Patents

Literature

68results about How to "Good antirust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

Organic composite reinforced concrete rust inhibitor and preparation method thereof

ActiveCN102432220AImprove resistance to chloride ion penetrationImprove permeabilityAlcoholReinforced concrete

The invention discloses an organic composite reinforced concrete rust inhibitor and a preparation method thereof. According to the invention, the rust inhibitor is prepared from well-mixed materials of, by weight: 30-40% of alcohol amine carboxylate, 5-10% of sodium monofluorophosphate, 0.1-0.5% of an anionic surfactant, and balance of water. The rust inhibitor has a good diffusion performance inconcrete, and can simultaneously acts upon the cathodes and the anodes of steel bars. The trust inhibitor forms stable chelate rings with the steel bars, and has an excellent rust inhibiting performance. Also, the anions in the rust inhibitor can be combined with calcium ions in the concrete, such that precipitates are formed. With the precipitates, capillary pores in the concrete can be obstructed, and the chloride ion penetration resistance of the concrete can be improved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Rust-resistant agent for concrete reinforcing bar and preparation method thereof

InactiveCN101948264AExcellent chelating antirust abilityGood migration and diffusion propertiesRebar corrosionAlkali soil

The invention discloses a rust-resistant agent for a concrete reinforcing bar and a preparation method thereof. The rust-resistant agent for the concrete reinforcing bar is prepared based on a gas-phase corrosion inhibitor prepared by reacting a dicarboxylic acid with organic amine. The rust-resistant agent for the concrete reinforcing bar comprises the following raw materials in percentage by mass: 5 to 10 percent of sodium monofluorophosphate, 2 to 5 percent of calcium gluconate, 20 to 40 percent of the gas-phase corrosion inhibitor and the balance of water. The rust-resistant agent for theconcrete reinforcing bar of the invention does not comprise nitrite, comprises the gas-phase corrosion inhibitor and has a function of migrating and diffusing in the concrete. Compared with the traditional rust-resistant agent for the reinforcing bar, the rust-resistant agent for the concrete reinforcing bar has the advantages of excellent corrosion inhibition and rust-resistant properties, high environmentally-friendly property and the like, can be widely applied to fresh reinforced concrete construction of harbour engineering, coastal buildings, buildings in saline and alkaline lands and other buildings with the requirements of preventing the concrete reinforcing bar from rust and corrosion, and can also be applied to the repair of the reinforced concrete structures in major construction projects and routine maintenance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Compound concrete anti-corrosion and rust-resistant agent

The invention discloses a compound concrete anti-corrosion and rust-resistant agent which comprises the following components in parts by weight: 15-30 parts of a polycarboxylic acid water reducing agent, 3-12 parts of sodium dodecyl sulfate, 15.7-20.6 parts of N-dimethylethanolamine, 1-5 parts of sodium molybdate, and 50-60 parts of water. The compound concrete anti-corrosion and rust-resistant agent can block capillary holes in the concrete, improves the chloride ion permeability resistance of concrete, can significantly alleviate the damage of chloride ions on a reinforcing steel bar passivation film, enhances the sulfate corrosion resistant ability of the concrete, has excellent rust-resistant performance and good repair performance, can enhance durability of the concrete and the comprehensive anti-corrosion ability of the concrete, and significantly improves the durability of buildings.

Owner:HUNAN CONSTR ENG GRP COR +1

Environment-friendly high temperature activated water-based rebar rust inhibitor

The invention relates to an environment-friendly high temperature activated water-based rebar rust inhibitor, which comprises the following components: 0.1%-0.5% of a silicate, 0.1%-0.6% of a meta-aluminate, 0.1%-0.6% of organic amine, 0.1%-0.6% of gluconic acid, and 98% of water, and the sum of the above components is 100%. By adopting a silicate and a meta-aluminate as main components and cooperating with other components, the rust inhibitor of the invention has the advantages of no toxicity, no pollution, low cost, environmental friendliness, and good rust inhibiting effect, etc.

Owner:TAISHAN MEDICAL UNIV

Reinforced concrete rust inhibitor and use method thereof

The invention discloses a reinforced concrete rust inhibitor. The rust inhibitor consists of the following three components: a mixture of CuO and Ca (NO2) 2 amino alcohols, and fatty acid esters; wherein the molar ratio of CuO and Ca (NO2)2 in the mixture of CuO and Ca (NO2)2 is 2:1; the usage amount of the mixture of CuO and Ca (NO2)2 is from 0.1 to 1.5% of the total amount of the reinforced concrete; the usage amount of the amino alcohols is from 0.1 to 3% of the total amount of the reinforced concrete; and the usage amount of the fatty acid esters is from 0.1% to 2.5% of the total amount of the reinforced concrete. The invention also discloses a use method for the reinforced concrete rust inhibitor. Three different components are used in the rust inhibitor provided by the invention in, so the rust inhibitor is good in anti-rust and repair performance, affordable, and environmentally friendly.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

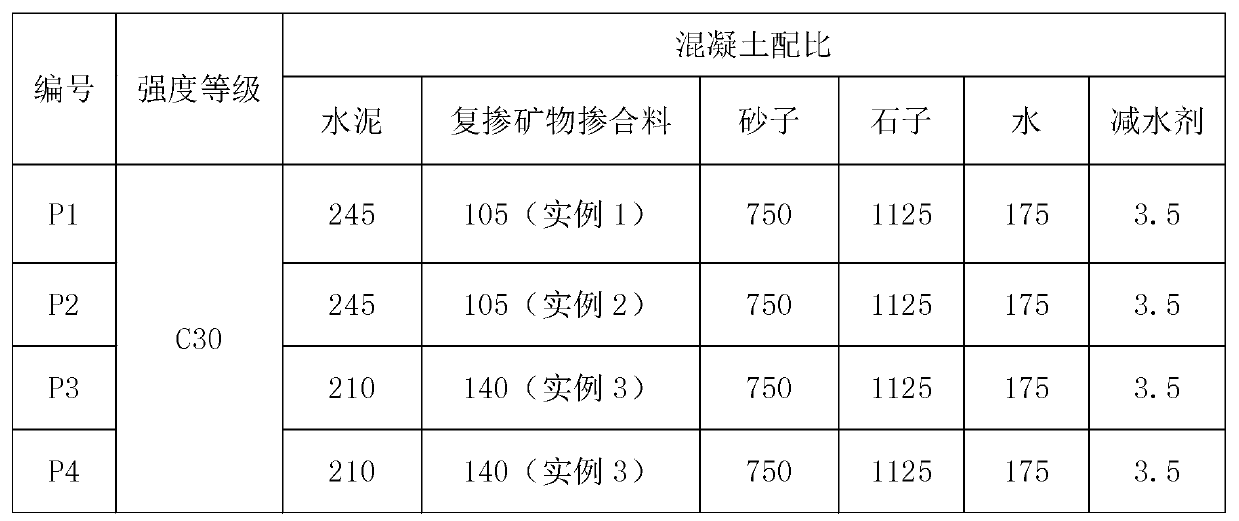

Compound-doped mineral admixture for reinforced concrete structure of oceanographic engineering

The invention relates to the field of concrete additives for oceanographic engineering, and aims at providing a compound-doped mineral admixture for a reinforced concrete structure of the oceanographic engineering. The compound-doped mineral admixture comprises the following components in percentage by mass: 20 to 35% of coal ash, 5 to 10% of zeolite, 20 to 40% of slag, 5 to 15% of silica fume, 5 to 15% of corrosion inhibitor, 2 to 5% of dispersing agent, 0 to 10% of shrinkage reducing agent, and 0 to 16% of antimitotic agent. According to the compound-doped mineral admixture, multi-component design is adopted, the functions of all the components are combined and coordinated, and thus the crack resistance and rust resistance of the structure are optimized, and the wear resistance of the oceanographic engineering can be improved; and a plurality of functional components are compounded into the admixture, so that the functional components can be uniformly dispersed in the concrete, and the effects of stably resisting crack and resisting rust can be realized. The compound-doped mineral admixture can reduce the concrete agitating conditions and reduce the usage cost of an enterprise, and is convenient for massive popularization and application.

