Patents

Literature

141results about How to "Increase binding energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

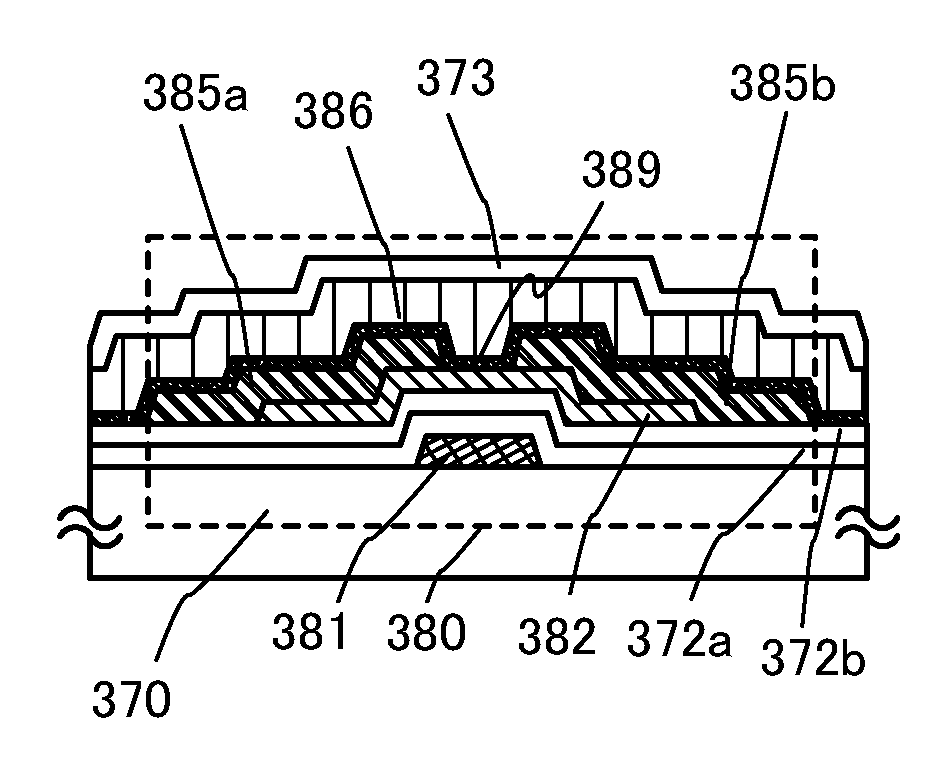

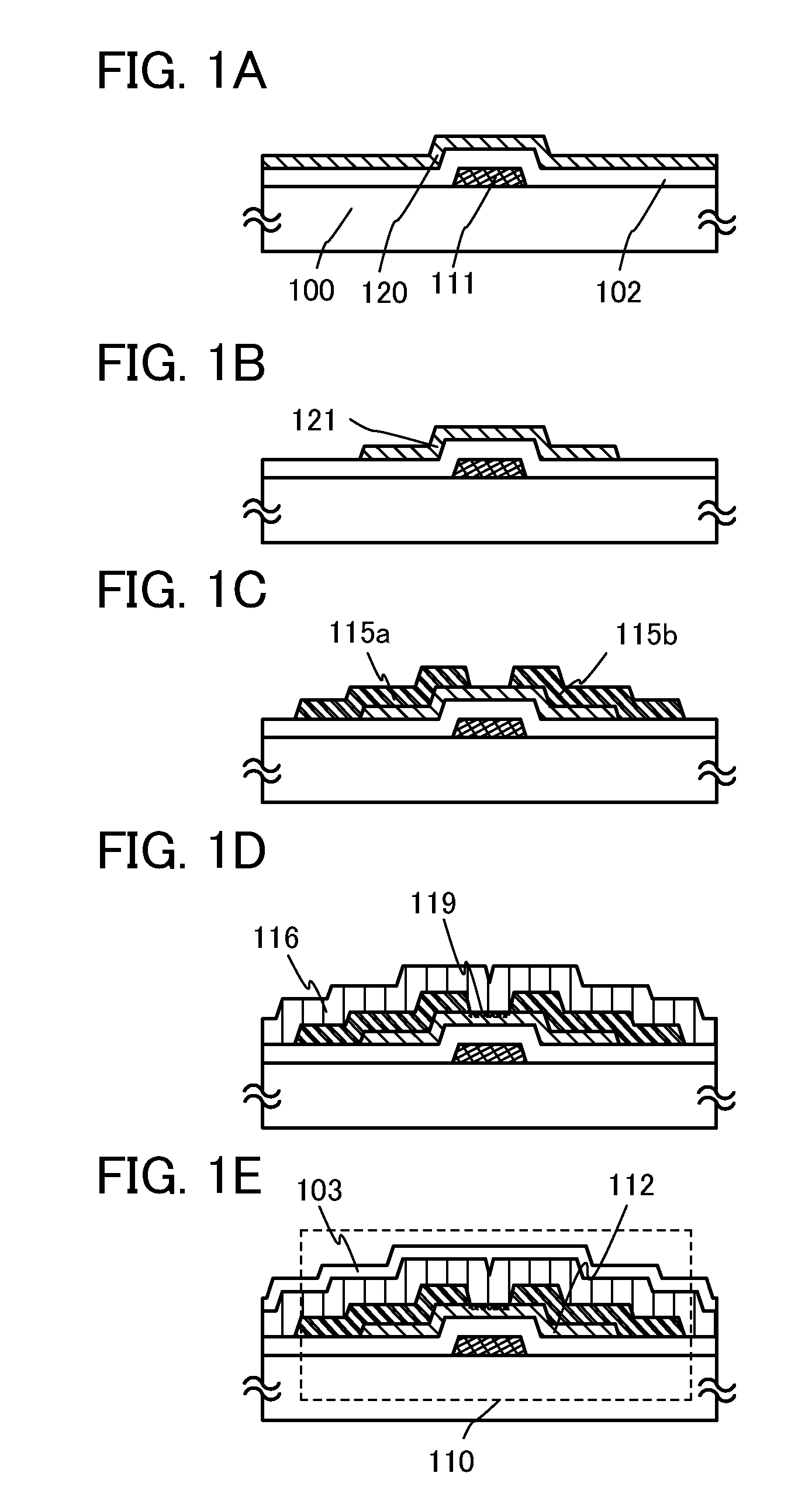

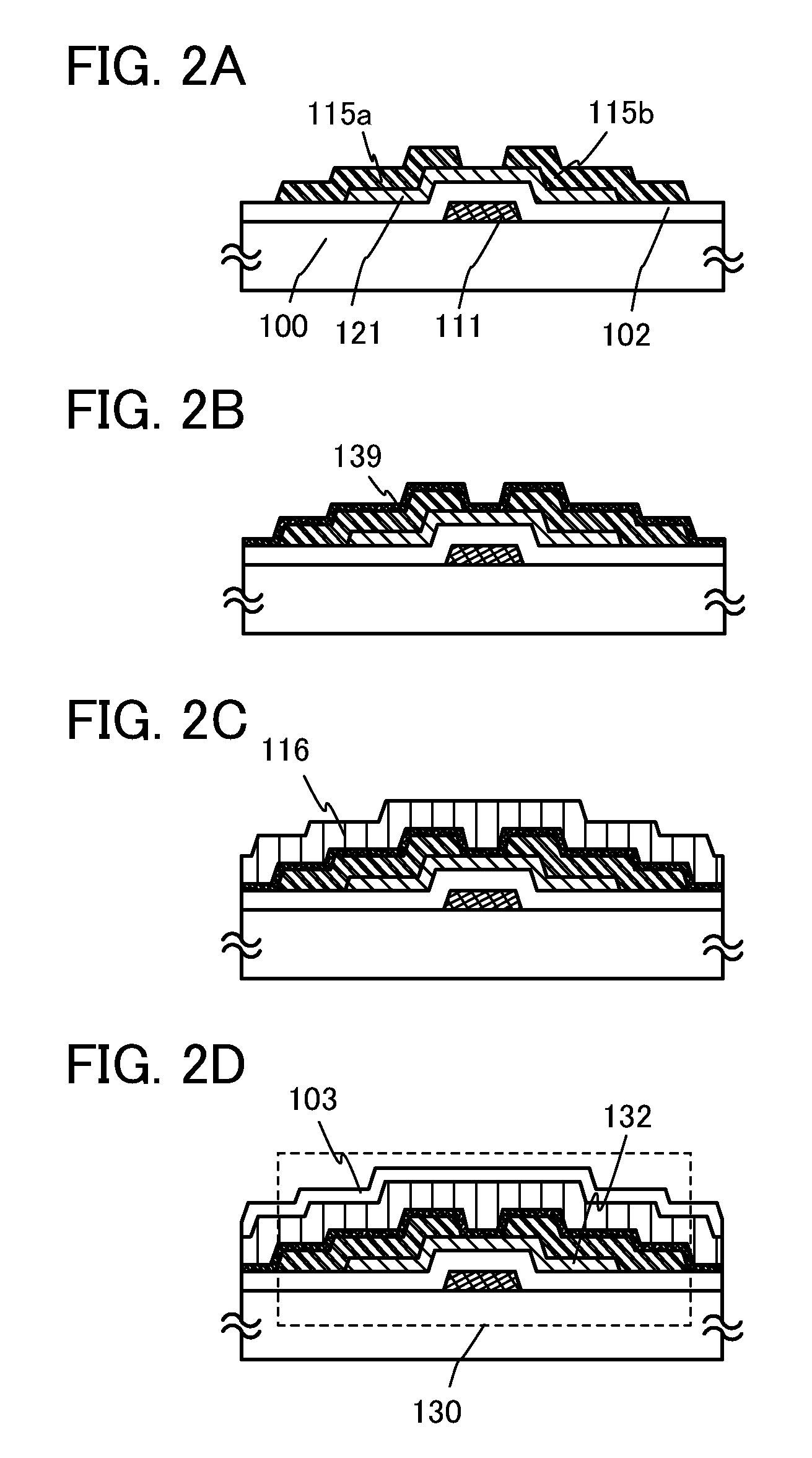

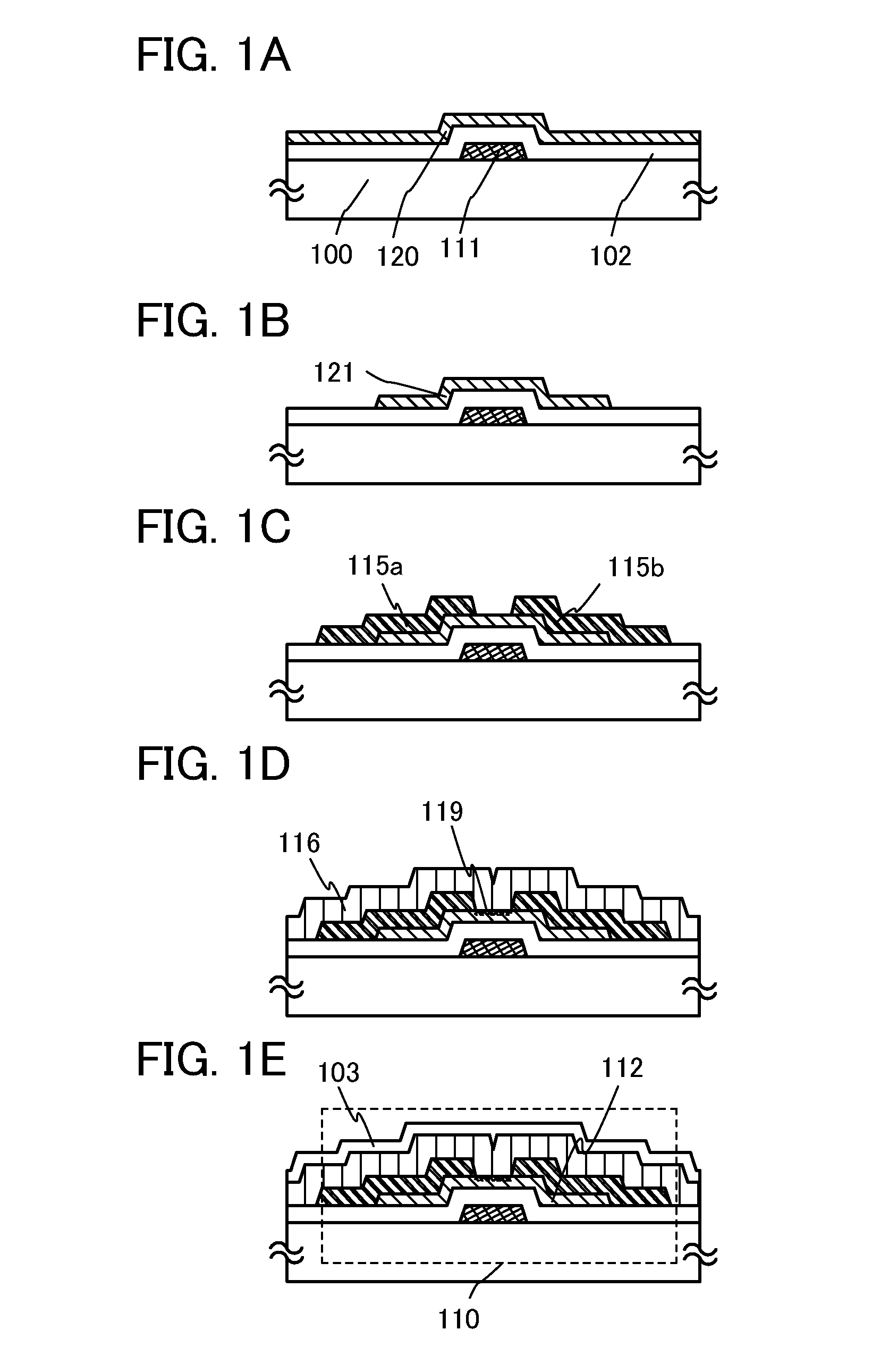

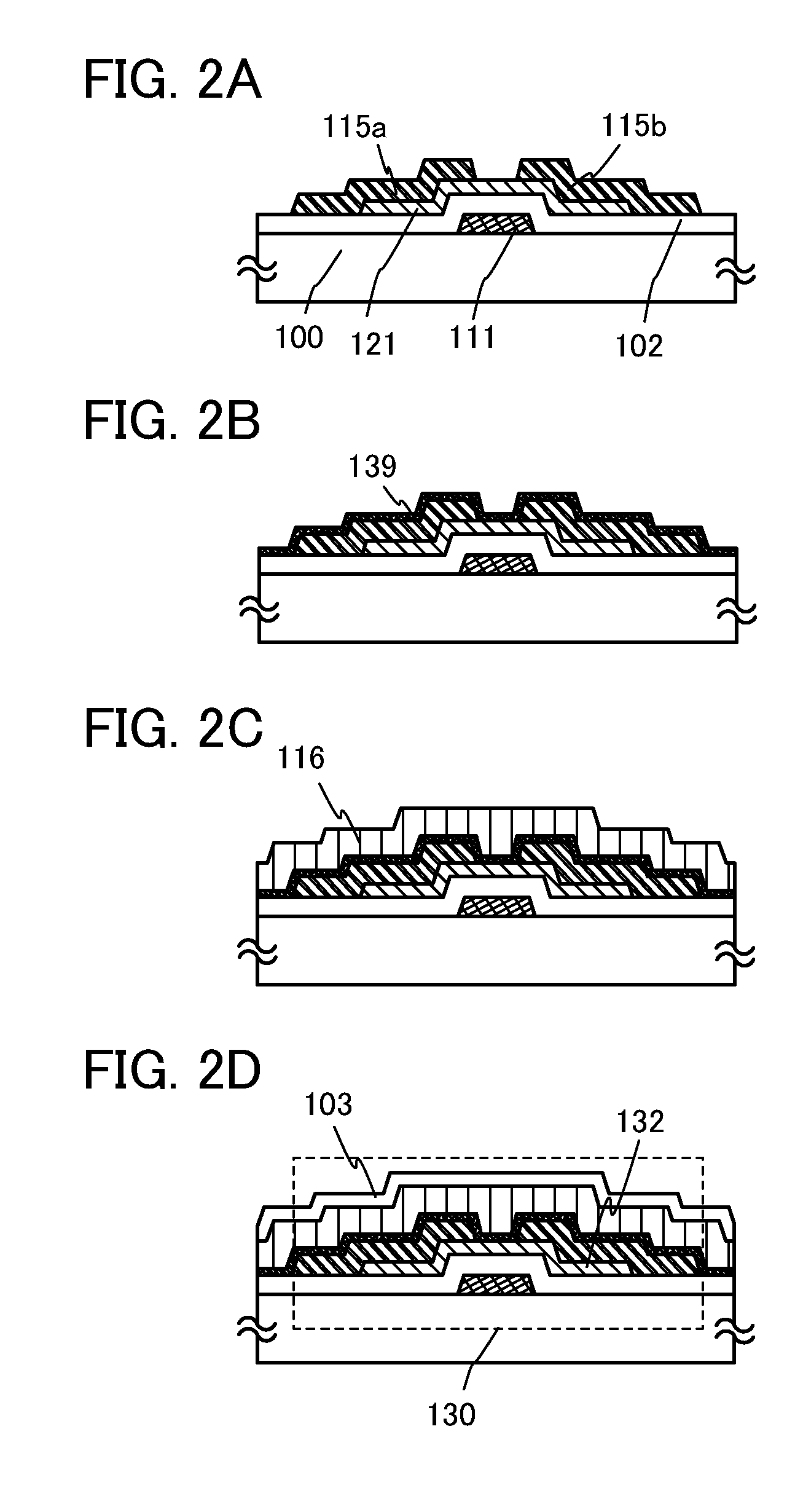

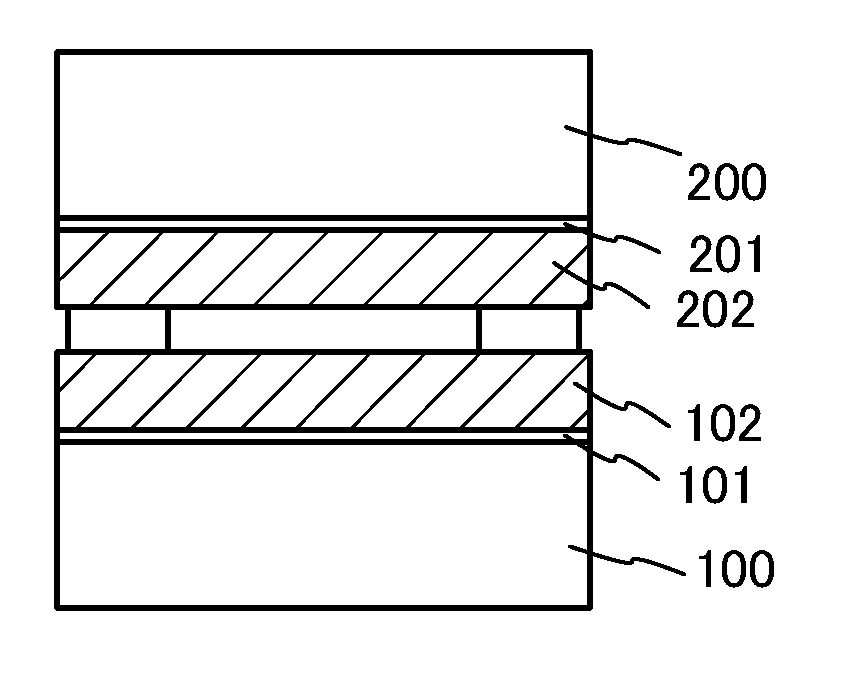

Semiconductor device and method for manufacturing the same

InactiveUS20110101335A1Stable electrical characteristicsReduce impurity concentrationSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen atomDangling bond

An object is to provide a semiconductor device including an oxide semiconductor with stable electric characteristics can be provided. An insulating layer having many defects typified by dangling bonds is formed over an oxide semiconductor layer with an oxygen-excess mixed region or an oxygen-excess oxide insulating layer interposed therebetween, whereby impurities in the oxide semiconductor layer, such as hydrogen or moisture (a hydrogen atom or a compound including a hydrogen atom such as H2O), are moved through the oxygen-excess mixed region or oxygen-excess oxide insulating layer and diffused into the insulating layer. Thus, the impurity concentration of the oxide semiconductor layer is reduced.

Owner:SEMICON ENERGY LAB CO LTD

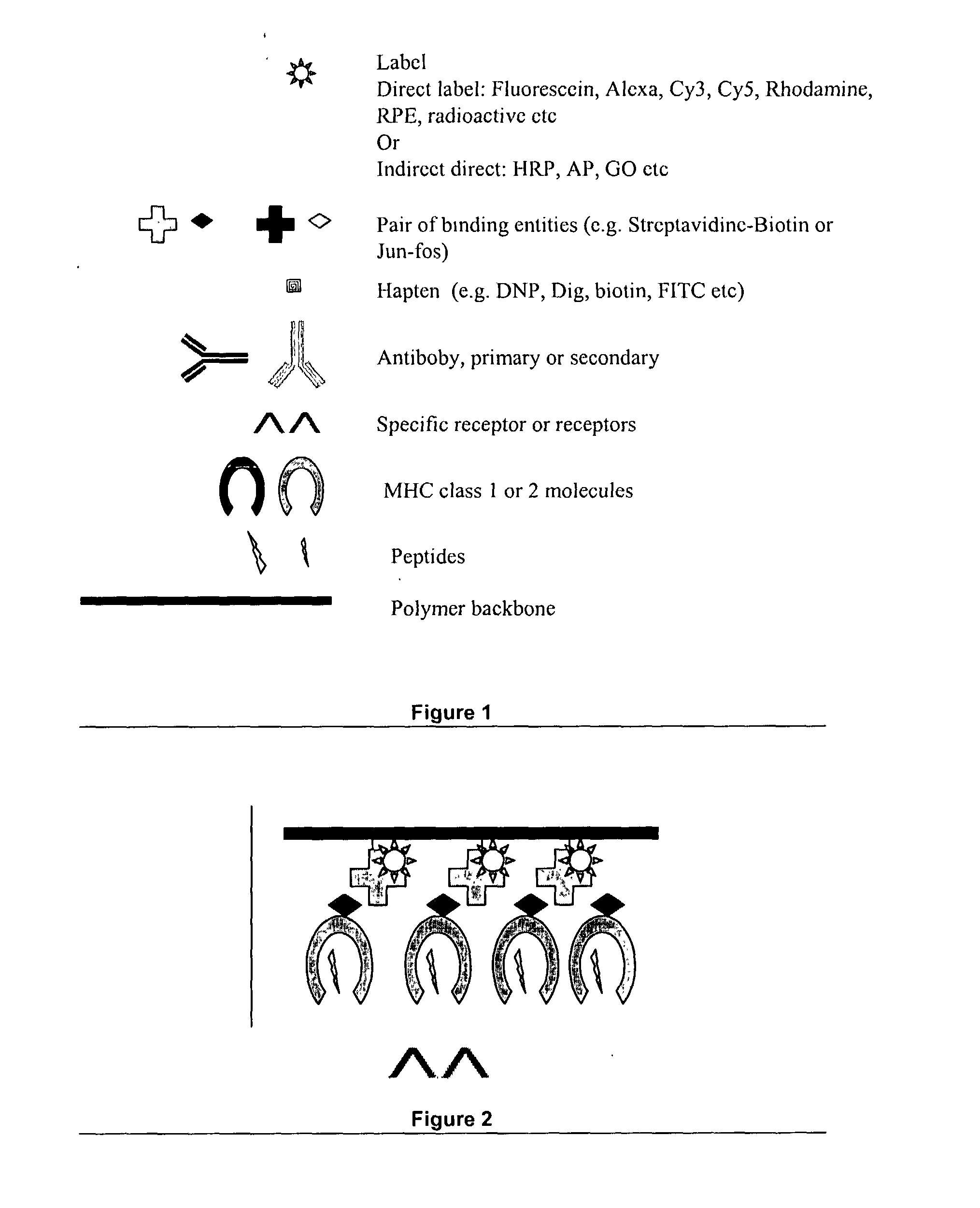

Novel MHC molecule constructs, and methods of employing these constructs for diagnosis and therapy, and uses of MHC molecules

InactiveUS20150329617A1Tall in constructionHigh expectationSugar derivativesPeptide/protein ingredientsBiochemistryAvidity

Novel compounds carrying ligands capable of ligating to counter receptors on relevant target cells are disclosed. The compounds possess a number of advantageous features, rendering them very suitable for a wide range of applications, including use as detection systems, detection of relevant target cells as well as in various methods. In particular, novel MHC molecule constructs comprising one or more MHC molecules are disclosed. The affinity and avidity of the MHC molecules of the constructs are surprisingly high. The possibility of presenting to the target cells a plurality of MHC molecules makes the MHC molecule constructs an extremely powerful tool e.g. in the field of diagnosis. The invention relates in general to the field of therapy, including therapeutic methods and therapeutic compositions. Also comprised by the present invention is the sample-mounted use of MHC molecules, MHC molecule multimers, and MHC molecule constructs.

