Patents

Literature

1007results about "Protein coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

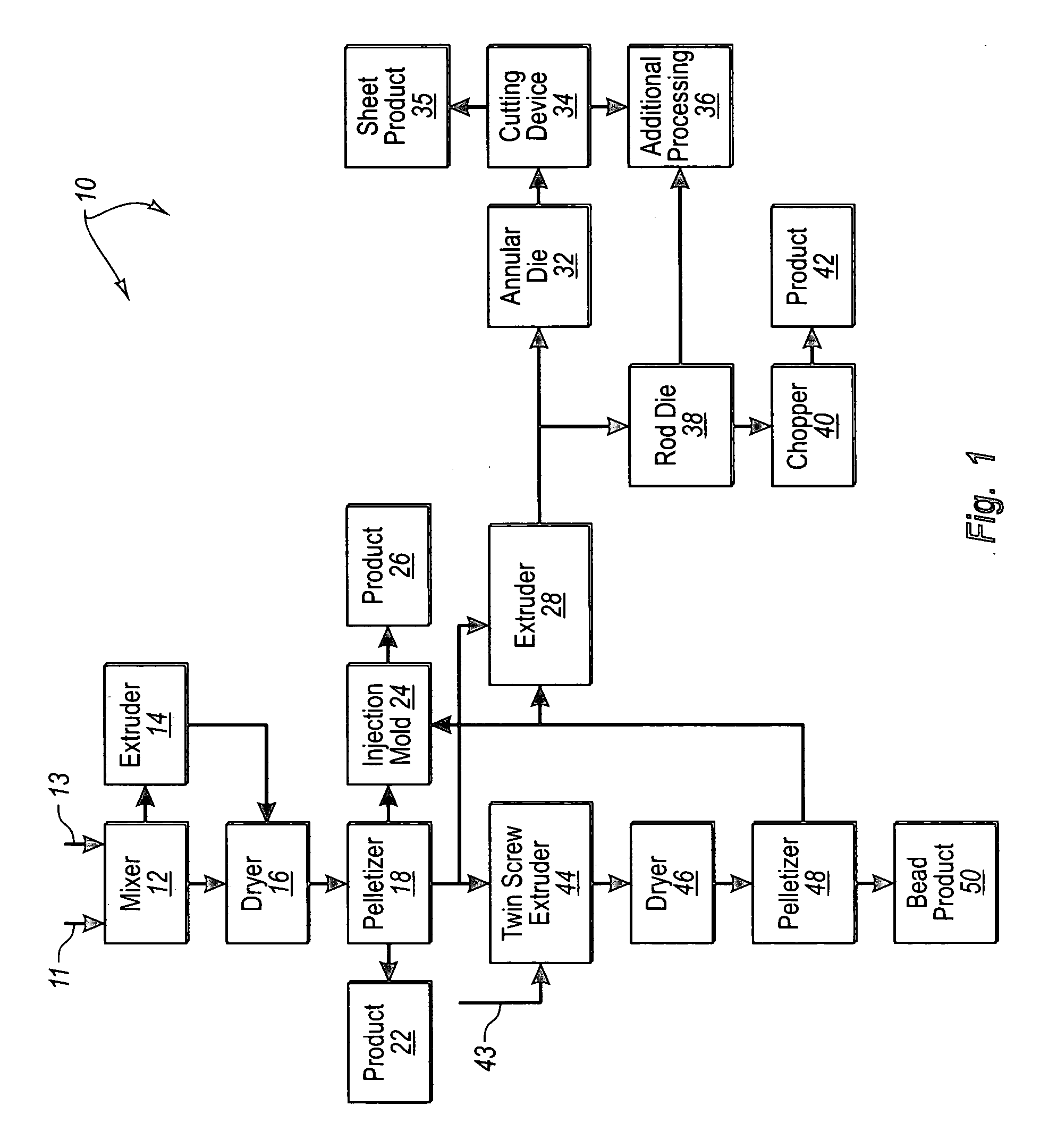

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

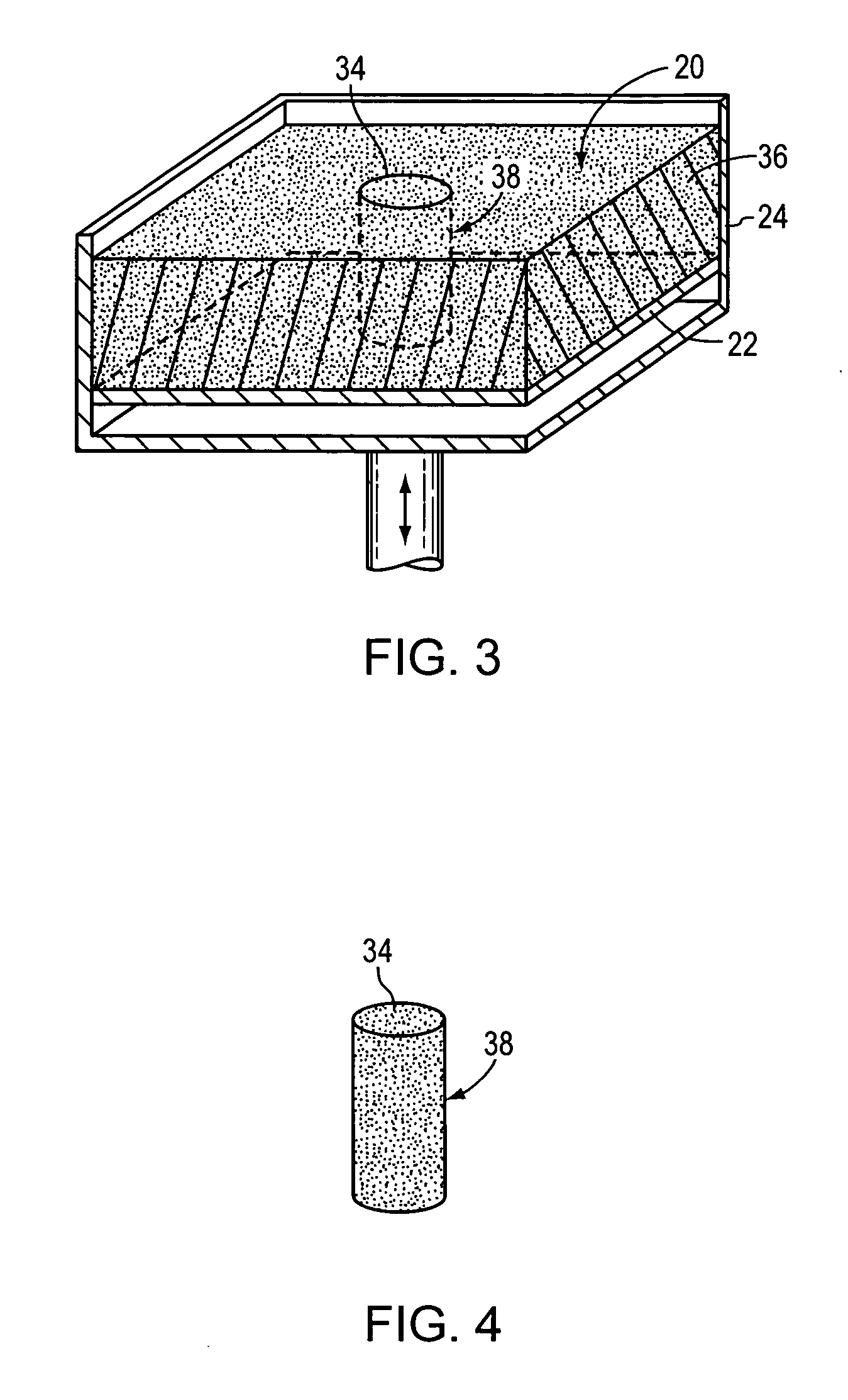

RF active compositions for use in adhesion, bonding and coating

A susceptor composition that can bond two or more layers or substrates to one another and that can be used to coat or cut a substrate. The susceptor composition is activated in the presence of radio frequency (RF) energy. In one embodiment, the susceptor composition of the present invention comprises a susceptor and a carrier. The carrier and susceptor are blended with one another and form a mixture, preferably a uniform mixture. The susceptor is present in an amount effective to allow the susceptor composition to be heated by RF energy. In a preferred embodiment, the susceptor also functions as an adhesive. The susceptor is an ionic or polar compound and acts as either a charge-carrying or an oscillating / vibrating component of the susceptor composition. The susceptor generates thermal energy in the presence of an RF electromagnetic or electrical field (hereafter RF field).

Owner:AMBRELL CORP

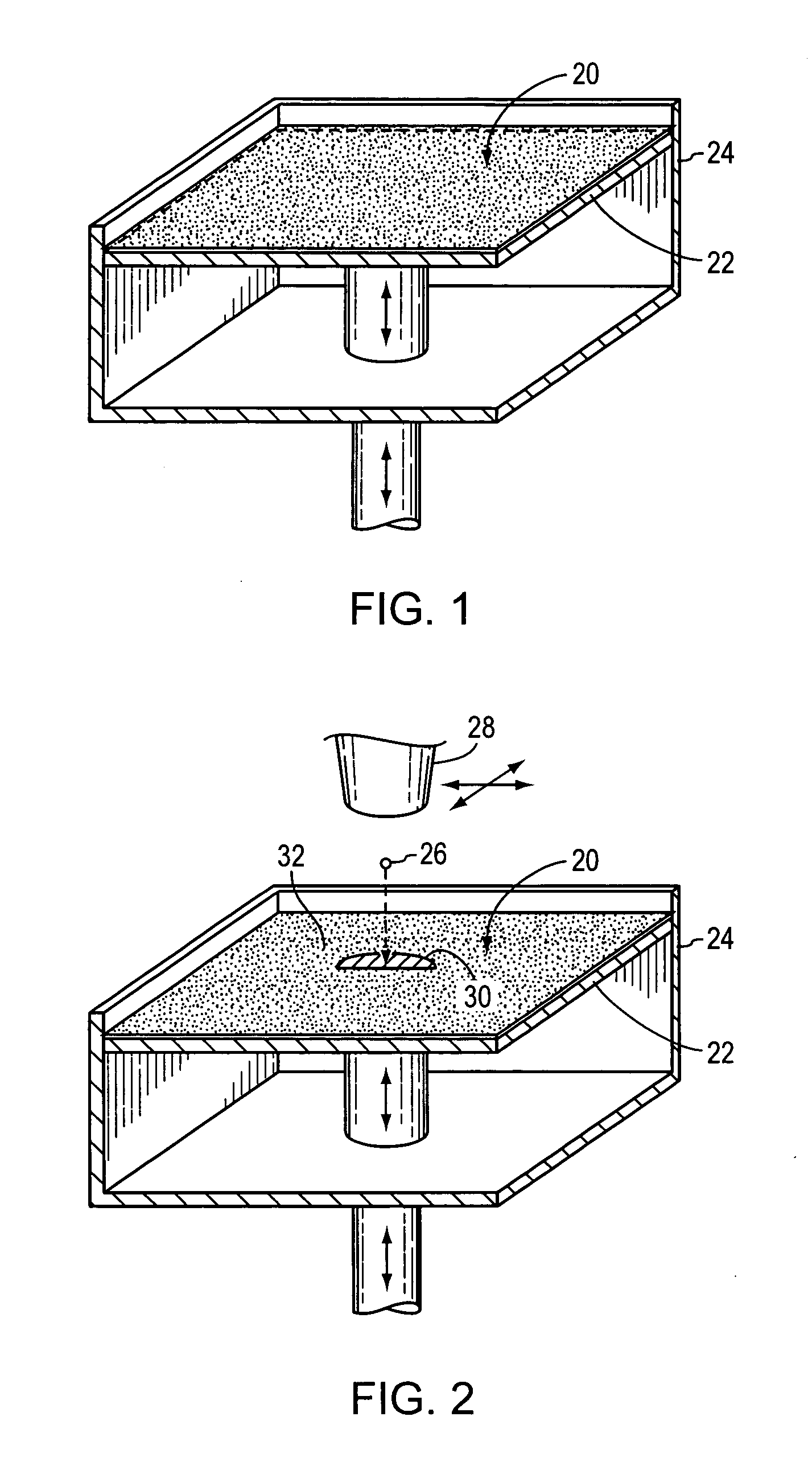

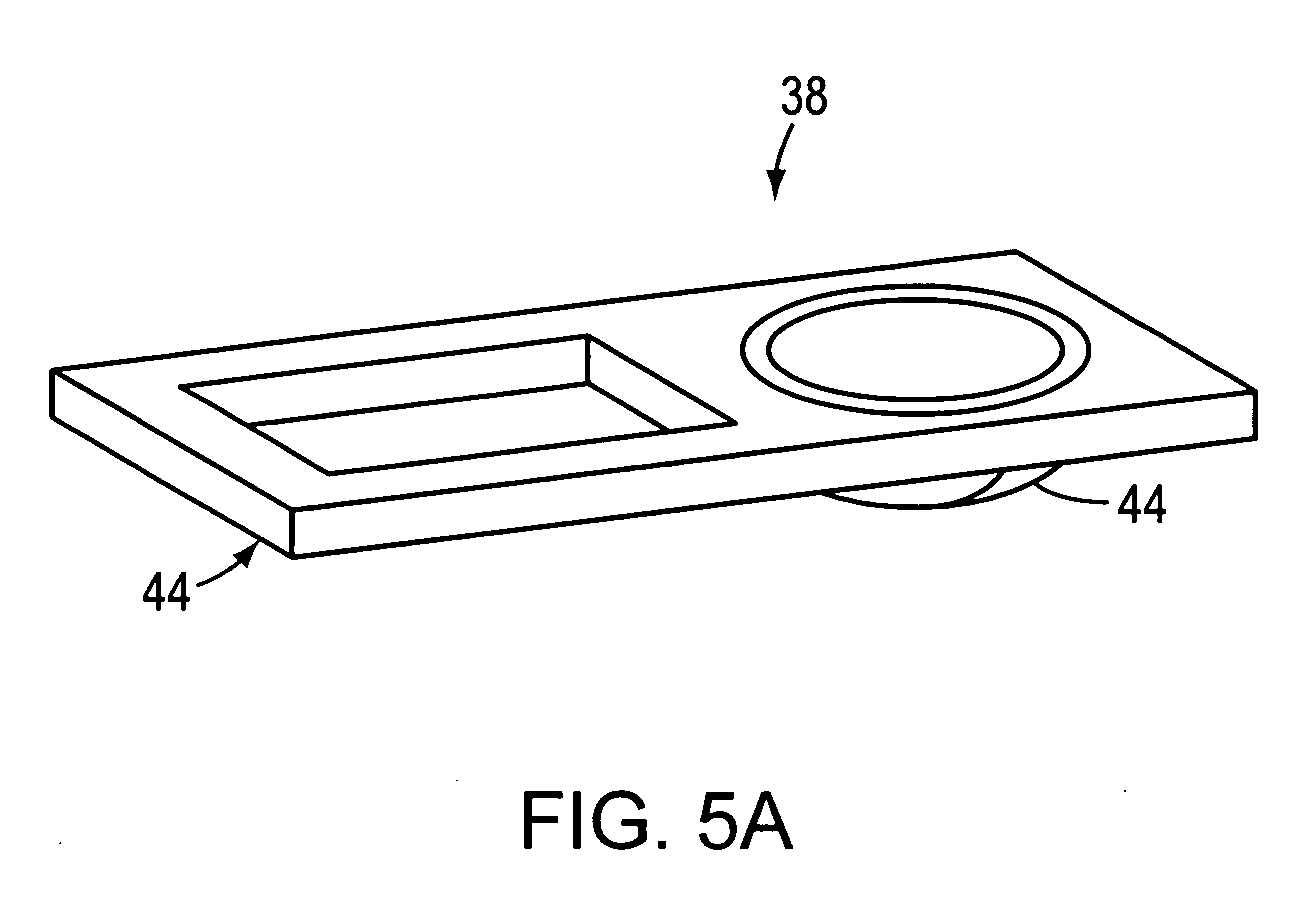

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

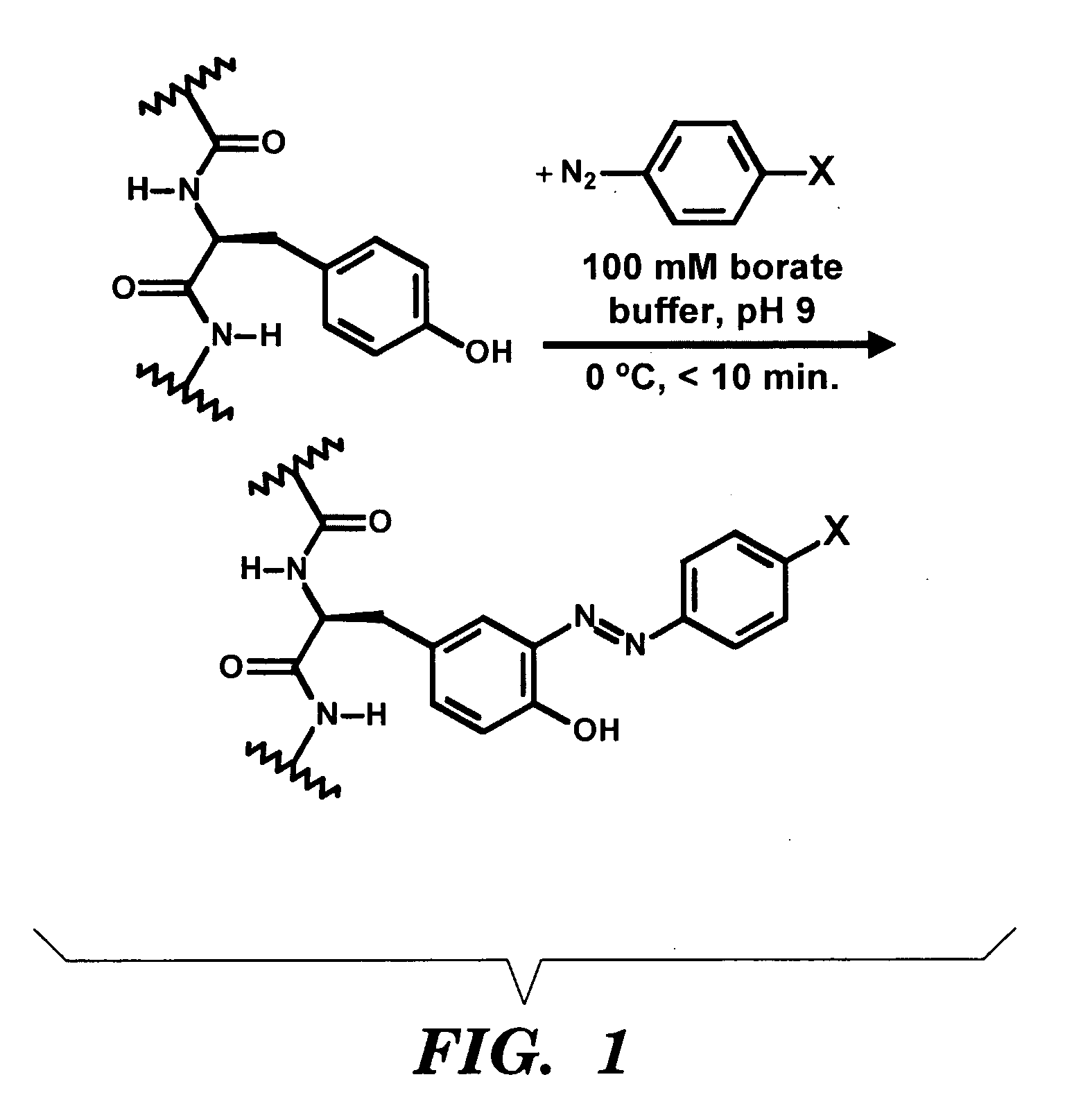

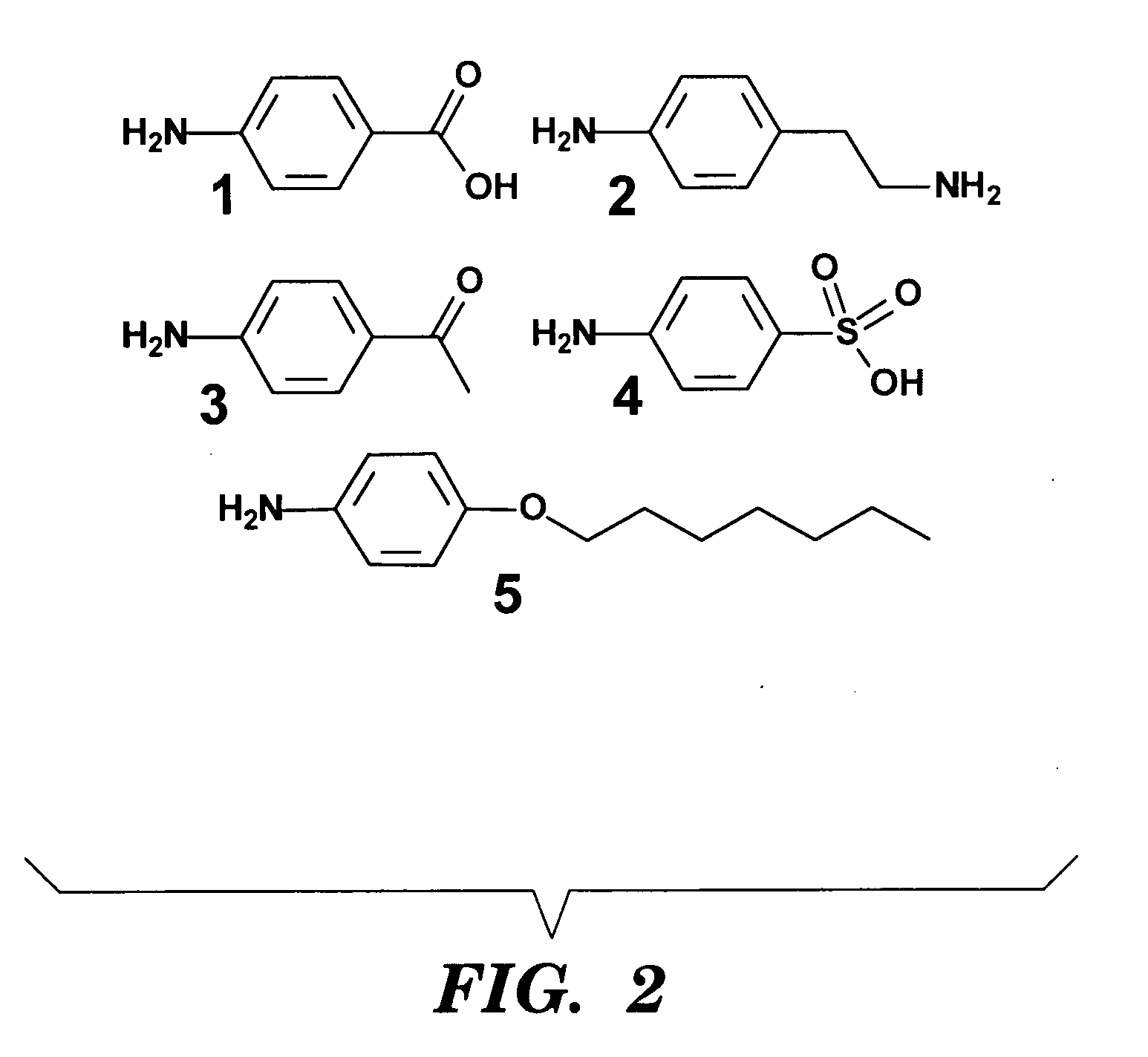

Diazonium salt modification of silk polymer

ActiveUS20090232963A1Change physical propertiesPeptide/protein ingredientsPharmaceutical containersChemical MoietyPolymer science