Owner:浙江合力海科新材料股份有限公司

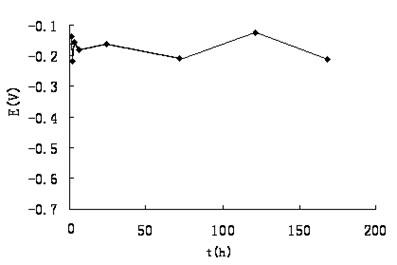

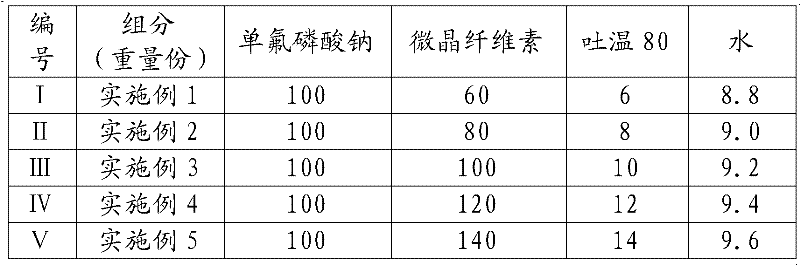

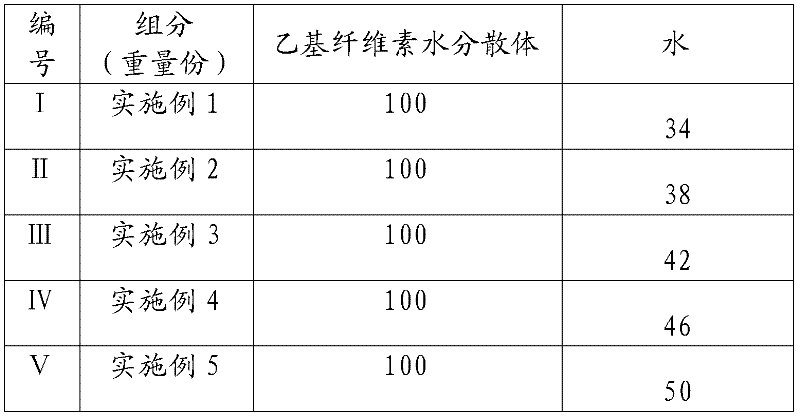

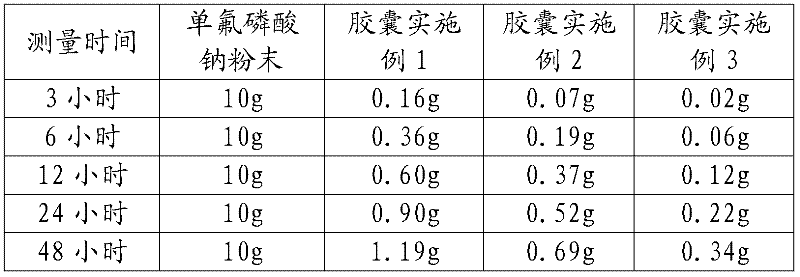

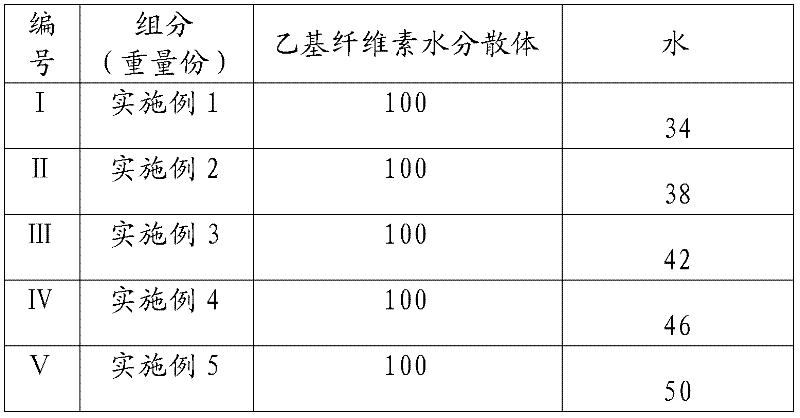

Ethyl cellulose sodium monofluorophosphate corrosion inhibitor and its preparation method

ActiveCN102392252AImprove stabilityControlled optimization of release rateSodium monofluorophosphateRust

The invention discloses an ethyl cellulose sodium monoflurophosphate corrosion inhibitor and its preparation method. The ethyl cellulose sodium monoflurophosphate corrosion inhibitor is in the form of a capsule comprising a capsule core and a coating. The capsule core is composed of sodium monoflurophosphate, microcrystalline cellulose and tween-80, while the coating material is ethyl cellulose aqueous dispersions. The sodium monoflurophosphate microcapsule corrosion inhibitor wrapped by ethyl cellulose aqueous dispersions in the invention has good stability. And through mass ratio variation of the capsule core materials and coating material, the release rate of the microcapsule can be controllably optimized. Thus, the ethyl cellulose sodium monoflurophosphate corrosion inhibitor of the invention has the advantages of long period of validity, good rust resisting effect, as well as green environmental protection.

Owner:SHENZHEN UNIV

Ultralow-dosage corrosion inhibitor and preparation method thereof

The invention relates to an ultralow-dosage corrosion inhibitor and a preparation method thereof, belonging to the technical field of building materials. The ultralow-dosage corrosion inhibitor is prepared from the following components: by mass percent, 0.4% to 1% of sodium monoflurophosphate and 99.6% to 99% of mineral admixtures. The corrosion inhibitor does not contain nitrite, poses no harm to the environment and human bodies and can improve concrete strength. Compared to traditional corrosion inhibitors, the corrosion inhibitor provided in the invention has the advantages of excellent anticorrosion performance, capacity of improving concrete strength, environment friendliness, no harm and the like and is widely applicable to industrial and civil buildings which mainly suffer from chloride corrosion, e.g., buildings in marine environment areas and a steel bar retarding concrete structure which adopts deicing salts.

Owner:武汉三源特种建材有限责任公司

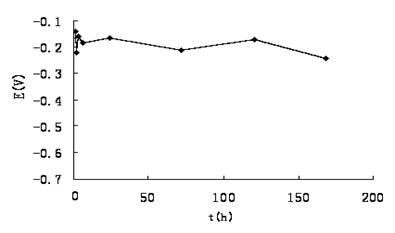

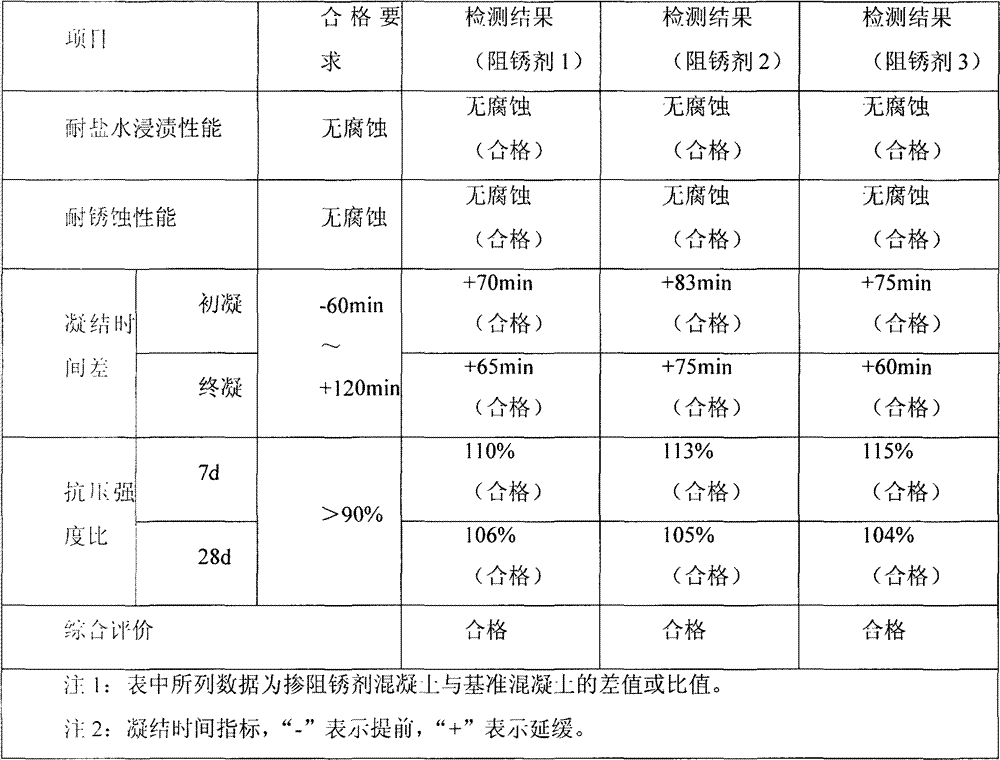

Ethyl cellulose type calcium nitrite corrosion inhibitor and preparation method thereof

ActiveCN102517587AImprove stabilityControlled optimization of release rateAdditive ingredientCalcium nitrite

The invention discloses an ethyl cellulose type calcium nitrite corrosion inhibitor and a preparation method thereof. The shape of the ethyl cellulose type calcium nitrite corrosion inhibitor is a capsule, the capsule comprises a capsule core and a coating; the ingredients of the capsule core comprise calcium nitrite, microcrystalline cellulose and Twin 80; and the coating is made from ethyl cellulose aqueous dispersion. According to the invention, the calcium nitrite microcapsule corrosion inhibitor coated by the ethyl cellulose aqueous dispersion has good stability, and the mass ratio of the capsule core material to the coating material is changed to guarantee controllable release speed, long validity period, good antirust effect and environmental friendliness for the microcapsule.

Owner:SHENZHEN UNIV

Application of pyridoxine as seawater rust inhibitor

The invention relates to a rust inhibitor for, in concrete environment or corresponding alkaline conditions, corrosion inhibition of steel (carbon steel) in seawater or a sodium chloride solution, and particularly relates to the application of pyridoxine as a seawater rust inhibitor in the concrete alkaline environment or corresponding alkaline conditions. The rust inhibitor is applied in the concrete alkaline environment or corresponding alkaline conditions for corrosion prevention of carbon steel materials and steel bar products thereof in the seawater or a sodium chloride medium, and the rust inhibitor of the invention is less in use amount, wide in source, non-toxic, green and environmentally friendly, high in efficiency, strong in continuous function ability, can effectively inhibit corrosion destruction of the carbon steel, and has substantial application values and broad market prospects.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

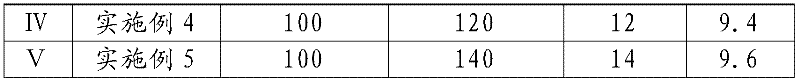

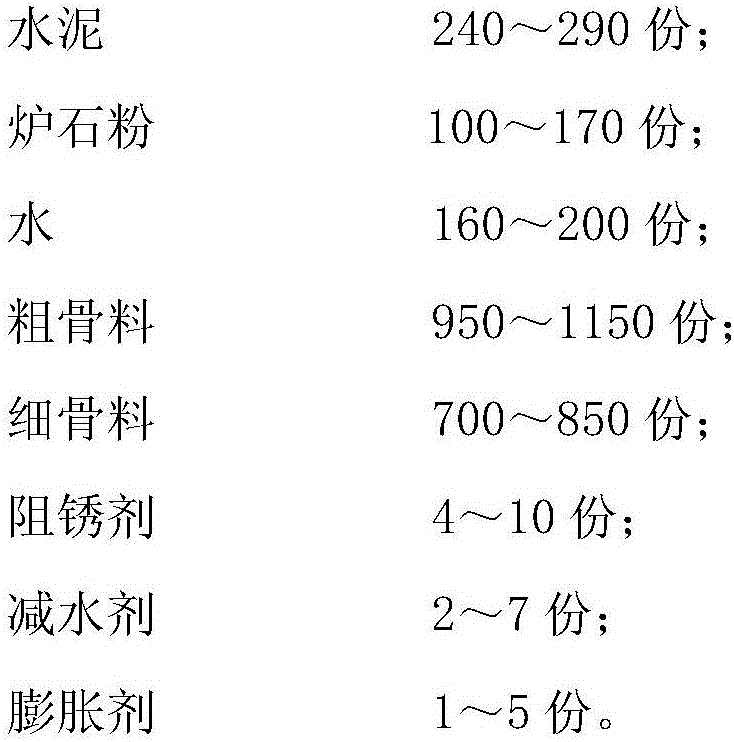

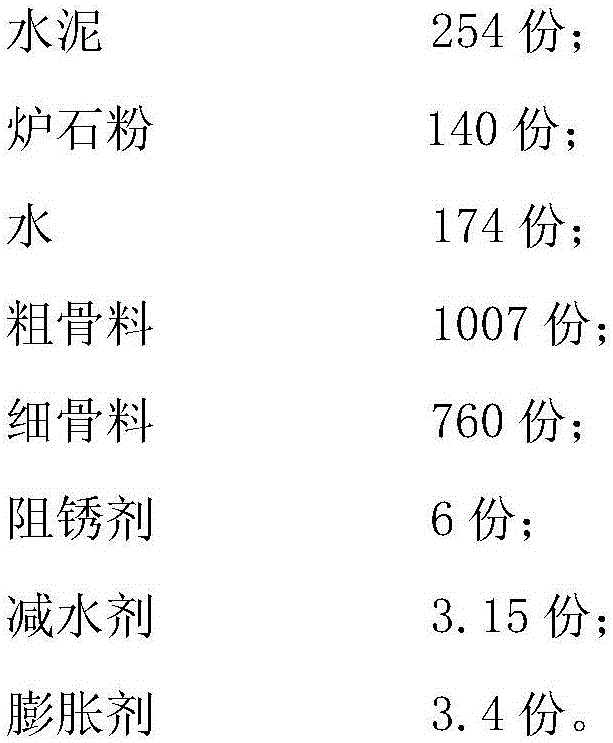

Rust-proof corrosion-resistant non-shrinkage concrete for blast furnace and preparation method thereof

