Patents

Literature

112results about How to "Reduced content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor polymer taking compound graphene/carbon black as conductive medium and preparation method

ActiveCN107011568AStructure remains intactAvoid reunionNon-conductive material with dispersed conductive materialIn situ polymerizationSolvent

The invention discloses a semiconductor polymer taking compound graphene / carbon black as a conductive medium and a preparation method. The semiconductor polymer comprises the following raw materials in percentage by weight: 60-70% of an ethylene-vinyl acetate copolymer, 1-3% of a graphene / polyaniline compound, 10-15% of inorganic filler, 15-20% of carbon black and 1-1.4% of a crosslinking agent. The preparation method comprises the following steps: (1) dispersing the graphene / polyaniline compound in an organic solvent, then mixing the mixture with the inorganic filler, and filtering and drying the mixture to obtain a filler compound; and (2) melting and blending the obtained filler compound with other components or mixing the same in the solvent, then removing the solvent, and performing thermal pressing to obtain the semiconductor polymer. According to the invention, polyaniline is polymerized to the surface of graphene in situ by means of a conjugate action of a benzene ring and graphene, so that the intact conjugate structure of graphene is kept; by compounded use with the inorganic filler and carbon black, the agglomeration problem when the graphene and the polymer is mixed is effectively solved, and meanwhile, the dosage of carbon black is reduced.

Owner:SHANGHAI ELECTRICGROUP CORP

Dandruff removal shampoo and method for manufacturing same

ActiveCN105267097APromote blood circulationEfficient removalCosmetic preparationsHair cosmeticsDIHYDROXYPROPYLTRIMONIUM CHLORIDEGuar gum

The invention provides dandruff removal shampoo. The dandruff removal shampoo comprises Chinese herbal medicine extract, shampoo base materials, essence and preservatives. The Chinese herbal medicine extract comprises, by weight, 20-30 parts of Chinese arborvitae twig extract, 10-15 parts of peppermint extract, 10-20 parts of ipomoea cairica extract, 12-18 parts of radix isatidis extract, 8-15 parts of aloe extract, 10-18 parts of green tea extract, 6-12 parts of onion extract, 6-12 parts of lemon extract, 5-8 parts of mulberry extract and 2-10 parts of polygonum multiflorum and ginseng joint extract which are mixed with one another to obtain the Chinese herbal medicine extract; the shampoo base materials comprise, by weight, 40-50 parts of sodium dodecyl sulfate, 40-60 parts of water, 5-10 parts of cocamides and 2-4 parts of guar gum hydroxypropyl trimethyl ammonium chloride. The invention further provides a method for manufacturing the dandruff removal shampoo. The dandruff removal shampoo and the method have the advantages that dandruff can be effectively removed by the dandruff removal shampoo manufactured by the aid of the method, the blood circulation of the scalp of users can be promoted, grease of the scalp can be removed, growth of bacteria of the scalp can be inhibited, and grease secretion of the scalp can be balanced by means of replenishing moisture to the scalp.

Owner:中山市长兴实业有限公司

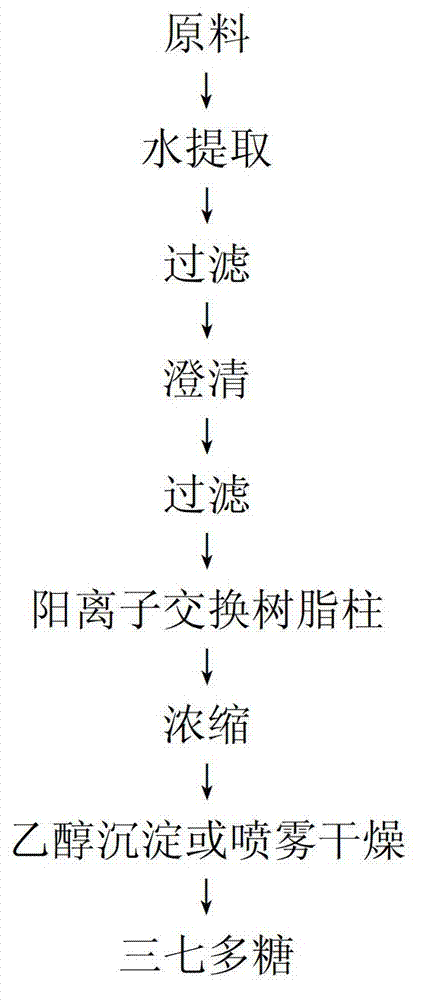

Method for reducing ash content of notoginseng polysaccharide

The invention discloses a method for reducing ash content of notoginseng polysaccharide and improving yield and purity thereof. The method regards notoginseng as a raw material and obtains the notoginseng polysaccharide of low ash by exacting, clearing, deionizing, sedimenting and drying, which is capable of effectively reducing the ash of notoginseng polysaccharide to below 1%, improving the yield for more than 5% and improving the content for more than 70%. The method for reducing ash content of notoginseng polysaccharide disclosed by the invention has the advantages of greatly reducing the content of ash and heavy metal, preventing the ion exchange resin from poisoning, reducing pressure of ion exchange resin, improving efficiency of ion exchange resin, improving product quality and providing advantageous security for production and application of notoginseng polysaccharide.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

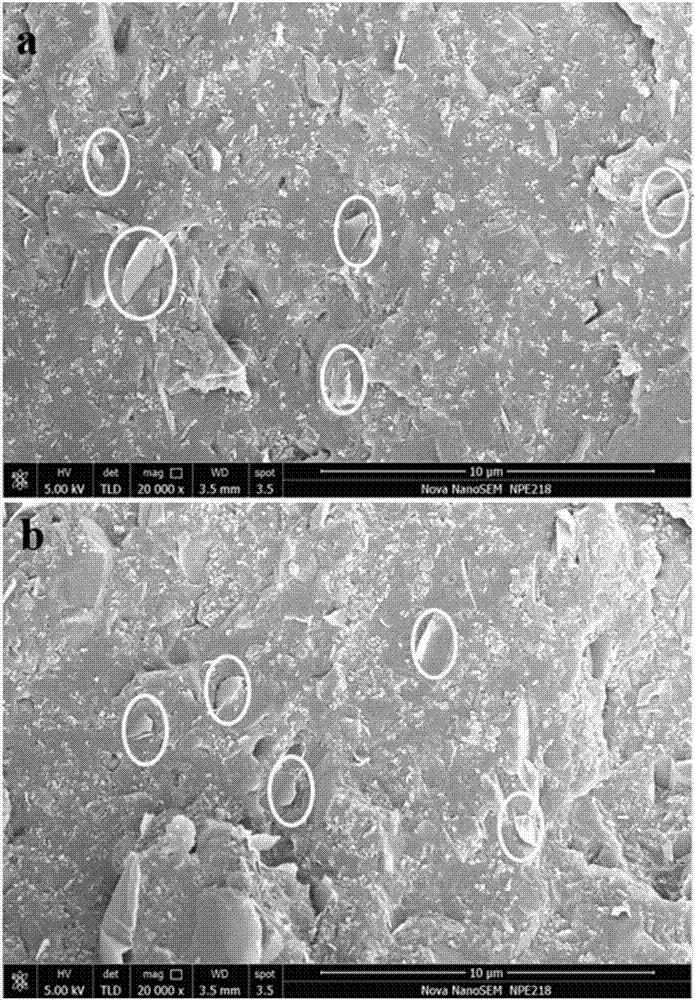

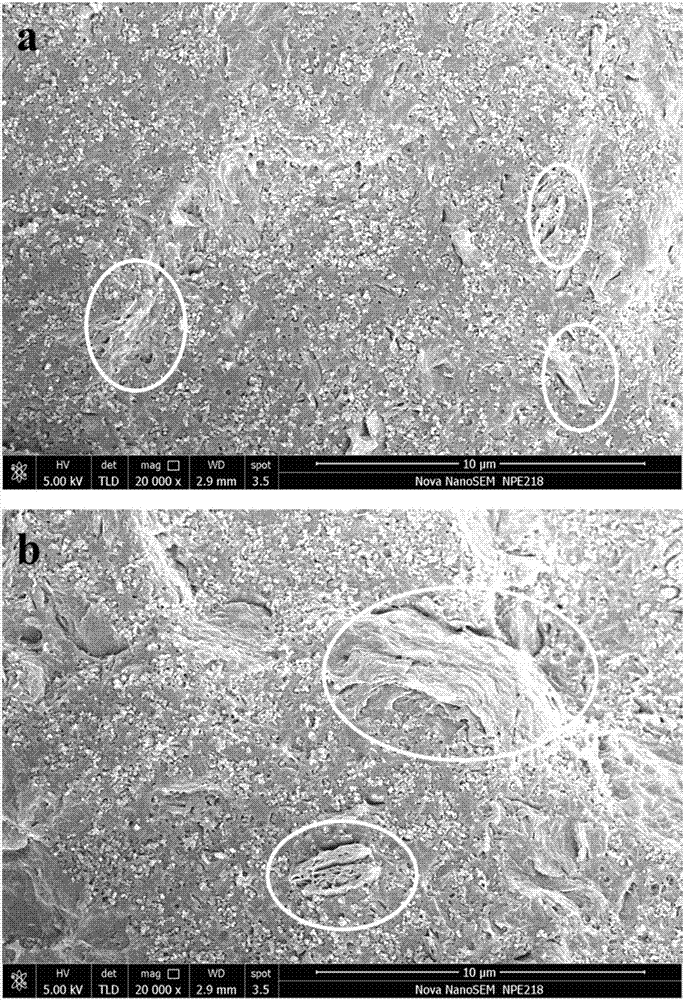

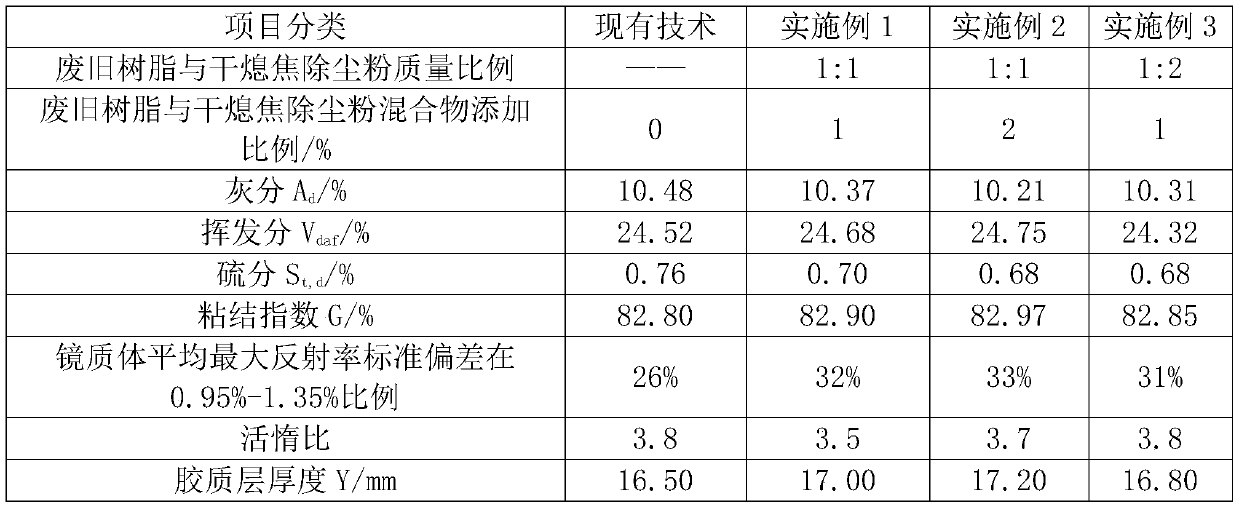

Method for preparing metallurgical coke

ActiveCN110819364AImprove quality indicatorsMeeting ever-increasing demandsProductsReagentsDusting powdersCoke oven

The invention relates to a method for preparing metallurgical coke. The method comprises the following steps: 1) taking blended coal, waste resin and dry quenching dedusting powder as raw materials; 2) intensively recovering the waste resin, and grinding the waste resin to make the particle size less than 3 mm; 3) fully mixing the waste resin with the dry quenching dedusting powder according to amass ratio of 1:1 to 1:5, and carrying out matching pelletizing to make the ball diameter be 1-3 cm; 4) respectively crushing and mixing various coal types in the blended coal, wherein the mass proportion of the average maximum reflectivity, in the interval range of 1.05-1.35%, of vitrinite in the blended coal is not lower than 45%; and 5) mixing the mixed balls of the waste resin and the dry quenching powder with the blended coal, and coking the obtained mixture in a coke oven, wherein the bending mass percentage of the mixed balls is 1-3%. The method achieves recycling of carbon-containing solid wastes of iron and steel enterprises, realizes complete recycling of the waste resin according to the characteristics of low dust, low sulfur and high iron of the waste resin, and achieves the effect of effectively improving the quality index of the coke through reasonable blending of the waste resin in a coal blending coking scheme.

