Patents

Literature

277results about How to "High closed cell rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Homogenous low-heat-conductivity inorganic heat insulation board and preparation method thereof

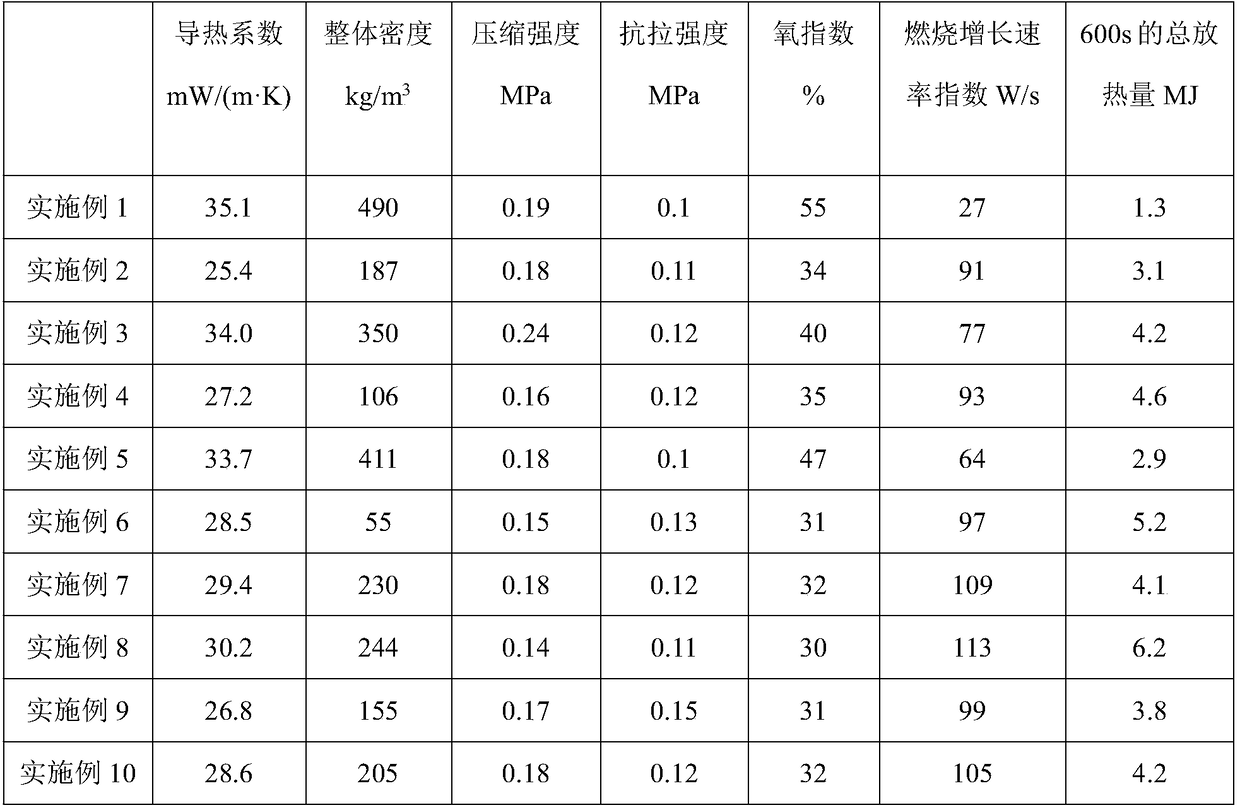

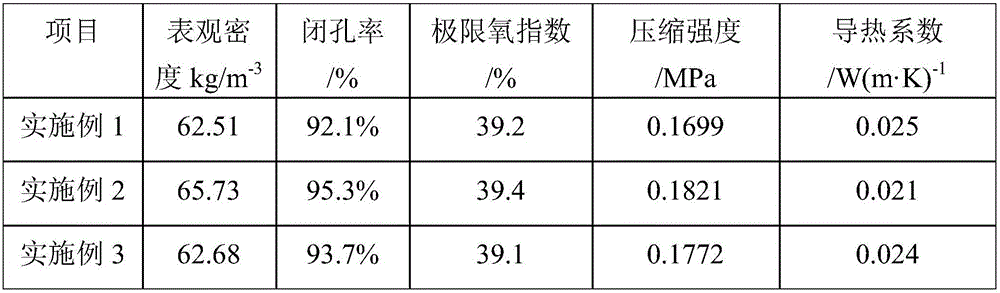

The invention discloses a homogenous low-heat-conductivity inorganic heat insulation board and a preparation method thereof. The homogenous low-heat-conductivity inorganic heat insulation board is prepared from the reaction of an inorganic material, filler and polyurethane hard foam and prepared from the following raw materials in parts by weight: 31 to 85 parts of the inorganic material, 0 to 20parts of the filler, and 15 to 49 parts of the polyurethane hard foam. The heat conduction coefficient of the prepared insulation board is less than 40mW / (m.K), the integral density is 35 to 500 kg / m<3>, and the thermal insulation and heat preservation performance is good. The compressive strength is greater than or equal to 0.1MPa, the tensile strength is greater than or equal to 0.1MPa, the mechanical strength is high, and the durability is good. The oxygen index is greater than or equal to 30 percent, the combustion growth rate index is less than or equal to 120W / s, the total heat release amount in 600s is less than or equal to 7.5MJ, and the homogeneous low-heat-conductivity inorganic insulation board is difficult to combust and high in fireproof grade. The preparation process is simple and suitable for the industrialized production.

