Patents

Literature

2373results about "Light beam reproducing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

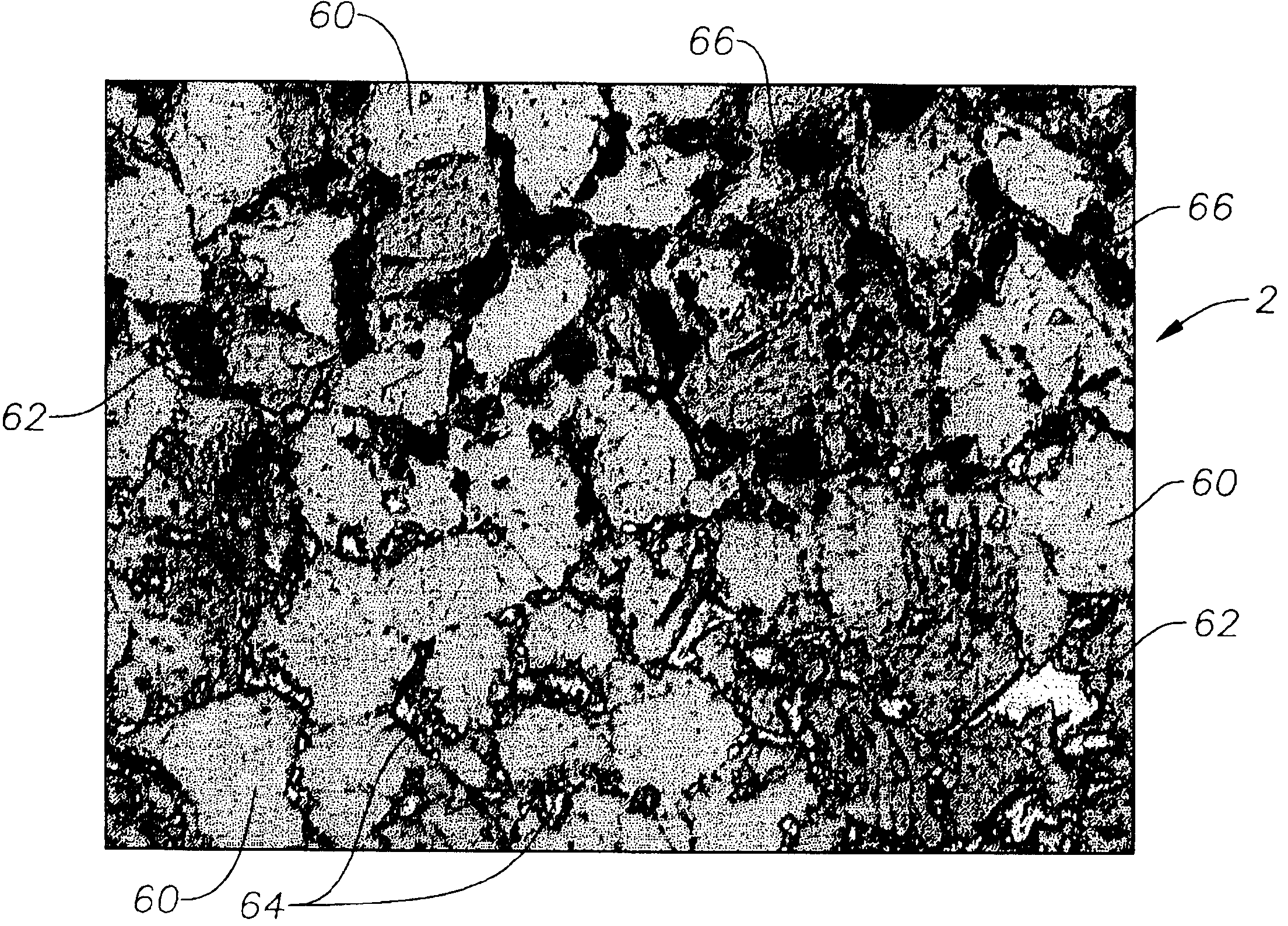

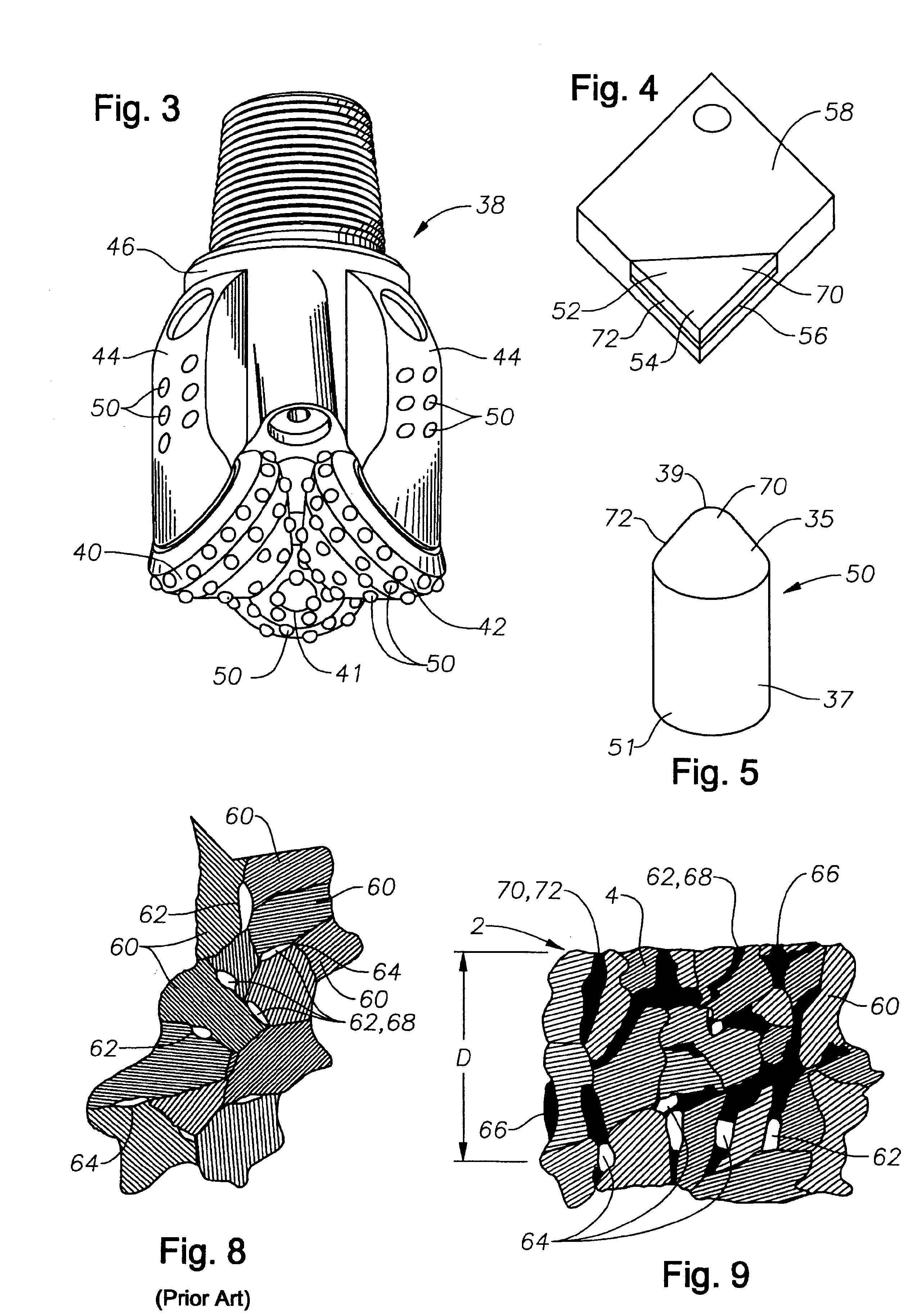

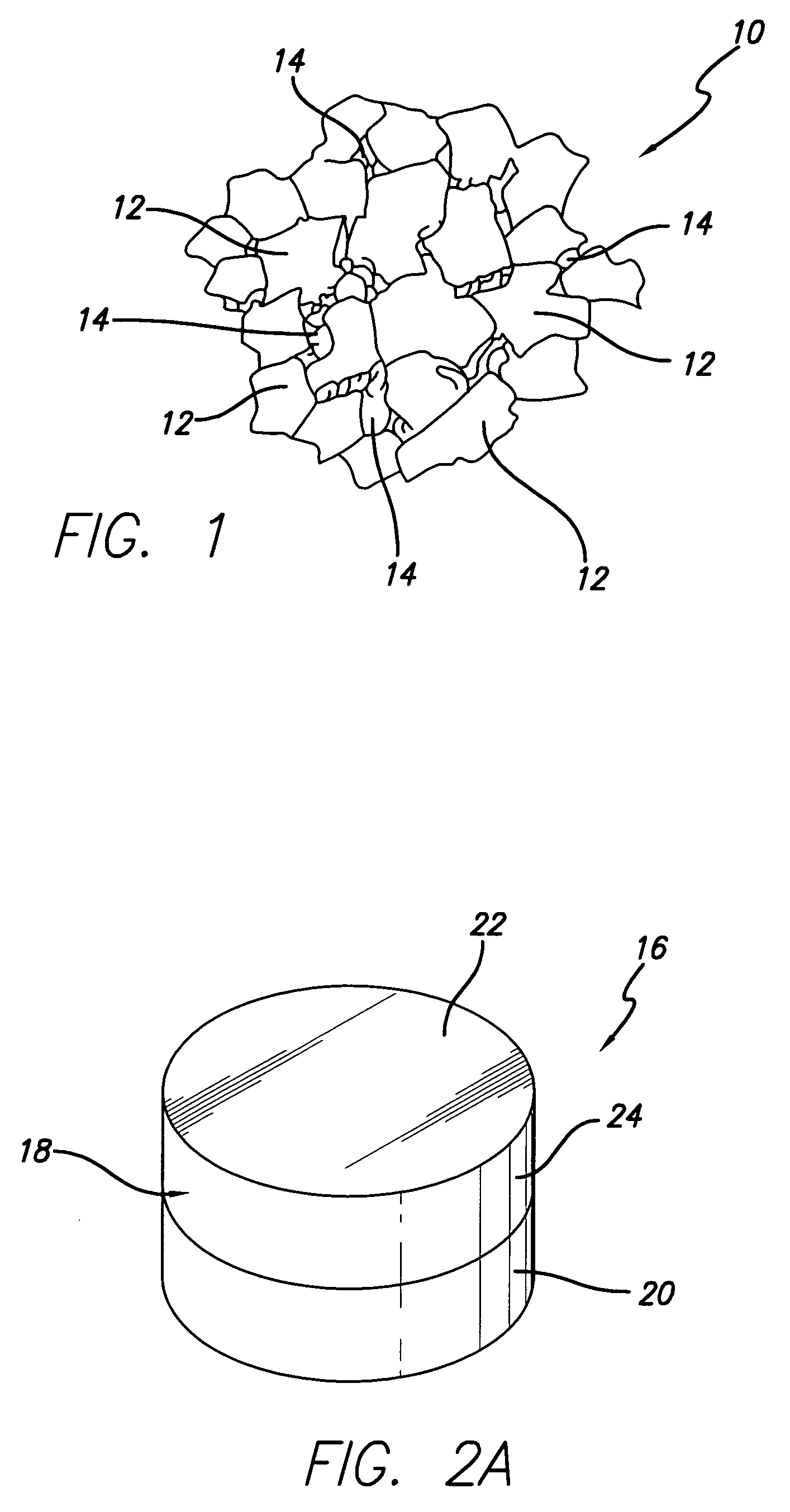

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

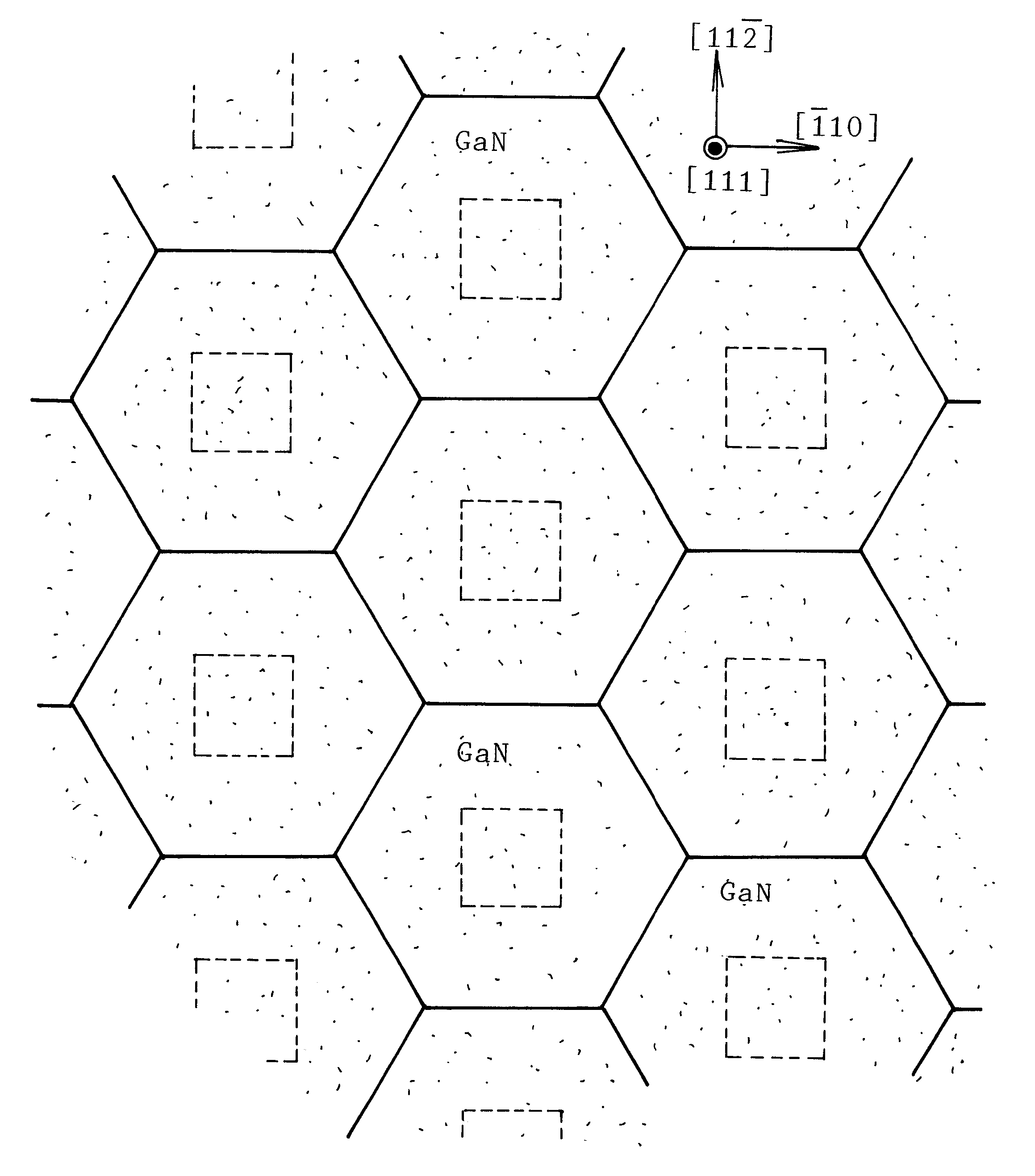

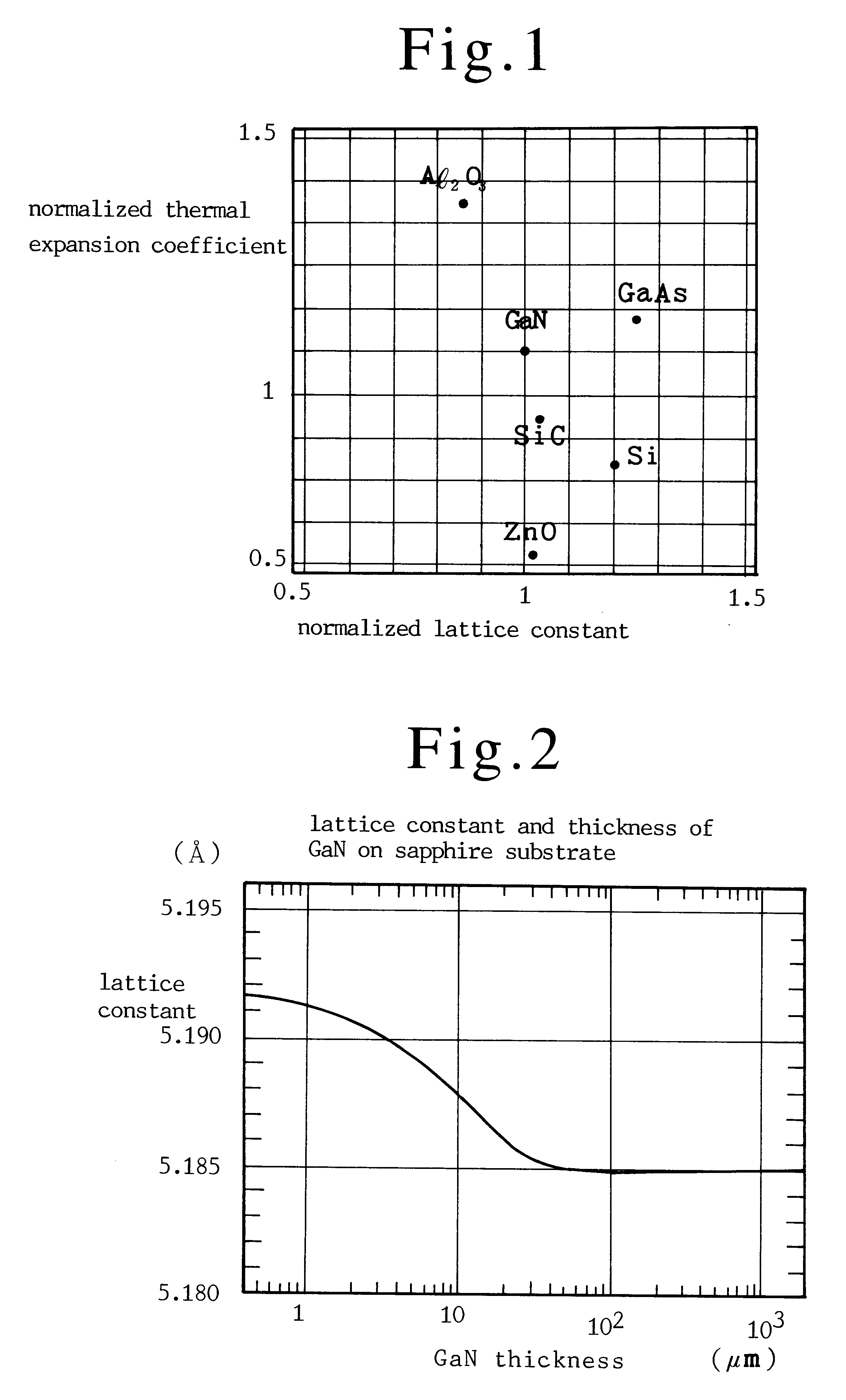

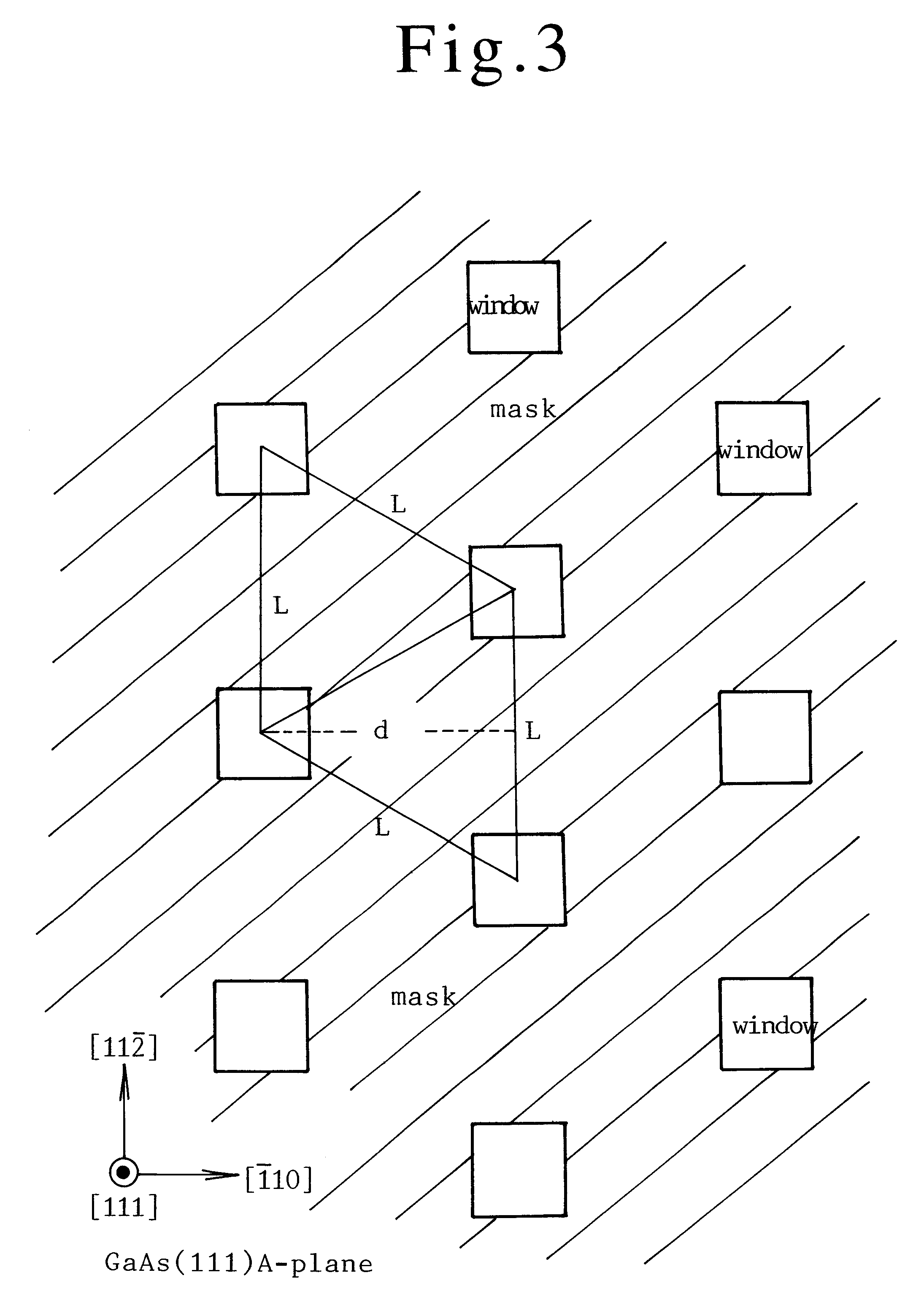

GaN single crystal substrate and method of producing same

InactiveUS6413627B1Polycrystalline material growthLayered productsDistortion freeSingle crystal substrate

A freestanding GaN single crystal substrate is made by the steps of preparing a (111) GaAs single crystal substrate, forming a mask having periodically arranged windows on the (111) GaAs substrate, making thin GaN buffer layers on the GaAs substrate in the windows of the mask, growing a GaN epitaxial layer on the buffer layers and the mask by an HVPE or an MOC, eliminating the GaAs substrate and the mask away and obtaining a freestanding GaN single crystal substrate. The GaN single crystal has a diameter larger than 20 mm and a thickness more than 0.07 mm, being freestanding and substantially distortion-free.