Owner:ANGANG STEEL CO LTD

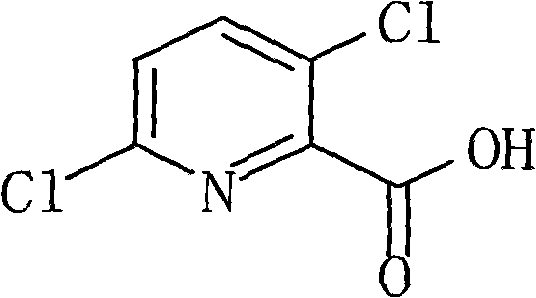

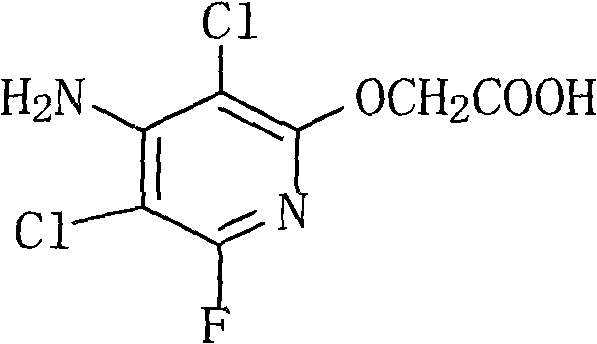

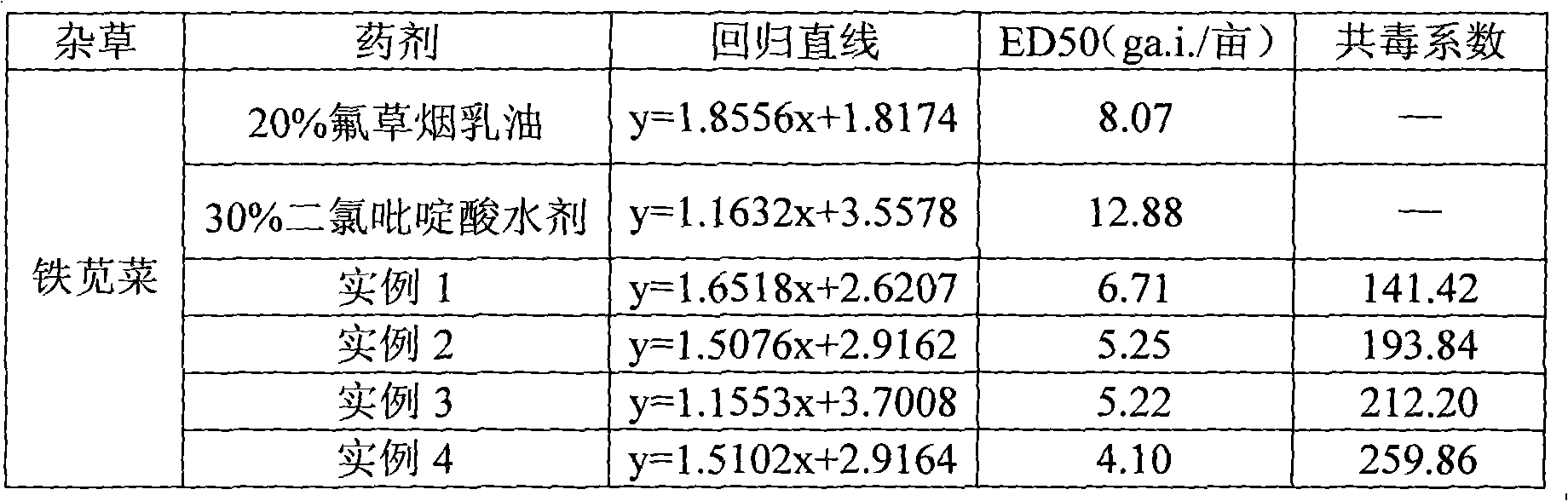

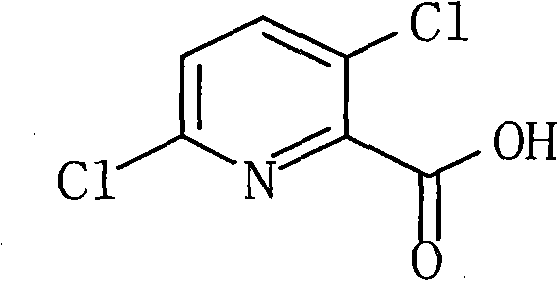

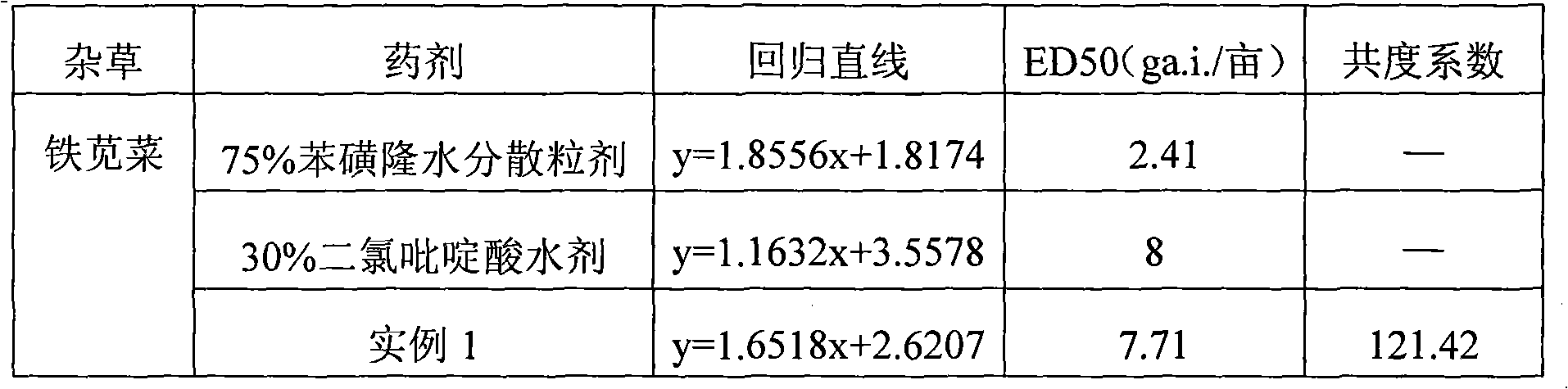

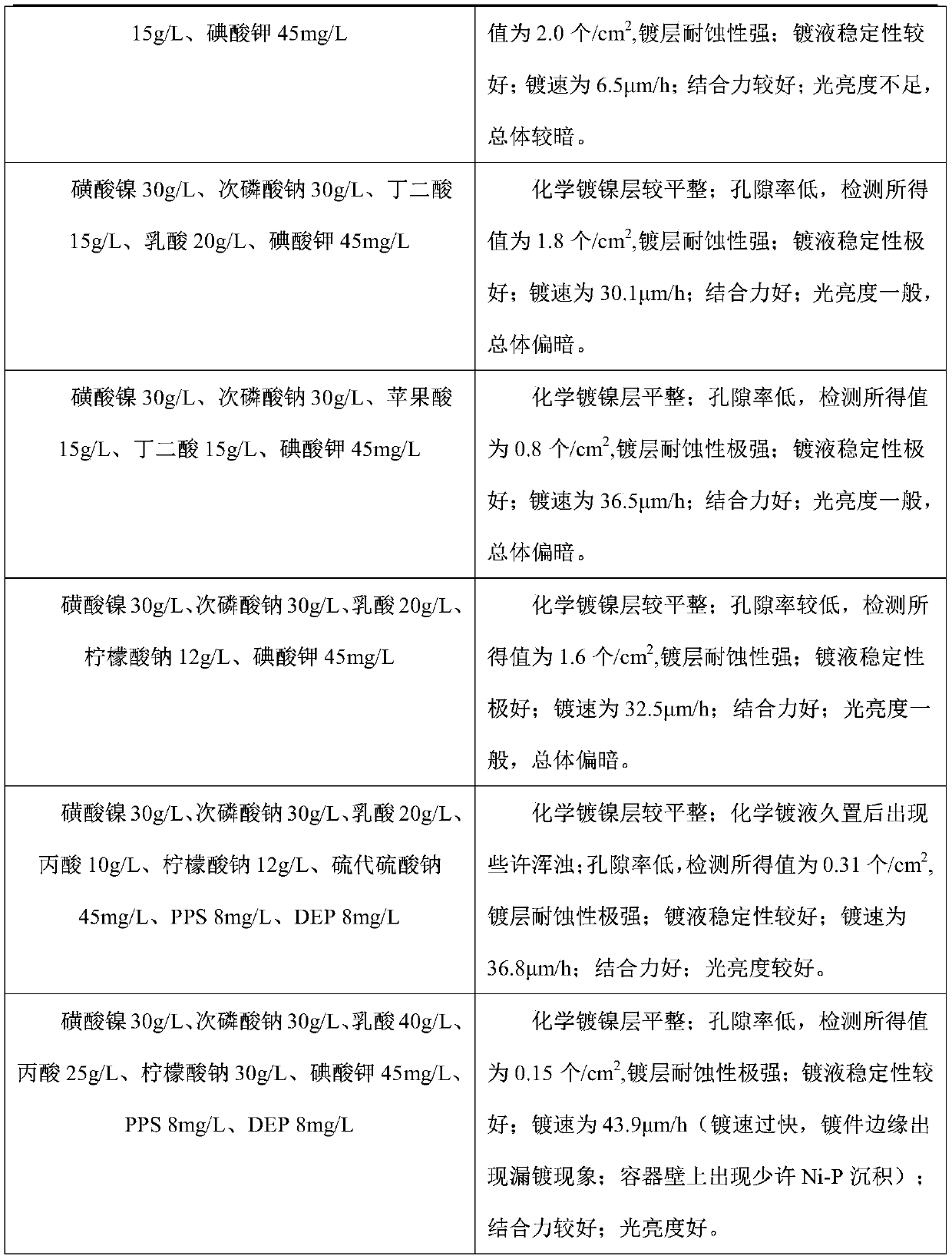

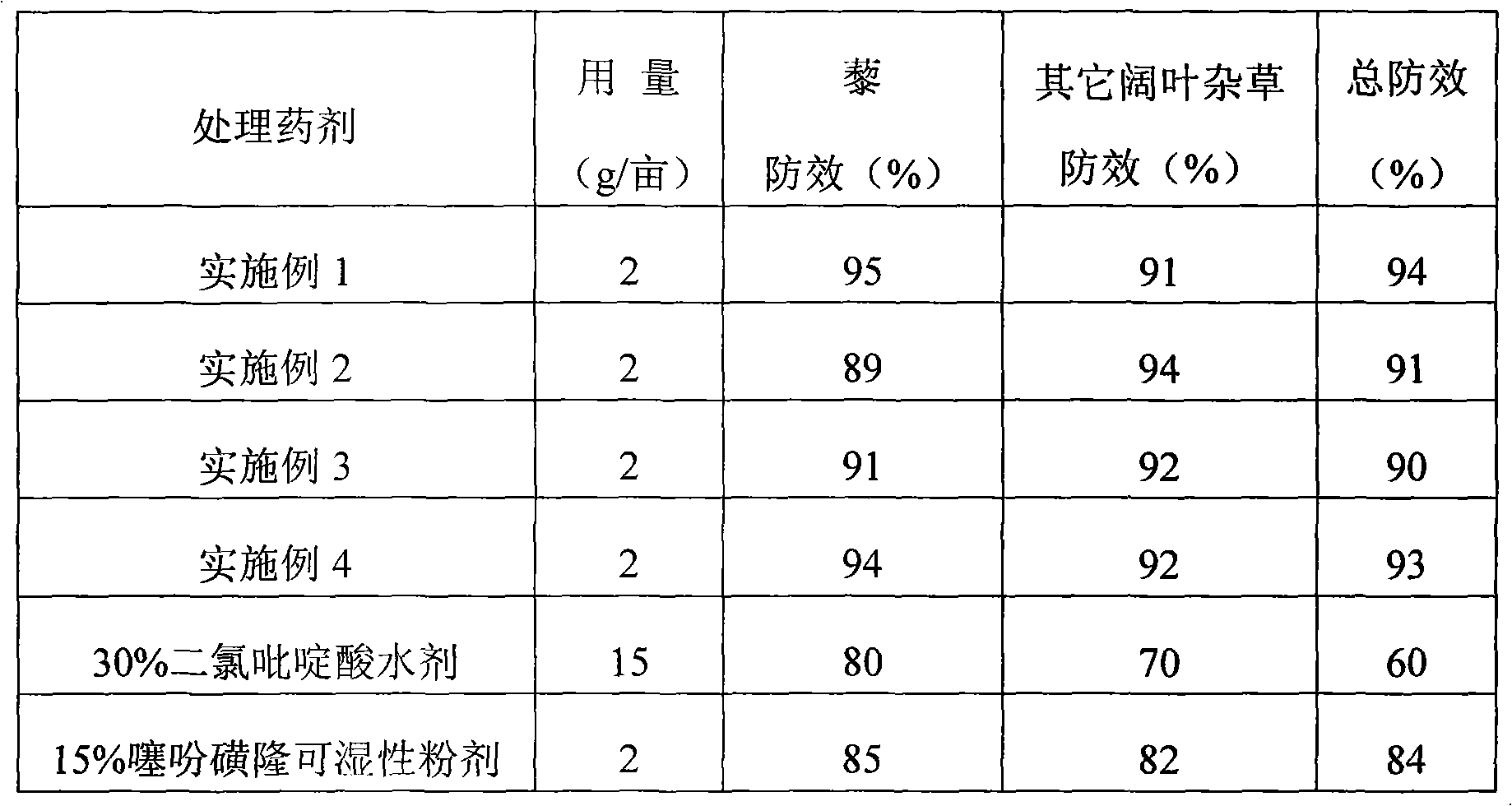

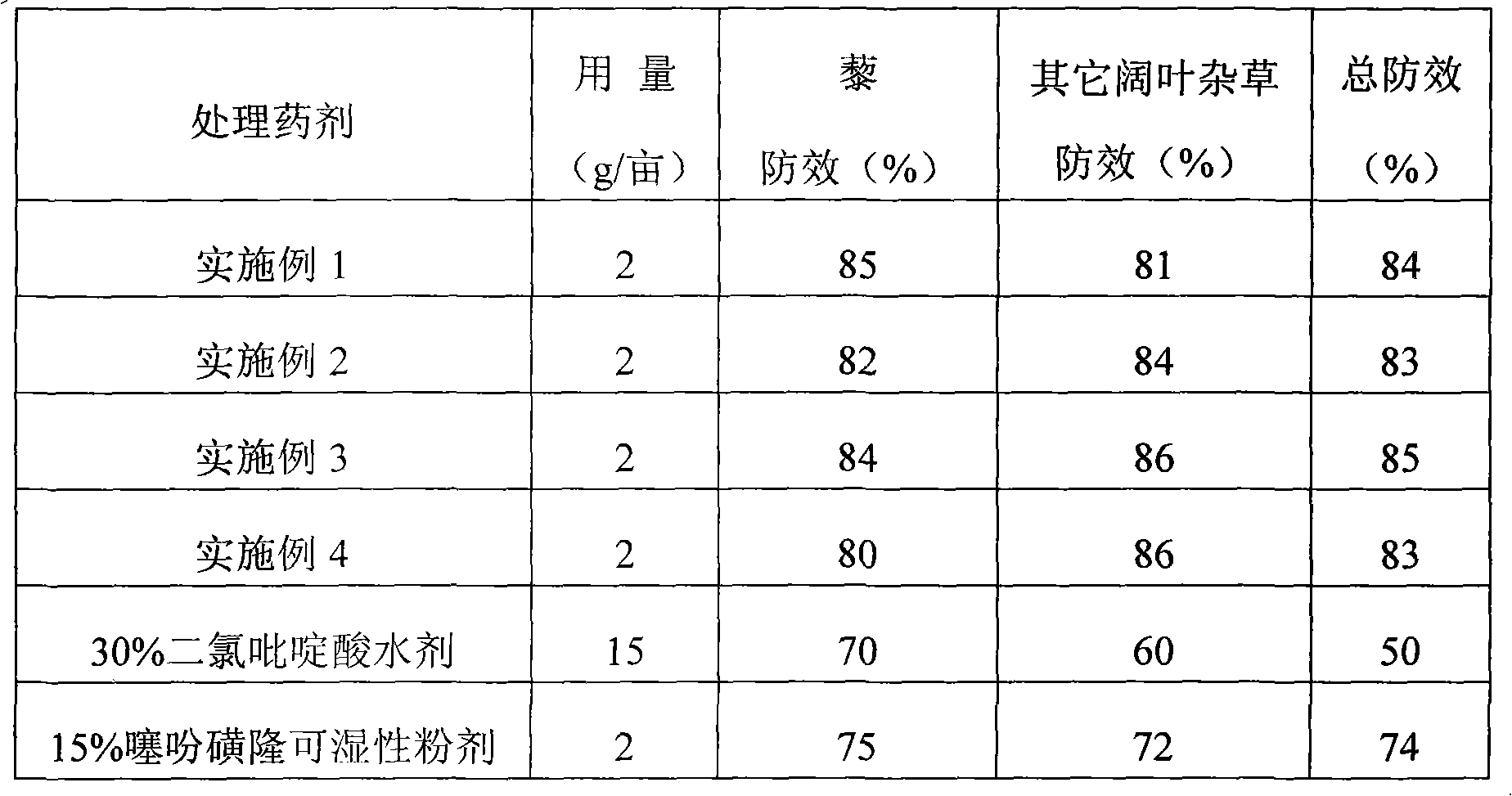

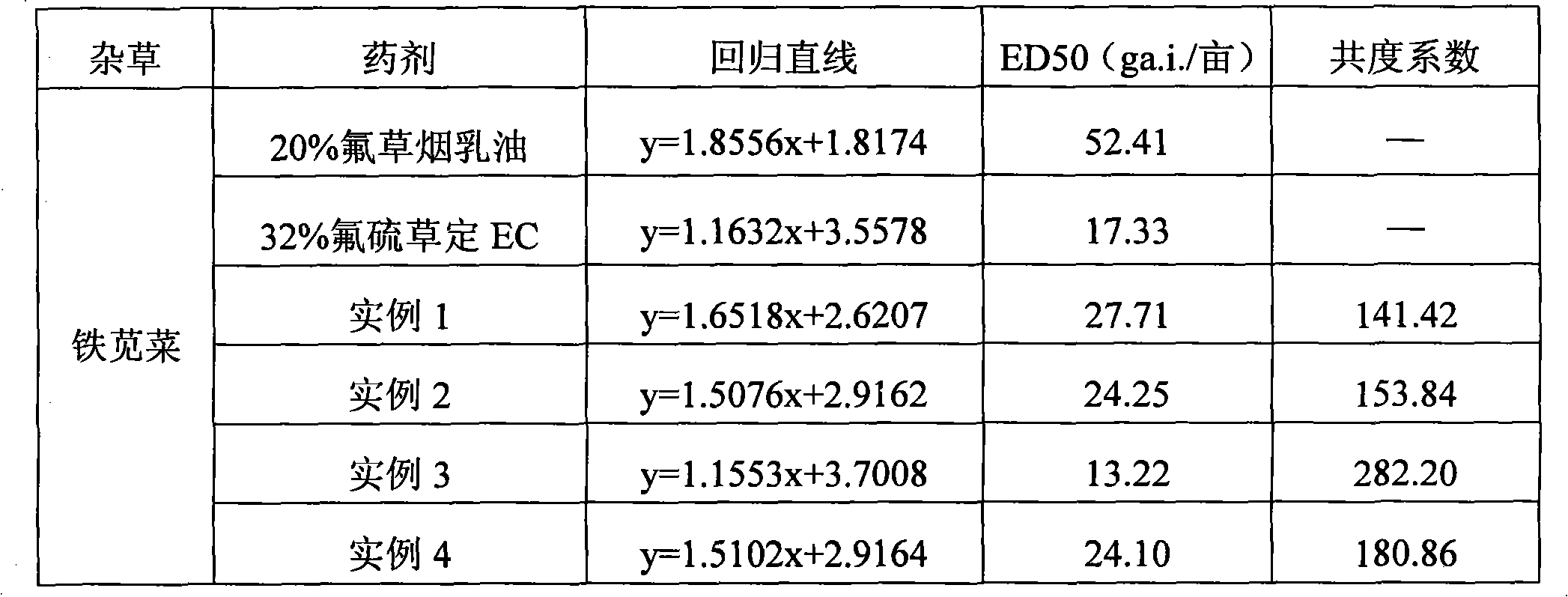

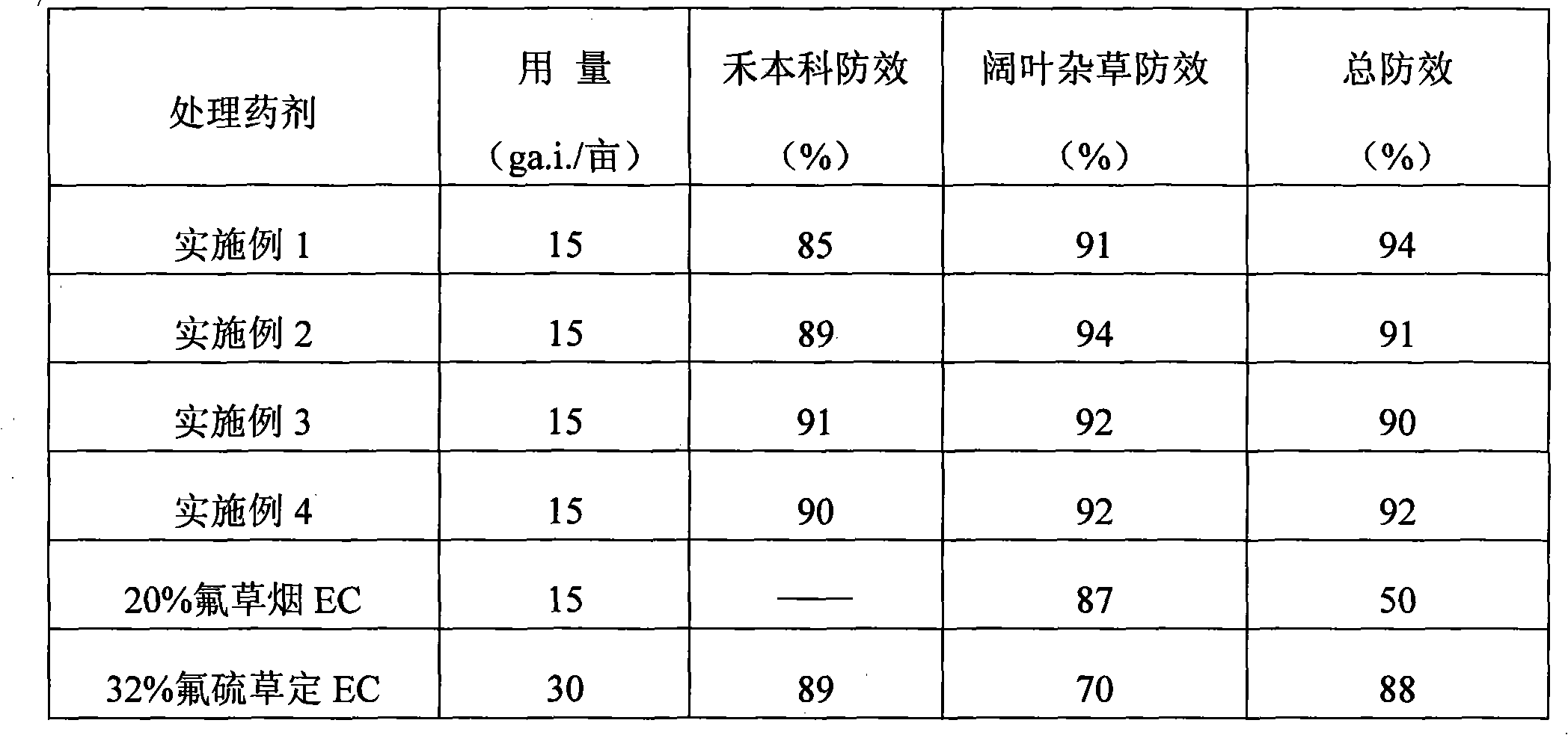

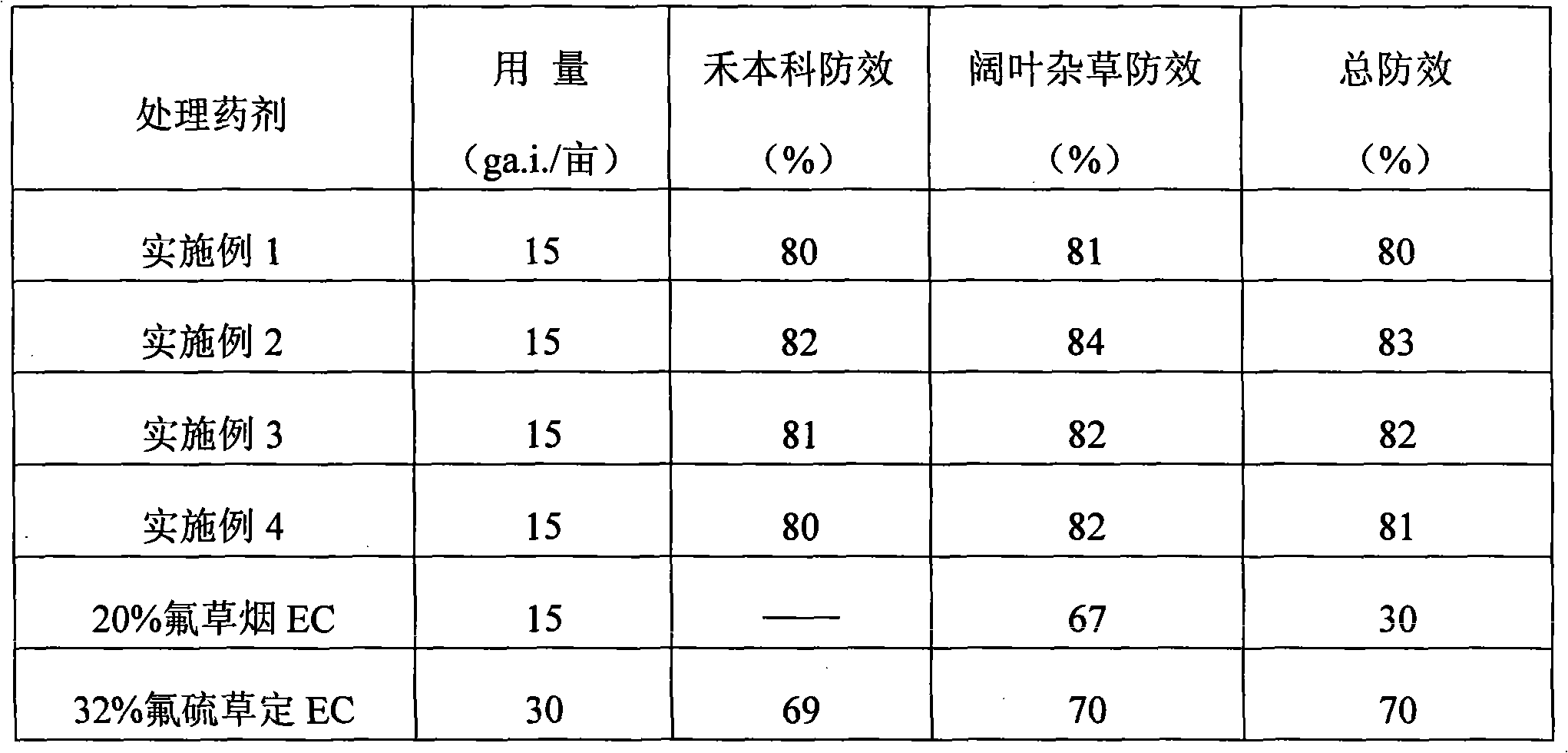

Synergic weeding composition containing clopyralid and fluroxypyr and application thereof

ActiveCN102027905AImprove herbicidal activityLong durationBiocideAnimal repellantsClopyralidFluroxypyr

The invention discloses a synergic weeding composition containing clopyralid and fluroxypyr and application thereof. The main active ingredients of the weeding composition are the clopyralid and the fluroxypyr in a mass ratio of 1-80:1-80. The synergic weeding composition is used for post-emergence weeding in a corn field, and particularly has obvious effect when used for preventing and killing various broadleaf weeds in the corn field. Compared with the single clopyralid or fluroxypyr, the weeding composition delays the resistance of the weeds, has a wide weeding spectrum and long effective duration, and is safe for corn and aftercrop on the premise of improving herbicide effect.

Owner:NANJING HUAZHOU PHARMA

Mink tanning process

ActiveCN105969917AReduce dosageReduced contentTanning treatmentPre-tanning chemical treatmentMinkOil pulling

