Patents

Literature

113results about How to "Accelerates the dehydration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

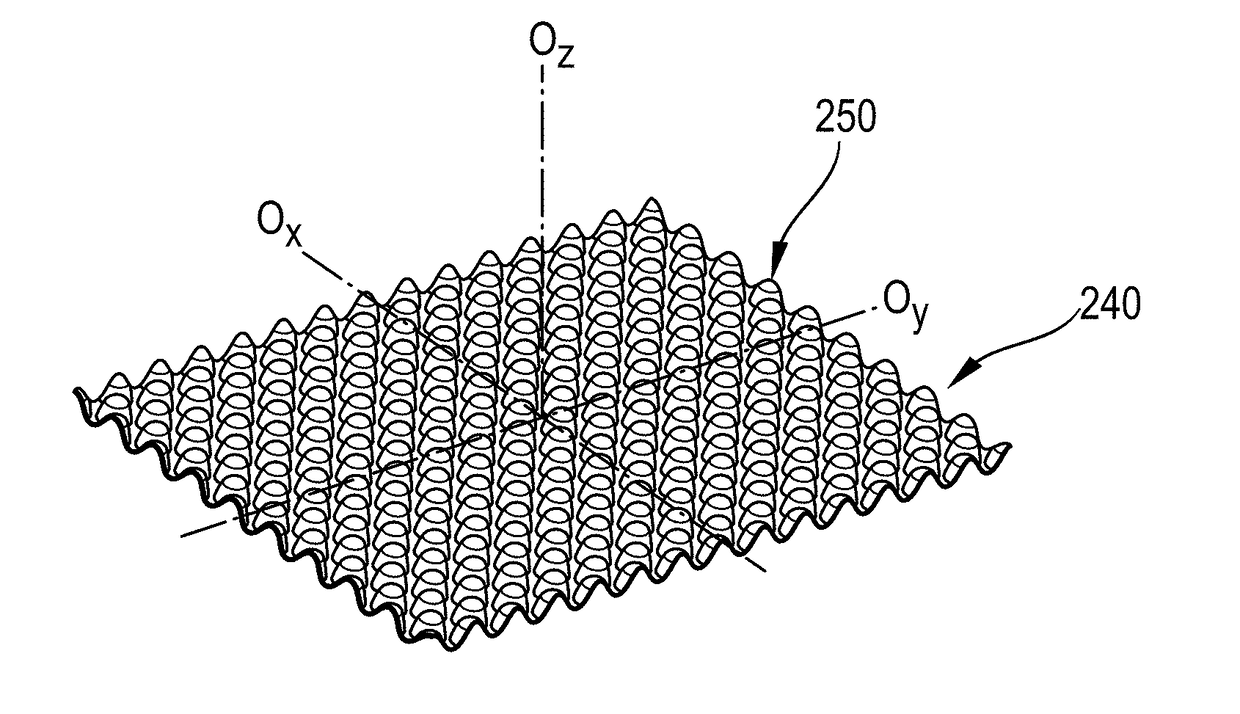

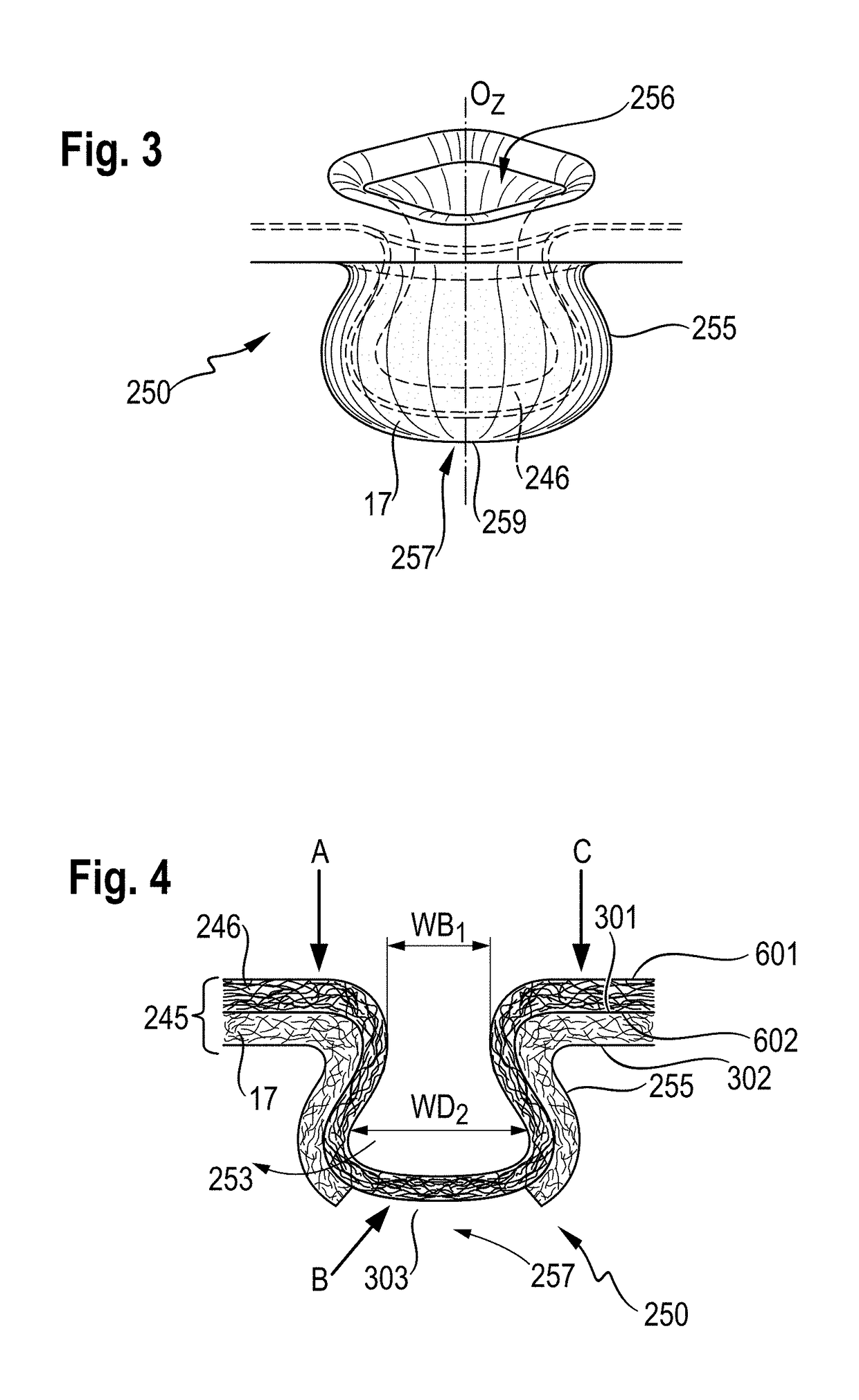

Three-dimensional substrate comprising a tissue layer

ActiveUS20170258647A1Promote absorptionAccelerates the dehydration processPersonal carePattern makingBiomedical engineeringFiber

Owner:THE PROCTER & GAMBLE COMPANY

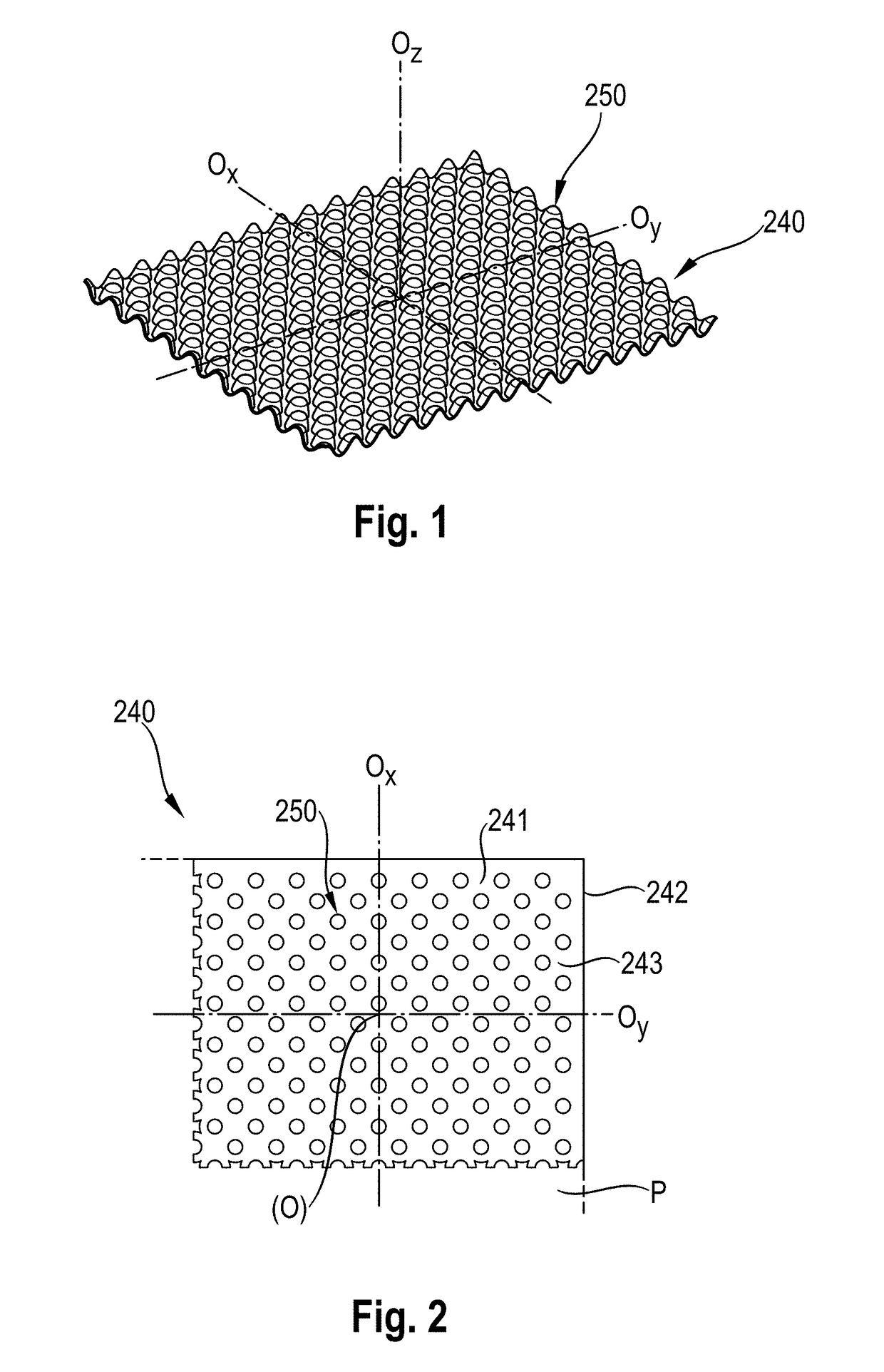

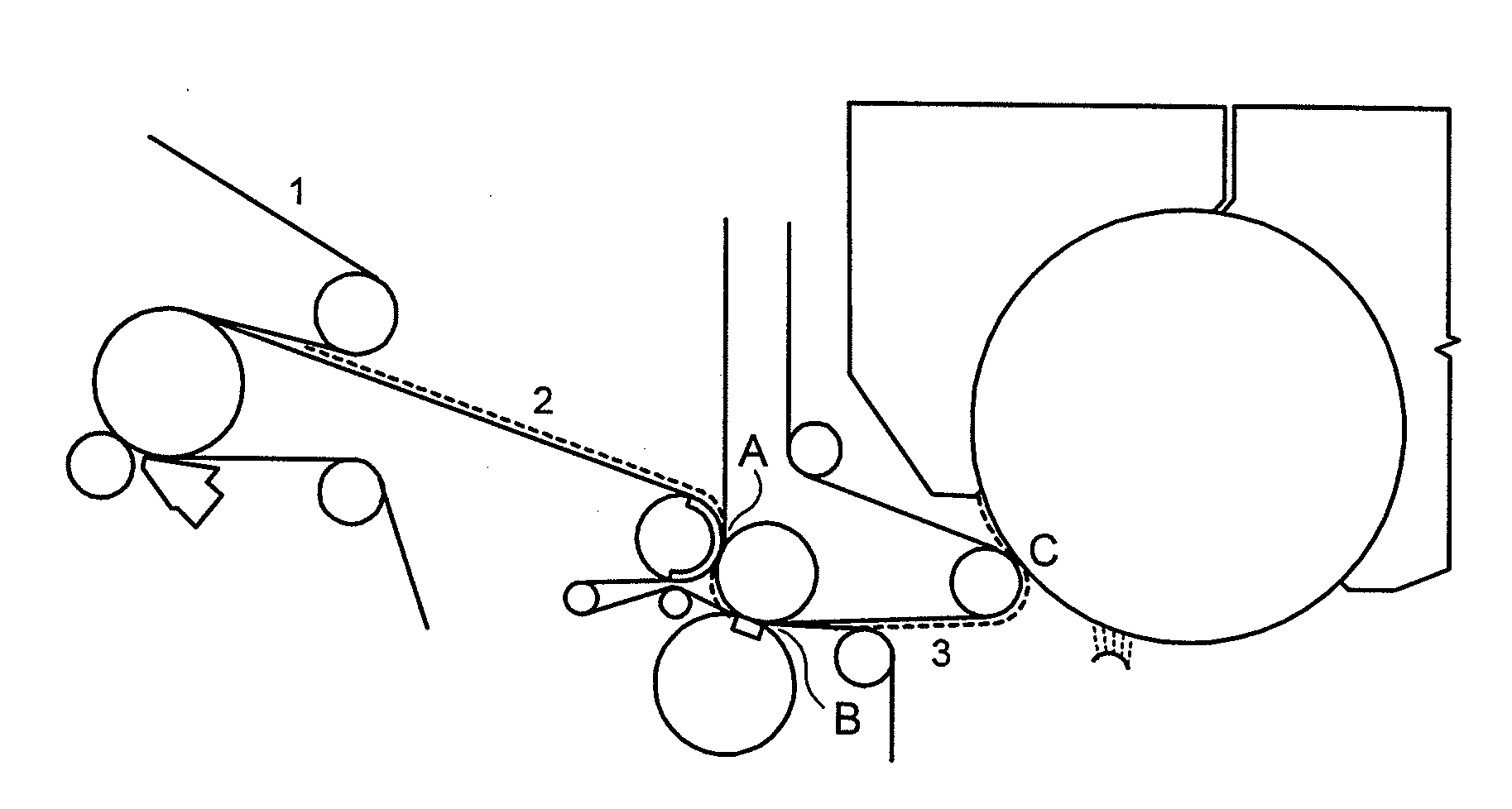

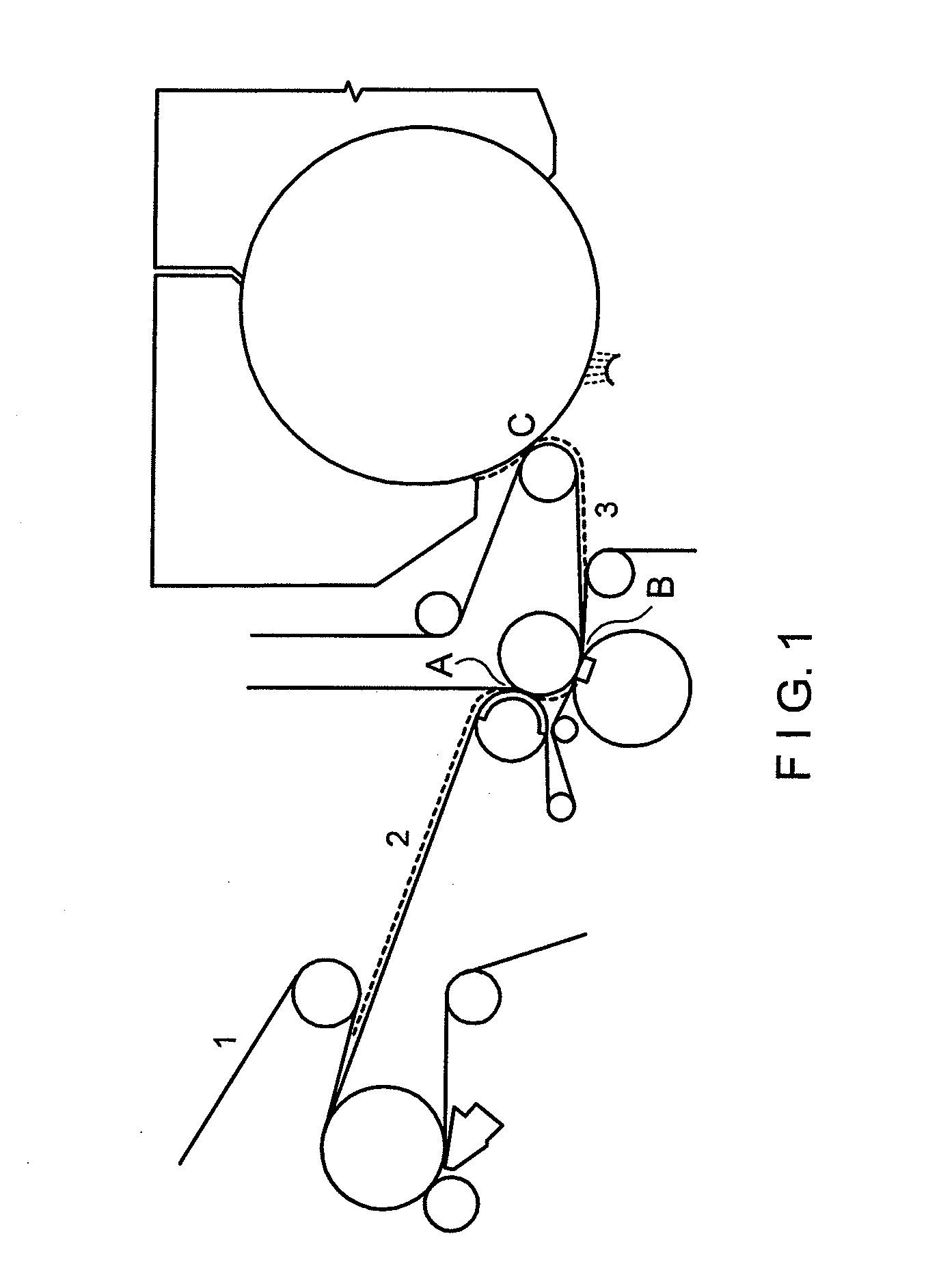

Permeable Belt for Nonwovens Production

ActiveUS20110272112A1Accelerates the dehydration processWood working apparatusMachine wet endEngineeringFabric structure

A fabric structure used to make textured nonwoven products, the structure being permeable to air and water, comprising a web contact surface having a pattern including a series of raised land areas and corresponding depressions adapted to impart a texture to the nonwoven product produced thereon, and a series of through voids adapted to allow passage of both water and / or air from the fabric surface into and / or through the structure.

