Patents

Literature

65results about How to "To achieve the purpose of anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

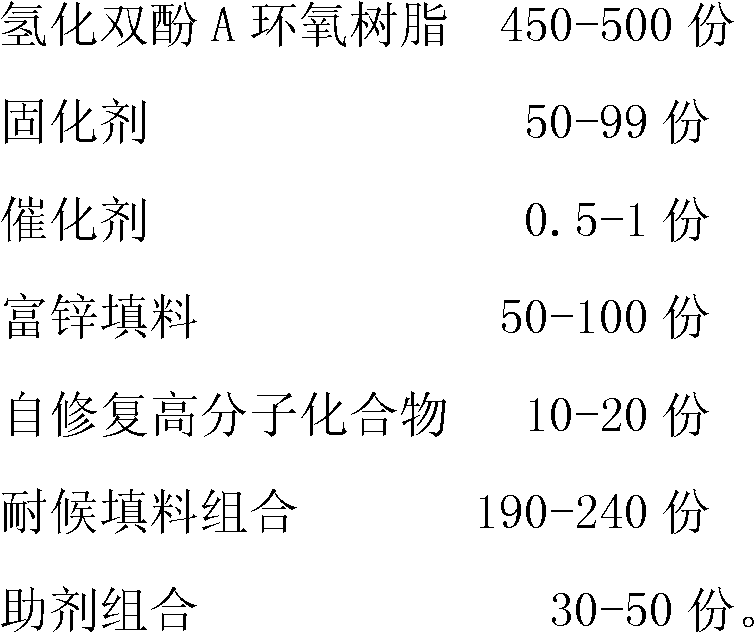

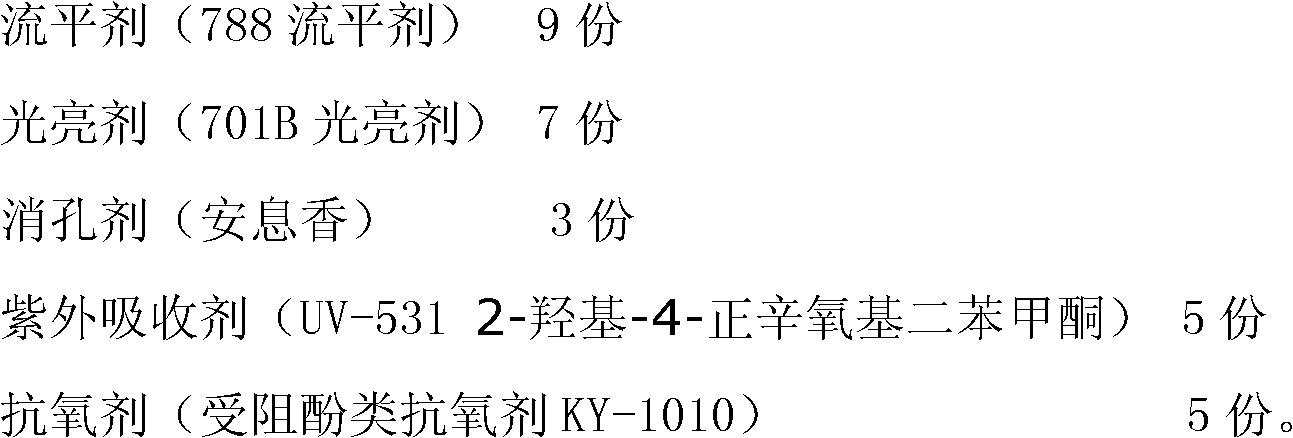

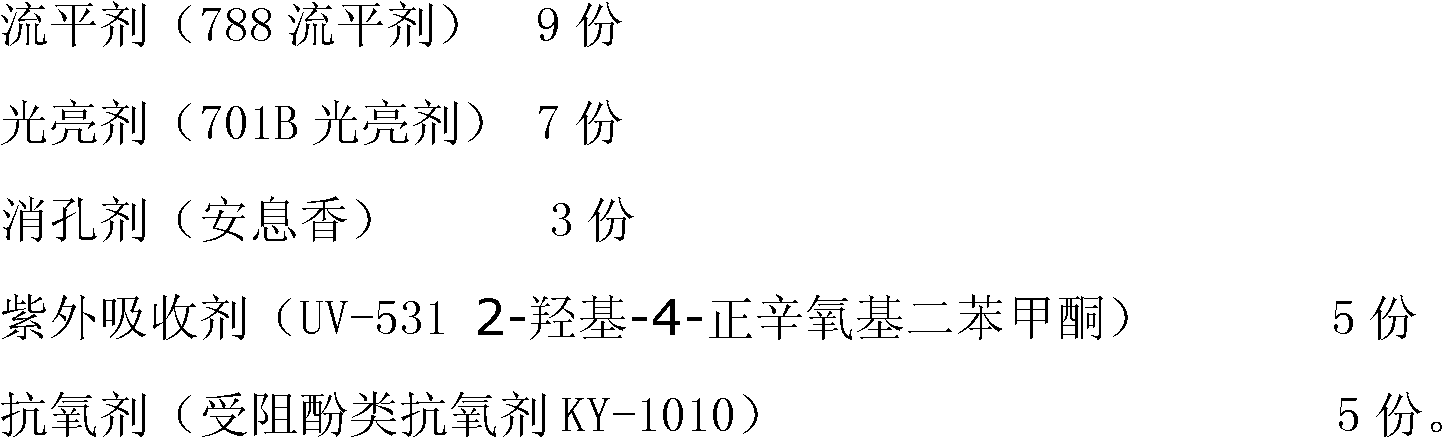

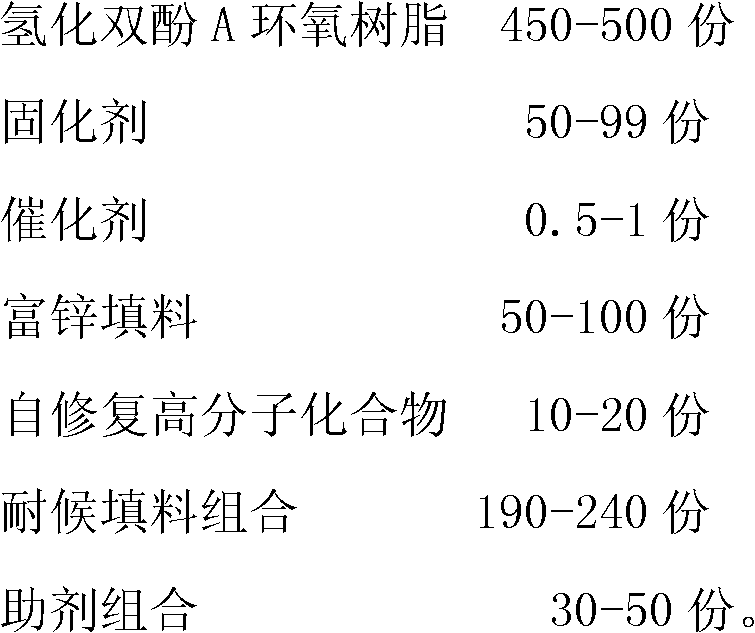

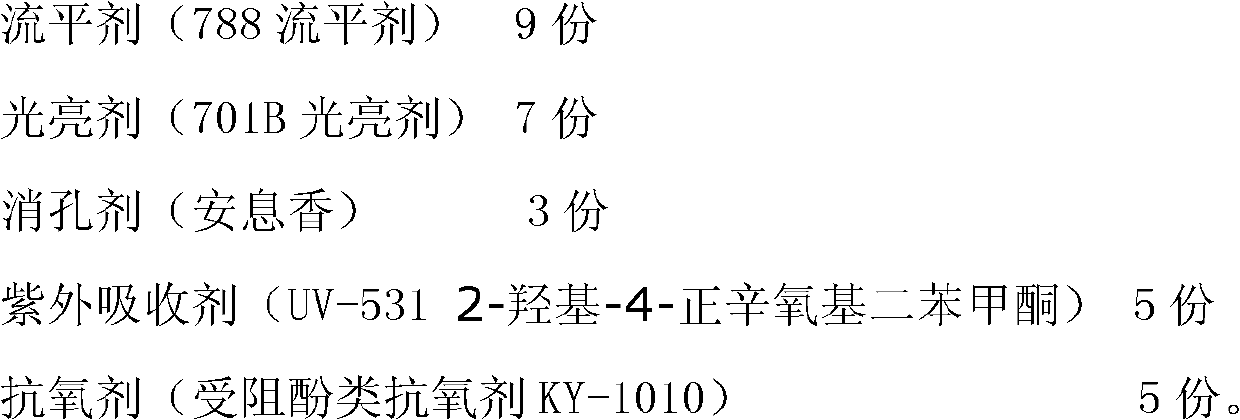

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Heavy anticorrosion super weatherproof powder coating as well as preparation method and application thereof

ActiveCN103173073AEasy to floatProtect against agingAnti-corrosive paintsPowdery paintsEpoxyFluorocarbon

The invention relates to a heavy anticorrosion super weatherproof powder coating. The heavy anticorrosion super weatherproof powder coating comprises the following components of: an epoxy resin particle system containing epoxy resin and an adaptive curing agent A and a fluorocarbon resin particle system containing fluorocarbon resin and an adaptive curing agent B, wherein the weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). The heavy anticorrosion super weatherproof powder coating provided by the invention has excellent weatherproof and anticorrosion properties and also can realize automatic stratification after once coating is carried out, and construction is simple.

Owner:NINGBO SOUTH SEA CHEM

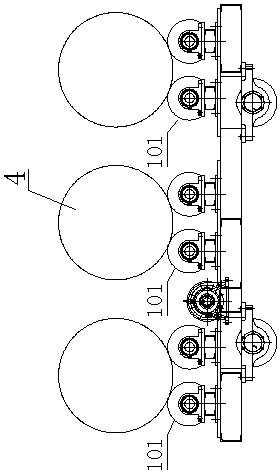

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

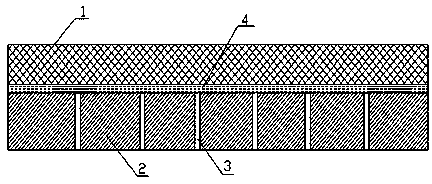

Aqueous antiseptic heat-insulating temperature keeping coating and its making method

The invention discloses a water-based antiseptic insulating paint, which comprises a substratum layer, an intermediate layer and a face layer, the formulation, process for preparation and use are provided for each layer of the paint. The paint has good antiseptic and heat insulation effects.

Owner:辽宁舜德国泰科工贸有限公司

Method for electroplating titanium on surface of metal

The invention relates to a method for electroplating titanium on the surface of metal. The method is characterized in that TiOxCy is taken as a positive pole, metal to be electroplated is taken as a negative pole and molten salt is taken as an electrolyte in the titanium electroplating process. By the method provided by the invention, the aim of corrosion resistance can be achieved through electroplating titanium on the surface of metal with the melting point of 800 DEG C, such as carbon steel, stainless steel, foamy copper and foamy nickel, and other matrixes, the use cost of a titanium material can be greatly reduced, the application field of the titanium metal is widened, and the titanium is not only taken as precious space metal. The electro-deposition on general metal can be realized with least reaction steps and cheapest raw materials; the titanium electroplating is directly finished from the step of electrolyzing the raw materials of titanium, so that the step for preparing the titanium through electrolysis is omitted, the loss of the raw materials and energy sources is reduced, the efficiency of electrolytic current and the utilization ratio of the raw materials are improved, and the titanium electroplating cost is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Food packaging bag

InactiveCN103381934AAvoid Food Safety IssuesImprove food safety performanceSynthetic resin layered productsContainers preventing decayFood packagingEngineering

The invention discloses a food packaging bag and relates to the field of packaging materials. The food packaging bag comprises an outer layer and an inner layer; the inner layer is a graphene antibacterial layer which is provided with small holes; the outer layer is a plastic layer; preservative is arranged between the inner layer and the outer layer. The food packaging bag has the advantages of reducing the contact area of the food preservative and food, achieving the antiseptic purpose, reducing the content of the preservative in the food, solving the food security problem caused by the preservative, avoiding bacteria breeding of the food due to the antibacterial layer and increasing the food security.