Owner:SUMITOMO ELECTRIC IND LTD

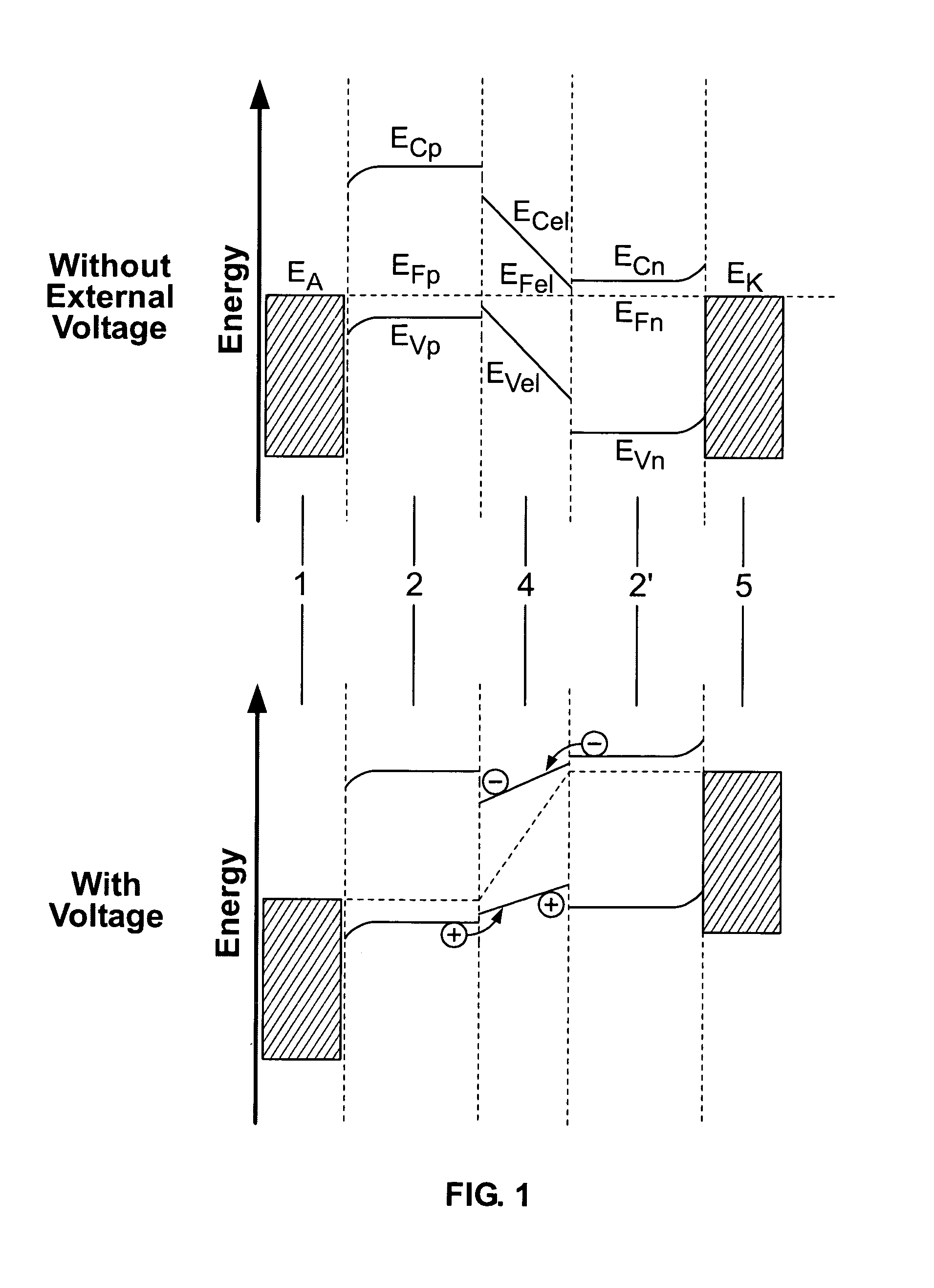

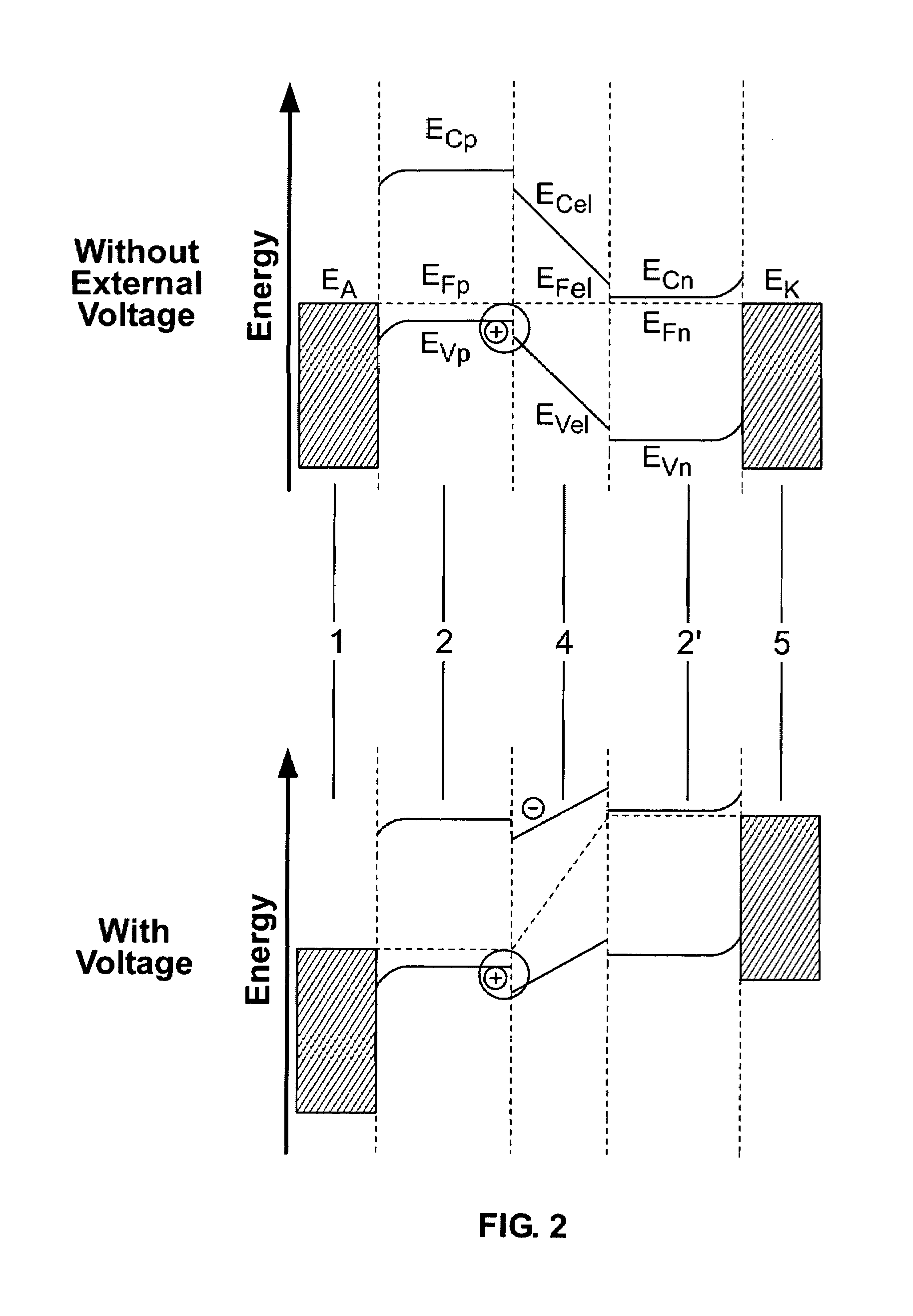

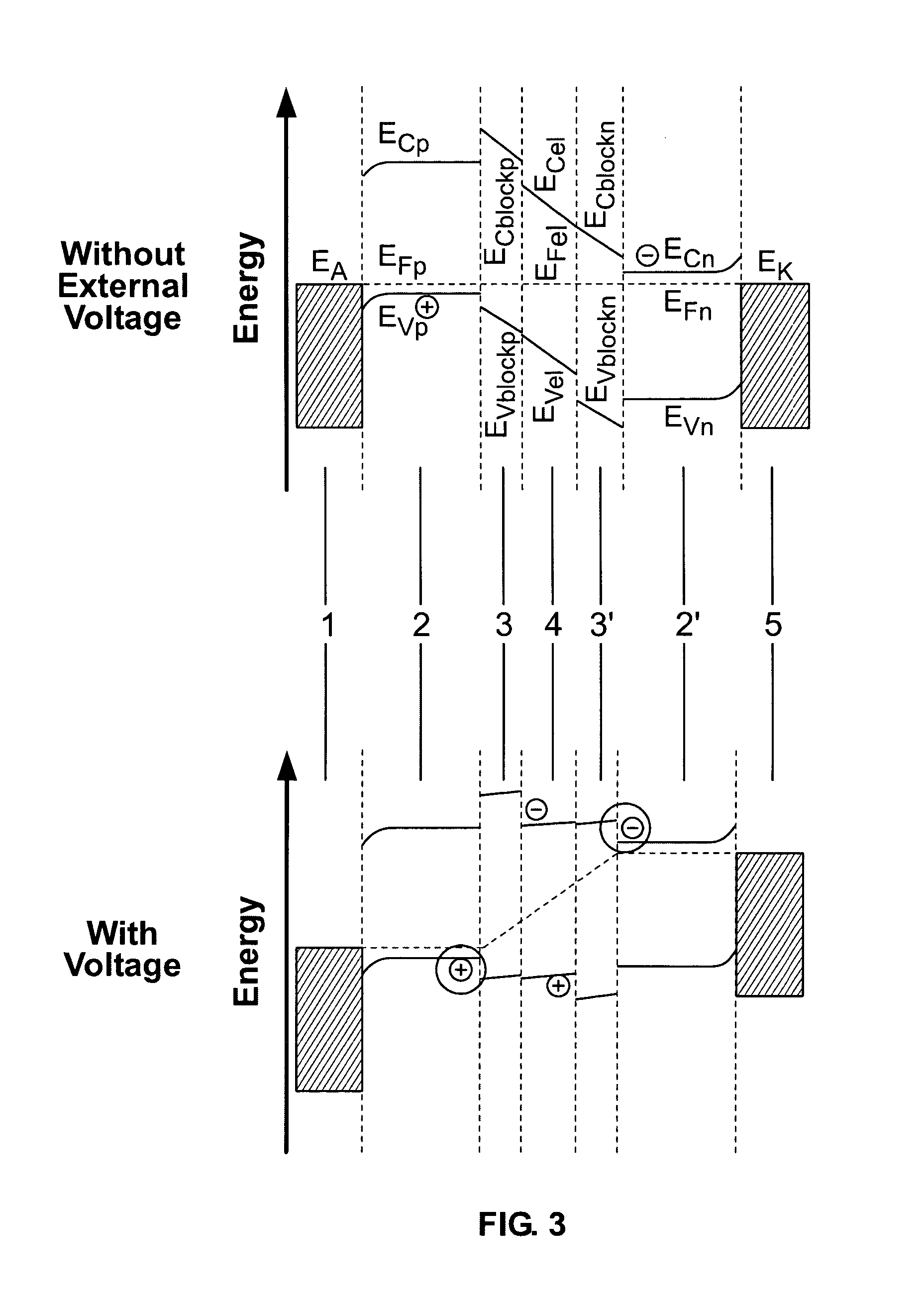

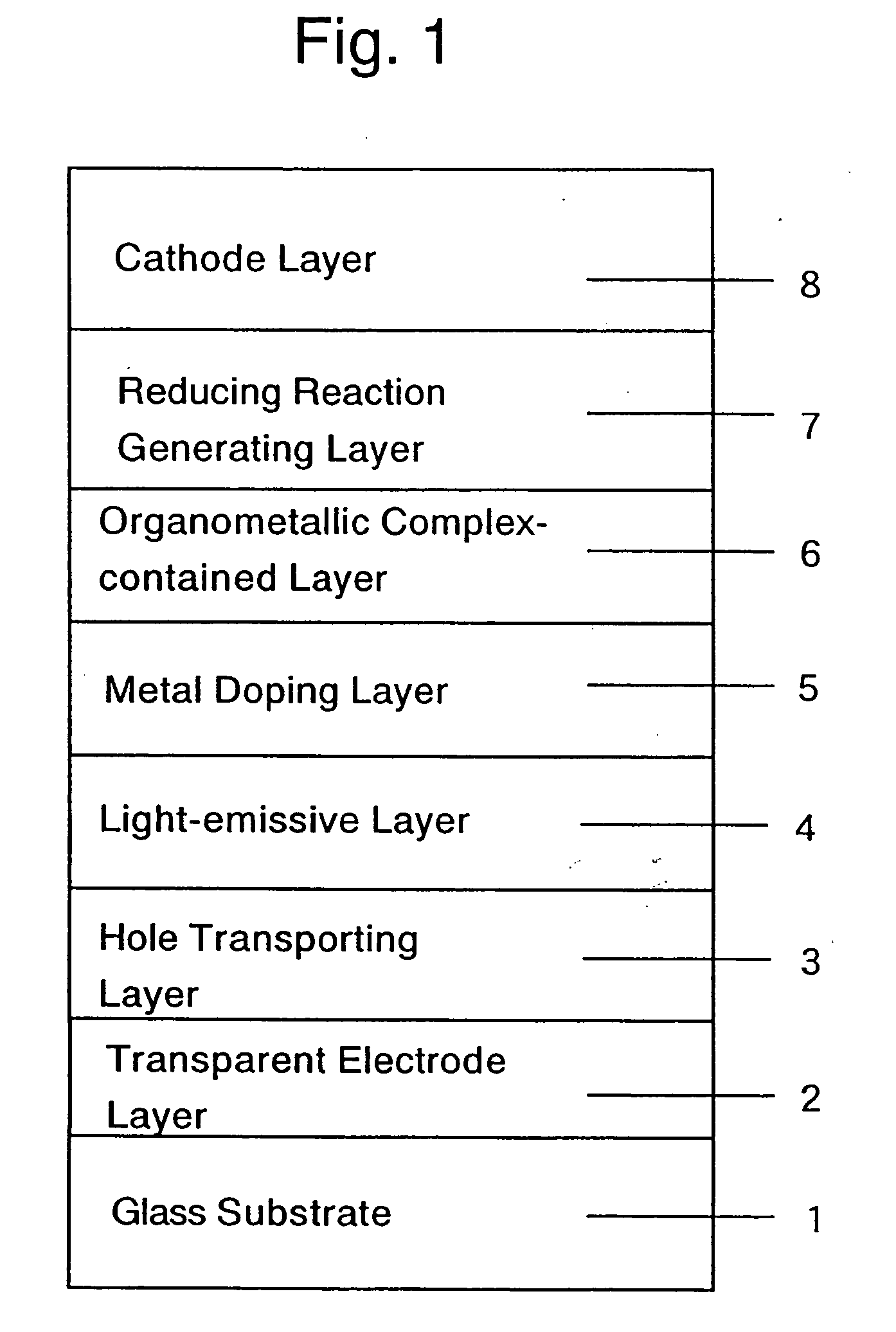

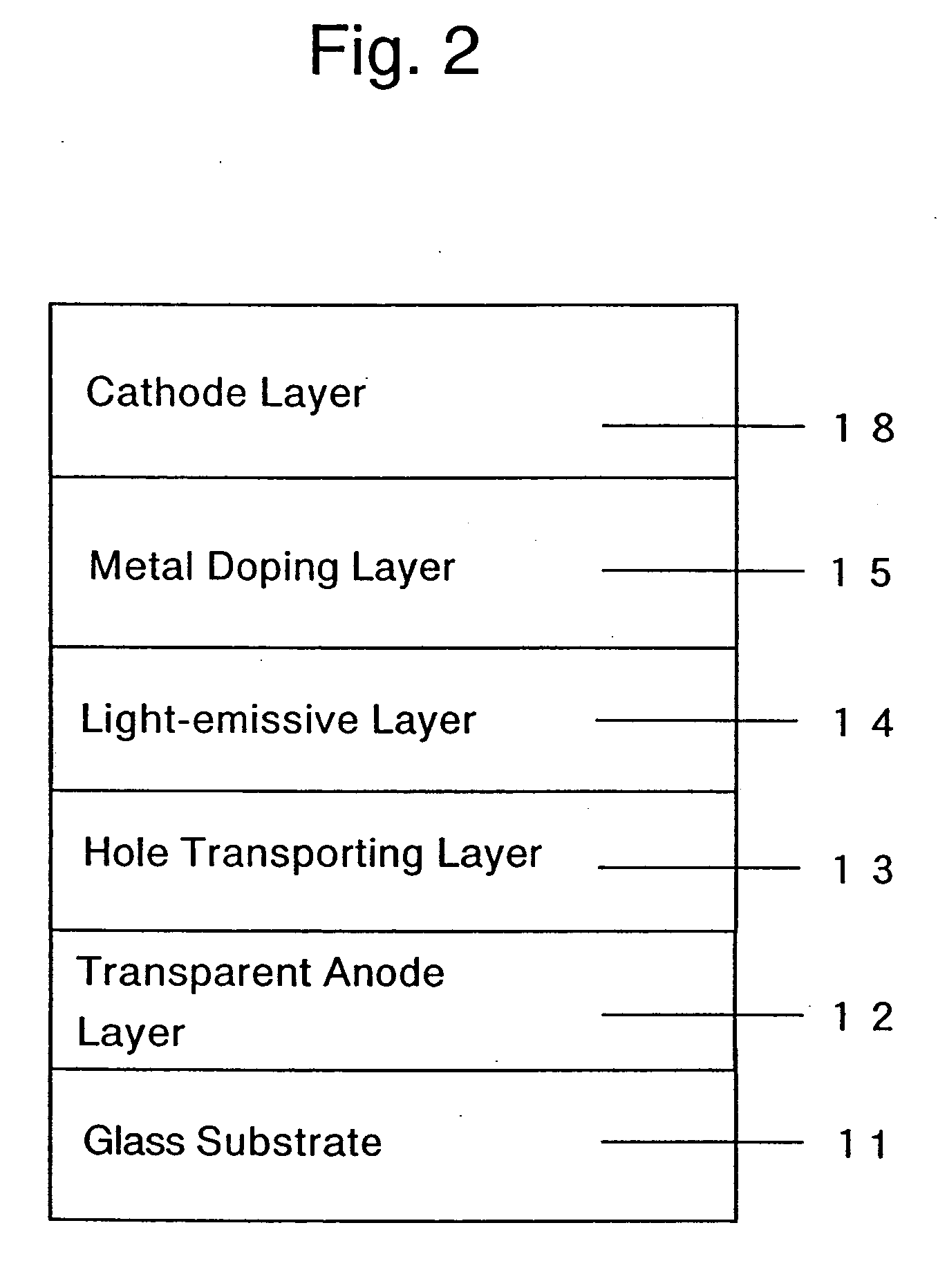

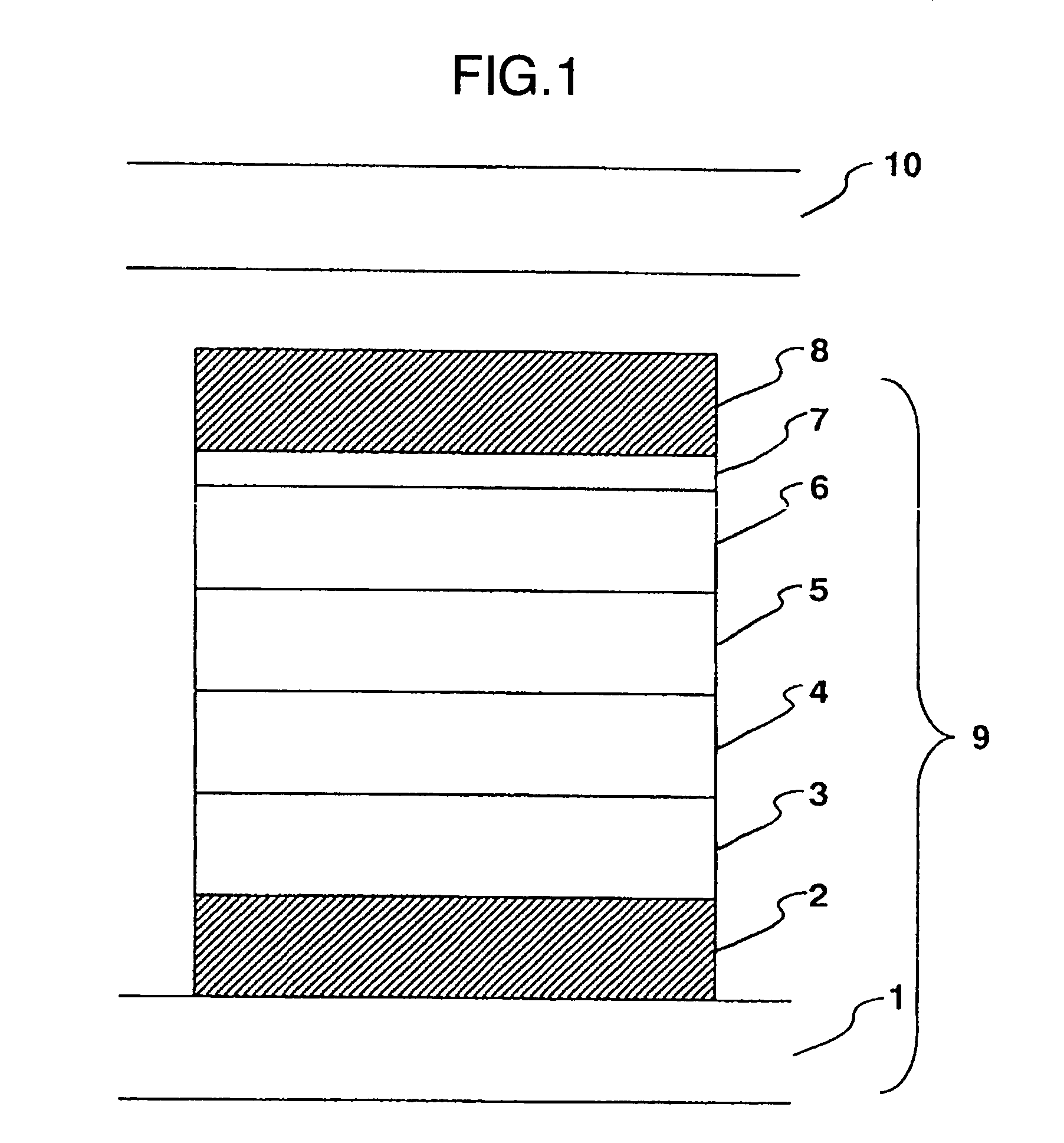

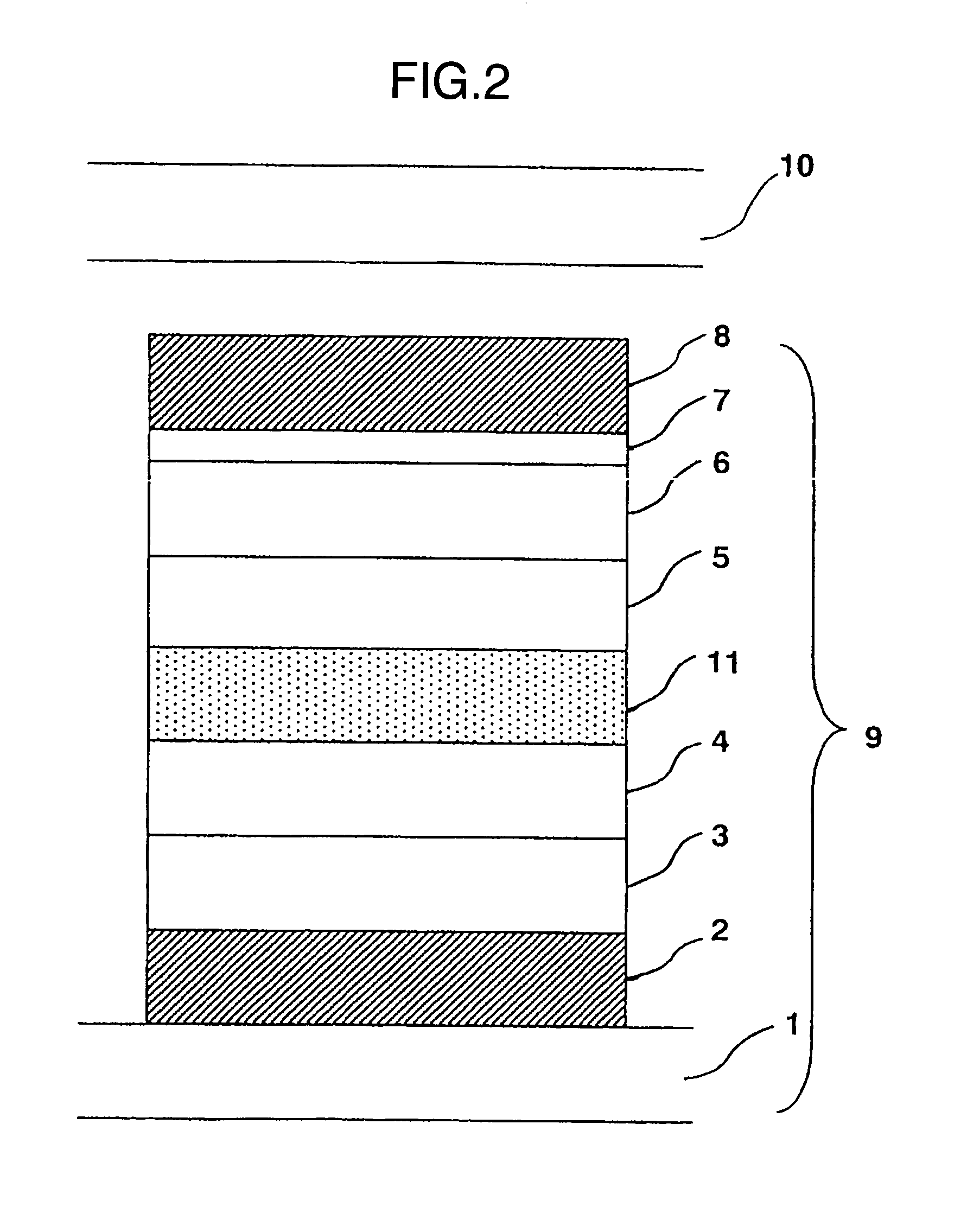

Light emitting component comprising organic layers

InactiveUS7074500B2Inhibit injectionDischarge tube luminescnet screensElectroluminescent light sourcesTransport layerCharge carrier

The invention relates to a light-emmiting component having organic layers, in particular to an organic light-emmiting diode. The component has at least one doped charge carrier transport layer (2), a light-emmiting layer (4) and contact layers (1, 5) and also has a blocking layer (3; 3′) wherein an organic material is provided between the charge carrier transport layer (2, 2′) and the light-emmiting layer (4). The energy levels of the charge carried transport layer are chosen in such a way that efficient doping is possible and the blocking layer nevertheless ensures that non-radiating recombination processes on the interface with the emitting layer are prevented.

Owner:NOVALED GMBH

Ceramic material resistant to halogen plasma and member utilizing the same

InactiveUS6916559B2Improve the immunityRecord information storageLight beam reproducingPorosityHalogen

A member used within a plasma processing apparatus and exposed to a plasma of a halogen gas such as BCl3 or Cl2 is formed from a sintered body of metals of Group IIIa of Periodic Table such as Y, La, Ce, Nd and Dy, and Al and / or Si, for example, 3Y2O3.5Al2O3, 2Y2O3.Al2O3, Y2O3.Al2O3 or disilicate or monosilicate, and in particular, in this sintered body, the content of impurity metals of Group IIa of Periodic Table contained in the sintered body is controlled to be 0.15 wt % or more in total. Specifically, for this member, an yttrium-aluminum-garnet sintered body having a porosity of 3% or less and also having a surface roughness of 1 μm or less in center line average roughness Ra is utilized.

