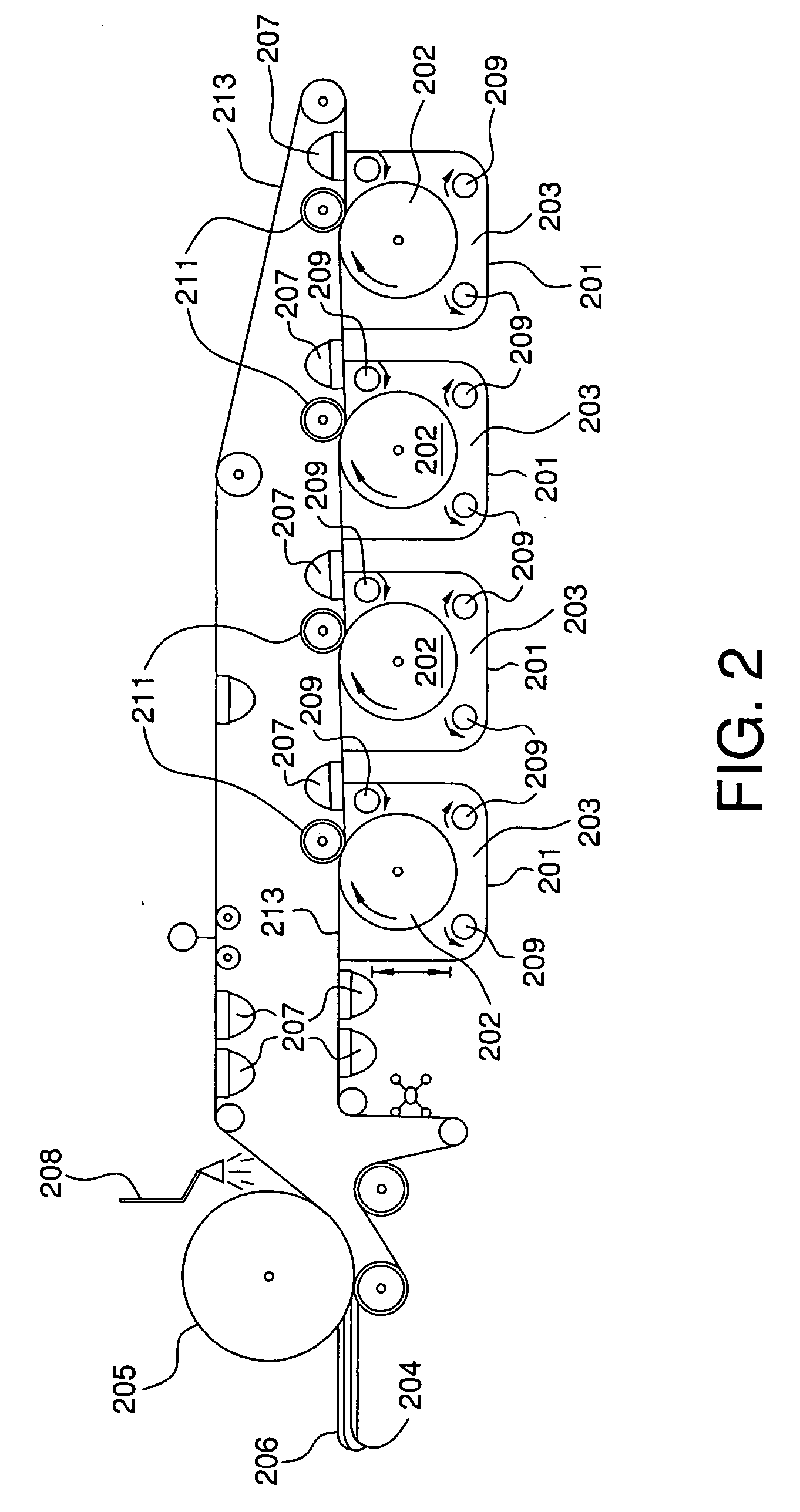

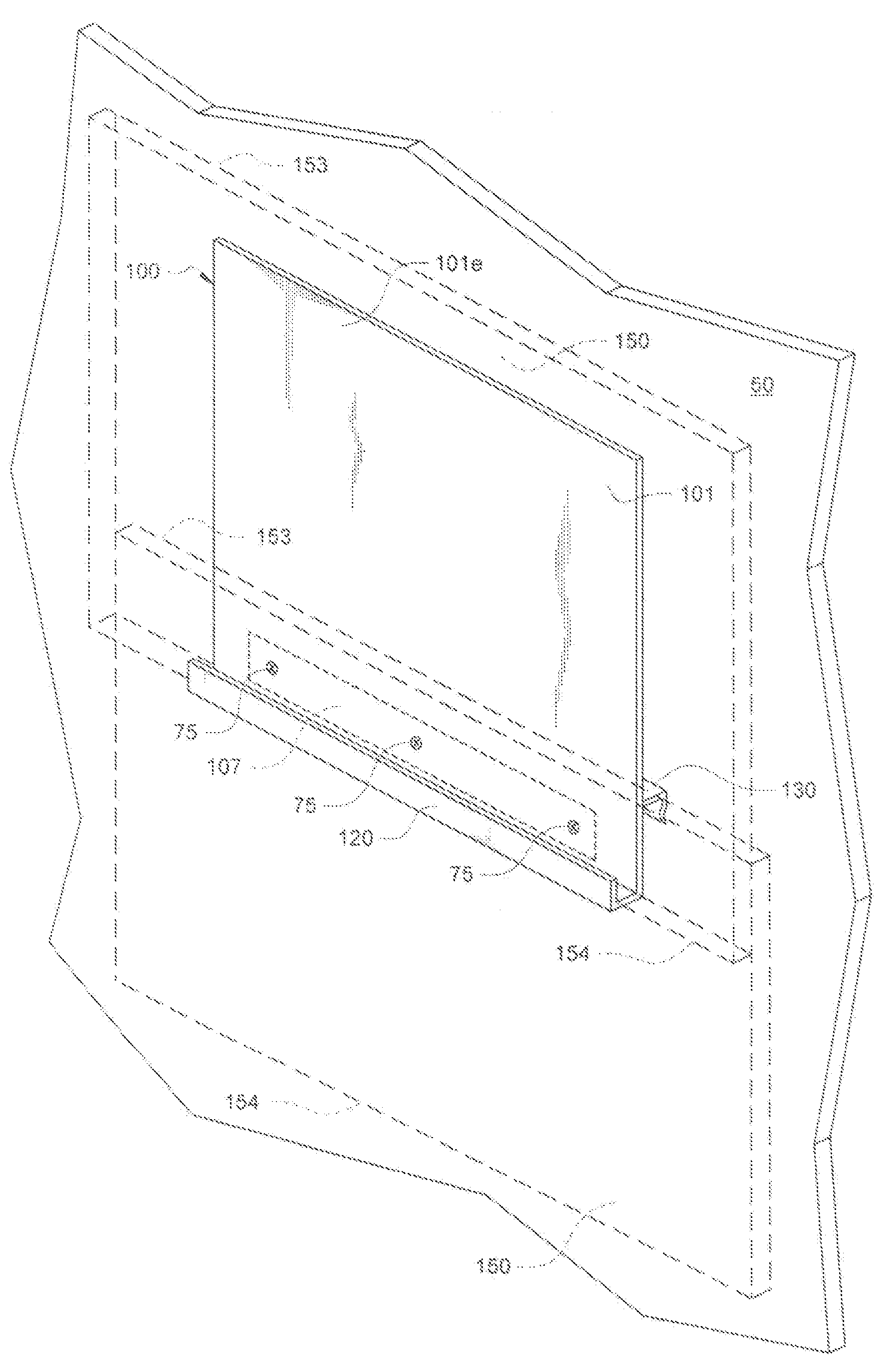

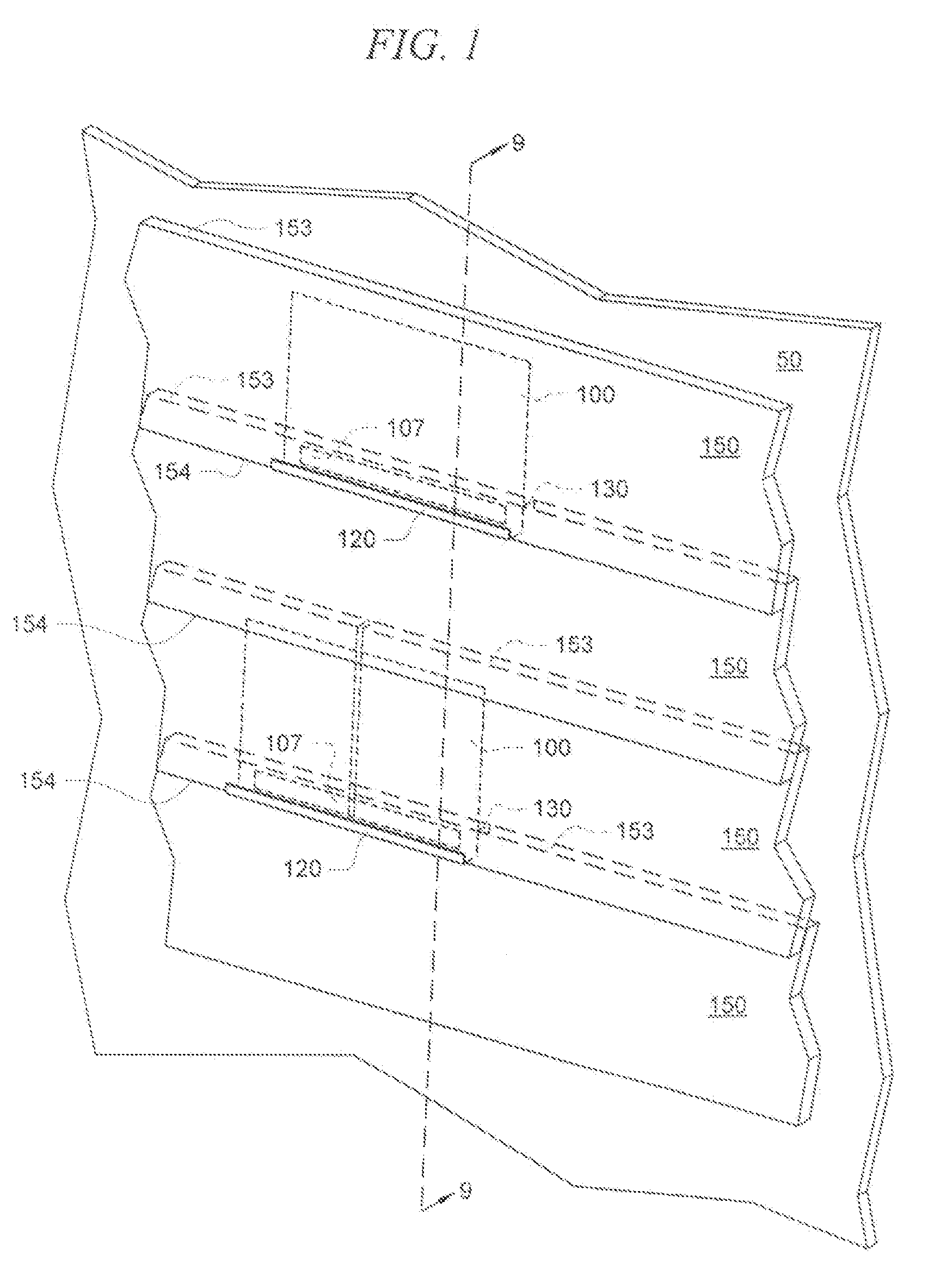

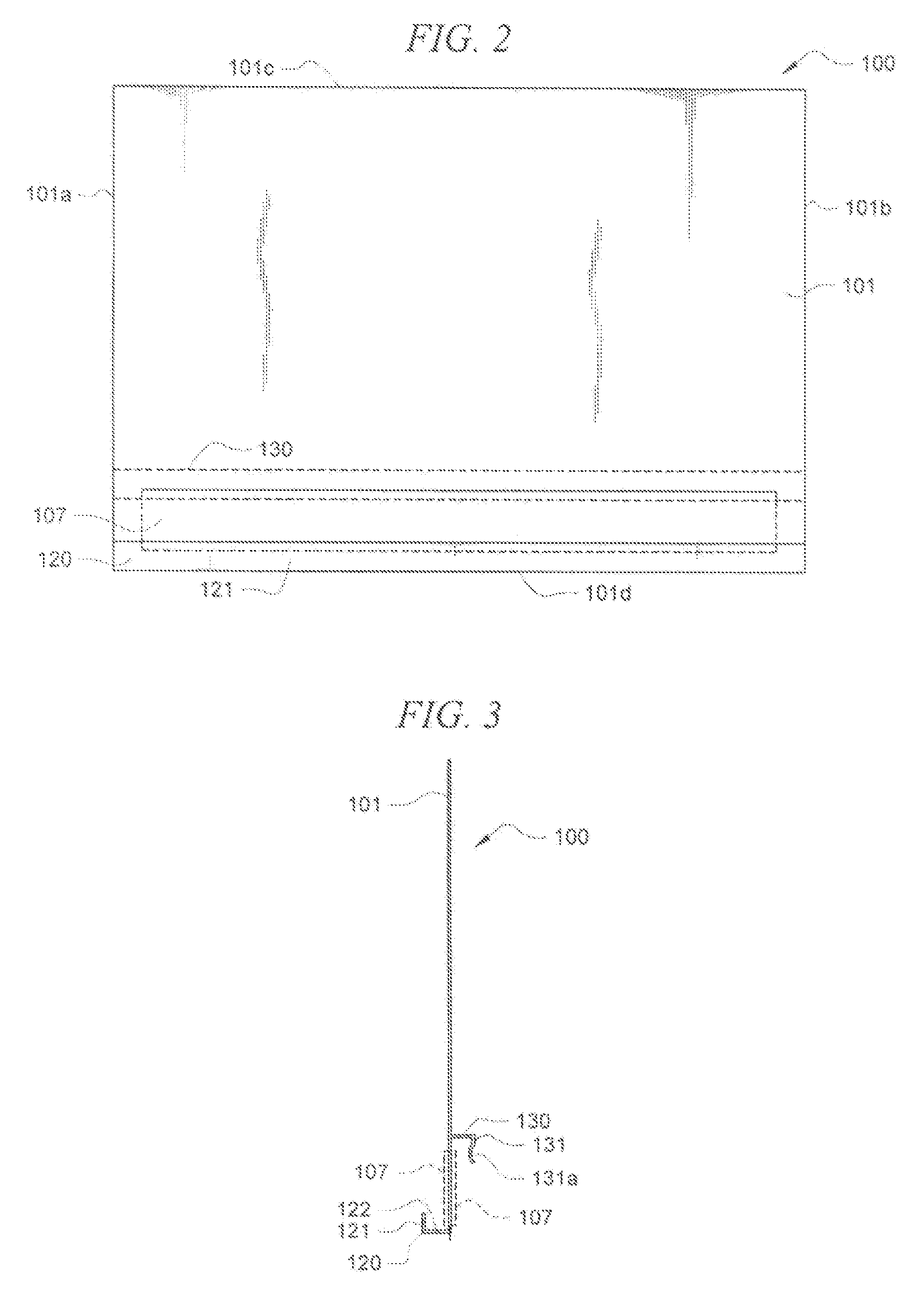

An apparatus (100) for aiding in the installation of successive horizontal layers of siding members (150) to a sidewall construction (50). The apparatus (100) also aids in the sealing of the seams between successive horizontal siding layers. In the exemplary embodiment of the invention, the apparatus (100) is used to aid in the installation and sealing of siding members (150) comprised of a fiber cement composite material. The fiber cement composite siding members (150) are heavier than traditional siding pieces and require more than one person to lift for installation. With the use of the apparatus (100), successive horizontal layers of composite siding members (150) can be installed on the sidewall construction (50) by a single person. One or more sealing members 207 secure and seal the siding members (150) to the apparatus (100) and provide a moisture impervious seal between the seams of successive layers of the horizontal siding members (150).