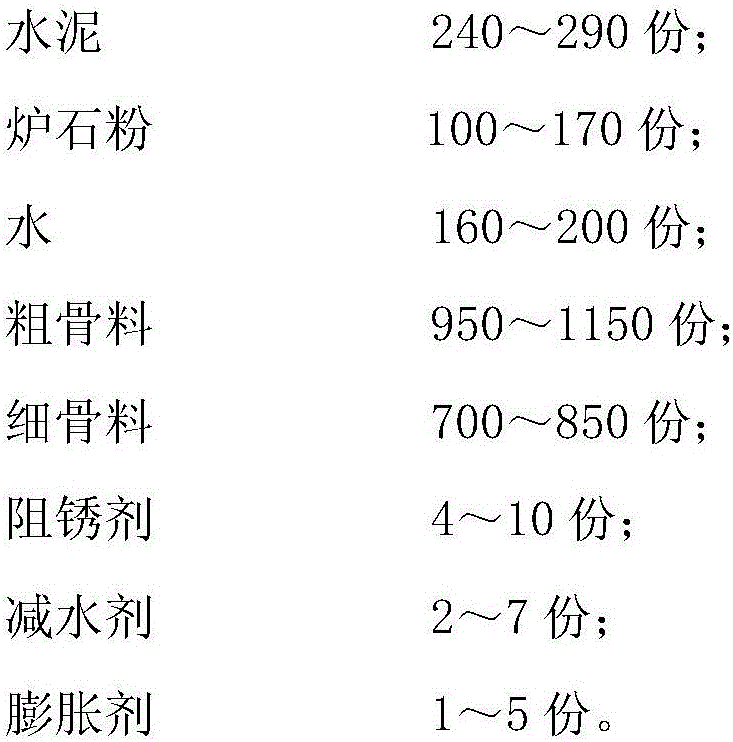

The invention relates to rust-proof corrosion-resistant non-shrinkage concrete for a blast furnace and a preparation method thereof and belongs to the technical field of building materials. The rust-proof corrosion-resistant non-shrinkage concrete comprises, by weight, 240-290 parts of cement, 100-170 parts of hearthstone powder, 160-200 parts of water, 950-1150 parts of crude aggregate, 700-850 parts of fine aggregate, 4-10 parts of a corrosion inhibitor, 2-7 parts of a water reducer and 1-5 parts of an expanding agent. The rust-proof corrosion-resistant non-shrinkage concrete suitable for saline-alkali soil is prepared from specific ingredients according to a ratio, has good workability and high strength, is convenient for construction time control and concrete construction, has a simple formula, saves a lot of cost, can be prepared through simple and easy processes, is free of a mineral admixture and can be promoted and used at home and abroad.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR

Migrating rust inhibitor

The invention relates to a migrating rust inhibitor, which is made of the following components by weight: 50-150 parts of a rust-inhibiting component, 15-30 parts of a water reducing agent, 5-45 parts of a coagulation retarding component, 0.5-3 parts of an air entraining component, and 200-800 parts of water. The migrating rust inhibitor provided by the invention adopts an amino acid rust-inhibiting molecule with a high steric hindrance structure as the rust-inhibiting component, thus having good rust-inhibiting effect and strong migration ability.

Owner:STATE GRID CORP OF CHINA +2

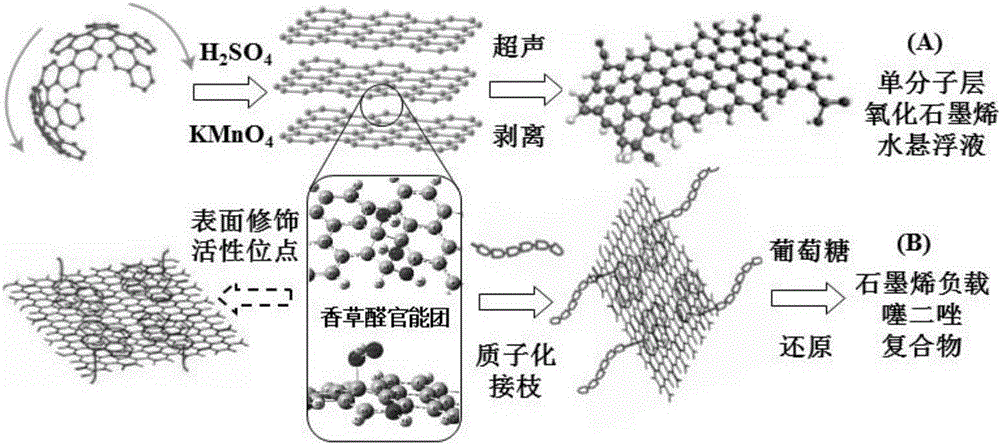

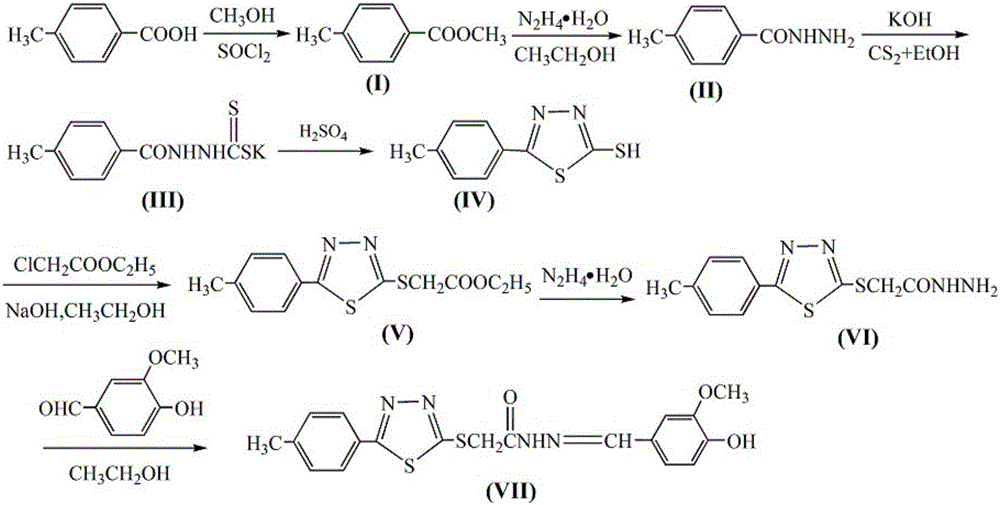

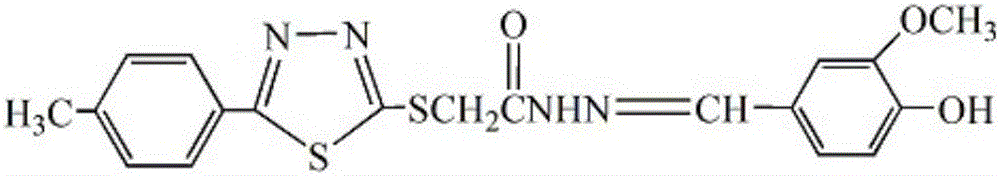

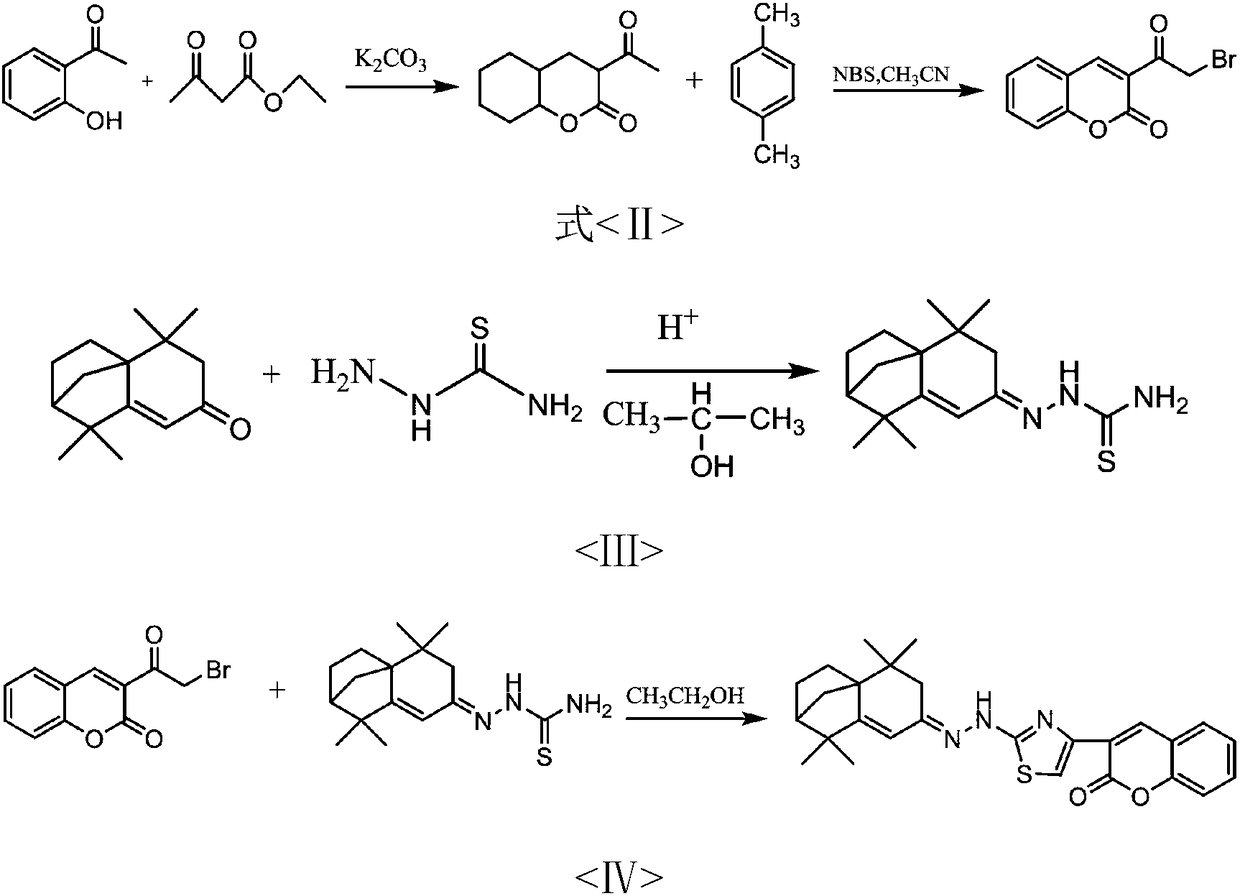

Graphene-loaded thiadiazole corrosion inhibitor containing vanillin active group and application thereof