Owner:ALBANY INT CORP

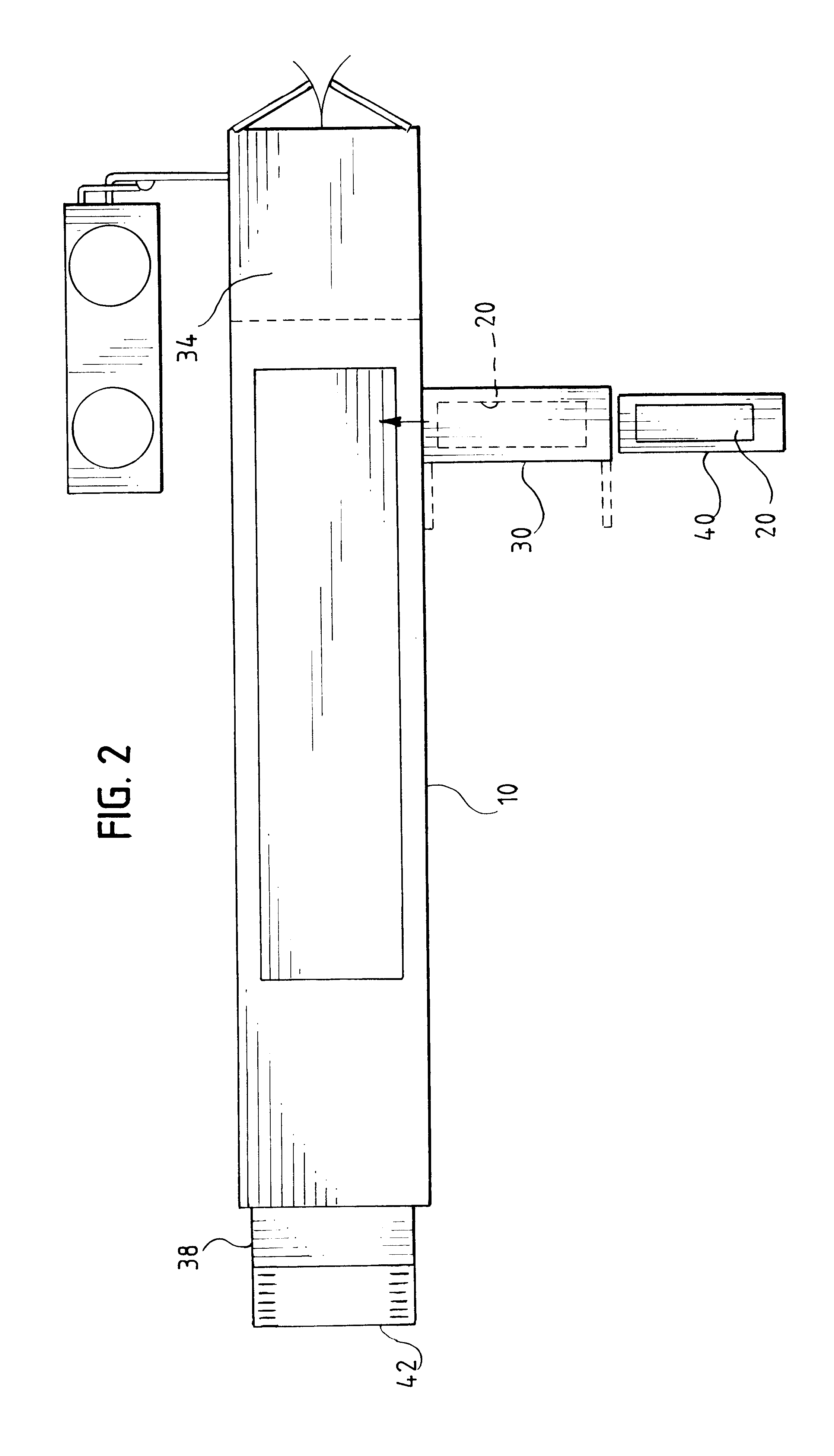

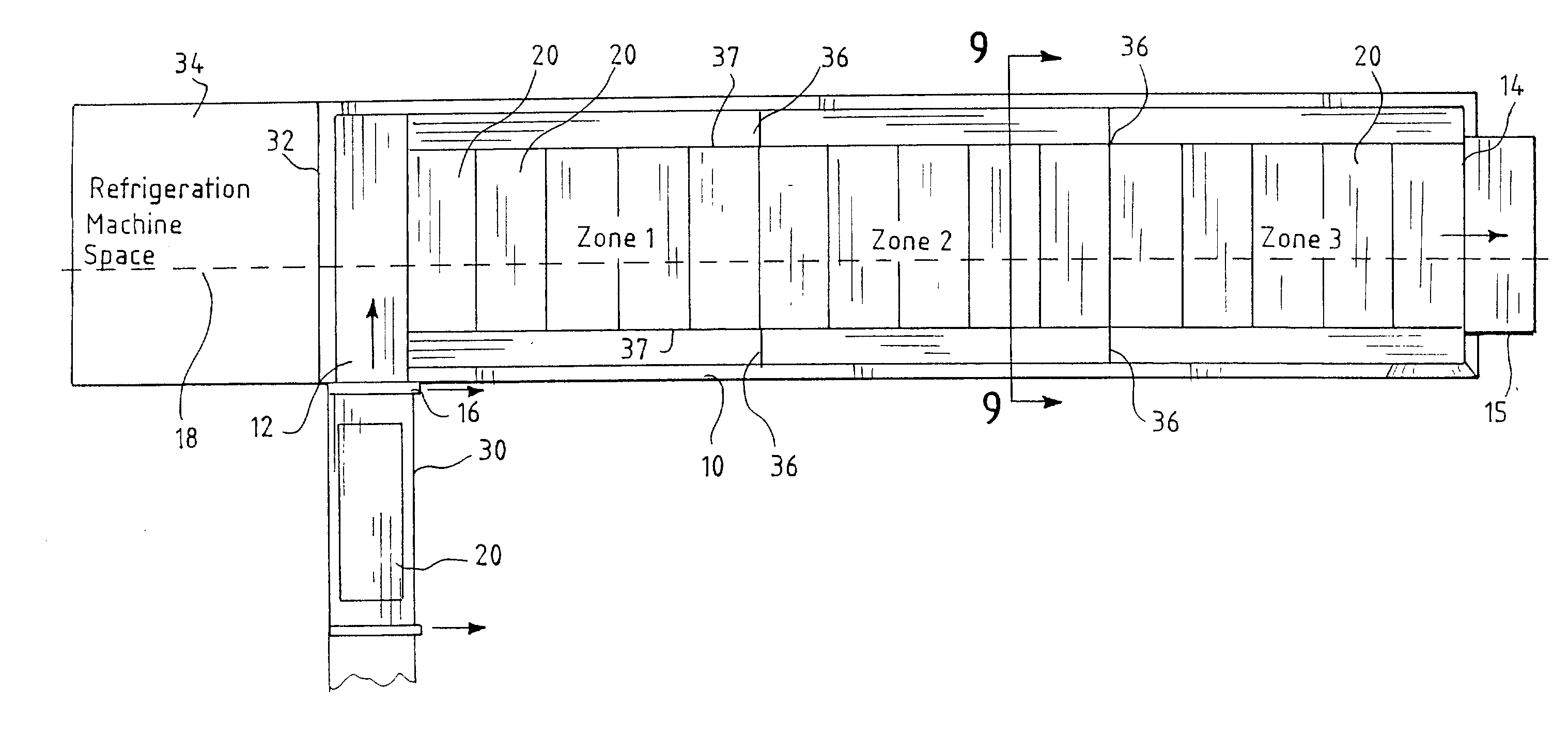

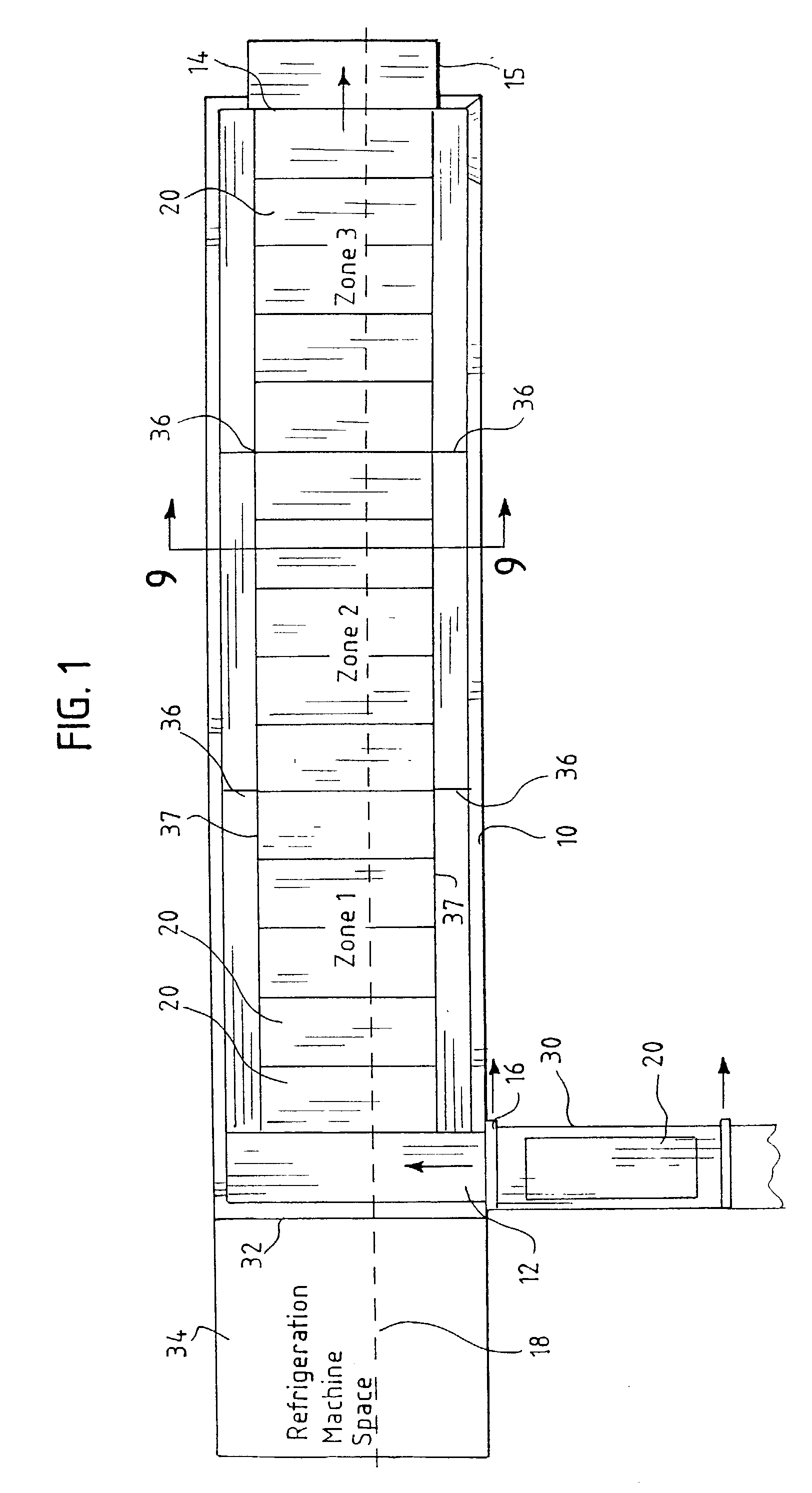

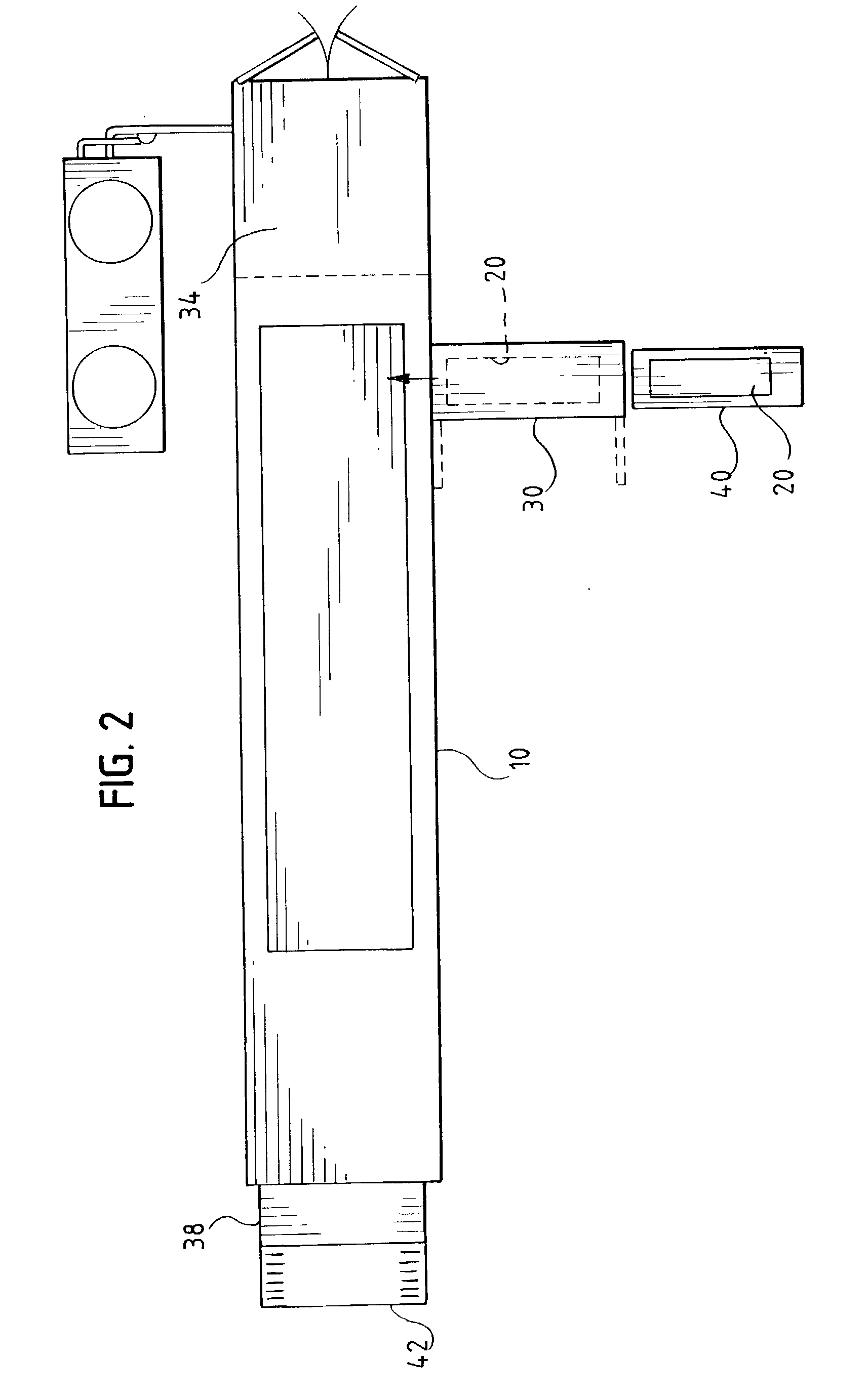

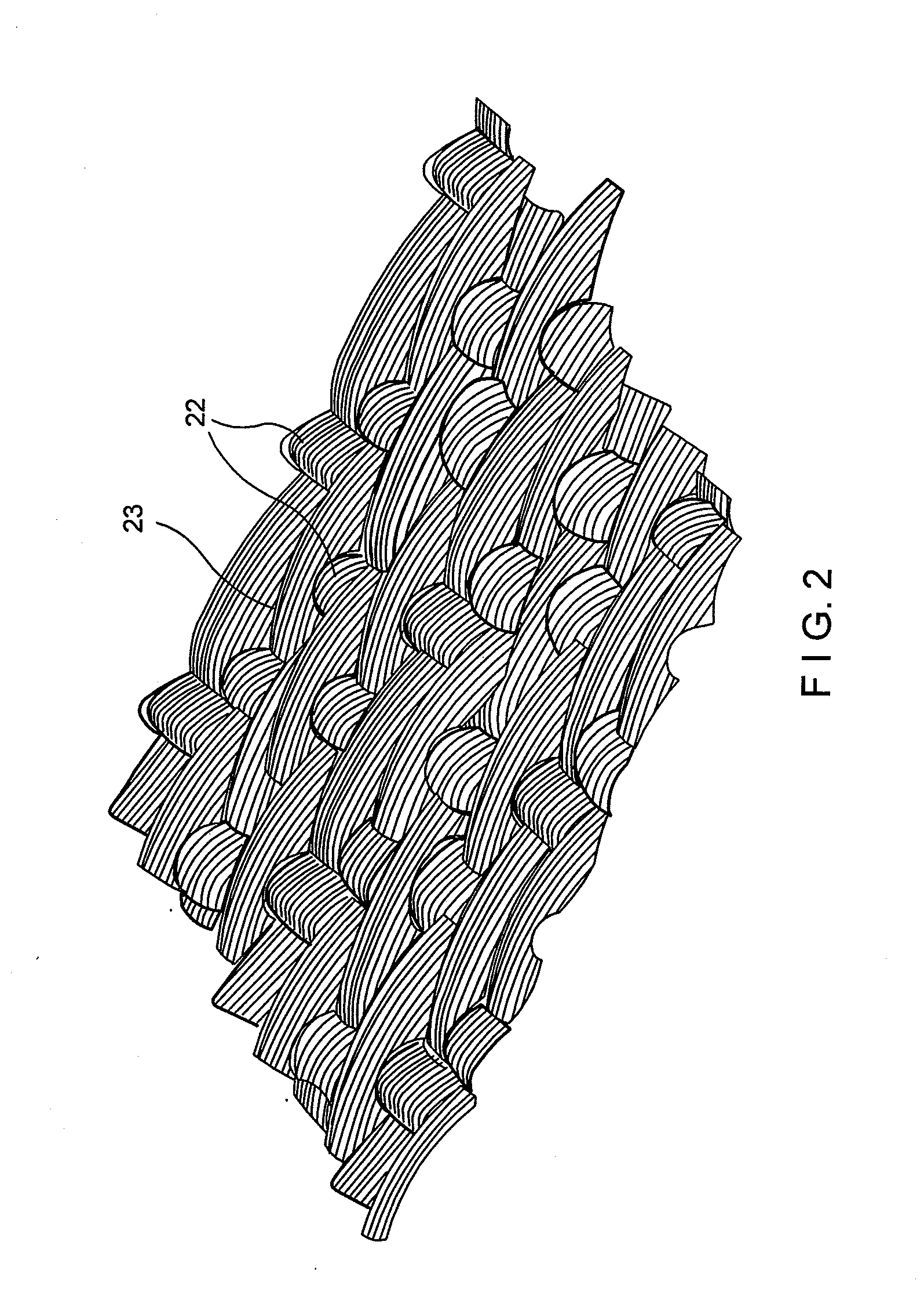

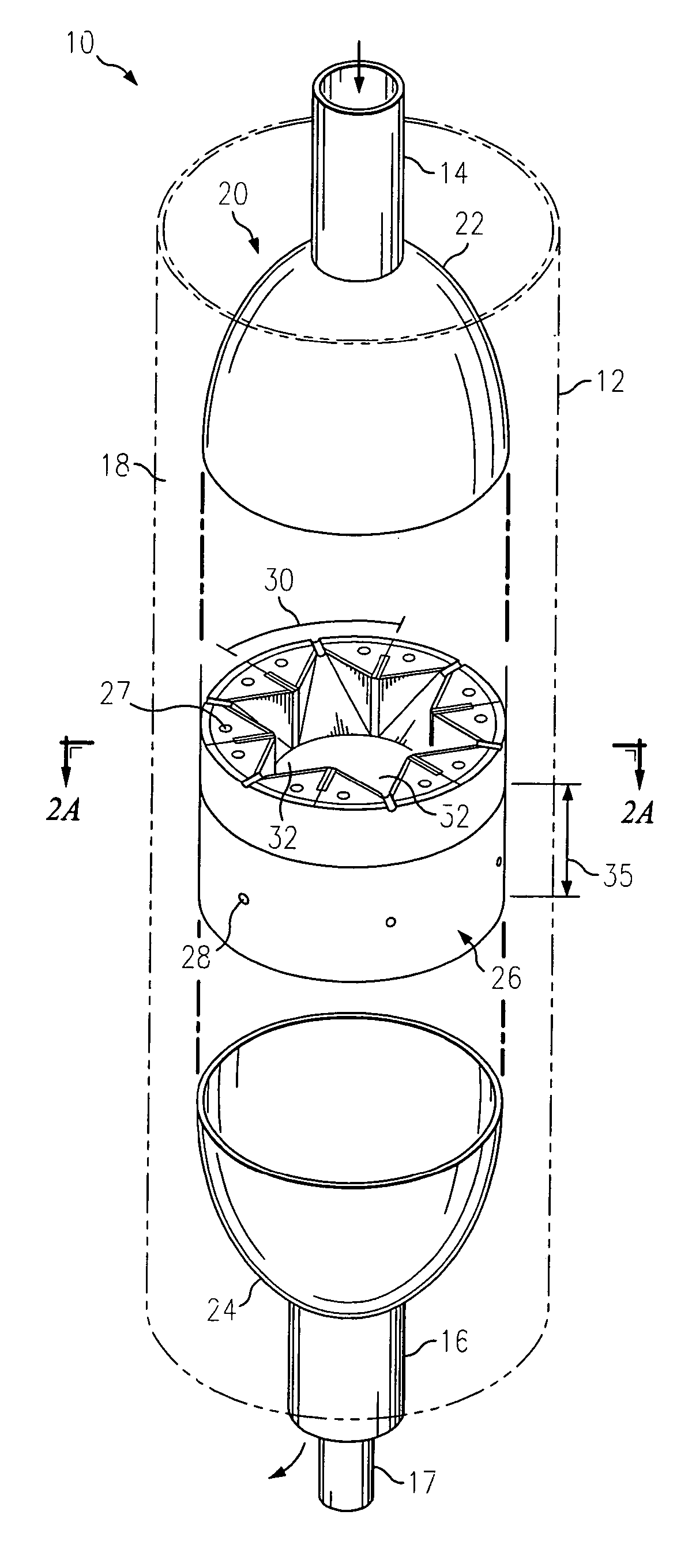

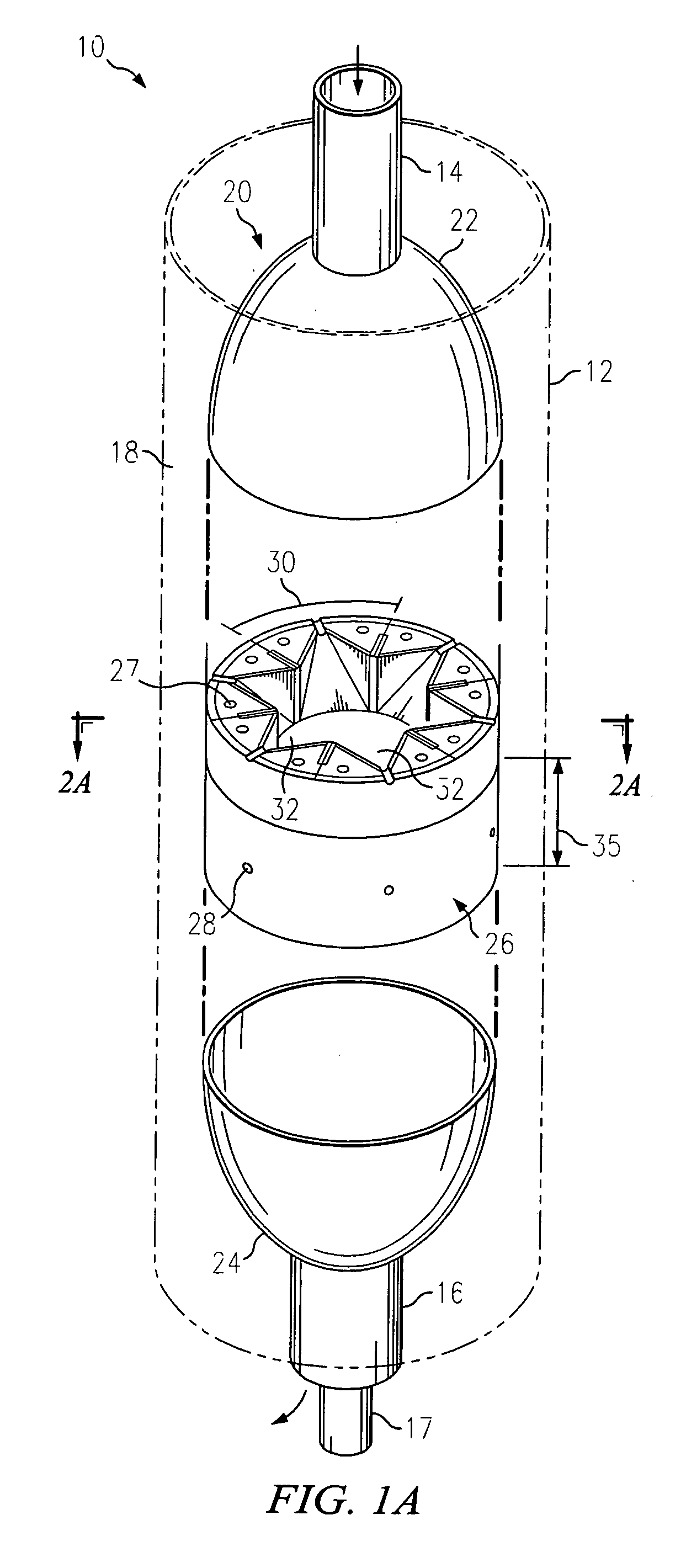

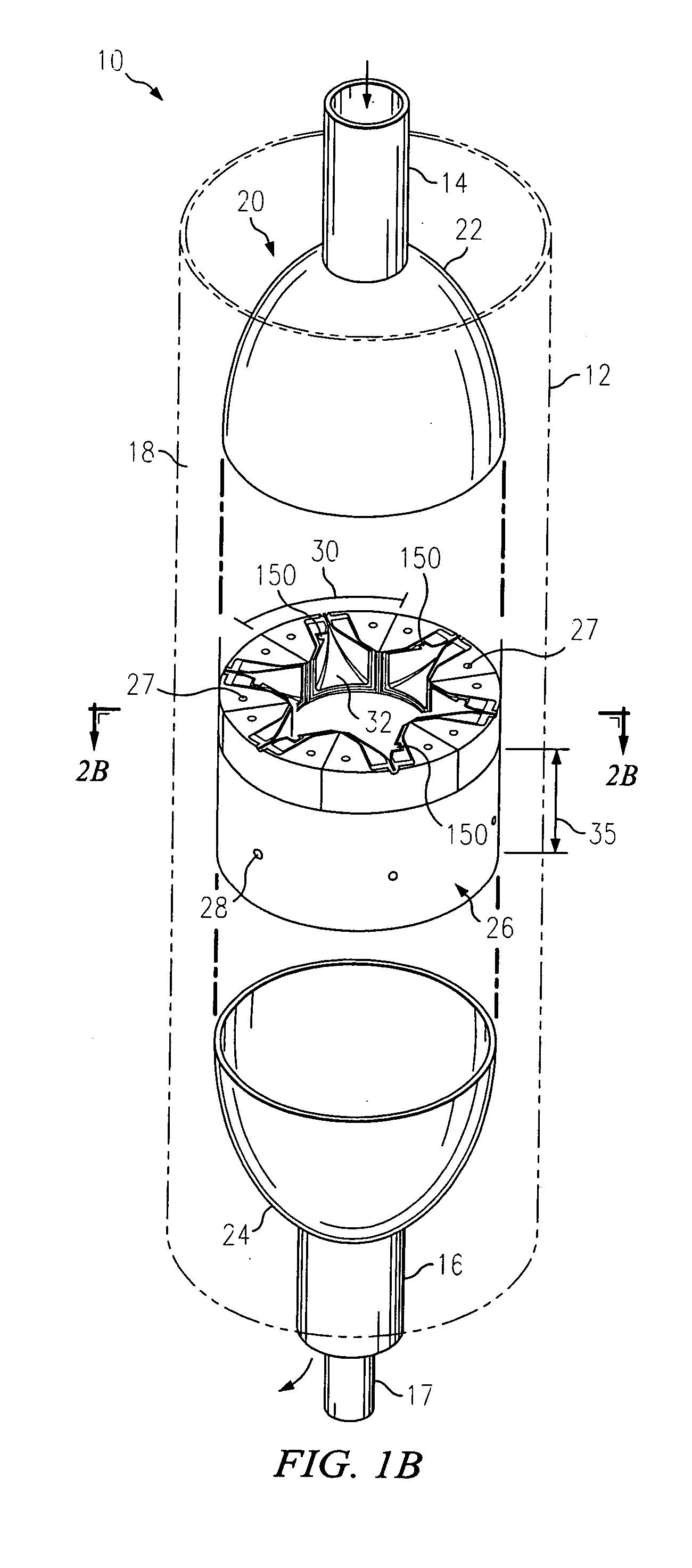

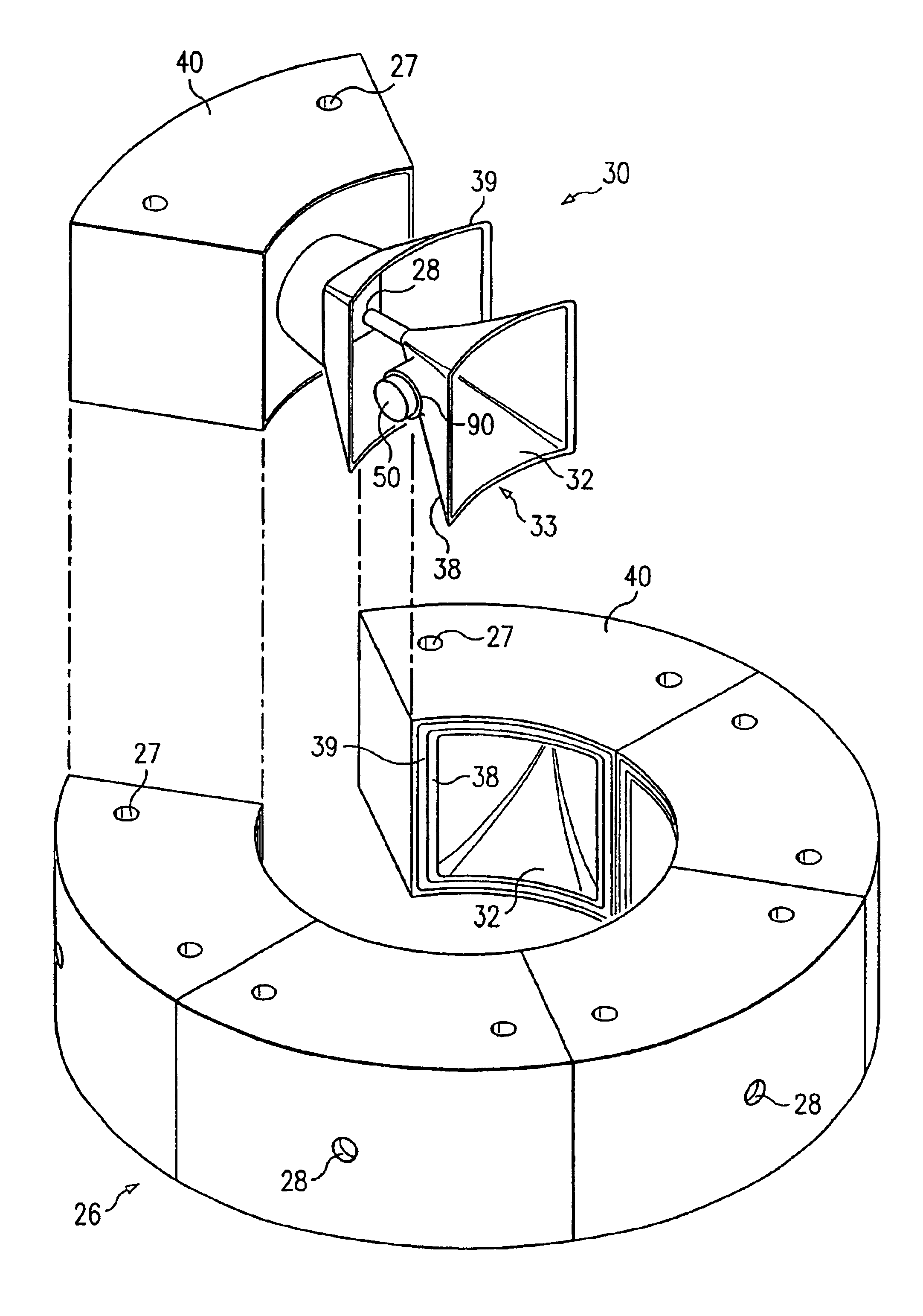

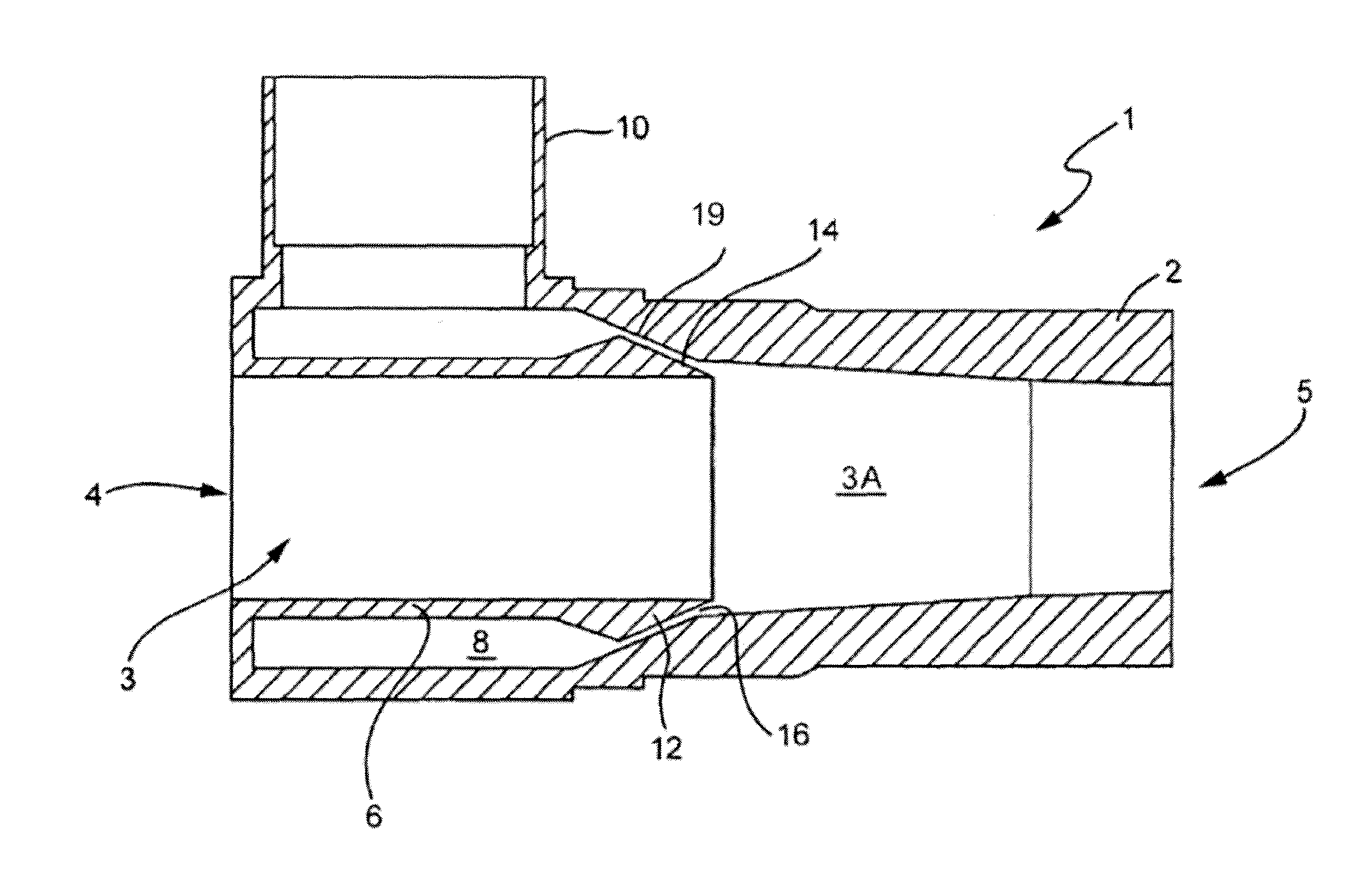

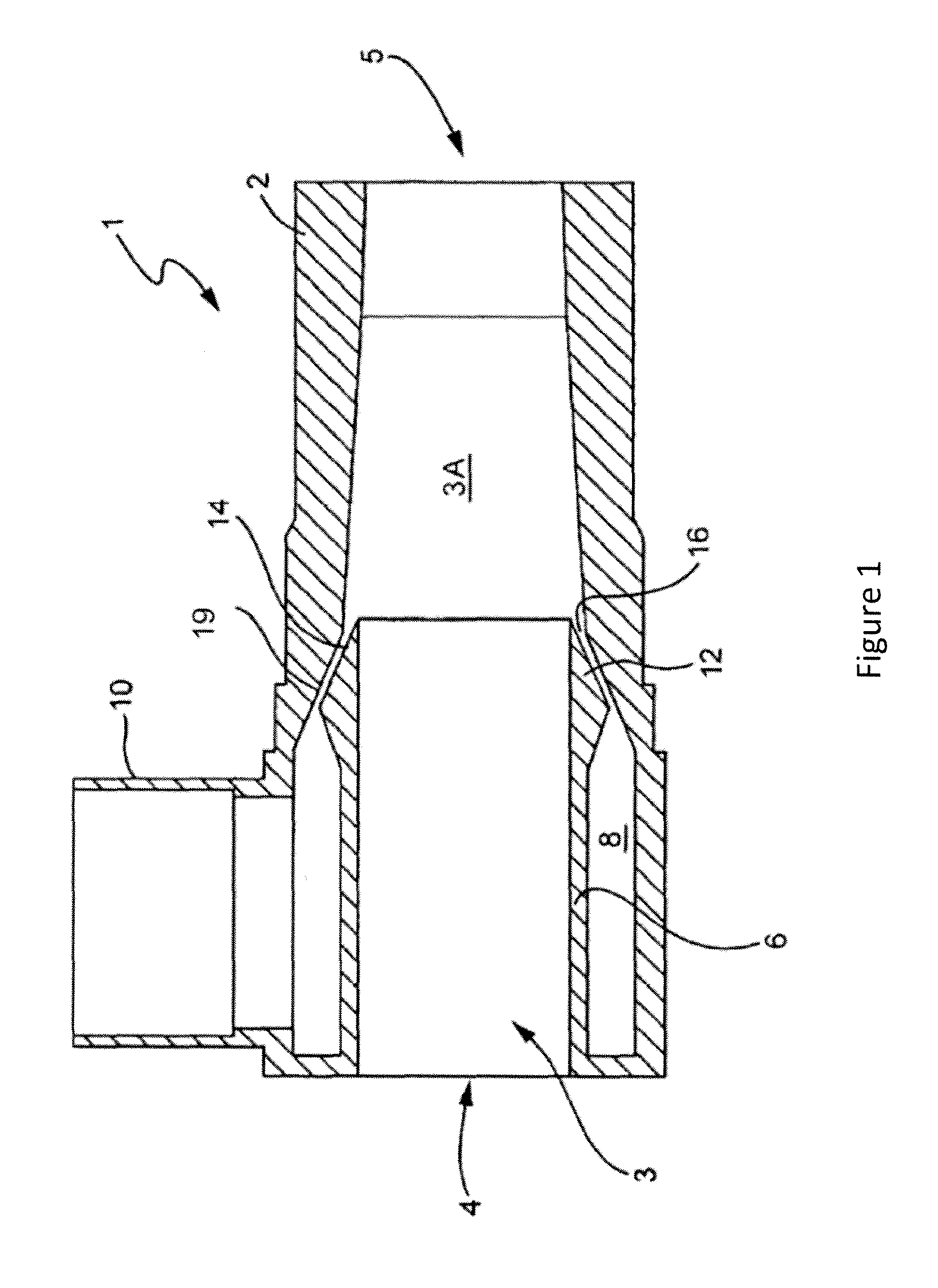

Continuous throughput blast freezer

InactiveUS6796142B2Decrease productivityLabor moreStationary refrigeration devicesCompression machines with several evaporatorsFrostMechanical equipment