Owner:南京红宝丽新材料有限公司

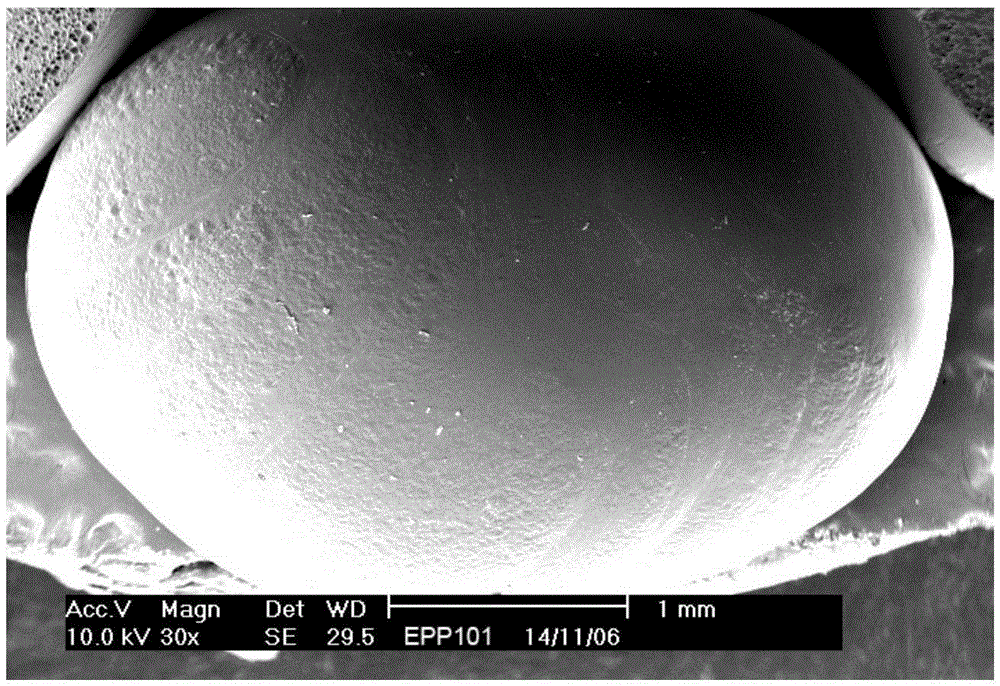

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

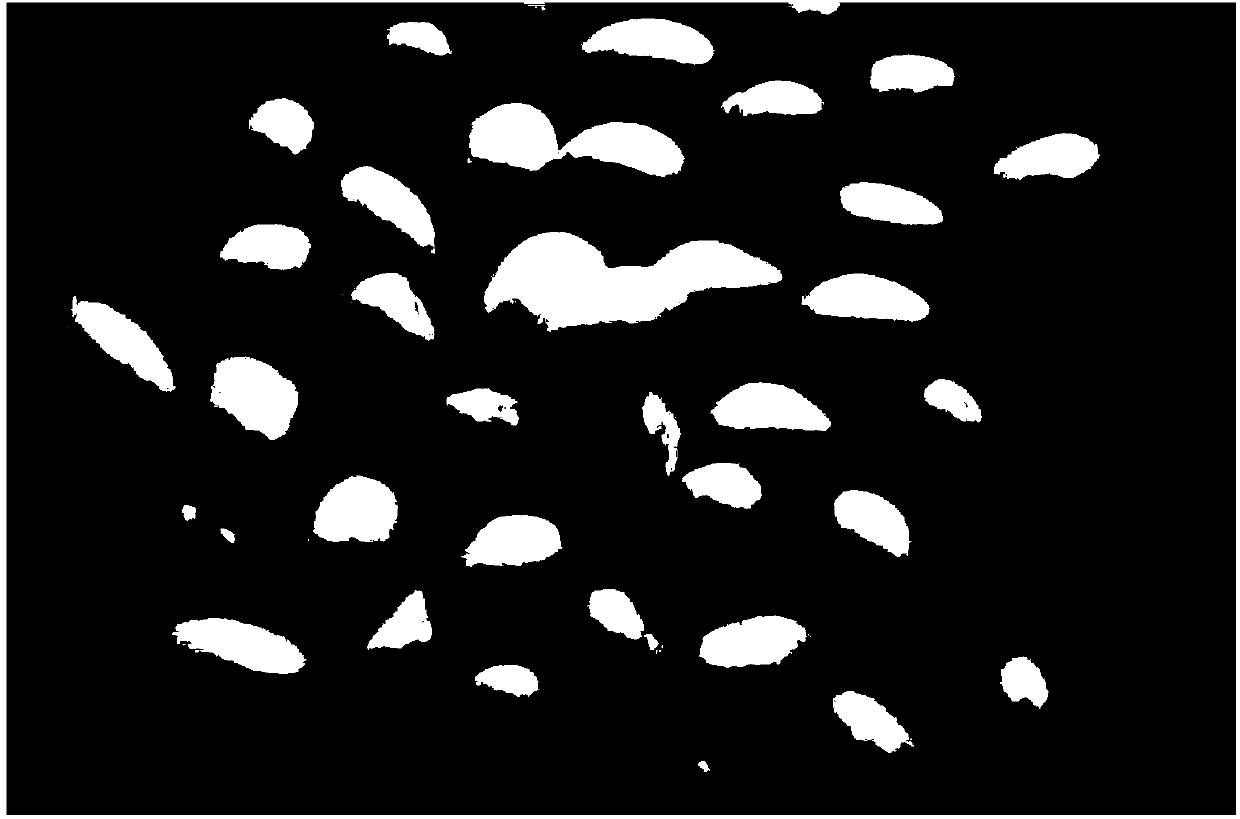

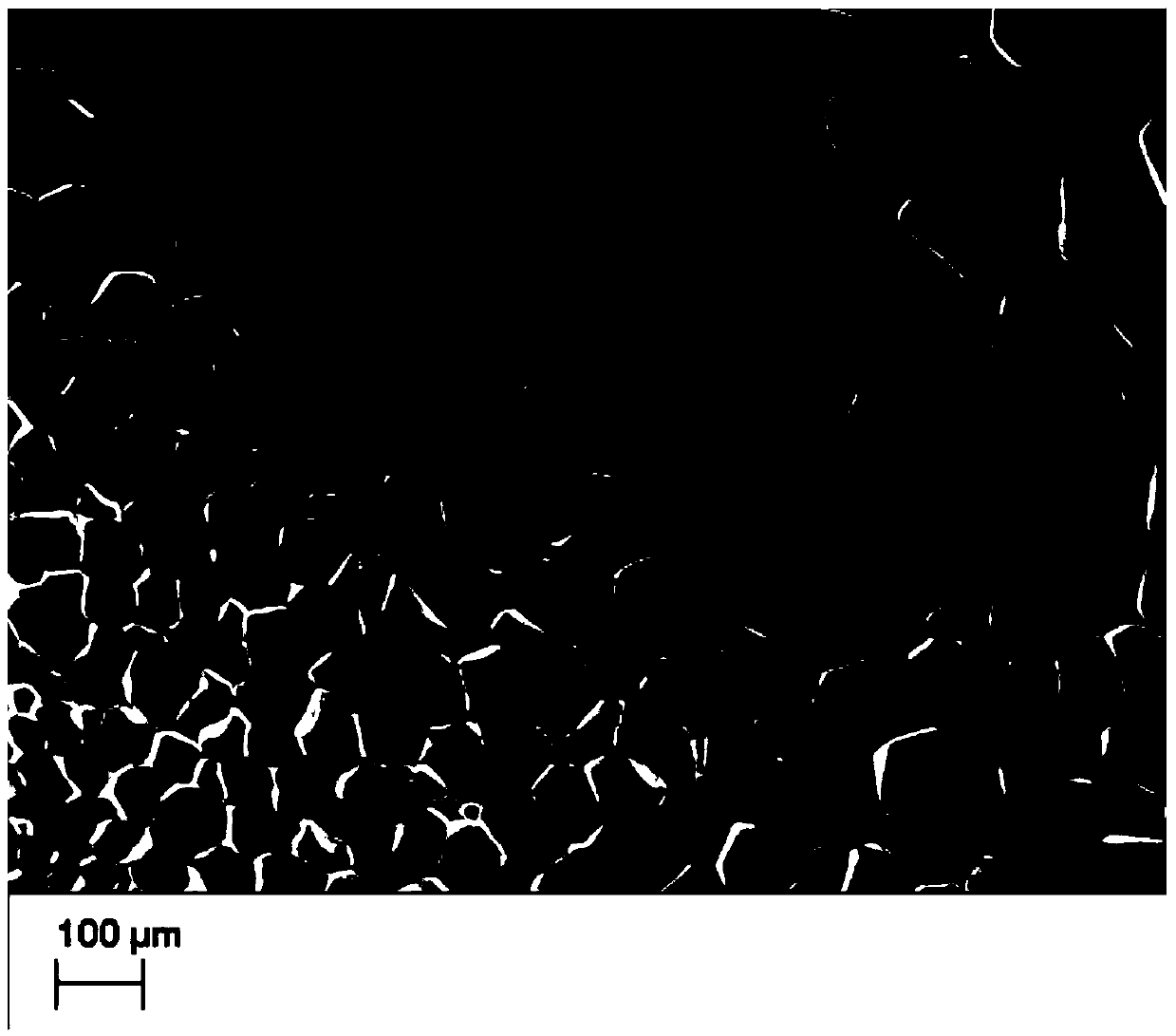

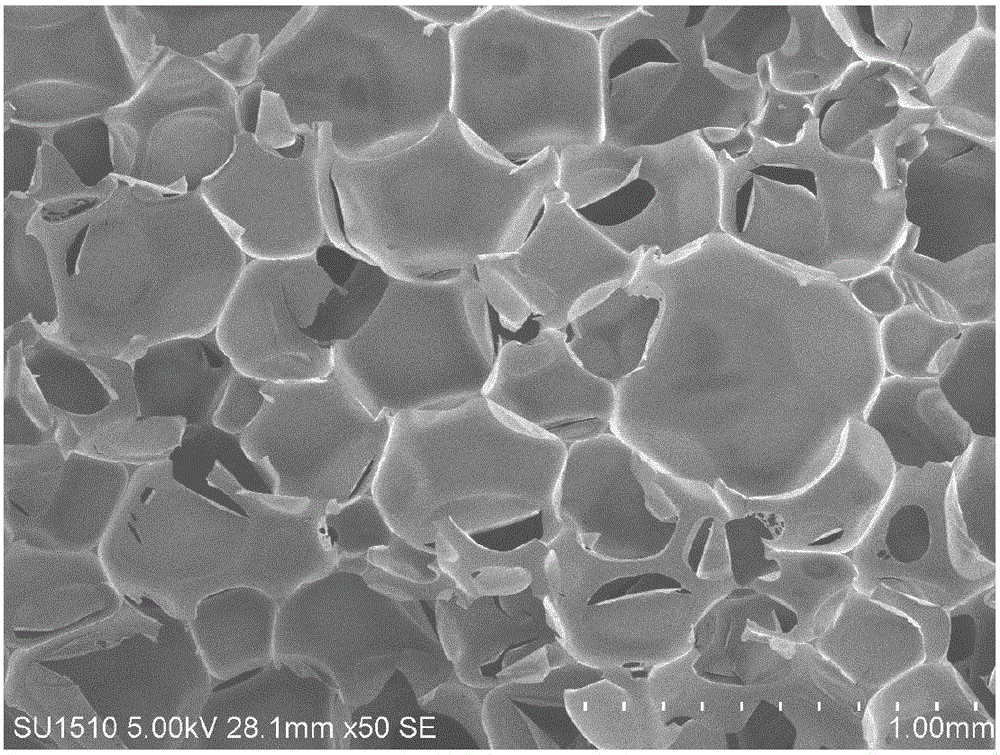

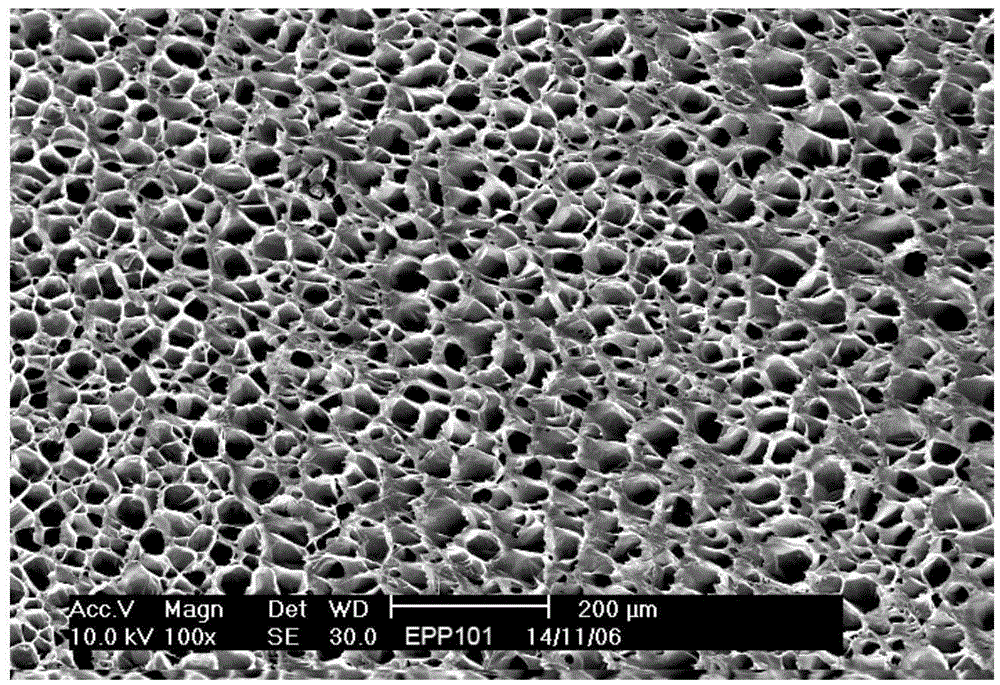

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

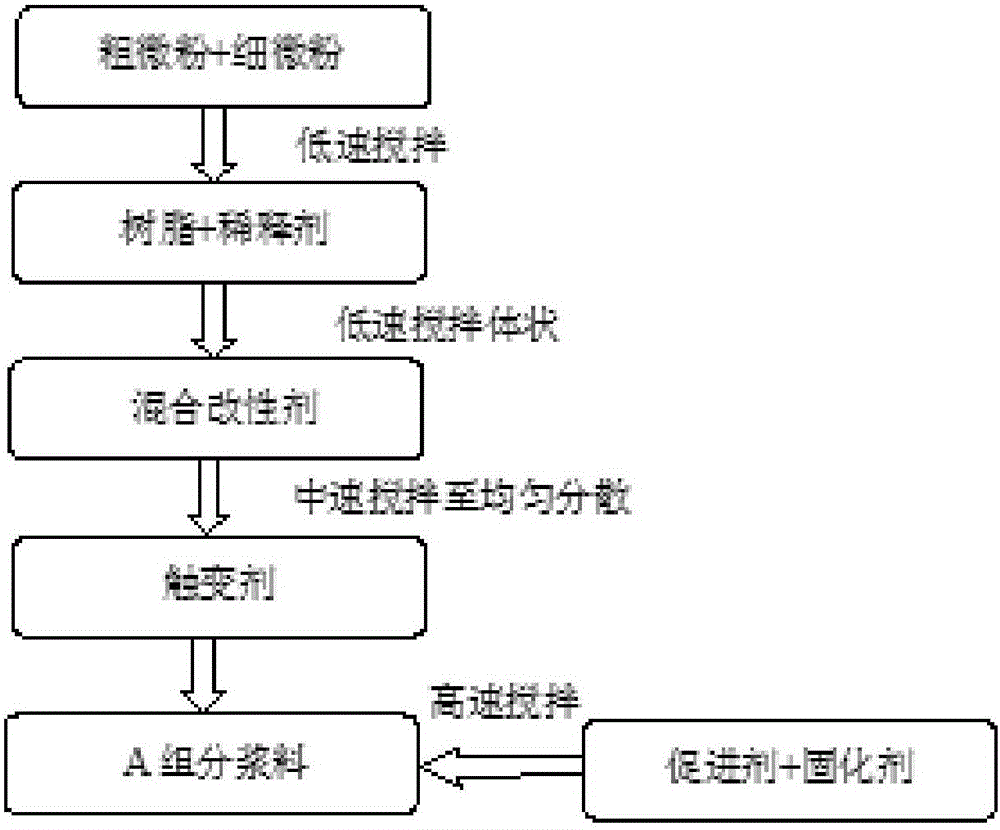

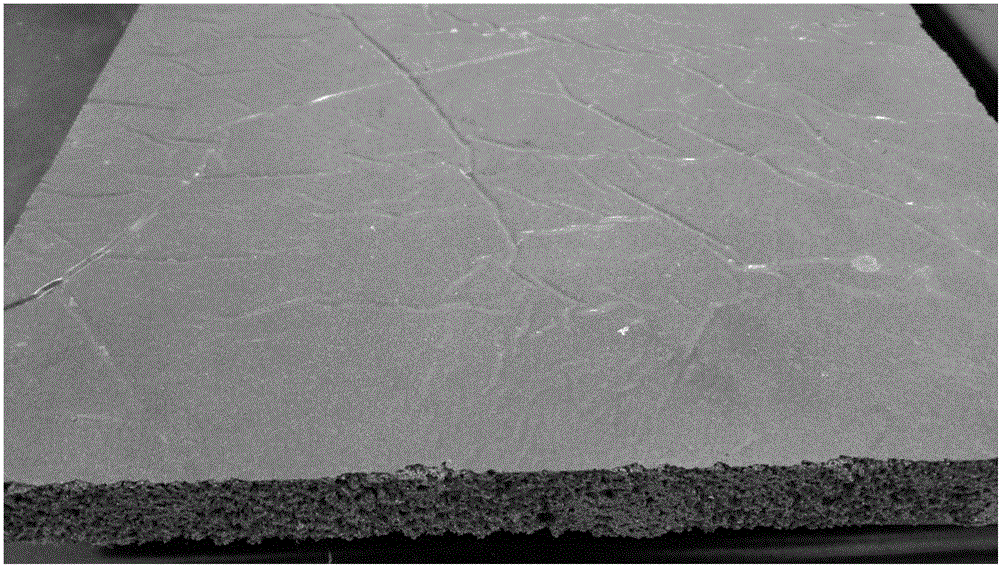

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

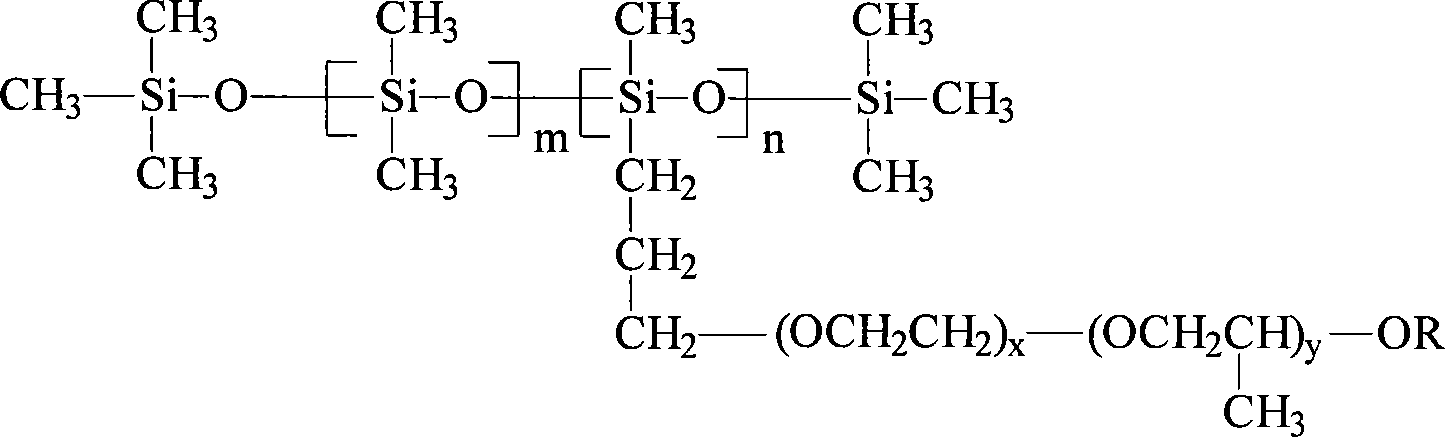

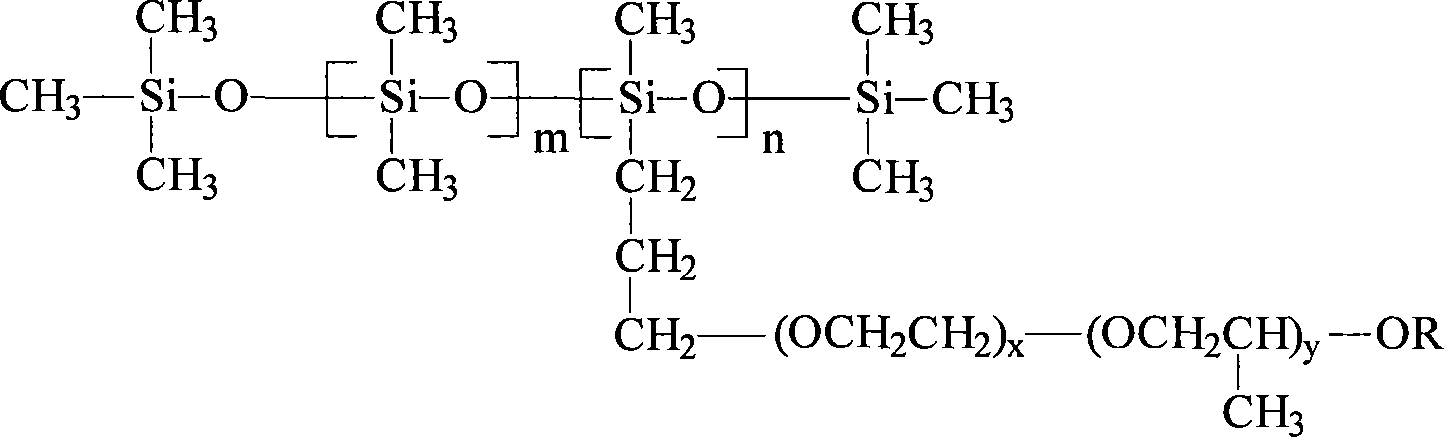

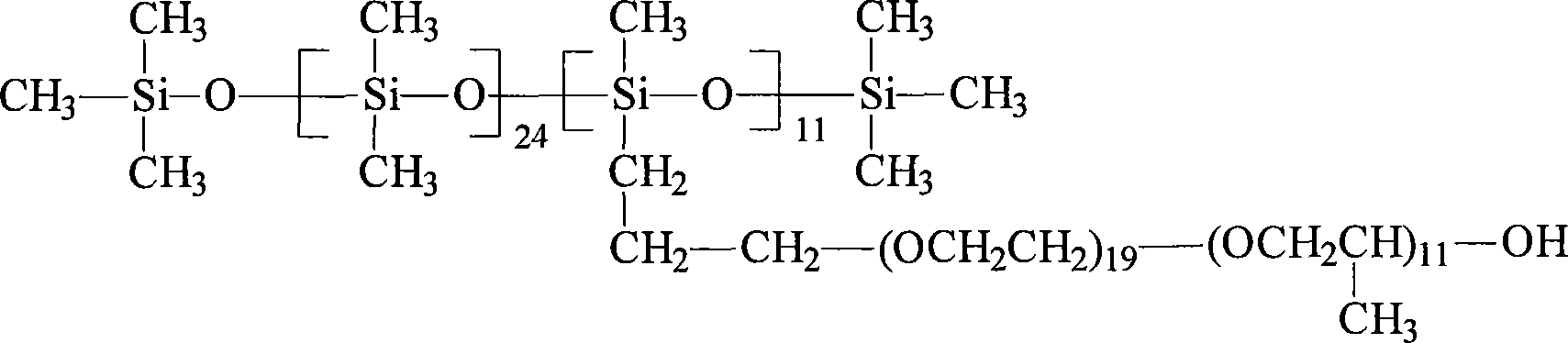

Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

The invention discloses a low-density and low thermal-conduction-index polyurethane foam stabilizer and a preparation method thereof. The stabilizer can be widely used in polyurethane blowing technique, and enable the thermal conduction index of the pentane-blowing polyurethane foam to be lowered down to 0.0195-0.0200W / m.K, and has excellent functions of heat protection and heat preservation. The low-density and low thermal-conduction-index polyurethane foam stabilizer of the invention is provided with the structures: wherein, the figure of m is 10-80, the figure of n is 1-10, the figure of x is 10-70, the figure of y is 0-30, and m plus n is 11-90, x plus y is 10-100; R can be paraffin, radical aromatic, acyloxy or hydrogen atom that contains 1-4 carbon atoms.

Owner:JIANGSU MAYSTA CHEM

Polyurethanes compound modified phenolic foam plastic and method for preparing same

The present invention is polyurethane compound modified phenolic foam plastic and its preparation process. The modified phenolic foam plastic is prepared with aniline phenolic resin 100 weight portions, polyurethane compound 15-30 weight portions and curing agent 15-30 weight portions, and through mixing, reaction and foaming. The polyurethane compound modified phenolic foam plastic has fine hand feeling, low density, low heat conducting coefficient, high heat insulating performance and environment friendship. It is used as the heat insulating material for outer wall and roof, and can raise the heat insulating and fire-proofing effect.

Owner:北京振利高新技术有限公司

Cross-linked polyvinyl chloride (PVC) foaming material and preparation method thereof

