Patents

Literature

1269results about How to "Production environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

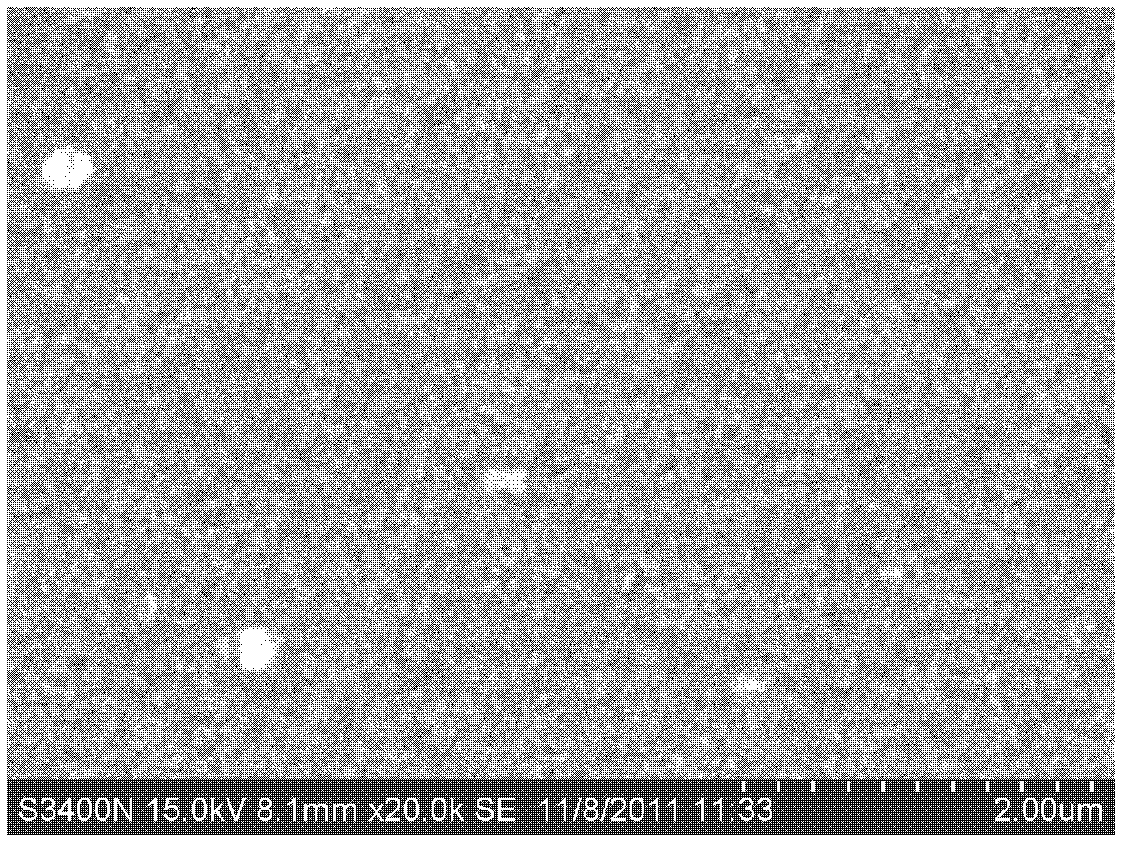

Special high-performance carbon paper for gas diffusion layer of fuel cell and preparation method of carbon paper

InactiveCN103556543ASimple processProduct quality is easy to controlSpecial paperCell electrodesThermal bondingPapermaking

The invention relates to carbon paper and a preparation method thereof and particularly relates to special high-performance carbon paper for a gas diffusion layer of a fuel cell and a preparation method of the carbon paper. By taking short carbon fibers, plant fibers, heat bonding fibers and carbon black as raw materials, the carbon paper is prepared by the following steps: defibering, pulping and proportioning; then carrying out papermaking by adopting a wet-method papermaking process; and carrying out waterproof pigment coating treatment. The ratios of all the raw materials are as follows in parts by weight: 65-75 parts of the short carbon fibers, 10-15 parts of the plant fibers, 10-15 parts of the heat bonding fibers and 0-10 parts of the carbon black. According to the special high-performance carbon paper for the gas diffusion layer of the fuel cell and the preparation method of the carbon paper, a production process combining wet-method formation, hot pressing and coating is adopted and has the characteristics of simple process flow, easiness for controlling product quality, environment-friendly production process and the like; the material ratio of each raw material can be accurately controlled in the production so as to be good for controlling the product quality.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

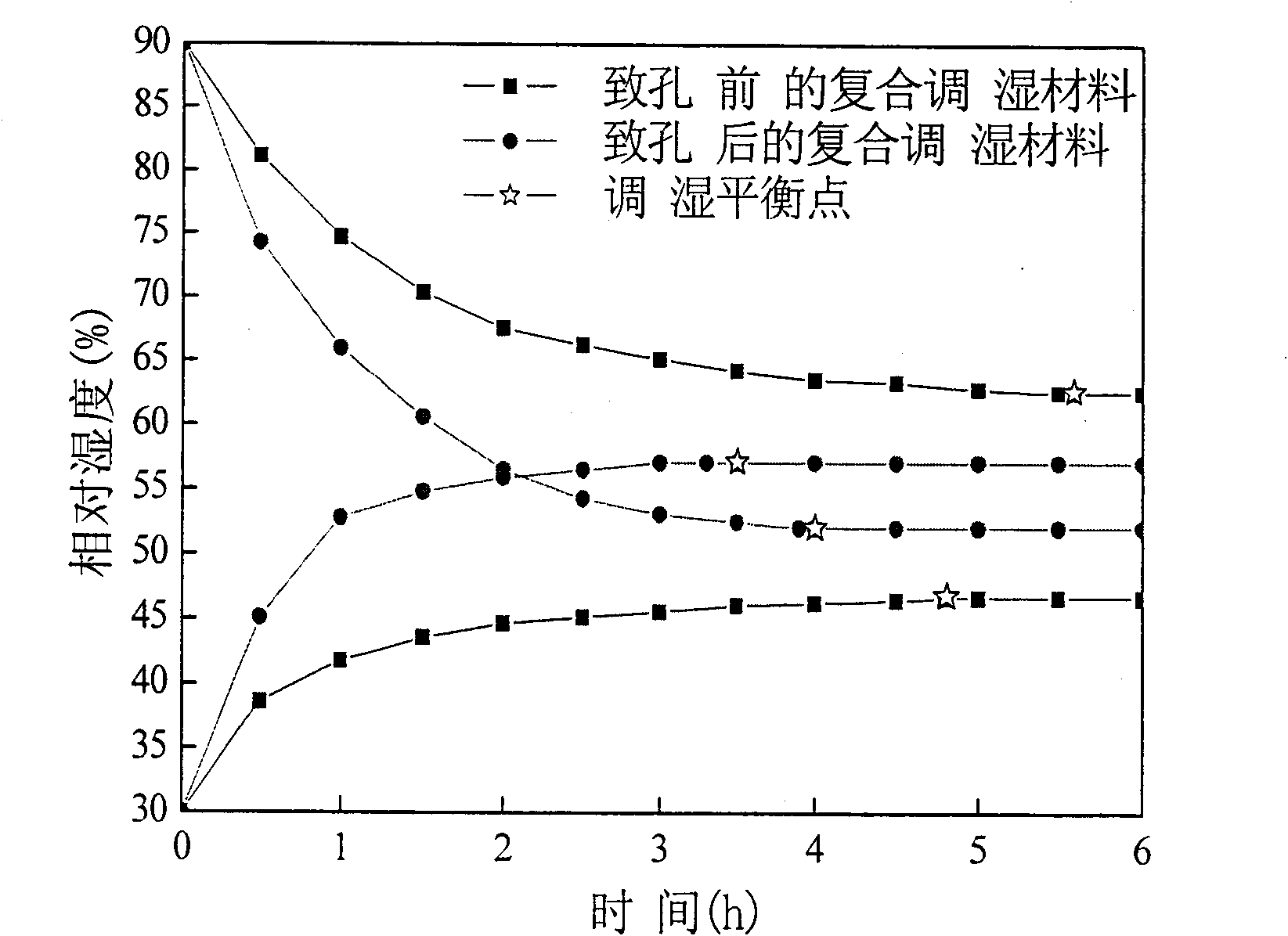

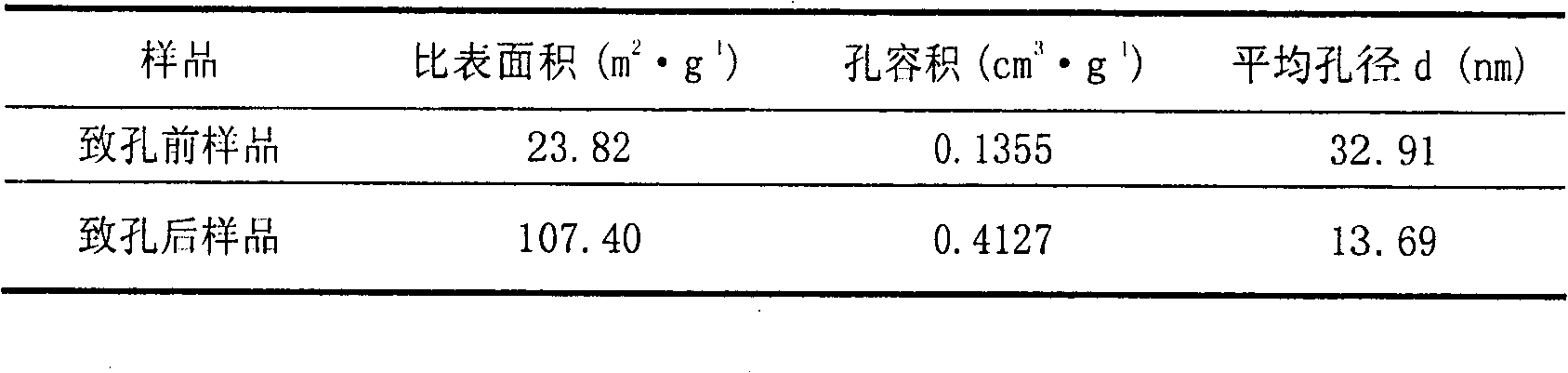

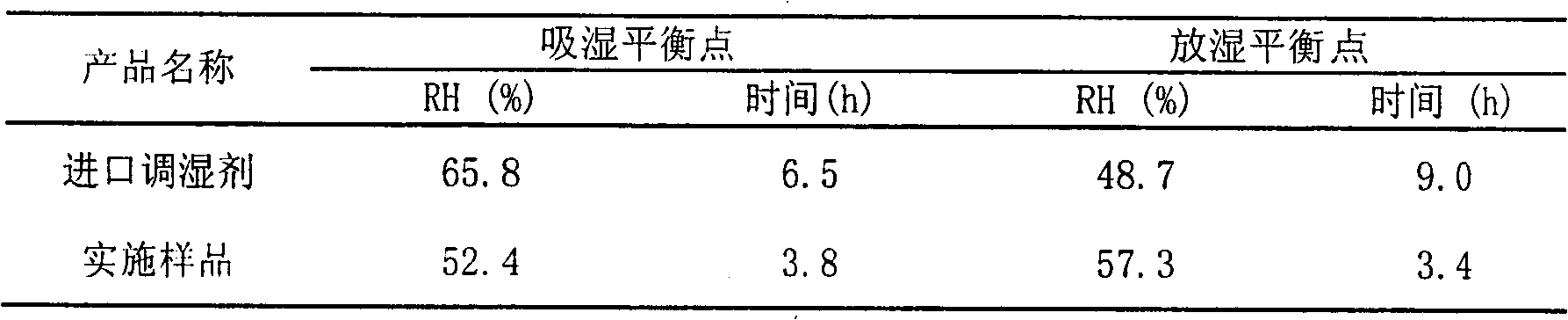

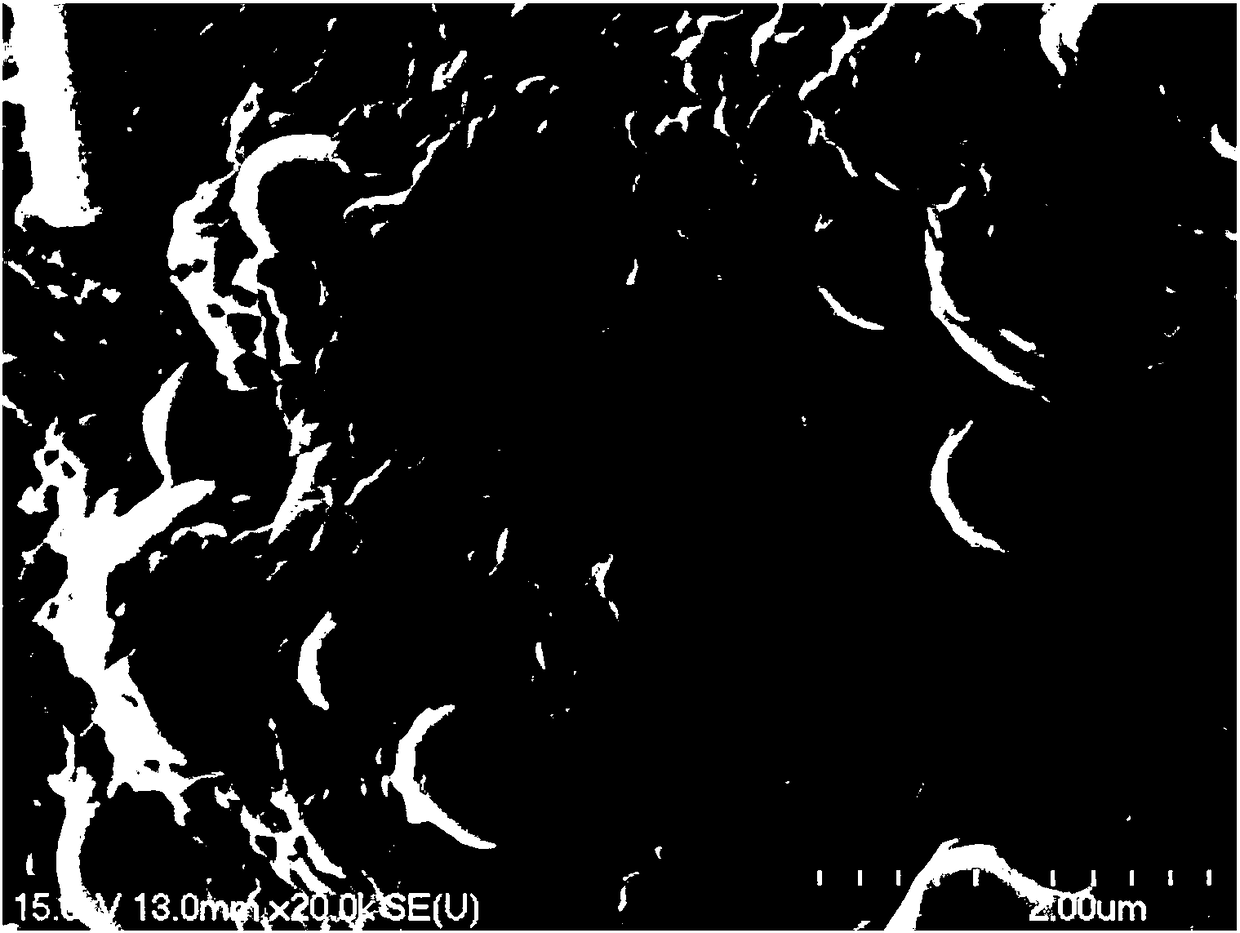

Method for preparing nano pore composite humidity adjusting material

InactiveCN101928438AQuickly adjust relative humidityLarge moisture absorption capacityOther chemical processesHigh humidityNano size

The invention discloses a method for preparing a nano pore composite humidity adjusting material. An organic macromolecular material, a natural macromolecular material and an inorganic porous material are compounded into the humidity adjusting material by synthesis so as to absorb the advantages of various humidity adjusting materials and improve the wet capacity and humidity adjusting performance of the synthesized material; and a large amount of nano-scale pore structures are formed on the material through the synthesis process so as to further improve the humidity absorbing and discharging performance of a product. Compared with the prior art, the method has the advantages that: 1) the material has high humidity absorbing and discharging capacity and high humidity absorbing and discharging response speed, and can efficiently and quickly adjust the relative humidity of a microenvironment; 2) the material is renewable and very convenient to reuse; 3) the production process and the production equipment are simple and easy for industrialization; and 4) the production process is environmentally-friendly.

Owner:ZHEJIANG SCI-TECH UNIV

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

Micro-nano mixed welding paste capable of being used for pressureless sintering and preparation method thereof

ActiveCN108526751AInhibition of violent contractionImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMicro nanoOrganic solvent

The invention provides a micro-nano mixed welding paste capable of being used for pressureless sintering preparation and a packaging method thereof. The interior of a material is filled with micron-sized spherical particles as a matrix, and the nano-particles are uniformly filled in the material, sintering driving force is provided, so that the whole material is subjected to pressureless sinteringforming at a low temperature. The preparation method comprises the following steps of S1, preparing micron particles with specific sizes and carrying out acid washing and drying; S2, mechanically stirring the micron particle powder with a surfactant, an organic carrier and an organic solvent to obtain a mixture A; S3, fully mixing the metal nano-particles with a dispersing agent, the organic carrier and the organic solvent to obtain a mixture B; and S4, mixing the mixture A and the mixture B to obtain the micro-nano mixed welding paste. According to the micro-nano mixed welding paste capableof being used for pressureless sintering and the preparation method thereof, the welding paste solves problems of volume shrinkage and cracks of the nano welding paste during sintering, the reliability of the welding spots is improved, and the welding paste can be used for packaging and manufacturing for power devices; and according to the scheme, the production process of the welding paste is simplified, the preparation process is green and environment-friendly, the packaging method provided is simple and practical and is beneficial to market popularization.