Owner:INTEGRATED MARINE SYST

Continuous throughput blast freezer

InactiveUS20030041614A1Decrease productivityLabor moreStationary refrigeration devicesCompression machines with several evaporatorsFrostMechanical equipment

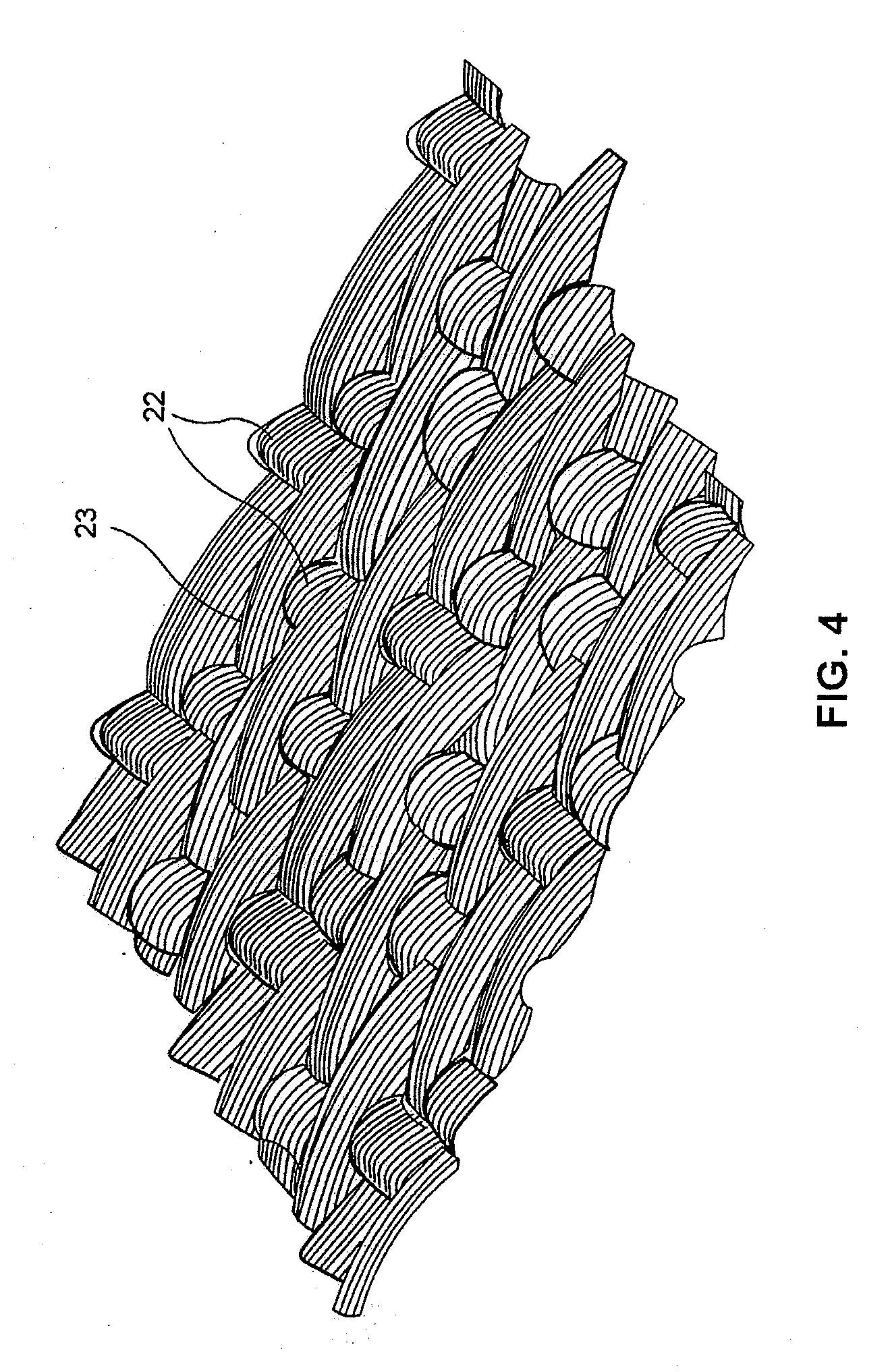

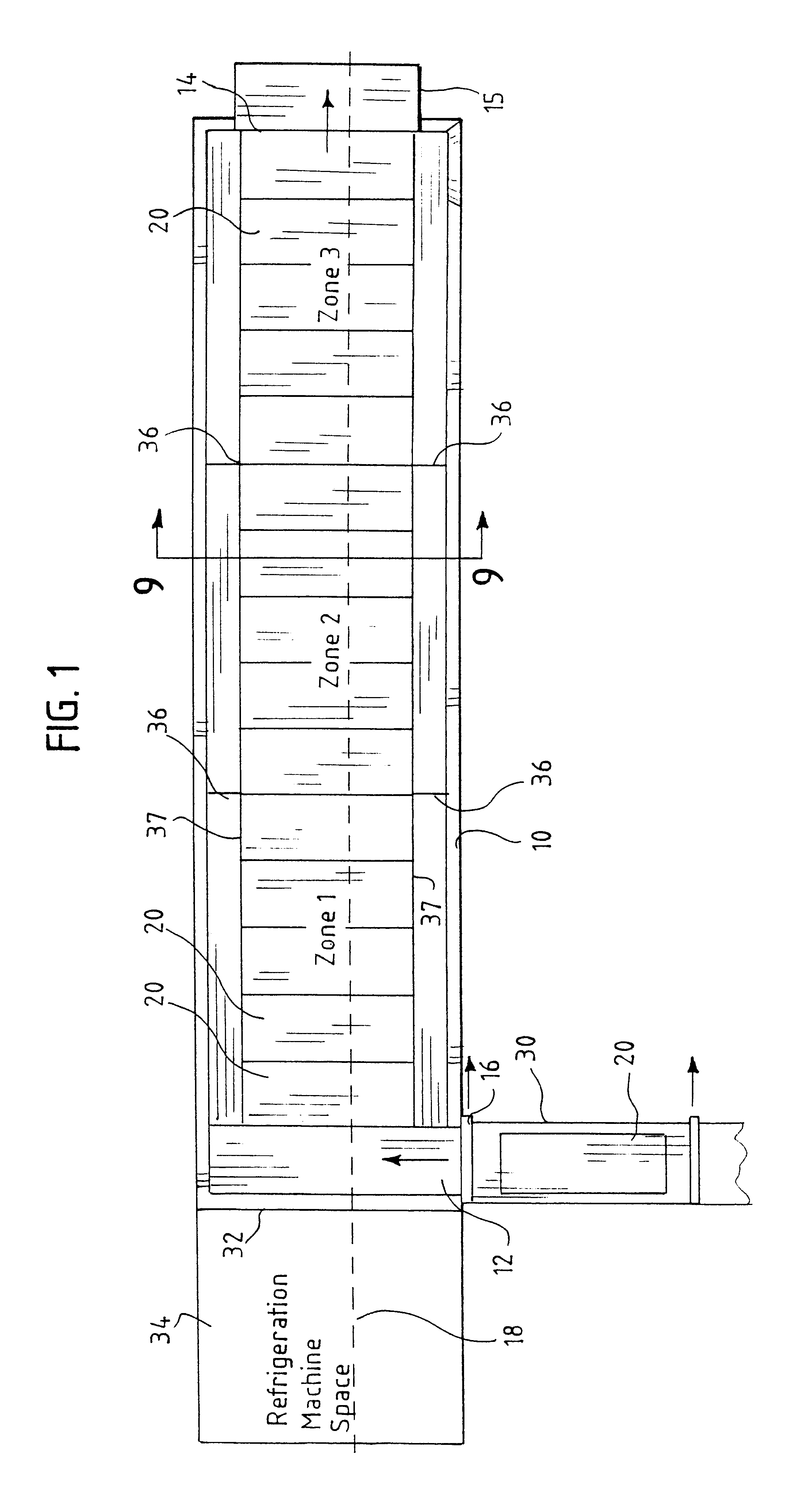

A high capacity, continuous production blast freezer includes an insulated enclosure and a plurality of adjustable product-carrying trolleys, individually moveable with the enclosure from an entrance location to an exit location. A heat exchanger in the form of an evaporator is provided in the enclosure. The mechanical equipment for the refrigeration system can be placed within the enclosure and separated from the freezing cell by a bulkhead. In one embodiment the enclosure is in the form of a container adapted to be transportable by ship, rail or truck. The arrangement of the heat exchanger or evaporator relative to the product carrying devices and the enclosure is designed to maximize the capacity of the heat exchanger and minimize frost formation, while providing for a maximum amount of product space within the enclosure to maximize throughput of the system.

Owner:INTEGRATED MARINE SYST

Permeable Belt for the Manufacture of Tissue, Towel and Nonwovens

ActiveUS20120027997A1Accelerates the dehydration processLayered productsMachine wet endEngineeringNonwoven fabric

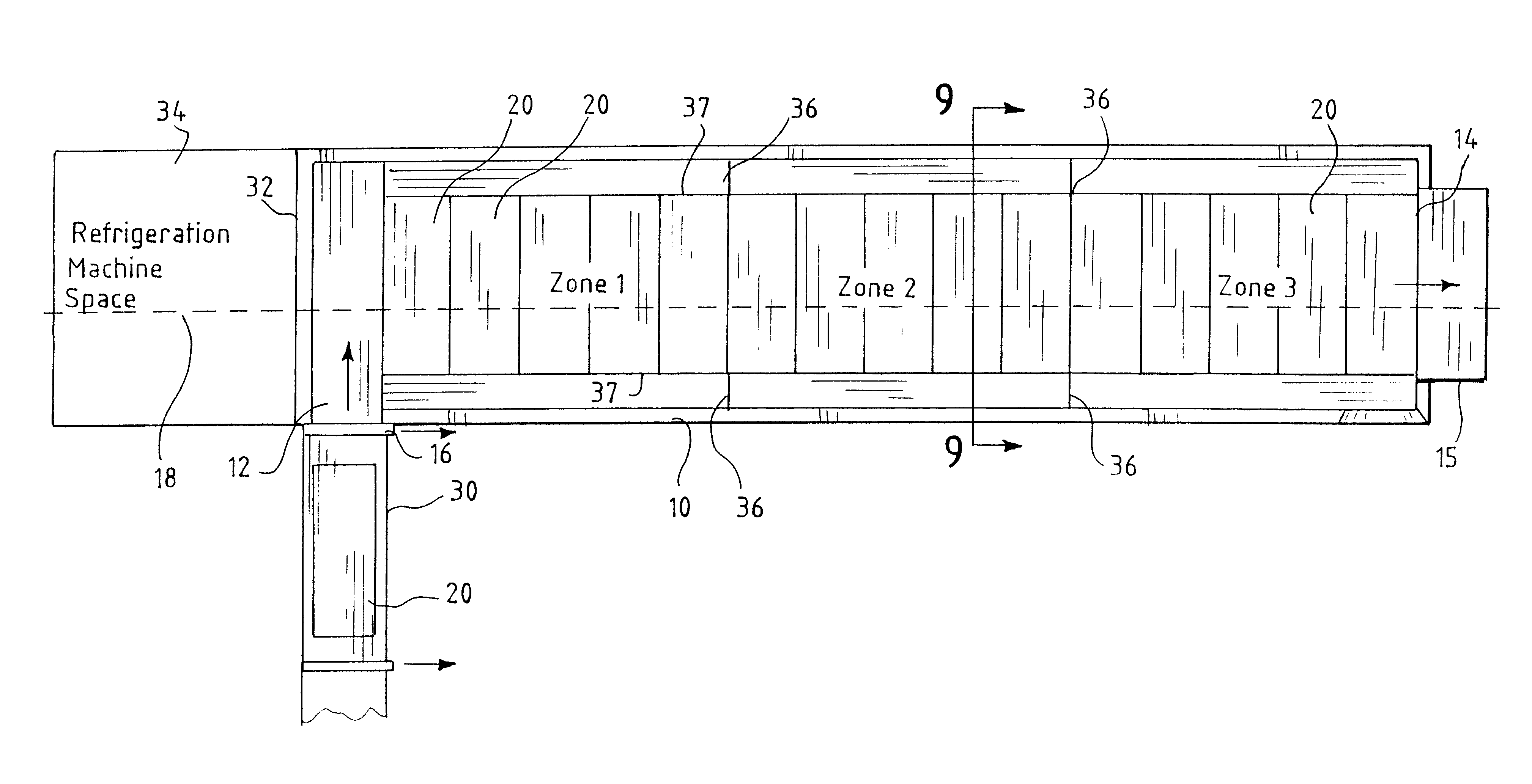

A fabric structure used to make textured tissue or towel or nonwovens, the structure being permeable to air and water, comprising a sheet contact surface having a pattern including a series of raised land areas and corresponding depressions adapted to impart a texture to the tissue or towel or nonwoven, and a series of through voids adapted to allow passage of both water and / or air from the fabric surface into and / or through the structure.

Owner:ALBANY INT CORP

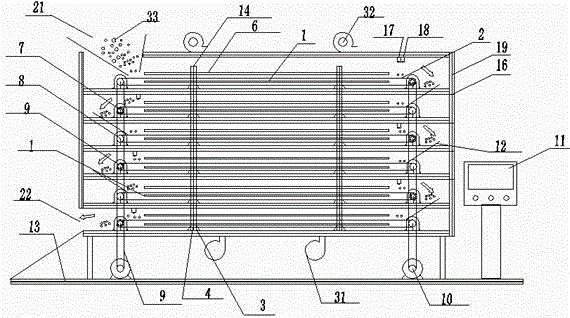

Belt-type infrared radiation drying system as well as mounting method and drying method thereof

InactiveCN105135851AHigh electrothermal conversion efficiencyImprove heat transfer efficiencyHeating arrangementControl systemEngineering

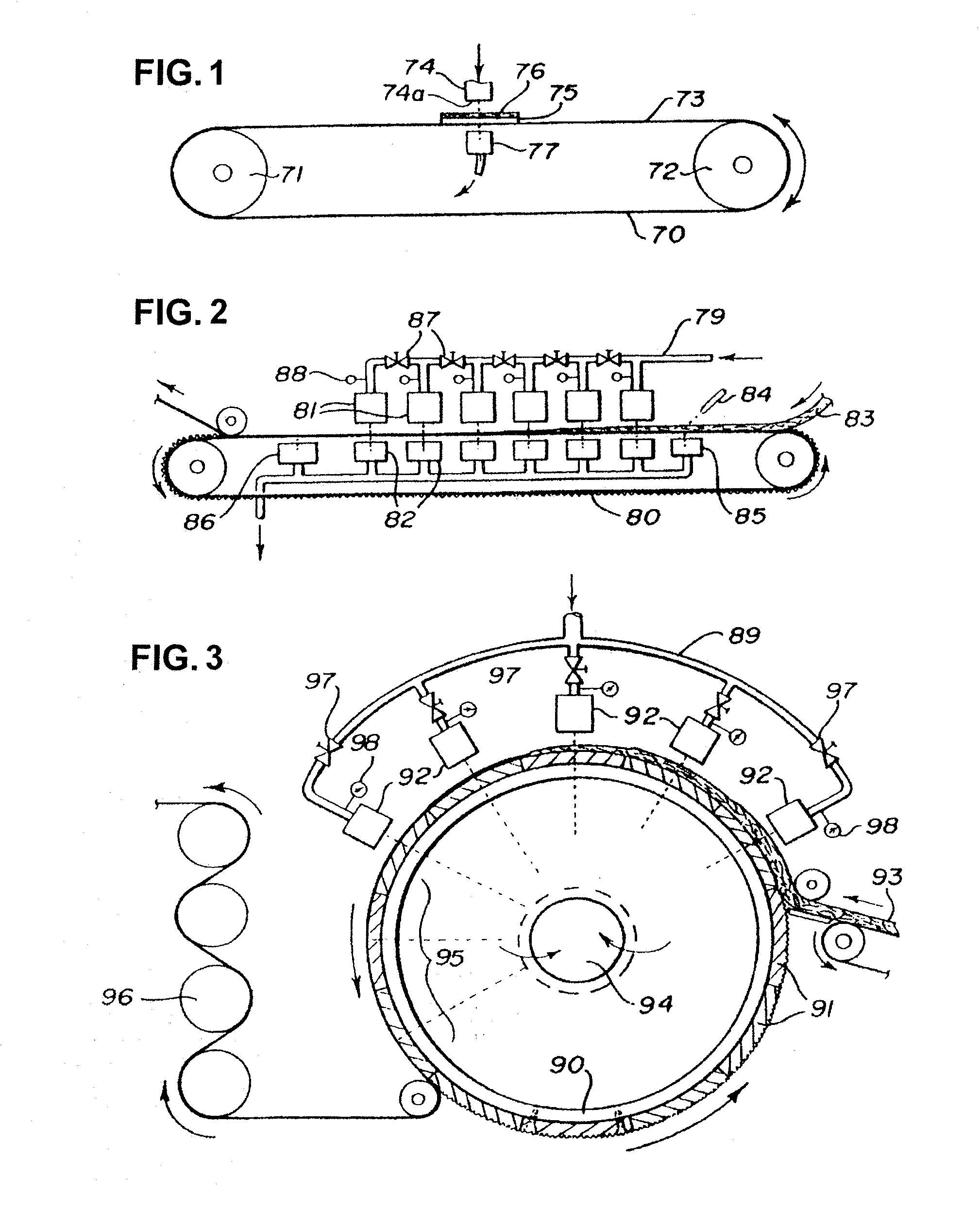

The invention discloses a belt-type infrared radiation drying system which comprises an infrared radiation drying unit, a control system and a main body, wherein the infrared radiation drying unit adopts a multilayer structure, and comprises infrared radiation light wave boards, a conveying belt, an L-shaped supporting rack, a fixing device, a supporting rack, a heating module clamping groove, a driving roller, a driven roller, a power chain and a motor; the infrared radiation light wave boards are mounted in the infrared radiation drying unit, and are correspondingly arranged above and below the conveying belt, and is used for uniformly radiating energy to a material on the conveying belt in an infrared radiation manner during work; the control system is used for matching of infrared wave wavelength and peak of the infrared energy according to the infrared spectrography of the material to be dried. The infrared radiation drying system has the advantages that the production cost is very low; the service life is long; the electro-thermal conversion efficiency reaches up to 99 percent; compared with those of the traditional infra-red drying equipment, the drying time of the infrared radiation drying system is shortened by 30 percent or higher, and the energy conservation effect is improved by 35 percent or higher.

