Patents

Literature

700 results about "Chlorotrifluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorotrifluoroethylene (CTFE) is a chlorofluorocarbon with chemical formula CFCl=CF₂. It is commonly used as a refrigerant in cryogenic applications. CTFE has a carbon-carbon double bond and so can be polymerized to form polychlorotrifluoroethylene or copolymerized to produce the plastic ECTFE. PCTFE has the trade name Neoflon PCTFE from Daikin Industries in Japan, and used to be produced under the trade name Kel-F from 3M Corporation in Minnesota.

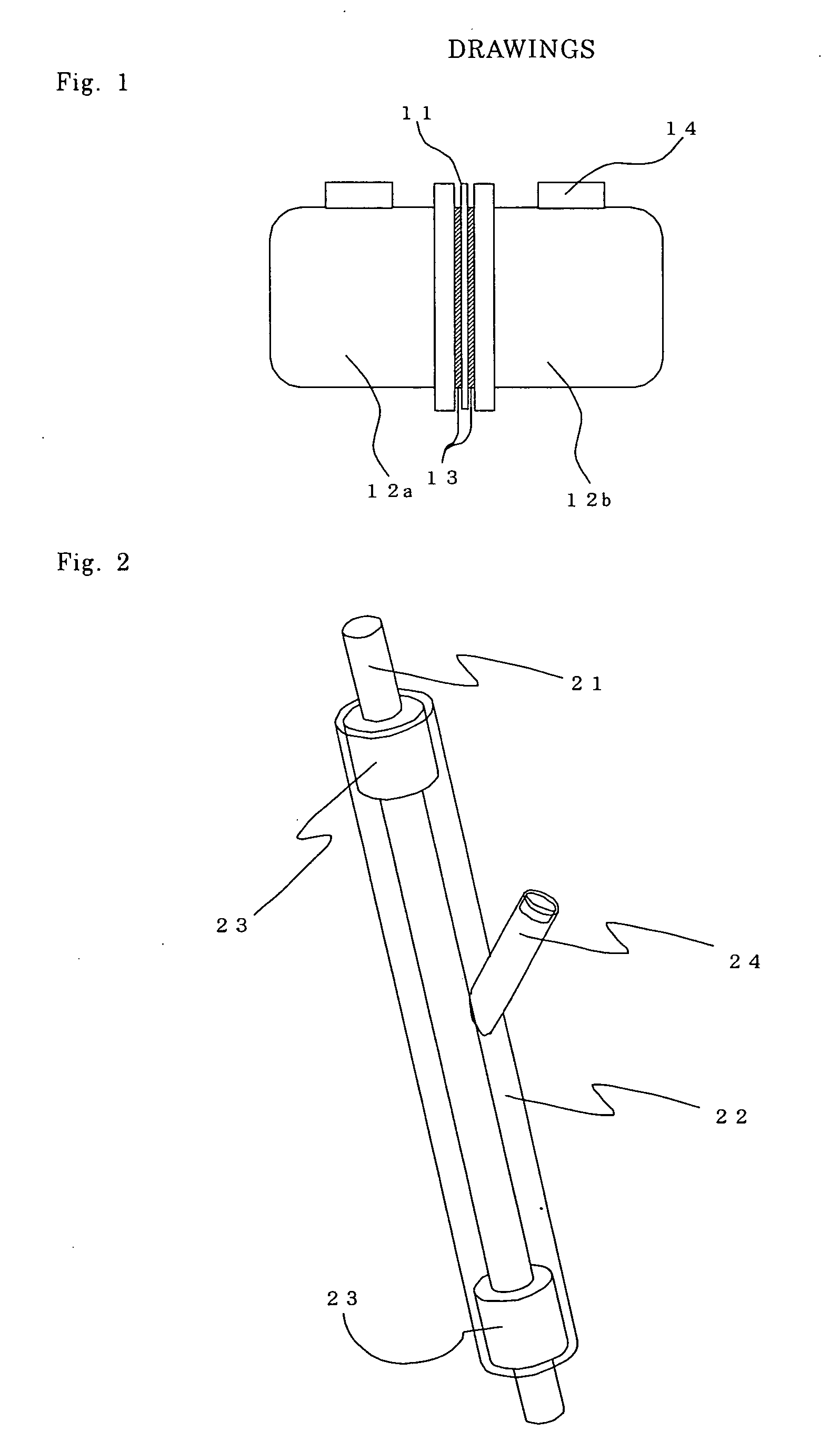

Poly(ethylene chlorotrifluoroethylene) membranes

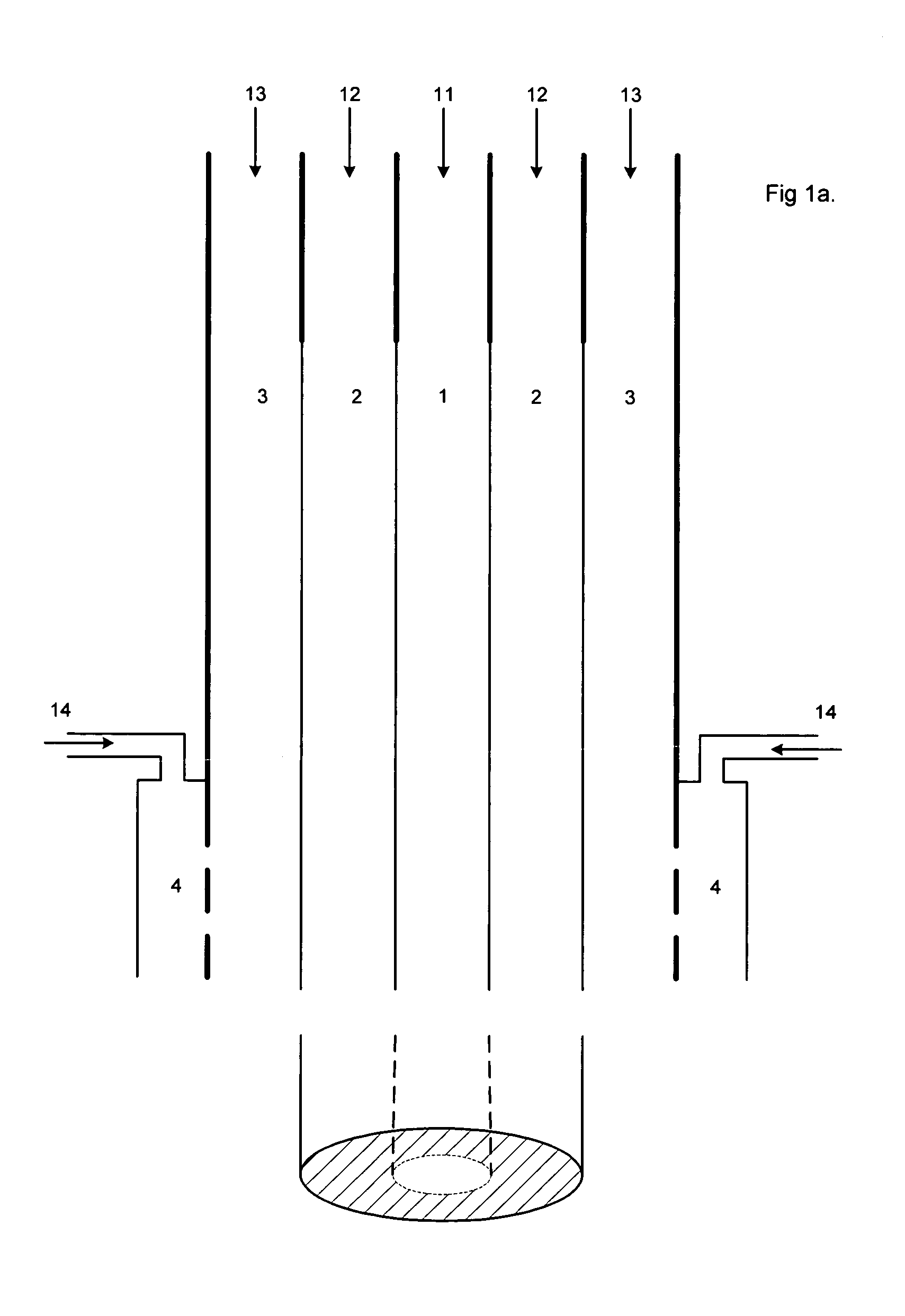

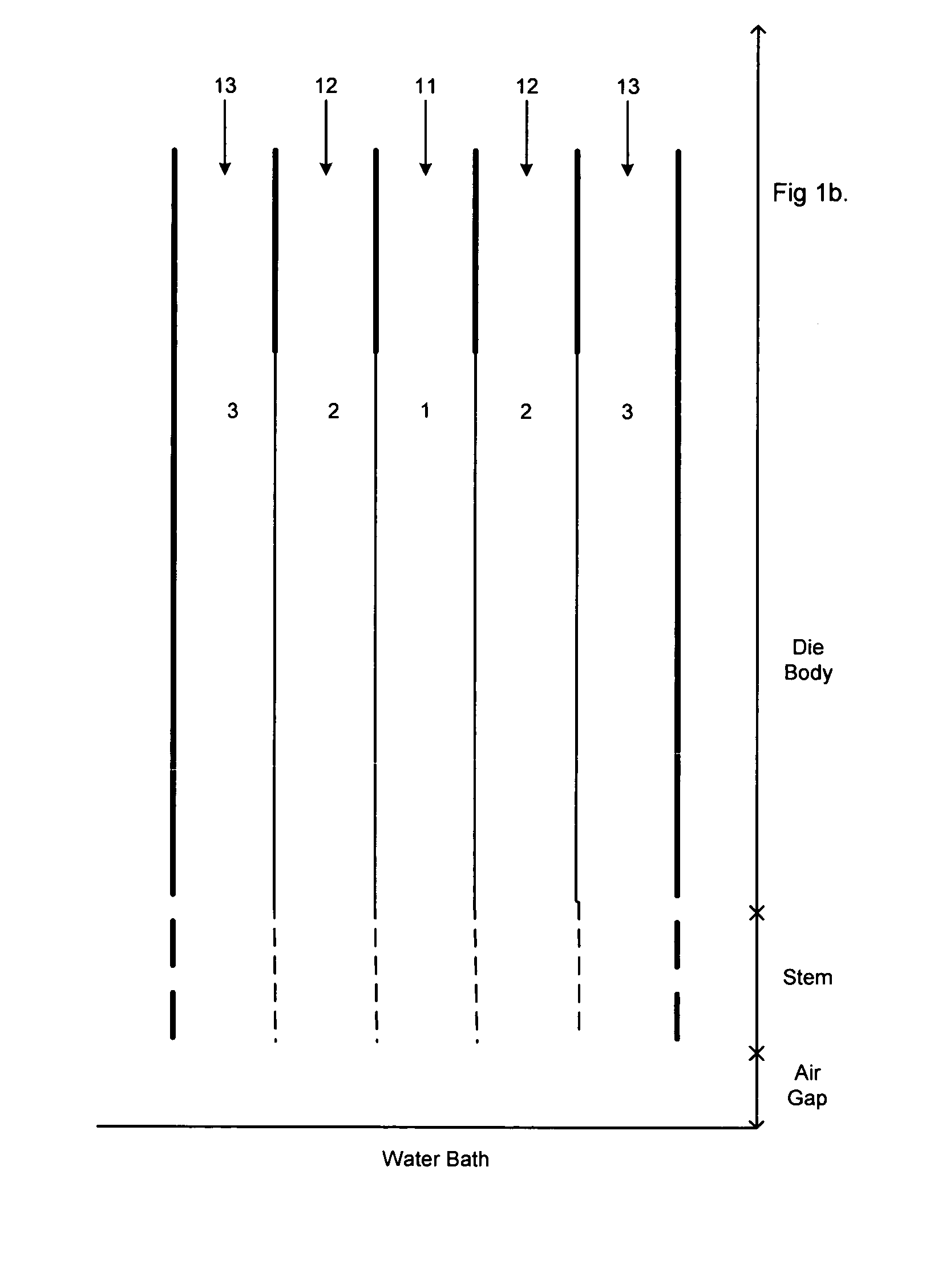

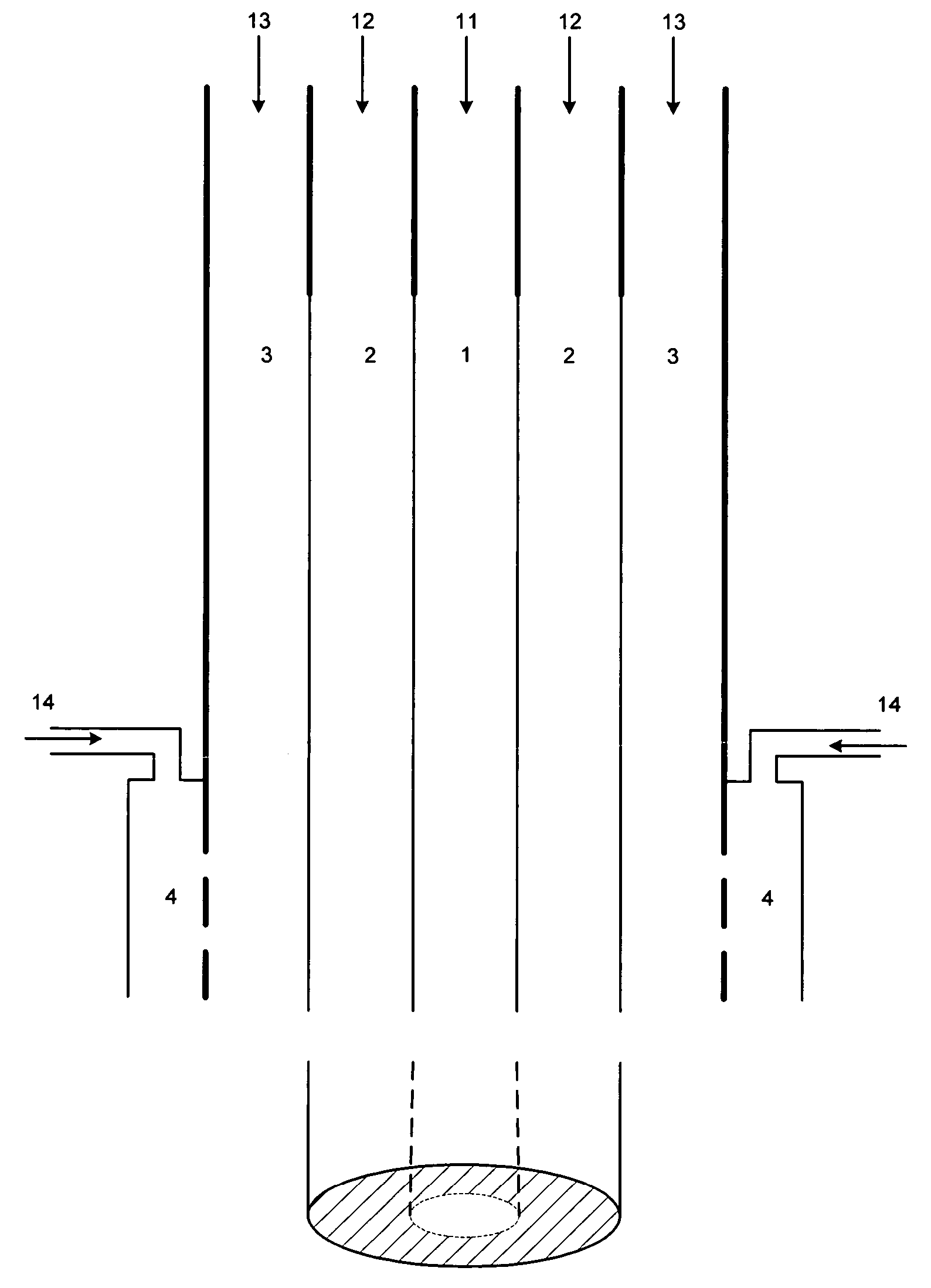

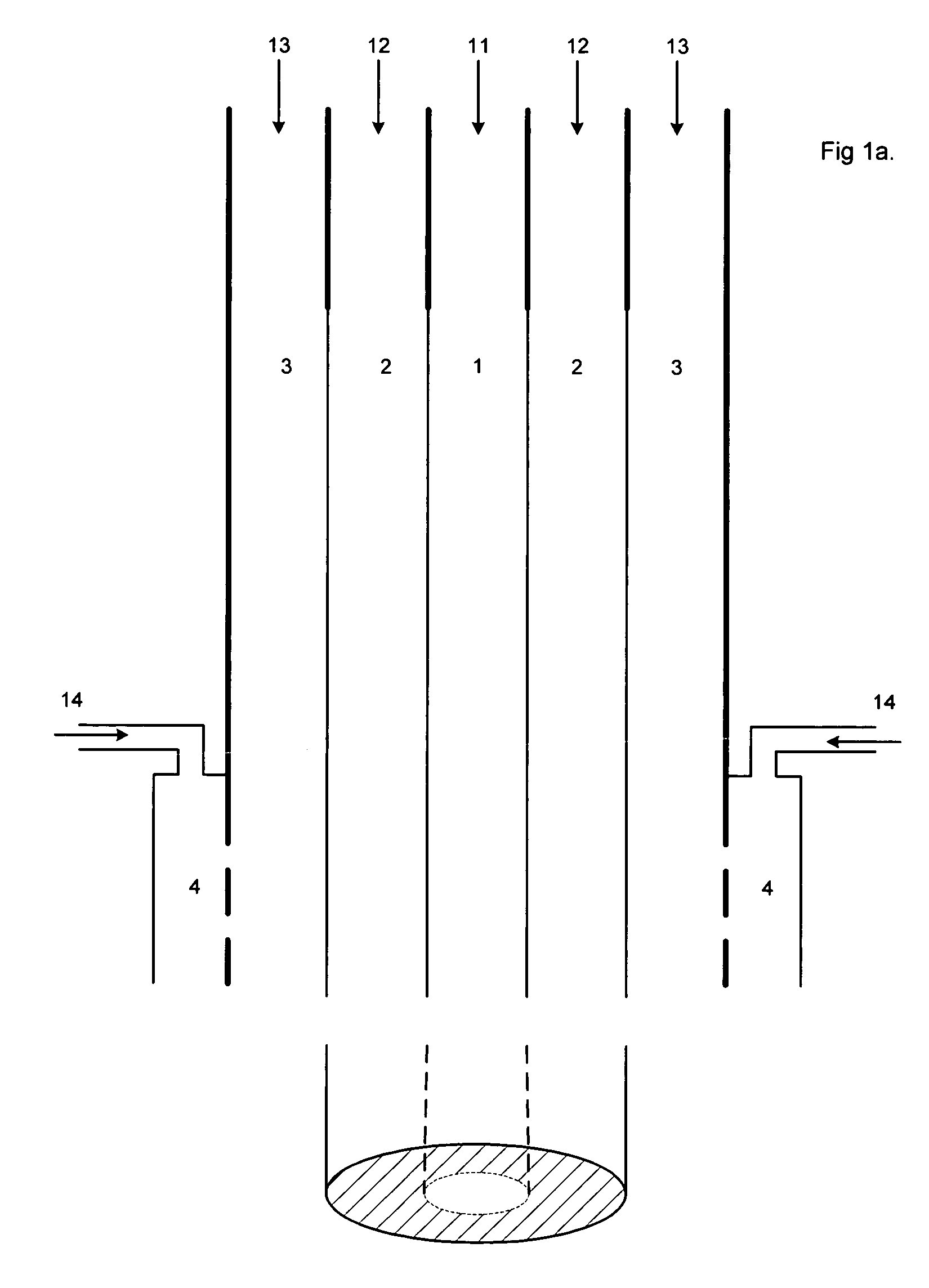

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

Halar membranes

InactiveUS20050098494A1Low toxicityImprove permeabilityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fibre or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

PROCESS FOR THE PREPARATION OF 2,3,3,3-TETRAFLUOROPROPENE (HFO-1234yf)

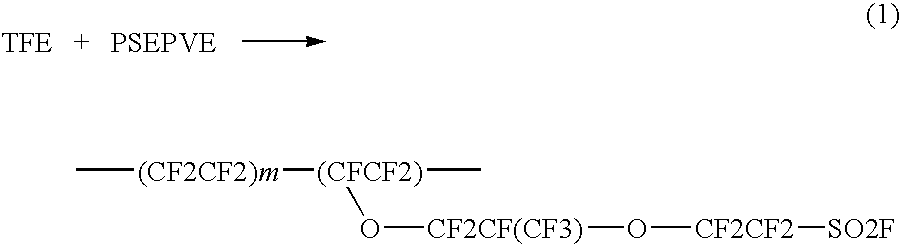

A process for the preparation of 2,3,3,3-tetrafluoropropene (HFO-1234yf). HFO-1234yf is a refrigerant with low global warming potential. A process comprises a) reacting chlorotrifluoroethylene with a methyl halide to form an intermediate product stream; and b) reacting the intermediate product stream with hydrogen fluoride to thereby produce a result comprising 2,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

