Thermoplastic polyurethane elastomer foamed bead and preparation method thereof

A technology of thermoplastic polyurethane and foaming beads, which is applied in the field of foaming materials, can solve the problems of insufficient cell density, difficulty in achieving, and poor elasticity, and achieve uniform cell density, easy foaming density, and high closed cell rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

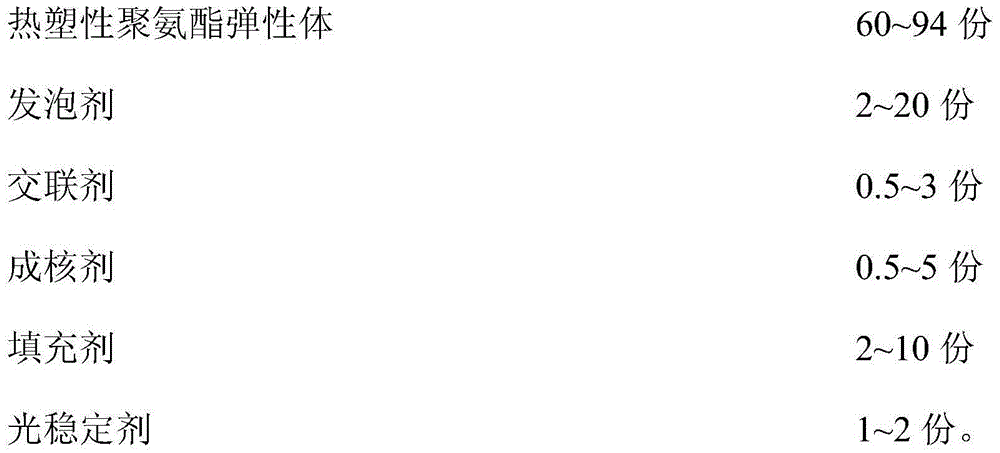

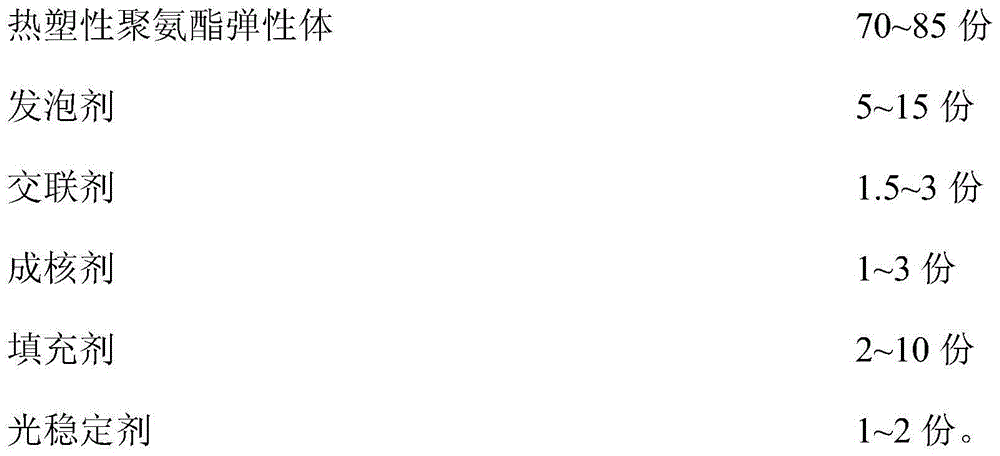

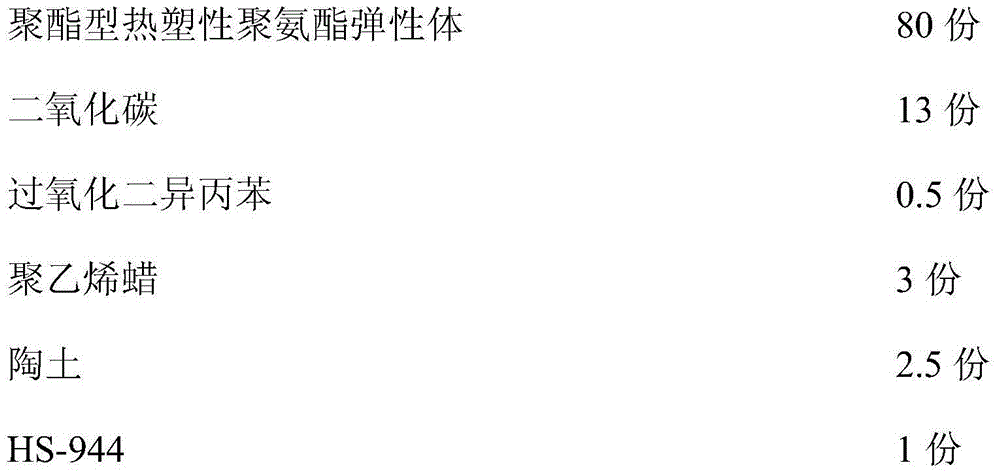

[0047] The thermoplastic polyurethane elastomer foaming beads are mainly prepared from the following raw materials in parts by weight:

[0048]

[0049] The clay has an average particle size of 1 μm.

[0050] The preparation method of the thermoplastic polyurethane elastomer expanded beads is as follows:

[0051] (1) heat-treating the above-mentioned polyester thermoplastic polyurethane elastomer at 45° C. for 8 hours;

[0052] (2) adding dicumyl peroxide, pottery clay, HS-944 and polyethylene wax to the polyester thermoplastic polyurethane elastomer after the heat treatment and the formula amount to fully mix in the mixer to obtain the mixture;

[0053] (3) Put the mixture into a twin-screw extruder with a length-to-diameter ratio of 55 through the feeding port. The melt temperature of the twin-screw extruder is set at 150°C. The blowing agent of the formulation amount injected at the place is mixed and extruded through a circular orifice die with a diameter of 2.5mm. Th...

Embodiment 2

[0057] The thermoplastic polyurethane elastomer foaming beads are mainly prepared from the following raw materials in parts by weight:

[0058]

[0059] The average particle size of the calcium carbonate is 50 μm.

