Surface application composite migration corrosion inhibitor and preparation method thereof

A rust inhibitor and composite technology, which is applied in the field of surface application composite migration rust inhibitor and its preparation, can solve the problem of less surface application, and achieve the effects of simple preparation method, small environmental side effects, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 8 g of triethanolamine and 40 g of deionized water were thoroughly mixed in a glass container at room temperature to obtain a triethanolamine solution. In a beaker, mix 2 g of diethanol monoisopropanolamine, 1 g of diethanolamine, and 15 g of water in a 20ml centrifuge tube, stir with a glass rod, and centrifuge to obtain the supernatant to obtain a mixed solution A. A is slowly added dropwise into the glassware containing the triethanolamine solution B, stirred until evenly mixed, and then sealed to obtain a surface-applied composite migration rust inhibitor organic component precursor. Add 1g of sodium nitrite and 33g of water to the above-mentioned equivalent organic component precursor, stir evenly and store in a sealed tank to obtain a finished surface-applied migration-type rust inhibitor. The entire test process needs to be maintained at room temperature ( Carry out at 25±1)°C; when used in an alkaline environment, add 0.15g per liter of water into chlorine-free ...

Embodiment 2

[0042] At room temperature, 8 g of triethanolamine and 40 g of deionized water were fully mixed in a hydrothermal reaction kettle to obtain a triethanolamine solution. In a beaker, mix 2 g of diethanol monoisopropanolamine, 1 g of diethanolamine, and 15 g of water in a 20ml centrifuge tube, stir with a glass rod, and centrifuge to obtain the supernatant to obtain a mixed solution A. A is slowly added dropwise into the glassware containing the triethanolamine solution B, stirred until evenly mixed, and then sealed to obtain a surface-applied composite migration rust inhibitor organic component precursor. Add 1g of sodium nitrite and 33g of water to the above-mentioned equivalent organic component precursor, stir evenly and store in a sealed tank to obtain a finished surface-applied migration-type rust inhibitor. The entire test process needs to be maintained at room temperature ( Carry out at 25±1)°C; when used in an alkaline environment, add 0.2g per liter of water into chlori...

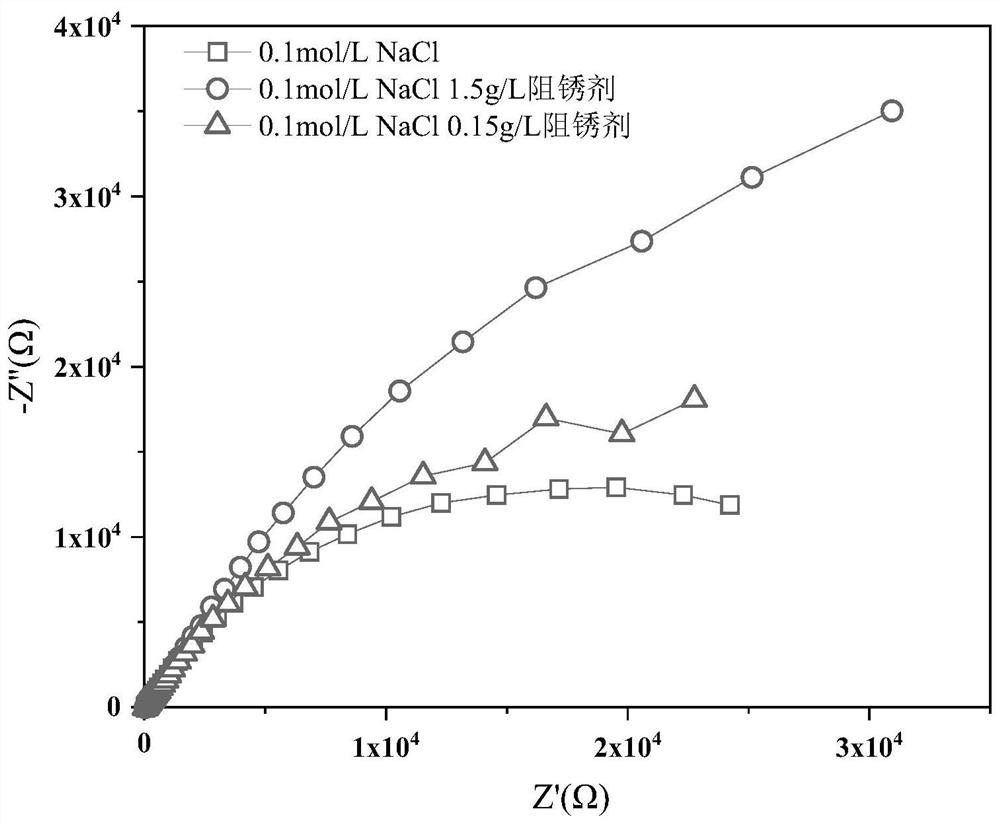

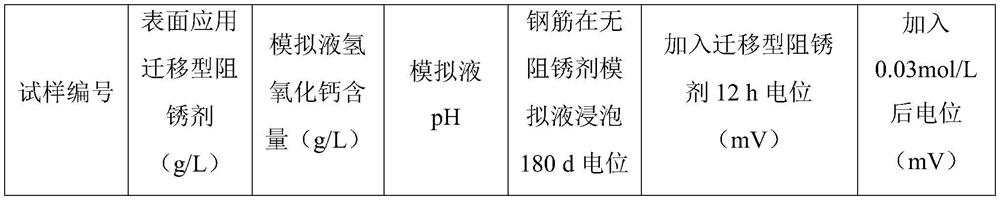

experiment example

[0044] First, the steel bar is immersed in the concrete simulation solution with a pH of 12.68 for 180d to simulate the process of forming a stable passivation film of the steel bar in the actual concrete. Then add, 0.15g / L and 1.5g / L embodiment 1 and the surface application migration type rust inhibitor of embodiment 2, reference sample does not add the surface application migration type rust inhibitor as a control group, after 12 hours with NaCl As a chlorine source, a gradient addition is added every hour to increase the concentration of chloride ions around the steel reinforcement in the simulated liquid, and before the next addition of chloride ions, two kinds of electrochemical tests, including open circuit potential (OCP) and electrochemical impedance spectroscopy (EIS), are performed. The US ASTM C876 standard conducts half-cell potential testing to evaluate the rust-inhibiting performance of the surface-applied migratory rust inhibitor. The test results of electrochem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com