Owner:KYOCERA CORP

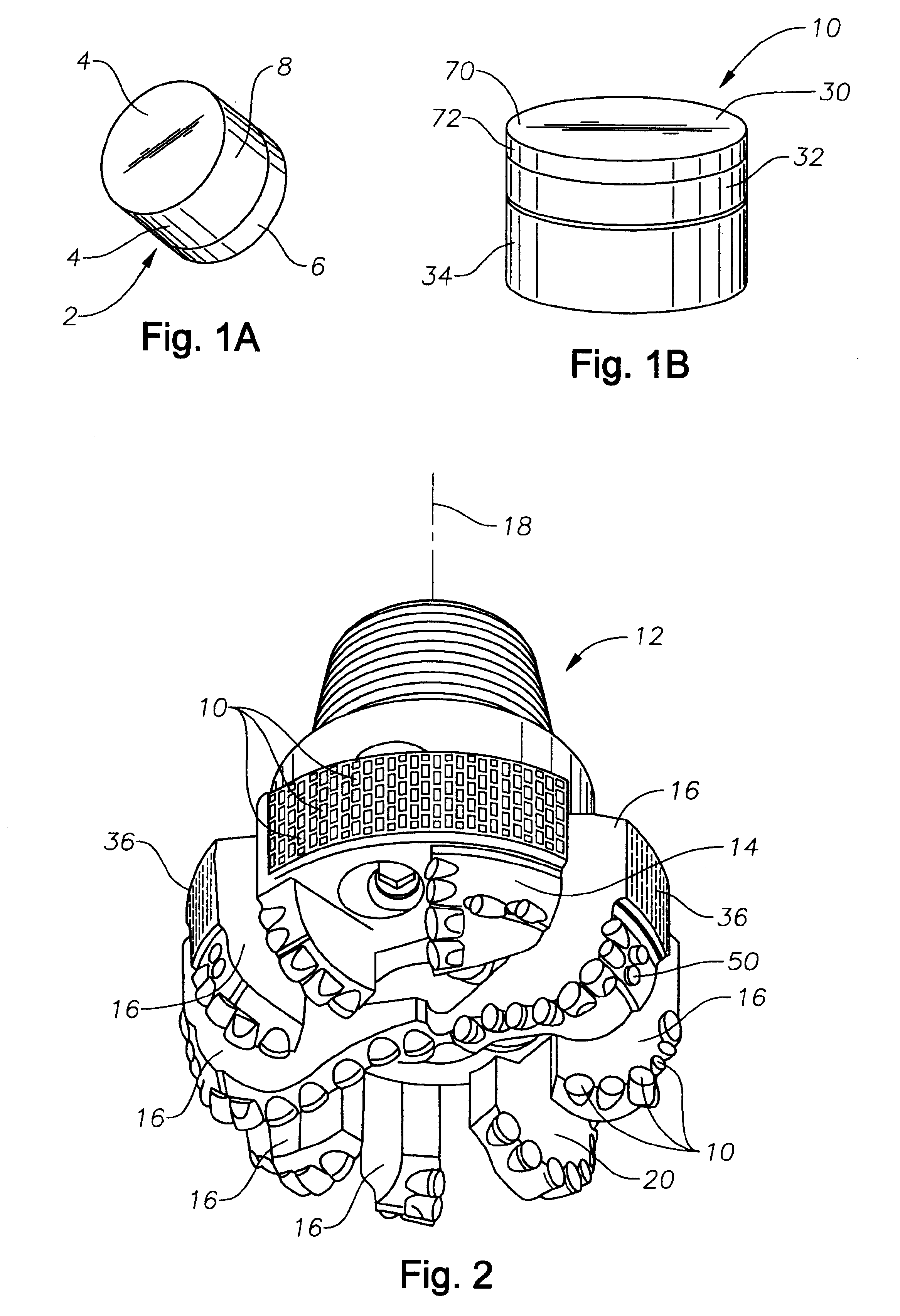

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Bright metal flake

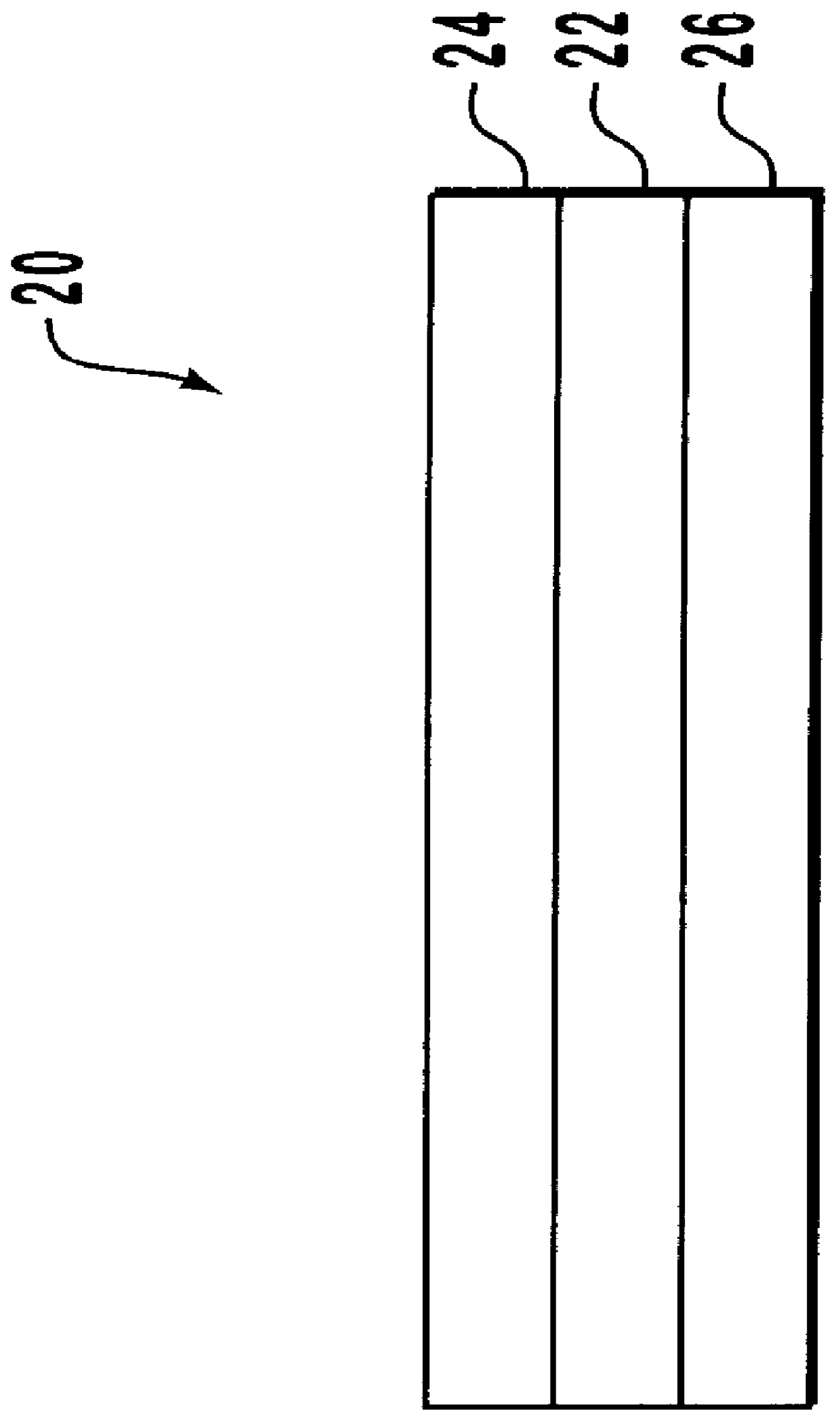

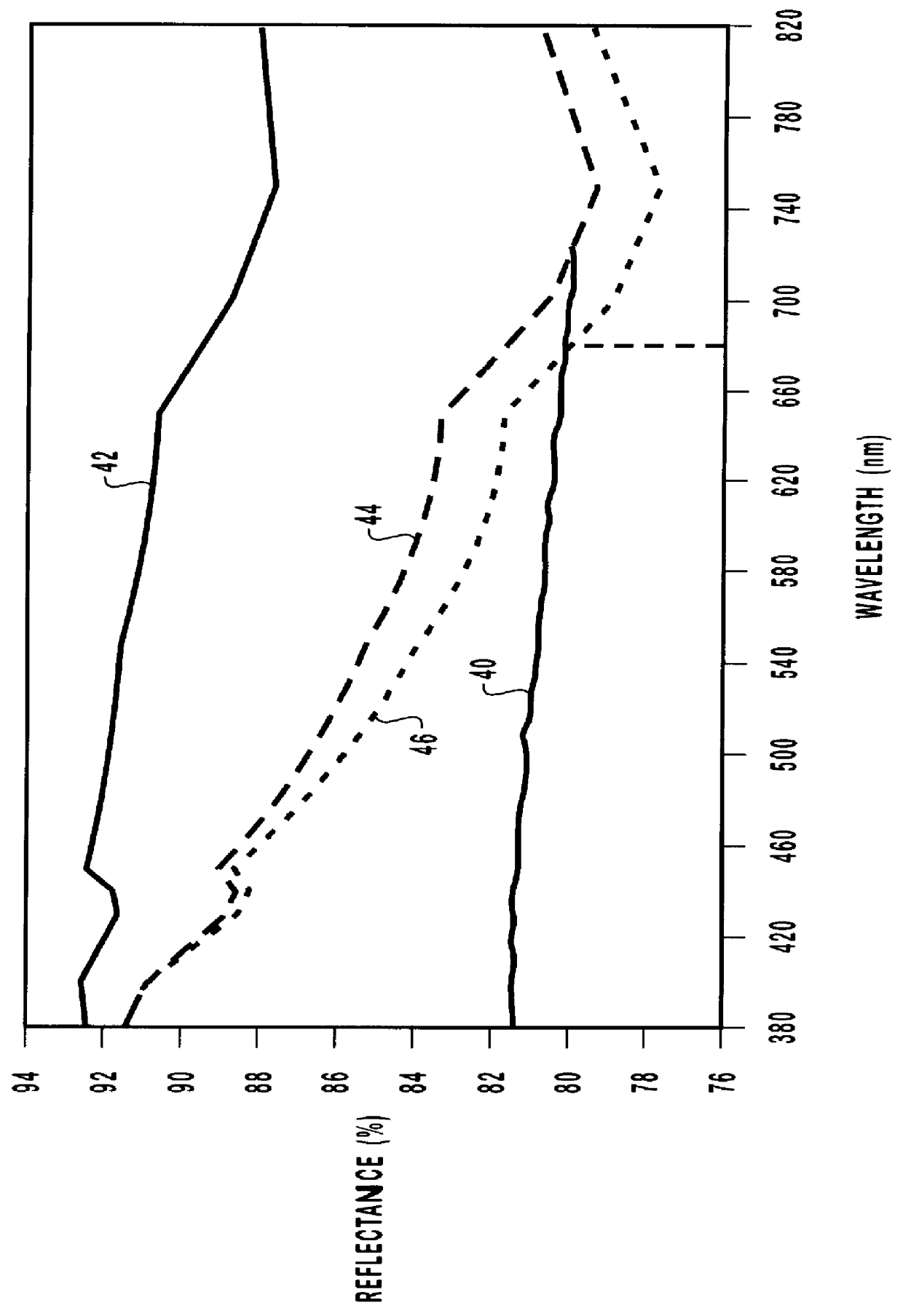

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

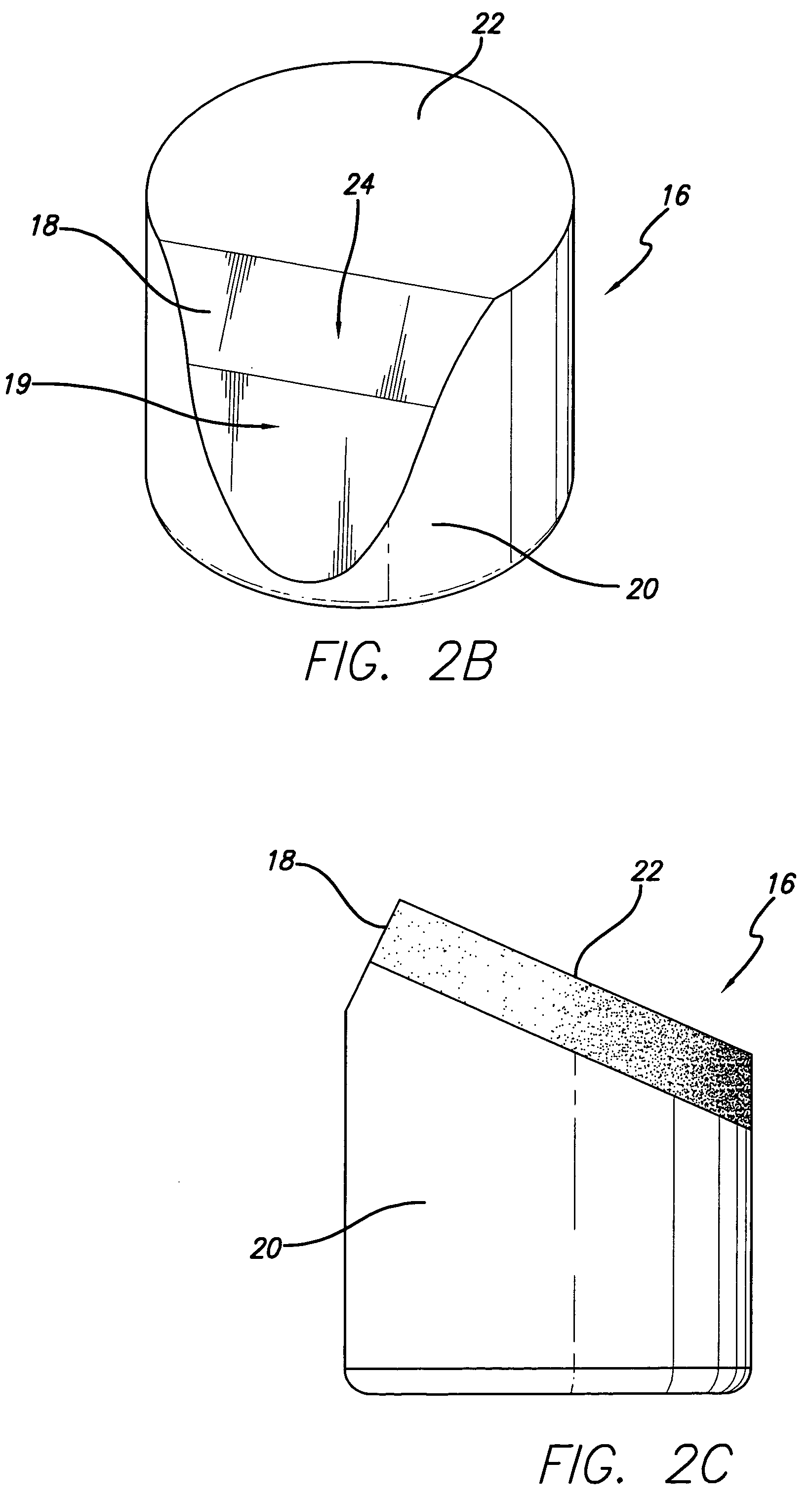

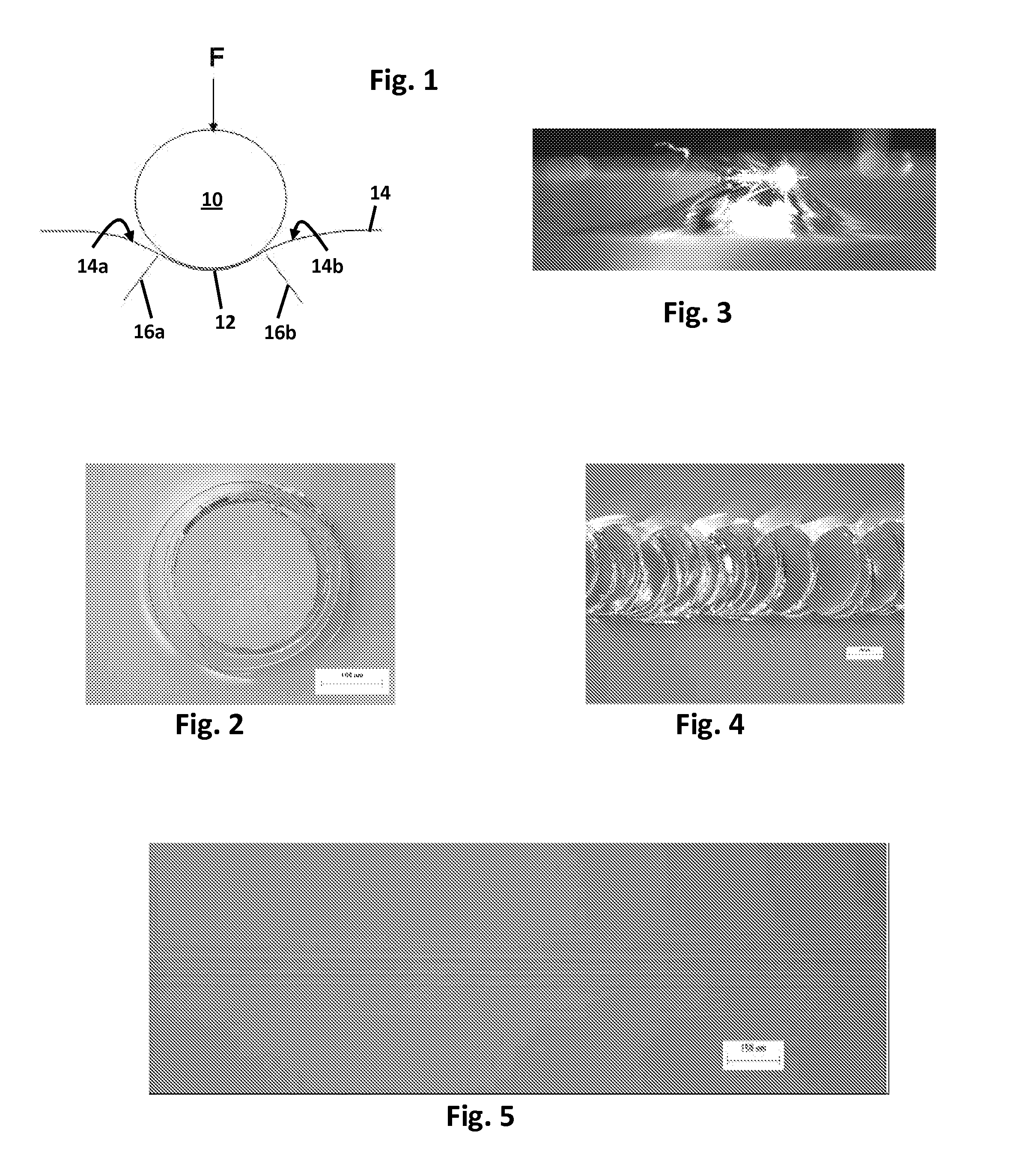

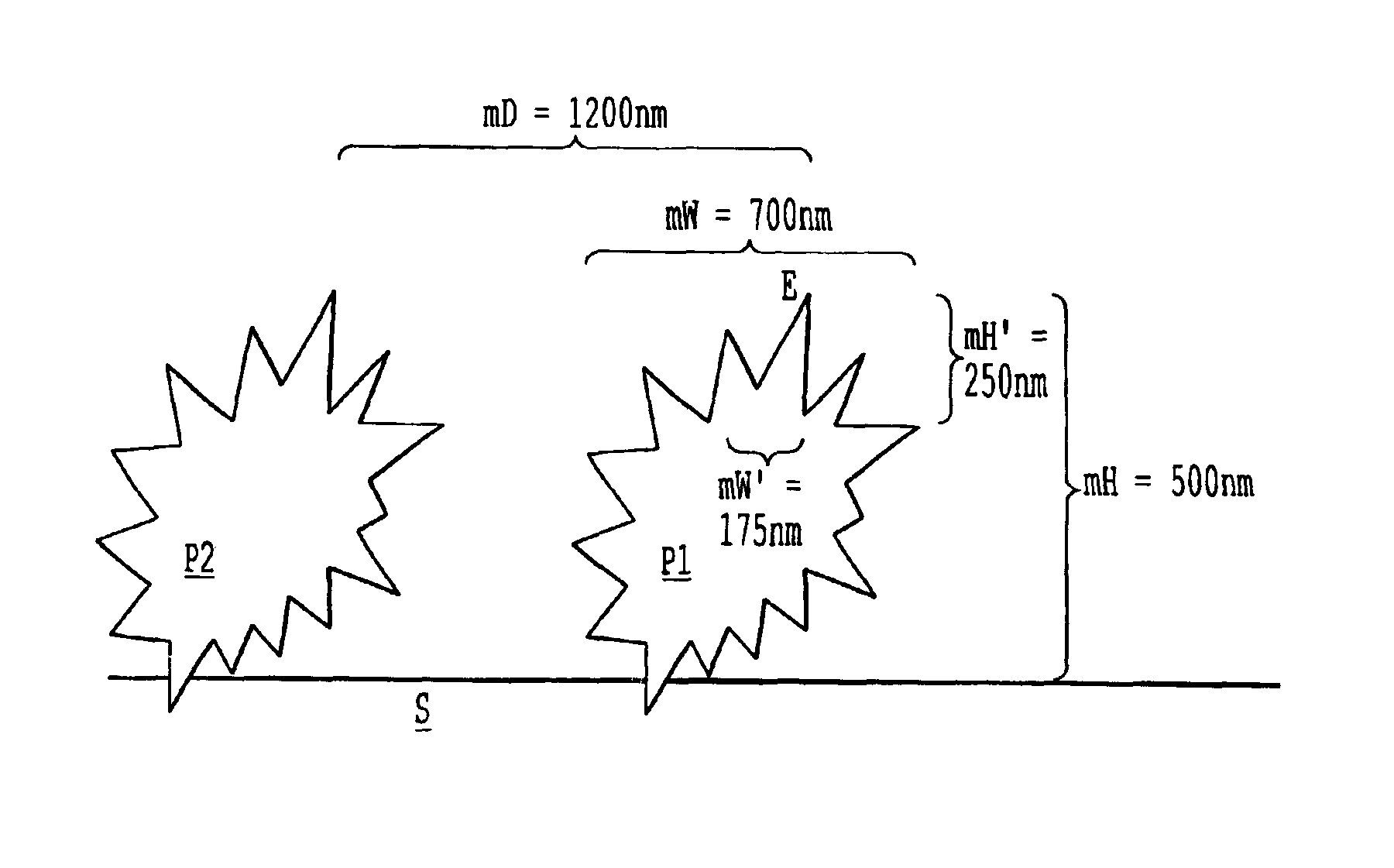

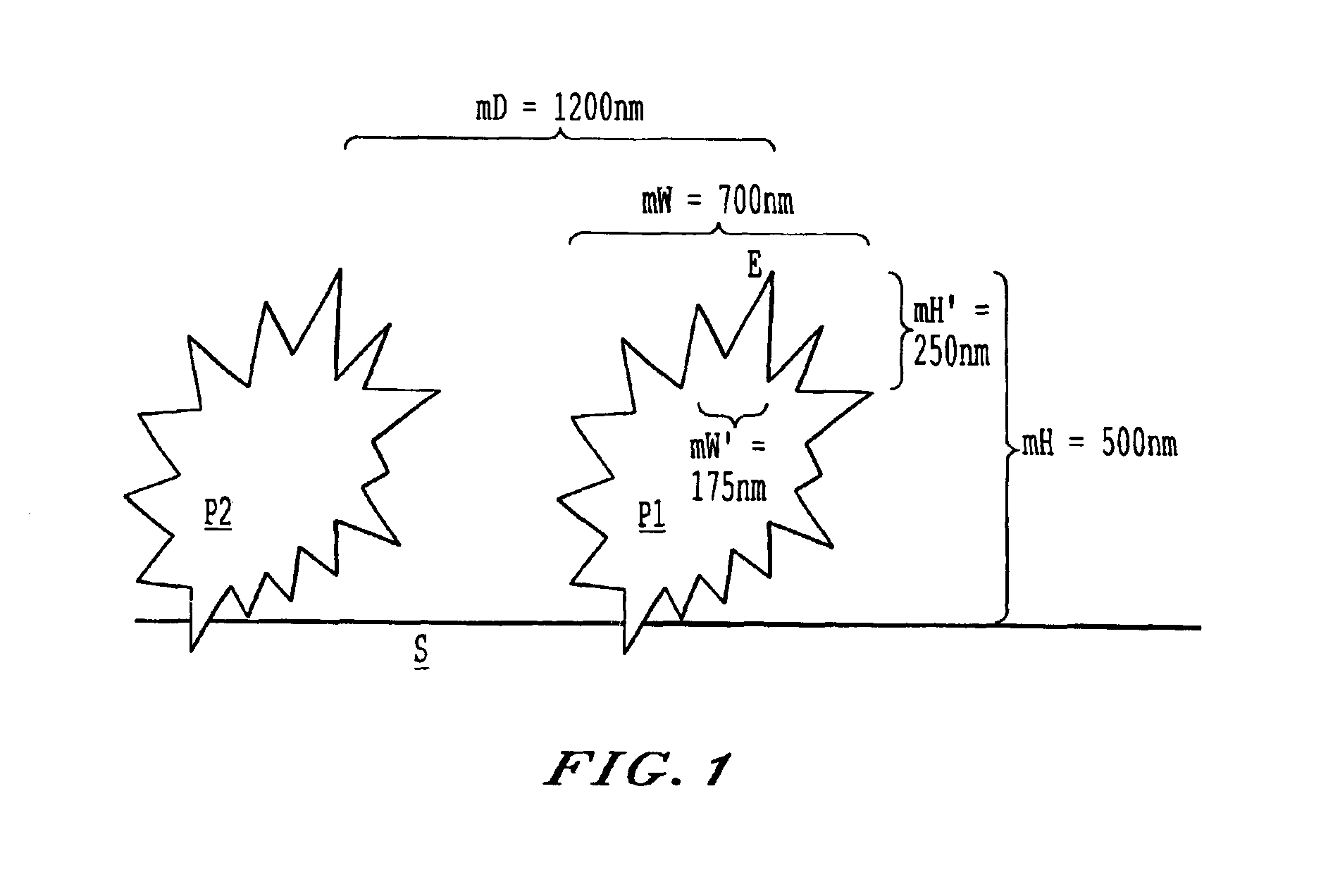

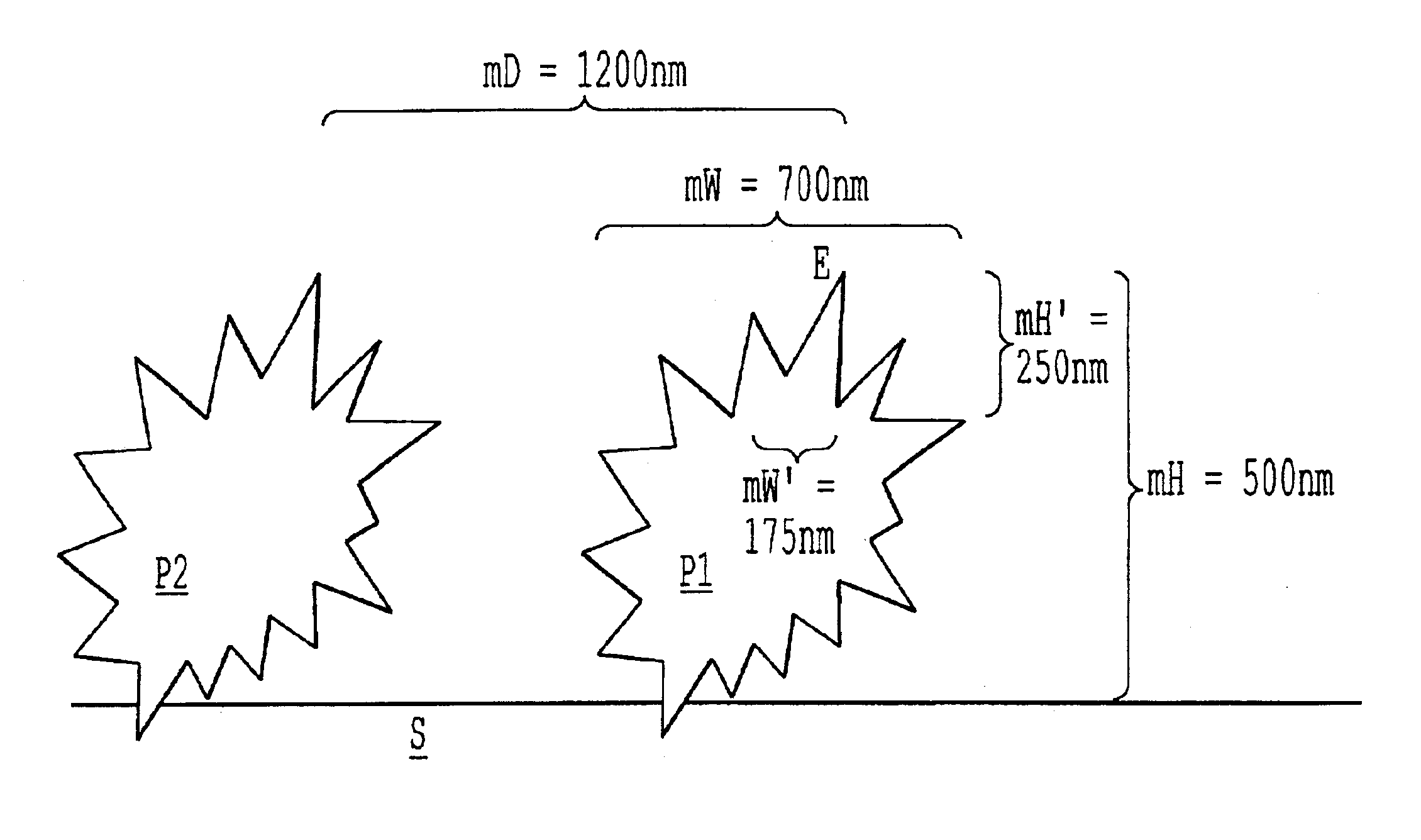

Near field optical scanning system employing microfabricated solid immersion lens

A solid immersion lens integrated on a flexible support such as a cantilever or membrane is described, together with a method of forming the integrated structure.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

