Anti-corrosion weather-proof waterproof paint

A waterproof coating and weather-resistant technology, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problems of no anti-corrosion and weather resistance, complicated process flow, and difficult to stabilize quality, so as to reduce hydrophilicity, reduce costs, Effect of reducing stringiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

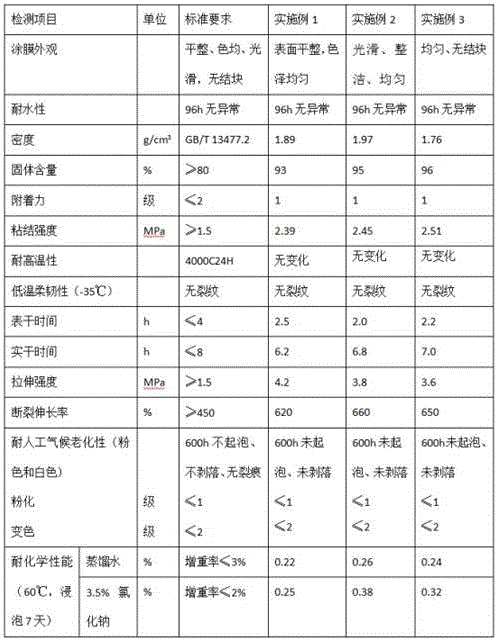

Examples

Embodiment 1

[0030] A kind of anti-corrosion and weather-resistant waterproof coating, in kg, the raw material is

[0031] Film-forming agent: modified casein resin 70kg

[0032] Solvent: Silicone acrylic emulsion 10kg, cellulose acetate butyl solution 10kg and ethylene glycol diacetate 10kg

[0033] Film-forming aids: propylene glycol methyl ether 8kg, ethylene glycol butyl ether 5kg, diethylene glycol monobutyl ether acetate 2kg

[0034] Pigments and fillers: aluminum tripolyphosphate 5kg, zinc oxide 1kg, zinc sulfate 1kg, modified montmorillonite powder 5kg, kaolin 2kg, wollastonite 5kg

[0035] Auxiliaries are plasticizers, dispersants, antifreeze agents, defoamers, and catalysts, of which plasticizers: butyl stearate 5kg, dioctyl phthalate 5kg; dispersants: sodium polyacrylate; antifreeze agents: Propylene glycol; defoamer is polyoxypropylene polyoxyethylene glyceryl ether 6kg; catalyst: zinc caprylate 2kg and dibutyltin dilaurate 1kg

[0036] The preparation method of present embo...

Embodiment 2

[0041] A kind of anti-corrosion and weather-resistant waterproof coating, in kg, the raw material is

[0042] Film-forming agent: modified casein resin 80kg

[0043] Solvent: Silicone acrylic emulsion 15kg, cellulose acetate butyl solution 15kg and ethylene glycol diacetate 15kg

[0044] Film-forming aids: propylene glycol methyl ether 6kg, diethylene glycol monobutyl ether acetate 5kg, ethylene glycol monomethyl ether acetate 4kg

[0045] Pigments and fillers: aluminum tripolyphosphate 2kg, zinc oxide 2kg, zinc sulfate 2kg, modified montmorillonite powder 3kg, kaolin 2kg, wollastonite 8kg

[0046] Auxiliaries are plasticizer, dispersant, antifreeze, defoamer, catalyst, among which plasticizer: dioctyl phthalate 6kg, linseed oil 6kg; dispersant: sodium polyacrylate 3kg; antifreeze: propylene glycol 4kg ; The defoamer is polydimethylsiloxane 6kg; Catalyst: zinc octoate 2kg and dibutyltin dilaurate 1kg

[0047] The preparation method of this embodiment is:

[0048] (1) Take ...

Embodiment 3

[0052] A kind of anti-corrosion and weather-resistant waterproof coating, in kg, the raw material is

[0053] Film-forming agent: modified casein resin 90kg

[0054] Solvent: Silicone acrylic emulsion 16kg, cellulose acetate butyl solution 16kg and ethylene glycol diacetate 16kg

[0055] Film-forming aids: Diethylene glycol monobutyl ether acetate 10kg, ethylene glycol monobutyl ether acetate 5kg

[0056] Pigments and fillers: aluminum tripolyphosphate 3kg, zinc oxide 1kg, zinc sulfate 2kg, modified montmorillonite powder 3kg, kaolin 4kg, wollastonite 7kg

[0057] Auxiliaries are plasticizer, dispersant, antifreeze, defoamer, catalyst, wherein plasticizer: dioctyl phthalate 10kg; Dispersant: sodium polyacrylate 4kg; Antifreeze: propylene glycol 3kg; Foaming agent: polyoxypropylene polyoxyethylene glyceryl ether 6kg; catalyst: zinc caprylate 1kg and dibutyltin dilaurate 1kg

[0058] The preparation method of this embodiment is:

[0059] (1) Take an appropriate amount of cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com