The invention relates to a corrosion inhibitor, specifically to a graphene-loaded thiadiazole corrosion inhibitor containing vanillin active group and application thereof. The compound is a compound formed after chemical loading of vanillin-[5-(p-methylphenyl)-1,3,4 thiadiazole-2-mercapto]-acetylhydrazone on active site of oxygen-containing functional group in a graphene molecular layer. The compound is applied in an alkaline environment of concrete or under a corresponding alkaline condition to carry out corrosion prevention on a carbon steel material and rebar products in seawater or a sodium chloride medium through the graphene molecular layer catalyzing a cathodic oxygen reduction reaction during the electrochemical process between a corrosion inhibitor and carbon steel. The corrosion inhibitor of the invention has wide sources, is easy for mass production, has less dosage, efficient performance and strong sustained action, can effectively inhibit corrosion damage to carbon steel, and has remarkable application value and wide market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

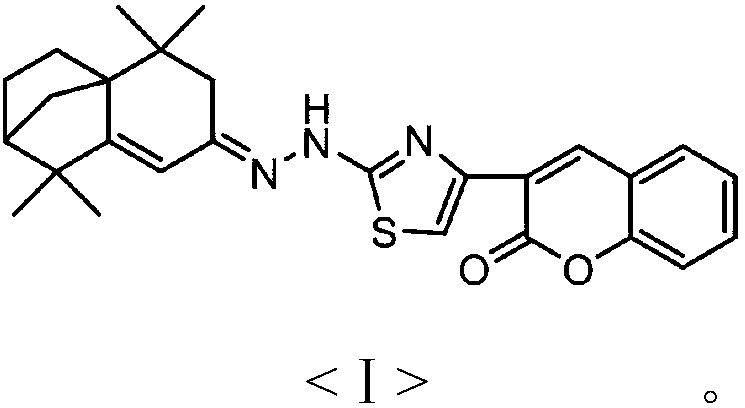

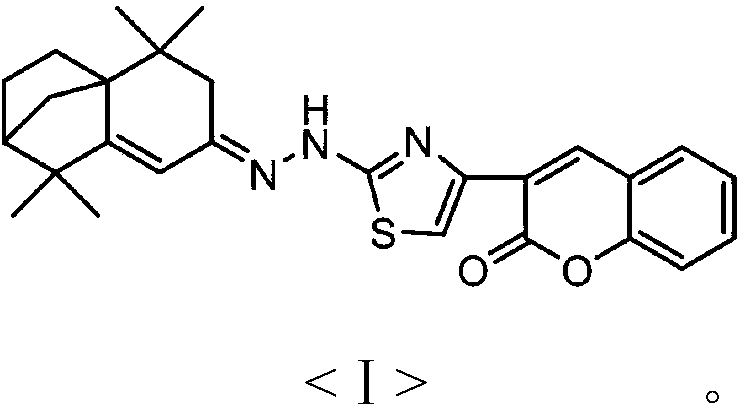

Steel rust inhibitor and preparation method and application thereof

ActiveCN108341809AWill not loadIn line with the development trendOrganic chemistryBenzopyranThiazole

The invention provides a steel rust inhibiting active ingredient and a rust inhibitor based on the steel rust inhibiting active ingredient, and the steel rust inhibiting active ingredient is 2-isolongifolenone hydrazino-4-(2-oxo-2H-benzopyran-3-yl) thiazole. The present invention also provides a preparation method of the active ingredient and application of the active ingredient in corrosion protection of carbon steel materials in seawater or a sodium chloride media. The active ingredient has the advantages of low toxicity, environmental protection, high efficiency, low dosage and strong continuous action ability, can effectively inhibit the corrosion damage of carbon steel, and has remarkable application value and broad market prospects.

Owner:NEIJIANG NORMAL UNIV

Concrete corrosion inhibitor

The invention discloses a concrete corrosion inhibitor, and belongs to the field of building materials. The concrete corrosion inhibitor is prepared from the following components in percentage by mass: 30 to 45 percent of a nitrite, 30 to 45 percent of benzotriazole, 3 to 5 percent of tetrakis hydroxymethyl phosphonium sulfate, 5 to 10 percent of polycarboxylate superplasticizer, 0.02 to 0.05 percent of an air entraining agent, 2 to 6 percent of pentasodium phosphate and the balance of sodium monofluorophosphate. The preparation method of the concrete corrosion inhibitor comprises the following steps: mixing sodium nitrite, benzotriazole and water, heating to 25-35 DEG C, adding the air entraining agent and pentasodium phosphate, uniformly stirring, keeping the temperature for 1-3 hours, cooling to room temperature, adding tetrakis (hydroxymethyl) phosphonium sulfate, the polycarboxylate superplasticizer and sodium monofluorophosphate, stirring, dissolving, and standing a solution for15-40 minutes to obtain the concrete corrosion inhibitor. The concrete corrosion inhibitor prepared by the invention can effectively improve the workability of concrete, slow down slump loss and enhance the corrosion inhibition performance, has long corrosion inhibition duration, and is suitable for coastal ports, salt pans and salinized soil areas.

Owner:广西科达新材料集团有限公司

Reinforcing steel bar corrosion inhibitor and preparation method thereof

The invention discloses a reinforcing steel bar corrosion inhibitor and a preparation method thereof. The reinforcing steel bar corrosion inhibitor is composed of the following raw materials in percentage by weight: 12-30% of diethylenetriamine, 8-20% of triethylene glycol, 4-15% of aminoacrylic acid and the balance of water. The reinforcing steel bar corrosion inhibitor disclosed by the invention has a good corrosion inhibition effect.

Owner:CHINA ACAD OF BUILDING RES +1

Durable concrete for wall columns

The invention discloses durable concrete for wall columns. The concrete is prepared from components of raw materials as follows: Portland cement, coarse sand, medium-coarse sand, gravel, water, mineral powder, coal ash, natural zeolite ultrafine powder, a polycarboxylate water reducer, stannous chloride, sodium chromate, calcium nitrate, acetamide, ethylene glycol, lignin salt, alkylbenzene sulfonate, triterpenoid saponins, sodium hexametaphosphate, citric acid, polyvinyl alcohol fibers, glass fibers and polyisobutene fibers. The durable concrete for the wall columns has the advantages of being high in strength, good in durability, wide in application range and the like.