The invention discloses a mink tanning process. The mink tanning process comprises the following steps of 1, mink washing, 2, sawdust rolling and degreasing, 3, circularly knifing, 4, oil pulling, 5, degreasing, 6, rinsing, 7, pickling and softening, 8, tanning, 9, rolling and drying; 10, oil feeding, 11, mink kicking, 12, oil rolling of sawdust, and 13, width stretching, elongating, powder kicking, width stretching, shaving, dry cleaning and arranging. According to the mink tanning process, energy conservation and environment protection are achieved, and the manufacturing cost is reduced.

Owner:桐乡市恒球皮草制品有限公司

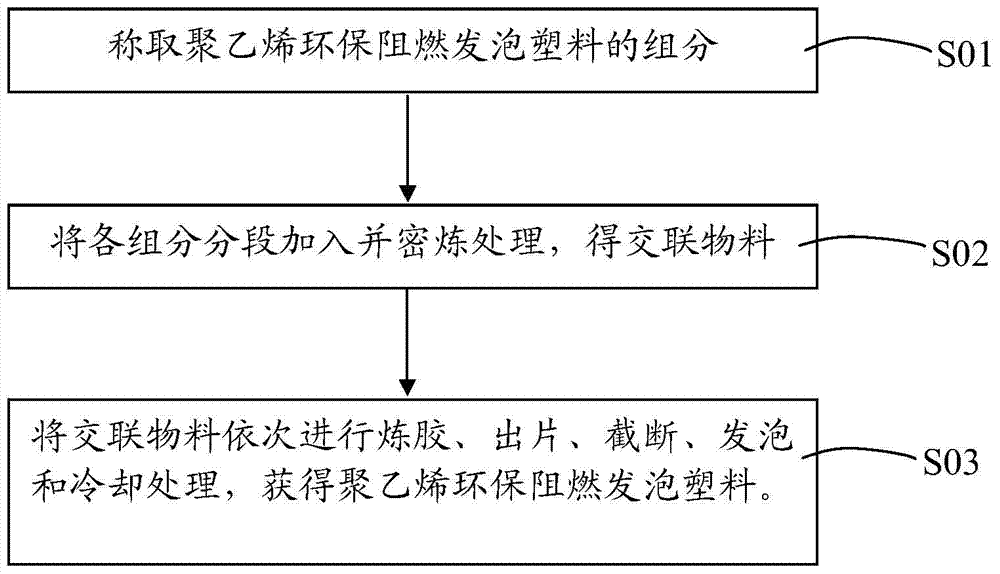

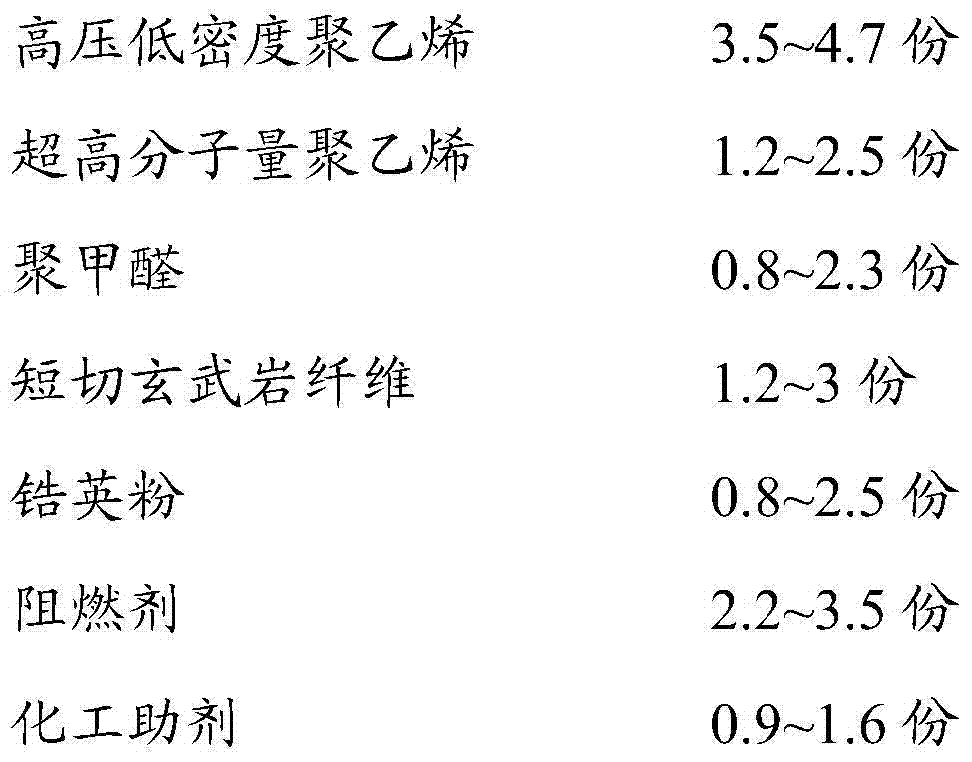

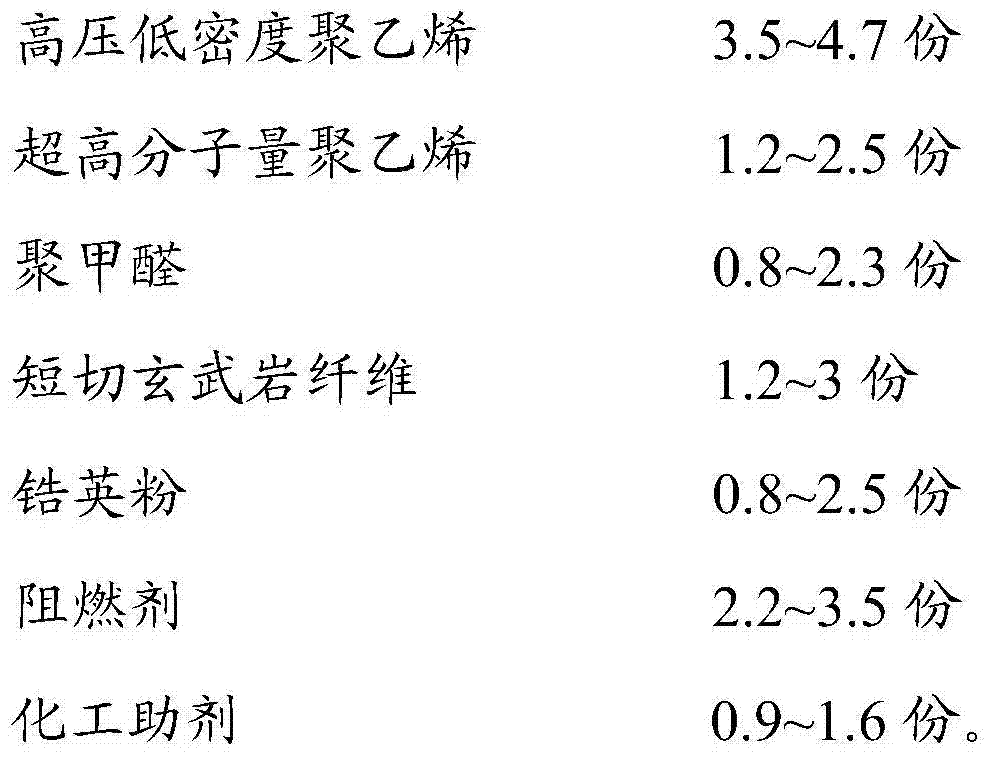

Polyethylene eco-friendly flame-retardant foaming plastic and preparation method thereof

InactiveCN104744761AEasy to stretchImprove flame retardant performanceLow-density polyethylenePolymer science

The invention discloses polyethylene eco-friendly flame-retardant foaming plastic and a preparation method thereof. The polyethylene eco-friendly flame-retardant foaming plastic comprises, by weight, 3.5-4.7 parts of high pressure low density polyethylene, 1.2-2.5 parts of ultrahigh molecular weight polyethylene, 0.8-2.3 parts of paraform, 1.2-3 parts of short cut basalt fibers, 0.8-2.5 parts of zirconium silicate powder, 2.2-3.5 parts of a fire retardant and 0.9-1.6 parts of chemical auxiliary agents. The preparation method improves polyethylene eco-friendly flame-retardant foaming plastic stretching performances, realizes excellent flame retardation effects, reduces a fire retardant use amount, and saves a production cost. The polyethylene eco-friendly flame-retardant foaming plastic is nontoxic and eco-friendly and obviously enlarges a product application scope. The preparation method substantially improves a yield of the polyethylene eco-friendly flame-retardant foaming plastic, has simple processes and a low cost, can be operated and controlled easily and is suitable for industrial production.