Owner:KUNSHAN HAOLIDA PACKING CO LTD

Composite gas drag reducer and preparation method thereof

ActiveCN103450471AGood energy saving effectRaw materials are cheap and easy to getPipeline systemsDibasic acidCarbon chain

The invention claims a composite gas drag reducer and a preparation method thereof. The method comprises the following step of: reacting organic dibasic acid or organic binary acid anhydride, organic amine and monocarboxylic acid with a long carbon chain, thereby obtaining the composite gas drag reducer, wherein the specific steps the reaction are as follows: (1) reacting the organic dibasic acid or organic binary acid anhydride and the organic amine in an inert atmosphere, (2) adding the monocarboxylic acid with the long carbon chain to the reaction system of the finished reaction in the step (1), thereby obtaining the composite gas drag reducer via reaction. The composite gas drag reducer is obvious in drag reduction of the pipeline gas and energy conservation, and has the advantages of cheap and easily available raw material, simplicity in operation, mild reaction conditions, simple processes, low equipment requirements and easiness for industrial production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

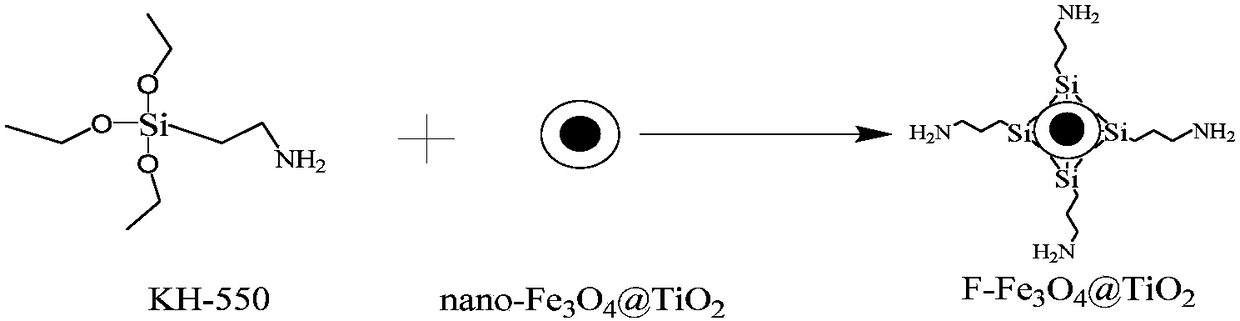

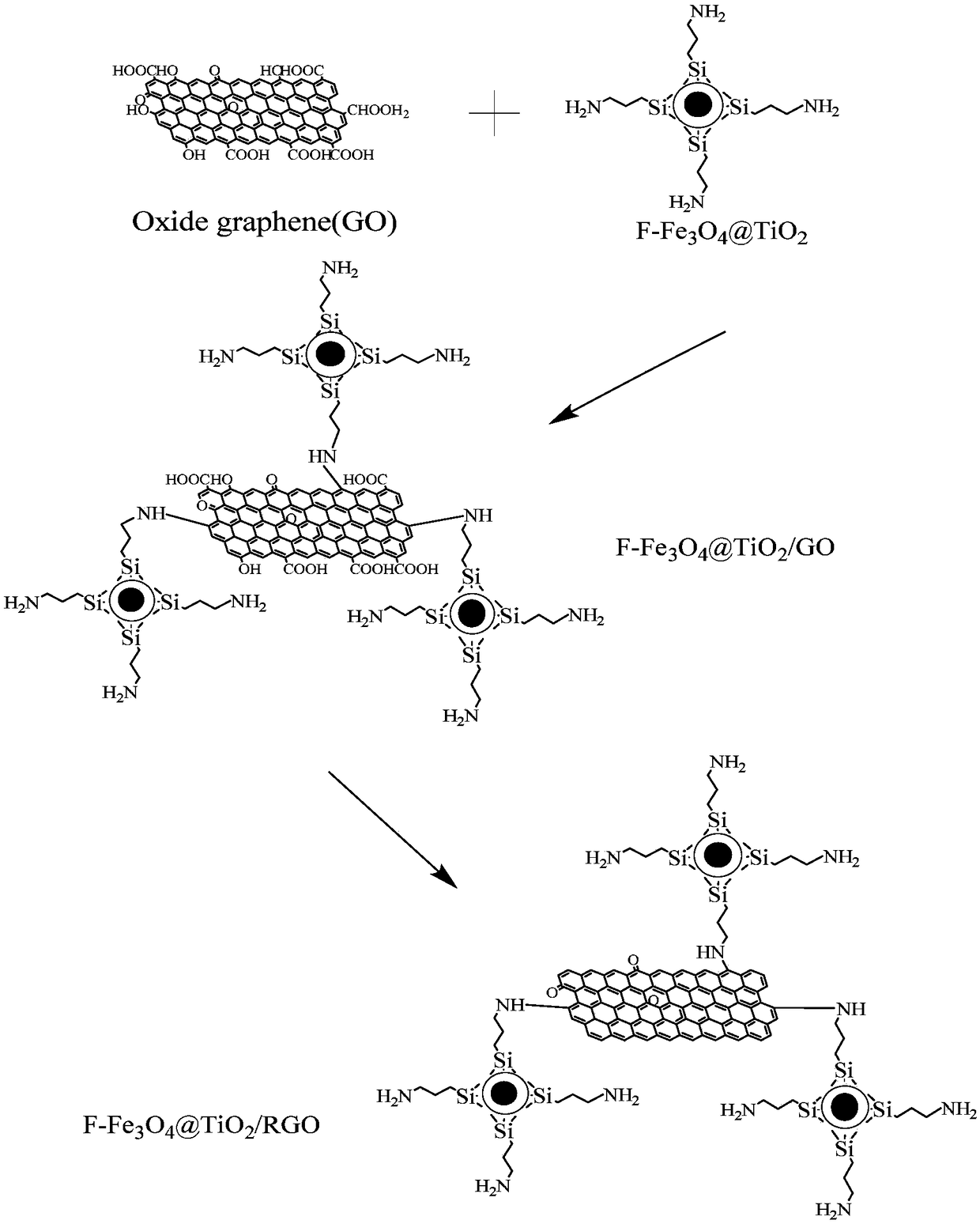

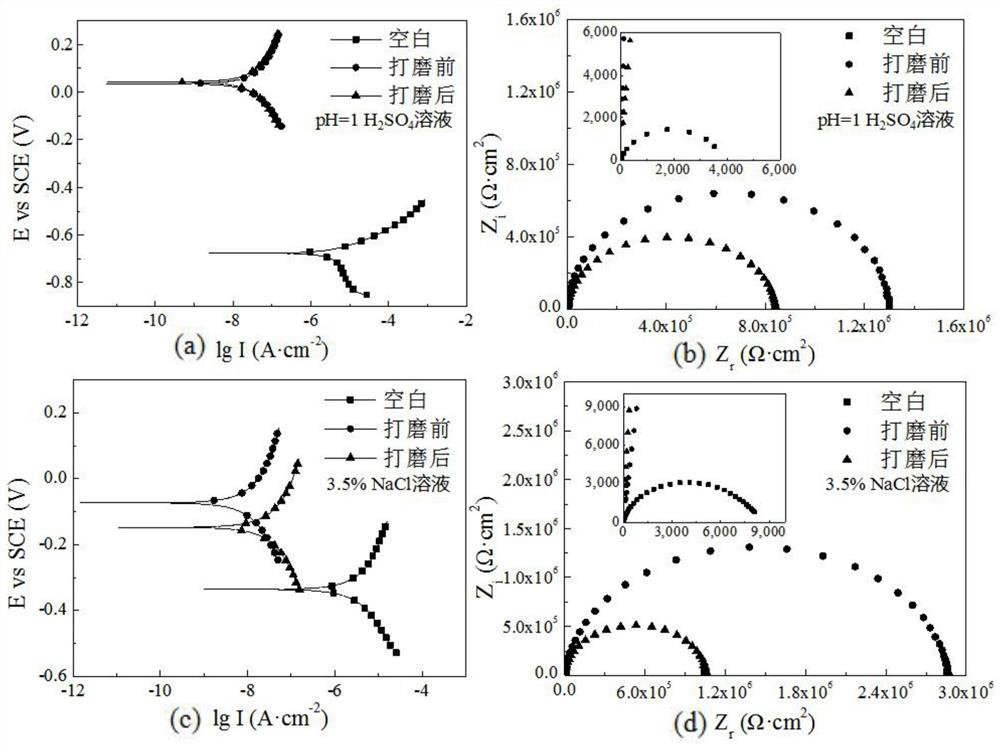

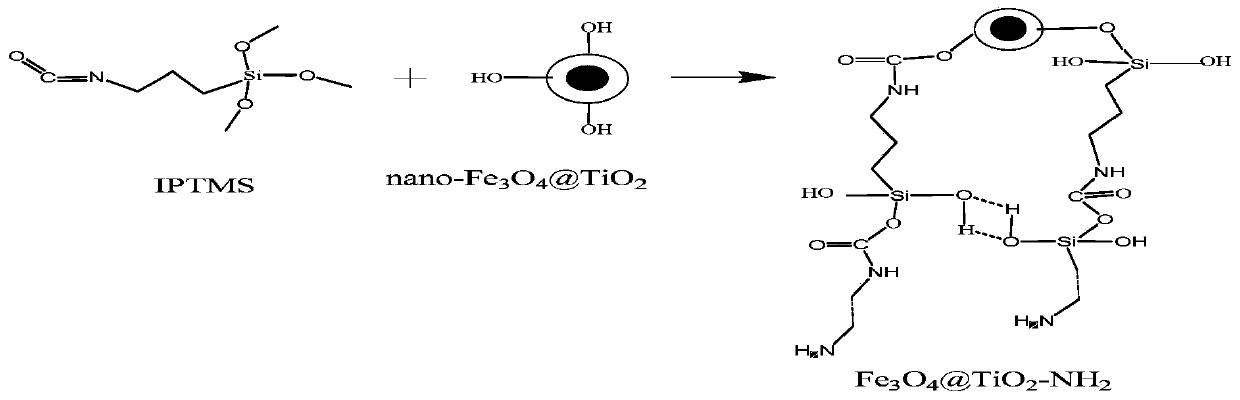

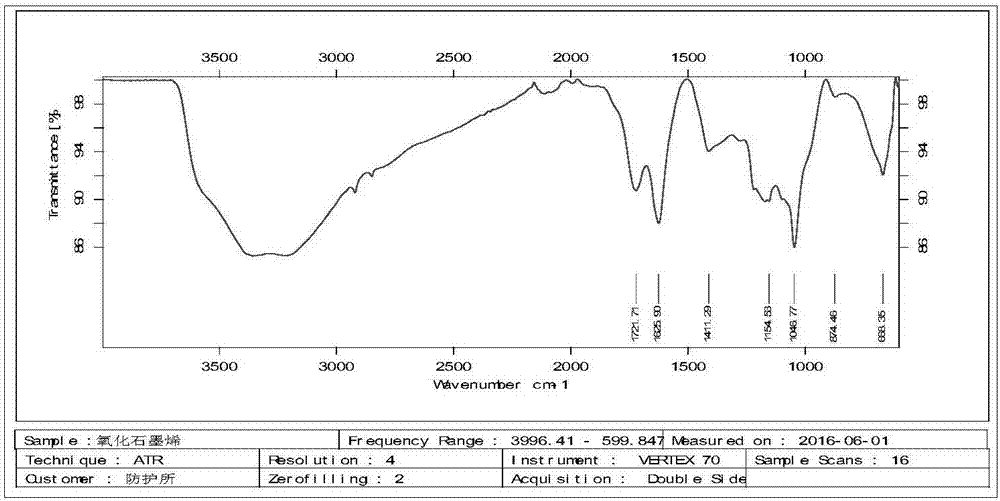

Seawater resistant graphene modified anticorrosive paint and preparation method thereof

InactiveCN108531038AHigh mechanical strengthHigh impact strengthAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention relates to seawater resistant graphene modified anticorrosive paint, which is prepared from the following ingredients in parts by weight: an ingredient A (20 to 30 percent of epoxy resin, 3 to 10 percent of Fe3O4@TiO2 / rGO composite materials, 20 to 30 percent of deionized water, 1 to 5 percent of zinc powder, 5 to 10 percent of zinc phosphate, 5 to 10 percent of talcum powder, 5 to 15 percent of calcium carbonate, 3 to 10 percent of water-based dispersants, 0.5 to 3 percent of coupling agents and 1.5 to 5 percent of other auxiliary agents) and an ingredient B (15 to 30 percent ofcuring agents). The paint has the advantages that the Fe3O4@TiO2 / rGO composite materials are formed at the material surface; Fe3O4@TiO2 nanometer of a core-shell structure has an efficient photocatalysis effect; ocean organic organisms are oxidized and decomposed; meanwhile, the photoinduced cathode protection is realized; the anticorrosive effect is achieved on a base material; rGO is of a unique laminar structure; the adhesive force of the coating can be improved; meanwhile, a physical blocking layer can also be formed; through the performance optimization in various aspects, the paint hasgood antifouling and anticorrosive performance. The seawater resistant graphene modified anticorrosive paint can be widely applied to the fields of facilities such as oil and gas pipelines in marine environment and steel frame structures.