Owner:蚌埠市宝运商品混凝土有限公司

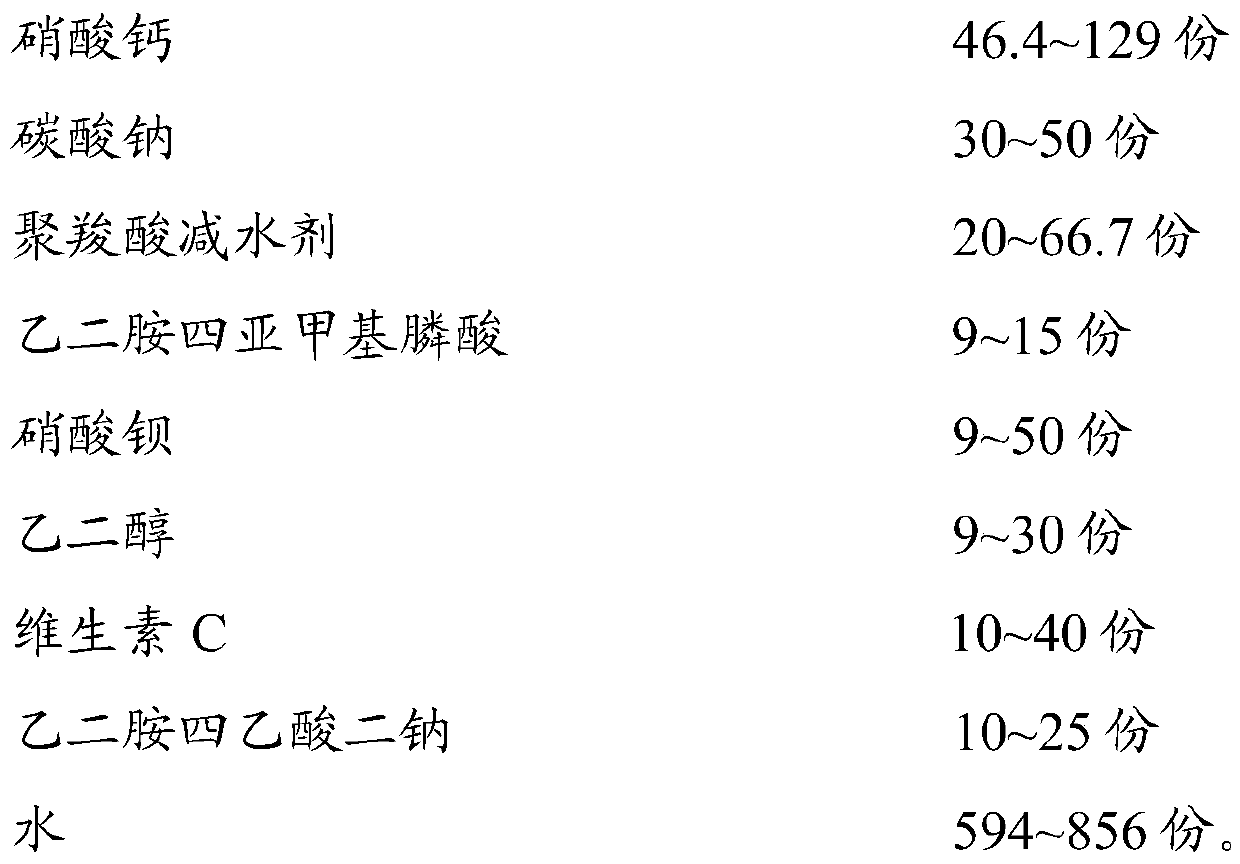

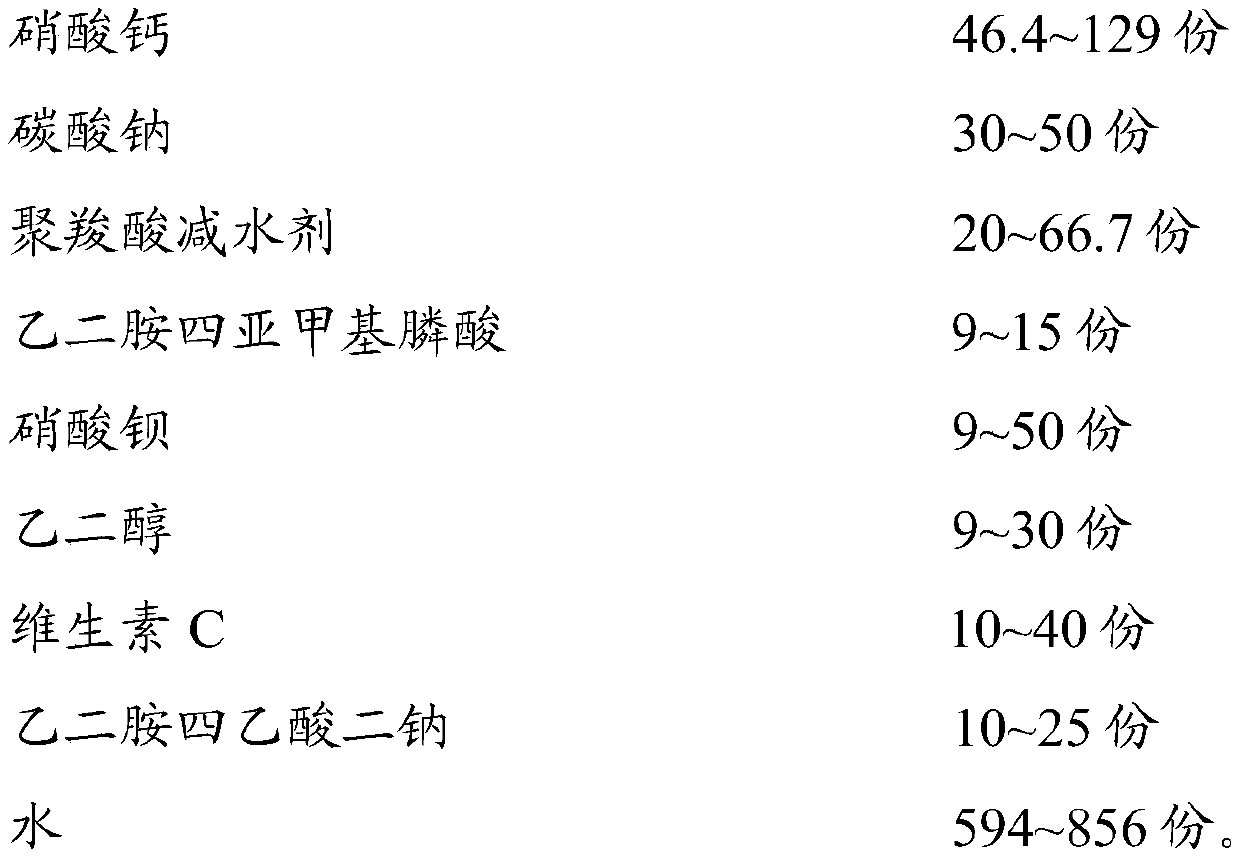

Anti-corrosion rust inhibitor for concrete and preparation method of anti-corrosion rust inhibitor

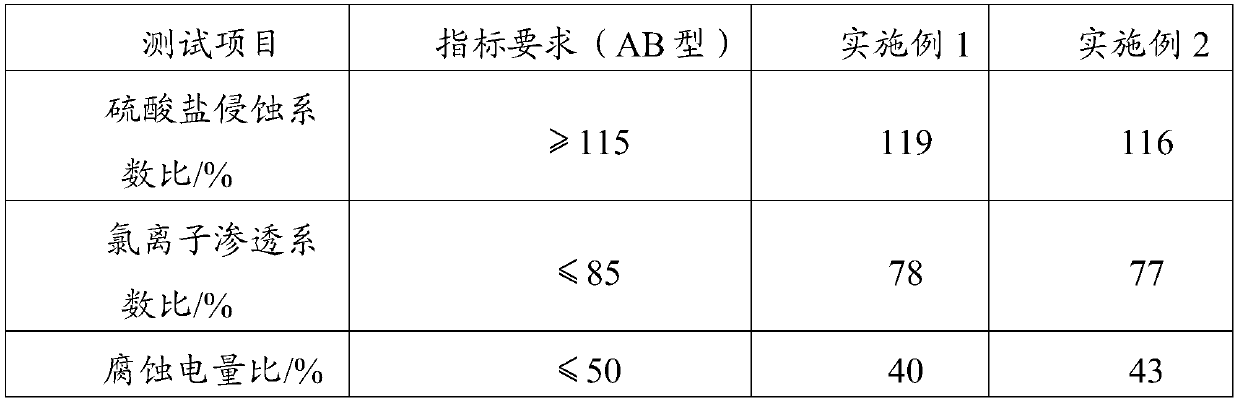

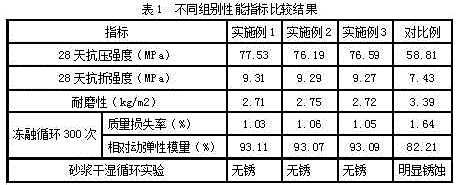

ActiveCN110183136AGood resistance to sulfate attack and rustSimple construction operationEthylenediaminetetra(methylenephosphonic)acidCorrosion inhibitor

The invention discloses an anti-corrosion rust inhibitor for concrete and a preparation method of the anti-corrosion rust inhibitor. The raw materials of the anti-corrosion rust inhibitor comprise calcium nitrate, sodium carbonate, a polycarboxylic acid water reducing agent, ethylenediaminetetramethylene phosphonic acid, barium nitrate, ethylene glycol, vitamin C, ethylenediamine disodium tetraacetate and water. The preparation method comprises the steps: preparing a calcium nitrate solution and a sodium carbonate aqueous solution separately, dissolving the polycarboxylic acid water reducing agent and ethylenediamine tetramethylene phosphonic acid in water, placing the solution of the polycarboxylic acid water reducing agent and ethylenediamine tetramethylene phosphonic acid in a four-necked flask, then adding the calcium nitrate solution and the sodium carbonate solution to the flask at a constant rate dropwise and simultaneously, performing a reaction at 20-35 DEG C, completing thewhole dropping process within 1-3 hours, dissolving the barium nitrate, ethylene glycol, vitamin C and ethylenediamine disodium tetraacetate in water, putting the obtained solution into a nanometer calcium carbonate suspension, and performing even stirring. The concrete which is manufactured through the provided anti-corrosion rust inhibitor for concrete has good resistance to sulfate corrosion and a rust-resisting effect, good workability is achieved at a water-to-binder ratio, and construction operation is convenient.

Owner:福建省建筑科学研究院有限责任公司 +3

Road and bridge concrete pavement repairing agent and preparation method thereof

A road and bridge concrete pavement repairing agent comprises the following components in parts by weight: 100 to 120 parts of ordinary Portland Cement, 15 to 20 parts of zinc oxide, 21 to 25 parts of kaolin, 21 to 25 parts of pyrophyllite, 12 to 15 parts of magnesium borate whiskers, 21 to 25 parts of redispersible latex powder, 2 to 3 parts of palmitoyl sodium glutamate, 3 to 4 parts of sodium tripolyphosphate, 4 to 6 parts of polyacrylonitrile fiber, 2 to 3 parts of [beta] aminopropionic acid, 4 to 5 parts of a polycarboxylate water reducing agent and 50 to 70 parts of water. The road and bridge concrete pavement repairing agent has the advantages of good rust resistance, good strength and toughness, especially-outstanding wear resistance and frost resistance, and the like, and is very suitable for fast and reliable repair of all kinds of damaged parts of road and bridge concrete pavements.

Owner:HENAN TRAFFIC HIGHWAY QUALITY SUPERVISION

Novel organic corrosion inhibitor for reinforced concrete

The invention provides a novel organic corrosion inhibitor for reinforced concrete. The corrosion inhibitor comprises the following components in mass percent: 20-60% of chitosan and the derivatives thereof and 40-80% of organic amine. The technical proposal provided by the invention that by adopting the technical scheme that the organic corrosion inhibitor for the reinforced concrete is used by being directly doped into the concrete, the corrosion resistance is greatly improved and the environmental protection performance is enhanced, thereby being widely applied to offshore reinforced concrete engineering projects such as harbor wharves and bridge tunnels.