Owner:冼冰

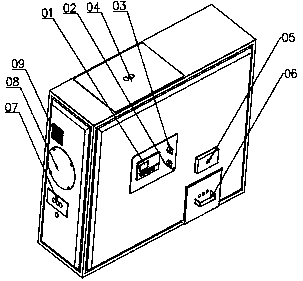

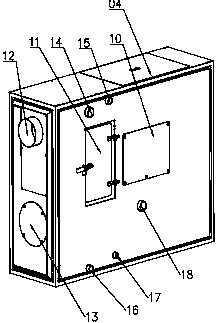

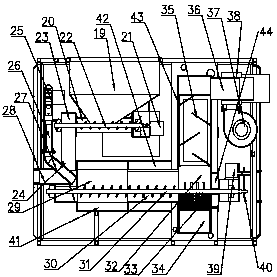

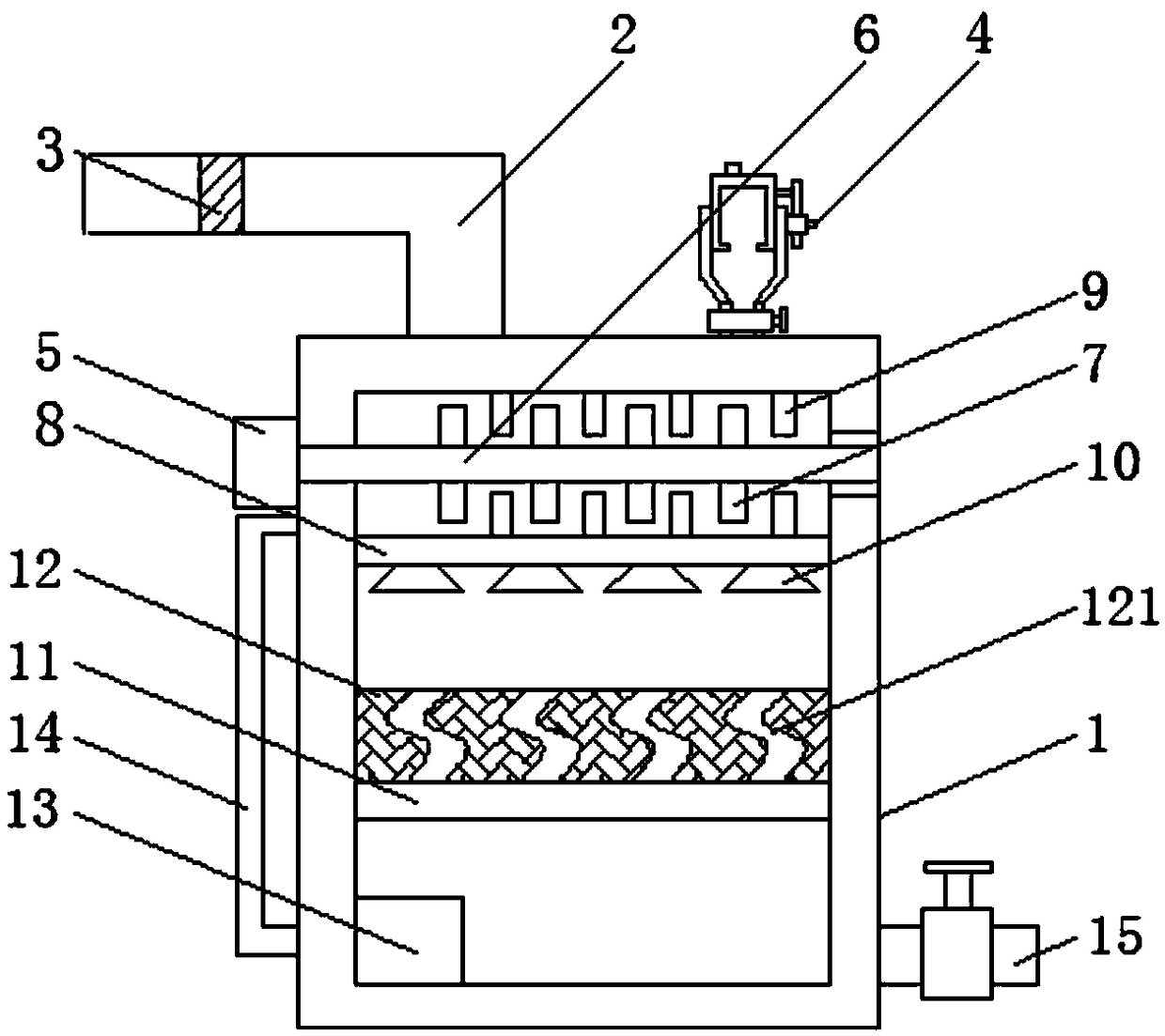

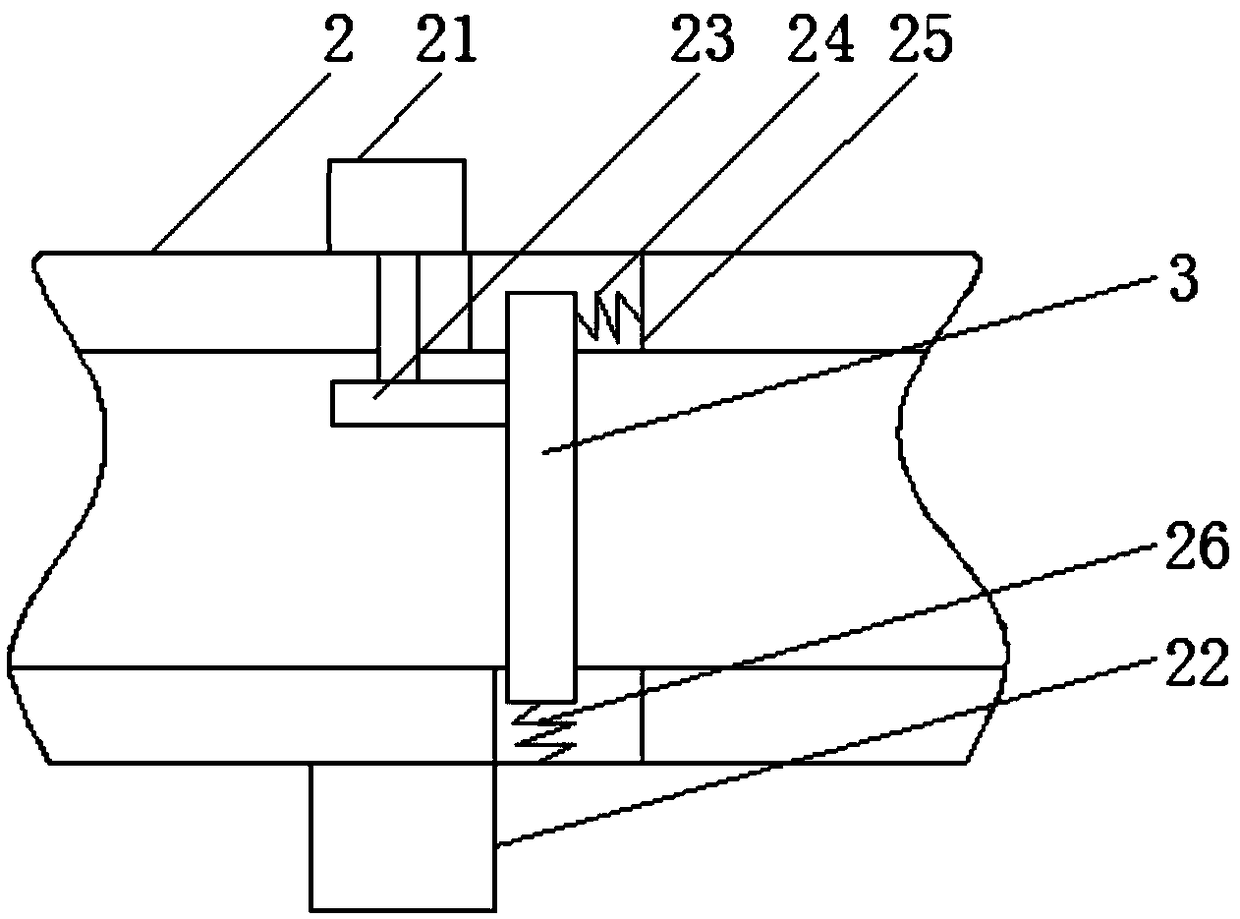

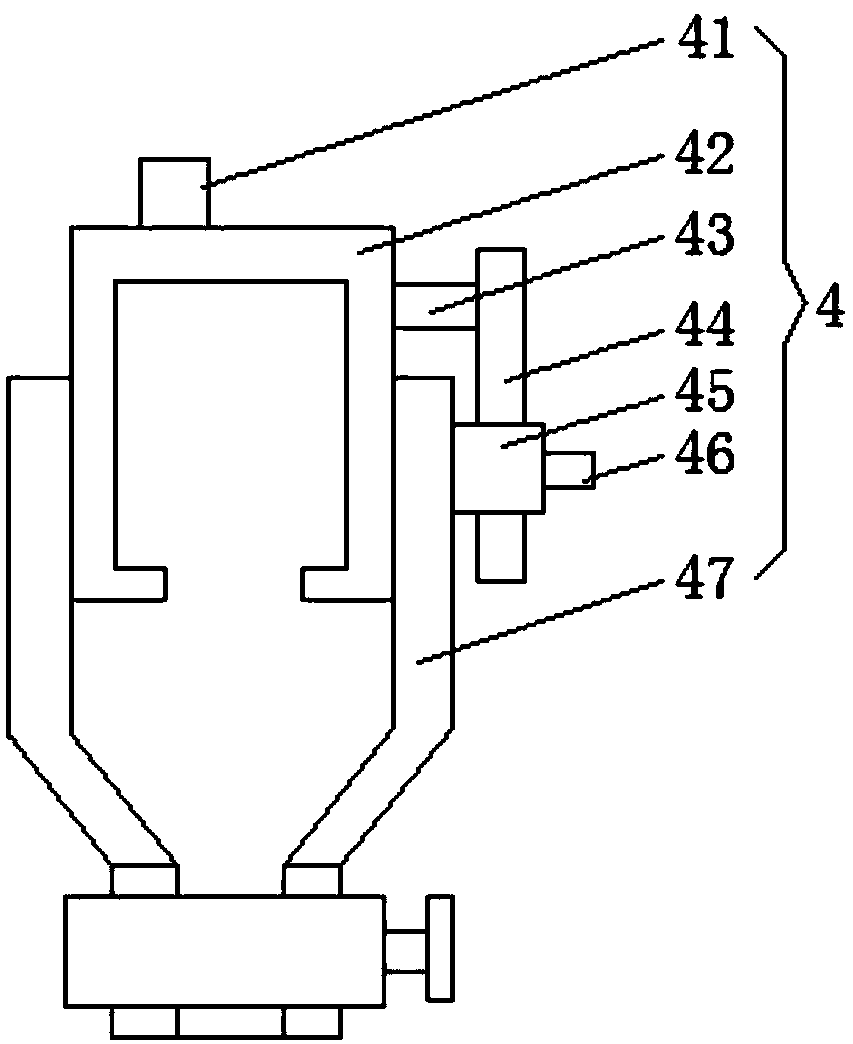

Novel anti-coking intelligent efficient biomass heating furnace

InactiveCN108105757AIncrease the itineraryReduced contentStove/ranges for heating waterSolid heating fuelProcess dynamicsCombustion chamber

The invention discloses a novel anti-coking intelligent efficient biomass heating furnace. The novel anti-coking intelligent efficient biomass heating furnace comprises a feed ignition device, a multi-chamber partition combustion chamber, a hot water output circulating device, a flame smoke aftertreatment device, a dynamic combustion deslagging transmission device, an intelligent control device and a maintenance device. The core of the novel anti-coking intelligent efficient biomass heating furnace is a three-chamber four-area segmentation gradual combustion chamber, and an auger and rake tooth whole-process dynamic structure is used for replacing a movable fire grate, so that the combustion efficiency is improved, and coking and slagging are prevented. A front-blowing back-leading micro-negative-pressure two-way ternary air distribution system is adopted. In addition, a high-temperature area of the heating furnace adopts an all water jacket structure; external heating output of circulating water is realized through smoke-water reverse heat exchange; operations are simplified through intelligent control and introduction of an automatic ignition system; and the heating furnace is excellent in fuel applicability and operation convenience, is dispersed heating equipment with cleanness, high efficiency, energy conservation and environmental protection, provides excellent heating solution schemes for national new urbanization, and is prominent in anticipant economy and social benefit.

Owner:联合优发生物质能源徐州有限公司

Alginic acid radical biomaterial with developing function and preparation method thereof

ActiveCN108578790AControl the actual injection volumeImprove blood pumping functionSurgeryPharmaceutical delivery mechanismCross-linkWater soluble

The invention relates to an alginic acid radical biomaterial with a developing function and a preparation method thereof. The alginic acid radical biomaterial is prepared from a group A, a group B, agroup C and the balance injection water, wherein the group A includes water-soluble alginate, and the content of the alginate in the alginic acid radical biomaterial is 0.1-10% (g / ml); the group B includes a cross-linking agent containing divalent or polyvalent metal cations, and the content of the cross-linking agent in the alginic acid radical biomaterial is 0.1-10% (g / ml); the group C includesa developing agent, the developing agent is a liquid agent or powdery agent with the developing function for medical use, and the content of the developing agent in the alginic acid radical biomaterial is 0.001-260% (g / ml). The biomaterial provides convenience for adopting a minimally invasive blood vessel interventional operation for injection and implantation, the mechanical supporting performance is uniform and stable, clinically required key performance indexes, such as a gelatinization process and mechanical supporting performance, can be adjusted and controlled by means of premixing andother various measures, and therefore sufficient mechanical supporting efficacy is achieved. The histocompatibility is high, the operation difficulty of the operation is low, the application range iswide, the risk is small, and the safety effectiveness is high.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

Sputtering target and binding method thereof

InactiveCN106032568AReduced contentAvoid bendingVacuum evaporation coatingSputtering coatingSputteringIndium

The invention relates to a sputtering target and a binding method thereof. A layer of indium is infiltrated on a solder side of a backboard component of the sputtering target material, and a binder containing conductive particles is used for binding a target material and the backboard component together. The low melting point characteristic of indium is used, so that during unbinding, mutual separation of the target material, the conductive binder and the backboard component is easy. A metal mesh is arranged in the conductive binder, and during unbinding, the conductive binder is attached to the metal mesh, so that after recovery, the surface of the backboard component does not have conductive binder residues.

