Method for recycling zirconium-based amorphous alloy waste

A zirconium-based amorphous alloy and waste technology is applied in the field of recycling of zirconium-based amorphous alloy waste, which can solve the problems of the decline of the performance of the amorphous alloy, the inability to meet the performance requirements of the products, the decline of the mechanical properties and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

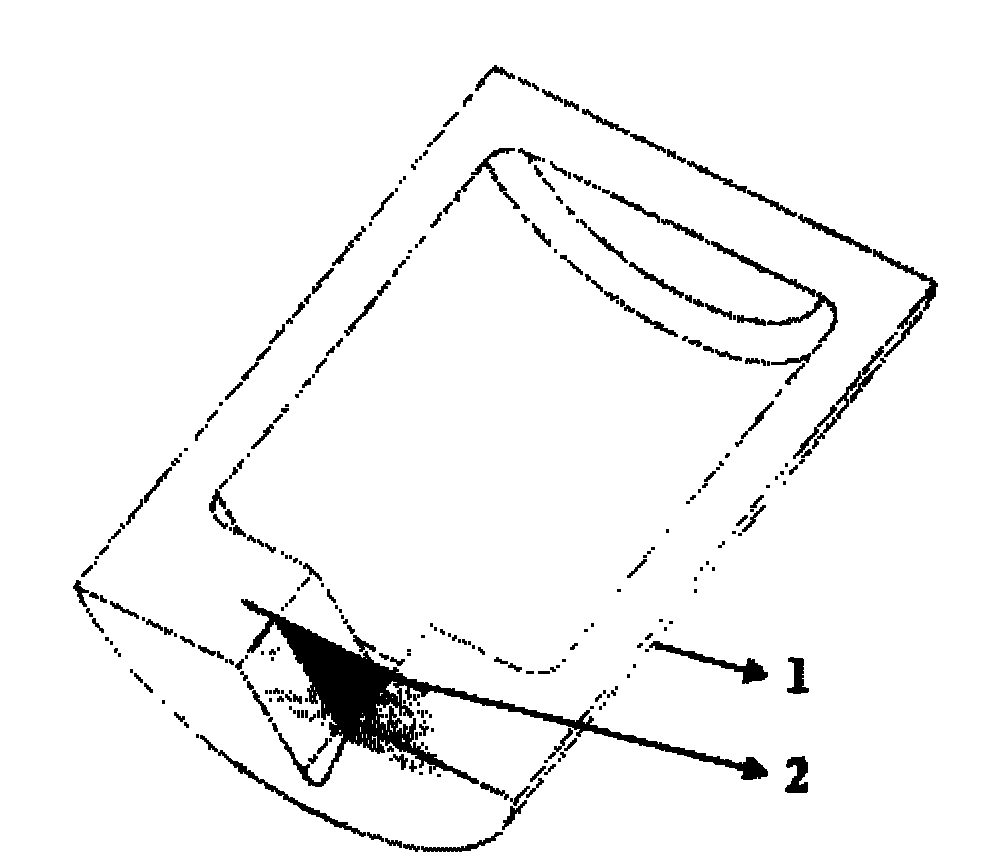

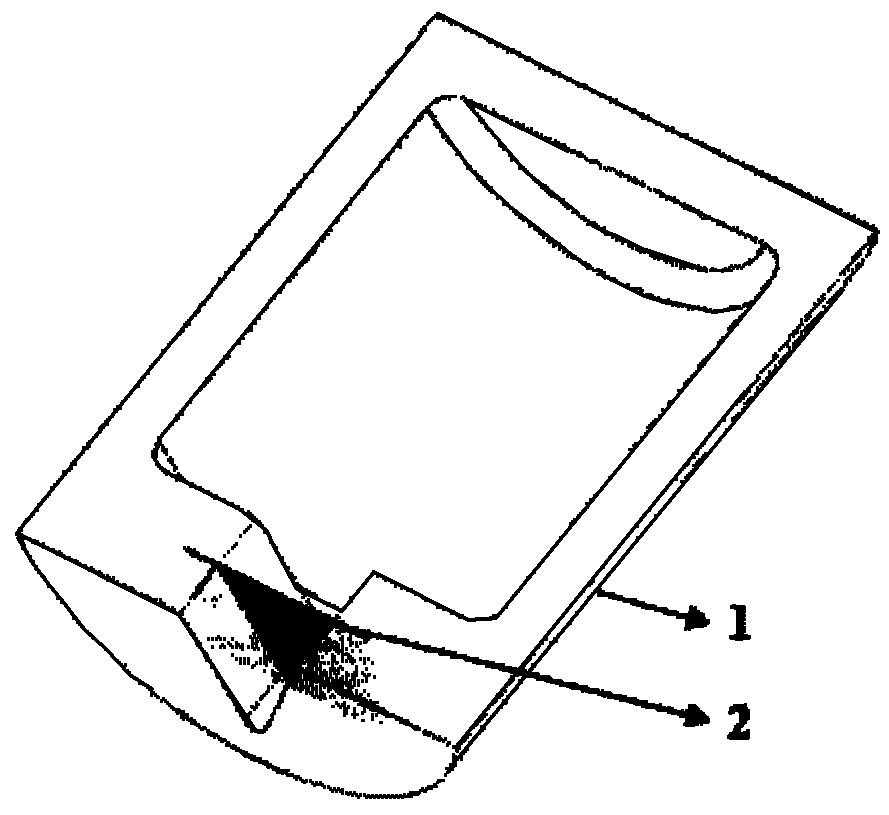

Image

Examples

Embodiment 1

[0020] This example is used to illustrate the recycling method of the zirconium-based amorphous alloy waste provided by the present invention.

[0021] The general formula of the alloy composition is Zr by jaw mechanical crushing method. 63.5 Al 3.6 Cu 26 Ni 5.9 Y 1 The zirconium-based amorphous alloy die-casting handle recycled material is broken into block recycled materials with an average size of 3-5 cm, and 5 kg of the recycled material is weighed, and the rust removal, surface oxide removal and degreasing treatment are sequentially carried out. Then, an IRO-II oxygen content analyzer was used to detect the oxygen content of the zirconium-based amorphous alloy reclaimed material. As a result, the oxygen content was 1085ppm (ie 0.1085% by weight, ie A was 0.1085). Make the zirconium-based amorphous alloy reclaimed material and 19.15 grams of Y 2 o 3 (i.e. W2 =3.53A parts by weight) and 30.87 grams of Zr (ie W 1 =5.69A parts by weight) are mixed, and the gained mixtu...

Embodiment 2

[0029] This example is used to illustrate the recycling method of the zirconium-based amorphous alloy waste provided by the present invention.