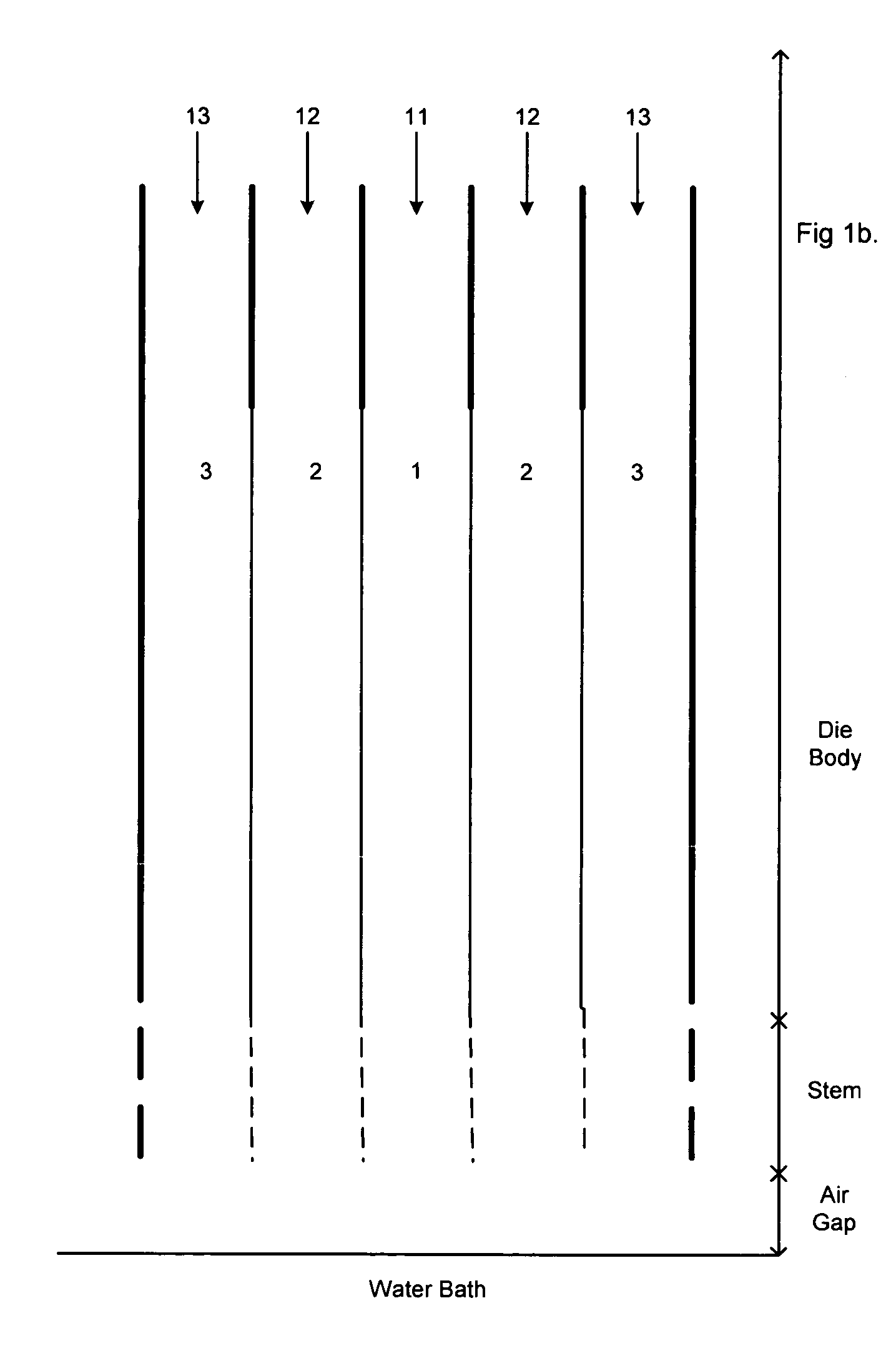

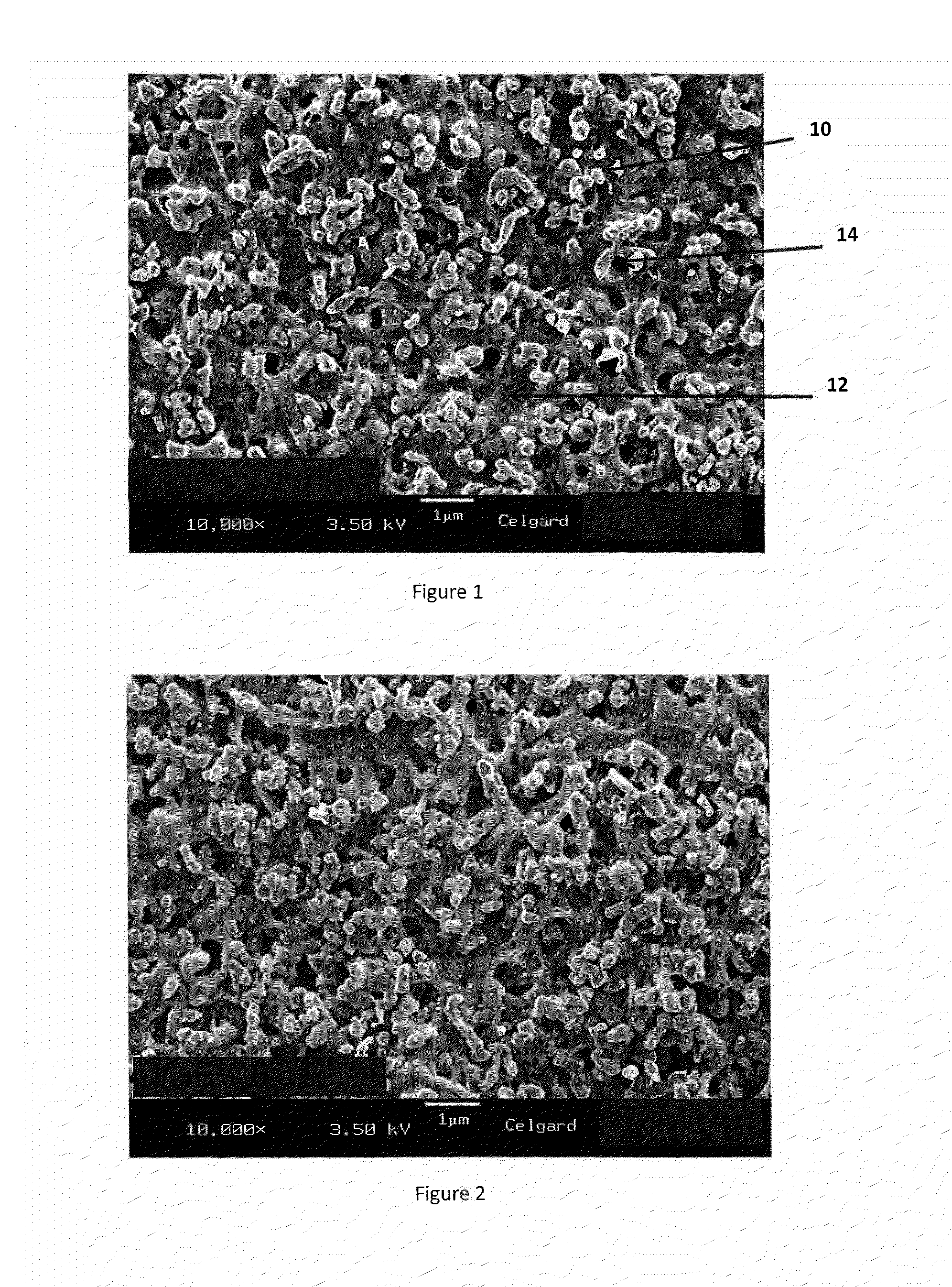

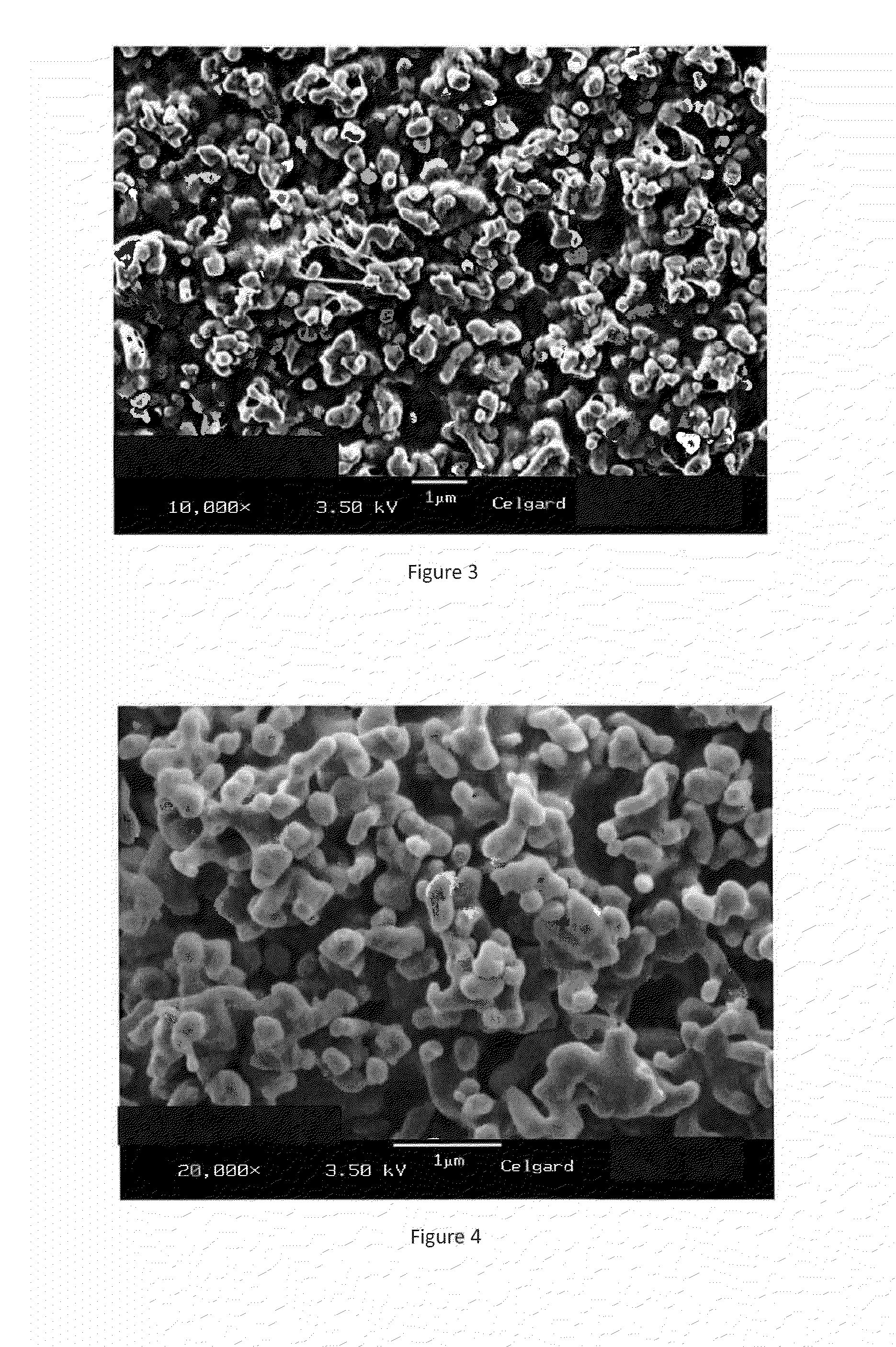

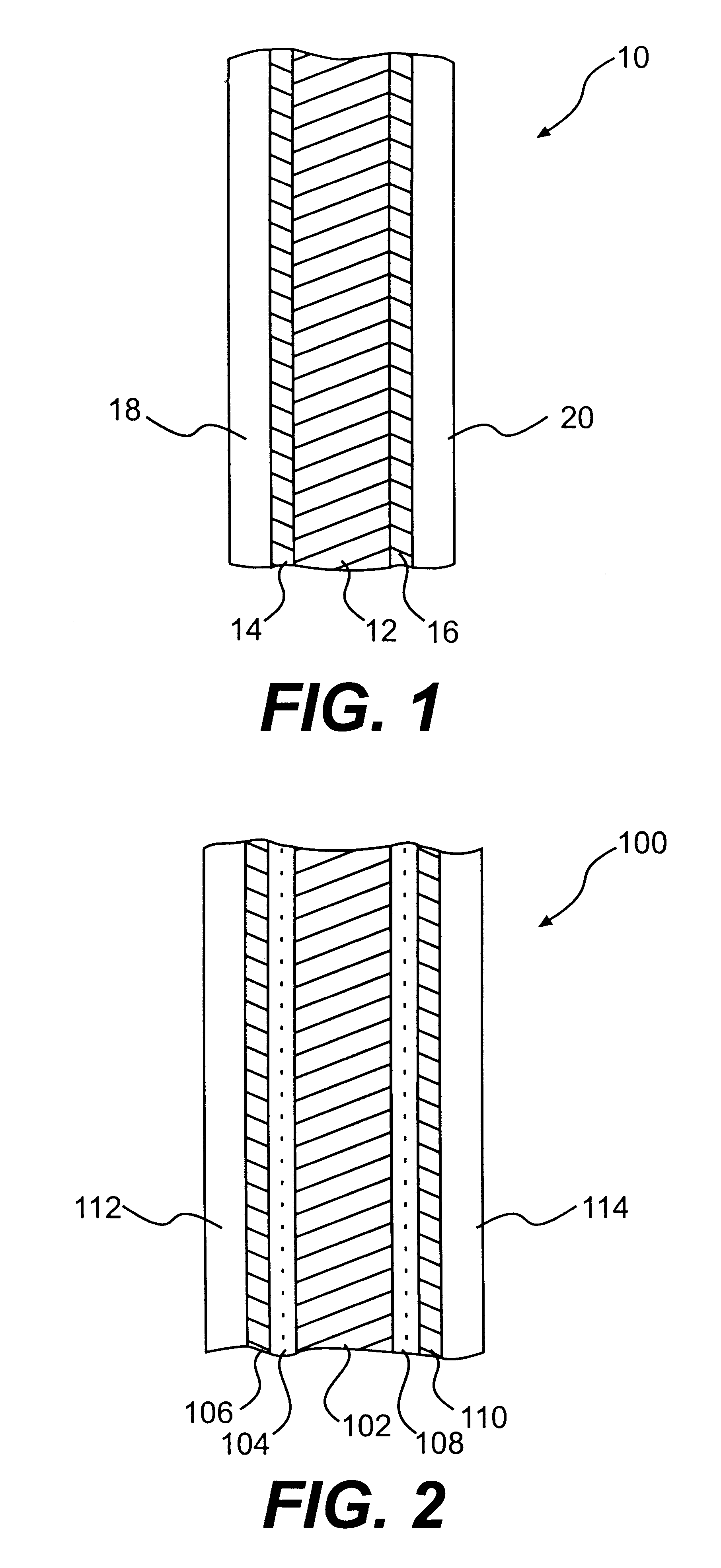

Coated separators for lithium batteries and related methods

PendingUS20160164060A1Desirable level of porosityImprove thermal stabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePolymer scienceHexafluoropropylene

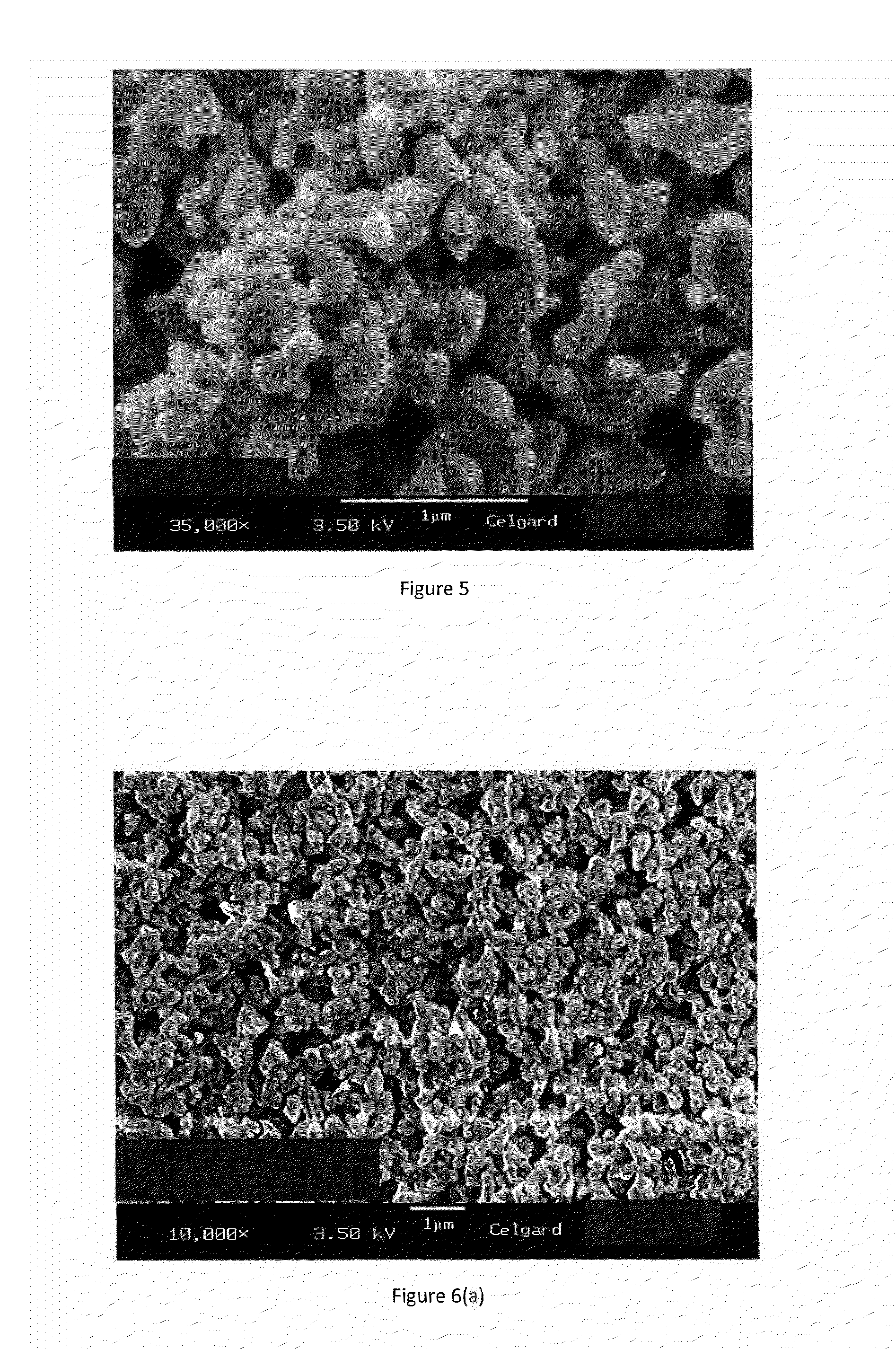

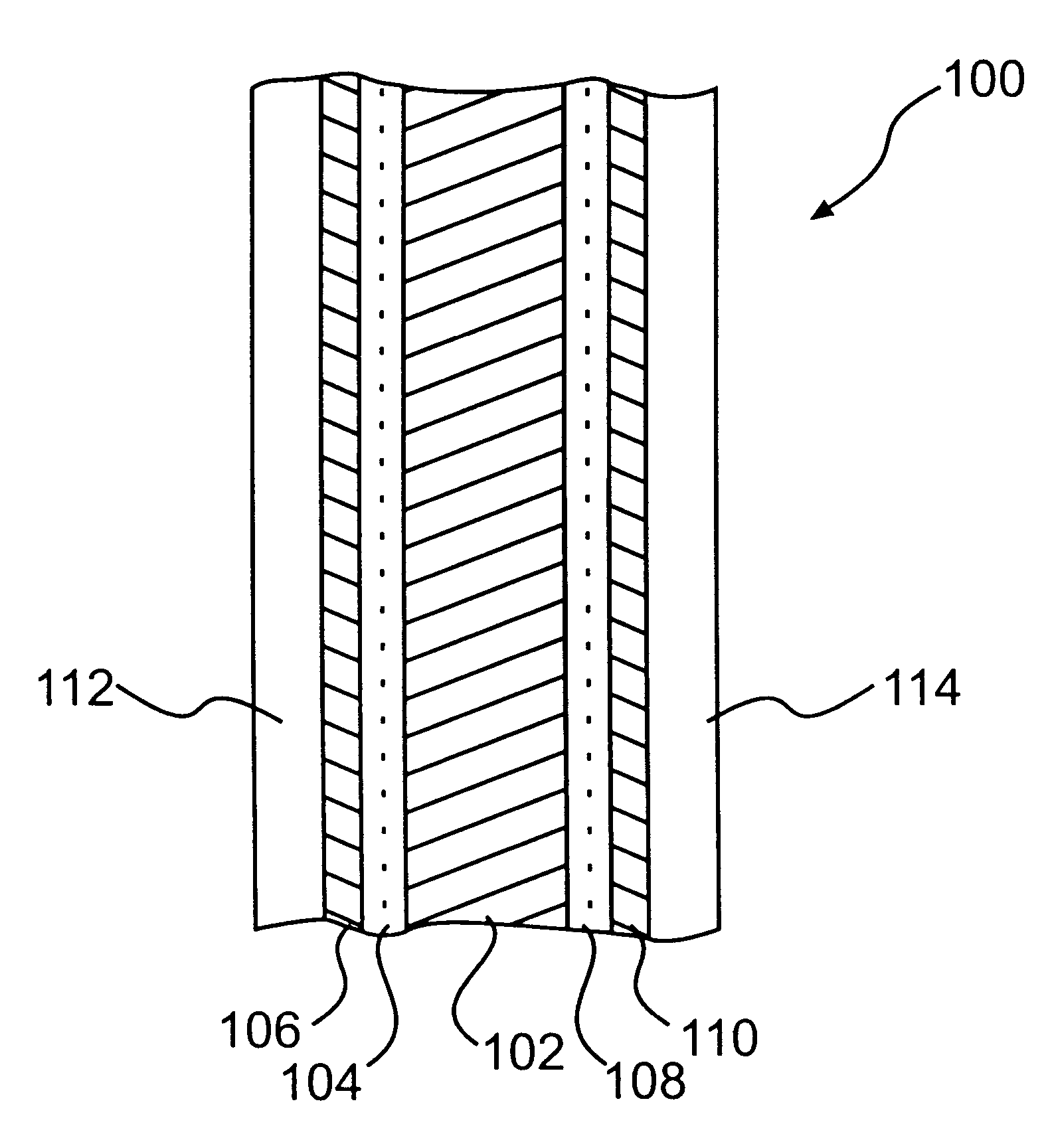

In accordance with at least selected embodiments, new or improved ceramic coated separators, membranes, films, or the like for use in lithium batteries, new or improved batteries including such ceramic coated separators, membranes, films, or the like, and methods of making or using such ceramic coated separators, membranes, films or the like are disclosed. In accordance with at least certain embodiments, new or improved aqueous or water-based polymeric coated separators, membranes, films, or the like are disclosed. In accordance with at least particular embodiments, new or improved aqueous or water-based polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) homopolymer or co-polymers of PVDF with hexafluoropropylene (HFP or [—CF(CF3)—CF2—]), chlorotrifluoroethylene (CTFE), vinylidene fluoride (VF2.HFP), tetrafluoroethylene (TFE), and / or the like, blends and / or mixtures thereof, coated separators, membranes, films or the like, new or improved porous separators for use in lithium batteries, new or improved coating or application methods for applying a coating or ceramic coating to a separator for use in a lithium battery, new or improved PVDF or PVDF:HFP films or membranes, and / or the like are disclosed.

Owner:CELGARD LLC

Narrow composition distribution polyvinylidene fluoride RECLT films, processes, articles of manufacture and compositions

InactiveUS6620342B1Liquid crystal compositionsLiquid surface applicatorsSolubilityOptical transparency

The disclosure relates to a reversible, electrically controllable light transmission (RECLT) film, article of manufacture composition, process and product produced by the process, comprising a conductive narrow composition distribution polyvinylidene fluoride copolymer in combination with an electrolyte and an RECLT material. The narrow composition distribution polyvinylidene fluoride copolymer has low solubility, high thermal stability and strength, and very high optical clarity. The polyvinylidene fluoride copolymer comprises a nonporous or porous copolymer of vinylidene fluoride preferably with either hexafluoropropylene or tetrafluoroethylene or chlorotrifluoroethylene, or vinyl acetate, or combinations thereof. The RECLT material includes organic or inorganic compounds known in the art. Typical RECLT materials include electrochromic materials, reversible metal electrodeposition materials, liquid crystal materials and dispersed particle materials.

Owner:ARKEMA INC

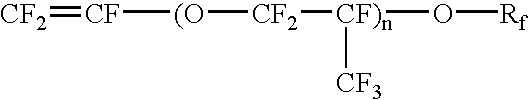

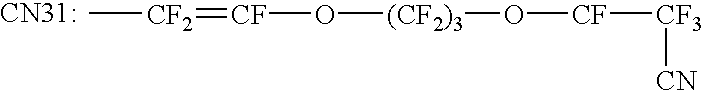

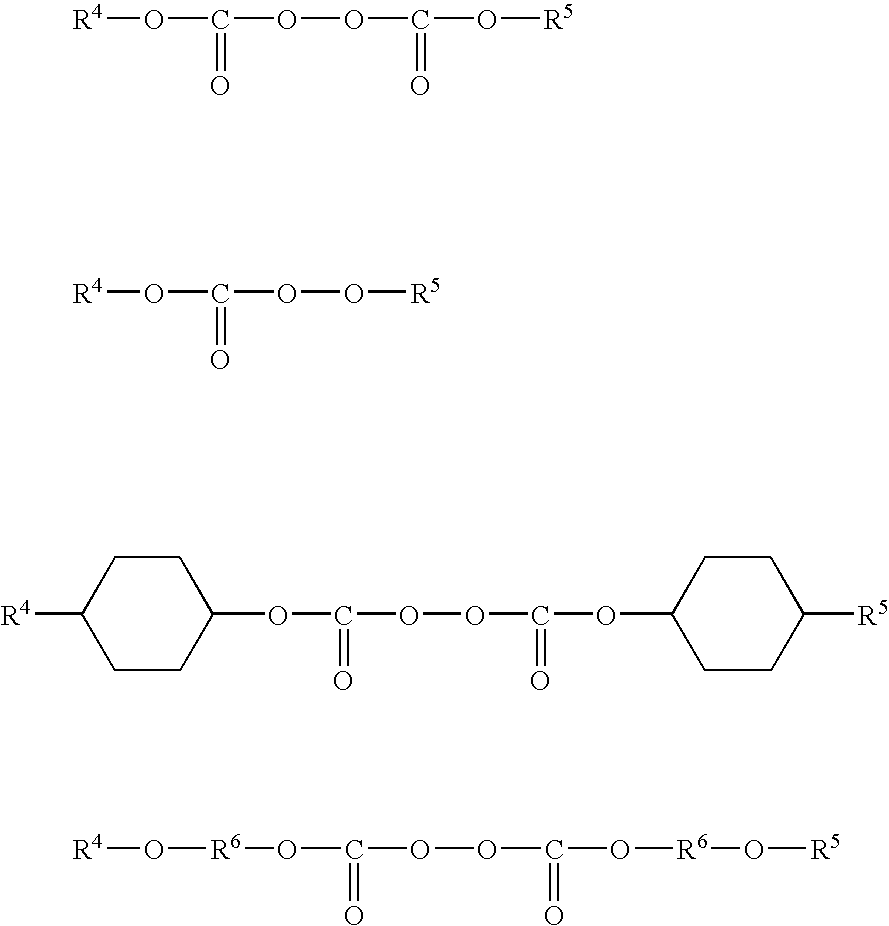

Perfluoroelastomers having a low glass transition temperature and method of making them

InactiveUS6730760B2The polymerization reaction is fastDesirable mechanical propertyVinyl etherVitrification

A method of making a curable fluoroelastomer is disclosed. The method comprises the steps ofpreemulsifying at least one perfluorovinylether in water, andcopolymerizing the preemulsified perfluorovinylether with a gaseous fluorinated monomer in the presence of a cure site monomer. The method provides a fluoroelastomer having a glass transition temperature of less than -10° C. Also disclosed is a fluoroelastomer that consists essentially of a perfluorovinylether of formula (I) as defined below, a cure site component, perfluoromethylvinylether, and tetrafluoroethylene and / or chlorotrifluoroethylene.

