Nano self-cleaning fiber reinforced cement product and production method for same

A fiber-reinforced cement, production method technology, applied in the field of air purification function, nano-photocatalytic anti-fouling and self-cleaning, can solve the problems of not finally achieving the expected effect, poor waterproof performance and durability, unable to meet the weather resistance of building exterior walls, etc. To achieve the effect of improving the quality of the atmospheric environment and maintaining human safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

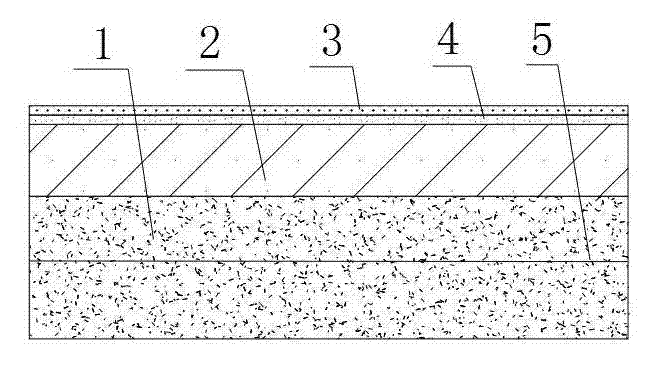

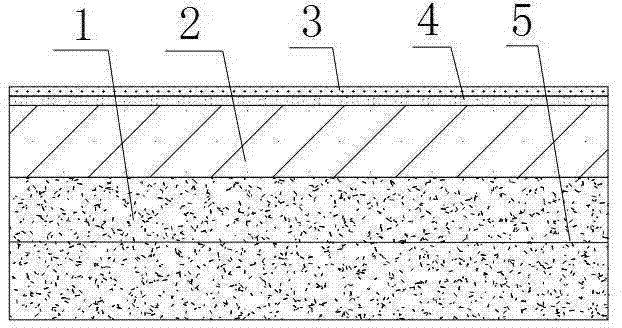

Embodiment 1

[0064] 1) Mix 25kg (25%) of cement, 35kg (35%) of sand, 13kg (13%) of glass chips, 1kg (1%) of PVA fiber, 1kg (1%) of PP fiber, and 5kg (5%) of powdered pigment. , dispersible latex powder 5kg (5%), water reducing agent naphthalene sulfonate formaldehyde condensate 0.3kg (0.3%), early strength agent sulfate 0.3kg (0.3%), antifreeze calcium chloride 0.2kg (0.2%) ), mixed siliceous powder waterproofing agent 0.2kg (0.2%), metakaolin 2kg (2%), stone powder 1kg (1%), water 11kg (11%) and mixed evenly to make fiber-reinforced cement decorative surface mortar .

[0065] 2) Use the prepared fiber reinforced cement decorative surface layer mortar to make the fiber reinforced cement decorative surface layer in the mold with decorative effect by spraying method. The thickness of the surface layer is 3mm, and it is cured naturally for 10 minutes.

[0066] 3) Mix 25kg (25%) of cement, 46kg (46%) of sand, 3kg (3%) of alkali-resistant glass fiber, 2kg (2%) of basalt fiber, 5kg (5%) of re...

Embodiment 2

[0074] 1) Mix 46kg (46%) of cement, 15kg (15%) of fine stones, 10kg (10%) of ceramic chips, 2kg (2%) of liquid pigment, and 0.5kg (0.5%) of water reducing agent sulfonated melamine formaldehyde condensate , early strength agent nitrite 0.5kg (0.5%), expansion agent sulfoaluminate 0.5g (0.5%), retarder citric acid 0.5kg (0.5%), fly ash 3kg (3%), silica fume 2kg (2%) and 20kg (20%) of water are mixed evenly to make fiber-reinforced cement decorative surface mortar.

[0075] 2) The prepared fiber reinforced cement decorative surface layer mortar is used to make a fiber reinforced cement decorative surface layer with a thickness of 4mm in a mold with a decorative effect by brushing, and it is naturally cured for 30 minutes.

[0076] 3) Mix cement 50kg (50%), sand 28kg (28%), carbon fiber 1kg (1%), water reducing agent sulfonated melamine formaldehyde condensate 0.2kg (0.2%), early strength agent nitrite 0.3kg (0.3 %), antifreeze potassium carbonate 0.3kg (0.3%), retarder wood c...

Embodiment 3

[0085] 1) Stir 28kg (28%) of cement, 36kg (36%) of sand, 20kg (20%) of metal chips, 1kg (1%) of PU fiber, 1kg (1%) of styrene-acrylic emulsion, and 14kg (14%) of water After uniformity, fiber-reinforced cement decorative surface layer mortar is made.

[0086] 2) The configured fiber reinforced cement decorative surface layer mortar is used to make a decorative surface layer with a thickness of 5mm in a mold with decorative effect by laying vibration method, and it is cured naturally for 60 minutes.

[0087] 3) 30kg (30%) of cement, 52kg (52%) of sand, 2kg (2%) of PVA fiber, 1kg (1%) of polypropylene emulsion, 1kg (1%) of fly ash, and 14kg (14%) of water are as follows: The weight percentage ratio is mixed, and the slurry is made into fiber-reinforced cement structural layer by stirring evenly.

[0088] 4) After the fiber reinforced cement structure layer slurry is configured, it is laid in a mold with a fiber reinforced cement decorative surface layer, and the slurry is scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com