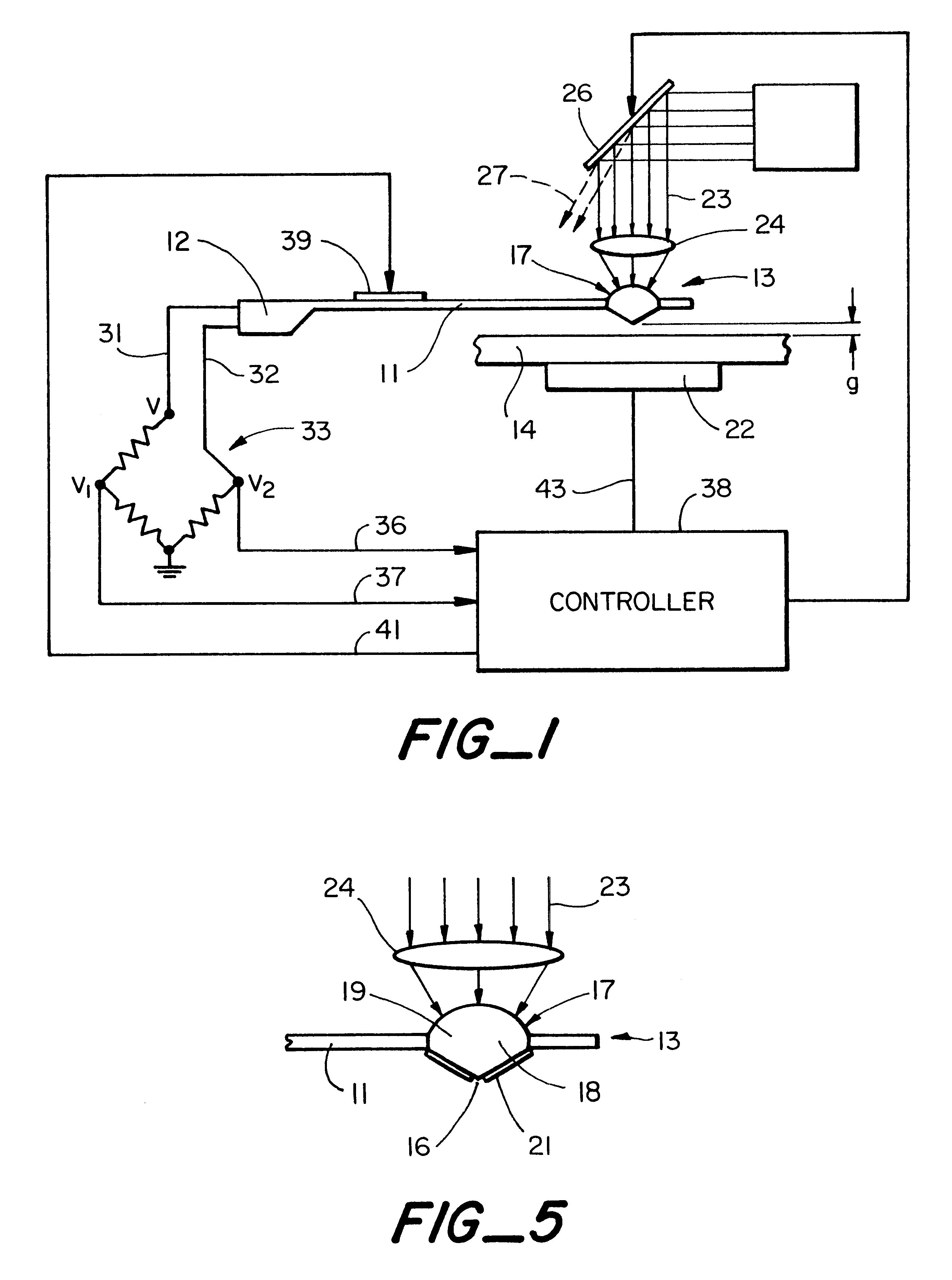

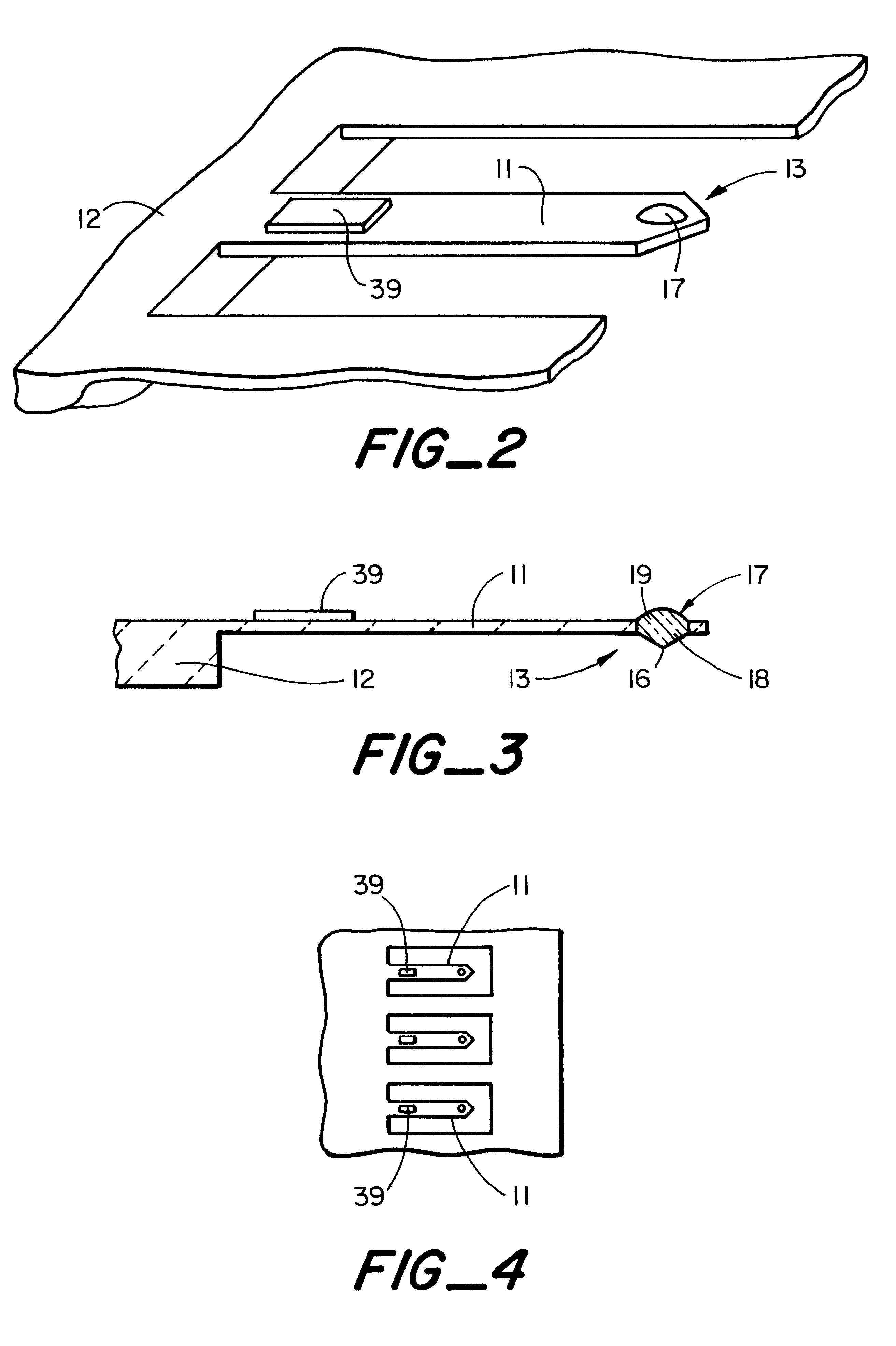

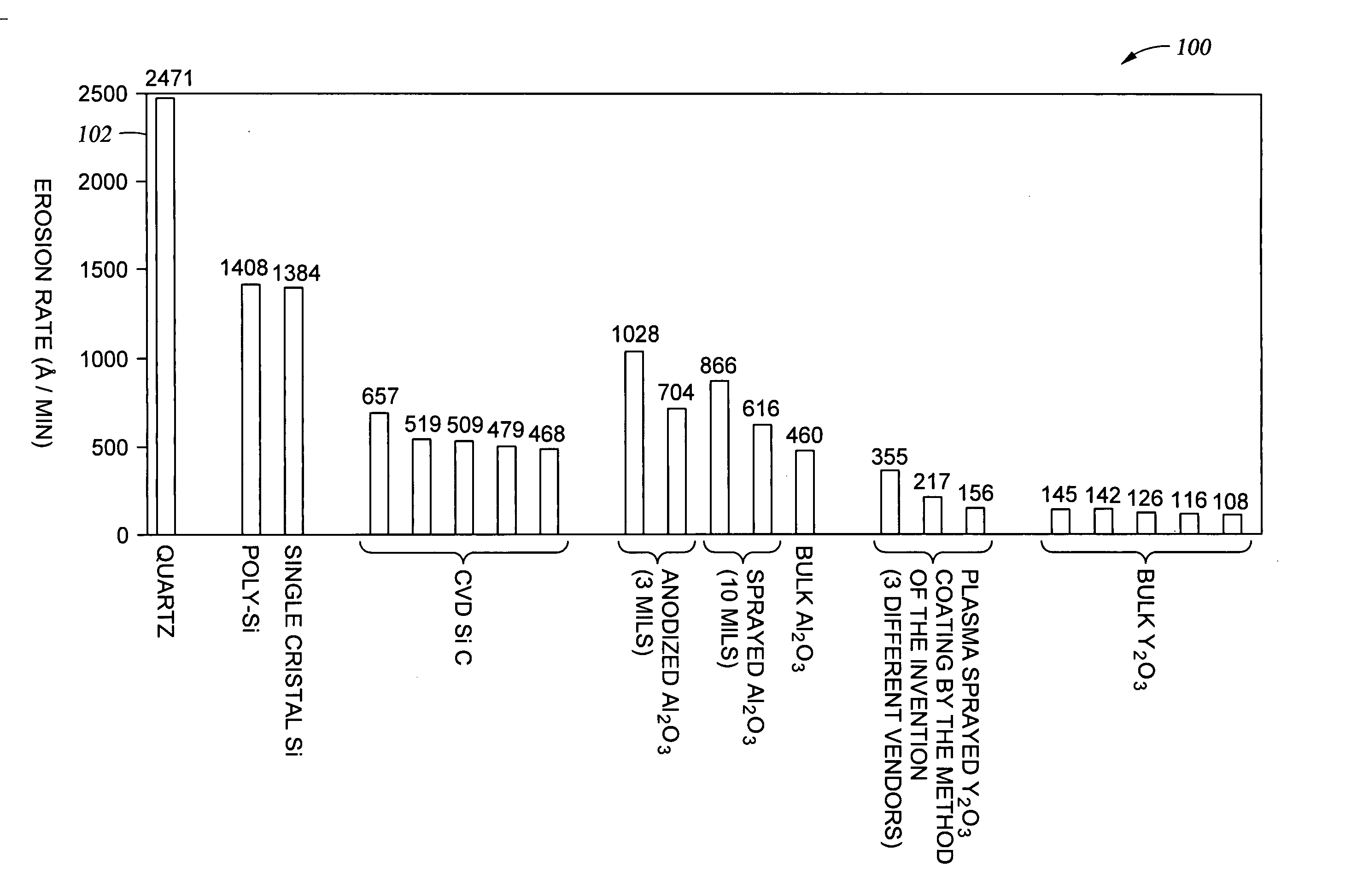

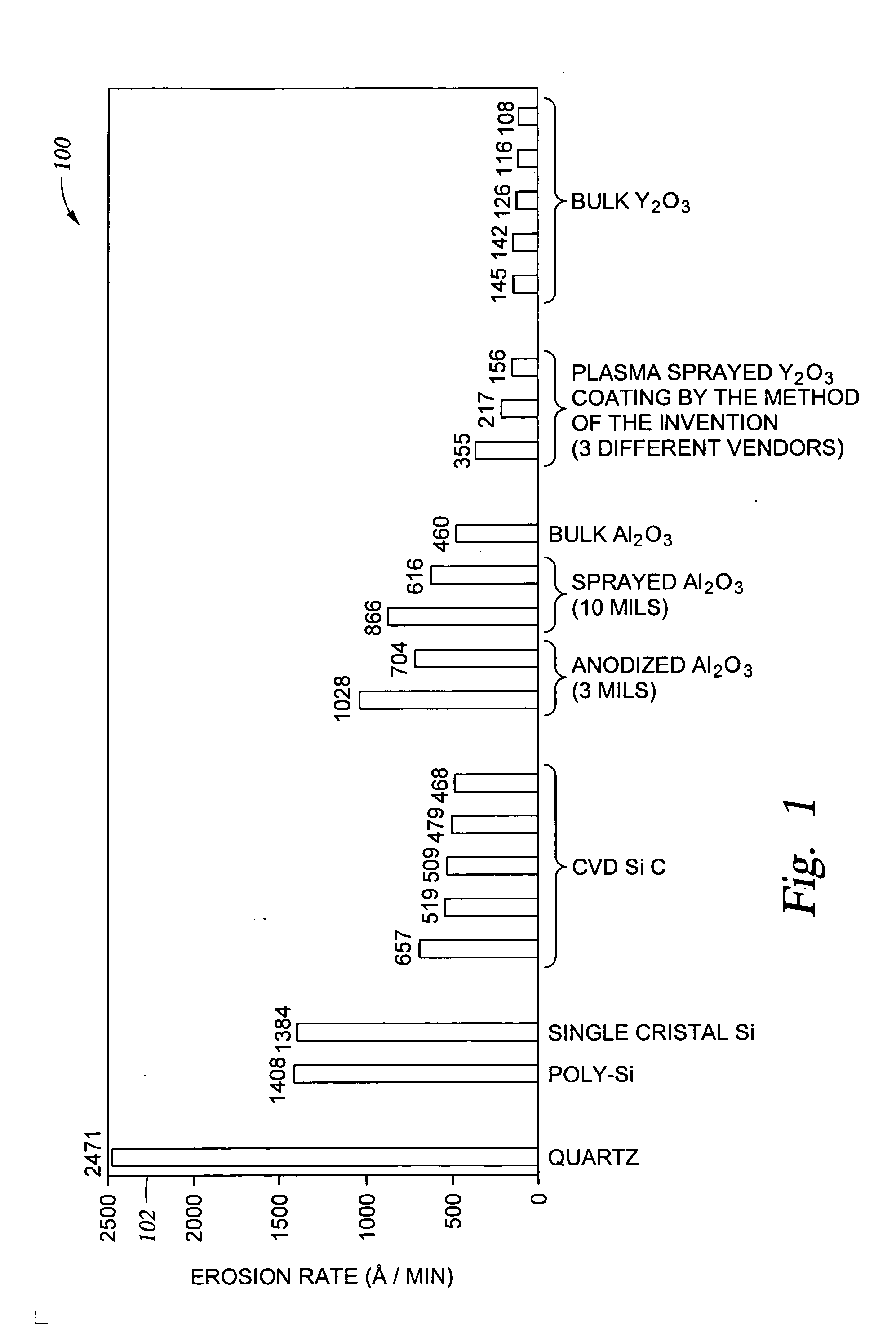

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

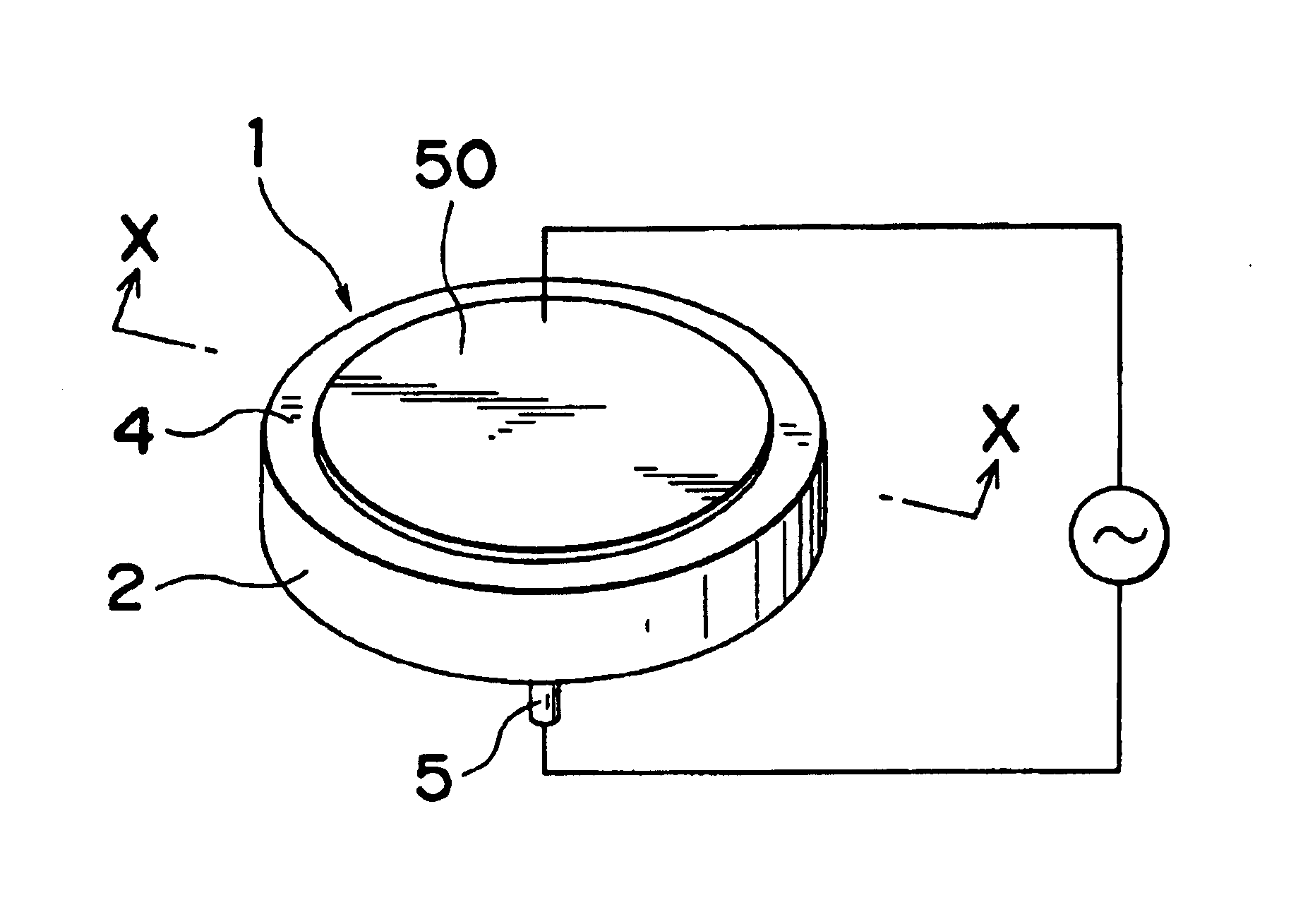

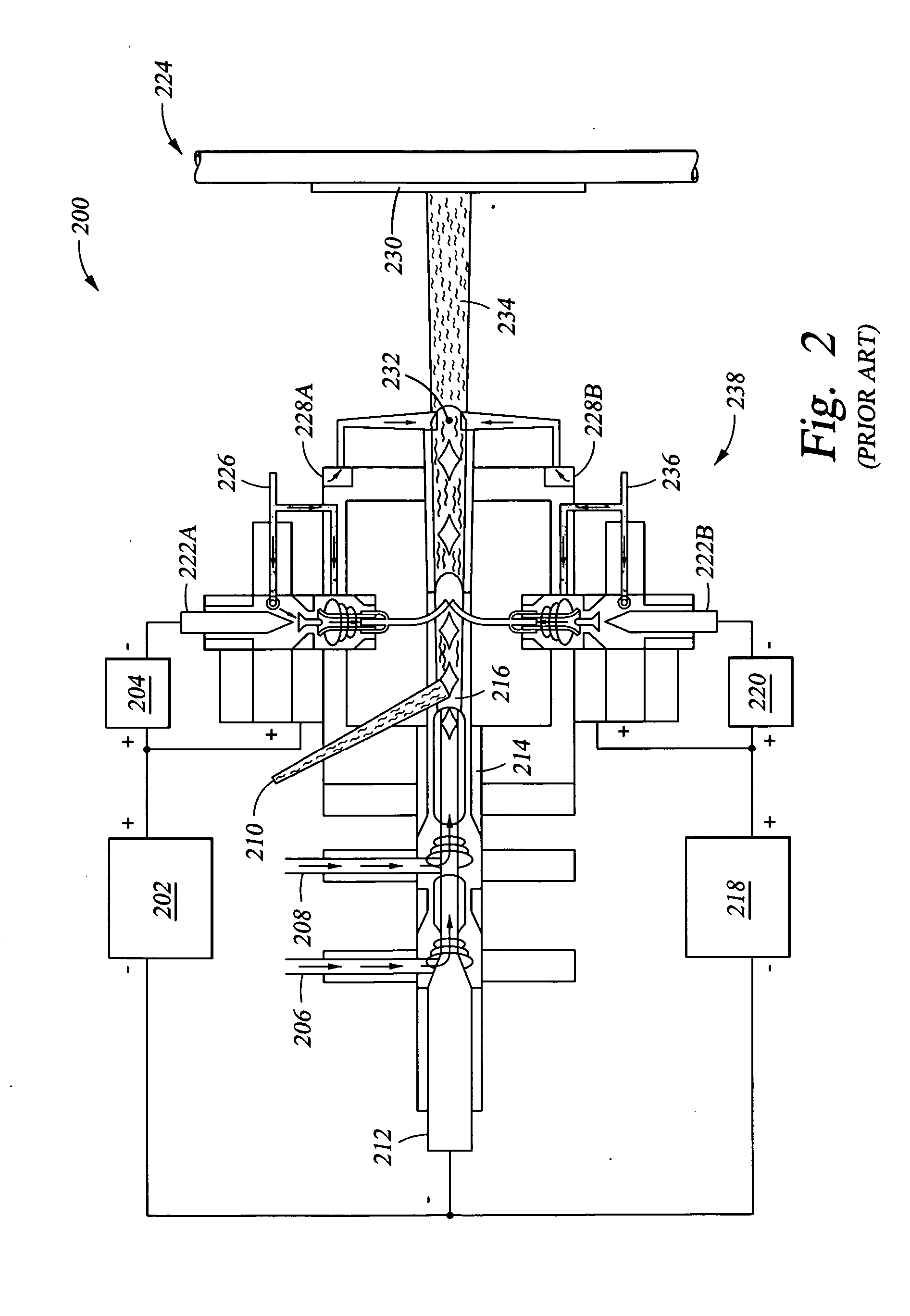

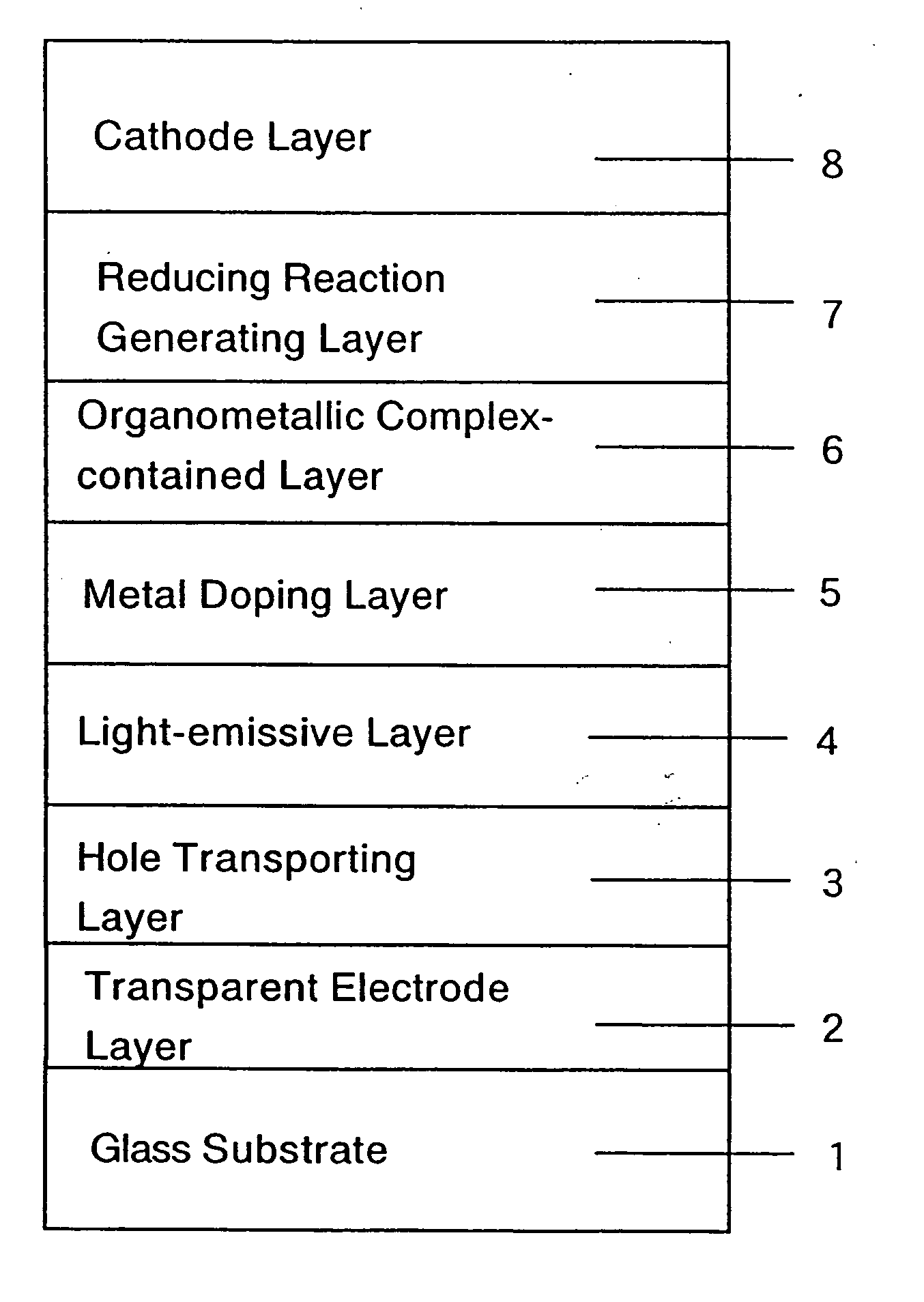

Organic electroluminescent device and production process thereof

ActiveUS20050084713A1Stable device propertyIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesOrganic structureAlkaline earth metal