Owner:深圳市先进连接科技有限公司

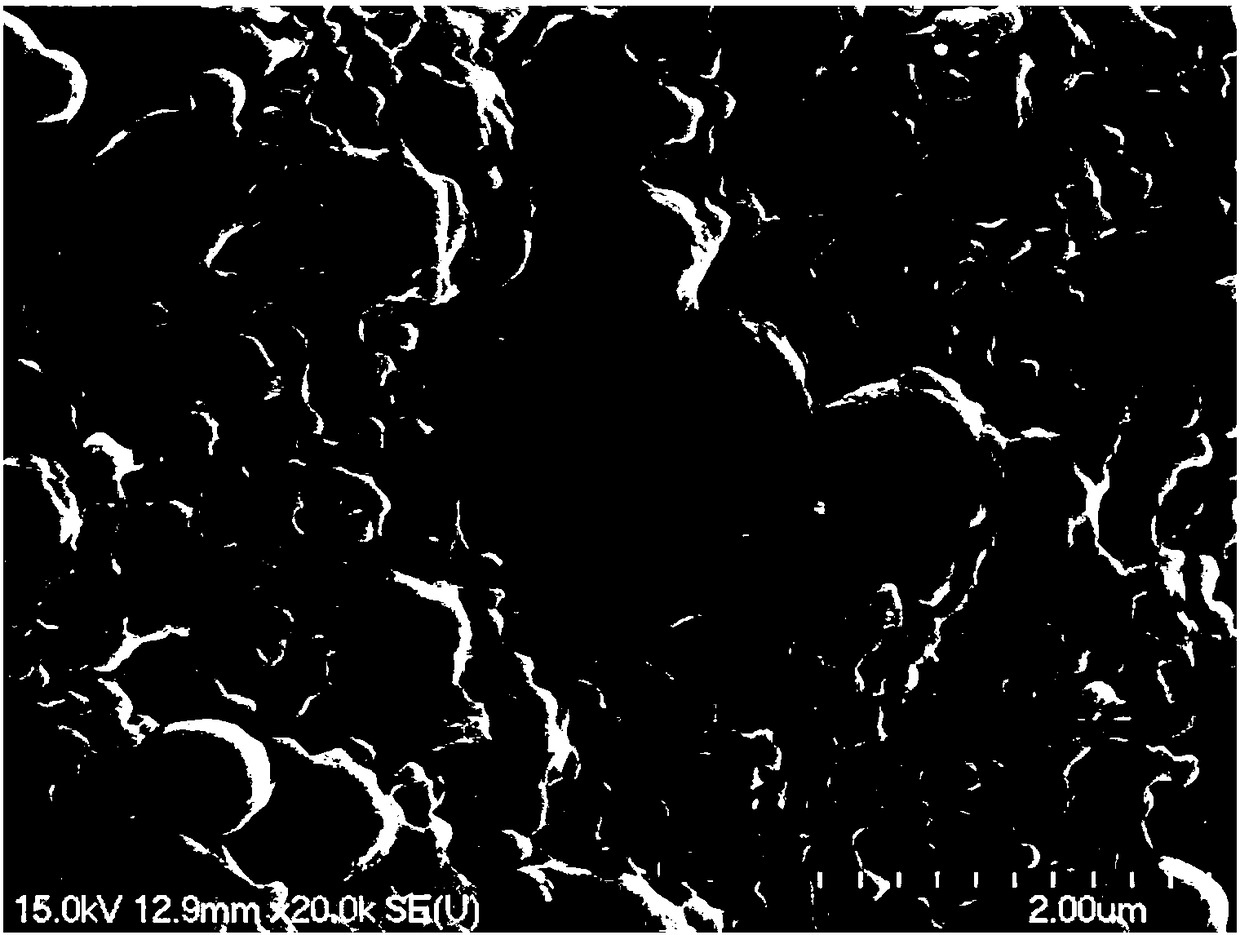

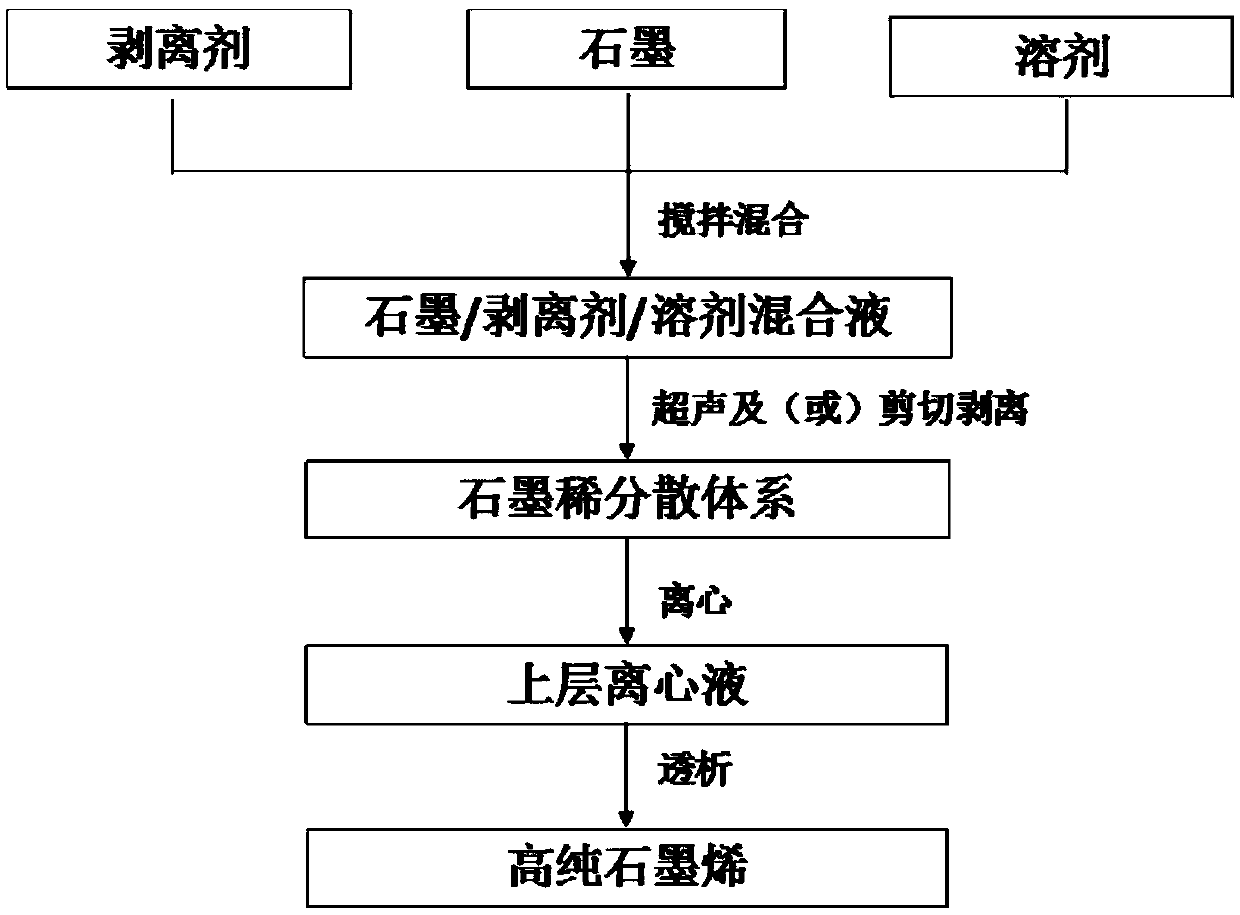

Liquid-phase stripping preparation method of graphene

ActiveCN105502371AReduce the number of layersHigh monolayer ratioSingle layer grapheneGraphiteCvd graphene

The invention provides a liquid-phase stripping preparation method of graphene. The liquid-phase stripping preparation method comprises the steps that first, an aromatic compound is used as a stripping agent to prepare a stripping agent solution, graphite powder is added, and graphite pre-stripping dispersion liquid is obtained after sufficient stirring; second, the graphite pre-stripping dispersion liquid obtained in the first step is subjected to stripping dispersion through ultrasonic and / or mechanical shear to obtain a graphene mixed dispersion system; third, the graphene mixed dispersion system obtained in the second step is centrifuged, the upper-layer solution can be taken for dialysis, and impurities are remove to obtain a pure graphene product. The liquid-phase stripping preparation method can effectively separate graphite flake layers, a large amount of graphene is obtained within a short period of time, and the prepared graphene is single-layer or double-layer graphene and is good in conductive / thermal performance and excellent in comprehensive performances. The liquid-phase stripping preparation method has the advantages of being simple in operation, high in efficiency and green, being environmentally-friendly and the like, and achievement of industrialized graphene preparation is hopeful.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

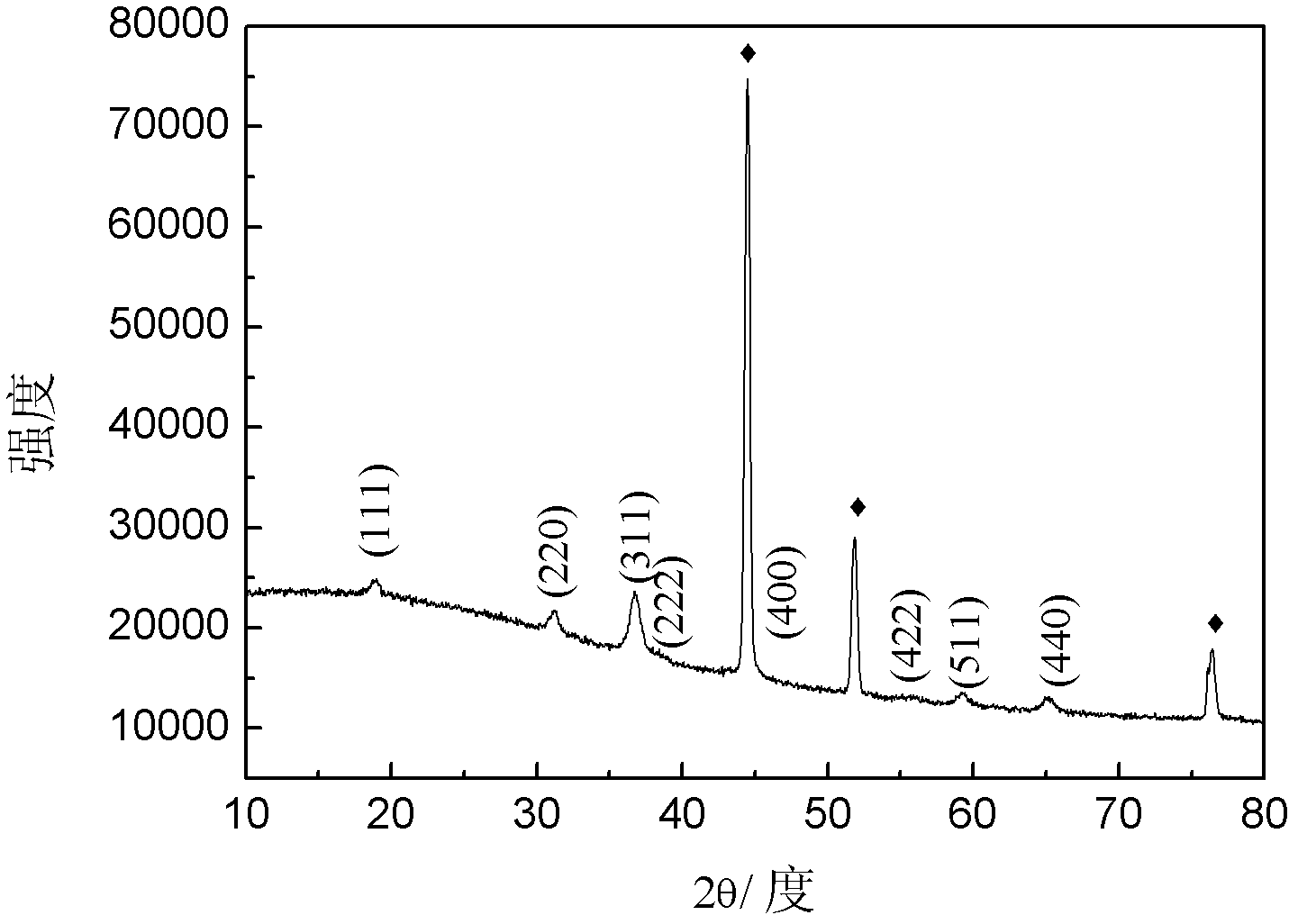

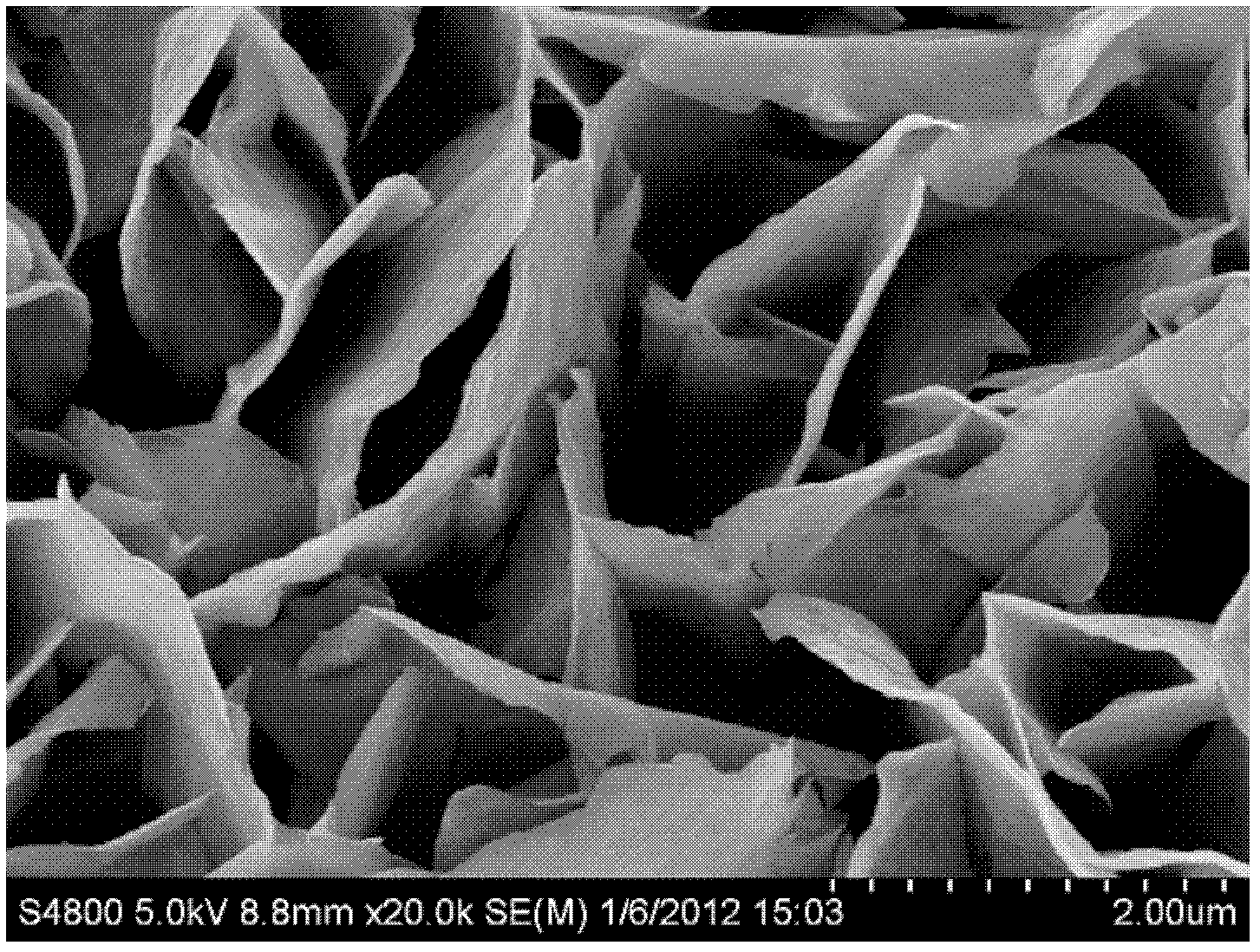

Cobalt oxide anode material, amorphous carbon coated cobalt oxide anode material and preparation method and application of cobalt oxide anode material and amorphous carbon coated cobalt oxide anode material

InactiveCN102659192ASimple preparation processPromote circulationCell electrodesCobalt oxides/hydroxidesHigh rateRetention ratio

The invention discloses a preparation method of a cobalt oxide anode material or an amorphous carbon coated cobalt oxide anode material, which comprises the following steps of: placing a conductive metal substrate in aqueous solution containing soluble cobalt salt and hexamethylene tetramine and carrying out heat preservation for 3h to 12h at a temperature of 80 DEG C to 150 DEG C to obtain the conductive metal substrate on which a cobalt hydroxide thin film is deposited; calcining the conductive metal substrate for 1h to 3h at a temperature of 200 DEG C to 400 DEG C to obtain the cobalt oxide anode material; and soaking the cobalt oxide anode material into aqueous solution of glucose, drying and calcining for 1h to 8h at a temperature of 300 DEG C to 500 DEG C to obtain the amorphous carbon coated cobalt oxide anode material. The preparation method has a simple preparation process and good reproducibility, is easy to implement, has an environmental-friendly production process and low cost and is beneficial to industrial production. The invention also provides the cobalt oxide anode material and the amorphous carbon coated cobalt oxide anode material. The cobalt oxide anode material and the amorphous carbon coated cobalt oxide anode material have high capacity retention ratios and good high-rate capabilities and are particularly suitable to use as a cathode electrode of a lithium ion battery.

Owner:ZHEJIANG UNIV

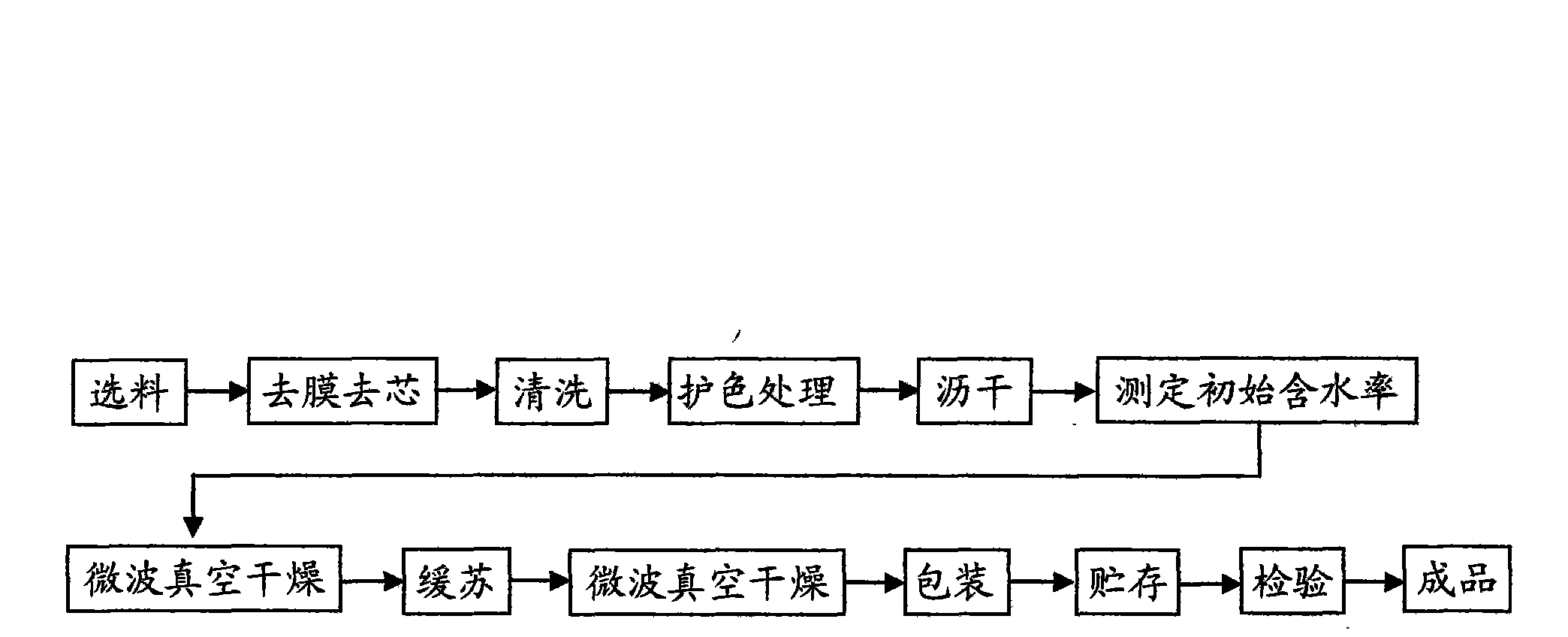

Microwave vacuum drying process for lotus seed

The invention provides a microwave vacuum drying process for lotus seeds, comprising the following steps of: selecting materials, removing films and cores, protecting color, dewatering, vacuum drying by microwave, packaging and storing, thus preparing the dry lotus seed product. The process aims at improving the quality research of the dry lotus seed and reducing the energy consumption, dries the fresh lotus seeds by microwave vacuum drying technology, improves the quality of the lotus seeds, and prolongs the shelf life of the product; the application of the high combination drying technology inaugurates another dry preparation way for drying preparation of fresh lotus seeds; the process is easy for instant control and the production is environment-protective; and the real continuous automatic clean production can be realized.