A method for modifying silk polymer by coupling a chemical moiety to a tyrosine residue of a silk polymer is described herein for the purpose of altering the physical properties of the silk protein. Thus, silk proteins with desired physical properties can be produced by the methods described herein. These methods are particularly useful when the introduction of cells to a mammal is desired, since modifications to the silk protein affect the physical properties and thus the adhesion, metabolic activity and cell morphology of the desired cells. The silk protein can be modified to produce, or modify, a structure that provides an optimal environment for the desired cells.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Methods for dispersing fibers within aqueous compositions

InactiveUS6379446B1Quantity maximizationMinimize interstitial spaceNon-fibrous pulp additionProtein adhesivesFiberSolid component

Compositions and methods in which dry-committed fibers are substantially homogeneously dispersed throughout a fibrous composition. The fibrous composition is characterized as having sufficient yield stress and viscosity such that the shearing forces from the mixing apparatus are effectively transferred down to the fiber level. This is accomplished by means of an appropriate thickening agent, e.g, gelatinized starch. The dry-committed fibers are exemplified by flash dry fibers or fibrous sheets that have been cut or torn into fragments less than 2 cm across. Providing fibers that have been dry-committed greatly reduces the time that it takes to obtain substantially homogeneous dispersion of the fibers throughout the fibrous composition. This, in turn, reduces the risk of mixture spoilage and mechanical or chemical damage to the solid components within the fibrous composition.