Owner:CHANGZHOU UNIV

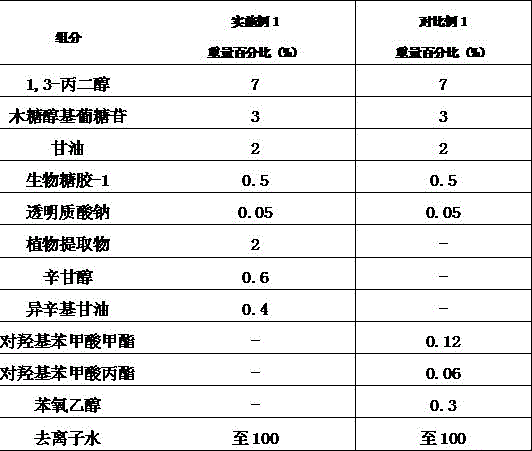

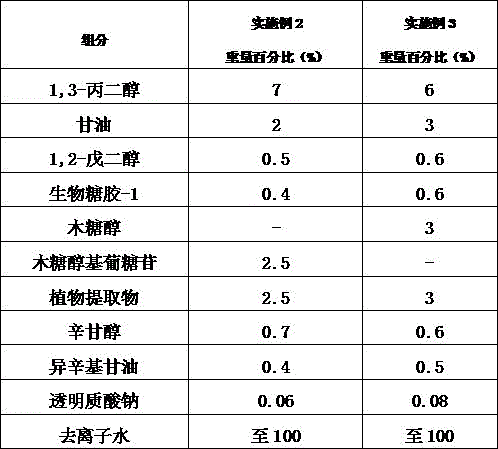

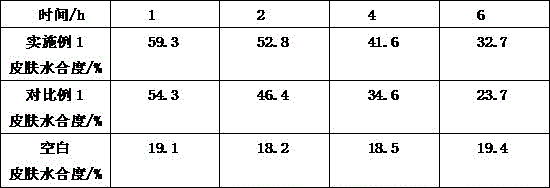

Hydrating toner composition free from preservatives

InactiveCN106377463AOvercoming irritationOvercome securityCosmetic preparationsToilet preparationsPreservative freeCaprylyl Glycol

The invention discloses a hydrating toner composition free from preservatives. The hydrating toner composition free from the preservatives is prepared from the following components in percentage by weight: 0.05 to 10 percent of plant extract, 1 to 20 percent of humectant, 0.1 to 5 percent of caprylyl glycol, 0.1 to 5 percent of isooctyl glycerinum, and the balance of deionized water to achieve 100 percent. The hydrating toner composition is free from any preservative specified by Cosmetic Safety Technology Specification (Year of 2015). Prepared hydrating toner does not use traditional preservatives but adopts an inherent anti-bacterial function of common raw materials of cosmetics to cooperate with plant antibiotic constituents, so as to achieve an antiseptic aim through a synergistic effect, and overcomes the defects of irritation and safety brought by the traditional preservatives.

Owner:GUANGDONG IND TECHN COLLEGE

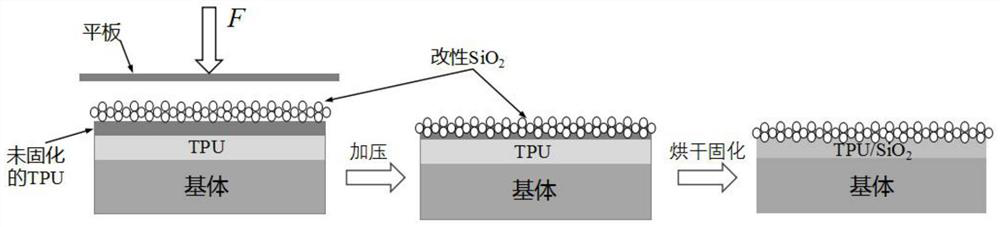

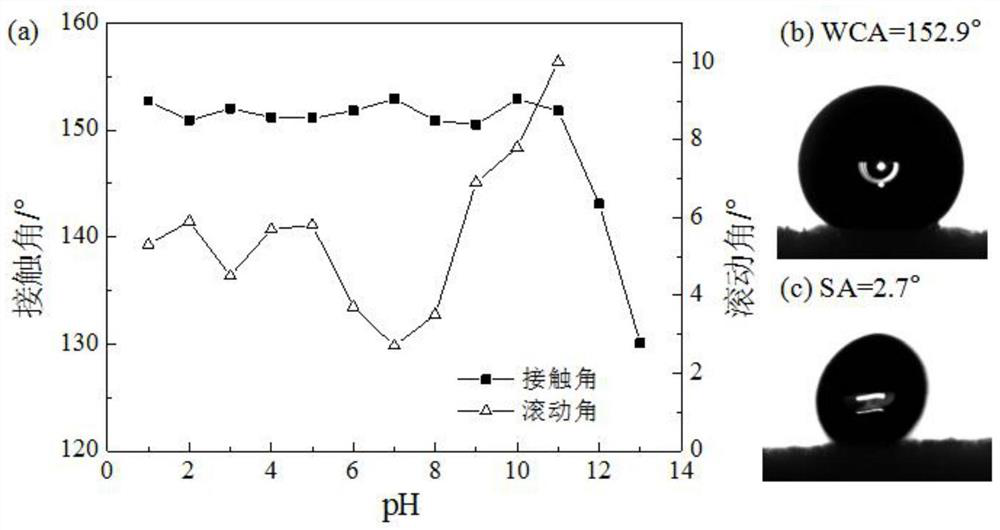

Anti-corrosion anti-icing wear-resistant super-hydrophobic coating and preparation method thereof

ActiveCN112898886AImprove hydrophobicityLow water adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsNano sio2Wear resistance

The invention discloses an anti-corrosion anti-icing and wear-resistant super-hydrophobic coating and a preparation method thereof, and belongs to the technical field of metal protection materials, and the preparation method comprises the following steps: preparation of modified nano SiO2 particles, preparation of TPU / DMF film forming liquid, pretreatment of base material film coating, and preparation of the anti-corrosion, anti-icing and wear-resistant super-hydrophobic coating. The prepared coating has excellent hydrophobicity, corrosion resistance, icing resistance and wear resistance, the safety risk of equipment and components is effectively reduced, and the service life is prolonged; the preparation method is simple, can realize industrial production, and has a good market prospect.

Owner:NORTHWEST UNIV(CN)