Owner:SHANGHAI RELI TECH GRP CO LTD

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

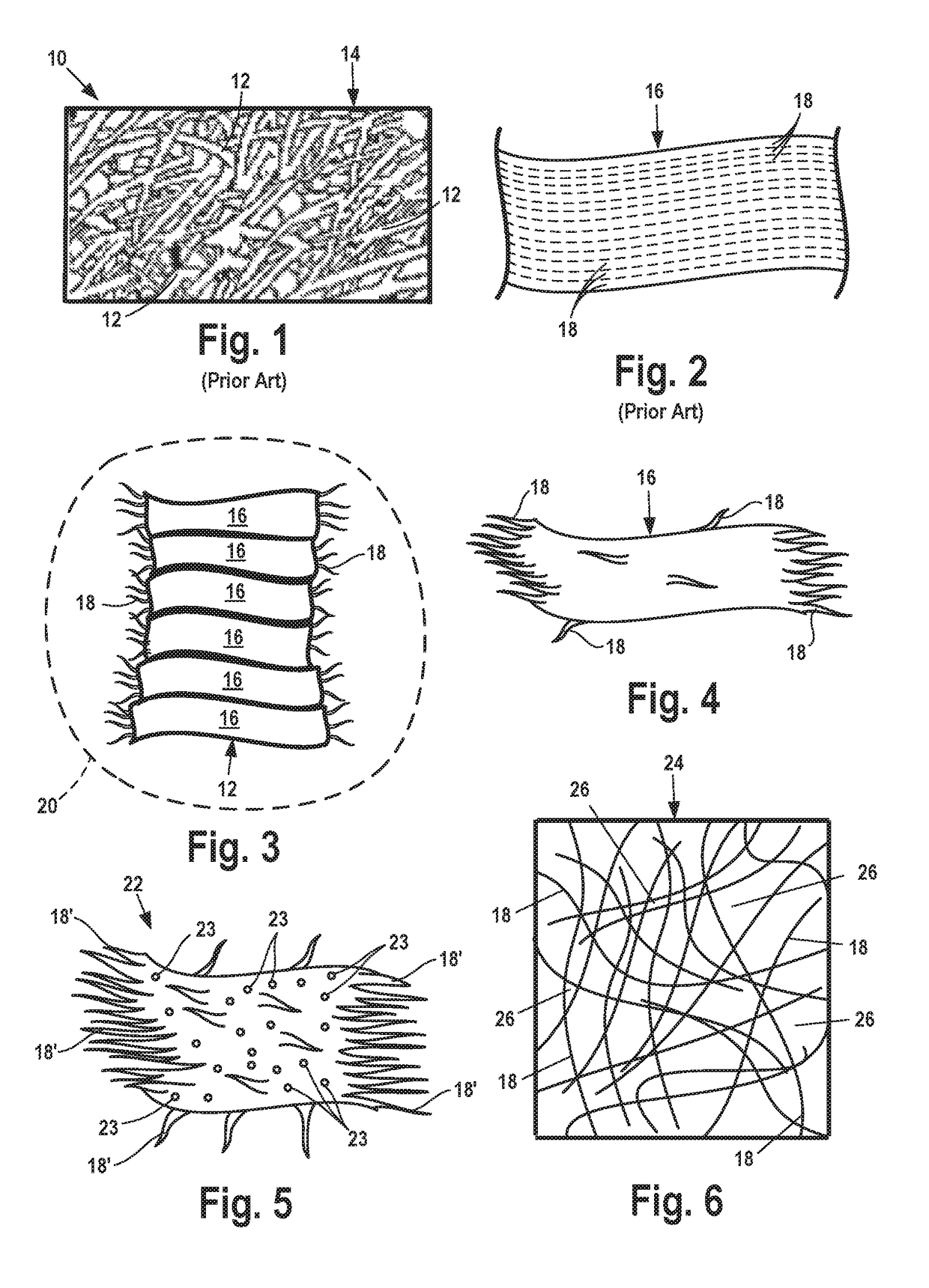

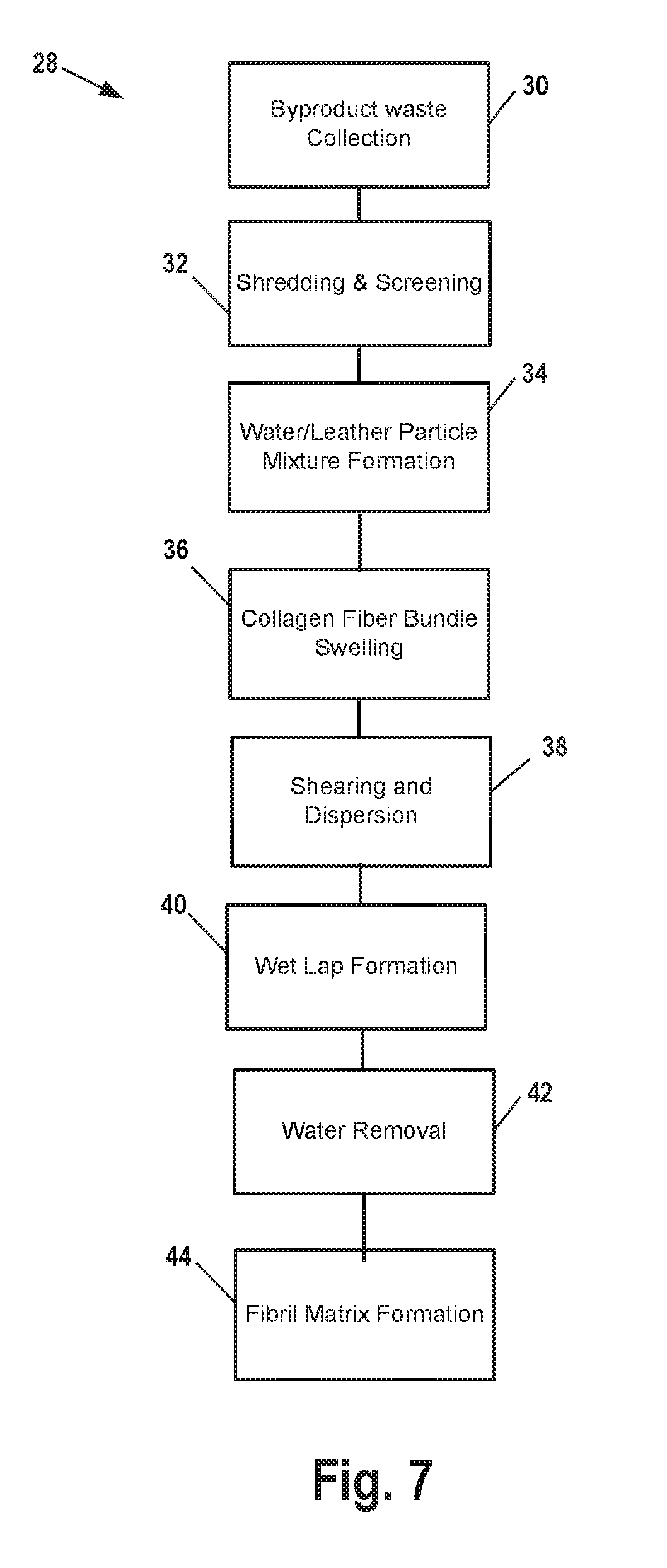

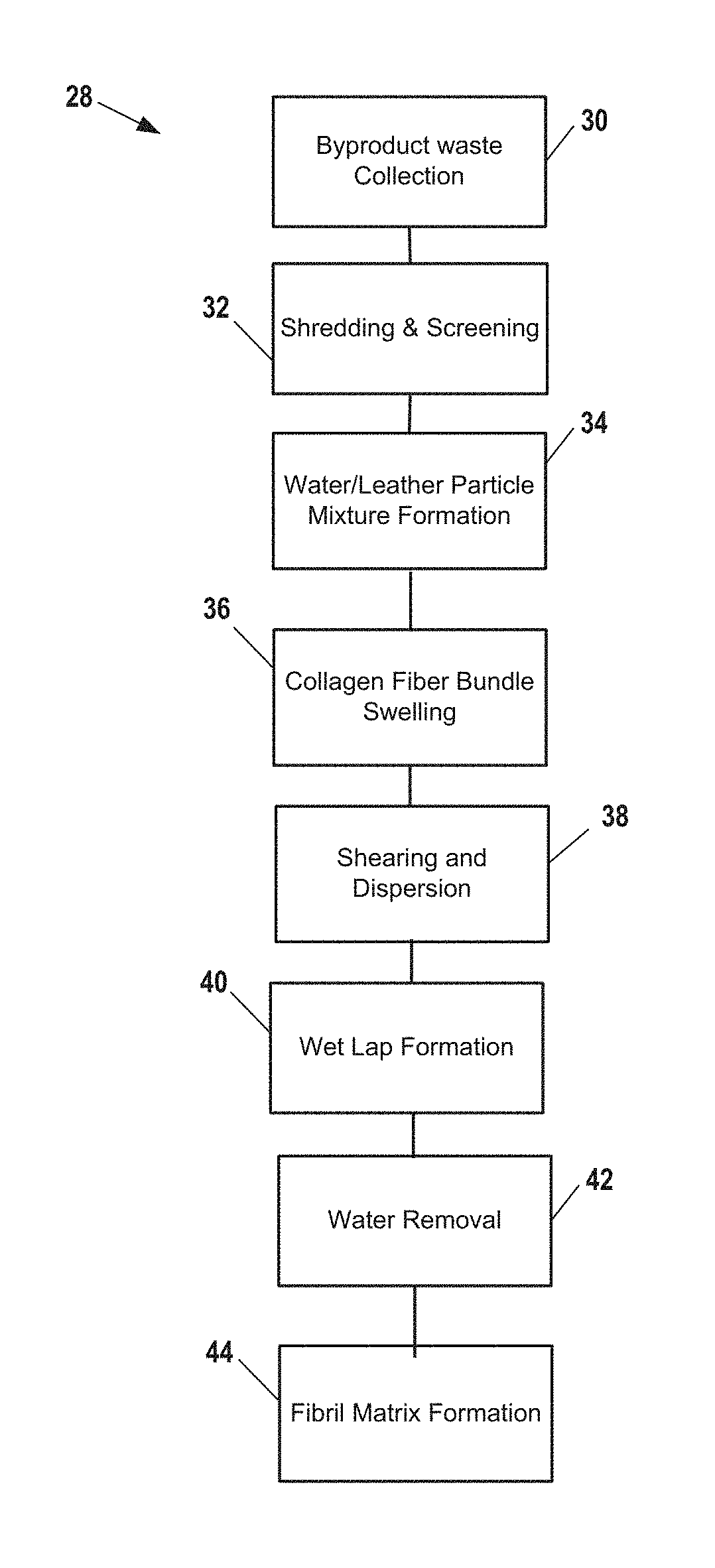

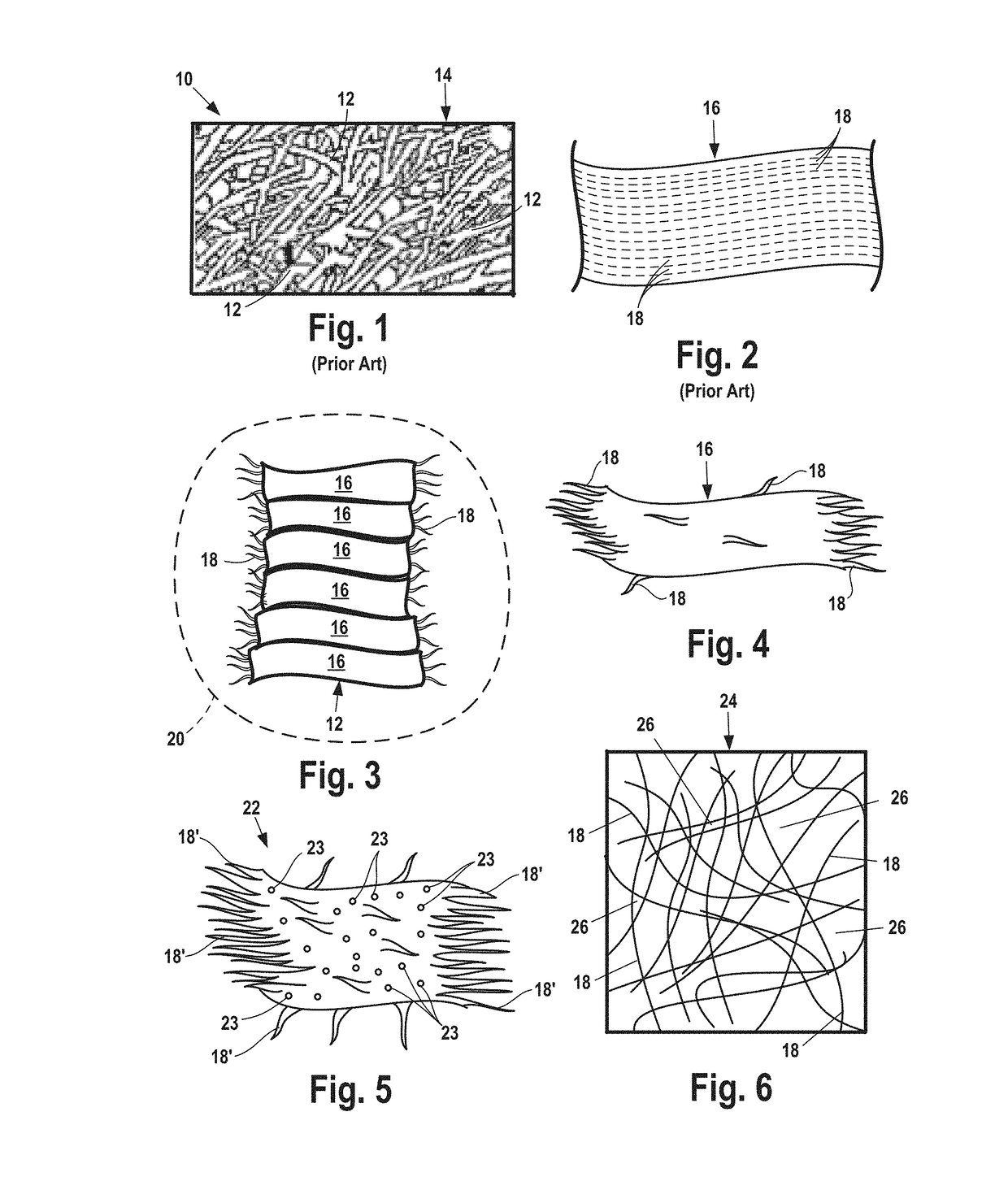

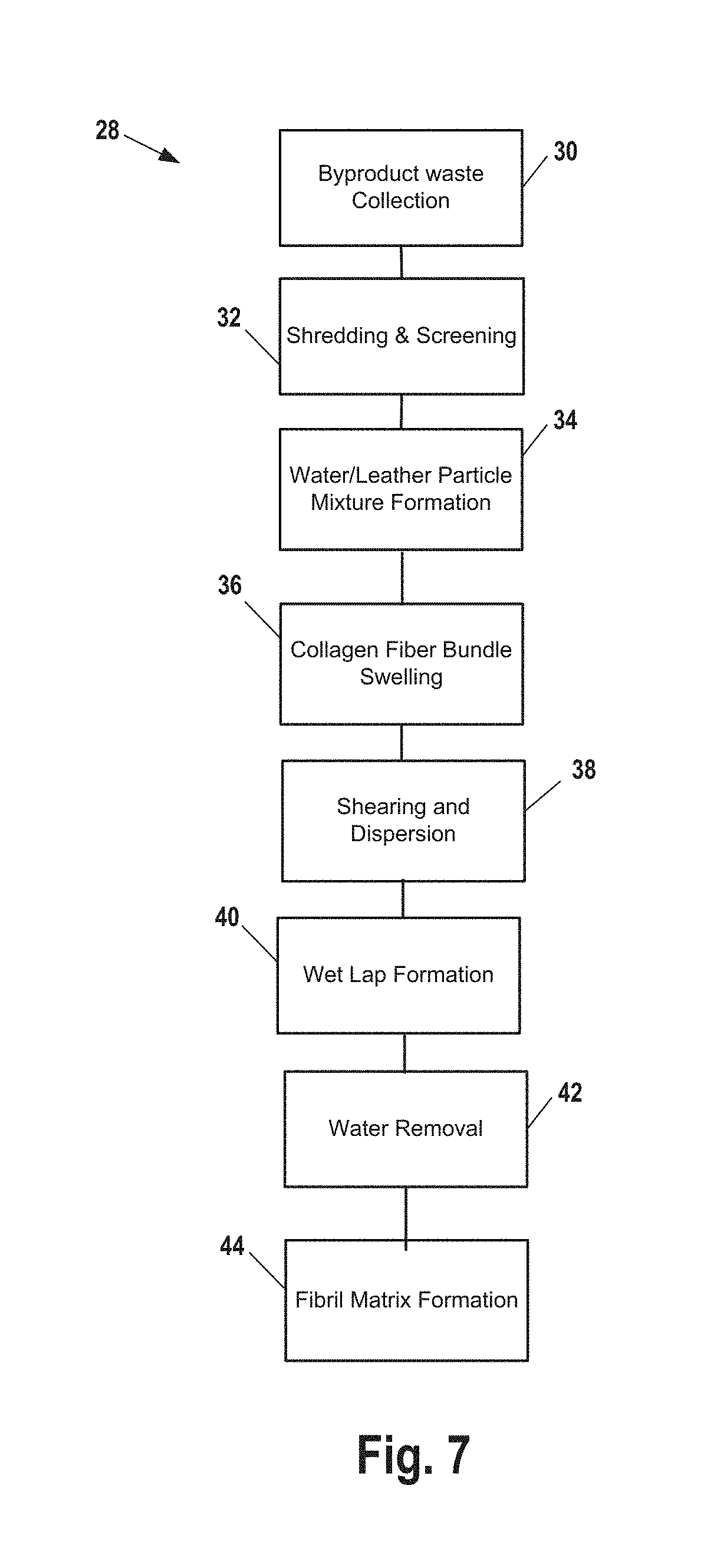

Dispersion processing aids for the formation of a leather material

ActiveUS10138595B1Accelerates the dehydration processFacilitate physically manipulatingOrganic non-cellulose fibresComposite leathersFiberEngineering

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

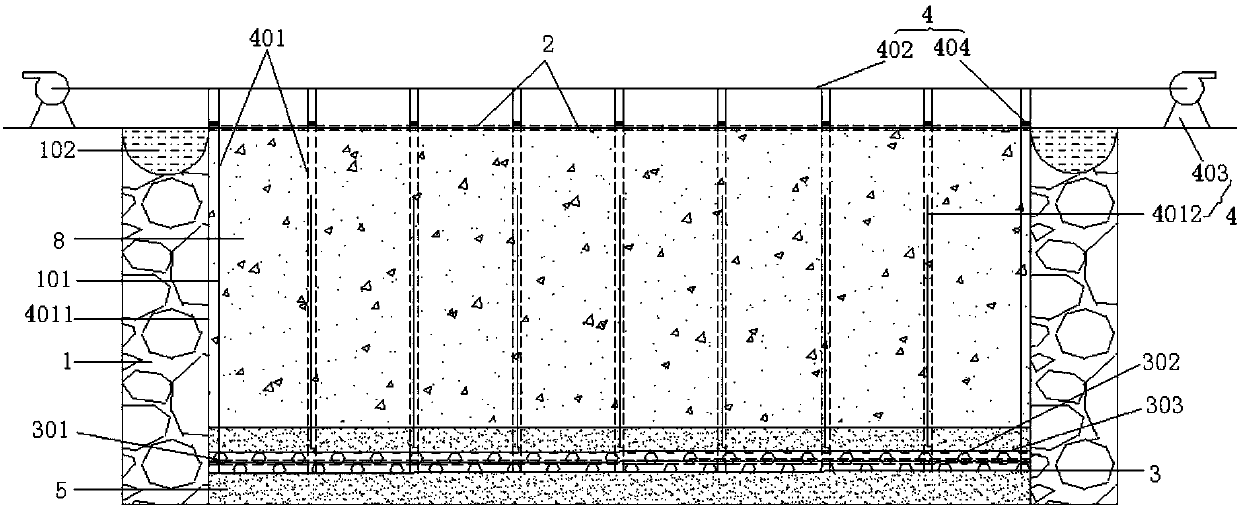

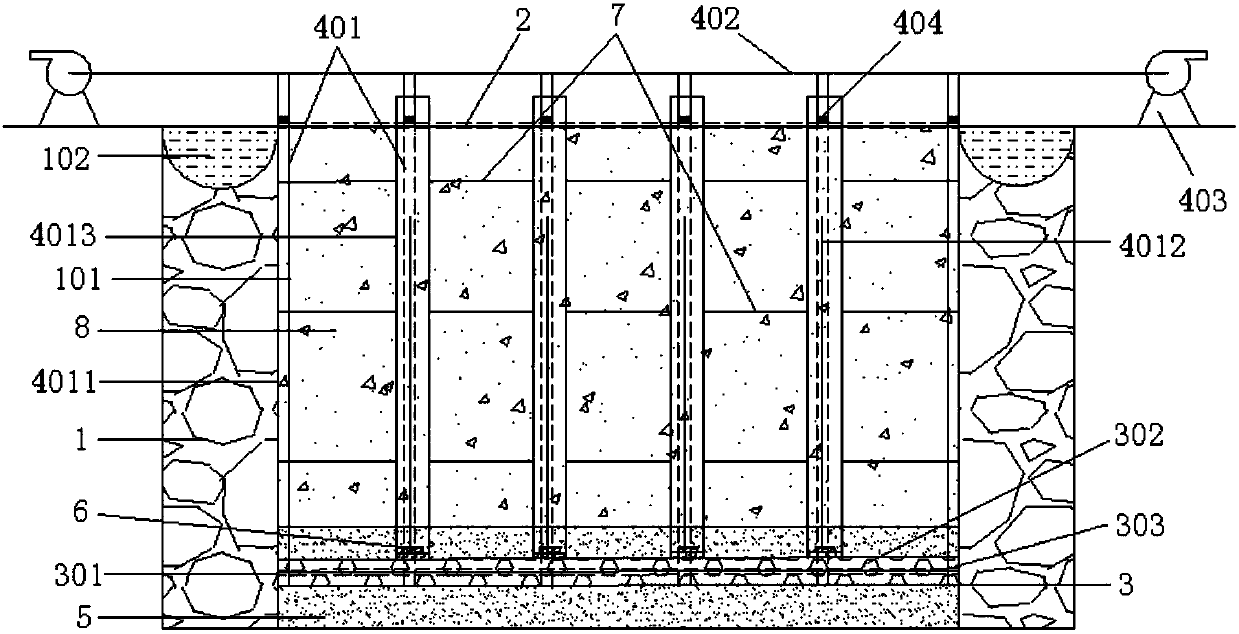

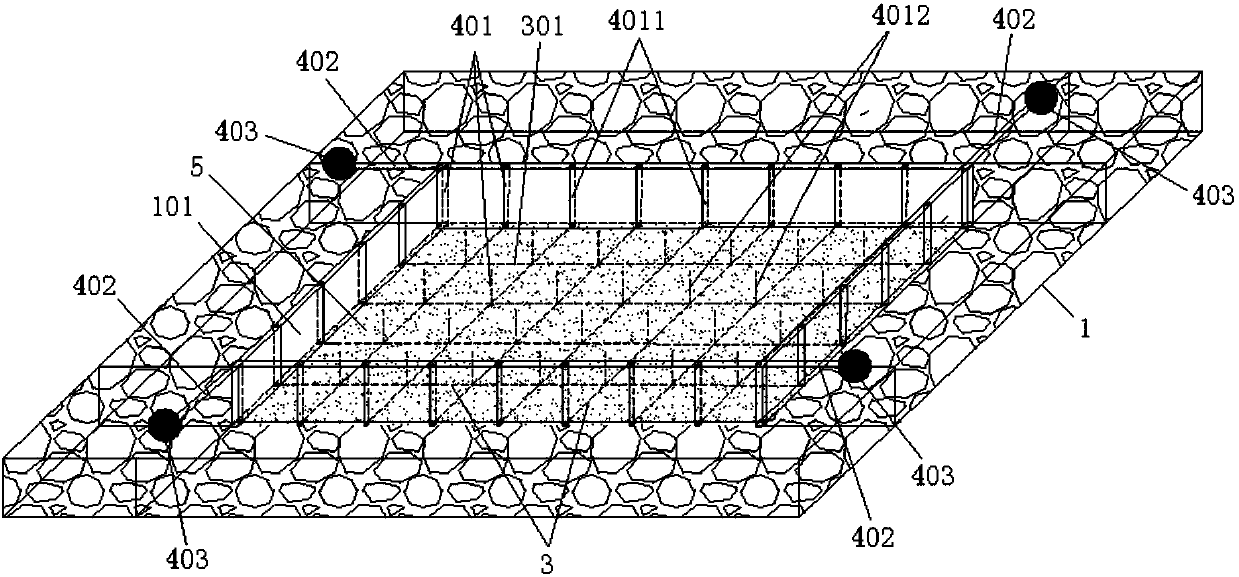

Drainage-type muck pond and multi-dimensional seepage and dehydration method of earth-pressure-balance shield muck

ActiveCN107587578AReduce moisture contentRealize harmless treatmentSewage drainingSoil preservationEarth pressure balanceEngineering

The invention discloses a drainage-type muck pond and a multi-dimensional seepage and dehydration method of earth-pressure-balance shield muck. The drainage-type muck pond comprises a pond base used for being loaded with the muck, a sealing structure is arranged in an opening of the upper portion of the pond base and used for sealing the pond base fully loaded with the muck and making an pond baseinner cavity loaded with the muck be sealed, a bottom pipe network used for collecting water seeping downward from the muck from the lower portion is arranged on the bottom of the pond base inner cavity, and a suction and drainage device is connected onto the bottom pipe network, wherein the suction and drainage device is used for sucking outward the water collected in the bottom pipe network andmaking the balanced negative pressure be formed in the sealed cavity so that water in the muck can be forced to seep outward fast. Through the action of the vacuum negative pressure, drainage of themuck to the surrounding and the bottom is forced, and moisture which enters a channel of the suction and drainage device is sucked by the suction and drainage device for being drained outward, so thatthe water content of the muck in the sealed space is lowered, harmless treatment is achieved, and a foundation is laid for resource utilization; the method is suitable for dehydration treatment of all shield construction muck and muck with high water content.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

High strength leather material

ActiveUS10131096B1High tensile strengthDesired elastic propertiesComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

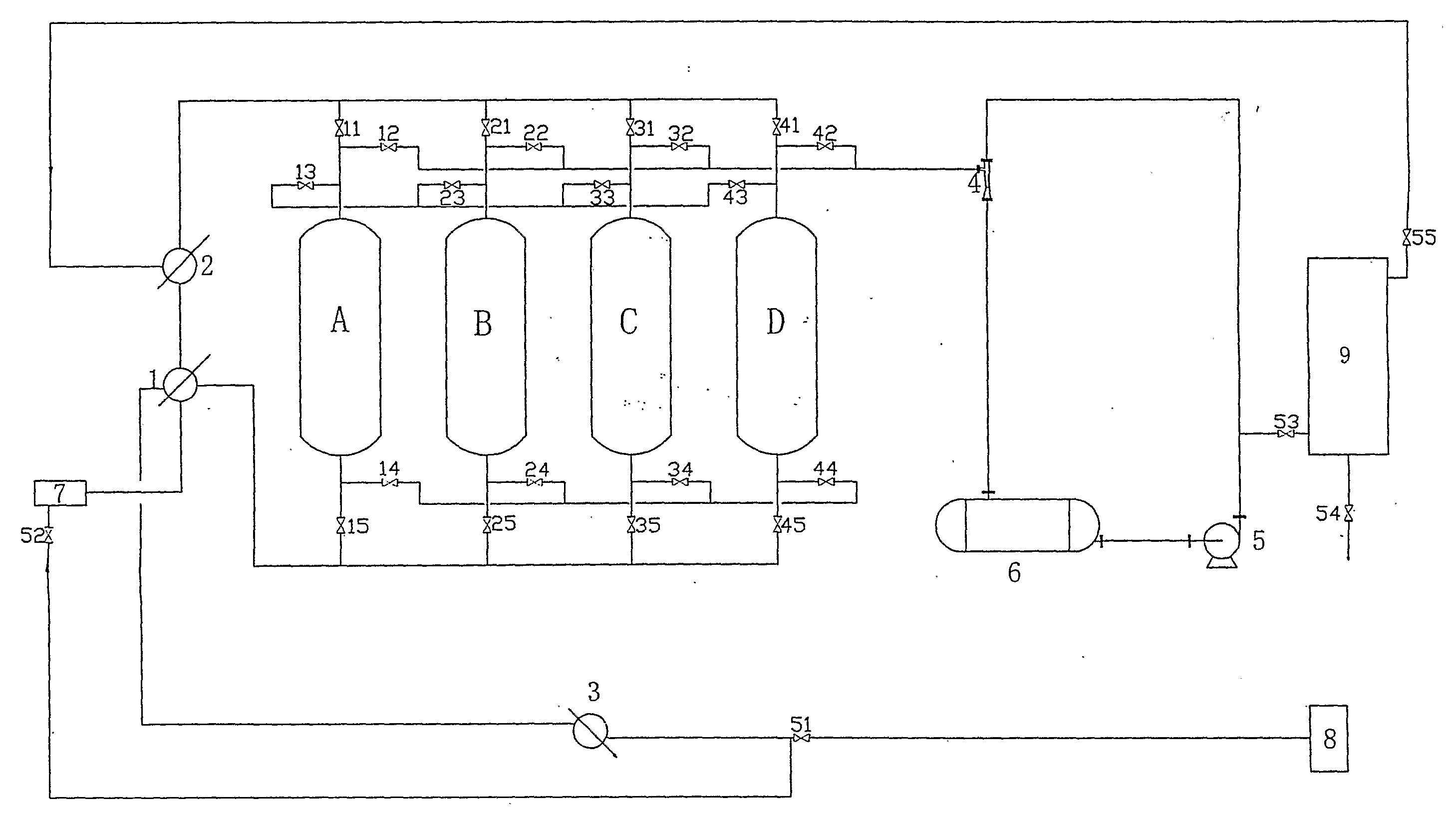

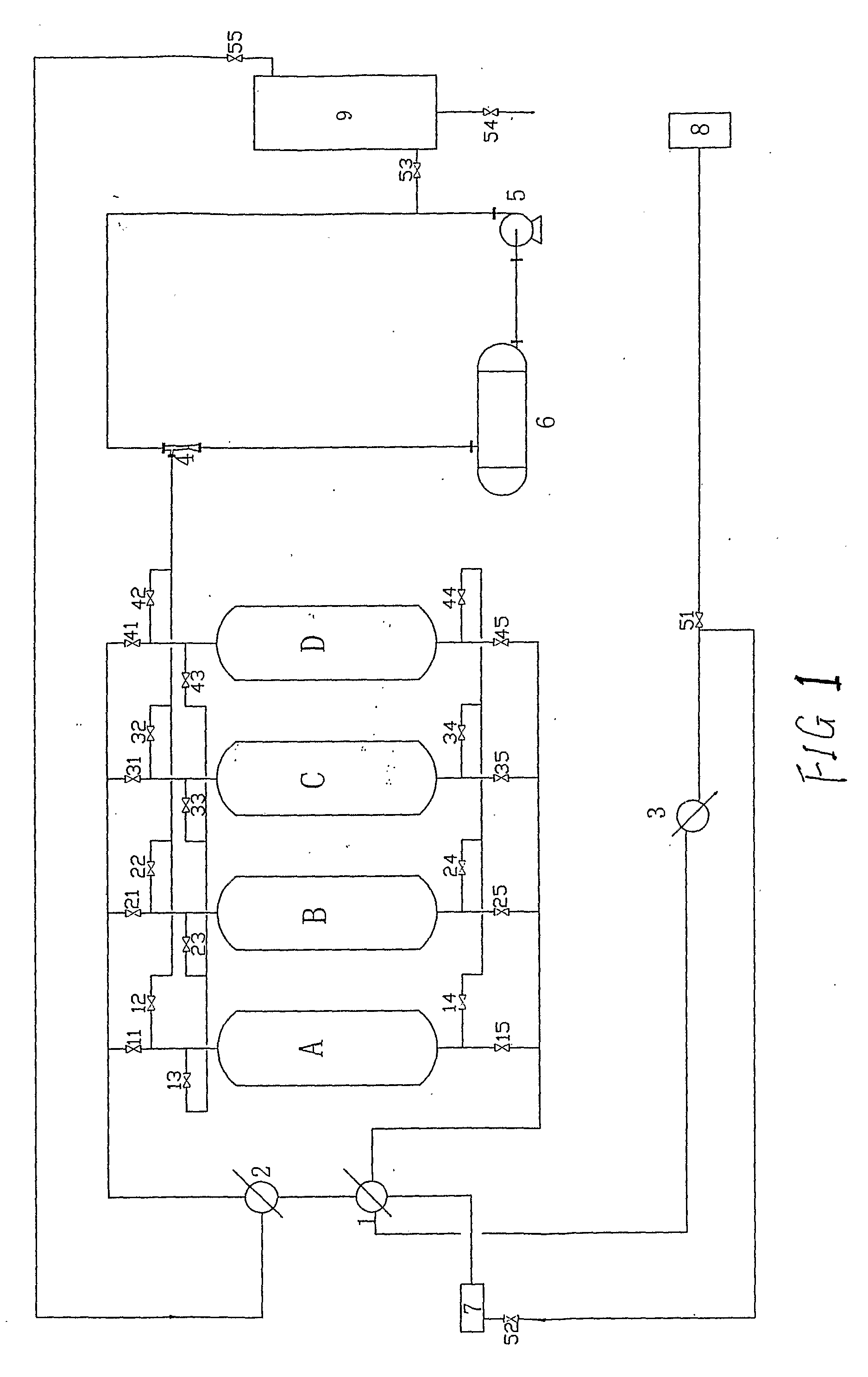

Method of anhydrous Ethanol Production Using Circulation by Multiple Towers Alternation

InactiveUS20080245653A1Reduce heatingSmall surface areaSolid sorbent liquid separationAlcoholic beverage preparationAnhydrous ethanolSorbent

The present invention relates to a method of anhydrous ethanol production using circulation by multiple towers' alternation, the procedure includes the steps of heating, adsorption, internal circulation, vacuum suction, washing and resolving etc. The method can prolong the life of adsorbent, reduce the heat exchanger's surface, cooling water, the equipment investment and energy consumption, provide high ethanol recovery rate and high dehydration, and protect environment.