Owner:E KHASHOGGI INDS

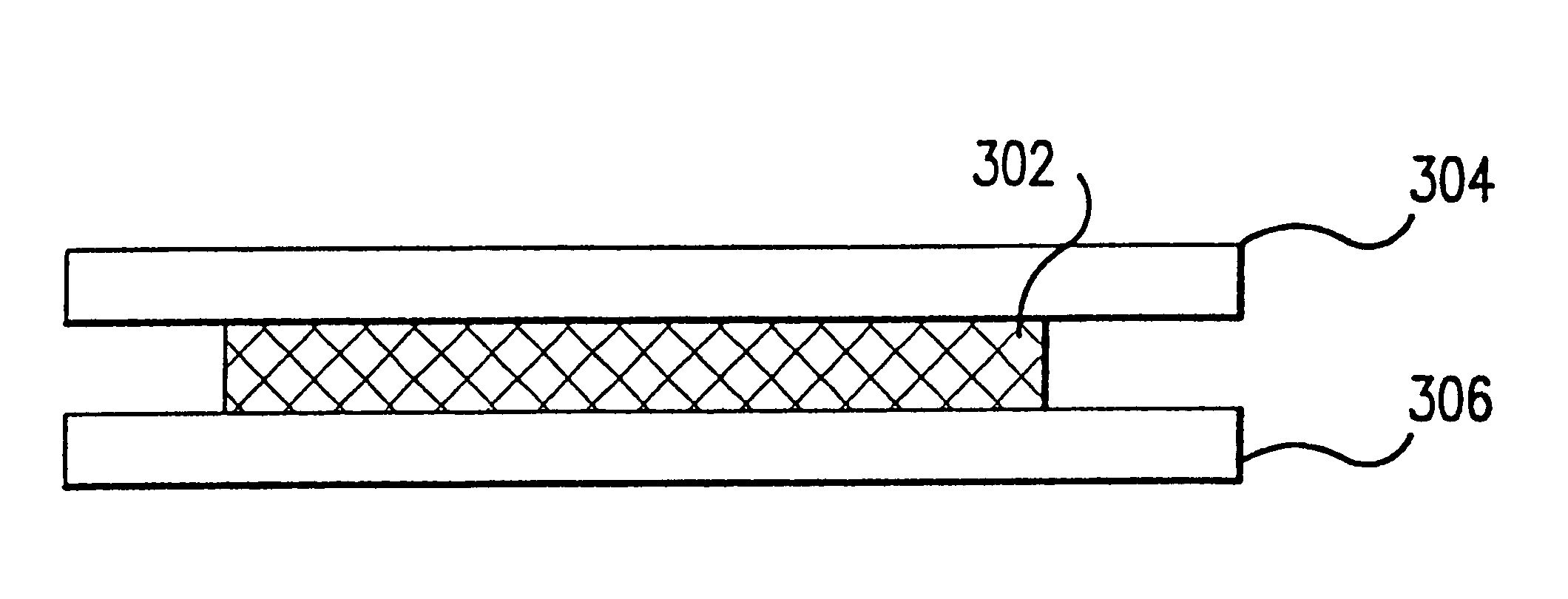

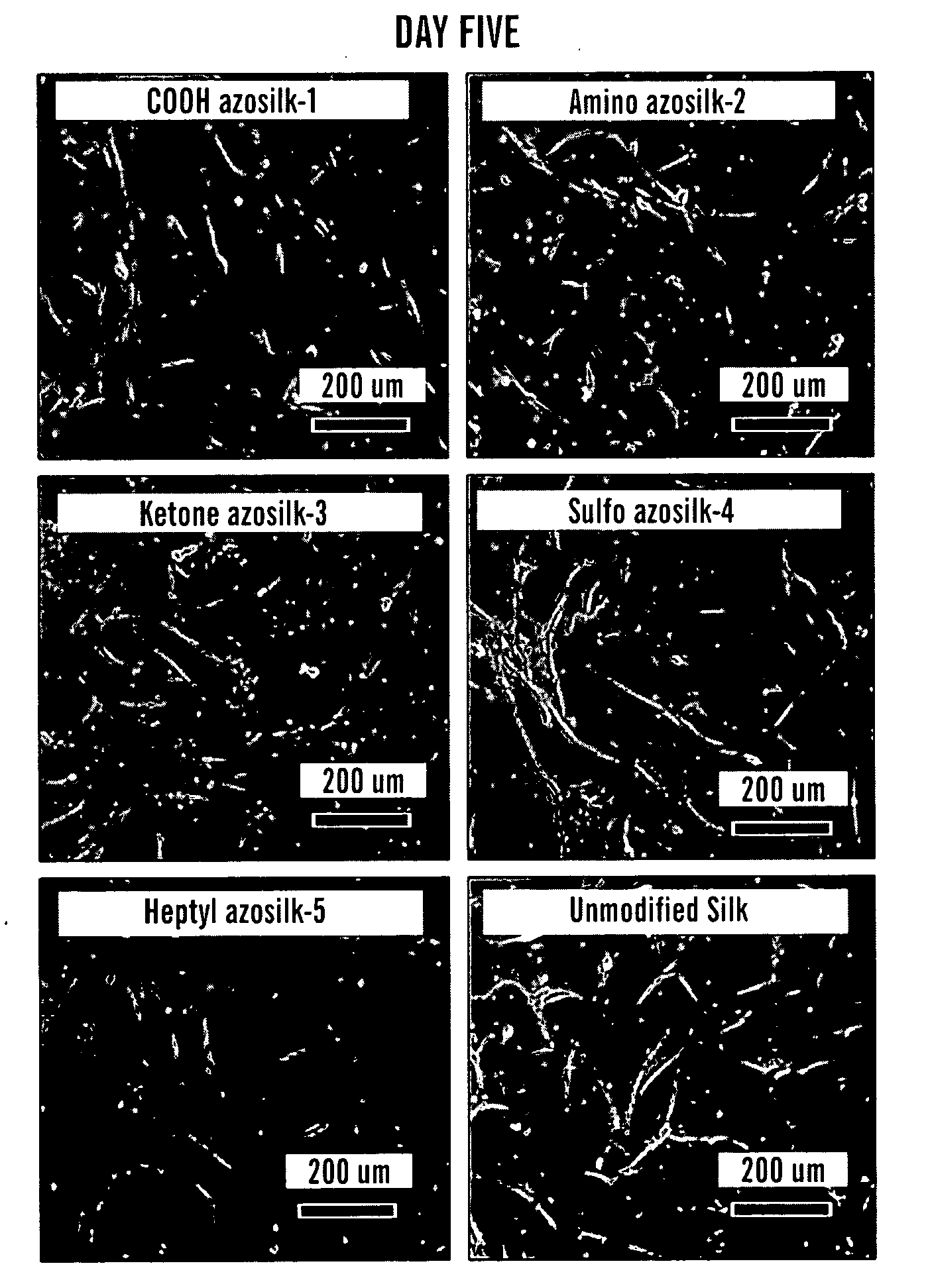

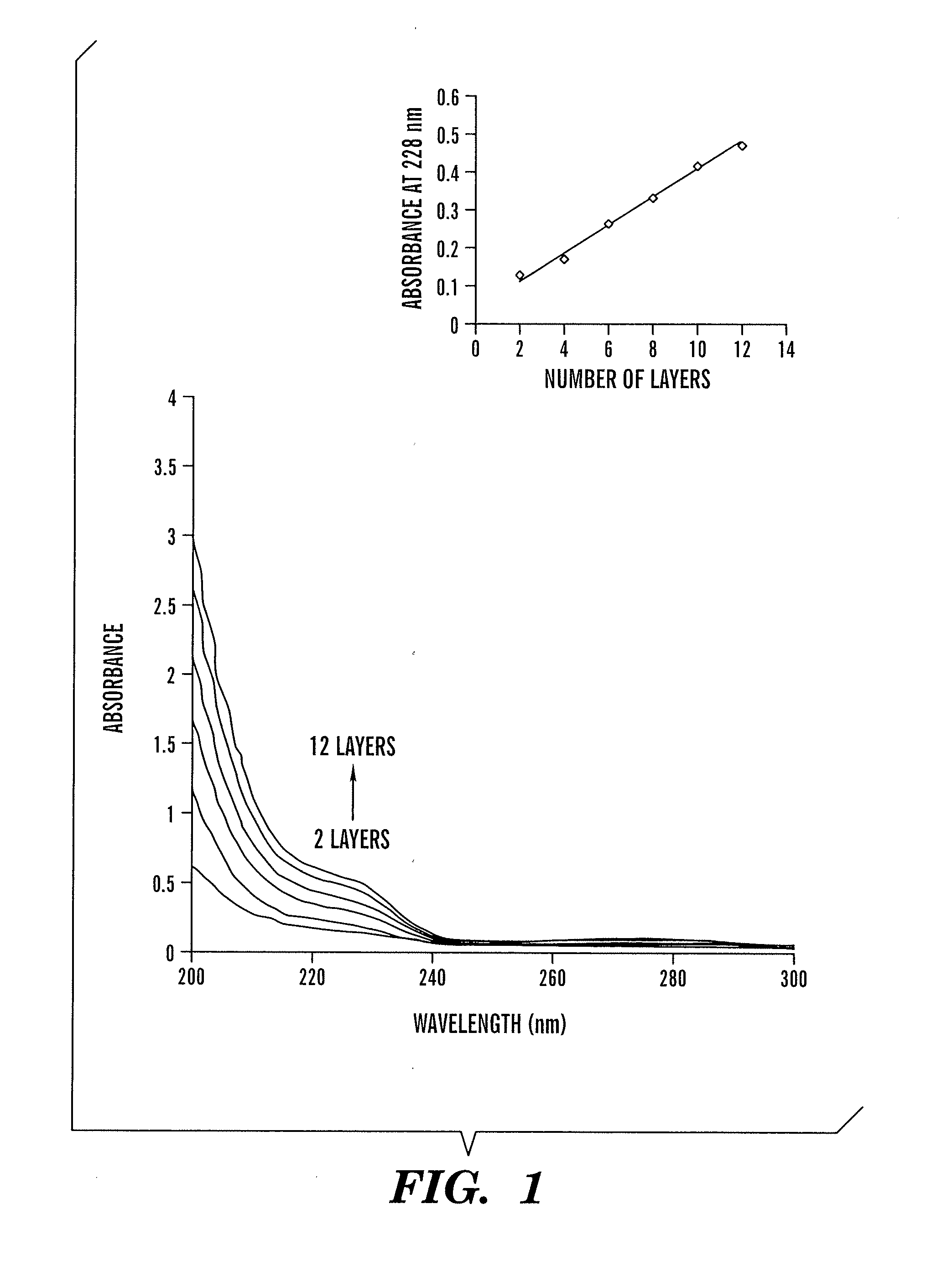

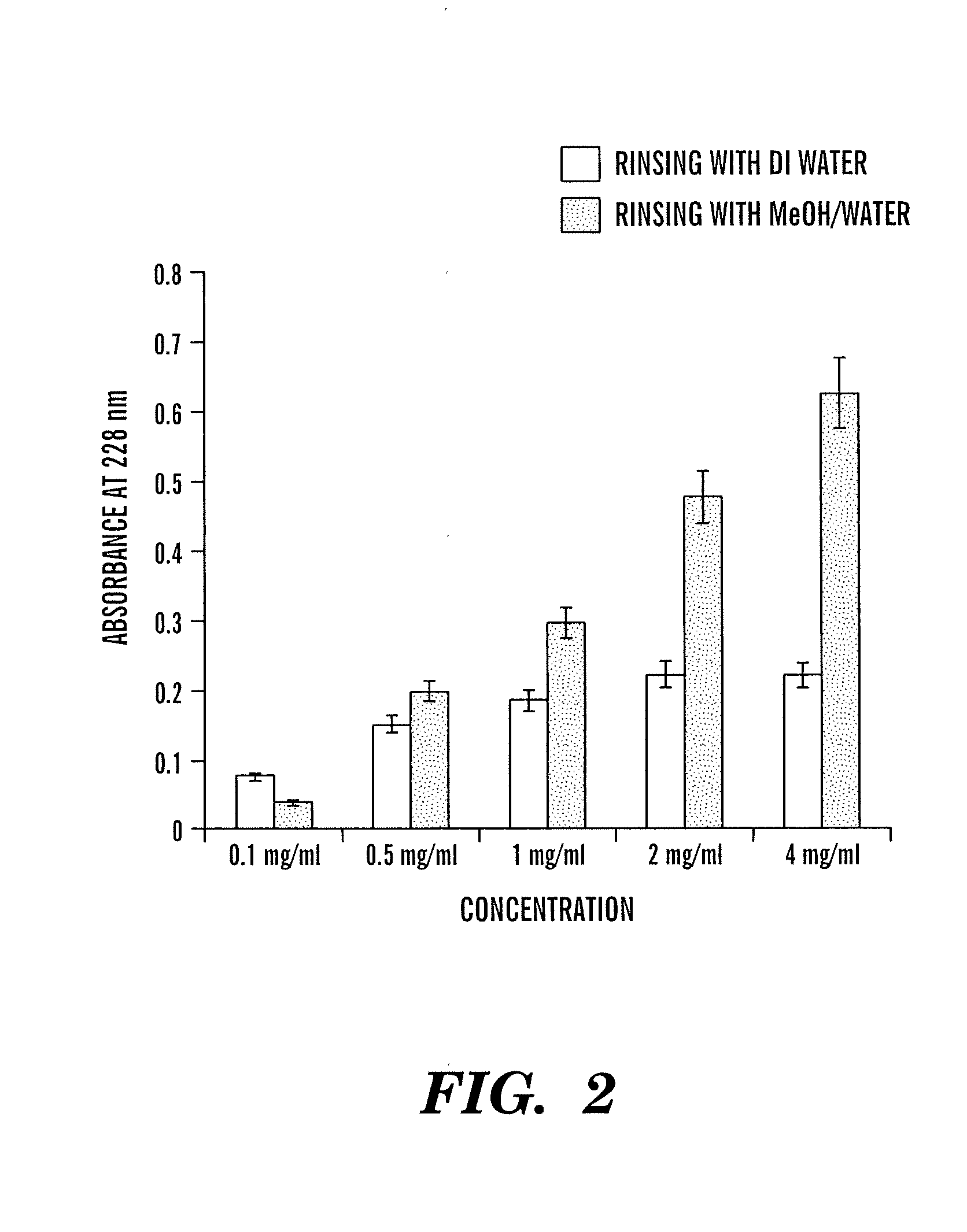

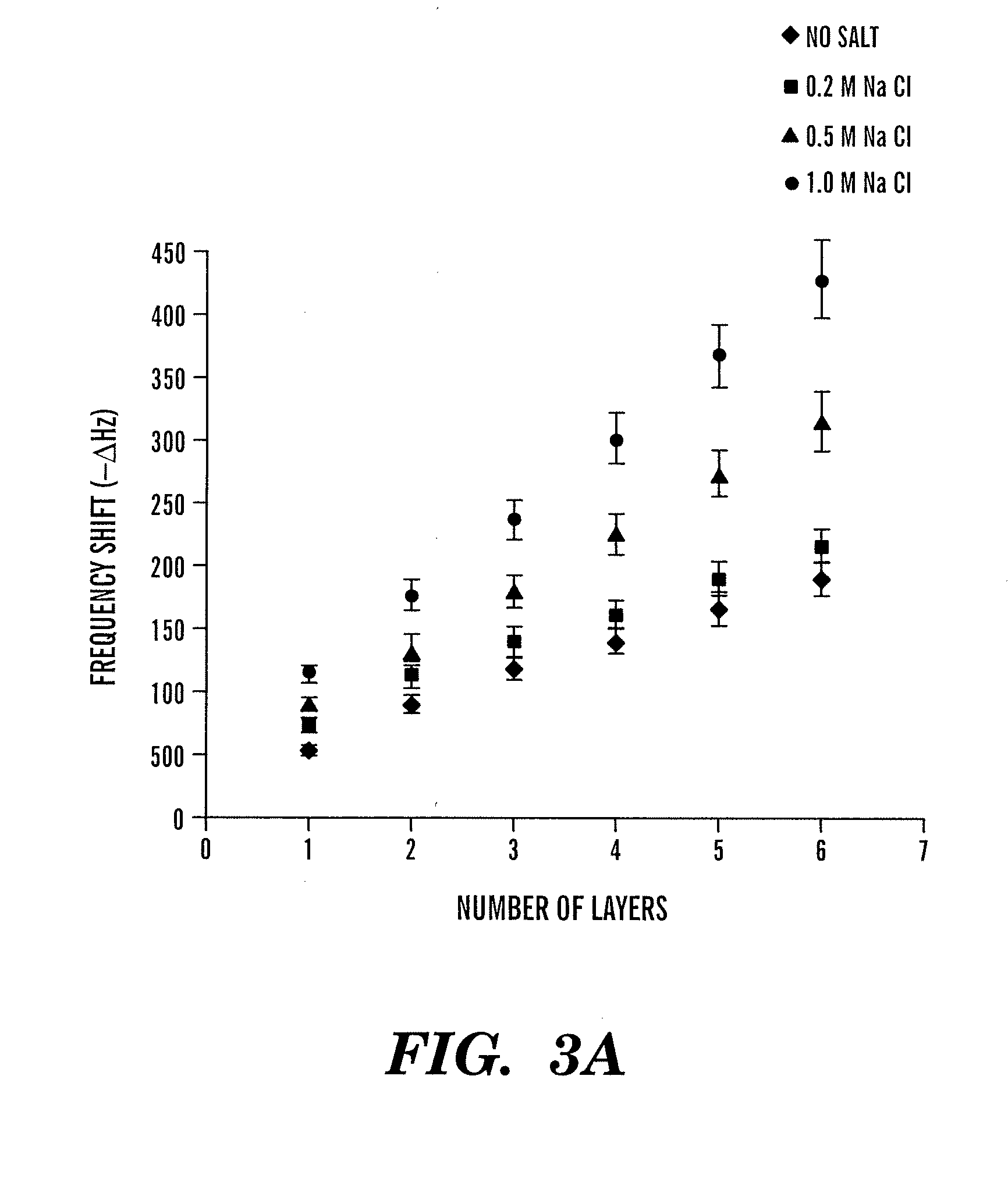

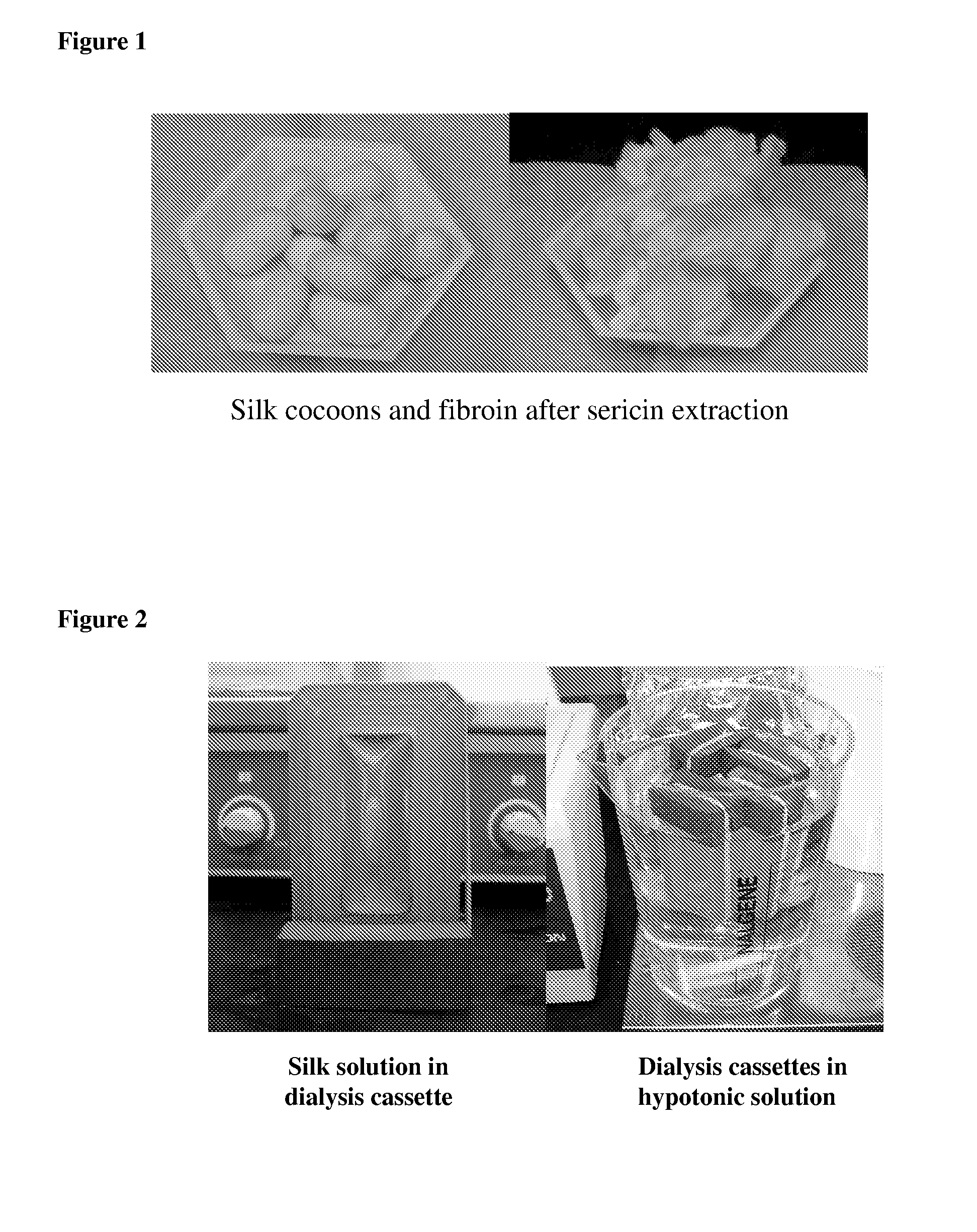

Methods for stepwise deposition of silk fibroin coatings

ActiveUS20090202614A1Suppression of initial burstFacilitated releasePeptide/protein ingredientsLayered productsChemical treatmentEntrapment

The invention provides a method for the controlled assembly of layered silk fibroin coatings using aqueous silk fibroin material. The methods described herein can be used to coat substrates of any material, shape, or size. Importantly, the described methods enable control of the biomaterial surface chemistry, thickness, morphology and structure using layered thin film coatings, or bulk coatings. Furthermore, the methods can be performed in all water and do not require intensive chemical processing enabling controlled entrapment of labile molecules such as, drugs, cytokines, and even cells or viruses to generate functional coatings that can be used in a variety of applications.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

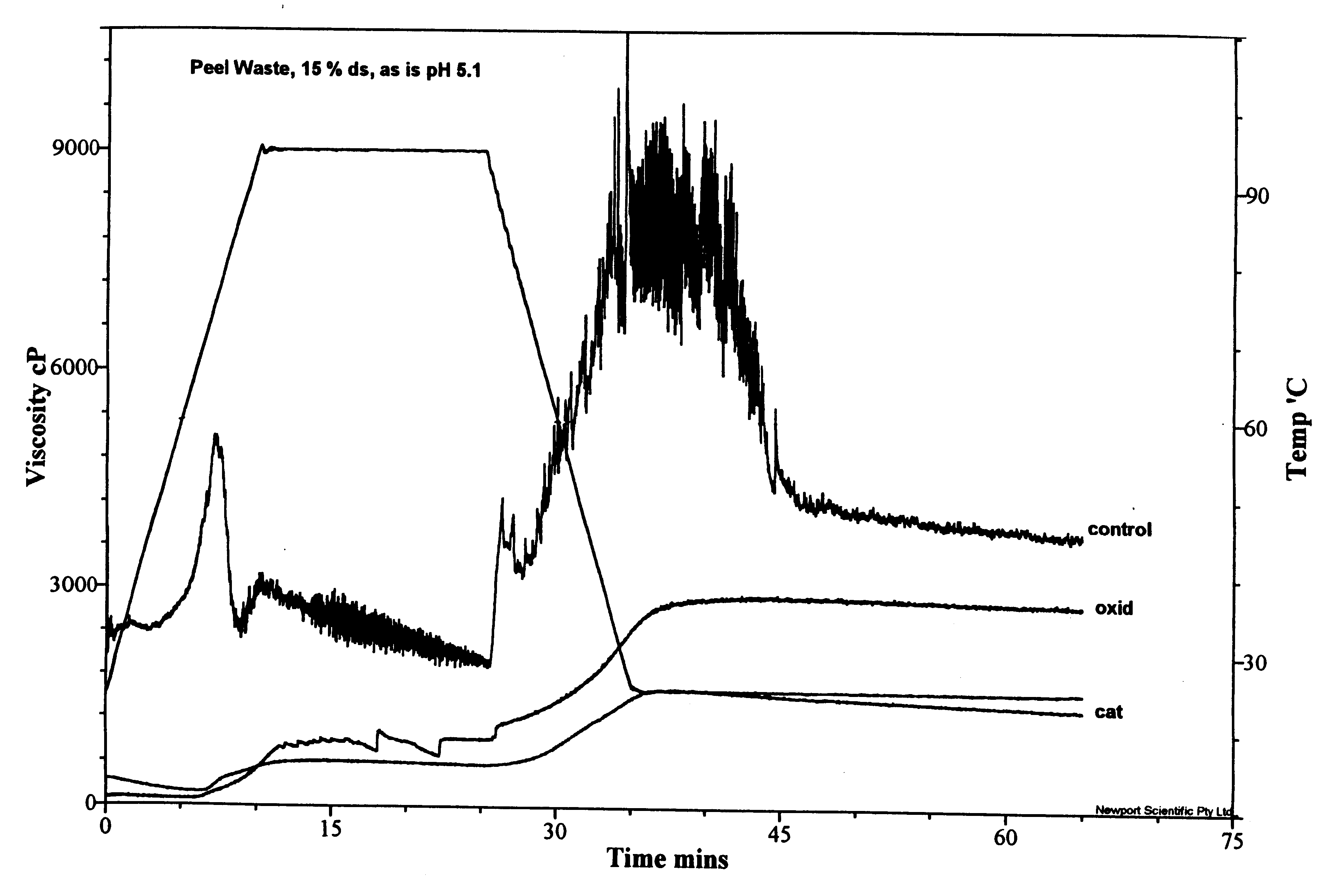

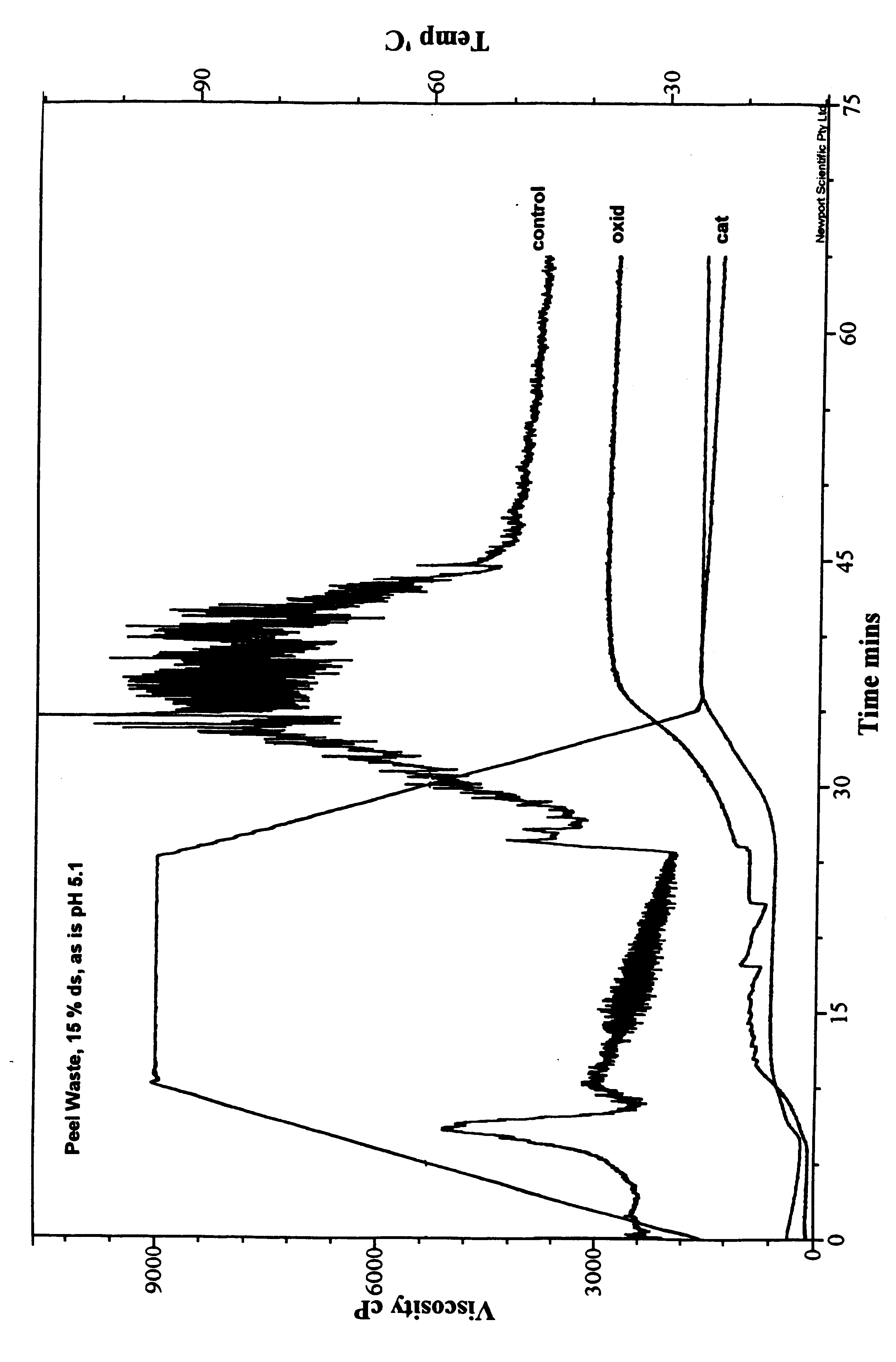

Packaging and structural materials comprising potato peel waste

InactiveUS6440204B1Inhibit migrationImprove stabilityProtein waste adhesivesLayered productsFiberAdhesive

Owner:HARRIS TRUST & SAVINGS BANK AS ADM AGENT +1

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

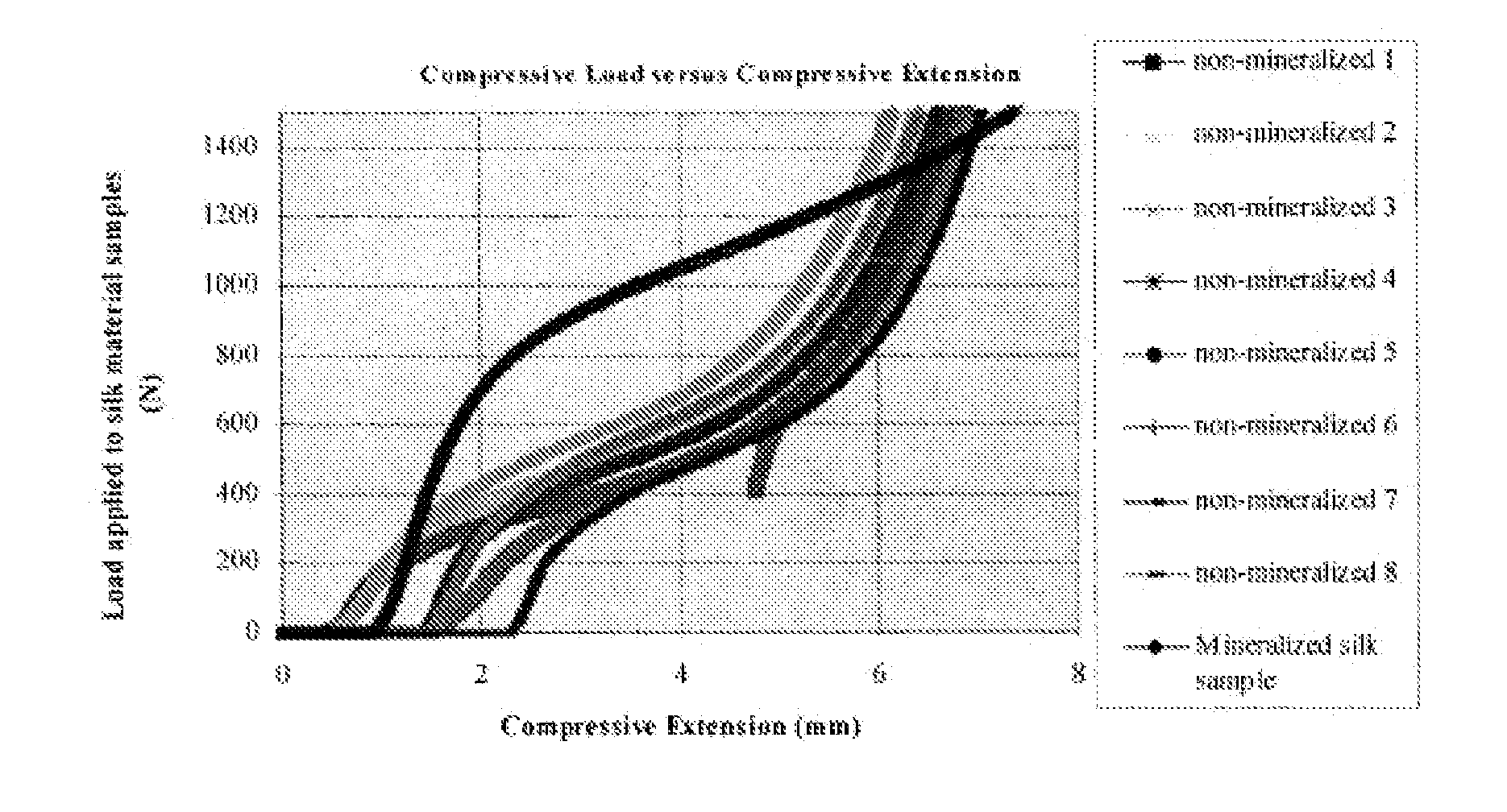

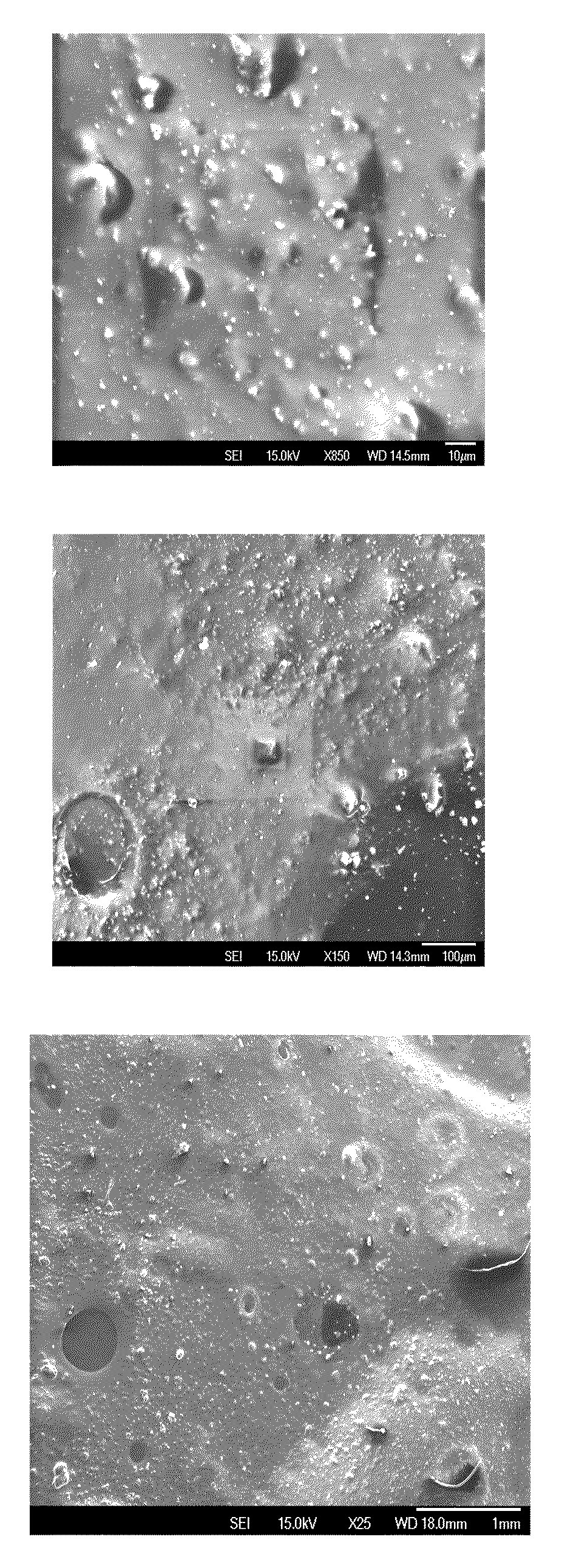

3-dimensional silk hydroxyapatite compositions

ActiveUS20110046686A1Facilitate bone healingFacilitate tooth structureBiocideImpression capsMedicineBone healing

Described herein are methods and compositions comprising a mixture of silk polymer and hydroxyapatite. The methods described herein can be used to prepare a mixture of silk polymer and hydroxyapatite and further provide mixtures that can be molded into a desired shape. Also encompassed herein are compositions comprising a mixture of silk polymer and hydroxyapatite having a desired shape, which can further be implanted, for example, to facilitate bone healing or tooth structure or support. Such compositions can also include agents, such as therapeutic agents, or cells.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Cellulosic composite

Provided is a cellulosic composite comprised of cellulosic material and a binder. The binder comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form a curable binder composition. The composition when mixed with cellulosic material and cured forms a cellulosic composite.