Owner:TROPICAL STAR

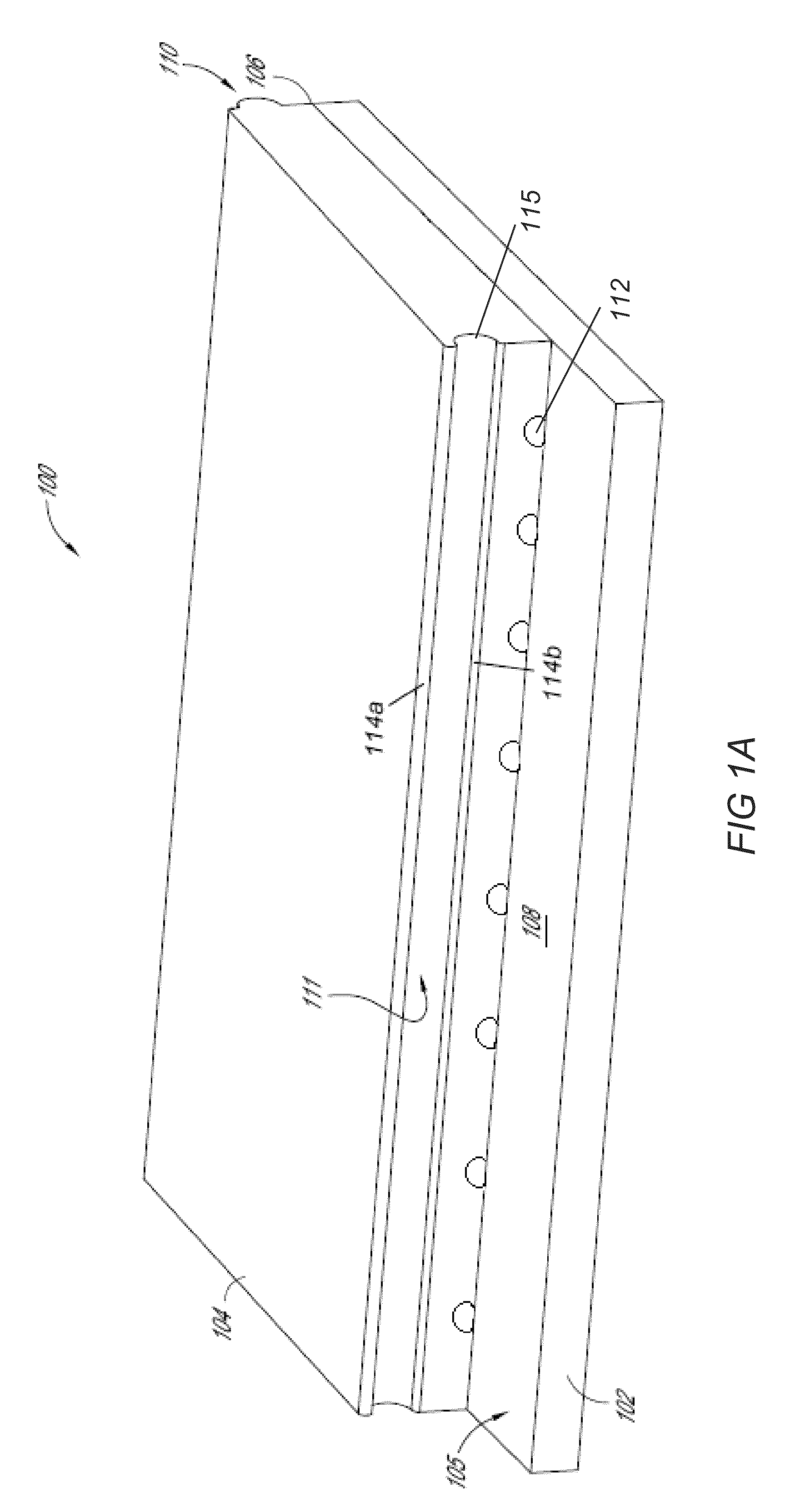

Building inner and outer wall decorating plate and manufacturing method thereof

ActiveCN102425284ASolve Adhesion ProblemsSolve the problems of transfer printing technologyCovering/liningsPretreated surfacesCalcium silicateCross-link

The invention discloses a method for building inner and outer wall decorating plate, which comprises two flows, each flow including steps of: a primer line processing flow: (1) thickness sanding and dedusting, (2) roller painting back seal coat and curing into a first UV seal coat layer, (3) roller painting UV penetrant twice, (4) leveling by infrared ray, (5) coating UV putty at the front and UV curing and generating a UV putty layer, (6) roller painting the UV seal coat for three times and respectively curing and generating three second UV seal coat layers, (7) fine sanding; and a roller painting finish line flow: (1) dedusting, (2) roller painting UV glue and generating a first UV glue layer, (3) coating the UV finish for five times and curing and generating five UV finish layers. The decorating plate can solve the problems that a UV curing penetrating agent is strongly, quickly and deeply penetrated into a fiber reinforced calcium silicate slab or a fiber cement slab, deeply cured to form a film and subjected to stereo chemical netlike cross-linking reaction with UV putty and UV sealing paint, and thoroughly solves the problem of adhesive force between the decorative surface layer and a substrate.

Owner:山东鲁泰装配式装修材料有限公司

Integrated fiber cement and foam as insulated cladding with enhancements

ActiveUS9260864B2Improve insulation performanceReduce the time required for installationConstruction materialCovering/liningsThermal energyMaterials science

An integrated fiber cement and foam cladding system is provided that incorporates foam or similar light weight material to improve the insulation capacity of the cladding system. The system includes at least a fiber cement layer and a foam layer disposed on the backside of the fiber cement layer. The system improves the R-value of the building, a measure of the building's resistance to transferring heat or thermal energy.