Owner:CHINA ELECTRIC POWER RES INST +2

A composite anticorrosion and rust inhibitor for concrete

InactiveCN104478286BImprove resistance to chloride ion penetrationEnhanced resistance to sulfate corrosionSodium molybdateAcid water

Owner:HUNAN CONSTR ENG GRP COR +1

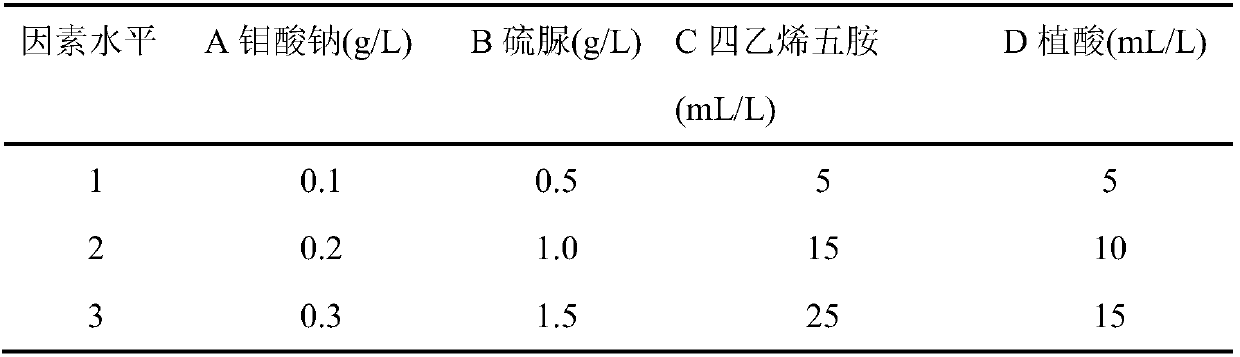

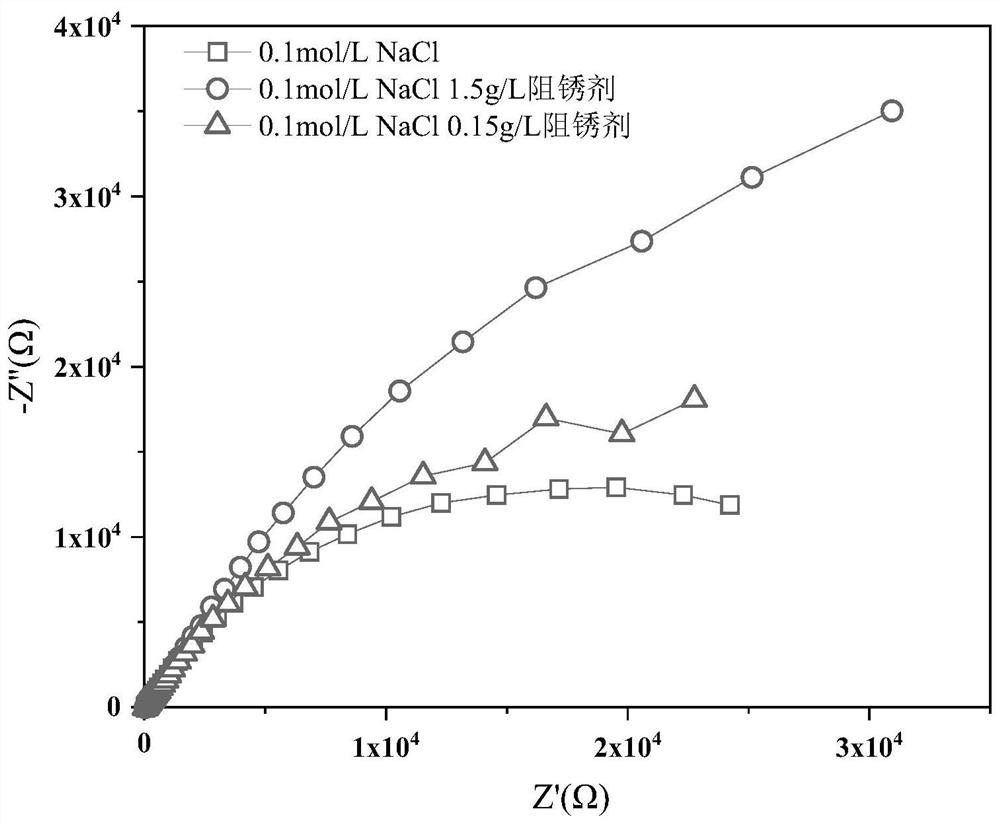

Green and high-efficiency rust inhibitor for reinforced concrete

The invention discloses a green and high-efficiency rust inhibitor for reinforced concrete. The green and high-efficiency rust inhibitor is characterized by being prepared from the following components: 0.15g / L to 0.25g / L of sodium molybdate, 0.8g / L to 1.2g / L of sulfourea, 4ml / L to 6mL / L of tetraethylenepentamine and 12mL / L to 17mL / L of phytic acid. The sodium molybdate and the sulfourea have a corrosion inhibition effect after being compounded; further, a formed precipitation film can make up a defect that the sodium molybdate forms a passive film; thus, a complete and compact protecting filmlayer is formed on the surface of a steel bar; generation and continuing of corrosion are inhibited; sulfur existing in a molecule of the sulfourea is combined with an atom Fe; the corrosion of the Fe is directly inhibited; a covered area of the surface of carbon steel is increased; the corrosion inhibition effect is enhanced. The tetraethylenepentamine can form an adsorption film on the surfaceof metal; the erosion of a chloride ion is inhibited, and meanwhile, a molybdate-radical ion can be used for enabling the passive film to become more compact.