Owner:3M INNOVATIVE PROPERTIES CO

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325ALower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsMetallurgyOrganic polymer

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

Catalystic hydrogenation and dechlorination catalyst for preparing trifluorochloroethylene and trichloroethylene

InactiveCN1351903AHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsActive componentRuthenium

A catalyst for hydrogenation and dechlorination to prepare trifluorochloroethylene and trichloroethylene has noble metal Ru and metal Cu as main active components, La-enriched RE mixture and alkali metal Li as modifying assistants and active coconut charcoal and carrier. It has excellent comprehensive reaction performance, including reaction activity, selectivity, service life, etc. as well as relative low cost.

Owner:大连振邦氟涂料股份有限公司

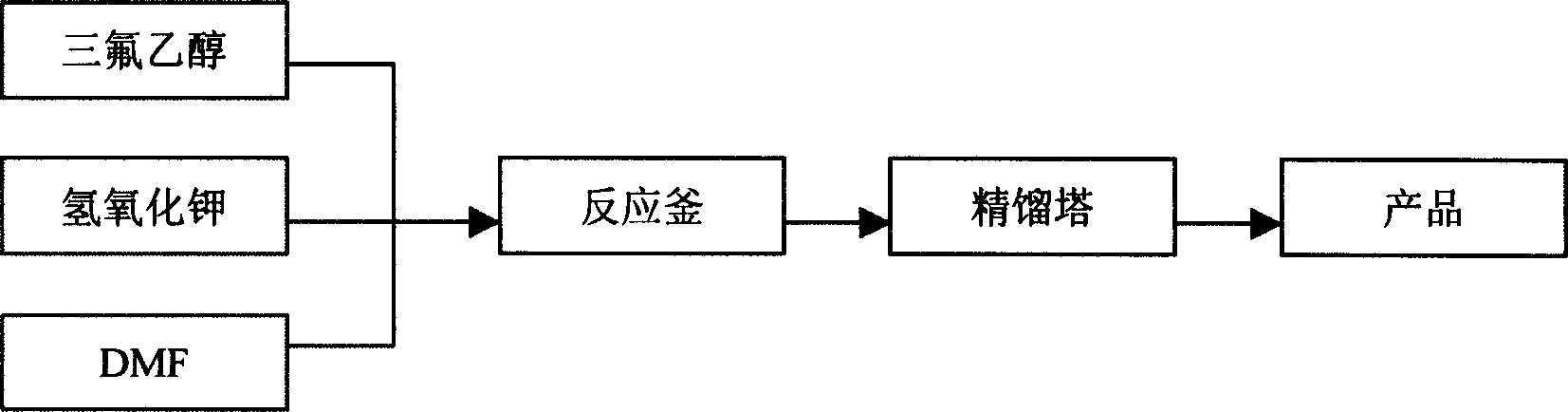

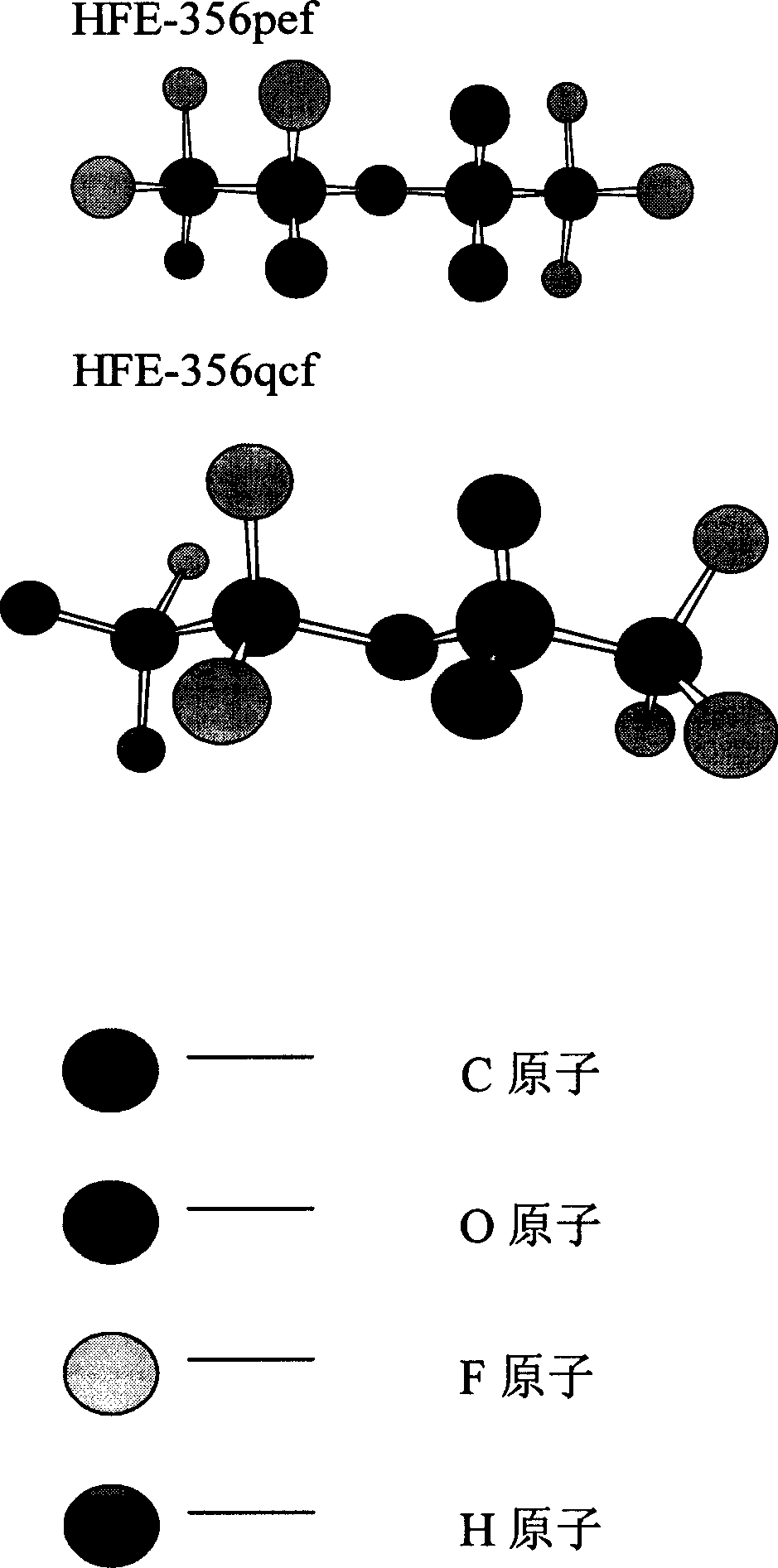

New hydrofluoro ether and its preparation method

InactiveCN1651378AHigh yieldEasy to separate and purifyEther preparationFoaming agentOrganic solvent

A process for preparing hydrofluoroether features the reaction between one of trifluoroethene, tetrafluoroethene, hexafluoro propene, etc and one of trifluoroethanol, trifluoropropanol, metanol, etc in organic solvent (DMF or DMSO). Its advantages are high output rate and easy purifying and separating.

Owner:大连振邦氟涂料股份有限公司

Thermosetting fluorine-carbon resin for metal coiled material and coating thereof

The invention relates to a thermosetting fluorocarbon resin and the coating thereof. The copolymerization chain segment of the resin comprises chlorotrifluoroethylene of 45.0-55.0mol percent, vinyl-acetic ester of 28.0-37.0mol percent, vinyl versatate of 4.0-10.0mol percent, hydroxyl vinyl ether of 10.0-14.0mol percent and aliphatic olefine acid of 0-0.6mol percent. The fluorocarbon coating mainly comprises the following components with certain weight percentage, thermosetting fluorocarbon resin of 20.0-40.0 percent, cross-linking agent of 0-15.0 percent, paint of 0-35.0 percent, promoter of 0.15-1.5 percent and mixed solvent of 30.0-60.0 percent. The fluorocarbon coating adopts no acid catalyst, has stable properties in storage, has excellent softness, methyl ethyl ketone wiping resistance and aging resistance, etc., and is applicable for rolling coating of metal rolling material.

Owner:万博新材料科技(南通)有限公司

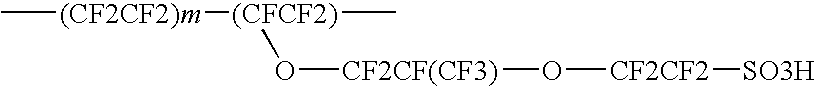

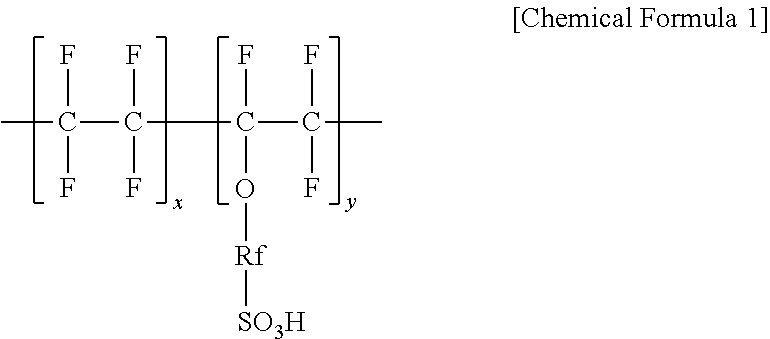

Fluorochloro Ionomers

This invention discloses novel fluorochloro ionomers and processes of making them. The first preferred body of invention is perfluorochloro ionomers having (1) equivalent weight between 600 and 1500, preferably between 800 and 1200, and most preferably between 900 and 1100; (2) chlorine content between 8% and 30% by weight. These ionomers are breathable and excellent barrier materials, capable of being processed into thin films or membranes and are well suited for low humidity or high temperature fuel cell applications and for chemical protective covering materials. The second preferred body of invention is partially fluorochloro ionomers having (1) moisture vapor permeability rate >3000 gram H2O / m2 / day (about ½ mil thick film); (2) chlorine content of between 10% and 39% by weight. These ionomers are breathable and excellent barrier materials that can also be processed into thin films or membranes and are suited for some fuel cell applications and more preferably for breathable protective covering applications. The membranes can be monolithic films or multi-layers films, or composite films, or bipolar membranes. These novel fluorochloro ionomers are made by radical copolymerization of at least one fluorochloro monomer and at least one comonomer consisting of at least ionic group or at least one precursor that can be converted to ionic groups such as acid groups or amines or quaternary amine groups. The said fluorochloro monomer containing at least one fluorine and at least one chlorine atom is free radical polymerizable including chlorotrifluoroethylene (CFCl═CF2) and dichlorodifluoroethylene (CFCl═CFCl).