Owner:ZHONG YALING

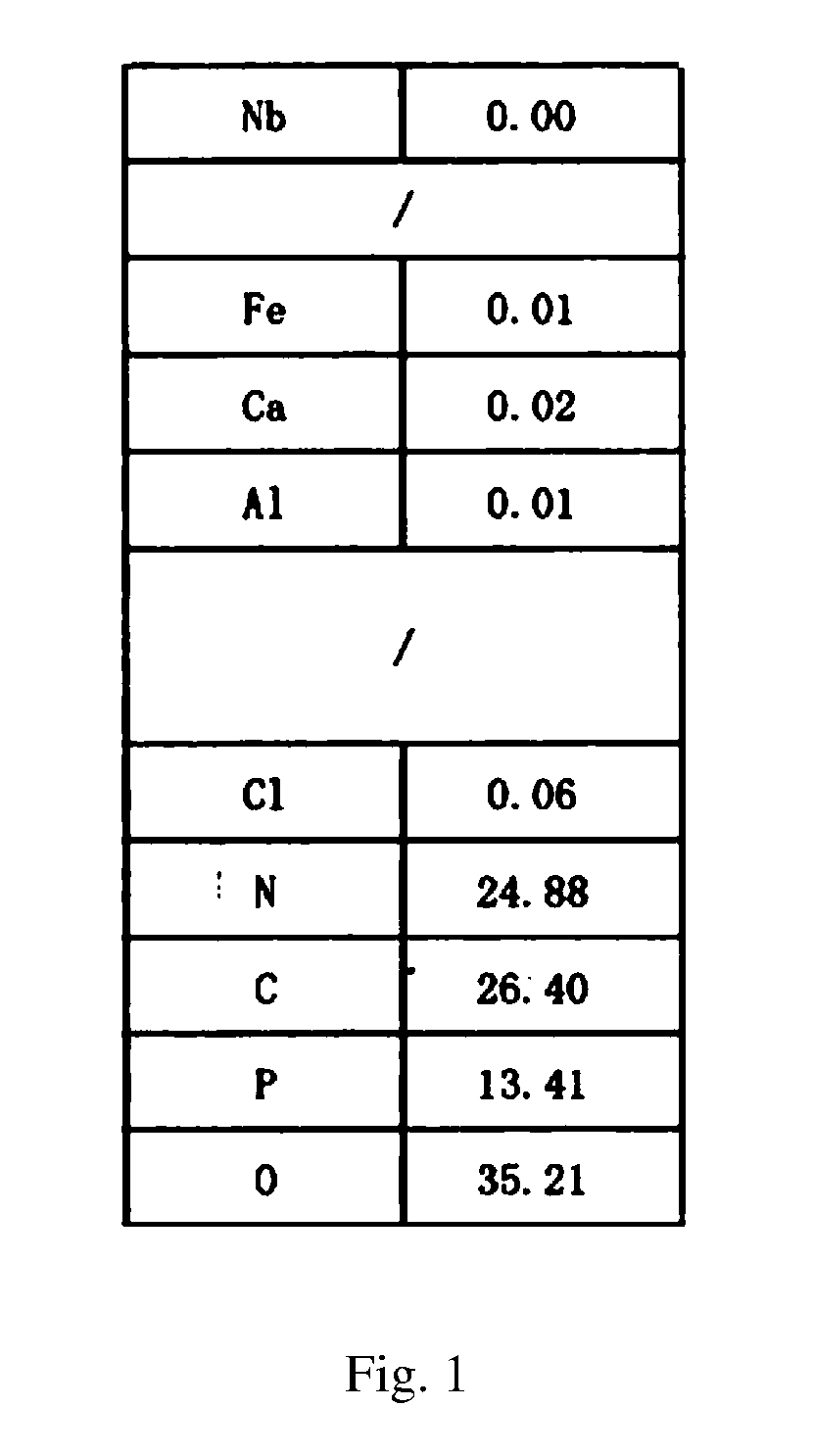

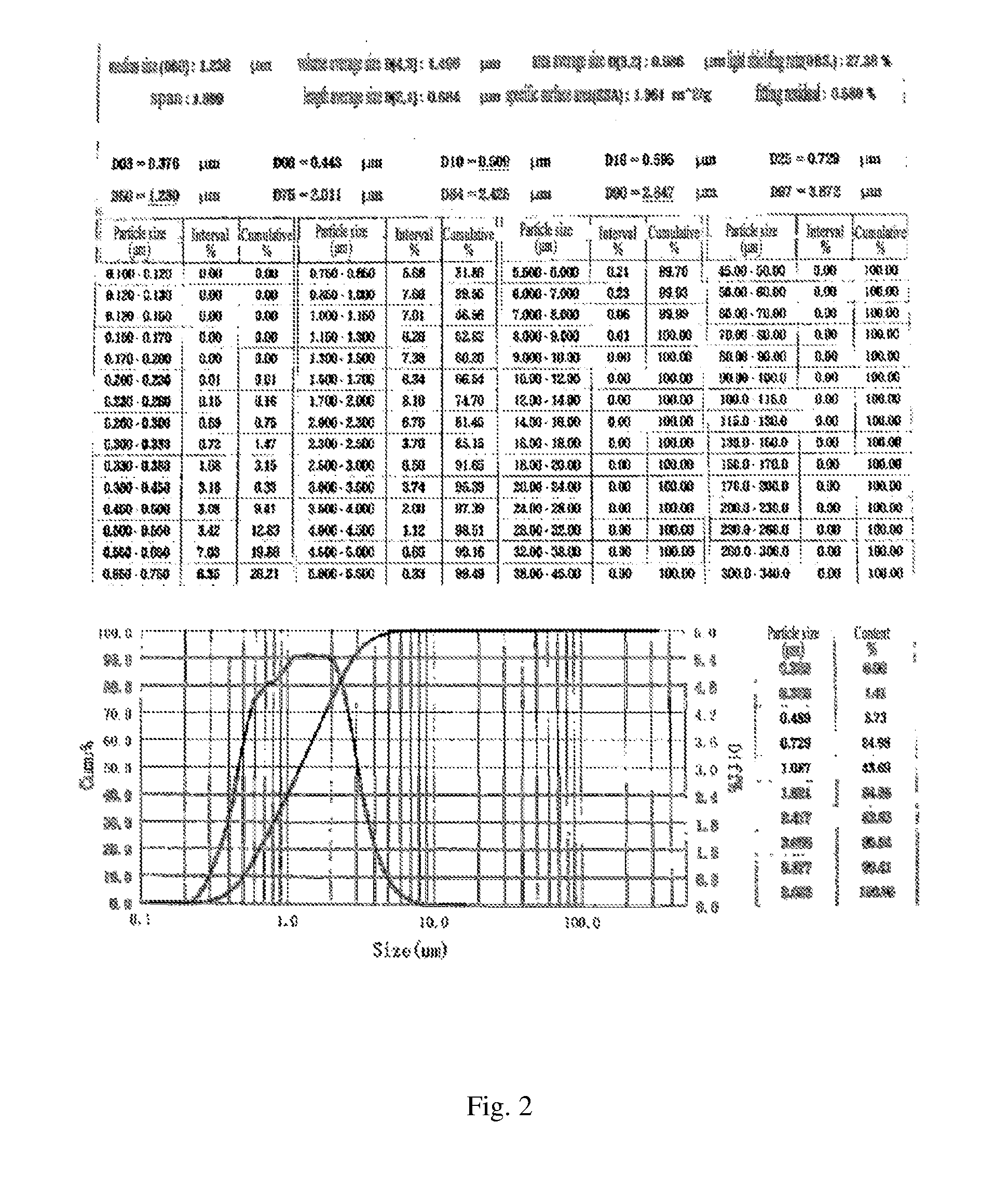

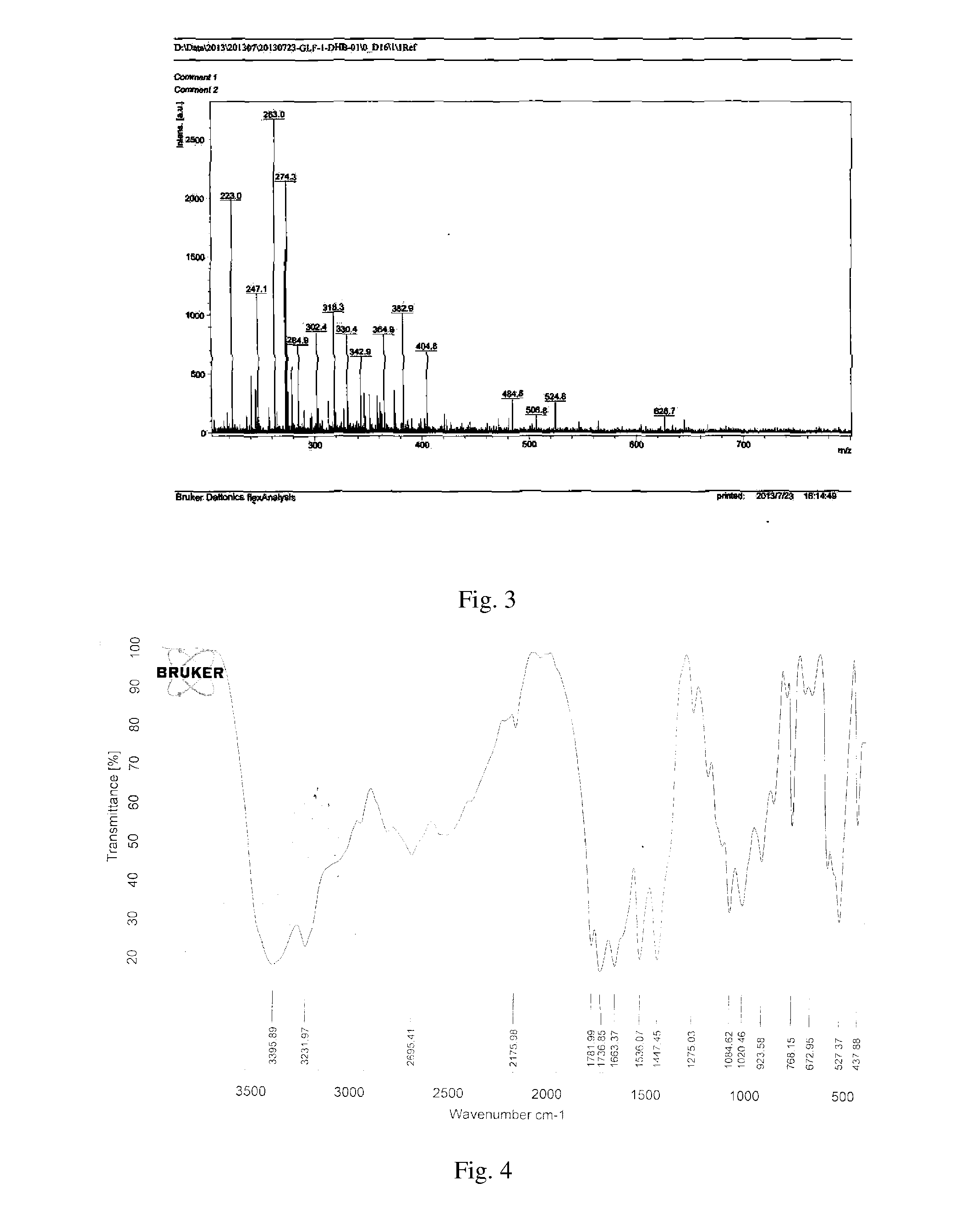

Phosphorus-nitrogen intumescent flame retardant, synthesis method therefor and use thereof

ActiveUS20160272892A1Total current dropAccelerates the dehydration processFireproof paintsNon-macromolecular organic additionFoaming agentSynthesis methods

This disclosure provides high-efficiency and low-energy-consumption synthetic methods of a series of phosphorus-nitrogen-based intumescent flame retardants and the use thereof in paint flame retarding. 1 part by weight of a phosphorization agent and 0.5-4.0 parts by weight of a nitrogen-containing foaming agent are uniformly mixed and stirred at room temperature, and an amount of water is further added to emit heat and initiate reaction. 0.5-3.0 parts by weight of a charring agent and 0.5-4.0 parts by weight of a hydroxy-containing polyfuctional crosslinking agent are then added, and reacted with stirring. An amine compound is finally added for neutralization until pH value is 5-8, and solid liquid separation is performed. The solid portion is dried to obtain a main body portion of a phosphorus-nitrogen-based intumescent flame retardant. The resultant filtrate is diluted with 1 / 3-2 / 3 volume of water, and a flame retardant product is obtained. This flame retardant product is mainly used in the flame retarding of paper and cotton fabrics. The main body and different proportions of other nitrogen-containing foaming agents and charring agents are uniformly mixed and pulverized into nano- and micro-scale, and a phosphorus-nitrogen-based intumescent flame retardant is obtained. The nano- and micro-scale phosphorus-nitrogen intumescent flame retardant is mixed into a paint at a weight ratio of 15-30%, to obtain a flame-retardant paint which is capable of maintaining mechanical and physical properties of the paint. The phosphorus-nitrogen-based intumescent flame retardant of this disclosure is an intumescent flame retardant having a synergistic effect of phosphorus and nitrogen.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

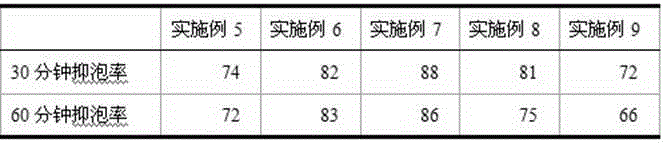

Emulsion-type silicone resin defoamer for papermaking and pulping

ActiveCN103572653BImprove washing effectQuality improvementDefoamers additionPaper/cardboardPapermakingPollution

The invention provides an emulsion type silicon resin defoaming agent for pulping in papermaking. The defoaming agent comprises 30-50% of nonvolatile matters and the balance being deionized water according to weight percentage; the nonvolatile matters comprises the following compositions in parts by weight as follows: 5-15 parts of special-effect silicon resin, 25-85.2 parts of polymethylsiloxane, 2-24 parts of hydrophobic white carbon black, 2.8-12 parts of an emulsifier, 5-24 parts of a dispersing agent; at 25 DEG C, the PH value is 6.0-8.0, the density is 0.98-1.05g / ml, the particle size of the emulsion ranges from 1mum to 25mum, most of the particle size of the emulsion is greater than 90%. The defoaming agent can fast eliminate foams generated by lignin and other surfactants, accelerate the dehydration process and improve a paper pulp washing effect, the water consumption is reduced, and the later pollution is avoided, and the quality of paper pulp is improved, and the relatively environment-friendly paper pulp production with relatively high profits can be realized.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

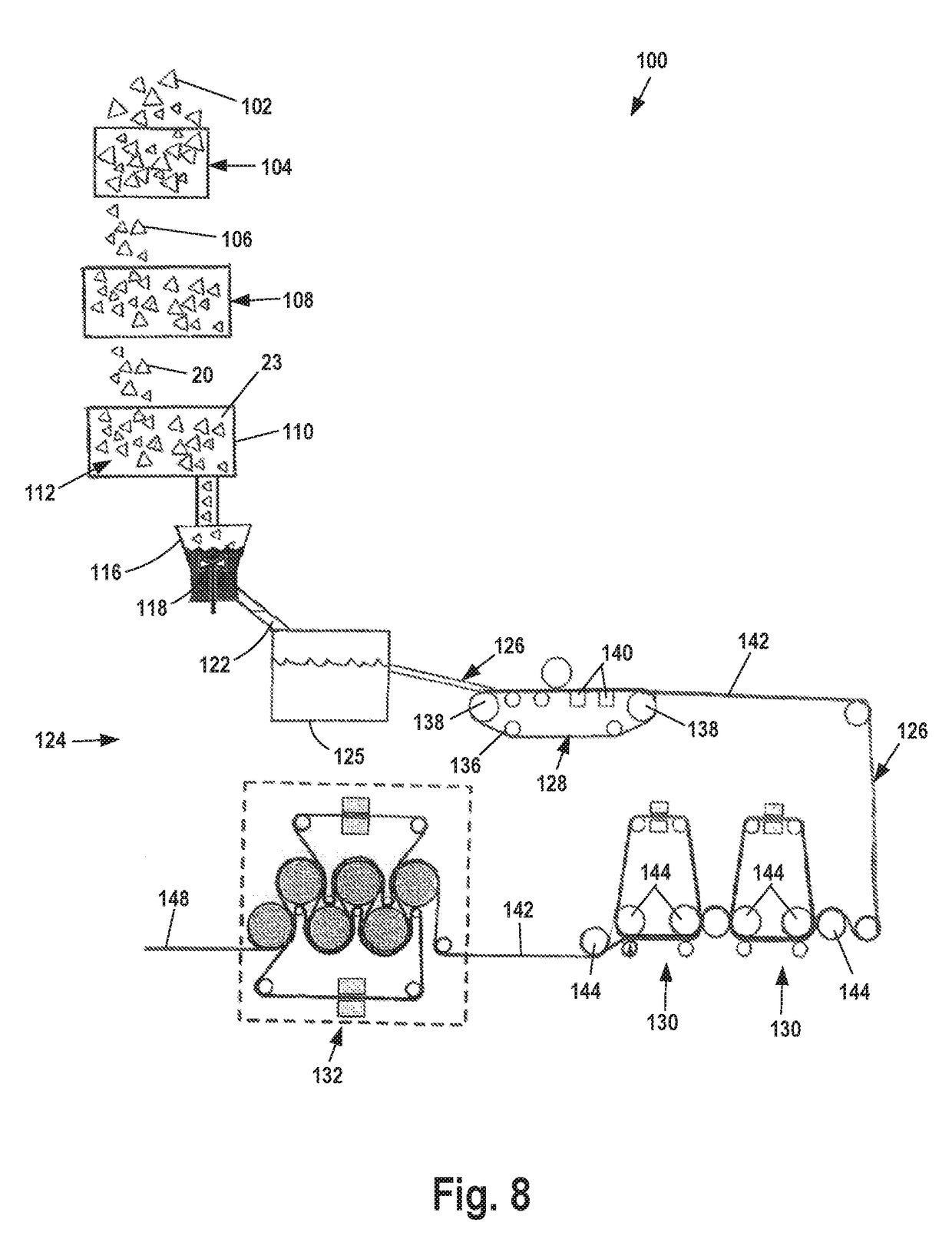

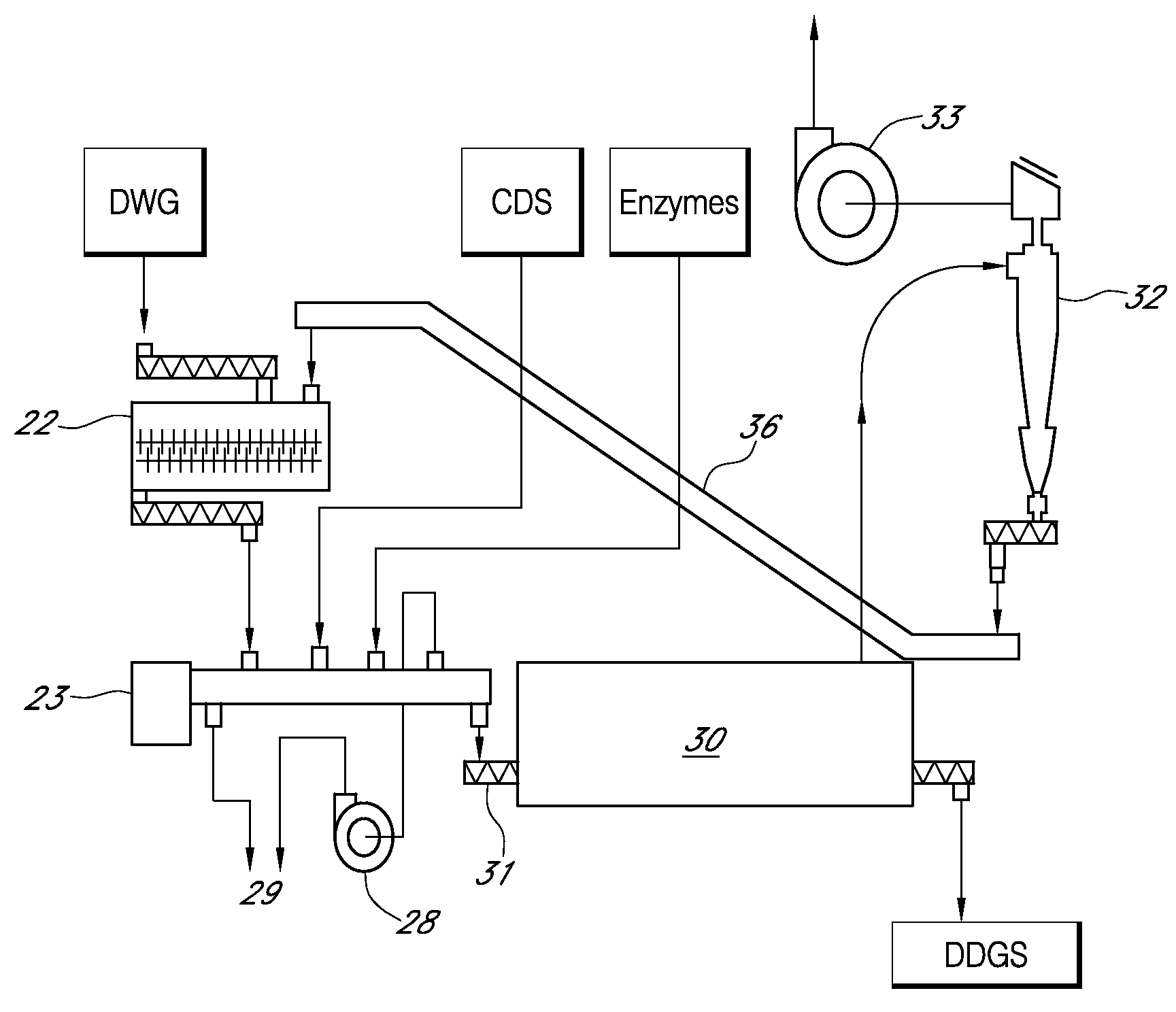

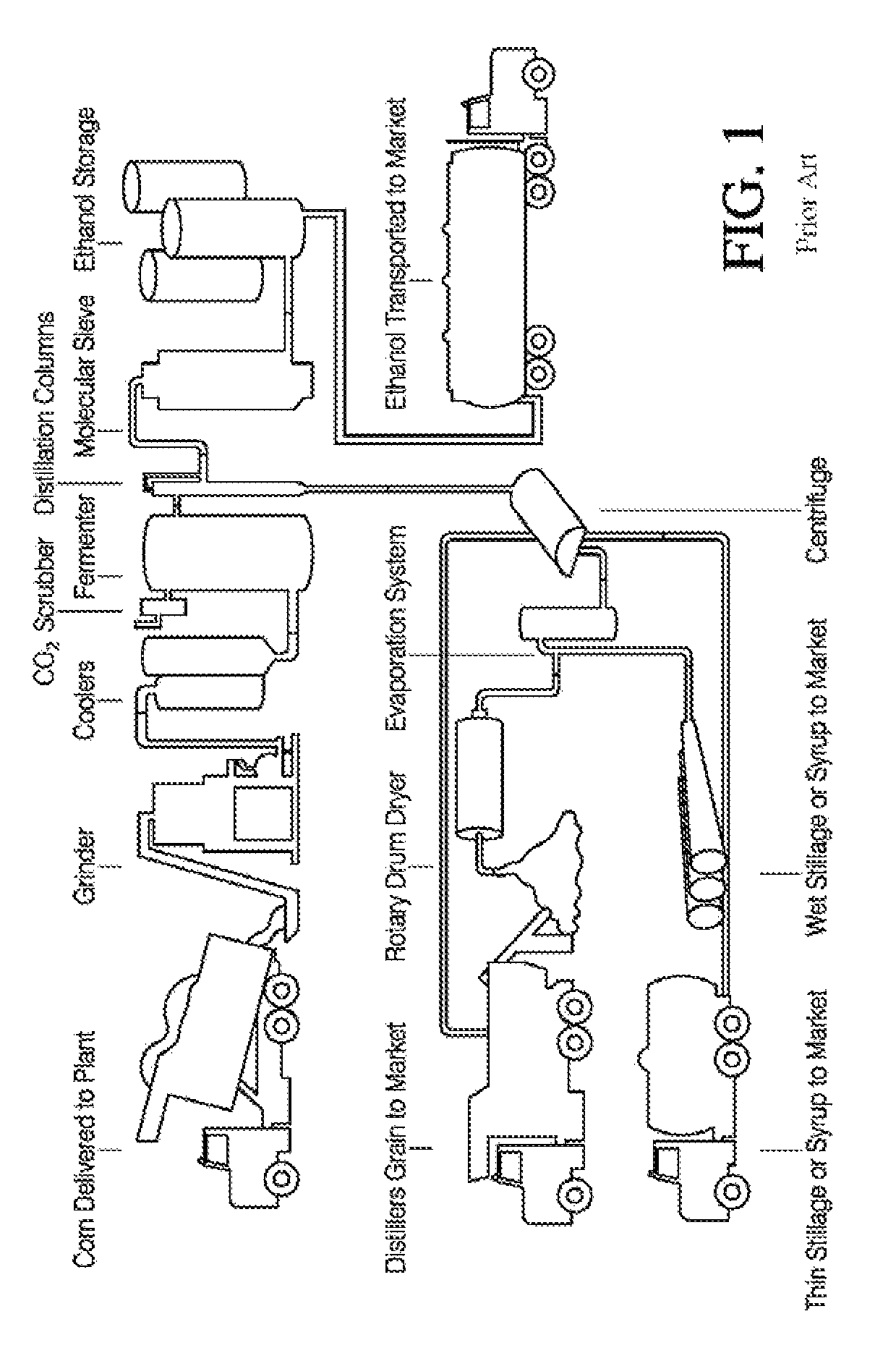

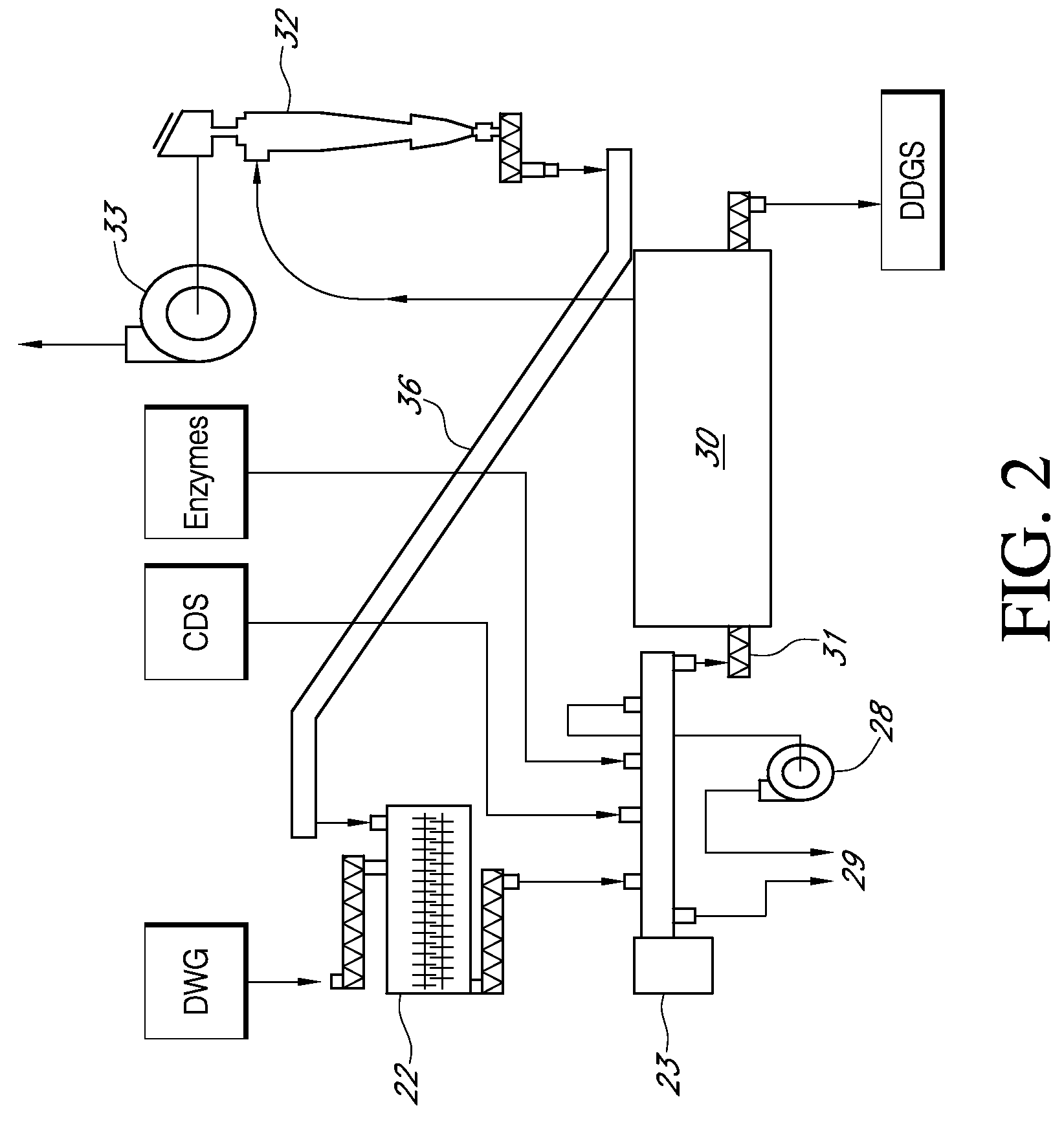

Method of producing dried distillers grain agglomerated particles

ActiveUS7695747B2Reduce Particle GenerationHigh water recoveryDough treatmentBiofuelsSufficient timeMoisture

A method of producing Dried Distiller's Grain with Solubles (DDGS) agglomerated particles is disclosed. The method comprises the steps of separating a first product stream out of the whole stillage that is primarily solid material from a second product stream that is primarily liquid, agglomerating the first product stream using a mechanical compression machine such as an extruder, and exposing the agglomerated particles to microwave radiation of a sufficient energy for a sufficient time so that the resulting moisture of the agglomerated particles is between 3% and 40% by weight. The second product stream may be condensed and blended with the first product stream prior to, or concurrently with, the step in which the agglomerated particles are formed. Additionally, other additives, such as enzymes, may be added to the first product stream to enhance the final product's desirability as a nutritional source.