Owner:JOHNS MANVILLE CORP

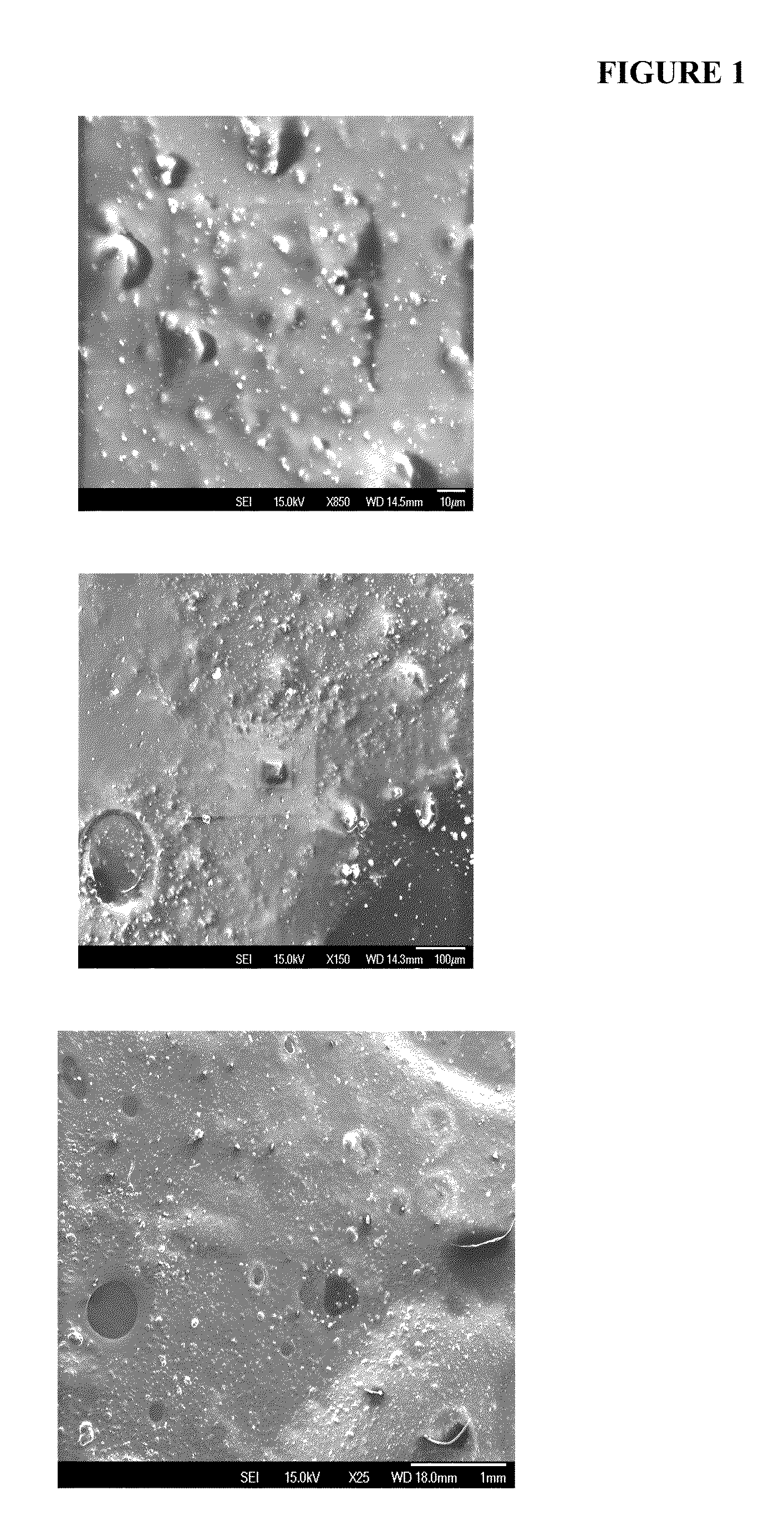

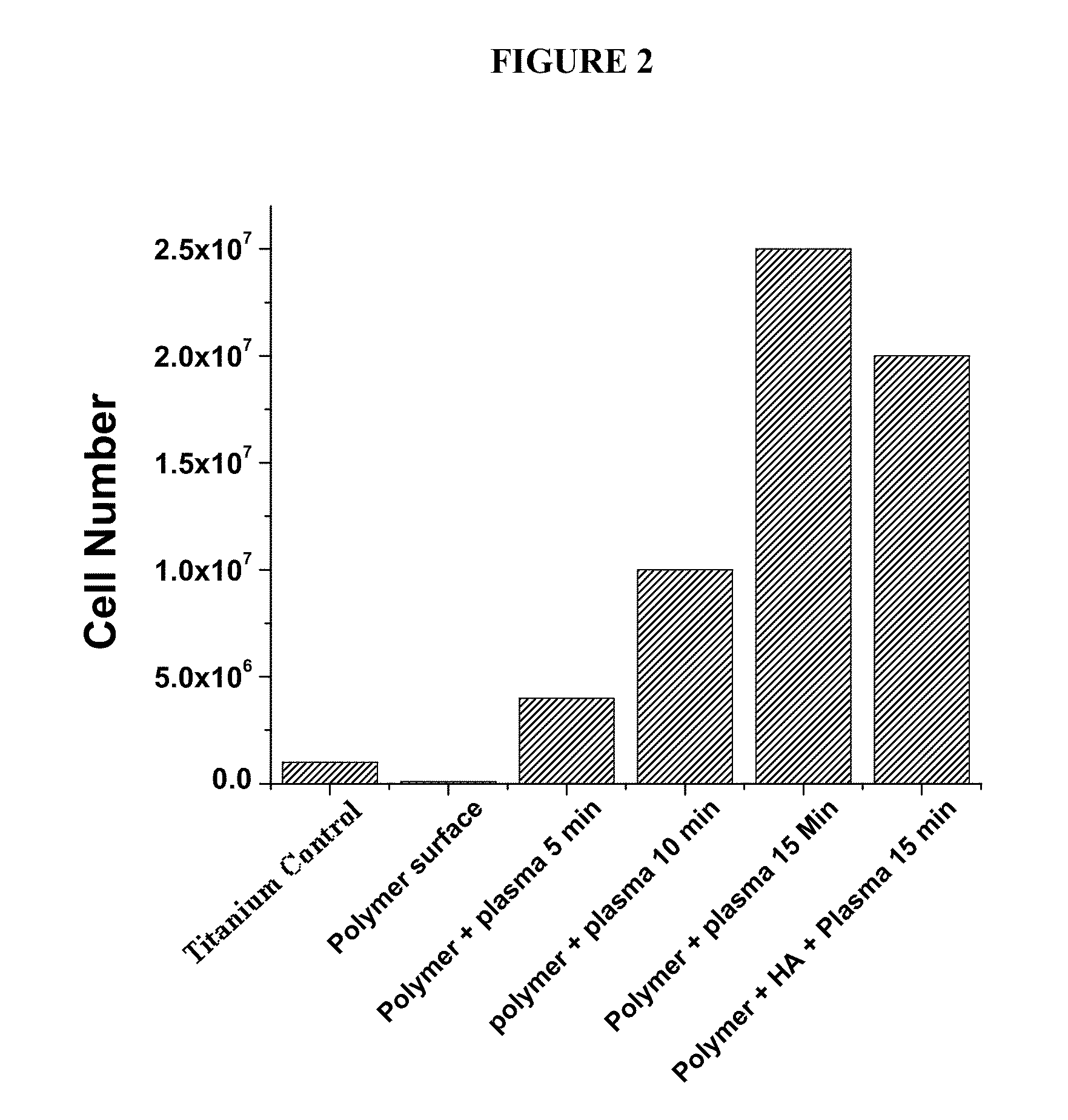

Advanced bio-compatible polymer surface coatings for implants and tissue engineering scaffolds

InactiveUS20100255447A1Improve bindingPromote cell adhesionOrganic active ingredientsDental implantsTissue engineering scaffoldChemistry

Disclosed herein are methodologies and compositions for coating materials, which can be used in a variety of biological applications.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

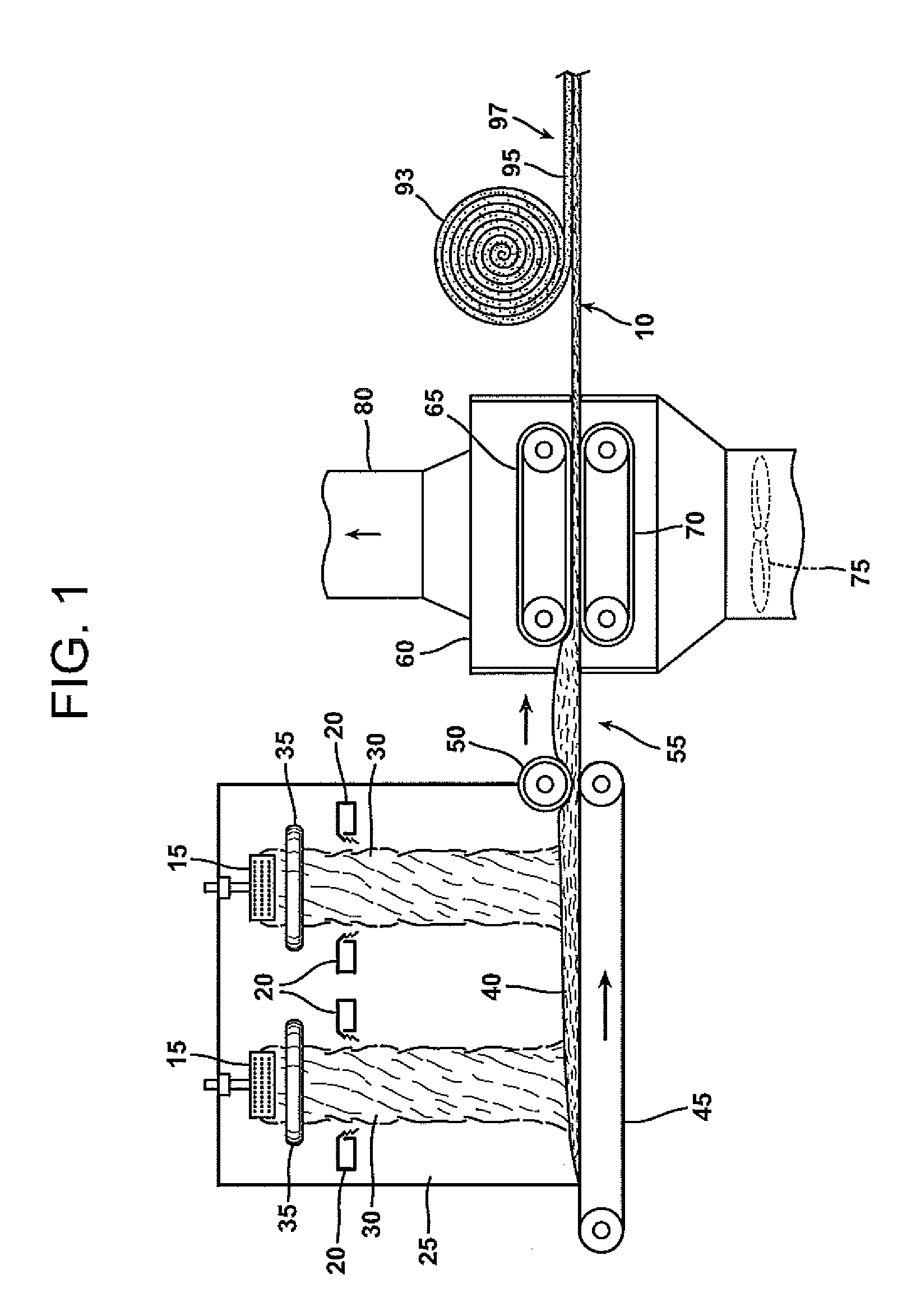

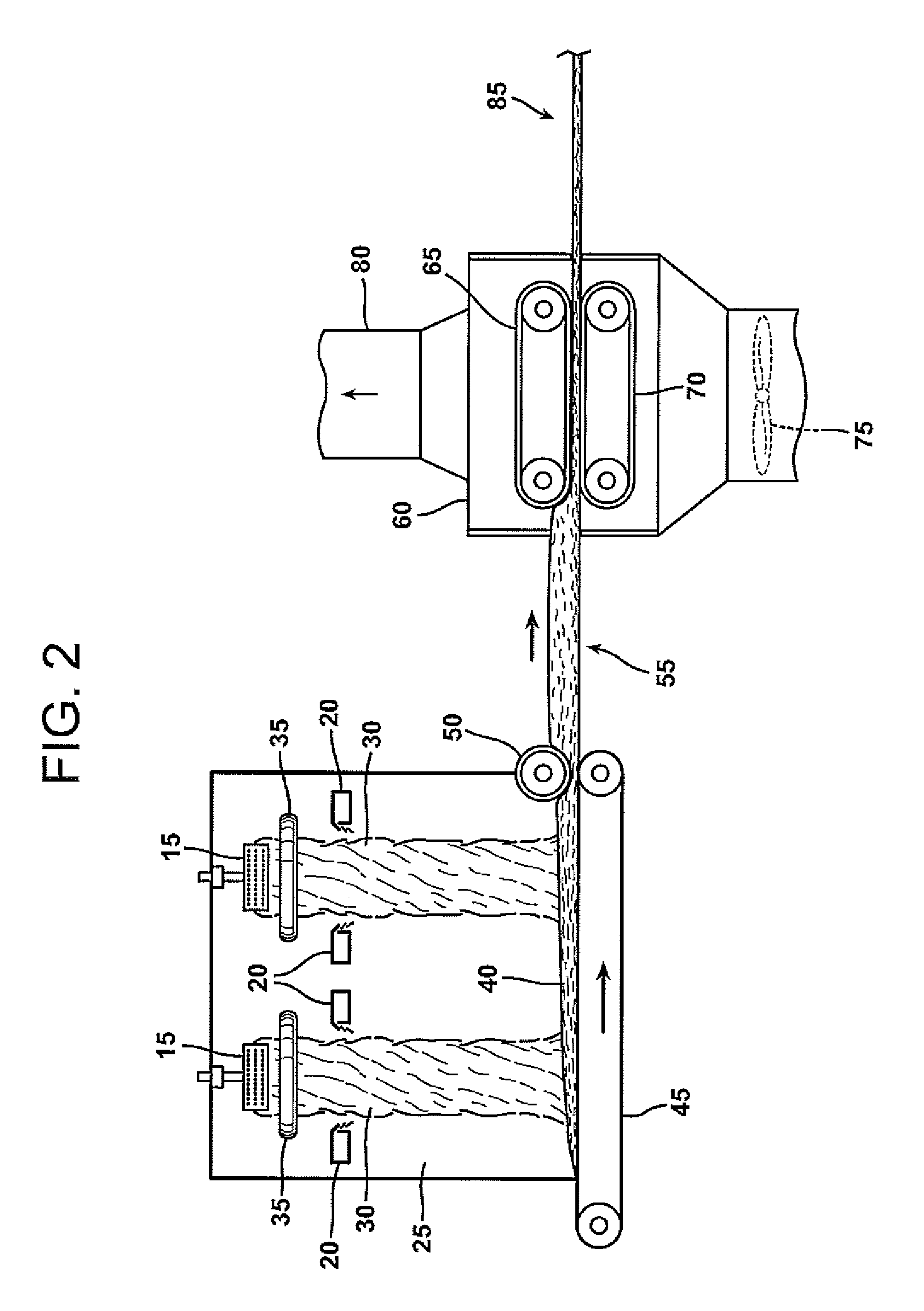

Insulative products having bio-based binders

InactiveUS20110223364A1Readily availableLow costStarch adhesivesStarch derivtive adhesivesFiberWater soluble polysaccharides

Fibrous insulation products have an aqueous binder composition that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

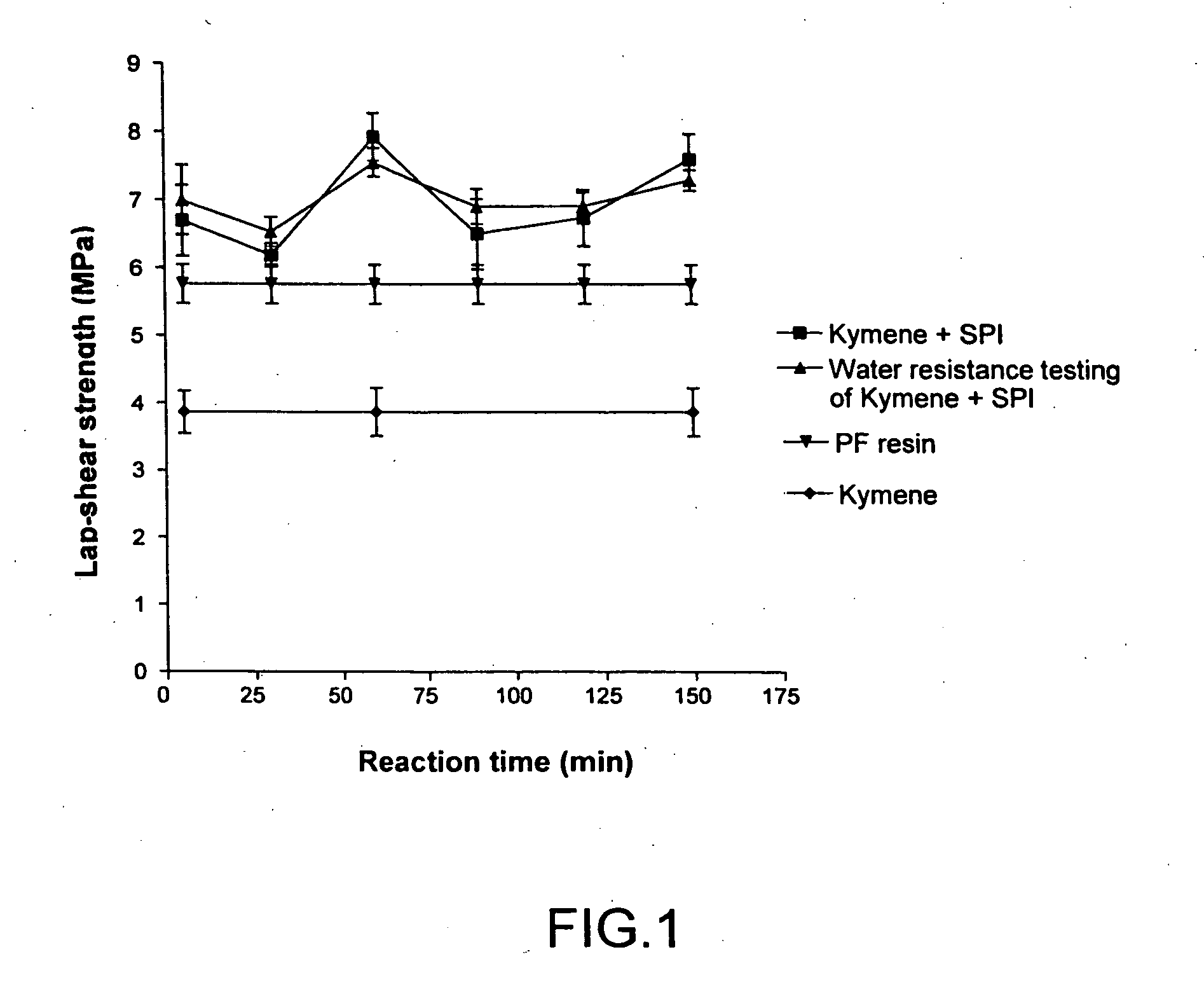

Adhesives from modified soy protein

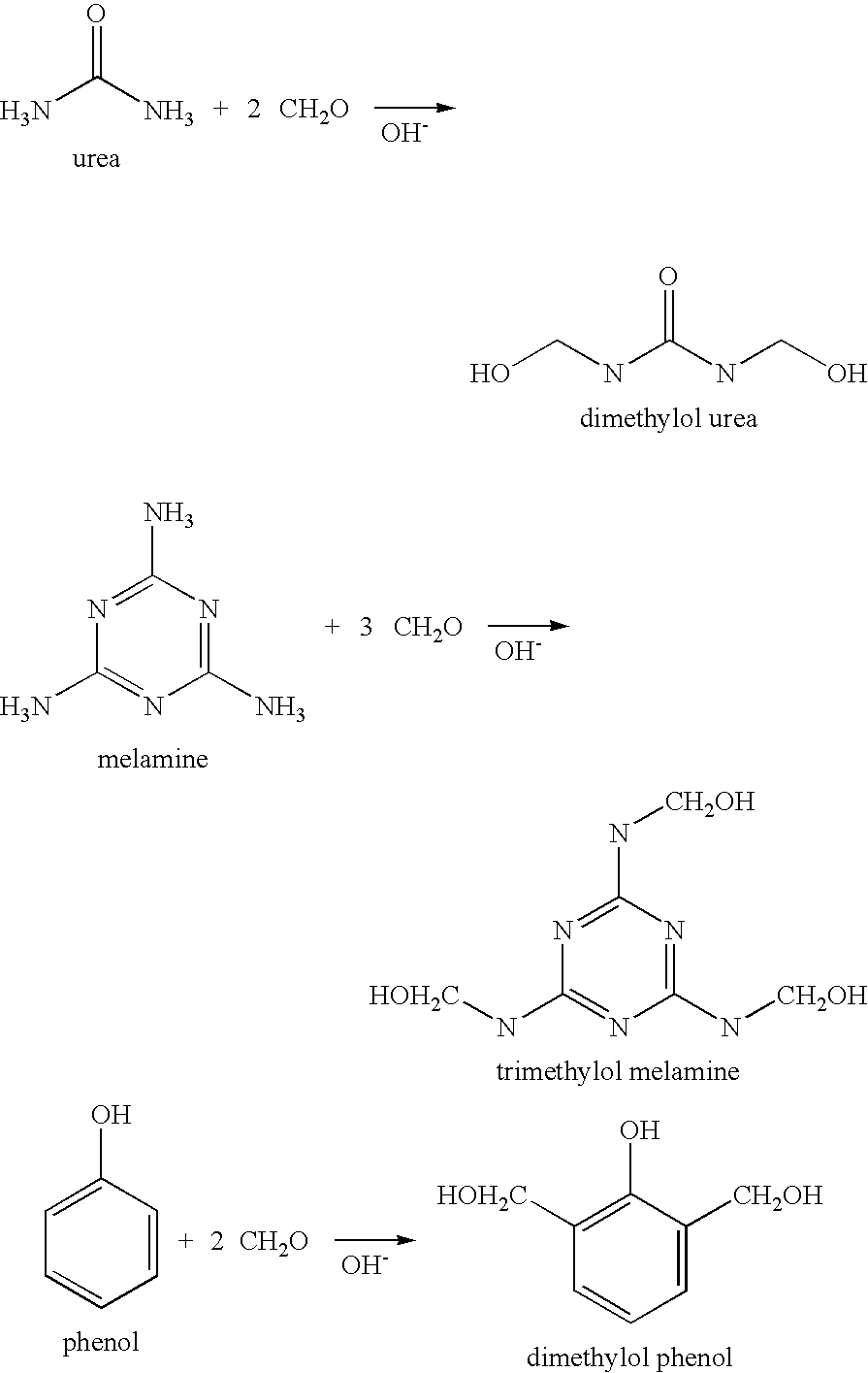

InactiveUS20050166796A1Easy to determineEasy to findProtein adhesivesOil/fat/wax adhesivesEpoxyAdhesive

The, present invention provides useful adhesive compositions having similar adhesive properties to conventional UF and PPF resins. The compositions generally include a protein portion and modifying ingredient portion selected from the group consisting of carboxyl-containing compounds, aldehyde-containing compounds, epoxy group-containing compounds, and mixtures thereof. The composition is preferably prepared at a pH level at or near the isoelectric point of the protein. In other preferred forms, the adhesive composition includes a protein portion and a carboxyl-containing group portion.