Owner:ZHEJIANG HYPROOF TECH CO LTD

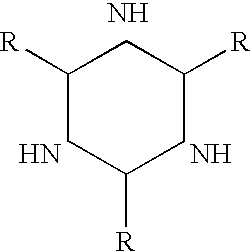

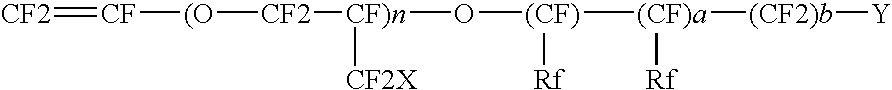

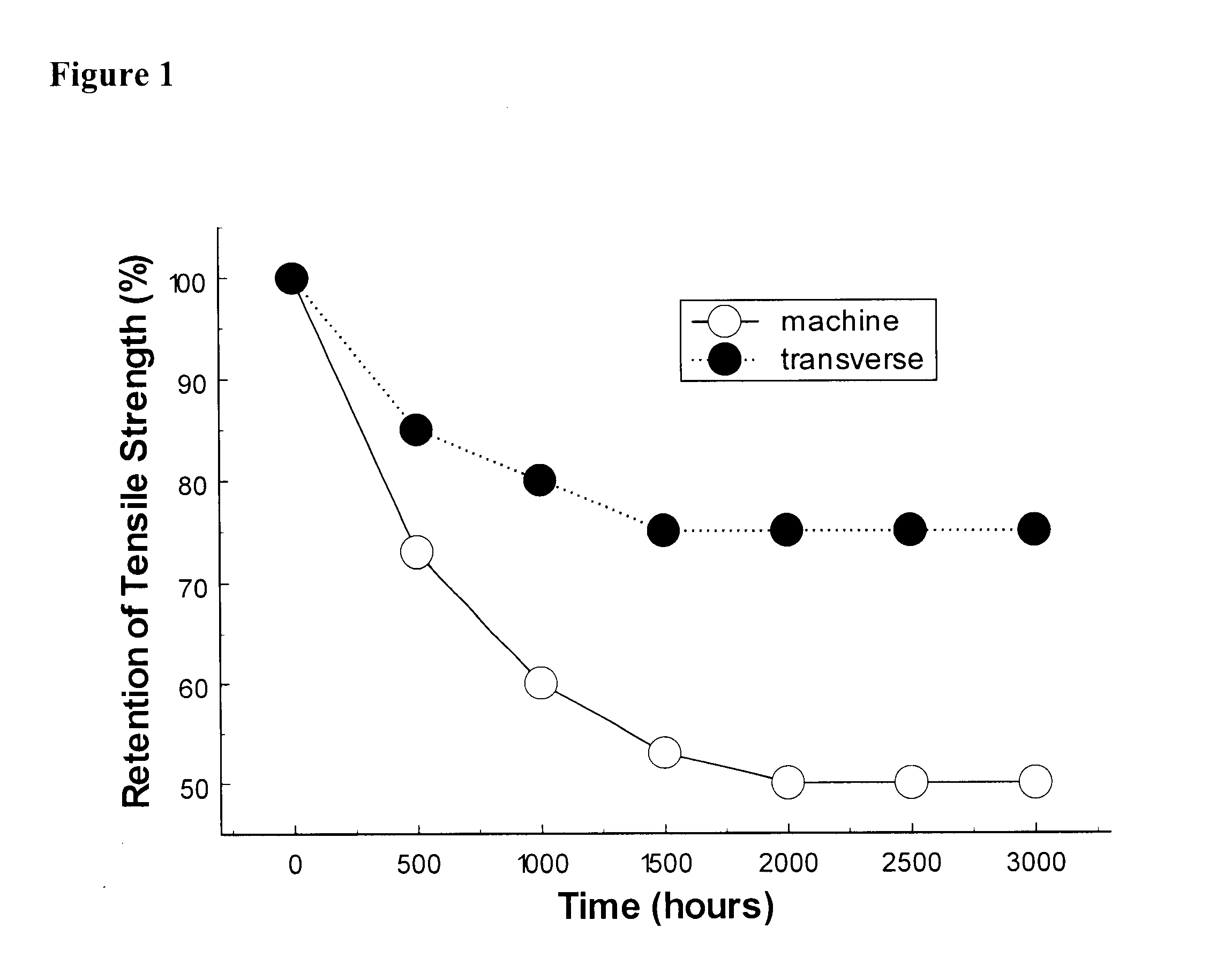

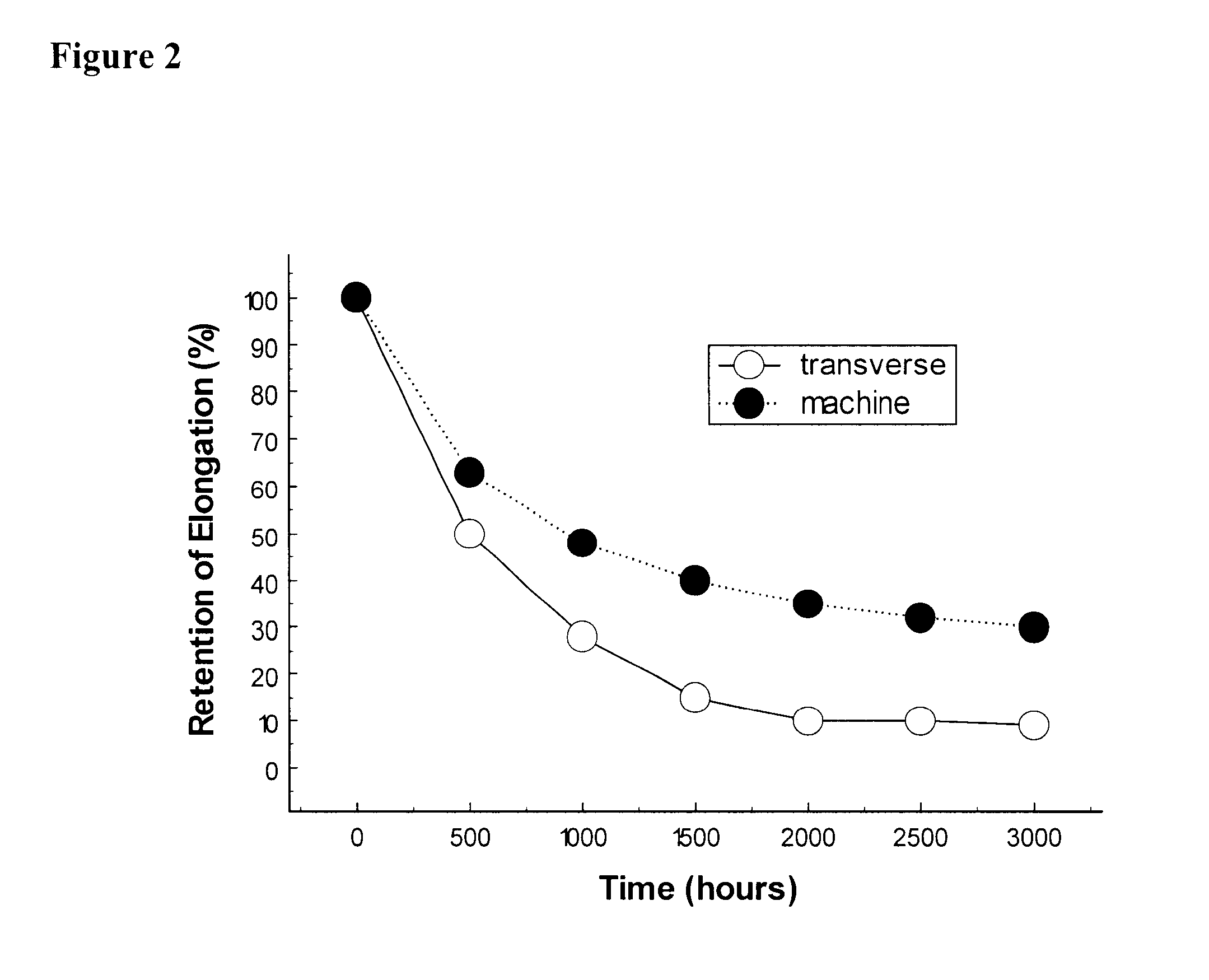

Poly (chlorotrifluoroethylene/vinylidenefluoride/vinylester) copolymers with excellent long-term ultraviolet light resistance

A composition containing a non-flammable chlorofluoro-olefin copolymer having a crystallinity index less than about 10% and a weight-average molecular weight greater than about 1,000,000 daltons, wherein the copolymer has at least two comonomer units of the formula:wherein each X is independently selected from H, Cl and F; Y is selected from H, Cl, F, O(CZ2)nCZ3, (CZ2)nCZ3, (OCZ2CZ2)nCZ3 and (O(CZ2)n)nCZ3, wherein each n is independently from about 1 to about 12 and each Z is independently selected from H, Cl and F; and A is selected from H, Cl and F, provided that for at least one comonomer unit, at least one of A, Y, either X or any Z is Cl. Substrates coated with the copolymer compositions are also disclosed.

Owner:ALLIEDSIGNAL INC

Narrow-arranged poly-phosphinodifluoro-ethylene reversible and electrocontrollable transparent film, its making mehtod, product and composition therefrom

The disclosure relates to a reversible, electrically controllable light transmission (RECLT) film, article of manufacture composition, process and product produced by the process, comprising a conductive narrow composition distribution polyvinylidene fluoride copolymer in combination with an electrolyte and an RECLT material. The narrow composition distribution polyvinylidene fluoride copolymer has low solubility, high thermal stability and strength, and very high optical clarity. The polyvinylidene fluoride copolymer comprises a nonporous or porous copolymer of vinylidene fluoride preferably with either hexafluoropropylene or tetrafluoroethylene or chlorotrifluoroethylene, or vinyl acetate, or combinations thereof. The RECLT material includes organic or inorganic compounds known in the art. Typical RECLT materials include electrochromic materials, reversible metal electrodeposition materials, liquid crystal materials and dispersed particle materials.

Owner:ATOCHEM OF NORTH AMERICA INC

Catalyst for tert-butyl alcohol cleavage reaction and preparation method thereof

ActiveCN103611572AIncreased intermolecular attractionNot easy to fall offOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsChlorinated polyvinyl chloridePolystyrene

The invention provides a catalyst for tert-butyl alcohol cleavage reaction, which is prepared by the following steps: by using a melt granulation process, blending and melting polystyrene, chlorinated polyvinyl chloride, polytrifluorochloroethylene and polyvinylidene fluoride, and granulating; and carrying out sulfonation reaction on the granulation product in the fixed bed and sulfur trioxide to obtain the catalyst. When being used for tert-butyl alcohol cleavage reaction, the catalyst has the advantages of high selectivity for technique reaction, fewer side reactions and low shedding tendency of sulfo-group under high-temperature conditions. The invention also provides a preparation method of the catalyst.

Owner:南通灵润医用新材料有限公司

Process for the preparation of 2,3,3,3-tetrafluoropropene (HFO-1234yf)

Owner:HONEYWELL INT INC

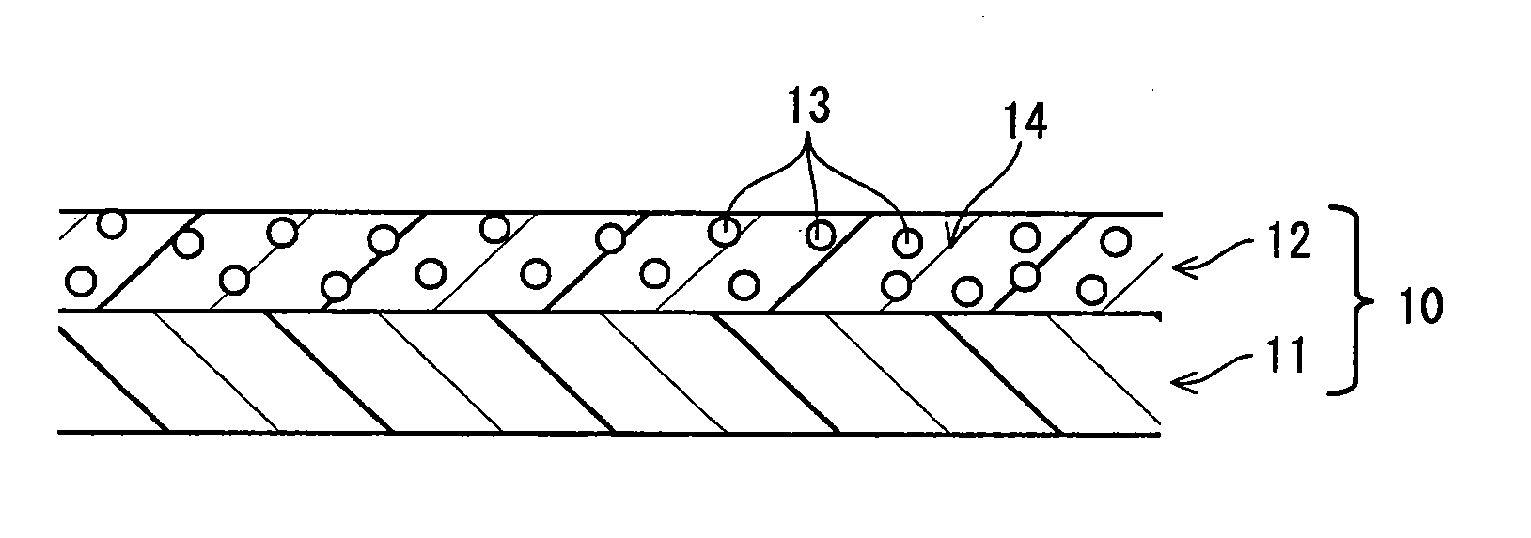

Dust removal and waste gas decomposition double-effect filter material and preparation method thereof

ActiveCN102512878AHigh catalytic activityImprove permeabilitySynthetic resin layered productsDispersed particle separationFiberDecomposition

The invention discloses a dust removal and waste gas decomposition double-effect filter material and a preparation method thereof. The filter material comprises a raw felt, catalyst powder and a coating. The filter material utilizes the raw felt as a carrier, the catalyst powder is adhered to the inside of the raw felt, and the coating is coated on the surface of the raw felt and is of a polytrifluorochloroethylene microporous film structure. The catalyst powder is in a grade of nanometer or micron and is selected from one or more of vanadium pentoxide, vanadium trioxide, tungsten trioxide, titanium dioxide and manganese dioxide. By utilizing the preparation method to prepare the filter material, the process is simple and easy to implement, and processing costs of preparation of catalyticfibers, film covering and the like are reduced. In addition, compared with a polytetrafluoroethylene microporous film, running resistance is low, and difficulties in follow-up sewing, transportation,installation and the like of the filter material are reduced simultaneously.

Owner:南京际华三五二一环保科技有限公司

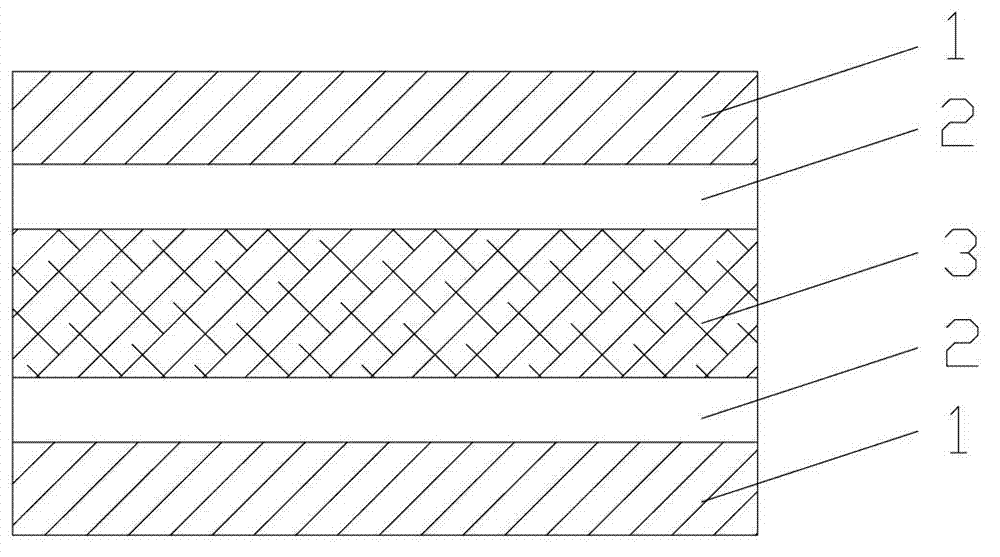

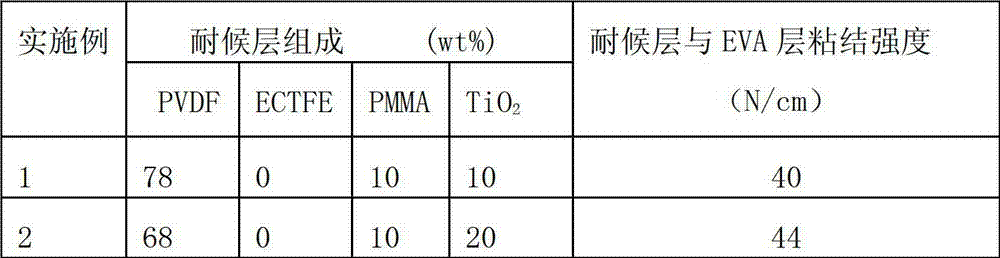

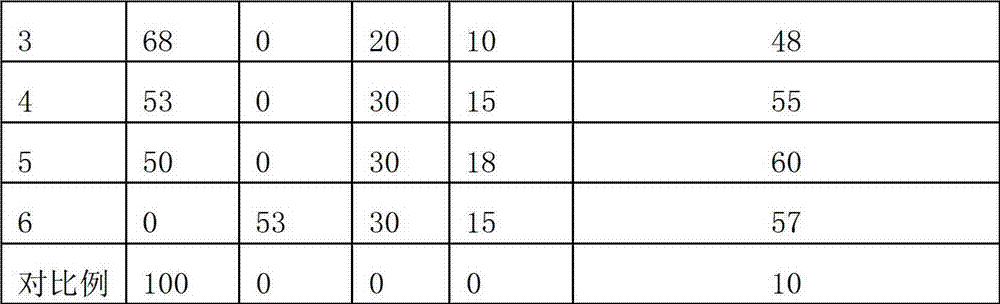

Solar cell back panel film with high bonding strength and preparation method thereof

ActiveCN102922843AMaterials are readily availableLow costSynthetic resin layered productsLaminationPolyesterWear resistant

The invention relates to a solar cell back panel film and a preparation method thereof. The solar cell back panel film is characterized in that the two sides of a polyester base layer are composited with wear-resistant layers by coating adhesive bonding layers; the wear-resistant layers are fluorine-containing films prepared by mixing fluorine plastic with polymer fillers, inorganic fillers and functional auxiliaries, then extruding and granulating the mixture and then carrying out casting or film blowing; the fluorine plastic is an ethylene-chlorotrifluoroethylene copolymer or polyvinylidene fluoride and accounts for 50-80wt% of the wear-resistant layers; the polymer fillers are polyacrylic ester polymers and account for 10-30wt% of the wear-resistant layers; the inorganic fillers are oxides containing titanium, aluminium, tin and silicon and account for 10-20wt% of the wear-resistant layers; and the functional auxiliaries account for 0-2wt% of the wear-resistant layers. The solar cell back panel film has the following beneficial effects that good adhesiveness is ensured between the wear-resistant layers and packaging materials; and the back panel film has tight structure, less production processes and low cost.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