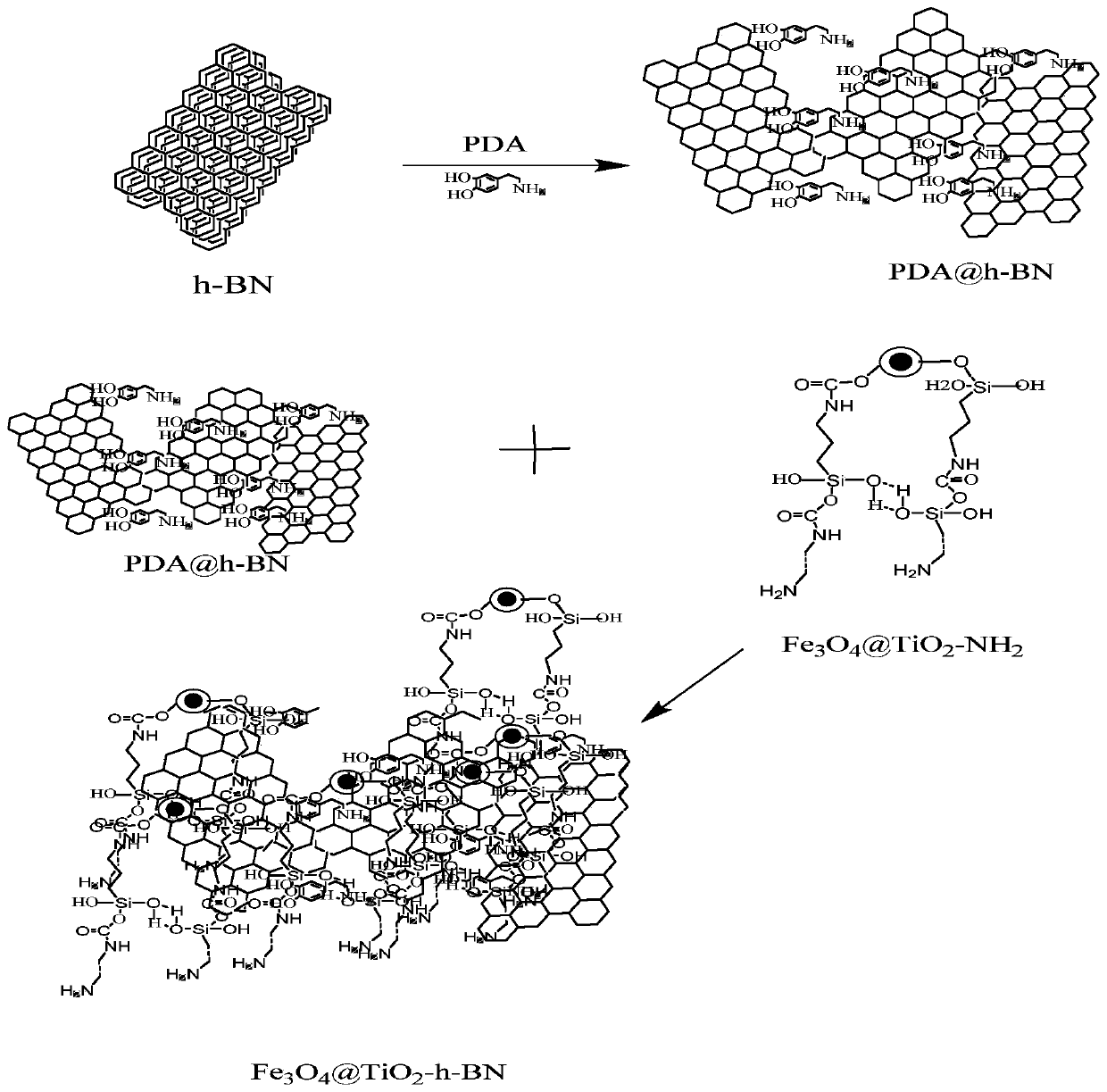

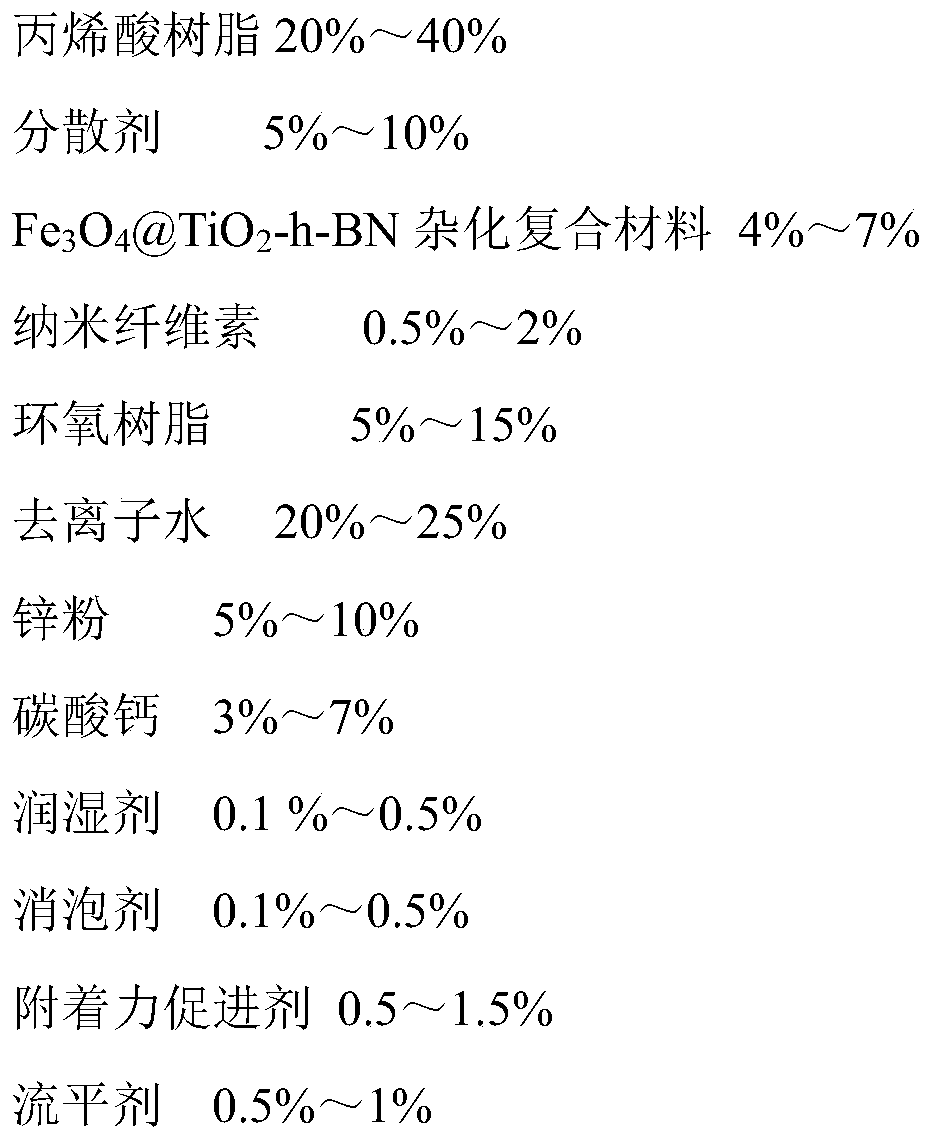

Nanometer composite ocean anticorrosion coating and preparation method thereof

ActiveCN109943169AReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

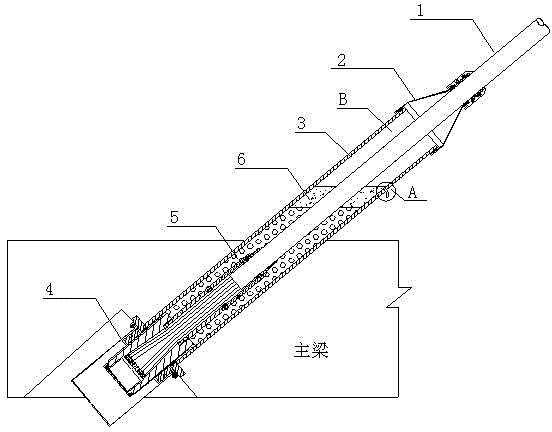

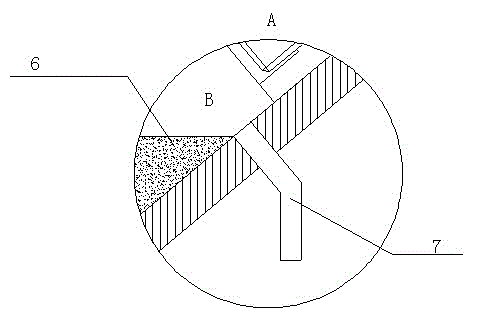

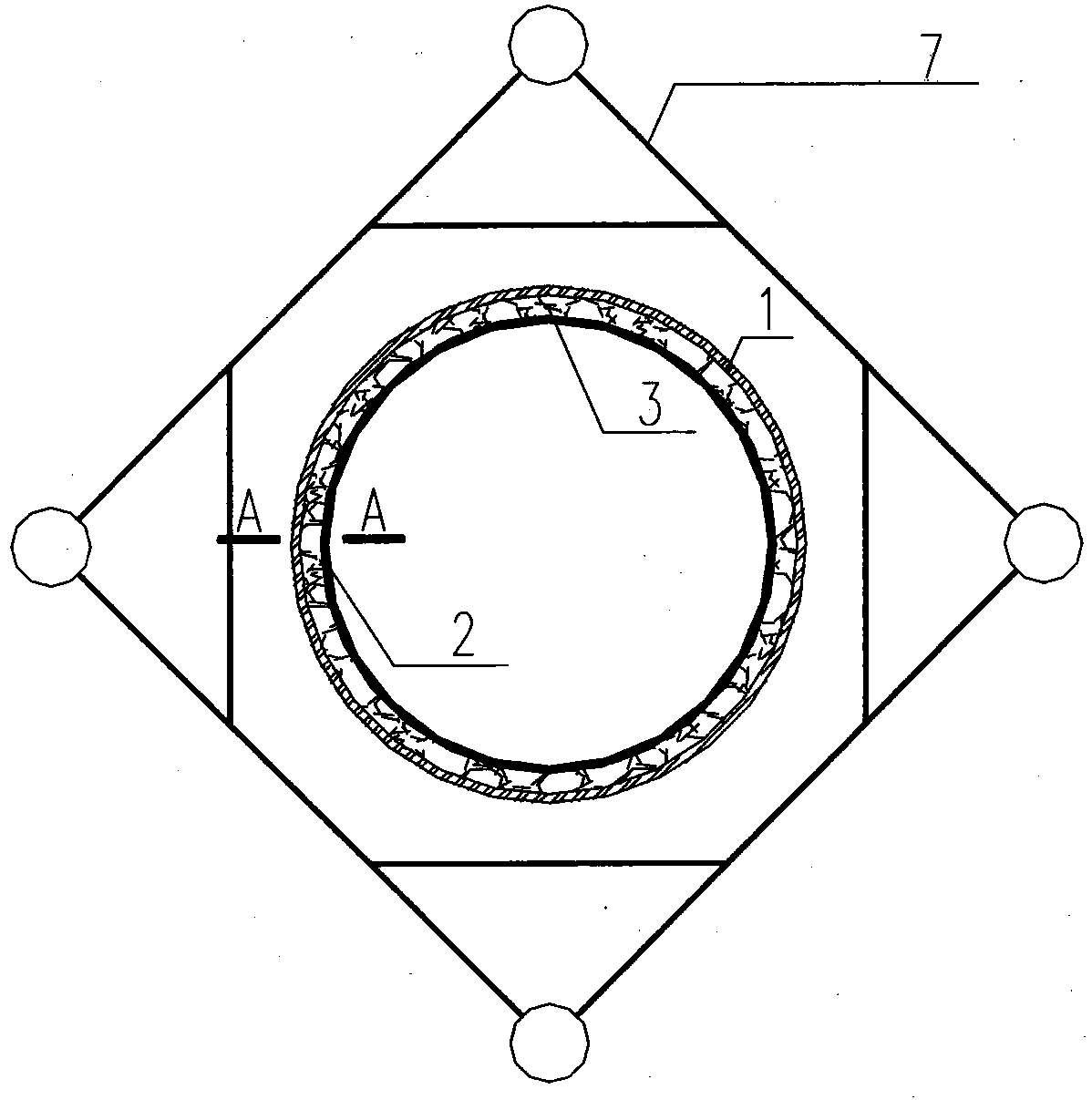

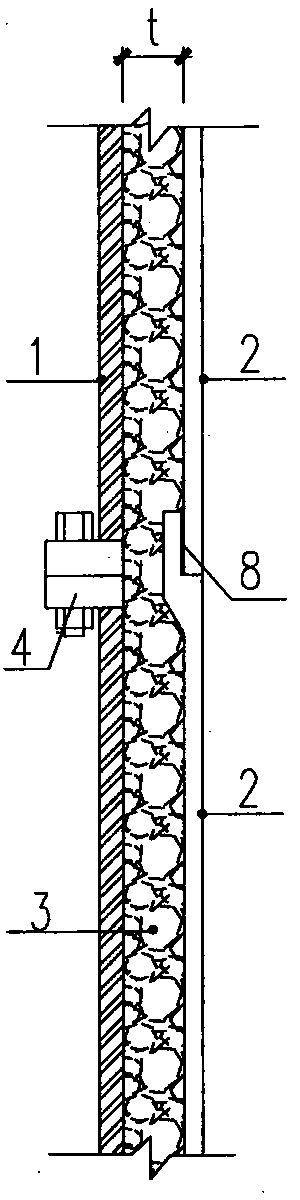

Beam-end embedded pipe sealing structure for stayed cable and sling

ActiveCN104695327ATo achieve the purpose of anti-corrosionAvoid enteringBridge structural detailsPipingCorrosion prevention

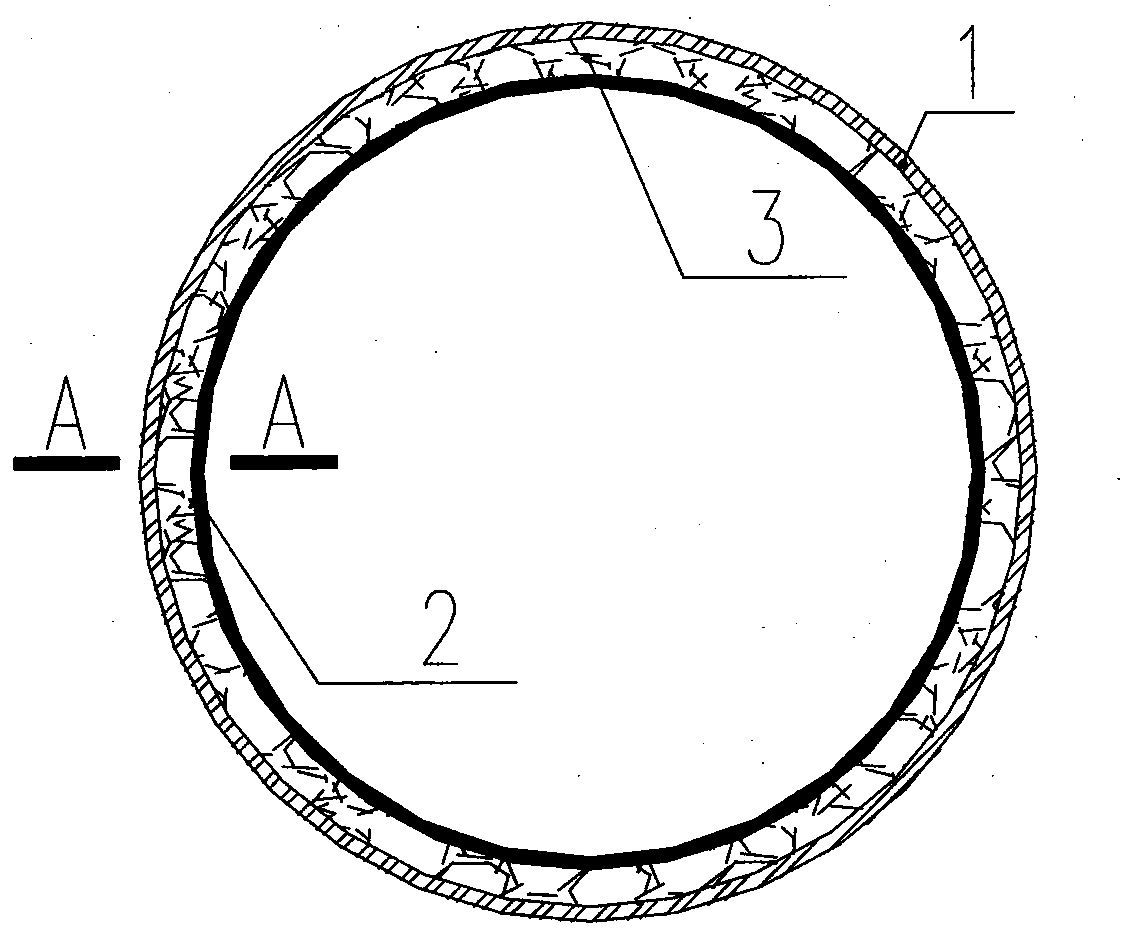

The invention relates to a beam-end embedded pipe sealing structure for a stayed cable and a sling. The beam-end embedded pipe sealing structure comprises an embedded pipe (3) sleeving the periphery of a beam-end stayed cable (1) in a penetrating manner; an annular clearance (B) is reserved between the embedded pipe (3) and the stayed cable (1); a waterproof hood (2) is arranged at the front end of the embedded pipe (3); the stayed cable (1) outwards penetrates through the waterproof hood (2); the beam-end embedded pipe sealing structure is characterized in that a filling layer is arranged in the annular clearance (B); a water drainage pipe (7) communicated with the annular clearance (B) is mounted on the pipe wall of the embedded pipe (3); a water inlet of the water drainage pipe (7) is positioned above the filling layer and is close to the upper surface of the filling layer. The embedded pipe sealing structure can prevent rainwater from entering the annular clearance between the embedded pipe and the stayed cable, and water gathered in the annular clearance can be discharged in time; the beam-end embedded pipe sealing structure is better in embedded pipe corrosion prevention effect.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