The invention discloses a cross-linked polyvinyl chloride (PVC) foaming material and a preparation method thereof. The foaming material is prepared by the following the steps of: uniformly mixing PVC, a heat-resisting modifier, a PVC processing aid, a plasticizer, a stabilizer, a foaming agent, a sensitizer, a lubricating agent and an inorganic filler in certain parts by weight, blending, granulating, and extruding into a sheet; and radiating through an electronic accelerator, and putting into an oil bath for foaming. The PVC can form a three-dimensional netlike structure under the condition of not adding any cross-linked polymer or cross-linked agent. The prepared PVC foaming material is cross-linked uniformly, foam holes are uniformly dispersed, and the cross-linked PVC foaming material has low production cost and high efficiency.

Owner:FSPG HI TECH

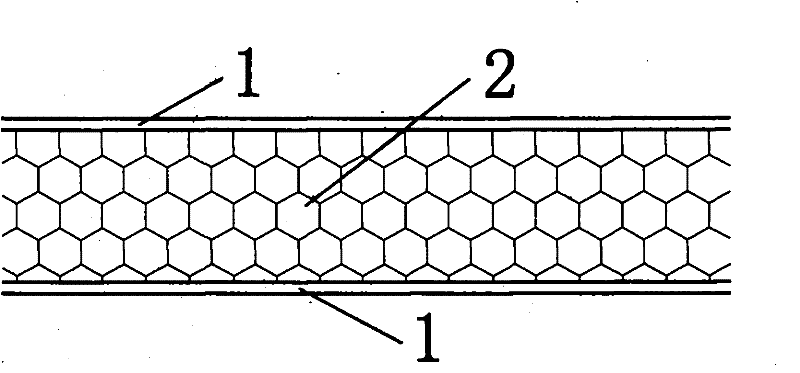

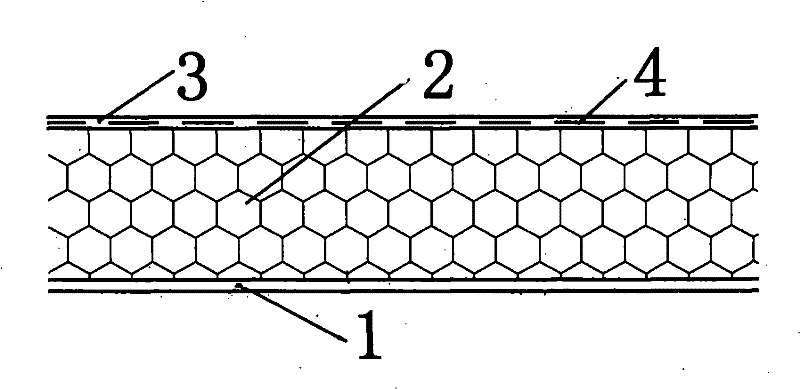

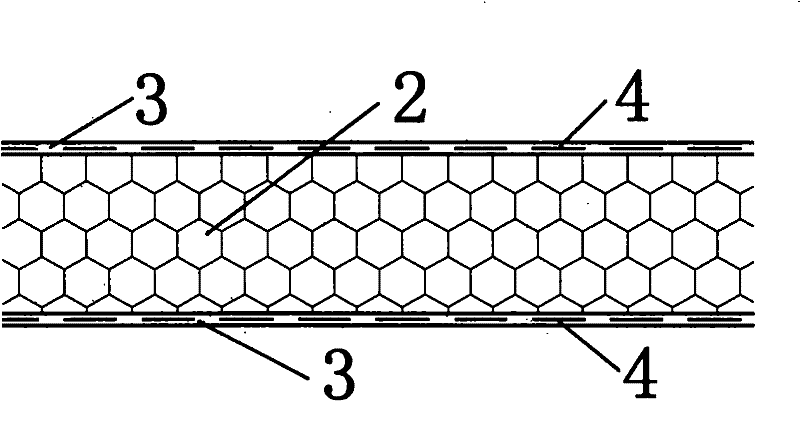

Modified hard bubble polyurethane composite plate and manufacturing method thereof

InactiveCN102173147AHigh closed cell rateLow thermal conductivitySynthetic resin layered productsInsulation layerComposite plate

The invention discloses a modified hard bubble polyurethane composite plate and a manufacturing method thereof. The manufacturing method comprises the following steps of: preparing a polymer coiled material in advance; and directly compounding the polymer coiled material to two surfaces of a hard bubble polyurethane insulation layer in the process of foaming polyisocyanate and polyether into the hard bubble polyurethane insulation layer. The manufacturing method is characterized in that an aerogel material is added to the hard bubble polyurethane insulation layer, the addition amount of the aerogel material is 0.05-6.5% of the weight of polyurethane foams, and the polymer coiled material is a waterproof and fireproof coiled material. The composite plate manufactured according to the method has the advantages of excellent heat insulation performance, high waterproof and impervious performances, more remarkable fireproof performance, convenience for use and high construction efficiency and can be used for large-area heat-insulation, waterproof and fireproof engineering of outer walls of a building.