Owner:DAKOAS +1

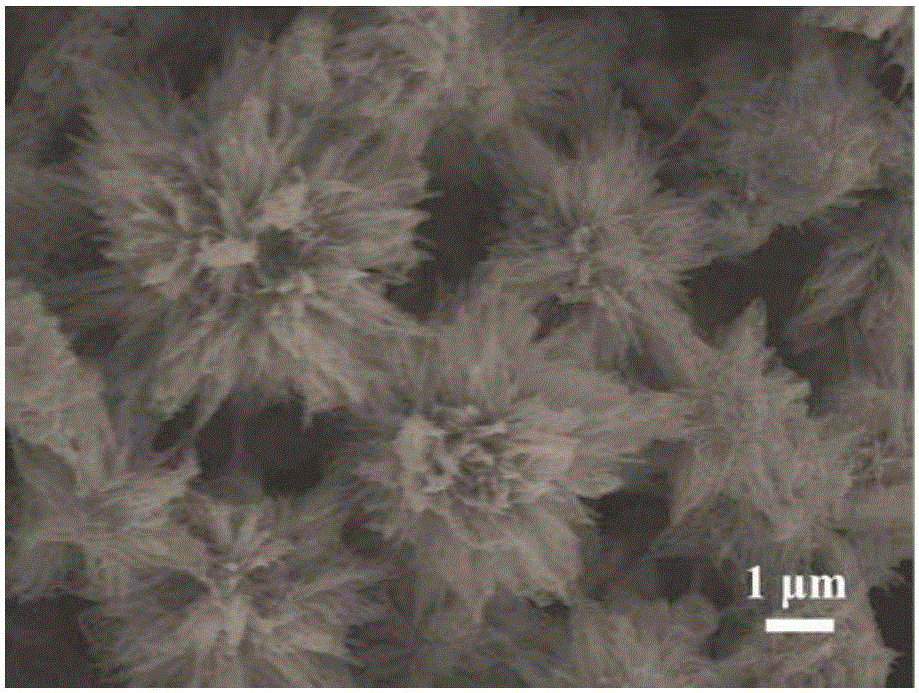

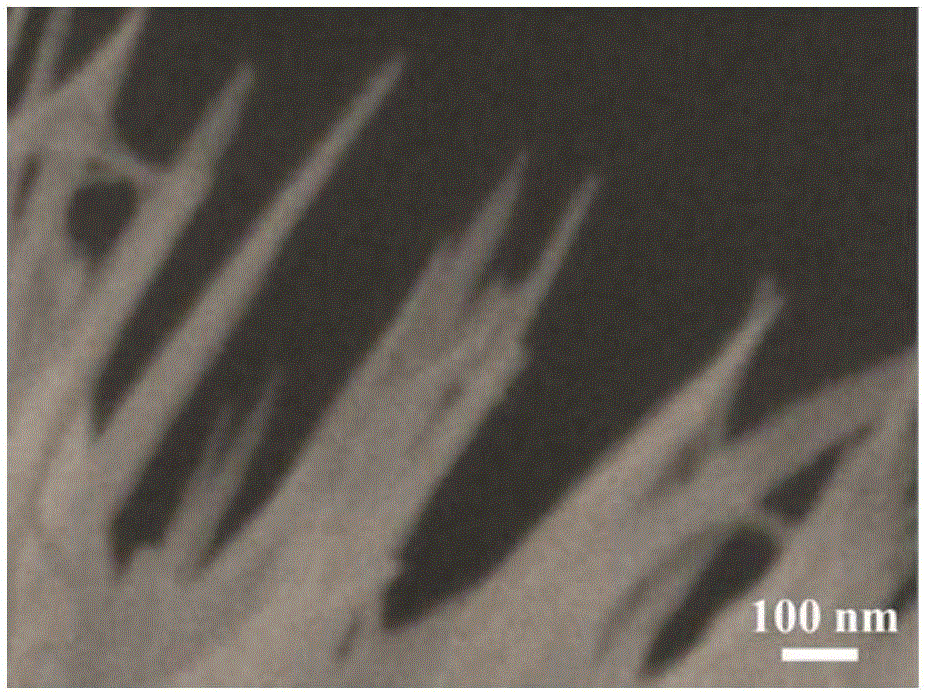

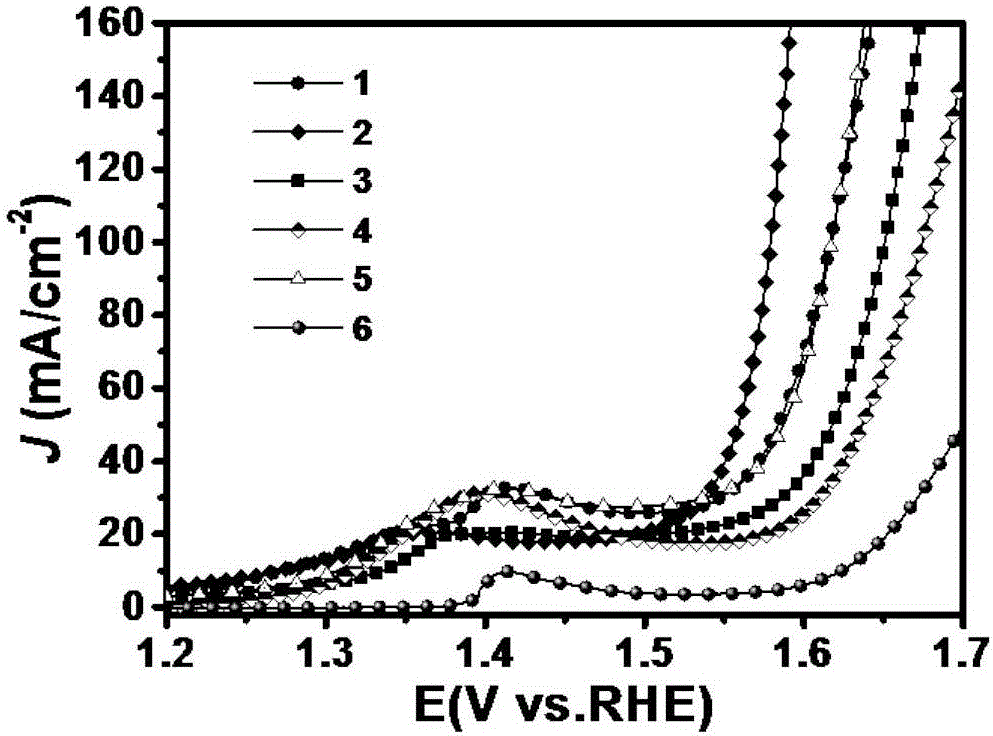

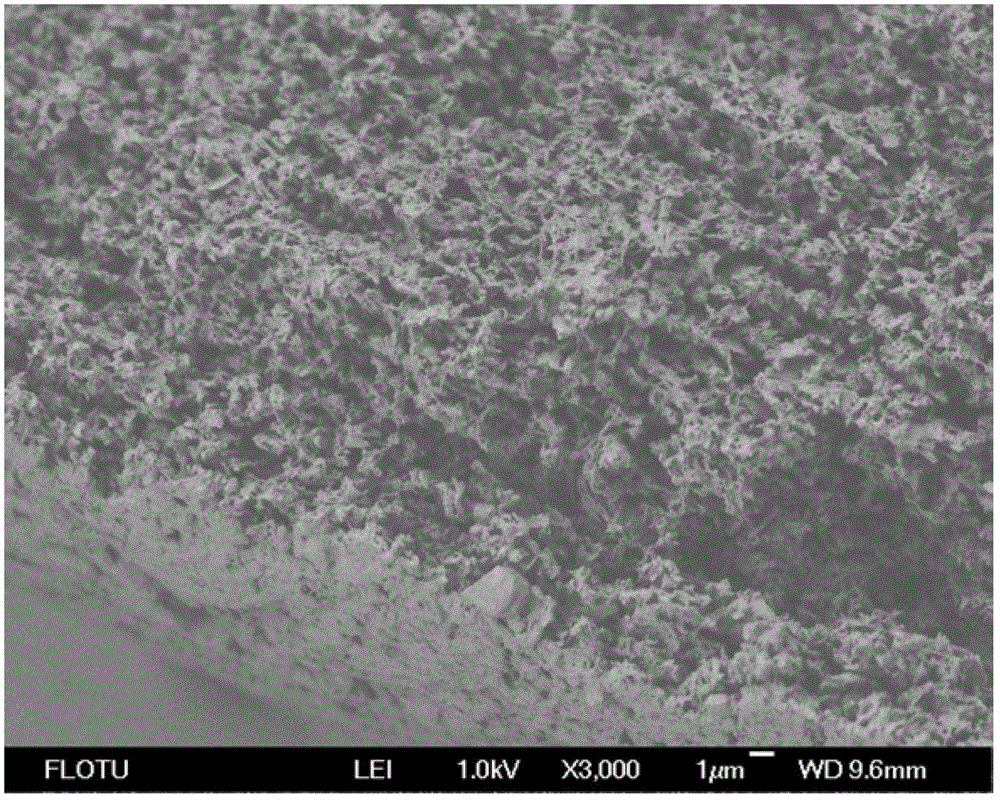

Method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide

InactiveCN106011911AIncrease intrinsic activityImprove bindingPhysical/chemical process catalystsElectrodesVulcanizationHydrothermal synthesis

The invention provides a method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide and belongs to the field of oxygen evolution catalyzation of electrolysis of water. The method comprises the following steps: firstly, pretreatment is carried out on nickel foam, then, special nano floriform metal hydroxide is formed on the surface of the nickel base after the pretreatment in an in-situ growth manner through the hydrothermal synthesis method, and finally, the prepared metal hydroxide and a sulphur source have hydrothermal reaction to prepare a hydroxyl metal sulfide oxygen evolution electrode. According to the invention, the method is novel, the demanded technology is simple, the production cost is low, requirements to equipment are lower, and industrial production is suitable; in addition, the prepared electrode has excellent oxygen evolution activity and stability, is large in specific surface area, firmly combines with a base, and can be applied to the field of oxygen evolution through industrial electrolysis of water.

Owner:CHONGQING UNIV

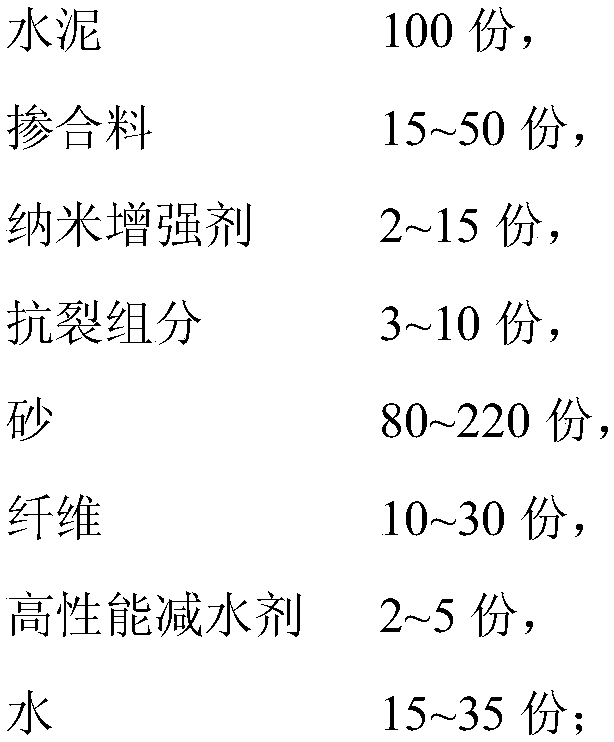

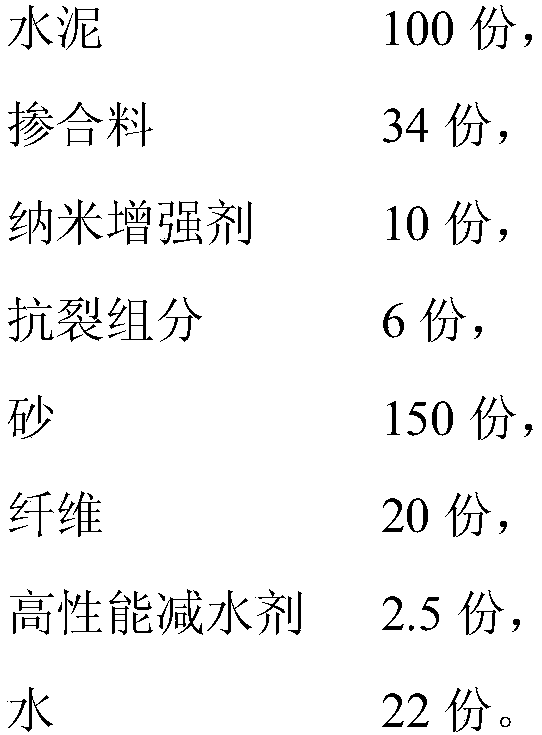

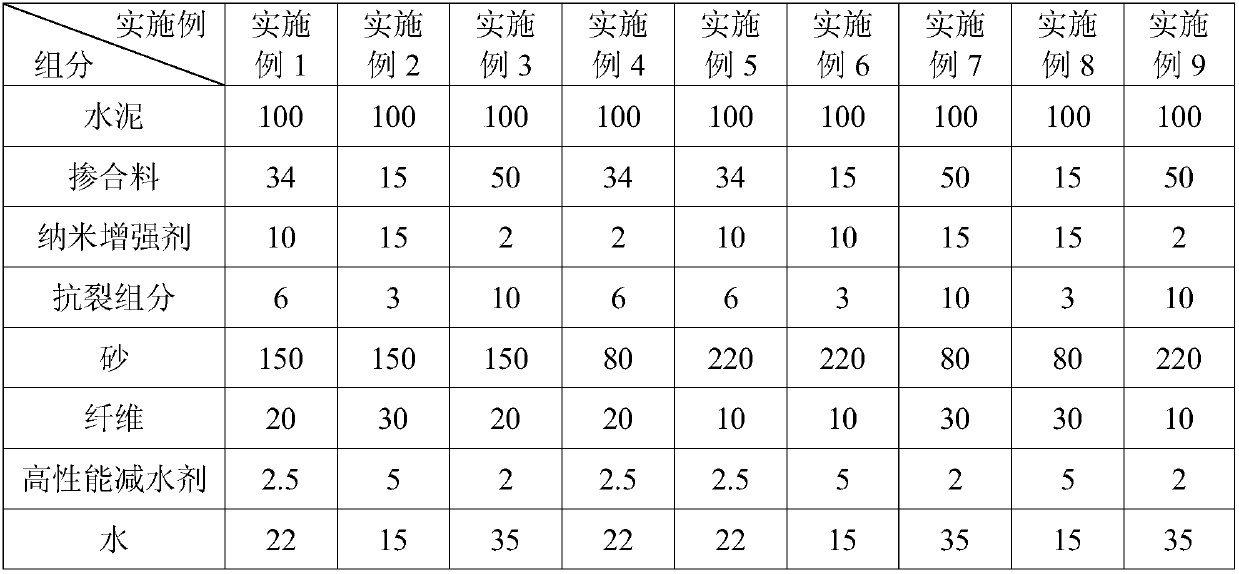

Super-high-performance cement base repairing material and preparing method thereof

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

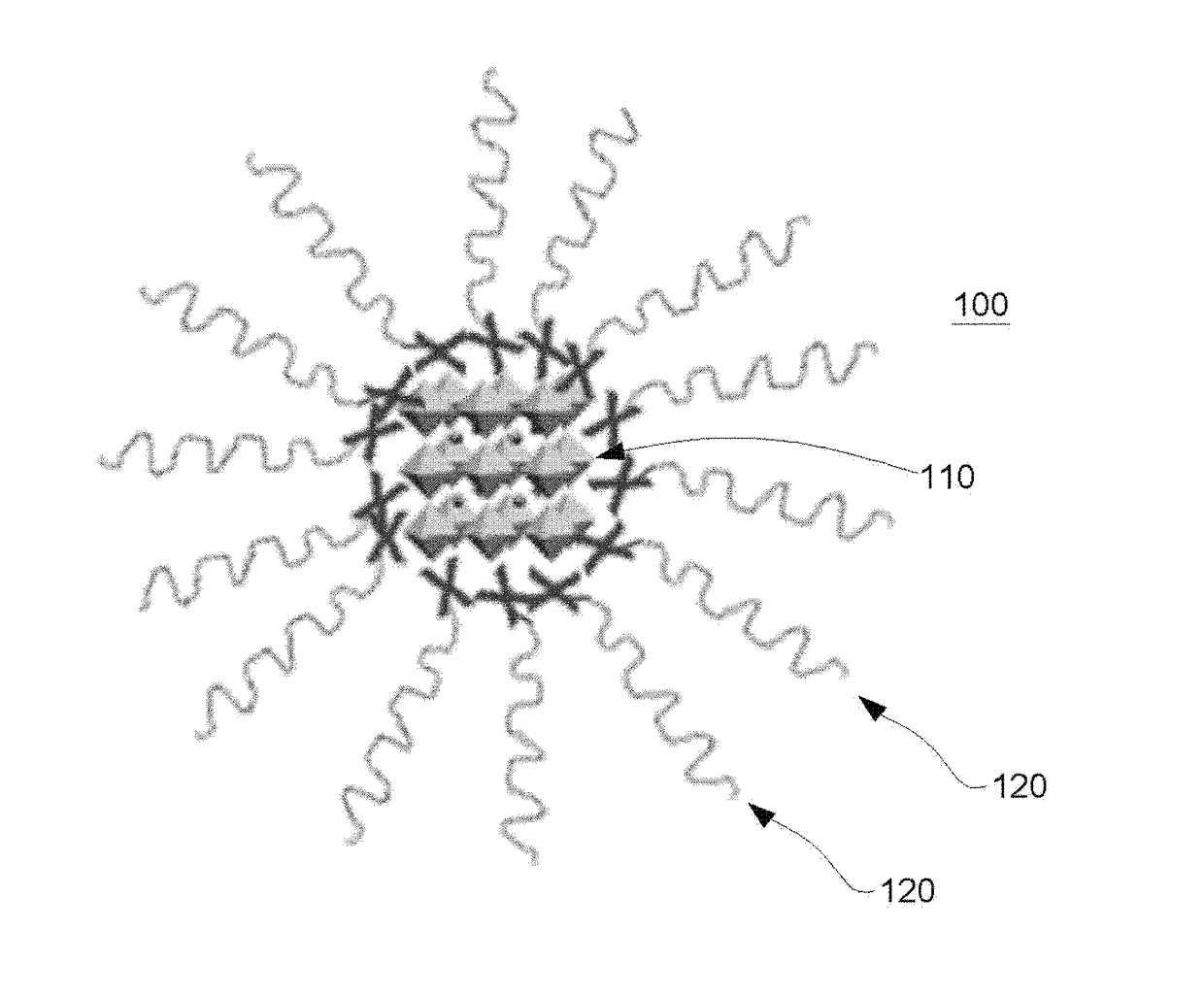

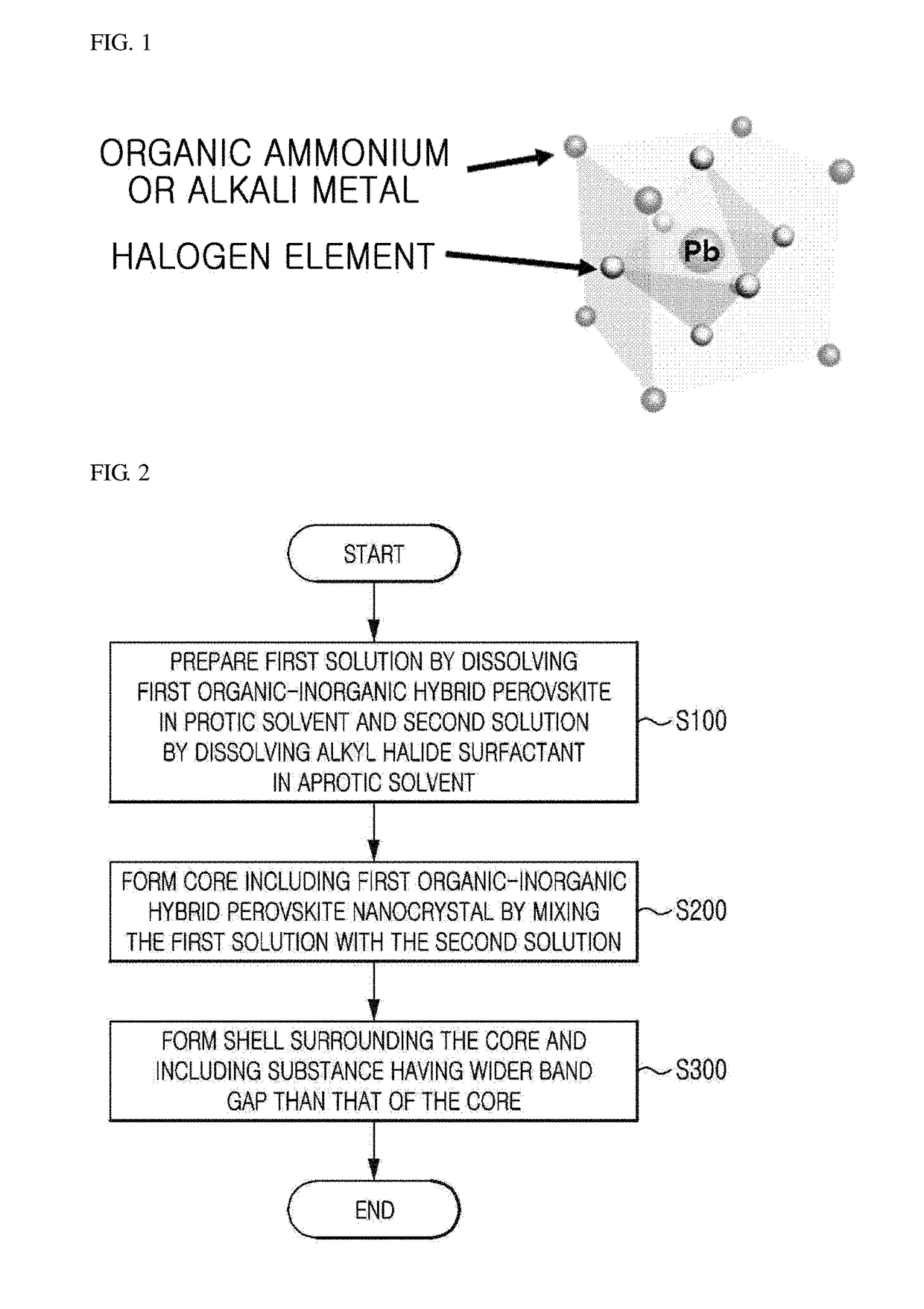

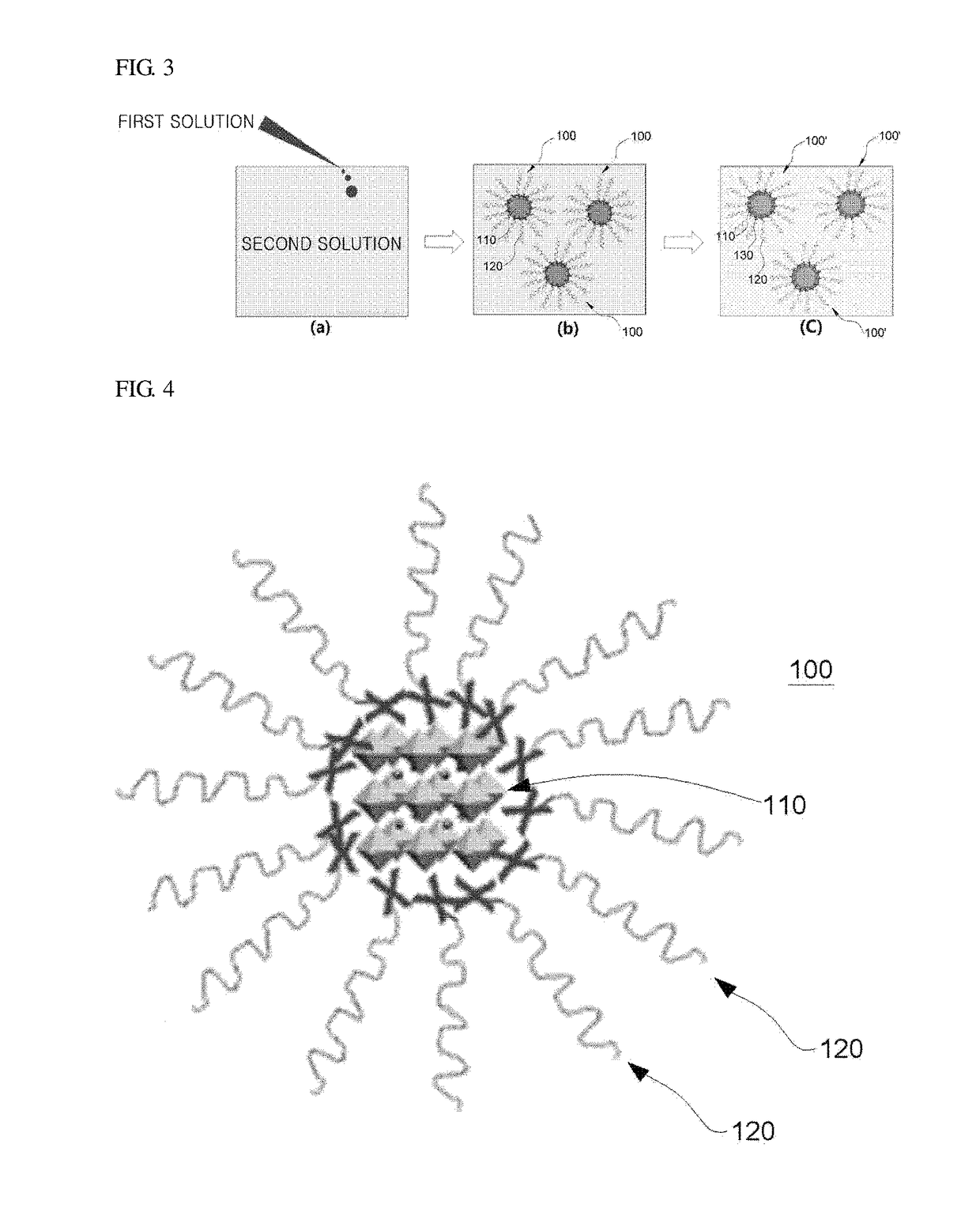

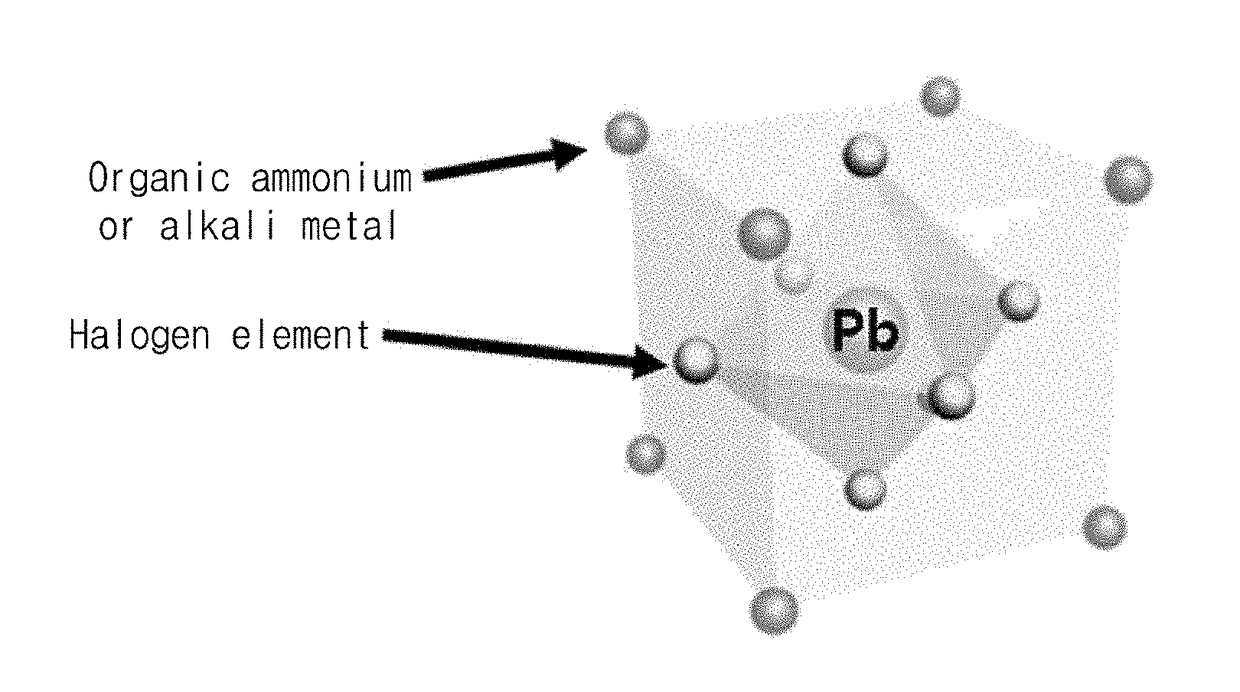

Perovskite nanocrystal particle light emitting body with core-shell structure, method for fabricating same, and light emitting element using same

ActiveUS20170346024A1High color purityReduced Diffusion LengthMaterial nanotechnologyLight-sensitive devicesLight emitting deviceOrganic polymer

Provided are a core-shell structured perovskite nanocrystalline particle light-emitting body, a method of preparing the same, and a light emitting device using the same. The core-shell structured organic-inorganic hybrid perovskite nanocrystalline particle light-emitting body or metal halide perovskite nanocrystalline particle light-emitting body is able to be dispersed in an organic solvent, and has a perovskite nanocrystal structure and a core-shell structured nanocrystalline particle structure. Therefore, in the perovskite nanocrystalline particle light-emitting body of the present invention, as a shell is formed of a substance having a wider band gap than that of a core, excitons may be more dominantly confined in the core, and durability of the nanocrystal may be improved to prevent exposure of the core perovskite to the air using a perovskite or inorganic semiconductor, which is stable in the air, or an organic polymer.