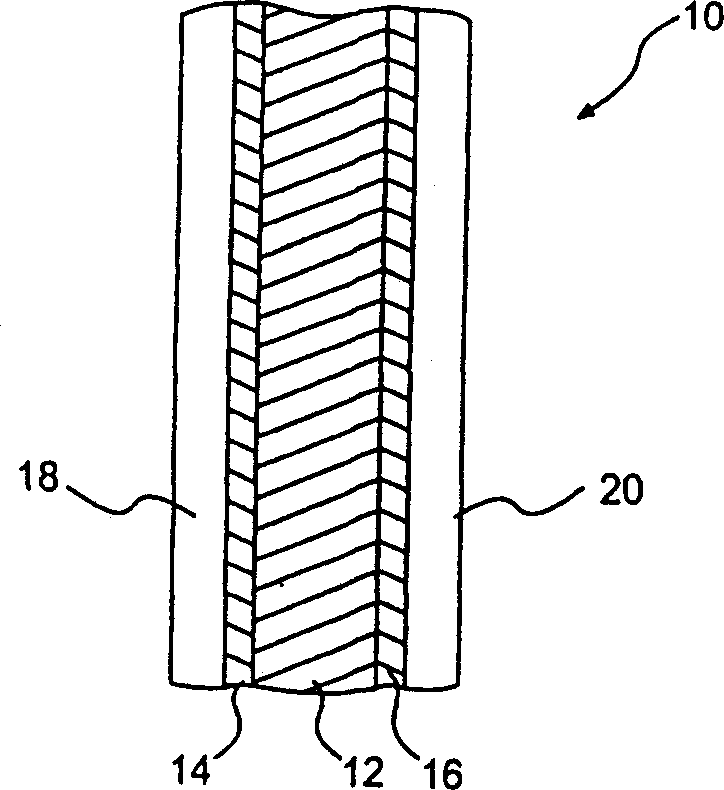

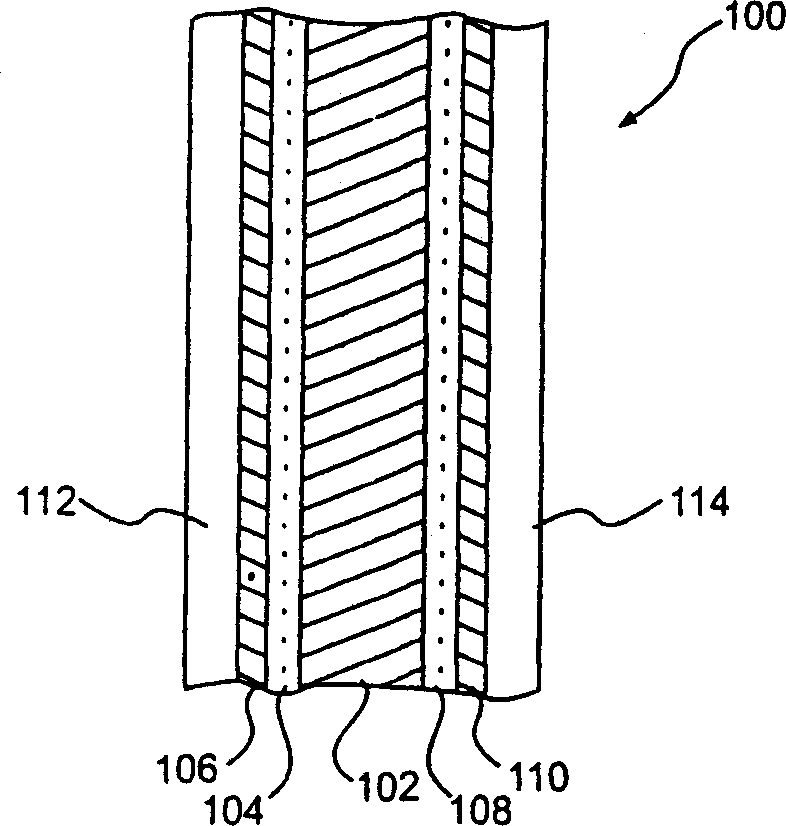

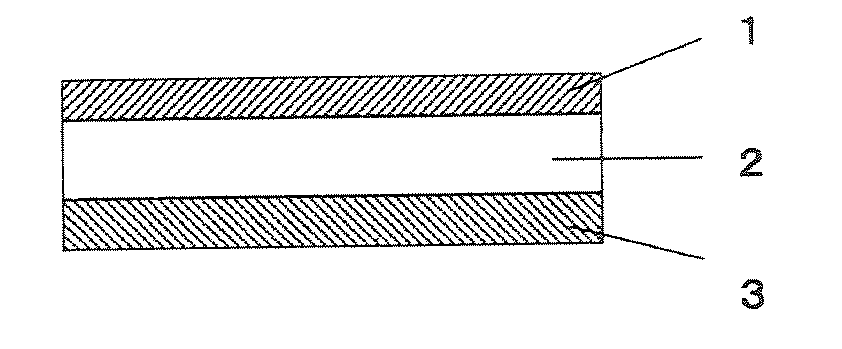

Laminate for flexible printed wiring board

ActiveUS20080107866A1Improve adhesionImprove bending resistanceDielectric materialsSynthetic resin layered productsSignal responsePolymer science

To provide a laminate for a flexible printed wiring board excellent in signal response in the high frequency region. A laminate for a flexible printed wiring board having a three-layer laminated structure where a reinforcing layer (A), an electrical insulator layer (B) and an electrical conductor layer (C) are laminated in this order, wherein the electrical insulator layer (B) is made of a fluorocopolymer comprising repeating units (a) based on tetrafluoroethylene and / or chlorotrifluoroethylene, repeating units (b) based on a fluoromonomer excluding tetrafluoroethylene and chlorotrifluoroethylene, and repeating units (c) based on a monomer having an acid anhydride residue and the electrical conductor layer (C) has a surface roughness of at most 10 μm on the side being in contact with the electrical insulator layer (B). The laminate for a flexible printed wiring board is excellent in signal response in the high frequency region and excellent in flex resistance.