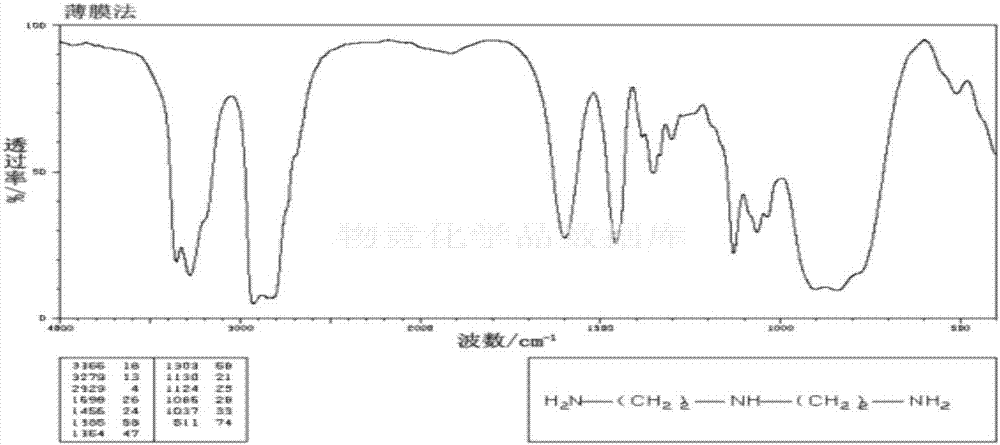

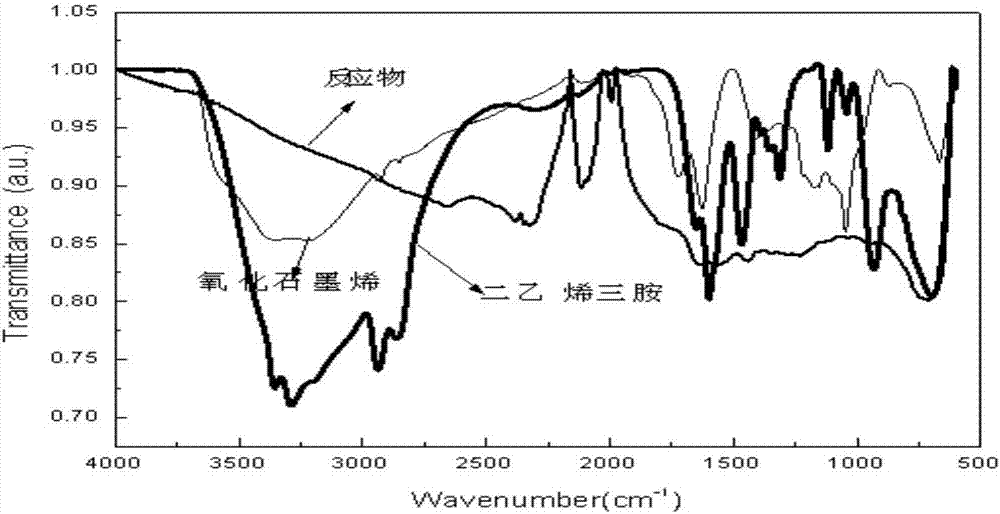

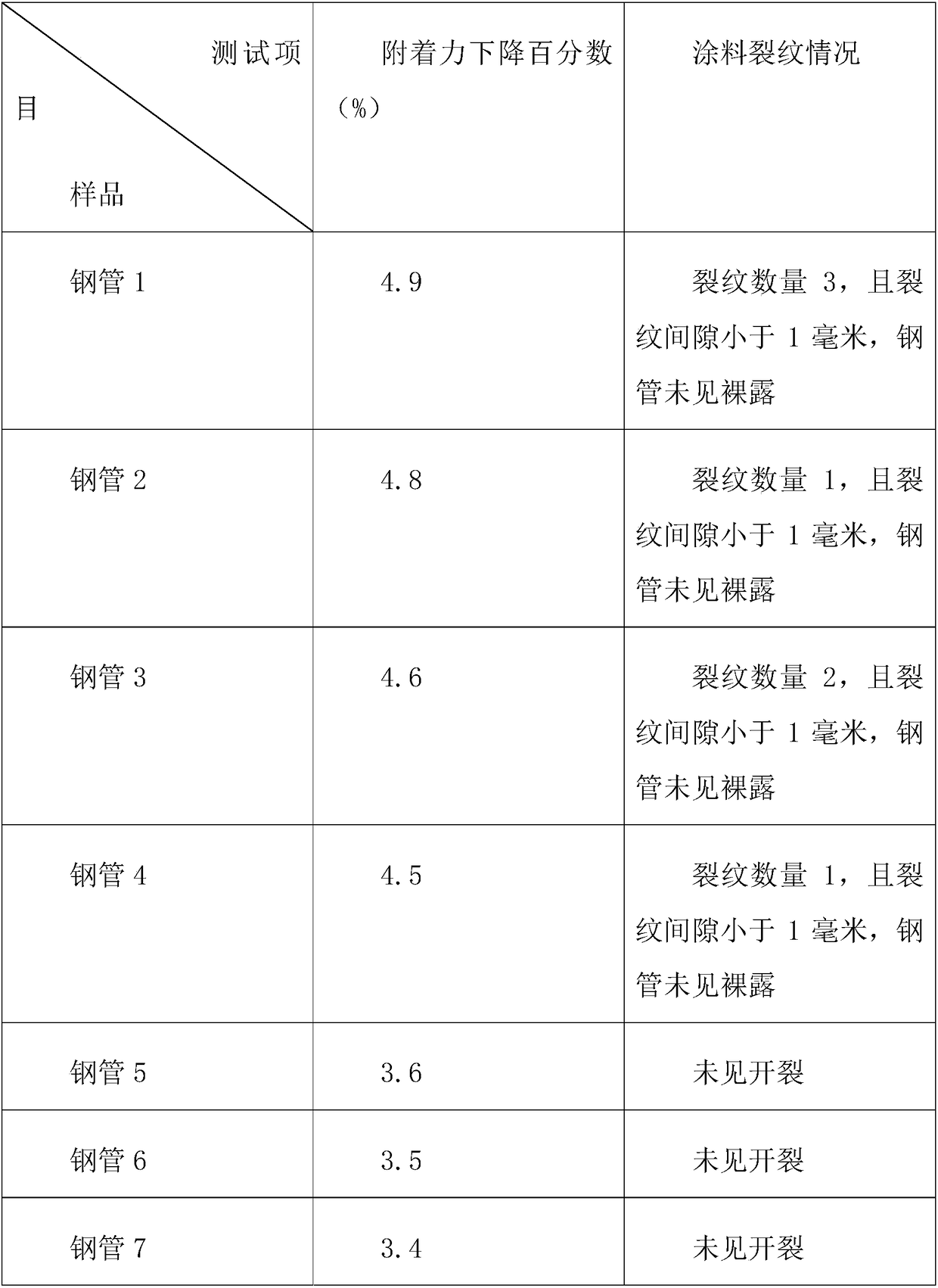

Method for preparing large-area graphene material by adopting suturing method

The invention relates to a method for preparing a large-area graphene material by adopting a suturing method. The preparation method comprises the following steps: adding graphene oxide into a conicalflask filled with one of ethylenediamine, diethylenetriamine, triethylenetetramine and paraphenylenediamine according to a mass ratio of 1 to (100 to 600); then performing dispersion for 30 to 60 minutes by using an ultrasonic dispersing machine, uniformly dispersing the solutions and instantly transferring the solutions into a three-neck flask; heating the flask while stirring, controlling a reaction temperature to be between 100 and 200 DEG C, and performing reaction for 20 to 24 hours; taking reaction solutions after the reaction is finished and uniformly coating a steel plate which is ground and smoothed in advance and is cleaned and dried by using absolute ethyl alcohol with the reaction solutions, and putting the steel plate in a baking oven to be dried for 3 hours at 120 DEG C so as to obtain a graphene film with a sutured continuous structure. According to the method disclosed by the invention, the method for suturing the micron-scale graphene oxide into the graphene film withlarge area, high heat conduction and capability of being firmly adhered on the surface of metal by utilizing a suture agent is innovatively provided.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Wear-resistant anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165097ASimple and easy to prepareSimple methodFireproof paintsLiquid surface applicatorsFiberCarbon fibers

The invention provides a wear-resistant anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The wear-resistant anticorrosivecoating is mainly prepared from the following raw materials in parts by weight: 5 to 25 parts of carbon fiber, 5 to 25 parts of polyphenylene sulfide, 10 to 50 parts of an additive, 30 to 80 parts ofa first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres, wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane couplingagent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the stripe structure of the carbon fiber facilitates dispersing and absorbing the wear force to the coating, so the wear-resistant capacity of the coating is improved; the polyphenylene sulfide can be used as a protective layer of the carbon fiber, so bonding among carbon fibers is more stable; meanwhile, by utilization of the wear resistance of the polyphenylene sulfide, a protective layer to the carbon fiber can be constituted.

Owner:东方工建集团有限公司

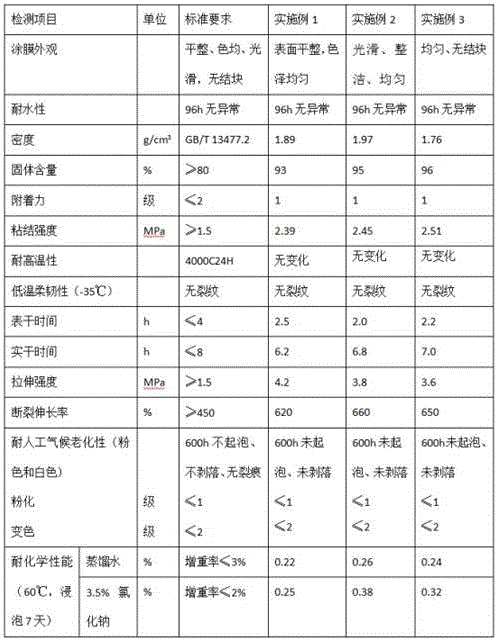

Anti-corrosion weather-proof waterproof paint

InactiveCN106497417AShorten drying timeGood extensibilityFireproof paintsAnti-corrosive paintsWeather resistanceFilm-forming agent

The invention discloses anti-corrosion weather-proof waterproof paint which is prepared from the following raw materials in parts by weight: 70 to 90 parts of film forming agent, 30 to 50 parts of solvent, 15 to 25 parts of coalescing agent, 10 to 20 parts of pigment filler and 10 to 30 parts of auxiliaries. A preparation method of the anti-corrosion weather-proof waterproof paint comprises the steps: grinding the pigment filler into powder in a ball milling mode; sequentially adding the pigment filler powder, the film forming agent, the solvent and the auxiliaries into a plastic tank; stirring for 8 to 10min until the materials are evenly mixed; stirring for 25 to 28min in a rotation speed of 1500r / min to fully disperse the materials; then adding the coalescing agent to disperse for 3 to 5min in a high speed to obtain a dispersion system; adding sodium hydroxide solution to adjust the pH value to 7.0 to 8.0; evenly mixing to obtain the anti-corrosion weather-proof waterproof paint. The tensile strength and the film hardness of the modified film forming agent are obviously improved, the paint which is prepared from the film forming agent matched with other ingredients has good weather resistance and waterproofness in the outdoor condition, also has the obvious effects of corrosion resistance and high temperature resistance and is simple in preparation process.

Owner:南宁马瑞娜装饰工程有限公司

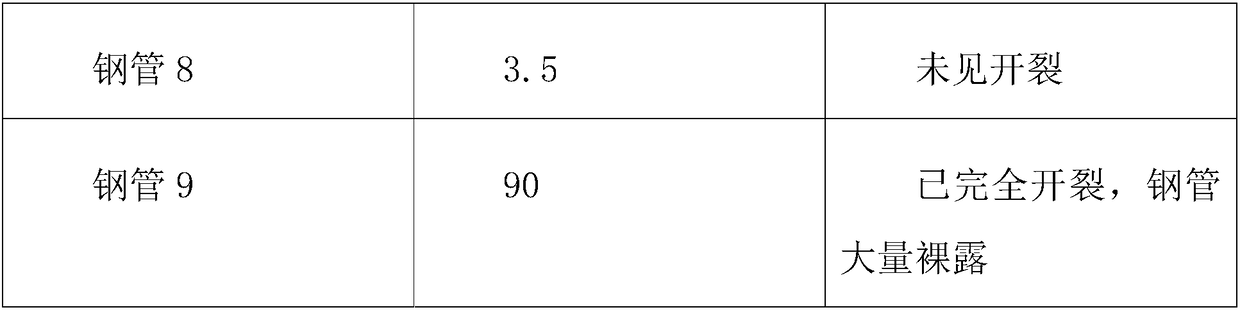

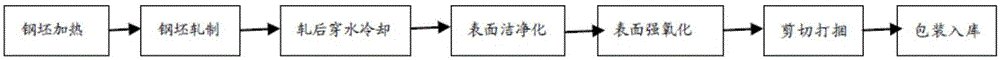

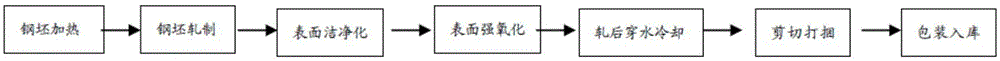

Novel process for producing hot rolled threaded steel with on-line surface rustproof function through post-rolling water penetration controlled cooling process

InactiveCN105132855AReduce the addition of strengthening alloying elementsMeet performance needsWork treatment devicesSolid state diffusion coatingCorrosionHot rolled

The invention relates to a novel process for producing hot rolled threaded steel with an on-line surface rustproof function through a post-rolling water penetration controlled cooling process, discloses a low-cost manufacturing process for producing the hot rolled threaded steel, and is mainly specific to a novel process for producing the hot rolled threaded steel with the on-line surface rustproof function by the adoption of the water penetration hot rolled threaded steel production process after hot rolling. By means of the thermodynamic and dynamic principles of an oxidation reaction of the threaded steel, the threaded steel is subjected to special surface cleaning treatment and an oxygen penetration process before or after the water penetration controlled cooling process of the hot rolled threaded steel, or before and after the cooling process of the hot rolled threaded steel, so that an even and compact oxidation film is formed on the surface of the hot rolled threaded steel rapidly; meanwhile, the components and uniformity of the oxidation film are controlled, so that the propose of corrosion resistance is achieved and the problem that the hot rolled threaded steel produced through the water penetration cooling is corroded severely in the atmosphere is solved. The novel process for producing the hot rolled threaded steel can not only improve the customer satisfaction degree, but also make a positive contribution to energy conservation and environmental protection of China.

Owner:WUHAN SAIEN METALLURGICAL TECH DEV

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266BGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsEpoxyHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Steel-fiberglass composite smoke discharging facility

The invention discloses a steel-fiberglass composite smoke discharging facility. The steel-fiberglass composite smoke discharging facility is characterized in that the steel-fiberglass composite smokedischarging facility comprises a steel outer cylinder and a fiberglass inner cylinder which are different in diameter, the fiberglass inner cylinder is arranged in the steel outer cylinder matched with the fiberglass inner cylinder, and a bearing ring is arranged on the steel outer cylinder; and the bottom of the fiberglass inner cylinder is arranged on the bearing ring, and the steel outer cylinder and the fiberglass inner cylinder are connected in a composite mode through a polymer foaming material. According to the steel-fiberglass composite smoke discharging facility, the structure is simple, joint stress can be achieved, the structure strength requirement is met, and meanwhile the anti-corrosion requirement is met; good heat-preservation performance is achieved, and a heat-preservation layer does not need to be additionally arranged; and the steel-fiberglass composite smoke discharging facility is specially suitable for transformation of an existing steel inner cylinder chimney,the anti-corrosion purpose is achieved by utilizing the existing structure under the premise that the existing steel inner cylinder is not dismounted, thus the engineering manufacturing cost can be greatly reduced, and economic benefits are remarkable.