Owner:MEIER RUSSELL

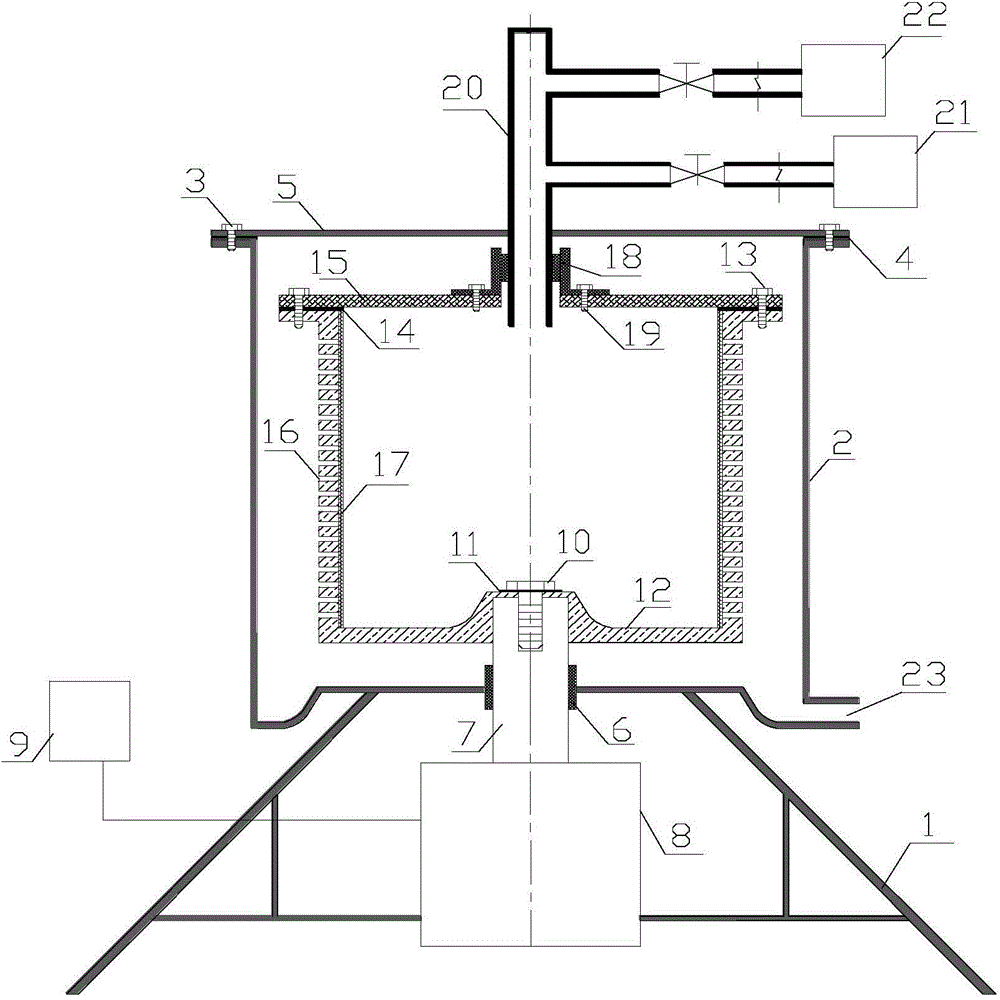

Fine-grain material centrifugal filtering and dewatering device

InactiveCN103977915AHigh centrifugal forceAdjustable centrifugal factorRotary centrifugesFilter mediaCentrifugal force

A fine-grain material centrifugal filtering and dewatering device comprises a frame, a housing, a motor, a drum and a speed regulator. A spindle of the motor penetrates the bottom of the housing to be connected with the drum, the spindle penetrates the housing to be provided with a sealing component, the upper portion of the housing is provided with an upper housing cover, the lower portion of the housing is provided with a liquid discharge outlet, the side wall of the drum is provided with a plurality of filtrate holes, and filter medium is attached to the inner wall of the drum. The upper portion of the drum is provided with an upper drum cover, the housing is provided with a feed pipe penetrating the upper housing cover and the upper drum cover to enter the drum, a mechanical sealing component is arranged at an inlet of the upper drum cover, the feed pipe is respectively provided with a suspension liquid feed system and an air feed system through pipelines, and the pipelines are provided with flow control valves. By coordinating pressurized filtering and centrifugal filtering, filtering speed can be accelerated by centrifugal force, dewatering speed is accelerated by compressed air, therefore dewatering process of a centrifugal filter is enhanced, solid-liquid separation efficiency is improved, residual water in centrifugal filter cakes is reduced and centrifugal dewatering effect of fine-grain materials is improved.

Owner:CHINA UNIV OF MINING & TECH

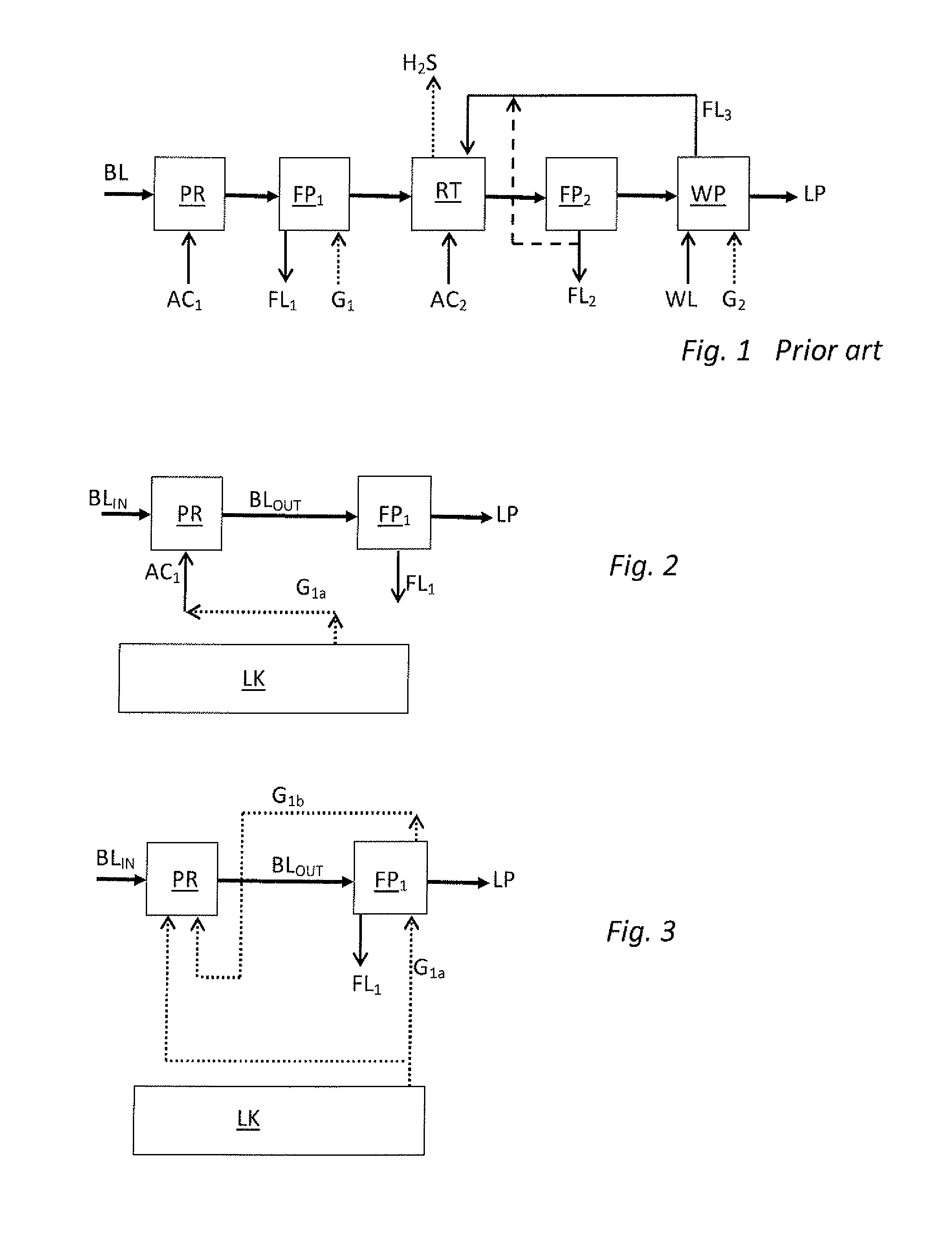

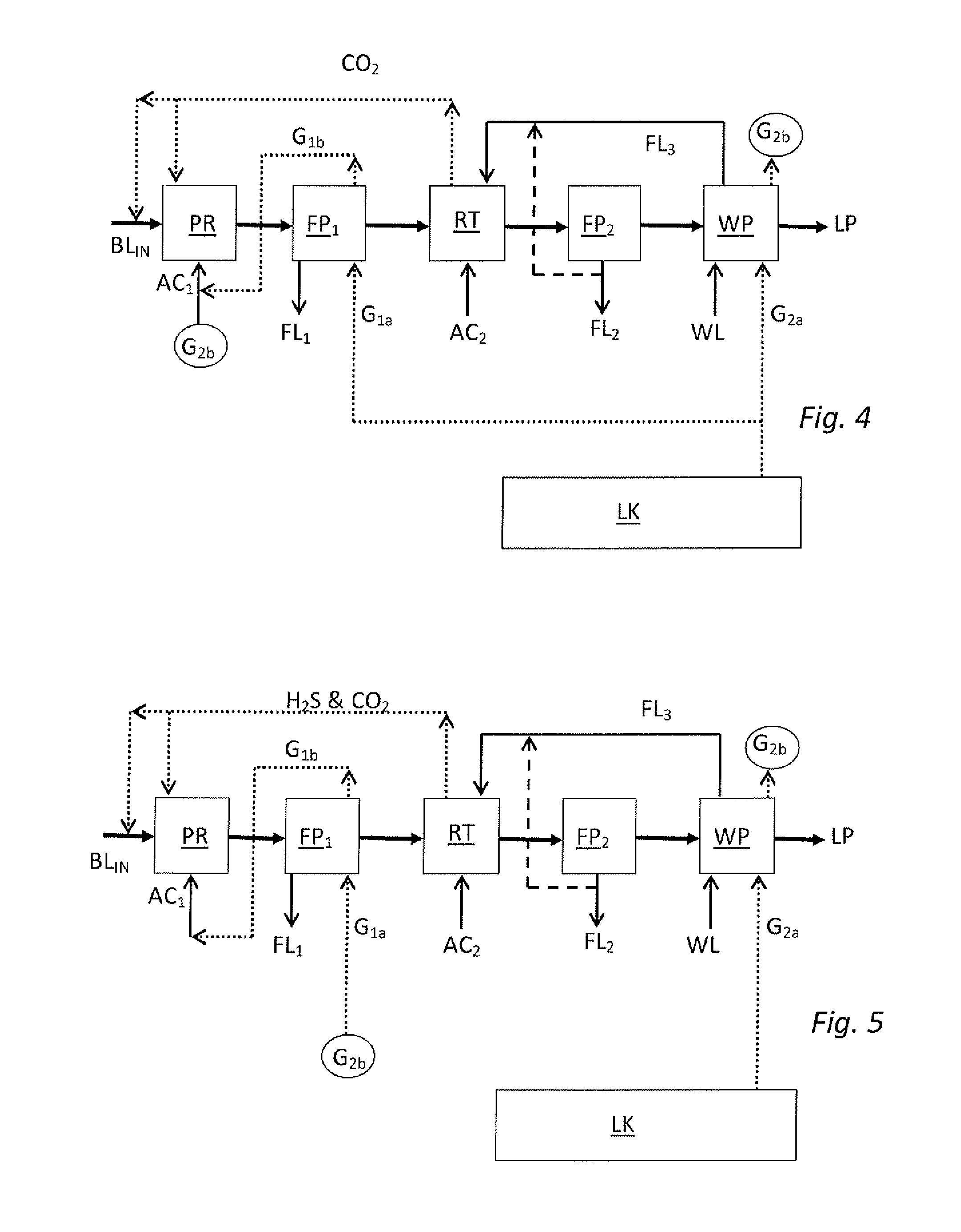

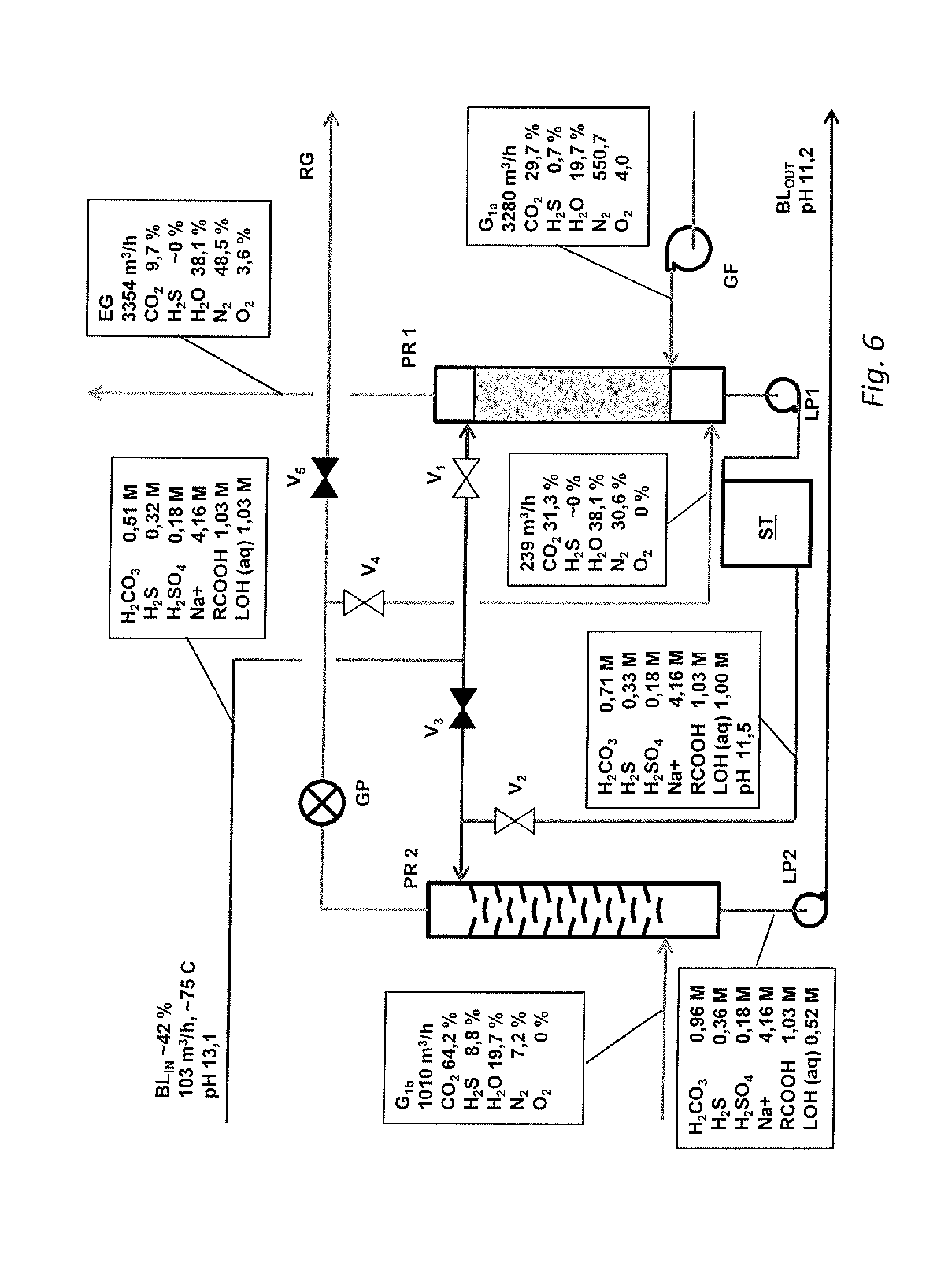

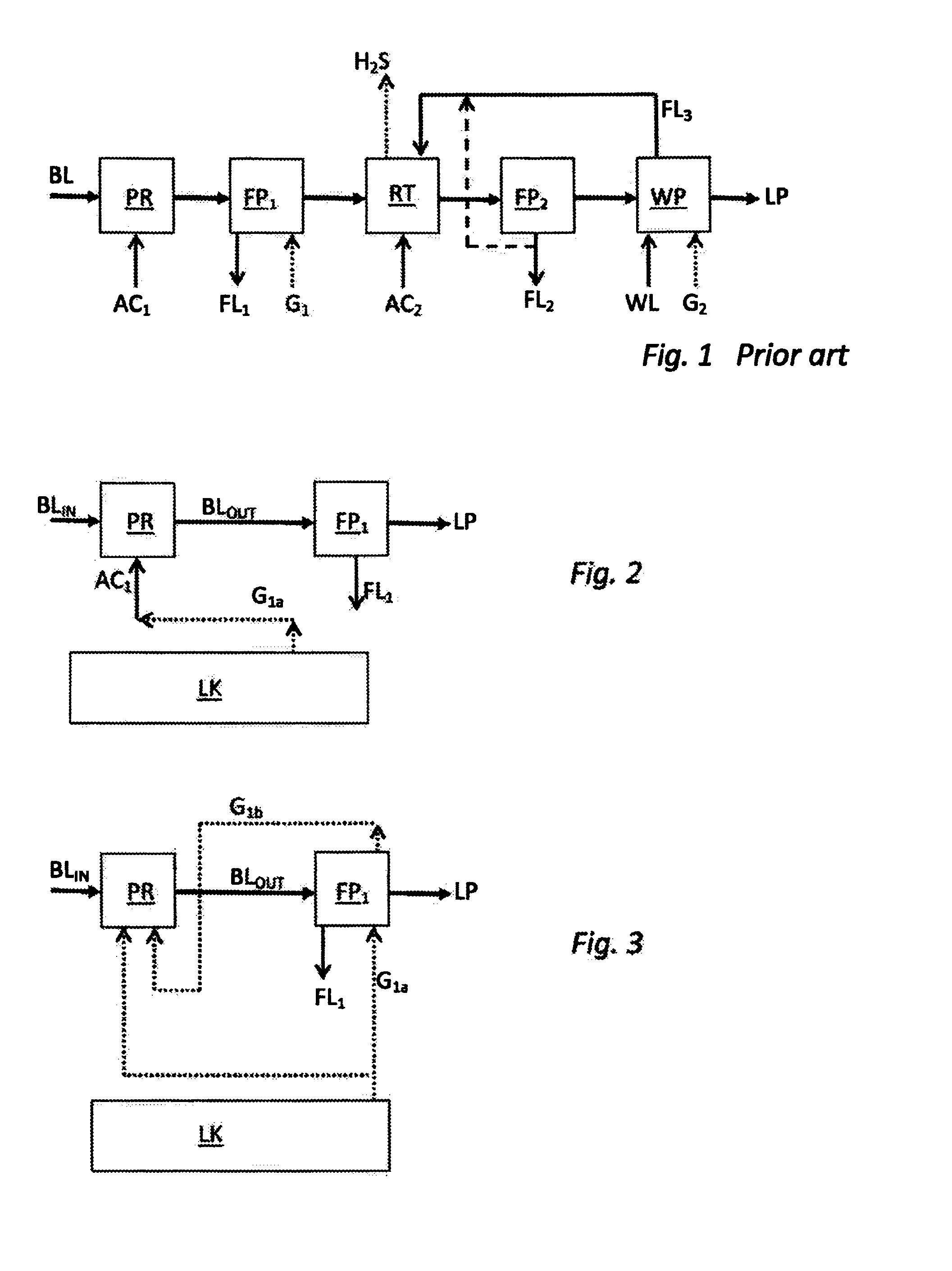

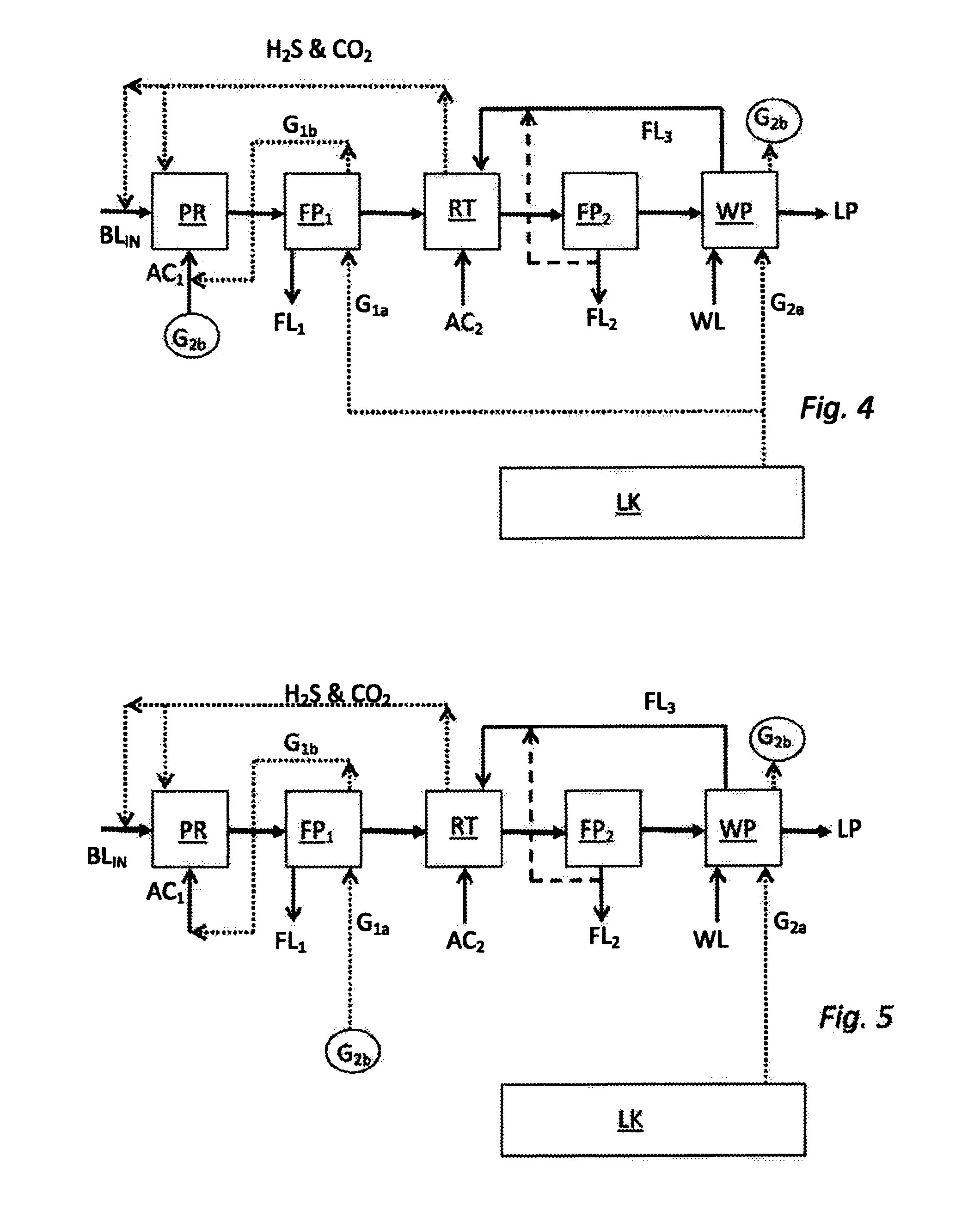

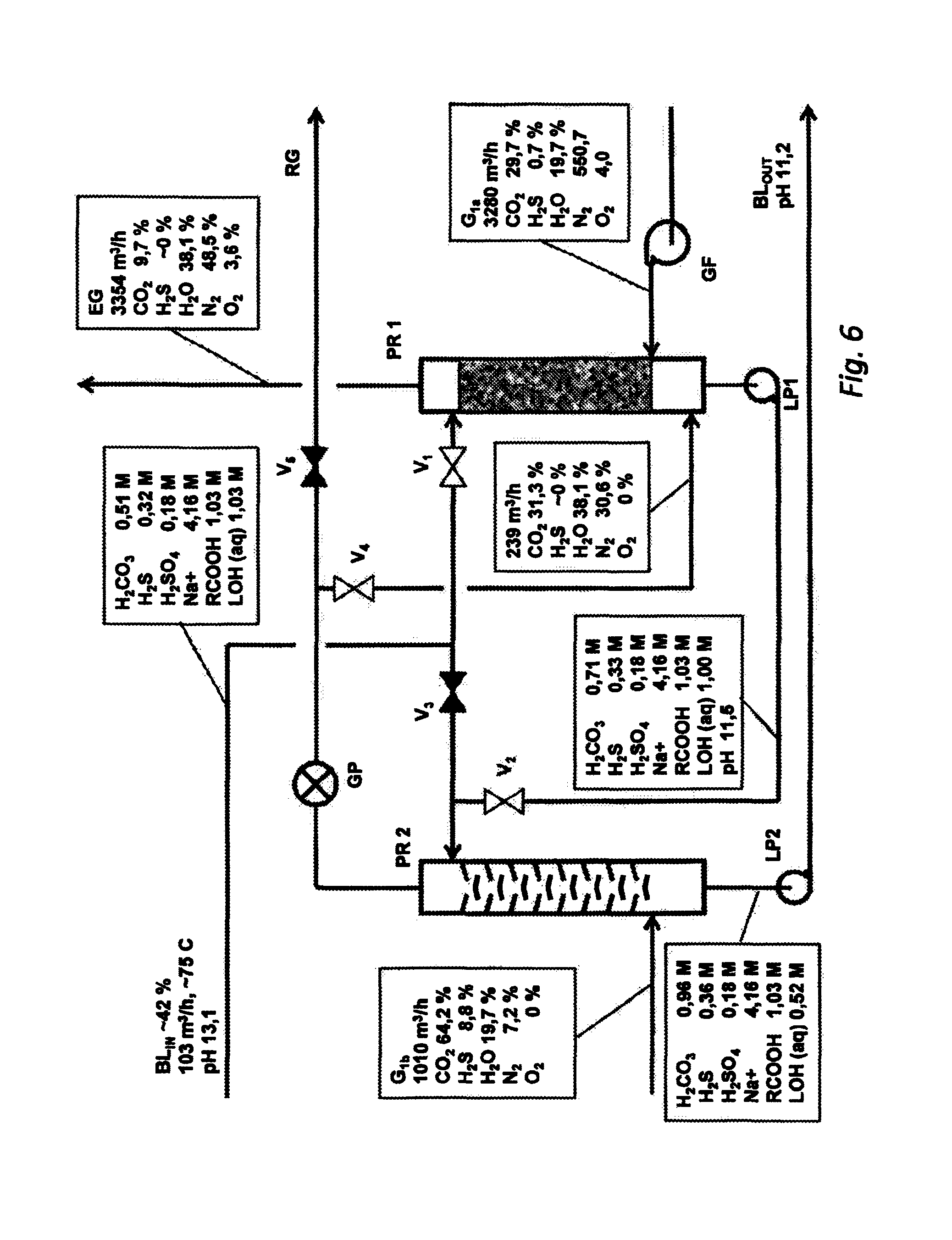

Method for lignin separation from black liquor involving multiple acidification steps

InactiveUS20150075738A1Process can be stoppedLong retention timePulp by-products recoveryLime productionBlack liquorPrecipitation

The method is for separation of lignin from original black liquor (BLIN) and has the following phases in sequence. A first precipitation phase (PR1) for precipitation of lignin by a first acidification of the original black liquor by adding a first acid or mixture of acids (G1a) followed by a first storage phase wherein precipitated lignin particles are allowed to increase in size, followed by a second precipitation phase (PR2) for precipitation of lignin by a further acidification of the original black liquor by adding a second acid or mixture of acids (G1b). By retaining the acidified black liquor for at least 25 minutes in the storage phase are the precipitated lignin particles allowed to grow in size and the filterability is improved considerably.

