Preparation method of electrostatic absorption heating slurry prepared from graphene carbon nano tube

A technology of graphene carbon and carbon nanotubes, which is applied in the direction of conductive coatings, etc., can solve the problems of high cost, difficult dispersion, and aggregation of graphene, and achieve the effects of reducing production costs, improving antistatic performance, and reducing the content of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

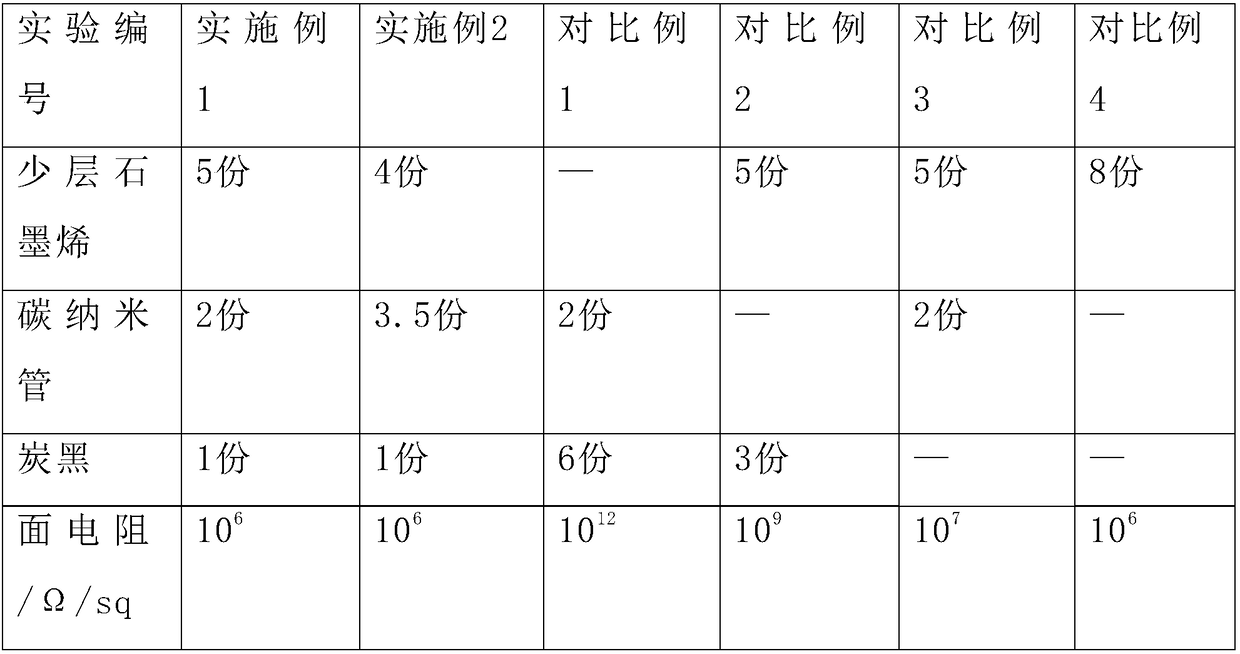

Embodiment 1

[0018] The static electricity heating slurry that a kind of graphene carbon nanotube is made comprises (mass part): 5 parts of few-layer graphene, 2 parts of carbon nanotubes, 1 part of carbon black, 30 parts of film-forming substances, 60 parts of solvent, 1 part 1 part acidic reagent, 1 part dispersant.

[0019] The preparation method of static electricity heating slurry is as follows: weigh the required amount of few-layer graphene, carbon nanotubes, and carbon black according to the proportion, add solvent, acidic reagent, film-forming substance, and dispersant to form a mixed solution, and mechanically disperse for a period of time. Wait until the mixed solution does not separate, and disperse at high speed for two hours to obtain a heat-generating slurry that absorbs static electricity.

Embodiment 2

[0021] The static electricity heating slurry that a kind of graphene carbon nanotube is made comprises (mass part): 4 parts of few-layer graphene, 3.5 parts of carbon nanotubes, 1 part of carbon black, 30 parts of film-forming substances, 60 parts of solvents, 0.5 parts 1 part acidic reagent, 1 part dispersant.

[0022] The preparation method of the static electricity heating slurry is as follows: select the required amount of few-layer graphene, carbon nanotubes, and carbon black, add solvents, acidic reagents, film-forming substances, and dispersants to form a mixed solution, and mechanically disperse for a period of time until the mixture is mixed. The liquid is not separated, and it is dispersed at high speed for two hours to obtain a heat-generating slurry that absorbs static electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com