Owner:夏良强

Composite foamed cement insulation board and production technology thereof

The invention relates to an insulation board and a production technology thereof, in particular to a composite foamed cement insulation board and a production technology thereof. The insulation board consists of the following components in percentage by weight: 55 to 60 percent of No. 525 cement, 30 to 35 percent of fly ash, 0.4 to 0.7 percent of stable master batch, 0.015 to 0.020 percent of lithium carbonate, 0.3 to 0.5 percent of fiber, 3 to 5 percent of foam stabilizer, and 5 to 8 percent of hydrogen peroxide. The production technology comprises the following steps of: (1) stirring the components in a stirring machine in a ratio till the components are stirred uniformly; (2) adding a foaming agent into the uniformly stirred mixture, stirring uniformly, pouring the mixture into a mold, and performing natural foaming; (3) sizing the foamed cement board passing foaming for 6 to 12 hours; (4) shifting the sized foamed cement board out of the mold; (5) after the foamed cement board is shifted out of the mold, performing air drying maintenance on the foamed cement board; and (6) after the foamed cement board is in accordance with the cutting conditions, cutting the foamed cement board into a finished product by using a cutting machine, and packing. The insulation board has the advantages of excellent fireproof and waterproof performance, insulation performance, stability, environment friendliness, energy conservation, heat insulation, sound insulation, light weight and compression resistance.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

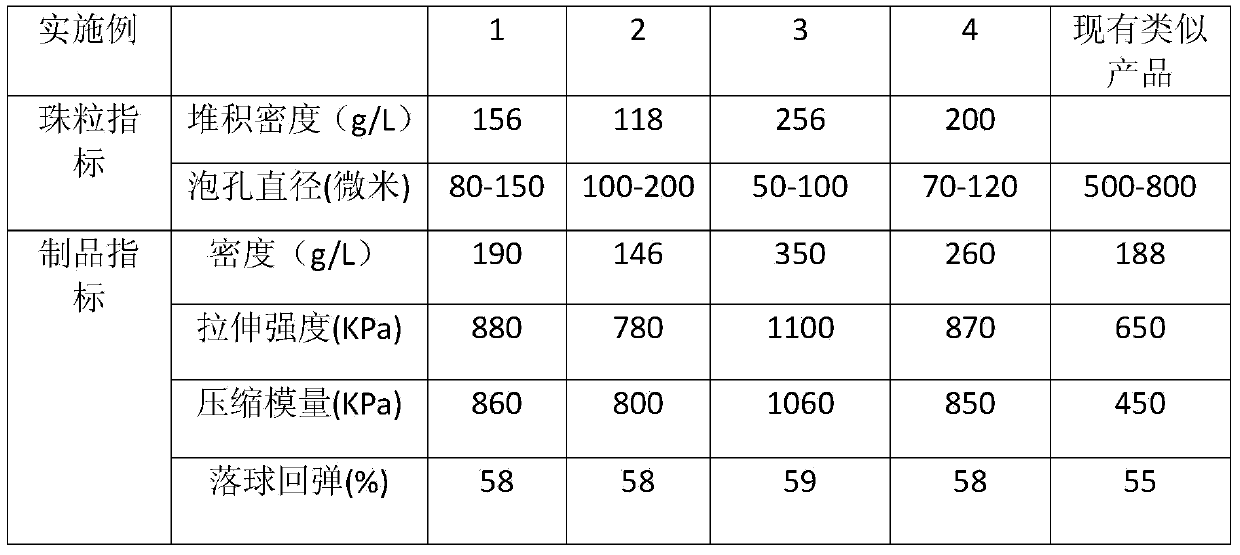

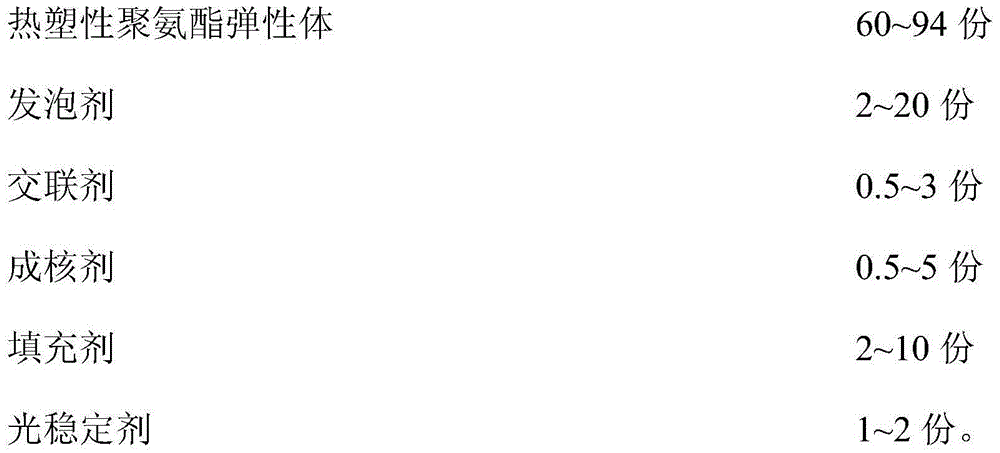

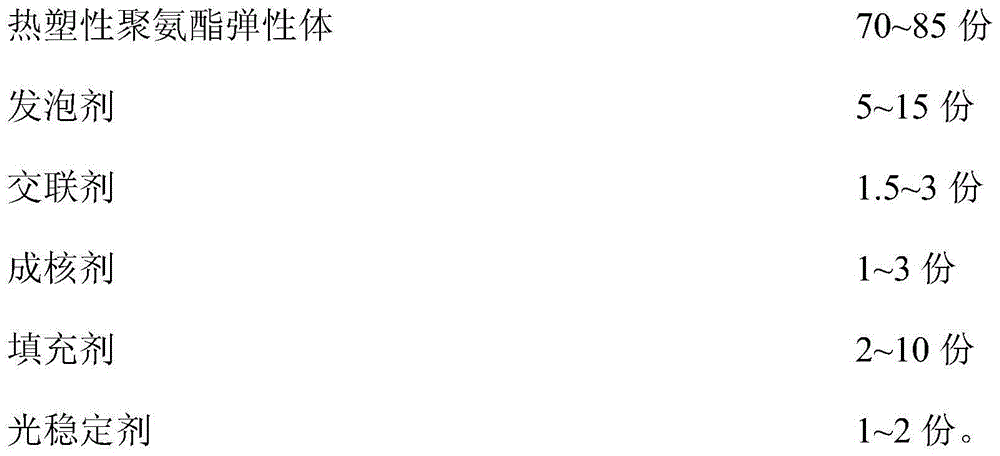

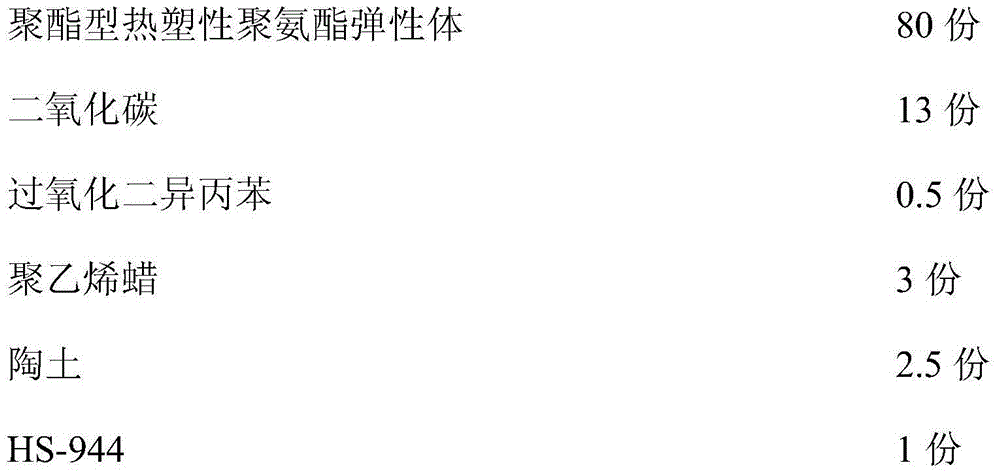

Thermoplastic polyurethane elastomer foamed bead and preparation method thereof

The invention provides a thermoplastic polyurethane elastomer foamed bead and a preparation method thereof. The thermoplastic polyurethane elastomer foamed bead is mainly prepared from the following raw materials in parts by weight: 60-94 parts of thermoplastic polyurethane elastomer, 2-20 parts of foaming agent, 0.5-3 parts of crosslinking agent, 0.5-5 parts of nucleator, 2-10 parts of filler and 1-2 parts of light stabilizer. The thermoplastic polyurethane elastomer foamed bead has the advantages of uniform particle size, high closed-cell rate, uniform pores and high strength. The preparation method is simple, has the advantages of fewer production steps, low required equipment investment, safe and environment-friendly production process and controllable foaming density, and is suitable for all thermoplastic polyurethane elastomers.

Owner:丁钰

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

Hard closed melamine foam and preparing method thereof

The invention discloses hard closed melamine foam and a preparing method thereof. The method comprises the steps of making melamine react with high-concentration formaldehyde solution; after reaction proceeds to a certain extent, adding a stabilizer to prepare expandable melamine resin high in solid content with the ice-water bath method; finally, mixing the expandable melamine resin with a surface active agent, a curing agent and a foaming agent, and placing the mixture in a mold for microwave or oven foaming to obtain the hard closed melamine foam. The hard closed melamine foam is small in diameter and density, high in flame retardant property, low in heat conductivity coefficient and high in compression strength. The preparing method is creative, and preparing steps are simple and convenient to implement.

Owner:JIANGNAN UNIV

Material for manufacturing modified phenolic fireproof insulating plate

The invention relates to the technical field of building materials, in particular to a material for manufacturing a modified phenolic fireproof insulating plate. The material for manufacturing the modified phenolic fireproof insulating plate comprises the following components in part by weight: 100 parts of expandable phenolic resin, 2 to 20 parts of polyurethane prepolymer, 2 to 4 parts of surfactant, 5 to 7 parts of foaming agent and 8 to 10 parts of curing agent. The material improves the closed porosity of the phenolic fireproof insulating plate, reduces the hygroscopicity, quickens the speed of curing and molding reaction, also improves the intensity and roughness of the phenolic fireproof insulating plate, reduces the crispness of phenolic foam, and meets the requirements on outer wall construction (an outer wall insulation system) of buildings.

Owner:上海雅达特种涂料有限公司

Nano modified phenolic aldehyde foam insulation board and preparation method thereof

The invention relates to a nano modified phenolic aldehyde foam insulation board and a preparation method thereof. The nano modified phenolic aldehyde foam insulation board comprises the following raw materials: 50-65 parts of phenolic resin, 20-25 parts of reactivity polyamide resin, 2-8 parts of fumed silica, 5-15 parts of liquid acrylonitrile-butadiene rubber, 4-8.5 parts of a modified surface-active agent, 9-18 parts of a toughness modifying agent, 4-10 parts of a foaming agent, 6-8 parts of a solidifying agent, and 1-5.5 parts of a catalyst promoter. The preparation method for the nano modified phenolic aldehyde foam insulation board comprises the following steps: firstly, raw materials are prepared; the raw materials are uniformly stirred; meanwhile, the solidifying agents and the catalyst promoters are added, so that the raw materials can be uniformly mixed; foaming mixture is placed on a sheet continuous production line and the temperature is kept to be 40-50 DEC G; after the foaming mixture is mixed, the foaming mixture is cross linked, expands foams and is solidified; the thermosetting phenolic resin rigid foam board is formed. According to the invention, properties of the phenolic aldehyde foam insulation boards prepared according to the technical scheme provided by the invention are improved, particularly the fire-resistant property is improved.

Owner:锦州市好为尔保温材料有限公司

High-resilience closed flame-retardant foam silicon rubber material and preparation method thereof

The invention discloses a high-resilience closed flame-retardant foam silicon rubber material. The high-resilience closed flame-retardant foam silicon rubber material is prepared from the following components in parts by weight: 40-60% of silicon rubber, 30-50% of additive, 0.5-2% of foaming agent, 1-3% of crosslinking agent, 0.5-2% of catalyst, 0.5-2% of inhibitor and 0.5-1.5% of coloring agent.

Owner:JIAXING ZHONGYI CARBON TECH

Environment protection type high-efficiency multiple mixing aerating powder for PU rigid foam

An environment protection type high-efficiency multiple mixing aerating powder for a PU rigid foam is composed of by weight 5-15 shares of HC, 2-20 shares of HFC, and 0-10 shares of adjuvant species; HC is a combination of one or more alkanes and / or cyclanes; HFC is a combination of one or more hydrofluorocarbon; and the adjuvant species is a combination of one or more fluorocarbon hydrocarbons. By means of combining a plurality of aerating powders and the assistance of the adjuvant, it is capable of obtaining a novel mixing foaming system, so as to obtain PU rigid foam with excellent combination property, especially PU rigid foam with excellent heat insulation performance.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

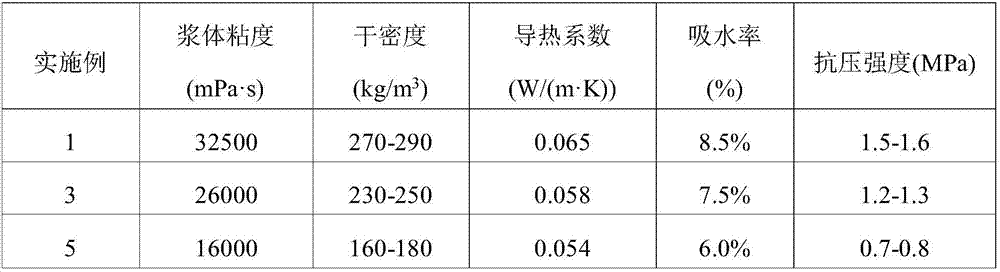

Super-light foam concrete and preparation method thereof

InactiveCN107324735AImprove production qualityFast setting and hardeningCeramicwareHydroxypropylmethyl celluloseSilica fume

The invention discloses super-light foam concrete. The super-light foam concrete is characterized by comprising the following materials in parts by mass: 60-80 parts of ordinary Portland cement, 10-20 parts of rapid hardening sulphoaluminate cement, 2-5 parts of silica fume, 8-15 parts of ultra-fine fly ash, 0.5-1.0 part of a polycarboxylate superplasticizer, 1-2 parts of redispersible powder, 0.05-0.2 part of hydroxypropyl methyl cellulose ether, 0.1-0.4 part of polypropylene fibers, 0.02-0.05 part of a superfine MnO2 catalyst, 4-6 parts of hydrogen peroxide and 50-60 parts of water, wherein a sustained-release gelatin capsule is filled with the superfine MnO2 catalyst and has the collapse time limit of 5-10 min. The invention also discloses a preparation method of the super-light foam concrete. The preparation method is characterized by comprising the steps of weighing, mixing, stirring and pouring. The super-light foam concrete has the advantages of high percentage of close area, low water absorption, high compressive strength and low heat conduction coefficient. The preparation method of the super-light concrete has the advantages that the hydrogen peroxide decomposition efficiency can be improved, and the hydrogen peroxide decomposition speed can be effectively controlled.