Owner:上海必立结构设计事务所有限公司

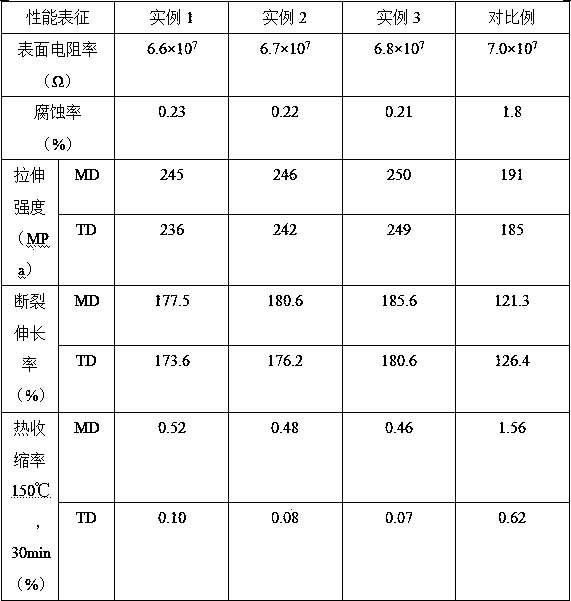

Preparation method for anticorrosion iron-coating film

InactiveCN108997604AImprove conductivityReduce static charge build-upAlkali metal silicate coatingsAnti-corrosive paintsTectorial membraneInositol hexakisphosphate binding

The invention relates to a preparation method for an anticorrosion iron-coating film, belonging to the technical field of metal coating films. According to the invention, a corrosion inhibitor is prepared by reacting ascorbic acid with phytic acid; since the ascorbic acid has the characteristics of low toxicity or non-toxicity and low price, and oxygen atoms in molecules thereof have strong electron donating ability, a firm adsorption protective film can be formed on a metal surface, and can stably exist under alkaline conditions; after bonding of the ascorbic acid with the phytic acid, when phosphate molecules contacts with the surface of a material, hydrophobic chains in the molecules are adsorbed on the surface of the material so as to form a continuous adsorption layer, and hydrophilicgroups thereof face air; since the molecules contain -OH, the molecules can form hydrogen bonds with water molecules, and an adsorbed water layer forms a conductive film, so the surface conductivityof the material is enhanced, static charge accumulation on the surface of the material is reduced, and an infiltration path which oxygen molecules takes to reach the surface of a substrate is extended; and the anticorrosion iron-coating film has excellent barrier properties, improved corrosion resistance, and good application prospects.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

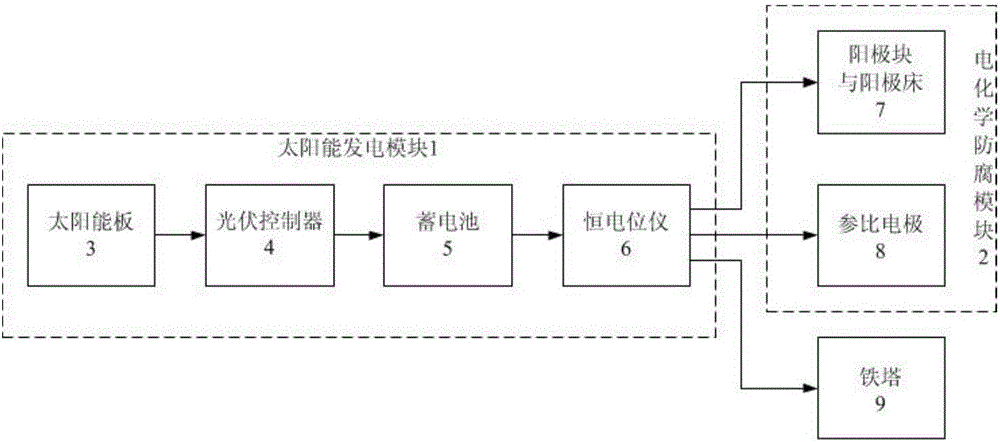

Iron tower corrosion preventing device based on solar power generation

InactiveCN106435599ASolve the problem of significant increase in corrosion rateExtend your lifeEngineeringSolar power

The invention discloses an iron tower corrosion preventing device based on solar power generation, and belongs to the technical field of iron towers. The corrosion preventing device comprises a solar power generation module and an electrochemistry corrosion preventing module. The solar power generation module comprises a solar panel, a photovoltaic controller, a storage battery and a potentiostat, all of which are sequentially connected through a wire. The output cathode end and the zero position cathode connecting end of the potentiostat are both connected with the lower middle portion of an iron tower. The electrochemistry corrosion preventing module comprises an anode block, an anode bed and a reference electrode. The anode block and the anode bed are both connected with the output anode end of the potentiostat. The reference electrode is connected with the sampling signal input end of the potentiostat. According to the iron tower corrosion preventing device, the impressed current cathode protection technology is utilized, the problem that in the coastal area or the industrial area with the severe environment, the corrosion rate of the iron tower is increased is solved, the defects of the traditional galvanizing technology are overcome, the service life of the iron tower is effectively prolonged, steel resources are saved, and the investment cost is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method of metal surface superhydrophobic coating

ActiveCN109127330AEffective isolationNothing producedPretreated surfacesSpecial surfacesGas phasePolyvinyl alcohol

The invention discloses a preparation method of a metal surface superhydrophobic coating. The preparation method comprises the following steps that impurities on the metal surface are cleared by a metal cleaning agent, and then processing is conducted by anti-rust liquid; a metal substrate is immersed in a poval-polyacrylic acid aqueous solution containing nanometer silica, and therefore mass hydroxide radical is attached to the metal surface; and the processed metal substrate and a silylating reagent are positioned in the vacuum conditions, and conduct gas phase reaction to obtain the superhydrophobic surface. The preparation method is simple, required production equipment is simple, and no waste water containing fluoride is produced. The coating can be effectively attached to brass, aluminum alloy and other metal surfaces, applicability is high, the attaching performance is high, and high temperature resistance is achieved.

Owner:SUN YAT SEN UNIV

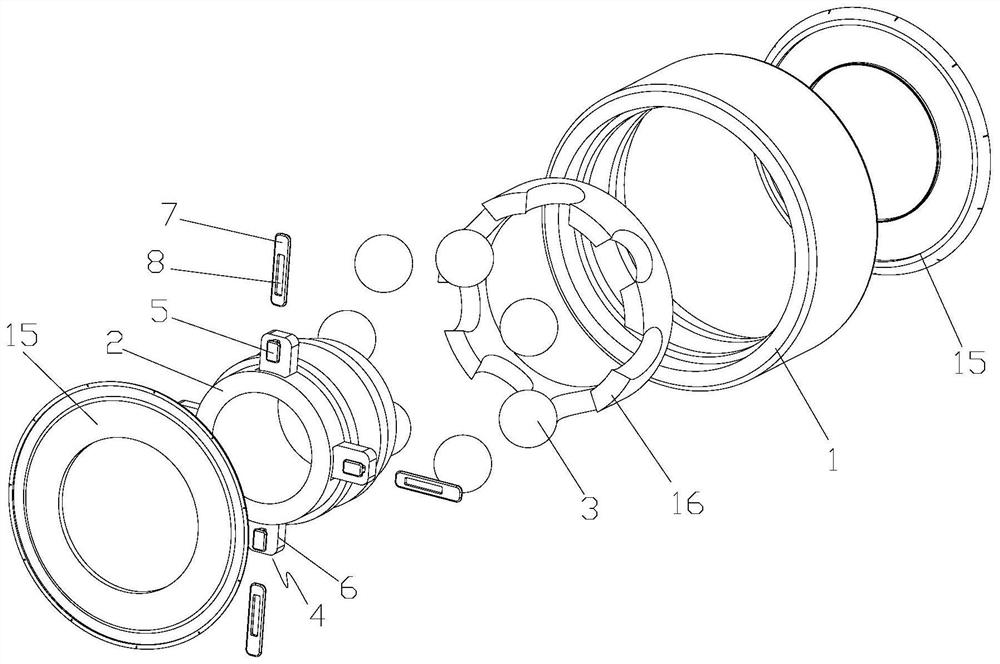

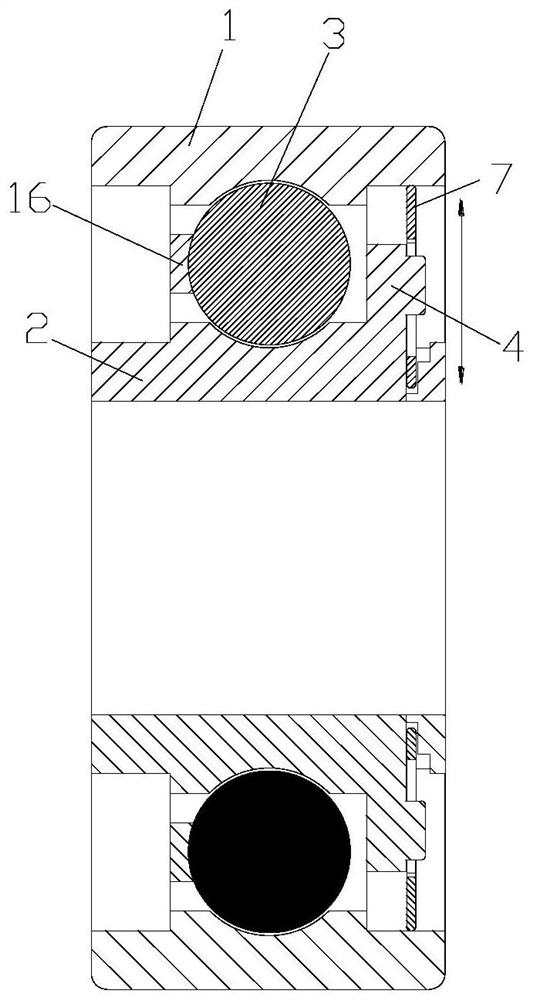

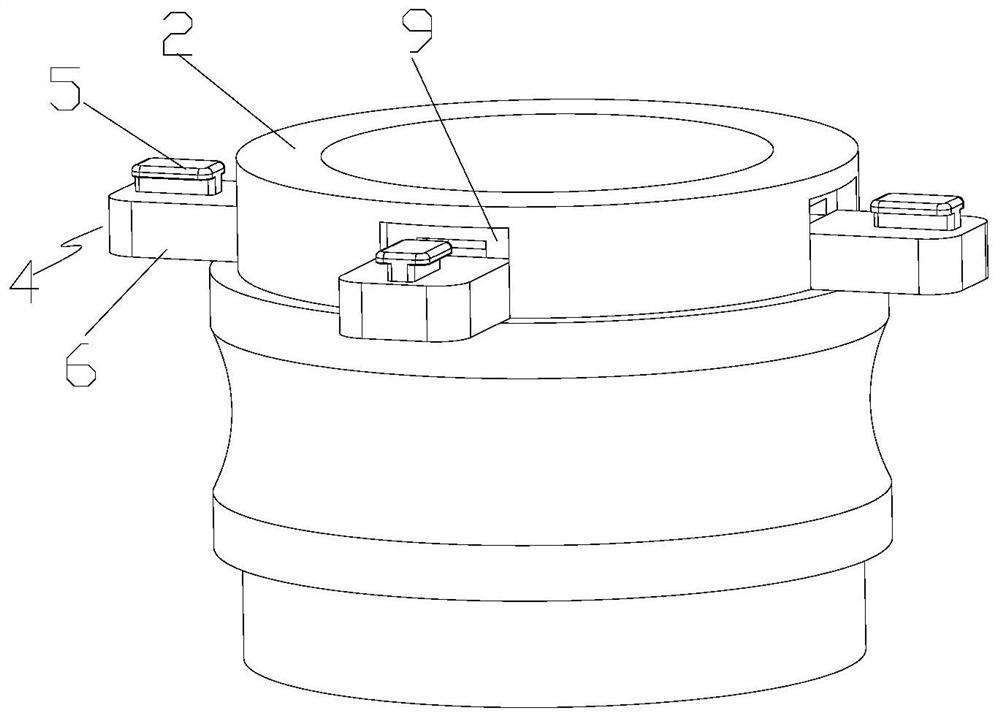

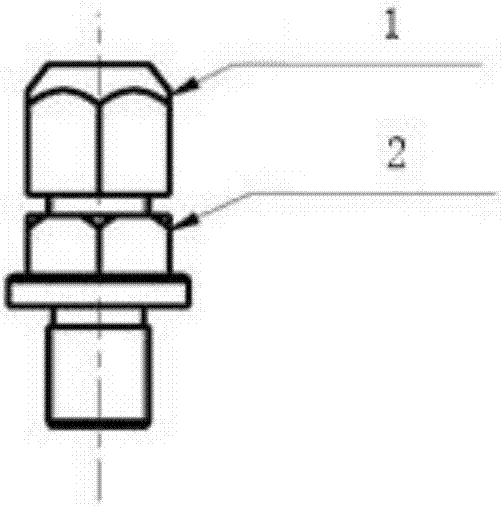

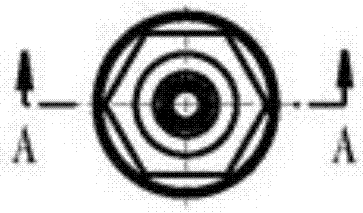

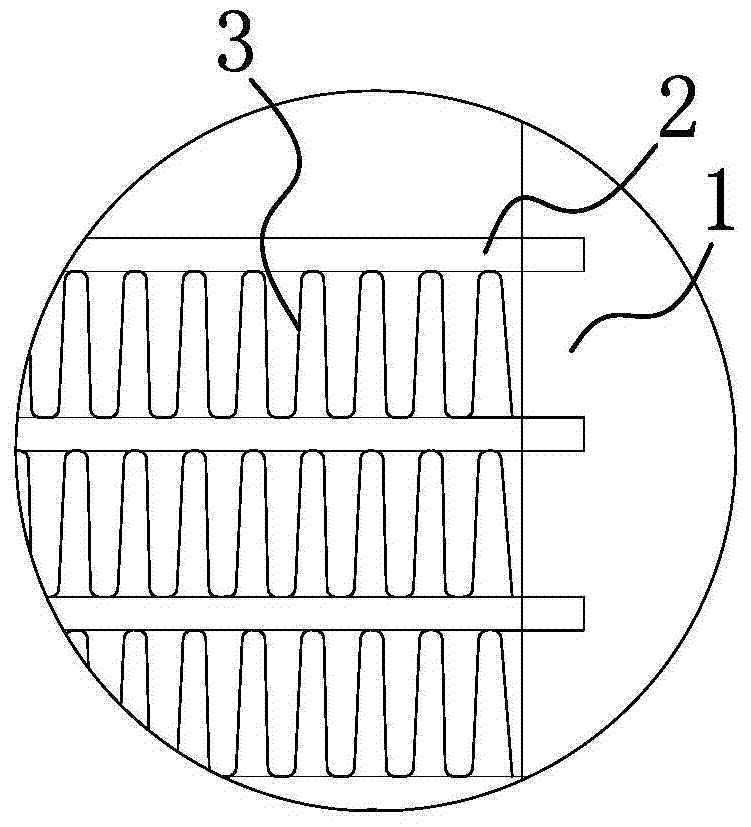

Bearing structure and motor

ActiveCN113431843AGuaranteed anti-corrosion abilityEliminate potential differenceBall bearingsBearing componentsElectric machineryEngineering