Owner:SN DISPLAY CO LTD

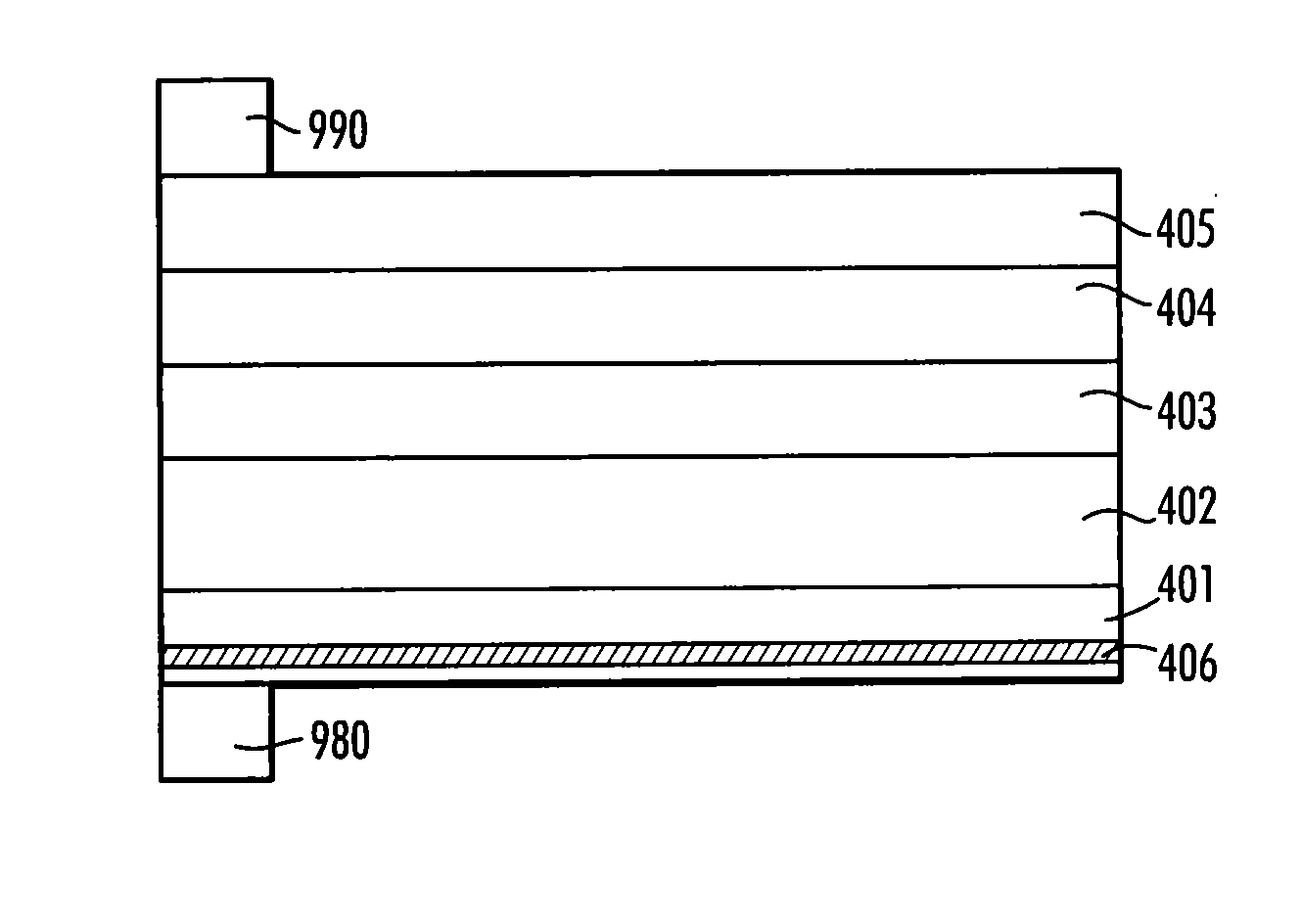

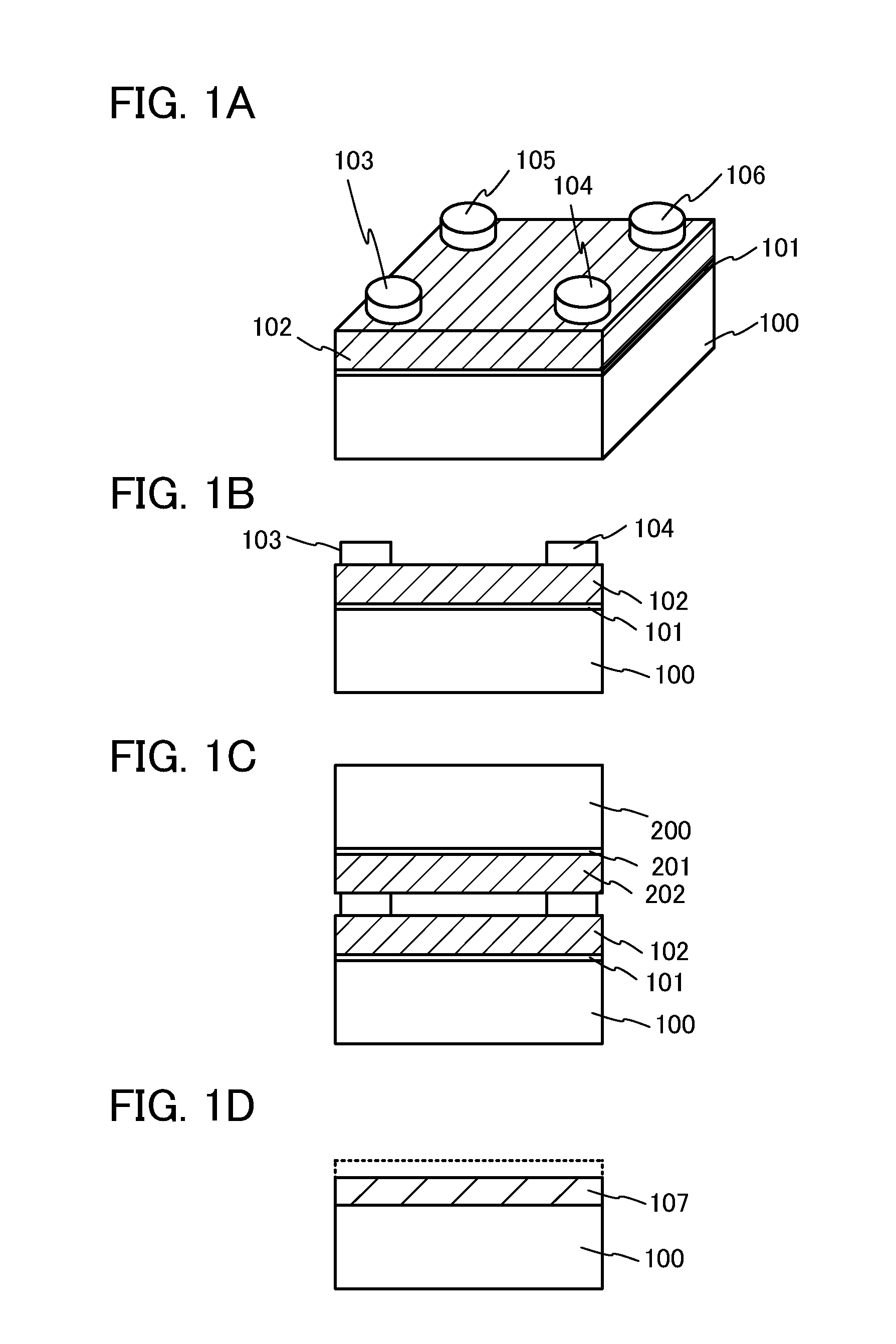

Low resistance ultraviolet light emitting device and method of fabricating the same

ActiveUS20110012089A1Surface roughness and film qualityMore surface mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesSecondary layerIndium

A low resistance light emitting device with an ultraviolet light-emitting structure having a first layer with a first conductivity, a second layer with a second conductivity; and a light emitting quantum well region between the first layer and second layer. A first electrical contact is in electrical connection with the first layer and a second electrical contact is in electrical connection with the second layer. A template serves as a platform for the light-emitting structure. The ultraviolet light-emitting structure has a first layer having a first portion and a second portion of AlXInYGa(1-X-Y)N with an amount of elemental indium, the first portion surface being treated with silicon and indium containing precursor sources, and a second layer. When an electrical potential is applied to the first layer and the second layer the device emits ultraviolet light.

Owner:NIITEK

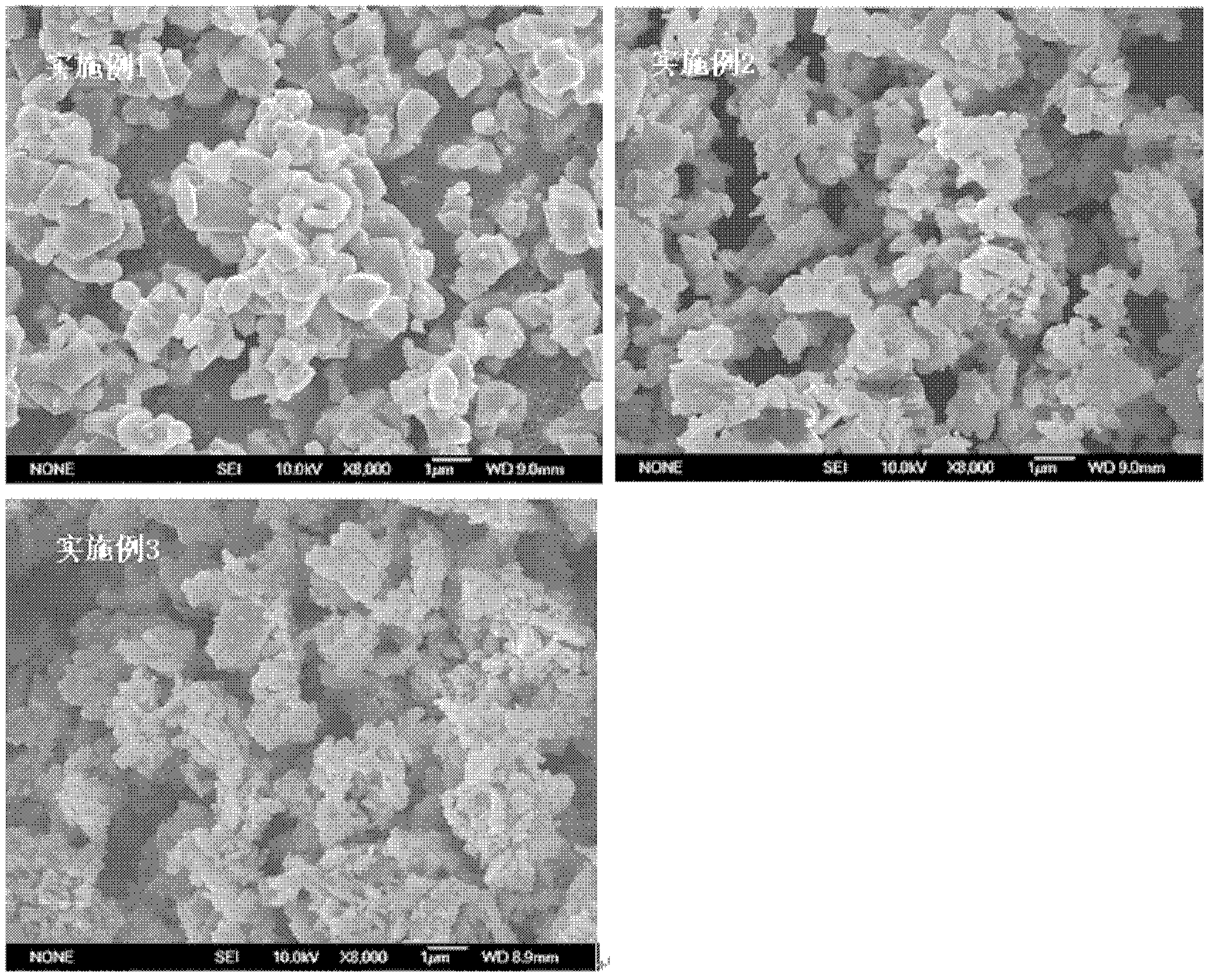

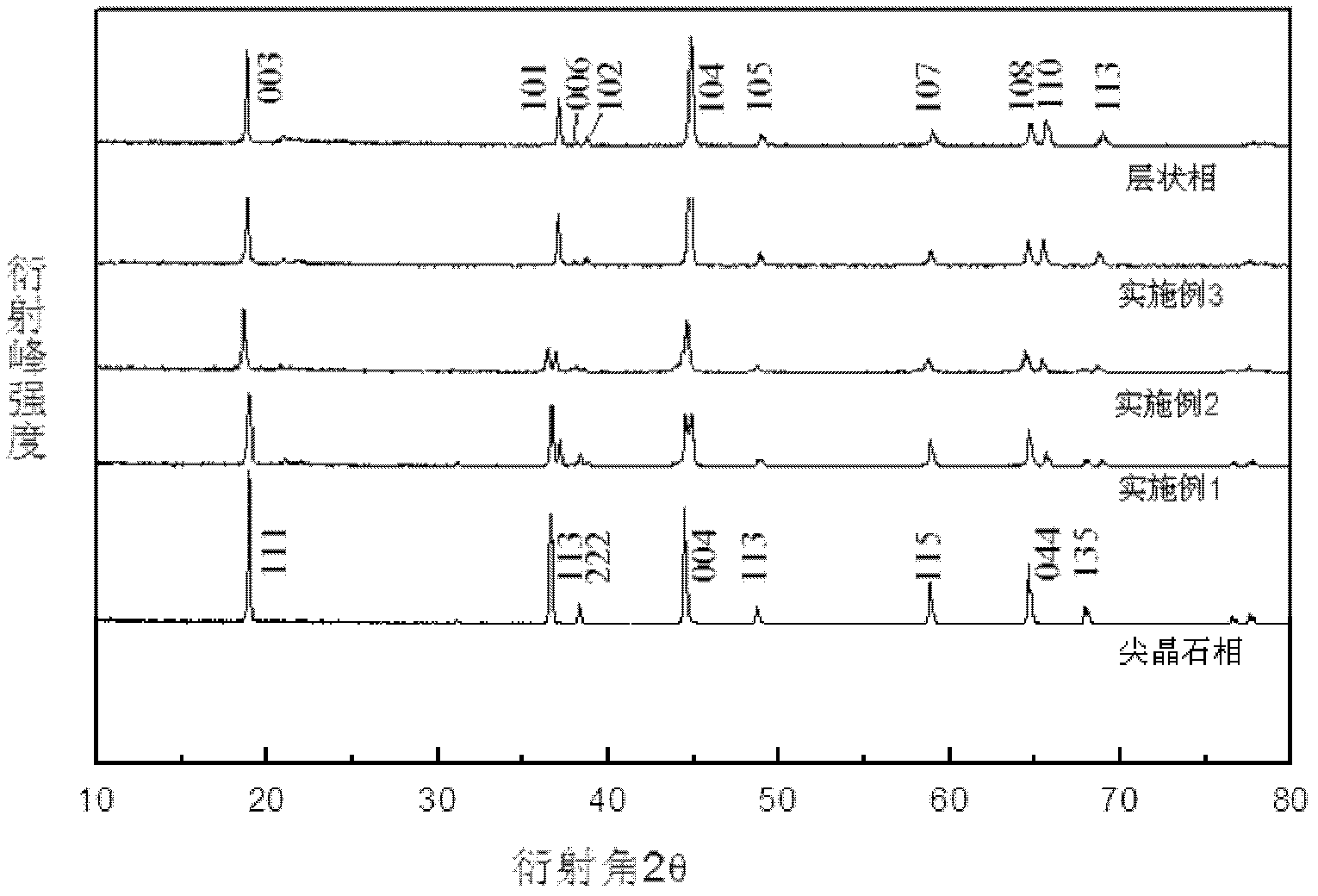

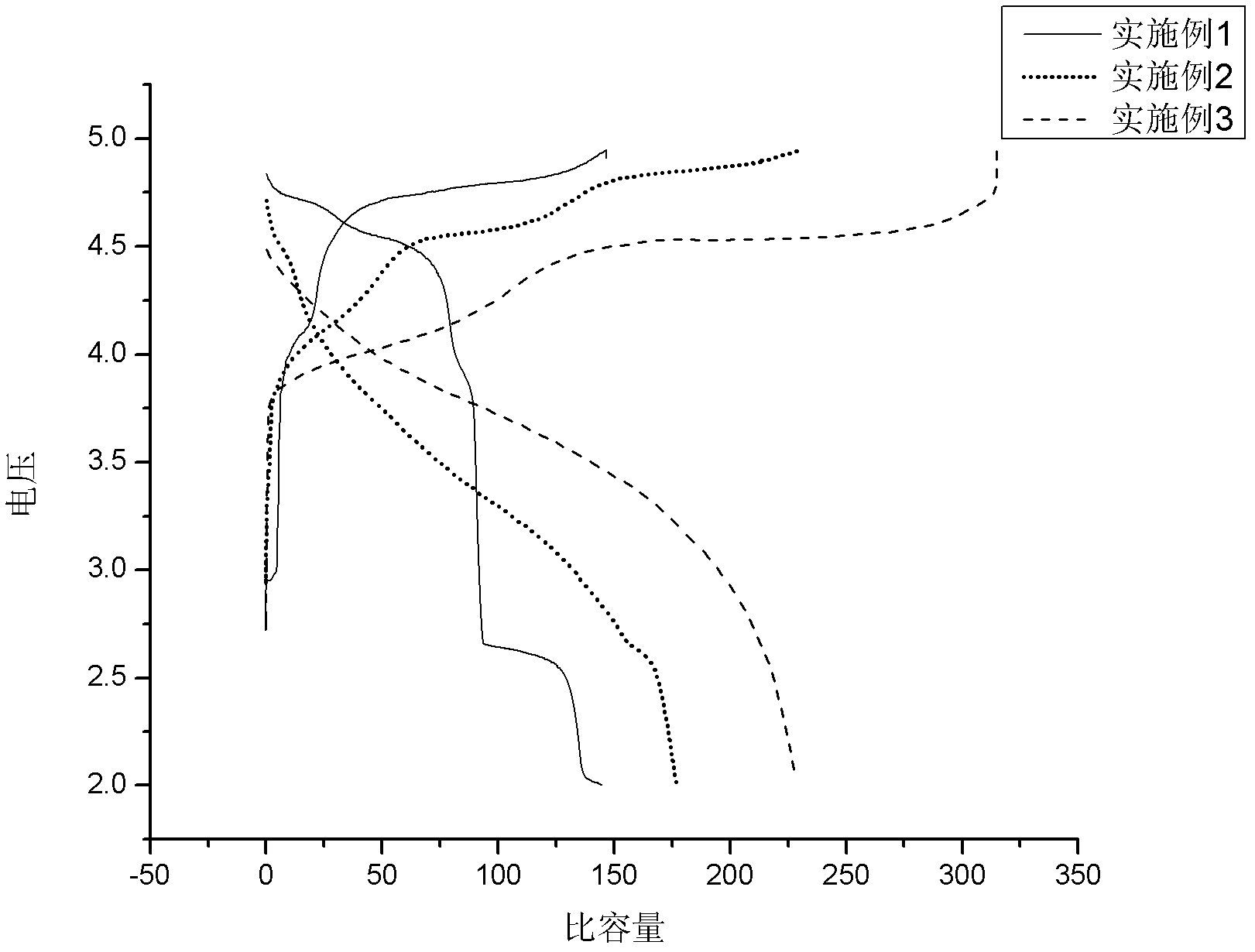

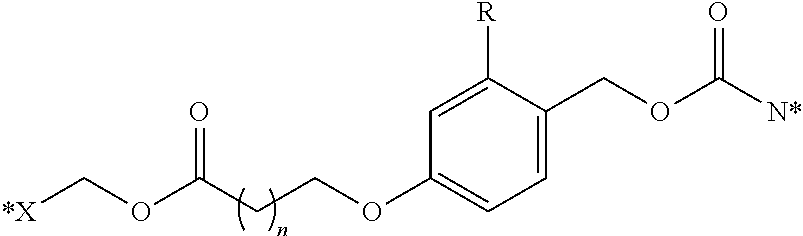

High-voltage lithium ion battery cathode material and preparation method thereof

ActiveCN102569781AExpand the voltage application rangeImprove cycle stabilityCell electrodesManganeseLithium-ion battery

The invention discloses a high-voltage lithium ion battery cathode material and a preparation method thereof. The high-voltage lithium ion battery cathode material is a solid solution material with a stratiform and spinel composite structure, and the molecular formula of the cathode material is LixNi0.25-zMn0.75-zM2zOy, wherein M is one or two of doped metals of Co, Al, Cr, Mn and Ga, x is more than 0 and less than 2, y is more than or equal to 2 and less than or equal to 3, and z is more than 0 and less than or equal to 0.25. The invention has the advantages that: the cathode material has the stratiform and spinel composite structure, the high specific capacity advantage of a manganese-based solid solution material is kept, and the cycle stability and the thermal stability of the material are improved; the impedance of the cathode material is reduced by doping, so that the thermal stability of the material is further improved, and the heat release is reduced to improve the comprehensive electrochemical performance of the material; and the preparation process of the material has high controllability, the manufacturing cost is low, and the manufacturing process has high repeatability and high batch stability, production management is facilitated, and the application demands on high-voltage and high-specific-capacity materials on the market are met.

Owner:徐源庆

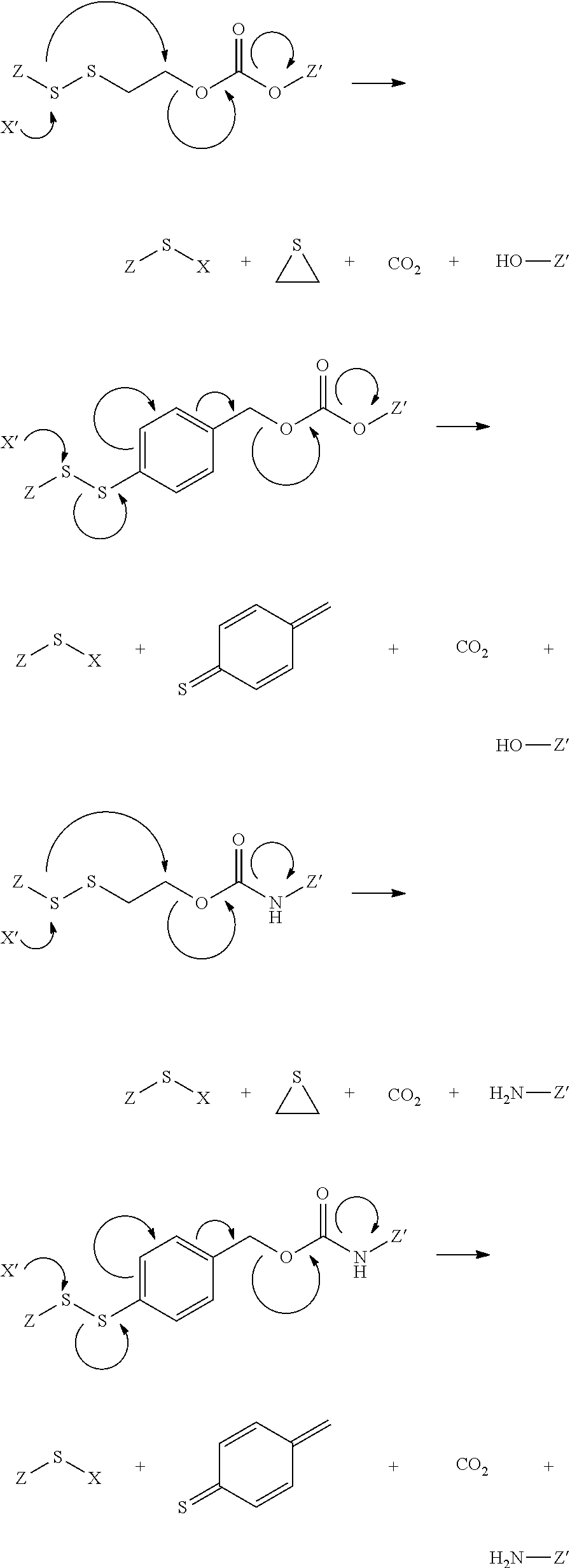

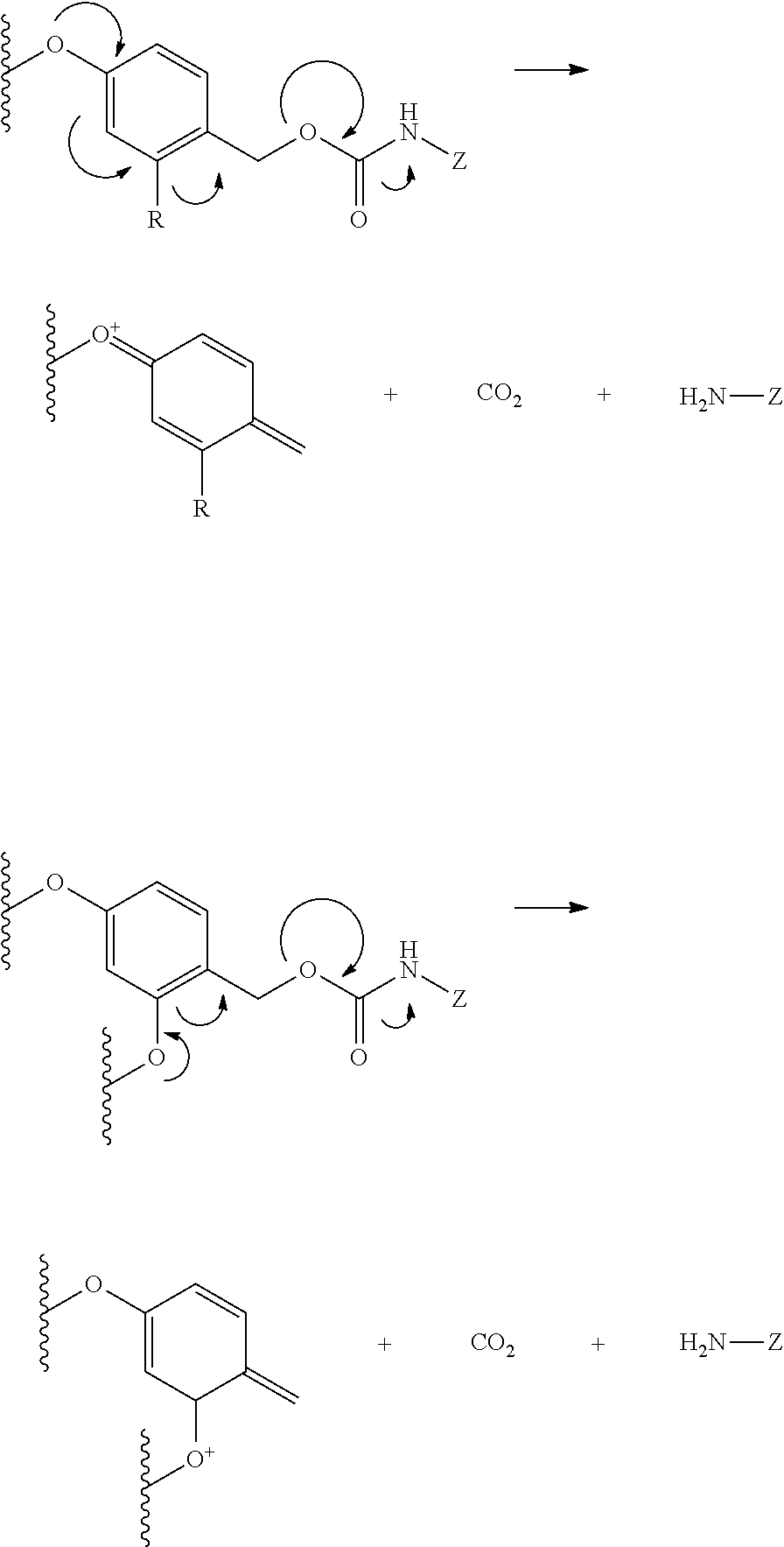

PSMA binding ligand-linker conjugates and methods for using

ActiveUS9951324B2Promoting extended conformationIncrease binding energyOrganic active ingredientsPeptide/protein ingredientsAntigenProstate specific membrane

Described herein are prostate specific membrane antigen (PSMA) binding conjugates that are useful for delivering therapeutic, diagnostic and imaging agents. Also described herein are pharmaceutical compositions containing them and methods of using the conjugates and compositions. Also described are processes for manufacture of the conjugates and the compositions containing them.