Owner:JAMES HARDIE TECH LTD

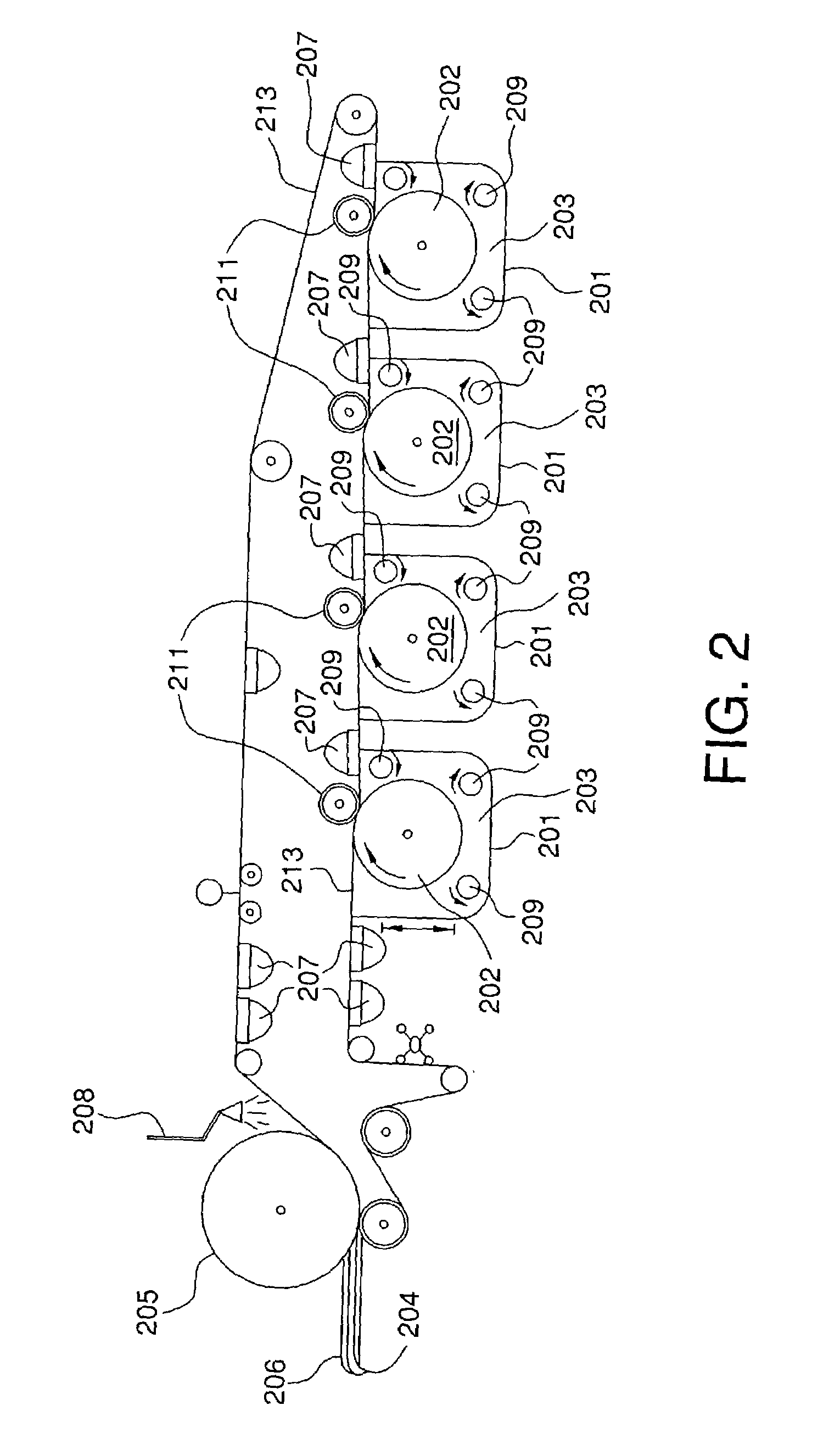

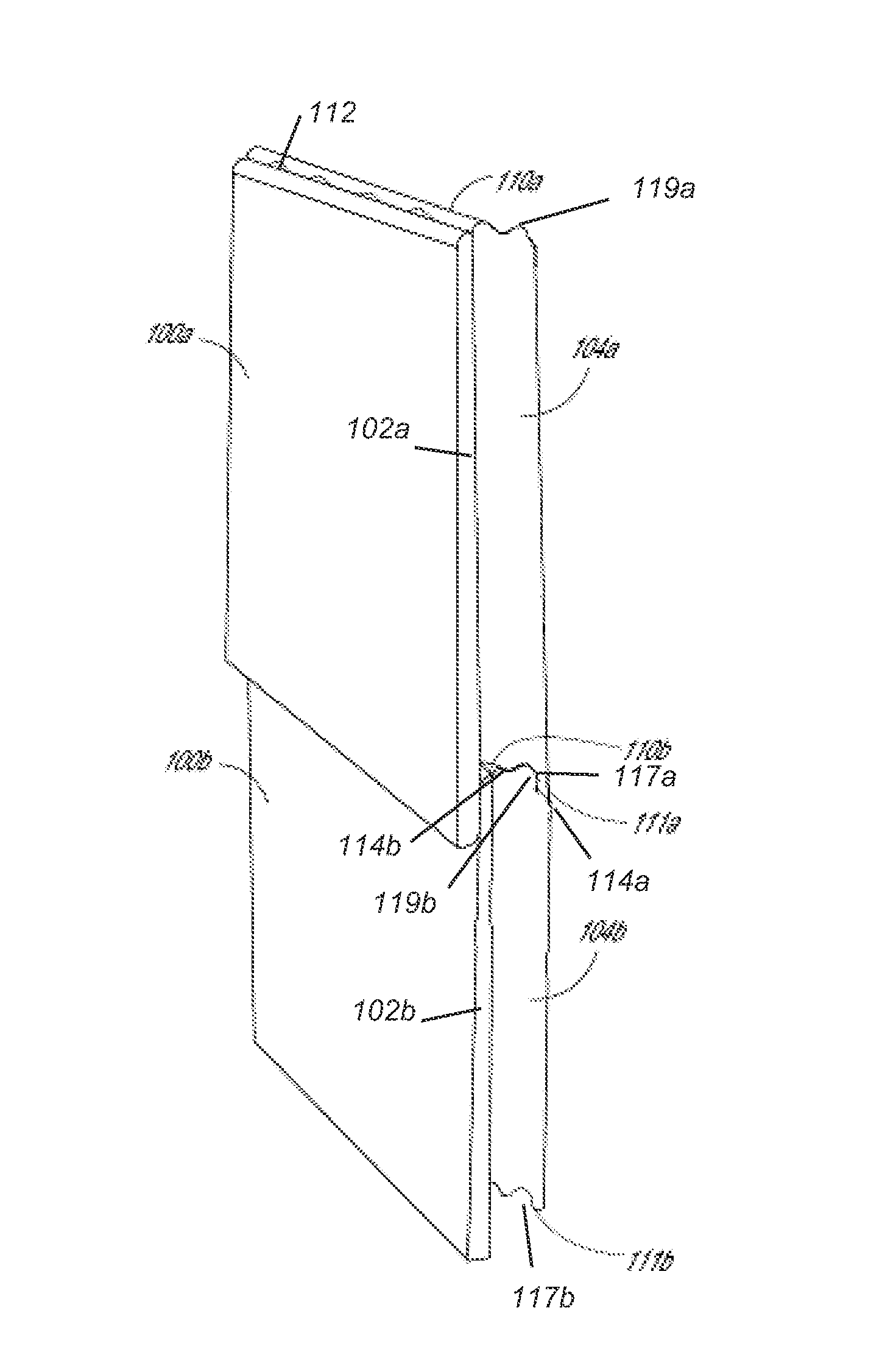

Apparatus for aiding in the installation and sealing of siding

InactiveUS7584587B2Prevent penetrationRoof covering using tiles/slatesCovering/liningsCement compositesEngineering

An apparatus (100) for aiding in the installation of successive horizontal layers of siding members (150) to a sidewall construction (50) of a building. The apparatus also seals the vertical and horizontal seams between adjoining and successive horizontal layers of the siding members (150). In the exemplary embodiment of the invention, the apparatus (100) is used to aid in the installation and sealing of siding members (150) comprised of a fiber cement composite material. The fiber cement composite siding members (150) are heavier than traditional siding pieces and require more than one person to lift for installation. With the use of the apparatus (100), successive horizontal layers of composite siding members (150) can be installed on the sidewall construction (50) by a single person. One or more sealing members (107) secure and seal the siding members (150) to the apparatus (100) and provide a moisture impervious seal between adjoining and successive horizontal layers of the siding members (150).