Owner:FUJIAN AGRI & FORESTRY UNIV

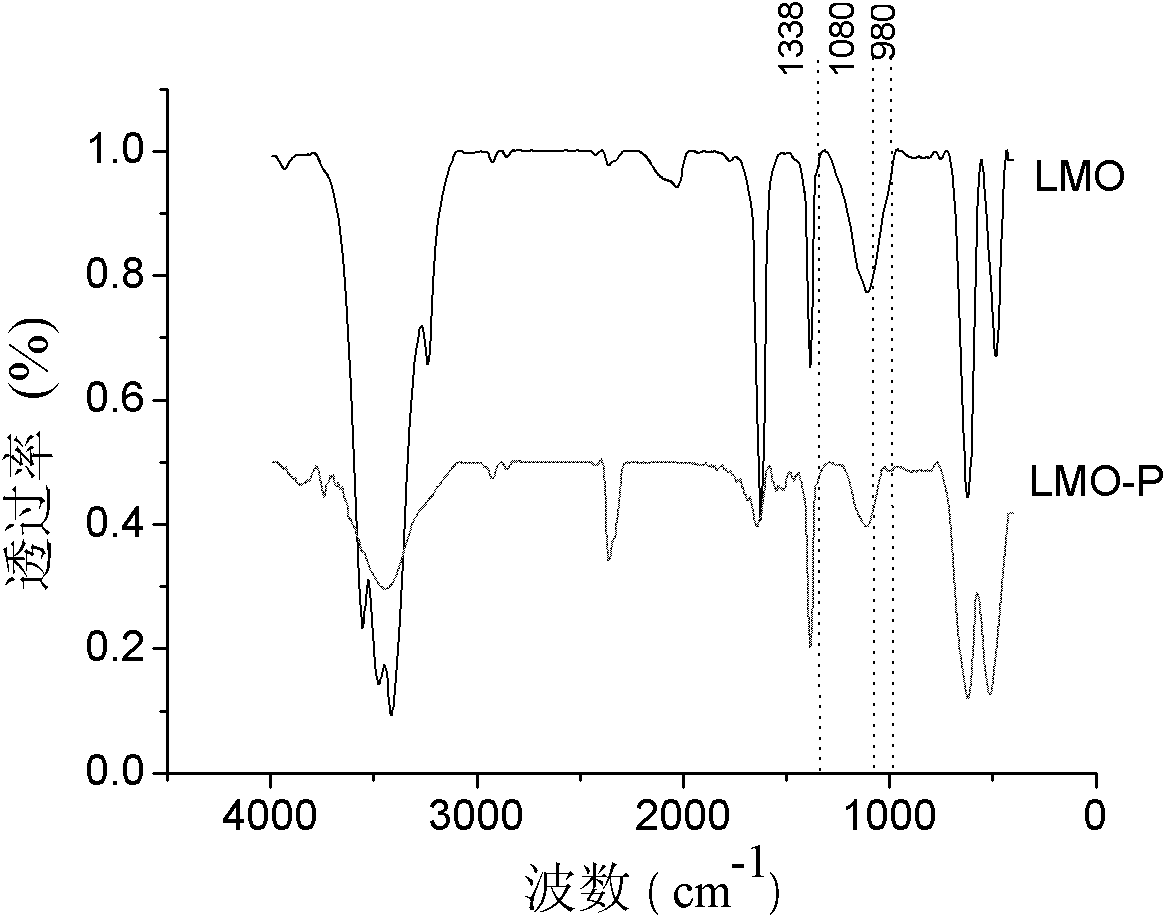

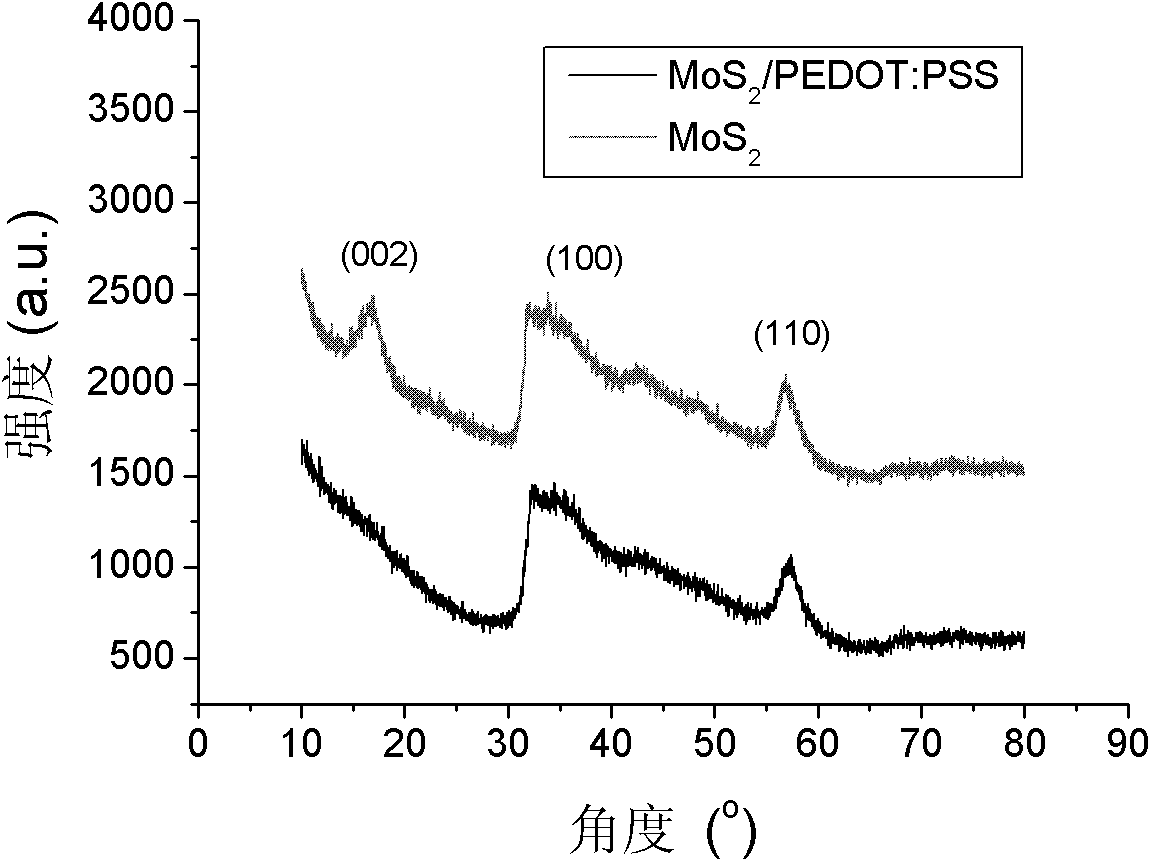

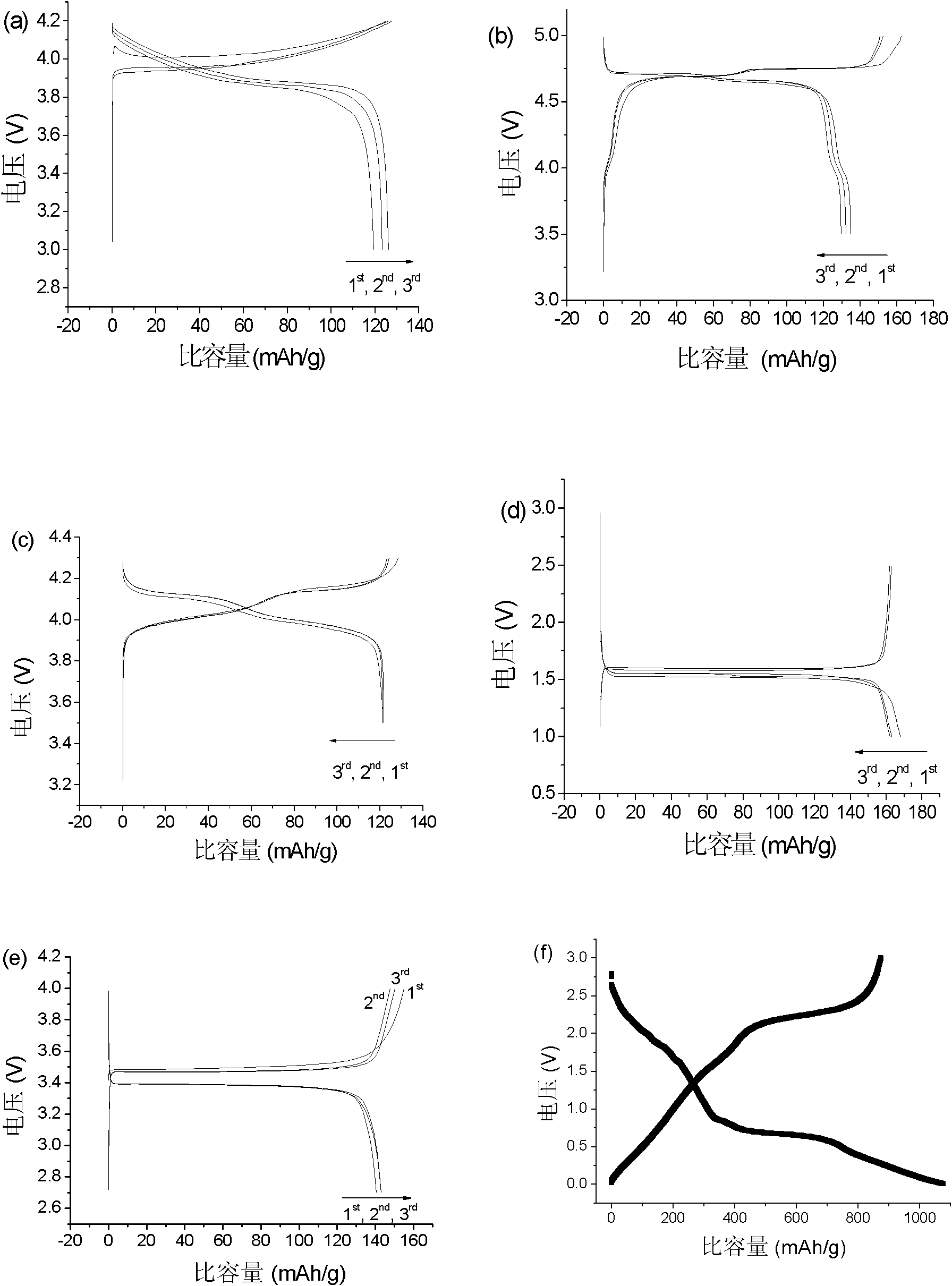

Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

InactiveCN102522563ADon't need protectionReduce energy consumptionHybrid capacitor electrodesLi-accumulatorsDischarge efficiencyConductive polymer

The invention provides a conducting-polymer dipped and coated lithium-ion battery composite-electrode material and a preparation method thereof. A high-polymer conducting polymer is coated on the lithium-ion battery electrode material of the composite electrode material, the conducting polymer is the conducting polymer which is easily dispersed into an aqueous solution, and the aqueous solution of dispersants, such as polystyrolsulfon acid and the like is used as a dispersing medium. The composite electrode material is prepared through the following steps of: dipping a lithium-ion anode material or cathode material into the aqueous solution of the high-polymer conducting polymer, and obtaining the surface-coated lithium-ion battery composite-electrode material through dipping and coating processing. The composite electrode material has cheap preparation raw materials, the surface of the novel composite electrode material is uniformly coated, and the composite electrode material has the advantages of high specific capacity, high charging and discharging efficiency and long cycling life. Compared with the prior art, the preparation method of the composite electrode material has the advantages of simple process, low cost, good effect and green and environment-friendly production process, is easy for industrial popularization and is convenient for large-scale industrialized production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

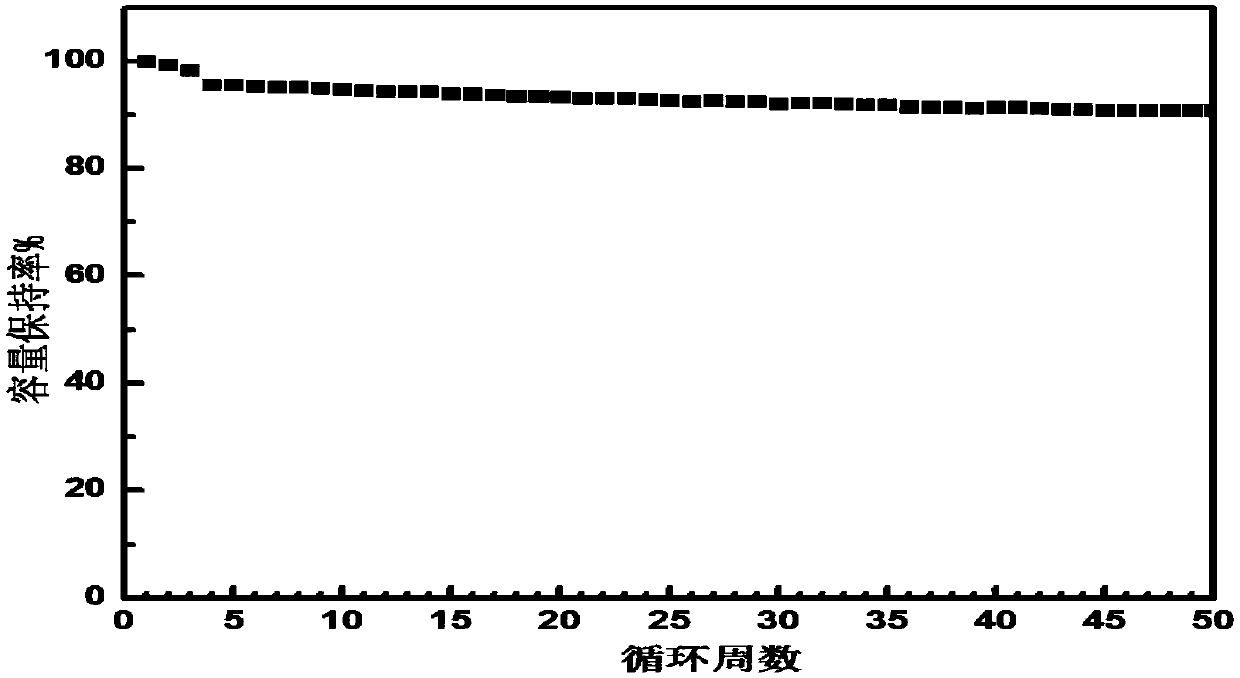

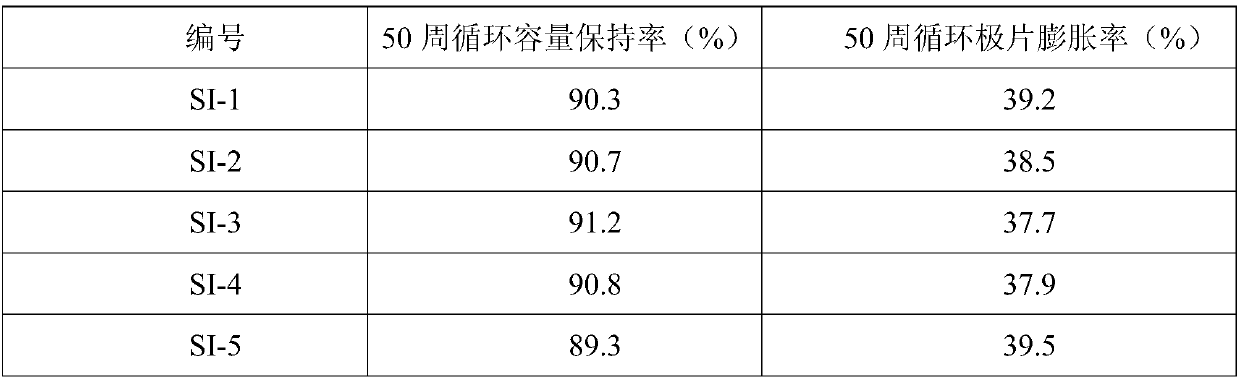

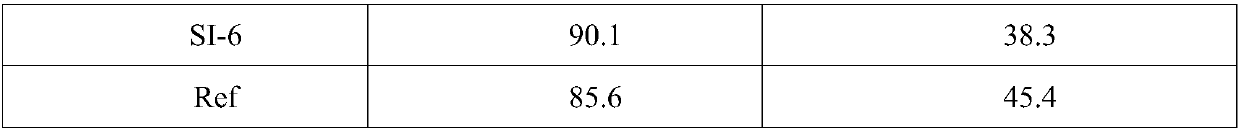

Silicon-based negative electrode material, preparation method thereof and application of silicon-based negative electrode material in lithium-ion battery

ActiveCN108054368AInhibit swellingImprove conductivityMaterial nanotechnologyElectrode thermal treatmentPolymer dissolutionAnti solvent

The invention relates to a silicon-based negative electrode material, a preparation method thereof and an application of the silicon-based negative electrode material in a lithium-ion battery. The silicon-based negative electrode material comprises a silicon-based active material and a composite layer, wherein the composite layer coats the surface of the silicon-based active material and is formedby a flexible polymer, flake graphite and a conductive material; and the method comprises the steps of (1) dissolving the flexible polymer into a solvent; (2) adding the flake graphite and the conductive material into a flexible polymer solution obtained in the step (1) under the stirring condition; (3) adding an anti-solvent to a mixed coating solution obtained in the step (2) and stirring; (4)adding the silicon-based active material to the supersaturated mixed coating solution obtained in step (3) under the stirring condition, stirring and separating; and (5) carrying out thermal treatmentto obtain the silicon-based negative electrode material. The silicon-based negative electrode material is simple in preparation method and low in cost, and industrial production is easy to implement;the prepared silicon-based negative electrode material has excellent electrochemical cycle performance and swelling inhibition performance, and the service life of the lithium-ion battery can be prolonged.

Owner:HUI ZHOU BTR NEW MATERIAL TECH

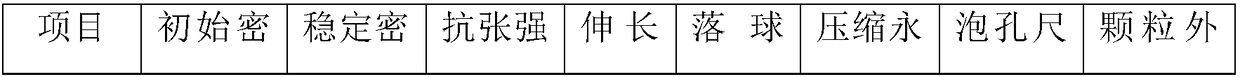

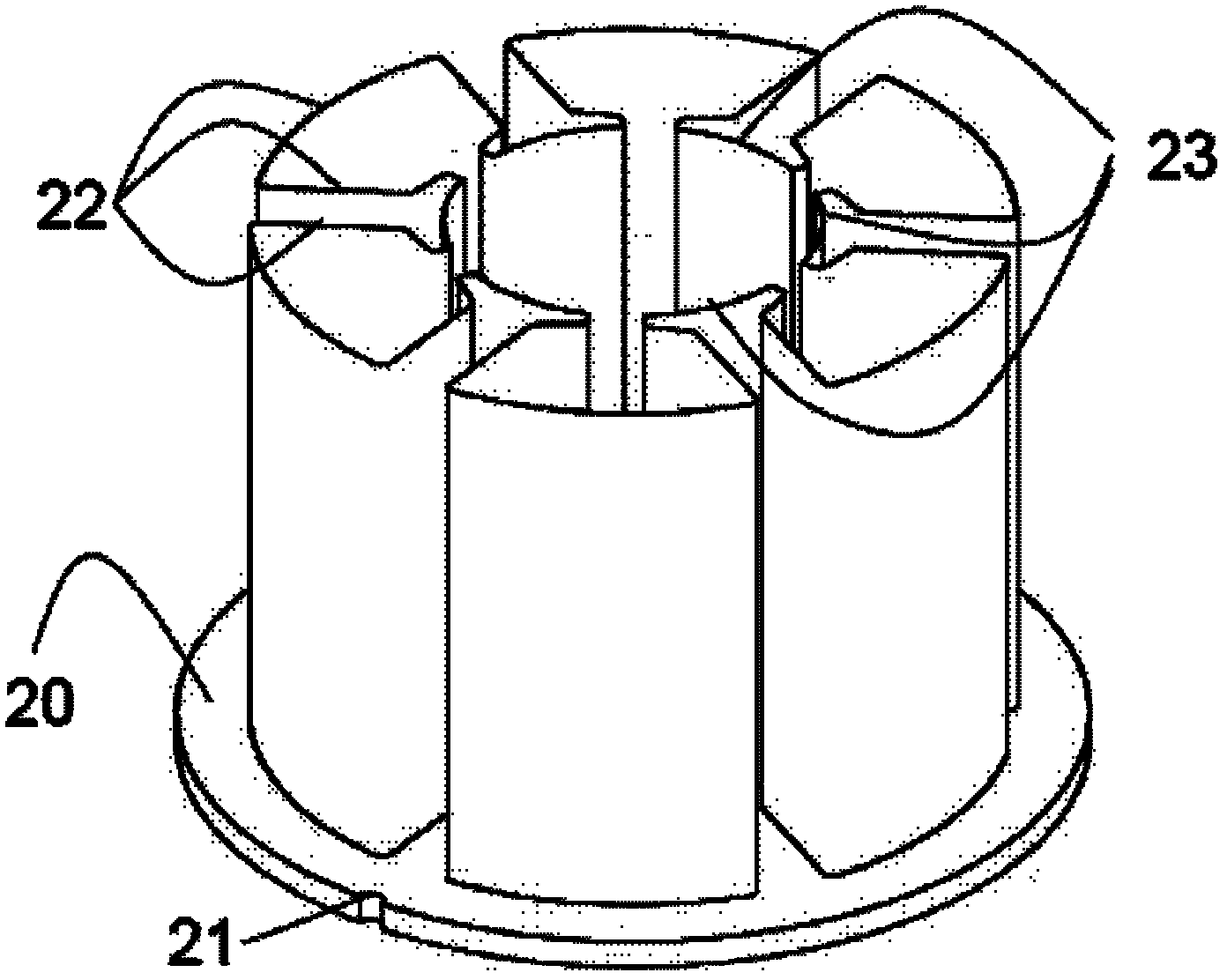

Thermoplastic polyurethane foaming particle and preparation method thereof

ActiveCN108239385AProduction environmental protectionSimple preparation processThermoplastic polyurethaneAlloy

The invention relates to a thermoplastic polyurethane foaming particle and a preparation method thereof. The thermoplastic polyurethane foaming particle comprises the following components in percentage by mass: (A) 65-90% of a thermoplastic polyurethane elastomer; (B) 2-30% of a thermoplastic resin polymer; and (C) 0-15% of a compatilizer. The preparation method comprises the following steps: adding blending alloy particles of the thermoplastic polyurethane elastomer, the thermoplastic resin polymer and the compatilizer into an autoclave, adding carbon dioxide into the autoclave, enabling carbon dioxide in the autoclave to be in a supercritical state, relieving pressure of the autoclave so as to obtain non-foaming particles containing carbon dioxide; heating and foaming the non-foaming particles containing carbon dioxide in hot air, thereby obtaining the foaming particles. The thermoplastic polyurethane foaming particle prepared by the method is stable in dimension, basically non-shrinkable, bright and full in surface, uniform in foam diameter, controllable in foam size of 10-100 microns and excellent in resilience.