Owner:PURDUE RES FOUND INC

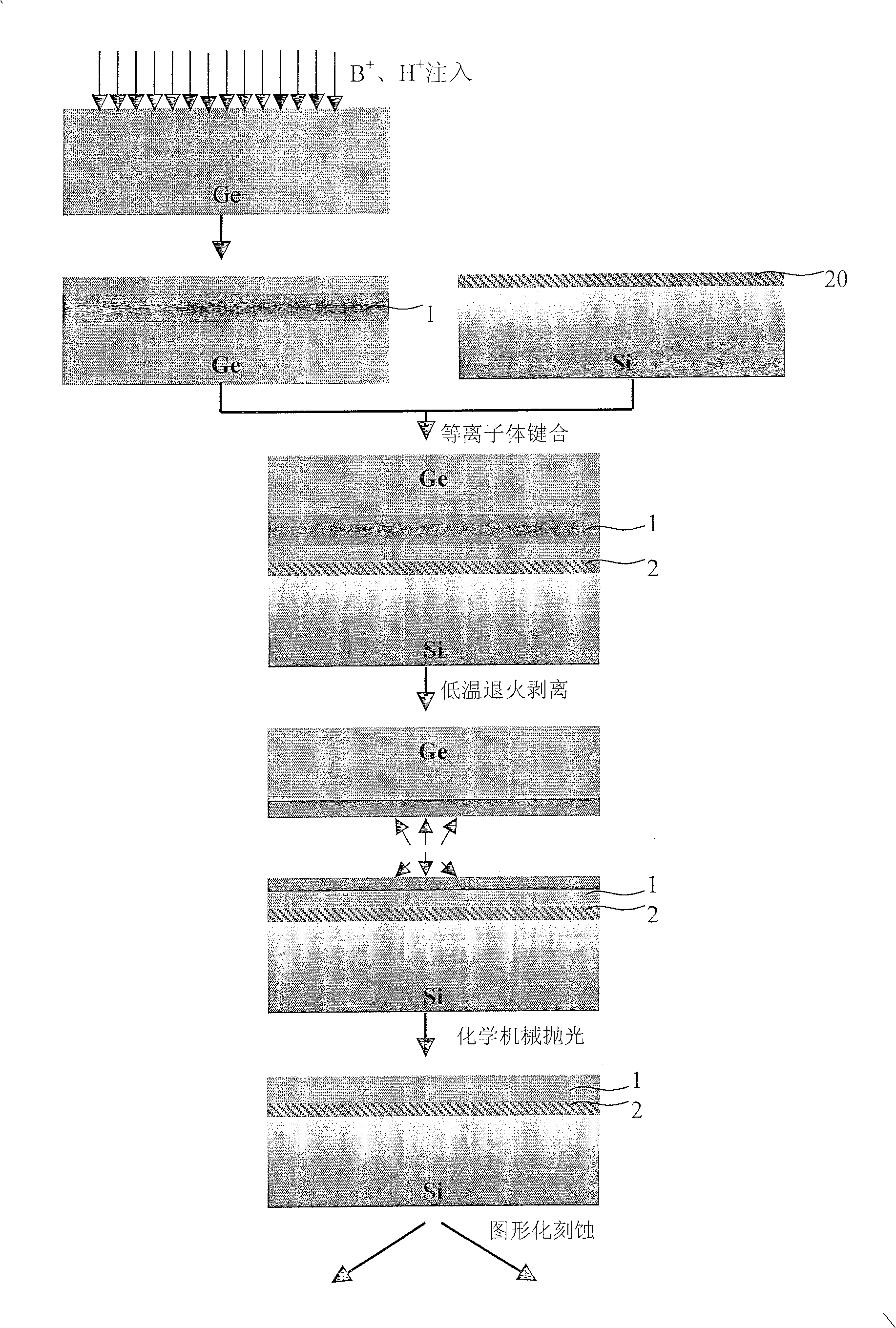

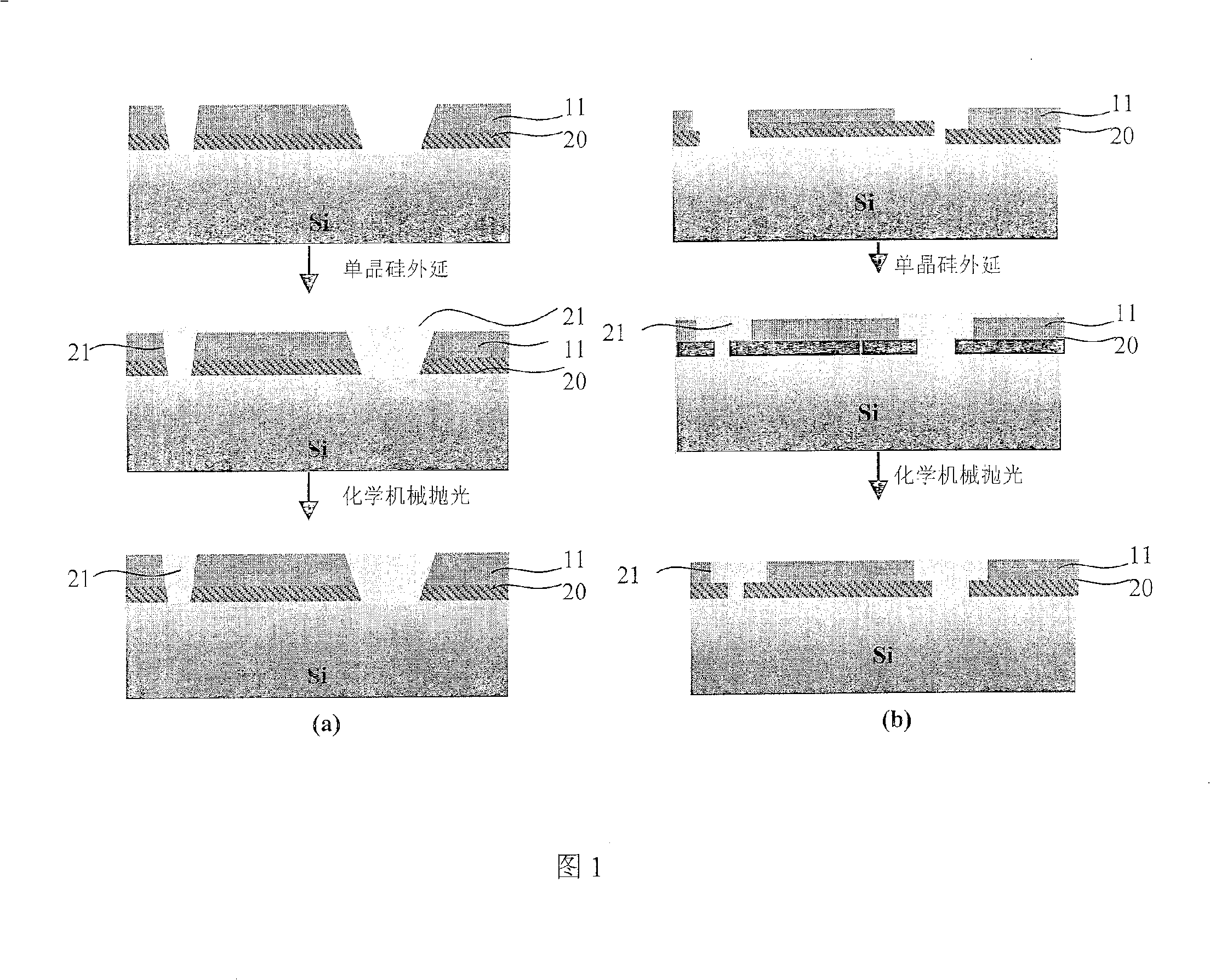

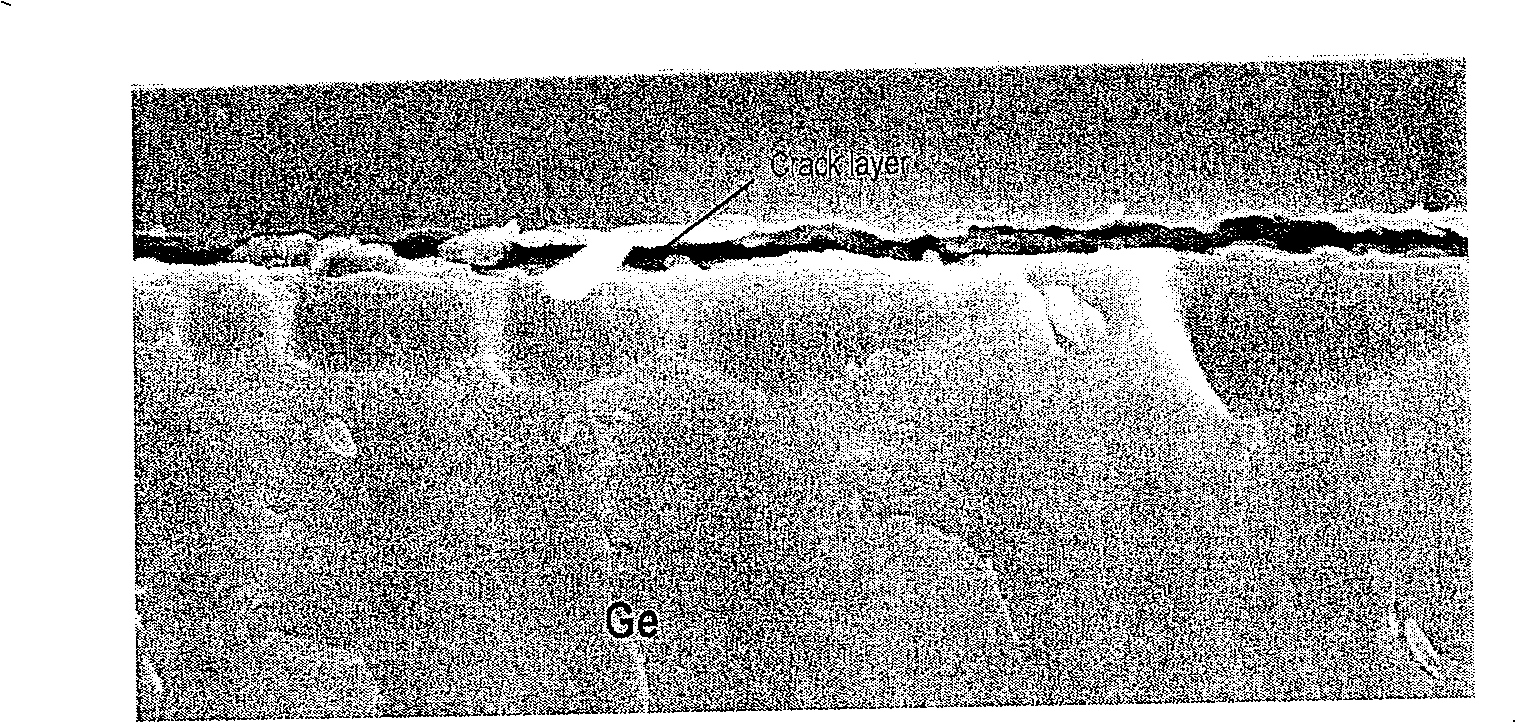

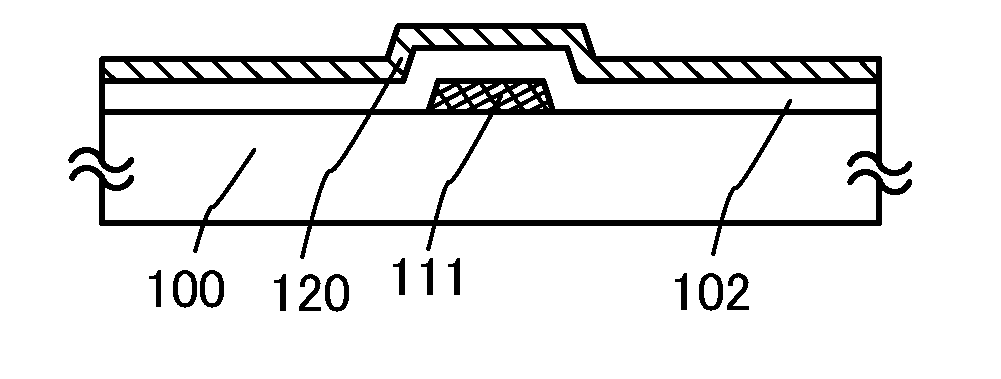

Germanium-painting structure for insulating layer of mixed graphical monocrystaline silicon as well as method and application thereof

InactiveCN101325154AReduce leakage currentWork fasterSemiconductor/solid-state device manufacturingCMOSPhotodetector

The invention relates to a germanium-on-insulator (GeOI) structure mixed with patterned single-crystal silicon and a manufacturing method thereof. The GeOI structure is characterized in that an active layer is composed of single-crystal germanium and single-crystal silicon, and the crystal orientation of the single-crystal silicon is determined by substrate silicon. The key point for preparing the structure is to prepare a GeOI single-crystal film. The substrate with the GeOI structure mixed with patterned single-crystal silicon is prepared by the steps of: transferring a single-crystal germanium film on an insulator by using plasma low temperature bonding and low temperature stripping techniques, and performing selective etching and single-crystal silicon epitaxy on the single-crystal germanium film. The inventive GeOI structure mixed with patterned single-crystal silicon can be used for gallium arsenide epitaxy, so as to integrate with III-V semiconductors. Meanwhile, the patterned single-crystal silicon material can be used for conventional CMOS processing to prepare conventional devices and circuits, so as to effectively solve the self healing effect of an embedded oxidation layer. The GeOI structure mixed with patterned single-crystal silicon has important application prospects in high-speed high-performance CMOS devices, optoelectronic integrated circuits, high-speed photodetectors, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

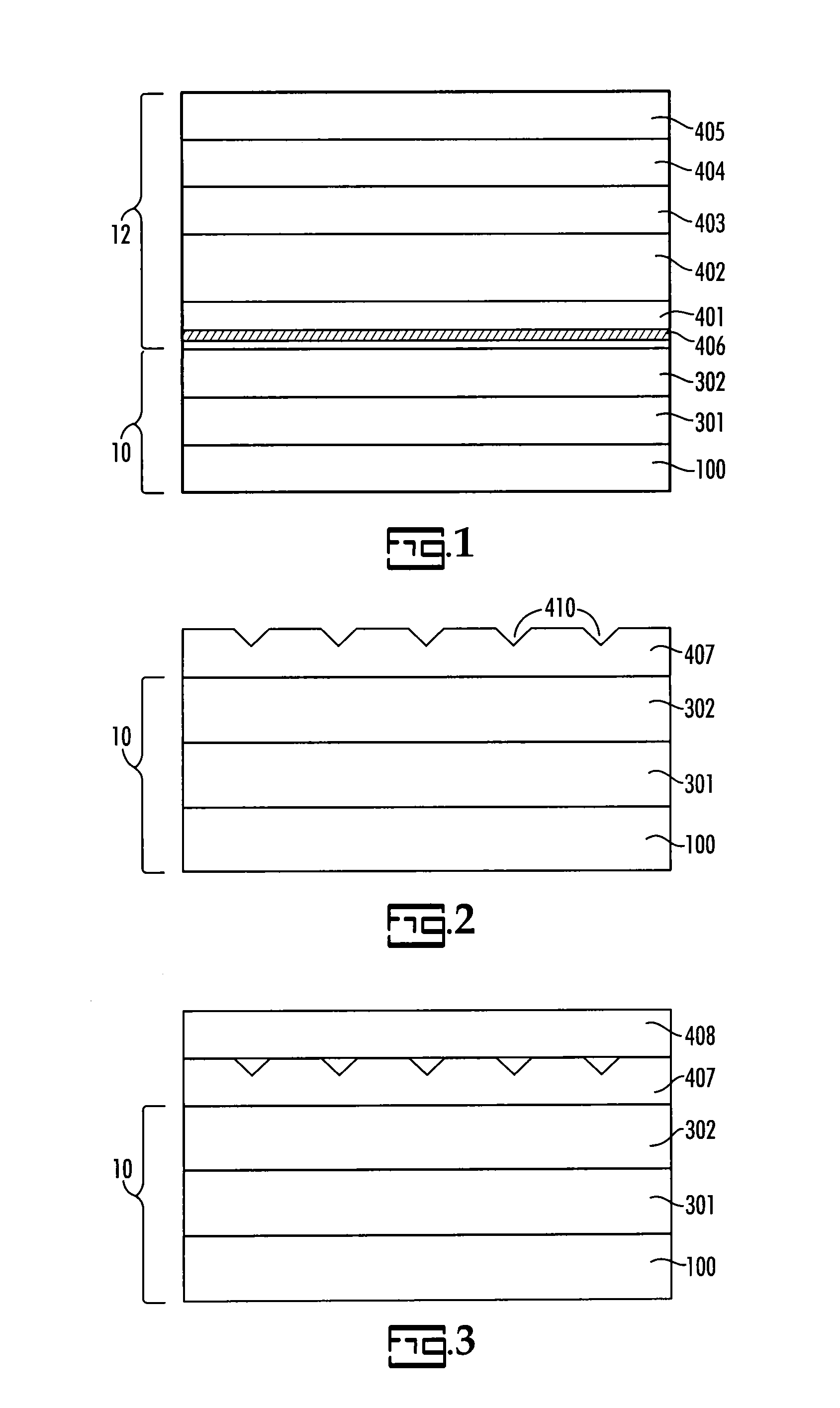

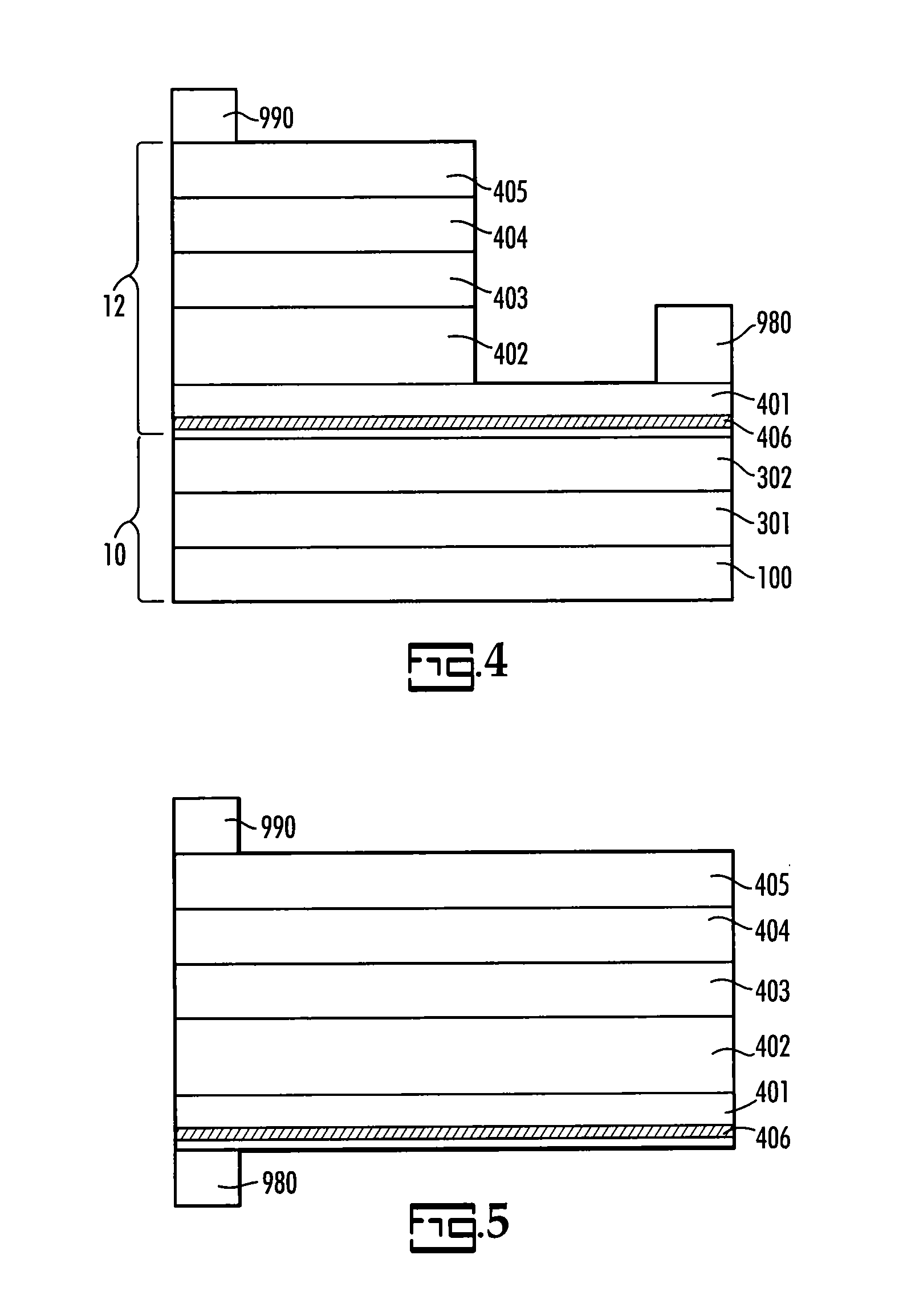

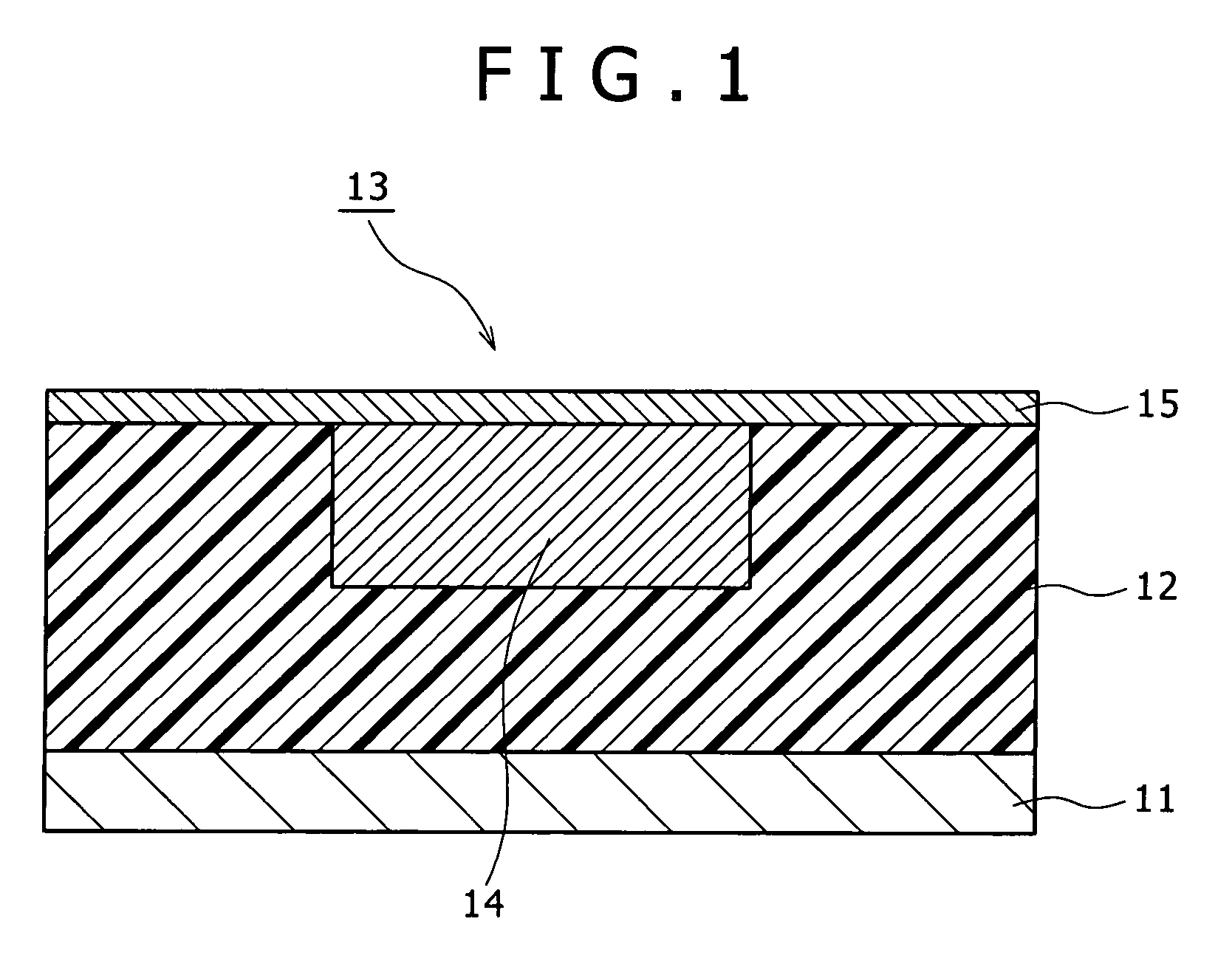

Semiconductor device and method for manufacturing the same

InactiveUS20140367682A1Reduce impurity concentrationIncrease binding energyTransistorSolid-state devicesHydrogen atomDangling bond

An object is to provide a semiconductor device including an oxide semiconductor with stable electric characteristics can be provided. An insulating layer having many defects typified by dangling bonds is formed over an oxide semiconductor layer with an oxygen-excess mixed region or an oxygen-excess oxide insulating layer interposed therebetween, whereby impurities in the oxide semiconductor layer, such as hydrogen or moisture (a hydrogen atom or a compound including a hydrogen atom such as H2O), are moved through the oxygen-excess mixed region or oxygen-excess oxide insulating layer and diffused into the insulating layer. Thus, the impurity concentration of the oxide semiconductor layer is reduced.

