Preparation method of 2-hexyldecanoic acid modified all-inorganic perovskite quantum dot material

A technology of quantum dot material and base decanoic acid, applied in inorganic chemistry, chemical instruments and methods, lead compounds, etc., can solve the problems affecting the luminescence stability, poor stability, and agglomeration of quantum dots, and achieve improved stability. and its optical properties, the effect of improving dispersion and stability, and increasing composite properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

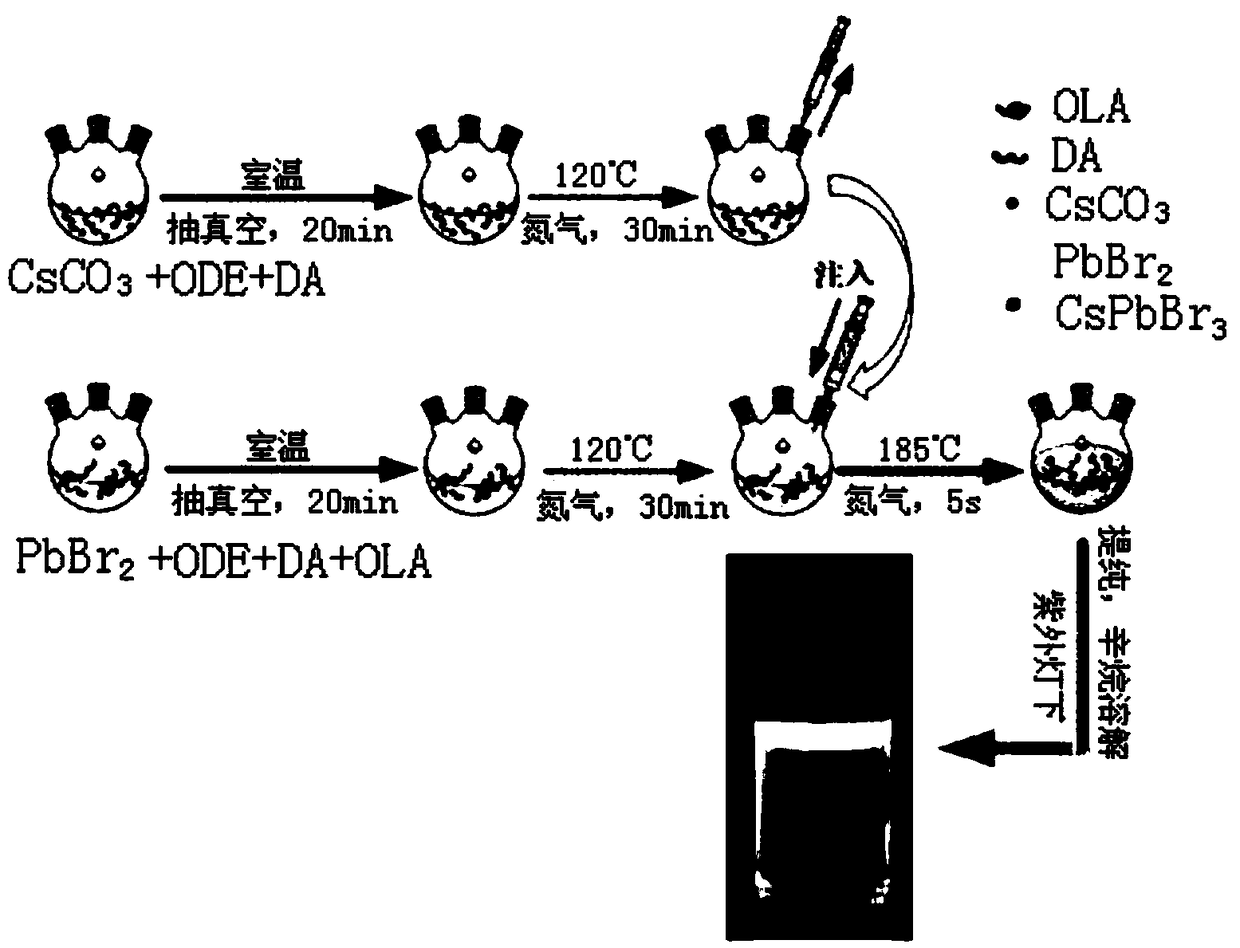

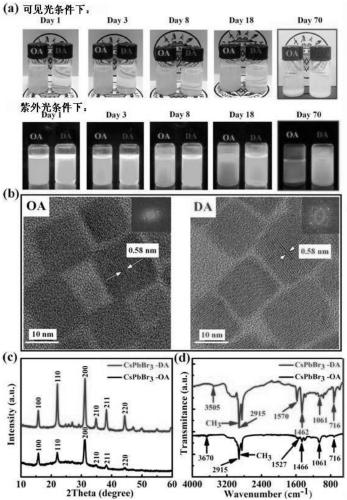

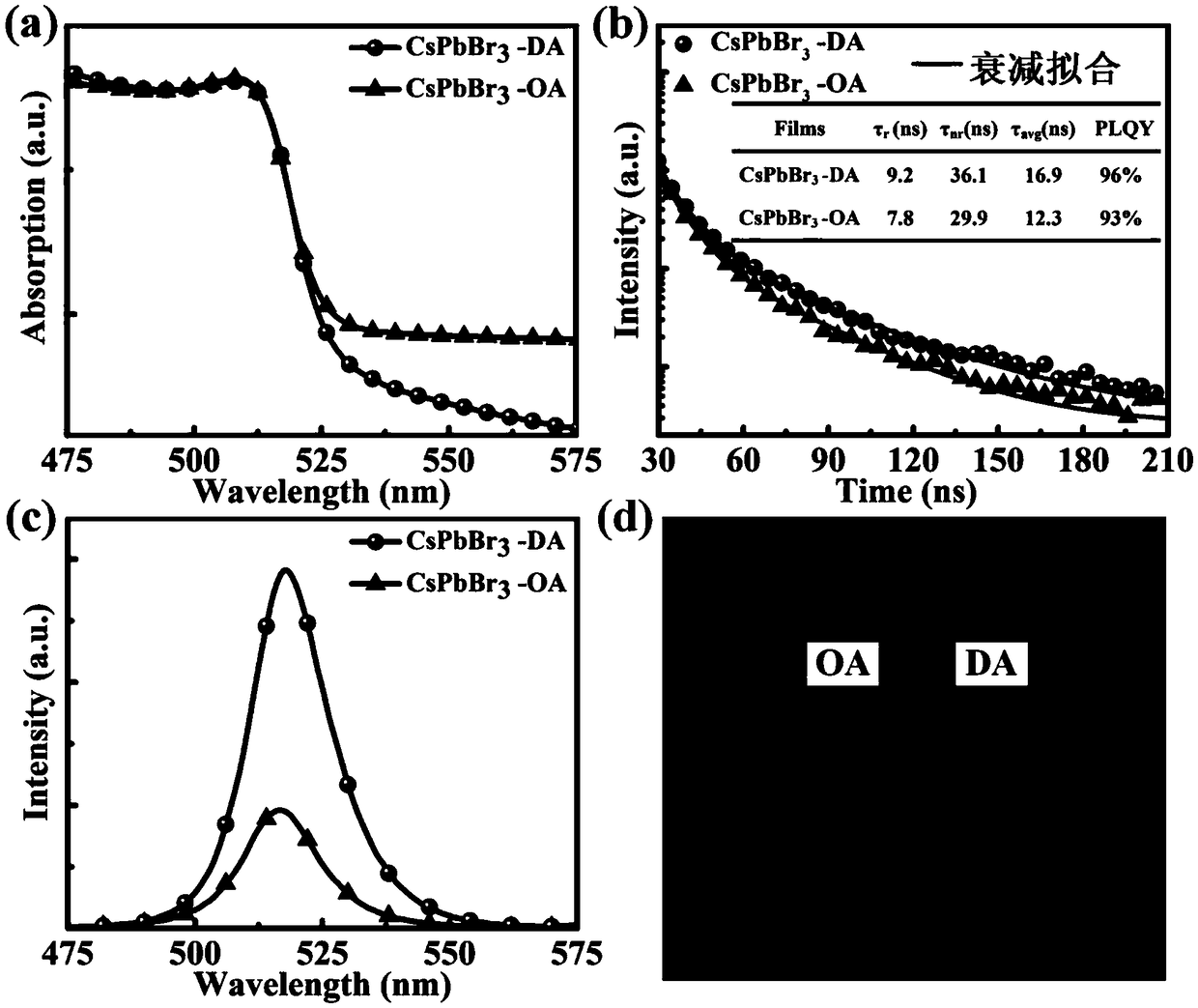

[0027] (1) Preparation of 2-hexyldecanoic acid cesium precursor solution: add 0.5mmol of cesium hydroxide CsOH, 4mL of octadecene (ODE) and 0.5mL of 2-hexyldecanoic acid (DA) into a 100mL three-necked flask, The three-necked flask was evacuated and placed on a heating mantle magnetic stirrer for magnetic stirring. After stirring for 20 minutes, it was heated to 120°C for reaction until cesium hydroxide was completely dissolved into 2-hexyl cesium decanoate precursor solution for later use. The whole reaction Vacuum state is kept in the process three-necked flask and magnetic stirring is continuously carried out;