Owner:TROPICAL STAR

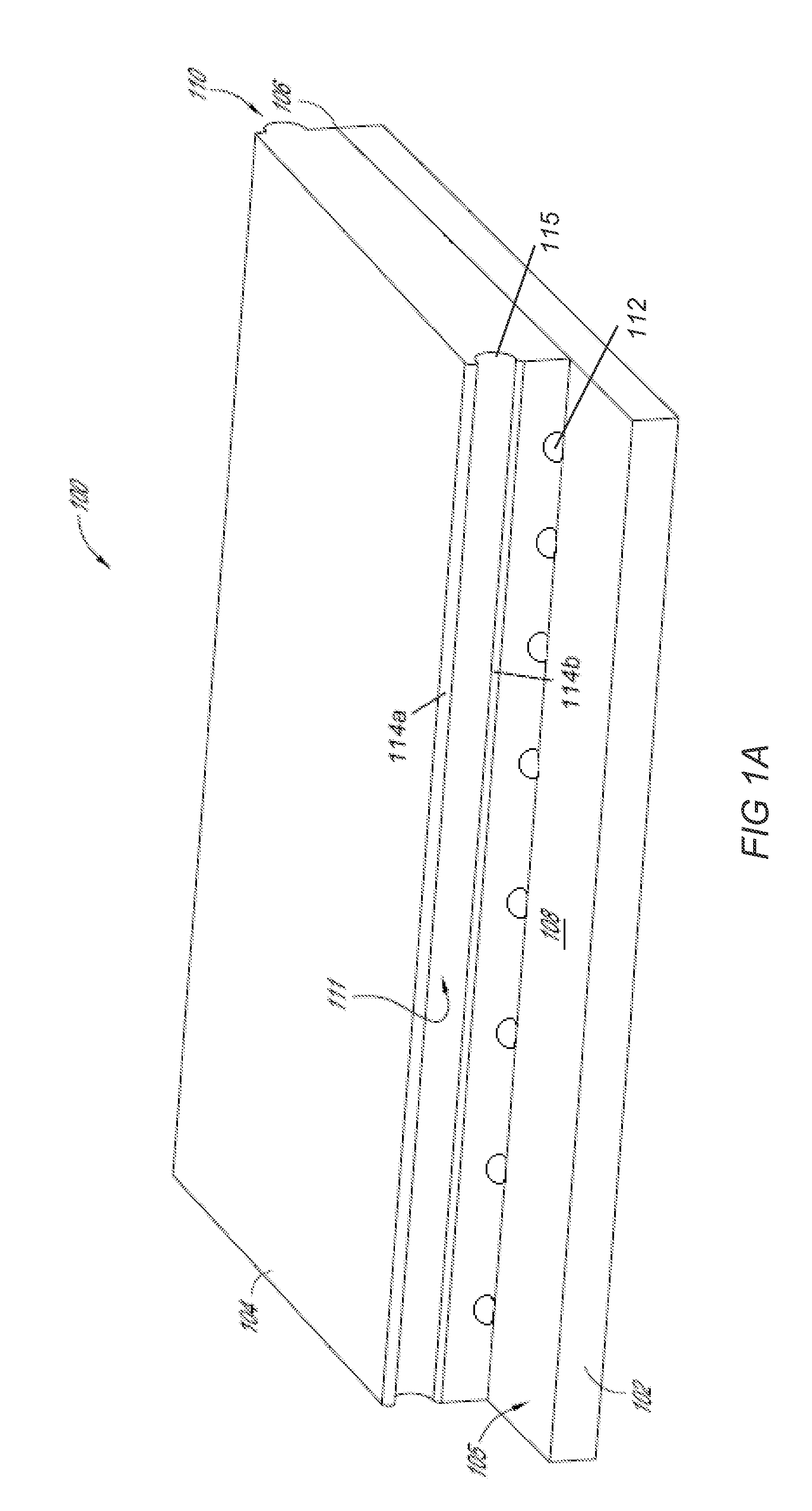

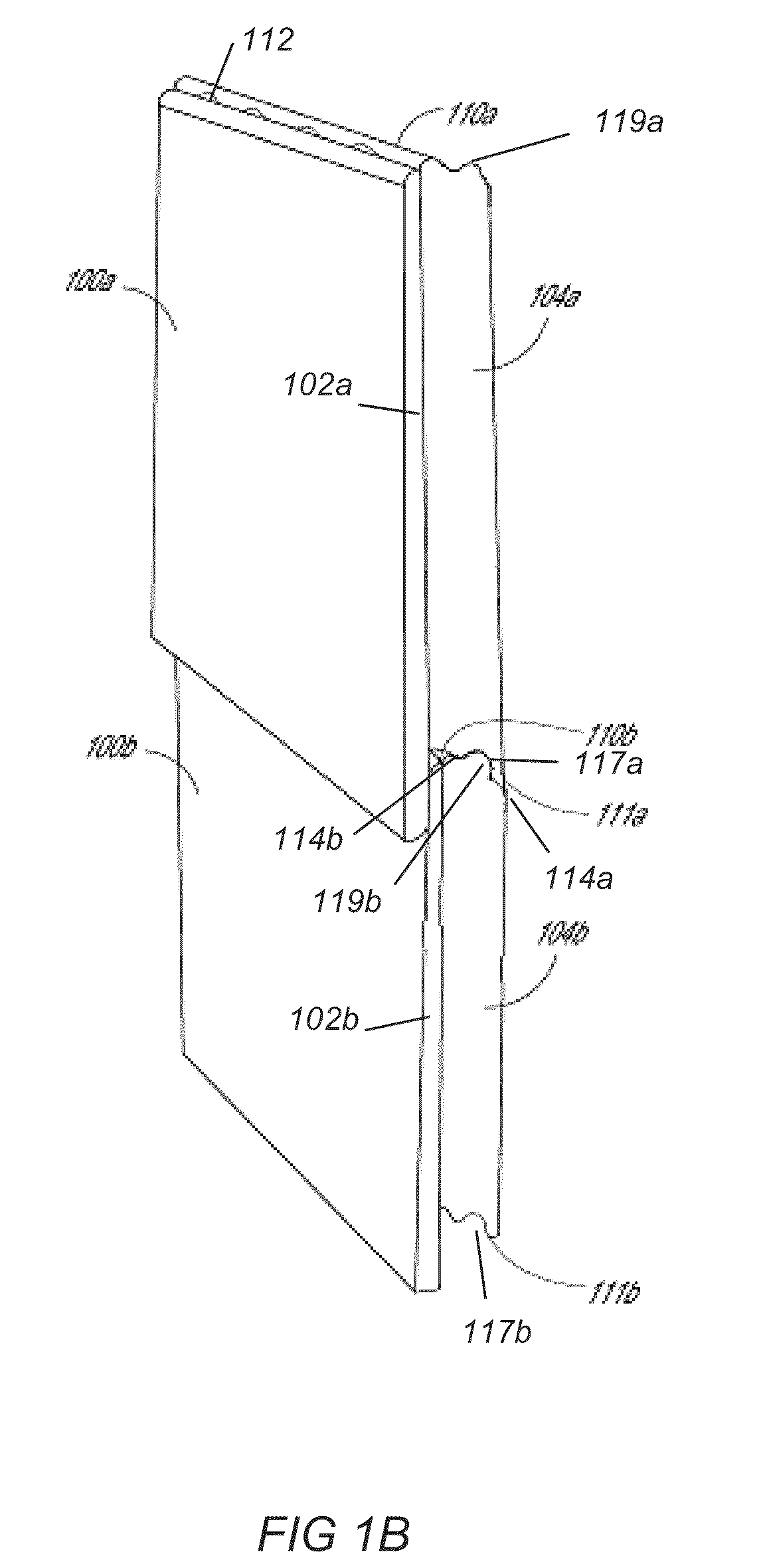

Reinforced fiber cement article and methods of making and installing the same

InactiveUS7713615B2High fiber strengthHigh tensile strengthRoof covering using tiles/slatesConstruction materialAdhesiveUltimate tensile strength

In one embodiment, a reinforced fiber cement article comprising a fiber cement piece and a reinforcing fixture bonded to a portion of the fiber cement piece for improving the performance, strength and durability of the fiber cement piece. The reinforcing fiber cement article could be used as or in conjunction with a siding plank assembly, which further comprises an interlocking feature that allows the siding plank to be stacked with other siding planks in a manner such that a uniform and deep shadow line is created. The interlocking feature sets the gauge of the exposed plank face and allows for leveling of the plank during installation. The reinforcing fixture could also serve as a thick butt piece or a plastic spline that produces a deep shadow line. A cementitious adhesive is used to bond the reinforcing fixture to the fiber cement piece.

Owner:JAMES HARDIE TECH LTD

Cast-in-situ light weight composite wall and its architecture construction method

InactiveCN101260693ASimplify the construction processFast constructionWallsJoistUltimate tensile strength

The invention discloses a cast-in-situ composite wall body and a construction method thereof, belonging to the construction field, wherein, the construction method comprises the following steps of: using fiber cement to prepare a precast wall panel; alternately arranging lightgage steel joists on the position to be constructed with the wall body; assembling precast wall panels which form wall surfaces of two sides of the wall body layer by layer against two sides of the lightgage steel joists respectively; respectively fixing anti-expansion moulds on two sides of the wall surfaces by means of positioning bolts / nuts; casting light-weight concrete through plug holes in space assembled by the precast wall panels at two sides; and removing the anti-expansion components and stopping the plug holes and the bolt holes on the precast wall panels after the precast wall panels and the light-weight concrete are congealed together. The method of the invention has the characteristics of simple construction, high efficiency and low cost, and the constructed wall body has the advantages of good sound insulation effect, good performance of heat insulation, and high strength of the wall body.