Owner:WANHUA CHEM GRP CO LTD

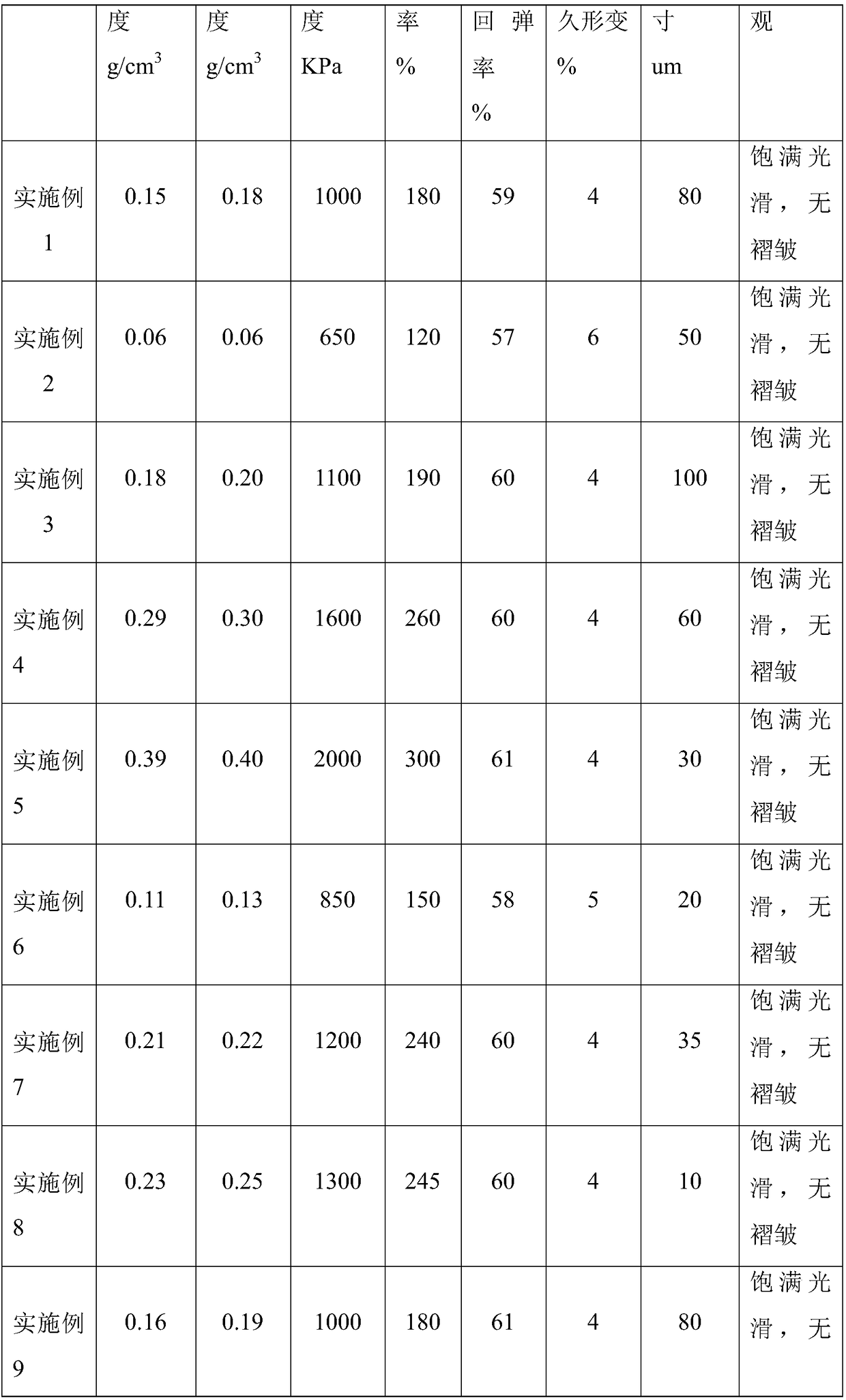

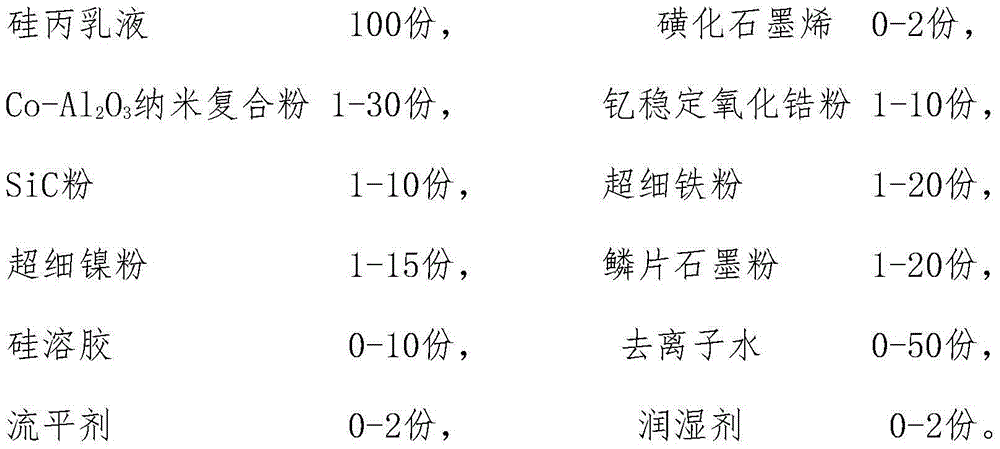

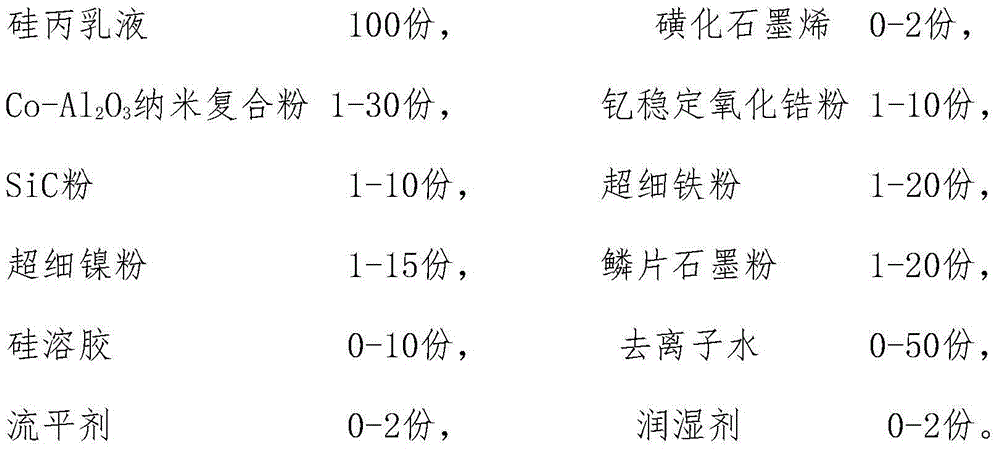

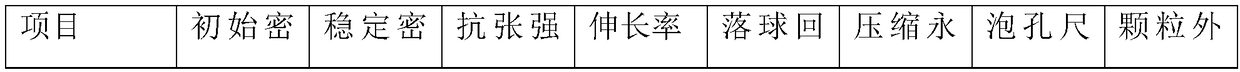

Aqueous solar energy heat-absorbing coating

ActiveCN104387880AImprove absorption rateImprove thermal conductivityRadiation-absorbing paintsRoom temperatureYttria-stabilized zirconia

The invention discloses an aqueous solar energy heat-absorbing coating. The uniformly mixed aqueous solar energy heat-absorbing coating is prepared by carrying out defibrination on an organosilicone-modifed acrylic emulsion (silicone-acrylic emulsion), sulfonated graphene, Co-Al2O3 nano-composite powder, yttria-stabilized zirconia powder, SiC powder, superfine iron powder, superfine nickel powder, flake graphite powder, silica sol, deionized water, a flatting agent and a wetting agent in a sand grinding machine at the room temperature in a certain proportion. The aqueous solar energy heat-absorbing coating has the properties that the absorptivity is 0.90-0.94, the emissivity is 0.18-0.20, the coating adhesive force is 4B-5B level, the pencil hardness is H, and the stability and the environmental protection property are high; the aqueous solar energy heat-absorbing coating is simple in preparation process, low in cost, suitable for industrial production and especially applicable to solar energy heat-absorbing coatings of a solar heat absorber.

Owner:ZHONGSHAN TAILAI PAINT CHEM

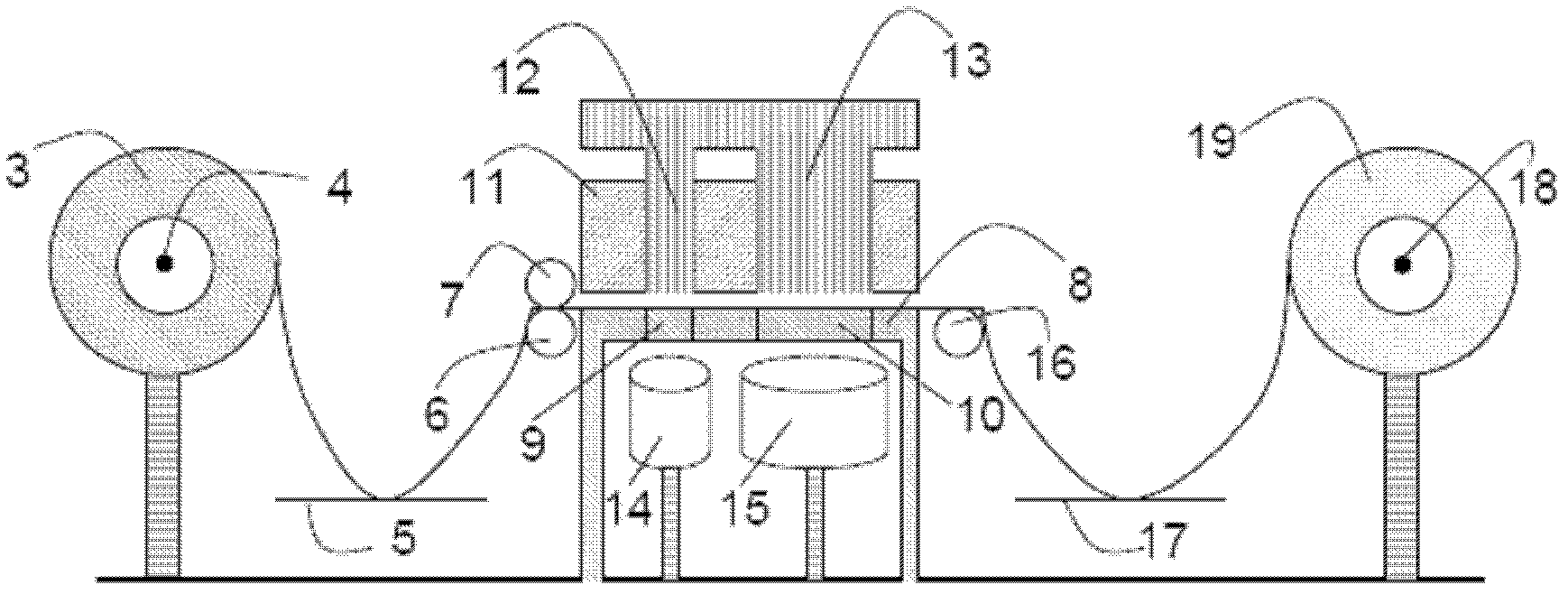

Extruded and foamed thermoplastic polyurethane elastomer particle and preparation method thereof

ActiveCN108239386AProduction environmental protectionSimple preparation processThermoplastic elastomerThermoplastic polyurethane

The invention relates to an extruded and foamed thermoplastic polyurethane elastomer particle and a preparation method thereof. The particle contains the following components in percentage by mass: (A) 65%-90% of a thermoplastic polyurethane elastomer, (B) 2%-30% of a thermoplastic resin polymer, (C) 0.5%-15% of a compatilizer and (D) 0.1%-5% of a foaming nucleating agent. The preparation method of a TPU formed particle comprises the following steps: uniformly mixing the thermoplastic polyurethane elastomer, the thermoplastic resin polymer, the compatilizer and the foaming nucleating agent, putting the mixture into melt extrusion equipment, and carrying out granulation, so as to obtain a blending alloy particle; and putting the blending alloy particle into foaming extrusion equipment, carrying out melting plastification so as to obtain a melt, dissolving supercritical carbon dioxide into the melt, foaming by virtue of a mouth mold, and carrying out underwater dicing, so as to obtain the formed particle. The prepared thermoplastic polyurethane foamed particle is stable in size and basically does not shrink, the surface is bright and plumy, and the diameters of foamed holes are uniform.

Owner:WANHUA CHEM GRP CO LTD

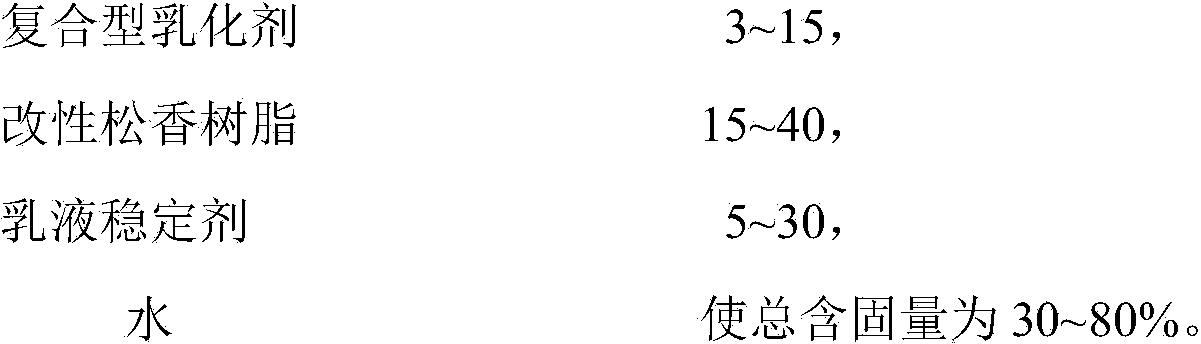

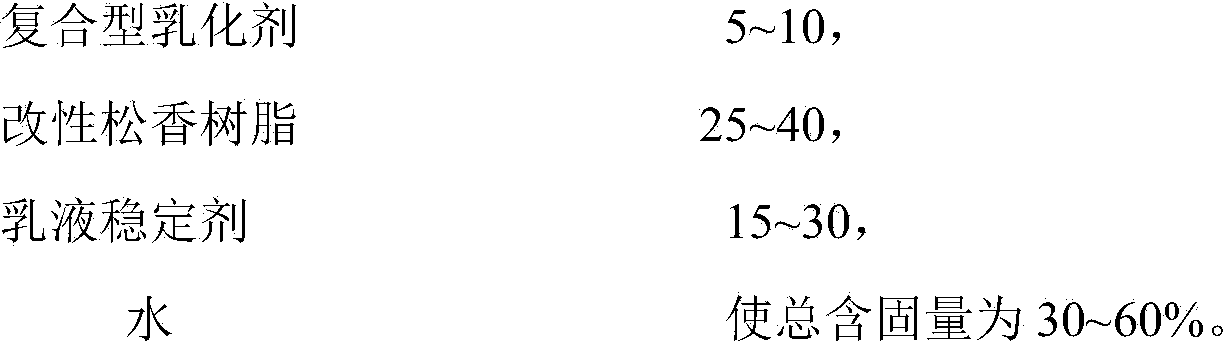

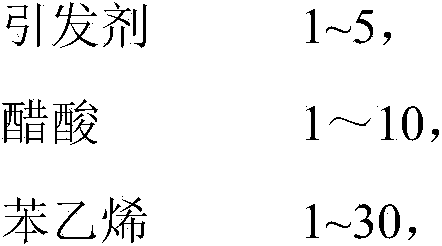

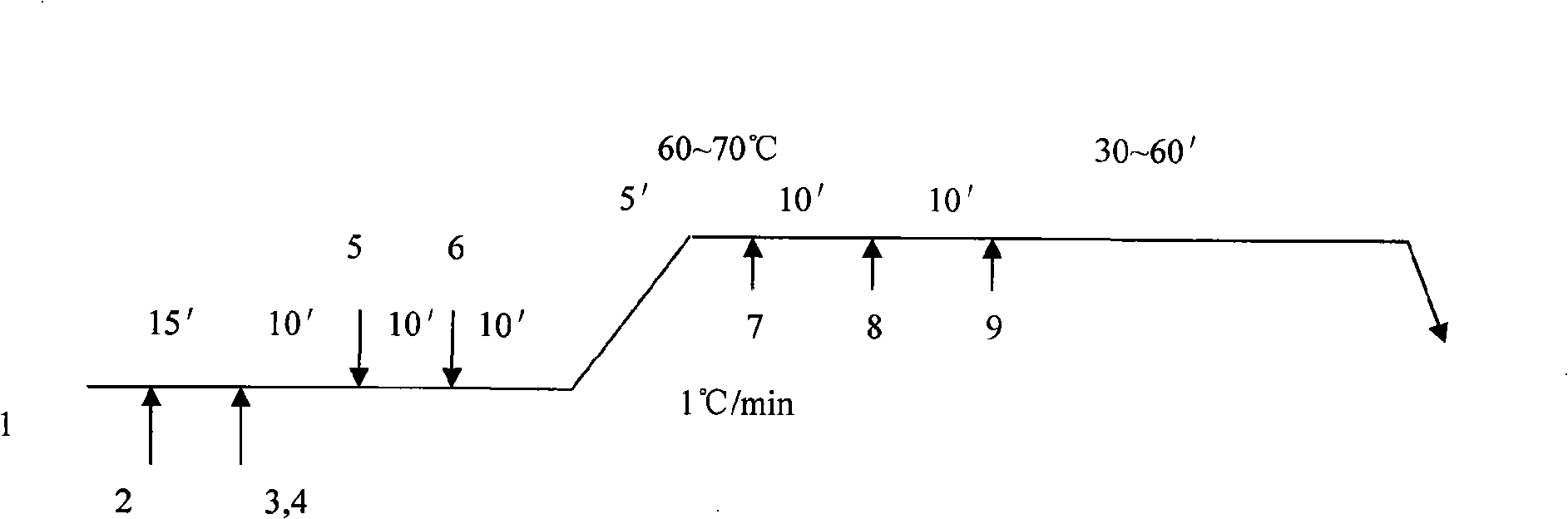

Novel cationic rosin sizing agent and application thereof

ActiveCN103628356AImprove mechanical stabilityGood chemical stabilityWater-repelling agents additionTotal solid contentEmulsion