Owner:CHONGQING UNIV +2

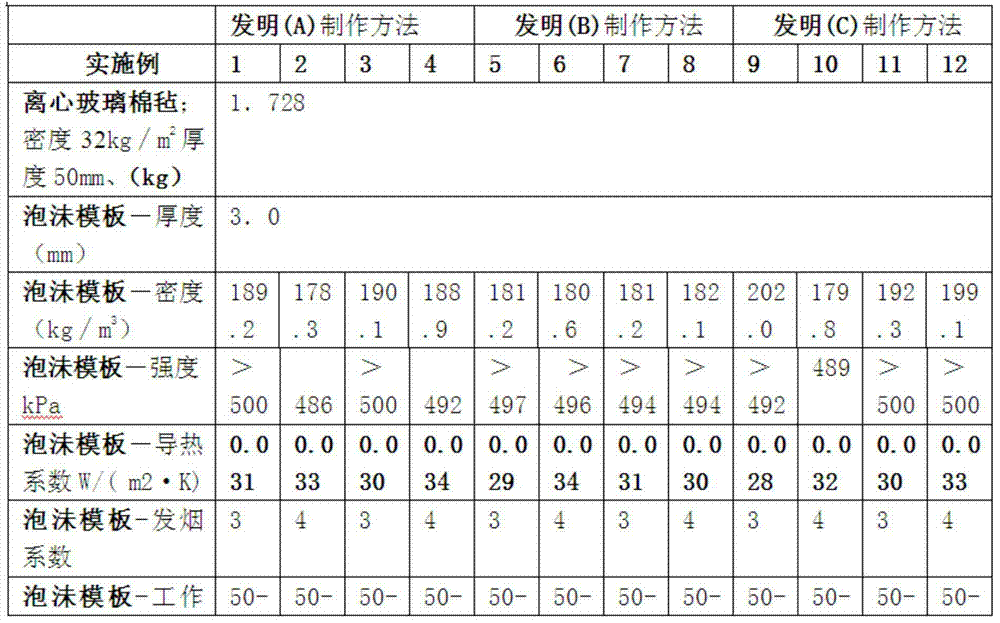

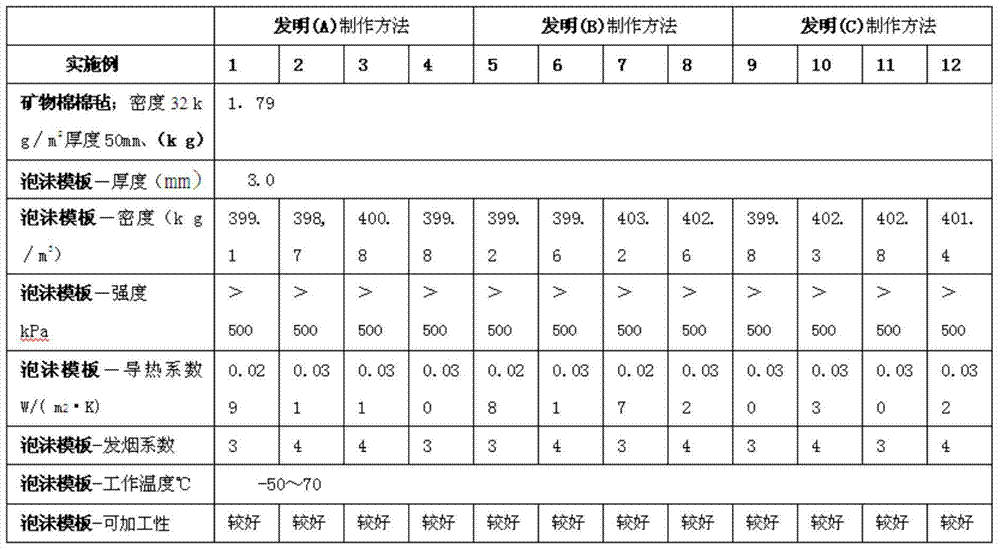

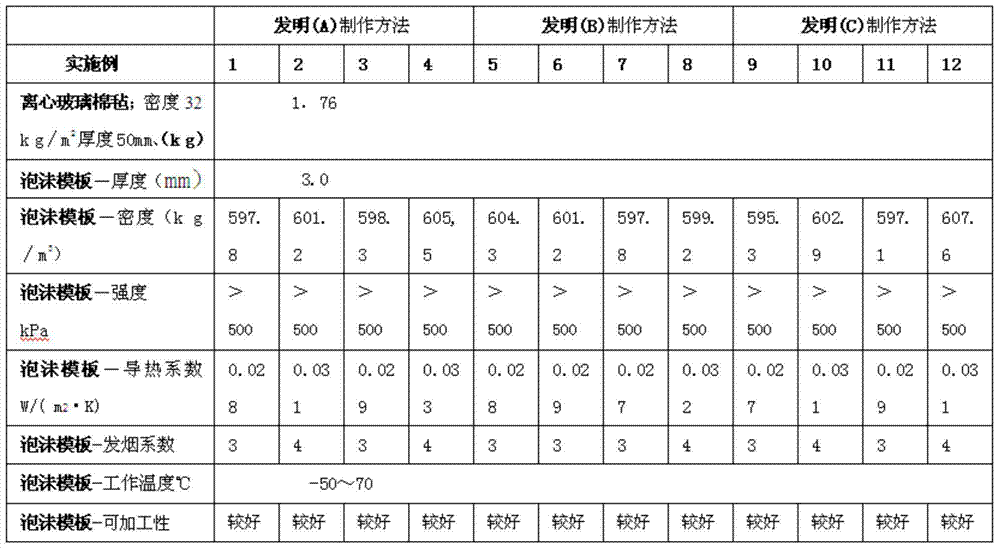

Enhanced foam stay-in-place building concrete template and manufacturing method thereof

ActiveCN104744886AFully impregnatedDip evenlyForming/stuttering elementsSustainable buildingsThermal insulationSurface-active agents

The invention relates to an enhanced foam stay-in-place building concrete template and a manufacturing method thereof. The enhanced foam stay-in-place building concrete template is an enhanced hard phenolic aldehyde foam template which is foamed and formed by taking phenolic resin and a glass wool or mineral wool blanket as the basic materials under the action of various additives including a glass wool or mineral wool fibre surface treatment agent, a foaming agent, a surface active agent, a curing agent, a modifying agent and a penetrating agent uniformly blended into the phenolic resin in advance. The enhanced foam stay-in-place building concrete template has a micro-porous structure of independent bubbles having uniformity, compactness and high closed pore rate; furthermore, because of the enhancement effect due to the fact that the micro-porous structure is bond to glass wool or mineral wool fibre in foam compactly and uniformly, the foam template not only has the excellent characteristics of phenolic aldehyde foam, such as fire resistance and heat insulation property, but also has higher compressive strength and impact resistance; therefore, the strength requirements of the building template can be satisfied; the construction processes of dismantling a poured concrete template and installing a thermal insulation layer in the construction process are avoided; the construction period and the cost are effectively saved; and the environment-friendly purposes of saving energy and reducing emission are achieved.

Owner:宁波与翼新材料科技有限公司

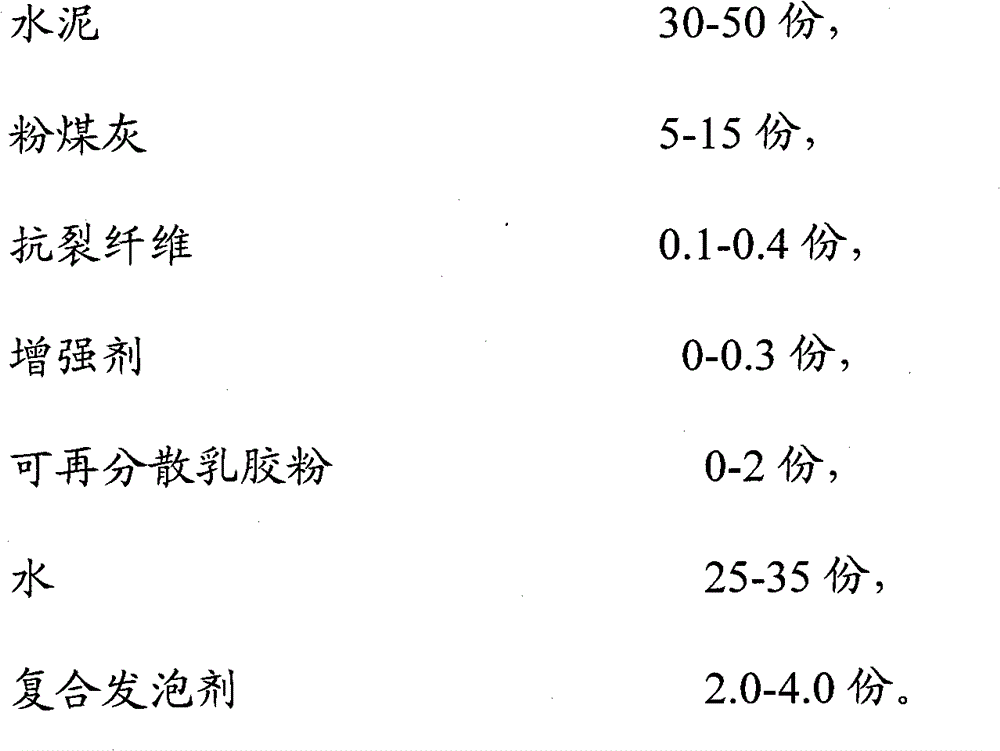

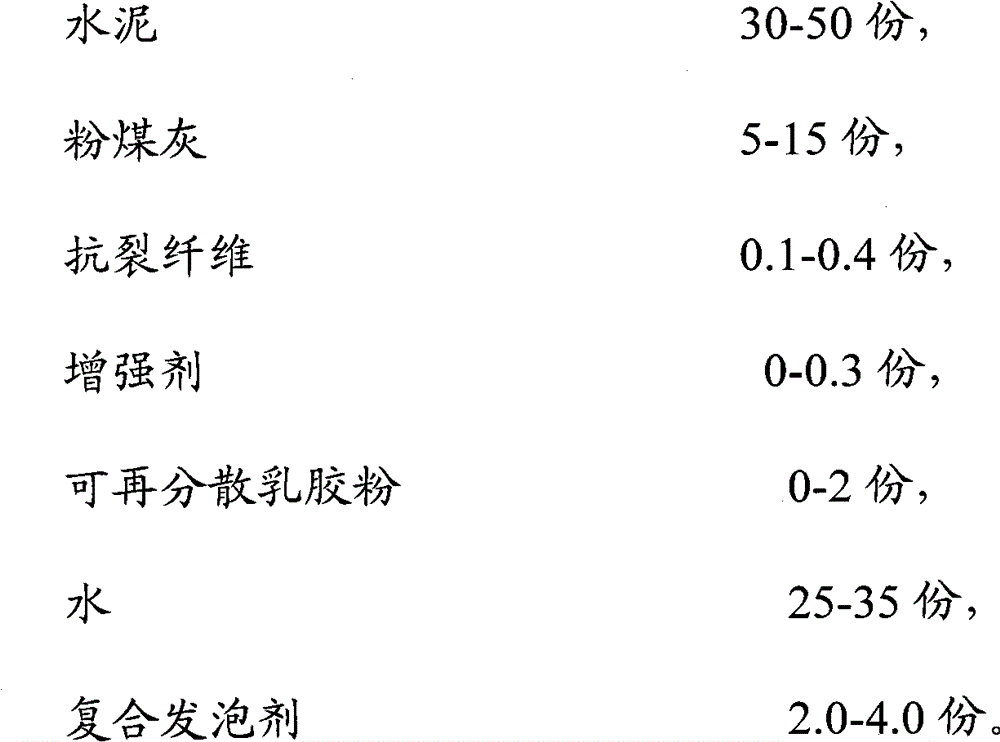

High performance polymer foaming cement thermal insulation material and preparation method thereof

