Emulsion-type silicone resin defoamer for papermaking and pulping

A technology of silicone resin and defoamer, which is applied in the direction of defoamer, papermaking, textiles and papermaking, etc., can solve the problems of unsatisfactory defoaming effect and high cost, and achieve the effect of improving washing effect, high profit and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

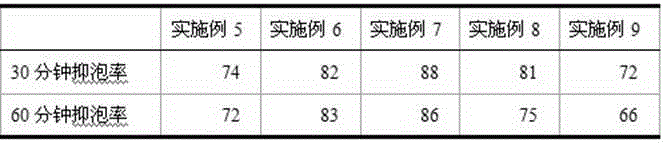

Examples

Embodiment 1

[0020] Example 1: Mix 20 parts of hexaphenyldisiloxane, 20 parts of tetramethoxysilane, 5 parts of water, 20 parts of ethanol, and 1 part of hydrochloric acid in 60 o C to react for 6 hours, then add 2 parts of NaOH to react until alkaline, remove water under reduced pressure; then add 30 parts of hydroxyl silicone oil (20cst), 50 parts of epoxy-containing siloxane, 10 parts of decanediamine, o C continued to react for 6 hours to obtain special-effect silicone resin A with a cross-linked network structure.

Embodiment 2

[0021] Example 2: 60 parts of hexaphenyldisiloxane, 5 parts of tetramethoxysilane, 20 parts of water, 5 parts of ethanol, and 5 parts of hydrochloric acid were mixed at 80 o C to react for 2 hours, then add 10 parts of NaOH to react to alkalinity, remove water under reduced pressure; then add 100 parts of hydroxyl silicone oil (1000cst), 30 parts of epoxy-containing siloxane, 1 part of hexamethylenediamine, at 200 o C continued to react for 0.5 hours to obtain special-effect silicone resin B with a cross-linked network structure.

Embodiment 3

[0022] Example 3: 20 parts of hexamethyldisiloxane, 20 parts of tetramethoxysilane, 5 parts of water, 20 parts of ethanol, and 1 part of hydrochloric acid were mixed at 60 o C to react for 6 hours, then add 2 parts of KOH to react until alkaline, remove water under reduced pressure; then add 30 parts of hydroxyl silicone oil (20cst), 50 parts of epoxy-containing siloxane, 10 parts of decanediamine, at 120 o C continued to react for 6 hours to obtain a special-effect silicone resin C with a cross-linked network structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com