Thermoplastic polyurethane foaming particle and preparation method thereof

A thermoplastic polyurethane, foam particle technology, applied in the field of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

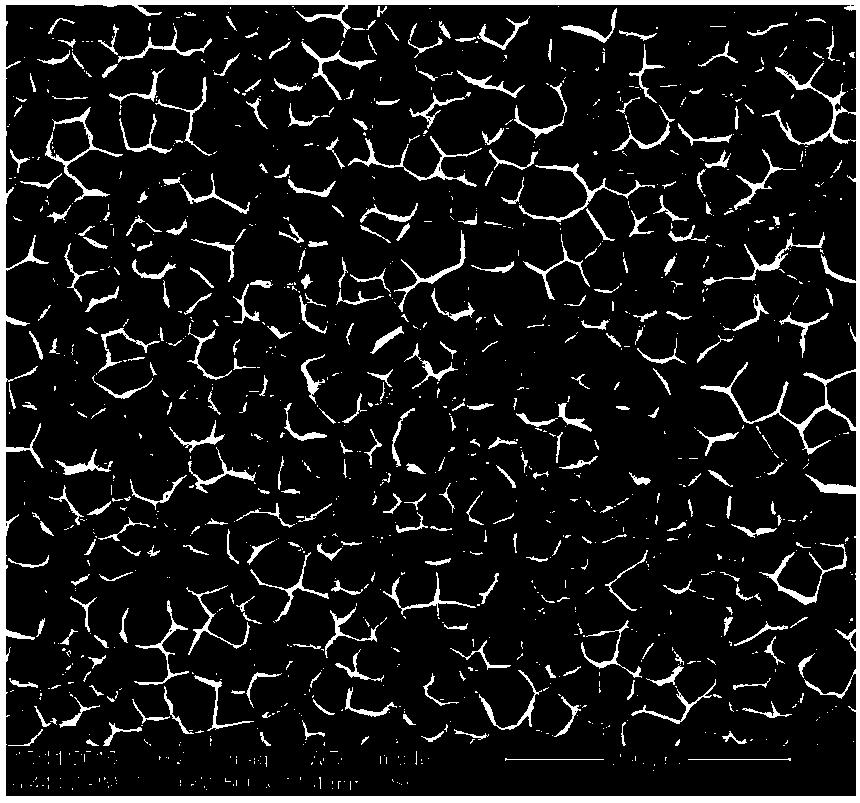

Image

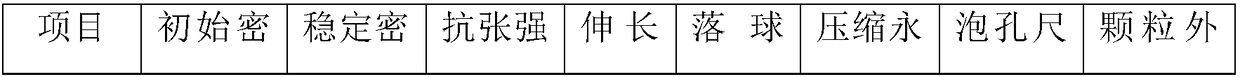

Examples

Embodiment 1

[0093] (1) According to mass percentage, 90% of thermoplastic polyether polyurethane (8190RV) and 10% of polybutylene terephthalate (1200-211L) were mixed evenly. the mixed composition in the Melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-235°C. After underwater granulation and drying, TPU blended gold particles are obtained;

[0094] (2) Add the TPU blended gold particles into the autoclave, feed carbon dioxide to impregnate the TPU blended gold particles, the temperature of the autoclave is 40°C, the pressure is 15MPa, and the impregnation time is 2 hours;

[0095] (3) After impregnation, the temperature of the autoclave is lowered to 35° C., and the pressure of the autoclave is released to normal pressure to obtain non-foaming polyurethane blended alloy particles dissolved in carbon dioxide;

[0096] (4) The obtained non-foaming polyurethane blend alloy particles were rapidly placed in hot air at 130° C. to be heate...

Embodiment 2

[0098] (1) Mix 85% of thermoplastic polyether polyurethane (8190RV) and 15% of polybutylene terephthalate (1100-211MD) evenly according to mass percentage. the mixed composition in the Melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-235°C. After underwater granulation and drying, TPU blended gold particles are obtained;

[0099] (2) Add the TPU blended gold particles into the autoclave, feed carbon dioxide to impregnate the TPU blended gold particles, the temperature of the autoclave is 160 ° C, the pressure is 10 MPa, and the impregnation time is 1 hour;

[0100] (3) After being impregnated, the materials in the autoclave are discharged into the atmosphere at a pressure release rate of 5 MPa / s to obtain expanded particles.

Embodiment 3

[0102] (1) According to mass percentage, 88% thermoplastic polyether polyurethane (8190RV), 2% thermoplastic polyester elastomer ( 7246) and 10% compatibilizer HDPE-G-MAH mixed evenly. the mixed composition in the The melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-230°C. After underwater granulation and drying, TPU blended gold particles are obtained;

[0103] (2) Add the TPU blended gold particles into the autoclave, feed carbon dioxide to impregnate the TPU blended gold particles, the temperature of the autoclave is 30°C, the pressure is 10MPa, and the impregnation time is 1.5 hours;

[0104] (3) After being impregnated, release the autoclave pressure to normal pressure at 30° C. to obtain non-foaming polyurethane blended alloy particles dissolved in carbon dioxide;

[0105] (4) The obtained non-foaming polyurethane blended alloy particles were rapidly placed in hot air at 150° C. to be heated and foamed to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com