Owner:SHANDONG ELECTRIC POWER IND BOILER & PRESSURE VESSEL INSPECTION CENT CO LTD

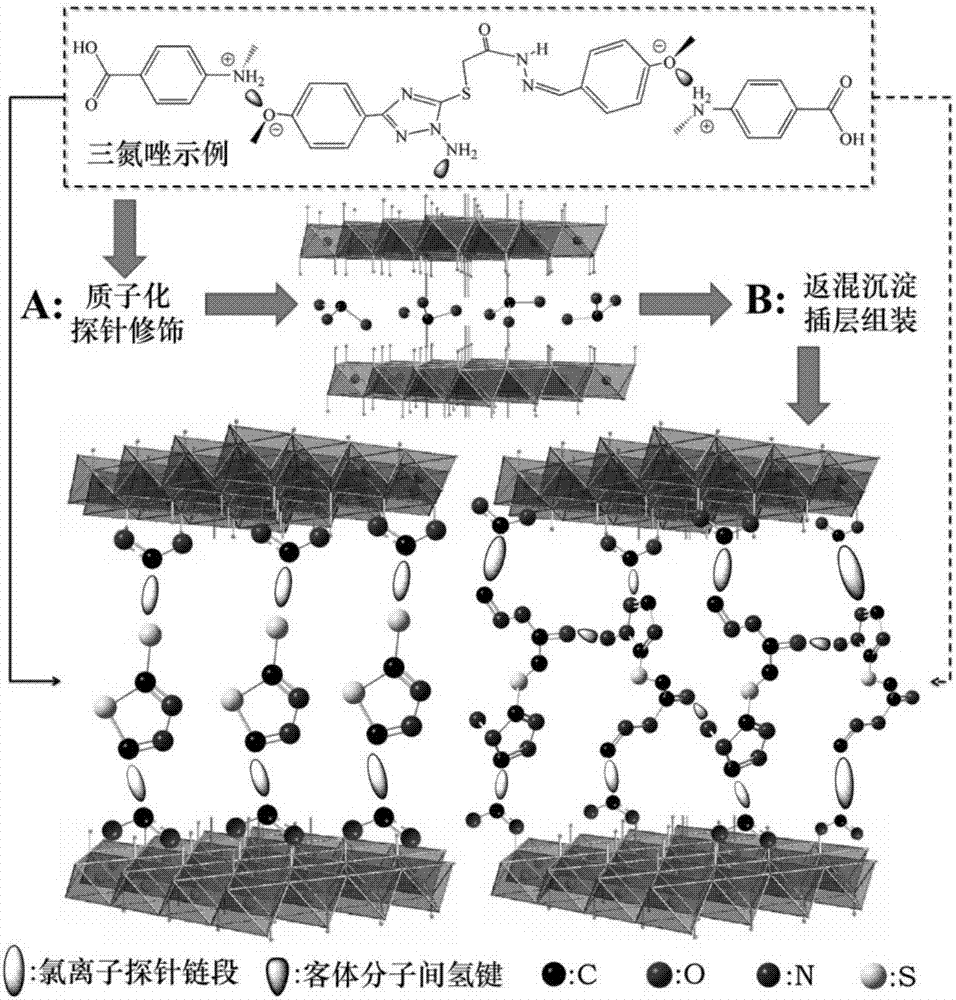

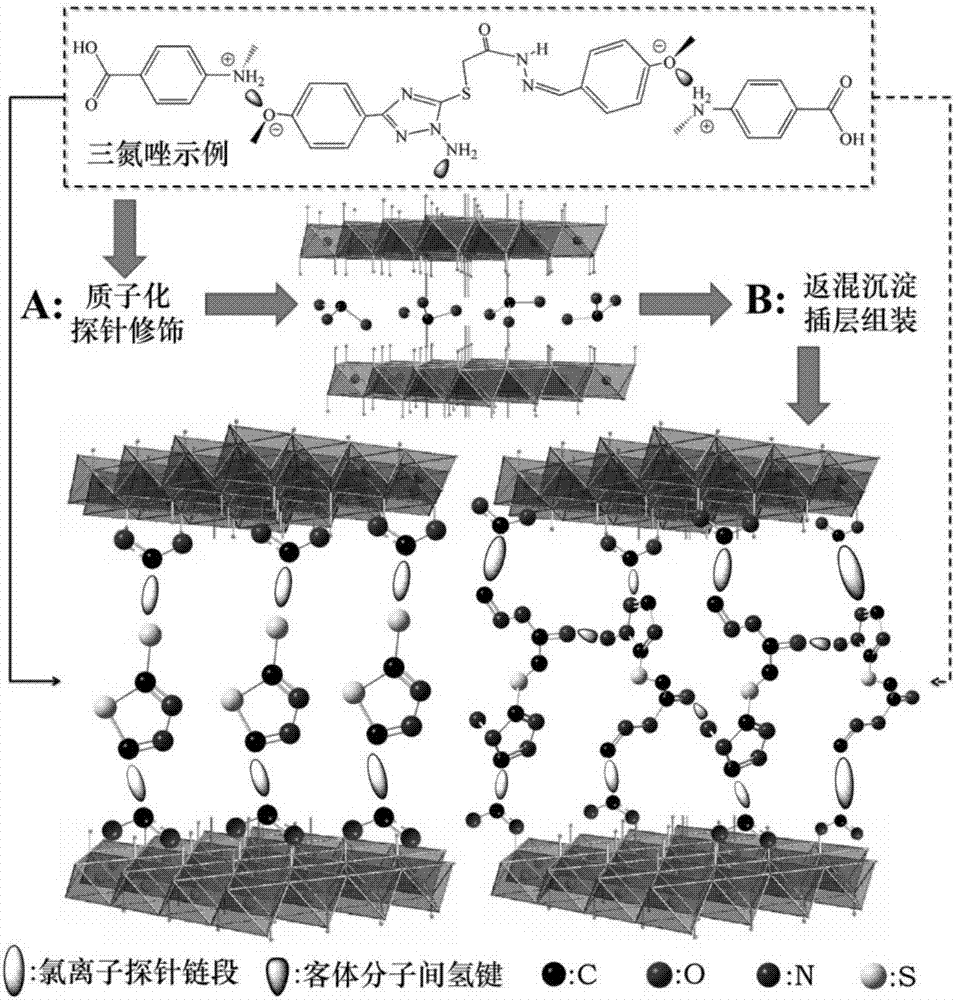

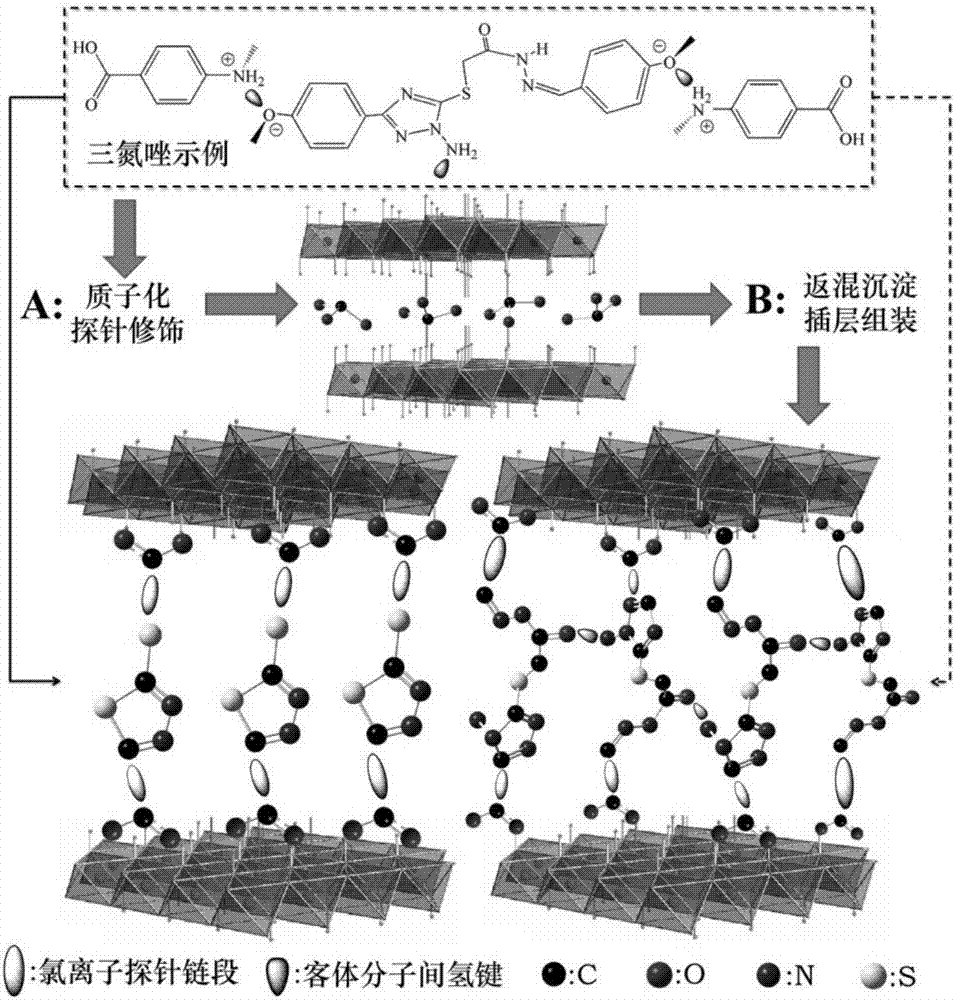

Hydrotalcite intercalation chloride ion probe modified sulfydryl-containing thiadiazole anti-rusting composition and application thereof

The invention relates to an anti-rusting agent and in particular to a hydrotalcite intercalation chloride ion probe modified sulfydryl-containing thiadiazole anti-rusting composition and application thereof. Through chloride ion probe modification and intercalation assembling, a chloride ion triggering switch for regulating and controlling release of a hydrosulfuryl thiadiazole type anti-rusting agent is embedded into zinc-aluminum hydrotalcite layers, and a composition is formed. The anti-rusting agent composition provided by the invention can be produced on scale, is capable of implementingresponse release to corrosive environments and repairing rusted carbon steel, in addition has a long-term protection function, is capable of implementing corrosion protection of carbon steel, and hasremarkable application values and wide market prospects.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Hydrotalcite intercalation chloride ion probe modified triazole corrosion inhibitor compound containing Schiff base and application thereof

The invention relates to a corrosion inhibitor, in particular to a hydrotalcite intercalation chloride ion probe modified triazole corrosion inhibitor compound containing Schiff base and application thereof. Through chloride ion probe modification and intercalation assembly, a chloride ion trigger switch which can regulate and control release of a triazole corrosion inhibitor containing the Schiffbase is embedded between zinc-aluminum hydrotalcite layers, and the compound is formed. By adopting the corrosion inhibitor compound provided by the invention, mass production can be realized, release responding to a corrosion environment and repairing of corroded carbon steel can be realized, and the corrosion inhibitor compound has long-term protective effect and can effectively carry out corrosion protection on the carbon steel, so that the corrosion inhibitor compound provided by the invention has obvious application value and a broad market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