Owner:ASAHI GLASS CO LTD

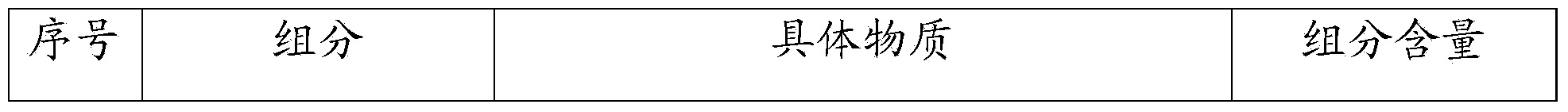

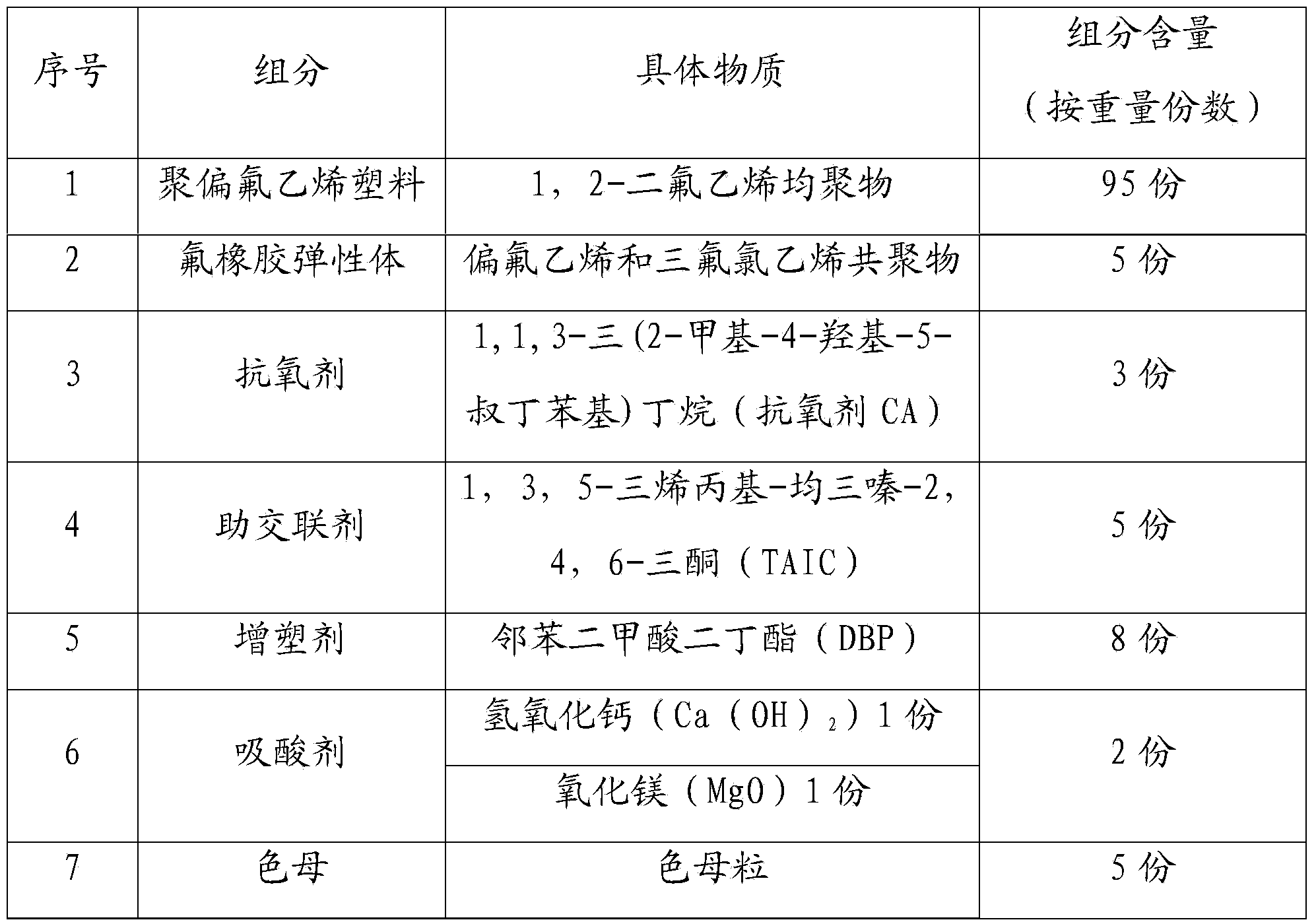

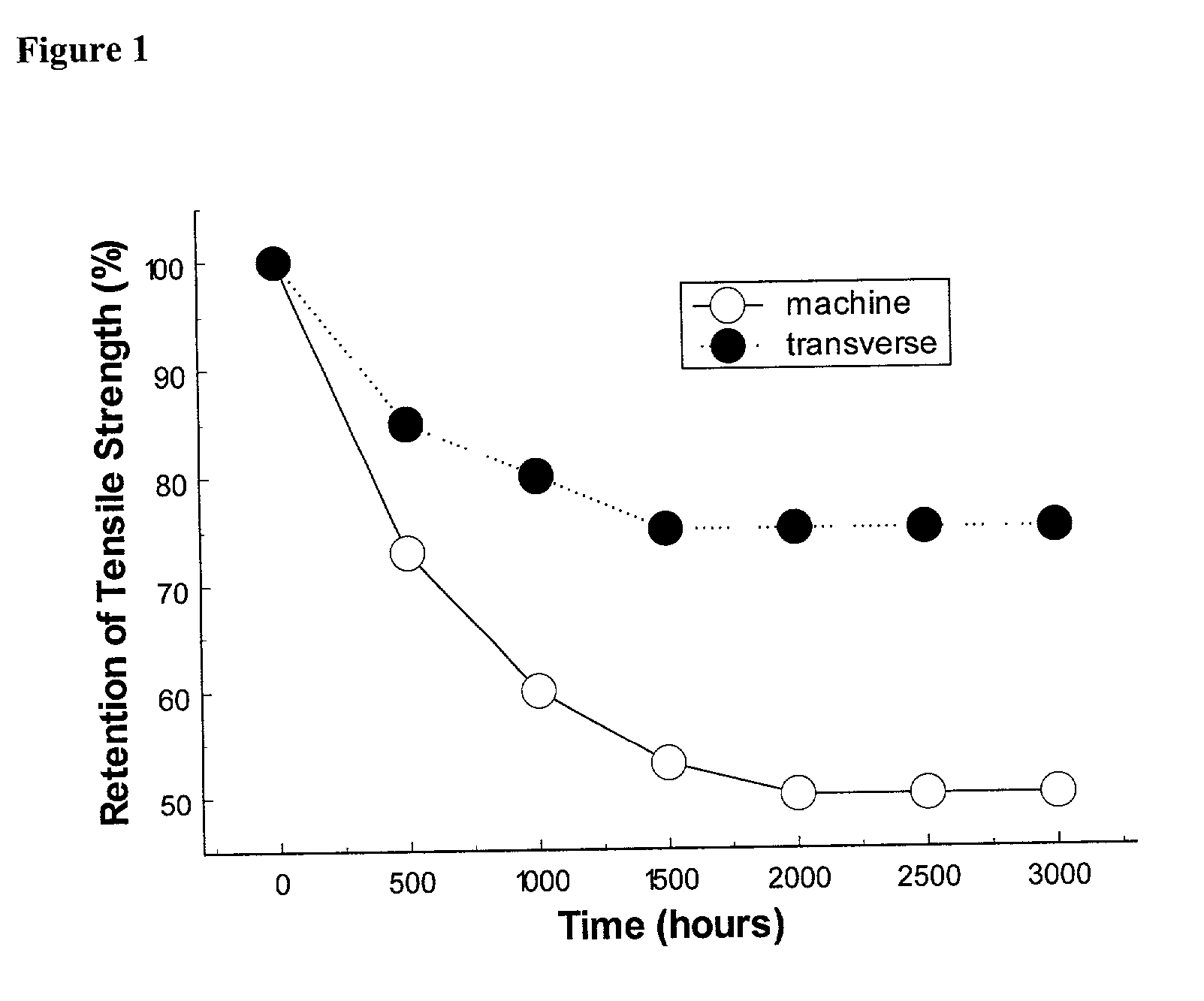

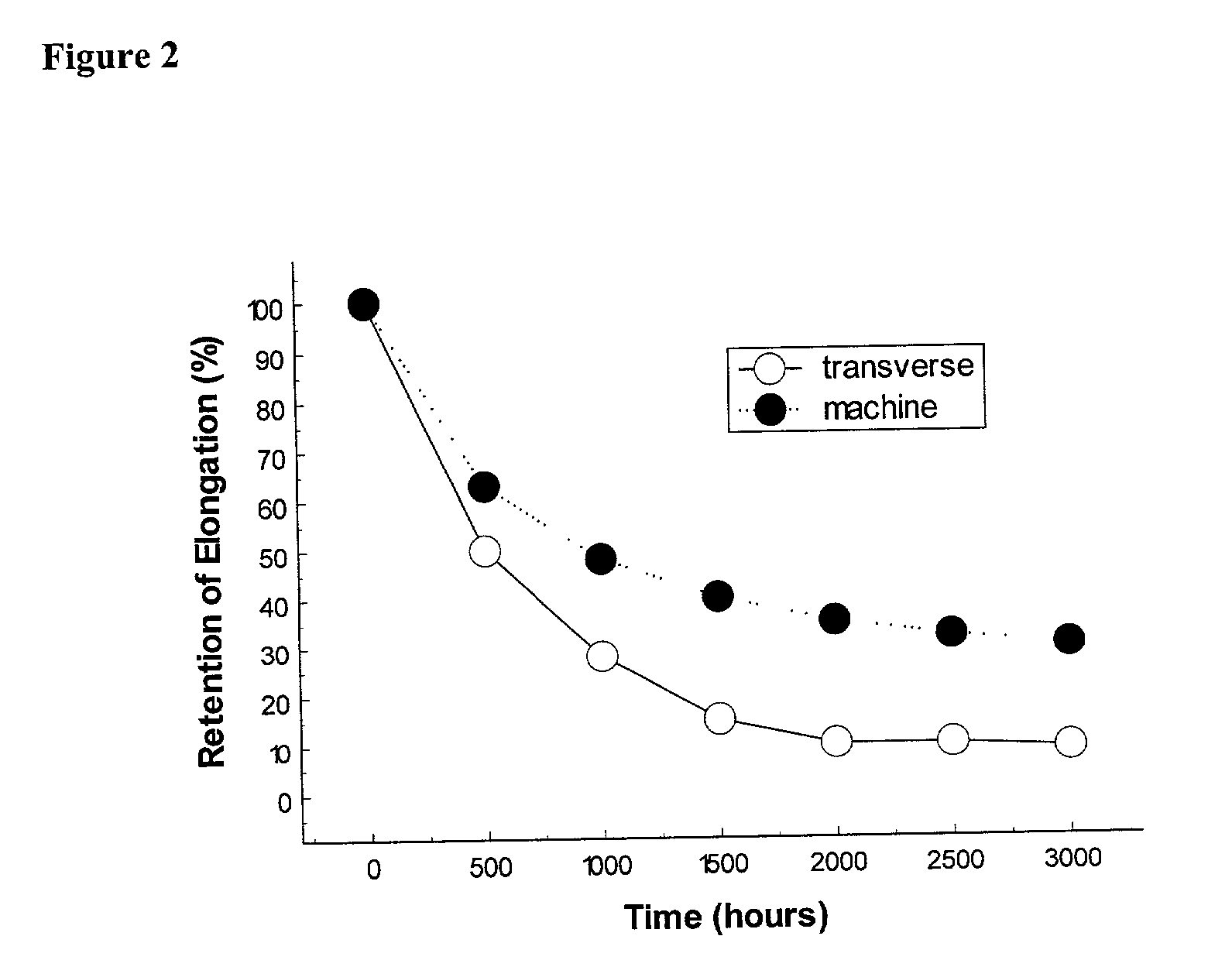

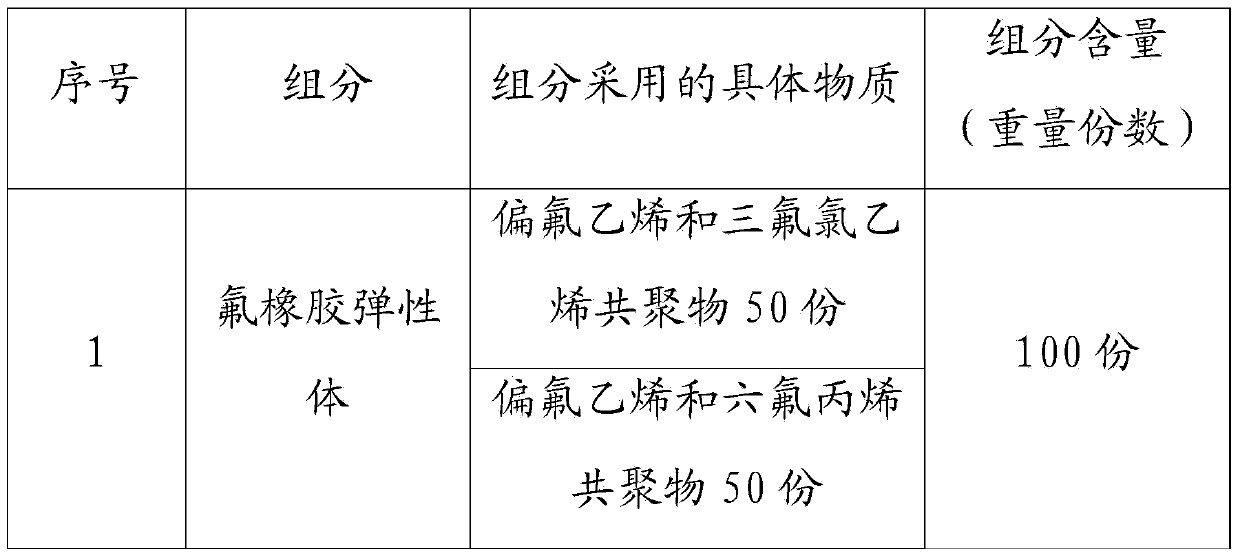

Elastic polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

The invention relates to an elastic polyvinylidene fluoride heat-shrinkable sleeve which is composed of the following components in parts by weight: 85-95 parts of polyvinylidene fluoride plastic, 5-15 parts of fluororubber elastomer, 1-3 parts of antioxygen, 2-5 parts of assistant crosslinker, 3-8 parts of plasticizer, 0.5-2 parts of acid accepter and 2-5 parts of color master. The polyvinylidene fluoride plastic is one or two of the following matters: 1,2-difluoroethene homopolymer and 1,2-difluoroethene- hexafluoropropylene homopolymer. The fluororubber elastomer is one, two or more than two of the following matters: vinylidene fluoride and chlorotrifluor ethylene copolymer, vinylidene fluoride and hexafluoropropylene copolymer, vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene terpolymer. According to the elastic polyvinylidene fluoride heat-shrinkable sleeve, such performances of fluoroplastic as wear resistance, mechanical damage resistance and the like are kept simultaneously, elasticity of the heat-shrinkable sleeve is improved, the elastic polyvinylidene fluoride heat-shrinkable sleeve has such specific performances of fluororubber as oil resistance simultaneously, application scope of the fluoride heat-shrinkable sleeve is broadened and risk in the process of use is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Poly(chlorotrifluoroethylene/vinylidenefluoride/vinylester) copolymers with excellent long term ultraviolet light resistance

Owner:ALLIED SIGNAL INC

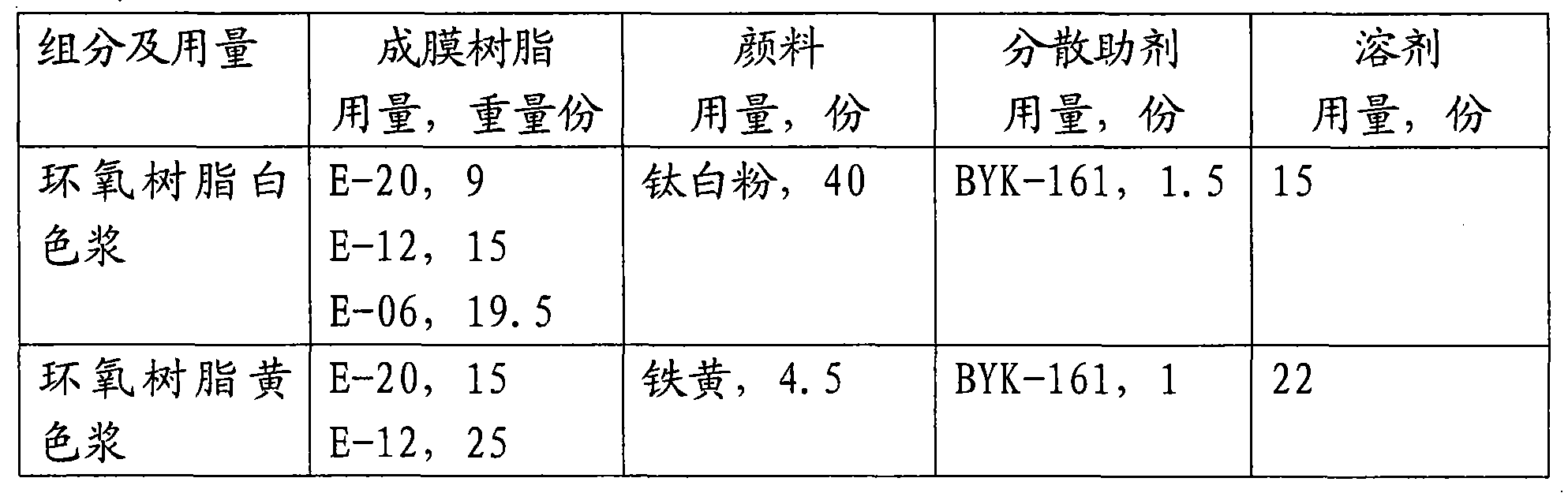

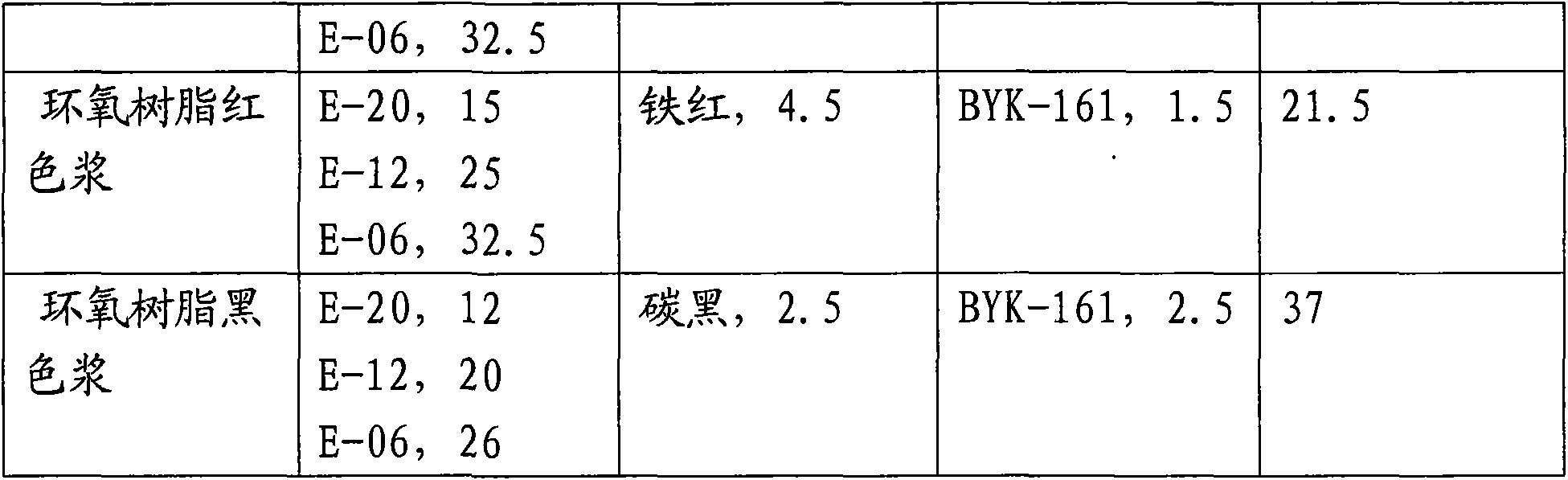

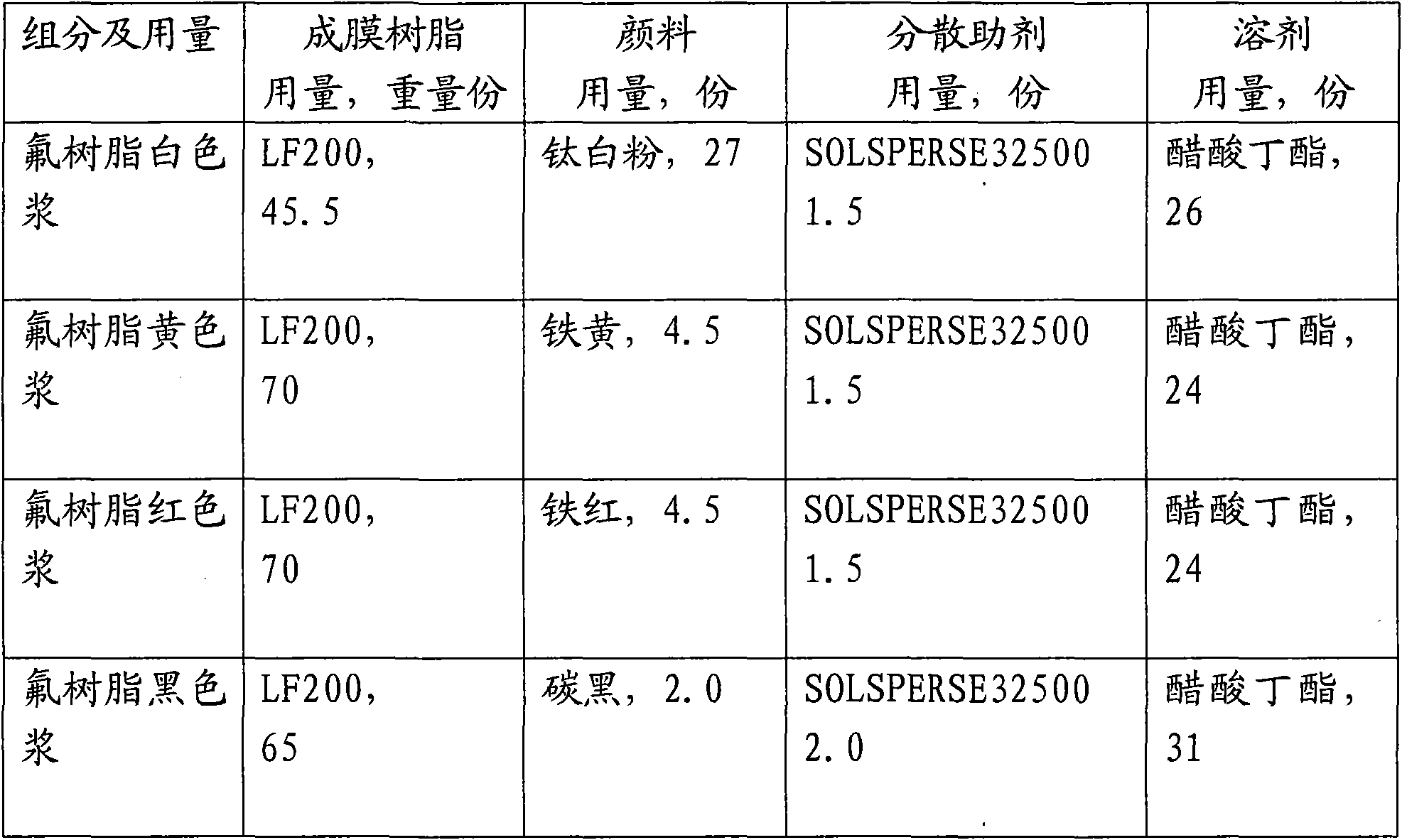