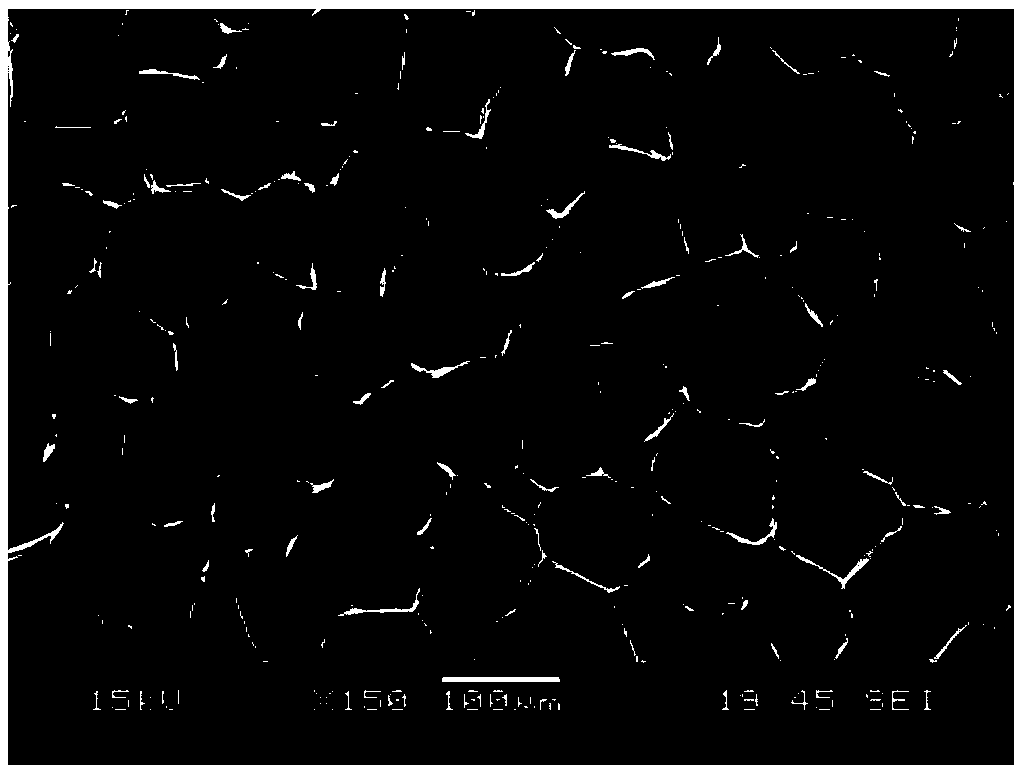

The present invention discloses a high performance polymer foaming cement thermal insulation material, which comprises, by weight, 30-50 parts of cement, 5-15 parts of fly ash, 0.1-0.4 part of anti-cracking fiber, 0-0.3 part of a reinforcing agent, 0-2 parts of redispersible latex powder or an emulsion, 25-35 parts of water, and 2.0-4.0 parts of a composite foaming agent. The preparation method comprises: weighing various components; adding the water, the anti-cracking fiber and the reinforcing agent; stirring for 1-2 minutes; then adding the fly ash and the cement, and stirring for 2-3 minutes; then adding the composite foaming agent, and stirring for 10-20 seconds; placing the resulting slurry in a mold, standing for 2-3 hours, and then carrying out demolding; and cutting after 24 hours, then packaging, and carrying out concrete curing until the curing time is 28 days. The foaming cement thermal insulation material of the present invention is a lightweight material with a fire-protection rating of class A, has characteristics of thermal insulation, durability, heat insulation, sound insulation and environment protection, and is used for building interior and exterior insulation materials, fire barriers, roofing thermal insulation materials, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

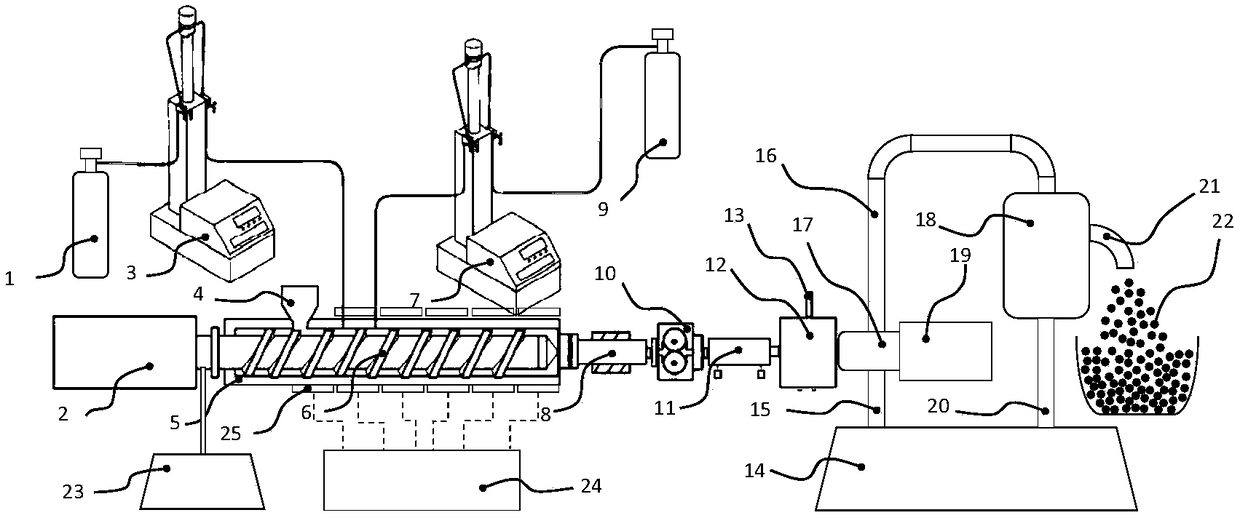

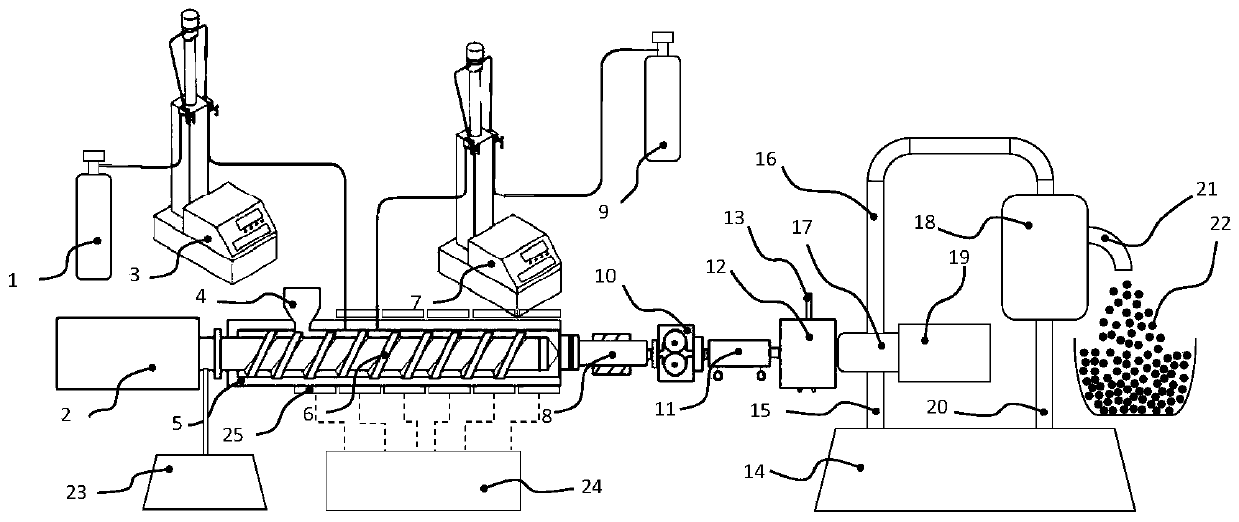

Device and method for preparing low-density polymeric foam beads by utilizing extrusion and foaming of supercritical mixed fluid

The invention discloses a device and a method for preparing low-density polymeric foam beads by utilizing extrusion and foaming of supercritical mixed fluid. The device comprises an extruding and mixing unit, a supercritical fluid injection unit, a static mixing unit, a gear pump, a melt cooler, an extruding mold head and an underwater granulating system and the like, wherein the main body of theextruding and mixing unit is a double-screw extruder, screws and a charging barrel are respectively equipped with a special temperature control unit, and the charging barrel is provided with two gas-injecting holes; the static mixing unit is arranged at the downstream of the extruding and mixing unit so as to enhance the mixing effect; the gear pump is arranged at the downstream of the static mixing unit so as to regulate the system pressure; the melt cooler is connected at the downstream of the gear pump so as to regulate the system temperature. The device and method disclosed by the invention have the advantages that the process is stable, the production efficiency is high, and the prepared polymeric foam beads are low in density and uniform in structure.

Owner:福建鑫瑞新材料科技有限公司

High-temperature-resistance and heat-insulation coating and production method thereof

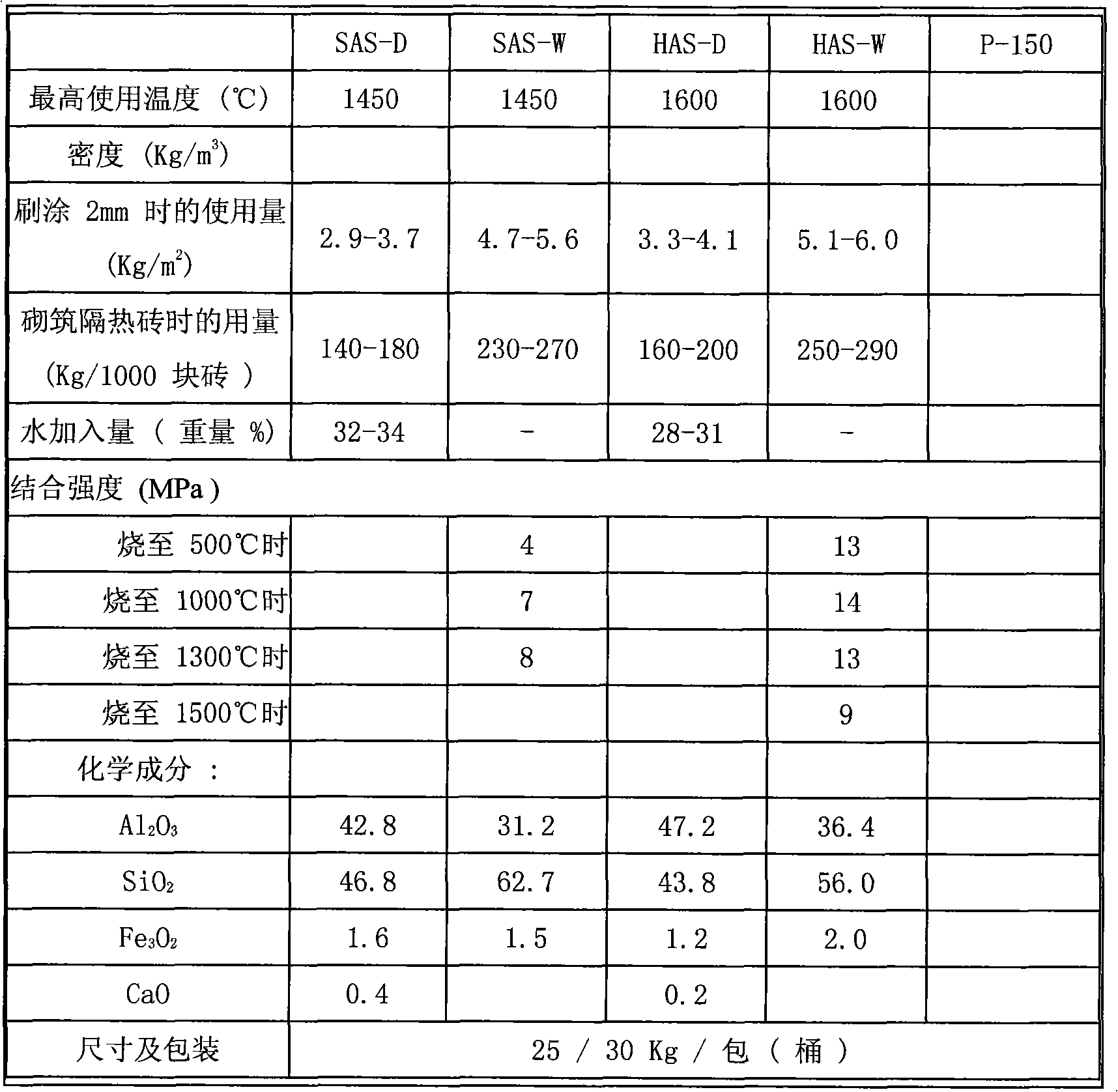

InactiveCN102030540AStable Temperature Coefficient CharacteristicsSmall molding shrinkageAlcoholRefractory