The invention relates to the field of papermaking, aims at solving the problems that in the preparation process of the existing cation dispersing rosin latex, a solvent does not have a complete environment-friendly effect and is troublesome in recovery; after the solvent is removed, instability is possibly brought to an emulsifying agent and dispersed rosin, so that a rosin sizing agent is poor in mechanical stability, and the rosin sizing efficiency is not ell improved. The invention provides a novel cationic rosin sizing agent and application of the novel cationic rosin sizing agent in papermaking additive. The novel cationic rosin sizing agent comprises the following components by weight percent: 3-15% of a composite type emulsifying agent, 15-40% of modified rosin resin and 5-30% of an emulsion stabilizer; water is added into the components, so that the total solid content is 30-80%. When the sizing agent is used, emulsion particles are stable in performance, the sizing effect is remarkable, and the environment-friendly production is achieved.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

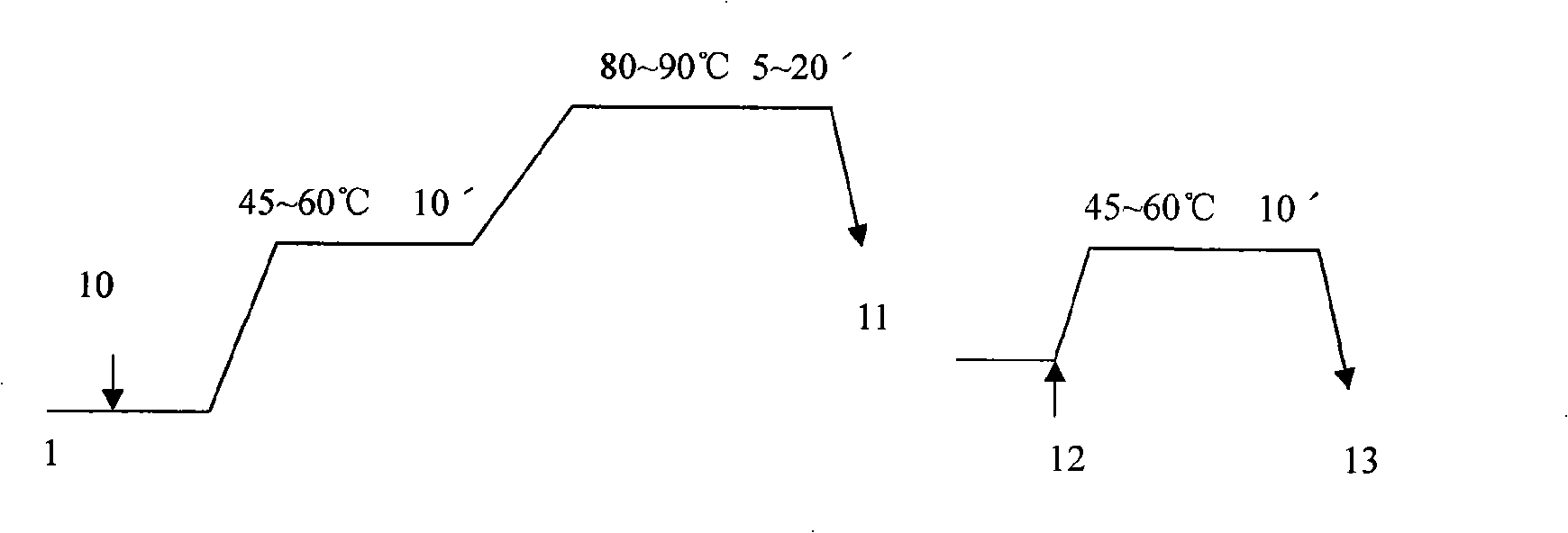

Cotton fibre rapid staining process

ActiveCN101260623AReduce consumptionLow process temperatureDry-cleaning apparatus for textilesDyeing processElectricityStaining

The invention relates to the dyeing and finishing project technical field in the printing and dyeing industry production and discloses a cotton loose fiber rapid dyeing technique, comprising the dyeing of the cotton loose fiber, the post treatment and the drying, wherein, in the dyeing technique, the apposition scouring and the dyeing technique are adopted. The prior cotton loose fiber dyeing adopts the high temperature boiling-off or the low temperature pre-treatment, angle water should be discharged after the processes, otherwise, the dye uptake is low and the dye use level is increased. The apposition scouring rapid dyeing technique can short the production flow time by 20 percent, decrease the energy such as water, electricity and air consumption by more than 20 percent; moreover, the ability of fiber is increased due to the shortened fiber processing time, the tactility and the spinnability are improved, the production cost is lower and the environment is protected.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Vanalium preparation method

The invention belongs to the field of metallurgy and particularly relates to a vanalium preparation method. The vanalium preparation method provided by the invention is low in cost and ensures high purity of obtained alloy. The technical scheme provided by the invention is as follows: in the vanalium preparation method, vanadium pentoxide and metallic aluminium are used as raw materials and are subjected to ignition reduction in a reaction device to obtain vanalium and furnace clinker; and a continuous feeding manner is adopted for the reaction device during feeding, and the feeding speed is 5-40kg / min. Compared with the prior art, the vanalium preparation method provided by the invention has the advantages that no coolant is added for controlling heat so that the cost is lower and the requirement for mass industrial production is completely met; and the produced vanalium is low in impurity content, the finished vanalium contains 65-91wt% of V, 9-35wt% of Al, not more than 0.3wt% of Fe and not more than 0.3wt% of Si, and the obtained vanalium has higher purity and meets the requirement of subsequent further processing.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

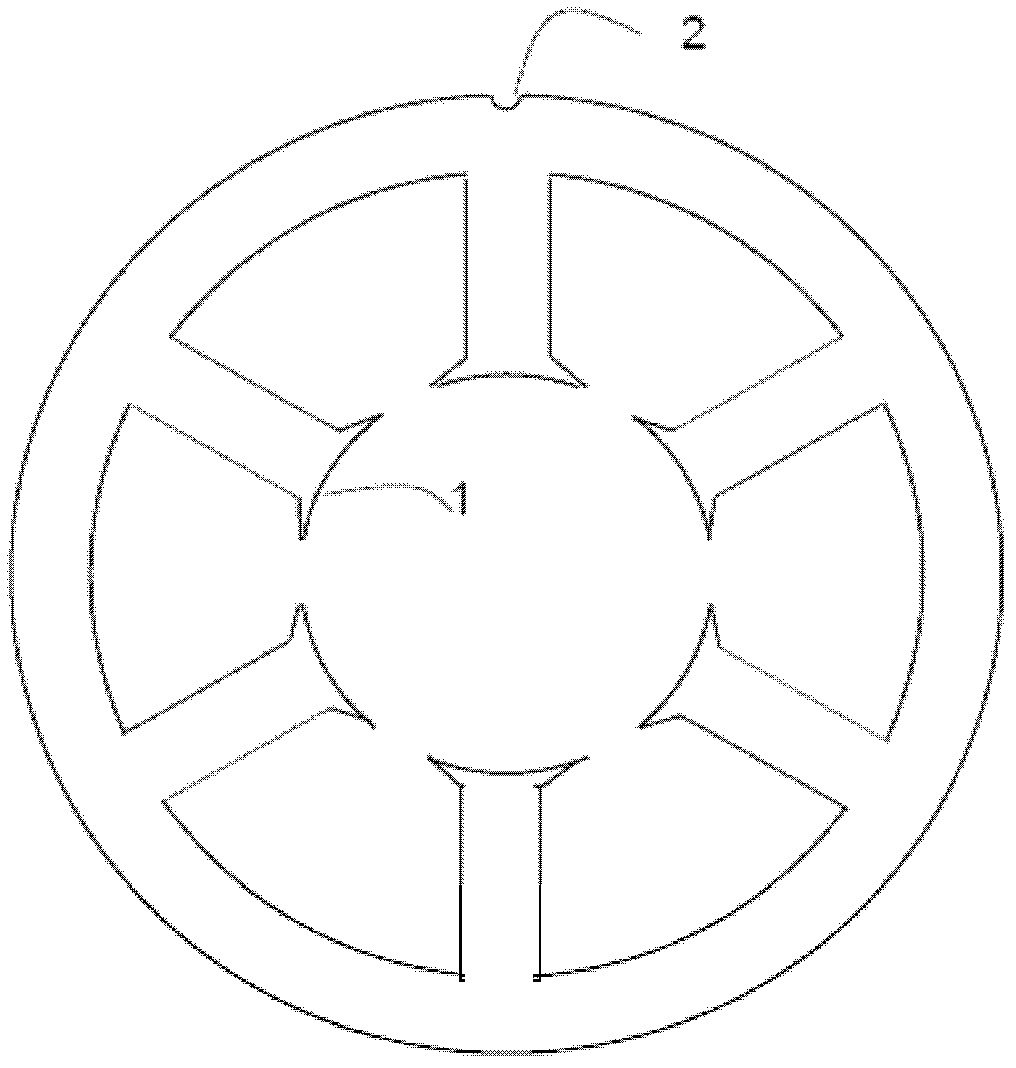

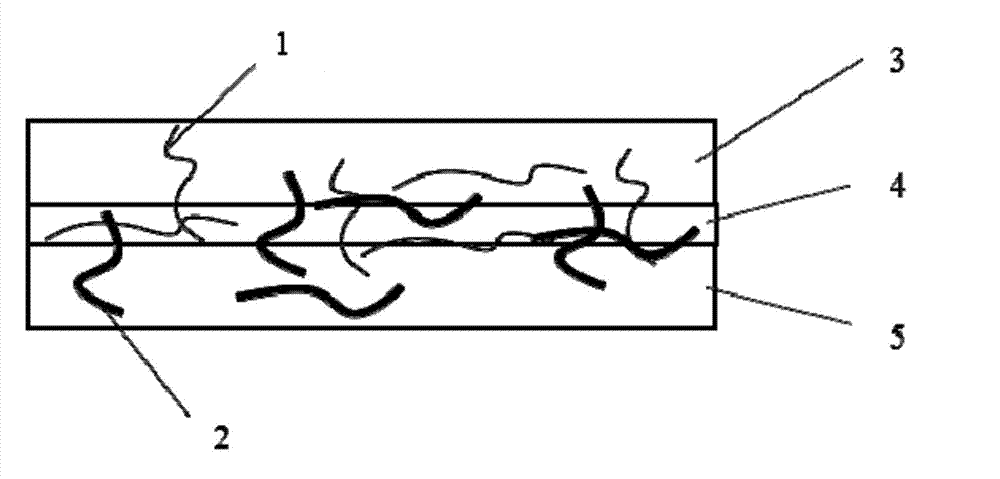

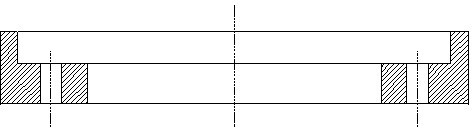

Protective box type amorphous, microcrystal or nano-crystal alloy stator core for motor and preparation method thereof

ActiveCN102361374AShort production processEnergy saving productionManufacturing stator/rotor bodiesDip-coatingNanocrystal

The invention belongs to the field of magnetic circuit parts of motors, and discloses a protective box type amorphous, microcrystal or nano-crystal alloy stator core for a motor and a preparation method thereof. The method comprises the following steps of: stamping a coiled alloy strip (3) to form a plurality of same annular stamped sheets, wherein the tooth ends of inner teeth (1) of the stampedsheets are positioned on the same circumference and the outer side of each stamped sheet is provided with at least one positioning groove (2); stacking the plurality of annular stamped sheets in a protective box with open upper end, putting the stamped sheets and the protective box into insulated coating solution together and performing insulated dip-coating treatment; taking out the stamped sheets and the protective box together, performing compactness treatment on the annular stamped sheets, fixing an upper end panel of the protective box and the inner center surface together, and forming the stator core; and performing integral annealing treatment on the stator core of the sealed protective box. By the method, the process problems that the stator core is easily damaged to drop residue and cracks among layers, the performance declines because the adhesive stress cannot be eliminated and the like are solved, and the performance of the stator core is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Moisturizing eye mask prepared from bacterial cellulose

InactiveCN102784071AReliable hardnessGood flexibilityCosmetic preparationsToilet preparationsBiotechnologyMembrane surface

The invention discloses a moisturizing eye mask prepared from bacterial cellulose. The method for preparing a moisturizing eye mask from bacterial cellulose comprises: inoculating 1-2 rings of activated inclined seed Gluconacetobacter xylinum into a medium, and conducting oscillating culture to obtain a seed solution; then inoculating the seed solution into the medium, fully oscillating the bacterial solution obtained by mixing the seed solution and the medium to make them mixed uniformly, then conducting stationary culture, thus generating a bacterial cellulose membrane floating on the solution surface, flushing the generated bacterial cellulose membrane with water to remove the medium and impurities on the membrane surface, then immersing the membrane in an alkali solution to remove thalli and residual medium from the membrane, and finally flushing the membrane with distilled water till the pH value of the membrane is measured up to 7-7.2, thus obtaining a bacterial cellulose wet membrane, which is then cut into an eye mask. The eye mask has the advantages of good moisturizing property and biological tissue compatibility, no toxicity, harmlessness, and simple material processing technology.

Owner:SHANGHAI INST OF TECH

Method for printing and decorating lacquerware surface with ultraviolet curing printing ink (UV ink)

InactiveCN102501698APrint in vivid colorsImprove corrosion resistanceDecorative surface effectsPrintingGamutWeather resistance

The invention discloses a method for printing and decorating lacquerware surfaces with ultraviolet curing printing ink (UV ink), which comprises the following processing steps of 1) selecting base material of the lacquerware; 2) drafting a digital picture; 3) printing; 4) painting the surface; 5) processing to obtain finished-product in a later period such as adding frame and base. The method of the invention has the advantages that the method has higher efficiency and lower cost in comparison with traditional painting technique and can also achieve exquisite art effect at the same time. The use of UV ink offers brighter color and wider color gamut and particularly provides excellent effect for the surface of special lacquerware. The picture surface of the finished product that is printed and decorated by UV ink on the lacquerware surface has the advantages of scratch resistance, corrosion resistance and good weather fastness; moreover, the UV ink can be cured in a very short period of time and the production process is featured in environmental friendliness. During the whole production process, the invention greatly reduces the time of manual color drawing and engraving in the process of making lacquerware; and the invention also reduces cost, improves the production efficiency and increases the yield. As a result, the manufacturing of traditional lacquerware handmade crafts can realize mass production with the help of modern technology.

Owner:NANJING FORESTRY UNIV

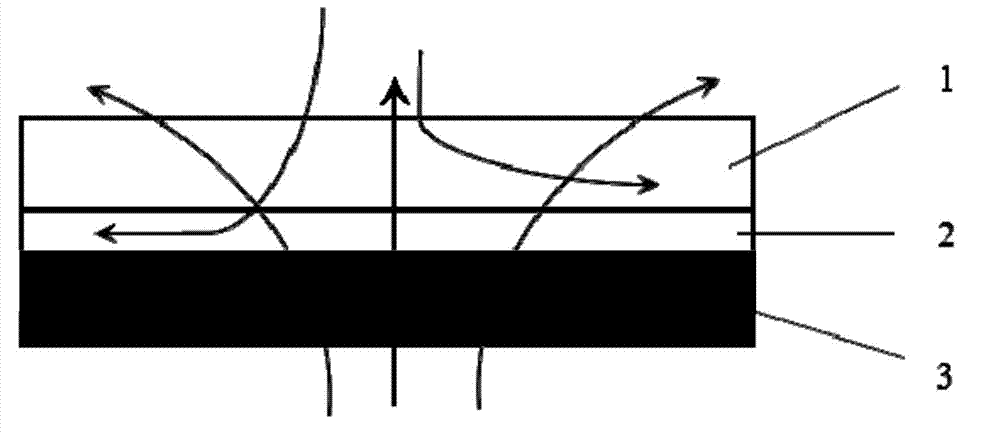

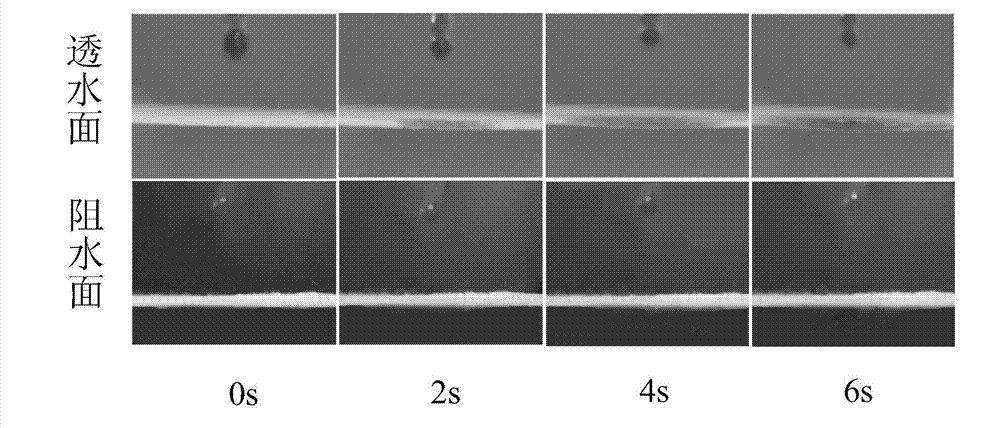

Spunlaced non-woven material with one-way water guide function and preparing method and application thereof

The invention relates to a spunlaced non-woven material with the one-way water guide function and a preparing method and application thereof. The spunlaced non-woven material is formed by respectively carding hydrophilic fiber and hydrophobic fiber into webs, then compositing the webs, and reinforcing the webs in a spunlaced mode. According to the preparing method, the hydrophilic fiber and the hydrophobic fiber are respectively carded to obtain the hydrophilic fiber web and the hydrophobic fiber web, the hydrophilic fiber web and the hydrophobic fiber web are laid and recombined to obtain a composite fiber web, and the composite fiber web is reinforced in the spunlaced mode, stand and is dried to obtain the spunlaced non-woven material. The spunlaced non-woven material is applied to medical protecting clothes, wound accessories and diaper coating layers, the method is wide in range of processed fiber, existing production equipment can be directly used, and the production process protects the environment and is free of pollution.