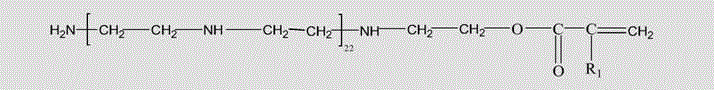

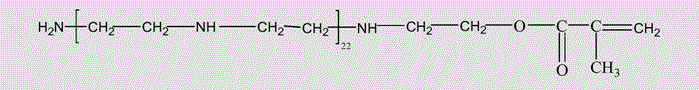

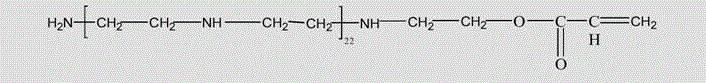

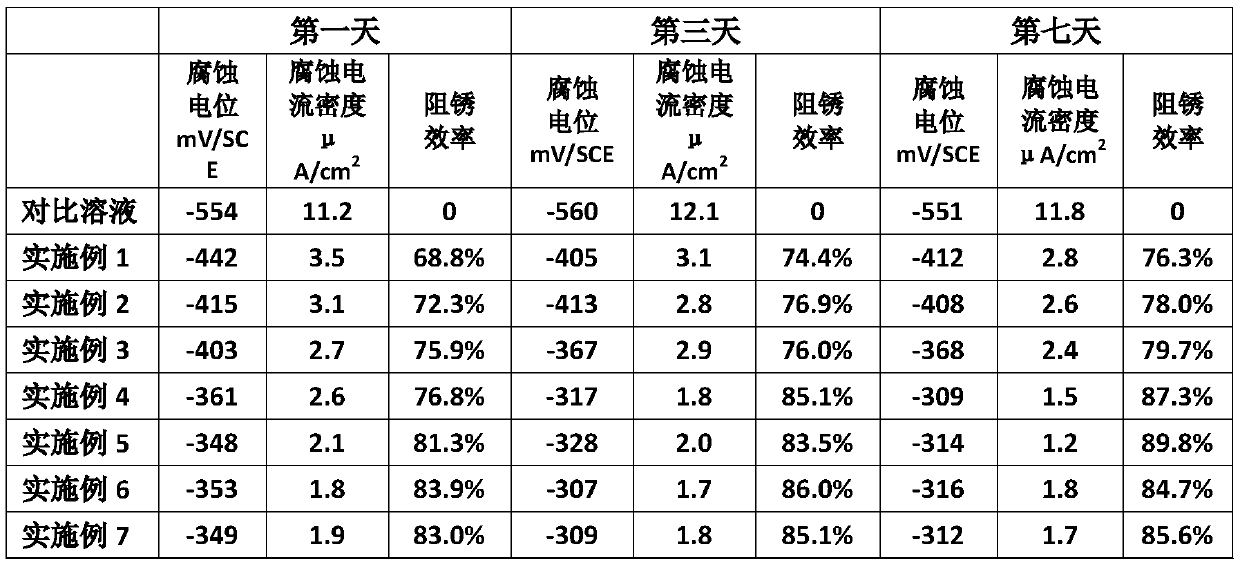

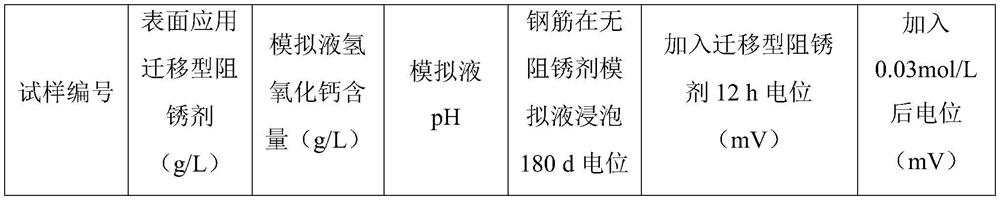

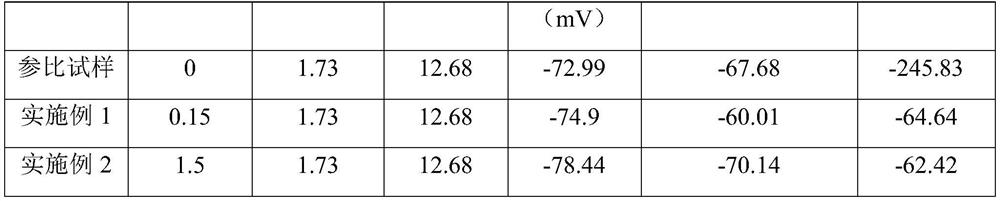

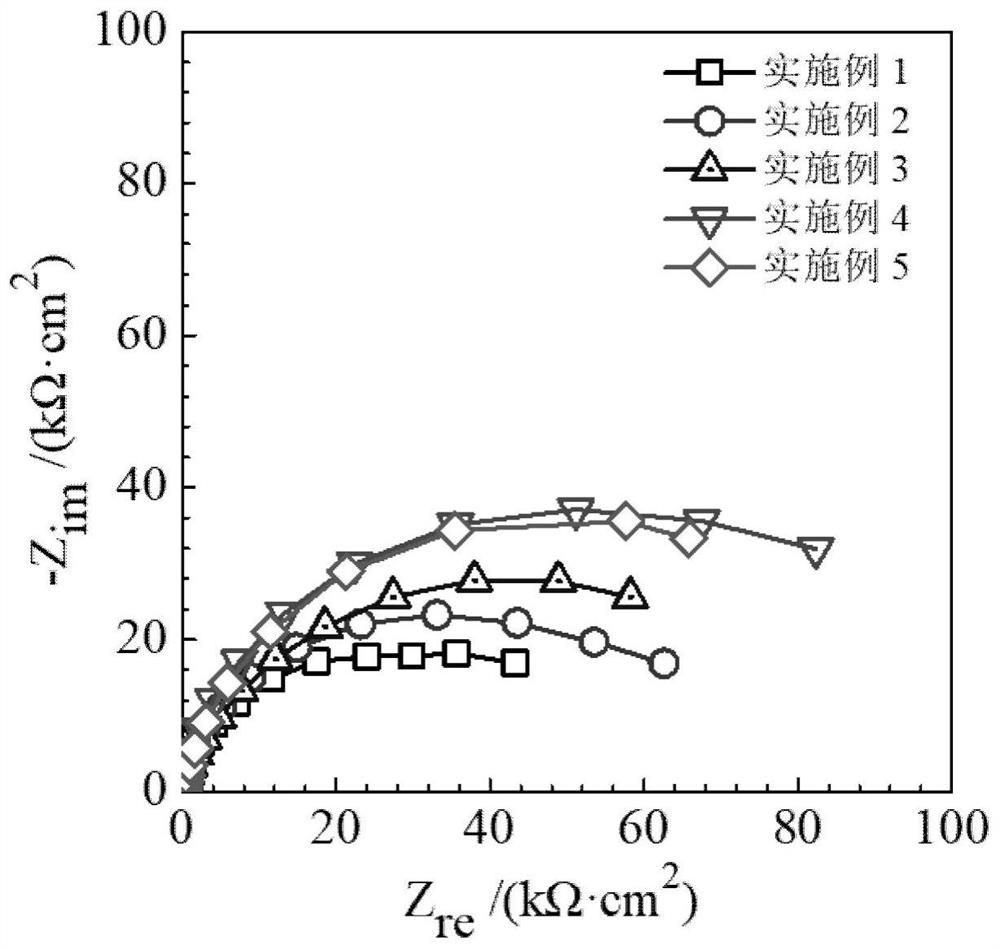

Surface application composite migration corrosion inhibitor and preparation method thereof

The invention relates to the technical field of building materials, in particular to a surface application composite migration corrosion inhibitor and a preparation method thereof. The surface application composite migration corrosion inhibitor comprises an organic component, an inorganic component and water, the organic component is formed by compounding diethanolisopropanolamine and alkylol amine Nn, the inorganic component is nitrite, and n is a natural number. The corrosion inhibitor can be used for corrosion media chloride ions and sulfate ions at the same time, and the defects that a traditional corrosion inhibitor is large in dosage, low in efficiency and single in effect are overcome. The triethanolamine and other alcohol amine components make up the risk of accelerated corrosion caused by insufficient mixing amount of sodium nitrite, and sodium nitrite makes up the possibility of corrosion inhibitor failure after the organic components are degraded under concrete or corresponding alkaline conditions. The organic component and the inorganic component are used together, and the double protection effect is achieved for the steel bar corrosion problem. The surface application composite migration corrosion inhibitor serves as an external component and can perform corrosion protection on an existing reinforced concrete structure in an external coating mode.

Owner:SUN YAT SEN UNIV

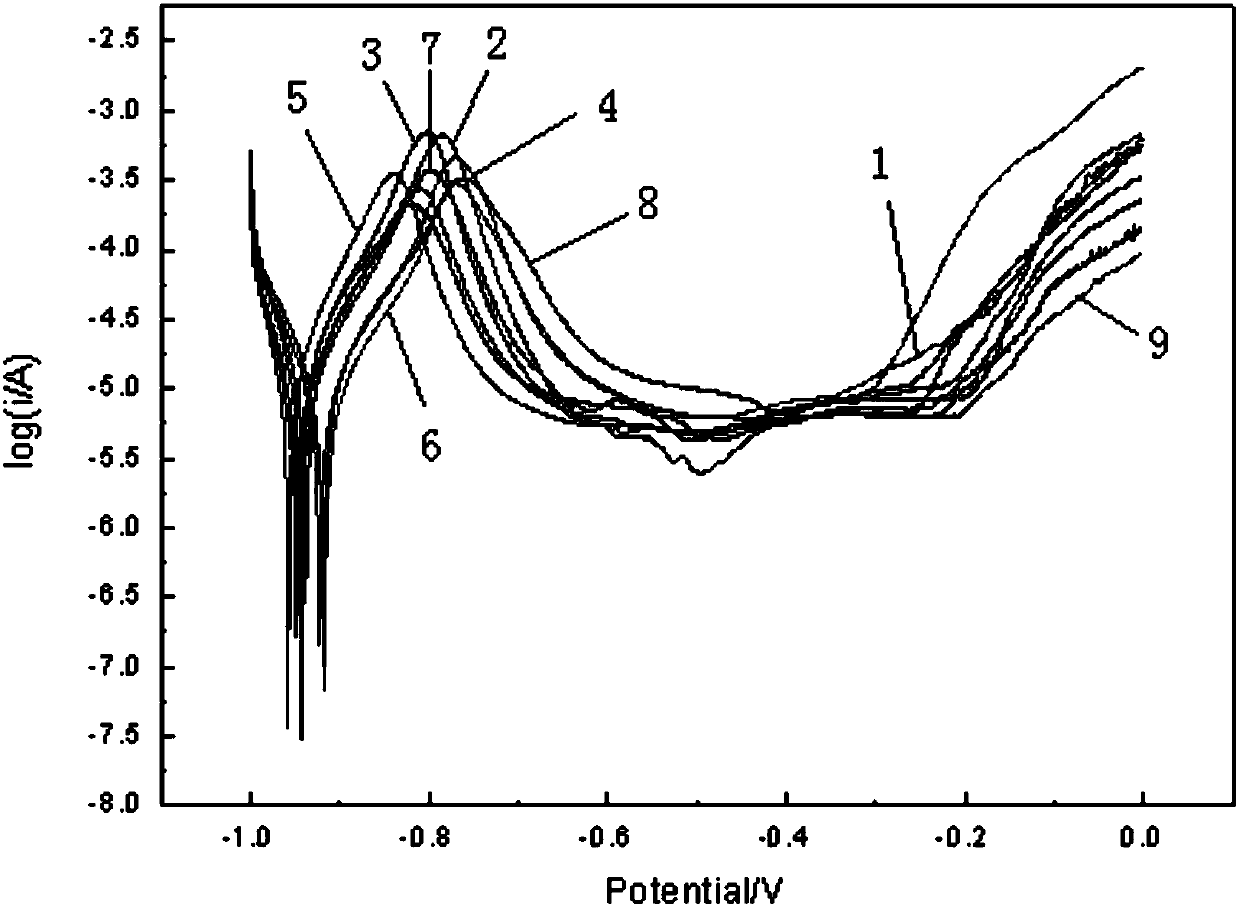

Environment-friendly composite steel bar corrosion inhibitor for marine environment and preparation method of corrosion inhibitor

The invention relates to an environment-friendly composite reinforcing steel bar corrosion inhibitor for a marine environment and a preparation method of the corrosion inhibitor, and belongs to the technical field of material science and engineering. The reinforcing steel bar corrosion inhibitor is prepared by compounding the following components in parts by mass: 0.15-0.35 part of molybdate, 0.1-0.65 part of benzotriazole and 100 parts of water. The preparation method comprises the following steps: firstly, weighing the molybdate and the benzotriazole in parts by mass, adding the molybdate and the benzotriazole into an alkaline solution with the pH value of 13.5 at room temperature, and uniformly stirring by using a glass rod. According to the invention, molybdate and benzotriazole which are harmless to the natural environment are compounded, so that harm of harmful corrosion inhibitors to the environment is reduced, and the composite corrosion inhibitor is green and environment-friendly. The molybdate and the benzotriazole are compounded to generate a synergistic effect, so that the reinforcing steel bar forms a layer of adsorption film in a marine environment, the film is high in compactness, can effectively prevent harmful ions from eroding the surface of the reinforcing steel bar and has a relatively good rust inhibition effect, and the preparation method is simple, economical in cost and convenient for industrial production.

Owner:SOUTHEAST UNIV

Concrete corrosion inhibitor and premixed concrete using same

The invention relates to the technical field of concrete additives, in particular to a concrete corrosion inhibitor and premixed concrete using the corrosion inhibitor, and the concrete corrosion inhibitor comprises the following components in parts by weight: 0.2-0.6 part of sodium molybdate, 10-16 parts of benzotriazole, 4-8 parts of an adhesive, 12-18 parts of octyl triethoxysilane and 30-40 parts of water. The concrete corrosion inhibitor provided by the invention can reduce the defect of soil pollution caused by the corrosion inhibitor while ensuring the corrosion inhibition performance of the corrosion inhibitor.

Owner:南通市展成商品混凝土有限公司

Hydrotalcite intercalation chloride ion probe modified s-triazole cyclic triazole containing corrosion inhibitor compound and application thereof

InactiveCN107973334AAvoid corrosionWide variety of sourcesZinc compounds preparationPhysical chemistryHydrotalcite

The invention relates to a corrosion inhibitor, and particularly speaking, discloses a hydrotalcite intercalation chloride ion probe modified s-triazole cyclic triazole containing corrosion inhibitorcompound and application thereof. Through chloride ion probe modification and intercalation assembly, a chloride ion trigger switch capable of regulating and controlling the release of an s-triazole cyclic triazole containing corrosion inhibitor is embedded between layers of zinc-aluminum hydrotalcite, so as to form the compound. The mass production can be realized by adopting the corrosion inhibitor compound provided by the invention; the release in response to a corrosive environment and the repair of already rusted carbon steel can be achieved; moreover, a long-time protection effect can beactualized; the corrosion prevention can be effectively carried out on carbon steel, and the corrosion inhibitor compound has obvious application value and a wide market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method for novel steel bar rust inhibitor

The invention provides a preparation method for a novel steel bar rust inhibitor. Reactants comprise organic alcohol amine, organic carboxylic acid and deionized water; the organic alcohol amine reacts with the organic carboxylic acid at a temperature of 85 DEG C for 2 h, and then deionized water is added so as to produce the novel steel bar rust inhibitor. The invention has the following beneficial effects: the prepared rust inhibitor poses no negative influence on slump, strength and coagulation time of concrete and has good compatibility with a concrete system and a substantial rust inhibition effect.

Owner:TIANJIN YUEMING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com