The invention relates to the field of high temperature resistance and heat insulation, in particular to a high-temperature-resistance and heat-insulation coating and the production method thereof. The finished product of the coating comprises the following components: 55 to 80 weight parts of inorganic high-temperature refractory adhesive mortar, 5 to 7 weight parts of SiO2 aerogel, 5 to 7 weight parts of hexapotassium titanate whisker, 3 to 5 weight parts of lamellar mica or lamellar metal and 90 to 120 weight parts of acetone or absolute alcohol. The production method comprises the following steps: a) firstly, screening the SiO2 aerogel containing grains with appropriate size, and pouring the appropriate amount of the acetone or the absolute alcohol into the SiO2 aerogel and fully stirring, wherein the contents of the SiO2 aerogel and the acetone or the absolute alcohol are 5 to 7 weight parts of the SiO2 aerogel and 90 to 120 weight parts of the acetone or the absolute alcohol; and b) adding 3 to 5 weight parts of the lamellar mica or 3 to 5 weight parts of the lamellar metal, 55 to 80 weight parts of the inorganic high-temperature refractory adhesive mortar and 5 to 7 weight parts of the hexapotassium titanate whisker to the mixture prepared in the step a), and fully stirring so as to prepare the high-temperature-resistance and heat-insulation coating. The production method is simple and easy to operate. The high-temperature-resistance and heat-insulation material obtained by using the method has the advantages of good heat insulation effect, high strength and wide prospect on the application.

Owner:武汉阜成科技股份有限公司

Foam insulation board with flame retardation function

InactiveCN105694253AHigh strengthReduce dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesCompression moldingAdhesive

The invention discloses a foam insulation board with a flame retardation function. A preparation method for the foam insulation board comprises the following steps: (1) coating of EPS particles: weighing 100 parts of prefoamed and cured EPS particles and 150 to 200 parts of a flame-retardant adhesive, carrying out uniform mixing under stirring, adding 10 to 15 parts of a curing agent and continuing stirring so as to obtain uniformly coated EPS particles; (2) gelation: subjecting the uniformly coated EPS particles to microwave heating for drying for 0.5 min and then delivering hot air for drying for 1 to 2 min so as to obtain gelated foam EPS particles; and (3) compression molding: putting the uniformly coated EPS foam particles into a die, closing the die, introducing water vapor with pressure intensity of 0.06 to 0.08 Mpa, maintaining the pressure for 1 to 2 min and then successively carrying out pressure relief, cooling and die-opening. The foam insulation board provided by the invention has good production efficiency, good flame retardation effect and high comprehensive properties.

Owner:SHANGHAI YIZUN WOOD

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

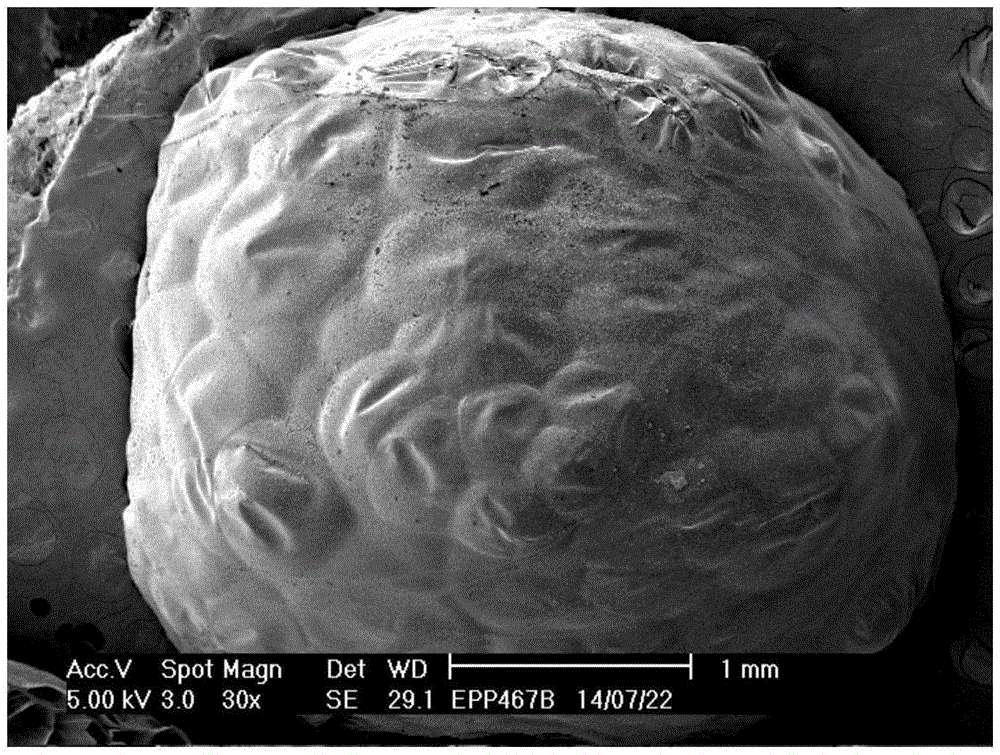

Low-density polypropylene bead foam as well as preparation method and application thereof

The invention belongs to the technical field of microporous plastic preparation, and particularly relates to low-density polypropylene bead foam as well as a preparation method and application thereof. The invention provides a method for preparing low-density polypropylene bead foam through extrusion foaming based on coupling modification of ultra-high molecular weight polyethylene and a nano carbon material. The preparation method comprises the following steps: mixing PP, UHMWPE and a nano carbon material in proportion, and then injecting a physical foaming agent into the mixture; fully and uniformly mixing the materials in a double-screw extruder, extruding the mixture, enabling the extruded mixture to sequentially flow through a static mixer, a gear pump, a melt cooler, an extrusion dieand the like which are arranged at the downstream of the double-screw extruder for extrusion foaming, and carrying out underwater pelletizing and drying to obtain the PP bead foam. The PP bead foam prepared by the method is low in density, uniform and full in appearance, small in shrinkage, uniform in cell structure, low in aperture ratio and easy for later steam molding.

Owner:福建鑫瑞新材料科技有限公司

Polyurethane thermal insulation board for refrigeration storage and refrigeration box and preparation method thereof

The invention discloses a polyurethane thermal insulation board for a refrigeration storage and a refrigeration box and a preparation method thereof. The polyurethane thermal insulation board comprises surface layer materials and a base material. The surface layer materials are arranged on the upper surface and the lower surface of the base material, and are fiber cloth or polycarbonate films. Thebase material formed by reaction of reinforcing fibers, a filler and a rigid polyurethane foam foaming material includes 0-60 parts by weight of the reinforcing fibers, 0-60 parts by weight of the filler and 40-80 parts by weight of the rigid polyurethane foam foaming material. The burning performance grade of the obtained polyurethane thermal insulation board is not lower than grade B2 in GB8624-2012 'classification for burning behavior of building materials and products'. The polyurethane thermal insulation board for the refrigeration storage / box has the advantages of waterproof and thermalinsulation decoration, lightweight, high strength, integral molding and continuous production and easy installation and maintenance.

Owner:南京红宝丽新材料有限公司

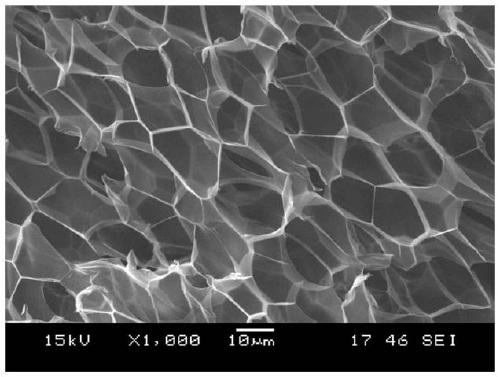

Preparation method of rigid polyimide foam material

The invention relates to a hard polyimide foam material and a preparation method thereof, and belongs to the technical field of preparation of high-molecular polyimide foam materials. The preparationmethod comprises the steps of adding an aromatic dianhydride into a tetrahydrofuran / fatty alcohol mixed solvent, and conducting heating to dissolve the aromatic dianhydride; after the solution is transparent, adding an aromatic diamine for reaction to form a foam precursor solution, then adding a foam stabilizer and a foaming aid, and conducting uniform mixing; placing the solution in a drying oven to remove the solvent, and then raising the temperature to carry out primary foaming; and carrying out mold pressing on a primary foamed product to a compact state, further raising the temperature,and carrying out secondary foaming to obtain the polyimide foam. The method has the characteristics of low preparation cost, rich candidate raw materials, easiness in realizing large-scale productionand the like; and the prepared foam material has the characteristics of being uniform in foam structure, adjustable in apparent density, high in compressive strength, high in closed cell rate and almost free of slag falling.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

Preparation method of hard closed-cell polyimide foam

The invention relates to a preparation method of hard closed-cell polyimide foam and belongs to the field of a preparation technology of a polymer polyimide foam material. The preparation method of the invention comprises the following steps: adding aromatic dianhydride into a polar solvent, and esterfying by adding an excessive amount of micromolecular fatty alcohol to obtain a solution A; addingdiamine, a foam stabilizer and an end-capping reagent into the solution A, reacting for 0.5-3 h to obtain a solution B, drying the solution B to remove the polar solvent, and crushing to obtain a precursor powder; placing the precursor powder into an open vessel and putting the open vessel with the precursor powder into a pressure vessel, vacuum-pumping to remove air and introducing CO2, heating,pressurizing, and finally cooling naturally and releasing pressure to obtain crosslinked polyimide foam. According to the method, nontoxic, odorless, non-combustible and cheap CO2 which is easily available is used as foaming gas. The preparation method is novel and has a wide application system.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

