Polyacrylic imide foam material, and preparation method and application thereof

A technology of polyacrylimide and foam materials, applied in the field of polyacrylimide foam materials, can solve the problem that it is difficult to effectively control the release rate of free radical polymerization heat, and achieve high compressive strength and closed cell ratio. High and high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

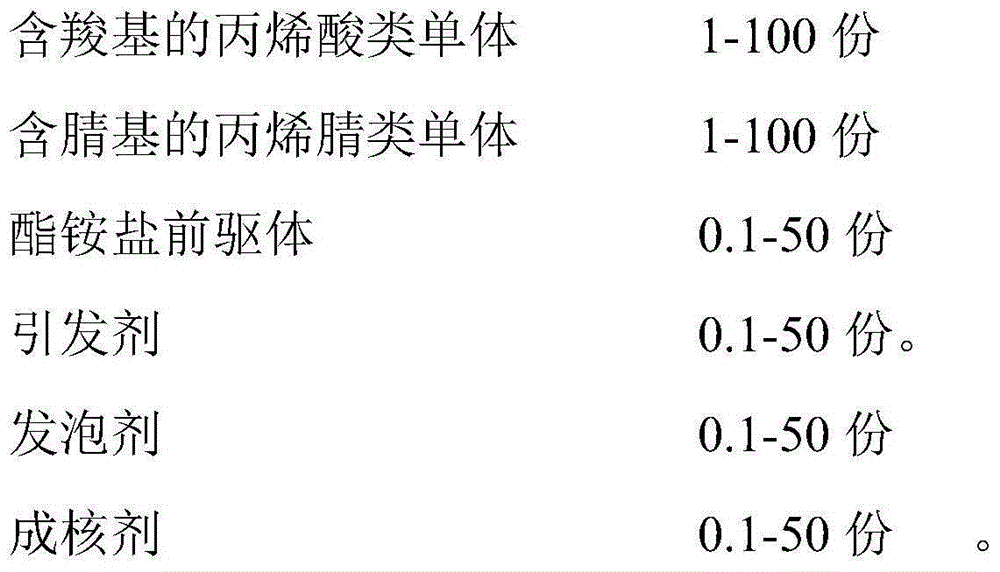

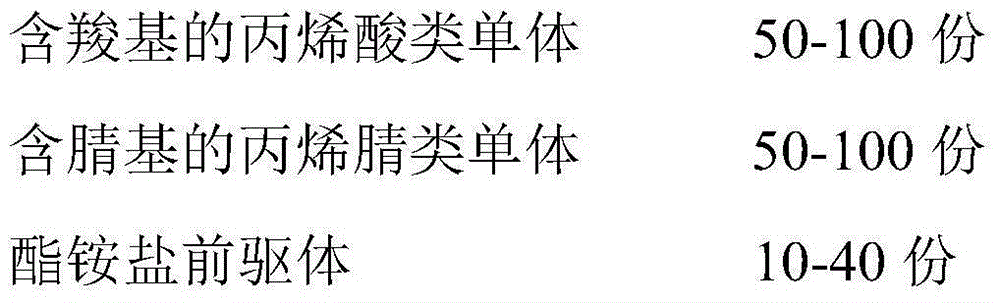

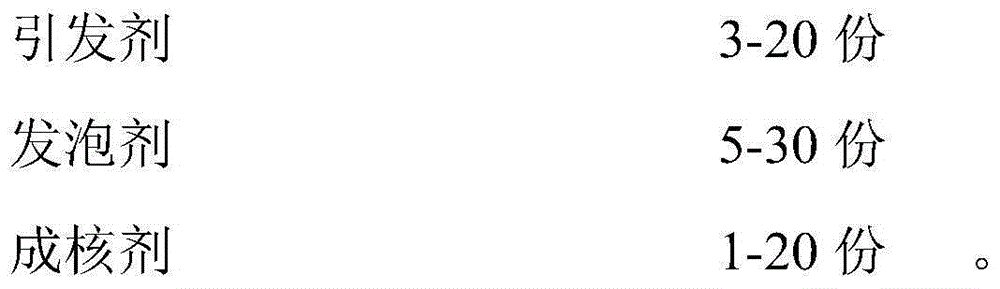

Method used

Image

Examples

Embodiment 1

[0051] Add 50 parts of methacrylic acid, 50 parts of methacrylonitrile, 20 parts of PMR ester ammonium salt 1, 3 parts of AIBN, 10 parts of TBPO, 5 parts of formamide, and 30 parts of amyl alcohol into a three-necked glass flask in sequence, , stirred at room temperature for 2 to 3 hours to form a homogeneous solution;

[0052] Transfer the above homogeneous solution to a mold consisting of 2 glass plates and a sealant frame, and polymerize under the following conditions: 80-90°C / 36-48 hours, 100-140°C / 48-60 hours to obtain a foam preform Polymer copolymer resin board;

[0053] Foaming the foam prepolymer copolymer resin plate obtained above at 200-220° C. to obtain a polyacrylimide foam plate blank;

[0054] The above obtained polyacrylimide foam board blank is machined to obtain a polyacrylimide foam material with a density of 110kg / m 3 , The cells are uniform, and the deformation at 180°C / 0.5MPa / 2h is 0.3%. After heat treatment (HT) at 190°C / 48h, the deformation at 180°C / ...

Embodiment 2

[0056] Add 50 parts of methacrylic acid, 45 parts of methacrylonitrile, 10 parts of PMR ester ammonium salt 3, 10 parts of TBPO, 8 parts of formamide, and 30 parts of isopropanol into a three-necked glass flask in sequence, under nitrogen protection, at room temperature Stir for 2 to 3 hours to form a homogeneous solution;

[0057] Transfer the above homogeneous solution to a mold consisting of 2 glass plates and a sealant frame, and polymerize under the following conditions: 80-90°C / 36-48 hours, 100-140°C / 48-60 hours to obtain a foam preform Polymer copolymer resin board;

[0058] Foaming the foam prepolymer copolymer resin plate obtained above at 200-220° C. to obtain a polyacrylimide foam plate blank;

[0059] The above obtained polyacrylimide foam board blank is machined to obtain a polyacrylimide foam material with a density of 50kg / m 3 , The cells are uniform, and the deformation at 130°C / 0.3MPa / 2h is 0.3%. After heat treatment (HT) at 190°C / 48h, the deformation at 150...

Embodiment 3

[0071] Add 50 parts of methacrylic acid, 50 parts of acrylonitrile, 15 parts of PMR ester ammonium salt 12, 5 parts of CABN, 10 parts of TAPB, 3 parts of formamide, 2 parts of carbonamide, 20 parts of tert-butanol, and 5 parts of water into In a three-necked glass flask, under the protection of nitrogen, stir at room temperature for 2 to 3 hours to form a homogeneous solution;

[0072] Transfer the above homogeneous solution to a mold consisting of 2 glass plates and a sealant frame, and polymerize under the following conditions: 80-90°C / 36-48 hours, 100-140°C / 48-60 hours to obtain a foam preform Polymer copolymer resin board;

[0073] Foaming the foam prepolymer copolymer resin plate obtained above at 200-220° C. to obtain a polyacrylimide foam plate blank;

[0074] The above obtained polyacrylimide foam board blank is machined to obtain a polyacrylimide foam material with a density of 75kg / m 3 , The cells are uniform, and the deformation at 150°C / 0.3MPa / 2h is 0.5%. After h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com