Owner:VALMET AB

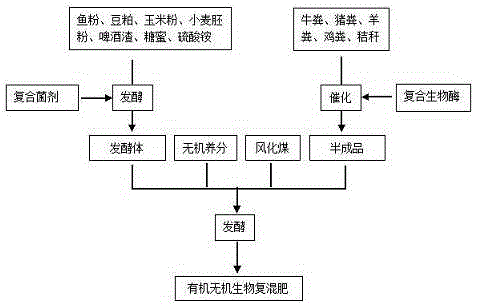

Organic and inorganic biological compound fertilizer

ActiveCN105175047AReduce utilizationIncrease profitBio-organic fraction processingOrganic fertiliser preparationBiotechnologyMicroorganism

The present invention discloses a composite microbial agent fermented organic and inorganic biological compound fertilizer, and belongs to the technical field of agricultural fertilizer. The compound fertilize is characterized by consisting of the following materials by weight: 50-55 parts of a semi-finished product, 35-40 parts of an inorganic nutrient, 8-12 parts of weathered coal, and a fermentation body accounting for 1.0-2.0% of the total weight of the above, wherein the biological composite enzyme accounts for 0.01-0.02% of the total weight of the semi-finished product. The present invention has the beneficial effects that microbial fermentation technology is utilized to convert organic materials and chemical fertilizers into organic ingredients, through bioconversion, so as to improve the utilization of fertilizers as well as make crops absorb the necessary nutrients faster and more timely. Chemical nutrients and composite microbial agents are added in a secondary fermentation process, the decreased temperature of the secondary fermentation and microbial fermentation are used to convert inorganic elements, in order not only to avoid the inorganic nutrient loss in high temperature fermentation but also improve the survival rate of microorganisms.

Owner:甘肃明德伟业生物科技有限公司

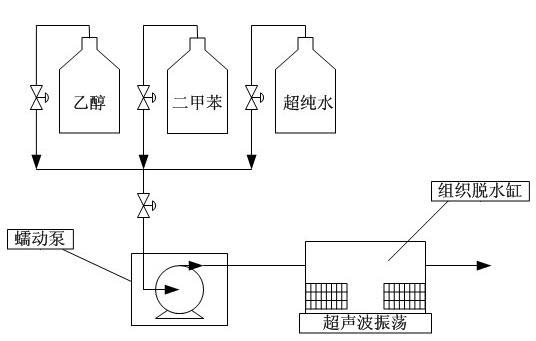

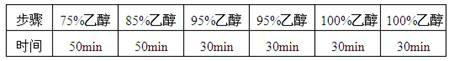

Biological tissue dehydrator and application thereof

InactiveCN101923018AEfficient dehydrationAvoid damagePreparing sample for investigationDiffusion theoryUltrasonic vibration

The invention relates to a dehydrated method using a biological tissue dehydrator, belonging to the field of biological pathology detection. The biological tissue dehydrator is a continuous feeding and discharging airtight sample slot. In the dehydrating mode of the dehydrator, a biological pathology tissue is fixed in the sample slot, and dehydrating agents the concentrations of which are from low to high are continuously introduced to carry out dehydration. In the process of tissue dehydration or transparency, the speed of molecular diffusion is increased, the tissue dehydration and transparency speed is accelerated and the high-efficiency dehydration and transparency of the pathology tissue are realized according to a diffusion theory through stirring or supersonic vibration in the sample slot. The invention has important facilitation on promoting the speed and the efficiency of biological pathology tissue detection.

Owner:FUZHOU UNIV

Electric dewatering apparatus for crude oil

InactiveCN1386824AReduce power consumptionStable operation processDewatering/demulsification with electric/magnetic meansSemiconductor electrodeOil field

An electric dewatering device for pretreating high-water crude oil in oil field is characterized by use of semiconductor electrode or the metal electrode coated with semiconductor layer for preventing the over-current caused by the high electric conductivity of crude oil due to high water content and the over-drop of voltage. Its advantages are high effect on removing water and salt, and saving electric energy by 50%.

Owner:CHINA PETROCHEMICAL CORP +1

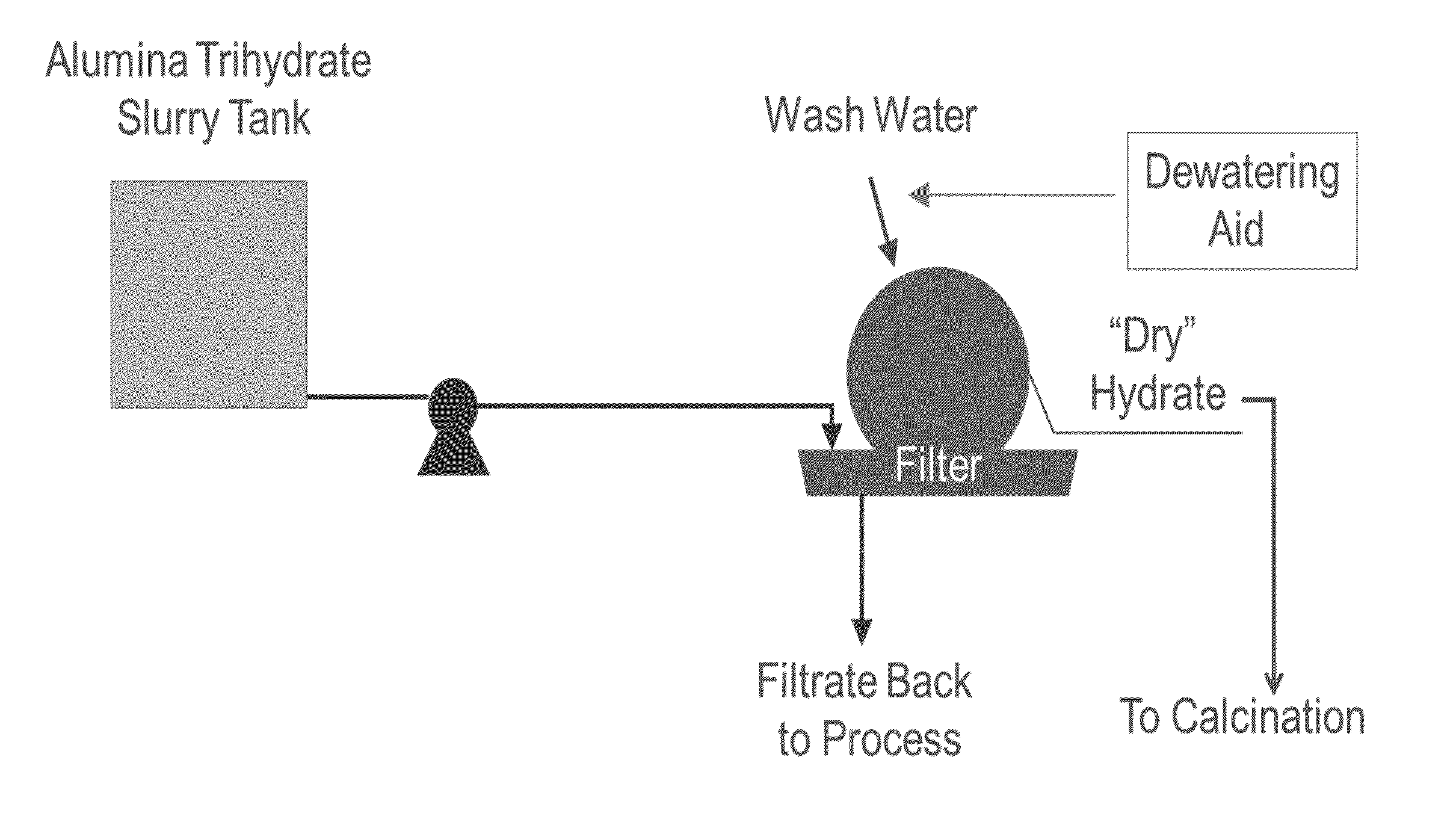

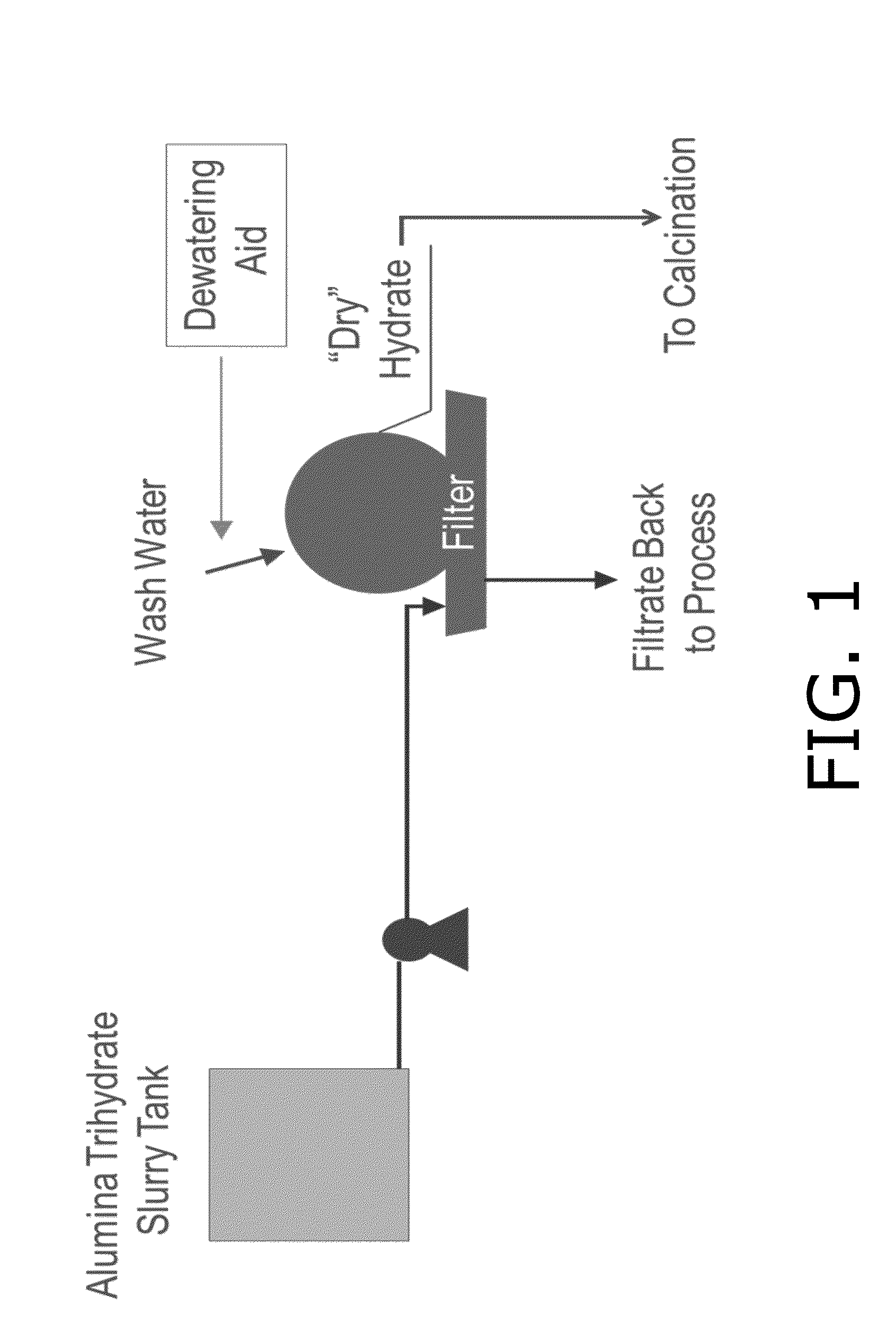

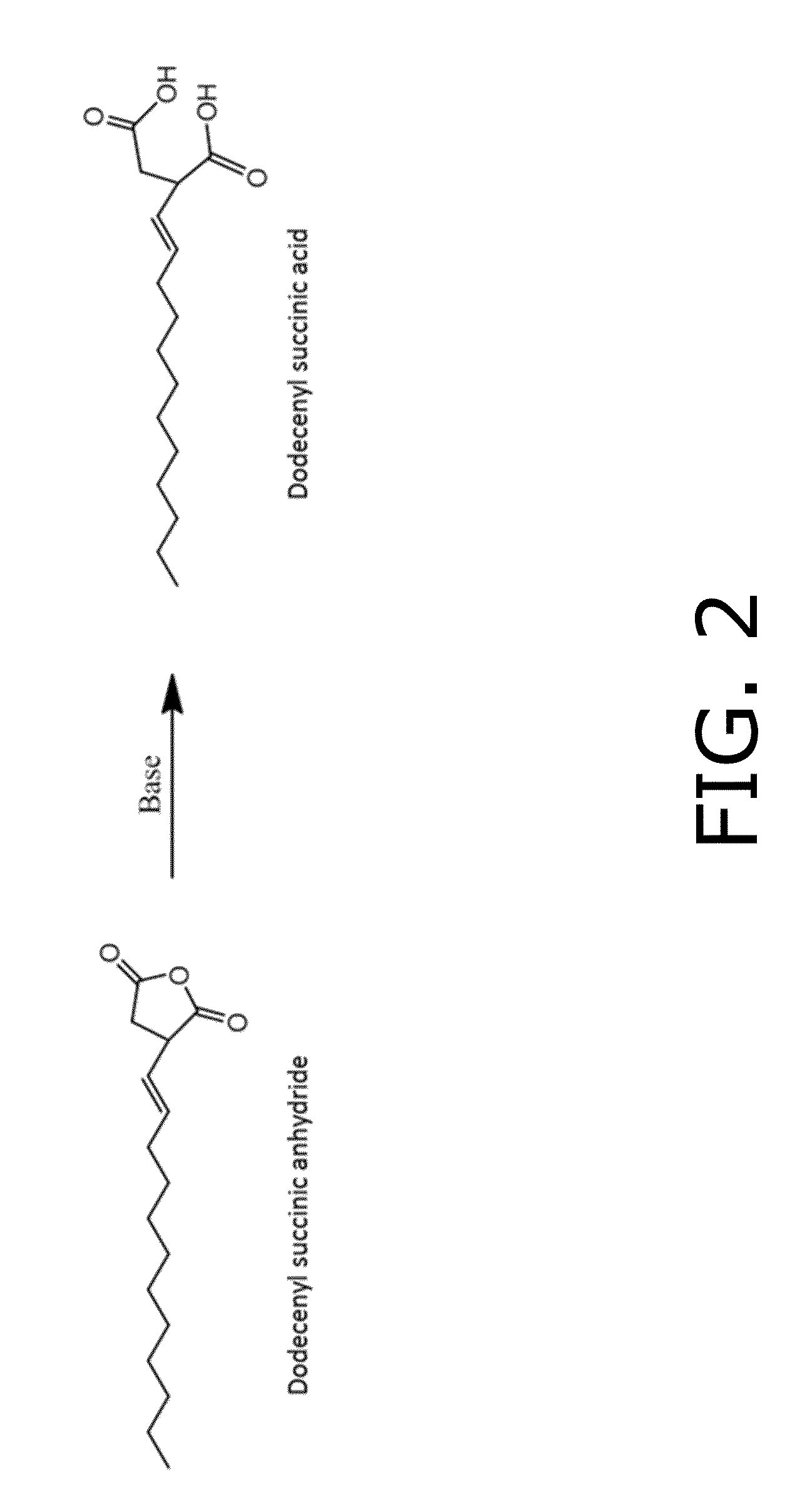

Alternative additives to enhance slurry dewatering

ActiveUS20150240328A1Accelerates the dehydration processGallium/indium/thallium compoundsBeryllium compoundsSlurrySuccinic acid

The invention provides methods and compositions for improving dewatering of Bayer Process alumina trihydrate slurry. The method comprises adding an R-Succinic Compound (such as octadecenyl succinic acid, hexadecenyl succinic acid, and / or dodecenyl succinic acid) to the slurry. The R-Succinic Compound removes water that would otherwise be trapped within the filtered slurry cake and therefore reduces the energy needed to calcine the resulting solids.

Owner:ECOLAB USA INC

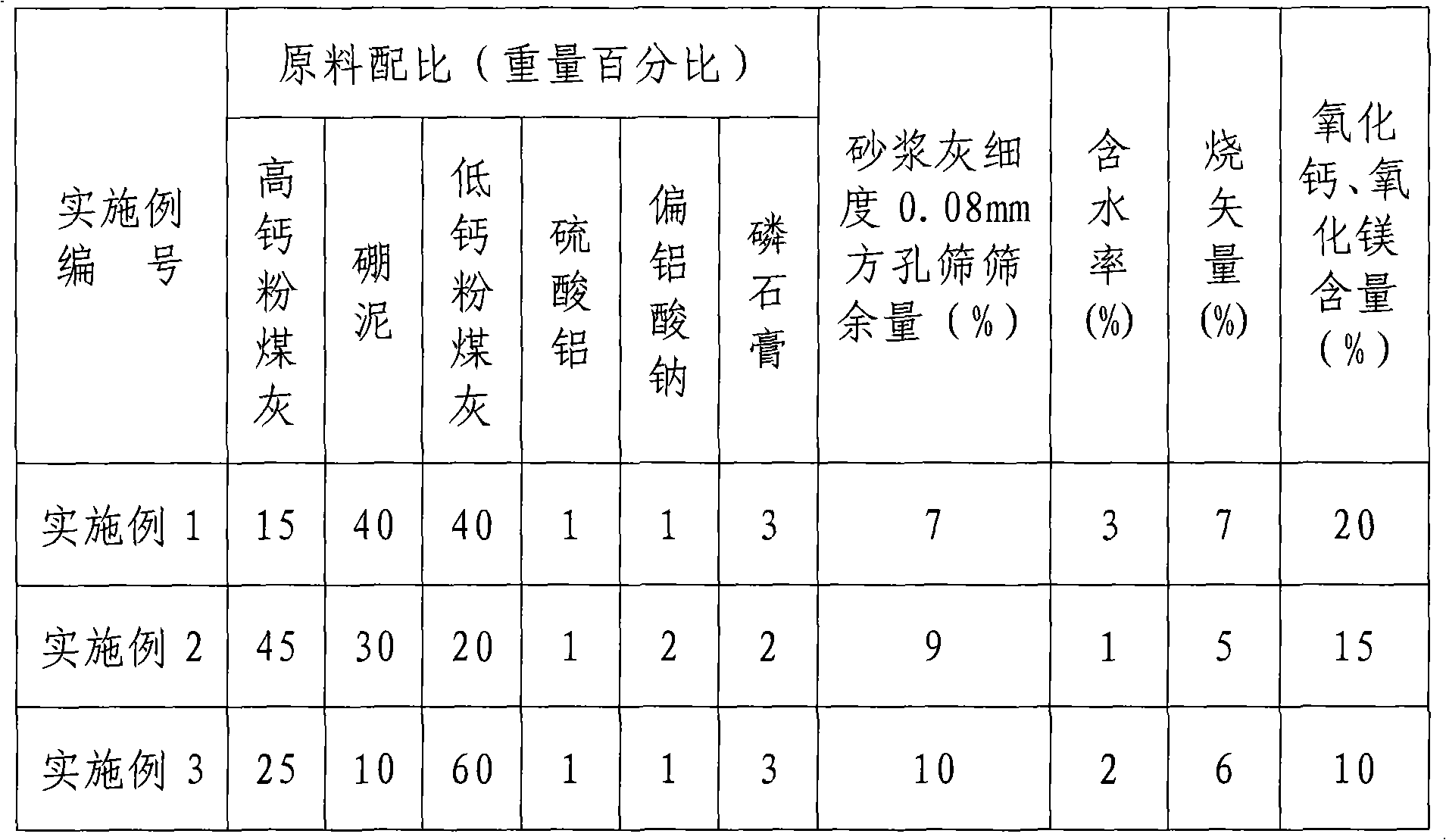

Method for producing mortar ash by using high-dopant fly ash and boron mud

The invention relates to a method for producing mortar ash by using high-dopant fly ash, boron mud, little ardealite and excitant. The produced mortar ash can completely replace lime, can replace 20% of five species of cement, and can be widely used for masonry, inner wall plasterer, highway subgrade and production of hollow bricks and floor tiles and the like. In the invention, the process is simple, cement clinker and crystal slab are not added during the course of processing, the dopant amounts of the boron mud and fly ash are up to 80%; and the investment is less, and the cost is low, the grade I and II mortar ashes produced by the method do not contain chloridions, and the properties (such as peaceability, microexpansibility, dehydration, strength and the like) of the grade I and II mortar ashes are far higher than those of the existing fly ash and mortar ash as well as calcined lime powder for construction.

Owner:芦素华

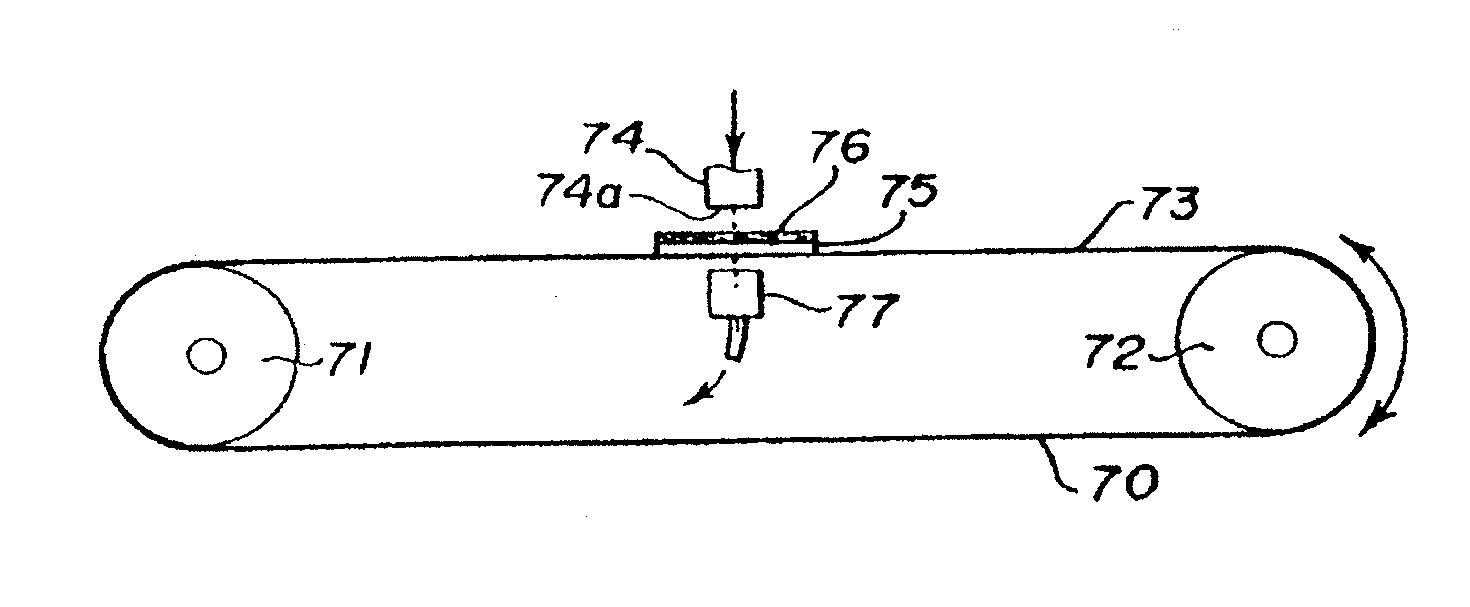

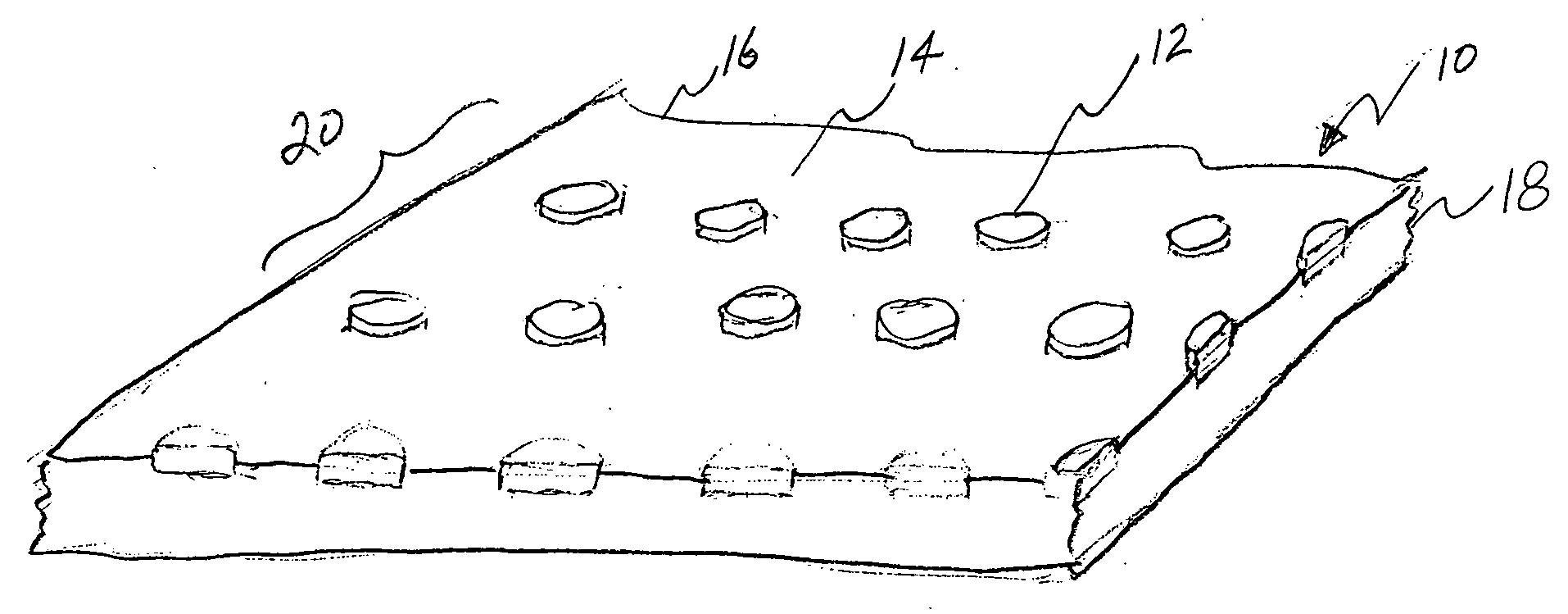

Patterned press fabric

InactiveUS20080163998A1Accelerates the dehydration processEffective markingWood working apparatusPaper/cardboardRegular gridGrid pattern

A press fabric having a plurality of surface pressing plates on a sheet side of the fabric imparts an impression onto a sheet of paper web during a pressing process. The surface pressing plates are preferably resin pressing plates, and form at least one of a random pattern of dots, a predetermined pattern of dots, a grid pattern of dots, a regular grid pattern of lines, an irregular grid pattern of lines a plurality of squiggly lines, a plurality of wavy lines, a plurality of straight lines, words and pictures.