Owner:SEMICON ENERGY LAB CO LTD

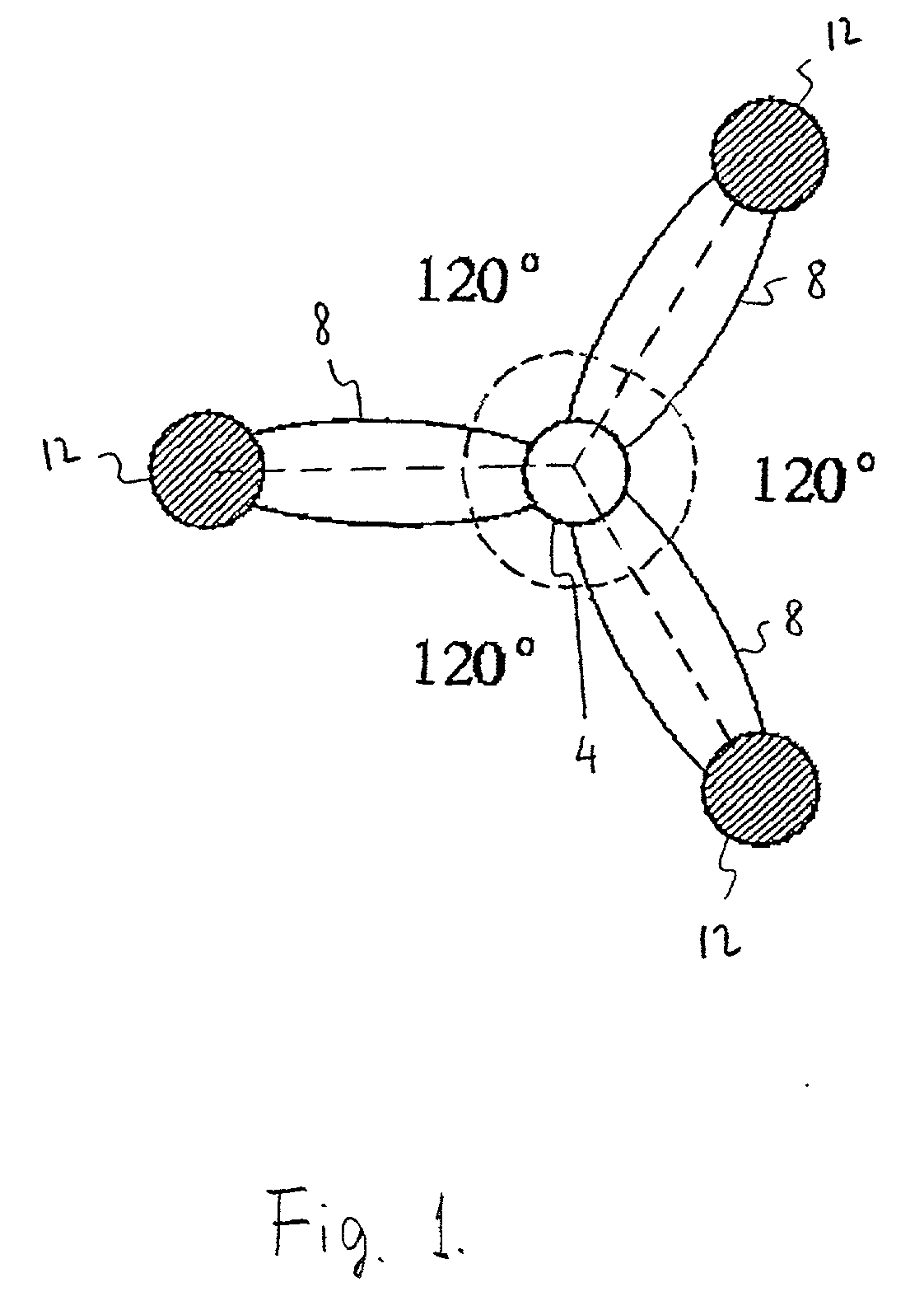

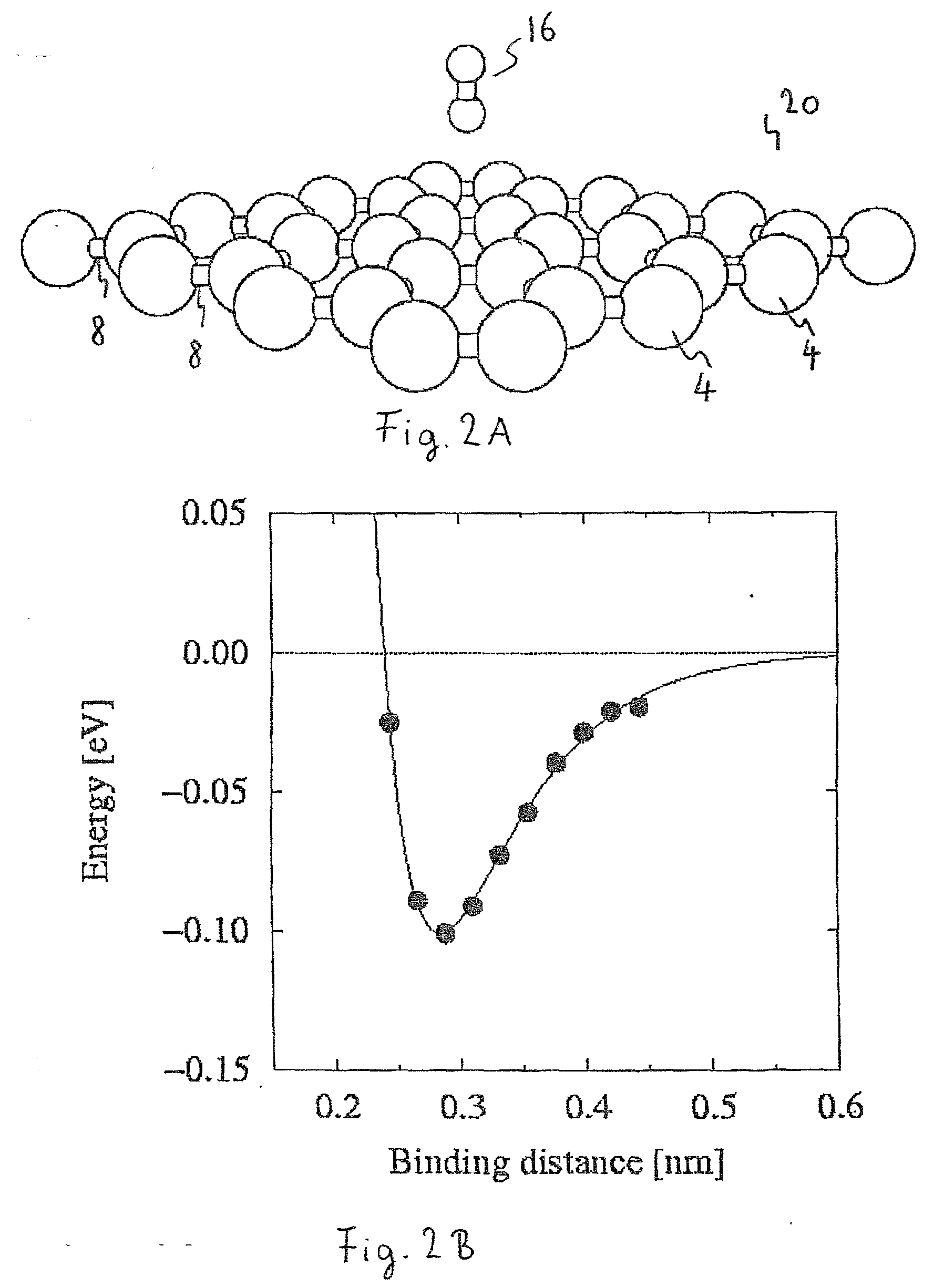

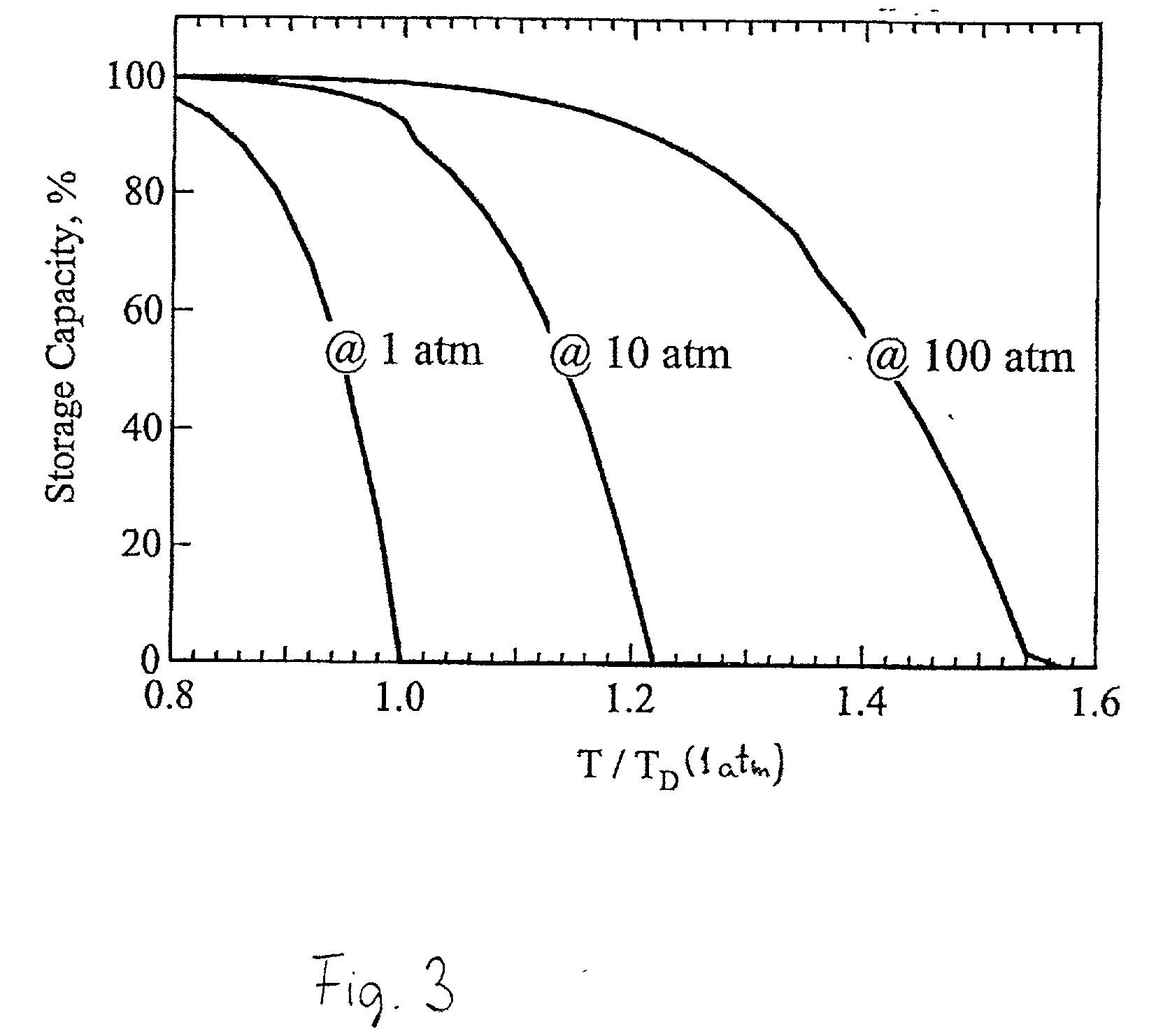

Increasing hydrogen adsorption of nanostructured storage materials by modifying sp2 covalent bonds

InactiveUS20070092437A1Improve weight % storage efficiency of storageMore competitiveMaterial nanotechnologyReversible hydrogen uptakeX-rayGamma ray

According to the invention, nanostructured storage materials are provided for storing hydrogen. The nanostructured storage materials can include a network of light elements, such as Be, B, C, N, O, F, Mg, P, S, and Cl, coupled with sp2 bonds. The hydrogen adsorption to the nanostructured storage material is improved by modifying the sp2 bonds. The sp2 bonds can be modified by forming the nanostructured storage material from the above light elements, possibly with a shape other than a planar layer, and by introducing defects. A chemical vapor deposition technique can be used for the synthesis, where doping gases are included into the flow. Methods for forming the nanostructured storage material with defects include removing light elements from the nanostructured storage material by irradiation with electrons, neutrons, ions, gamma rays, X-rays, and microwaves.

Owner:NANOMIX

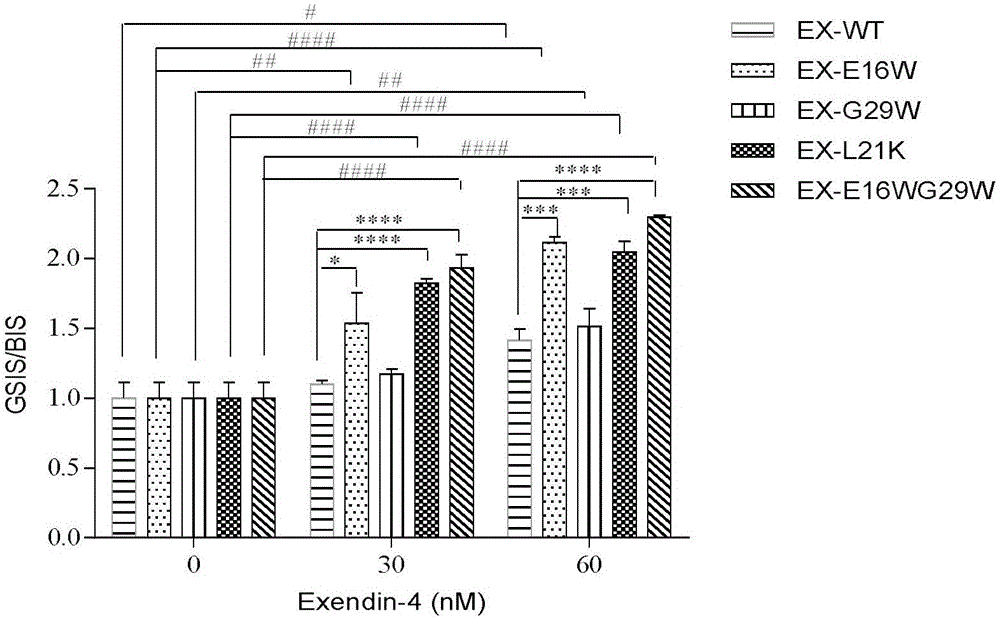

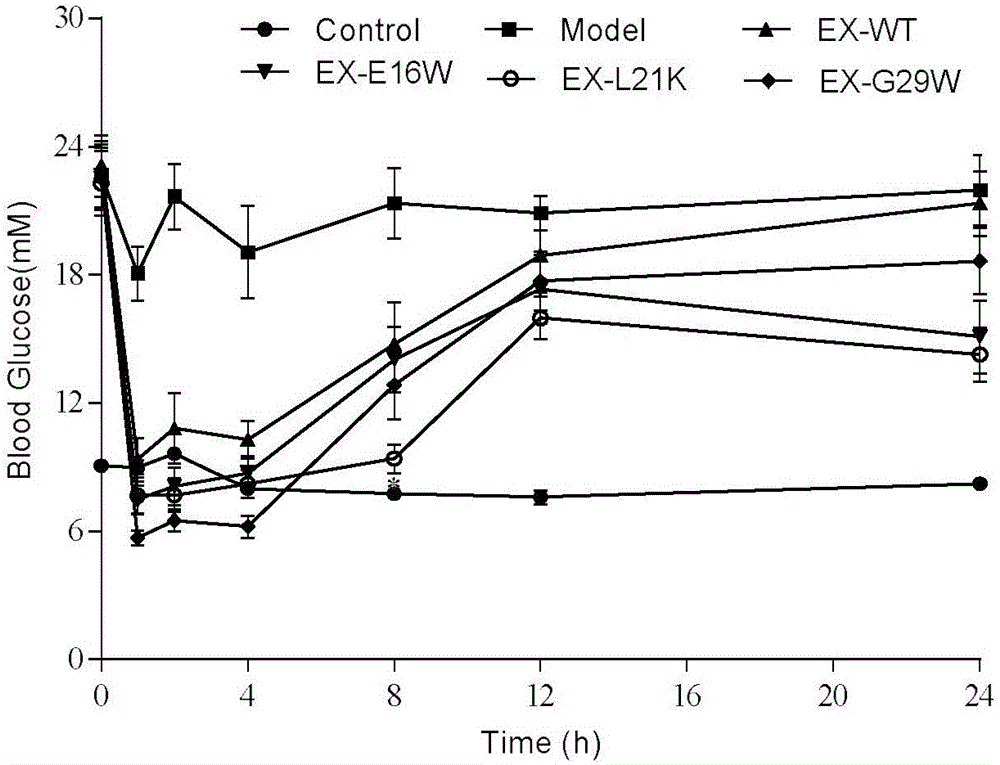

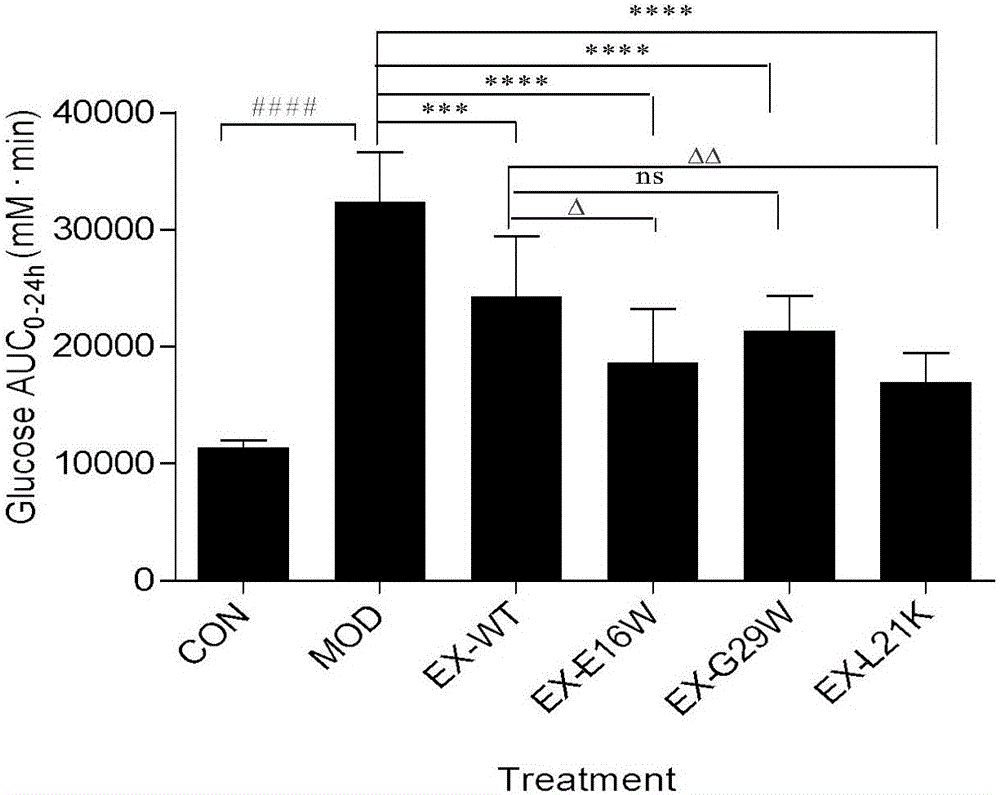

High-activity exendin-4 analogue and pharmaceutical application thereof

ActiveCN105753963ATreat or reduce diabetes and obesityLower blood sugarHormone peptidesPeptide/protein ingredientsExenatideUnder-stimulation

The invention discloses an exendin-4 analogue.Under stimulation of the analogue, islet cell tumor cells INS-1 of a rat can secrete insulin significantly more actively than that under the simulation of wild exendin-4, and hypoglycemic activity in the body of a diabetic model mouse C57B L / KsJ-db / db is significantly better than that under the simulation of wild exendin-4; the exendin-4 analogue is useful to prevent, treat or alleviate diabetics and obesity as well as other diseases benefiting from glucose reduction, gastrointestinal activity inhibition and gastric emptying.

Owner:CHINA PHARM UNIV

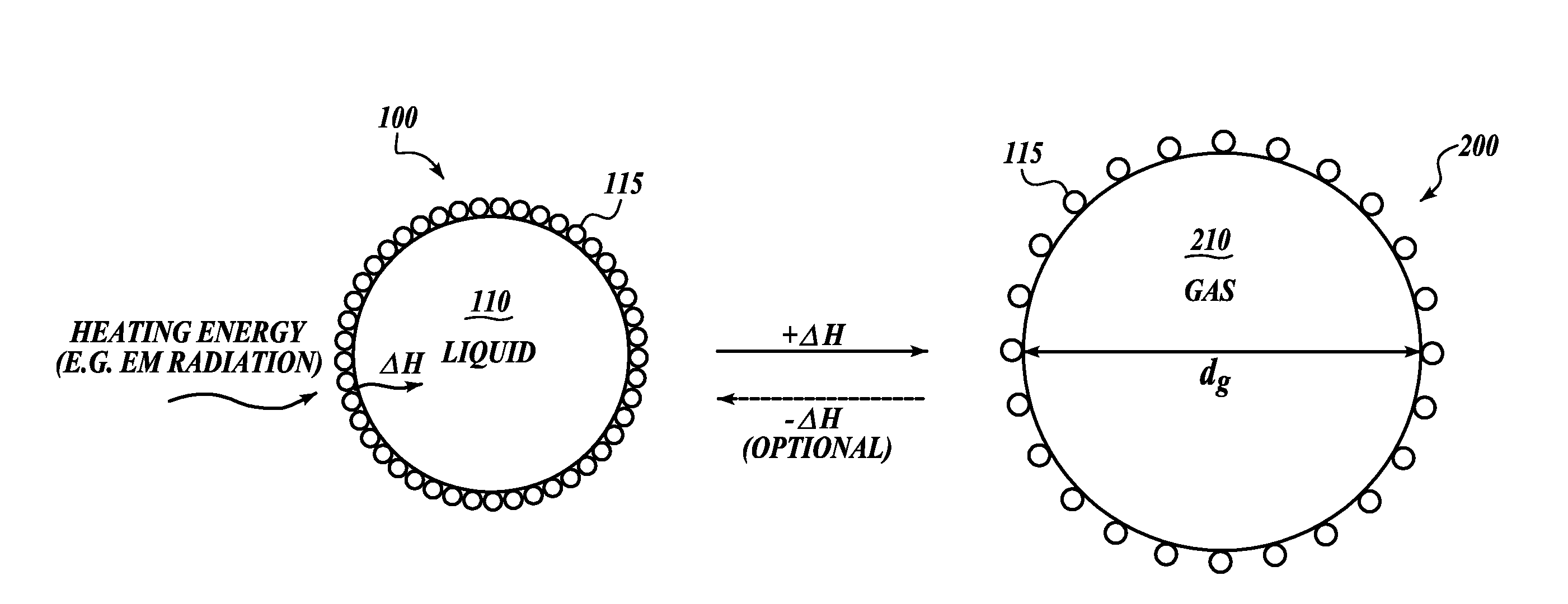

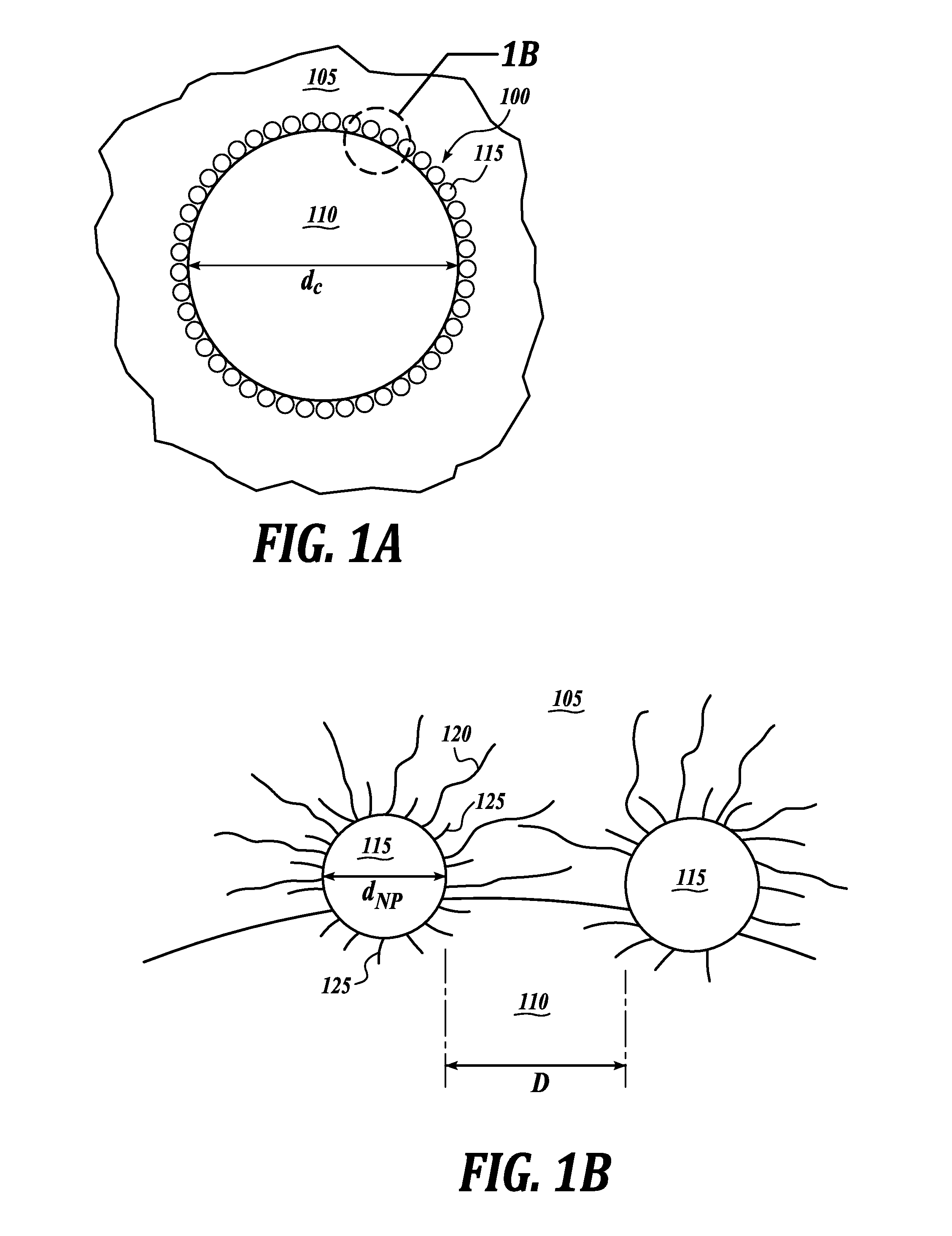

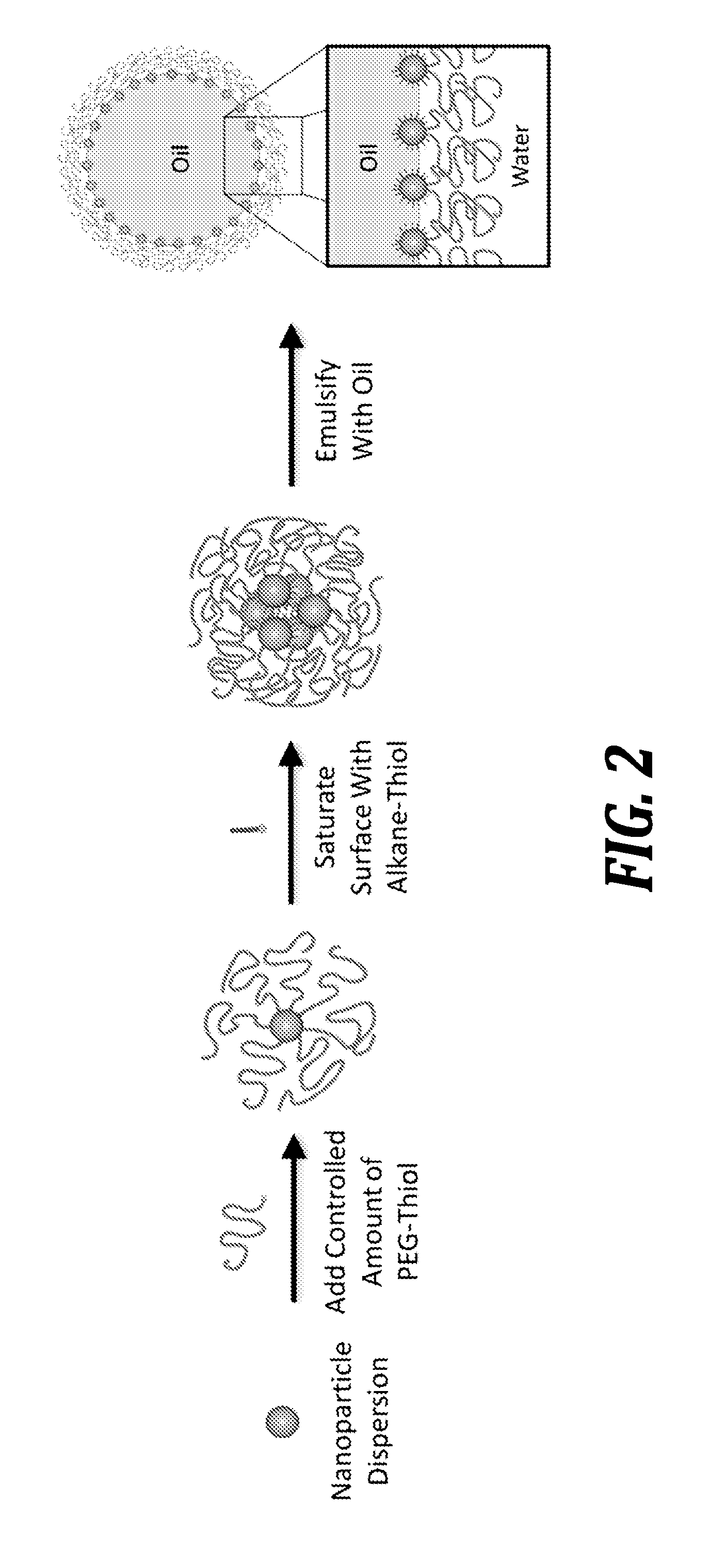

Nanoparticle emulsions

InactiveUS20150231282A1Highly effective emulsifying agentEnhancing near-infrared optical absorptionUltrasonic/sonic/infrasonic diagnosticsPowder deliveryLiquid coreEmulsion

Composites formed from a liquid core encapsulated by a plurality of nanoparticles are provided herein. The composites in certain embodiments are droplets comprising a hydrophobic dispersed phase within a hydrophilic continuous phase, thereby forming an emulsion. The composites can be used as contrast agents for imaging, therapeutic agents, and adapted for other uses according to the unique properties of the composites disclosed herein.