Owner:HANERGY CO INNO MOBILE ENERGY INVESTMENT CO LTD

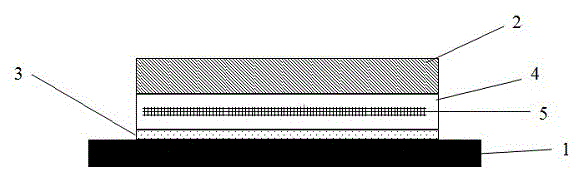

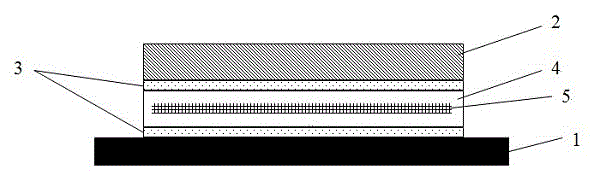

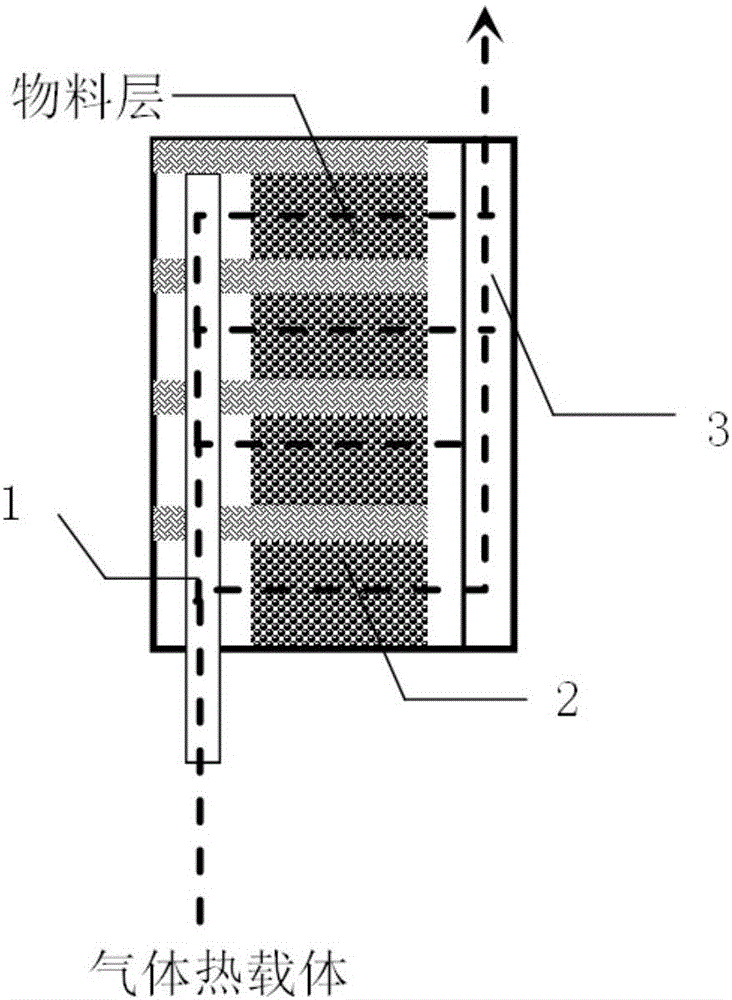

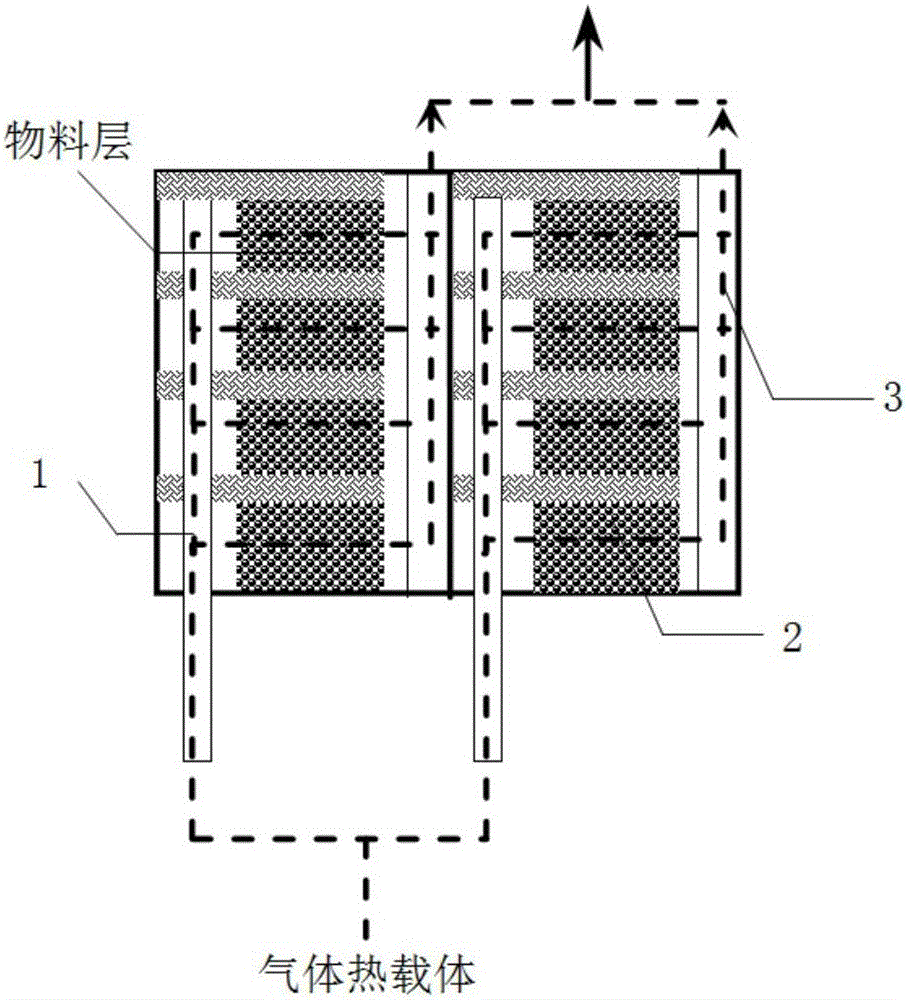

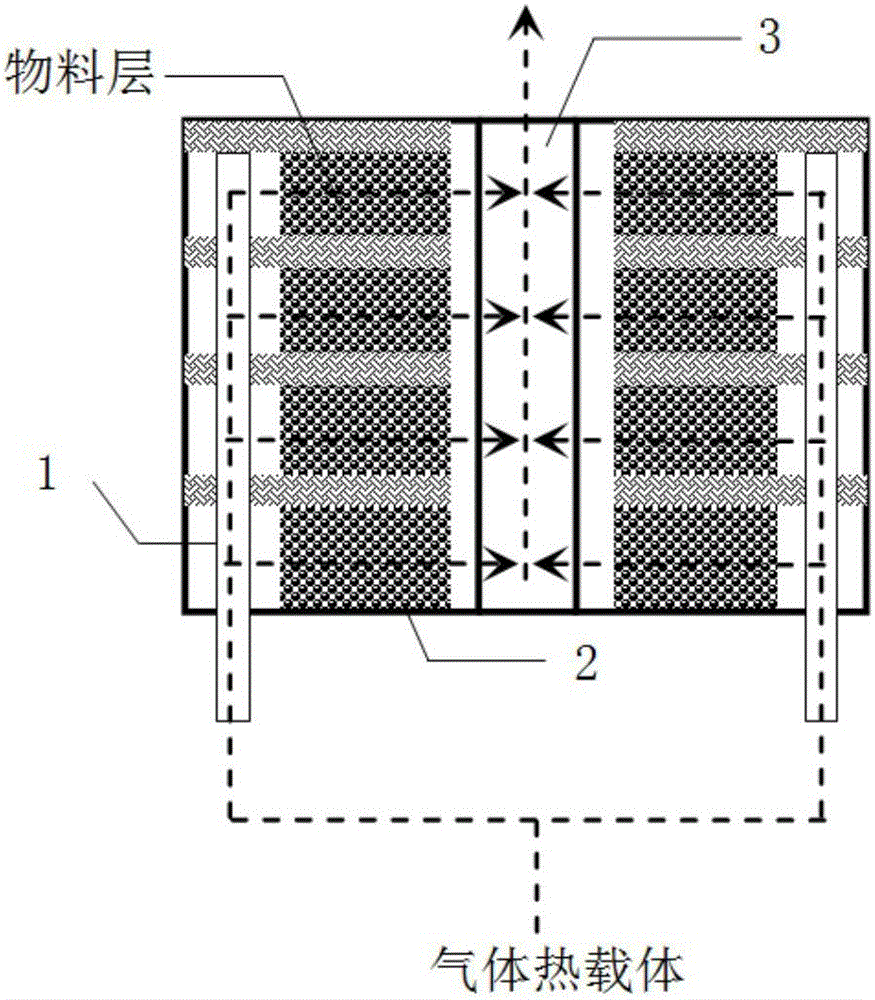

Pyrolysis method for low-rank coal or oil shale with higher tar yield

InactiveCN105018116AHigh yieldReduce resistanceDirect heating destructive distillationSpecial form destructive distillationHeat carrierCombustion chamber

The invention relates to a pyrolysis method for low-rank coal or oil shale with higher tar yield, and is suitable for a heat upgrading process of a low-rank coal moving bed with the purpose of obtaining high-yield tar. The method is a gas heat carrier technology, high-temperature gas flows to the cold end of a collection chamber from a combustion chamber at the hot end of a carbonization chamber by traversing a coal material, quick gas-solid heat exchange between hot carrier gas and the coal material is performed, and the coal material is heated to perform low-temperature pyrolysis. A gas-oil mixture generated by pyrolysis, together with the hot carrier gas, is introduced by the collection chamber at the cold end of the carbonization chamber. The pyrolysis method is characterized in that oil gas and a hot carrier generated by pyrolysis quickly pass through the coal material with the average radial temperature gradient of 600 DEG C / m, and flow to a low-temperature area from a high-temperature area, so that obvious secondary splitting is avoided in time. On the other hand, the method adopts the gas hot carrier to radially penetrate a coal layer, and heat is transferred to the internal coal material at a short transverse distance by the hot carrier, so that the material layer resistance can be obviously reduced, pulverization and semi-coke bringing is reduced, and the heat transfer efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

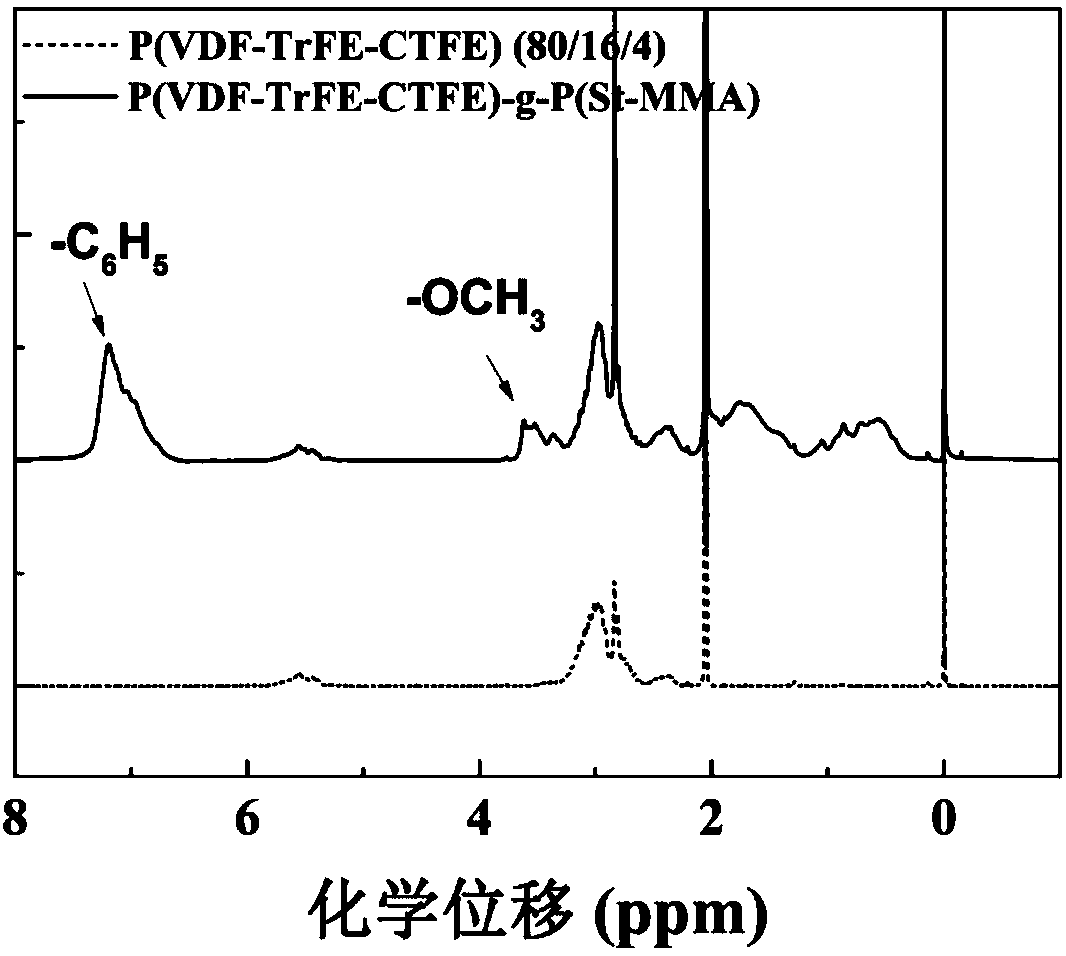

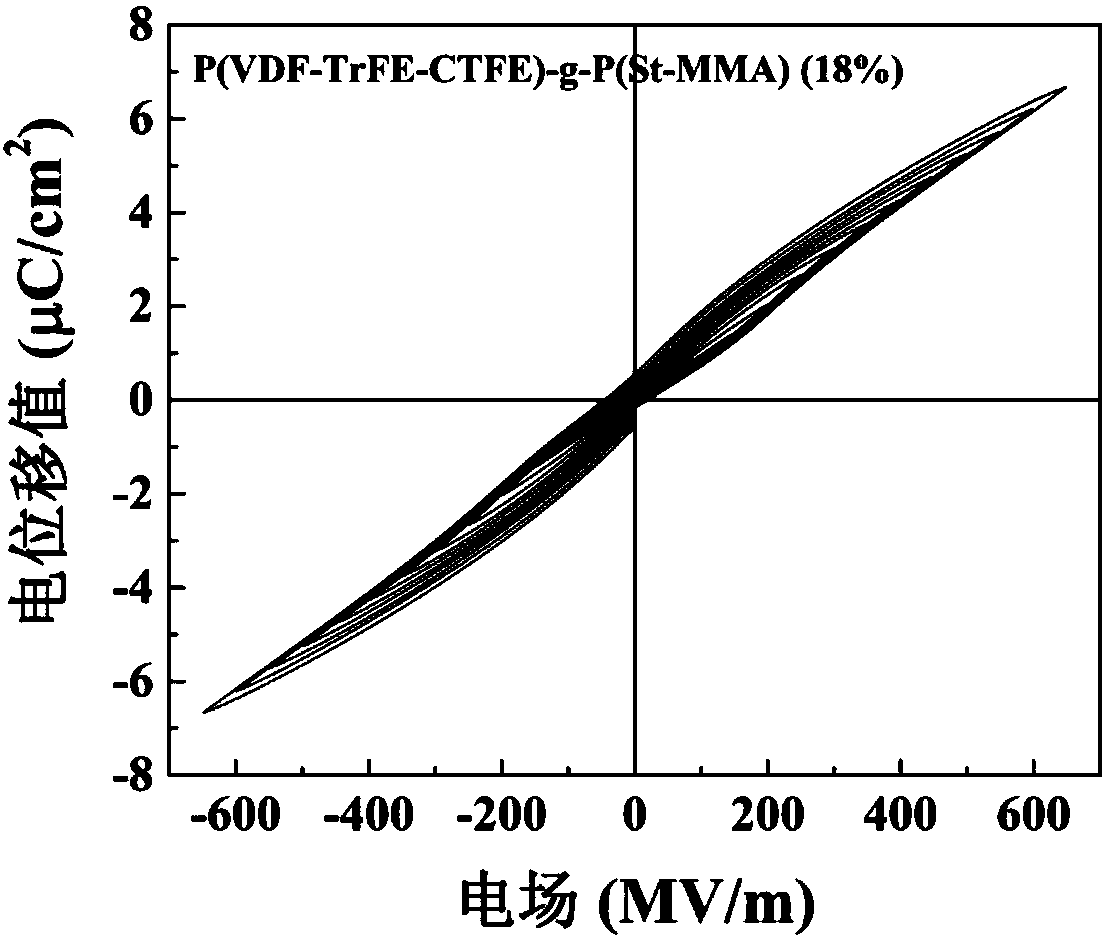

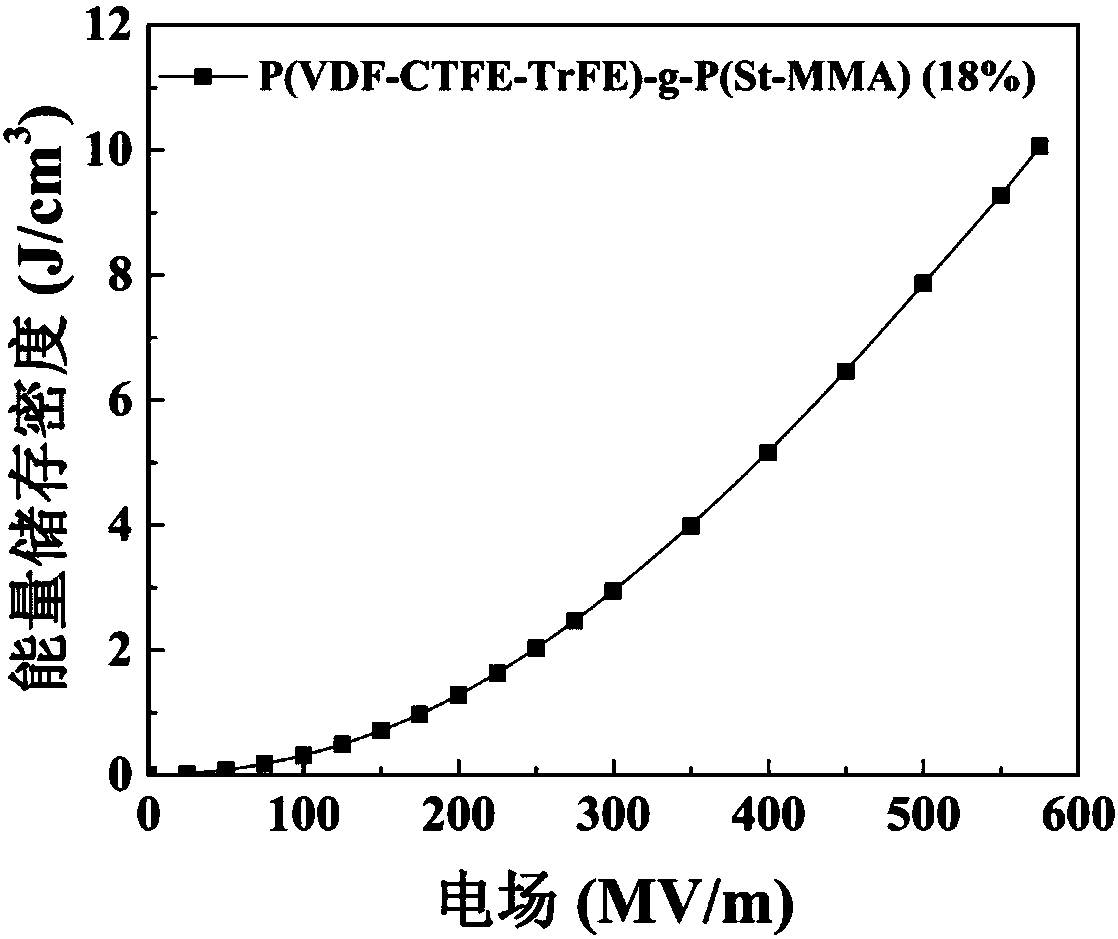

Preparation method of anti-ferroelectric poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) grafted polymer