Owner:DONGHUA UNIV

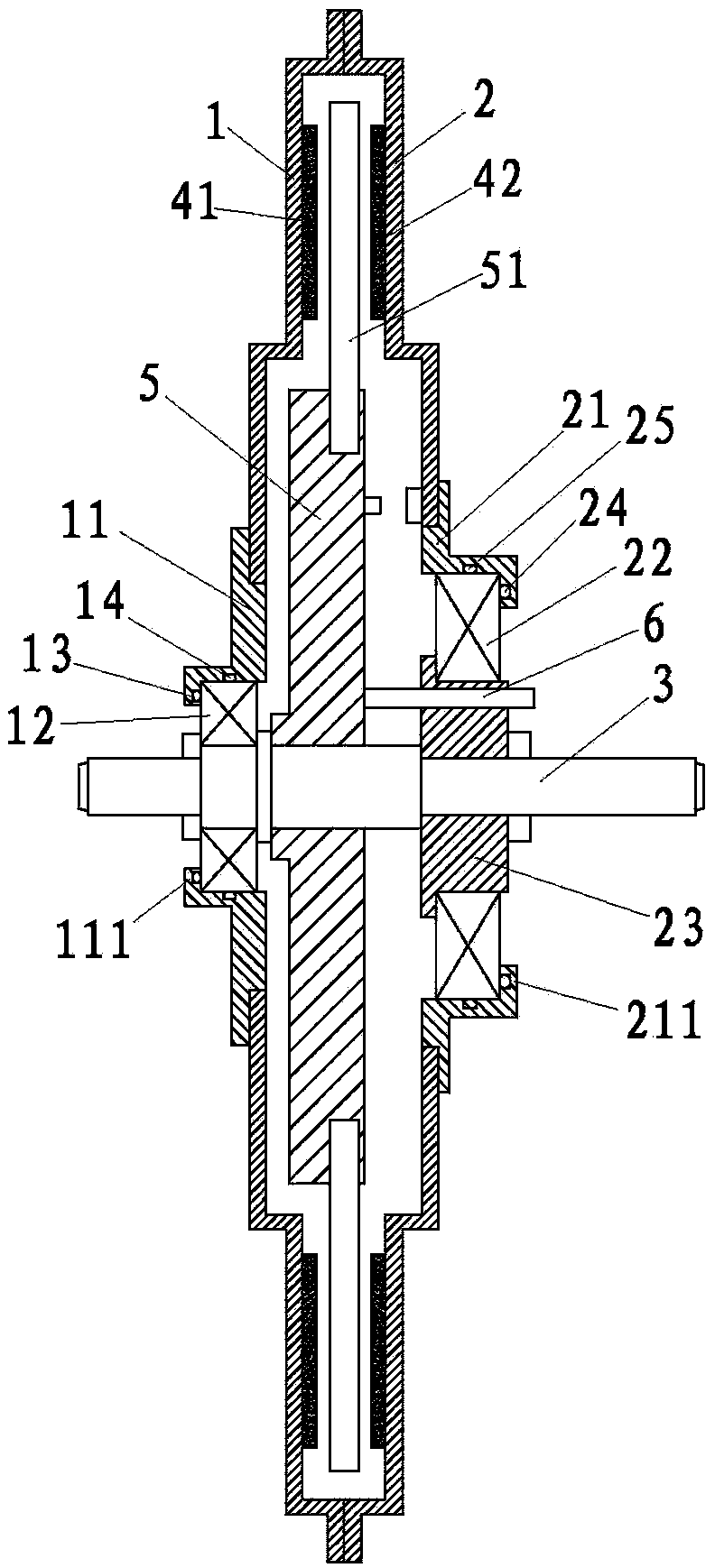

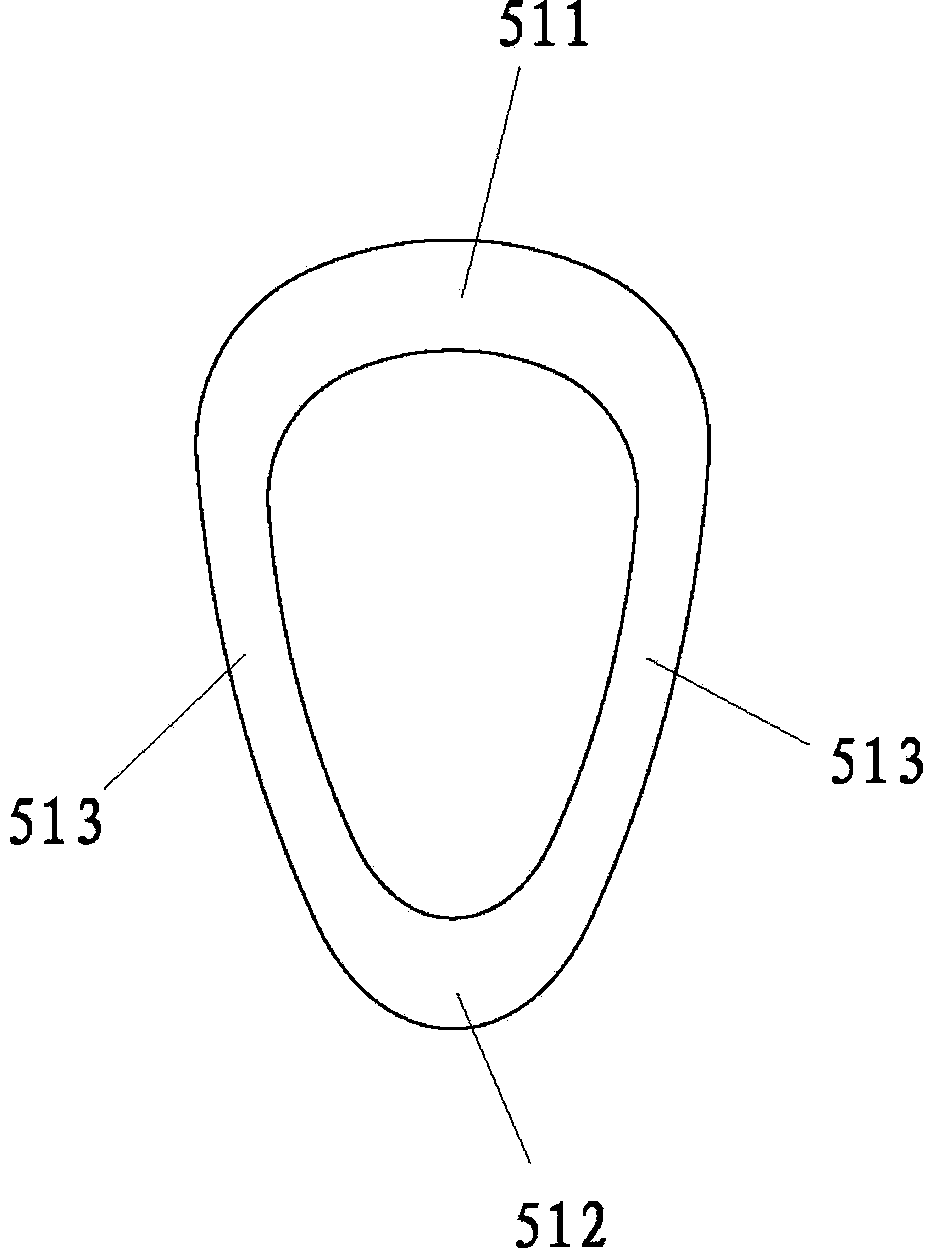

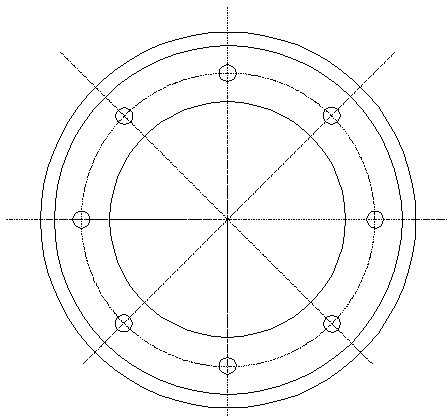

Disk-type coreless permanent-magnetic brushless DC (direct current) motor

InactiveCN103384107AImprove sealingIncrease magnetic loadElectronic commutation motor controlMagnetic circuit stationary partsElectricityEngineering

The invention relates to disk-type DC motors, particularly to a disk-type coreless permanent-magnetic brushless DC motor. The technical scheme comprises that the disk-type coreless permanent-magnetic brushless DC motor comprises two housings which are connected in a sealed mode, two end covers correspondingly arranged on the housings, and two bearings correspondingly arranged on the end covers. Each end cover is provided with a stop flange which extends to the end surface of the corresponding bearing, and an O-shaped seal ring is arranged between each stop flange and the end surface of the corresponding bearing. The disk-type coreless permanent-magnetic brushless DC motor also comprises an armature winding, the armature winding is in a ring shape and comprises an arc-shaped first part away from the a shaft, an arc-shaped second part close to the shaft, and arc-shaped third parts connected between both ends of the first part and the corresponding ends of the second part; the connection line of the centers of the first part and the second part is disposed in the middle section of the armature winding; the inner diameter of the first part is 1.5-2 times as large as that of the second part. The disk-type coreless permanent-magnetic brushless DC motor has good sealing performance and a high magneto-electricity conversion rate.

Owner:HUZHOU YUNTIAN NEW ENERGY TECH

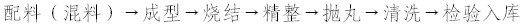

Process method for manufacturing balance weight for compressor by powder metallurgy

InactiveCN102528040AHigh dimensional accuracyNo oxidationTurbinesOther manufacturing equipments/toolsAir compressorMechanical press

The invention discloses a process method for producing a balance weight for a compressor by powder metallurgy, which comprises the steps that: (1), raw materials comprising Mn (17-25%), C (0.5-1.5%) and Fe (the rest) are uniformly blended to produce raw material powder required by production; (2), the raw material powder is put into a mechanical press (or four-column hydraulic press) for compression moulding so as to obtain a pressing compact for the balance weight; (3), the pressing compact for the balance weight is put into a continuous mesh belt furnace (or push rod furnace) for sintering to obtain a sintering compact for the balance weight; and (4), the sintering compact for the balance weight is subjected to shot blasting treatment to obtain a finished product of the high manganese steel weight balance for the air compressor. According to the production method disclosed by the invention, the stability of the sizes of workpieces is good, no impurity is generated, the quality of the surface is excellent, and the components are uniform and stable; the weight variation among products of different batches is small and can be controlled within 1%; no oxidation is generated in the production process, the internal organization of metal is excellent, the crystalline grain is finer, and the bad organizations such as coarse crystal and mixed crystal can be avoided.

Owner:王兴民

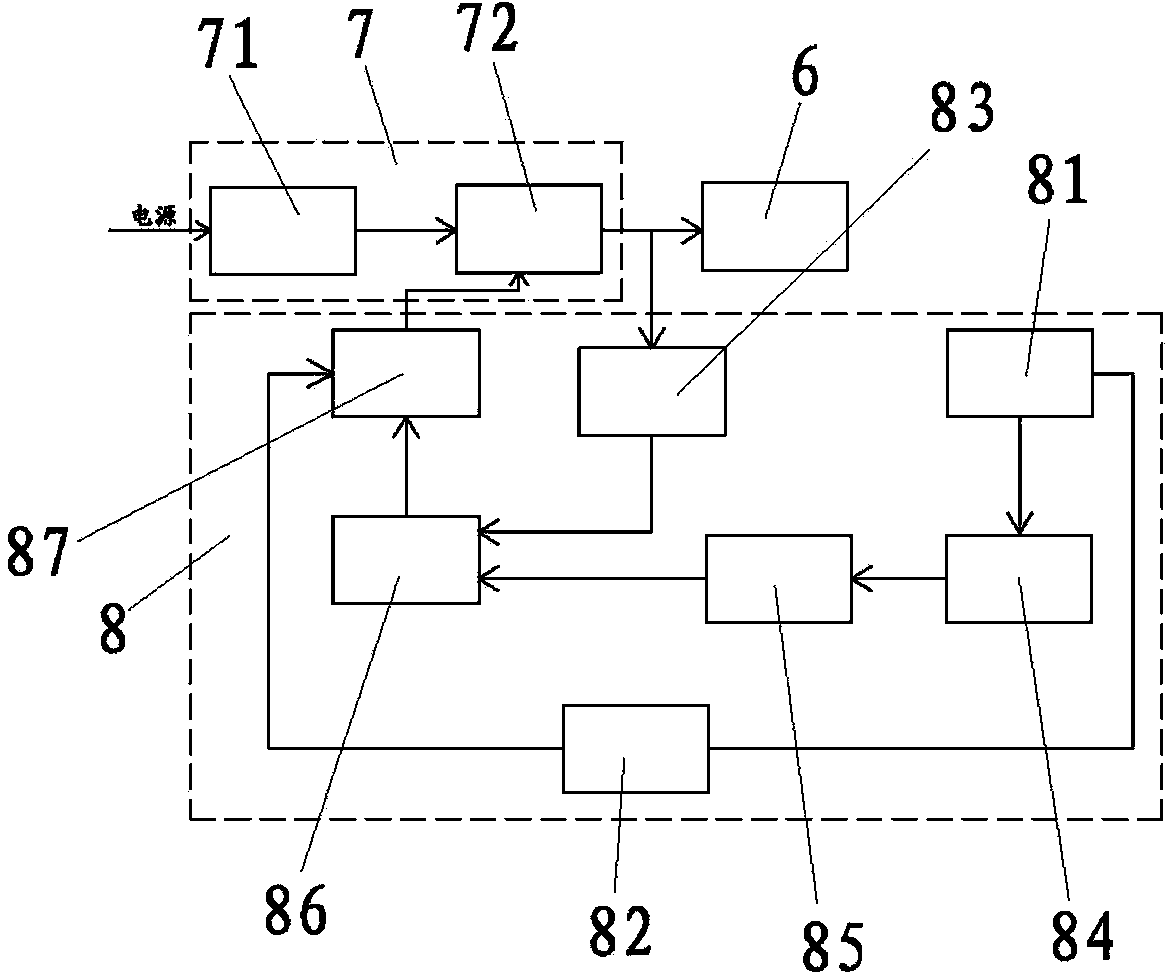

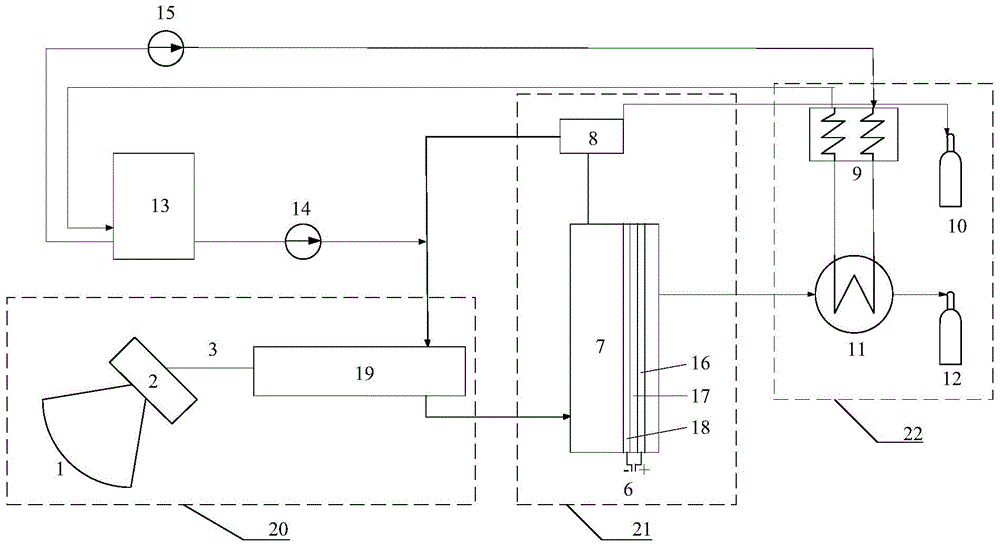

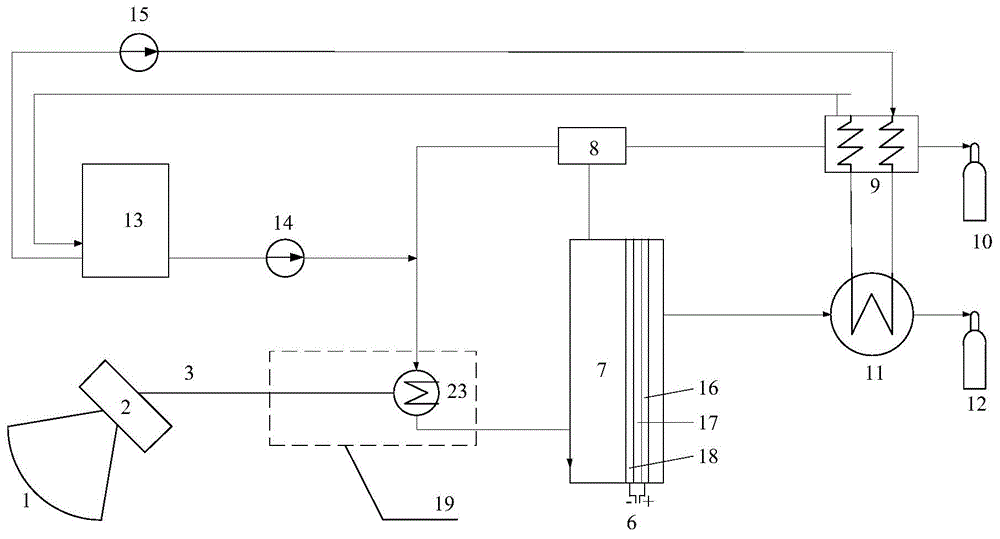

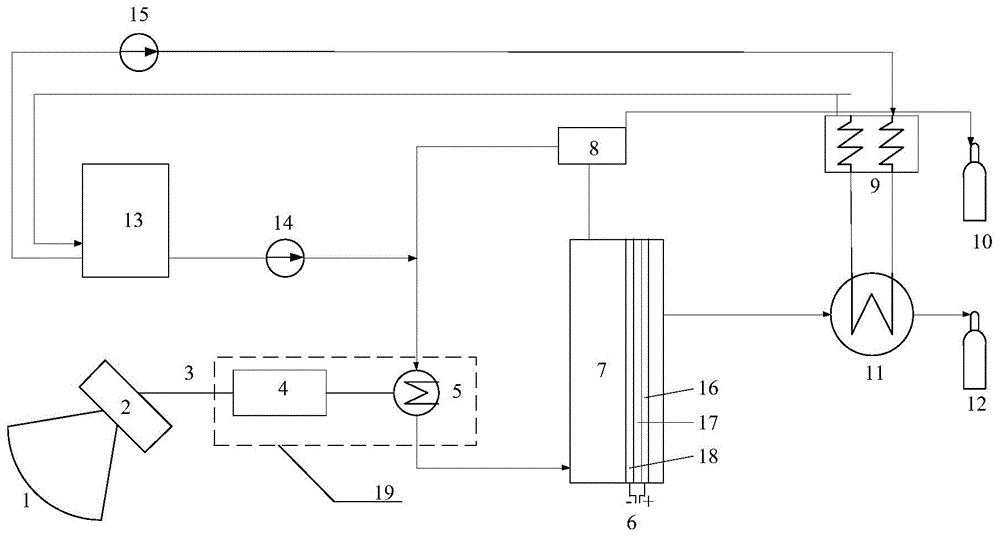

Solar optothermal coupled high-temperature water electrolysis hydrogen production system

ActiveCN104694950AResolve unstable situationsProduction environmental protectionCellsThermal energyProcess engineering

The invention provides a solar optothermal coupled high-temperature water electrolysis hydrogen production system. The system comprises a heat energy supply module, a hydrogen production and separation module and a storage module which are sequentially connected; the heat energy supply module comprises a condensation device, a heat collection device, a heat storage high-temperature heat pipe heat exchanger and a heat exchanger unit which are sequentially connected, and hydrogen and hydrogen are separated through electrolysis after a water and hydrogen mixture in the hydrogen production and separation module is heated into a steam and hydrogen mixture above 800 DEG C. Compared with the prior art, the hydrogen production system has the advantages that fossil energy does not need to be consumed, the productive process is more green and environmentally friendly, and the power consumption is greatly reduced; a stable heat source is provided through the system, the problem that a photo-thermal system is not stable due to changes in the weather is solved, the availability of the system is improved, and meanwhile the electrolytic efficiency of the system is improved.