Owner:UNIV OF WASHINGTON CENT FOR COMMERICIALIZATION

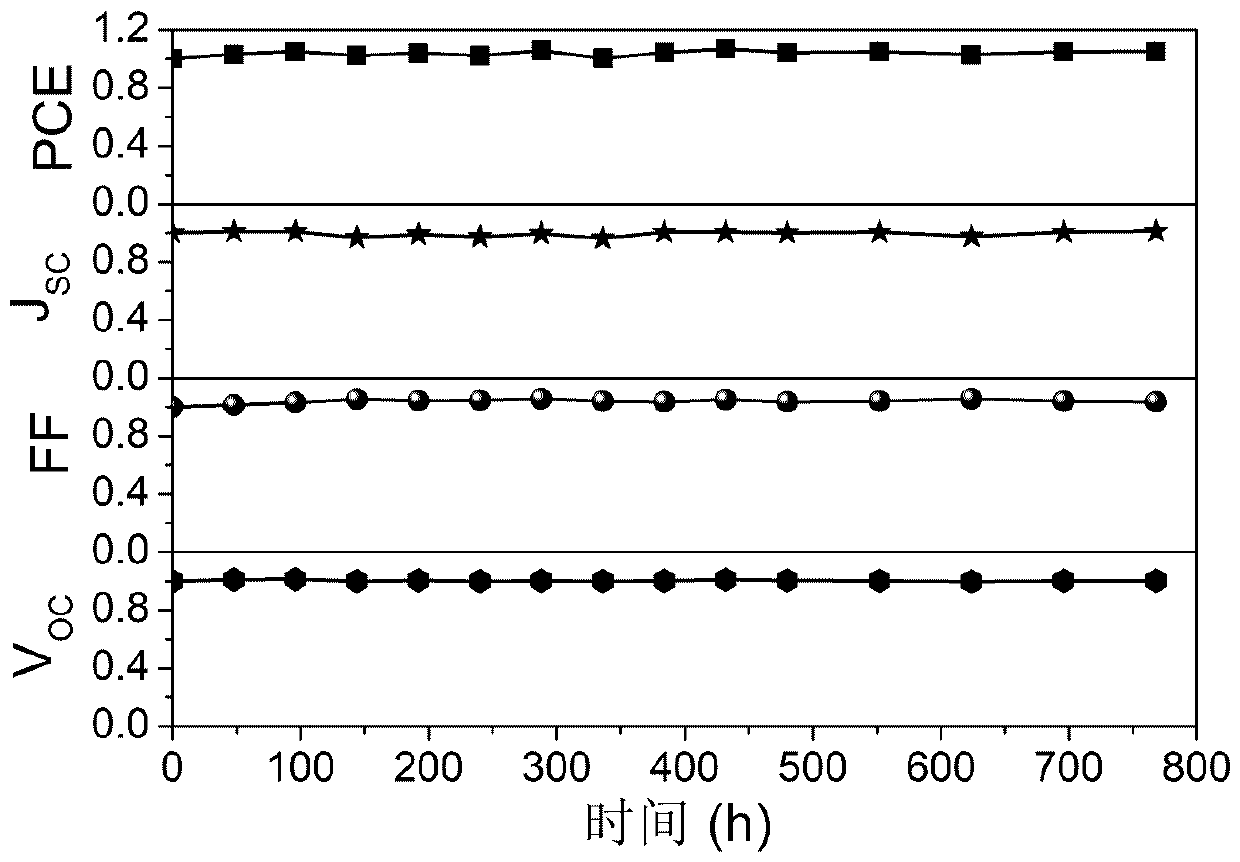

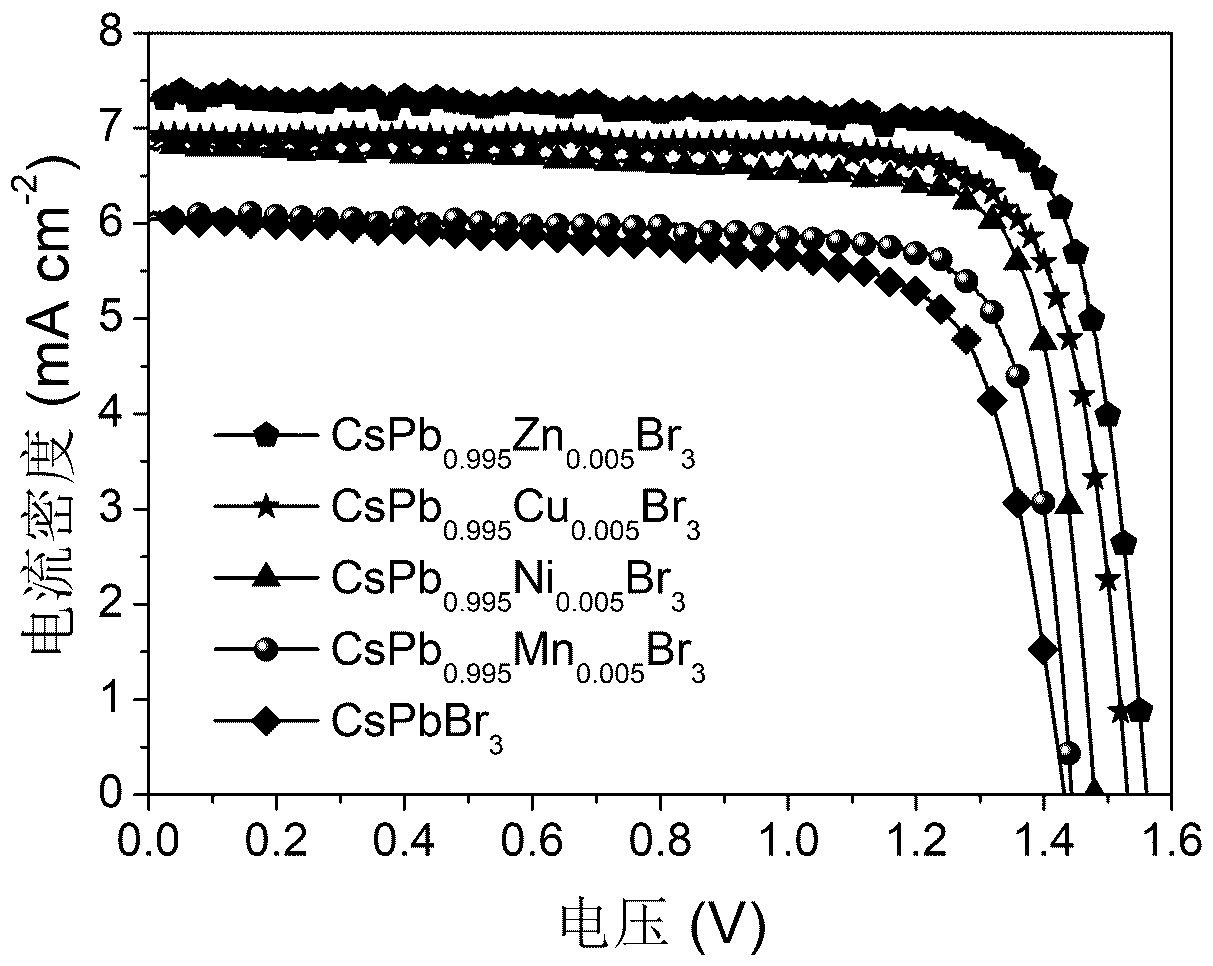

Preparation and application of all-inorganic perovskite cell based on transition metal ion doping

ActiveCN110047951AIncrease binding energyInhibition formationFinal product manufacturePhotovoltaic energy generationHole transport layerCrystallinity

The present invention provides an all-inorganic perovskite solar cell based on transition metal ions doped CsPbBr<3> and a preparation method and an application thereof. Specifically, the invention isthat conductive glass is first spin-coated with an electron transfer layer and subsequently spin-coated with a lead bromide solution mixed with transition metal ions, then is spin-coated with a cesium bromide solution repeatedly; the non-porous perovskite film with a high crystallinity and a large grain size is prepared; and finally the all-inorganic perovskite solar cell based on transition metal ions doped CsPbBr<3> is assembled by blade coating of carbon back electrode. The invention reduces the defect density in the perovskite film by doping transition metal ions, simultaneously the energy band structure is adjusted; the energy loss of charge migration is reduced; and the separation, extraction and transfer of photogenerated charges and charge recombination are reduced, thereby the photoelectric conversion efficiency and long-term operation stability of the cell are improved. The invention has the advantages such as simple and feasible preparation method, large optimization spaceof material combination, no noble metal back electrode or hole transporting layer and low cost.

Owner:OCEAN UNIV OF CHINA

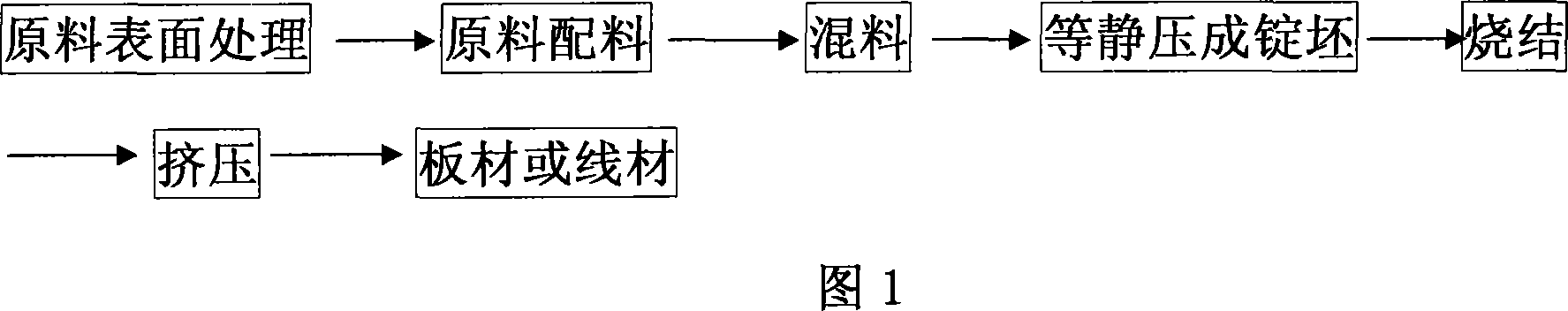

Method for preparing silver copper oxide electric contacting material

A method of preparing silver copper oxide electrical contact material is disclosed. The raw material composition, particle size, weight percentage are in that: base metal: silver powder and copper oxide powder have powder particle size of 1.5 mu m -50 mu m, copper oxide powder takes the quantity of more than 2%-25%, based on total weight, the rest is silver; additive: bismuth oxide does not exceed 0.9% of the total weight, nickel oxide does not exceed 1% of total weight. Raw material is surface treated, after batching, the raw material is mixed uniformly in a powder mixing machine to form an isostatic pressing ingot after isostatic pressed; The isostatic pressing ingot is sintered in a heating furnace to obtain a sintered ingot; then the sintered ingot is transported into a extruder to extrude into a plate or wire material. The produced silver copper oxide electrical contact material can satisfy the operation requirement of high-performance low-voltage electrical apparatus, thus is applicable to a DC contactor especially.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

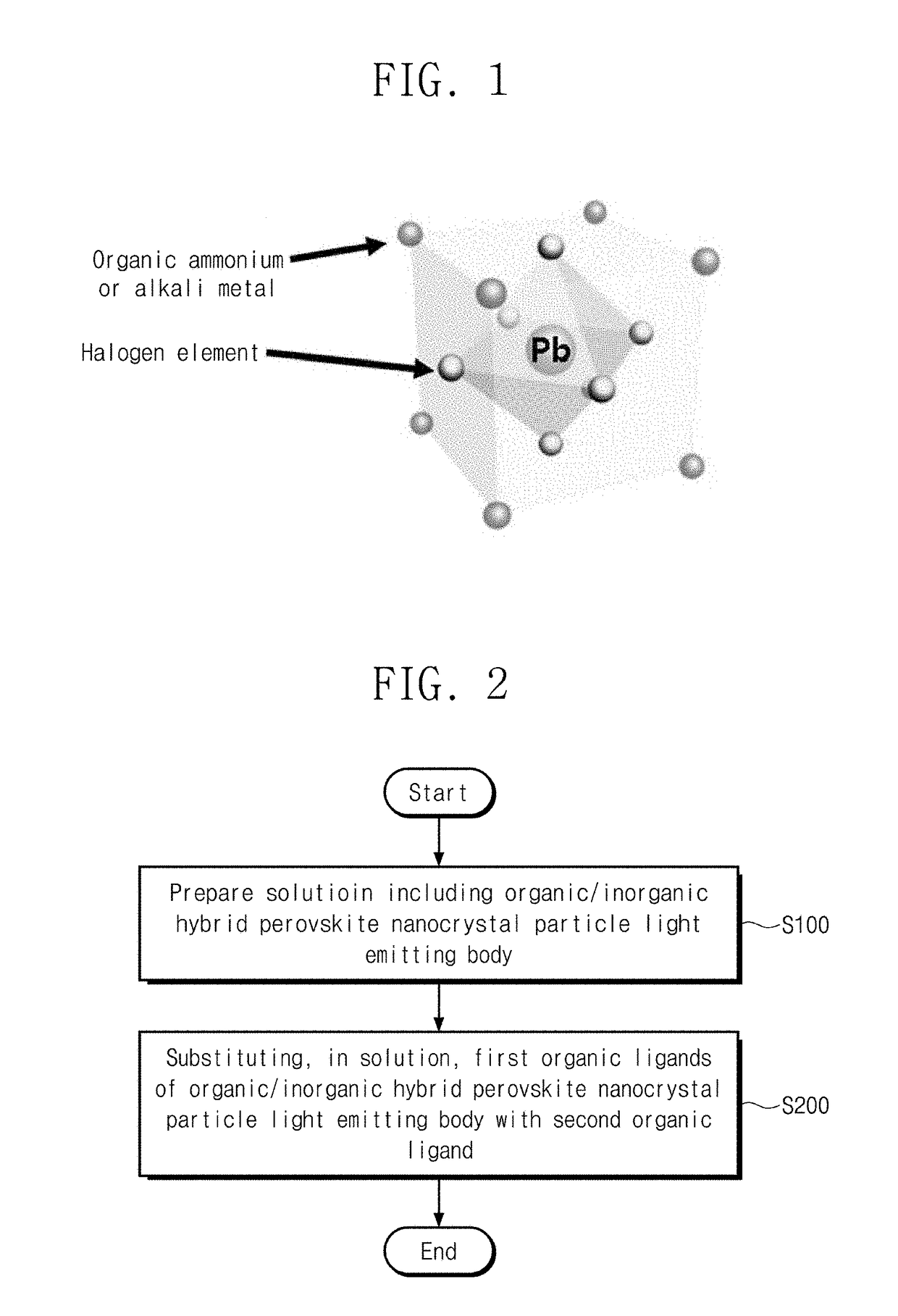

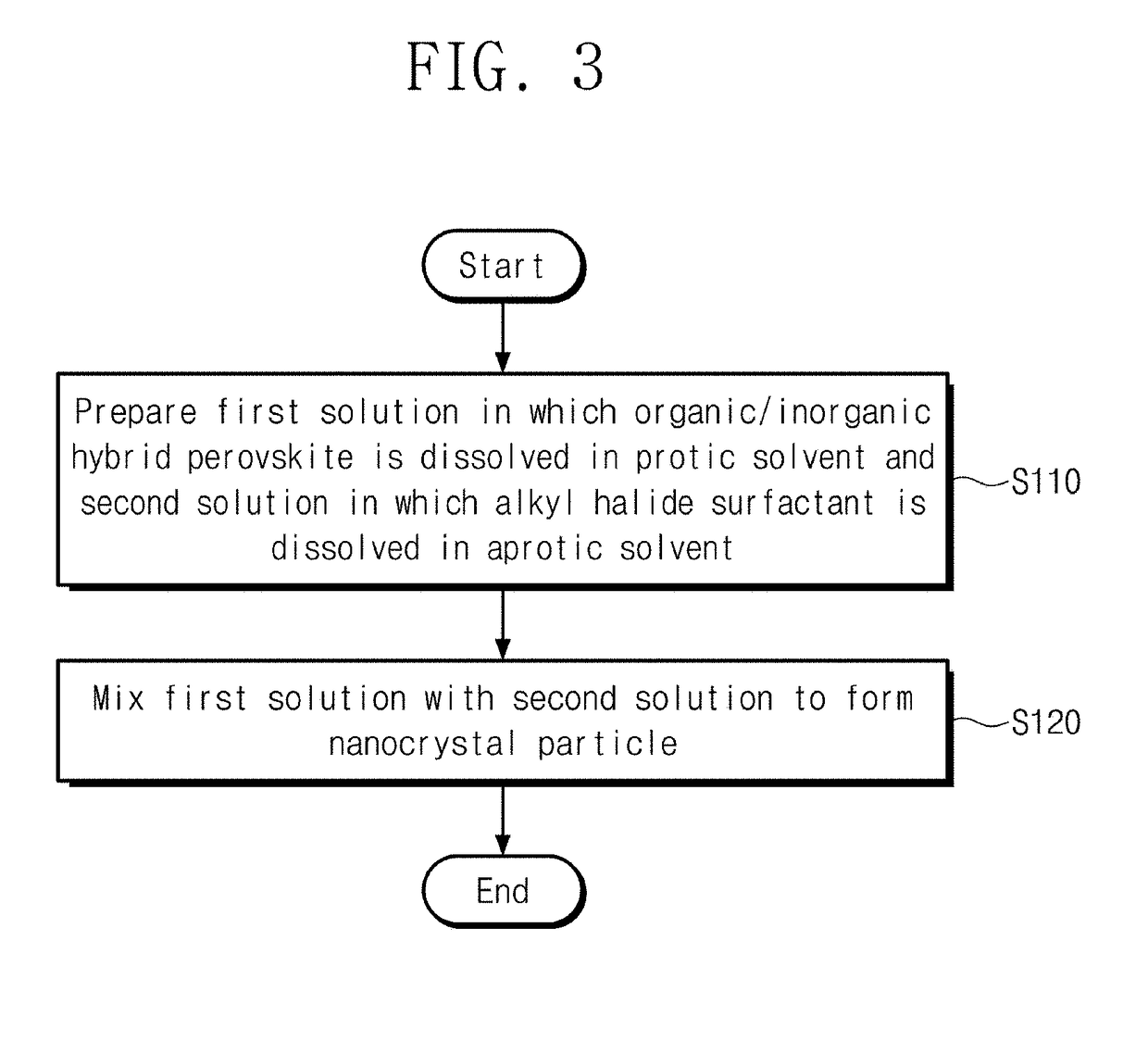

Method for manufacturing perovskite nanocrystal particle light emitting body where organic ligand is substituted, nanocrystal particle light emitting body manufactured thereby, and light emitting device using same

ActiveUS20170369772A1High color purityReduced Diffusion LengthLight-sensitive devicesSolid-state devicesPhenyl groupLight emitting device

Provided are a method for manufacturing a perovskite nanocrystal particle light-emitter where an organic ligand is substituted, a light-emitter manufactured thereby, and a light emitting device using the same. A method for manufacturing an organic-inorganic-hybrid perovskite nanocrystal particle light-emitter where an organic ligand is substituted may comprise the steps of: preparing a solution including an organic-inorganic-hybrid perovskite nanocrystal particle light-emitter, wherein the organic-inorganic-hybrid perovskite nanocrystal particle light-emitter comprises an organic-inorganic-hybrid perovskite nanocrystal structure and a plurality of first organic ligands surrounding the organic-inorganic-hybrid perovskite nanocrystal structure; and adding, to the solution, a second organic ligand which is shorter than the first organic ligands or includes a phenyl group or a fluorine group, thereby substitutes the first organic ligands with the second organic ligand. Thus, since energy transfer or charge injection into the nanocrystal structure increases through ligand substitution, it is possible to further increase light emitting efficiency and increase durability and stability by means of a hydrophobic ligand.

Owner:SN DISPLAY CO LTD

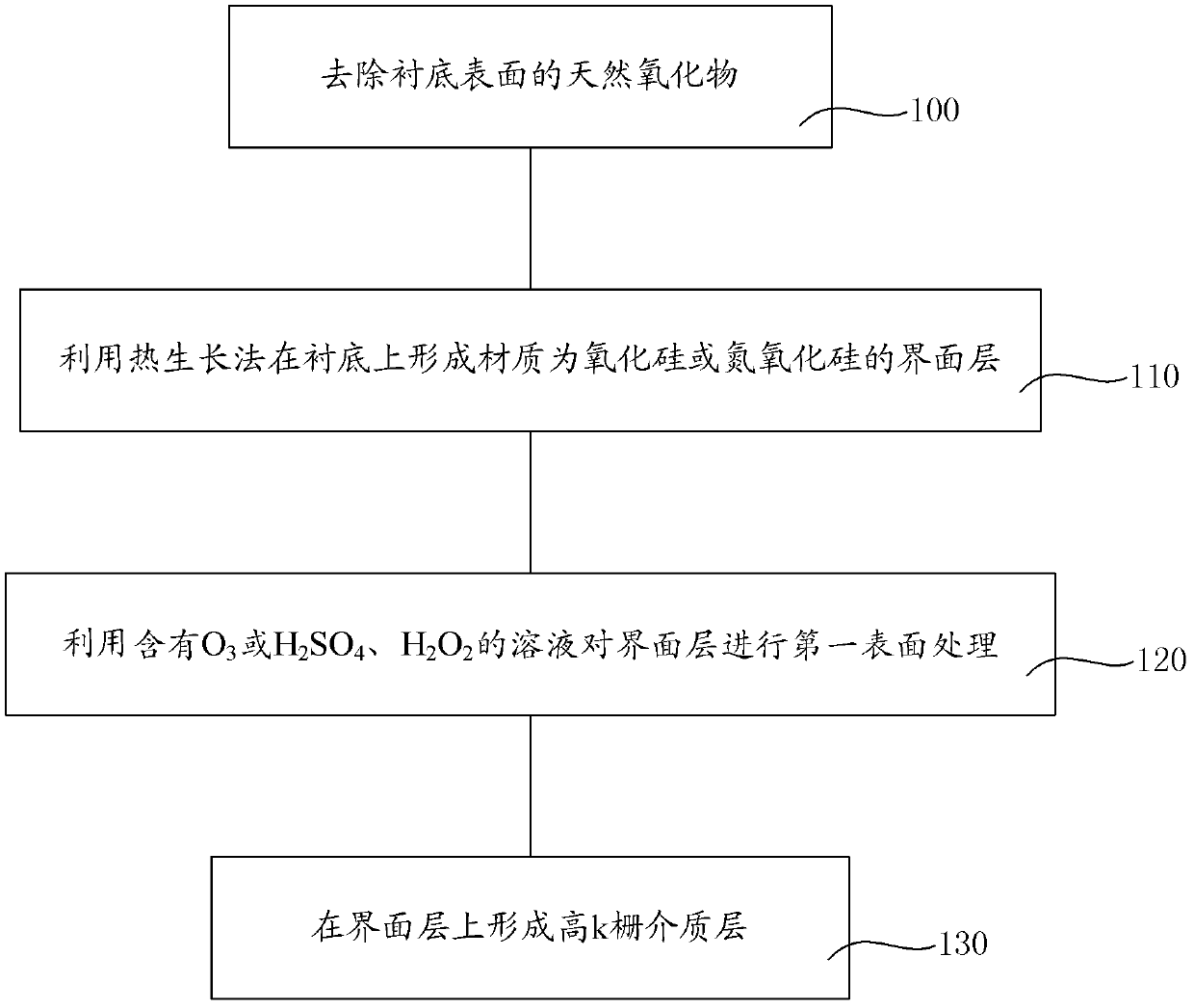

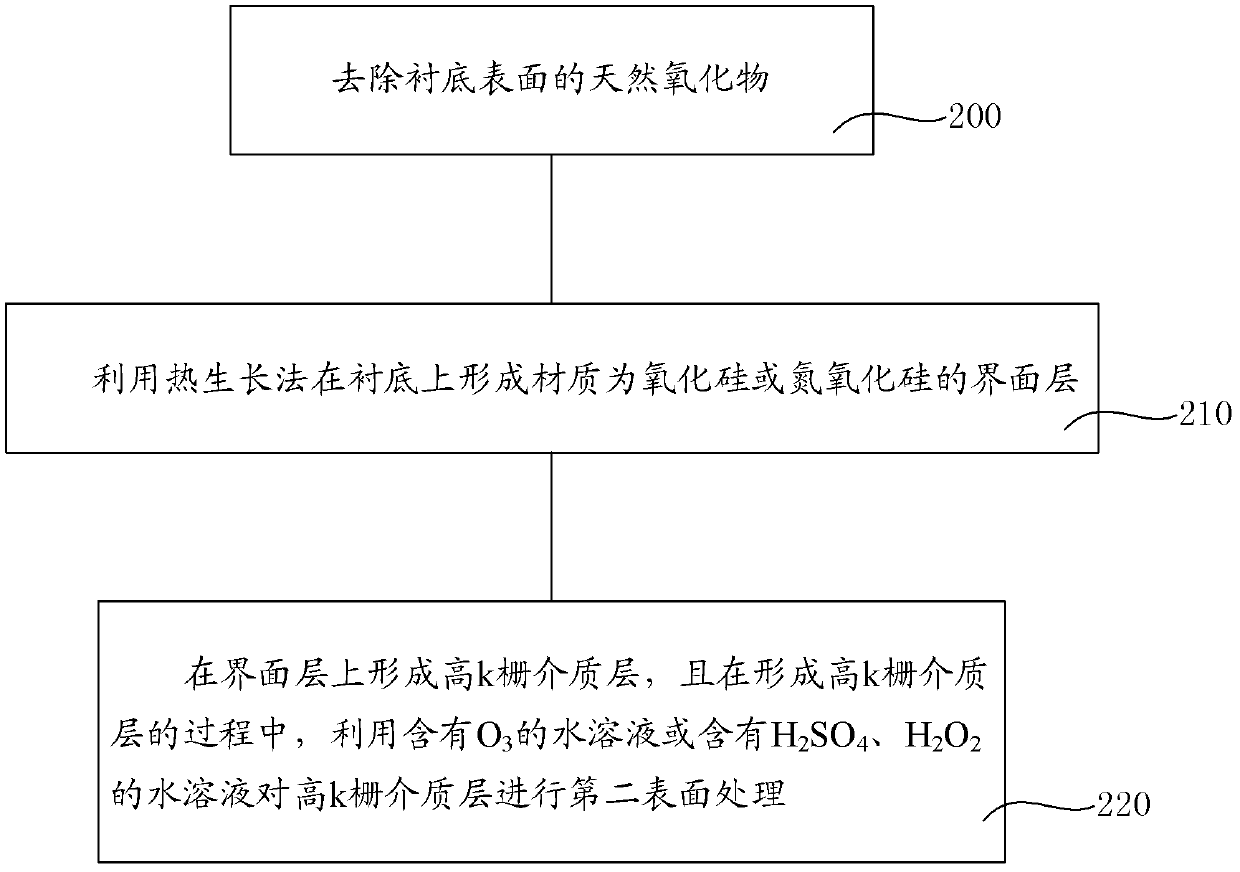

Manufacturing method for gate dielectric layer and manufacturing method for transistor

ActiveCN103295891AIncrease OH bondNucleation is easySemiconductor/solid-state device manufacturingGate dielectricInterface layer

The invention provides a manufacturing method for a gate dielectric layer and a manufacturing method for a transistor. The manufacturing method for the gate dielectric layer comprises the steps that an interface layer is formed on a substrate by the adoption of a thermal growth method; a high-k gate dielectric layer is formed on the interface layer; surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of aqueous solution containing O3 or H2SO4 and H2O2. According to the manufacturing method for the gate dielectric layer and the manufacturing method for the transistor, due to the facts that the best interface layer is formed by the adoption of the thermal growth method, and the surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of the aqueous solution containing O3 or H2SO4 and H2O2, a large number of OH keys which are suitable for improving the coverage rate of the high-k gate dielectric layer are formed on the surface of the interface layer or the high-k gate dielectric layer, the high-k gate dielectric layer can nucleate more easily on the interface layer, and interfacial characterization between the interface layer and the high-k gate dielectric layer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

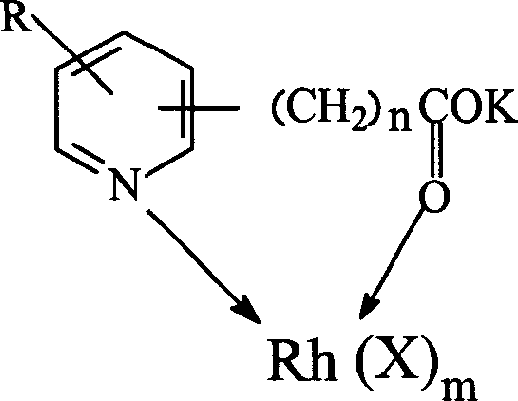

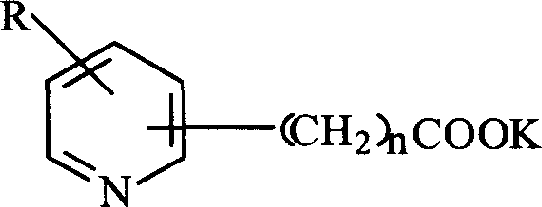

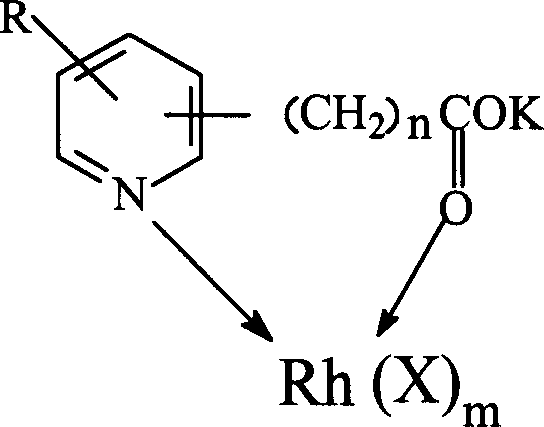

Catalytic system used for homogeneous hydroxylation reaction and its manufacturing method and application

InactiveCN1517150AIncrease binding energyBinding energy stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionPotassiumPotassium hydroxide

A homologeous catalyst system for the hydroxylation reaction of methanol to obtain acetic acid or the carbonylating reaction of methyl acetate to obtain ethylanhydride is composed of the primary catalyst (rhodium acetate (or nitrate) as coordination center and potassium), cocatalyst (iodomethane), additive (lithium iodide, potassium iodide, or lithium acetate), and polar solvent (acetic acid, ethylanhydride, methyl acetate, or water). Its preparing process includes dissolving picolinic acid and hydrated potassium in methanol or water to obtain organic potassium ligand, dissolving in water or methanol solution, and dripping rhodium solution.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nanometer organic carbon fertilizer and preparation method thereof

The invention discloses nanometer organic carbon fertilizer. The nanometer organic carbon fertilizer comprises, by mass, 10-30% of a nitrogen raw material, 8-30% of a phosphor raw material, 5-25% of a potassium raw material, 0.1-15% of a nanometer synergist, 1-15% of nanometer organic carbon and the balance accessory material. The accessory material is stone flour. The preparation method of the nanometer organic carbon fertilizer utilizes microwave digestion advantages to realize high efficiency treatment on organic waste water under the case of less acid use amount and production of the nanometer organic carbon as a fertilizer carbon source. The nanometer organic carbon can be easily absorbed by crops, and through combination with nitrogen, phosphor and potassium and the nanometer synergist, nitrogen, phosphor and potassium absorption and utilization are promoted and carbon, nitrogen, phosphor and potassium demands of plants are satisfied.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