[0030] The general formula of the alloy composition is Zr by jaw mechanical crushing method. 62.4 Ti 11.2 Cu1 3.3 Ni 9.8 be 3.3 The zirconium-based amorphous alloy die-casting handle recycled material is broken into block recycled materials with an average size of 3-5 cm, and 5 kg of the recycled material is weighed, and the rust removal, surface oxide removal and degreasing treatment are sequentially carried out. Then, an IRO-II oxygen content analyzer was used to detect the oxygen content of the zirconium-based amorphous alloy reclaimed material. As a result, the oxygen content was 2103ppm (ie 0.2103% by weight, ie A was 0.2103). Make the zirconium-based amorphous alloy reclaimed material and 37.12 grams of Y 2 o 3 (i.e. W 2 =3.53A parts by weight) and 59.83 grams of Zr (ie W 1 =5.69A parts by weight) are mixed, and the gain...

Embodiment 3

[0038] This example is used to illustrate the recycling method of the zirconium-based amorphous alloy waste provided by the present invention.

[0039] Adopt the zirconium-based amorphous alloy recovery material in embodiment 2 (oxygen content is 2103ppm, and A is 0.2103), and make the described zirconium-based amorphous alloy of 5 kilograms and the Y of 31.86 grams 2 o 3 (i.e. W 2 =3.03A parts by weight) and 72.45 grams of Zr (ie W 1 =6.89A parts by weight) are mixed, and the gained mixture is added to the vacuum melting chamber of the intermediate frequency vacuum induction melting furnace (produced by Jinzhou Sante Vacuum Metallurgical Technology Industry Co., Ltd., model ZG-03) with rated capacity of 25 kilograms, Vacuum the furnace body, fill it with argon, wash the furnace with argon, and control the absolute vacuum degree of the vacuum smelting chamber to be 0.08Pa, so that the resulting mixture is smelted at a power of 25kW until it is completely melted. 300° C. abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com