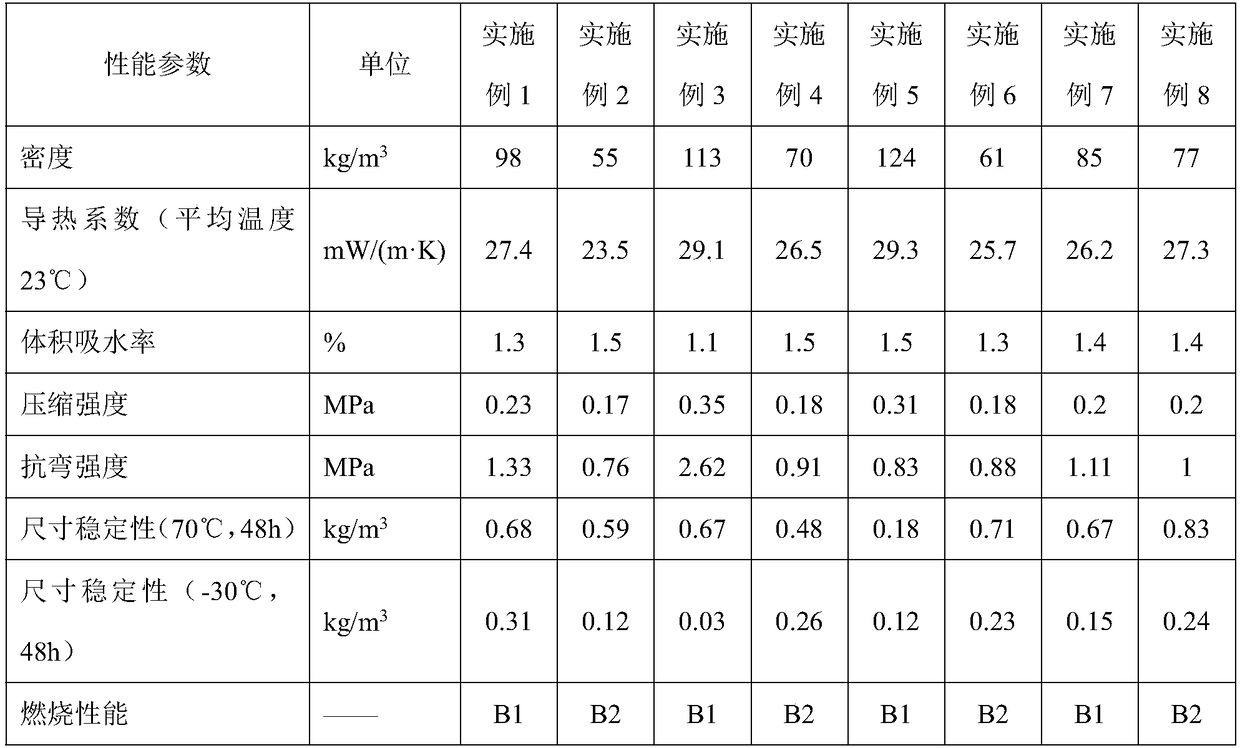

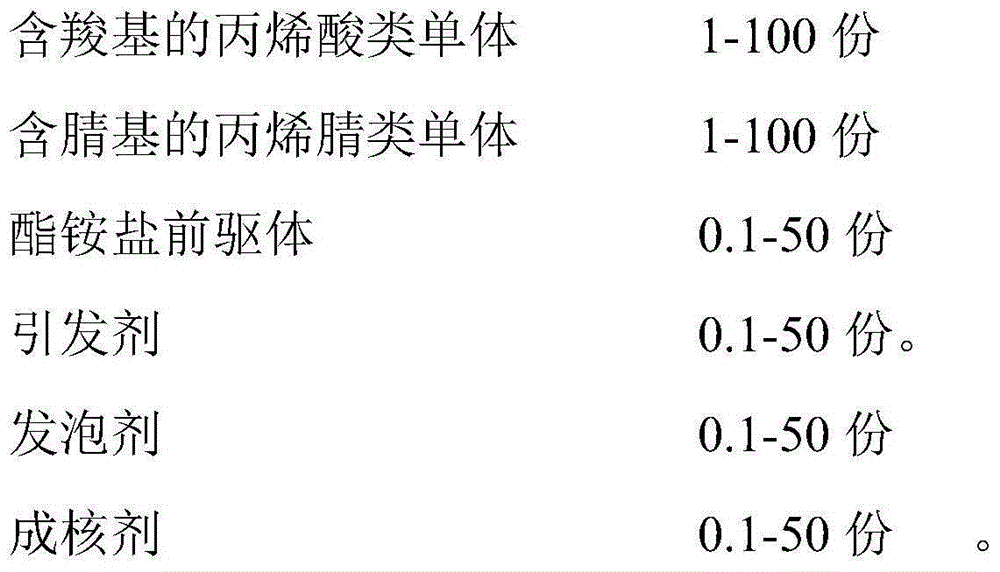

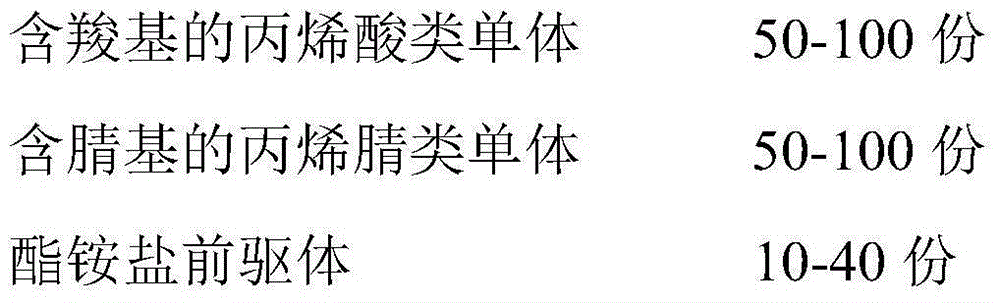

Polyacrylic imide foam material, and preparation method and application thereof

The invention relates to a polyacrylic imide foam material prepared by an esterquat precursor, and a preparation method and application of the polyacrylic imide foam material. In a preparation process of polyacrylic imide foam prepolymer, the esterquat precursor of PMR type polyimide is added, endothermic reaction of amidation of the esterquat precursor is matched with exothermic reaction of free radical polymerization in the preparation process of the polyacrylic imide foam prepolymer, and the purpose of effectively controlling reaction speed of polyacrylic imide is achieved. The prepared polyacrylic imide foam material has the advantages of high closed porosity, good high-temperature resistance and high compression resistance. The density of prepared foam is 30-250kg / m (3), closed porosity is greater than 90%, and a glass transition temperature is greater than 220 DEG C. At a room temperature, the density of the prepared foam is greater than 110kg / m (3), and compression strength of the foam is greater than 3.0MPa; and at a high temperature of 180 DEG C and under pressure of 0.3MPa, the compression deformation rate of the foam of which the density is 110kg / m (3) is lower than 1% after the foam is technologically treated for 2 hours.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

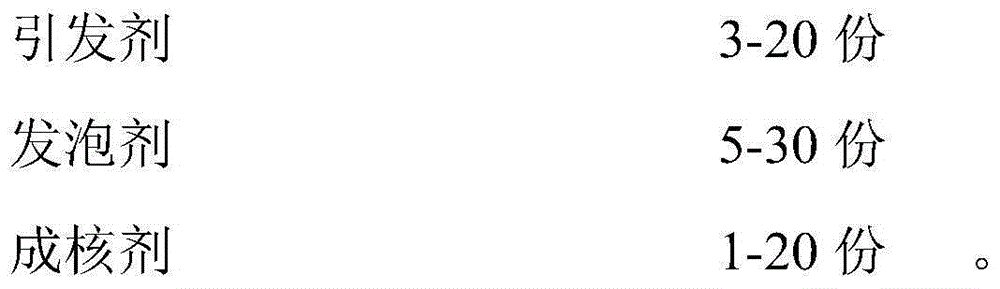

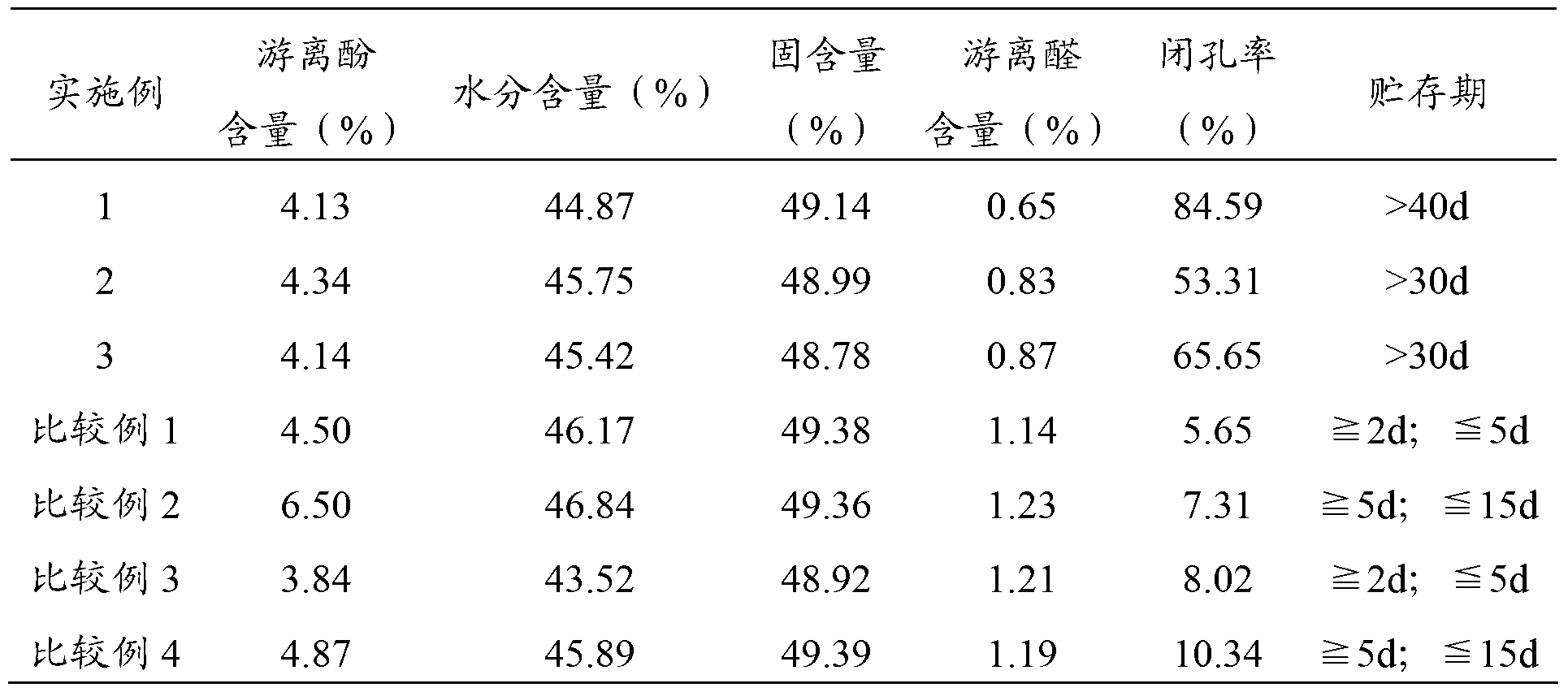

Preparation method of phenol modified urea resin

ActiveCN103242500AHigh closed cell rateLow free formaldehyde contentAldehyde/ketone condensation polymer adhesivesAlcoholPhenol

The invention provides a preparation method of phenol modified urea resin. The preparation method comprises the following steps of: (a), mixing phenol, formaldehyde and an alkali catalyst for reacting to obtain reaction products, wherein the reaction products include a phenol-alcohol mixture and formaldehyde; and (b), mixing the reaction products obtained in the step (a) with urea, an alcohol compound and an weak acid compound for reacting to obtain the phenol modified urea resin. The preparation method of the phenol modified urea resin provided by the invention can be used for enabling the phenol and the formaldehyde to react in the presence of the alkali catalyst, enabling the reaction products to react with the urea and the alcohol compound under an weak acid condition, so that the alcohol compound and excessive formaldehyde react to generate alcohol formaldehyde in the reaction process; moreover, the alcohol compound further can be cross-linked with the urea resin to form macromolecules, so that the content of the free formaldehyde is lowered and the storage period is prolonged. Moreover, the phenol modified urea resin obtained by the preparation method disclosed by the invention is foamed and cured to obtain a foaming body with a higher percentage of close area.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Preparation method of high efficient and energy saving phenolic foam board

InactiveCN105733173AConducive to the initial formationEasy to moveChemical industryFoaming agentFire retardant

The invention relates to a preparation method of a high efficient and energy saving phenolic foam board, which includes the steps of: (1) preparing raw materials according to the following components and weight parts: 100 parts of expandable resol resin, 2-6 parts of a foaming agent, 5-15 parts of a fire retardant, 2-4 parts of a foam stabilizer, and 10-20 parts of a curing agent; (2) mixing above raw materials and stirring infirmly the raw materials at the high speed, pouring the raw materials into a die, sealing the die, and putting the die into a baking oven; and (3) controlling the temperature of the baking oven, carrying out staging foaming treatment on the die at different temperatures, taking out the die after the staging foaming treatment ends, namely preparing the high efficient and energy saving phenolic foam board. Compared with the prior art, the prepared product accords with high efficient, energy saving, and light characteristics. The thermal conduction coefficient may be low to 0.022W / m*K.

Owner:苏州美克思新能源科技有限公司

High-melt strength high-impact polypropylene foaming expanded beads and preparation method thereof

The invention provides polypropylene foaming expanded beads and a preparation method thereof. The foaming expanded beads take high-melt strength high-impact polypropylene as a basic resin, and are prepared by foamed impregnation; wherein, the high-melt strength high-impact polypropylene comprise a propylene homopolymer component and a propylene-ethene copolymer component, molecular weight distribution ratio of Mw to Mn is less than or equal to 10 and greater than or equal to 4; the ratio of Mz+1 to Mw is greater than 10 and less than 20; the content of a room temperature xylene soluble substance is greater than 10 weight% and less than 30 weight%; and the ratio of Mw of a room-temperature trichloro-benzenes soluble substance to Mw of a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less or equal to 1 The polypropylene foaming expanded beads have the advantages of uniform size and distribution of foaming pore and aperture, high percentage of close area, good high / low temperature high-impact performance, and high melt-strength; and can be widely used for the fields of automobile part, food, electronic package and building decoration; the preparation method is simple, operation is easy, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com