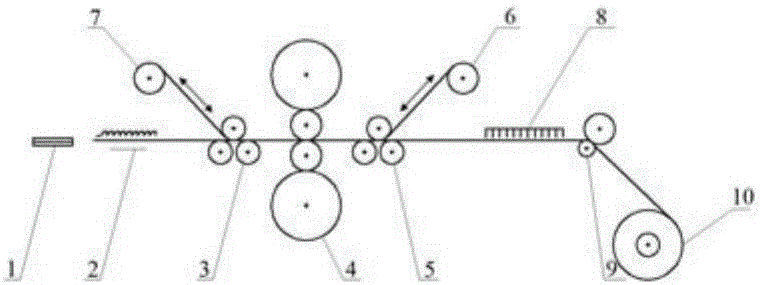

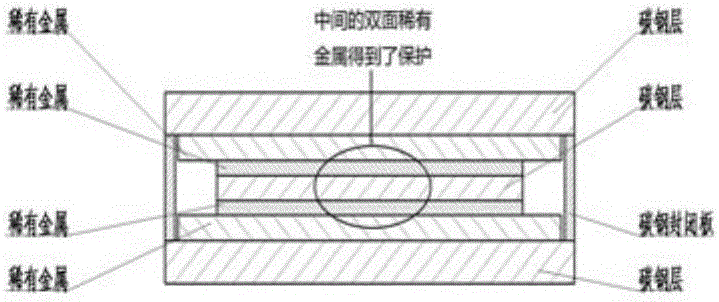

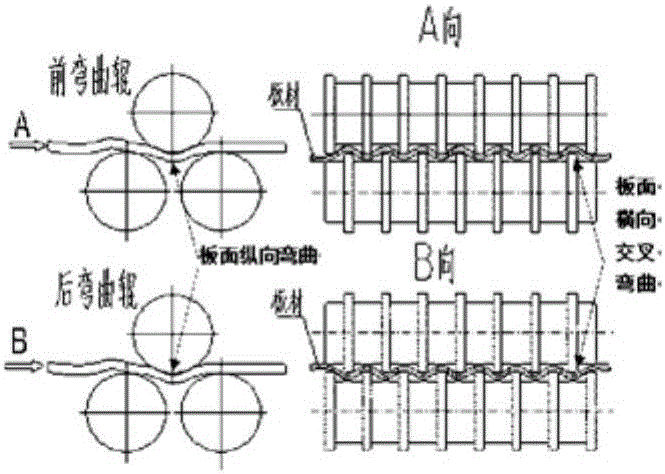

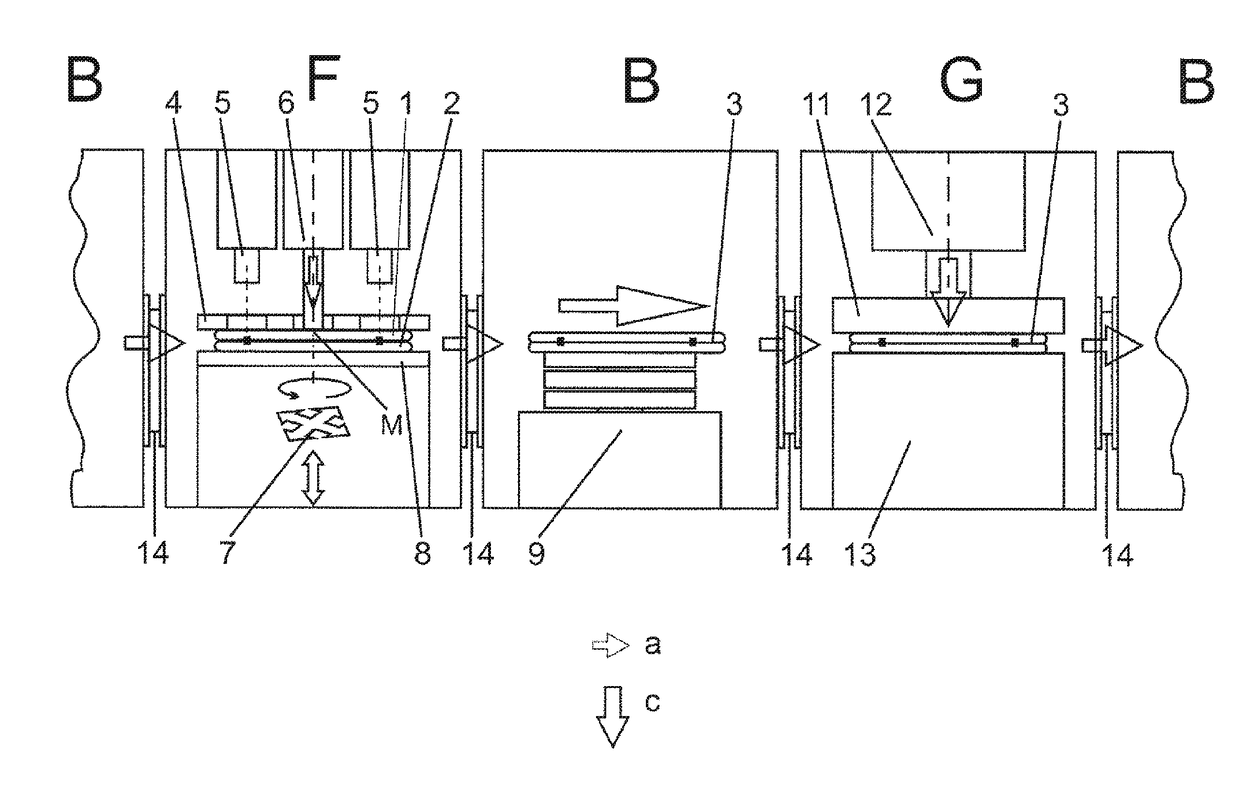

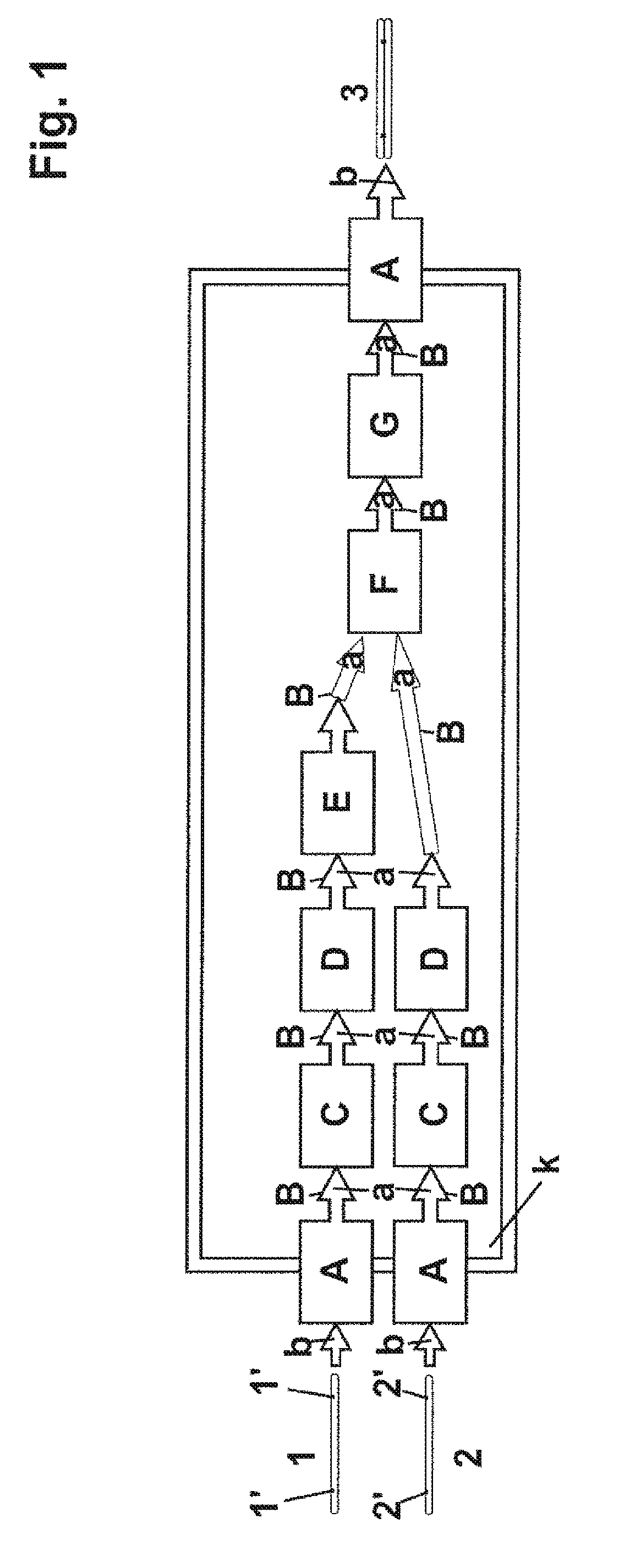

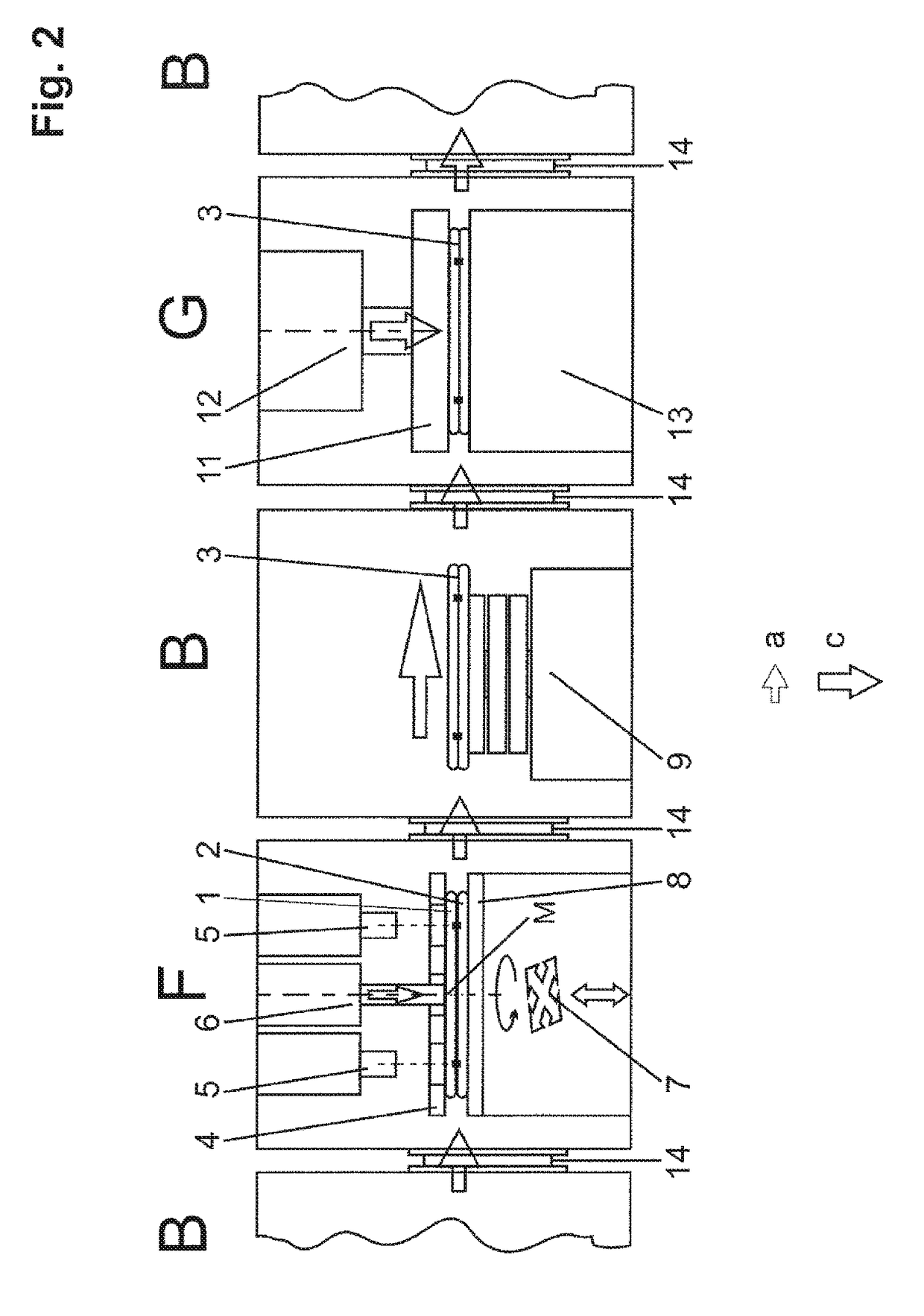

Multilayer metal coupling deformation rolling combined method and device

ActiveCN106001110AReduce the number of rolling millsLess investmentTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

The invention provides a multilayer metal coupling deformation rolling combined method and device. The device comprises a compound blank heating furnace, a high-pressure water descaling machine, a four-roller reversible rolling mill, a front reeling holding furnace, a rear reeling holding furnace, a front board criss cross bending deformation unit, a rear board criss cross bending deformation unit, a laminar cooling unit and a finished product reeling machine. According to the method, the reeling heating furnaces are equipped in front of and in rear of the single-frame four-roller reversible rolling mill, and the tension bending units are arranged between the front reeling furnace and the rear reeling furnace, the tension bending rollers are flower rollers of which the surfaces are of a convex and concave structure, three flower rollers form a reverse bending deformation unit, and a convex-concave structure of a front roller surface and a convex-concave structure of a rear roller surface are arranged in a staggered mode, so that a temperature controlling reeling coupling deformation rolling combined mechanism used for applying tension and achieving board criss cross bending deformation is formed, residual stress of a compound interface is remarkably reduced, and board shape quality is ensured; and meanwhile, the bonding strength and binding rate of the compound interfaces are greatly improved, the structure performance and comprehensive mechanical performance of composite boards are improved, and the production efficiency and yield are remarkably improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

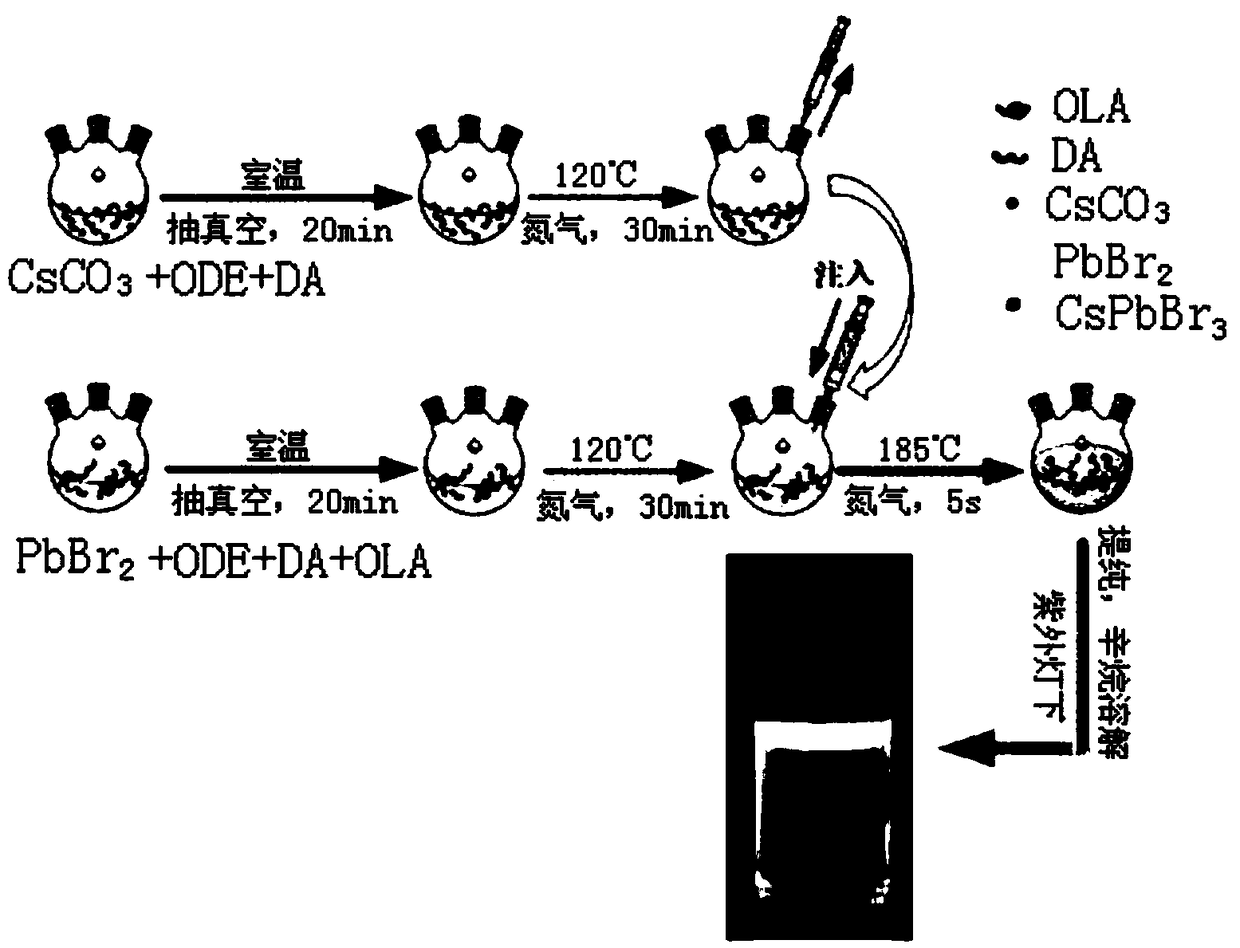

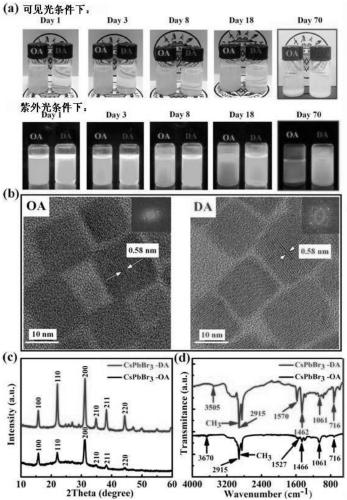

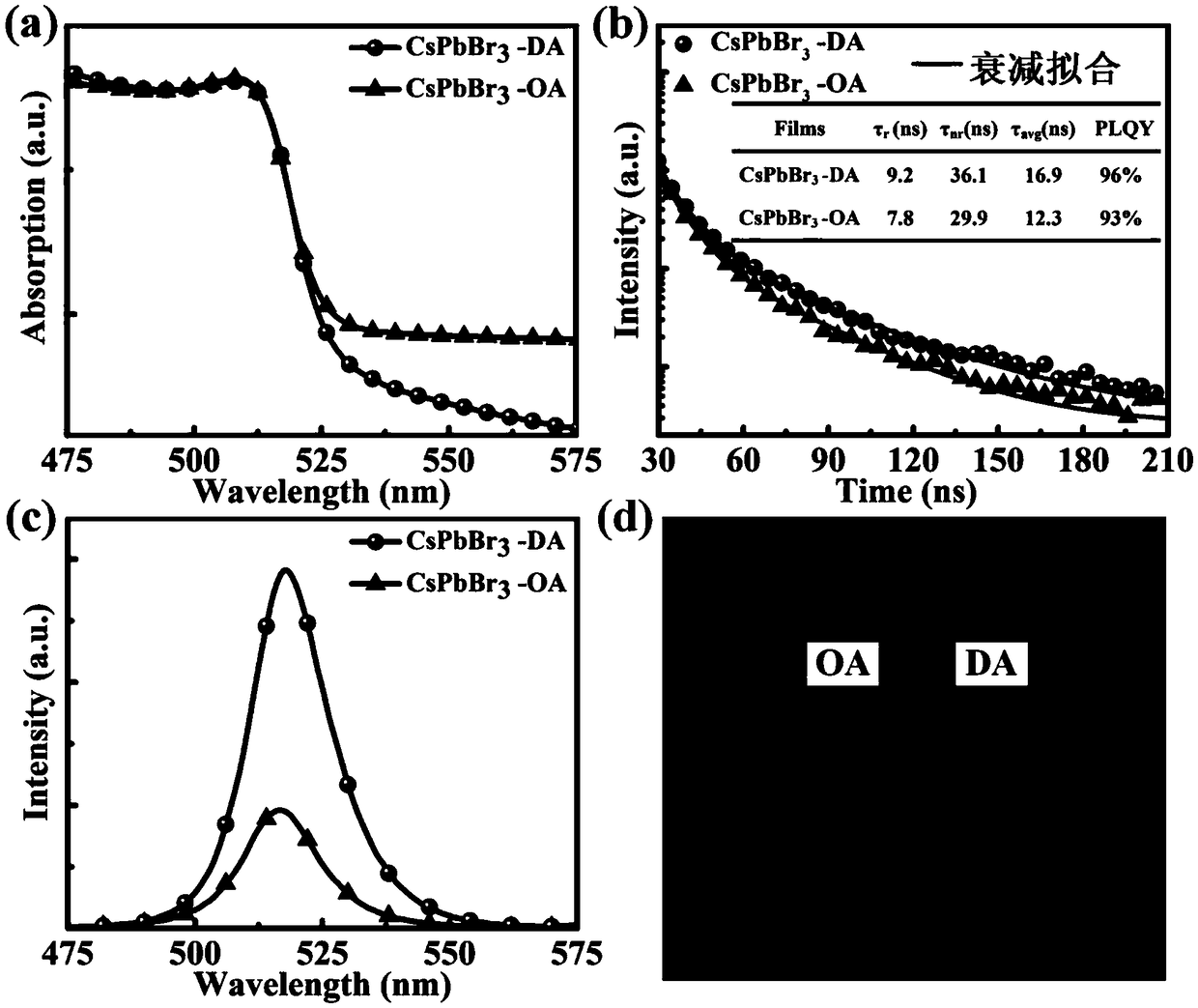

Preparation method of 2-hexyldecanoic acid modified all-inorganic perovskite quantum dot material

ActiveCN109279648AImprove stabilityImprove dispersibility and stabilityNanotechnologyLead compoundsBinding energyQuantum dot

The invention discloses a preparation method of a 2-hexyldecanoic acid modified all-inorganic perovskite quantum dot material. The 2-hexyldecanoic acid modified calcium-titanium quantum dot material with high stability, good dispersity and excellent optical properties is prepared by the following steps: modifying a perovskite quantum dot material through 2-hexyldecanoic acid, preparing a cesium 2-hexyldecanoate precursor solution, preparing a lead halide precursor solution, preparing a reaction stock solution of the perovskite quantum dot material, and purifying the 2-hexyldecanoic acid modified perovskite quantum dot material. According to the invention, binding energy between branched chains and the perovskite quantum dot material is improved by utilizing shorter branched chains in the 2-hexyldecanoic acid, so that dispersity and stability of the perovskite quantum dot material are improved. Meanwhile, the shorter branched chains in the 2-hexyldecanoic acid are also beneficial to recombination of electrons and holes in the perovskite quantum dot material, and stability and optical characteristics of the perovskite quantum dot material are further improved.