The invention provides a preparation method of an anti-ferroelectric poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) grafted polymer. The preparation method takes N-methyl pyrrolidone and the like as a solvent, cuprous chloride, 2,2-dipyridine, copper and the like as a catalysis system, poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) (P(VDF-TrFE-CTFE)) as polymer raw materials, and methyl methacrylate, styrene, acrylonitrile and the like as grafting monomers; after the materials are stirred to react for certain time under the condition of raising the temperature by sections, grafted polymers including P(VDF-TrFE-CTFE)-g-P(St-MMA) and the like are synthesized. The method provided by the invention is simple to operate and easy to control; the use amount of a catalyst is low and a high-purity target product is easy to obtain; the method has a good industrial application prospect.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD +1

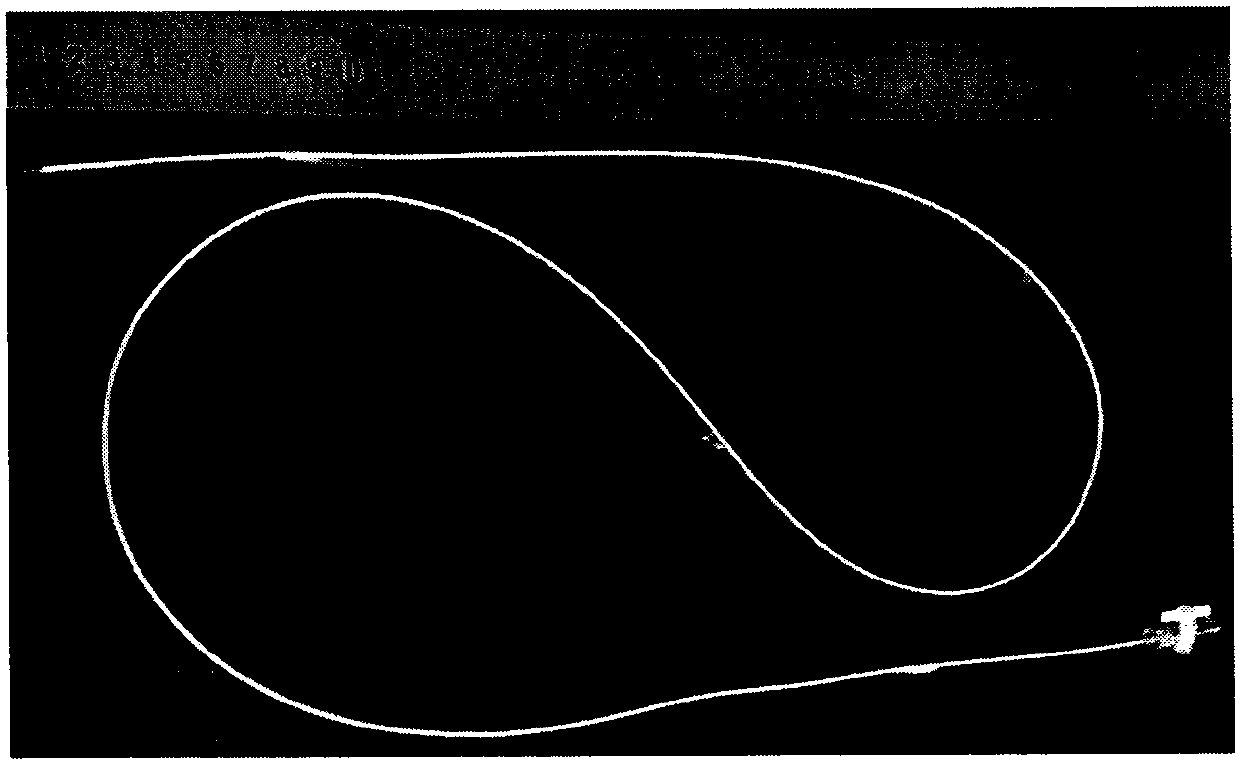

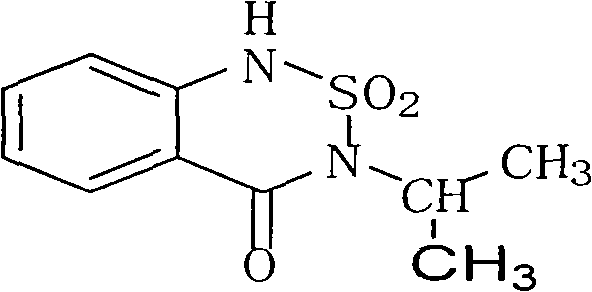

Energy-saving and environment-friendly flue gas denitrification device and method

PendingCN108704477AAvoid affecting the emission effectMaintain the ecological environmentGas treatmentDispersed particle filtrationFlue gasSpray nozzle

The invention discloses an energy-saving and environment-friendly flue gas denitrification device and belongs to the technical field of flue gas denitrification. The energy-saving and environment-friendly flue gas denitrification device comprises a body, wherein a gas inlet pipe is arranged at the left side of the top of the body; a filtering layer is arranged in an inner cavity of the gas inlet pipe; spraying nozzles are uniformly arranged at the bottom of a liquid collection box; a catalysis layer is located just below the spraying nozzles; S-shaped circulation pipelines are uniformly formedin the inner cavity of the catalysis layer; a liquid suction pump is arranged at the left side of the bottom of an inner cavity of the body; a left-side outlet of the liquid suction pump extends to aleft-side outer wall of the body and is connected with a refluxing pipe; a discharging opening is formed in a right-side outer wall of the body; a valve is mounted on the discharging opening; flue gas is filtered through the filtering layer in the device and a condition that the device is blocked when large-particle dust enters the device is avoided; a reactant and flue gas are mixed completely through rotating a stirring blade, and the S-shaped circulation pipelines arranged in the inner cavity of the catalysis layer enable a mixture and the catalysis layer to be in contact for longer time,and furthermore, the flue gas denitrification efficiency is improved.

Owner:张燕

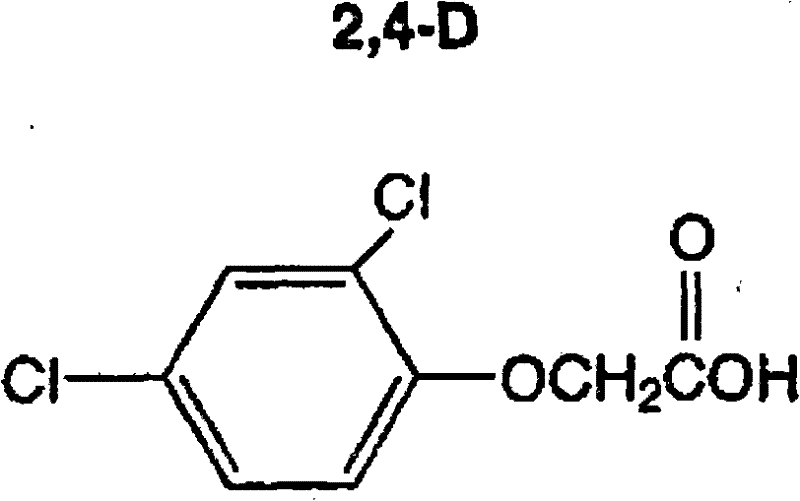

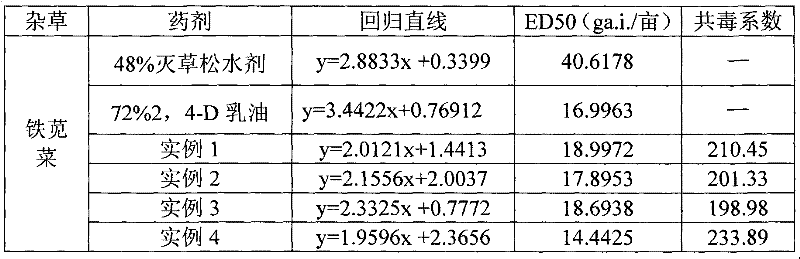

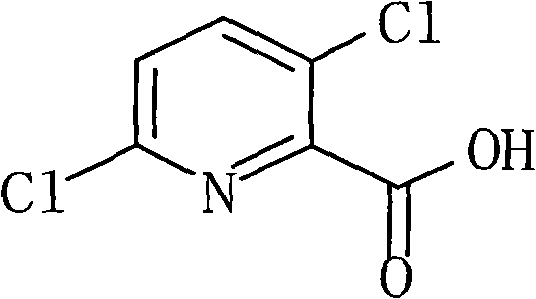

A herbicidal composition containing bentazone and 2,4-dichlorophenoxyacetic acid and its application

InactiveCN102265871AImprove herbicidal activityBroad spectrum herbicideBiocideAnimal repellantsChemical compositionBentazon

The invention discloses a herbicidal composition containing bentazone and 2,4-dichlorophenoxyacetic acid. The herbicidal composition uses bentazone and 2,4-dichlorophenoxyacetic acid as main active ingredients. The mass ratio of pine to 2,4-dichlorophenoxyacetic acid is 1-80:1-80. The herbicidal composition of the present invention is applied to post-emergence weeding in wheat and paddy fields, especially for controlling broad-leaved weeds in wheat and paddy fields, and has remarkable effects. Compared with a single dose, the herbicidal composition of the present invention delays weed resistance, has a wide herbicidal spectrum, long duration of action and is safe to wheat and subsequent crops on the premise of improving the efficacy of a single agent.

Owner:NANJING HUAZHOU PHARMA

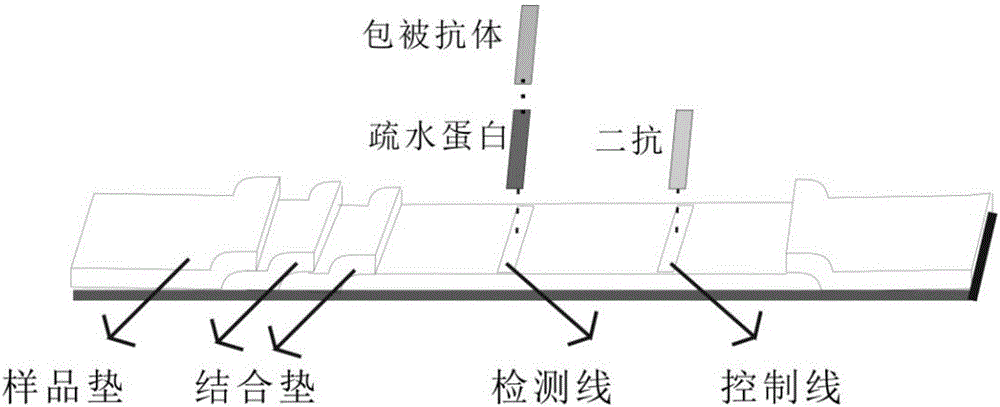

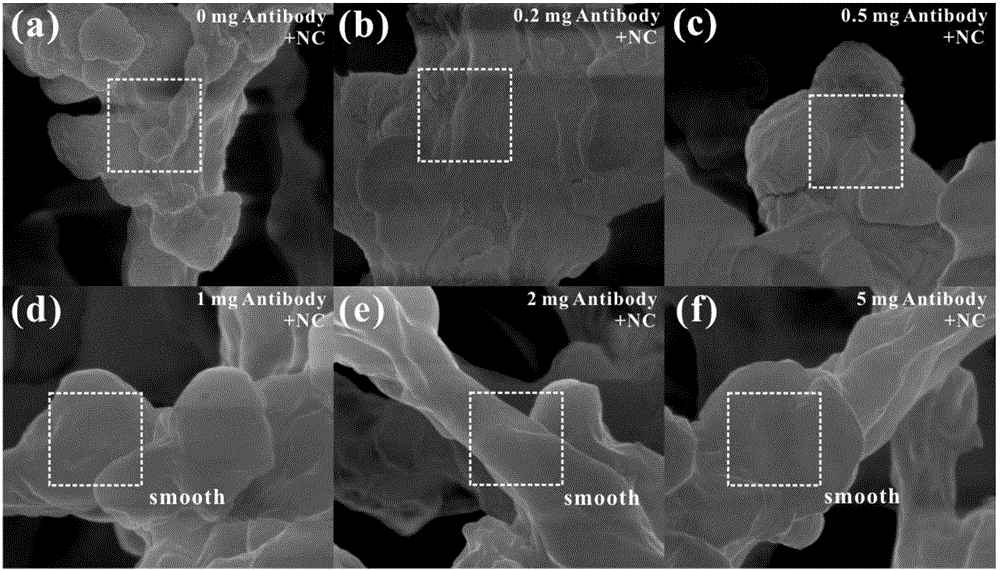

Method for preparing prostate cancer antigen immunochromatography test paper based on hydrophobin high-efficiency fixed low-concentration antibody

InactiveCN106771143AHigh antibody activityEnhanced ability to capture antigensMaterial analysisAntigenNovel technique

The invention relates to a method for preparing prostate cancer antigen immunochromatography test paper based on a hydrophobin high-efficiency fixed low-concentration antibody. As exogenous biomolecules can be subjected to oriented immobilization of type-II hydrophobin, antibodies sprayed to a test paper nitrocellulose membrane can be arranged in an oriented manner, the 'Fab' ends of the antibodies are sufficiently exposed, the utilization rate of an antibody active site can be increased, the detection sensitivity can be improved, the amount of the antibodies can be reduced, the detection cost can be lowered, the nitrocellulose membrane is modified by using the hydrophobin, novel immunochromatography test paper based on the hydrophobin high-efficiency fixed low-concentration antibody can be prepared, the test paper comprises a sample pad and two conjugate pads, a detection line, the nitrocellulose membrane with the detection line and a quality control line antibody, an absorption pad and a bottom plate are simultaneously modified with the hydrophobin, and the method is a novel technique applicable to tumor marker detection.