Owner:VOITH PATENT GMBH

Yellow card paper and manufacturing method thereof

InactiveCN104195877AGuaranteed evennessAvoid strong dryingWater-repelling agents additionLuminescent/fluorescent substance additionSulfateHue

The invention relates to a yellow card paper and a manufacturing method thereof. The manufacturing method is mainly characterized by comprising the following steps: respectively preparing bleached sulfate softwood pulp, bleached sulfate reed pulp and poplar PRC-APMP pulp; making paper from the bleached sulfate softwood pulp, the bleached sulfate reed pulp and the poplar PRC-APMP pulp according to the weight ratio of (15%-25%) to (35%-45%) to (35%-40%); optimizing dye types and different dye ratios; and with a CPAM and cationic starch retention system, carrying out soft roll calendaring treatment. The prepared yellow card paper has the characteristics that the fixed amount is 103-106g / m<2>, the thickness is greater than or equal to 140 microns, the moisture content is 4%-6%, the hygroscopic property is smaller than or equal to 30g / m<2>, the transverse folding strength is greater than or equal to 6 times, the transverse expansion rate is smaller than or equal to 3.2%, the longitudinal fracture length is greater than or equal to 3500m, the smoothness is greater than or equal to 20s, the two side difference is smaller than or equal to 30%, the b value is 26, and the content of dust of 0.2mm<2> to 1.5mm<2> is smaller than or equal to 60 / m<2>. The yellow card paper disclosed by the method is stable in hue and low in cost.

Owner:YUEYANG FOREST & PAPER CO LTD

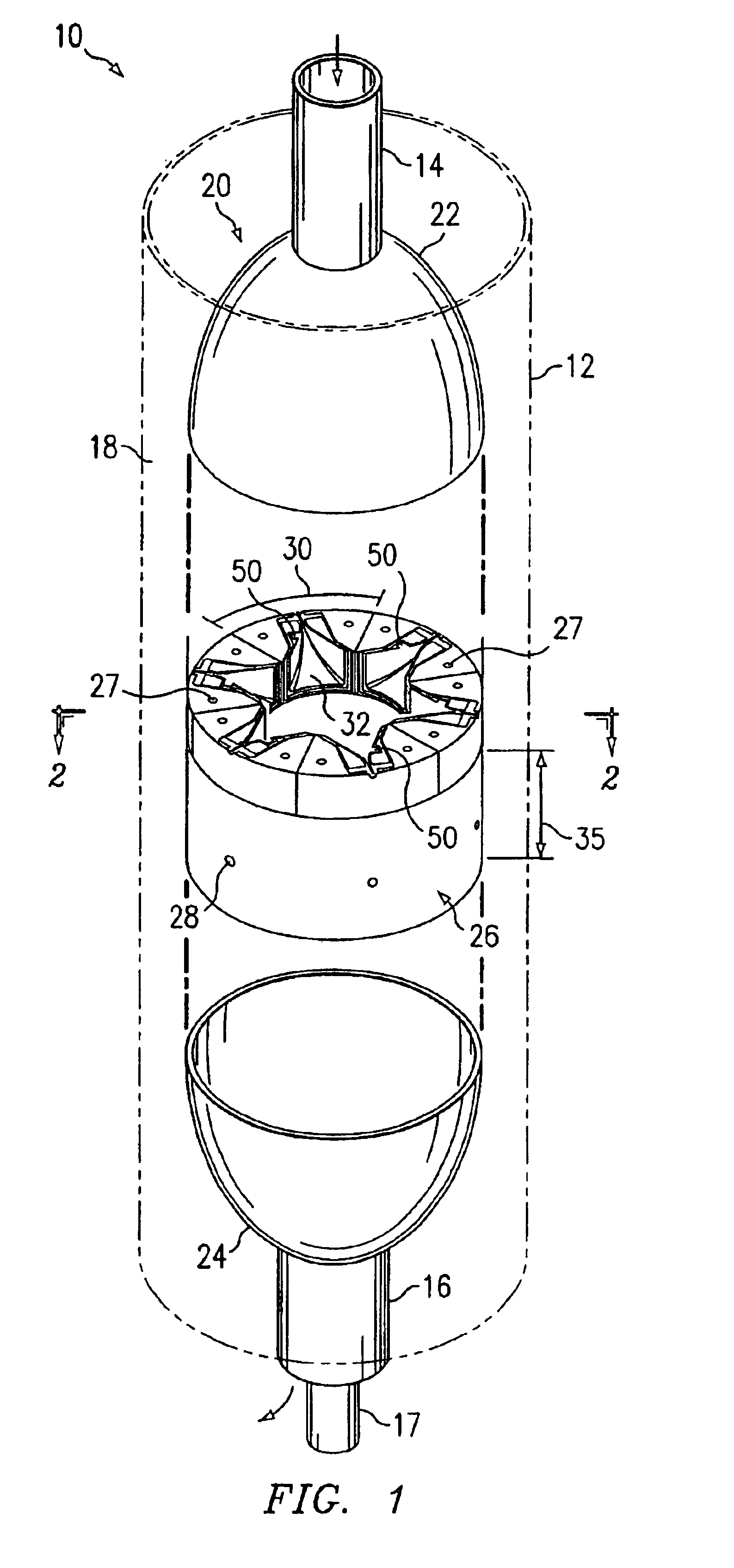

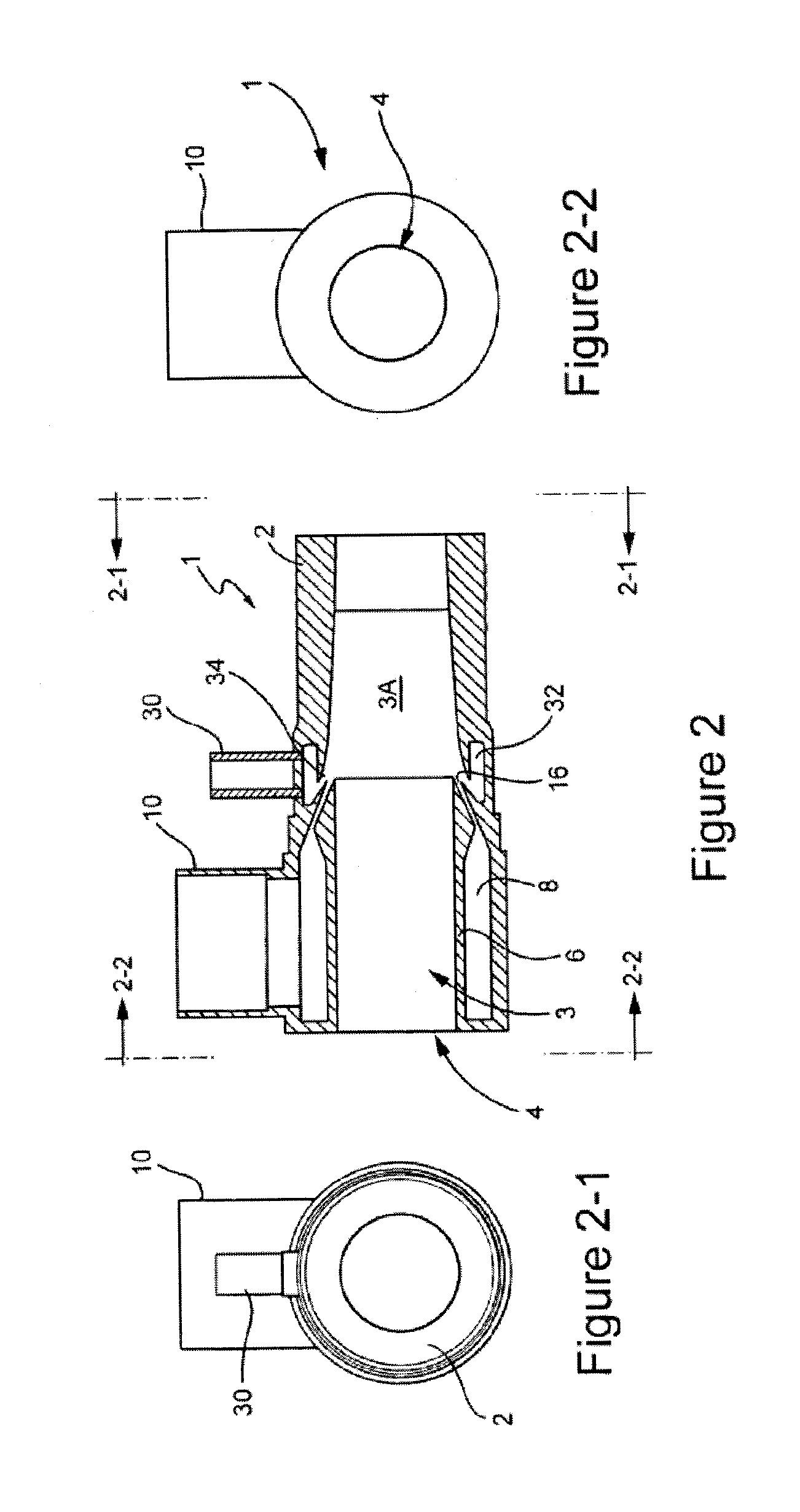

Centrifuge with combinations of multiple features

InactiveUS20060065605A1Reduce the effects of frictionReduce frictionWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationVolumetric Mass DensityVALVE PORT

A centrifuge with combinations of multiple features is disclosed. In one aspect, a centrifuge for removing more dense material from a fluid medium includes a fluid separation wall placed within a sleeve. The fluid separation wall rotates around the axis of rotation. A receptacle aids in separation of the more dense material from the fluid medium. The receptacle defined in a part by a respective geometry and a respective shape. An opening extends from the void area to the outer surface to transport the more dense material to the containment zone. An excitation apparatus associated with the receptacle creates a vibration within the receptacle. The centrifuge may further include a valve ring including a valve orifice the valve ring having a first position which blocks the more dense material from exiting the receptacle and a second position that allows the more dense material to move into the containment zone.

Owner:PHASE

Method for vibration in a centrifuge

InactiveUS6932913B2Reduce the effects of frictionReduce frictionWater/sewage treatment by centrifugal separationDispersed particle separationEngineeringVoid space

A system and method for vibration in a centrifuge is disclosed. A centrifuge for removing more dense material from a fluid medium includes a fluid separation wall placed within a non-rotating sleeve. The fluid separation wall rotates around the axis of rotation and includes an inner surface and an outer surface with at least one receptacle formed on the inner surface of the fluid separation wall. The receptacle aids in separation of more dense material from the fluid medium by forming a void space between the inner and outer surface. An excitation apparatus associated with the receptacle to create a vibration within the receptacle. A flow path may extend through the wall from the void area to the outer surface to transport more dense material to the containment zone.

Owner:PHASE

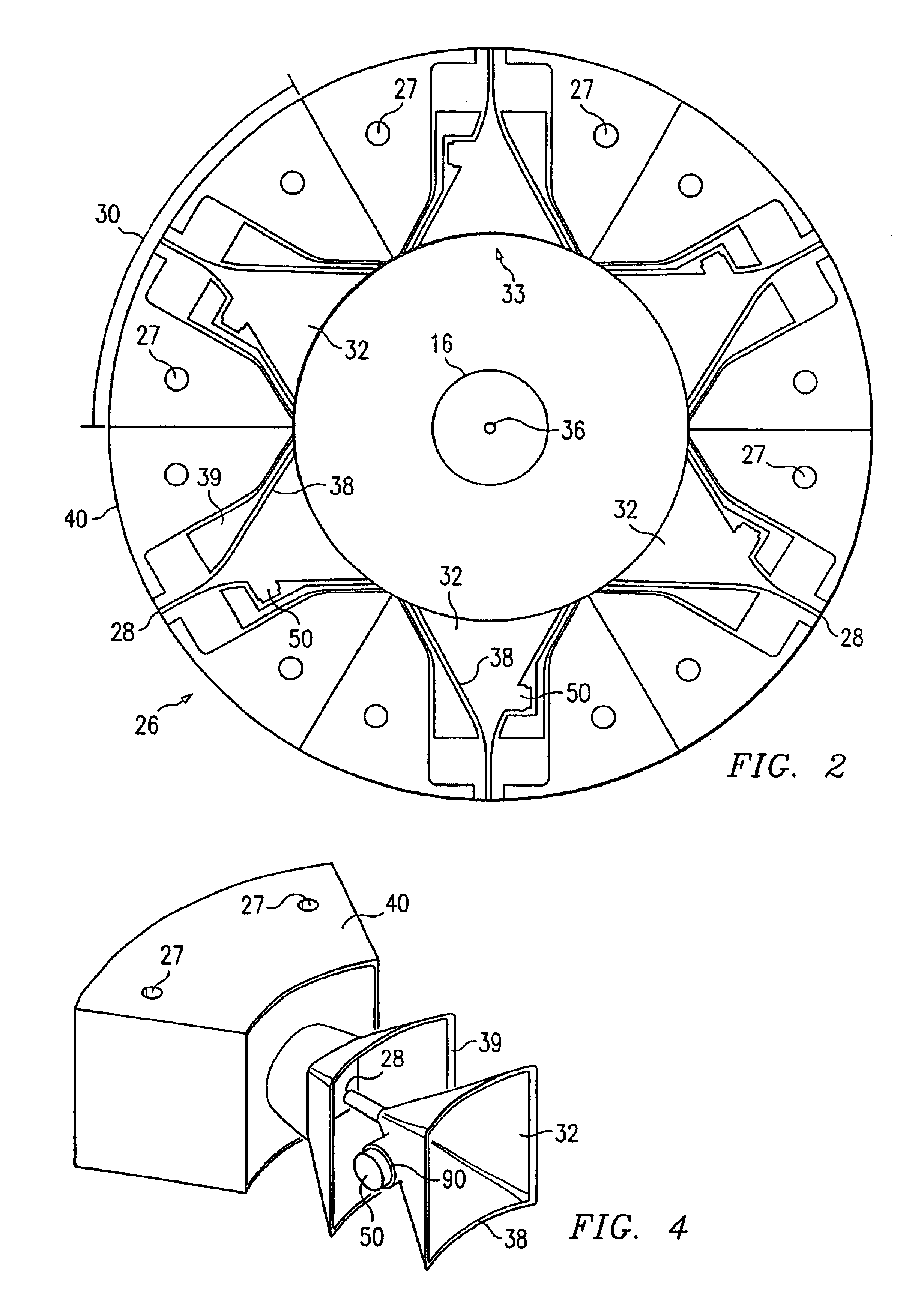

Phosphogypsum desulfurization calcining treatment system and method

PendingCN112142350ANo cloggingSmall finenessSulfur compoundsCalcium/strontium/barium oxides/hydroxidesThermodynamicsPortland cement

A phosphogypsum desulfurization calcining treatment system and method are included. the phosphogypsum desulfurization calcining treatment system comprises a low temperature dehydration system, a hightemperature calcination system and an acid making system, the low temperature dehydration system sequentially comprises a dryer, a drying mill and a pipeline furnace, the high temperature calcinationsystem sequentially comprises a preheating device, a rotary kiln and a cooler, natural water and crystal water are removed from phosphogypsum through low-temperature drying and high-temperature grinding and drying to obtain anhydrous gypsum, high-temperature calcination is carried out on the anhydrous gypsum, air cooling is carried out, the calcined anhydrous gypsum is sent to a cement productionline as a cement raw material, and gas generated in the calcination process is collected, and then sent to an acid making system to prepare sulfuric acid. According to the invention, a phosphogypsum acid making system and a cement system are separated, phosphogypsum dehydration, phosphogypsum decomposition, kiln gas acid making and resource comprehensive utilization of kiln slag are included, so that mutual interference between a desulfurization process and a cement process can be reduced, production of high-quality Portland cement and high-quality sulfuric acid is ensured, and harmless, resource and large-batch treatment of phosphogypsum is realized.

Owner:长沙中硅环保科技有限公司

Mixed demulsifier of asp flooding produced liquid

InactiveUS20090186782A1Accelerates the dehydration processFast dehydrationDewatering/demulsification with chemical meansFatty/oily/floating substances removal devicesSolventPropanediol

The present invention discloses a mixed demulsifier of ASP flooding production liquid. The demulsifier consists of a functional demulsifier from 70 to 30% by mass and a mixed solvent from 30 to 70% by mass based on the mass of the demulsifier; the functional demulsifier is formed by mixing a polyethylidene polyamine polyoxypropylene polyoxyethylene ether from 35 to 70% by mass and a propanediol polyoxypropylene polyoxyethylene ether from 30 to 65% by mass based on the mass of the functional demulsifier; the mixed solvent comprises one or more of xylene, ethylbenzene, mixed benzene, solvent oil, methanol and isopropanol, or a mixed solution thereof with water. The demulsifier of the present invention has the advantages of high dehydration ratio, quick dehydration speed and flush oil-water interface over the prior art. Upon the demulsification of the production liquid, the oil content of the sewage is less than 200 mg / L and the water content of the oil is less than 8%, so that the effect of oil-water separation of the production liquid is far better than that of the control demulsifier. The demulsifier of the present invention is an excellent mixed demulsifier for treating the ASP flooding production liquid.

Owner:BEIJING HAIEN RUNDE CHEM SCI & TECH +1

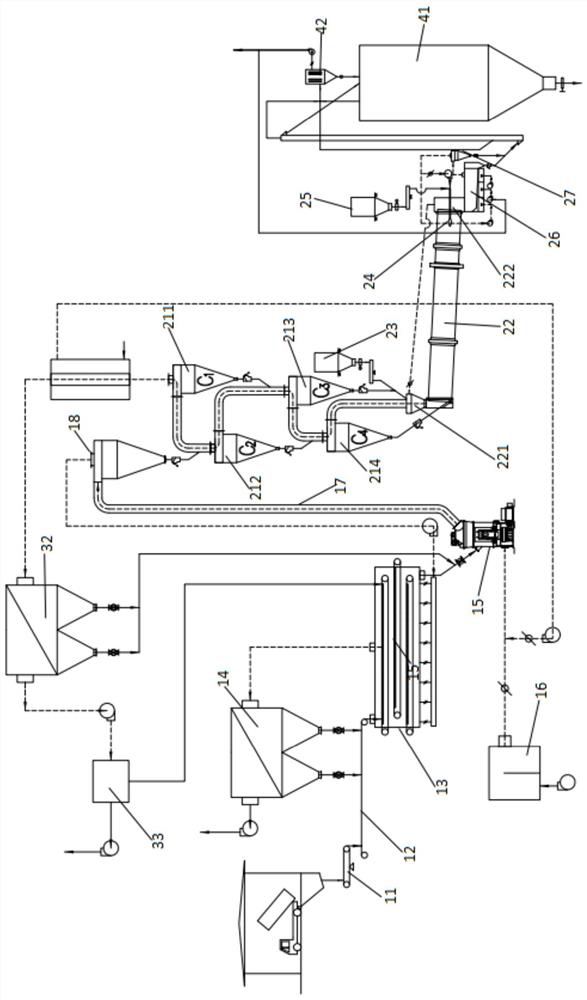

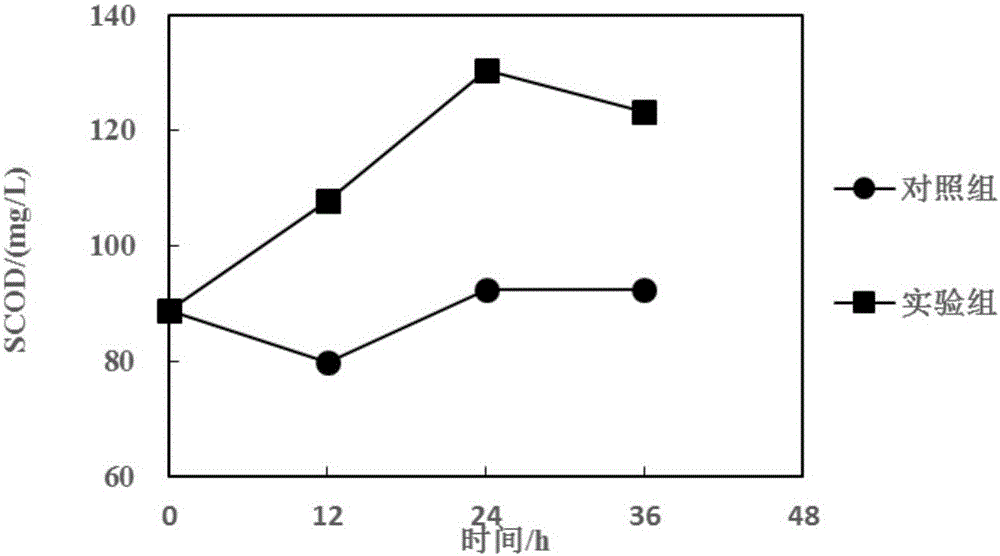

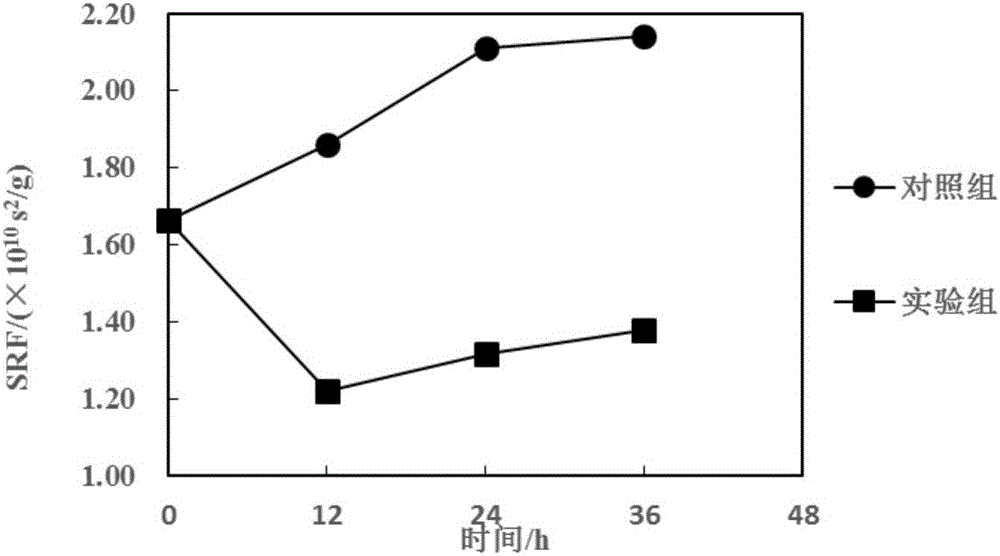

Phagocytosing type bacterium and application thereof in reducing sludge

ActiveCN105969690AImprove dehydration and weight loss performanceImprove biodegradabilityBacteriaSpecific water treatment objectivesMicroorganismEcological safety

The invention discloses a phagocytosing type bacterium. The phagocytosing type bacterium is identified to be a bdellovibrio organism, called bdellovibrio for short and classified and named as Bdellovibrio sp., the strain is preserved in the China General Microbiological Culture Collection Center on May 12th, 2016, and the preservation serial number is CGMCC No.11671. The invention further discloses application of the phagocytosing type bacterium in reducing sludge, and further discloses a bacterium extract. The strain is obtained through screening in sludge of a secondary sedimentation tank of a municipal wastewater treatment plant and meets the biosafety regulations; the strain serves as the phagocytosing type bacterium to be applied in sludge cell disruption dewatering, and the sludge dewatering and reducing performance is greatly improved by phagocytosing suspension bacteria and splitting sludge flocs, so that the operation cost of the wastewater treatment plant is reduced, both ecological safety and sanitary safety are considered, and the ecological civilization construction of the environment is promoted.

Owner:SOUTHEAST UNIV

Methods and systems for biodegradable waste flow treatment using a transport fluid nozzle

InactiveUS20150096343A1Improve balanceFocusBio-organic fraction processingExcrement fertilisersWaste streamSewage

The present invention is directed to methods and systems for pre-treating sewage sludge in a sewage treatment works (STW) to facilitate anaerobic digestion. These methods include (a) passing sewage sludge through one or more pre-treatment devices, wherein each pre-treatment device comprises (i) a passage of substantially constant diameter having an inlet in fluid communication with the STW and an outlet; and (ii) a transport fluid nozzle communicating with the passage and adapted to inject high velocity transport fluid into the passage; (b) passing the sewage sludge treated in step (a) to an anaerobic digester; and (c) collecting methane produced in step (b). Other methods are also provided for pre-treating a bio-degradable waste flow. Such methods include (a) passing bio-degradable waste flow through one or more pre-treatment devices, wherein each pre-treatment device comprises (i) a passage of substantially constant diameter having an inlet in fluid communication with the bio-degradable waste flow and an outlet; and (ii) a transport fluid nozzle communicating with the passage and adapted to inject high velocity transport fluid into the passage; (b) dewatering the bio-degradable waste flow from step (a); and (c) optionally compacting the material resulting from step (b).

Owner:PURSUIT MARINE DRIVE

Method for lignin separation from black liquor comprising multiple acidification steps

InactiveUS20140288284A1Process can be stoppedLong retention timeLignin derivativesPulp by-products recoveryBlack liquorPrecipitation

The method is for separation of lignin from original black liquor (BLIN) having the following phases in sequence; a first precipitation phase (PR1) for precipitation of lignin by a first acidification of the original black liquor by adding a first acid or mixture of acids (G1a); followed by a second precipitation phase (PR2) for precipitation of lignin by a further acidification of the original black liquor by adding a second acid or mixture of acids (G1b). The first phase is implemented to lower the pH while avoiding any larger amount of precipitation, i.e. less than 2-5%, while the second phase is implemented in order to obtain the larger part of the precipitation. In total is 40-70% of the total lignin content of the original black liquor precipitated while the residual black liquor after precipitation is still strongly alkaline.

Owner:VALMET AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com