Coating for inner wall of oil field pipeline and preparation method thereof

ActiveCN101948648AKey lengthImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsVinyl etherToluene diisocyanate

The invention relates to a coating for the inner wall of an oil field pipeline and a preparation method thereof. A component A of the coating consists of the following components in part by weight: 15 to 50 parts of trifluoroethylene-vinyl ether fluoro-resin, 8 to 30 parts of lubricating filler, 1 to 3 parts of dispersing auxiliary agent, 10 to 20 parts of solvent, 15 to 45 parts of colour paste and 1 to 6 parts of lubricating auxiliary agent, wherein the colour paste consists of the following components in part by weight: 40 to 80 parts of film forming resin, 1 to 3 parts of dispersing auxiliary agent, 10 to 40 parts of solvent and 2 to 40 parts of pigment; and the film forming resin is three kinds of biphenol A epoxy resins, namely biphenol A epoxy resinE-20, biphenol A epoxy resin E-12 and biphenol A epoxy resin E-06, or is trifluorochloroethylene-vinyl ether fluoro-resin. A component B of the coating is a curing agent aromatic toluene diisocyanate addition product. Before construction, the component A and the component B are mixed according to a weight ratio of 10 to 1. The coating of the invention is used for coating the inner wall of the oil field pipeline, is corrosion resistant, makes the inner wall of the pipeline have hydrophobic performance and fulfils the aim of reducing resistance and enhancing effect.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Crosslinkable Vinyl Fluoride Copolymer Coated Film and Process for Making Same

ActiveUS20080156367A1Film/foil adhesivesSynthetic resin layered productsPhosphoric Acid EstersIodide

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD +1

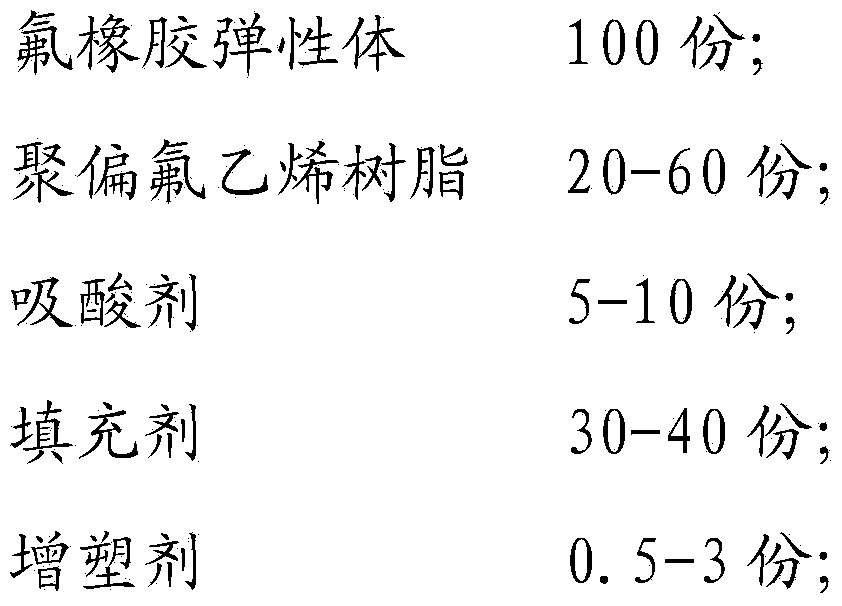

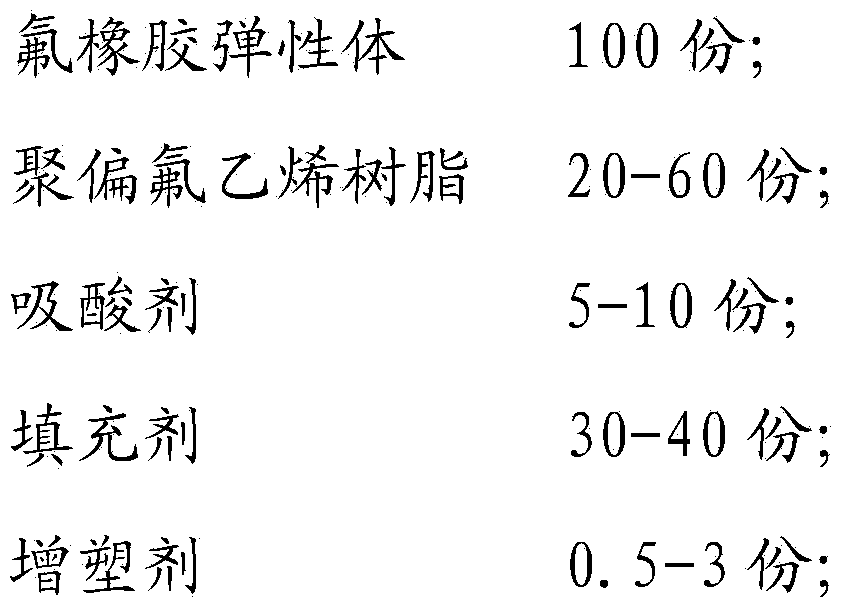

Low-temperature-resistant fluororubber heat-shrinkable casing and manufacturing method thereof