Owner:TIANJIN UNIV

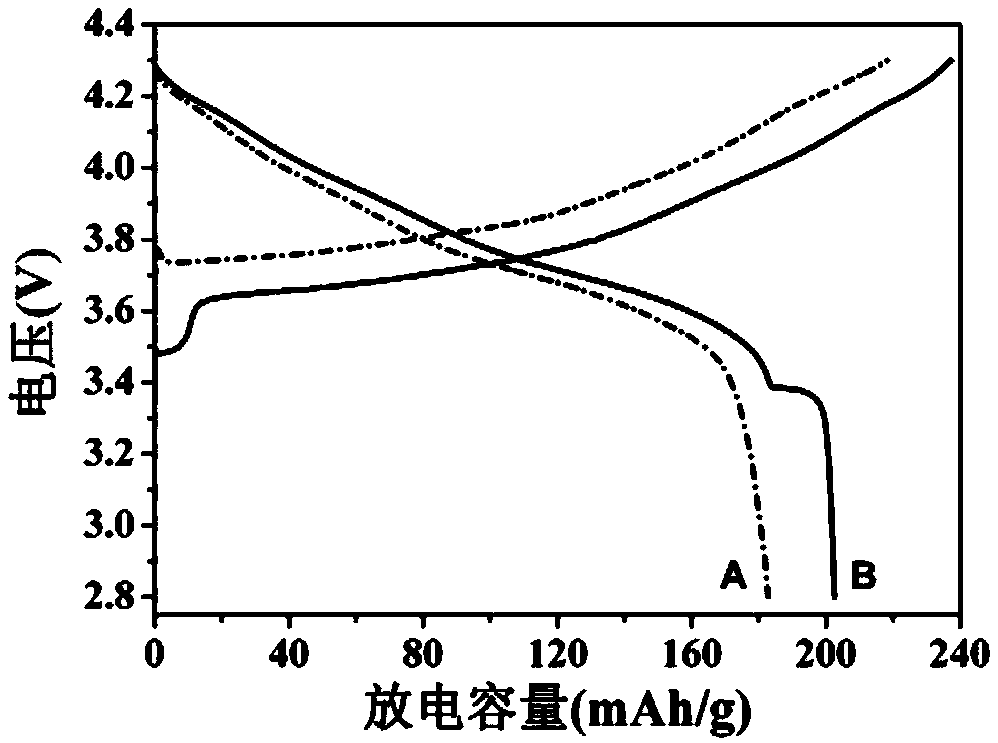

High-performance lithium ion battery composite cathode material and preparation method thereof

InactiveCN109461912AImprove discharge capacityImproved magnification performanceCell electrodesSecondary cells servicing/maintenanceOlivineLithium-ion battery

The invention discloses a high-performance lithium ion battery composite cathode material and a preparation method thereof. The cathode material comprises a nickel-based lamellar cathode material subjected to polyvinylidene fluoride pretreatment and serving as a first electrode material, and an olivine cathode material which completely coats the first electrode material through lamellar graphene;the graphene accounts for 0.1-0.5% of the total mass of the composite cathode material; polyvinylidene fluoride accounts for 0.5-2.0% of the mass of the composite cathode material; the olivine cathodematerial accounts for 5-20% of the total mass of the composite cathode material, and the balance is the nickel-based lamellar cathode material; a particle diameter ratio of the nickel-based lamellarcathode material to the olivine cathode material is 50 : 1 to 300 : 1. A conductive network is formed among the nickel-based lamellar cathode material, the olivine cathode material and the graphene, so that the ion transmission is facilitated; the structure is firm, so that the discharge capacity of the composite cathode material is higher than that of any one component material; and compared witha traditional nickel-based lamellar cathode material, the nickel-based lamellar cathode material is improved in capacity performance, rate performance, cycle performance and safety performance.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

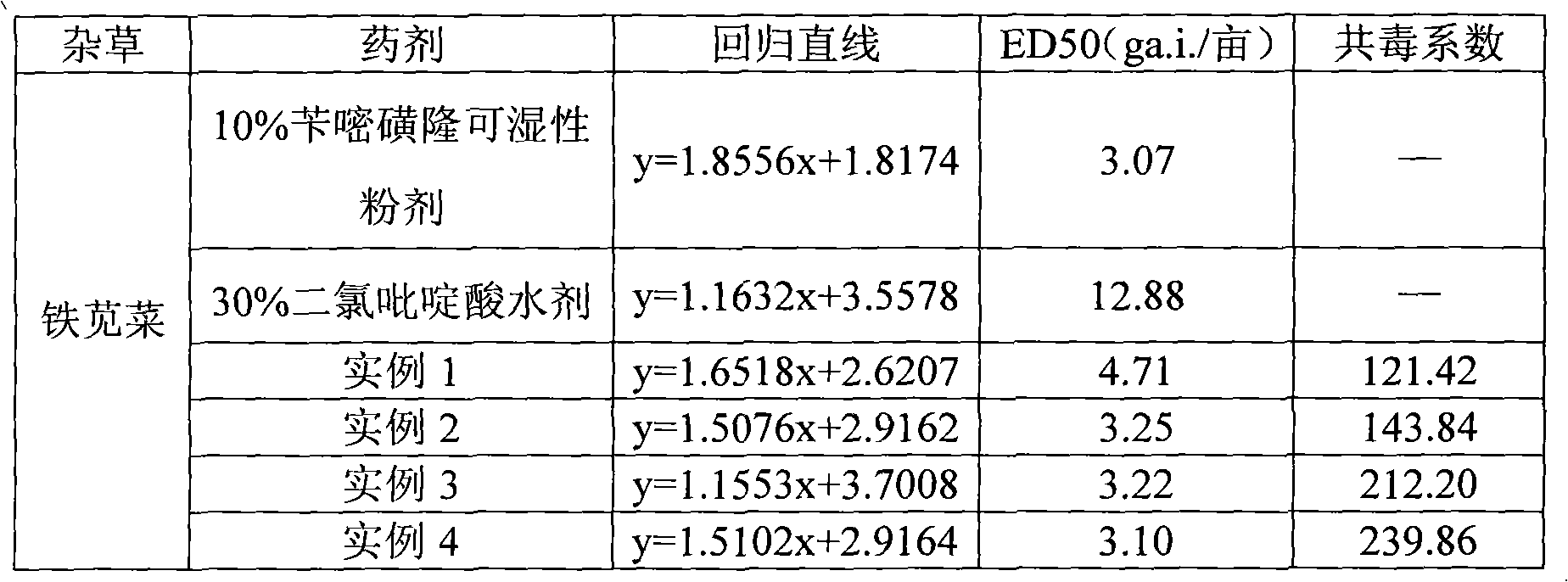

Herbicidal composition containing clopyralid and tribenuron-methyl and application thereof

InactiveCN102027969AImprove herbicidal activityBroad spectrum herbicideBiocideAnimal repellantsChemical compositionClopyralid

The invention belongs to the field of pesticides, and discloses a herbicidal composition containing clopyralid and tribenuron-methyl and application thereof. The main active ingredients of the herbicidal composition are clopyralid and tribenuron-methyl in a mass ratio of 1-80:1-80, wherein the clopyralid and the tribenuron-methyl account for 1 to 85 percent of the total mass of the herbicidal composition. The herbicidal composition can be used for preparing herbicides for controlling post-emergence weeds in a wheat field, and particularly has an obvious effect when used for preparing herbicides for controlling various broadleaf weeds in the wheat field. Compared with single-component herbicide, the herbicidal composition delays the resistance of the weeds, has a broad herbicidal spectrum and acts for a long time on the premise of improving herbicide effect, and is safe for wheat and afterculture crops.

Owner:NANJING HUAZHOU PHARMA

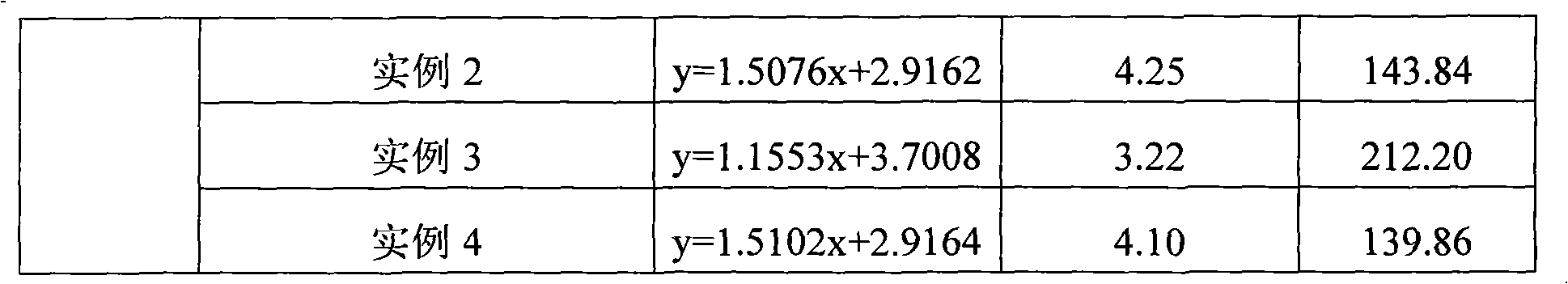

Thermal conducting polymer composite material and preparation method thereof

The invention belongs to the field of high polymer materials, and in particular relates to a thermal conducting polymer composite material and a preparation method thereof. The thermal conducting polymer composite material provided by the invention is prepared from a polymer 1, a polymer 2 and thermal conductive filler and is prepared by means of melt blending and a micro injection molding method;the polymer 2 in the composite material has a microfiber structure; the ratio of the polymer 1, the polymer 2 and the thermal conductive filler is as follows: 80-95 parts by weight of the polymer 1,5-20 parts by weight of the polymer 2 and 1-10 parts by weight of the thermal conductive filler; the melting point of the polymer 1 is less than that of the polymer 2; the melt index of the polymer 1is less than that of the polymer 2; the thermal conductive filler is selectively distributed in the polymer 2 or on the surface thereof. The composite material obtained by the method has good thermalconductivity and mechanical properties at the same time.

Owner:江苏新其石墨烯科技有限公司

Preparation method of silver-copper-oxide electrical contact material

The invention discloses a preparation method of a silver-copper-oxide electrical contact material, which comprises the following steps: 1 weighing oxide powder and abrading-ball respectively and processing the weighed oxide powder through the high energy ball milling method to obtain a nanometer level oxide powder; 2 mixing a silver powder, a copper powder and a nanometer level oxide powder obtained from step 1 to obtain a mixed powder A, and conducting mechanical alloyage surface treatment to the mixed powder A to obtain a mixed powder B; and 3 conducting procedures of annealing, moulding, sintering and extruding to the mixed powder B obtained from step 2 to obtain the silver-copper-oxide electrical contact material. According to the preparation method of the silver-copper-oxide electrical contact material, the cheap metal copper is used to substitute partial precious metals silver; at the same time, oxide is added to prepare the electrical contact material; in this way, not only the preparation cost is low; the obtained electrical contact material has good conductive performance and long service life.

Owner:XI'AN POLYTECHNIC UNIVERSITY

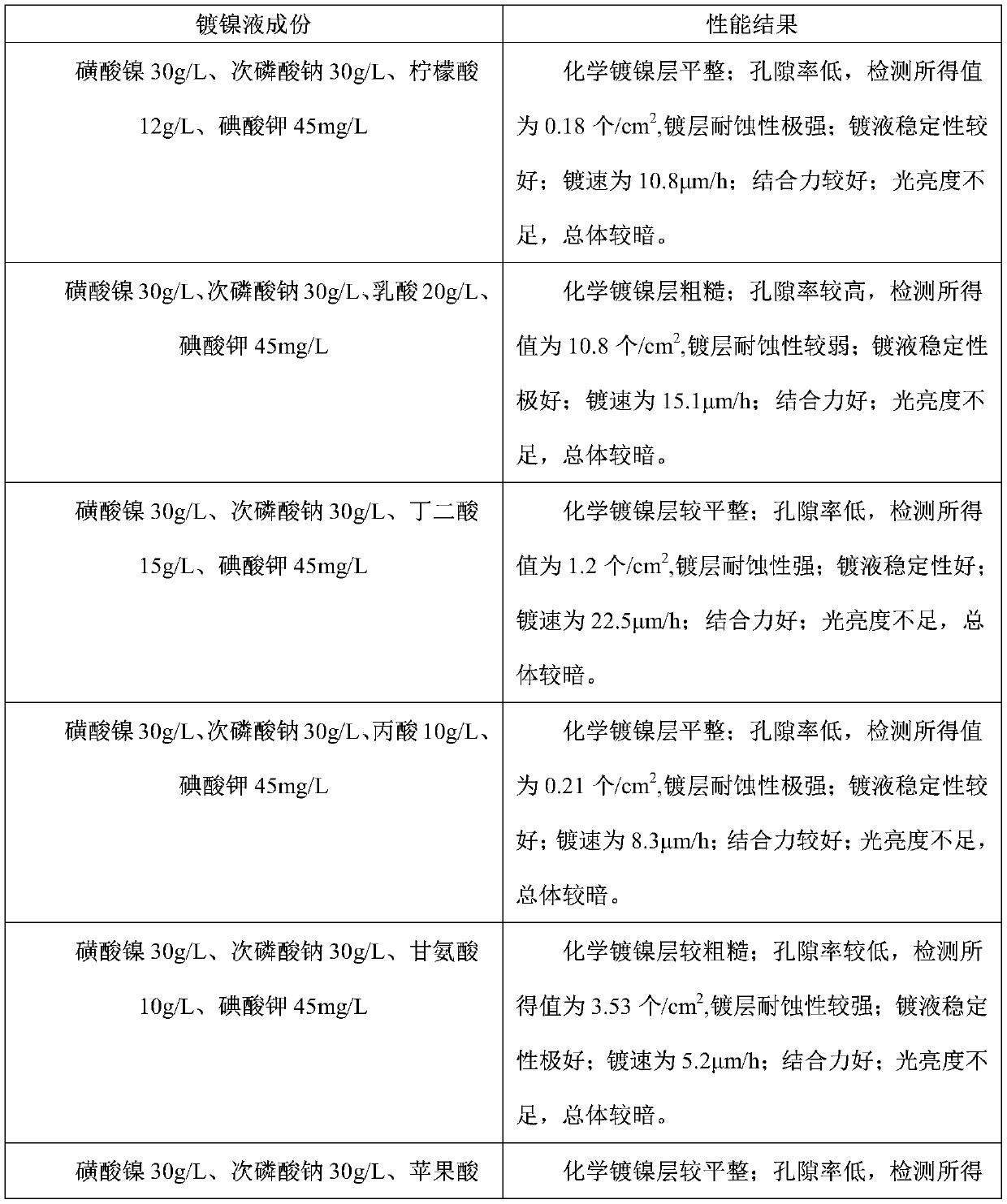

Silver-based circuit board chemically plated with nickel, palladium and gold and preparation method of silver-based circuit board

ActiveCN110468394AReduce thicknessReduced contentLiquid/solution decomposition chemical coatingChemical platingThermal conductivity

The invention discloses a silver-based circuit board chemically plated with nickel, palladium and gold and a preparation method of the silver-based circuit board. The silver-based circuit board comprises a silver-based substrate, wherein a nickel layer, a palladium layer and a gold layer are sequentially plated on the surface of the silver-based substrate from inside to outside. The preparation method comprises the steps of sequentially carrying out pretreatments of micro etching, acid pickling, pre-pickling, palladium activation and post-pickling on the cleaned silver-based substrate, and then sequentially carrying out chemical nickel plating, chemical palladium plating and chemical gold plating on the pretreated silver-based substrate to obtain the silver-based circuit board with the nickel, palladium and gold plating layers. Compared with the traditional chemical plating of nickel, palladium and gold on a copper-based substrate, the thickness of the nickel, palladium and gold plating layers can be greatly reduced, so that the use content of the metal is saved, and the problem of environmental pollution is avoided; and in addition, the substrate is silver-based, so that the wholecircuit board is higher in electrical conductivity and thermal conductivity, higher in sensitivity, longer in service life, and more excellent in overall performance.

Owner:珠海联鼎化工设备有限公司

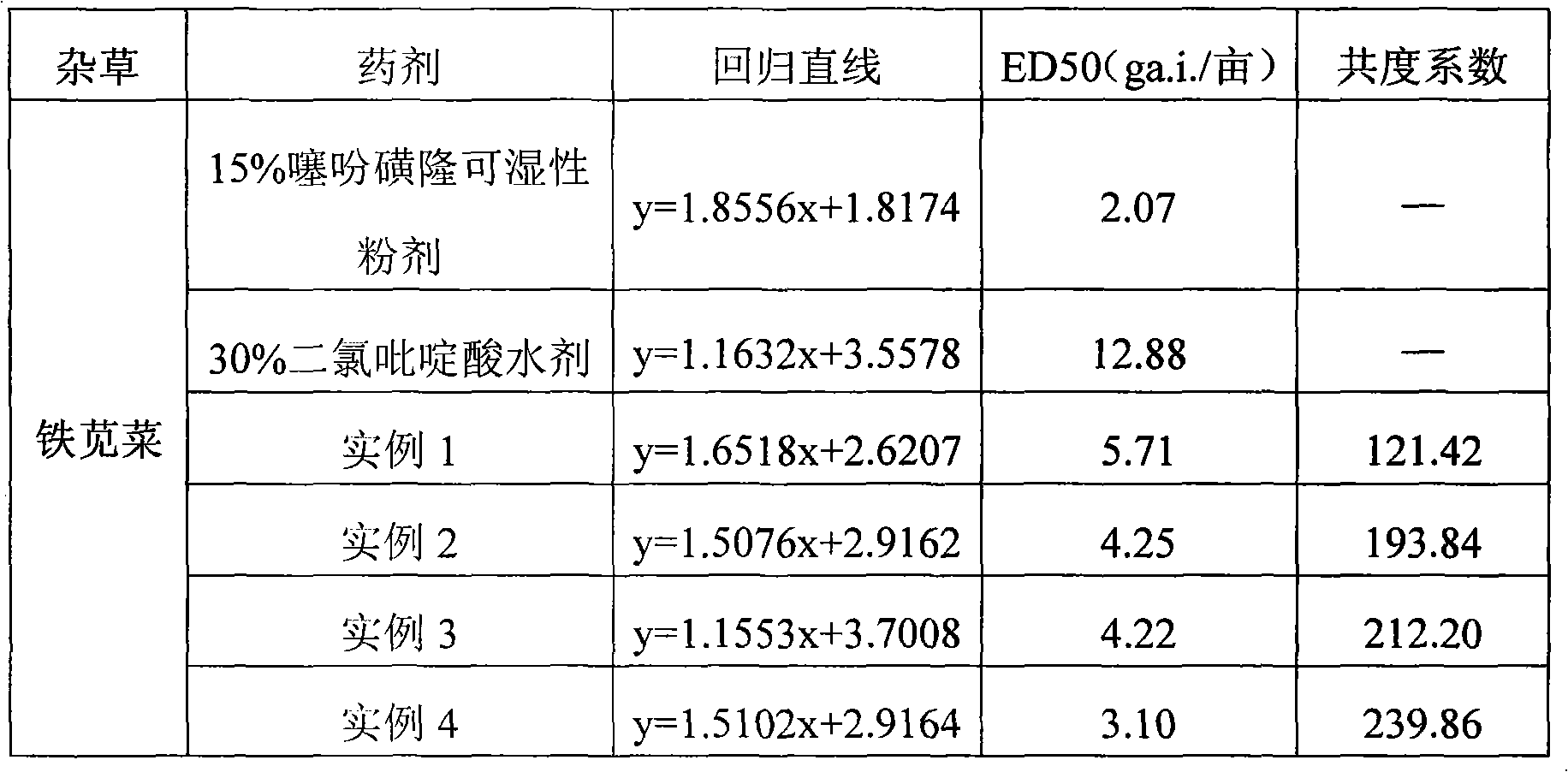

Synergistic herbicidal composition containing clopyralid and bensulfuron-methyl and application thereof

ActiveCN102027968AImprove herbicidal activityExpand the spectrum of weed controlBiocideAnimal repellantsBensulfuron methylClopyralid

The invention discloses a synergistic herbicidal composition containing clopyralid and bensulfuron-methyl and application thereof. The main active ingredients of the herbicidal composition are the clopyralid and the bensulfuron-methyl in a mass ratio of 1-70:1-60. The synergistic herbicidal composition can be used for controlling post-emergence weeds in a wheat field, and particularly has an obvious effect of controlling various broadleaf weeds in the wheat field. Compared with a single-component herbicide, the herbicidal composition delays resistance of weeds, has broad herbicidal spectrum and acts for a long time on the premise of improving herbicide effect, and is safe for wheat and afterculture crops.