Owner:刘文博

Road surface structure of rolling flexiable fibre cement concrete as based and construction method thereof

InactiveCN100999888AReduce plastic shrinkageEnhanced resistance to shrinkage crackingPaving reinforcementsIn situ pavingsSurface layerFrost

The present invention relates to road structure and construction technology, and is especially road structure with rolled flexible fiber cement concrete layer as the base layer and its construction process. The road structure includes one bottom layer; one base layer and one paved surface layer, and the base layer of rolled flexible fiber cement concrete is formed through mixing flexible fiber, cement and water to form cementing material, adhering aggregate, stuffing, admixture, etc with the cementing material, and rolling. The rolled flexible fiber cement concrete has obviously improved early plastic shrinking, dry shrinking and hot shrinking performance, obviously raised anticracking performance, toughness, impact strength, frost resistance and erosion resistance, and doubled antifatigue performance. The road with the base layer of rolled flexible fiber cement concrete has raised performance and increased service life.

Owner:易志坚 +3

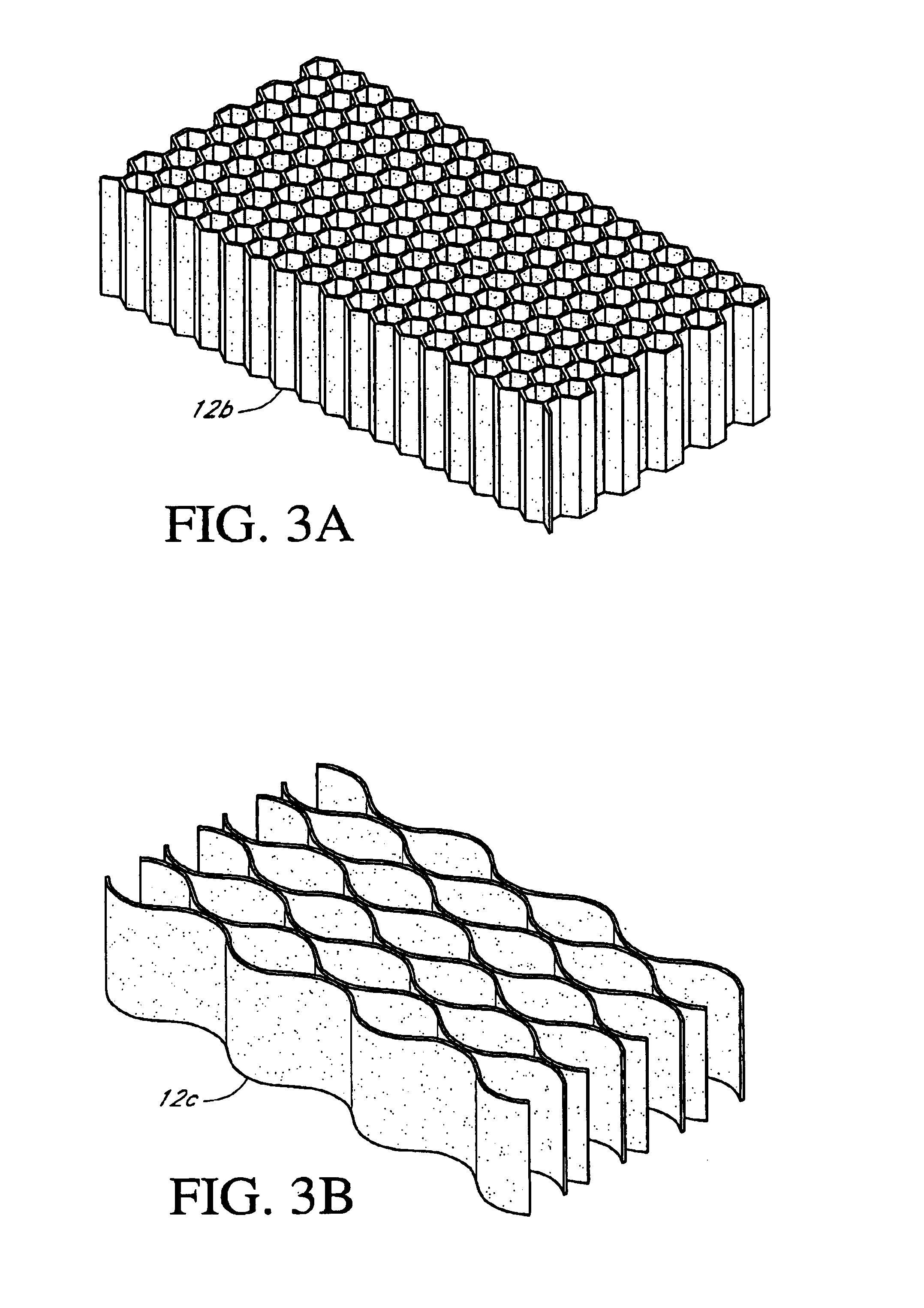

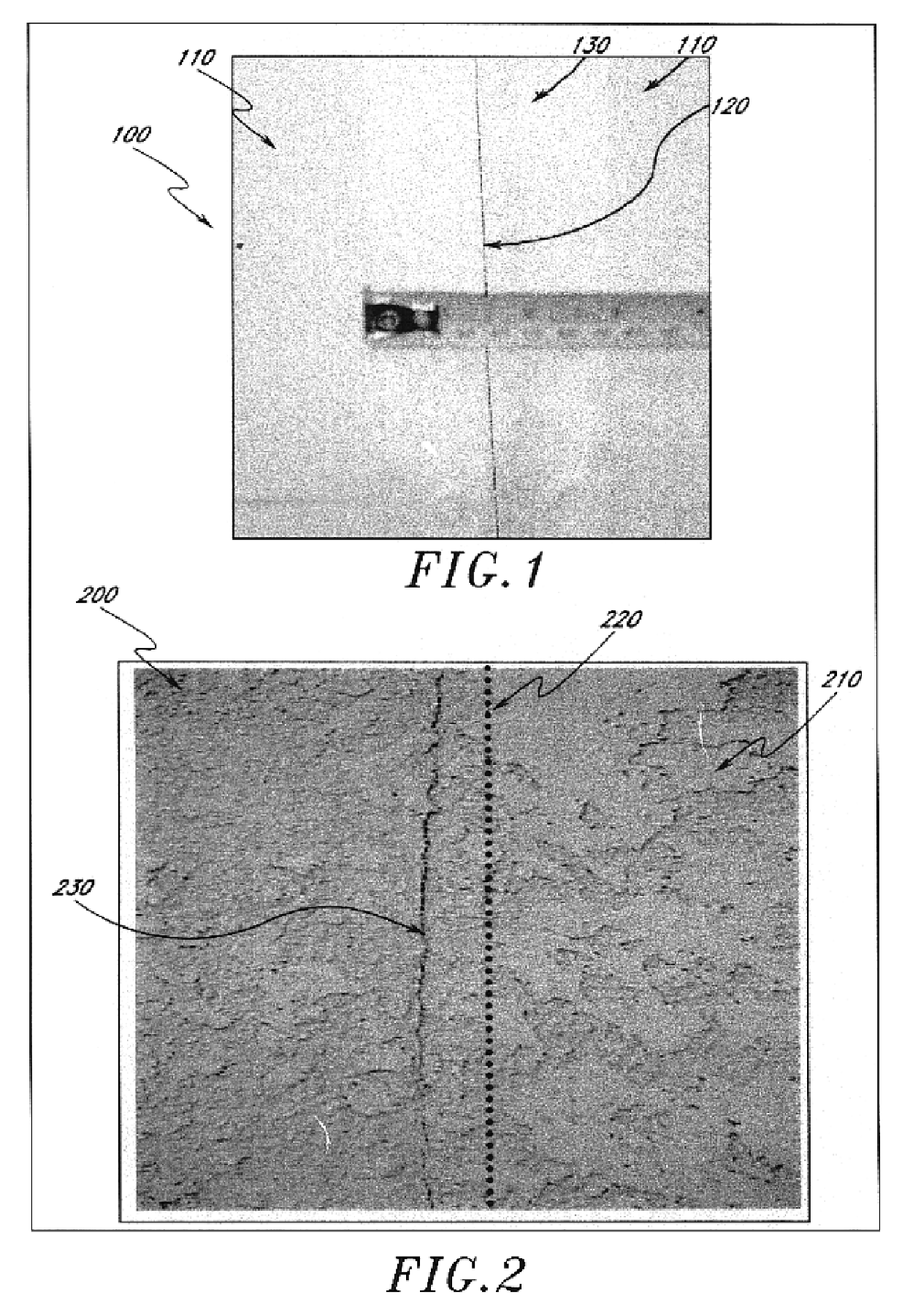

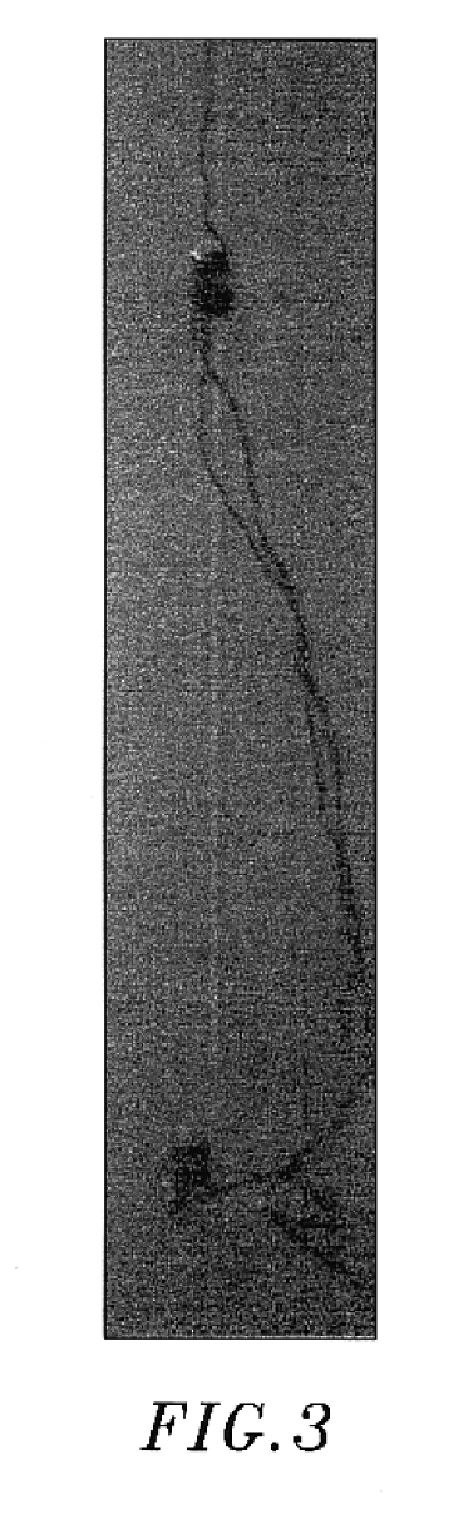

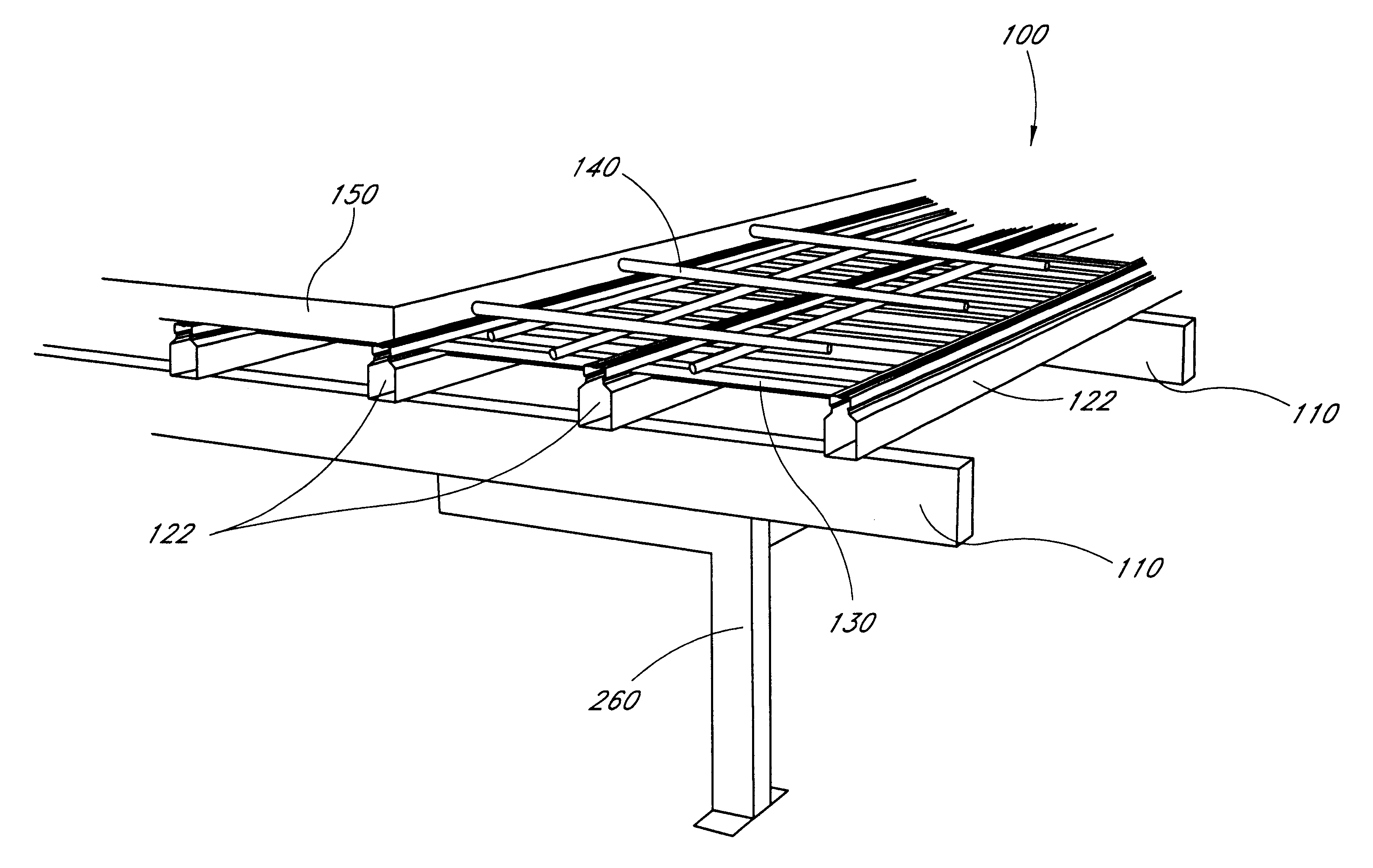

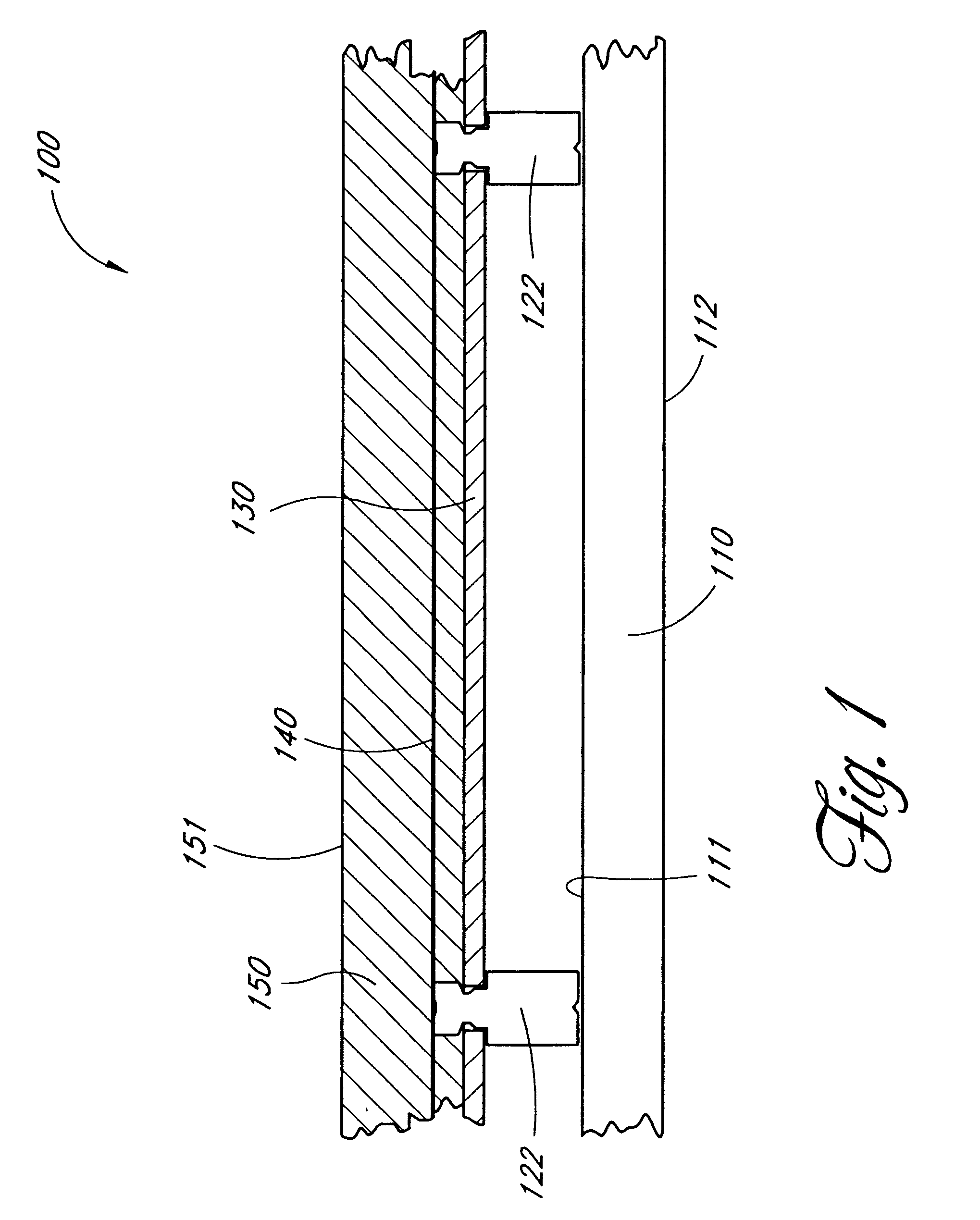

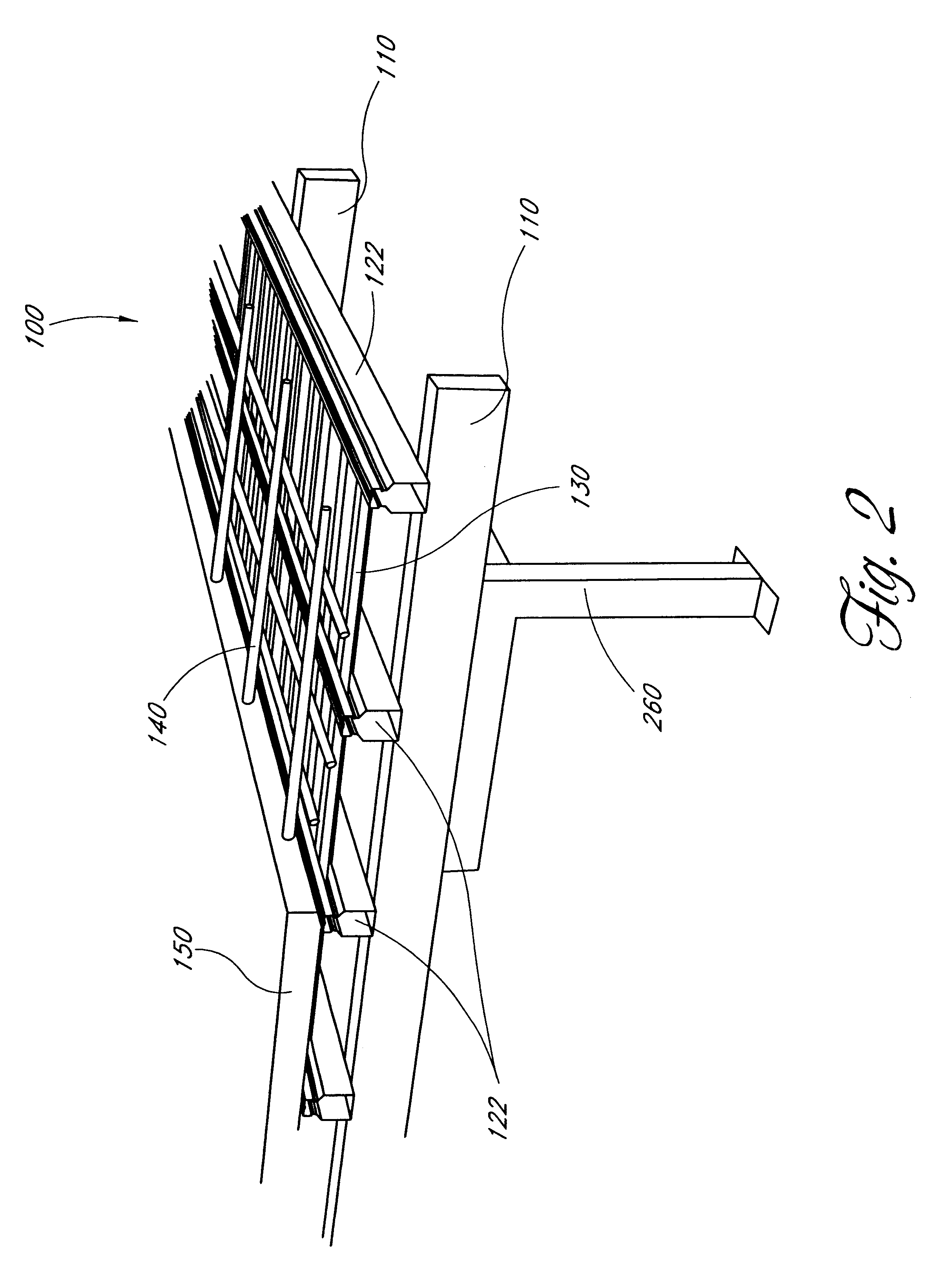

Suspended concrete flooring system and method

A suspended concrete flooring system (100) comprising a plurality of spaced-apart load-bearing members (110) or supporting walls that support a plurality of joists (122) having opposing sides and arranged substantially at right-angles to the load-bearing members. The joists have a support shelf (127) running the length of each opposing side for the purpose of supporting a plurality of fiber cement corrugated sheets (130) that span the space between the joists. A shrinkage control mesh (140) is arranged atop the corrugated sheets and is oriented generally in the direction of the load-bearing members and the joists. A thin layer of concrete (150) is formed over the corrugated sheets and the shrinkage control mesh, to form a flat, horizontal floor surface (151). The load-bearing members and the joists are made of strong, lightweight materials, such as steel. The combination of the light-weight structural materials, the fiber cement corrugated sheets, and the thin concrete layer allows for a suspended concrete floor system that is easily constructed and that has a relatively wide span as compared to conventional suspended concrete floor systems.

Owner:JAMES HARDIE TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com