Owner:KANSAS STATE UNIV RES FOUND

Joint compounds using thickeners prepared from raw cotton linters

InactiveUS20050235878A1Reduce the amount requiredWorkability of wetPropellersSolid waste managementJoint compoundEther

A mixture composition of a cellulose ether made from raw cotton linters and at least one additive is used in a ready mixed joint compound composition wherein the amount of the cellulose ether in the joint compound composition is significantly reduced. When this joint compound composition is mixed with water and applied to a substrate, the water retention, sag resistance, and workability of the wet joint compound are comparable or improved as compared to when using conventional similar cellulose ethers.

Owner:HERCULES INC

Cellulosic composite

Provided is a cellulosic composite comprised of cellulosic material and a binder. The binder comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form a curable binder composition. The composition when mixed with cellulosic material and cured forms a cellulosic composite.

Owner:JOHNS MANVILLE CORP

Adhesives from modified soy protein

InactiveUS7416598B2Improve water resistanceStable structureProtein adhesivesOil/fat/wax adhesivesEpoxyAdhesive

The, present invention provides useful adhesive compositions having similar adhesive properties to conventional UF and PPF resins. The compositions generally include a protein portion and modifying ingredient portion selected from the group consisting of carboxyl-containing compounds, aldehyde-containing compounds, epoxy group-containing compounds, and mixtures thereof. The composition is preferably prepared at a pH level at or near the isoelectric point of the protein. In other preferred forms, the adhesive composition includes a protein portion and a carboxyl-containing group portion.

Owner:KANSAS STATE UNIV RES FOUND

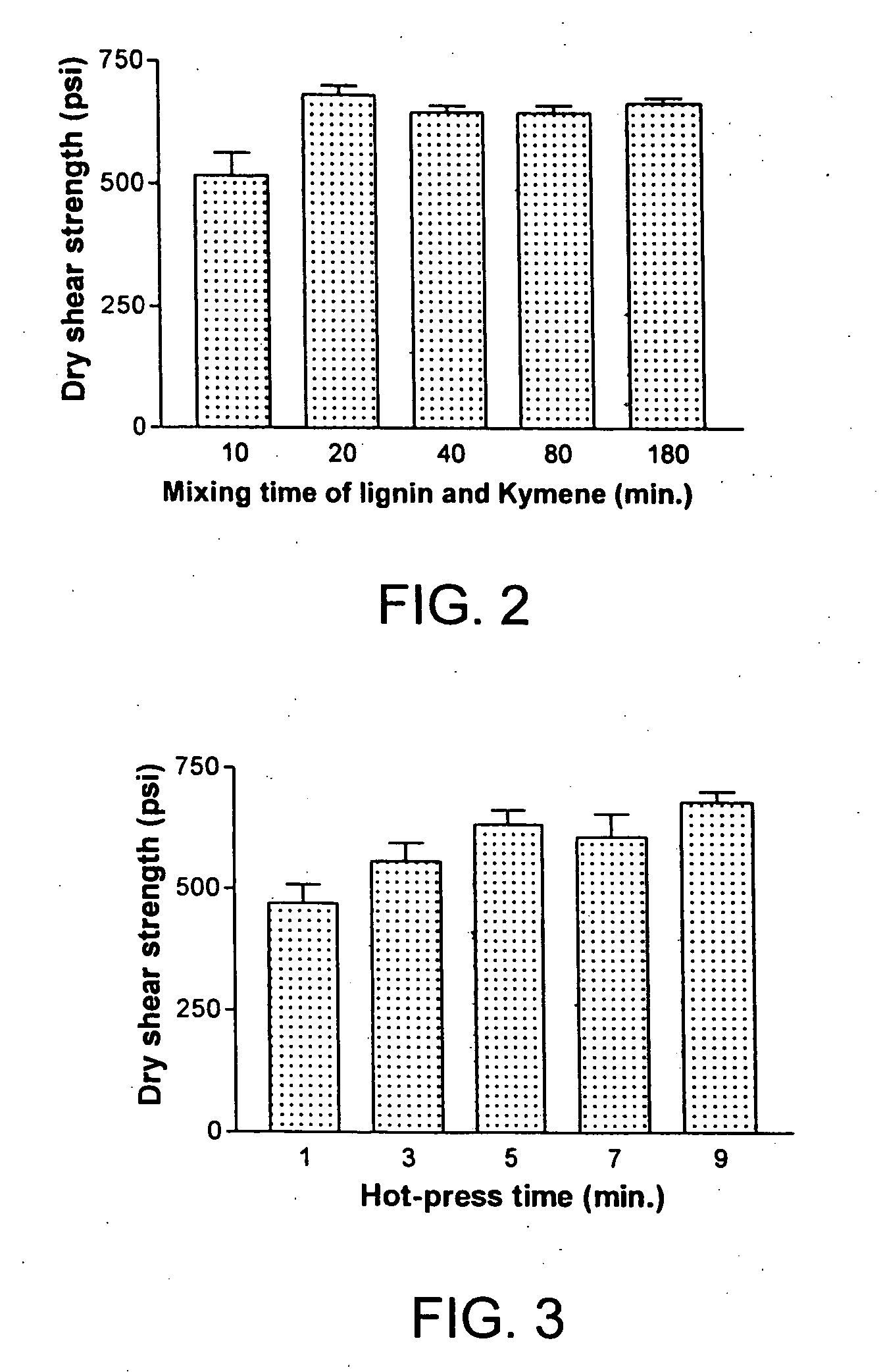

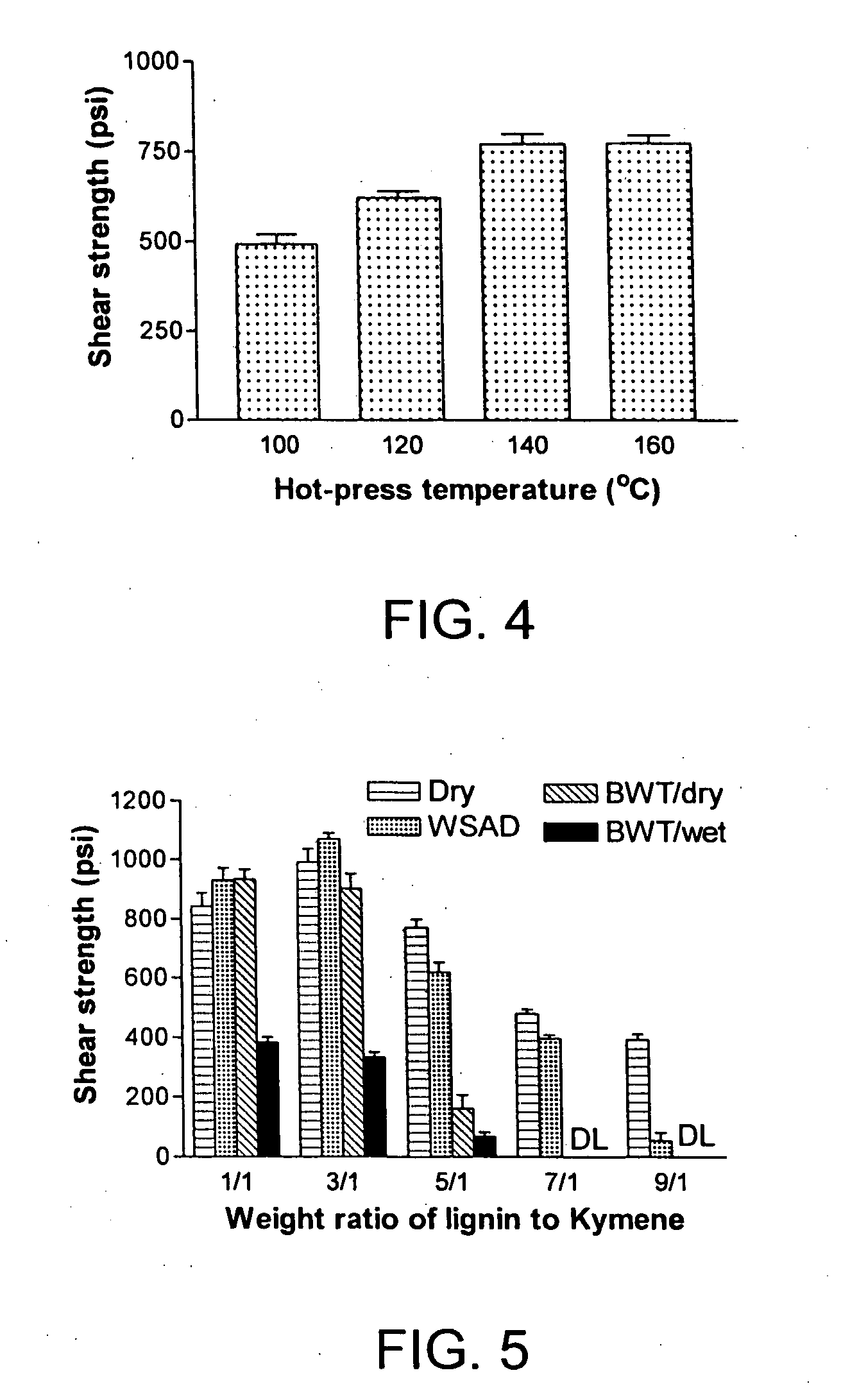

Formaldehyde-Free Adhesives and Lignocellulosic Composites Made from the Adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

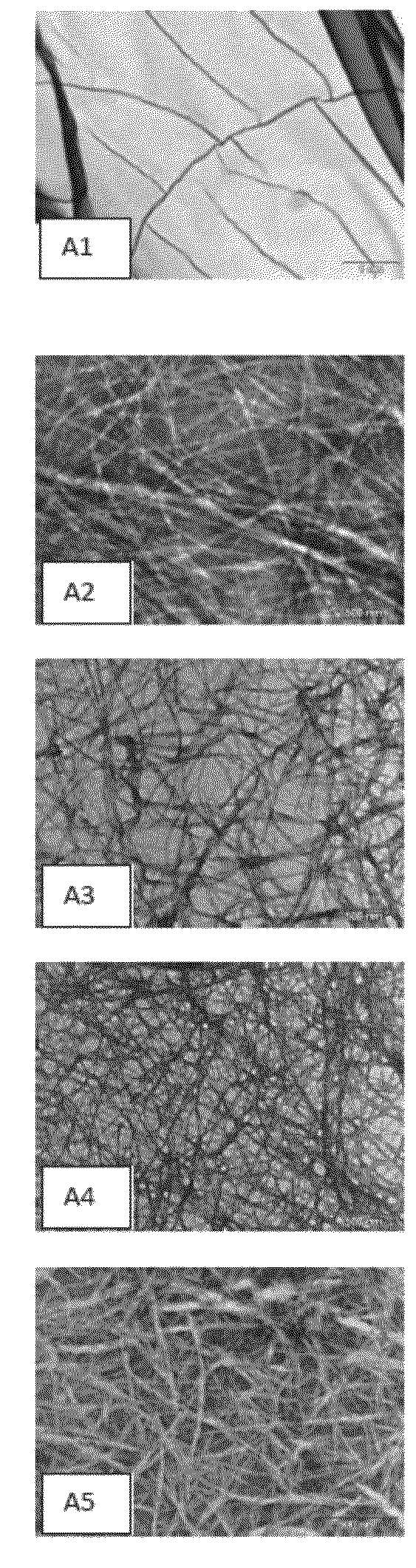

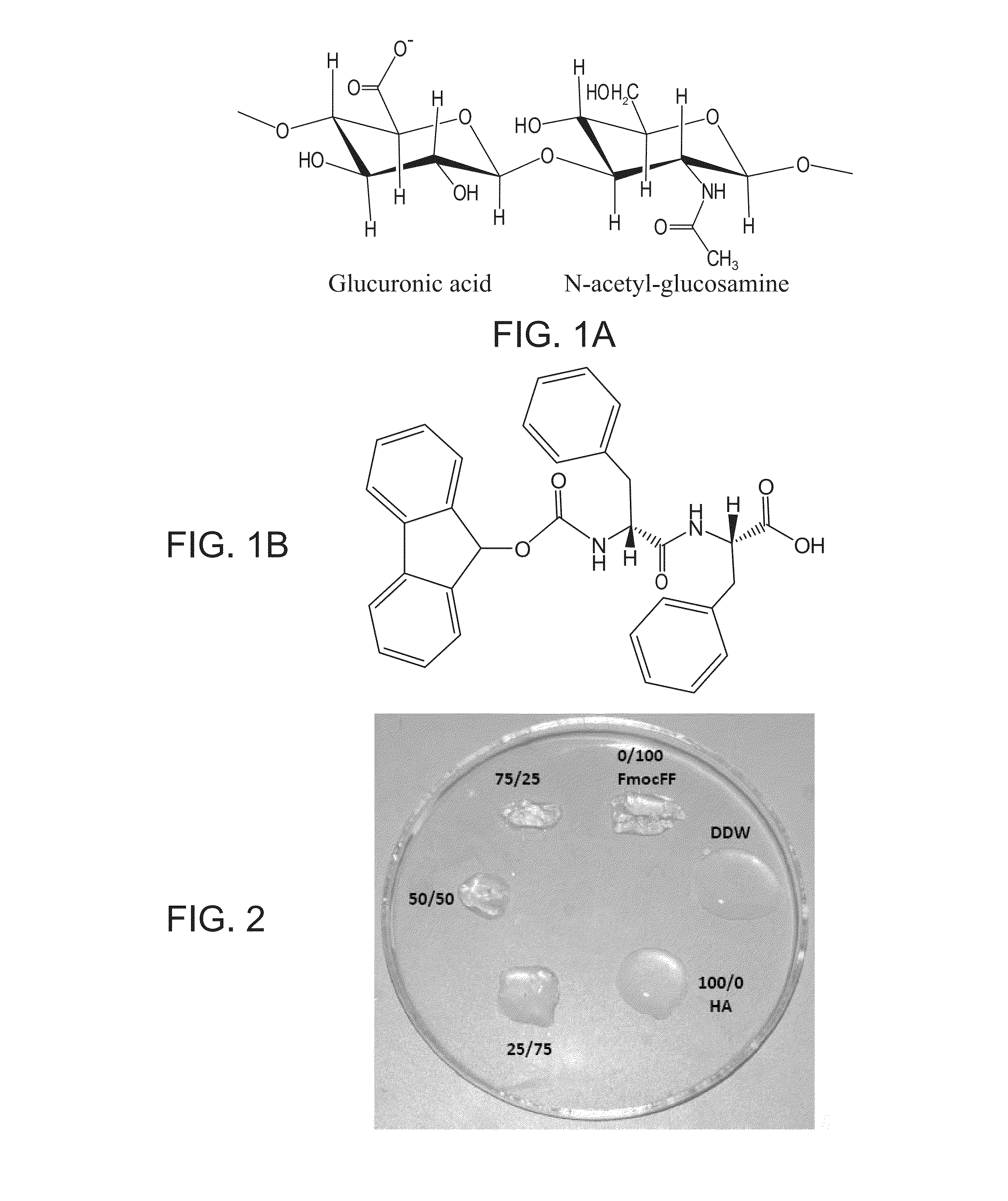

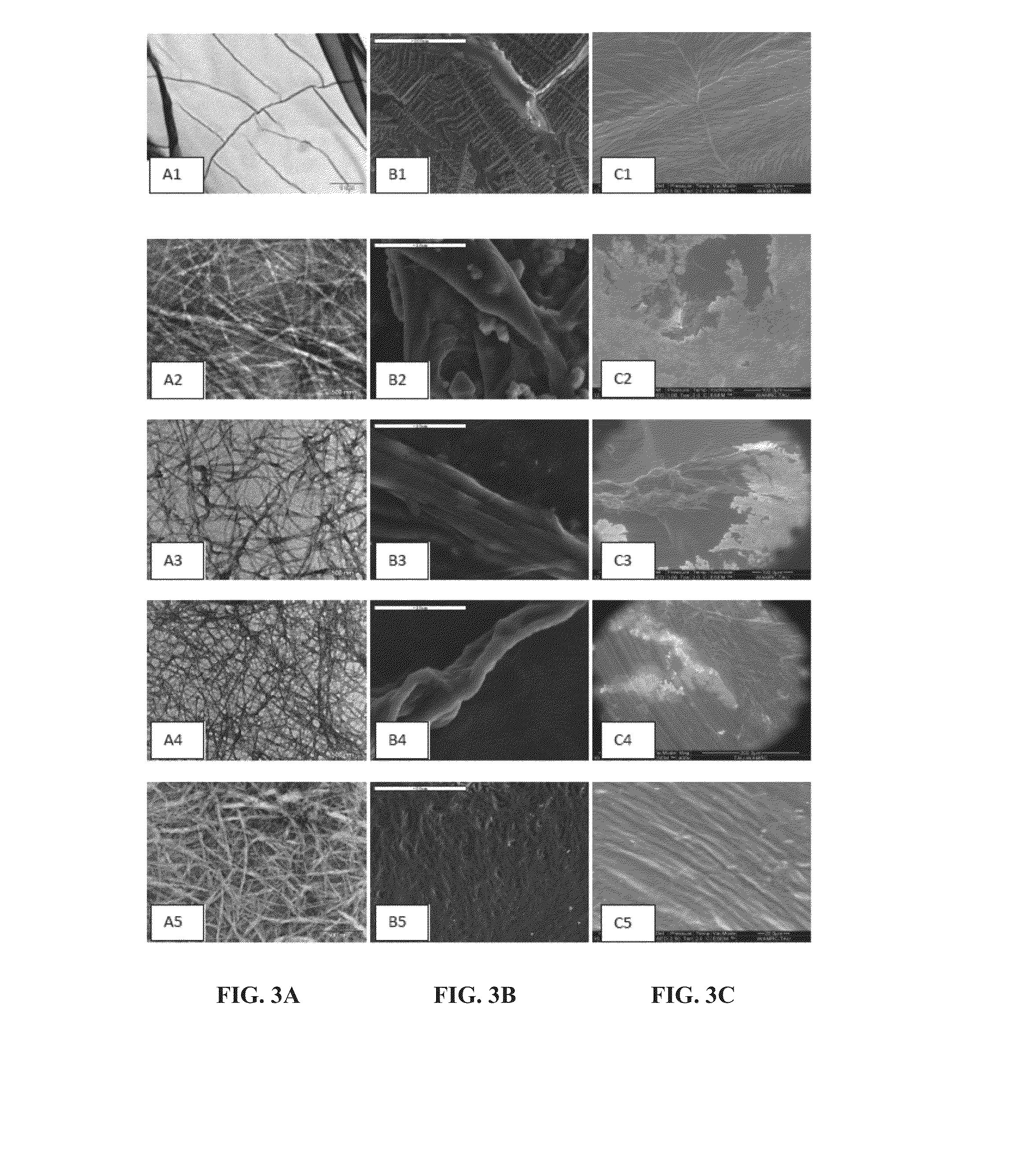

Malleable hydrogel hybrids made of self-assembled peptides and biocompatible polymers and uses thereof

Hybrid hydrogels formed of a plurality of peptides that are capable of self-assembling into a hydrogel in an aqueous solution and a biocompatible polymer that is characterized by high swelling capability, high elasticity and low mechanical strength are disclosed, with exemplary hybrid hydrogels being formed of a plurality of aromatic dipeptides and hyaluronic acid. The hybrid hydrogels are characterized by controllable mechanical and biological properties which can be adjusted by controlling the concentration ratio of the peptides and the polymer, and which average the mechanical and biological properties of the peptides and the polymer. Processes of preparing the hydrogels and uses thereof in pharmaceutical, cosmetic or cosmeceutic applications such as tissue engineering and / or regeneration are further disclosed.