Owner:北京京通光能科技有限公司

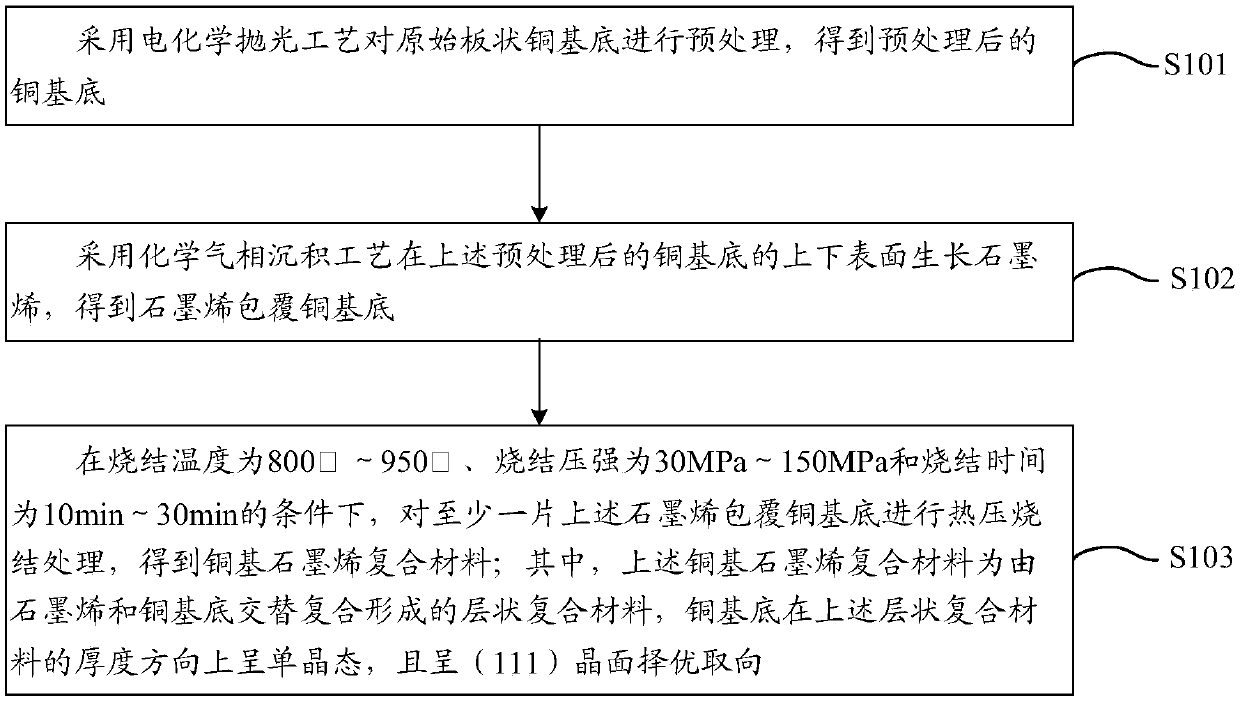

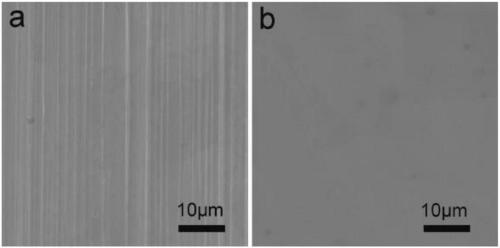

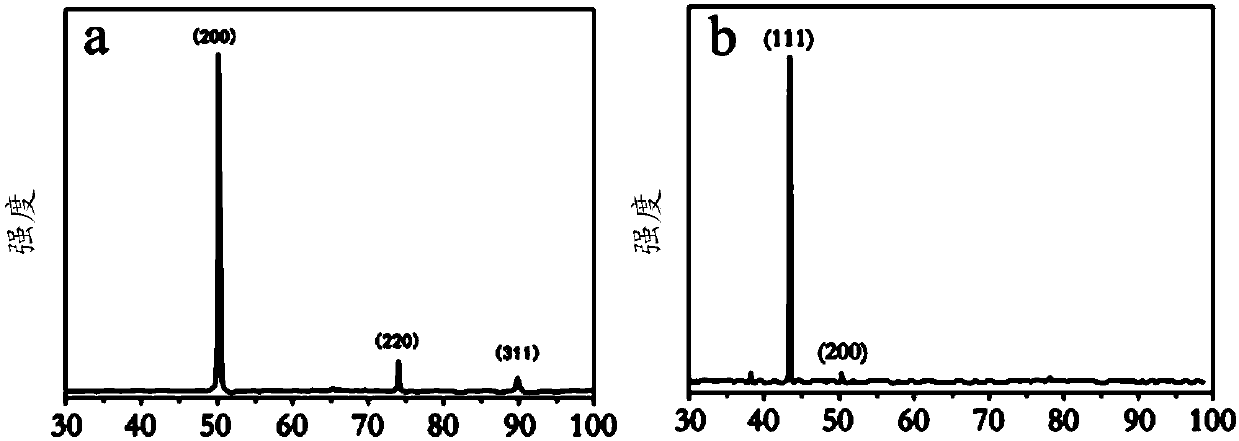

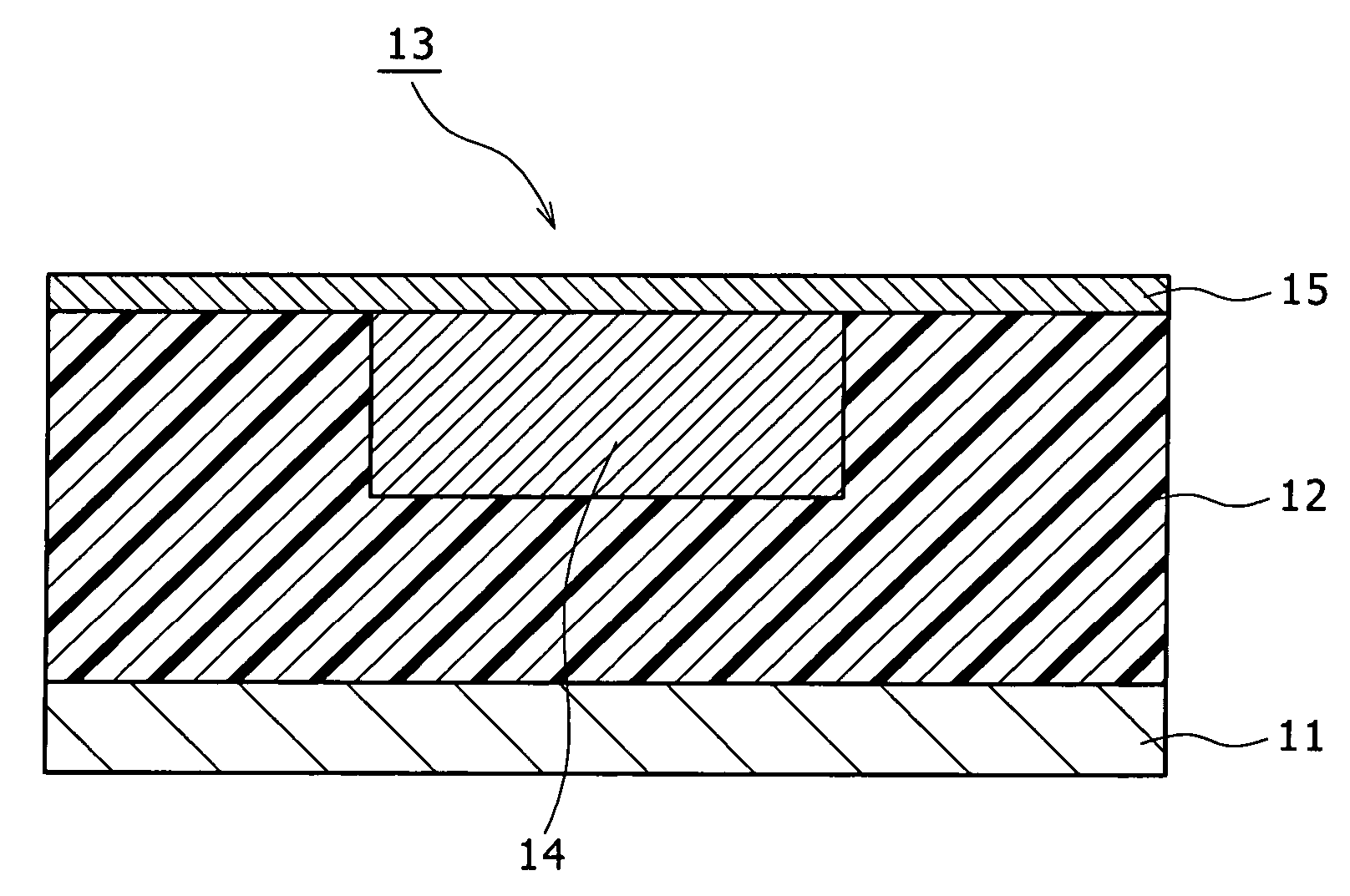

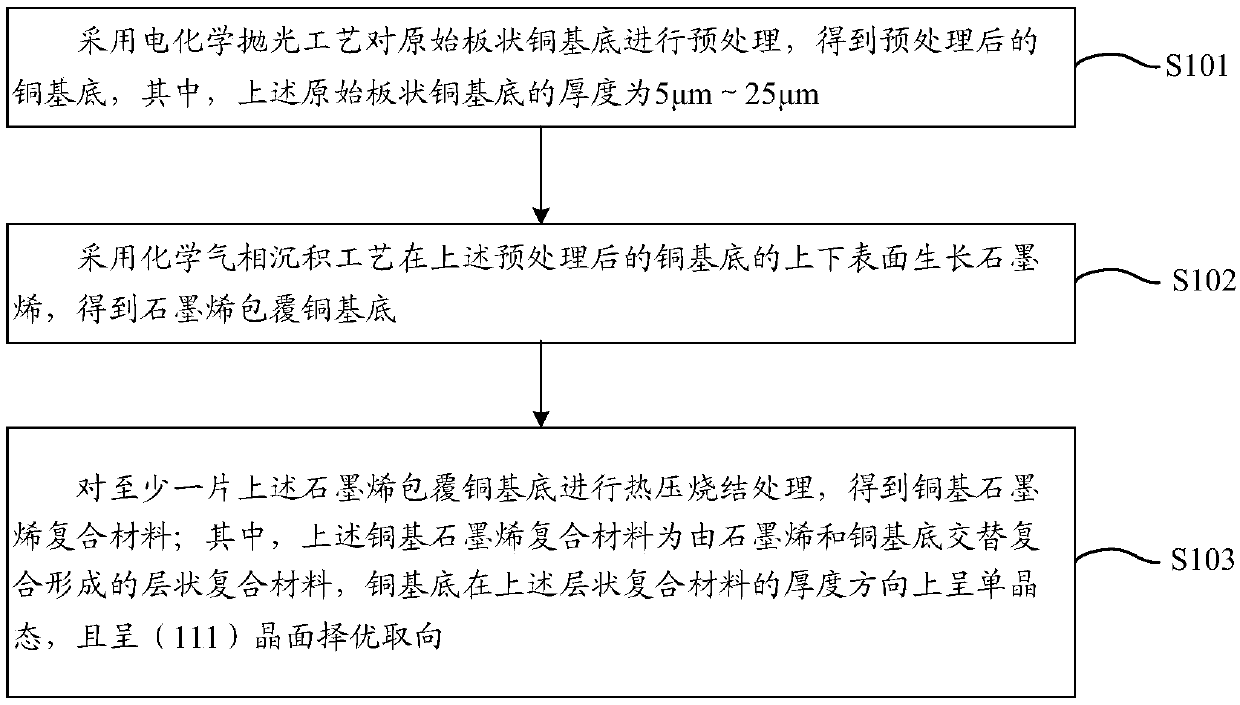

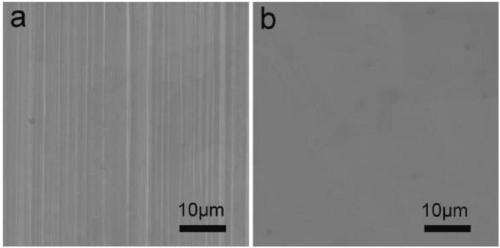

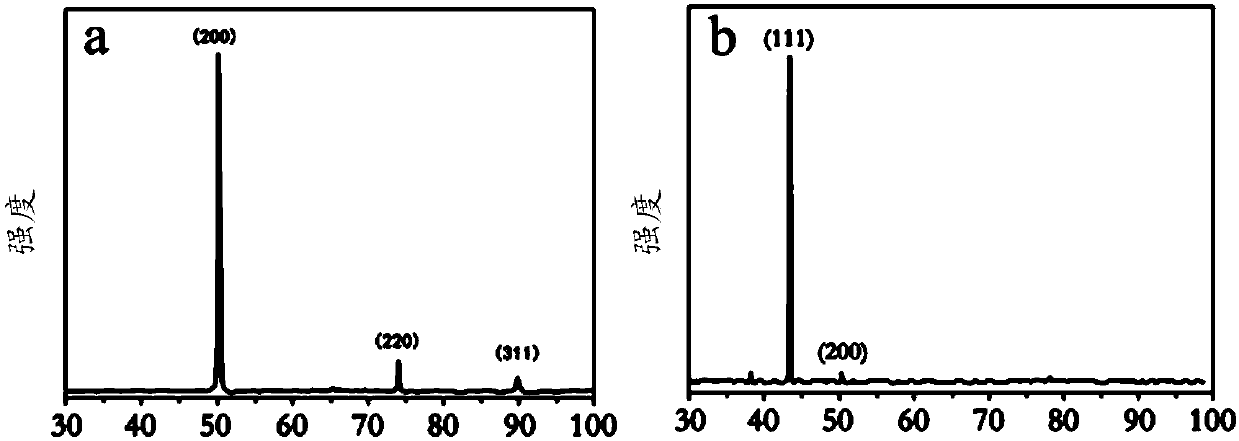

Preparation method of copper-based graphene composite material and copper-based graphene composite material

InactiveCN110079784AImprove conductivityLarge grainChemical vapor deposition coatingGas phaseCrystal plane

The invention provides a preparation method of a copper-based graphene composite material. The preparation method comprises the following steps that an original plate-shaped copper substrate is pretreated by adopting an electrochemical polishing process to obtain a pretreated copper substrate; graphene is grown on the upper and lower surfaces of the pretreated copper substrate by adopting a chemical vapor deposition process to obtain a graphene-coated copper substrate; and under the condition that the sintering temperature is 800-950 DEG C, the sintering pressure is 30-150 MPa and the sintering time is 10-30 min, hot-pressing sintering treatment is carried out on at least one piece of graphene-coated copper substrate to obtain the copper-based graphene composite material, wherein the copper substrate is in a single crystal state in the thickness direction of the copper-based graphene composite material and has a preferred orientation of (111) crystal plane. The preparation method of the copper-based graphene composite material can be used for preparing the copper-based graphene composite material with relatively high electrical conductivity.

Owner:CRRC IND INST CO LTD

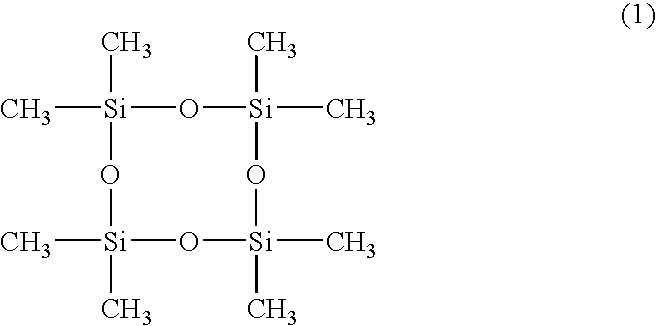

Method of fabricating a semiconductor device using plasma to form an insulating film

InactiveUS7579286B2High film strengthDeterioration of a wiring line characteristic can be preventedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasSilanes

A fabrication method of a semiconductor device is disclosed by which damage to another film or exfoliation of a film is prevented and an insulating film having a dielectric constant of 2.5 or less can be formed while a film strength is maintained without deteriorating a wiring line characteristic. According to an embodiment, an insulating film is formed on a substrate by a plasma process, which uses film-forming gas having a ring structure of Si—O bonds, such that it maintains the ring structure of the Si—O bonds. According to another embodiment, an insulating film is formed on a substrate by a plasma process, which uses film-forming gas which contains silane-containing gas and oxygen gas or film-forming gas which contains Si—O bond-containing gas, such that it has a ring structure of the Si—O bonds.

Owner:SONY CORP

Cold rolling work roller used for non-ferrous metal calendaring and preparing method of cold rolling work roller

ActiveCN106756620AGood thermal conductivityEven heat distributionFurnace typesQuenching agentsHeat distributionNon-ferrous metal

The invention discloses a cold rolling work roller used for non-ferrous metal calendaring and a preparing method of the cold rolling work roller and belongs to the field of cold rolling roller materials. The cold rolling roller comprises, by weight percent, 1.65%-1.92% of C, 0.32%-0.40% of Si, 1.25%-1.60% of Mn, 4.6%-6.5% of Cr, 1.55%-2.40% of Ni, 0.5%-1.0% of Mo, 4.30%-5.4% of W, 1.40%-1.65% of V, 0.3%-0.45% of Zr, 0.40%-0.65% of Ag, 0.20%-0.35% of Zn, smaller than or equal to 0.04% of S, smaller than or equal to 0.03% of P and the balance Fe. A preparing method of the cold rolling work roller comprises the steps that annealing treatment is conducted on a forging blank firstly, then rough turning is conducted, then semifinishing is conducted after quenching and tempering treatment, then tempering is conducted again after heat treatment, and finally the roller is obtained through finish grinding. The roller has high strength and high wear resistance, meanwhile, the roller has good heat conductivity and heat dissipation, heat distribution of the roller is even in the rolling process, local overheat is effectively avoided, the probability of metal calendaring material sticking can be lowered, the service life of the roller is prolonged, and the quality of rolled products is improved.

Owner:马鞍山市恒强合金科技股份有限公司

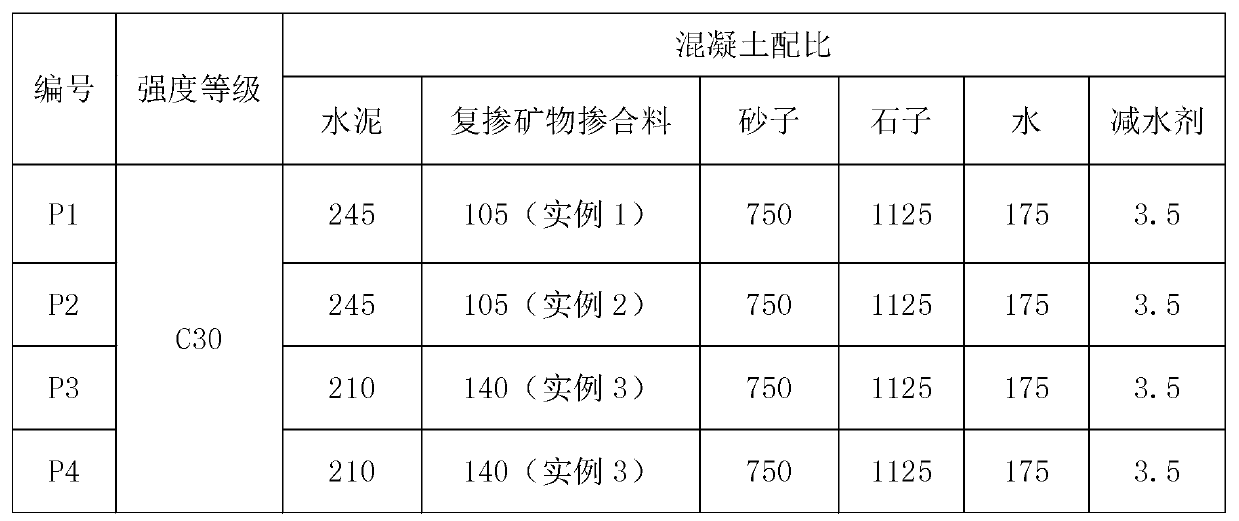

Compound-doped mineral admixture for reinforced concrete structure of oceanographic engineering

The invention relates to the field of concrete additives for oceanographic engineering, and aims at providing a compound-doped mineral admixture for a reinforced concrete structure of the oceanographic engineering. The compound-doped mineral admixture comprises the following components in percentage by mass: 20 to 35% of coal ash, 5 to 10% of zeolite, 20 to 40% of slag, 5 to 15% of silica fume, 5 to 15% of corrosion inhibitor, 2 to 5% of dispersing agent, 0 to 10% of shrinkage reducing agent, and 0 to 16% of antimitotic agent. According to the compound-doped mineral admixture, multi-component design is adopted, the functions of all the components are combined and coordinated, and thus the crack resistance and rust resistance of the structure are optimized, and the wear resistance of the oceanographic engineering can be improved; and a plurality of functional components are compounded into the admixture, so that the functional components can be uniformly dispersed in the concrete, and the effects of stably resisting crack and resisting rust can be realized. The compound-doped mineral admixture can reduce the concrete agitating conditions and reduce the usage cost of an enterprise, and is convenient for massive popularization and application.

Owner:浙江合力海科新材料股份有限公司

Preparation method of copper-based graphene composite material and copper-based graphene composite material

InactiveCN110079785AImprove conductivityLarge grainChemical vapor deposition coatingSuperimposed coating processGas phaseCrystal orientation

The invention provides a preparation method of a copper-based graphene composite material. The preparation method of the copper-based graphene composite material comprises the following steps: pretreating an original plate-shaped copper base by an electrochemical polishing process to obtain a pretreated copper base, wherein the thickness of the original plate-shaped copper base is 5 to 25 microns;growing graphene on the upper surface and the lower surface of the pretreated copper base by a chemical vapor deposition process to obtain graphene coated copper bases; and performing hot pressed sintering treatment on at least one graphene coated copper base to obtain the copper-based graphene composite material, wherein the copper-based graphene composite material is a layered composite material formed by alternately compounding graphene and the copper base, and the copper base is in a single crystalline state in the thickness direction of the copper-based graphene composite material and takes on predominant crystal orientation (111). By the preparation method of the copper-based graphene composite material provided by the invention, the copper-based graphene composite material with high conductivity can be prepared.

Owner:CRRC IND INST CO LTD

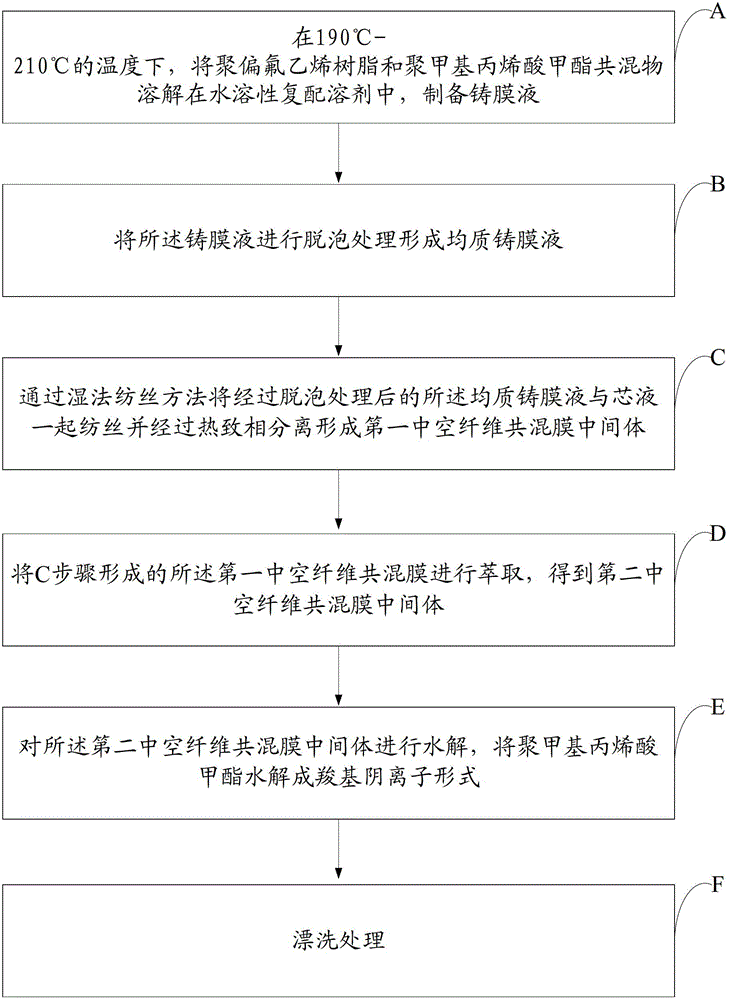

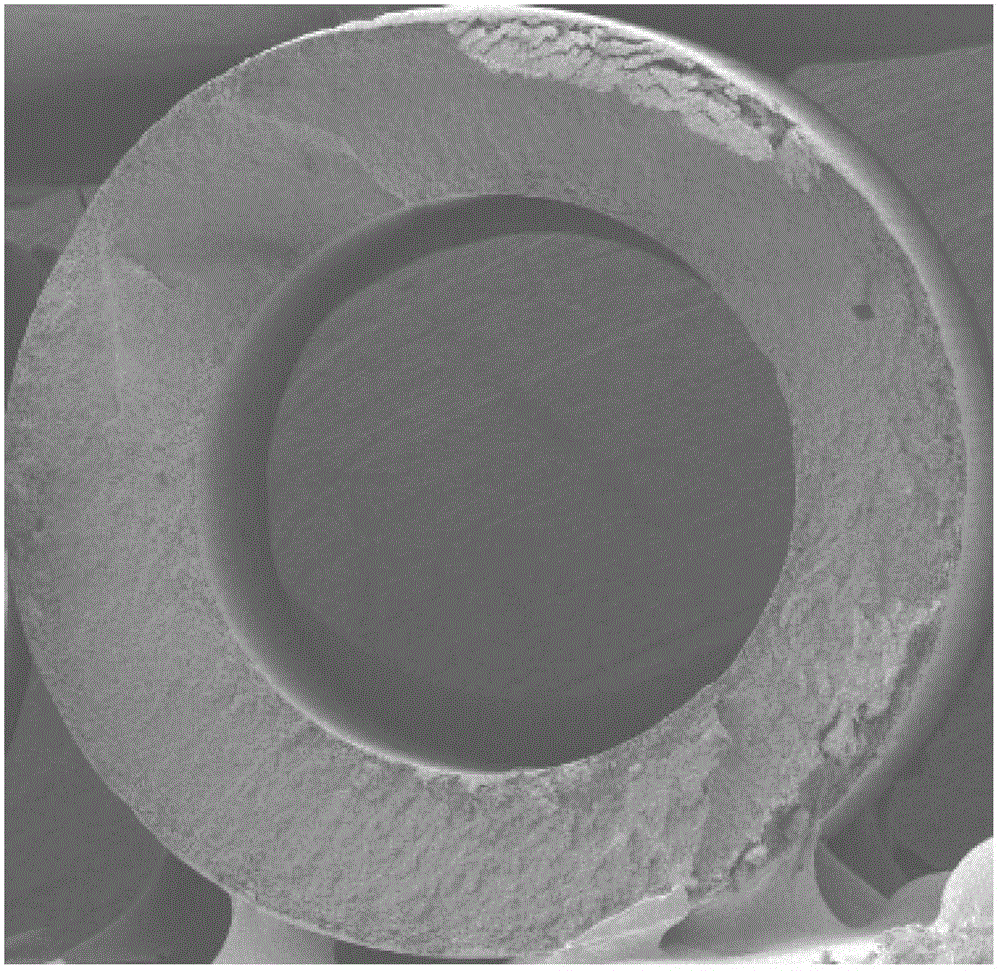

Hollow fiber blend membrane and method for manufacturing same

ActiveCN102872731AImprove propertiesHigh selectivitySemi-permeable membranesSolventPolyvinylidene fluoride

The invention relates to a hollow fiber blend membrane and a method for manufacturing the same. The hollow fiber blend membrane comprises polyvinylidene fluoride resin and polymethyl methacrylate, and the polymethyl methacrylate is in a carboxyl anion form in the hollow fiber blend membrane. The method for manufacturing the hollow fiber blend membrane includes A, dissolving blends of the polyvinylidene fluoride resin and the polymethyl methacrylate in water-soluble compound solvents at the temperature ranging from 190 DEG C to 210 DEG C to prepare cast film liquid; B, defoaming the cast film liquid to form homogenous cast film liquid; C, spinning the homogenous cast film liquid obtained after defoaming and core liquid and performing thermally induced phase separation for the homogenous cast film liquid and the core liquid to form a first hollow fiber blend membrane intermediate; D, extracting the first hollow fiber blend membrane intermediate formed in the step C to obtain a second hollow fiber blend membrane intermediate; and E, hydrolyzing the second hollow fiber blend membrane intermediate and hydropyzing the polymethyl methacrylate into the carboxyl anion form. The hollow fiber blend membrane and the method have the advantage that the hydrophilicity of the membrane can be improved.

Owner:宁波博乐宝科技有限公司 +1

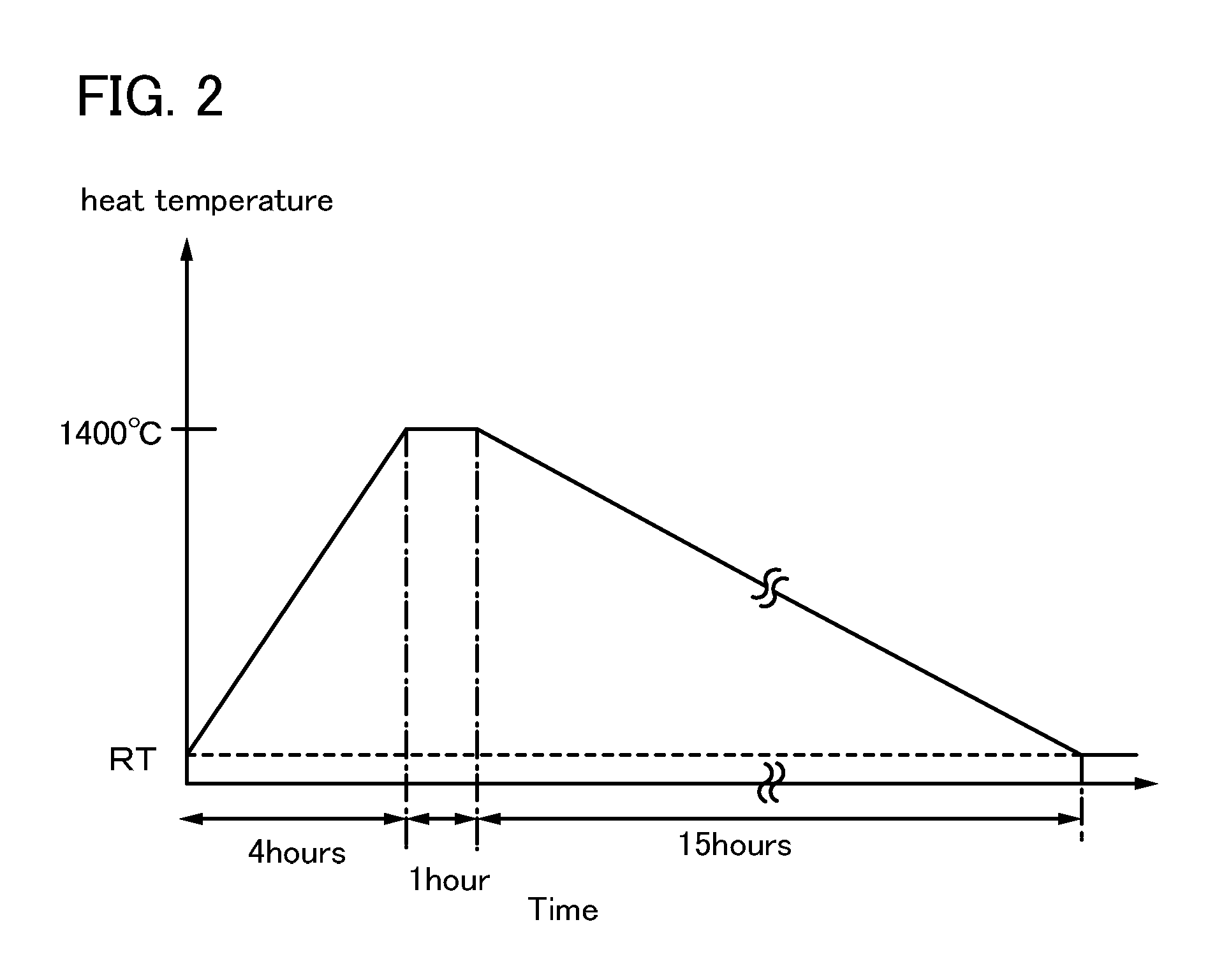

Manufacturing method of gallium oxide single crystal

InactiveUS20110220011A1Increase manufacturing costLow costFrom gel statePolycrystalline material growthBinding energySingle crystal

A method of growing a single crystal of gallium oxide at a lower temperature than the melting point (1900° C.) of gallium oxide is provided. A compound film (hereinafter referred to as “gallium oxide compound film”) containing Ga atoms, O atoms, and atoms or molecules that easily sublimate, is heated to sublimate the atoms or molecules that easily sublimate from inside the gallium oxide compound film, thereby growing a single crystal of gallium oxide with a heat energy that is lower than a binding energy of gallium oxide.

Owner:SEMICON ENERGY LAB CO LTD

Method for recycling zirconium-based amorphous alloy waste

ActiveCN102061430AIncrease binding energyInhibition of low temperature phase transitionShielding gasAlloy

The invention provides a method for recycling zirconium-based amorphous alloy waste, which comprises the steps of mixing the zirconium-based amorphous alloy waste with an additive, fusing the mixture under vacuum, filtering fusant, pouring and cooling in the presence of a protective gas, wherein the additive is the mixture of Zr and Y2O3. When the zirconium-based amorphous alloy waste is treated by the method for recycling zirconium-based amorphous alloy waste provided by the invention, the oxygen content and bending strength of the obtained zirconium-based amorphous alloy are very close to those of the conventional zirconium-based amorphous alloy, and the impact toughness of the obtained zirconium-based amorphous alloy is even higher than the conventional zirconium-based amorphous alloy.

Owner:BYD CO LTD

Method and device for prefixing of substrates

ActiveUS20170345690A1Improve adhesionIncrease binding energySemiconductor/solid-state device manufacturingNon-electric welding apparatusEngineeringBiomedical engineering

A method and a device for prefixing substrates, whereby at least one substrate surface of the substrates is amorphized in at least one surface area, characterized in that the substrates are aligned and then make contact and are prefixed on the amorphized surface areas.

Owner:EV GRP E THALLNER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com