Owner:ROHM CO LTD +1

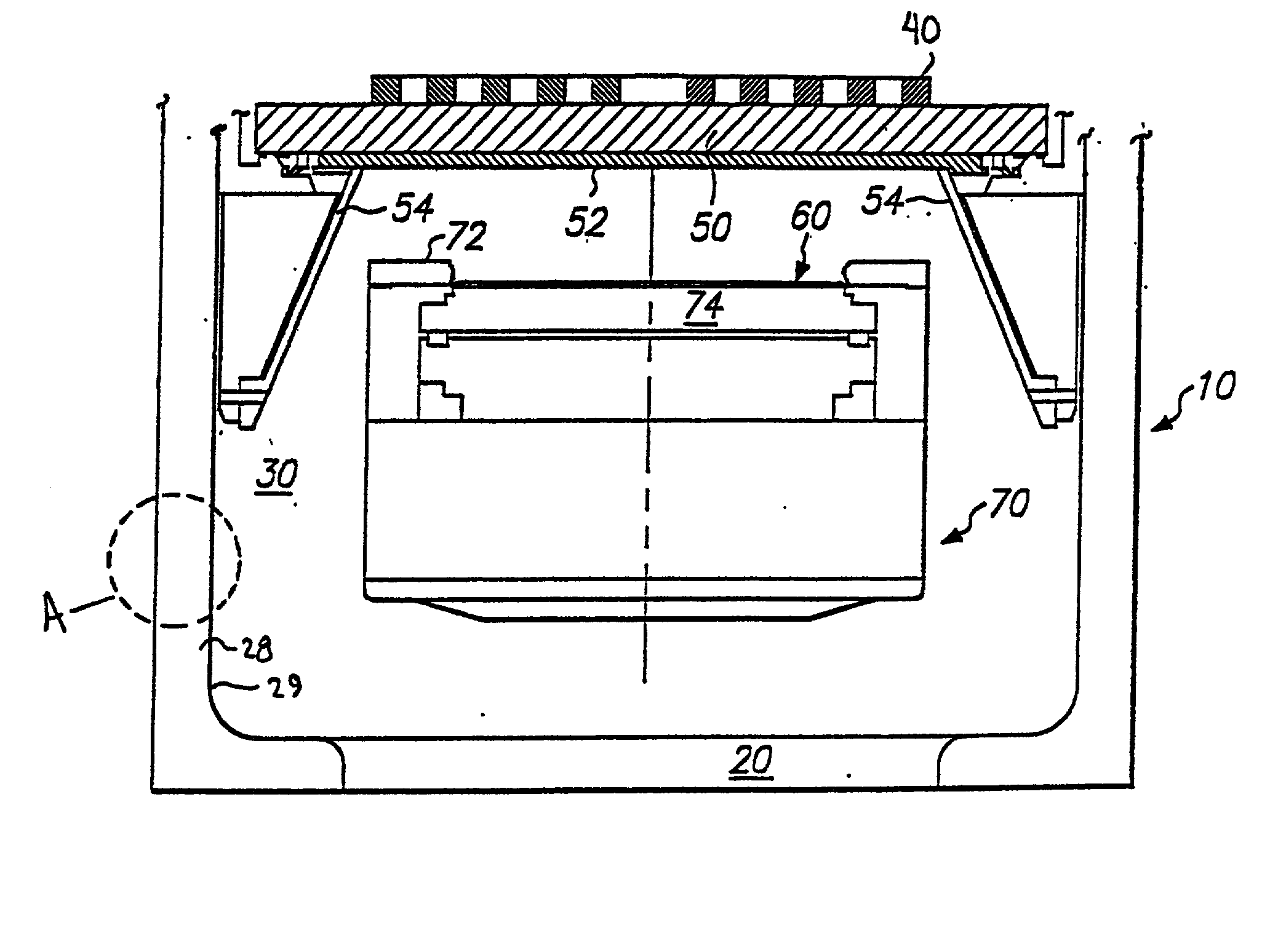

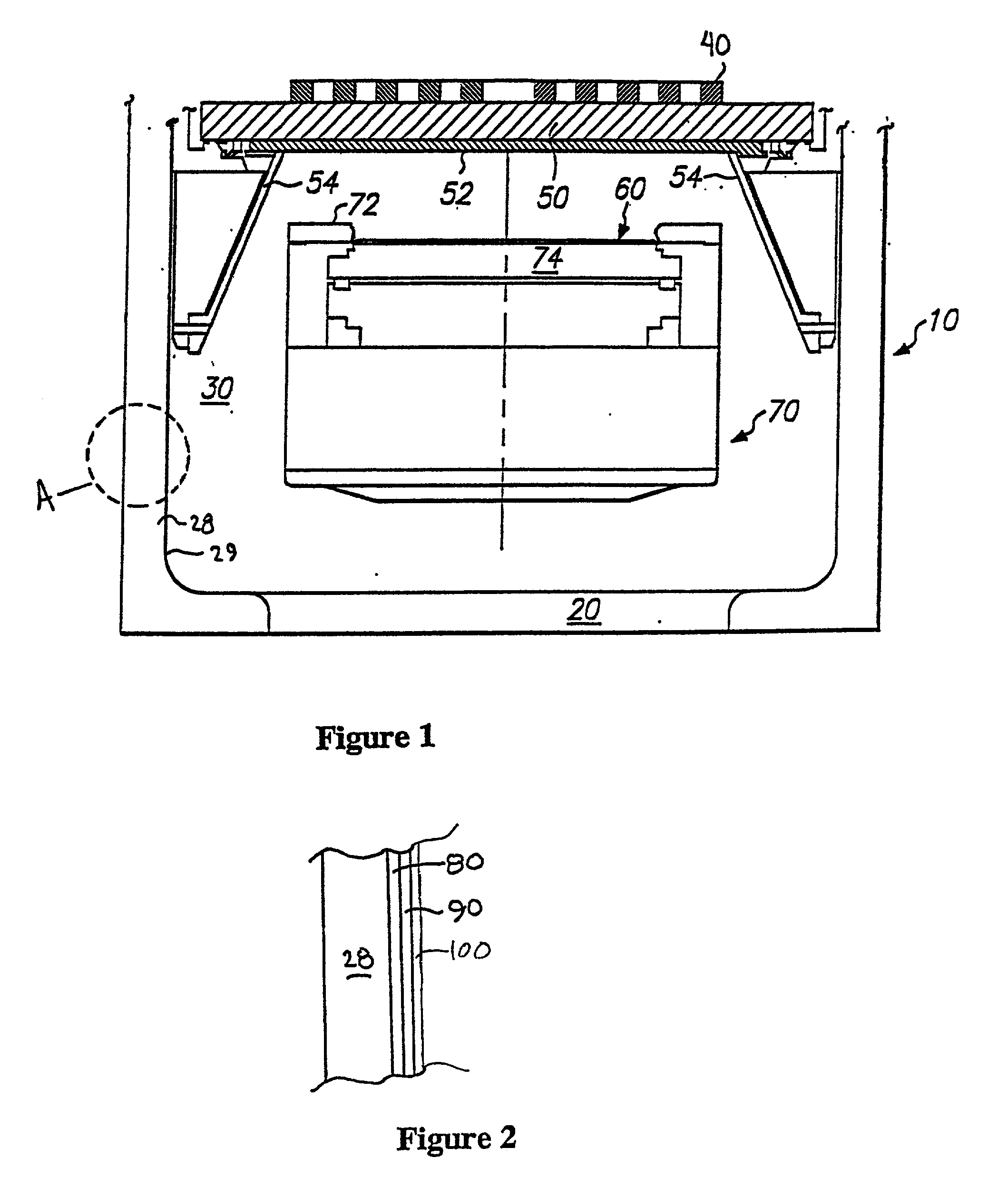

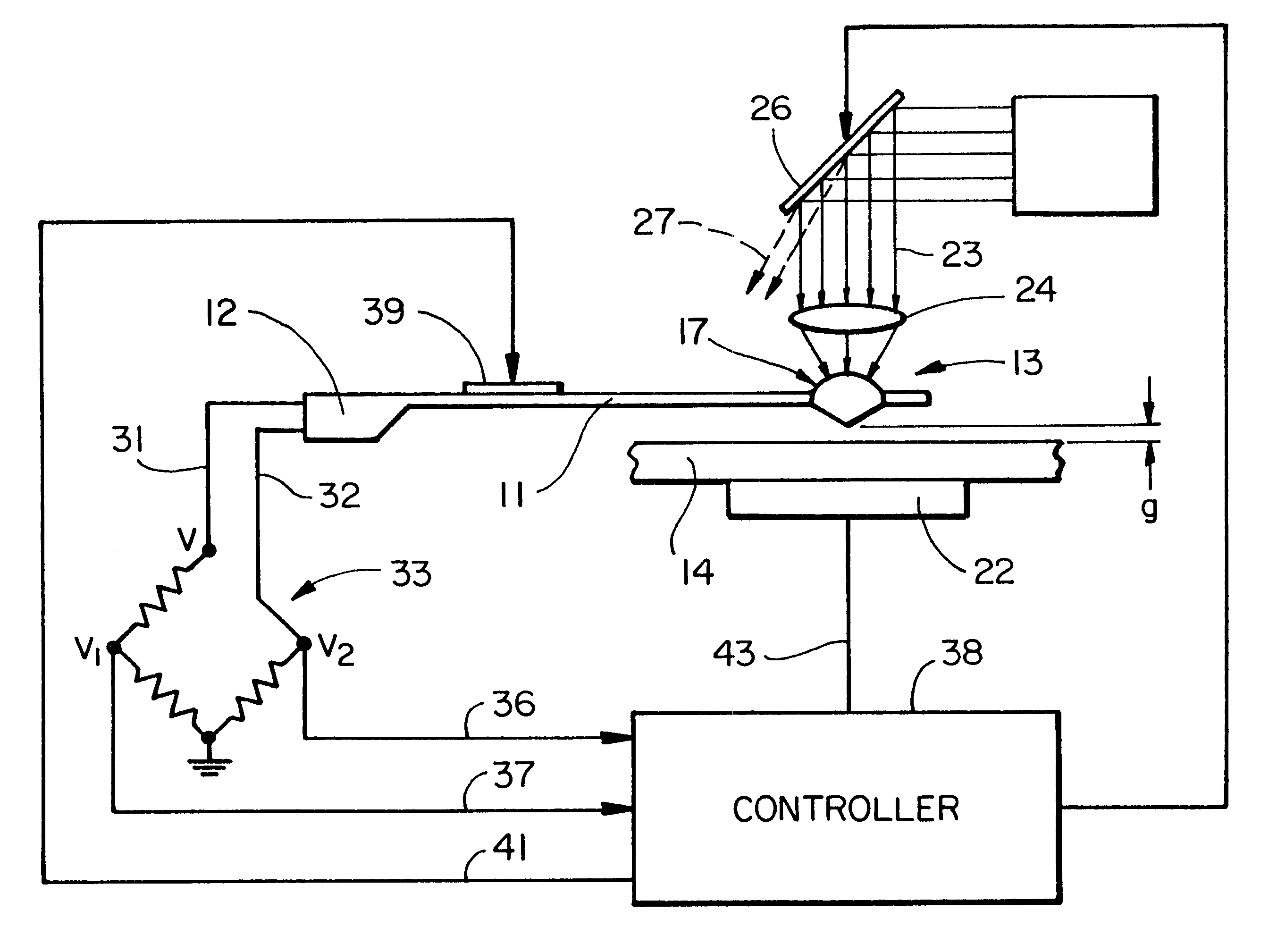

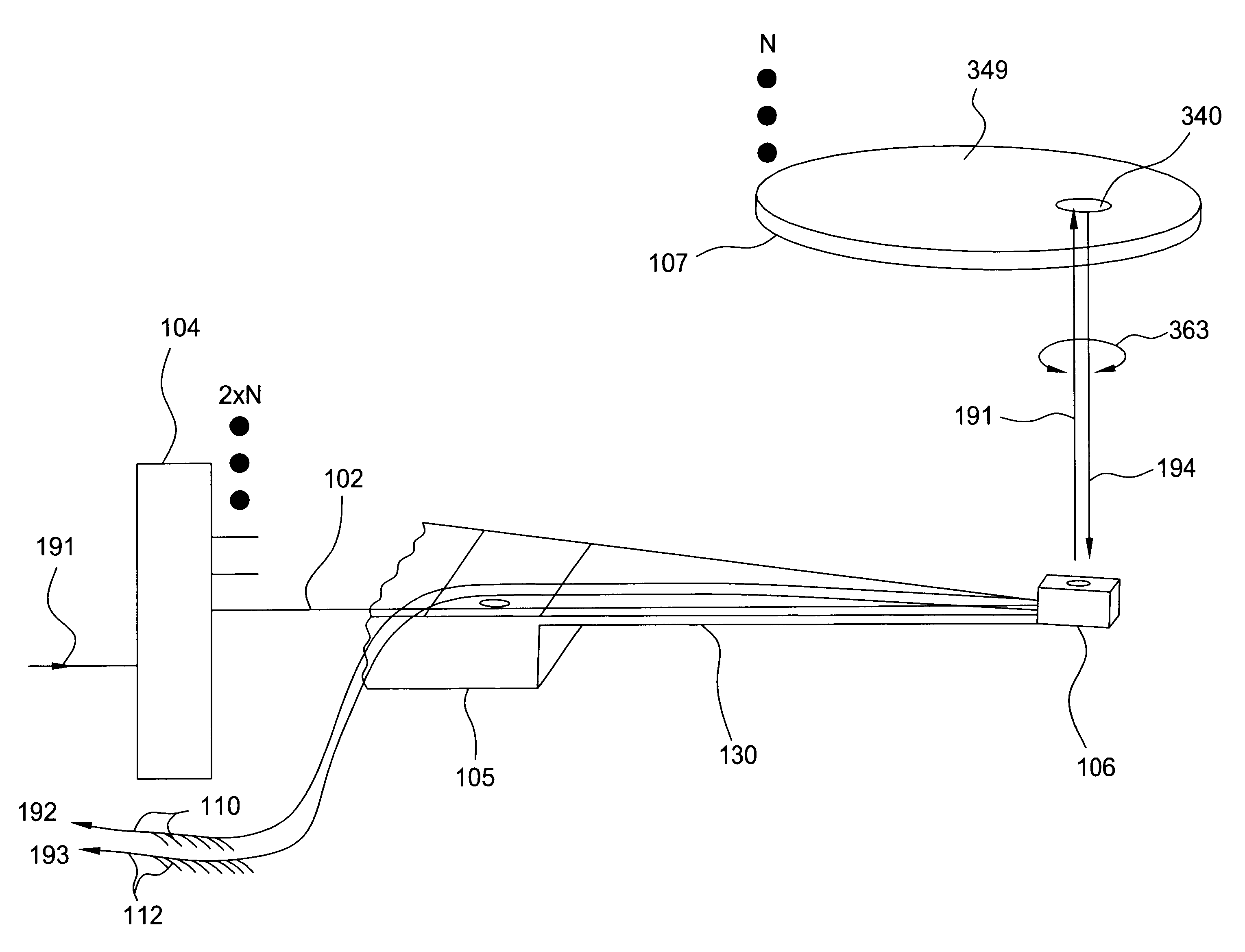

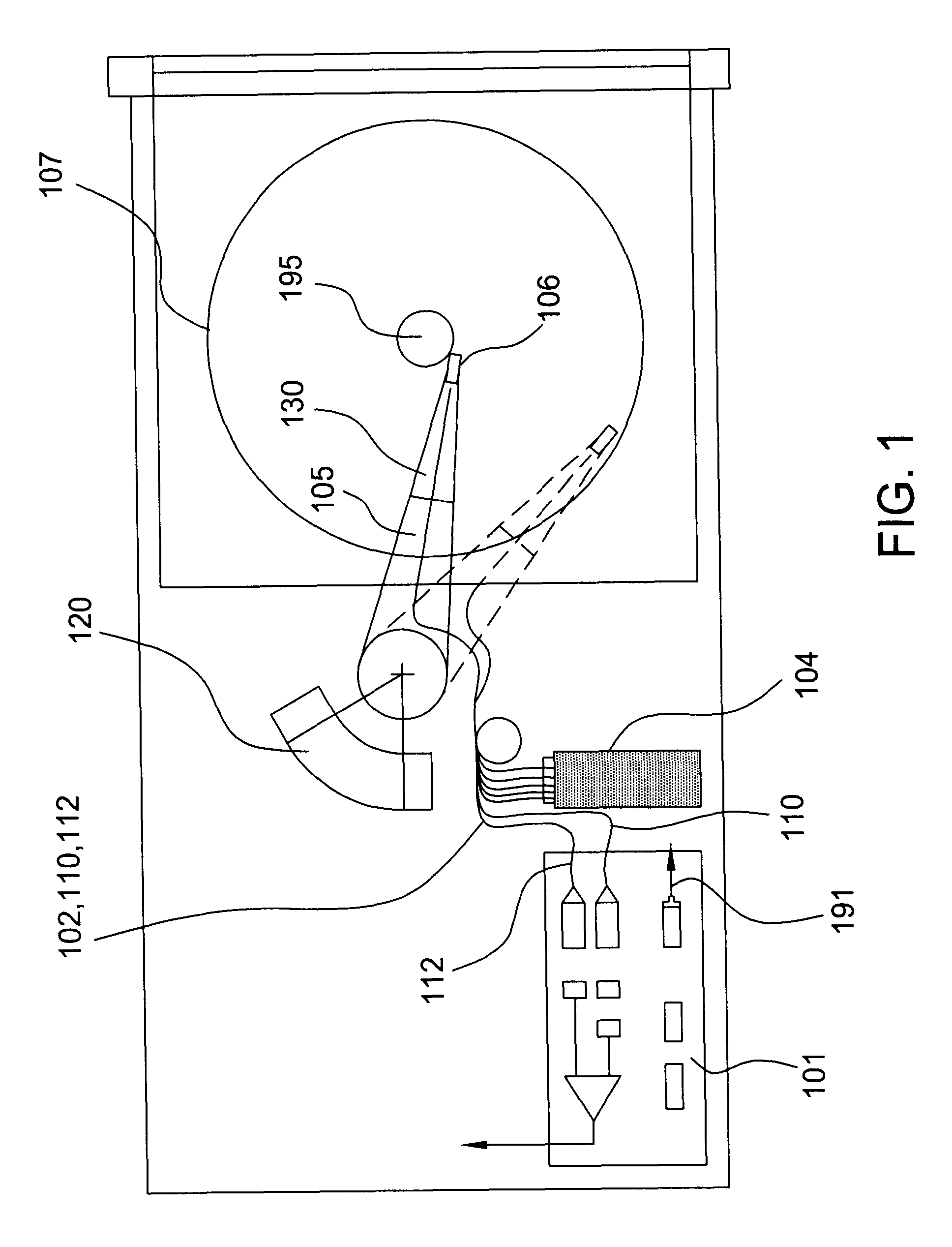

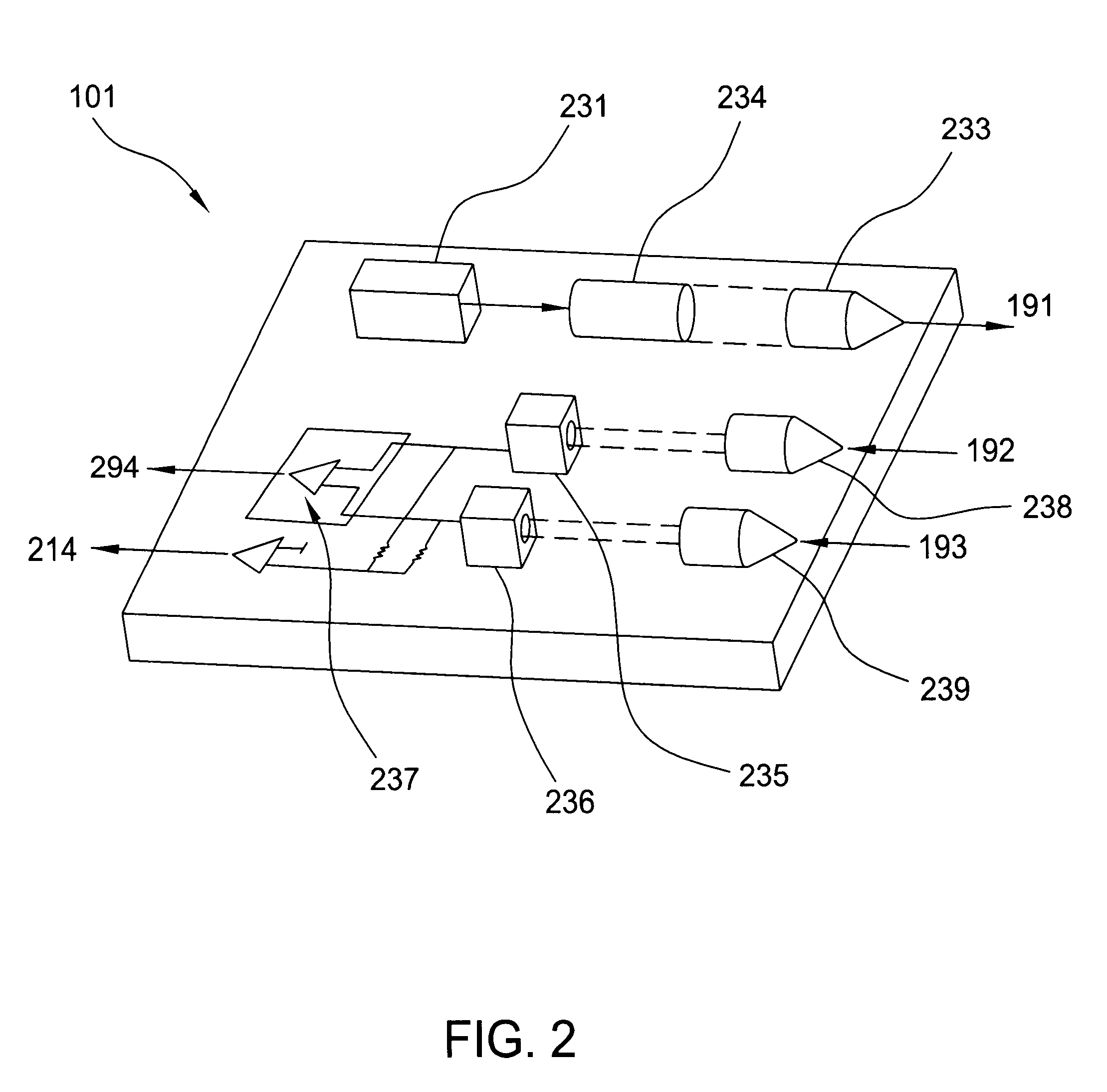

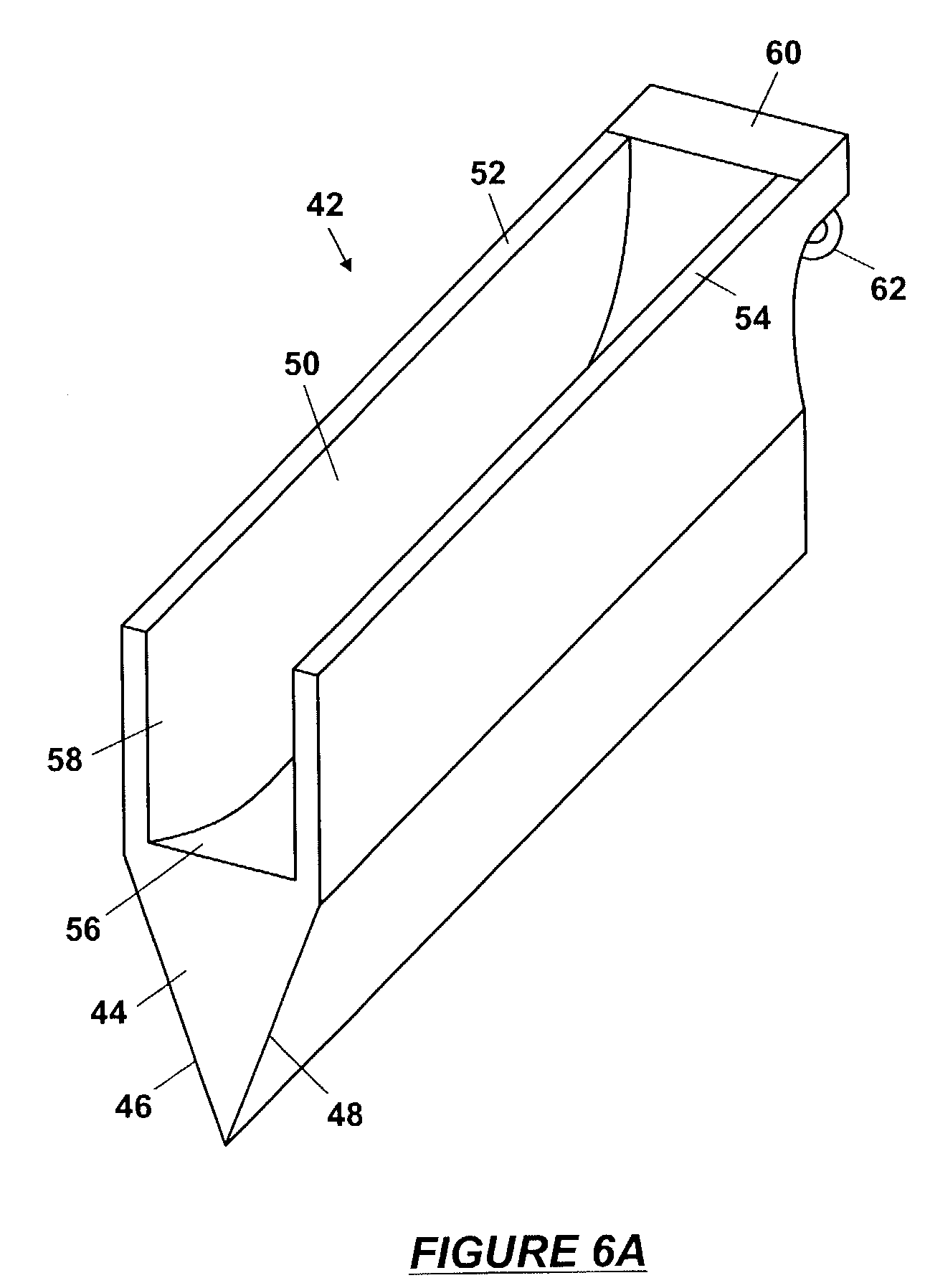

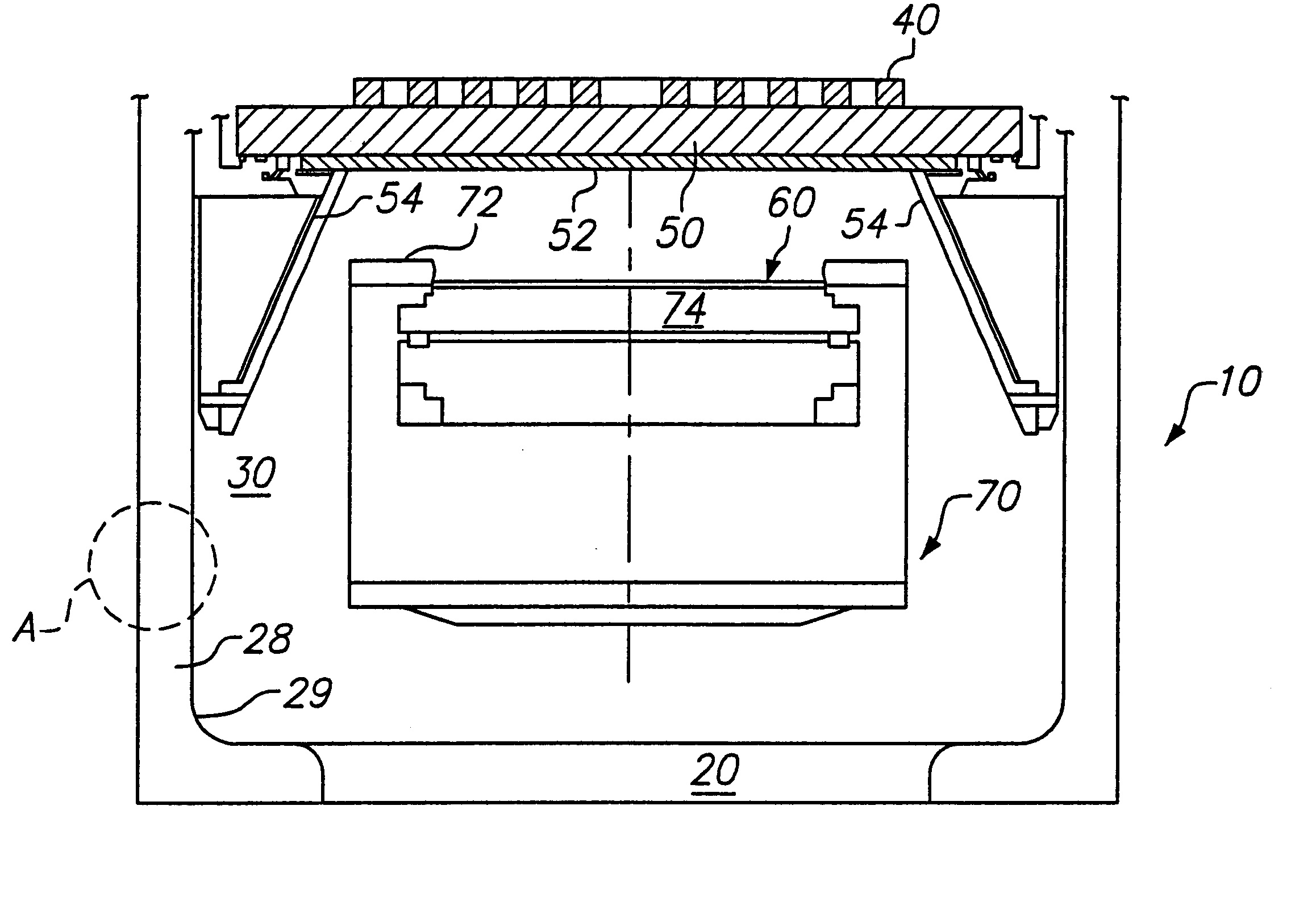

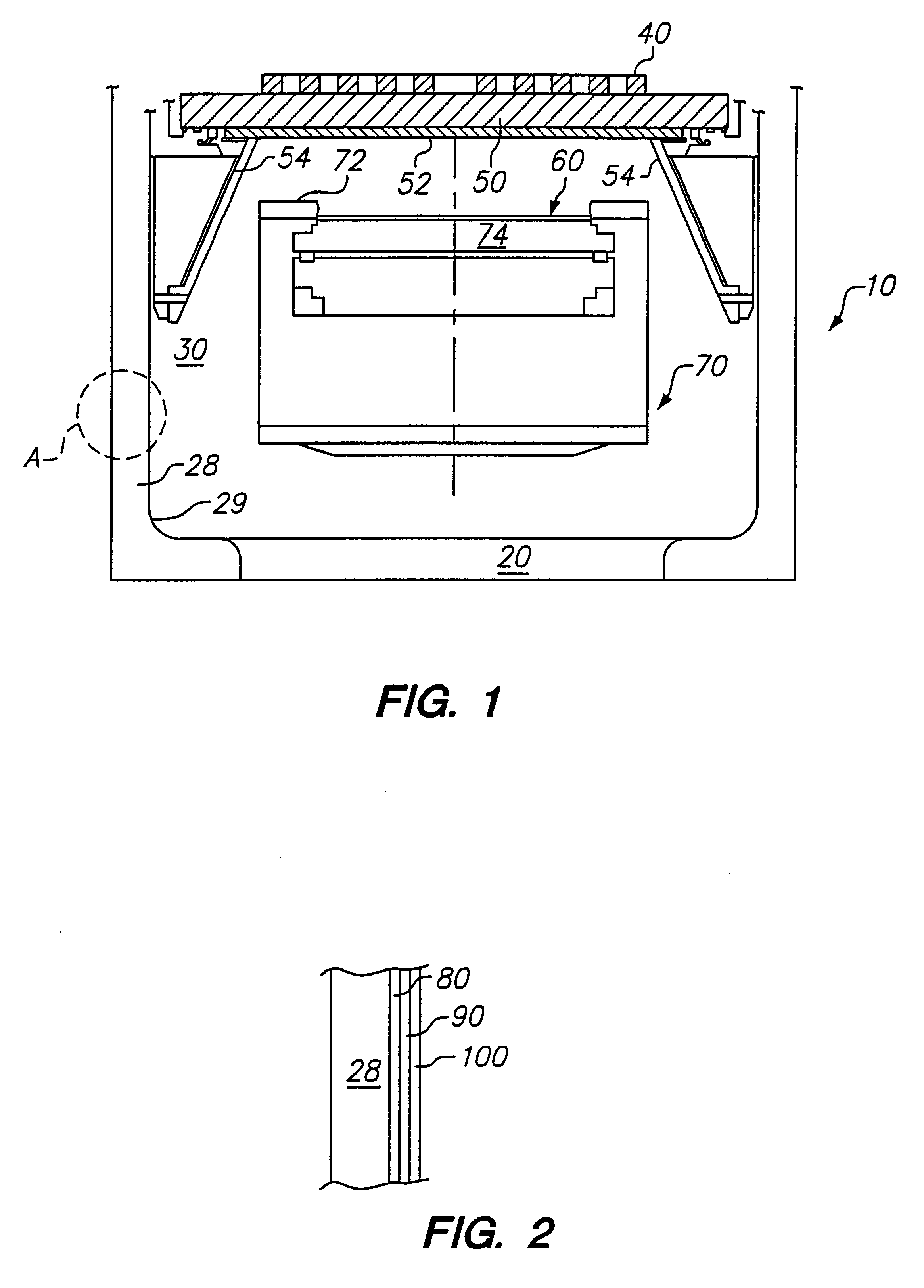

Data storage system having an optical processing flying head

InactiveUS6781927B1Low costOptical flying-type headsOptical beam sourcesDigital dataData information

An optical data storage and retrieval system uses a flying head. The flying head is supported on a moving media having information stored in a plurality of stored data locations thereon. Information is stored in each of the plurality of media locations as physical structures capable of modulating the polarization state of incident light into one of two output polarization states. The flying head includes an optical processing assembly which directs an incident light beam having a source polarization state onto the moving media, accessing successive data locations. A reflected light beam having the source polarization state of the incident light beam modulated by a respective polarization modifying data location into one of the output polarization states is received by the flying head. The optical processing assembly optically transforms the modulated output polarization state of the reflected light beam into two return light beams having differentially modulated intensity related to the output polarization state of the reflected light beam. The two intensity modulated return light beams are optically coupled to a distal differential detector which outputs digital data representing the stored data information for the subject data location. A preferred embodiment includes optical fibers for coupling the incident and return light beams between the detector and the flying head. The optical assembly of a preferred embodiment includes an optical plate having pre-shaped and dimensioned recesses for automatically locating and aligning multiple optical components comprising the assembly. The flying head may also include a servo-controlled micro machined mirror for directing the incident and reflected light beams to and from the media.

Owner:WESTERN DIGITAL (FREMONT LLC)

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

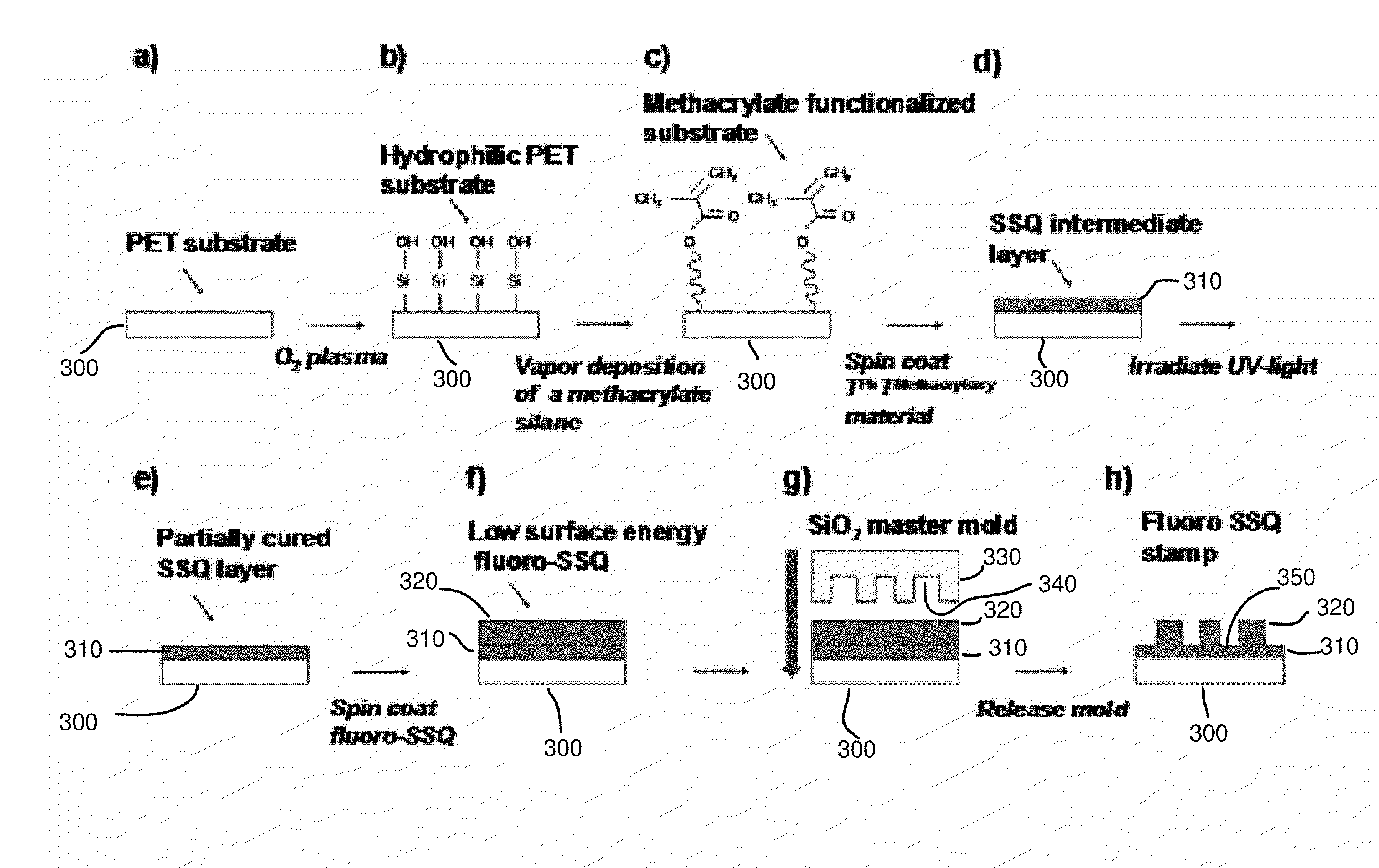

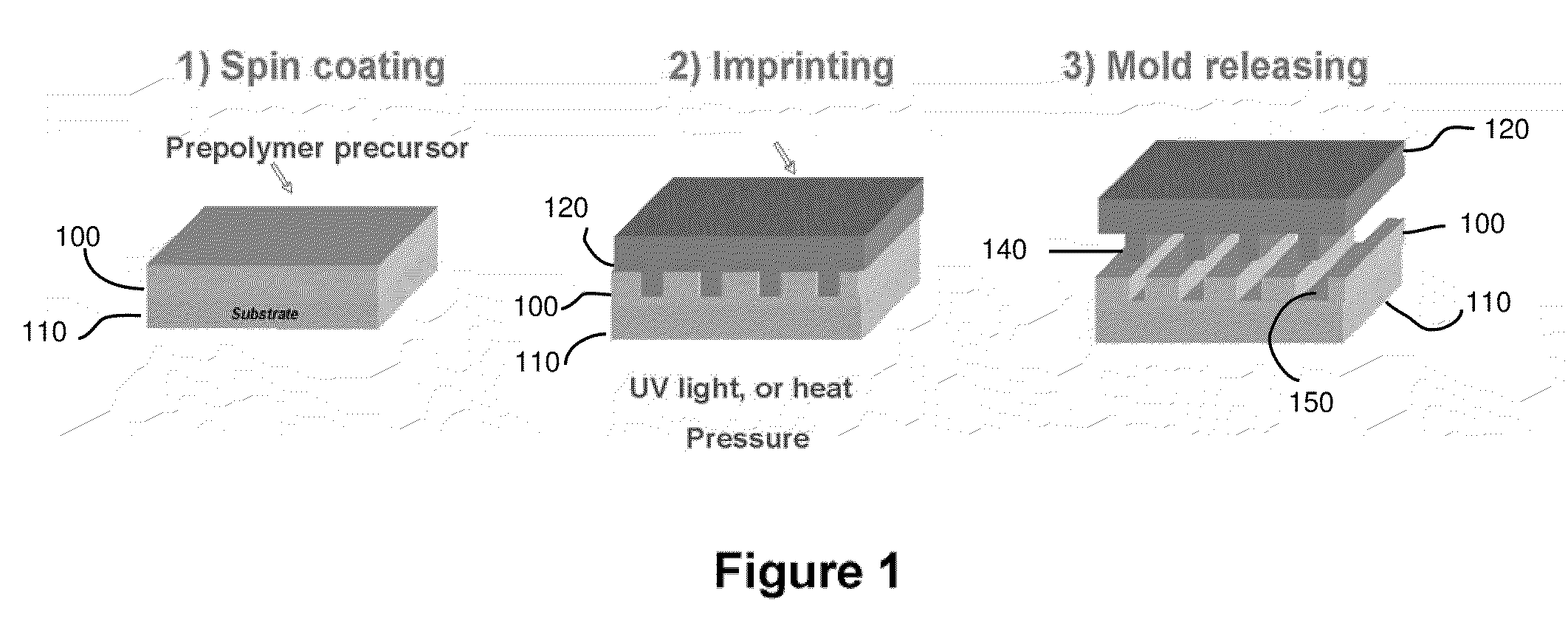

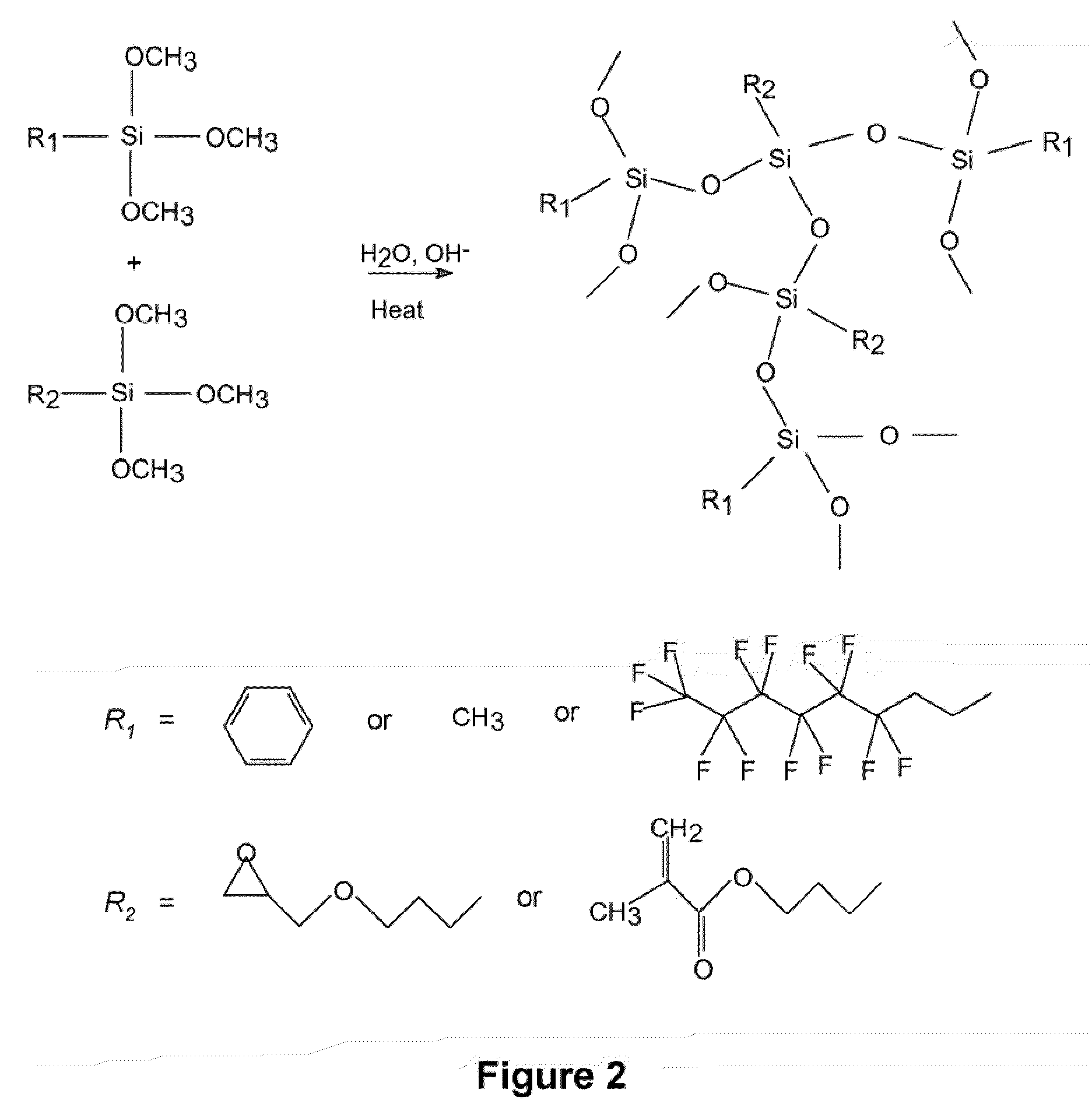

UV Curable Silsesquioxane Resins For Nanoprint Lithography

ActiveUS20090256287A1Simple compositionImprove methodPhotosensitive materialsNanoinformaticsNanolithographyResist

Radiation-curable silsesquioxane resin materials are employed for micro- and nanolithography. The resin materials can include a radiation-curable silsesquioxane resin and a photo-initiator having low viscosity. The low viscosity of the liquid system allows imprinting with low pressure and low temperature; e.g. room temperature. The resist's dry etching resistance is increased and the cured film is more easily separated from the mask. Due to its high modulus after cure, the material allows the fabrication of micro- and nano-features having high aspect ratios while providing a high throughput. Various pattern sizes, for example, ranging from tens of microns to as small as a few nanometers, may be achieved with the UV-curable material system.

Owner:RGT UNIV OF MICHIGAN

Glass with high frictive damage resistance

ActiveUS20120282449A1Improve initial strengthImprove the immunityDecorative surface effectsSynthetic resin layered productsPolymer scienceLayer thickness

A glass article exhibiting improved resistance to fictive surface damage and a method for making it, the method comprising removing a layer of glass from at least a portion of a surface of the article that is of a layer thickness at least effective to reduce the number and / or depth of flaws on the surface of the article, and then applying a friction-reducing coating to the portion of the article from which the layer of surface glass has been removed.

Owner:CORNING INC

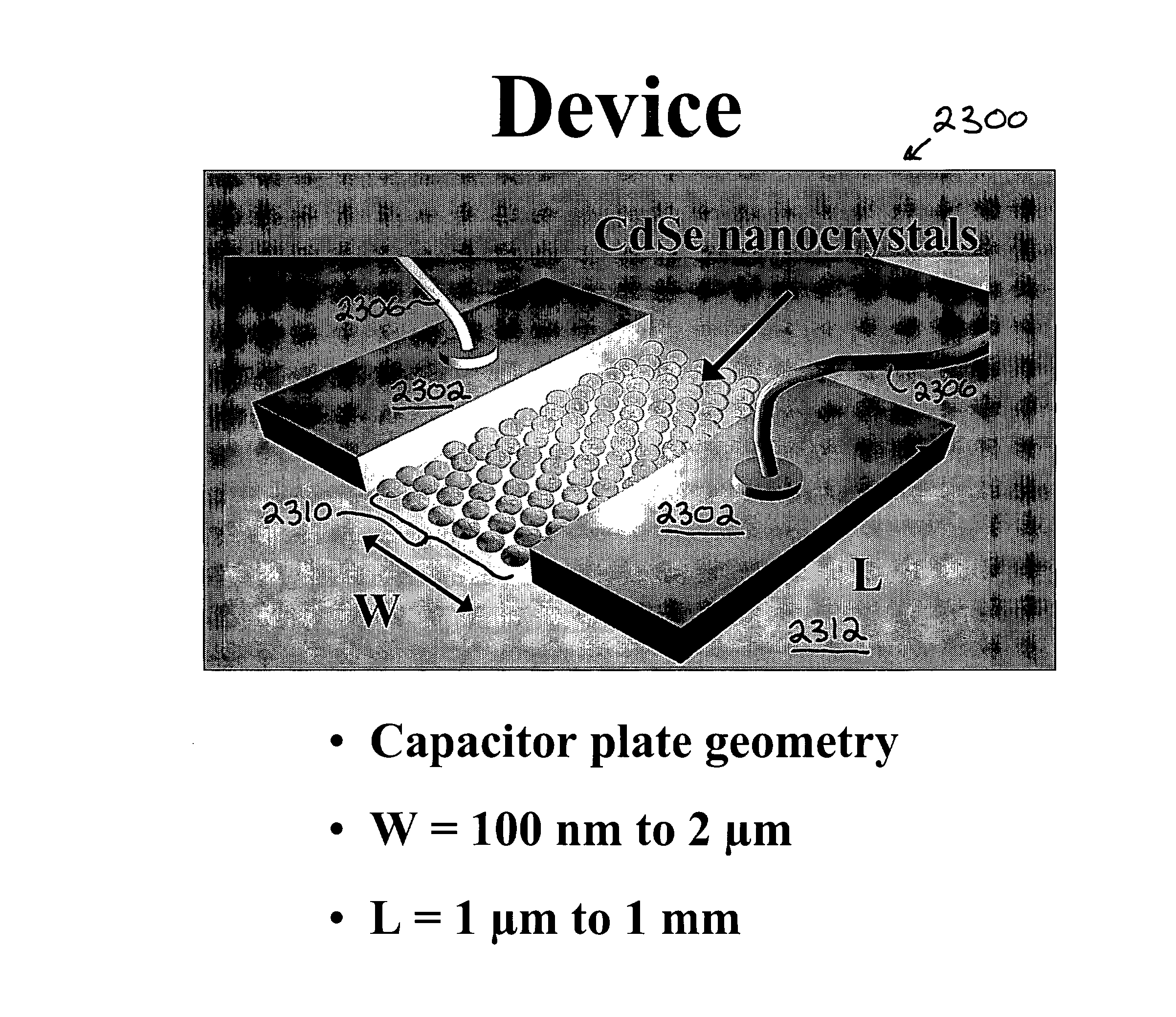

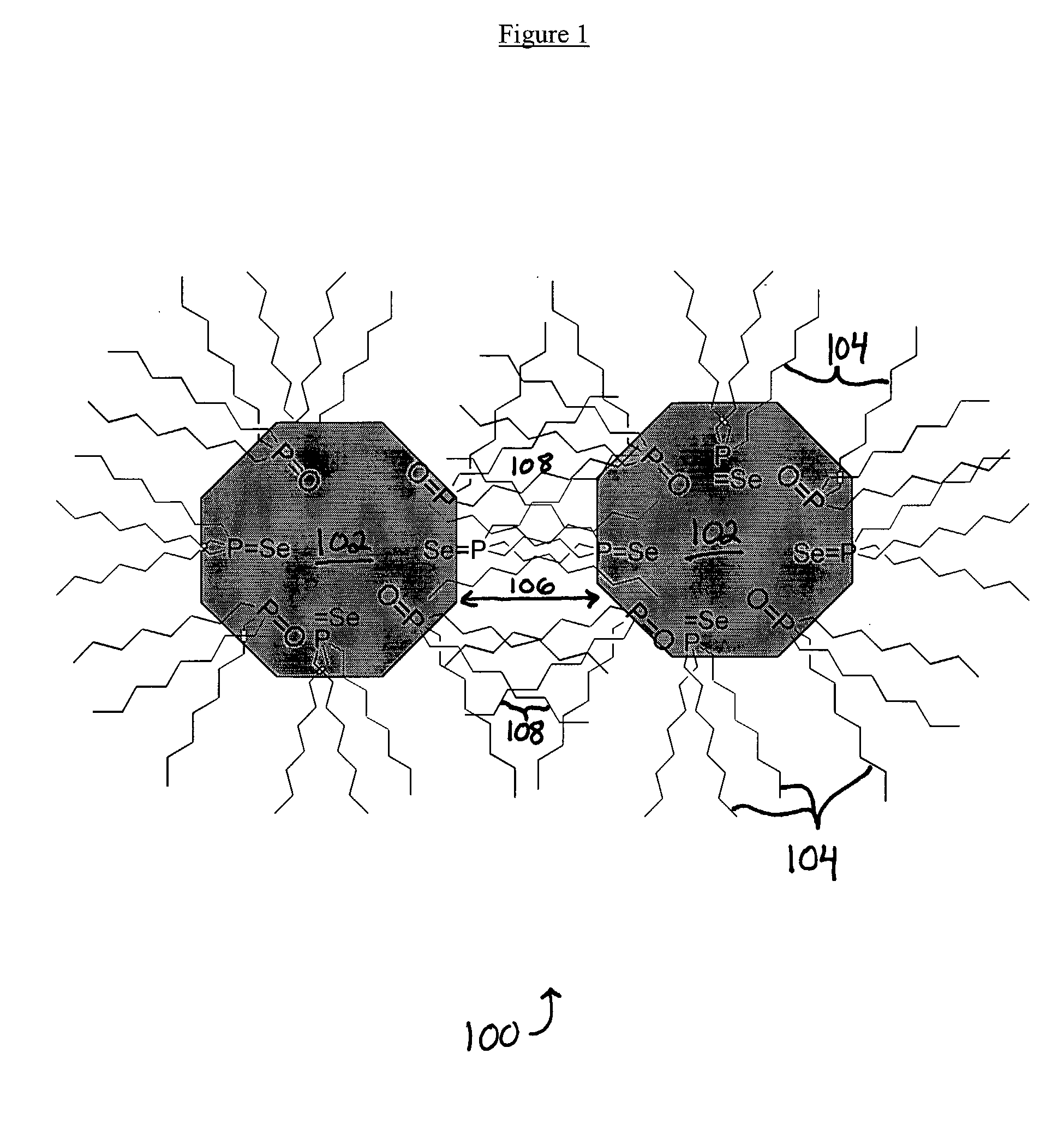

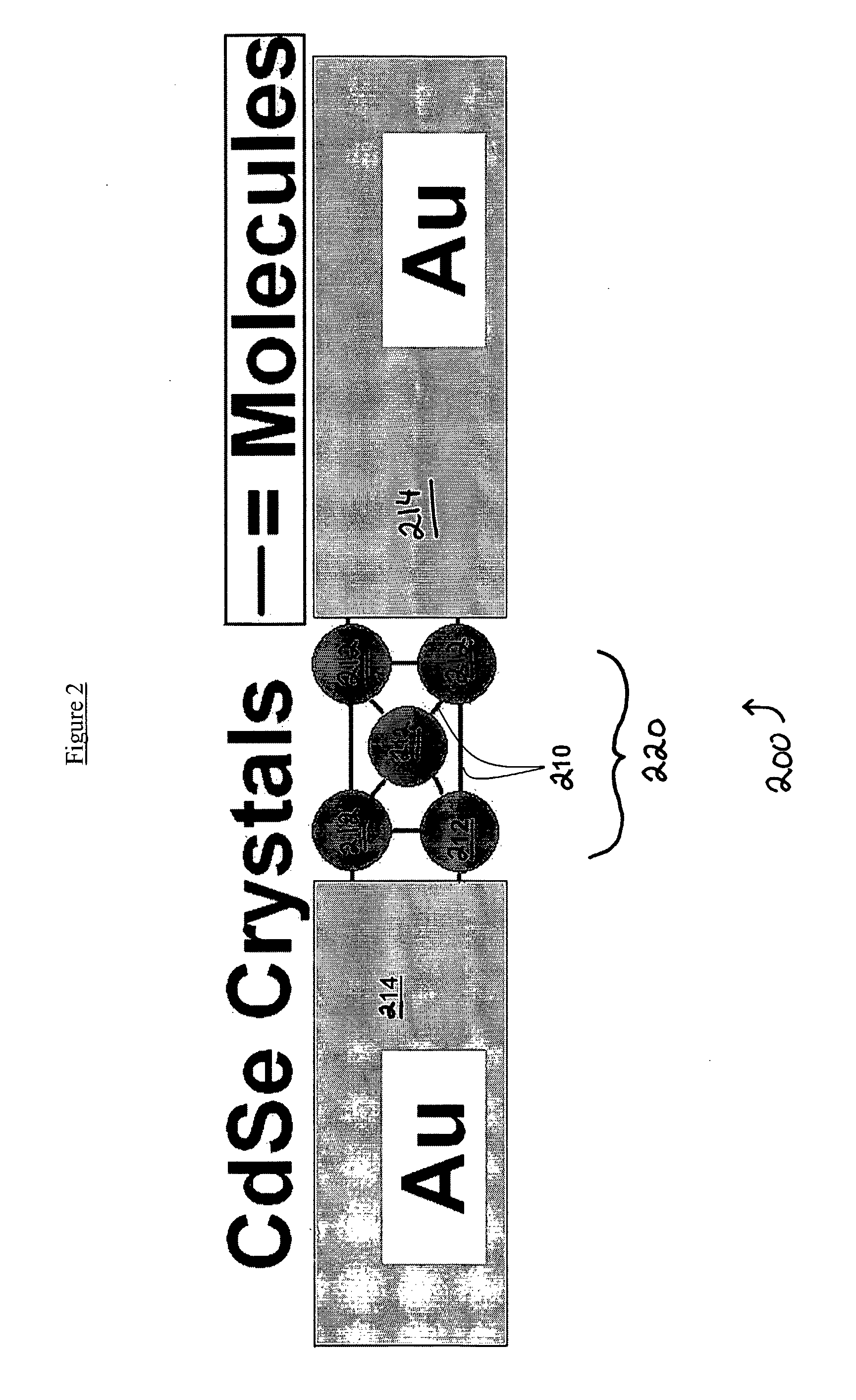

Nanostructure Assemblies, Methods And Devices Thereof

ActiveUS20080017845A1Material nanotechnologyNanostructure manufactureEngineeringField-effect transistor

Disclosed herein are methods for assembling nanostructures. The assembling methods include contacting the plurality of nanostructures to a substrate having one or more discontinuities. At least a portion of the plurality of nanostructures assemble adjacent to the discontinuity, the assembled nanostructures including at least one nanostructure having a bridging, molecule. Devices, such as field-effect transistors, are also disclosed.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

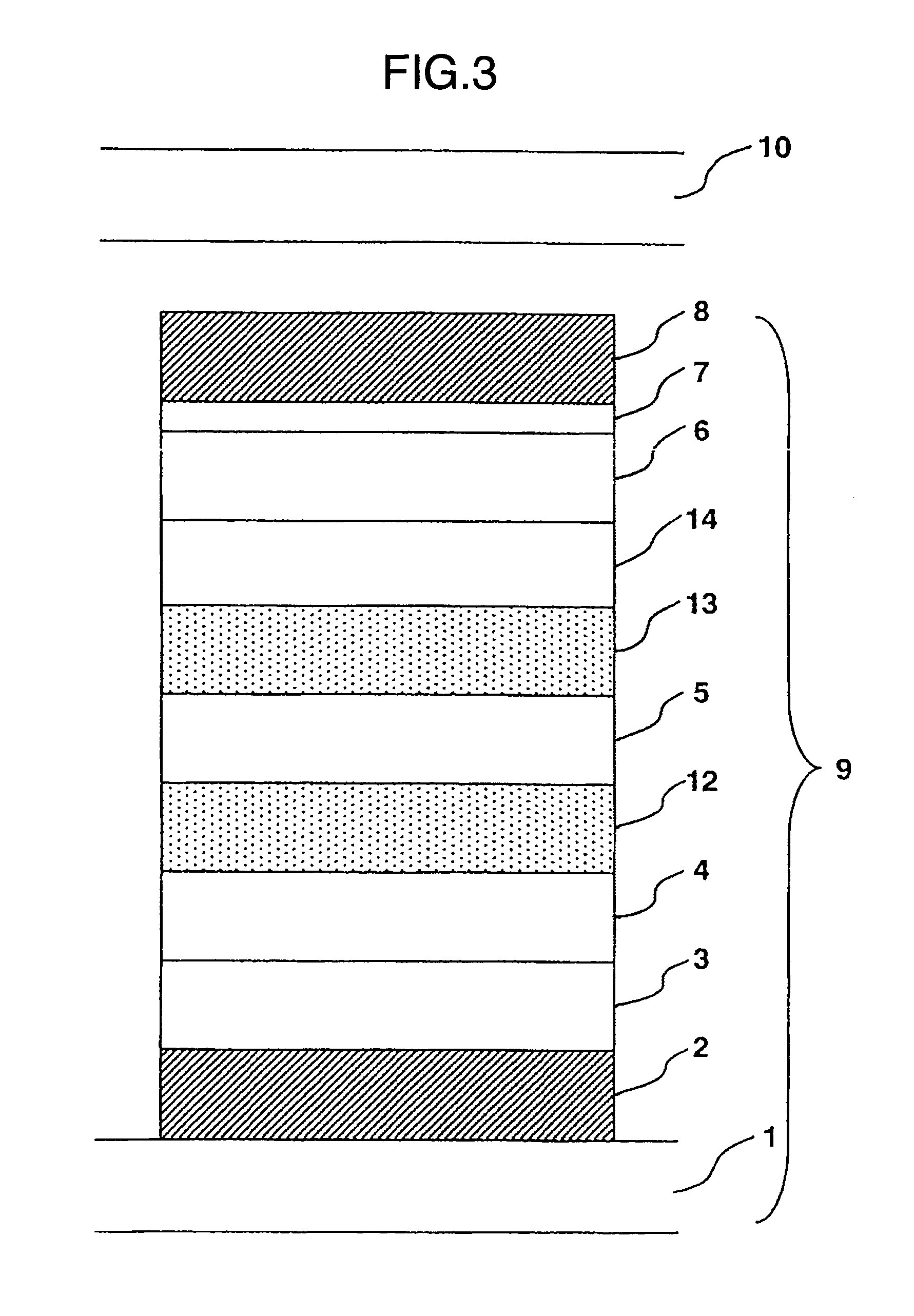

Organic light-emitting element, image display device and production method thereof

ActiveUS20050221121A1High structural reliabilityLight interference effectSolid-state devicesSemiconductor/solid-state device manufacturingDopantElectron

It is an object to provide an organic light-emitting element having two or more light-emitting layers, wherein degradation of each constituent material for the light-emitting layer is reduced to improve reliability of the element. The present invention provides an organic light-emitting element having a laminated structure with a first mixed light-emitting layer 4 composed of a hole transport material, an electron transport material and a dopant which determines a color of an emitted light, and a second mixed light-emitting layer 5 composed of a hole transport material, an electron transport material and a dopant which determines a color of an emitted light, and also provides an image display device which uses the organic light-emitting element.