Owner:TECH INNOVATION MOMENTUM FUND ISRAEL

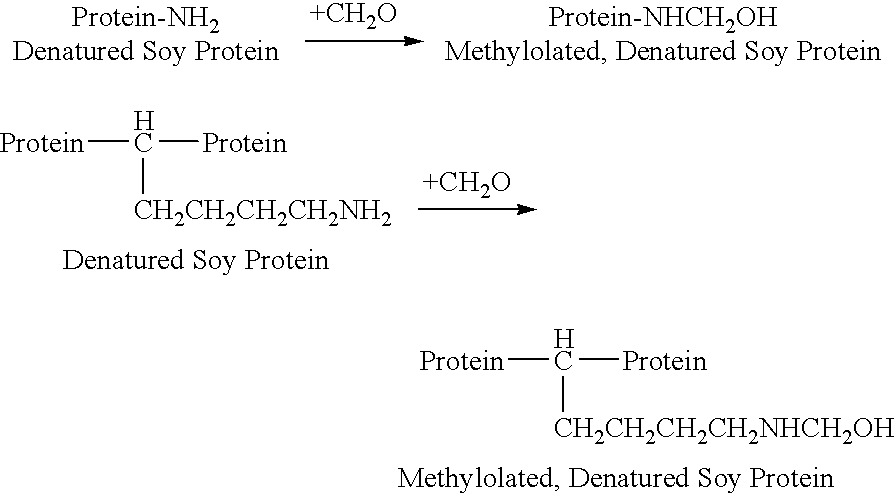

Water-resistant vegetable protein adhesive dispersion compositions

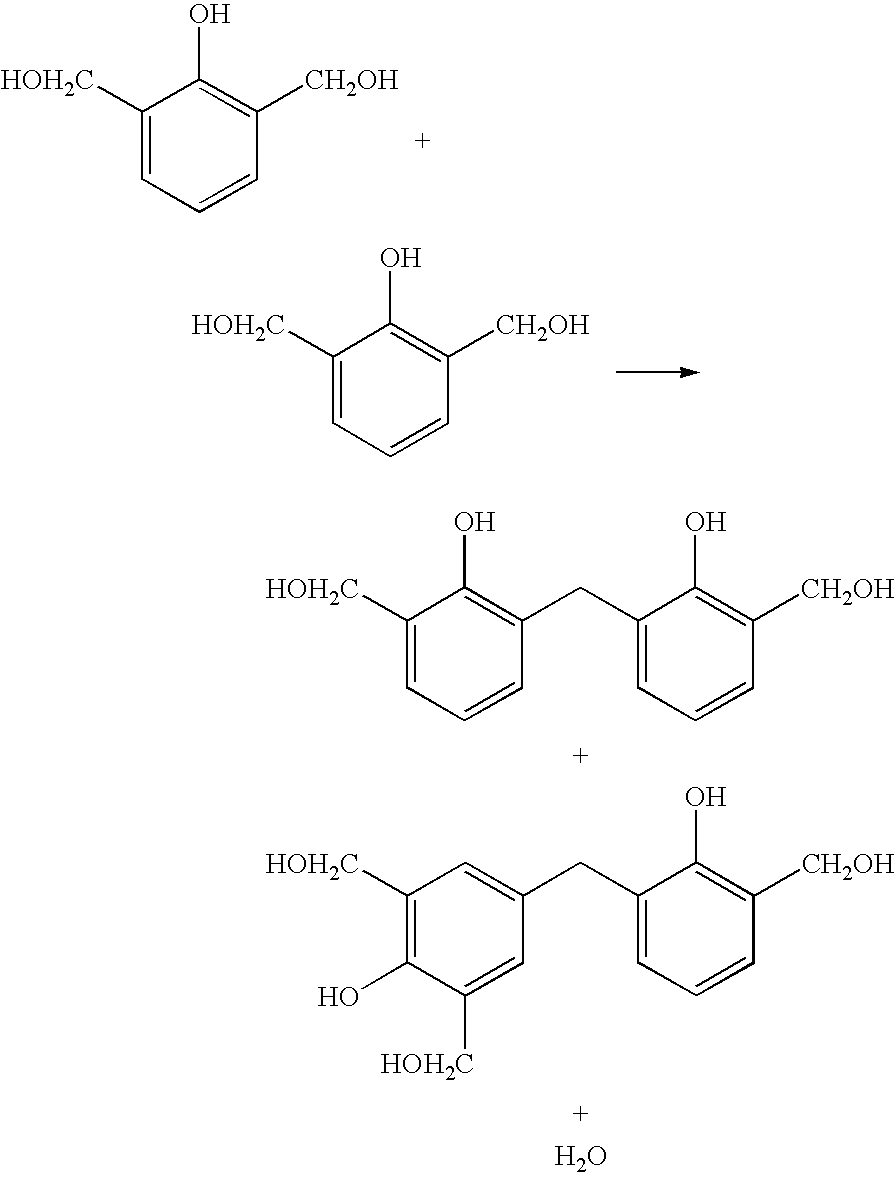

ActiveUS7345136B2Low costIncreased durabilityFibreboardPeptide preparation methodsAdhesiveWater resistant

Water-resistant, protein-based adhesive dispersion compositions and methods for preparing them are provided. The adhesive dispersions are prepared by copolymerizing a denatured vegetable protein, such as soy flour, that has been functionalized with methylol groups with one or more reactive comonomers, and preparing an acidic dispersion of the adhesive. The adhesive dispersions exhibit superior water resistance, and can be used to bond wood substrates, such as panels or laminate, or in the preparation of composite materials.

Owner:US SEC AGRI +1

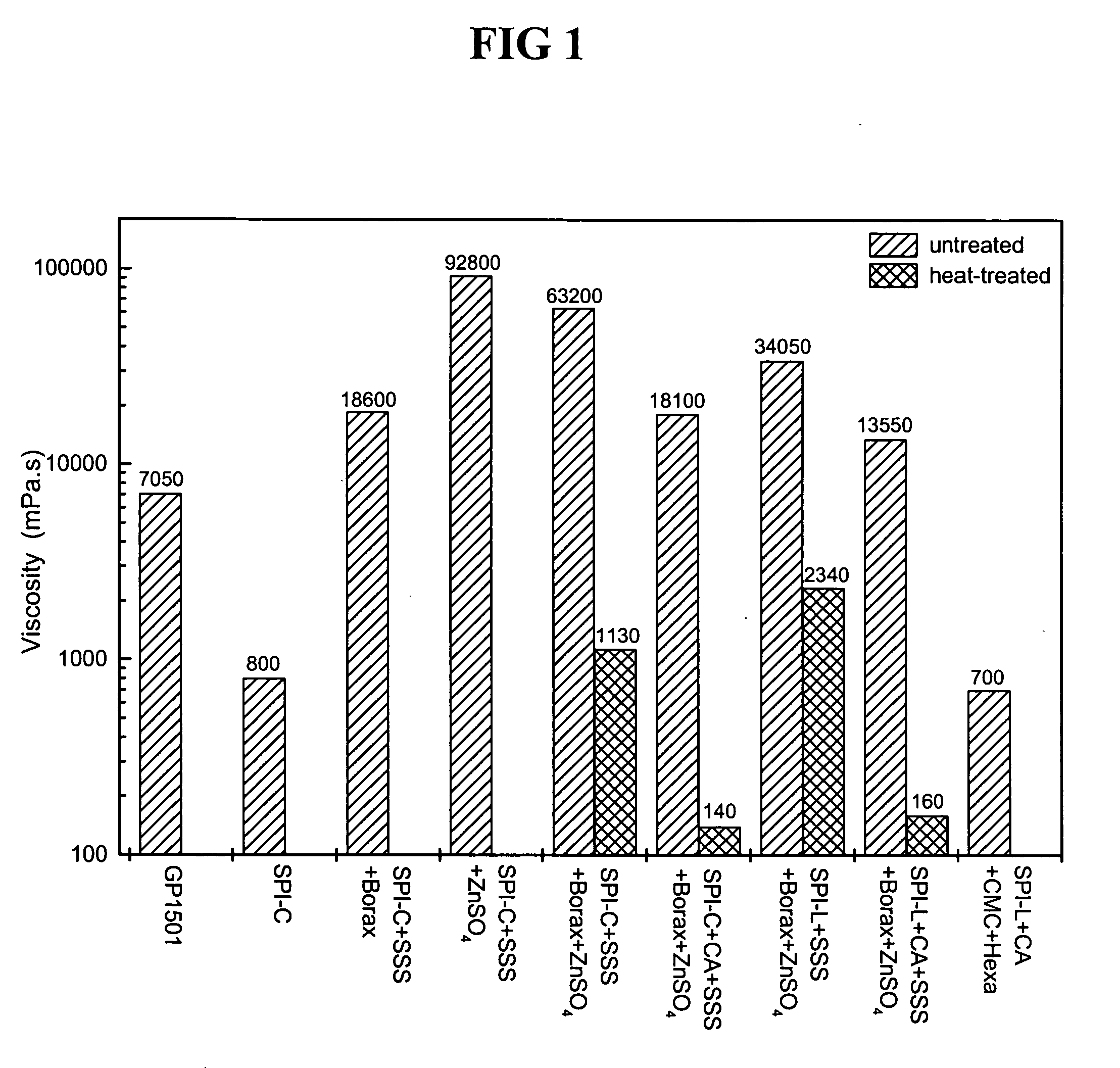

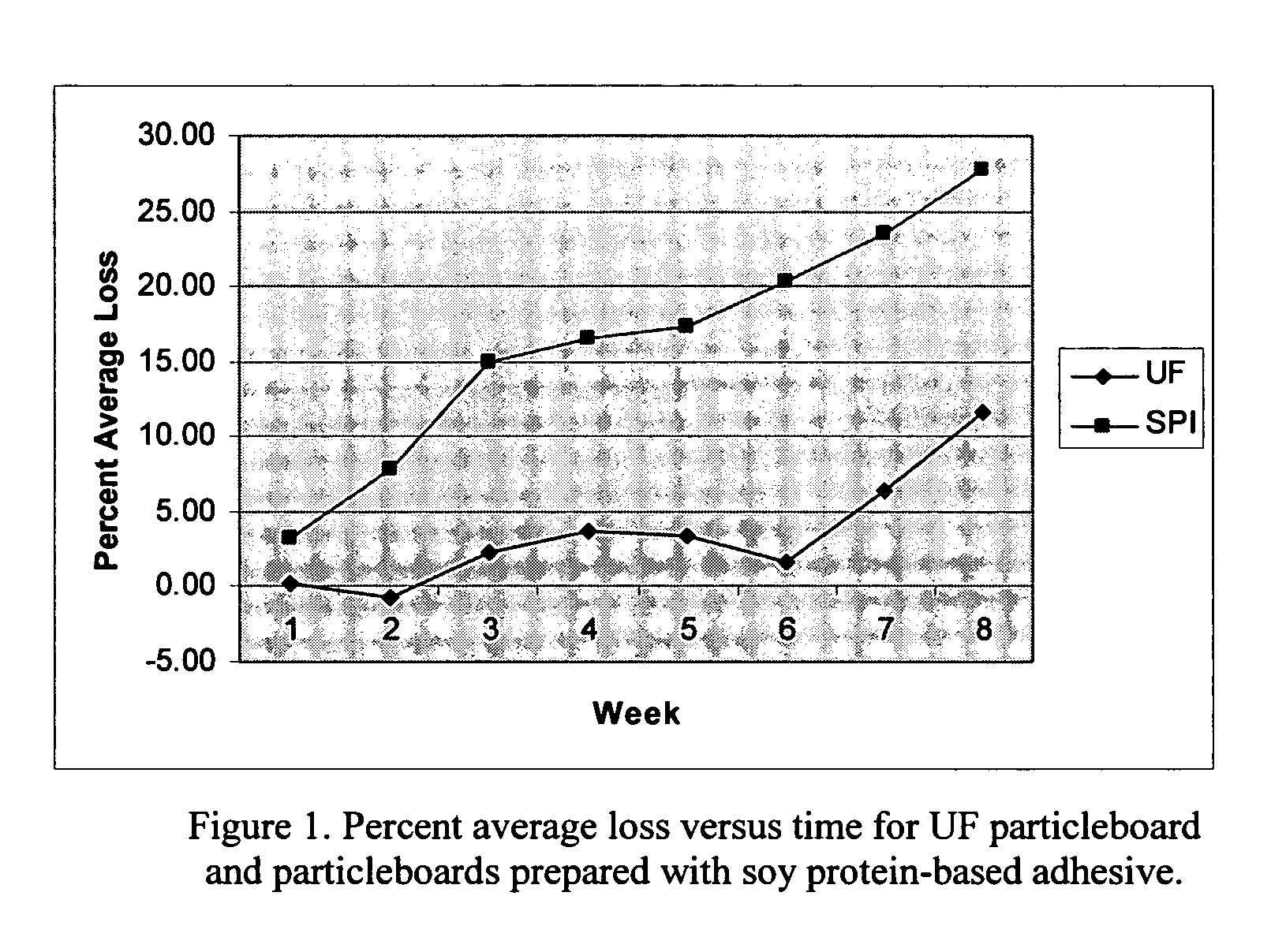

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Antifouling paint composition comprising rosin and enzyme

An antifouling paint composition comprising an enzyme, such as endopeptidase, Subtilisin (EC 3.4.21.62) and Alcalase(R), and a rosin compound, wherein the enzyme is effective to reduce or prevent fouling by aquatic organisms of a surface coated with the composition. Also disclosed is a method for preventing fouling of a surface by aquatic organisms.

Owner:BIOLOCUS

Biodegradable resin composites

InactiveUS20110229698A1More rigidityMore strengthAdhesive processesDecorative surface effectsPolymer scienceResin composite