[0060] The preparation method of the thermoplastic polyurethane elastomer expanded beads is as follows:

[0061] (1) heat-treating the polyether thermoplastic polyurethane elastomer of the above formula amount at 110° C. for 5 hours;

[0062] (2) Add the heat-treated polyether thermoplastic polyurethane elastomer and the formula amount of bis(2,4-dichlorobenzoyl peroxide), calcium carbonate, BW-10LD and monoglyceride into the mixer and mix thoroughly , to get the mixture;

[0063] (3) Put the mixture into a twin-screw extruder with a length-to-diameter ratio of 50 through the feeding port. The melt temperature of the twin-screw extruder is set at 195°C. The blowing agent of the formulation amount injected at the place is mixed and extruded through a circular ...

Embodiment 3

[0067] Thermoplastic polyurethane elastomer foam beads include the following raw materials by weight percentage:

[0068]

[0069] The average particle diameters of the calcium carbonate and magnesium hydroxide are both 25 μm.

[0070] The preparation method of the thermoplastic polyurethane elastomer expanded beads is as follows:

[0071] (1) heat-treating the polyether thermoplastic polyurethane elastomer of the above formula amount at 90° C. for 1 hour;

[0072] (2) The heat-treated polyether thermoplastic polyurethane elastomer and the formula amount of toluene diisocyanate, a mixture of monoglyceride and tristearin, a mixture of calcium carbonate and magnesium hydroxide, and BW-10LD and HS-950 The mixture is added into the mixer and fully mixed to obtain a mixture;

[0073] (3) Put the mixture into a twin-screw extruder with a length-to-diameter ratio of 50 through the feeding port. The melt temperature of the twin-screw extruder is set at 170°C. The blowing agent o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com