The invention provides a bearing structure and a motor. The bearing structure comprises a bearing outer ring (1), a bearing inner ring (2), a rolling body (3) and a conductive structure, the bearing inner ring (2) is sleeved with the bearing outer ring (1), the rolling body (3) rolls in a raceway formed by the bearing outer ring (1) and the bearing inner ring (2), and the conductive structure is arranged between the bearing outer ring (1) and the bearing inner ring (2) and conductively connects the bearing inner ring (2) and the bearing outer ring (1). According to the bearing structure, the potential difference of the bearing inner ring and the bearing outer ring can be effectively eliminated, and the electric corrosion resistance of a bearing is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

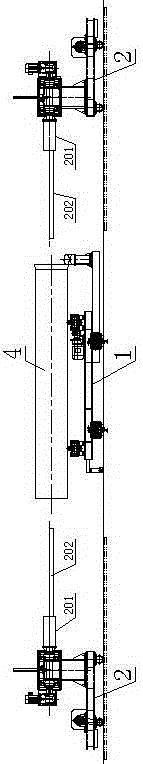

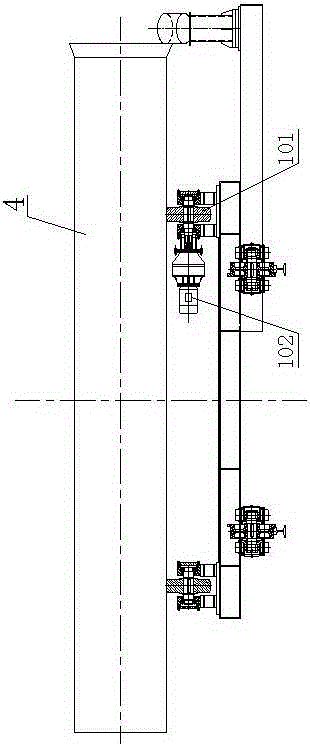

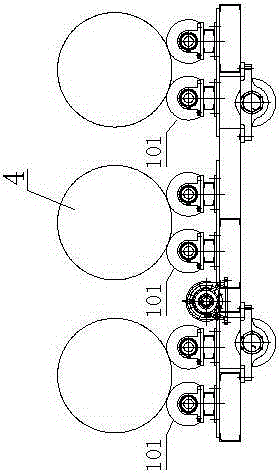

Lining Process of Ductile Iron Pipe

ActiveCN103691625BWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

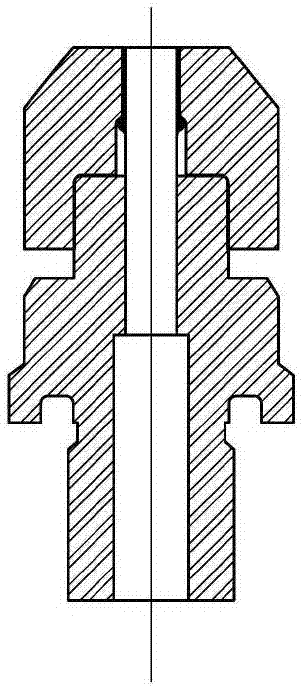

Corrosion-preventing and leakage-proof device for direct-current converter valve cooling water channel

PendingCN107314142AImproved electrical corrosion resistanceAvoiding electrolytic corrosion problemsJoints with sealing surfacesValve housingsEngineeringMechanical engineering

The invention relates to a corrosion-preventing and leakage-proof device for a direct-current converter valve cooling water channel. The corrosion-preventing and leakage-proof device comprises a ferrule connector and a ferrule nut, wherein the ferrule connector and the ferrule nut are arranged coaxially. One end of the ferrule nut is provided with a flexible tube coaxial with the ferrule connector, and arc protrusions are arranged on the inner wall of the portion, making contact with one end of the flexible tube, of the ferrule connector. According to the technical scheme, by adoption of the design of corrosion prevention and leakage prevention for the stainless steel cooling water channel, the purpose of corrosion prevention is achieved through equipotential holding within working time of a converter valve; and the FEP flexible tube is pushed into the tail of the ferrule connector, the ferrule nut is screwed gradually, along with deep-going of the ferrule nut, the FEP flexible tube is gradually pressed through diameter changing and the arc protrusions, proper locking moment of force is achieved, the sealing effect is generated, and thus fluid prevention is avoided.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

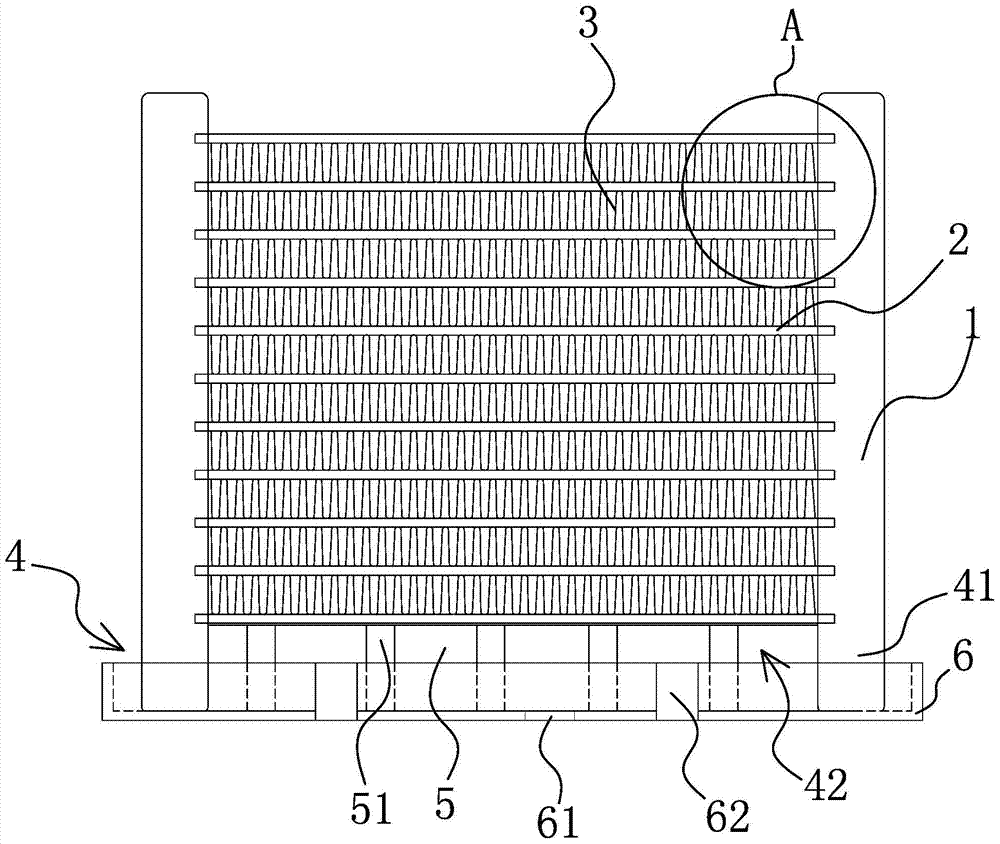

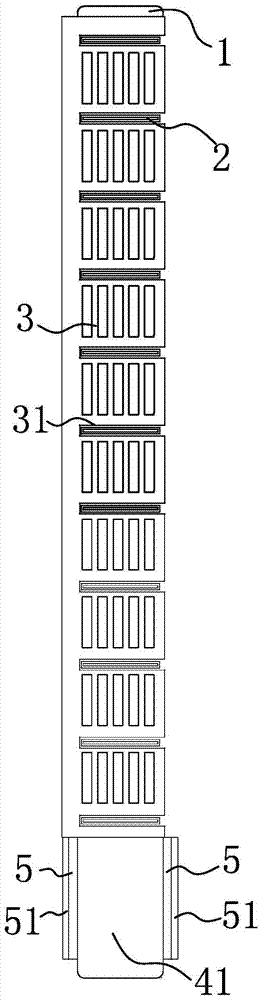

Heat Exchanger

ActiveCN105115318BImprove installation stabilityPlug firmlyStationary conduit assembliesIce removalEngineeringExudate

Owner:浙江新金宸机械有限公司

Method for manufacturing waterproof cable holder

InactiveCN102051857ATo achieve the purpose of anti-corrosionFirmly connectedBridge structural detailsHigh intensityMoisture

The invention relates to a suspension bridge beam, in particular to a cable holder for a suspension bridge. In a method for manufacturing a waterproof cable holder, a left semi-cable holder and a right semi-cable holder and a high-strength bolt for clamping a cable strand are used, and the cable strand comprises a steel wire and a polyethylene sheath outside the steel wire; and the method for manufacturing the waterproof cable holder comprises the following steps of: 1, stripping certain length of polyethylene (PE) from the cable strand, uniformly coating one layer of wet putty on the surface of the naked steel wire, and filling the gap in the steel wire; 2, coating multiple passes of sealant on the inner side contacted with each semi-cable holder, and arranging the cable holders; 3, arranging seal rings at the two ends of the cable holders, coating sealant on the ports of an outlets, coating a layer of sealant on the periphery of the gap generated by closing the two cable holders, and sealing the whole cable holder comprising a bolt hole and a hole inner wall; and 4, fastening two semi-cable holders by using the high-strength bolt. Rainwater or moisture can be effectively prevented from entering the cable holder so as to protect the steel wire in the cable holder from being rusted, and prolong the service life of an inhaul cable.