Owner:SAMSUNG DISPLAY CO LTD +1

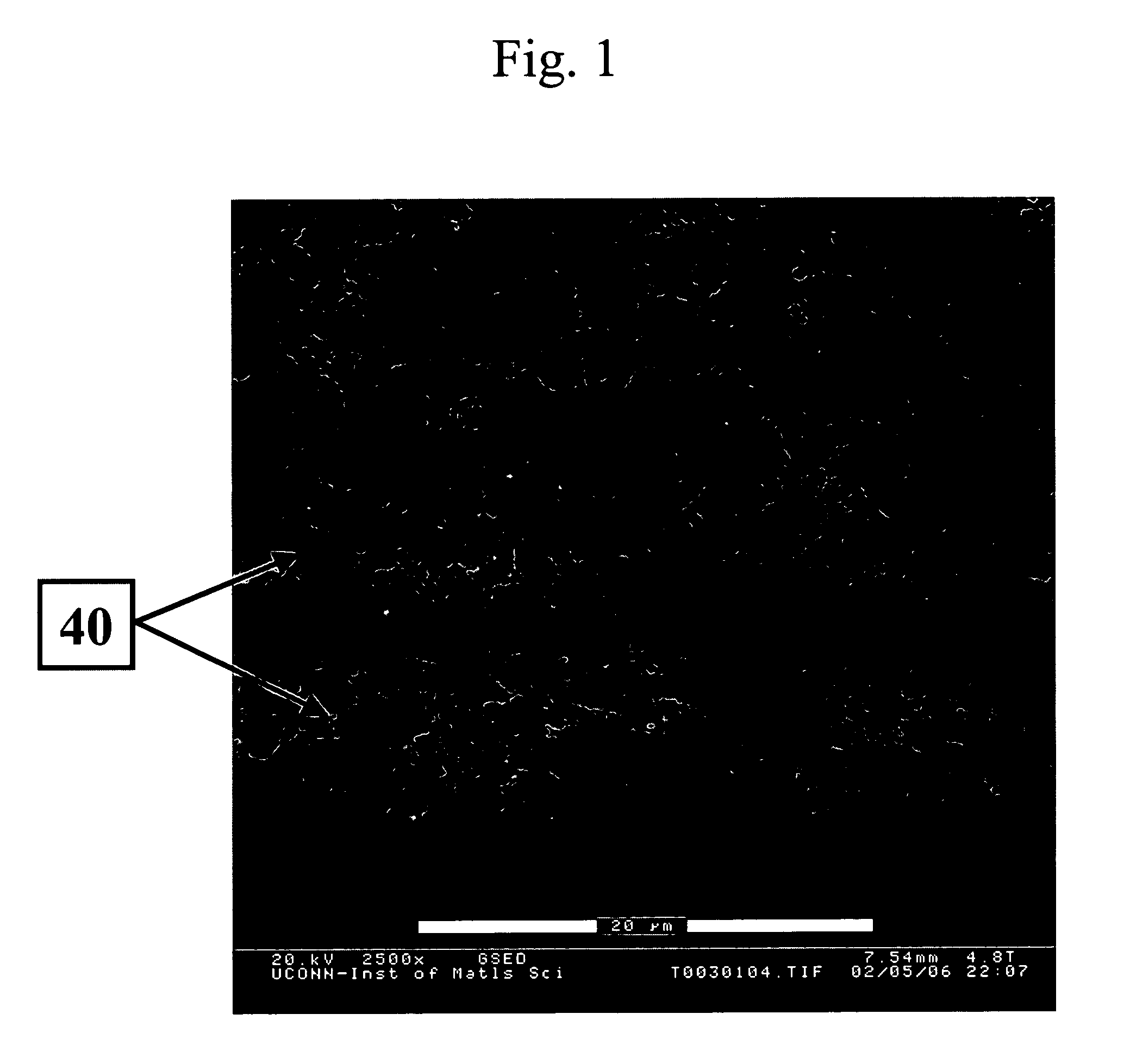

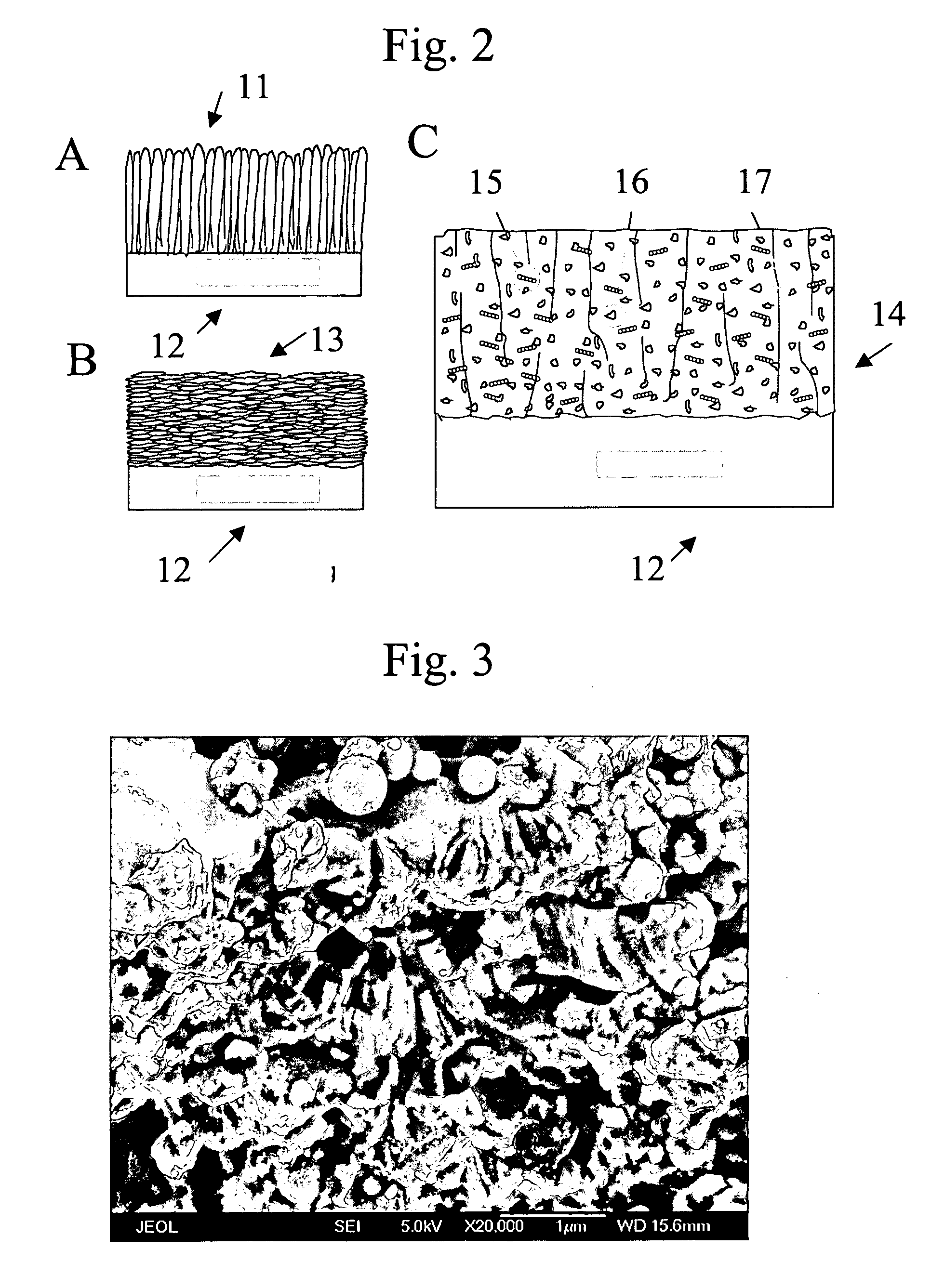

Coatings, materials, articles, and methods of making thereof

ActiveUS20040229031A1Low costSufficient powerMaterial nanotechnologyLiquid surface applicatorsHot zoneMaterials science

Owner:UNIV OF CONNECTICUT +2

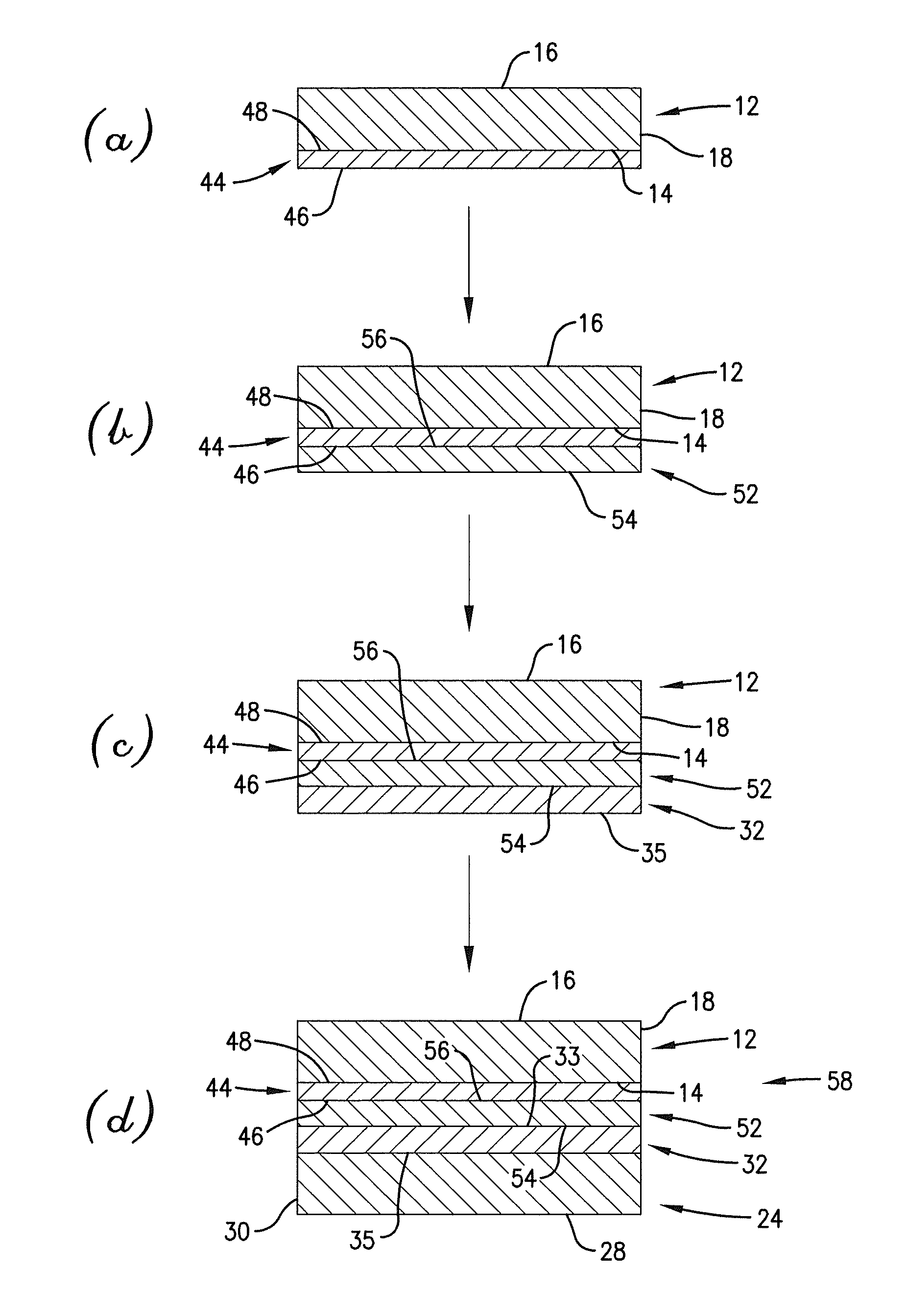

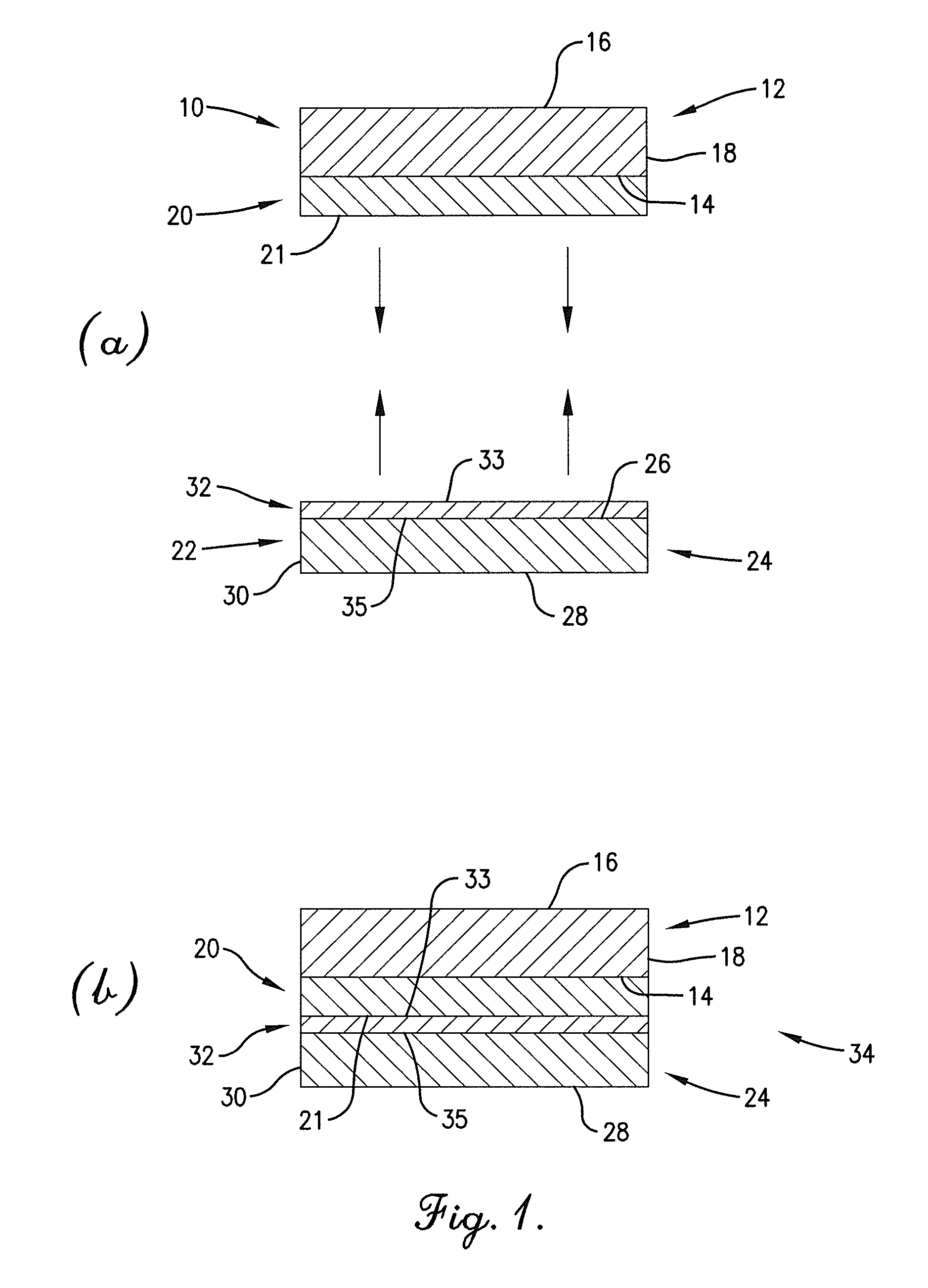

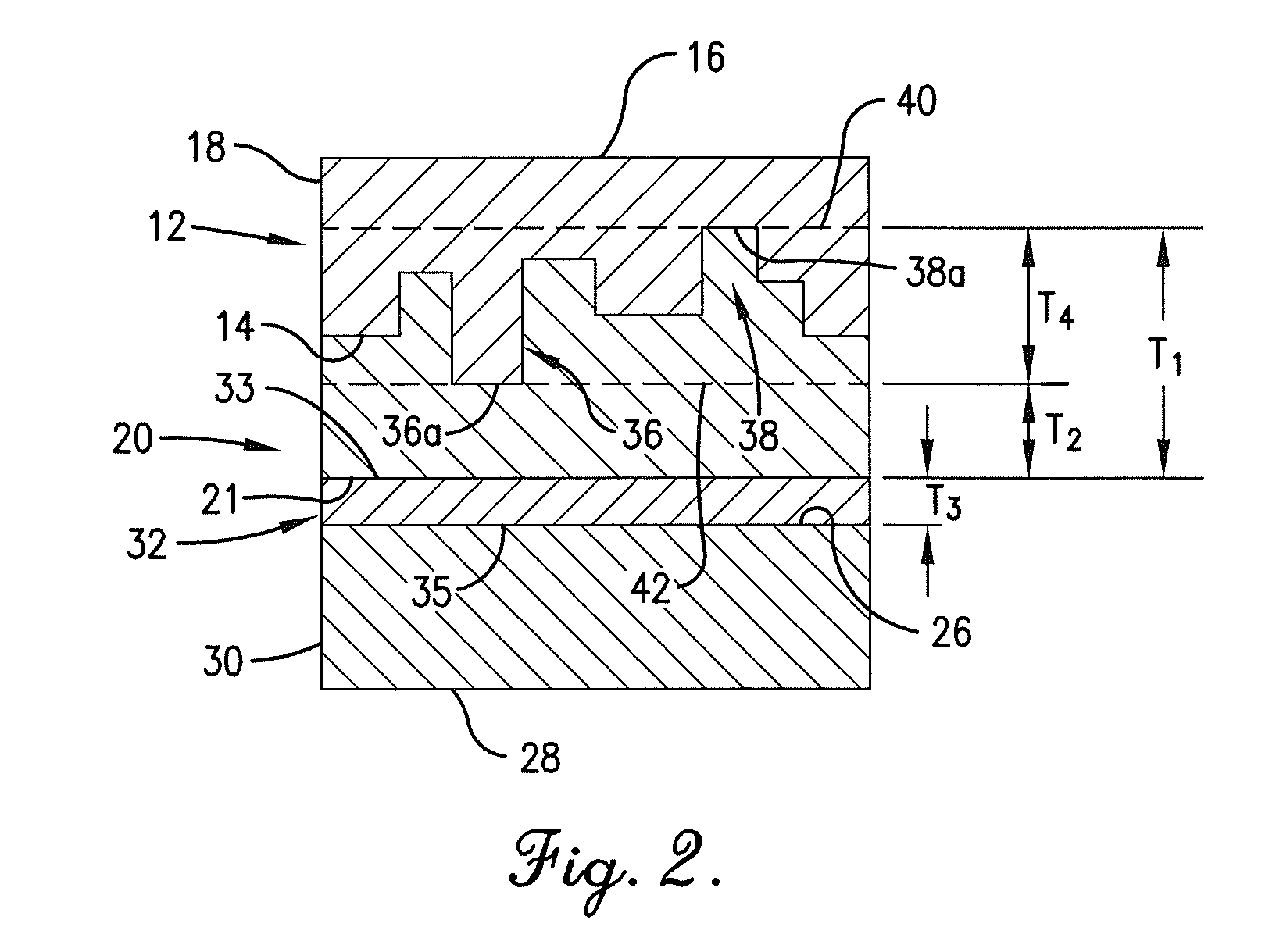

Multiple bonding layers for thin-wafer handling

ActiveUS20120034437A1Lamination ancillary operationsSynthetic resin layered productsSpecific functionEngineering

Multiple bonding layer schemes that temporarily join semiconductor substrates are provided. In the inventive bonding scheme, at least one of the layers is directly in contact with the semiconductor substrate and at least two layers within the scheme are in direct contact with one another. The present invention provides several processing options as the different layers within the multilayer structure perform specific functions. More importantly, it will improve performance of the thin-wafer handling solution by providing higher thermal stability, greater compatibility with harsh backside processing steps, protection of bumps on the front side of the wafer by encapsulation, lower stress in the debonding step, and fewer defects on the front side.