Owner:E2E MATERIALS

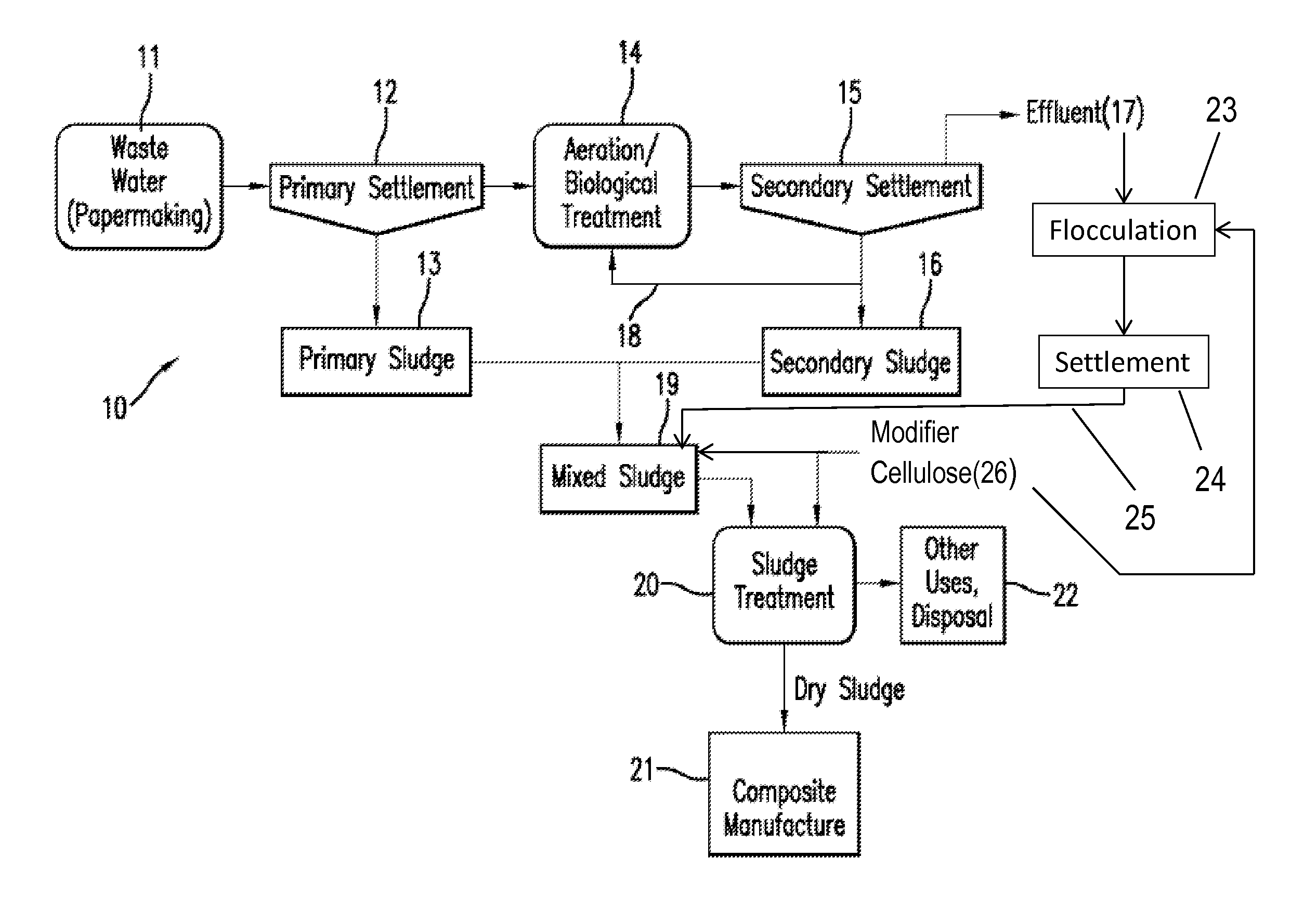

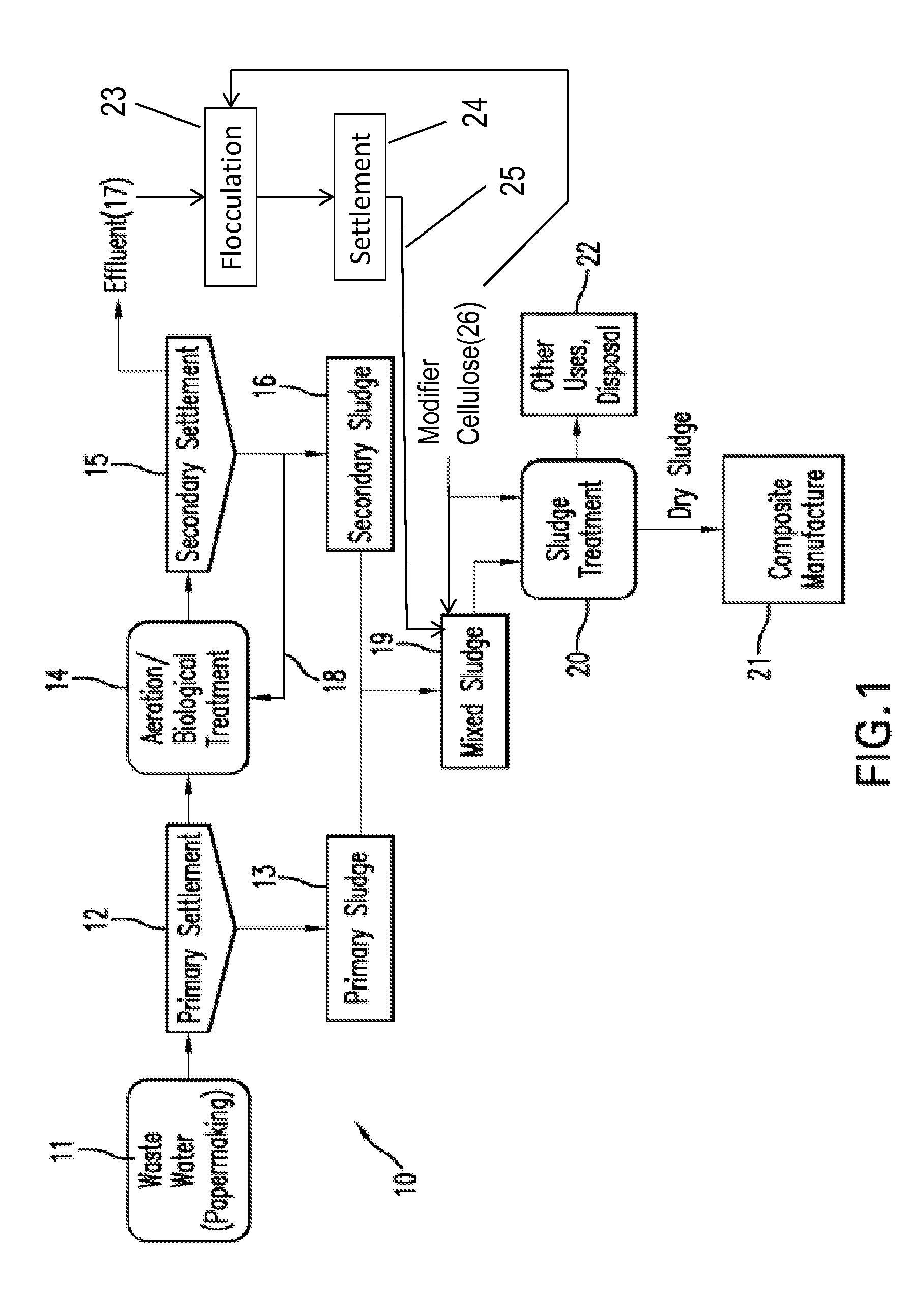

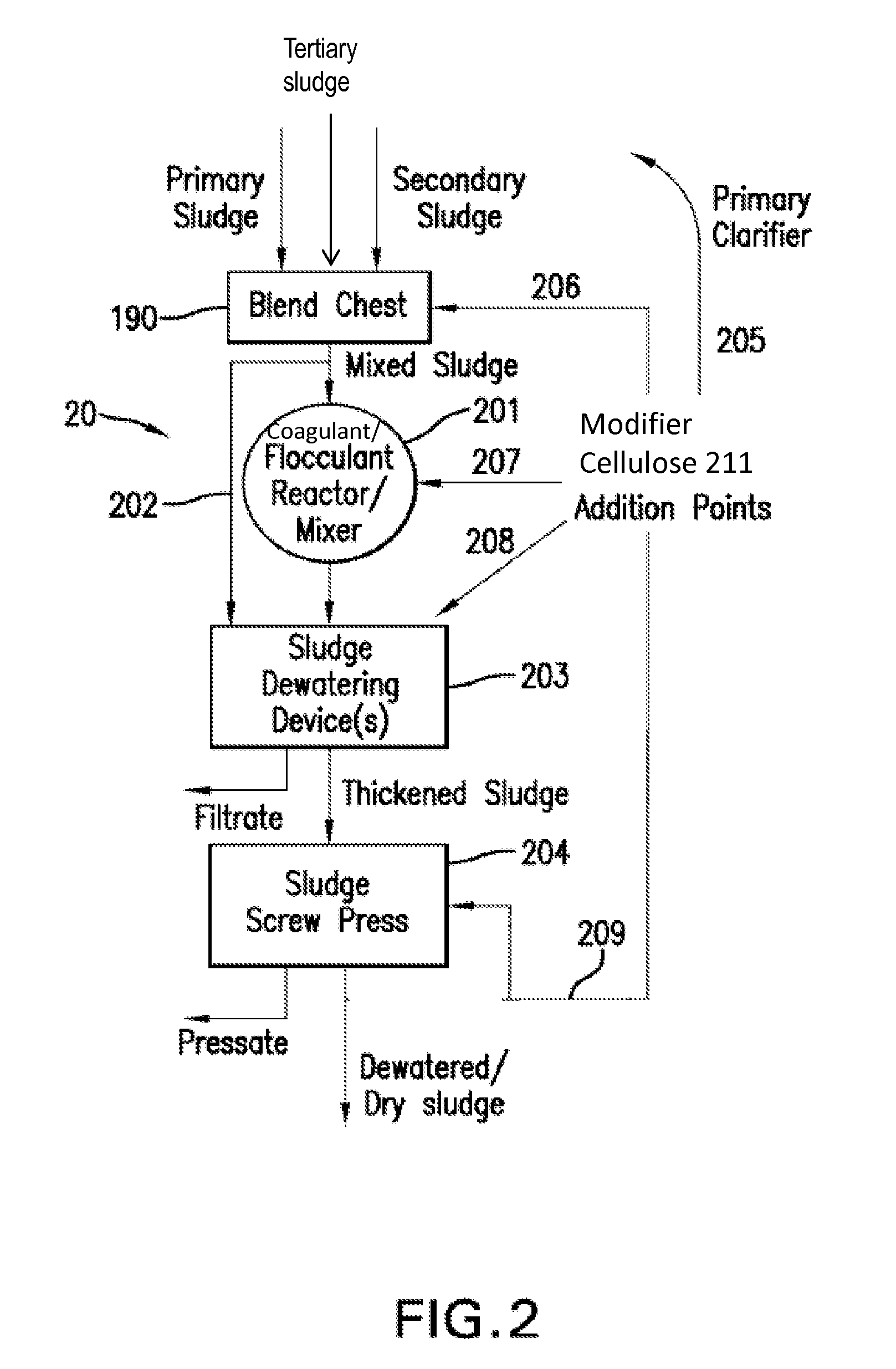

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

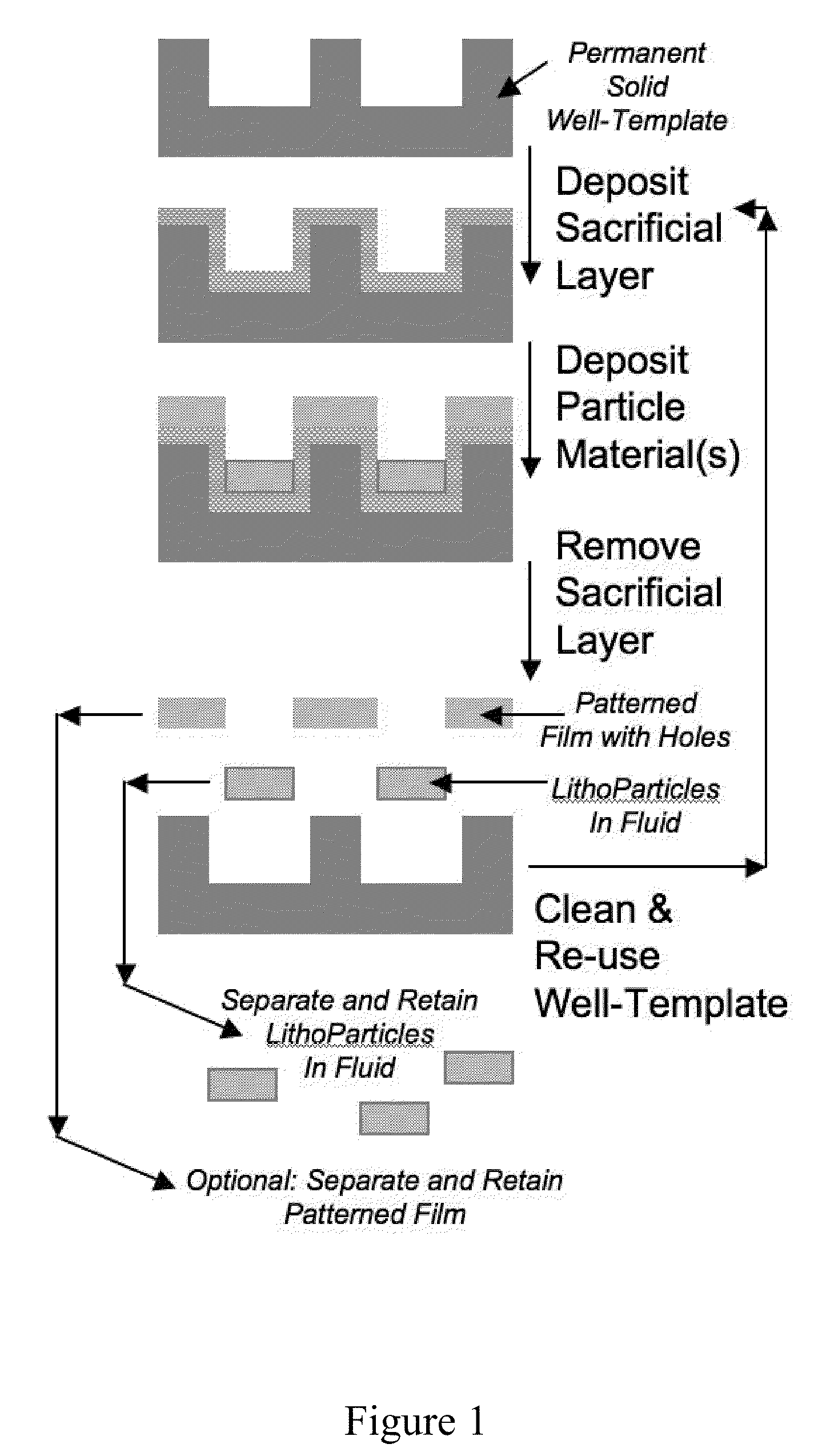

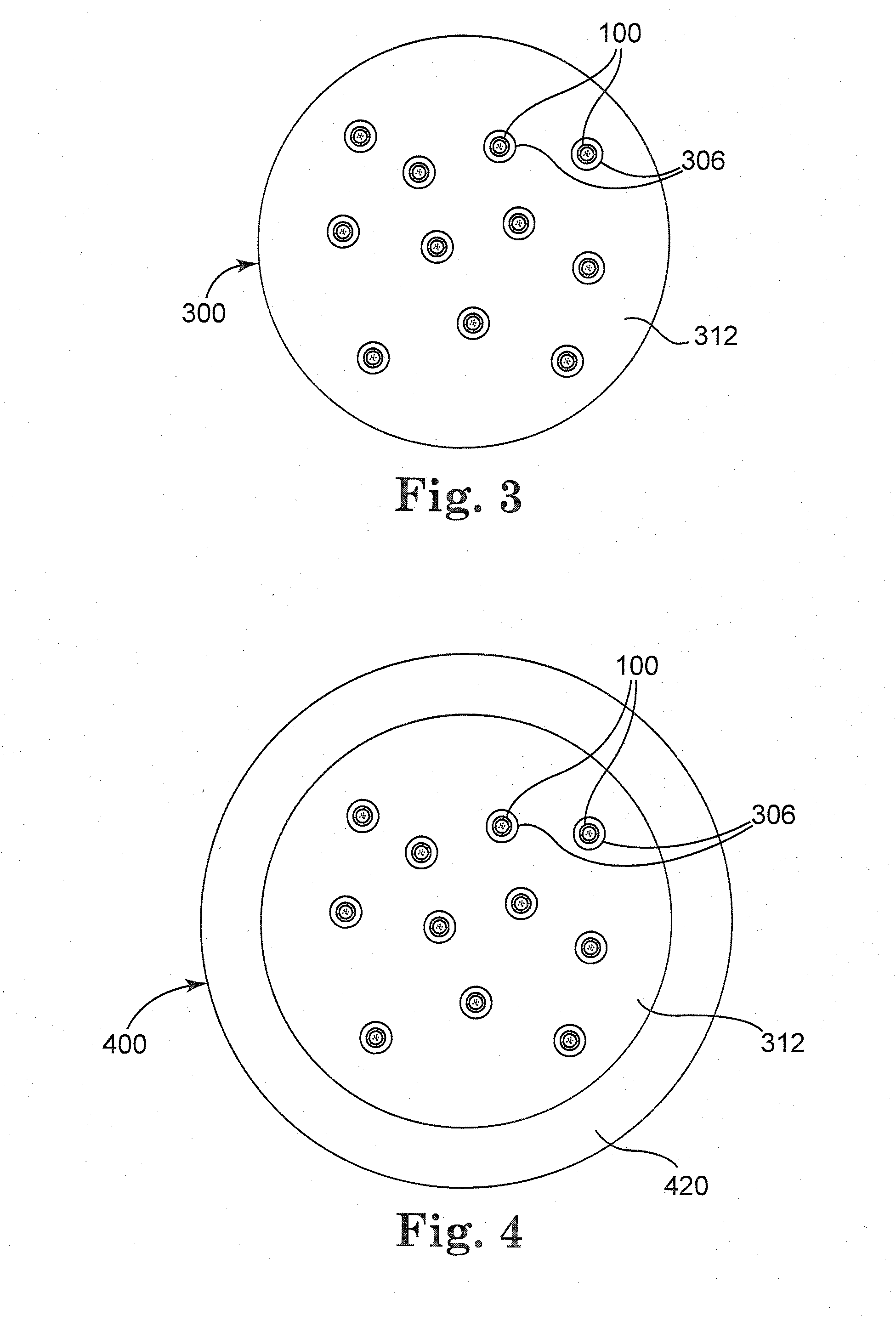

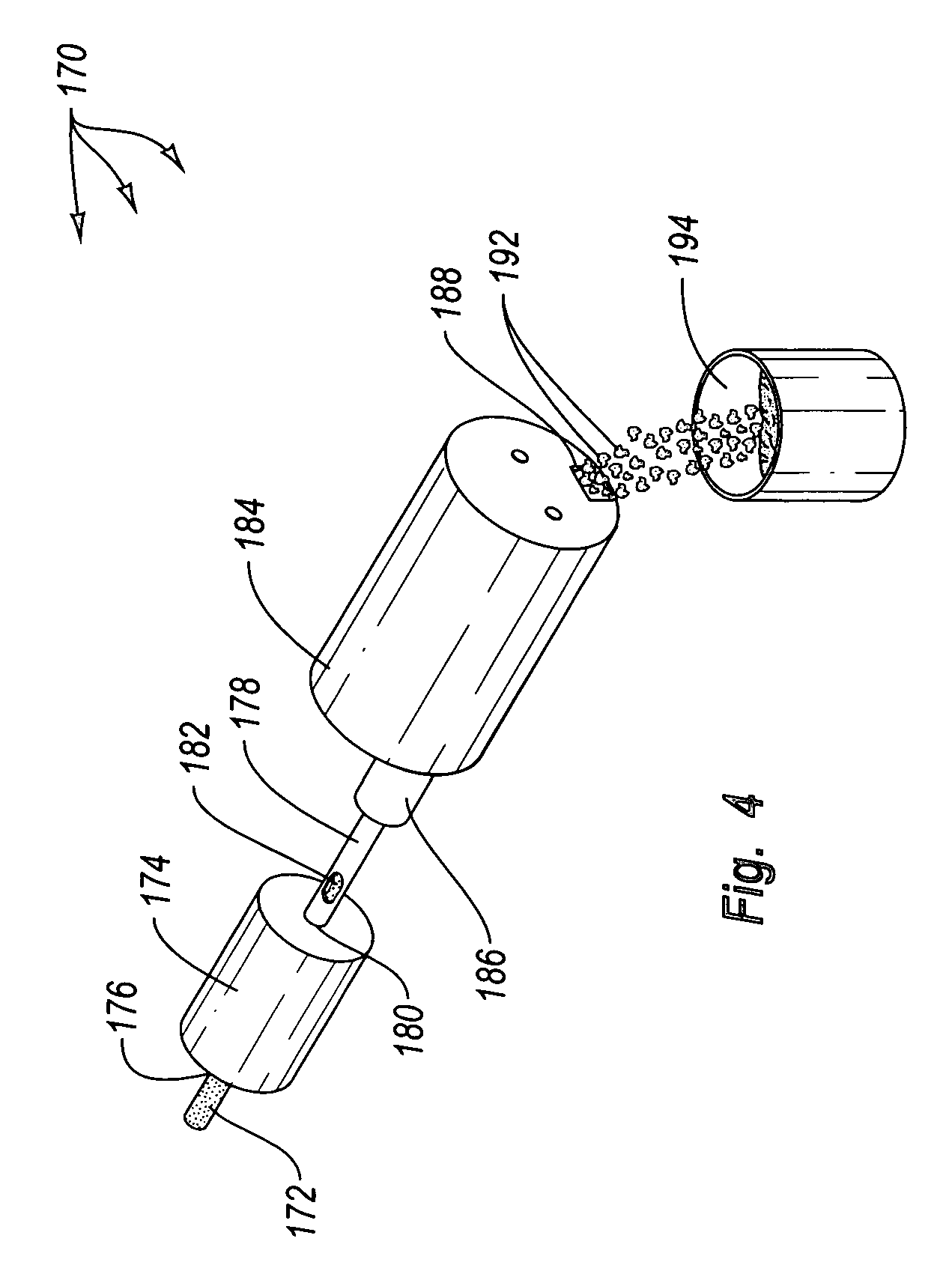

Mechanical process for creating particles in fluid

InactiveUS20100021985A1Impart propertyNanomagnetismLiquid surface applicatorsSurface geometryMaterials science