Owner:STATE GRID CORP OF CHINA +1

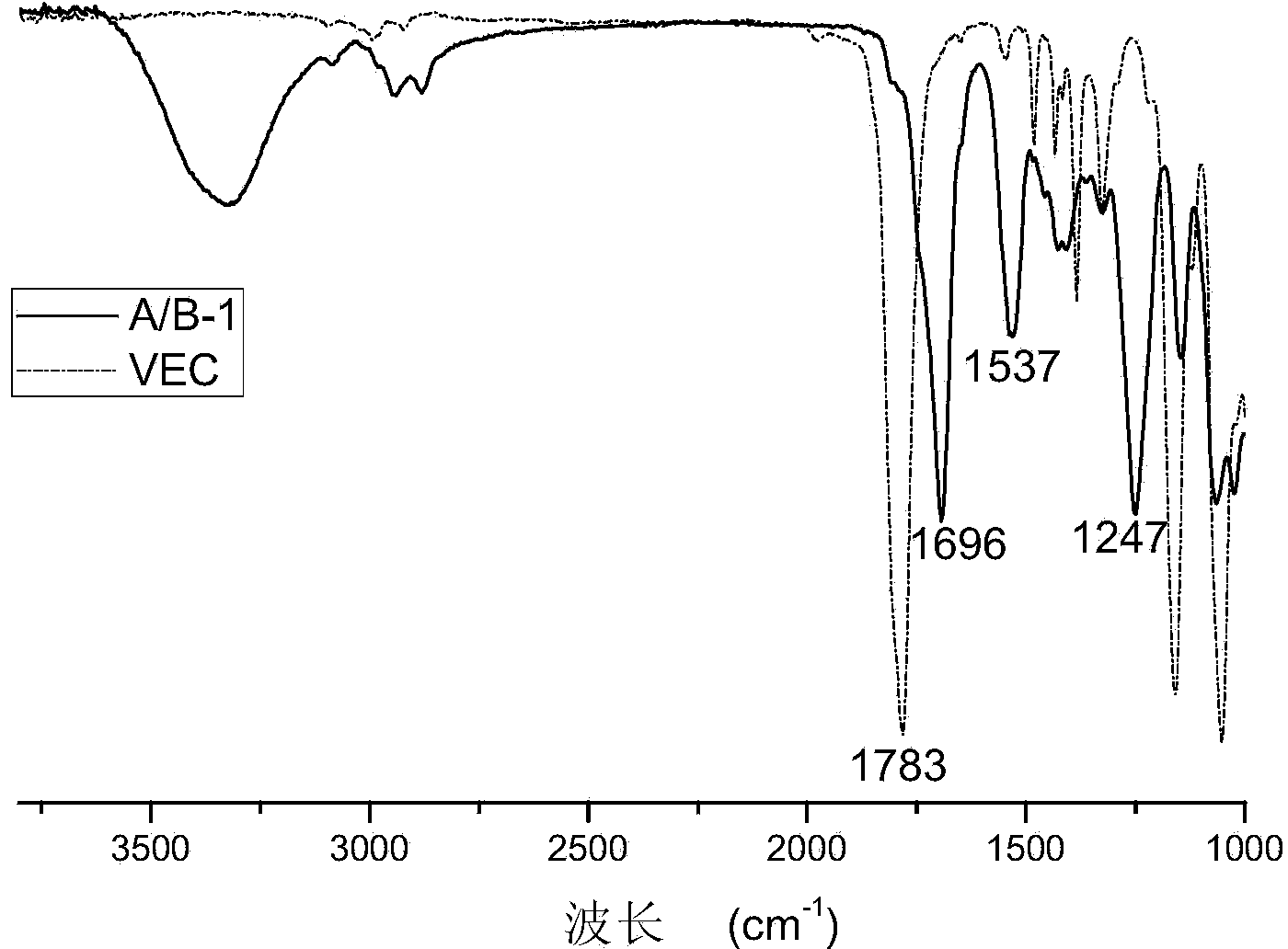

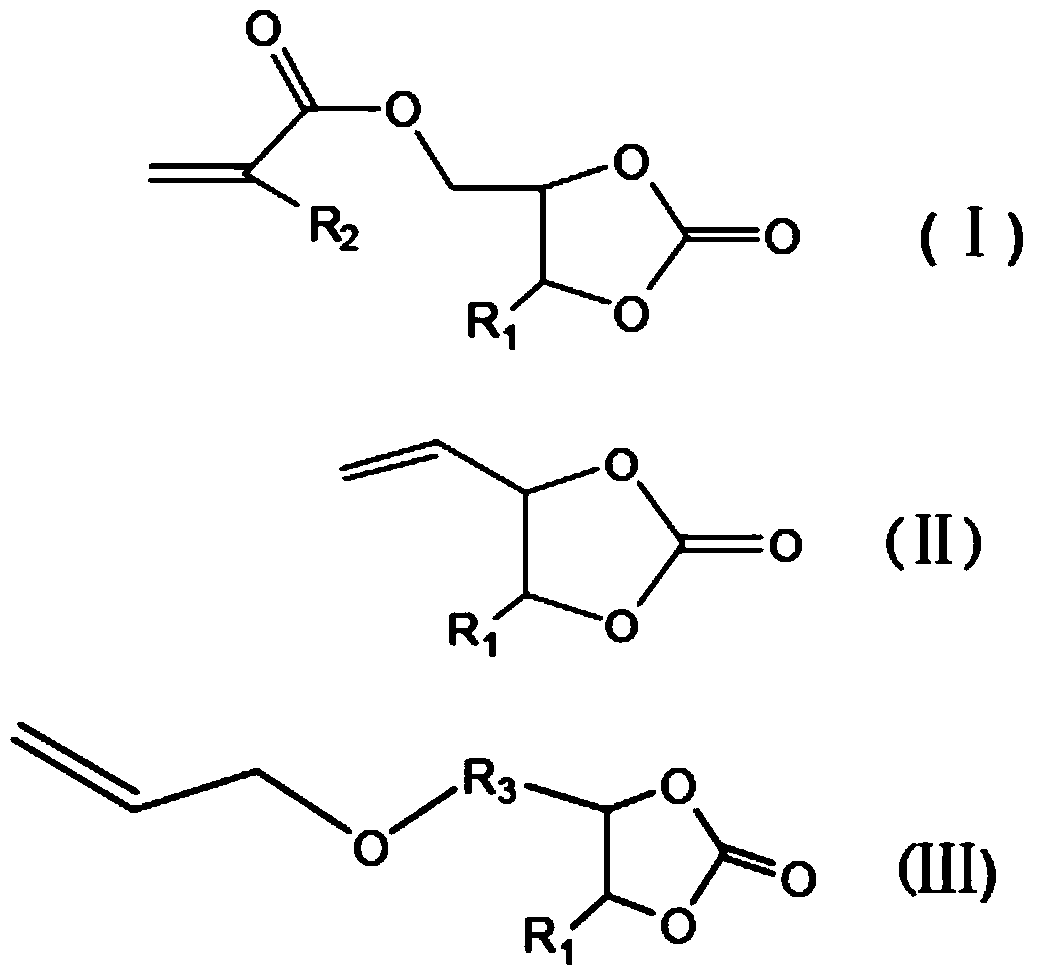

Preparation method of waterborne non-isocyanate polyurethane modified polyester

The invention relates to a preparation method of waterborne non-isocyanate polyurethane modified polyester and provides a preparation method of the waterborne non-isocyanate polyurethane modified polyester. The preparation method comprises the following steps: (1) preparation of unsaturated prepolymer containing a urethane bond; (2) preparation of polyester containing an unsaturated double bond; (3) graft polymerization of the prepared polyester containing the unsaturated double bond, and the prepolymer; and (4) dispersion of a graft polymer. The invention also provides an application of the prepared waterborne non-isocyanate polyurethane modified polyester in vehicle coatings.

Owner:上海金力泰化工股份有限公司

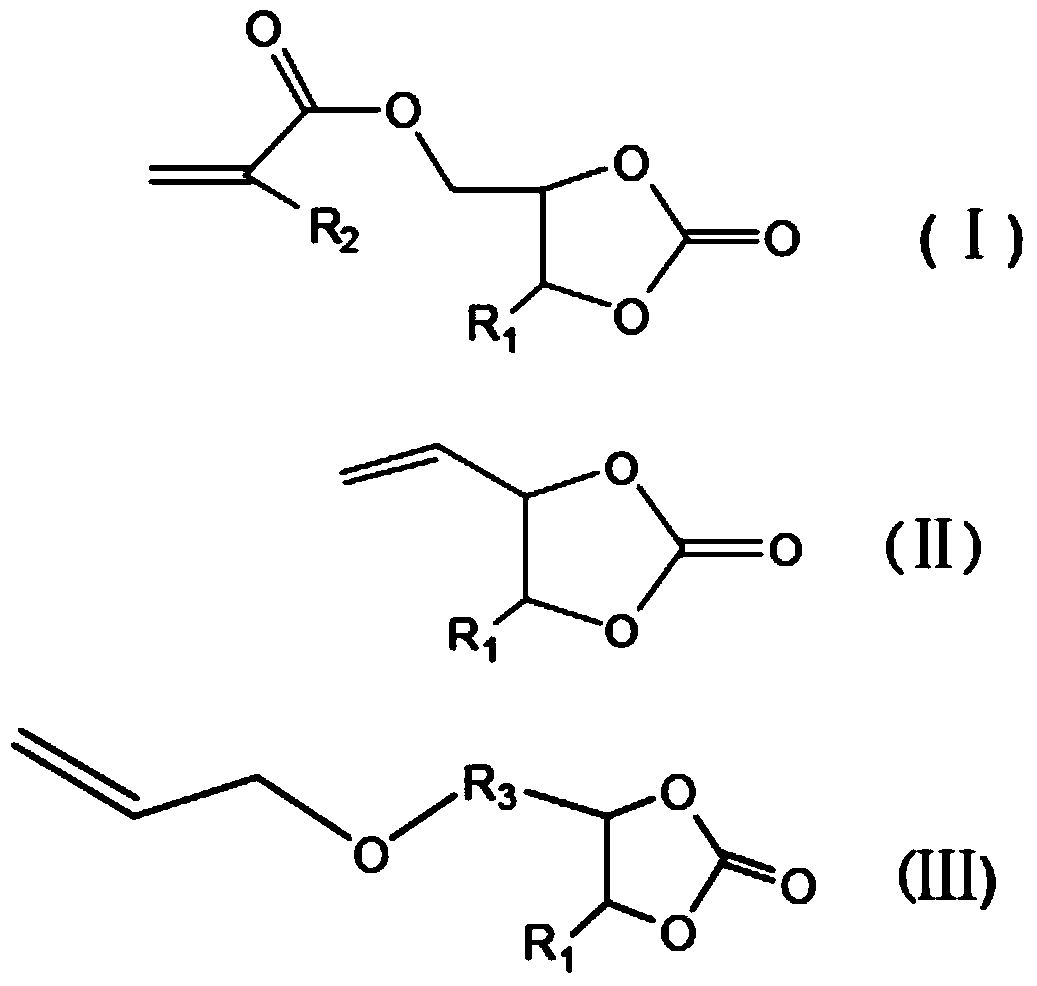

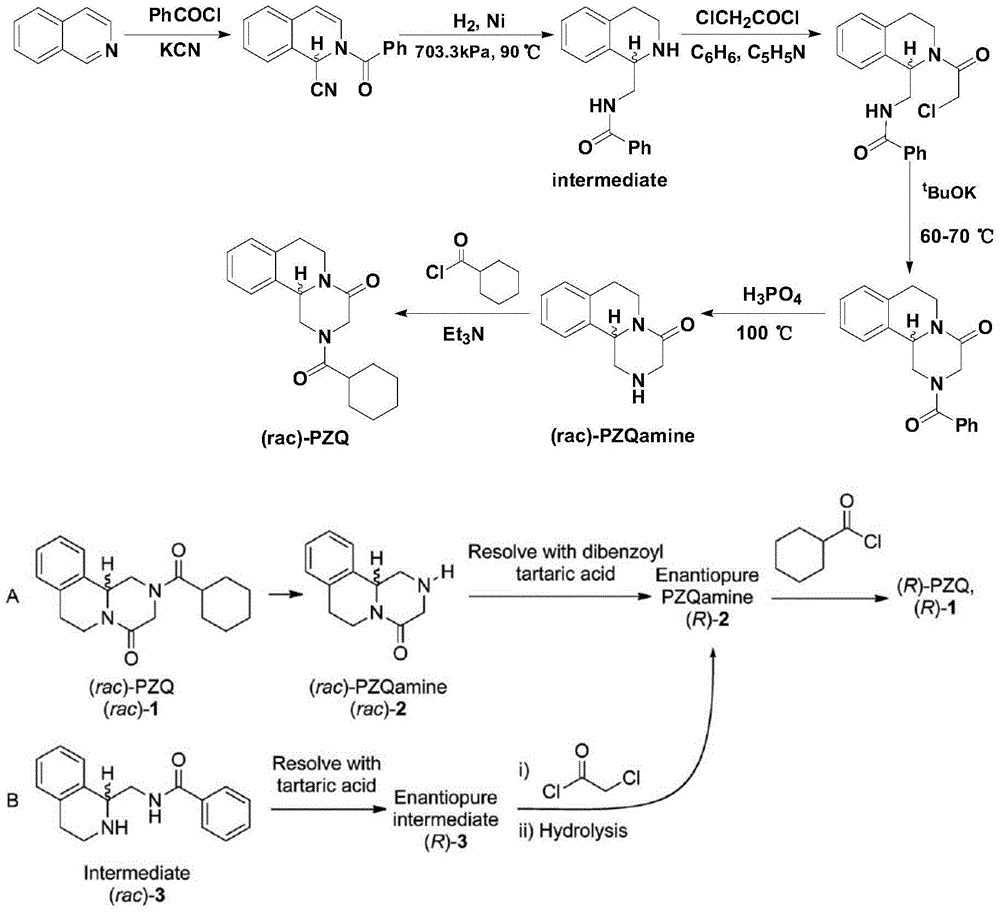

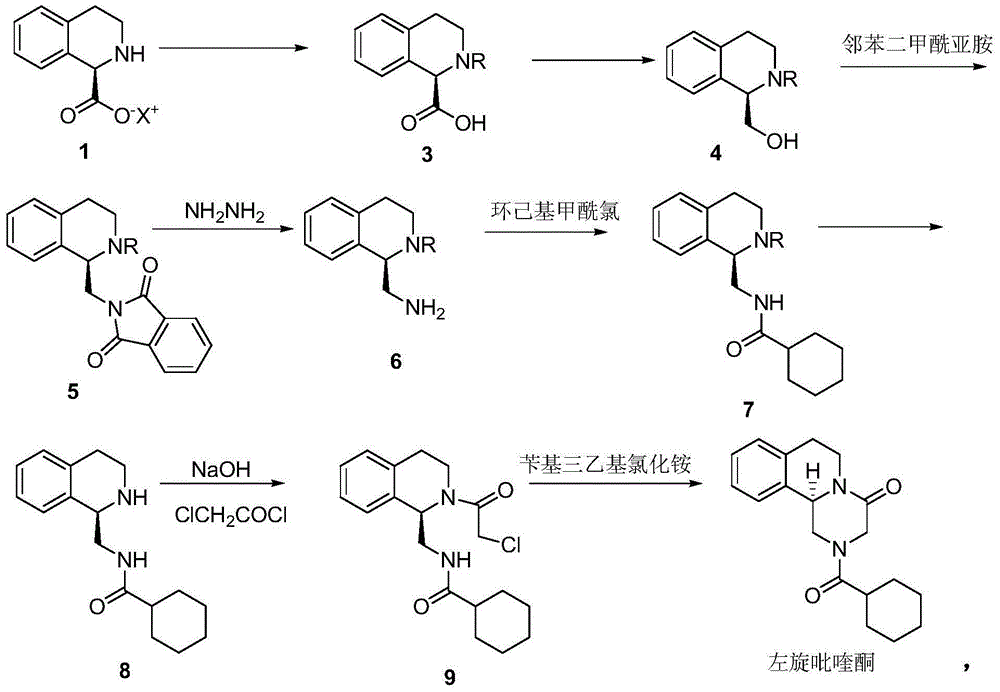

Preparation method of (R)-praziquantel

ActiveCN104557911AHigh optical purityLow costOrganic chemistryFermentationEnvironmental resistanceD-amino acid

The present invention relates to an (R)-praziquantel preparation method, comprising steps of using (R,S)-tetrahydroisoquinoline-1-formate or salts thereof, or 1-(S)-tetrahydroisoquinoline-1-formate or salts thereof as a raw material to prepare 1-(R)-tetrahydroisoquinoline-1-formate salts, and steps of preparing (R)-praziquantel from said 1-(R)-tetrahydroisoquinoline-1-formate salts. The preparation method for 1-(R)-tetrahydroisoquinoline-1-formate or salts thereof is as follows: perform an oxidation reaction between the raw material described above and oxygen in the presence of recombinant D-amino acid oxidase and catalase, then perform a reduction reaction on the resulting product under the effect of a borane-amine complex, thus successively converting 1-(S)-tetrahydroisoquinoline-1-formate or salts thereof into the 1-(R)-tetrahydroisoquinoline-1-formate or salts thereof isomer. The present method not only produces an (R)-praziquantel product with a high optical purity, but is also low-cost and environmentally friendly in terms of production.

Owner:TONGLI BIOMEDICAL

Colored asphalt and preparation method thereof

ActiveCN102952405AEasy constructionEasy to manufactureIn situ pavingsRoads maintainencePetroleum resinRoad surface

The invention relates to asphalt and a preparation method thereof, and specifically relates to colored asphalt and a preparation method thereof. The colored asphalt comprises the components of, by weight: 30-50% of C5 petroleum resin, 30-55% of C9 petroleum resin, 5-30% of an inorganic pigment, 1-6% of a powdery styrene-butadiene rubber SBR modifying agent, 0.5-6% of a powdery thermoplastic styrene-butadiene rubber SBS modifying agent, and 5-20% of powdery solid rosin. According to the colored asphalt and the preparation method thereof provided by the invention, the colored asphalt is prepared into powdery solid or solid particles, and is directly added into a stirring tank and is mixed with heated graded stones with a certain temperature, such that colored asphalts with various colors can be directly produced, and road pavement and rolling constructions can be carried out. With the method, colored asphalt mixture preparation process is greatly simplified, and colored pavement construction is greatly simplified.

Owner:SHENZHEN TEAMTECH ROAD MATERIALS CO LTD

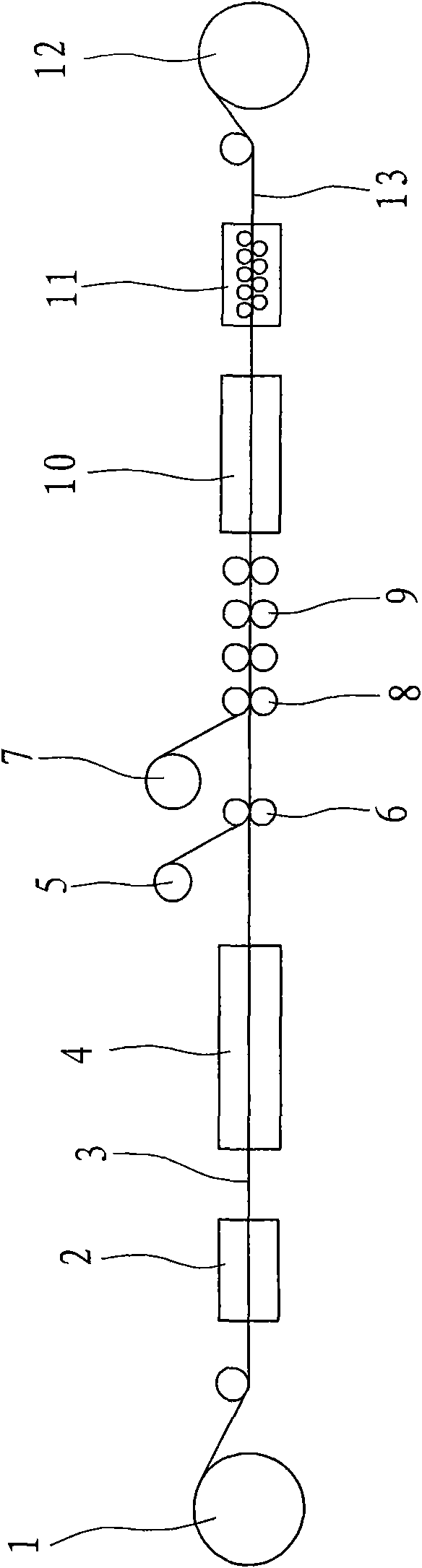

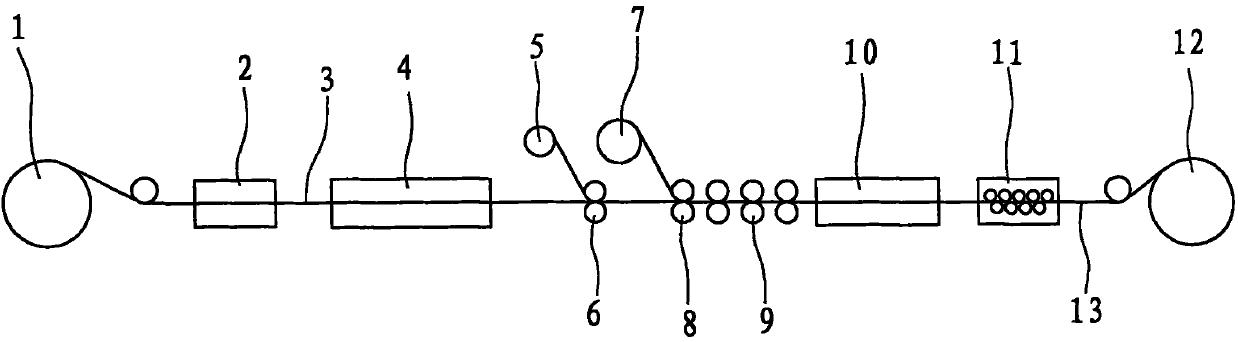

Production process for stainless steel damping composite board

InactiveCN101905558AGuaranteed surface qualityImprove the shock and noise reduction effectSynthetic resin layered productsLaminationMetallurgyComposite plate

The invention discloses a production process for a stainless steel damping composite board, which comprises the following steps of: firstly, preheating a hot galvanizing cold-rolled steel sheet; secondly, rolling and adhering a macromolecular damping adhesive film on the preheated hot galvanizing cold-rolled steel sheet by using a film coating roller; thirdly, rolling and combining the stainless steel sheet on the macromolecular damping adhesive film by a sheet coating roller, heating the whole sheet body by a pressing roller at the same time and further performing rolling and adhesion to realize stable solidification; and finally, cooling the whole sheet body by using forced air cooling and rolling the cooled sheet to obtain the stainless steel damping composite board, wherein the stainless steel sheet is a surface plate, the hot galvanizing cold-rolled steel sheet is a base plate and the macromolecular damping adhesive film is a middle layer; the preheating temperature of the hot galvanizing cold-rolled steel sheet is 80 to 120 DEG C; the temperature of the film coating roller is 120 to 150 DEG C; the temperature of the sheet coating roller and the pressing roller is 170 to 220 DEG C; and the composite board is cooled to 20 to 30 DEG C by the forced air cooling. The process has the advantages that: the production is simple; the cost is low; and the product uses few stainless steel, has a high strength, and can damp and reduce noises and be produced continuously with low cost and high production process.