Owner:BREWER SCI

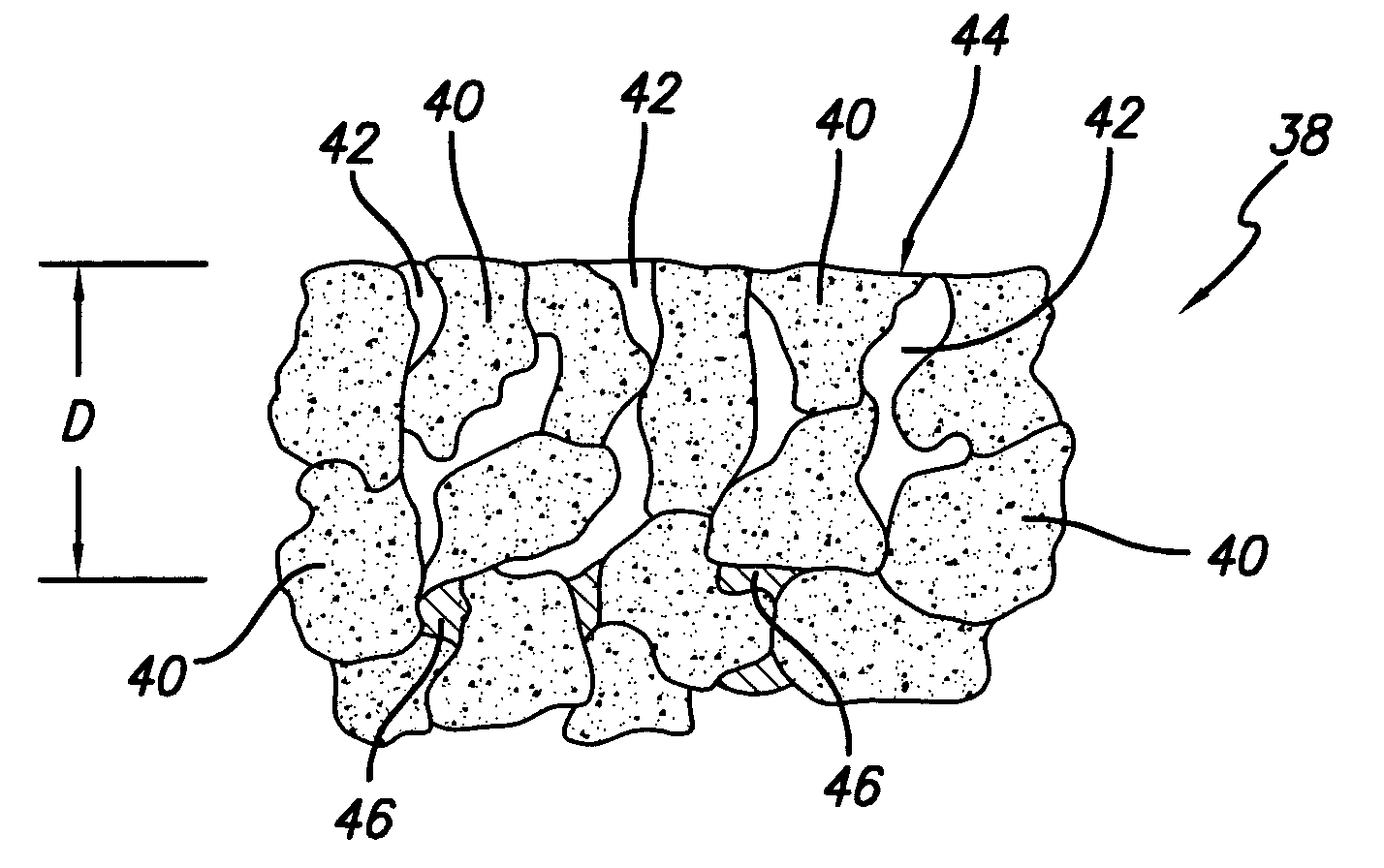

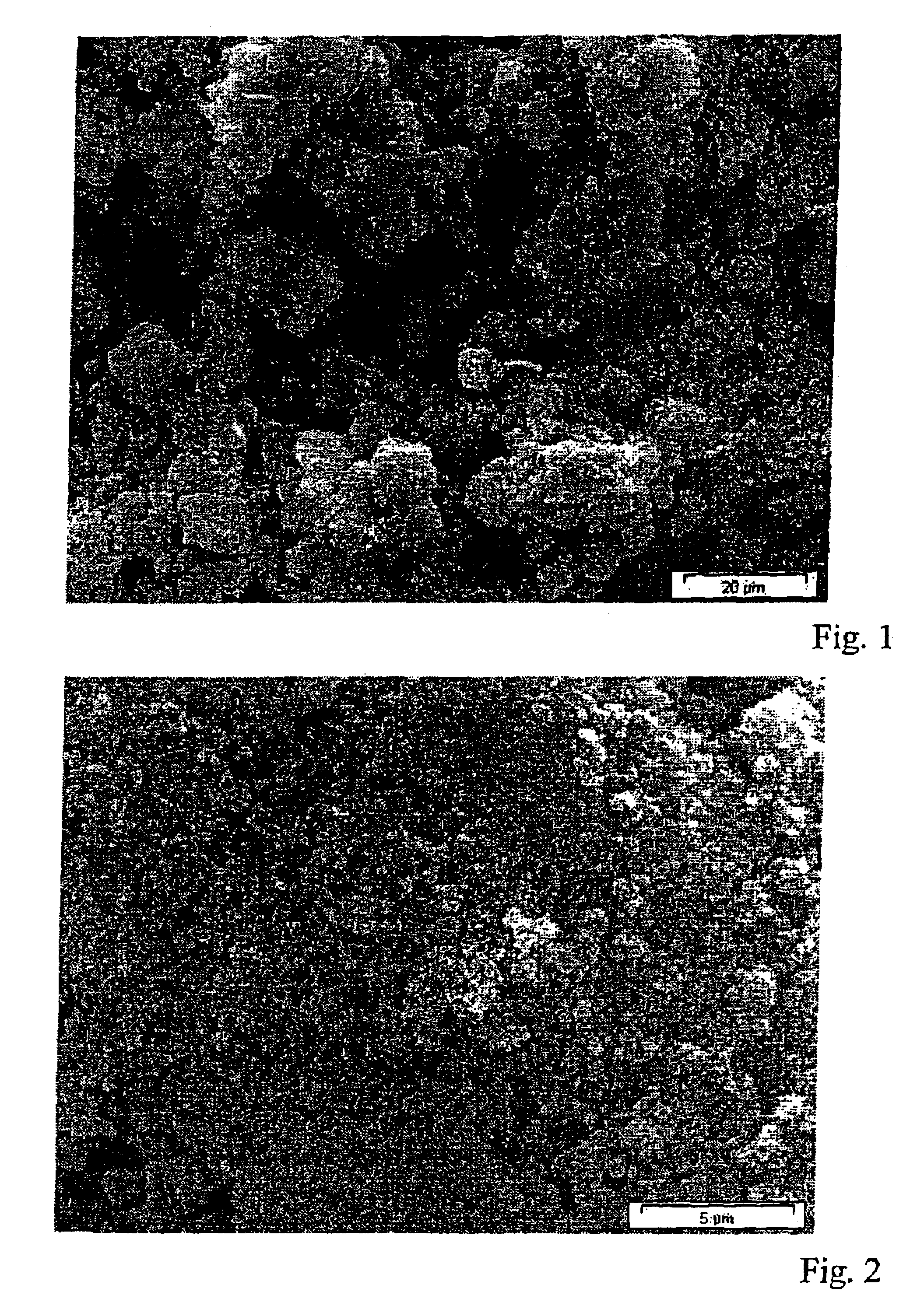

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

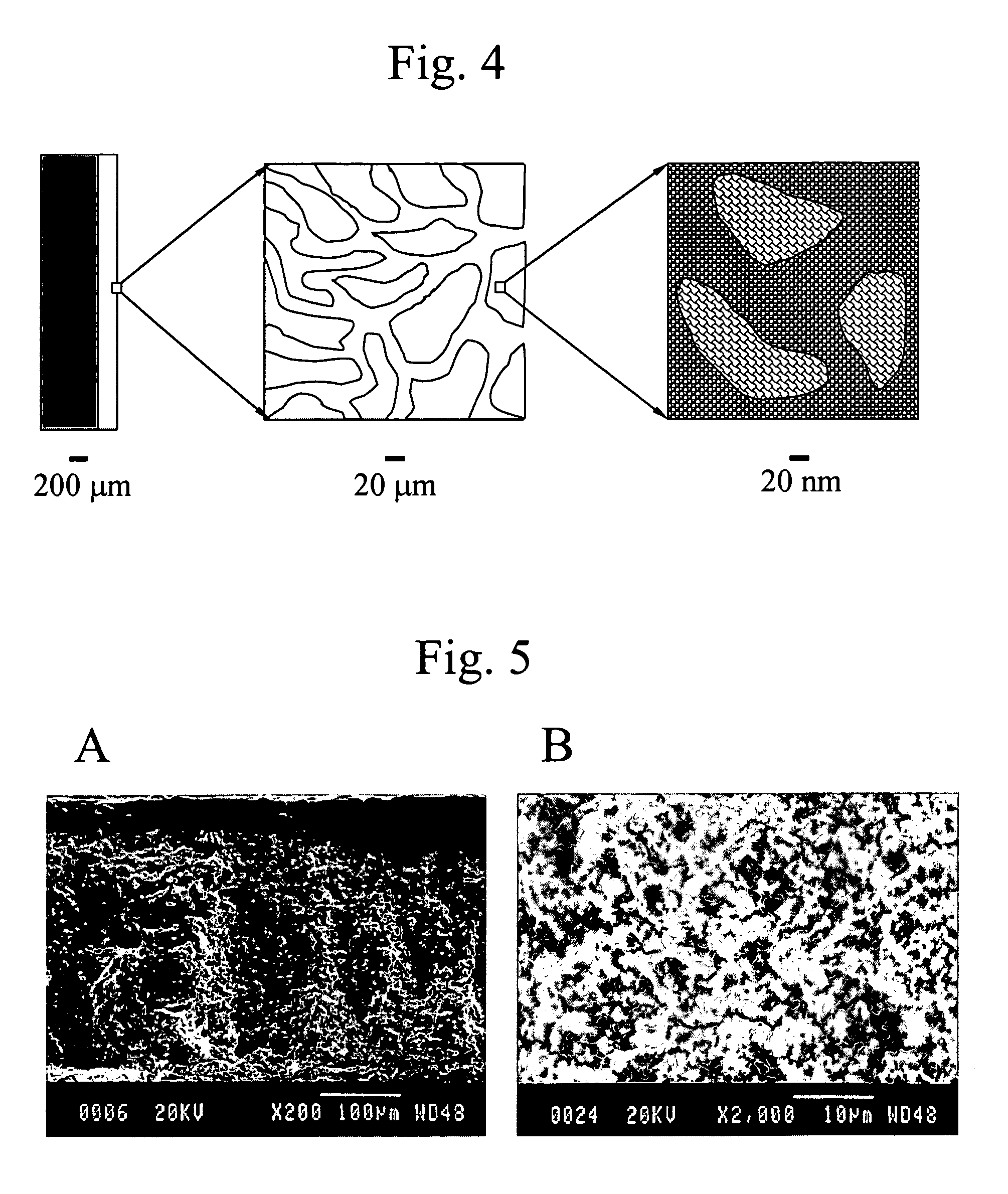

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

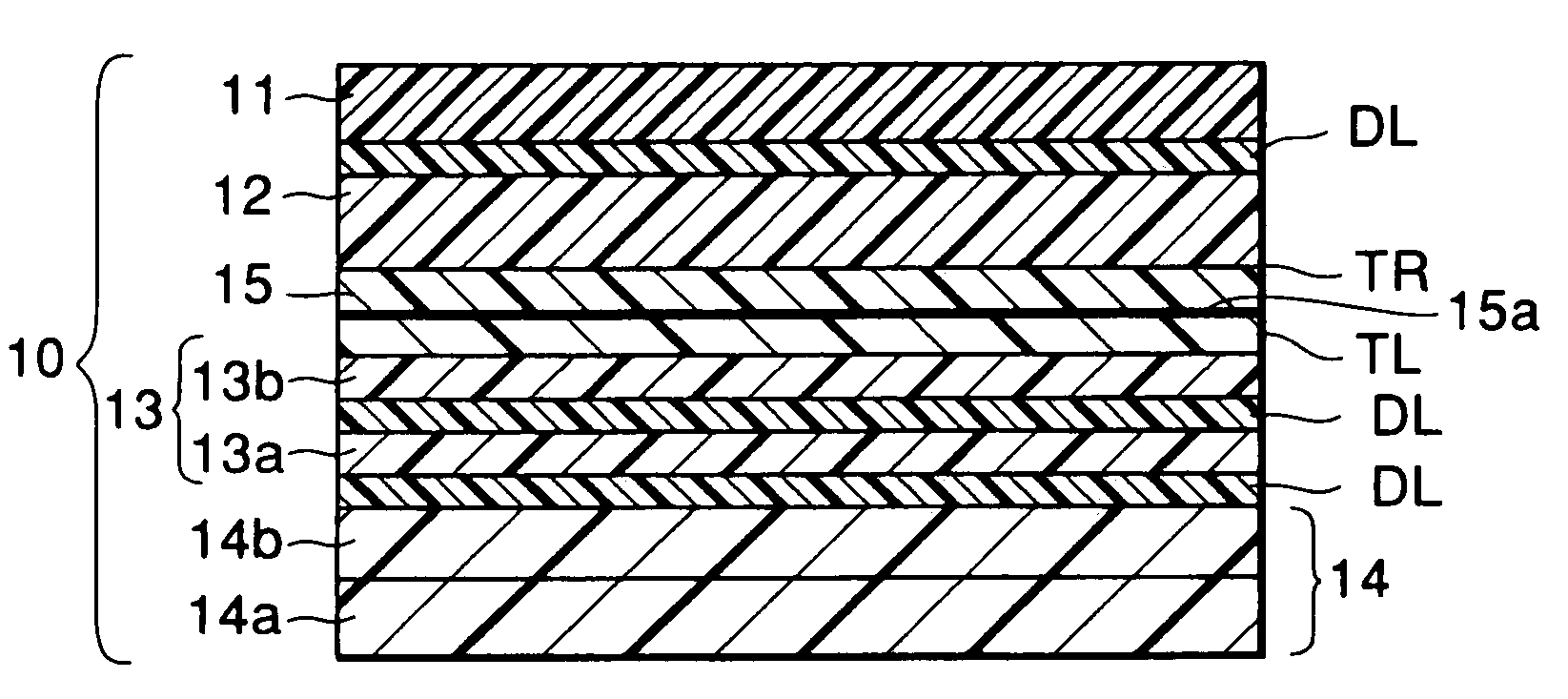

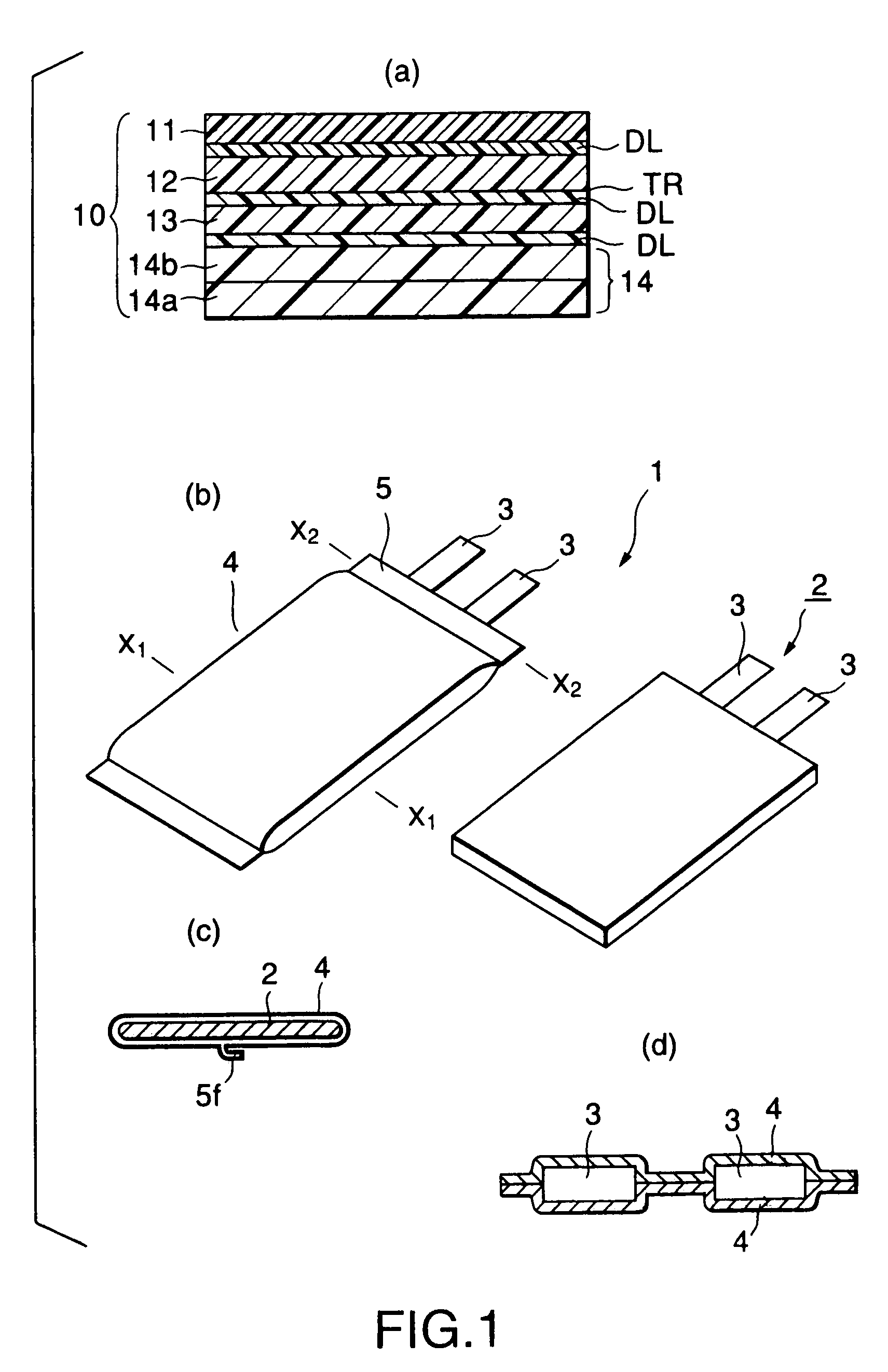

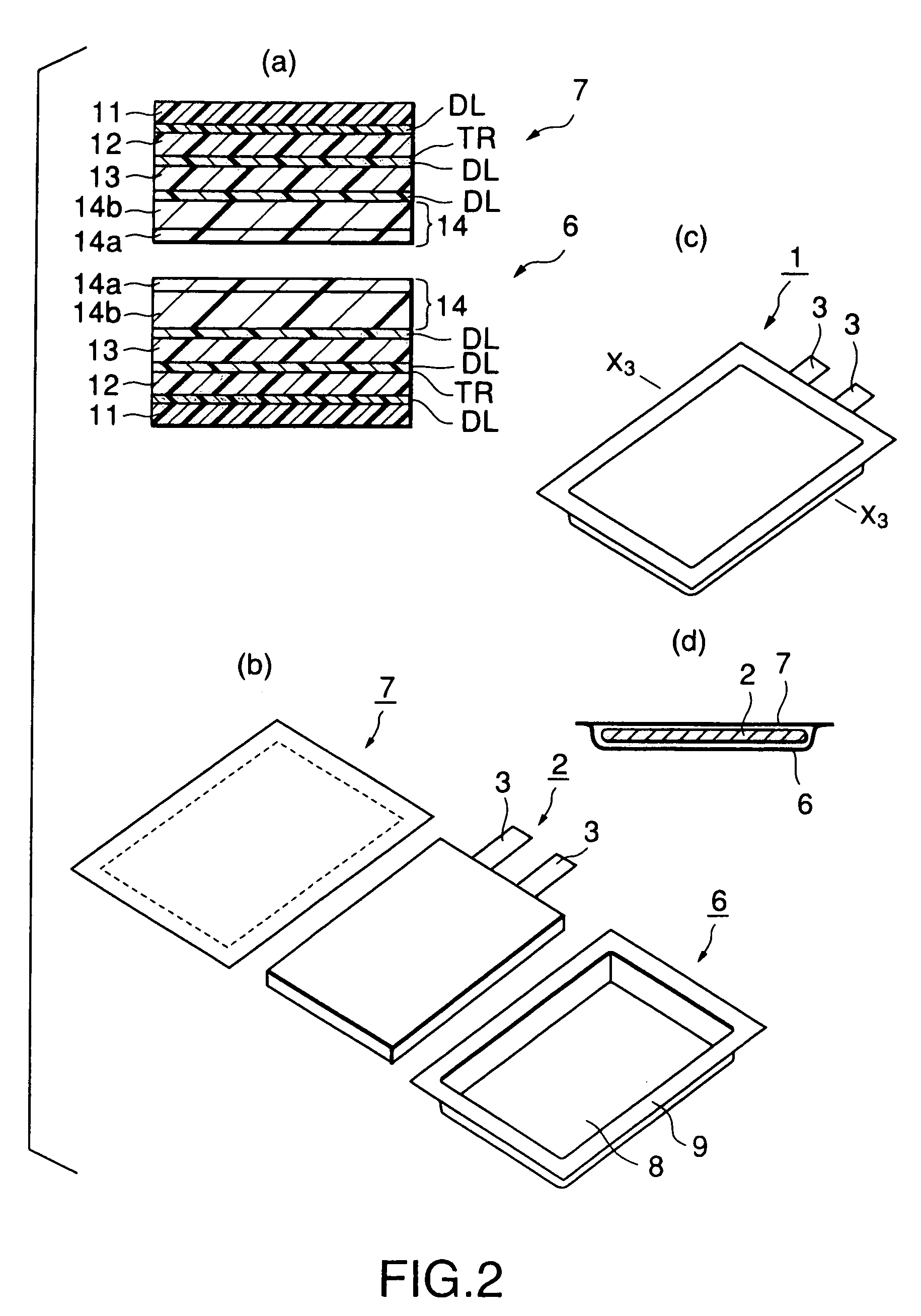

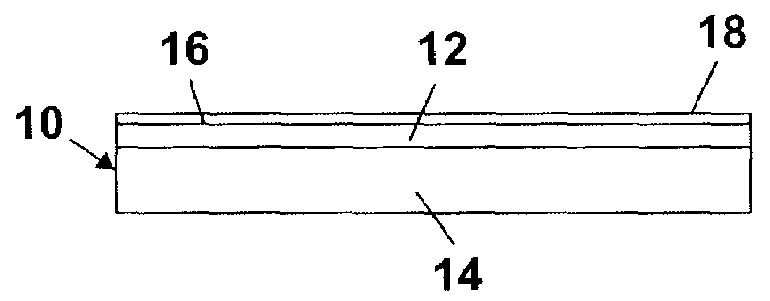

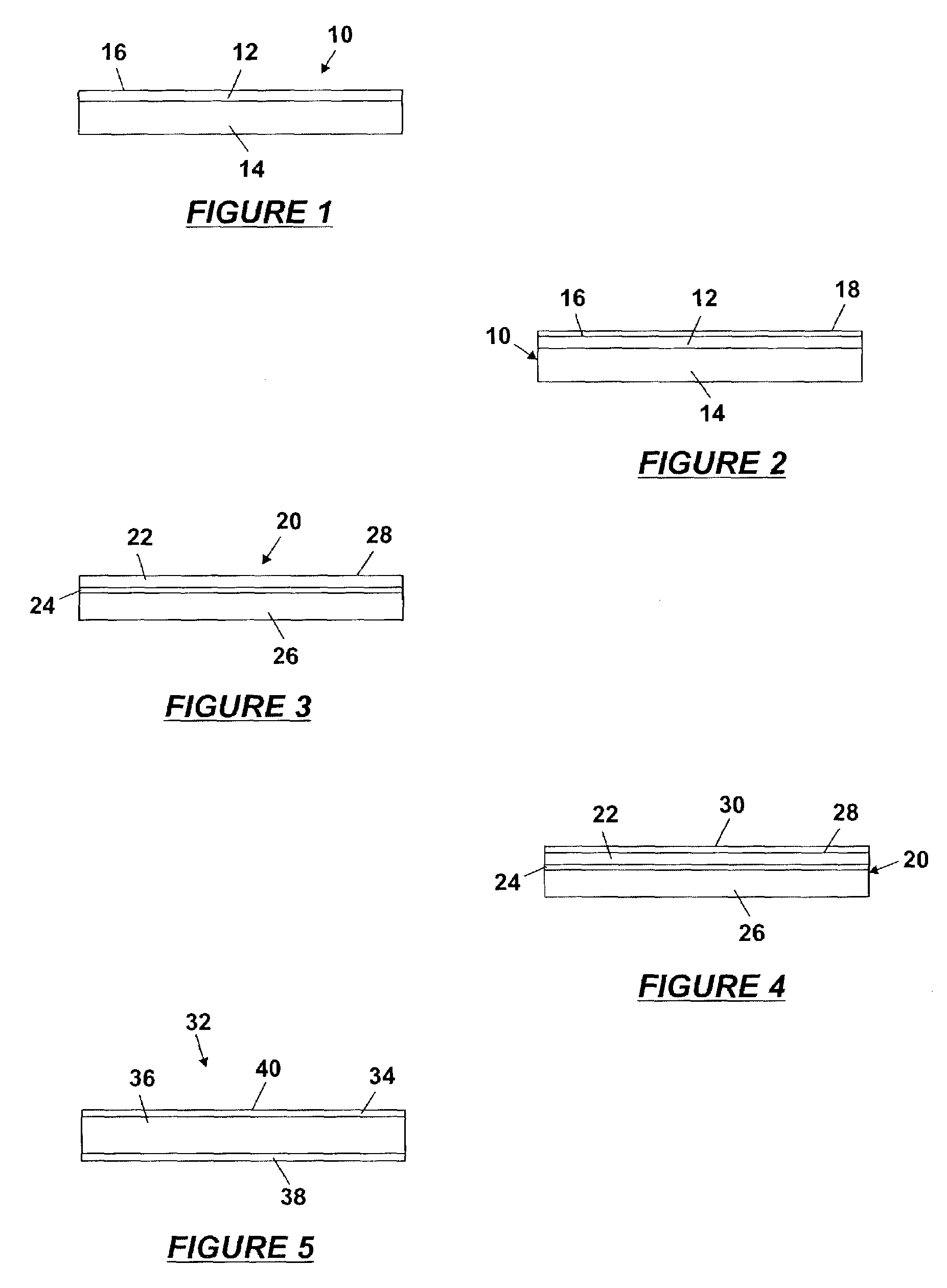

Material for packaging cell, bag for packaging cell, and its production method

InactiveUS7285334B1Excellent gas barrier performanceHigh mechanical strengthNon-aqueous electrolyte accumulatorsSynthetic resin layered productsEngineeringMethods of production

A lithium battery comprises a pouch (4) and a lithium battery module (2) packaged in the pouch (4). The pouch (4) is formed from a battery packaging laminated structure (10). The laminated structure (10) has an outermost layer (11), a barrier layer (12) and an innermost layer (14), or an outermost layer (11), a barrier layer (12), an intermediate layer (13) and an innermost layer (14) superposed in that order. The outermost layer (11) is formed of a formable base material, the barrier layer (12) is formed of a impermeable base material having a barrier property, the intermediate layer (13) is formed of a formable base material and the innermost layer (14) is formed of a heat-adhesive base material.