Owner:SHANGHAI PUJIANG CABLE

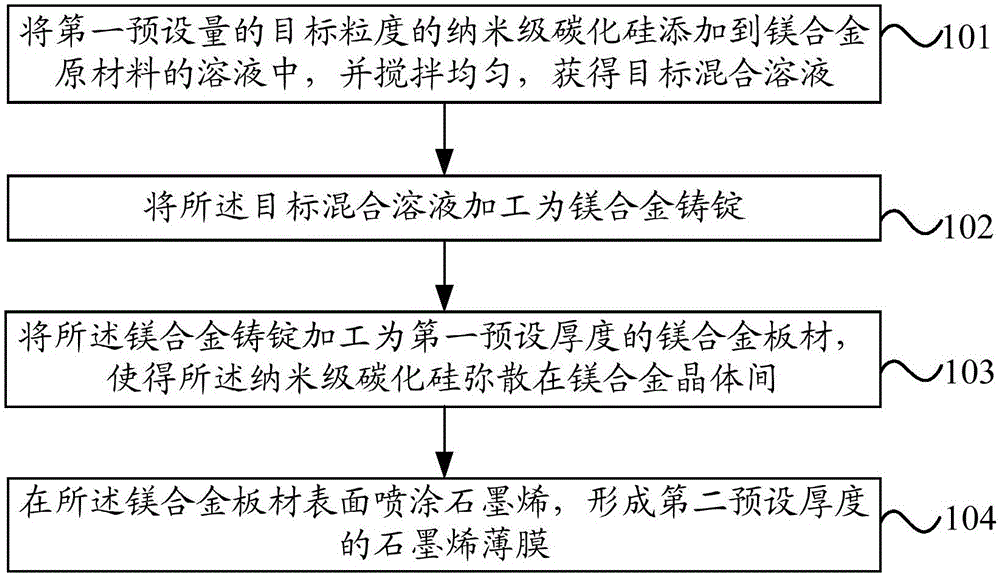

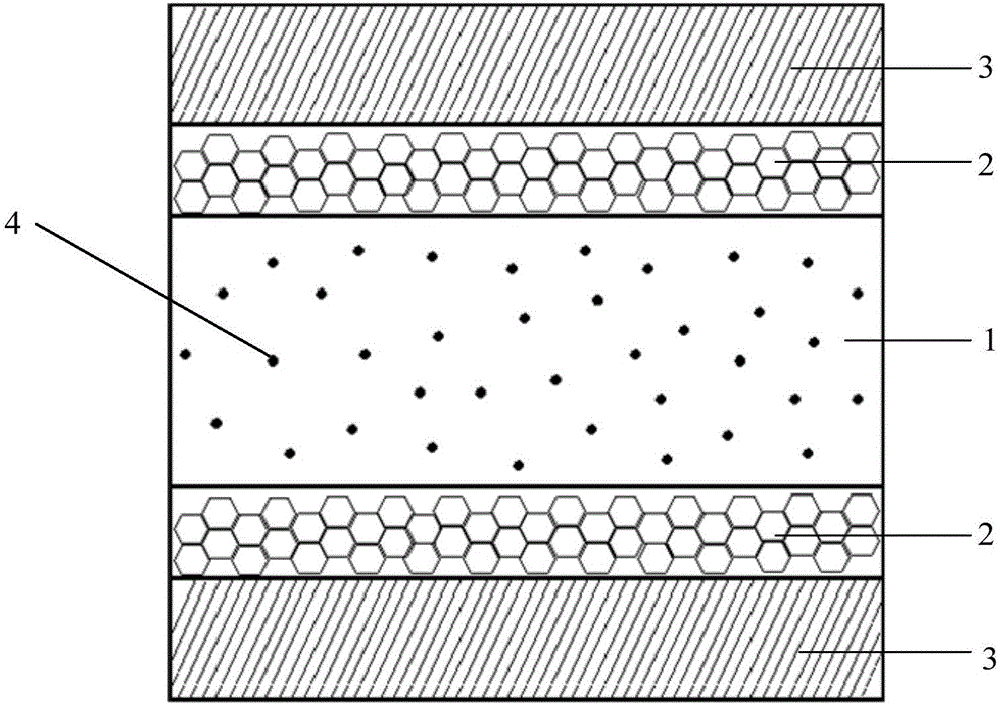

Magnesium alloy plate machining method and magnesium alloy plate

The invention provides a magnesium alloy plate machining method and a magnesium alloy plate. The method comprises the following steps: a first preset quantity of nanoscale silicon carbide with a target particle size is added in solution of a magnesium alloy raw material for uniform stirring to obtain target mixed solution; the target mixed solution is machined as a magnesium alloy ingot; the magnesium alloy ingot is machined as a magnesium alloy plate with a first preset thickness, so that the nanoscale silicon carbide is dispersed in a magnesium alloy crystal; and graphene is sprayed on the surface of the magnesium alloy plate to form a graphene film with a second preset thickness. The nanoscale silicon carbide particles are added in a magnesium alloy to disperse in the magnesium alloy crystal; a graphene corrosion resistant film is sprayed on the surface of the magnesium alloy to obtain the magnesium alloy plate with high strength and corrosion resistance; the application range is widened; and the problems of low strength and weak corrosion resistance in a traditional magnesium alloy plate are solved.

Owner:BEIJING ELECTRIC VEHICLE

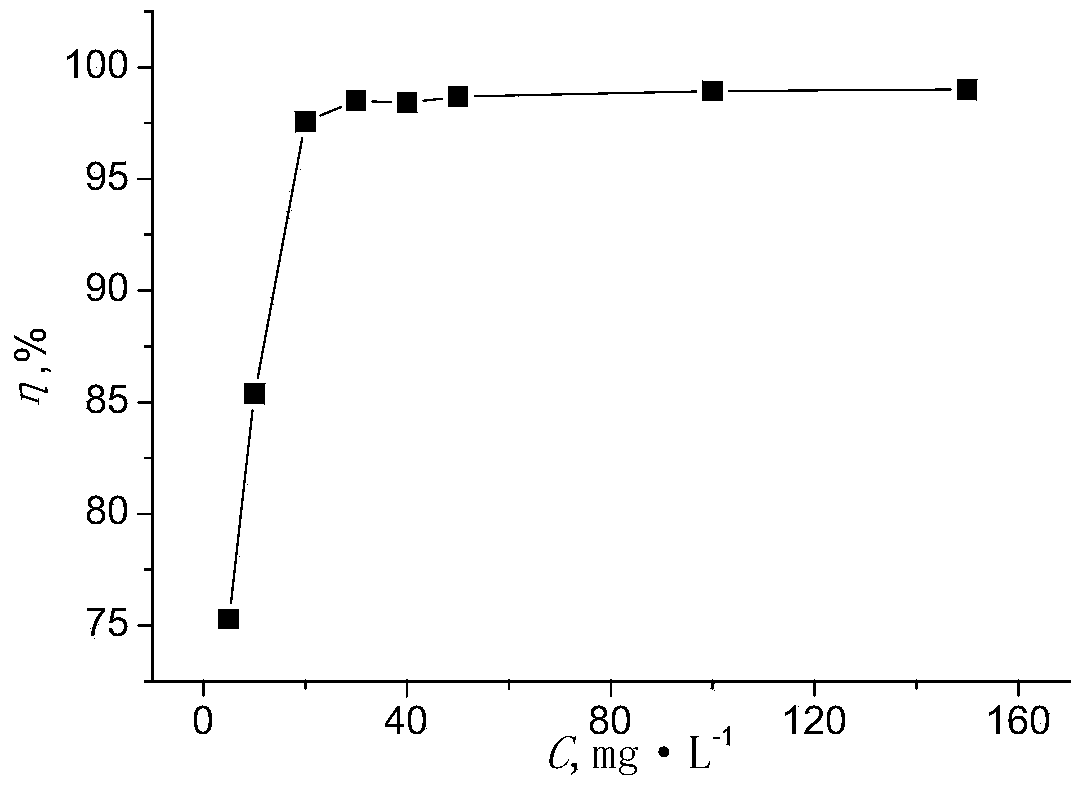

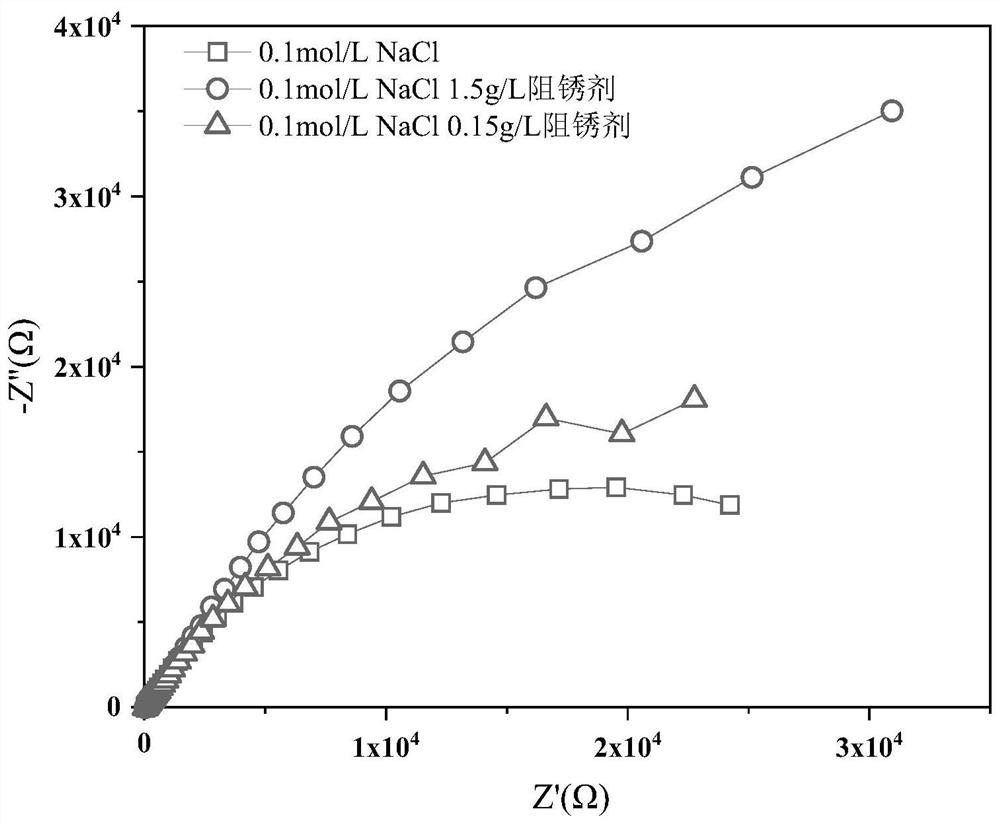

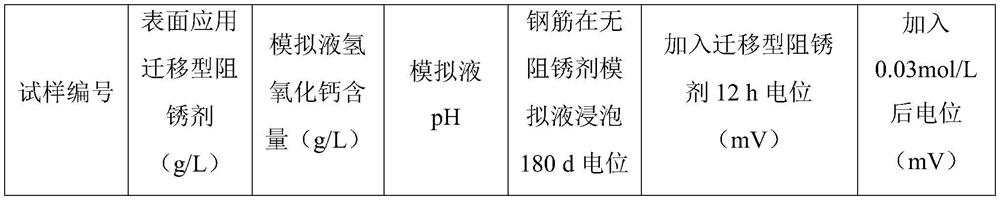

Surface application composite migration corrosion inhibitor and preparation method thereof

The invention relates to the technical field of building materials, in particular to a surface application composite migration corrosion inhibitor and a preparation method thereof. The surface application composite migration corrosion inhibitor comprises an organic component, an inorganic component and water, the organic component is formed by compounding diethanolisopropanolamine and alkylol amine Nn, the inorganic component is nitrite, and n is a natural number. The corrosion inhibitor can be used for corrosion media chloride ions and sulfate ions at the same time, and the defects that a traditional corrosion inhibitor is large in dosage, low in efficiency and single in effect are overcome. The triethanolamine and other alcohol amine components make up the risk of accelerated corrosion caused by insufficient mixing amount of sodium nitrite, and sodium nitrite makes up the possibility of corrosion inhibitor failure after the organic components are degraded under concrete or corresponding alkaline conditions. The organic component and the inorganic component are used together, and the double protection effect is achieved for the steel bar corrosion problem. The surface application composite migration corrosion inhibitor serves as an external component and can perform corrosion protection on an existing reinforced concrete structure in an external coating mode.

Owner:SUN YAT SEN UNIV

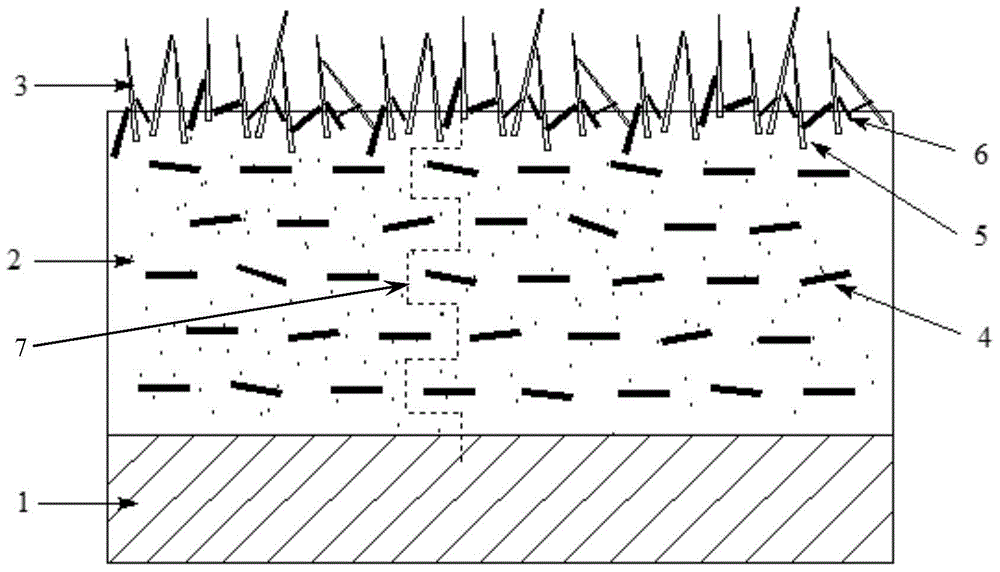

Anticorrosive coating on substrate surface and preparation method thereof

The invention discloses an anticorrosive coating on a substrate surface. The anticorrosive coating is composed of an organic coating on the substrate surface and a hydrophobic modified glass flake assembly structure adhered to the surface of the organic coating. According to the organic coating, chopped glass flakes with surface undergoing compatibility modification are used as a filling material. The glass flake assembly structure is composed of long and chopped glass flakes which have undergone hydrophobic modification. Hydrophobic modified chopped glass flakes are mixed with the hydrophobic modified long glass flakes. One end of at least part of the long glass flakes is embedded into the organic coating, thus achieving a fixation effect; and the other end bulges out of the surface of the organic coating, thus forming a hydrophobic capillary structure with a sharp-pointed surface. When a corrosive liquid drop impacts the material surface, the organic coating has an excellent corrosion protection effect, is especially suitable for dynamic impact wear corrosive liquid environments, such as corrosion protection of ocean splash zone's material surface, turbine blades, oil hydraulic pumps and the like, and is especially suitable for corrosion protection of ocean splash zone's material surface.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165129ASimple and easy to prepareSimple methodAnti-corrosive paintsPolyether coatingsEpoxyMicrosphere

The invention provides an anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The anticorrosive coating is mainly prepared from the following raw materials in parts by weight: 10 to 50 parts of an additive, 30 to 80 parts of a first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres,wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the organic additive is one or two selected from the group consisting ofan ethylene-methacrylic acid copolymer and an ethylene-acrylic acid copolymer; the inorganic additive is one or more selected from the group consisting of TiO2, silicon-based oxides and A12O3; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane coupling agent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the epoxy resin is uniformly coated by a mesh structure, so the time of complete covering of a substrate with the coating is greatly prolonged, and the coating has more durable anticorrosive capacity.

Owner:东方工建集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com