The invention discloses a low-temperature-resistant fluororubber heat-shrinkable casing, which consists of the following components in parts by weight: 100 parts of fluororubber elastomer, 20-60 parts of polyvinylidene fluoride resin, 5-10 parts of an acid-acceptor, 30-40 parts of a filling agent and 0.5-3 parts of a plasticizer, wherein the fluororubber elastomer is a blend of two or more of a vinylidene fluoride-trifluorochloroethylene copolymer, a vinylidene fluoride-hexafluoropropylene copolymer and a vinylidene fluoride-trifluorochloroethylene-hexafluoropropylene copolymer; the polyvinylidene fluoride resin is one or a mixture of a 1,2-polyvinylidene difluoride homopolymer and a 1,2-polyvinylidene difluoride-hexafluoropropylene copolymer. The low-temperature-resistant fluororubber heat-shrinkable casing is excellent in low temperature resistance, flame retardation, mechanical property, aging resistance and thermal shock performance.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

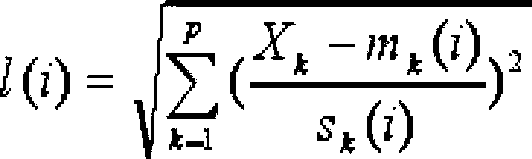

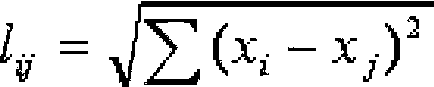

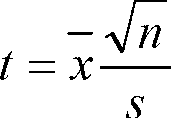

Method for determination of PCTFE content in PBX explosive by near infrared spectrum

ActiveCN103018195AImprove robustnessImprove accuracyColor/spectral properties measurementsPolymer-bonded explosiveRoot mean square

The invention discloses a method for determination of the polychlorotrifluoroethylene (PCTFE) content in a polymer-bonded explosive (PBX) by near infrared spectroscopy. The method includes the steps of: preparing and collecting 260 PBX samples, taking 180 samples of them as a calibration set for establishing a calibration model, taking the remaining 80 samples as a validation set for model validation, and acquiring the near infrared spectrum data of all the samples; using a standard method to determine the PCTFE content in the samples; subjecting the spectrum data of the validation set samples in the wave bands of 6102.0cm<-1>-5697.0cm<-1> and 4680.2cm<-1>-4242.9cm<-1> to a first order derivative treatment, correlating the treated spectrum data with the PCTFE content by a partial least squares method, and establishing the calibration model by cross validation; employing the calibration model to predetermine the PCTFE content of the validation set samples, and selecting an optimal model according to a minimum root mean squared error of prediction (RMSEP) of the validation set; and acquiring the near infrared spectrum data of the samples to be determined, and making use of the optimal model to obtain the PCTFE content directly. Being suitable for determination of the PCTFE content in a PBX explosive, the method has the characteristics of convenient operation, and rapid and accurate analysis.

Owner:XIAN MODERN CHEM RES INST

Highly filled unsaturated fluoropolymer compositions for cables

A non-dripping, flame retardant, fluoropolymeric composition comprising: (a) a fluoropolymeric base polymer; (b) at least one char forming agent; and (c) a compatibilizer agent. The fluoropolymeric base polymer is preferably selected from the group consisting of PVDF (polyvinylidene fluoride), ECTFE, poly-ethylene chlorotrifluoroethylene, and ETFE poly-ethylene tetrafluoroethylene. Such compositions are especially useful for appliance wire, aerospace / military wire, cable raceways, blown fiber tubes, fire alarm cables, circuit integrity cables, fiber optic distribution cables & breakout components, heat tracing cable jacket, stage lighting cable, industrial cable, shipboard cable (military & passenger), shielded cable jackets.

Owner:MEXICHEM AMANCO HLDG DE C V

Manufacturing method of improved high temperature polymer PTC beat-sensitire resistor

ActiveCN1794369AImprove recovery effectReduce the rise in resistance valuePositive temperature coefficient thermistorsMetallic foilInsulation layer

This invention relates to a manufacturing method for an improved high temperature macromolecule PTC thermistor composed of a core, metallic foils adhered to both sides of the core, a lead out electrode welded on the outer surface of the foil and an insulation layer covering the outside, in which, said core is pressed by a powder conduction macromolecule material mixed by a macromolecule polymer, carbon black, carbon black dispersant and other processed aids in the following weight percentage: macromolecule polymer: 35-60%, carbon black:35-55%, Teflon powder: 0.5-20% and aids: 0.1-10%, in which, said macromolecule polymer is: PVDF, soluble Teflon, ethane and TFE multi-polymers, nylon, perfluoro-ethane and propene, ethane TFCE or their multi-polymer or their mixture.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

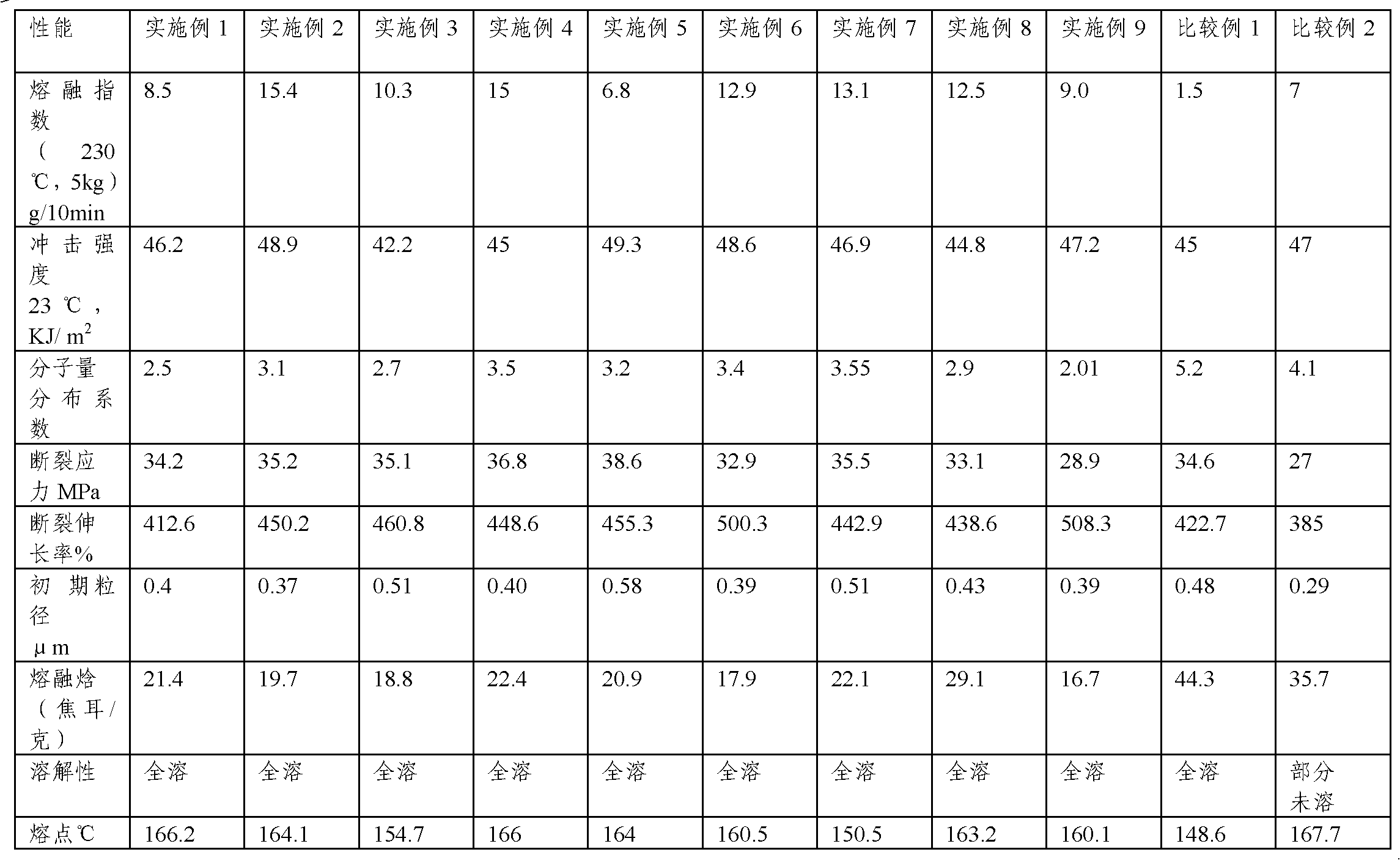

Preparation method of modified polyvinylidene fluoride through chlorotrifluoroethylene

The invention relates to a preparation method of modified polyvinylidene fluoride through trifluorochlor oethylene and applications of the modified polyvinylidene fluoride. The preparation method comprises the steps of a) adding the mixture of gas monomers of vinylidene fluoride and chlorotrifluoroethylene into an aqueous medium containing a fluorinated emulsifier so as to form dispersoid; b) then adding an organic peroxide initiator and a chain transfer agent in the dispersoid obtained from the step a); and c) adjusting and supplementing polymerization monomers, controlling the content of the chlorotrifluoroethylene, keeping gas phases in a kettle to be constant relatively, and stopping reaction until the solid content of the emulsion in a reactor to be 30%.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

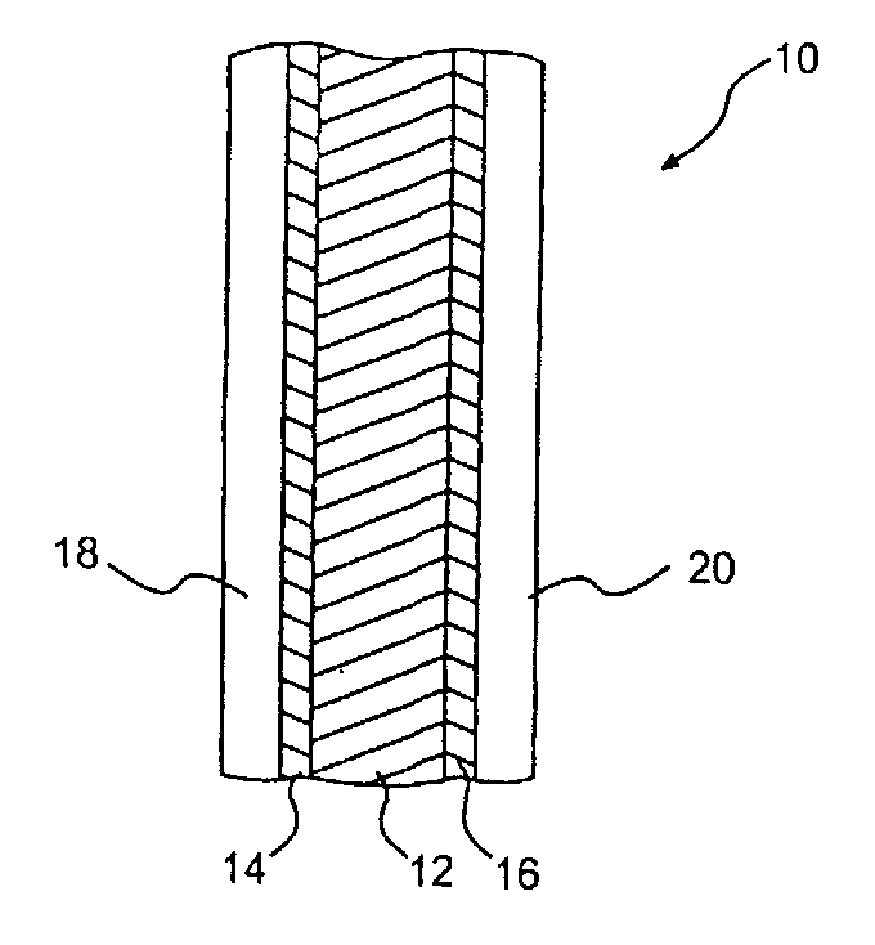

Fluid transfer member

ActiveUS20070166497A1Reduce penetrationChemical resistance as well as thermal stabilitySynthetic resin layered productsFlexible pipesCrack resistanceCompound (substance)

The present invention provides a fluid transfer member having thermal stability on the occasion of molding, stress cracking resistance and low liquid chemical permeability at the same time. The present invention is a fluid transfer member which is composed by a laminate containing a layer [P] comprising a fluoropolymer and / or a fluorine-free organic material and a layer [Q] comprising a chlorotrifluoroethylene copolymer.

Owner:DAIKIN IND LTD

Waterborne FEVE (chlorotrifluoroethylene copolymer) fluorocarbon coating and preparation method thereof

The invention relates to a waterborne FEVE (chlorotrifluoroethylene copolymer) fluorocarbon coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 0.05-0.20% of alkaline pH value regulator, 0.05-0.20% of hydroxyl cellulose, 0.10-0.50% of wetting agent, 0.20-1.00% of dispersing agent, 0.05-0.20% of defoaming agent, 1.00-30.00% of pigment, 0.00-30.00% of filler, 0.10-1.00% of nanometer anatase titanium dioxide, 1.00-3.00% of film-forming additive, 0.20-1.00% of thickening agent, 0.00-1.00% of flatting agent, 45-65% of FEVE fluorocarbon resin emulsion and the balance of water. The preparation method comprises the steps of: color paste preparation, paint mixing and the like. The production time is shortened, and air bubbles in the coating are effectively eliminated by combining the effects of machines and auxiliaries. The coating prepared by the invention is a waterborne single-component normal-temperature cured fluorocarbon coating, has excellent weather resistance, pollution resistance, acid rain resistance and mildew resistance, and has the characteristics of environment friendliness, safety, no toxicity and the like.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Photocatalyst coating composition

InactiveUS20110143924A1Avoid problemsIncrease binding energyOrganic-compounds/hydrides/coordination-complexes catalystsCoatingsVinyl etherVinyl ester

To aim to provide a photocatalyst coating composition having a predefined photocatalytic function, which is to be formed as a coating film after being applied to a substrate and dried. The photocatalyst coating composition can improve adhesion property and abrasion resistance of the coating film. There is also provided a photocatalyst coating composition that has a shorter drying time after applied. The present invention provides a photocatalyst coating composition that is composed of a blend including: a graft copolymer of PTFE and perfluoro acid selected from the group consisting of perfluorosulfonic acid and perfluorocarbonic acid; a photocatalyst material; and at least one fluororesin selected from the group consisting of PVDF, PVF, PTFE, ETFE, PVDF-HFP, PCTFE, trifluorochloroethylene-alkyl vinyl ether copolymer, tetrafluoroethylene-alkyl vinyl ether copolymer, and trifluorochloroethylene-alkyl vinyl ether-alkyl vinyl ester copolymer.

Owner:HISATA YOSHIKATSU +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com