Owner:DAI NIPPON PRINTING CO LTD

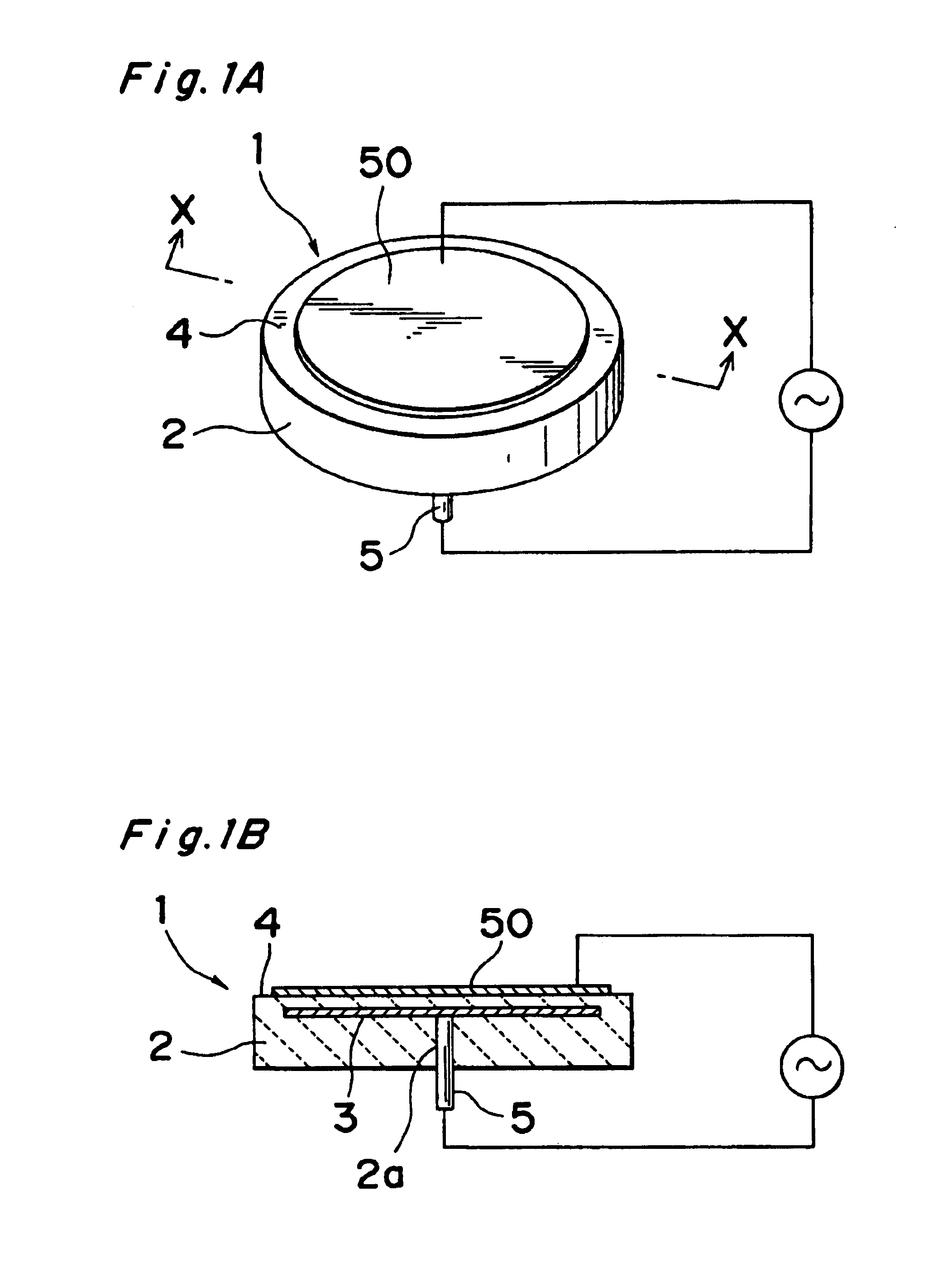

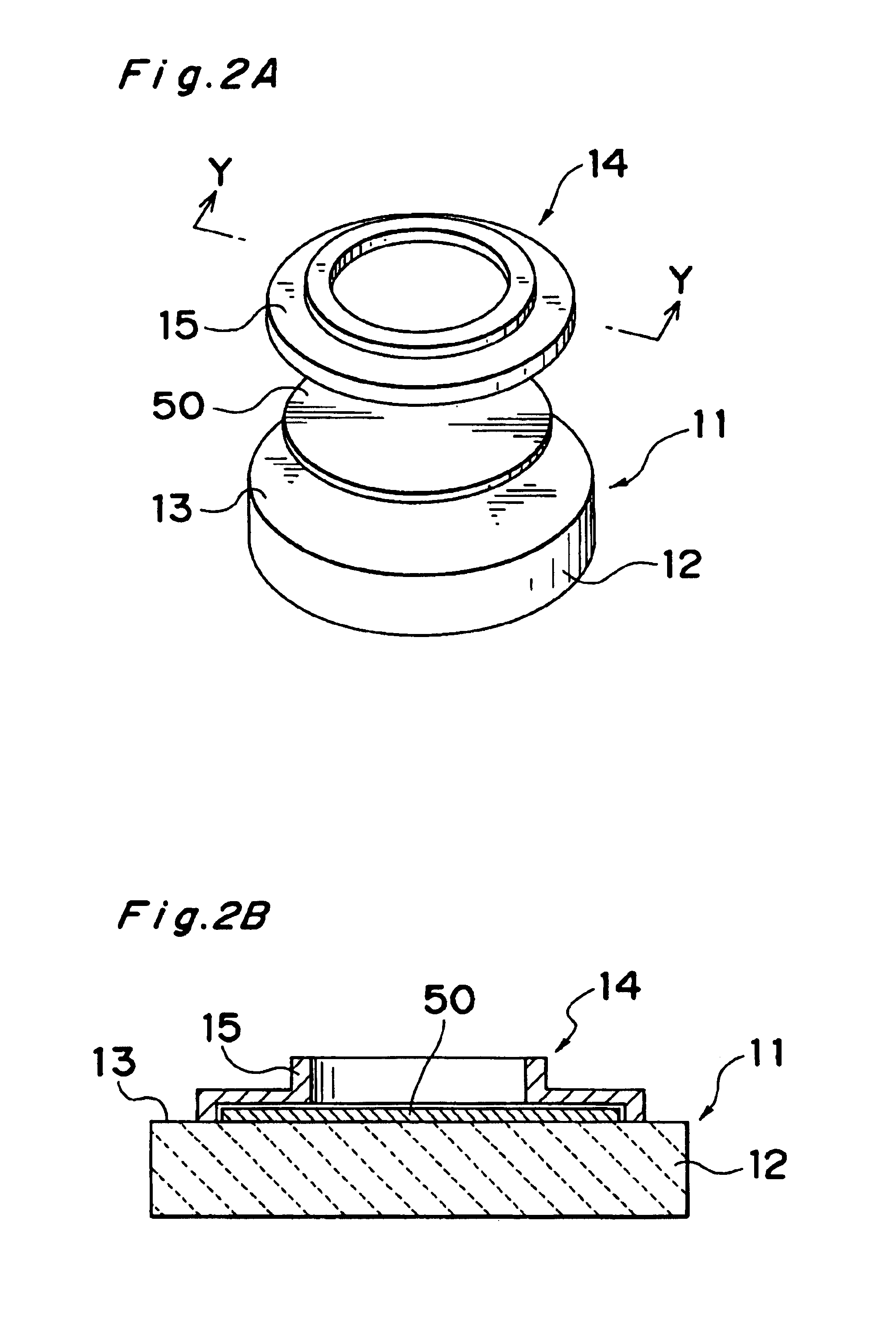

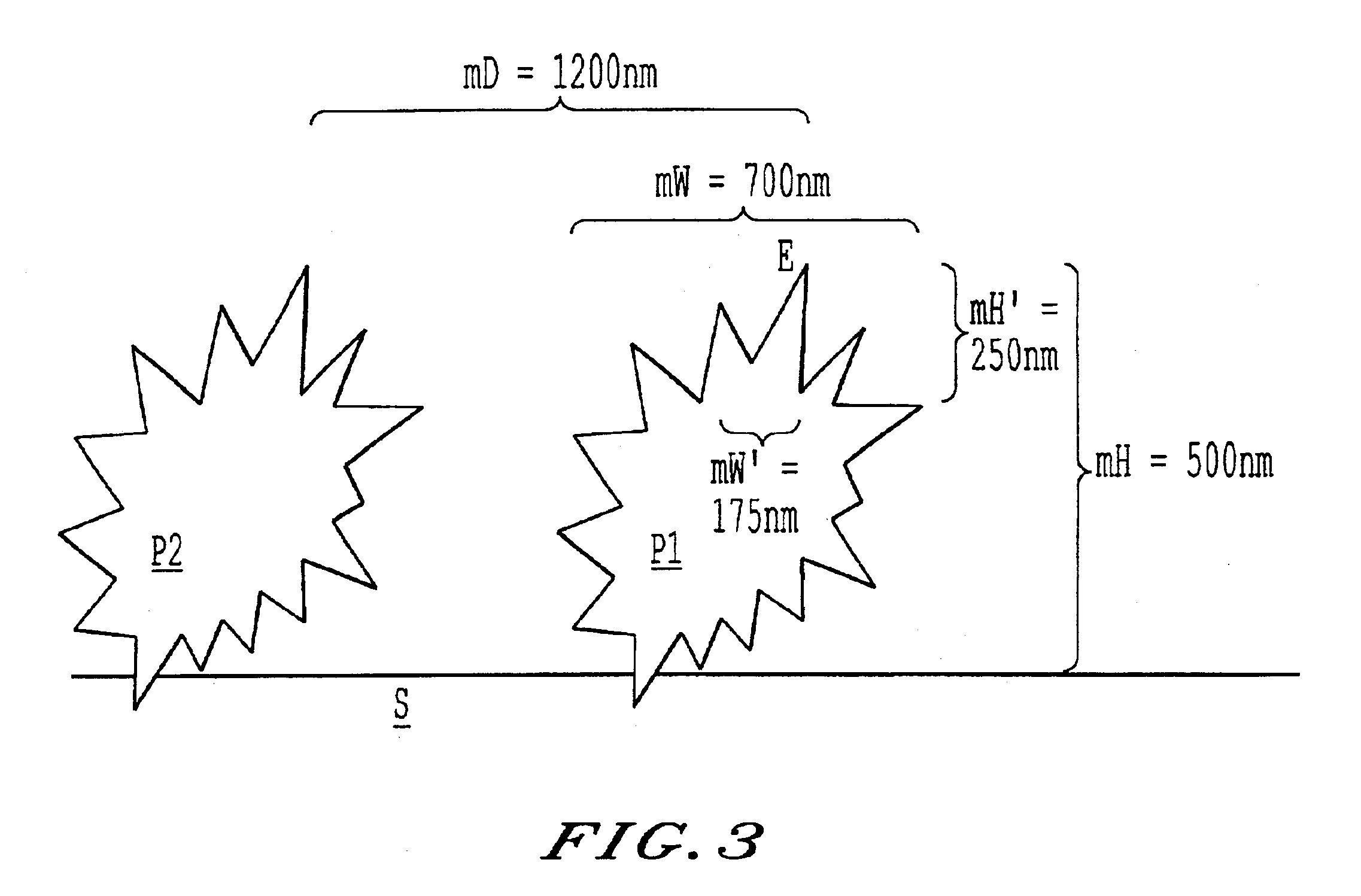

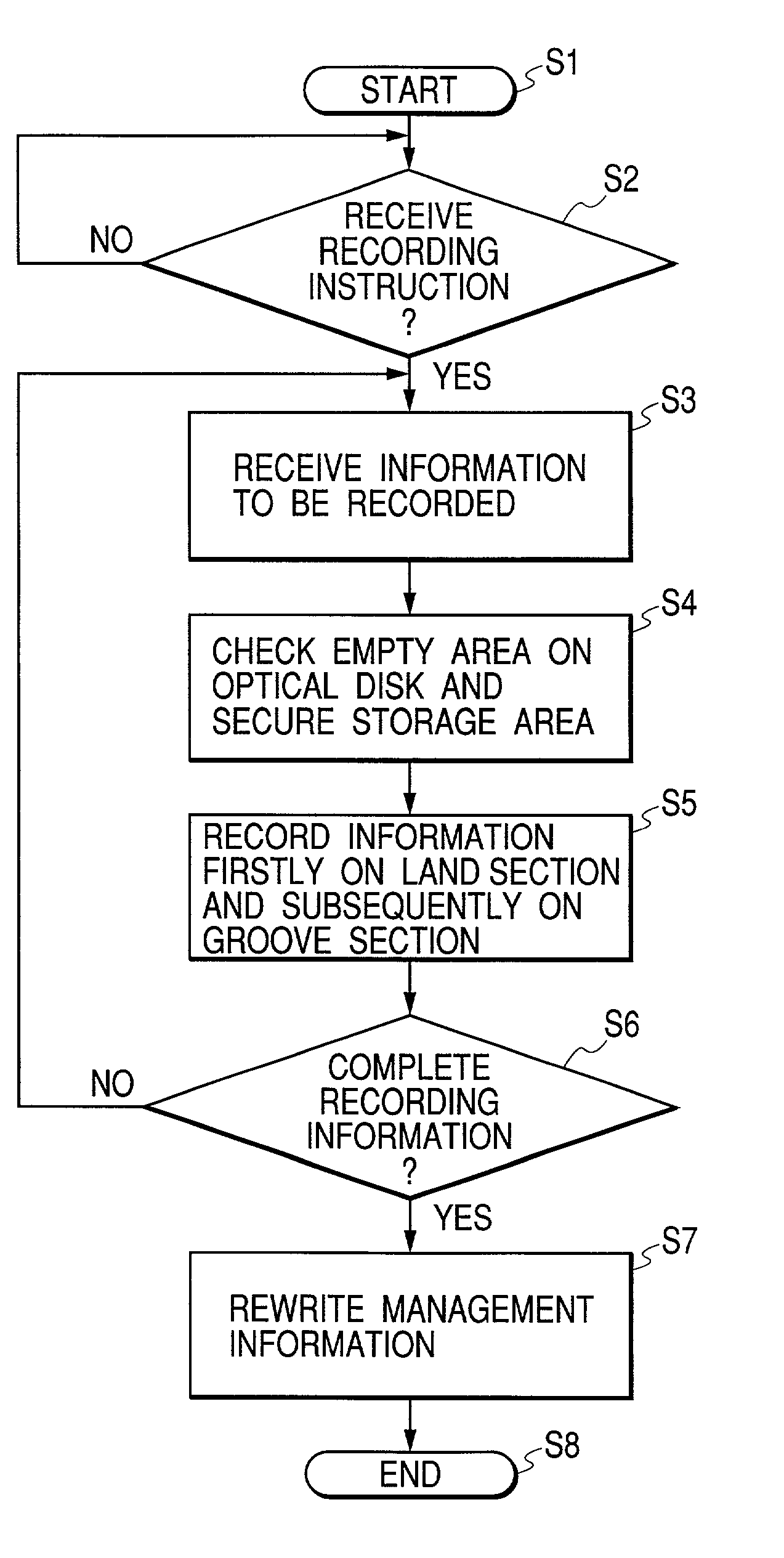

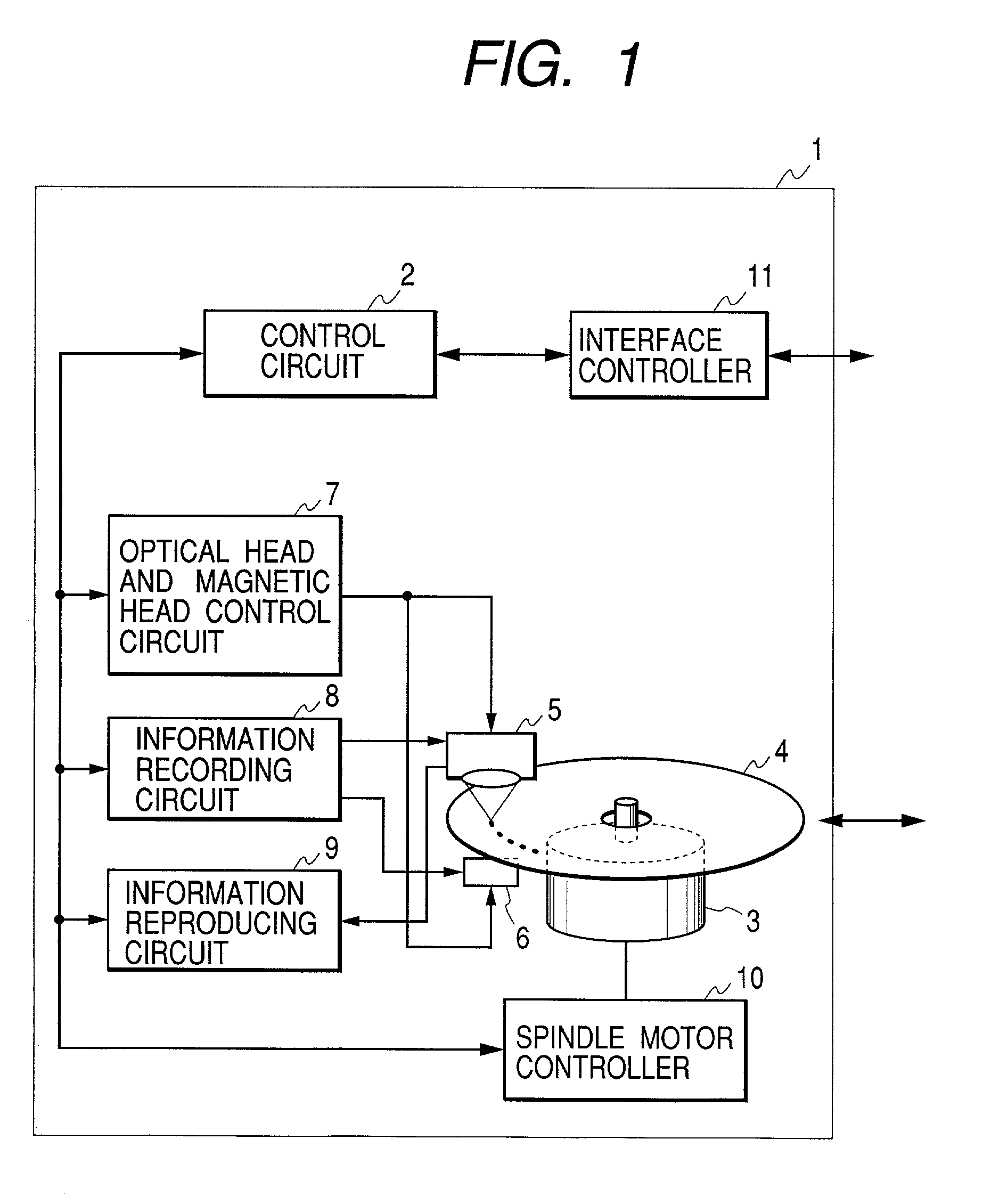

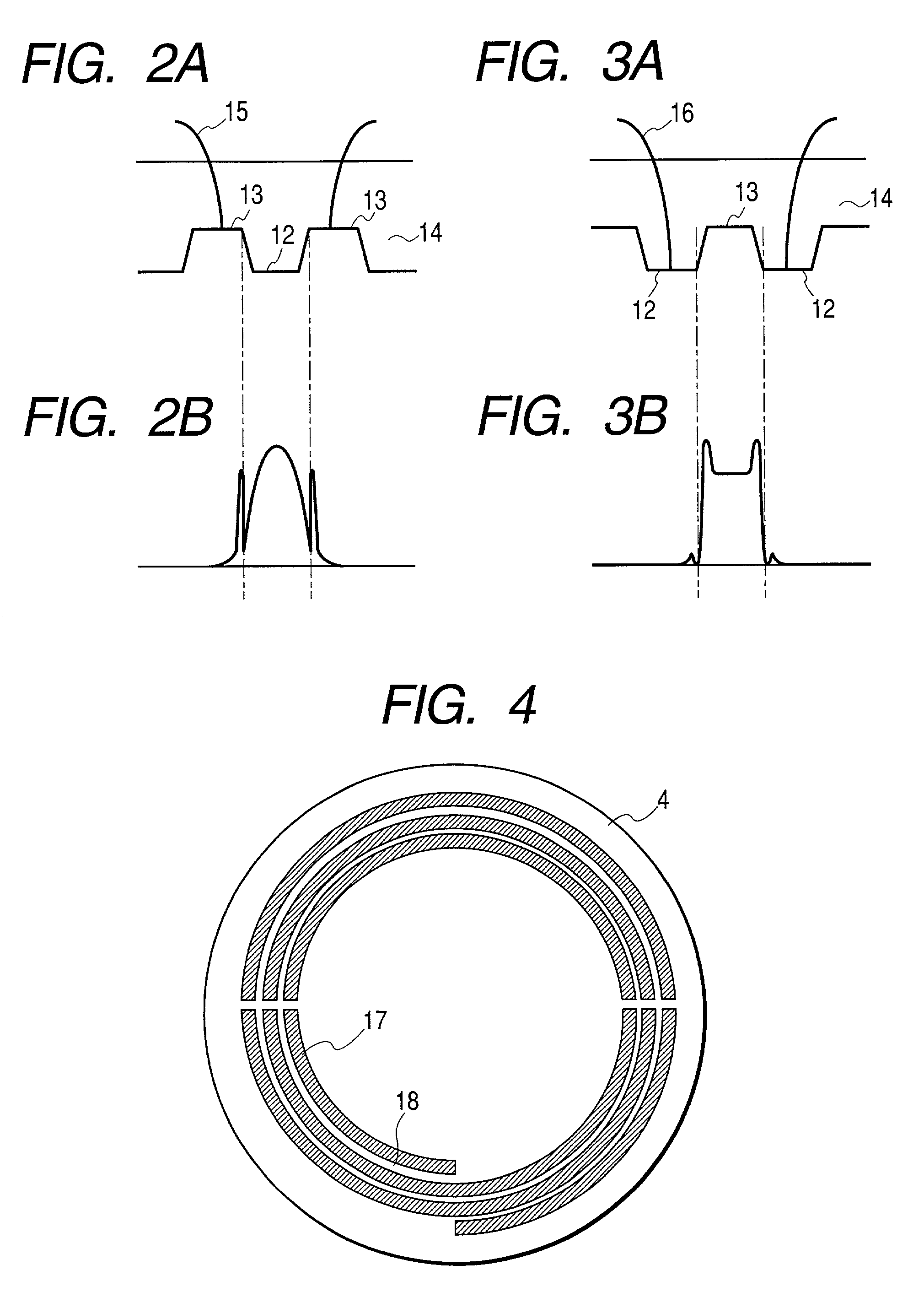

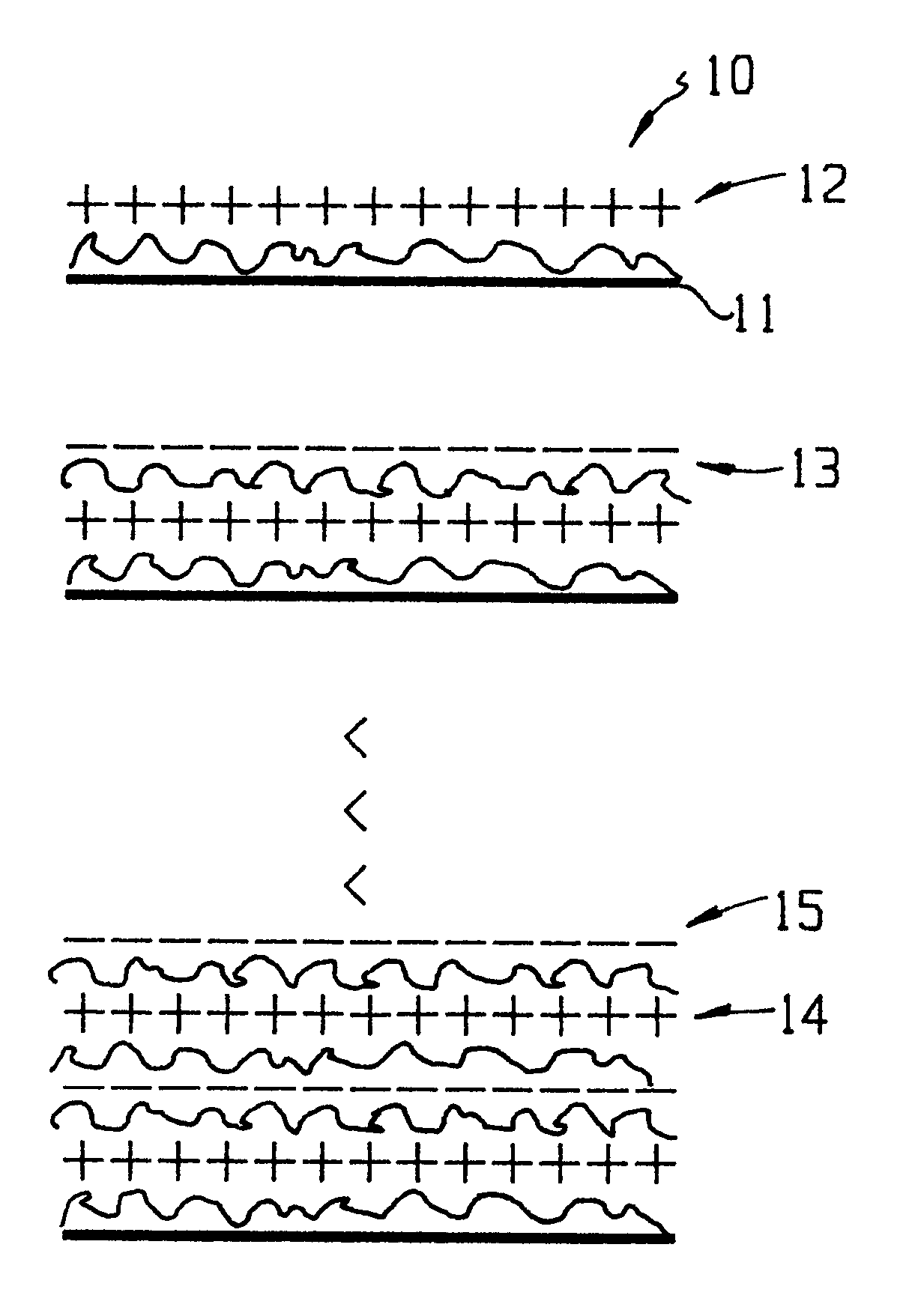

Method and apparatus for recording information on information recording medium

InactiveUS6999398B2Reduce decreaseHigh track densityRecord information storageLight beam reproducingComputer hardwareMagneto optical

Information is recorded on an information recording medium such as a magneto-optical recording medium, having two recording tracks arranged alternately, typically in a double spiral manner. The two recording tracks have different recording characteristics and information is firstly recorded on the recording track less liable to cross write, typically on a land section, and subsequently on the recording track more liable to cross write, typically on a groove section.

Owner:CANON KK

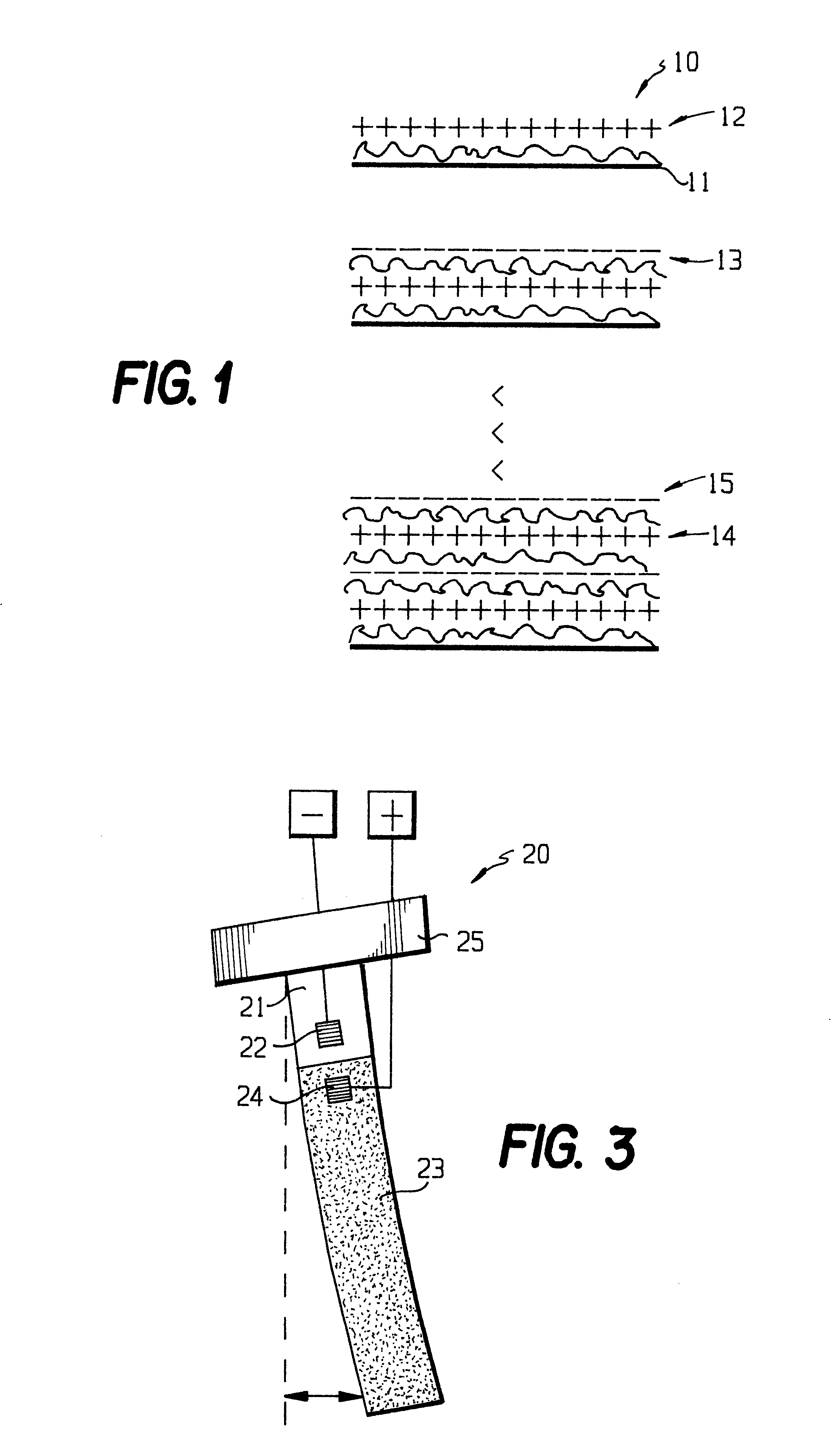

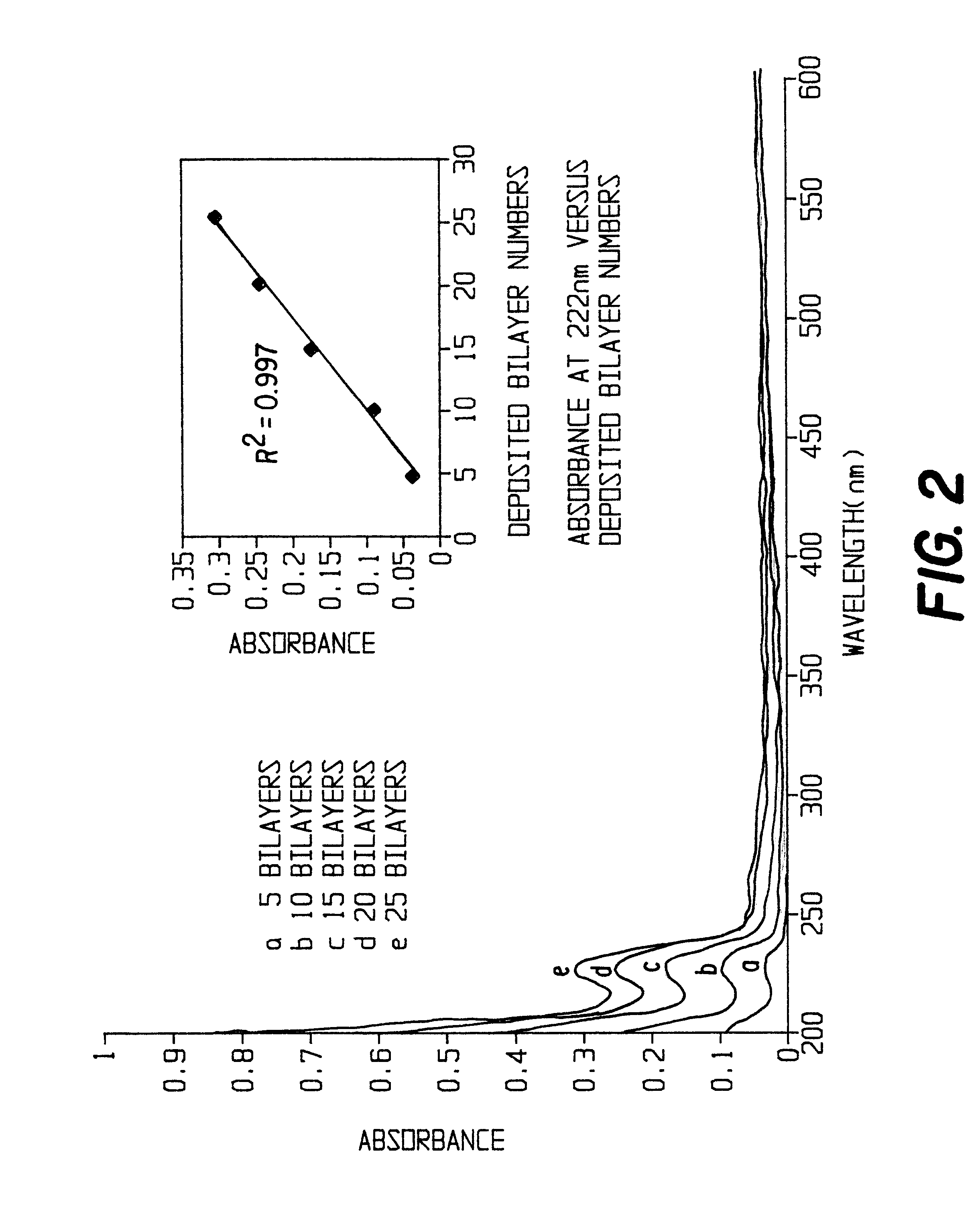

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

Mold-resistant gypsum panel and method of making same

InactiveUS6893752B2Reduce the growth of moldImprove anti-mold performancePretreated surfacesRecord information storageSodium PyrithioneEvaporation

A mold-resistant gypsum panel includes a core of an interlocking matrix of calcium sulfate dihydrate crystals, a facing material on at least one side of the panel and a salt of pyrithione dispersed through both the core and the facing materials. A method of making a mold-resistant gypsum product is also provided. A slurry of calcined gypsum, water and a water-soluble pyrithione salt is formed, then deposited on a sheet of facing material. The slurry on the facing material is shaped into a panel and maintained under conditions sufficient for the calcined gypsum to react with the water to form a core comprising an interlocking matrix of set gypsum crystals. Heating of the panel causes evaporation of the water that did not react with the calcined gypsum.

Owner:UNITED STATES GYPSUM CO

High-strength laminated sheet for optical applications

InactiveUS7514149B2Increase stiffnessHigh modulusGlass forming apparatusRecord information storageSurface layerHigh intensity

A laminated sheet includes a surface layer having an optical surface that is of fire-polished quality and a core layer having a higher modulus than the surface layer to increase an overall stiffness or fracture toughness of the laminated sheet.

Owner:CORNING INC

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS6537429B2High purityIncrease resistanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSemiconductorPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

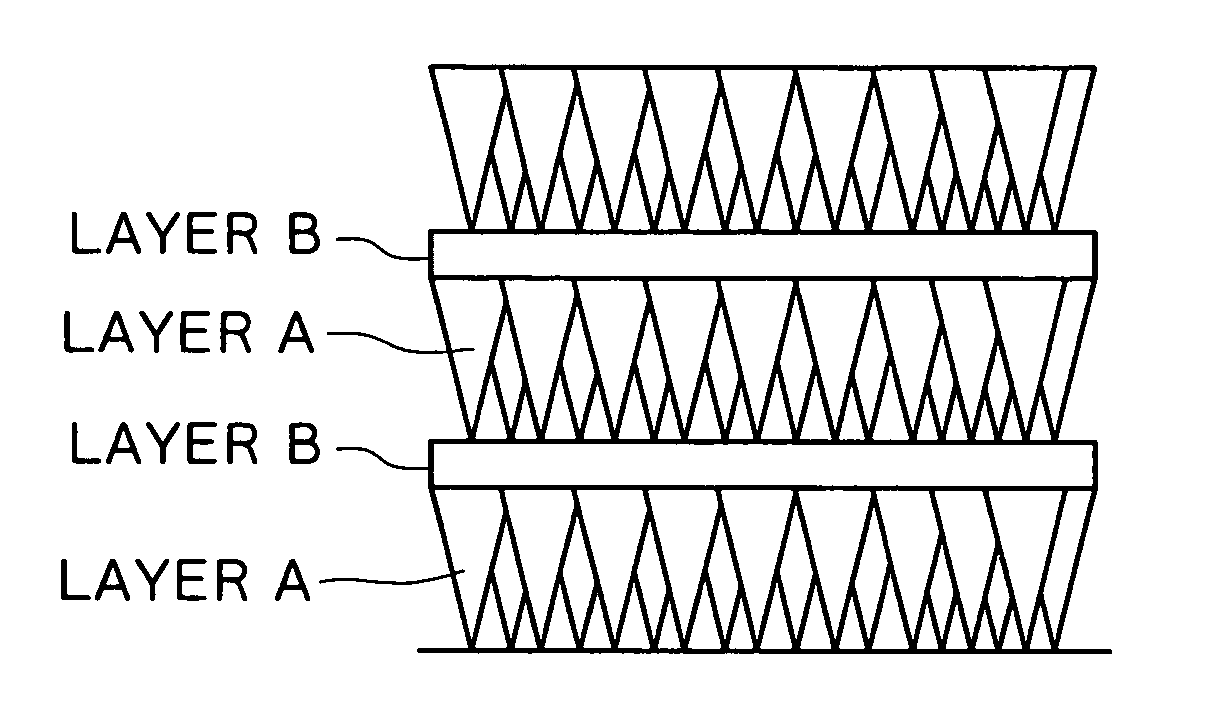

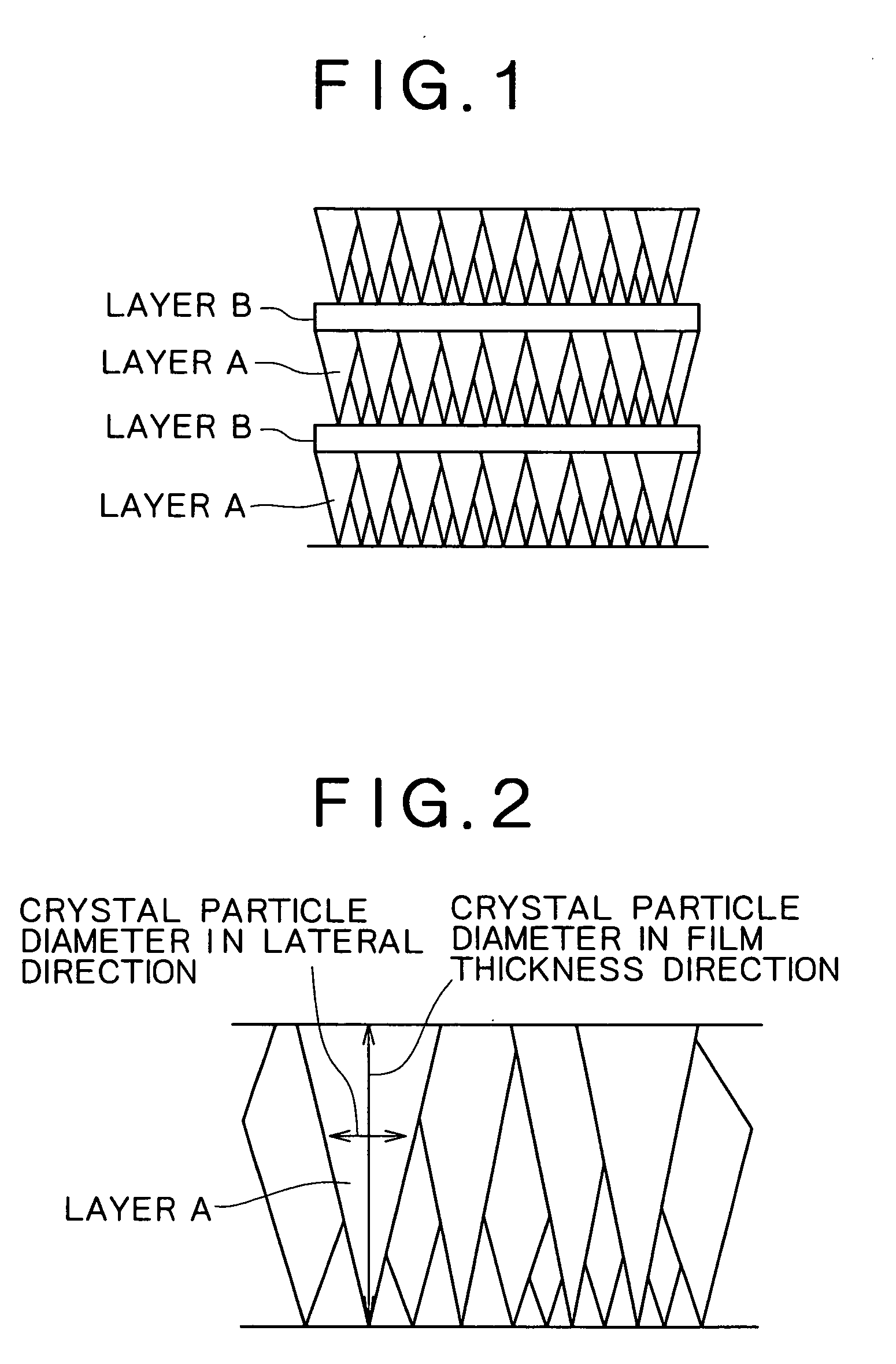

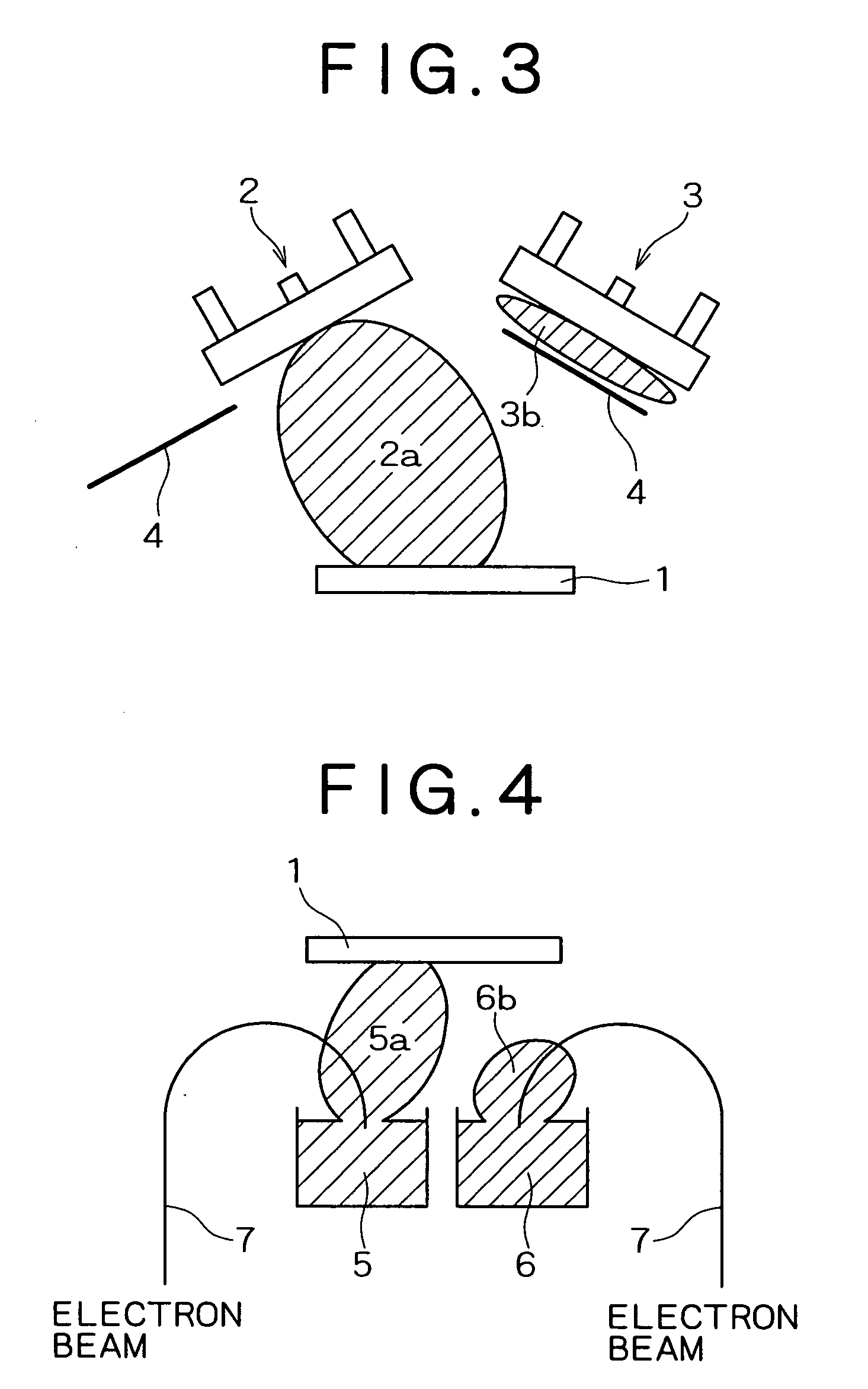

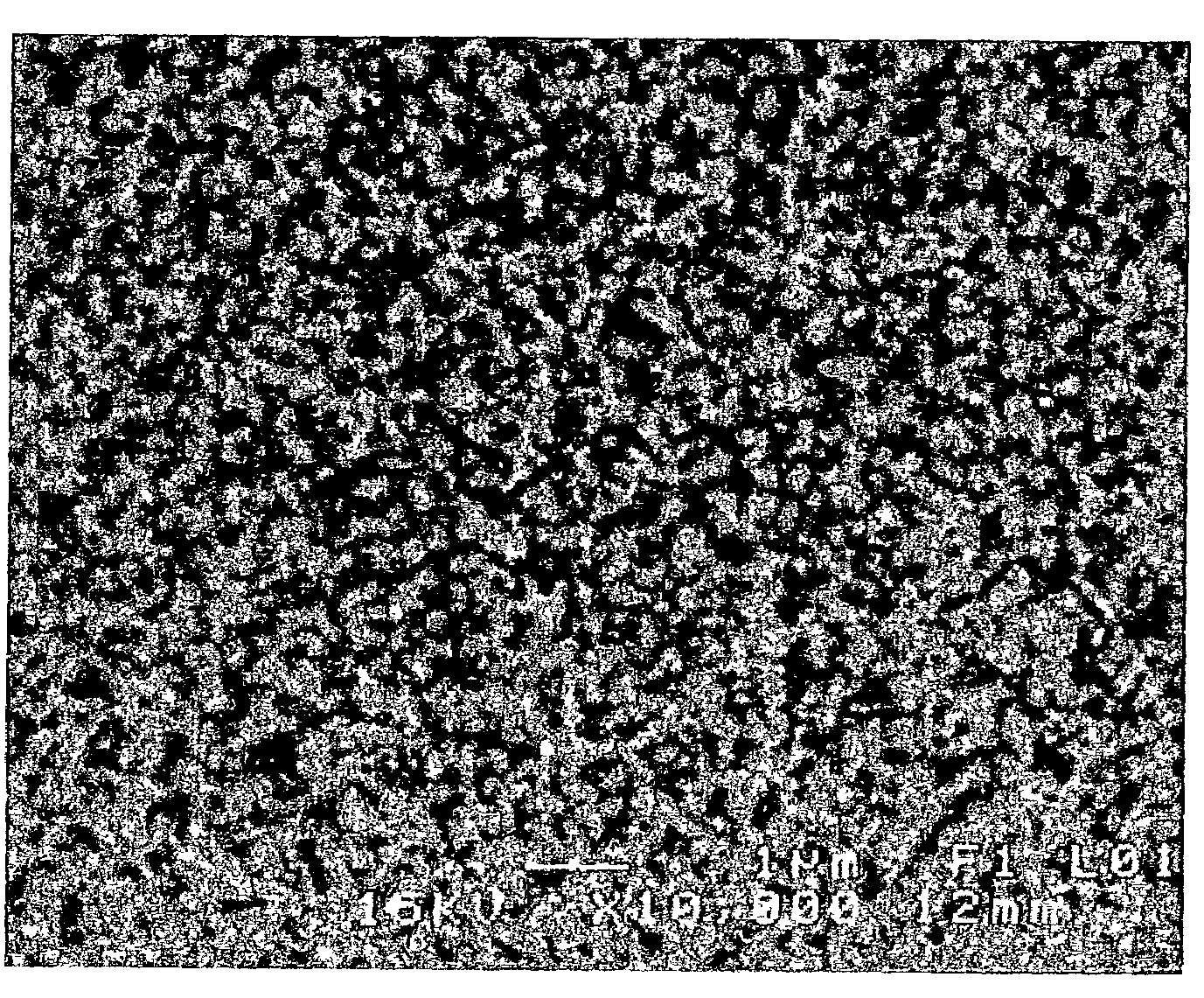

Hard laminated film, method of manufacturing the same and film-forming device

ActiveUS20050170162A1Simply and easily and finely controlledHigh ionizationVacuum evaporation coatingSputtering coatingChemical compositionCarbide

A hard laminated film wherein a layer A and a layer B having specific compositions are deposited alternately so that the compositions of layer A and layer B are different. The thickness of layer A per layer is twice or more the thickness of layer B per layer, the thickness of layer B per layer is 0.5 nm or more, and the thickness of layer A per layer is 200 nm or less. Layer A has a cubic rock-salt crystal structure such as that of Ti, Cr, Al, V nitride, carbonitride or carbide, and layer B is a hard film having a crystal structure other than cubic such as that of BN, BCN, SiN, SiC, SiCN, B—C, Cu, CuN, CuCN or metallic Cu. Alternatively, layer A has a chemical composition satisfying the following formula (1), and layer B has a chemical composition satisfying the following formula (2). Layer A: Cr(BaCbN1-a-b-cOc) 0≦a≦0.15, 0≦b≦0.3, 0≦c≦0.1, 0.2≦e≦1.1 (1) Layer B: B1-s-tCsNt 0≦s 0.25, (1−s−t) / t≦1.5 (2) Alternatively, Layer A has a specific atomic ratio composition of (Ti1-x-yAlxMy)(BaCbN1-a-b-cOc) and Layer B has one or more specific atomic ratio compositions selected from among the compositions B1-x-yCxNy, Si1-x-yCxNy, C1-xNx, Cu1-y(CxN1-x)y. Alternatively, Layer A has one of the following Compositional Formulae 1 or 2. Formula 1: (Ti1-x-yAlxMy), (BaCbN1-a-b-cOc), Formula 2: (Cr1-αXα)(BaCbN1-a-b-cOc)e (X is one or more metal elements selected from among Ti, Zr, Hf, V, Nb, Ta, Mo, W, Al, Si. Layer B has the following compositional formula 3. Formula 3 M(BaCbN1-a-b-cOc). M is one or more metal elements selected from among W, Mo, V, Nb.

Owner:KOBE STEEL LTD

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

Multi-layer Transdermal Patch

This invention pertains to a construction consisting of in the order from the outside towards the inside: An occlusive or non occlusive external film layer; a non-curing pressure sensitive adhesive (PSA) that has been blended with a therapeutic concentration of at least one or a combination of cosmetic or pharmaceutical active ingredients; and a silicone gel adhesive that is used as the skin contact layer.

Owner:DOW CORNING CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com