Owner:XUCHANG AUSTAR AUTOMATION EQUIP

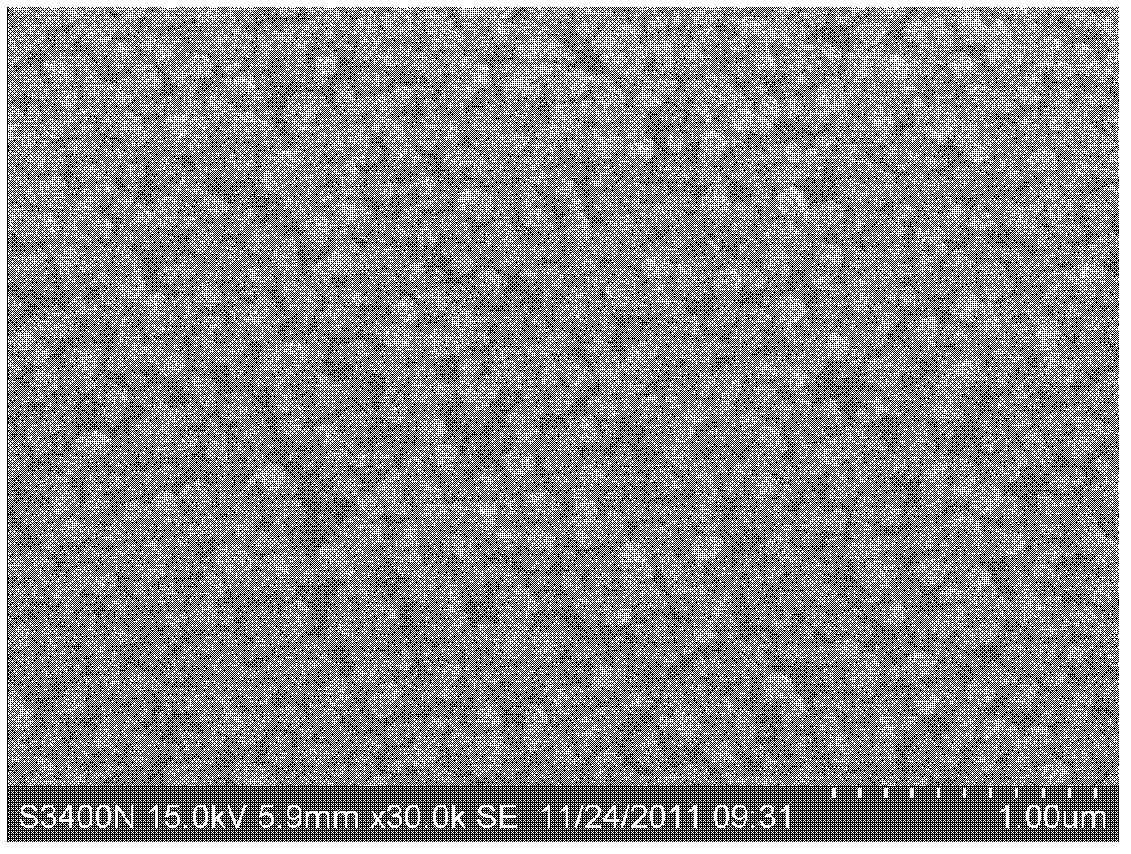

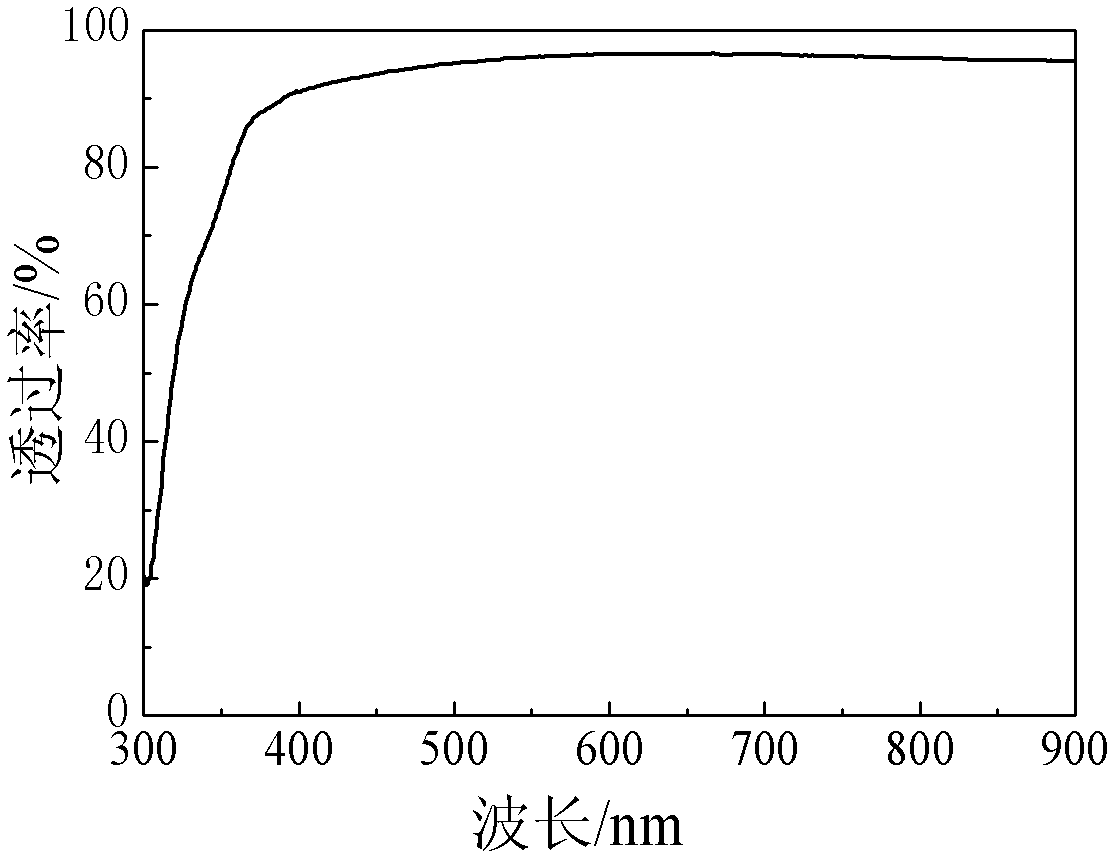

Preparation method for buffering layer material of copper indium gallium selenide film solar battery

InactiveCN102544237AQuality improvementControl reaction speedFinal product manufactureSemiconductor devicesIndiumElectrical battery

The invention discloses a preparation method for a buffering layer material of a copper indium gallium selenide film solar battery. By the method, a precursor of chemical bath reaction is prepared by using a zinc sulfate solution as a Zn<2+> source, a thiourea solution as a S<2-> source, ammonia water as a buffering agent and sodium citrate as a complexing agent; and a Zn(O,S) semiconductor film with uniform and compact grain size distribution and good adhesive force is prepared on a copper indium gallium selenide film and the common glass substrate and serves as the buffering layer of the copper indium gallium selenide film solar battery. The Zn(O,S) instead of CdS serves as the buffering layer of the copper indium gallium selenide film solar battery, so production of the copper indium gallium selenide film solar battery is environment-friendly and economic. The band gap width of the Zn(O,S) is more than that of the CdS, so more incident photons can reach an absorption layer through the buffering layer, short-circuit current of the battery is increased and photoelectric conversion efficiency of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

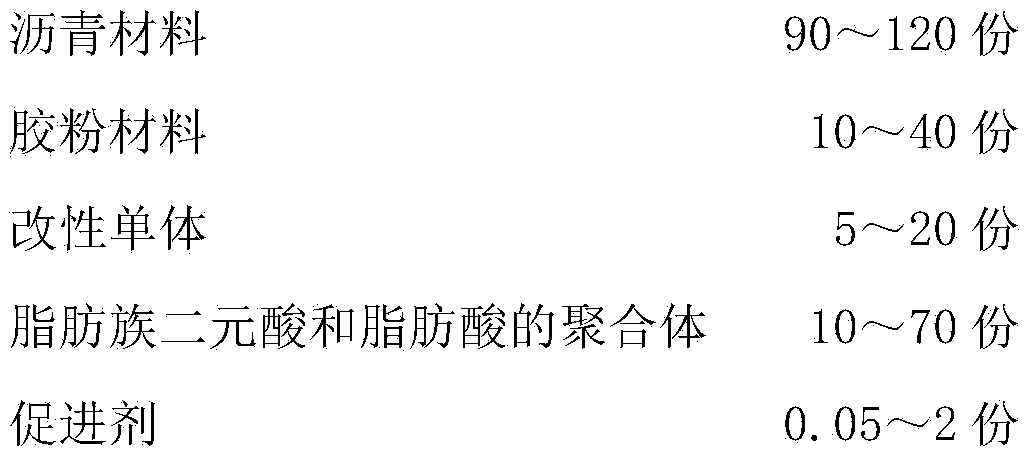

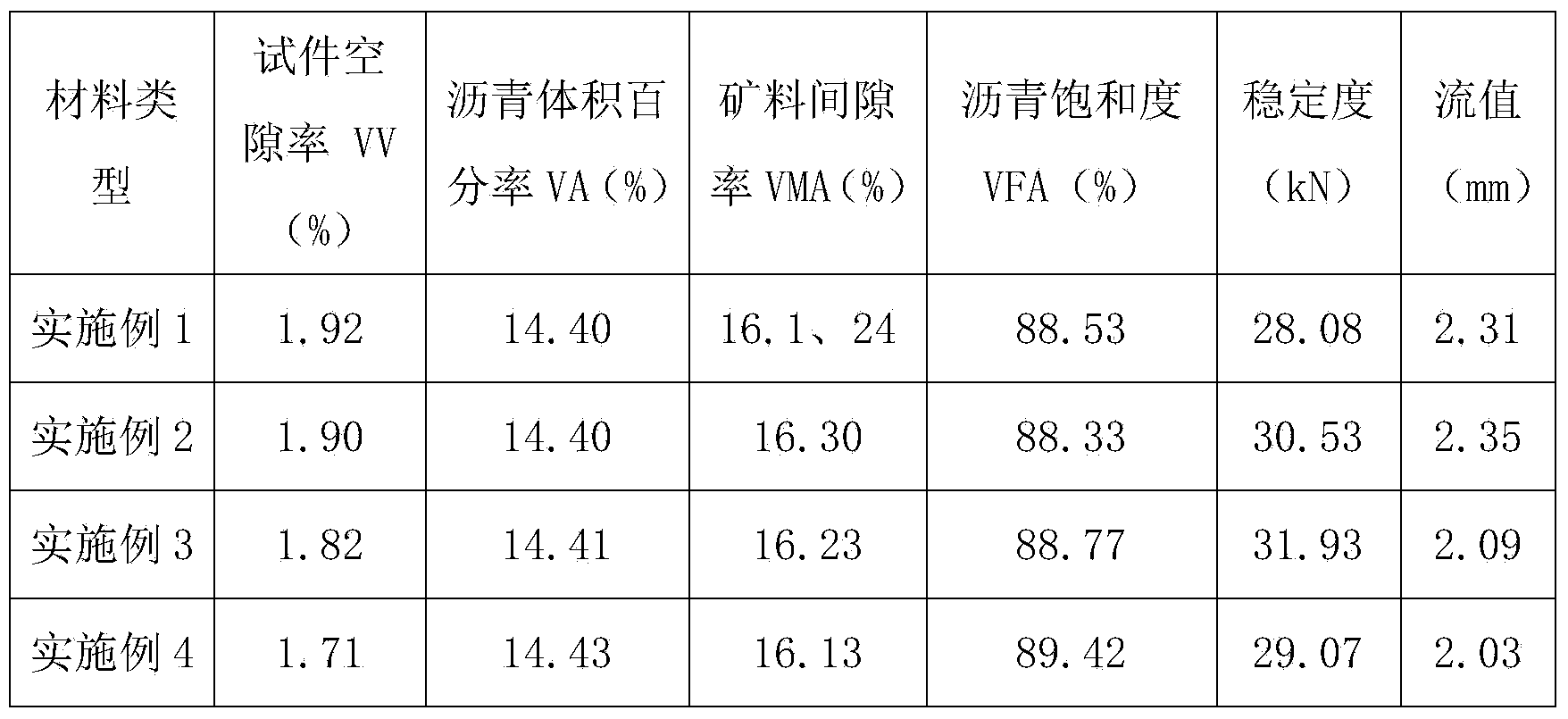

Rubber powder epoxy resin asphalt material as well as preparation method and using method thereof

ActiveCN103396673AProduction environmental protectionReduce energy consumptionIn situ pavingsBridge structural detailsEpoxyPolymer science

The invention discloses a rubber powder epoxy resin asphalt material, as well as a preparation method and a using method thereof. Modified asphalt comprises an A component and a B component, wherein a weight ratio of the A component to the B component is 1:(2-20); the A component comprises 100 parts of epoxy resin by weight; and the B component comprises 90-120 parts of asphalt material, 10-40 parts of rubber powder material, 5-20 parts of modified monomer, 10-70 parts of fatty group binary acid and fatty acid polymer and 0.05-2 parts of accelerant. According to the rubber powder epoxy resin asphalt material, the rubber powder material is adopted, so that the unit price of the epoxy resin asphalt material can be reduced, the low-temperature flexibility of the epoxy resin asphalt material can be improved, and waste rubber can be fully used; and the rubber powder epoxy resin asphalt material, the preparation method and the using method are energy-saving and environment-friendly. The rubber powder epoxy resin asphalt material can serve as a cementing material of a bonding layer and a waterproof layer of a deck and a pavement, asphalt concrete in road engineering, top dressing and the like, and can also be used for waterproofness and anticorrosion of a structure and a building.

Owner:黄卫 +1

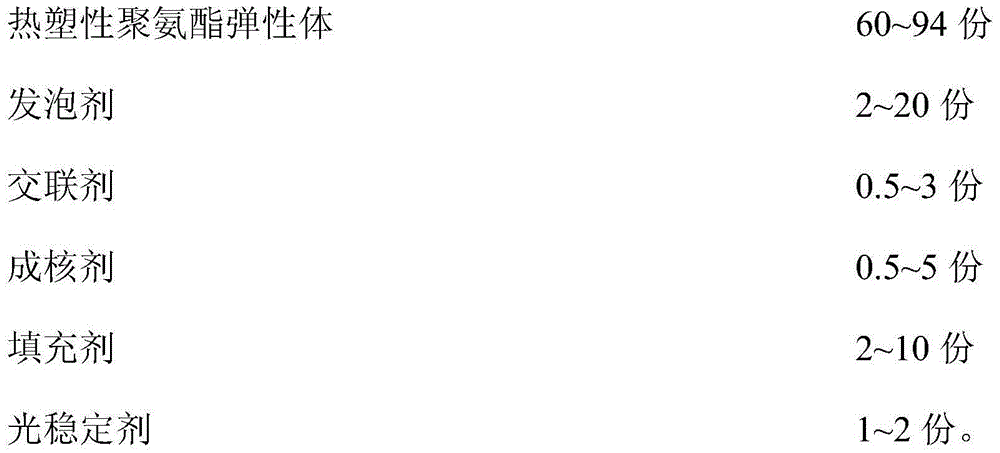

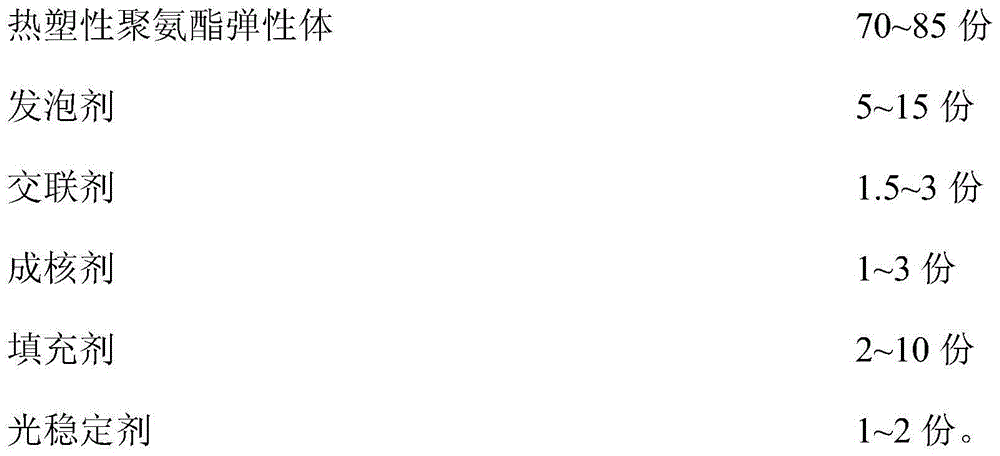

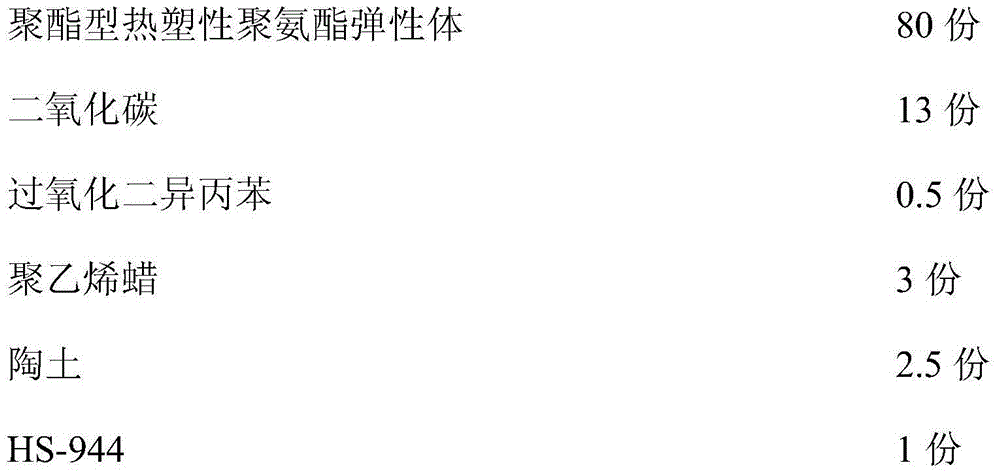

Thermoplastic polyurethane elastomer foamed bead and preparation method thereof

The invention provides a thermoplastic polyurethane elastomer foamed bead and a preparation method thereof. The thermoplastic polyurethane elastomer foamed bead is mainly prepared from the following raw materials in parts by weight: 60-94 parts of thermoplastic polyurethane elastomer, 2-20 parts of foaming agent, 0.5-3 parts of crosslinking agent, 0.5-5 parts of nucleator, 2-10 parts of filler and 1-2 parts of light stabilizer. The thermoplastic polyurethane elastomer foamed bead has the advantages of uniform particle size, high closed-cell rate, uniform pores and high strength. The preparation method is simple, has the advantages of fewer production steps, low required equipment investment, safe and environment-friendly production process and controllable foaming density, and is suitable for all thermoplastic polyurethane elastomers.

Owner:丁钰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com