[0028] (2) Preparation of lead chloride precursor solution: the lead chloride PbCl of 0.188mmol 2 , 5mL of octadecene (ODE), 0.5mL of 2-hexyldecanoic acid (DA) and 0.5mL of oleylamine (OLA) were added to an empty 100mL three-necked flask, and the three-necked flask was evacuated to vacuum. Magnetic stirring was carried out on the heating mantle magnetic stirrer. Aft...

Embodiment 2

[0032] (1) Preparation of 2-hexyldecanoate cesium precursor solution: 0.25 mmol of cesium carbonate Cs 2 CO 3 , 4 mL of octadecene (ODE) and 0.5 mL of 2-hexyldecanoic acid (DA) were added to a 100 mL three-necked flask, and the three-necked flask was evacuated to a vacuum and placed on a heating mantle magnetic stirrer for magnetic stirring, and stirred for 20 min Then start heating to 120°C for reaction until cesium carbonate is completely dissolved into 2-hexyl cesium decanoate precursor solution for future use, and the vacuum state is kept in the three-necked flask during the whole reaction process and magnetic stirring is continued;

[0033] (2) Preparation of lead bromide precursor solution: the lead chloride PbBr of 0.188mmol 2 , 5mL of octadecene (ODE), 0.5mL of 2-hexyldecanoic acid (DA) and 0.5mL of oleylamine (OLA) were added to an empty 100mL three-necked flask, and the three-necked flask was evacuated to vacuum. Magnetic stirring was carried out on the heating man...

Embodiment 3

[0037] (1) Preparation of 2-hexyldecanoic cesium precursor solution: 0.5 mmol of cesium acetate CH 3 Add COOCs, 4mL of octadecene (ODE) and 0.5mL of 2-hexyldecanoic acid (DA) into a 100mL three-necked flask, evacuate the three-necked flask to a vacuum and place it on a heating mantle magnetic stirrer for magnetic stirring, stirring After 20 minutes, start heating to 120°C for reaction until cesium acetate is completely dissolved into 2-hexyl cesium decanoate precursor for later use. During the whole reaction process, the three-necked flask is kept in a vacuum state and continues to be magnetically stirred;

[0038] (2) Preparation of lead iodide precursor solution: the lead iodide PbI of 0.18mmol 2 , 5mL of octadecene (ODE), 0.5mL of 2-hexyldecanoic acid and 0.5mL of oleylamine (OLA) were added to an empty 100mL three-necked flask, and the three-necked flask was evacuated and placed on a heating mantle Magnetic stirring was carried out on a magnetic stirrer, and after stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com