Emulsified waste water treatment oil removing agent and preparation method and use method thereof

A technology for emulsifying wastewater and clearing oil, applied in separation methods, grease/oily substances/suspton removal devices, liquid separation, etc., can solve the problem of poor treatment effect of high-temperature emulsified sewage, affecting normal production process, clogging of air flotation aerators, etc. problem, to achieve significant treatment effect, good stability of treatment effect, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 4

[0018] Example 4 of preparation of oil clearing agent for emulsified wastewater treatment: According to the data in Table 1, formula 4, 95.95 grams of water was poured into the reactor, and 0.03 grams of glycerin was added while stirring in the water, and the stirring was continued for at least 10 minutes; Add 0.95 grams of sodium silicate to the solution while stirring, and continue to stir for at least 20 minutes; add 0.07 grams of polydiallyldimethylammonium chloride to the solution obtained in the above steps, heat to 30 ° C and stir for 3 hours; Add 1.40 gram of magnesium sulfate, 1.60 gram of aluminum potassium sulfate successively while stirring in the solution that above-mentioned steps obtains, after continuing to stir for 2 hours, cool to room temperature to obtain emulsified waste water treatment clear oil agent, this emulsified waste water treatment oil clear agent is light yellow liquid visually, pH Value 7.2.

preparation Embodiment 5

[0019] Example 5 of preparation of oil clearing agent for emulsified wastewater treatment: According to the data in Table 1, formula 5, 95.95 grams of water was poured into the reactor, and 0.04 grams of glycerol was added while stirring in the water, and the stirring was continued for at least 10 minutes; Add 0.95 grams of sodium silicate to the solution while stirring, and continue to stir for at least 20 minutes; add 0.06 grams of polydiallyldimethylammonium chloride to the solution obtained in the above steps, heat to 30 ° C and stir for 3 hours; Add 1.20 grams of magnesium sulfate and 1.80 grams of potassium aluminum sulfate successively to the solution obtained in the above steps while stirring, and then continue to stir for 2 hours and then cool to room temperature to obtain an emulsified wastewater treatment oil clearing agent. Value 7.2.

preparation Embodiment 6

[0020] Example 6 of preparation of oil clearing agent for emulsified wastewater treatment: According to the data in Table 1, formula 6, 95.89 grams of water was poured into the reaction kettle, and 0.05 grams of glycerin was added while stirring in the water, and the stirring was continued for at least 10 minutes; to the above steps to obtain Add 1.00 g of sodium silicate to the solution while stirring, and continue to stir for at least 20 minutes; add 0.06 g of polydiallyldimethylammonium chloride to the solution obtained in the above steps, heat to 30 ° C and stir for 3 hours; Add 1.00 gram of magnesium sulfate and 2.00 gram of potassium aluminum sulfate successively to the solution obtained in the above steps while stirring, and then continue to stir for 2 hours and then cool to room temperature to obtain an emulsified wastewater treatment oil clearing agent, which is a colorless liquid by visual inspection, pH Value 7.3.

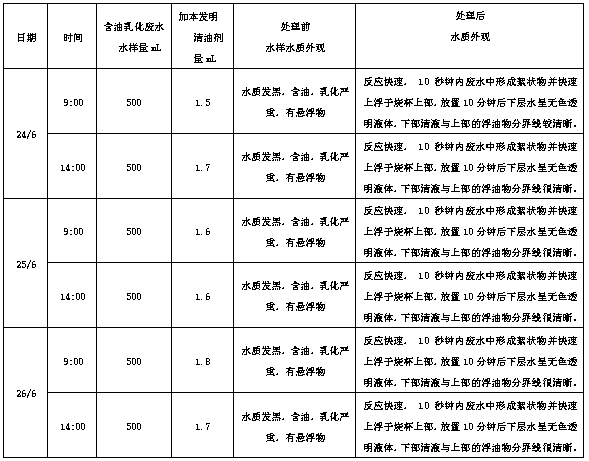

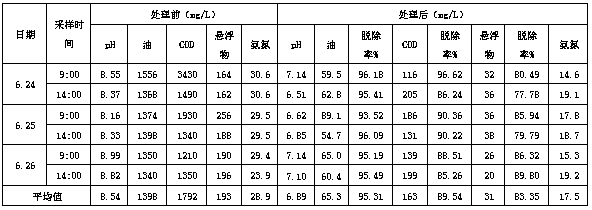

[0021] When the emulsified waste water treatment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com