Owner:NANJING HUAZHOU PHARMA +1

Low-toxicity, high-fire-retardant, and uvioresistant cable sheath and preparation method thereof

The invention discloses a low-toxicity, high-fire-retardant, and uvioresistant cable sheath. The cable sheath comprises the following raw materials in parts by weight: 30-40 parts of chlorosulfonated polyethylene, 5-15 parts of semi-reinforced carbon black, 0.2-0.3 part of an anti-aging agent, 0.4-0.6 part of stearic acid, 0.4-0.6 part of paraffin, 0.5-1.5 parts of transformer oil, 0.5-1.5 parts of epoxidized soybean oil, 3-4 parts of chlorinated paraffin with the concentration of 52%, 1.5-2.5 parts of a plasticizer, 2-3 parts of antimony trioxide, 4-6 parts of light calcium carbonate, 4-6 parts of pottery clay powder, 4-6 parts of aluminium hydroxide, 1.5-3.0 parts of magnesium oxide, 0.6-0.9 part of a vulcanizing agent and 0.1-0.3 part of a silane coupling agent. Besides, the invention provides a method for preparing the sheath. The cable sheath has the benefit that the sheath has the properties of being low in toxicity, high in flame retardance, and excellent in anti-ultraviolet aging.

Owner:NANYANG CABLE TIANJIN

Herbicidal composition containing clopyralid and thifensulfuron-methyl and application thereof

ActiveCN102027970AImprove herbicidal activityBroad spectrum herbicideBiocideAnimal repellantsChemical compositionClopyralid

The invention belongs to the field of pesticides and discloses a herbicidal composition containing clopyralid and thifensulfuron-methyl and application thereof. The herbicide takes clopyralid and thifensulfuron-methyl as the main active ingredients, wherein the mass ratio of clopyralid to thifensulfuron-methyl is (1-80):(1-70) and clopyralid and thifensulfuron-methyl account for 5-85% of the herbicidal composition by mass. The herbicidal composition has obvious effect on preparing the herbicides for controlling the postemergence weeds in the wheat fields, especially the herbicides for controlling various broadleaf weeds in the wheat fields. Compared with the single agent, the herbicidal composition delays weed resistance, has wide herbicidal spectrum and long efficacy duration and does noharm to the wheat and the aftercrops on the premise of improving the drug effect.

Owner:NANJING HUAZHOU PHARMA

Conductive silver adhesive long in room-temperature use time and capable of being cured at low temperature and preparation method thereof

InactiveCN112080221AExtend storage periodExtension of timeEpoxy resin adhesivesElectrically-conducting adhesivesAdhesive cementPolymer science

The invention relates to the technical field of adhesives for the 3C electronic industry, in particular to a conductive silver adhesive capable of being used for a long time at room temperature and cured at a low temperature and a preparation method of the conductive silver adhesive. The conductive silver adhesive comprises 70-75 parts of silver powder, 17.5-21.3 parts of epoxy resin, 1.5-2.2 parts of diisocyanate modified imidazole, 4-5.5 parts of a reactive diluent, 0.18-0.26 part of a coupling agent, 0.036-0.052 part of a defoamer and 0.09-0.13 part of a dispersant. According to the conductive silver adhesive prepared by the formula and the preparation method thereof, the storage period of the conductive silver adhesive can be prolonged, and the viscosity of the conductive silver adhesive is not increased.

Owner:镝普材料(深圳)有限公司

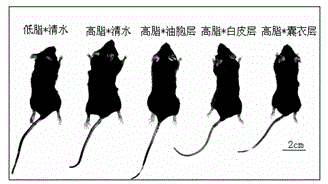

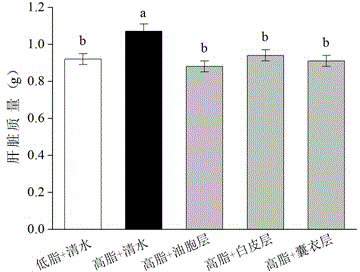

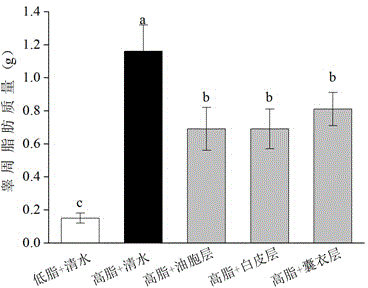

Applications of grapefruit extract

InactiveCN104547166ALight in massReduced contentMetabolism disorderFood preparationGrapefruit oilDisease

The invention provides applications of a grapefruit extract in preparation of lipid-lowering functional food, healthy food or medicines. The grapefruit extract is prepared by the following steps: performing acetone ultrasonic extraction, rotary evaporation, solid-phase extraction column passing and vacuum drying to freeze-dried powder of extracts of a grapefruit oil gland layer, an albedo layer and a mesocarp layer. The body weight of high-lipid induced fat C57BL / 6 mouse can be reduced in vivo through the grapefruit extract, the masses of the liver and adipose tissues can be obviously decreased, the triglyceride, total cholesterol and low-density lipoprotein cholesterol containing in serum can be obviously reduced, and the triglyceride and total cholesterol contained in the liver can be reduced. The grapefruit extract can be used for prevention and treatment of fat metabolism abnormality related diseases as functional food, healthy products or preventive and treatment drugs.

Owner:ZHEJIANG UNIV

Herbicide composition containing dithiopyr and fluroxypyr and application thereof

ActiveCN102027914AReduce the amount of active ingredientsImprove herbicidal activityBiocideAnimal repellantsDithiopyrFluroxypyr

The invention belongs to the field of pesticides, and discloses a herbicide composition containing dithiopyr and fluroxypyr and application thereof. In the herbicide composition, the dithiopyr and the fluroxypyr are taken as main active ingredients, wherein the mass ratio of the dithiopyr to the fluroxypyr is 1-80: 1-80, and the dithiopyr and the fluroxypyr account for 1 to 85 percent of the total mass of the herbicide composition. The herbicide composition can be used for preparing a herbicide for controlling post-emergence weeds in a lawn, has an obvious effect when used for preparing herbicide for controlling pre-emergency weeds in a planted lawn, and is particularly suitable for preparing herbicide for controlling tall fescue and bluegrass in a lawn. Compared with a single-composition herbicide, the herbicide composition postpones the resistance of weeds, has a broad herbicide spectrum and acts for a long time on the premise of improving herbicide effect, and is safe for the lawns and the succeeding crops.

Owner:NANJING HUAZHOU PHARMA

Method for improving electric conduction and heat conduction performance and mechanical property of polymers

The invention belongs to the field of a high molecular material, and particularly relates to a method for improving electric conduction and heat conduction performance and mechanical property of polymers. The invention provides the method for improving the electric conduction and heat conduction performance and mechanical property of polymers. The method comprises the following steps of adding low-melting-point alloy in polymers; performing melting blending in 260 DEG C to obtain a polymer / low-melting-point alloy mixture; then, performing micro injection shaping on the mixture so that the low-melting-point alloy forms micro fiber in the polymers, wherein the ratio of the polymers to the low-melting-point alloy is shown as follows: the polymers account for 100 weight parts, and the low-melting-point alloy accounts for 1 to 20 weight parts. The low-melting-point alloy is added into the polymers; through the micro injection forming method, the formation of the in-situ fiber with the goodform in the polymers by the low-melting-point alloy is realized; a network structure is formed, so that the enhancing effect is achieved; the use content of the metal materials can be obviously reduced; the higher conduction and heat conduction effects are achieved.

Owner:SICHUAN UNIV

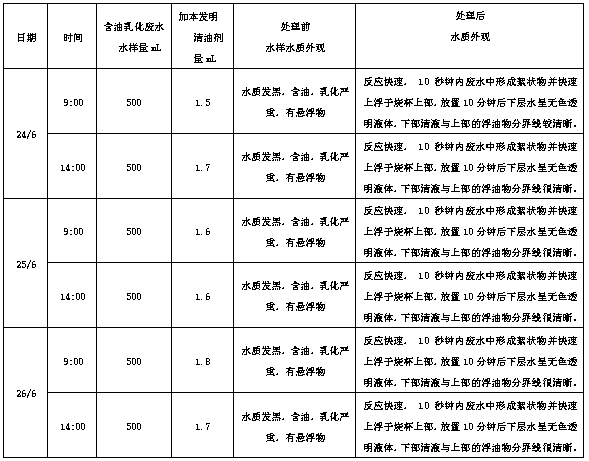

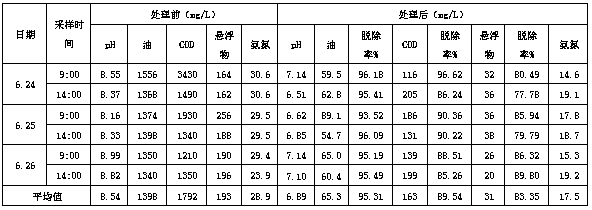

Emulsified waste water treatment oil removing agent and preparation method and use method thereof

InactiveCN105502575AReduce dosageReduce processing costsFatty/oily/floating substances removal devicesLiquid separationChemistrySodium silicate

The invention discloses an emulsified waste water treatment oil removing agent and a preparation method and use method thereof. The emulsified waste water treatment oil removing agent is prepared from, by weight, 0.02% to 0.05% of glycerol, 0.06% to 0.08% of poly(diallyldimethylammonium chloride), 0.80% to 1.00% of sodium silicate, 1.00% to 2.00% of magnesium sulfate, 1.00% to 2.00% of aluminum potassium sulfate and 95.89% to 96.10% of water. The content of oil, suspended solids, COD and other pollutants in emulsified waste water treated through the emulsified waste water treatment oil removing agent is greatly reduced, and when the emulsified waste water treatment oil removing agent is used, the feeding quantity is small, and treatment cost is low. Waste oil can be recycled after being treated, the waste water reaches the standard, and benefits can also be created. When the emulsified waste water treatment oil removing agent is applied, equipment modification is very small, investment is small, and the treatment effect is remarkable. The treatment operation is easy, high reliability is achieved, and management is facilitated. The emulsified waste water treatment oil removing agent is free of toxins, harm and secondary pollution, and up-to-standard emissions of the waste water can be ensured. The treatment effect is good in stability, and popularization is facilitated. The application range is wide, the recovery rate of oil products can be increased, the oil content in drained water can be reduced, and stable running of subsequent treatment units is promoted.

Owner:LANZHOU YISHUN CHEM PROD CO LTD

Production method for non-oil instant edible fungus chips

ActiveCN102302134BEfficient crushingIncrease penetration rateFood preparationBiotechnologyUltrasonic assisted

The invention discloses a production method for non-oil instant edible fungus chips and belongs to the technical field of agricultural product deep processing. The production method for the edible fungus chips comprises the following steps: selecting, cleaning, precisely cutting, ironing, bleaching, deactivating enzyme and cooling the edible fungus raw materials, and then performing ultrasonic auxiliary dipping, leachating, quick-freezing, vacuum freeze drying, vacuum microwave puffing drying, seasoning and packaging on the pretreated edible fungus raw materials. In the production method, a new process of ultrasonic auxiliary dipping, vacuum freeze drying and follow-up vacuum microwave staged combination drying is adopted, thereby reserving the thermal sensitivity nutritive components andbiological activity functional components of the edible fungus to the largest extent, obviously shortening the drying time and saving the production cost. The product has the characteristics of non-frying property, high puffing rate, attractive color, crisp mouthfeel, and the like, and is natural and environmentally-friendly as well as healthy. Compared with the vacuum freeze drying, the process has the advantages that the production period of the finished product can be greatly shortened, the production cost is saved, the puffing effect of the product is good, the mouthfeel of the product iscrisp and the drying quality of the product is improved. A new practical and feasible way for deep processing of the edible fungus is provided.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

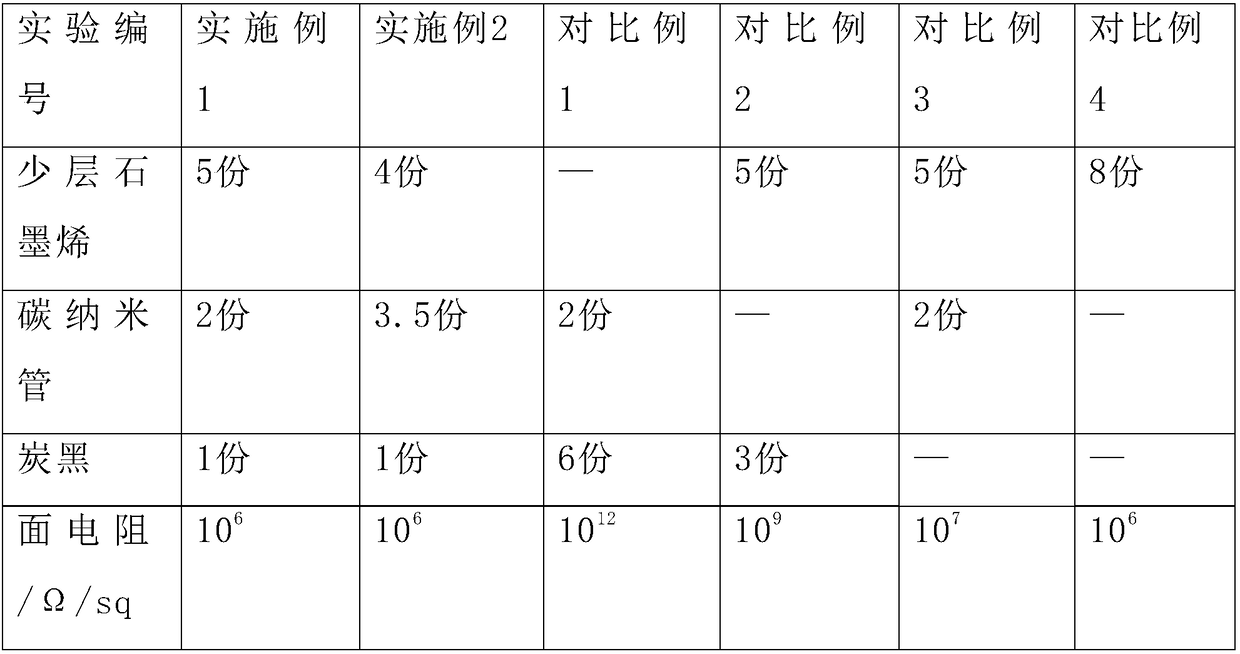

Preparation method of electrostatic absorption heating slurry prepared from graphene carbon nano tube

InactiveCN108822607AEnvironmentally friendly and non-toxicIncrease heatElectrically-conductive paintsElectrical resistance and conductanceCarbon nanotube

The invention relates to a preparation method of an electrostatic absorption heating slurry prepared from a graphene carbon nano tube. The electrostatic absorption heating slurry comprises 3-10 partsof graphene, 1-5 parts of carbon nano tube and 0.5-2 parts of carbon black according to mass percentage; and the resistance of a film surface is less than 107 Omega / sq. The preparation method of the electrostatic absorption heating slurry prepared from the graphene carbon nano tube, provided by the invention, has the advantages that the content of the graphene is reduced, and the production cost is reduced because the graphene, the carbon nano tube and the carbon black are used in a coordinated manner; moreover, by adjusting the mixing ratio of the graphene, the carbon nano tube and the carbonblack to an appropriate mixing ratio, the anti-static electricity performance of a heating film is enhanced, and the content of the graphene can also be reduced.

Owner:杭州牛墨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com