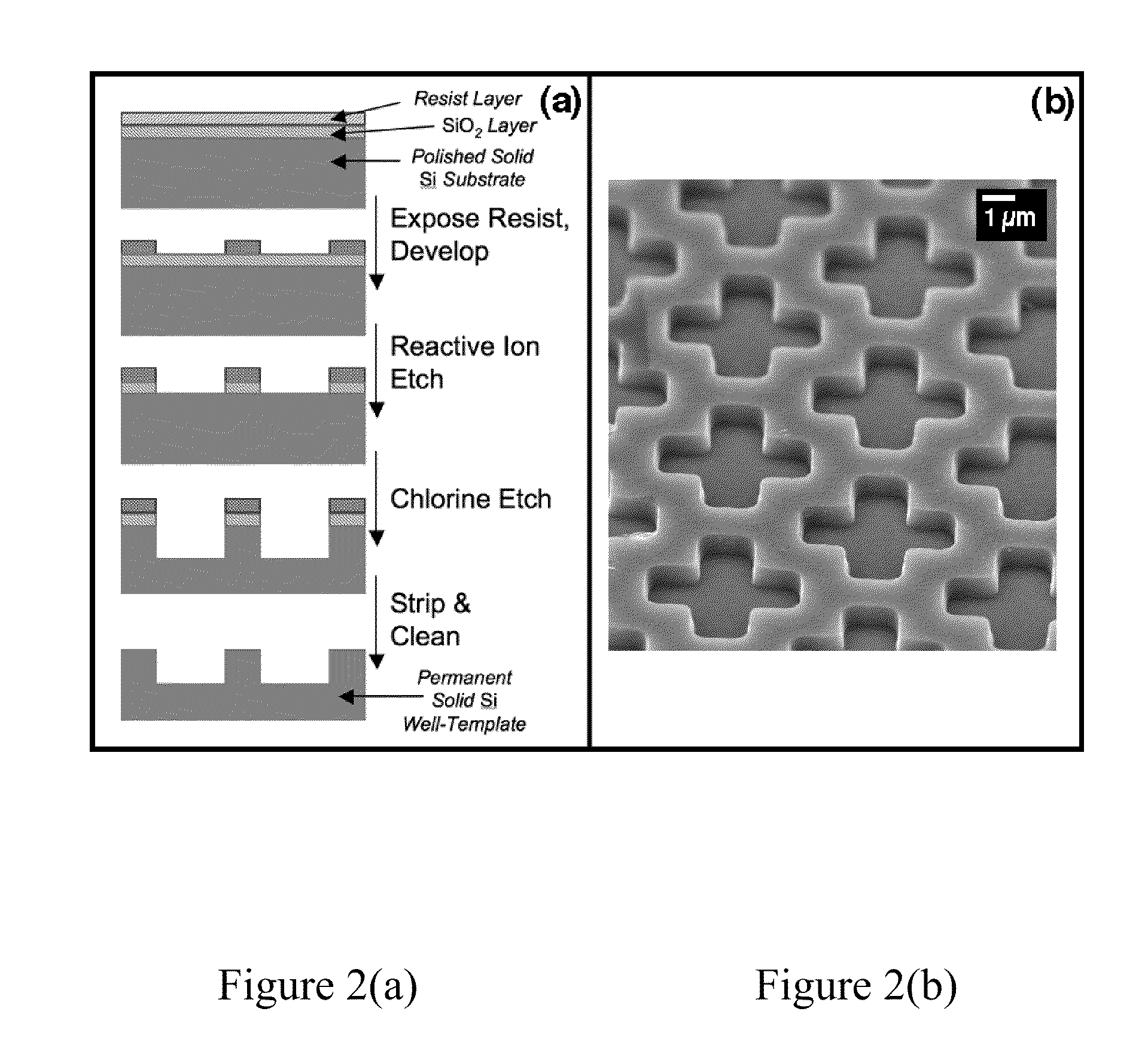

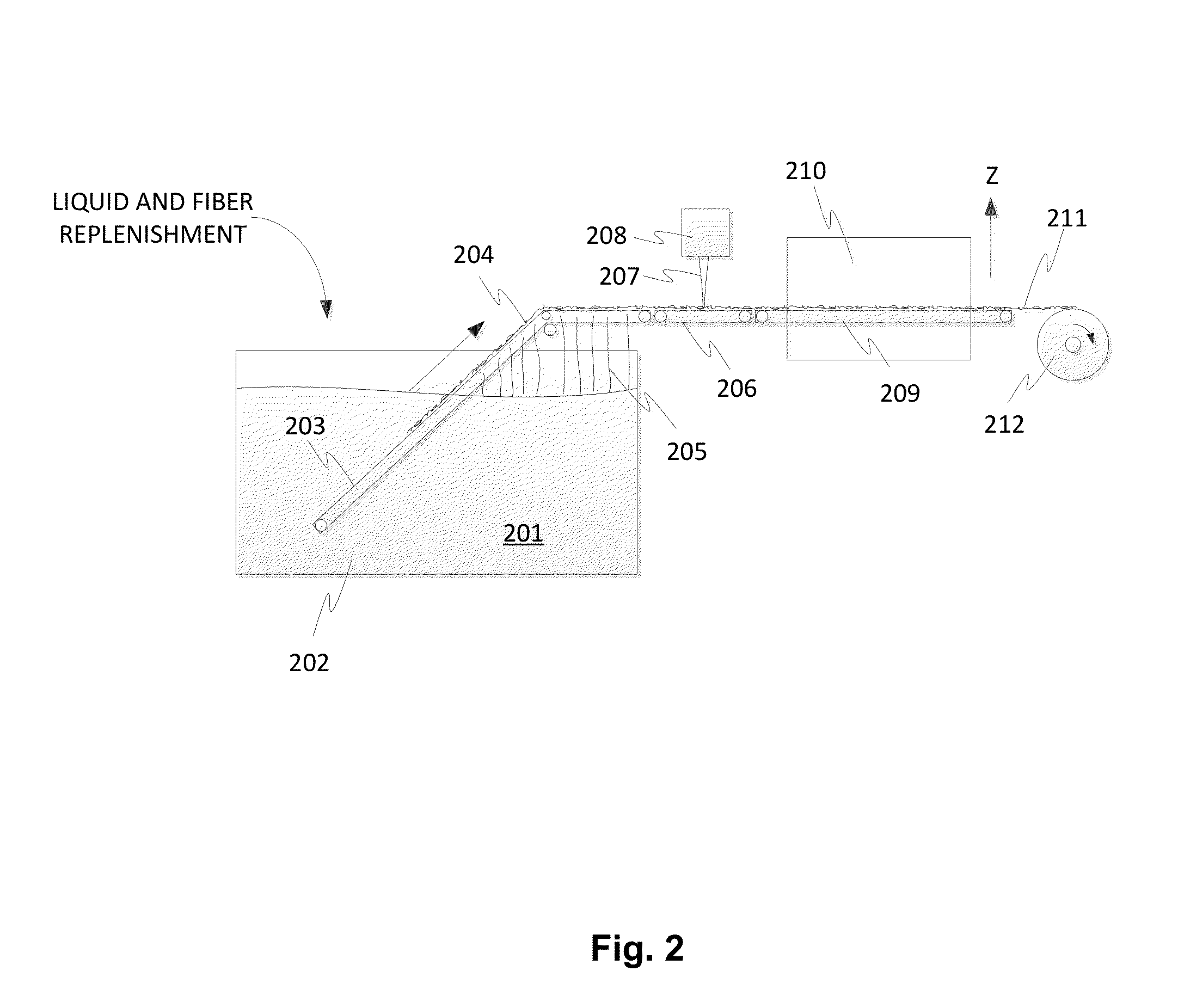

A method of producing at least one of microscopic and submicroscopic particles includes providing a template that has a plurality of discrete surface portions, each discrete surface portion having a surface geometry selected to impart a desired geometrical property to a particle while being produced; depositing a constituent material of the at least one of microscopic and submicroscopic particles being produced onto the plurality of discrete surface portions of the template to form at least portions of the particles; separating the at least one of microscopic and submicroscopic particles comprising the constituent material from the template into a fluid material, the particles being separate from each other at respective discrete surface portions of the template; and processing the template for subsequent use in producing additional at least one of microscopic and submicroscopic particles. A multi-component composition includes a first material component in which particles can be dispersed, and a plurality of particles dispersed in the first material component. The plurality of particles is produced by methods according to embodiments of the current invention.

Owner:RGT UNIV OF CALIFORNIA

Viscosity modified formaldehyde-free binder compositions

ActiveUS20140134909A1High viscosityLaminate strength deterioratesNon-fibrous pulp additionNon-macromolecular adhesive additivesGuar gumHydroxyethyl cellulose

Viscosity-modified carbohydrate binder compositions are described. The binder compositions may include a carbohydrate, a nitrogen-containing compound, and a thickening agent. The binder compositions may have a Brookfield viscosity of 7 to 50 centipoise at 20° C. The thickening agents may include modified celluloses such as hydroxyethyl cellulose (HEC) and carboxymethyl cellulose (CMC), and polysaccharides such as xanthan gum, guar gum, and starches.

Owner:JOHNS MANVILLE CORP

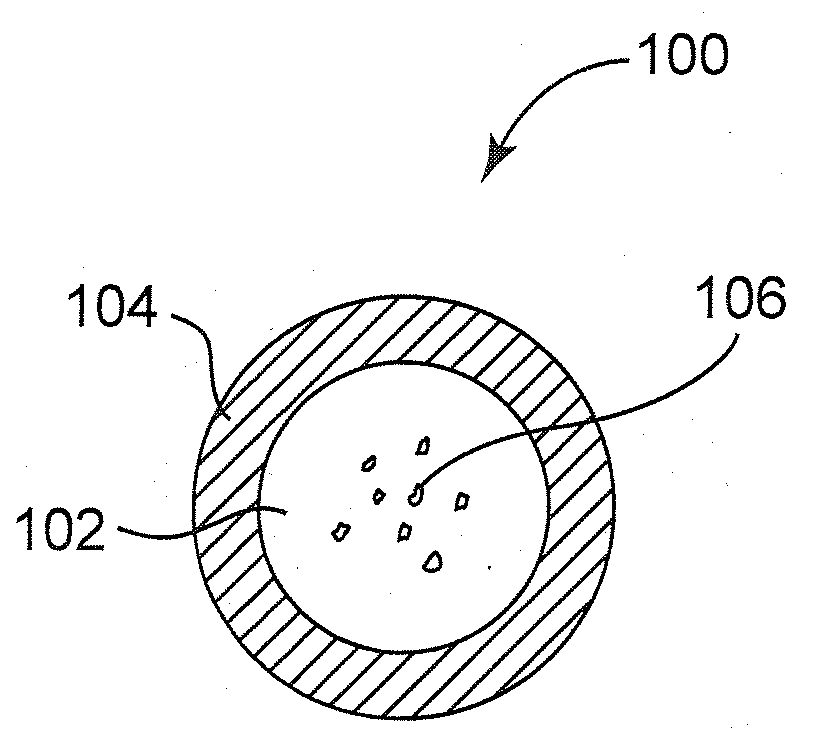

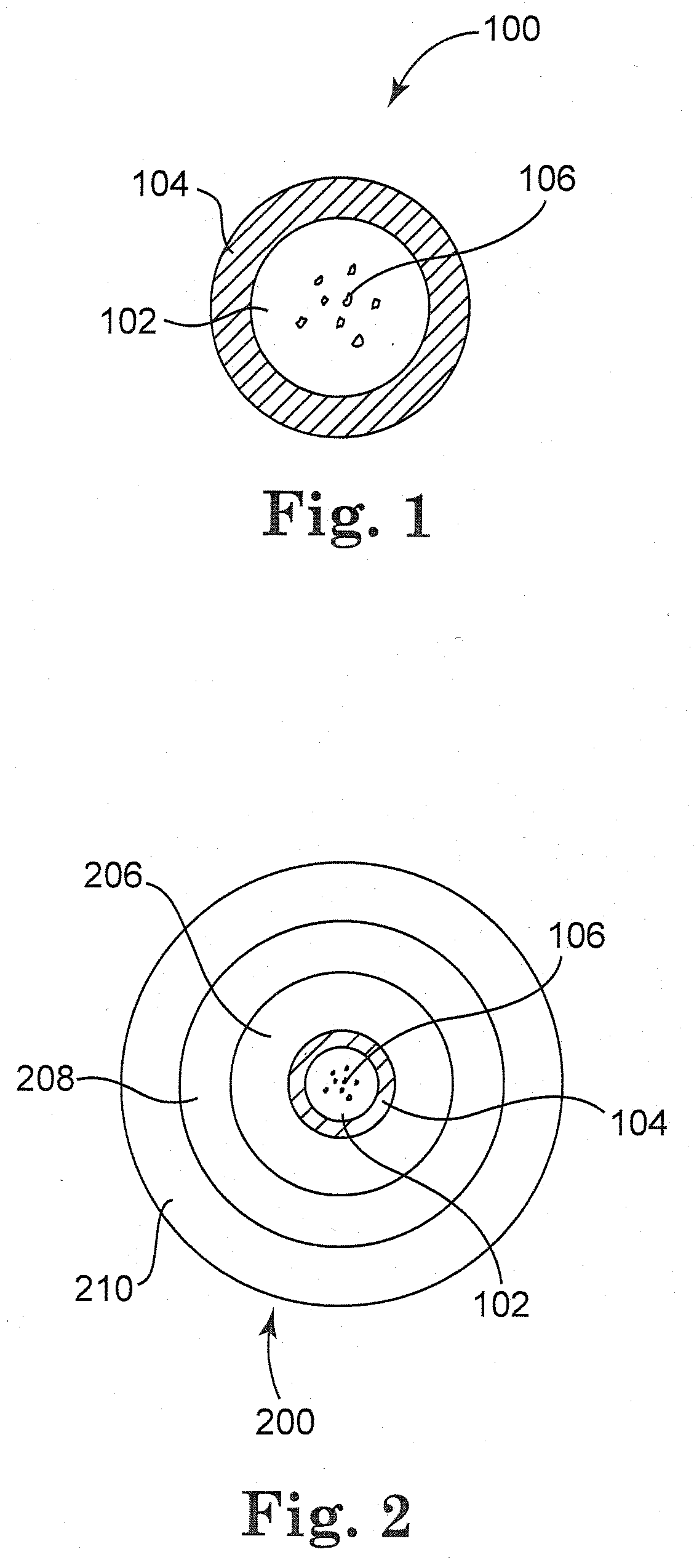

Encapsulation of oxidatively unstable compounds

InactiveUS20110052680A1Improve Oxidation StabilityDry powder formImmobilised enzymesOrganic active ingredientsPhospholipidPhytosterol

An encapsulated material containing an oxidation-sensitive core is covered by at least a dried phospholipid layer, and contains at least one phytosterol in the core, the phospholipid layer or in a further layer or layers. By using microencapsulation, oxidatively unstable materials may be provided with a synthetic protective barrier and rendered less susceptible to oxidative degradation.

Owner:AVEKA INC

Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

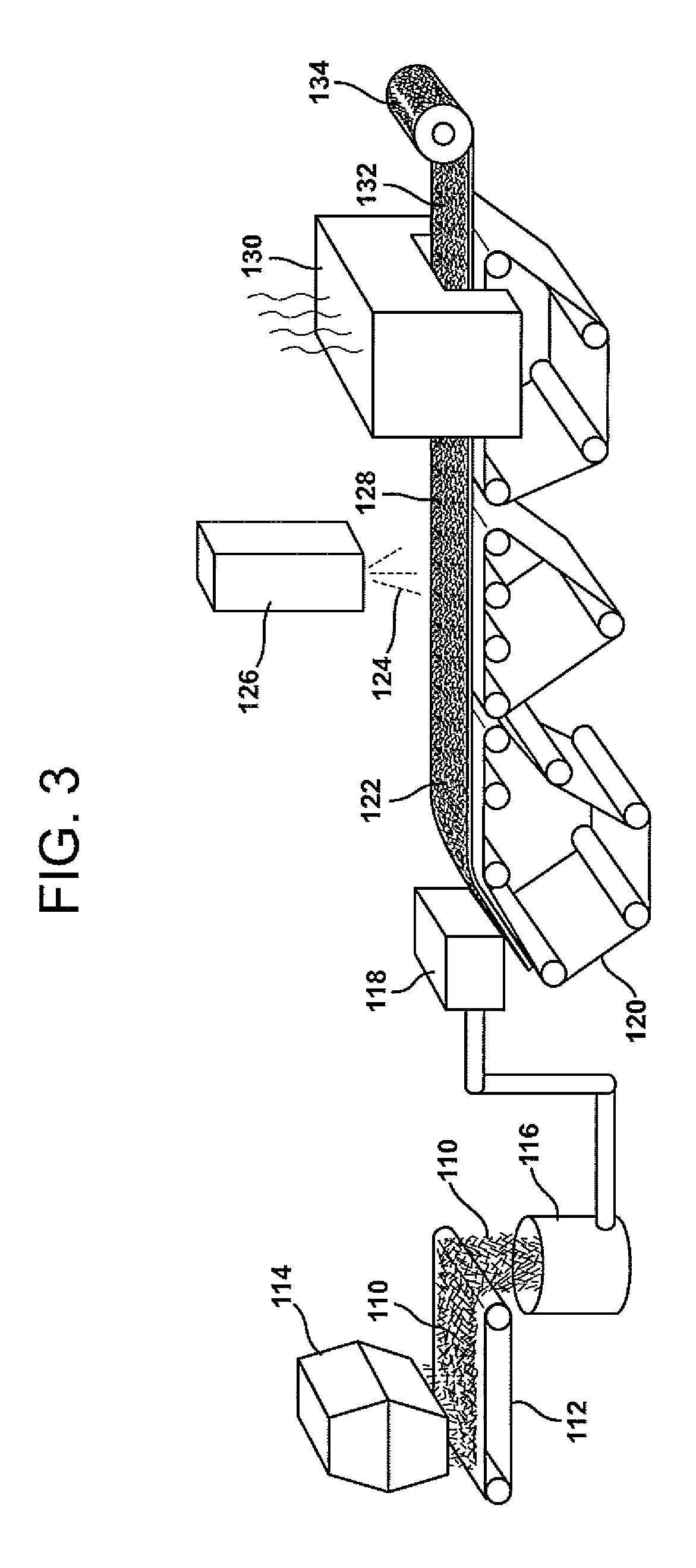

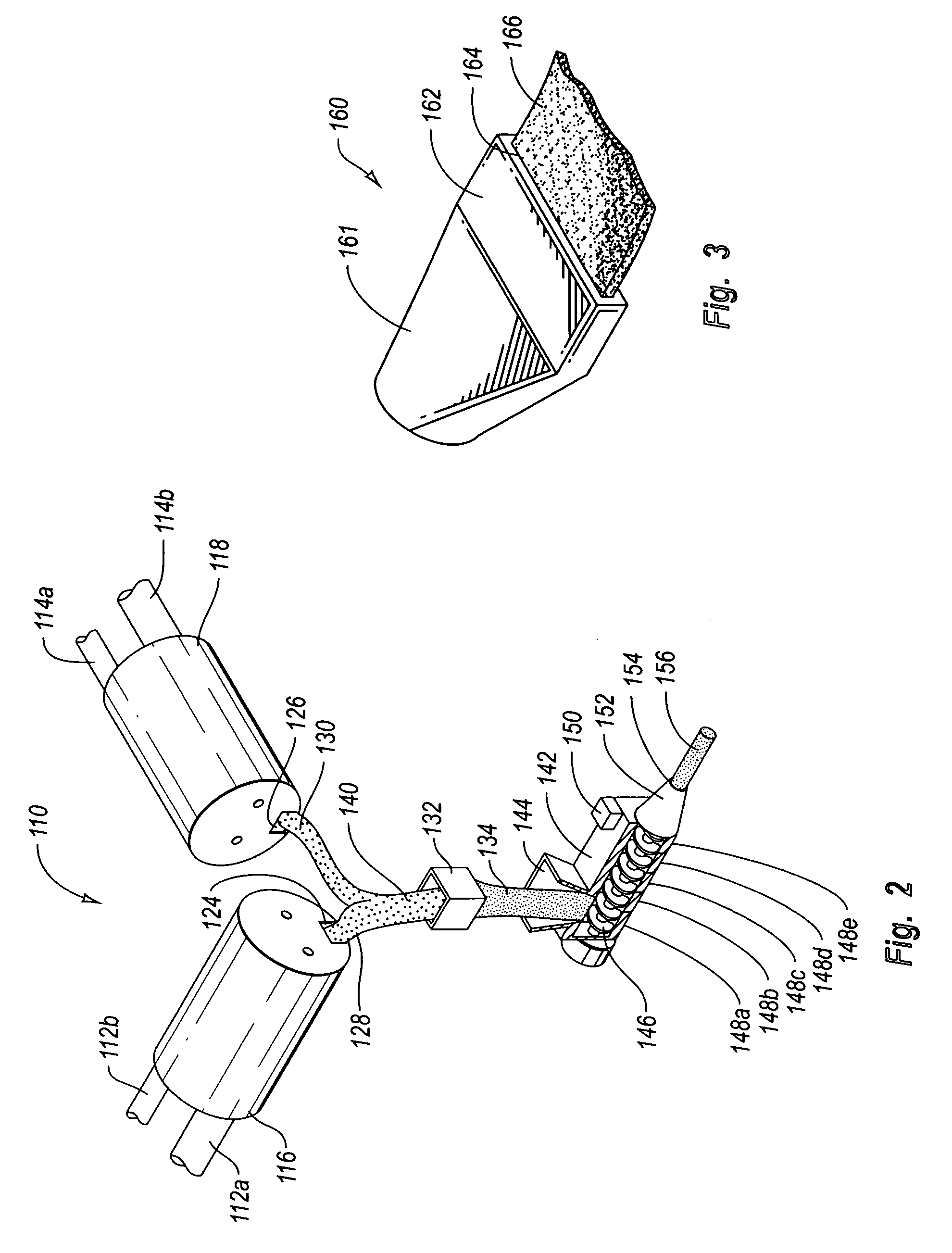

Fiber-reinforced starch-based compositions and methods of manufacture and use

A fiber-reinforced and starch-based composition can be prepared by combining two fractions. The first fraction can include a gelatinized starch, water, and fibers, wherein the fibers are substantially homogenously mixed with the starch in an amount sufficient to structurally reinforce the mechanical characteristics of the starch-based composition. The second fraction is then combined with the first fraction, wherein the second fraction can include non-gelatinized starch, non-volatile plasticizer, and a water-resistant polymer. The composition is mixed so as to form a thermoplastic composition being capable of expanding when rapidly heated to above the boiling point of water and the softening point of the plasticized starch. Additionally, fiber-reinforced articles can be prepared from a method of processing the starch-based compositions. Such a method includes introducing the fiber-reinforced starch-based composition into a mold, and molding the composition into a fiber-reinforced article.

Owner:E KHASHOGGI INDS

Basic biomass synthetic resin and preparation method and application thereof

ActiveCN101629019AGood film formingIncrease stickinessProtein adhesivesGlue/gelatin preparationPolymer scienceAdhesive

The invention belongs to the material science field, in particular to a basic biomass synthetic resin and a preparation method and an application thereof. The basic biomass synthetic resin is prepared by the following steps: taking acidity regulator to prepare a water solution with pH value of 6.0-10.0, adding plant protein powder in the water solution under the stirring state; adding a molecular structure modifying agent under the stirring state, performing the modifying reaction for 15-240 min at 5-75 DEG C; sequentially adding modified starch and a resin assistant, performing the polymerization reaction for 15-240min at 5-90 DEG C, adding preservative in a reaction system within the last 5-20min of the polymerization reaction; adding or not adding packing after finishing the reaction, and stirring uniformly to obtain the basic biomass synthetic resin, wherein the part of the materials is taken by weight. The basic biomass synthetic resin has wide application range on the respect of preparing bonding adhesive or coating.

Owner:郑州佰沃科技发展有限公司

Method for producing fine particle dispersion and fine particle dispersion

InactiveUS20090321689A1Good dispersionImprove adhesionMaterial nanotechnologyNon-insulated conductorsAlloyPolymer

Disclosed is a method for producing a fine particle dispersion such as a dispersion of metal fine particles which is superior in dispersibility and storage stability. Specifically disclosed is a method for producing a fine particle dispersion wherein fine particles of a metal or the like, having a mean particle diameter of between 1 nm and 150 nm for primary particles, are dispersed in an organic solvent. This method for producing a fine particle dispersion is characterized by comprising the steps of: reducing a metal ion by liquid phase reduction in an aqueous solution wherein the metal ion and a polymer dispersing agent are dissolved, thereby forming a fine particle dispersion aqueous solution wherein fine particles having a mean particle diameter of between 1 nm and 150 nm for the primary particles and dispersed with being coated by the polymer dispersing agent (Process 1); adding an aggregation accelerator into the fine particle dispersion aqueous solution, the resulting solution is agitated for agglomerating or precipitating the fine particles, and then the agglomerated or precipitated fine particles are separated from the aqueous solution, thereby obtaining fine particles comprised of one type or not less than two types of a metal, an alloy and a metallic compound (Process 2); and re-dispersing the thus-obtained fine particles into an organic solvent or the like which contains an organic solvent (A) as between 25% and 70% by volume having an amide group, a low boiling point organic solvent (B) as between 5% and 25% by volume having a boiling point of between 20° C. and 100° C. at a normal pressure, and an organic solvent (C) as between 5% and 70% by volume having a boiling point of higher than 100° C. at a normal pressure and comprised of an alcohol and / or a polyhydric alcohol having one or not less than two hydroxyl groups in a molecule thereof (Process 3).

Owner:FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com